Patents

Literature

50results about How to "To achieve the purpose of dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supercritical dewatering and drying method for small water-saturated bamboo and wood articles

InactiveCN103331793ATo achieve the purpose of dehydrationClear wood grainWood treatment detailsWood impregnation detailsSupercritical dryingPulp and paper industry

The invention relates to a supercritical dewatering and drying method for small water-saturated bamboo and wood articles, belonging to the technical field of dewatering protection for cultural relics. The small water-saturated bamboo and wood articles of which the length, the width and the height are respectively at most 20cm are respectively soaked for certain time in three kinds of ethanol with different concentrations, then the supercritical drying method is adopted, and therefore the water of the water-saturated bamboo and wood articles is gradually replaced to achieve the purpose of dewatering. Compared with the prior art, the supercritical dewatering and drying method has the advantages that the purpose of dewatering of the water-saturated bamboo and wood articles can be achieved without filling chemical materials; the dewatered bamboo and wood articles have clear wood grains, and the color tends to be normal; the dewatered bamboo and wood articles have good stability under the condition of temperature and humidity fluctuation, and each shrinking percentage is within 5 percent; the complete shape of the cultural relics can be completely ensured, and the method conforms to the basic principle, namely the minimal intervention to protection of the cultural relics; the method has high research and extension values and significance.

Owner:荆州文物保护中心

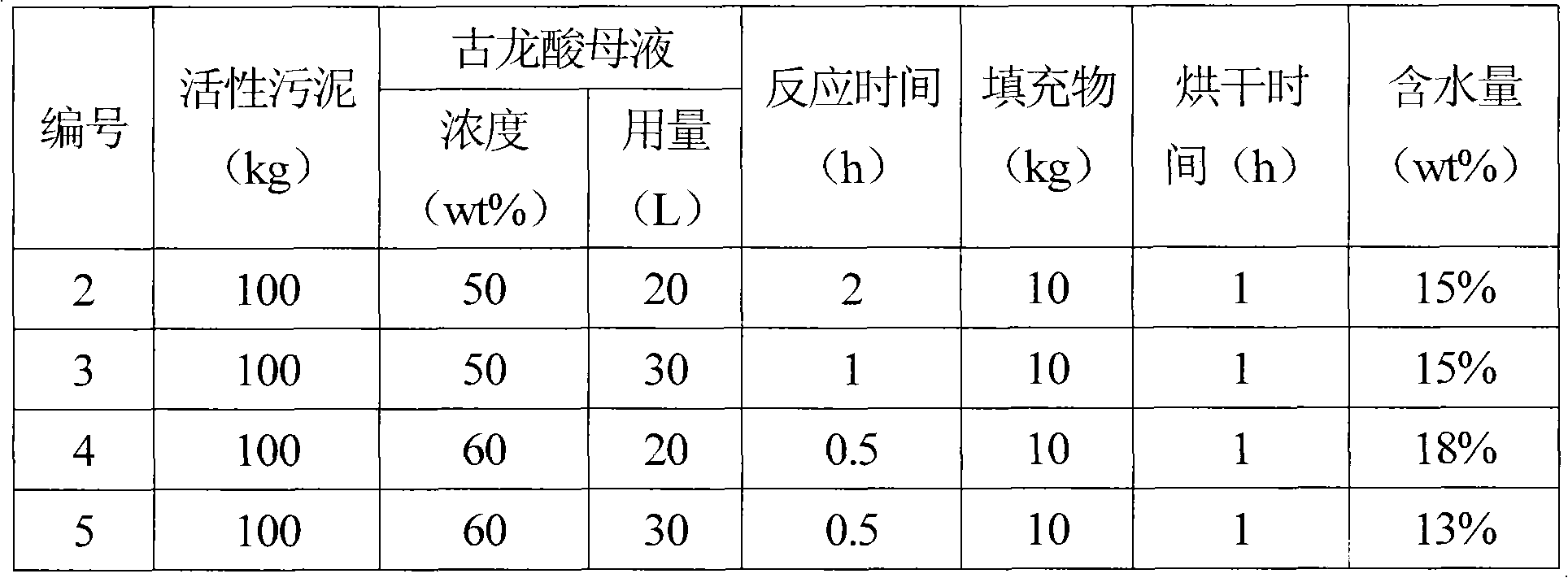

Method for deep dehydration of residual activated sludge

InactiveCN101781074ATo achieve the purpose of dehydrationAchieving processing powerBio-organic fraction processingSludge treatment by de-watering/drying/thickeningActivated sludgeIntensive treatment

The invention relates to a method for deep dehydration of residual activated sludge, particularly to a novel technique for realizing deep dehydration of residual activated sludge by applying waste organic acid mother liquor. The method is as follows: collecting the residual activated sludge which is dehydrated mechanically, adding 20-50% of waste organic acid mother liquor based on weight of the residual activated sludge, mixing the mixture to be slurry, putting the slurry into a reaction kettle and heating to 60-100 DEG C for reaction for 0.5-5h, during which the living biological substances contained in the sludge are decomposed, the protein denatures and the bound water in the sludge changes to be free water and exudes; and after the reaction is finished, transferring the resultants into a mixing pool, adding plant debris and the like which serve as fillers, when the mixture turns to be thick catsup, putting the mixing pool into a drying device, and drying until the water content is 10-20wt% to get dry sludge. After heavy metal content detection, the dry sludge can be classified into different grades to be used as compost for farmers or to be as fuel for fuel suppliers. The invention solves the problems that due to high water content, the residual activated sludge is difficult to be effectively used in the prior art, and the method is suitable for large-scale intensive treatment and reclamation of residual activated sludge.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

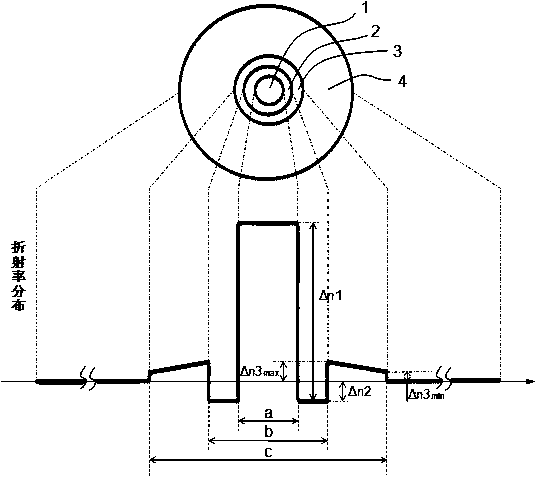

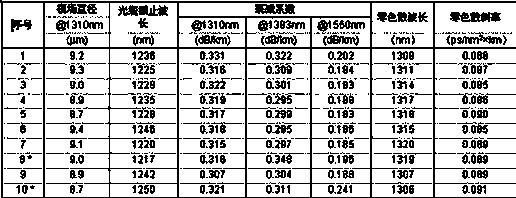

Single mode fiber

ActiveCN103760634AReduce manufacturing costSmall attenuationOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingAttenuation coefficientUltrasound attenuation

The invention relates to a single mode fiber with the lower manufacturing cost. The single mode fiber comprises a core layer, wherein a first inner wrapping layer, a second inner wrapping layer and an outer wrapping layer wrap the core layer in sequence. The single mode fiber is characterized in that the outer wrapping layer is made of natural siliceous sand, the absolute refraction index of the outer wrapping layer ranges from 1.4572 to 1.4574, the diameter alpha of the core layer is 8-10 micrometers, the refraction index difference delta n1 of the core layer and the outer wrapping layer ranges from 4.1*10<-3> to 6.4*10<-3>, the ratio b / a of the diameter b of the first inner wrapping layer to the diameter a of the core layer is greater than or equal to 1.6, the refraction index difference delta n2 of the first inner wrapping layer and the outer wrapping layer ranges from -2.4*10<-3> to -0.7*10<-3>, and the ratio c / a of the diameter c of the second inner wrapping layer to the diameter a of the core layer is greater than or equal to 3.6. The outer wrapping layer of an optical fiber prefabricated bar is made of the natural siliceous sand with the lower cost, so that the manufacturing cost of the optical fiber is lowered greatly; the structure of the inner wrapping layers and the outer wrapping layer is adopted, the ratio of the inner wrapping layers to the core layer is selected reasonably, and the fluorine mixing amount and the chloride ion concentration in the second inner wrapping layer are controlled, so that influence on optical attenuation from the impurities of the outer wrapping layer made of the natural siliceous land is reduced, and the water peak performance and the attenuation coefficient of the single mode fiber are reduced effectively.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

