Method and device for rapidly manufacturing pulverized coal polished section by ultrasonic defoaming

An ultrasonic and optical sheet technology, applied in the field of making pulverized coal optical sheets, can solve problems such as low efficiency, long time consumption, and influence on experimental observation, and achieve the effects of eliminating air bubbles, reducing waste, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

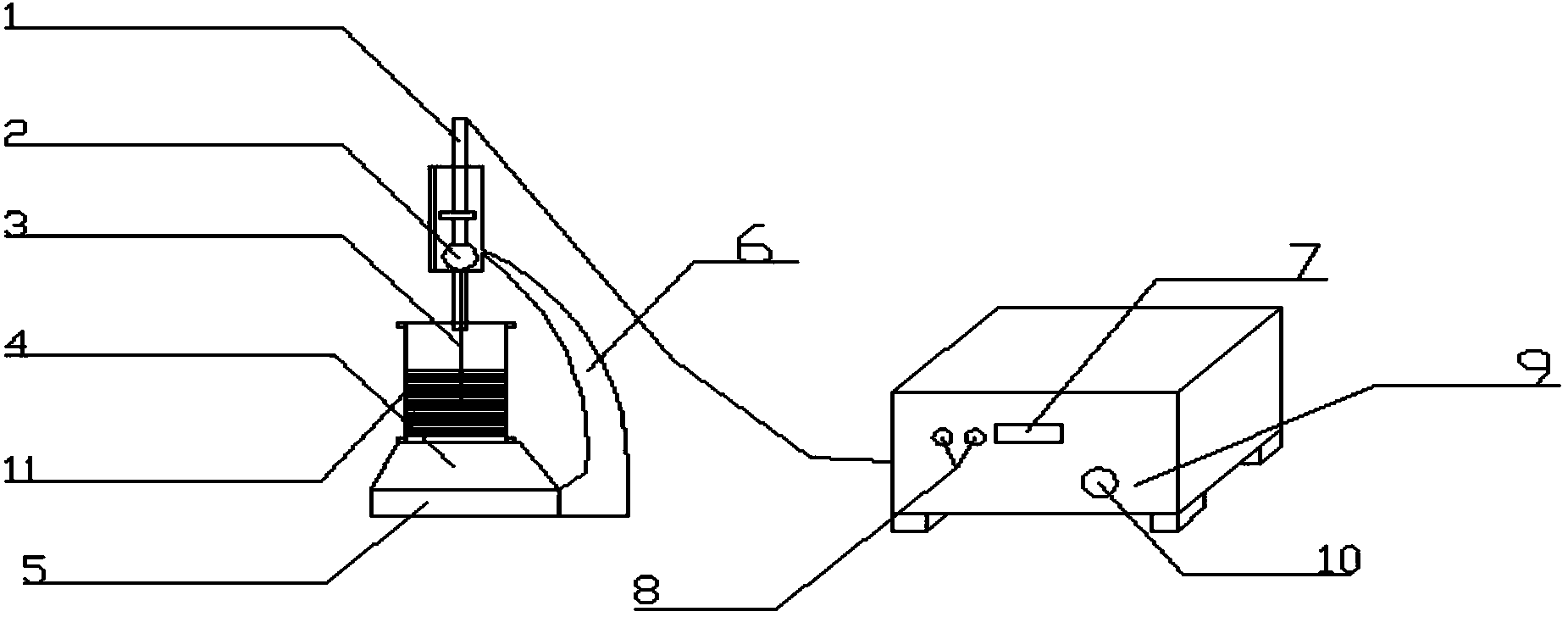

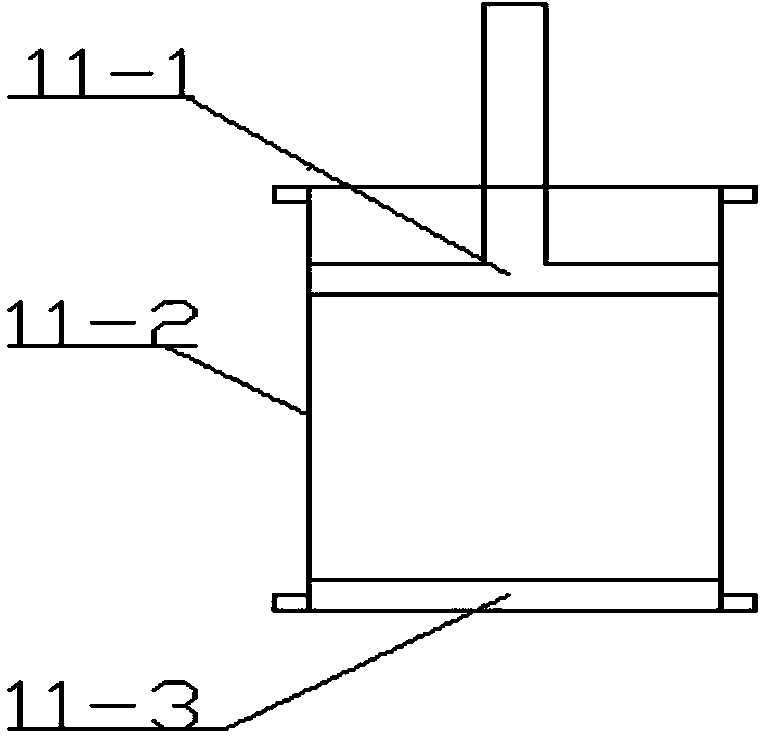

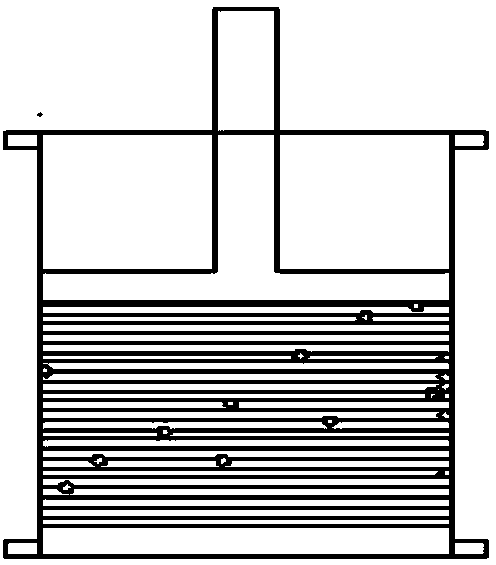

[0036]The pulverized coal light sheet rapid production device of the present invention mainly includes an ultrasonic defoamer and a light sheet forming device, and the ultrasonic defoamer includes: a transducer 1, a height adjustment screw 2, a tool head 3, a stage 4, and a base 5. Base 6, display screen 7, FM knob 8, ultrasonic generator 9 and socket 10; ultrasonic generator 9 is connected to transducer 1 through wires, and transducer 1 is connected to base 6 through height adjustment screw , the base 6 is connected to the base 5, there is a stage 4 on the upper end of the base 5, and the light sheet forming device is located on the stage 4; there is a tool head 3 above the stage 4, and the tool head 3 is connected to the transducer 1; display screen 7, frequency tuning knob 8 and socket 10 are arranged on ultrasonic generator 9; described optical sheet fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com