Patents

Literature

111results about "Tar working-up by water removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

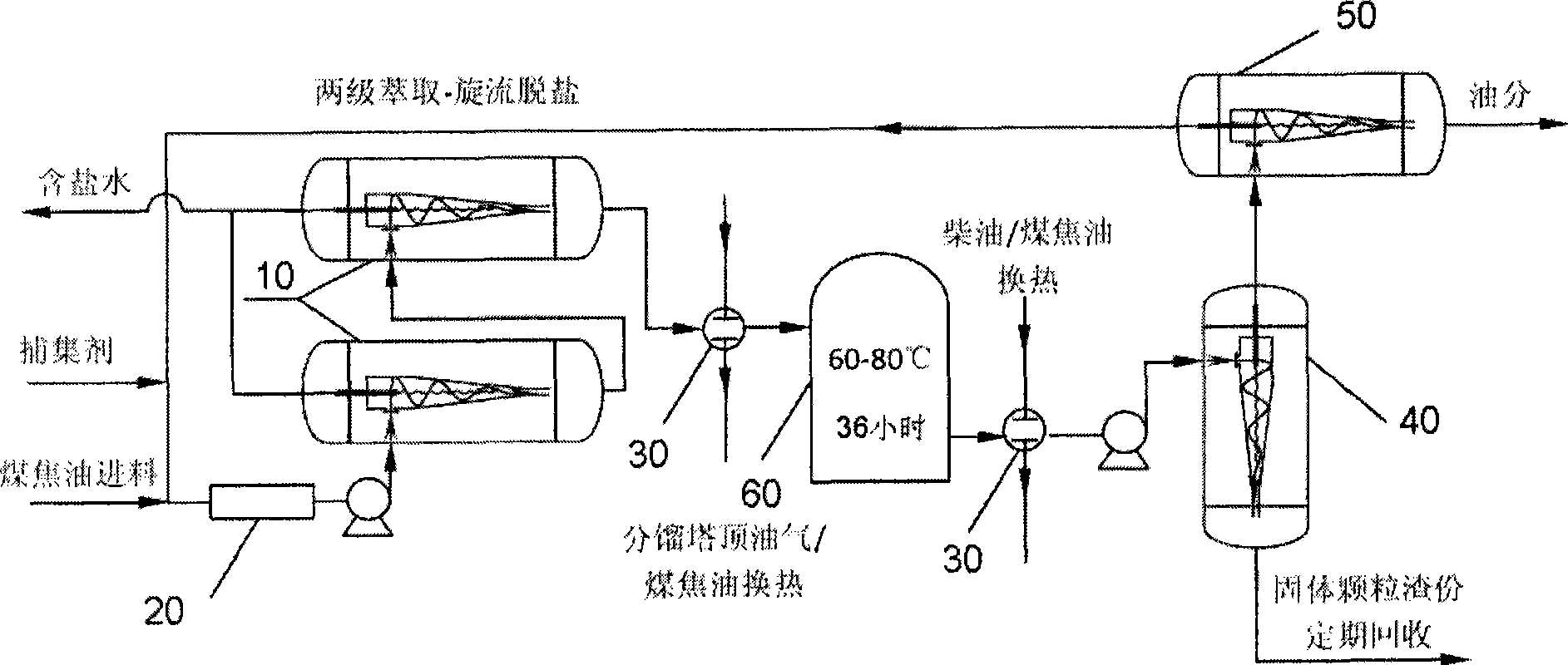

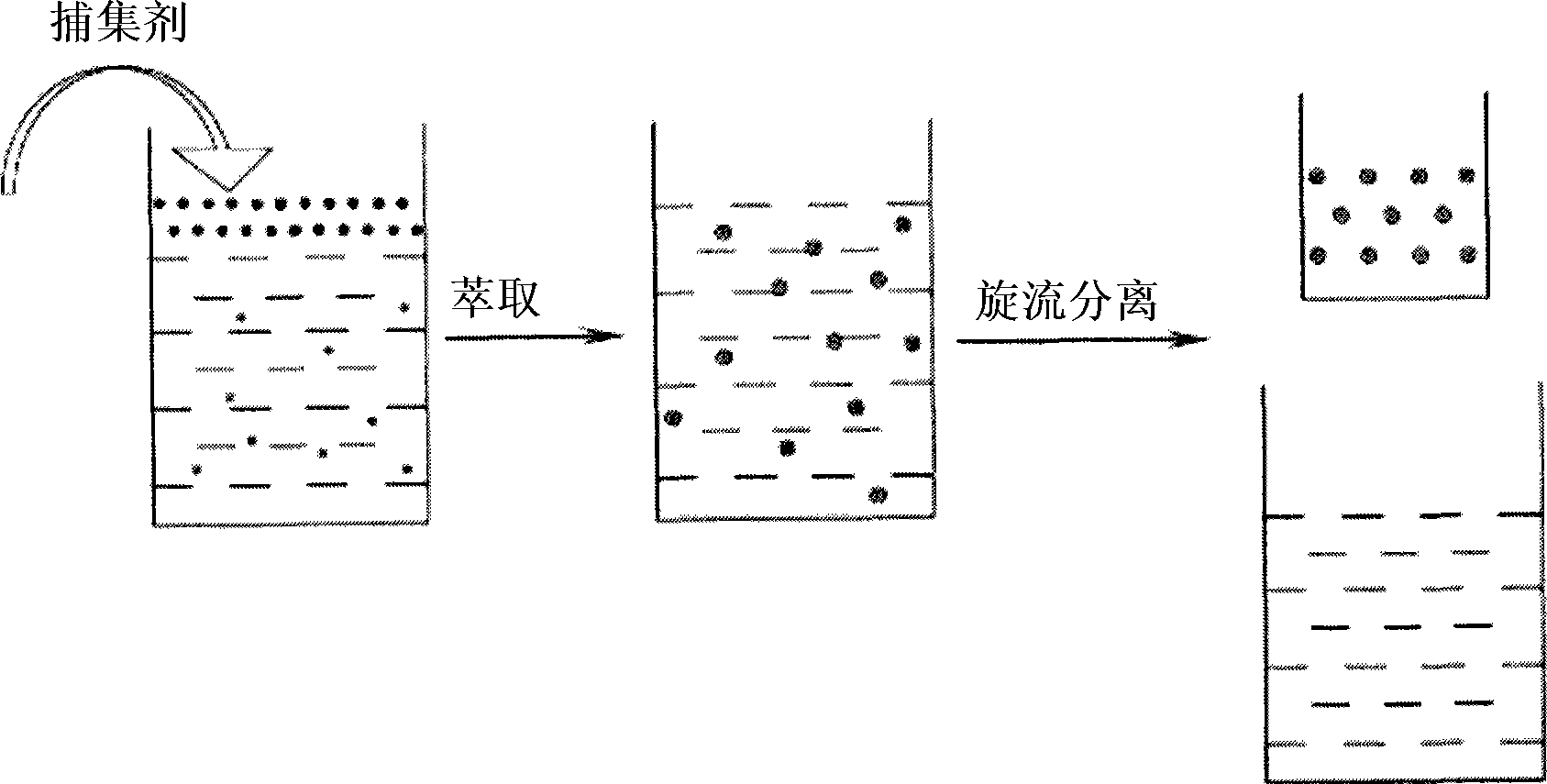

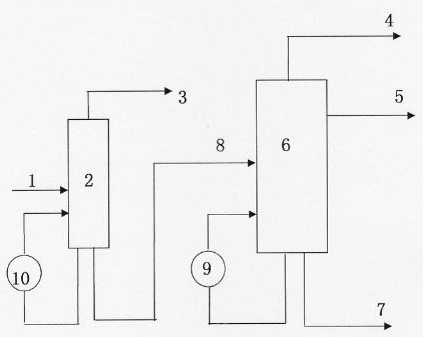

Coal tar coupled rotational flow purification method and apparatus

ActiveCN101475818AReduce heat consumptionReduce resistanceTar working-up by water removalTar working-up by solvent extractionPurification methodsPhysical chemistry

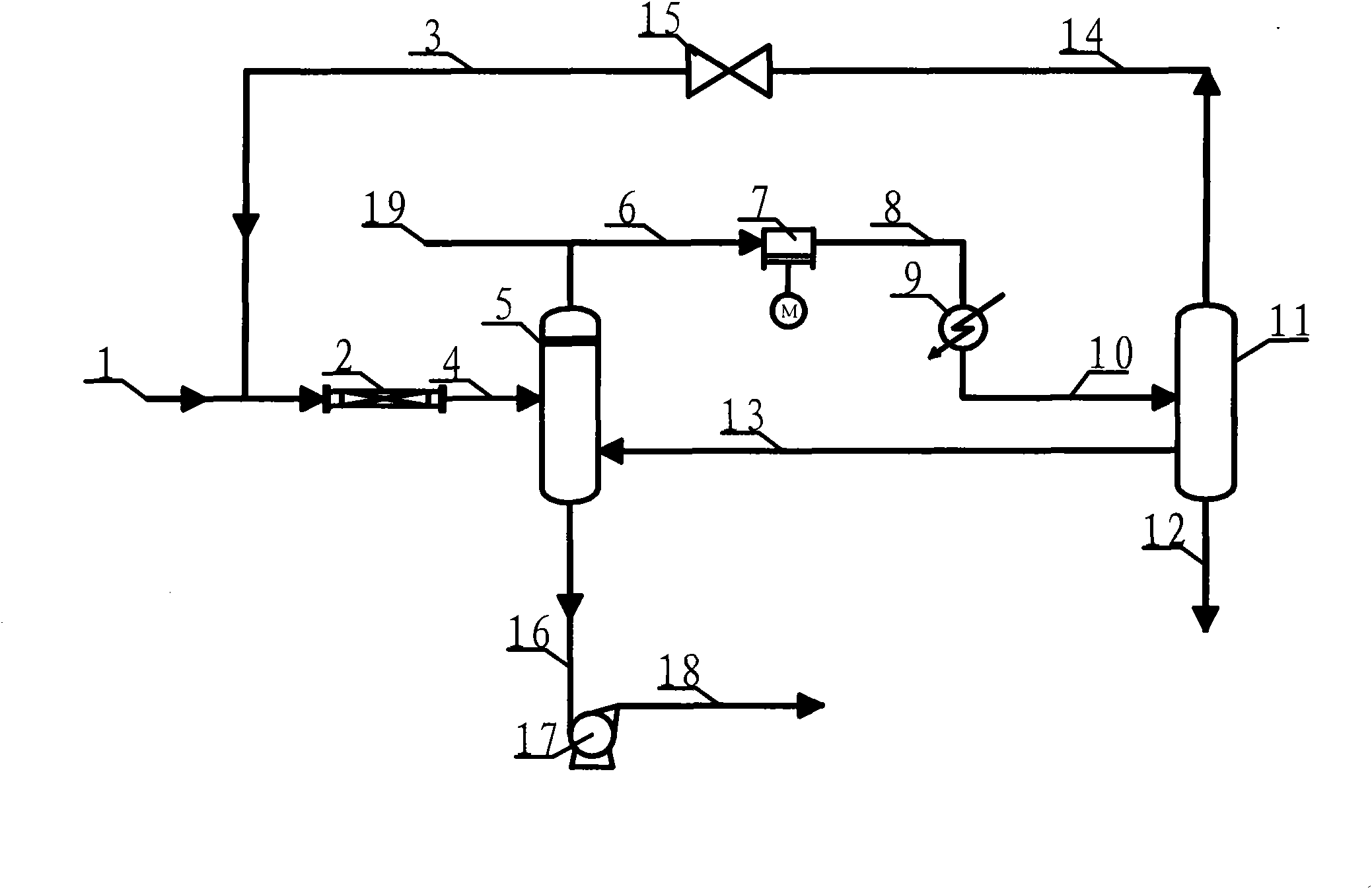

The invention relates to a method and a device for purifying coal tar through coupling rotational flow, wherein the method for purifying the coal tar through coupling rotational flow comprises the following steps: (a) mixing coal tar feed with a trapping agent sufficiently so as to extract out saline matters dispersed in the coal tar; (b) performing liquid-liquid rotational flow separation on thecoal tar in which the dispersed saline matters are extracted out for separating out the saline matters so as to obtain desalinated coal tar; (c) keeping stand and depositing the desalinated coal tar so as to remove the moisture therein and obtain dehydrated coal tar; (d) performing solid-liquid rotational flow separation on the dehydrated coal tar so as to remove solid particles therein and obtain the coal tar without the solid particles; and (e) performing micro rotational flow separation on the coal tar without the solid particles so as to remove the micro moisture therein. The invention also provides a device for purifying the coal tar through the coupling rotational flow.

