Patents

Literature

176results about How to "Wide range of cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

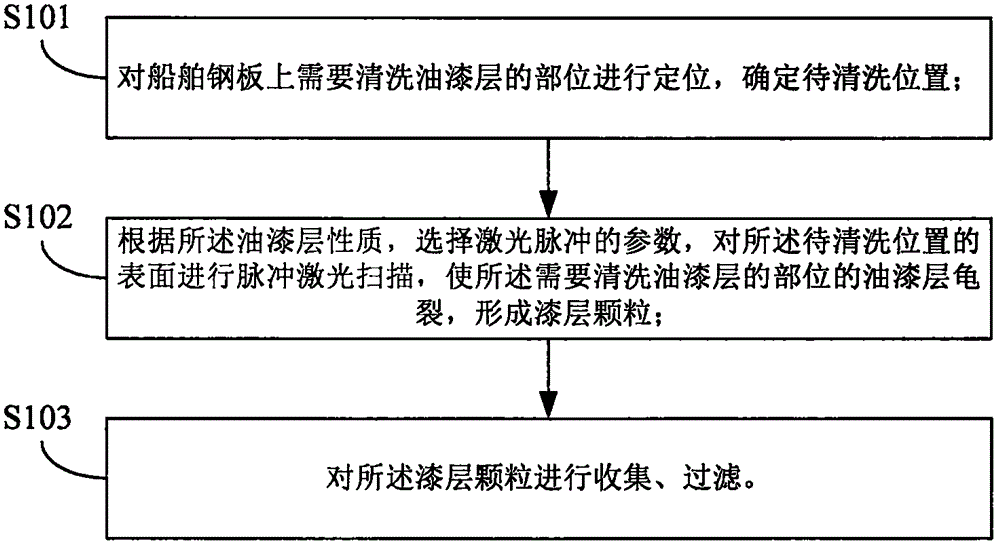

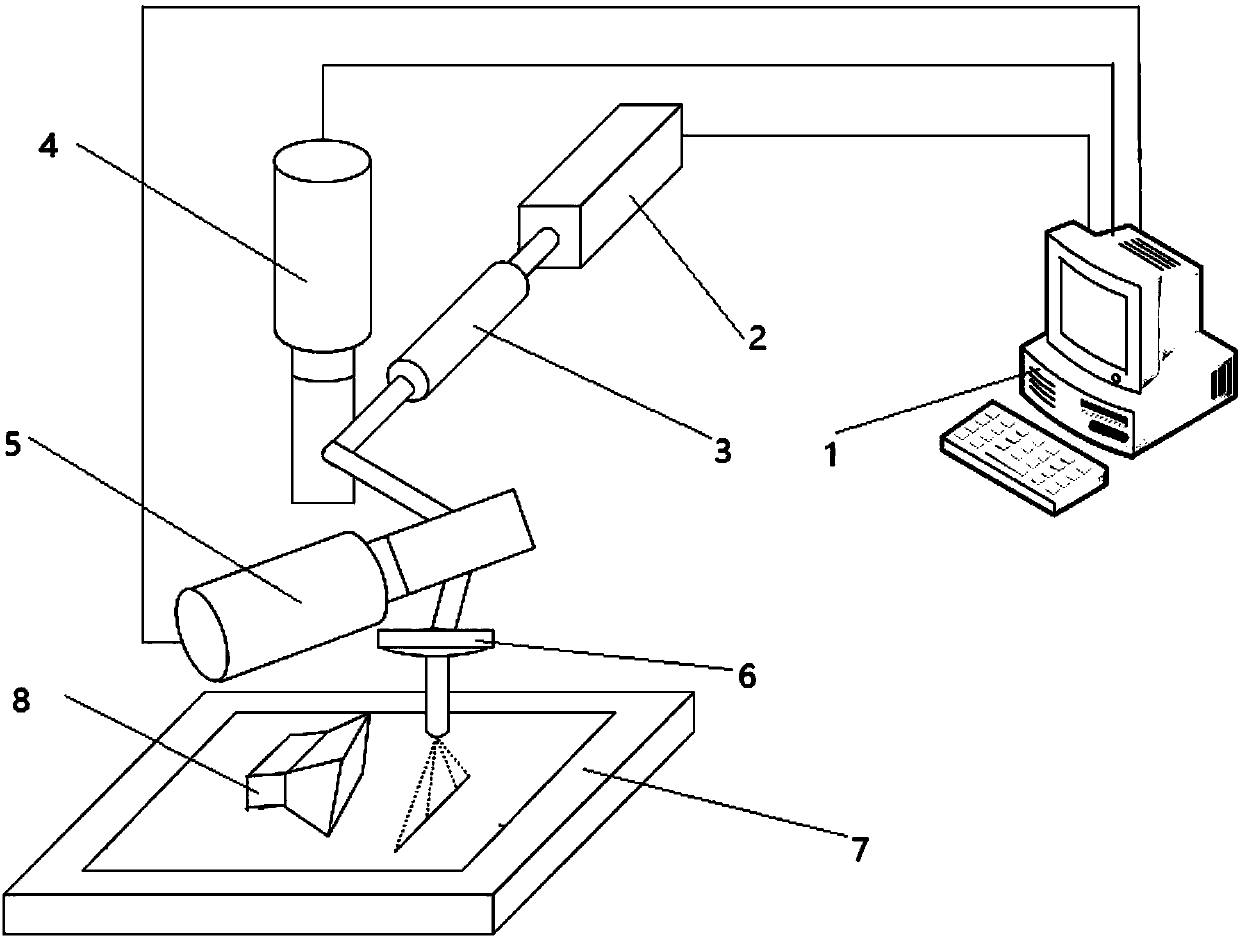

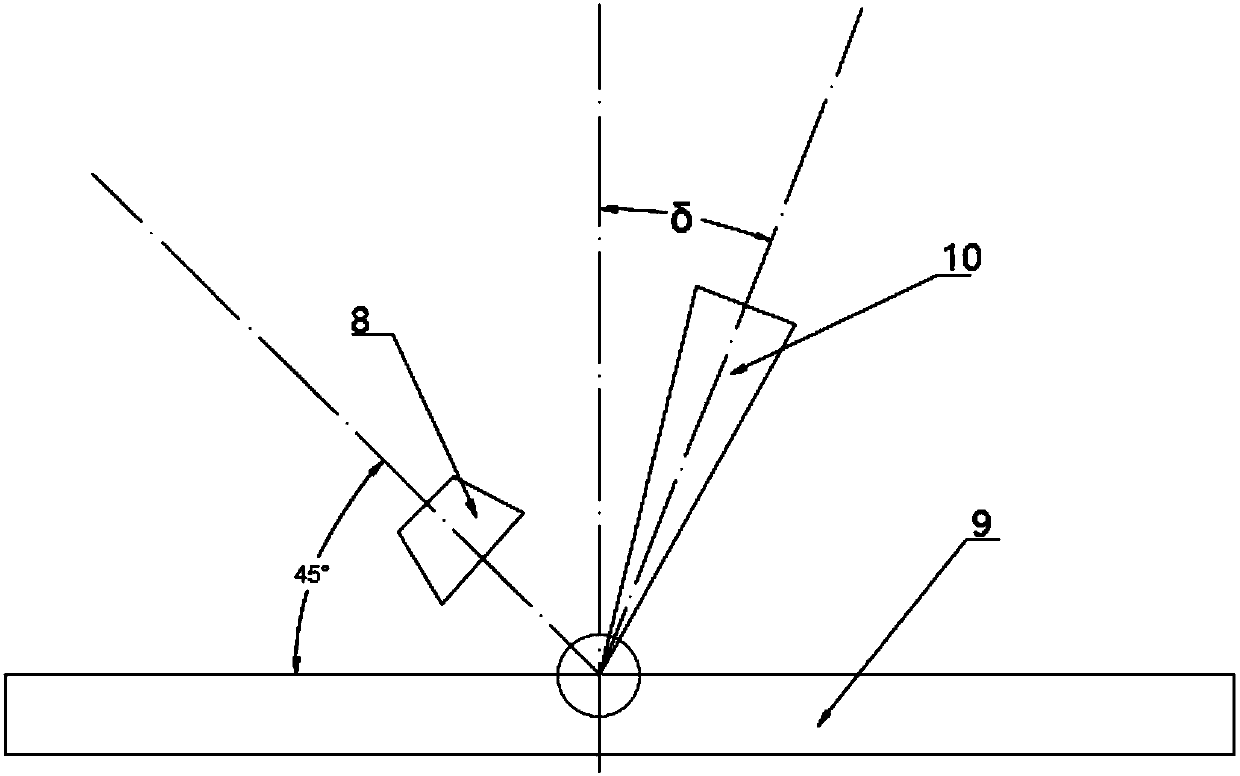

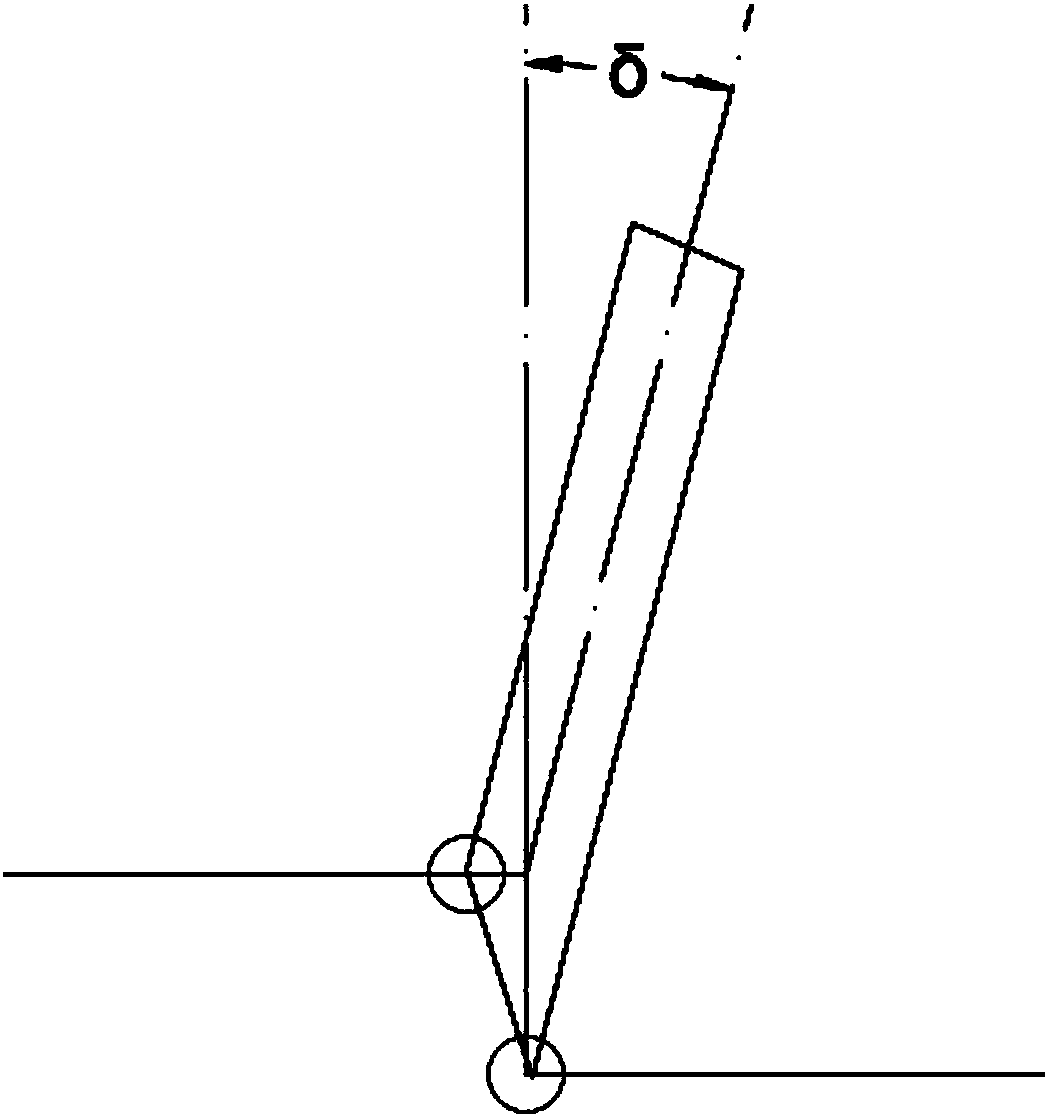

Laser cleaning method for marine paint

The invention provides a laser cleaning method for marine paint. The laser cleaning method for the marine paint has the characteristics of being good in marine paint cleaning effect and high in efficiency. The laser cleaning method for the marine paint is green and environmentally friendly, wide in cleaning range, low in cost and capable of realizing automatic cleaning. The laser cleaning method for the marine paint comprises the following steps of (1) positioning the part, with the need for cleaning of a paint layer, on a ship steel plate and determining a position to be cleaned; (2) selecting parameters of laser pulse according to the property of the paint layer and then conducting pulse laser scanning on the surface of the position to be cleaned to make the paint layer of the position to be cleaned crack and form paint layer particles; and (3) collecting and filtering the paint layer particles.

Owner:上海临仕激光科技有限公司 +1

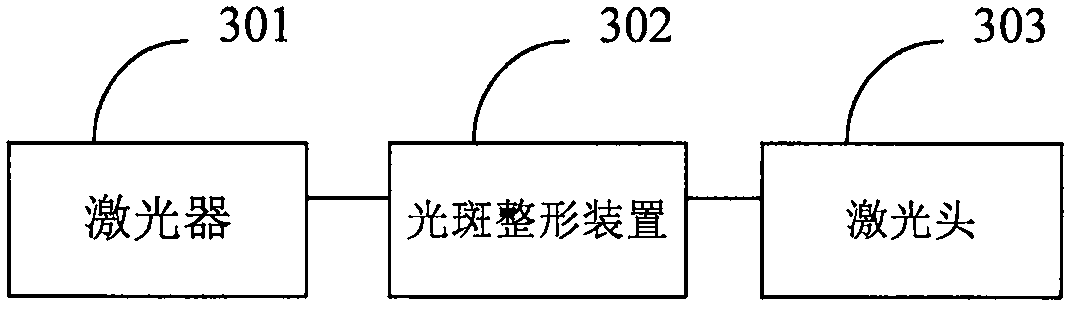

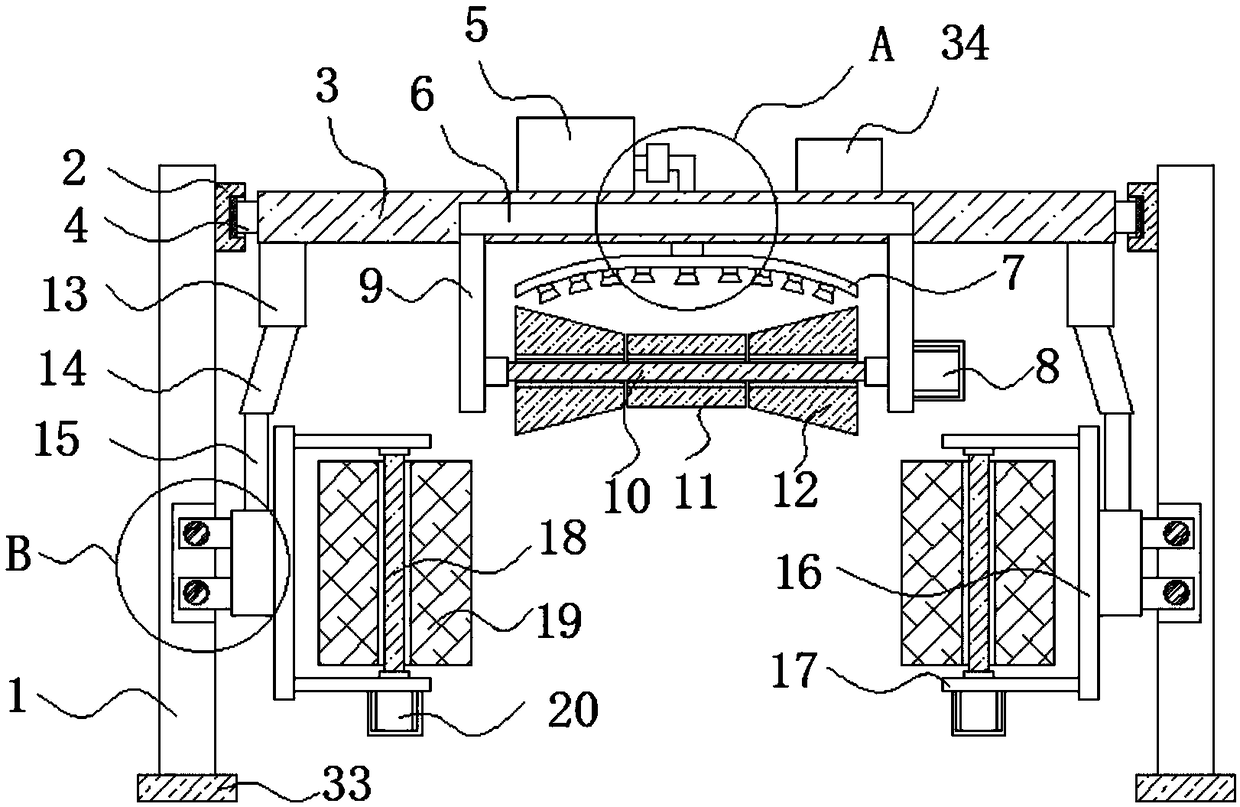

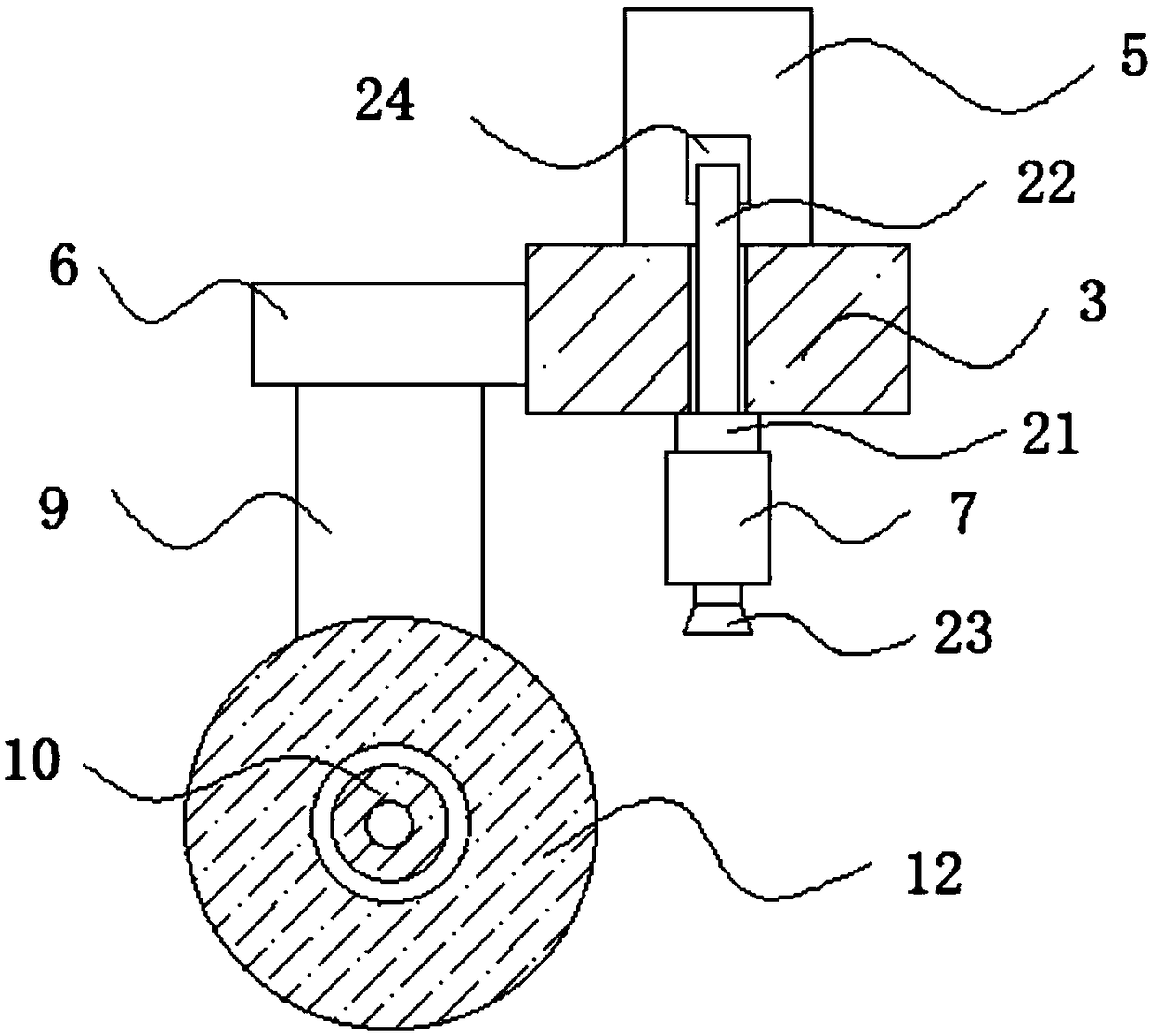

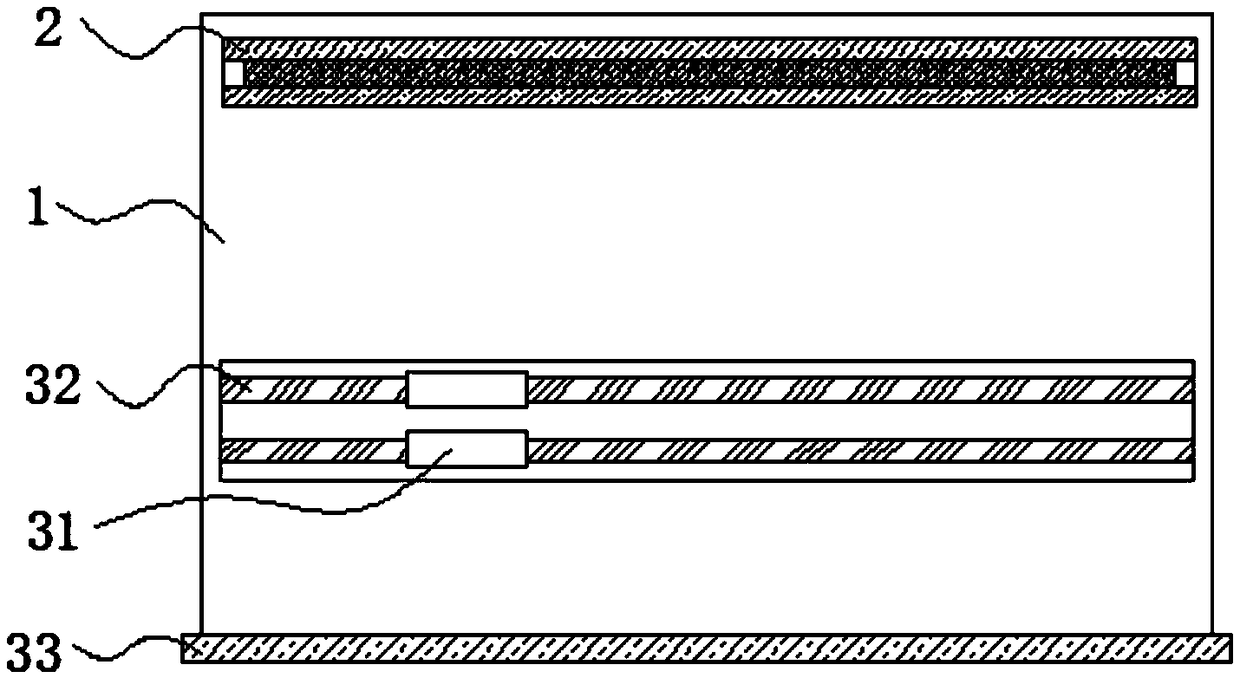

Laser dry type cleaning equipment and method for aluminum alloy anodic oxide films

InactiveCN107639083AImprove cleaning efficiencyEasy to cleanDirt cleaningCleaning using gasesLaser transmitterControl system

The invention discloses laser dry type cleaning equipment for aluminum alloy anodic oxide films. The laser dry type cleaning equipment comprises a cleaning platform and a laser cleaning device, the laser cleaning device comprises a laser cleaning main machine and a light source emitting system arranged on the laser cleaning main machine, and the laser cleaning main machine is of an all-in-one machine frame type; the light source emitting system comprises a control system and a laser emitter, the control system is used for controlling the laser emitter, and a laser device in the laser emitter is a pulse laser; the cleaning platform is located at the bottom of the light emitting surface of the laser cleaning device, and a workbench is used for placing aluminum alloy workpieces to be machined. The cleaning equipment is used for solving the problems existing in the prior art; a laser cleaning head is used for emitting linear light spots to clean the anodic oxide films of the aluminum alloyworkpieces, the cleaning effect is guaranteed, a cleaning solution is not needed, and the cleaning equipment is an environment-friendly cleaning scheme. The invention further provides an aluminum alloy anodic oxide film laser dry type cleaning method high in cleaning efficiency and good in cleaning effect.

