A method for preparing pharmaceutical grade soybean linoleic acid by thin film distillation

A technology of linoleic acid and film, which is applied in the preparation/refining of fatty acids, the separation/purification of carboxylic acid compounds, and the production of fatty acids, and can solve problems such as inability to continue production, uncertainty in process control, and high labor intensity. Achieve the effects of low production intensity, simple and feasible equipment, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

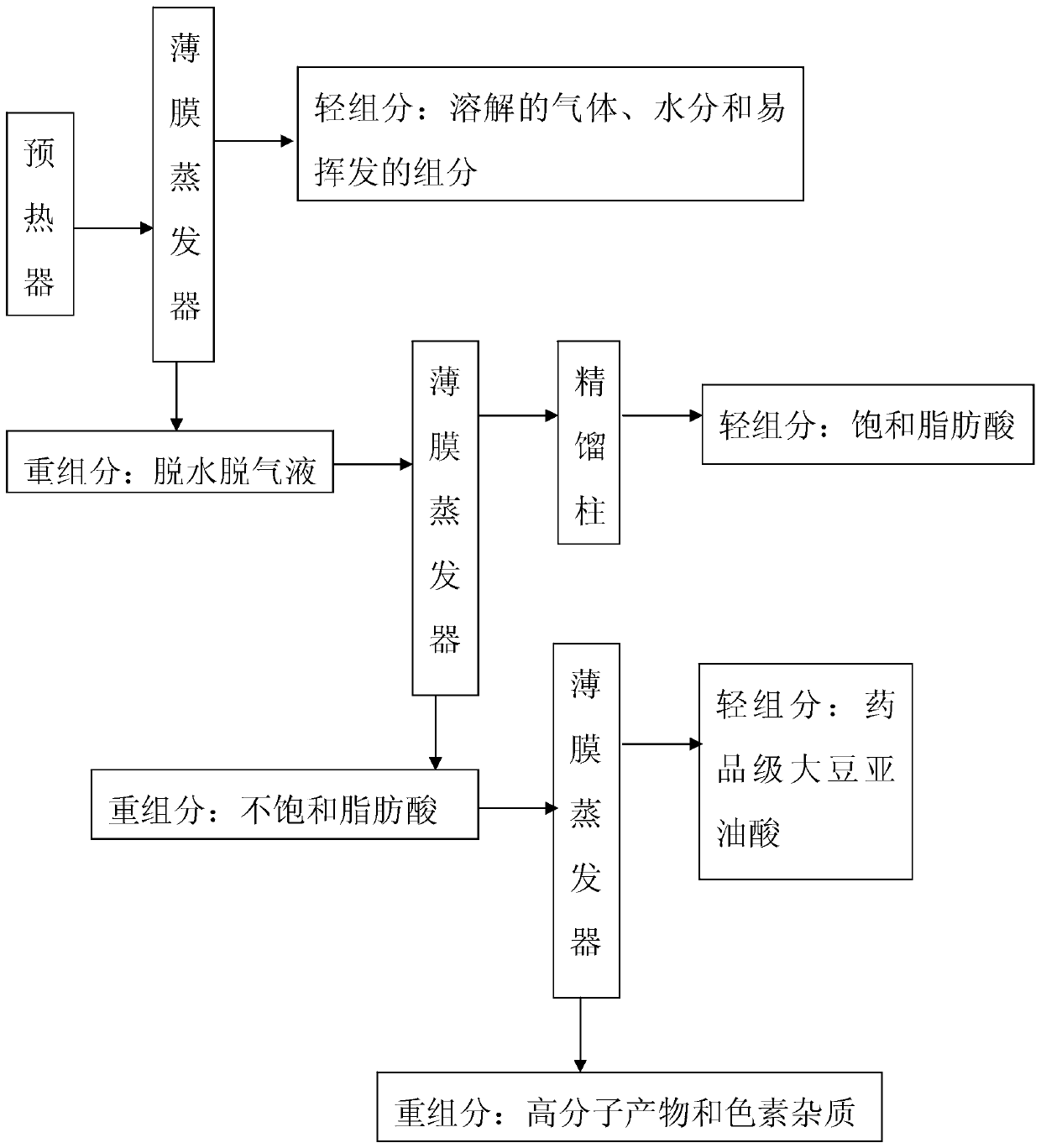

Method used

Image

Examples

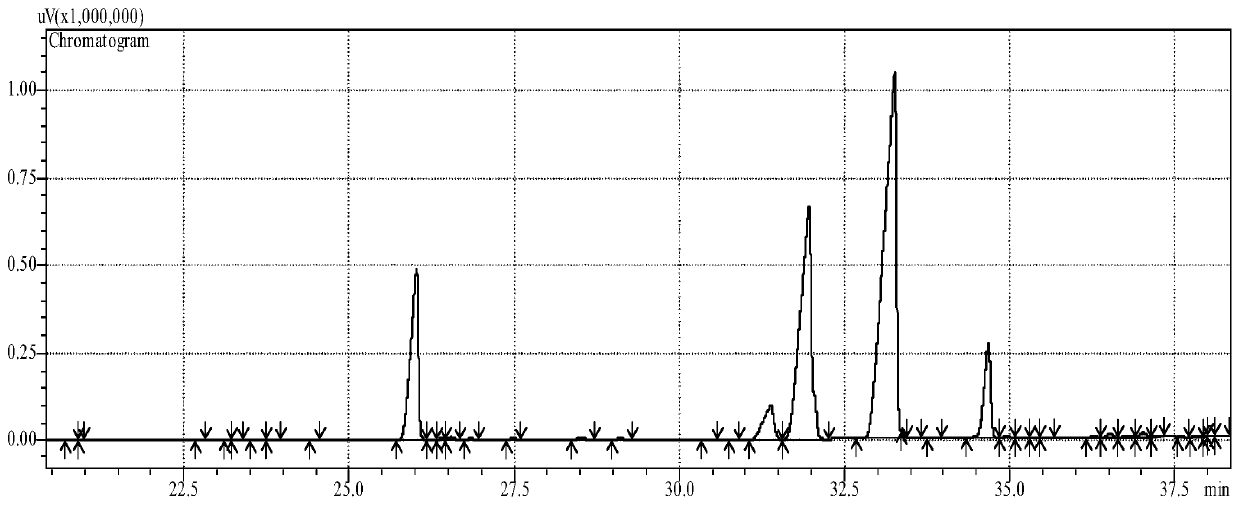

Embodiment 1

[0042] The steps and conditions of a method for preparing pharmaceutical-grade soybean linoleic acid by thin film distillation are as follows:

[0043] First stage thin film evaporation:

[0044] 1kg of soybean soapstock mixed fatty acid (iodine value 119gI / 100g) melted and preheated (70°C) in the storage tank is sent to the thin film evaporator through the delivery pump at a flow rate of 2.0kg / h, and the temperature of the thin film heater is controlled 90°C, system vacuum degree ≦ 1000Pa, wiper speed 100r / min, condensation temperature at room temperature, to remove dissolved gas, moisture and volatile components. The material that has not been evaporated (heavy components) re-enters the storage tank.

[0045] Two-stage thin film distillation:

[0046] The heavy component dehydration and degassing liquid after the first-stage thin film evaporation is sent to the thin film evaporator through the delivery pump at a flow rate of 0.5kg / h, and the temperature of the thin film he...

