Patents

Literature

584 results about "Soil mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

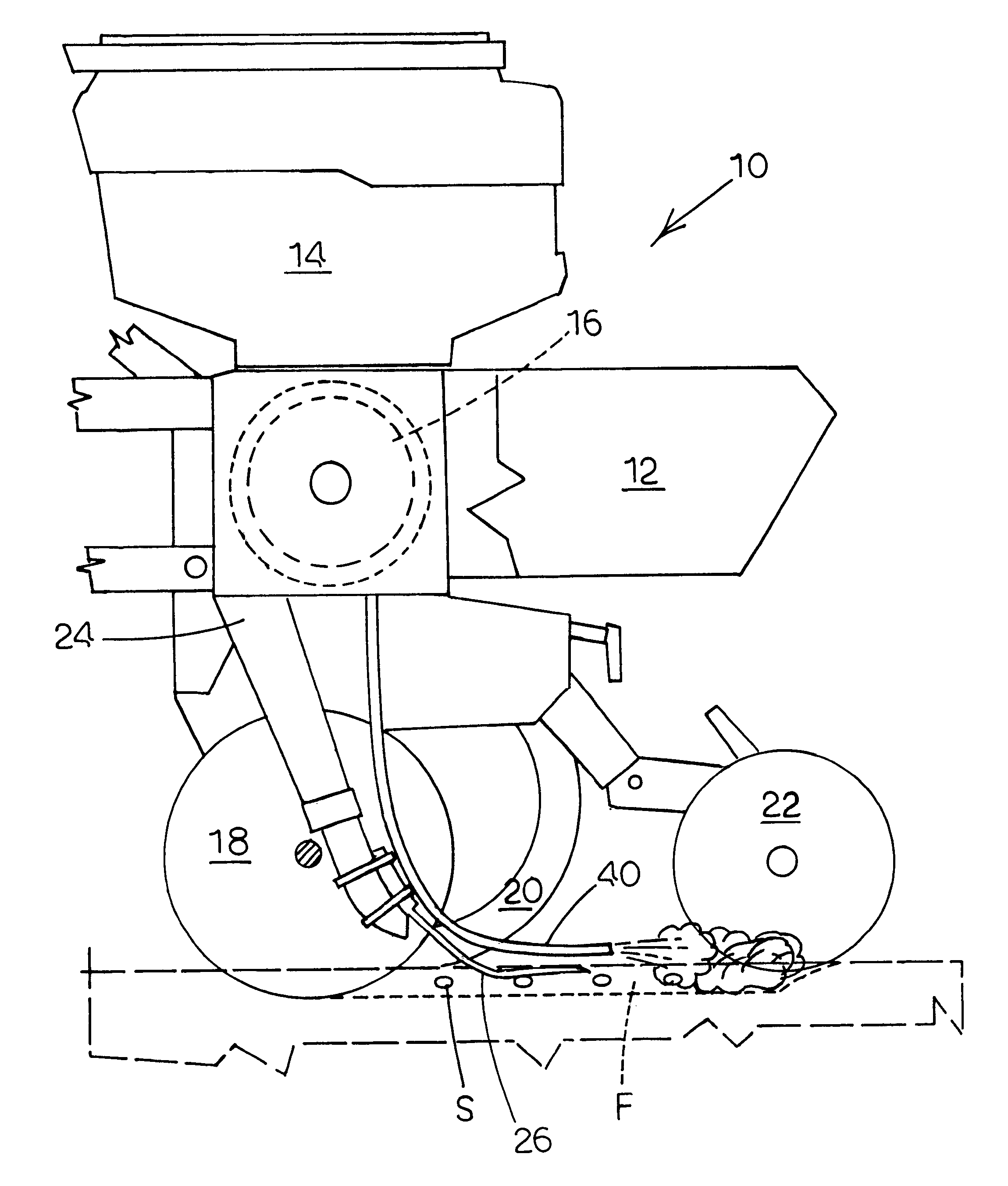

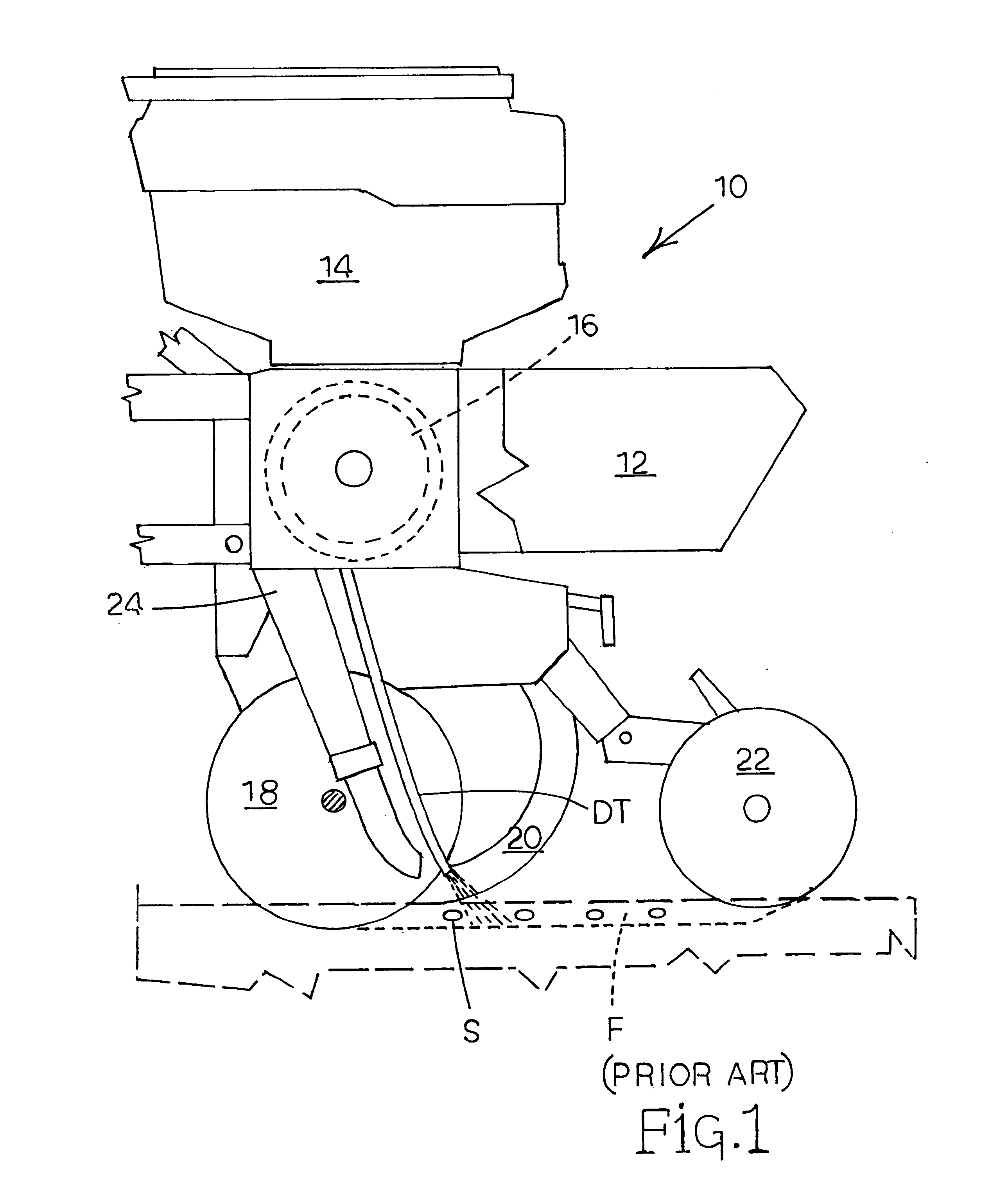

Planting apparatus with improved liquid pesticide delivery device and related method for delivering liquid pesticide

A planting machine for delivering liquid pesticides to the soil mixing zone preceding the furrow closing mechanism to effectively distribute liquid pesticide throughout soil covering seed in a furrow. The planting machine has a furrow opening mechanism, seed dispensing means, and furrow closing mechanism and includes a seed positioning means mounted on the seed dispensing means for effectively locating seeds in the furrow. Also, the planting machine includes means for liquid pesticide spray delivery mounted thereon so as to direct a spray towards the furrow closing mechanism and into the soil mixing zone being created by the furrow closing mechanism. The means for spray delivery can be mounted on the conventional seed positioning means as well as independently mounted on the planting machine.

Owner:MERIAL LTD +1

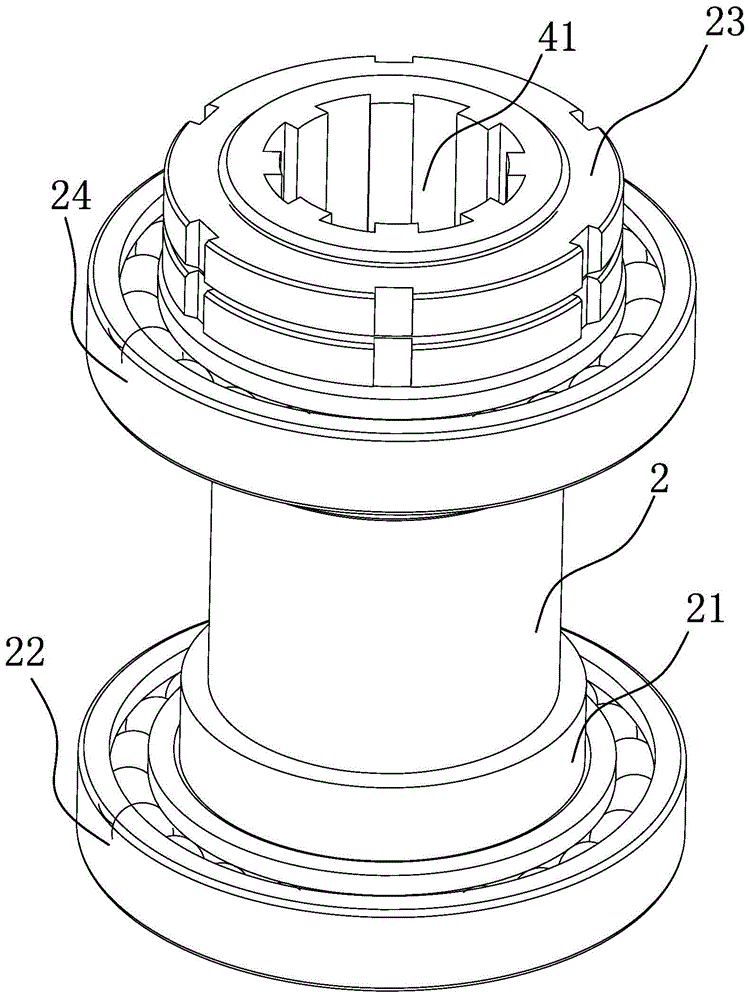

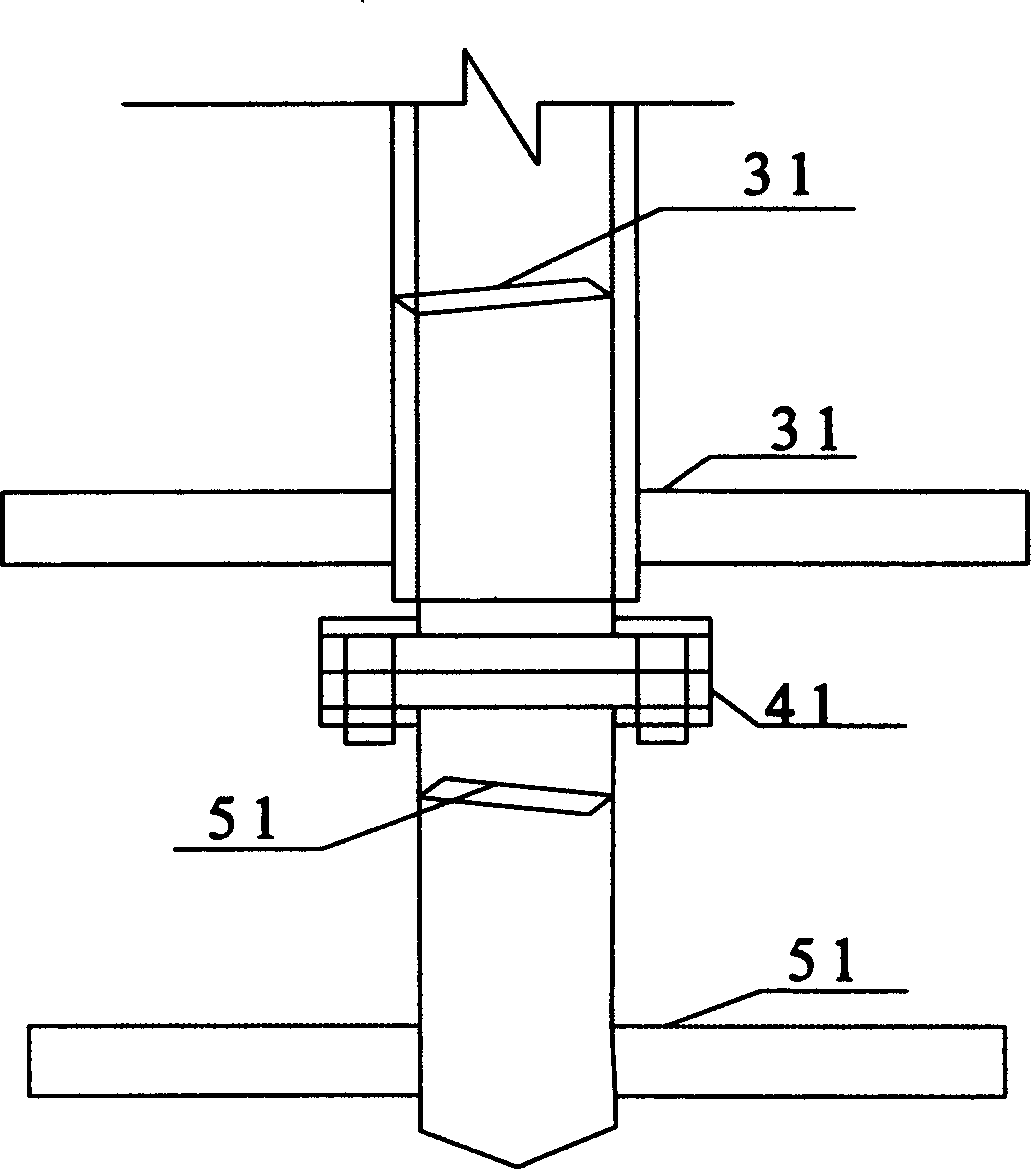

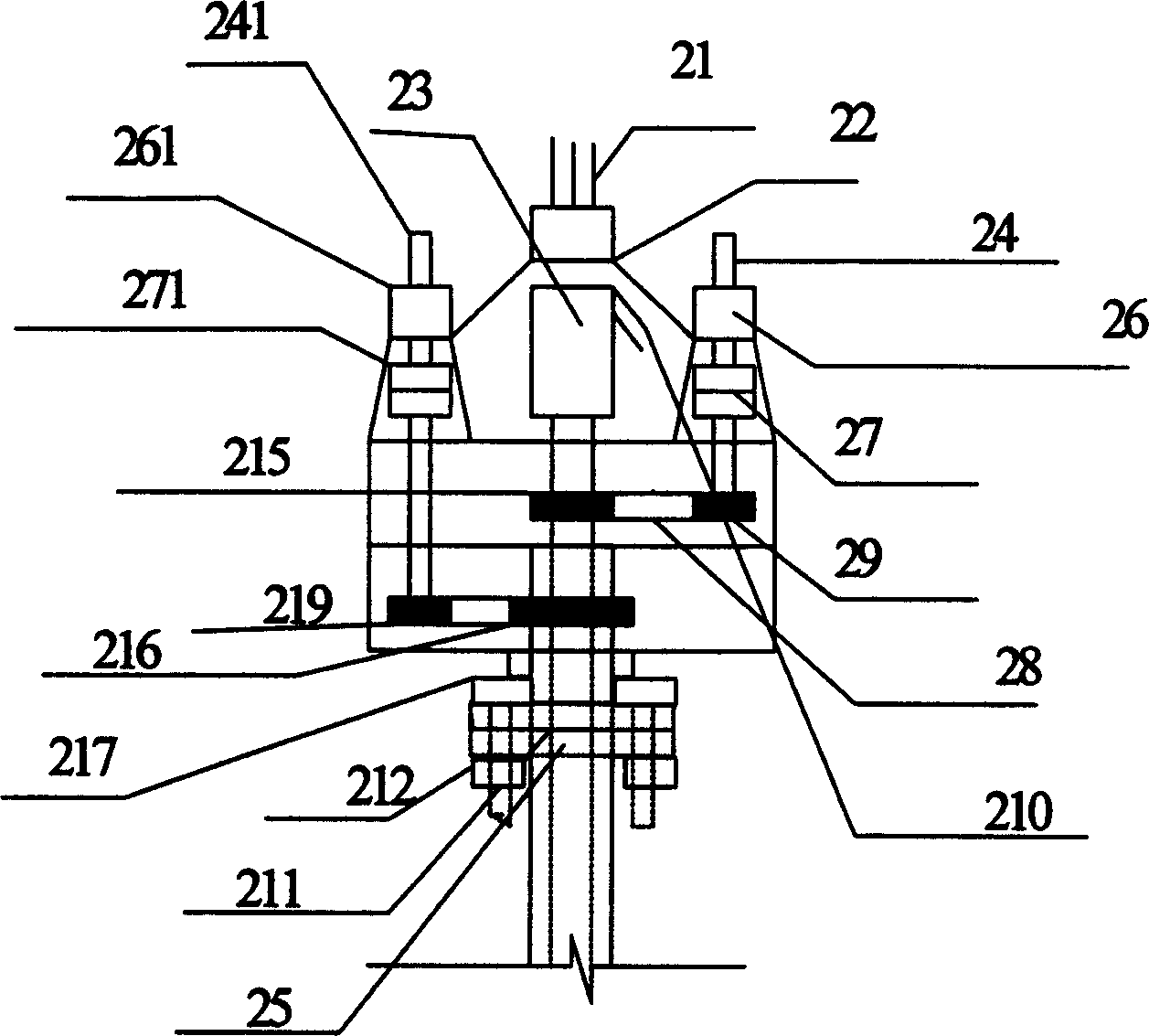

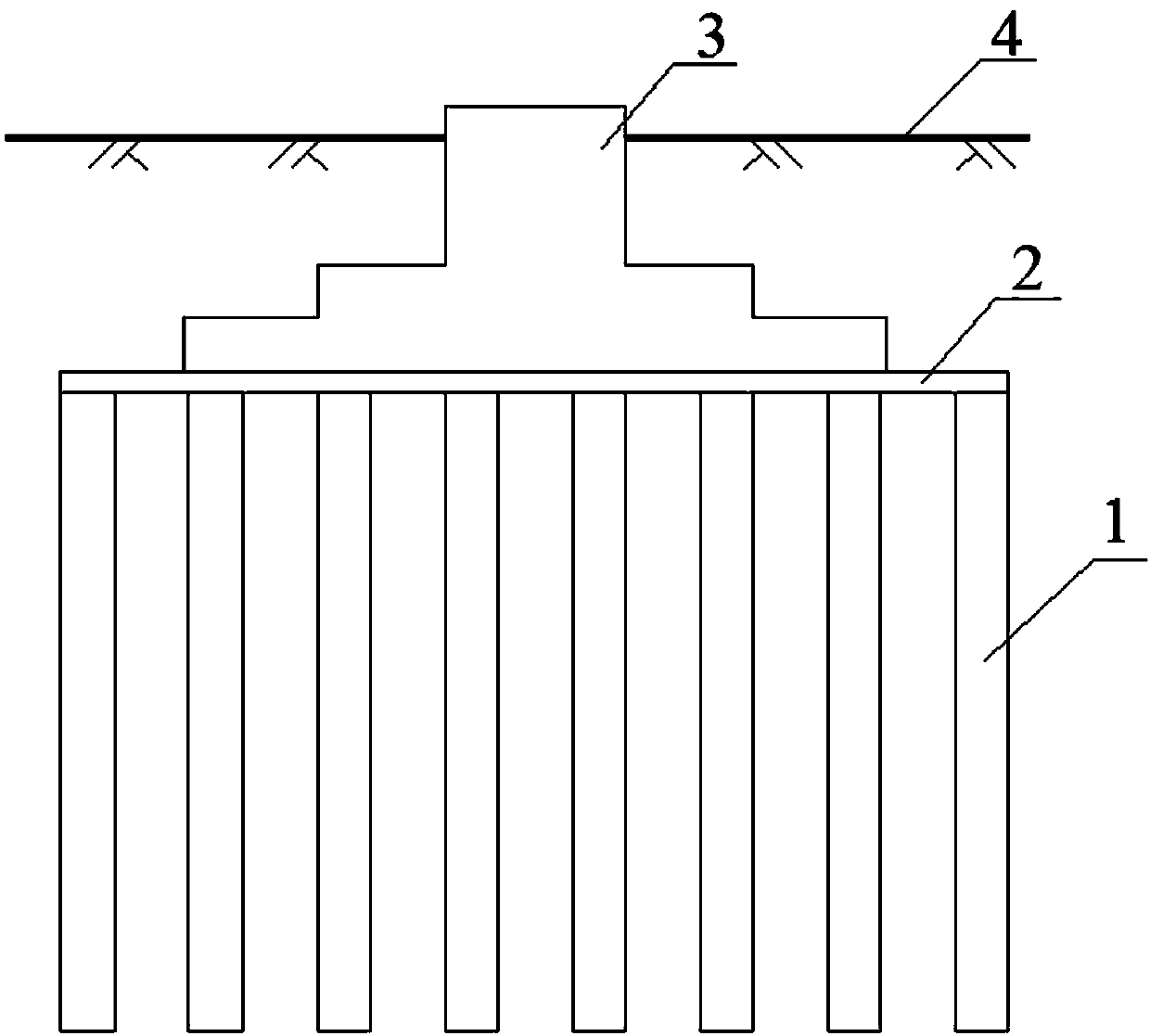

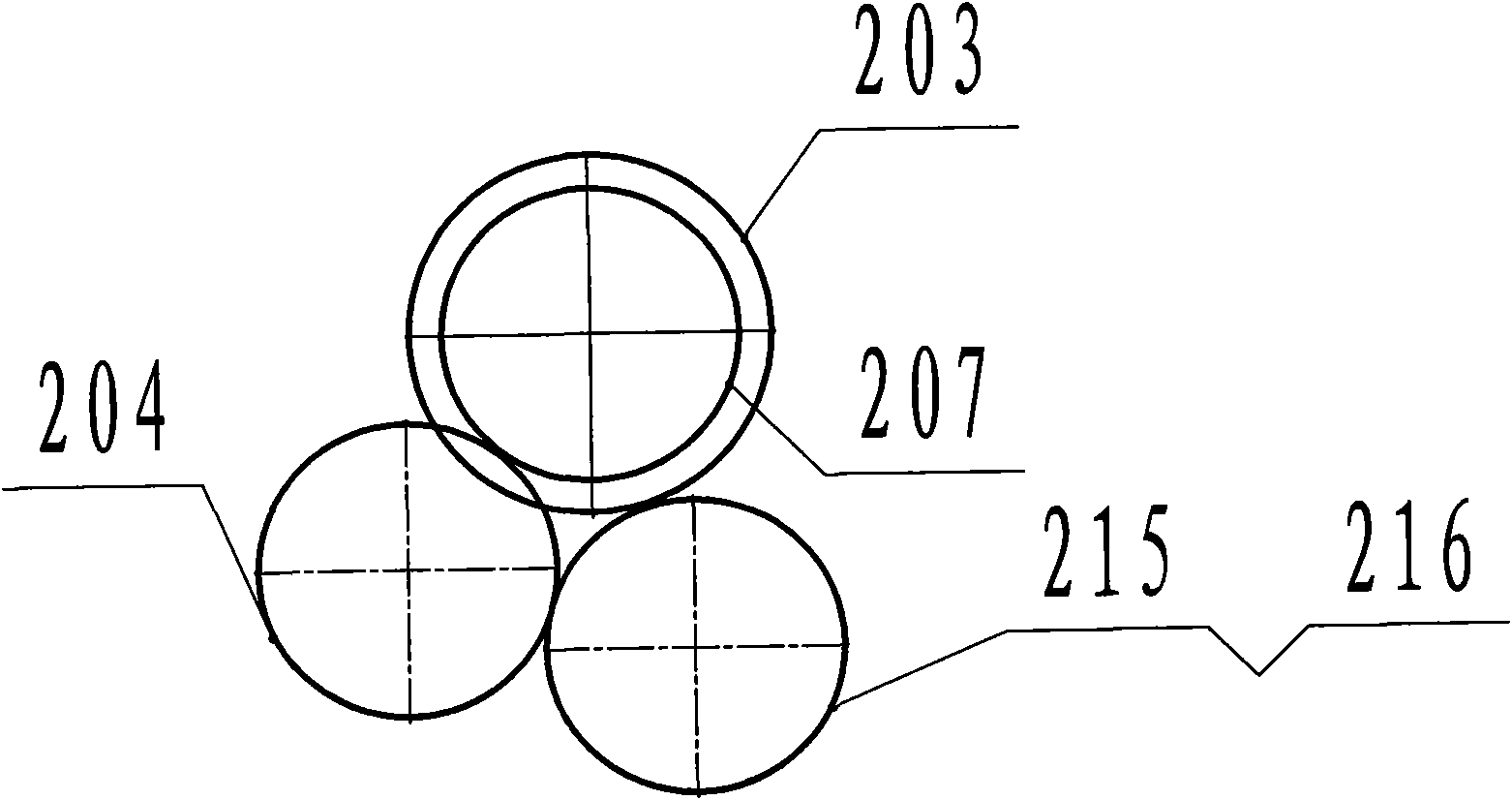

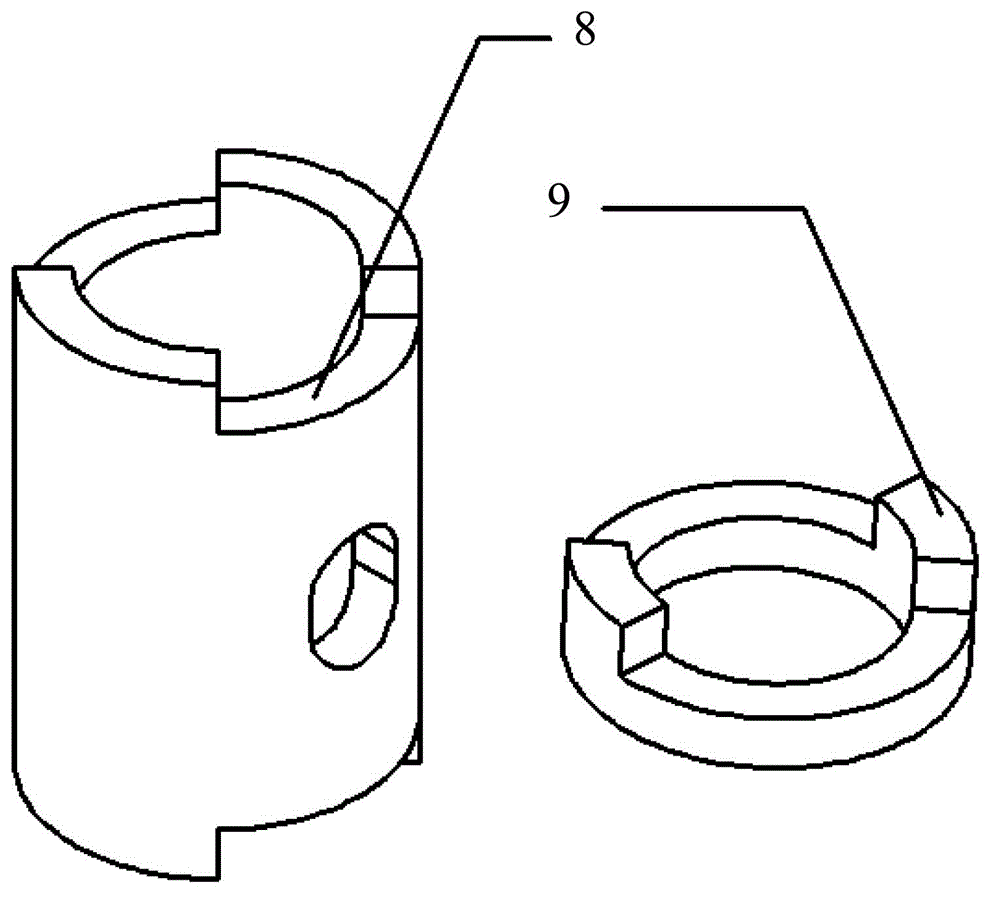

Moving drill rod of cement-soil mixing pile driver

ActiveCN105064911AImprove pullout resistanceIncrease girthRotary drillingRotary-drilling machinesDrill pipeSoil mixing

The invention belongs to the technical field of building equipment, and particularly relates to a moving drill rod of a cement-soil mixing pile driver. The moving drill rod solves the problem that existing cement-soil mixing pile drivers are prone to drill failures when drilling and the like, and comprises a driving box with an inner cavity, wherein the driving box is provided with at least one through hole which runs through the whole driving box in the axial direction; a guiding sleeve which can rotate in the circumferential direction and is cylindrical is arranged in the through hole; a drill rod which runs through the whole driving box is arranged in the guiding sleeve in a penetrating manner; an axial guiding structure is arranged between the drill rod and the guiding sleeve; the guiding sleeve is connected with a circumferential rotating mechanism which can drive the guiding sleeve to rotate in the circumferential direction; and the drill rod is connected with an axial driving mechanism which can drive the drill rod to slide back and forth in the axial direction. The moving drill rod of the cement-soil mixing pile driver has the advantages that a drill rod body can stretch in the axial direction, can rotate in the circumferential direction and slide in the axial direction at the same time, and thus is not prone to rotation failures; the perimeter of the cross section of a cement-soil mixing pile after constructing is increased; and the pull-out capacity of the cement-soil mixing pile is improved.