Owner:武汉翔明激光科技有限公司

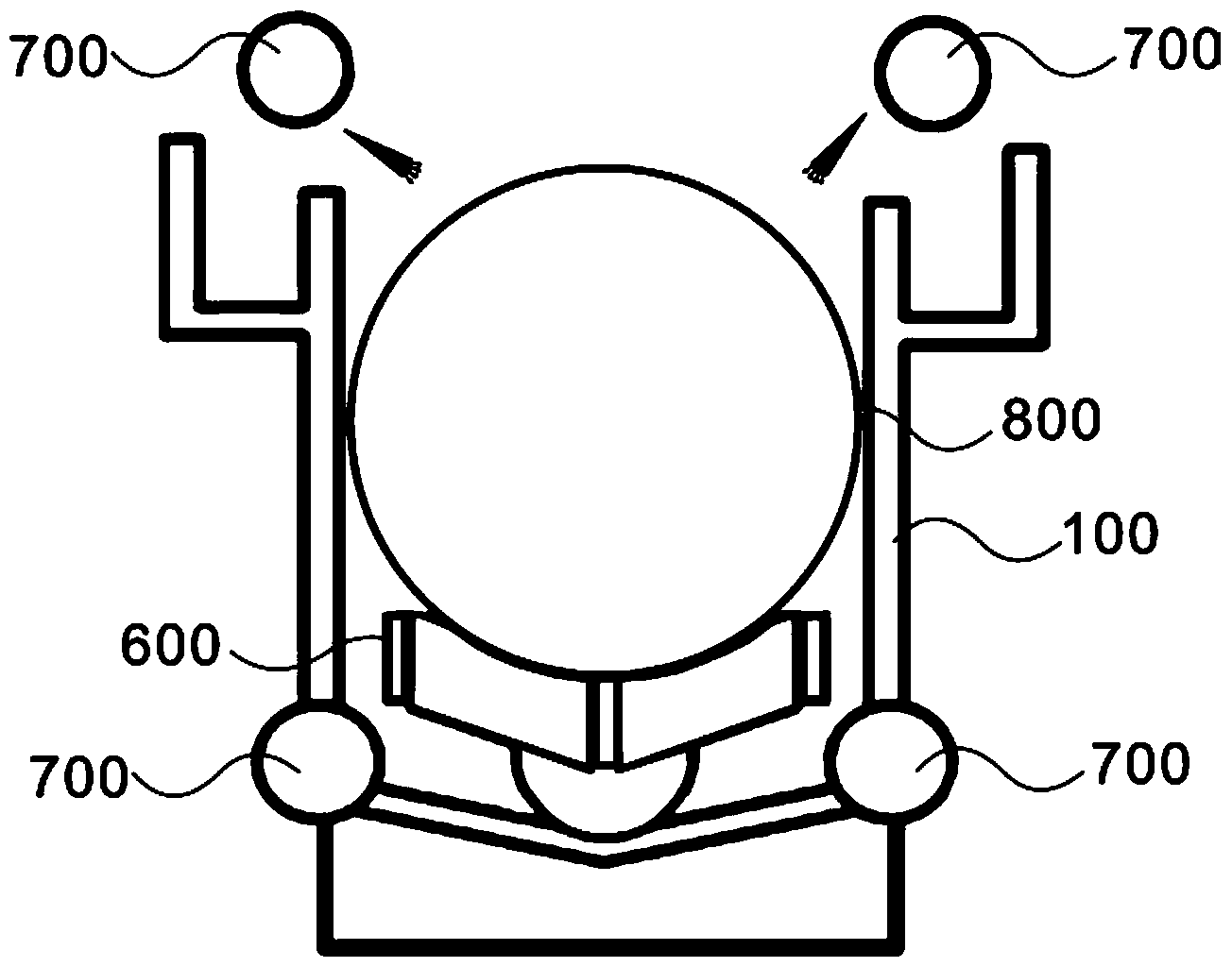

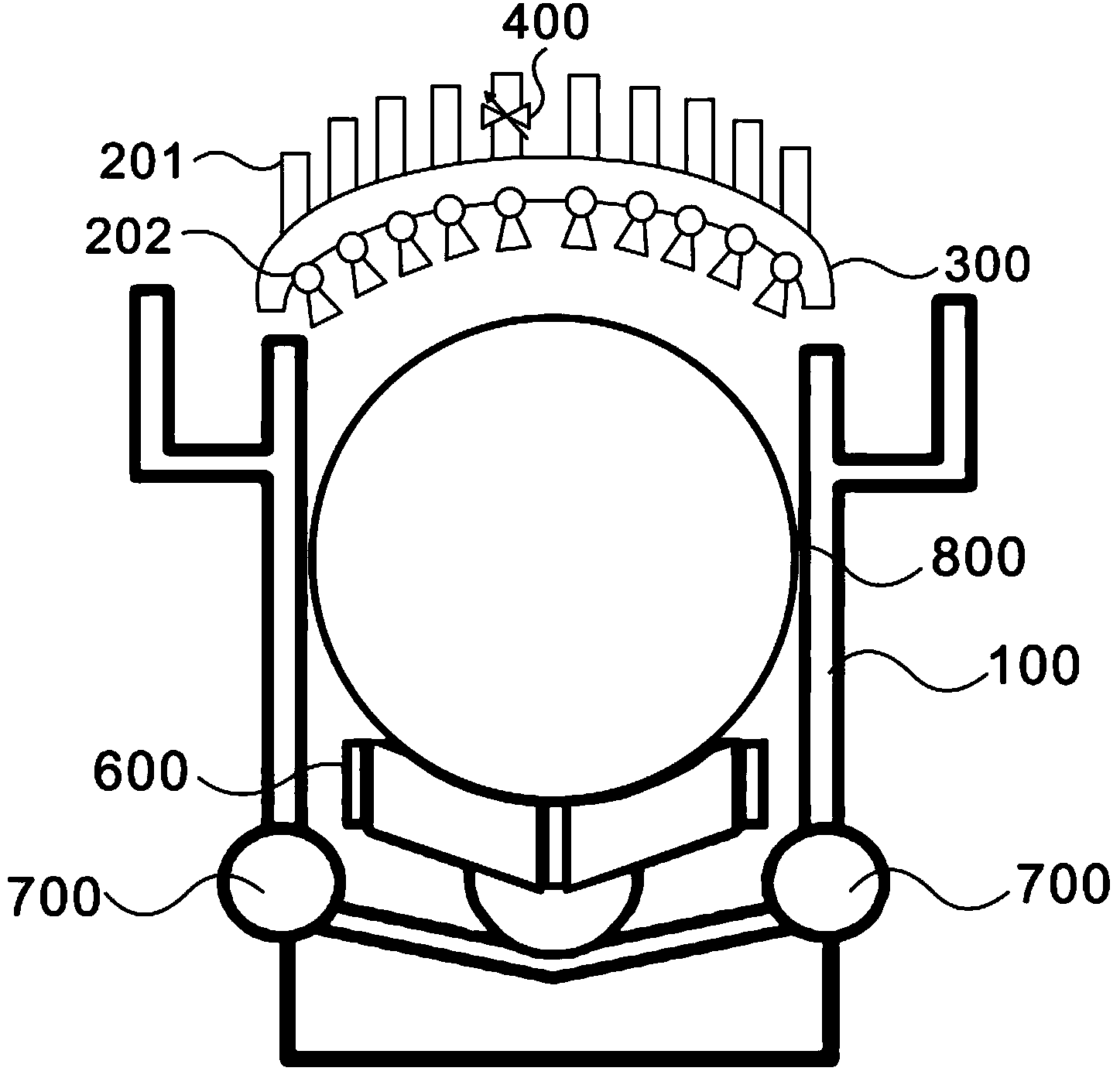

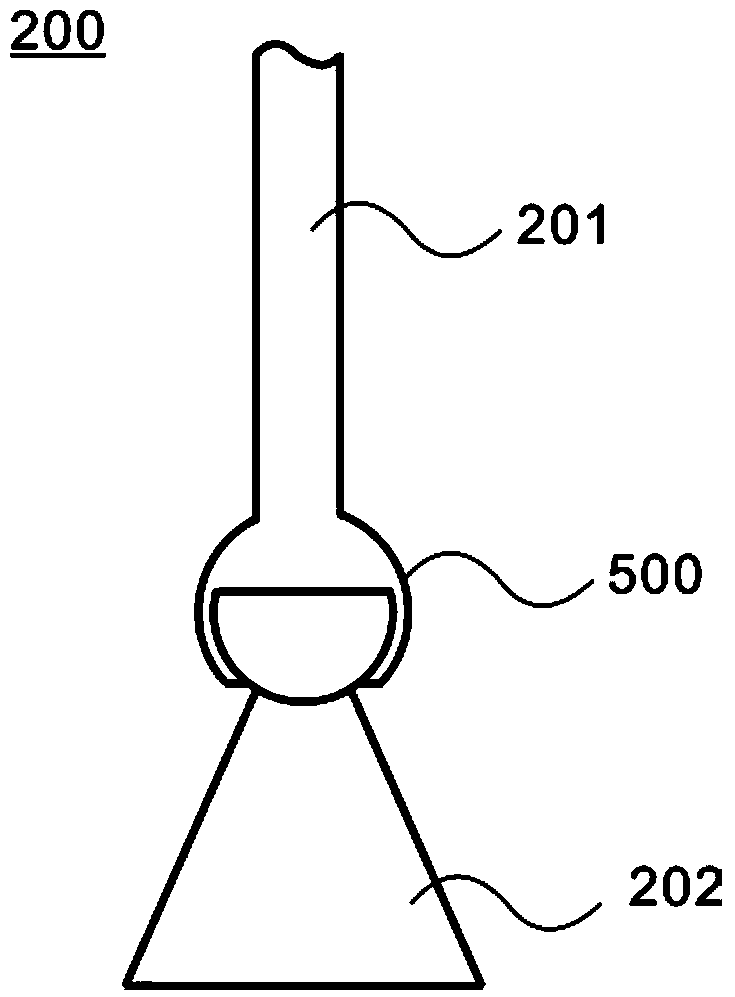

Rinse tank for rinsing semiconductor wafer

ActiveCN103871938AEasy to cleanWide range of cleaningSemiconductor/solid-state device manufacturingSpray nozzleSemiconductor

The invention provides a rinse tank for rinsing a semiconductor wafer and belongs to the technical field of the semiconductor wafer technology. The rinse tank comprises a rinse tank body and a sprinkler, wherein a tank cover used for sealing the rinsing tank body is arranged over the rinsing tank body, the sprinkler used for rinsing the wafer is arranged on the tank cover and comprises multiple sprinkler pipes and multiple nozzles communicated with the sprinkler pipes, the nozzles are evenly distributed on the tank cover in a matrix mode, the sprinkling angles of the nozzles can be adjusted, and valves used for controlling rinsing fluid to pass through are arranged on the sprinkler pipes. According to the rinse tank, the tank cover is arranged on the upper portion of the rinse tank, the multiple nozzles with adjustable sprinkling angles are evenly distributed on the tank cover, the rinsing fluid can be jetted to rinse the wafer from different directions, and different positions and angles of the wafer can be covered; the rinsing capacity is higher, the rinsing surface is wider, rinsing time can be shortened, and the yield can be increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

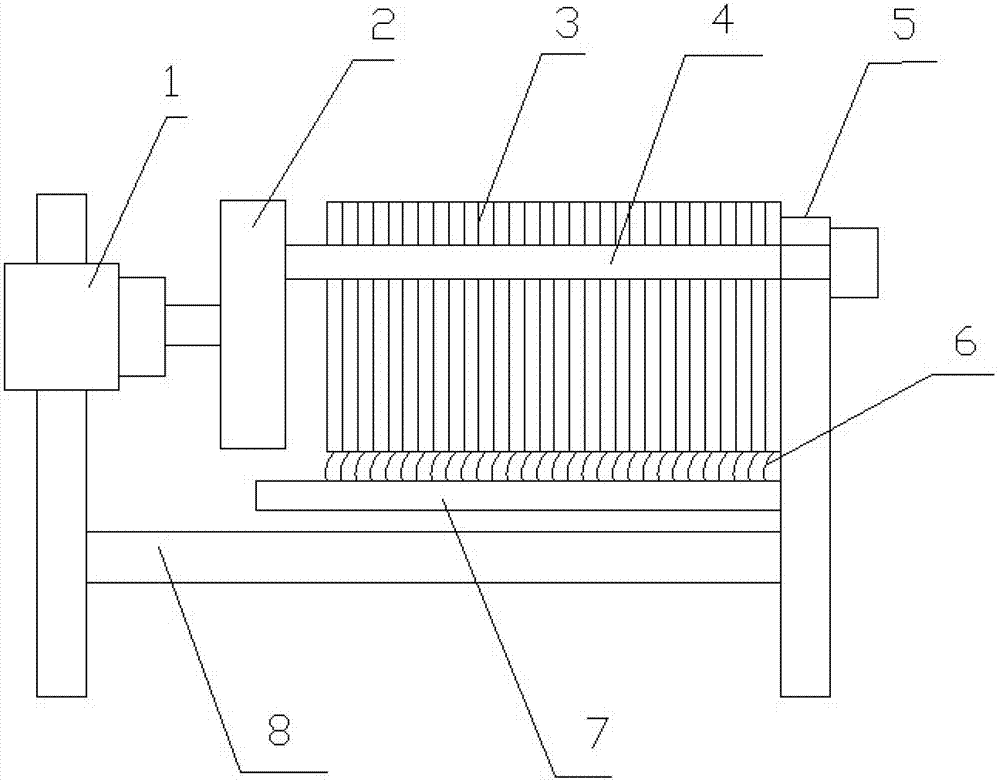

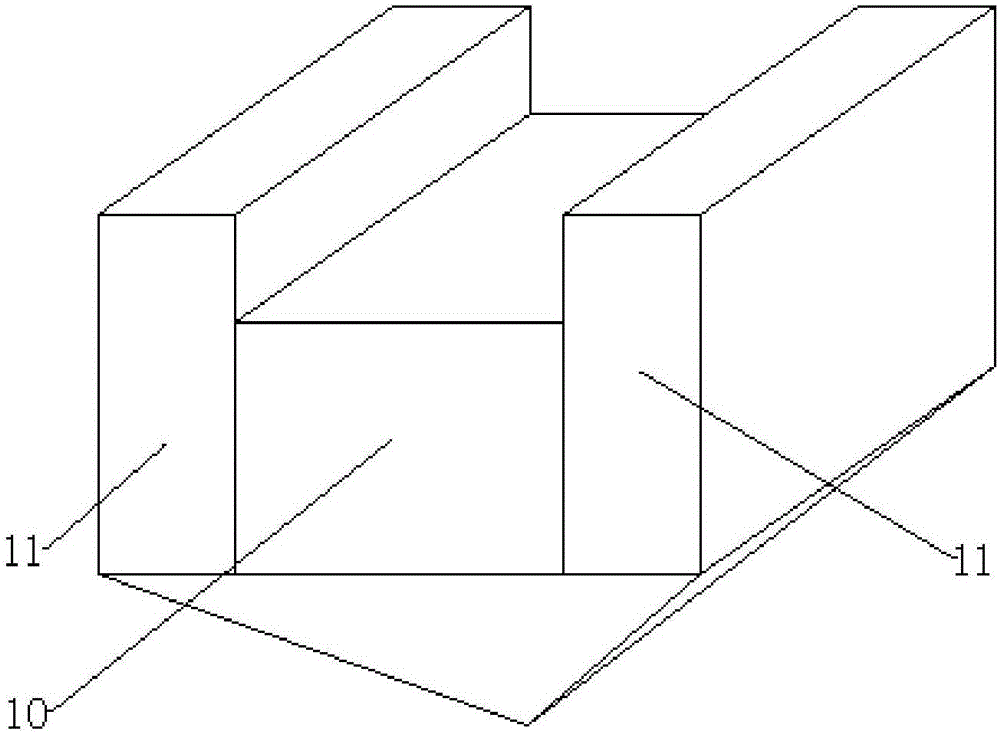

Plate-and-frame filter press

InactiveCN103111106AImprove cleaning efficiencyTightly boundFiltration separationEngineeringMechanical engineering

The invention relates to a plate-and-frame filter press which comprises a support, two cross beams and a hydraulic compressing device arranged on the support, wherein a push plate, a stop plate and a plate-and-frame group are arranged between the two cross beams, one side of each plate frame is in a plane structure, another side of each plate frame is a frame convex, each plate frame has a concave structure inside, one side of each plate frame plane is provided with a plate frame extruding balance beam, a spring and a small hydraulic cylinder are arranged between each plate frame and each plate frame extruding balance beam, a hydraulic oil opening is arranged on a small hydraulic cylinder body, the hydraulic oil opening is connected with a hydraulic oil support pipe, and a hydraulic oil branch pipe on each plate frame is communicated with a hydraulic oil main pipe on each plate frame. The position except a material inlet on the surface at one side of each plate frame is provided with an automatic filter cloth cleaning device. The plate-and-frame filter press is simple in structure, each plate frame can be synchronously pushed in the process of filter-press, the plate frames can be compacted with one another, the material can not be lost, the plate-and-frame filter press is high in filter-press efficiency, the workload of the hydraulic compressing device can be effectively reduced, each plate frame can not deform or be damaged, and the plate-and-frame filter press has a function for cleaning a filter cloth on line.

Owner:王焕坤

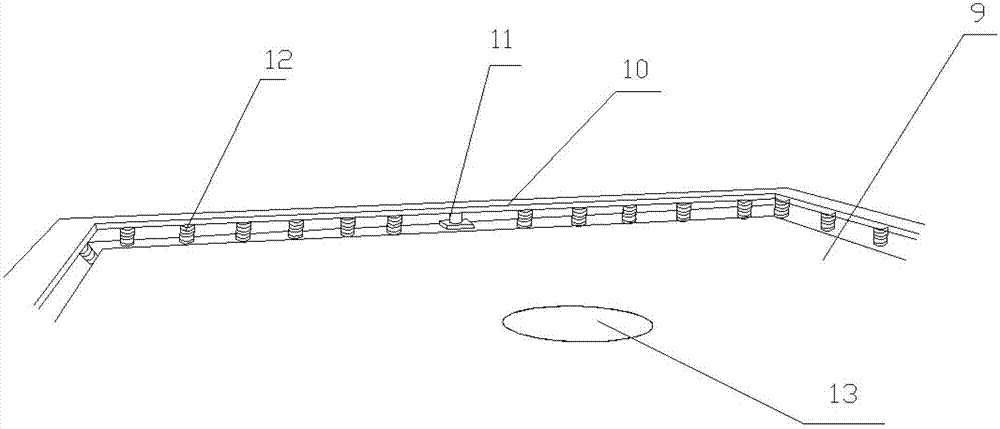

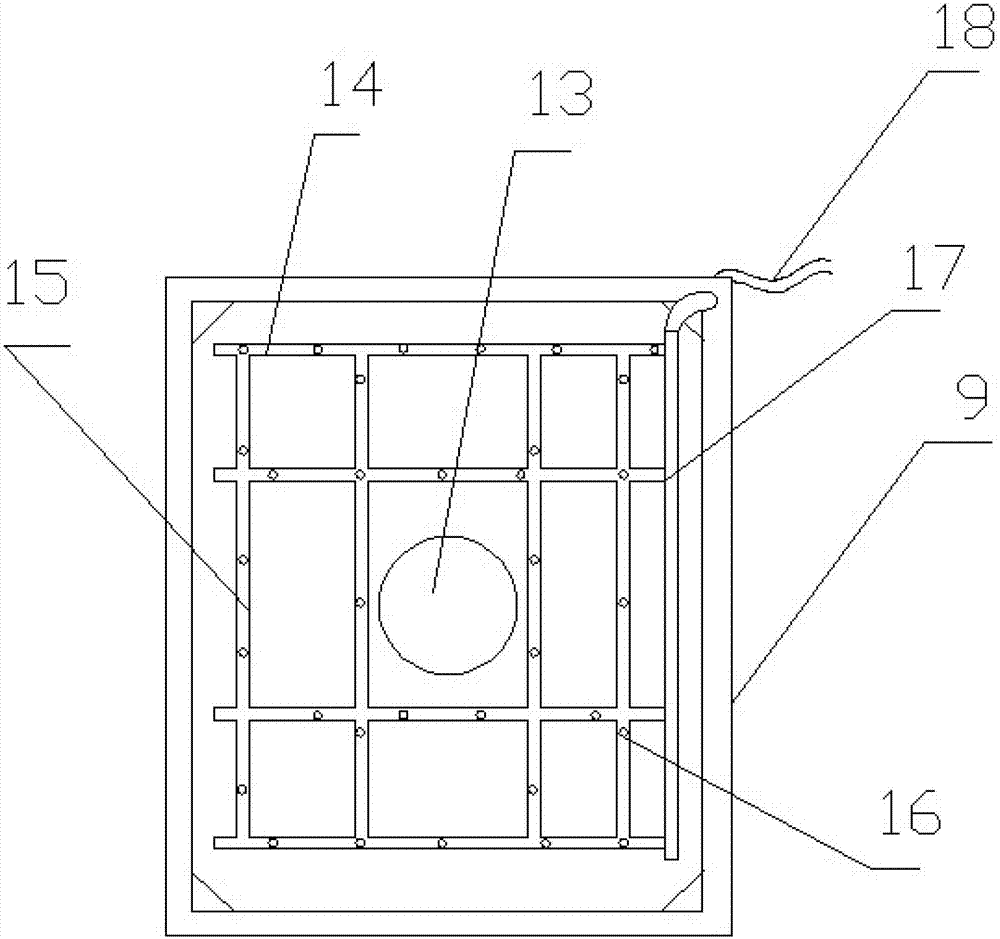

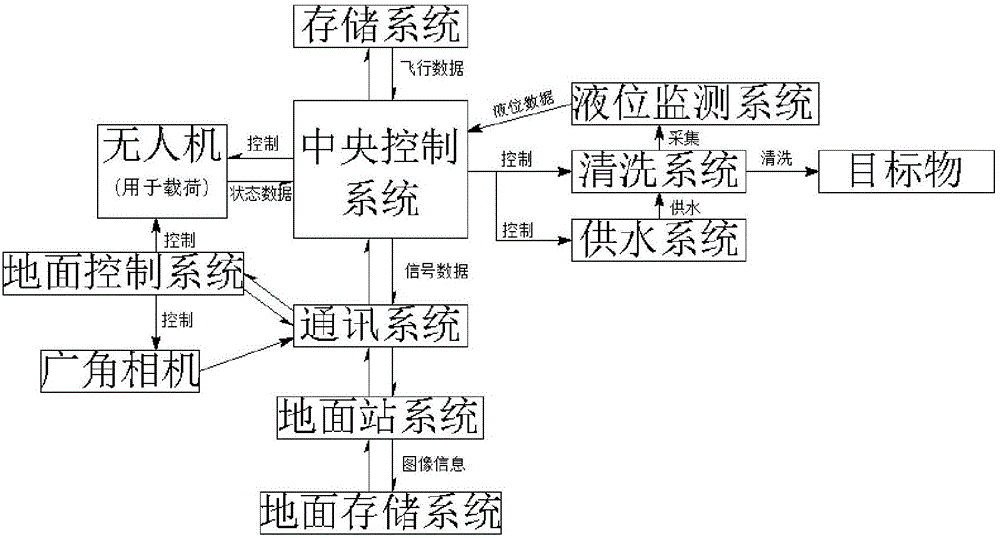

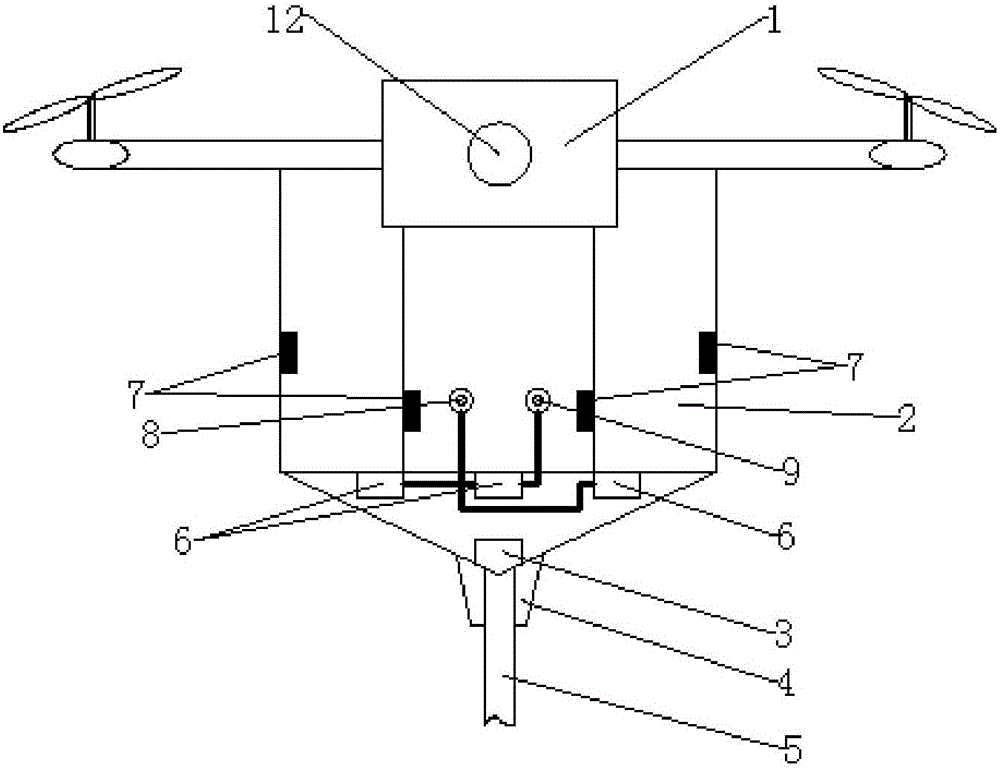

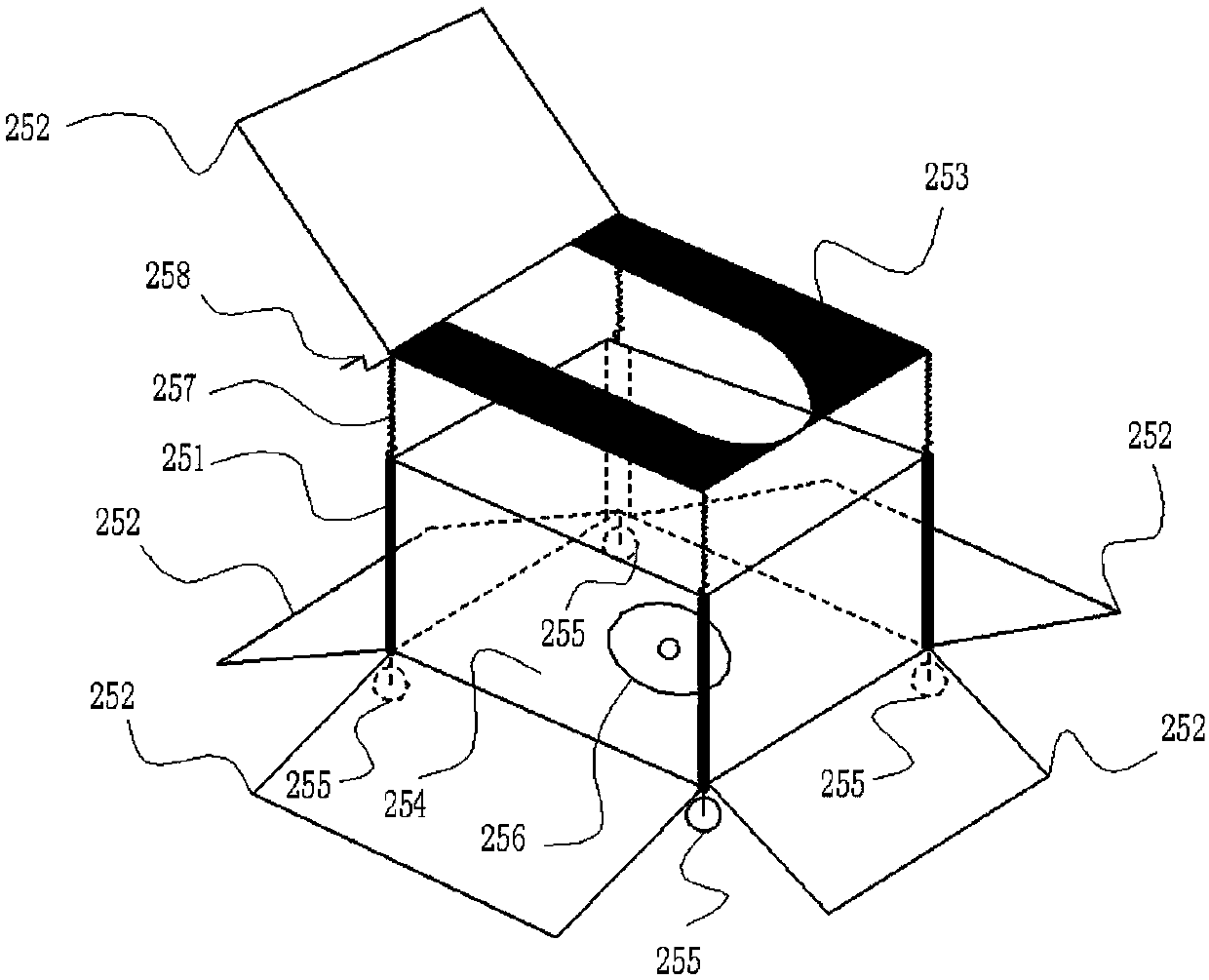

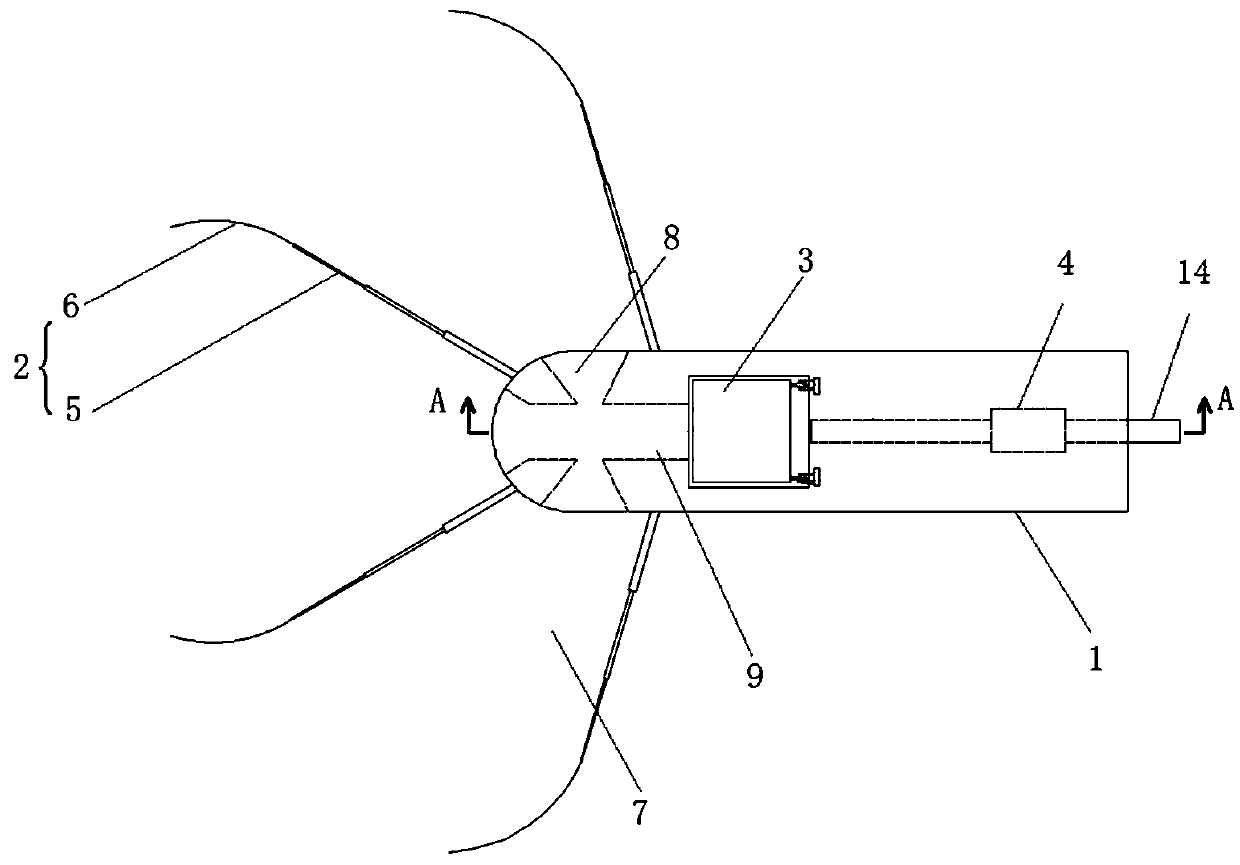

Cleaning system of multi-rotor unmanned aerial vehicle

InactiveCN106184810AReduce in quantityRealize multi-angle adjustmentGround installationsRotocraftCommunications systemControl system

The invention discloses a cleaning system of a multi-rotor unmanned aerial vehicle. The system comprises a central control system, the unmanned aerial vehicle, a storage system, a communication system, a ground station system, a ground storage system, a water supply system, a cleaning system and a liquid level monitoring system. The unmanned aerial vehicle, the storage system, the communication system are connected with a central control system in two directions. The water supply system, the cleaning system and the liquid level monitoring system are connected with the central control system in signal direction. The ground control system is connected with the unmanned aerial vehicle in signal direction. The communication system is connected with the ground station system in two directions. The ground station system is connected with the ground storage system in two directions. A wide-angle lens camera is arranged on the unmanned aerial vehicle. By an ordinary spray head and a high-pressure spray head of the cleaning system and the presence of a steering engine, cleaning efficiency is improved and cleaning degree is ensured. The structures of water tanks of the cleaning system are symmetrical so that stability of the unmanned aerial vehicle during cleaning is ensured.

