Patents

Literature

141 results about "Zinc titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc titanate, also known as zinc titanium oxide, is an inorganic compound existing in three major forms: ZnTiO₃ (ZnO-TiO₂), Zn₂TiO₄ (2ZnO-TiO₂) and Zn₂Ti₃O₈ (2ZnO-3TiO₂). It is used as a regenerable catalyst, a pigment and a sorbent of sulfur compounds at elevated temperatures. It is a white powder that is insoluble in water.

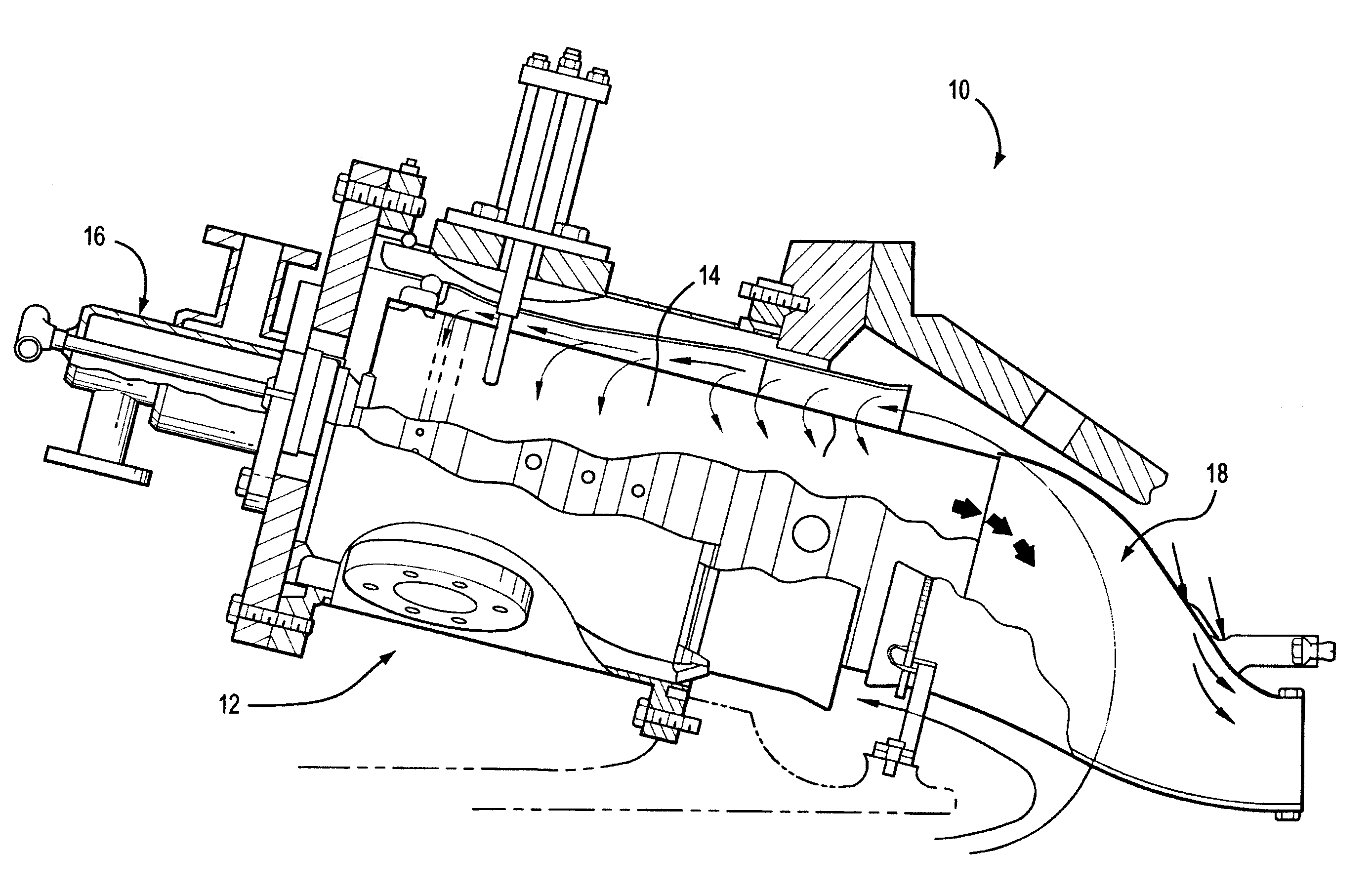

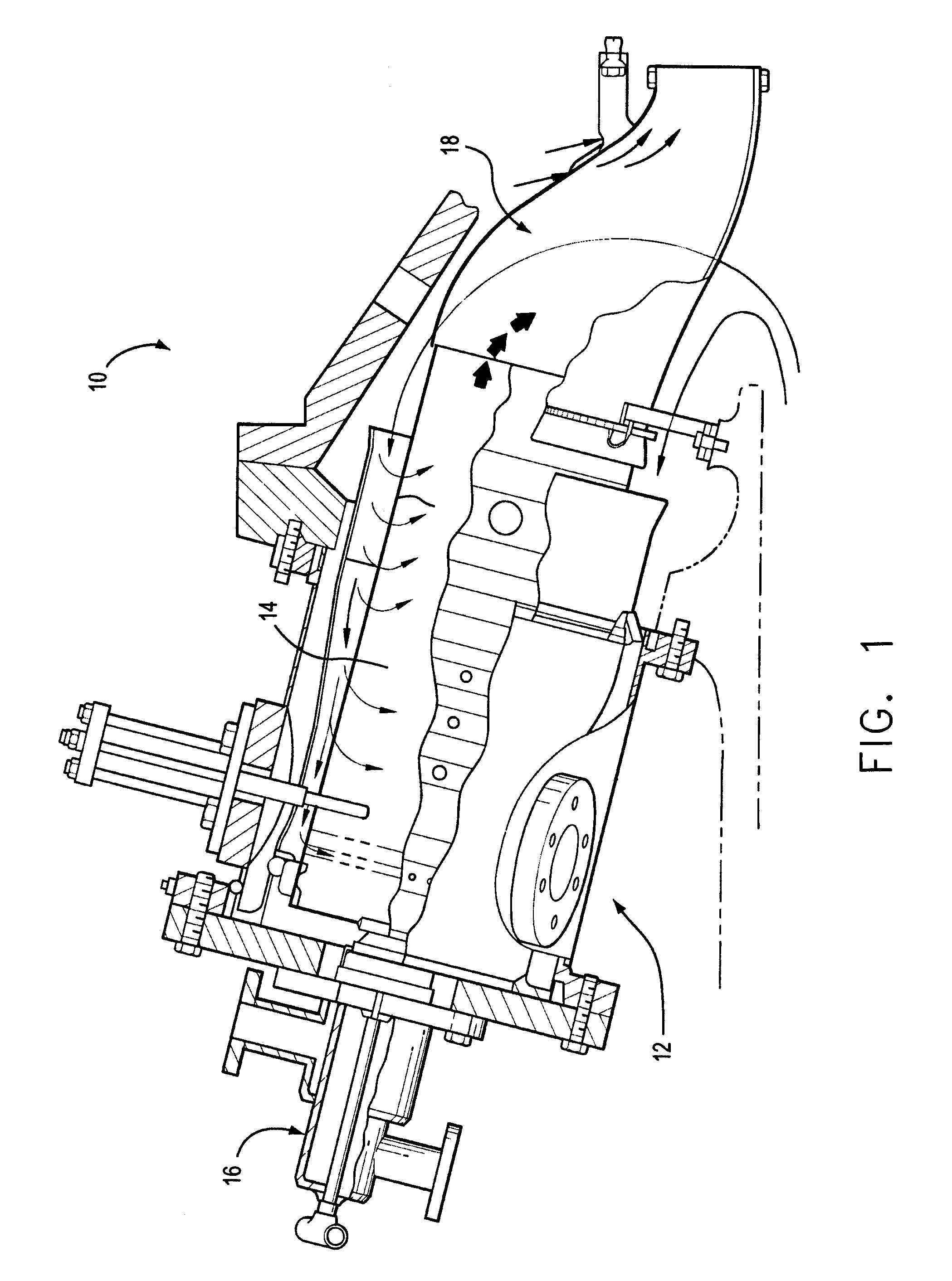

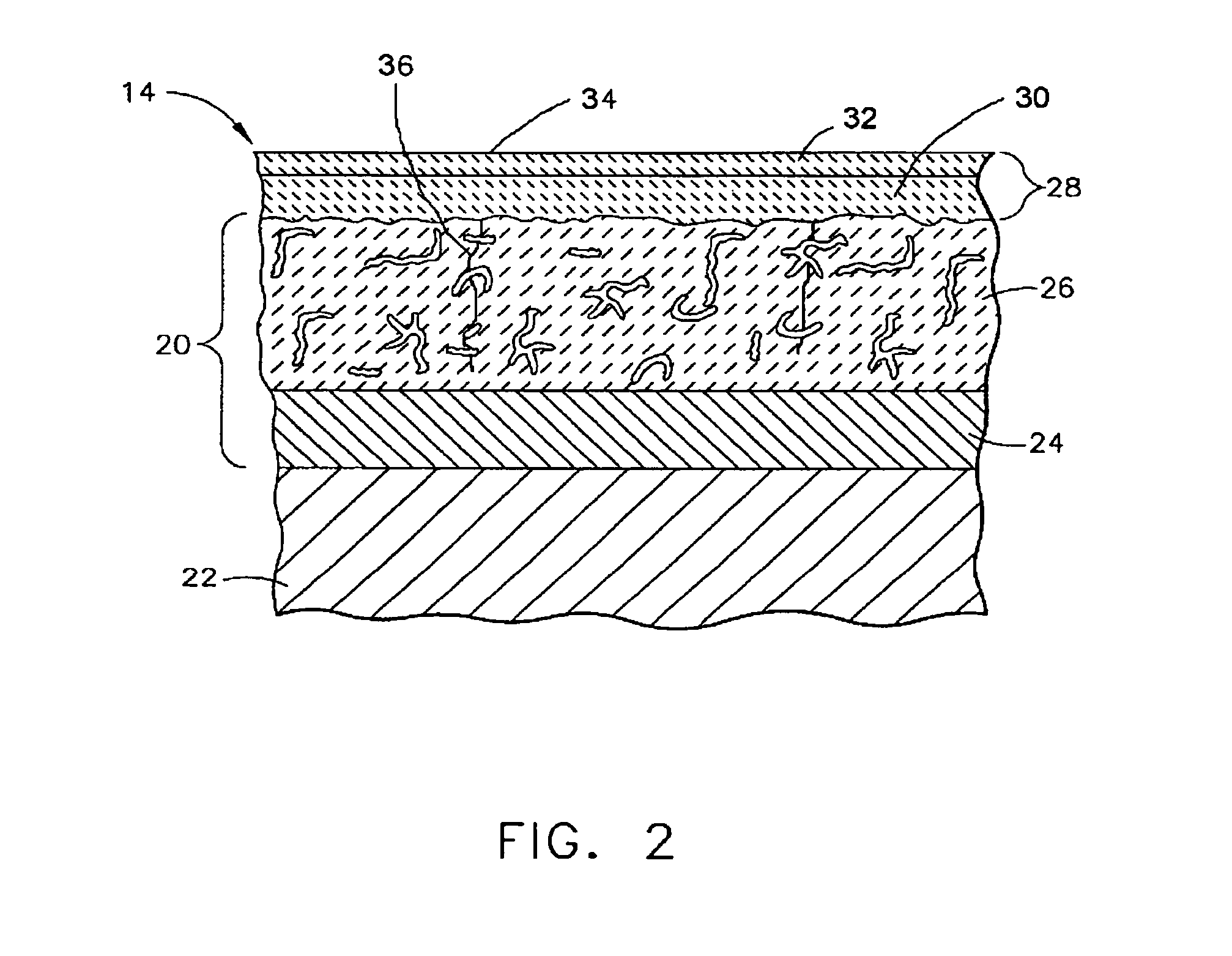

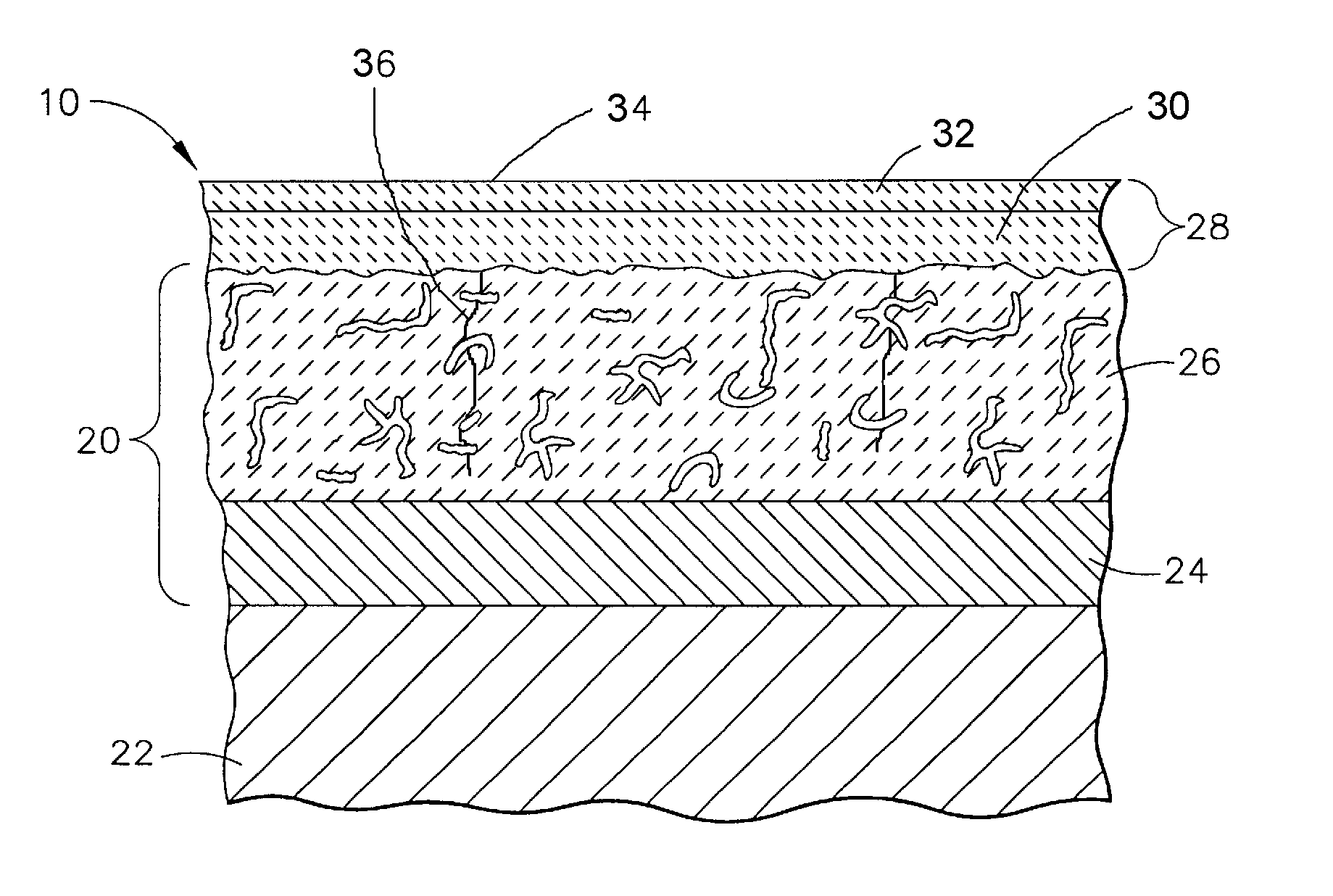

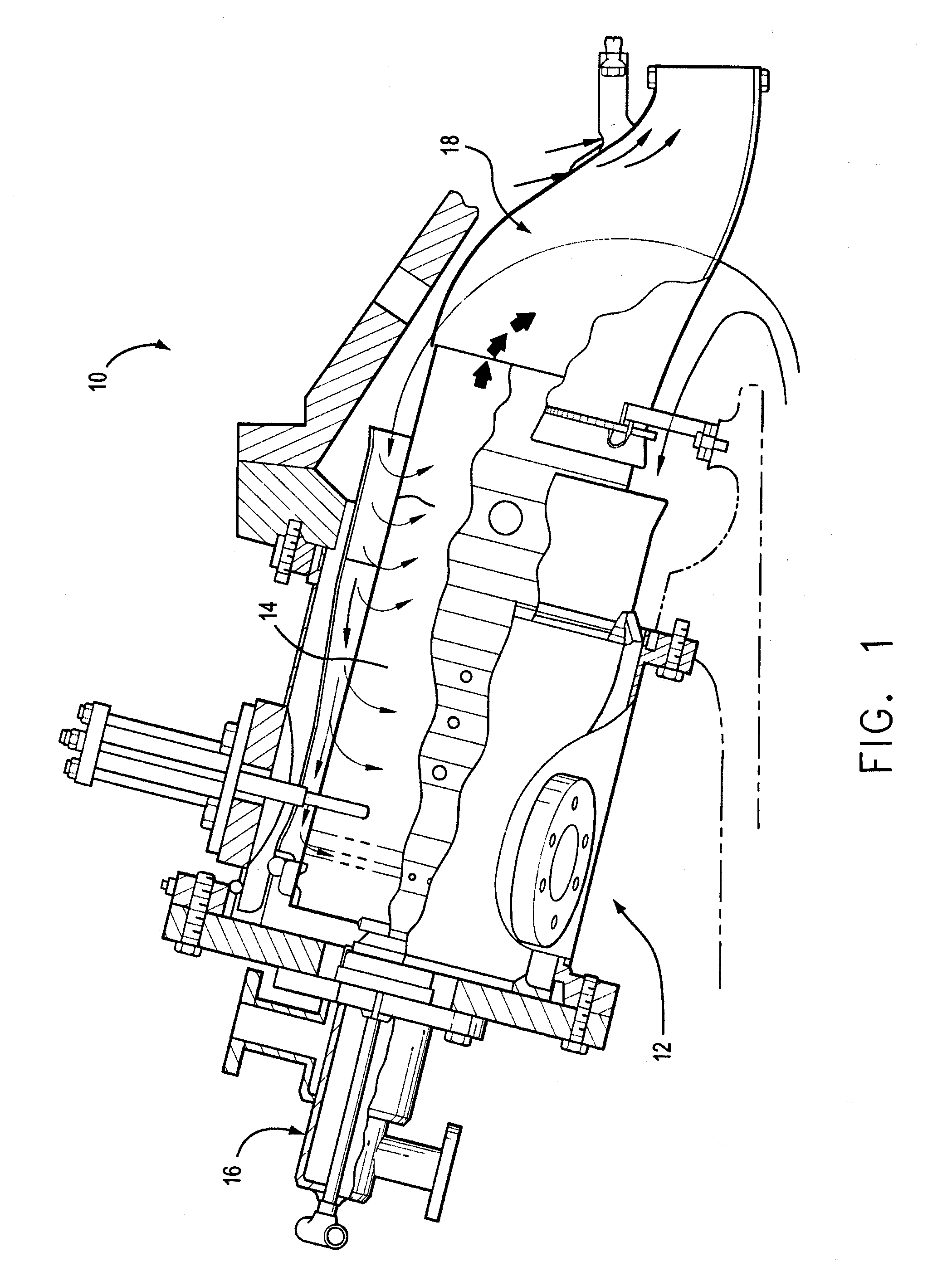

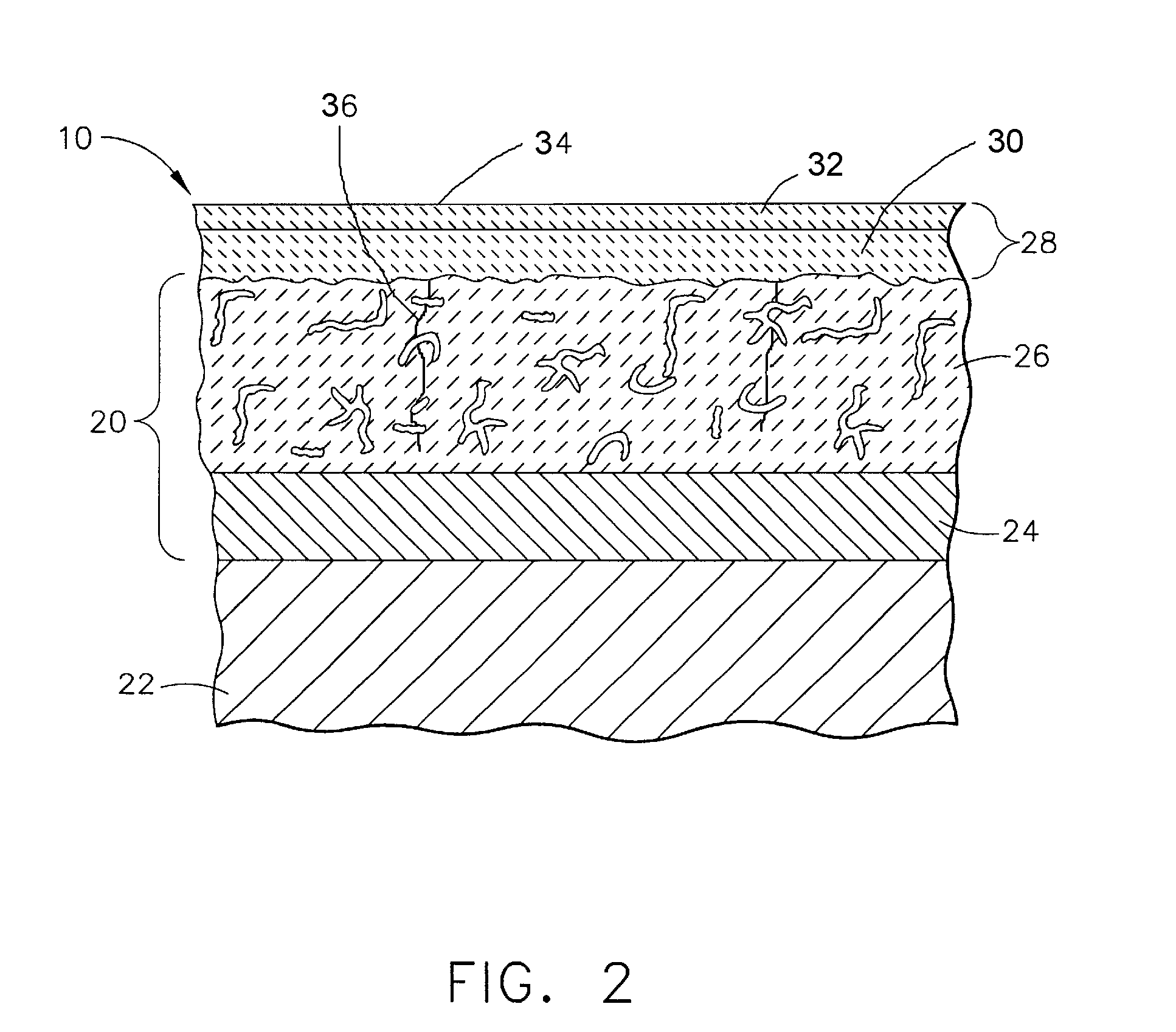

Smooth outer coating for combustor components and coating method therefor

InactiveUS7368164B2Suppresses component temperature riseReduce transferMolten spray coatingPropellersZinc titanateSilica matrix

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

Smooth outer coating for combustor components and coating method therefor

ActiveUS20050282020A1Suppresses component temperature riseReducing convective transferLiquid surface applicatorsMolten spray coatingZinc titanateSilica matrix