Owner:周兆弟

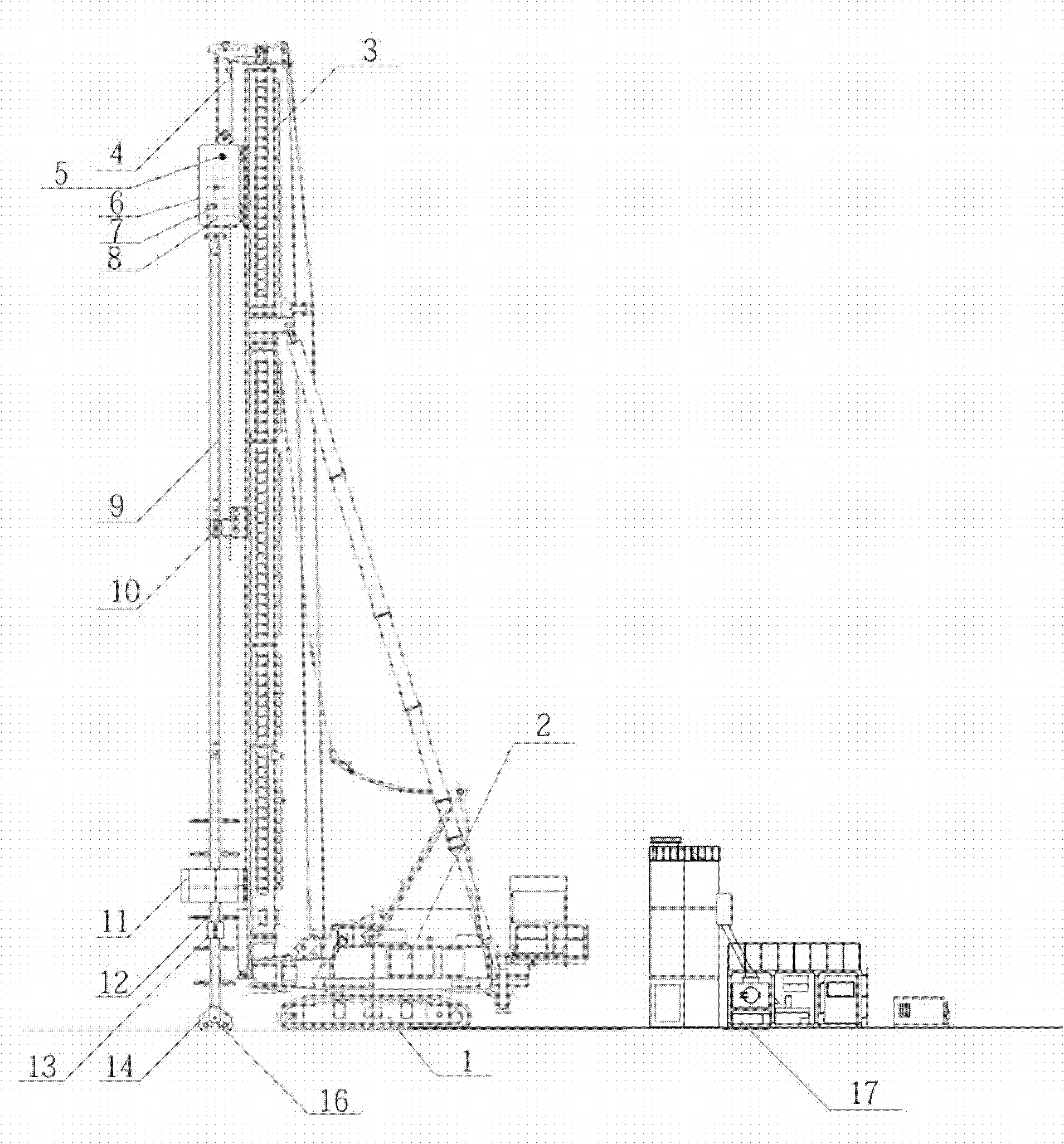

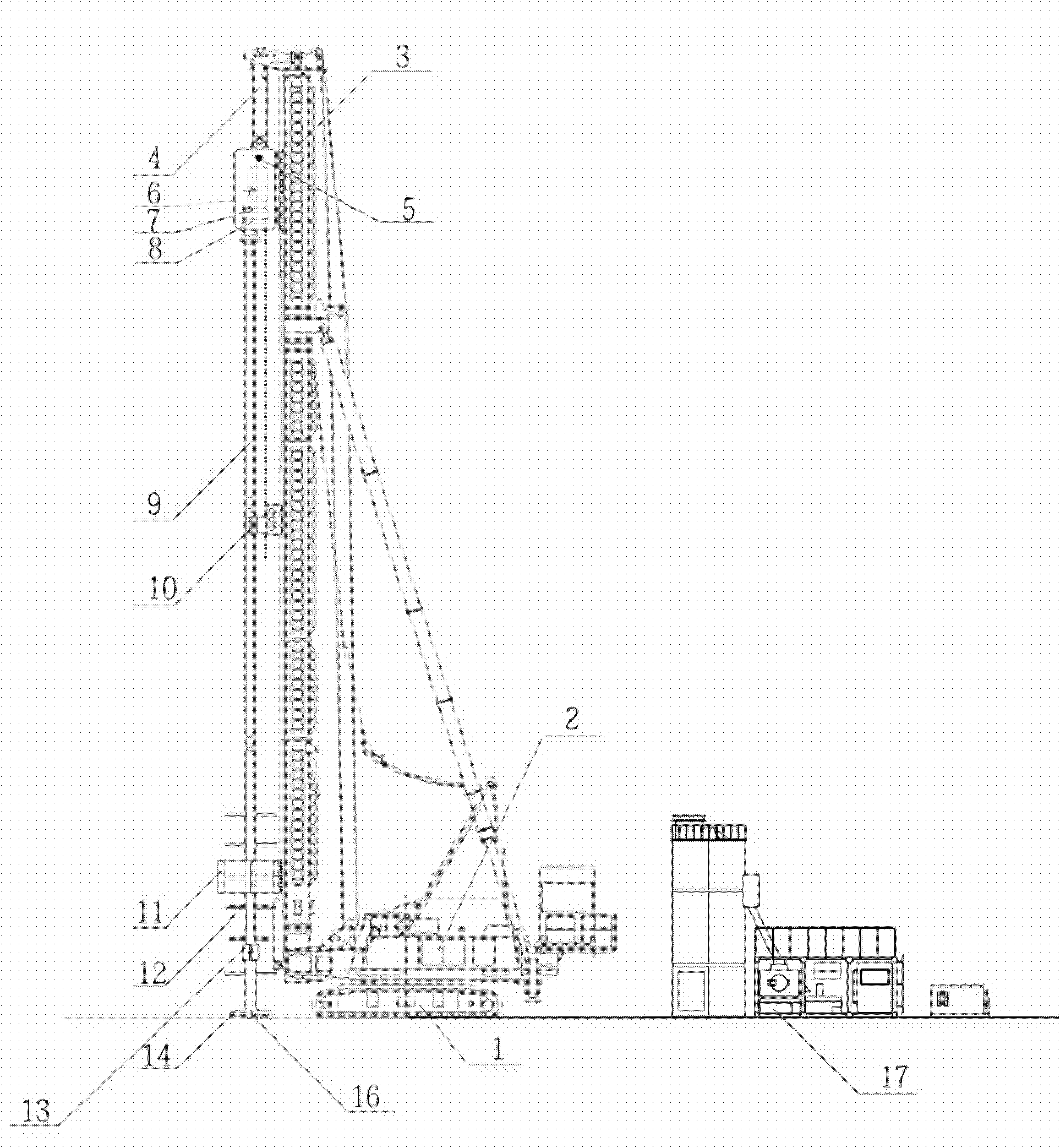

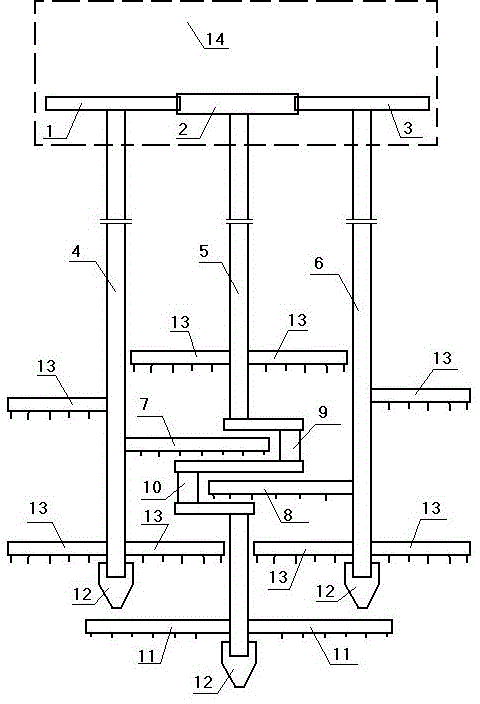

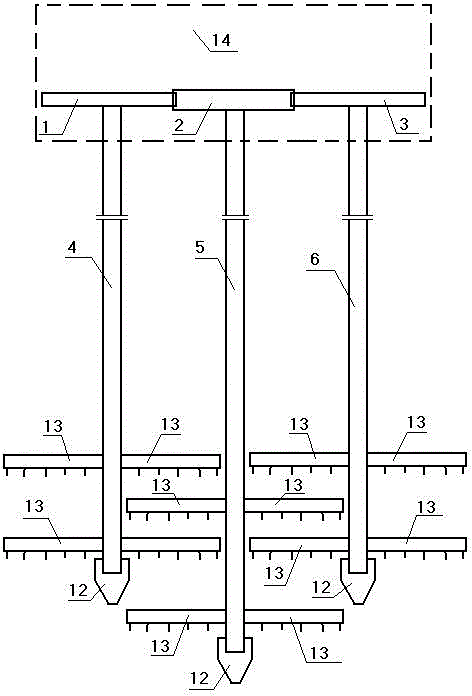

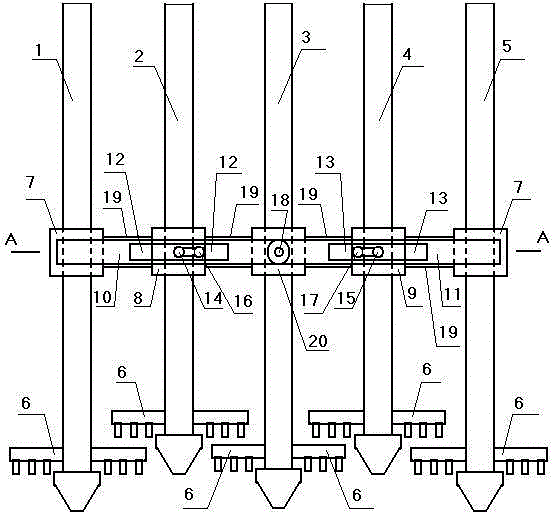

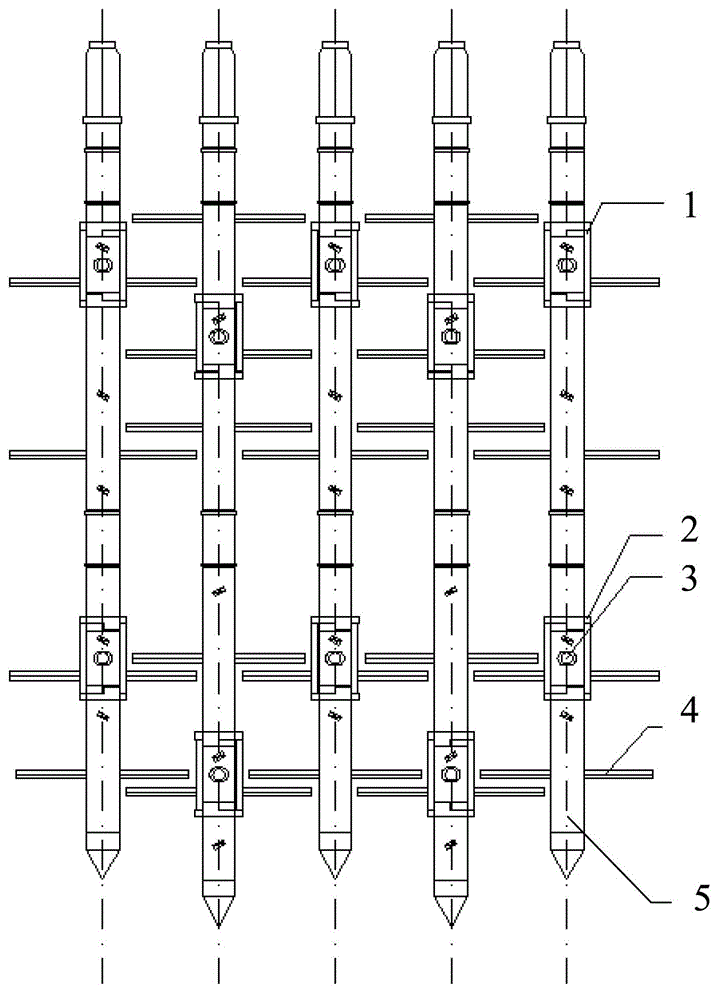

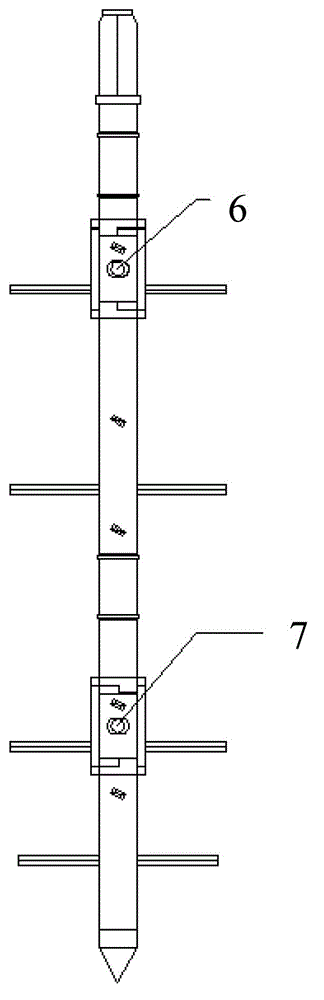

Five-axis cement-soil mixing pile device and construction method

The invention relates to a five-axis cement-soil mixing pile device and a construction method. The device comprises a walking-type and crawler-type host machine, a winding machine, a guide rod, a steel wire rope, a slurry inlet, a power head, a speed change box, a speed reducer, drill stems, a middle support frame, a lower support frame, drill stems with wings, hoops, a multifunctional drill head, a slurry spraying opening and a background cement slurry mixing system, wherein the winding machine and the guide rod are fixed on the host machine; the power head is connected with a pulley on the top of the guide rod through the steel wire rope; the steel wire rope drives the power head to rise and fall in a vertical direction; the power head is connected with five drill stems sequentially through the speed change box and the speed reducer; the middle support frame is arranged on the middle parts of the five drill stems, and the lower support frame is arranged on the lower parts of the five drill stems; the drill stems with wings are connected to the lower ends of the drill stems; the hoops are arranged on the drill stems with the wings; the lower ends of the drill stems with the wings are connected with the multifunctional drill head; and the slurry spraying opening is formed in the multifunctional drill head. Compared with the prior art, the five-axis cement-soil mixing pile device has the advantages of guaranteeing the safety and the quality, reducing the cost, shortening the work period and the like along with no noise, no vibration and high efficiency.

Owner:SHANGHAI CHENGDI CONSTR

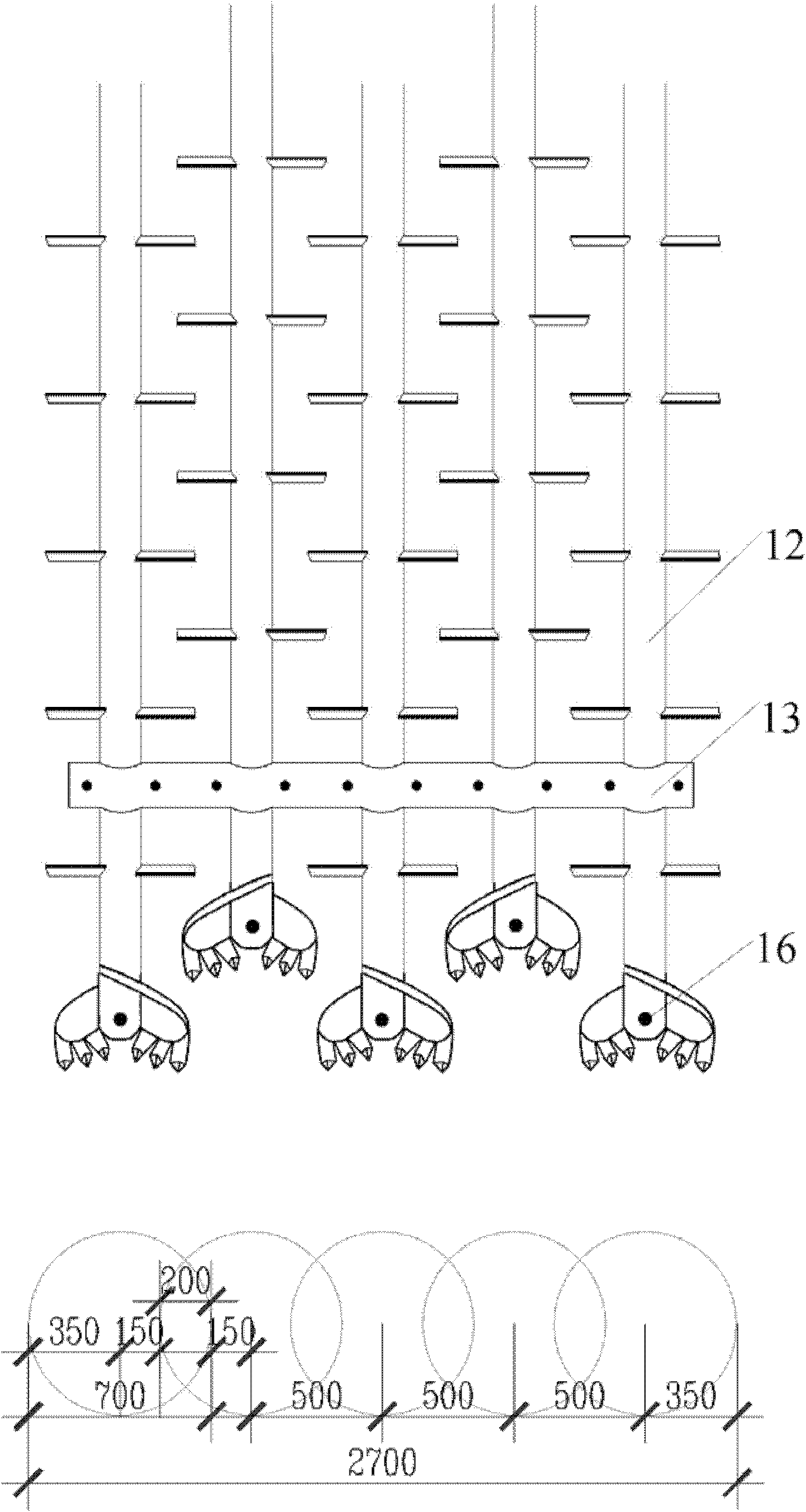

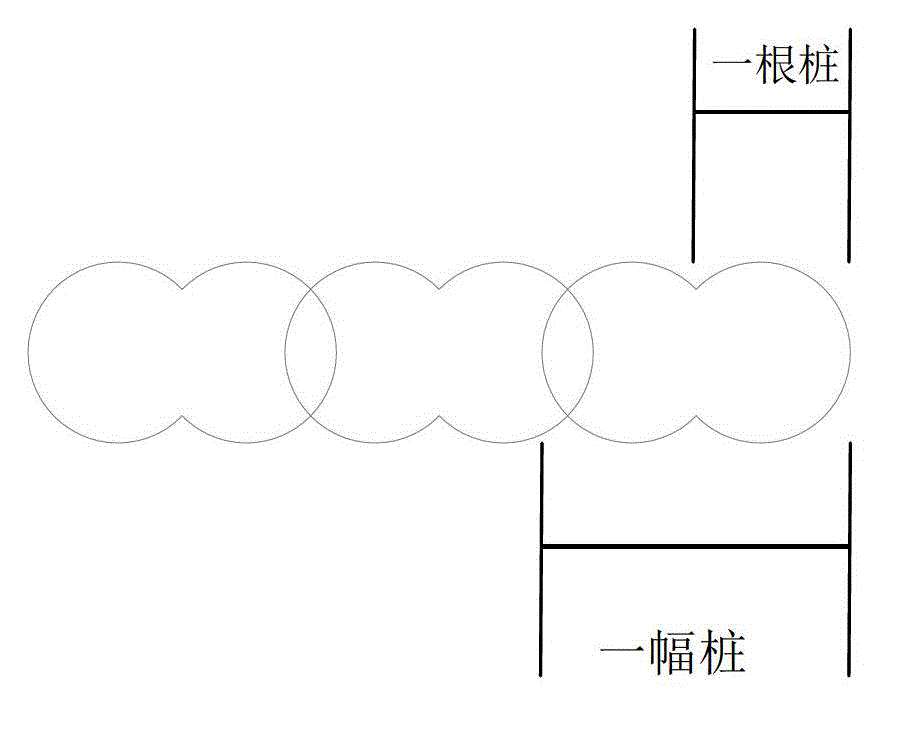

Large-diameter SMW (soil mixing wall) pile machine

Disclosed is a large-diameter SMW (soil mixing wall) pile machine. A gear A, a gear B and a gear C are arranged in a transmission, a drill rod A is fixed to the lower end of the gear A, two short stirring blades are fixed to the left of the lower portion of the drill rod A, a long stirring blade A and a short stirring blade are fixed to the right of the lower portion of the drill rod A; a drill rod C is fixed to the lower end of the gear C, two short stirring blades are fixed to the right of the lower portion of the drill rod C, and a long stirring blade B and a short stirring blade are fixed to the left of the lower portion of the drill rod C; a drilling rod B is fixed to the lower end of the gear B, a short stirring blade is fixed to each of the left and right sides of the lower portion of the drill rod B, a crankshaft with a crank pin A and a crank pin B are fixed on the drill rod on the lower portions of the short stirring blades, and a long stirring blade C is fixed to each of the left and right of the drill rod of the lower portion of the crankshaft.

Owner:孔月洽

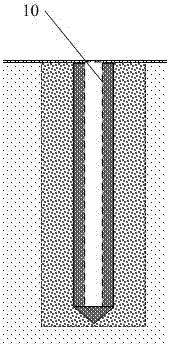

Treatment system and method for consolidating soft soil foundation by utilizing industrial waste gas heat

ActiveCN103147434AEmission reductionReduce leakageSoil preservationDecompositionResource utilization

The invention provides a treatment system and a method for consolidating a soft soil foundation by utilizing industrial waste gas heat. The treatment system comprises an industrial waste gas heat separation device, a waste gas purification device, a tail gas collection and treatment system, a foundation soil mixing device and a gas pumping device. The method comprises the following steps of extracting pure carbon dioxide from the dedusted, desulfurized and denitrated waste gas heat by the separation device and the purification device; mixing a curing agent to foundation soil by the mixing device; and pumping the pure carbon dioxide into mixed soil by the gas pumping device to carbonize and consolidate the soft soil foundation. The waste gas purification device comprises an absorption chamber and a decomposition chamber which are sealed devices with valves, and a purification solution in the device is an alkali solution or a carbonate solution, or a mixture thereof, and can be recycled. The method and the treatment system fully utilize the industrial waste gas heat, so that the difficulty of resource utilization of the industrial waste gas heat is solved, and meanwhile, the construction efficiency of foundation consolidation and the strength of foundation soil are improved.

