A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method using same

A technology for dredging silt and industrial waste, applied to roads, roads, buildings, etc., can solve problems such as land occupation, environmental pollution, and shortage of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below.

[0064] A construction method for layered filling of dredged silt, industrial waste residue, composite solidified light soil and roadbed, comprising the following steps:

[0065] (1) Selection of solidified light soil raw materials

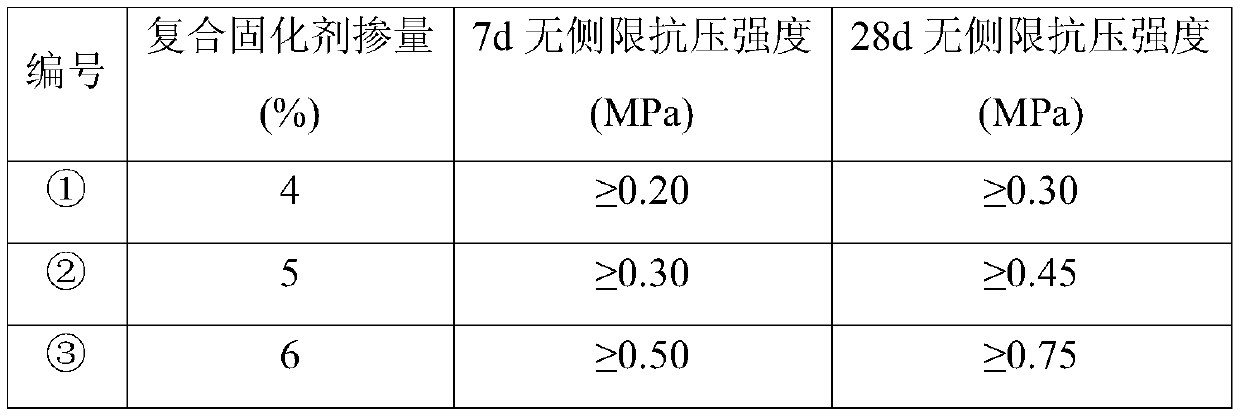

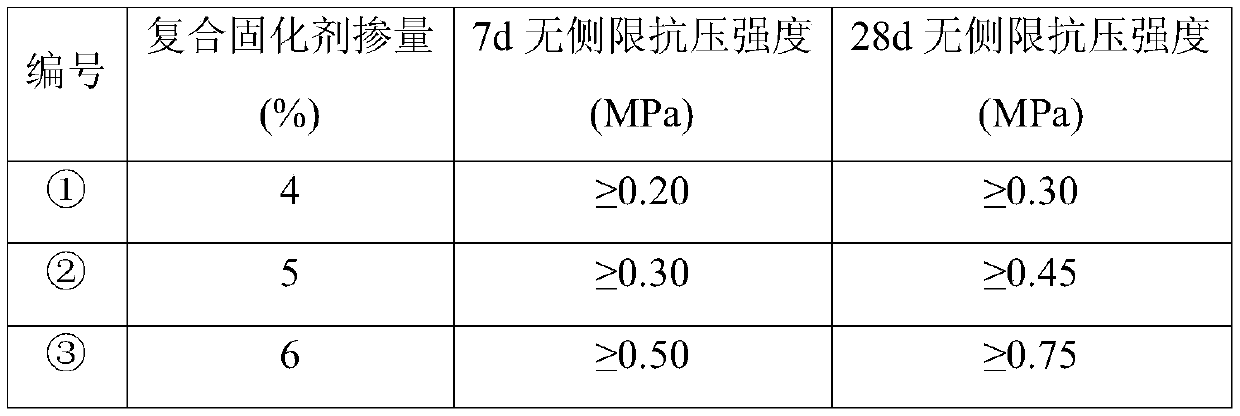

[0066] The mixing ratio of (dewatered) dredging silt and waste tire rubber powder is 70:30, and the dosage of 5% of composite curing agent is used to configure dredging silt and industrial waste residue to compound and solidify light soil. The selection of raw materials is as follows:

[0067] (Dehydration) dredging silt: high moisture content silt produced by dredging and remediation of inland lakes, rivers, ponds, and coastal ports, waterways, and wharves. After adopting technical measures such as ventilating, vacuum and rapid mud-water separation, the dredged silt with high water content is transformed into clay with high liquid limit (water content is reduced to less than 120%). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com