Owner:EAST CHINA UNIV OF SCI & TECH

Process and complete equipment for pretreating coal tar

InactiveCN102079983AReduce the impactLess investmentTar working-up by water removalDesalinationThree-phase

Owner:江苏三星化工有限公司

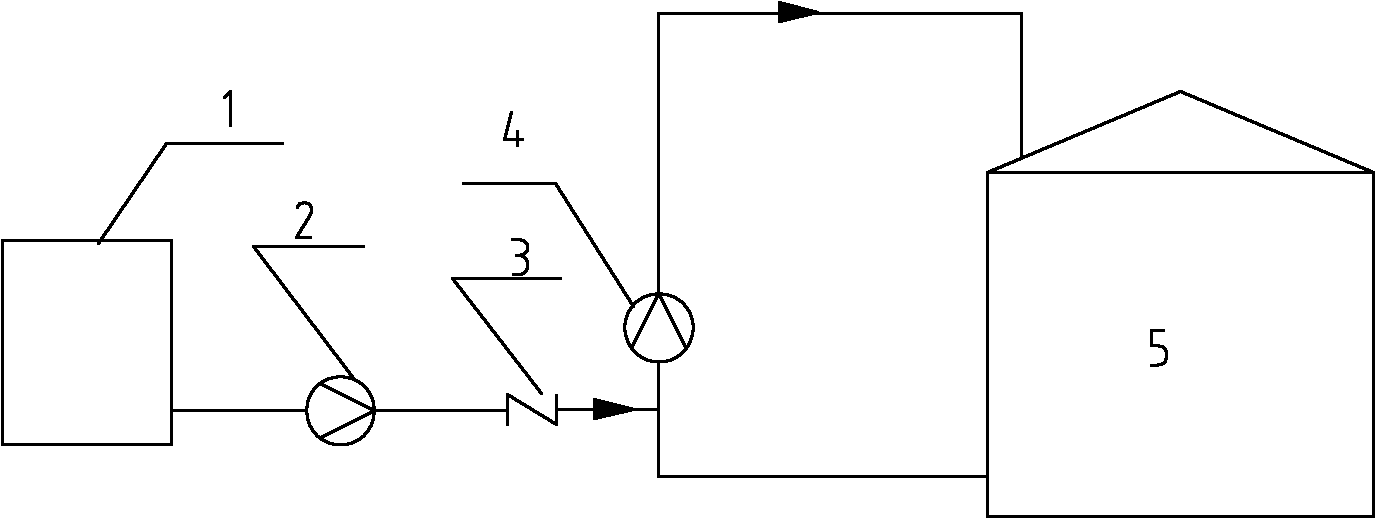

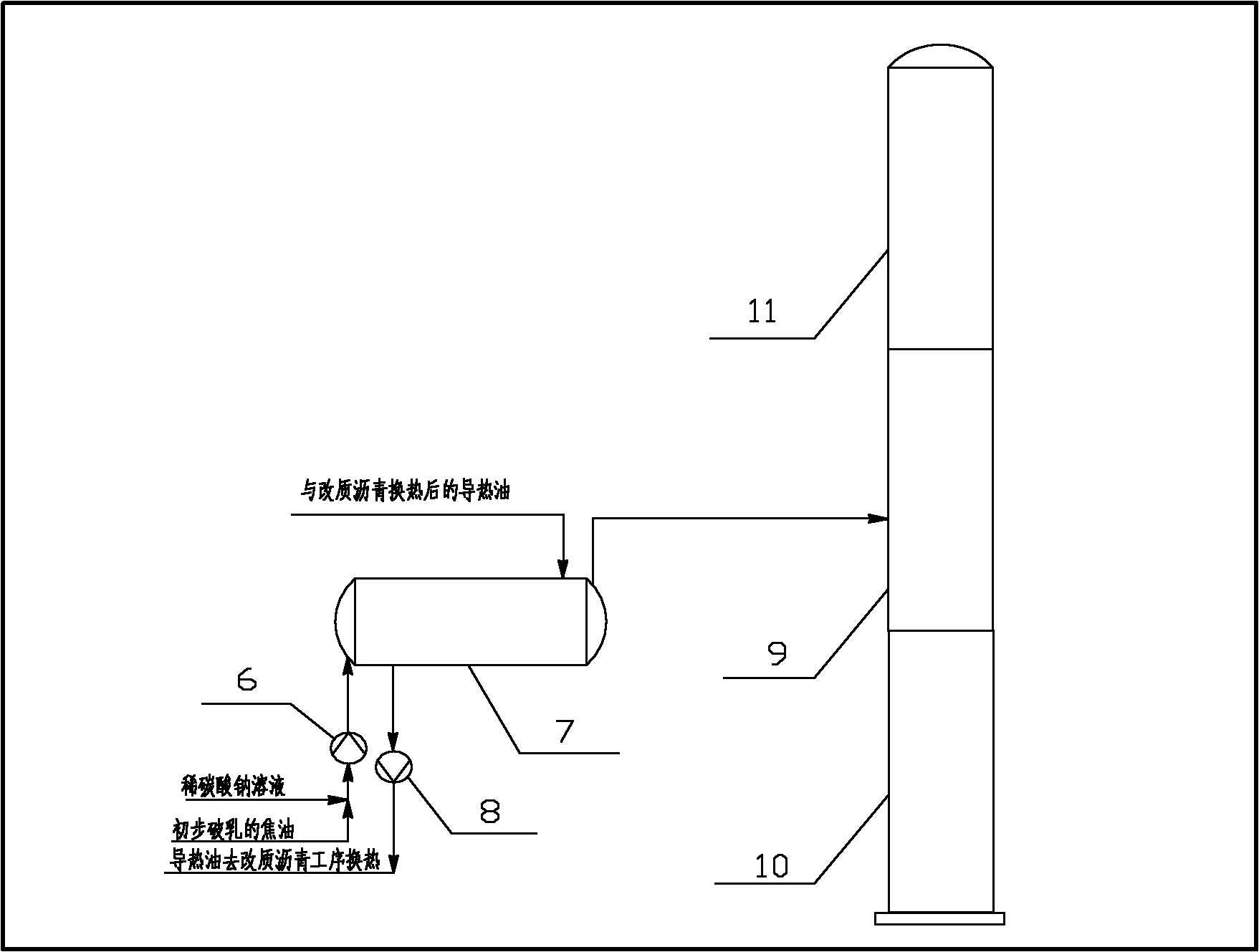

Demulsification, neutralization and dehydration method of acidic emulsified tar

InactiveCN102839007AAvoid Operational DeteriorationReduce economic lossTar working-up by water removalDistillationTar

The invention provides a demulsification, neutralization and dehydration method of acidic emulsified tar. A certain proportion of demulsification agent, such as a nonionic surfactant, is added to the acidic emulsified tar for mixing, stirring, heating and standing to change performances of an tar-water interface and ensure that water drops in the W / O type emulsified tar are condensed, thereby achieving preliminary demulsification and preliminary separation of the tar from water; alkali is added for neutralization; waste heat of heat conduction oil for producing modified pitch is used to heat the preliminarily demulsified tar to 110-140 DEG C; pressure is increased to 0.2-0.4Mpa; the tar is subjected to flash evaporation and dehydration in a primary evaporator; the moisture is further reduced; the tar is neutral; and the dehydrated tar is prepared for use and can satisfy the distillation production.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

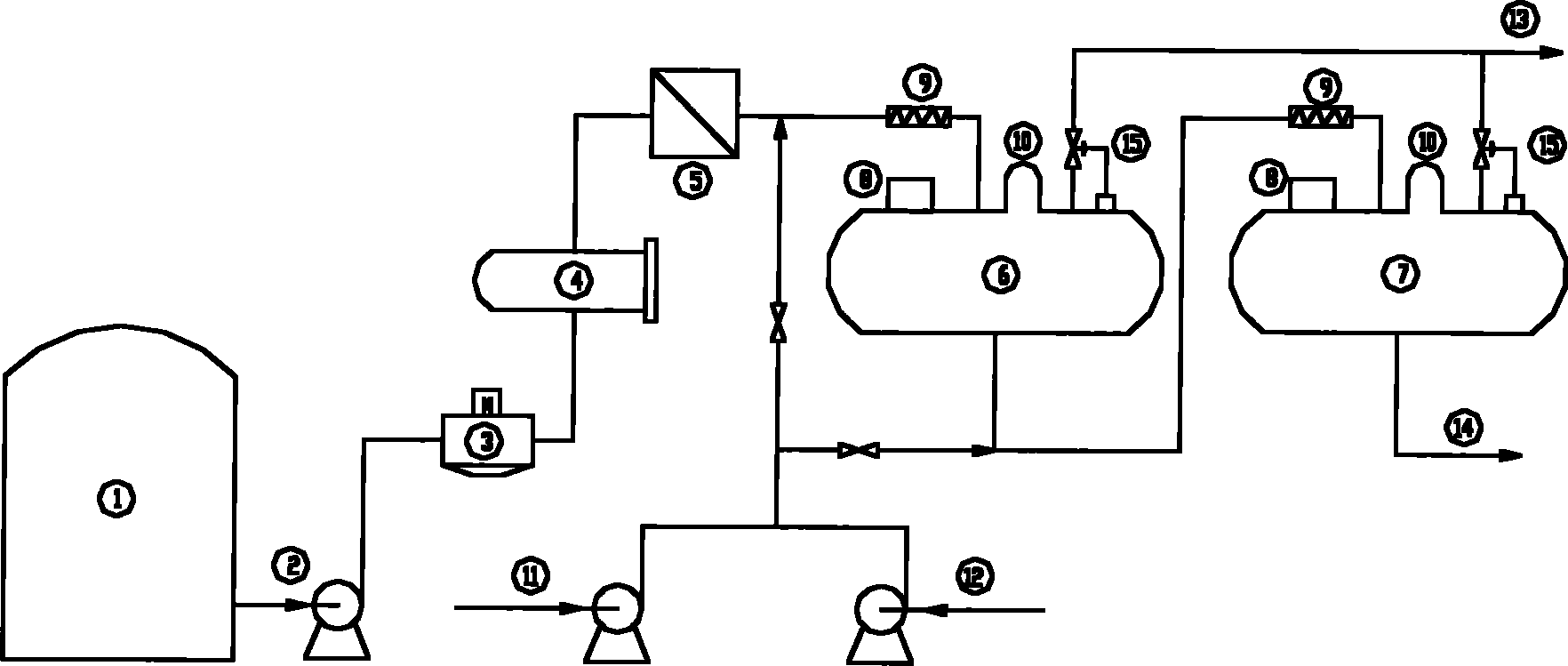

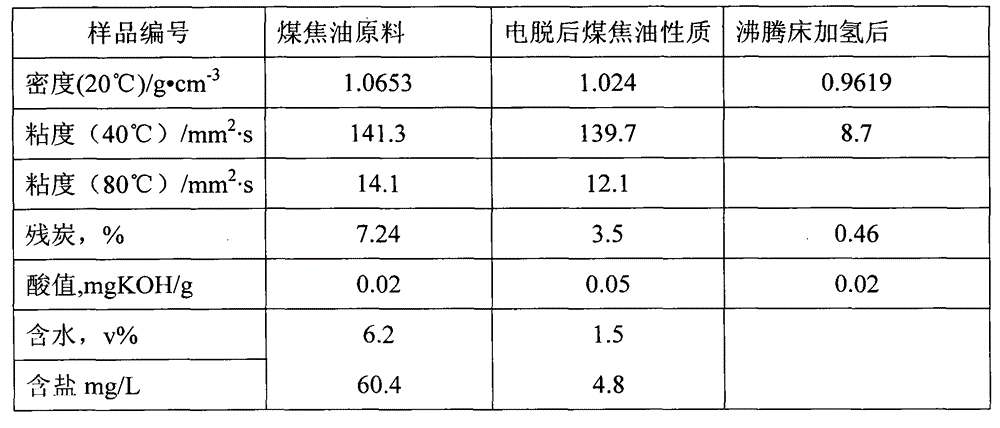

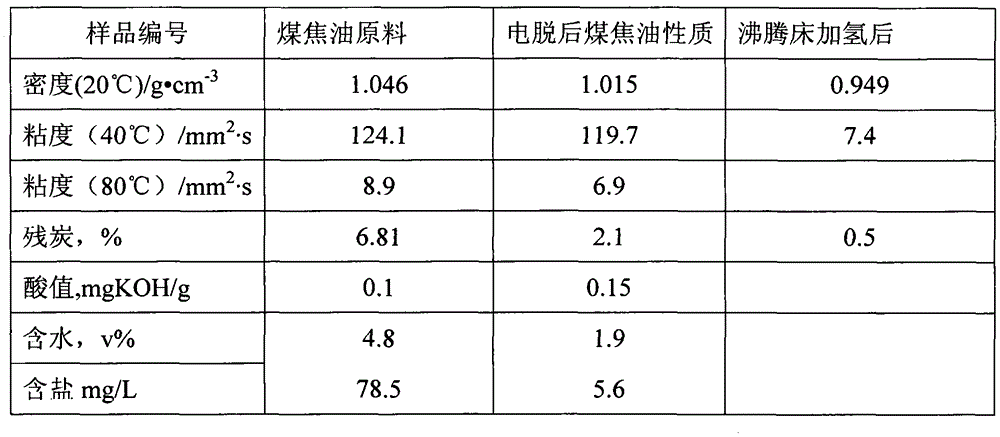

Electric desalting, dewatering and deslagging method for coal tar

InactiveCN103102933AAvoid latent heat of vaporizationTreatment with plural serial refining stagesTar working-up by water removalSoftened waterWater quality

The invention discloses an electric desalting, dewatering and deslagging method for coal tar, which is suitable for deep desalting, dewatering and impurity-removing treatment of high-temperature coal tar, medium-temperature coal tar and low-temperature coal tar. The method comprises the following steps: adding a sodium carbonate solution with the concentration of 5%-10% into the coal tar, increasing the temperature to 100-120 DEG C to form a stable sodium salt, filtering the coal tar twice, enabling the particle size of mechanical impurities to be not more than 15 mu m, heating the coal tar to 110 DEG C-150 DEG C and injecting water accounting for 5%-10% of the total weight of the coal tar, wherein the water is of softened water or purified water with the pH value of 5-11; and adding an emulsion breaking agent accounting for 0-100 mu g / g of the total weight of the coal tar, mixing, and then performing desalting, dewatering and deslagging in a high-voltage electric field to get the purified coal tar meeting the follow-up processing requirements.

