Patents

Literature

145 results about "Vertical mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vertical mixing. Definition. vertical mixing rate. (Noun) The mixing of water in a water column that occurs only when the surface water becomes more dense than the water beneath it.

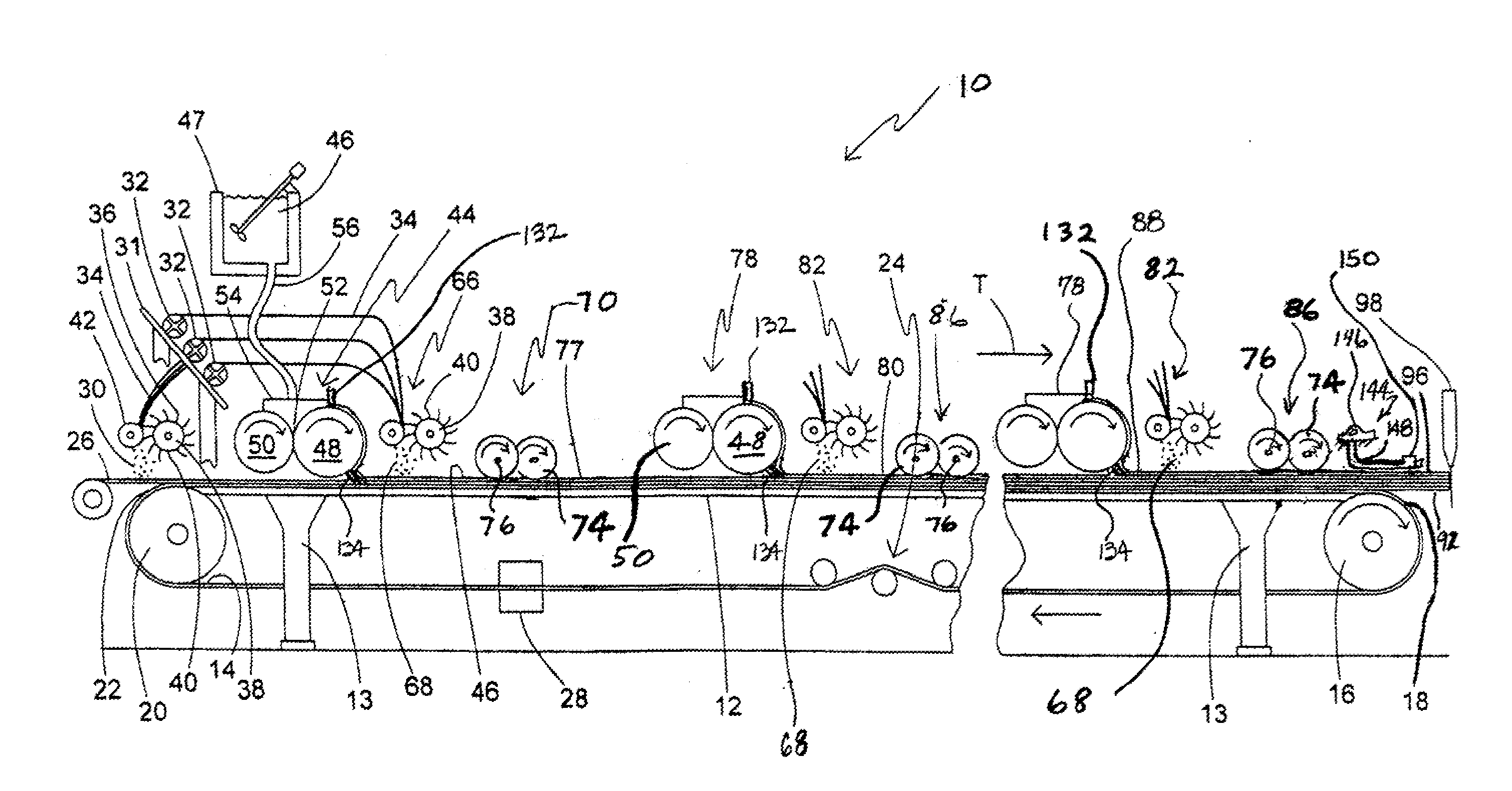

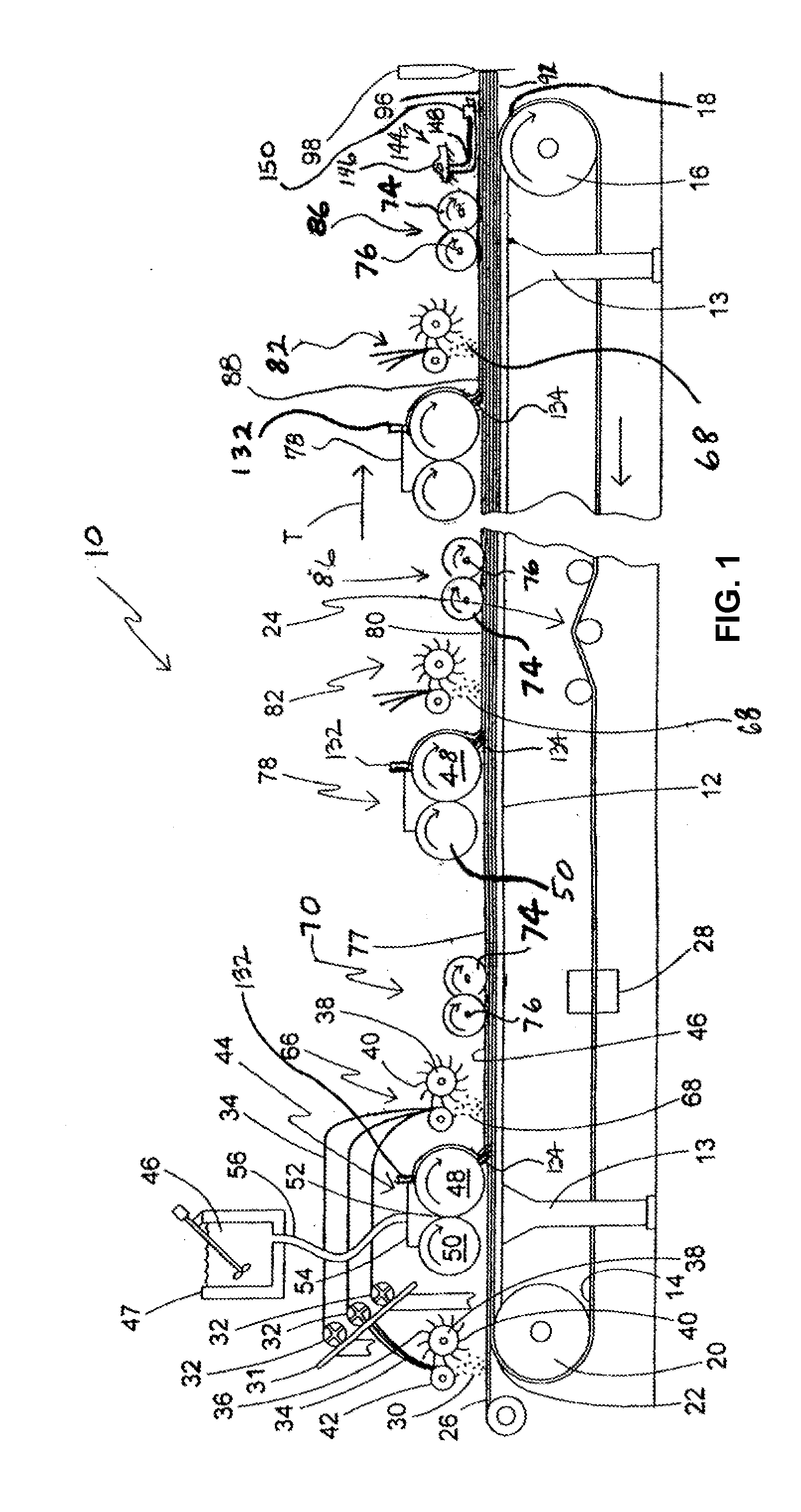

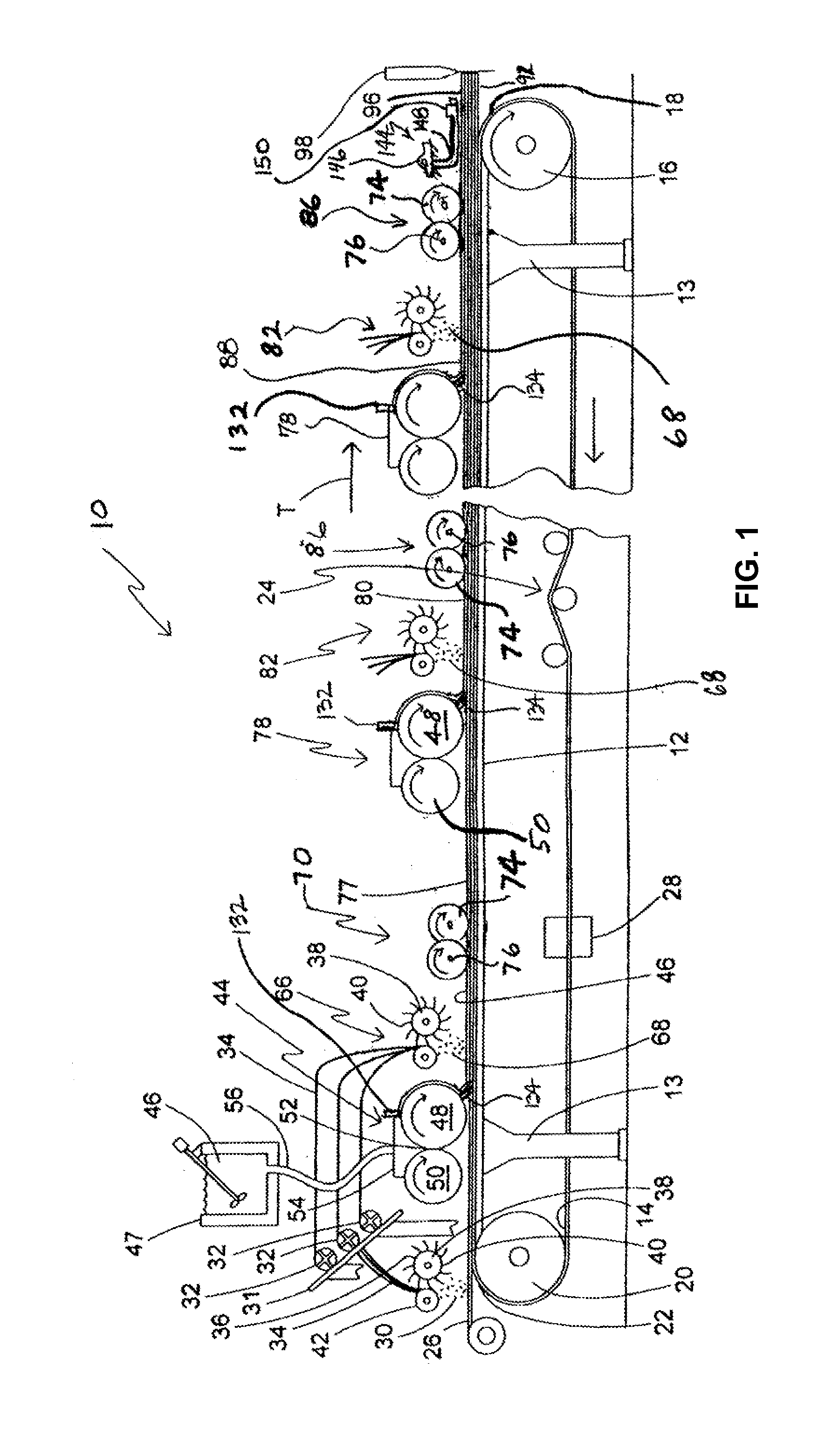

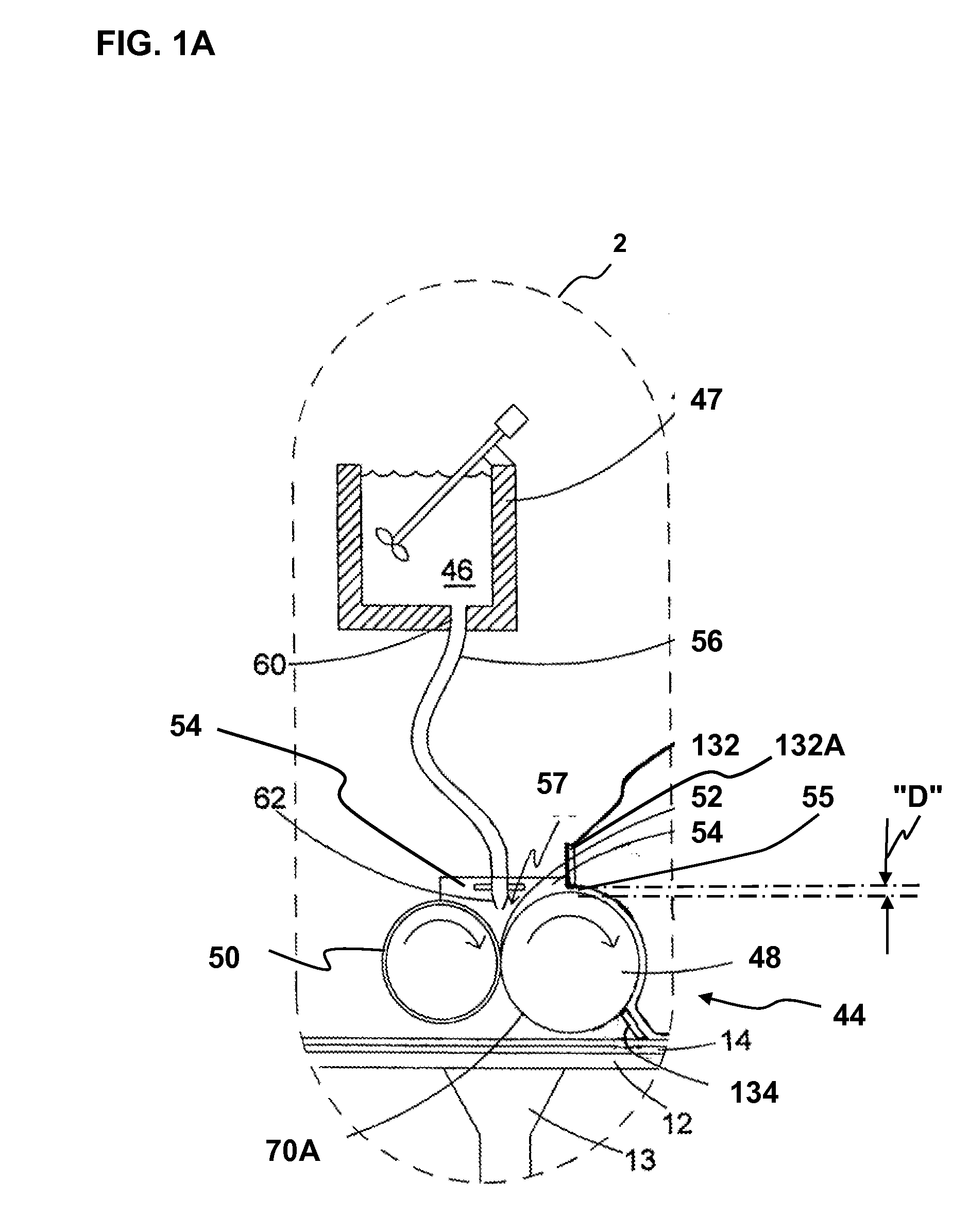

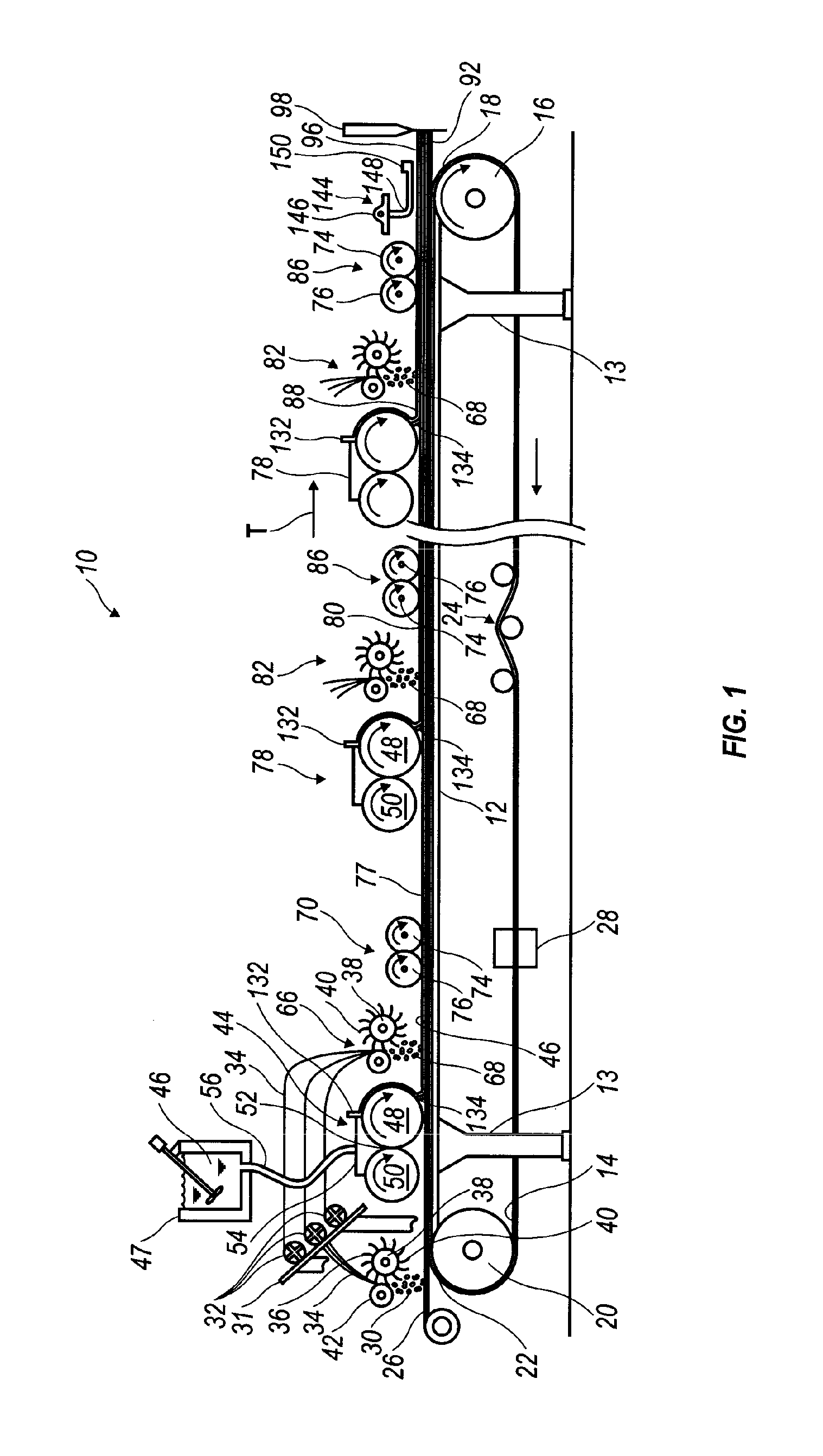

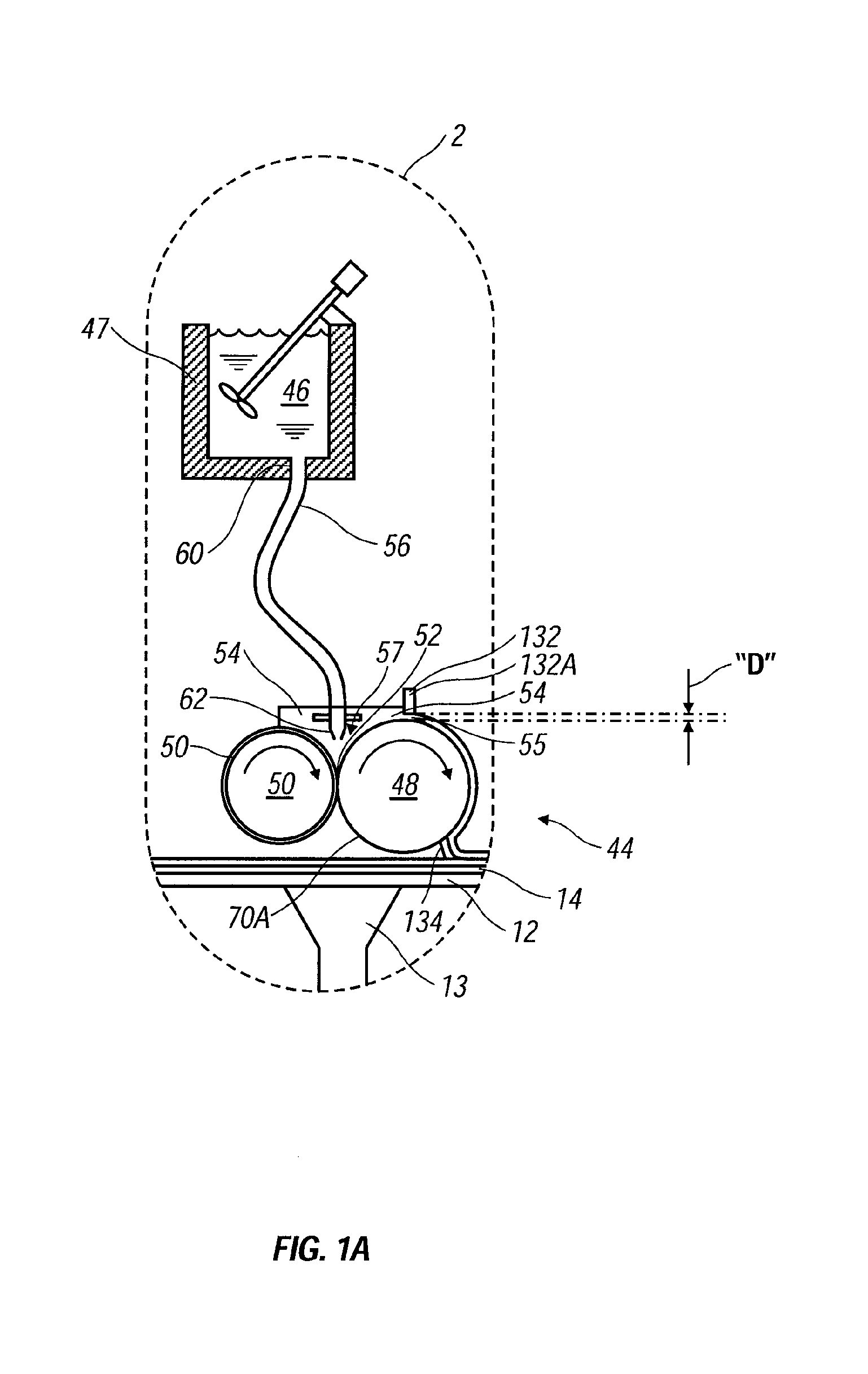

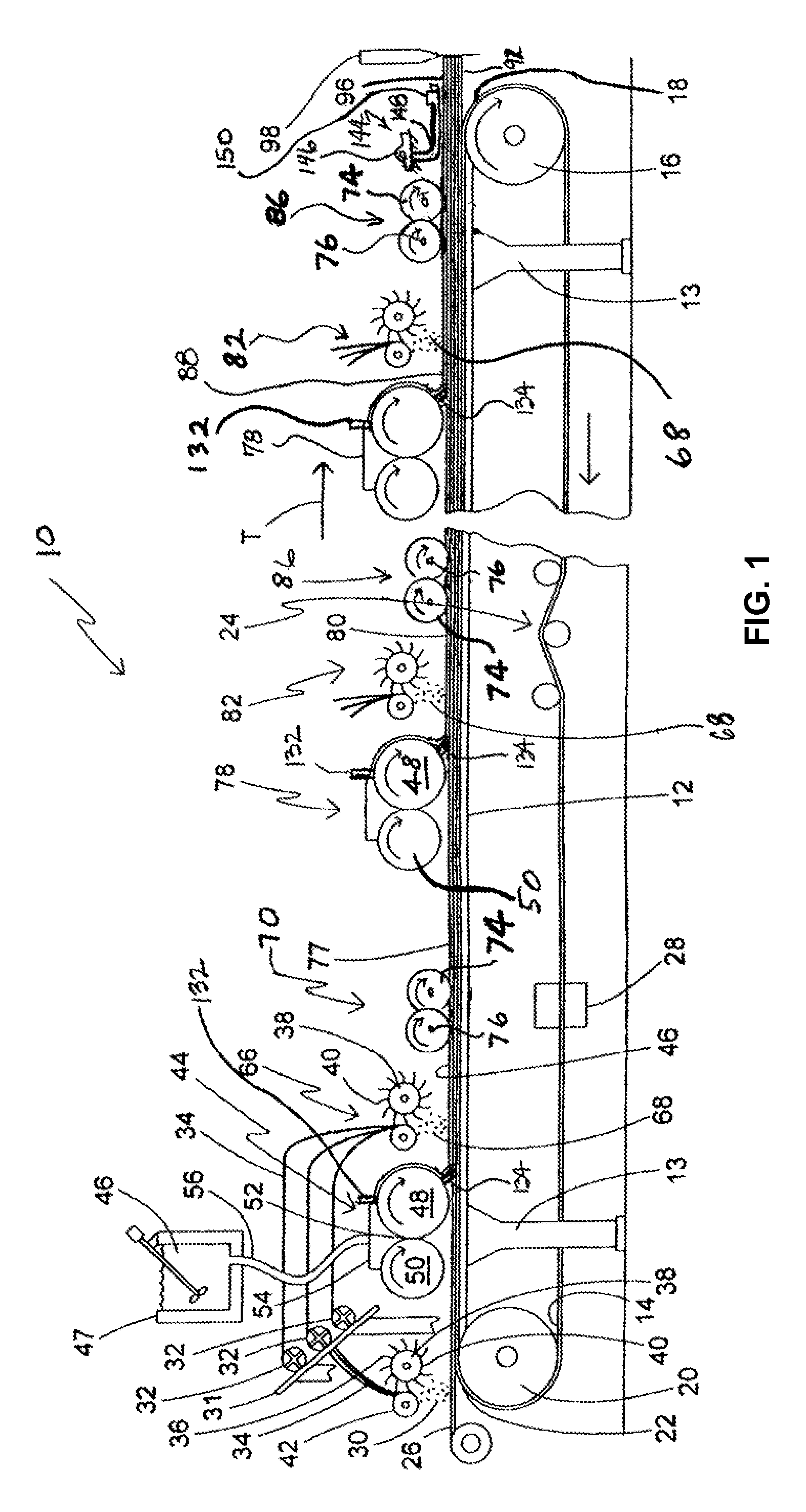

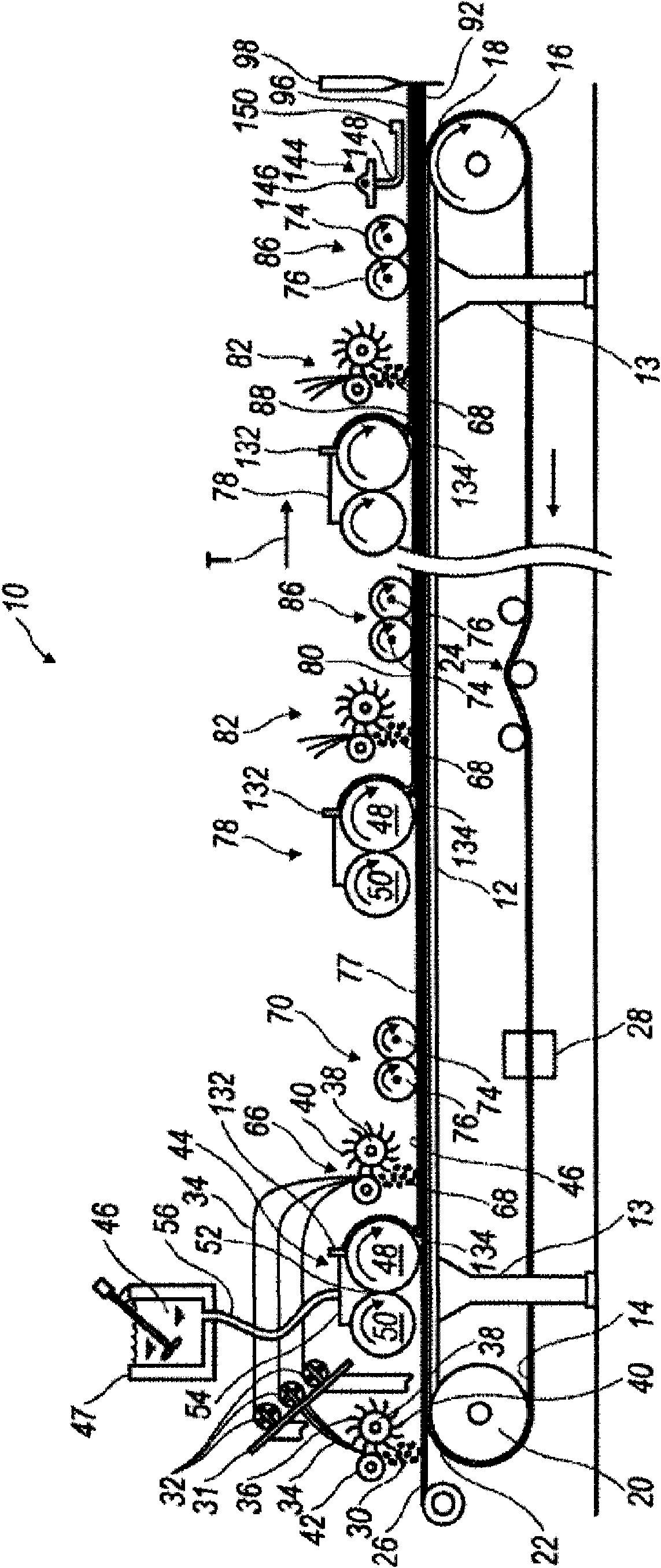

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS20080101150A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

