Patents

Literature

36results about How to "Good rebound characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Golf ball

InactiveUS6921345B2Solid comfortable feelGood rebound characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

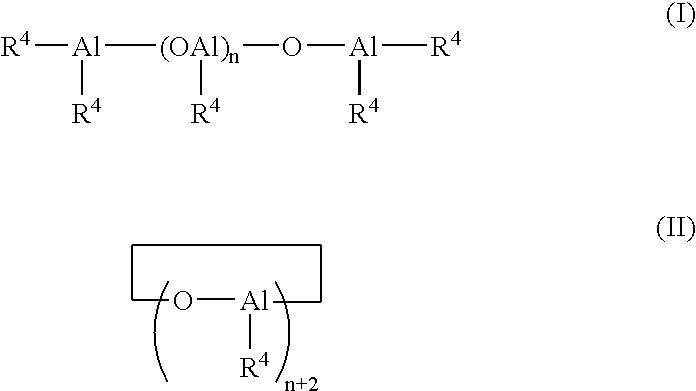

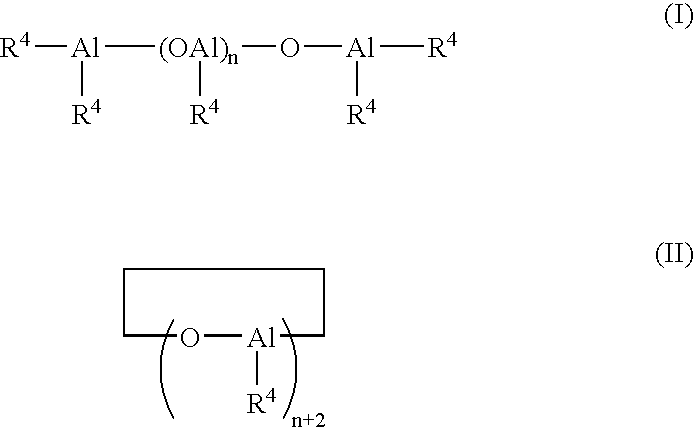

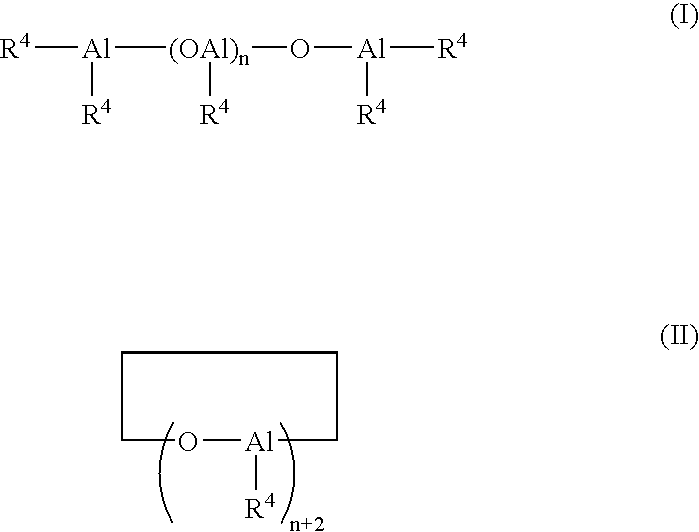

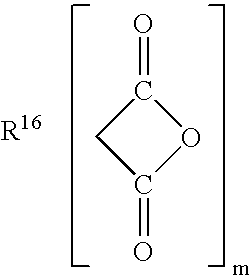

A golf ball includes a hot-molded product of a rubber composition comprising a base rubber composed of (a) 20-100 wt % of a polybutadiene having a high cis-1,4 content, a minimal 1,2 vinyl content, and a viscosity η of up to 600 mPa·s at 25° C. as a 5 wt % toluene solution, and satisfying a certain relationship between Mooney viscosity and polydispersity index Mw / Mn, in combination with (b) 0-80 wt % of another diene rubber, (c) an unsaturated carboxylic acid, (d) an organosulfur compound, (e) an inorganic filler, (f) an organic peroxide, and optionally, (g) an antioxidant. The hot-molded product has a difference in JIS-C hardness between the center and surface thereof of up to 15 units. The composition and hardness characteristics of the hot-molded product provide the golf ball with a solid comfortable feel upon impact and an excellent rebound.

Owner:BRIDGESTONE SPORTS

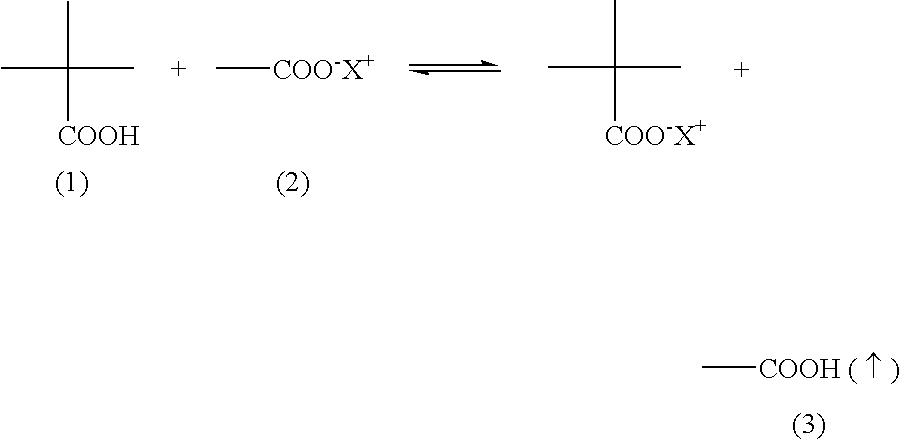

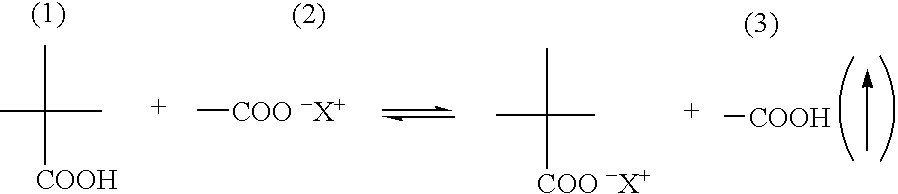

Golf ball material and golf ball

InactiveUS6838501B2Easy to reboundSpeed up the flowFibre treatmentConductive materialIonomerElastomer

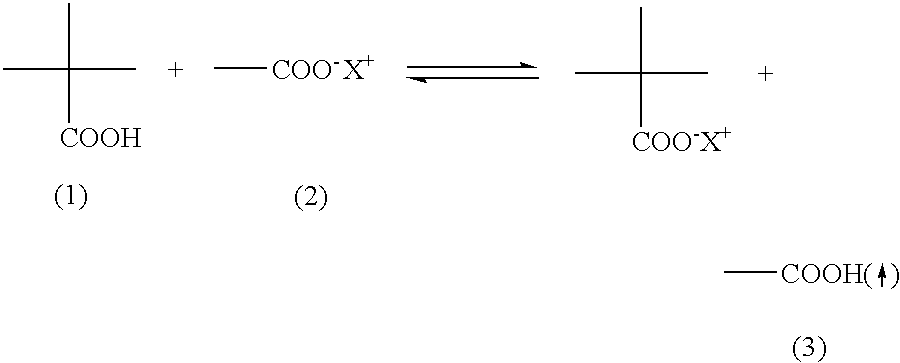

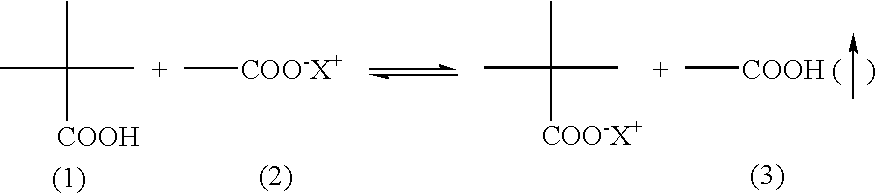

A mixture having good thermal stability, flow and moldability and suitable as a golf ball-forming material is obtained when a resinous component including a base resin of an ionomer resin or resins and optionally a non-ionomer thermoplastic elastomer is blended with specific proportions of a fatty acid and / or fatty acid derivative and a basic inorganic metal compound capable of neutralizing acidic groups left unneutralized in the base resin and fatty acid. Using the same material, high-rebound golf balls can be effectively manufactured.

Owner:BRIDGESTONE SPORTS

Golf ball material and golf ball

InactiveUS6894097B2Improve thermal stabilitySpeed up the flowSynthetic resin layered productsGolf ballsGolf BallThermal stability

A mixture having good thermal stability, flow and moldability and suitable as a golf ball-forming material is obtained when a base resin comprising a (metal ion-neutralized) olefin-unsaturated carboxylic acid-unsaturated carboxylate ternary random copolymer and optionally a (metal ion-neutralized) olefin-unsaturated carboxylic acid binary random copolymer is blended with specific proportions of a fatty acid and / or fatty acid derivative and a basic inorganic metal compound capable of neutralizing acidic groups left unneutralized in the base resin and fatty acid. Using the same material, high-rebound golf balls can be effectively manufactured.

