Stirring-cage type wet-spraying machine

A wet spraying machine and cage-type technology, which is applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of easy kneading of concrete aggregate, complicated maintenance of hydraulic system, and inability to transport concrete, etc. Large working space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

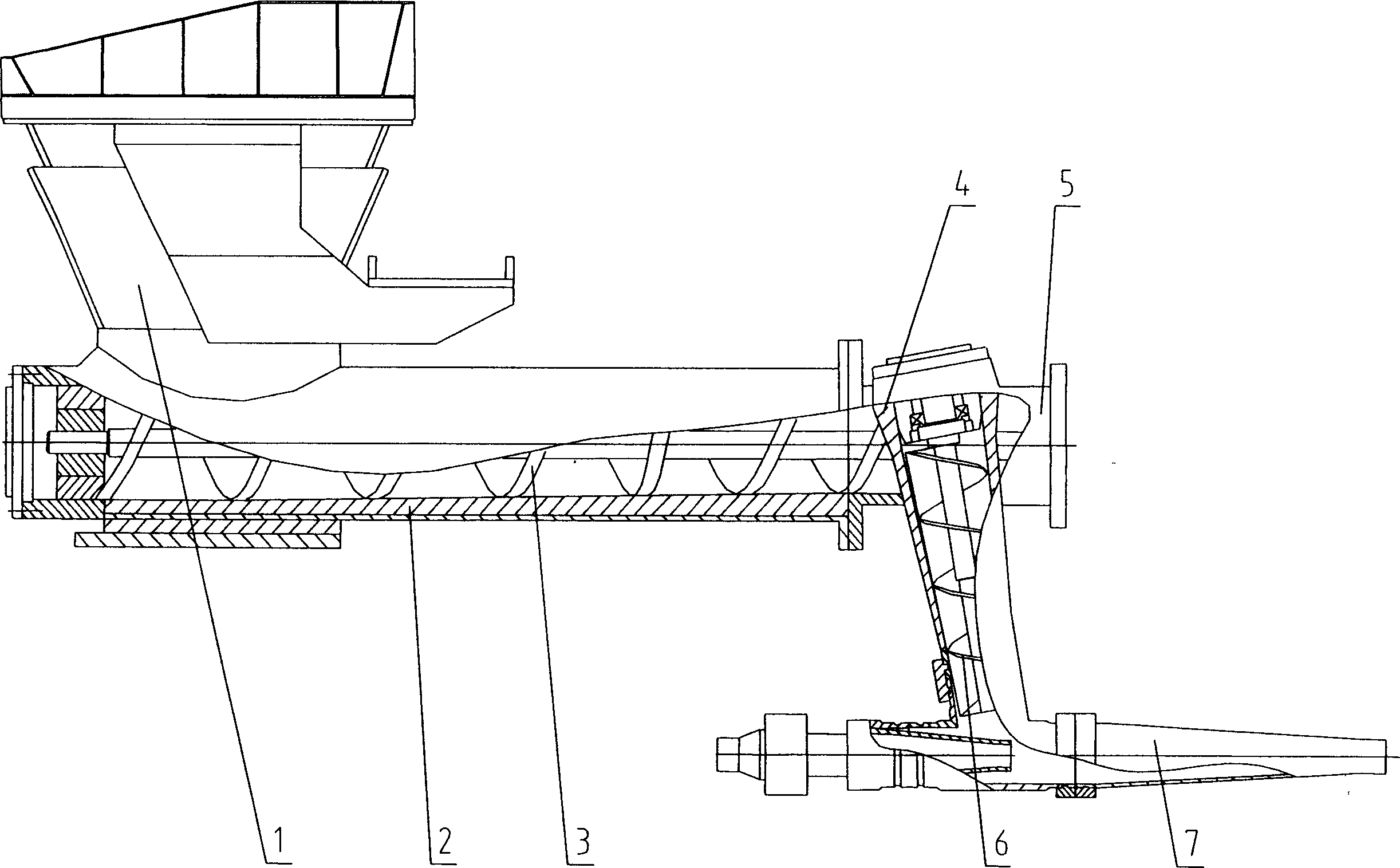

[0006] The present invention will be further described in conjunction with the accompanying drawings. First, the conical stirring cage and the vertical stirring cage are rotated by the power source to enter the working state, and then the high-pressure air valve is opened to allow the high-pressure airflow to enter from the left end of the spray pipe. The above preparatory work can be completed Pour the well-mixed concrete material from the feed port, and the concrete is pushed to the small end of the cone sleeve of the mixing cage under the push of the spiral blade of the conical mixing cage, and then sent into the discharge box. When the concrete in the discharge box reaches the After a certain amount, it is squeezed into the upper end of the vertical mixing cage, and under the push of the vertical mixing helical blade, the concrete is sent down into the injection pipe, and the concrete is sprayed from the right end of the injection pipe by the high-pressure airflow at the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com