Owner:SOUTHEAST UNIV

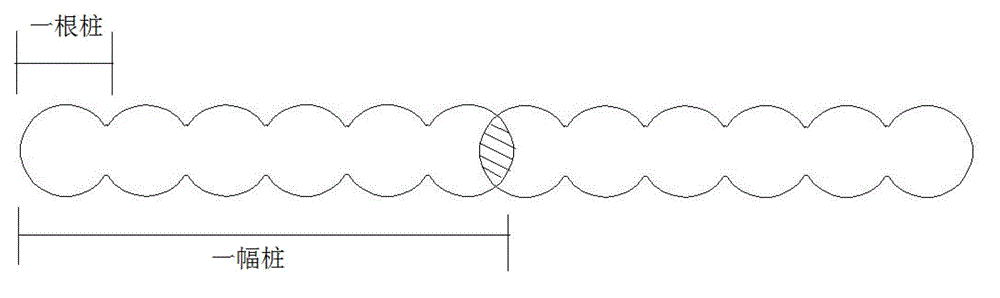

Six-axis cement soil mixing pile

InactiveCN102943467AMake up for replacement soilCompensate for large water-cement ratioBulkheads/pilesSoil mixingMaterials science

The invention provides a six-axis cement soil mixing pile. Six cement soil mixing piles are formed at one time and overlapped seamlessly, so that joints formed by original single-axis or two-axis cement soil mixing pile are reduced, the water-stopping effect and construction efficiency can be improved, the amount of labor used is reduced, and the construction period can be shortened by more than 2 / 3.

Owner:SHANGHAI STRONG FOUND ENG

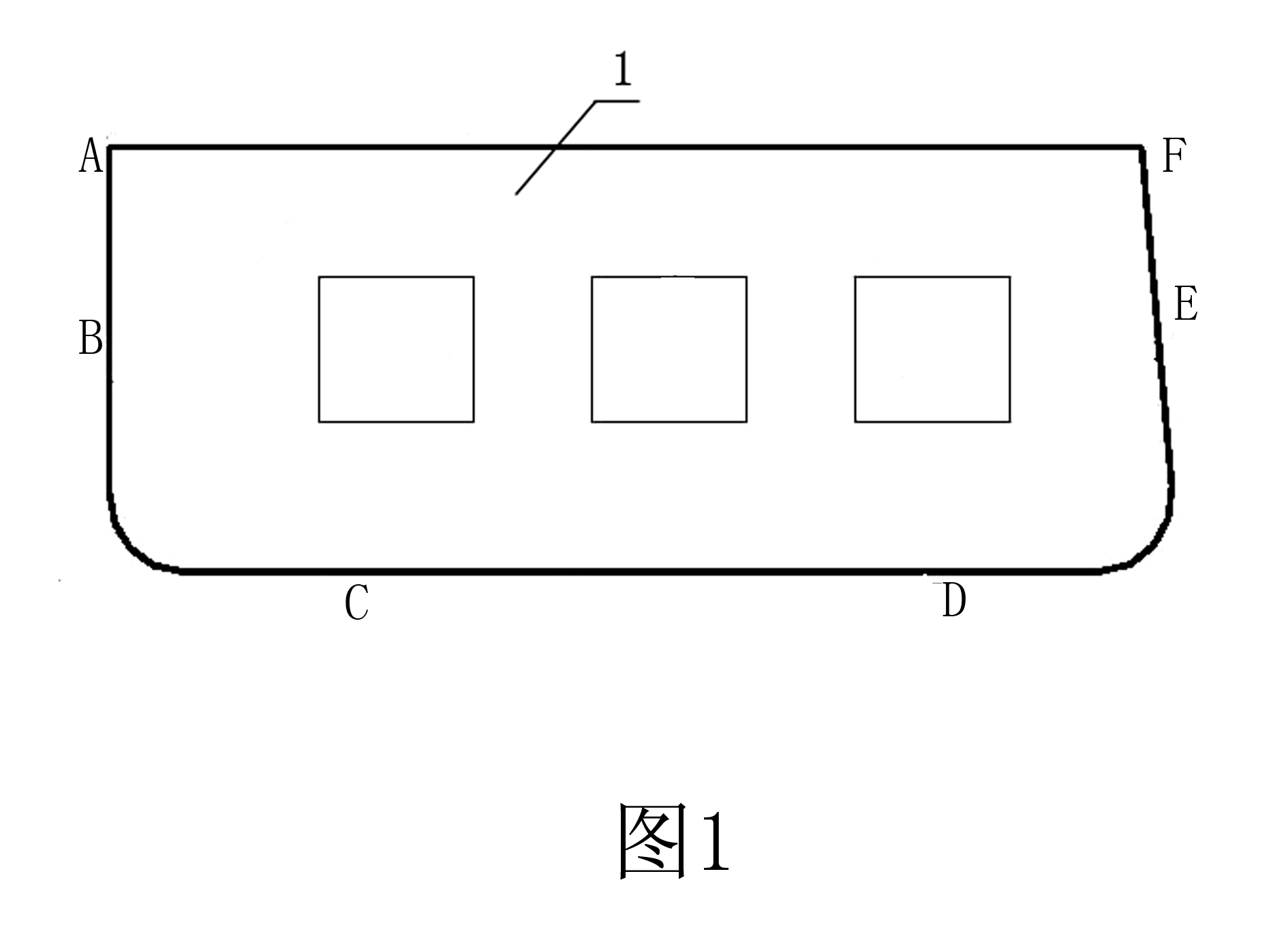

Foundation pit support device and construction method

The invention relates to a foundation pit support device and a construction method. For different address conditions, two or more of an SMW (soil mixing wall) construction method pile system, an internal supporting system, a concrete revetment system and a soil nailing wall revetment system are comprehensively applied. A concrete circuit girt is arranged at the top end of an SMW construction method pile; and profiled bars are inserted into the pile, and have equal or unequal lengths. The internal support system is a slanting steel pipe support or a horizontal support. The soil nailing wall revetment system is formed in a way that: a concrete revetment is arranged on the inner side, from the pit top to the pit bottom, of a foundation pit, and is paved with a reinforced concrete surface layer; and soil nails are inserted into soil around the foundation pit vertical to the reinforced concrete surface layer. The foundation pit support device and the construction method have the advantages of effectively reducing foundation pit support cost and construction cost and accelerating the construction, and are particularly suitable for the support of the large-area foundation pits and construction plants of which infrared spaces between subsurface structures and the ground are small.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

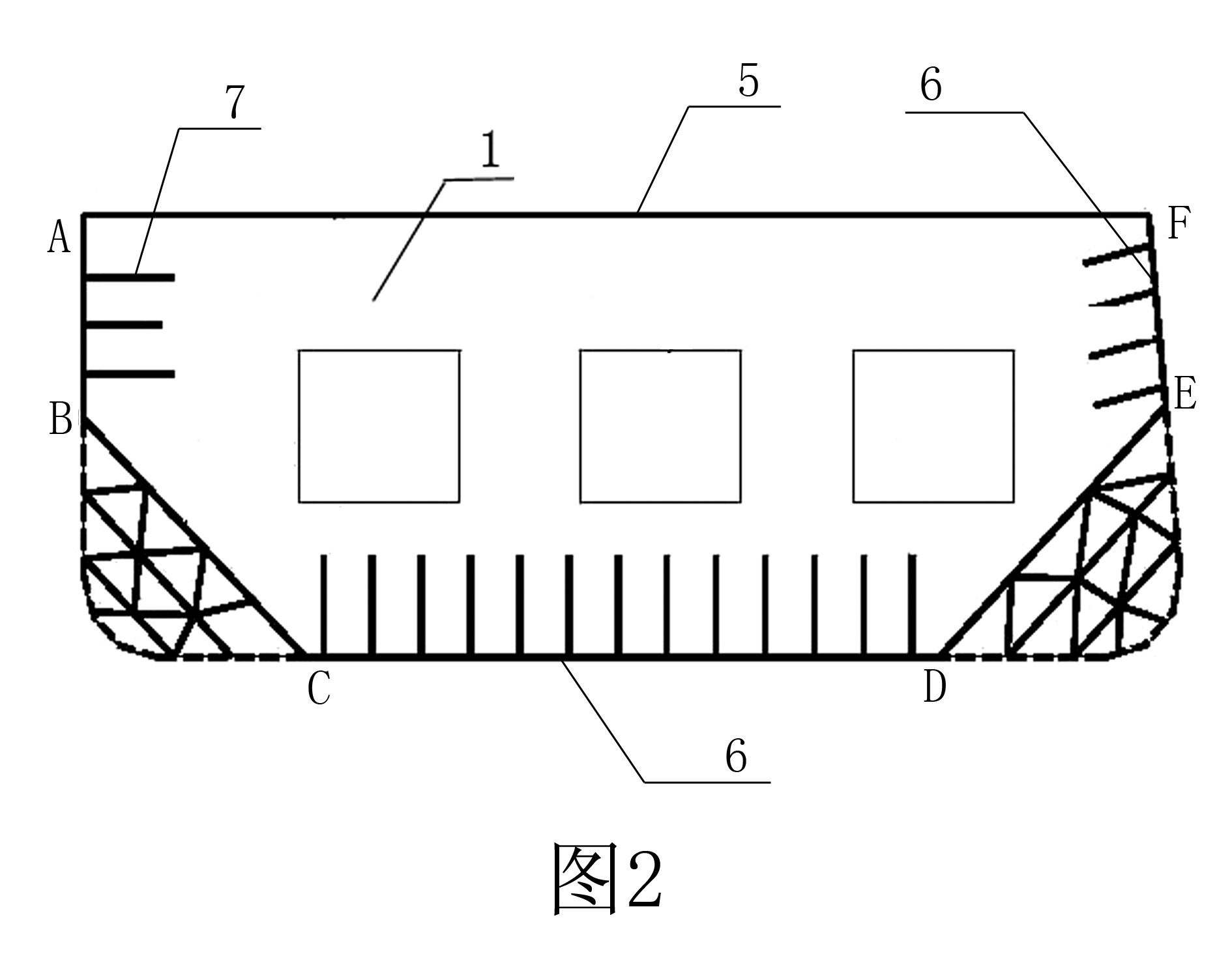

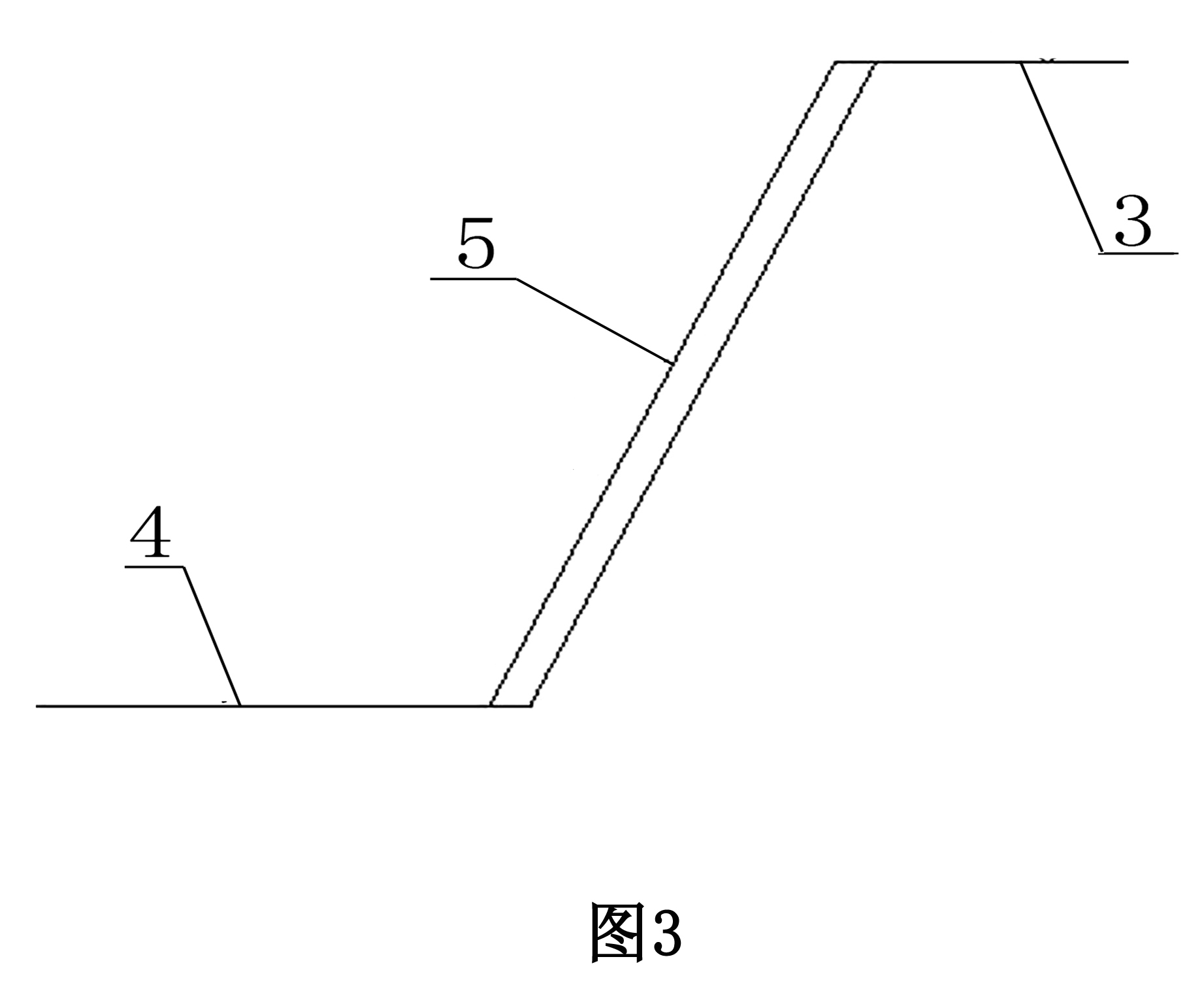

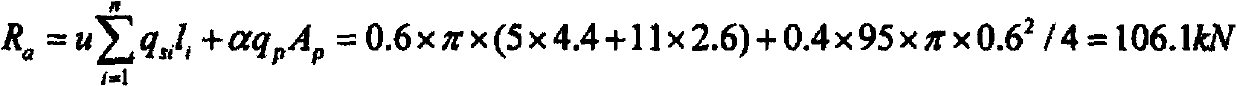

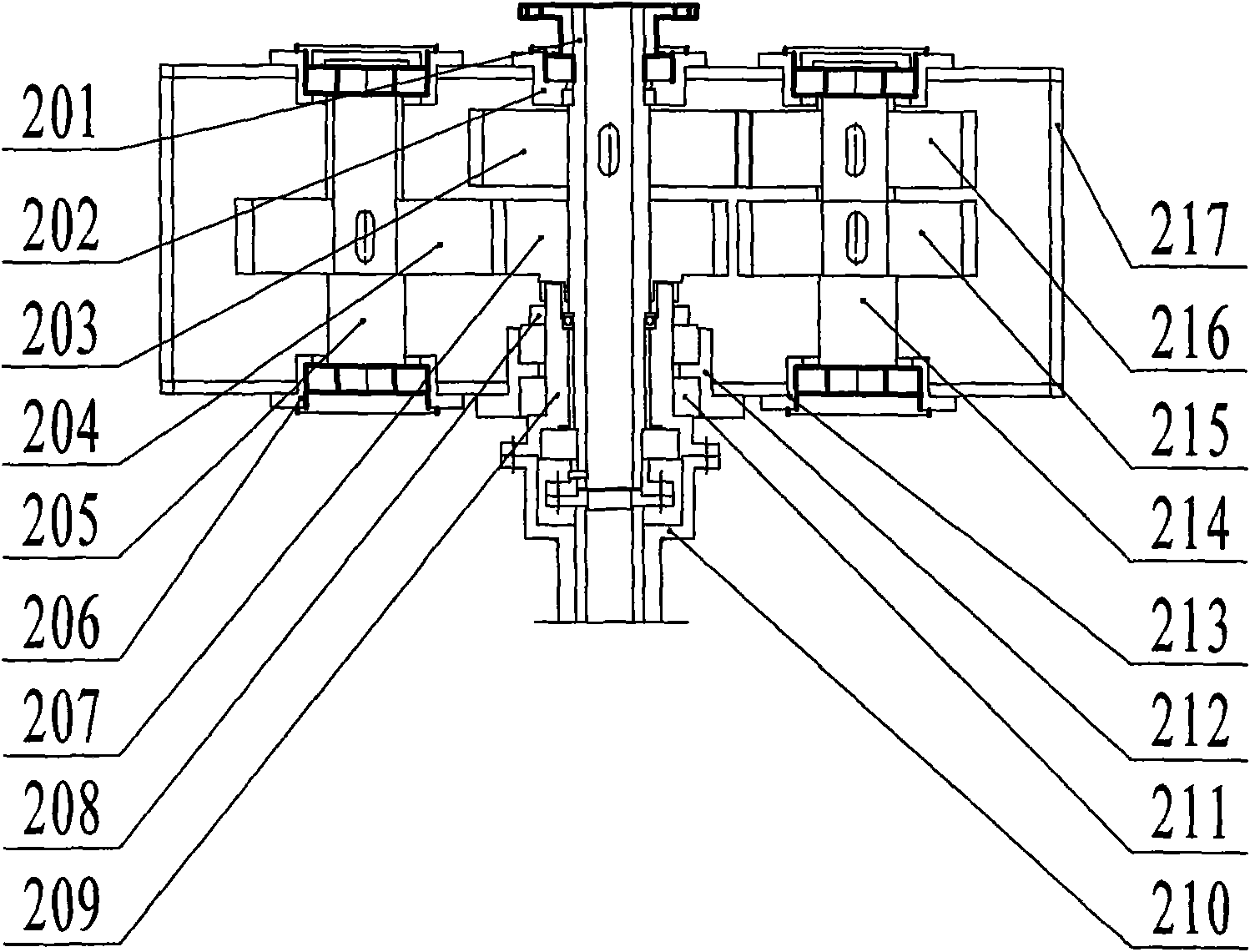

Bi-directional cement soil mixing pile machine

ActiveCN1632232AStir fully and evenlyWon't be lostBulkheads/pilesDrilling machines and methodsDrivetrainSoil mixing

Two-way cement-soil mixer is a kind of construction machinery equipment suitable for soft soil foundation treatment. The mixer consists of body (1), power transmission system (2), outer drill rod (3), inner drill rod (4), drill bit ( 5) Composition, wherein the power transmission system is located on the upper part of the fuselage (1), the inner drill rod (4) is located in the outer drill rod (3), and the inner drill rod (4) and the inner drill rod in the power transmission system (2) The rod power transmission system connection flange (211) is connected, the outer drill rod (3) is connected with the outer drill rod power transmission system connection flange (25), and the drill bit (5) is located at the bottom of the inner drill rod (4). The machine is easy to construct, easy to operate, and easy to master. The two-axis two-way rotation drives two sets of mixing blades to rotate in two directions at the same time, which can ensure the mixing amount of cement slurry in the pile body, and there will be no slurry phenomenon; at the same time, it can ensure that the pile body cement The soil is fully stirred evenly to ensure the quality of the pile and the quality of the pile body; the efficiency is more than doubled.

Owner:南京路鼎搅拌桩特种技术有限公司

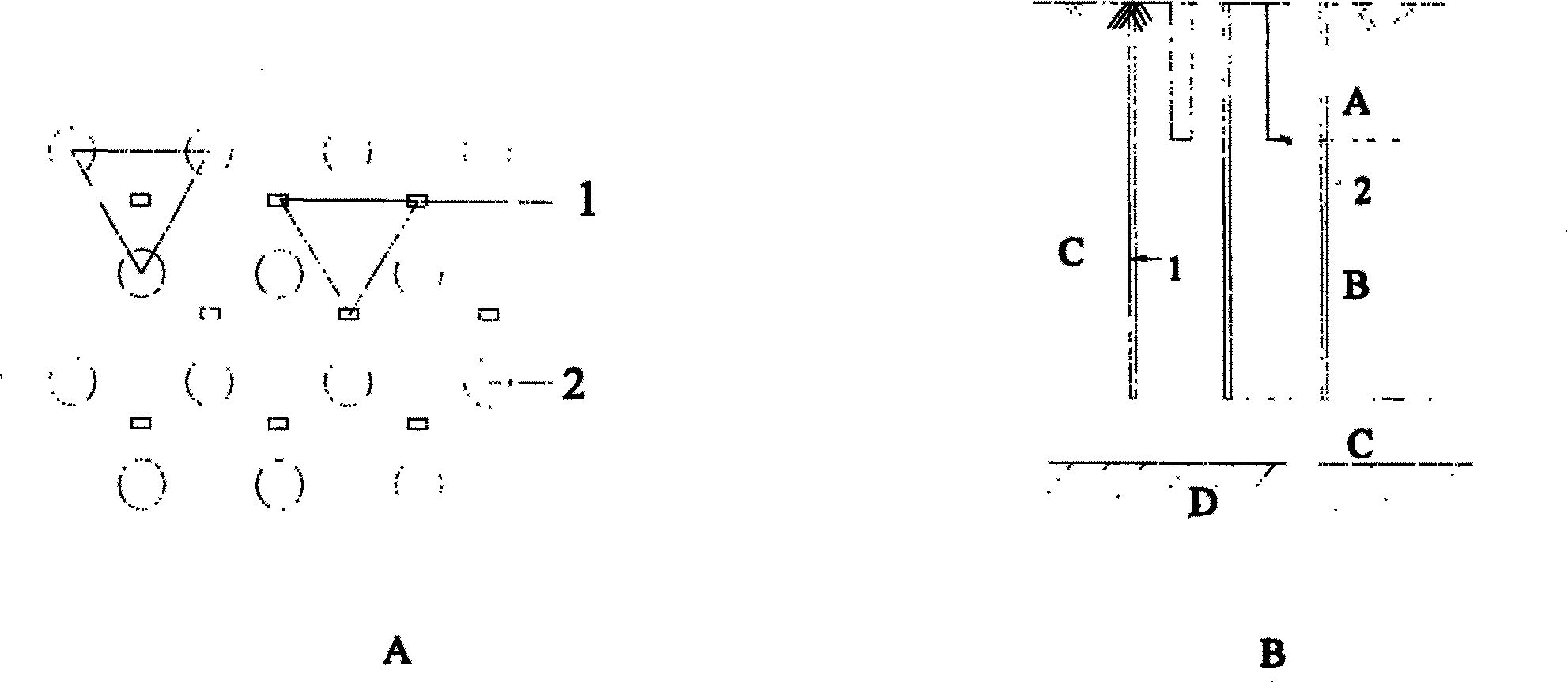

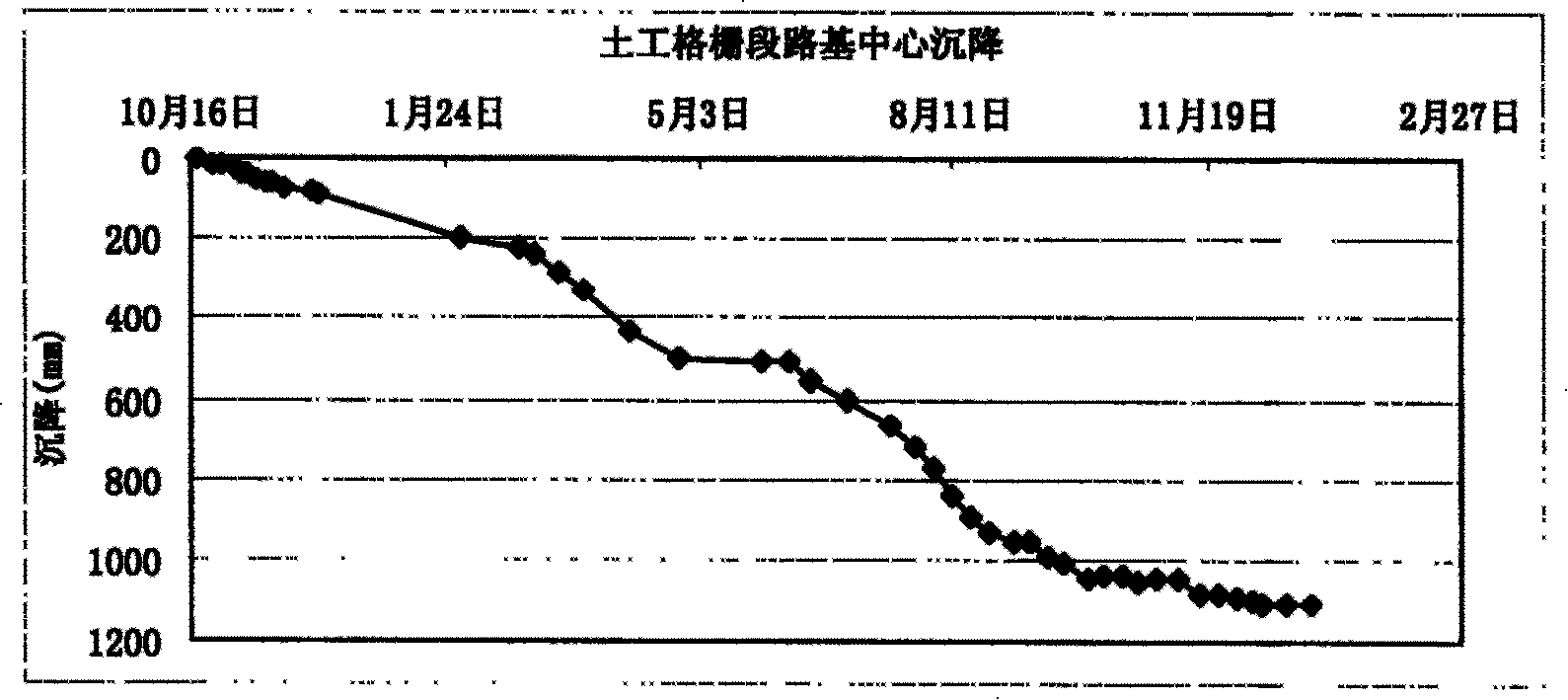

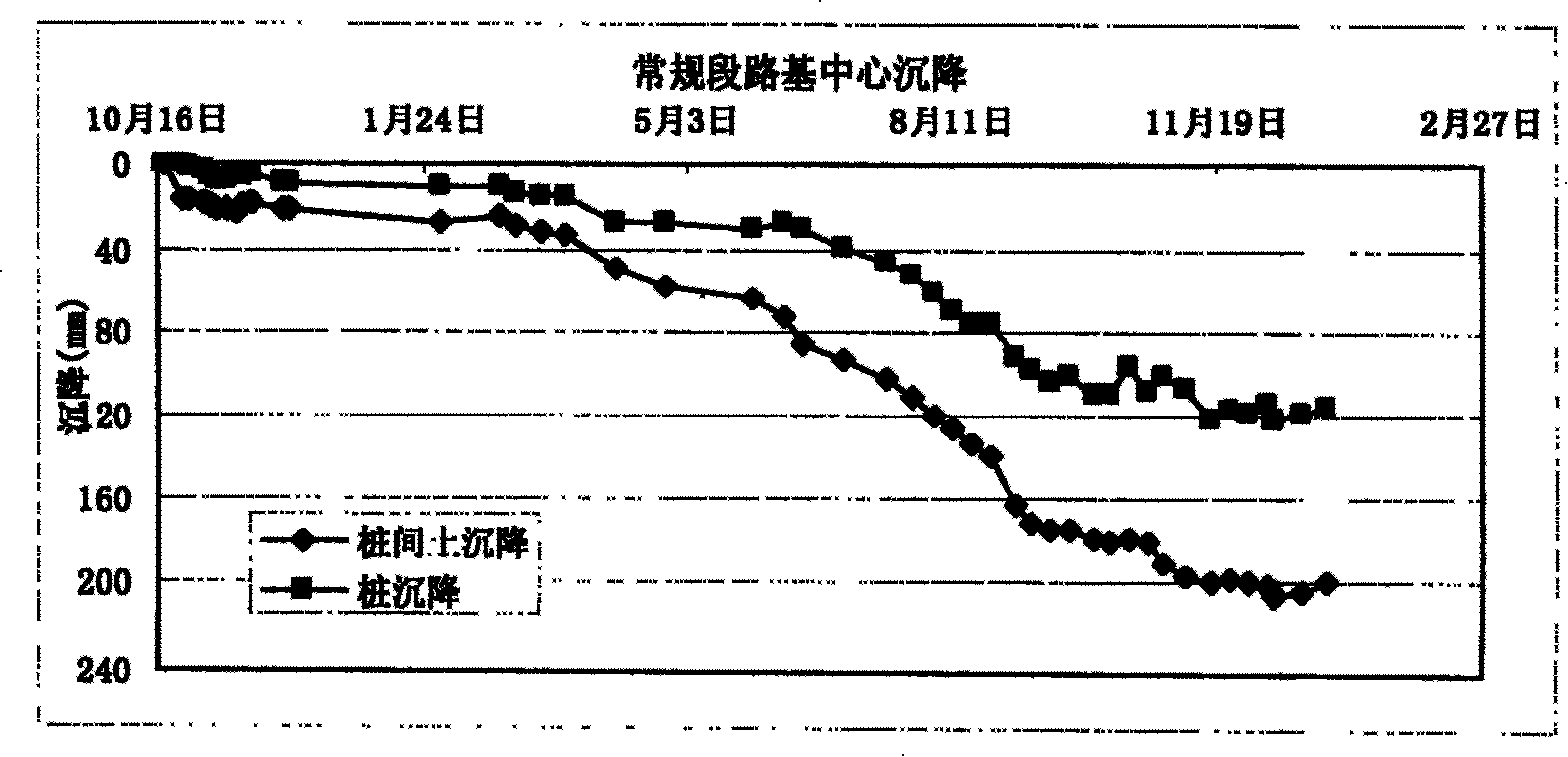

Soft base processing method

InactiveCN101220588AReduce settlementSolve the carrying capacityBulkheads/pilesSoil preservationSoil mixingBuilding construction

The invention relates to a method for adopting long plastic drainage plate (or sand drain) and short cement-soil mixing pile in connection to deal with highway soft foundation (abbr. a long plate-short pile working method, or called a D-M working method). Compared with the single prepressing drainage method, such method has the advantages of effectively raising the stability of foundation effectively and accelerating the construction of road embankment owing to the existence of a short pile, thus shortening the constructing period correspondingly. Compared with a single deep mixing pile, the method can accelerate the consolidation settlement of deep soft soil owing to the existence of a long plate; therefore, the settlement after working is controlled in a certain range; besides, the coordination of settlement speed rates among different sections becomes possible by adjusting the space, the length and the prepressing style between the pile and the plate.

