Fully-automatic cleaning instrument for RTFO (rolling thin film oven) sample-containing bottles

A technology of rotating thin film and cleaning instrument, which is applied in the direction of drying, drying machine, cleaning hollow objects, etc., can solve the problems of damage to the health of the tester, long cleaning cycle, residual cleaning liquid, etc., to reduce the residue of cleaning liquid and save Time and energy, the effect of eliminating the liquid in the bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

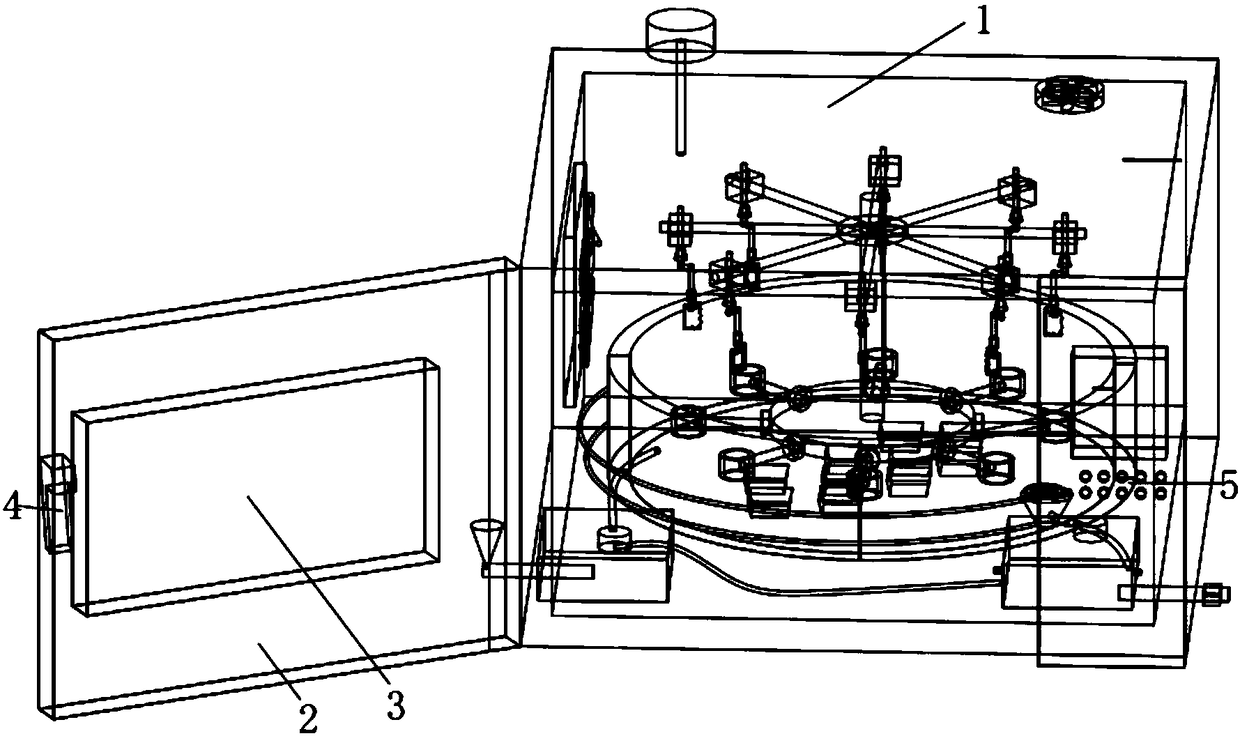

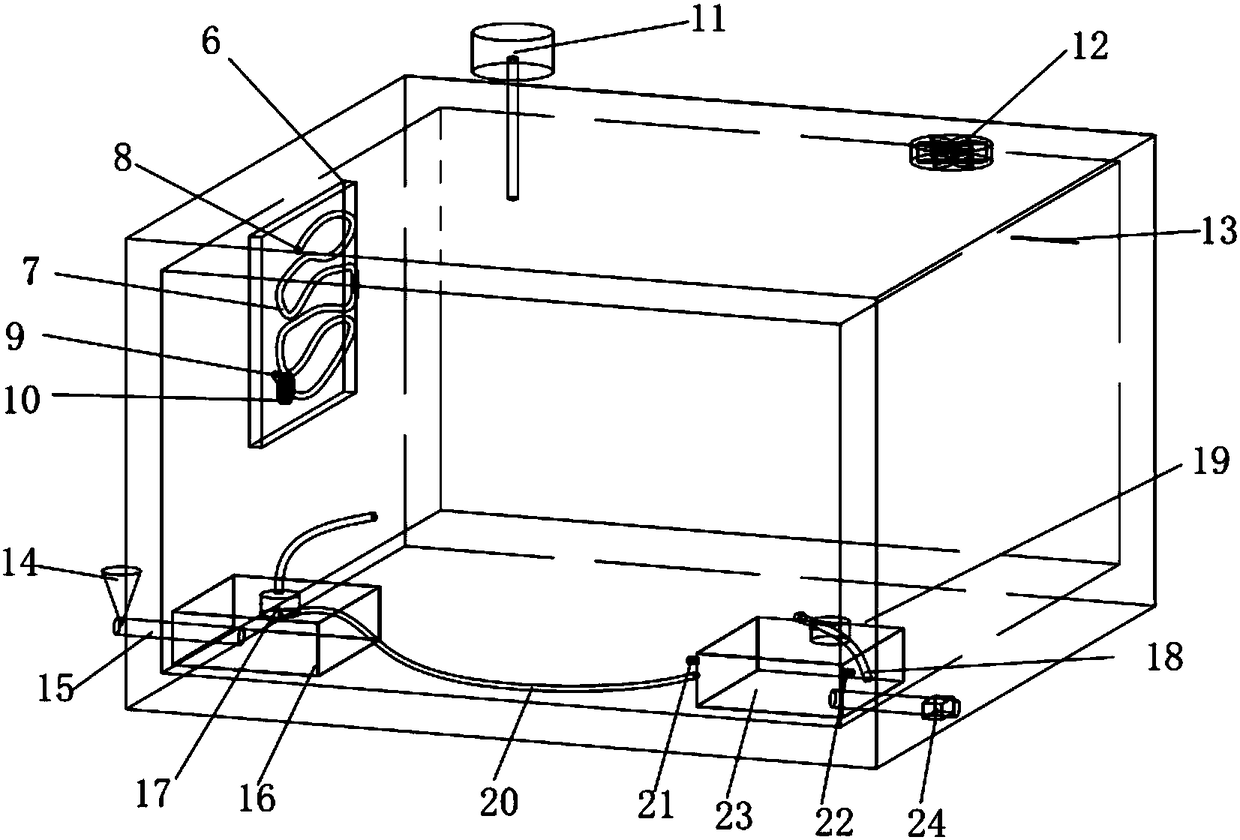

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

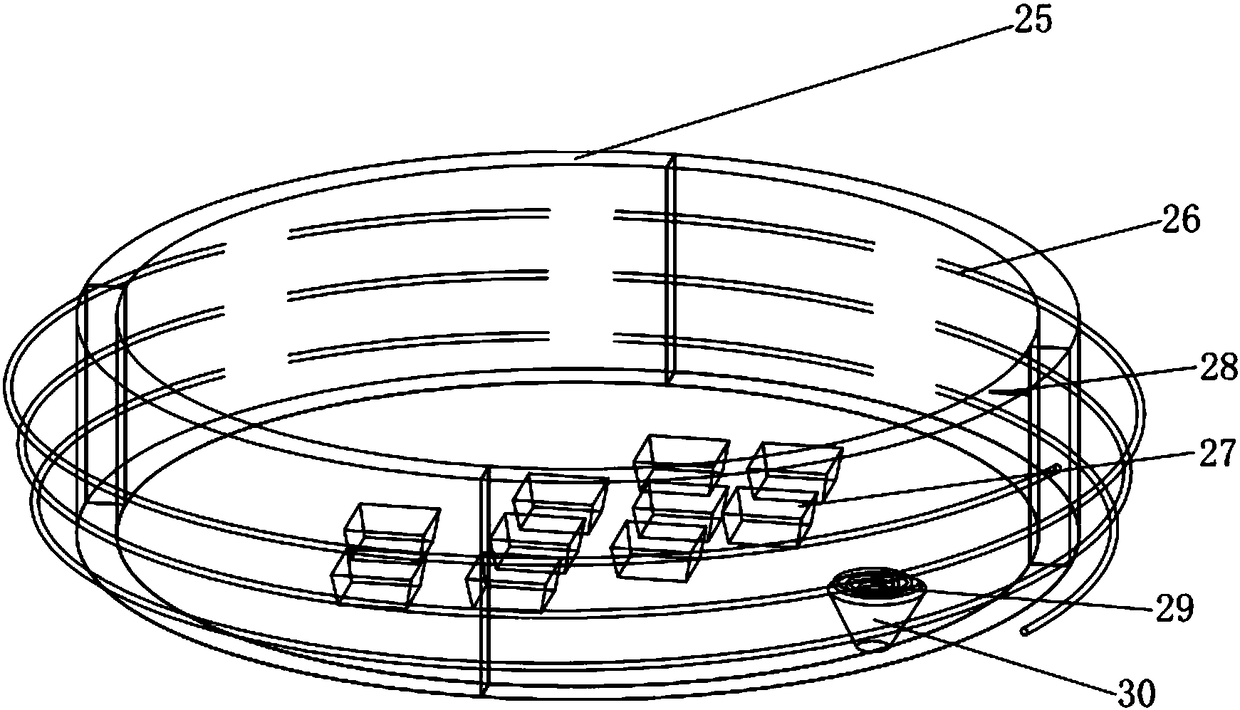

[0034] Such as Figure 1 to Figure 6 As shown, a fully automatic rotary film oven sample bottle cleaning instrument includes a controller 5, a cleaning instrument cabinet 1, an annular sound wave washing tank 25, a fixed sample bottle cleaning device, a heating device and a drying device; The fixed cleaning device is connected to the controller (5);

[0035] Controller 5 comprises a control system and a control display panel;

[0036] The ring-shaped acoustic wave washing tank 25 is fixed in the cleaning instrument casing 1, and the cleaning device includes a cleaning liquid system and an ultrasonic transmitter 27 arranged at the lower end of the ring-shaped acoustic wave washing tank 25; the cleaning liquid system is used to provide cleaning liquid for the cleaning tank;

[0037] The cleaning liquid system includes a cleaning liquid supply system and a cleaning liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com