Patents

Literature

41 results about "Gaseous formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formaldehyde in its gaseous state is highly flammable with a broad explosive range (7% - 73%). Formaldehyde in solution as formalin (37% formaldehyde) is combustible and is highly reactive with many chemicals.

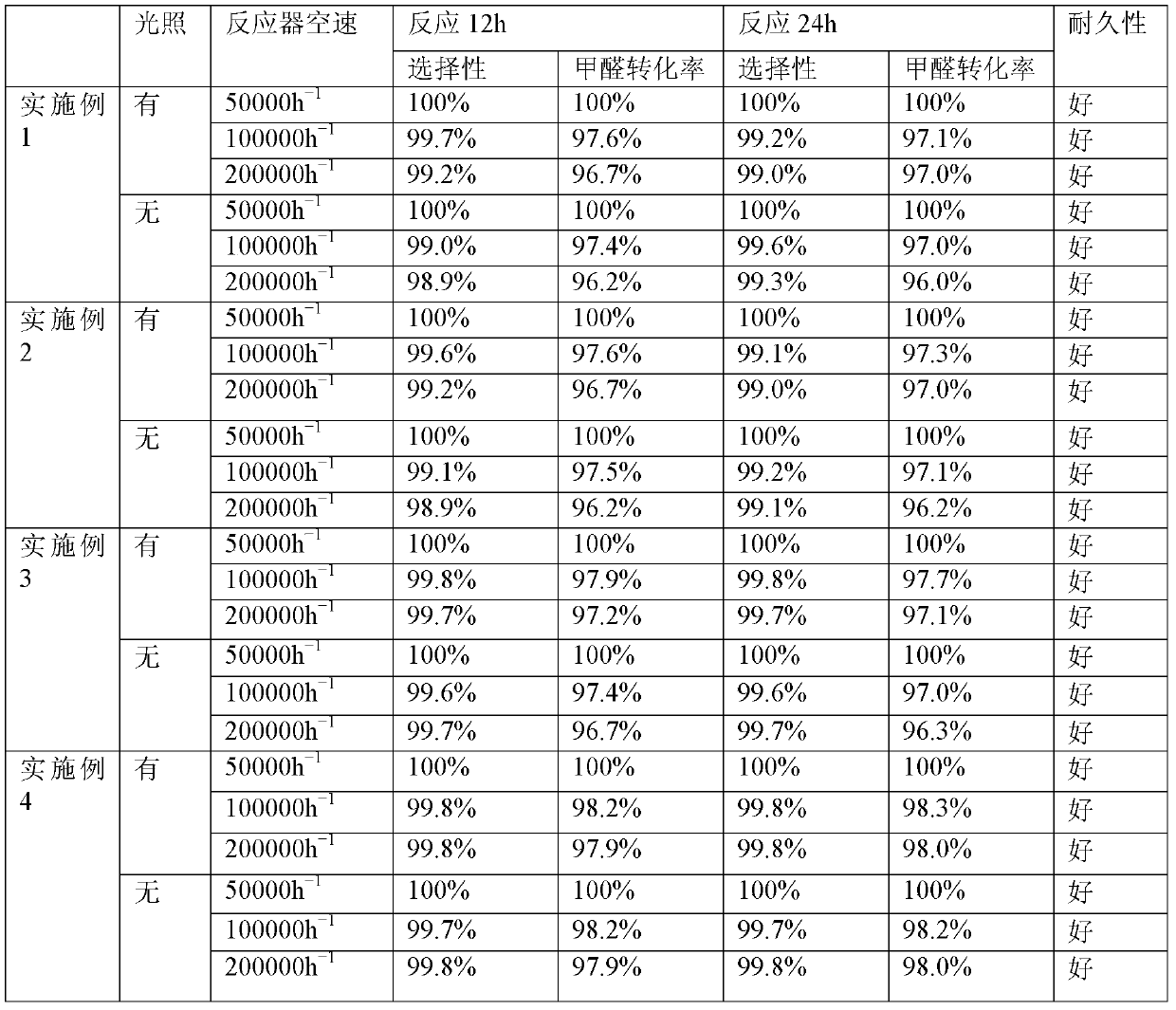

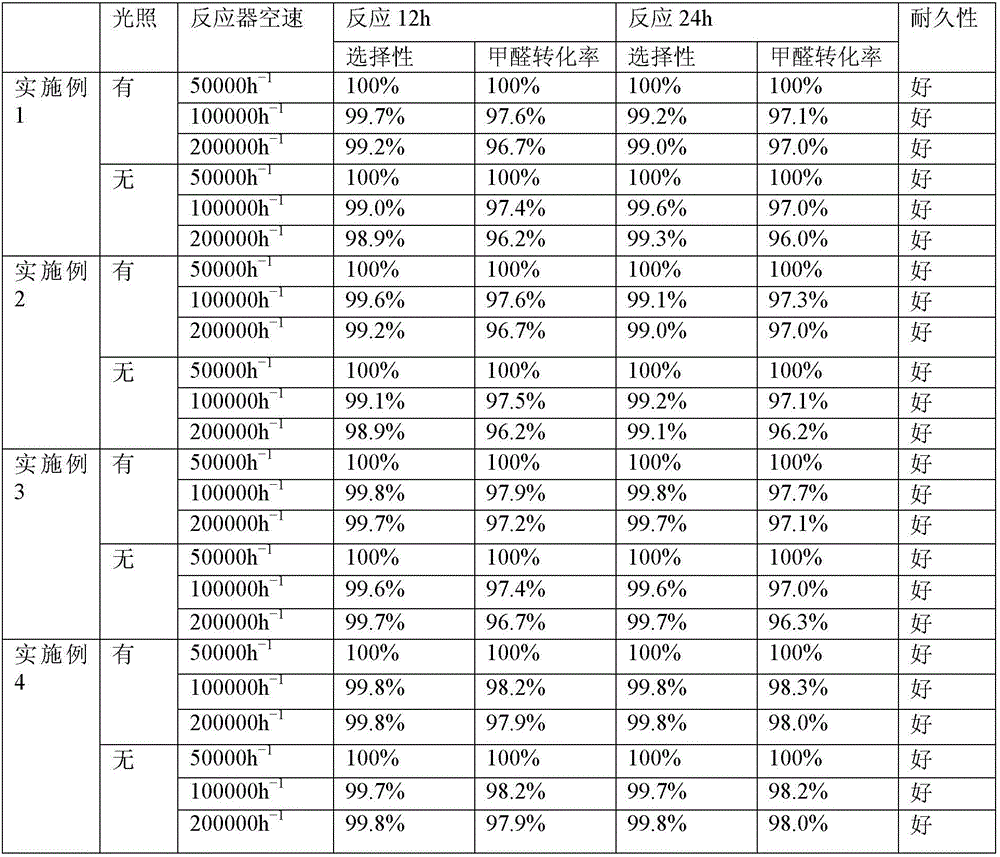

M-MnOx-CeO2 catalyst and application thereof

ActiveCN109107567AImprove stabilitySolve pollutionGas treatmentDispersed particle separationCatalytic oxidationGaseous formaldehyde

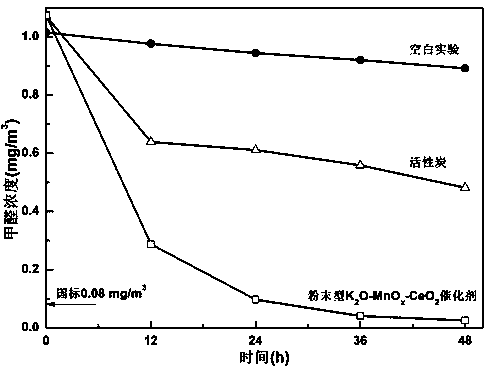

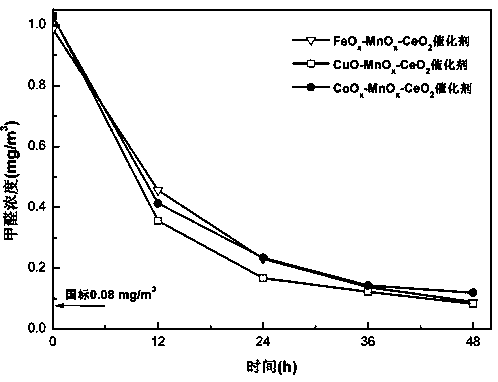

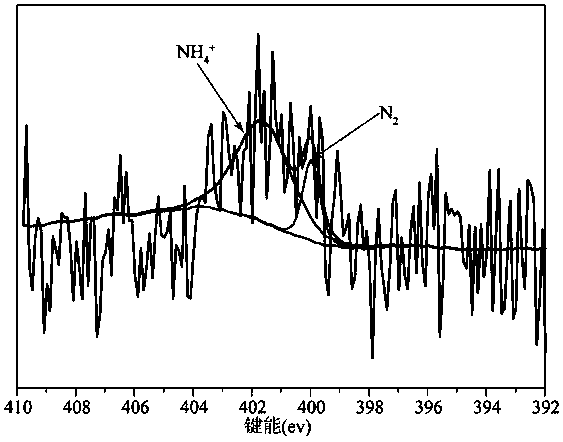

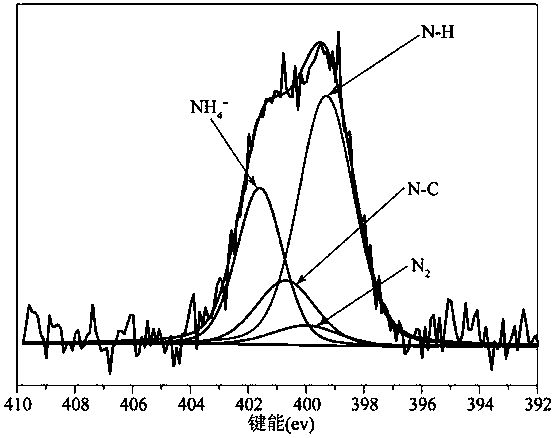

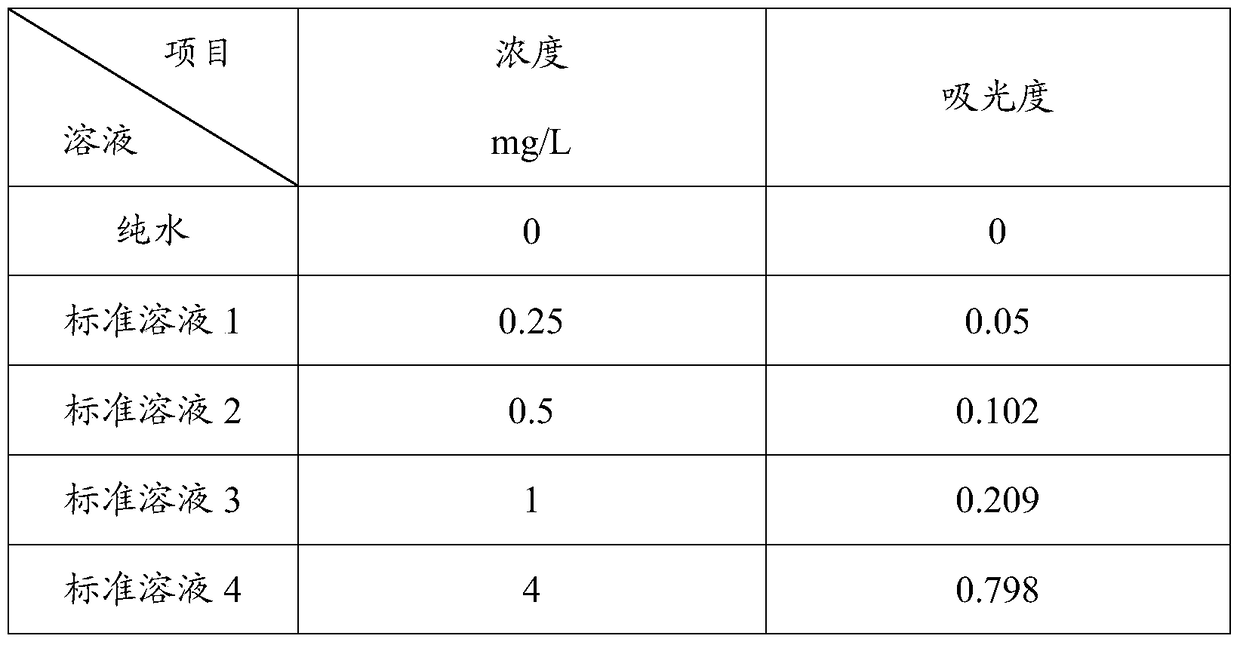

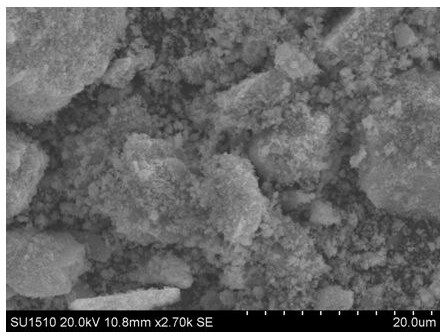

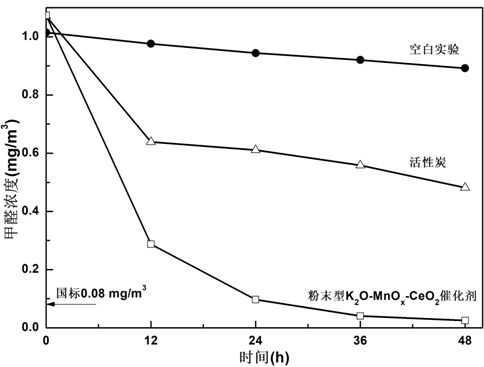

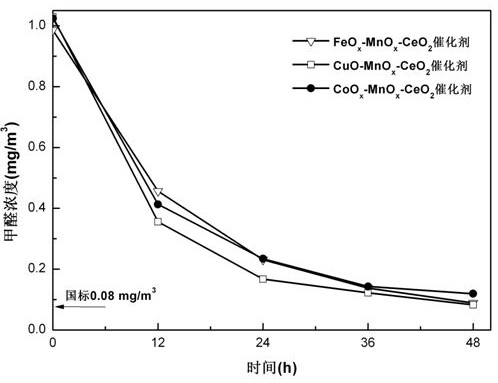

The invention discloses an M-MnOx-CeO2 catalyst. The catalyst is prepared by adopting citric acid complexometry through the steps of taking MnOX and CeO2 as active ingredients and taking M as an adulterant; M is FeOx, CuO, CoOx or K2O; the molar ratio of Mn to Ce in the catalyst is (6 to 1) to (1 to 1); when M is FeOx, CuO or CoOx, the molar ratio of metal ions to Ce in M is (1 to 4) to (1 to 1),and when M is K2O, the doping content of K2O is 1wt%. The catalyst can be used for catalytic oxidation of gaseous formaldehyde in a normal temperature condition or used for thermal catalytic oxidationof CVOCs.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

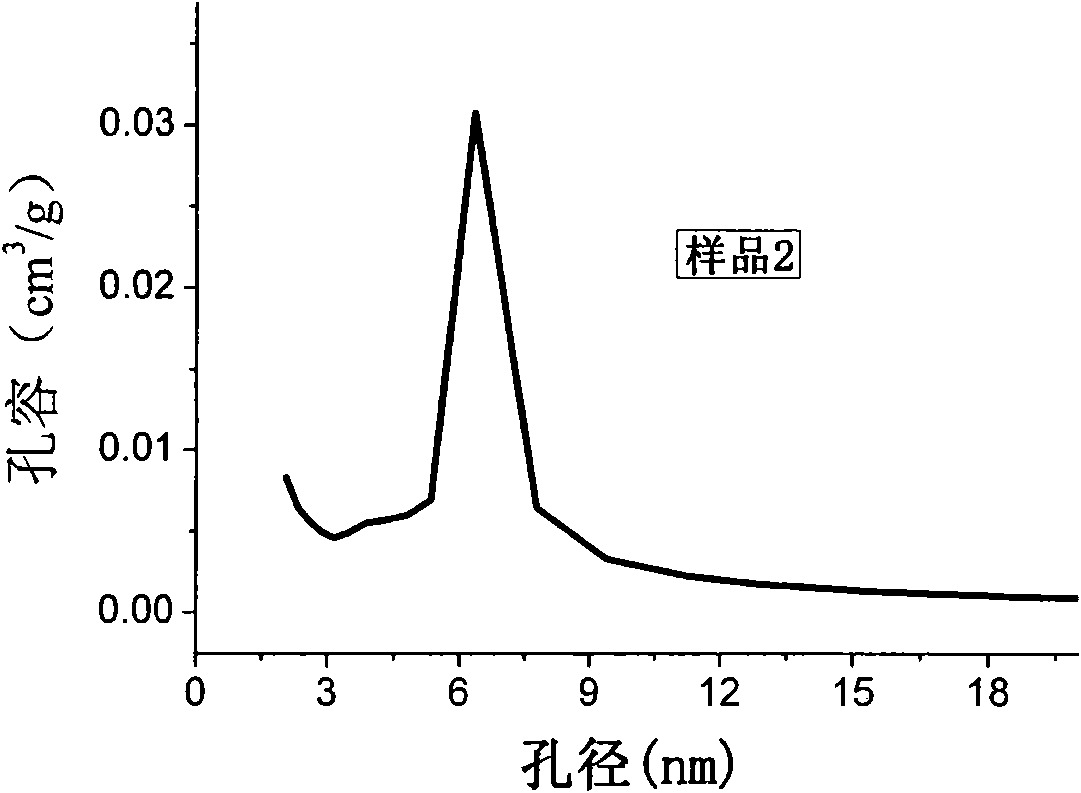

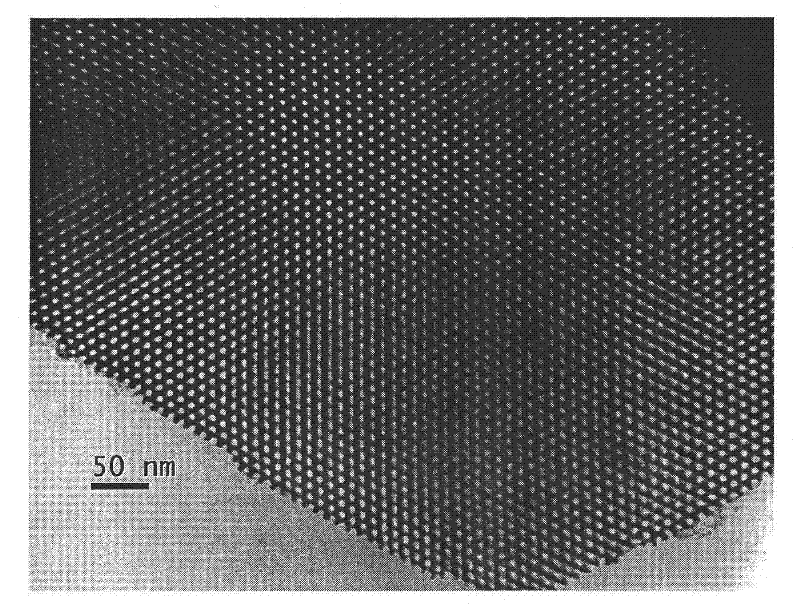

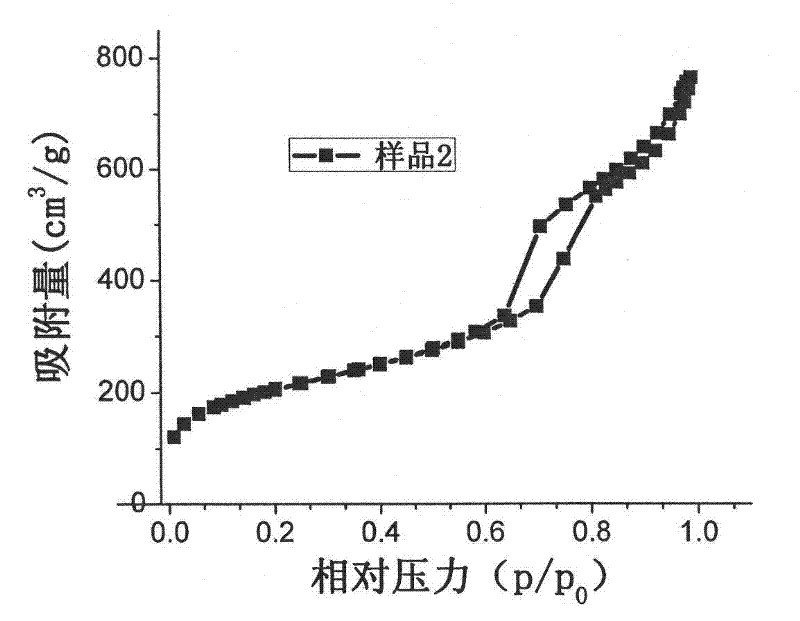

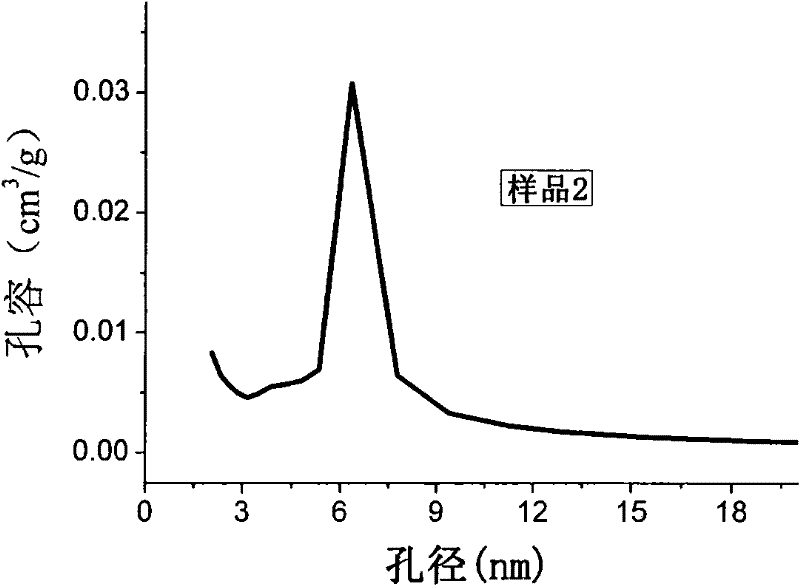

Preparation method of mass type formaldehyde sensor based on functionalized SBA-15

InactiveCN102033028AHigh sensitivityHigh selectivityMaterial weighingGaseous formaldehydeUltrasonic dispersion