Owner:BRIDGESTONE SPORTS

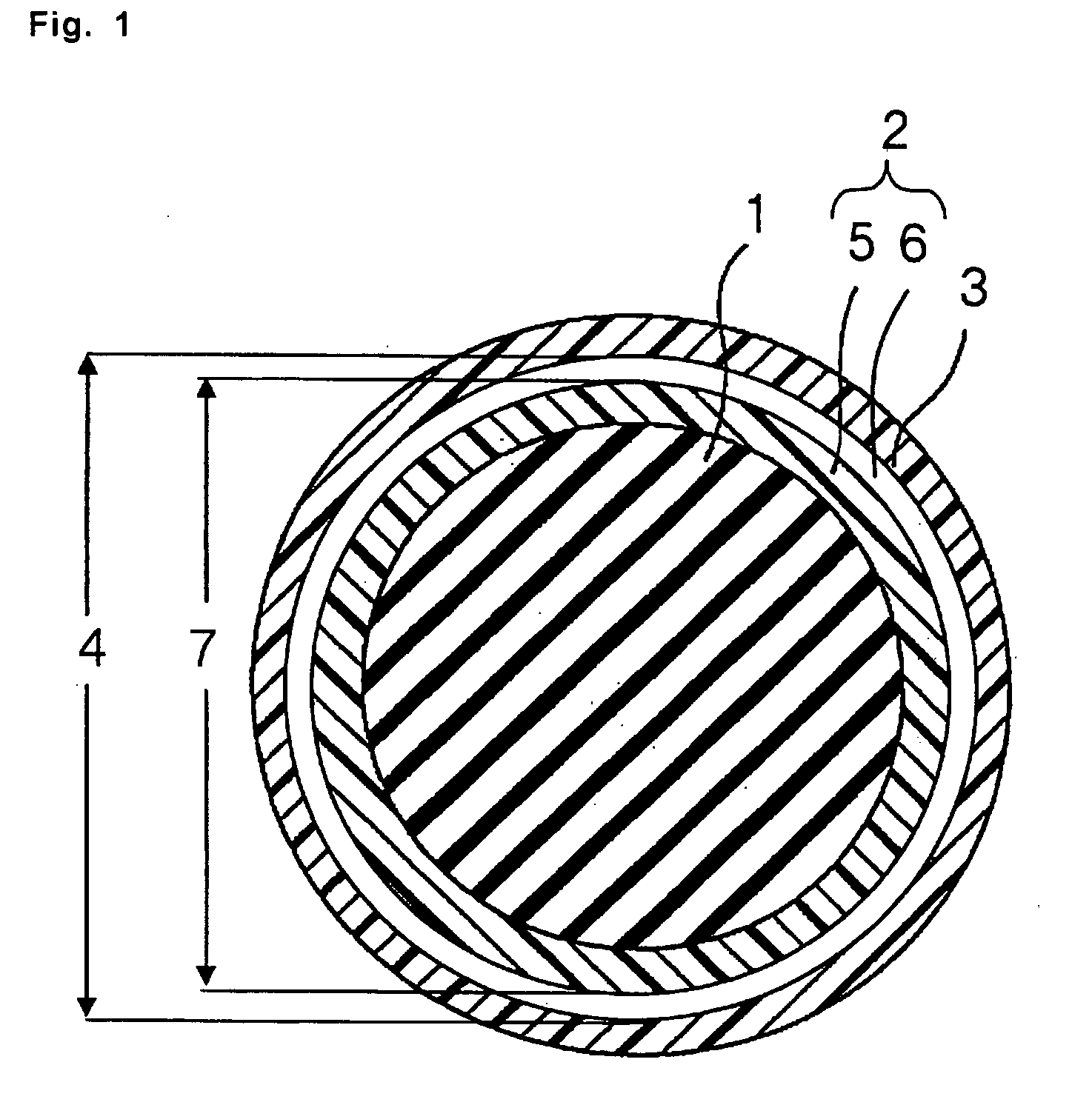

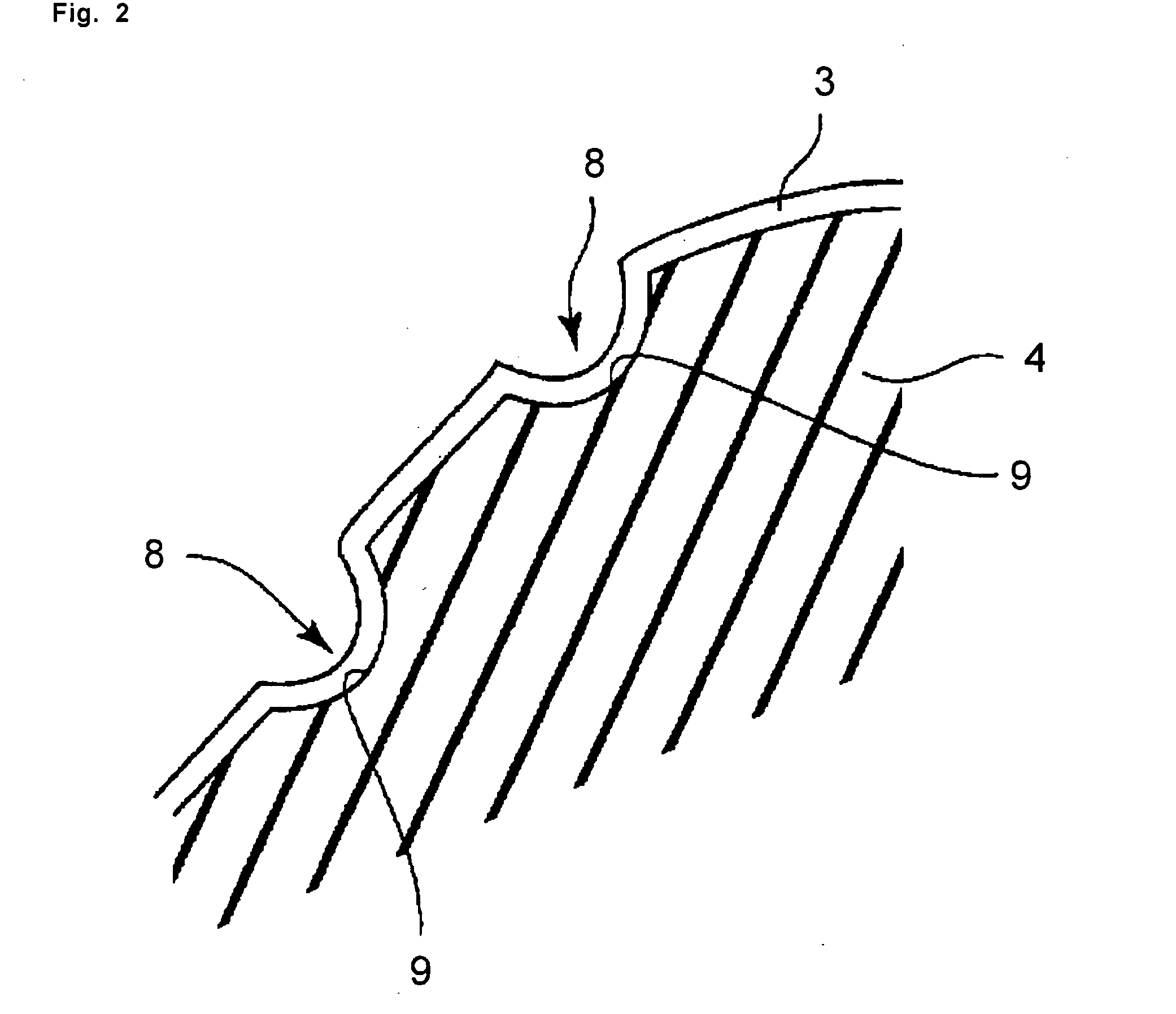

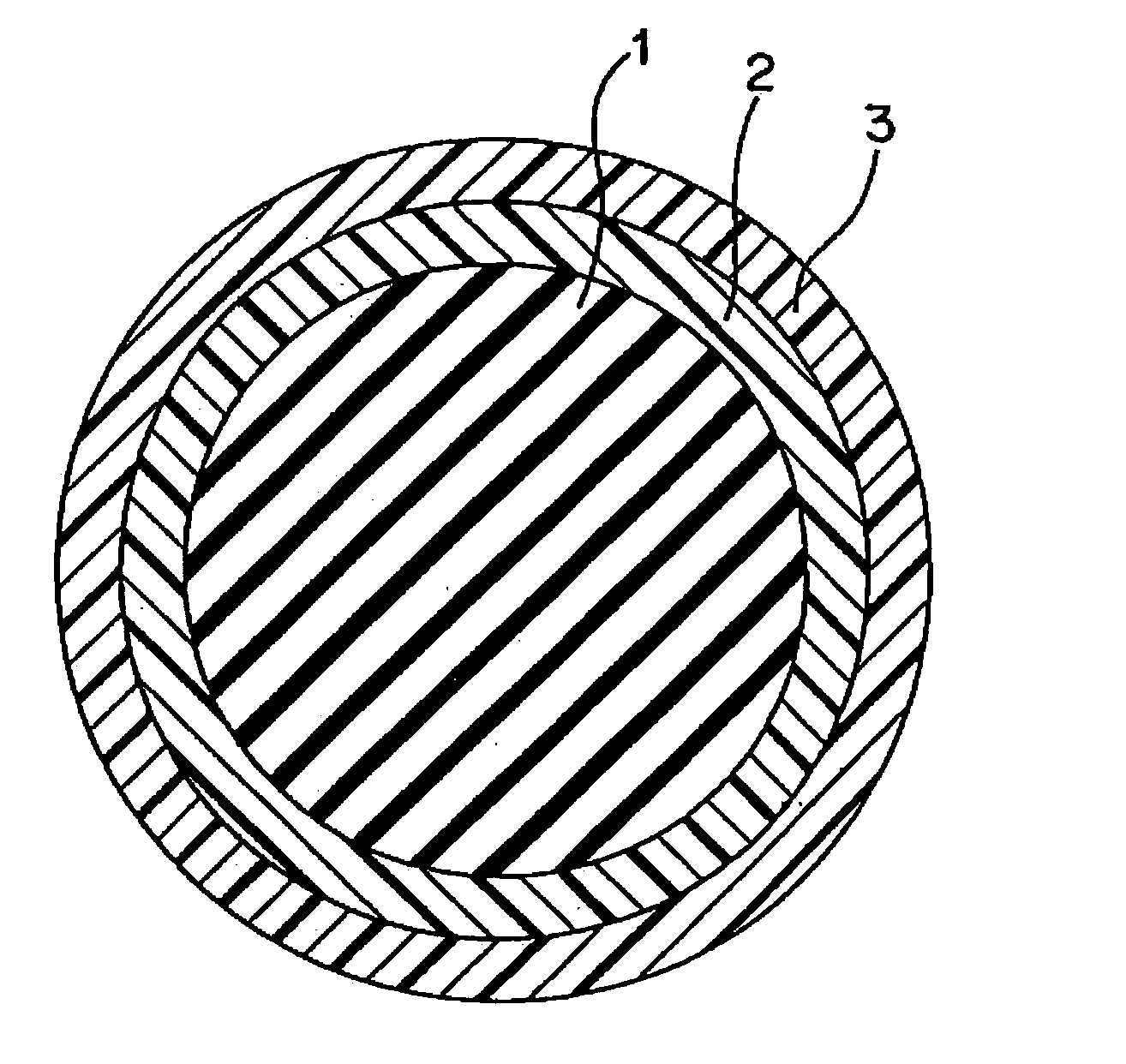

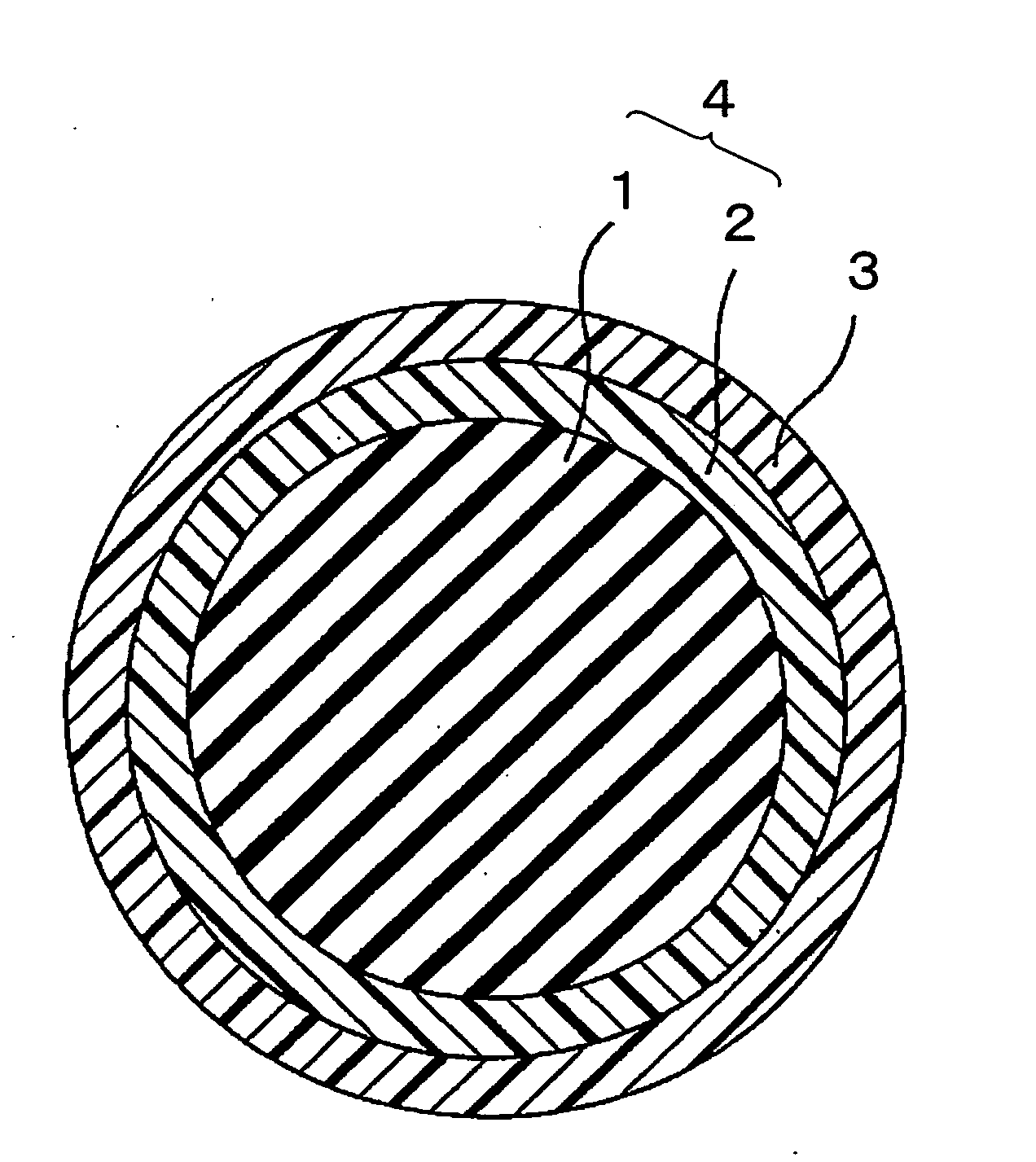

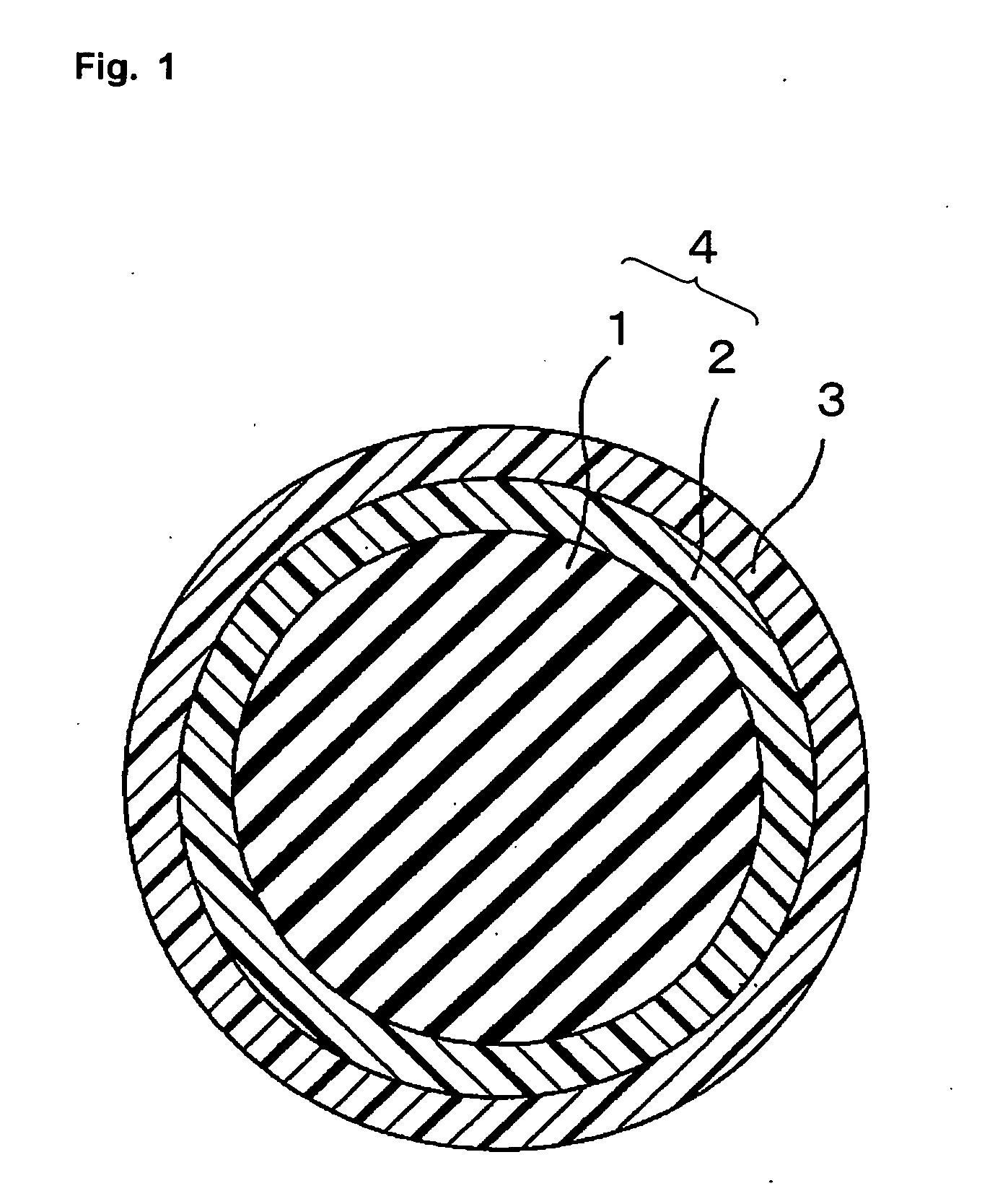

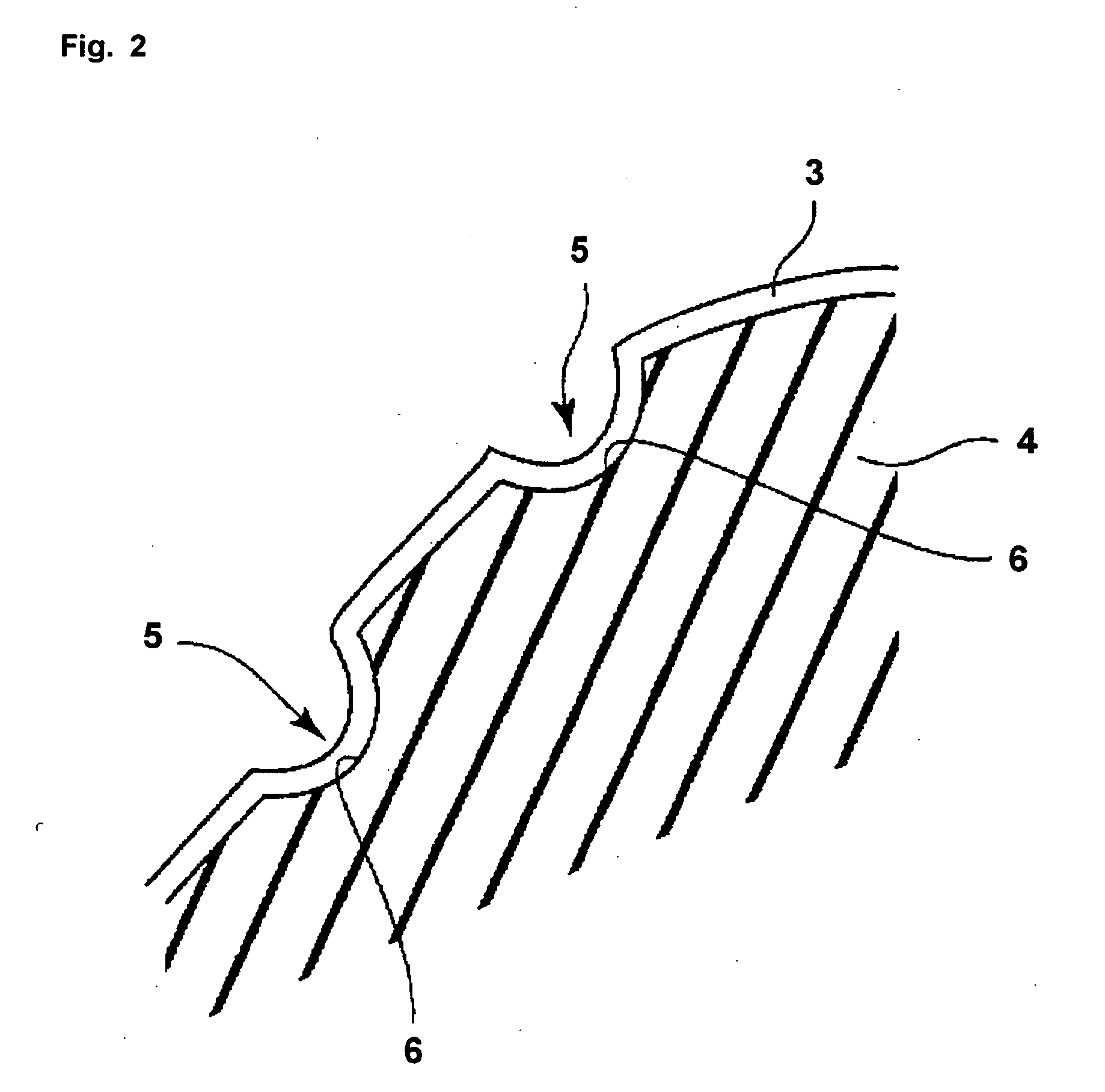

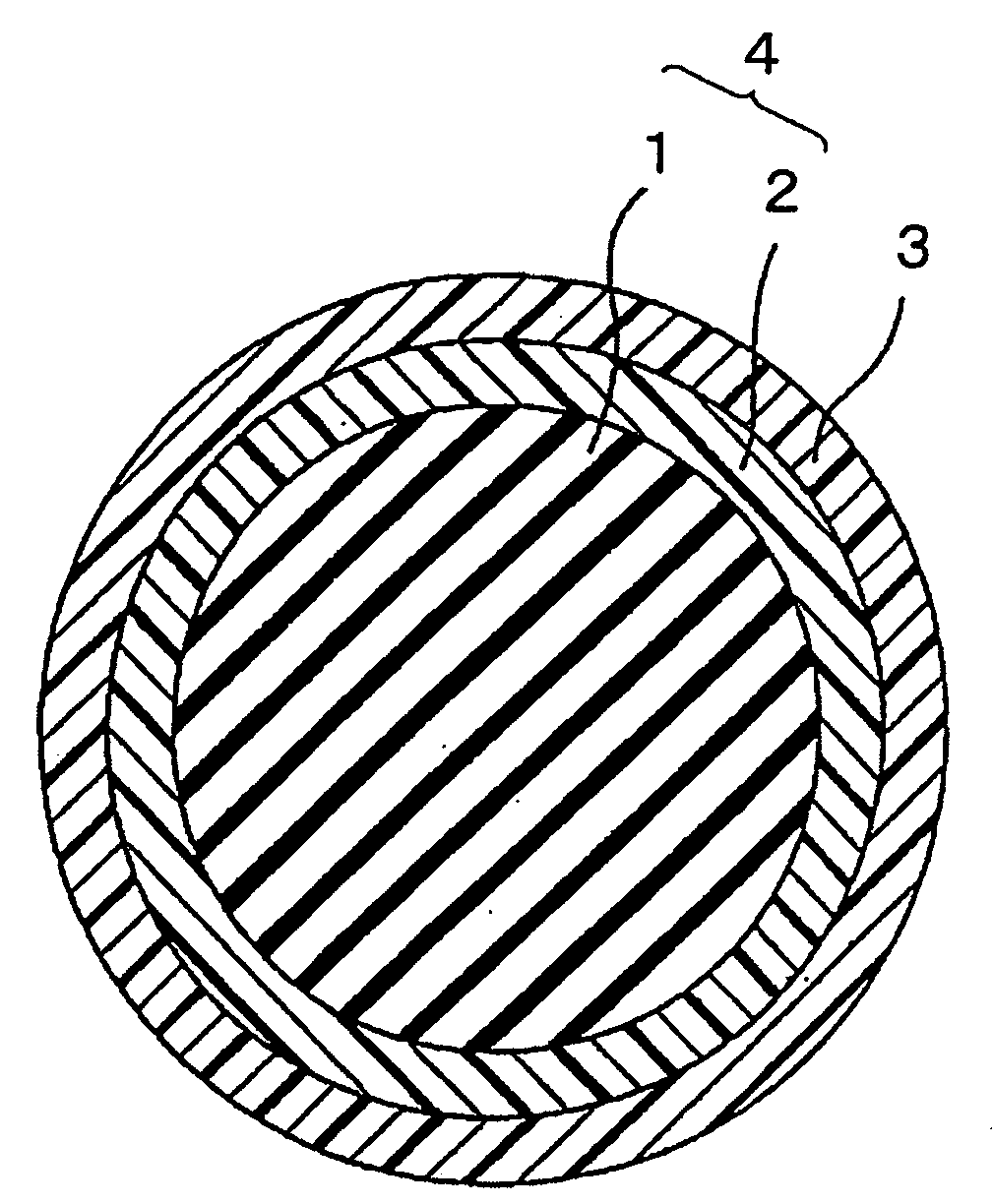

Multi-piece solid golf ball

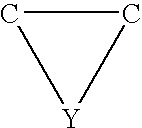

A multi-piece solid golf ball has a solid core obtained by molding and vulcanizing a rubber composition which includes (A) a base rubber containing a polybutadiene synthesized using a rare-earth catalyst, (B) an unsaturated carboxylic acid and / or a metal salt thereof, (C) an organic sulfur compound, (D) an inorganic filler and (E) an organic peroxide. The core is enclosed within a mantle of one or more layer which is made primarily of a thermoplastic resin and has a Durometer D hardness of 30 to 70. The mantle is enclosed within a cover which is made primarily of a thermoplastic polyurethane and which has a Durometer D hardness of 40 to 60 that is lower than the Durometer D hardness of the outermost layer of the mantle. This construction provides the golf ball with an outstanding rebound.

Owner:BRIDGESTONE SPORTS

Solid golf ball

ActiveUS20060128900A1Soft touchGood rebound characteristicsGolf ballsSolid ballsRare earthCarboxylic acid

The present invention provides a solid golf ball comprising a hot-molded product of a rubber composition comprising (a) 100 parts by weight of a polybutadiene synthesized using a rare-earth catalyst and having a cis-1,4 content of at least 60% and a 1,2 vinyl content of at most 2%, having a viscosity η at 25° C. as a 5 wt % solution in toluene of up to 600 mPa·s, and having Mooney viscosity (ML1+4 (100° C.)) of more than 30, (b) 0.01 to 0.5 parts by weight of a sulfur, (c) 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, (d) 0.1 to 5 parts by weight of an organosulfur compound, (e) 5 to 80 parts by weight of an inorganic filler, and (f) 0.1 to 5 parts by weight of an organic peroxide, wherein the hot-molded product has a difference in JIS-C hardness between the center and surface thereof of more than 20 and up to 40. The solid golf balls of the invention have a soft feel upon impact and excellent rebound characteristics. Moreover, the solid golf balls are improved in flight performance by making its spin rate reduced when shot with a driver.

Owner:BRIDGESTONE SPORTS

High-hardness high-rebound polyurethane elastomer material and application thereof

InactiveCN101633717AImprove mechanical propertiesImprove wear resistancePolyurethane elastomerAlcohol

The invention discloses a high-hardness high-rebound polyurethane elastomer material and introduces an application thereof. The material is obtained by mixing an isocyanate component and a polyhydric alcohol component at the temperature of 25-40 DEG C according to the weight ratio of 100:(50-100), pouring into a mould of 40-60 DEG C and vulcanizing for 30-60min. The hardness is 86-93A, the rebound rate is greater than 70%, the abrasion is smaller than 20mg, the tensile strength is greater than 25MPa, and the tearing strength is greater than 100kN / m. The isocyanate component is a performed polymer with the content of 6-18% of isocyanic acid radicals, and the performed polymer is generated in such a way that 20-60% of PTMG with the molecular weight smaller than or equal to 1,000 and 40-80% of doped PTMG with the molecular weight greater than 1,000 react with isocyanate or a derivative thereof; the polyhydric alcohol component comprises 69.2-89.4% of PTMG with the average molecular weight greater than 1000, 10-30% of fatty group dihydric alcohol, 0.2-0.3% of catalyst and 0.4-0.5% of antiaging agent. The polyurethane elastomer material can be used for preparing butterfly boards, active boards, pulleys used for rapid slide, pulleys of ice skates, pulleys of sliding boards and various castors.

Owner:LIMING RES INST OF CHEM IND

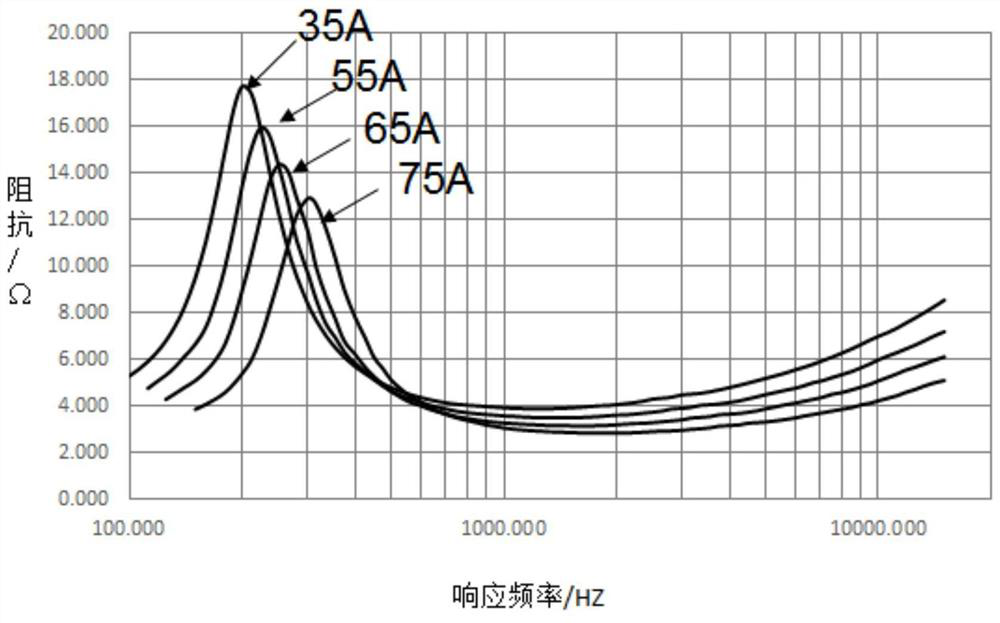

Vibrating diaphragm of sound generating device and sound generating device

PendingCN110804154AProper damping characteristicsReduce noisePolymeric diaphragmsSynthetic resin layered productsPolymer sciencePolyol

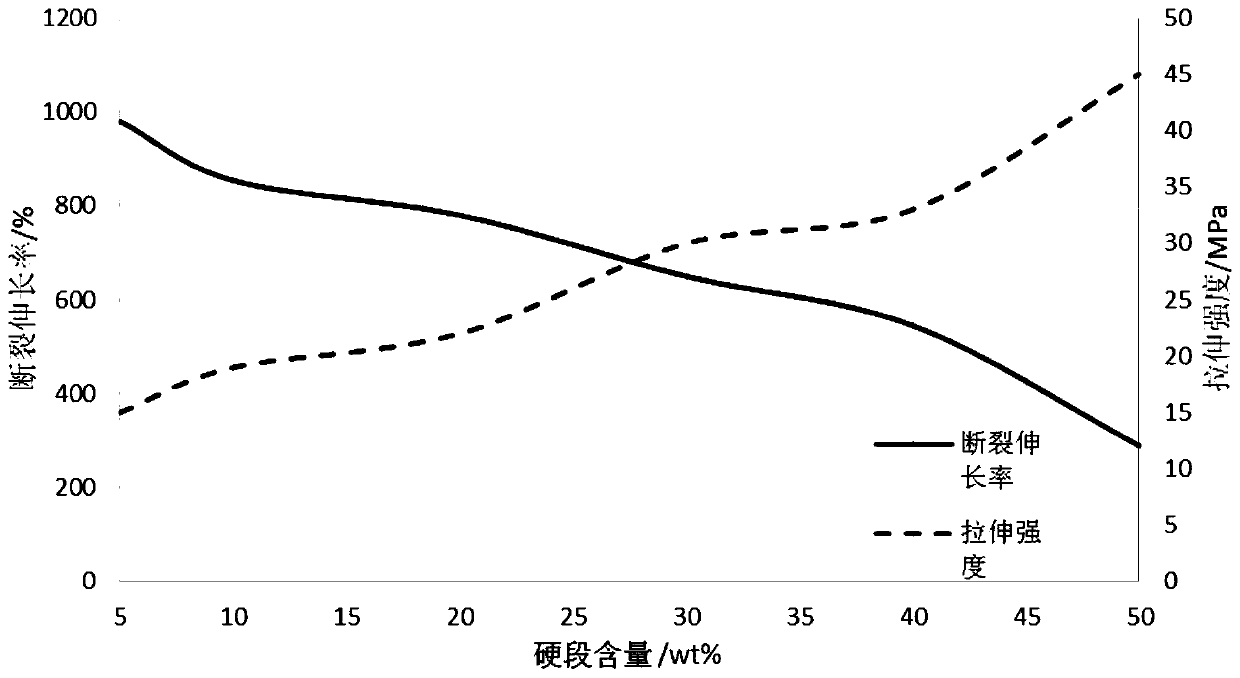

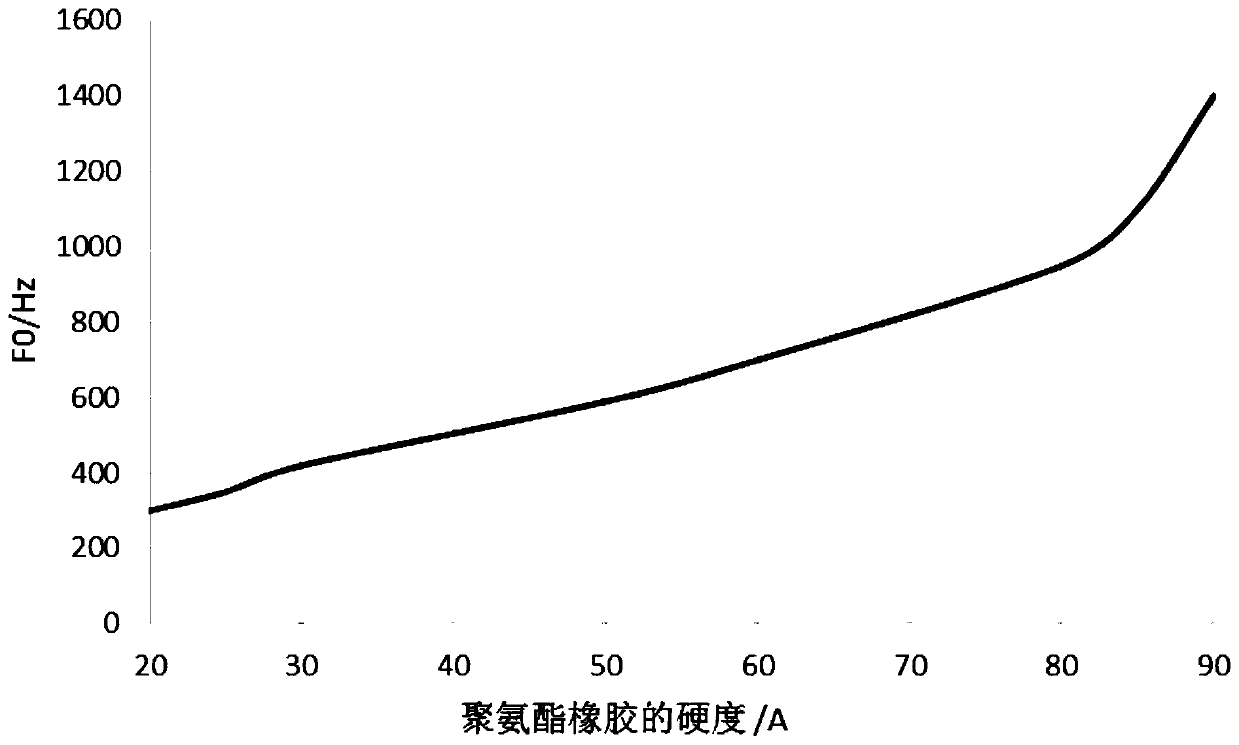

The invention discloses a vibrating diaphragm of a sound generating device and the sound generating device. The vibrating diaphragm includes a polyurethane rubber film layer, and polyurethane rubber includes a block polymer formed by alternately arranging soft segment parts and hard segment parts, wherein the soft segment parts include a polyol and the hard segment parts include isocyanate and a chain extender; and the polyurethane rubber is represented by a structural formula shown in the specification, wherein R is the chain extender, R1 is the polyol, and n is a natural number.

