Flexible fibrous surface-treating article with low formaldehyde off-gassing

A technology for surface treatment and flexible fibers, which is applied in the field of preparing flexible fiber surface treatment products and can solve problems such as formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Preparation of floor mats

[0053] The webs were formed using a conventional web making machine (trade designation "Rando Webber"). The resulting web was a blend of fibers comprising 75% by weight crimped polyethylene terephthalate ("PET") staple fibers (50 denier, 58 mm long) and 25% by weight crimped sheath Core-type melt-bondable polyester staple fiber (15 denier, 58 mm long; with a core of polyethylene terephthalate and a copolymer of polyethylene terephthalate and isophthalate the skin of the object). The formed web was heated in a convection oven at 320°F (160°C) for about 3 minutes to fuse the melt-bondable fibers together at the intersection points to form a pre-bonded web. The prebonded web weight was about 400 grams per square meter.

[0054] Samples of the prebonded web were cut to dimensions of 1 x 7 inches in the crossweb direction (ie, where the long dimension ran sideways across the web as it was manufactured, rather than the longitudinal ...

Embodiment 2

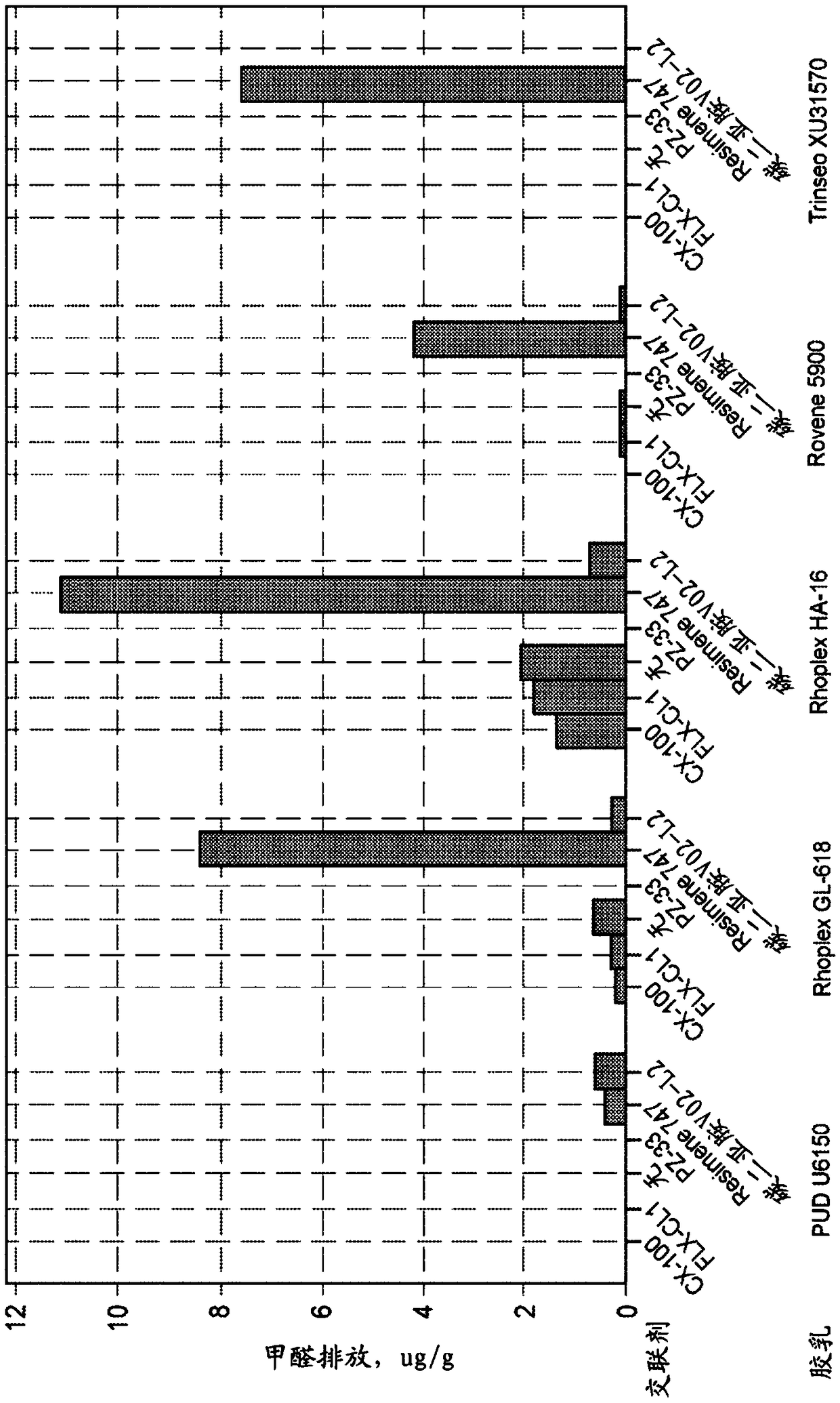

[0058] Example 2: Formaldehyde emission .