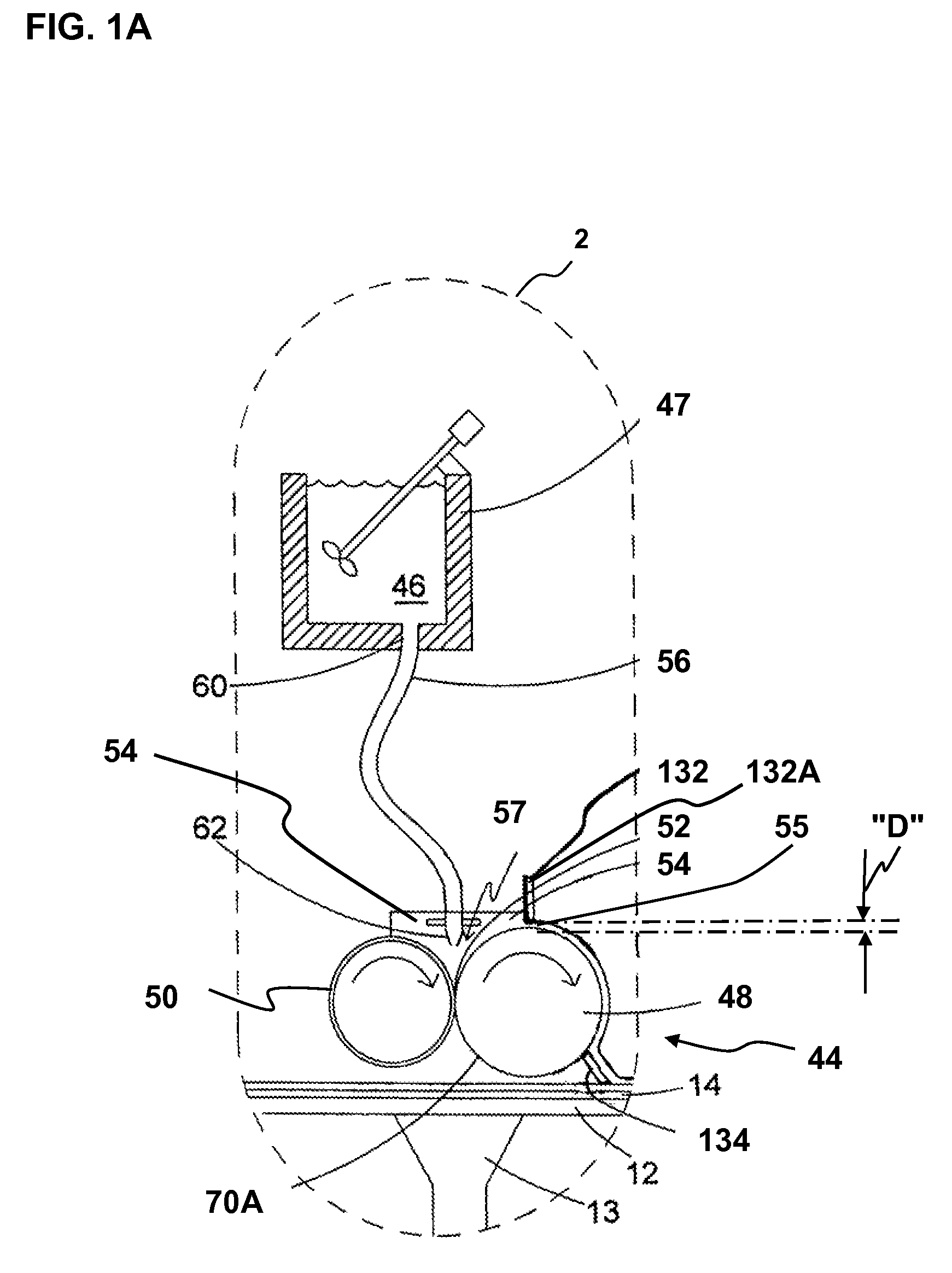

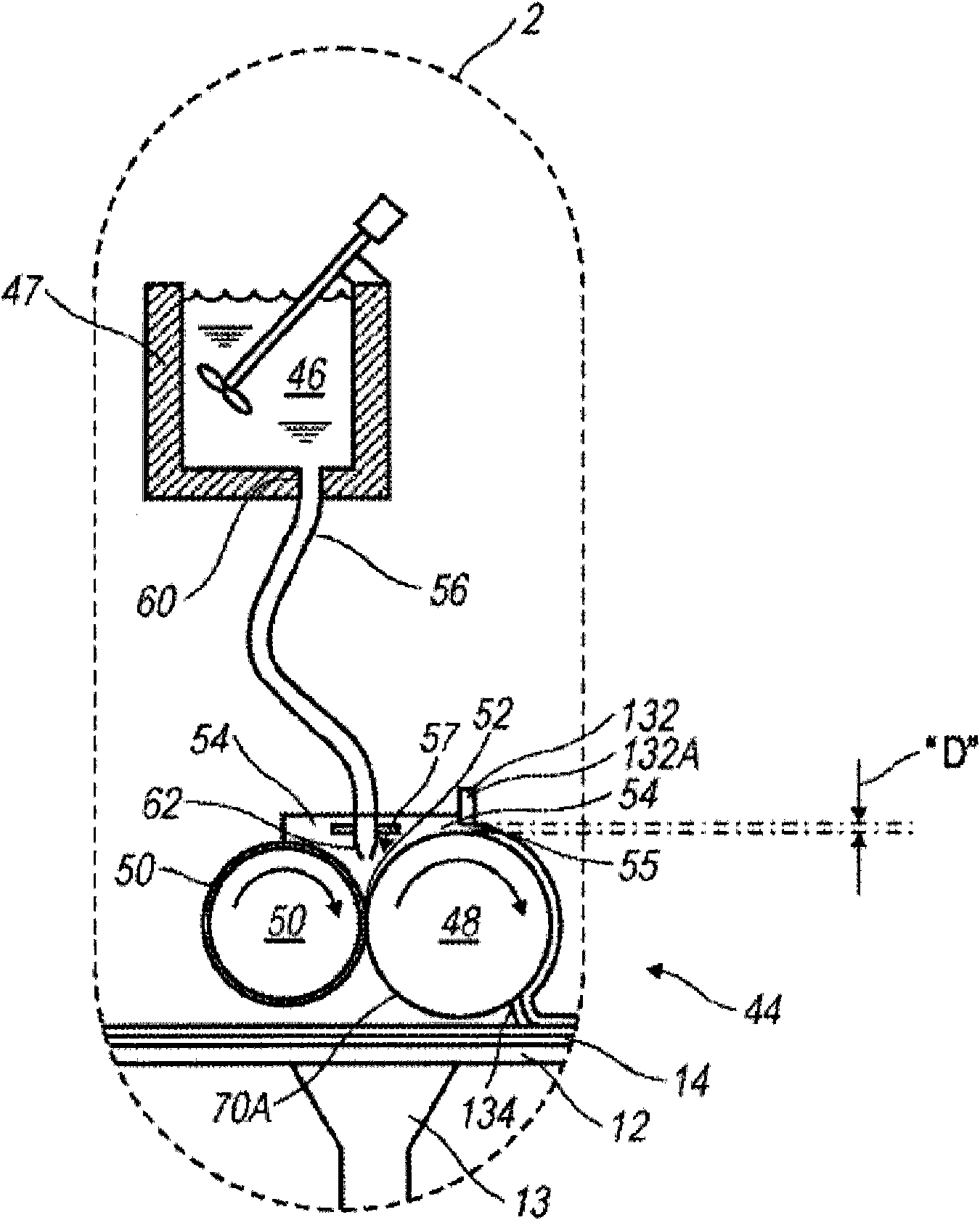

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed means for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

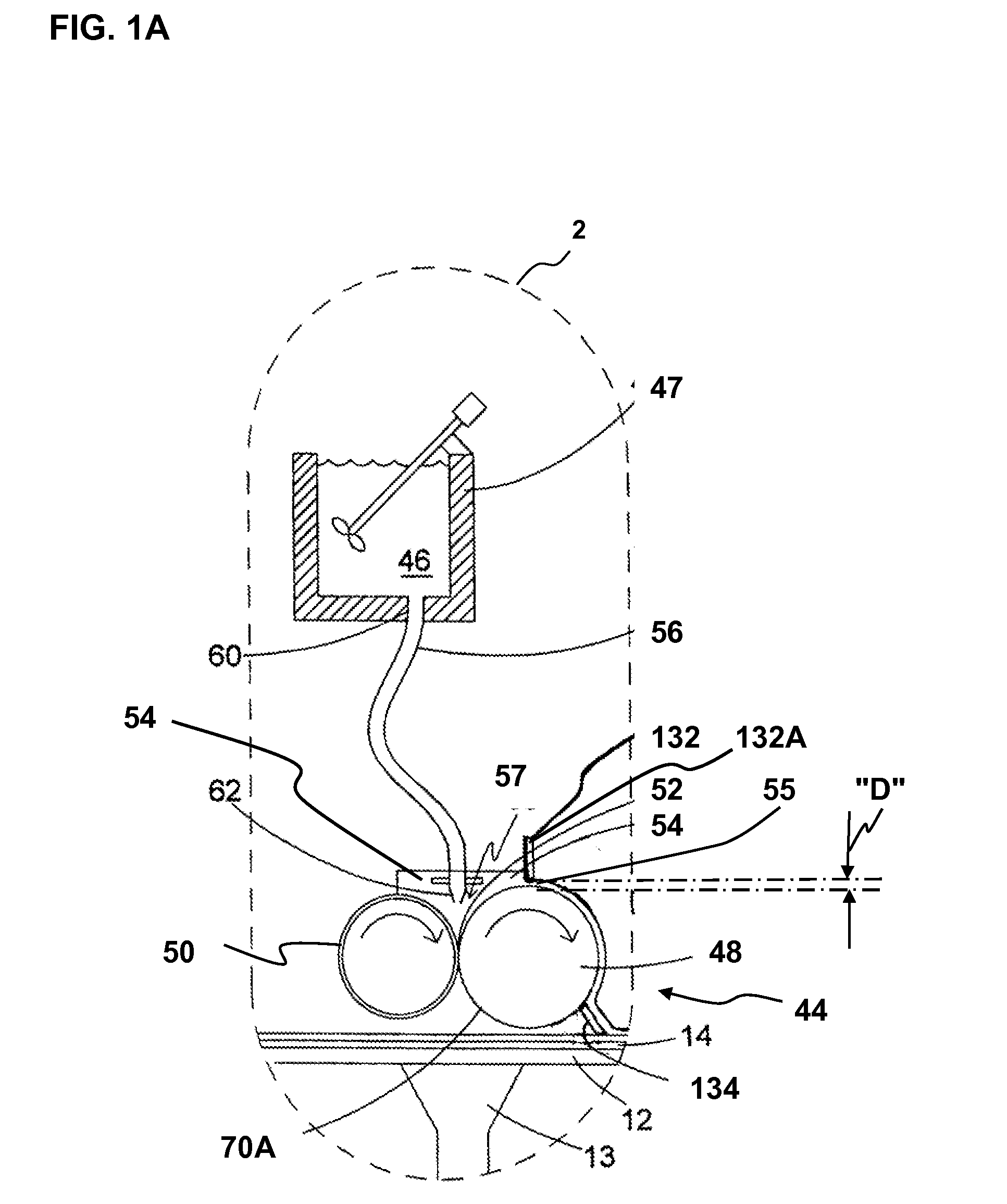

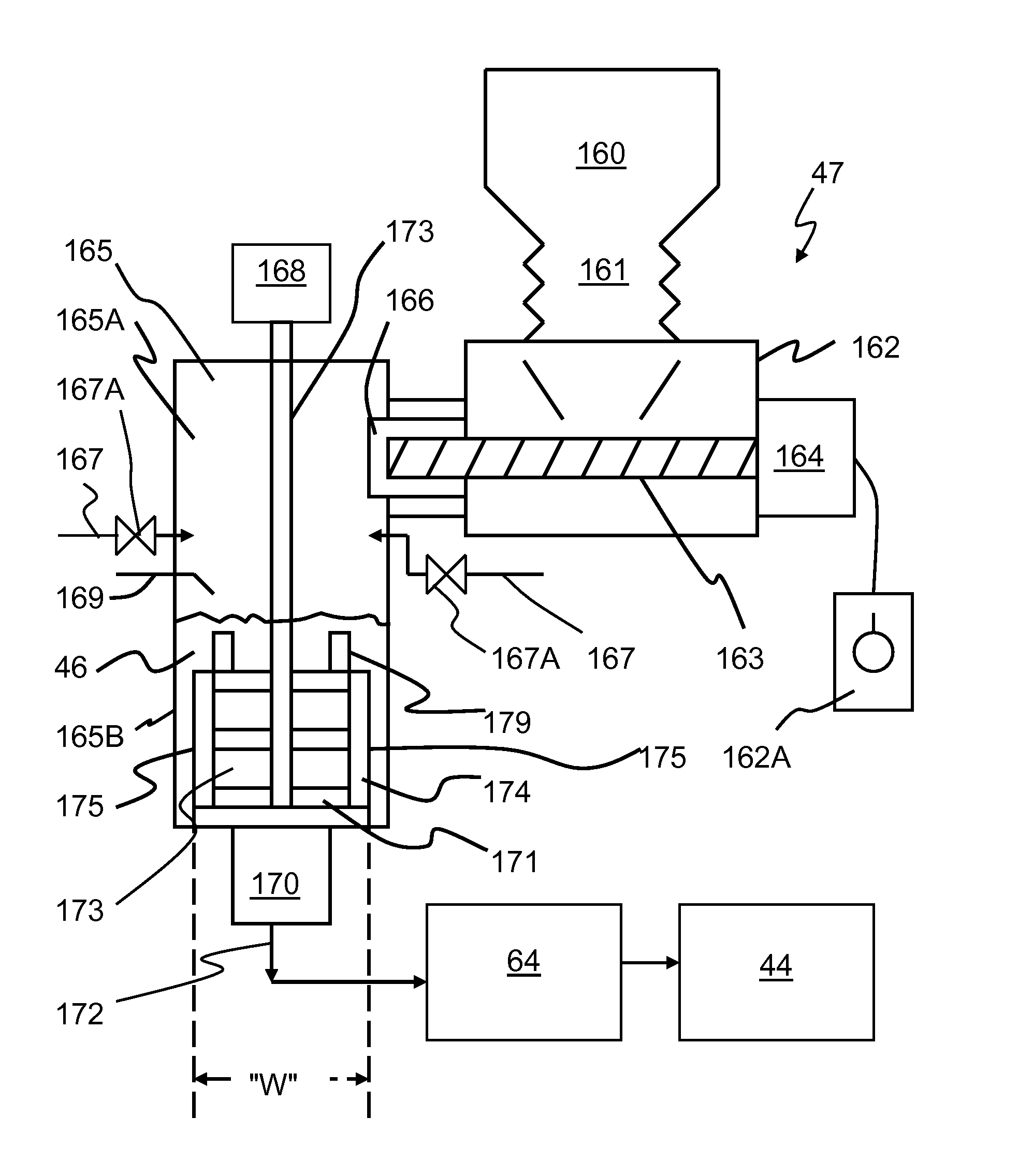

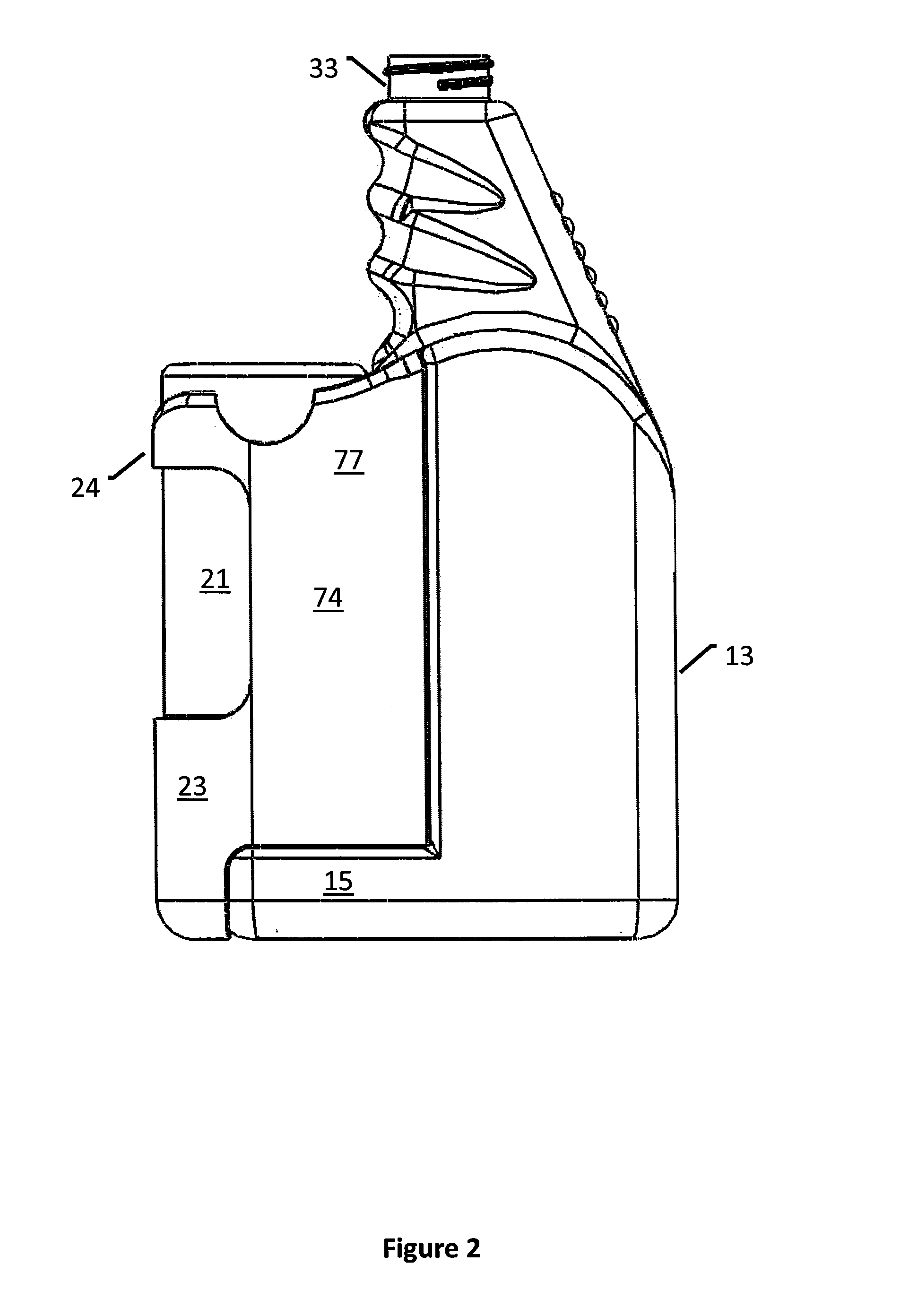

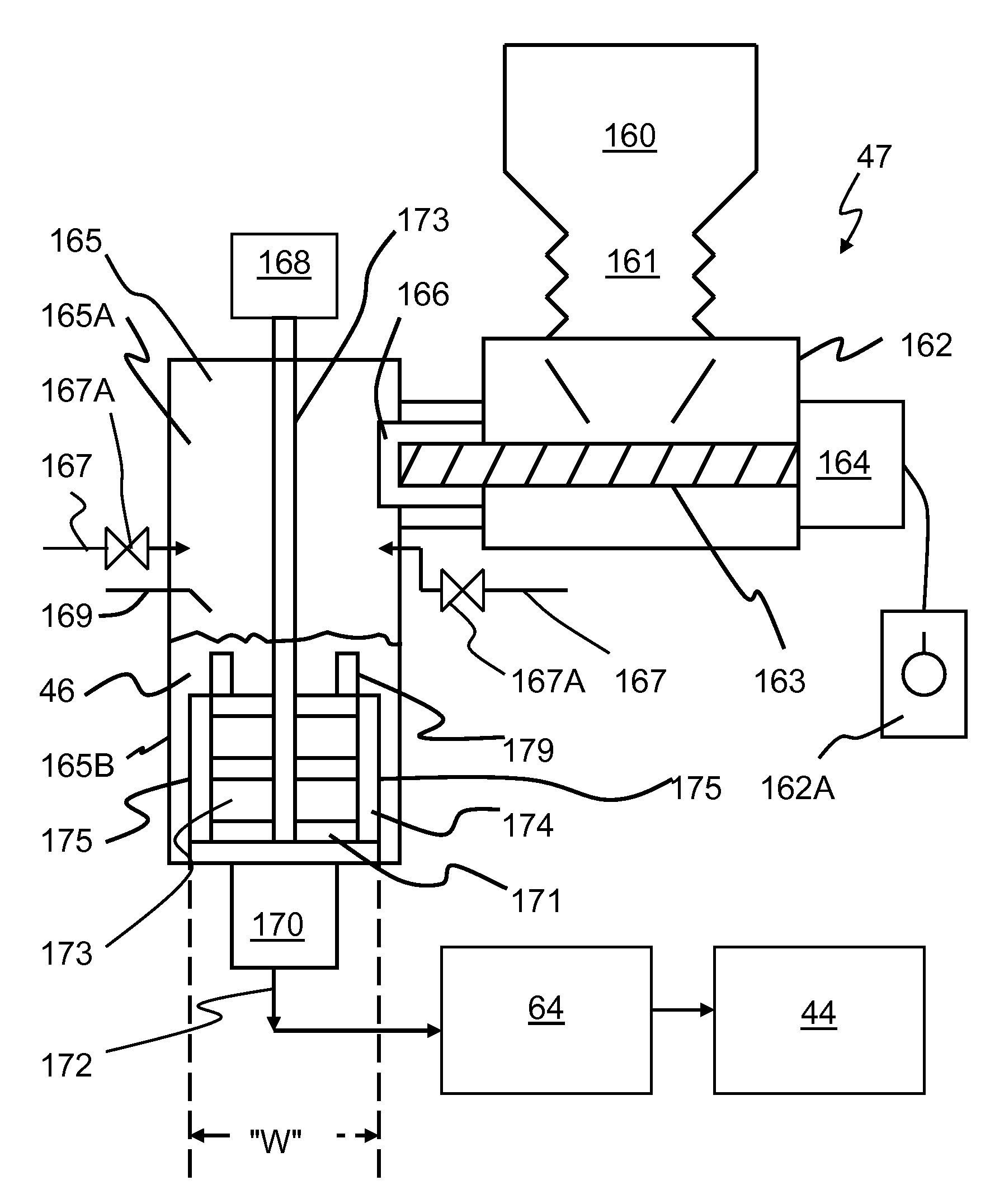

Apparatus and method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080101151A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

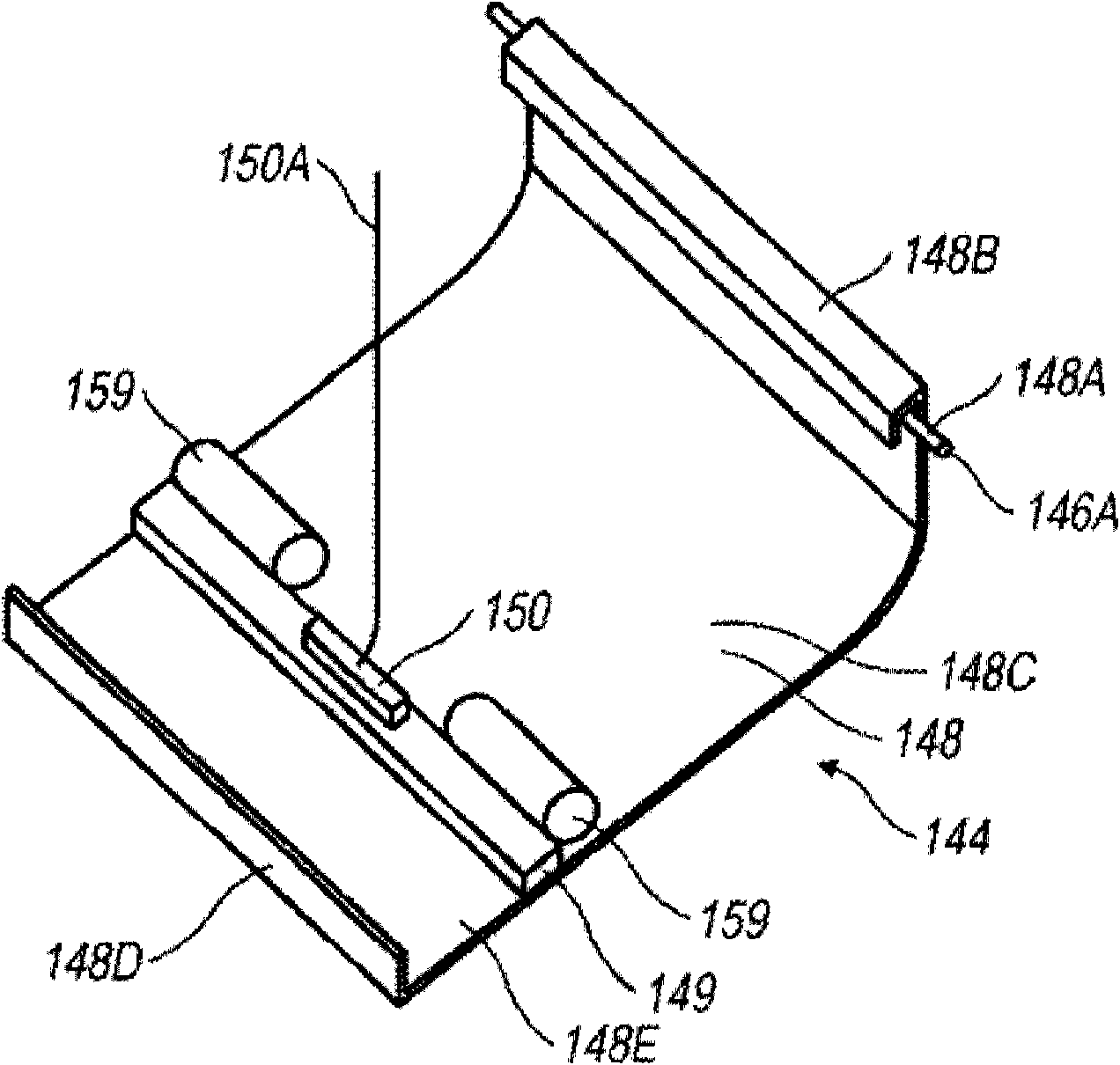

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

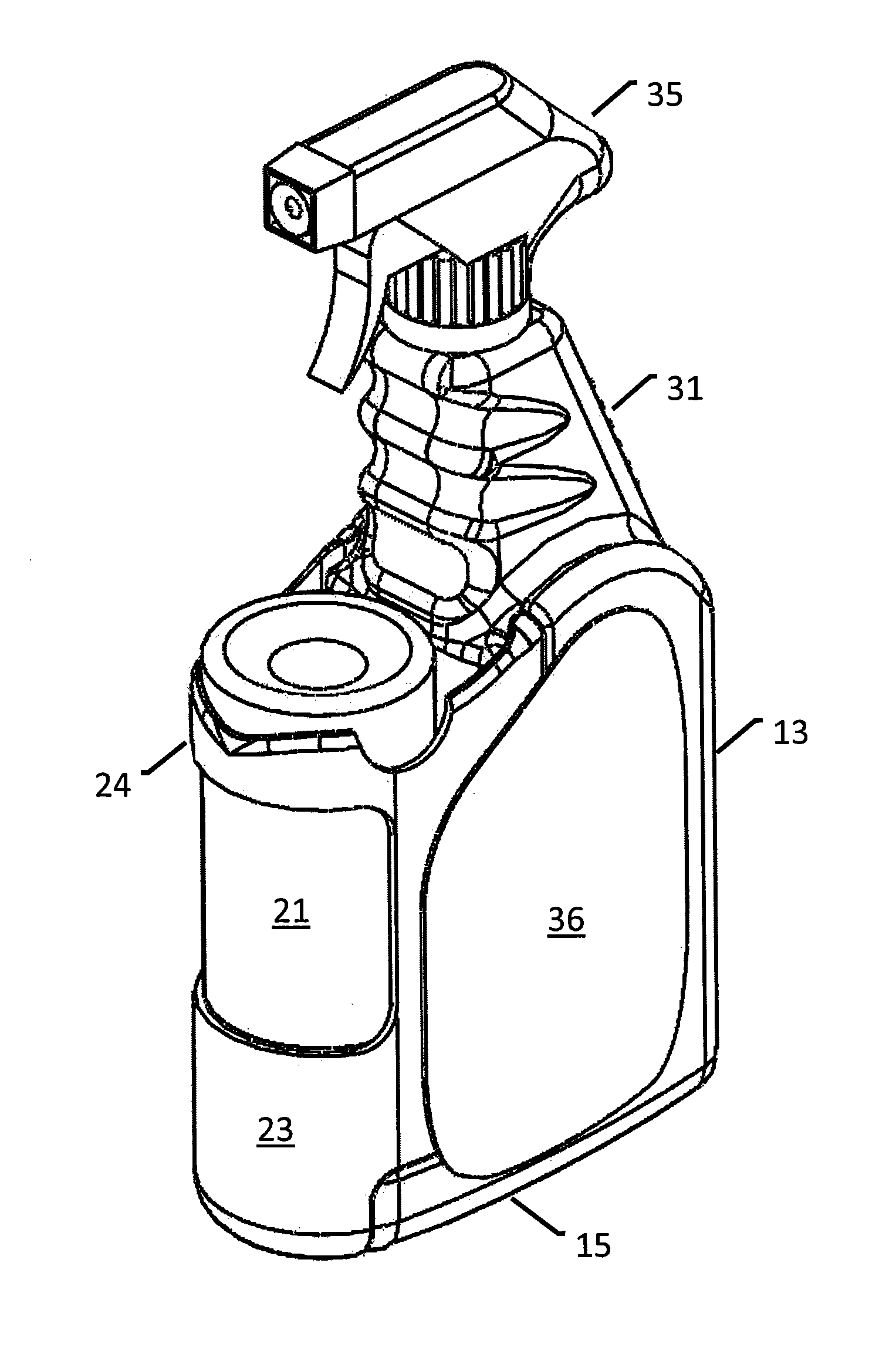

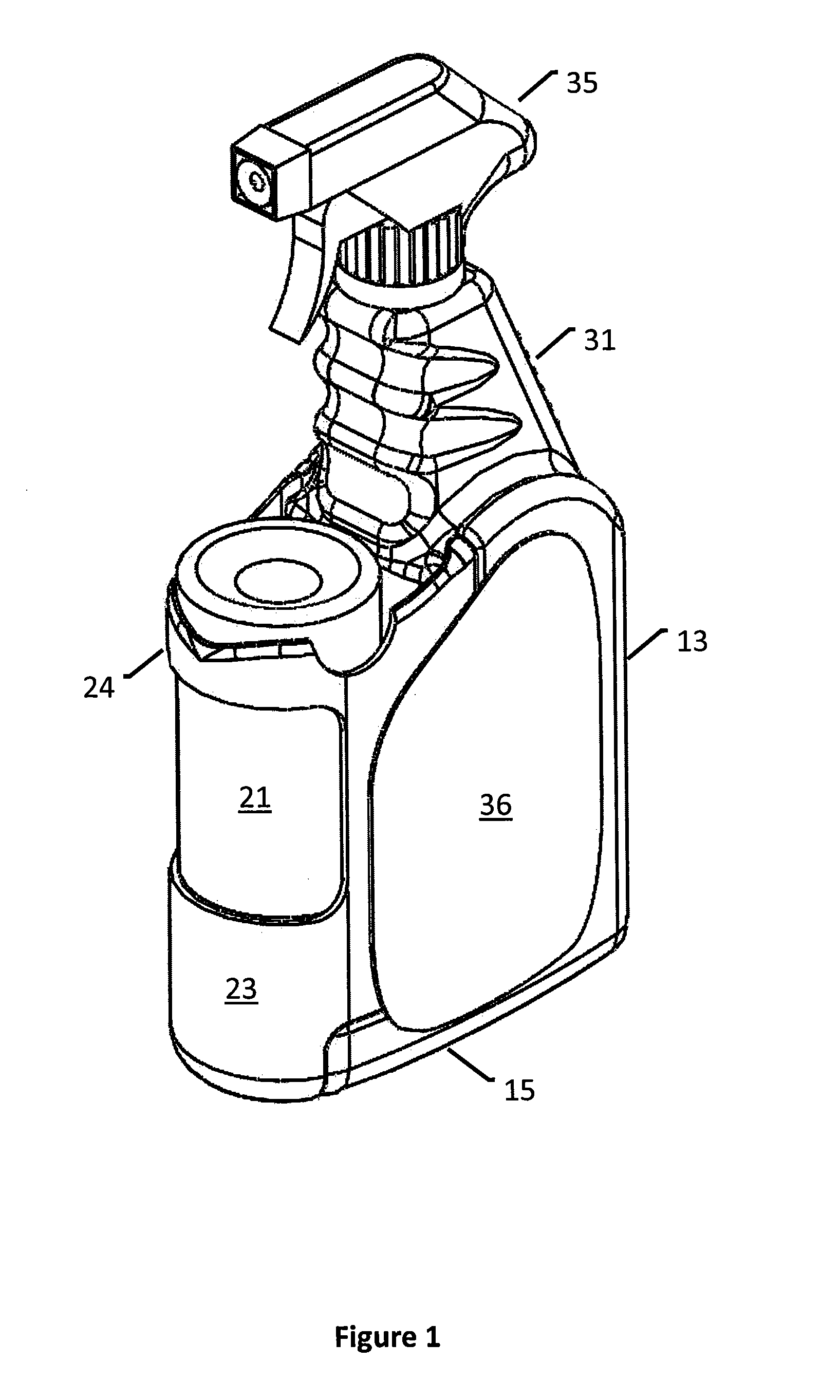

Apparatus for mixing measured amounts of concentrate with a dilutant and method of using same

A vertical mixing chamber with a forwardly projecting dock having a receiver in its top wall for receiving the spout of a pre-pressurized cartridge mounted from the container by a holder providing for reciprocation to engage a spout with the receiver and open a valve in the cartridge.