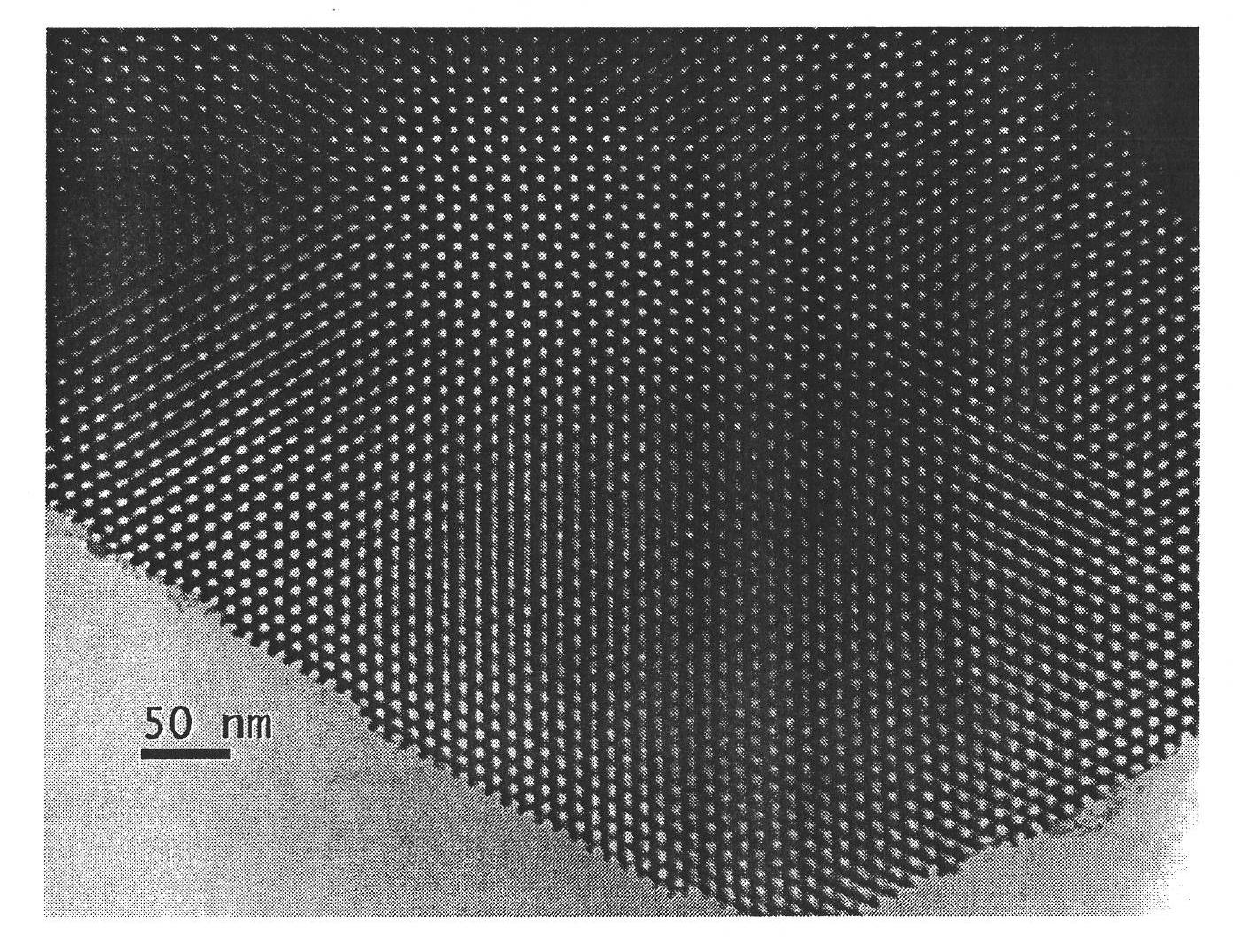

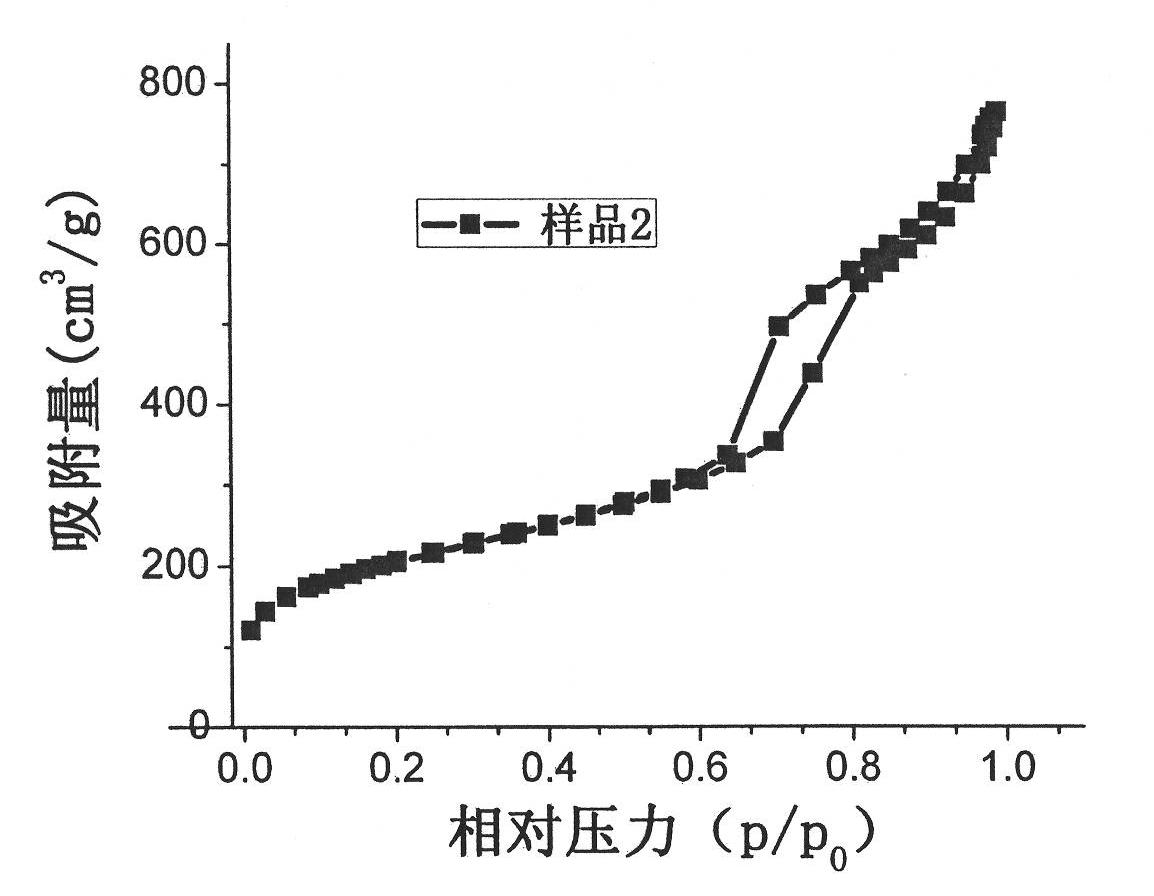

The invention relates to a preparation method of a quartz crystal microbalance (QCM) formaldehyde sensor based on amino-functionalized SBA-15, belonging to the technical fields of sensitive materials and gas sensors. By first using functionalized SBA-15 as the sensitive material of the QCM mass type sensor to construct the formaldehyde sensor having favorable performance, the preparation method comprises the following steps: carrying out ultrasonic dispersion on self-prepared beta-carboxyl ethyl trimethoxysilane functionalized SBA-15 of which the pore diameter is 2-50 nm in a certain medium for 20-50 minutes to obtain a coating liquid, wherein the used medium is any one of water, acetone or ethanol; and uniformly spreading the coating liquid on the electrode surface of a cleaned quartz crystal microbalance, and drying at 80-120 DEG C for 3-8 hours to obtain the formaldehyde sensor. The mass type sensor has sensitive response to indoor air pollutant gaseous formaldehyde (the lower detection limit can reach the ppm level), and has the advantages of good selectivity, high stability, economy and environmental friendliness. Thus, the invention provides a favorable formaldehyde sensitive material for QCM and opens up a new application area for functionalized SBA-15.

Owner:萨驰机械工程(上海)有限公司

Fibrous products having reduced formaldehyde emissions

A method for reducing formaldehyde emission from a fibrous product prepared using a binder based on a formaldehyde-containing resin, the method comprising isolating the fibrous product in an enclosed space, introducing a gaseous formaldehyde scavenger into the space and maintaining the gaseous scavenger in the space for a time sufficient to reduce the level of formaldehyde emission, with the result that the fibrous product exhibits a reduced level of formaldehyde emissions.

Owner:GEORGIA PACIFIC CHEM LLC

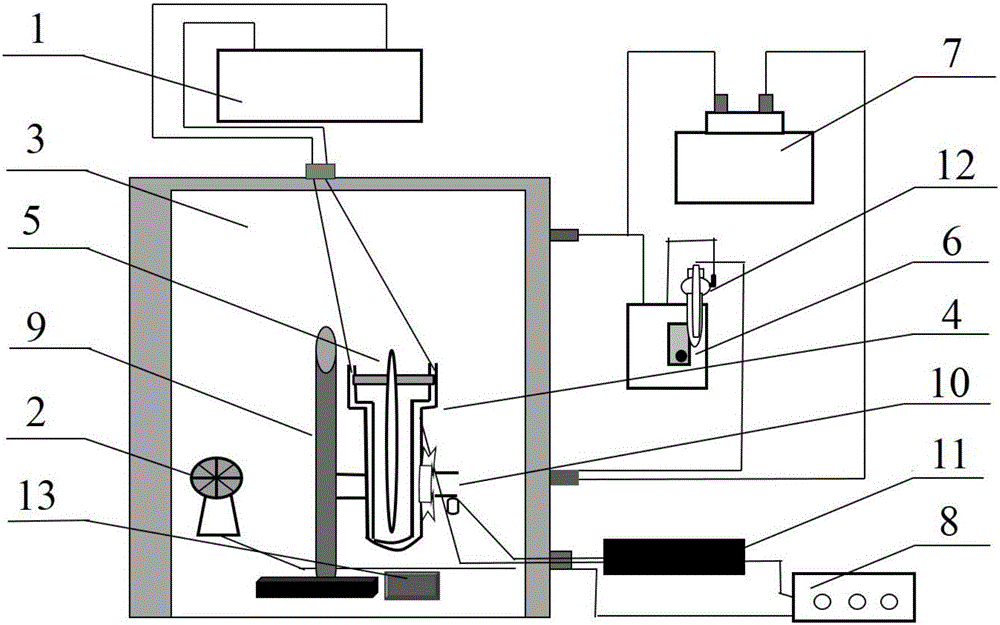

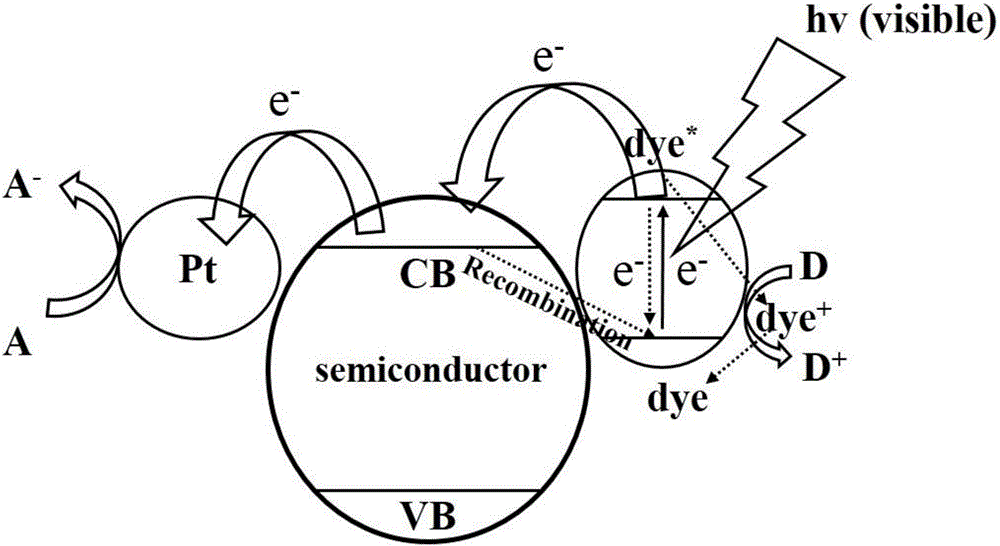

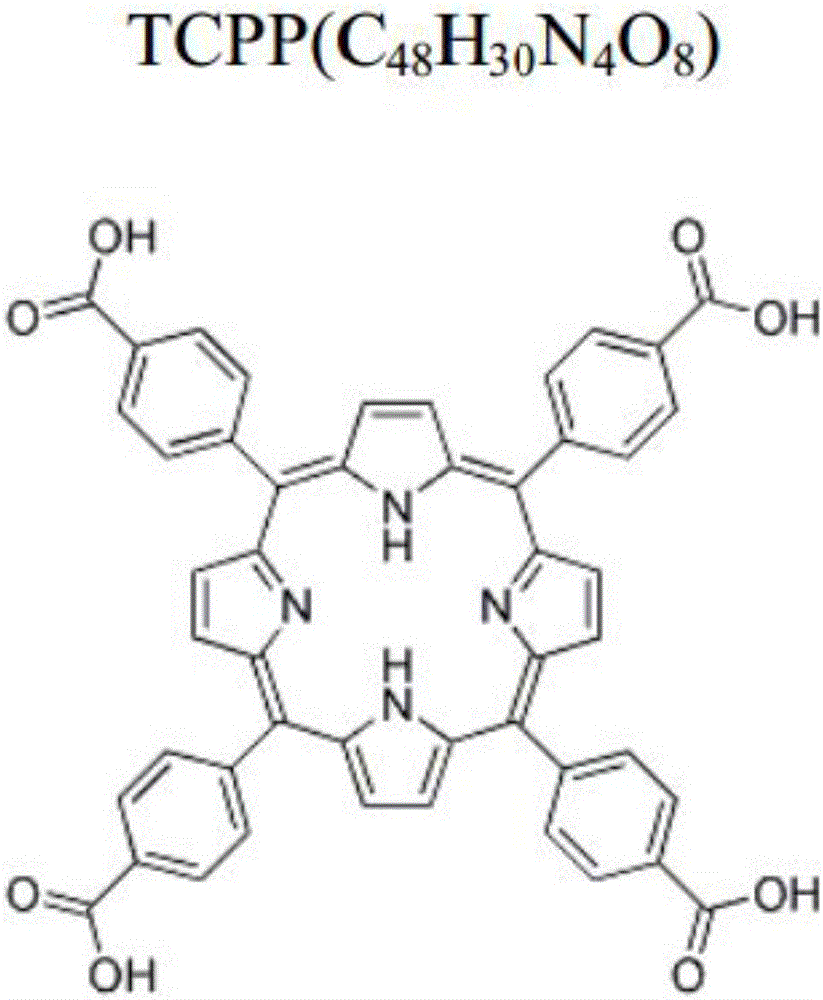

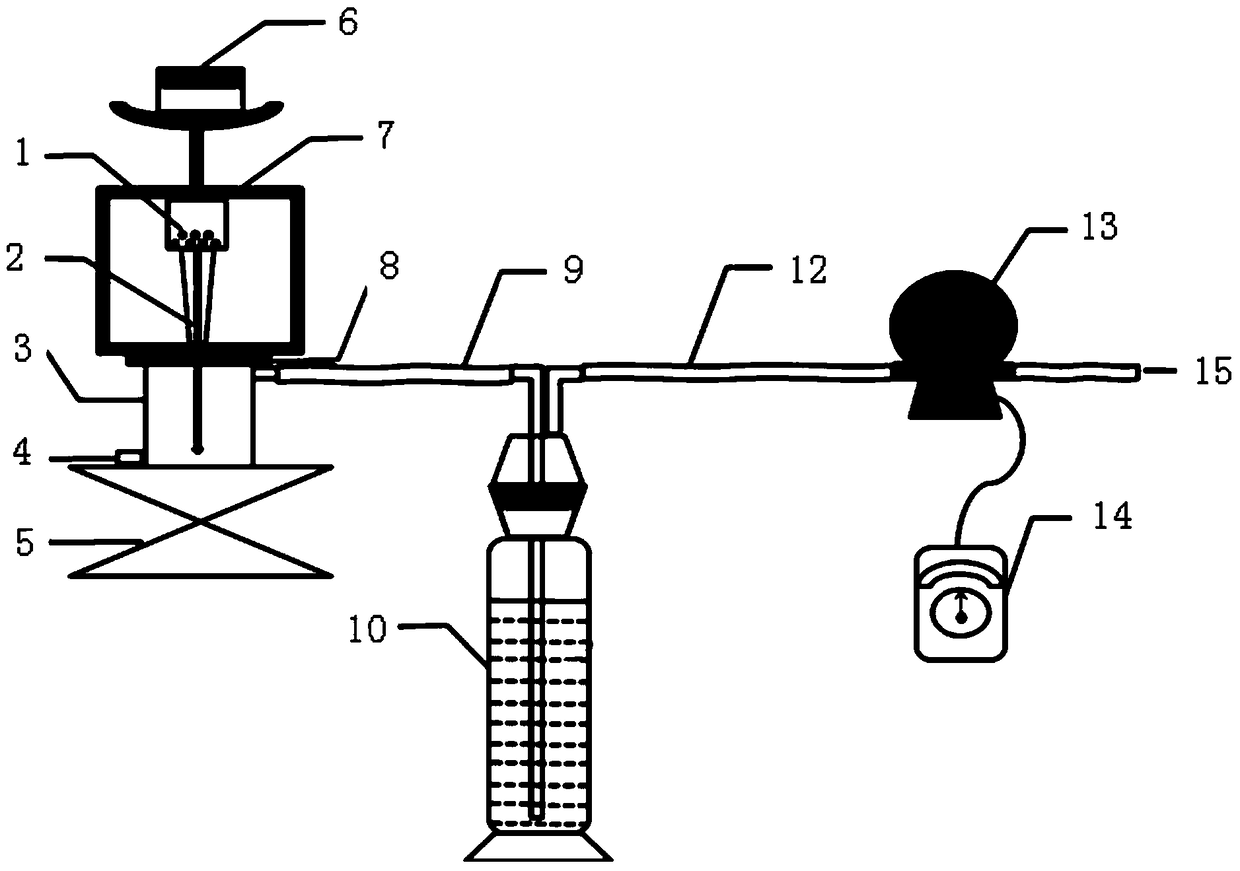

Device and method of visible light photocatalytic degradation of gaseous formaldehyde with dye-sensitized TiO<2>

InactiveCN106621803AImprove stabilityImprove efficiencyGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsVaporization

The present invention relates to a device and method of visible light photocatalytic degradation of gaseous formaldehyde with dye-sensitized TiO<2>, and belongs to the field of photocatalysis. The device is mainly composed of a stainless steel cubic reaction vessel, a constant temperature water bath tank, a gas sampler, a diaphragm vacuum pump and a gas absorption bottle. The method using the reaction device comprises the following steps: a dye-sensitized TiO<2> thin film is used as a base material, then a formaldehyde standard liquid and the dye-sensitized TiO<2> thin film are put into the reaction device, the initial formaldehyde gas concentration after a vaporization balance is detected, then light source is turned on to conduct the photocatalytic degradation experiment of the gaseous formaldehyde, after 3 h of the lighting, a sampling inspection of the degraded formaldehyde concentration is conducted, the degradation rate of the formaldehyde is calculated to obtain the degradation rate of the gaseous formaldehyde after the photocatalytic degradation with the dye-sensitized TiO<2>. The device has many advantages of being circular and high in efficiency, green and healthy, simple in operation, low in costs, etc., and has important values and research significances for solving environmental pollution, indoor air purification, etc.

Owner:JILIN UNIV

Normal-temperature formaldehyde-removing modified activated carbon and preparation method thereof

InactiveCN105597682ASimple manufacturing methodQuick snapGas treatmentOther chemical processesActivated carbonWork cycle

For solving the problem that an existing technology for removing formaldehyde in air is not ideal in formaldehyde removing effect or is not suitable for industrial production, the invention provides a normal-temperature formaldehyde-removing modified activated carbon and a preparation method thereof. The modified activated carbon is prepared by using a granular, cylindrical, spherical or honeycomb coconut shell activated carbon with large specific surface area as a carrier, using CuCl2 and FeCl3 mixed metal salt as a modified component and adopting dipping, drying and calcination processes. The modified activated carbon has the advantages of rapid capture, efficient adsorption, long working cycle and the like to gaseous formaldehyde and can meet the requirement for long-time effective formaldehyde removal in an indoor environment.

Owner:北京天宫环境科技(重庆)有限公司

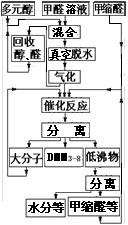

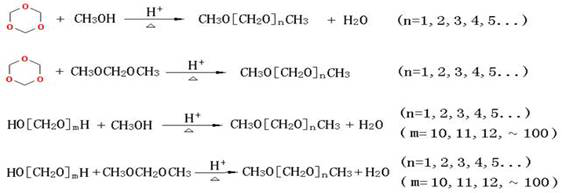

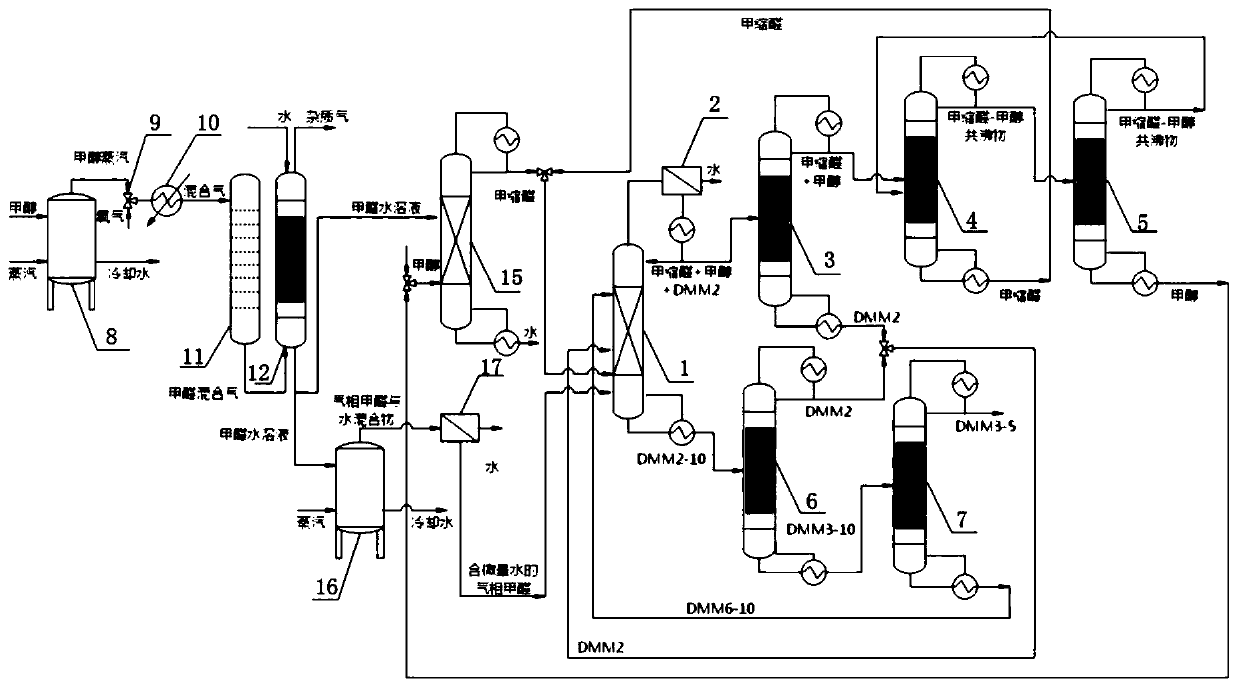

Preparation method of polyoxymethylene dimethyl ether (DMMn)

PendingCN112574013ALow costImprove efficiencyOrganic compound preparationCarbonyl compound preparationChemical industryPolyoxymethylene

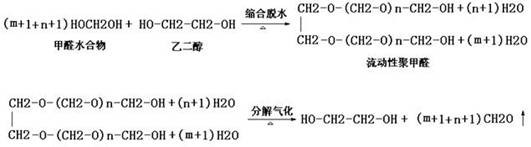

The invention belongs to the technical field of energy and chemical industry, and provides a preparation method of a fuel additive and an environment-friendly solvent polyoxymethylene dimethyl ether (DMMNn, generally n=3-8), which comprises the following steps: mixing a formaldehyde water solution and polyol according to a certain proportion, and conducting heating and dehydrating under vacuum conditions to obtain flowing polyoxymethylene with lower moisture content in one step; heating and gasifying flowing polyformaldehyde with the lower moisture content to obtain purer gaseous formaldehyde,mixing the obtained gaseous formaldehyde with methylal, mechanically used last-batch low-boiling-point substances, macromolecules and the like in the presence of a catalyst, carrying out catalytic reaction at a certain temperature, filtering out the catalyst after the reaction is balanced, purifying the synthetic liquid, respectively carrying out atmospheric pressure and reduced pressure distillation, conducting separating to obtain a low-boiling-point substance, macromolecules and a DMMn finished product, and carrying out reduced pressure distillation on the DMMn finished product to obtain each single component; and after the formaldehyde is gasified, returning the residual polyhydric alcohol for application of next-batch concentrating of formaldehyde to prepare the flowing polyformaldehyde with lower moisture content.

Owner:SHANDONG CHENXIN NEW ENERGY

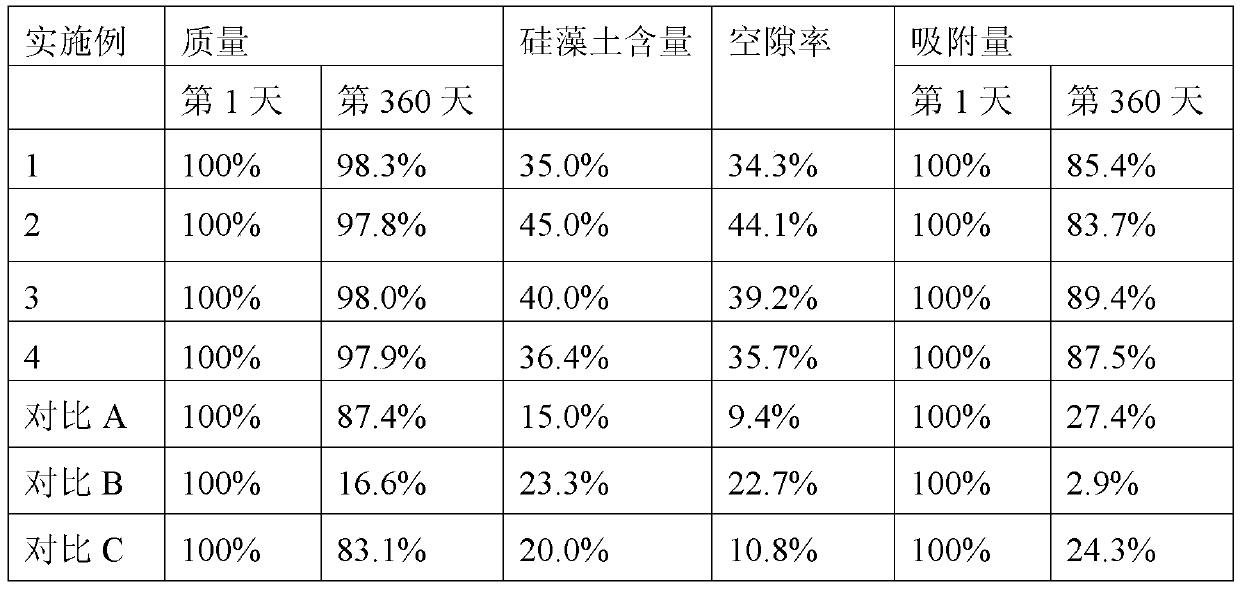

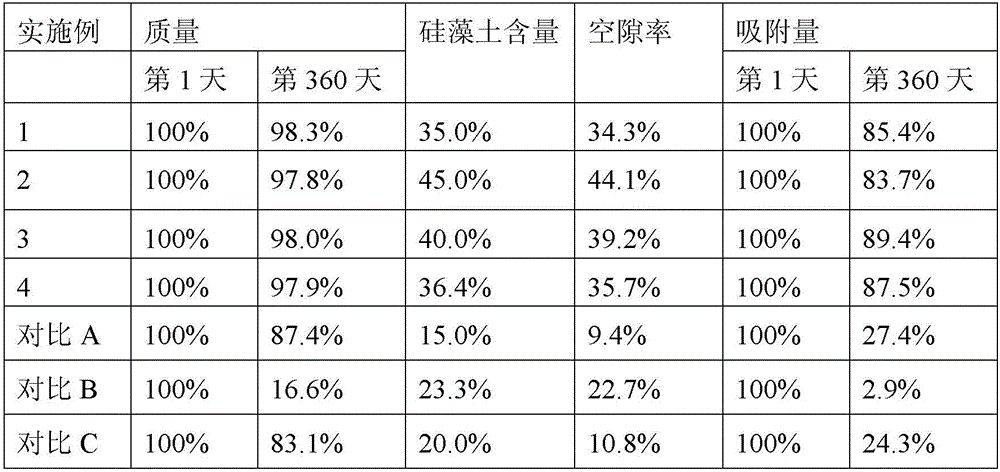

A non-glue-type non-photocatalytic diatom mud material for purifying formaldehyde in the air

The invention provides an adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air and relates to a diatomite wall material capable of purifying air. The existing problems that a diatomite coating added with a chemical adhesive is hardened and solidified and loses original filtration and absorption functions and that chemical adhesive-free diatomite is poor in adhesiveness and has such serious problems as dusting and peeling off after moisturizing are solved. The diatomite wall material is mainly prepared from diatomite, starch, lanthanide oxide and opal in parts by weight. The adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air in the invention is chemical adhesive-free and thus harmless to human body, and achieves true green and environmental protection.