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

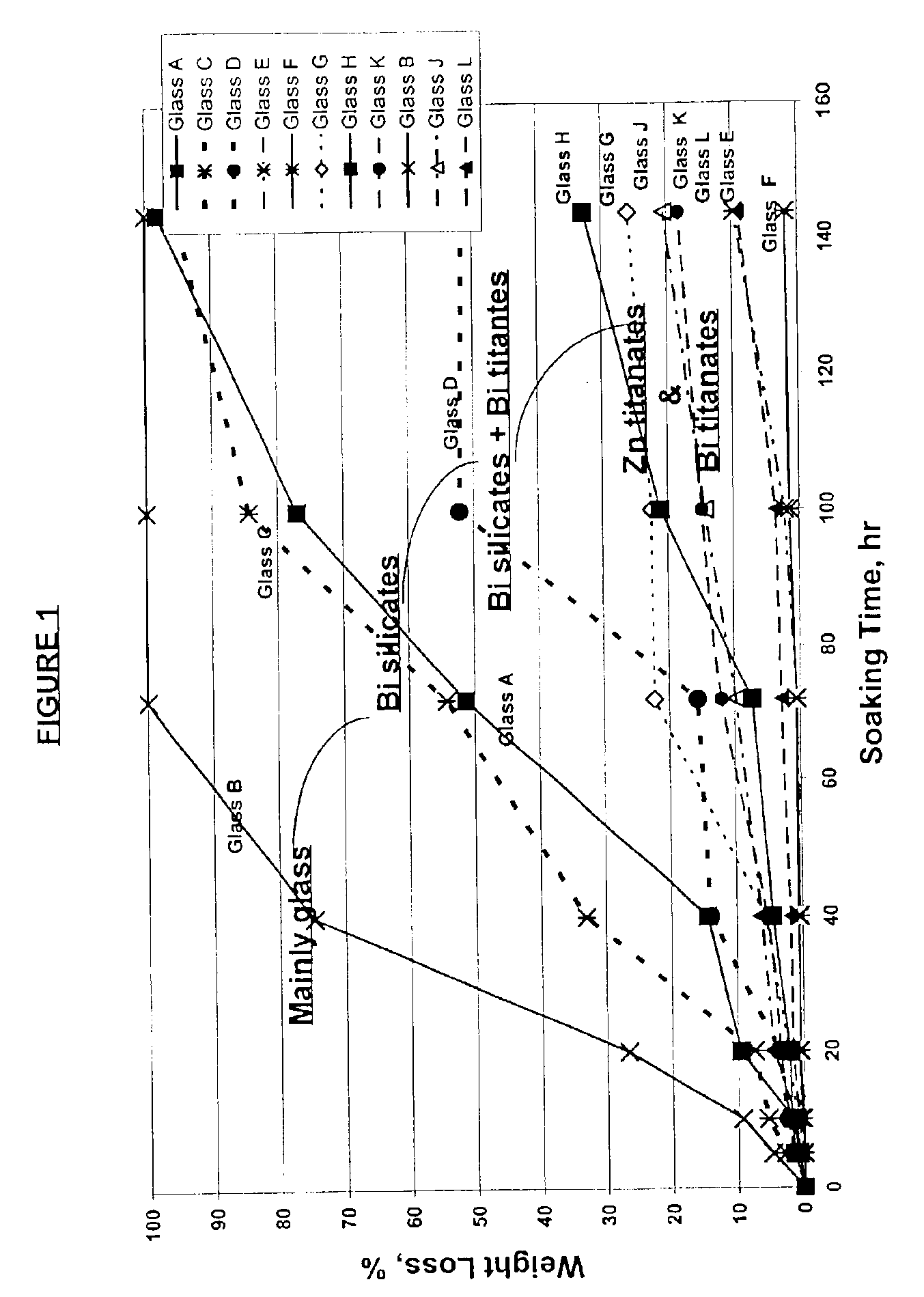

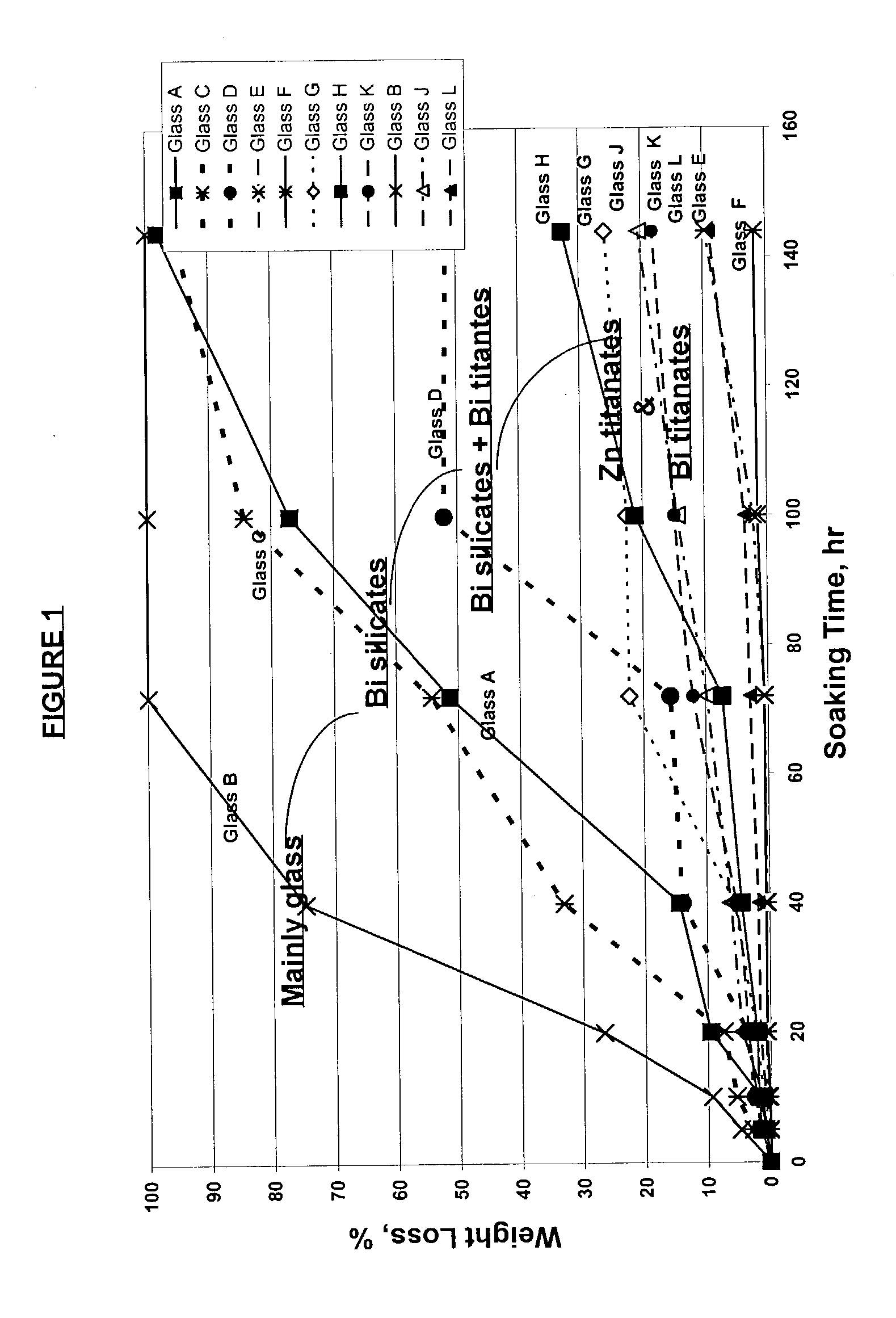

Durable glass enamel composition

The present invention provides partially crystallizing lead-free and cadmium-free glass enamel composition that fuse at low temperatures. Glass enamel compositions according to the present invention form predominantly bismuth titanate and optionally zinc titanate crystals upon firing. Preferably, glass enamel compositions according to the invention include a glass component that includes by weight from about 11% to about 52% SiO2, from 10.2% to about 40% TiO2, from about 5% to about 75% Bi2O3, up to about 8% B2O3, up to about 14% BaO+SrO, and up to about 45% by weight ZnO, where the sum of Bi2O3 and ZnO comprises from about 30% to about 85% of the glass component by weight.