Owner:FIT SYST

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS7524386B2Increase volumeSmall sizeSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

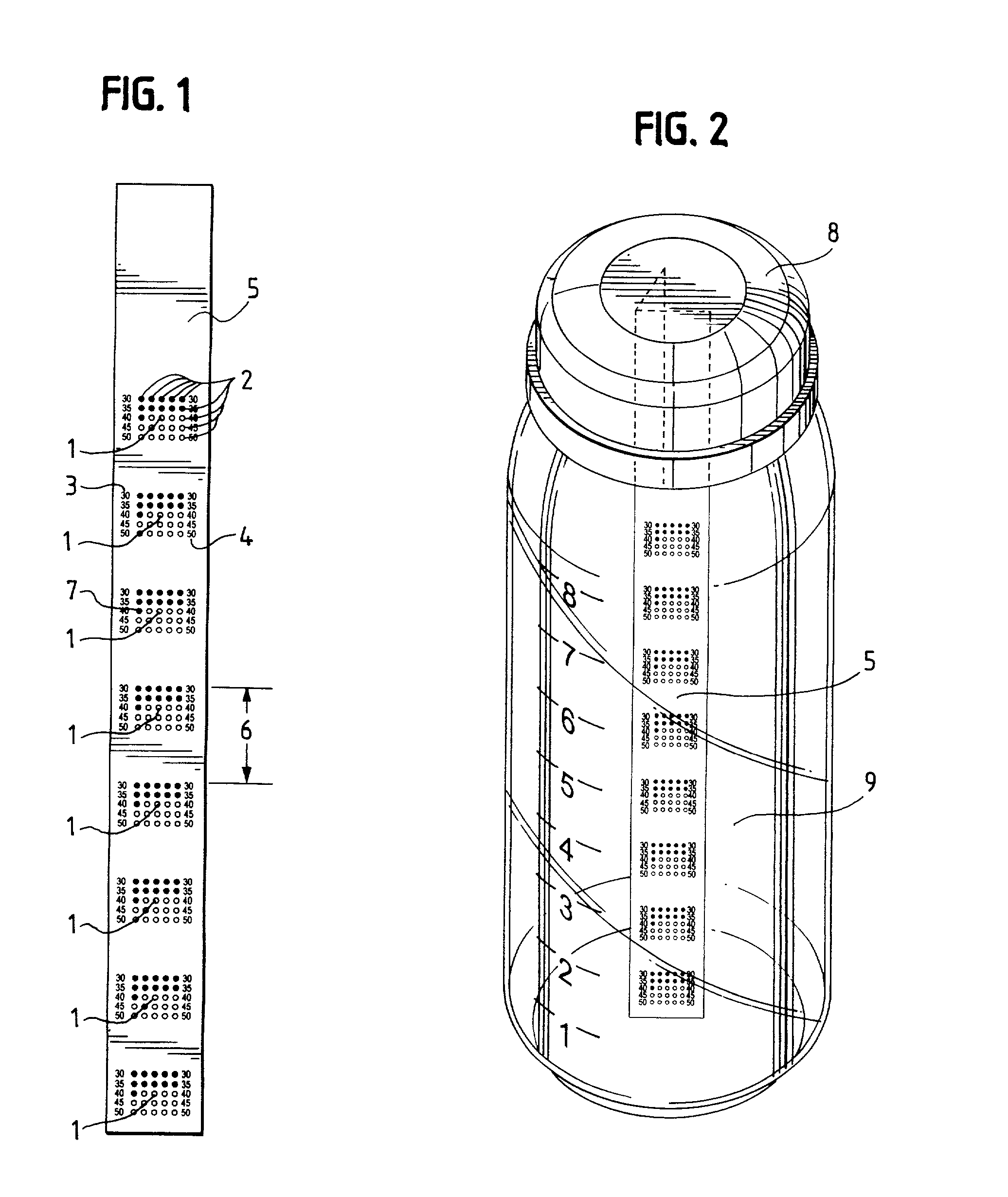

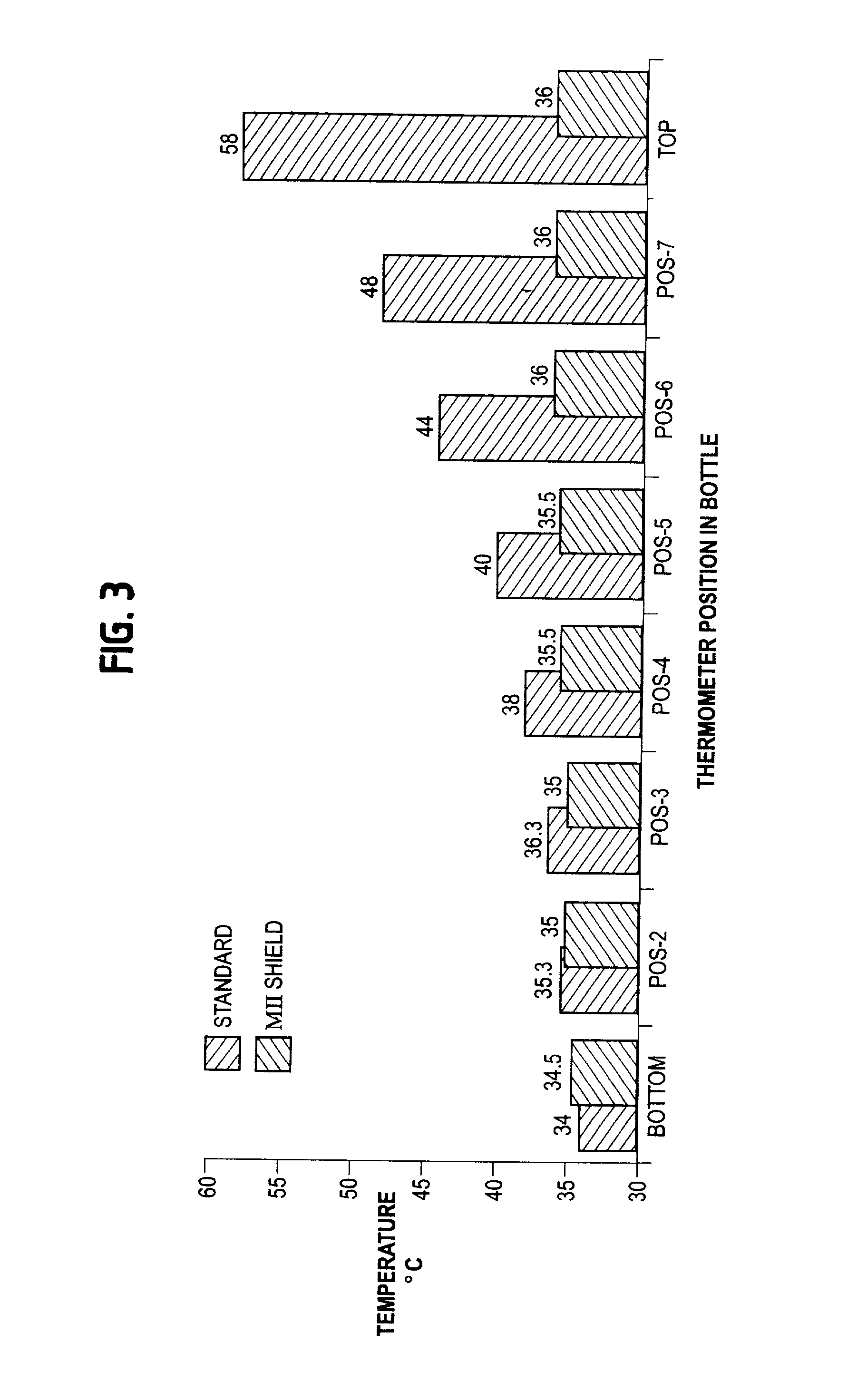

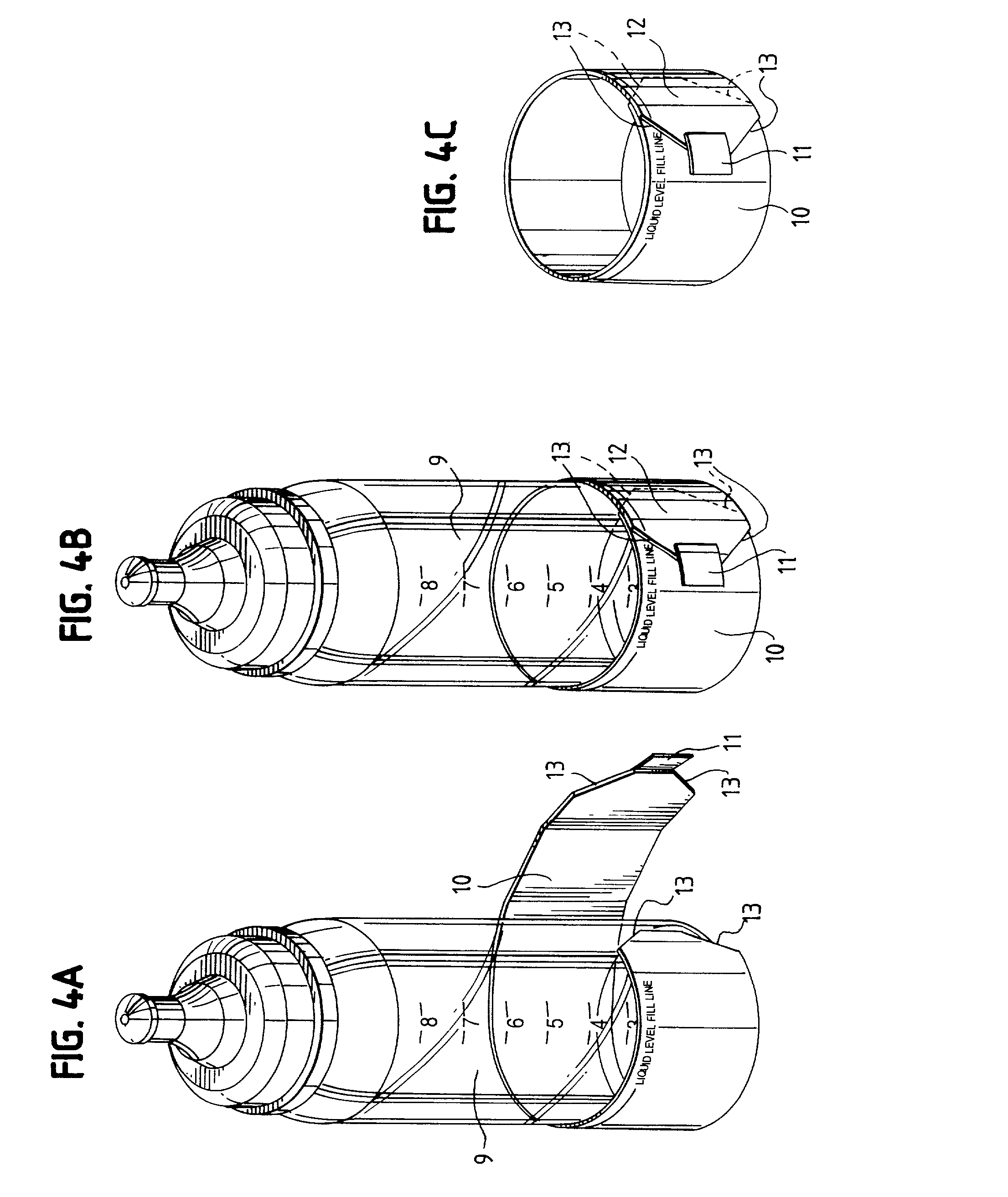

Shielding method for microwave heating of infant formula to a safe and uniform temperature

InactiveUS6410896B2Minimal reflectionMinimize electric field intensityThermometer detailsDough treatmentVertical mixingEngineering

Owner:MEDICAL INDICATORS INC

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS7513963B2Increase volumeSmall sizeSolid waste managementTransportation and packagingProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

Nano carbon-fiber composite electrical heating material and preparing method thereof

InactiveCN102348297AAbundant raw materialsEasy to buyHeating element materialsCable/conductor manufactureCarbon fibersFire retardant

The invention relates to a nano carbon-fiber composite electrical heating material and a preparing method thereof. The nano carbon-fiber composite electrical heating material can effectively solve the problem that the dispersion uniformity of the electrical heating coating is influenced even the phenomenon of aggregation flocculation is formed. The nano carbon-fiber composite electrical heating material is prepared from the following components by weight percentage: 5-15% of nano carbon fiber powder, 10-25% of conductive acetylene carbon black powder, 10-25% of conductive graphite powder, 10-25% of nano bamboo charcoal powder, 0.1-3% of coupling agent, 0.3-4% of dispersing agent, 1-10% of fire retardant, 1-10% of binding agent, 0.1-1% of defoaming agent and the balance of water. The preparation method comprises the following steps of: uniformly mixing the nano carbon fiber powder and the nano bamboo charcoal powder, adding the water and the coupling agent in the mixture and stirring to obtain a first mixture; uniformly mixing and stirring the conductive acetylene carbon black powder and the conductive graphite powder, then putting into the first mixture, adding the dispersing agent and then putting into a vertical mixing ball mill for dispersed processing to obtain a second mixture; and adding the fire retardant, the binding agent and the defoaming agent to the second mixture,and continuously stirring to obtain the nano carbon-fiber composite electrical heating material. The nano carbon-fiber composite electrical heating material has the advantages of rich raw materials, simple preparing method, easiness in operation, good quality of product, safety and environment friendliness, wide application and huge economic and social benefits.

