Large-diameter SMW (soil mixing wall) pile machine

A technology of construction method pile and large diameter, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of inability to manufacture SMW piles and the length of stirring wings cannot be large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

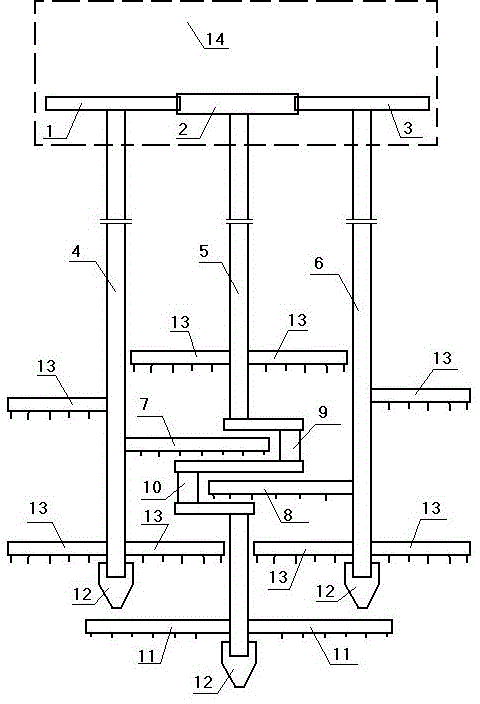

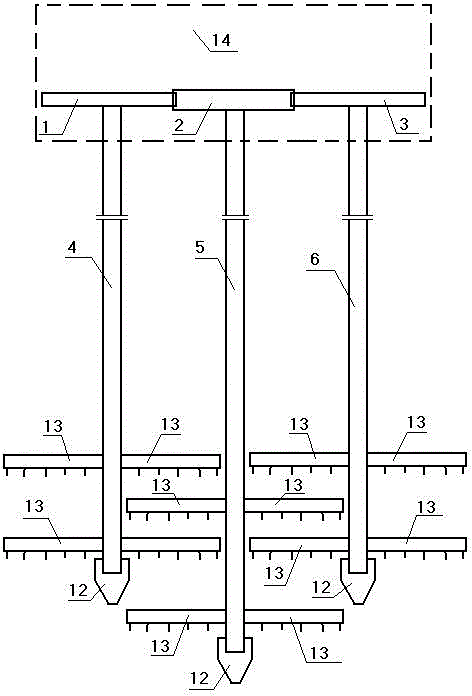

[0012] Accompanying drawing is a kind of specific embodiment of the present invention, and this embodiment gear A1, gear B2, gear C3 are arranged in the gearbox 14, and the lower end of gear A is fixed with drilling rod A4, and the left side of the lower part of drilling rod A is fixed with two short stirring wings 13. A long stirring wing A7 and a short stirring wing are fixed on the right side of the lower part of the drill pipe A; a drill pipe C6 is fixed on the lower end of the gear C, two short stirring wings are fixed on the right side of the lower part of the drill pipe C, and a long stirring wing is fixed on the left side of the lower part of the drill pipe C B8 and a short stirring wing; the lower end of the gear B is fixed to the drill pipe B5, and the left and right sides of the lower part of the drill pipe B are respectively fixed with a short stirring wing. A long stirring wing C11 is respectively fixed on the left and right sides of the lower drill rod.

[0013] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com