Owner:GUANGDONG RONGQE INTELLIGENT TECH CO LTD

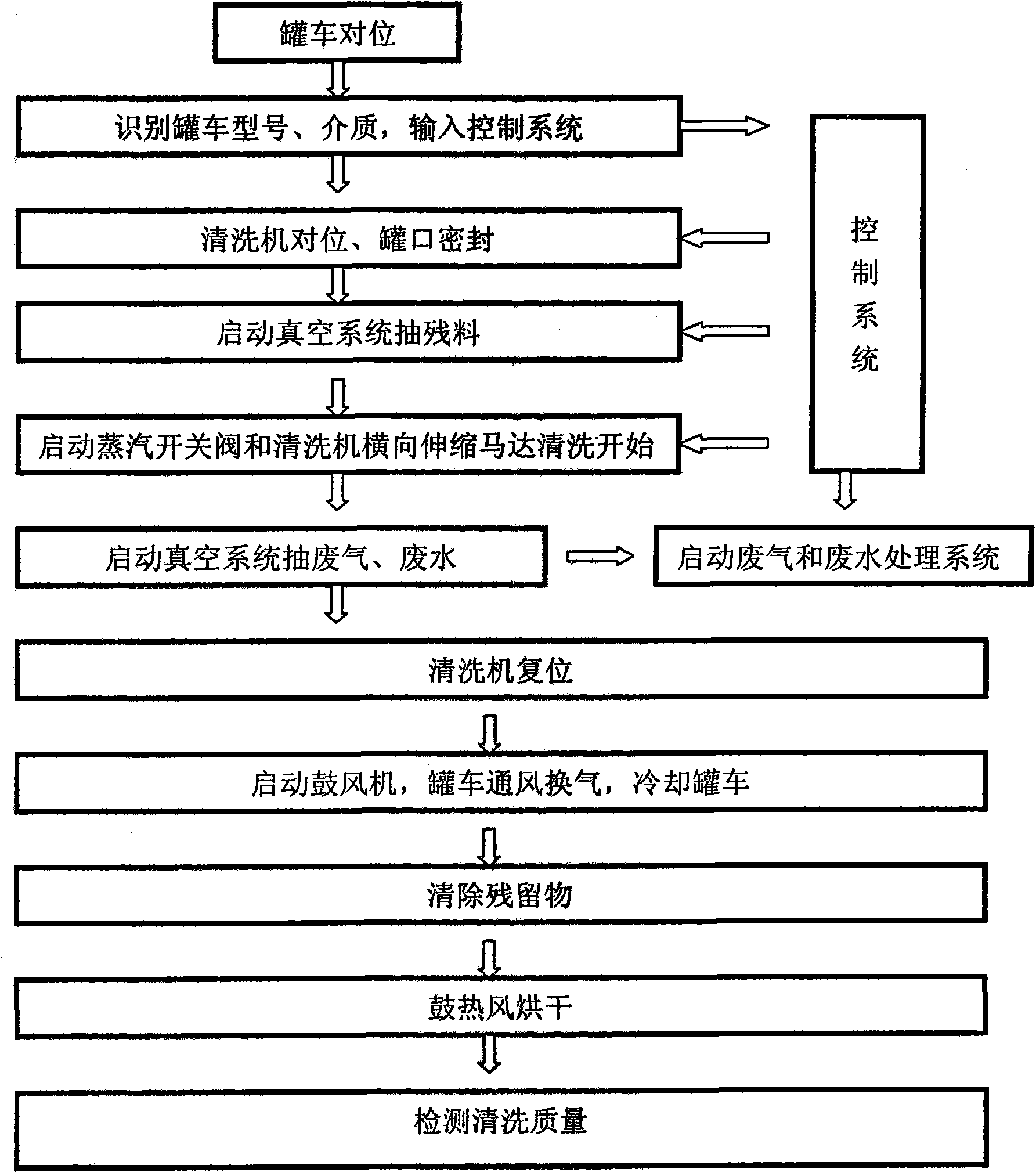

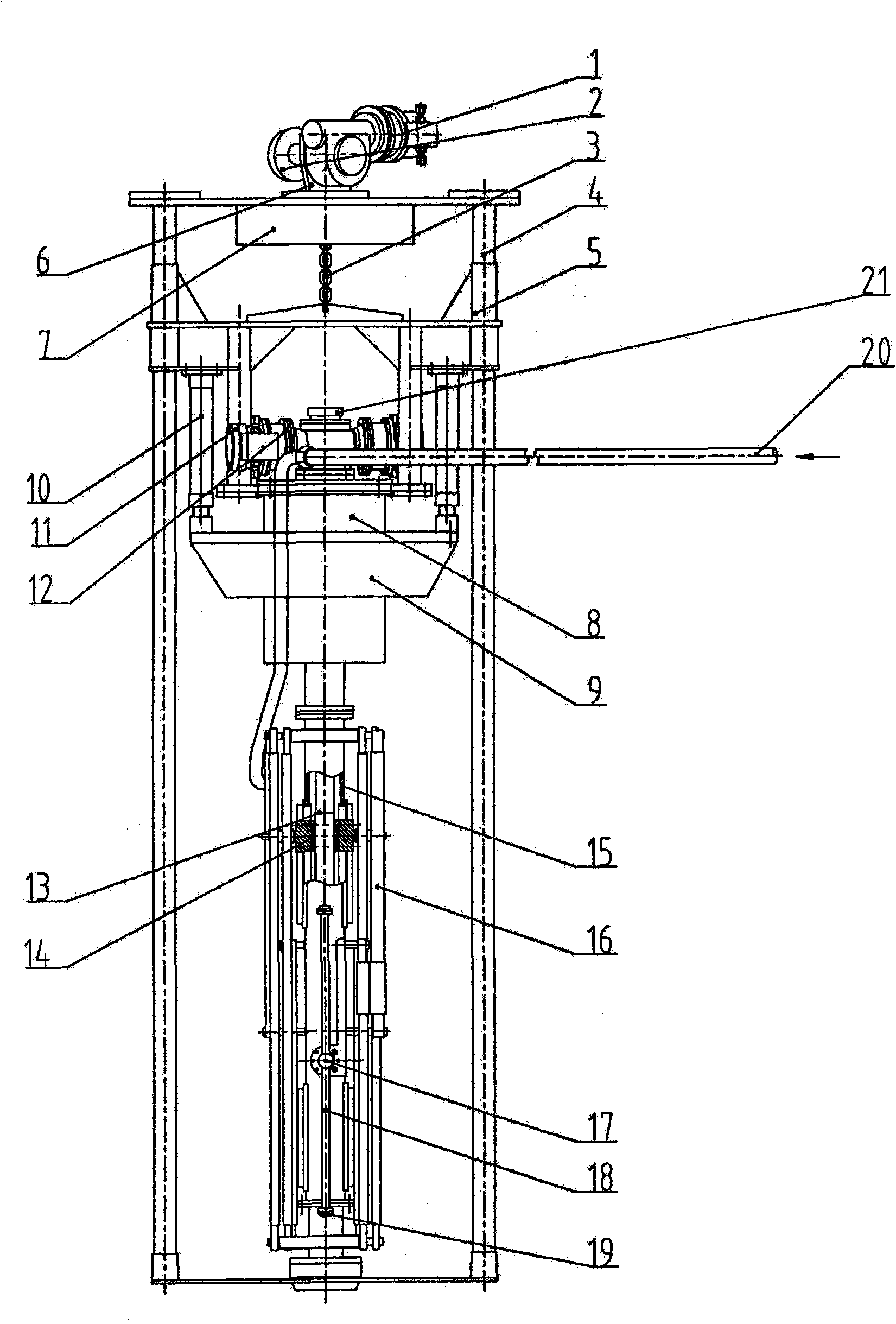

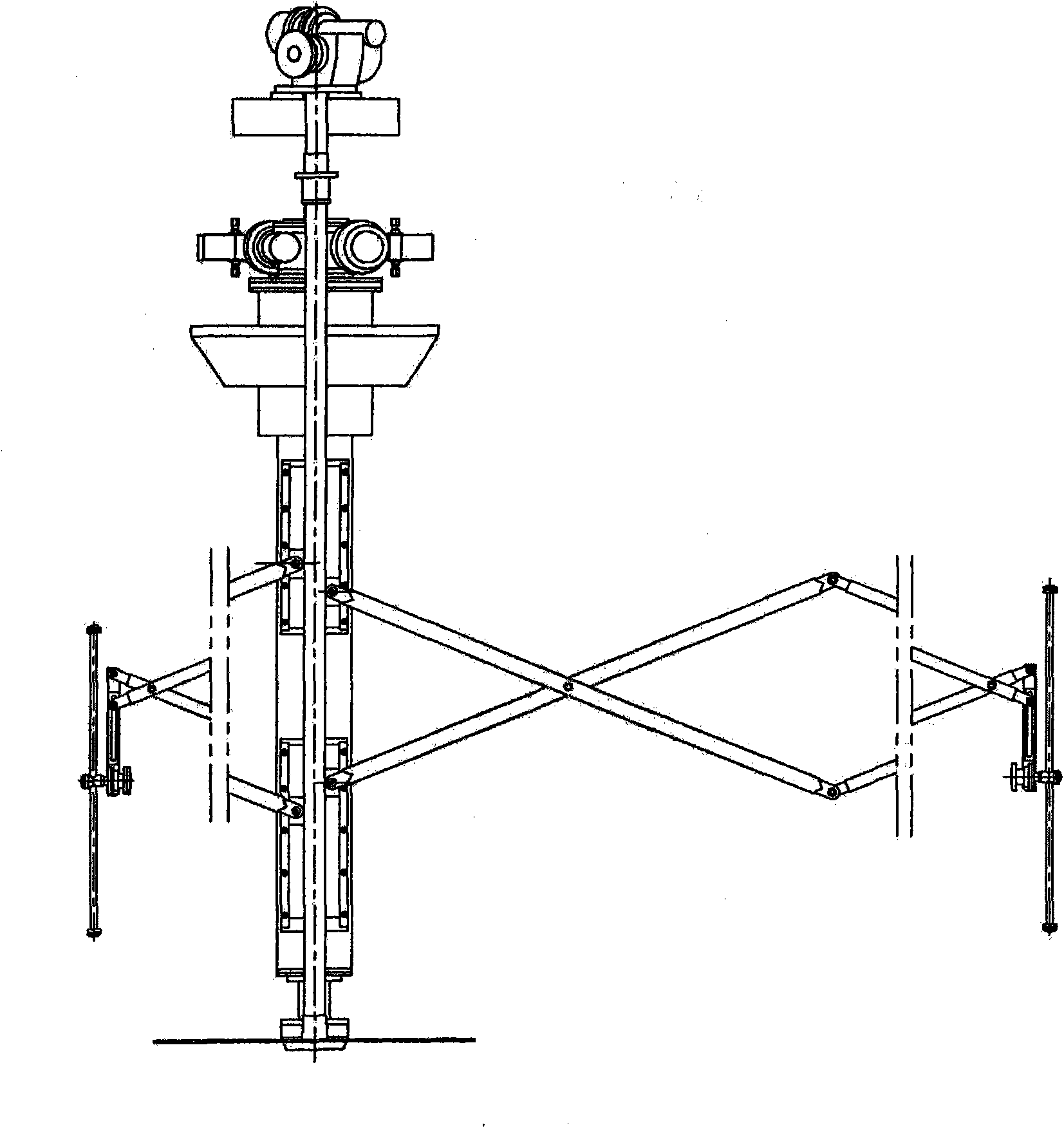

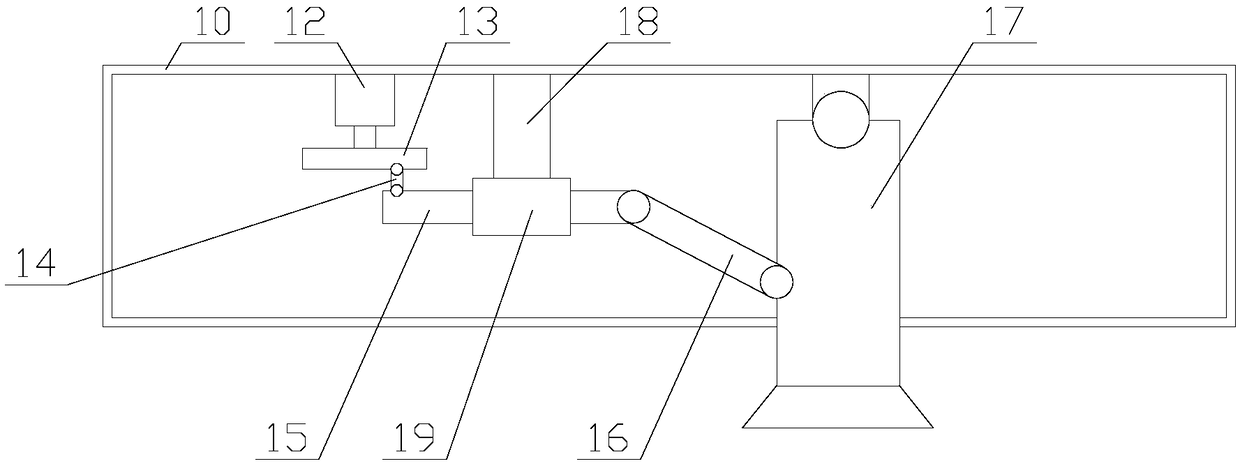

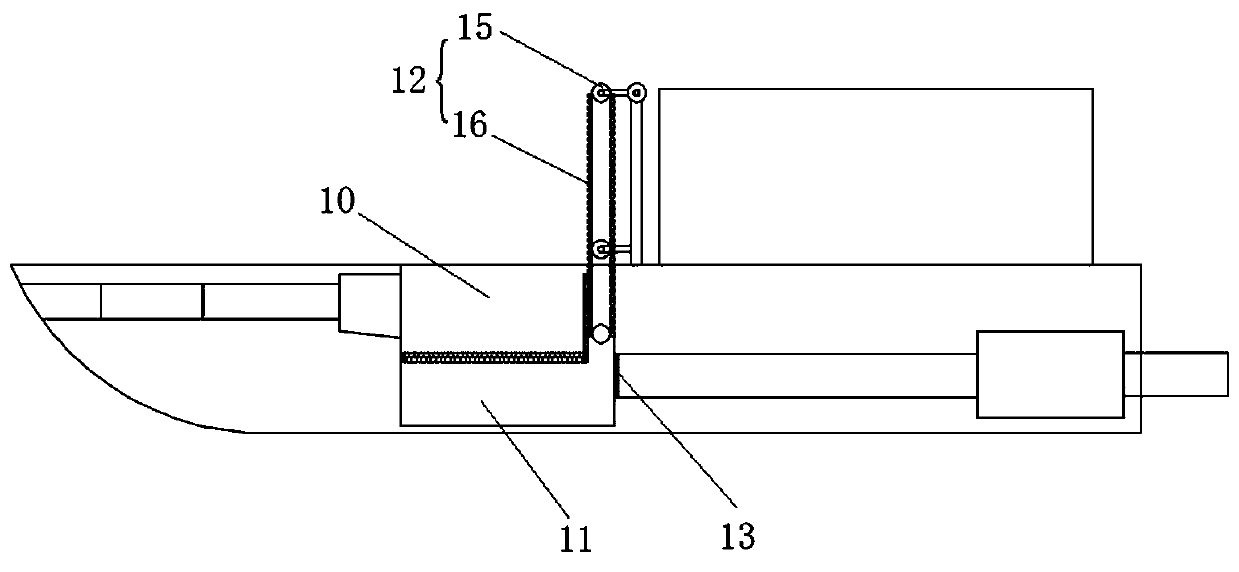

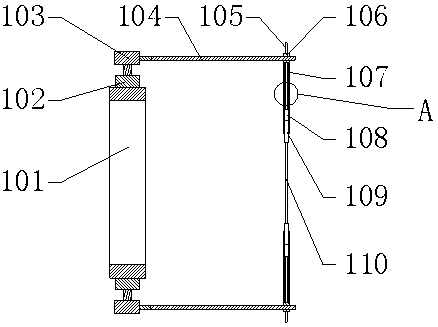

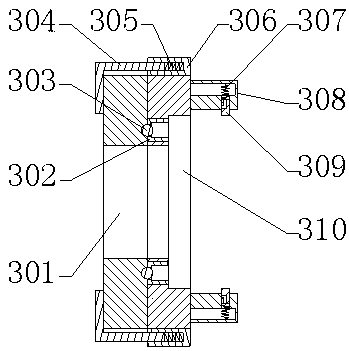

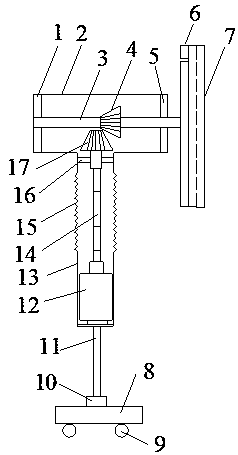

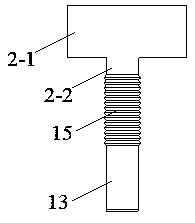

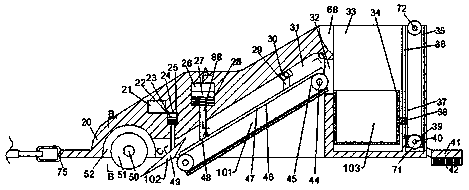

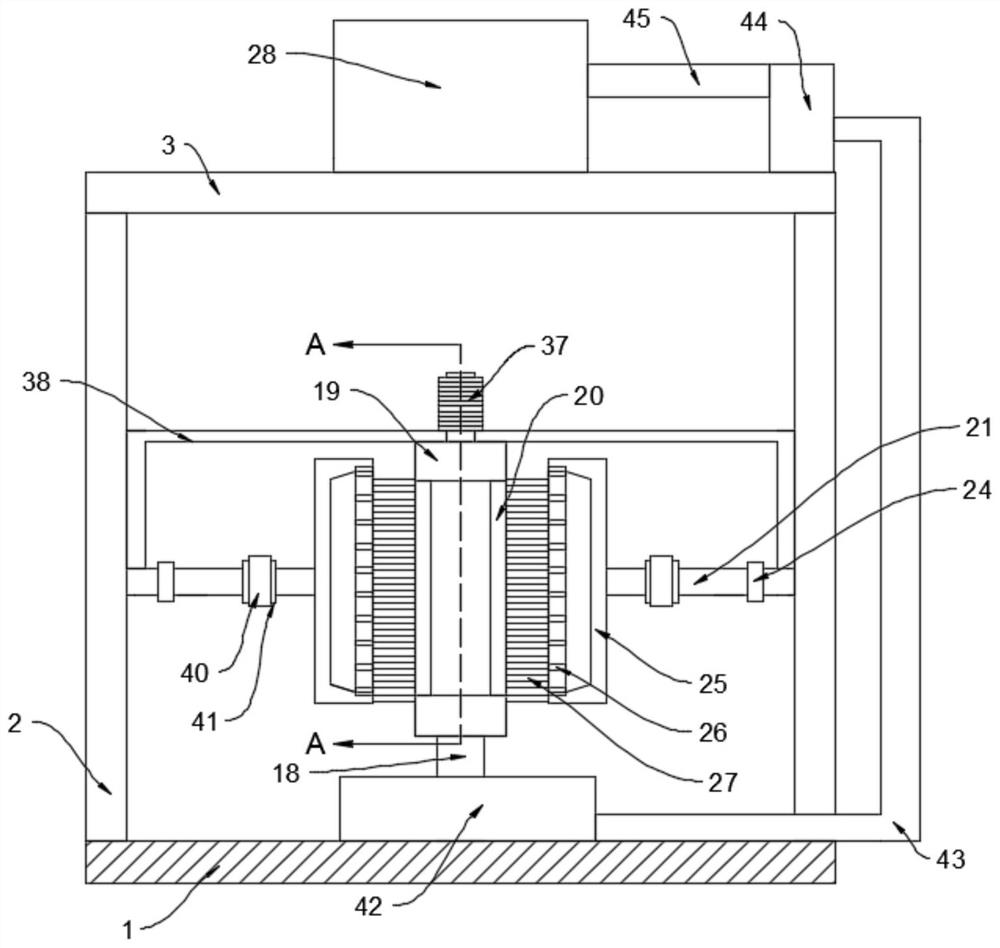

Steam jet flow type tank car cleaning method and device thereof

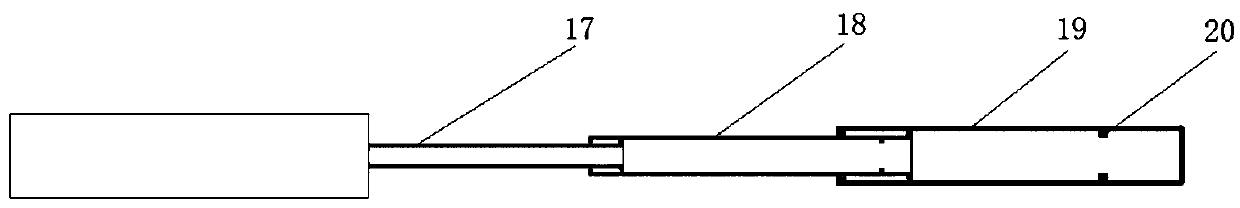

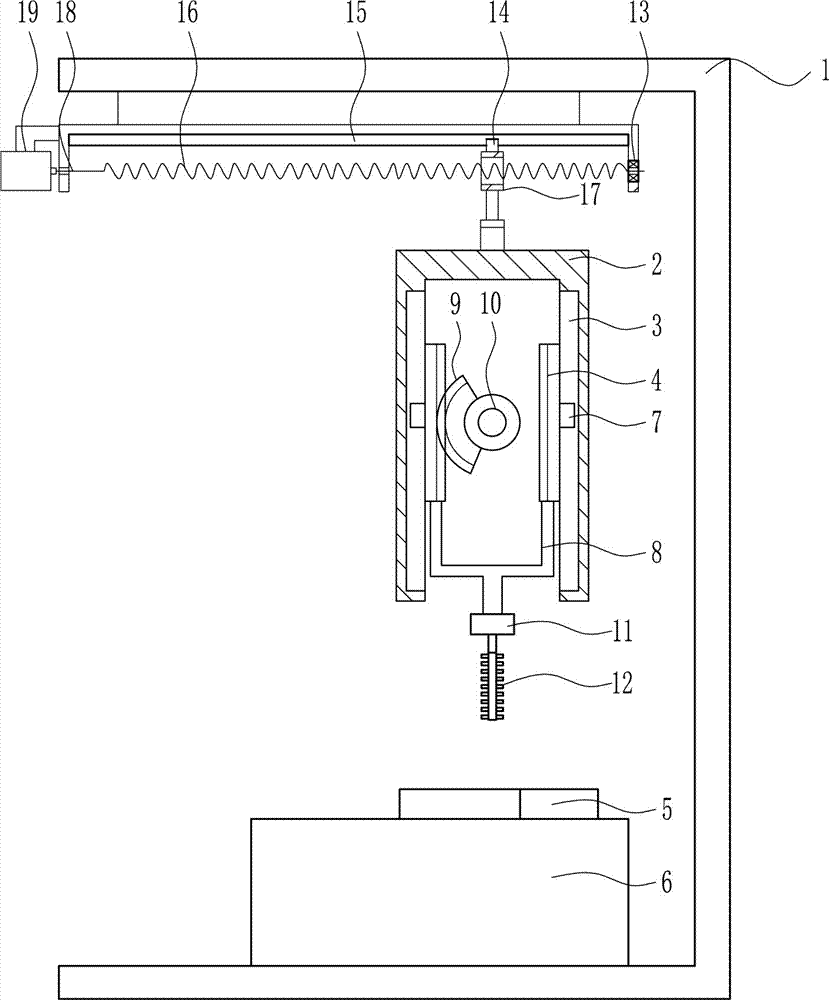

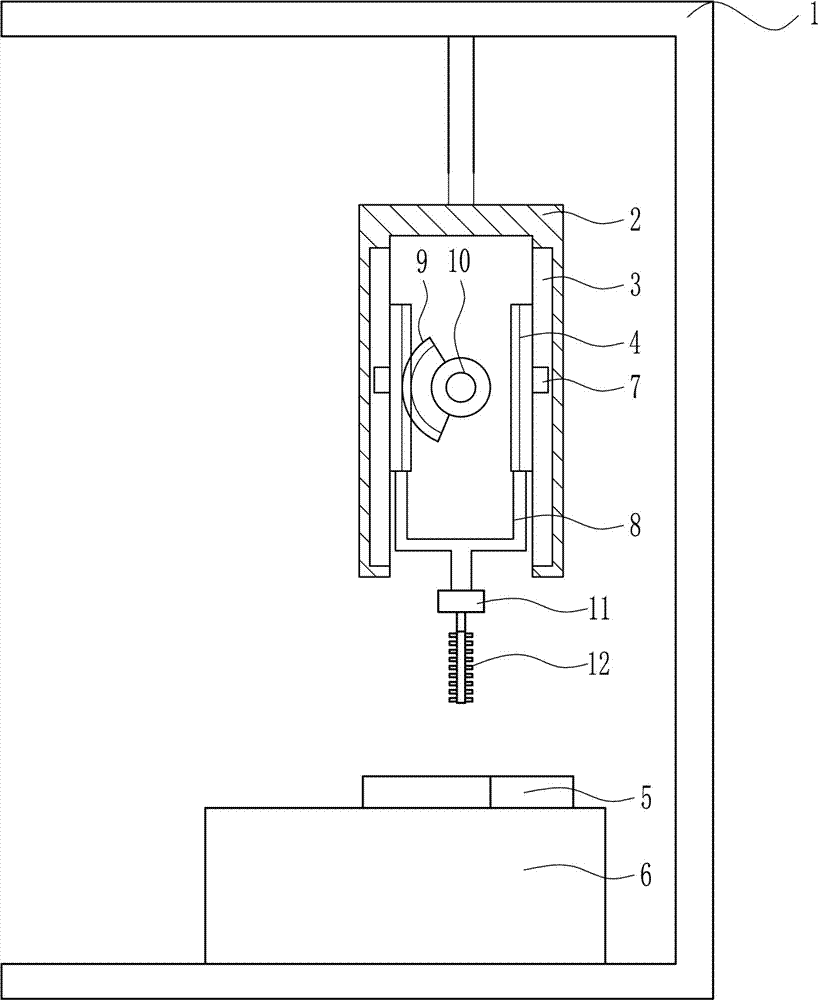

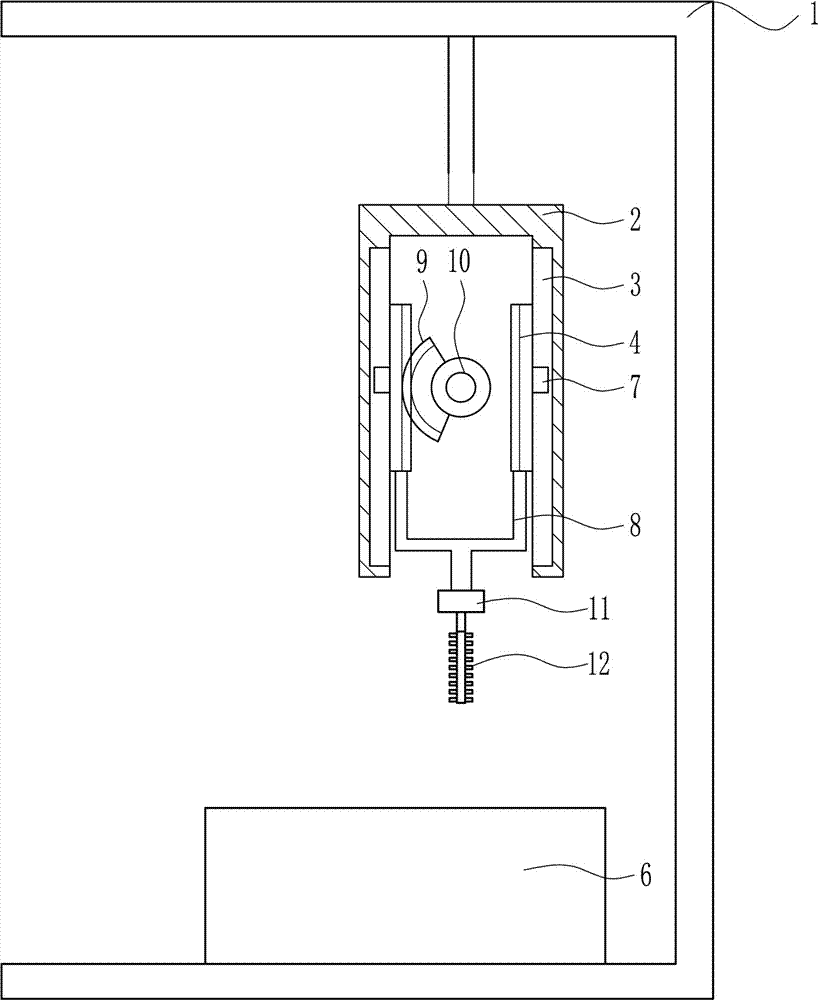

InactiveCN102101117AIncrease temperatureImprove efficiencyHollow article cleaningAutomatic controlShortest distance

The invention relates to a steam jet flow type tank car cleaning method which mainly comprises the steps of: aligning a tank car, extracting residual material, aligning a cleaning machine, adopting the inner wall of the steam jet flow cleaning tank car at the short distance, carrying out purification treatment on waste gas and waste water, and automatically controlling the cleaning of the cleaning machine. The equipment cleaning machine specially designed for the cleaning method comprises an up and down stretching mechanism of the cleaning machine, a tank hole sealing mechanism, a transverse stretching mechanism of the cleaning machine, a spray head and a steam pipeline. The stretching distance of the transverse stretching mechanism of the cleaning machine can be controlled by a stroke control mechanism. Compared with the prior art, the railway tank car inner wall cleaning method and the device thereof are safer, less in investment, energy-saving, wide in cleaning range and high in efficiency.

Owner:乐清市金宇科技有限公司

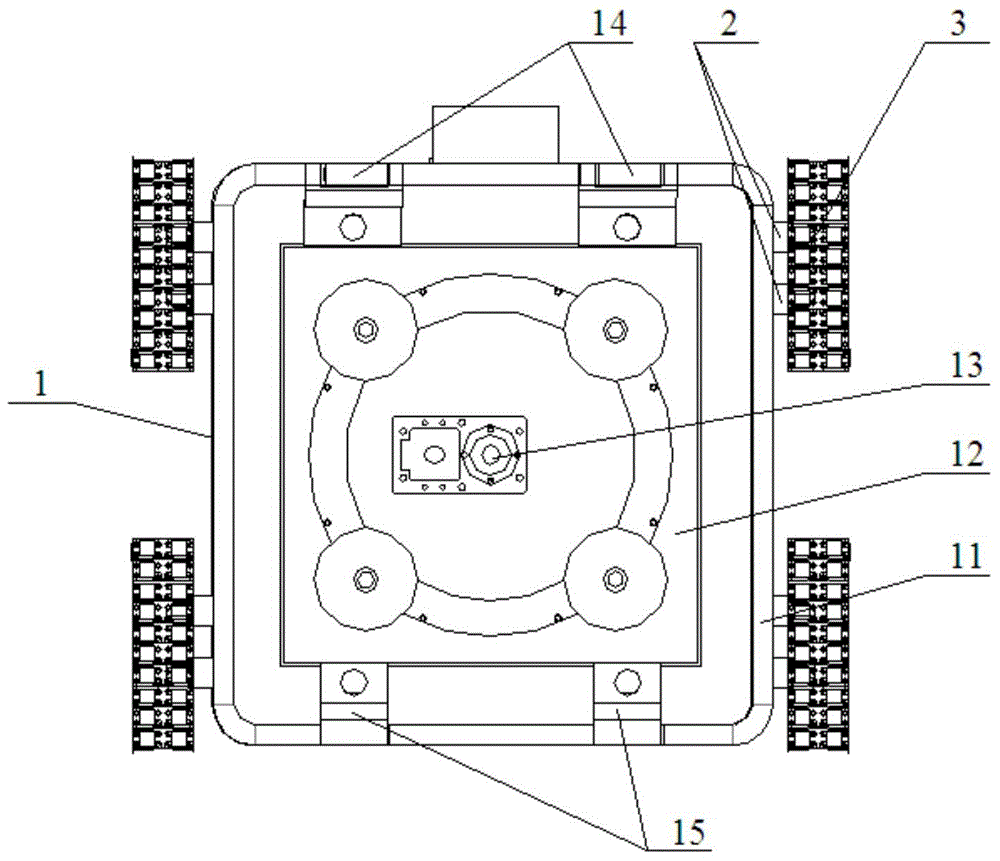

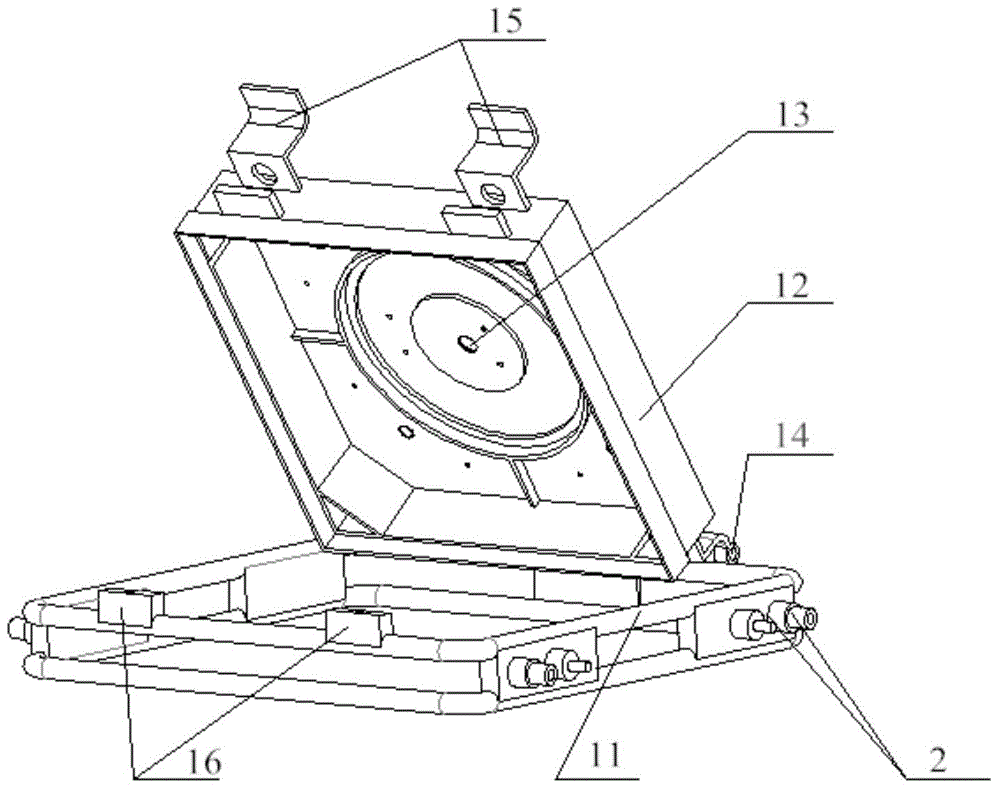

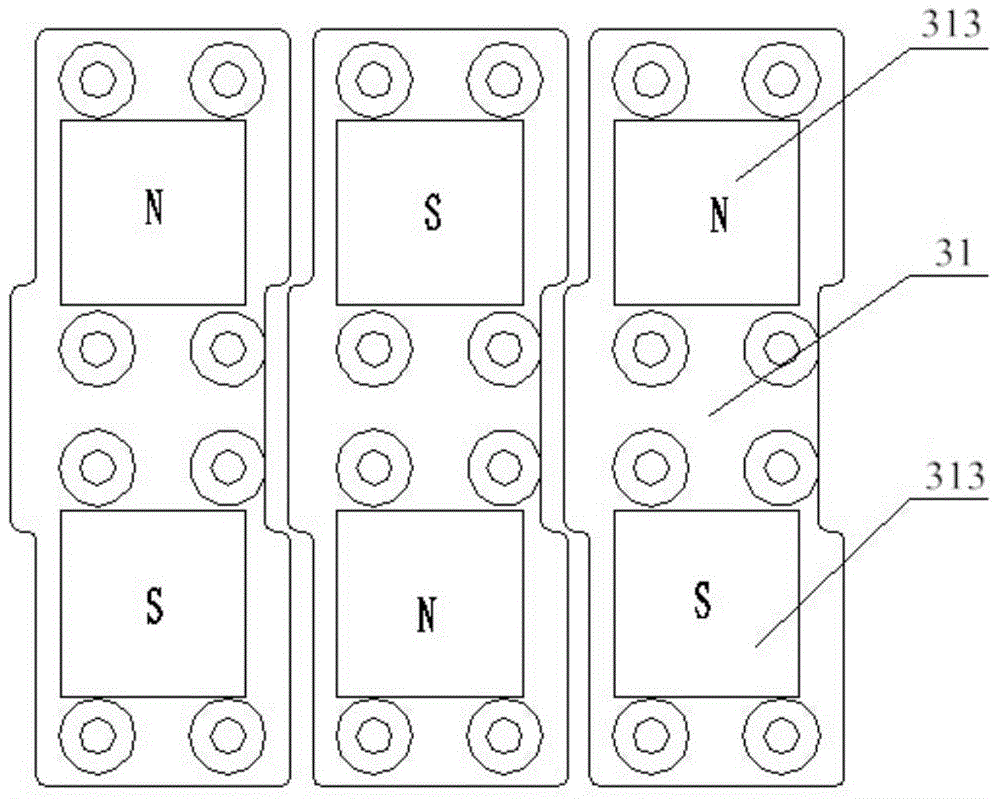

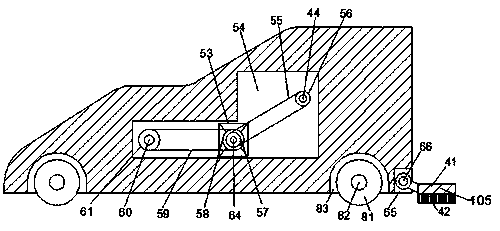

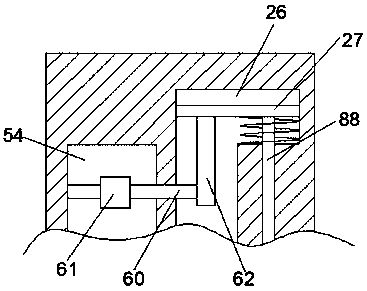

Wall climbing robot

The invention discloses a wall climbing robot. The wall climbing robot comprises a vehicle body, four driving units and four crawler belts, wherein two of the driving units are respectively mounted on the left side and the right side of the vehicle body, and the four driving units are connected with the crawler belts separately; each of the crawler belts comprises a plurality of crawler belt plates in annular connection, each of the crawler belt plates comprises a magnetism conductive