Owner:HARBIN AOBAO DIATOM NEW MATERIALS CO LTD

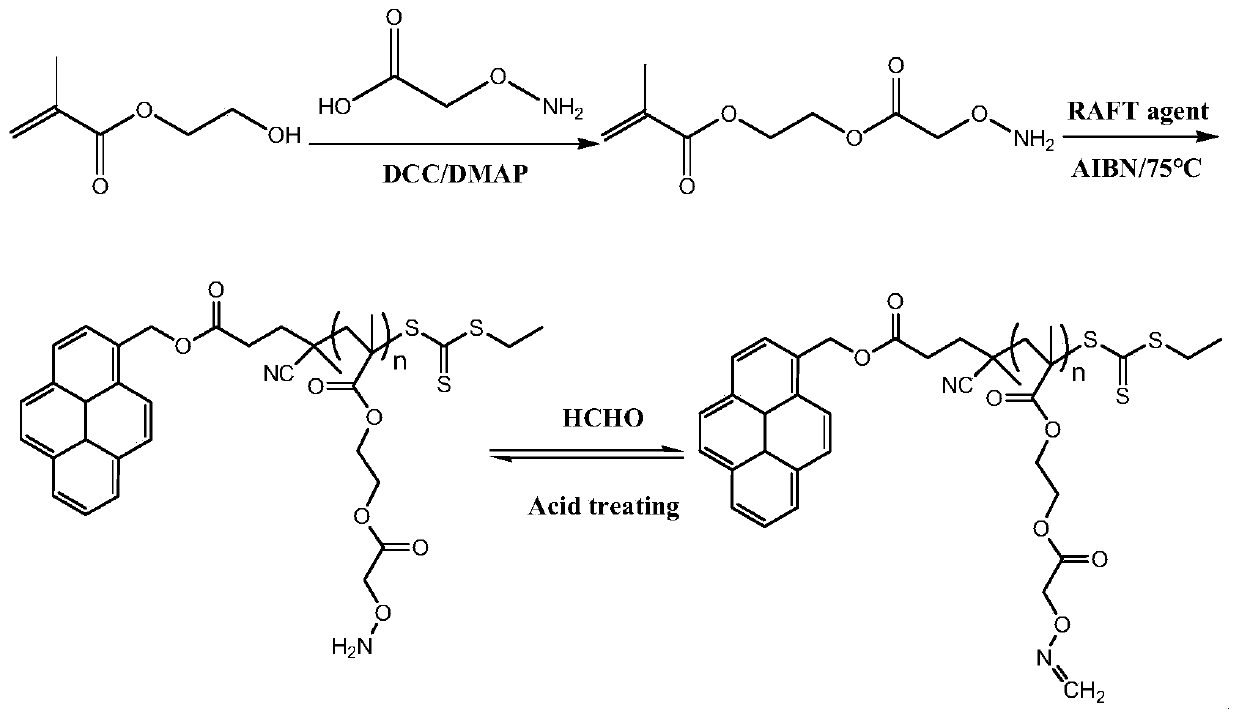

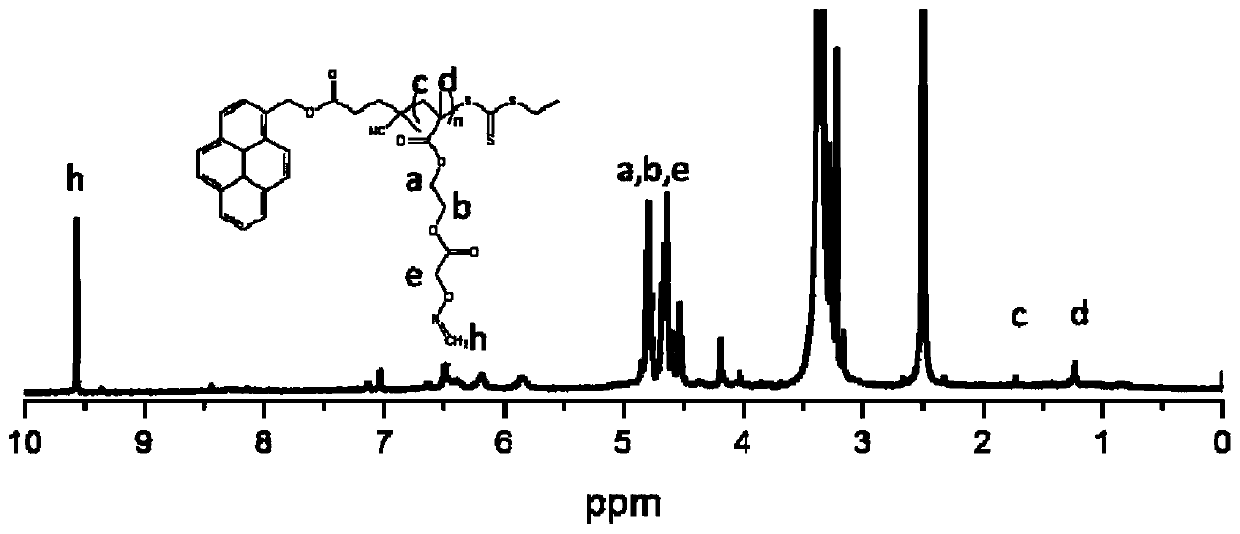

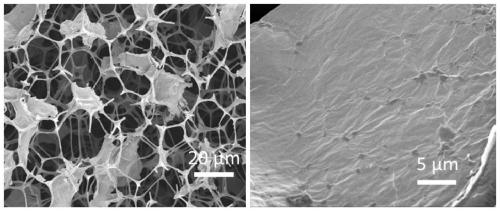

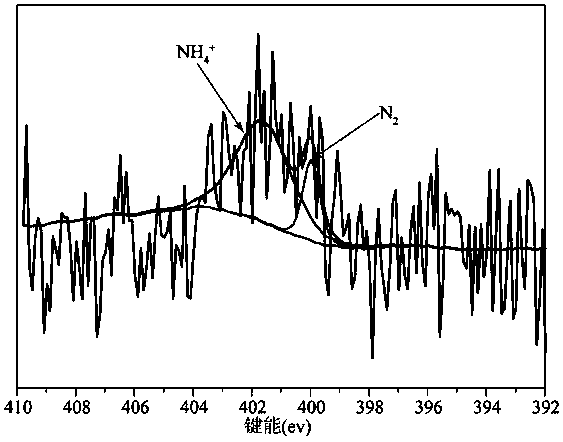

Aminooxy structure-containing polymer and formaldehyde adsorbent, and preparation methods thereof

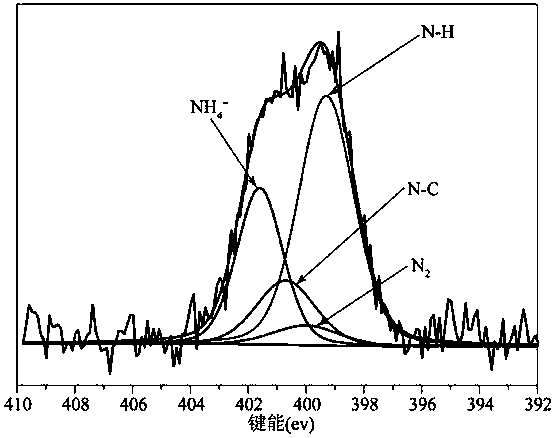

ActiveCN110204638AImprove stabilityGuaranteed stabilityOther chemical processesDispersed particle separationSorbentAtom-transfer radical-polymerization

The invention belongs to the technical fields of polymer materials technologies and harmful gas treatment, and particularly relates to an aminooxy structure-containing polymer and a formaldehyde adsorbent including the polymer, and preparation methods thereof. Reversible addition-fragmentation chain transfer (RAFT) polymerization or atom transfer radical polymerization (ATRP) is used to obtain thepolymer containing a large amount of aminooxy groups, the polymer and a two-dimensional carrier material are commonly loaded on porous melamine foam or polyurethane foam to prepare an aerogel material, and the aerogel material is a three-dimensional material capable of efficiently adsorbing gaseous formaldehyde, that is, the formaldehyde adsorbent. The formaldehyde adsorbent in the invention realizes reversible chemical adsorption of the formaldehyde gas at normal temperature under normal pressure in the absence of a catalyst, combines the high specific surface area of the carrier and the three-dimensional porous structure of the foam, and can be used for specifically and efficiently adsorbing the gaseous formaldehyde; and the formaldehyde can be desorbed under the action of dilute hydrochloric acid, so the formaldehyde adsorbent can be repeatedly used.

