Patents

Literature

219results about How to "Achieve dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

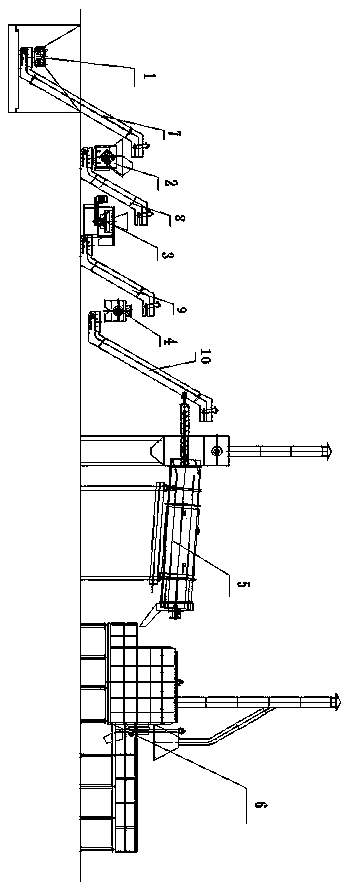

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Organic composite flocculant for conditioning and dehydration of sludge

InactiveCN102531329AFormation is smallLow tendency to formSludge treatment by de-watering/drying/thickeningFlocculationFiltration

The invention discloses an organic composite flocculant for conditioning and dehydration of sludge. An active substance of the organic composite flocculant mainly comprises a cationic organic compound A and a polymeric organic flocculant B in a mass ratio of (1-20):1. By combination of the two compounds, the unexpected synergistic effect can be obtained on the basis of no increase of the cost of the flocculant for sludge treatment, so that flocs formed in the flocculation process of the sludge are dense, the formation of large gelatinous flocs caused by adding a polymeric flocculant is avoided, and the moisture in the flocs can be optimally released so as to reduce the final water content in the sludge; and meanwhile, the specific resistance of the sludge can be remarkably improved, so that the filtration characteristic of the sludge is improved.

Owner:苏州格瑞特环保科技产业发展有限公司

Process method for preparing polyoxymethylene dimethyl ethers

ActiveCN105566077AAvoid cloggingAchieve dehydrationOrganic compound preparationCarbonyl compound separation/purificationCyclic processLiquid water

The invention discloses a process method for preparing polyoxymethylene dimethyl ethers. The method includes the steps that formaldehyde gas is cooled to 100 DEG C and below, so that vapor is removed; dehydrated gas formaldehyde is directly absorbed by a mixture of polyoxymethylene dimethyl ethers DMM1-2 and polyoxymethylene dimethyl ethers DMM6-10 of different degrees of polymerization, then a reaction is conducted, polyoxymethylene dimethyl ethers DMM 3-5 are prepared, and DMM1-2 and DMM 6-10 with the DMM 3-5 separated continuously serve as raw materials and are recycled. According to the method, formaldehyde gas generated by methanol oxidation is cooled to 100 DEG C and below, vapor is condensed into liquid water, the purpose of dehydration is achieved, and due to the fact that water in the formaldehyde is removed before being absorbed by reactant, and the situations that a polycondensation reaction occurs and device is blocked by paraformaldehyde generated by formaldehyde polycondensation are avoided; the mixture of the DMM1-2 and DMM6-10 also participates in a polymerization reaction and a depropagation reaction in the cyclic process and is finally converted to the polyoxymethylene dimethyl ethers DMM3-5 of the target degree of polymerization. The method is simple in process and easy to operate, the speed for generating the DMM3-5 is high, the conversion rate of the DMM3-5 is high, and energy consumption and equipment investment are lowered.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Sludge deep dehydration method

ActiveCN1962496AAchieve dehydrationSludge treatment by de-watering/drying/thickeningSludgeFilter press

The invention discloses a deep dehydrating method of sludge, which comprises the following steps: a. tempering; adding filtrate in the sludge; adding chemical raw material with Fe3+ to stir; reacting for 2-12min; adding chemical raw material with Ca2+ to stir; reacting for 3-15min; b. dehydrating; introducing tempered sludge into filter press; filtering the water in the sludge; maintaining pressure at 1.5Mpa-2.5Mpa for 30-70min.

Owner:广州优特利环保科技有限公司

Washing machine and washing method

InactiveCN103061086ASimplify the process of separation and recoverySimplify the laundry processOther washing machinesControl devices for washing apparatusEngineeringSolid particle

The invention relates to a washing machine and a washing method. The washing machine comprises an inner barrel, an outer barrel and solid particles as washing medium. The inner barrel is rotatably arranged on the inner side of the outer barrel, the inner barrel is divided into two layers which are respectively a first inner barrel and a second inner barrel, the second inner barrel surrounds the outer side of the first inner barrel, a plurality of discharge ports enabling the particles to be left out are formed in the barrel wall of the second inner barrel, and a turnover plate capable of turning over and being opened is arranged on each discharge port. The washing machine enables the turnover plate to be opened automatically through centrifugal force generated by the inner barrel rotating at high speed enables, the particles are left out to from the inner barrel to the outer barrel, and are recovered to a material storing space, and therefore separating and recovering of the particles are achieved, and not only is the process of the separating and the recovering of the particles simplified, but also a washing process is simplified.

Owner:XEROS LTD

Phase transition temperature-adjusting cellulosic fiber prepared by solvent method and preparation method thereof

ActiveCN105369380AGood textile processing performanceReduce churnMonocomponent cellulose artificial filamentWet spinning methodsMacromoleculePhysical chemistry

The invention discloses phase transition temperature-adjusting cellulosic fiber prepared by a solvent method. The fiber comprises a porous material, a macromolecular phase-changing material and a substance with a far infrared absorption function, wherein mass ratio of the porous adsorption material to the substance with the far infrared absorption function to the macromolecular phase-changing material is 1-30:1-50:10-100. Melting enthalpy value of the fiber is greater than or equal to 5.5 J / g, and crystalline enthalpy value is greater than or equal to 5.3 J / g. a preparation method of the fiber comprises the following steps: preparing a composite macromolecular phase-changing porous material; preparing a spinning solution; and spinning. According to preparation of the composite macromolecular phase-changing porous material, the porous adsorption material and the substance with the far infrared absorption function are added into the molten macromolecular phase-changing material to carry out adsorption and mixing. The phase transition temperature-adjusting cellulosic fiber prepared by the method has characteristics of pollution-free production process and green and environmental-protection product. As the porous adsorption material is used to adsorb the macromolecular phase-changing material, loss during formation process is minimized, and the phase transition temperature-adjusting function of the fiber is guaranteed.

Owner:潍坊欣龙生物材料有限公司

Supercritical dewatering and drying method for small water-saturated bamboo and wood articles

InactiveCN103331793ATo achieve the purpose of dehydrationClear wood grainWood treatment detailsWood impregnation detailsSupercritical dryingPulp and paper industry

The invention relates to a supercritical dewatering and drying method for small water-saturated bamboo and wood articles, belonging to the technical field of dewatering protection for cultural relics. The small water-saturated bamboo and wood articles of which the length, the width and the height are respectively at most 20cm are respectively soaked for certain time in three kinds of ethanol with different concentrations, then the supercritical drying method is adopted, and therefore the water of the water-saturated bamboo and wood articles is gradually replaced to achieve the purpose of dewatering. Compared with the prior art, the supercritical dewatering and drying method has the advantages that the purpose of dewatering of the water-saturated bamboo and wood articles can be achieved without filling chemical materials; the dewatered bamboo and wood articles have clear wood grains, and the color tends to be normal; the dewatered bamboo and wood articles have good stability under the condition of temperature and humidity fluctuation, and each shrinking percentage is within 5 percent; the complete shape of the cultural relics can be completely ensured, and the method conforms to the basic principle, namely the minimal intervention to protection of the cultural relics; the method has high research and extension values and significance.

Owner:荆州文物保护中心

Fusion-method-prepared functional graphene cellulose fiber and preparation method thereof

ActiveCN106149083AGood physical and mechanical propertiesFar infrared is goodSpinning head liquid feederMonocomponent cellulose artificial filamentCellulose fiberUltraviolet protection

The invention discloses fusion-method-prepared functional graphene cellulose fiber. The fiber mainly comprises 0.5-10.0% of graphene and 90.0-99.5% of cellulose. A preparation method of the graphene cellulose fiber comprises procedures of graphene dispersion liquid preparation, cellulose / ionic liquid mixture preparation, mixing, pre-fusing, spinning solution preparation and spinning. The far infrared normal emissivity of the prepared functional graphene cellulose fiber reaches 0.83-0.98, the ultraviolet protection coefficient reaches 62.78-560.21, the ultraviolet a transmittance is smaller than 4.92%, and compared with common viscose, the graphene cellulose fiber has the advantage that the thermal decomposition temperature is raised by 10-42 DEG C. By means of the method, the production process is short, less pollution is caused to the environment, the requirement of sustainable development is met, and the method has great significance for achieving a high-temperature melt spinning route of the functional cellulose.