Owner:TONGJI UNIV

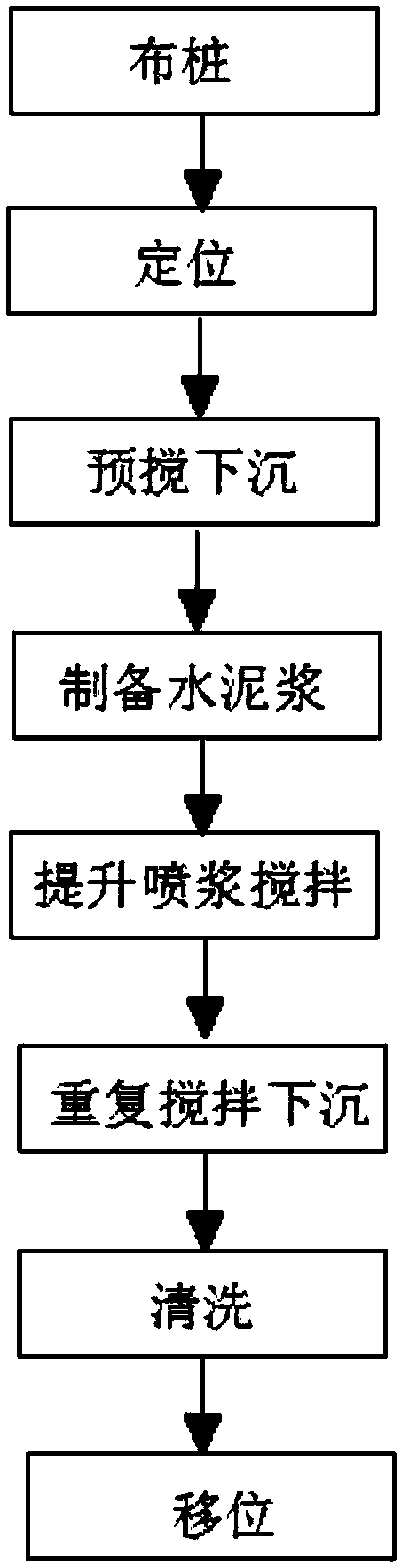

Method for reinforcing soft soil foundation by using cement-soil mixing pile

The invention relates to a method for reinforcing a soft soil foundation by using cement-soil mixing piles. The method comprises the steps of 1) arranging pile positions on the soft soil foundation; 2) lifting a mixing machine to one pile position on the soft soil foundation by using a tower crane; 3) starting up the mixing machine, wherein a mixing head cuts soil while rotating and then sinks to design depth; 4) preparing cement grout; 5) lifting the mixing head, spraying the grout and performing mixing to enable the cement grout to be fully mixed with the soil till the mixing head is lifted up to the ground; 6) repeating the step 3 to the step 5, wherein each pile requires for re-mixing and re-spraying; 7) filling clean water into an aggregate bin, starting up a grout pump to clean residual grout in all pipelines and cleaning the mixing head; and 8) moving the mixing machine to the next pile position and repeating the step 2 to the step 7 to carry out the construction of the next pile. Compared with the prior art, the method for reinforcing the soft soil foundation by using the cement-soil mixing piles has the advantages that the water-cement ratio is proper, the goal of uniform mixing is easy to realize, the pile forming quality is high, the strength is high, the construction is convenient to carry out, the construction cost is low and the economic benefits are remarkable.

Owner:STATE GRID CORP OF CHINA +2

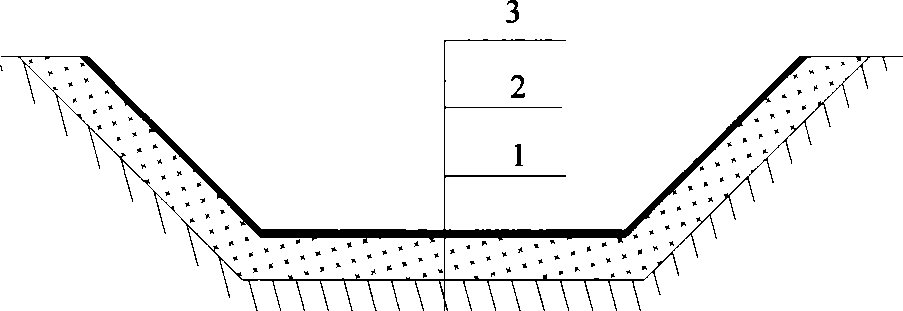

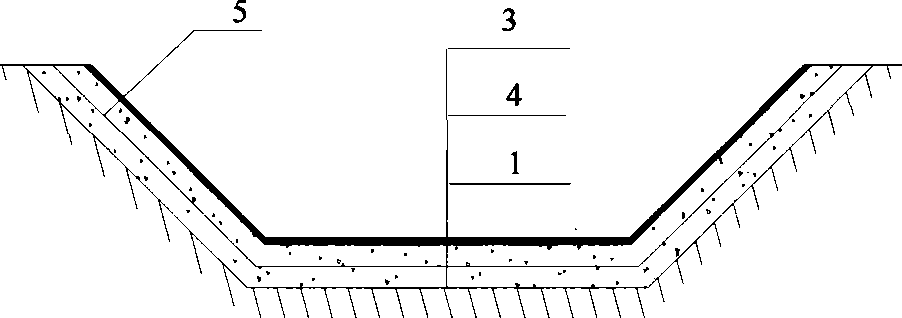

Construction method of building anti-permeability channel using soil curing agent

InactiveCN101446082AHigh strengthImprove anti-seepage performanceIrrigation ditchesArtificial water canalsFiberSoil mixing

The invention discloses a construction method of building anti-permeability channels using soil curing agent. The method comprises the following steps: blending soil, a soil curing agent, water and fiber to form a curing soil mixing material; and dividing the curing soil mixing material into dry and solid curing soil and plastic curing soil by the water content of the curing soil mixing material, compacting the dry and solid curing soil with tamp equipment to form an intensive strengthened soil anti-permeability layer, and as for the plastic curing soil, adopting cement mortar spray gun technology to muddy spray curing soil to channel base to form a strengthened soil anti-permeability layer, further laying cement mortar on the surface of the strengthened soil anti-permeability layer to form a protection layer, so that frost heaving and destruction of anti-permeability channels in northern cold area can be effectively avoided. The method can solve the problem in the prior construction method of building anti-permeability channels using soil curing agent, increase construction speed of building anti-permeability channels using the soil curing agent, reduce the construction cost, and prolong the service life of the channels. The invention is of great significance for the development of water-saving irrigation and establishment of conservation-oriented society.

Owner:NORTHWEST A & F UNIV

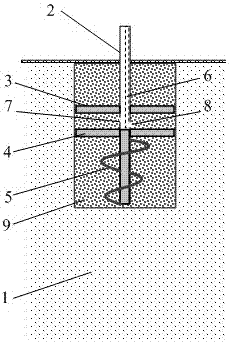

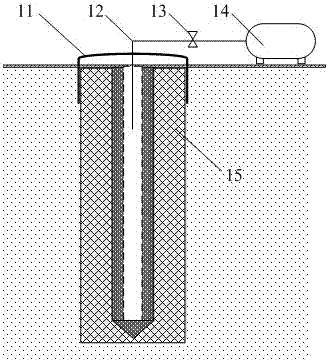

Carbonization mixing pile-ventilating pipe pile composite foundation and construction method thereof

ActiveCN106869120AImprove bearing capacityImprove construction efficiencyBulkheads/pilesResource utilizationSoil mixing

The invention relates to a carbonization mixing pile-ventilating pipe pile composite foundation and a construction method thereof, belongs to the technical field of foundation treatment for civil construction engineering, and provides the carbonization mixing pile (CMP)-ventilating pipe pile composite foundation which is high in bearing capacity, high in construction efficiency, reliable in quality, low-carbon and environmentally-friendly and the construction method of the composite foundation so as to overcome and solve the defects and the problems in existing reinforcement technologies and magnesium oxide carbonization reinforcement methods for thick and soft foundation composite piles. The carbonization mixing pile-ventilating pipe pile composite foundation comprises a carbonization magnesium oxide cement soil mixing pile and a ventilating pipe pile; and the ventilating pipe pile is composited inside the carbonization magnesium oxide cement soil mixing pile. The requirements for reinforcement of the soft foundation and carbon dioxide resource utilization are realized.

Owner:SOUTHEAST UNIV

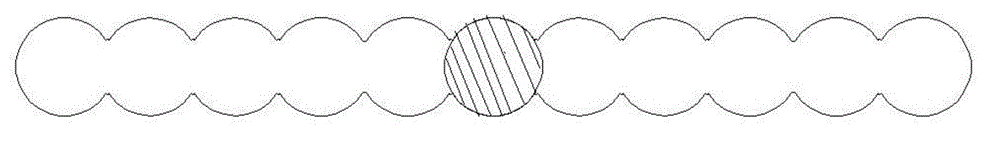

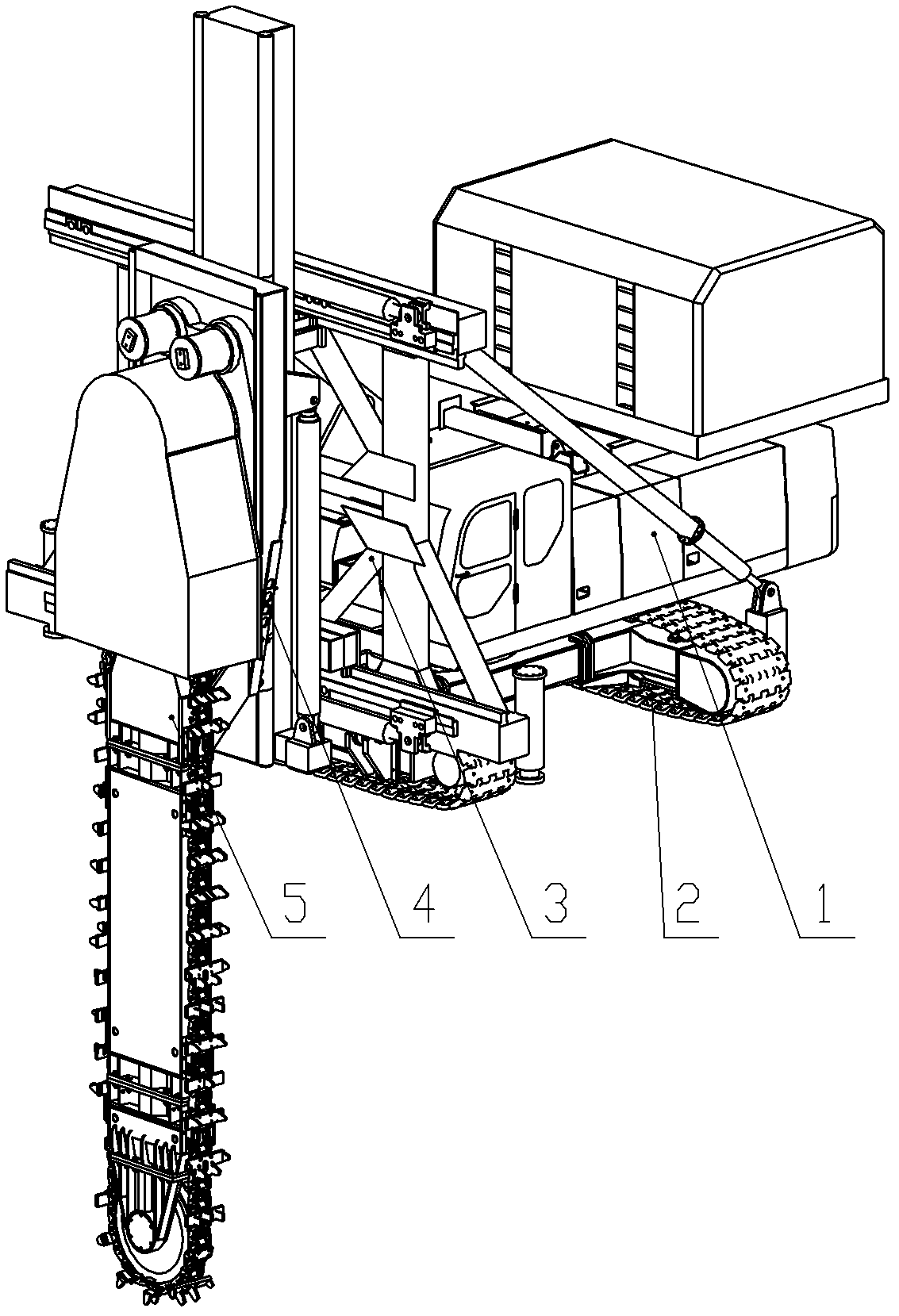

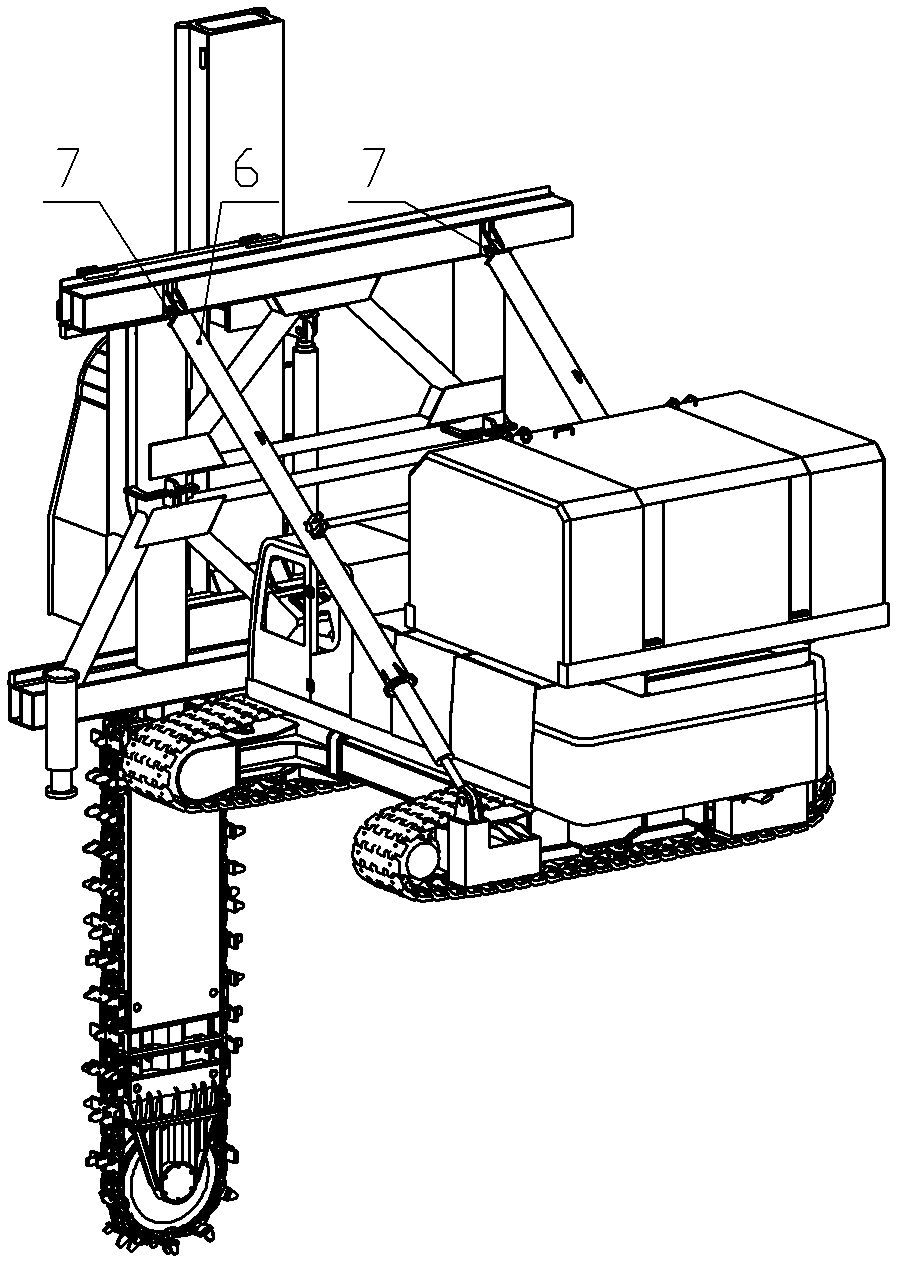

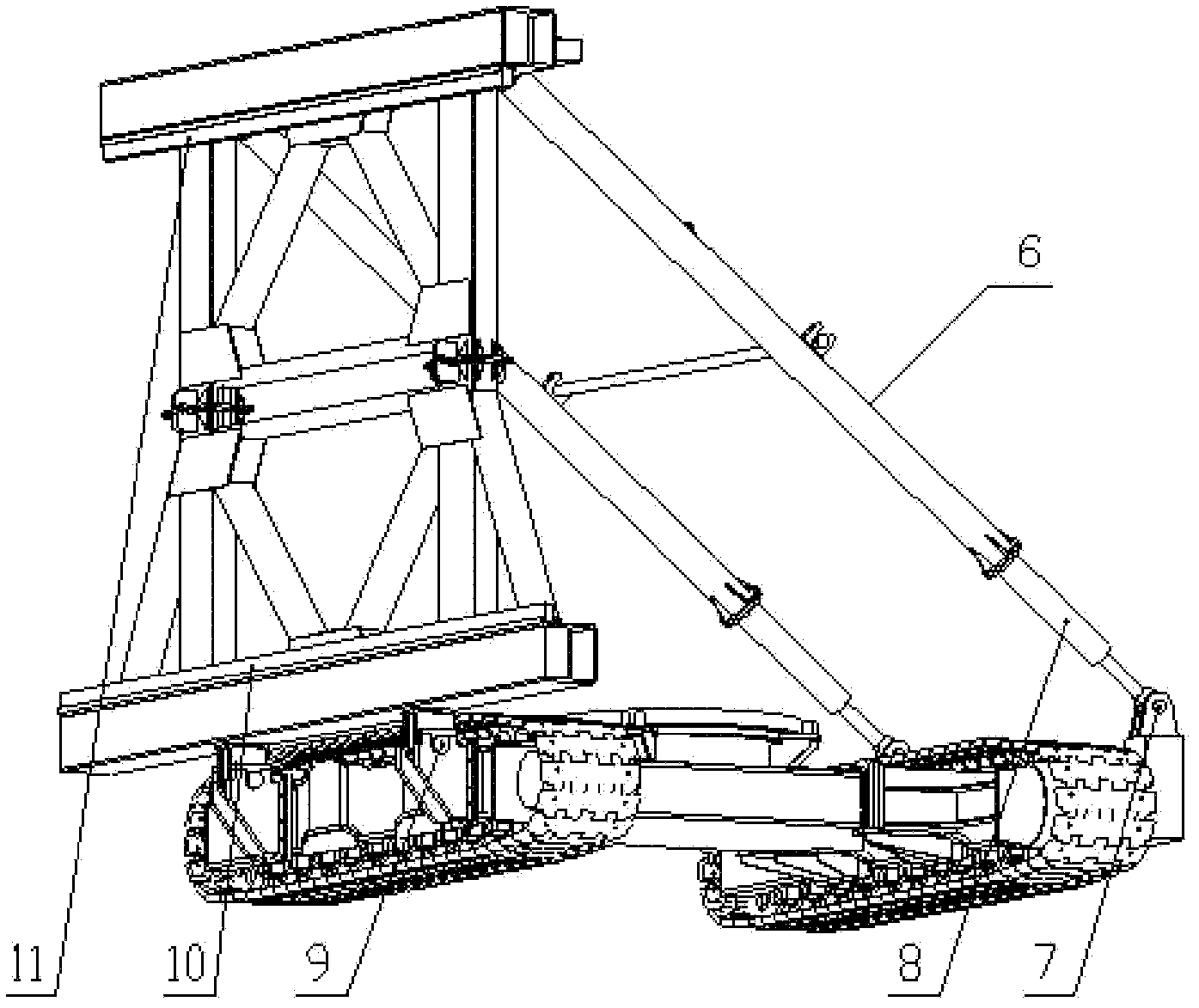

Chain cutter type mixing pile wall forming equipment

InactiveCN102535559AUniform qualityHigh strengthSoil-shifting machines/dredgersDrive wheelSoil mixing

The invention discloses chain cutter type mixing pile wall forming equipment, which comprises a main machine, a base plate assembly, a chain cutter connecting frame, a synchronous grouting system and a chain cutter cutting box assembly, wherein the main machine is arranged on the base plate assembly; a power device and an electrohydraulic system are arranged on the main machine; one side of the base plate is provided with the chain cutter connecting frame; the chain cutter cutting box assembly is connected to the chain cutter connecting frame through a two-dimensional planar positioning device; the chain cutter cutting box assembly comprises driving wheel boxes at upper and lower ends, an idle wheel box and a multi-section standard tool box which is positioned between the driving wheel boxes and the idle wheel box; driving chain wheels and idle wheels are arranged in the driving wheel boxes and the idle wheel box respectively; chain tracks surrounding the driving chain wheels and the idle wheels are embedded on two sides of a standard tool box; and a plurality of groups of cutting tools with different widths are regularly fixed on the chain tracks in a certain arrangement law. By the equipment, the requirements of depth, rapidness and strength of a cement soil mixing pile wall supporting a deep foundation pit can be met.