Owner:临沂中科芯华新材料科技有限公司

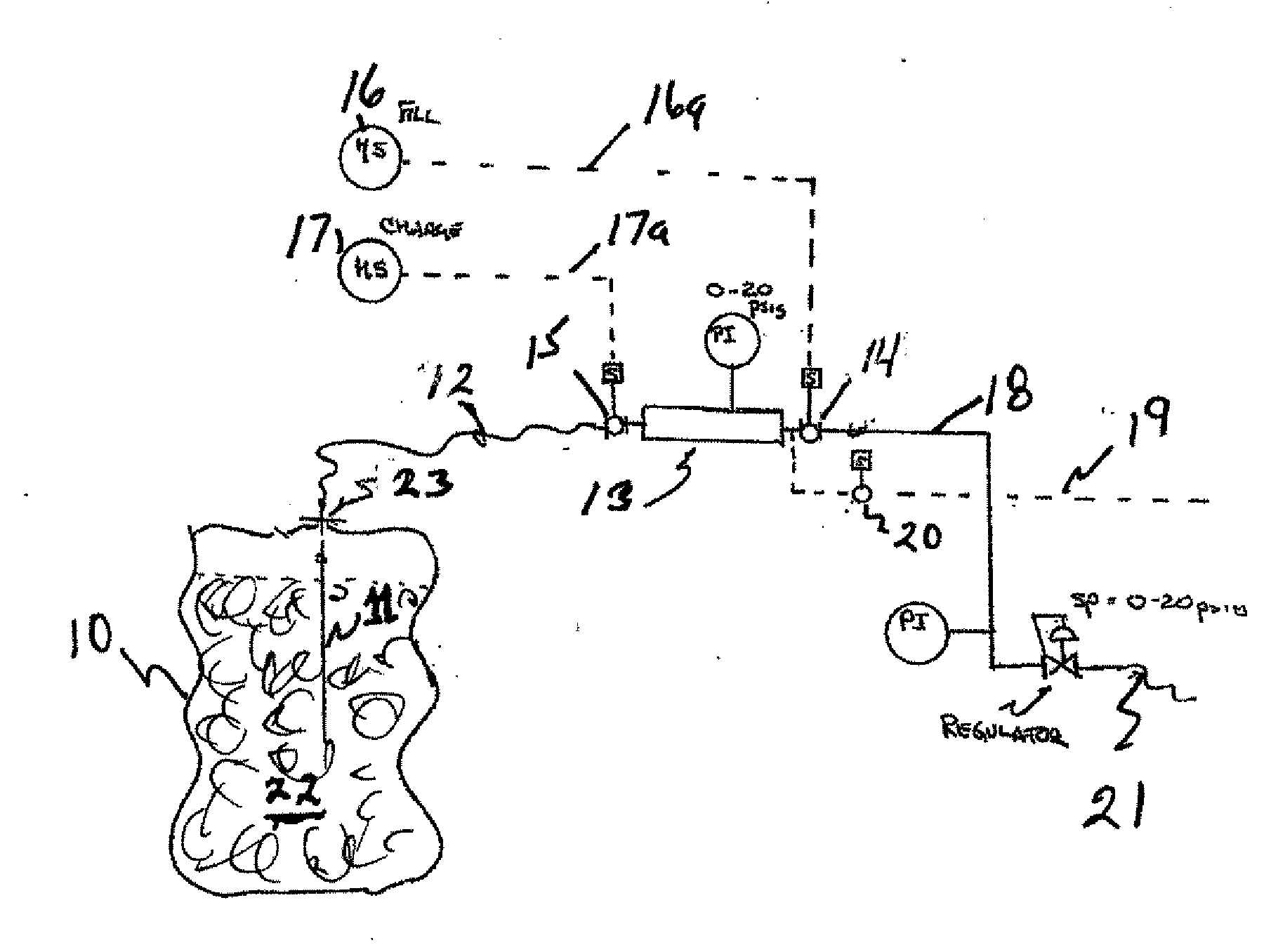

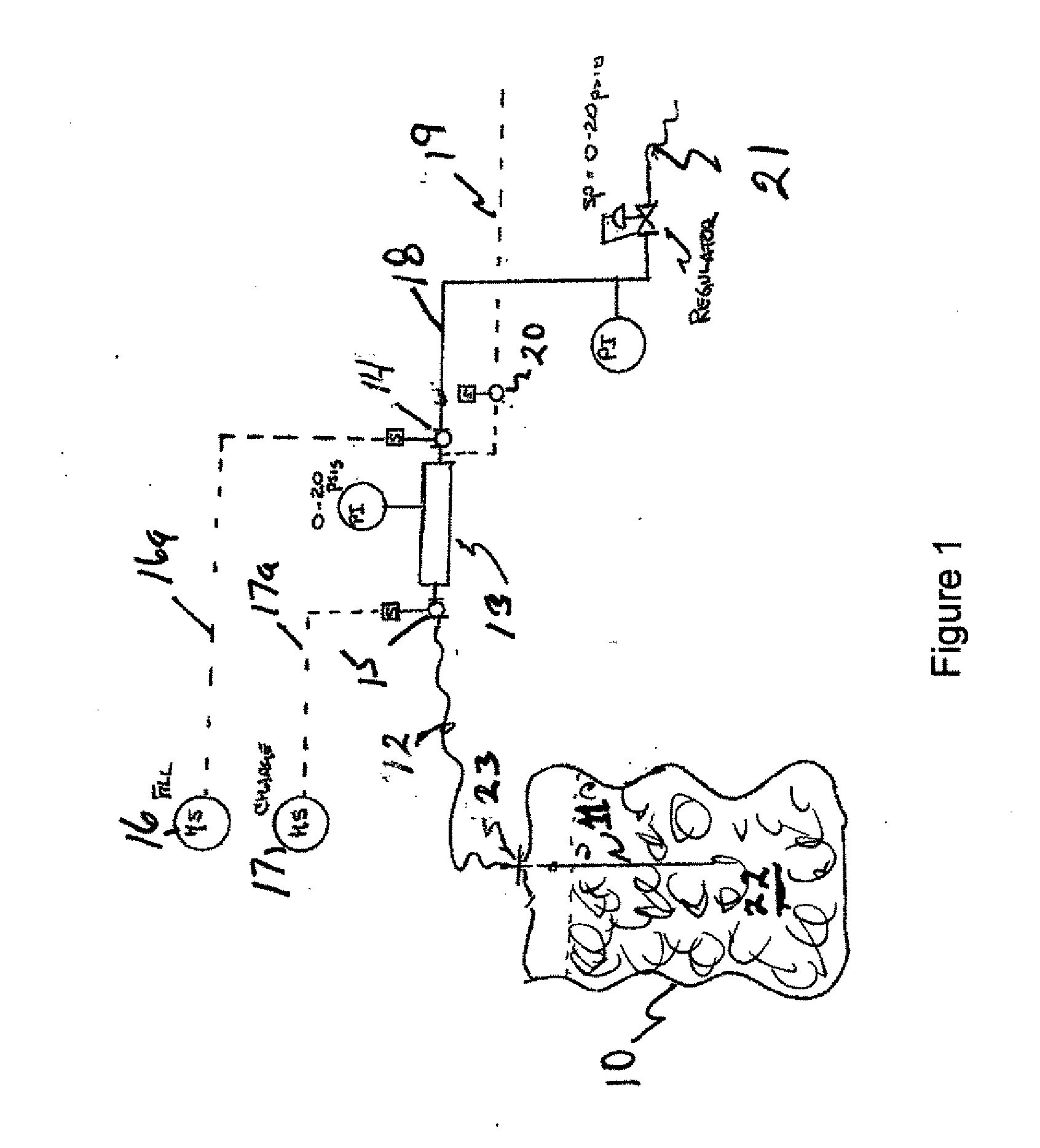

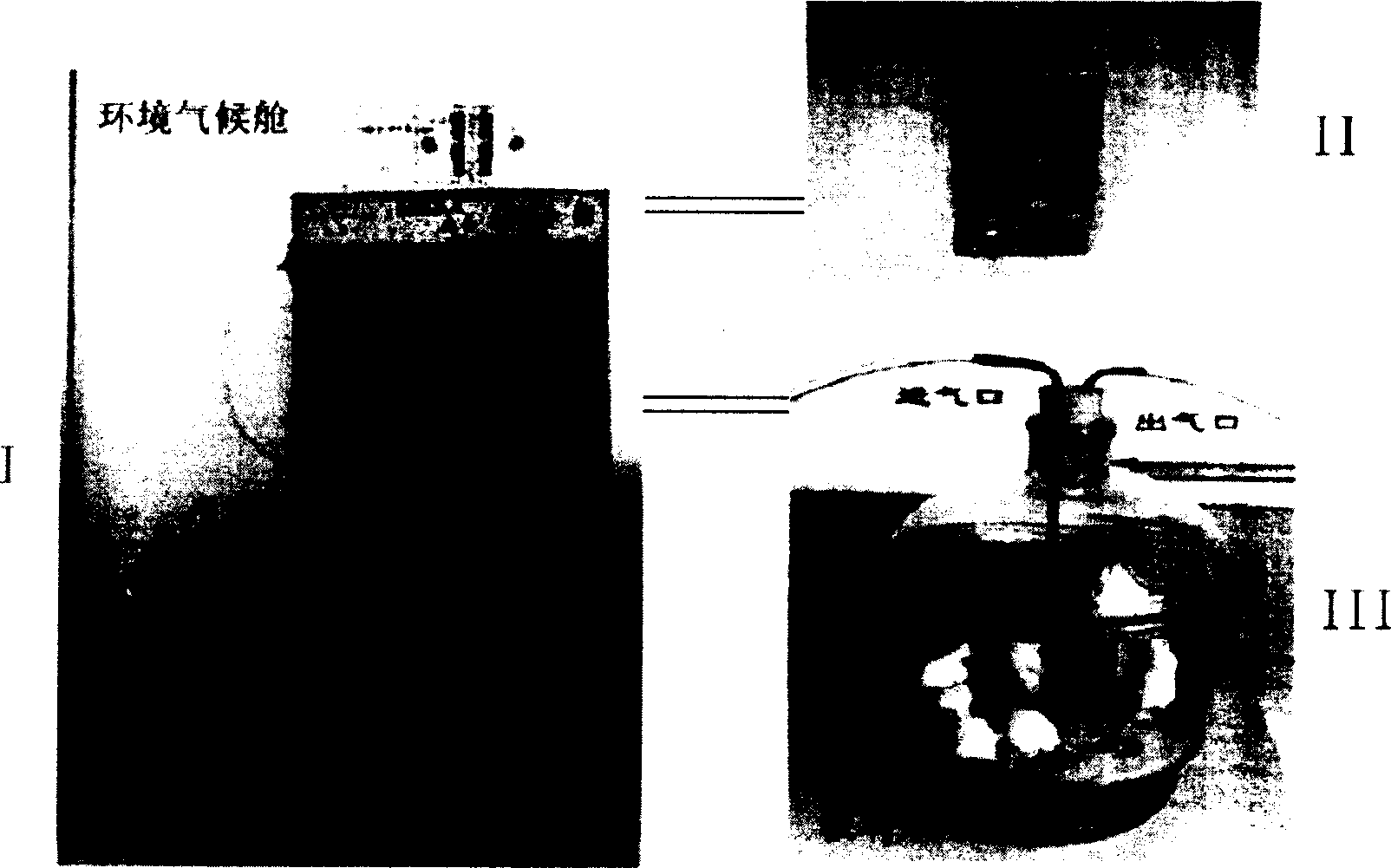

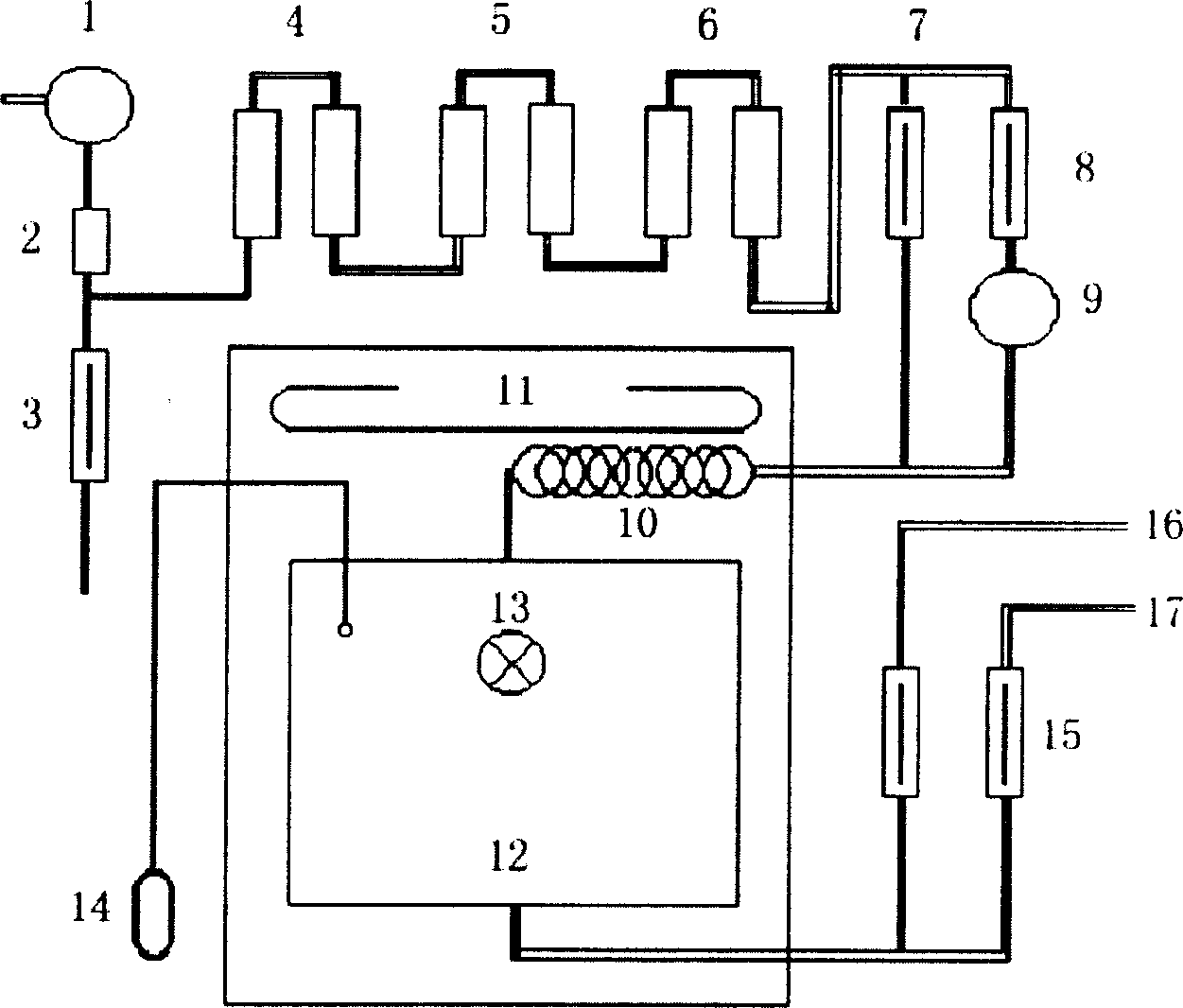

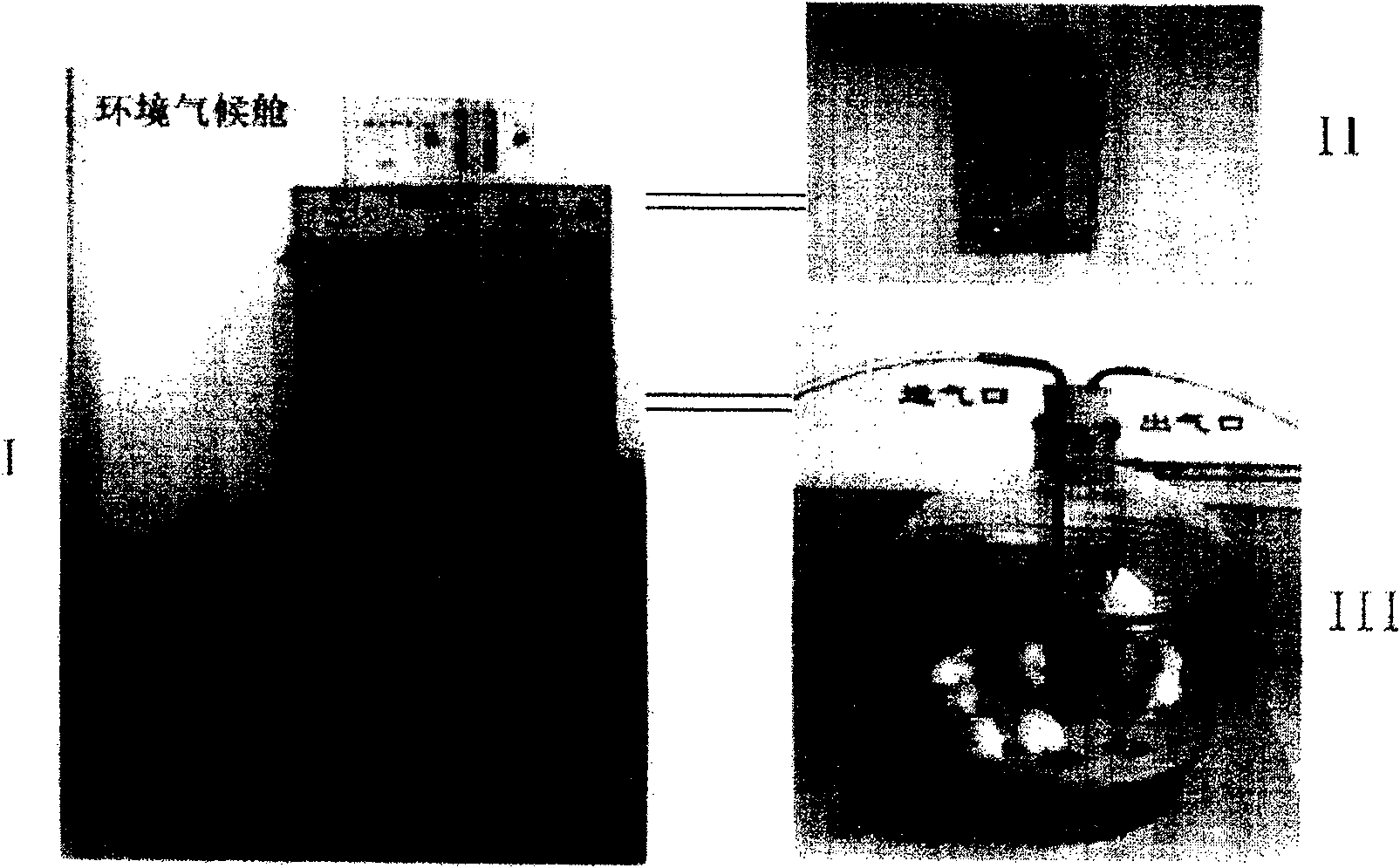

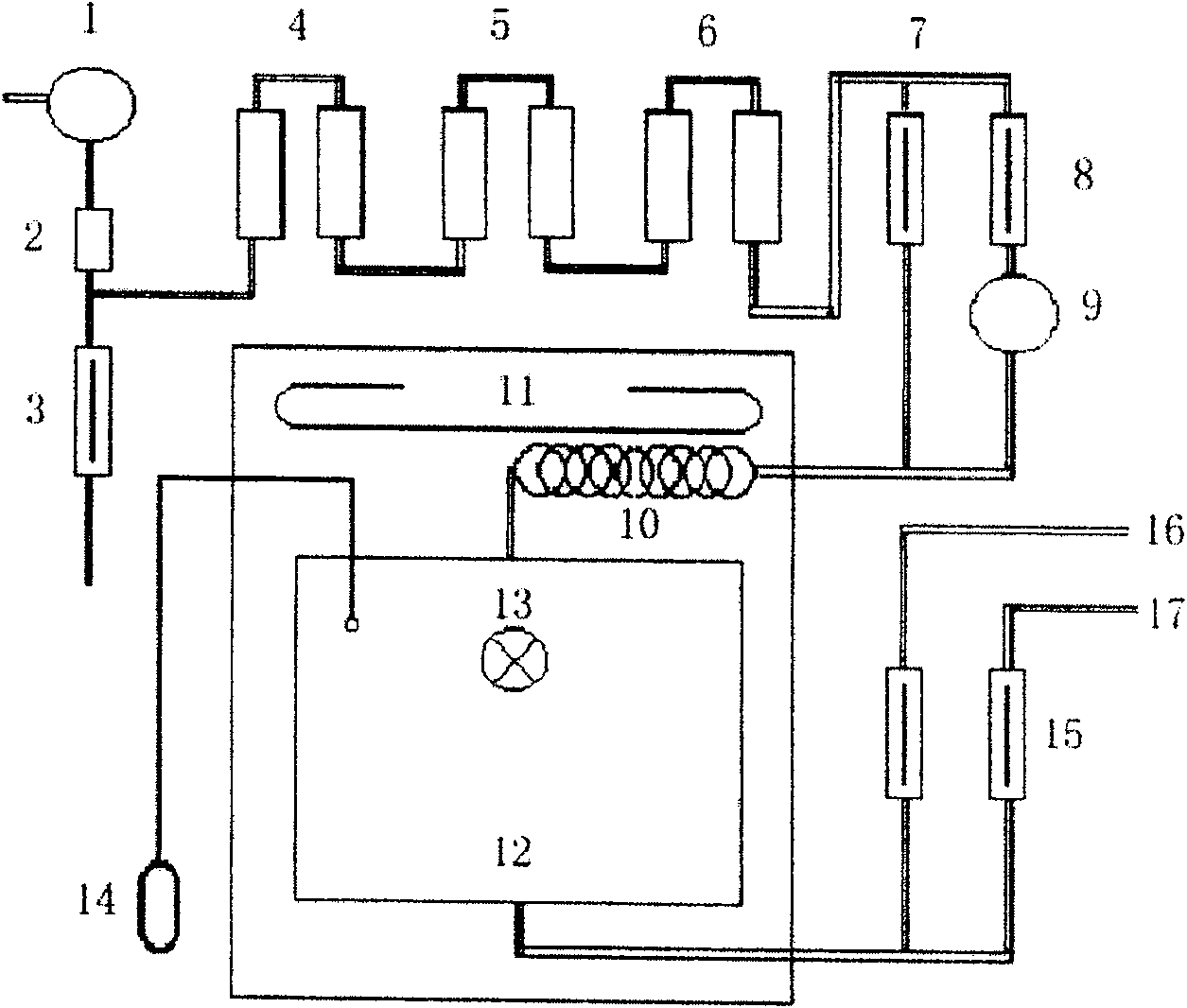

Standard gaseous formaldehyde dynamic contamination device

InactiveCN1904611AEliminate distractionsPrecise and constant dose of poisonVeterinary instrumentsMaterial analysisControl systemPhysical chemistry

The invention relates to a standard gas state formaldehyde dynamic toxin coating device that is made up of environment climate compartment (I), formaldehyde analyzer (II), and 8.4L aeration glass toxin coating jar. The main feather is that it uses environment climate compartment as source generator, using standard formaldehyde solution produced by Sigma Corp., standard gas state formaldehyde of the needed thickness would be generated by environment climate compartment humidity controlling system to take standard gas state formaldehyde toxin coating to biology sample and take real time dynamic accuracy testing to ensure the stability of the formaldehyde state and thickness. It is a reliable gas state formaldehyde toxin coating device.

Owner:HUAZHONG NORMAL UNIV

Preparation method of mass type formaldehyde sensor based on functionalized SBA-15

InactiveCN102033028BHigh sensitivityHigh selectivityMaterial weighingEnvironmental resistanceGaseous formaldehyde

The invention relates to a preparation method of a quartz crystal microbalance (QCM) formaldehyde sensor based on amino-functionalized SBA-15, belonging to the technical fields of sensitive materials and gas sensors. By first using functionalized SBA-15 as the sensitive material of the QCM mass type sensor to construct the formaldehyde sensor having favorable performance, the preparation method comprises the following steps: carrying out ultrasonic dispersion on self-prepared beta-carboxyl ethyl trimethoxysilane functionalized SBA-15 of which the pore diameter is 2-50 nm in a certain medium for 20-50 minutes to obtain a coating liquid, wherein the used medium is any one of water, acetone or ethanol; and uniformly spreading the coating liquid on the electrode surface of a cleaned quartz crystal microbalance, and drying at 80-120 DEG C for 3-8 hours to obtain the formaldehyde sensor. The mass type sensor has sensitive response to indoor air pollutant gaseous formaldehyde (the lower detection limit can reach the ppm level), and has the advantages of good selectivity, high stability, economy and environmental friendliness. Thus, the invention provides a favorable formaldehyde sensitive material for QCM and opens up a new application area for functionalized SBA-15.

Owner:萨驰机械工程(上海)有限公司

Opal composite formaldehyde purification material and preparation method thereof

ActiveCN109317107ASolve the problem of weak purification abilityImproved adsorption and capture performanceGas treatmentOther chemical processesSilanesProduct gas

The invention relates to an opal composite formaldehyde purification material and a preparation method thereof, and belongs to the field of nonmetallic mineral materials and environmental engineering.The preparation method comprises the following steps of: using opal as a carrier and amino silane as a modifier, adding an amino group on the surface of the opal by adopting a surface graft modification method to prepare the opal composite formaldehyde purification material. By use of relatively high affinity of the amino group to formaldehyde, the amino group on the surface of the opal is addedthrough graft modification on the surface of the opal, so that the gaseous formaldehyde pollutant capture performance of the prepared composite material is greatly improved, and the problem that the natural opal has relatively low formaldehyde adsorption and purification capacity is solved; and the required raw material is cheap and easy to get, the preparation process is simple, the reaction condition is mild, and the opal composite formaldehyde purification material has a relatively high application value in the field of indoor formaldehyde gas purification.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

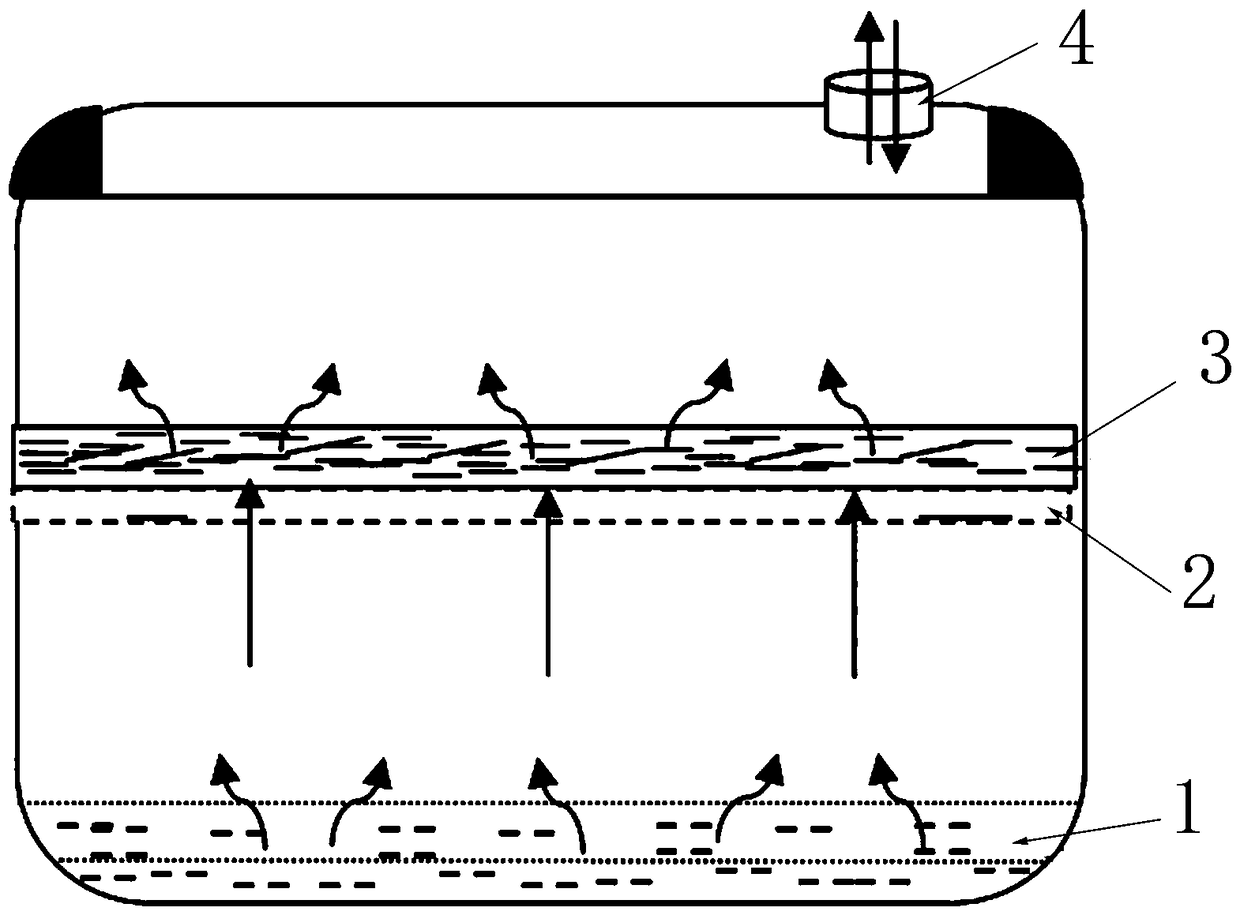

Method for degrading gaseous formaldehyde by using methylotrophic bacterium

InactiveCN109260942AGas treatmentDispersed particle separationHigh concentrationGaseous formaldehyde

The invention discloses a method for degrading gaseous formaldehyde by using a methylotrophic bacterium. The methylotrophic bacterium used is Methylobacterium sp.XJLW. A mesh bracket is arranged abovea formaldehyde gas source to be treated, and a polymer water absorbent resin SAP is placed on the mesh bracket as a bacterium carrier, and the methylotrophic bacterium is placed in the bacterium carrier to degrade the gaseous formaldehyde. XJLW has the significant capability to reduce the formaldehyde in the air in a closed environment that continuously releases the high-concentration gaseous formaldehyde.

Owner:ZHEJIANG UNIV OF TECH

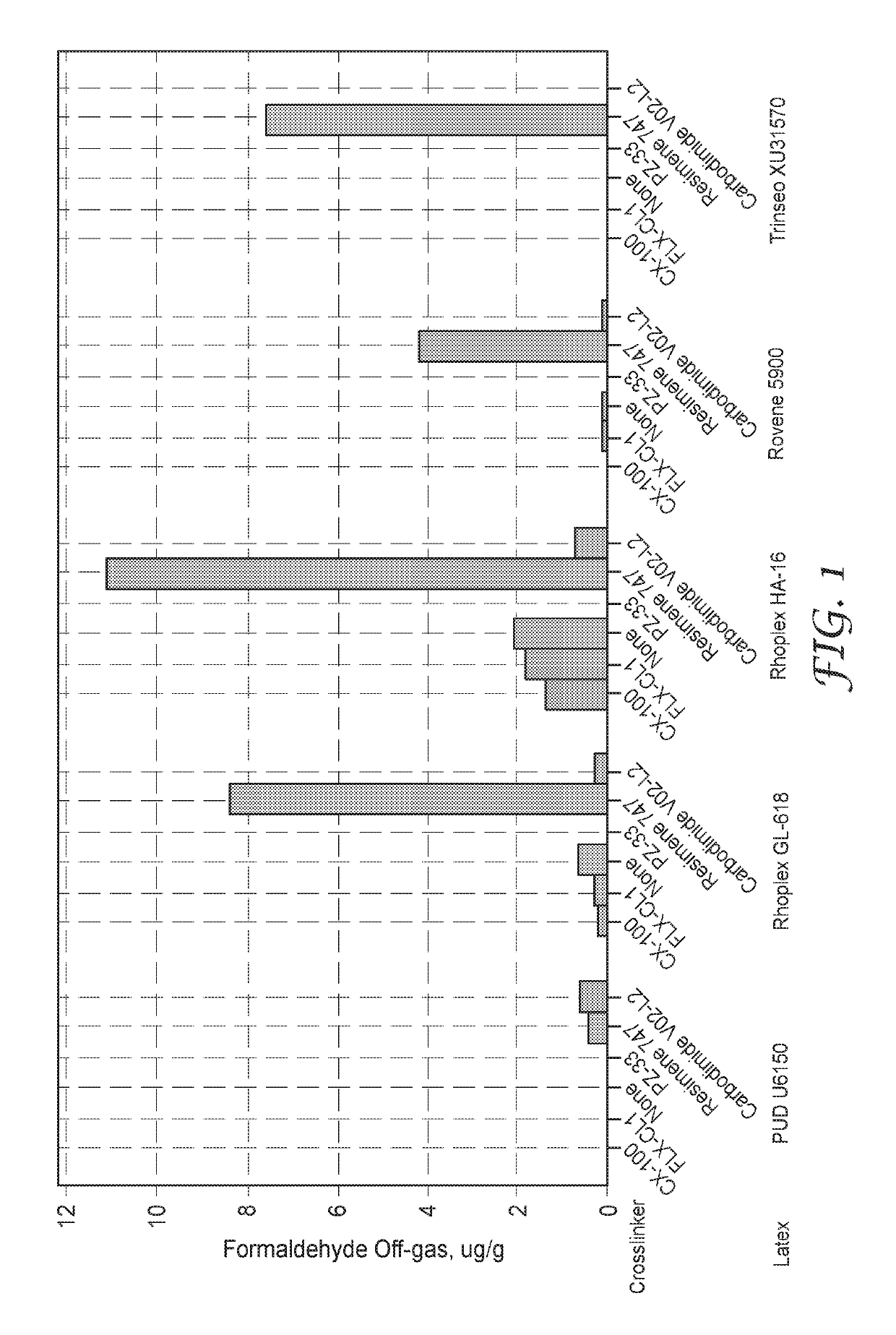

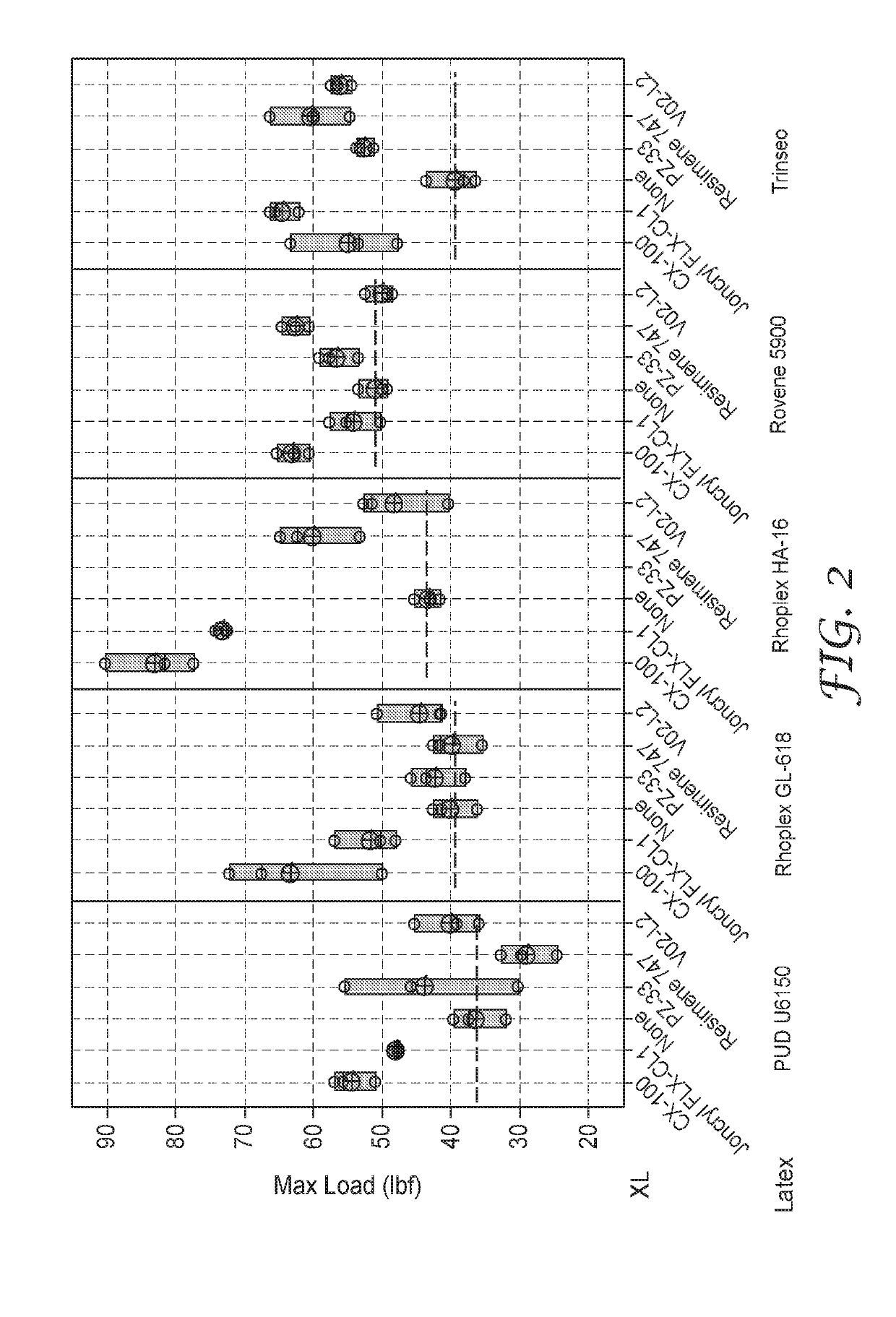

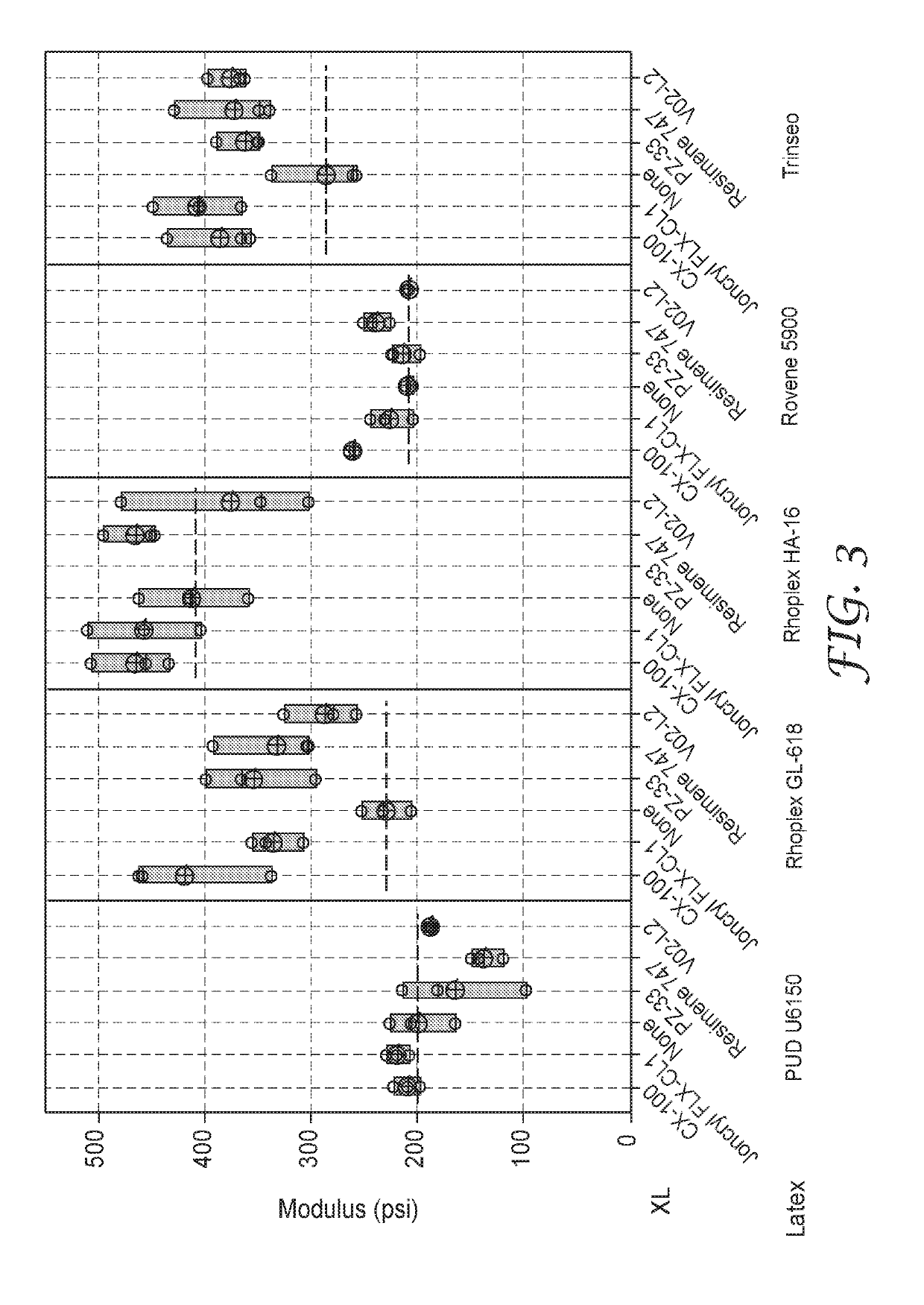

Flexible fibrous surface-treating article with low formaldehyde off-gassing

InactiveCN109415859AFull cleaning effectEasy to polishFibre typesNon-woven fabricsPolymer scienceGaseous formaldehyde

Various embodiments disclosed related to flexible fibrous surface-treating articles with low formaldehyde off-gassing. In various embodiments, the present invention provides a flexible fibrous surface-treating article including an open, lofty, nonwoven web including fibers. The flexible fibrous surface-treating article also includes a binder that coats the fibers of the nonwoven web. The binder includes a cured product of a curable composition including a latex and a crosslinker. The flexible fibrous surface-treating article heated to 65 DEG C in a closed space for 30 minutes emits less than about 6 micrograms of gaseous formaldehyde total per gram of the flexible fibrous surface-treating article.