mounting plate, a magnetism isolating plate and permanent magnets, the magnetism isolating plate is arranged on the magnetism conductive mounting plate, and the two permanent magnets in contrary magnetism are embedded at lateral symmetrical positions of the magnetism isolating plate; the magnetism of one of the two adjacent permanent magnets on the two adjacent crawler belt plates is contrary to the other; the vehicle body comprises a frame, a turning and mounting device and a cleaner main body, wherein one end of the turning and mounting device is connected with the front end of the frame through hinges; the cleaner main body is arranged at the central position of the turning and mounting device; an pneumatic motor is arranged in the vehicle body. The wall climbing robot disclosed by the invention has the advantages of being flexible and smooth, being good in loading property, being wide in cleaning range, and being high in magnetic adsorption efficiency, and is suitable for hulls and large-scale tank bodies.

Owner:TIANJIN TONGJIE HIGH PRESSURE PUMP

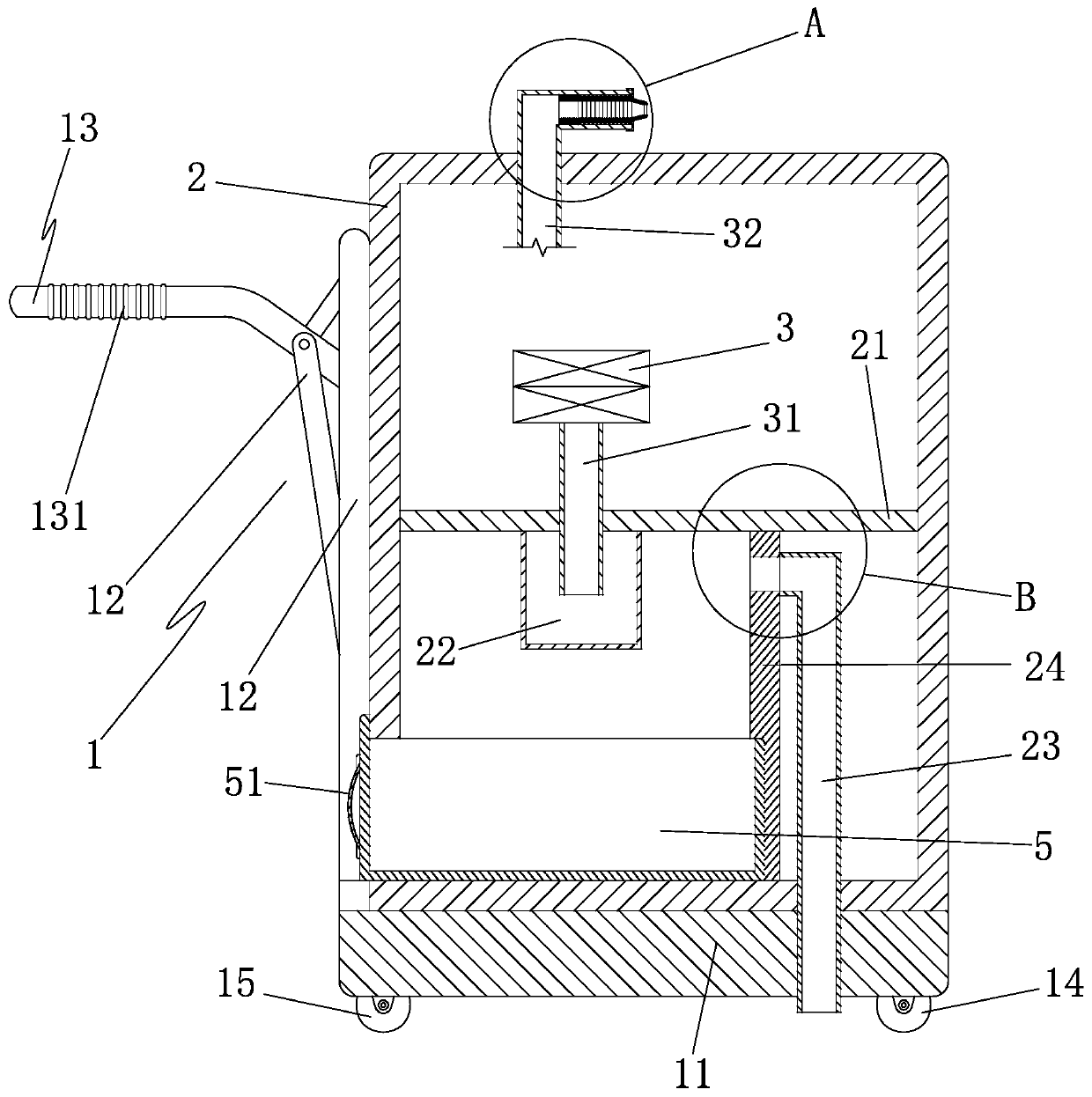

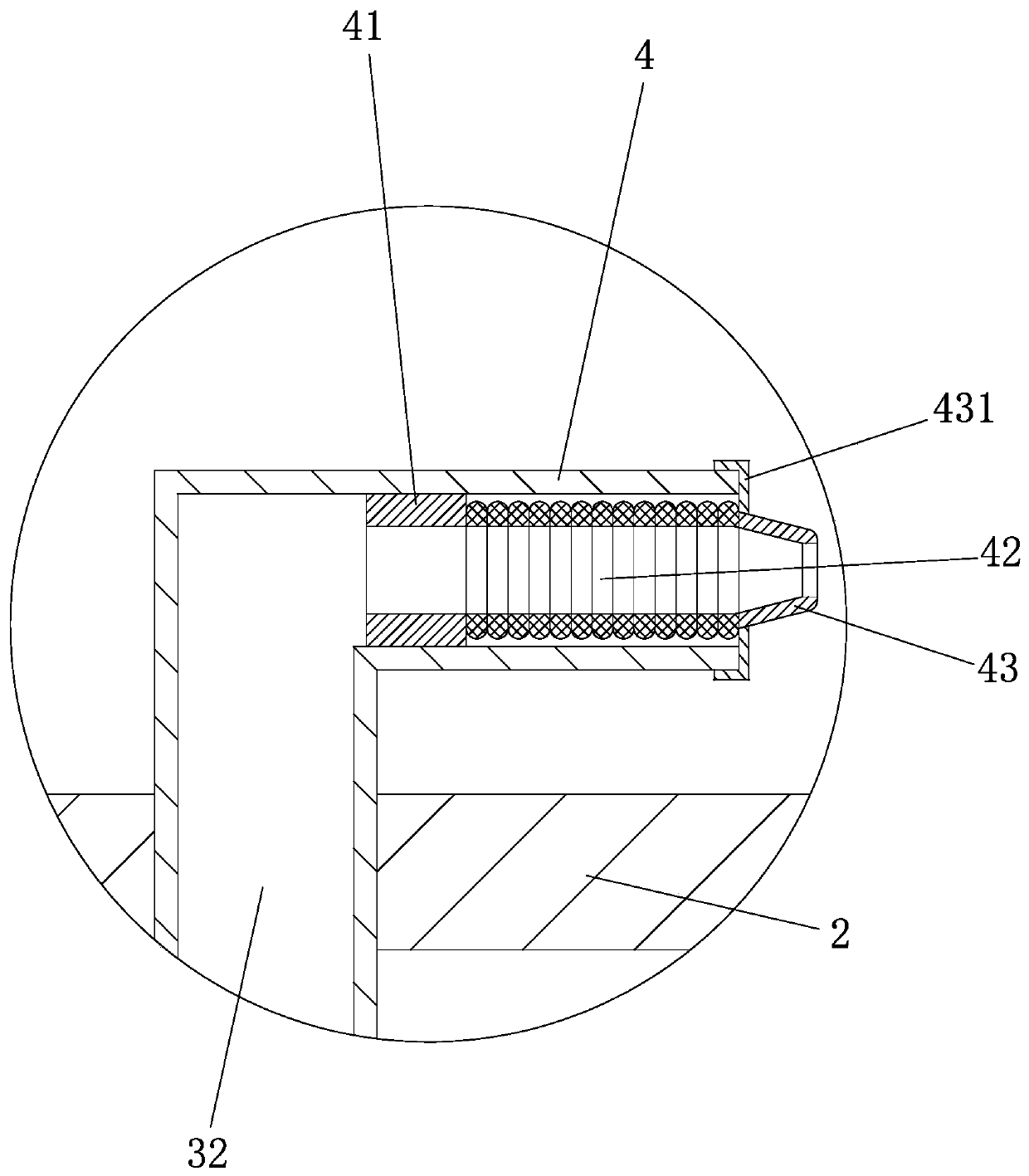

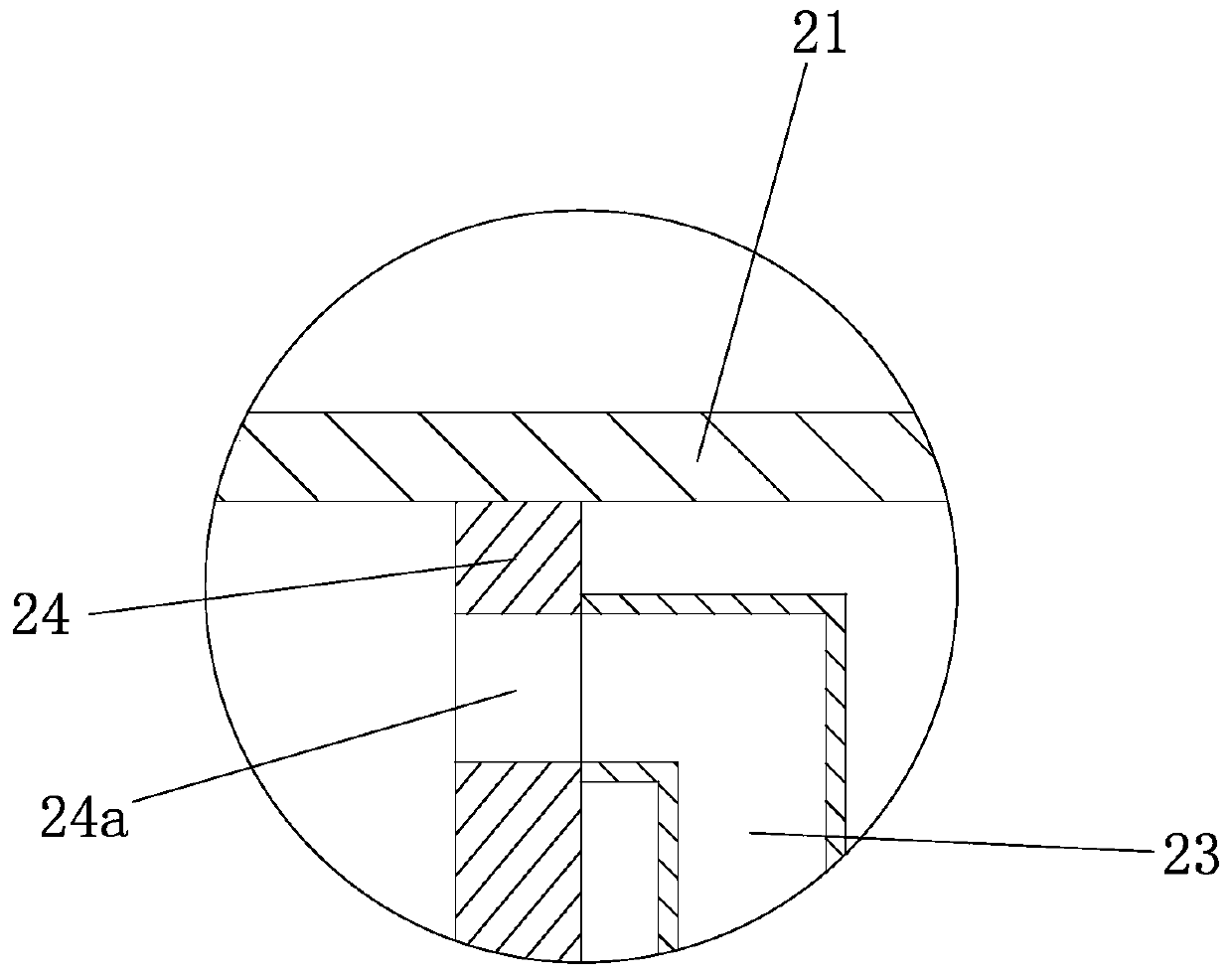

Portable fumigation and internal and external cleaning equipment for gynecology department

InactiveCN107583123AIncrease elasticityPrevent overflowEnemata/irrigatorsMedical devicesImpellerLiquid waste

The invention discloses portable fumigation and internal and external cleaning equipment for the gynecology department. The equipment can be used for cleaning the inside and outside of the vagina at the same time, and also can be used for fumigation for further sterilization and disinfection, a soft cup structure built in a cleaning nozzle is inserted into the vagina by folding and shrinking, thenrebounds and is clamped in the vagina, no hands are needed for holding, a blocking handle on the soft cup prevents the situation the soft cup is placed in a deep place and makes the soft cup convenient to take out, waste liquid is discharged from a waste liquid guide pipe below the soft cup, the dwell time of liquid drugs is prolonged, and overflowing of the waste liquid is prevented; the top ofthe external cleaning nozzle drives the rotating nozzle through a rotating driving impeller, and the cleaning range is more extensive. Moreover, external supports make the equipment more convenient tomove and store, the equipment is suitable for use in hospital and home, the cleaning and sterilization effects are obvious, safety and reliability are high, no liquid leakage occur, and operation andstorage are convenient.