Owner:CHINA RAILWAY CONSTR HEAVY IND

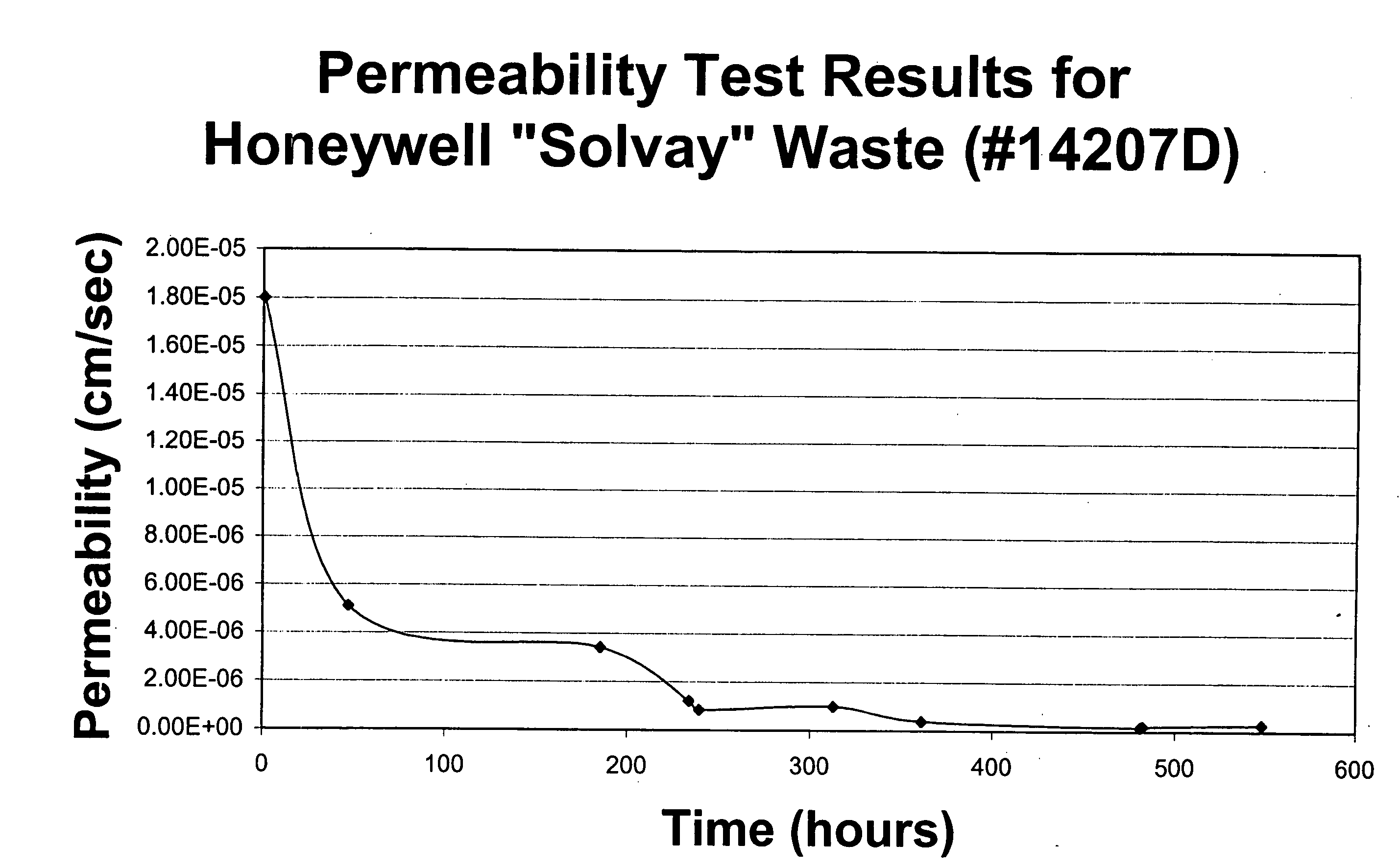

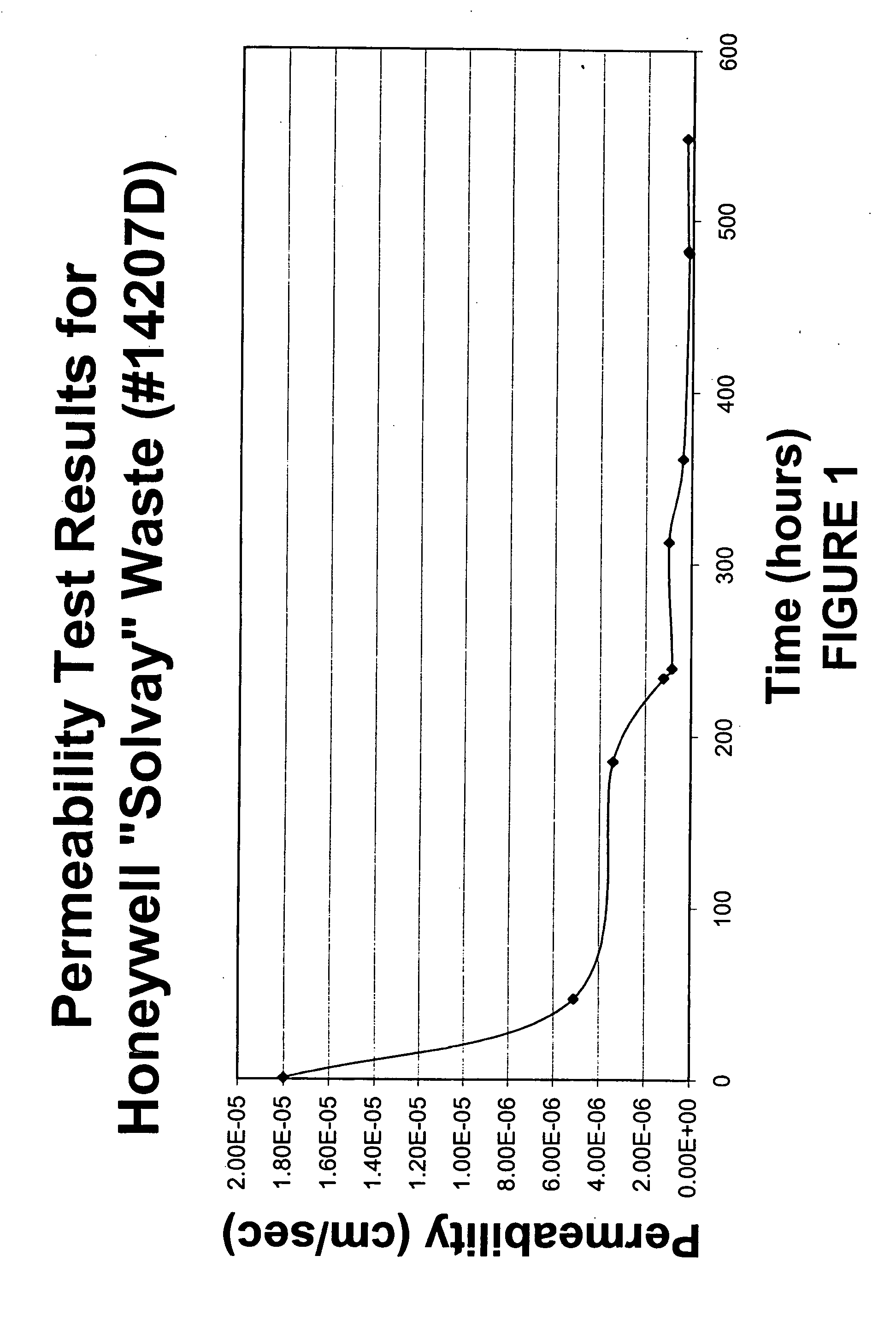

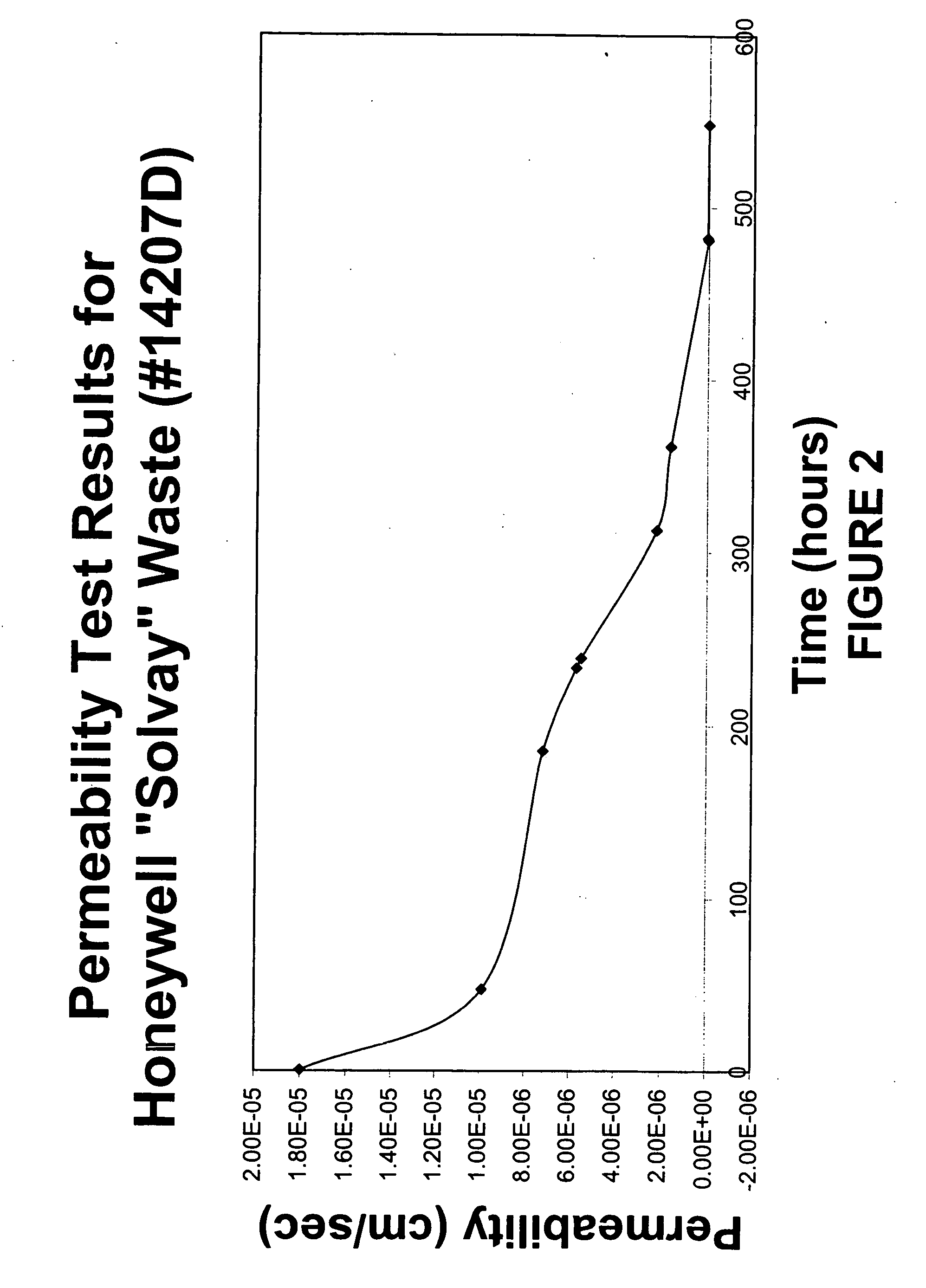

Natural analog system for reducing permeability of ground

InactiveUS20080200746A1Reduce penetrationReduce transmissionSolid waste disposalContaminated soil reclamationTreatment resultsSoil mixing

A method of chemically and physically treating unconsolidated soils, over burden, fill and certain waste materials (the “ground”), or partly consolidated materials that can be excavated and broken up by normal earth moving and soil mixing equipment. This treatment results in the reduction of permeability in the ground, and as a result permits the prevention or control of contaminant migration from a site containing ground wastes of various types, thereby isolating these wastes.

Owner:TERRA SEAL

Novel cement soil composite mixing pile and pile formation method thereof

The invention belongs to the technical field of soft soil foundation treatment methods and particularly relates to a novel cement oil composite mixing pile and a pile formation method thereof. The mixing pile comprises the variable-section cement soil mixing pile and a quadrangular frustum pyramid-shaped reinforced concrete core pile, wherein the core pile is inserted into the mixing pile along the center of the section of the mixing pile and in close fit with the mixing pile. The novel cement soil composite mixing pile is manufactured by well using existing equipment and materials through changing material structure, construction process steps, the section of a pile body and the force transfer way and has the advantages of good pile formation quality, high strength of cement soil, high pile foundation bearing capacity and low cost.

Owner:岳建伟

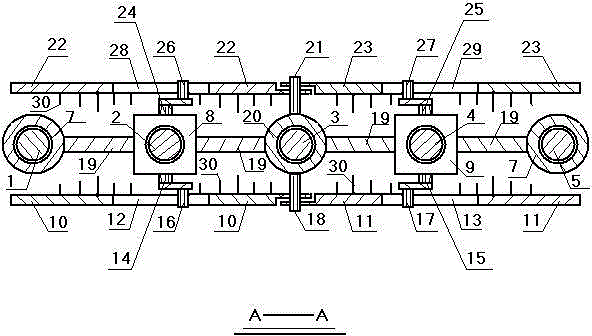

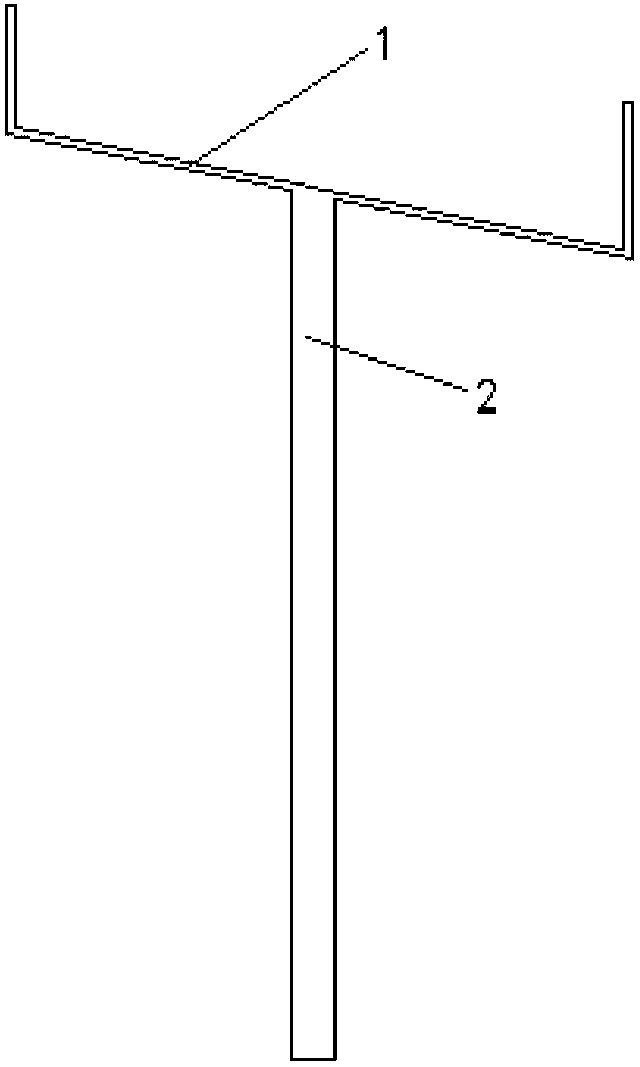

Cement-soil mixing wall former

Disclosed is a cement-soil mixing wall former. A first crankshaft is arranged on the front side of a first driving box, a first crankshaft pin of the first crankshaft is inserted into a first rectangular hole of a first hinging arm, and a first straight pin is hinged to the right end of the first hinging arm and fixed to the front side of a second steel pipe sleeve; a third crankshaft is arranged on the back side of the first driving box, a third crankshaft pin of the third crankshaft is inserted into a third rectangular hole of a third hinging arm, and a second straight pin is hinged to the right end of the third hinging arm and fixed to the back side of the second steel pipe sleeve; a second crankshaft is arranged on the front side of a second driving box, a second crankshaft pin of the second crankshaft is inserted into a second rectangular hole of a second hinging arm, and a first straight pin is hinged to the left end of the second hinging arm; a fourth crankshaft is arranged on the back side of the second driving box, a fourth crankshaft pin of the fourth crankshaft is inserted into a fourth rectangular hole of a fourth hinging arm, and a second straight pin is hinged to the left end of the fourth hinging arm; multiple stirring blades are arranged on the first hinging arm, multiple stirring blades are arranged on the second hinging arm, multiple stirring blades are arranged on the third hinging arm, and multiple stirring blades are arranged on the fourth hinging arm.

Owner:江苏福克斯电气集团有限公司

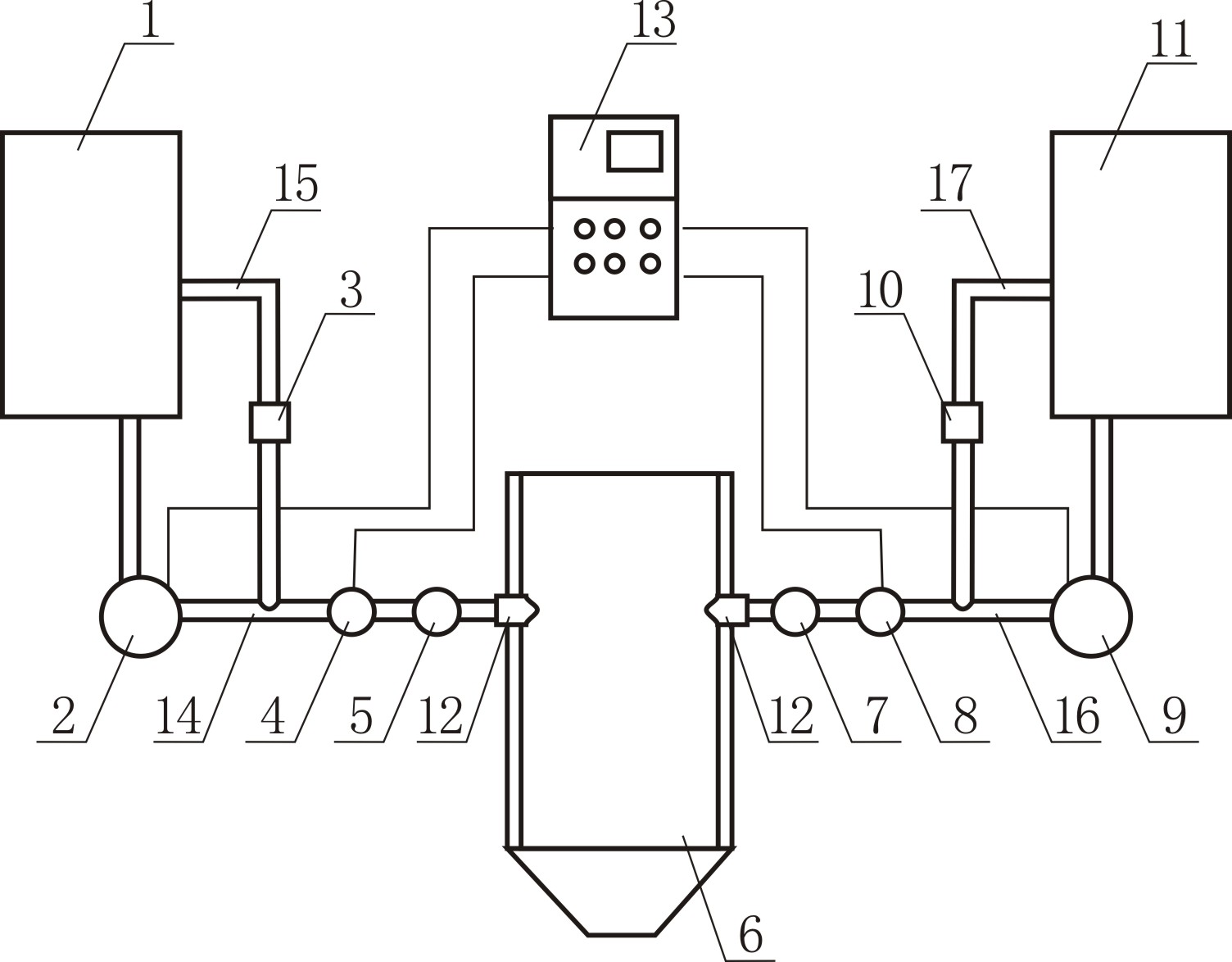

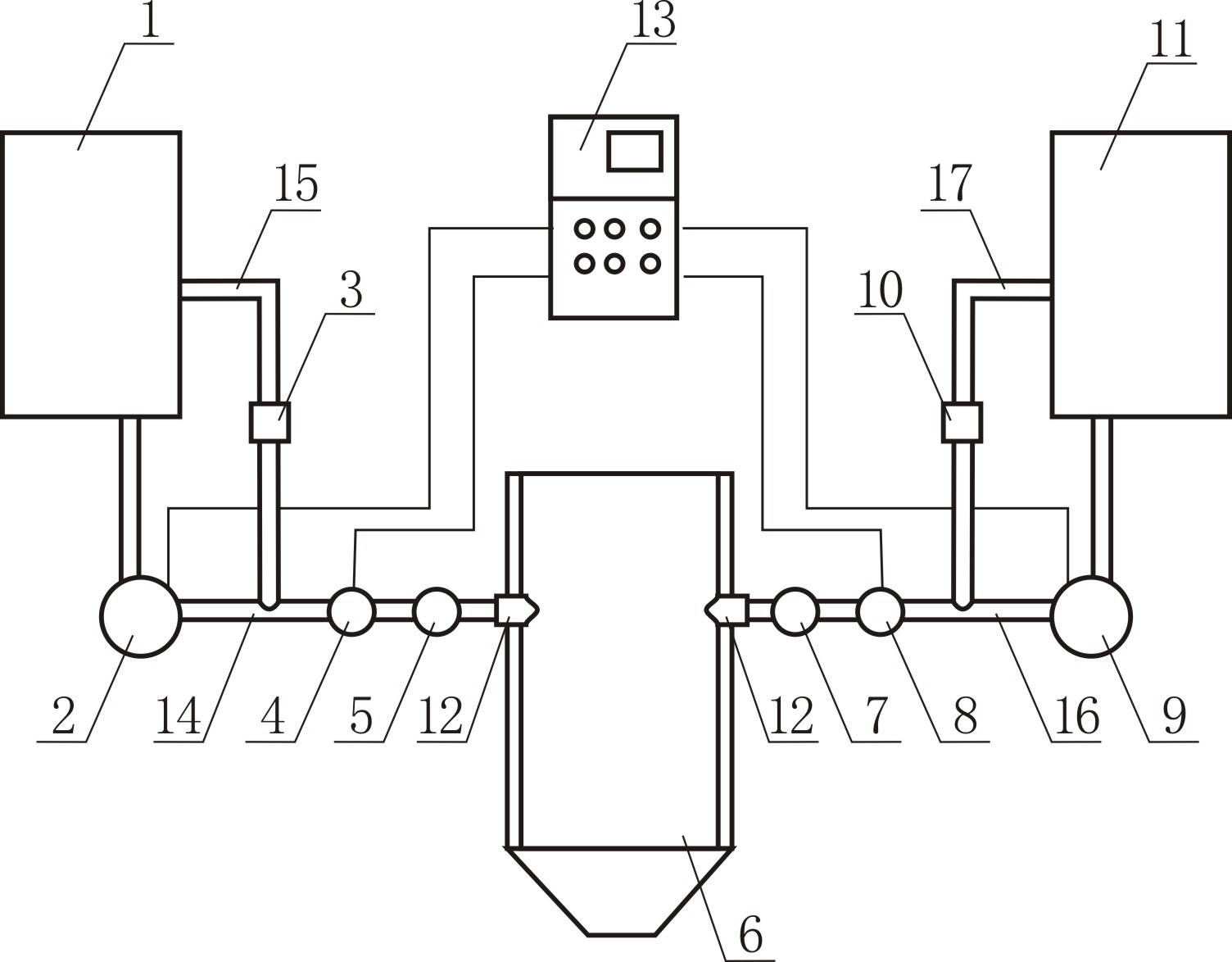

Cold plant-mixed regenerated asphalt foaming device

InactiveCN102425093AEasy to mix and installEasy to debugRoads maintainenceWater storage tankAtomizer nozzle

The invention discloses a cold plant-mixed regenerated asphalt foaming device, which comprises a foaming container, a water storage tank, an asphalt heating storage tank and two atomizing nozzles. The cold plant-mixed regenerated asphalt foaming device is characterized in that: the two atomizing nozzles are arranged on two sides of the foaming container, and a controller is arranged on one side of the foaming container; the water storage tank is connected with one atomizing nozzle through a water delivery pipe, and a plunger type speed regulating pump, a water flow meter, a water pressure gauge and a water pressure regulating reflux pipe are arranged on the water pressure; and the asphalt heating storage tank is connected with the other atomizing nozzle through an asphalt delivery pipe, and a variable frequency speed regulating pump, an asphalt flow meter, a pressure gauge and an asphalt pressure regulating reflux pipe are arranged on the asphalt delivery pipe. The integrated system device integrates multiple functions of heating the asphalt, pumping asphalt and water, foaming the asphalt, metering the asphalt, metering the water and the like into a whole, can be conveniently installed in a stable soil mixing plant, is easy to debug, has the characteristics of energy conservation, environment friendliness and high foaming efficiency, and can realize accurate metering.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