Owner:XINYANG HUANYU KNITTING GARMENT

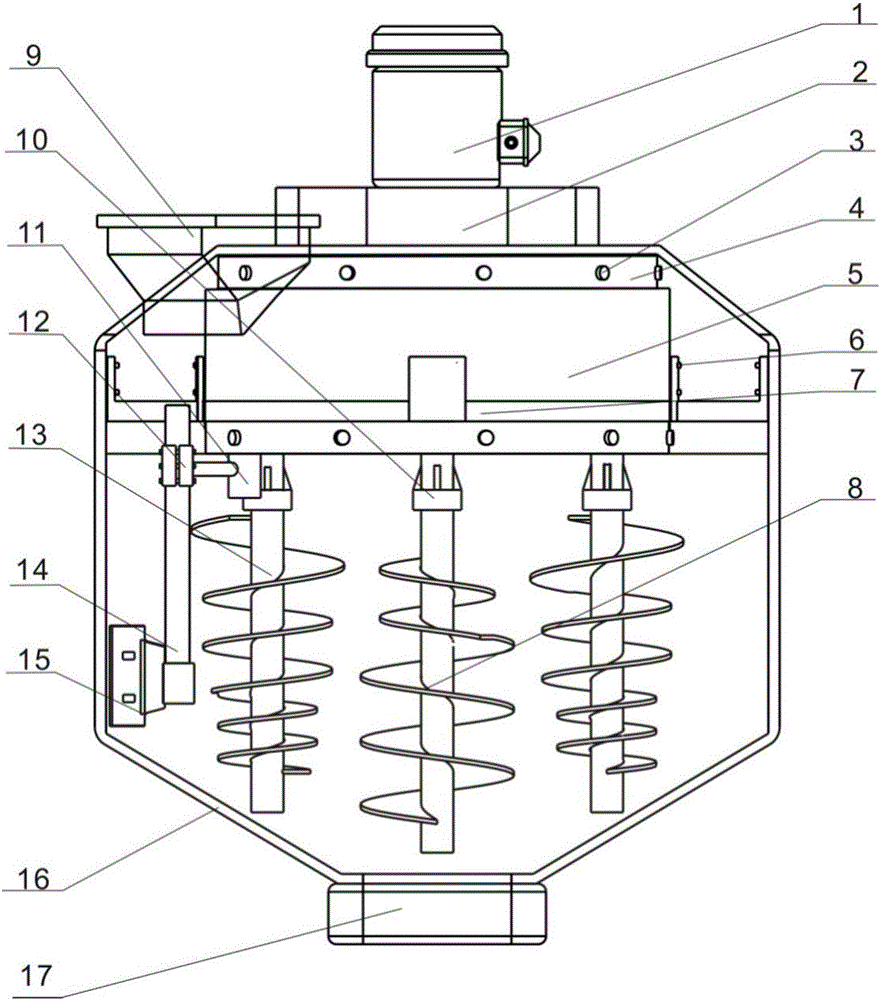

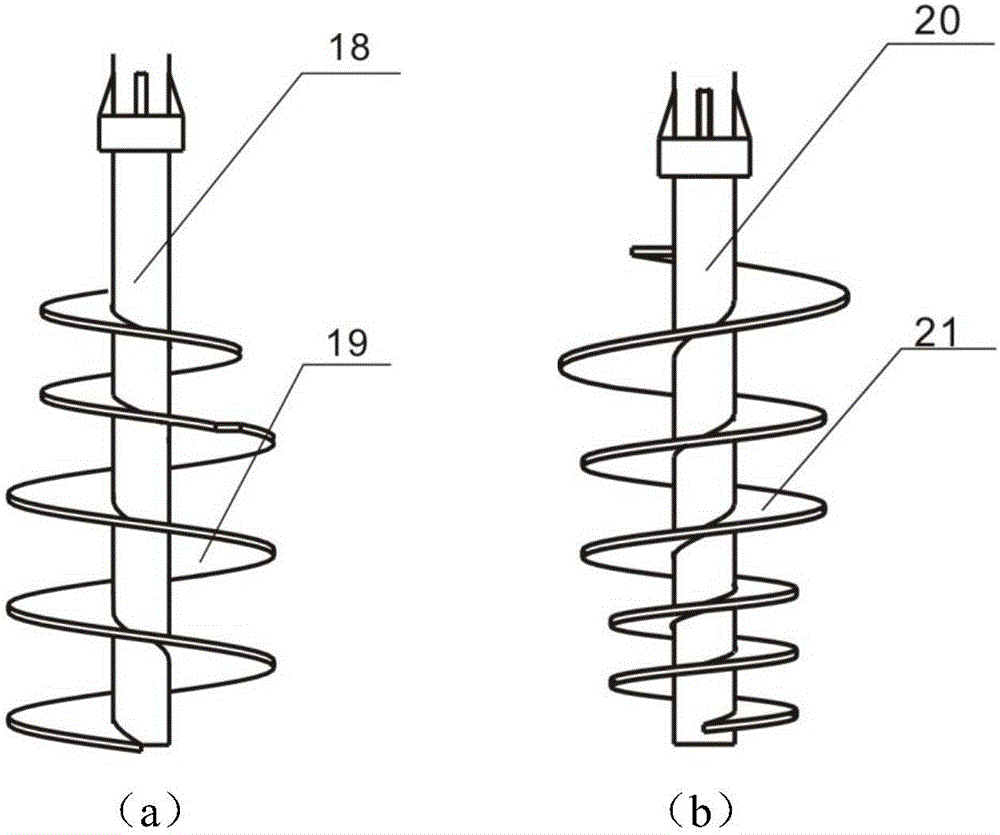

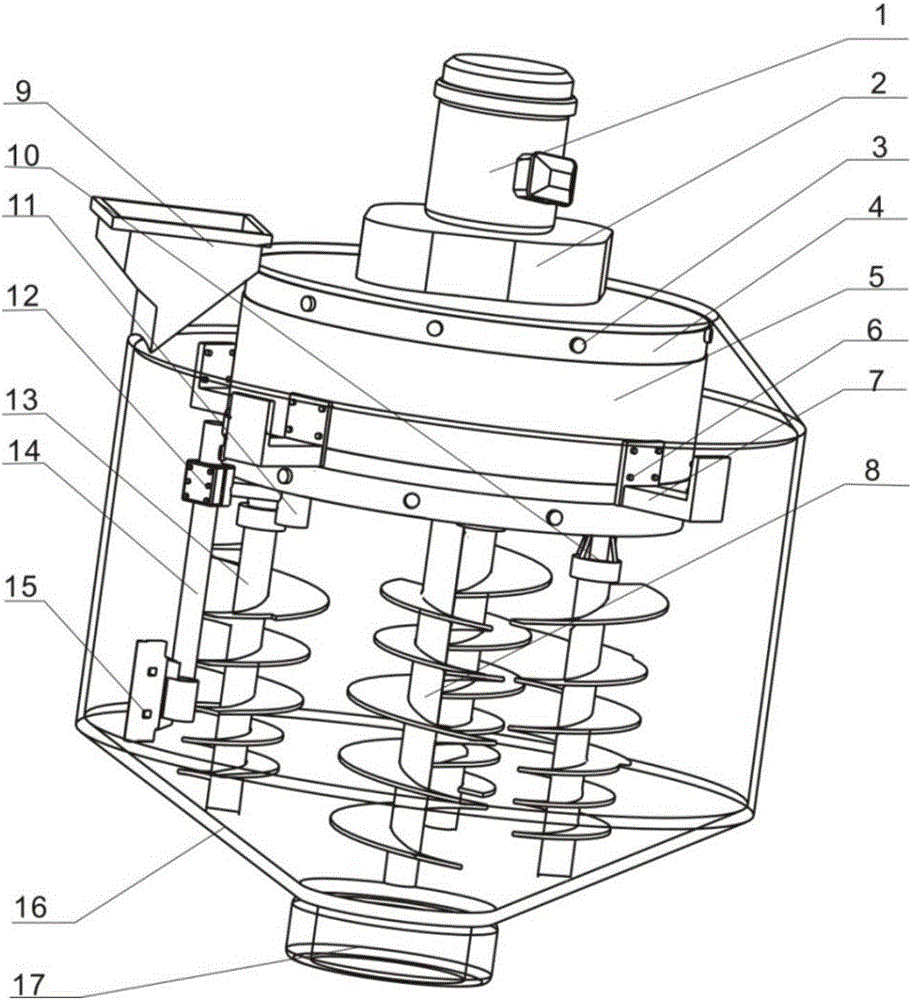

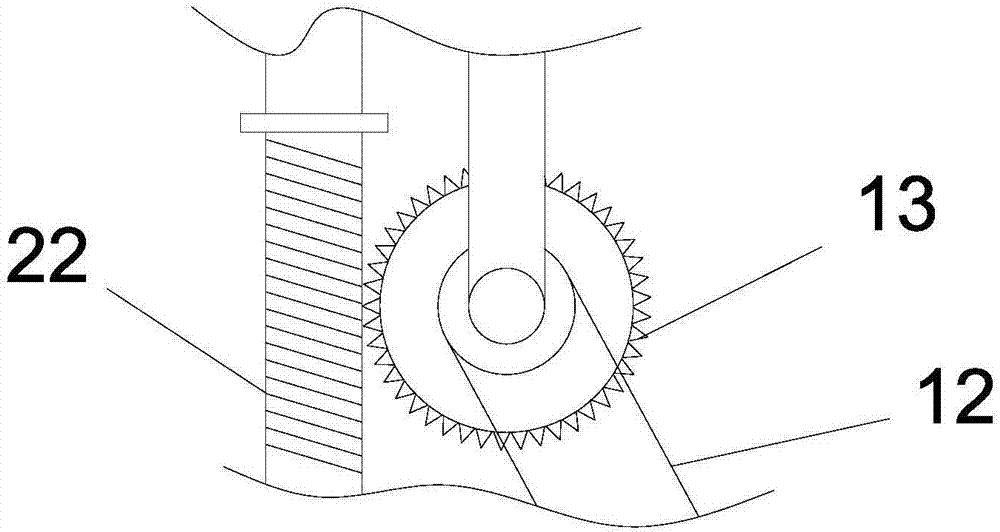

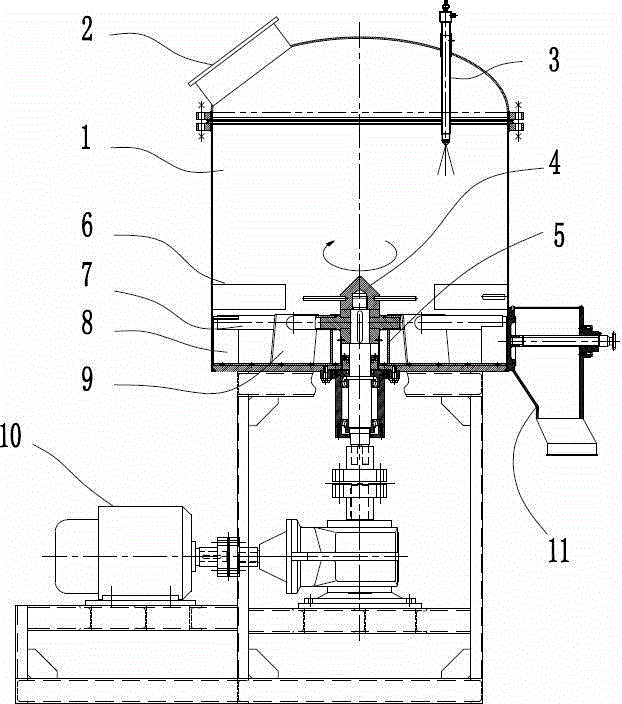

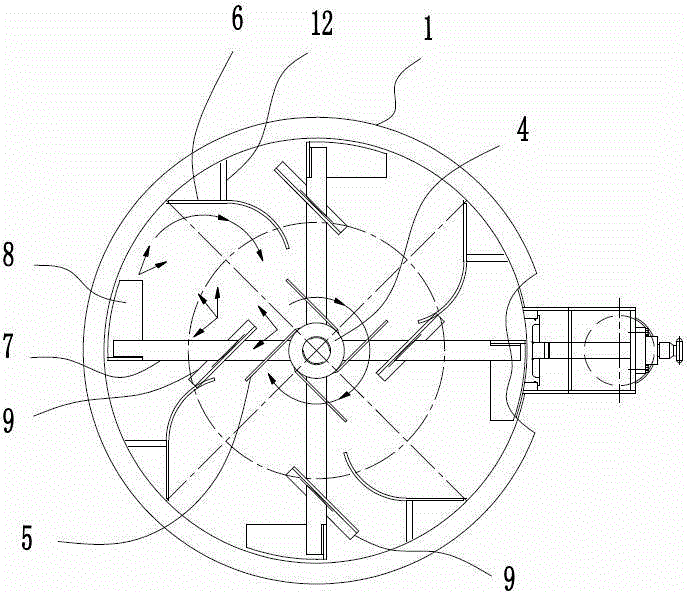

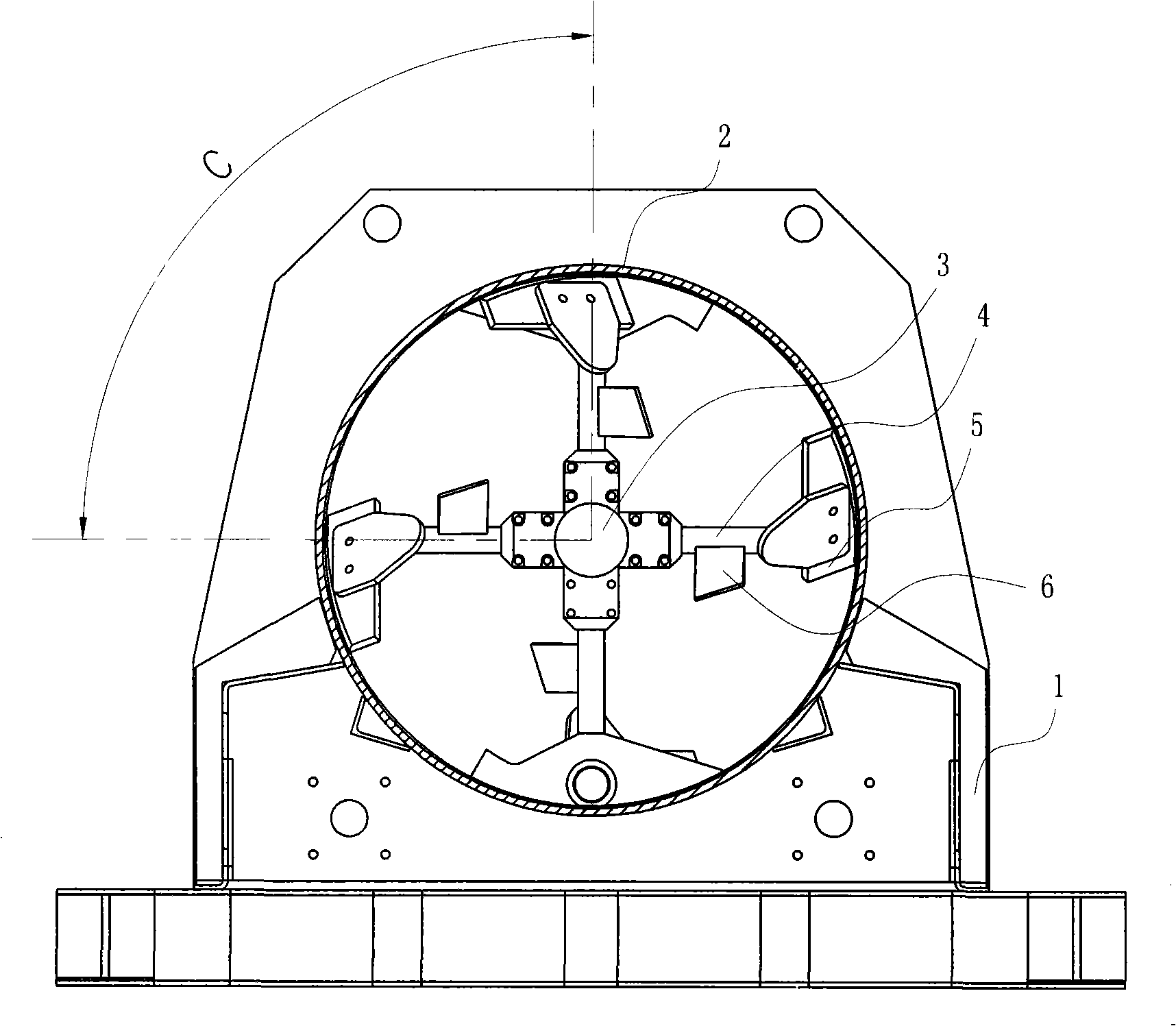

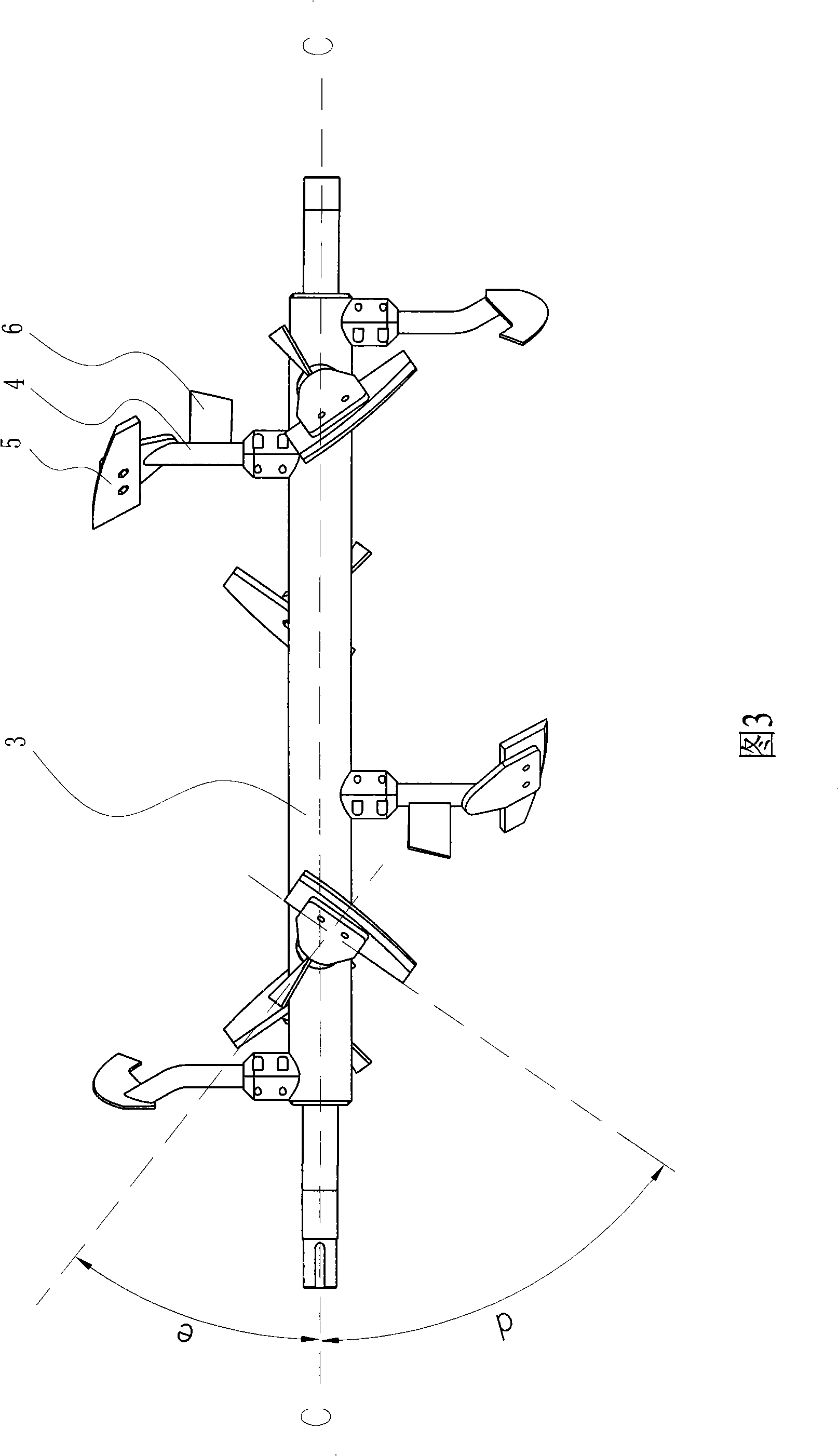

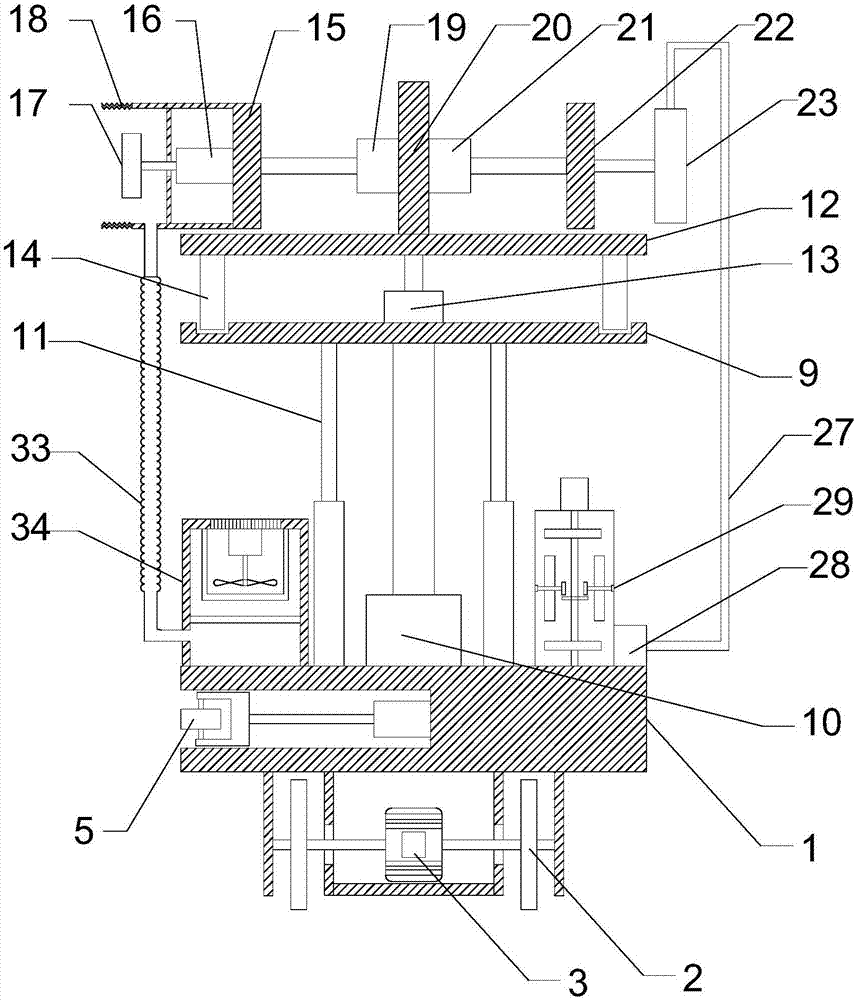

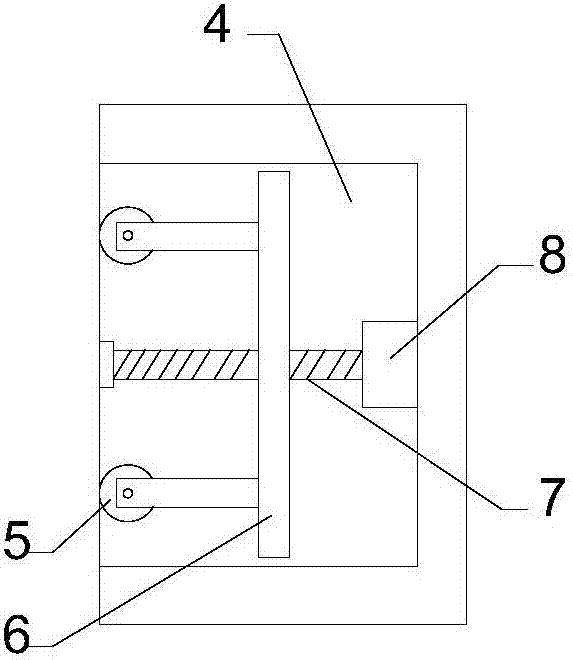

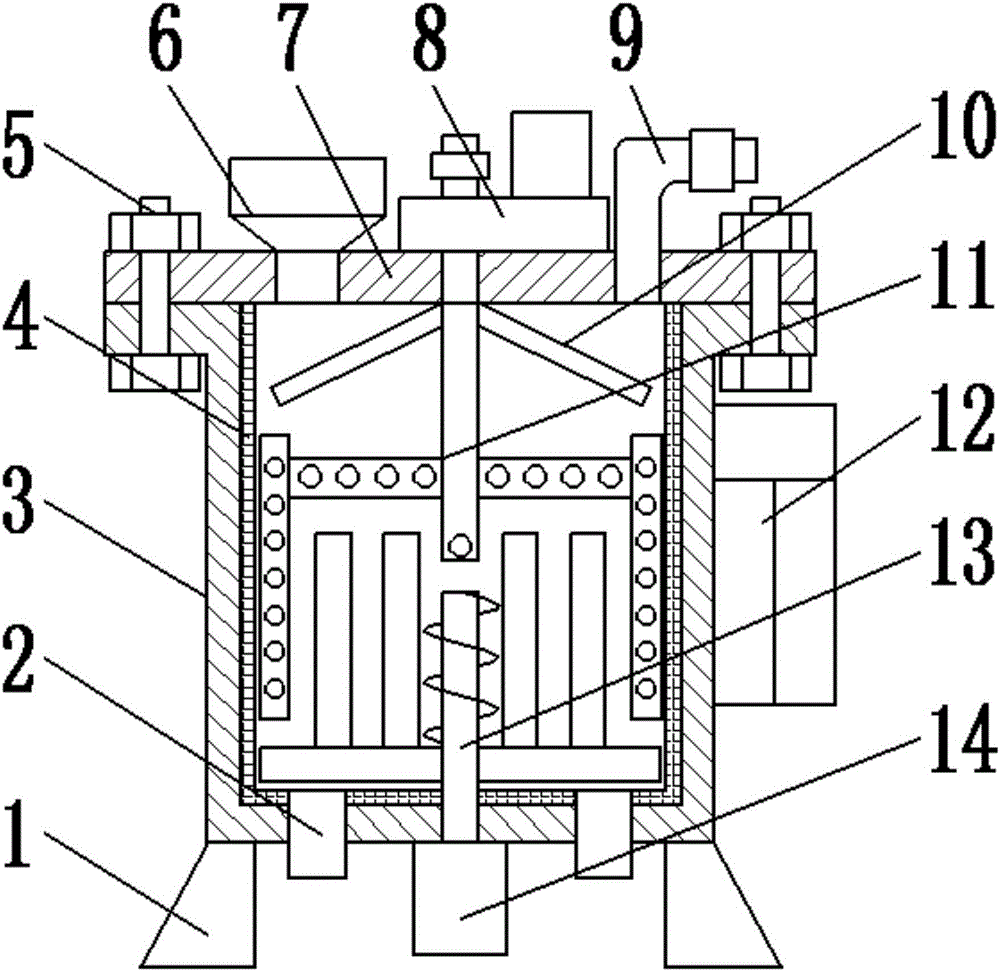

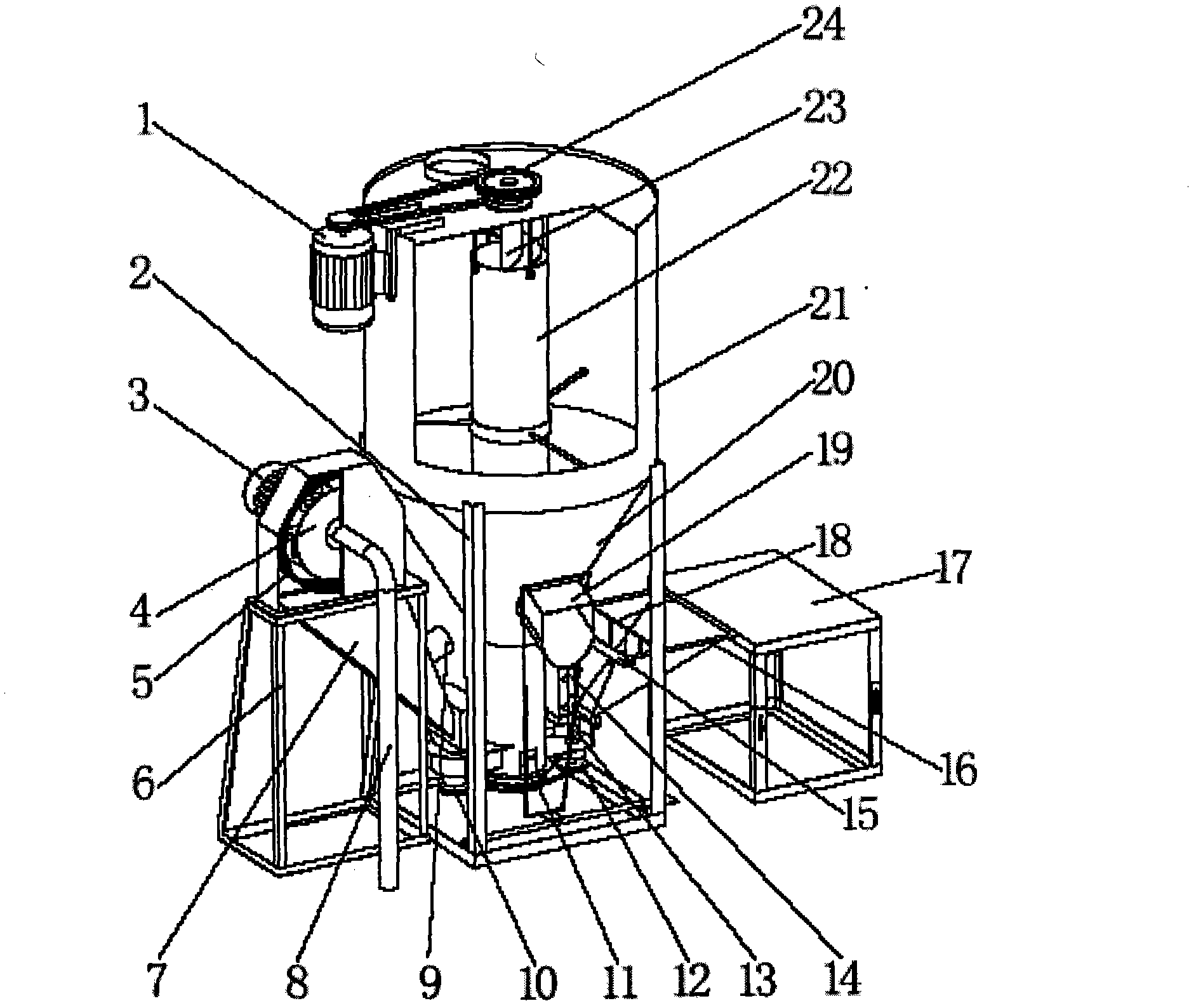

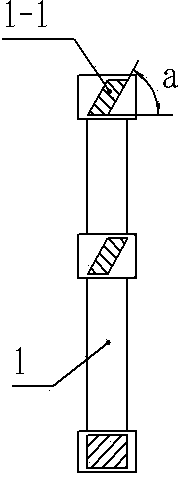

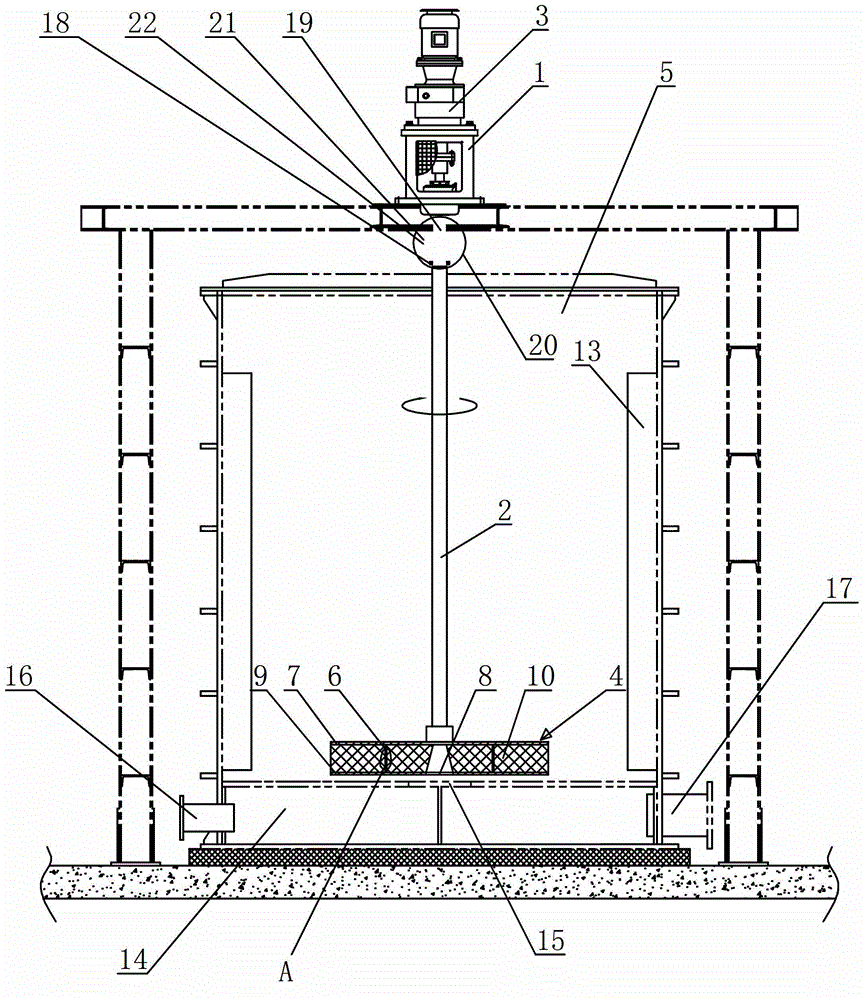

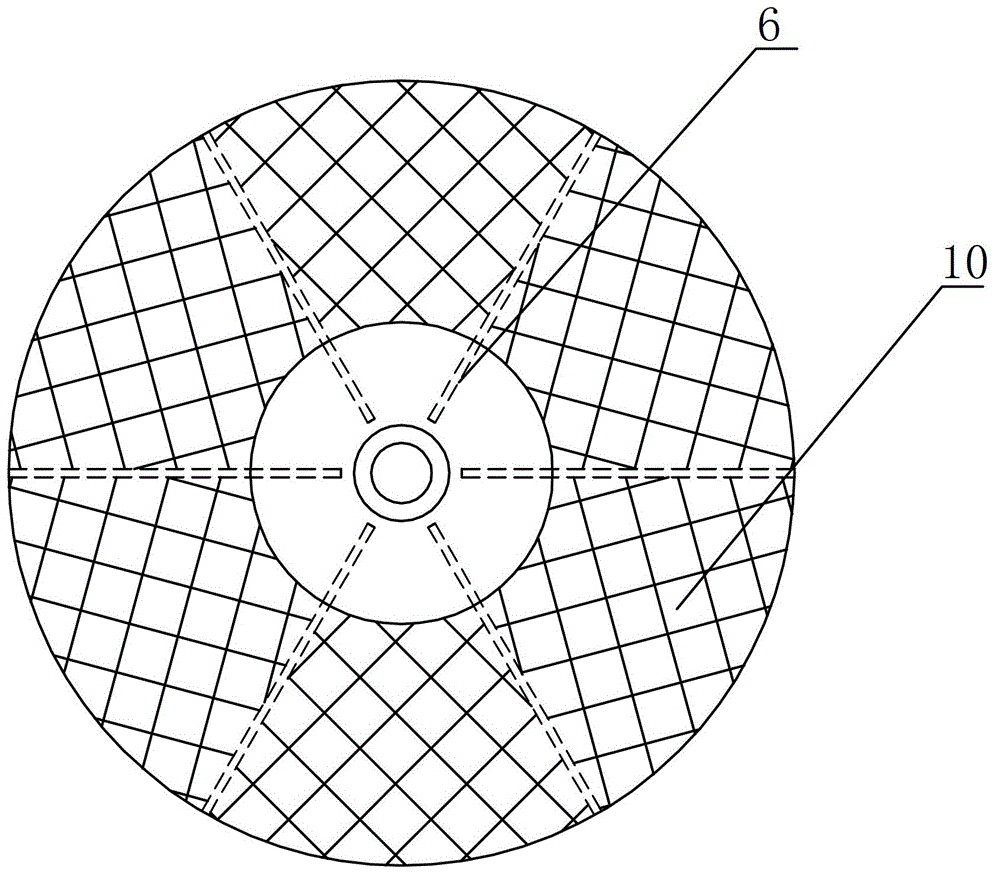

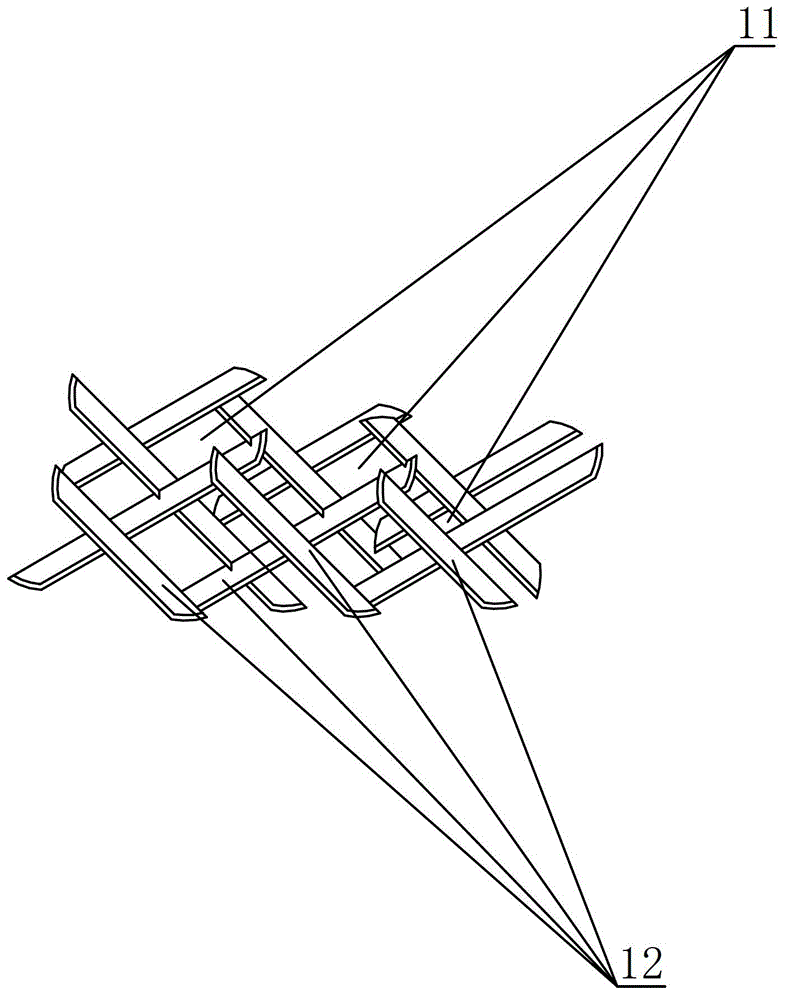

Variable-diameter variable-pitch spiral vertical planetary mixer

InactiveCN106738338AReduce use costImprove stirring efficiencyCement mixing apparatusVertical mixingEngineering

The invention discloses a variable-diameter variable-pitch spiral vertical planetary mixer. The mixer comprises a central screw rod doing fixed-axis rotation, a plurality of planetary screw rods doing planetary motion, a movable scraping plate doing fixed-axis rotation, a planetary gear device and a driving device, wherein a central blade is arranged on the central screw rod, planetary blades are arranged on the planetary screw rods, and the center blade and the planetary blades are variable-diameter and variable-pitch spirals. The mixer is a vertical mixing device which integrates the principles of spiral conveying, planetary motion, gravity and the like, and under the action of the central screw rod, the planetary screw rods, the self-weight and the movable scraping plate, a mixture forms large motion cycles from bottom to top and then from top to bottom while the mixture in the material field also forms a plurality of small motion cycles. According to the mixer, inefficient mixing zones can be effectively reduced, and the mixing efficiency and quality can be improved. Thus, the mixer is suitable for occasions mixing materials such as concrete.

Owner:CHANGAN UNIV

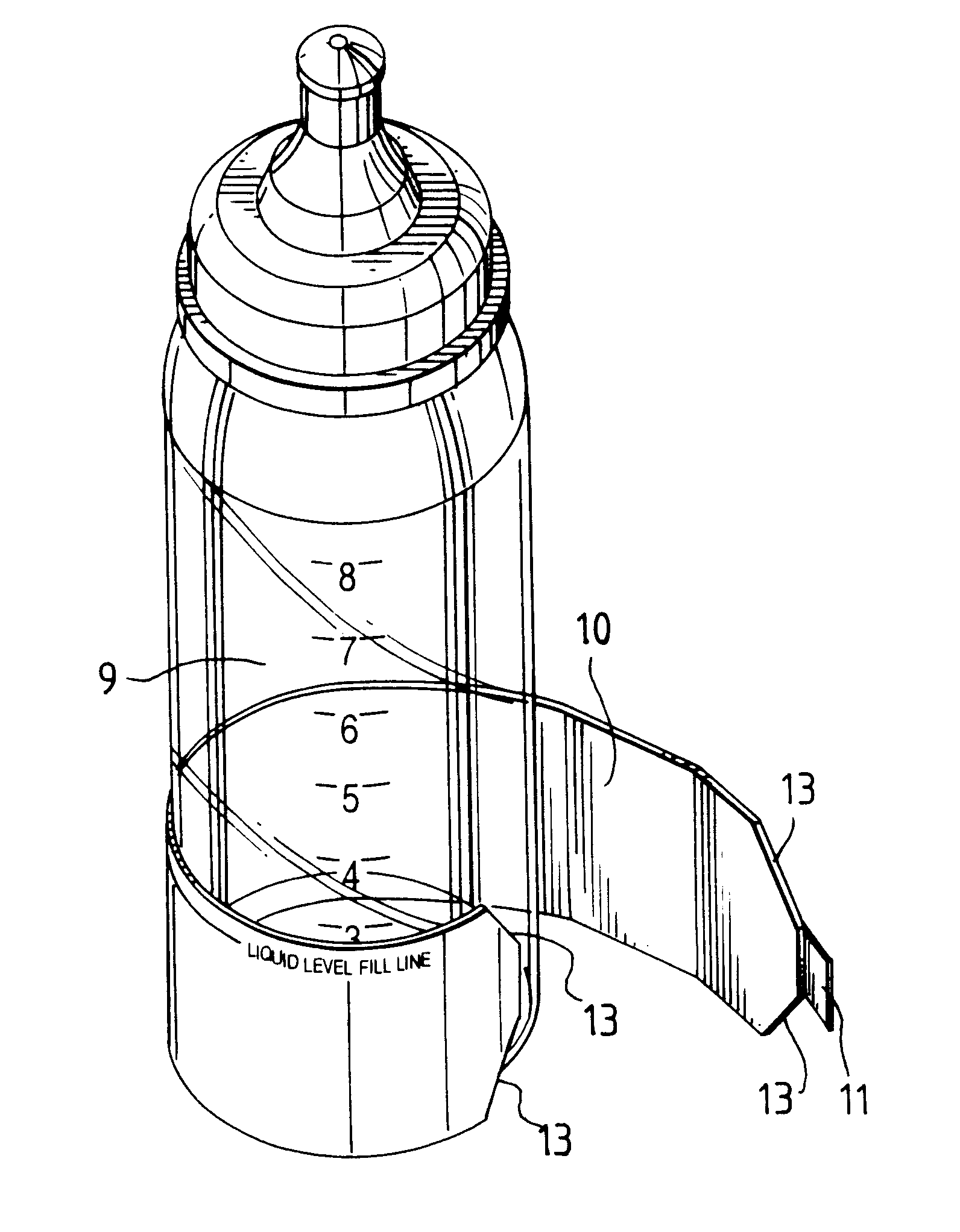

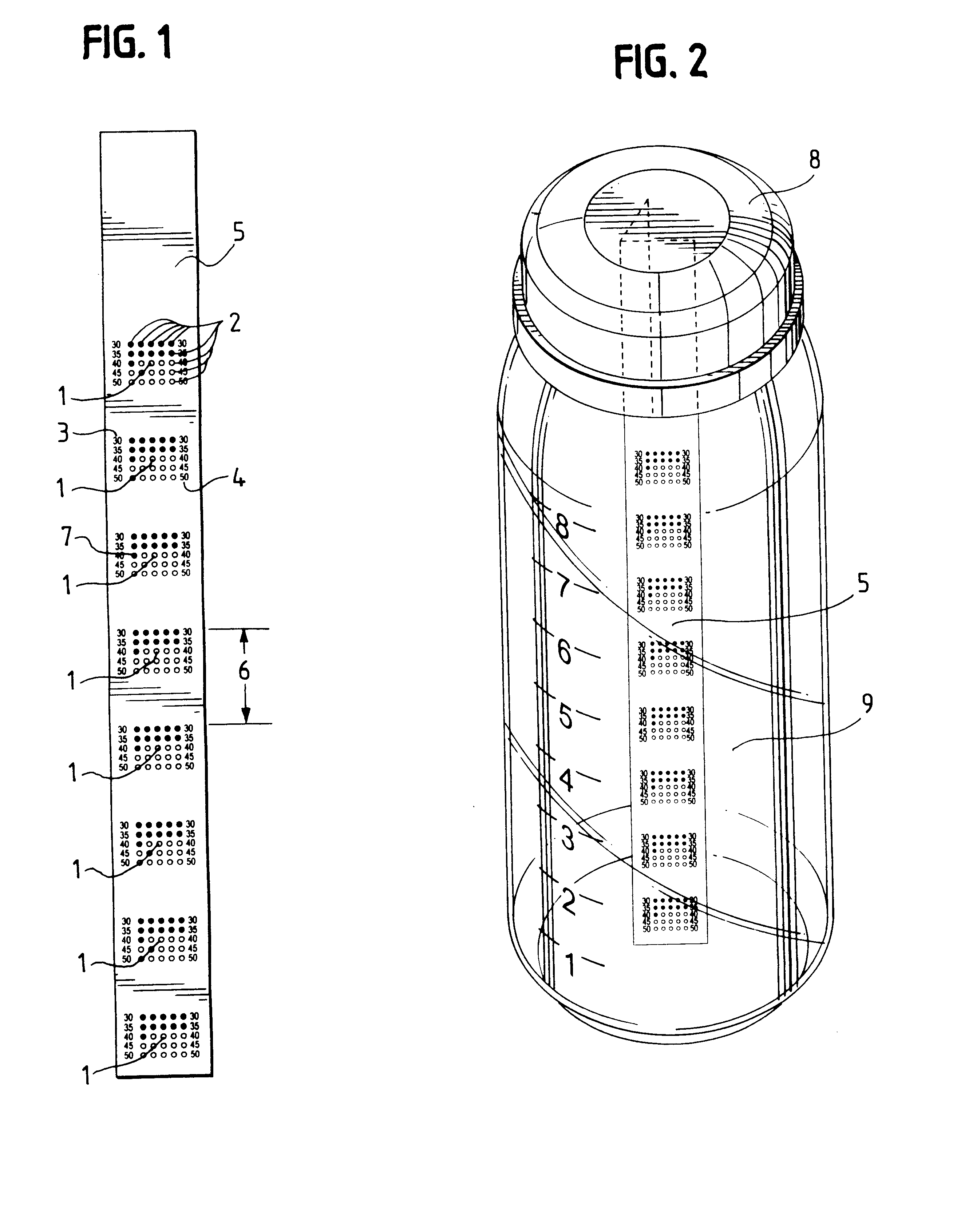

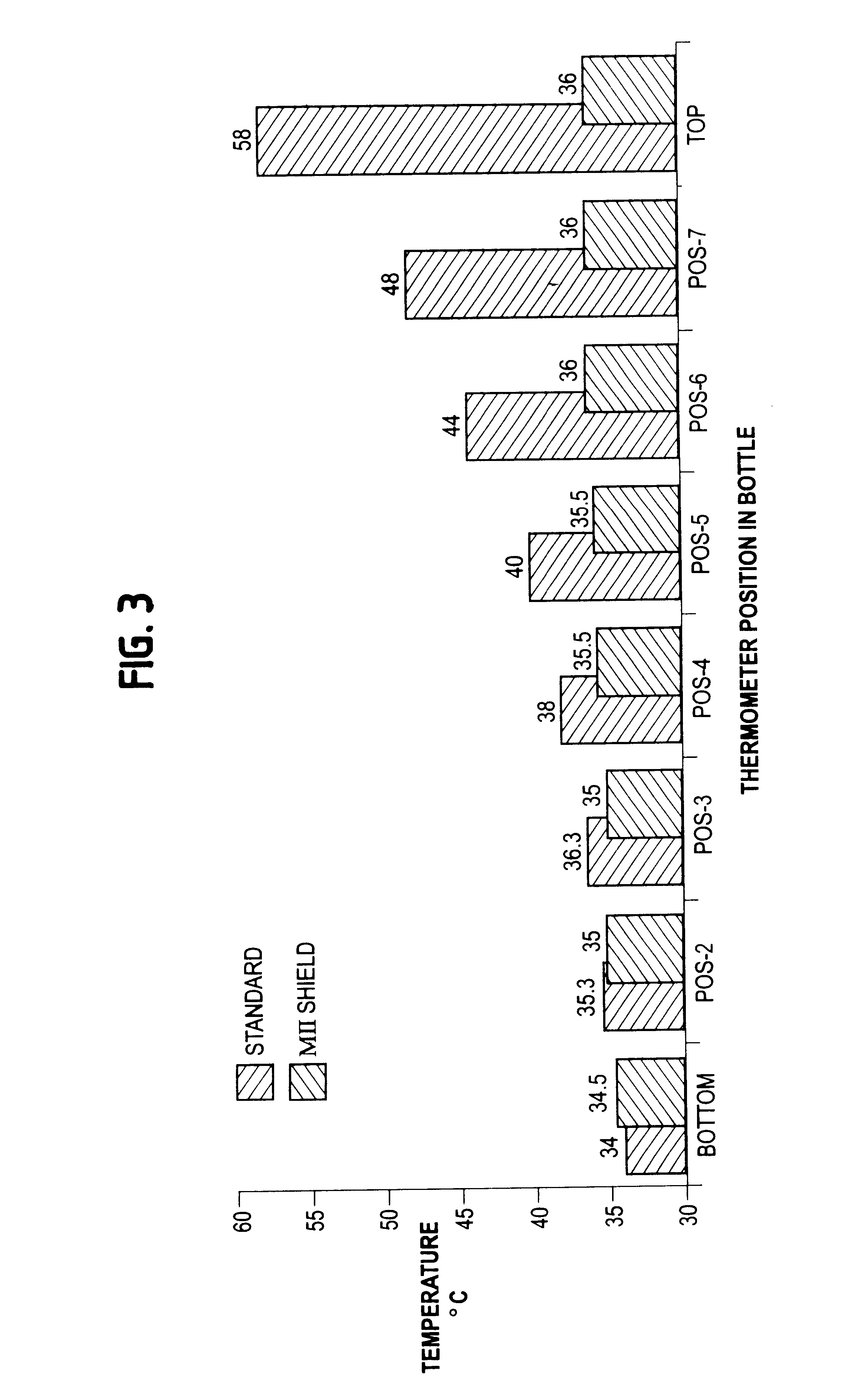

Shielding method for microwave heating of infant formula to a safe and uniform temperature

InactiveUS20010008238A1Minimize electric field intensityAvoid arcingThermometer detailsDough treatmentVertical mixingSize selective

A shielding method for achieving highly uniform temperatures in liquids during microwave heating by substantially enhancing vertical mixing currents in said liquids, making determinations of final temperature reached in said liquids either by touch or the use of a temperature indicator efficacious, comprising: a electrically conductive shield having very low impedance at microwave frequencies; having, a generally cylindrical shape, and dimensions chosen to accommodate a variety of microwaveable containers. said shield: to be concentric with a microwaveable container, containing a liquid to be heated by microwave radiation; and, to be located so as the top edge of said shield is at or above a vertical level corresponding to the level of the liquid in said container; and, to be of sufficient height as to cover at least 10% of the height of the liquid in said container. In a preferred embodiment, the shield has a height "h", covering between 10% and 90% of the of the liquid contained in the container to be heated; and, a circumference / length "L" covering at least 90% of the circumference of the container to be heated.