Owner:潍坊欣龙生物材料有限公司

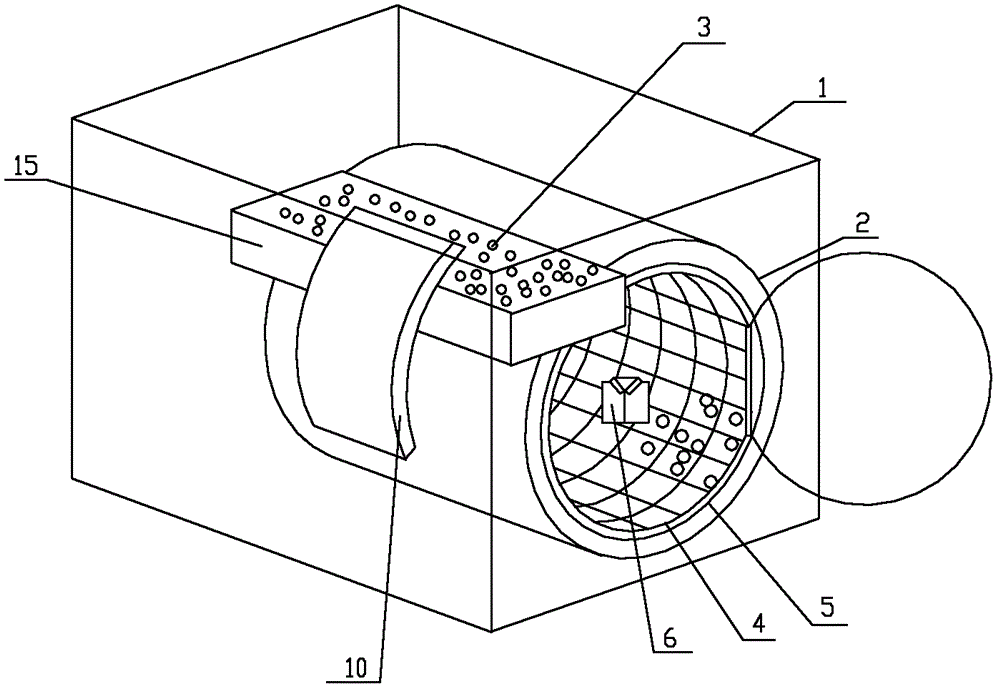

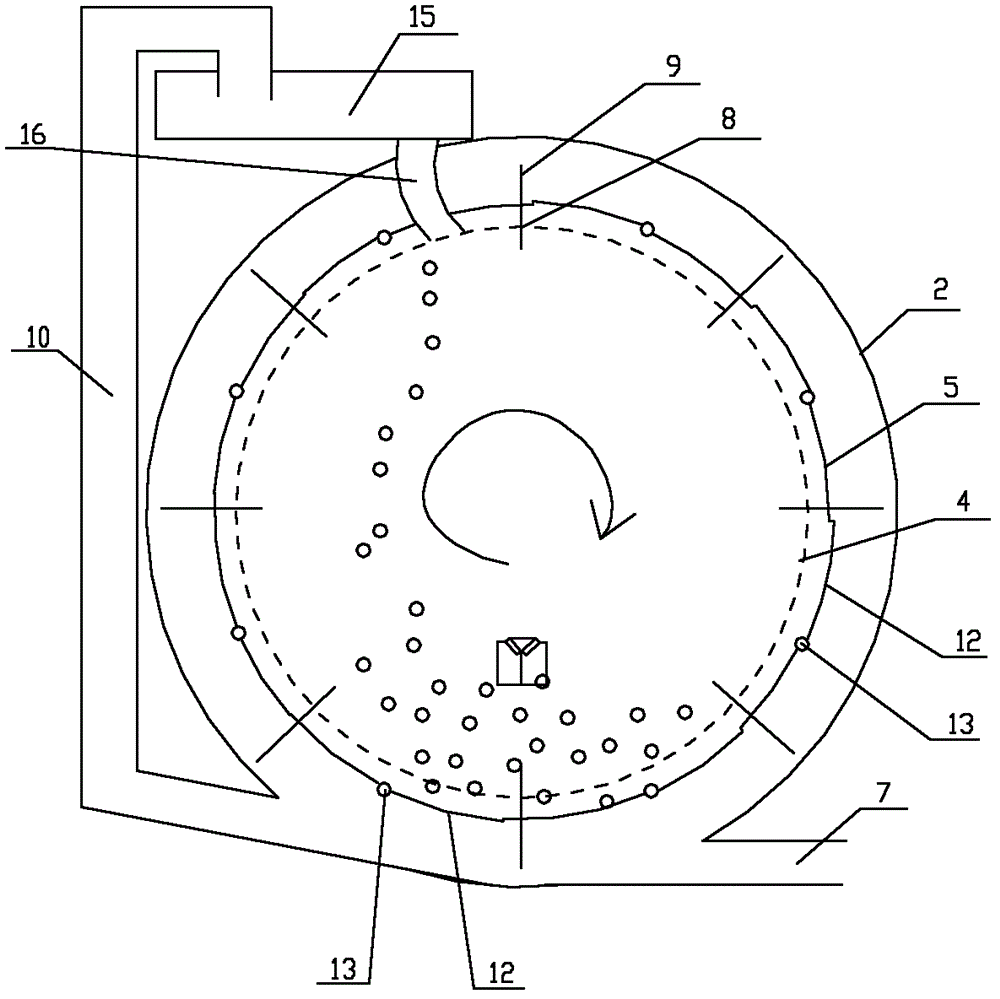

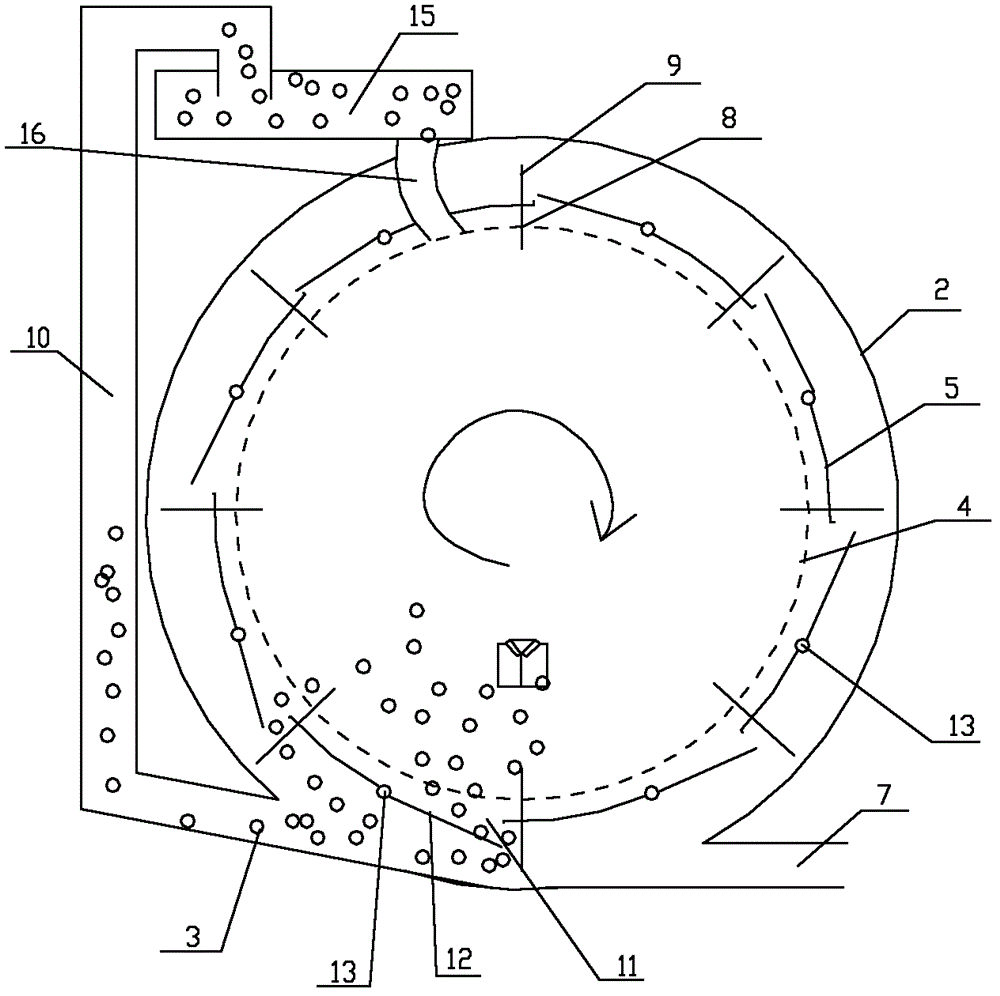

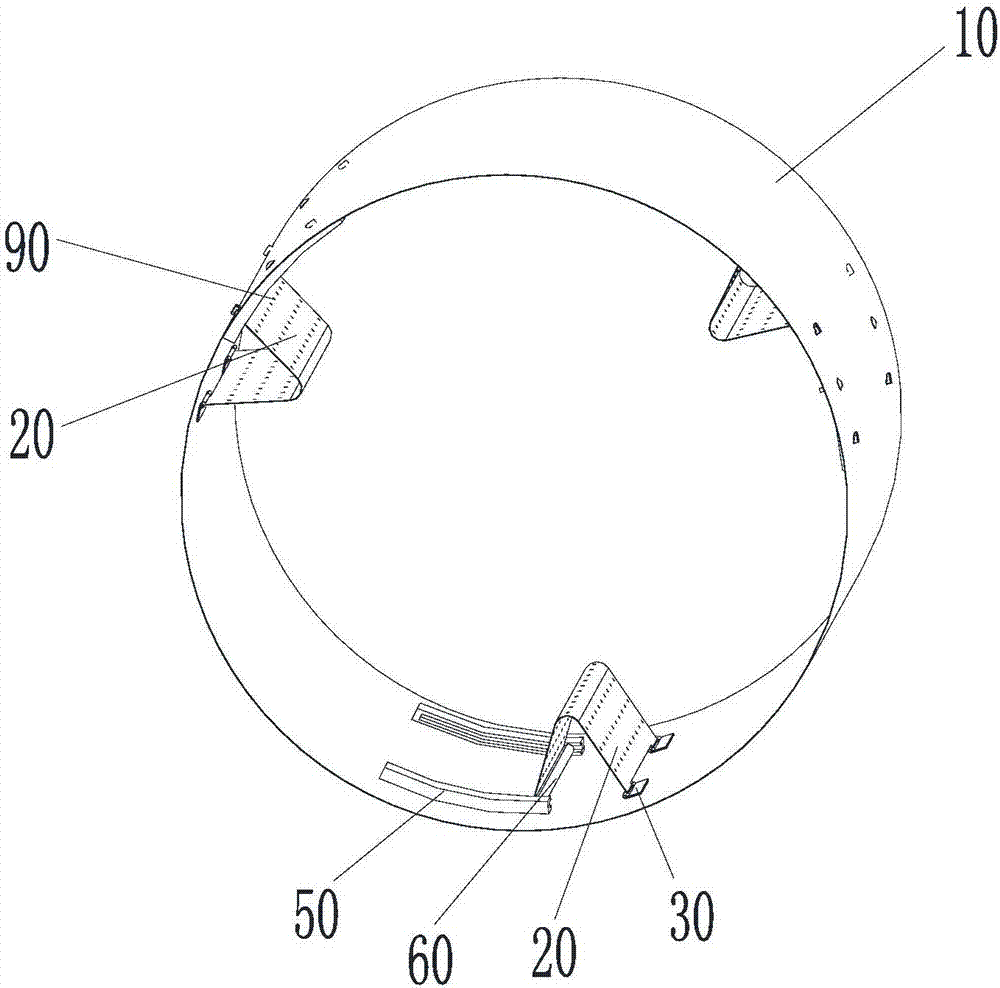

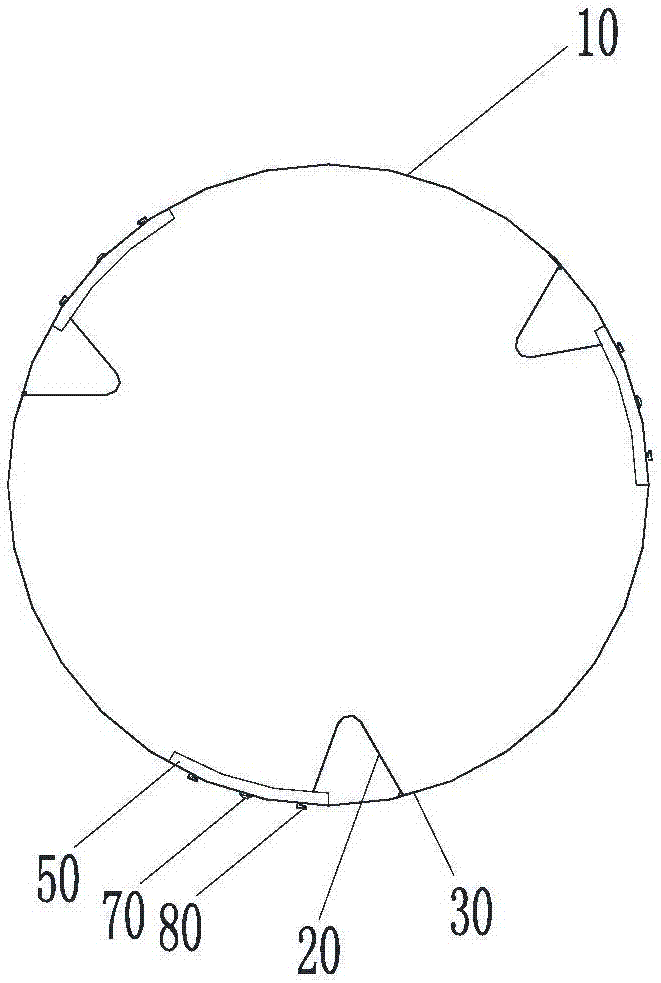

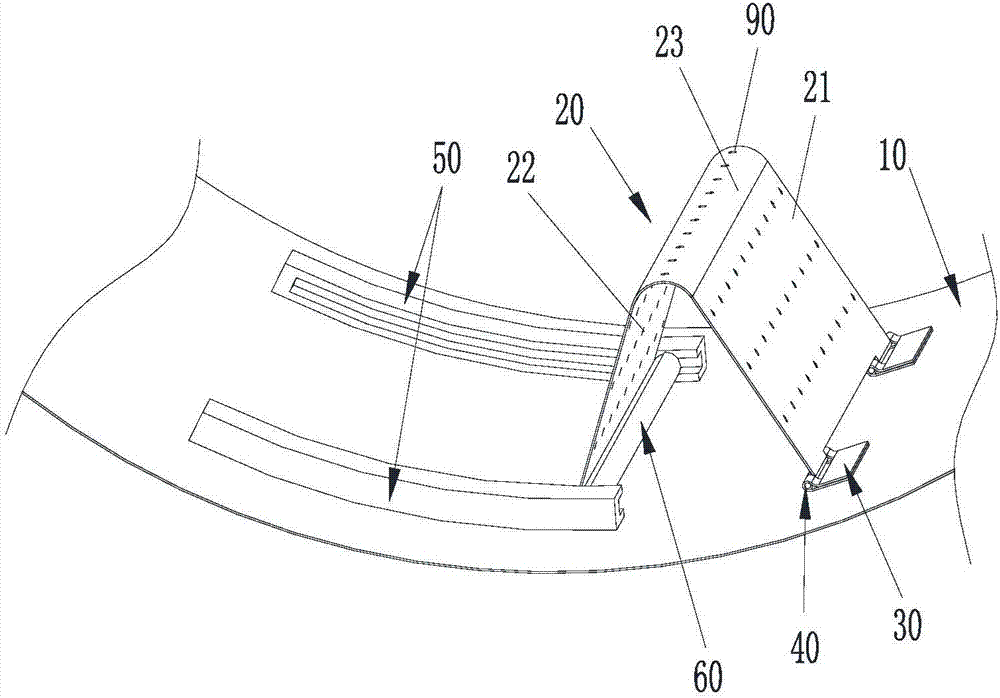

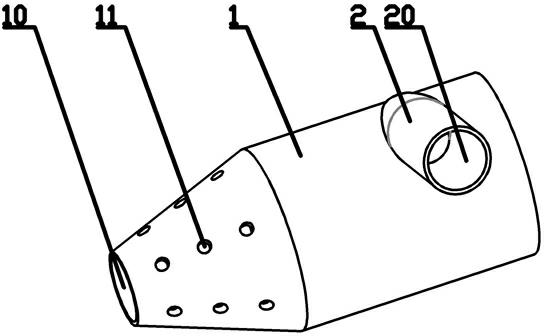

Internal cylinder of washing machine and washing machine with same

ActiveCN107130396AAchieve washingAchieve dehydrationOther washing machinesWashing machine with receptaclesPulp and paper industry

The invention provides an internal cylinder of a washing machine and the washing machine with same. The internal cylinder of the washing machine comprises an internal cylinder body, and a lifting rib which is arranged on the inner wall of the internal cylinder body, wherein the internal cylinder body is provided with a mounting part on which the lifting rib is mounted; at least part of the lifting rib is radially and movably arranged along the internal cylinder body, so that the maximum distance between a preset part of the lifting rib and the mounting part gradually decreases until meeting the preset dewatering distance when the internal cylinder body is in the dewatering state. With the adoption of the internal cylinder of the washing machine, the problems of high vibration and loud noise which easily occur in the dewatering process of a roller washing machine in the prior art can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Comprehensive utilization method of low metamorphic bituminous coal

ActiveCN102851047AMaximize utilizationAchieve dehydrationSpecial form destructive distillationCarbonizationEnvironmental engineering

The invention discloses a comprehensive utilization method of low metamorphic bituminous coal. The comprehensive utilization method comprises steps of (1) coaling; (2) preheating hot exhaust gas; (3) conducting high-temperature pyrolysis and carbonization; (4) modifying smokeless coal after pyrolysis; (5) conducting dry quenching on modified smokeless coal to generate high-temperature combustible hot exhaust gas; (6) discharging smokeless coal after dry quenching; (7) leading out raw coke oven gas produced by pyrolysis in the step (3), purifying and burning; (8) conducting dry quenching on the smokeless coal by exhaust gas after burning, namely the step (5); (9) modifying the smokeless coal by the high-temperature combustible hot exhaust gas produced by dry quenching, namely the step (4); (10) preheating hot exhaust gas for gas supplement and burning of the high-temperature combustible hot exhaust gas, namely the step (2); (11) dewatering the low metamorphic bituminous coal with big moisture content by preheated hot exhaust gas; (12) discharging moisture; (13) sending the low metamorphic bituminous coal after dewatering to the step (1); and (14) supplementing new low metamorphic bituminous coal with big moisture content.

Owner:山西睿得新材料科技有限公司

Sludge dewatering additive

InactiveCN102108003ANo secondary pollutionExcellent adhesionSludge treatment by de-watering/drying/thickeningClimate change adaptationPlant rootsDolomite

The invention discloses a sludge dewatering additive. The sludge dewatering additive comprises raw materials with the weight ratios as follows: 20 to 70 parts of magnesium chloride, 30 to 80 parts of modified dolomite, 0 to 5 parts of calcium chloride, and 8 to 10 parts of heavy calcium carbonate. The sludge dewatering additive disclosed by the invention destroys cell water in sludge, so that after a large number of moisture contained in the cell water of the sludge is lost and the sludge is filter-pressed and then placed in a natural environment, the moisture in the cell water of the sludge can continuously evaporates; and after the sludge is naturally desiccated for 36 hours, the water content in the sludge can be reduced to around 10 percent, thereby providing a very good basis for reutilization of the sludge. Meanwhile, by using the sludge dewatering additive disclosed by the invention, heavy metal in the sludge can be solidified in the sludge, cannot be absorbed by plant roots, and cannot be diffused into soil and water. Therefore, the sludge dewatered by using the sludge dewatering additive disclosed by the invention cannot cause secondary pollution, and when the dewatered sludge is used as raw material of fertilizer, fuel or building material, secondary pollution cannot be caused.

Owner:郑建国

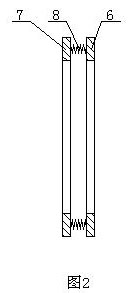

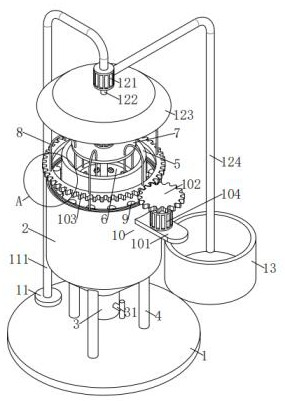

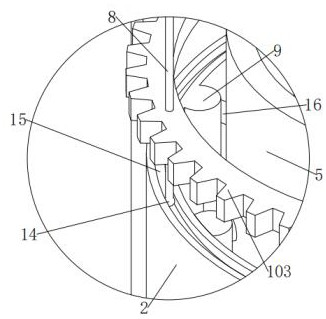

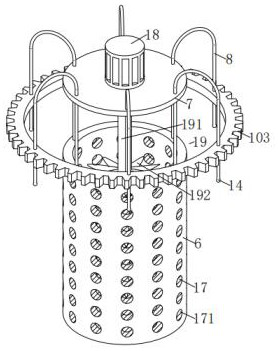

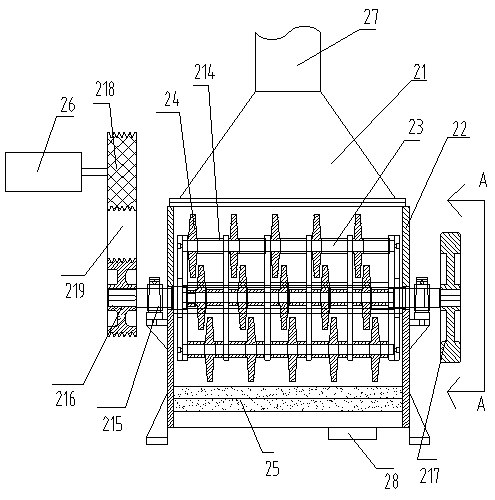

Oil-water slag separation device for kitchen garbage

InactiveCN103382058AImprove collection efficiencyReduce oilWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSlagResource utilization

The invention discloses an oil-water slag separation device for kitchen garbage. The separation device comprises a feeding box, an oil-water separator and a solid-liquid separation rotary drum; a material outlet of the feeding box is communicated with a material inlet of the oil-water separator, and a material outlet of the oil-water separator is communicated with a material inlet of the solid-liquid separation rotary drum; the upper part of the oil-water separator is provided with an oil scraping collector, the middle part of the oil-water separator is provided with inclined plates, the bottom part of the oil-water separator is provided with aerator pipes, and each inclined plate is inclined in the reverse material flow direction; the inner wall of the solid-liquid separation rotary drum is provided with a conveying screw, and the side wall of the solid-liquid separation rotary drum is provided with sieve holes. The oil-water slag separation device for the kitchen garbage has the characteristics of simple structure, convenient operation, small power consumption, short treatment cycle, high degree of automation and the like, can effectively dewater the kitchen garbage, simultaneously separates out oil and water, and meets the needs of further treatment and utilization; and the oil-water slag separation device for the kitchen garbage can significantly decrease the oil content and the water ratio of solid matters, shortens the treatment cycle in a greater degree, and is more conducive to subsequent resource utilization.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