Owner:陕西省肿瘤医院

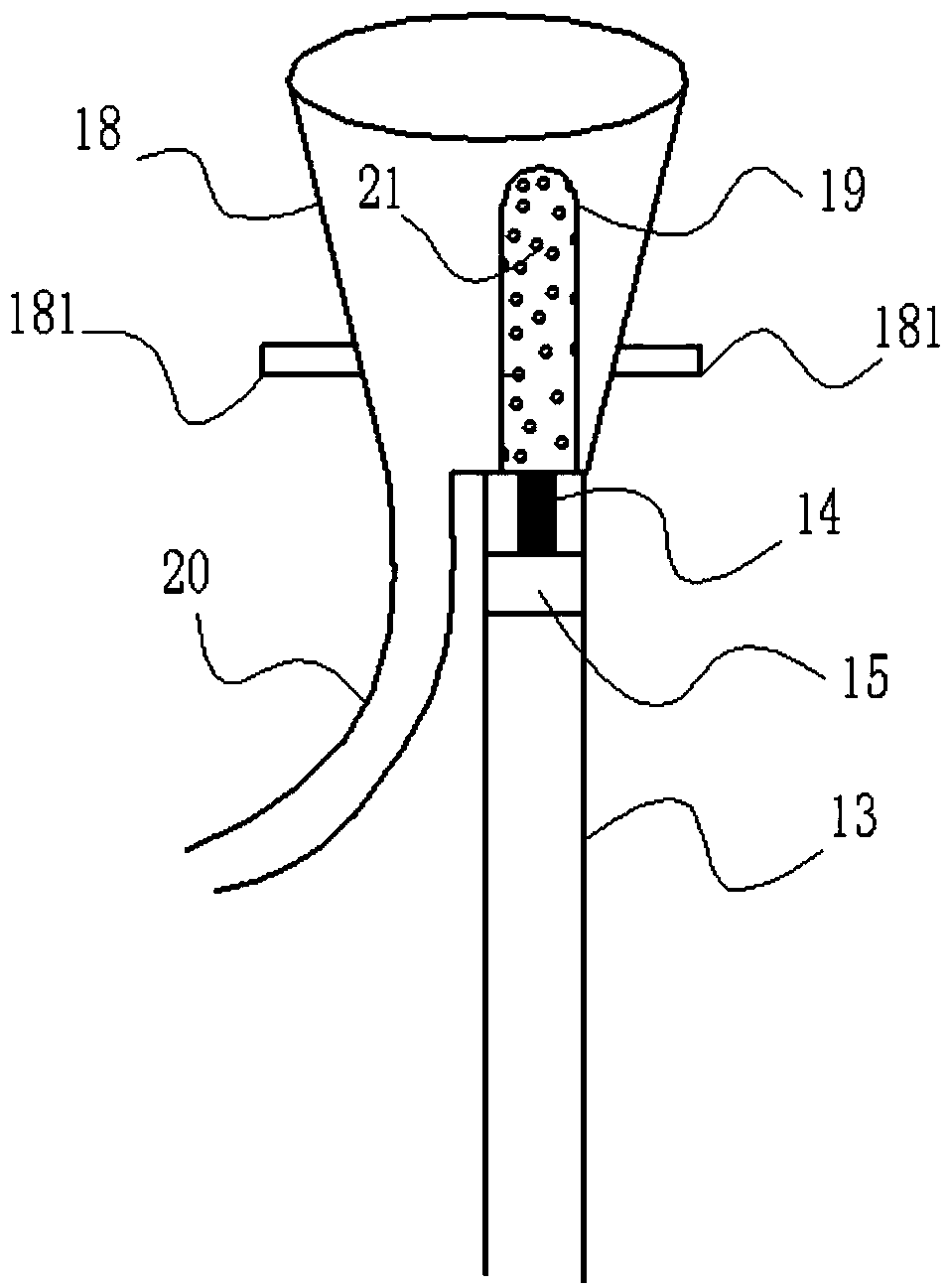

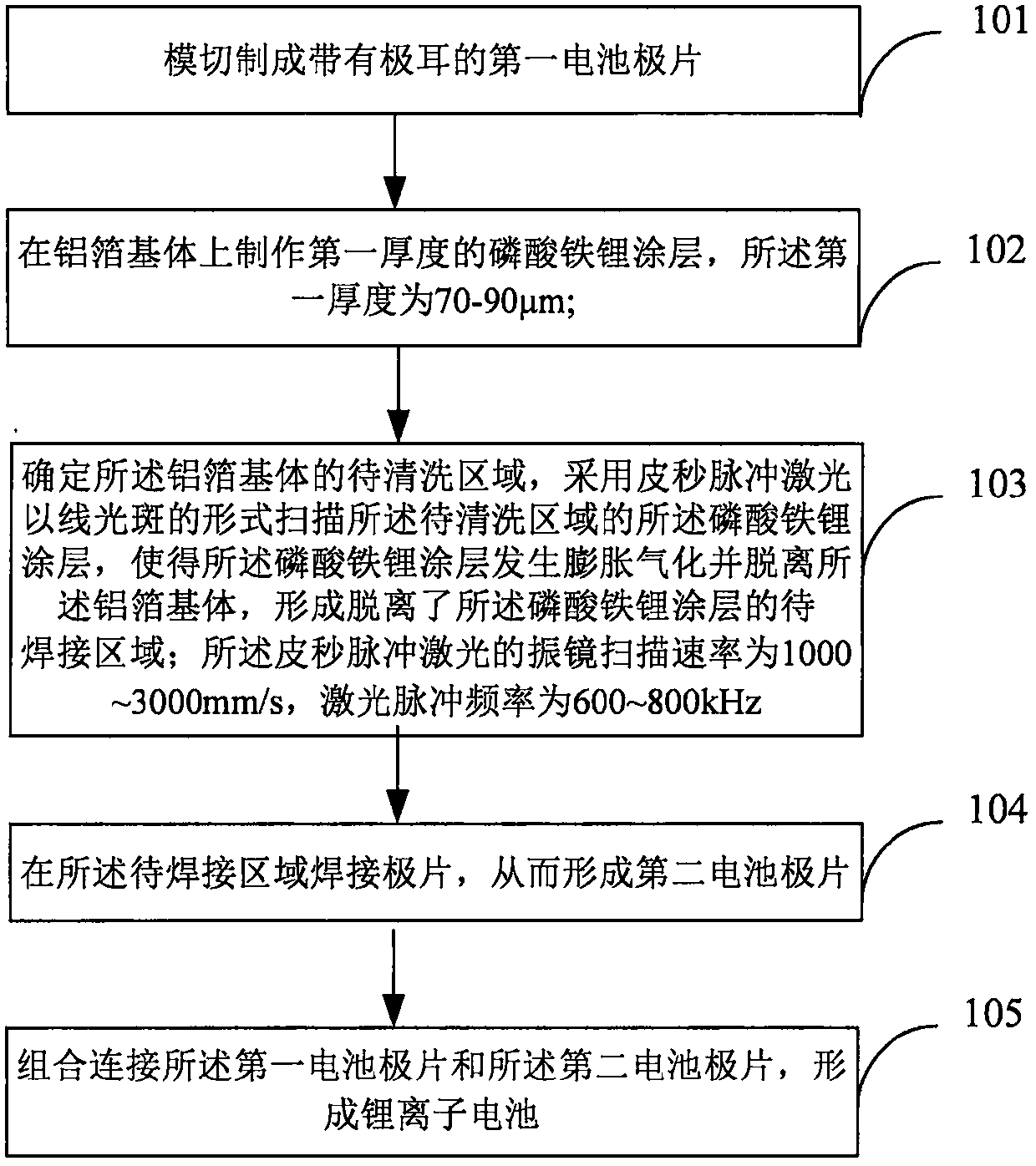

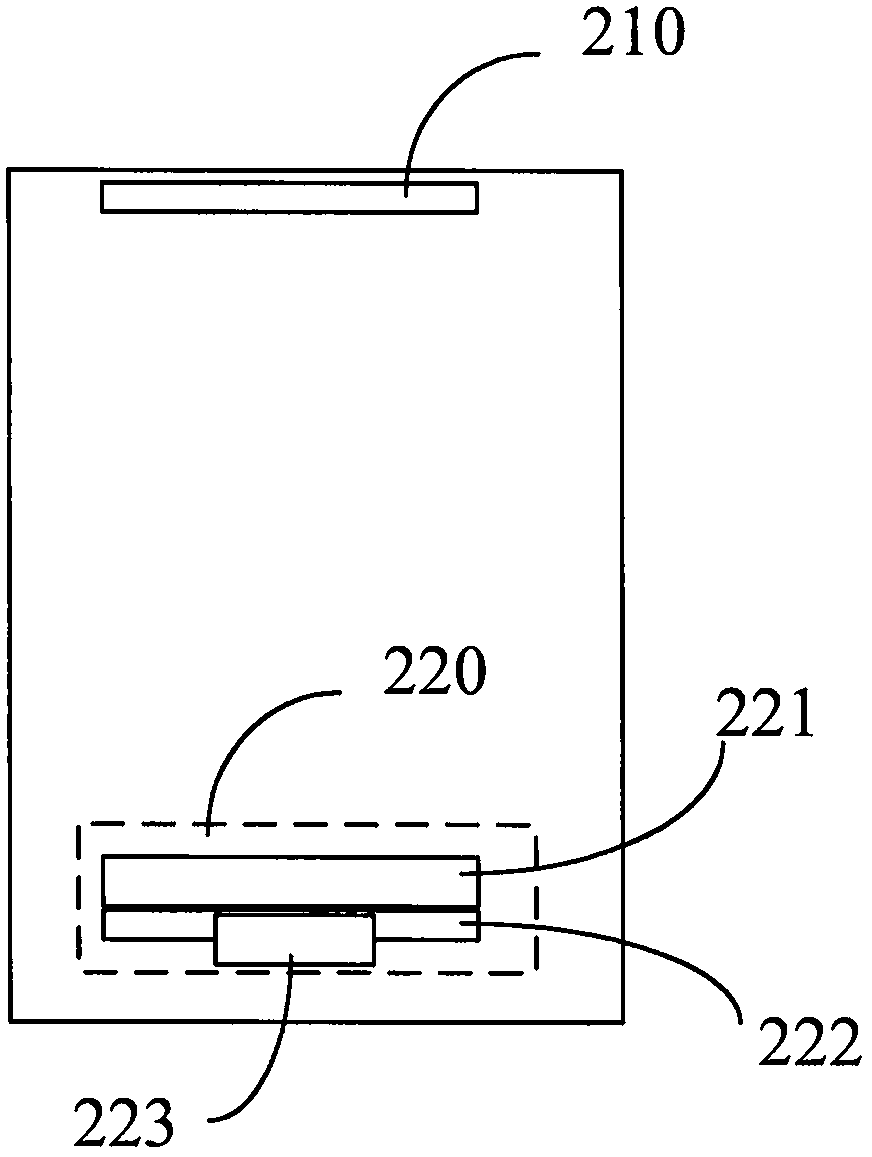

Lithium ion battery, laser manufacturing method thereof and laser washing device

PendingCN107946654AAccurately and neatly obtainedImprove production efficiencyFinal product manufactureElectrode collector coatingManufacturing technologyPicosecond pulsed laser

The invention provides a lithium ion battery, a laser manufacturing method thereof and a laser washing device. Coatings at the specific surface positions of battery pole pieces can be eliminated efficiently, environmentally and stably at high quality, so that the manufacturing technology of the lithium ion battery is simplified, and the manufacturing efficiency is improved. The laser manufacturingmethod comprises the following steps: carrying out die cutting to manufacture a first battery pole piece with a lug; manufacturing a lithium iron phosphate coating with a first thickness on an aluminum foil base body; determining an area to be washed of the aluminum foil base body, and adopting picosecond pulse lasers to scan the lithium iron phosphate coating in the area to be washed in a linearlight spot manner, so that expansion and gasification occur on the lithium iron phosphate coating, the lithium iron phosphate coating is separated from the aluminum foil base body, and an area to bewelded separated from the lithium iron phosphate coating is formed; welding a pole piece in the area to be welded so as to form a second battery pole piece; and combining and connecting the first battery pole piece and the second battery pole piece so as to form the lithium ion battery.

Owner:上海临仕激光科技有限公司

Automobile automatic cleaning device

InactiveCN108705991AExpand the scope of cleaningImprove efficiencyCleaning apparatus for vehicle exteriorsWater storage tankCombined use

The invention discloses an automobile automatic cleaning device. The automobile automatic cleaning device comprises two supporting plates, wherein a placing plate is arranged between the opposite sidewalls, near the upper ends, of the two supporting plates; electric sliding rails are arranged on the opposite side walls, corresponding to the position of the placing plate, of the two supporting plates, and the electric sliding rails are slidably connected to the two ends of the placing plate by sliding plates; a water storage tank is fixedly connected to the upper end of the placing plate, andan arc-shaped water through pipe is fixedly connected to the lower end of the placing plate by a connecting column; and a plurality of spray heads are disposed on the side wall of the arc-shaped waterthrough pipe at equal intervals, and a water pipe is arranged on a water outlet of the water storage tank. The automobile automatic cleaning device is compact in structure, through the combination use of the spray heads with a first cleaning brush, a second cleaning brush, a third cleaning brush and a front and rear cleaning soft brushes, reciprocating cleaning of an automobile in an all-round manner to a certain extent is achieved, the cleaning efficiency is high, the cleaning range is wide, and the effect is good.

Owner:广西工业职业技术学院

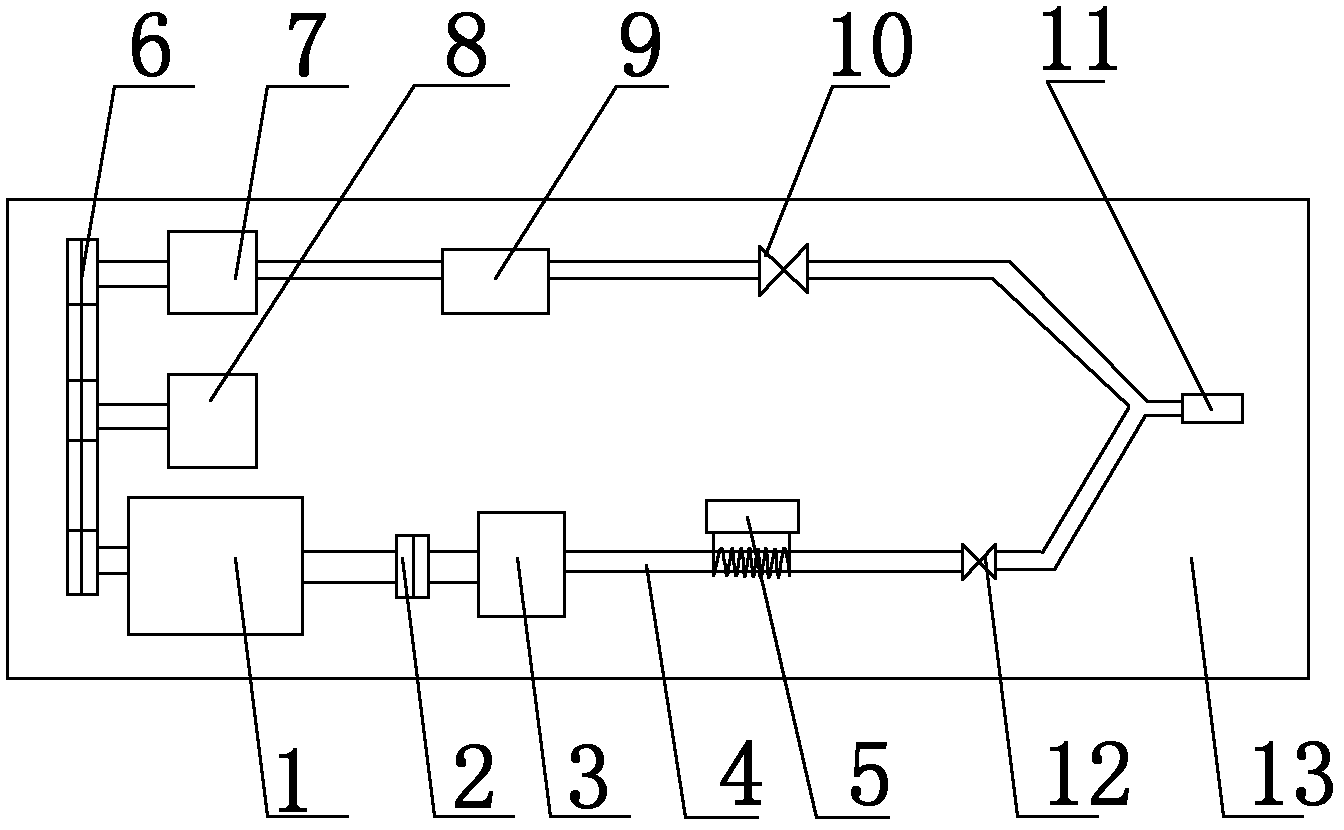

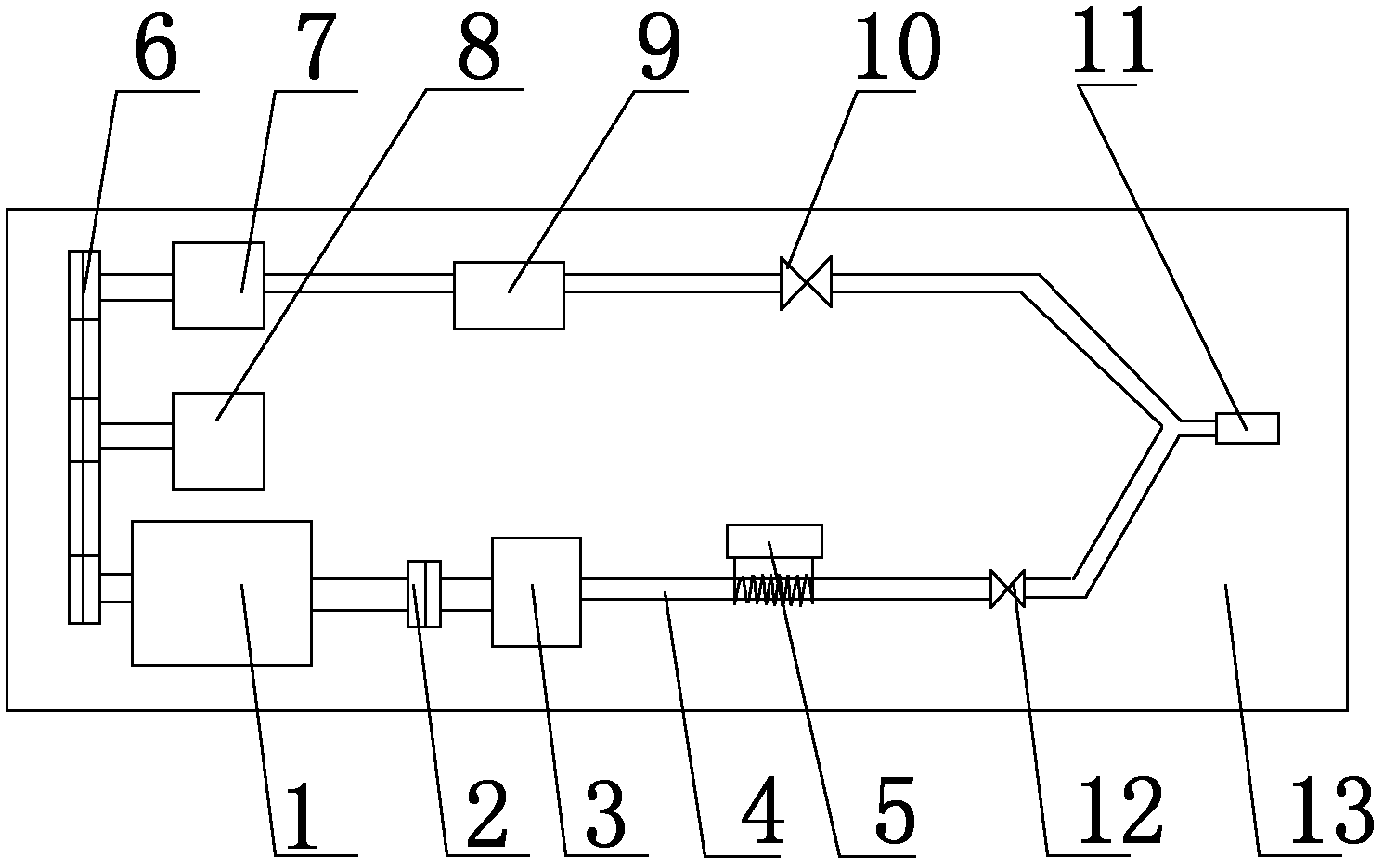

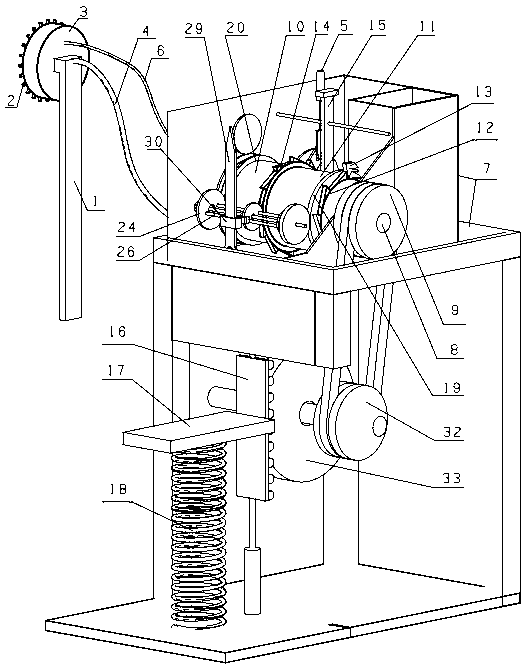

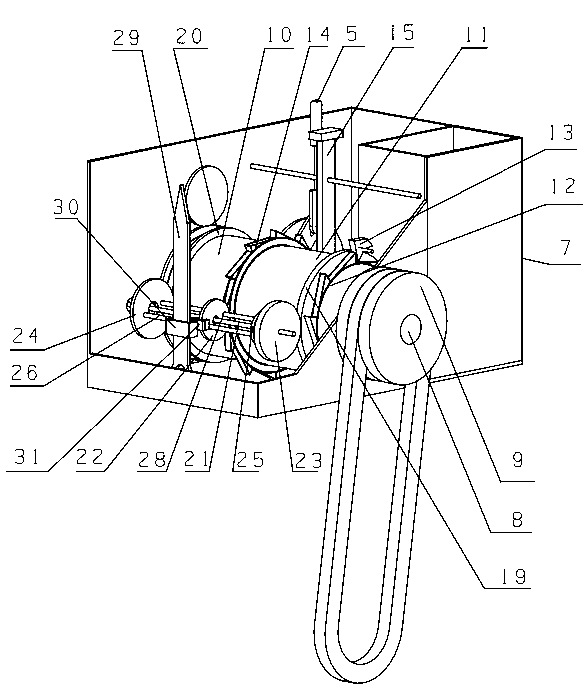

Multi-element composite high-pressure water jet cleaning device

InactiveCN102580957AWide range of cleaningSolve the fragileHollow article cleaningNumerical controlAir pump

The invention relates to a multi-element composite high-pressure water jet cleaning device for cleaning gathering pipeline networks of oil fields. The aim of the invention is to break the limitation of the existing high-pressure water jet cleaning. The multi-element composite high-pressure water jet cleaning device comprises a diesel engine served as a power source and a high-pressure cleaning pump connected with the diesel engine by a clutch, wherein a water outlet end of the high-pressure cleaning pump is connected with a high-pressure one-way valve by a high-pressure steel pipe; the high-pressure steel pipe between the high-pressure cleaning pump and the high-pressure one-way valve penetrates through a numerical control electromagnetic heating system; an output shaft at the rear end of the diesel engine is connected with an air pump and a driving shaft of a generator by a transmission belt; an output end of the air pump is connected with a pulse control system and an air one-way valve in turn; and the air one-way valve and the high-pressure one-way valve are connected with a high-pressure quick coupling. The device adopts a mode of combining air pulsing and high-pressure water jet, so that the device has the characteristics of wide applicable range, good cleaning effect, fast cleaning speed, safety, reliability, low cost and environmental friendliness.

Owner:NORTHEAST GASOLINEEUM UNIV +1

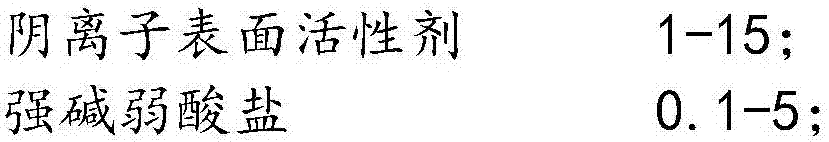

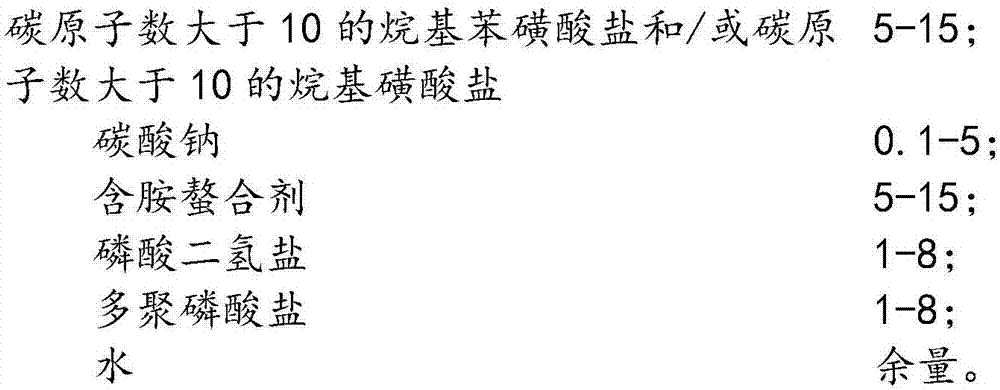

Reclaimed water reuse membrane alkaline cleaning agent

InactiveCN107149877AWide range of cleaningSave cleaning agentSemi-permeable membranesPhosphateReclaimed water

The present invention provides a reclaimed water reuse membrane alkaline cleaning agent, which is prepared from the following components by mass: 1-15% of an anionic surfactant, 0.1-5% of a strong alkali weak acid salt, 3-25% of a metal chelating agent, 1-15% of phosphate, and the balance of water. The reclaimed water reuse membrane alkaline cleaning agent of the present invention can provide advantages of excellent cleaning effect, wide cleaning range and cleaning agent consumption saving during membrane cleaning.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Cleaning device for glass production

PendingCN106378337AWide range of cleaningImprove cleanlinessDrying gas arrangementsCleaning using toolsEngineeringMechanical engineering

The invention belongs to the field of glass processing, and particularly provides a cleaning device for glass production. The device comprises a workbench, a scouring chamber, a drying chamber, a water collecting device, a water collecting tank and a water outlet pipe. The workbench is sequentially provided with the scouring chamber and the drying chamber from left to right. The bench surface of the workbench is provided with a detachable filter screen. A conveying belt is arranged on the surface of the workbench. The conveying belt sequentially penetrates through the scouring chamber and the drying chamber from left to right and is provided with a plurality of through holes. The conveying belt is fixedly provided with one to twenty supports. The upper portions and lower portions of the supports are both provided with tongs. The water collecting device is arranged under the workbench. The water collecting device is connected with the water collecting tank through the water outlet pipe. According to the cleaning device for glass production, the vertical cleaning structure is adopted, and the cleaning range is wide; and moreover, two surfaces of glass can be cleaned at the same time, and the cleanliness is higher.