Owner:MEDICAL INDICATORS INC

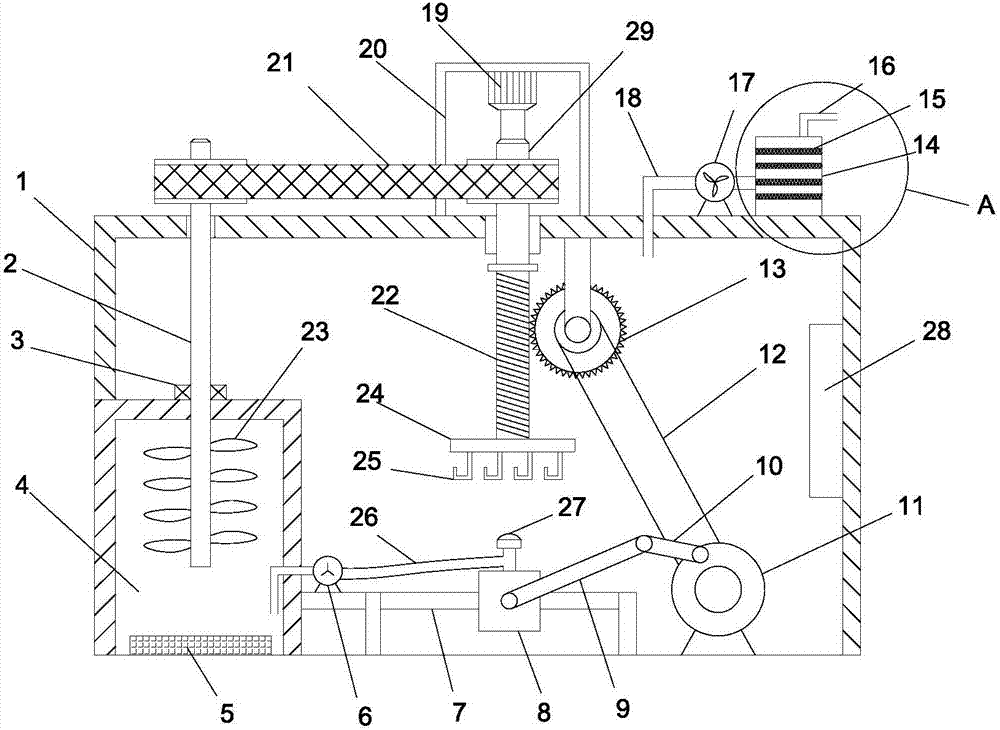

Efficient environmentally-friendly paint spraying device for workpiece

InactiveCN107051791AReduce viscosityAvoid aggregation and condensationLiquid surface applicatorsLiquid spraying apparatusMotor driveVertical mixing

A high-efficiency and environment-friendly paint spraying device for workpieces, comprising a main body, a mixing bucket is arranged inside the main body, a stirring shaft is vertically arranged on the mixing bucket, a driving shaft is fixedly installed on the motor shaft of a driving motor, and a coaxial fixed installation is installed at the bottom end of the driving shaft. The worm, the worm is located inside the body, the body is equipped with a worm wheel, the bottom of the worm is fixedly installed with a turntable, the bottom of the body is equipped with a horizontal rod, the horizontal rod is covered with a sleeve, the top of the sleeve is fixedly installed with a nozzle, and the sleeve is hinged. The first connecting rod, the second connecting rod is hinged on the first connecting rod, the stirring blade stirs and mixes the paint, avoids the accumulation and condensation of the paint, and facilitates the spraying of the paint from the nozzle, and the nozzle reciprocates along the horizontal bar to spray paint on the workpiece , the workpiece can rotate with the turntable, the workpiece can be sprayed with paint in all directions, the spraying is uniform, and the painting efficiency is high; the fan transports the dispersed paint inside the main body to the air purification box for purification treatment, which is more environmentally friendly.

Owner:合肥智慧殿机械设计有限公司

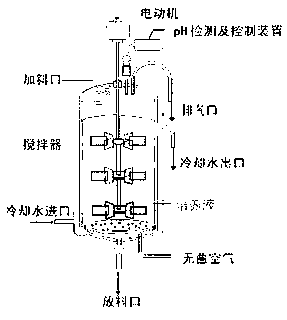

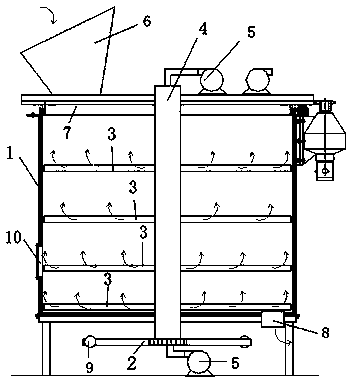

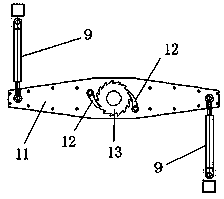

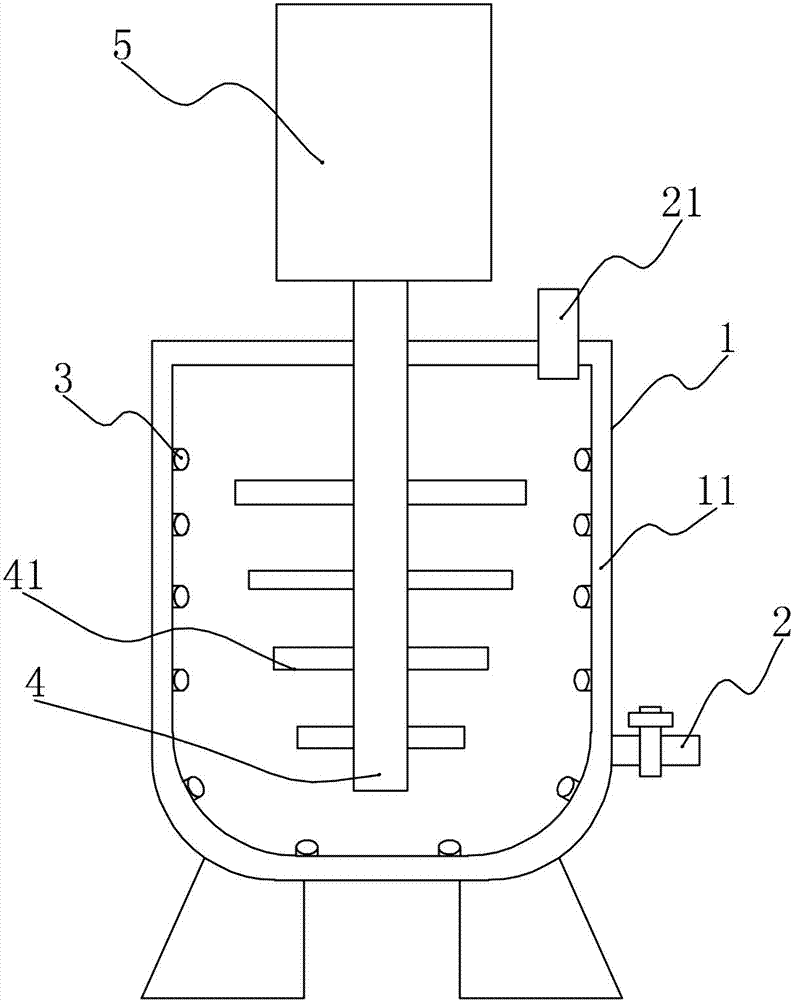

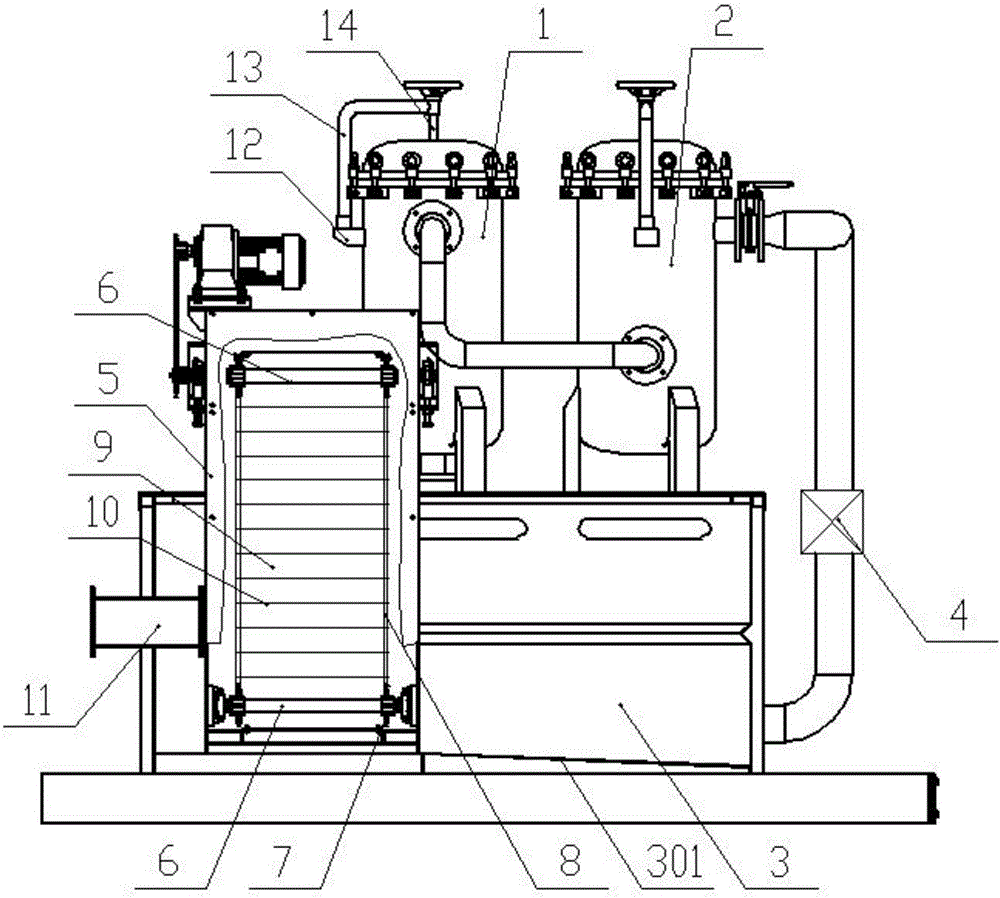

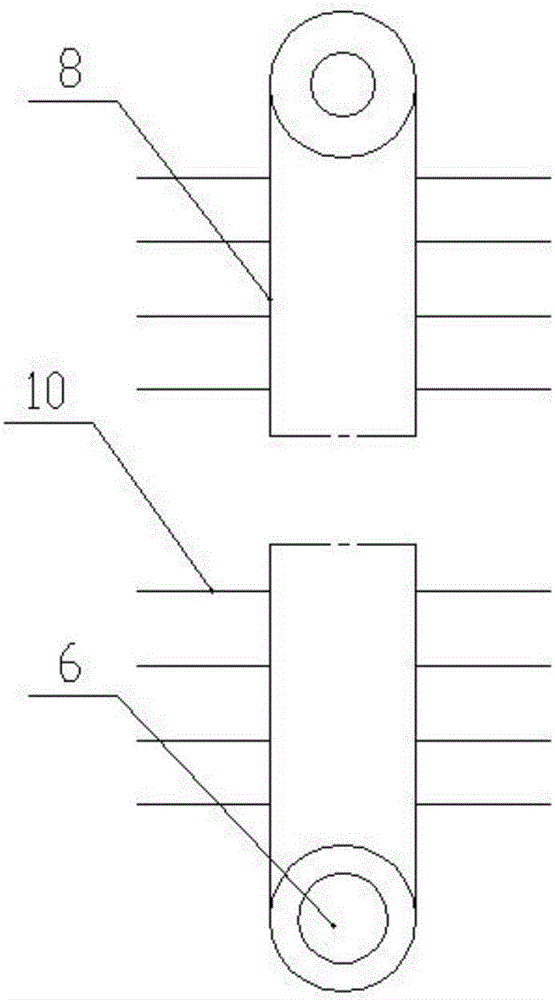

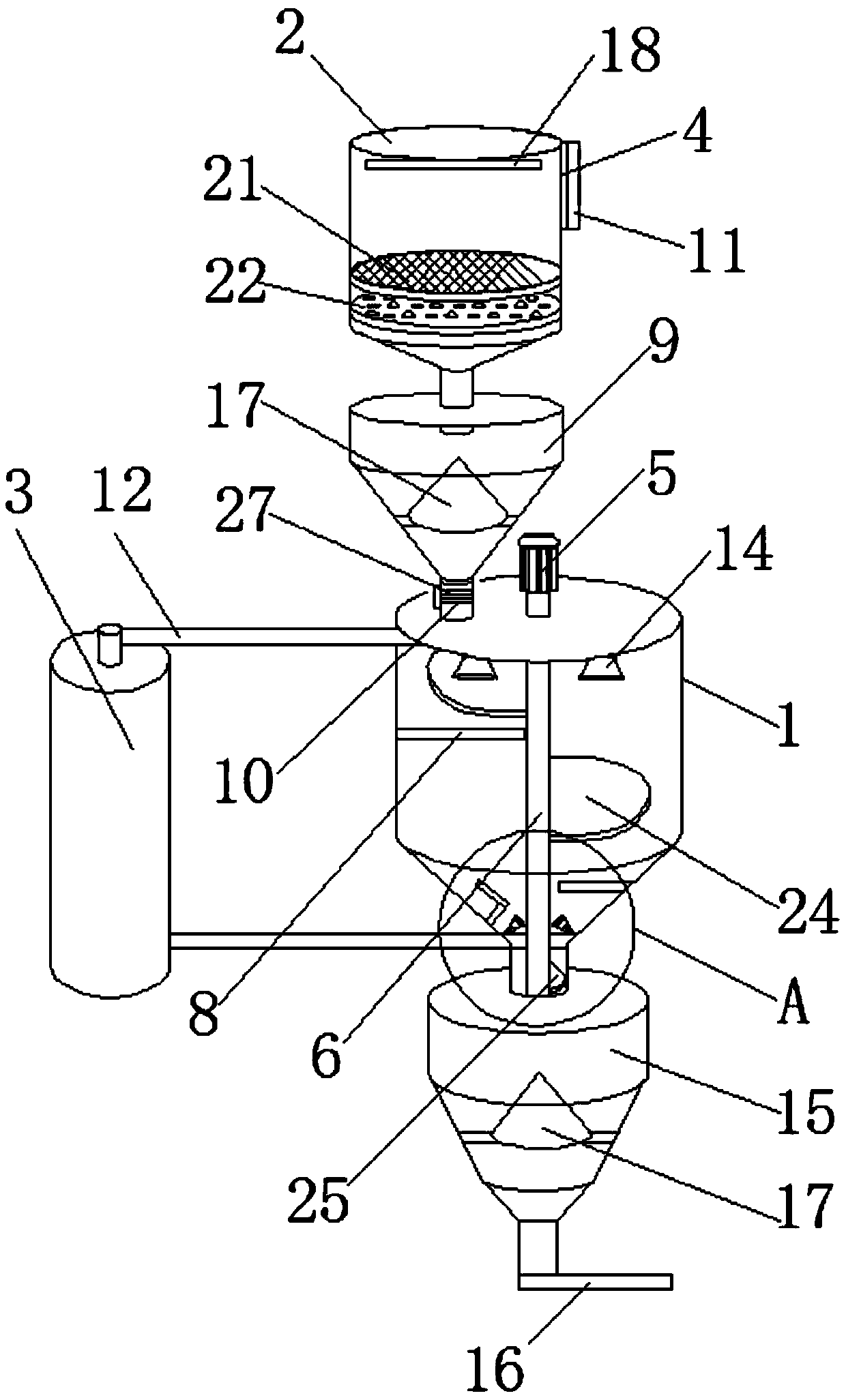

Vertical mixing fermentation tank

The invention provides a vertical mixing fermentation tank which comprises an upper cover, a tank body, a mixing discharging device, a feeding device, a blower device and a ventilation device, wherein the mixing discharging device comprises a hollow mixing shaft, a plurality of mixing blades connected onto the mixing shaft and a ratchet mechanism at the bottom of the tank body; the mixing blades attached to the bottom of the tank body have functions of discharge blades; the mixing blades are hollow, and air outlets are formed in the mixing blades; and the hollow mixing shaft is connected with the ratchet mechanism at the bottom of the tank body, and the ratchet mechanism is pushed by a push-pull mechanism. The power required by a mixing motor of a large fermentation tank is remarkably reduced by changing mixing and transmission manners, the mechanical structure is simplified while energy consumption is reduced, the probability of failures of a machine is reduced, and the vertical mixing fermentation tank is suitable for omnibearing uniform mixing and easy discharging of the large fermentation tank.

Owner:麦行

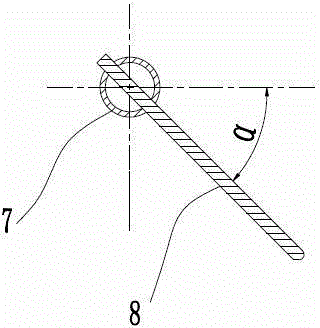

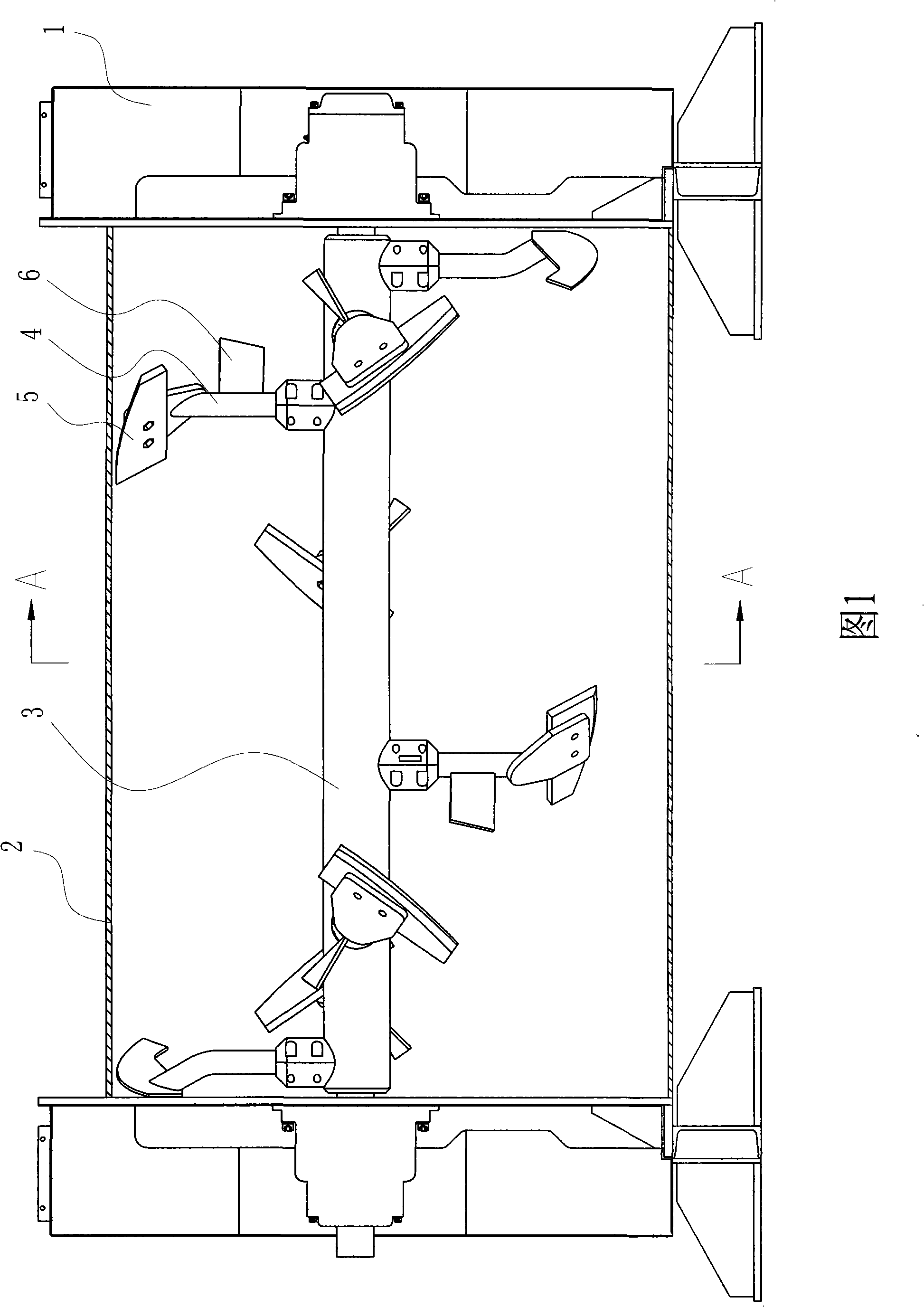

Vertical irregular agitating blade type mixer

ActiveCN104587867AImprove mixing efficiencyImprove the mixing effectRotary stirring mixersVertical mixingEngineering

The invention relates to a vertical irregular agitating blade type mixer, and aims at solving the problem of low mixing efficiency of a traditional vertical mixer. The vertical irregular agitating blade type mixer comprises a vertical mixing barrel; a feeding opening is formed in the top of the mixing barrel while a discharging opening is formed in the bottom of the mixing barrel; a rotating shaft is arranged on an axis of the mixing barrel; a plurality of agitating blades outward extend from the side surface of the rotating shaft in the radial direction. The vertical irregular agitating blade type mixer is characterized in that paddles for pushing materials are arranged on the agitating blades; the upwards inclined angles of the working surfaces of the paddles are increased according to the distance to the outer ends of the agitating blades from long to short; fixed arc-shaped baffles are arranged above the agitating blades; outer ends of the baffles are fixed on the inner wall of the mixing barrel while the inner ends of the baffles are bent in an arc shape; the inner arc-shaped surfaces of the baffles face the material incoming direction. According to the vertical irregular agitating blade type mixer, the agitating blades, the paddles and the arc-shaped baffles are matched to enable a complex three-dimensional fluidized movement track of materials in the mixing barrel to be generated, and therefore, the mixing efficiency is improved, the mixing effect is improved, and the mixing time is shortened.

Owner:史学明 +2

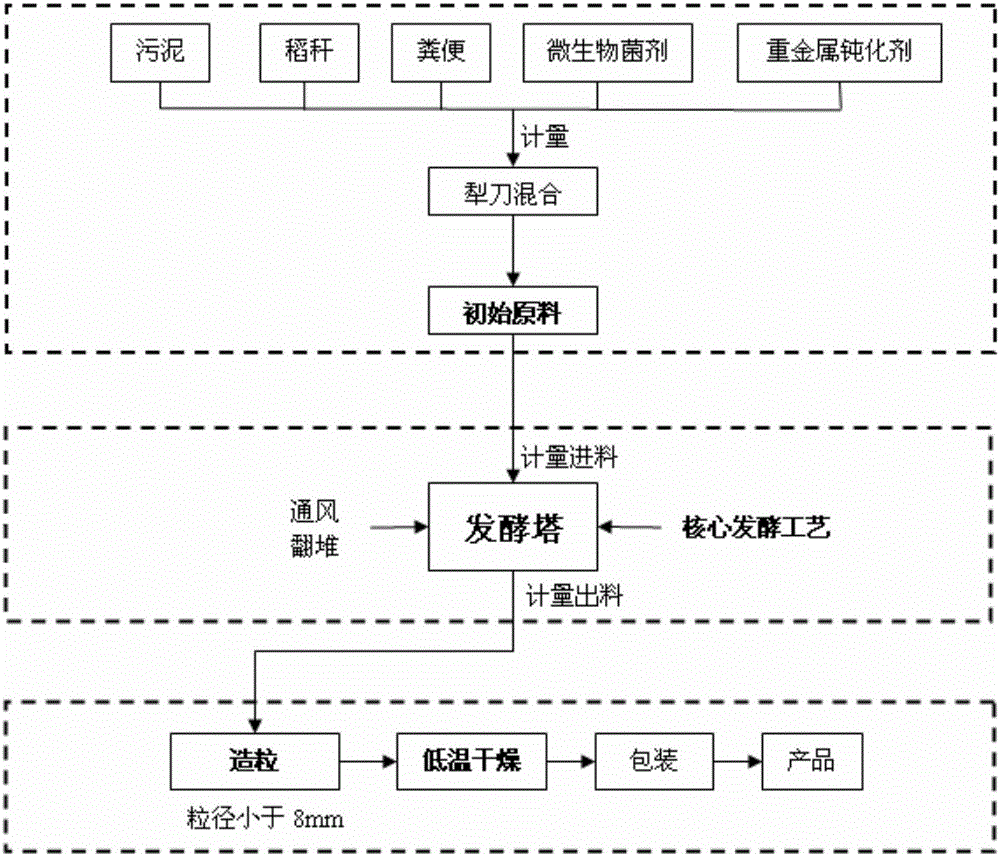

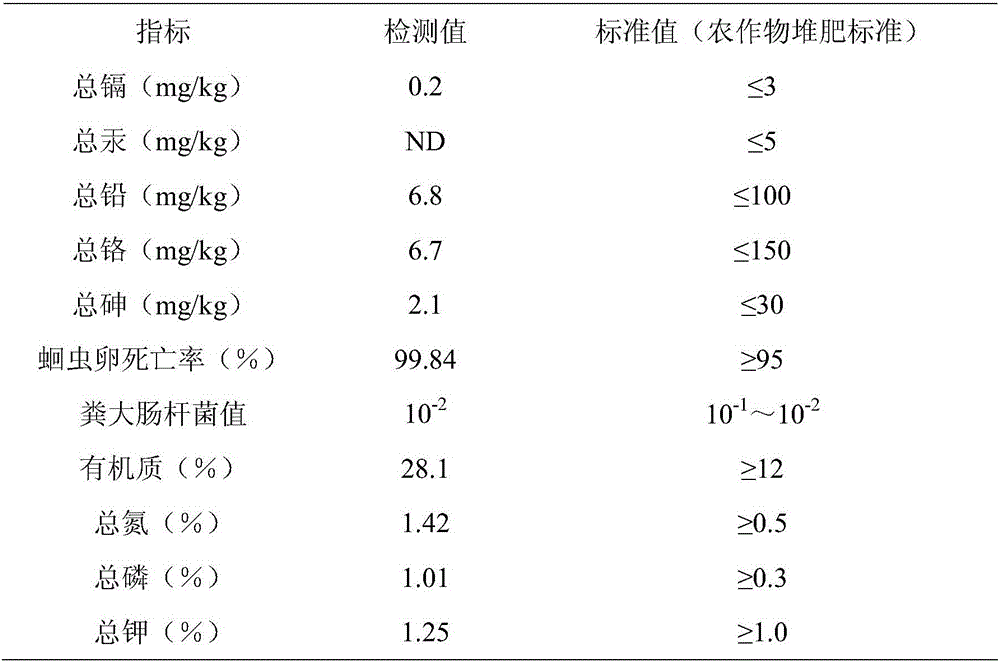

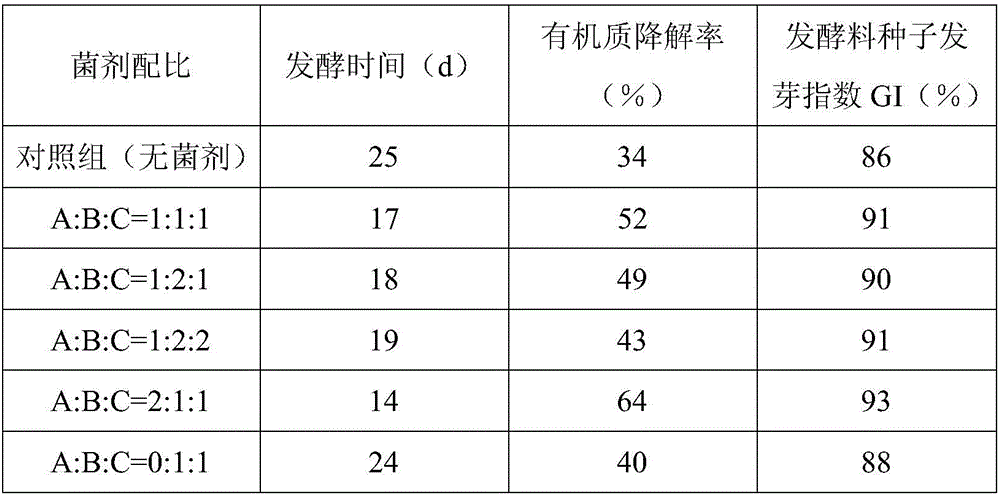

Method for quickly preparing soil conditioner with municipal sludge

ActiveCN106495945ALow running costAchieve stabilizationExcrement fertilisersSewage/sludge fertilisersAutomatic controlSludge

The invention discloses a method for quickly preparing a soil conditioner with municipal sludge. The method includes uniformly mixing raw materials including domestic sludge, rice straw, livestock and poultry manure, heavy metal passivator and microorganism bacterium agent to obtain mixed material; subjecting the mixed material to high-temperatureaerobic fermentation with a multi-layer vertical mixing and turning fermentation tower to obtain fermented material; subjecting the fermented material to granulation prior to low-temperature drying to obtain the soil conditioner. With the method, stabilized, harmless, reducing and resourceful treatment of sludge is realized, sludge can be prepared into the soil conditioner capable of heightening soil quality and improving plant growth, preparation cost is low, the device is small in floor area, full-automatic control in process can be realized, and industrial production is facilitated.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

Hot air mixing reaction device

InactiveCN104324638AAvoid cakingTransportation and packagingRotary stirring mixersVertical mixingVertical cylinder

The invention discloses a hot air mixing reaction device which comprises a vertical cylinder body, wherein a vertical mixing rod is arranged in the cylinder body, mixing blades are arranged on the mixing rod, a hollow layer is arranged in the cylinder body, a hot air pipe communicated with the hollow layer is arranged on the cylinder body, and an air outlet pipe communicated with the hollow layer is arranged on the inner wall of the cylinder body. The air outlet pipe communicated with the hollow layer is arranged on the inner wall of the cylinder body, thus heated air is introduced through the hot air pipe, hot air enters the cylinder body from the air outlet pipe, a raw material in the cylinder body is heated and insulated by means of the hot air; meanwhile, the raw material is stirred and mixed by means of the hot air, the hot air mixing reaction device is superior to a manner of single mixing by means of the mixing blades on the aspect of the effect; furthermore, because the air outlet pipe is arranged on the inner wall, lumps attached on the inner wall can be blown off through the hot air of the air outlet pipe; finally, because the hollow layer is arranged on the inner wall of the cylinder body, the hot air flows through the hollow layer for insulating the raw material in the cylinder body.