Owner:FERRO CORP

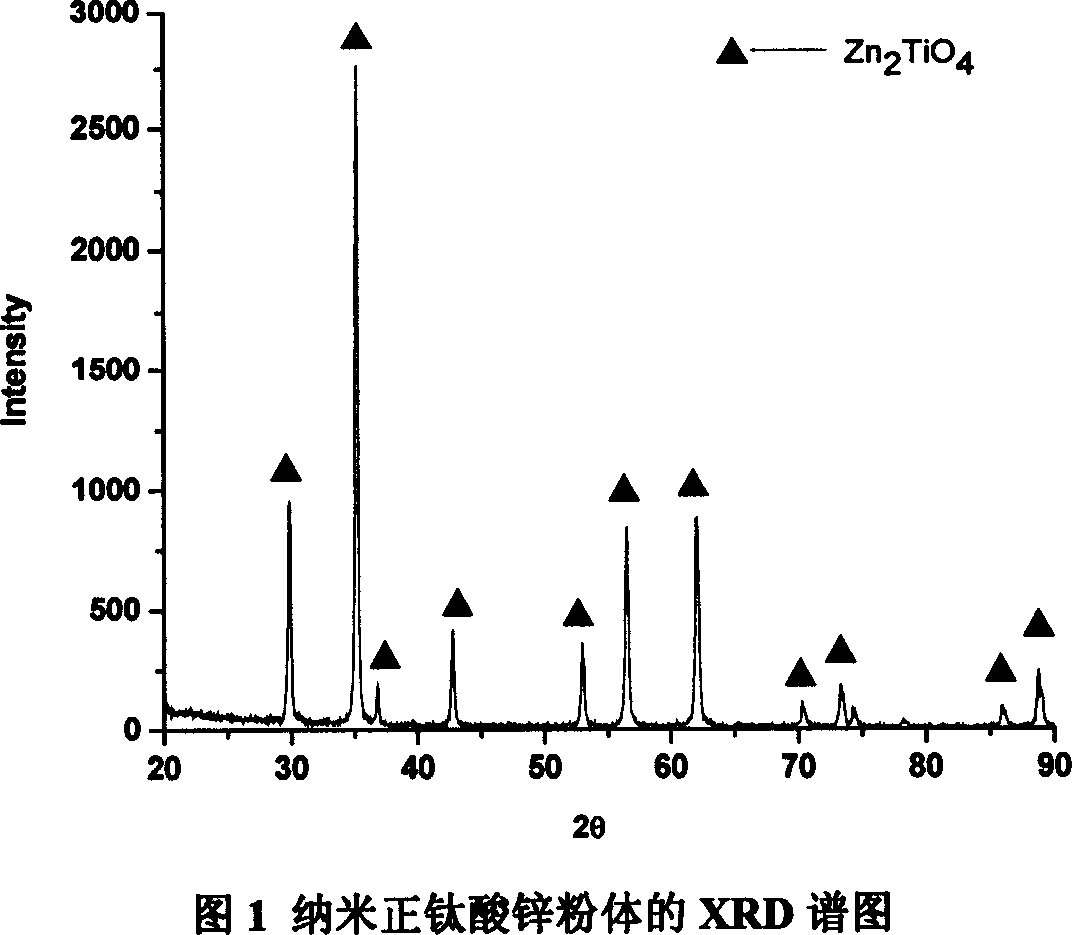

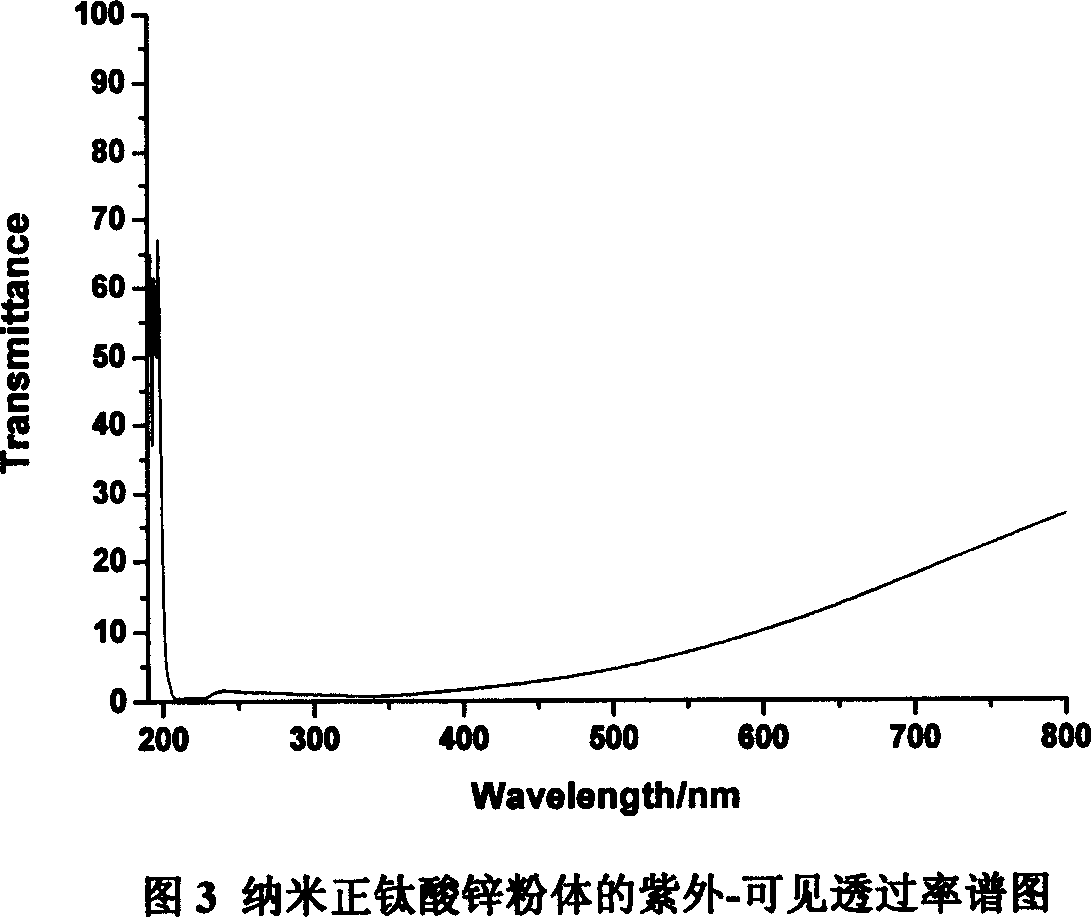

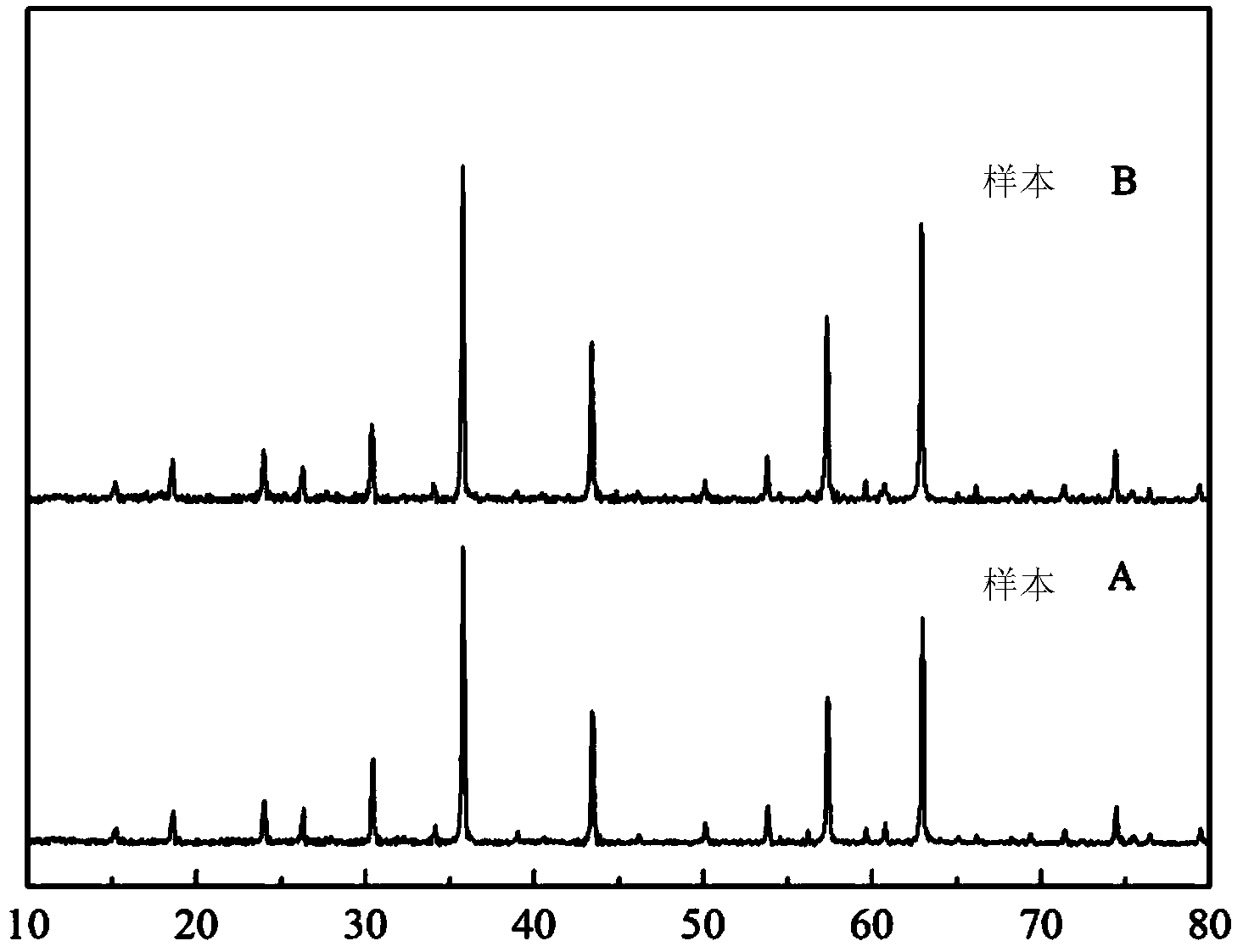

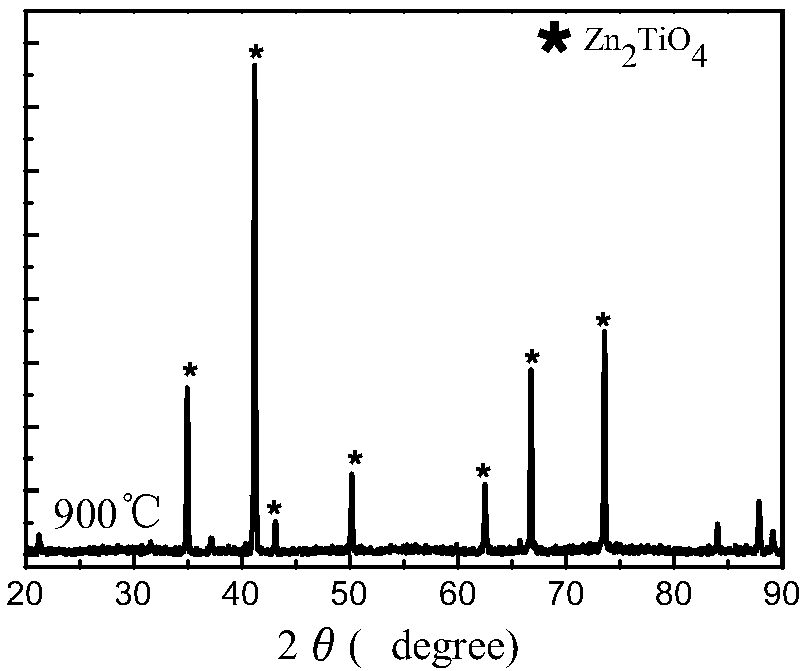

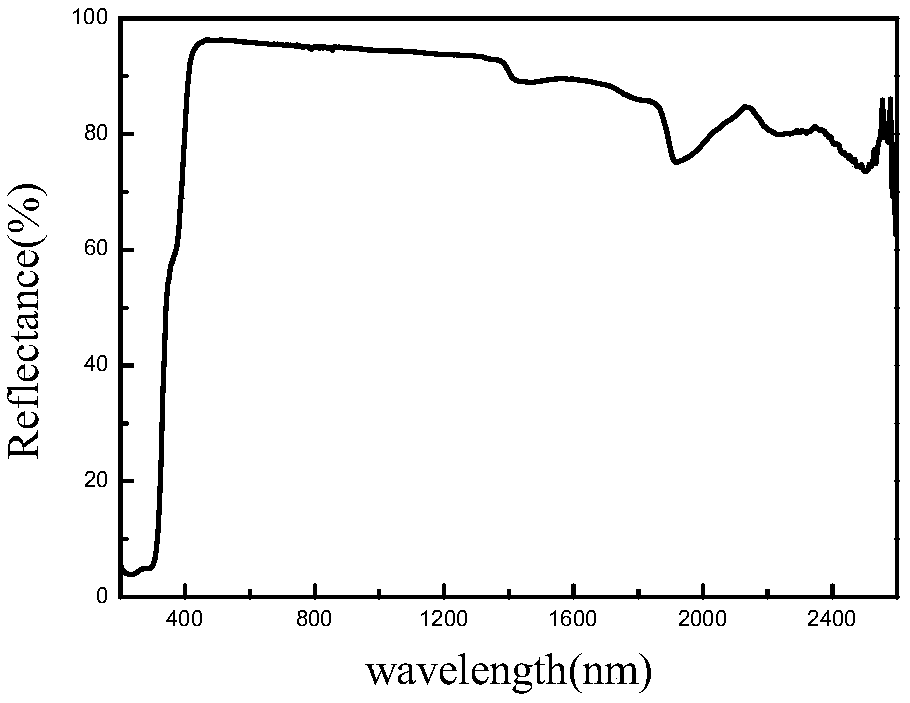

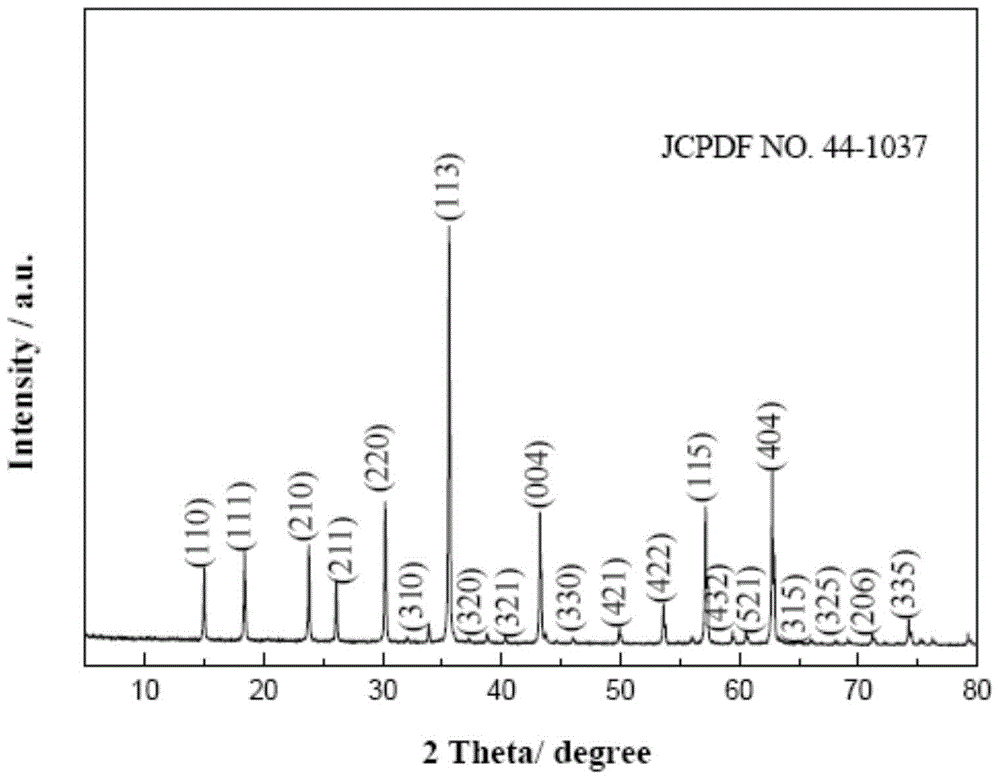

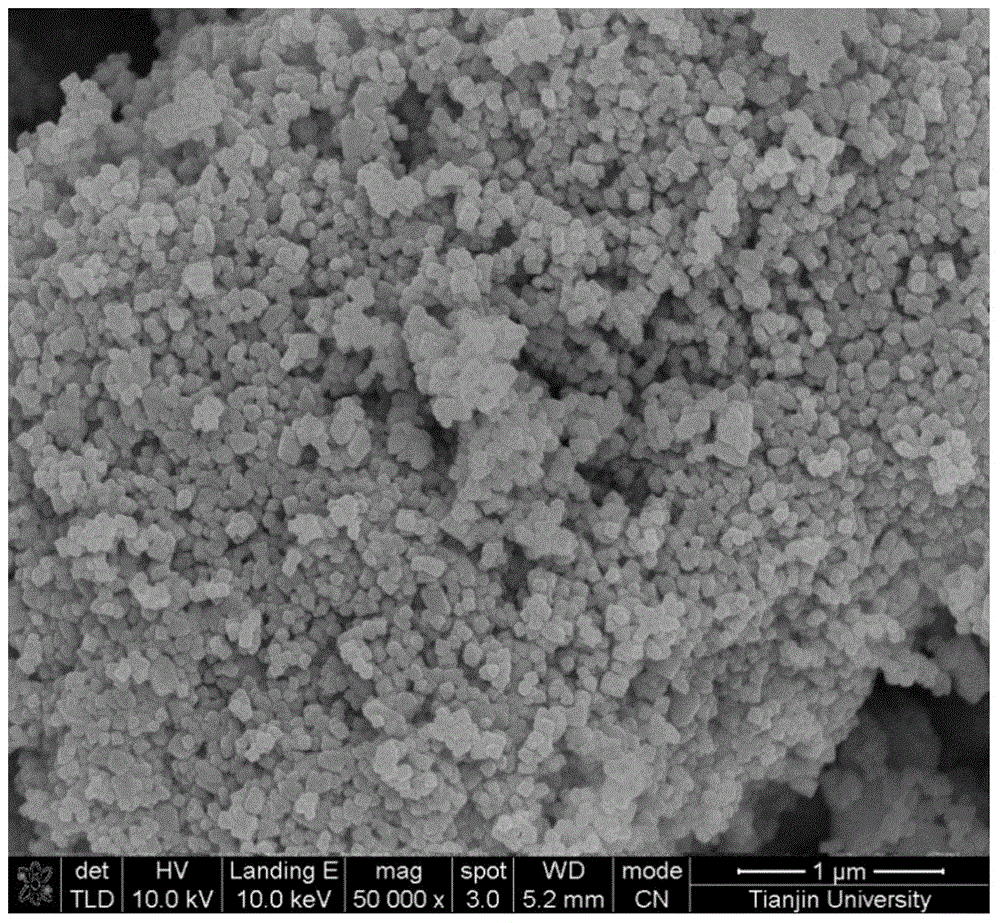

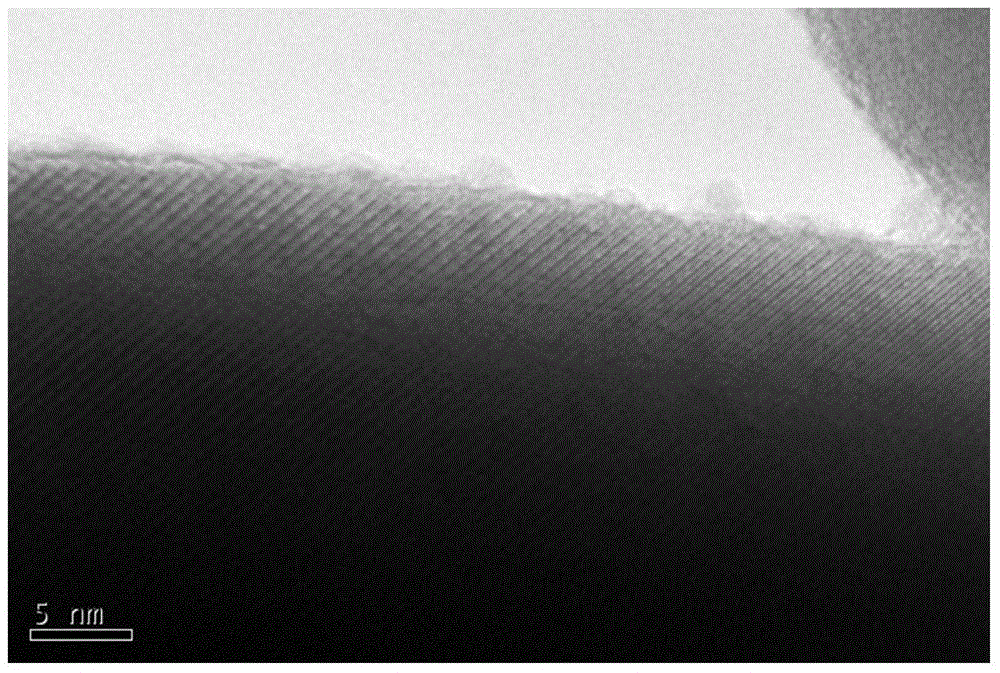

UV-shielding nano normal zinc titanate powder and process for preparing same

InactiveCN1884095AImprove shielding effectLow costCosmetic preparationsToilet preparationsSal ammoniacSulfate

The invention discloses a new ultraviolet nanometer screening titanate zinc powder and preparing method; which is characterized by the following: adopting industrial metatitanate, zinc sulfate as raw material to prepare TiOSO4 solution; blending TiOSO4 and ZnSO4; adding surface activist PEG400; utilizing ammonia as sedimenting agent to adjust system pH value to generate priority sedimentation; filtering; washing; drying; grinding; sintering to obtain Zn2TiO4 powder. The invention provides pure Zn2TiO4 analyzed by XRD phase with 70 nm for TEM observing grain size, which screens ultraviolet effectively by over 95 percent.

Owner:SICHUAN UNIV

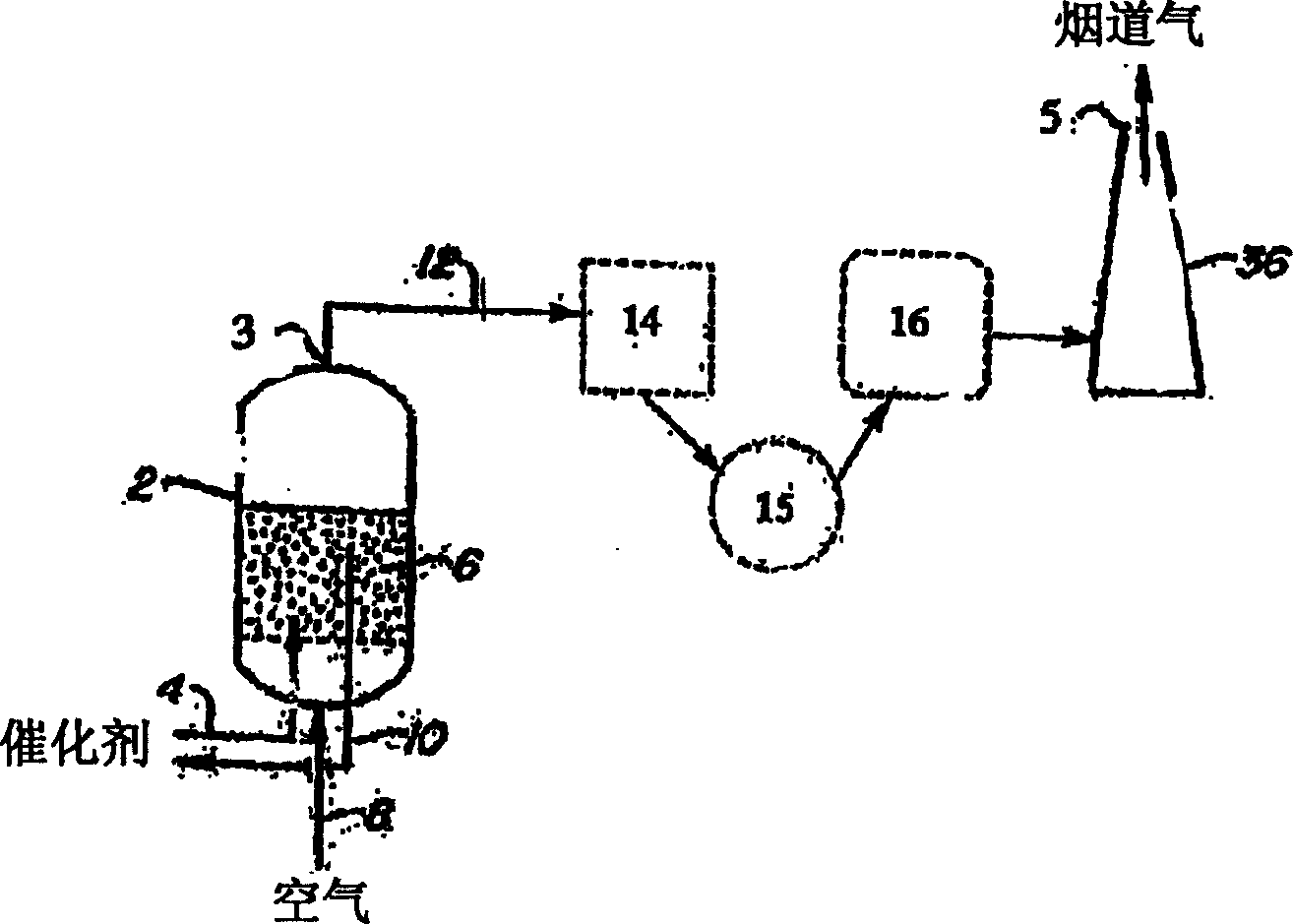

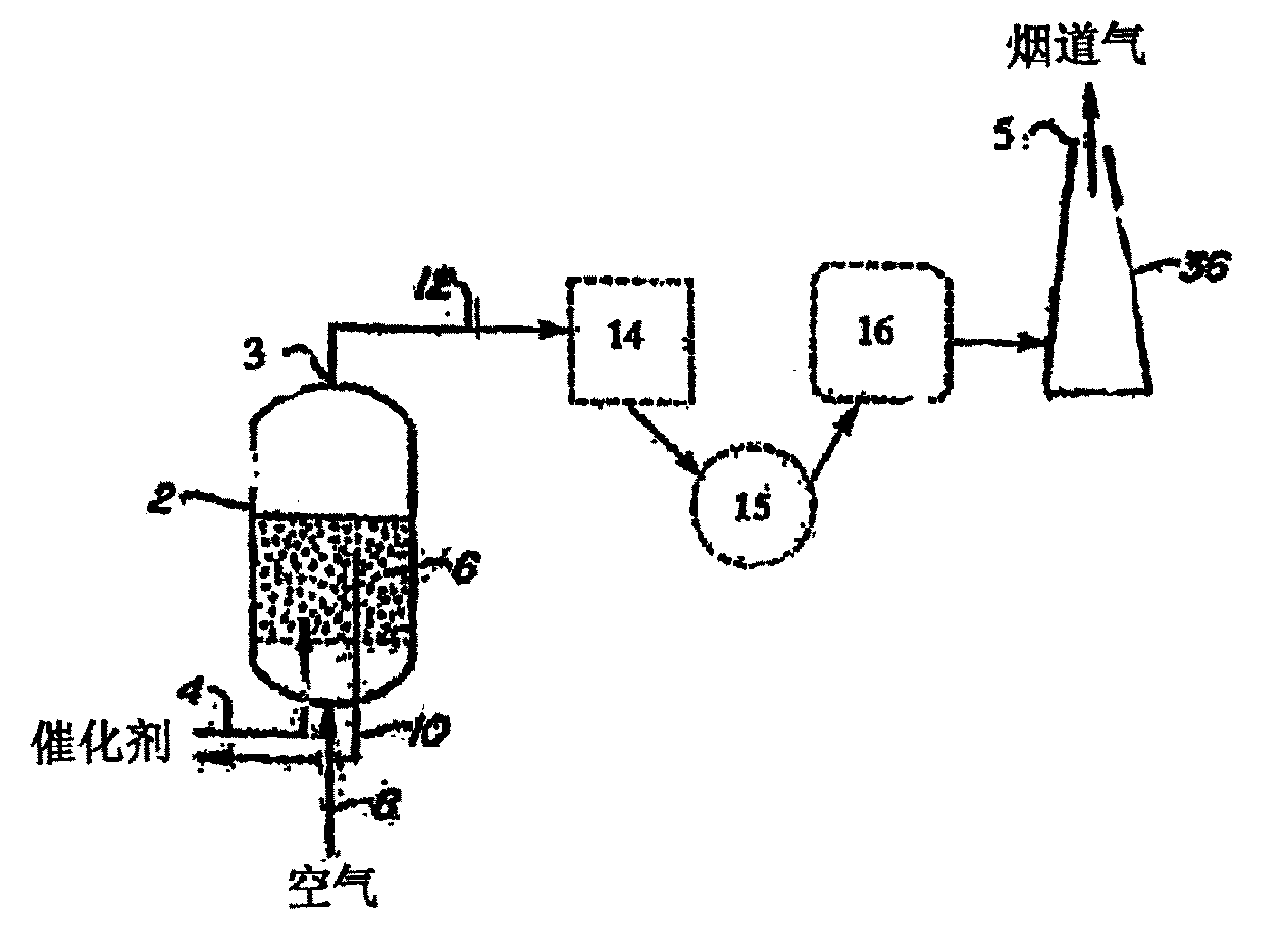

Desulfurization method and novel sorbents for same

InactiveCN1382201AOctane dropReduce hydrocarbon contentSolid sorbent liquid separationAlkali metal oxides/hydroxidesParticulatesSorbent

Provided is a particulate sorbent composition comprising a zinc titanate support loaded with a promoter metal in a substantially reduced valence state selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium, or mixtures thereof , for desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by contacting said feed stream in a desulfurization zone with a particulate adsorbent composition and then subjecting the resulting low sulfur content The stream is separated from the sulfided sorbent, which is then regenerated and activated before being recycled back to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Flue gas treatments to reduce NOx and CO emissions

The invention provides compositions and methods to reduce NOx emissions from the flue gas of a fluid catalytic cracking (FCC) unit (10). The invention also provides methods for reducing CO emissions from the regenerator (2) and / or the flue of an FCC unit. The compositions (4) of the invention comprise copper and / or cobalt and a carrier. The carrier can be, for example, hydrotalcite like compounds, spinels, alumina, zinc titanate, zinc aluminate, zinc titanate / zinc aluminate, and the like.

Owner:英特凯特公司

Attrition resistant, zinc titanate-containing, reduced sulfur sorbents and methods of use thereof