Owner:长江(扬中)电脱盐设备有限公司

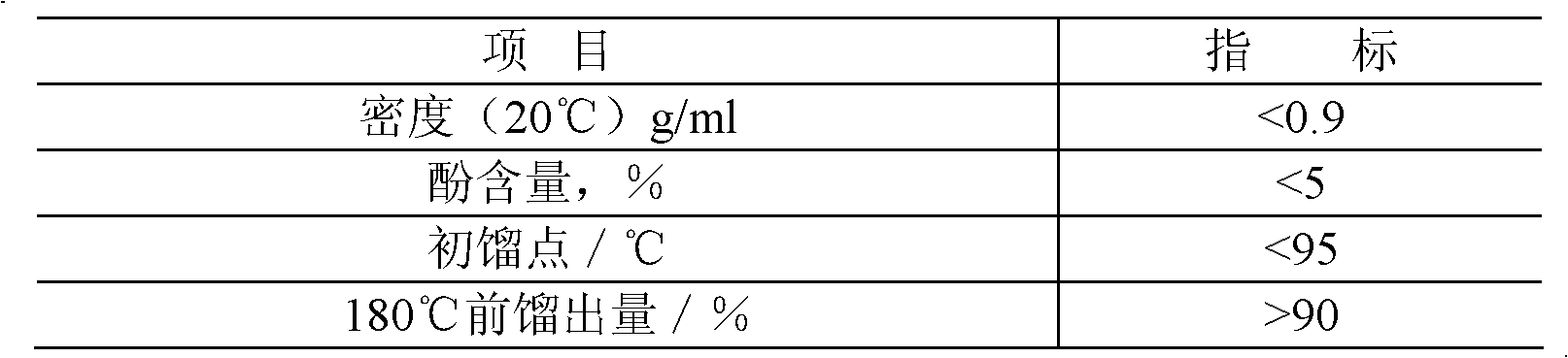

Method for harmony production of bunker fuel by coal oil

InactiveCN101113346ASimple and fast operationEase of industrial implementationLiquid carbonaceous fuelsTar working-up by water removalCarbonizationEnvironmental engineering

The invention relates to a method used for producing bunker fuel oil by blending low-temperature carbonization coal tar. The method is to respectively measure the properties of the part over water and the part below water of the low-temperature carbonization coal tar, a blending experiment of the part over water and the part below water of coal tar is practiced according to the measurement result and bunker fuel oil standards and the main indexes of the blend oil are determined to obtain proper blending ration and polypropylene higher alcohols ester additive is added to get qualified bunker fuel oil.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM +1

Pretreatment method for deep processing of coal tar

ActiveCN105316018AIncrease added valueTreatment with hydrotreatment processesTar working-up by water removalPretreatment methodHigh pressure

The invention relates to a pretreatment method for deep processing of coal tar. A technology for carrying out deslagging, ammonia water removing, dephenolizing and desalting separation on the coal tar through centrifugal separation, gas backwashing filtering, distilling and high-voltage electric field is adopted, the pretreatment method is applicable to the pretreatment of high-temperature coat tar, medium-temperature coal tar and low-temperature coat tar, the separated ammonia water can be recycled, and phenols are sold as a chemical raw material directly or after the phenols are refined, so that the problems that wastewater containing ammonia and phenol is discharged, a hydrogen source of energy is wasted due to phenol hydrogenation, and the like are avoided, and the added value of the coal tar is increased.

Owner:长江三星能源科技股份有限公司

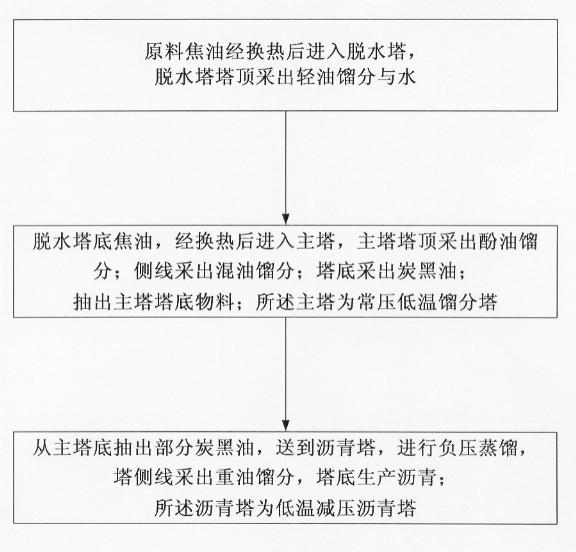

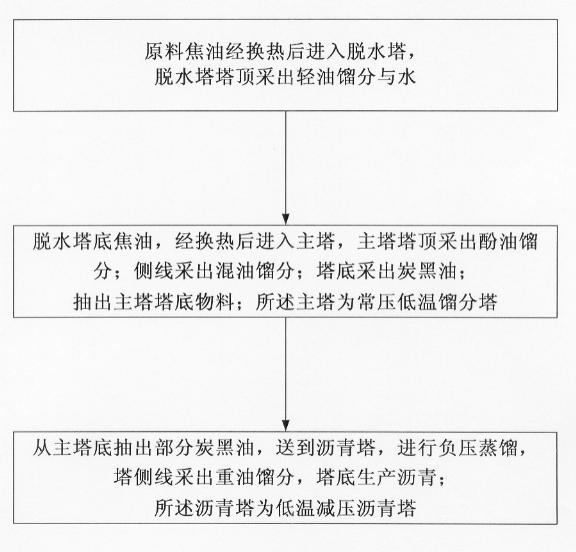

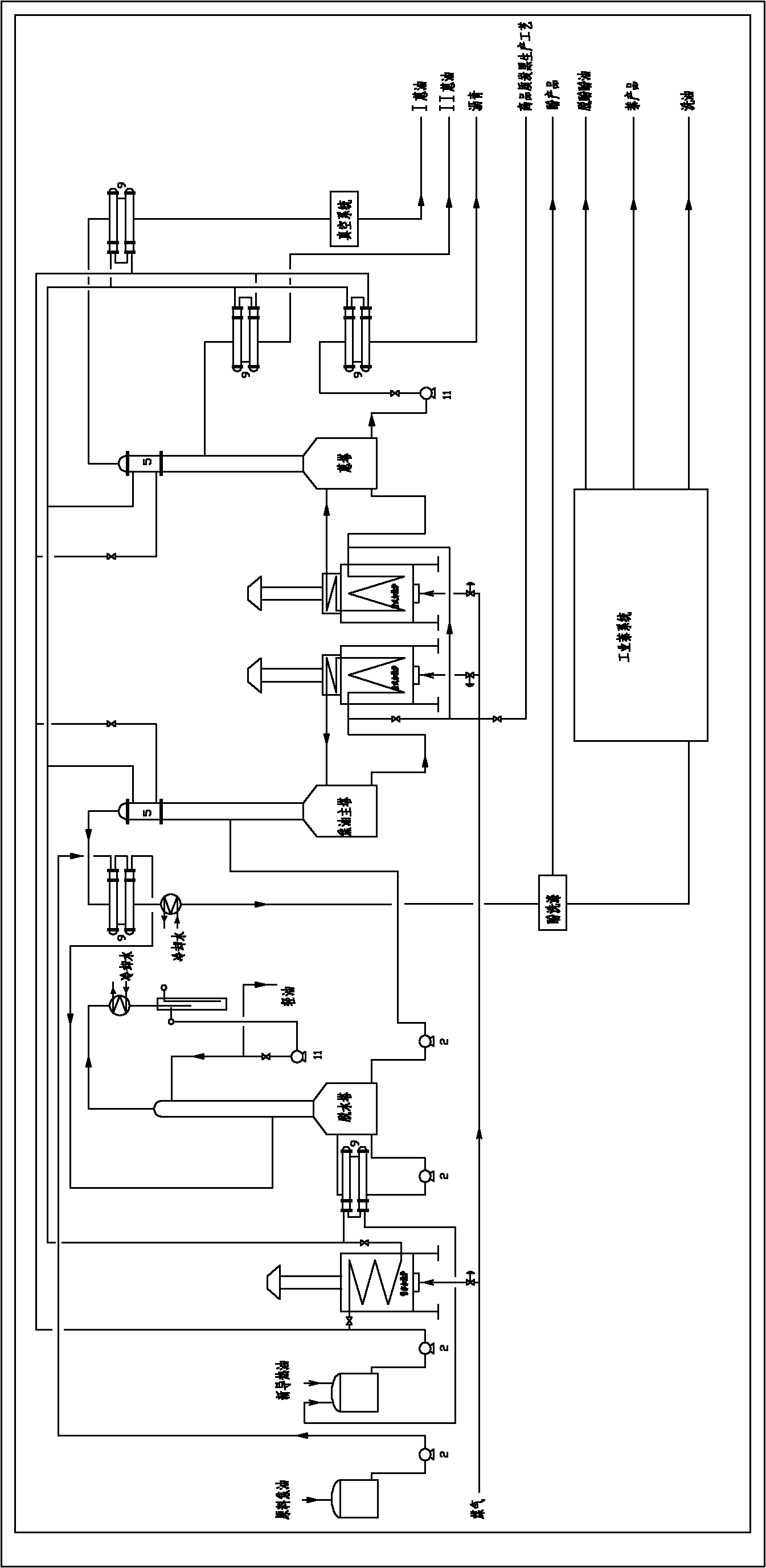

Coal tar alkali-free normal/reduced-pressure distillation process and device

ActiveCN102161901AReduce sodium ion contentAvoid corrosionTar working-up by water removalTar working-up by distillationAlkali freeDistillation

The invention relates to a coal tar alkali-free normal / reduced-pressure distillation process and a coal tar alkali-free normal / reduced-pressure distillation device. In the process, raw material coal tar is subjected to heat exchange and delivered into a dehydrating tower, and light oil distillate and water are collected from the top of the dehydrating tower; the coal tar at the bottom of the dehydrating tower is subjected to heat exchange and delivered to a main tower, and a carbolic oil distillate is collected from the top of the main tower; a mixed oil distillate is collected from a lateralline; carbon black oil or soft asphalt is collected from the bottom of the tower; bottom material of the main tower is pumped out; part of soft asphalt is pumped out from the bottom of the main towerand delivered to an asphalt tower for distillation under a negative pressure, a heavy oil distillate is collected from a lateral line of the tower, and asphalt is produced at the bottom of the tower;and the main tower is a normal-pressure low-temperature distillate tower, the asphalt tower is a low-temperature reduced-pressure asphalt tower, and all distillates are not added with alkali in the whole flow. In the device, the bottom of the dehydrating tower is connected with the middle of the main tower through a pipe, and the bottom of the main tower is connected with the middle of the asphalt tower through a pipe. The internal circulation at bottom of the main tower is realized through a heating furnace, and internal circulation at the bottom of the asphalt tower is realized through a heating furnace. The process and the device have the advantages that: all distillates are not added with alkali; distillates are cut according to market demands and temperature gradient; direct super-heated steam is not used; new process waste water is avoided; the energy consumption is low; the product quality is high; and the like.