Owner:CHONGQING CHANGFENG CHEM IND

Horizontal type mixer with improved stirring device

InactiveCN101323148AIncrease productivityIncrease production capacityCement mixing apparatusVertical mixingEngineering

A horizontal stirring mill provided with an improved stirring device comprises a horizontal cylinder body, a mixer shaft which penetrates the cylinder body along the axial direction and can act as support rotationally and a plurality of stirring units arranged on the mixer shaft. Each mixer shaft comprises a vertical mixing arm connected to the mixer shaft, a first mixing blade arranged at the end of the mixing arm and a second mixing blade which is vertically arranged in the middle of the mixing arm and extends with facing away from the first mixing blade. A mixed motion of convection, cutting and diffusion of the stirred material can be generated to create a 3D mixing effect by reasonably arranging the mixing arm and the first and second mixing blades, so that the material can be mixed evenly and perfectly within a short time. The horizontal stirring mill has high production efficiency, great production capacity and good mixing performance, can ensure the mixing effect of the material reaches an optimum level, thus being especially suitable for producing high-quality commercial sand pulp efficiently.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

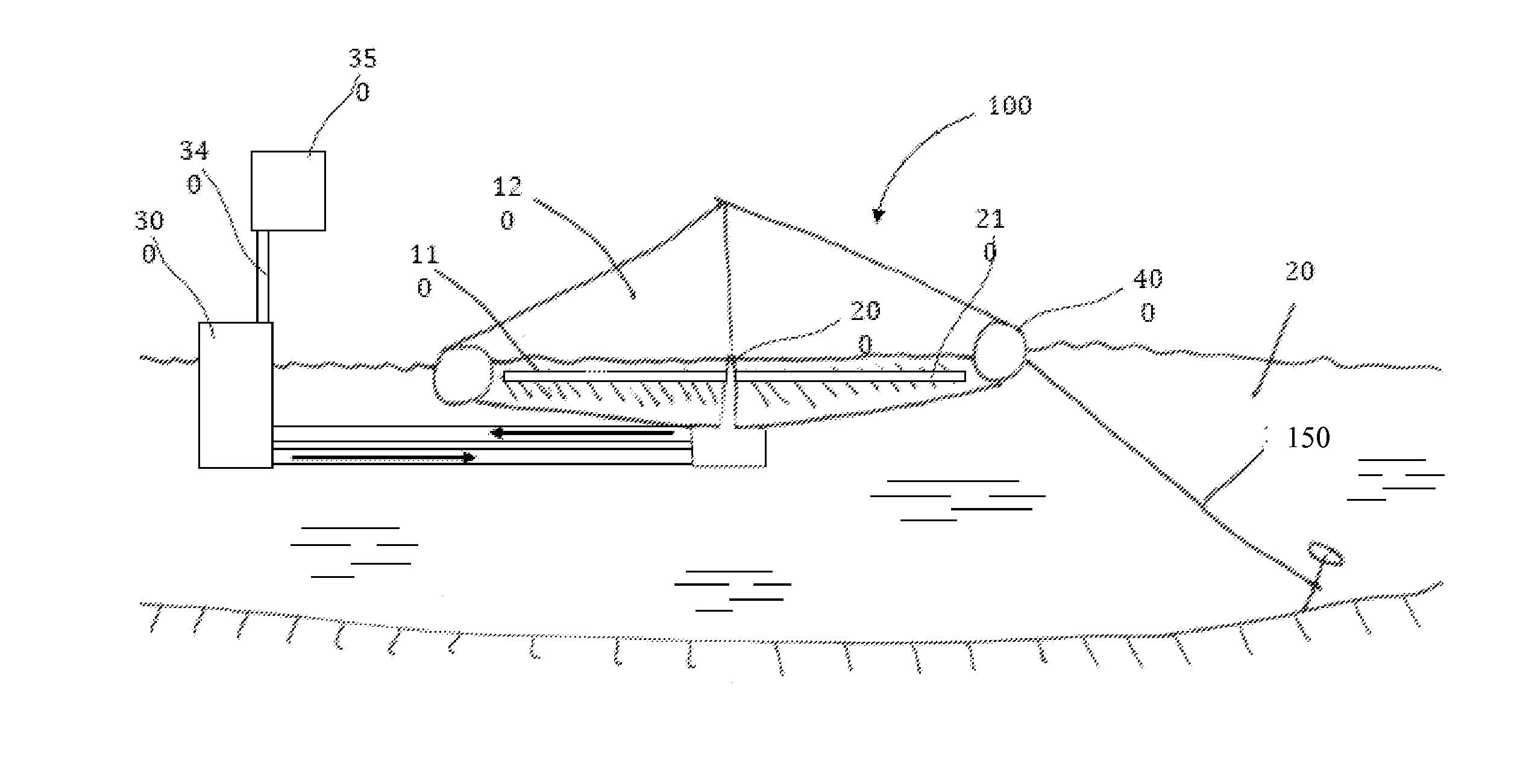

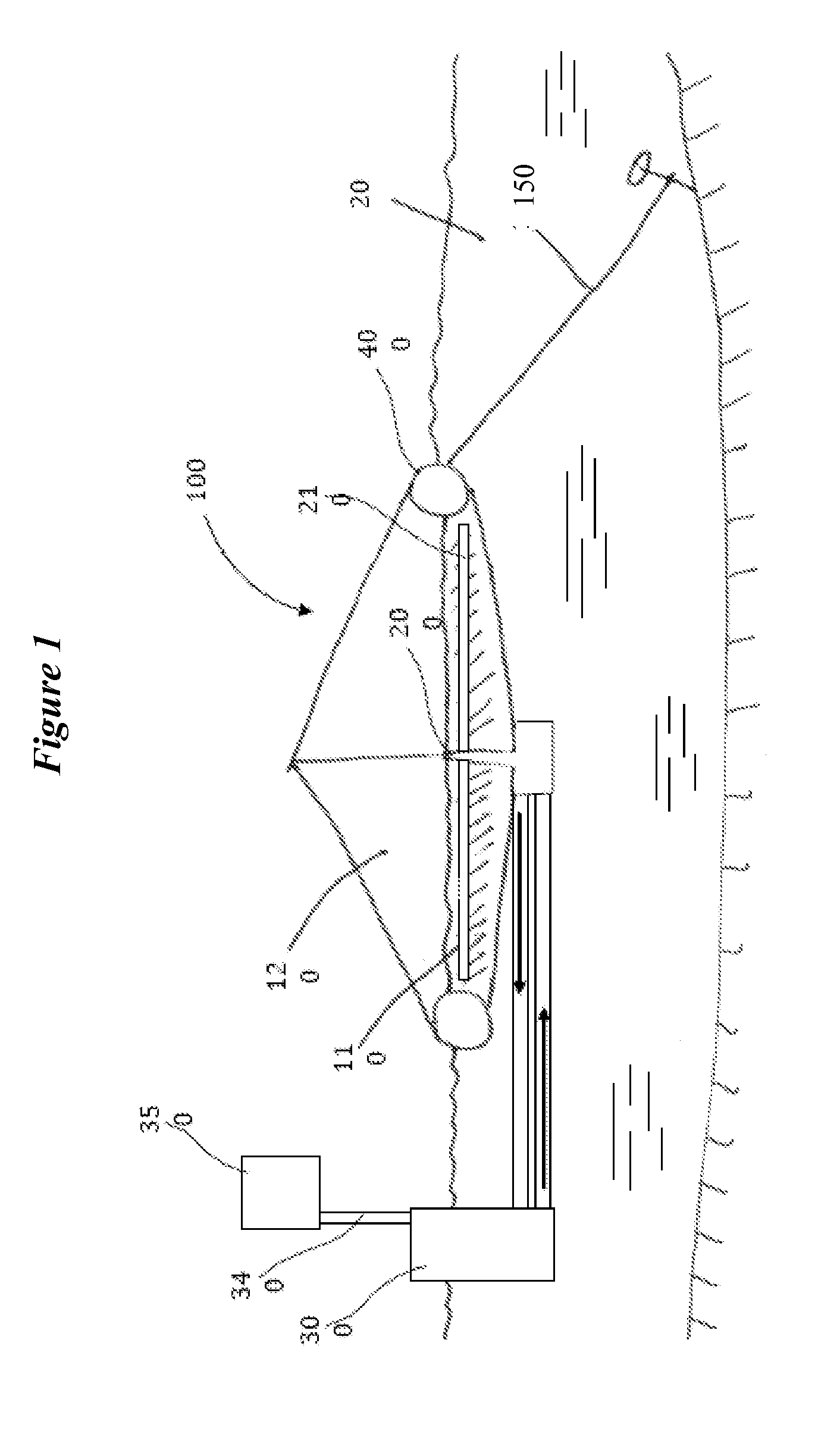

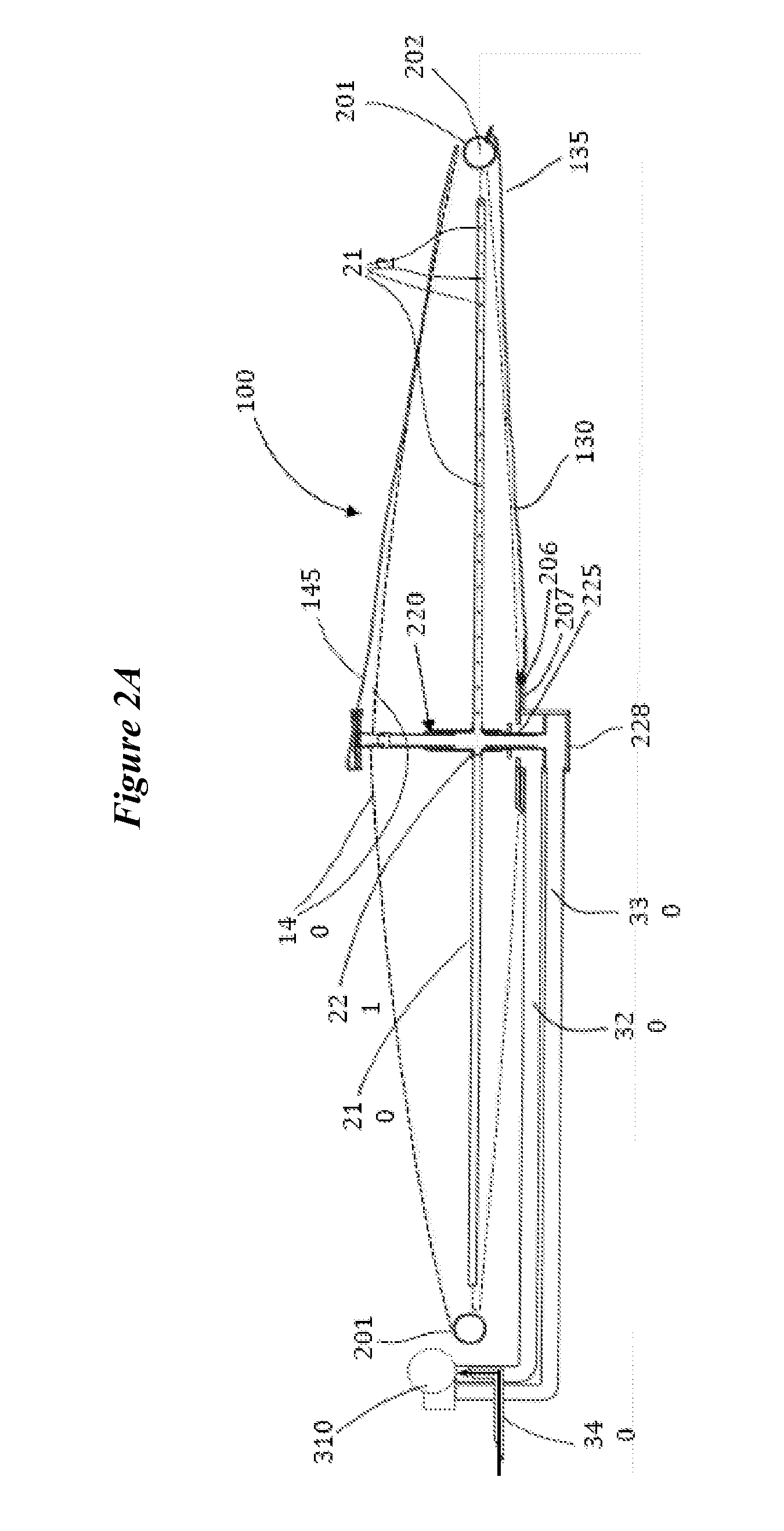

Outdoor cultivator for photosynthetic microorganisms

InactiveUS20120115210A1Good thermal controlReuseBioreactor/fermenter combinationsBiological substance pretreatmentsOrganismContamination

A novel waterborne cultivator, which provides the benefits of known systems for culture of photosynthetic micro-organisms in a novel configuration, incorporating a simplified, two-phase rotary mixing and gas injection system, the two phases being liquid and gas (CO2). The mixing system provides optimum growth conditions through increased turbulent vertical mixing and increased levels of dissolved CO2 throughout the cultivator via injection of flue gas or other CO2-bearing gas stream. The system thus provides efficient capture and sequestration or reuse of CO2 while producing valuable biomass for food, feed, and fuel use. The waterborne configuration provides further benefits of passive temperature control and automatic leveling for consistent culture depth. Additional benefit is provided by an enclosed design which reduces contamination and evaporative loss by isolating the photosynthetic culture from the outside environment. The simplified and well-integrated design of the cultivator and mixing system greatly reduces capital and operating costs compared to previously known systems.

Owner:ELEMENT CLEANTECH

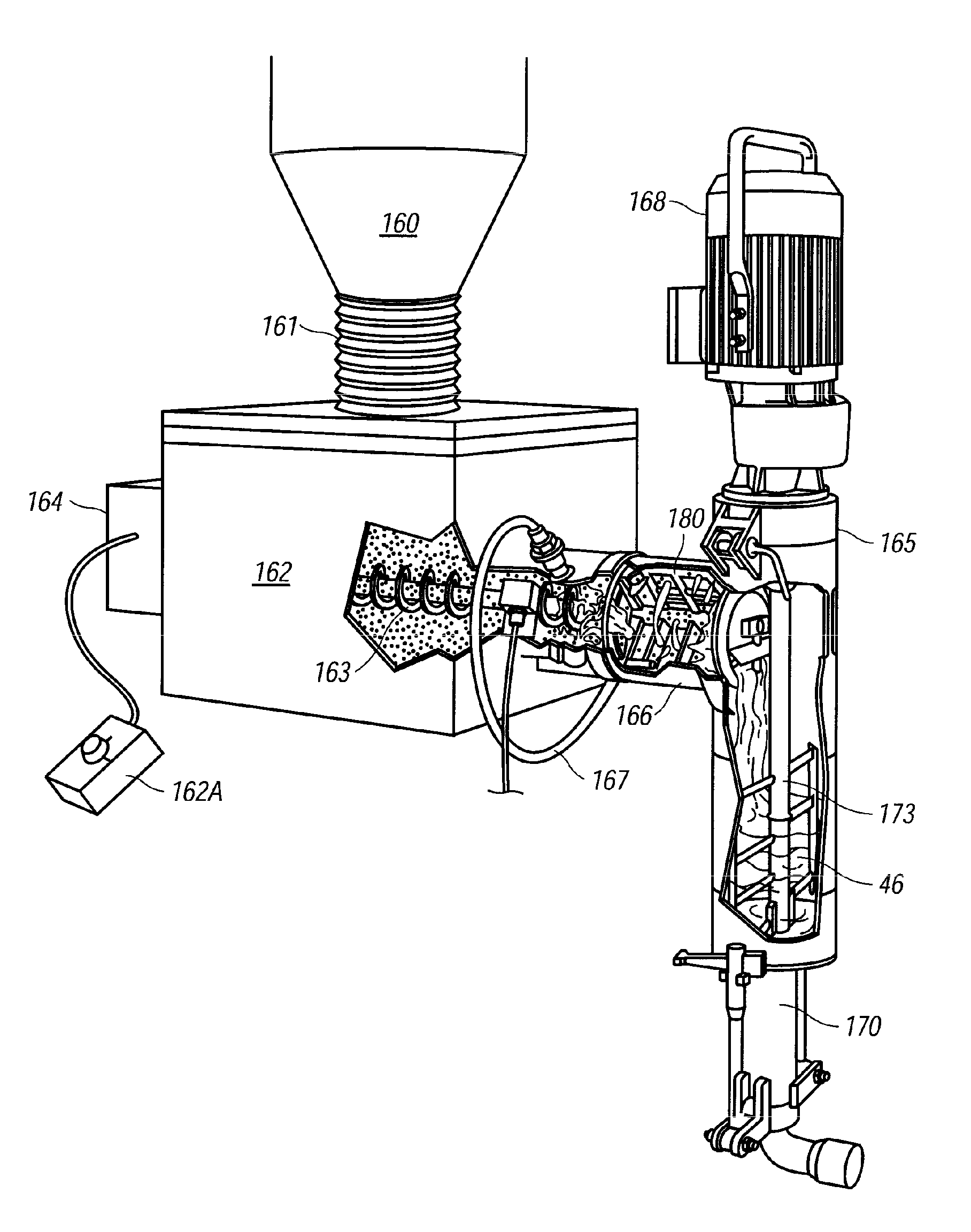

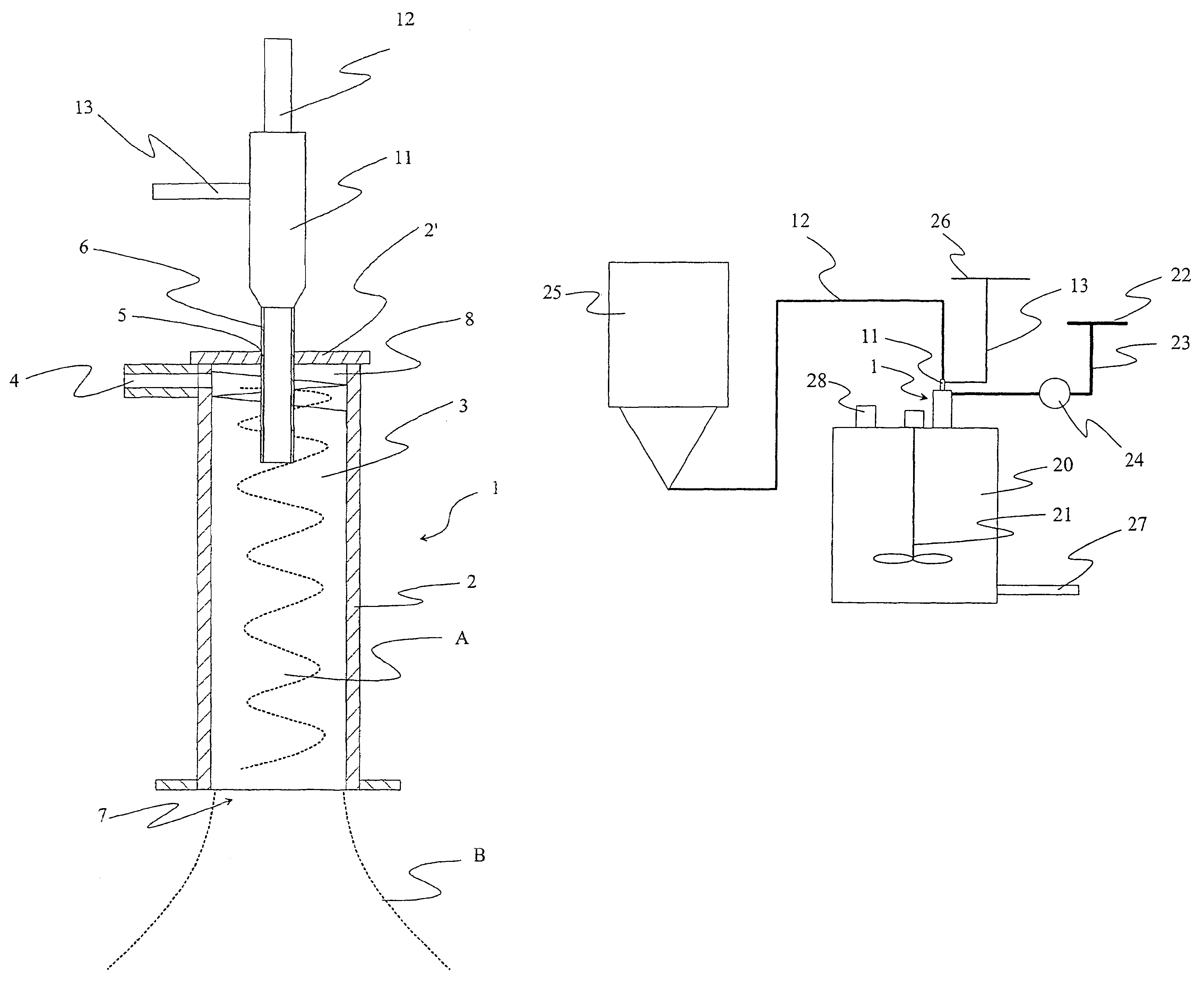

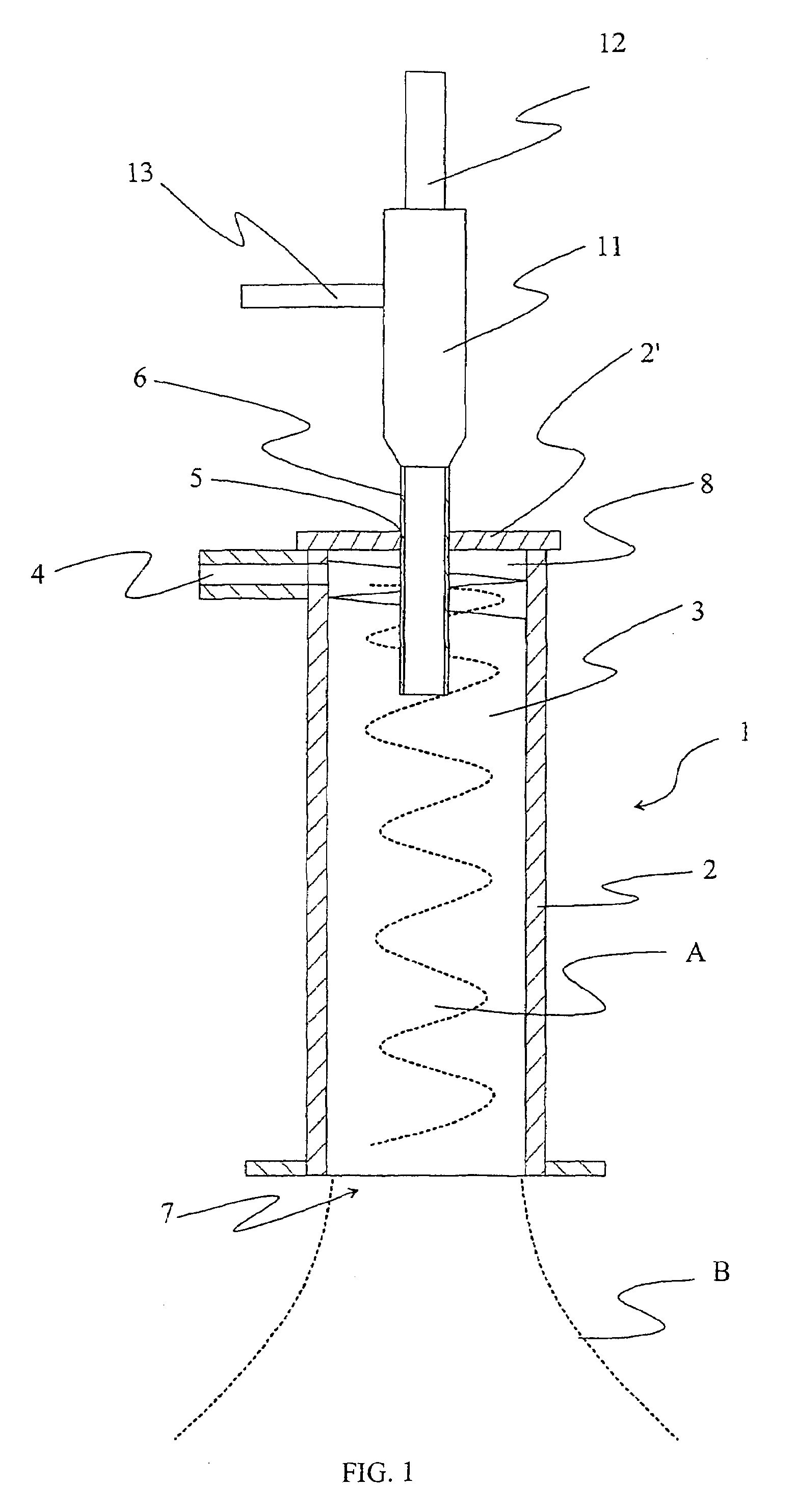

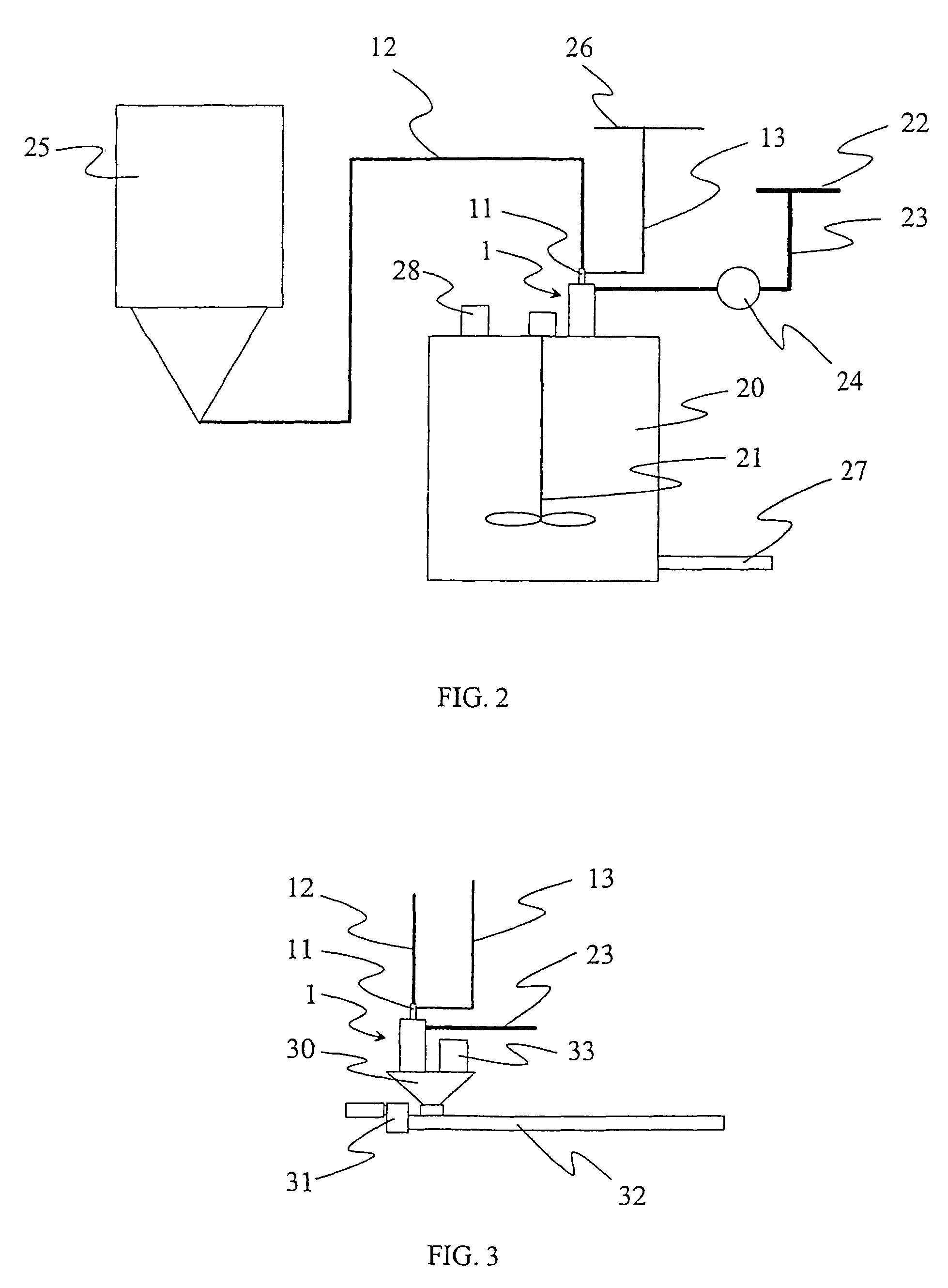

Method and apparatus for mixing pulverous material with liquid

InactiveUS7175337B2Effectively and reliably mixingReduce amountFlow mixersTransportation and packagingVertical mixingAir core

Liquid is supplied within a substantially vertical mixing chamber in a substantially tangential manner from a chamber top section, such that the liquid is deflected for rotatory motion against a chamber wall while advancing, in response to a pressure difference, downwards in the direction of a chamber longitudinal axis. Pulverous material is supplied by compressed air into the chamber (3) from the top section and into an air core (A) established by the liquid in rotatory motion, such that the pulverous material containing little air, and by being heavier than the air contained in the pulverous material and / or used for carrying the same, is driven in response to a centrifugal force into the liquid in rotatory motion, and the air separates towards the eddy center, and that the liquid containing pulverous material and the air supplied into the chamber, are discharged through an open bottom section of the chamber (3).

Owner:VALMET TECH INC

Multifunctional wall surface treatment device for buildings

InactiveCN107447967AImprove flatnessEasy to paintRotary stirring mixersTransportation and packagingVertical mixingDrive shaft

The invention discloses a multifunctional wall surface treatment device for buildings. The multifunctional wall surface treatment device comprises a movable table, a lifting table is arranged on the movable table, a rotating plate is arranged on the lifting table, a slidable frame is slidably connected on the left side of the rotating plate, a grinding motor is fixedly connected in the slidable frame and connected with a grinding wheel through a driving shaft, a corrugated cover sleeves the outer side of the grinding wheel, the bottom of the corrugated cover is communicated with a dust collection box through a telescopic corrugated pipe, and a putty spraying device is arranged on the right side of the slidable frame. The treatment device is provided with the grinding wheel, a wall surface is grinded by the grinding wheel, the flatness of the wall surface is improved, follow-up putty spraying is facilitated, and putty consumption is reduced. The treatment device is provided with a mixing box with a vertical mixing plate and a horizontal mixing plate, so that putty preparation raw materials are sufficiently mixed, putty slurry is uniform, fine and smooth, spraying is facilitated, and spraying effects are better.

