Sol-gel preparation method of lithium zinc titanate as lithium ion battery cathode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as unfavorable mass production, limited development and application, complicated process, etc., and achieve high production efficiency and low equipment investment Less, shorter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

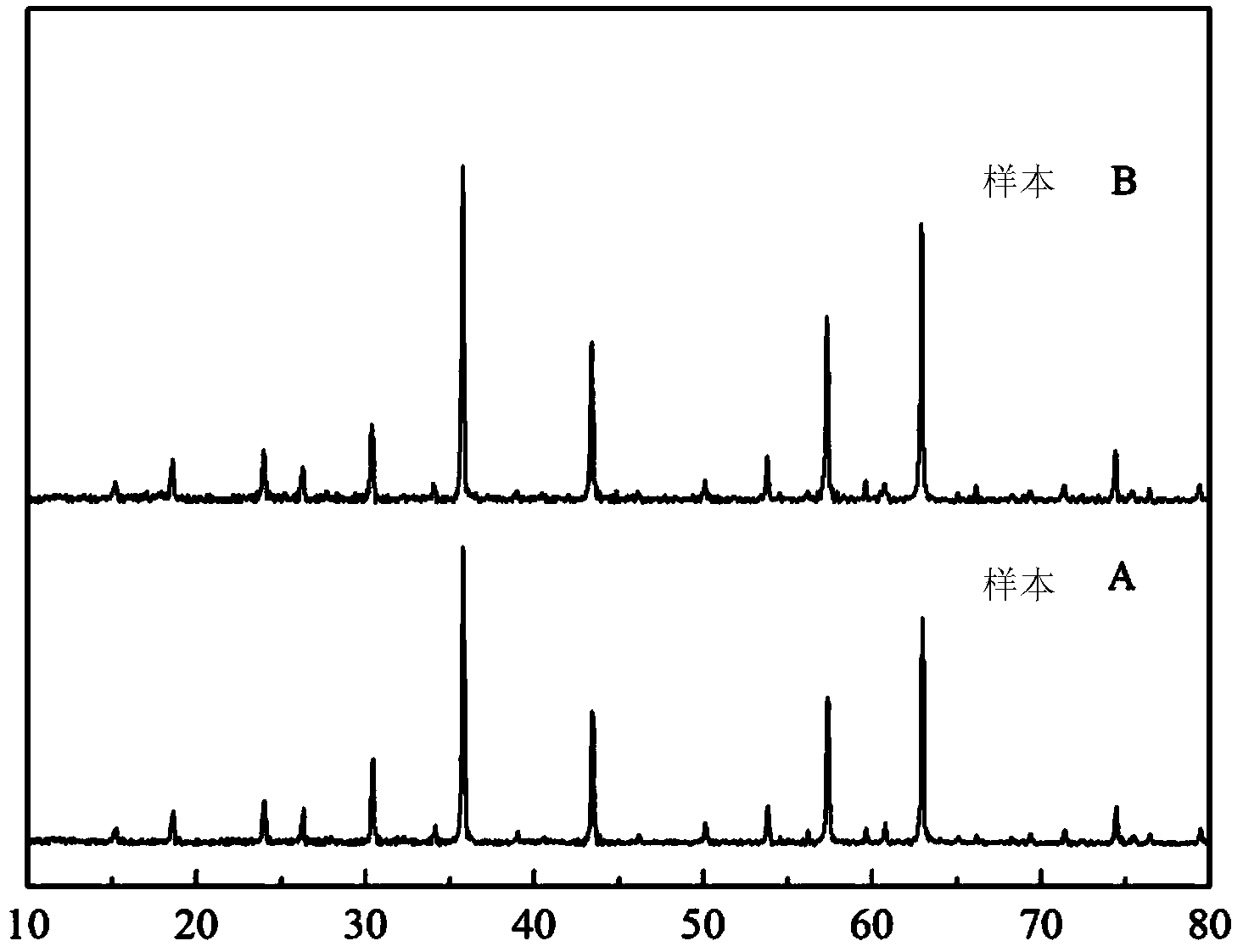

[0022] Weigh 8.180 grams of citric acid and dissolve it in distilled water, add 5.288 grams of ethylene glycol, mix well, weigh 6.054 grams of isopropyl titanate, 0.525 grams of lithium carbonate and 1.558 grams of zinc acetate and add them to the above solution. After vigorously stirring for 2 hours, the solution turned into a yellow transparent sol, and continued to stir at 80°C for 4 hours to form a gel. The gel was transferred to a muffle furnace, heated to 800°C, and calcined for 3 hours to obtain a lithium zinc titanate negative electrode material, which was marked as "sample A".