Owner:3M INNOVATIVE PROPERTIES CO

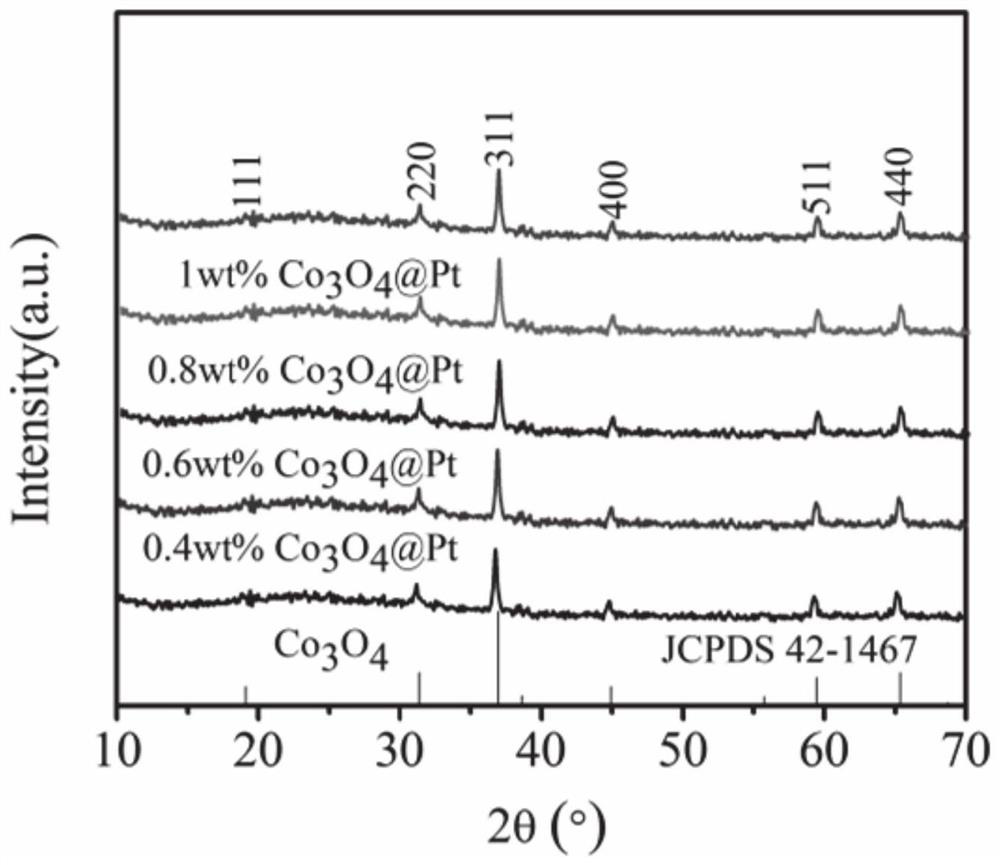

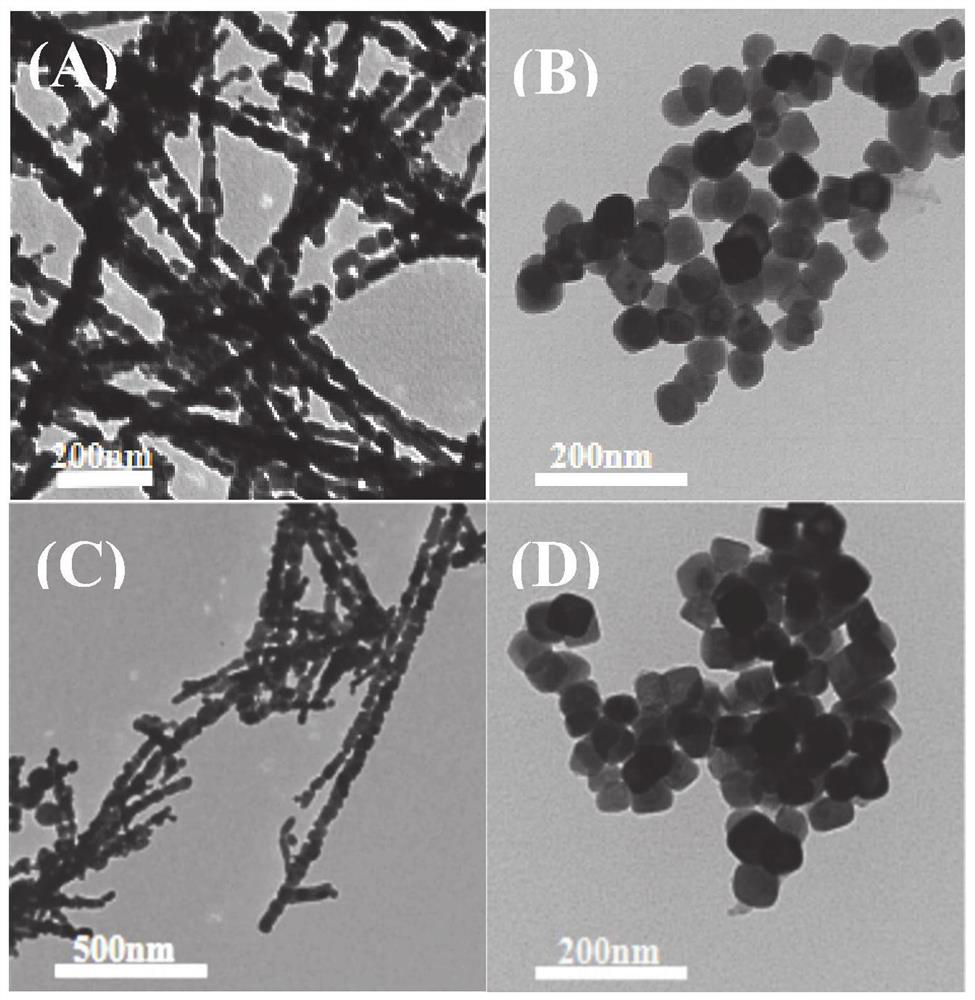

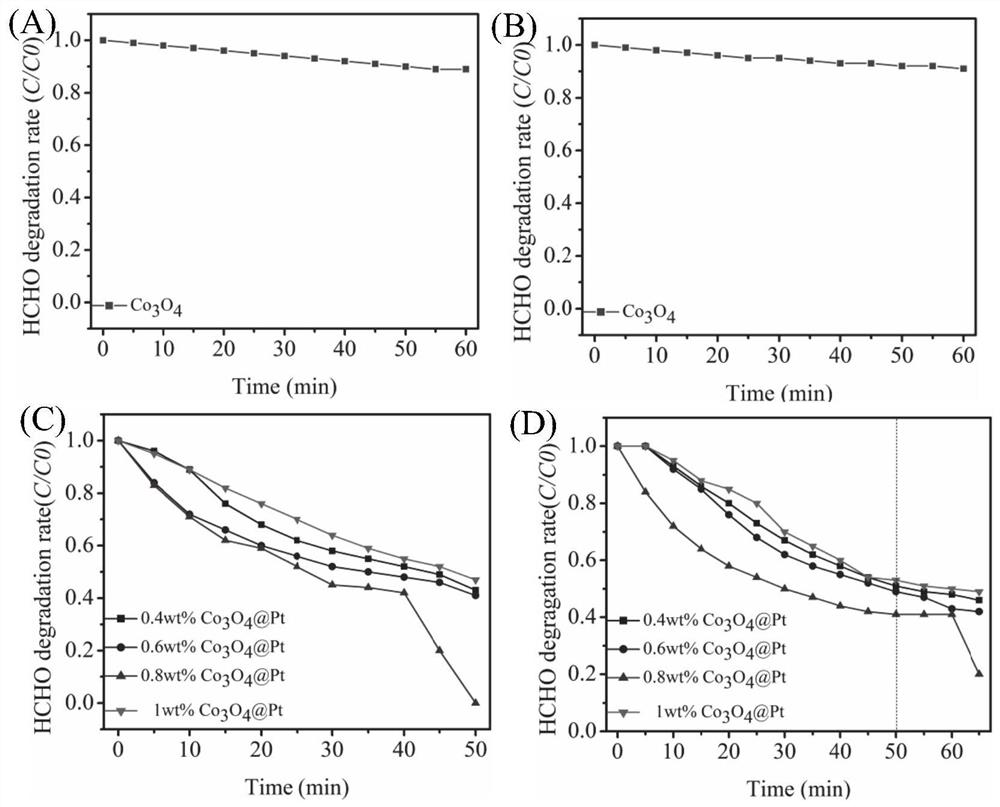

Preparation method and application of nanoscale Co3O4 (at) Pt

PendingCN114160155AAdjust catalytic performanceIncrease flexibilityOrganic compound preparationCarboxylic compound preparationPtru catalystNanoparticle

The invention relates to a nanoscale Co3O4 (at) Pt oxidation-reduction preparation method, which comprises the following steps: adding a solution containing non-zero oxidation state Pt into nanoscale Co3O4, carrying out oxidation-reduction reaction between Co (II) and high oxidation state Pt, and loading reduction product Pt nanoparticles on the surface of the nanoscale Co3O4. Pt particles in the prepared catalyst have excellent dispersity on a Co3O4 carrier with a large surface area, adsorption of gaseous formaldehyde molecules is enhanced through interaction between the carrier and metal, and the HCHO catalyst formed by loading the Pt nanoparticles with nanoscale Co3O4 as the carrier can be subjected to catalytic oxidation at room temperature under air conditions, so that the catalyst can be applied to the field of catalytic oxidation of formaldehyde. The HCHO catalytic efficiency of the rod-like Co3O4 (at) Pt catalyst can reach 100%.

Owner:SHANDONG NORMAL UNIV

Standard gaseous formaldehyde dynamic contamination device

InactiveCN100549692CEliminate distractionsPrecise and constant dose of poisonVeterinary instrumentsMaterial analysisControl systemBackground exposure

A standard gaseous formaldehyde dynamic poisoning device. The invention belongs to the technical field of standard gas dynamic poisoning. The device consists of an environmental climate chamber (I), a formaldehyde analyzer (II) and an 8.4-liter ventilated glass poisoning tank (III). Its main feature is that the environmental climate chamber is used as the source generator, the standard formaldehyde solution produced by Sigma is used, and the standard gaseous formaldehyde of the concentration required for the experiment is generated through the humidity control system of the environmental climate chamber, and the standard gaseous formaldehyde is poisoned on biological samples. It also conducts real-time dynamic and accurate detection of gaseous formaldehyde to ensure the stability of the state and concentration of gaseous formaldehyde. It overcomes the shortcomings of traditional static poisoning methods that are difficult to quantify and unstable. It is a reliable gaseous formaldehyde poisoning device.

Owner:HUAZHONG NORMAL UNIV

Adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air

The invention provides an adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air and relates to a diatomite wall material capable of purifying air. The existing problems that a diatomite coating added with a chemical adhesive is hardened and solidified and loses original filtration and absorption functions and that chemical adhesive-free diatomite is poor in adhesiveness and has such serious problems as dusting and peeling off after moisturizing are solved. The diatomite wall material is mainly prepared from diatomite, starch, lanthanide oxide and opal in parts by weight. The adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air in the invention is chemical adhesive-free and thus harmless to human body, and achieves true green and environmental protection.

Owner:HARBIN AOBAO DIATOM NEW MATERIALS CO LTD

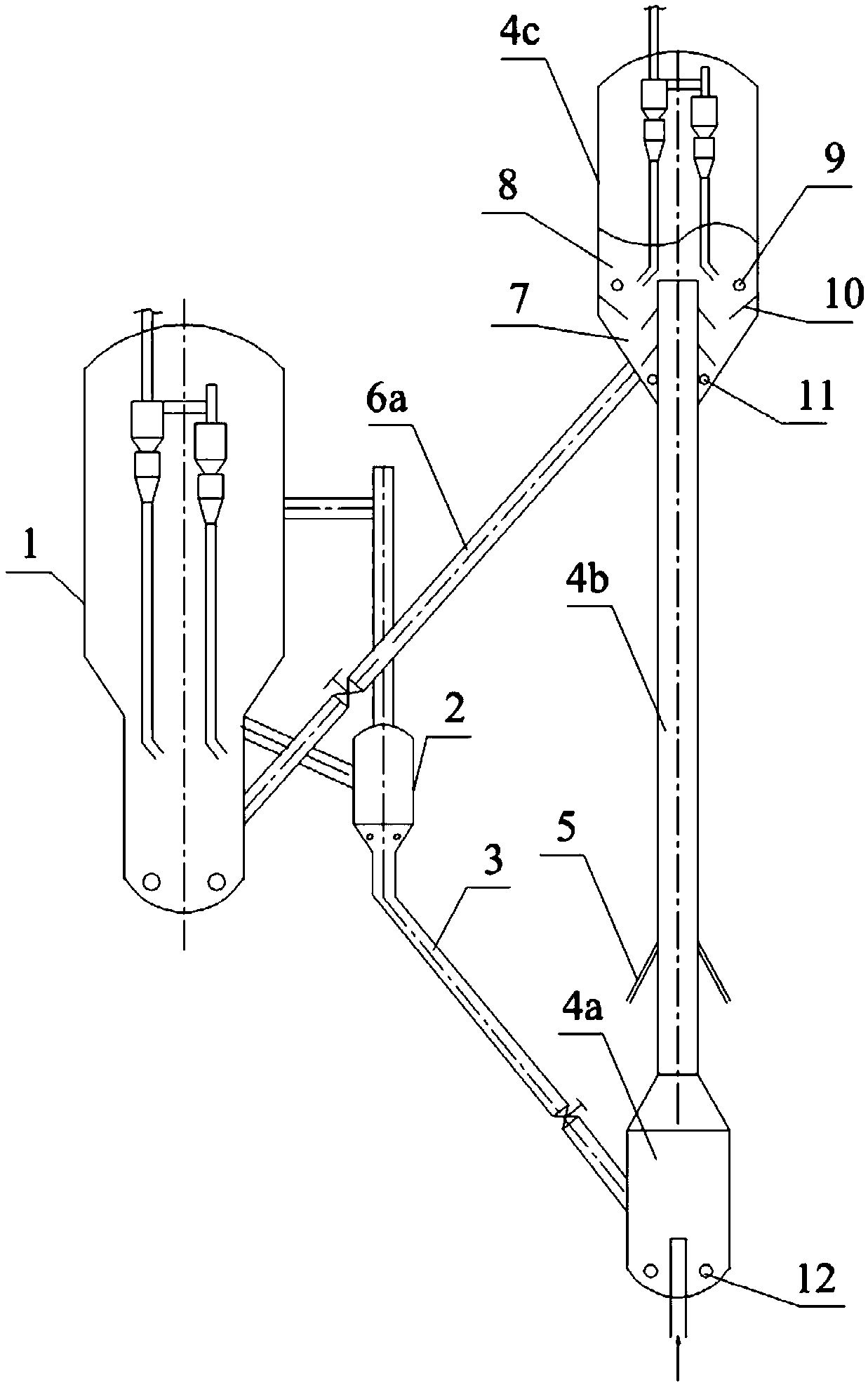

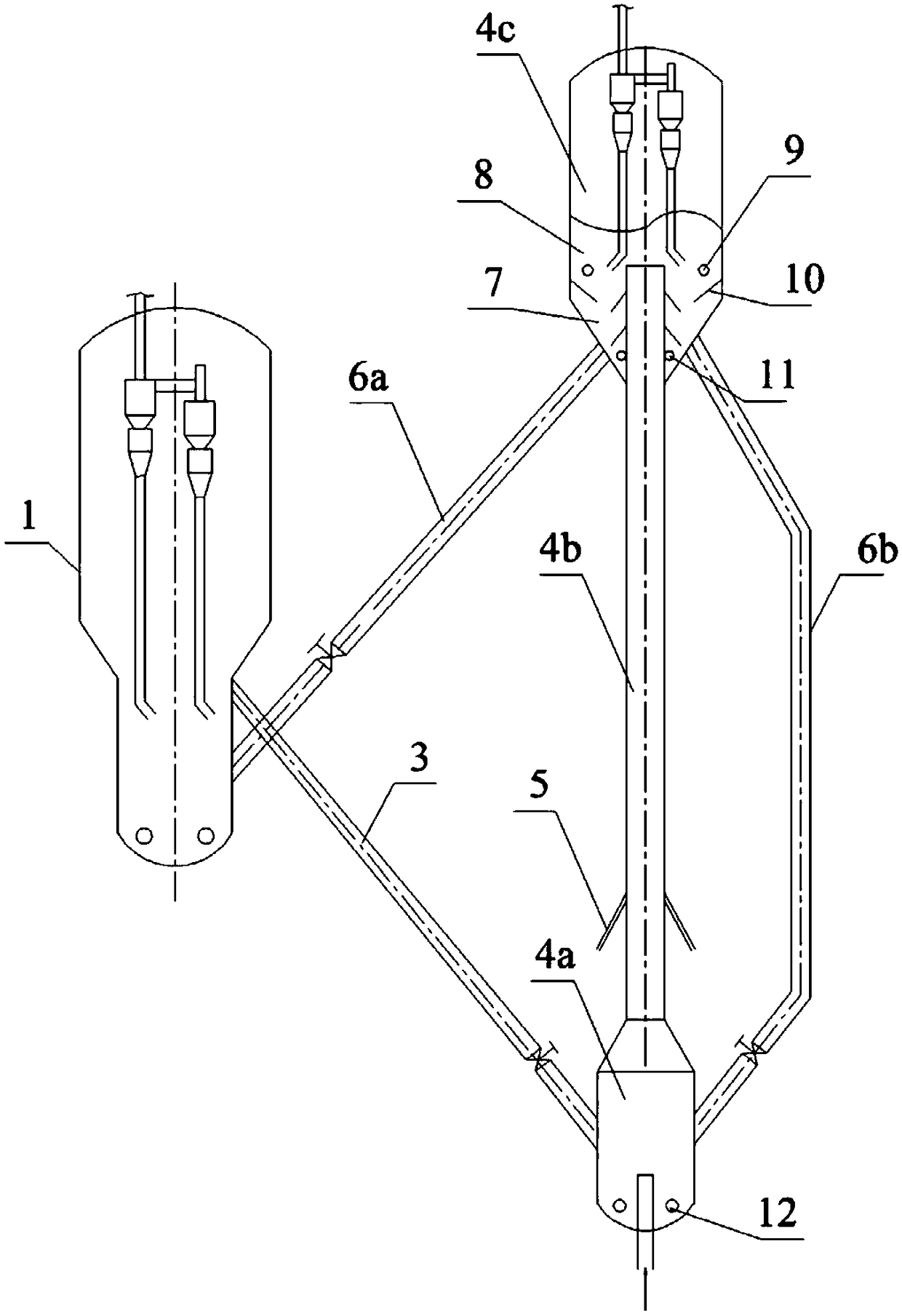

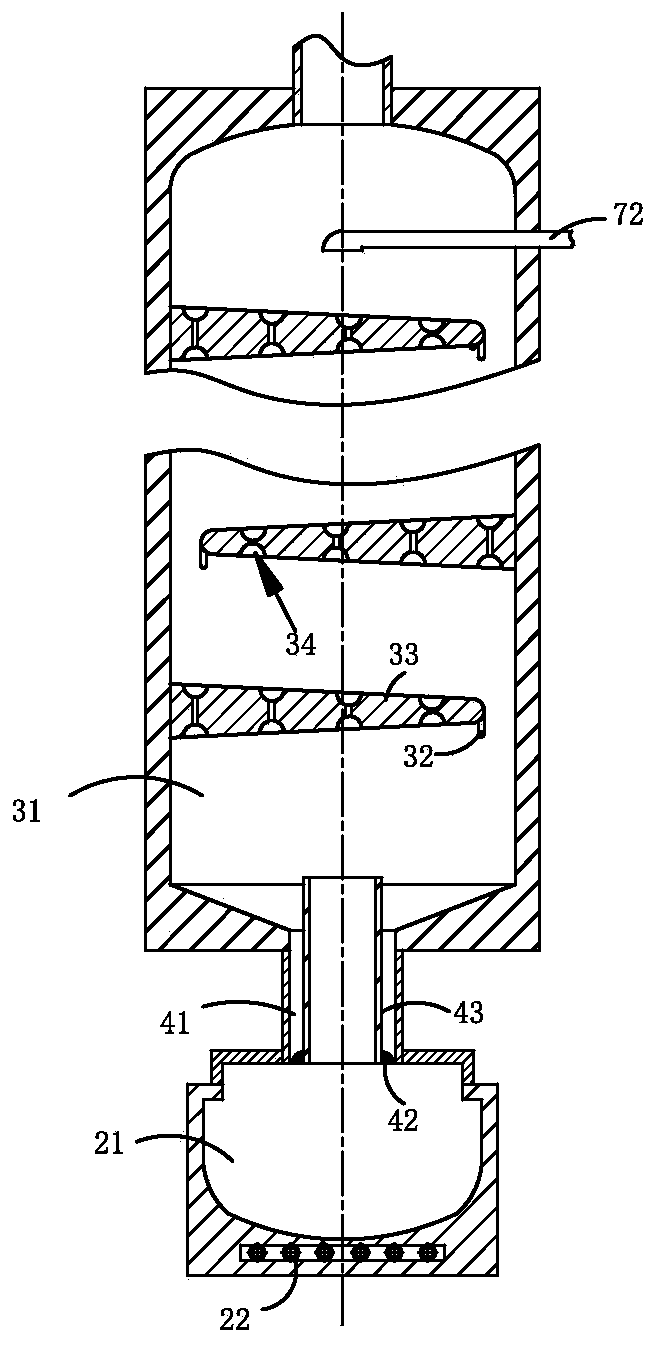

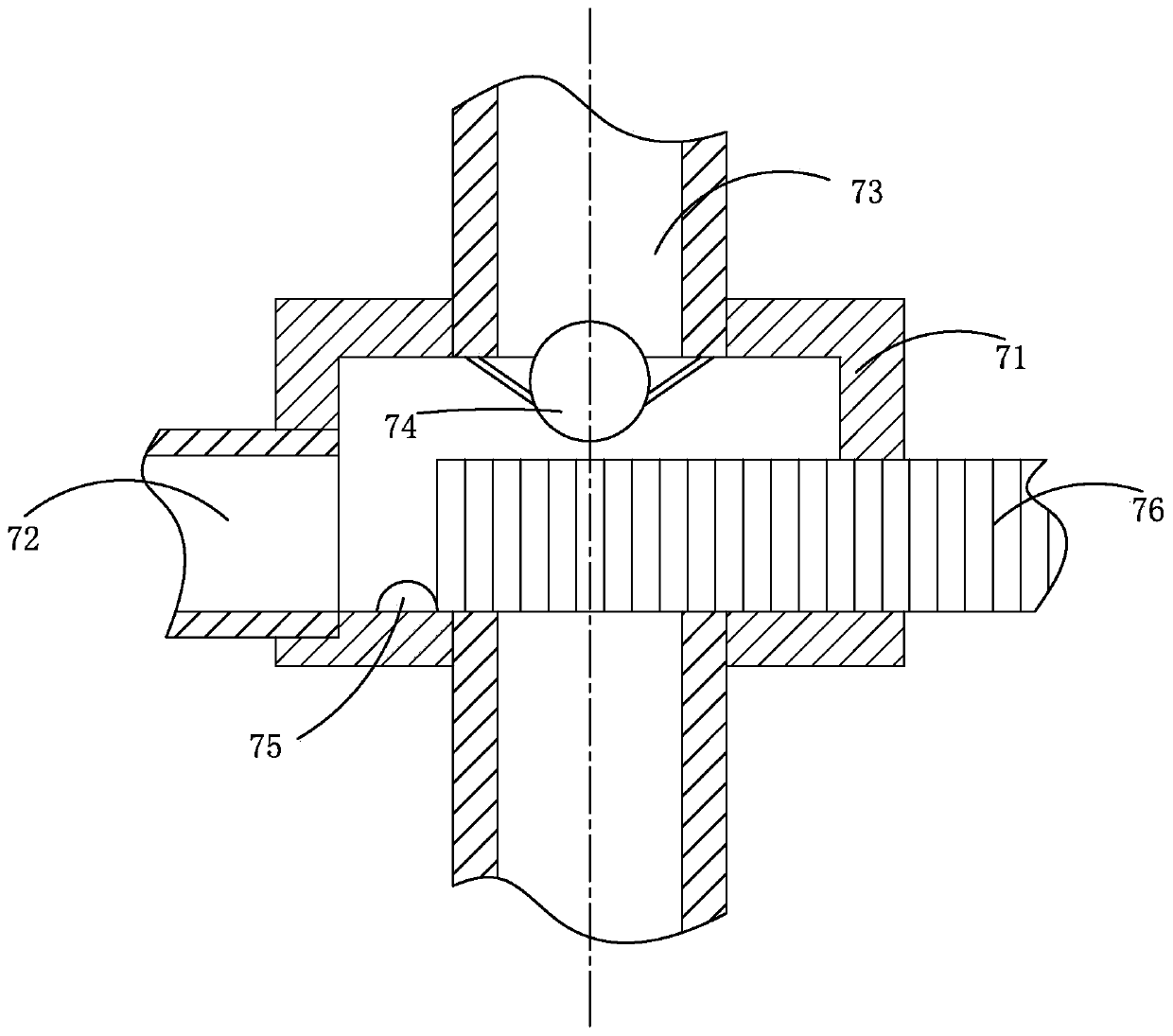

Circulating fluidized bed pyridine base preparing reaction equipment

InactiveCN108636303AImprove contact efficiencyHigh yieldOrganic chemistryChemical recyclingFluidized bedSpray nozzle

The invention relates to the technical field of carbon and nitrogen containing compound production, in particular to circulating fluidized bed pyridine base preparing reaction equipment. The equipmentcomprises a regenerator, a reactor assembly, a regenerated catalyst circulation line and a spent catalyst circulation line I; the mode of connecting a first reactor, a second reactor and a third reactor in series is adopted for making gaseous formaldehyde, acetaldehyde and ammonia gas make sufficient contact with and react with a catalyst, and meanwhile the third reactor makes the reaction conducted more thoroughly; the contact efficiency of reactant is greatly improved, and the yield of products is increased; feeding adopts spray nozzle spraying, and compared with an original distribution loop distributor, a spray nozzle is not subjected to coking; the regenerated catalyst circulation line and the spent catalyst circulation line are adopted, the activity of the catalyst and the catalyst-oil ratio can be flexibly adjusted, and the tube catalyst concentration can be improved. The whole device is simple in structure, capable of saving materials, low in manufacturing cost, easy to make and beneficial to continuous and automatic production and environmental protection processing of the production process.