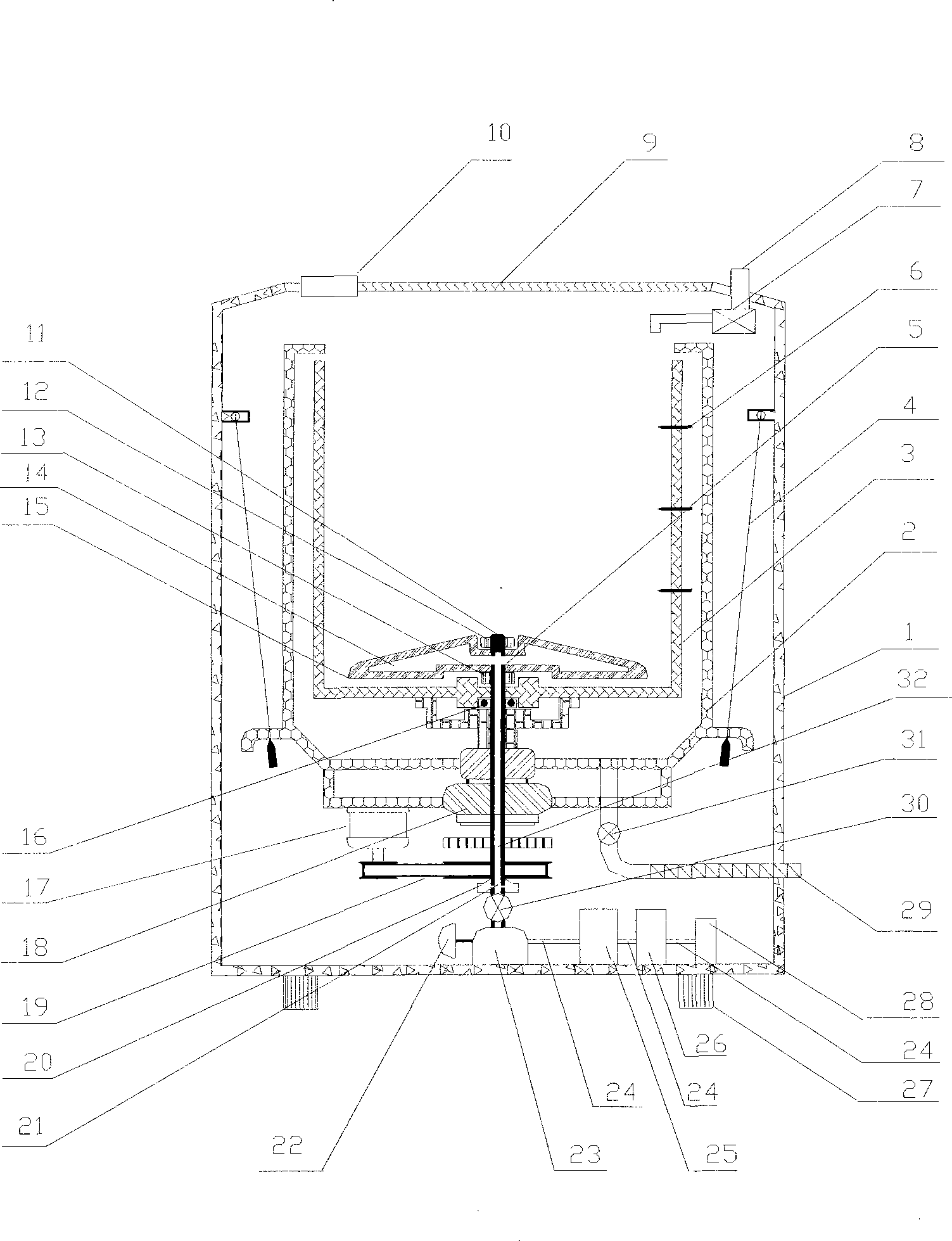

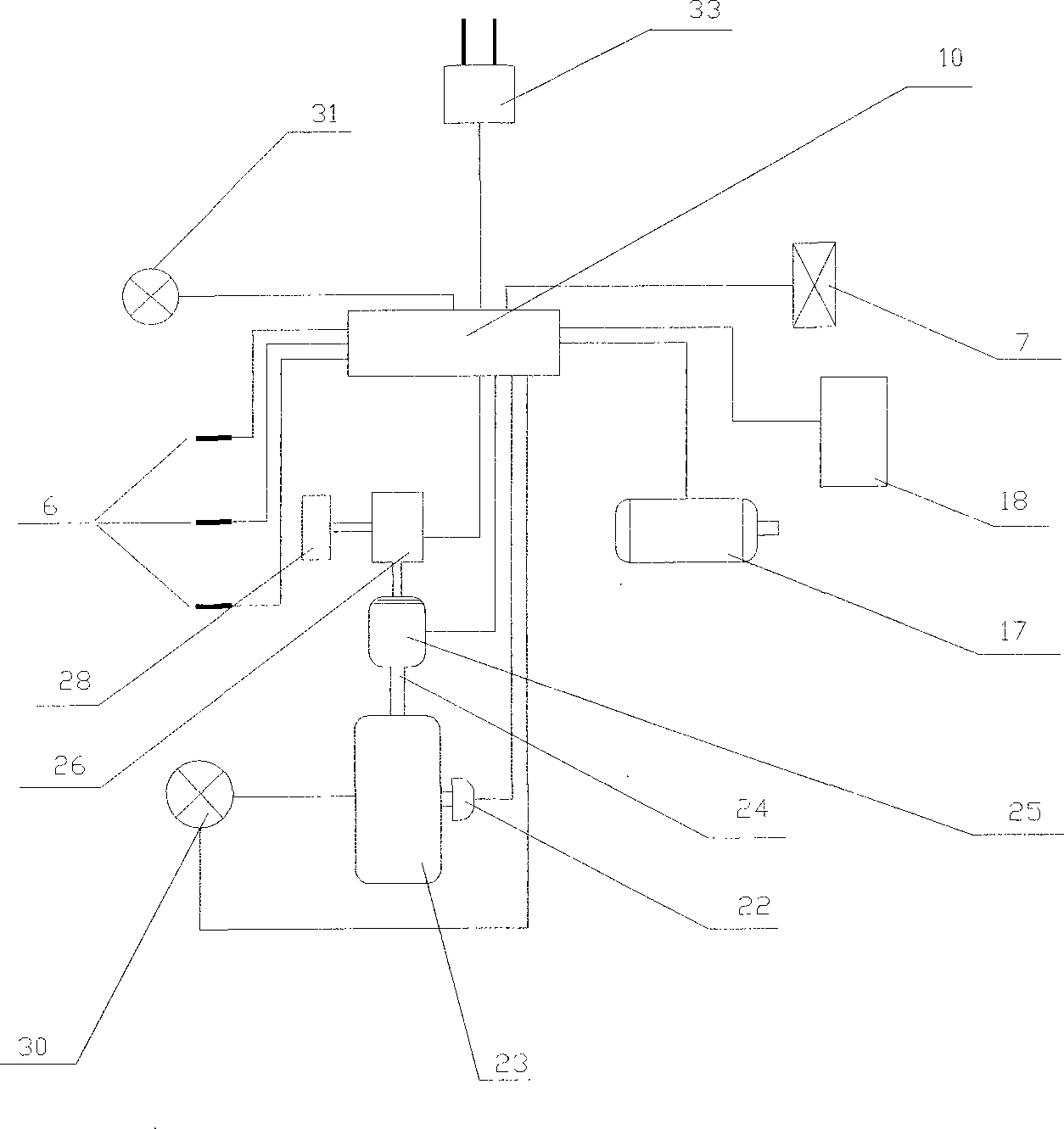

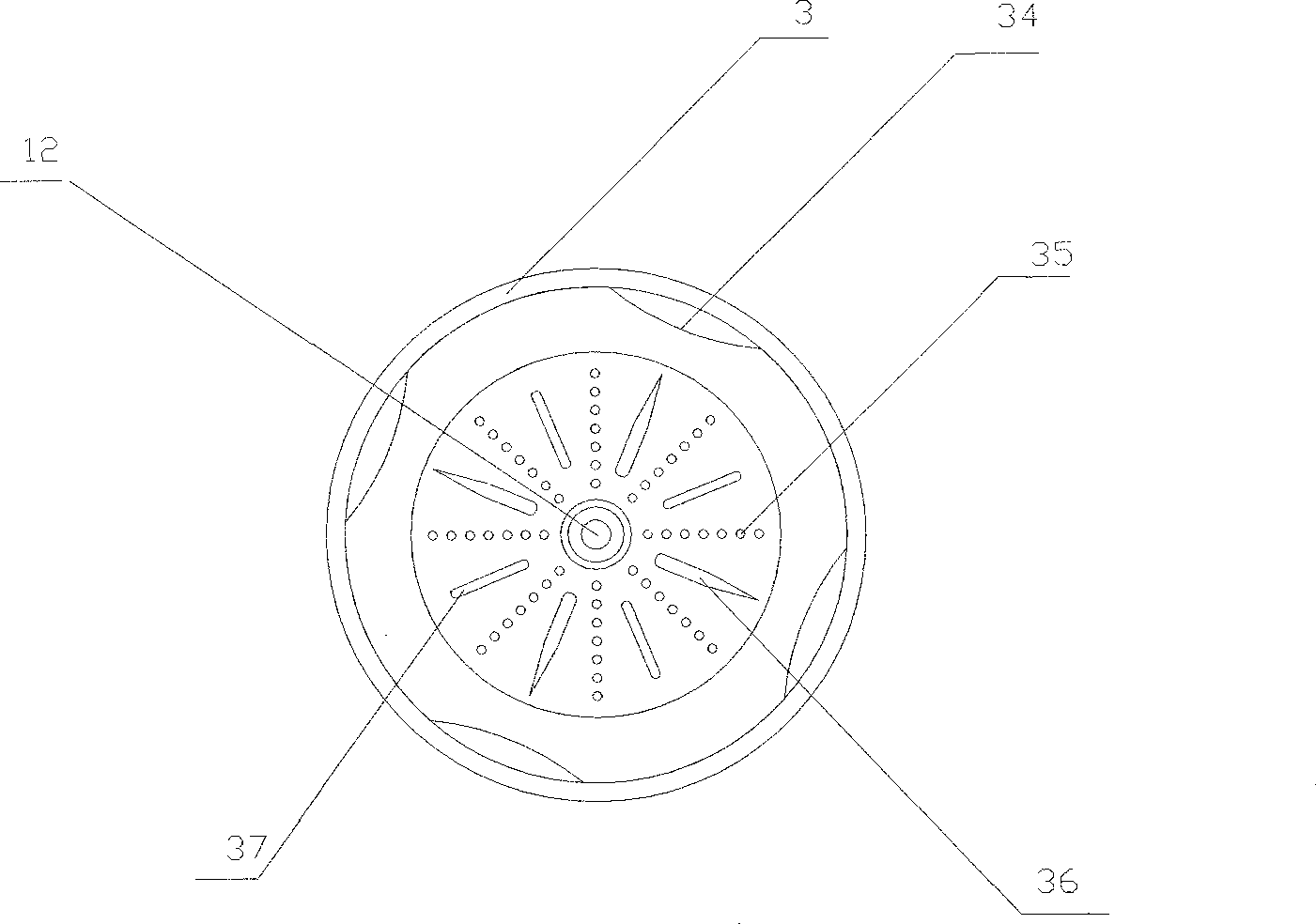

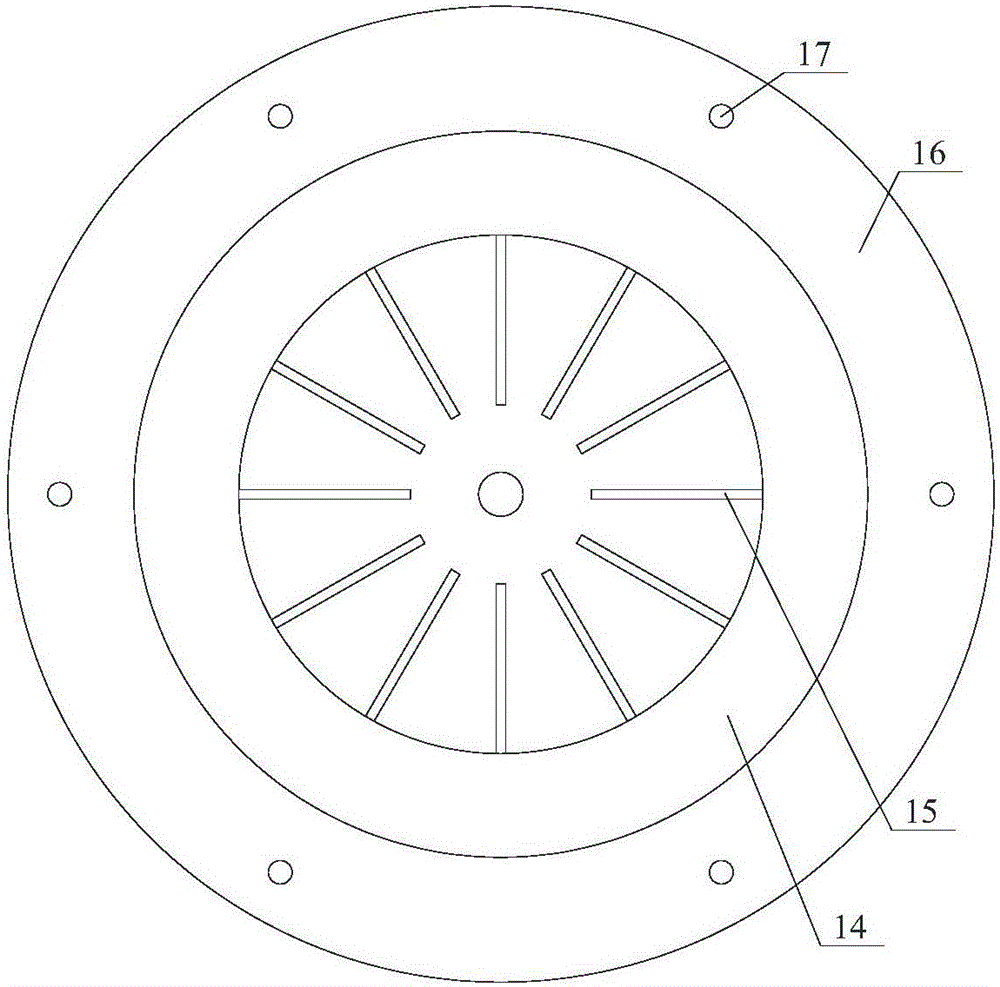

Washing machine without using washing powder

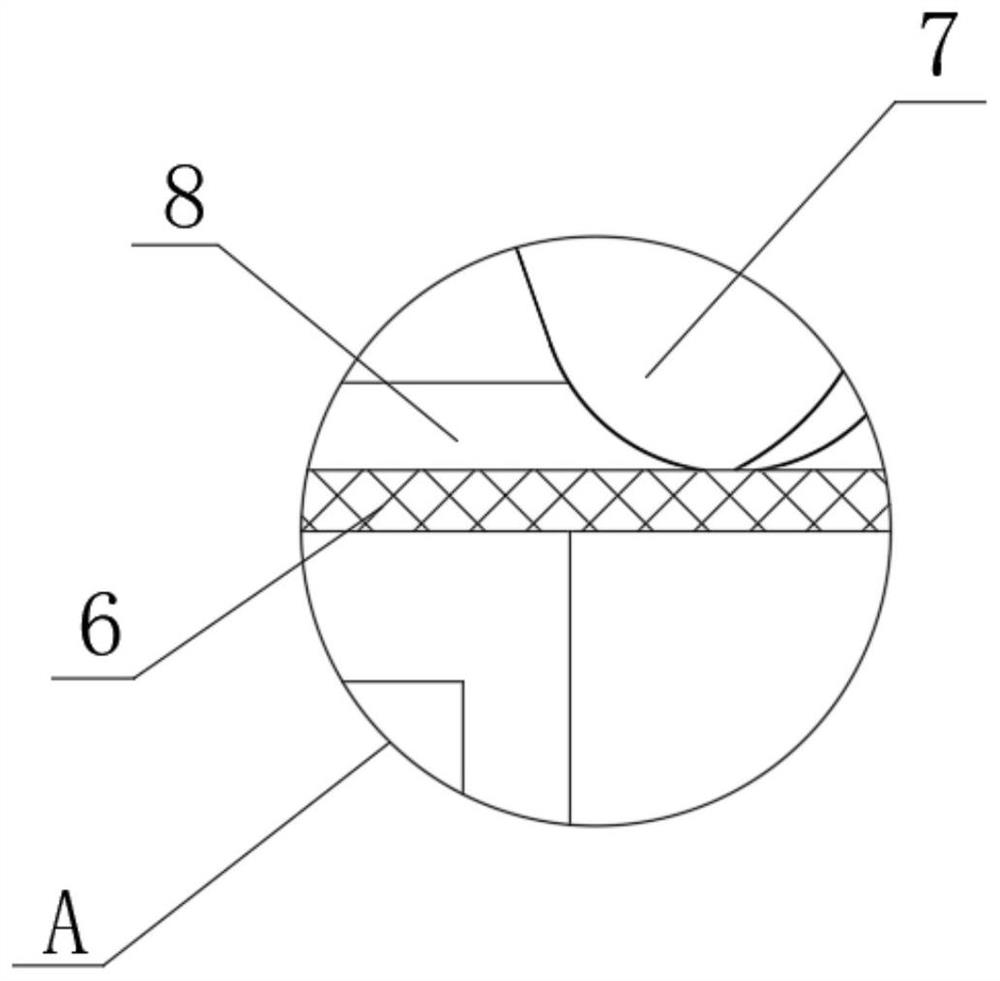

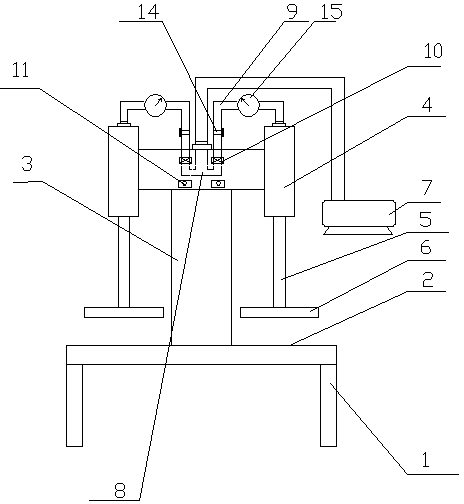

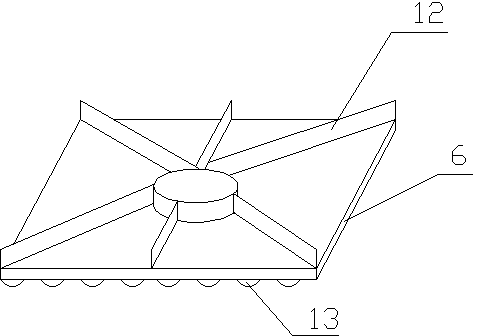

InactiveCN101463544ATo achieve the purpose of dehydrationImprove solubilityOther washing machinesControl devices for washing apparatusAir pumpInlet valve

The invention discloses a function figure of a washing machine which uses ozone for sterilization, disinfection, washing and decontamination without washing-powder. The washing machine without using washing-powder comprises the following main components: a shell 1, an inner barrel 2, a washing barrel 3, a hanging rod 4, an ozone delivery outlet 5, a water level detector 6, a water inlet valve 7, a water inlet tube 8, a cover 9, a control panel 10, a central axis 11, a fixed screw cap 12, a fixed screw cap 13, a slope wheel ozone outlet chamber 14, a slope wheel 15, a bearing 16, an electric motor 17, a clutch 18, a leather belt 19, a connecting loose piece 20 for an ozone inlet, an ozone inlet 21, a pressure controller 22, a pressure storage tank 23, a pressure tube 24, a pressure air pump 25, an ozone generator 26, a rubber footing 27, an air pump 28, a drainpipe 29, a control air valve 30, a drain valve 31, a central axis inner hole 32, a power cord 33, a resistance round strip 34, a slope wheel ozone air outlet hole 35, a slope strip 36 and a slope strip 37. The invention has the advantages of no use of any washing agents, good cleaning capability, good sterilization effect, environmental protection, energy and power saving, easy popularization and broad market prospect.

Owner:张繁荣

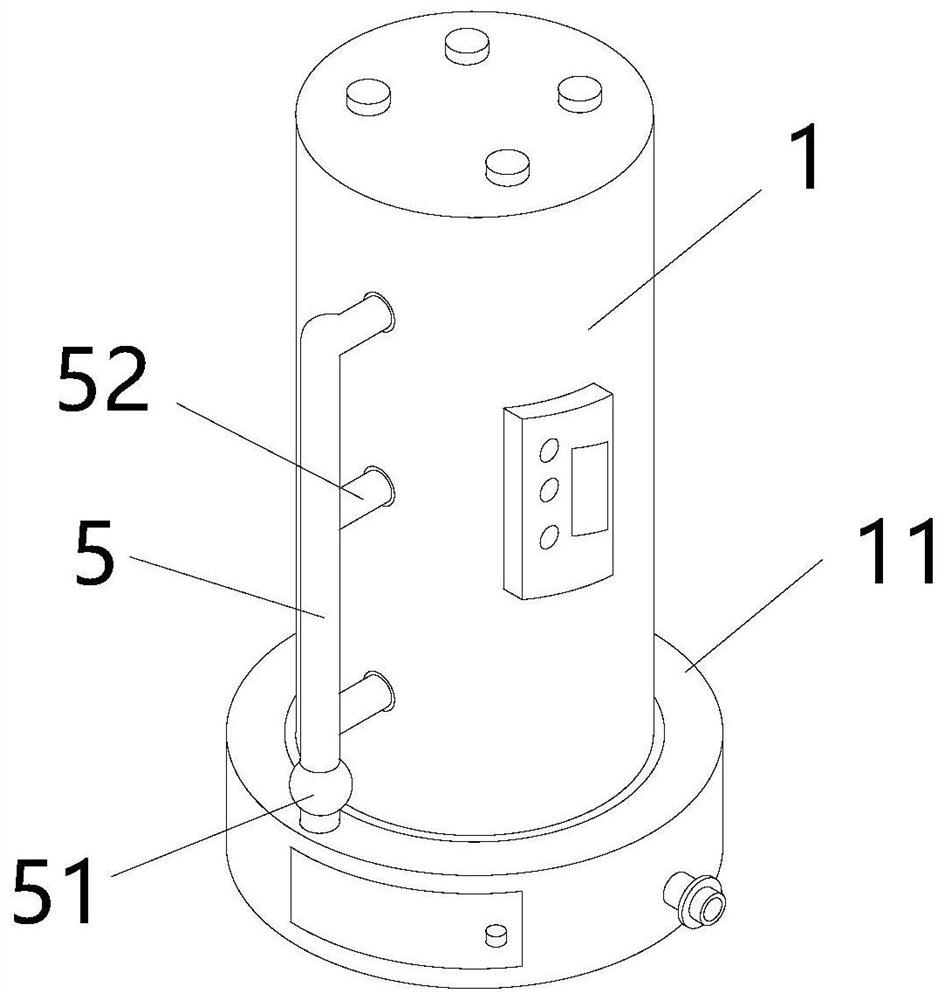

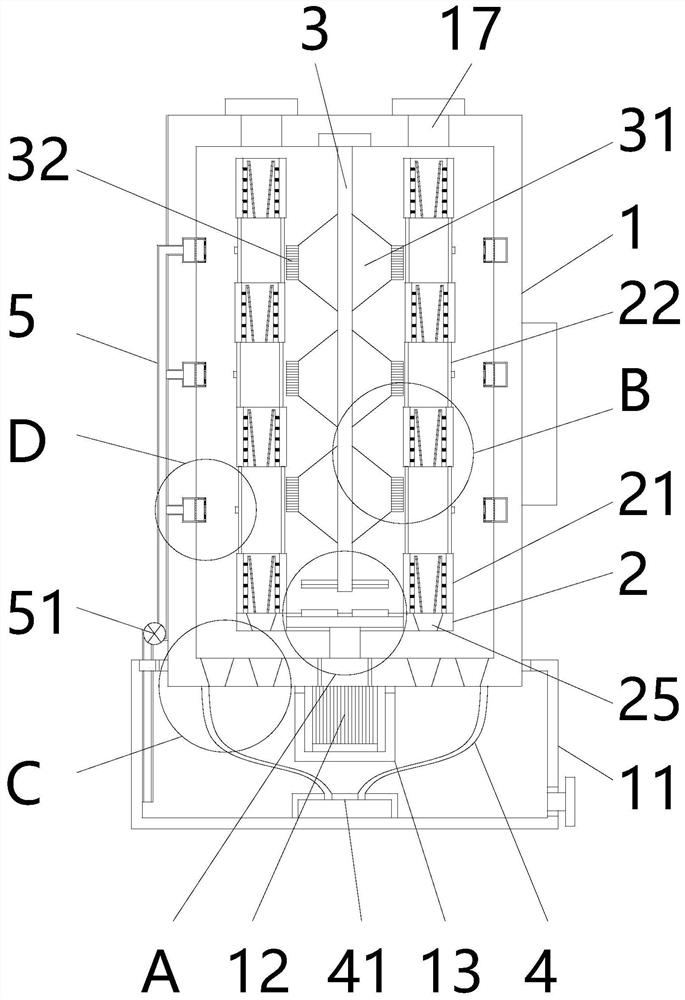

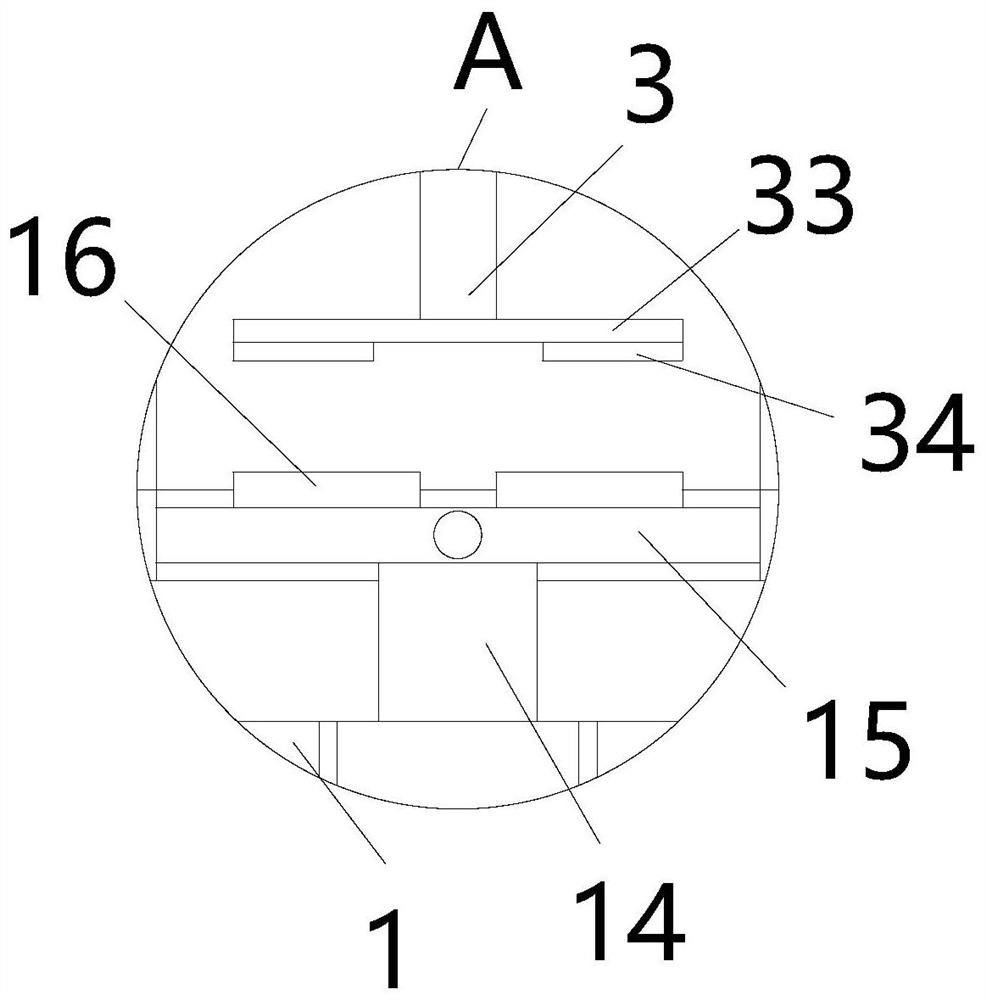

Demulsification dehydration apparatus for aged crude oil

PendingCN109722274ARealize demulsification and dehydrationAchieve separationDewatering/demulsification with mechanical meansDewatering/demulsification regulation/controlOil waterEngineering

The invention relates to the field of oil field crude oil treatment, particularly to a demulsification dehydration apparatus for aged crude oil. The demulsification dehydration apparatus comprises a box body, wherein a constant temperature circulation system for providing high temperature active water is arranged in the box body, the upper portion of the box body is provided with an oil overflow port, at least a rotary rolling kneading demulsification mechanism is arranged in the box body, each rotary rolling kneading demulsification mechanism has a fixed end surface and a relatively fixed endsurface rotary end surface, the two end surfaces cooperatively perform rotary motion, the fixed end surface has an aged crude oil inlet hole and a matched liquid supply pipeline, and the rotary end surface is supplied with rotary power by a mechanical transmission device, and is provided with a spring applying mechanism. According to the present invention, the aged oil mechanical treatment deviceis provided, the oil-water separation is achieved, the demulsification dehydration of the aged oil is effectively achieved, the utilization rate of the recovered crude oil is improved, and the purposes of cost reduction, yield increase and efficiency increase are achieved.