Owner:GOERTEK INC

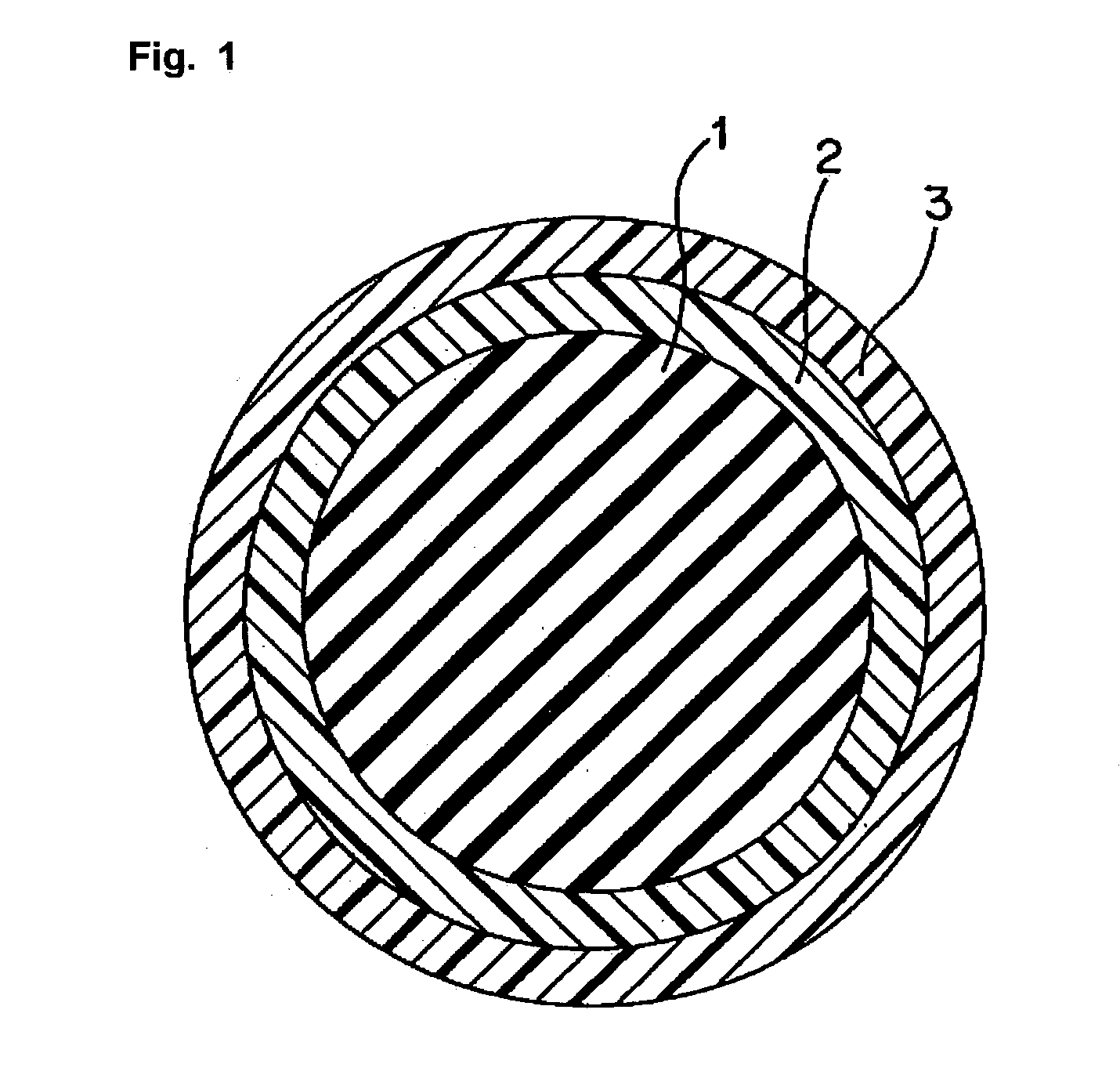

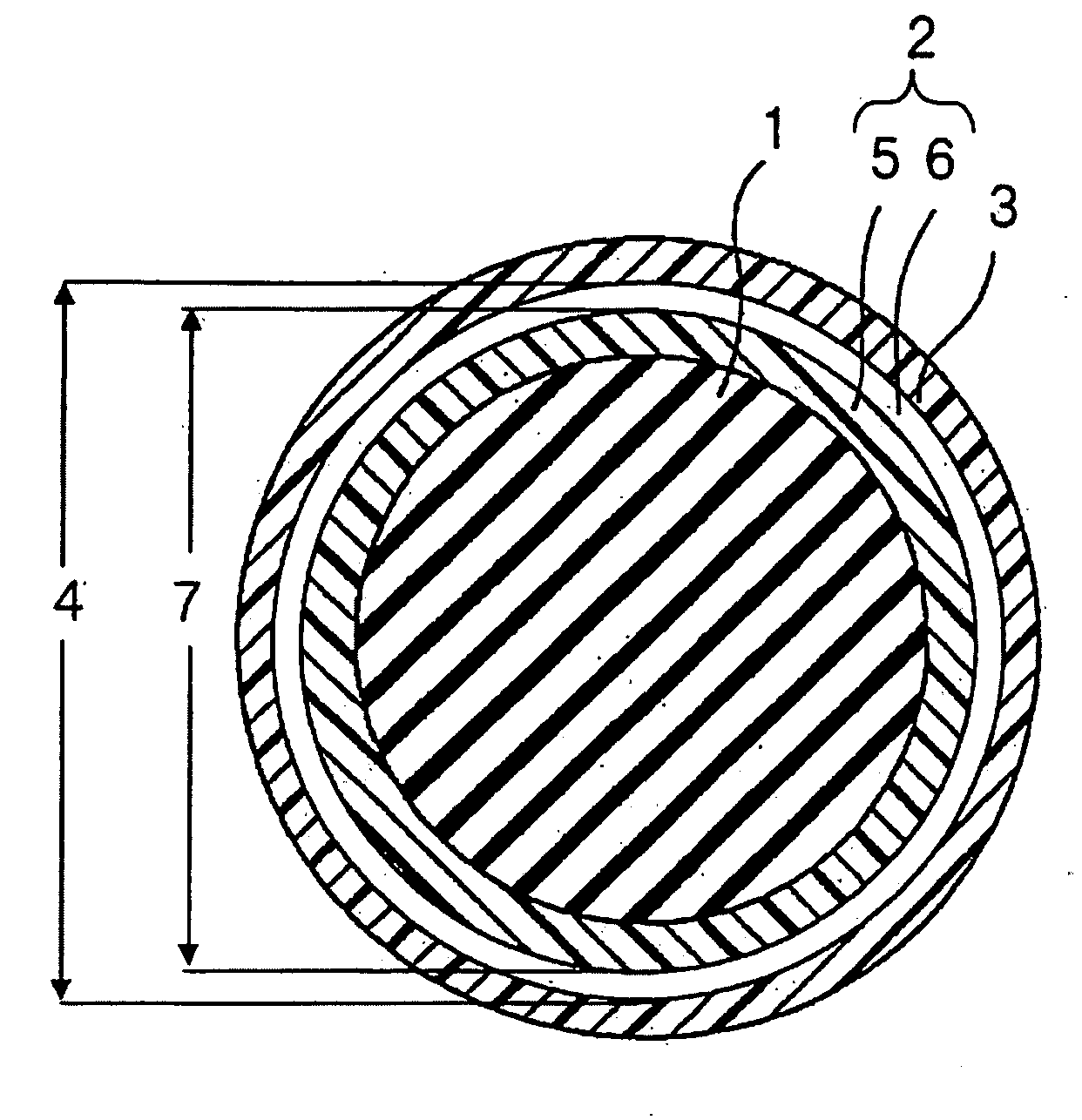

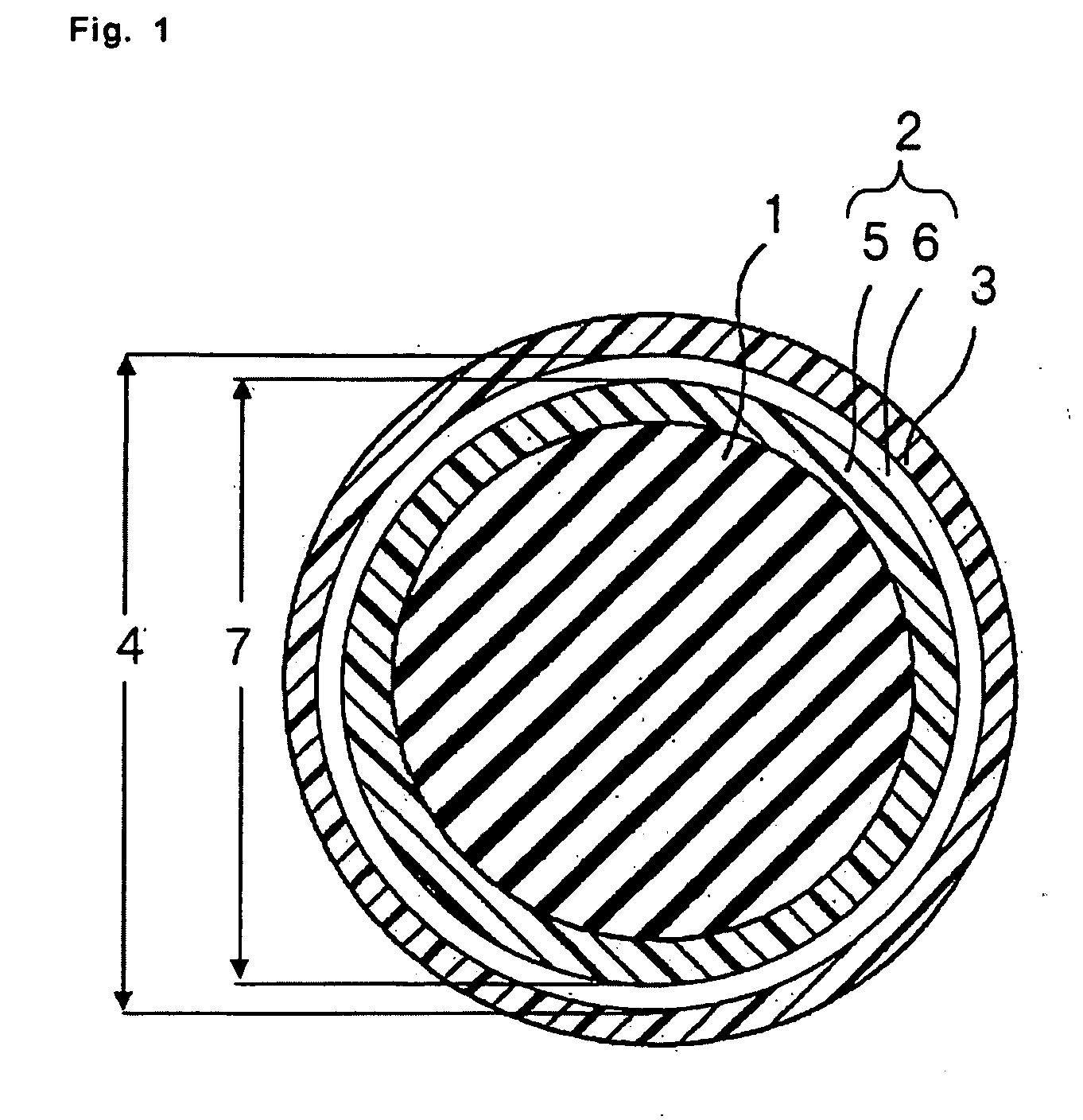

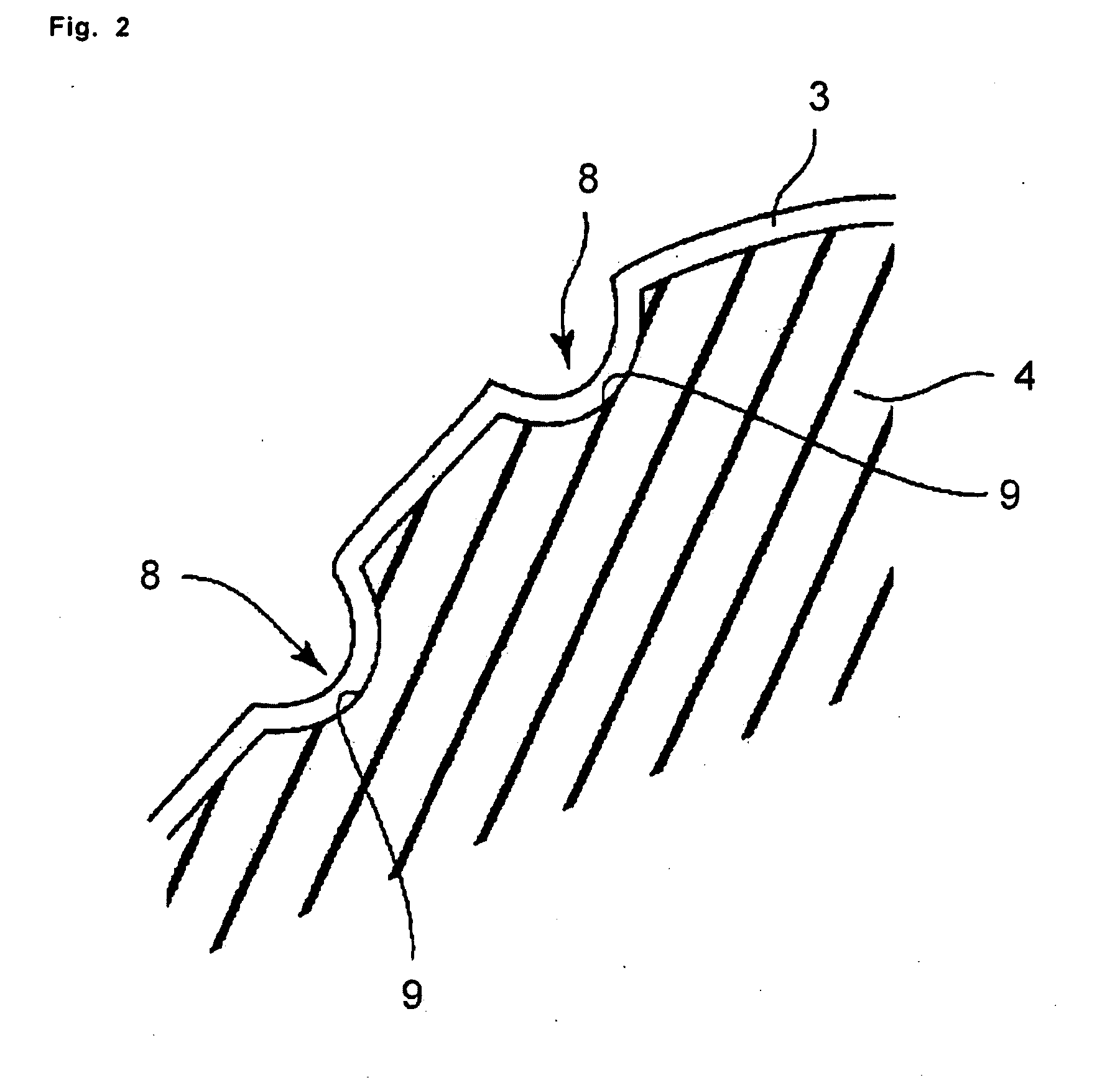

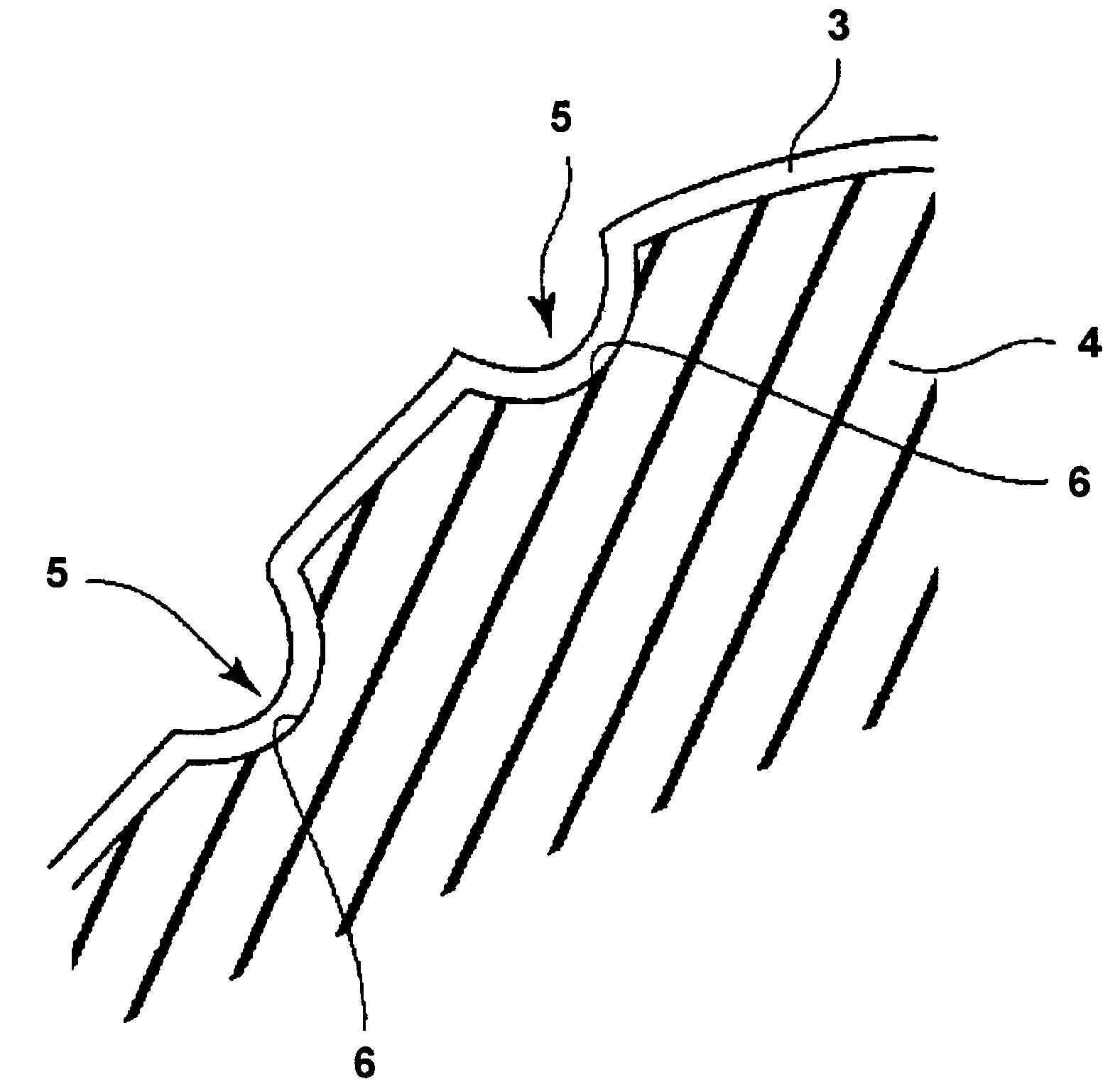

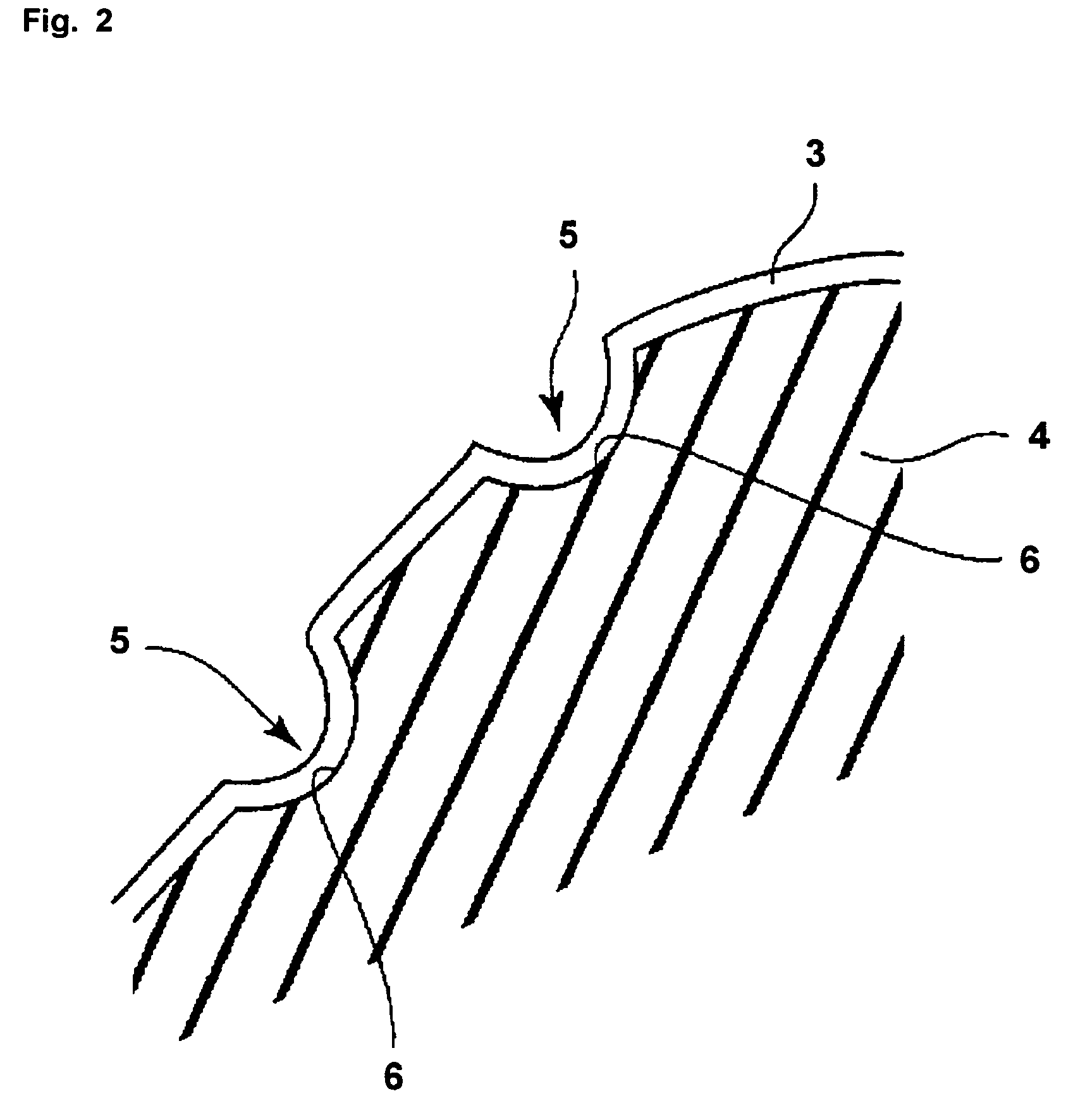

Thread wound golf ball

The present invention provides a thread wound golf ball having excellent rebound characteristics. The present invention relates to a thread wound golf ball comprising a solid center, a thread rubber layer formed on the solid center, and at least one layer of a cover covering the thread rubber layer, wherein the solid center comprises at least one rubber layer, the rubber layer is formed from a rubber composition comprising a polybutadiene mixture, a metal salt of an unsaturated carboxylic acid, an organic peroxide and an inorganic filler, and the polybutadiene mixture includes (a) a polybutadiene containing a cis-l,4 bond of not less than 80% and having a Mooney viscosity of 50 to 100 ML1+4(100° C.), synthesized using nickel-containing catalyst, and (b) a polybutadiene containing a cis-1,4 bond of not less than 40% and having a Mooney viscosity of 20 to 90 ML1+4(100° C.), synthesized using lanthanide-containing catalyst, a weight ratio (a) / (b) being 30 / 70 to 90 / 10.