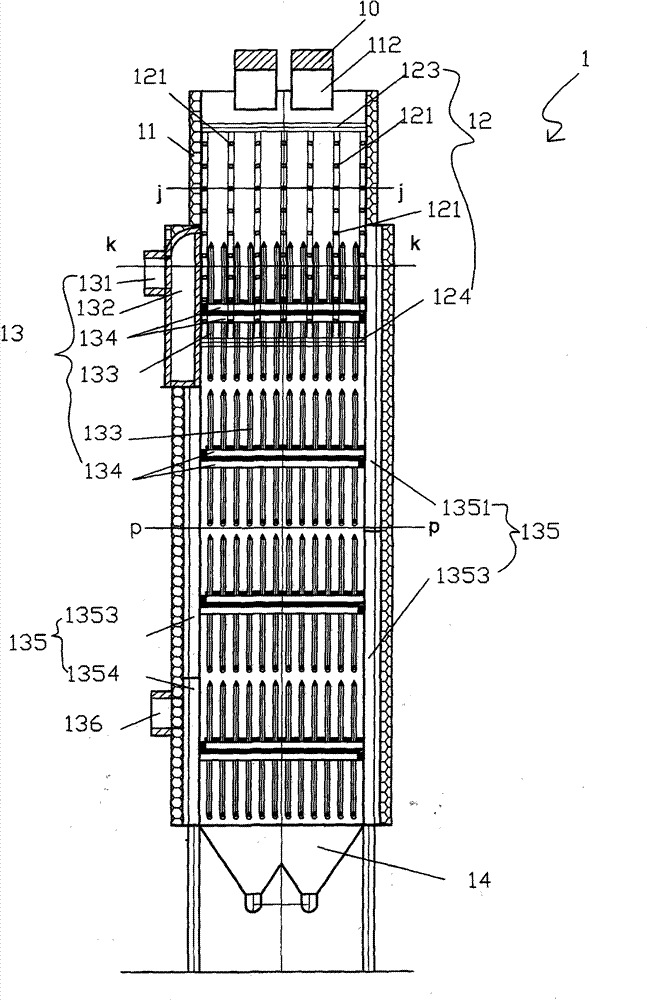

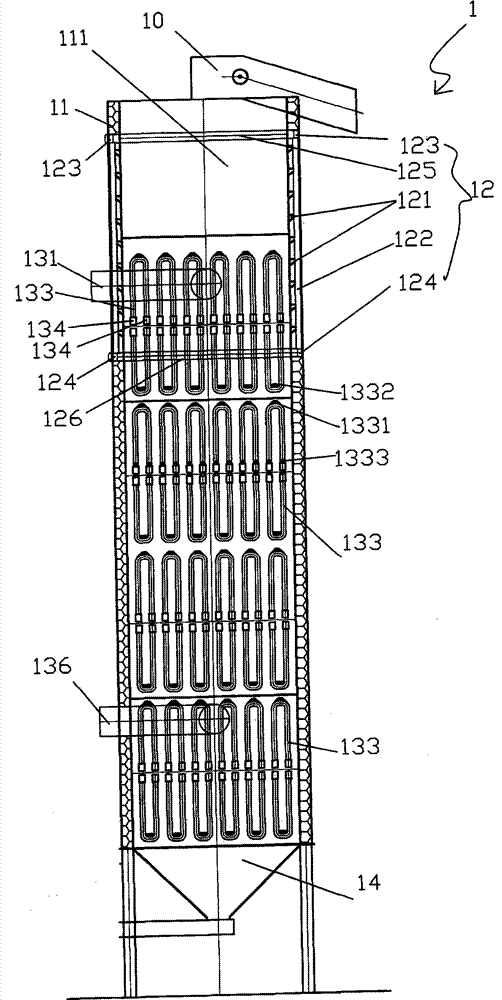

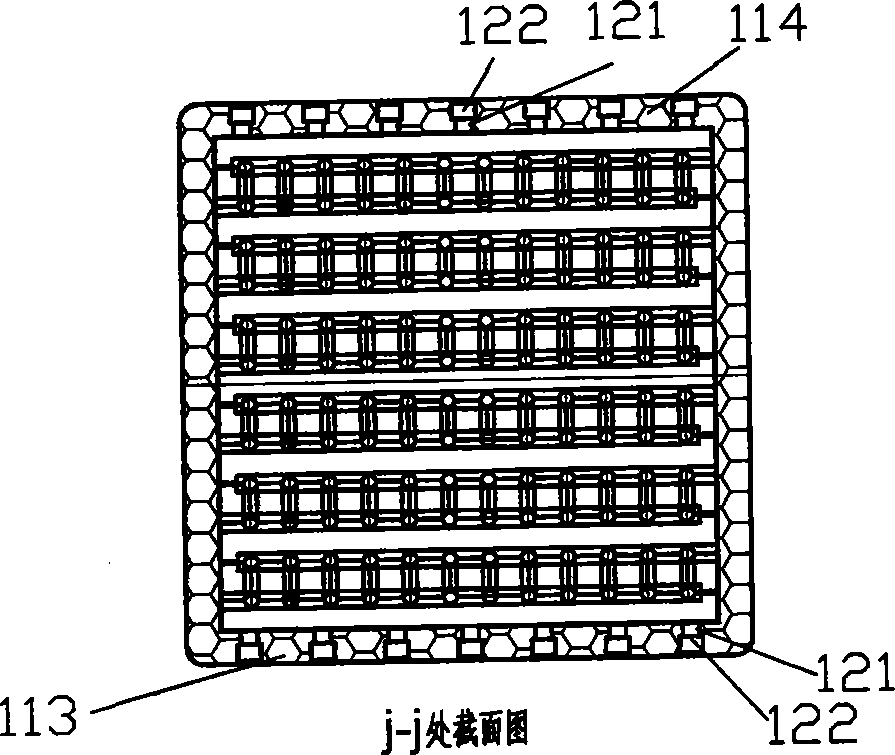

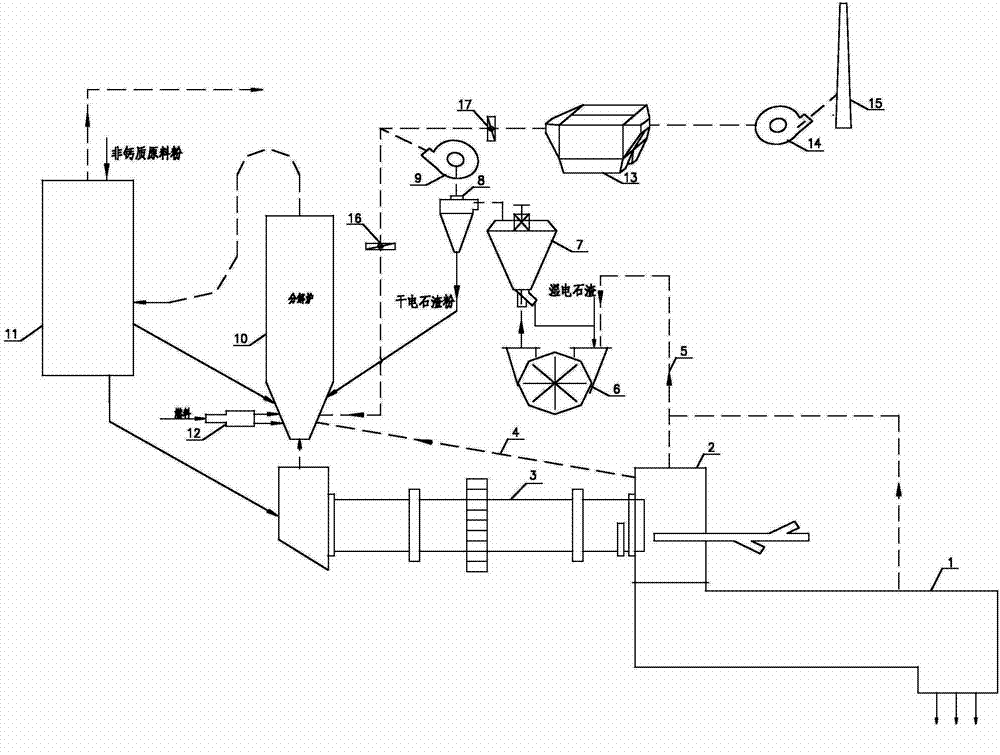

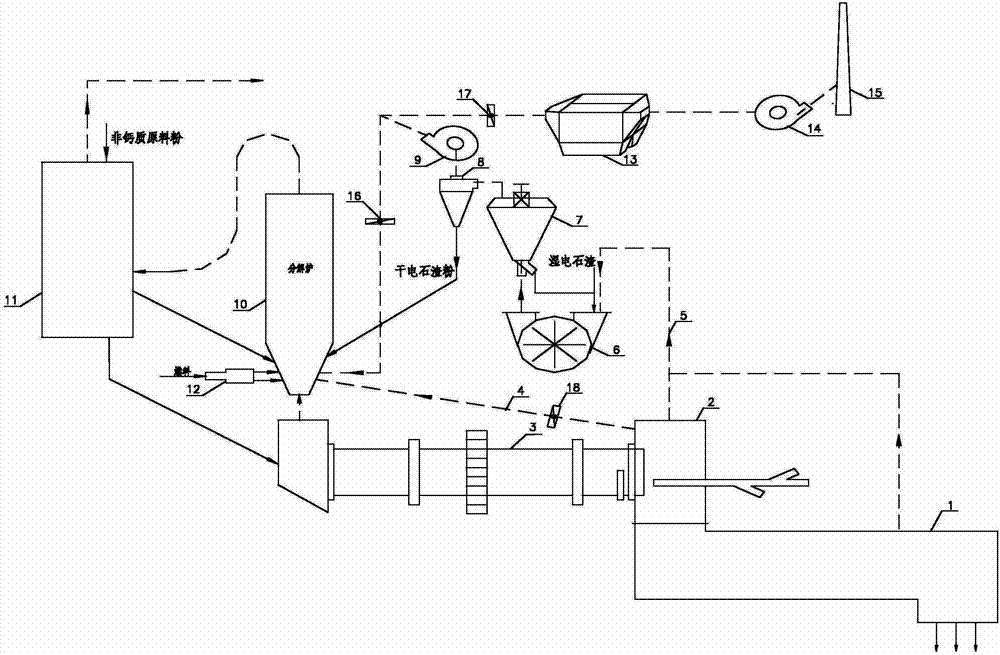

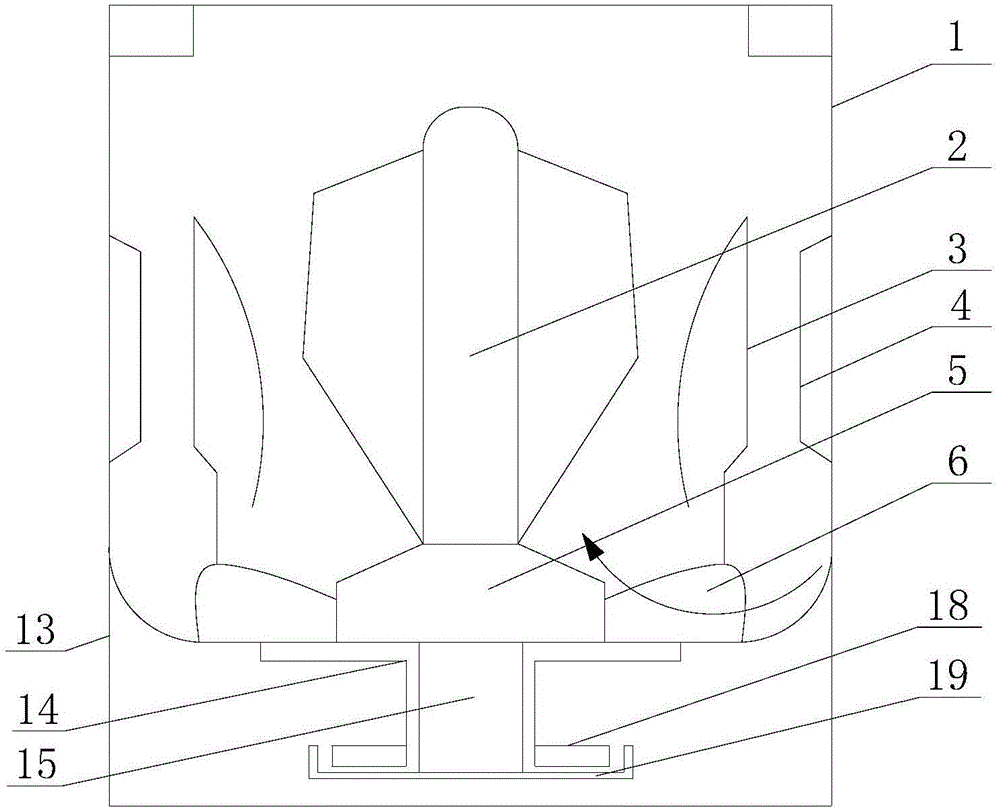

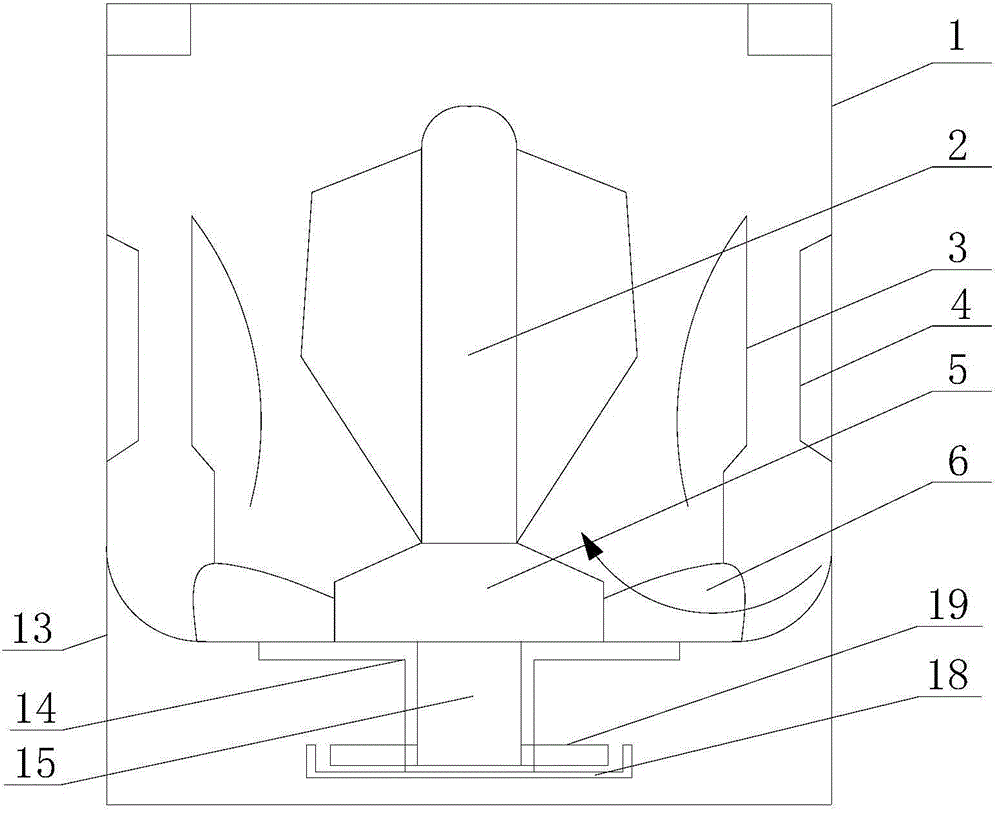

System for drying and decomposing wet acetylene sludge and firing cement clinker by using wet acetylene sludge as calcium raw material

The invention provides a system for drying and decomposing wet acetylene sludge and firing cement clinker by using the wet acetylene sludge as a calcium raw material. The system is characterized in that hot air drawn off from a clinker cooler and / or a kiln head cover is mixed in an air collecting pipe, then enters a drying crusher, exchanges heat with the calcium raw material fed into the drying crusher, finally passes through a powder concentrator, a cyclone dust collector and an exhaust gas draught fan and enters the bottom of a decomposing furnace for burning of fuel in the decomposing furnace; the calcium raw material is dried by hot air in a kiln head and subjected to powder concentration, then is directly and separately fed into the decomposing furnace and decomposed in the decomposing furnace, and finally is converged with non-calcium raw material powder preheated by a preheater system in the decomposing furnace, the calcium raw material and the non-calcium raw material powder enter a rotary kiln together so as to fire the cement clinker, and all the calcium raw material is the wet acetylene sludge. The system has the advantages that the wet acetylene sludge and the carbon dioxide reaction mechanism are fully combined, hot air mainly comprising nitrogen and oxygen is used as a drying hot source, and the acetylene sludge and the carbon dioxide are effectively prevented from being synthesized into calcium carbonate, so that the decomposition temperature and decomposition heat of calcium hydroxide are reduced.

Owner:NANJING KISEN INT ENG

Mechanical dehydration treatment method for sludge modification

InactiveCN101811814ASignificant dehydration reduction effectAchieve dehydrationSludge treatment by de-watering/drying/thickeningSludge cakeSulfate

The invention relates to a mechanical dehydration treatment method for sludge modification, which comprises the following steps that: (1) after dehydrating agent, ferrous sulfate, lime and deodorant are added into original sludge with water content of 80-85 percent, agitation is conducted to form original sludge A; (2) water with weight accounting for 30-50 percent of the weight of the original sludge is added in the original sludge A and agitation is continuously conducted to form sludge slurry; (3) the sludge slurry is treated in a coarse crusher to enable small liquid drops in the sludge slurry to be gathered into large liquid beads which take a demulsification effect and to remove solid impurities in the sludge slurry; (4) the sludge slurry treated by the coarse crusher is pressurized in a pressure filter to ensure that solid and liquid in the sludge slurry are separated to form sludge cakes; and (5) the sludge cakes are evenly stacked, the stacking height is 30-50cm, the sludge cakes are naturally dried for 48-72 hours and dried sludge cakes with water content of 20-30 percent are obtained. The invention has the advantages that the sludge dehydration decrement effect is obvious; and no secondary pollution is caused in the process of treatment.

