Comprehensive utilization method of low metamorphic bituminous coal

A low-metamorphic, bituminous coal technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of high energy consumption and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A specific embodiment of a comprehensive utilization method of low-metamorphic bituminous coal of the present invention is mainly introduced in detail below.

[0052] Part 1 Particle Size Control of Low Metamorphic Bituminous Coal

[0053] Before the dehydration and drying of low metamorphic bituminous coal and lignite, the mixed coal material between 0 and 60mm can be selected by the particle size controller. Research shows that the dehydration and drying of low metamorphic bituminous coal and lignite within this particle size range can be fully dried and the dehydration efficiency is high. But this does not constitute a limitation to the low-modified bituminous coal and lignite required by the present invention, and the present invention is also applicable to low-modified bituminous coal and lignite with a particle size larger than 60mm.

[0054] Part II Dehydration of Low Metamorphic Bituminous Coal

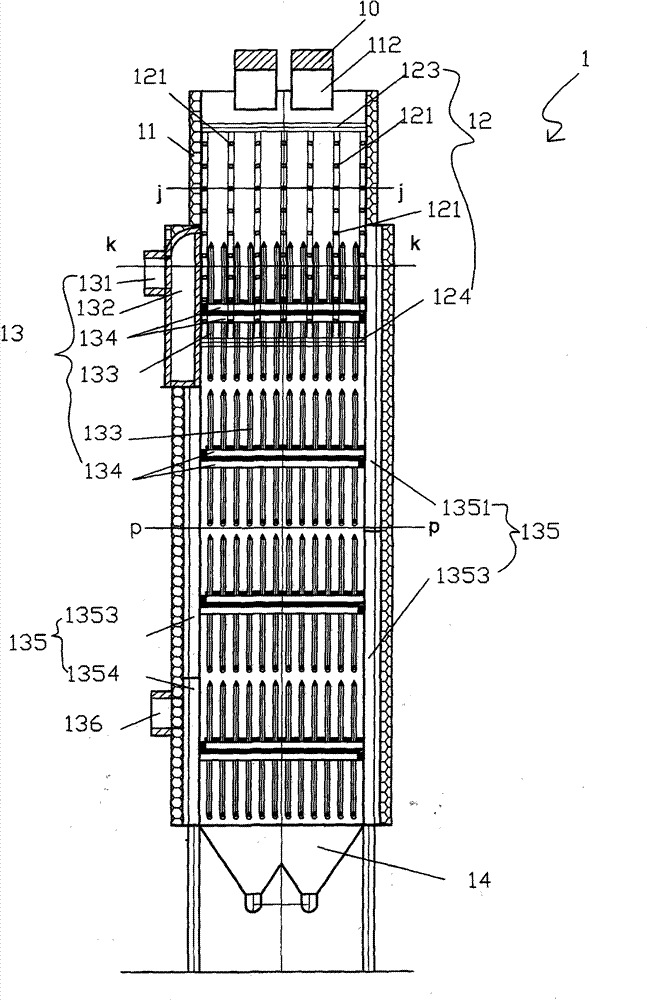

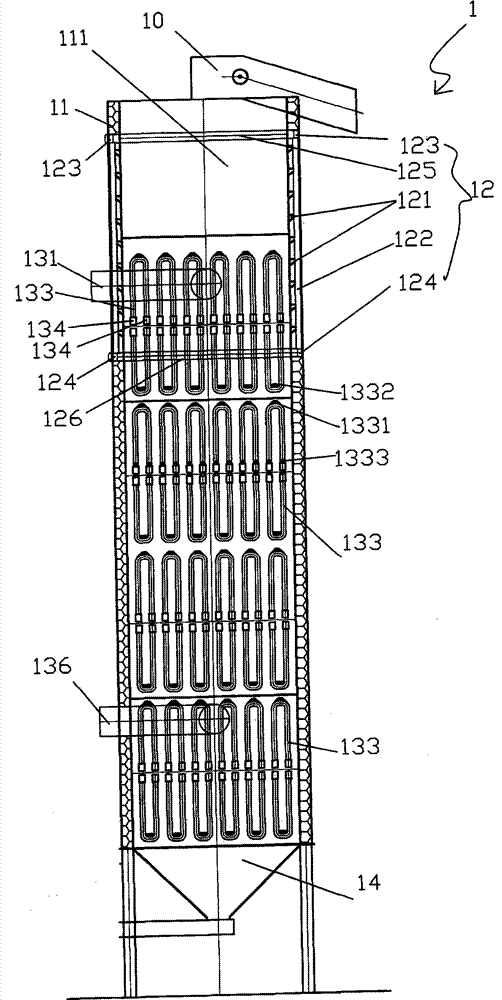

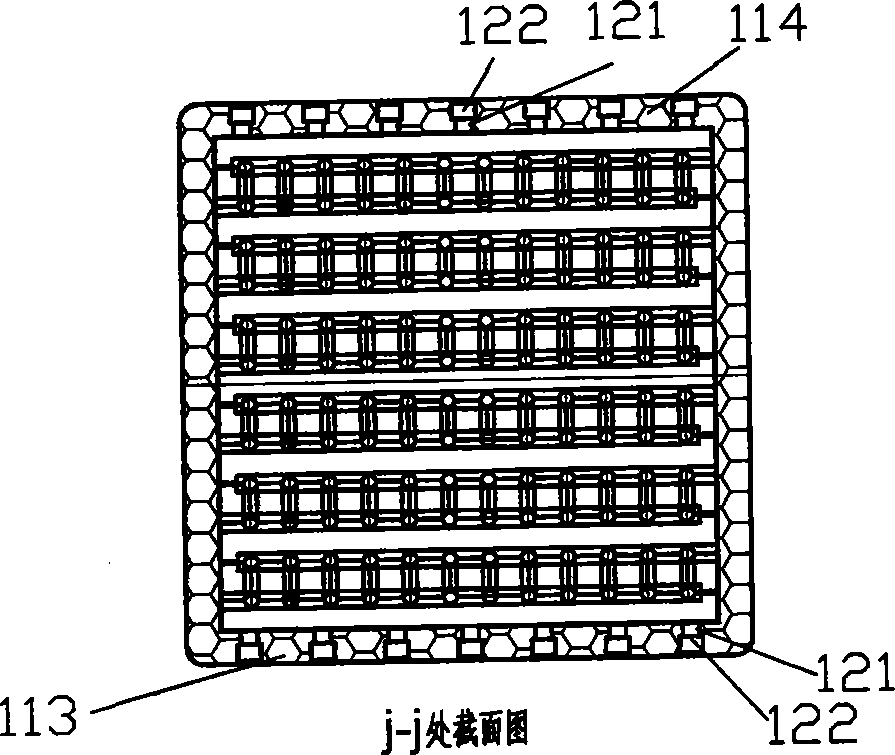

[0055] Such as figure 1 , figure 2Shown: a hot waste gas dehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com