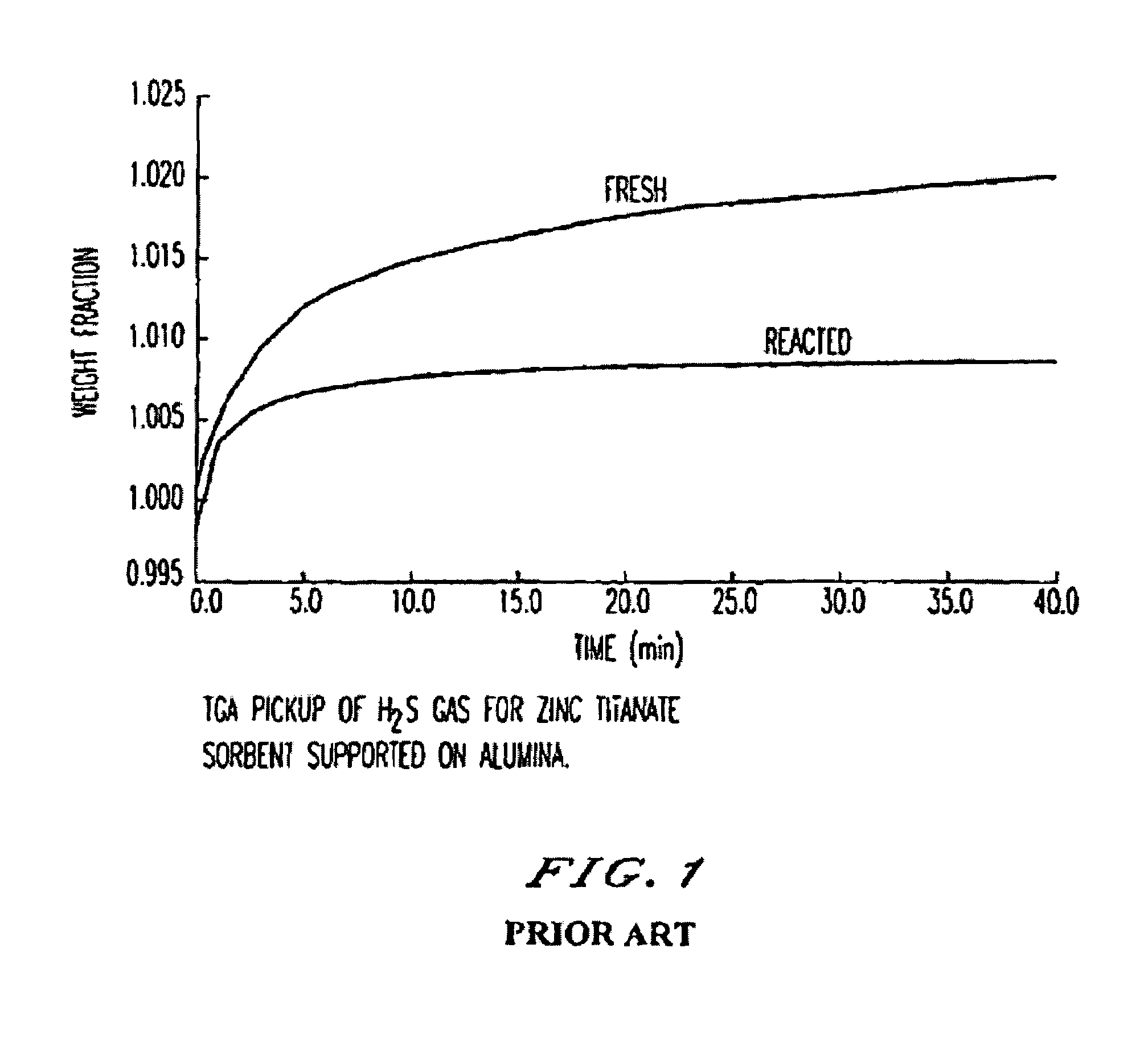

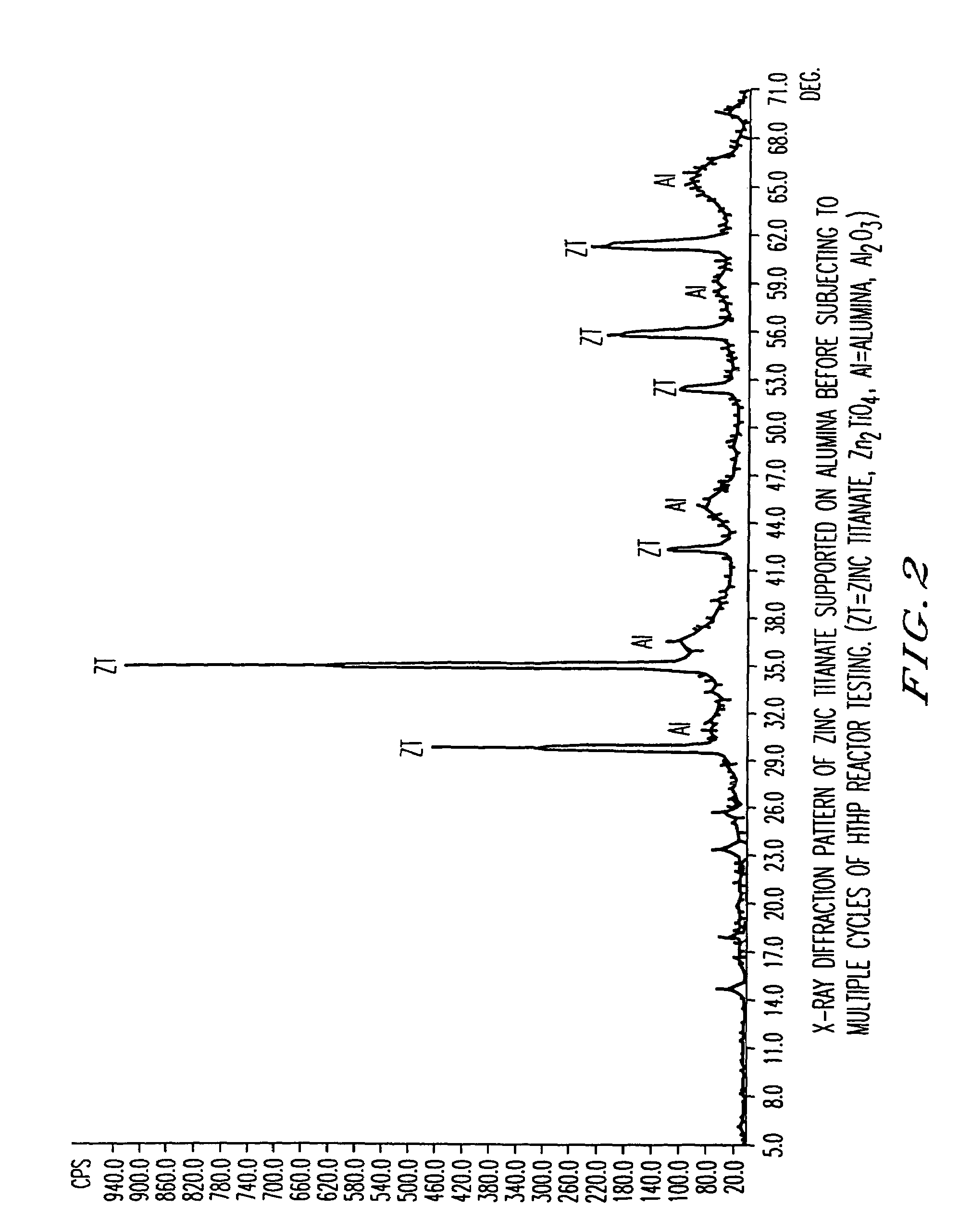

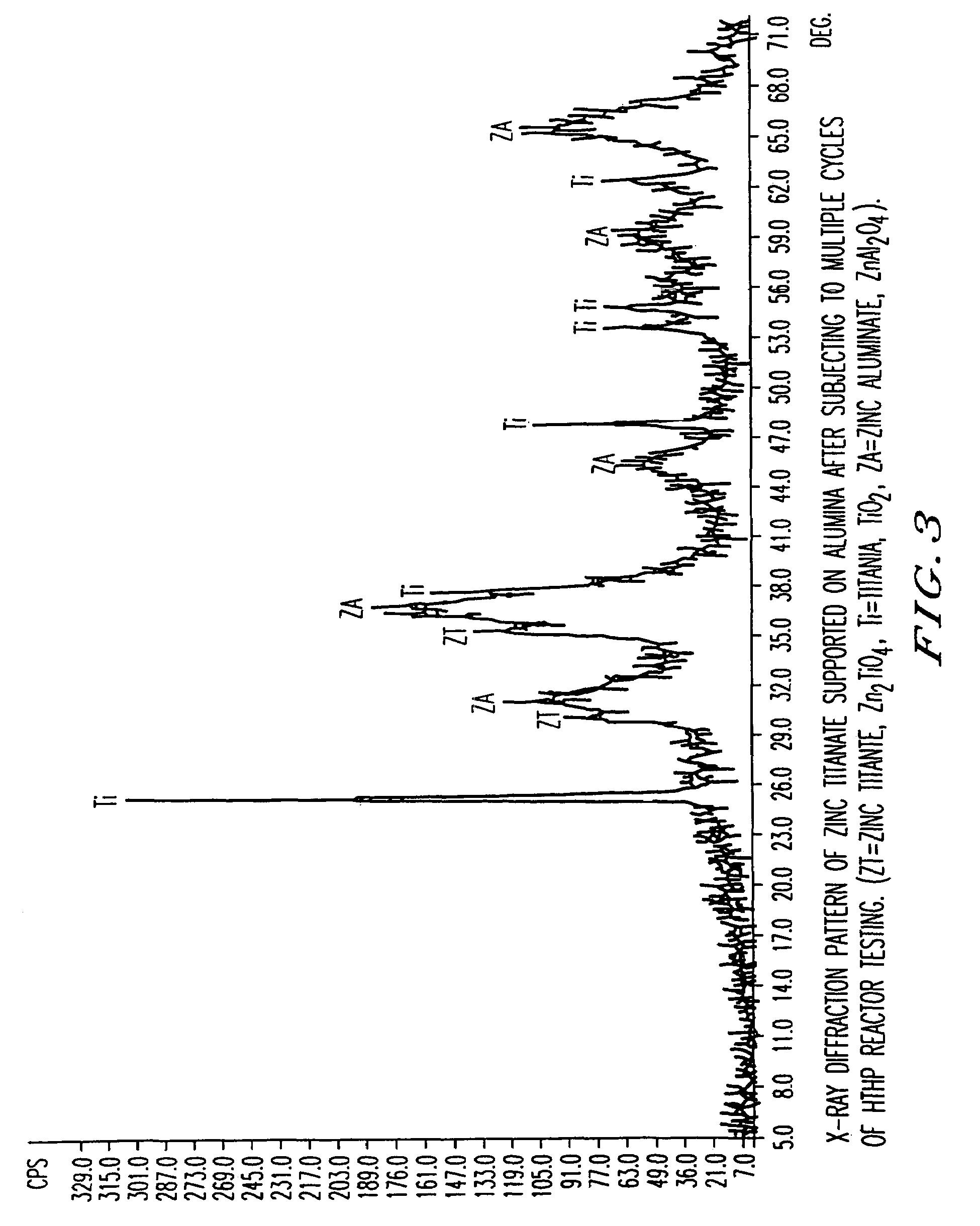

Reduced sulfur gas species (e.g., H2S, COS and CS2) are removed from a gas stream by compositions wherein a zinc titanate ingredient is associated with a metal oxide-aluminate phase material in the same particle species. Nonlimiting examples of metal oxides comprising the compositions include magnesium oxide, zinc oxide, calcium oxide, nickel oxide, etc.

Owner:RES TRIANGLE INST +1

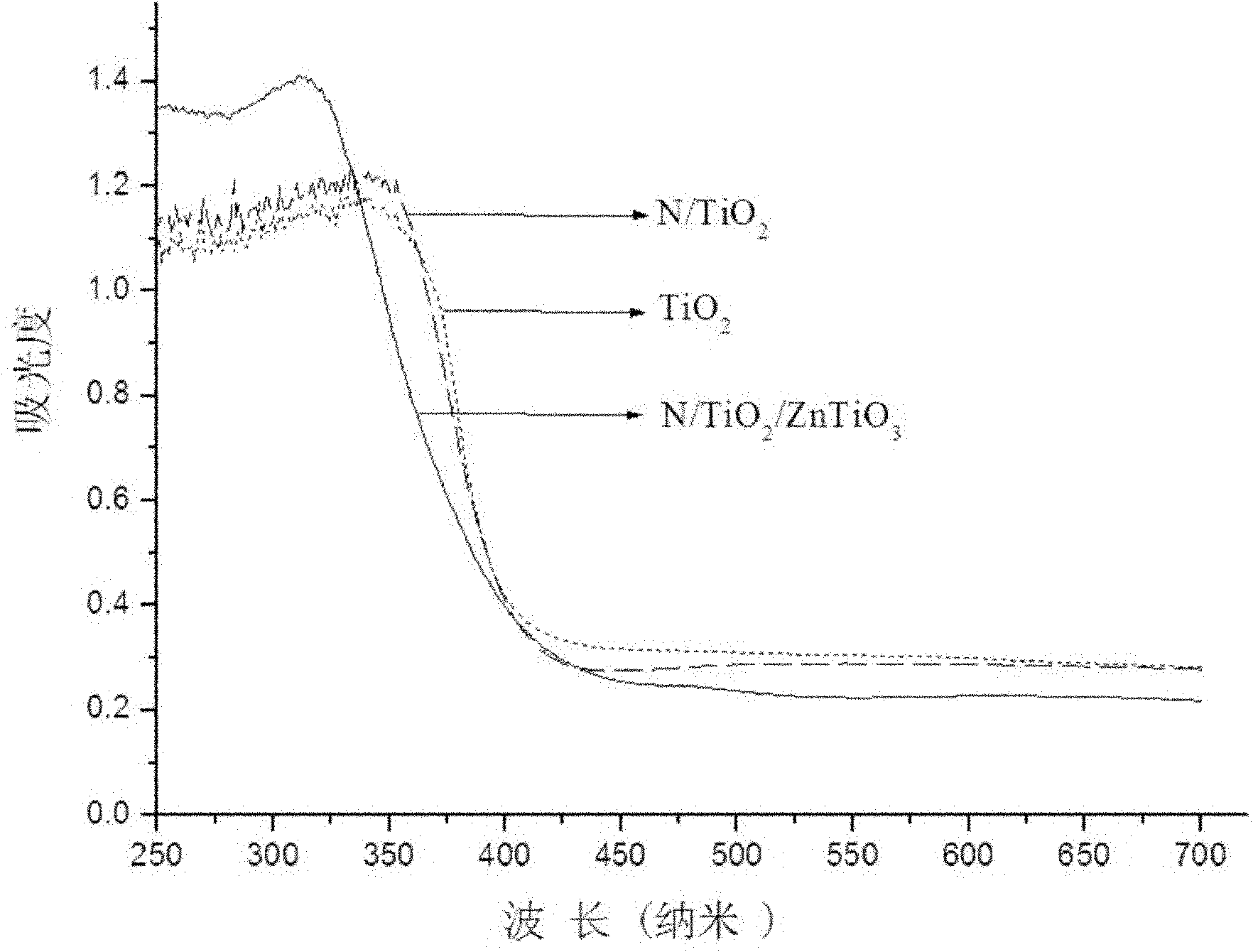

Preparation method of composite photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate

InactiveCN102139206AImprove surface propertiesMild reaction conditionsBiocideWater/sewage treatment by irradiationWater bathsSpectral response

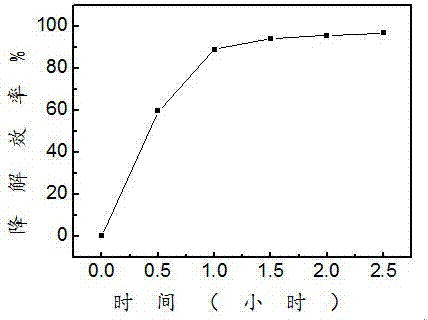

The invention relates to a preparation method of semiconductor composite antibacterial photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate, and belongs to the technical field of the treatment of environmental pollution. The semiconductor composite antibacterial photocatalyst is prepared a uniform coprecipitation method which comprises the following steps of: preparing a mixed solution in the amount-of-substance ratio of titanium sulfate to urea to zinc ions of 1:10:0; continuously mixing the mixed solution; raising the temperature of a water bath to 60 DEG C; adding a surfactant (sodium dodecyl benzene sulfonate) into the mixed solution based on the concentration of 20mg / 150ml; keeping a constant temperature for 0.5h; raising the temperature to 90-100 DEG C again; keeping the temperature for 3-6h; adding ammonia water into the solution to regulate to pH (potential of hydrogen) to be 6-8; washing and drying the obtained product; and forging the product at the temperature of 400-800 DEG C. The preparation method has the advantages of short process flow, simple equipment, simple and convenient operation, and low price of raw materials. The prepared semiconductor composite has the advantages of having good dispersibility, visible spectral response and low energy consumption, and is an environment-friendly antibacterial purification material.

Owner:WUHAN UNIV OF TECH

High-temperature-resistance zinc titanate/silicon dioxide protection material and preparation method therefor

ActiveCN102587039AGood flexibilityBend freelyFilament/thread formingHeating/cooling textile fabricsFiberDecomposition

The invention discloses a preparation method for a high-temperature-resistance zinc titanate / silicon dioxide protection material and the protection material obtained through the method. The preparation method is characterized in that: the specific steps includes adding template polymers into solvent to obtain template polymer solution, mixing organic silicon or nanometer silicon dioxide, water and inorganic acid to obtain silicon source solution, uniformly mixing the template polymer solution and the silicon source solution to obtain spinning solution A, mixing titanium isopropoxy, zinc acetate and ethanol and adding template polymers to the mixture to obtain spinning solution B, performing electrostatic spinning for the spinning solution A and the spinning solution B to obtain a composite fiber membrane, and burning the composite fiber membrane to obtain the high-flexibility and high-temperature-resistance zinc titanate / silicon dioxide protection material. The protection material can serve as a protection material efficient-decomposition biochemical reagent under the high-temperature condition, and the decomposition ratio of paraoxon in simulation agent of the biochemical reagent is 80-95% in 10 minutes.

Owner:嘉兴富瑞邦新材料科技有限公司

Durable glass enamel composition

The present invention provides partially crystallizing lead-free and cadmium-free glass enamel composition that fuse at low temperatures. Glass enamel compositions according to the present invention form predominantly bismuth titanate and optionally zinc titanate crystals upon firing. Preferably, glass enamel compositions according to the invention include a glass component that includes by weight from about 11% to about 52% SiO2, from 10.2% to about 40% TiO2, from about 5% to about 75% Bi2O3, up to about 8% B2O3, up to about 14% BaO+SrO, and up to about 45% by weight ZnO, where the sum of Bi2O3 and ZnO comprises from about 30% to about 85% of the glass component by weight.

Owner:FERRO CORP

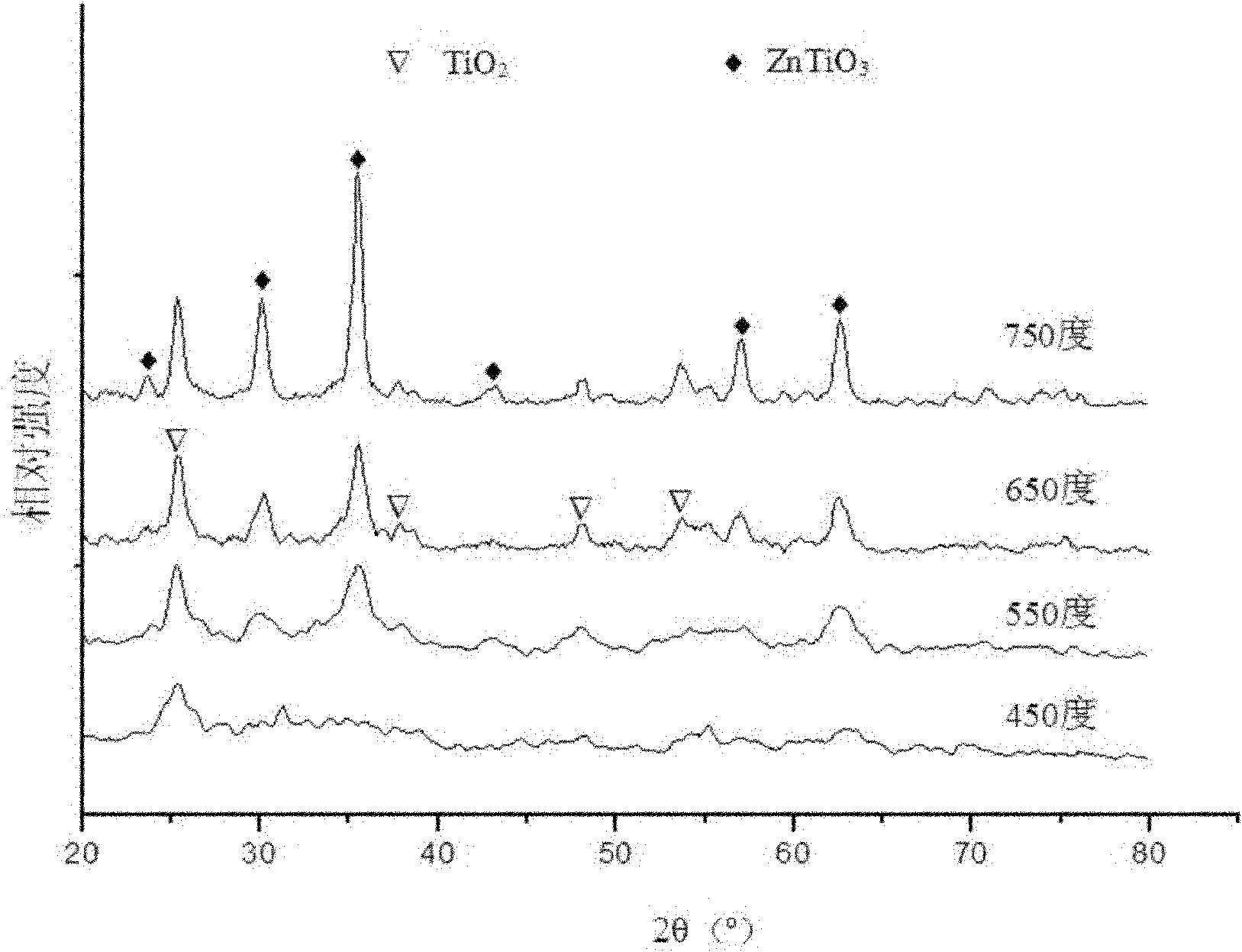

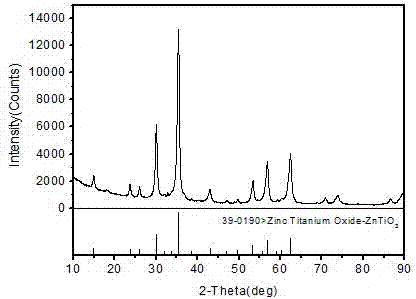

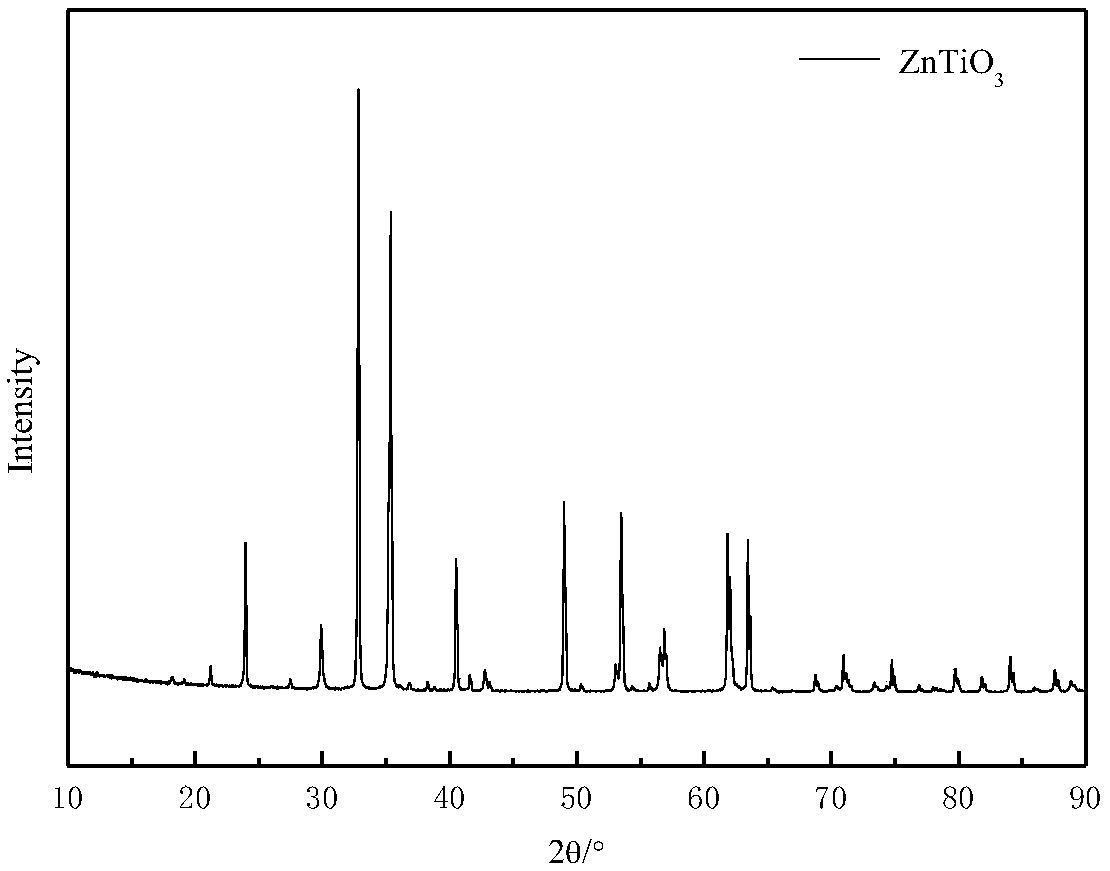

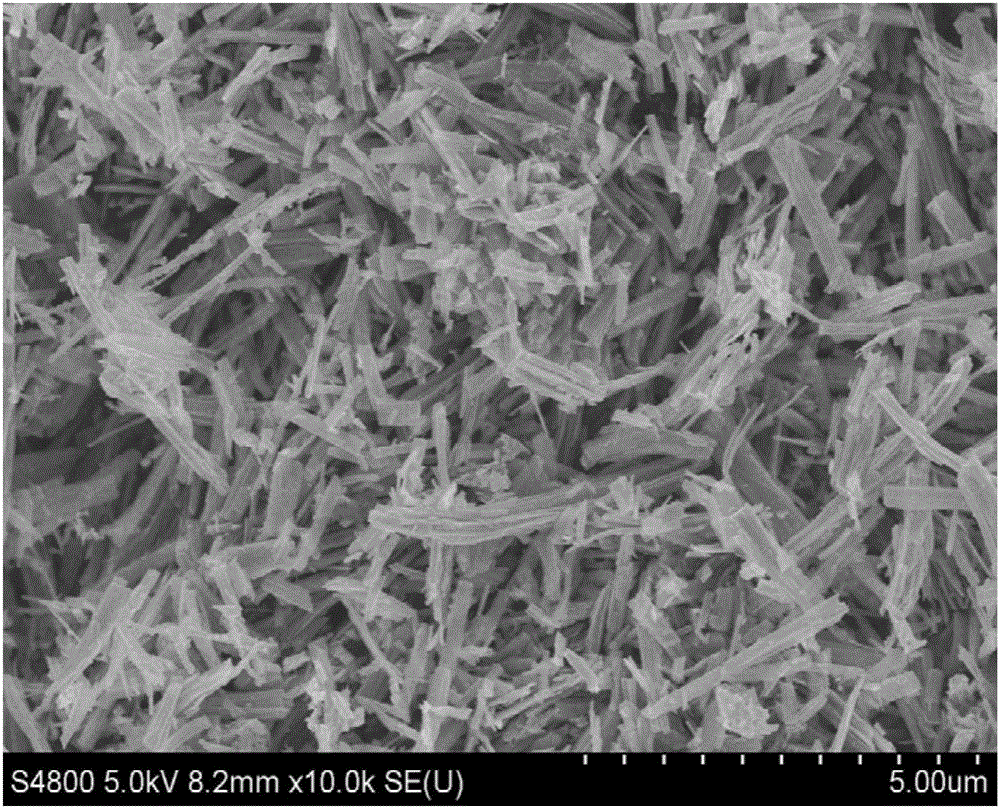

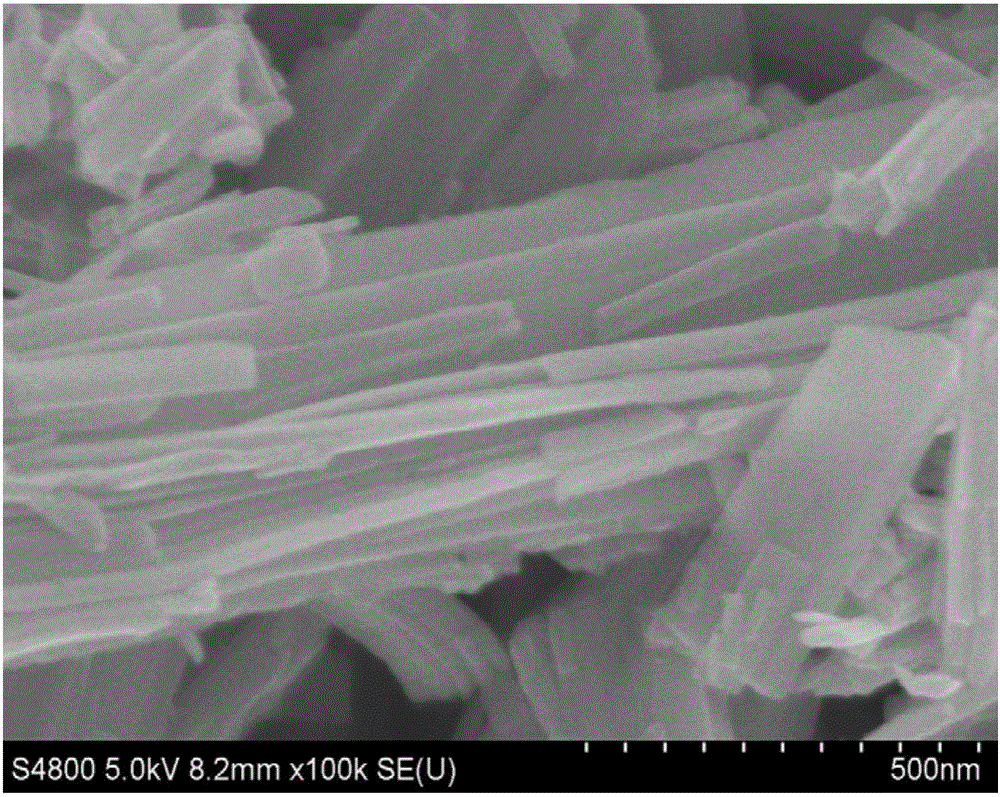

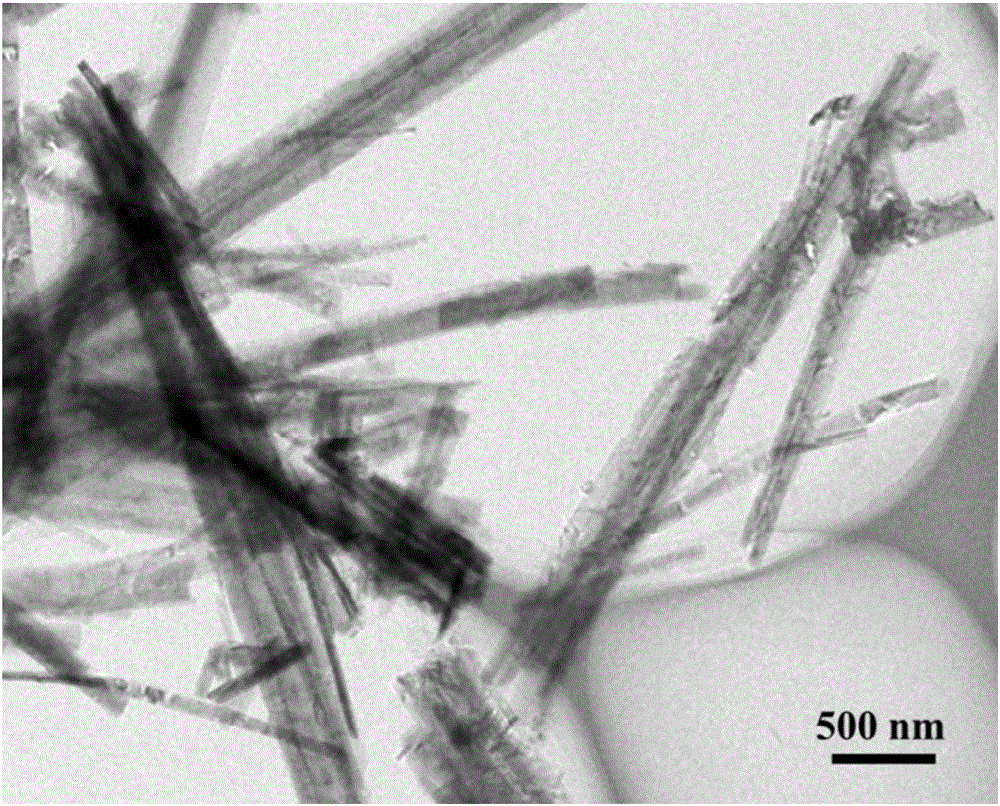

Preparation method for zinc titanate photocatalytic material with special morphology