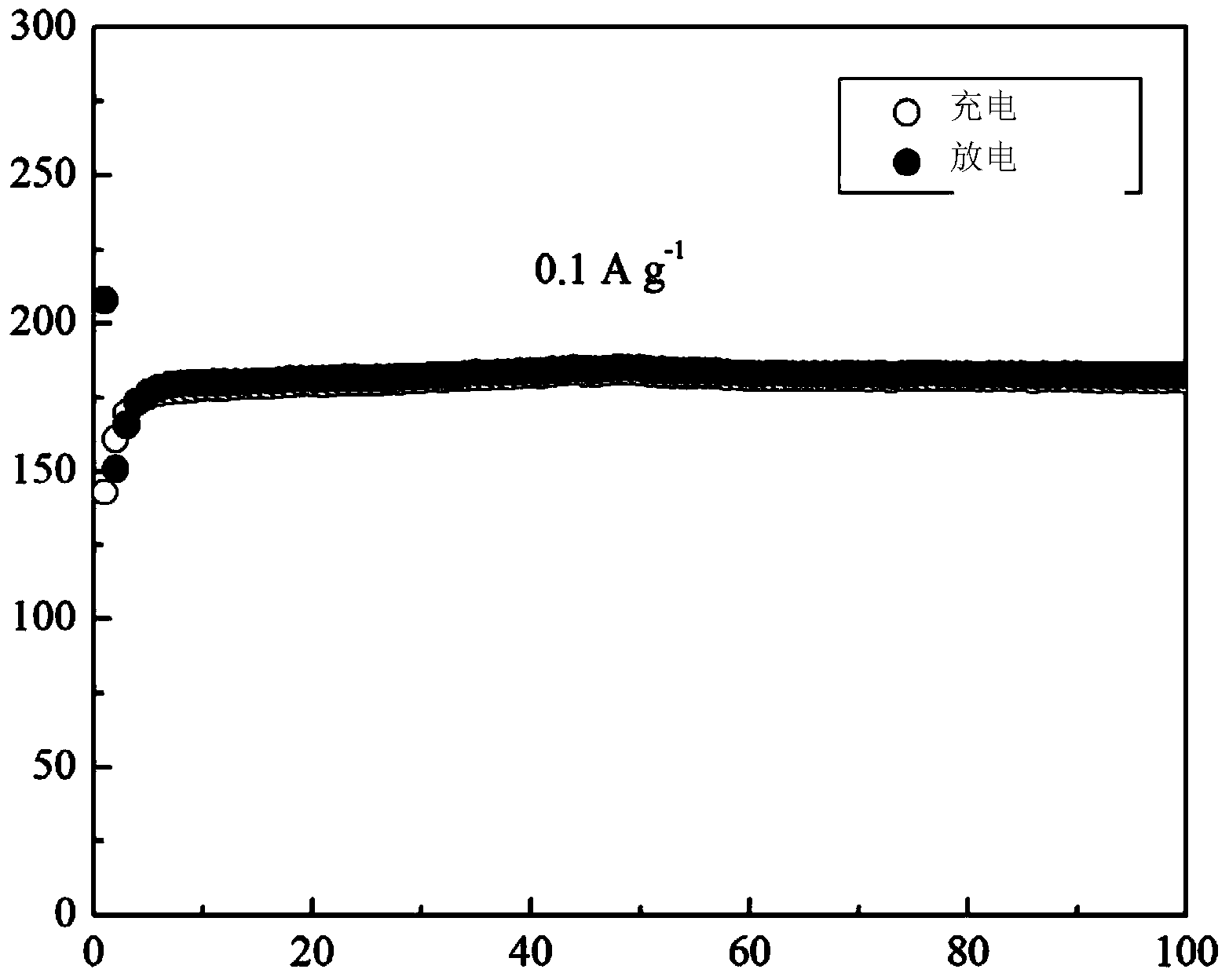

[0023] Weigh 0.8 g of sample A, mix it with acetylene black and PVDF at a mass ratio of 80:10:10, stir evenly, coat it on a copper foil, place it in a vacuum drying oven, and dry it under vacuum at 120°C for 24 Hours, after rolling and punching, the electrode sheet was obtained; with the metal lithium sheet as the counter electrode and 1M LiPF6 EC:DEC:EMC solution as the electrolyte, a simulat...

Embodiment 2

[0025] Weigh 12.270 grams of citric acid and dissolve it in distilled water, add 7.932 grams of ethylene glycol, mix well, weigh 9.081 grams of isopropyl titanate, 0.788 grams of lithium carbonate and 3.168 grams of zinc nitrate and add them to the above solution. After vigorously stirring for 2 hours, the solution turned into a yellow transparent sol, and continued to stir at 80°C for 4 hours to form a gel. The gel was transferred to a muffle furnace, the temperature was raised to 800° C., and calcined for 3 hours to obtain a lithium zinc titanate negative electrode material. This material is labeled "Sample B".

Embodiment 3

[0027] Weigh 12.270 grams of citric acid and dissolve it in distilled water, add 15.864 grams of ethylene glycol, mix well, weigh 9.081 grams of isopropyl titanate, 0.788 grams of lithium carbonate and 2.337 grams of zinc acetate and add them to the above solution. After vigorously stirring for 2 hours, the solution turned into a yellow transparent sol, and continued to stir at 80°C for 4 hours to form a gel. The gel was transferred to a muffle furnace, the temperature was raised to 800° C., and calcined for 3 hours to obtain a lithium zinc titanate negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com