Owner:通化市远通石油机械有限责任公司

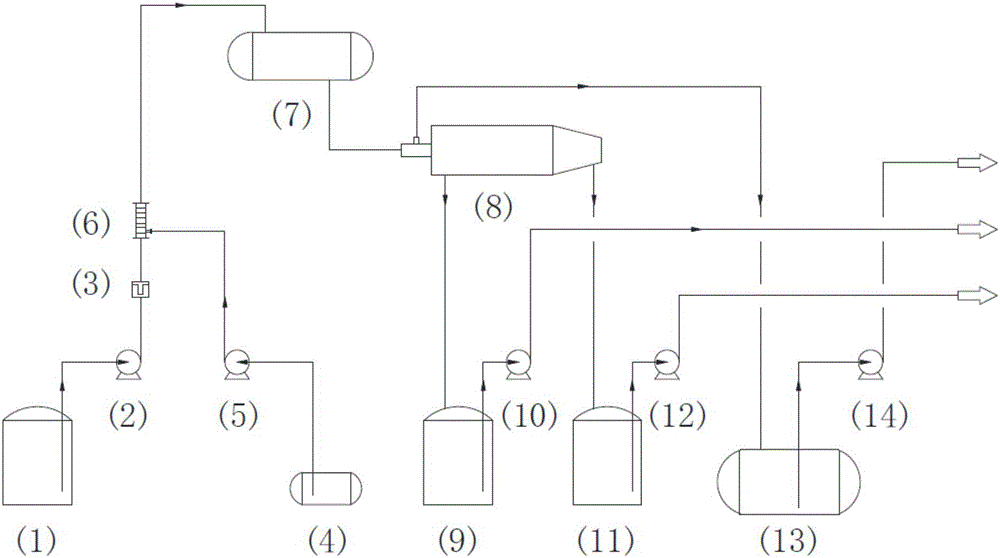

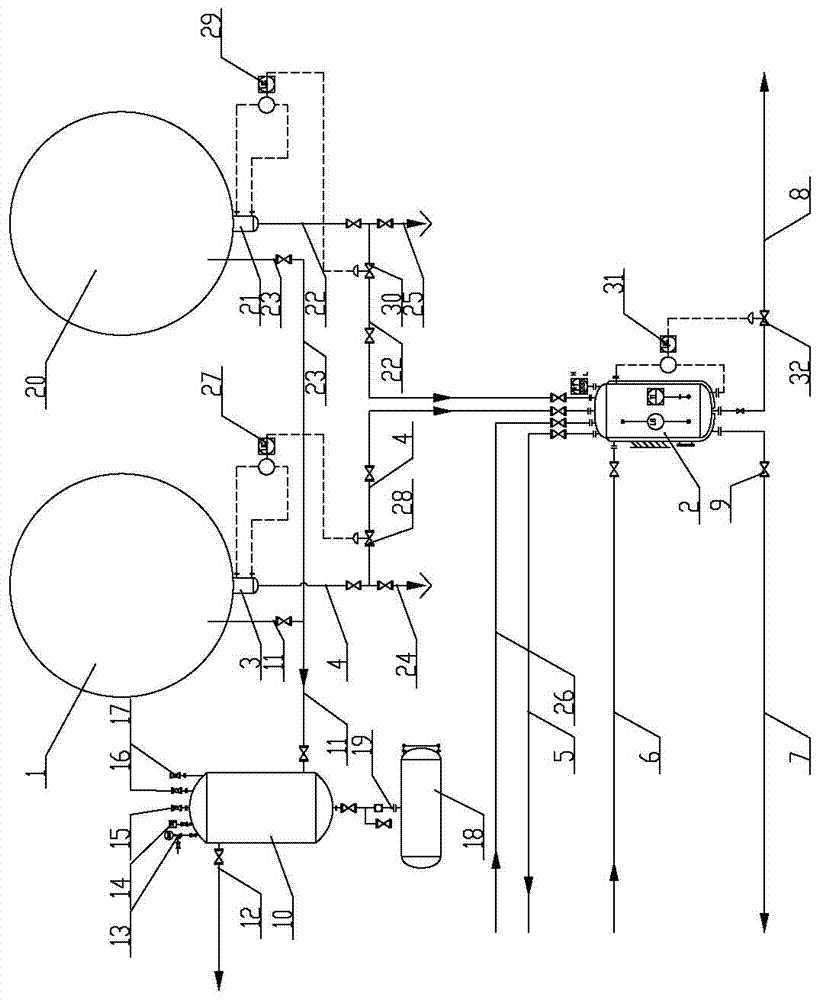

Coal tar pretreatment combined system and method

PendingCN106118703ATo achieve the purpose of dehydrationBreak the patternTar working-up by water removalDemulsifierSlag

The invention discloses a coal tar pretreatment combined system and method. The coal tar pretreatment combined system comprises a coal tar tank, a demulsifier tank, a separating and feeding buffer tank, a three-phase separator, a sewage tank, a slag tank, and an oil tank. The coal tar tank is connected with the separating and feeding tank through a coal tar pump, an automatic backwashing filter and a static mixer, and the demulsifier tank is connected with the static mixer through a demulsifier pump. Before separation, by adding the demulsifier, small-particle-size hydrone can be combined under the action of the demulsifier. Meanwhile, small-particle-size oil molecules can be combined to thereby break up the pattern of oil in water and water in oil thoroughly and release emulsified water from oil thoroughly. At this time, coal tar can be centrifugally separated, oil and water can be well separated and the purpose for dehydrated coal tar can be achieved.