[0059] The formaldehyde emission of the samples prepared in Example 1 was measured. Emissions were measured by reaction with 2,4-dinitrophenylhydrazine [DNPH] to form the corresponding hydrazone, which is easily and sensitively detected by liquid chromatography. A sampling tube containing silica gel impregnated with 2,4-DNPH was placed on a heated microchamber device (Marks microchamber) with a volume of 44 mL, and the coated Covered nonwoven samples were placed therein. The sample was heated to 65 °C (150 °F) for 30 minutes with a flow of helium at 50 mL / min through the sample chamber and into the collection tube. The tube was then cut open and desorbed with 5 mL of acetonitrile, and the extraction solution was run through HPLC. The formaldehyde-DNPH content was determined from a standard calibration curve, and the formaldehyde concentration was calculated by multiplying the formaldehyde-DNPH result by the molecular weight rati...

Embodiment 3

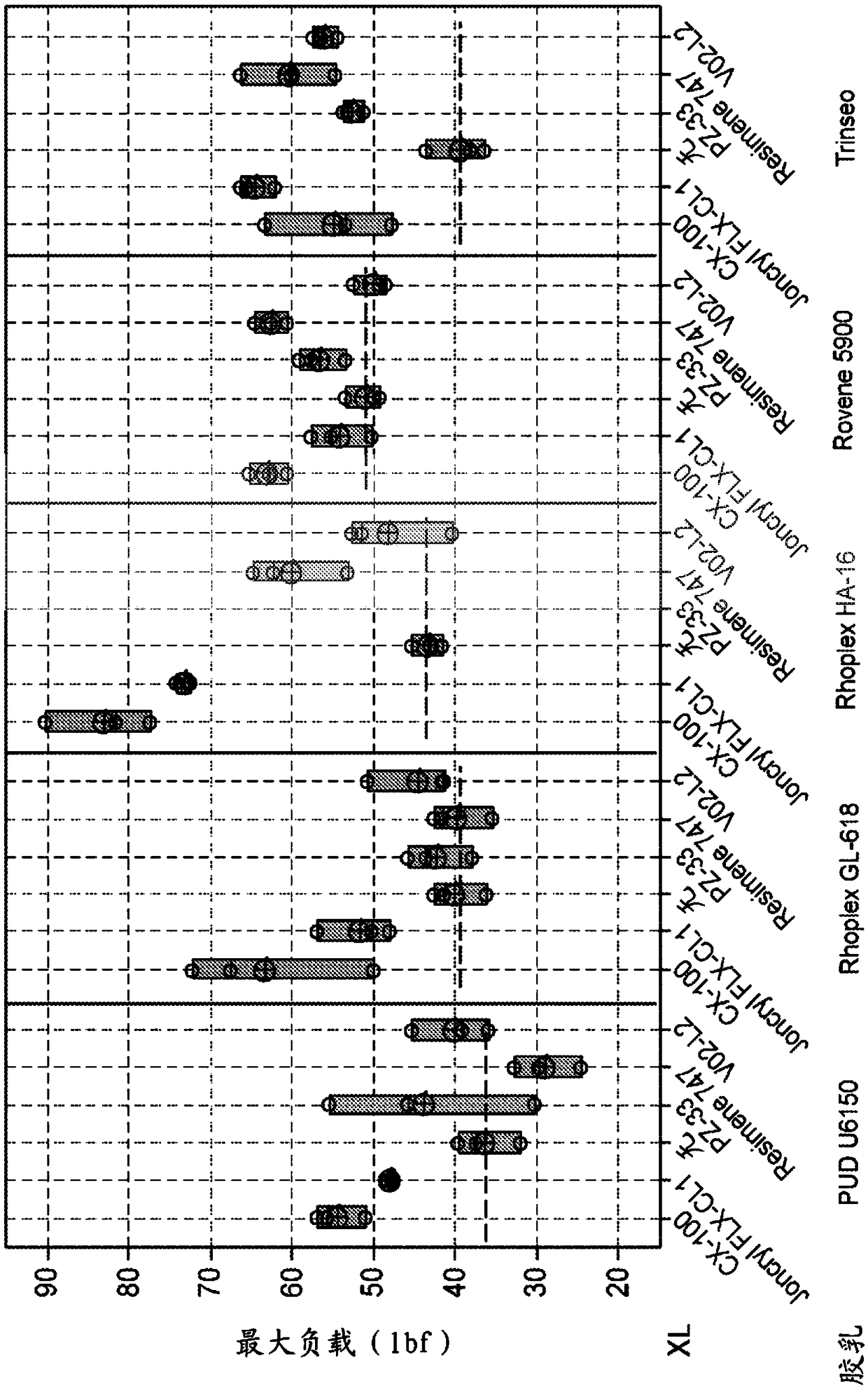

[0065] Example 3: Physical properties at room temperature .