ActiveCN107098381AControl shapeSmall particle sizeMaterial nanotechnologyTitanium compoundsCentrifugationZinc titanate

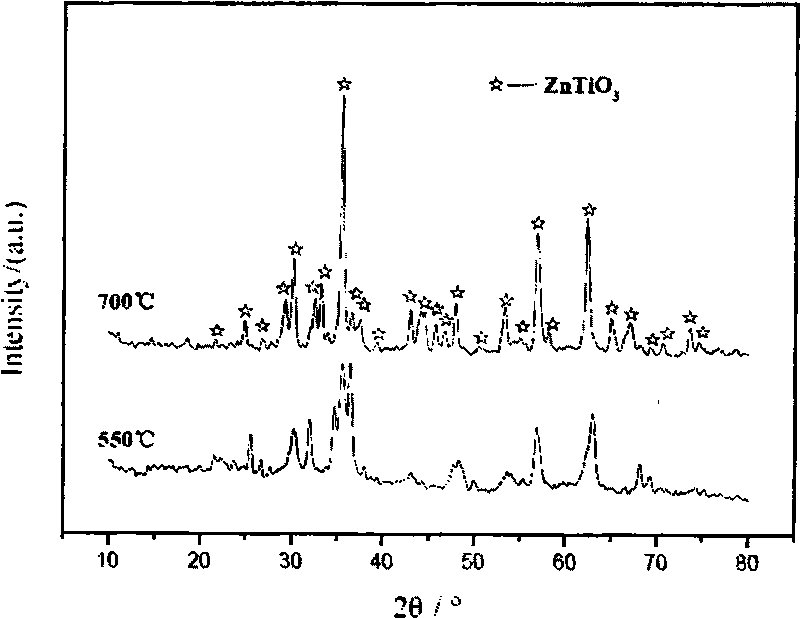

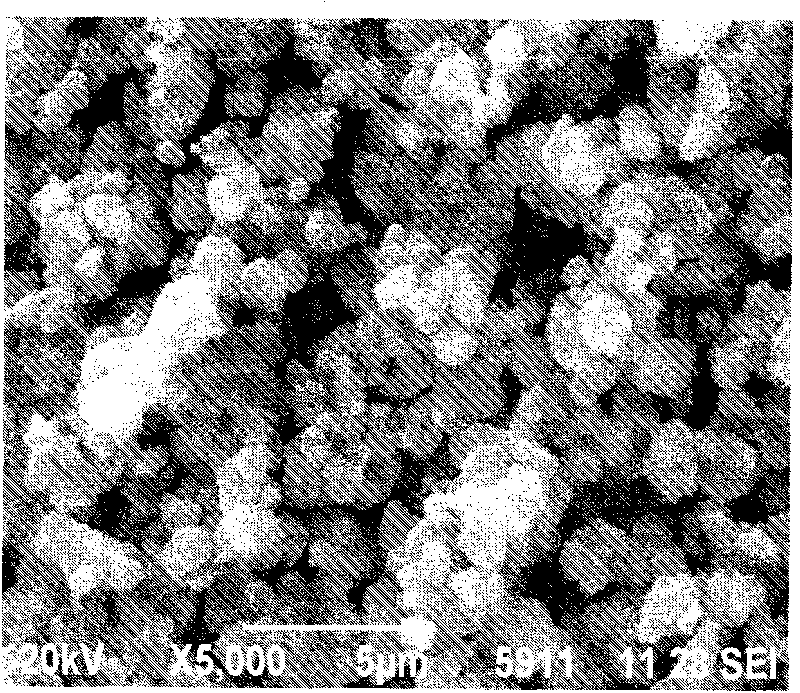

The invention provides a preparation method for a photocatalytic material ZnTiO3 with special morphology. The preparation method comprises the following steps: 1) separately preparing a surfactant solution, a Zn source solution and a Ti source solution with specific concentrations and uniformly mixing the Zn source solution with the Ti source solution; 2) with the surfactant solution as mother liquor, slowly adding a mixed solution and a precipitating agent into the mother liquor drop by drop, controlling the temperature and acid-base value of a reaction system, and carrying out intense stirring so as to produce a ZnTiO3 precursor suspension; and 3) subjecting the suspension to centrifugation, washing and drying successively and then carrying out calcining in the air so as to obtain the ZnTiO3photocatalytic material with special morphology. The synthetic method provided by the invention is low in temperature, energy-saving and free of secondary pollution; and the synthesized photocatalytic material has the characteristics of uniform particle size, unified morphology, excellent performance, etc. The preparation method for the photocatalytic material ZnTiO3 with special morphology belongs to the field of photocatalytic materials.

Owner:HARBIN UNIV OF COMMERCE

Self-cleaning water-resistant paint and preparation method thereof

InactiveCN105153861AImprove heat resistanceImprove stain resistanceCoatingsZinc titanateWater resistant

The invention provides a self-cleaning water-resistant paint which is composed of a modified acrylate emulsion, water, a mineral filler, a nano photocatalyst and a chemical additive, wherein the mineral filler comprises cellular quartz powder, calcined kaolin and pyrauxite; the photocatalyst comprises doped nano titanium oxide powder, doped nano zinc oxide powder, nano zinc titanate powder, nano bismuth titanate powder and graphene; and the chemical additive comprises a thickener, a waterproofing agent, a dispersing agent, a plasticizer, a defoaming agent, a preservative and a film formation assistant. Thus, the paint has the advantages of high binding force, favorable water resistance and favorable self-cleaning capacity.

Owner:宁波申泰干粉建材有限公司

Cobalt doped niobium zinc titanate microwave dielectric ceramics and preparation method thereof

InactiveCN102815944AImprove performanceLower sintering temperatureCeramicsNiobiumDielectric ceramics

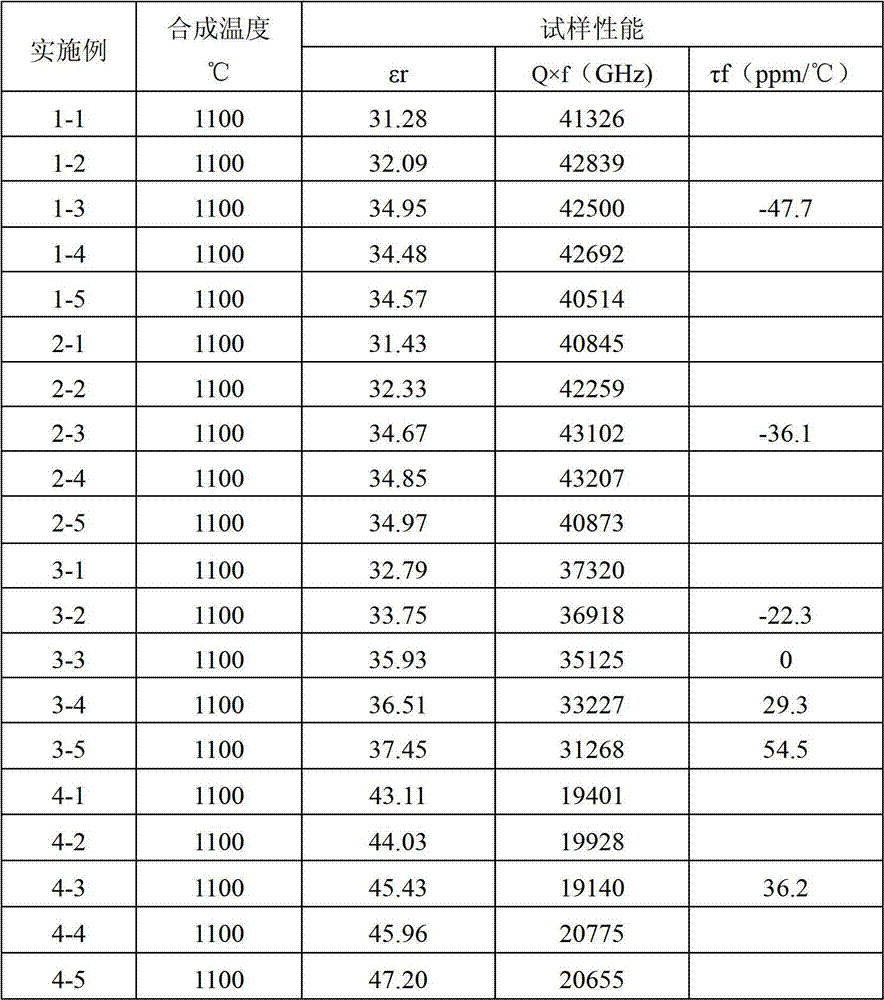

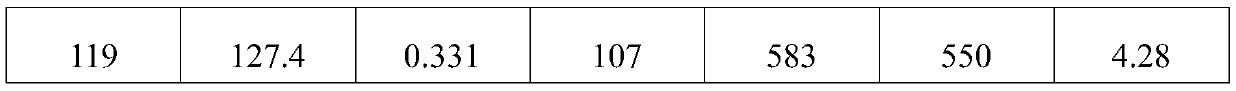

The invention discloses cobalt doped niobium zinc titanate microwave dielectric ceramics and a preparation method thereof. The dielectric ceramics comprise the following component by mole percentage: (Zn1-xCox)TiNb2O8, wherein x is greater than 0 and smaller than or equal to 0.40. In the invention, ZnTiNb2O8 system microwave dielectric ceramics are adopted as the basis. A traditional oxide mixing method is employed, and Co2O3 is added for doping modification, thus obtaining the (Zn0.7Co0.3)TiNb2O8 microwave dielectric ceramic material with good comprehensive performance. The provided microwave ceramics have a relatively low sintering temperature and good comprehensive performance. When the sintering temperature is 1075DEG C, epsilon r=35.93, Q*f=35125GHz, and tau f=0ppm / DEG C. The microwave dielectric ceramics provided in the invention are mainly used in MLCC ceramic devices co-fired with base metal inner electrodes at a low temperature.

Owner:TIANJIN UNIV

Carbon nanofiber/zinc titanate composite for personal protection and production method of carbon nanofiber/zinc titanate composite for personal protection

InactiveCN102560890ALarge specific surface areaImprove adsorption capacityHeating/cooling textile fabricsNon-woven fabricsSpinningTitanium isopropoxide

The invention discloses a production method of carbon nanofiber / zinc titanate composite for personal protection, and the composite obtained by the production method. The production method is characterized by including the steps of: adding titanium isopropoxide and zinc acetate into ethanol solvent, and adding polyvinylpyrrolidone to obtain spinning dope A; adding polyacrylonitrile into N, N-dimethyl formamide solvent to obtain spinning dope B; subjecting the spinning dope A and the spinning dope B to electrostatic spinning to obtain composite fibrous membranes; and allowing the drawn composite fibrous membranes to stand in air to be pre-oxidized, and carbonizing the membranes under nitrogen protection. The carbon nanofiber / zinc titanate composite has the advantages of light weight, high rate of biochemical disintegration, and fine mechanical properties.

Owner:DONGHUA UNIV

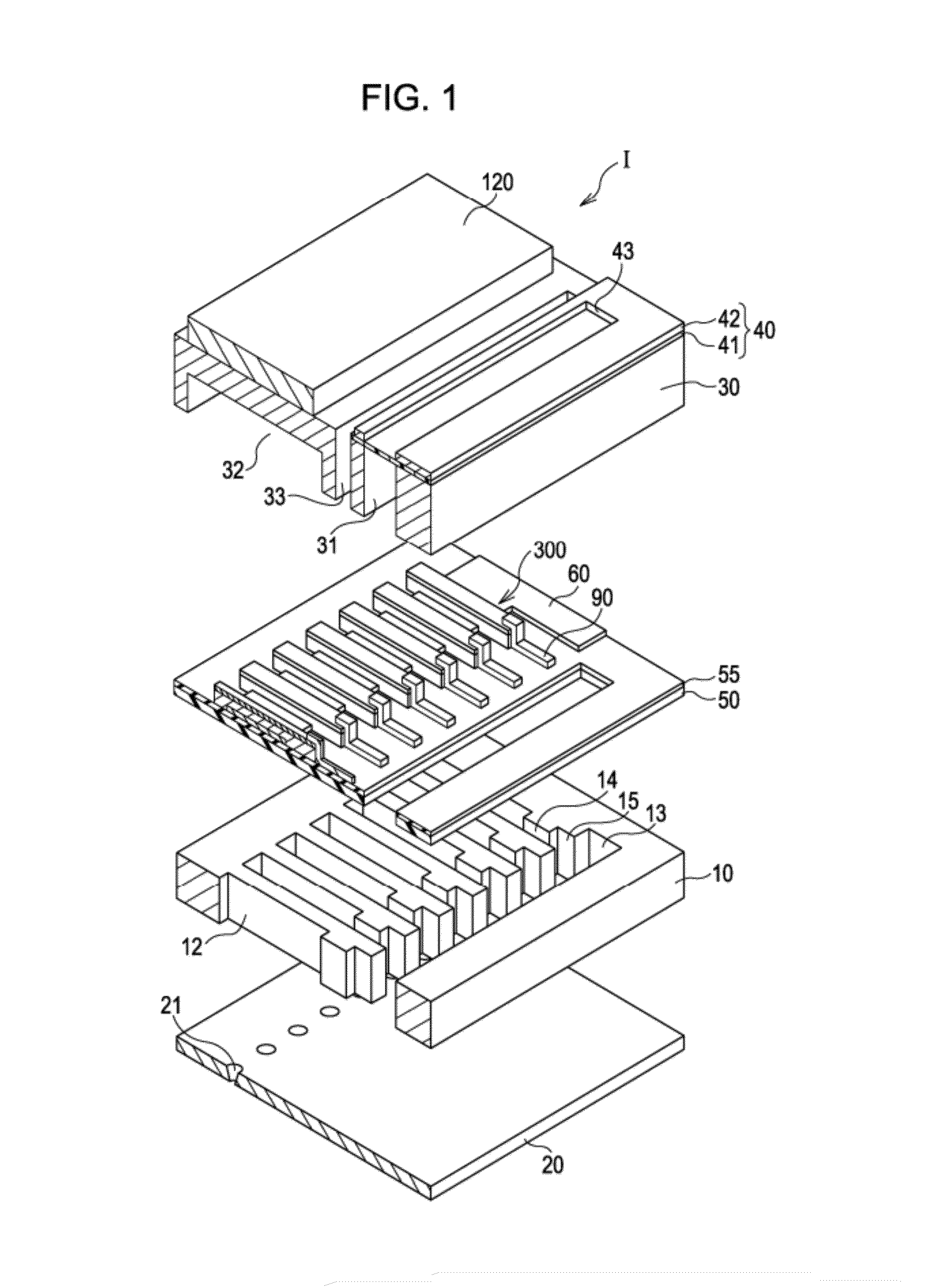

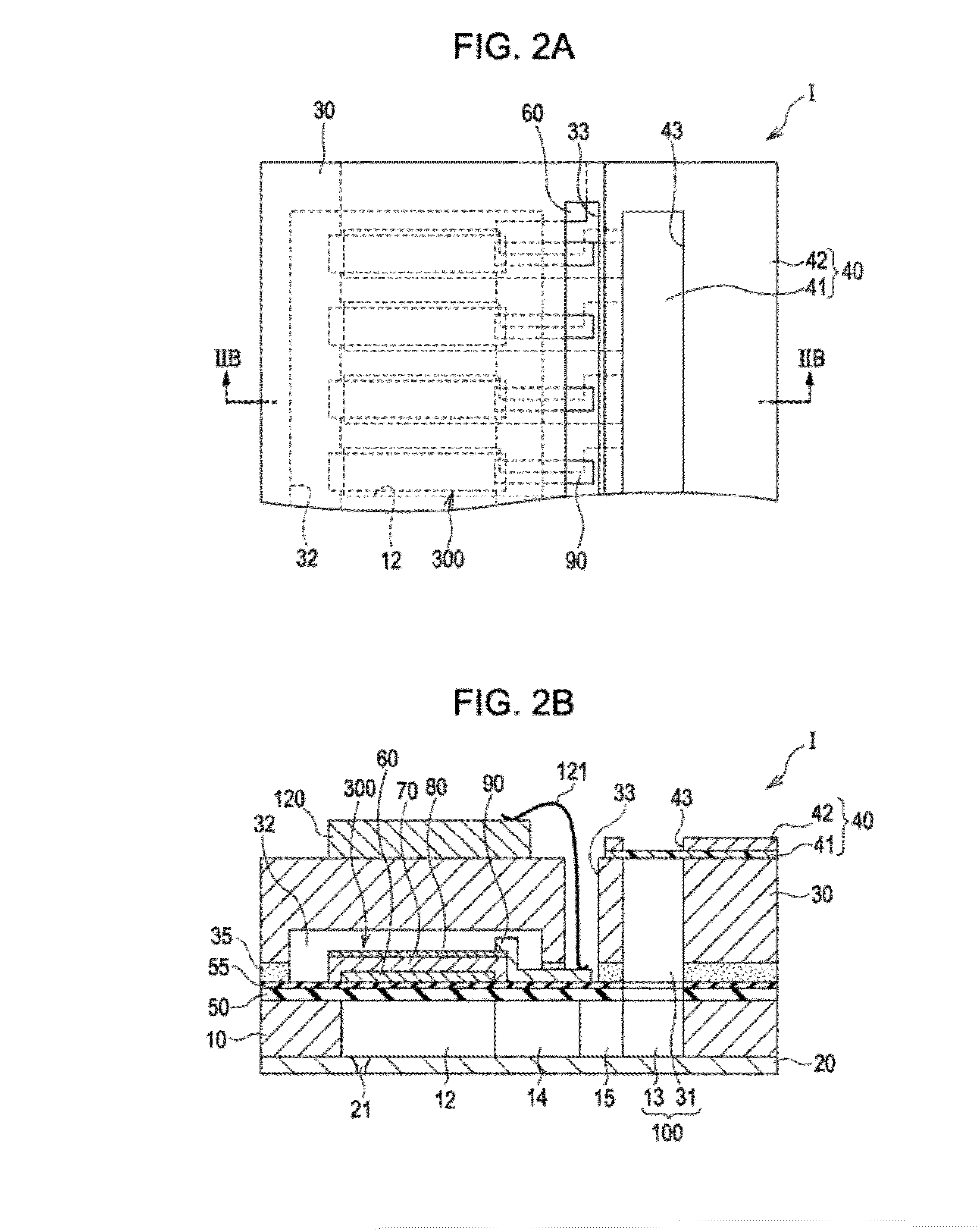

Piezoelectric element, liquid ejecting head, and liquid ejecting apparatus

InactiveUS20120217430A1Low environmental burdenPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusBarium titanateZinc titanate