Owner:BEIJING HUAFU ENG

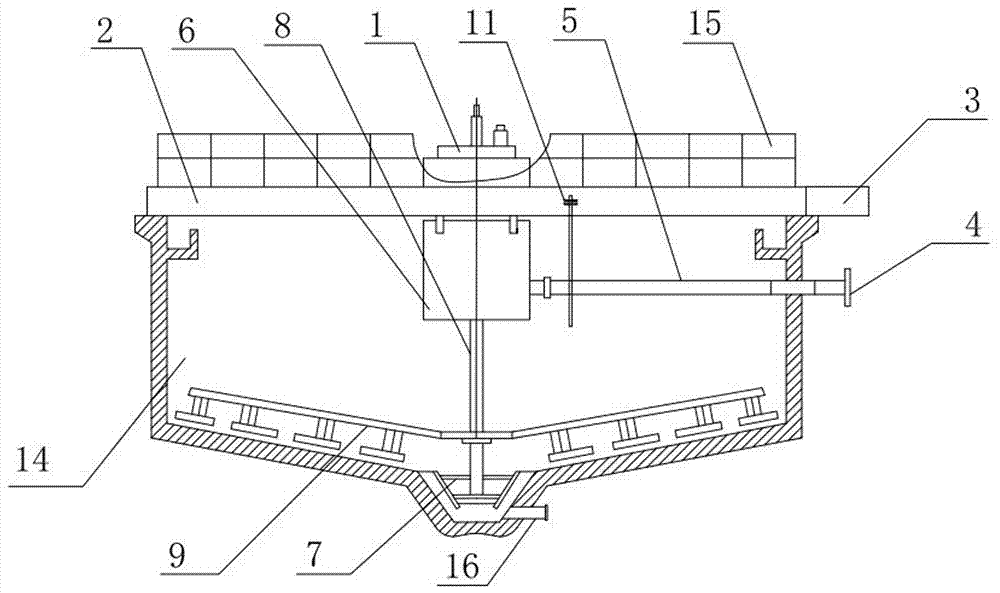

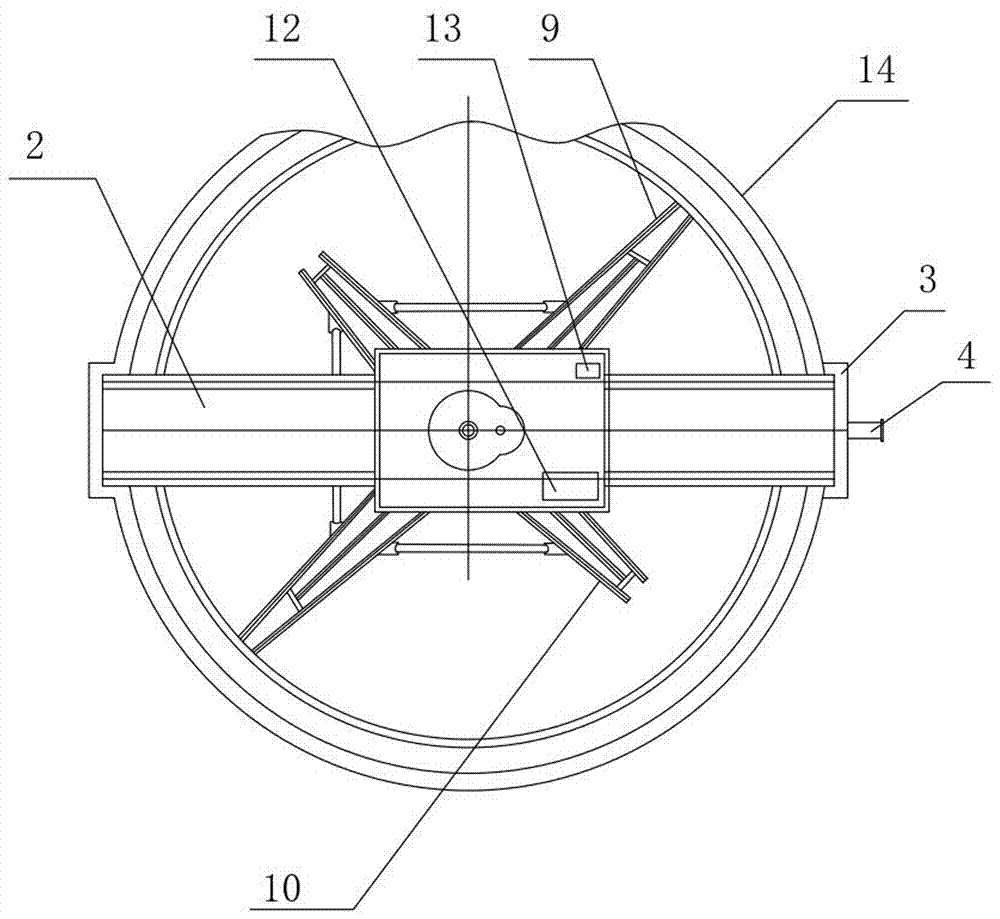

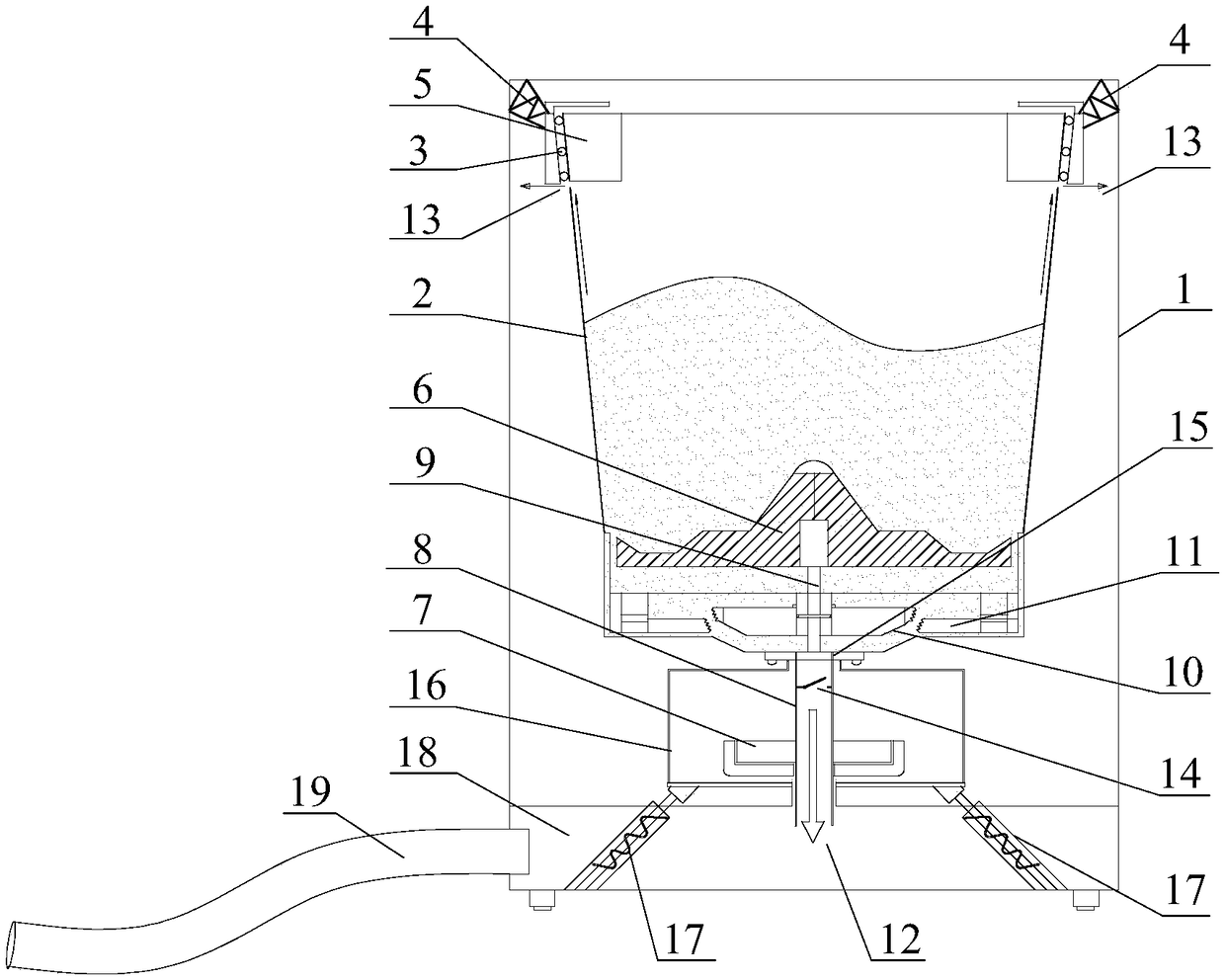

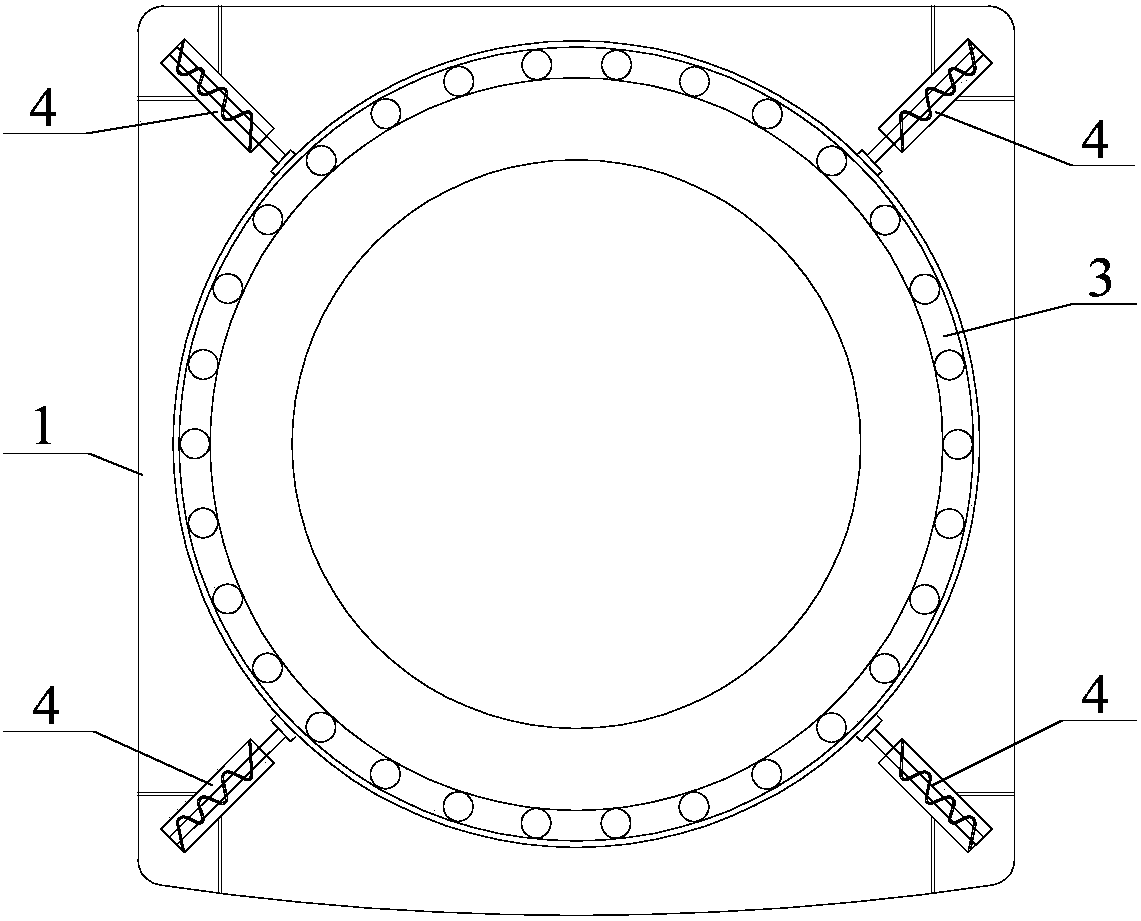

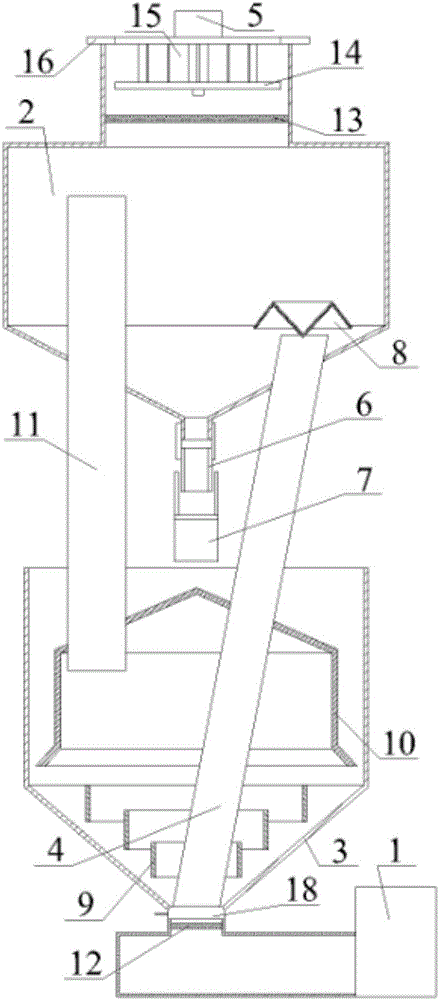

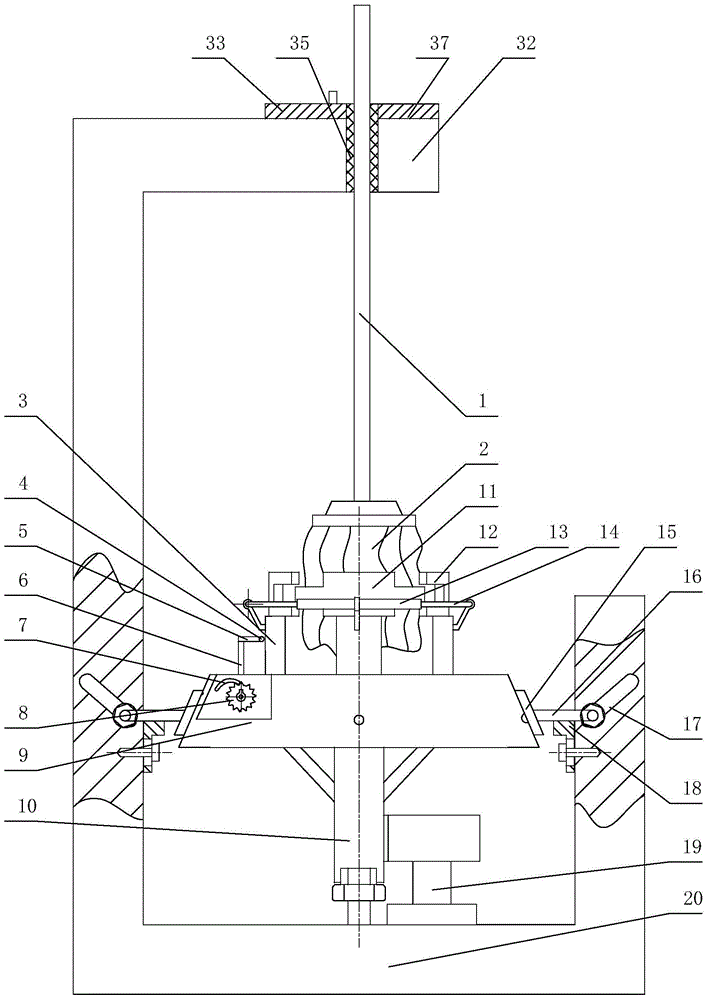

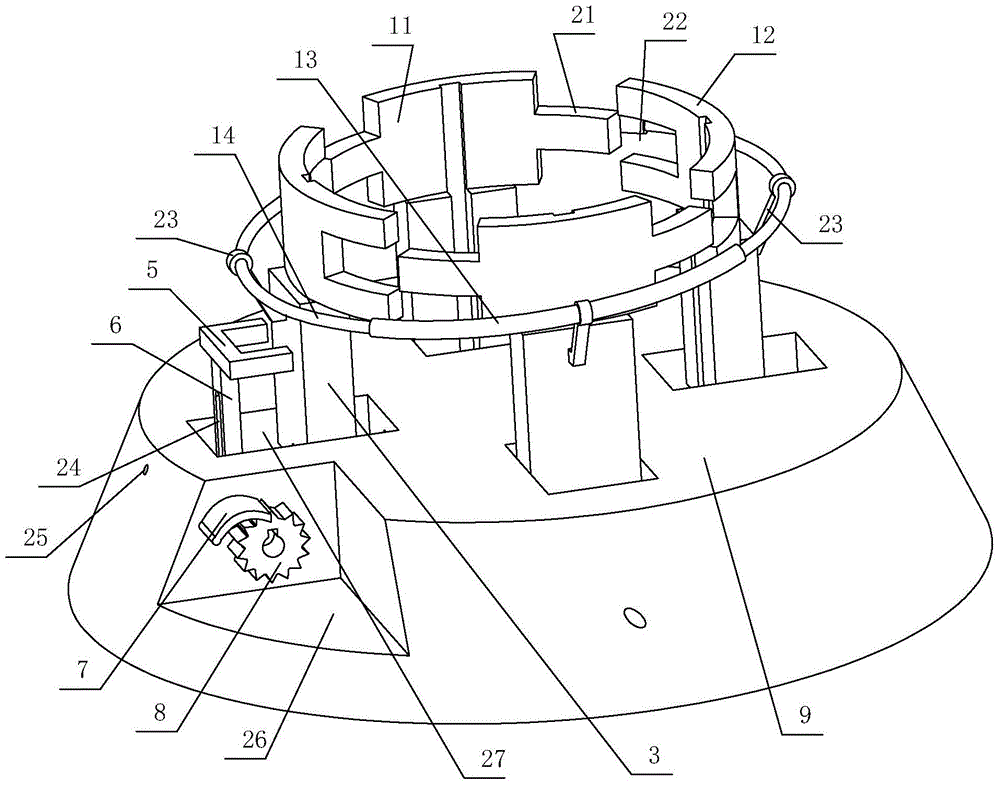

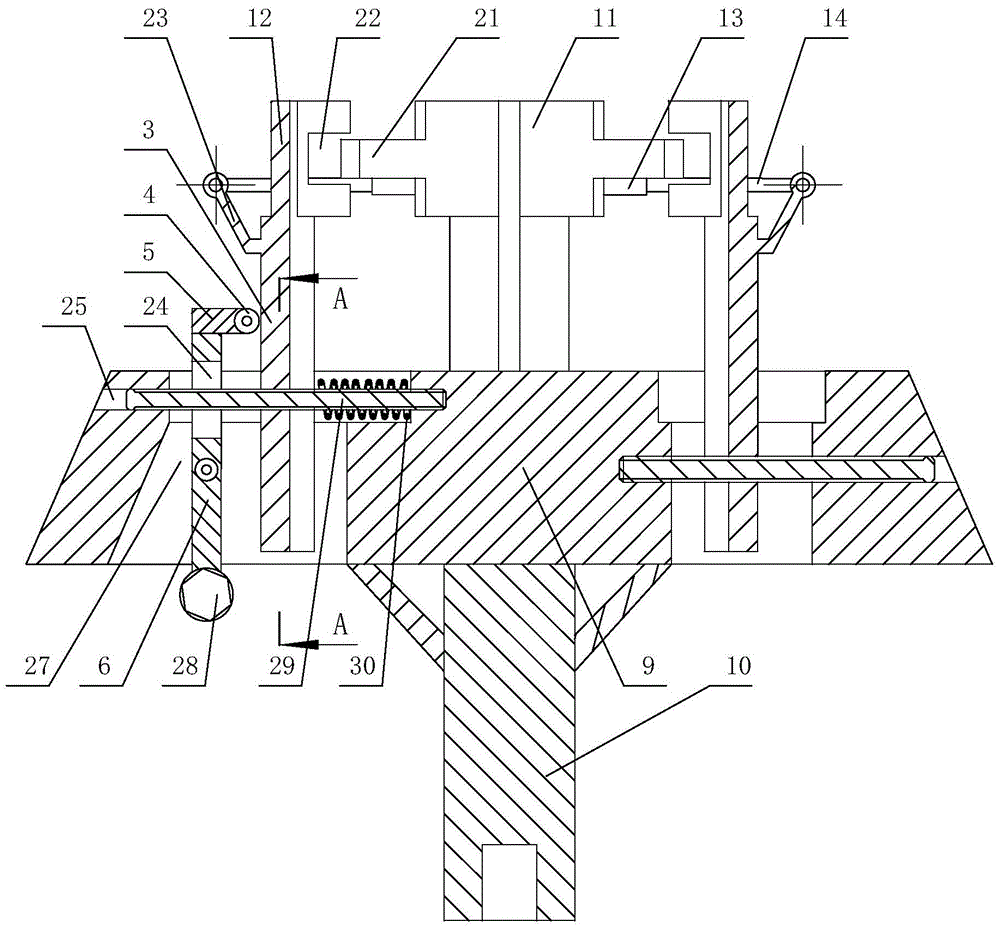

Ore pulp thickener

PendingCN107469418AEasy to use and maintainTo achieve the purpose of dehydrationSedimentation settling tanksDrive shaftEngineering

The invention relates to an ore pulp thickener which comprises a thickening tank and further comprises a transmission device, a bridge, a ladder, a feeding hole, a feed pipe, a fixed cylinder, a scraper, a shaft, a transmission shaft rake, a lifting rod, a hydraulic pressure station, an electric control device and a delivery pipe, wherein the bridge is arranged on the top of the thickening tank; the transmission device is arranged on the bridge; the ladder is connected with the bridge; the feeding hole is formed in one side of the thickening tank; the feed pipe is arranged in the thickening tank; two ends of the feed pipe are respectively connected with the feeding hole and the fixed cylinder; the fixed cylinder is arranged below the bridge; the shaft is arranged in the thickening tank and connected with the transmission device; the scraper is arranged in the center at the bottom of the thickening tank; the transmission shaft rake is connected with the shaft; the lifting rod is arranged on the bridge; the hydraulic pressure station and the electric control device are arranged on the bridge; and the delivery pipe is arranged at the bottom of the thickening tank. The thickener is simple in structure, convenient to use and maintain and excellent in clarifying and thickening effects.

Owner:沧源县云矿金腊资源有限公司

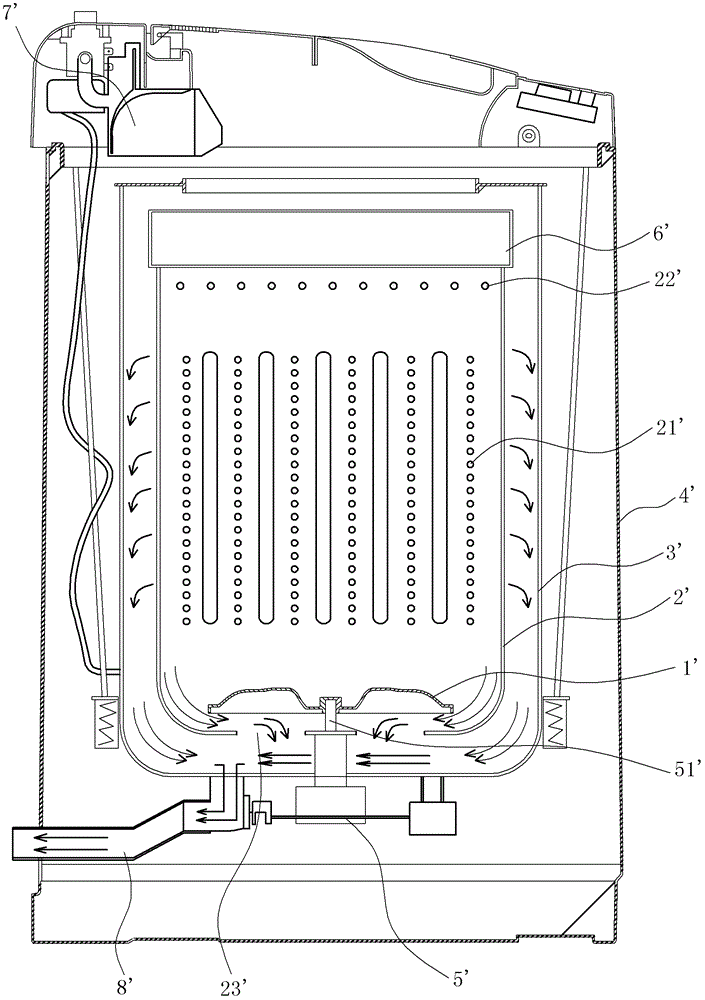

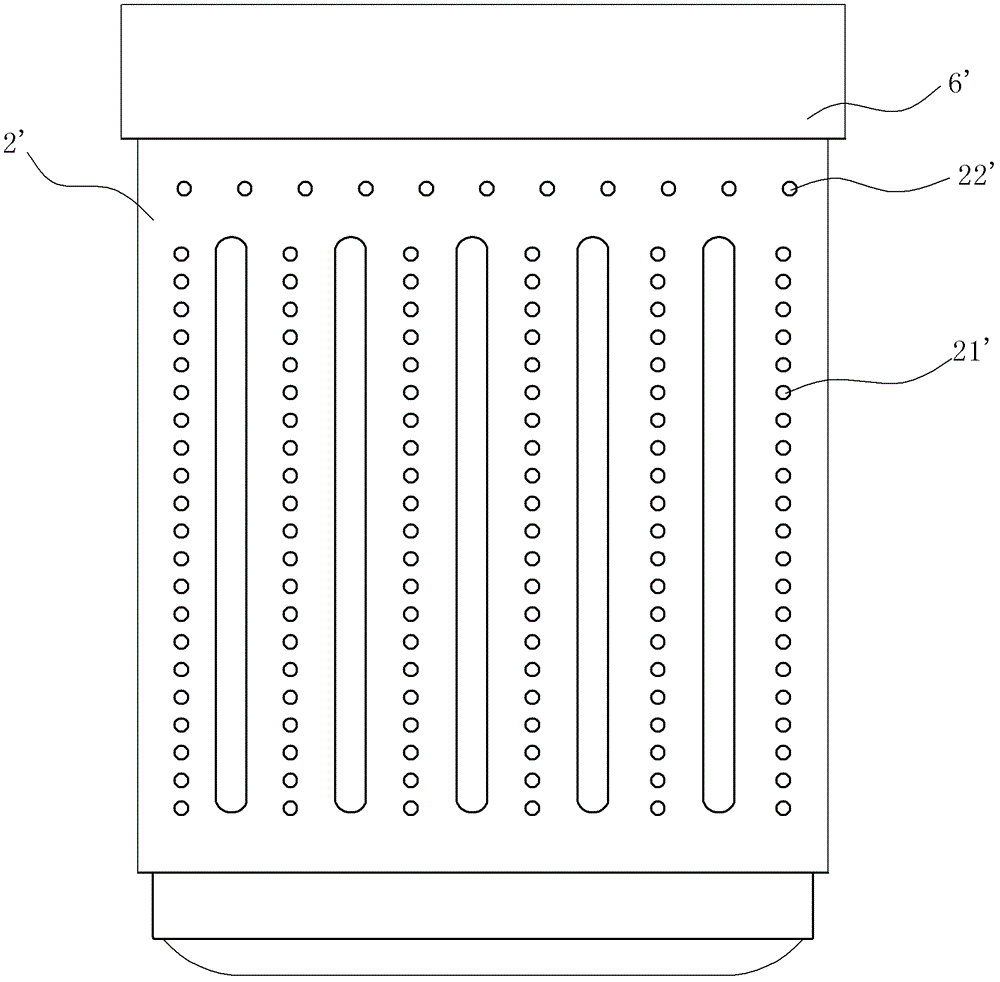

Washing machine

PendingCN109423825AOvercoming speed bottleneckReduce shakingOther washing machinesTextiles and paperLaundry washing machineAbsorbed energy

The invention provides a washing machine which comprises a box body, a tub body, a driving device and multiple shock absorbers. The tub body is located in the box body, the upper portion of the tub body sleeves a rolling bearing, and the driving device is located at the bottom of the box body and used for driving the tub body to rotate; the multiple shock absorbers are connected between the rolling bearing and the box body so that the tub body can rotate in the box body relative to the box body. By connecting the multiple shock absorbers between the upper portion of the tub body and the box body, the shock absorbers are used for absorbing energy when the upper portion of the tub body is imbalanced, shake of the upper portion of the tub body in the horizontal direction (namely the radial direction of the tub body) is effectively weakened, the phenomenon is avoided that the swing of the tub body is too large and accordingly the upper portion of the tub body bumps against the box body toproduce noise, and meanwhile the rotation speed bottleneck of an existing washing machine can be overcome. In addition, by means of the rolling bearing sleeved by the upper portion of the tub body andfree of frictional noise, it is achieved that the multiple shock absorbers are fixed to the upper portion of the tub body, the tub body can rotate in the box body relative to the box body, and smoothexecution of the dewatering process is ensured.

Owner:HEFEI MIDEA WASHING MACHINE

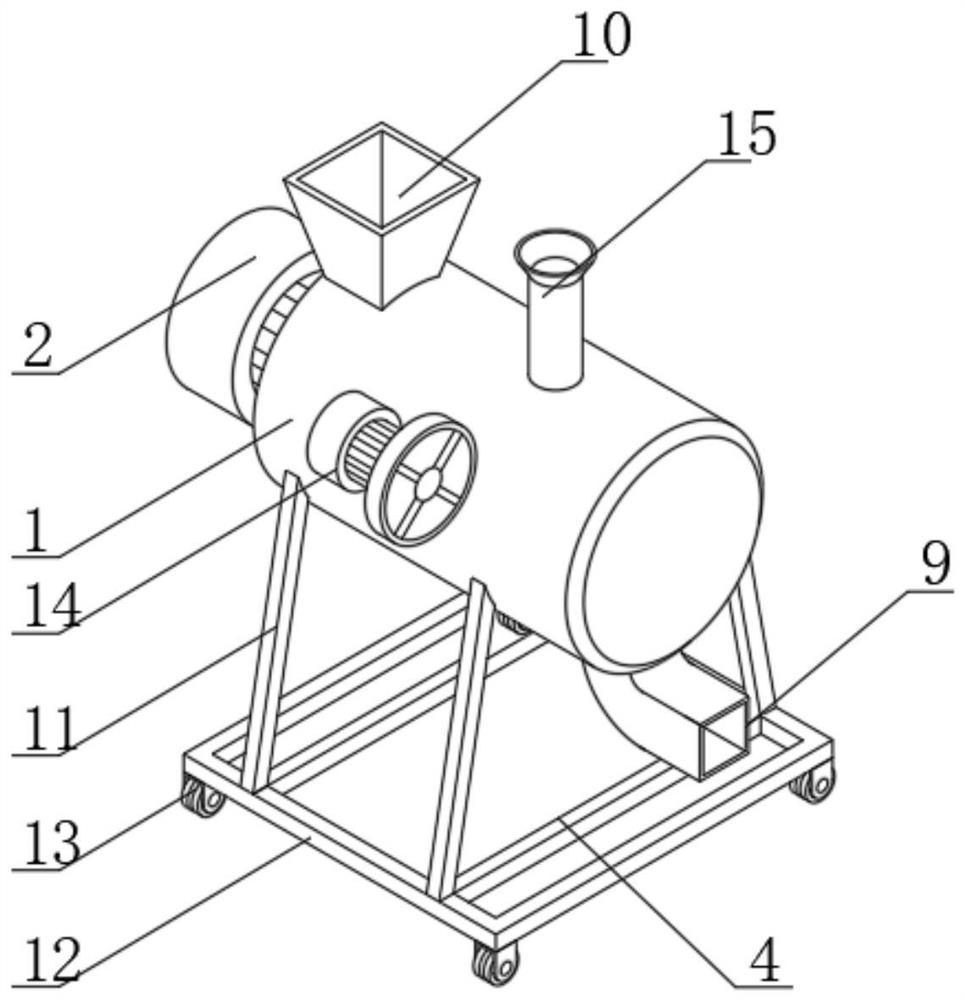

Pneumatic circulating grain drier

ActiveCN105918454APrevent mildewPrevent the situationSeed preservation by dryingFood dryingGrain storageAgricultural engineering

The invention discloses a pneumatic circulating grain drier and belongs to the technical field of drying equipment. A louver board is fixedly connected with a lower grain storage room; a hollow cavity between the louver board and a funnel-shaped structure is a distribution cavity; the hollow structure of the louver board forms an air inlet cavity which communicates with a hot air outlet of a heat source; a drying grain ascending tube passes through the air inlet cavity and reaches to the lower part of the louver board to form a feeding air inlet; the upper end of the drying grain ascending tube is located in an upper separation room; a coaxially arranged weather cap is arranged at the upper part of the drying grain ascending tube; a channel is reserved between the weather cap and the drying grain ascending tube to form a discharge air outlet; and the drying grain ascending tube forms a drying channel by virtue of a fan arranged at the top part of the upper separation room. The grain and hot air are in direct and full contact in the ascending process, so that the grain is dried; the drying effect is good by medium-free suction-type drying; the uniformity is good; the conditions of deterioration such as mildew and sprout of the grain in the links of storage, transportation, processing and the like can be effectively prevented; and the pneumatic circulating grain drier is simple in structure, convenient and fast to use, time-saving and labor-saving.

Owner:河北皓凯农业机械有限公司

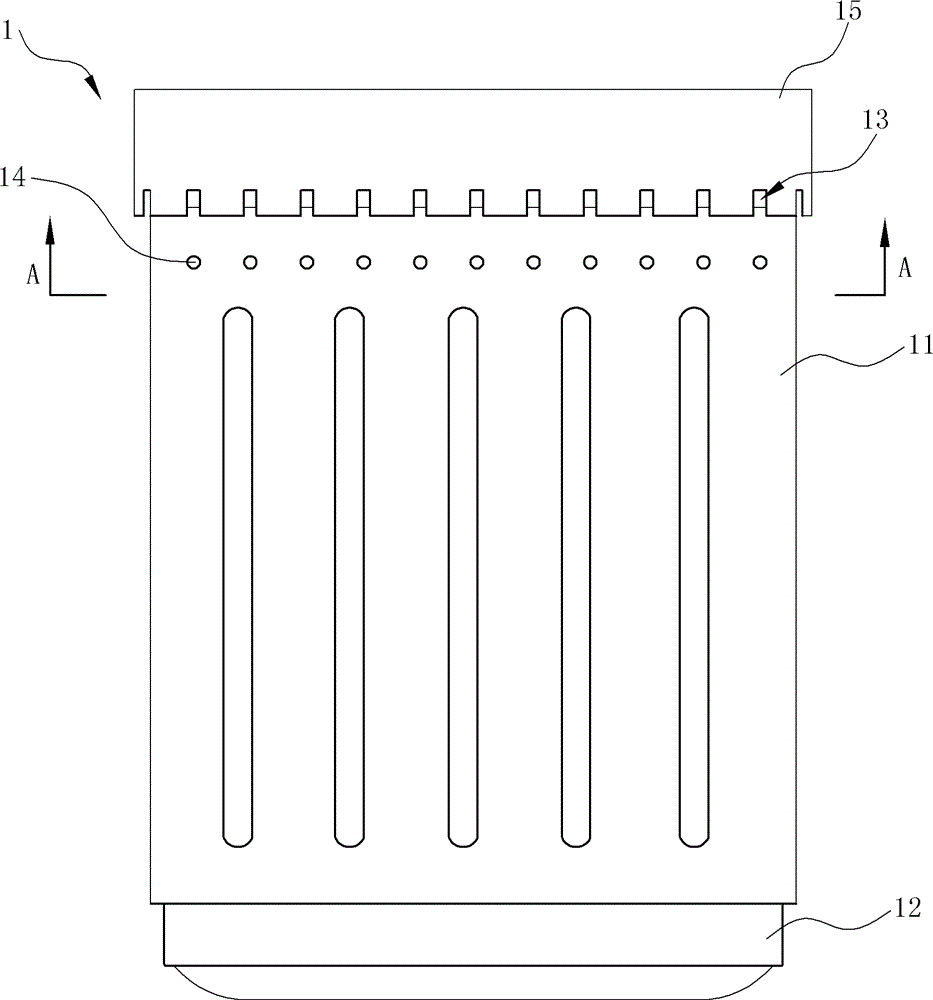

Sealed inner barrel, washing machine using the same, and washing method of the washing machine

ActiveCN102560961BAvoid cross infectionHygienic useOther washing machinesTextiles and paperWater flowPulp and paper industry

Disclosed is a sealing inner barrel comprising an integrally connected side wall (11) and bottom (12). The side wall (11) and the bottom (12) are arranged in a sealed way. A water drainage groove (13) is arranged at the top of the side wall (11), and water flow in inner barrel (1) and water in laundry are all discharged out of inner barrel (1) via water drainage groove (13). Further, a washing machine using the sealing inner barrel, and washing method for the washing machine are disclosed. Compared with the prior art, with the hole-free design of inner barrel, no washing water is required to enter the region between inner barrel and outer barrel, and therefore, washing water is substantially saved. At the same time, the dirt and bacteria in the region will not contact with clothes in the inner barrel by the water, thereby effectively avoiding cross infection of bacteria, hence, the washing machine is hygienic, environment-friendly and safe in use.