Owner:宣城市万成机械科技有限公司

Reactor

InactiveCN103406085BWell mixedAvoid uneven mixingRotary stirring mixersTransportation and packagingVertical mixingProcess engineering

Owner:GUANGXI ZHONGCHANG RESIN

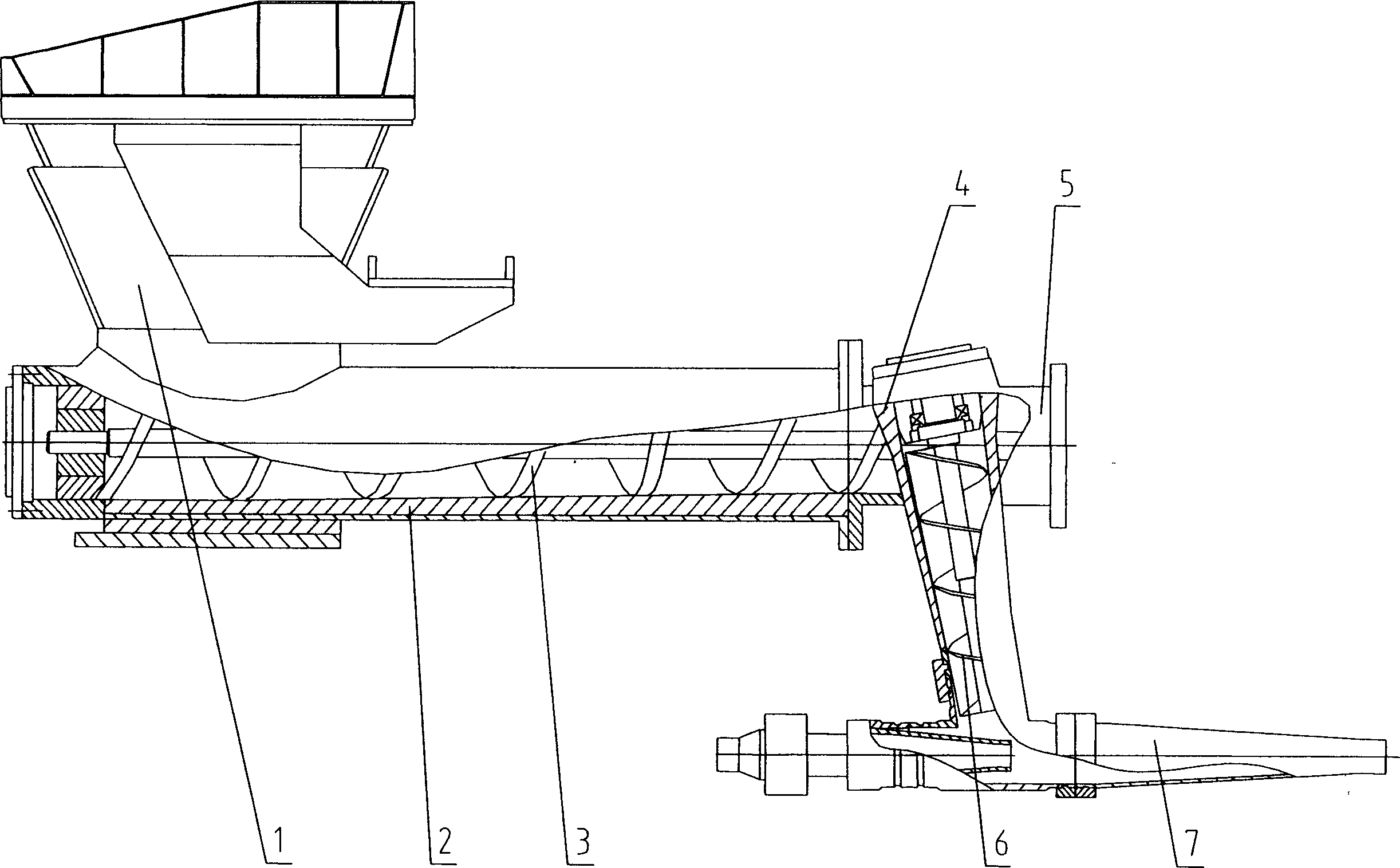

Stirring-cage type wet-spraying machine

InactiveCN1891954ALarge working spaceEasy to transport and pushUnderground chambersBuilding material handlingShotcreteVertical mixing

The invention is a mixing cage-type wet shotcrete machine, relating to constructional engineering machinery, characterized in that the lower part of a feed hopper is connected with the big end of a mixing cage taper bush, the small end is connected with a discharge tank, the discharge tank is connected with the upper end of a vertical mixing cage cover, and the lower end is connected with the middle of a jet pipe. And the concrete enters through the feed hopper, enters the discharge tank under the drive of spiral vanes of a taper mixing cage and then enters the upper end of the vertical mixing cage, and then enters the jet pipe under the drive of spiral vanes of a vertical mixing cage, and here, the high pressure air at the left end of the jet pipe enters and jets out concrete grout from the right end of the jet pipe onto a working surface. And its advantages: the space of its spiral vanes is large and convenient to continuously push concrete grout with aggregate; its structure is simple, convenient to move and occupies a little space, easy to maintain; and its manufacturing cost is lower.

Owner:SHANDONG UNIV OF SCI & TECH

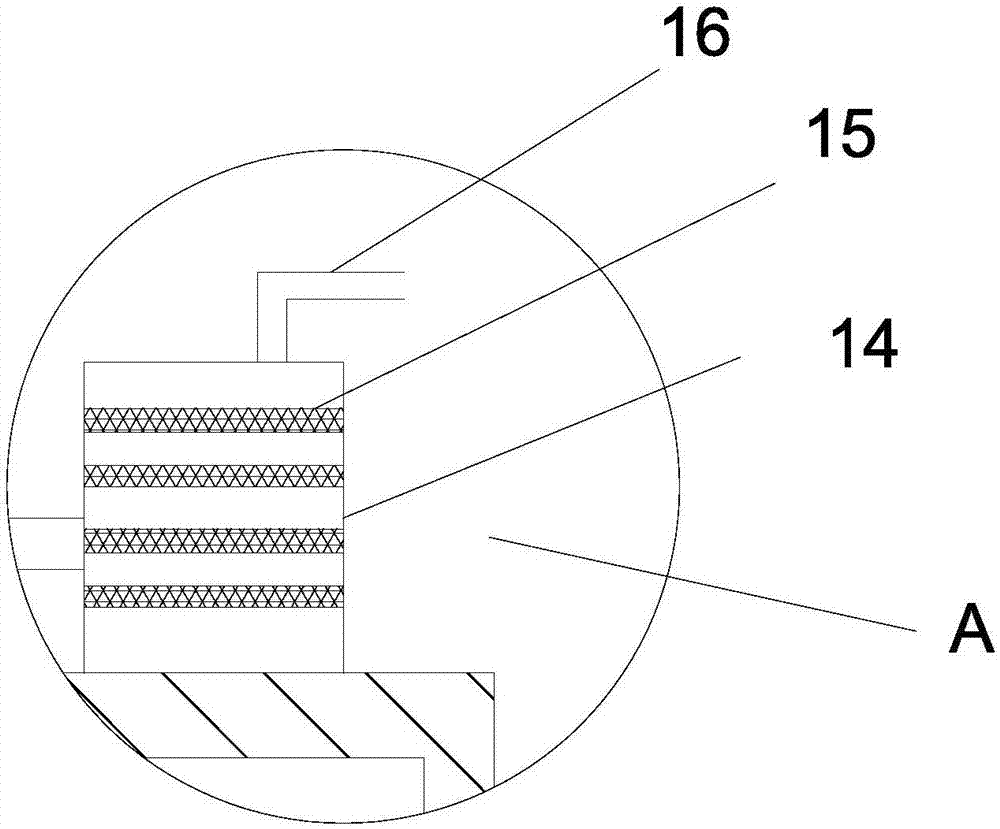

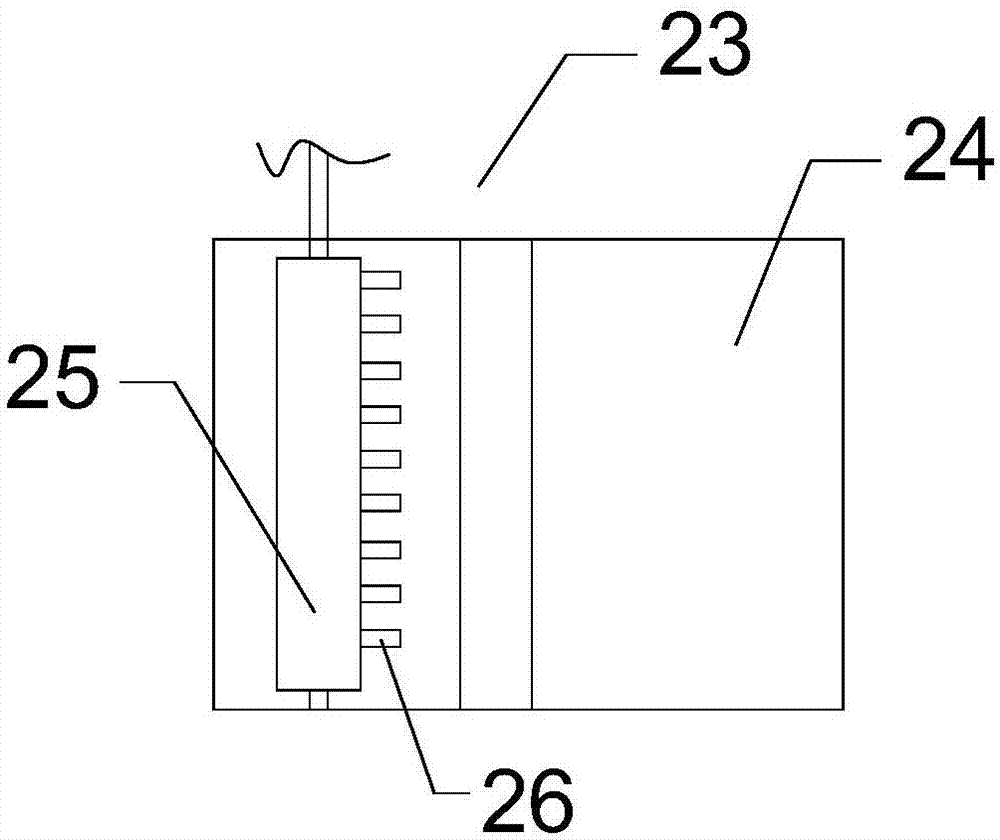

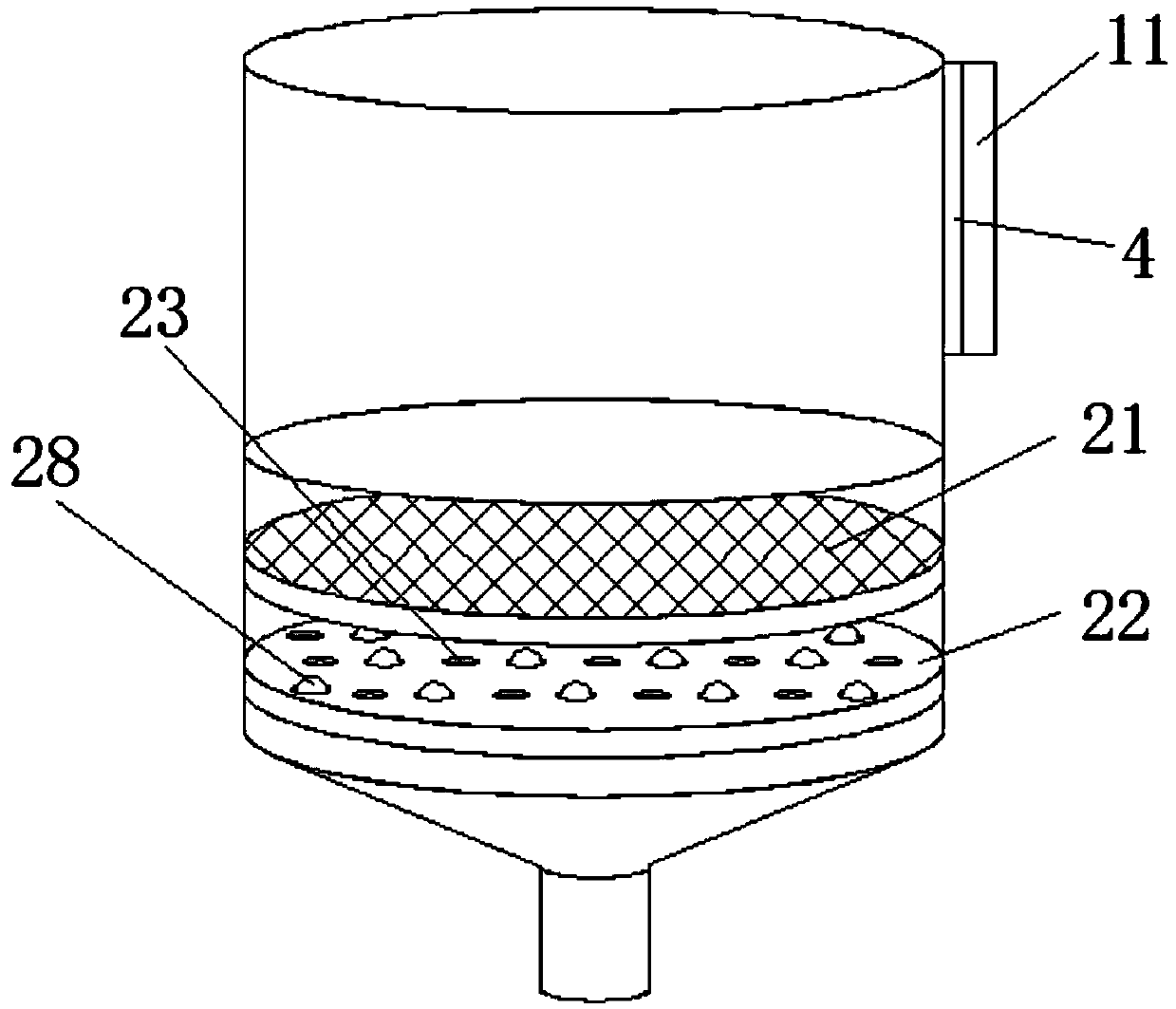

Vertical mixing plant for processing sticky rice adhesive

InactiveCN106621912AStir wellGood dispersionRotary stirring mixersTransportation and packagingHeating timeVertical mixing

The invention discloses a vertical mixing plant for processing a sticky rice adhesive. The vertical mixing plant comprises a base; a mixing tank is arranged at the top of the base; a discharge pipe is arranged at the bottom of the mixing tank; a support plate is arranged at the top of the mixing tank; a thermal insulation layer, a first mixing device, a material scattering plate and a second mixing device are arranged in the mixing tank; a display device is arranged on the right side of the mixing tank; and a feed hopper, a rotating device and an exhaust pipe are arranged at the top of the support plate. The vertical mixing plant is simple in structure, reasonable in design and convenient in use; due to the arrangement of the first mixing device and the second mixing device, the material is fully mixed, a bottom scraper blade mixes the material at the bottom to avoid the mixing blind angles, a spiral mixing blade drives the material to turn up and down, so that the material is more sufficiently mixed; and due to the arrangement of a heating vertical rod, the material is heated, and the heating time and the temperature in the mixing tank can be controlled through the display device.

Owner:郑州吉音动漫科技有限公司

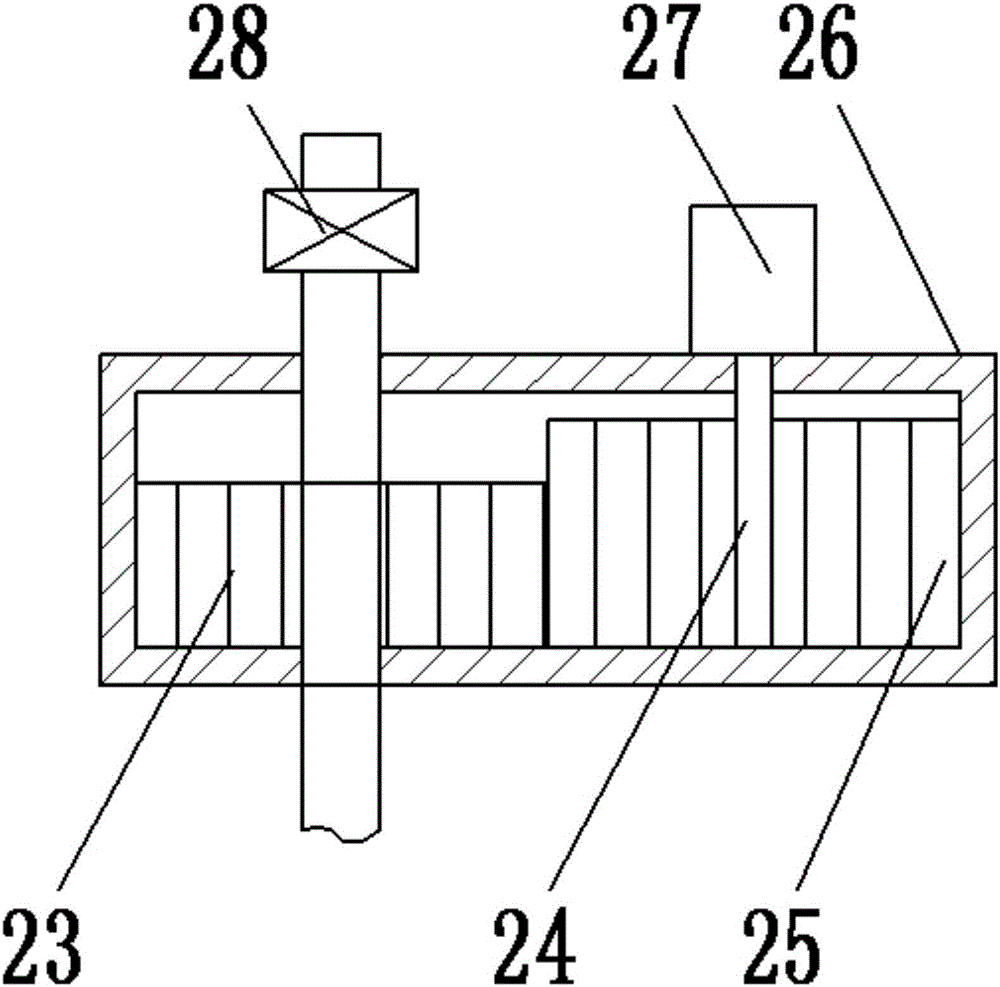

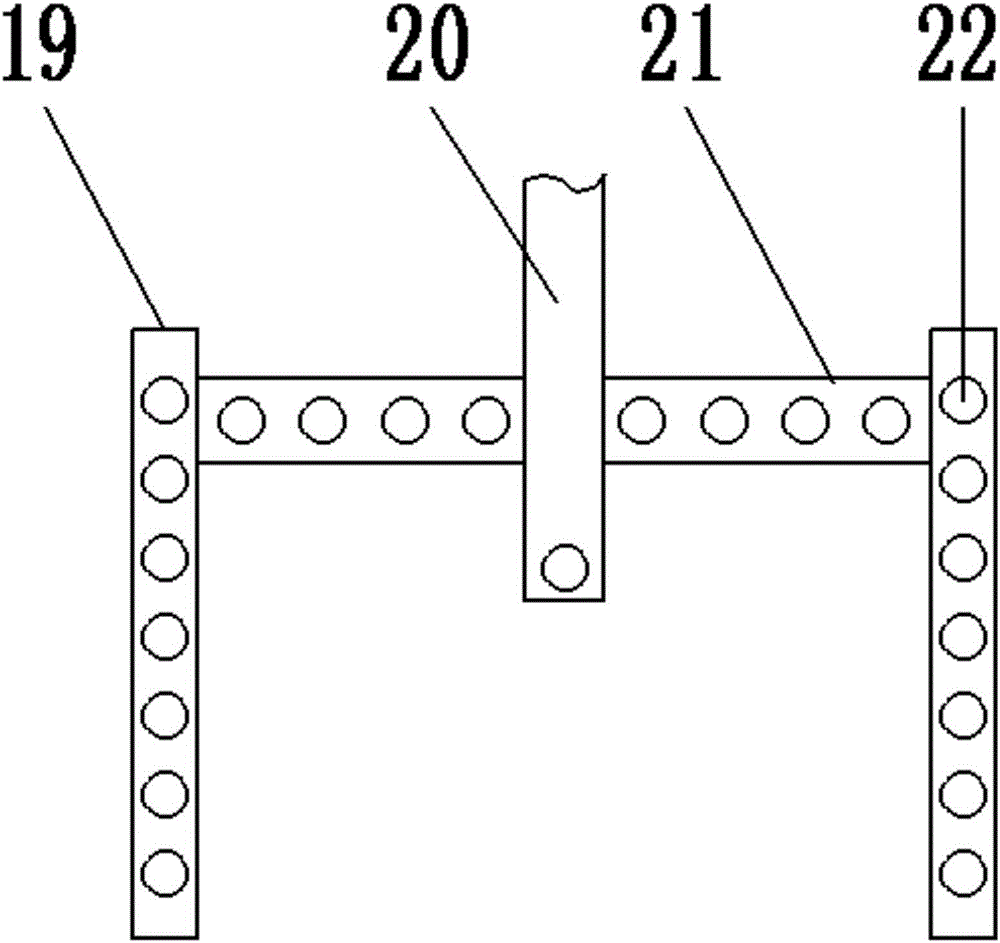

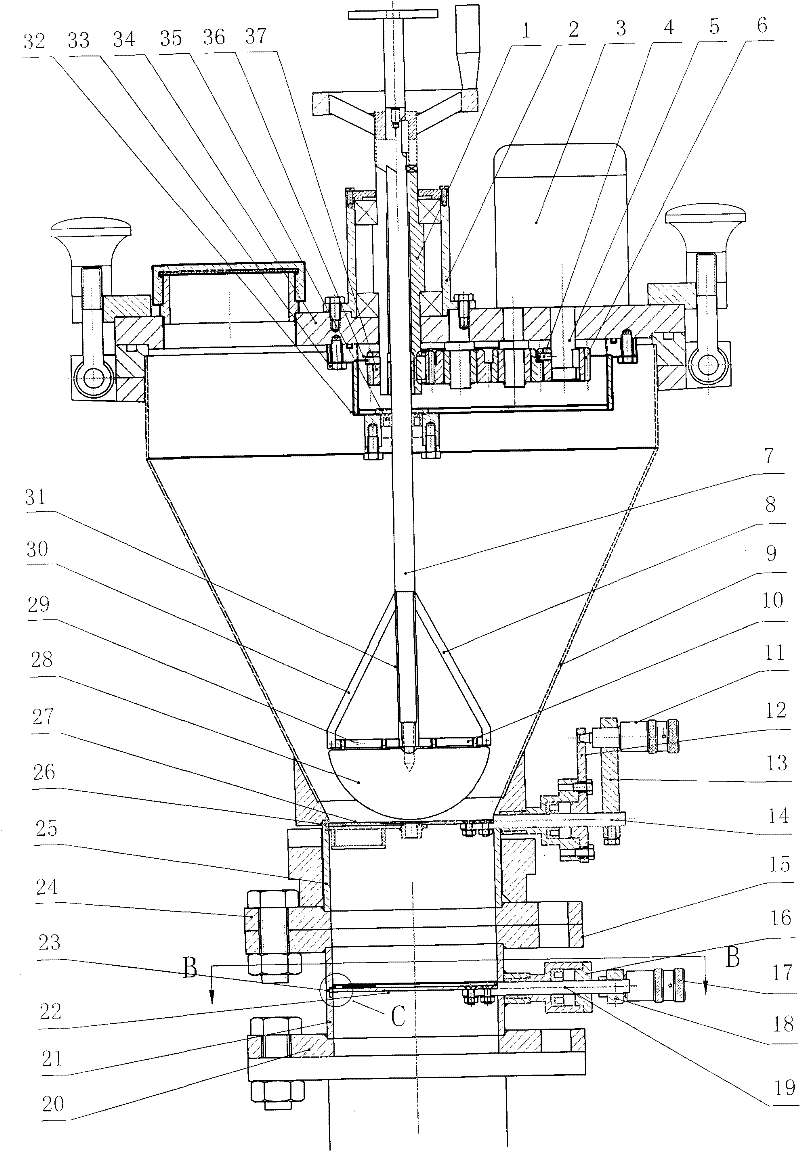

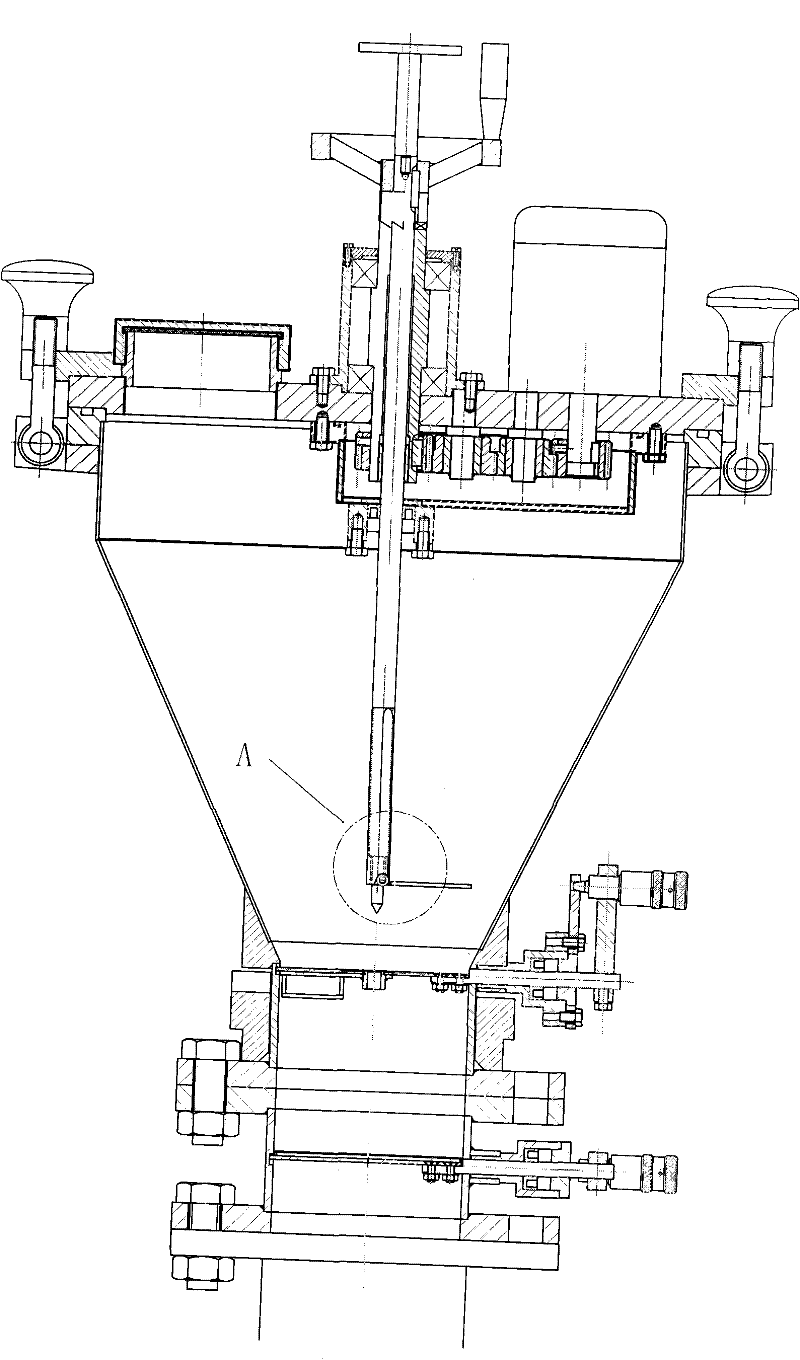

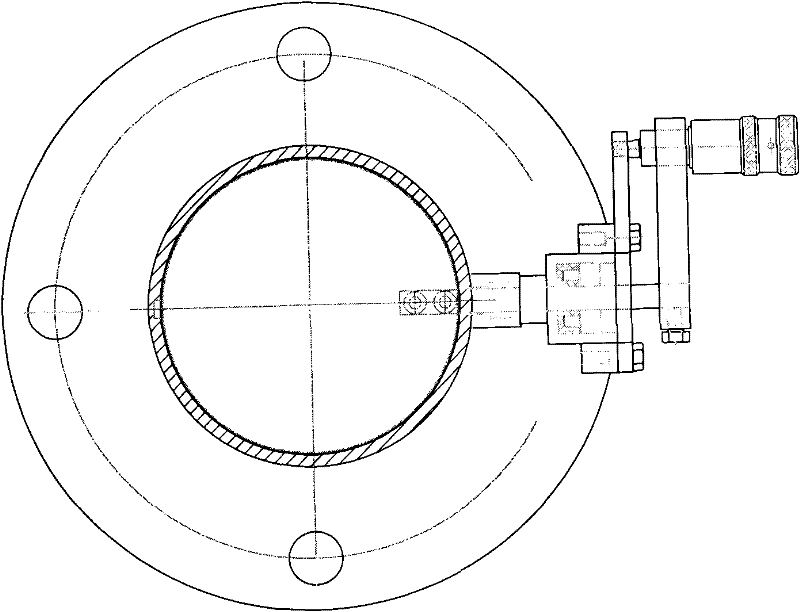

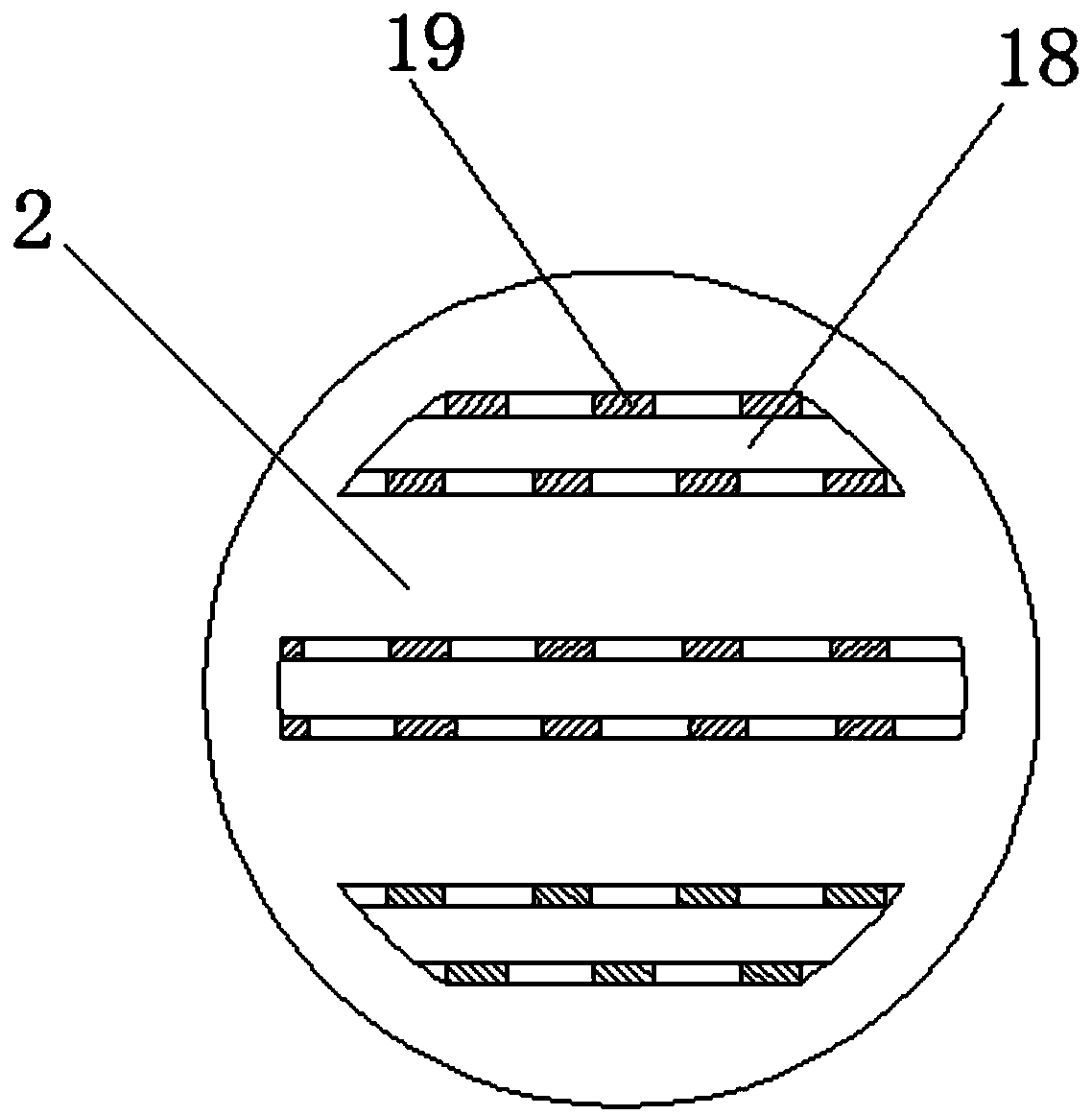

Novel apparatus for solid particle falling

The invention provides a novel apparatus for solid particle falling. A vertical mixing shaft is arranged in the center of an inverted frustum shaped container of the apparatus, the vertical mixing shaft is mounted in a shaft sleeve, and the shaft sleeve is mounted in a bearing pedestal on a container cover. The vertical mixing shaft can be moved up and down and rotated in the shaft sleeve. A mixing head is arranged at the lower end of the mixing shaft, and the shape of the mixing head is a portion enveloped by a right circular cone. A gear is arranged at the lower portion of the shaft sleeve, and the gear forms a transmission pair with the gear on a motor shaft. A clutch located between the mixing shaft and the shaft sleeve is disengaged , and the rotation of the mixing shaft is driven by a motor. The clutch is engaged, and the rotation of the mixing shaft can be driven manually. Two bottom portions which are overlapped to each other are arranged at a small end of the material container. The upper bottom portion is integral with the container, and a movable circular multilayer sheet component is arranged inside the upper bottom portion. The normal operating condition is a horizontal condition. The multilayer sheet can be rotated about a horizontal axis. The lower bottom portion is a completely independent bottom portion. A movable circular bilayer sheet which is closed or opened is arranged inside of the lower bottom portion. The circular bilayer sheet consists of a cover and a bottom sheet. A vibration sensor or a sound sensor or a pressure sensor is arranged inside of the circular bilayer sheet.