Owner:BAOSTEEL ENG & TECH GRP

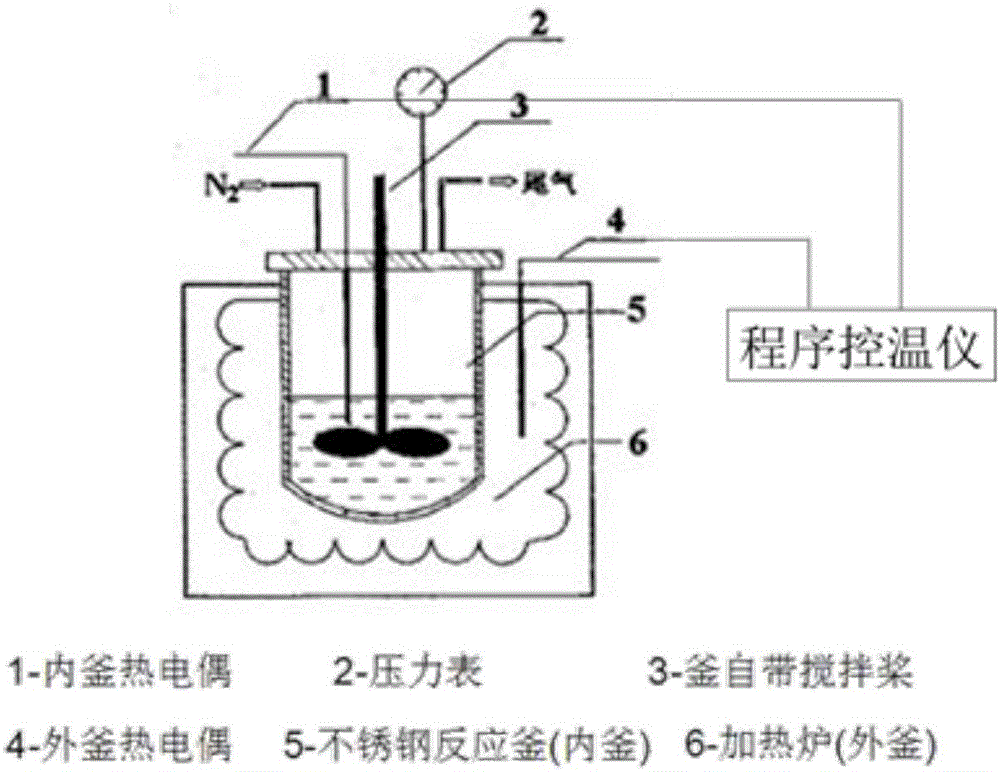

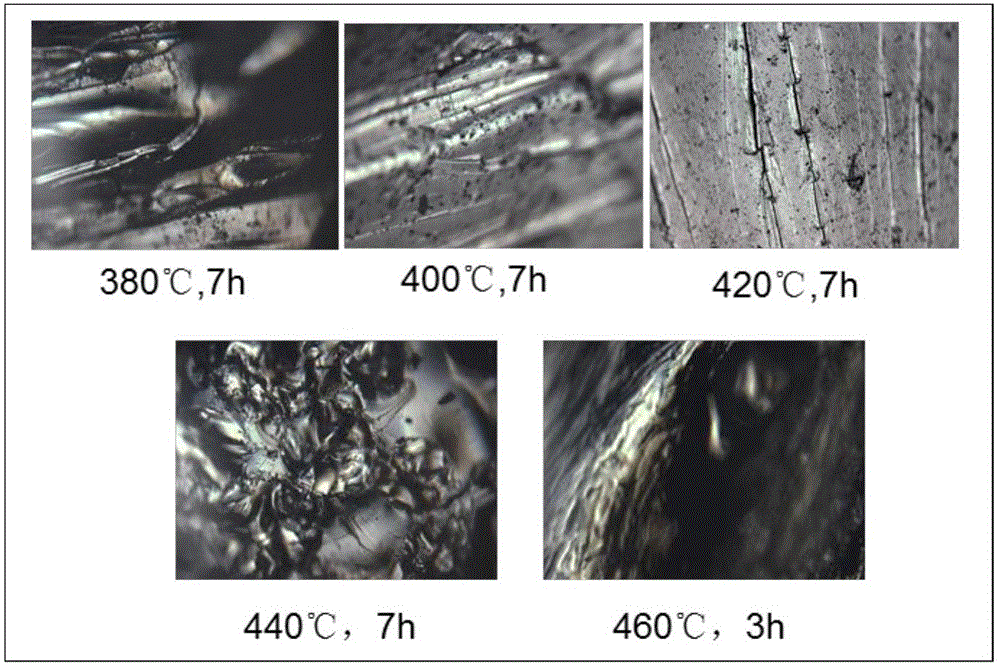

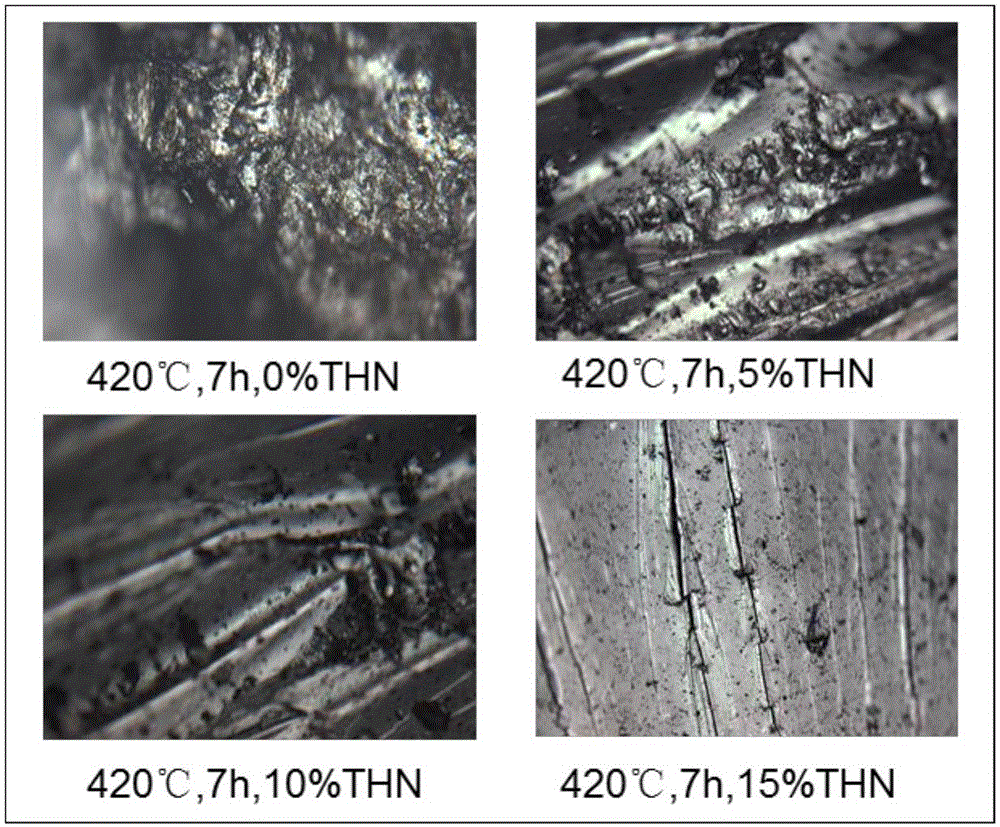

Preparation method of low-ash mesophase pitch

InactiveCN106367093AGood flexibilityOrderly stackingWorking-up pitch/asphalt/bitumen by chemical meansTar working-up by water removalFiberCarbon fibers

The invention provides a preparation method of low-ash high-property mesophase pitch. The method comprises the steps that the raw material coal tar is purified, a fraction is put into a reaction kettle, temperature programming and heat preservation are conducted in sequence, and purified coal tar pitch is obtained. The purified coal tar pitch and a co-carbonization agent are mixed, the mixture is added into a high pressure reactor, under certain pressure condition, the temperature is increased to a certain temperature, then heat preservation is conducted, and the mesophase pitch is obtained. According to the method, a series of physical methods such as gravity settlement centrifugation and circulating filtration are adopted to purify the coal tar, the very good effect of removing ash impurities is achieved, quinoline insoluble matter formed by mesophase is especially hindered, the content of the mesophase pitch ash is lower than 50 ppm, the content of mesophase reaches up to 100%, and carbon fibers with excellent properties can be prepared continuously; meanwhile, by mixing the pitch with the co-carbonization agent, the rheological property of the mesophase pitch is improved. Compared with a coal tar pitch purification process, the coal tar purification technology is simple, the cost is low, and the high-purity purified coal tar pitch can be obtained through preparation, so that the low-ash high-property mesophase pitch is obtained.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

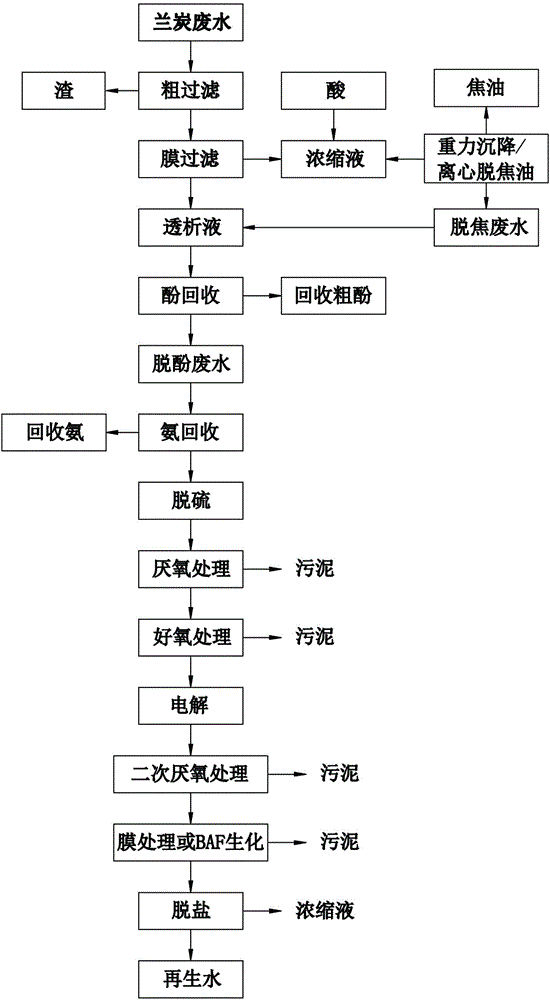

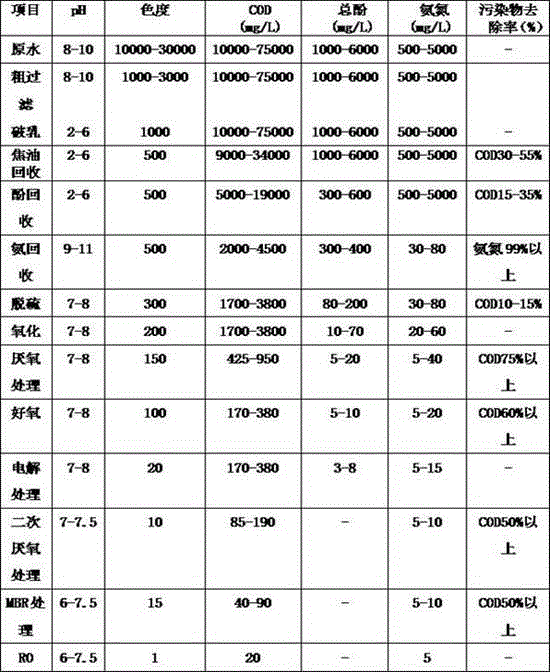

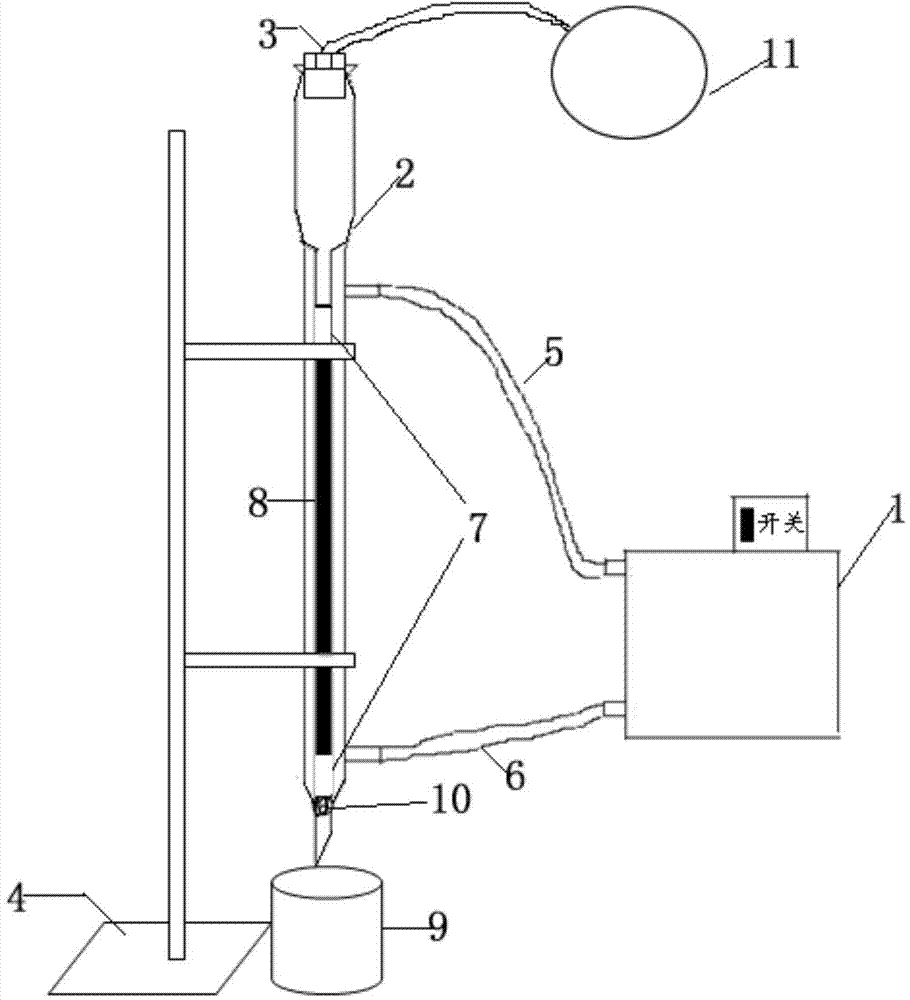

Method for carrying out treatment and regenerative cyclic utilization on semi-coke wastewater and recycling resources

InactiveCN104860483AReduce volumeReduce dosageOrganic chemistryOrganic compound preparationElectrolysisFiltration

The invention discloses a method for carrying out treatment and regenerative cyclic utilization on semi-coke wastewater and recycling resources. The method comprises the steps of (1) coarse filtration, (2) membrane filtration, (3) coal tar recovery, (4) phenol recovery, (5) ammonia recovery, (6) anaerobic treatment, (7) aerobic treatment, (8) electrolysis, (9) secondary anaerobic treatment, (10) membrane treatment or biochemical reaction of a biological aerated filter, and (11) desalting. According to the method, through a combined treatment process of the membrane filtration, the coal tar recovery, the phenol recovery, the ammonia recovery, the anaerobic treatment, the aerobic treatment, the electrolysis, the desalting and the like, the semi-coke wastewater is deeply treated, so that the resources such as coal tar, phenol and ammonia are recycled, and the treatment cost of the semi-coke wastewater is greatly reduced.