Owner:柳州赛宝隆电器有限公司

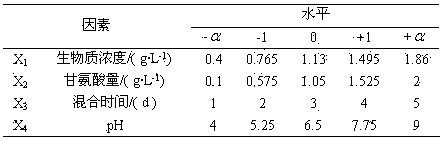

Method for biofloculating microalgae by using glycine

InactiveCN103757055APromote growthWon't breakMicroorganism based processesFermentationBiotechnologyGlycine

The invention discloses a method for biofloculating microalgae by using glycine, which comprises the following steps: adding glycine into a microalgae culture solution, sufficiently stirring, continuing culture, regulating the pH value of the culture solution, standing until the microalgae flocculates and the culture solution stratifies, and separating the microalgae biomass, thereby achieving the goals of dehydration and collection. The glycine used as the flocculant is utilized to stimulate the microalgae to secrete a viscous extracellular polymer with three-dimensional space structure which can wrap the microalgae cells, thereby achieving the goal of floculation. The dehydration rate can reach more than 90%, and the biomass recovery rate is up to 70-90%. Besides, the glycine is nontoxic and harmless, can not destroy the water quality, and can be used as an organic nitrogen source and carbon source to be absorbed and utilized by the microalgae cells so as to promote the continuous growth of the microalgae, thereby achieving the goal of cyclic utilization of the culture solution. Therefore, the method can lower the microalgae culture and collection cost, is simple to operate and simple in technique, and is suitable for industrialized collection of the microalgae biomass.

Owner:FUZHOU UNIV

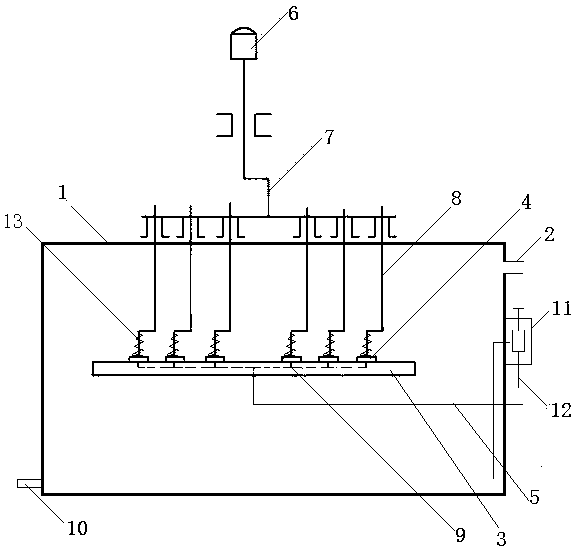

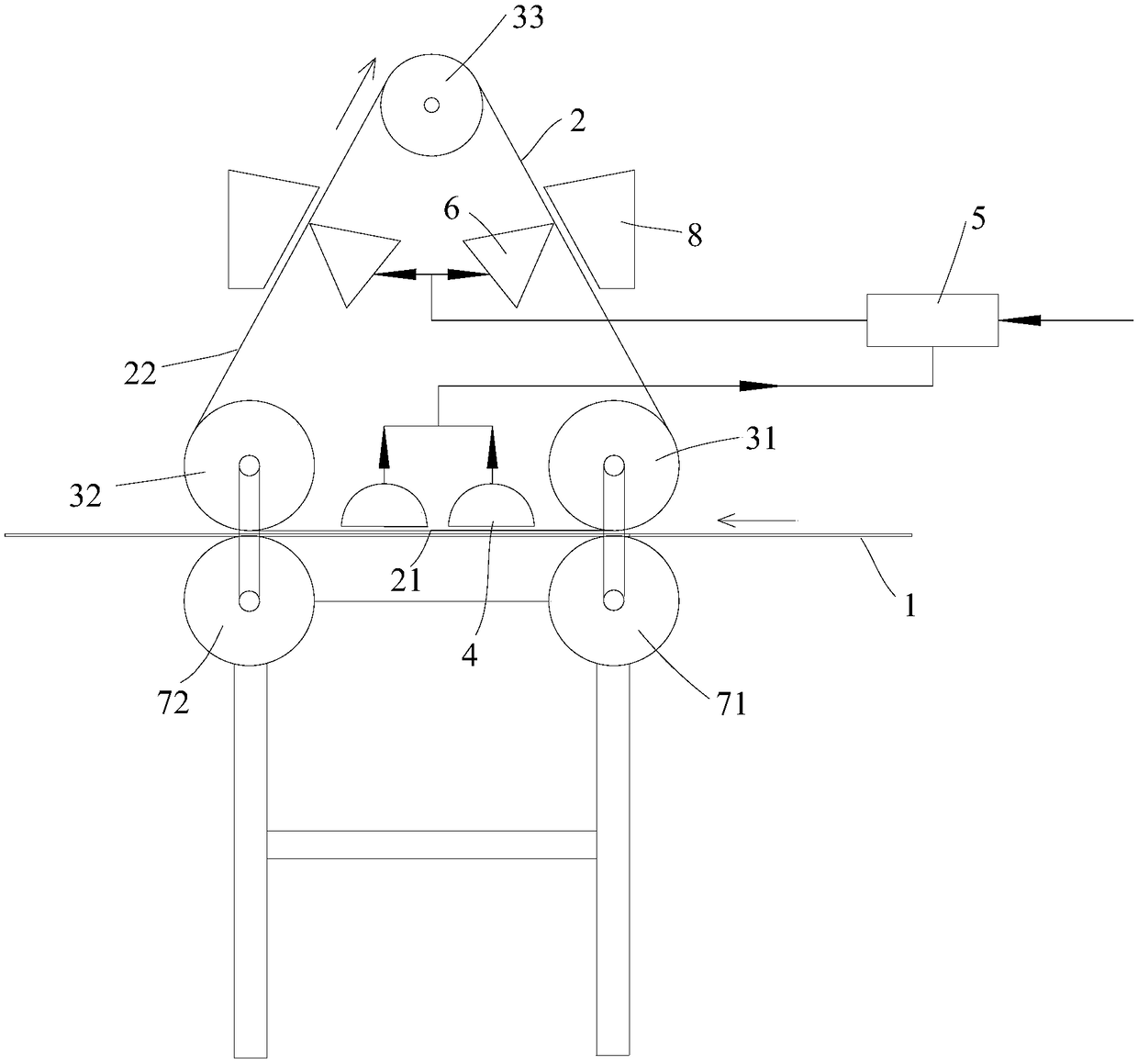

Lead-acid storage battery polar plate dewatering device

ActiveCN108258200AAvoid crackingReduce water contentLead-acid accumulator electrodesEngineeringConveyor belt

The invention discloses a lead-acid storage battery polar plate dewatering device, which belongs to the technical field of storage battery preparation. The lead-acid storage battery polar plate dewatering device comprises a conveyor belt used for conveying a polar plate, wherein a plate pressing belt which is provided with a hole and can circularly move is arranged above the conveyor belt; the plate pressing belt is provided with a water adsorption section which simultaneously advances to the same direction along with the conveyor belt; when the polar plate is conveyed, a water adsorption section of the plate pressing belt and the conveyor belt are respectively abutted against two surfaces of the polar plate; a water adsorption cover which is tightly against the plate pressing belt and isconnected with a vacuum suction device through a pipeline is arranged above the water adsorption section; the plate pressing belt is divided into the water adsorption section and a dewatering section;under the function of a driving roller, the plate pressing belt is circularly driven, the water adsorption cover adsorbs parts of water in the polar plate to the plate pressing belt in a polar plateconveying process, the water is removed in the dewatering section along with the transmission of the plate pressing belt, a purpose of the partial dewatering of the polar plate is realized, and the drying temperature of a dryer of a next working procedure is effectively lowered.

Owner:TIANNENG BATTERY GROUP

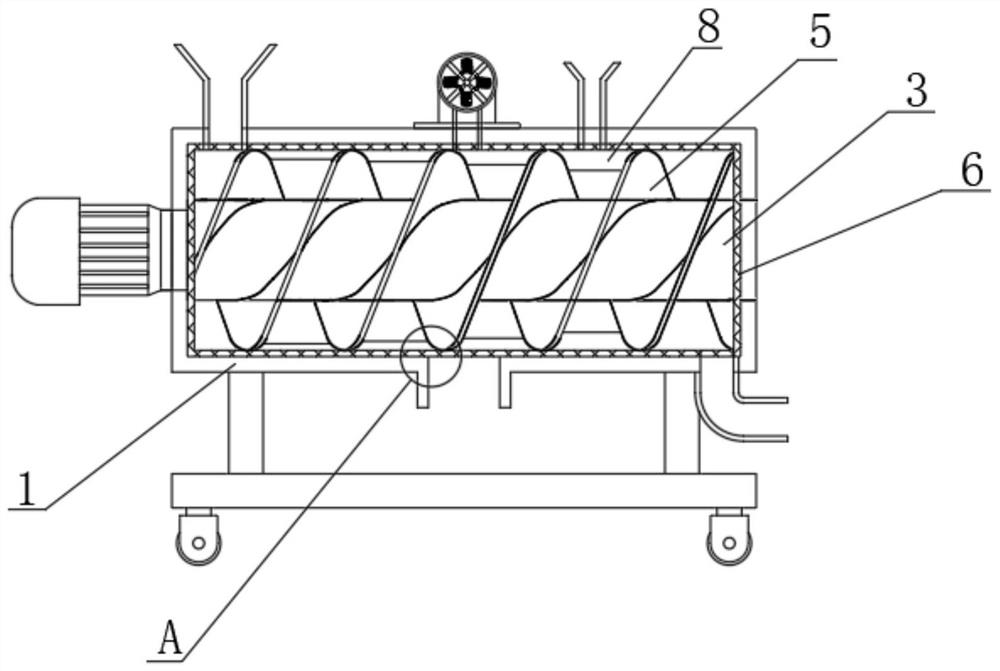

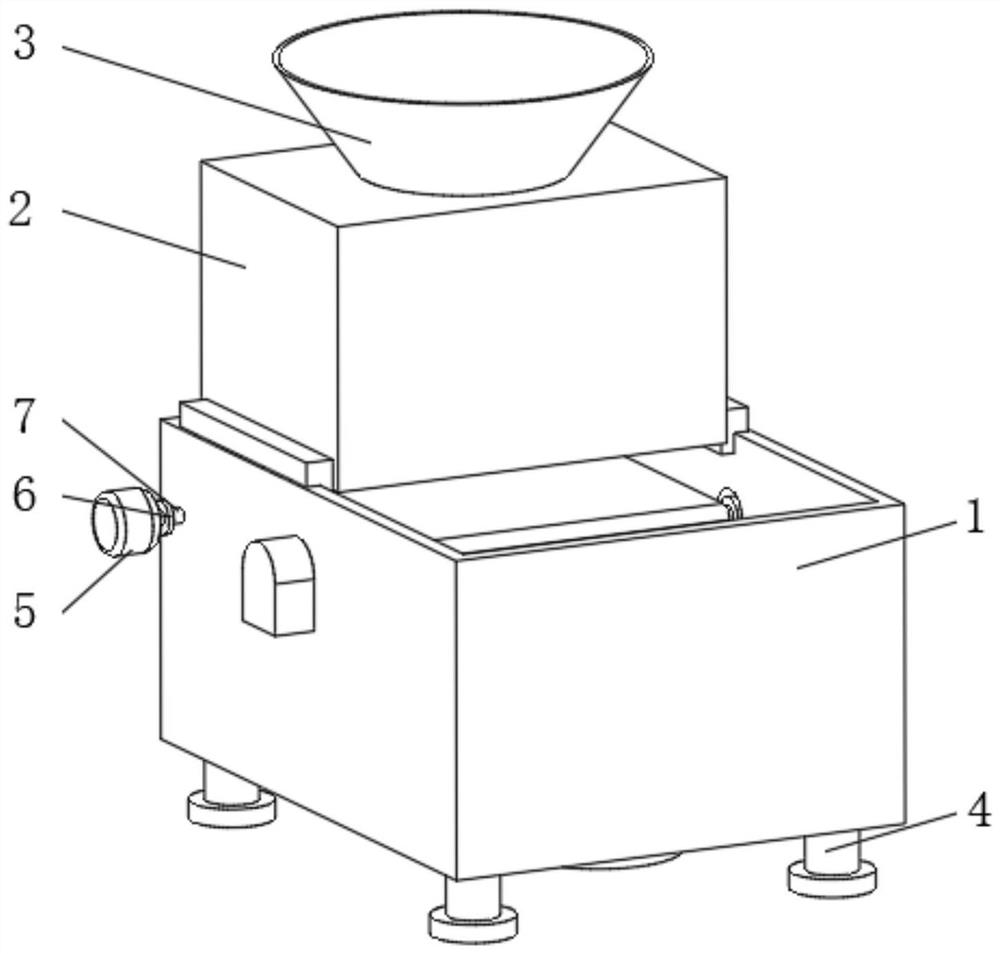

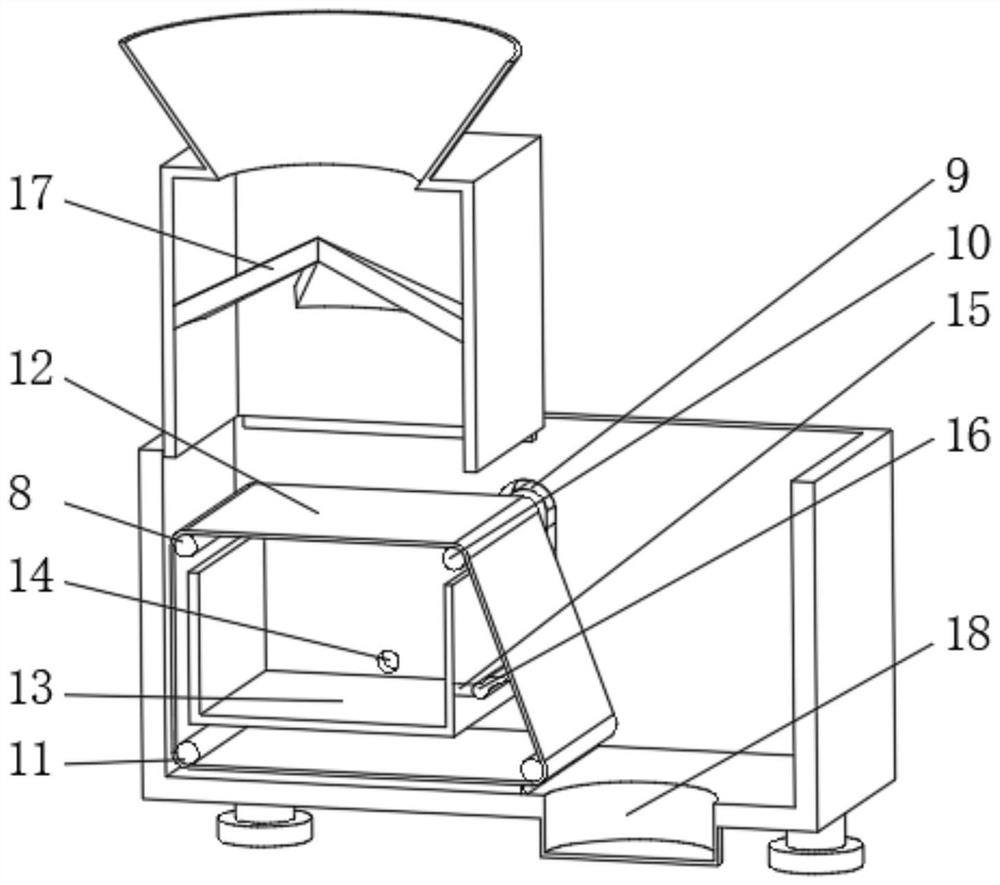

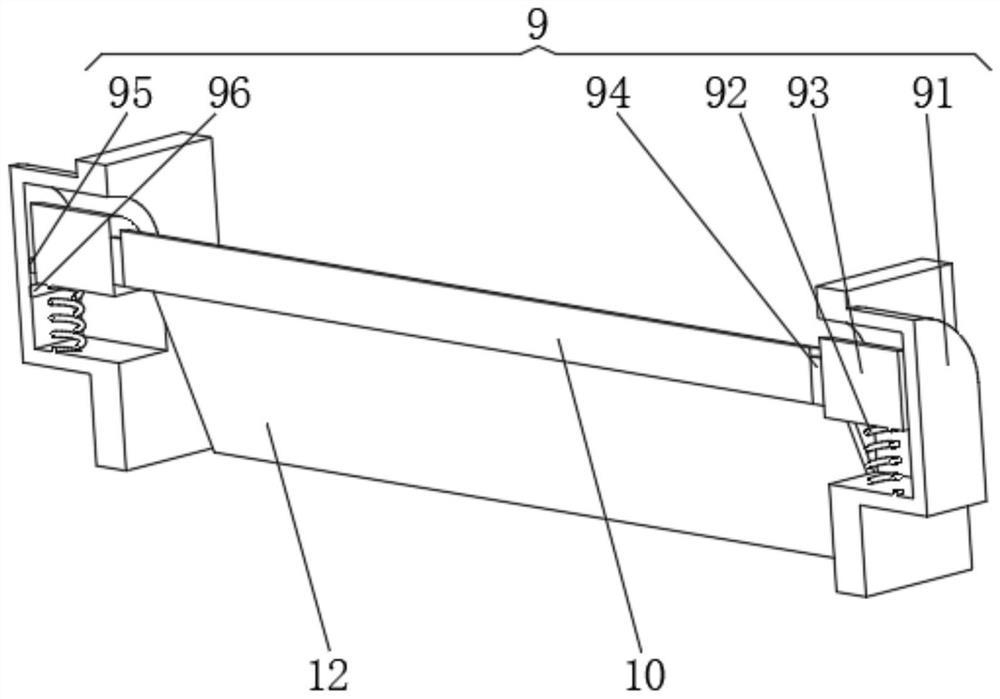

Environment-friendly sludge separation device

PendingCN111704342ATo achieve the purpose of dehydrationImprove dehydration effectSludge treatmentSludgeElectric machinery

The invention discloses an environment-friendly sludge separation device, which comprises a separation box. A motor is arranged on one side of the separation box; an output end of the motor is rotationally connected with a rotating rod; a separating box is movably connected to the other end of the rotating rod; a pushing piece is fixedly connected to the outer surface of the rotating rod; a filtering box is fixedly connected to the inner wall of the separating box; a pushing piece is movably connected to the surface of the filtering box; an extruding plate is fixedly connected to the inner wall of the pushing piece; and a through hole is formed in the upper surface of the filtering box. According to the environment-friendly sludge separation device, the motor drives the rotating rod to rotate, so that the pushing piece can drive sludge to propel forwards; by arranging the wheels, the device can be conveniently pushed; the motor drives the sludge to be extruded by extrusion plates, water in the sludge is discharged through the filtering box, so that the dehydration purpose is achieved; in addition, the sizes of the extrusion plates are gradually increased one by one, the dehydrationeffect is improved, and the sludge is dried under the action of a fan.