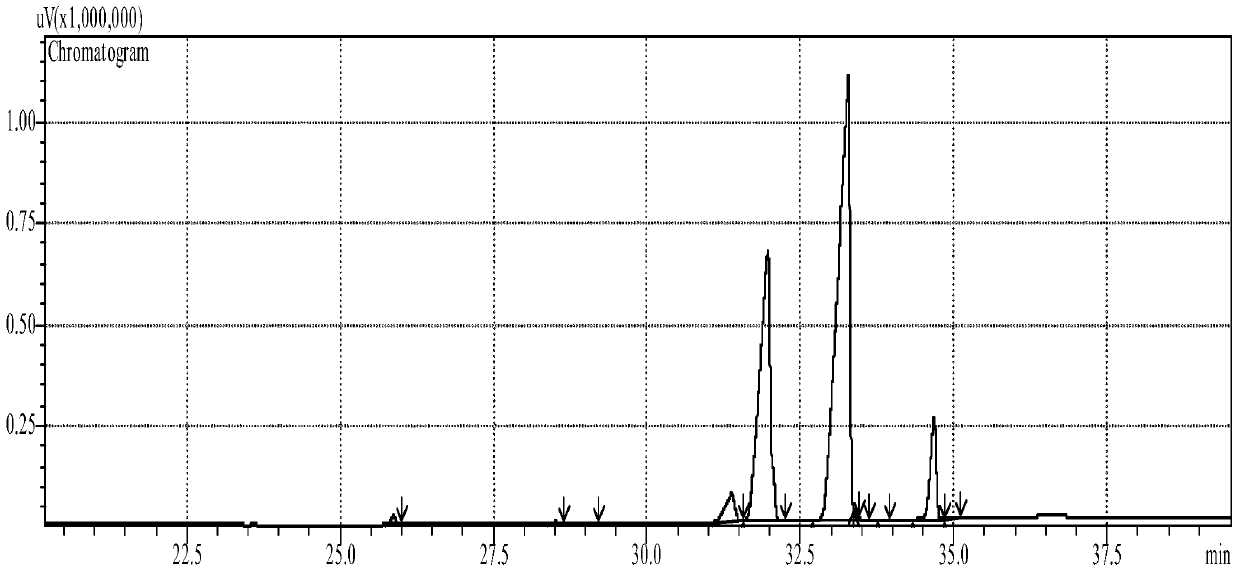

Embodiment 2

[0050] The steps and conditions of a method for preparing pharmaceutical-grade soybean linoleic acid by thin film distillation are as follows:

[0051] First stage thin film evaporation:

[0052] 1kg of soybean soapstock mixed fatty acid (iodine value 119gI / 100g) melted and preheated (70°C) in the storage tank is sent to the thin film evaporator through the delivery pump at a flow rate of 2.0kg / h, and the temperature of the thin film heater is controlled 80°C, system vacuum degree ≦1000Pa, wiper speed 100r / min, condensation temperature at room temperature, to remove dissolved gas, moisture and volatile components. The material that has not been evaporated (heavy components) re-enters the storage tank.

[0053] Two-stage thin film distillation:

[0054] The heavy component dehydration and degassing liquid after the first-stage thin film evaporation is sent to the thin film evaporator through the delivery pump at a flow rate of 0.5kg / h, and the temperature of the thin film hea...

Embodiment 3

[0058] The steps and conditions of a method for preparing pharmaceutical-grade soybean linoleic acid by thin film distillation are as follows:

[0059] First stage thin film evaporation:

[0060] 1kg of soybean soapstock mixed fatty acid (iodine value 119gI / 100g) melted and preheated (70°C) in the storage tank is sent to the thin film evaporator through the delivery pump at a flow rate of 2.0kg / h, and the temperature of the thin film heater is controlled 70°C, system vacuum degree ≦ 1000Pa, wiper speed 100r / min, condensation temperature at room temperature, to remove dissolved gas, moisture and volatile components. The material that has not been evaporated (heavy components) re-enters the storage tank.

[0061] Two-stage thin film distillation:

[0062] The heavy component dehydration and degassing liquid after the primary thin film evaporation is sent to the thin film evaporator through the delivery pump at a flow rate of 0.5kg / h, the temperature of the thin film heater is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com