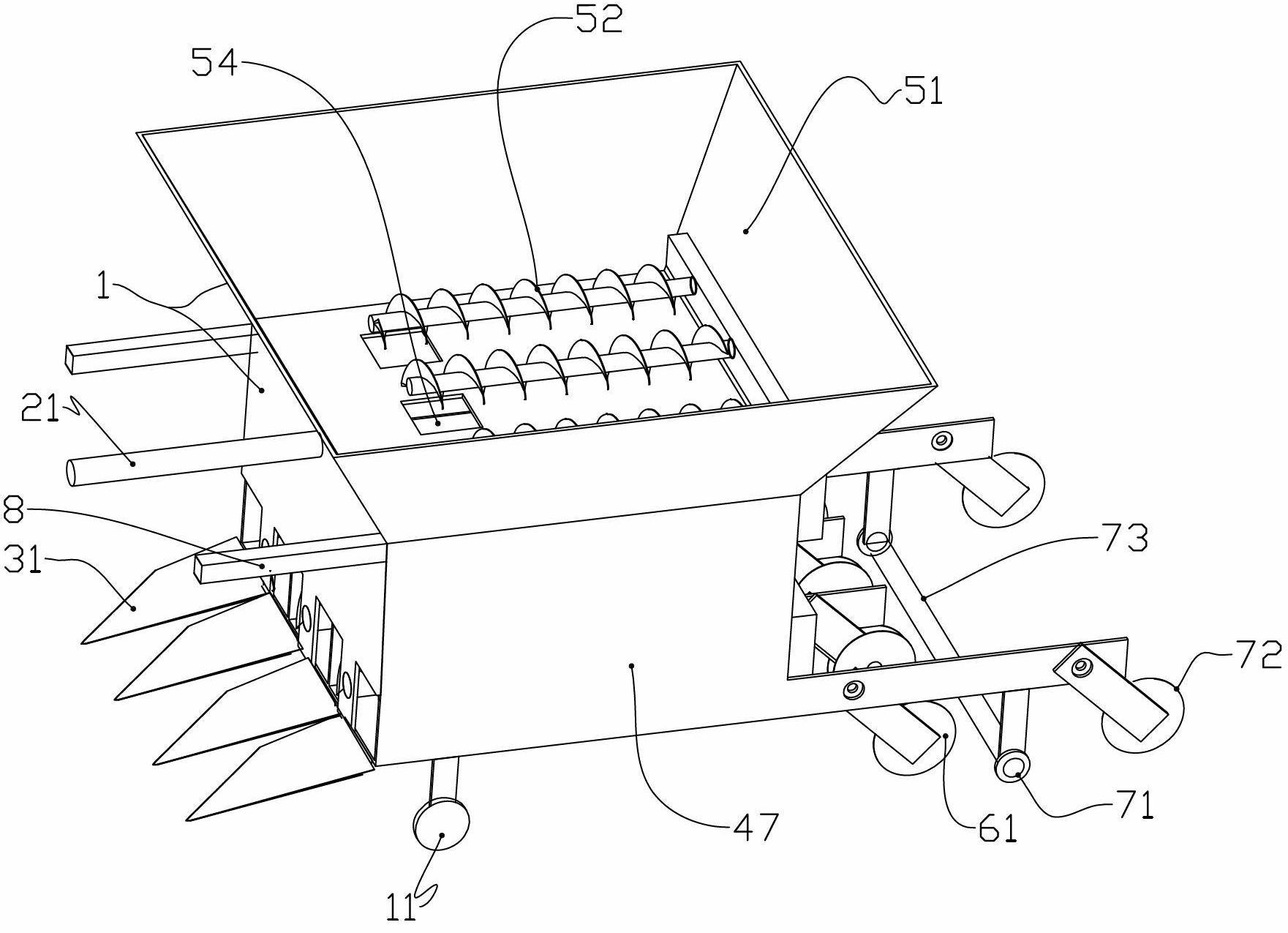

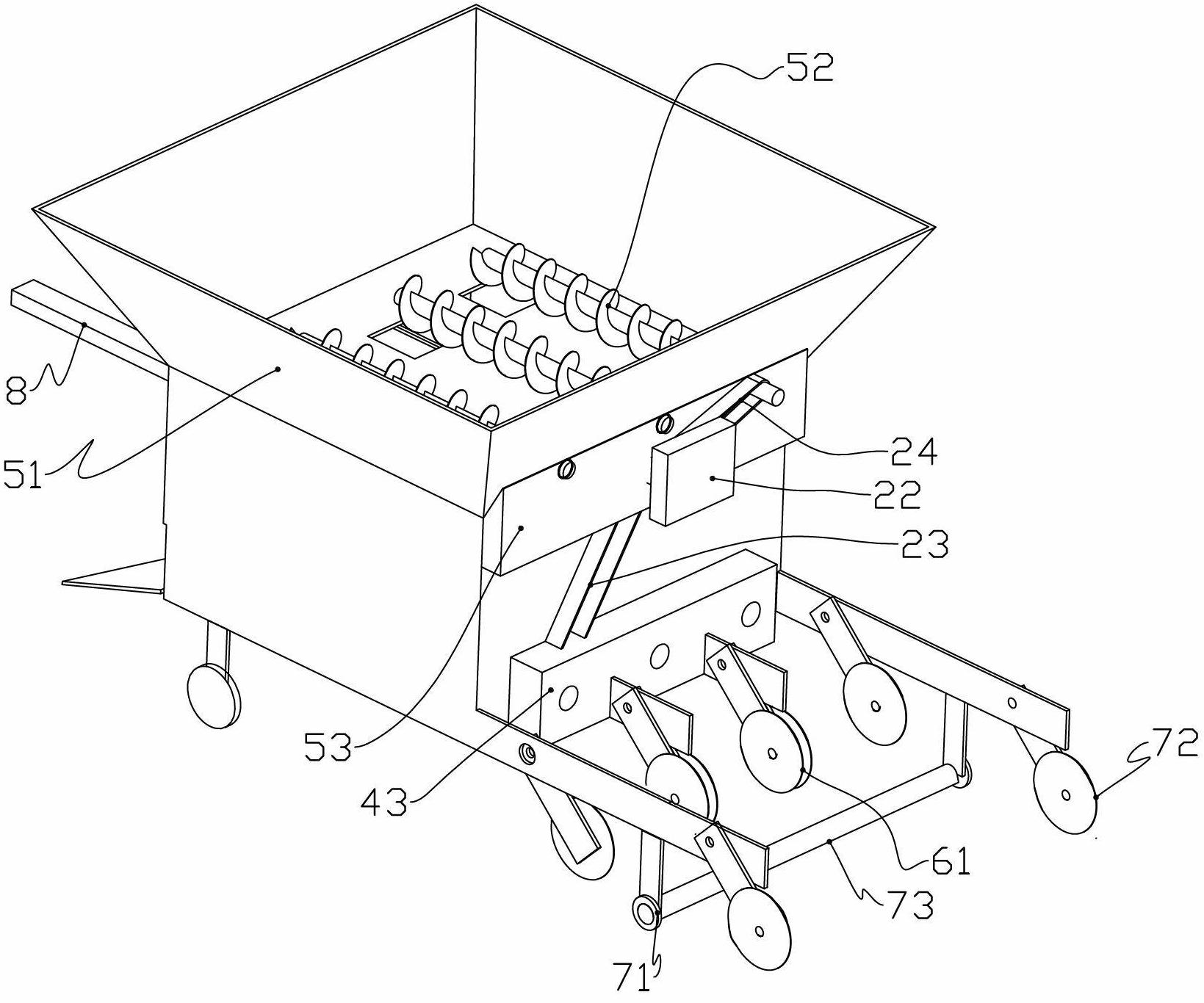

Soil Improvement and preparation all-in-one machine for salvia miltiorrhiza cultivation

InactiveCN102668756AWide range of valuesSpadesClimate change adaptationSalvia miltiorrhizaSoil mixing

The invention discloses a soil improvement and preparation all-in-one machine for salvia miltiorrhiza cultivation, comprising a rack, a power input shaft, soil turning-up parts, a soil mixing part, and an auxiliary material adding part, wherein the rack is of a welded-type structure and used for installing other components; the soil turning-up parts are a plurality of plough blades fixed at soil inlets at the front side of a soil material-mixing cavity, and used for turning up the soil; the soil mixing part is used for mixing the soil with auxiliary materials; the auxiliary material adding part is used for adding the auxiliary materials; and the power input shaft is installed on the rack and used for transferring power. According to the invention, the soil improvement and preparation all-in-one machine is dragged by virtue of a tractor, and the soil on the earth surface is lifted into the machine by the plough blades on the front side of the machine at first, and then an opening of an auxiliary material storage box for organic fertilizers and straw is opened, and straw and organic fertilizers are continuously added, mixed and added in the soil. The soil is unloaded from the machine, soil covering wheels are standardized, and a mulching film soil covering wheels are used for mulching films, thus finishing soil improvement.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

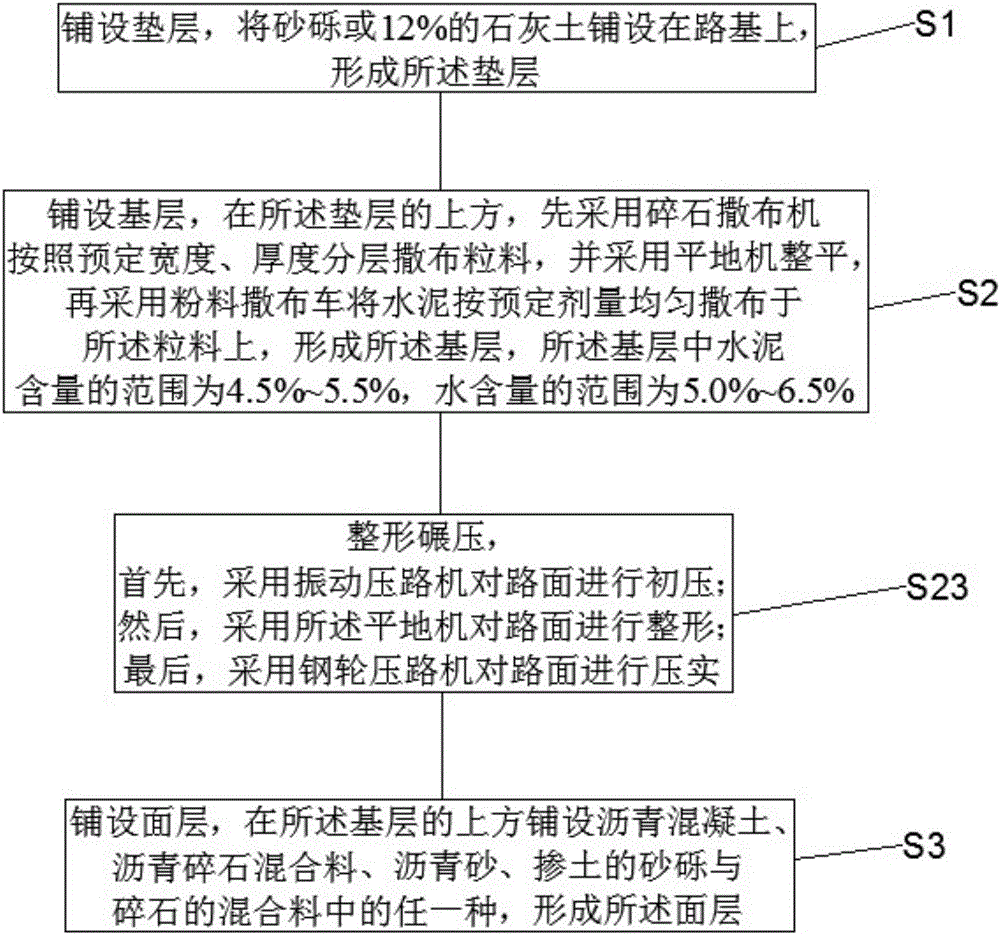

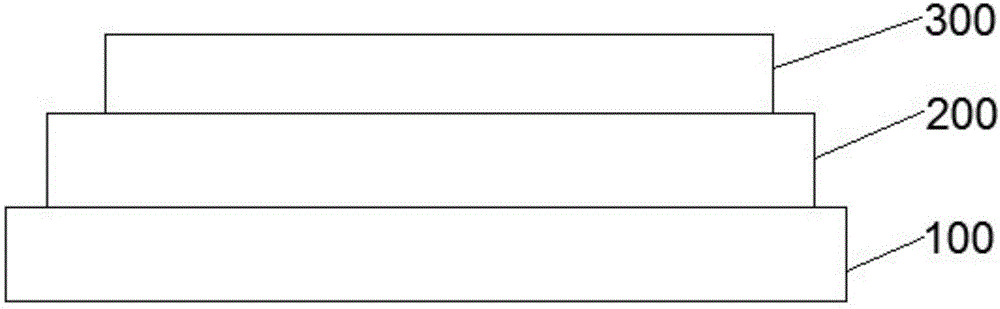

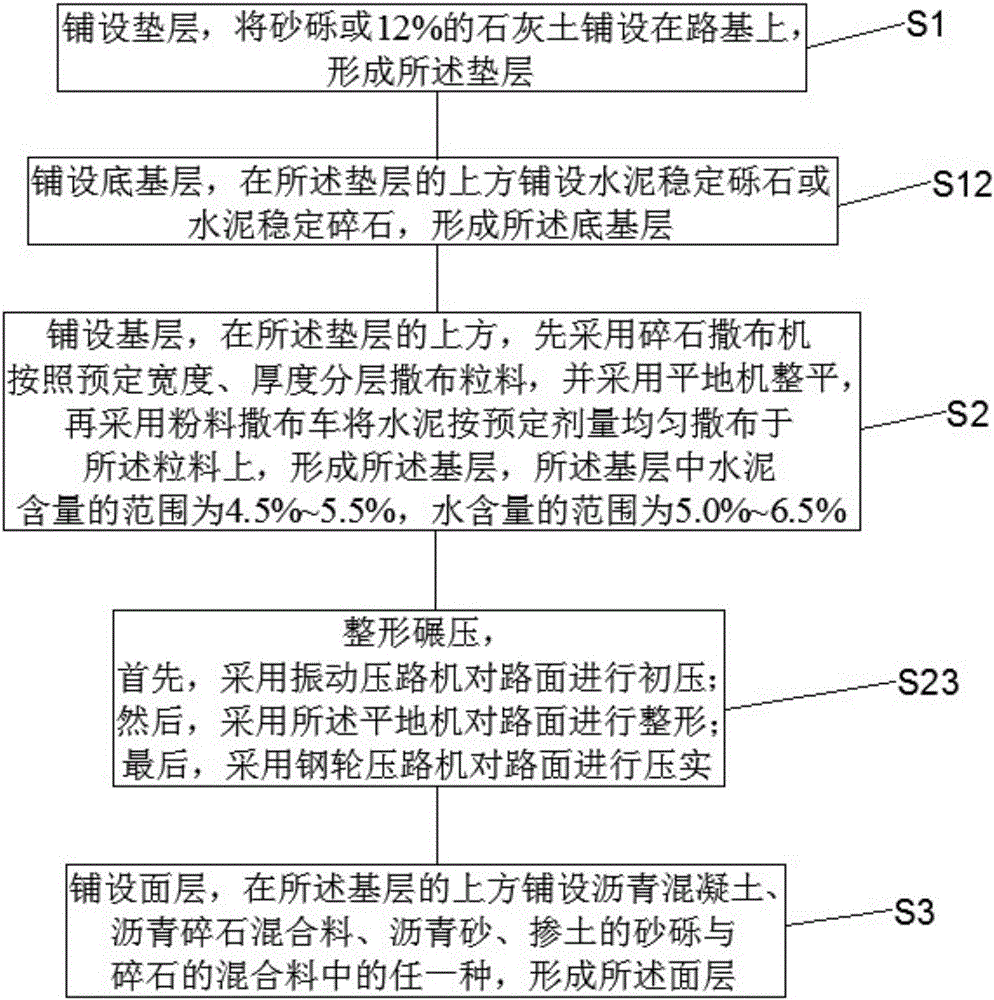

Highway pavement structure and construction method thereof

ActiveCN106192660AAvoid double bad luckHigh degree of mechanizationIn situ pavingsChipsealSoil mixing