Owner:ZHEJIANG QIANCHEN ECOLOGICAL ENVIRONMENTAL PROTECTION TECH CO LTD

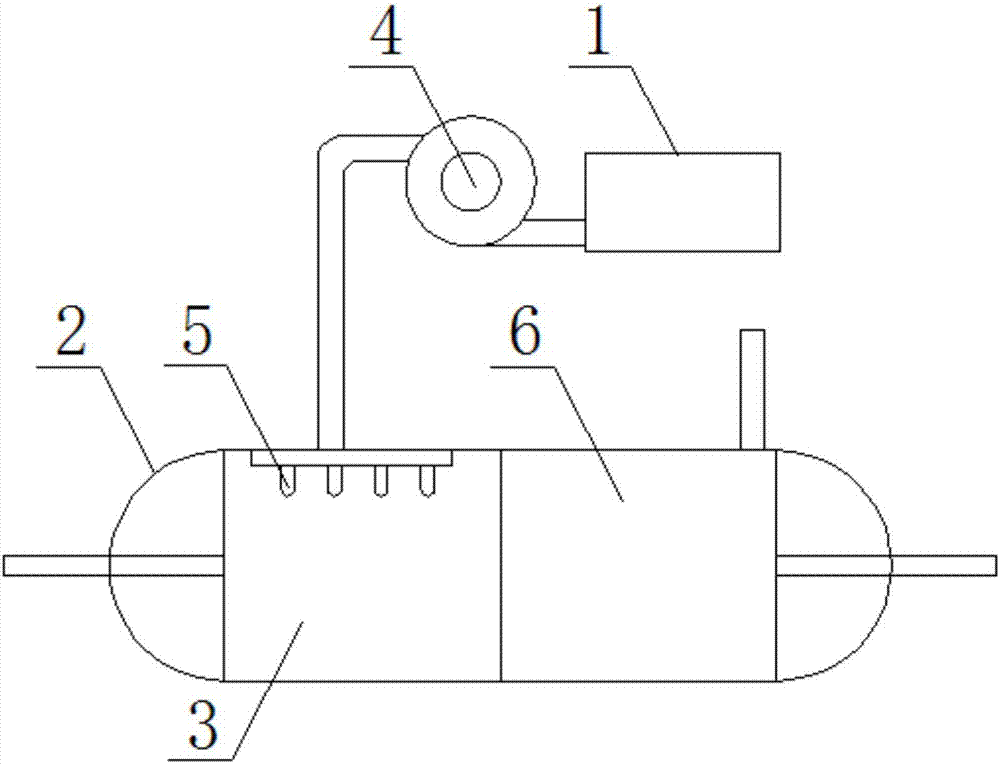

Fast dewatering machine

InactiveCN104188052AImprove dehydration efficiencyTo achieve the purpose of dehydrationMeat/fish preservationFood preparationElectricityPulp and paper industry

The invention relates to a food processing machine. In order to overcome the technical problem of lower dewatering efficiency of a centrifugal dewatering machine adopted in the food-processing process in the prior art, the invention provides a fast dewatering machine. The fast dewatering machine comprises a rack, wherein the rack is provided with a material platform surface. The fast dewatering machine is characterized in that a vertical column is arranged in the middle of the rack; the two sides of the vertical column are respectively and fixedly provided with a cylinder; cylinder rods point to the material platform surface of the rack; and a horizontal pressing plate is fixed at the bottom part of each cylinder rod. The fast dewatering machine also comprises an air compressor, wherein an air outlet pipe of the air compressor is connected with a main pipe of a three-way pipe; two branch pipes of the three-way pipe are respectively connected with gas supplying pipes of the two cylinders; pipelines of the gas supplying pipes of the cylinders are provided with electromagnetic valves; the vertical column is provided with cylinder control switches; and the electromagnetic valves are electrically connected with the cylinder control switches. The fast dewatering machine provided by the invention has the advantages that the structure is simple, the operation is convenient, the dewatering efficiency is good and the dewatering efficiency for materials in the production process is improved to a greater extent.

Owner:RONGCHENG HONGYE IND

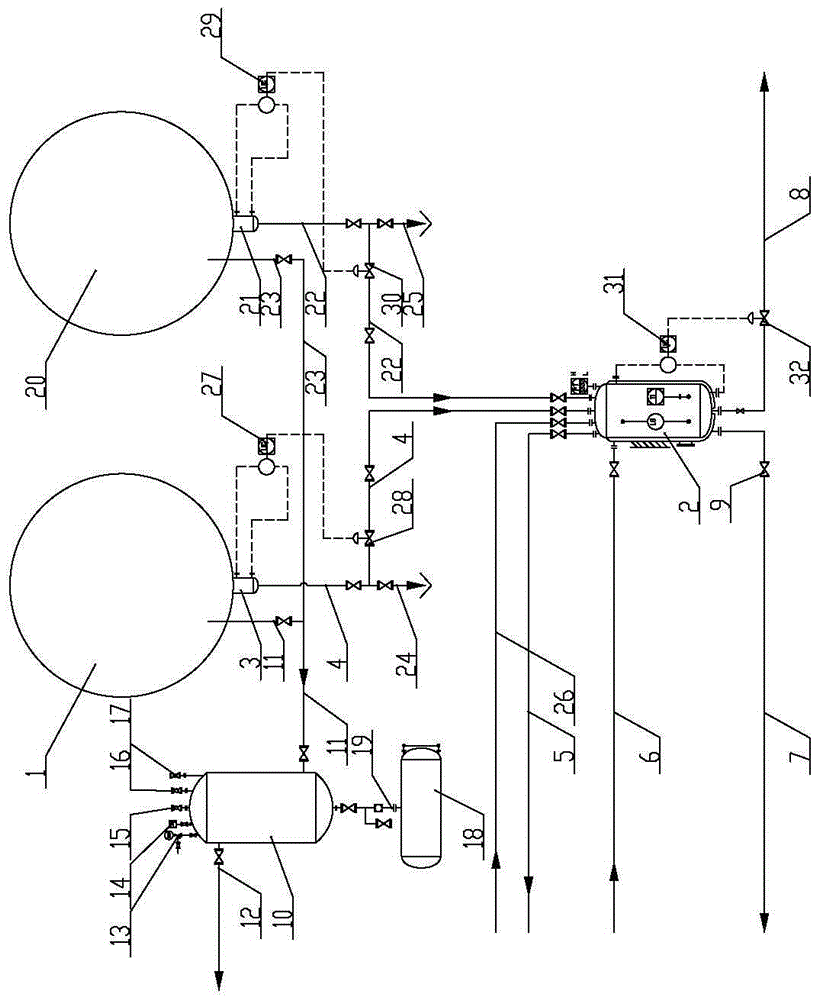

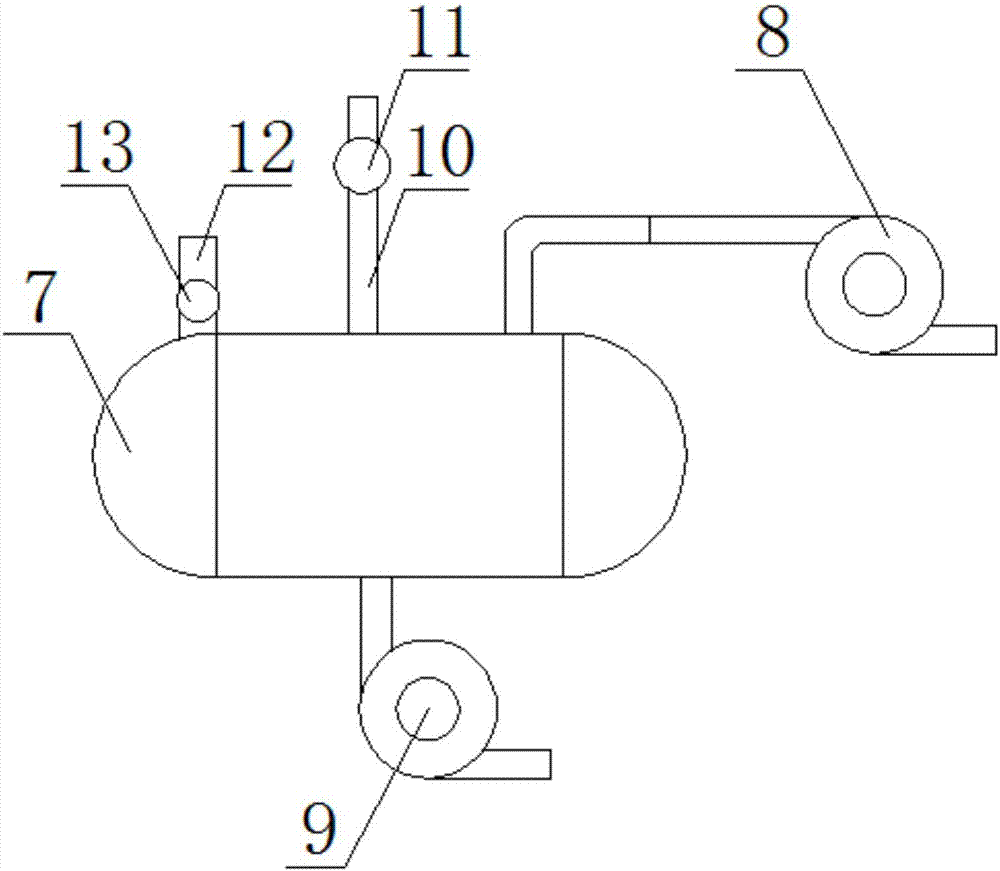

Water-containing vinyl chloride monomer dehydrating device and dehydrating method thereof

ActiveCN105294389ATo achieve the purpose of dehydrationCompact and reasonable structureHalogenated hydrocarbon separation/purificationPolymer sciencePolymer chemistry

The invention relates to the technical field of dehydrating devices, and specially relates to a water-containing vinyl chloride monomer dehydrating device and a dehydrating method thereof. The dehydrating device comprises a first spherical tank and a steam-water separator. A first water storing bag that is communicated with the cavity of the first spherical tank is integrally fixed on the bottom of the first spherical tank, the bottom of the first water storing bag is provided with a water outlet end, the top of the steam-water separator is provided with a vinyl chloride recovering opening end and a first water inlet end; the water outlet end of the first water storing bag and the first water inlet end of the steam-water separator are fixedly connected through a first water outlet pipe, and a vinyl chloride recovering pipe is fixedly arranged on the vinyl chloride recovering opening end of the steam-water separator. The provided dehydrating device has the advantages of reasonable and compact structure and user-friendliness. Through the cooperation among the first spherical tank, second spherical tank, steam-water separator, and solid alkali dryer, water-containing vinyl chloride monomers can be dehydrated, the dehydration is safe and reliable, the dehydration effect is good, the operation is convenient, the work efficiency is improved, and the production cost is reduced.

Owner:XINJIANG ZHONGTAI CHEM CO LTD

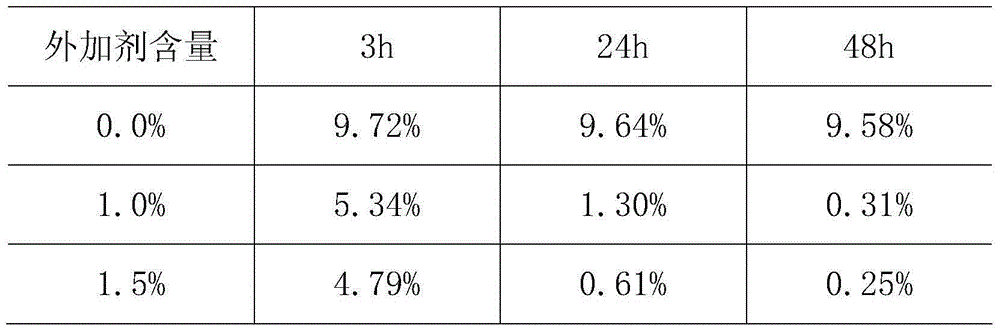

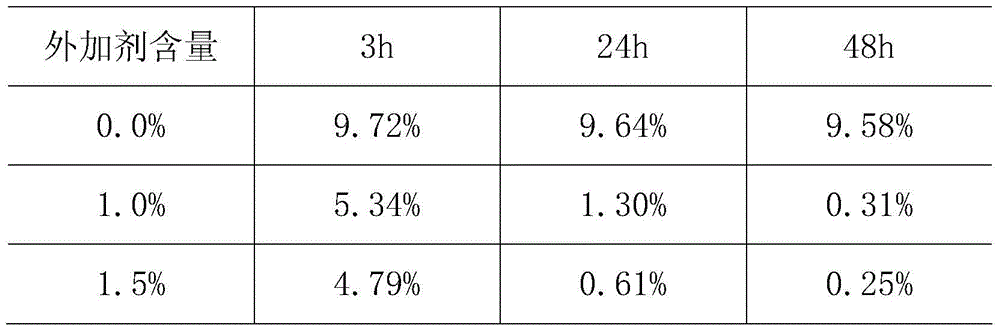

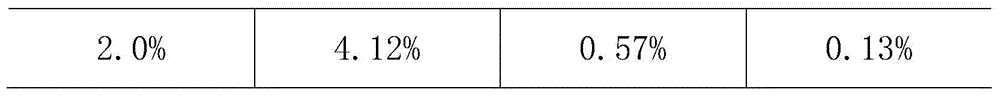

Method for quickly drying flue gas desulfurization gypsum

The invention discloses a method for quickly drying flue gas desulfurization gypsum. The method comprises the following steps: adding 1.0-2.0wt% of an additive into the flue gas desulfurization gypsum, uniformly stirring, and then naturally standing until the flue gas desulfurization gypsum reaches drying requirements. According to the method, industrial waste residue is used as the additive of raw materials, and conventional energy resources do not need to be consumed. The additive is made from industrial waste residues, does not consume conventional energy resources and is simple in production process; since the raw material is the industrial waste residue, resource utilization of the industrial waste residue is achieved, and energy resources are saved simultaneously. By utilizing the method, operation is simple and convenient, the purpose of dewatering can be achieved in natural state, the effect is good, the operation period is short, and the performance of a product can not be changed due to low mixing amount of the additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

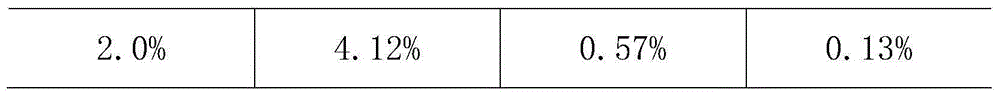

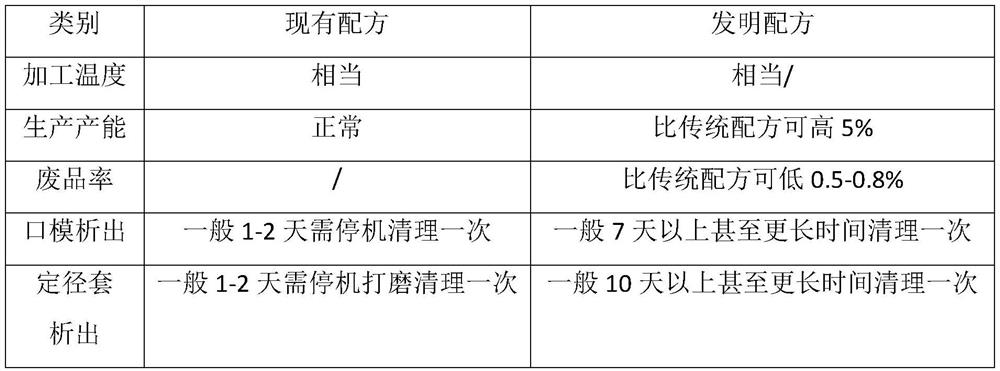

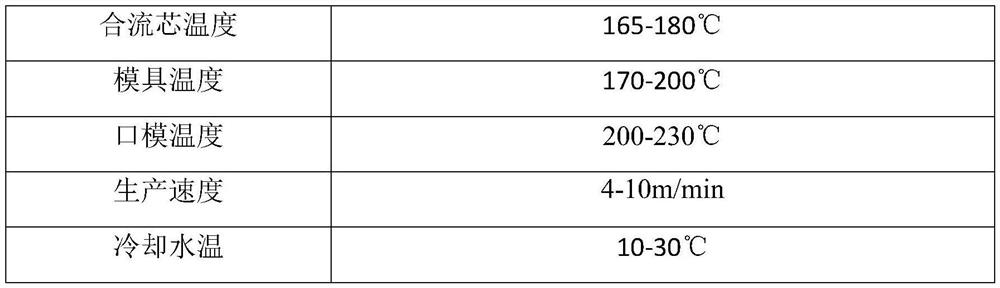

Production formula for solving easy precipitation in rigid polyvinyl chloride pipe production and pipe preparation process thereof

InactiveCN111808386AAccelerated precipitationImproved long-term processabilityPolyvinyl chlorideUltraviolet lights

The invention provides a production formula for solving easy precipitation in rigid polyvinyl chloride pipe production and a pipe preparation process thereof. The production formula comprises the following components in parts by weight: 100 parts of PVC resin, 5-15 parts of a filler, 3-8 parts of a processing aid, 2-8 parts of an impact modifier, 3-5 parts of a calcium-zinc stabilizer, 2-5 parts of a coloring agent, 0.5-1 part of stearic acid, 0.5-1 part of polyethylene wax and 0.02-0.05 part of an ultraviolet light absorber. By using the formula of the rigid polyvinyl chloride pipe, the precipitation phenomenon of pipes in the processing process can be remarkably solved, and the problem that processing is difficult by adopting a conventional or common calcium-zinc stabilizer formula is solved.