Owner:张世文

Method of separating components of coal tar

InactiveCN104845651AGood qualityEasy to quantifyTar working-up by water removalRefractive indexTetrahydrofuran

The invention provides a method of separating components of coal tar. The method comprises the steps of: adding the coal tar to a separation column; sequentially eluting the separation column by using a first solvent, a second solvent, a third solvent and a fourth solvent so as to respectively obtain a saturated hydrocarbon component, an aromatic component, a light polar substance component with the average molecular weight of 302-333 and a heavy polar substance component with the average molecular weight of 425-525; the elution terminal point of the first solvent is judged by an indicator; and the elution terminal points of the second solvent, the third solvent and the fourth solvent are judged through refractive indexes; the first solvent is selected from normal hexane, pentane or butane; the second solvent is selected from methylbenzene, benzene or xylene; the third solvent is selected from methyl alcohol or ethyl alcohol; and the fourth solvent is selected from tetrahydrofuran. The method has the advantages that the different components are eluted by adopting the simple separation on the column through different elution solvents, each component can be obtained by using the aromatic hydrocarbon indicator and the refractive index for separation, and the method is simple and convenient to operate and convenient for determining the property and quantity of the coal tar components, and the solvents are easy to obtain.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

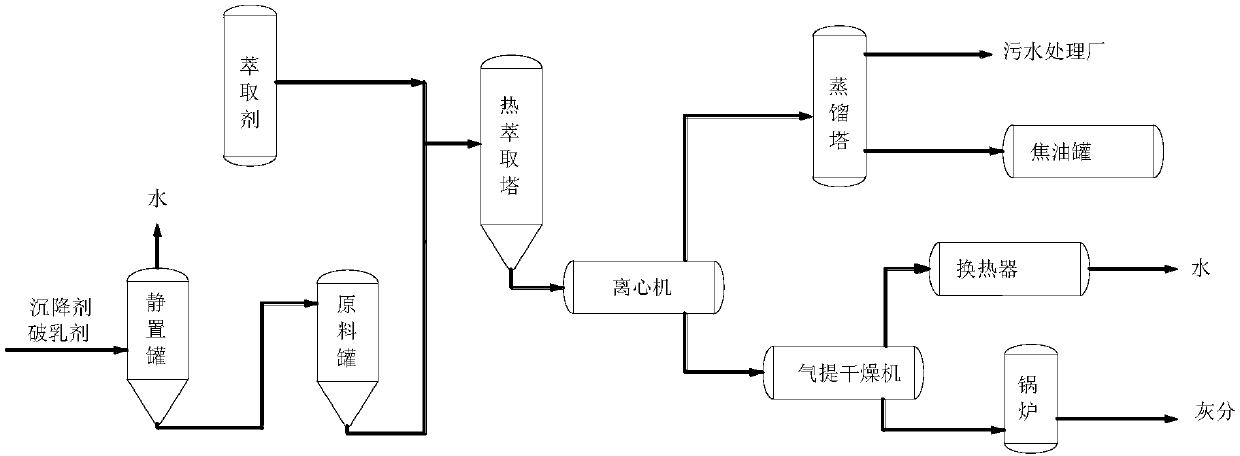

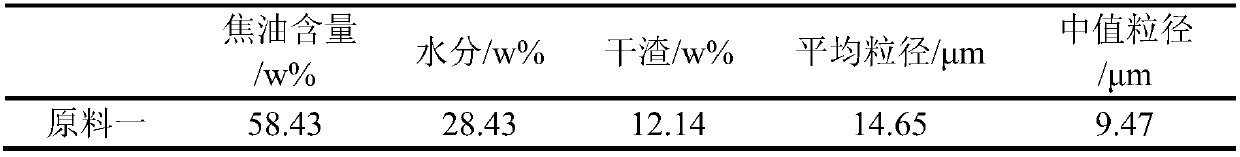

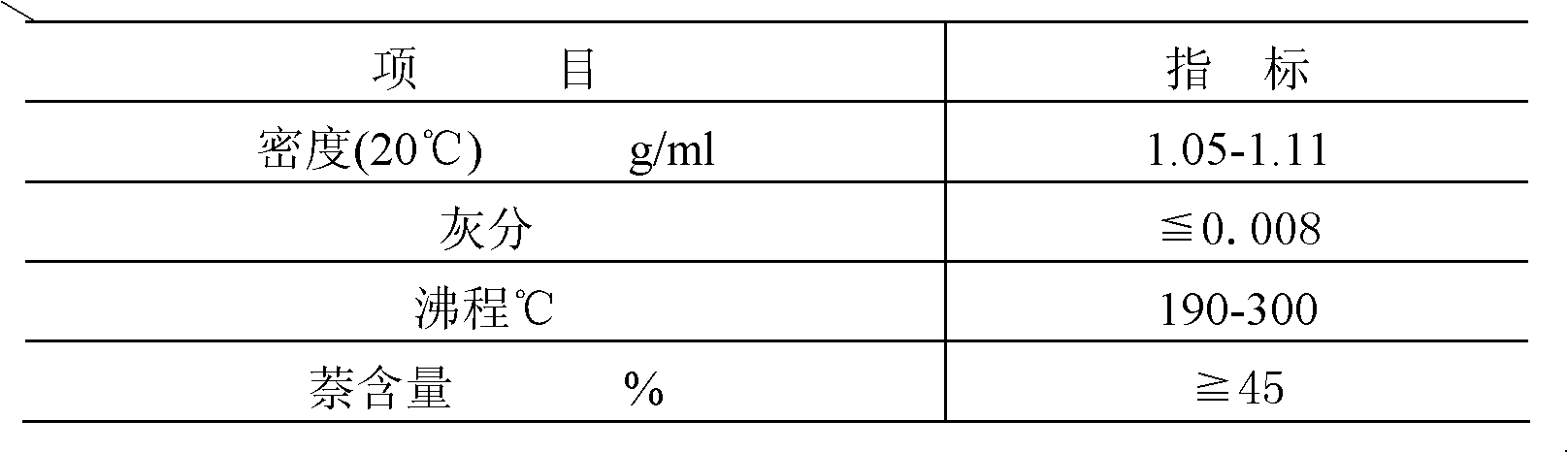

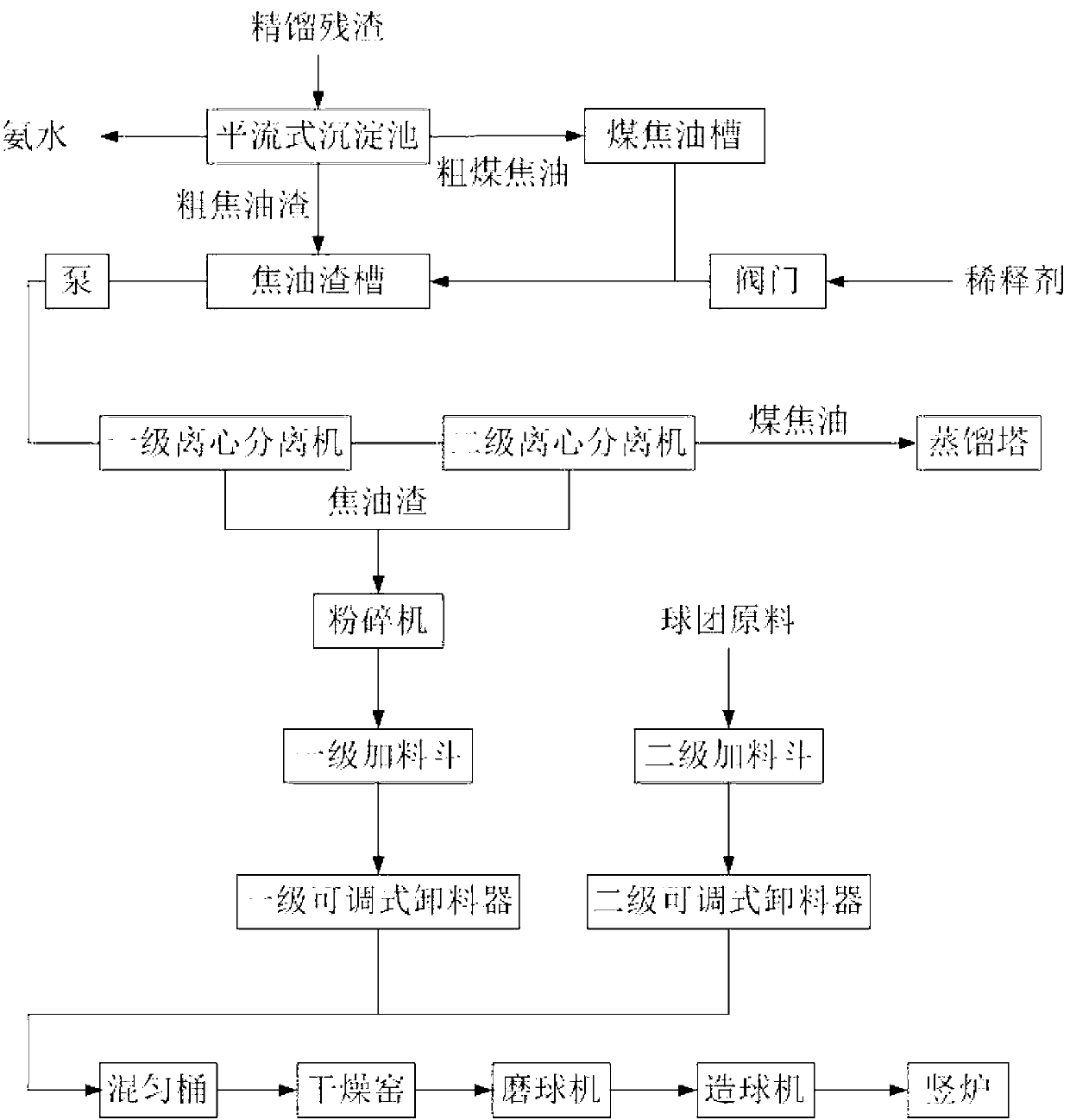

Resourceful treatment process of tar residue

ActiveCN107557044AAchieve three-phase separationEasy to separateTar working-up by water removalTar working-up by distillationSolventWater content

The invention provides a resourceful treatment process of tar residue. The resourceful treatment process is characterized in that demulsification dehydration, solvent extraction and centrifugal separation are taken as the core, distillate oil, obtained at the temperature of 200-230 DEG C, of coal tar is used as a main extracting agent, a small amount of crude benzene and industrial naphthalene areadded so as to form a composite extracting agent, and the proportion of all the components used in the process is as follows: 90-95wt / % of the distillate oil, obtained at the temperature of 200-230 DEG C, of the coal tar, 4.1-9.7wt / % of the crude benzene and 0.3-0.9wt / % of the industrial naphthalene; a technology of combining heat extraction and centrifugation is adopted under the conditions thatthe temperature of the demulsification dehydration is 35-55 DEG C, extraction temperature is 55-60DEG C, the pressure is 101.325kPa, the pump circulating flow rate is 15-20m<3> / h, the extraction timeis 3-4h, the centrifuge rotating speed is 2500-3000r / min, and the like, so that the recovery rate of tar in the tar residue reaches up to 95% or above. The resourceful treatment process is verified to be capable of well adapting to the raw material tar residue with water content of 20-60% in the aspect of raw material adaptability; the extracting agent used in the process does not need to be recovered after oil-water-residue separation is finished, can be directly used as an oil product component in the oil so as to be stored and utilized, and does not need to be recycled, so that the separation link is simplified, waste is avoided, and energy is saved; the resourceful treatment process effectively solves the problems of the tar residue in the aspects of energy utilization and environment-friendly treatment.