Owner:ANHUI COSTAR BIOCHEM CO LTD

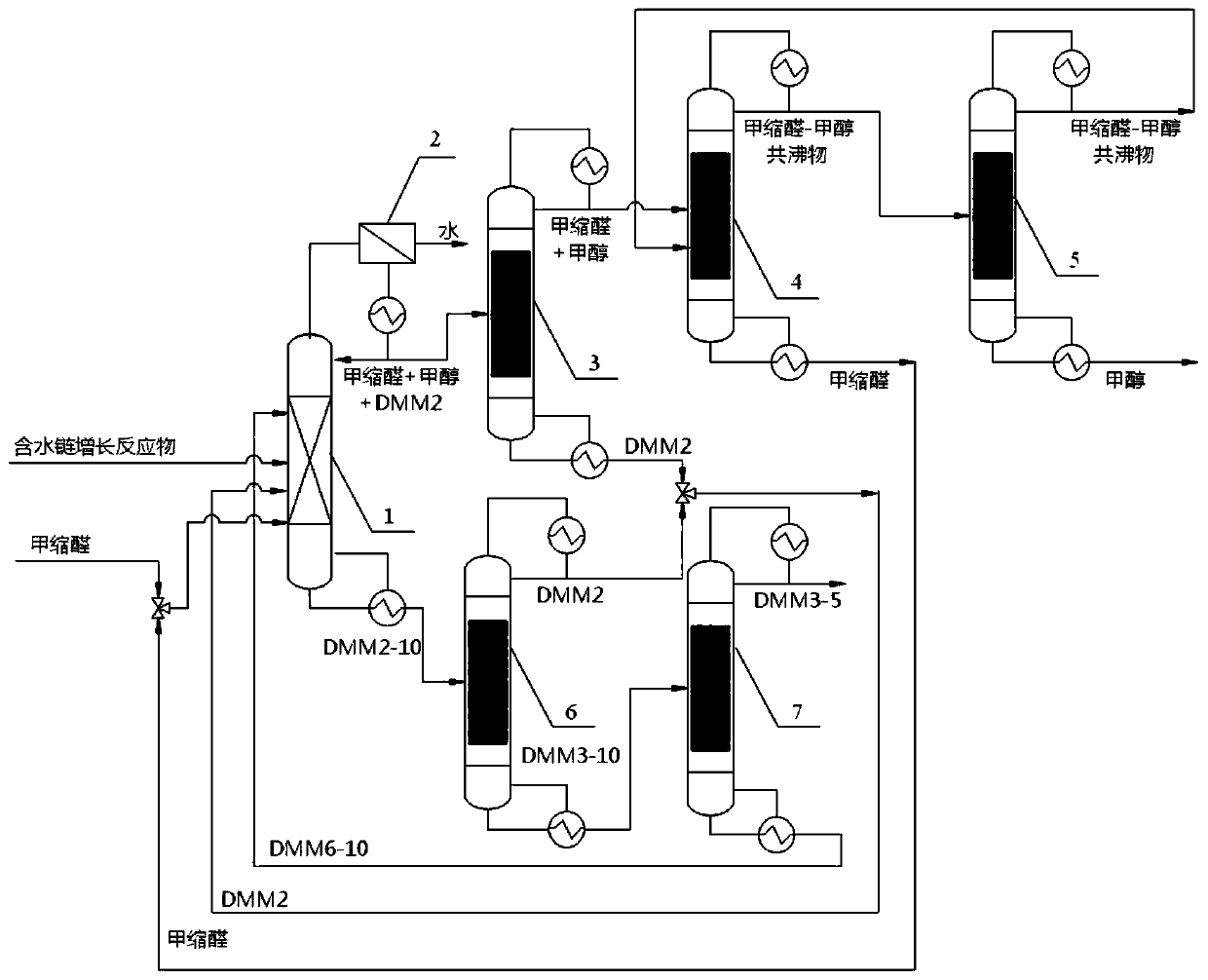

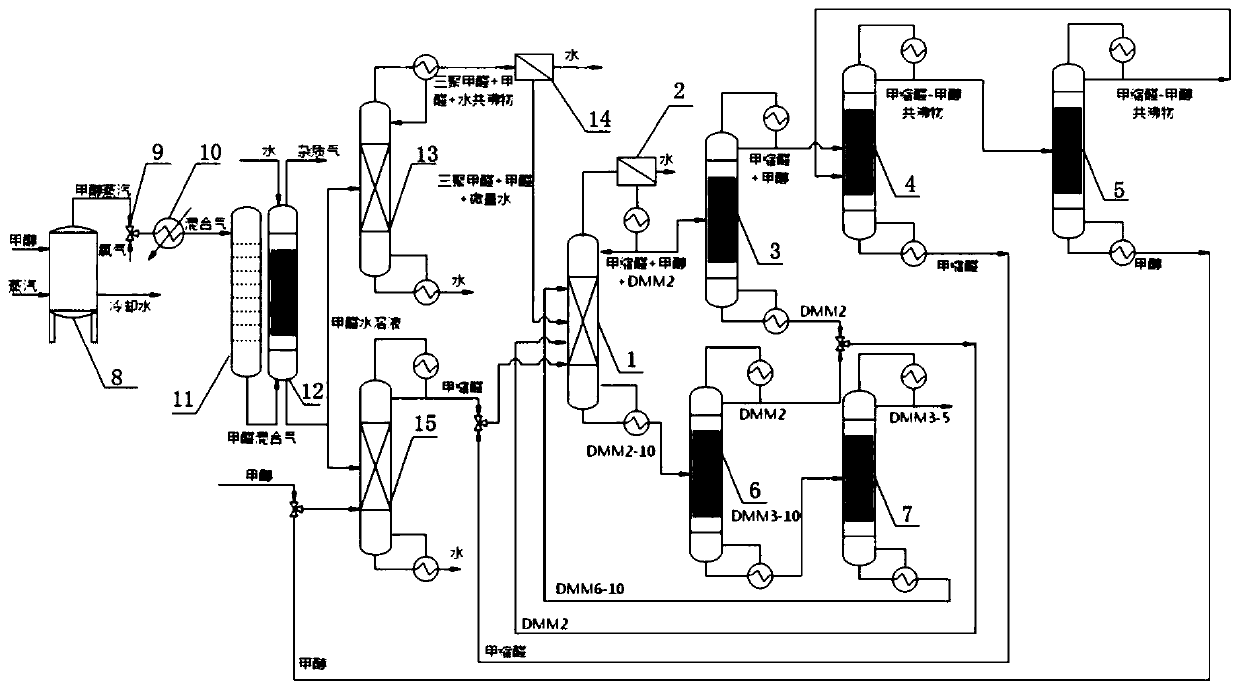

Reactive distillation-vapor permeation coupling process for polyoxymethylene dimethyl ether synthesis

ActiveCN110156575AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationGaseous formaldehydeParaformaldehyde

The invention relates to a reactive distillation-vapor permeation coupling process for the polyoxymethylene dimethyl ether synthesis. According to the coupling process, a methylal and a formaldehyde solution, a hydrous trioxymethylene, a hydrous paraformaldehyde, a hydrous gaseous formaldehyde or a mixture of substances are used as raw materials, a polyoxymethylene dimethyl ether mixed product with multiple polymerization degrees is obtained by carrying out a reaction under the action of an acidic catalyst, by the separation action of a polyoxymethylene dimethyl ether reactive distillation tower, reaction products with polymerization degrees of more than 2 are extracted out from the tower kettle, DMM2 with low polymerization degrees, unreacted methylal, reaction by-product methanol, and water in the reaction system are extracted out from the tower top, the extracted products from the tower kettle is subjected to product refining tower separation, and the target product DMM3-5 is obtained. According to the process, defects in the existing process that the target product DMM3-5 has low yield, the circulation amount in the process is large, the energy consumption is high, and the likeare solved, the reaction balance limit can be broken, the conversion rate of the raw material and the selectivity and yield of DMM3-5 are greatly improved.

Owner:TIANJIN UNIV

Flexible fibrous surface-treating article with low formaldehyde off-gassing

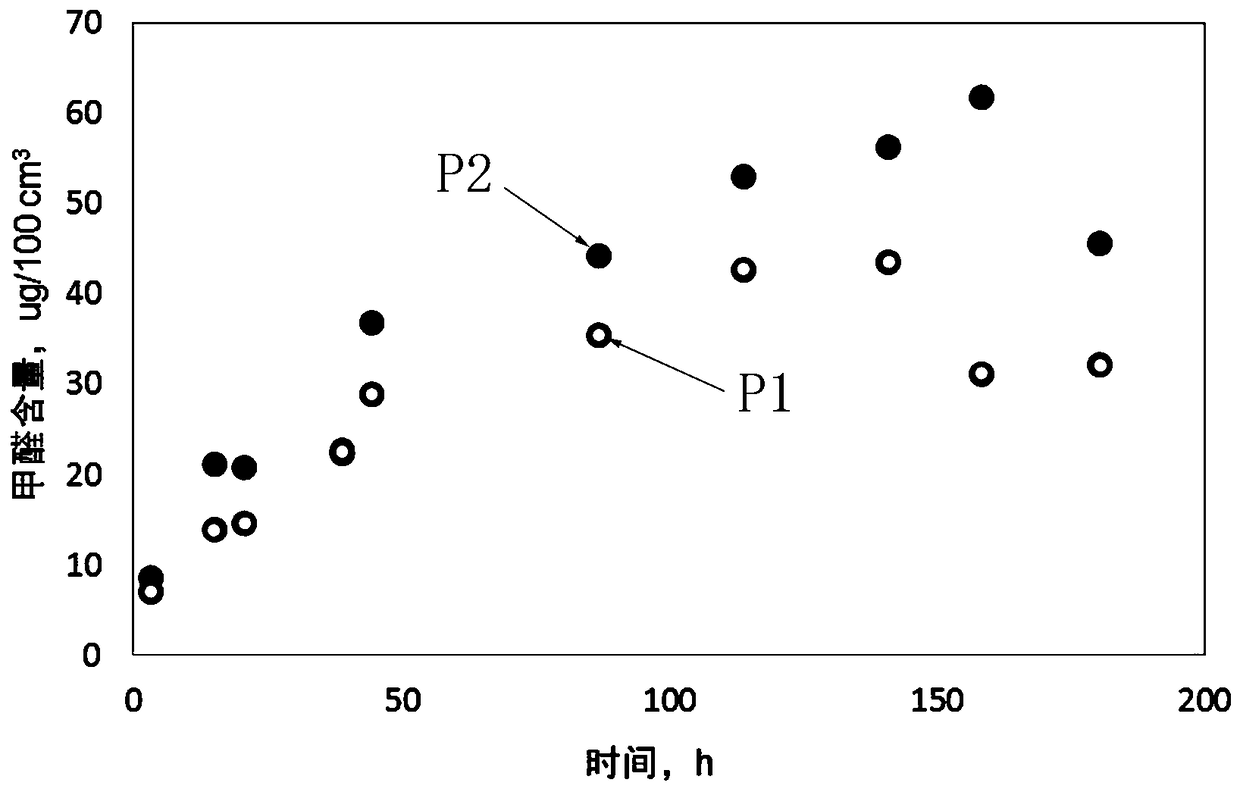

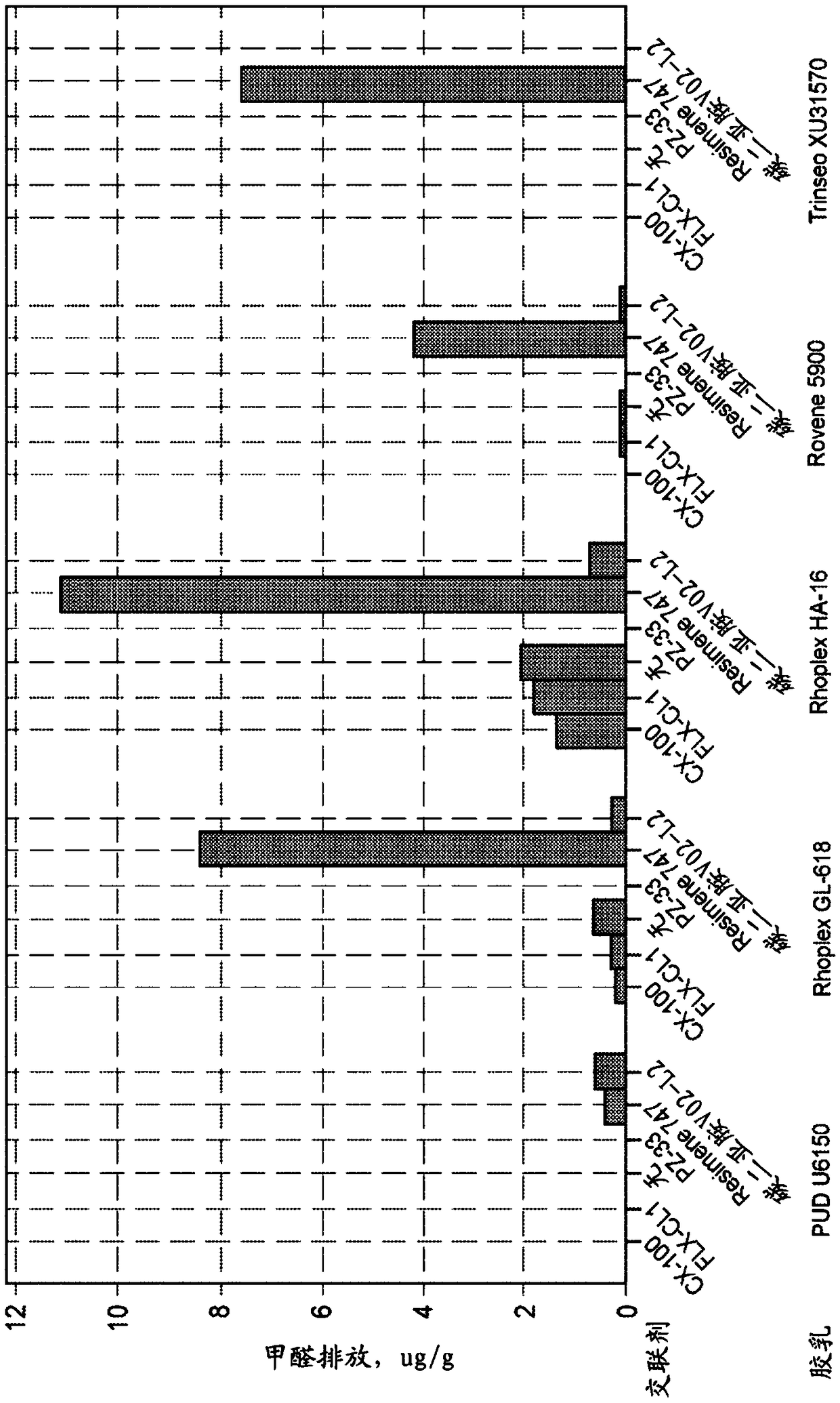

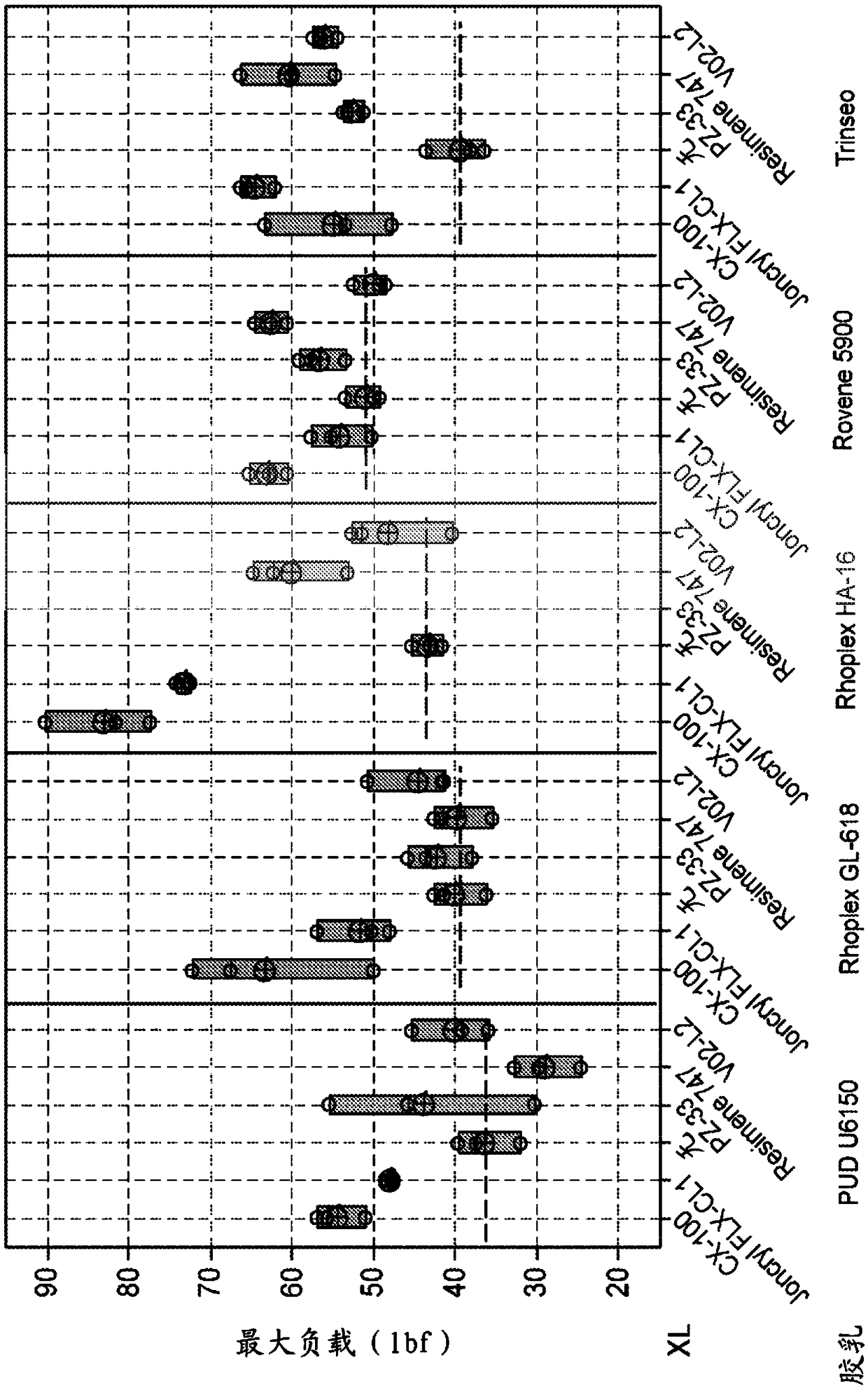

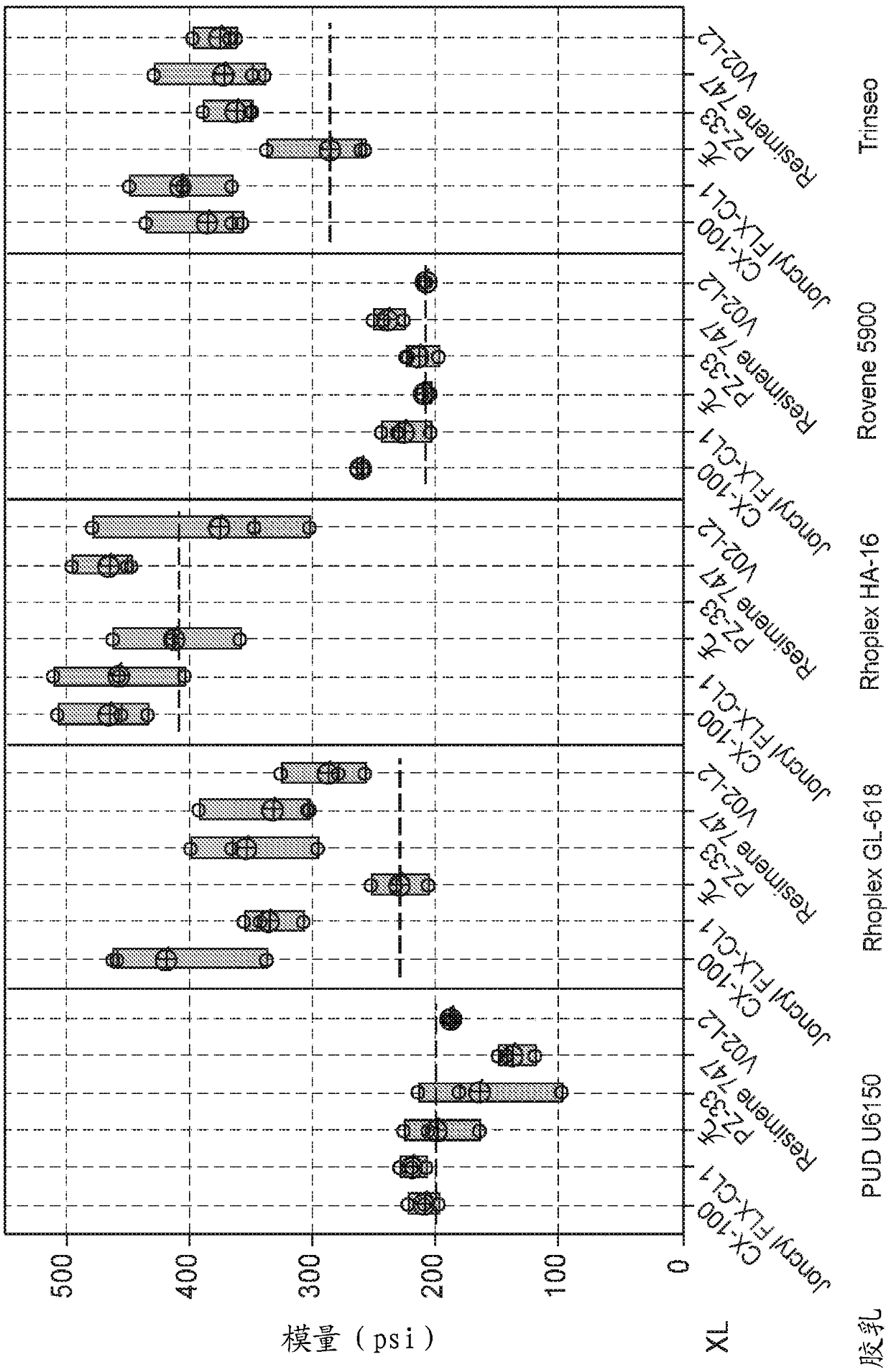

InactiveUS20190242042A1Increase the maximum loadGood physical propertiesFibre typesNon-woven fabricsPolymer scienceGram

Various embodiments disclosed related to flexible fibrous surface-treating articles with low formaldehyde off-gassing. In various embodiments, the present invention provides a flexible fibrous surface-treating article including an open, lofty, nonwoven web including fibers. The flexible fibrous surface-treating article also includes a binder that coats the fibers of the nonwoven web. The binder includes a cured product of a curable composition including a latex and a crosslinker. The flexible fibrous surface-treating article heated to 65° C. in a closed space for 30 minutes emits less than about 6 micrograms of gaseous formaldehyde total per gram of the flexible fibrous surface-treating article.

