Reaction kettle

The technology of a reaction kettle and a kettle body is applied in the field of reaction kettles for producing rosin derivative products, which can solve the problems of insufficient material reaction, slow reaction speed and high production cost, so as to avoid uneven stirring, accelerated reaction speed and high production cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

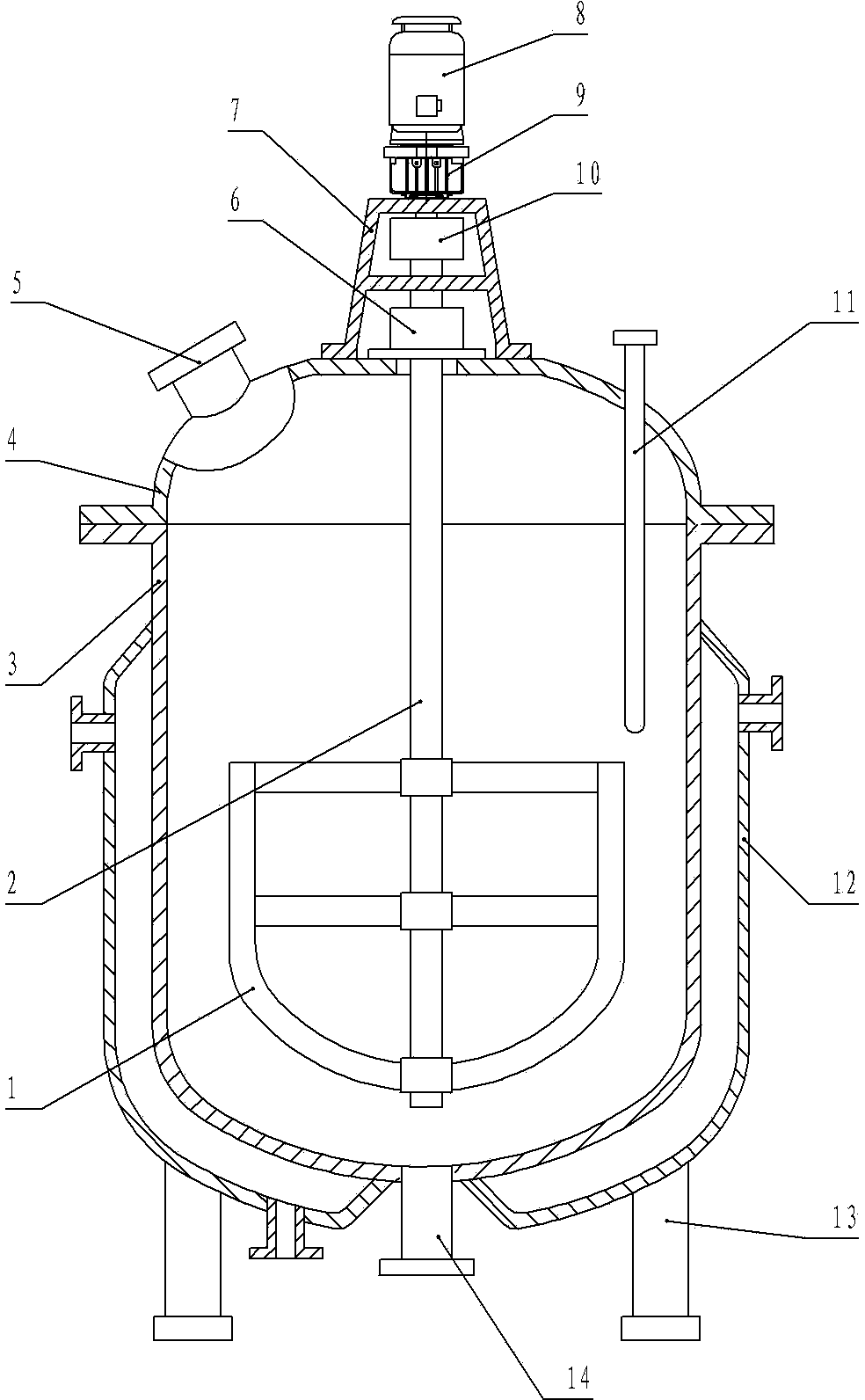

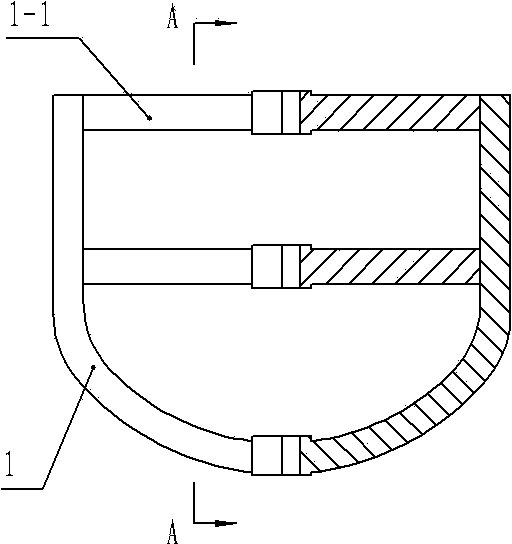

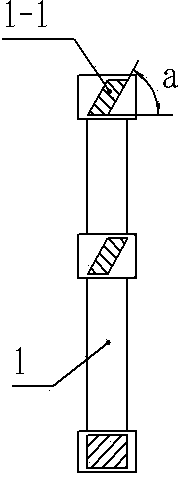

[0014] Such as figure 1 The shown reaction kettle comprises a kettle body 3 welded with a jacket 12 on the periphery and a discharge port 14 welded on the bottom, and four legs 13 are welded on the bottom of the kettle body 3; A gasket is installed between the connection surface between the body 3 and the kettle cover 4, and the kettle body 3 and the kettle cover 4 are connected by bolts; the upper end of the kettle cover 4 is respectively provided with a feed port 5 and a temperature measuring sleeve 11, and the middle is installed There is a stirring device, which includes a stirring shaft 2 and a stirring frame 1 set on the stirring shaft 2. The stirring frame 1 is composed of an arc-shaped stirring rod and a vertical stirring rod connected to both ends of the stirring rod. The vertical stirring rods at both ends are welded and connected, and two ob...

Embodiment 2

[0017] The included angle a between the plate surface of the stirring paddle 1-1 and the horizontal plane is 65 degrees, and other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com