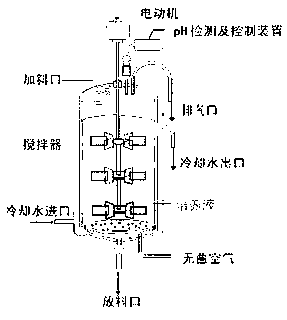

Vertical mixing fermentation tank

A fermenter and stirring shaft technology, applied in the field of fermenter, can solve problems such as difficulty in stirring evenly and thoroughly, large mechanical structure, and large mechanical agitator resistance, and achieve the effects of reducing the probability of failure, simplifying the mechanical structure, and reducing the need

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

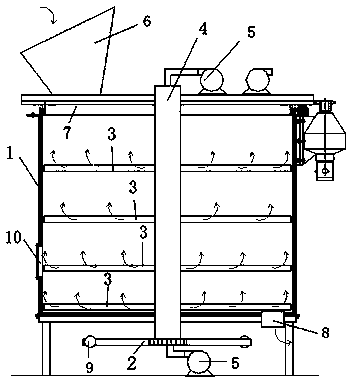

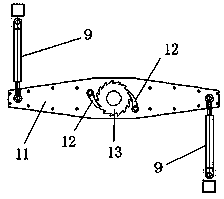

[0036] This embodiment provides a vertical stirring fermenter, which includes a tank body 1 and an upper cover, a feeding device 6, an air blowing device 5, an air exhausting device and a stirring and discharging device.

[0037] The bottom of the tank body 1 is flat, with a discharge port, a door switch, a discharge device, and a wind net. The tank body 1 can be a double-layer structure, and the middle of the double-layer is filled with heat-insulating material, and there are multiple air outlets on the inner surface to supply oxygen for the fermented product in the fermenter. The tank body 1 is provided with a manhole 10 that allows people to pass through, which is convenient for repair.

[0038] The feeding device 6 includes a receiving hopper located on the upper cover 7, and a gate is installed under the receiving hopper, so that the sealing of the tank body 1 can be effectively maintained.

[0039] The blower device 5 and the draft device can be installed in a suitable ...

Embodiment 2

[0054] Example 2 Research on energy consumption of motors.

[0055] According to the structure of Example 1, the present invention has designed fermentors with volumes of 3, 5, 10, 20, 40 and 60 cubic meters respectively, and adopted a conventional solid fermentor of 10 cubic meters for comparison, and packed Waste, measure the required power of each fermentation tank, the results are shown in Table 1

[0056] Table 1 Power required by each fermenter

[0057] Fermenter type required power 10 cubic meters of conventional solid fermenter The required power of the stirring motor is 37 kW 3 cubic meters of fermenters designed according to embodiment 1 The power provided to the hydraulic cylinder is 0.75 kW 5 cubic meters of fermenters designed according to embodiment 1 The power provided to the hydraulic cylinder is 0.75 kW 10 cubic meters of fermentation tank designed according to embodiment 1 The power provided to the hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com