Owner:张国清

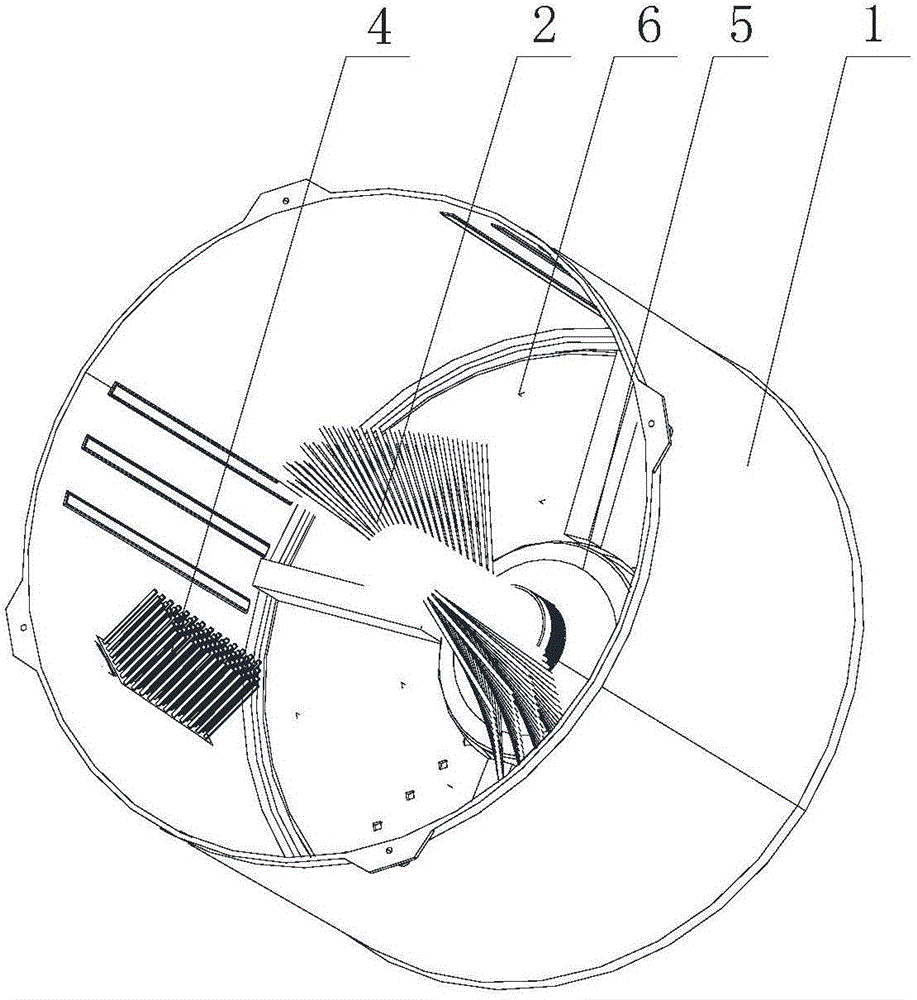

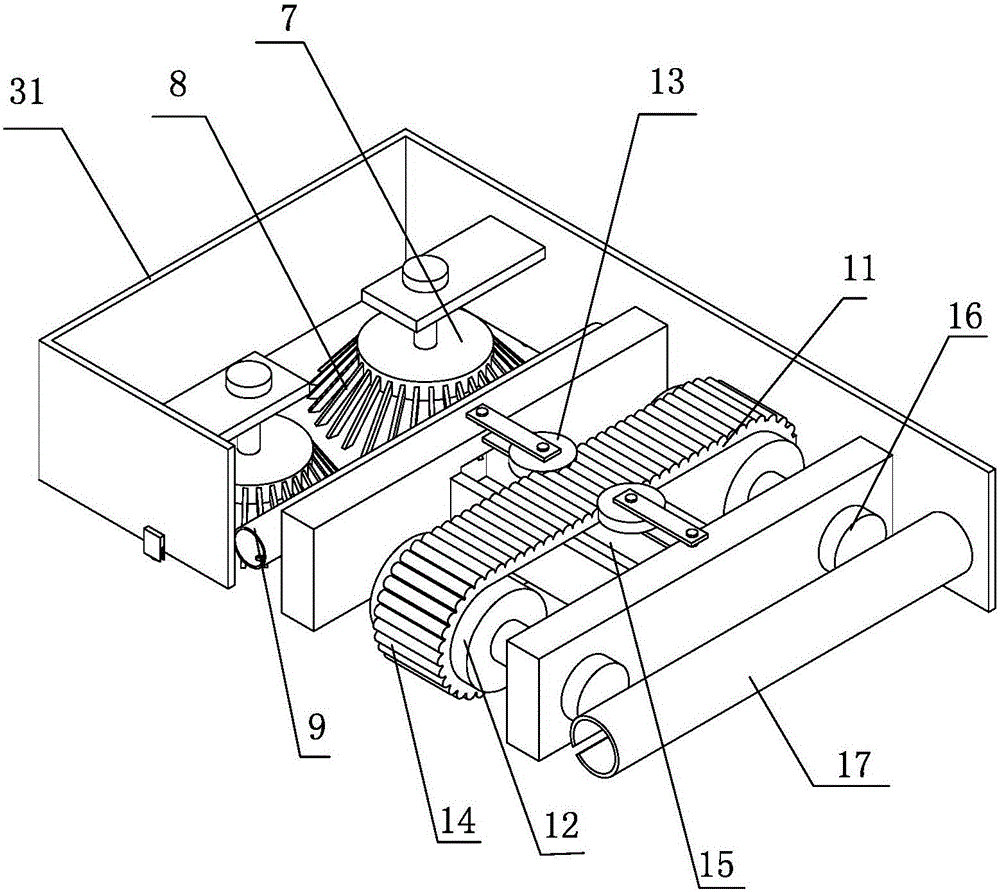

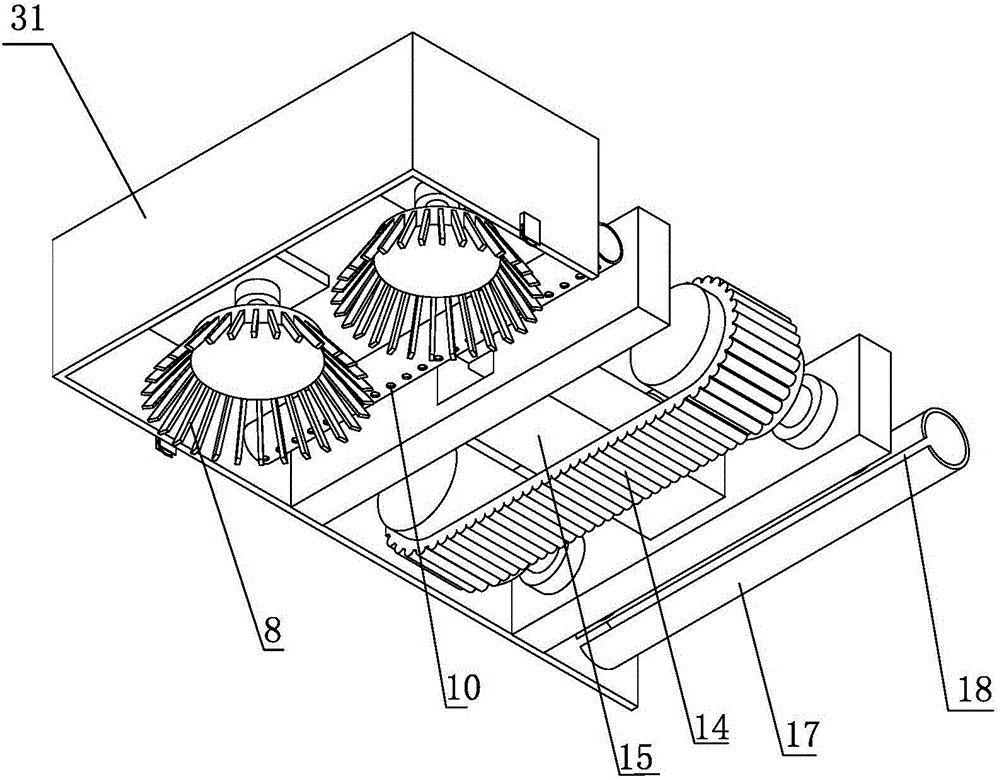

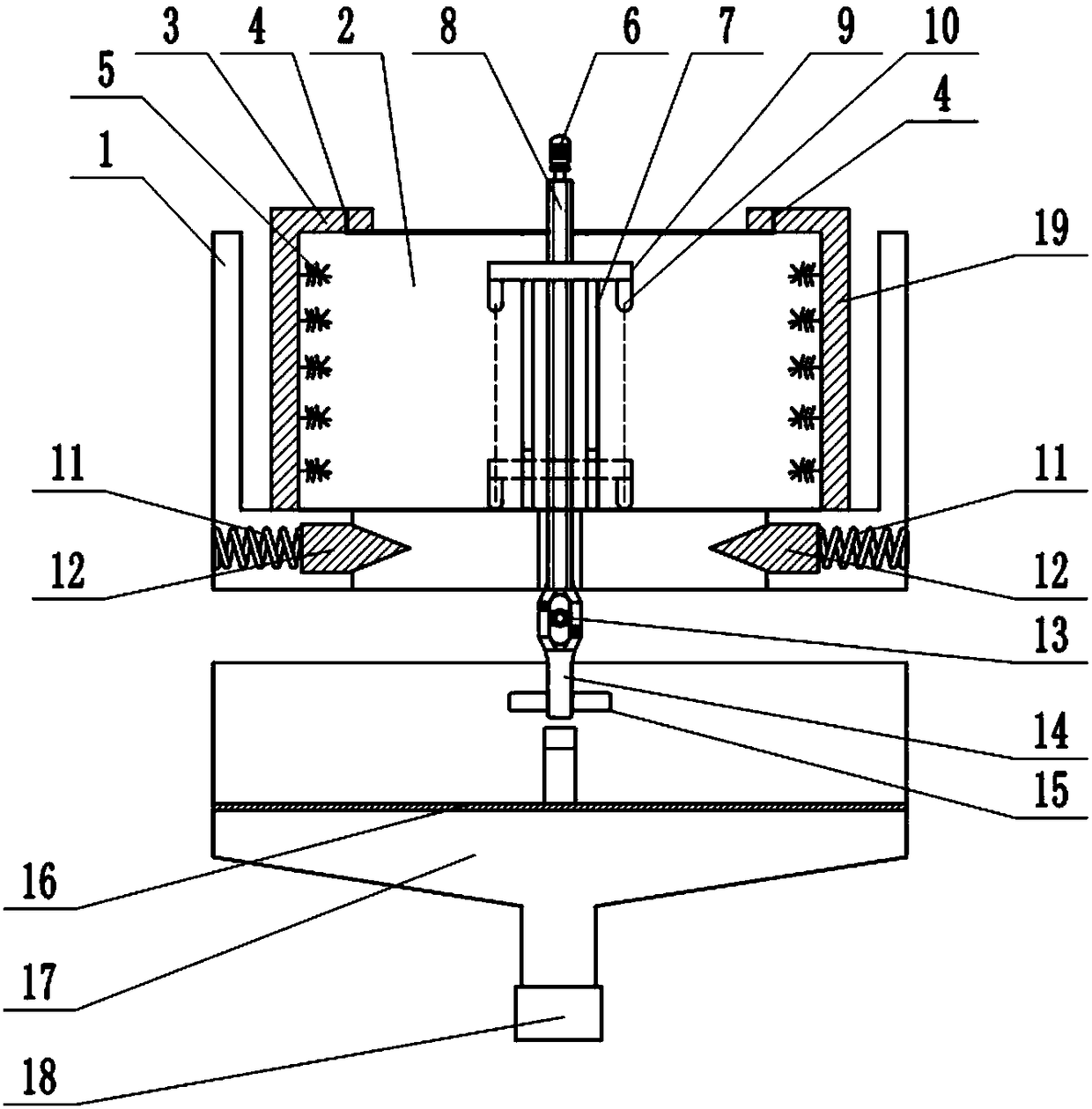

Shoe-washing machine

The invention provides a shoe-washing machine. The shoe-washing machine comprises a water-containing barrel, as well as an inner impeller and an outer impeller which are arranged inside the water-containing barrel, wherein the inner impeller is fixedly arranged in the central position of the bottom of the water-containing barrel, and the outer impeller is rotatably arranged on the periphery of the inner impeller; a central hairbrush is arranged on the inner impeller, and a barrel wall hairbrush is arranged on the inner wall of the water-containing barrel. According to the shoe-washing machine, two impellers, namely, the inner impeller and the outer impeller are arranged inside the water-containing barrel, the inner impeller is fixedly arranged in the central position of the bottom of the water-containing barrel, the outer impeller is rotatably arranged on the periphery of the inner impeller, the central hairbrush is arranged on the inner impeller, and the barrel wall hairbrush is arranged on the inner wall of the water-containing barrel. In the washing state, the outer impeller rotates to drive shoes to move, in the moving process of the shoes, the shoes have contact friction with the fixed central hairbrush so as to be washed, and meanwhile, the barrel wall hairbrush can rub the other sides of the shoes, so that the washing effect is further improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

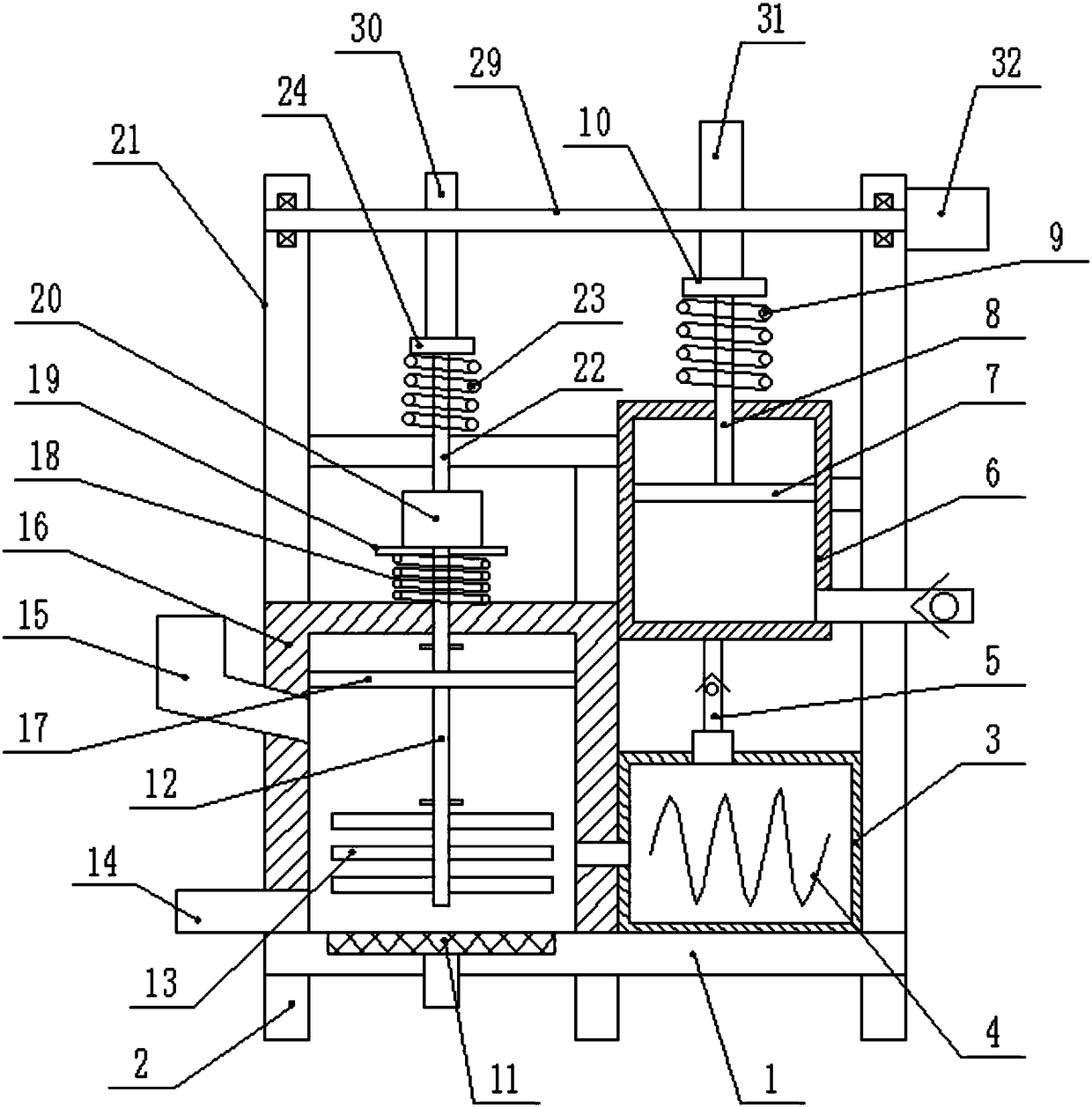

Household waste pretreatment device and pretreatment method adopting same

ActiveCN111659711AAchieve dehydrationAchieve liquefactionTransportation and packagingSolid waste disposalPretreatment methodHeat conducting

The invention discloses a household waste pretreatment device and a pretreatment method adopting same and belongs to the technical field of waste pretreatment. The household waste pretreatment devicecomprises a base, an outer cylinder arranged on the upper side of the base, a plurality of far-infrared heating pipes arranged on the inner wall of the outer cylinder in an annular array, an annular baffle plate arranged on the inner side of the outer cylinder and an inner cylinder arranged on the inner side of the annular baffle plate; the outer cylinder and the base are connected through a plurality of supporting legs for supporting; the upper part of the outer cylinder is open; the lower part of the outer cylinder is closed; a water outlet is formed in the lower part of the outer cylinder;a water discharging valve is mounted on the water outlet; the annular baffle plate is connected with the supporting legs through a plurality of groups of heat conducting connecting rods; the upper part and the lower part of the annular baffle plate are open; the upper part of the inner cylinder is open; the lower part of the inner cylinder is closed; a plurality of water draining holes are uniformly formed in the circumferential surface of the inner cylinder. The household waste pretreatment device skillfully integrates smashing, drying and solid-liquid separation and is skillful in concept.