Owner:DUNLOP SPORTS CO LTD

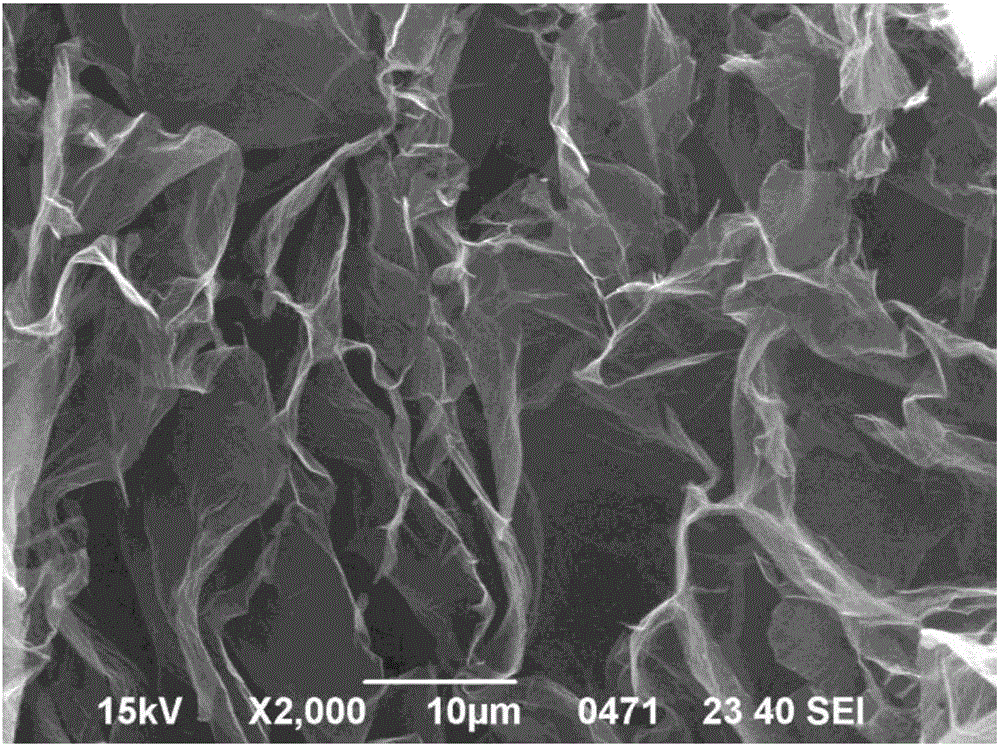

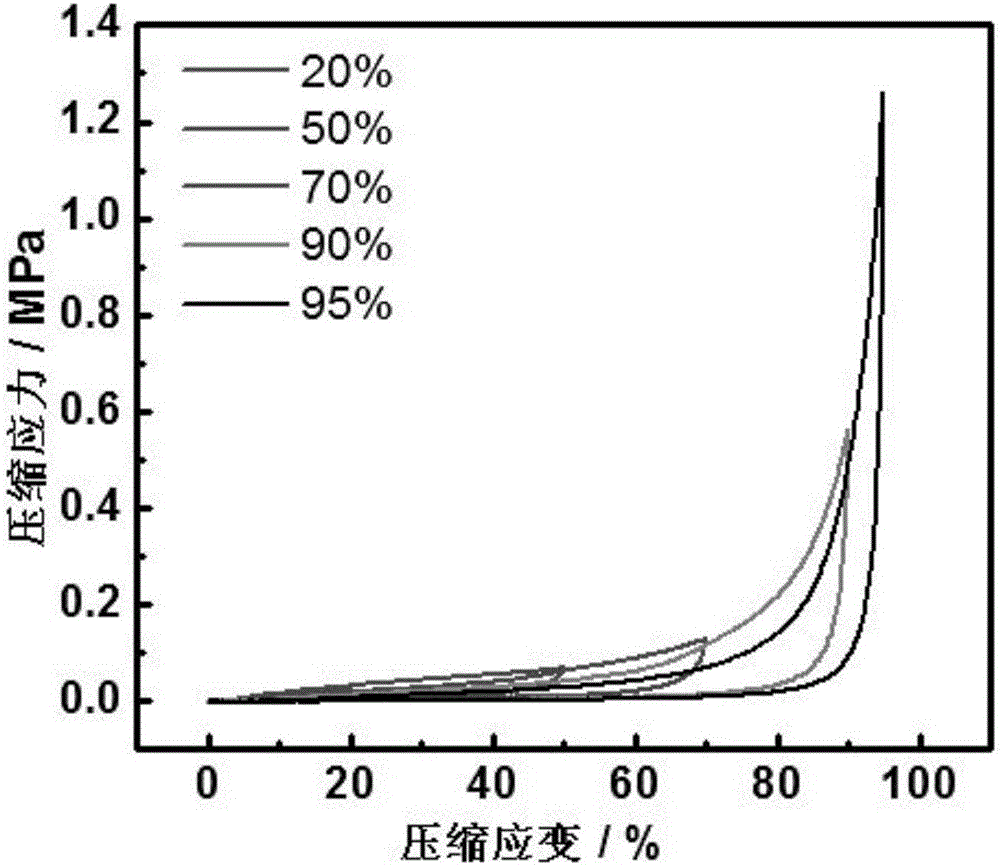

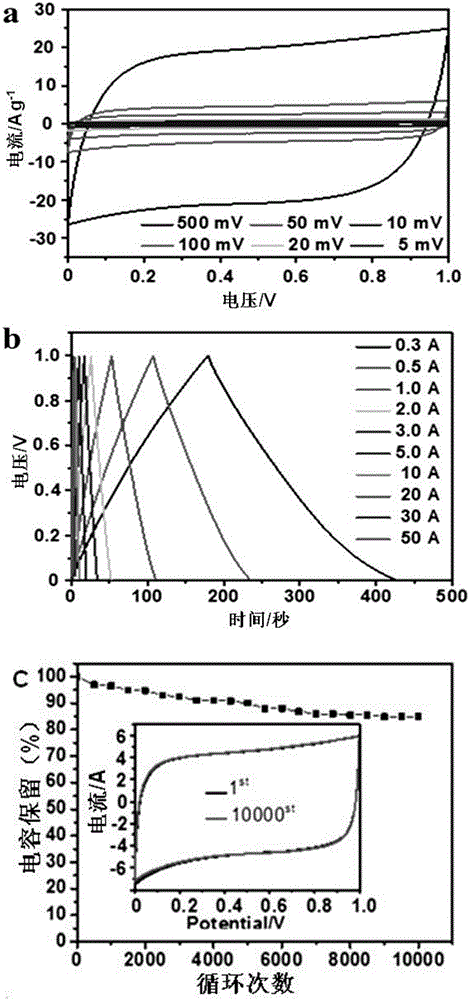

Preparation method of super-elasticity graphene aerogel

ActiveCN106809822AImprove electrochemical performanceReduce manufacturing costGrapheneFreeze-dryingElectrochemistry

The invention belongs to the technical field of aerogel preparation and relates to a preparation method of super-elasticity graphene aerogel. The preparation method includes: adding a proper amount of reducing agent into oxidized graphene dispersion, using a polymer foam block to adsorb the oxidized graphene dispersion, and performing oil path heating on the foam block to reduce oxidized graphene; drying a sample through freeze-drying; removing polymer foam through high-temperature thermal treatment to obtain graphene aerogel. Shape of final graphene aerogel is regulated by designing shape of the polymer foam, but the shape of the graphene aerogel is regulated by changing shape of containers in other preparation processes of graphene aerogel, so that preparation cost of the graphene aerogel is lowered greatly, and the graphene aerogel in complex shape can be prepared. The preparation method is simple in preparation process, ingenious in design concept, easy-to-get in raw material for preparation and high inpreparation efficiency, and the graphene aerogel prepared by the method is excellent in electrochemical performance, friendly to application environment and wide in market prospect.

Owner:戴天元

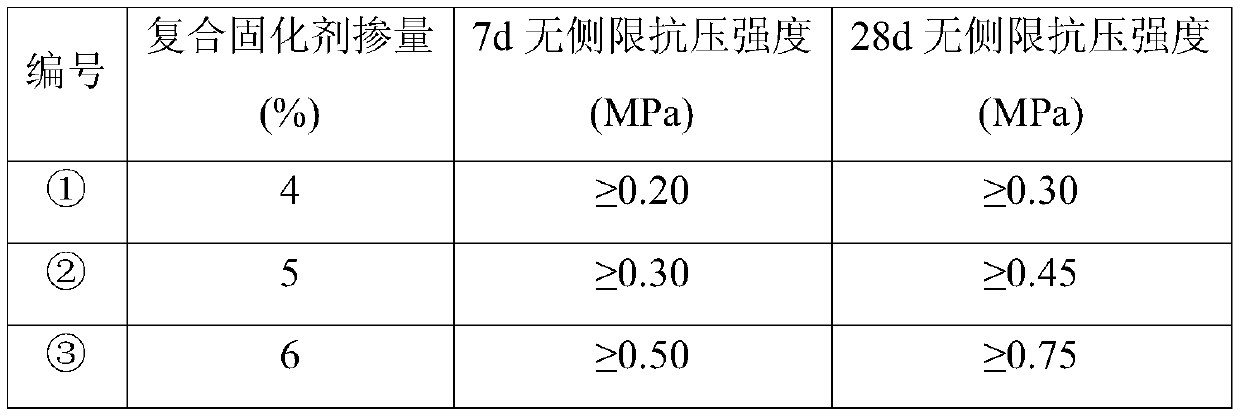

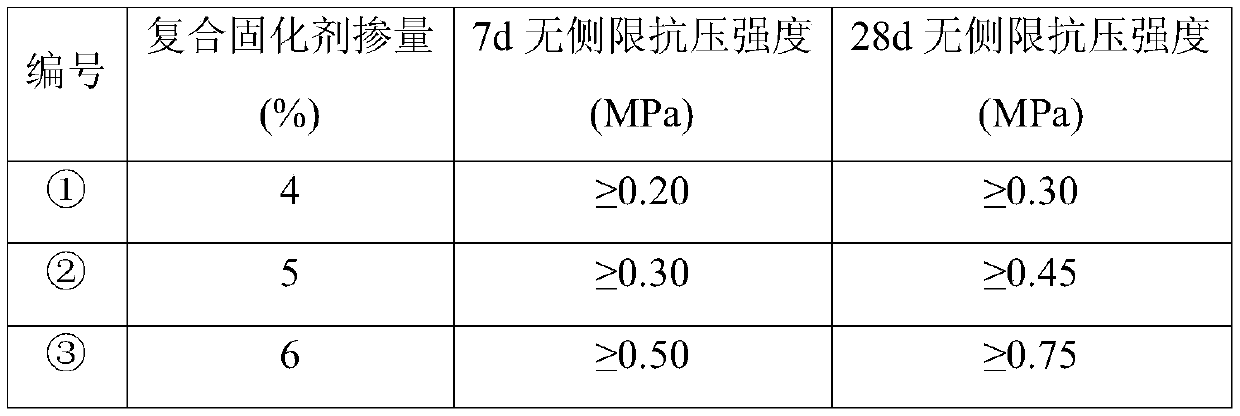

A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method using same

A dredged sludge industrial waste residue composite solidified light soil and a roadbed layered filling construction method thereof are provided; the method is characterized by comprising the following steps: (1), solidified light soil raw materials are selected, specifically, dehydrated dredged sludge, waste tire rubber powder and an industrial waste residue composite solidifying agent are selected; (2) solidified light soil mixing proportion design refers to the mass ratio of the dehydrated dredged sludge to the waste tire rubber powder to the industrial waste residue composite solidifying agent to the water, wherein the mixing ratio (volume ratio) of the dehydrated dredged sludge to the waste tire rubber powder is 80: 20-60: 40, and the mixing amount of the composite solidifying agent is 4-6%; and (3), roadbed layered filling construction: the solidified light soil roadbed construction comprises construction preparation, mixing, paving, rolling compaction, quality inspection, maintenance and slope protection. The method effectively solves the problem of recycling production and domestic solid waste, reduces the consumption of natural earthwork, and has the effects of saving resources, protecting the environment and the like.

Owner:ZHEJIANG UNIV OF TECH

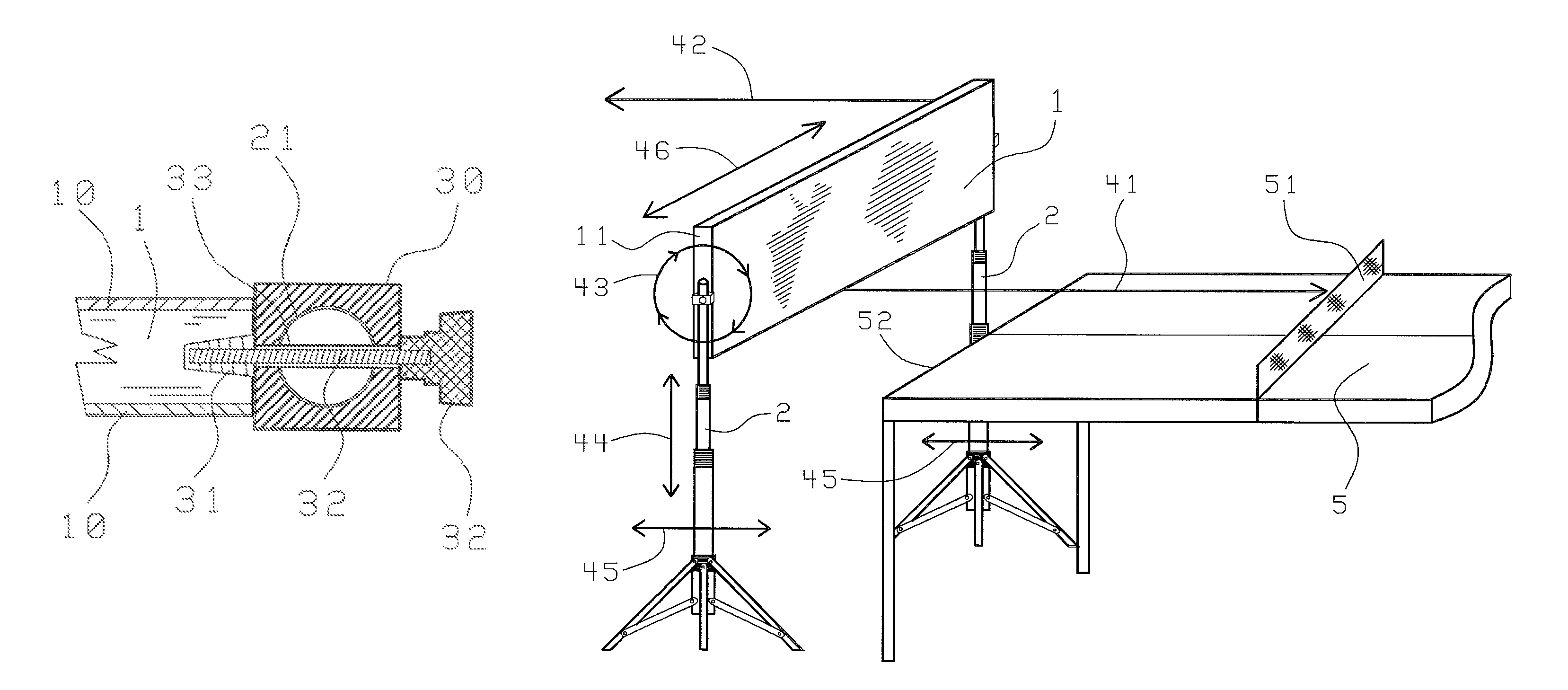

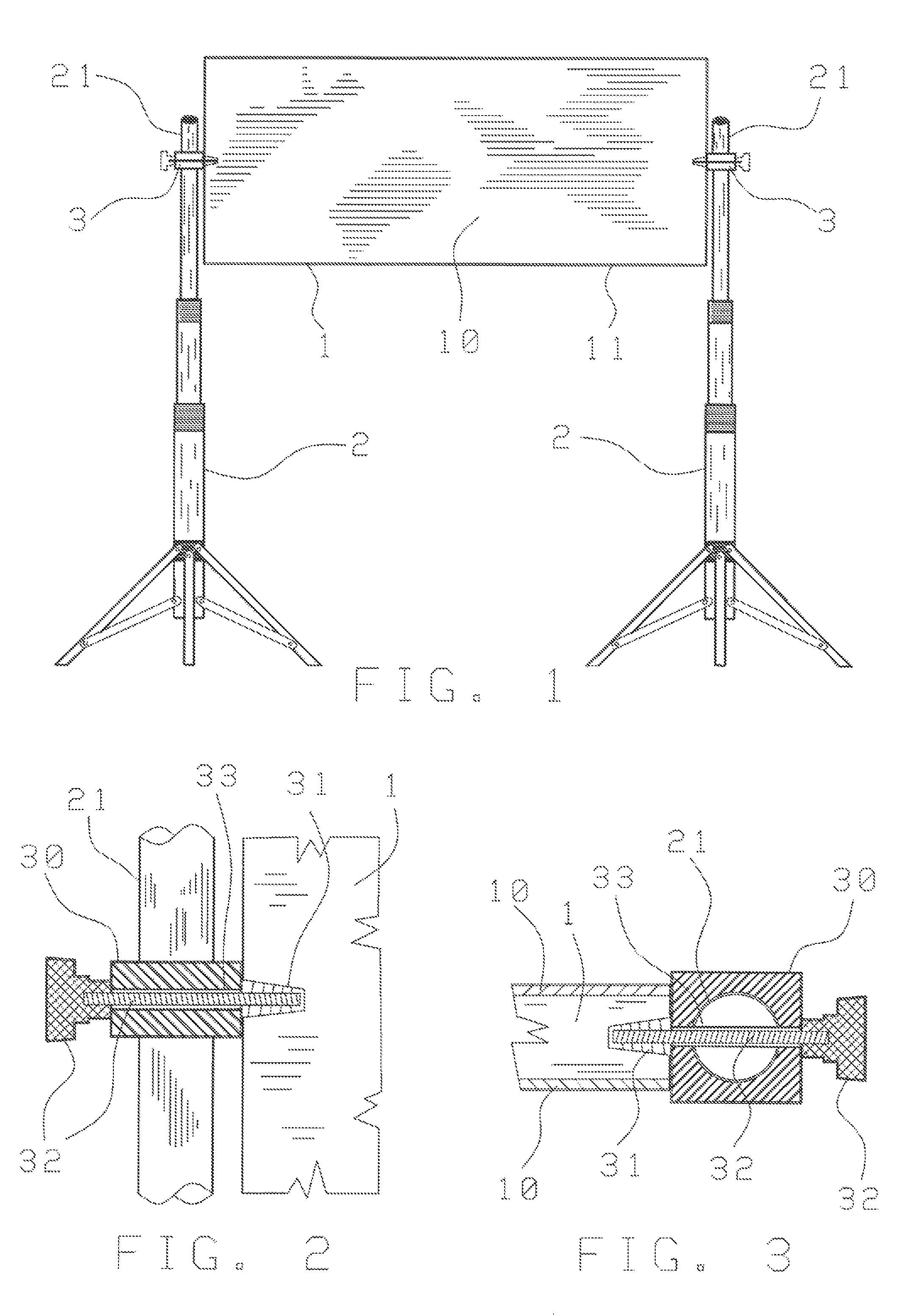

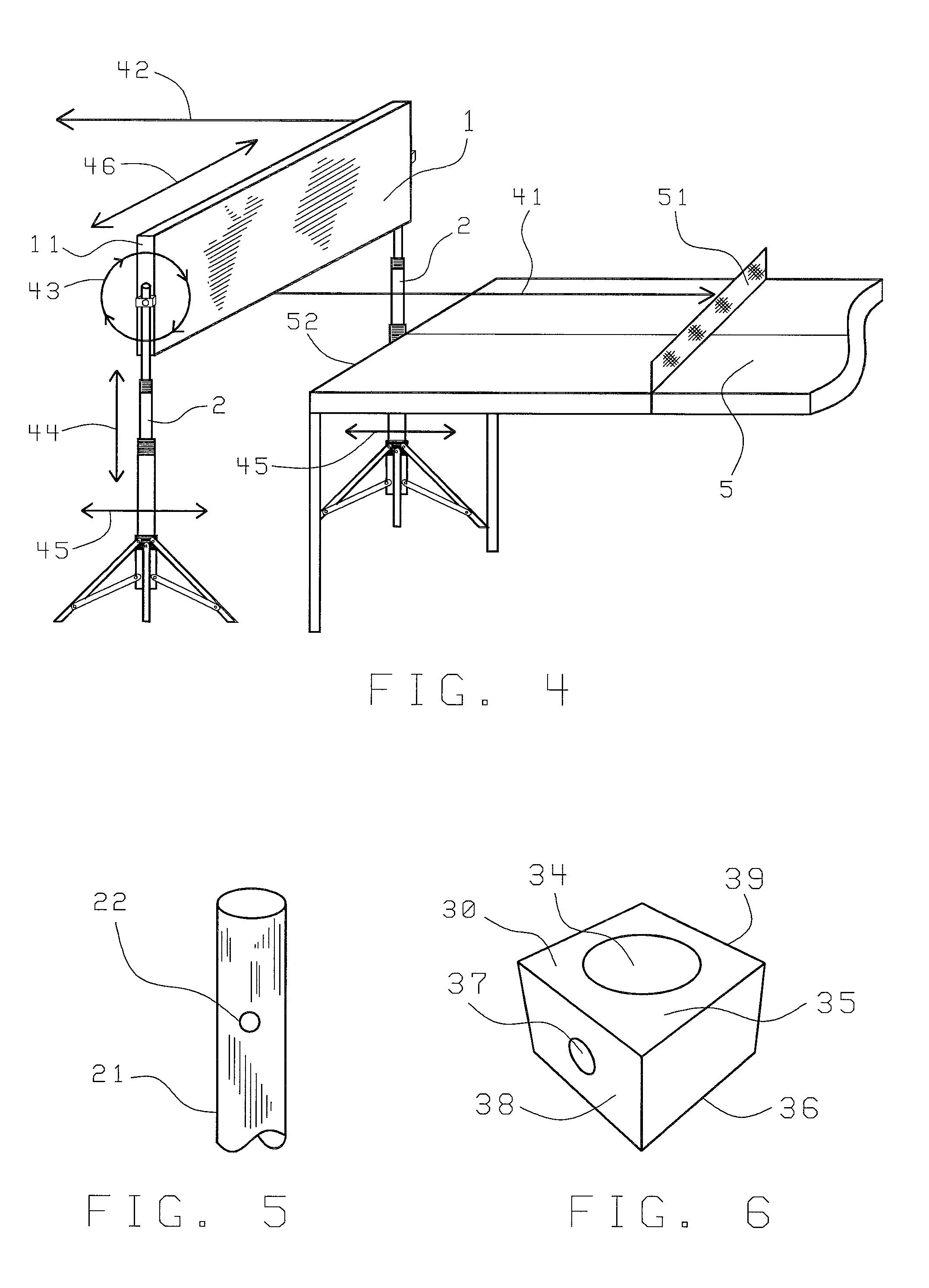

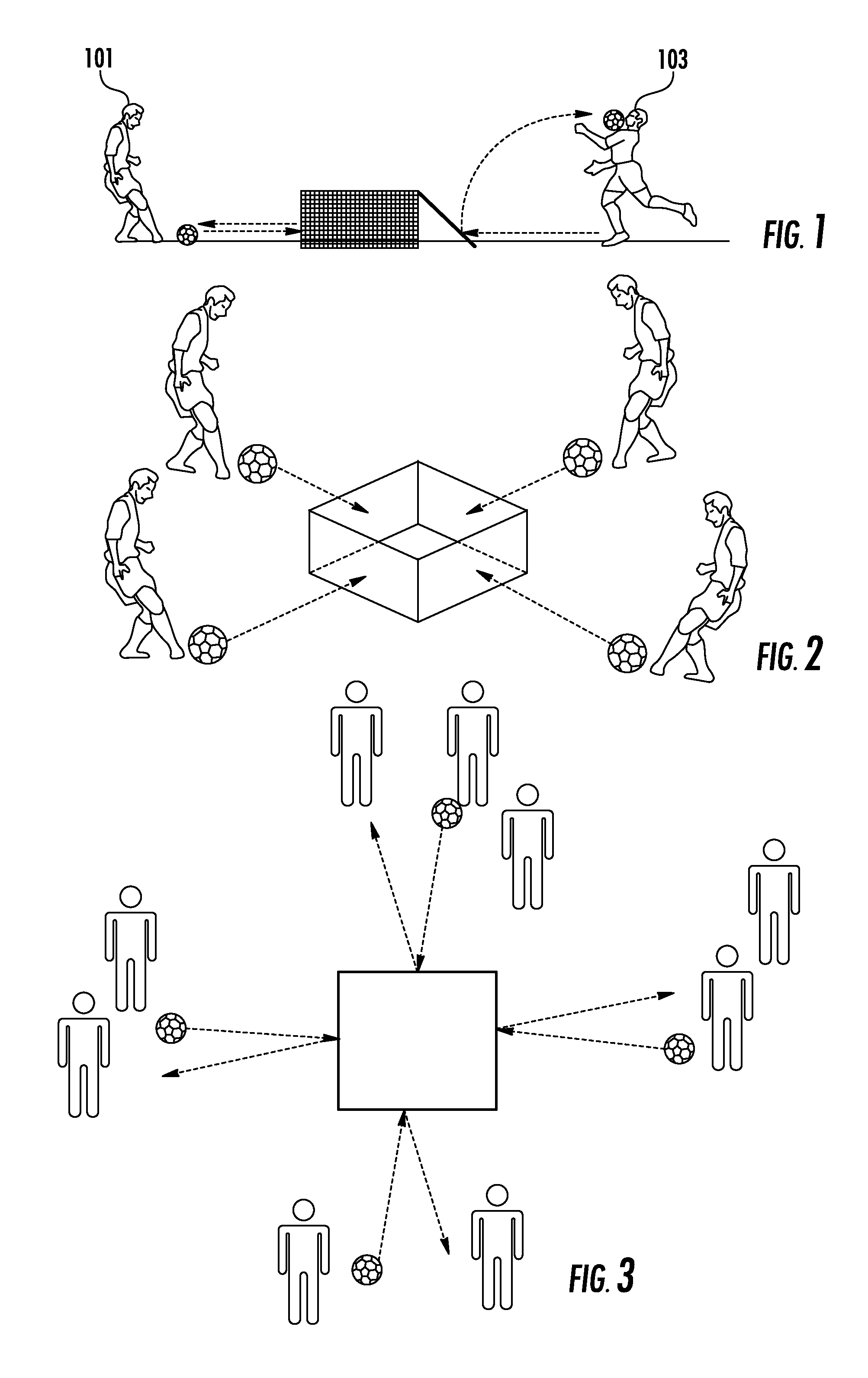

Free-standing table tennis rebound system

InactiveUS8079922B1Easy dismountingReadily and inexpensivelyBall sportsSpace saving gamesEngineeringShaft collar