Owner:天津南玻节能玻璃有限公司

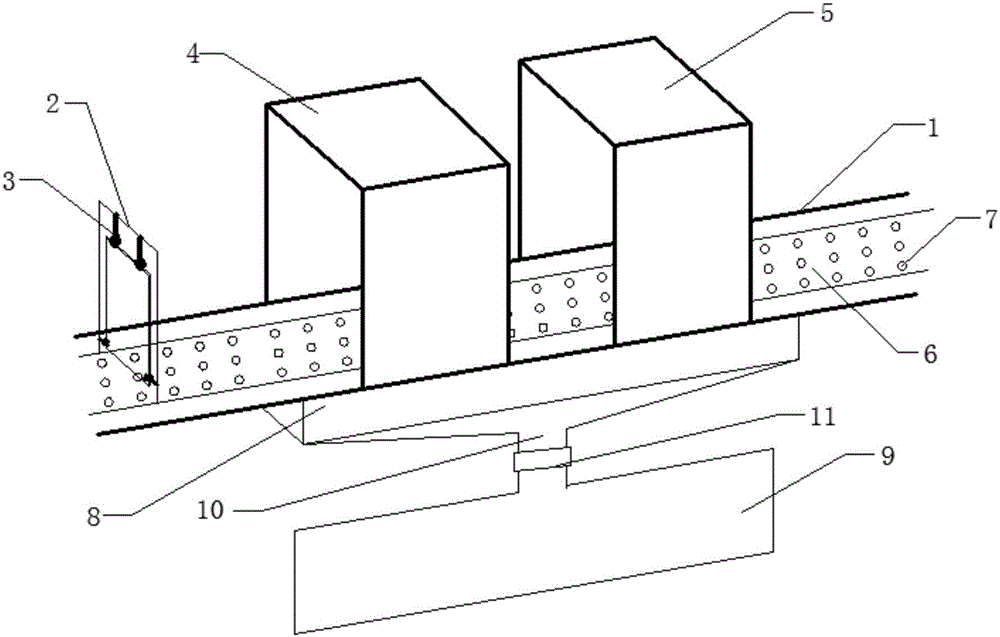

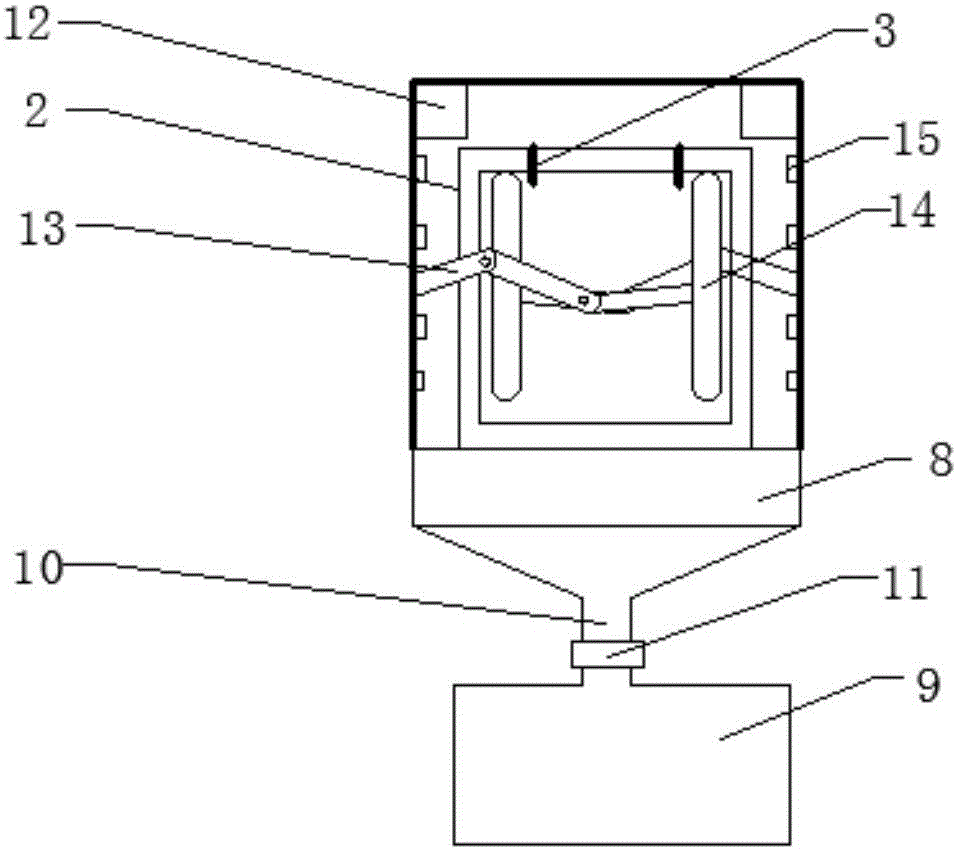

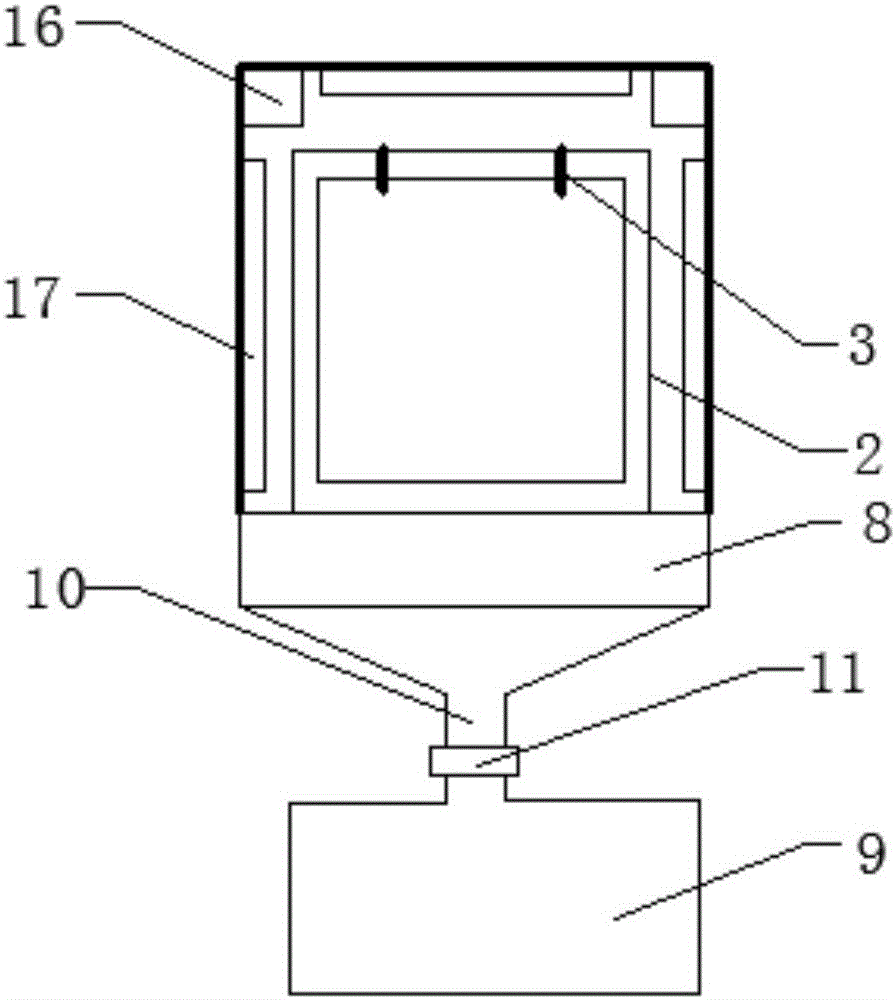

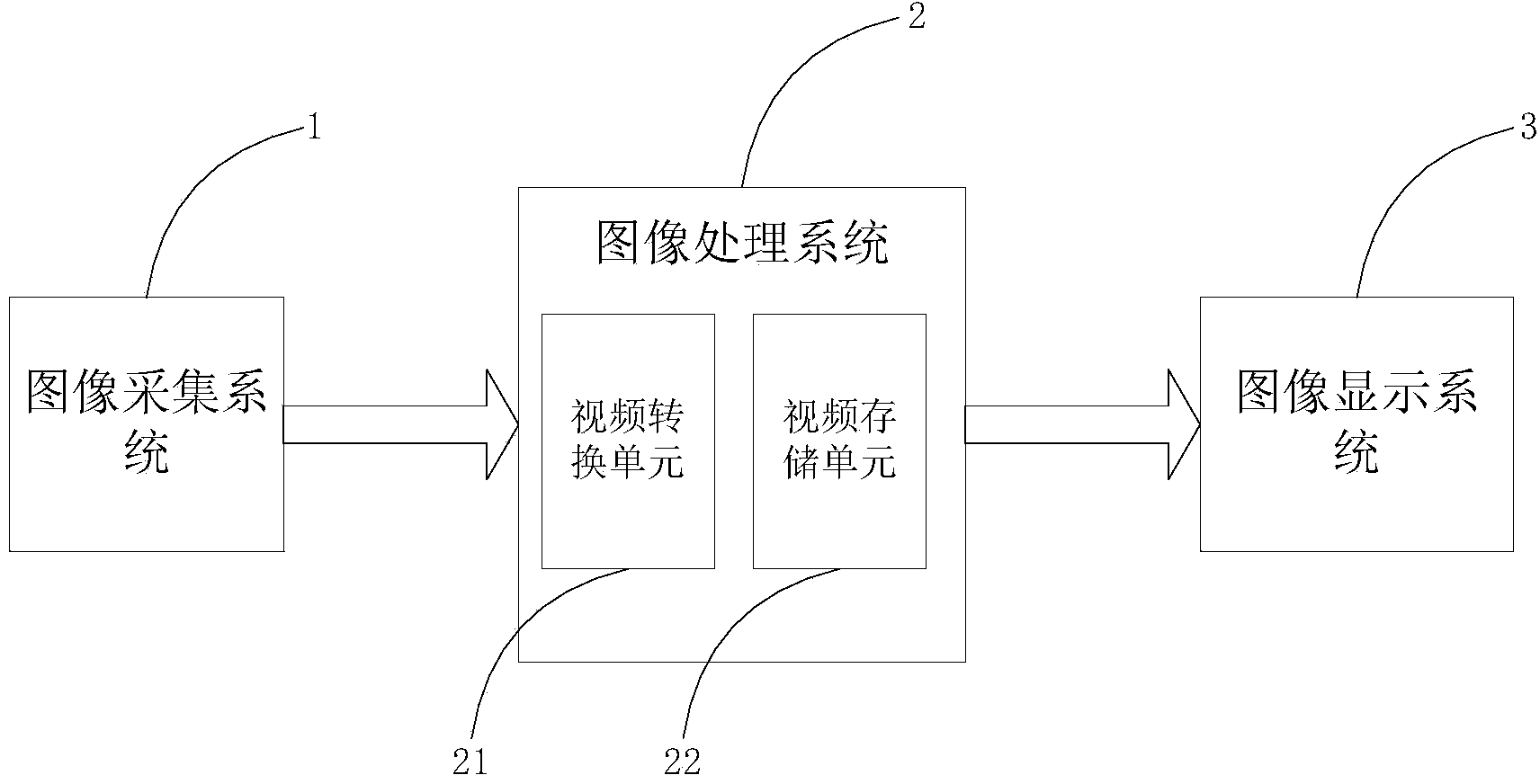

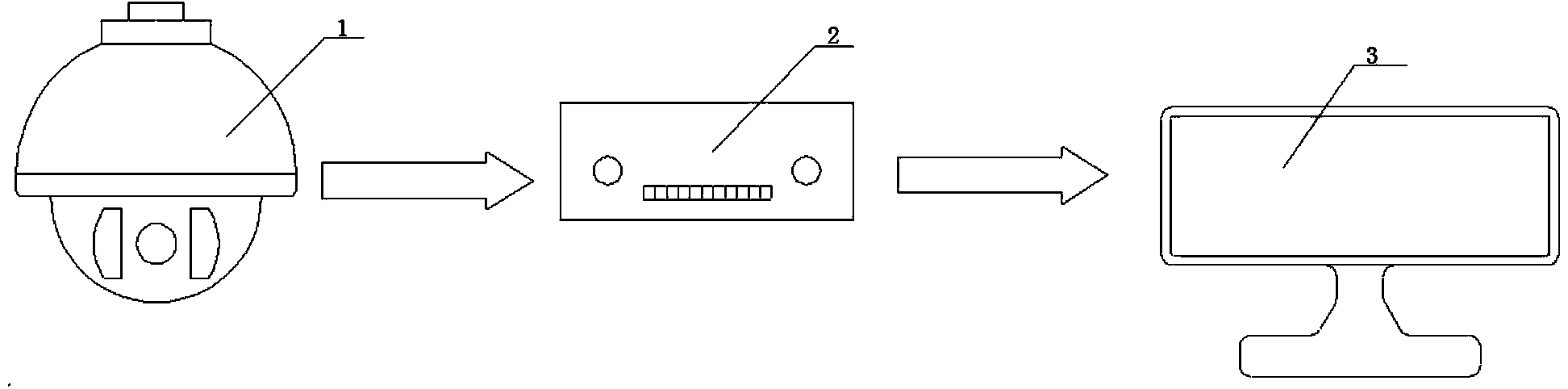

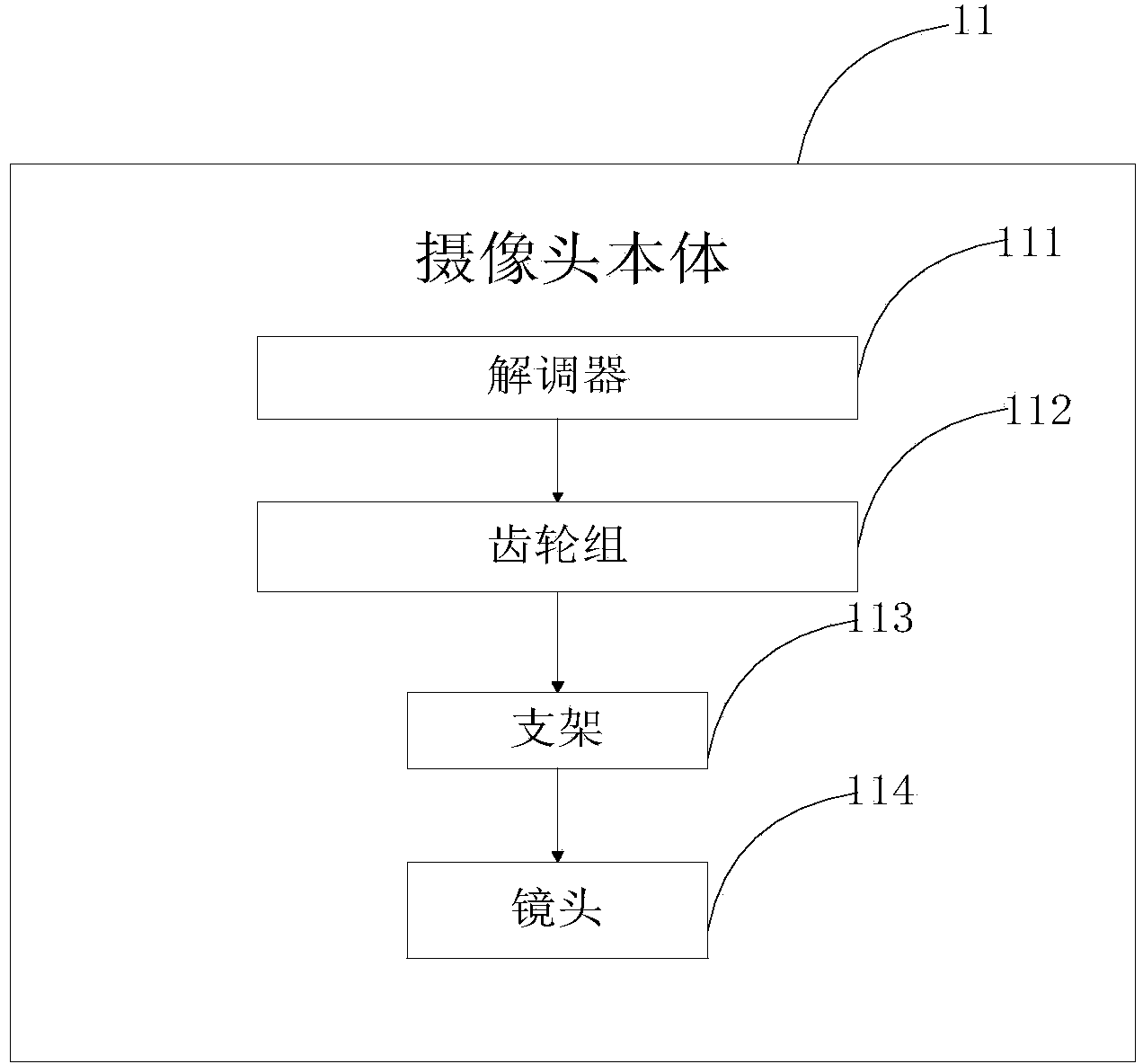

Internet of Things video monitoring system with automatic camera cleaning function

InactiveCN104284157ASimple structureEasy to disassembleTelevision system detailsColor television detailsVideo monitoringVideo storage

The invention provides an Internet of Things video monitoring system with the automatic camera cleaning function. The Internet of Things video monitoring system comprises an image collecting subsystem, an image processing subsystem and an image displaying subsystem. The image processing subsystem comprises a video converting unit and a video storing unit, and the video converting unit is used for carrying out format conversion on images of a monitoring picture. The video storing unit is used for storing the images with the processed format. The image collecting subsystem is a camera, the camera comprises a camera body and a cleaning device, and the camera body is used for monitoring real-time pictures. The cleaning device is used for cleaning dust and small particles on the surface of the camera body. The cleaning device not only can clean the dust on the mirror surface of the camera, but also can reduce light reflection and refraction, and the video pictures can be clearer.

Owner:嘉兴市新飞腾塑业有限公司

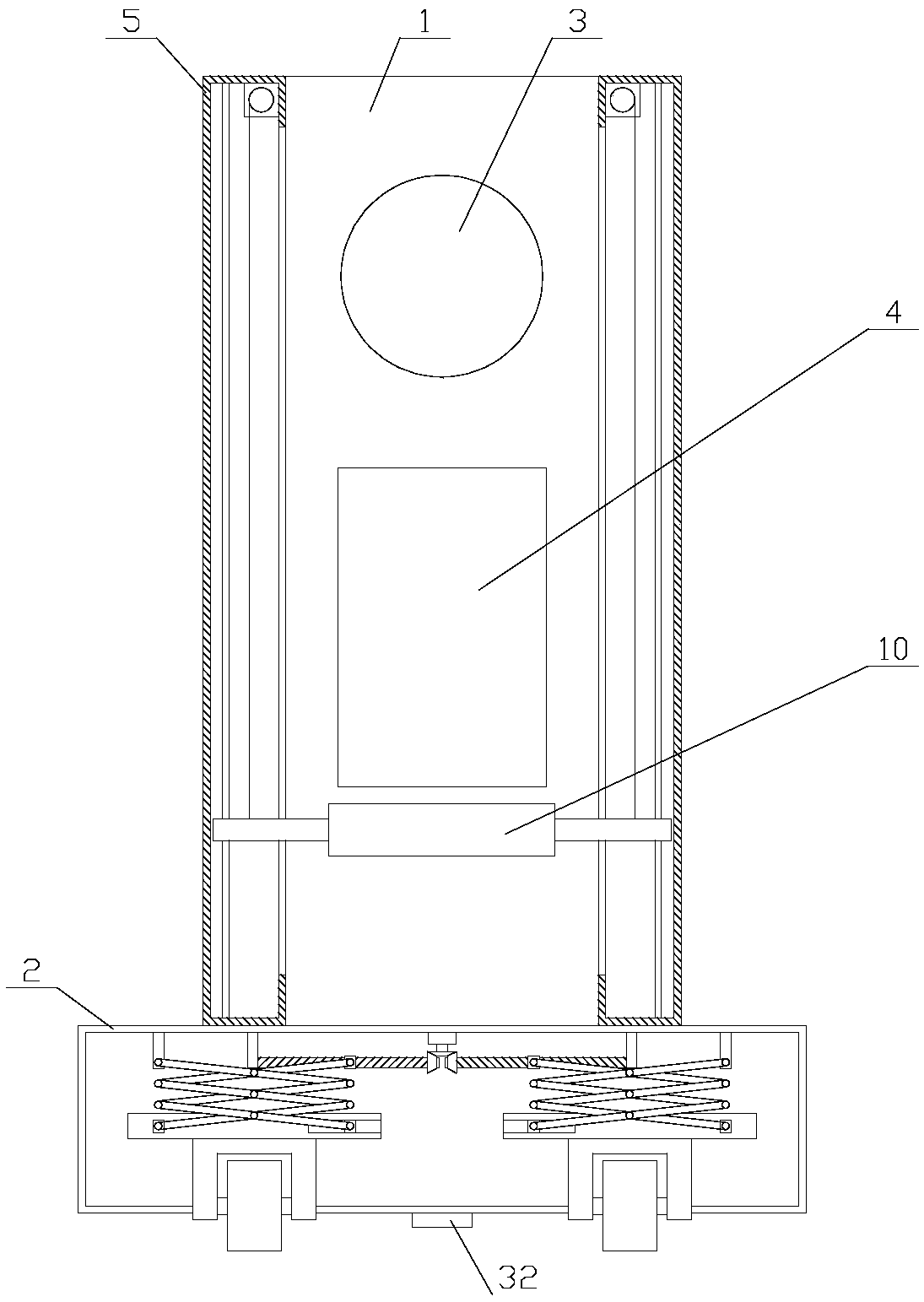

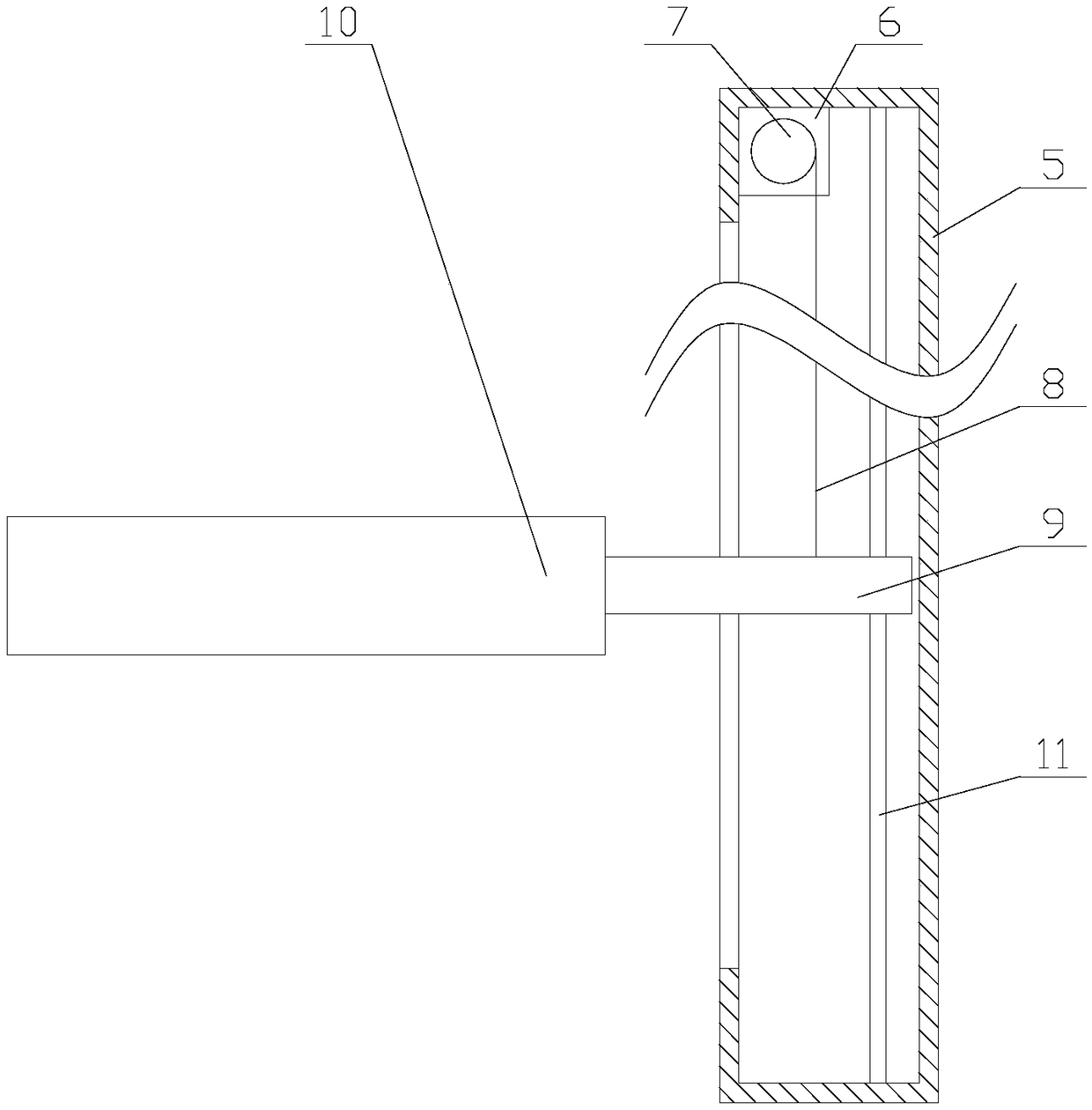

Automatic security robot with cleaning and height adjustment functions

The invention relates to an automatic security robot with the cleaning and height adjustment functions. The robot comprises a main body, a pedestal and two baffle plates, and also comprises a cleaningmechanism and an adjusting mechanism; the cleaning mechanism comprises a cleaning box and two lifting assemblies; the cleaning box is provided with a cleaning assembly therein; the cleaning assemblycomprises a first motor, a rotating disk, a connecting rod, a moving rod, an adjusting rod, a fixed shaft and a nozzle; the adjusting mechanism comprises a power assembly, two moving assemblies and two telescoping assemblies; the telescoping assembly comprises a fixing block, a telescoping rack, a telescoping plate and two hinge blocks. According to the automatic security robot with the cleaning and height adjustment functions, by means of the adjusting mechanism, the safety robot can be lifted up when there is water on the ground to avoid the water enters the main body and influence the workof the safety robot, thereby increasing the safety of the safety robot; by means of the cleaning mechanism, the main body surface can be cleaned; dust is prevented from covering the camera and displaysurface, affecting security robot monitoring.

Owner:SHENZHEN JIUPIN AIR PURIFICATION TECH CO LTD

Medical dirt eraser

InactiveCN103191876AIncrease distanceReduce the amount of movementCleaning using toolsCleaning using liquidsInfection riskEngineering

The invention discloses a medical dirt eraser which comprises a brush head rotatably installed on a brush handle. The brush handle is fixedly provided with a brush cover covering the brush head. The brush head is in transmission connection with the output shaft of a power device through a universal hose. The eraser further comprises a liquid sprayer driven by the power device. The liquid sprayer is connected with a cavity of the brush cover through a water pipe. A speed regulating unit is arranged between a main wheel and a rack. The rack drives the main wheel to rotate through the speed regulating unit. The speed regulating unit comprises a transmission wheel and a driving gear axially and fixedly arranged. The transmission wheel is in transmission match with the main wheel, and the driving gear is in transmission match with the rack. The medical dirt eraser in the structure is reasonable in structure, and can quickly clean or eliminate splodge or dirt to prevent medical personnel from being contacted with dirt manually, so that the medical infection risk is reduced. The eraser is time-saving and labor-saving and convenient to operate, so that the safety and sanitation of medical personnel are ensured.