Owner:JIANGSU HEHAI WATER SUPPLY & DRAINAGE EQUIP CO LTD

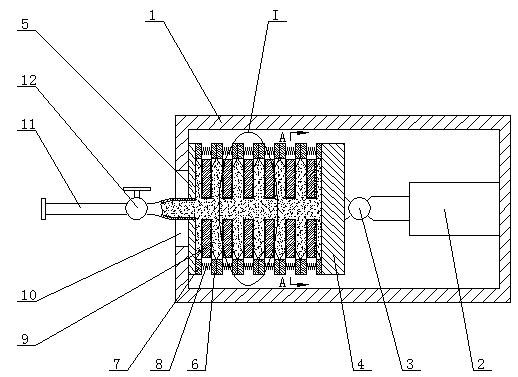

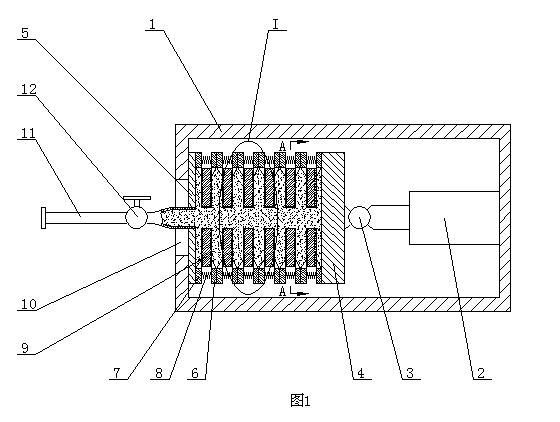

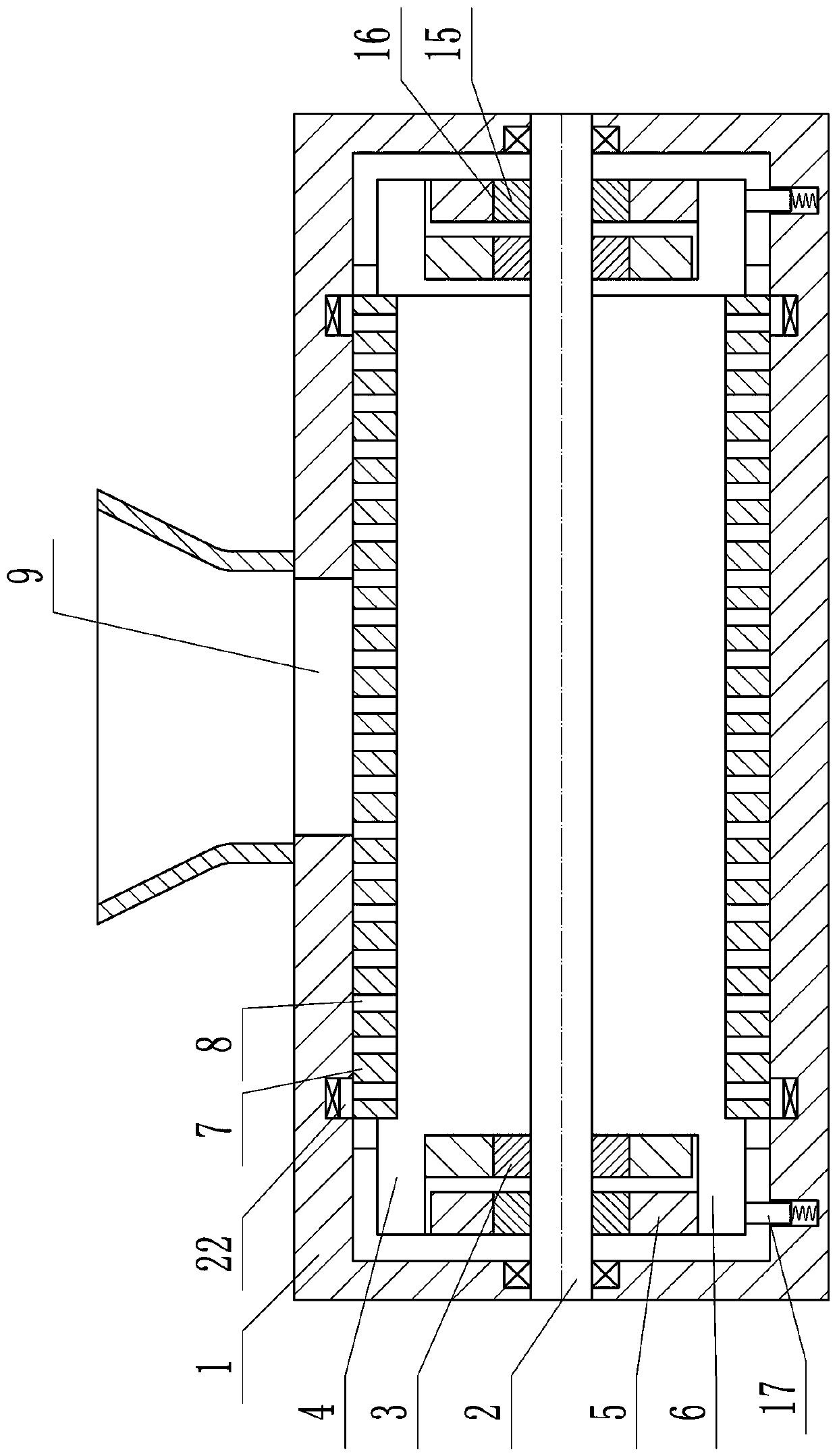

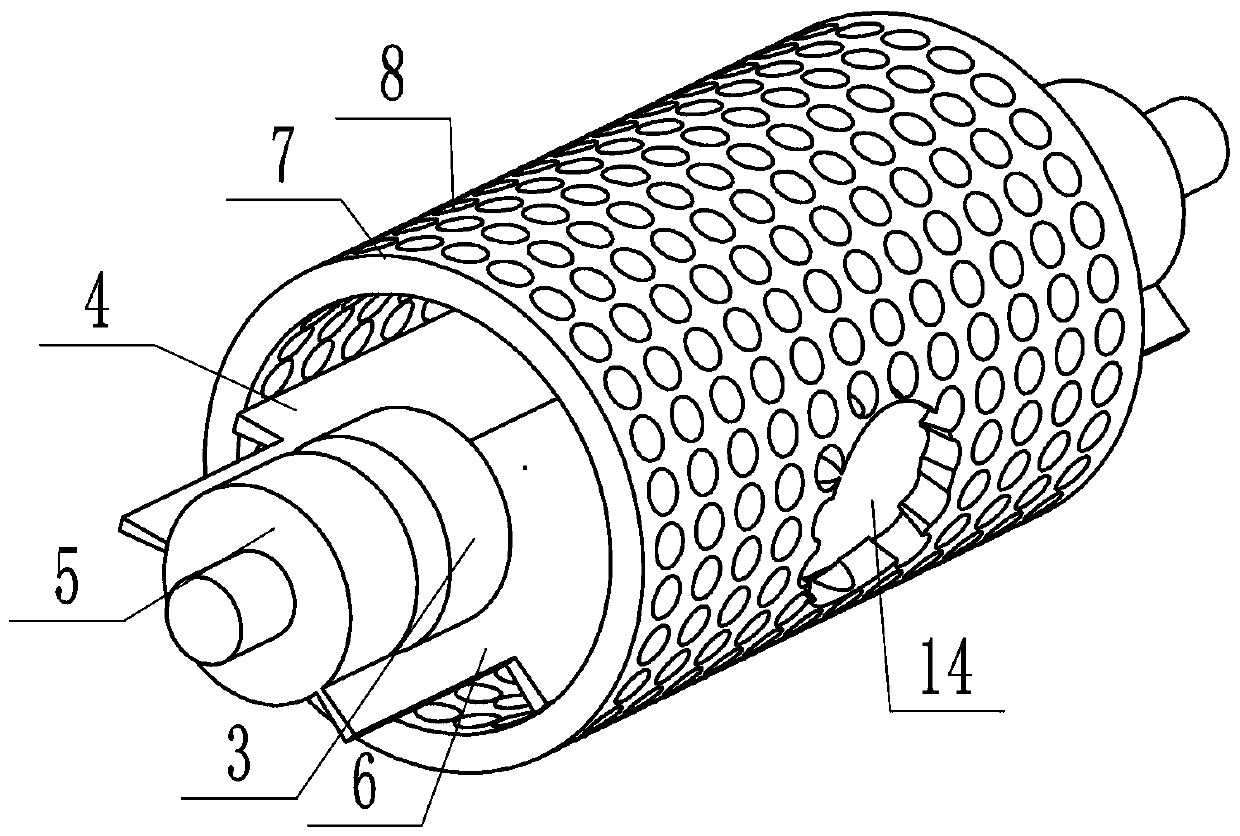

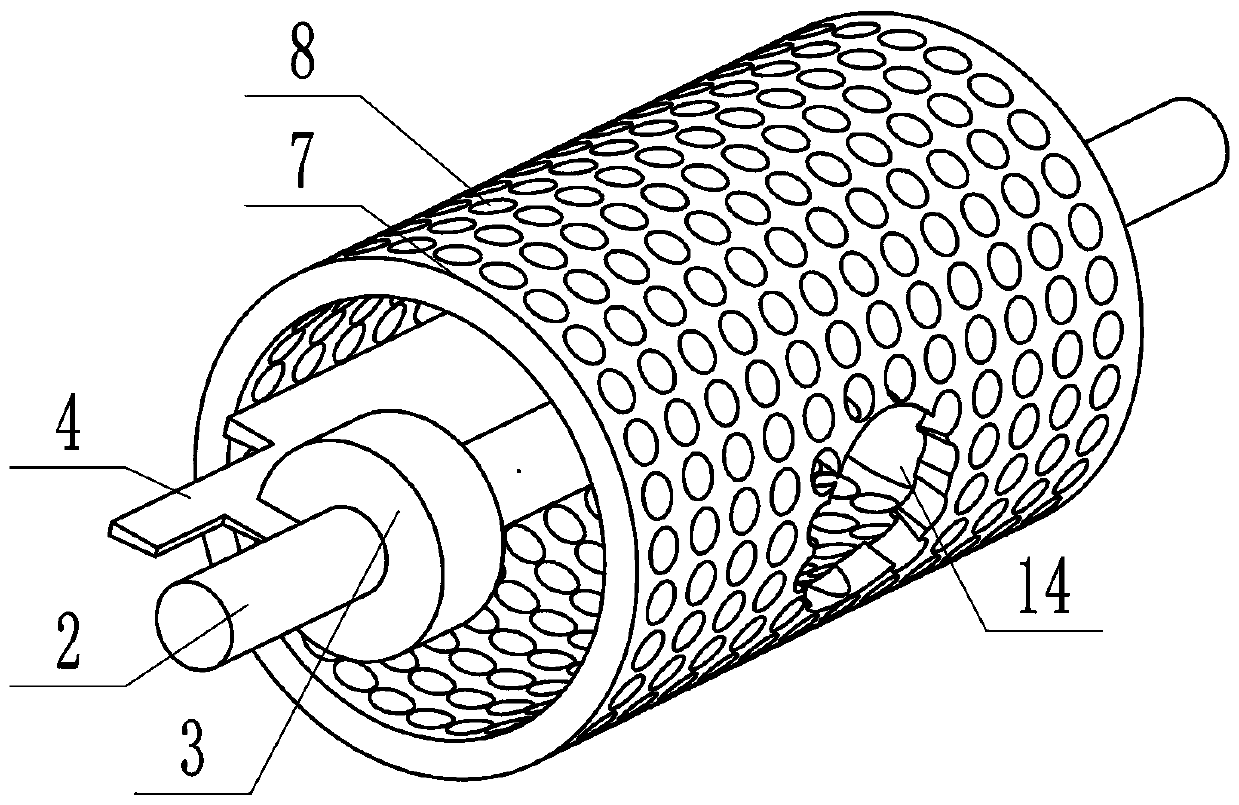

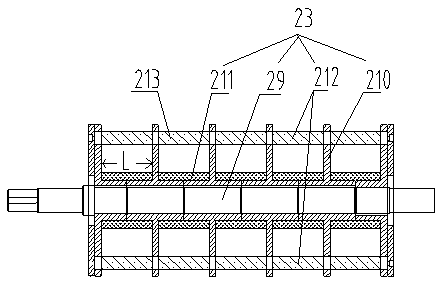

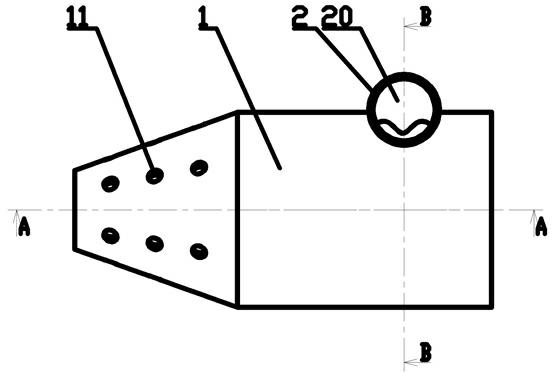

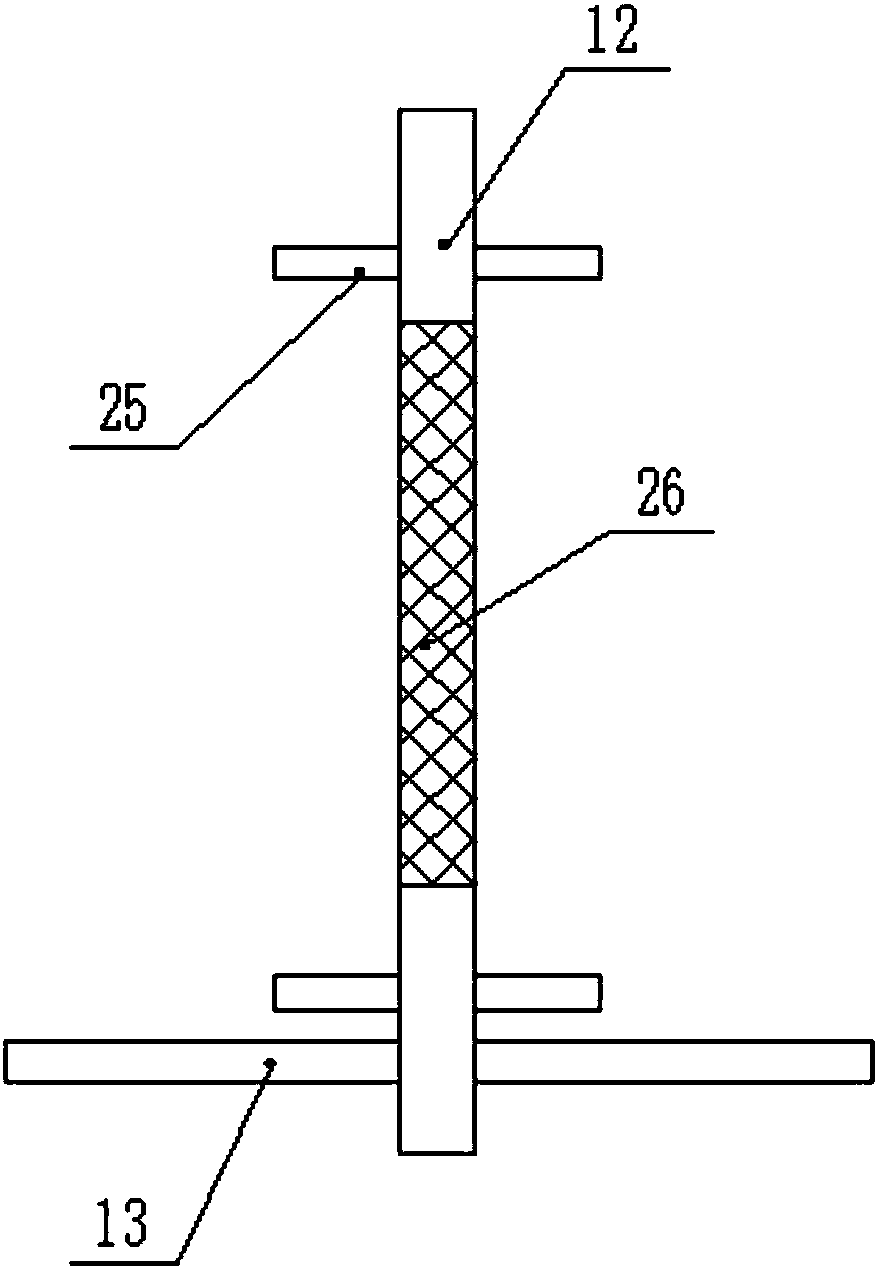

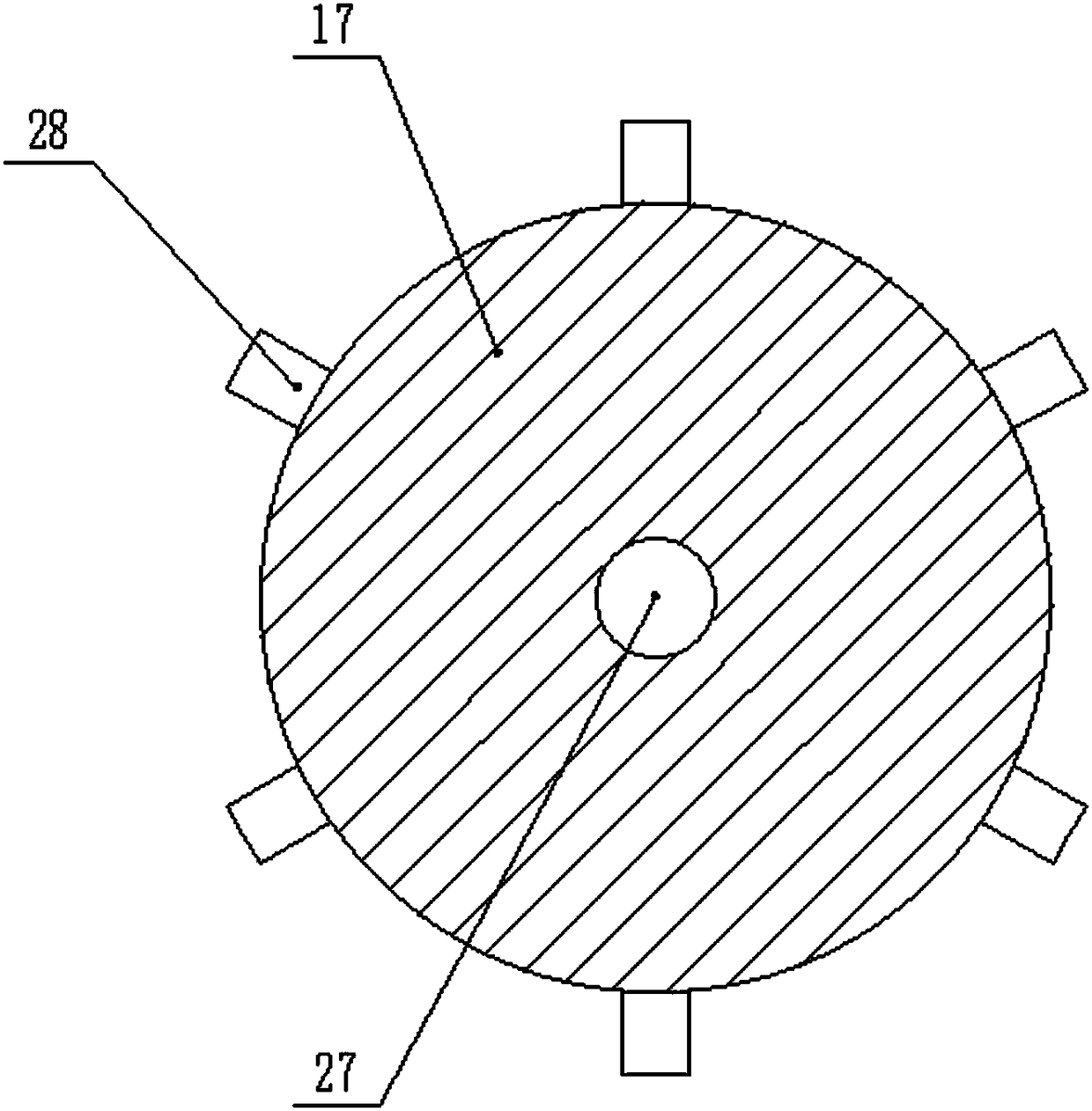

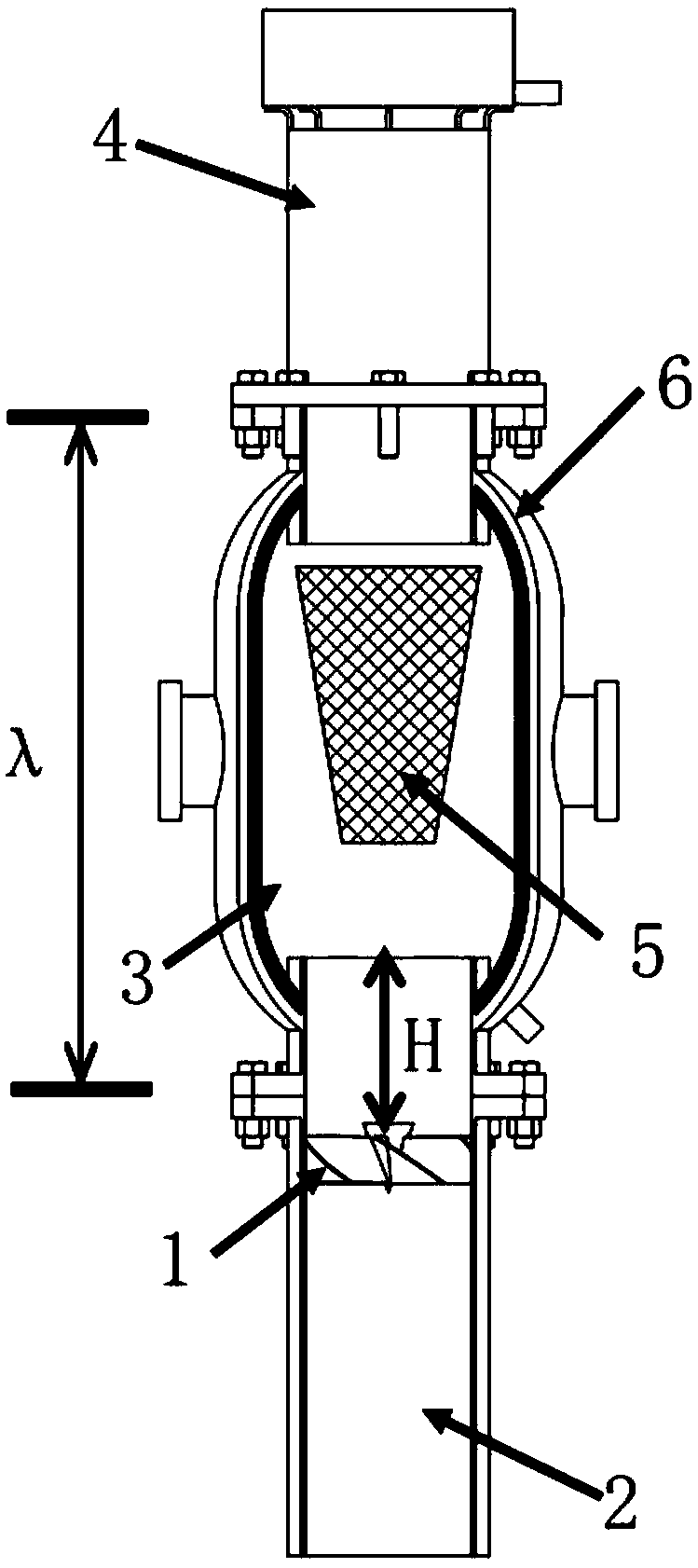

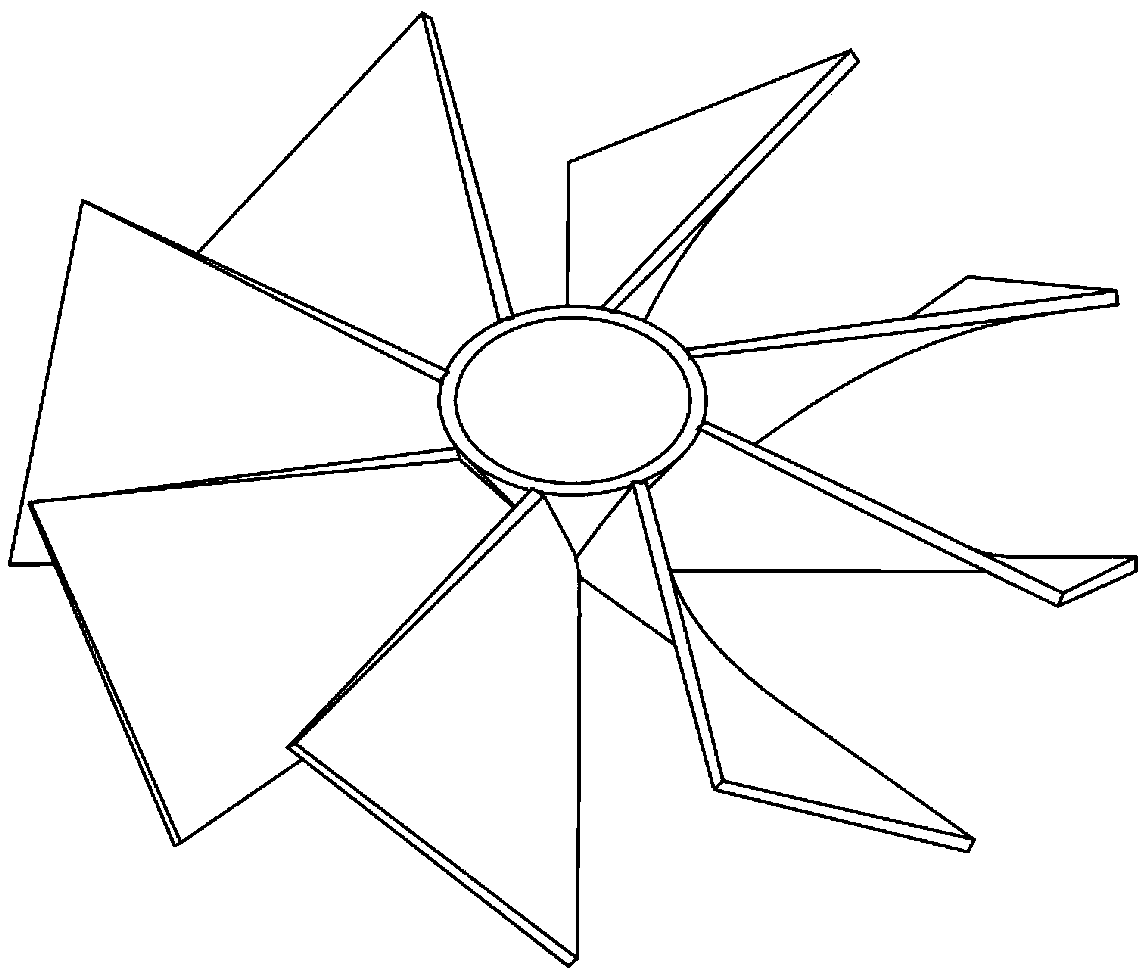

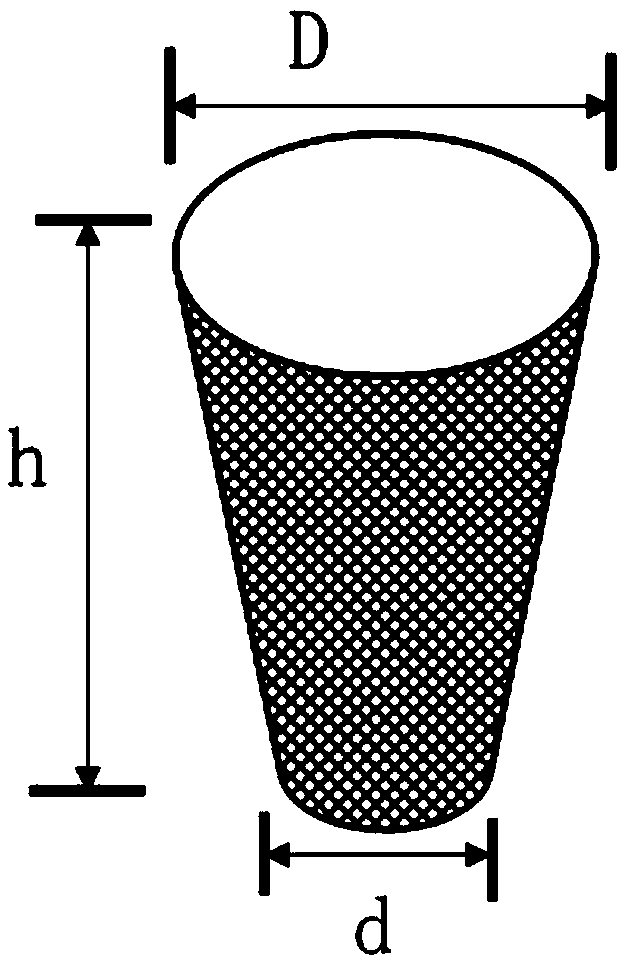

Extrusion type sludge dewatering device

ActiveCN109775954AAchieve dehydrationImprove dehydration efficiencySludge treatmentSewageEngineering

The invention relates to an extrusion type sludge dewatering device, and solves the problems that the water content of mud cakes cannot be ensured, the filter pressing efficiency is low, the working strength is large, and the energy dissipation is high in the prior art. According to the technical scheme, the extrusion type sludge dewatering device comprises a drum, wherein the drum is internally provided with a rotating shaft, the rotating shaft is provided with a first rotating block, the first rotating block is provided with a first extrusion plate, the rotating shaft is provided with a second rotating block, and the second rotating block