Owner:天津市伟星新型建材有限公司

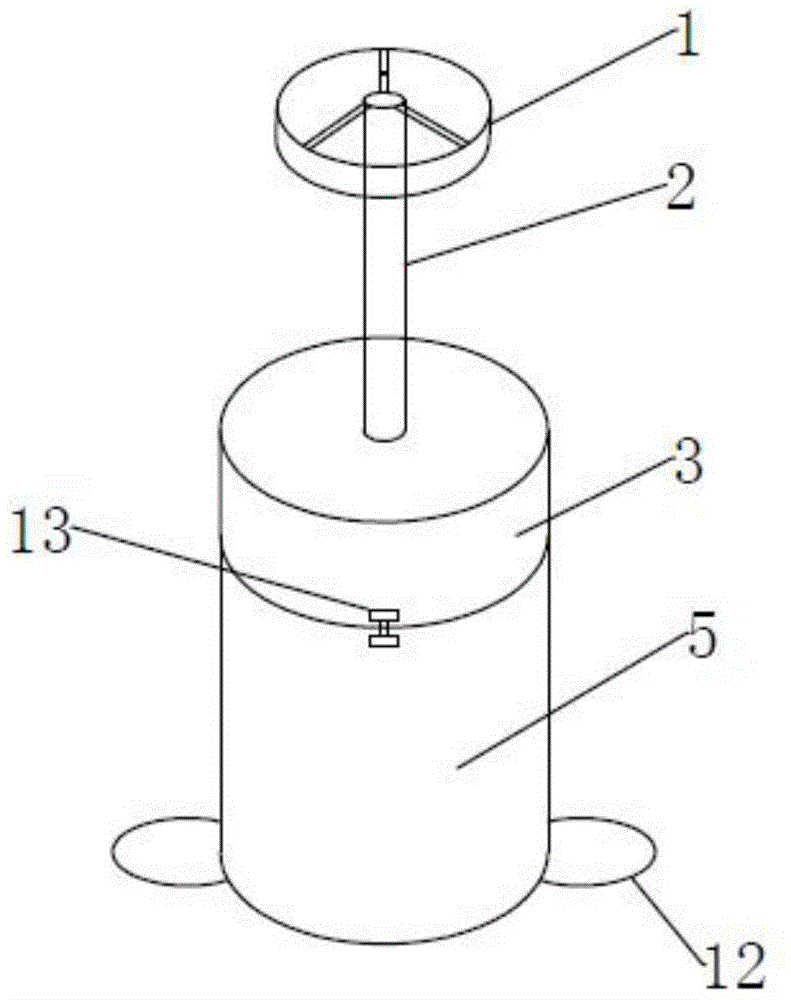

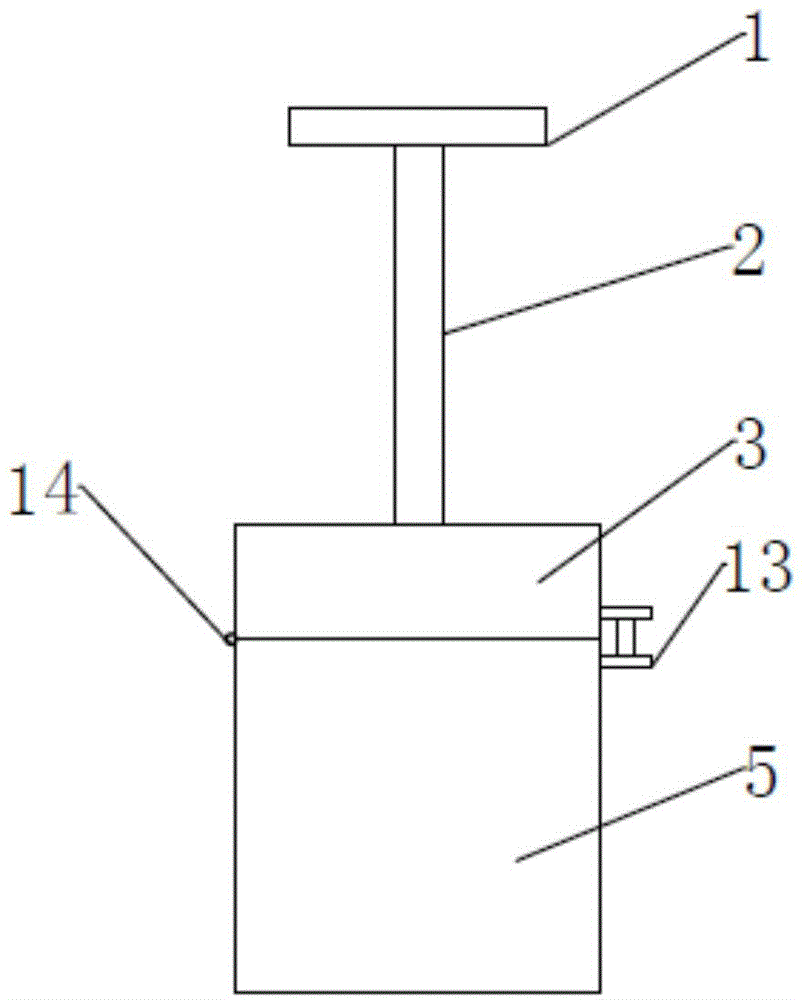

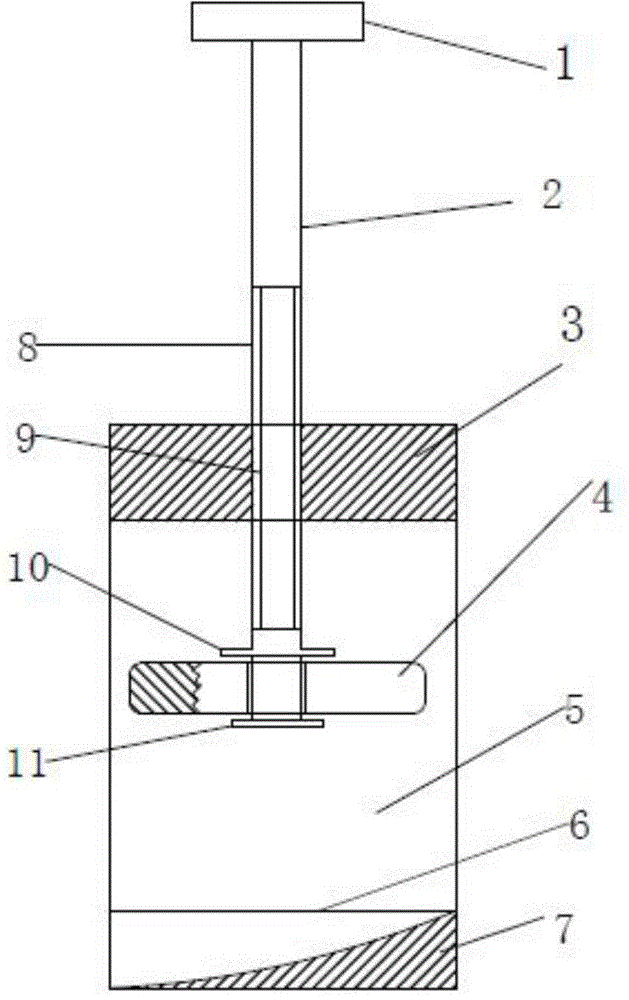

Thread propelling type manual clothes dewatering barrel

InactiveCN104358079ATo achieve the purpose of dehydrationReduce deformation and discolorationWashing apparatusTextiles and paperDewateringWater discharge

The invention relates to a manual clothes dewatering device and particularly relates to a thread propelling type manual clothes dewatering barrel. The thread propelling type manual clothes dewatering barrel comprises a dewatering barrel and a barrel cover, wherein the barrel cover is arranged above the dewatering barrel and a water discharging groove is formed in the bottom in the dewatering barrel; the barrel cover is provided with a hole and a rotary rod is mounted in the hole; the rotary rod upwards extends out of the barrel cover and downwards extends into the dewatering barrel; a rotary table is fixed at the top of the rotary rod and a pressing body sleeves the bottom of the rotary rod; pedals which are located at the two ends of the bottom of the dewatering barrel are arranged below the rotary rod; the pedals can drive the rotary rod to move up and down. The thread propelling type manual clothes dewatering barrel is low in cost and simple to operate; the working amount of manual dewatering is greatly reduced; meanwhile, clothes are only extruded in a dewatering process and are not rotated, and the deformation and fading problems of the clothes are alleviated, so that the clothes can be protected very well.

Owner:CHANGAN UNIV

Vehicle-mounted umbrella storage device

ActiveCN111964363AAchieve dehydration effectAchieve scrub cleaning effectGeneral water supply conservationDrying solid materials without heatIn vehicleStructural engineering

The invention relates to the technical field of vehicle-mounted equipment, and discloses a vehicle-mounted umbrella storage device. The vehicle-mounted umbrella storage device comprises a water-spinning barrel, a water tank and a servo motor, wherein a rotating column is fixedly arranged at the output end of the servo motor; a cross-shaped rotating rod is fixedly arranged on the top of the rotating column; rotating rings are fixedly arranged on the outer wall of the rotating rod; and combinations of rotating rings and limiting sleeves being assembled one above the other at intervals are arranged on the tops of the rotating rings. The vehicle-mounted umbrella storage device is simple in structure. Through work of a power source, not only the dehydration effect of a long-rod umbrella is achieved, but also the repeated washing-cleaning effect is achieved for the outer wall of the long-rod umbrella, a water body spun from an umbrella is filtered, and then the outer wall of the long-rod umbrella is washed, so that the effect of washing in a matching way is achieved. Moreover, the spun rain water is utilized fully and reused, the long-rod umbrella can be dehydrated easily and rapidly after passengers get on vehicles, the rainwater on the long-rod umbrella is prevented from falling in a bus, and the problem of wet and slip ground in the vehicles is solved.

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

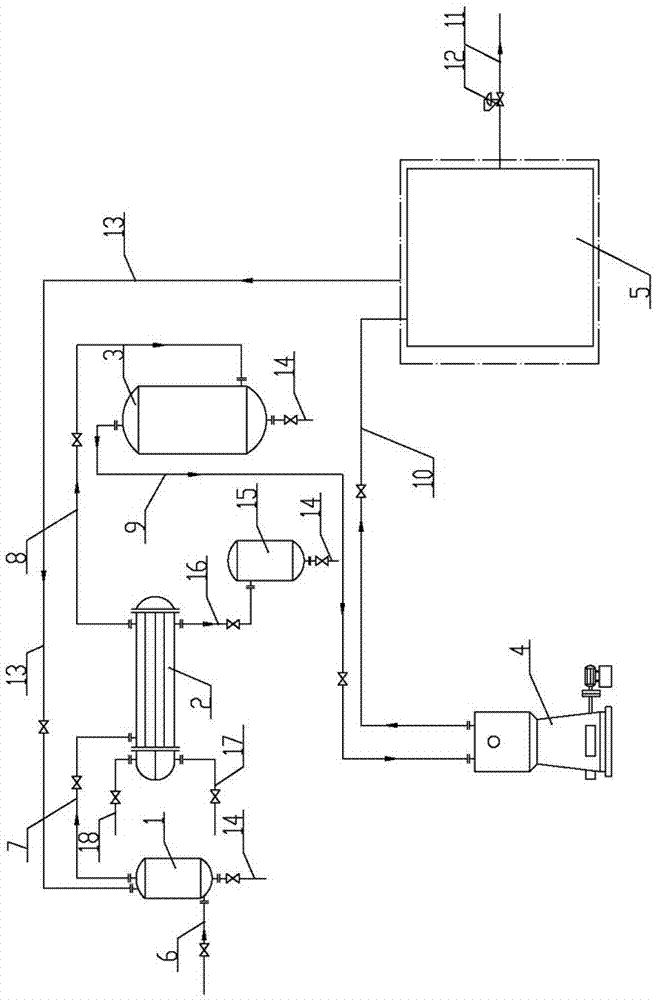

Acetylene gas dehydrating apparatus

InactiveCN107158738ATo achieve the purpose of dehydrationCompact and reasonable structureGas treatmentDispersed particle separationAcetyleneChemistry

The invention relates to the technical field of dehydrating apparatuses, in particular to an acetylene gas dehydrating apparatus. The acetylene gas dehydrating apparatus comprises an acetylene flame arrestor, a cooler, an acetylene defogger, an acetylene compressor and an acetylene dryer; the lower portion of the acetylene flame arrestor is provided with a gas inlet end, the top of the acetylene flame arrestor is provided with a gas outlet end, the gas inlet end of the acetylene flame arrestor is fixedly connected with a gas inlet pipe, the gas outlet end of the acetylene flame arrestor is fixedly connected with the gas inlet end of the cooler by virtue of a first pipeline, the lower portion of the acetylene defogger is provided with a gas inlet end, the top of the acetylene defogger is provided with a gas outlet end, the gas outlet end of the cooler is fixedly connected with the gas inlet end of the acetylene defogger by virtue of a second pipeline, the gas outlet end of the acetylene defogger is fixedly connected with the gas inlet end of the acetylene compressor by virtue of a third pipeline, the gas outlet end of the acetylene compressor is fixedly connected with the gas inlet end of the acetylene dryer by virtue of a fourth pipeline, the gas outlet end of the acetylene dryer is fixedly connected with a gas outlet pipe, and the gas outlet pipe is fixedly provided with a self-power adjusting valve. The acetylene gas dehydrating apparatus is reasonable and compact in structure and convenient to use; and by virtue of the cooperative use of the acetylene flame arrestor, the cooler, the acetylene defogger, the acetylene compressor and the acetylene dryer, an acetylene dehydrating purpose is achieved; and the acetylene gas dehydrating apparatus has the characteristics of safety, reliability and good dehydrating effect, is convenient to operate, reduces the maintenance frequency and safety potential hazard of the equipment, prolongs the service life of the device, and decreases the production cost.

Owner:新疆中泰新鑫化工科技股份有限公司

Sludge recycling device

PendingCN114315084ASpeed up filteringHigh recovery rateSludge treatmentStationary filtering element filtersElectric machineDrive shaft

The invention discloses a sludge recycling device which comprises a recycling frame, the top of the recycling frame communicates with a connecting frame, the side, away from the recycling frame, of the connecting frame communicates with a feeding pipe, supporting bases are evenly installed at the bottom of the recycling frame, and a driving motor is installed on the outer side of the recycling frame. The output end of the driving motor is connected with a rotating shaft through a transmission, the end, away from the transmission, of the rotating shaft penetrates through the recycling frame to be connected with a driving shaft, the inner wall of the recycling frame is rotationally connected with a control shaft through a control device, and a water collecting frame is installed at the position, close to the driving shaft, of the inner wall of the recycling frame. And one side of the water collecting frame communicates with a water outlet pipe, and conical baffles are evenly installed on the inner wall of the connecting frame. According to the sludge recycling device, dewatered sludge can be automatically collected, the purpose of automatically replacing the filter screen is achieved, and the sludge filtering speed is effectively increased.

Owner:席芳芳

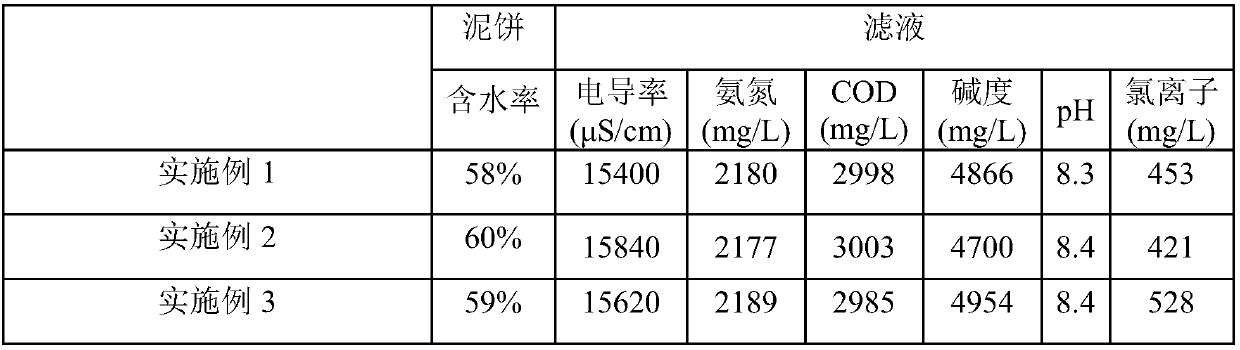

Dehydration conditioner for high temperature anaerobic digested sludge and dehydration method of high temperature anaerobic digested sludge

InactiveCN109970313AImprove dehydration effectReduce mutual exclusionSludge treatment by de-watering/drying/thickeningSludgeSolid content

The invention discloses a dehydration conditioner for high temperature anaerobic digested sludge and a dehydration method of high temperature anaerobic digested sludge. The dehydration conditioner comprises an acryloyloxyethyl trimethyl copolymer and cationic polyacrylamide, the weight ratio of the acryloyloxyethyl trimethyl copolymer is 1.1%-1.37% of the solid content of the high temperature anaerobic digested sludge, and the weight ratio of the cationic polyacrylamide is 0.27%-0.36% of the solid content of the high temperature anaerobic digested sludge. The dehydration method of the high temperature anaerobic digested sludge adopts the dehydration conditioner for conditioning. The dehydration conditioner provided by the invention has the advantages of no corrosiveness, no increase of sludge ash content, no change of the properties of the filter cake and filtrate, good dehydration performance, good applicability, low cost, no secondary pollution, etc., is an environment-friendly conditioner that has good application prospects and can efficiently condition high temperature anaerobic digested sludge, and can achieve the advantages of simple method, good dehydration effect and the like when used for dehydration of high temperature anaerobic digested sludge.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Exhaust funnel and exhaust method for wet dedusting purification

ActiveCN110639284ASmall footprintRealize gas-water separationDispersed particle separationEngineeringDust control

The invention discloses an exhaust funnel and an exhaust method for wet dedusting purification. The exhaust funnel comprises a barrel, a core tube, a spiral partition plate, a heating mechanism and awater collecting funnel, the core tube is mounted in the barrel, the heating mechanism is mounted at the top end of the core tube, and is used for heating dehydrated smoke, the water collecting funnelis mounted at the bottom of the barrel of the exhaust funnel, a gap is formed between the core tube and the barrel of the exhaust funnel, the spiral partition plate is mounted between the barrel andthe core tube to form a continuous spiral channel, and the spiral channel is used for heating the dehydrated smoke and then discharging the heated dehydrated smoke.

Owner:BERIS ENG & RES CORP

High pressure water-saving jet dyeing technology for wool fabrics and vaporized water recovery system

InactiveCN106854839ATo achieve the purpose of dehydrationAvoid Damage DefectsTextile treatment machine arrangementsDyeing processExhaust valveInlet valve

The invention discloses a high pressure water-saving jet dyeing technology for wool fabrics and a vaporized water recovery system. The specific steps include: adding dye and water into a dye vat to conduct mixing; performing uniform jet dyeing on wool fabrics; and outputting the wool fabrics from a low pressure cavity, thus finishing jet dyeing of the wool fabrics. The invention also provides a vaporized water recovery system, which consists of a water collection tank, a vacuum pump and a pneumatic pump, the water collection tank is fixedly equipped with a water inlet pipe, the water inlet pipe is provided with a water inlet valve, an exhaust port is fixedly disposed on the water collection tank, an exhaust valve is mounted on the exhaust port, an air outlet of the vacuum pump is connected to the water collection tank through a pipeline, and a water inlet of the pneumatic pump is connected to the water collection tank through a pipeline. The technology provided by the invention has the advantages of high dyeing uniformity, water resource saving and high production efficiency, etc.

Owner:JIANGSU NEW REBA TECH CO LTD

A method for rapidly drying desulfurized gypsum

The invention discloses a method for quickly drying flue gas desulfurization gypsum. The method comprises the following steps: adding 1.0-2.0wt% of an additive into the flue gas desulfurization gypsum, uniformly stirring, and then naturally standing until the flue gas desulfurization gypsum reaches drying requirements. According to the method, industrial waste residue is used as the additive of raw materials, and conventional energy resources do not need to be consumed. The additive is made from industrial waste residues, does not consume conventional energy resources and is simple in production process; since the raw material is the industrial waste residue, resource utilization of the industrial waste residue is achieved, and energy resources are saved simultaneously. By utilizing the method, operation is simple and convenient, the purpose of dewatering can be achieved in natural state, the effect is good, the operation period is short, and the performance of a product can not be changed due to low mixing amount of the additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for dehydrating mops

InactiveCN104799790BEasy clampingTo achieve the purpose of dehydrationCarpet cleanersFloor cleanersEngineeringDehydration

The invention discloses a device for dewatering a mop. The device comprises a circular truncated cone, a mop rod clamping device, a mop head clamping device and a mop head clamping driving device, wherein the mop head clamping driving device comprises a ratchet wheel, pawl, a balance weight block, a swing rod and a horizontal U-shaped pressing rod; the upper end of the swing rod is fixedly connected with the U-shaped pressing rod; the middle part of the swing rod is hinged to the circular truncated cone; the balance weight block is fixedly connected to the lower end of the swing rod; the rod parts of the two free ends of the U-shaped pressing rod are pressed against the mop head clamping device; the ratchet wheel is fixedly connected to a hinge pin shaft of the swing rod and the circular truncated cone; one end of the pawl is hinged to the circular truncated cone, and the other end of the pawl is clamped with the ratchet wheel. By adoption of the structure, the working noise is greatly reduced, and the mop can be dried more deeply, so that cleaning the ground is facilitated; meanwhile, the mop head clamping driving device adopts a structure for combining the balance weight block with the swing rod; the device for dewatering the mop is simple in structure and convenient to operate.

