Preparation method of n-zinc titanate powder and application

A technology of zinc orthotitanate and powder, which is applied in the direction of titanate, chemical instruments and methods, titanium compounds, etc., can solve the problems affecting the absorption performance and performance degradation of the coating, and achieve high yield and strong stain resistance , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

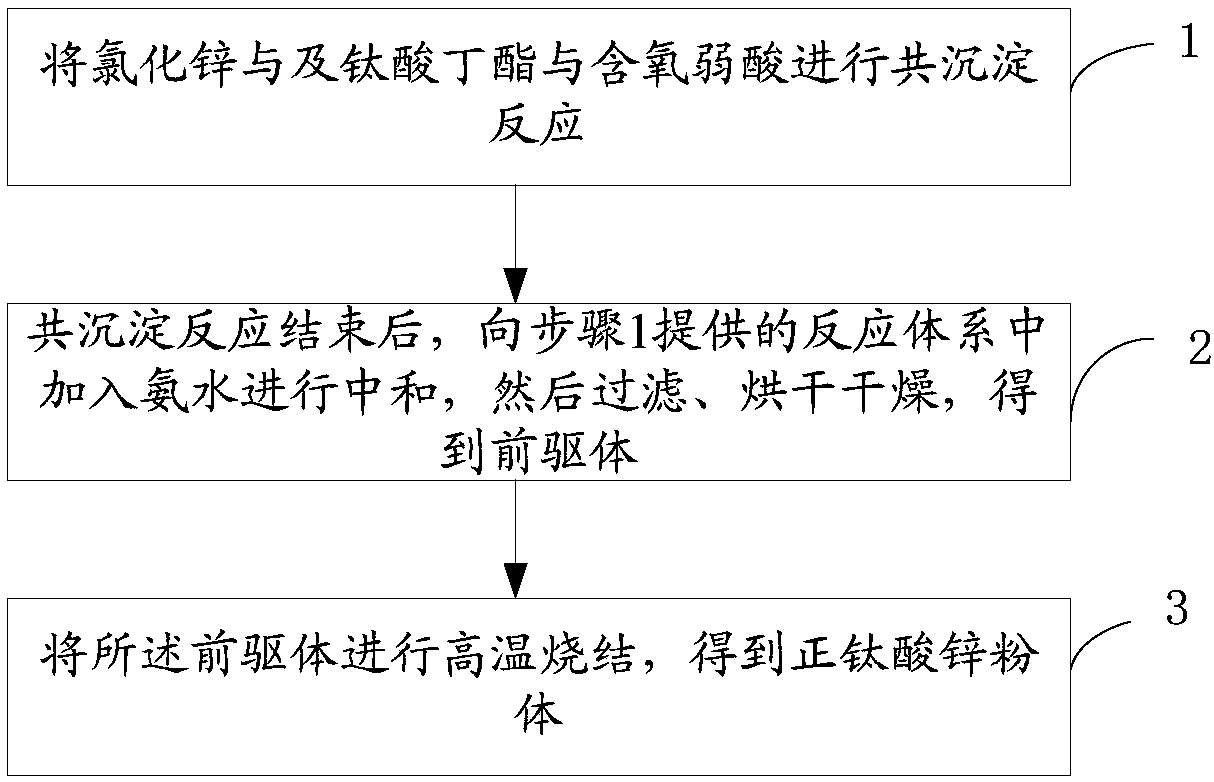

[0035] see figure 1 , the embodiment of the present invention provides a preparation method of zinc orthotitanate powder, comprising the following steps:

[0036] Step 1. Co-precipitate zinc chloride and butyl titanate with oxygen-containing weak acid; specifically, the oxygen-containing weak acid used in the present invention can be any oxygen-containing acid that reacts with zinc chloride and butyl titanate to form oxide precipitate Weak acids, preferably carboxylic acids;

[0037] Step 2. After the co-precipitation reaction is completed, ammonia water is added to the reaction system provided in step 1 for neutralization, and then filtered and dried to obtain the precursor; specifically, it can be dried by natural drying or drying.

[0038] Step 3. Sintering the precursor at high temperature to obtain zinc orthotitanate powder.