is provided with a second extrusion plate; the drum is internally provided with an inner bucket, the inner bucket is provided with liquid outlet holes,each liquid outlet hole is internally provided with a filter net, the drum is provided with a feed port, the drum is provided with a rotating block, the rotating block is provided with through holes,the rotating block is provided with clamping blocks, the inner bucket is provided with a check block, the drum is provided with a discharge port, the discharge port is provided with a pressure switch, and the drum is provided with a fixing device; the first extrusion plate is fixed, the second extrusion plate rotates to extrude sludge, the inner bucket rotates, the rotating block rotates, the feed port is opened, the sewage enters into the feed port, the discharge is opened, and the sewage falls off; the inner bucket rotates and resets, the feed port is closed, the first extrusion plate rotates, and the second extrusion plate is fixed; efficient dewatering of the sludge can be achieved.

Owner:JIANGSU XINGXIN SEPARATION EQUIP MFR

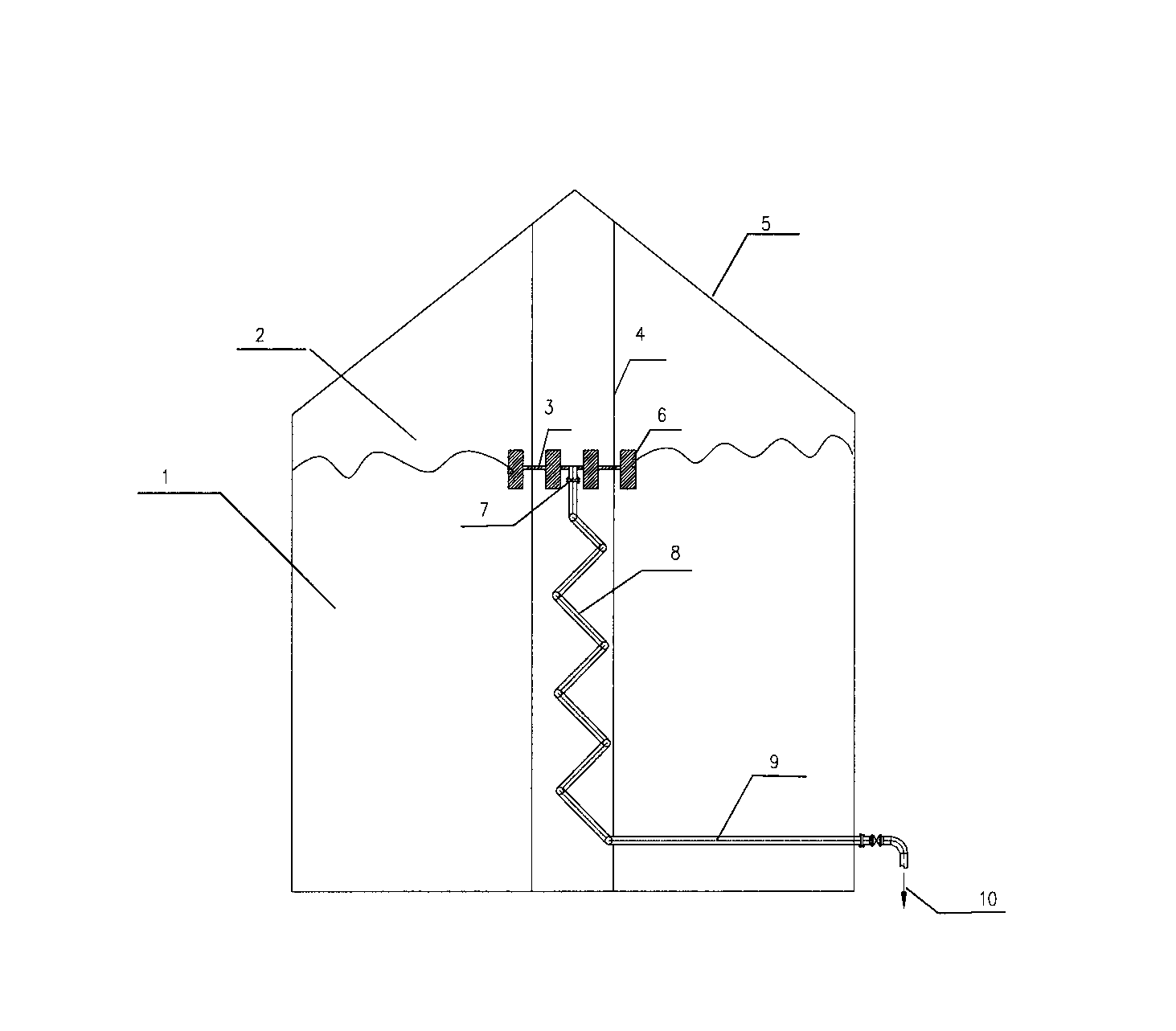

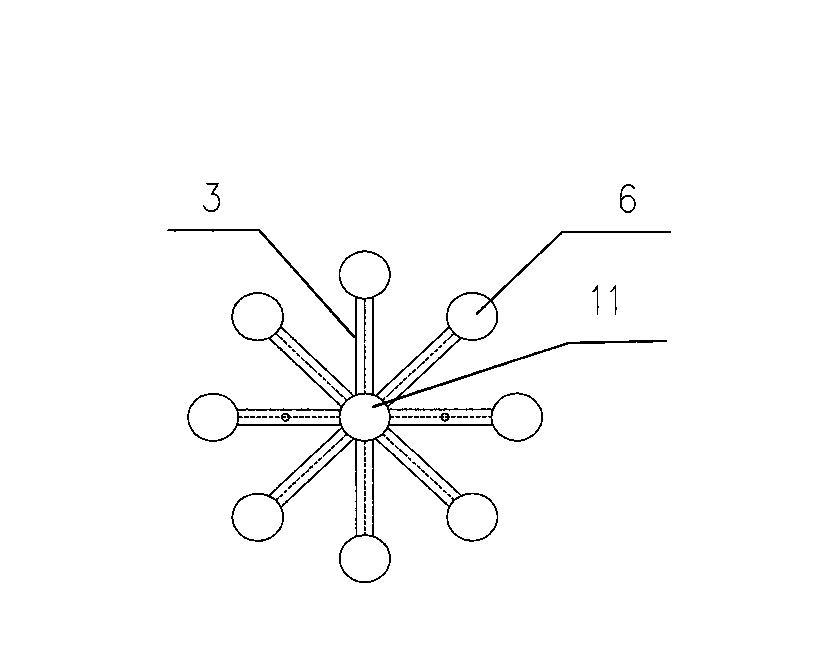

Heavy oil storage tank dehydration device

ActiveCN104046379AAchieve dehydrationSimple structureHydrocarbon oil dewatering/demulsificationStraight tubeBiochemical engineering