Owner:鄂尔多斯市路泰公路工程有限责任公司

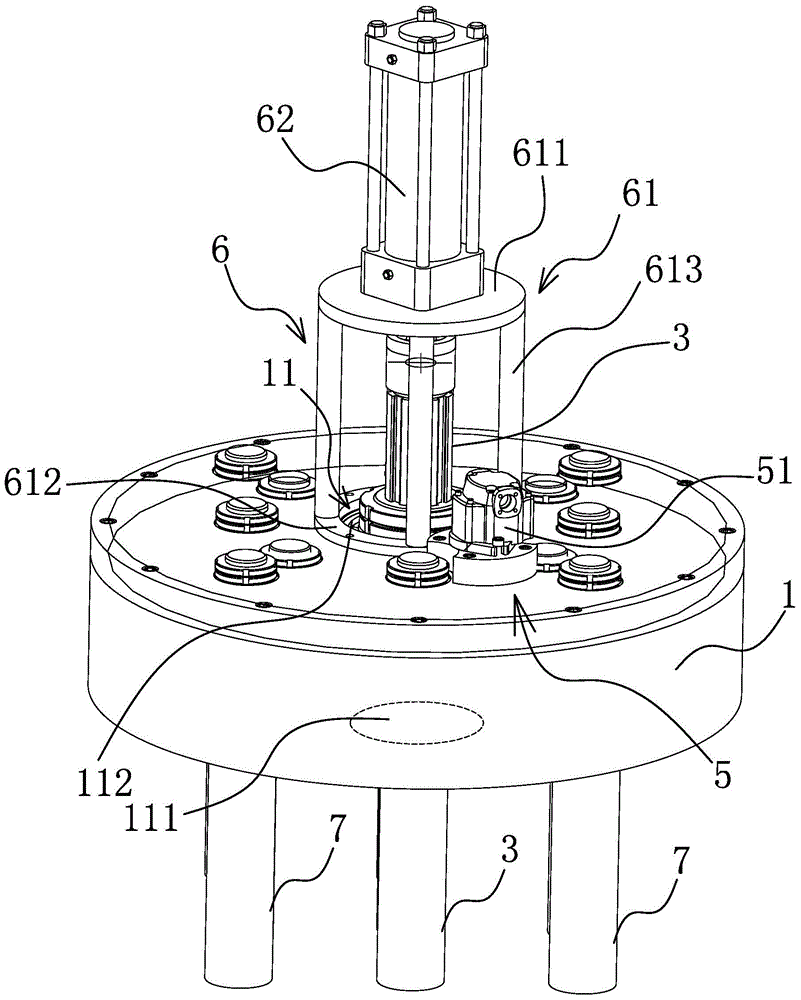

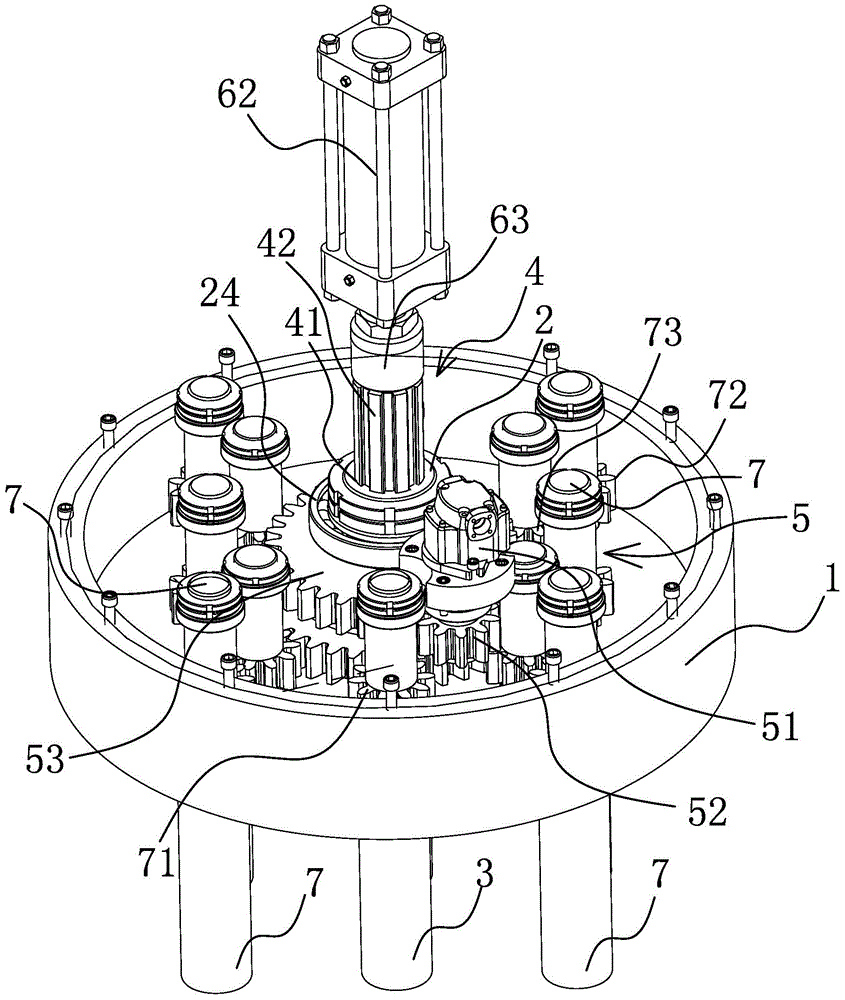

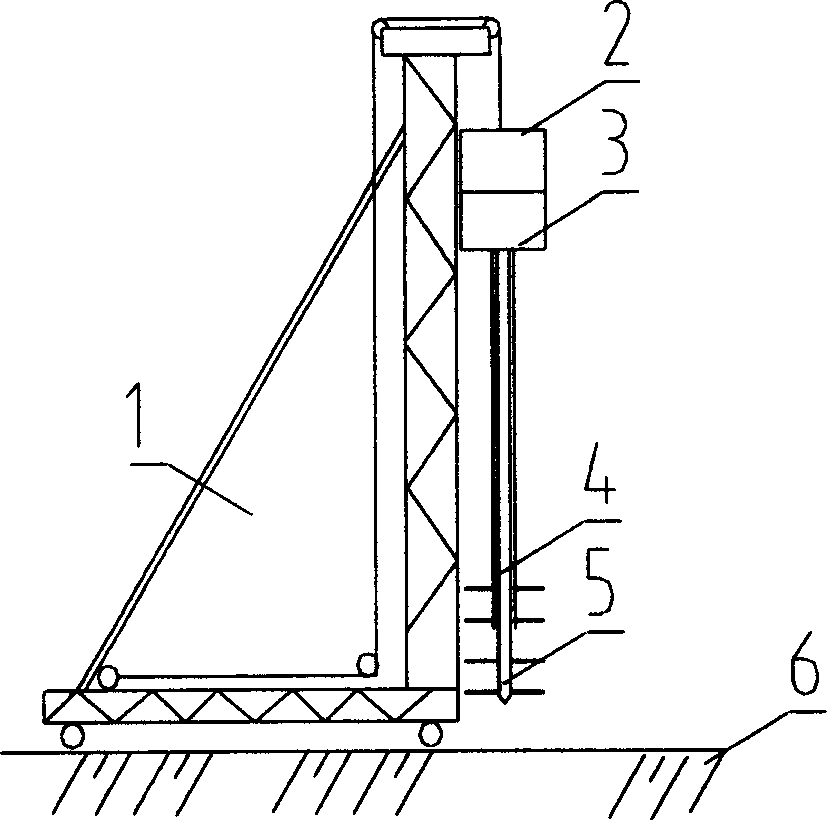

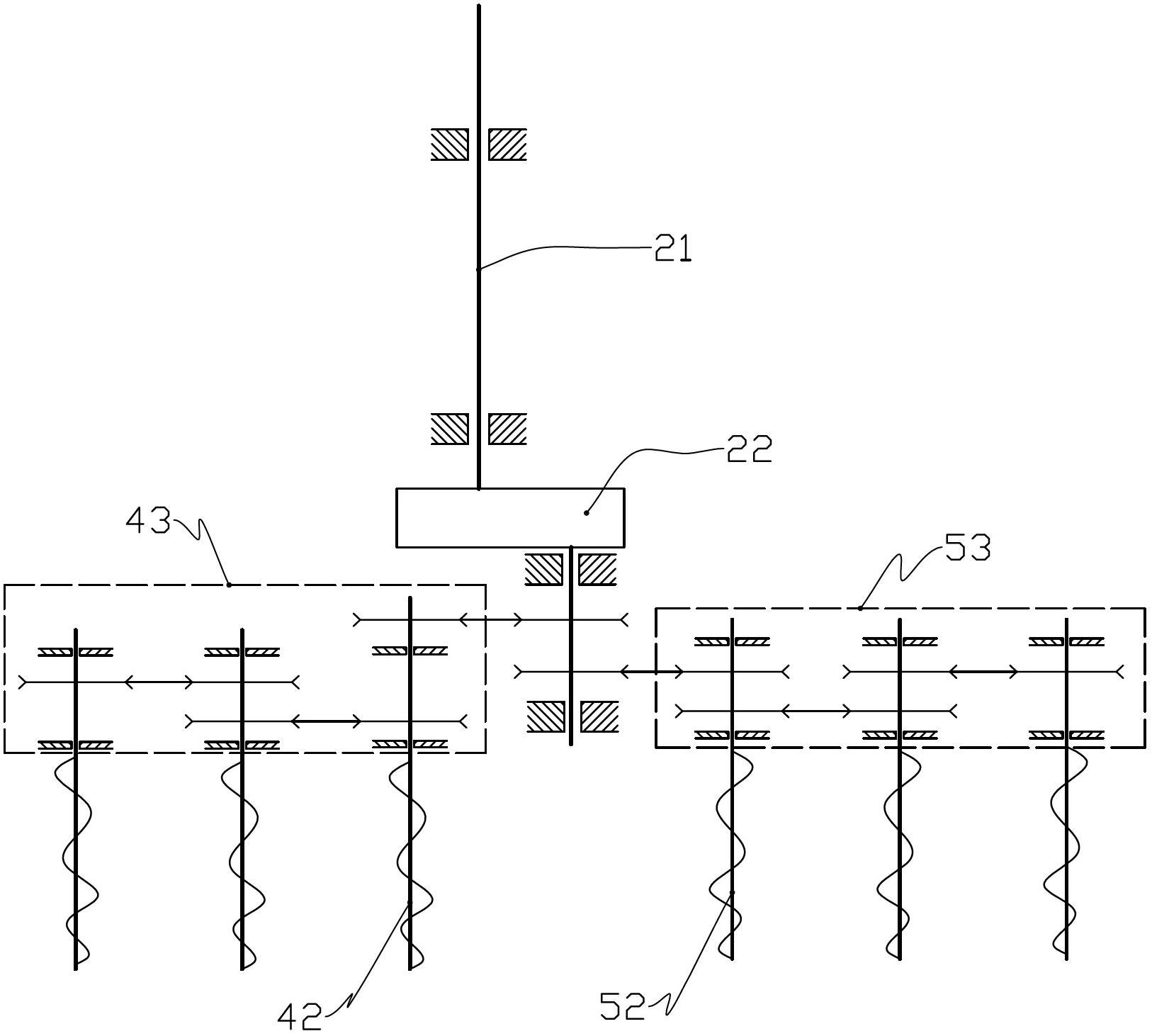

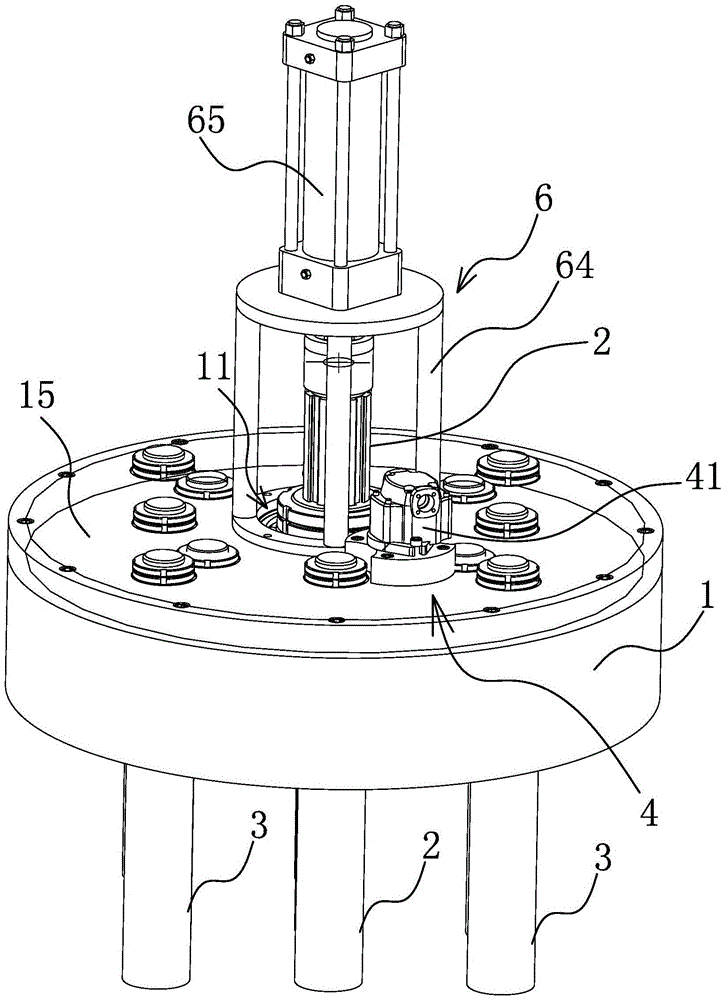

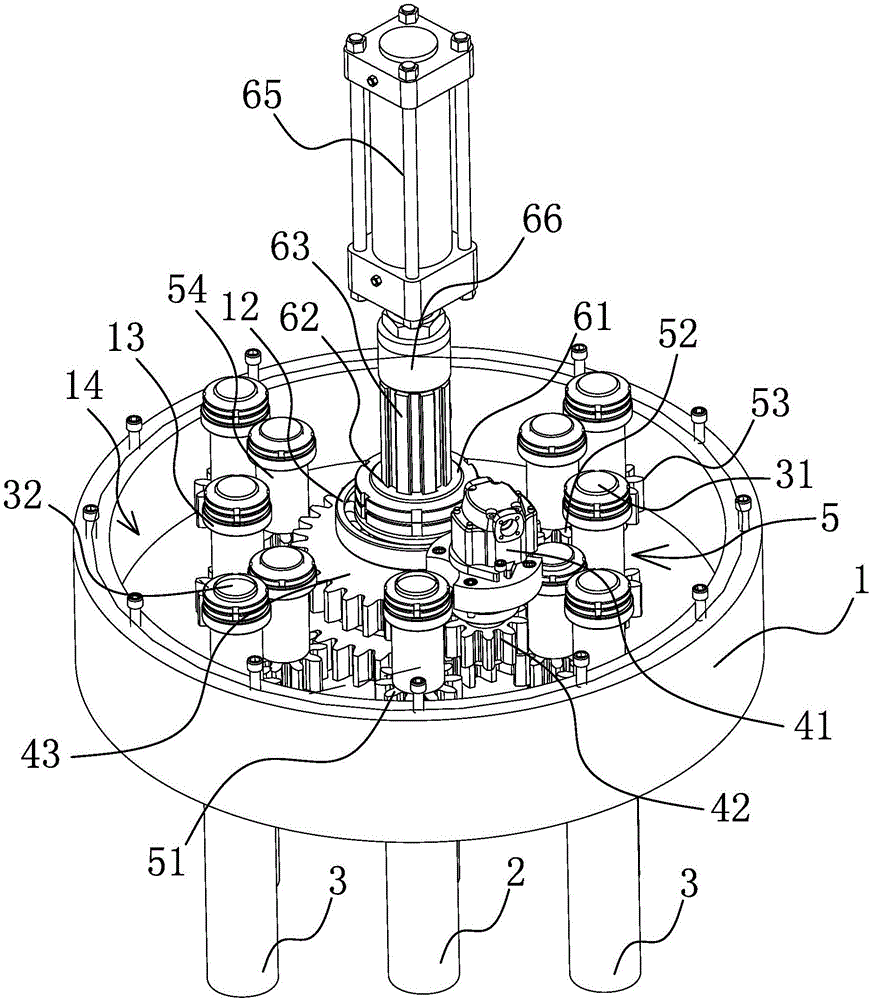

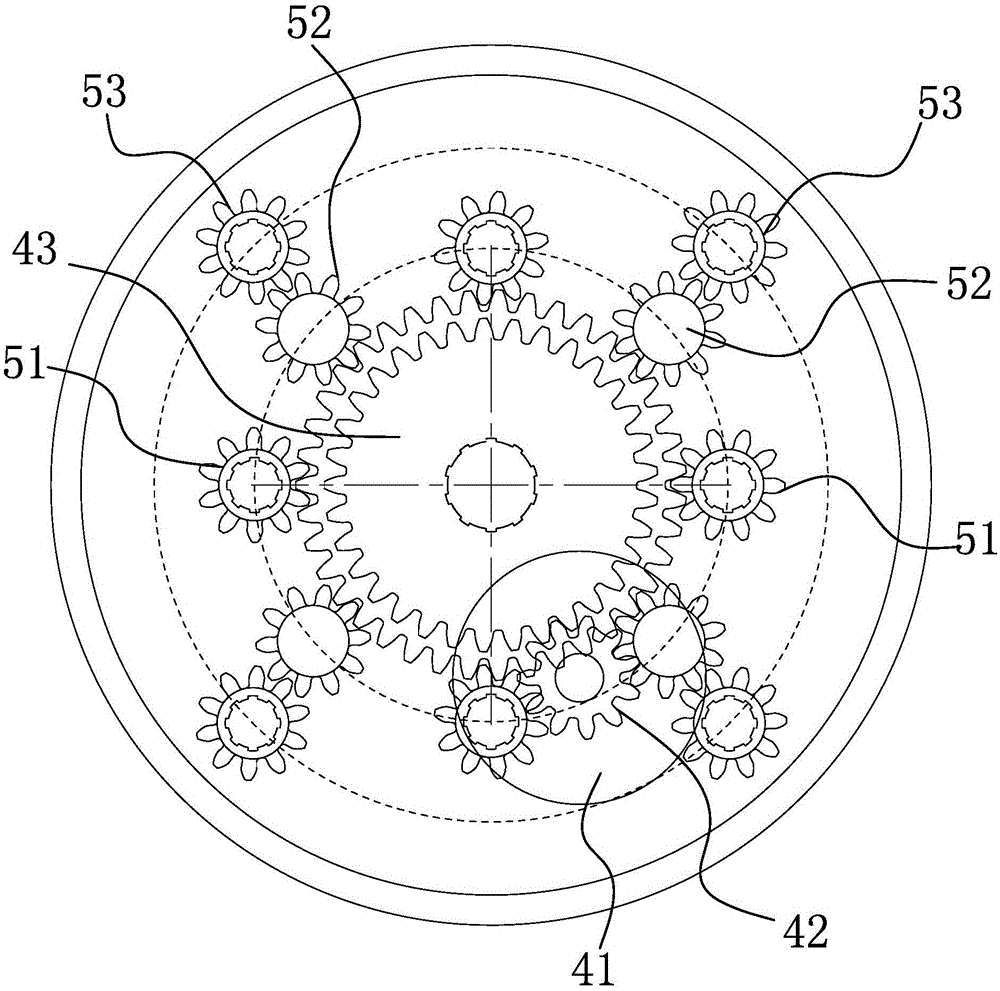

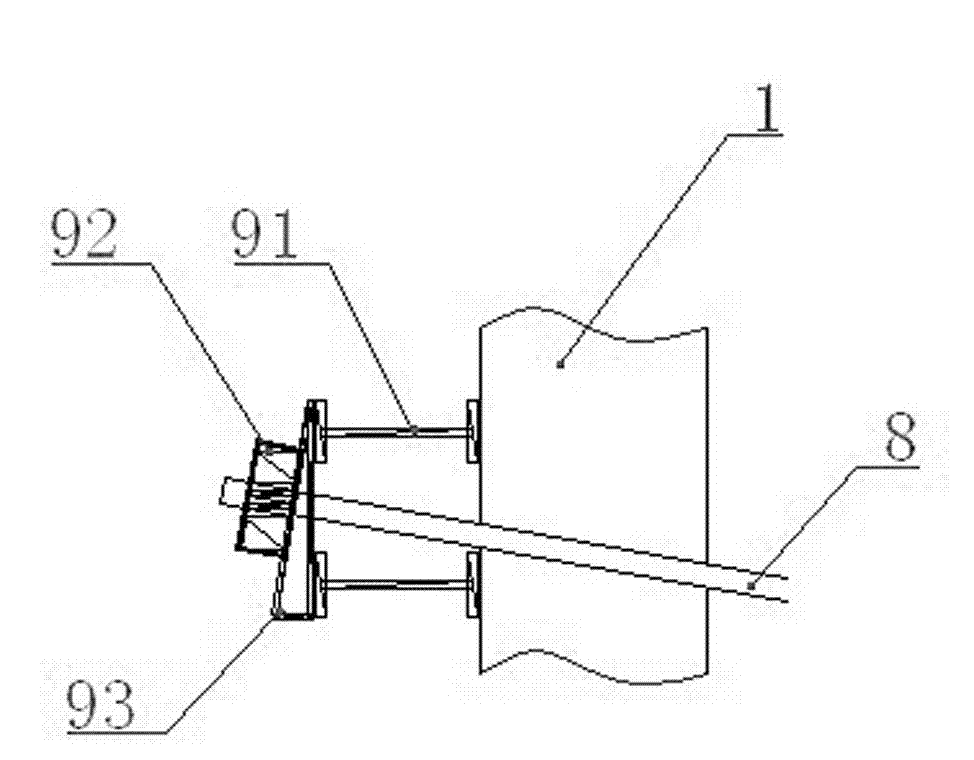

Drill rod rotation driving mechanism of cement soil mixing pile driver

ActiveCN105002898AImprove pullout resistanceIncrease girthBorehole drivesBulkheads/pilesSoil mixingPile driver

The invention belongs to the technical field of construction equipment, and particularly relates to a drill rod rotation driving mechanism of a cement soil mixing pile driver. The drill rod rotation driving mechanism of the cement soil mixing pile driver solves the problem that stirring is uneven when an existing cement soil mixing pile driver is used for drilling. The drill rod rotation driving mechanism of the cement soil mixing pile mixer comprises a drive box with an inner cavity; the drive box is provided with at least one main drill rod arranged in the vertical direction; at least two auxiliary drill rods are arranged on the outer side of the circumference of the main drill rod; the main drill rod is connected with a main drill rod driving structure capable of driving the main drill rod to rotate in the circumferential direction; an auxiliary drill rod transmission structure is arranged between the main drill rod and the auxiliary drill rods. The drill rod rotation driving mechanism of the cement soil mixing pile driver has the advantages that a single driver can achieve homodromous and reverse-direction movement of the main drill rod and the auxiliary drill rods, so that stirring uniformity is improved; drill rod bodies can axially stretch out and draw back and can axially slide while rotating circumferentially, the phenomenon of being unable to drill is not prone to happening, the perimeter of the cross section of a cement soil mixing pile after construction is increased, and the anti-pulling capacity of the cement soil mixing pile is improved.

Owner:周兆弟

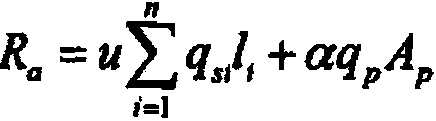

Reinforcement method for transmission tower shallow base foundation under composite soft soil foundation

The invention relates to a reinforcement method for a transmission tower shallow base foundation under a composite soft soil foundation. A cement-soil mixing pile composite base is adopted for reinforcement, and the foundation reinforcement method comprises the following steps: (1) pile positions are distributed on the soft soil foundation in the form of square or quincunx distribution mode, and the pile diameter, pile length and pile spacing are determined; (2) pile holes are drilled in the base foundation, cement slurry is injected into the pile holes to form cement piles, and anchor bars are arranged in the cement piles within 2 hours after the cement piles are finished; (3) a mattress cushion layer is paved on the treated foundation, and the anchor bars extend out of the mattress cushion layer; (4) a flexible platy foundation is mounted on the mattress cushion layer, the anchor bars in the cement piles are welded with the main bars of the flexible platy foundation, and the flexible platy foundation is used as a bearing layer. Compared with the flexible platy foundation reinforcement or bored pile reinforcement, the reinforcement method not only can meet the design requirements, extend the application range of shallow foundation, but also can reduce the total cost and have remarkable economic benefits.

Owner:STATE GRID CORP OF CHINA +2

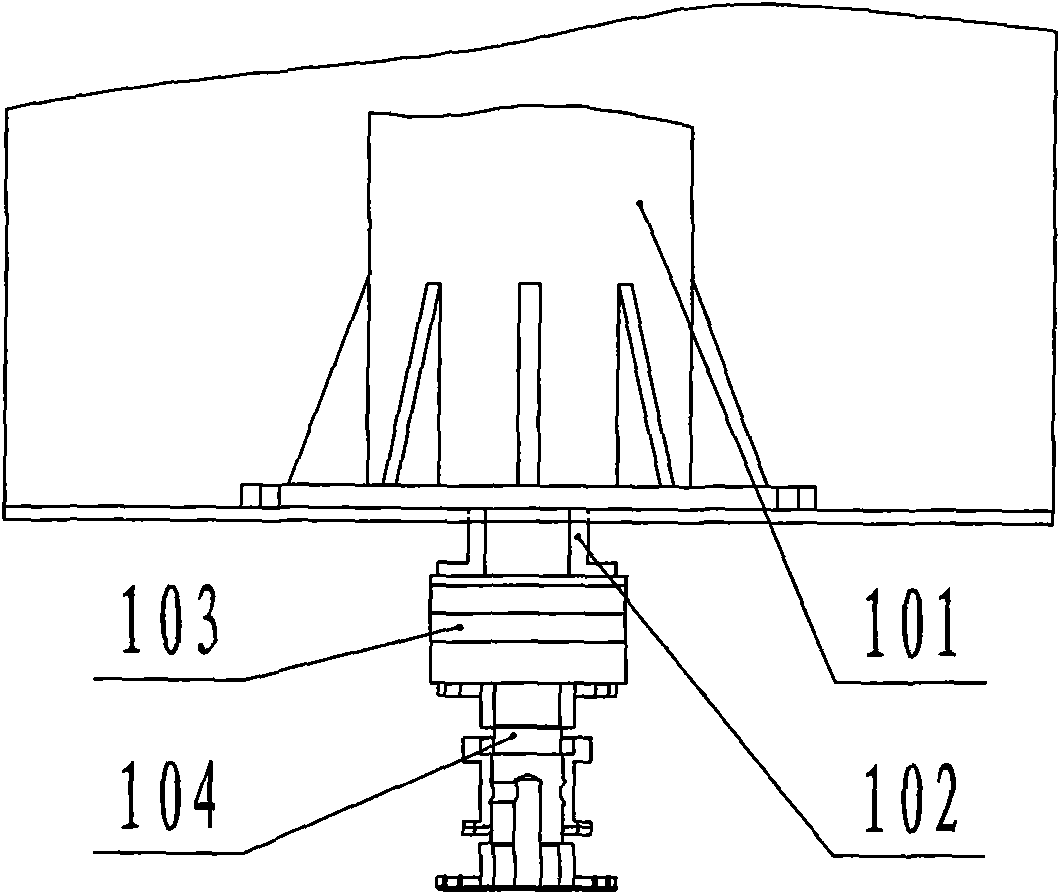

Bidirectional cement-soil mixing pile machine

The invention relates to a bidirectional cement-soil mixing pile machine, which comprises a power source, a transmission mechanism, a bit body and a frame, and is characterized in that the power source comprises a single motor and a reducer which are in mechanical connection in turn, a motor flange, a coupling and a grout injection connector, and the single motor and the reducer are hoisted on the frame; the transmission mechanism comprises a gear box, a main shaft vertically arranged in the gear box, a half shaft sleeved on the lower part of the main shaft, an external sleeve shaft sleeved outside of the half shaft, and a left intermediate shaft and a right intermediate shaft parallel to the main shaft; and the bit body comprises an inner shaft, an inner bit and an outer bit. The pile machine only adopts one motor to drive, uses structural characteristics of gear transmission and kinematic principle, realizes the diversion and mergence of transmission speed and routes and the change of rotation direction, and realizes the bidirectional rotation cement-soil mixing function.

Owner:HEBEI UNIV OF TECH

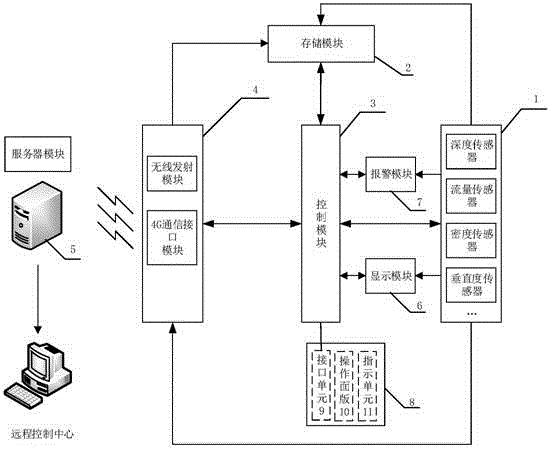

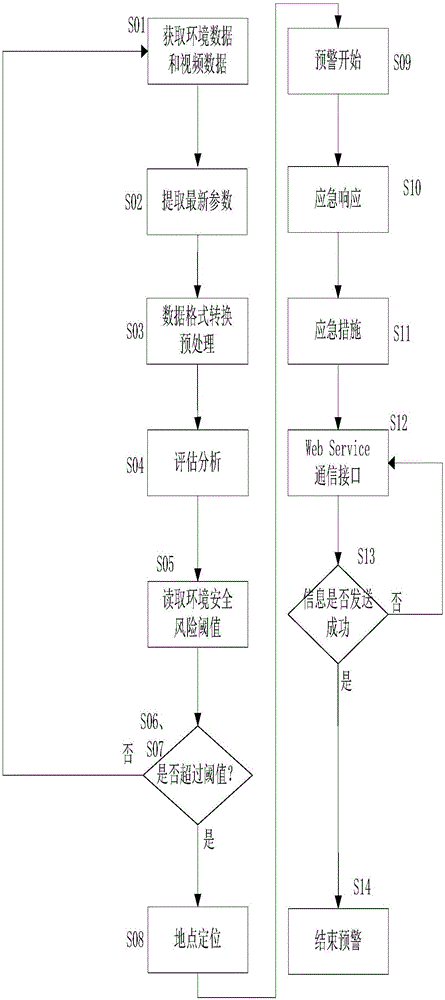

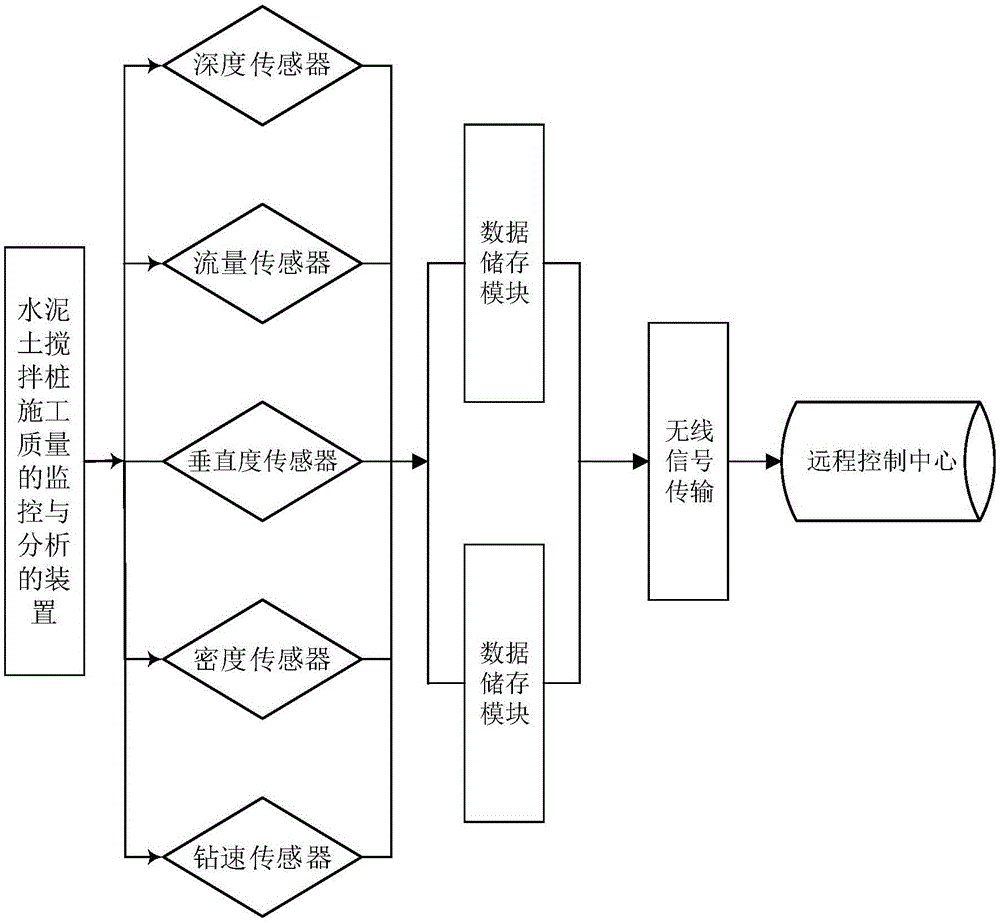

Remote information monitoring and analyzing device and method for cement soil mixing pile

InactiveCN105155599AImprove construction efficiencyReduce usageFoundation testingReal-time dataSoil mixing

The invention provides a remote information monitoring and analyzing system for a cement soil mixing pile. The system is composed of a field data collection module, a control module, a server module, a display module, a storage module, an alarm module and a signal transmission module. The control module is connected with the field data collection module, the display module, the signal transmission module and the alarm module and controls the functions of all the modules to be enabled. A construction analysis report of a project field is generated in time and field construction quality is accessed through accurate monitoring in the construction process. According to the remote information monitoring and analyzing system and method for the cement soil mixing pile, real-time data monitoring of the working process of the cement soil mixing pile can be achieved.

Owner:NANJING UNIV OF SCI & TECH

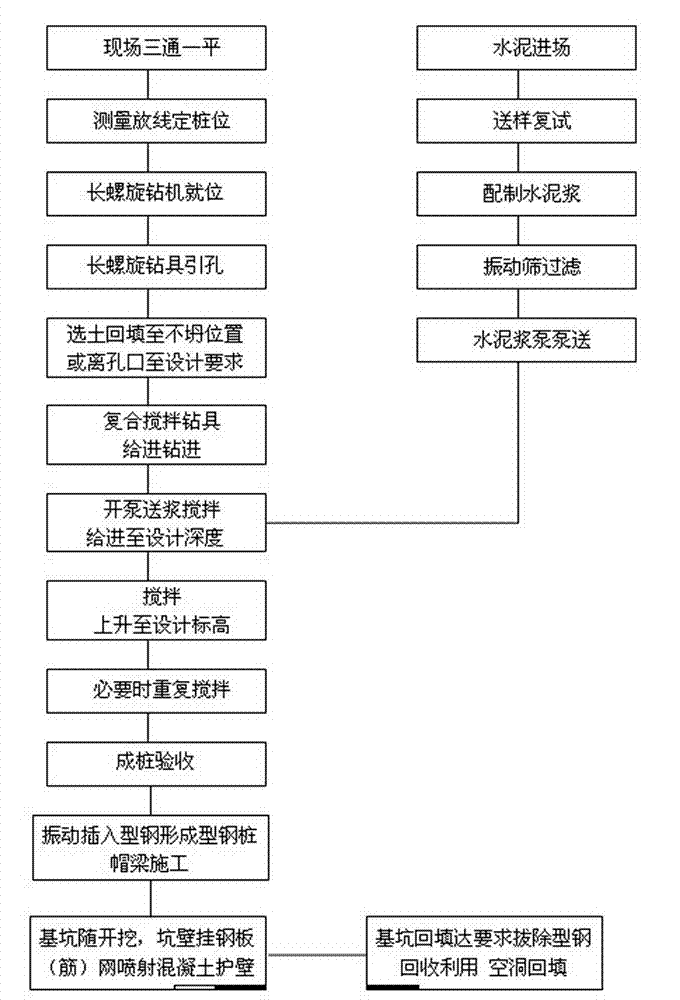

Foundation pit water-sealing supporting method by using long spiral cement soil mixing structural steel pile

InactiveCN103046557AImprove reliabilityOvercome drillingExcavationsBulkheads/pilesSoil mixingSoil cement

A foundation pit water-sealing supporting method by using a long spiral cement soil mixing structural steel pile. Construction steps include that a long spiral drill is used for constructing a cement soil mixing pile; after construction of each cement soil mixing pile, structural steel is inserted into the top end of each cement soil mixing pile; inner supports or detachable anchor rods are used for conducting composite supporting when a foundation pit is deep; pile top beam connecting construction of the cement soil structural steel pile is conducted; the foundation pit is dug, a net is hung on an inner lateral wall of the foundation pit, and concrete is sprayed; and the anchor rods or the inner supports are detached when backfilling of grooves of the foundation pit meets a requirement, and finally the structural steel is removed. The foundation pit water-sealing supporting method has the advantage that the long spiral drill can drill hard soil layers and can reach the designed depth by overcoming the hard soil layers, simultaneously designed pile diameter can be achieved, meshing reliability is guaranteed, and water sealing reliability is guaranteed. The structural steel is inserted later to achieve an effect of supporting the foundation pit, and a two-in-one effect of water sealing and supporting is achieved. Due to recycling of the structural steel and removing of the anchor rods, cost of supporting construction of the foundation pit is greatly reduced, and the method is environment-friendly.

