Foundation pit support device and construction method

A construction method and technology of foundation pit support, which is applied in the direction of infrastructure engineering, excavation, construction, etc., can solve problems such as environmental pollution, long construction period, poor soil quality of foundation pit, etc., and achieve the effect of reducing cost and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific combination of the following Figure 1-6 The present invention will be further described.

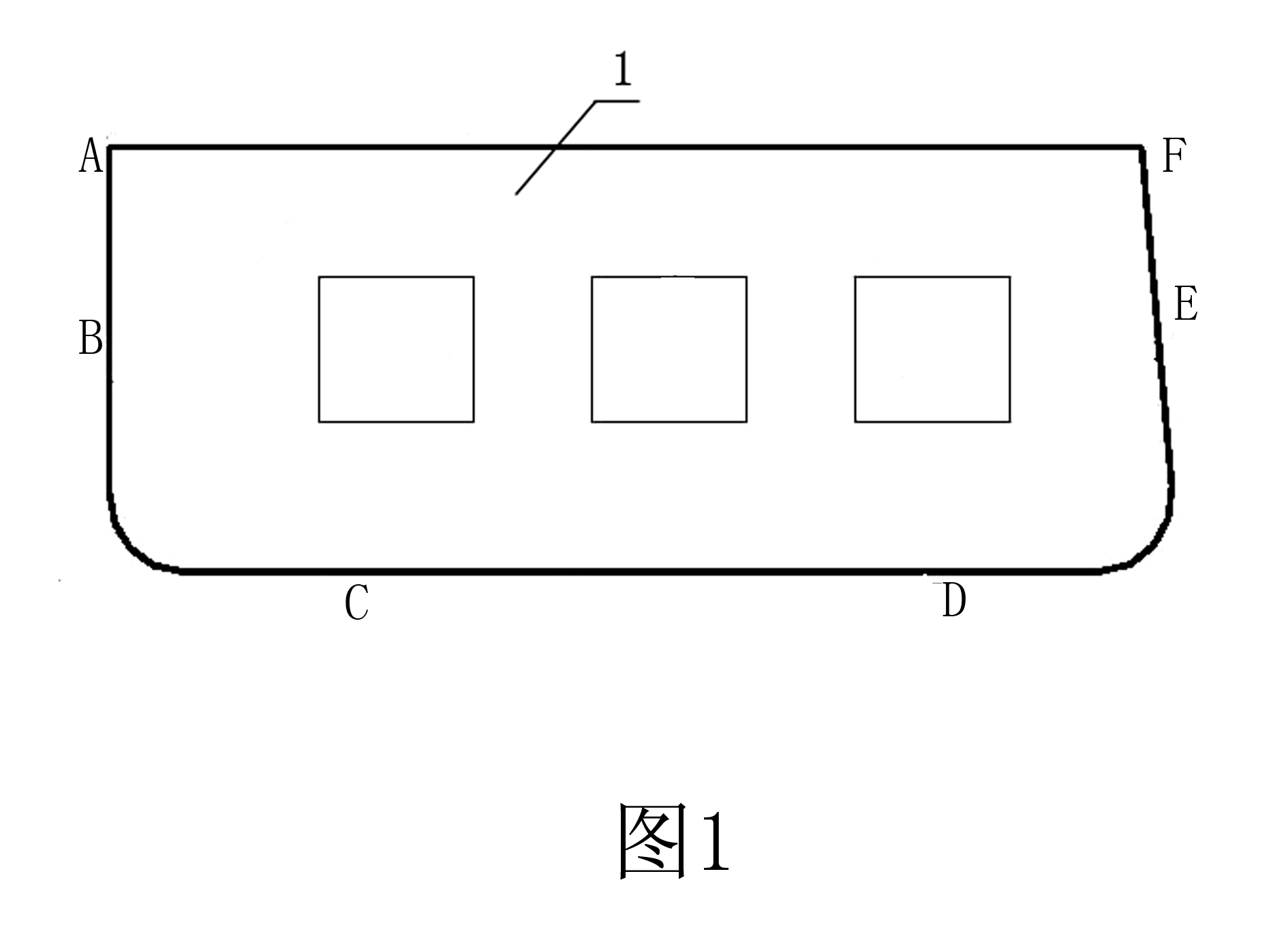

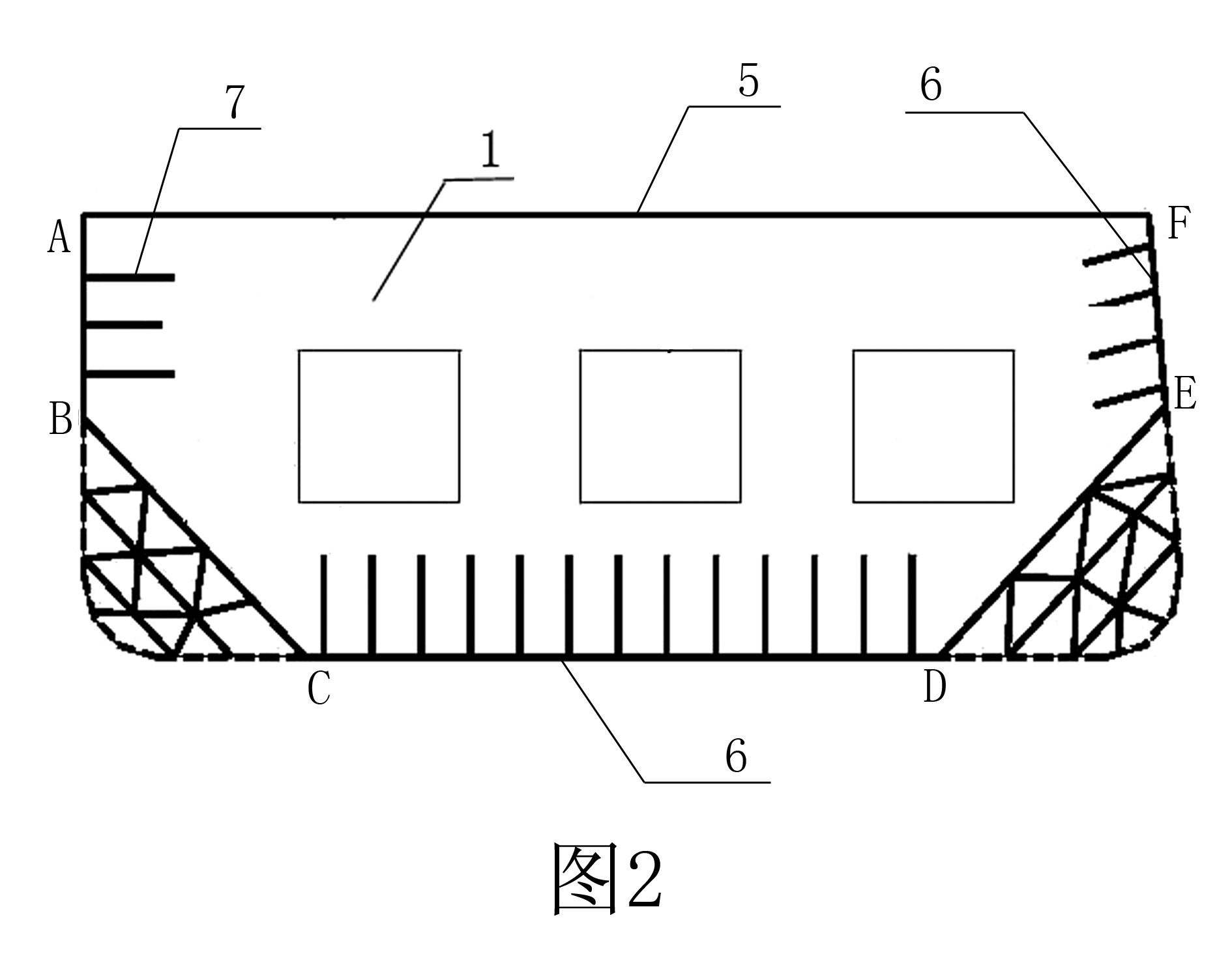

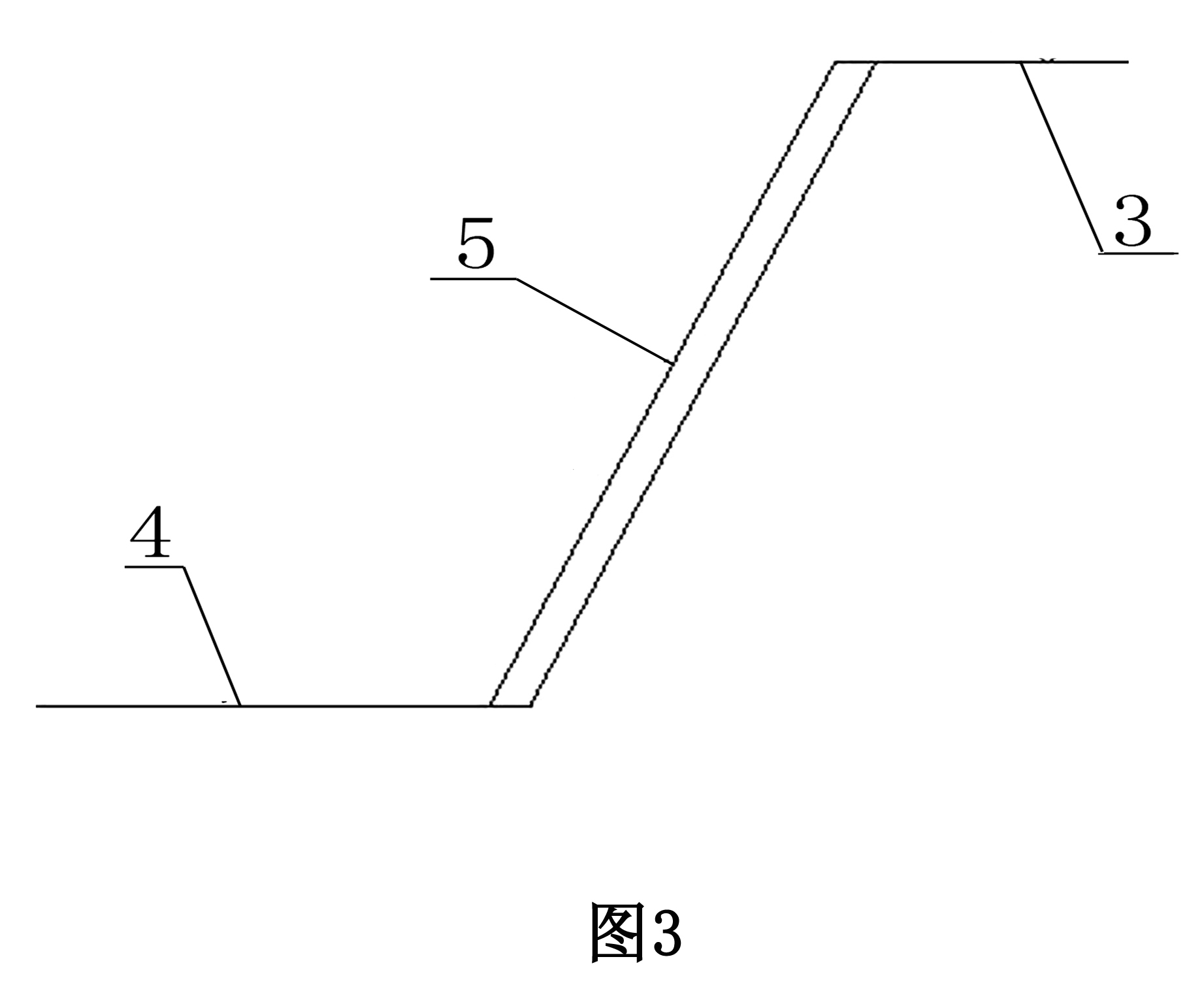

[0045] A typical implementation project of the present invention: the project has 2 underground floors, the elevation of the pit bottom 4 is -11.6m, the base elevation of the local pit 2 is -17.3m, the plane size of the foundation pit 1 is 82 × 223 meters, and the area of the foundation pit 1 is about 18,000 square meters. Super large foundation pit. The north and east sides of the project are open spaces, the west side is the Fortune Financial Center Building project under construction, and the south side is the Forest Park, about 300 meters away from the Qiantang River. According to the surrounding environment of the above foundation pit, the foundation pit support is divided into six construction sections A-B, B-C, C-D, D-E, E-F and F-A. For the six construction sections above -5.50 meters, please refer to the attached plan for the plan layout of the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com