The invention discloses a heavy oil storage tank dehydration device which is composed of a float (6), a drainage folding tube (8), a guide bar (4), a balance arm (3) and a drainage straight tube (9). The middle of the balance arm is provided with a water inlet (11) which is communicated with one end of the drainage folding tube (8), and the other end of the drainage folding tube (8) is communicated with the drainage straight tube (9). The float (6) is communicated with the balance arm (3) which moves along the guide bar (4). The equipment provided by the invention has a simple structure, is convenient to install, has less investment, and is convenient to operate.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Multifunctional floor cleaning device

ActiveCN106175610AAchieve cleaningImprove efficiencyCarpet cleanersFloor cleanersWater dischargeEngineering

The invention provides a multifunctional floor cleaning device, aiming at solving the technical problems of the prior art that it is complex in process and is time-consuming and labor-consuming when cleaning floor. The multifunctional floor cleaning device comprises a front cleaning portion, a middle connecting portion and a rear device portion, wherein the front cleaning portion comprises a fixed shell, a cleaning mechanism, a watering mechanism, a mopping mechanism and a blow-drying mechanism; the middle connecting portion is mainly in charge of connecting the front cleaning portion and the rear device portion; the middle connecting portion comprises a loop bar, a dust suction tube, a water discharging pipe, a blow-off pipe and an air intake pipe; and the rear device portion comprises a mounting box, a dust collector, a water intake pump, a water suction pump, an air compressor, a water tank and a blow-off box. With the implementation of the multifunctional floor cleaning device disclosed by the invention, functions of cleaning the floor, mopping the floor and blow-drying the floor can be simultaneously achieved; and in addition, by cleaning dead angles by virtue of a local cleaning device, the multifunctional floor cleaning device is high in efficiency and is labor-saving.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

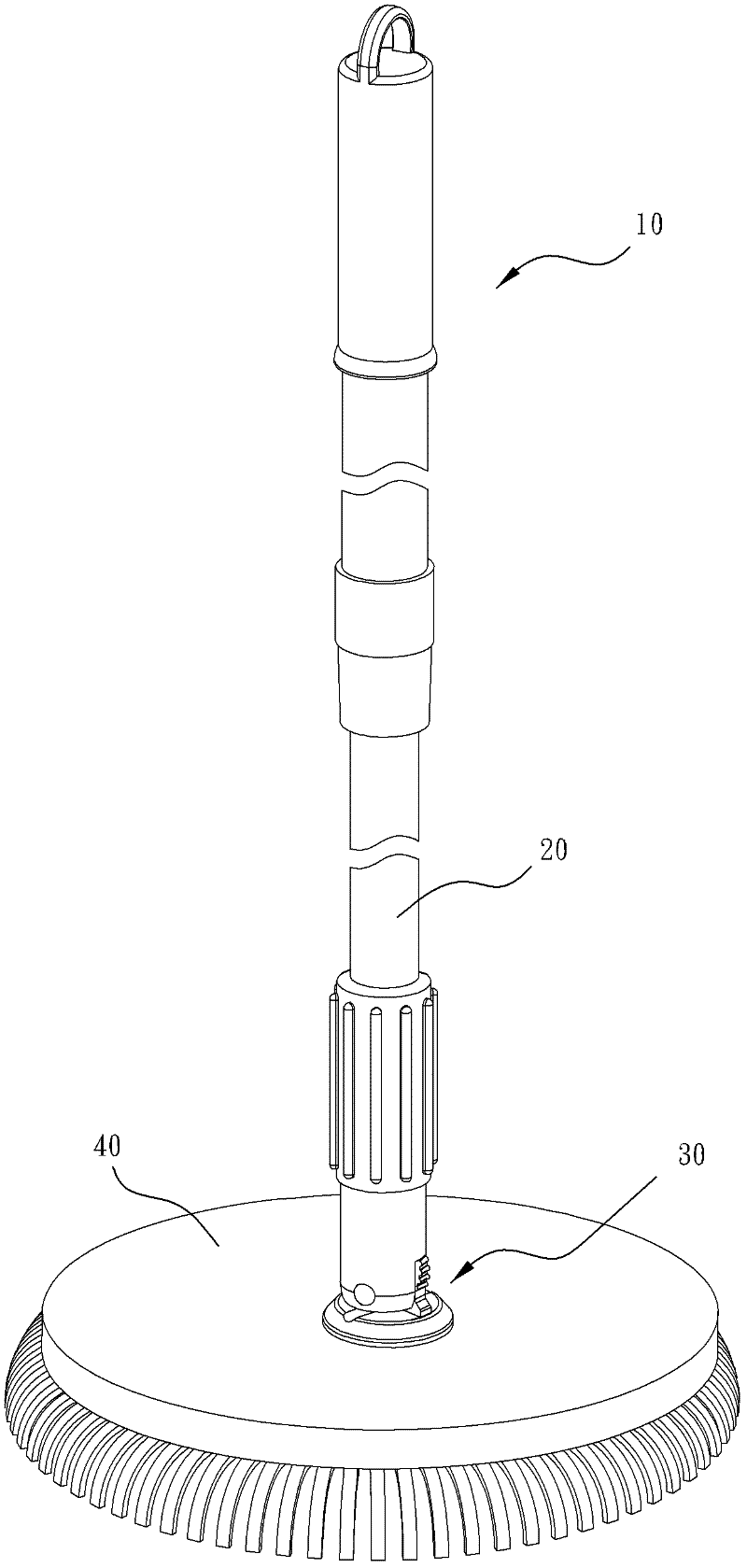

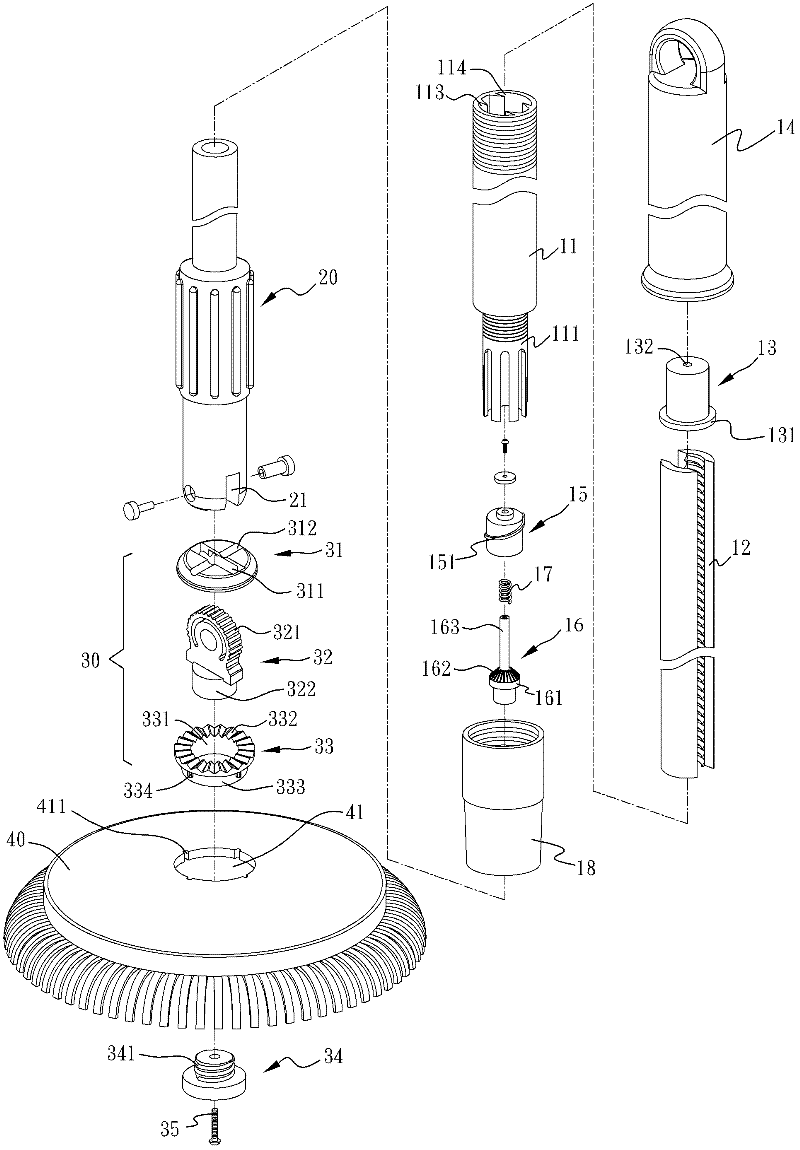

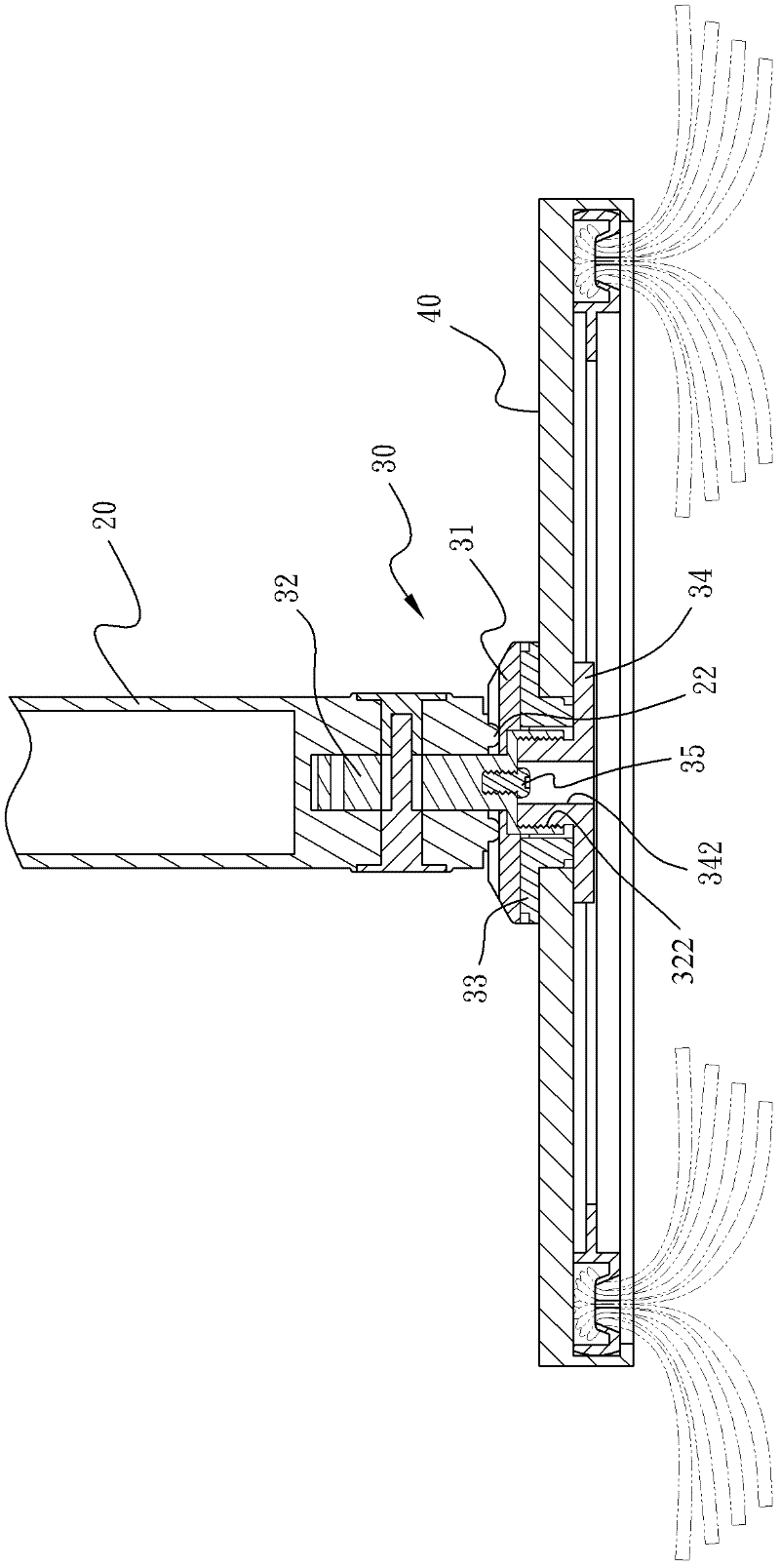

Spiral driving device and mop using same

ActiveCN102389282AOvercome the shortcoming of short service lifeAchieve dehydrationCarpet cleanersFloor cleanersClutchEngineering

The invention relates to a spiral driving device and a mop using the same. The spiral driving device comprises an outer pipe, a sleeve, a guide screw block, a connecting rod and a driven piece, wherein two pairs of convex ribs are longitudinally arranged on the inner wall of the outer pipe, and a dovetail groove is formed between each pair of convex ribs; a dental plate with threads on one inner surface is inserted and clamped in each dovetail groove, and the sleeve is coaxially arranged at the top end of the outer pipe in a locking way; the guide screw block is clamped between the two dental plates, and the connecting pipe is axially inserted in the outer pipe; and the driven piece is fixedly arranged at the top end of the connecting rod, and is selectively driven by the guide screw block and rotates together with the connecting rod. In the invention, the spiral driving device with an automatic clutch function is utilized to drive the mop to rotate at high speed so as to achieve the dehydration object by centrifugal force generated by high-speed rotation; and the invention overcomes the defects that the usual self-rotating mop is easily damaged and the service life of a one-way bearing is short.

Owner:林义斌

Aluminum scrap recycling device

ActiveCN105522434AReduce energy consumptionIncrease productivityMagnetic separationMaintainance and safety accessoriesMagnetic separatorEngineering

The invention relates to an aluminum scrap recycling device which comprises a duplex packing auger, a crusher, a dehydrator, a magnetic separator, a dryer and a melting tank, wherein a first spreading plate lifter is arranged between the duplex packing auger and the crusher; a second spreading plate lifter is arranged between the crusher and the dehydrator; a third spreading plate lifter is arranged between the dehydrator and the magnetic separator; and a fourth spreading plate lifter is arranged between the magnetic separator and the dryer. The aluminum scrap recycling device is used for recycling aluminum scraps, is low in energy consumption, is high in production efficiency, is safe and reliable, and saves cost.

Owner:ZHENJIANG YUJIU INTELLIGENT EQUIP LTD BY SHARE LTD

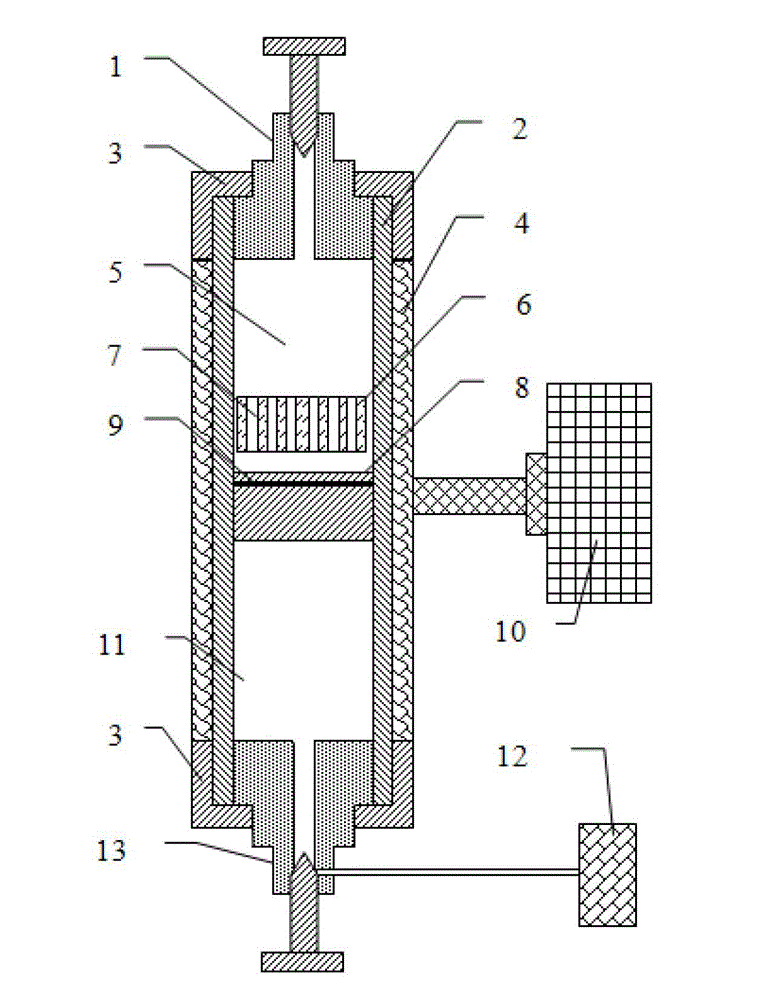

Device and method for dehydrating crude oil

InactiveCN102876354AFast layeringEasy to drainHydrocarbon oil dewatering/demulsificationControl systemReciprocating motion

The invention relates to a device and a method for dehydrating crude oil. The device mainly comprises a reaction kettle, a crude oil sample cavity, a stirrer, a piston and a pressure transferring liquid cavity; the reaction kettle is divided by the piston into the crude oil sample cavity and the pressure transferring liquid cavity; the stirrer is arranged in the crude oil sample cavity; a heating thermal insulation sleeve is arranged outside the reaction kettle; the reaction kettle is connected with a rotation and control system; and the pressure transferring liquid cavity is connected with a power system. According to the device, the crude oil to be treated is heated and pressurized by the reaction kettle; the reaction kettle rotates in the vertical direction to drive the stirrer to do reciprocating motion in the crude oil to be treated, so that the crude oil is subjected to mechanical demulsification and dehydrated; and the physical and chemical properties of the dehydrated crude oil cannot be influenced. A principle is reliable; the device and the method are convenient to operate; any chemical agent is not needed to be added; the phenomenon that the dehydrated crude oil hangs on a wall can be reduced; in-place oil compound composition experiment can be directly performed; the high temperature and high pressure physical characteristics of the crude oil can be kept; and the device and the method can be used for relative industry of performance test of the crude oil.