A free-standing rebound system for use with a table tennis table wherein the system comprises: paired multi-legged telescoping support stands with an uppermost shaft having an uppermost portion with a hole therein; a mounting assembly including a shaft collar, screw spacer dowel pin and a thumbscrew; and a rectangular, framed rebound board having two rebounding surfaces which may be coated in natural and / or synthetic rubber blends and paired wood insert nuts oppositely arranged at the midpoint on two shorter sides. The apparatus is adjustable to orient the rebound board above the table tennis table at any distance from the net, at any latitudinal angle, or behind the back edge of the table opposite the player at any distance, height or angle as required by the abilities and training goals of the player.

Owner:WALLYTEC

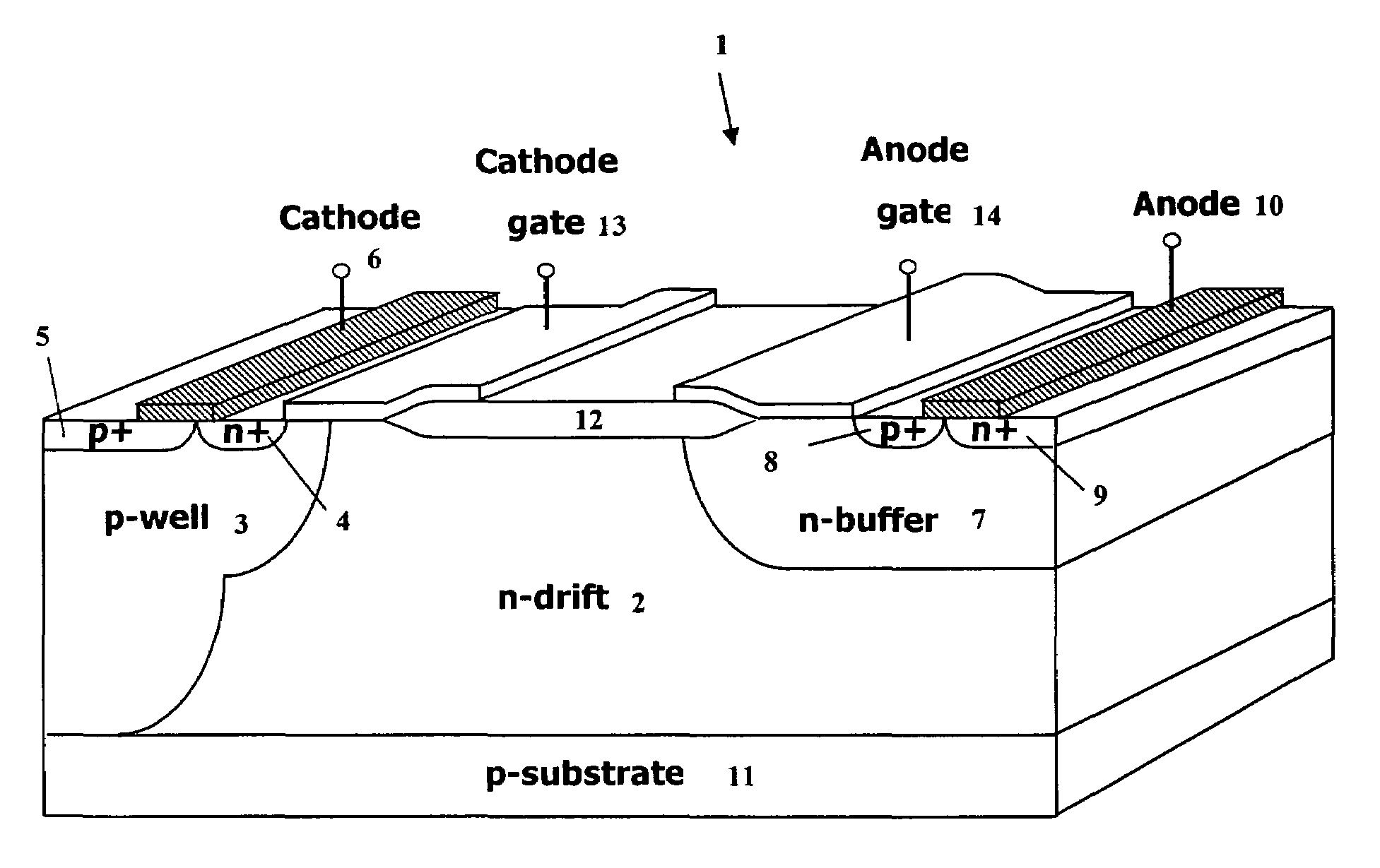

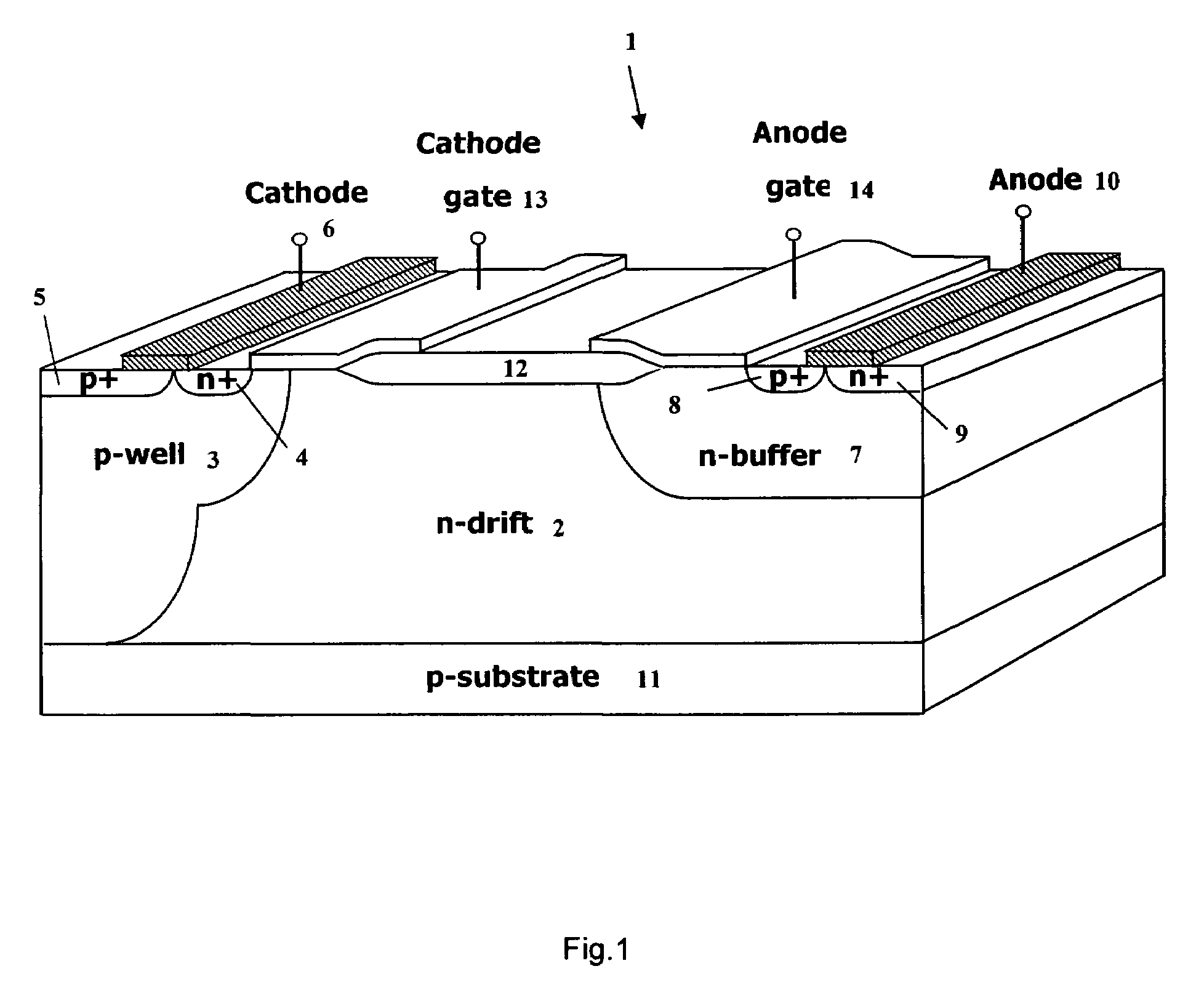

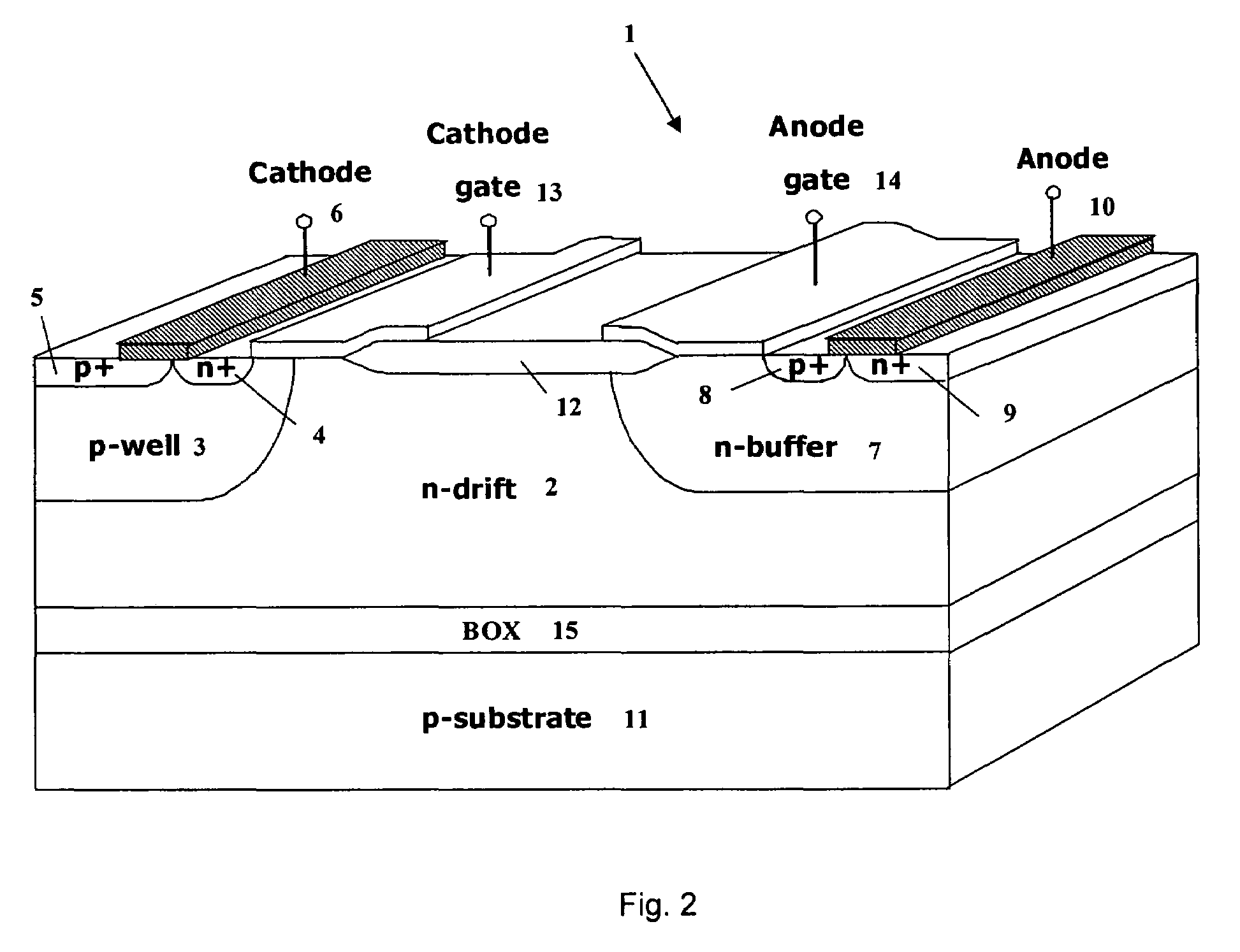

Bipolar high voltage/power semiconductor device having first and second insulated gated and method of operation

InactiveUS7605446B2Excessive chargingHigh speedTransistorSemiconductor/solid-state device detailsPower semiconductor deviceLow voltage

A bipolar high voltage / power semiconductor device has a drift region having adjacent its ends regions of different conductivity types respectively. High and low voltage terminals are provided. A first insulated gate terminal and a second insulated gate terminal are also provided. One or more drive circuits provide appropriate voltages to the first and second insulated gate terminals so as to allow current conduction in a first direction or in a second direction that is opposite the first direction.