Owner:SEIKO EPSON CORP

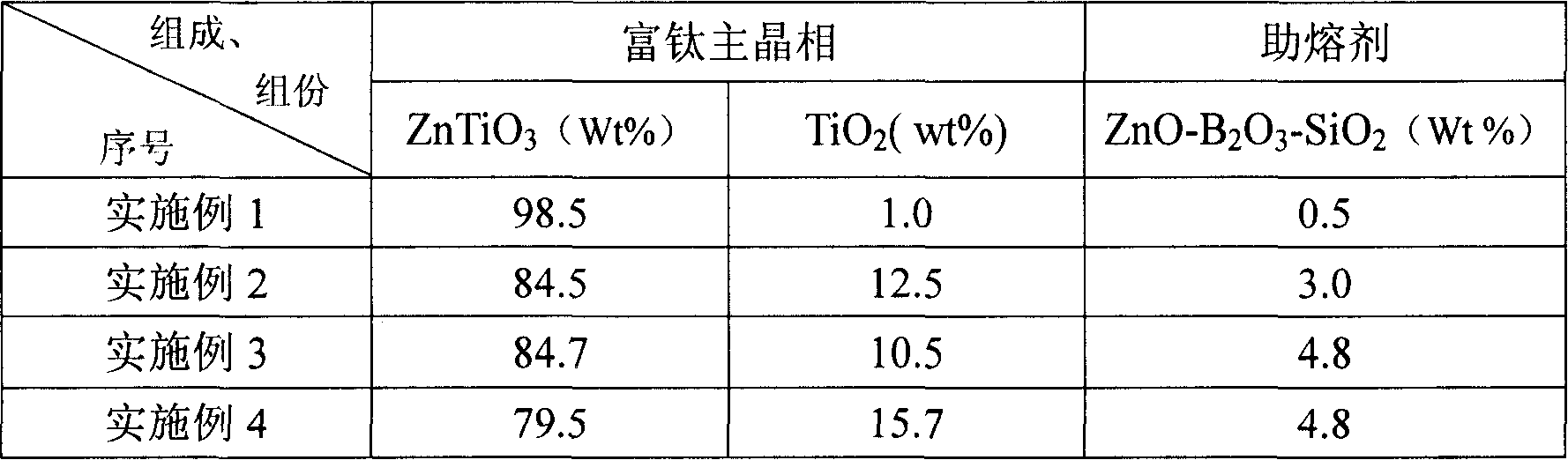

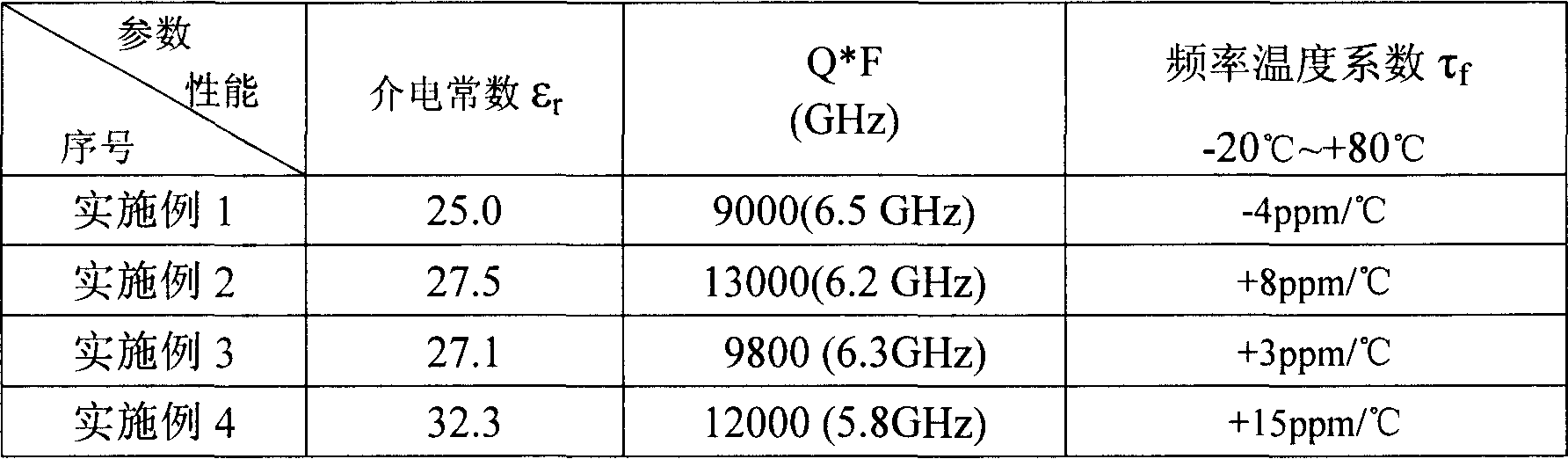

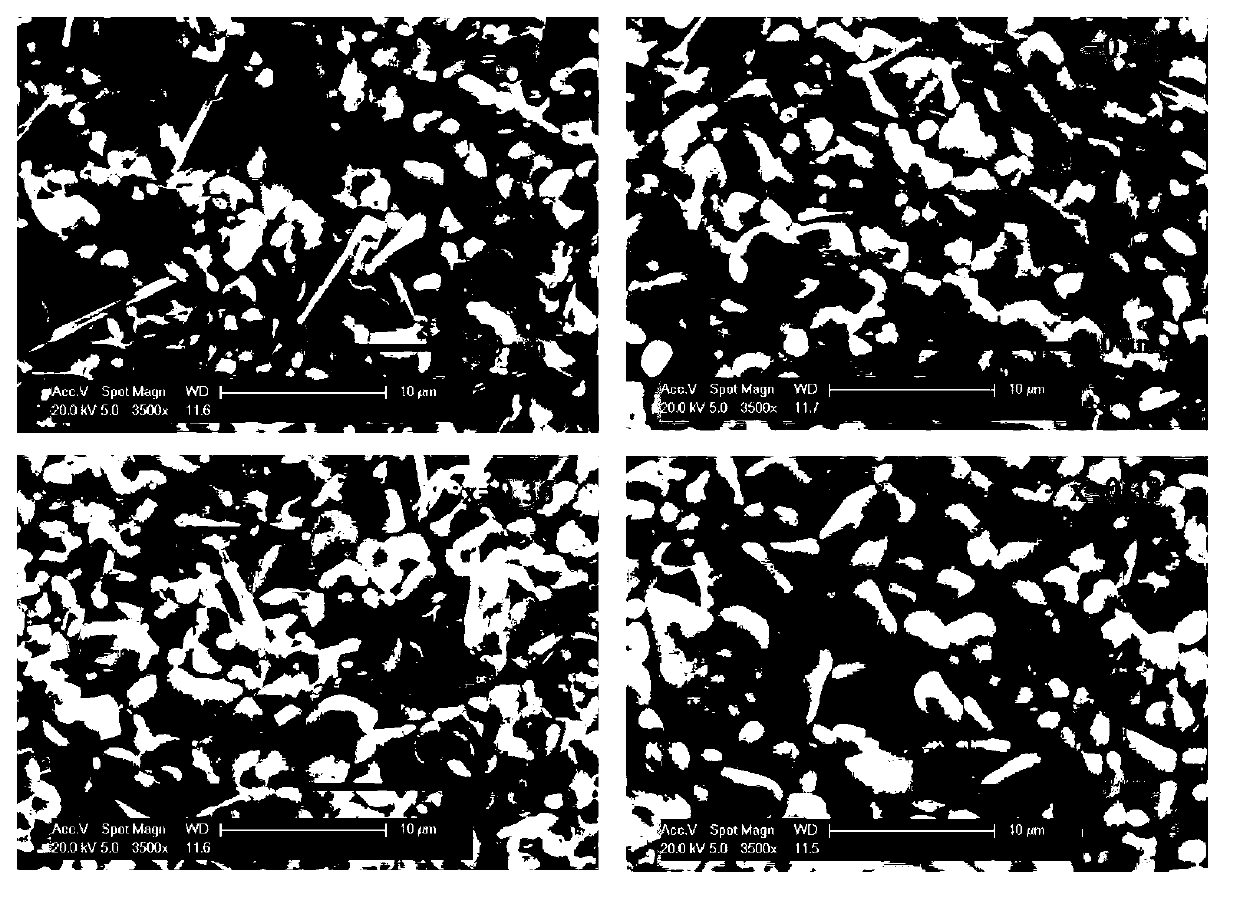

ZnO-TiO2 series low-temperature co-burning ceramic material and preparation method thereof

Owner:JIAXING GLEAD ELECTRONICS CO LTD

Microwave dielectric ceramics doped with cobalt oxide and niobium zinc titanate

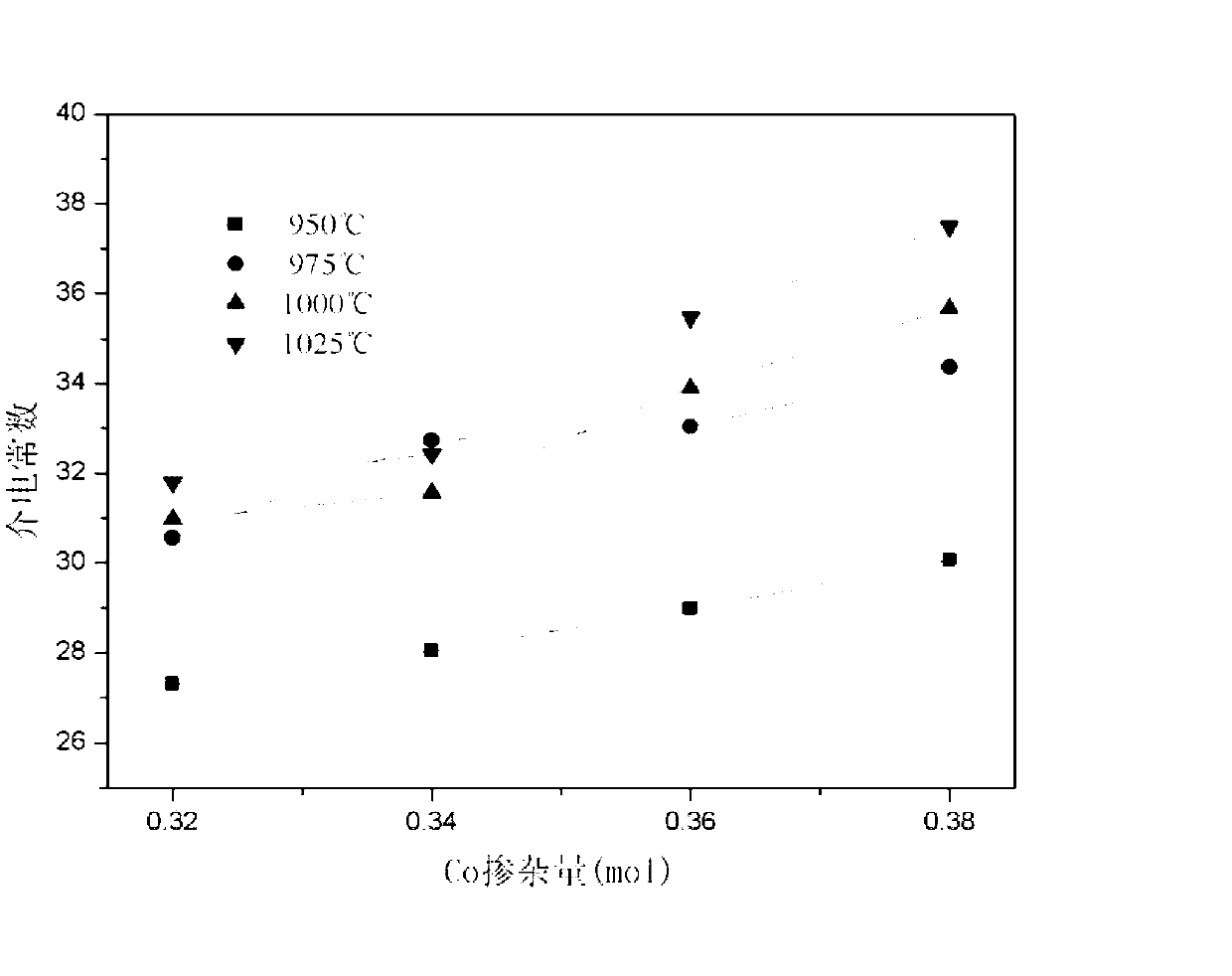

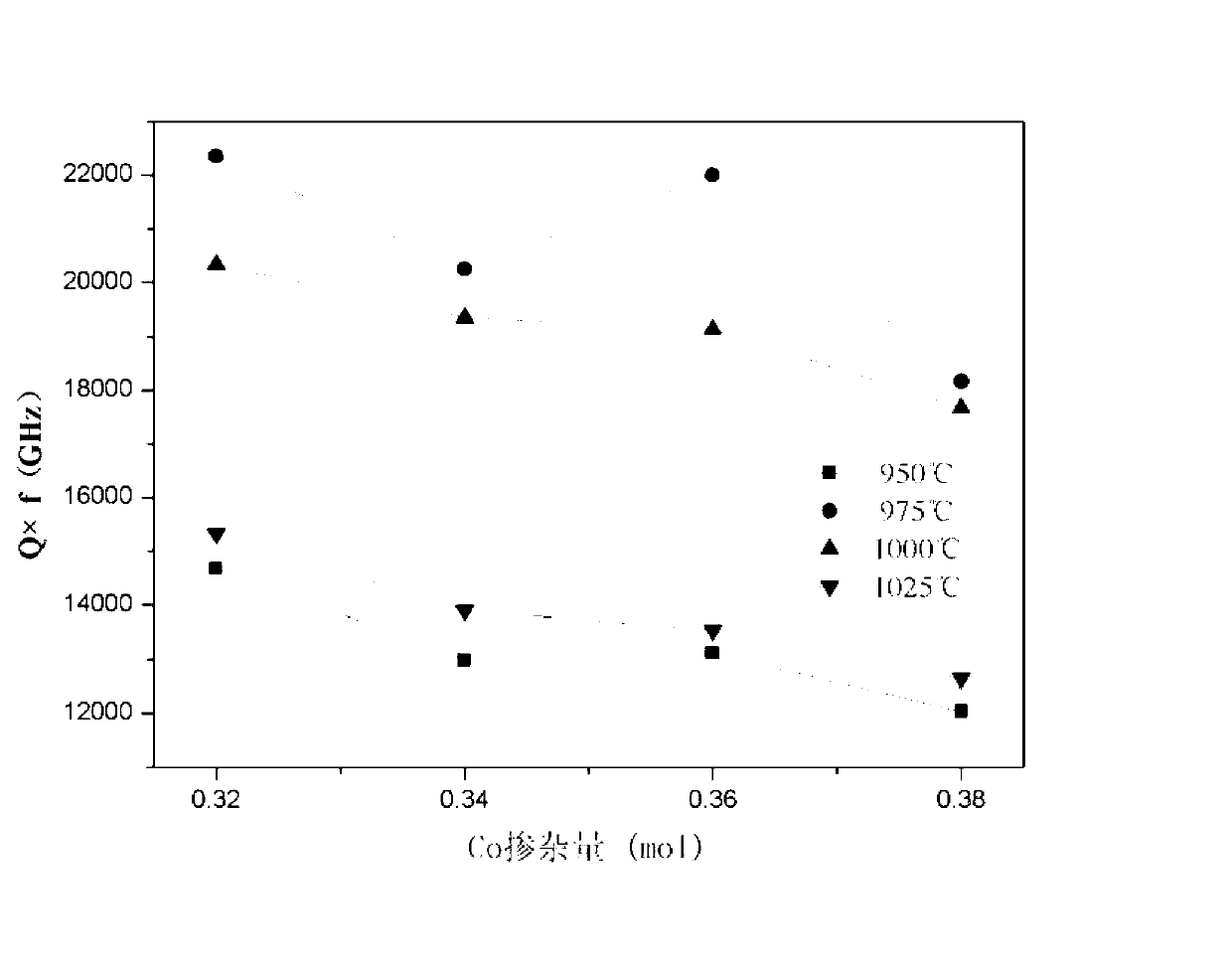

The invention discloses a microwave dielectric ceramics doped with Co2O3 (cobalt oxide) and niobium zinc titanate and a preparation method of the microwave dielectric ceramics. The chemometry formula is (Zn1-xCox) TiNb2O8-1 wt. % BaCu (B2O5); BaCu (B2O5) is BCB for short; in the formula, x is equal to 0.32-0.38. The (Zn1-xCox) TiNb2O8-1wt. % BCB microwave dielectric ceramics with a good comprehensive performance is prepared by the step of adding Co2O3 to a ZnTiNb2O8-1wt. %BCB system microwave dielectric ceramics serving as a base by by a traditional oxide mixing method to reduce a sintering temperature. The microwave ceramics is low in sintering temperature and good in comprehensive performance; the best sintering temperature is 975 DEG C, wherein epsilon r is equal to 33.04, Q*f is equal to 22000GHz, and Tauf is equal to -2.7 ppm / DEG C. The microwave dielectric ceramics is mainly applied to MLCC (Multiplayer Ceramic Chip Capacitors) ceramics device co-fired with a base metal electrode at a low temperature, and has wide application in industries such as information, war industry, mobile communication, electronic and electrical appliances, aviation, oil exploration and the like.

Owner:TIANJIN UNIV

Low-temperature sintered zinc titanate high-frequency dielectric ceramic and preparation method thereof

The invention relates to a low-temperature sintered zinc titanate high-frequency dielectric ceramic and preparation method, wherein the ceramic comprises zinc oxide produced by decomposing one portion of basic zinc carbonate, one portion of anatase nano-TiO2 and 0.75-1.00 wt% of vanadium pentoxide and diboron trioxide additive, wherein the basic zinc carbonate is used for producing zinc oxide, the preparation comprises ball grinding, drying, grinding, forming, pre-calcination, sintering and silvering.

Owner:西安广芯电子科技有限公司

Zinc titanate micro-nano photocatalysis material and preparation method thereof

ActiveCN101716501AFully contactedImprove photocatalytic abilityMetal/metal-oxides/metal-hydroxide catalystsMicro nanoZinc titanate

The invention relates to a catalyst which is relevant to zinc and titanium and a chemical method for preparing the catalyst. The zinc titanate micro-nano photocatalysis material has a spheroid structure with a plurality of protrusions. The preparation method of the zinc titanate micro-nano photocatalysis material comprises the following steps of: mixing uniform concentrated ammonia water suspension A of TiO2; slowly adding a zinc salt solution or ZnO powder into the suspension A in the titanium / zinc molar ratio of 1:1 to obtain uniform suspension B; processing the suspension B at high temperature and high pressure and then centrifugally washing the suspension B with deionized water many times to obtain a precursor C; drying the precursor C, burning at high temperature, and finally ball-milling. The prepared material has high specific surface area which reaches 160.6m2 / g and has stronger visible light photocatalysis performance. The preparation method has low production cost and is suitable for scale industrial production.

Owner:广州远达环保科技有限公司

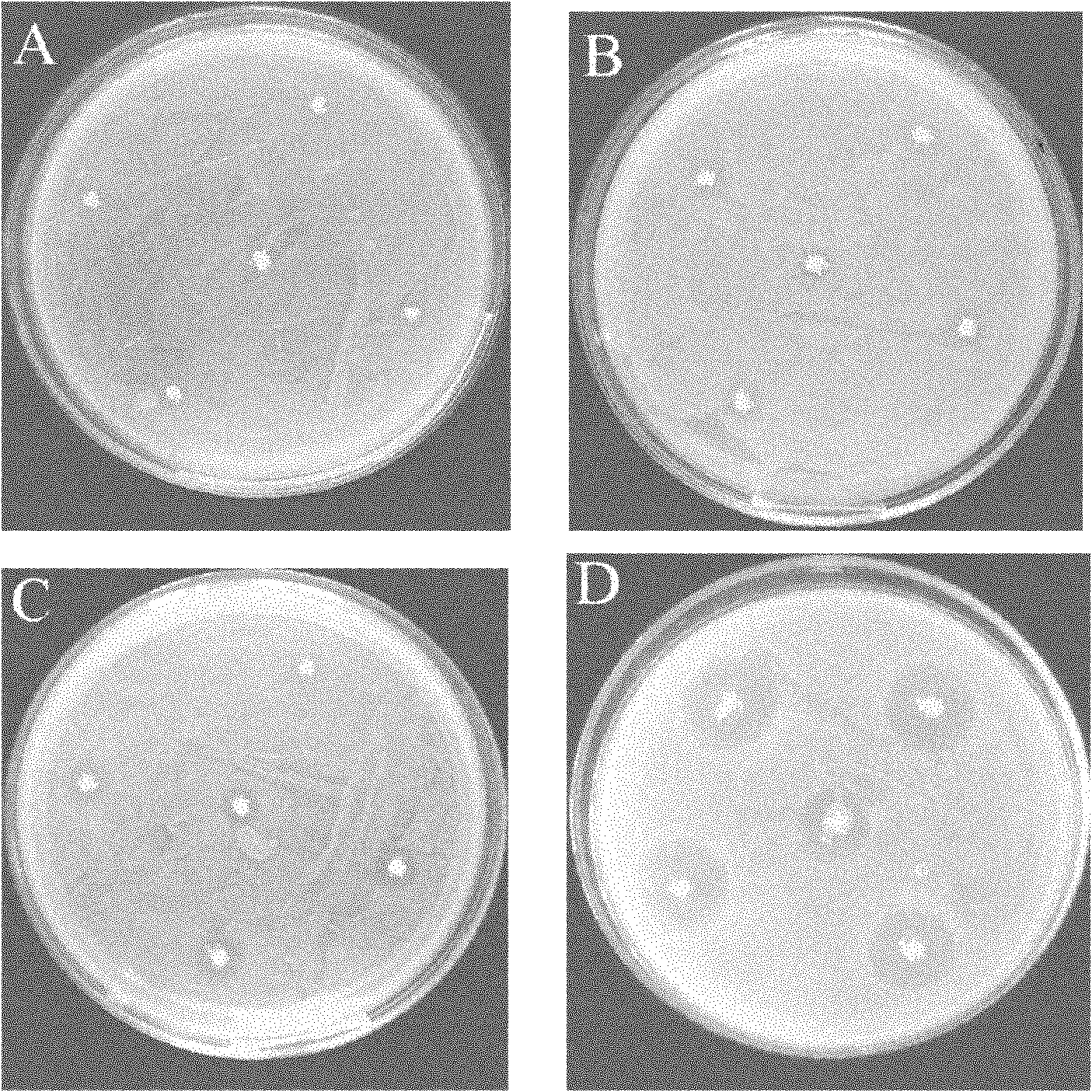

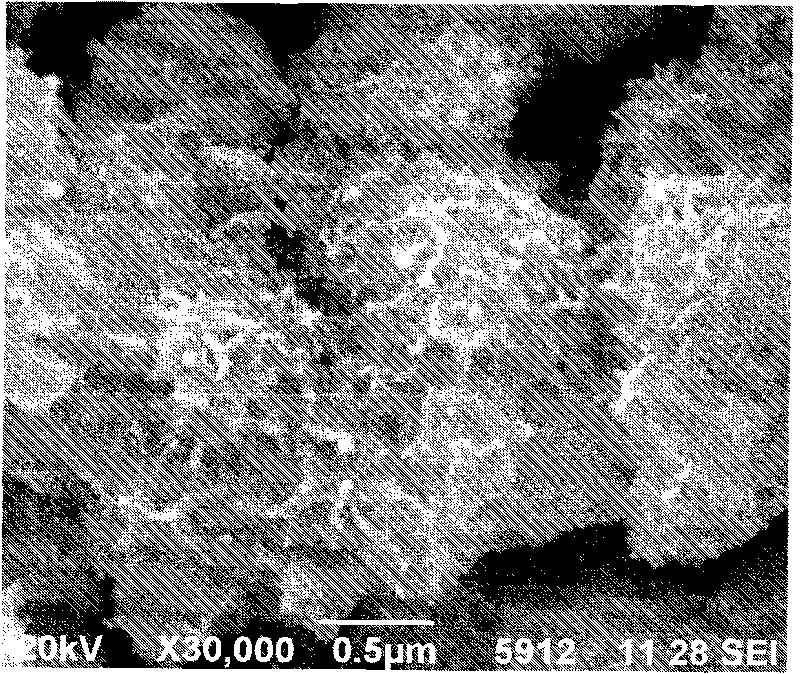

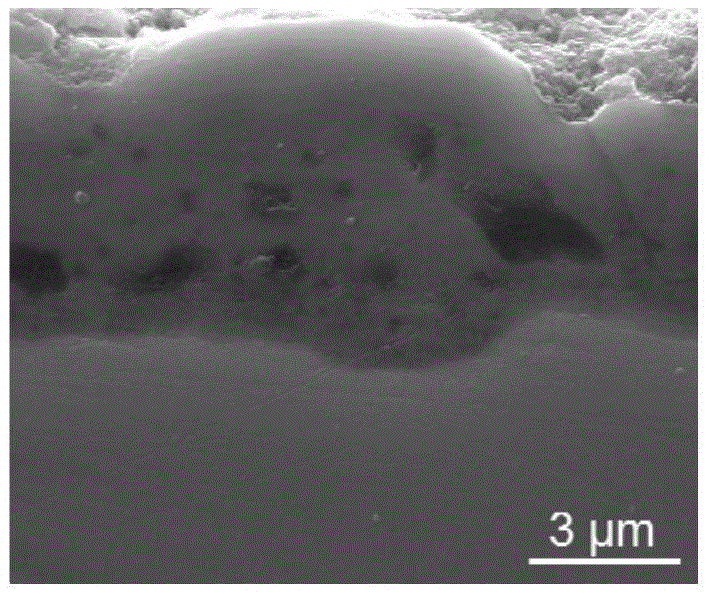

Zinc titanate-titanium oxide composite antibacterial coating on surface of titanium and preparation method of zinc titanate-titanium oxide composite antibacterial coating

ActiveCN105648497ASimple ingredientsRaw materials are easy to getElectrolytic inorganic material coatingSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a zinc titanate-titanium oxide composite antibacterial coating on the surface of titanium and a preparation method of the zinc titanate-titanium oxide composite antibacterial coating and belongs to the technical field of titanium-based surface treatment. The preparation method comprises the steps that a combination solution of a (CH3COO)2Zn solution and a beta-C3H7Na2O6P solution serves as an electrolyte; and a metallic titanium sheet serves as the anode, stainless steel serves as the cathode, the metallic titanium sheet and the stainless steel are placed into the electrolyte, the metallic titanium sheet is treated through a micro-arc oxidation process, and the zinc titanate-titanium oxide composite antibacterial coating is prepared on the surface of the titanium sheet. According to the preparation method, raw materials are easy to obtained, operation is easy, control is easy, and the stability is good; and the antibacterial coating prepared through the preparation method has high biological activity as well as antibacterial property, no discontinuous interface exists between the antibacterial coating and a basal body, and high combination strength is achieved.