Owner:黄建

Novel vertical all-in-one machine for dry and wet feed smashing and mixing

The invention discloses a novel vertical all-in-one machine for dry and wet feed smashing and mixing. To prevent a feeding port from being jammed by wet feed (fermented feed) and a feeding stirring shaft from being locked, pre-stirring shaft components with support are designed for performing added feed pre-stirring, so that the dry and wet feed and additive can smoothly enter on side of a threaded stirring shaft through a feeding stirring shaft; the feed is vertically conveyed upwards by the threaded stirring shaft, is thrown out when conveyed to the end of the threaded stirring shaft, slides downwards along the inner wall of a cylinder and a cone part of a shell, flows to the bottom, and is lifted upwards and thrown by the vertical threaded stirring shaft again; and the circulation is repeated, and evenly mixed feed can be acquired. A set of the pre-stirring shaft components with support is arranged in a main feeding chute; a workbench with adjustable height and convenience in operation and a safe screen preventing a feeding woven bag from entering the pre-stirring shaft are added; and the application range of vertical mixing machines is expanded.

Owner:ANHUI AGRICULTURAL UNIVERSITY

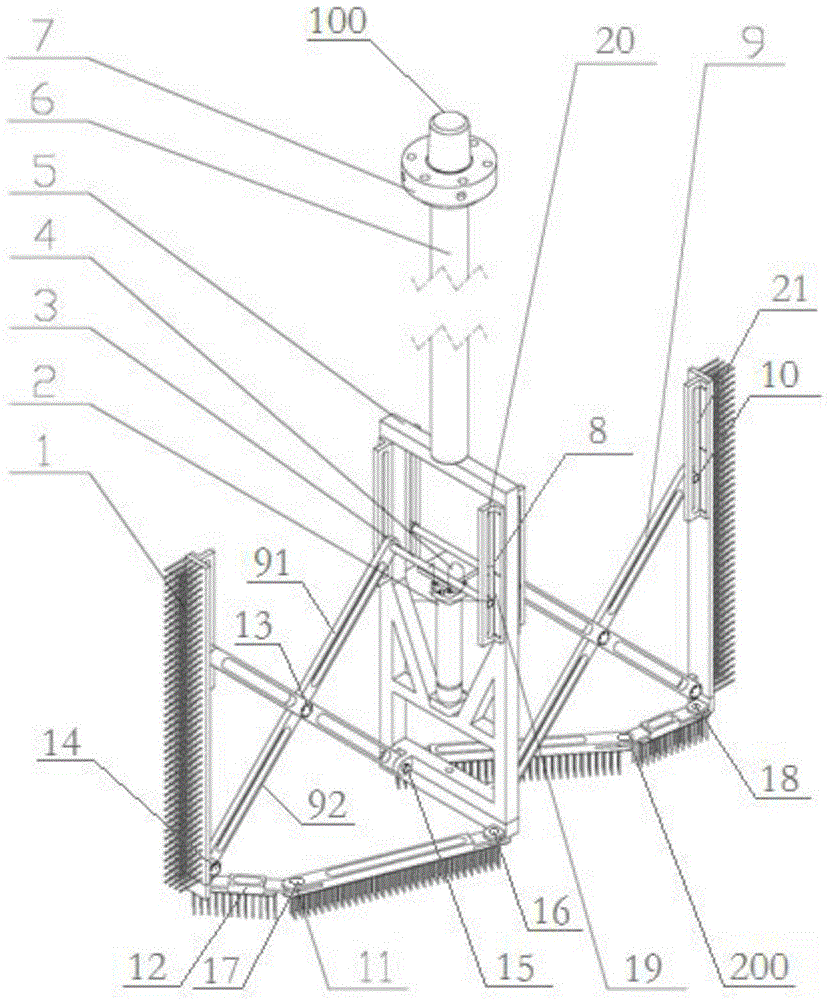

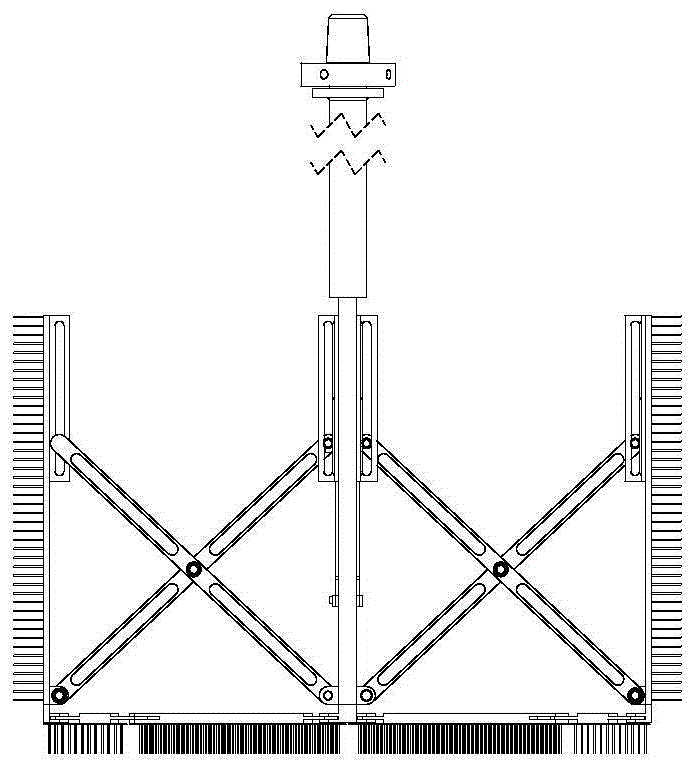

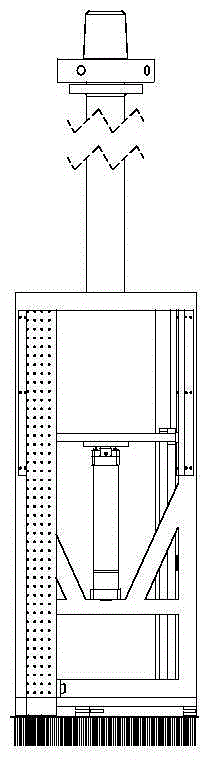

Mixing pan cleaning device of vertical mixing machine

ActiveCN105686334AAchieve scaleEasy to separateBrush bodiesHollow article cleaningVertical mixingEngineering

The invention discloses a mixing pan cleaning device of a vertical mixing machine. The mixing pan cleaning device comprises a rotary spindle assembly and spatial connecting rod type shears-fork extensible hairbrush assemblies, wherein the rotary spindle assembly comprises an upper-portion rotary shaft, a connecting flange and a lower-portion connecting support, each spatial connecting rod type shears-fork extensible hairbrush assembly comprises an air cylinder, a first guide frame, an air cylinder ejection block, a moving rod, a side cleaning hairbrush and a shear type expansion plate. The mixing pan cleaning device adopts the design of a spatial connecting rod mechanism, is simple in structure, safe and reliable, can achieve the expansion, can be suitable for cleaning of mixing pans of different volumes, and meanwhile facilitates the separation of the device and the mixing pans after installation and cleaning operations are completed.

Owner:武汉乾峯智能科技有限公司

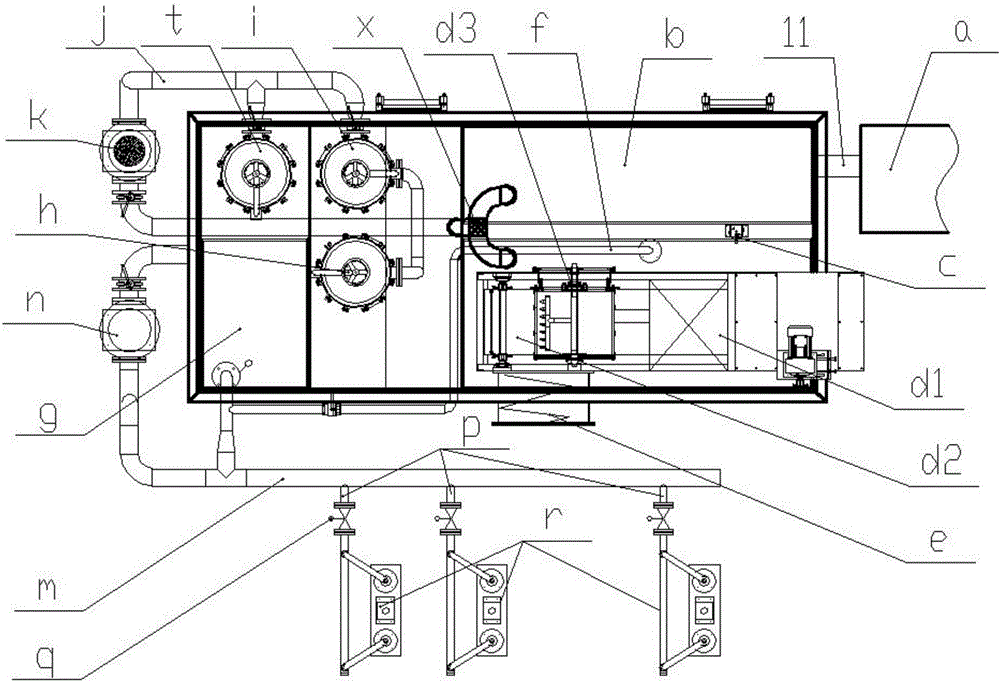

Circulatory fluid-supply cleaning system

ActiveCN106475354AAchieve recyclingTo achieve the purpose of circulating water supplyCleaning using liquidsVertical mixingMegasonic cleaning

The present invention discloses a circulatory fluid-supply cleaning system, comprising a first fitted bucket and a second fitted bucket that communicate with each other. The top of the second fitted bucket communicates with a bottom bin. A left end of the bottom bin communicates with the bottom of a vertical mixing bin. Chain wheel shafts on which chains are installed are disposed at both upper and lower ends within the vertical mixing bin, and a soft large stainless steel mesh connected with a small stainless steel mesh is disposed between the two chains. A liquid outlet is disposed at a left side of the vertical mixing bin, and communicates with a cleaning fluid mixing bin. A mixing device is disposed in the cleaning fluid mixing bin. The cleaning fluid mixing bin communicates with a cleaning bin. The cleaning bin comprises an ultrasonic cleaning bin in which an ultrasonic cleaning machine is disposed, and a waste water bin on which a filtering residue removing machine is disposed. The cleaning bin communicates with a clarifying tank that communicates with primary and secondary filters in order, and the secondary filter communicates with the cleaning fluid mixing bin. The system is capable of realizing circulatory supply and recovery of a cleaning fluid, such that the efficiency and quality of cleaning are improved while energy saving and consumption reduction are achieved.

Owner:CHONGQING KEBEN TECH

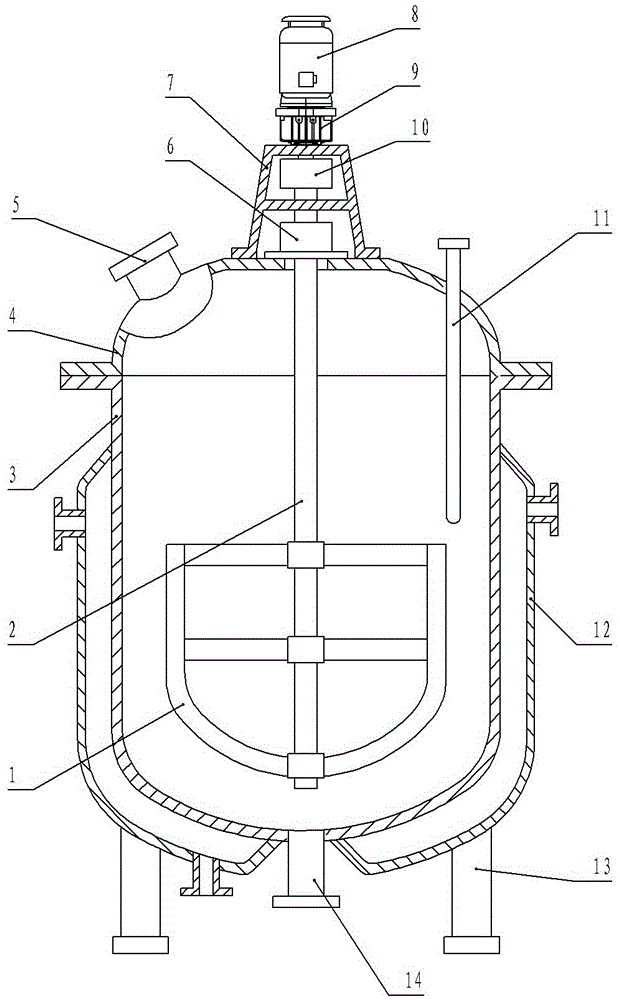

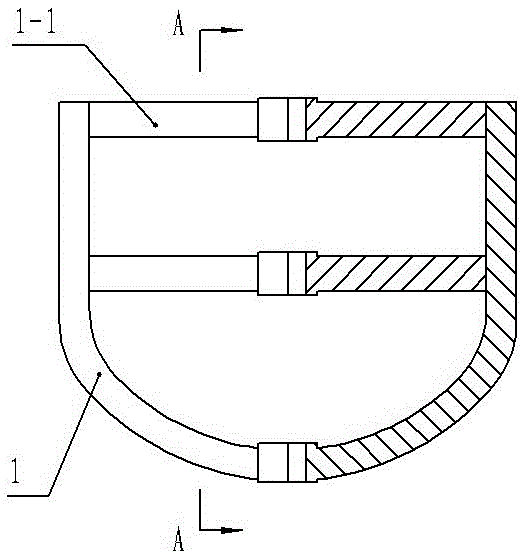

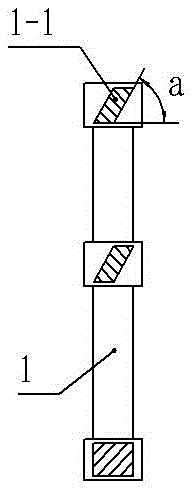

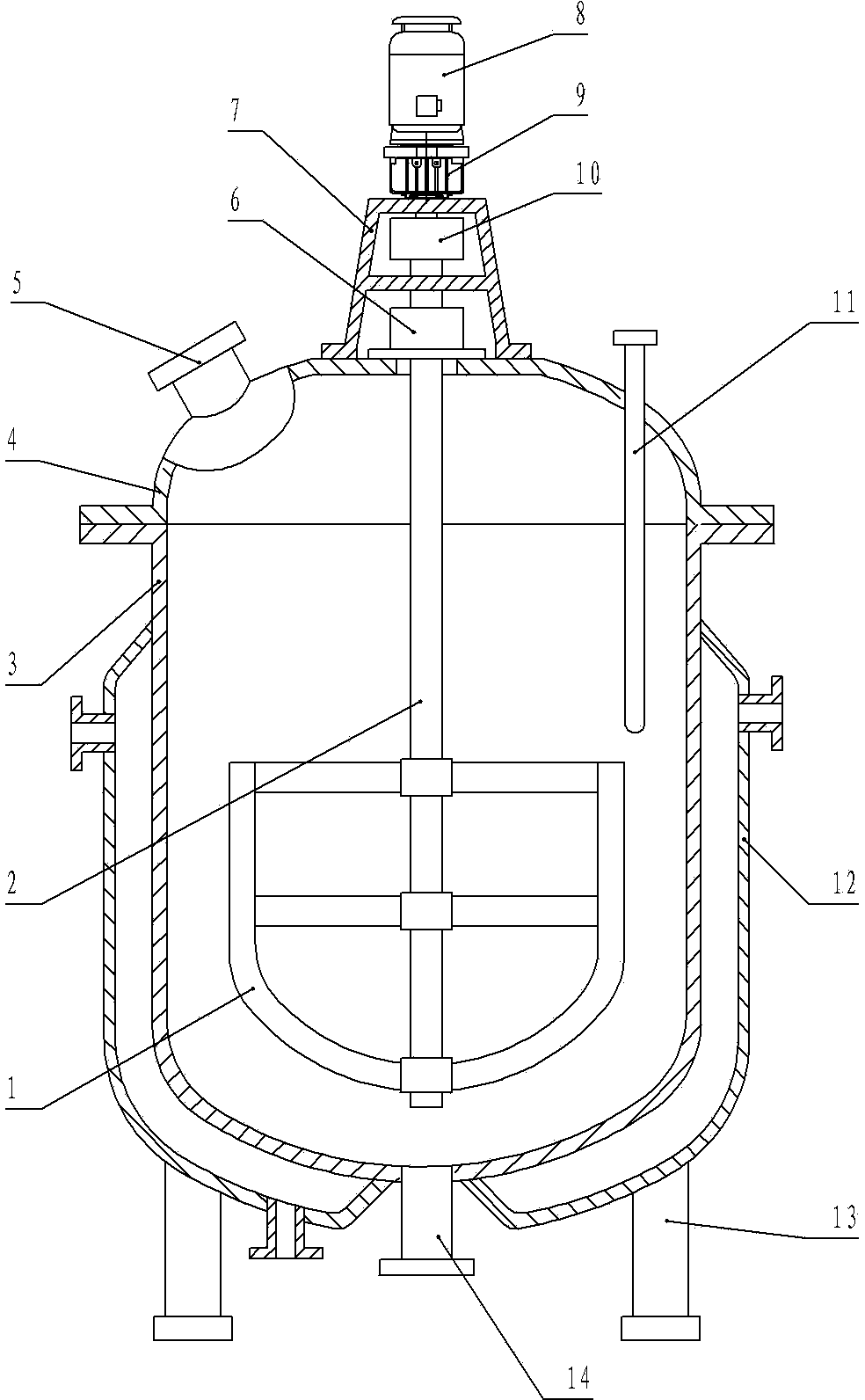

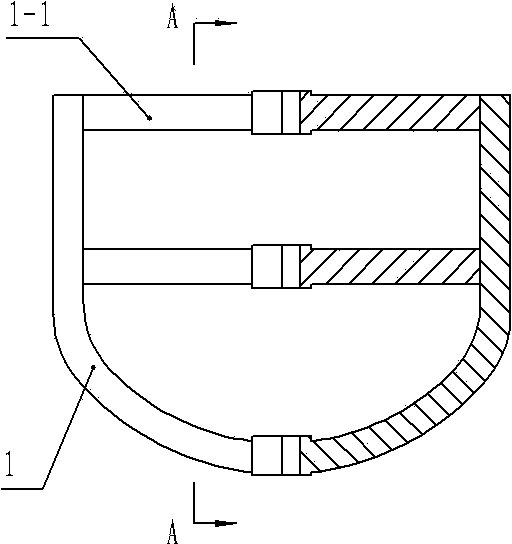

Reaction kettle

InactiveCN103406085AWell mixedAvoid uneven mixingTransportation and packagingRotary stirring mixersVertical mixingProcess engineering

The invention discloses a reaction kettle, and relates to the technical field of chemical engineering equipment manufacturing. The reaction kettles a kettle body, wherein a kettle cover with a feed opening is mounted on the kettle body; a mixing unit is arranged on the kettle cover, and comprises a mixing shaft and a mixing frame sleeved with the mixing shaft; the mixing frame is composed of an arc mixing rod and vertical mixing rods connected with two ends of the mixing rod; a plurality of oblique mixing paddles are arranged between the two vertical mixing rods; the included angle formed between the horizontal plane and the plane of each mixing paddle is 55-65 degrees. Compared with the prior art, the plurality of oblique mixing paddles are arranged between the two vertical mixing rods of the mixing frame, so that the material in the reaction kettle can be uniformly mixed, the temperature is uniform, the reaction is accelerated, the material can react completely, the yield of the product is increased, and the manufacturing cost is lowered.

Owner:GUANGXI ZHONGCHANG RESIN

Extraction and mixing blender

ActiveCN102743996AGood radial blending effectWell mixedRotary stirring mixersMixing methodsMixed flowVertical mixing

The invention relates to an extraction and mixing blender, which is characterized in that an upper blocking cover plate is arranged above a blade, a lower cover plate with a fluid suction port at the center is arranged under the blade, a mixing component for radial flow and mixing of fluid is arranged between the upper cover plate and the lower cover plate and is provided with a plurality of fluid through holes for radial flow of the fluid, and flow paths of the fluid in the blender are staggered after the fluid flows through the fluid through holes. By adopting the technical scheme, good effects of radial mixing of the fluid in the blender can be achieved, vertical mixed flow which is staggered vertically can be formed by radial flow discharged by the blender under effects of a vertical baffle, oil-water mixture is improved further, and the purpose of uniform mixing can be achieved. Meanwhile, when the positions of threads of the mixing shaft and the lower coupling are adjusted, the distance between the suction port of the blender and the oil-water fluid collection outlet on the upper part of the bottom sandwich can be adjusted according to oil-water flow in the process, and the amount of sucked fluid can be controlled.

Owner:ZHEJIANG YANGTSE RIVER MIXERS

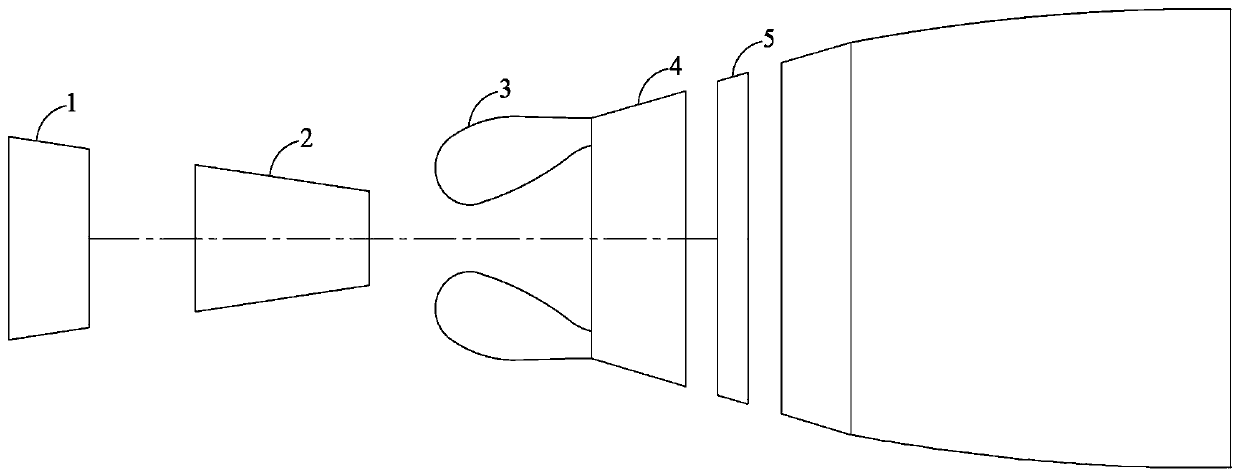

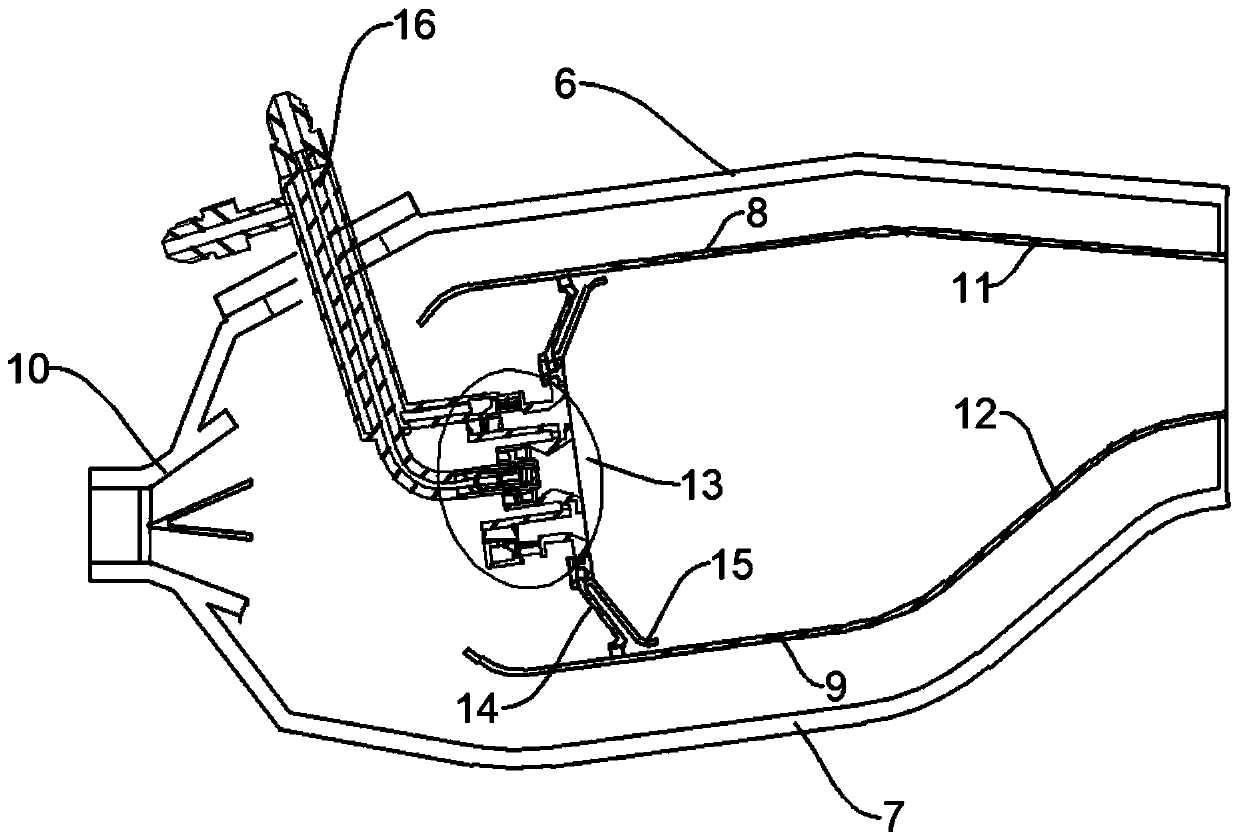

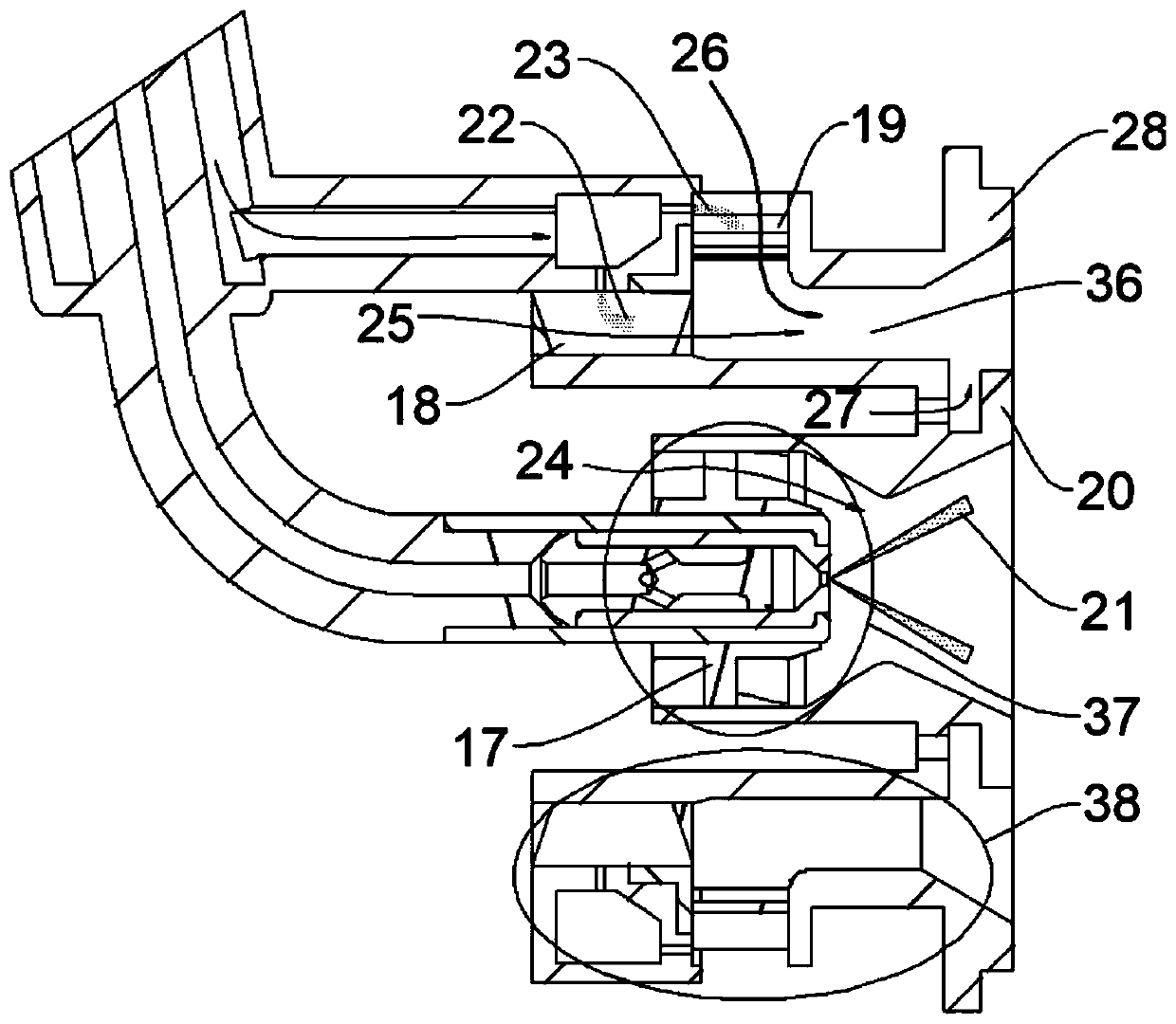

Low-emission combustion chamber with main combustion stage adopting two-stage vertical mixing

The invention discloses a low-emission combustion chamber with a main combustion stage adopting two-stage vertical mixing, and relates to the technical field of aviation gas turbines. The low-emissioncombustion chamber adopts a classification combustion scheme; the head part of the combustion chamber is divided into a precombustion stage and the main combustion stage; the precombustion stage adopts a centrifugal nozzle to directly spray fuels to form dispersion combustion to stabilize flame of the combustion chamber; and fuels of the main combustion stage adopt an unique two-stage spraying vertical mixing mode to spray into a first-grade cyclone and a second-grade cyclone to form primary mixing; and then, the fuels adopt two-stage vertical mixing to enter a premixing channel for secondarymixing. The fuels of the main combustion stage adopt a twice-division mixing mode to greatly improve the mixing uniformity of the fuels and air, so that the pollution emission of the whole landing and takeoff cycle of an aviation engine combustion chamber is further reduced.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

Owner:USG CORP

Horn ribbon vertical mixing integrated flavoring powder production equipment and production process thereof

ActiveCN109529704AEffective zoom outEliminate zoom outRotary stirring mixersTransportation and packagingBiochemical engineeringVertical mixing

The invention provides horn ribbon vertical mixing integrated flavoring powder production equipment and a production process thereof. The horn ribbon vertical mixing integrated flavoring powder production equipment comprises a stirring barrel, a feeding screening barrel, a dust absorbing device, a spice storage barrel and a feeding port, a motor is arranged in the middle of the stirring barrel, astirring shaft is arranged on an output shaft of the motor, main shaft stirring propellers are alternately arranged on both sides of the stirring shaft, a main shaft scraper is arranged on the inner wall of the stirring barrel, a first umbrella-shaped temporary-storage barrel is arranged above the stirring barrel, the feeding screening barrel is arranged above the first umbrella-shaped temporary-storage barrel, a dust-absorption device is arranged in the feeding screening barrel, and the spice storage barrel is arranged at one side of the stirring barrel. The cooperation of a first main shaft stirring propeller and a second main shaft stirring propeller, the main shaft scraper and a side flying knife propeller is used for cutting and stirring to ensure the stirring uniformity, the stirring time is shortened, the production efficiency is improved, the production automation is realized, the spice is sprayed on the surface of other materials through a high-pressure liquid nozzle, and mixed and stirred at the same time to complete the operation of scenting the product.

Owner:潮州市顺冠生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com