Owner:POWER INTEGRATIONS INC

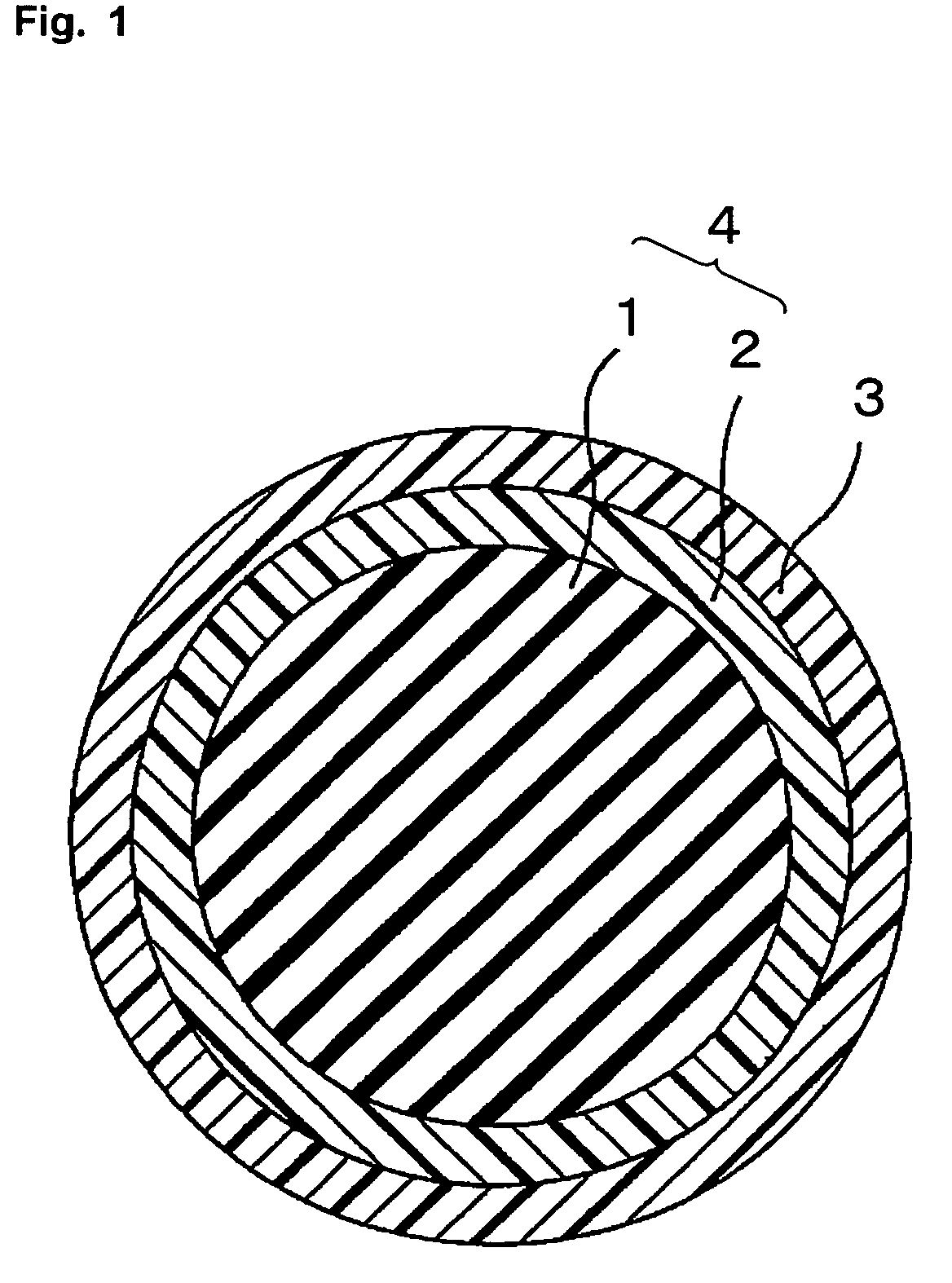

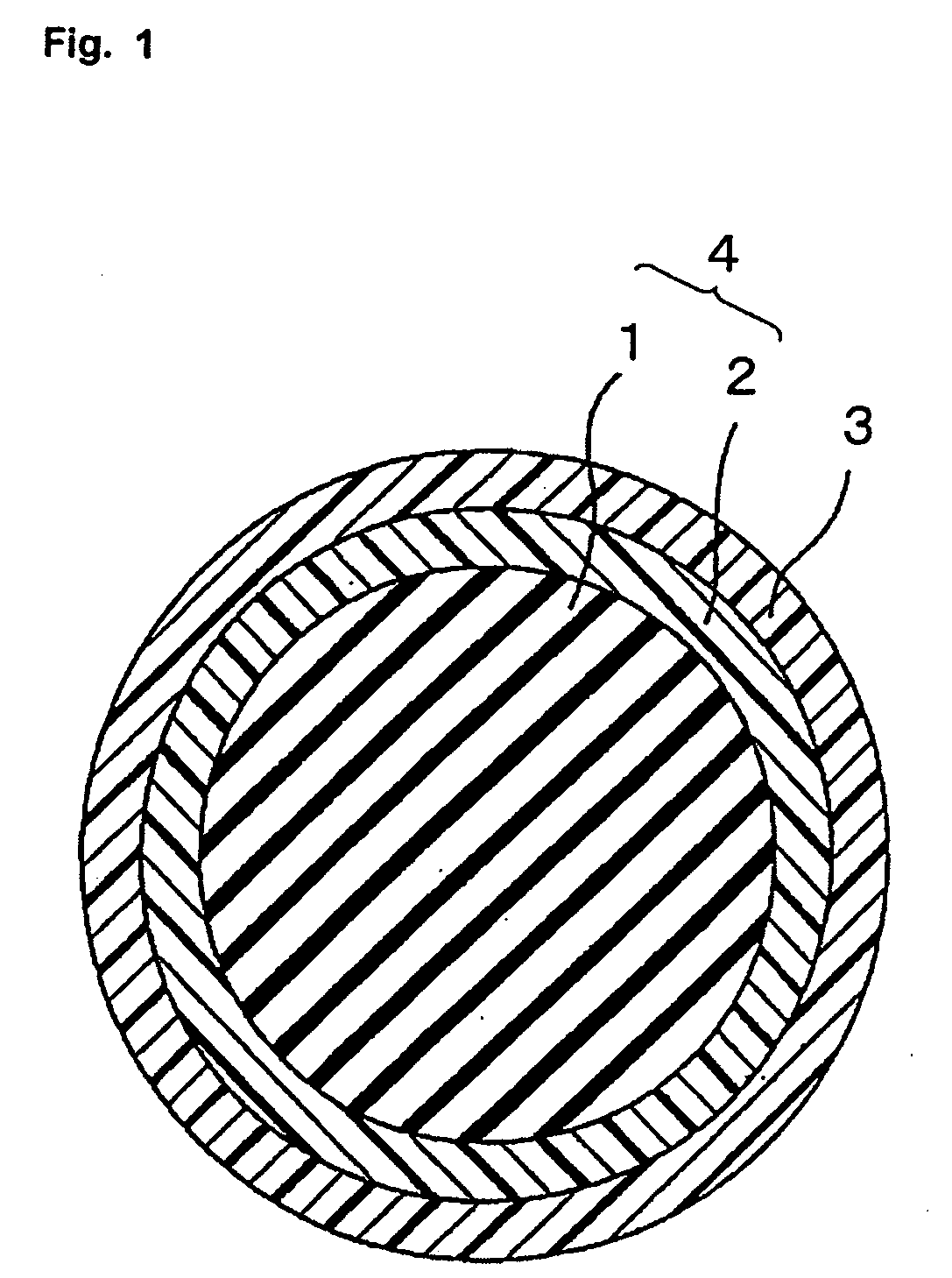

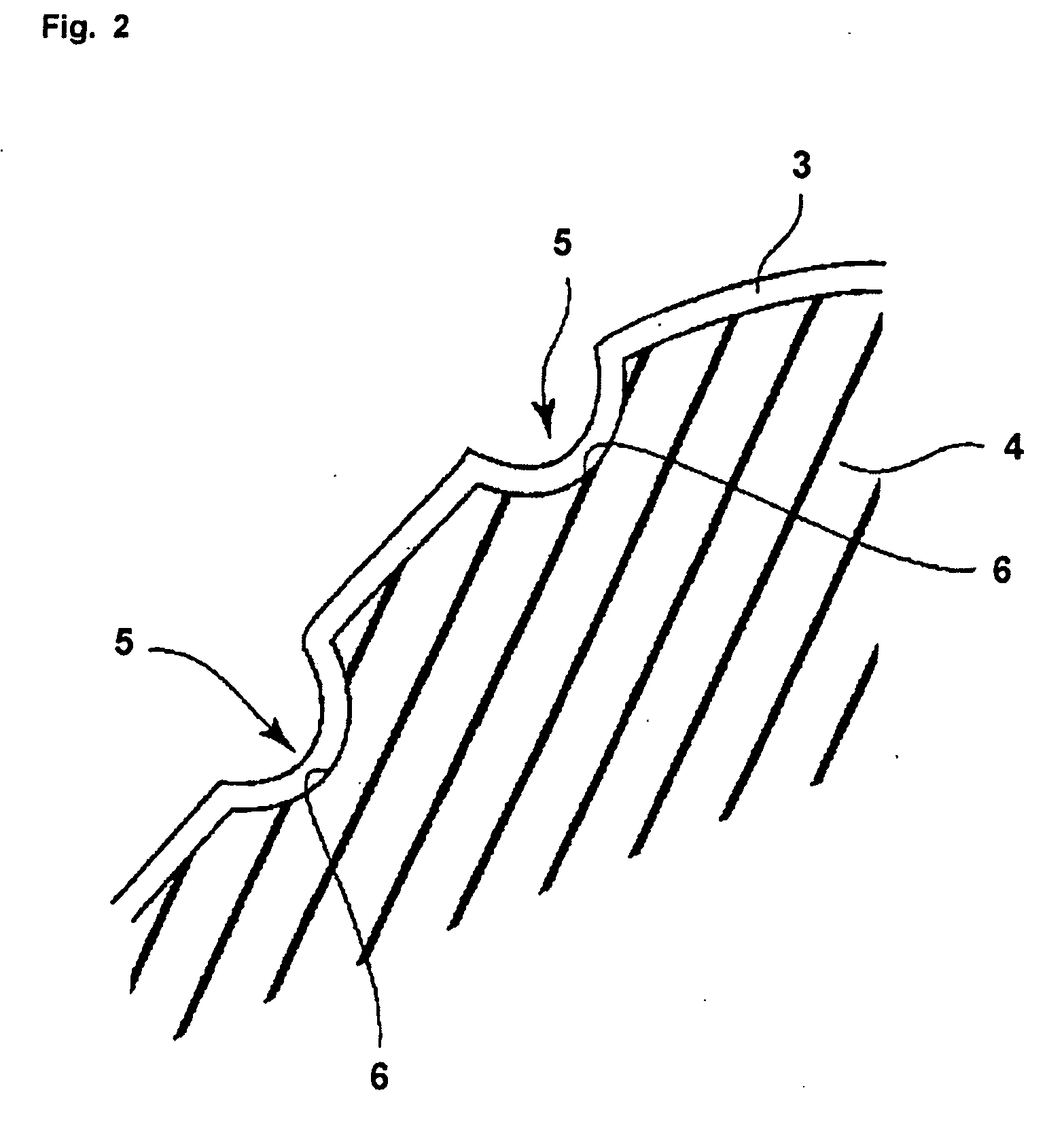

Golf ball

InactiveUS20060025242A1Improve featuresIncreased durabilityGolf ballsSolid ballsEngineeringGolf Ball

The present invention provides a golf ball having excellent rebound characteristics and flight performance, while maintaining good durability and appearance. The present invention relates to a golf ball comprising a center, an intermediate layer and a cover, the intermediate layer comprises an outermost layer and a second layer adjacent to the underside of the outermost layer, and the cover has many dimples on the surface thereof, wherein the second layer is formed from thermoplastic resin and has a thickness of 0.5 to 2.0 mm, the outermost layer is formed from thermosetting or thermoplastic resin and has a thickness of 1 to 100 μm, the intermediate layer has depressions on the surface thereof at the position and shape corresponding to the dimples through the cover, and the cover is formed from thermoplastic resin and has a thickness of 0.1 to 0.8 mm in land portion having no dimple.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

InactiveUS7067572B2Efficient preparationGood rebound characteristicsFibre treatmentOrganic dyesPolymer sciencePtru catalyst

A golf ball is manufactured by molding and vulcanizing a rubber composition comprising 100 pbw of a base rubber composed primarily of a polybutadiene having a cis-1,4 content of at least 60 wt % and a Mooney viscosity of at least 30 and synthesized using a rare-earth catalyst, 15–50 pbw of an unsaturated carboxylic acid and / or a metal salt thereof, at least 2 pbw of a processing aid having a highest melting point of up to 115° C., and 1–5 pbw of an organic peroxide. The golf ball can be efficiently manufactured and has excellent rebound characteristics.

Owner:BRIDGESTONE SPORTS

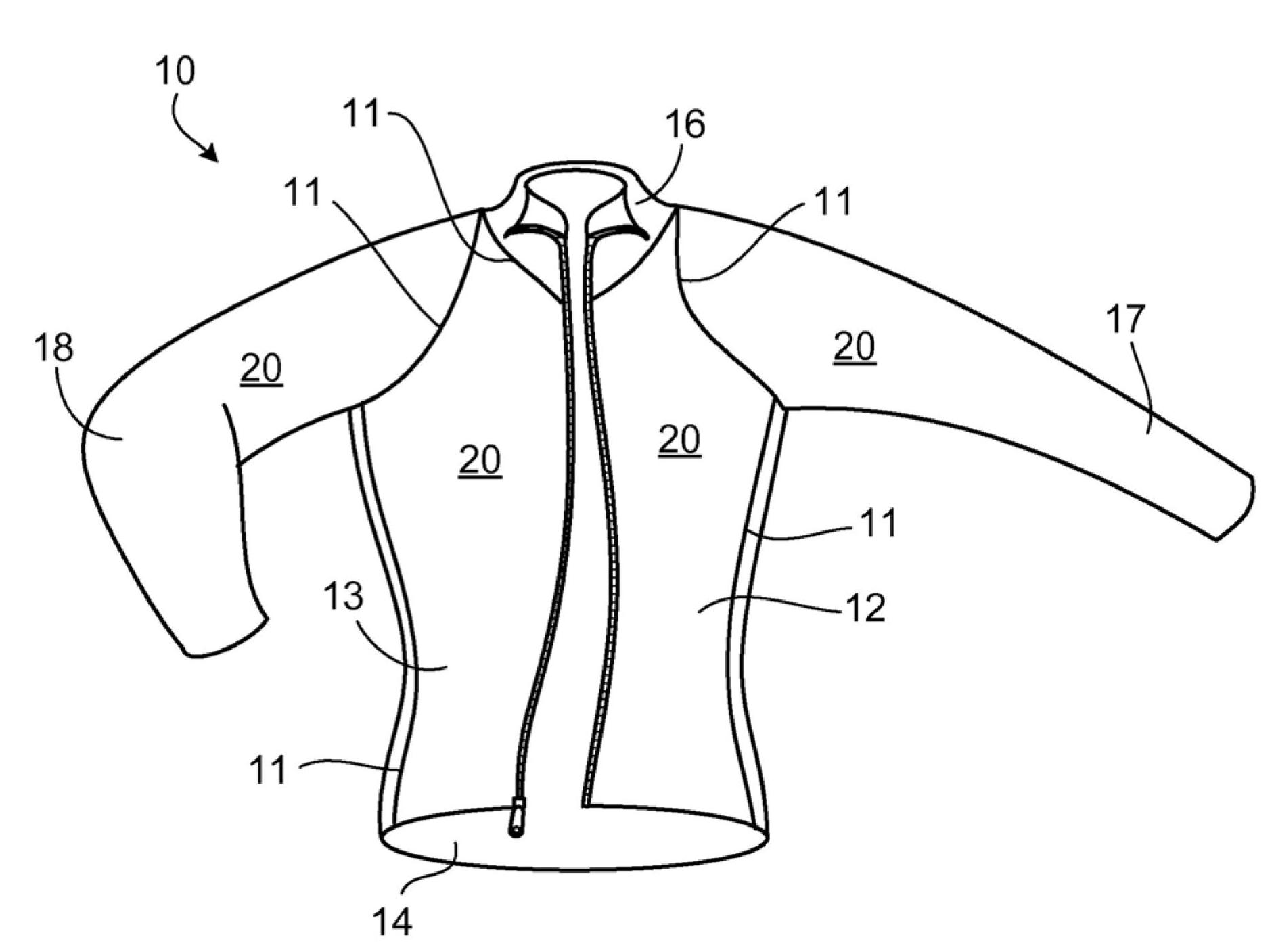

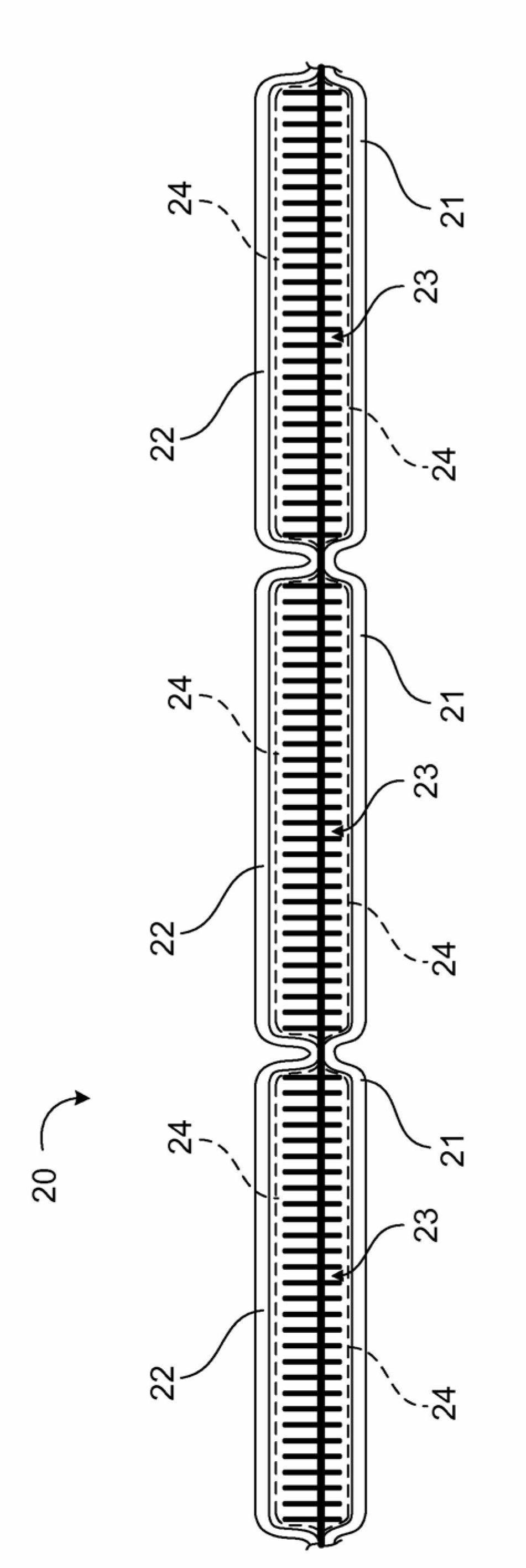

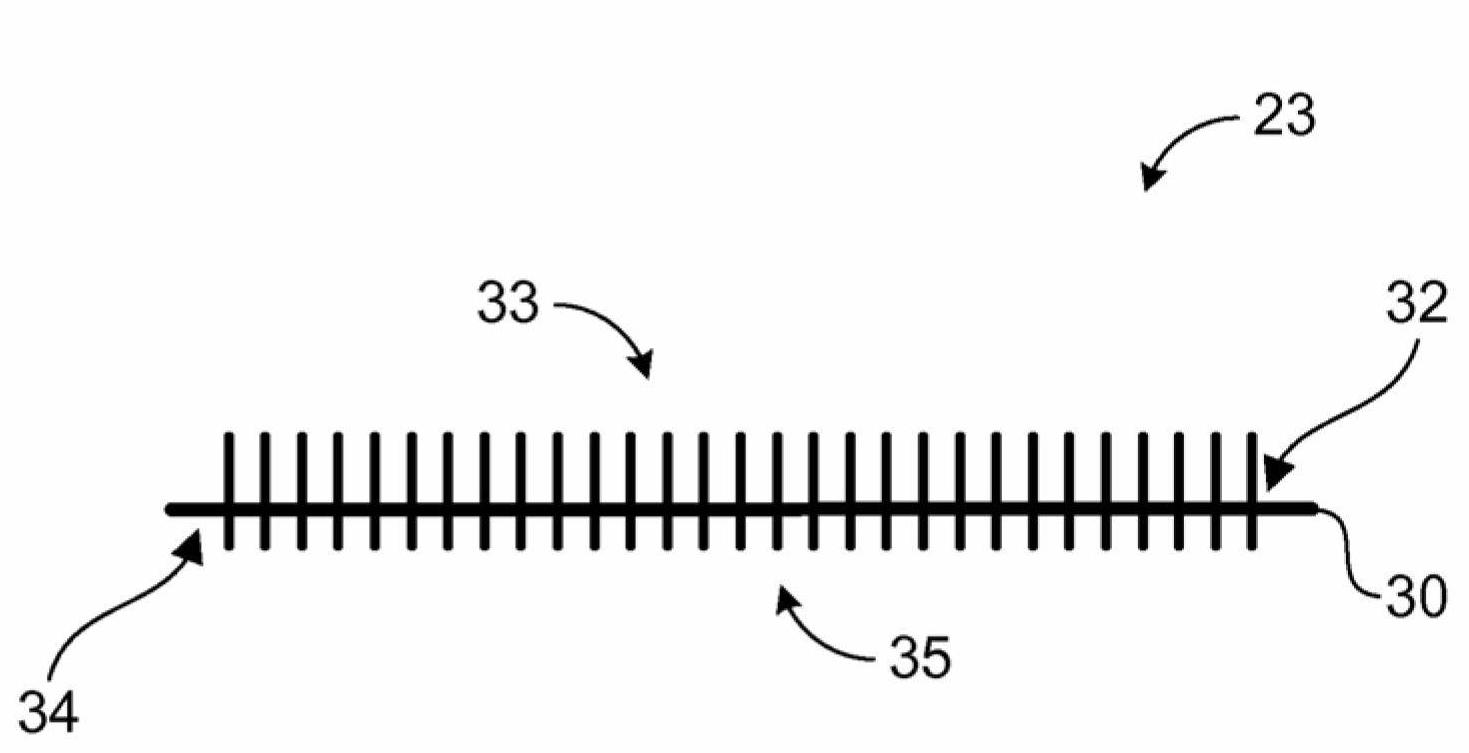

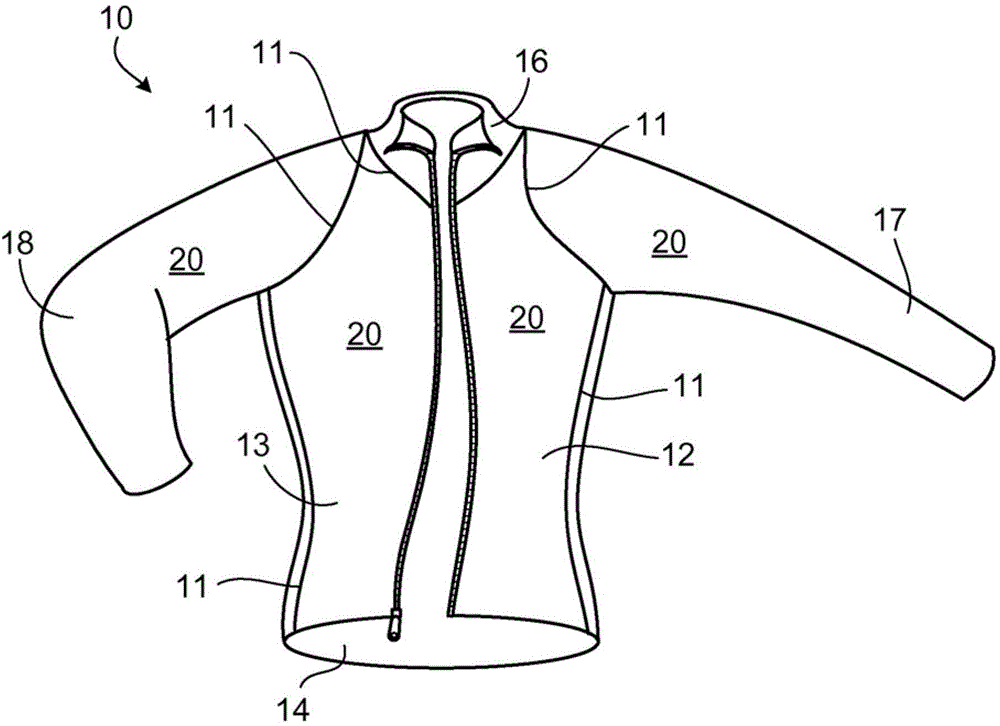

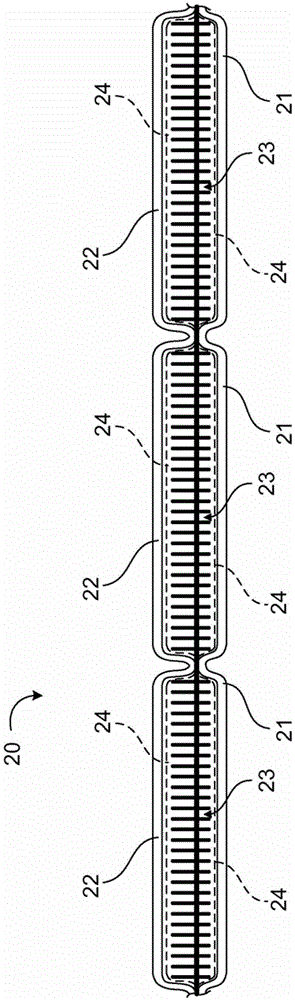

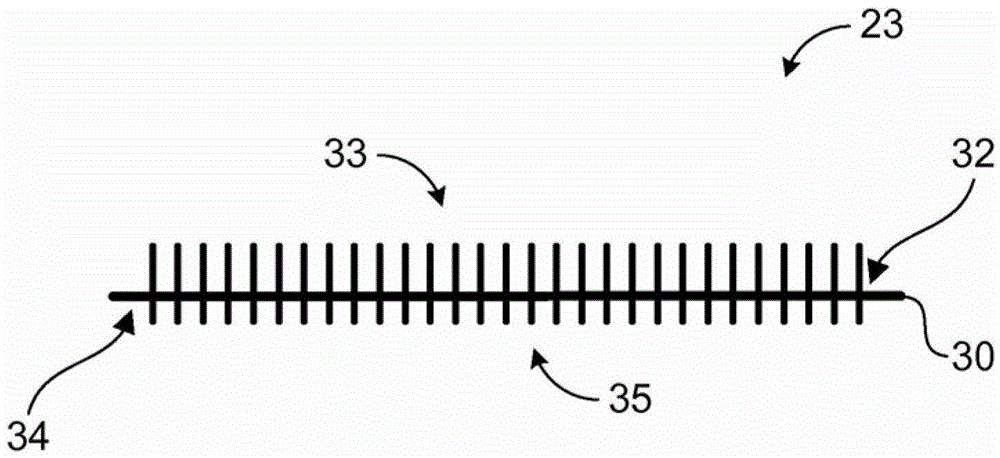

Insulated Composite Fabric

ActiveCN102639020ALimit air permeabilityReduces worry of running through the face fabricTufting apparatusLaminationCivil engineering

An insulated composite fabric that includes an inner fabric layer, an outer fabric layer, and an insulating-filler fabric layer enclosed between the inner fabric layer and the outer fabric layer. The insulating-filler fabric layer is a textile fabric with a raised surface on at least one side of the fabric.