Owner:XI AN JIAOTONG UNIV

Ceramic material and ceramic material and ferrite material low-temperature lamination cofiring method

InactiveCN102863222AImprove production stabilityImprove efficiencyCeramic layered productsZinc titanateCopper oxide

The invention discloses a ceramic material and a ceramic material and ferrite material low-temperature lamination cofiring method. The ceramic material consists of 85 to 95 parts by weight of main component zinc titanate barium and 5 to 15 parts by weight of fluxing agent a, and the ferrite material is formed by placing 0.5 to 5 parts by weight of fluxing agent a into nickel zinc copper ferrite with mol ratio of copper oxide (CuO) of 3 to 10 percent. The ceramic material and the method have following effects that (1) the fluxing agent a plays a role in riveting, when the ceramic and the ferrite are sintered, the ceramic and the ferrite can be mutually bonded; (2) the zinc oxide plays a role of a bridge in cofiring, so that the cohesion between the ceramic material and the ferrite material is increased, and the layering or fracturing of the sintering process can be prevented; and (3) the low-temperature co-firing ceramic (LTCC) process is adopted, so that the production stability is high, the efficiency is high, the cost is low, and mass production can be realized.

Owner:SHENZHEN GUDIAN ELECTRONICS

Preparation method of zinc titanate and titanium dioxide composite nano material

InactiveCN105771953AReduce craft production costControllableMetal/metal-oxides/metal-hydroxide catalystsZinc titanateDysprosium titanate

The invention belongs to the technical field of functional material preparation, and relates to a preparation method of zinc titanate and titanium dioxide composite nano material. The method comprises the steps that zinc acetylacetonate and titanium acetylacetonate are dissolved and mixed to be uniform in an alcoholic solution, a cross-linking reaction is conducted at certain temperature, the materials are subjected to heat treatment in a muffle furnace, and the zinc titanate and titanium dioxide composite nano material is obtained. According to the preparation method of the zinc titanate and titanium dioxide composite nano material, the technology is simple and convenient and easy to carry out, the purity is high, the impurity content is low, the product is low in preparation cost and excellent in property, and industrial batched production can be achieved. The prepared zinc titanate and titanium dioxide composite nano material is used as a photocatalytic material, has higher catalytic activity and has wide application prospects in the fields of dyestuff wastewater and indoor harmful gas degradation, photocatalytic disinfection and the like.

Owner:BOHAI UNIV

Bismuth ferrate-barium titanate-bismuth zinc titanate-bismuth aluminate high-temperature lead-free piezoelectric ceramic and preparation method thereof

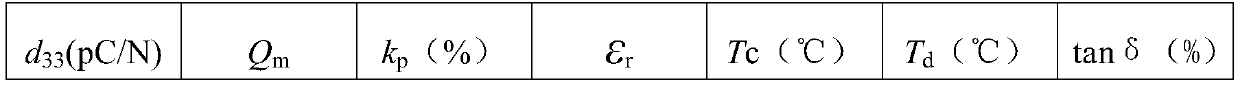

The invention discloses a bismuth ferrate-barium titanate-bismuth zinc titanate-bismuth aluminate high-temperature lead-free piezoelectric ceramic and a preparation method thereof. The composition general formula of the piezoelectric ceramic is: xBiFeO3-yBaTiO3-zBi(Ti0.5Zn0.5)O3+tBiAlO3+mP+nMnCO3+2.5%Bi2O3, wherein x, y, z, t, m and n represent mole fractions, 0.6<=x<=0.8, 0.15<=y<=0.3, 0.05<=z<=0.15, 0<t<=0.10, 0<m<=0.1, 0<n<=0.1, and 2.5% mol of Bi2O3 is used to make up the volatilization of the Bi element in the sintering process, and is used as a sintering aid; and P is one or a combination of several sintering aids of Ba(W0.5Cu0.5)O3, CuO and Li2CO3. The preparation method comprises the working procedures of batching according to the composition general formula, ball milling, molding,glue discharge, sintering and the like. The high-temperature lead-free piezoelectric ceramic is prepared, the Curie temperature T<c> is up to 596 DEG C, the depolarization temperature T<d> is up to 580 DEG C, and the highest piezoelectric constant is up to 137 pC / N. The system ceramics are expected to be applied in high temperature fields such as aerospace, nuclear power, petroleum exploration and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

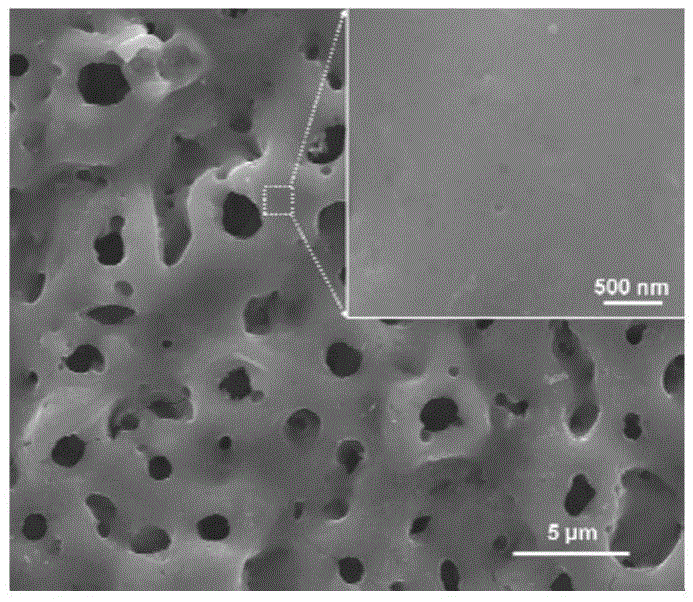

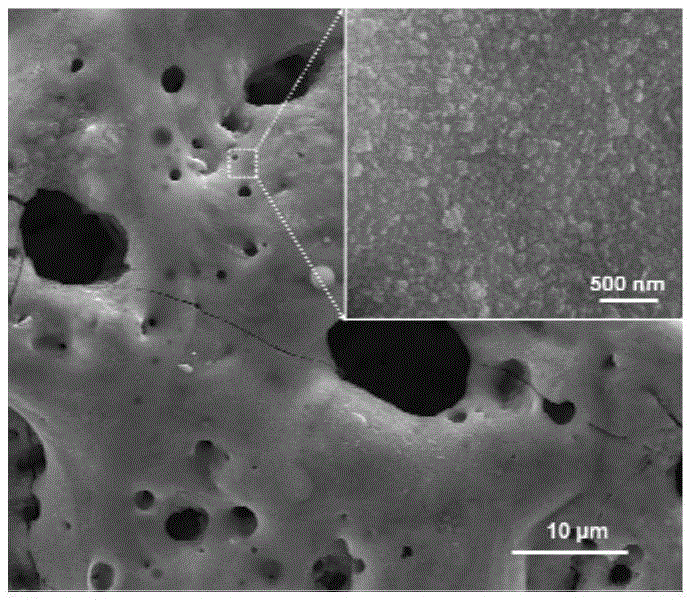

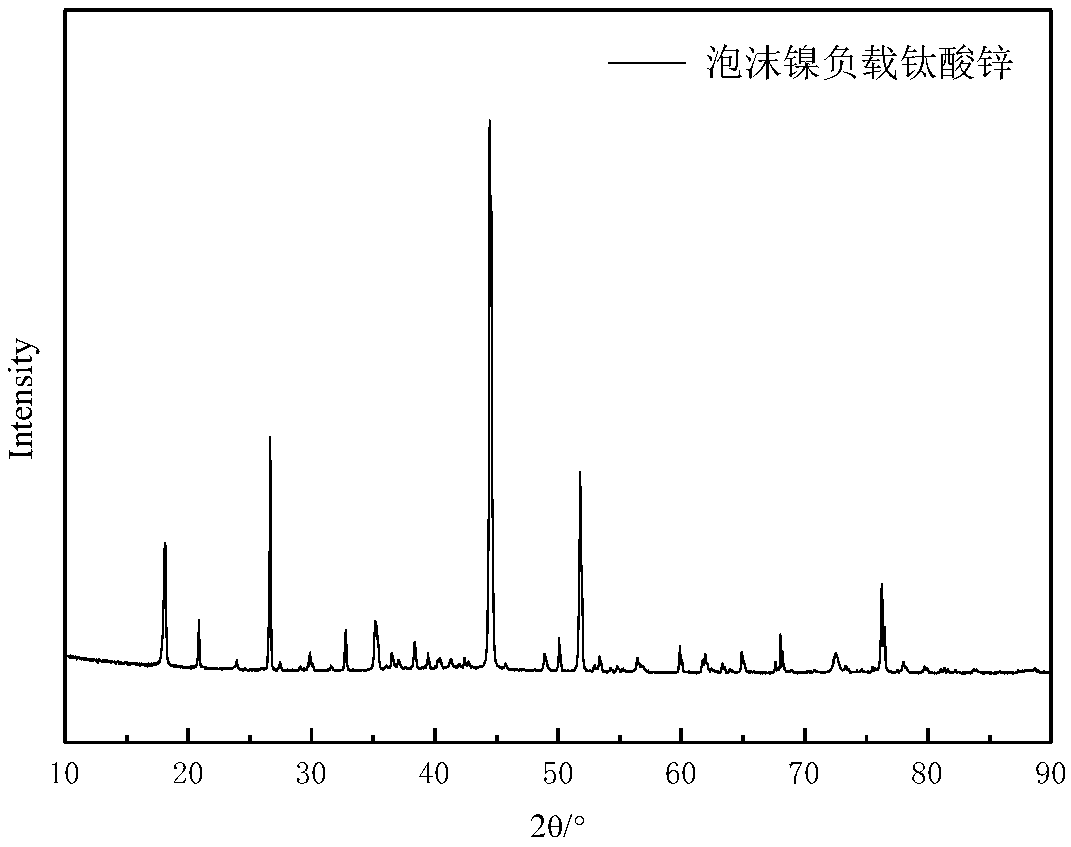

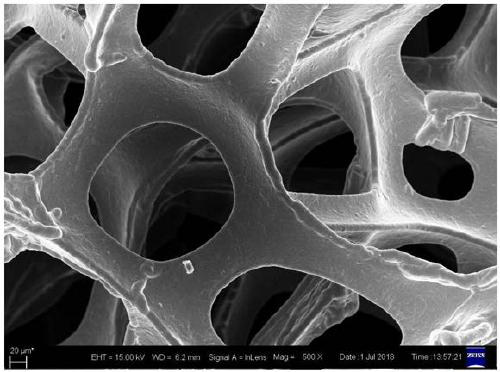

Foamed nickel-loaded zinc titanate photocatalytic material and preparation method thereof

ActiveCN109482190AHigh porosityIncrease surface areaWater/sewage treatment by irradiationWater treatment compoundsZinc titanateBinding force

The invention relates to a foamed nickel-loaded zinc titanate photocatalytic material and a preparation method thereof. The preparation method comprises the following steps: taking foamed nickel as amatrix, uniformly coating zinc titanate template agent mixed suspension on a thin layer to form a zinc titanate / template agent composite carrier; soaking and dissolving out by the template agent, anddrying to form the foamed nickel-loaded zinc titanate (ZnTiO3) photocatalytic material. The preparation method specifically comprises the following steps: forming turbid liquid A from polytetrafluoroethylene (PTFE) and ethanol, and adding ZnTiO3 and the template agent into the turbid liquid A according to a certain ratio so as to form turbid liquid B; uniformly coating the turbid liquid B onto thefoamed nickel, drying and soaking into the template dissolved-out solution for dissolving out the template agent, and flushing with deionized water and drying; and finally obtaining the foamed nickel-loaded ZnTiO3 photocatalytic material. According to the method disclosed by the invention, preparation of the foamed nickel-loaded ZnTiO3 photocatalytic material is realized, the binding force between materials is firm, and the prepared product has high catalytic activity on organic matter degradation in an ultraviolet light range, and has obvious advantages of being long in service life, easy torecover, free in secondary pollution and the like; and the whole process is simple in operation, short in cycle, energy-saving and low in manufacturing cost. The invention relates to a photocatalyticmaterial for water treatment.

Owner:HARBIN UNIV OF COMMERCE

Sol-gel preparation method of lithium zinc titanate as lithium ion battery cathode material

ActiveCN103715408AAvoid uneven mixingCalcination temperature is lowCell electrodesSecondary cellsZinc titanateSolid state reaction method

The invention discloses a sol-gel preparation method of lithium zinc titanate as a lithium ion battery cathode material. The sol-gel preparation method comprises the following steps of step1, dissolving citric acid and ethylene glycol in deionized water; step 2, weighing a titanium source, a lithium source and a zinc source according to the mole ratio of 3:1:1 into the obtained solution in the step1; step 3, stirring the system in the step 2 for two hours at 60 DEG C to obtain transparent sol; step 4, sequentially stirring the obtained sol in the step 3 for four hours at 80 DEG C; and step 5, transferring the obtained sol in the step 4 into a muffle furnace, and raising the temperature to700-800 DEG C and calcining for 3-5 hours to obtain the final product. The sol-gel preparation method disclosed by the invention solves the problem that a reactant is not uniform to mix caused by material mixing by ball milling or direct roasting in a process of preparing lithium zinc titanate by adopting a solid-phase reaction method.

Owner:天津顺捷通科技有限公司

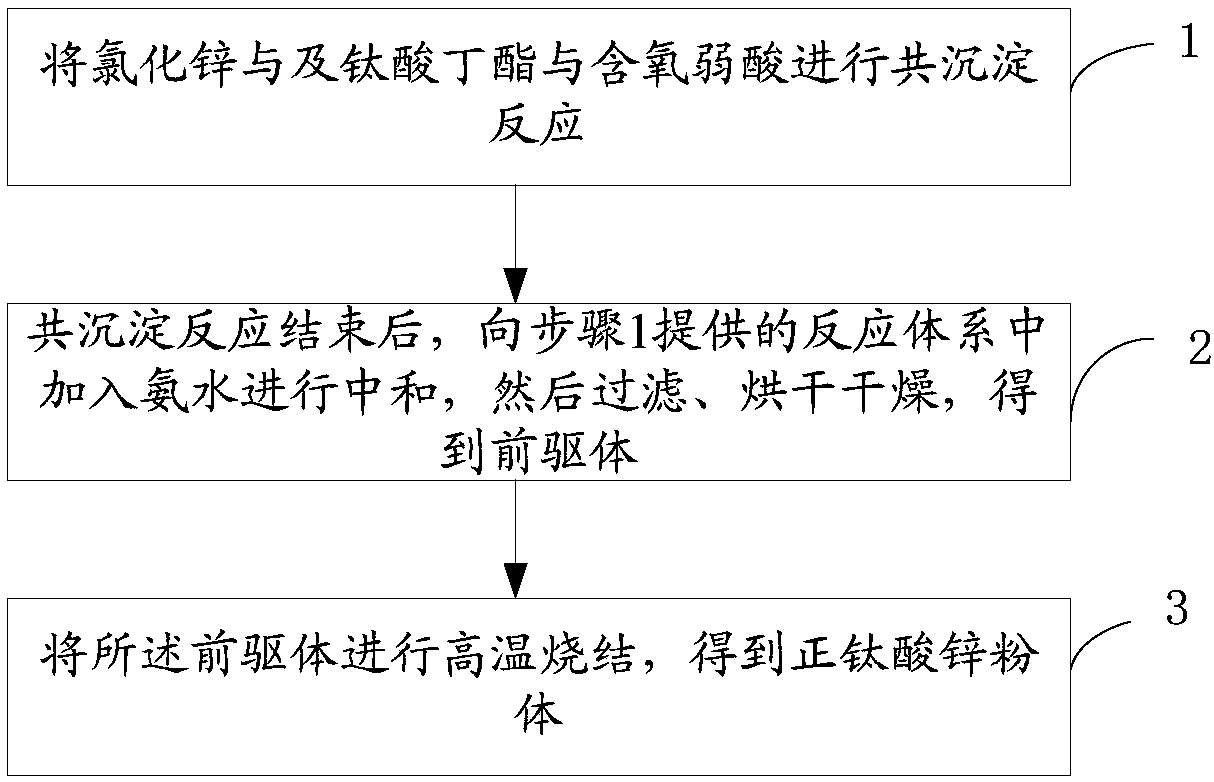

Preparation method of n-zinc titanate powder and application

The invention provides a preparation method of n-zinc titanate powder and application and belongs to the technical field of thermal control coatings of spacecrafts. The preparation method comprises the following steps: performing a co-precipitation reaction on zinc chloride and butyl titanate with a weak acid; after the co-precipitation reaction is completed, putting ammonium hydroxide into the reaction system provided by the step 1, implementing neutralization, filtring, and drying so as to obtain a precursor; performing high-temperature sintering on the precursor, thereby obtaining the n-zinc titanate powder. By adopting the preparation method of the n-zinc titanate powder provided by the embodiment of the invention, butyl titanate is adopted as a titanium source, n-zinc titanate powderwhich is relatively high in purity and small in particle size is prepared, and the powder is relatively low in sunshine absorption rate and good in space environment stability when being used as thermal control packing, and a thermal control coating prepared from the powder is relatively high in hardness and relatively good in stain resistance.

Owner:BEIJING SATELLITE MFG FACTORY

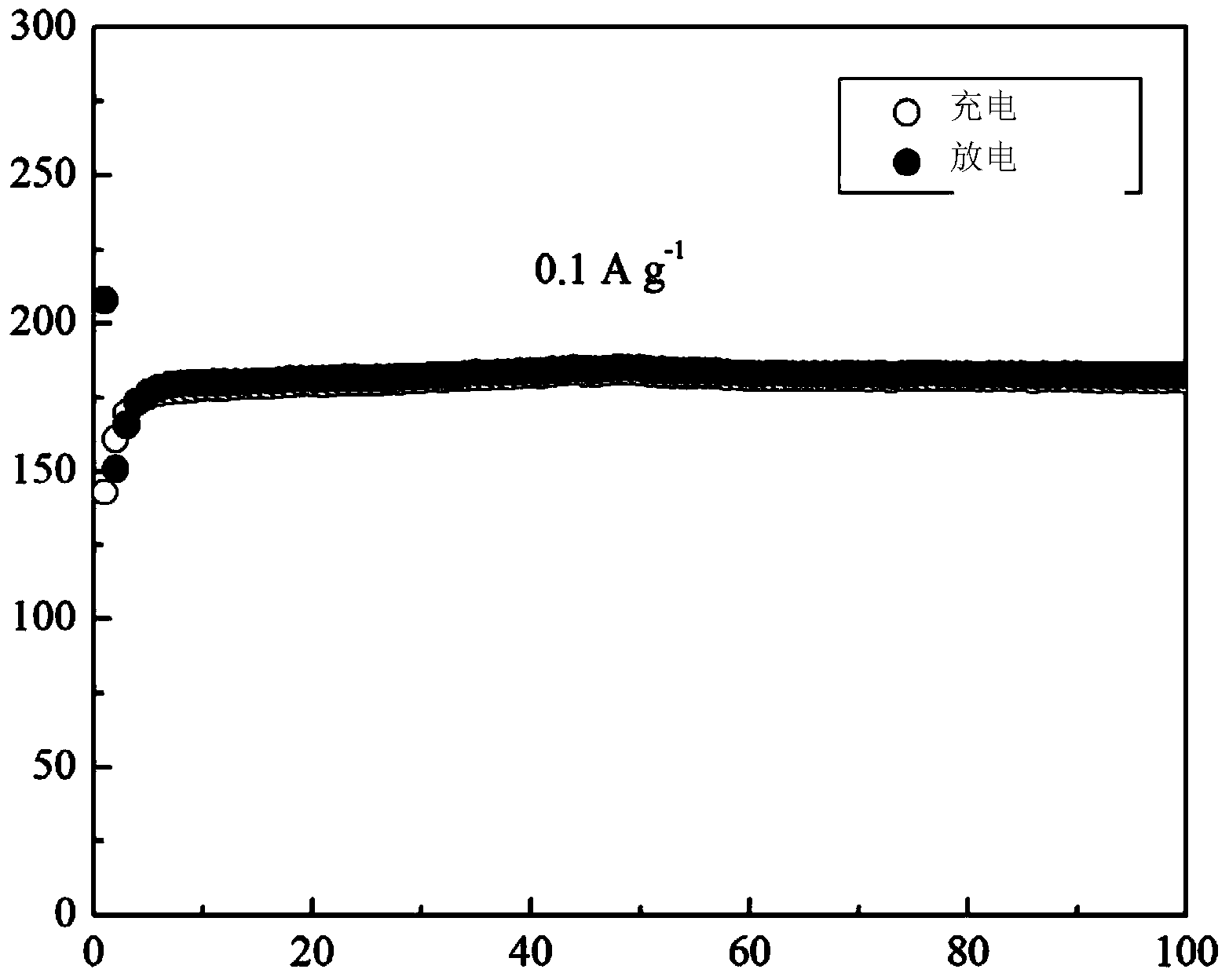

Lithium ion battery negative electrode material Li2ZnTi3O8 preparation method

InactiveCN104617285AReduce high temperature environmentAbundant and cheapMaterial nanotechnologyAlkali titanatesPotassiumZinc titanate

The invention relates to a lithium ion battery electrode material Li2ZnTi3O8 preparation method, and aims at the defects of high temperature, longer reaction time, high organic material cost, toxicity and the like of lithium zinc titanate material preparation method in the prior art. The technical scheme is as follows: titanium dioxide (TiO2), lithium carbonate (Li2CO3) and zinc acetate (Zn (CH3COO) 2.2H2O) and mixed molten salt sodium chloride (NaCl) and potassium chloride (KCl) are mixed and stirred, in the high temperature sintering process, reactant precursors can be sufficiently contacted and reacted in liquid environment facilitating molten salts, prepared nanoscale particular material is uniform in size and free of obvious agglomeration, accumulation holes are among particles, and the structural features is conducive to play the electrochemical properties of the material.