Owner:3M INNOVATIVE PROPERTIES CO

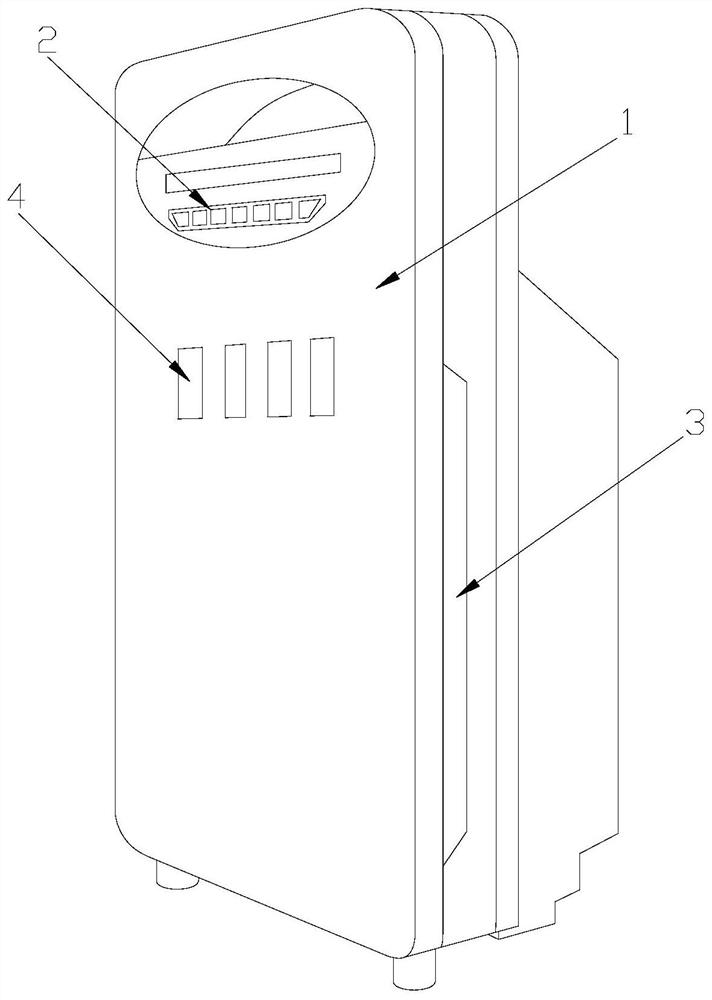

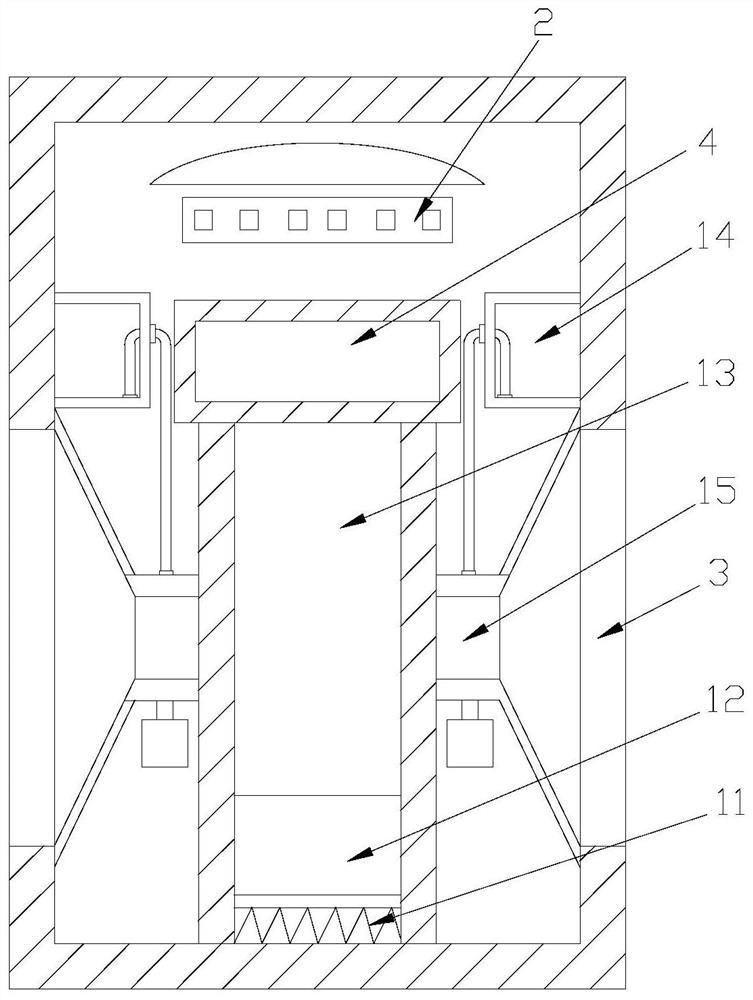

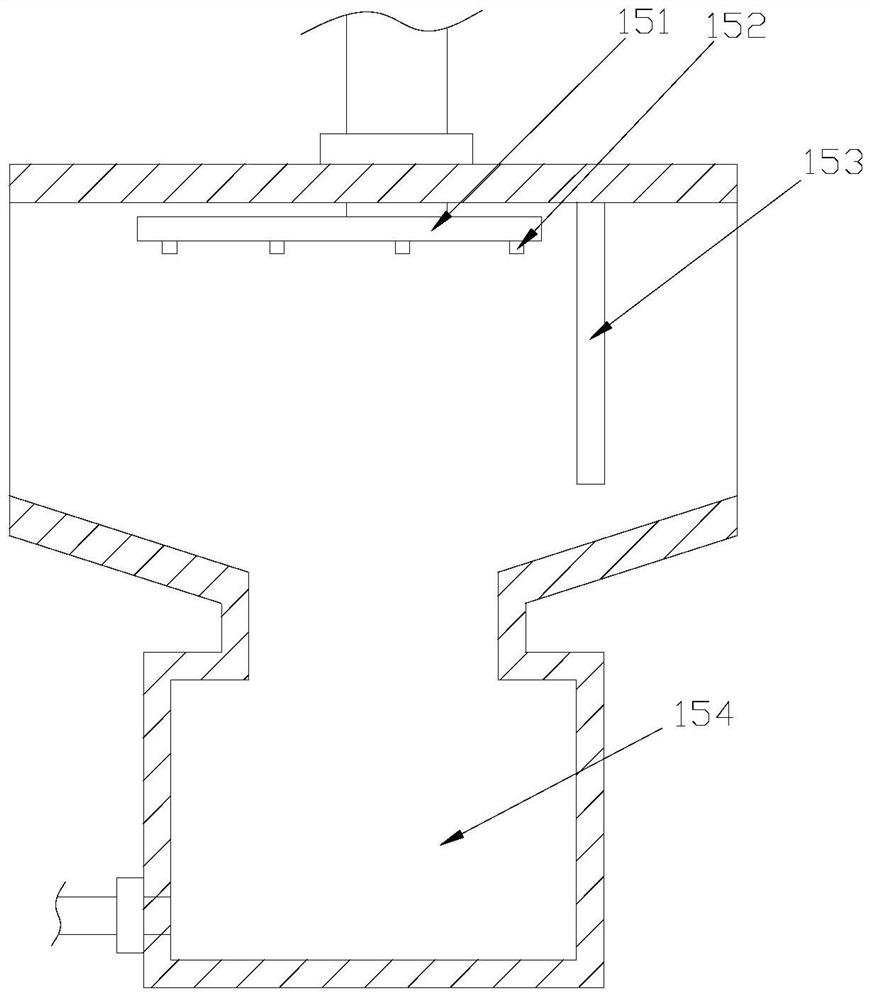

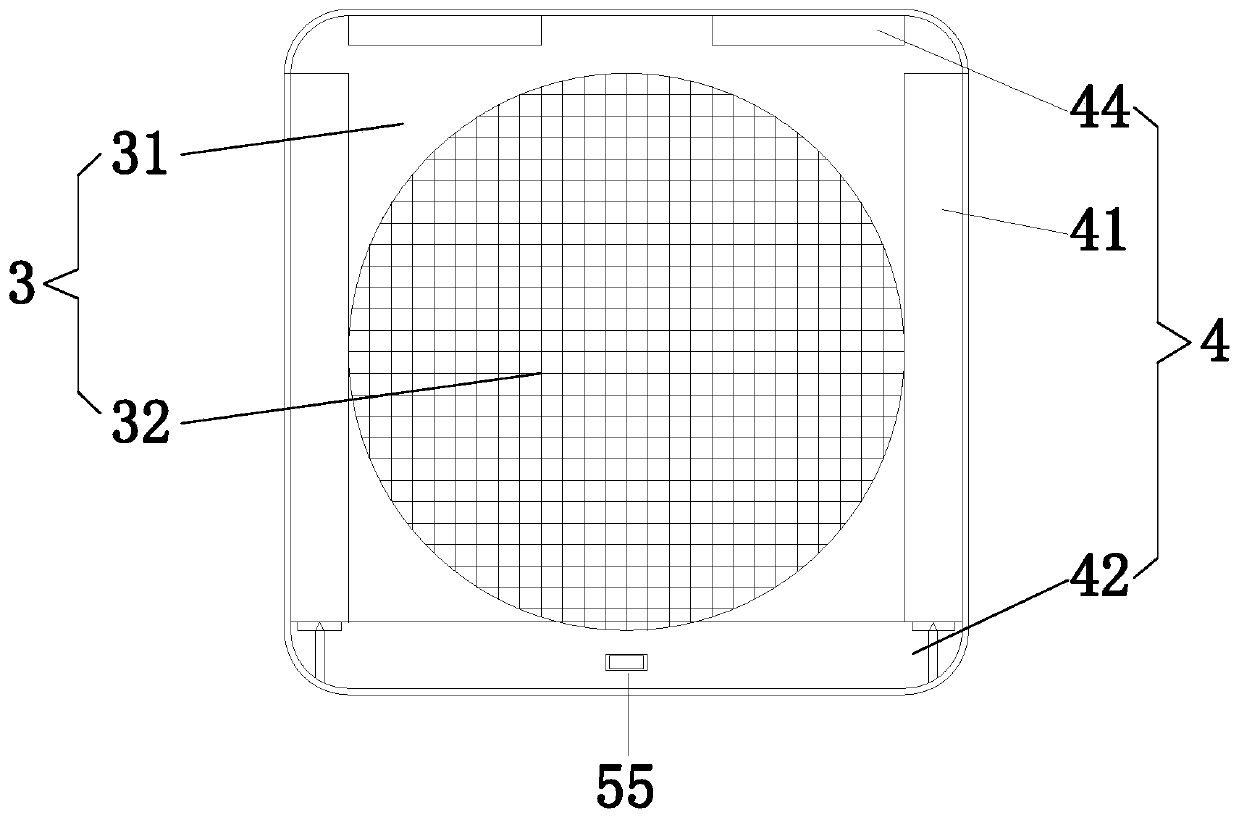

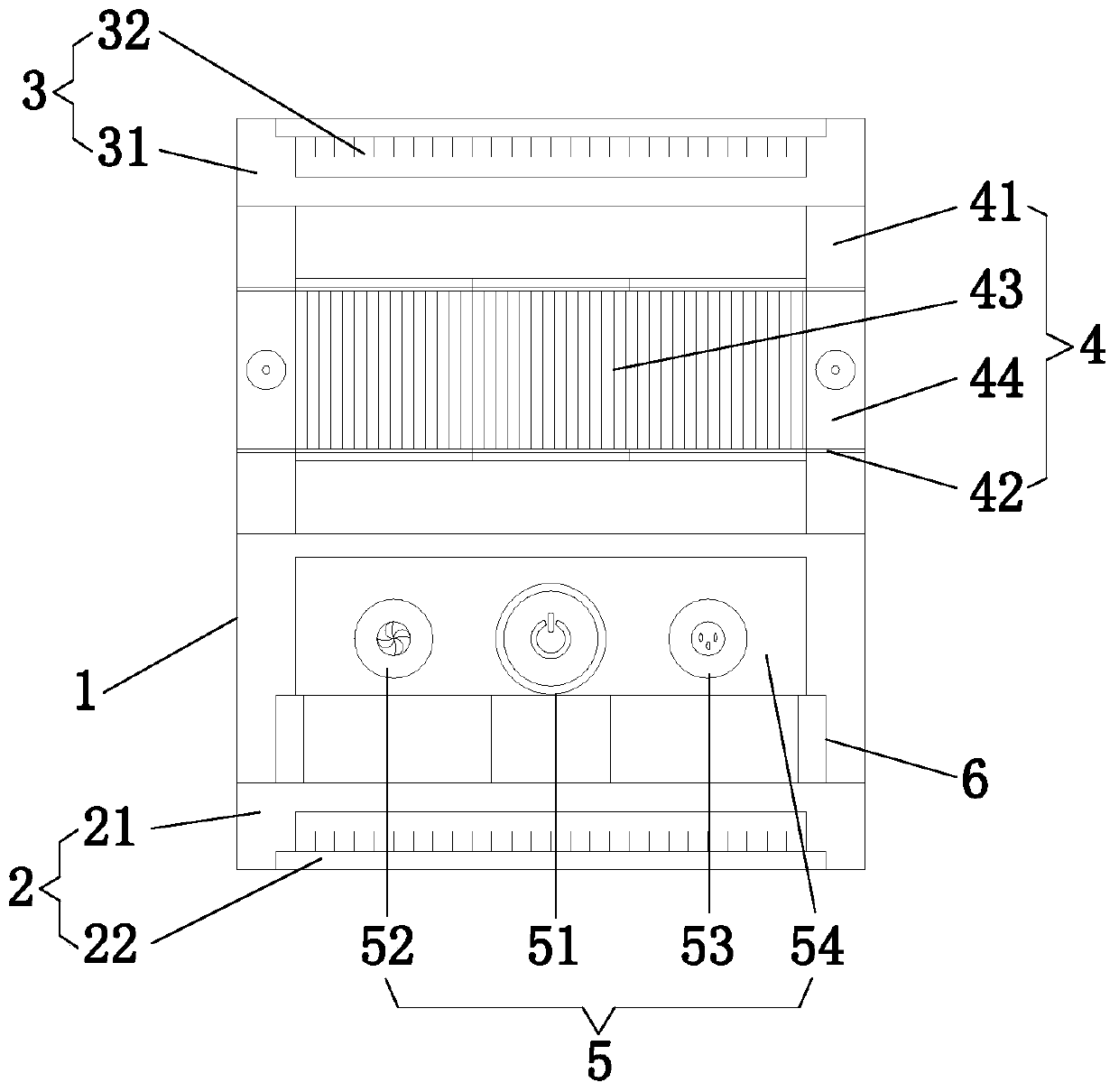

A household formaldehyde remover

ActiveCN111389160BDifficult to clean dustCombination devicesGas treatmentWater storageWater storage tank

The invention discloses a household formaldehyde remover, the structure of which includes a main body, a control panel, an air inlet, and an air outlet. The main body includes a heating wire, an oxidant storage tank, a ventilation pipe, a water tank, and an air vent. In the middle, the oxidant storage tank is set on the top of the heating wire; the vent includes a spray pipe, an atomizing nozzle, a filter plate, and a water storage tank; the filter plate includes a water tank and a through hole; the through hole includes a support block, a dust shield, and a support block It is arranged at the side end of the through hole, the dust shield is installed in the support block, and the dust shield is movably engaged with the support block; the present invention degrades the dust in the air by spraying water from the atomizing nozzle, and The filter plate at the end of the tuyere is set in a through hole inclined at 30 degrees from the horizontal plane, so that the gaseous formaldehyde can pass through the solid dust that has not been degraded, and avoid the situation where the dust is attached to the ventilation pipe through the through hole, which makes it difficult to clean the dust Case.

Owner:福建泉州台商投资区莉沓科技有限公司

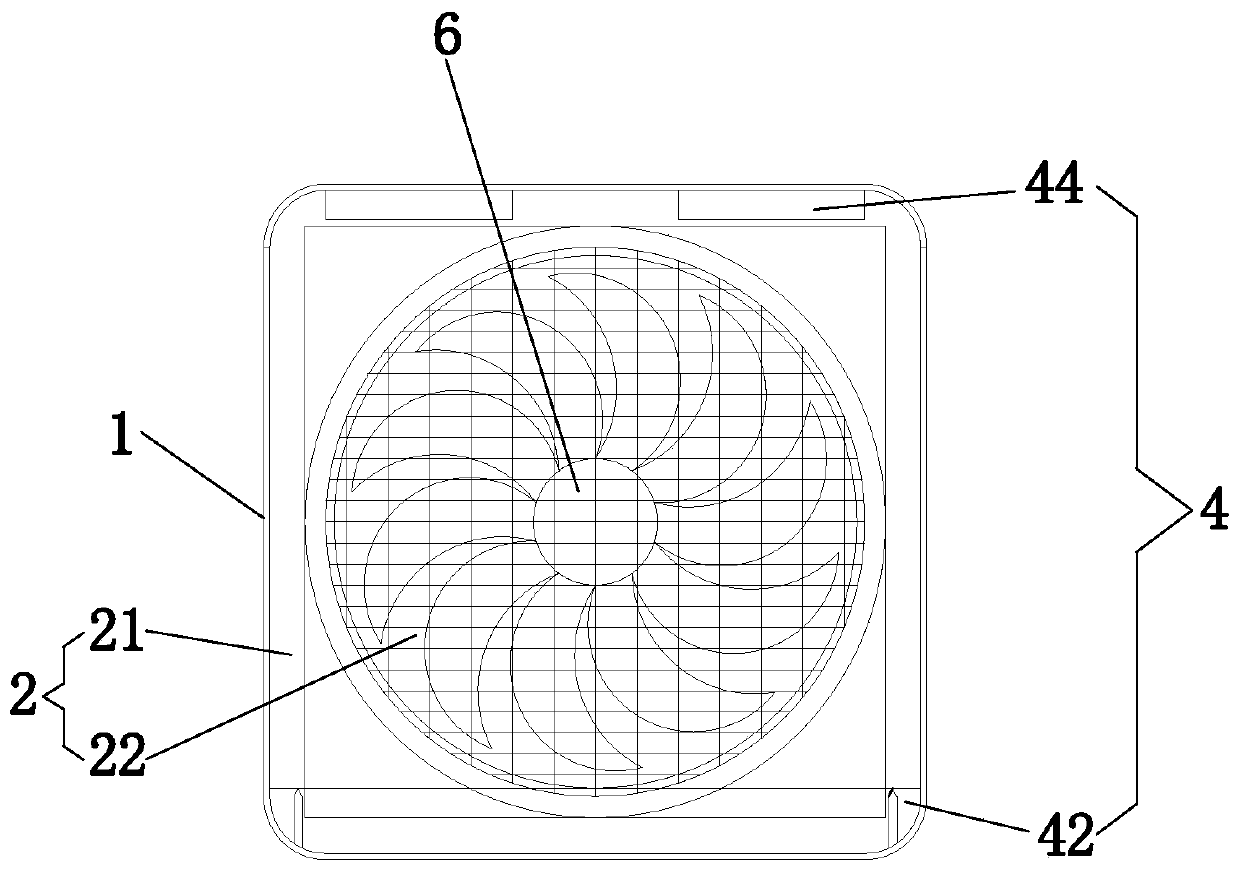

Cold volatilization type formaldehyde removal device and working principle thereof

PendingCN111013364ANo lossAchieve removalGas treatmentDispersed particle filtrationSiphonAir velocity

The invention discloses a cold volatilization type formaldehyde removal device and a working principle thereof. The device comprises a main shell, wherein a front air outlet module is arranged on thefront face of the main shell; a rear air inlet module is arranged on the back face of the main shell; a moisture absorption and formaldehyde removal module, an electric control module and a fan are arranged in the main shell; and the fan is located on the back of the front air outlet module. According to the working principle, the self-absorption siphon effect of a wet curtain is utilized, a formaldehyde removal active liquid forms a molecular-level dispersion liquid film on the surface of the wet curtain, formaldehyde in air blown through the wet curtain can be rapidly captured and removed, and moisture is volatilized in a cold mode and enters the air for humidification. The device is easy and convenient to assemble, adjustable in air speed, free of consumable consumption and capable of efficiently removing indoor polluting formaldehyde and adjusting space humidity, and a formaldehyde bonded product does not enter air and is safe and reliable; 2400 mg or more of gaseous formaldehyde in the air can be effectively removed by filling a water tank with 100 mL of the active liquid at a time, and the amount is far higher than the accumulated purification amount of 1500 mg prescribed inthe national standard F4 for a household air purifier; and a formaldehyde content can be reduced to 0.02 mg / m<3> or below from 1-1.2 mg / m<3> after the device is tested in an environment cabin with a volume of 3 m<3> for 20 min, and the removal efficiency is higher than 98%.

Owner:南通得力净化器材厂有限公司

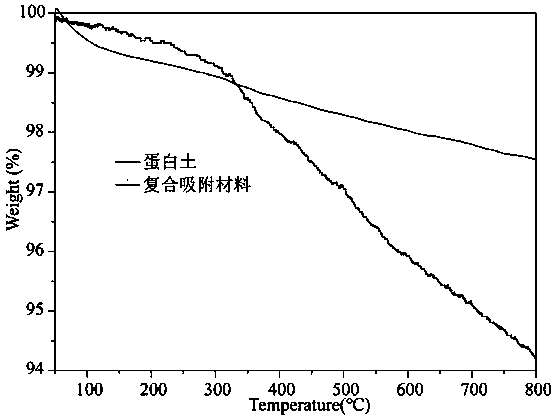

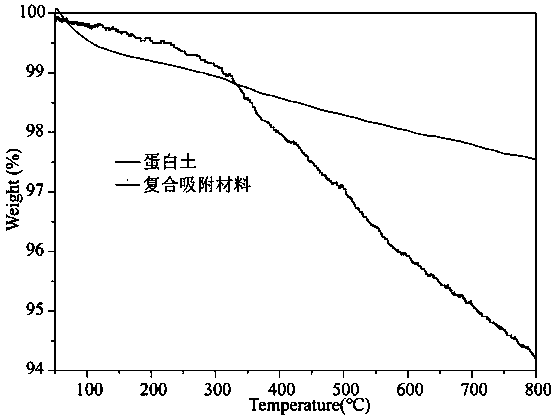

A kind of protein clay composite formaldehyde purification material and preparation method thereof

ActiveCN109317107BSolve the problem of weak purification abilityImproved adsorption and capture performanceGas treatmentOther chemical processesGaseous formaldehydeRaw material

The invention relates to an opal composite formaldehyde purification material and a preparation method thereof, and belongs to the field of nonmetallic mineral materials and environmental engineering.The preparation method comprises the following steps of: using opal as a carrier and amino silane as a modifier, adding an amino group on the surface of the opal by adopting a surface graft modification method to prepare the opal composite formaldehyde purification material. By use of relatively high affinity of the amino group to formaldehyde, the amino group on the surface of the opal is addedthrough graft modification on the surface of the opal, so that the gaseous formaldehyde pollutant capture performance of the prepared composite material is greatly improved, and the problem that the natural opal has relatively low formaldehyde adsorption and purification capacity is solved; and the required raw material is cheap and easy to get, the preparation process is simple, the reaction condition is mild, and the opal composite formaldehyde purification material has a relatively high application value in the field of indoor formaldehyde gas purification.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

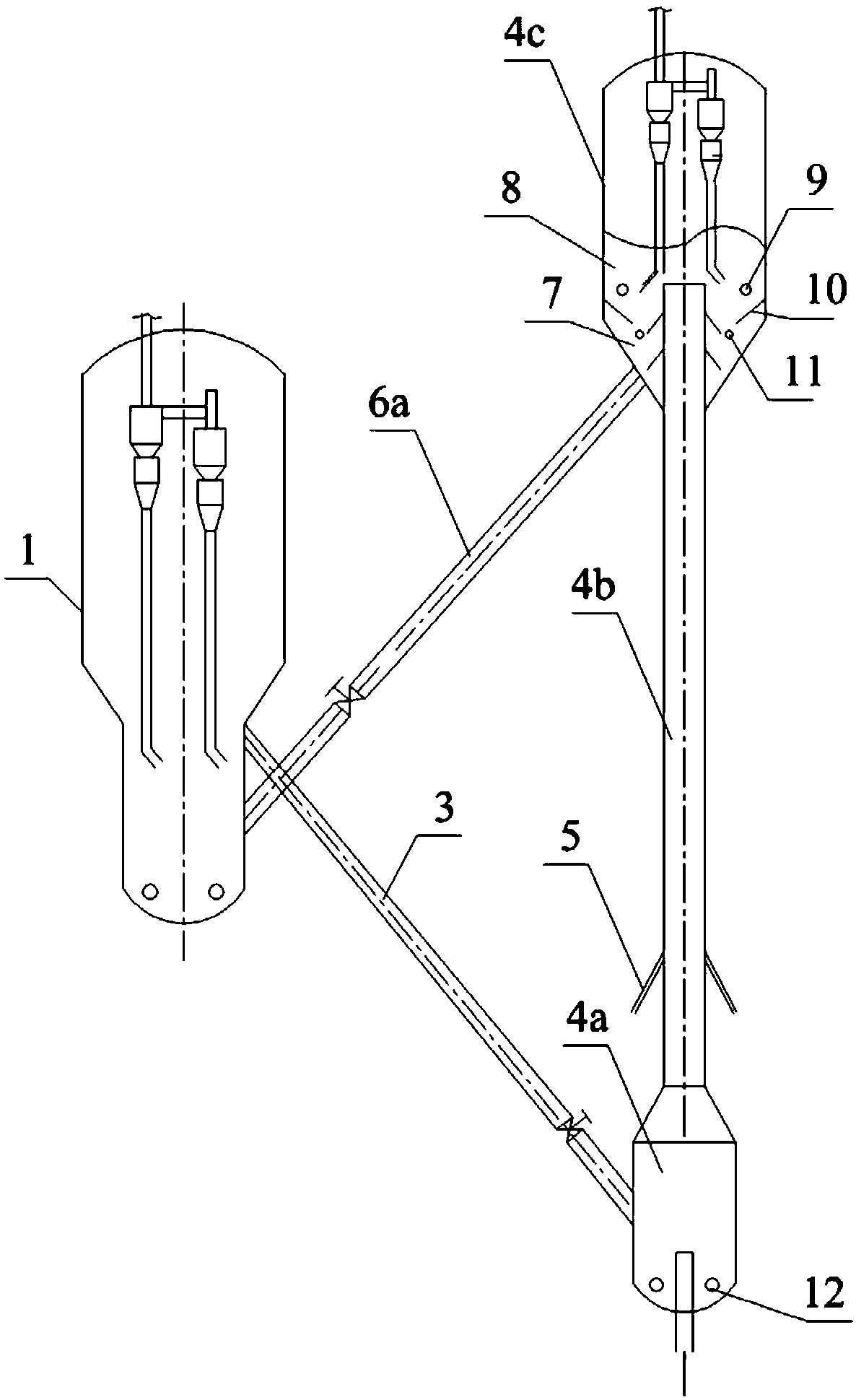

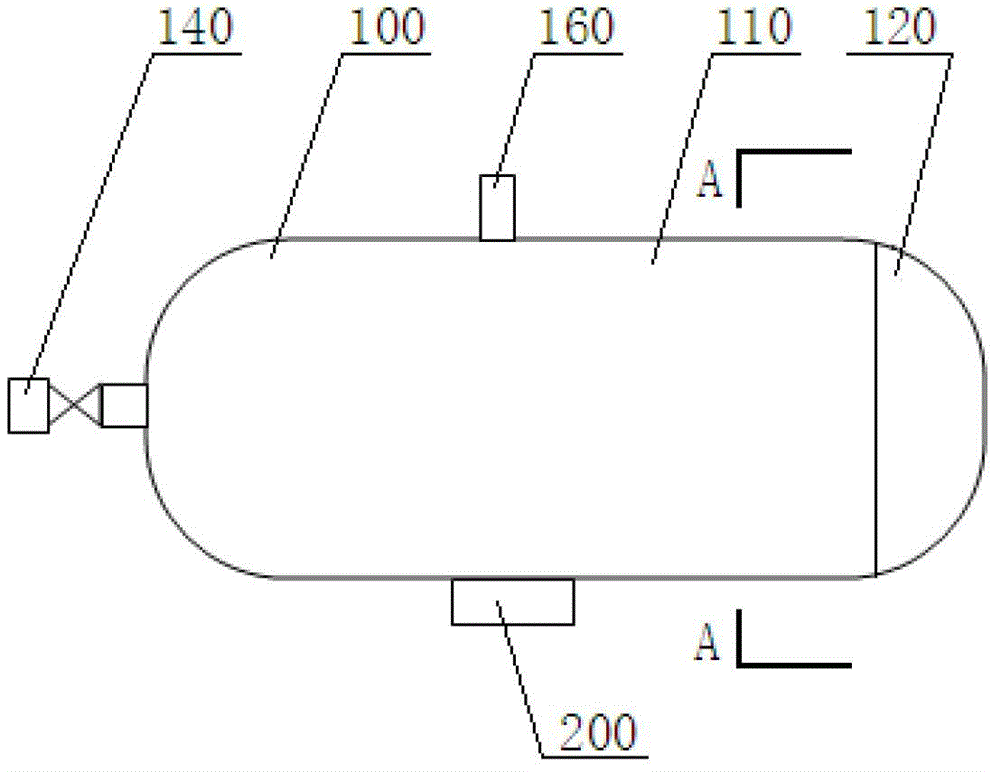

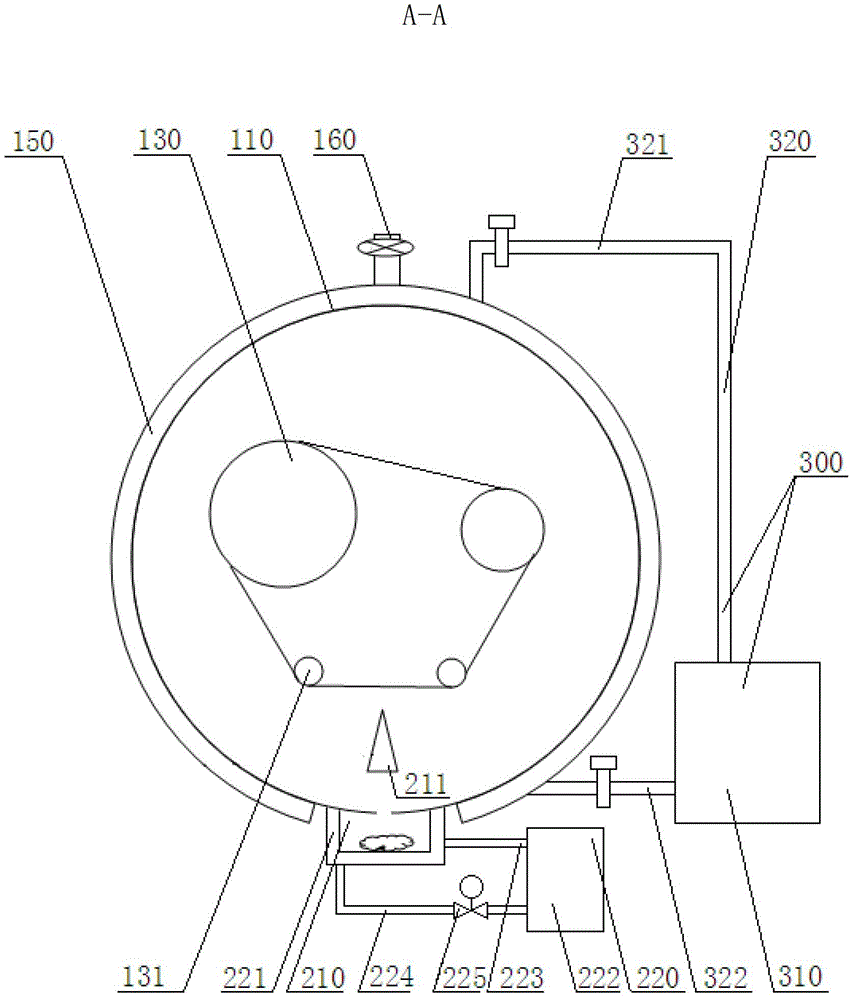

Fabric finishing device by using formaldehyde and method for processing woven fabric by using fabric finishing device

ActiveCN103194869BOrganize safe and efficientTextile treatment containersTextile treatment machine arrangementsProduct gasProcess engineering

The invention relates to a fabric finishing device by using formaldehyde. The fabric finishing device comprises a reactor, a gaseous formaldehyde generation device and an air washing device, wherein the reactor comprises a reactor body, a reactor sealing door, a fabric roll shaft set, a roll shaft set driving device and a reactor heating device; the fabric roll shaft set comprises a plurality of fabric roll shafts; the gaseous formaldehyde generation device comprises a paraformaldehyde reactor and a heating device; the paraformaldehyde reactor is sealed and communicated with a reaction space; the heating device is used for heating paraformaldehyde arranged in the paraformaldehyde reactor and releasing formaldehyde gas to a reaction space; the air washing device comprises an air washing chamber and an air washing pipe system; and the air washing pipe system comprises an air inlet pipe and an air outlet pipe. The processing method disclosed by the invention comprises a discharge step, a vapor deposition step, an air washing step, a receiving step and the like. According to the fabric finishing device and the processing method disclosed by the invention, due to the adoption of a sealing heating and waste gas recovering scheme, the aim of finishing the fabric by safely and efficiently using formaldehyde gas is achieved.