Owner:孙英华 +2

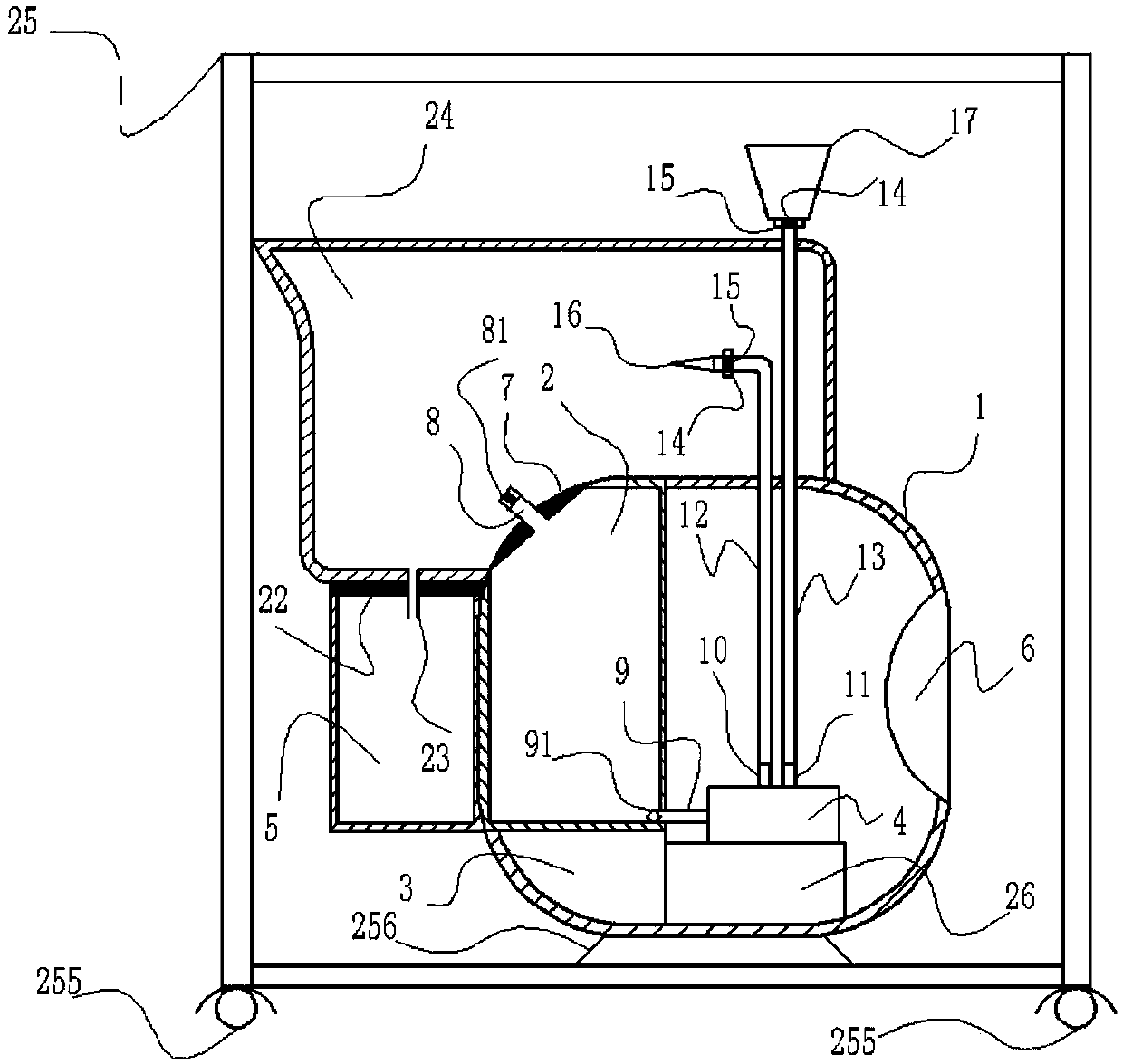

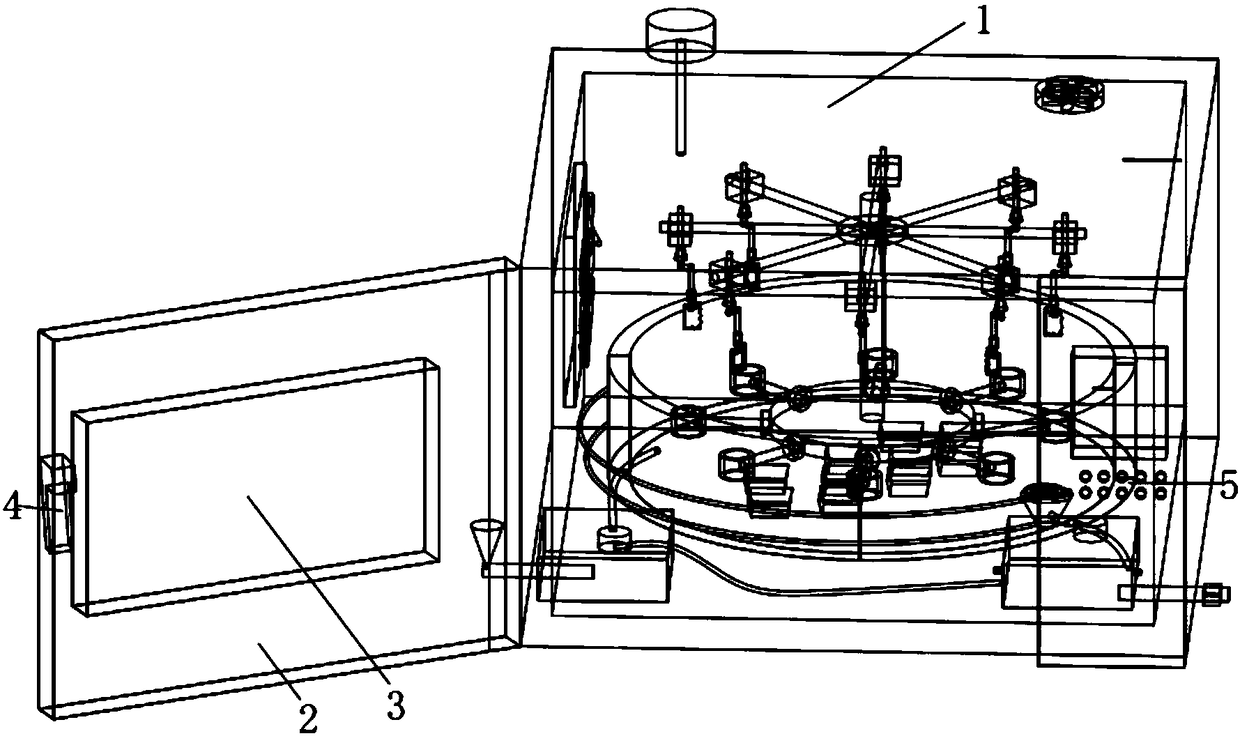

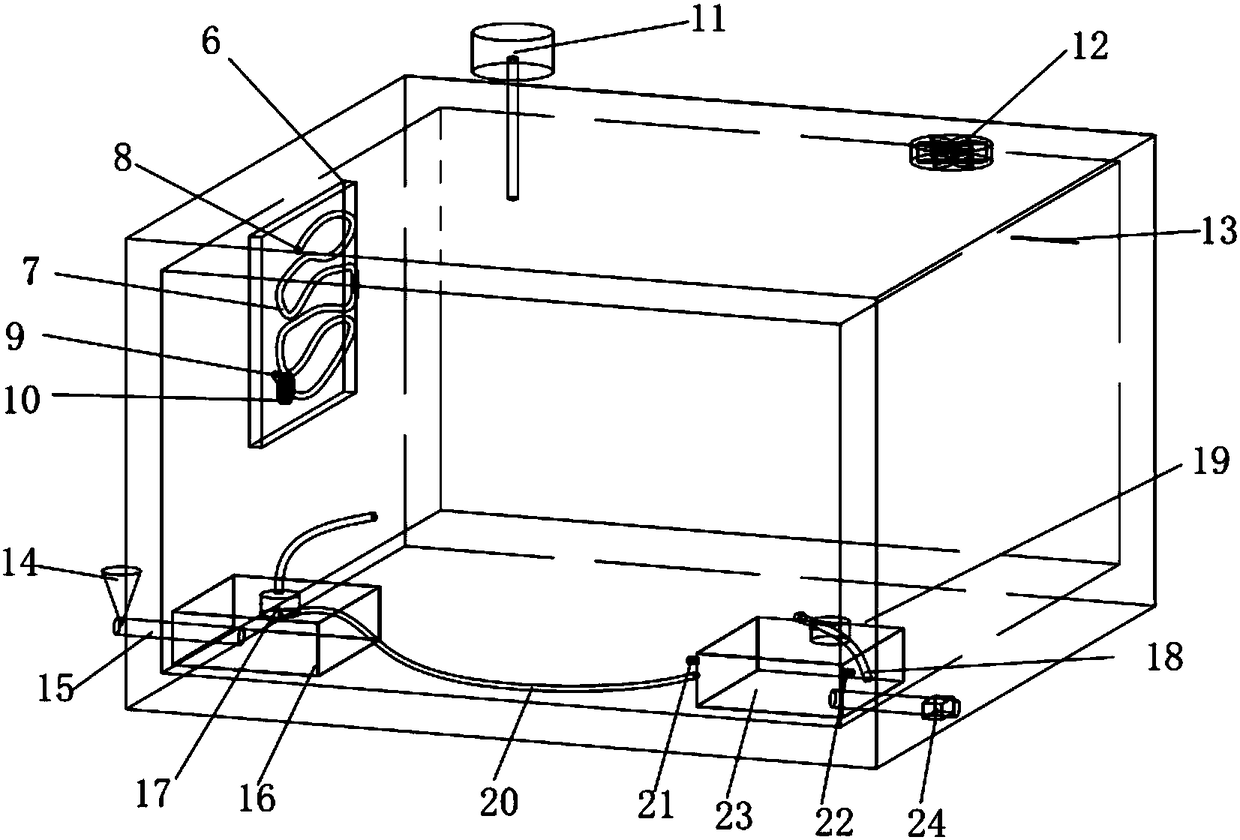

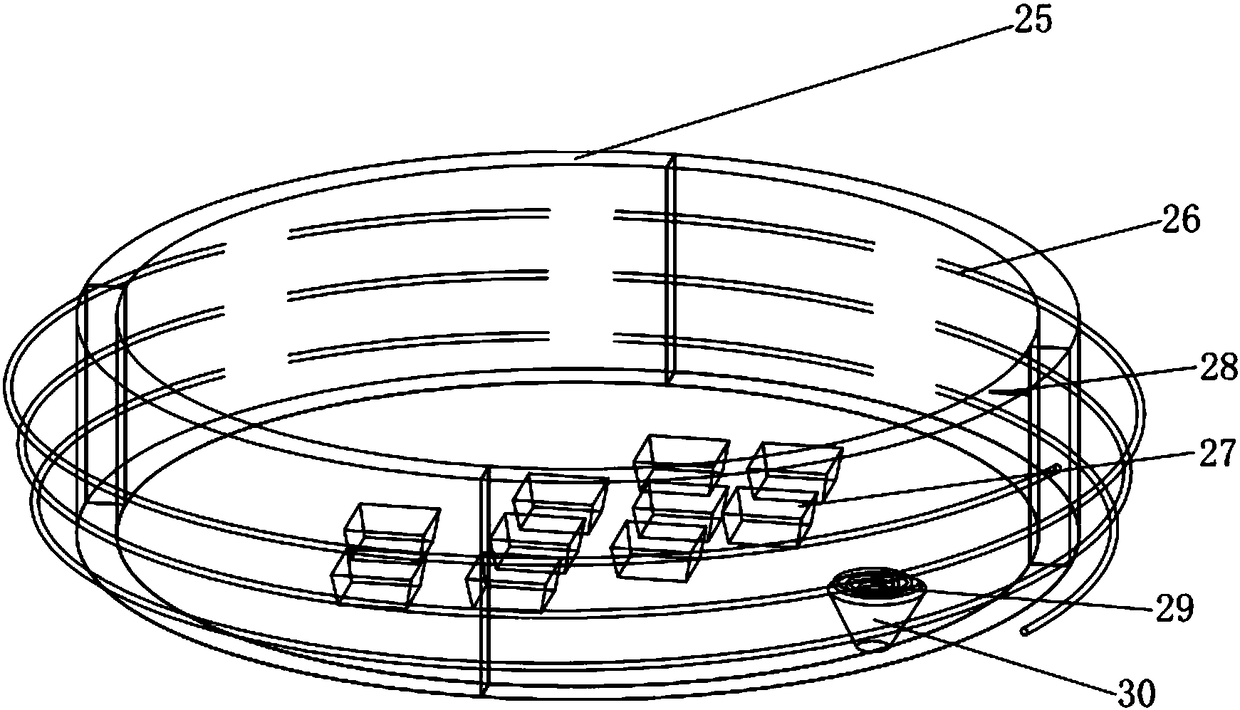

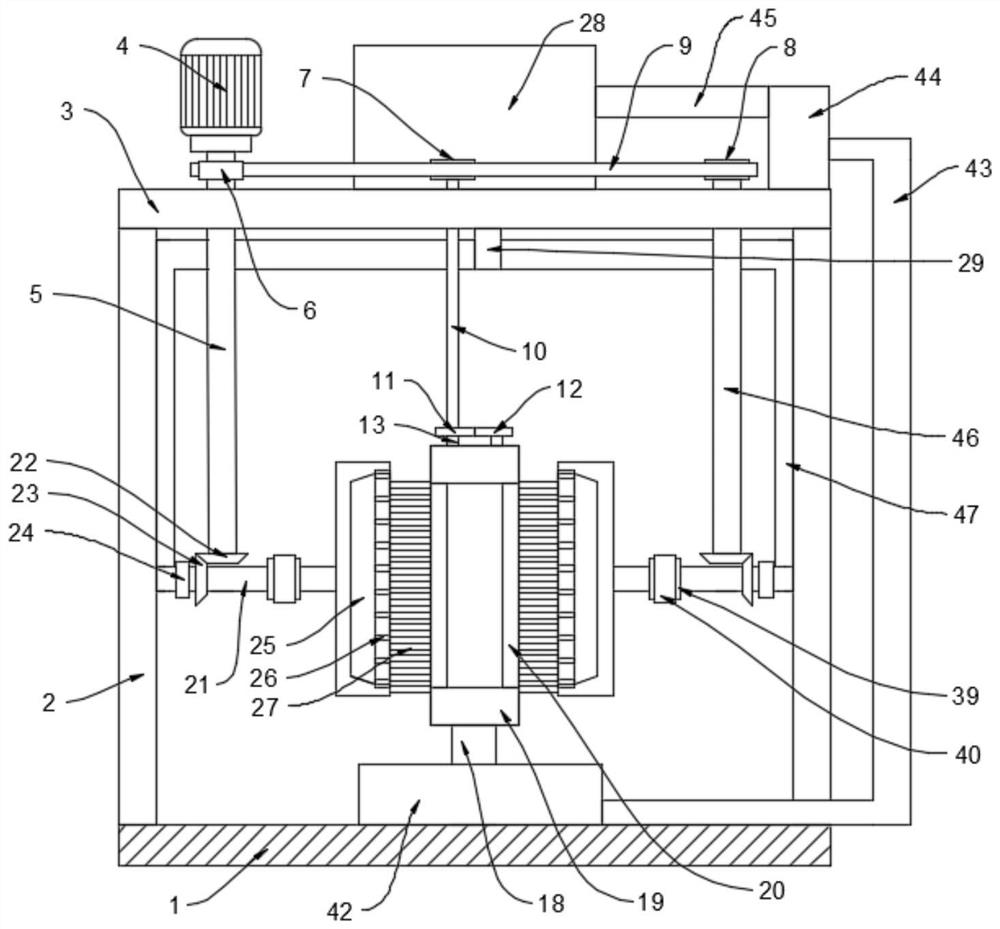

Fully-automatic cleaning instrument for RTFO (rolling thin film oven) sample-containing bottles

PendingCN108325932AAchieve the purpose of purificationRealize automatic cleaningHollow article cleaningDrying gas arrangementsAcoustic waveSolid particle

The invention discloses a fully-automatic cleaning instrument for RTFO (rolling thin film oven) sample-containing bottles. An annular sound wave washing tank and a sample-containing bottle fixing andcleaning device are arranged in a cleaning instrument box; an ultrasonic generator is arranged in the annular sound wave washing tank, asphalt residues can be dispersed in a cleaning solution by soundwave vibration, asphalt is emulsified, solid particles are separated in time, cleaning brushes are moved towards the inner wall by an upper support bracket, a certain pressure is applied to the innerwall, and stubborn stains can be cleaned by cooperation with ultrasonic wave vibration and high temperature effects in the rotating process of hard brush edges; the residual cleaning solution can betreated by soft brush edges, manual supplementary wiping after cleaning is avoided, and time and vigor of a lab assistant are saved; cleaning parameters of the sample-containing bottle fixing and cleaning device is controlled by a controller, and automatic cleaning can be realized; meanwhile, the multiple sample-containing bottles can be cleaned simultaneously, cleaning efficiency is improved, bottle bodies are fixed by sample-containing bottle chucks, and the problem of rotation of the bottle bodies in the cleaning process is effectively solved.

Owner:CHANGAN UNIV

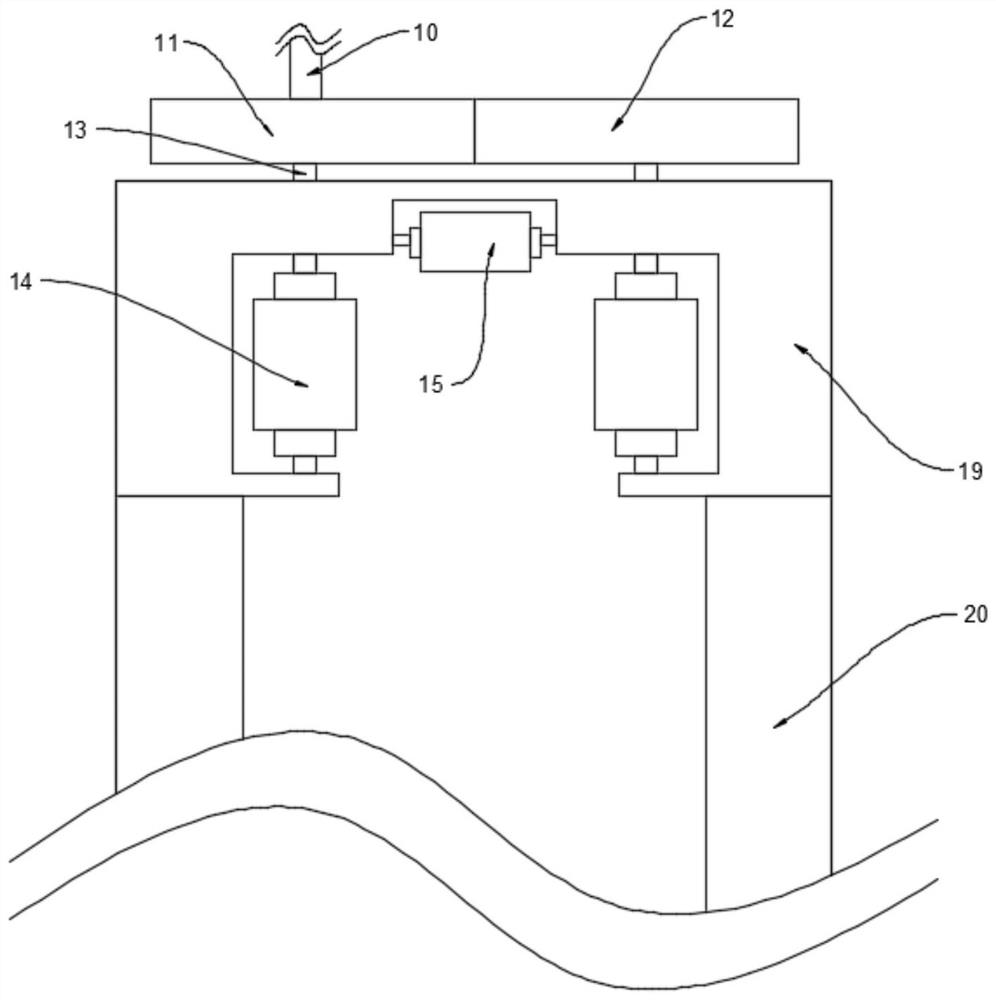

Riverway floating garbage cleaning ship

InactiveCN110080186ASimple structural designImprove cleaning efficiencyWater cleaningWaterborne vesselsInlet channelRefuse collection

The invention discloses a riverway floating garbage cleaning ship. The device comprises a ship body, a collecting board, a classification garbage bin and a water pump, a flow channel shrinking inwardsis formed between every two adjacent collecting boards, a water inlet is formed in the ship body between every two adjacent collecting boards, each water inlet is connected with a water inlet channelin the ship body, the water inlet channel communicates with the classification garbage bin, the classification garbage bin comprises a first garbage collection bin and a second garbage collection bin, the first garbage collection bin and the second garbage collection bin collect different types of garbage respectively, the first garbage collection bin is connected with the lifting device, a communicating hole is formed in the second garbage collection bin and connected with the water suction pump through a pipeline, the other end of the water pump communicates with the water outlet, and the water outlet extends out of the ship body. The garbage can is simple and reasonable in structural design, high in cleaning efficiency, wide in cleaning range and capable of classifying garbage.

Owner:严培峻

Bar goblet washing device

InactiveCN107997711AWide range of cleaningEasy to cleanTableware washing/rinsing machine detailsFixed frameEngineering

The invention relates to a washing device and in particular relates to a bar goblet washing device. A technical problem to be solved is to provide a bar goblet washing device capable of replacing labor work, quickly cleaning and thoroughly cleaning. The bar goblet washing device comprises a fixed rack, a U-shaped frame, first slide rails, a rack, a supporting bench, a first slide block, a first elevating lever, an incomplete gear and a first motor, wherein the U-shaped frame and the supporting bench are orderly arranged on the fixed frame from top to bottom; the first slide rails are arrangedon the left and right sides of the interior of the U-shaped frame in a symmetric way; the first slide block is slideably arranged on the first slide rails; and the first slide block is provided with the rack. The bar goblet washing device can replace manual work, quickly clean and thoroughly clean the goblets; and by the use of the bar goblet washing device, plenty of human work can be saved and time consumption can be reduced; and the bar goblets can be well cleaned and washed, and convenience is brought to workers.

Owner:叶成雨

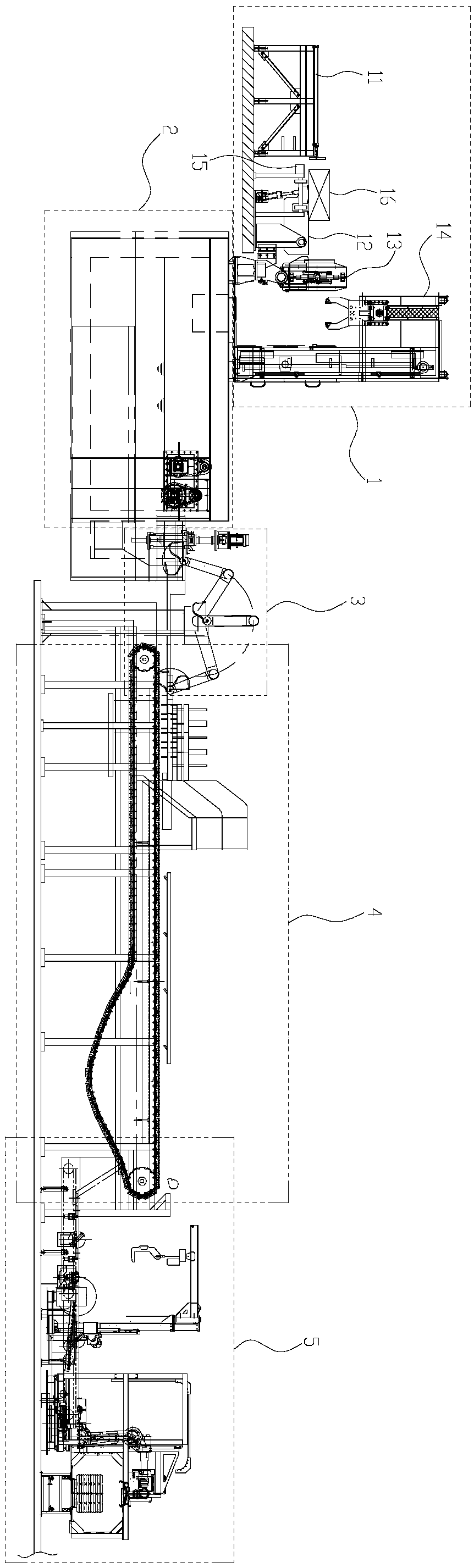

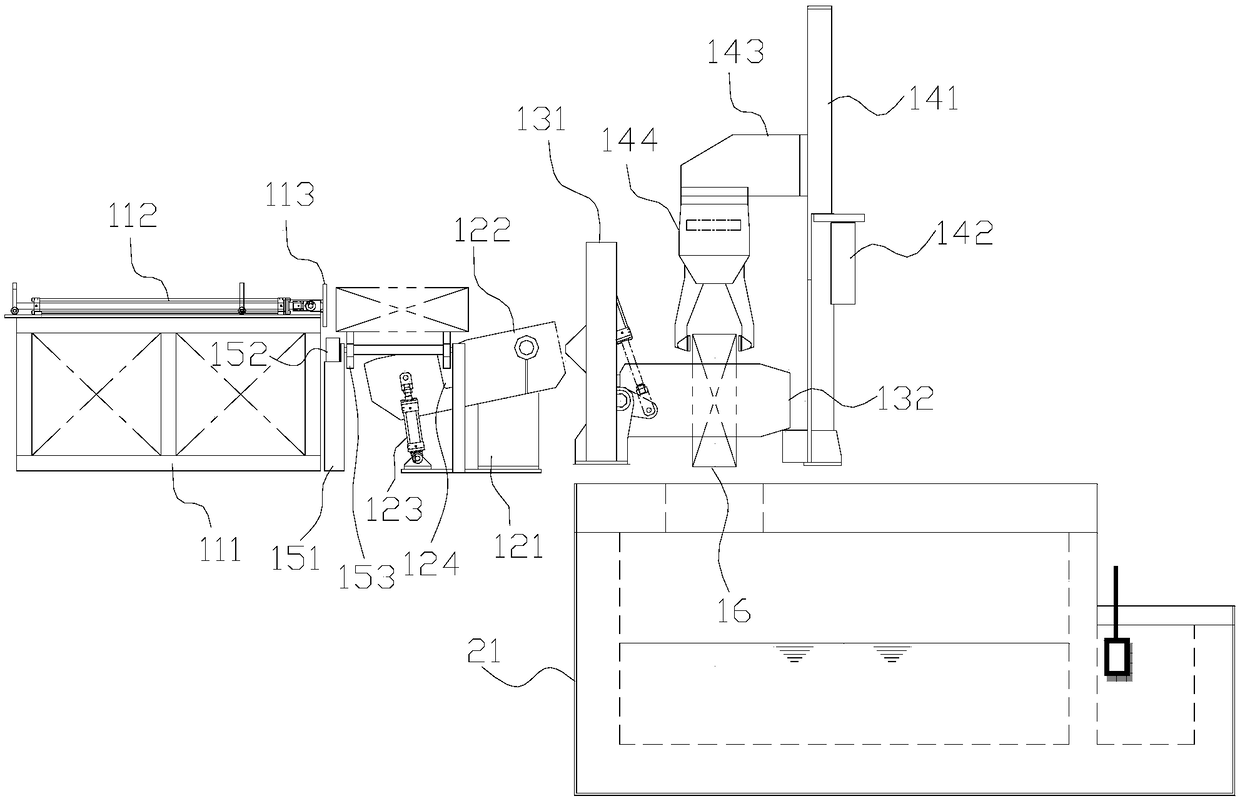

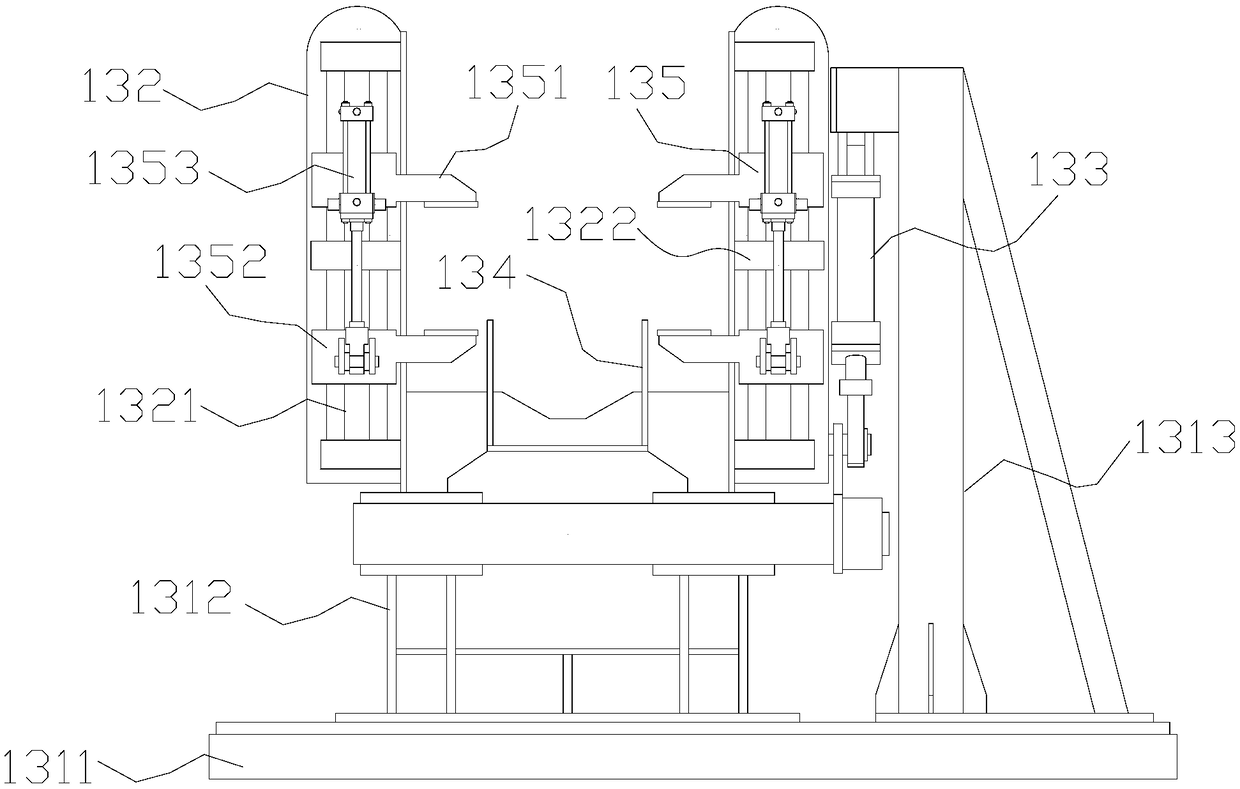

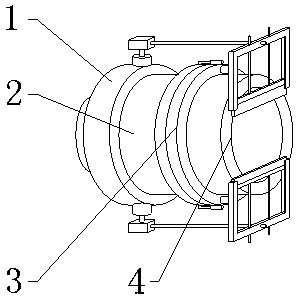

Automatic production line for zinc casting

PendingCN109454223ALow energy consumption for melting and castingHigh casting yieldIngot casting plantsProduction lineAutomatic control