Owner:TIANJIN UNIV

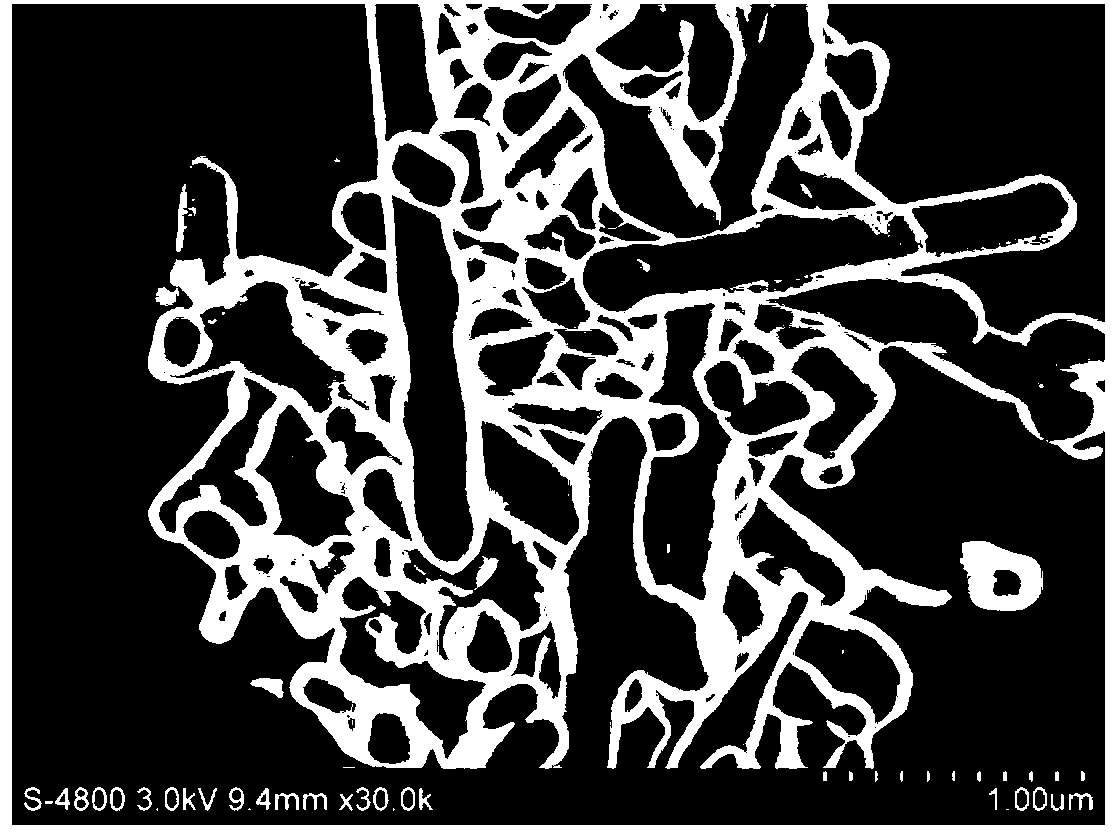

Method for preparing carbon-coated lithium zinc titanate nanoribbon

ActiveCN105280902ASimple processReduce energy consumptionCell electrodesSecondary cellsPhysical chemistryEngineering

The invention relates to a method for preparing a carbon-coated lithium zinc titanate nanoribbon. TiO2 particles are put in a NaOH solution for performing a hydrothermal reaction to obtain a precursor; and then the carbon-coated lithium zinc titanate nanoribbon is prepared, under the condition of the existence of glucose, by a high-temperature calcining method. The preparation method for the carbon-coated lithium zinc titanate nanoribbon is simple, low in cost, low in energy consumption and high in repeatability.

Owner:CHINA TOBACCO FUJIAN IND +1

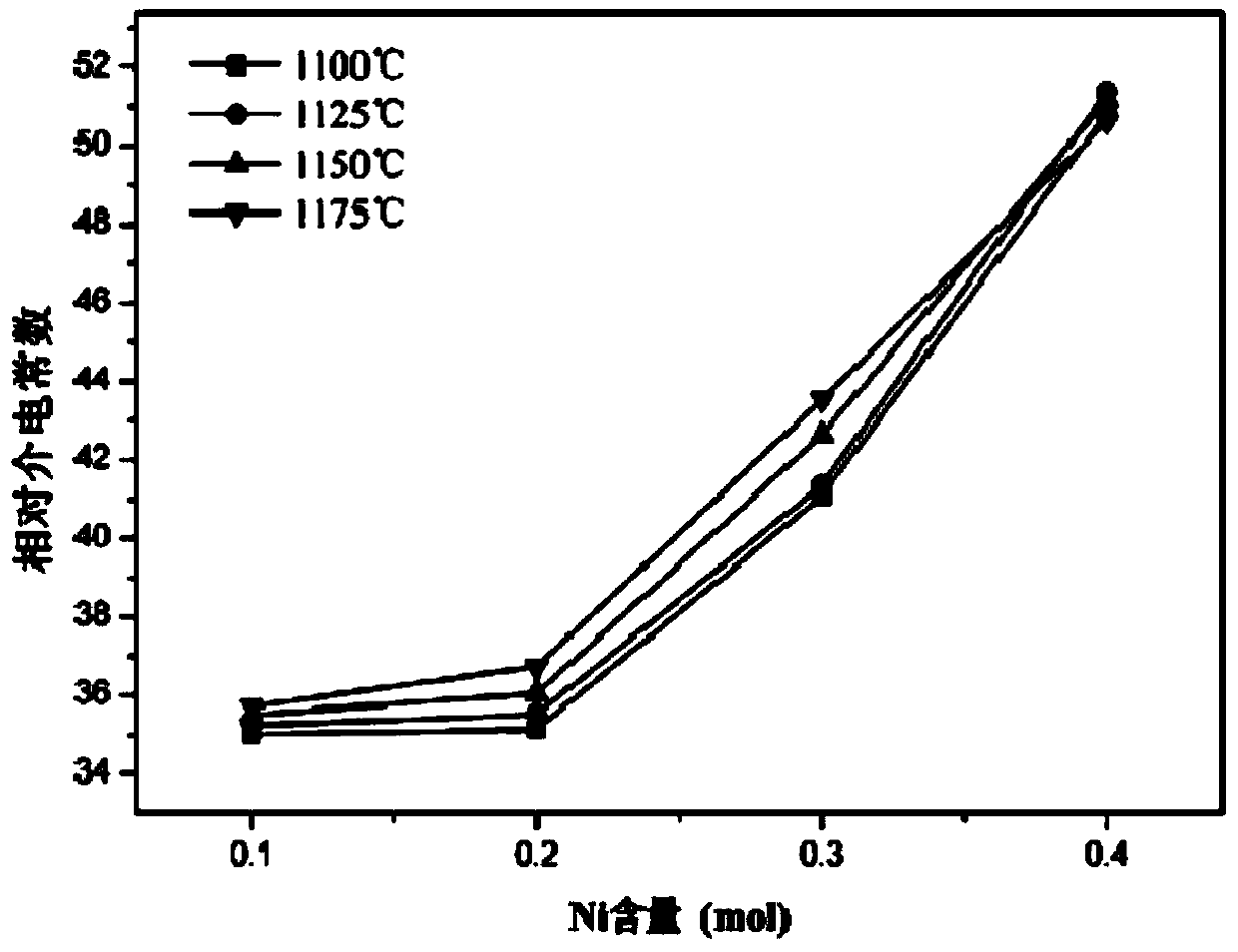

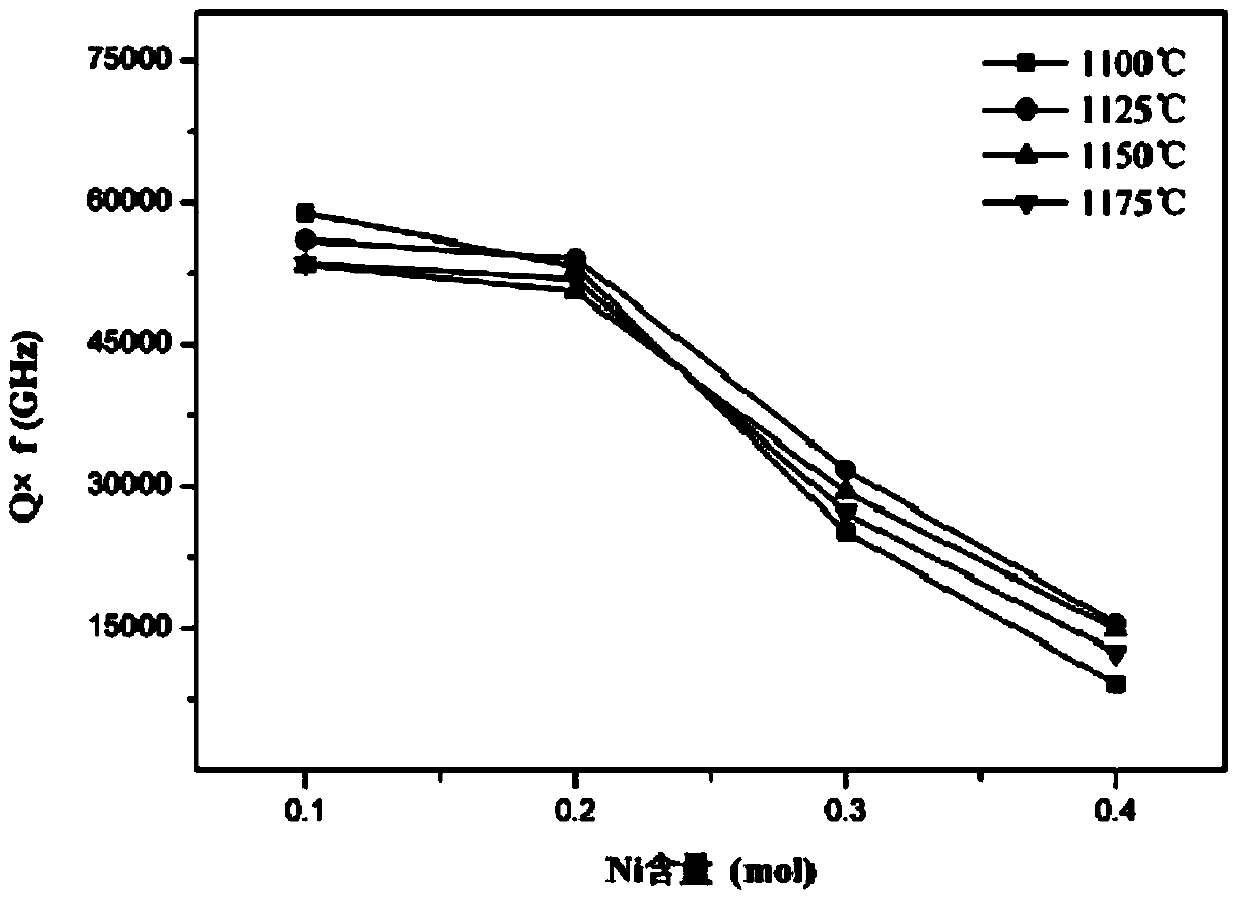

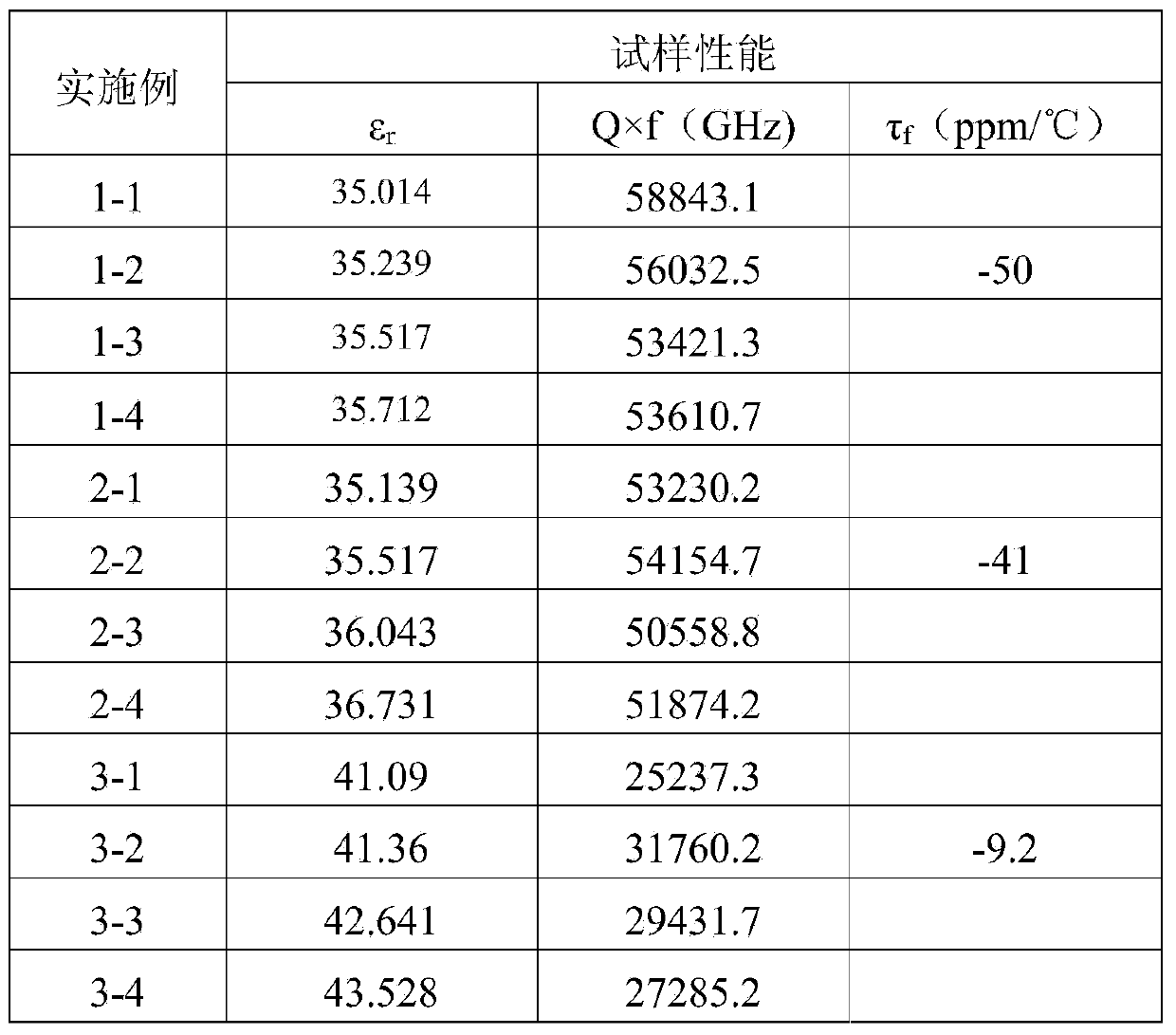

Nickel oxide-doped niobium zinc titanate microwave dielectric ceramic and preparation method thereof

The invention discloses nickel oxide-doped niobium zinc titanate microwave dielectric ceramic and a preparation method thereof. The stoichiometric equation is (Zn1-xNix)TiNb2O8, wherein x is equal to 0.1 to 0.4. According to the invention, ZnTiNb2O8 system microwave dielectric ceramic serves as basis, the traditional oxide mixing method is adopted and Ni2O3 is added to increase the dielectric constant, so that the (Zn1-xNix)TiNb2O8 microwave dielectric ceramic material with excellent comprehensive performance is prepared, wherein the optimal sintering temperature is 1,125 DEG C; and epsilon r=41.36, Q*f=31760.2 GHz, and tau f=-9.2 ppm / DEG C. The nickel oxide-doped niobium zinc titanate microwave dielectric ceramic and the preparation method thereof are mainly used for realizing miniaturization of a resonant loop and are widely applied to industries of information, military industry, mobile communication, electrical and electronic appliances, aviation, petroleum exploration and the like.

Owner:TIANJIN UNIV

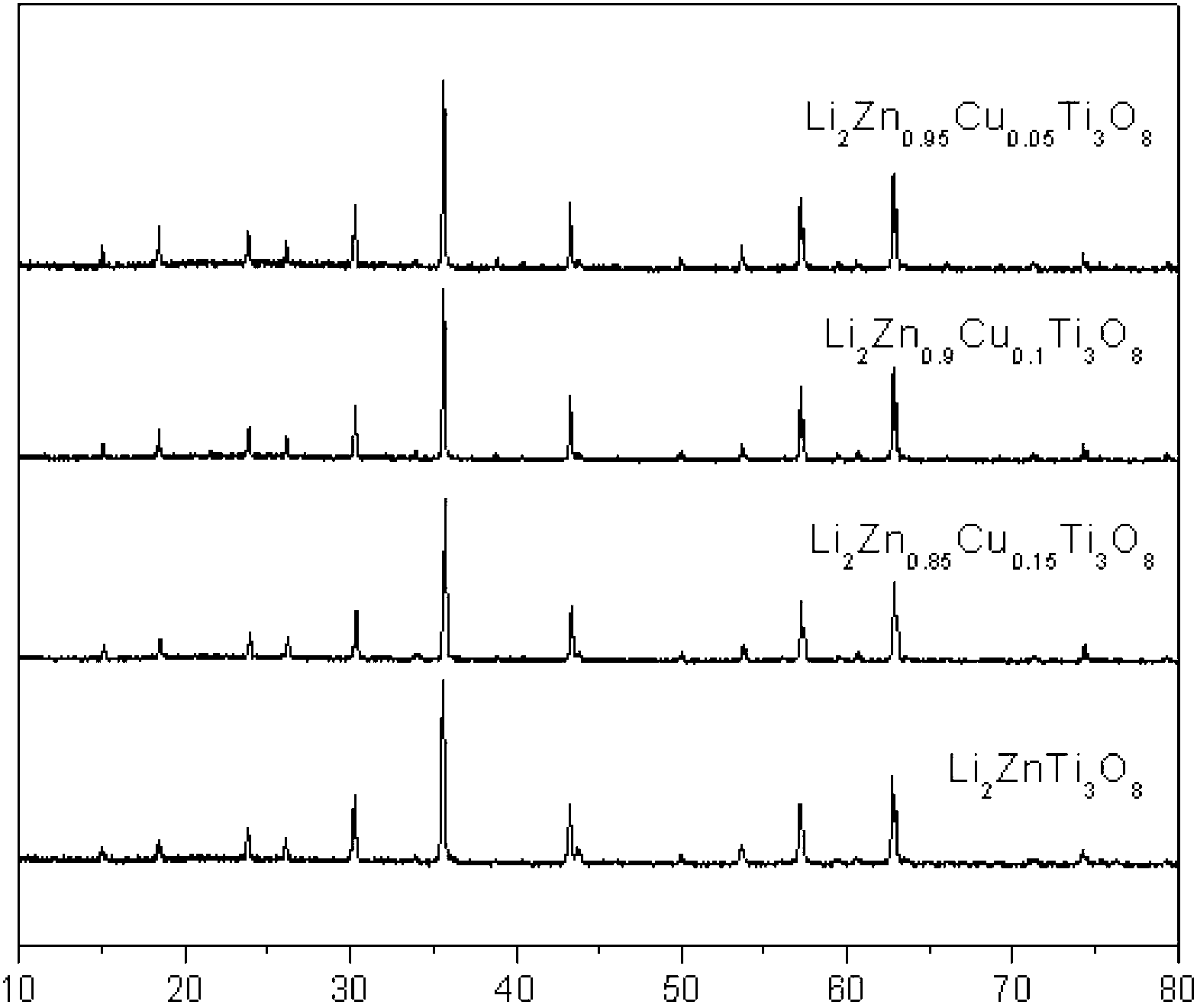

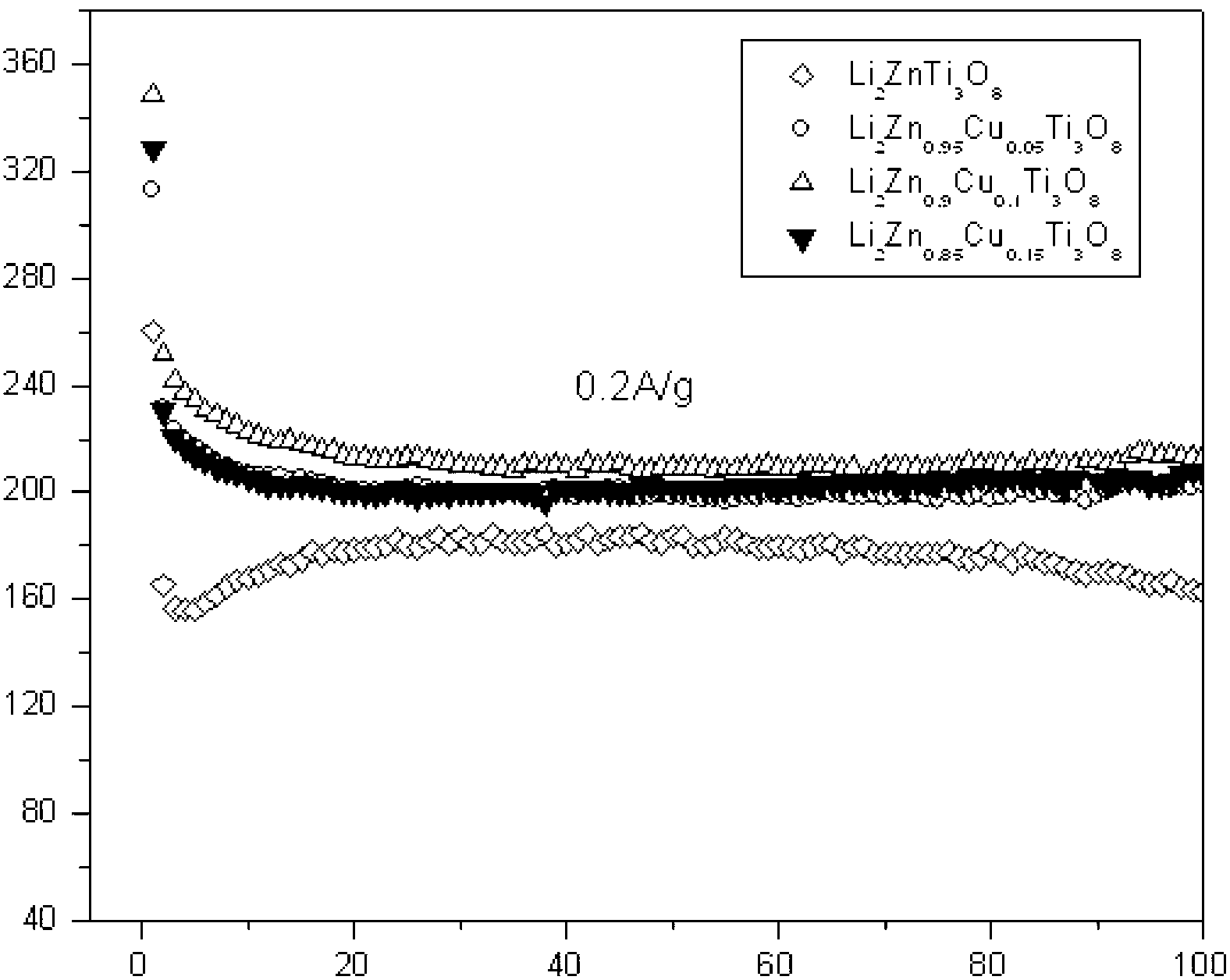

Cu-doped lithium zinc titanate negative electrode material and preparation method thereof

The invention relates to an electrode material and a preparation method thereof, and in particular relates to a Cu-doped lithium zinc titanate negative electrode material and a preparation method thereof. The Cu-doped lithium zinc titanate negative material is characterized by having a molecular formula of Li2Zn1-xCuxTi3O8, wherein x is more than 0 and less than or equal to 0.15. The preparation method comprises the following steps of: weighing a titanium source, a lithium source, a zinc source and a copper source, uniformly mixing and then drying; and sintering at 750 DEG C for 5 hours, then naturally cooling to the room temperature, and grinding. After Cu is doped, Cu<2+> can be distributed at a tetrahedron position and an octahedron position in a ratio of 3:2, so that the arrangement of ions in the material generates changes slightly, and the stability of a crystal structure of the material during charging and discharging is improved.

Owner:珠海长兴新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com