Owner:浙江九龙山实业股份有限公司

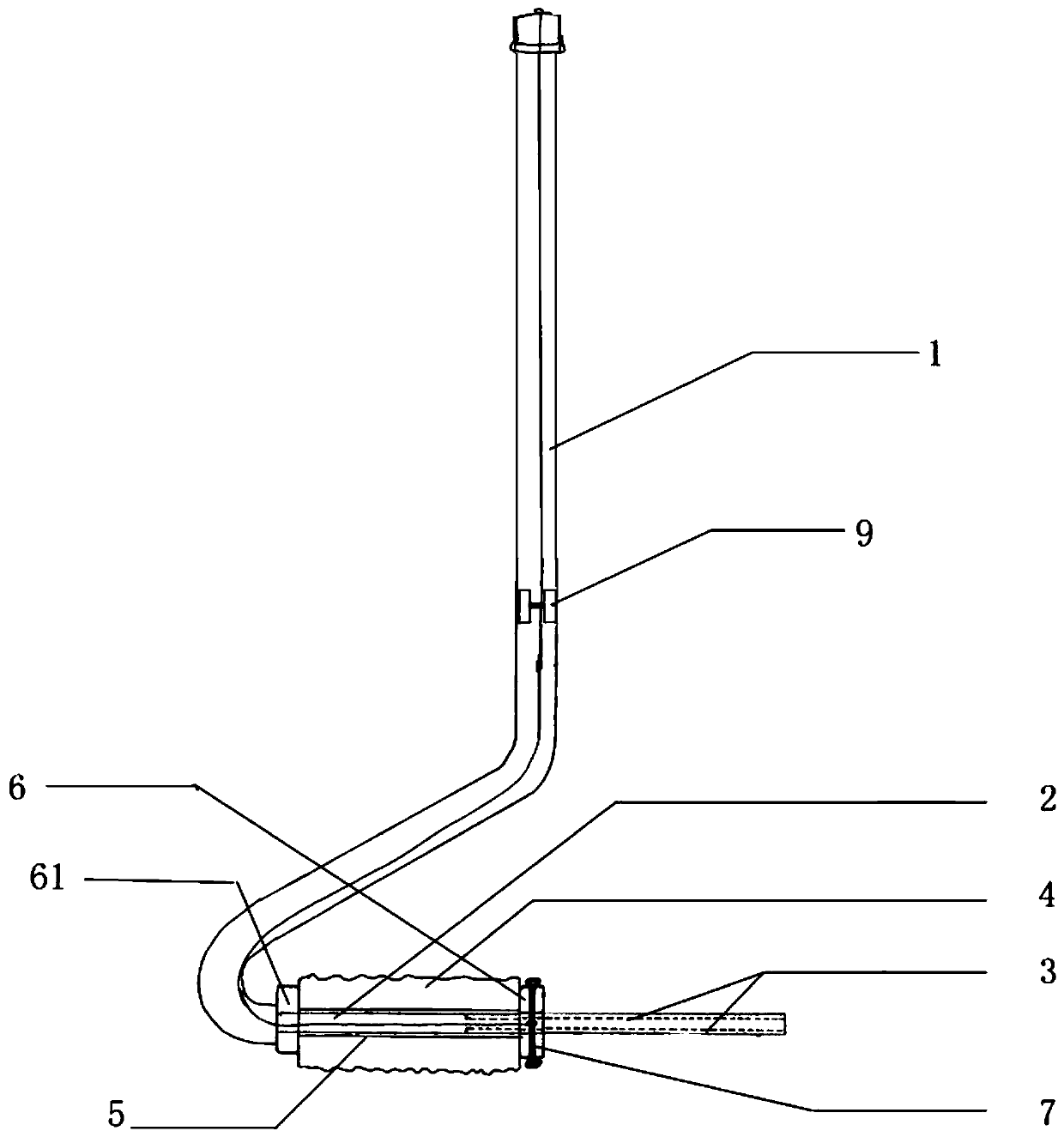

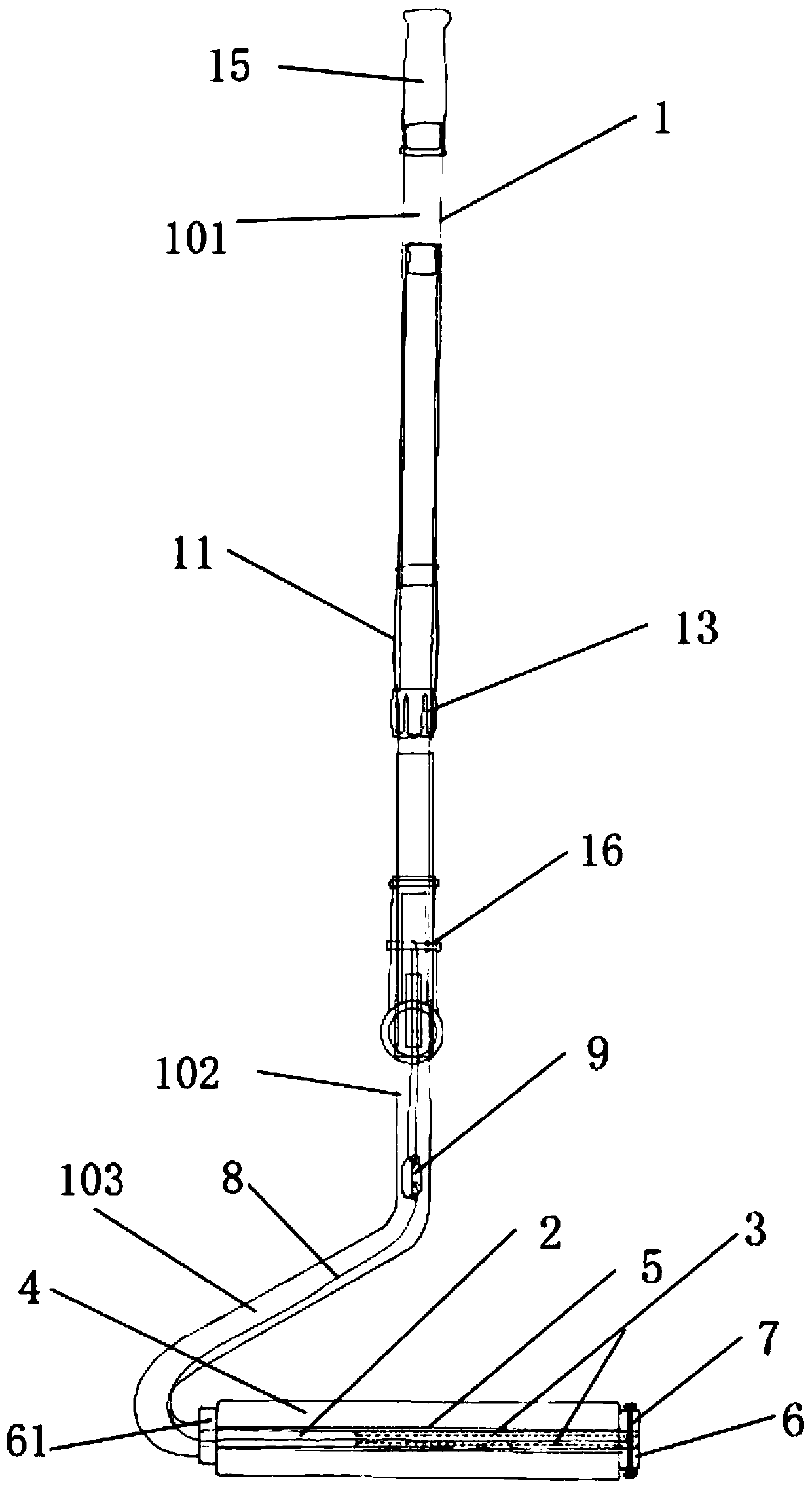

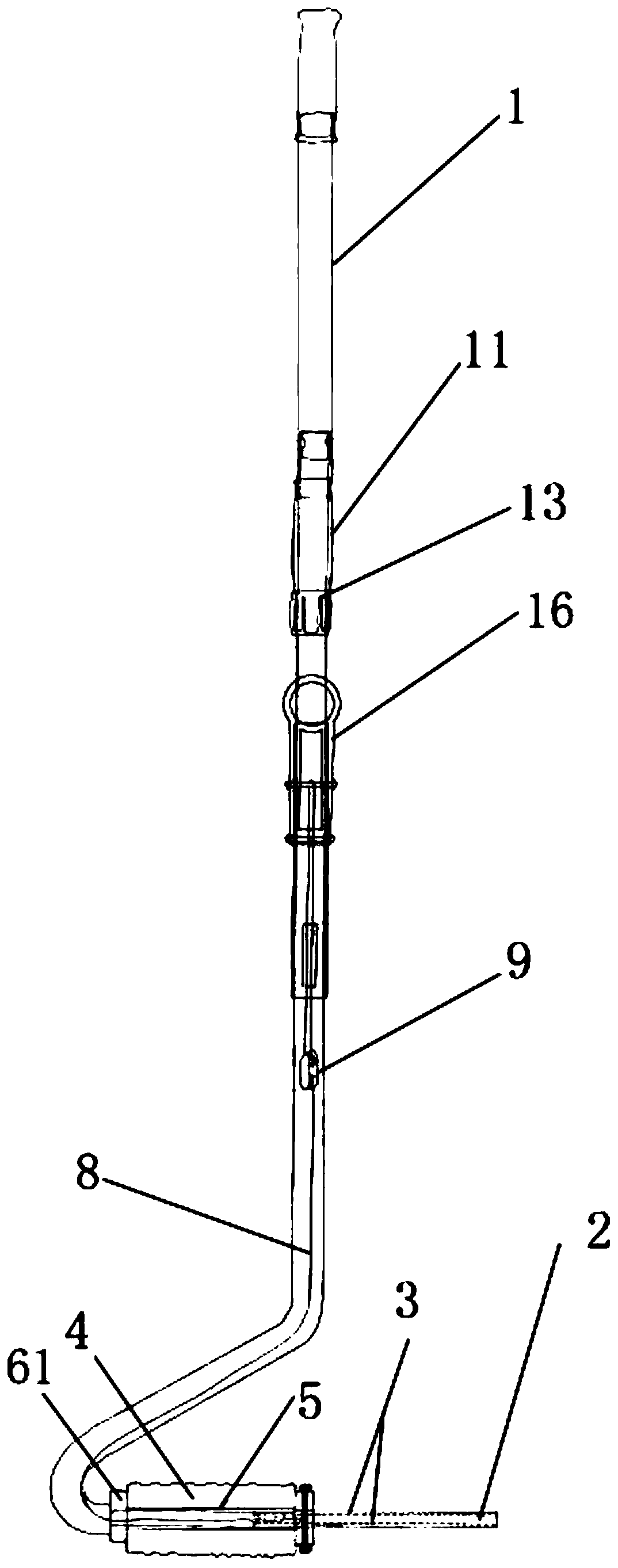

7-shaped rolling type mop

PendingCN111067442ASimple structureReduce production processCarpet cleanersFloor cleanersStructural engineeringMechanical engineering

A 7-shaped rolling type mop comprises a mop rod and a mop head arranged at the lower end of the mop rod, and further comprises a pull rope. The mop rod is hollow and comprises a straight rod and a transverse rod. One end of the straight rod is communicated with one end of the transverse rod to form a 7 shape. The pull rope is arranged in the mop rod, and the two ends of the pull rope are located in the straight rod and the transverse rod respectively. The mop head comprises a strip-shaped elastic cleaning body, a first clamping piece and a movable shaft, through slots are formed in the two walls of the cross rod, a mounting hole is formed in the elastic cleaning body in the length direction, and the elastic cleaning body is arranged on the cross rod in a sleeving mode through the mountinghole. The movable shaft is installed in the radial direction of the first clamping piece, the other end of the cross rod is sleeved with the first clamping piece, and the movable shaft can slide in the slot. One end of the pull rope is located in the transverse rod and fixed to the movable shaft, and the other end of the pull rope extends outwards from the straight rod. The pull rope is pulled todrive the movable shaft and the first clamping piece to move towards the communication position of the straight rod and the cross rod, the elastic cleaning body is compressed, water is squeezed out, dewatering is completed, a special mop bucket is not needed, and a mop head does not need to be directly contacted and cleaned.

Owner:许刚

Dehydration device and dehydration method for aqueous vinyl chloride monomer

ActiveCN105294389BTo achieve the purpose of dehydrationCompact and reasonable structureHalogenated hydrocarbon separation/purificationEthyl ChlorideChloride vinyl

The invention relates to the technical field of dehydration devices, and relates to a dehydration device and a dehydration method for aqueous vinyl chloride monomers; the dehydration device for aqueous vinyl chloride monomers includes a first spherical tank and a steam-water separator; A first water storage bag communicating with the cavity of the first spherical tank is fixed, there is a water outlet port at the bottom of the first water storage bag, and a vinyl chloride recovery port and a first water inlet port are respectively arranged at the top of the steam-water separator The water outlet end of the first accumulated water bag and the first water inlet end of the steam-water separator are fixedly connected together through the first water outlet pipe, and a vinyl chloride recovery pipe is fixedly installed on the vinyl chloride recovery port end of the steam-water separator. The invention has a reasonable and compact structure and is easy to use. Through the cooperative use of the first spherical tank, the second spherical tank, the steam-water separator and the solid alkali dryer, the purpose of dehydrating the hydrous vinyl chloride monomer is realized, and it is safe, reliable and has a good dehydration effect. The characteristics are convenient for operation, improve work efficiency and reduce production cost.

Owner:XINJIANG ZHONGTAI CHEM CO LTD

ABS (Acrylonitrile Butadiene Styrene) and PA (Polyamide) dewatering master batch and preparation method thereof

ActiveCN101942127BDoes not affect appearanceMechanical strength is not affectedPolymer sciencePolyamide

The invention provides an ABS (Acrylonitrile Butadiene Styrene) and PA (Polyamide) dewatering master batch and a preparation method thereof. The dewatering master batch mainly comprises a dewatering agent, an inorganic filler, a surfactant, a processing aid and carrier resin by a weight ratio of (50-80):(20-40):(1-5):(5-10):(15-30). The preparation method of the dewatering master batch comprises the following steps of: firstly, carrying out surface activation treatment on the dewatering agent and the inorganic filler in a high-speed stirrer by using the surfactant; then adding the processing aid and the carrier resin and uniformly mixing; and finally, granulating by using a double-screw extruder. The dewatering master batch prepared by the invention is convenient to use, has good dewatering effect and does not influence the appearance and the mechanical strength of ABS and PA products.

Owner:杭州嘉和材料科技有限公司

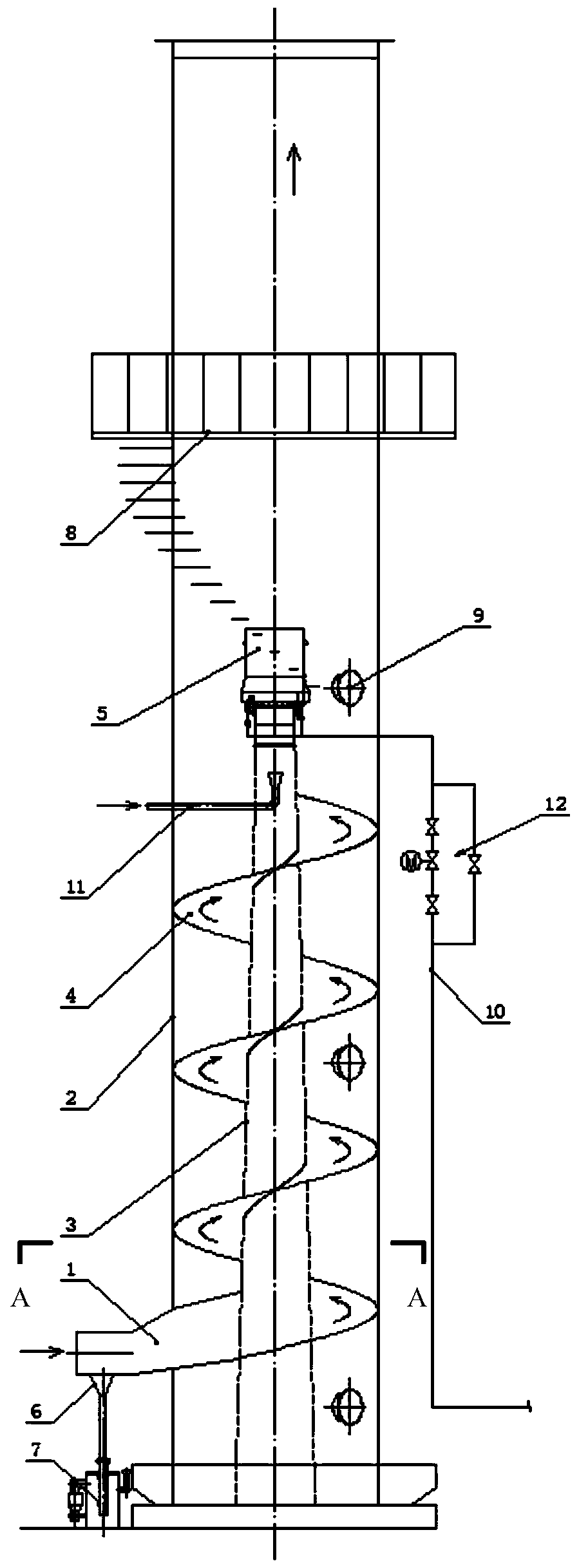

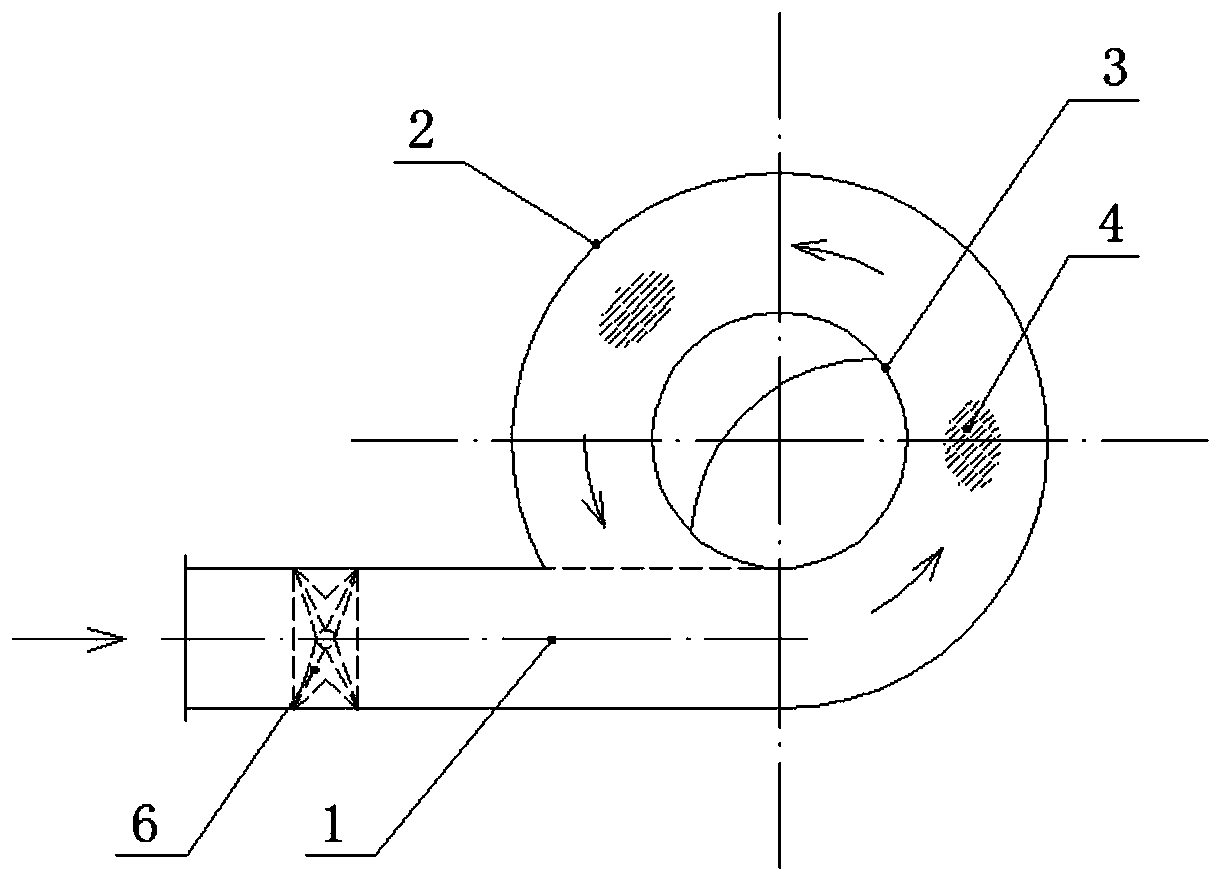

Method for conditioning and modifying sludge generated in landfill leachate

InactiveCN109592880ALower specific resistanceFast water flowSludge treatment by de-watering/drying/thickeningContaminated groundwater/leachate treatmentSludgeOrganic compound

The invention relates to a method for conditioning and modifying sludge generated in landfill leachate. The method comprises the following steps: diluting organic compound conditioning modifier to a solution having the concentration of 0.1-5percent (W / W); uniformly stirring in landfill leachate sludge, and keeping the sludge concentration to be 1-10 percent; uniformly stirring with 5-60 percent ofsolid frame powder; delivering through a feed pump to dehydration equipment, and dehydrating; and controlling the water content of output mud cake. The method for conditioning and modifying sludge generated in landfill leachate is environment-friendly since the special organic compound sludge conditioning modifier and solid frame powder are adopted to replace existing conditioning modifying agentwith metal ion ingredients, and can greatly reduce the sludge specific resistance, achieves the aim of deep dehydrating sludge since the free water outlet speed is increased by forming a water filterchannel, and cannot influence the landfill leachate film system.

Owner:湖州智清环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com