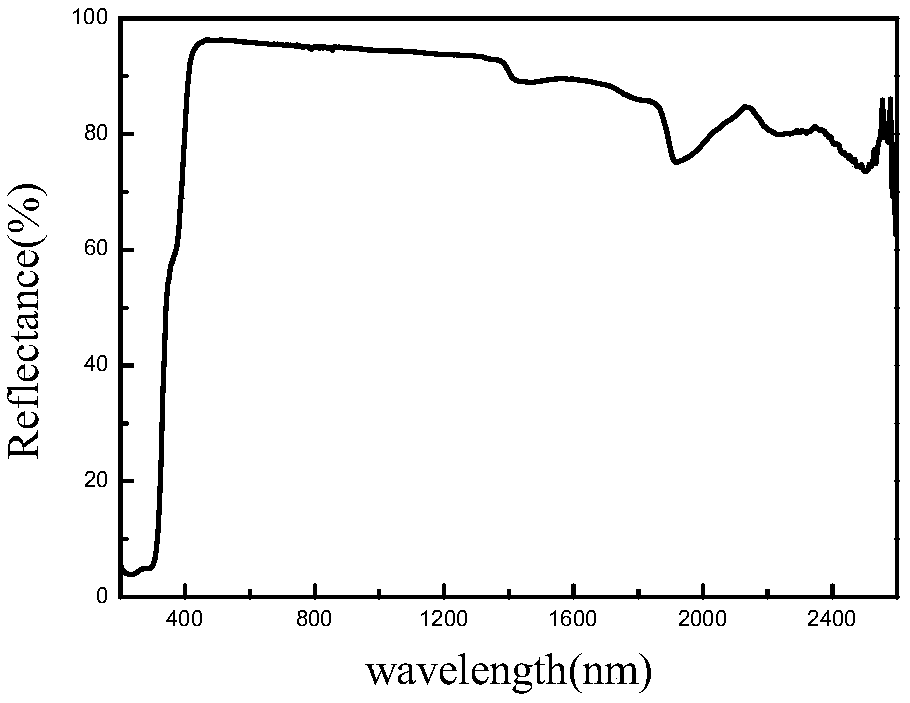

[0039] The preparation method of zinc orthotitanate powder provided in the embodiment of the present invention adopts butyl titanate as a titaniu...

Embodiment 1

[0055] Preparation

[0056] 1) Weigh 270g oxalic acid and dissolve it in 1200g deionized water to make oxalic acid solution B;

[0057] 2) Weigh 270g of zinc chloride and 340g of butyl titanate into 400g of absolute ethanol and stir for 30min to make solution A;

[0058] 3) Drop A solution into oxalic acid solution B with a constant pressure burette, and stir for 1 hour to prepare solution C;

[0059] 4) Drop ammonia water into solution C with a constant pressure burette to adjust the pH value to about 7, and stir for 1 hour to obtain D;

[0060] 5) Filter D and wash it with deionized water for 3 times, then put it into a vacuum oven and heat at 120°C for 10 hours to dry;

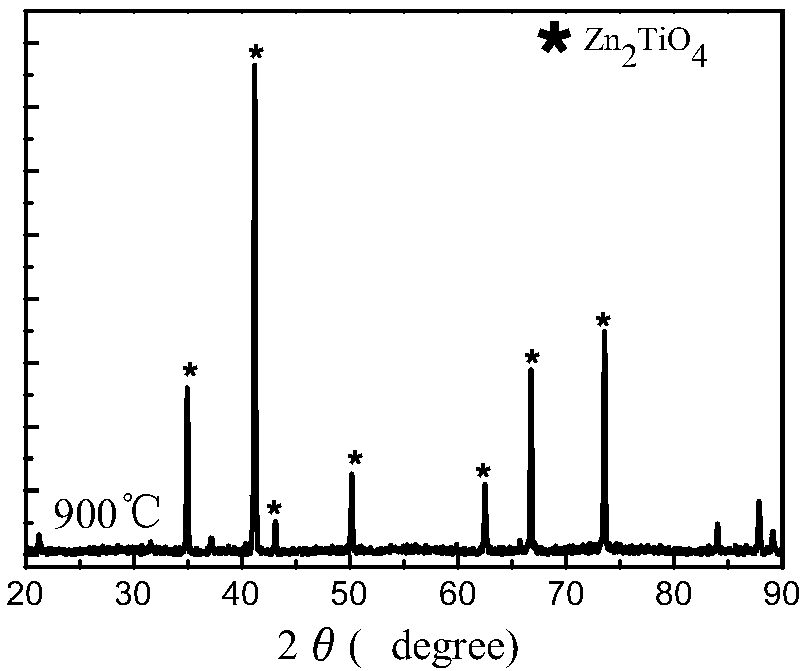

[0061] 6) Put the powder obtained after drying into a muffle furnace and heat at 500°C for 2 hours, then raise the temperature to 900°C and heat for 2 hours, take it out and cool;

[0062] 7) Weigh 100 g of concentrated sulfuric acid and add it into 1000 ml of deionized water to prepare a dilute sulfuric a...

Embodiment 2

[0069] 1) Weigh 100g oxalic acid and dissolve it in 500g deionized water to make oxalic acid solution B;

[0070] 2) Weigh 150g of zinc chloride and 180g of butyl titanate into 300g of absolute ethanol and stir for 30min to make solution A.;

[0071] 3) Drop A solution into oxalic acid solution B with a constant pressure burette, and stir for 1 hour to prepare solution C;

[0072] 4) Drop ammonia water into solution C with a constant pressure burette, adjust the pH value to about 7, and stir for 1 hour to obtain D;

[0073] 5) Filter D and wash it with deionized water for 3 times, then put it into a vacuum oven and heat it at 100°C for 15h to dry;

[0074] 6) Mill the dried powder with a planetary ball mill at 30 Hz for 10 hours;

[0075] 7) Put the ball-milled powder into a muffle furnace and heat at 450°C for 3 hours, then raise the temperature to 900°C and heat for 3 hours, take it out and cool;

[0076] 8) Weigh 100 g of concentrated sulfuric acid and add it into 1000 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com