Coal tar pretreatment combined system and method

A coal tar and pretreatment technology, applied in tar processing, tar removal through water, petroleum industry, etc., can solve the problems of adverse effects of coal tar processing, large loss of raw materials, high energy consumption of distillation treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

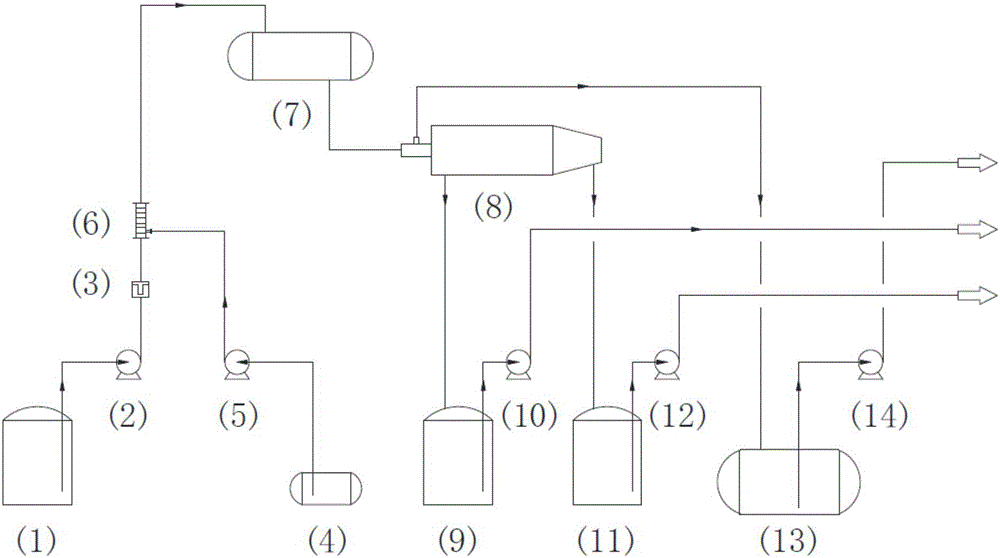

[0020] Coal tar pretreatment combined system and method of the present invention, its preferred embodiment is:

[0021] Including coal tar raw material tanks, demulsifier tanks, separated feed buffer tanks, three-phase separators, sewage tanks, slag tanks, and oil tanks;

[0022] The coal tar raw material tank is sequentially connected with the separation feeding buffer tank through a coal tar raw material pump, an automatic backwash filter, and a static mixer, and the separation feeding buffer tank is connected with the three-phase separator. The three-phase separator is connected with the sewage tank, slag tank and oil tank respectively, and the sewage tank, slag tank and oil tank are respectively connected with the sewage pump, slag pump and oil pump, and the demulsifier tank is connected with the demulsifier tank through the demulsifier pump. connection to the static mixer described above.

[0023] The above-mentioned coal tar raw material pretreatment combined system of ...

Embodiment 1

[0041] Continuous pretreatment of medium and low temperature coal tar with an annual processing capacity of 50,000 tons, with an hourly flow rate of 6.25 tons / hour. The water content of untreated coal tar is 9.13%, and the mechanical impurity content is 8.9%. The coal tar is heated to 75°C through the heating coil of the storage tank, and after standing for 24 hours, after the oil and water in the coal tar have settled and stratified, the water content of the bottom tar is 6.5%, and the impurity content is 8.2%. After passing through the automatic backwashing device with a filtration precision of 100 μm, the impurity content in the tar is reduced to 4.3%. The filtered coal tar and demulsifier are mixed in a static mixer according to the ratio of 1000 (g): 1 (mL), and the fully mixed coal tar is allowed to stand for 5 minutes in a separate feed buffer tank, and then sent to the three-phase separation Water and impurities are further separated in the machine. The centrifugal sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com