Owner:NORTHWEST UNIV(CN)

Method for improving yield of coal microwave pyrolysis tar by using methane and carbon dioxide as reactant gases

InactiveCN105925317AHigh activityHigh yieldGasification catalystsGasification processes detailsMicrowave pyrolysisHydrogen

The invention discloses a method for improving the yield of coal microwave pyrolysis tar by using methane and carbon dioxide as reactant gases. The method is characterized in that: methane of which the volume ratio is 50-90% and carbon dioxide of which the volume ratio is 10-50% are used as reactant gases, methane and carbon dioxide are mixed together, then the mixed gas is introduced into a pyrolysis reactor and is subjected to co-pyrolysis with a mixture containing coal of which the mass percent is 30-90% and semi-coke of which the mass percent is 10-70% under the condition that the microwave heating temperature is 400-700 DEG C for a constant temperature time of 10-40min, volatile products after pyrolysis leave the reactor and then enter a condensing system for gas-liquid separation, and then a tar product is collected. The method disclosed by the invention has the advantages that the semi-coke is used as a catalyst, and methane and carbon dioxide replace hydrogen and serve as hydro-pyrolysis reactant gases, so that the yield of the pyrolysis tar can be obviously improved, and the hydro-pyrolysis cost is reduced; and the semi-coke is used as a catalyst for activating methane and carbon dioxide, the catalyst does not need to be recovered and separated from the product, the semi-coke is generated continuously during pyrolysis, and the problem of catalyst deactivation is avoided.

Owner:HENAN POLYTECHNIC UNIV

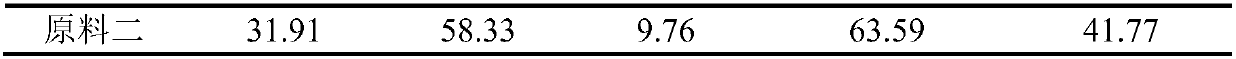

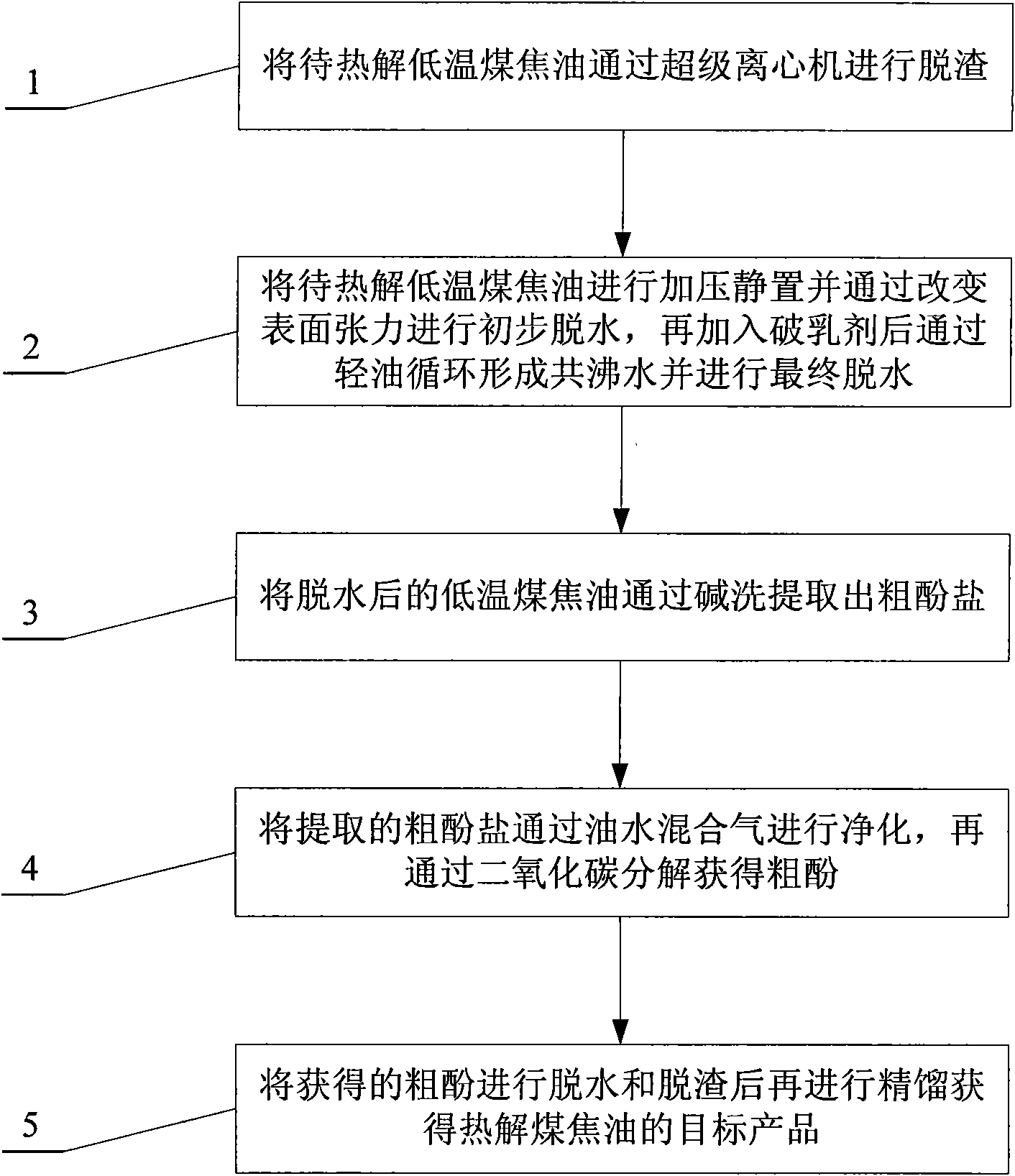

Method for processing low-temperature pyrolyzed coal tar

InactiveCN101974345AEasy to separateLow costTar working-up by water removalTar working-up by chemical refiningPhenolCoal tar

The invention relates to a method for processing low-temperature pyrolyzed coal tar. The method comprises the following steps of: pressurizing and standing low-temperature coal tar to be pyrolyzed, dehydrating initially by changing surface tension, adding a demulsifying agent to form azeotropic water through light oil circulation and performing final dehydration; extracting crude phenate from the dehydrated low-temperature coal tar by alkaline washing; purifying the extracted crude phenate through oil-water mixed gas and decomposing through carbon dioxide so as to obtain crude phenol; and dehydrating the obtained crude phenol, deslagging and rectifying so as to obtain a target product. By the method, the phenol extraction rate of the low-temperature pyrolyzed coal tar is over 95 percent, the problem of difficult oil and water separation can be solved and the dehydration rate after processing is between 0.5 and 1 percent. The method is a processing method which has low cost and reasonably utilizes a low-temperature coal tar resource.