The invention relates to an automatic production line for zinc casting. The automatic production line comprises a charging system, a melting system, casting systems, ingot casting systems and a packaging system; the charging, melting, casting, ingot casting and packaging of a melting and casting technology are automatically finished though the charging system, the melting system, the casting systems, the ingot casting systems and the packaging system separately; a negative plate is conveyed and put into the melting system through the charging system, and melted into zinc liquid through the melting system; and the zinc liquid in the melting system is extracted and poured into the ingot casting systems through the casting systems; the zinc liquid is cast into zinc ingots through the ingot casting systems, and the zinc ingots are conveyed to the packaging system, and stacked, packaged, weighed and labeled through the packaging system; and the zinc ingots packaged properly are obtained finally. The whole melting and casting production process is controlled automatically, and the melting and casting energy consumption is low; the direct recovery rate of melting and casting is high, andproduction interruption due to artificial causes is reduced; and the labor cost is reduced.

Owner:广西南丹南方金属有限公司

Lamp cup convenient to demount and mount

ActiveCN108518662AEasy to carryQuick cleanLighting elementsLighting heating/cooling arrangementsEngineeringSlide plate

The invention provides a lamp cup convenient to demount and mount. The lamp cup comprises a cleaning mechanism, a lamp cup body, a fixing mechanism and a shell, the cleaning mechanism is installed onthe lamp cup body, the fixing mechanism is arranged at the right end of the lamp cup body, the shell is installed at the right end of the fixing mechanism, the shell and the fixing mechanism are arranged inside the cleaning mechanism, the cleaning mechanism comprises a fixed ring, an electric push rod, a motor, a lead screw, a guide rod, a frame, a first spring, a sliding plate, a cleaning felt and a connecting rod, and the fixing mechanism comprises a rotating ring, a suction disc, a rolling ball, an L-shaped clamping rod, a second spring, a hollow sleeve, a third spring, a fixing pipe, a limiting column and a connecting ring. Compared with the prior art, the lamp cup has the beneficial effects that the quick cleaning aim is achieved, operation is simple, carrying is facilitated, the quick mounting and demounting functions are achieved, the fixing effect is good, and meanwhile, radiating can be achieved.

Owner:天津智投技术成果转化有限公司

Device for cleaning ceramic tile wall

PendingCN108670137AEasy to cleanWide range of cleaningCarpet cleanersFloor cleanersCeramic tilesControl engineering

The invention discloses a device for cleaning a ceramic tile wall, and belongs to the field of cleaning devices. The device comprises a base, and the base is connected with a motor shell through a height adjusting device; the upper portion of the motor shell is connected with a telescopic shell, and the upper portion of the telescopic shell is connected with a T-shaped shell; a motor is arranged in the motor shell, and an output shaft of the motor is vertical; the output shaft of the motor is coaxially connected with a telescopic shaft, and the top of the telescopic shaft is fixedly connectedwith a first bevel gear; the first bevel gear is rotatably connected with a vertical part of the T-shaped shell through a first bearing; a horizontal part of the T-shaped shell is provided with a horizontal rotation shaft, and one end of the horizontal rotation shaft stretches out of the horizontal part of the T-shaped shell; the horizontal rotation shaft is perpendicular to the telescopic shaft;a second bevel gear is fixedly arranged on the horizontal rotation shaft and meshed with the first bevel gear; the end, located outside the horizontal part of the T-shaped shell, of the horizontal rotation shaft is connected with a cleaning shelf; the cleaning shelf is provided with a cleaning brush. The device is simple in structure, low in cost, and wide in cleaning range, has a good cleaning effect and is suitable for being applied and popularized.

Owner:吕歌川

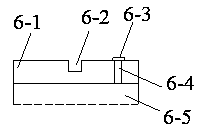

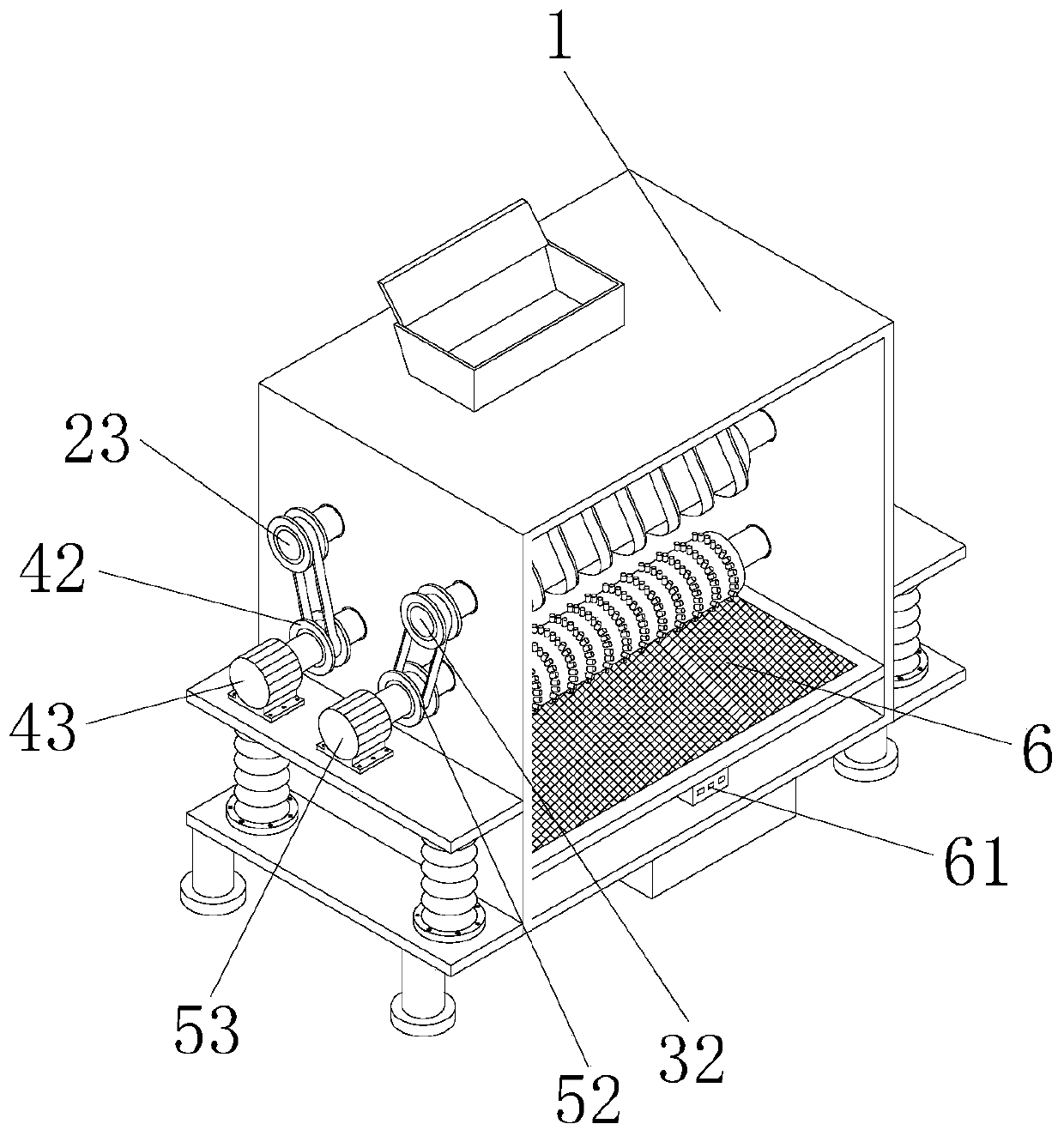

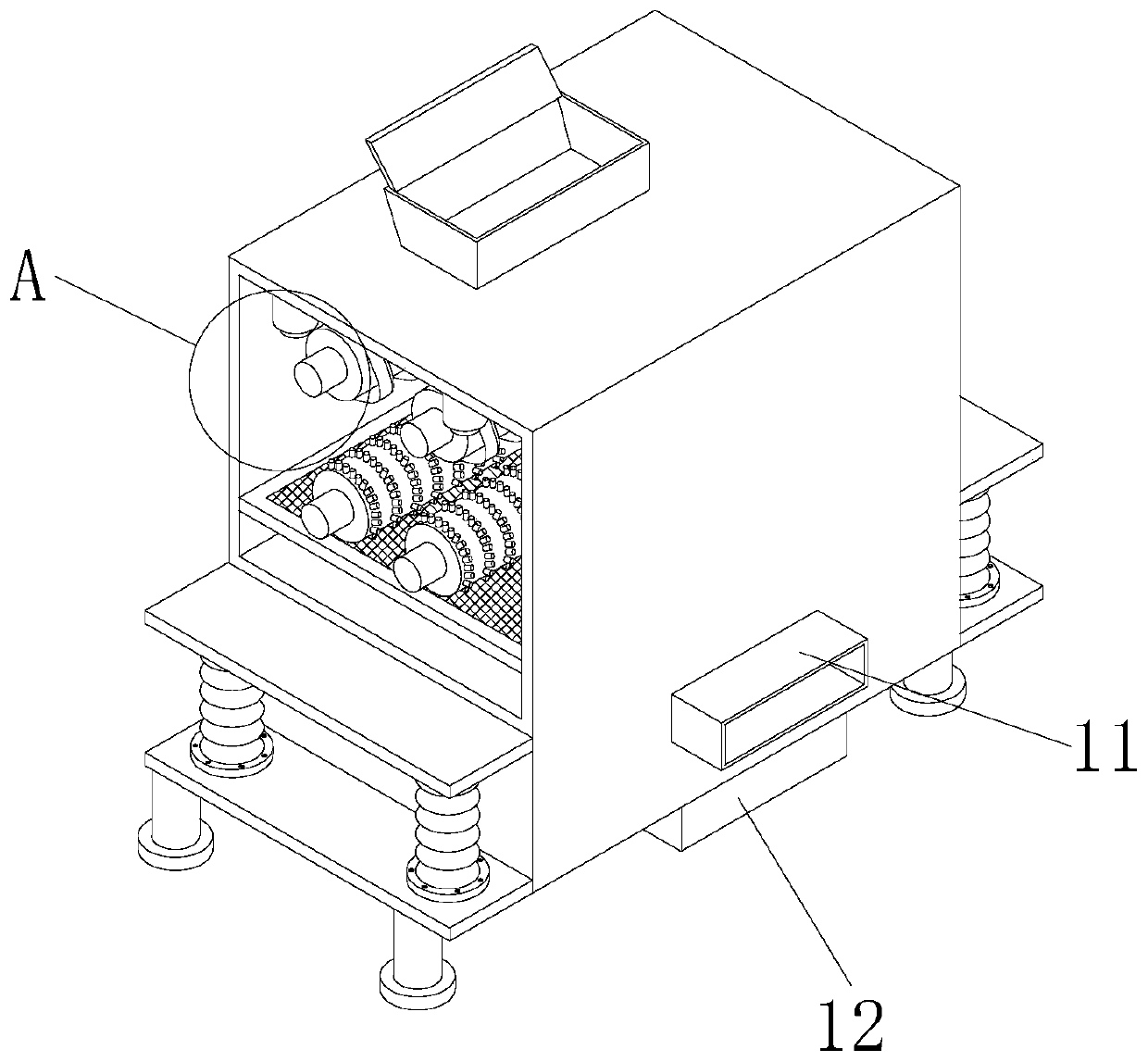

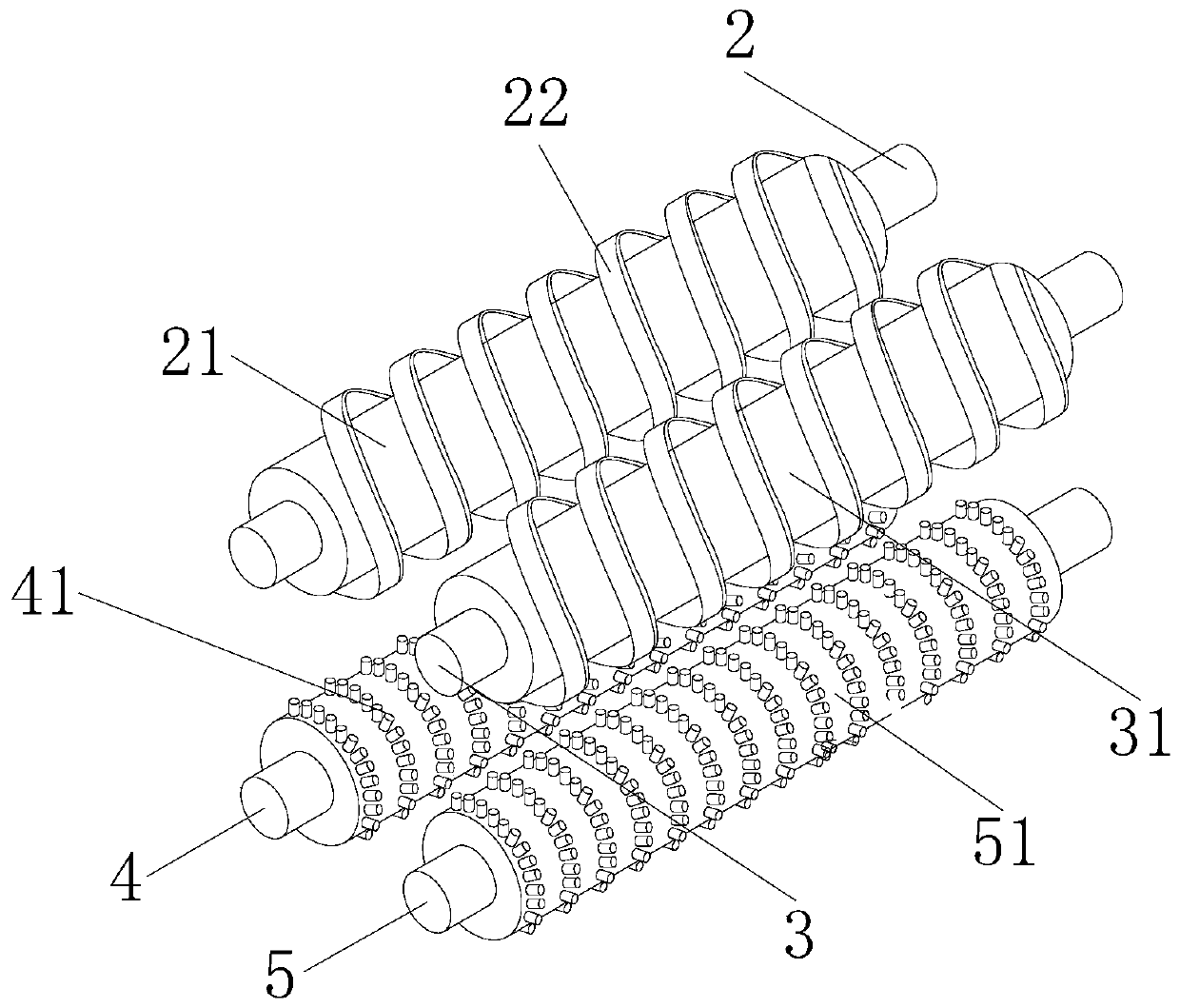

Cleaning and shelling device for camellia seeds

InactiveCN110839907AGood peeling effectEasy to cleanSievingScreeningAgricultural engineeringStructural engineering

The invention provides a cleaning and shelling device for camellia seeds. The cleaning and shelling device comprises a shelling tank and is characterized in that a third rotary shaft and a fourth rotary shaft are horizontally symmetrically mounted in the cavity of the shelling tank, a third rotary roller is fixedly mounted on the outer wall of the third rotary shaft, a fourth rotary roller is fixedly mounted on the outer wall of the fourth rotary shaft, a spiral shelling cutter is fixedly mounted on the outer wall of each of the third rotary roller and the fourth rotary roller, a first rotaryshaft and a second rotary shaft are horizontally symmetrically mounted below the third rotary roller and the fourth rotary roller, a first brush roller is mounted on the outer wall of the first rotaryshaft, and a second brush roller is mounted on the outer wall of the second rotary shaft. The cleaning and shelling device has the advantages that the reverse rotation of the third rotary roller andthe fourth rotary roller drives the spiral shelling cutters to perform primary shelling on the camellia seeds, the camellia seeds after the primary shelling is subjected to secondary shelling throughthe reverse rotation of the first brush roller and the second brush roller, a good shelling effect is achieved, and the shelling efficiency of the camellia seeds is increased.

Owner:湖南省康多利油脂有限公司

Garbage and fine sand separating device used for sandbeach

The invention discloses a garbage and fine sand separating device used for a sandbeach. The garbage and fine sand separating device comprises a body. A screening cavity is formed in the body, an eccentric wheel cavity is formed in the upper side of the screening cavity, a power cavity is formed in the back side of the eccentric wheel cavity, a sliding cavity is formed in the upper side of the screening cavity, a T-shaped plate is slidably connected in the sliding cavity, a sand shoveling spring is connected between the T-shaped plate and the bottom wall of the sliding cavity, and a sand shoveling plate is fixedly arranged on the lower side of the sand shoveling spring. A hydraulic motor is started to extrude the T-shaped plate downward so as to push the sand shoveling plate downward to adjust a sand digging depth. A hanging buckle is arranged on the front side of the body and the device can be directly hung to a tow hook of a dune buggy, so that the sandbeach is cleaned by means of power of the dune buggy, the resources are saved to a certain extent, and discharge of pollution is reduced.

Owner:YUYAO XINZHI NEW ENERGY TECH CO LTD

Efficient water-based compound detergent

InactiveCN105647663AImprove cleaning efficiencyWide range of cleaningInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistrySodium triphosphate

The invention discloses an efficient water-based compound detergent. The efficient water-based compound detergent comprises a surfactant, a thickener, a complexing agent, an inorganic detergent builder, a stabilizer and water, wherein the surfactant is sodium fatty acid methyl ester sulfonate, the thickener is sodium carboxymethylcellulose, the complexing agent is ethylene diamine tetra (methylene phosphonic acid) sodium, the inorganic detergent builder is sodium tripolyphosphate, and the stabilizer is polypropylene glycol. The efficient water-based compound detergent comprises the surfactant, the thickener, the complexing agent, the inorganic detergent builder, the stabilizer and the water and has the characteristics of high cleaning efficiency, wide cleaning range, good quality, low cost, good safety and good use effect.

Owner:SUZHOU LOTTE CHEM TECH

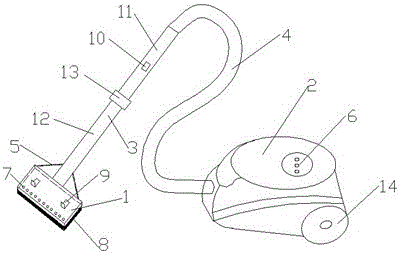

Multifunctional vacuum cleaner

InactiveCN106063690AWon't shakeImprove cleanlinessLighting elementsSuction nozzlesEngineeringMechanical engineering

A multifunctional vacuum cleaner comprises a brush head, a suction tube and a main machine, wherein the brush head and the main machine are connected with each other through the suction tube; the suction tube comprises a hard tube and a hose; the hose is connected with the main machine; the hard tube is in detachable and movable connection with the brush head, so that the brush head can rotate left and right relative to the hard tube; reset springs are fixedly arranged on two sides of the brush head respectively; the other ends of the reset springs are fixedly arranged on two sides of the hard tube respectively; a control display screen is arranged on the main machine; a plurality of led lighting lamps are arranged at the top end of the brush head; a cleaning sponge is arranged on the lower side of the brush head. The multifunctional vacuum cleaner is simple in structure, low in cost, and time-saving and labor-saving in movement; dust in sheltered places can be swept up easily; the practicability is enhanced; the dust collection effect is improved; burden of cleaning can be reduced; convenience is brought for people's operation.

Owner:陈小磊

Plant ash removing device

The invention discloses a plant ash removing device. The plant ash removing device comprises a cart, a machine shell and a dust collection motor; a filtering drum is arranged in a lower cabin, an airexhausting pipe is arranged on the machine shell, and a fixed pipe is arranged on the air exhausting pipe; an inner join pipe, an elastic corrugated pipe and a main gas ejector pipe which are sequentially communicated are arranged on the fixed pipe, an outer cover frame is arranged on the main gas ejector pipe, and is clamped to the fixed pipe, the inner join pipe and the elastic corrugated pipe are located in the fixed pipe, and the outer side wall of the inner join pipe and the inner side wall of the fixed pipe are fixedly sealed; a dust collection pipe penetrating through the bottom of themachine shell and a cart plate is arranged on the machine shell, the upper end of the dust collection pipe is located in the lower cabin, a vertical partition plate is arranged in the lower cabin, theinside of the lower cabin is divided by the vertical partition plate into a dust collecting cavity and a working cavity, a vertical plate hole is formed in the vertical partition plate, the upper endof the dust collection pipe is communicated with the vertical plate hole, and an ash cleaning opening is communicated with the dust collecting cavity. The plant ash removing device has the advantagesthat dust collection, isolation and air exhausting functions can be automatically completed, a user only needs to conduct pushing operation, moving cleaning can be achieved, dead angles can be injected through clean air, the cleaning range is wide, and the adaptability is high.

Owner:王铁霞

Solvent type efficient compound cleaning detergent

InactiveCN105647695AImprove cleaning efficiencyWide range of cleaningNon-surface-active detergent solventsTetrachloroethyleneHalohydrocarbon

The invention discloses a solvent type efficient compound cleaning detergent. The solvent type efficient compound cleaning detergent comprises a halohydrocarbon solvent, alcohol solvents, ether solvents, ketone solvents, ester solvents, phenol solvents and water, wherein the halohydrocarbon solvent is tetrachloroethylene, the alcohol solvents are butanol, the ether solvents are diisopropyl ether, the ketone solvents are acetone, the ester solvents are methyl acetate, and the phenol solvents are phenol. The solvent type efficient compound cleaning detergent comprises the halohydrocarbon solvent, the alcohol solvents, the ether solvents, the ketone solvents, the ester solvents, the phenol solvents and the water and has the characteristics of high cleaning efficiency, wide cleaning range, low cost, good safety and good use effect.

Owner:SUZHOU LOTTE CHEM TECH

Environment-friendly degradable cleaning agent and preparation process thereof

InactiveCN104560426AReduce cleaning costsWide range of cleaningNon-ionic surface-active compoundsDetergent compounding agentsIonChemistry

The invention relates to an environment-friendly degradable cleaning agent and a preparation process thereof. The cleaning agent is prepared from the following raw materials in percentage by weight: 20-25% of alkyl glycoside, 5-10% of sodium gluconate, 3-8% of active protease, 5-10% of ethanol, 2-5% of plant extracting solution, 1-5% of additives and 46-55% of deionized water. The cleaning agent provided by the invention contains no hazardous substance, for example, strong acid, strong base and the like, is non-toxic and harmless to the environment, completely biodegradable, free of carcinogenic chemical, harmless to such surfaces as rubber, plastic and paint, free of irritation to human skin, low in cleaning cost, wide in cleaning range, strong in cleaning capability, free of workpiece damage and reusable.

Owner:HANGZHOU LUOHE TECH

Automatic dust removal equipment for electronic glass

InactiveCN112355011AImprove cleaning efficiencyEasy to cleanDrying solid materials without heatDrying gas arrangementsDust controlWater resources

The invention discloses automatic dust removal equipment for electronic glass. The automatic dust removal equipment comprises a base; two support plates are fixedly connected to the base; the tops ofthe two support plates are jointly and fixedly connected with a fixed plate; the top of the fixed plate is fixedly connected with a motor; a conveying mechanism is fixedly connected to the base; a cleaning mechanism is arranged between a transmission rod and the support plates; a drying mechanism fixedly connected with the support plates is arranged on the rear side of the cleaning mechanism; anda water circulation mechanism is arranged between the base and the fixed plate. The automatic dust removal equipment for the electronic glass provided by the invention is reasonable in structure, theto-be-dedusted circular electronic glass with different radiuses can be conveyed through the conveying mechanism, and the dedusting efficiency is improved; the whole outer wall of the electronic glasscan be cleaned through the cleaning mechanism, and the cleaning range is wide; liquid on the electronic glass can be dried through the drying mechanism, so that the next procedure can be convenientlycarried out; and water after cleaning can be collected and recycled through the water circulation mechanism, so that water resources are saved.

Owner:德清县诚达金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com