Owner:MMI IPCO LLC

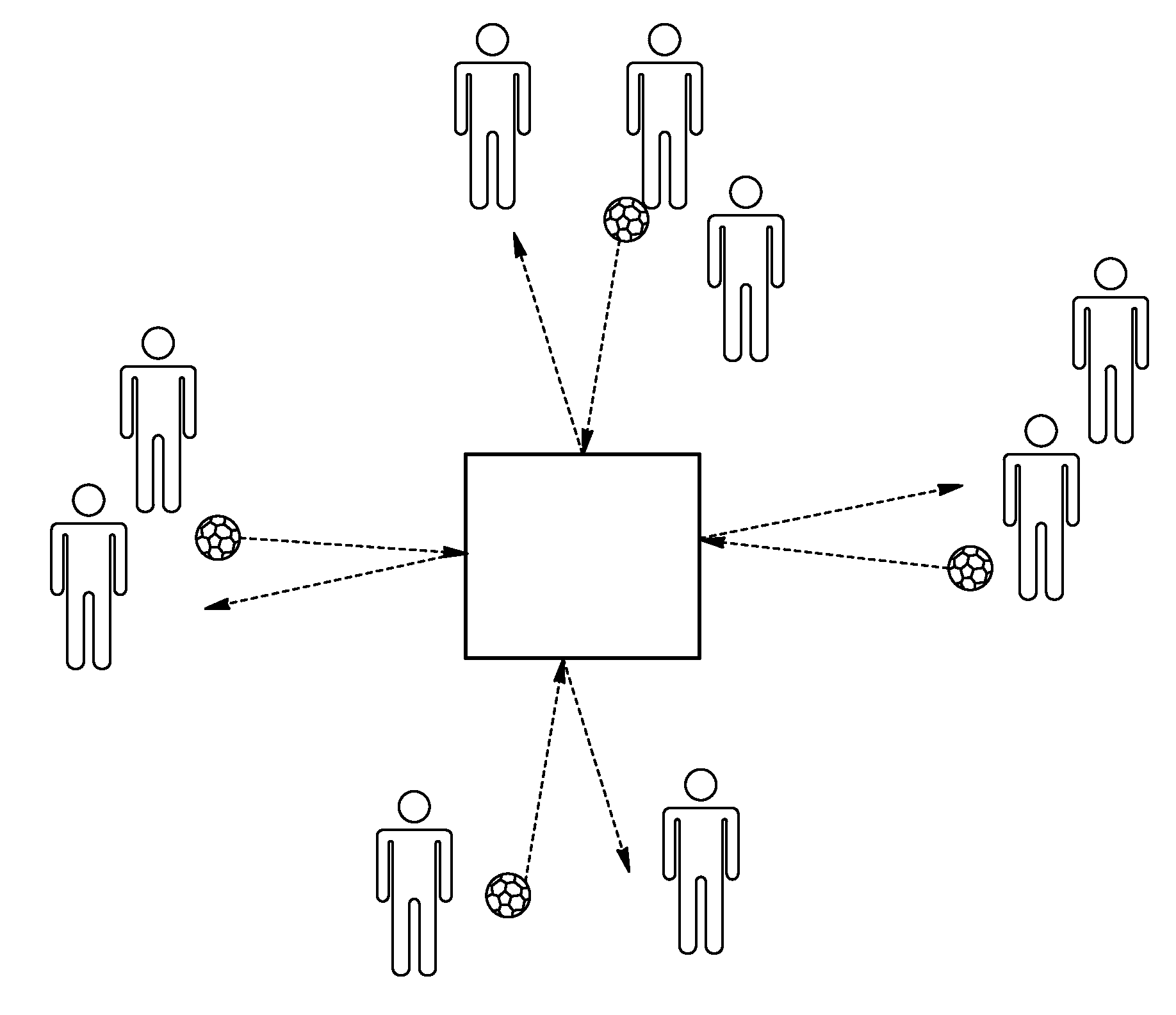

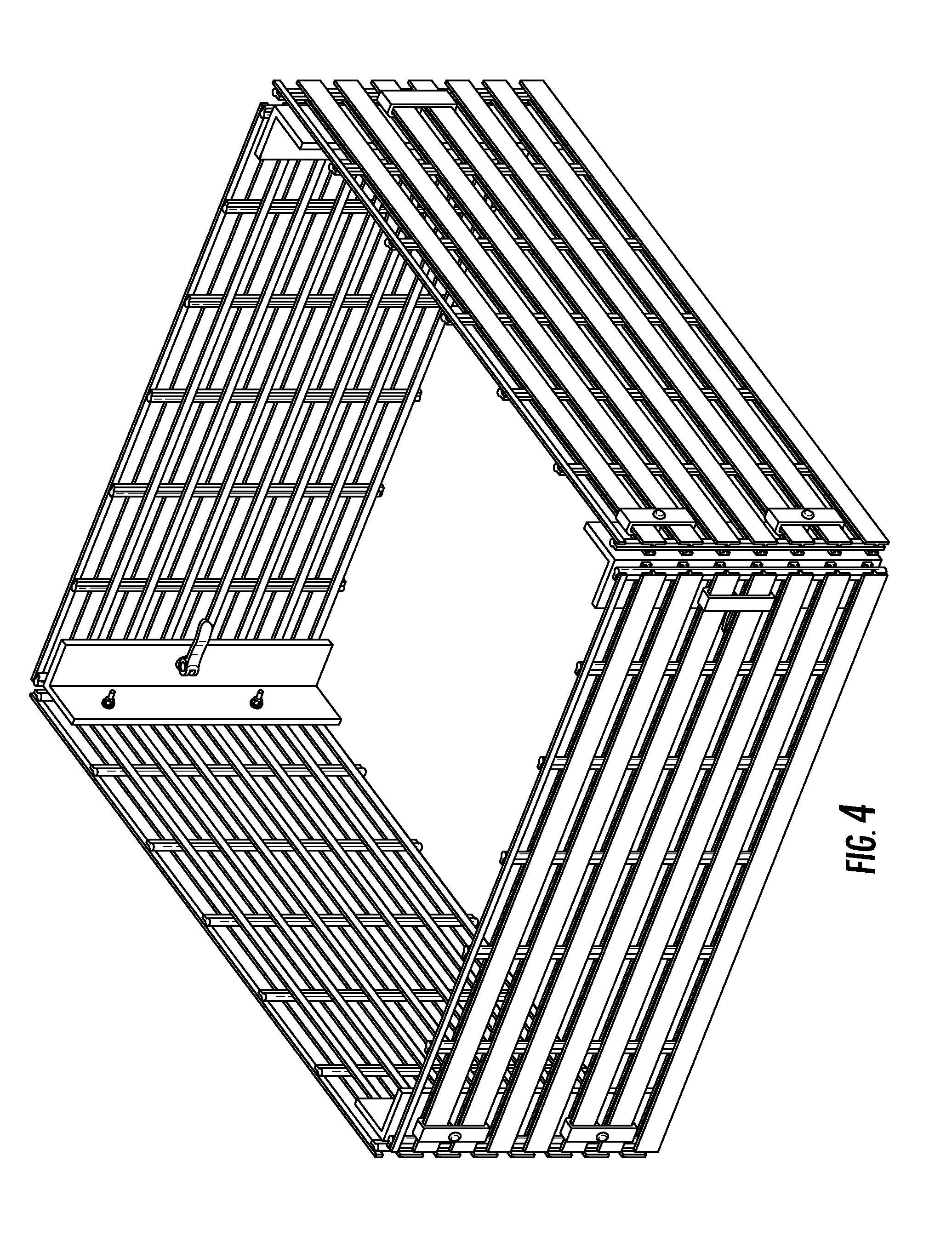

Soccer box

InactiveUS8974325B1Enhance rebound characteristicEasily assemble and disassembleBall sportsSpace saving gamesEngineeringBall soccer

A portable, lightweight soccer rebounding wall with good rebound characteristics, whereby the pace of the rebounding soccer ball is similar to that of the pace at which it was imparted against the wall. The system is easily assembled and disassembled and is sufficiently light to be carried by one person for several hundred yards. In a specific implementation, the rebounding wall includes a panel of pultruded, fiberglass cross bar grating.

Owner:ZUCCA MATTHEW +1

Golf ball material and golf ball

InactiveUS7084198B2Improve thermal stabilitySpeed up the flowFibre treatmentSynthetic resin layered productsPolymer scienceChemical compound

A golf ball material comprising a heated mixture of (a) a random copolymer containing at least 5% by weight of a metal ion-neutralized unsaturated carboxylic acid having an acid content of at least 16% by weight, (b) a thermoplastic elastomer, (c) a fatty acid and / or derivative thereof having a molecular weight of 280–1,500, and (d) a basic metal compound capable of neutralizing unneutralized acid groups in components (a) and (c) has good thermal stability, flow and moldability, and can be molded into a part exhibiting excellent rebound, ensuring the manufacture of golf balls with high performance.

Owner:BRIDGESTONE SPORTS

Multi-piece solid golf ball

InactiveUS20040018893A1Good rebound characteristicsImprove flight performanceGolf ballsSolid ballsInter layerEngineering

The present invention provides a multi-piece solid golf ball, which is superior in rebound characteristics, flight performance and durability, while maintaining good productivity. The present invention relates to a multi-piece solid golf ball comprising a core, an intermediate layer formed on the core and a cover covering the intermediate layer, wherein the intermediate layer is formed from an intermediate layer composition comprising a functional group modified resin as a main component, the cover is formed from a cover composition comprising a resin having polar site that can react with the functional group of the functional group modified resin in the intermediate layer as a main component, and a hardness of the intermediate layer is lower than that of the cover.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

InactiveUS20090091060A1Improve featuresIncreased durabilityCeramic shaping apparatusGolf ballsEngineeringGolf Ball

The present invention provides a golf ball having excellent rebound characteristics and flight performance, while maintaining good durability and appearance. The present invention relates to a golf ball comprising a center, an intermediate layer and a cover, the intermediate layer comprises an outermost layer and a second layer adjacent to the underside of the outermost layer, and the cover has many dimples on the surface thereof, wherein the second layer is formed from thermoplastic resin and has a thickness of 0.5 to 2.0 mm, the outermost layer is formed from thermosetting or thermoplastic resin and has a thickness of 1 to 100 μm, the intermediate layer has depressions on the surface thereof at the position and shape corresponding to the dimples through the cover, and the cover is formed from thermoplastic resin and has a thickness of 0.1 to 0.8 mm in land portion having no dimple.

Owner:SUMITOMO RUBBER IND LTD

High-hardness high-rebound polyurethane elastomer material and application thereof

InactiveCN101633717BImprove mechanical propertiesImprove wear resistancePolyurethane elastomerAlcohol

The invention discloses a high-hardness high-rebound polyurethane elastomer material and introduces an application thereof. The material is obtained by mixing an isocyanate component and a polyhydric alcohol component at the temperature of 25-40 DEG C according to the weight ratio of 100:(50-100), pouring into a mould of 40-60 DEG C and vulcanizing for 30-60min. The hardness is 86-93A, the rebound rate is greater than 70%, the abrasion is smaller than 20mg, the tensile strength is greater than 25MPa, and the tearing strength is greater than 100kN / m. The isocyanate component is a performed polymer with the content of 6-18% of isocyanic acid radicals, and the performed polymer is generated in such a way that 20-60% of PTMG with the molecular weight smaller than or equal to 1,000 and 40-80% of doped PTMG with the molecular weight greater than 1,000 react with isocyanate or a derivative thereof; the polyhydric alcohol component comprises 69.2-89.4% of PTMG with the average molecular weight greater than 1000, 10-30% of fatty group dihydric alcohol, 0.2-0.3% of catalyst and 0.4-0.5% of antiaging agent. The polyurethane elastomer material can be used for preparing butterfly boards, active boards, pulleys used for rapid slide, pulleys of ice skates, pulleys of sliding boards and various castors.

Owner:LIMING RES INST OF CHEM IND

Golf ball

ActiveUS7628715B2Improve featuresIncreased durabilityGolf ballsDomestic articlesEngineeringGolf Ball

The present invention provides a golf ball having excellent rebound characteristics and excellent flight performance, while maintaining good durability and good appearance. The present invention relates to a golf ball comprising a core composed of a center and at least one intermediate layer formed on the center, and a cover covering the core, and having many dimples on the surface thereof, wherein the outermost layer of the intermediate layer is formed from thermoplastic resin, has a thickness of 0.5 to 3.0 mm, and has depressions on the surface thereof at the position and shape corresponding to the dimples through the cover, and the cover is formed from thermoplastic resin and has a thickness of 0.1 to 0.8 mm in land portion having no dimple.

Owner:SUMITOMO RUBBER IND LTD

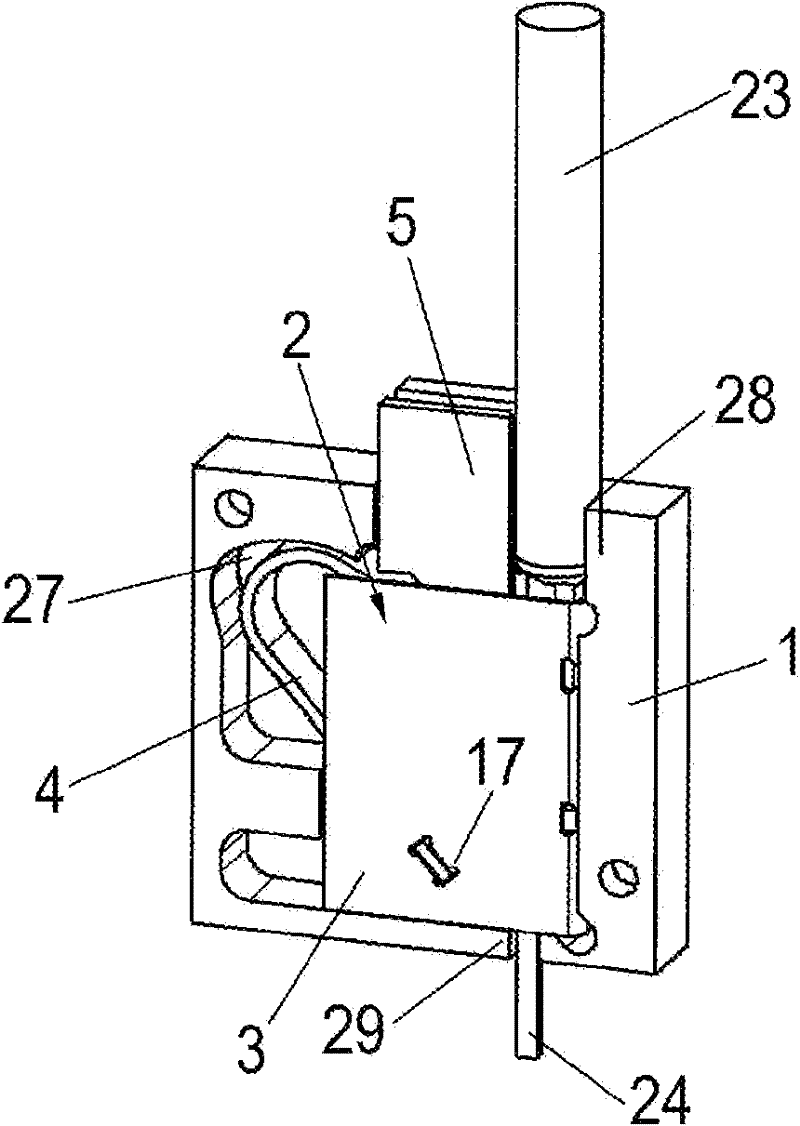

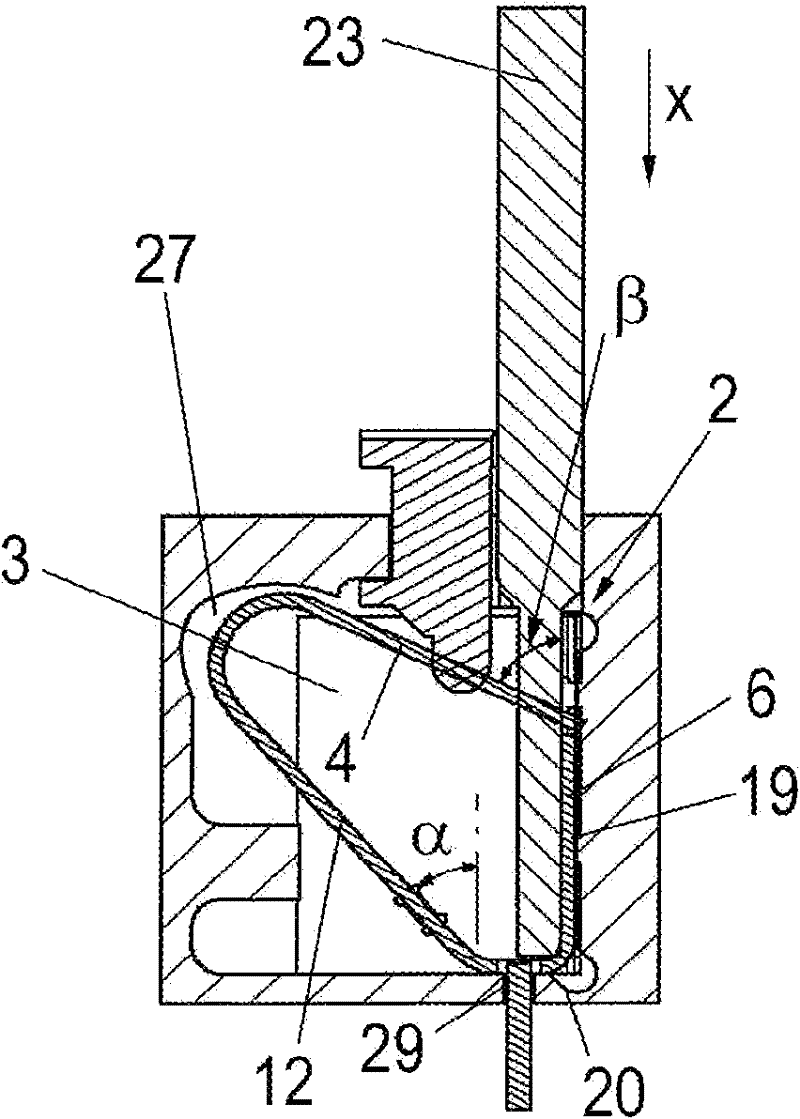

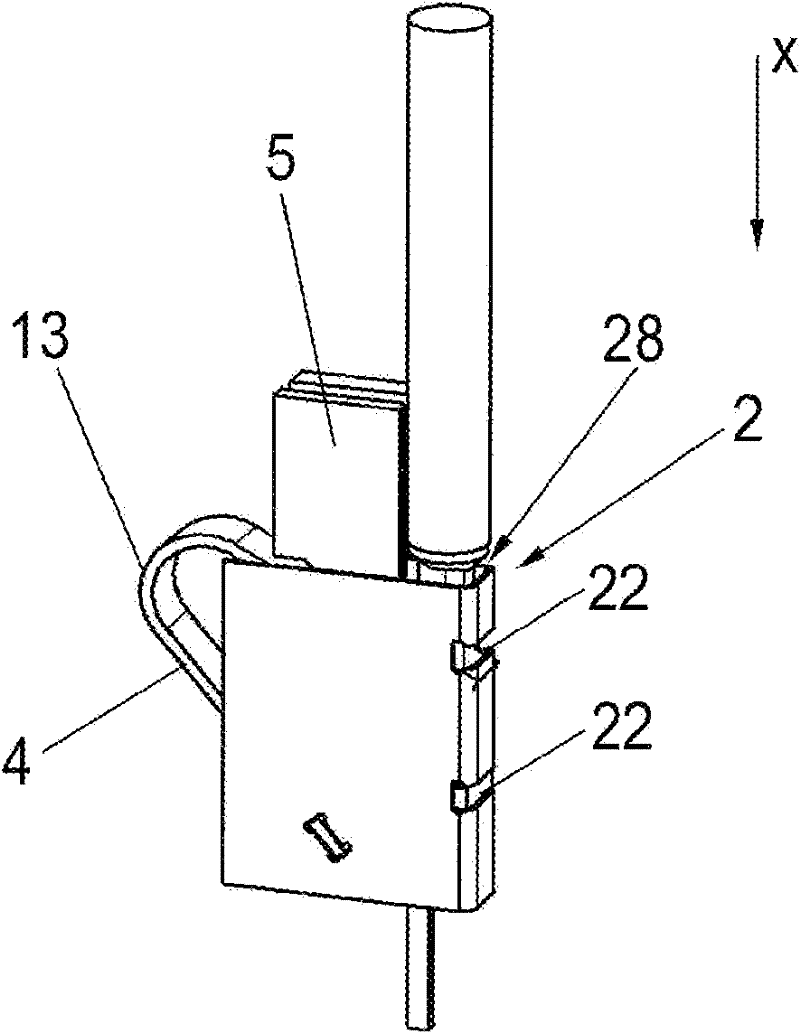

Connection device for conductor

InactiveCN102474018AGood rebound characteristicsGood electrical conductivityClamped/spring connectionsElectrical conductorEngineering

The present invention relates to a connection device, particularly for disposing in an insulating material housing, implemented for directly connecting to a conductor without tools, and comprising the following: a clamping frame, and a clamping spring for clamping the conductor that can be inserted into the clamping frame in a conductor insertion direction against a conductive support element in the clamping frame, wherein the clamping spring comprises at least one attachment leg and a clamping leg connected to the attachment leg by means of a bend, having one or both of the following characteristics: the clamping frame is designed as a U-profile made of a sheet metal spring, and / or the attachment leg is aligned at an angle to the conductor insertion direction.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

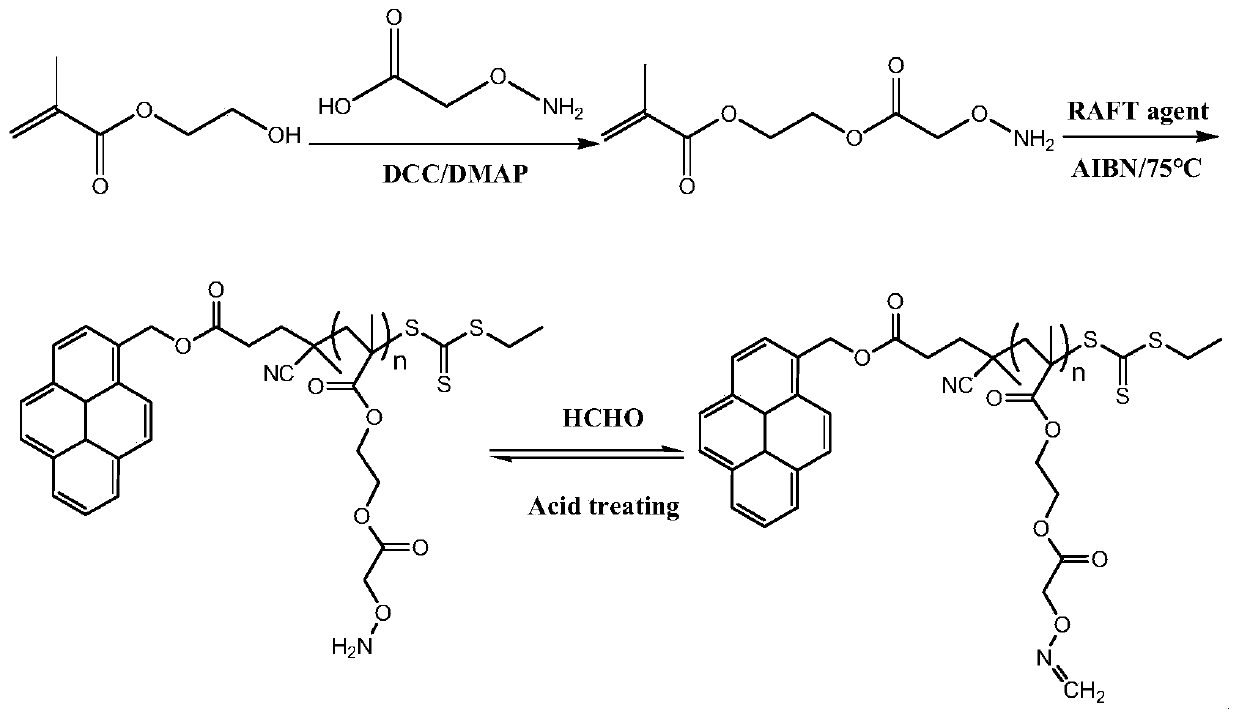

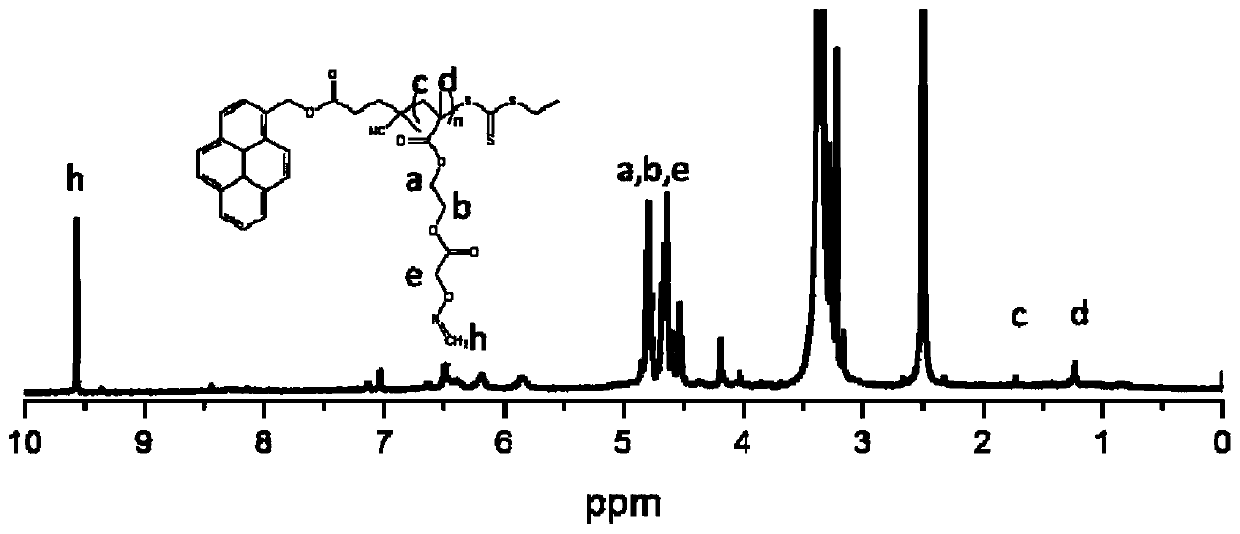

Aminooxy structure-containing polymer and formaldehyde adsorbent, and preparation methods thereof

ActiveCN110204638AImprove stabilityGuaranteed stabilityOther chemical processesDispersed particle separationSorbentAtom-transfer radical-polymerization

The invention belongs to the technical fields of polymer materials technologies and harmful gas treatment, and particularly relates to an aminooxy structure-containing polymer and a formaldehyde adsorbent including the polymer, and preparation methods thereof. Reversible addition-fragmentation chain transfer (RAFT) polymerization or atom transfer radical polymerization (ATRP) is used to obtain thepolymer containing a large amount of aminooxy groups, the polymer and a two-dimensional carrier material are commonly loaded on porous melamine foam or polyurethane foam to prepare an aerogel material, and the aerogel material is a three-dimensional material capable of efficiently adsorbing gaseous formaldehyde, that is, the formaldehyde adsorbent. The formaldehyde adsorbent in the invention realizes reversible chemical adsorption of the formaldehyde gas at normal temperature under normal pressure in the absence of a catalyst, combines the high specific surface area of the carrier and the three-dimensional porous structure of the foam, and can be used for specifically and efficiently adsorbing the gaseous formaldehyde; and the formaldehyde can be desorbed under the action of dilute hydrochloric acid, so the formaldehyde adsorbent can be repeatedly used.