Owner:CHINA COAL RES INST

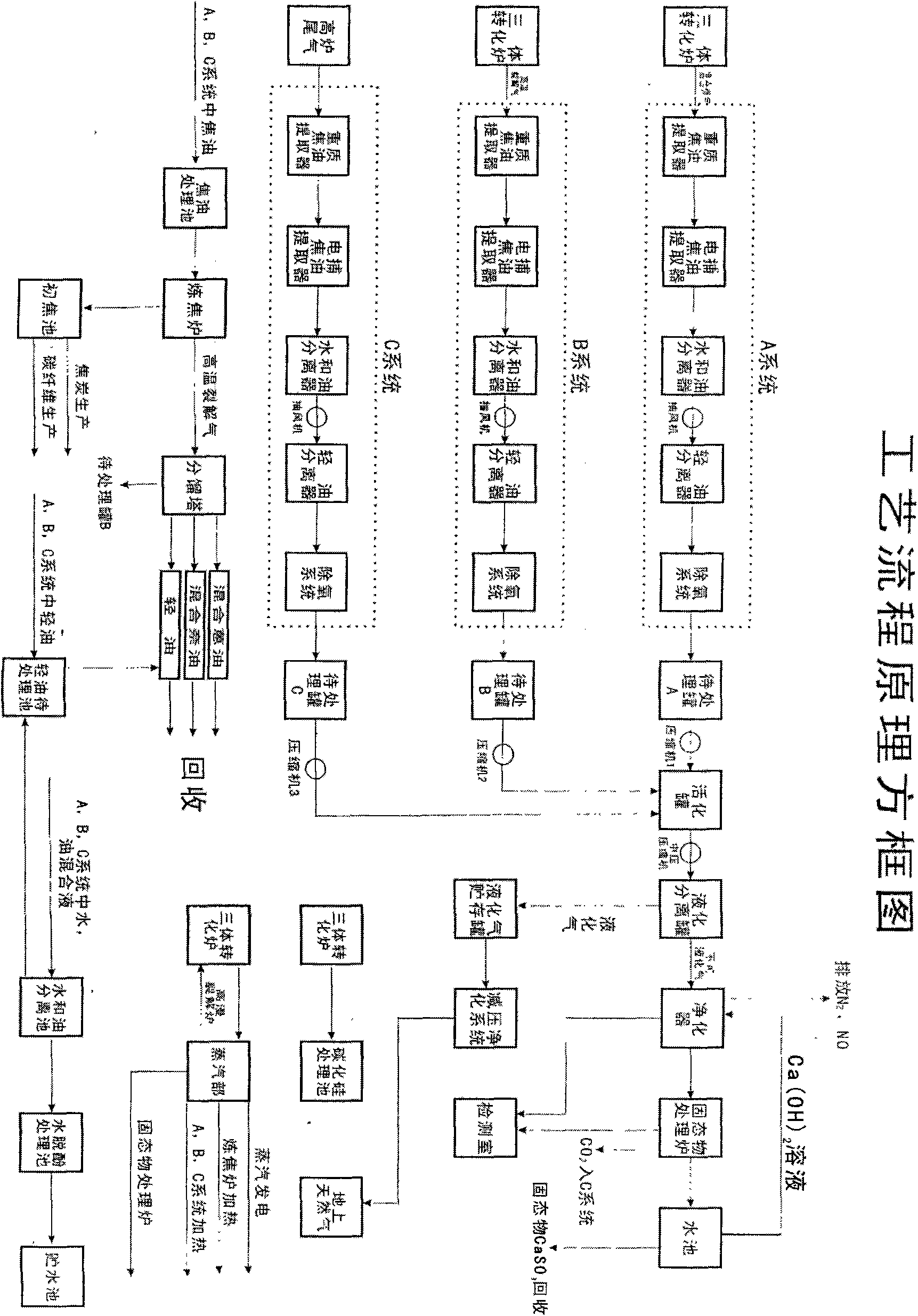

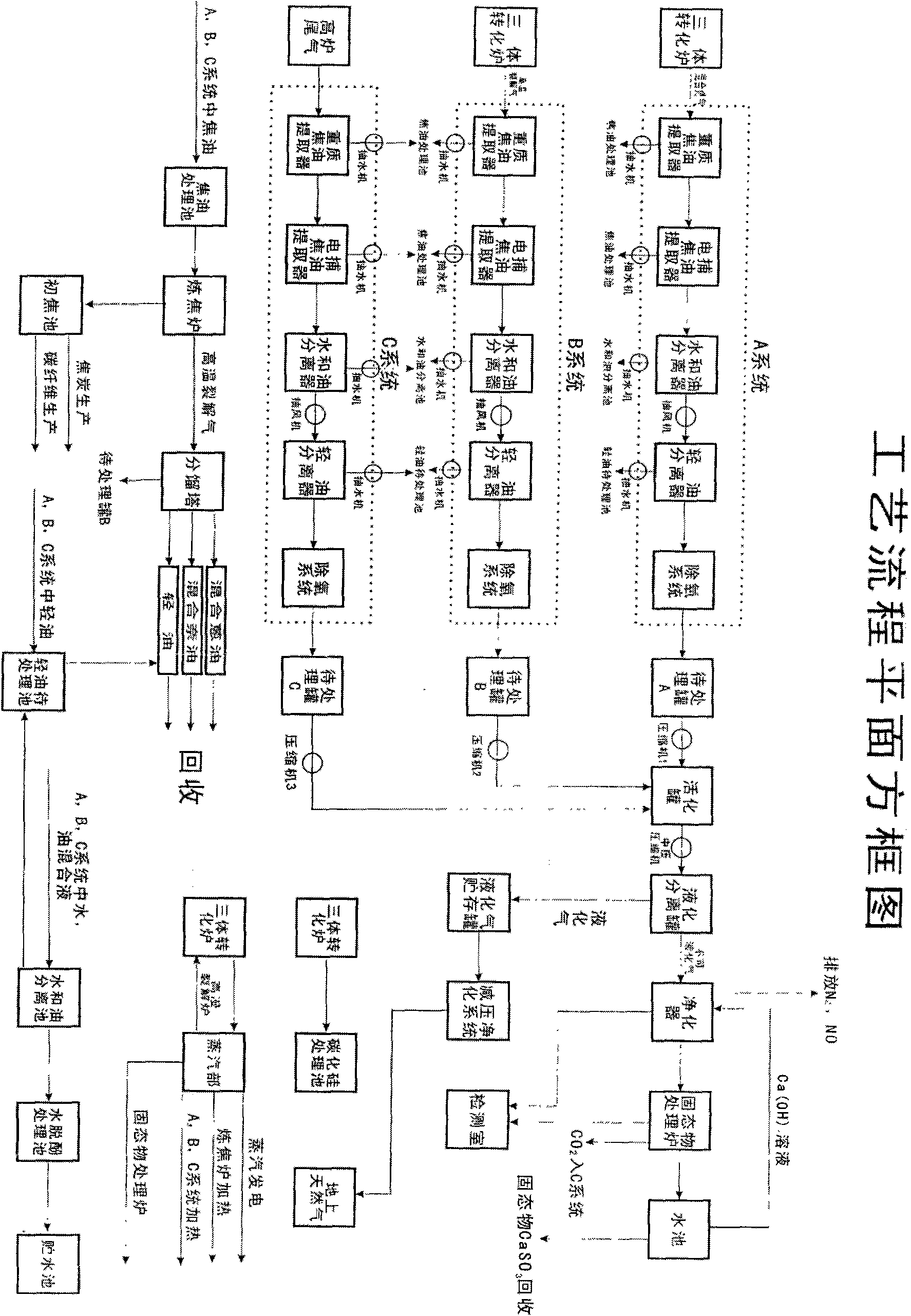

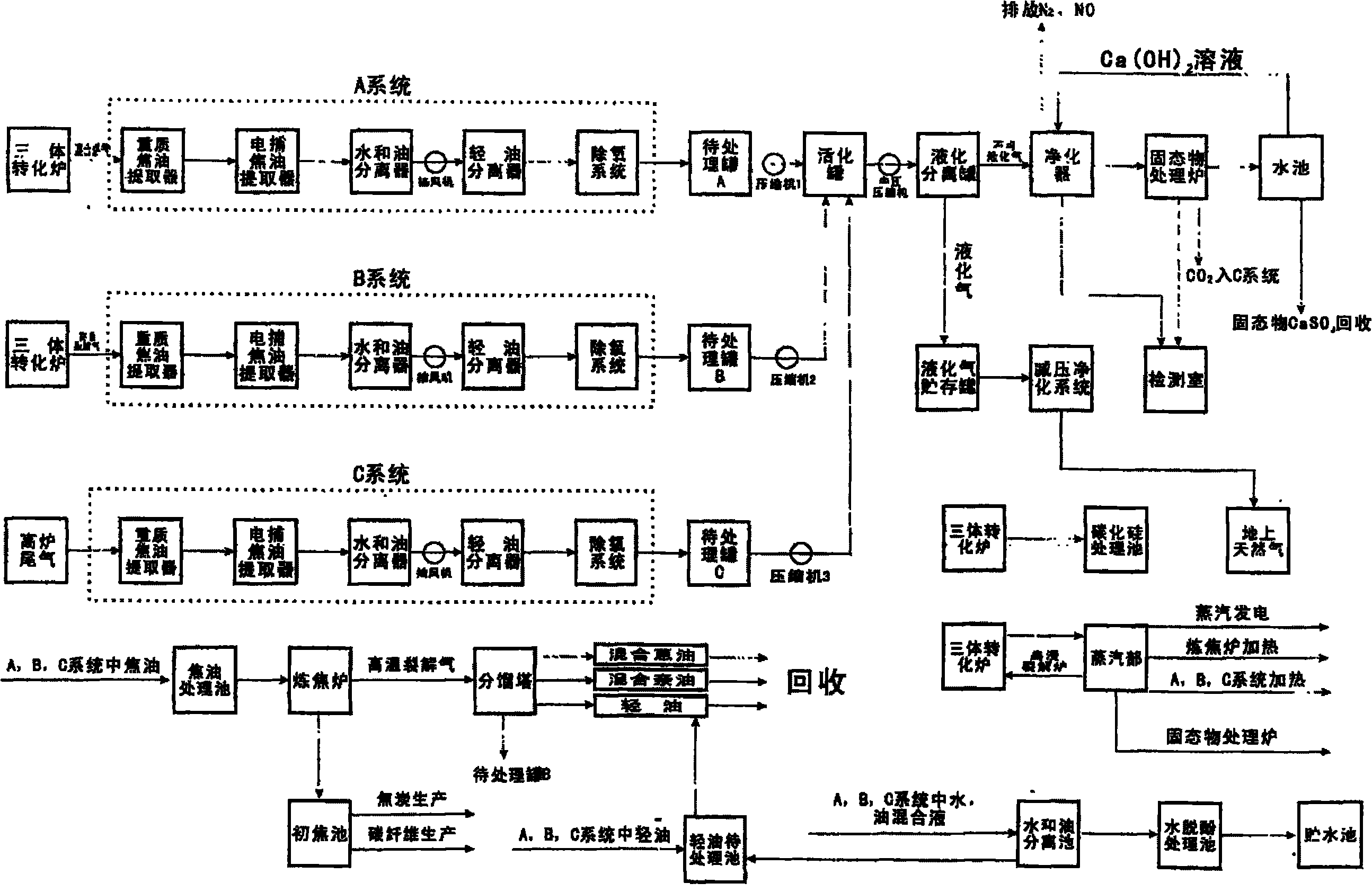

Technique for producing new energy by using firewood, grass and straws to treat CO2 in blast furnace tail gas

InactiveCN101948700ARelieve stressRelieve pressureCombustible gas chemical modificationMethane captureNew energyBiological activation

The invention discloses a technique for producing new energy by using firewood, grass and straws to treat CO2 in blast furnace tail gas. The technique comprises the following steps of: scientifically treating the firewood, the grass and the straws to obtain mixed gas, filling the tail gas into treatment tanks A and B for later use after the mixed gas is treated by A and B treatment systems respectively, reclaiming all the blast furnace tail gas through a C treatment system and filling the tail gas into a treatment tank C, then conveying the gas in the treatment tanks A, B and C to an activation tank with compressing respectively, compressing the activated gas to form liquefied gas and non-liquefied gas, directly charging the liquefied gas for users, treating and reclaiming the non-liquefied gas, and discharging the pollution-free gas to the atmosphere. The whole production system does not consume the conventional energy; the pollution emission is zero; ground natural gas, liquefied gas, mixed anthracene oil, mixed naphthalene oil, light oil, steam generated power and the like are produced at the same time; the economic and social benefits are very good; and the energy conservation and emission reduction effects are very obvious.

Owner:伍思宇

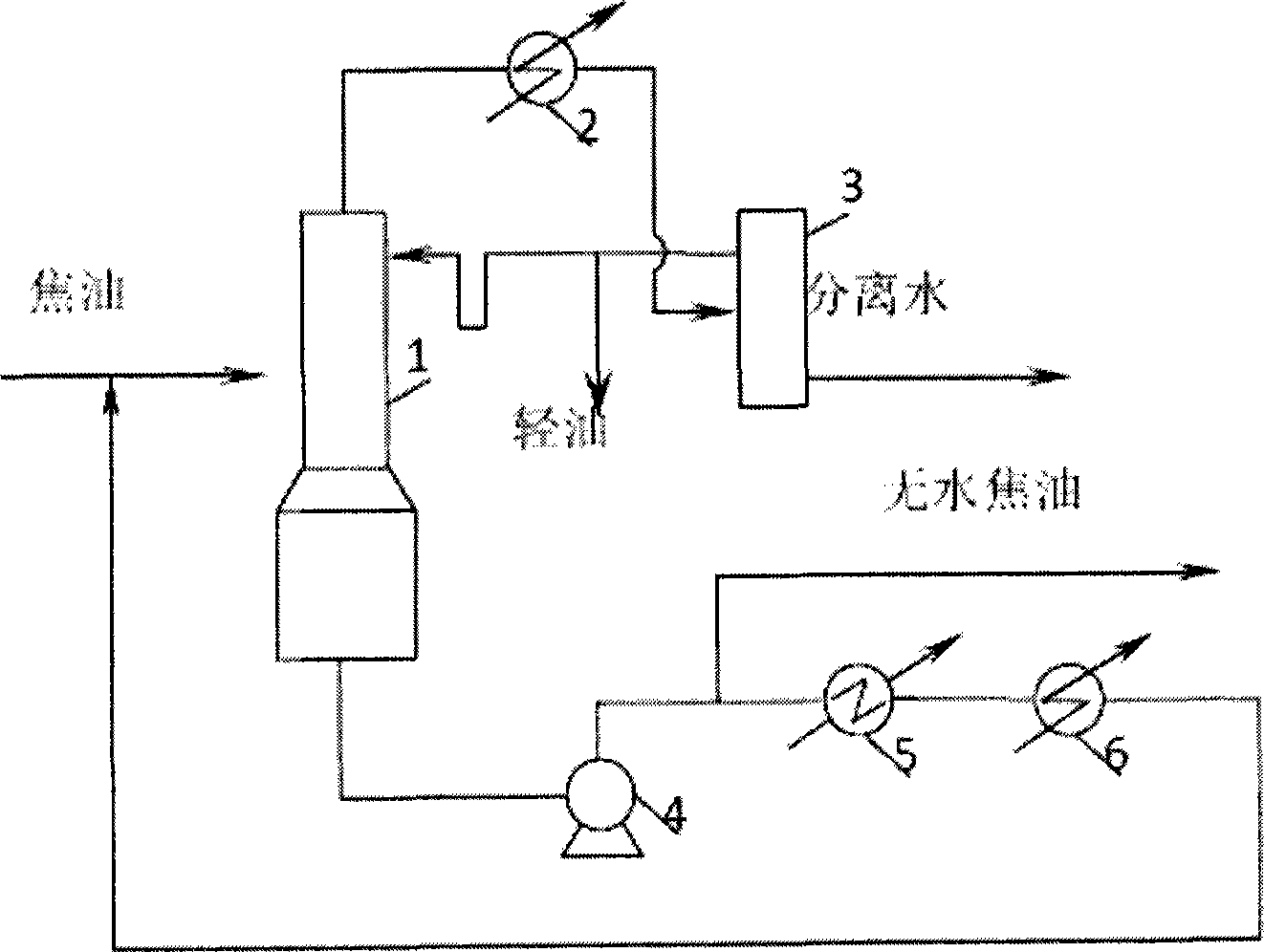

Coal tar deep processing technology based on four mixed fractions

InactiveCN102161902AReasonable designImprove product qualityTar working-up by water removalTar working-up by distillationTarEngineering

The invention discloses a coal tar deep processing technology based on four mixed fractions. The coal tar deep processing technology comprises the following steps: heating raw material tar by a coke tar heat exchanger to 105-130 DEG C and then entering into a dehydrating tower with 4-12 layers of trays; separating out water and partial light oil from the tower top of the dehydrating tower, and separating out anhydrous tar from the tower bottom of the dehydrating tower; processing the dehydrated tar through a conductive oil heat exchanger and heating to 240 DEG C-300 DEG C by a tubular heating furnace, and then entering into the lower middle part of a main tar tower which is provided with 15-35 layers of trays and is provided with 2-10 layers of trays in a stripping section; performing heating circulation by using the tubular heating furnace at the tower bottom; washing four mixed fractions with light phenol naphthalene cut at the tower top, cooling the four mixed fractions and dephenolizing to obtain a phenol product and a washed fraction, and processing the washed fraction in an industrial naphthalene processing device so as to obtain dephenolized phenol oil, an industrial naphthalene product and high-quality absorber oil; and obtaining mixed oil from the tower bottom, wherein the mixed oil can be directly used for producing high-quality carbon black or mesothermal pitch according to the market conditon.