Owner:SOUTHWEST PETROLEUM UNIV

Fruit cleaning device

InactiveCN108125260AEasy to dischargeIncrease productivityFood treatmentBatch productionAgricultural engineering

The invention belongs to the technical field of fruit processing, and particularly discloses a fruit cleaning device. The fruit cleaning device comprises a machine frame and a cleaning mechanism, wherein the cleaning mechanism comprises an outer cylinder and an inner roller; a plurality of vertical rods and a plurality of horizontal rods are arranged on the side wall of the inner roller; magnets are respectively arranged on the outer cylinder and the vertical rods; a plurality of brushes are respectively arranged on each of the vertical rods; a rotating shaft is connected to a driving mechanism; a transmission shaft is connected to the bottom of the rotating shaft through a universal joint; a push rod is in threaded connection to the rotating shaft; a guide rail is connected to the push rod; a telescopic rod is arranged at the bottom of the guide rail; press blocks are symmetrically arranged at two ends of the push rod; an annular door is arranged at the bottom of the outer cylinder; ablind hole is formed in the bottom of the outer cylinder; a tapped block is connected to the blind hole through a spring; a groove is formed in the annular door; a lug is arranged at the bottom of the transmission shaft; a discharging mechanism is arranged just below the cleaning mechanism; a feeding opening is formed in the top of a discharging cavity of the discharging mechanism; a mesh screenis arranged at the middle part of the discharging cavity; and a water collecting tank is connected to the bottom of the discharging cavity. Through adoption of the technical scheme of the fruit cleaning device disclosed by the invention, the problems of being poor in fruit cleaning effect, low in efficiency and not suitable for batch production are solved.

Owner:重庆市长寿区石猫儿农业有限公司

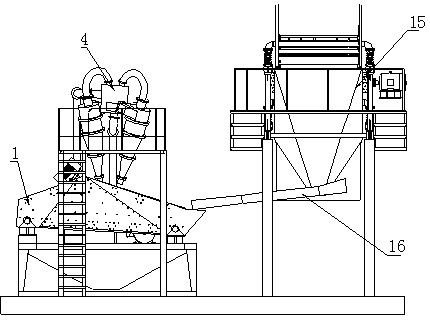

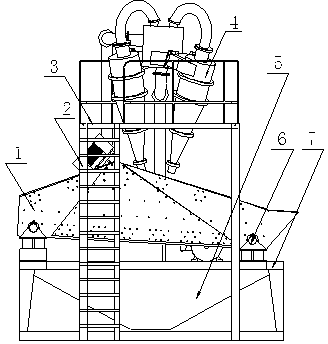

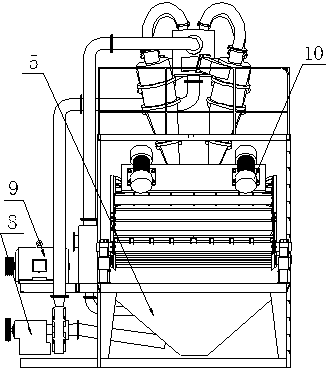

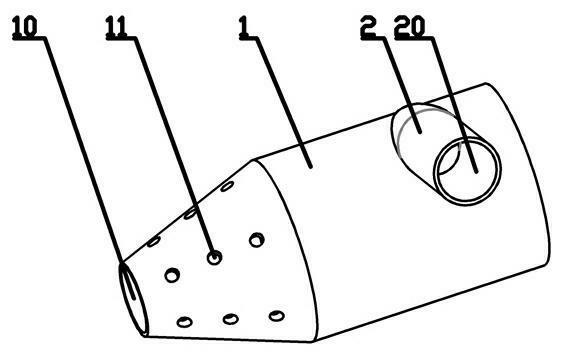

Sand and water separation system and method

ActiveCN103212243AAchieve separabilityAchieve dehydrationFiltration circuitsMoving filtering element filtersWater storageMotor drive

The invention relates to a sand and water separation system and method, can effectively separate mud, water and sand in a mud, sand and water mixture, and also can dehydrate the sand and the water efficiently. The sand and water separation system comprises a dehydration screen, a rotational flow device or a rotational flow device group and a vibrating and screening device; the vibrating and screening device and a wide-amplitude water-storage-type dehydration screen are integrated on a base; the rotational flow device or the rotational flow device group is integrated above the wide-amplitude water-storage-type dehydration screen through a support frame; a sand and water mixture is conveyed between the vibrating and screening device and the wide-amplitude water-storage-type dehydration screen through a sand flowing groove; the wide-amplitude water-storage-type dehydration screen is positioned on a rack through a shock absorber; the wide-amplitude water-storage-type dehydration screen is driven by a shock excitation motor or a cam wheel driving mechanism; a wide-amplitude water storage groove is positioned below the wide-amplitude water-storage-type dehydration screen; a material inlet of the rotational flow device or the rotational flow device group is communicated with an outlet of a slurry pump at the side part of the rack through a conveying pipeline; and the motor drives the slurry pump through a belt driving mechanism.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Snail-like centrifugal ventilation device

InactiveCN102095237AIncrease ventilationImprove work efficiencyLighting and heating apparatusDispersed particle separationAgricultural engineeringSmall hole

The invention discloses a snail-like centrifugal ventilation device, and aims to provide the snail-like centrifugal ventilation device which can improve the ventilation volume of an air purification system and the working efficiency of the system. The snail-like centrifugal ventilation device comprises a main ventilation pipe (1) and an air inducing pipe (2), wherein the front half part of the main ventilation pipe (1) is circular, and the rear half part of the main ventilation pipe (1) is a reducing conical part; a port of the front half part of the main ventilation pipe (1) is sealed, and the port of the rear half part of the main ventilation pipe (1) is an air outlet (10); the side wall of the rear half part of the main ventilation pipe (1) is provided with a plurality of small holes (11); and the air inducing pipe (2) is communicated with the front half part of the main ventilation pipe (1), is perpendicular to the main ventilation pipe (1) and is tangent to the main ventilation pipe (1). The ventilation device can be widely applied to purification systems.

Owner:ZHUHAI FEIPENG PURIFICATION TECH

Additive for sludge deep dehydration

InactiveCN1962495AInterfere with gatheringHamper growing upSludge treatment by de-watering/drying/thickeningSludgeColloid

The invention discloses an additive of deep dehydrated sludge, which consists of 0.3-2% Fe3+ chemical raw material and 0.5-5% Ca2+ chemical raw material. The charge of colloid particle is neutralized with particle unstably, which sediments to filter water.

Owner:GUANGZHOU PUDE ENVIRONMENTAL EQUIP

Method for deeply dehydrating sludge

InactiveCN101863611AImprove hydrophilic abilityRepulsive Potential Energy DecreasedSludge treatment by de-watering/drying/thickeningSludge cakeCombustion

The invention relates to a method for deeply dehydrating sludge, which comprises the following two steps of: 1, tempering, namely adding a polymeric flocculant into sludge slurry, stirring for 0.5 to 20 minutes, adding a chemical raw material containing Fe<3+> to perform reaction for 0.5 to 20 minutes with stirring, and adding a chemical raw material containing Ca<2+> to perform reaction for 0.5 to 20 minutes with stirring; and 2, dehydrating, namely introducing the tempered sludge into a filter press to filter off moisture in the sludge, keeping the sludge under the pressure of between 0.1 and 2.5MPa for 15 to 120 minutes, and keeping the sludge under the pressure of between 1.0 and 3.5MPa for 15 to 120 minutes. The method has the advantages of small additive amount of medicament, low cost, simple process and high dehydrating efficiency by combining chemistry and machinery. The moisture content of the dehydrated sludge is reduced to below 65 percent and the combustion calorific value of dry sludge is reduced to less than 10 percent. The dehydrated sludge cake is very suitable for drying and incinerating the sludge and provides beneficial conditions for subsequent treatment and comprehensive utilization.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

Environmentally-friendly automatic medical plastic garbage treating device

InactiveCN108126969AReasonable structureInnovative designSolid waste disposalTransportation and packagingDrive shaftEngineering

The invention discloses an environmentally-friendly automatic medical plastic garbage treating device, which comprises a base. A treating tank is arranged on the left side of the upper end of the base; a rotary shaft is arranged in the treating tank; a lifting plate is in movable threaded connection to the middle of the rotary shaft; a first lifting rod is connected to the upper end of a rotary motor; a heating tank is arranged on the right side of the upper end of the base; the upper end of the heating tank is connected with an air guiding tank through an air guiding pipe; a piston is arranged in the air guiding tank; a second lifting rod is arranged in the middle of the upper end of a piston; support frames are arranged on the left side of the upper end of the treating tank and the rightside of the upper end of the base; and a drive shaft is arranged in the middle of the top end of the support frames through bearings. According to the environmentally-friendly automatic medical plastic garbage treating device provided by the invention, stirring blades can move up and down during a rotation process, so that a smashing effect on medical plastic garbage is improved; and meanwhile, the air guiding tank can feed hot air into the treating box, so that a medical garbage treatment effect is improved, and the medical garbage can be fully dried and drained during a smashing process.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Rear spiral-separation dewatering device for smoke water removal

ActiveCN109621558AAchieve dehydrationGas treatmentDispersed particle separationFlueDisposal Technique

The invention belongs to the technical field of wet method desulfurization technology tail gas dewatering postprocessing, and provides a rear spiral-separation dewatering device for smoke water removal. A water removal pipeline is added on the basis of a smoke water removal device, after smoke enters a smoke inlet to be sequentially dewatered and processed by a spiral-separation blade and the water removal pipeline, gas is discharged out of a smoke outlet, and a water body is discharged out of a drain outlet in the lower portion of the water removal pipeline. In actual work, after the water-containing smoke enters the water removal pipeline through a gas inlet pipeline under the flow guide effect of the spiral-separation device and inverted circular truncated cone-shaped filler, the smokehits wall surface drainage filler, and under the effect of a high-molecular drainage material, liquid drops condense and converge and then flow out of a smoke duct so that the final smoke dewatering aim is achieved.

Owner:中国石油集团东北炼化工程有限公司 +1

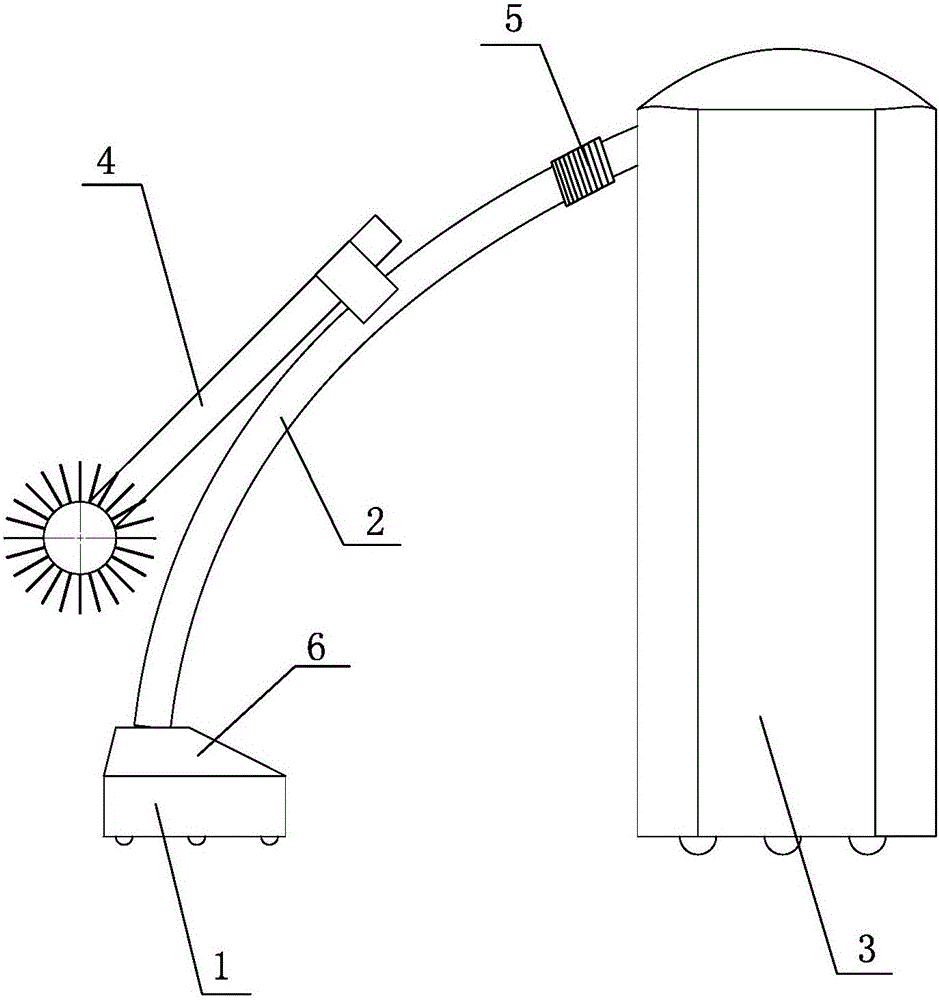

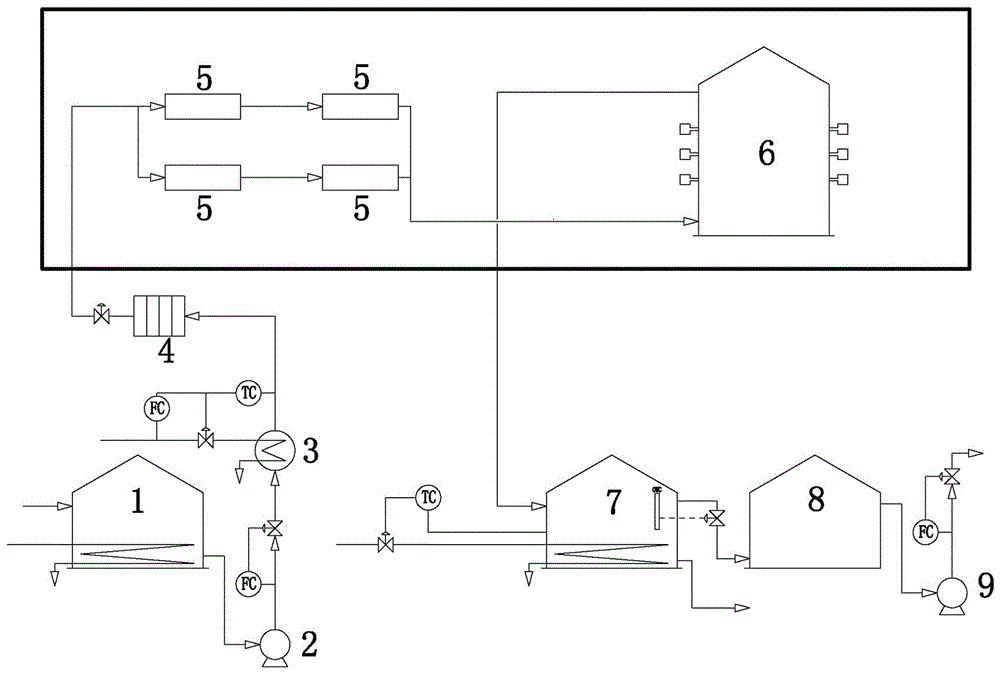

Super-high power ultrasonic sump oil emulsion breaking dehydration method

InactiveCN105776704AAchieve dehydrationAchieve recyclingFatty/oily/floating substances removal devicesWater/sewage treatment with mechanical oscillationsUltrasound - actionOil emulsion

The invention discloses a super-high power ultrasonic sump oil emulsion breaking dehydration method.The method comprises the steps that water-containing sump oil in a sump oil stock tank (1) is preheated and pressurized through a water-containing sump oil pump (2) and fed into a sump oil heater (3) to be heated to 50-85 DEG C; the heated water-containing sump oil is fed into an ultrasonic actuator (5) for continuous ultrasonic initial emulsion breaking; the sump oil obtained after initial emulsion breaking is fed into a pulse type ultrasonic emulsion breaking tank (6) through a pipeline for secondary emulsion breaking; the water-containing sump oil obtained after secondary emulsion breaking flows into a settlement separation dehydration tank (7) to be heated to 40-80 DEG C for settlement and layering to obtain sump oil, sewage and solid flocculent impurities; the sump oil located at the upper portion of the settlement separation dehydration tank (7) automatically flows into a finished sump oil tank (8); sewage and impurities enter a settling pond from the bottom of the settlement separation dehydration tank (7) through a sewage disposal well.According to the two-time ultrasonic emulsion breaking, sump oil dehydration is achieved, the sump oil dehydration rate is larger than 90%, and the sewage oil content is smaller than 500 mg / L.

Owner:JIANGSU DAXUAN PETROCHEM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com