Owner:临沂中科芯华新材料科技有限公司

Golf ball

ActiveUS20060003853A1Improve featuresIncreased durabilityGolf ballsDomestic articlesEngineeringGolf Ball

The present invention provides a golf ball having excellent rebound characteristics and excellent flight performance, while maintaining good durability and good appearance. The present invention relates to a golf ball comprising a core composed of a center and at least one intermediate layer formed on the center, and a cover covering the core, and having many dimples on the surface thereof, wherein the outermost layer of the intermediate layer is formed from thermoplastic resin, has a thickness of 0.5 to 3.0 mm, and has depressions on the surface thereof at the position and shape corresponding to the dimples through the cover, and the cover is formed from thermoplastic resin and has a thickness of 0.1 to 0.8 mm in land portion having no dimple.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

The present invention provides a golf ball having excellent rebound characteristics and excellent flight performance, while maintaining good durability and good appearance. The present invention relates to a golf ball comprising a core composed of a center and at least one intermediate layer formed on the center, and a cover covering the. core, and having many dimples on the surface thereof, wherein the outermost layer of the intermediate layer is formed from thermoplastic resin, has a thickness of 0.5 to 3.0 mm, and has depressions on the surface thereof at the position and shape corresponding to the dimples through the cover, and the cover is formed from thermoplastic resin and has a thickness of 0.1 to 0.8 mm in land portion having no dimple.

Owner:SUMITOMO RUBBER IND LTD

Golf ball material and golf ball

InactiveUS20050182192A1Easy to reboundSpeed up the flowGolf ballsSolid ballsThermal stabilityGolf Ball

Owner:BRIDGESTONE SPORTS

Insulation Composite Fabric

ActiveCN102639020BLimit air permeabilityReduces worry of running through the face fabricTufting apparatusLaminationCivil engineering

An insulated composite fabric that includes an inner fabric layer, an outer fabric layer, and an insulating-filler fabric layer enclosed between the inner fabric layer and the outer fabric layer. The insulating-filler fabric layer is a textile fabric with a raised surface on at least one side of the fabric.

Owner:MMI IPCO LLC

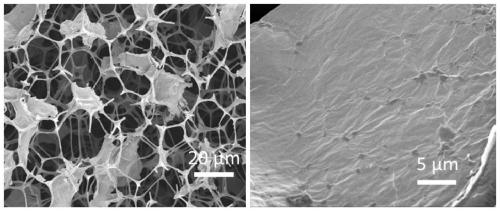

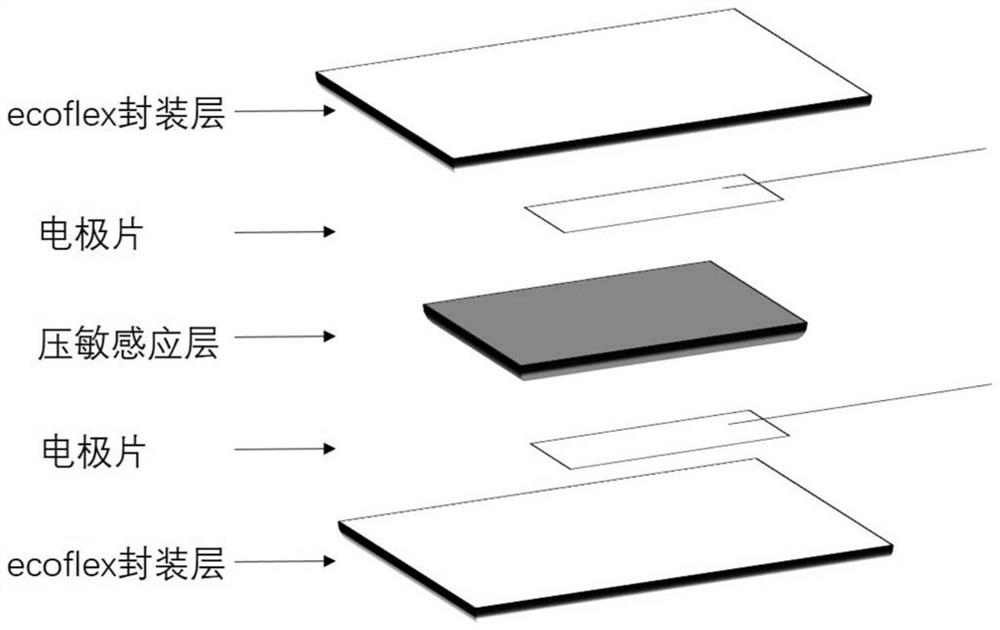

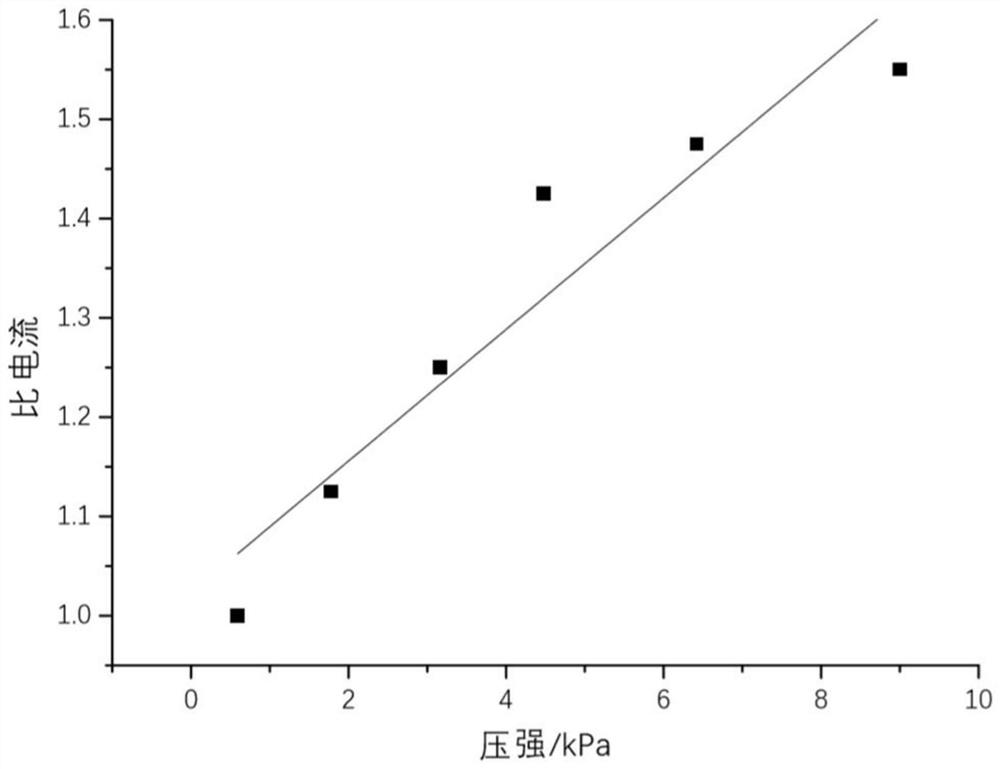

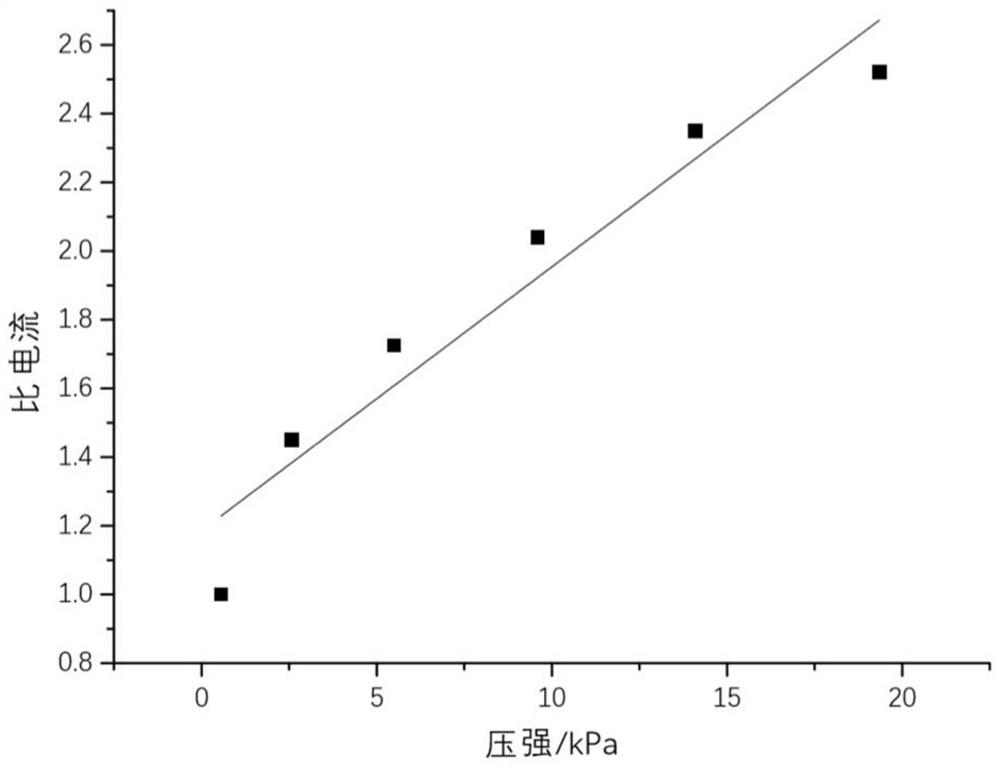

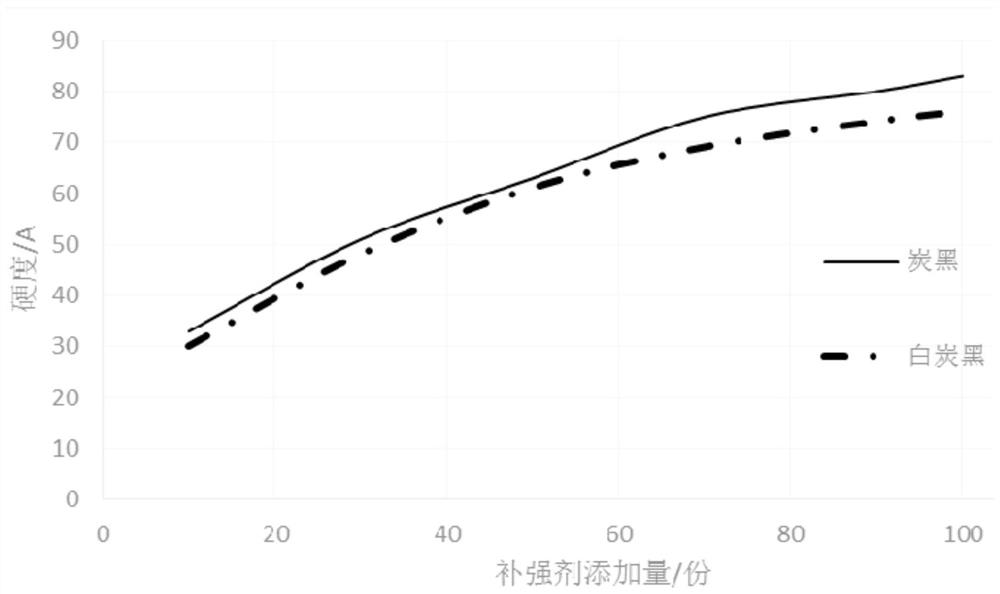

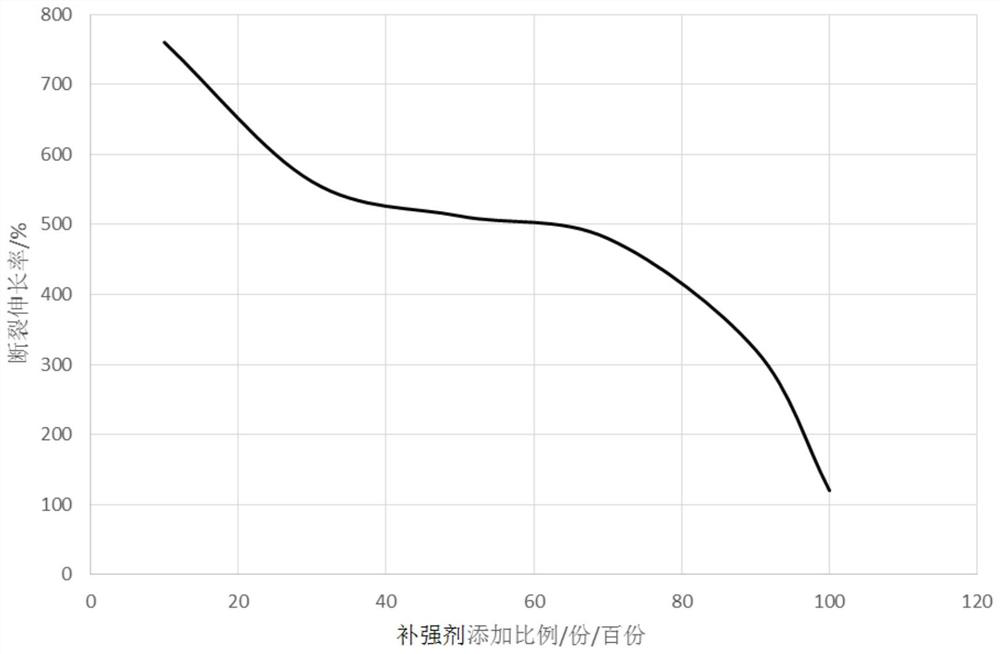

A piezoresistive sensor with a porous structure and its preparation method

ActiveCN109830594BLow elastic modulusHigh sensitivityPiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionRoboticsProtection layer

The invention discloses a piezoresistive sensor with a porous structure and a preparation method thereof. The piezoresistive sensor structure includes from the outside to the inside: a flexible protective layer, an electrode sheet, and a pressure-sensitive layer, wherein the pressure-sensitive layer is made of Ecoflex As the base, acetylene black is the conductive phase, and rice wine and starch are blended and foamed to form a cell structure. Its sensitivity can reach 0.272kPa at the upper limit of the total pressure sensitivity range. ‑1 . The piezoresistive sensor and its preparation method in the present invention are novel and simple, have excellent performance and low cost, and have great potential and advantages in the fields of biomedical detection and robotics.

Owner:ZHEJIANG UNIV

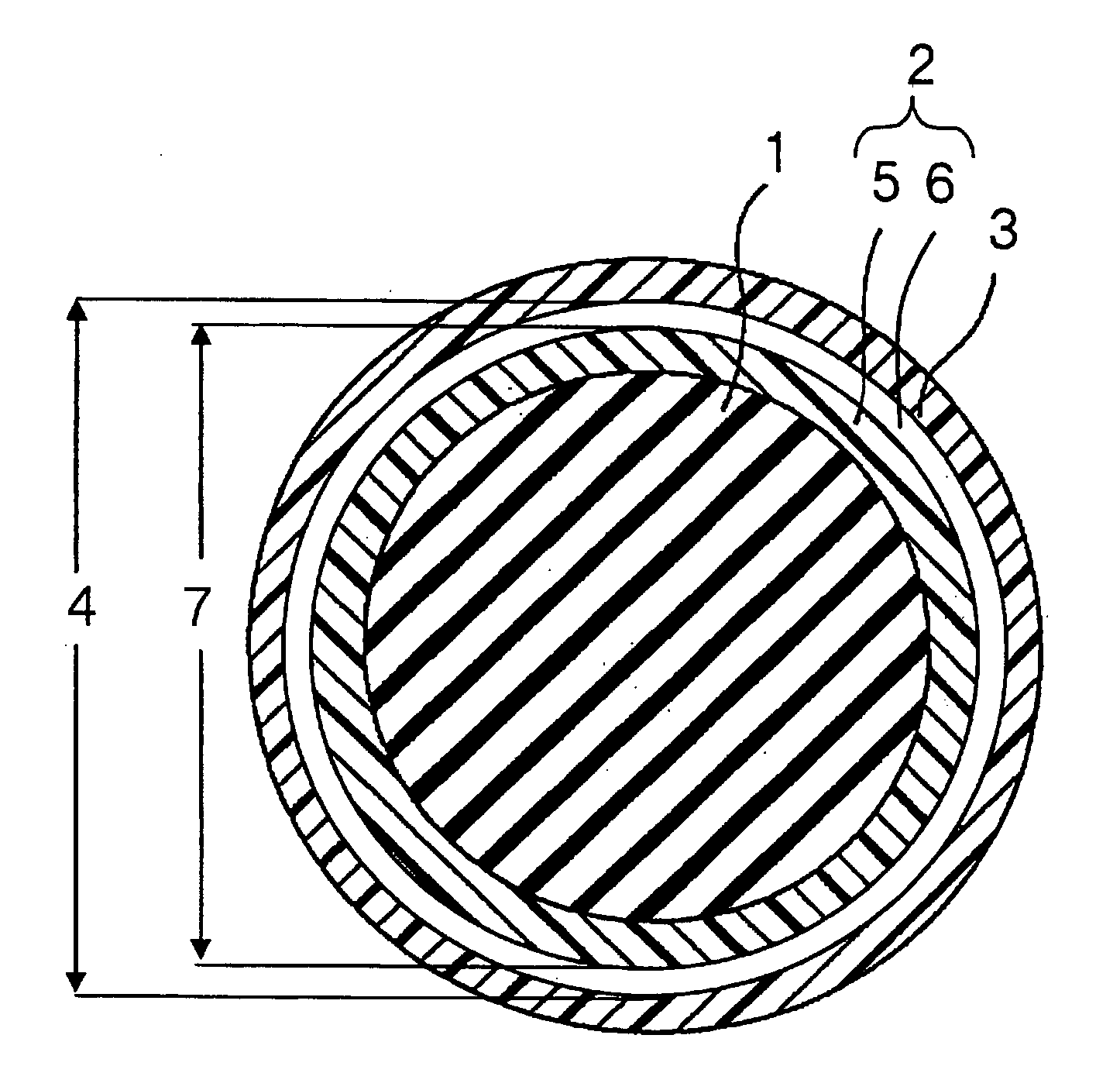

Preparation method of high-hardness polyurethane forklift wheel

The invention discloses a preparation method of a high-hardness polyurethane forklift wheel. The method includes the steps of: 1) mixing sepiolite powder, lecithin and water, heating and stirring themixture and regulating pH value of the mixture to 5-5.7; 2) continuously heating and stirring the mixture, centrifuging the mixture, and washing and spray-drying the mixture to obtain pretreated sepiolite; 3) uniformly mixing a polyurethane prepolymer, the pretreated sepiolite and neopentyl glycol, placing the mixture in a mould, demolding the mixture, heating the mixture, and maintaining the temperature to produce the high-hardness polyurethane forklift wheel. By means of the method, the polyurethane forklift wheel has high hardness and good rebound resilience, is high in mechanical strengthand bearing force, is free of damaging ground, has good anti-impact and anti-fatigue property, and is extensive in available temperature range, is low in cost and has long service life.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

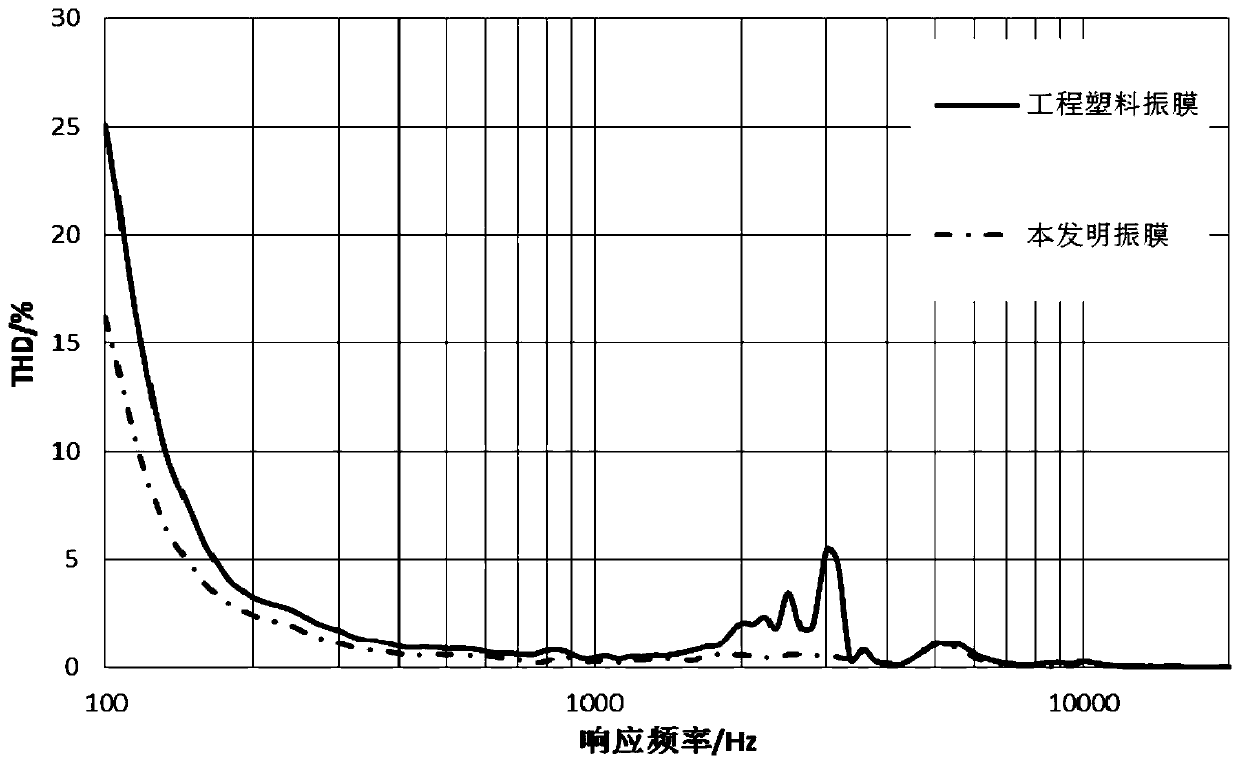

Diaphragm of sounding device and sounding device

ActiveCN110708635BGood rebound characteristicsIncrease the loudnessDiaphragm extensionsPlane diaphragmsPolymer scienceRubber membrane

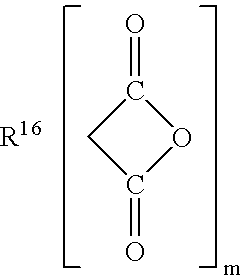

The invention discloses a vibrating membrane used for a sounding device and a sounding device. The diaphragm includes an isoprene rubber film layer. The isoprene rubber film layer is a film layer prepared by isoprene polymer through cross-linking reaction. The isoprene polymer is represented by the following general formula: Isoprene rubber is a synthetic rubber prepared by polymerization of isoprene monomer. Compared with engineering plastics, isoprene rubber has better rebound properties. At room temperature, isoprene rubber exhibits a high elastic state, and no yield strain will occur in a large strain range. The vibrating membrane made of this material not only has a larger effective vibration range, but also can make the loudness of the sounding device higher under the same driving power.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com