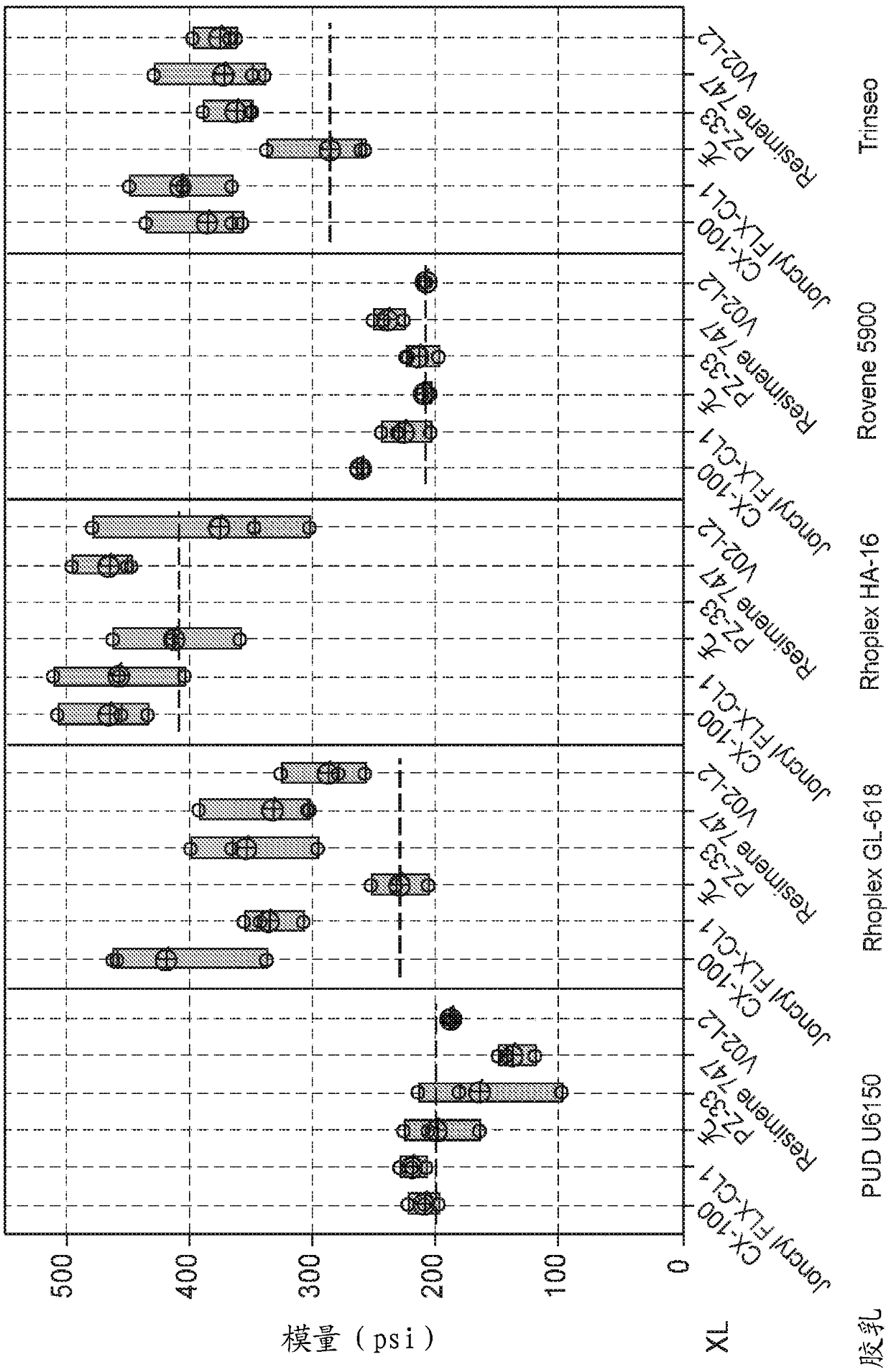

[0066] The maximum load and tensile modulus of the samples prepared in Example 1 were measured at room temperature. Tensile characterizations were performed on an Instron testing machine (model 59CP) using Bluehill 3 analysis software. Maximum load and modulus were determined at a throat flow rate of 10 inches / minute. Sample testing was performed in triplicate.

[0067] The maximum load and tensile modulus of the samples are given in Table 4. Table 5 describes the change in maximum loading caused by crosslinker compared to the condition without crosslinker. figure 2 The maximum loading of the sample at room temperature is shown.

[0068] Table 4: Maximum load and tensile modulus of samples at room temperature .

[0069]

[0070]

[0071] Table 5: Changes in maximum loading of samples at room temperature due to cross-linking agents .

[0072]

[0073] Table 6 describes the change in tensile modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com