Efficient environmentally-friendly paint spraying device for workpiece

An environment-friendly and workpiece-friendly technology, which is applied in spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of uneven spraying, low painting efficiency, and high labor intensity, so as to avoid aggregation, condensation, and spraying Uniform, high-efficiency painting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

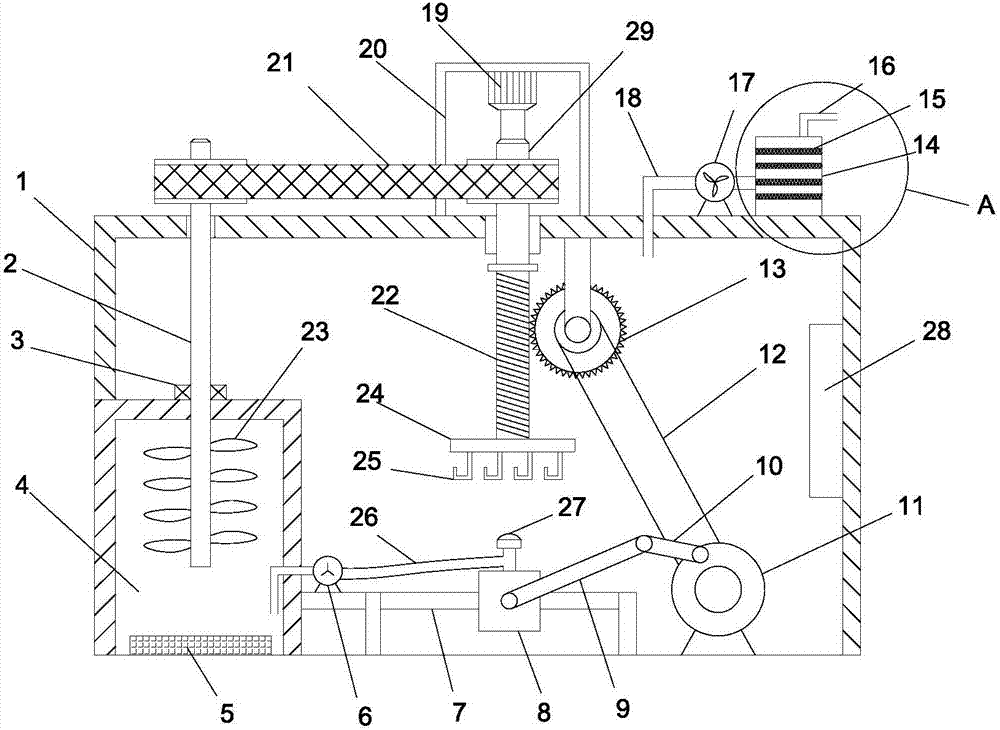

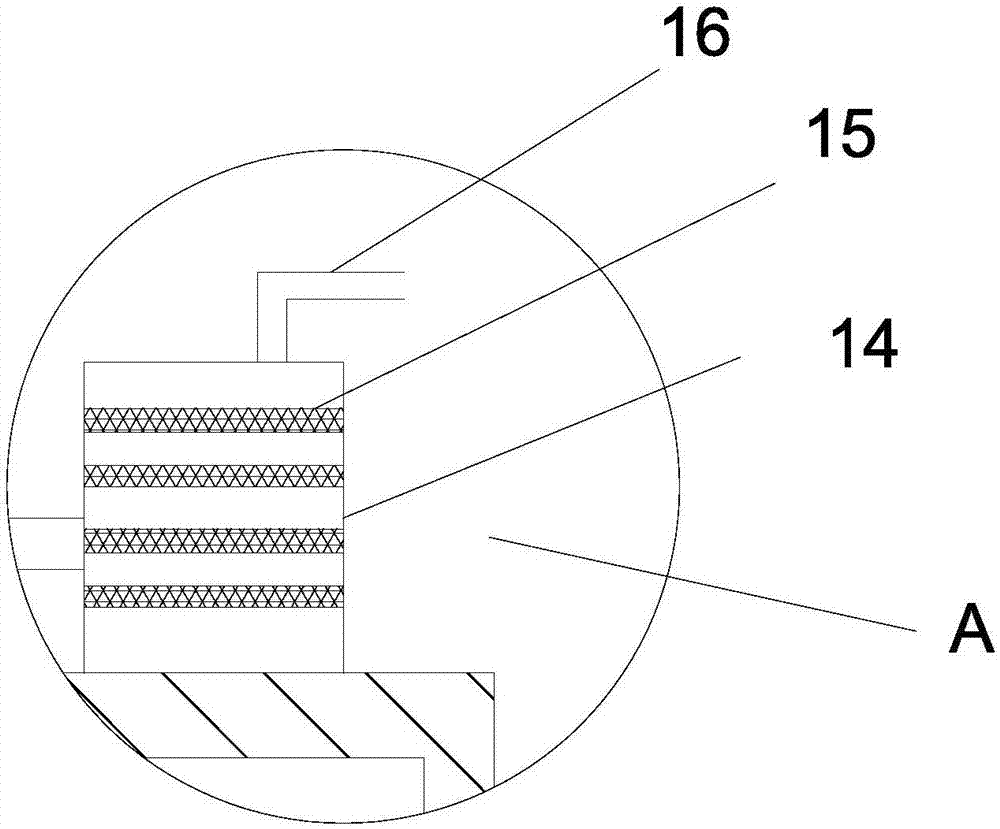

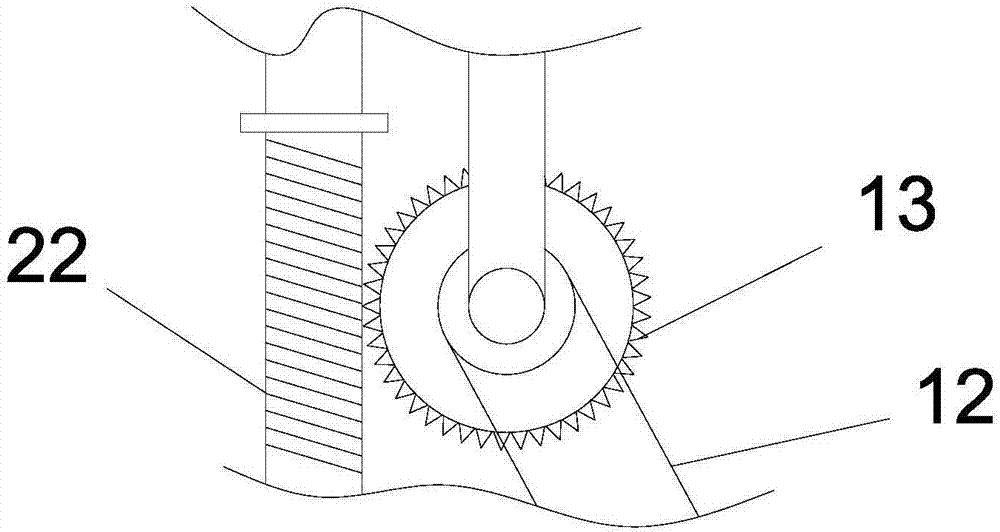

[0019] see Figure 1-3 , a high-efficiency and environment-friendly workpiece painting device, comprising a body 1, characterized in that, the body 1 is provided with a mixing tank 4, the mixing tank 4 is filled with paint, the bottom of the mixing tank 4 is provided with a heater 5, and the mixing tank 4 is vertically provided with a stirring shaft 2, the stirring shaft 2 is provided with a stirring blade, and the stirring shaft 2 is provided with a bearing 3; the top of the body 1 is provided with a motor frame 20, and the motor frame 20 is provided with a drive motor 19 for driving A drive shaft 29 is fixedly installed on the motor shaft of the motor 19, and a second belt drive mechanism 21 is connected between the drive shaft 29 and the stirring shaft 2, and the second belt drive mechanism 21 is located above the outside of the body 1; the drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com