Owner:SHANGHAI JIALE

Formaldehyde rectifying tower

ActiveCN110327646AReduce evaporation rateMaintain formaldehyde concentrationCarbonyl compound separation/purificationFractional distillationRefluxFixed frame

The invention relates to the field of formaldehyde preparation, in particular to a formaldehyde rectifying tower. The formaldehyde rectifying tower comprises a fixed frame, a heating mechanism, a rectifying mechanism, a feeding mechanism, a condenser pipe, a cooling mechanism, a connecting mechanism and a collecting mechanism; gas is pre-cooled and liquefied inside the condenser pipe into a formaldehyde solution to enter the cooling mechanism; the formaldehyde solution tortuously moves inside the cooling mechanism, and the re-cooled formaldehyde solution penetrates through the connecting mechanism to enter the collecting mechanism; at a room temperature, formaldehyde in the formaldehyde solution inside the collecting mechanism evaporates, and the gaseous formaldehyde is in contact with low-temperature formaldehyde solution to be liquefied into the low-temperature formaldehyde solution, so that the evaporation speed of the formaldehyde in the collecting mechanism is reduced; in the rectifying process, part of the low-temperature formaldehyde solution slides inside the connecting mechanism to enter the rectifying mechanism; reflux fluid inside the rectifying mechanism is at a low temperature, and the boiling point of the formaldehyde is low, so that the formaldehyde inside the reflux fluid evaporates into the condenser pipe, and the content of the gaseous formaldehyde is increased.

Owner:广东利而安化工集团有限公司

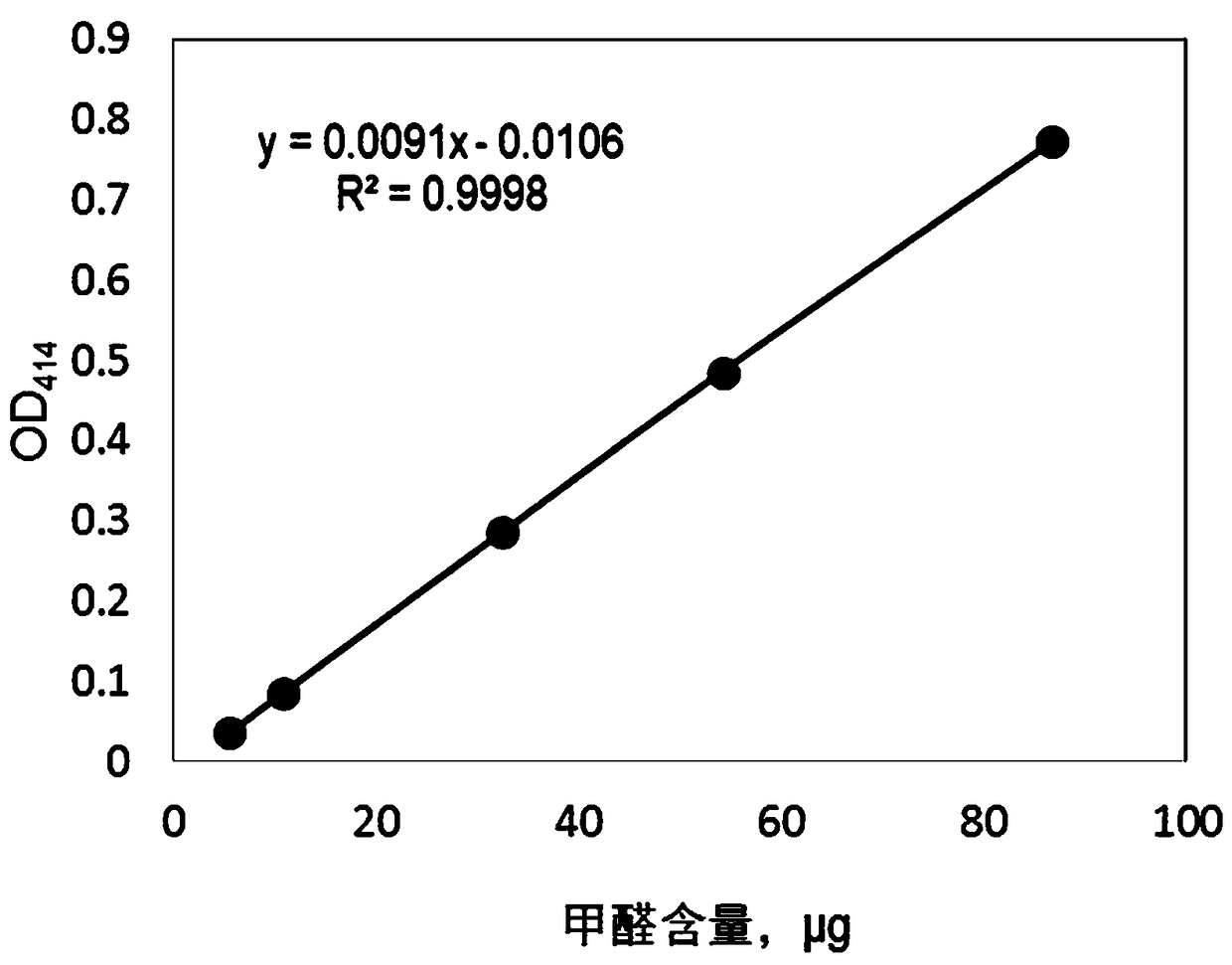

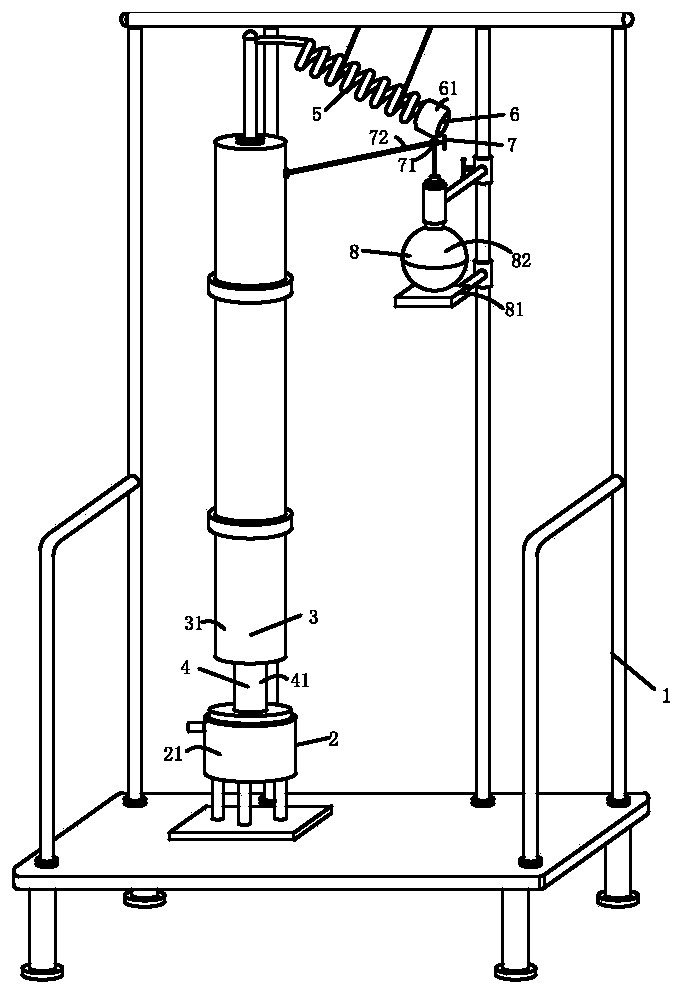

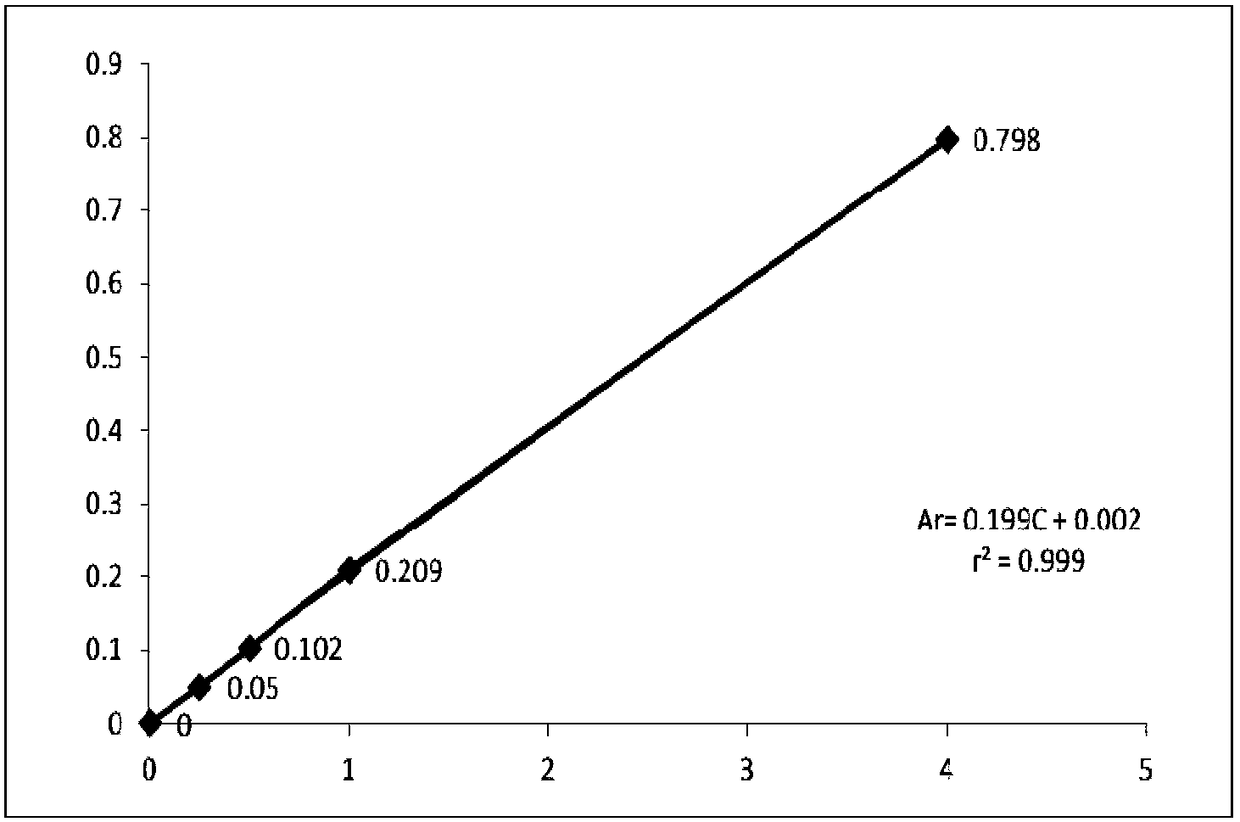

A method for measuring the content of gaseous formaldehyde in polyoxymethylene and a collection device

ActiveCN105498454BPrevent inflowThe content determination result is accurateDispersed particle separationDirt cleaningHot meltBottle

The invention provides a content determination method and a collection device of gas-state formaldehyde in polyformaldehyde. The content determination method comprises the following steps: (1) collecting gas-state formaldehyde in polyformaldehyde and dissolving gas-state formaldehyde into water to obtain a formaldehyde solution with unknown concentration; (2) determining the concentration of the formaldehyde solution with unknown concentration; and (3) calculating the content of gas-state formaldehyde in polyformaldehyde, wherein in the step (1), polyformaldehyde particles are hot melted and then gas-state formaldehyde, which is released after hot melting, is dissolved into water to obtain the formaldehyde solution with unknown concentration. The collection device comprises a hot melting device, a gas-state formaldehyde collection bottle, a gas absorption bottle and a mixed gas conveying pipeline. According to the content determination method and the collection device, provided by the invention, polyformaldehyde is hot melted, obtained gas-state formaldehyde is dissolved into water, and thus gas-state formaldehyde on the surface of and in polyformaldehyde is completely collected, so that a content determination result of gas-state formaldehyde in polyformaldehyde is accurate, and polyformaldehyde with the gas-state formaldehyde content exceeding the standard is prevented from being available to the markets; and the feasibility and the operability are very high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of m-mno x - CEO 2 Catalysts and their applications

ActiveCN109107567BHigh catalytic oxidation activityLarge specific surface areaGas treatmentDispersed particle separationPtru catalystMetallurgy

The invention discloses a M‑MnO X -CeO 2 Catalyst, the catalyst is MnO X , CeO 2 It is the active component, with M as the dopant, prepared by citric acid complexation method; M is FeO x , CuO, CoO x or K 2 O; the molar ratio of Mn and Ce in the catalyst is 6:1‑1:1; when M is FeO x , CuO or CoO x , the molar ratio of metal ions to Ce in M is 1:4‑1:1; when M is K 2 O, K 2 The doping amount of O is 1 wt%. The catalyst of the invention can be used for catalytic oxidation of gaseous formaldehyde under normal temperature conditions, or for thermal catalytic oxidation of CVOCs.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

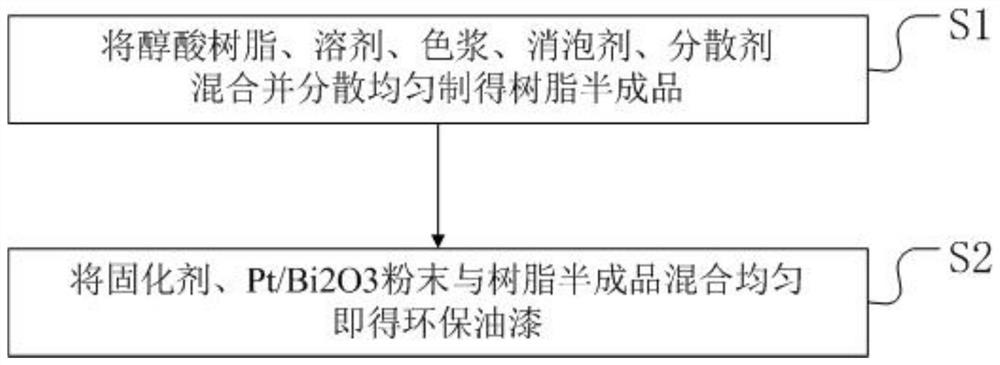

Environment-friendly water-based paint capable of quickly decomposing formaldehyde

PendingCN114381189AAccelerate volatilizationAccelerate evaporationPolyester coatingsEnvironmental engineeringGaseous formaldehyde

The invention provides an environment-friendly water-based paint capable of quickly decomposing formaldehyde. The environment-friendly water-based paint comprises the following components in parts by mass: 45-55 parts of alkyd resin; 25-35 parts of a solvent; 15-25 parts of color paste; 0.5 to 0.8 part of a defoaming agent; 1.0 to 1.5 parts of a dispersant; 5-15 parts of a curing agent; 5 to 15 parts of Pt / Bi2O3 powder; the Pt / Bi2O3 powder is added into the environment-friendly water-based paint capable of quickly decomposing formaldehyde, the Pt / Bi2O3 powder can degrade gaseous formaldehyde on the outer side of a paint surface and reduce the concentration of the formaldehyde on the outer side of the paint surface under the same action of room temperature and indoor illumination, so that outward volatilization of the formaldehyde on the paint surface is accelerated, the volatilized formaldehyde can be continuously decomposed by the Pt / Bi2O3 powder, and the formaldehyde can be quickly decomposed by the Pt / Bi2O3 powder. The virtuous cycle is achieved, and formaldehyde volatilization of the paint surface is accelerated; formaldehyde volatilized after the paint surface is arranged can be decomposed in time, so that the damage to the health of people is avoided.

Owner:苏州海戈斯环保科技有限公司

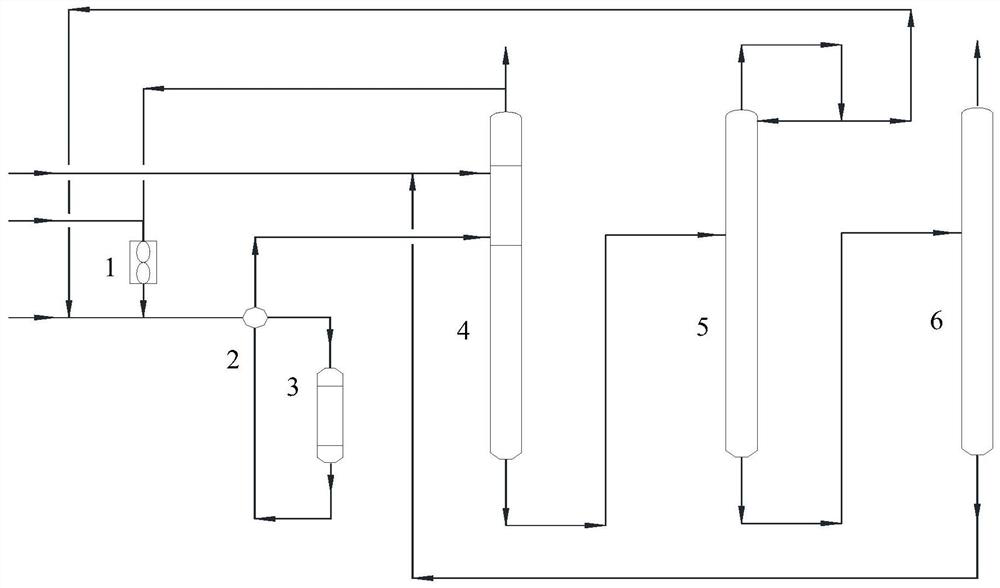

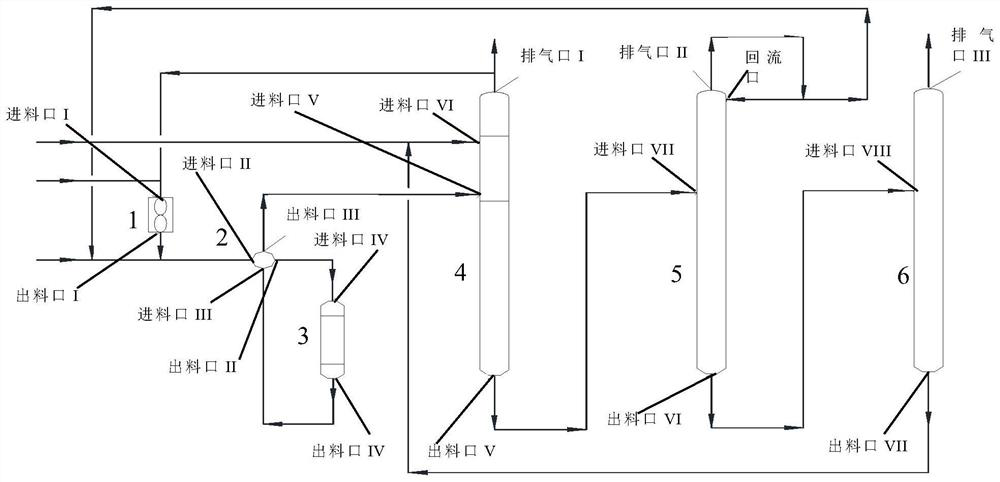

Device and method for producing high-concentration formaldehyde by using methanol

PendingCN111943822AImprove product qualityEasy to aggregateOrganic compound preparationCarbonyl compound separation/purificationHemiacetalFixed bed

The invention discloses a device and a method for producing high-concentration formaldehyde by using methanol. The device comprises a fan, a heat exchanger, a fixed bed reactor, an absorption tower, arefining tower and a pyrolysis tower which are connected in sequence. According to the method, air is pressurized by a fan, mixed with a methanol raw material, flows through a heat exchanger and thenenters a fixed bed reactor for an oxidation reaction, a primary product flows through the heat exchanger and then enters an absorption tower for a hemiacetal reaction, a secondary reaction product sequentially flows through a refining tower and a pyrolysis tower for separation and pyrolysis, an absorbent is discharged from the bottom of the tower for cyclic utilization after pyrolysis, and a gaseous formaldehyde product is collected at the tower top. The product disclosed by the invention is dry gas formaldehyde and is quite stable, so that the method has obvious economic benefits and environmental protection advantages; and the product provided by the invention has excellent quality: the concentration of formaldehyde is greater than or equal to 99.9%, and water is less than or equal to 0.05%.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

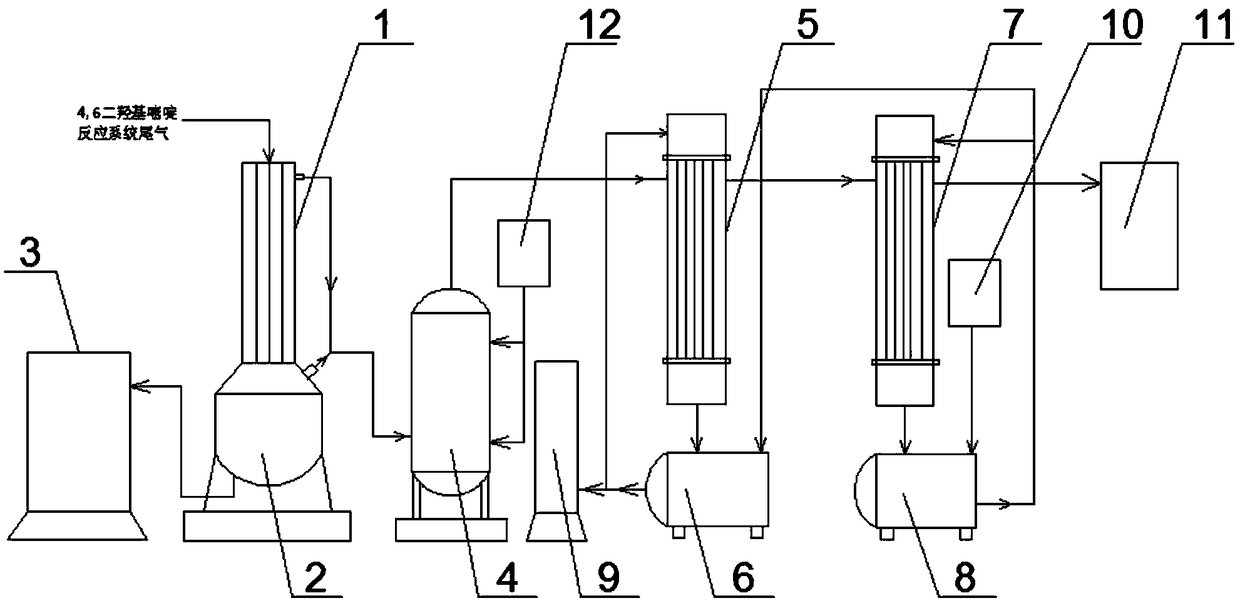

A 4,6-dihydroxypyrimidine reaction system tail gas treatment process

ActiveCN106215449BHigh puritySolve pollutionGas treatmentDispersed particle separationChemical productsGaseous formaldehyde

The invention relates to a 4,6-dyhydroxy pyrimidine reaction system tail gas treatment process, and belongs to the technical field of chemical product recycling. The process comprises the steps that firstly, tail gas is conveyed into a condenser, gaseous formaldehyde is converted into liquid formaldehyde through low-temperature condensation to be collected, and the tail gas obtained after the formaldehyde is removed is conveyed into a stabilization tank and subjected to stabilization introducing pressure maintaining; the rear end of the stabilization tank is sequentially connected with two stages of falling film absorbers, each falling film absorber is connected with an absorption liquid circulating tank for providing absorption liquid, the absorption liquid circulating tanks absorb ammonia in the tail gas, and then the tail gas enters an incinerator to be incinerated. In the whole technological process, equipment is simple, operation is easy and convenient, no high-temperature high-pressure equipment exists, the safety coefficient is high, the formaldehyde and ammonium hydroxide can be recycled in the tail gas treatment process, formaldehyde in production raw materials is supplemented, and the ammonium hydroxide can be sold as chemical materials; in the tail gas treatment process, the work environment is improved, and atmospheric pollution is relieved.

Owner:石家庄杰克化工有限公司

Oil-soluble formaldehyde scavenger

InactiveCN109092024ASpeed up the removal processEfficient removalGas treatmentDispersed particle separationEnvironmental engineeringGaseous formaldehyde

The invention discloses an oil-soluble formaldehyde scavenger and belongs to the technical field of indoor air scavengers. The scavenger specifically comprises a spherical carrier and a dicyandiamidepowder reactant adhering to the spherical carrier, wherein the spherical carrier is subjected to surface modification with N-octadecyl biquaternary ammonium salt. The spherical carrier formed throughmodification with N-octadecyl biquaternary ammonium salt adopts a hydrophobic structure on the surface and can penetrate through an artificial board to adhere to the surface of the board; gaseous formaldehyde around the board can be gathered to the periphery of the spherical carrier under the trapping action of N-octadecyl biquaternary ammonium salt, so that the formaldehyde can make contact and react with dicyandiamide, after water molecules of a product are absorbed, dicyandiamide resin gradually settles on the surface of the spherical carrier and adsorbed by the spherical carrier, and the scavenger has high formaldehyde scavenging efficiency and lasting effects under the synergistic effect of the three factors.

Owner:襄阳云创环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com