Owner:北京建材地质工程有限公司 +2

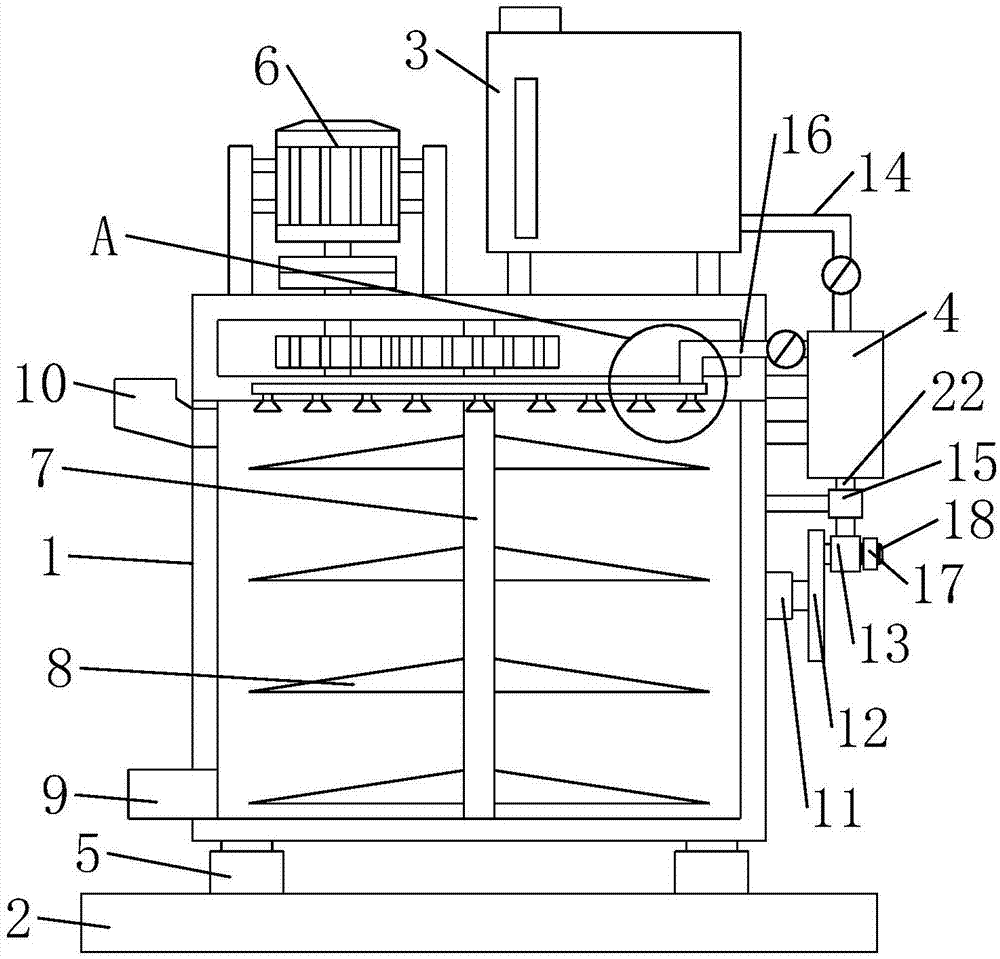

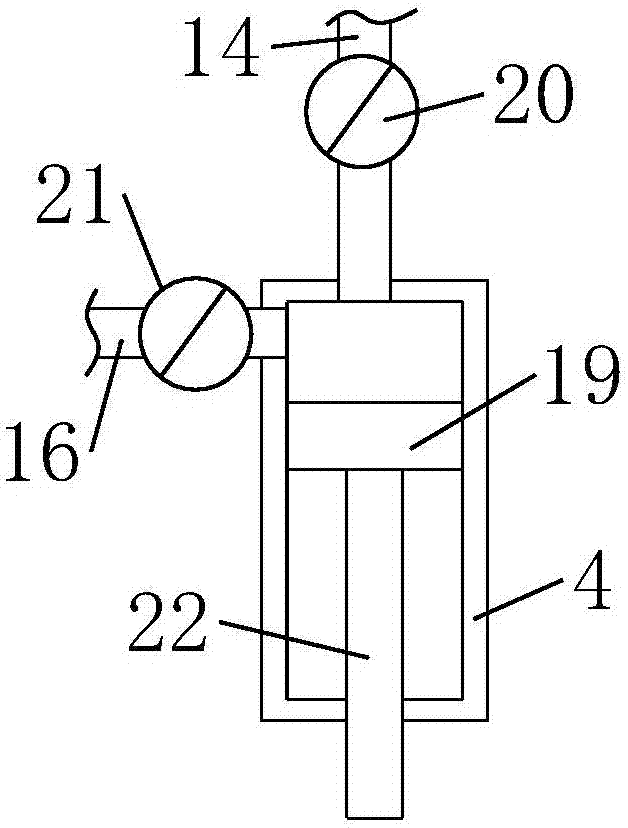

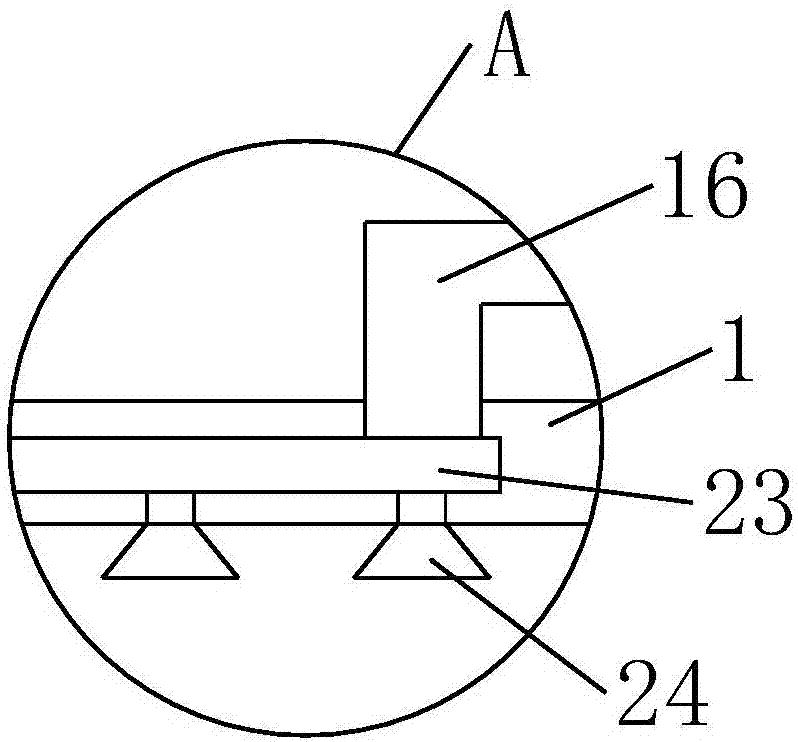

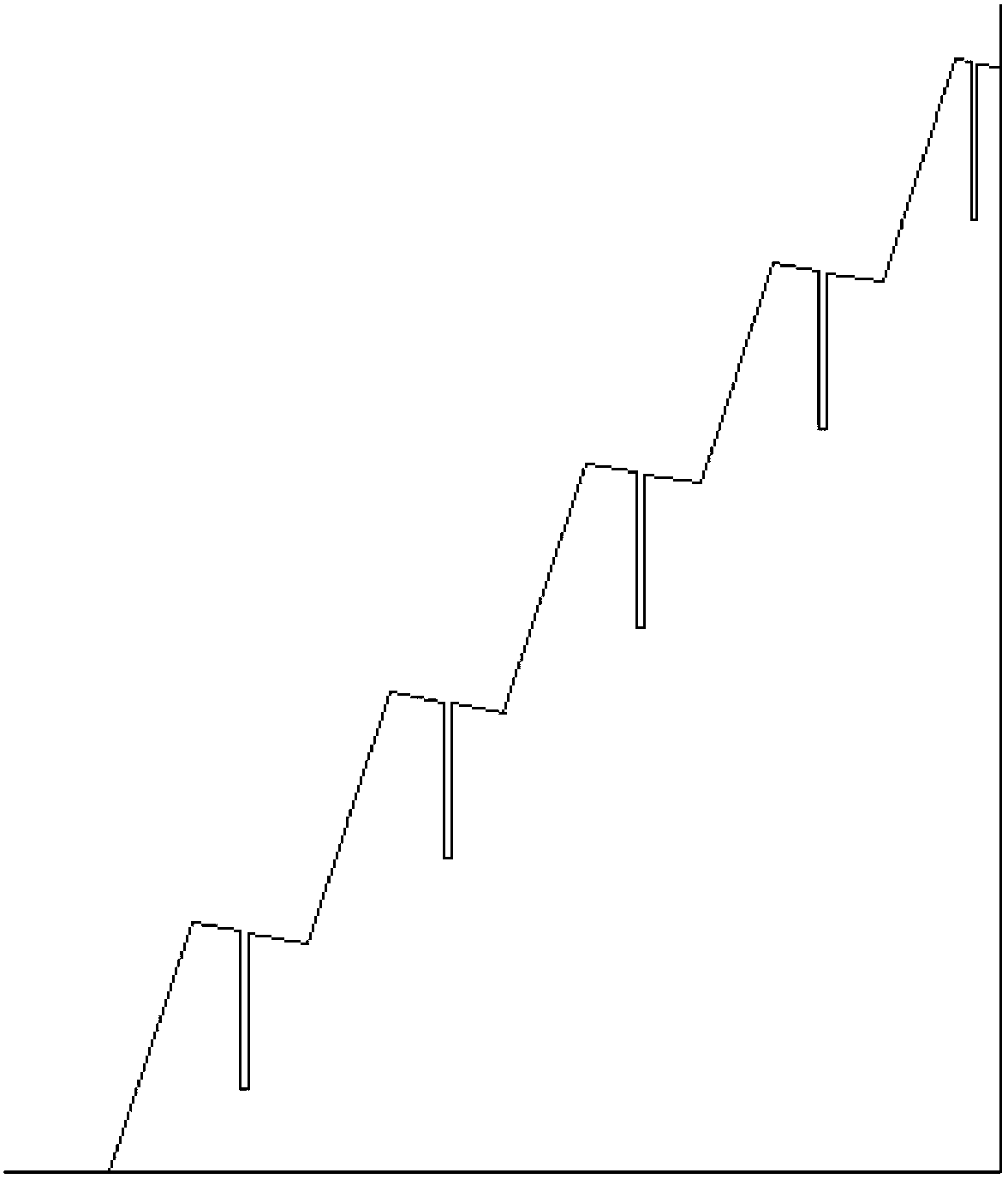

Intermittent type pesticide spraying soil repairing equipment

ActiveCN107999534AImprove governance effectImprove the shock and noise reduction effectContaminated soil reclamationCircular discHydraulic cylinder

The invention discloses intermittent type pesticide spraying soil repairing equipment. The intermittent type pesticide spraying soil repairing equipment comprises a box, a base, a liquid pesticide box, a hydraulic cylinder, a damping base, a rotation rod, stirring blades and a liquid spraying pipe. The box is arranged on the top of the base in an erected through the damping base arranged at the bottom end of the box. The rotation rod is rotationally erected in the box. The multiple stirring blades are evenly distributed on the rotation rod. The bottom of an inner cavity of the liquid pesticidebox communicates with an inner cavity in the upper portion of the hydraulic cylinder. The liquid spraying pipe is embedded in the inner wall of a top plate of an inner cavity of the box. The liquid spraying pipe communicates with the inner cavity in the upper portion of the hydraulic cylinder through a hydraulic cylinder outlet pipe. A guiding column is arranged on the outer end face of a rotation disc and sleeved with a lifting loop bar in a sliding manner. A push-pull rod is fixedly arranged at the top end of the middle portion of the lifting loop bar. The top end of the push-pull rod is fixedly connected with the bottom of a piston in the inner cavity of the hydraulic cylinder. The intermittent type pesticide spraying soil repairing equipment is good in damping and noise lowering effect, intermittent supply of liquid pesticide can be achieved, sufficient mixing of liquid pesticide and soil is achieved, the soil treatment effect is good, and the intermittent type pesticide sprayingsoil repairing equipment is suitable for usage and popularization.

Owner:东方铭科建设有限公司

Ecological restoration method for rocky slope

ActiveCN103074900APromote growthNot easy to dropExcavationsReceptacle cultivationRestoration methodSlurry

The invention relates to an ecological restoration method for a rocky slope. The method comprises the following steps that the rocky slope is built into multiple ladder-like steps, and the step surface of each ladder-like step is inward tilted and has a 5-10-degree inclined angle with the ground; after broken rock is removed, viscose slurry is injected into cracks; at least one inserting hole is respectively drilled at two edges of the middle part of the step surface of each ladder-like step and is vertical to the ground; a support frame is installed on the step surface of each ladder-like step, and the support frame comprises a frame and two support pillars which are connected with two edges of the bottom surface of the frame and are respectively inserted into the inserting holes in the step surface; a planting frame is put on the support frame, and soil materials are put in the planting frame to plant vegetations; and the soil materials comprise a sand layer, a humus layer, a soil layer, a membrane layer and a fertilizer-soil mixing layer from top to bottom. The rocky slope is restored through the method, so that the construction strength and the construction capacity are greatly reduced, the fast restoration and greening of the exposed rocky slope are realized, and meanwhile, the safety and the stability of an ecological restoration body and the rocky slope are effectively increased.

Owner:LINGNAN LANDSCAPE

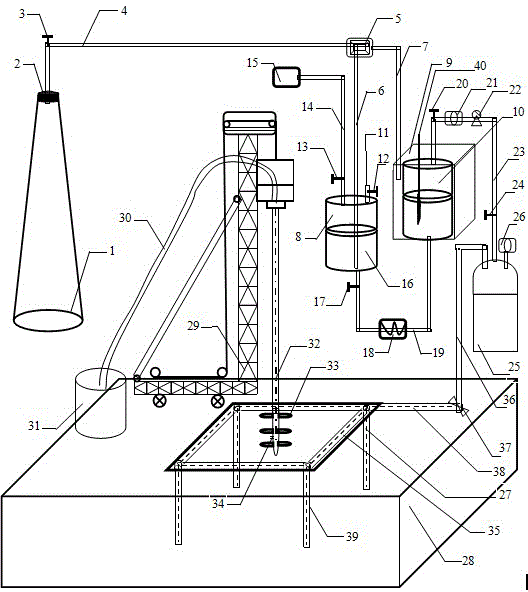

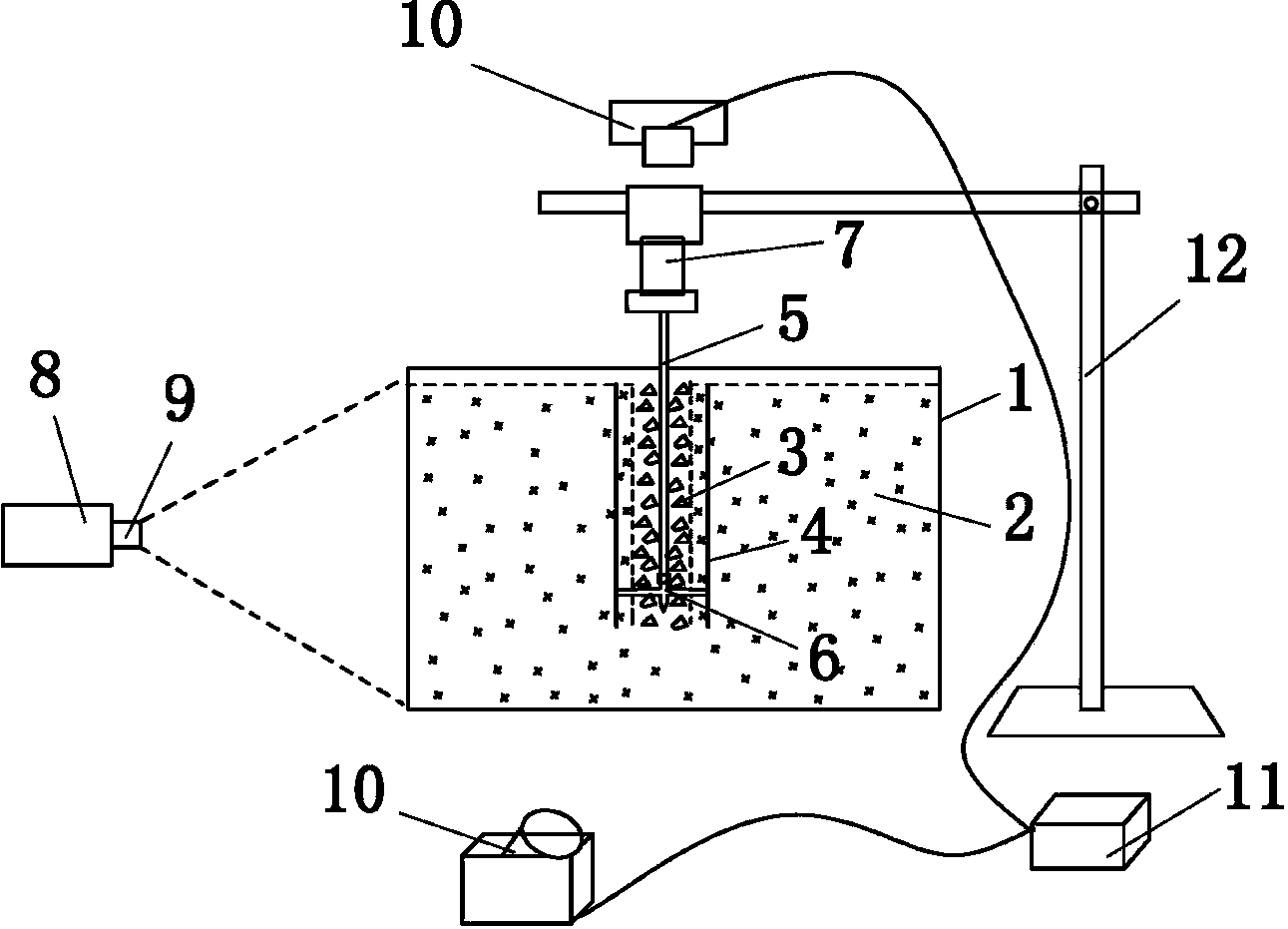

Grouting gravel cemented soil mixing combined pile model testing device and method

InactiveCN103940981ASimple and fast operationGood repeatabilityUsing optical meansMaterial testing goodsSoil characteristicsSoil properties

The invention discloses a visual grouting gravel cemented soil mixing combined pile model testing device and method. The device is characterized by comprising a transparent model tank, wherein a grouting gravel cemented soil mixing combined pile and transparent soil for simulating pile periphery soil are arranged in the transparent model tank; a drilling mechanism which is arranged on a bracket and comprises a drilling machine, a drill rod and a drill bit is arranged above the transparent model tank; a laser source is arranged on one side outside the transparent model tank; a digital camera capable of observing the space in the transparent model tank is arranged on the front and overhead view surface outsides the transparent model tank; the digital camera is connected with a processing device through a data line. The testing device is simple and convenient to operate and high in repeatability; the similarity between the prepared transparent soil and natural soil is high in soil properties; the testing method can visually observe and measure a pile-soil interaction mechanism of the grouting gravel cemented soil mixing combined pile under the conditions of different pile periphery soil characteristics, drill bit rotating radiuses, combined pile diameters and pile lengths and can be used for exploring and guiding the design and the construction of the cement soil mixing pile.

Owner:HUNAN CITY UNIV

Cement soil mixing pile device capable of switching up and down to spray slurry and construction method

ActiveCN104032733AImprove mixing uniformityShorten the mixing timeDrilling rodsDrilling casingsSoil mixingSlurry

The invention relates to a cement soil mixing pile device capable of switching up and down to spray slurry and a construction method. The device is improved and optimized on the basis of an original cement soil mixing pile machine. The device comprises movable hoop vanes, fixing sleeves, mixing vanes, a drill rod and slurry spraying opening groups. Upper and lower slurry spraying openings are automatically closed or opened under the action of the mechanical force of the movable hoop vanes according to different mixing directions, the lower slurry spraying opening sprays slurry when the drill rod drills downwards, and the upper slurry spraying opening sprays slurry when the drill rod is lifted. Compared with cement soil mixing pile devices and construction methods in the prior art, the cement soil mixing pile device capable of switching up and down to spray slurry and the construction method have the advantages that the mixing is uniform, the mixing efficiency is high, costs are low, the efficiency is high, the construction period is shortened, and the like.

Owner:SHANGHAI CHENGDI CONSTR +1

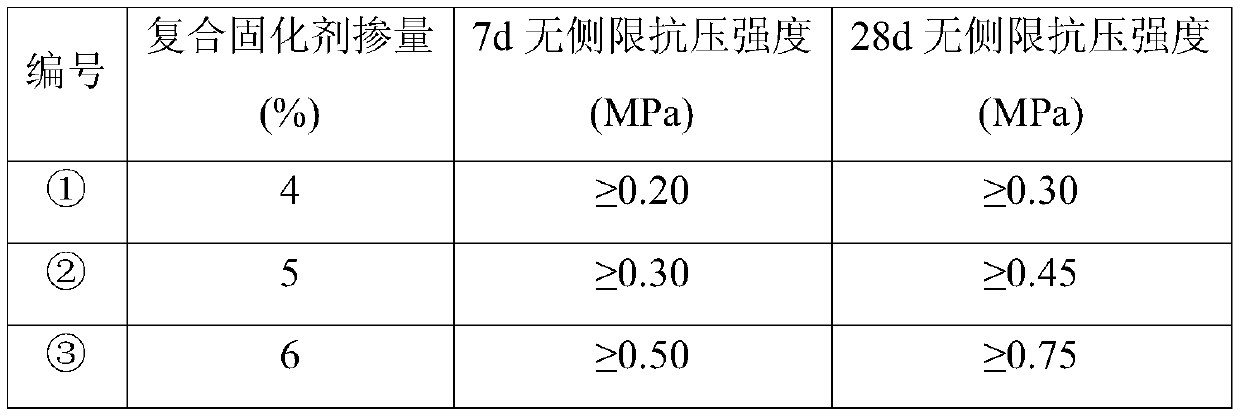

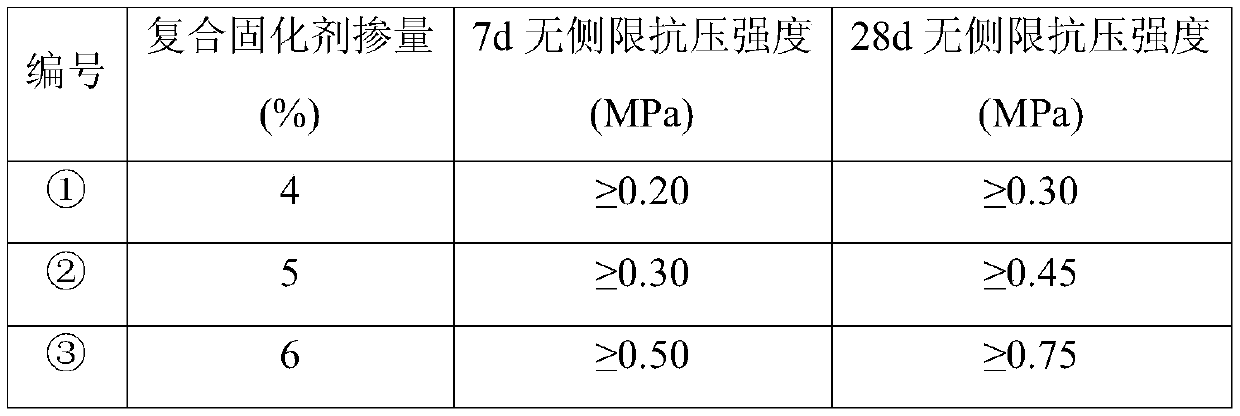

A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method using same

A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method thereof are provided; the method is characterized by comprising the following steps: (1), solidified light soil raw materials are selected, specifically, dehydrated dredged sludge, waste tire rubber powder and an industrial waste residue composite solidifying agent are selected; (2) solidified light soil mixing proportion design refers to the mass ratio of the dehydrated dredged sludge to the waste tire rubber powder to the industrial waste residue composite solidifying agent to the water, wherein the mixing ratio (volume ratio) of the dehydrated dredged sludge to the waste tire rubber powder is 80: 20-60: 40, and the mixing amount of the composite solidifying agent is 4-6%; and (3), roadbed layered filling construction: the solidified light soil roadbed construction comprises construction preparation, mixing, paving, rolling compaction, quality inspection, maintenance and slope protection. The method effectively solves the problem of recycling production and domestic solid waste, reduces the consumption of natural earthwork, and has the effects of saving resources, protecting the environment and the like.

Owner:ZHEJIANG UNIV OF TECH

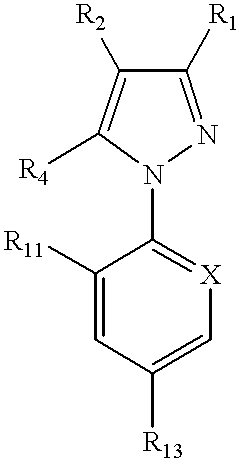

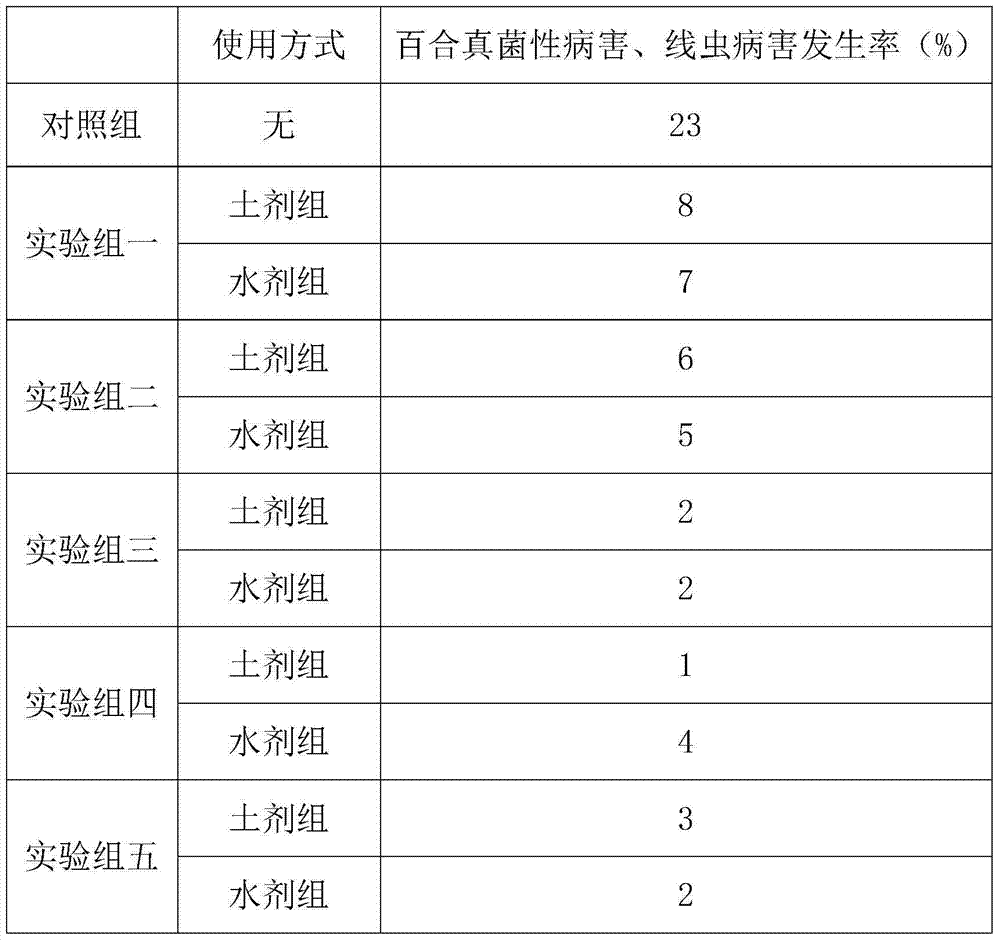

Novel special plant source insecticidal and bacteriostatic agent for lily

InactiveCN104839252AStrong anti-infectionStrong anti-allergicBiocideFungicidesHouttuyniaPlant Sources

The invention discloses a novel special plant source insecticidal and bacteriostatic agent for lily. The agent comprises the following components in parts by weight: 2 to 5 parts of Chinese yam, 1 to 2 parts of angled bittersweet, 3 to 5 parts of fructus cnidii, 2 to 3 parts of dandelion, 1 to 2 parts of cordate houttuynia, 1 to 2 parts of acanthopanax, 2 to 3 parts of pseudo-ginseng, 6 to 7 parts of garlic, 8 to 10 parts of folium artemisiae argyi and 6 to 10 parts of pericarpium citri reticulatae. Two use patterns of soil mixing and water extraction are adopted. The novel special plant source insecticidal and bacteriostatic agent has good preventive effects on fungus diseases and nematodiasis of the lily, is good in effect, durable in pesticide effect, free of public hazard and residue, green, healthy and efficient, and has great application and population value.

Owner:湖州桑农生态农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com