Owner:上海同特化工科技有限公司

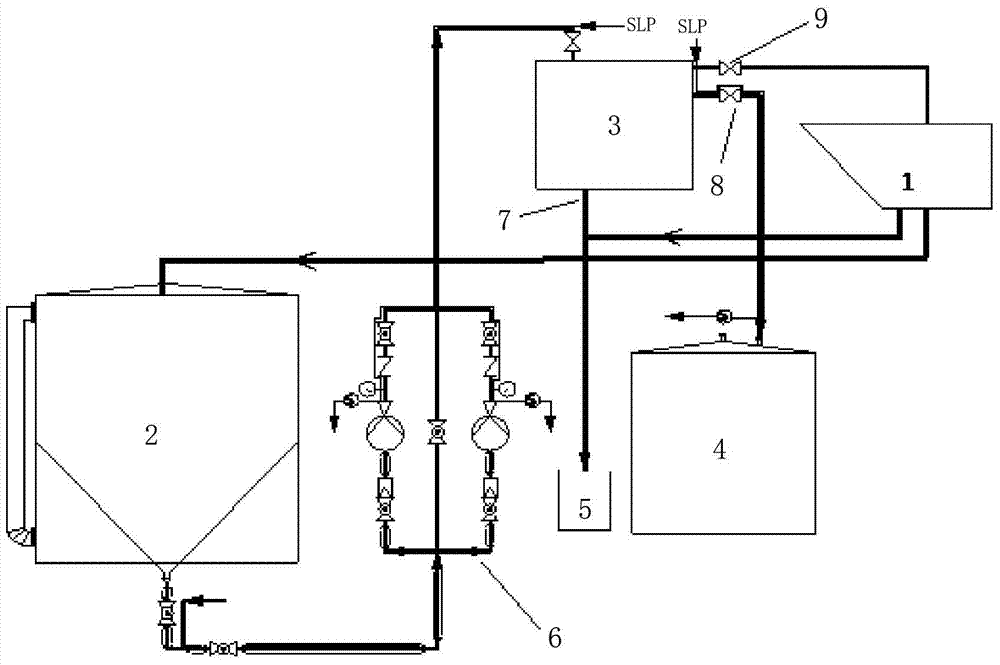

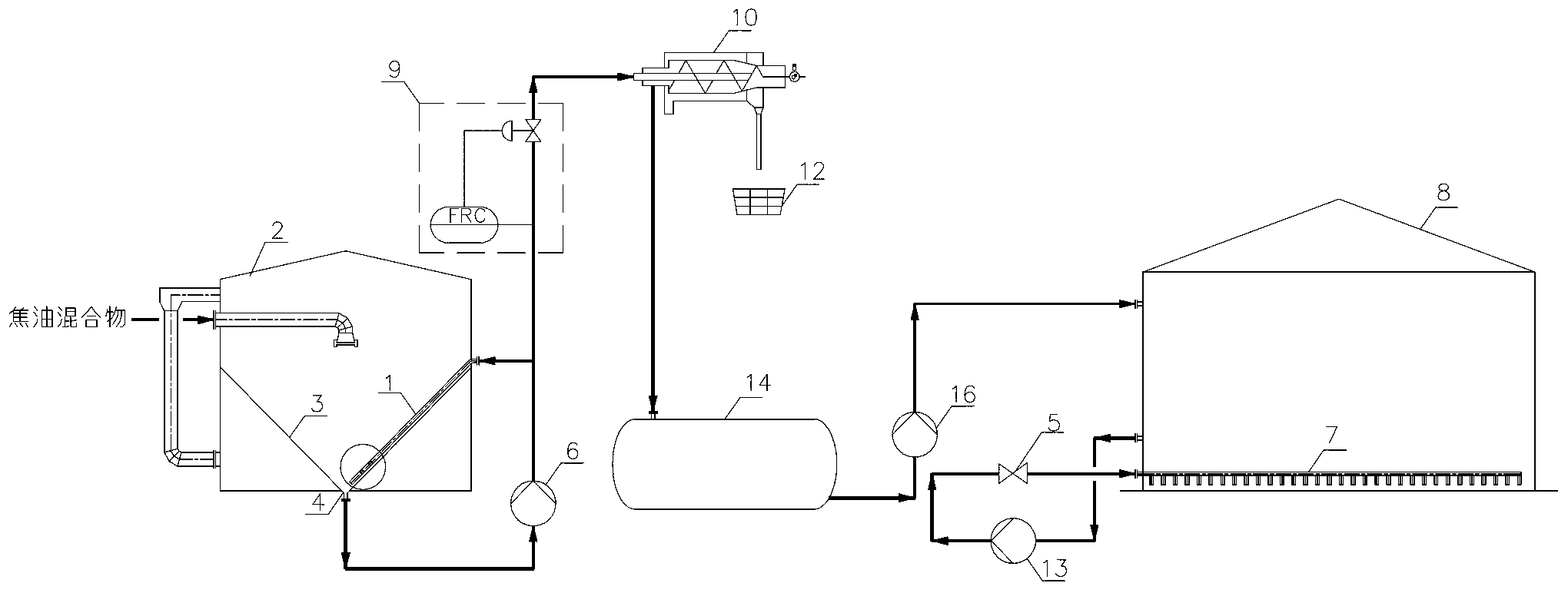

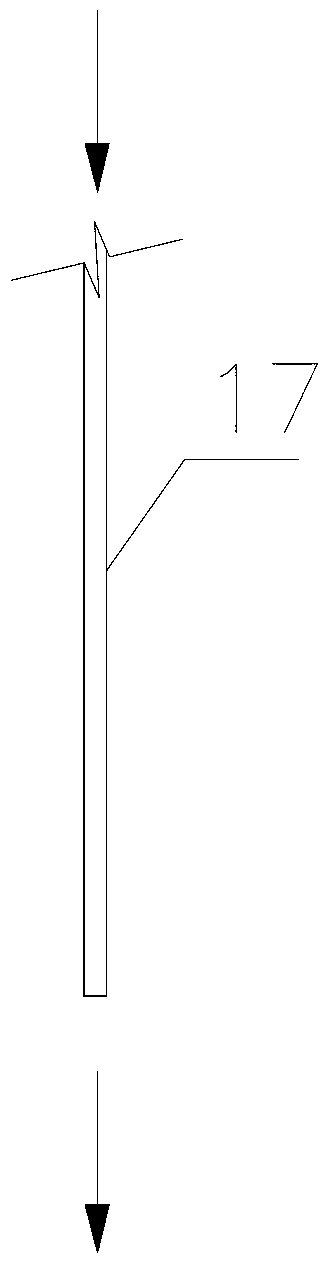

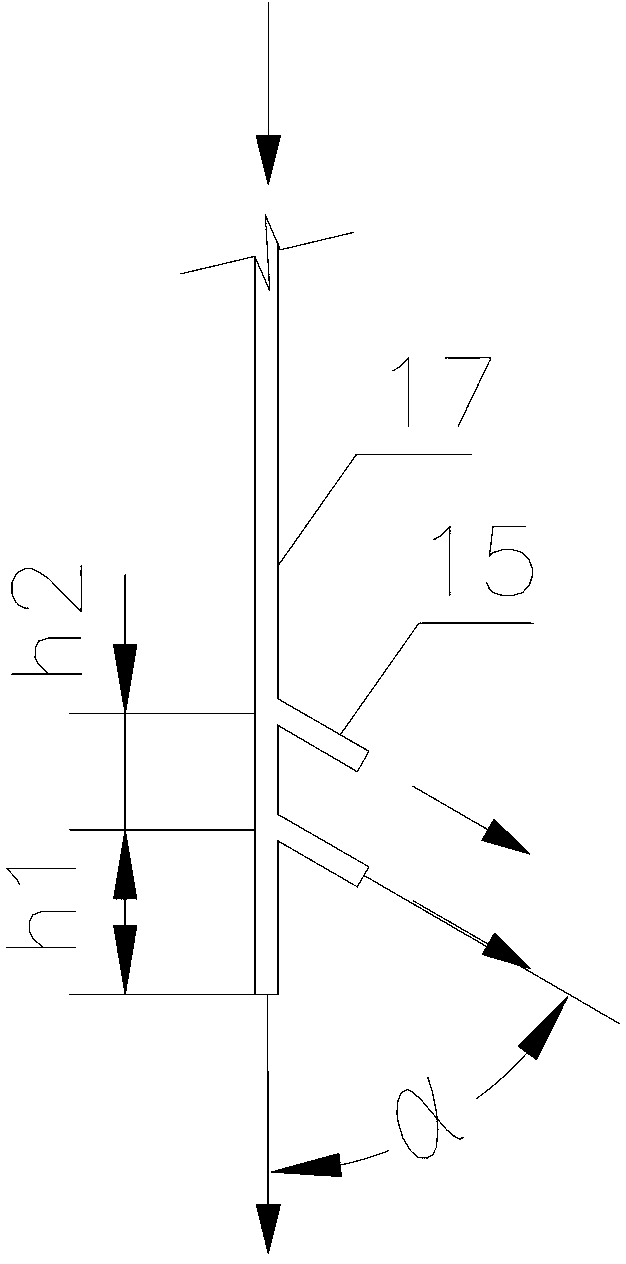

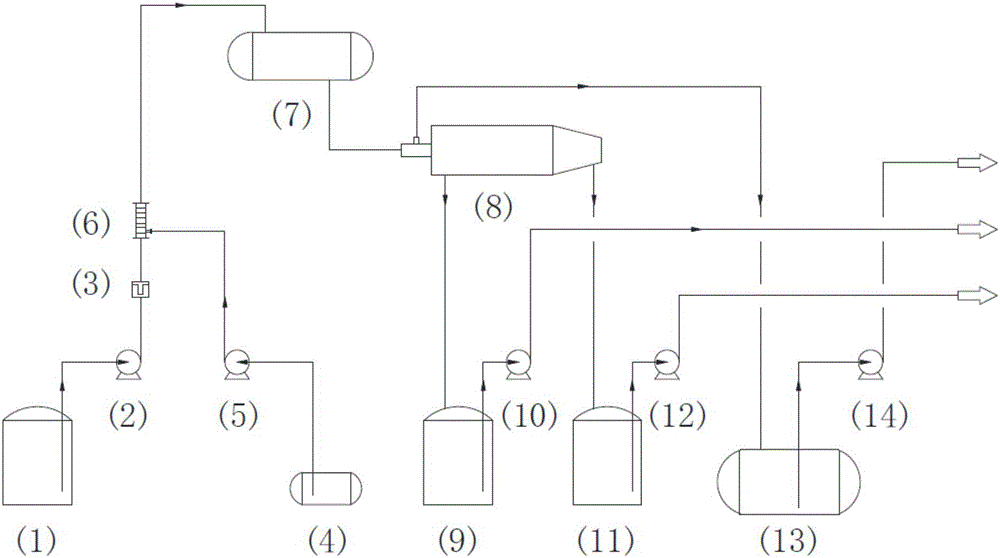

Oil extraction and slag removal method and system for vertical tar-ammonia water separating process

ActiveCN103496796AImprove removal effectEasy to controlFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSlagTar

The invention provides an oil extraction and slag removal method and system for a vertical tar-ammonia water separating process. The system comprises a mechanical slag scrapping tank, a tar-ammonia water separating tank used for receiving a mixture of tar, ammonia water and small-granule tar slag obtained in primary separation, a tar slag pump used for extracting the small-granule tar slag and the tar at the bottom of the tar-ammonia water separating tank, a secondary slag removal apparatus used for receiving the small-granule tar slag and the tar extracted from the bottom of the tar-ammonia water separating tank through the tar slag pump and carrying out secondary separation on the small-granule tar slag and the tar, a tar slag bucket used for receiving large granule tar slag obtained in primary separation and small-granule tar slag obtained in secondary separation and a tar intermediate tank used for receiving tar discharged from the secondary slag removal apparatus and having undergone secondary separation. The system has the advantages of convenience in extraction of the tar, good tar slag removal effects and capacity of thorough discharge of the small-granule tar slag from the system, so blockage of the system is avoided and production of the system is continuous and stable.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Reclaimed rubber plasticizer and preparation method thereof

InactiveCN101817935ALow naphthaleneLow naphthalene contentSolid fuelsTar working-up by water removalChemical industryPolymer science

The invention relates to a reclaimed rubber plasticizer and a preparation method thereof, and belongs to the fields of environmental protection and chemical industry. All the reclaimed rubber plasticizers in the region adopt high-temperature coal tar. Due to the adjustment of raw materials of a coking plant and a process, the quality stabilization of the reclaimed rubber plasticizer is influenced. In a rubber product made of the reclaimed rubber, due to the sublimation of naphthalene, a layer of white sublimated naphthalene is condensed on the surface of the product so as to influence the quality of the product. Coal tar slag in the coking plants in the region is dumped out of the plants as rubbish, so that resources are wasted and environments are polluted. In order to solve the problems, the invention provides the reclaimed rubber plasticizer and the preparation method thereof. The preparation method comprises the following steps of: separating the coal tar from coke powder in the coal tar slag by an anthracene oil extracting process to obtain the coal tar with lower naphthalene content; dehydrating the coal tar with lower naphthalene content; and adjusting the viscosity of the dehydrated coal tar to prepare the reclaimed rubber plasticizer with stable quality. When the produced reclaimed rubber plasticizers are conveyed to a plurality of reclaimed rubber manufacturing plants to be used, the using amount is low, the quality is stable, and no white sublimated naphthalene is on the surface of the product.

Owner:石其贵

Technique and device for preventing deposition and blockage of tar residues of tar system

ActiveCN103254919AImprove cloggingHigh continuity of operationTar working-up by water removalUltracentrifugeTar

The invention belongs to the field of coking chemical products in metallurgical coking industry and particularly relates to a technique and a device for preventing deposition and blockage of tar residues of a tar system. The technique is characterized in that fluid dredging devices are arranged at positions liable to generate deposition and blockage in a tar-ammonia water separating tank and a tar storage tank, and the fluid dredging devices are controlled by controllers to periodically work so as to eliminate the blockage phenomenon caused by the deposition of tar residue. The device comprises a first fluid dredging device and a second fluid dredging device, wherein the first fluid dredging device is of a hollow tubular structure and is arranged along the bottom part of a conical groove of the tar-ammonia water separating tank in parallel, and the second fluid dredging device is of a multi-branch tubular structure and is arranged at the bottom part of the tar storage tank in parallel. Compared with the prior art, the technique and the device have the advantages that (1) the tar residue deposition and pipeline blockage phenomena of the equipment are greatly improved; (2) the operation continuity is improved and the maintenance time is greatly decreased; (3) the operation of an ultracentrifuge is stable and the separating effect is greatly improved; and (4) the operating environment is obviously improved and the safety is high.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Technology for producing modified pitch by one-step heating

ActiveCN104726122AImprove energy savingImprove product qualityTar working-up by water removalTar working-up by distillationTube furnaceReboiler

The invention relates to a technology for producing modified pitch by one-step heating. An alkali-free technology is adopted, only one tube furnace is used during heating, an energy saving effect is obvious, the modified pitch with ultra-low alkali metal ions can be produced, and the quality of products is high. A dehydration column reboiler is used for heating by sufficiently using heat of flashing oil and heat of the modified pitch, and energy consumption is greatly reduced. The technology for producing the modified pitch by one-step heating has the advantages that energy is saved, the quality of products is high, corrosion of equipment is slowed down, investment is low and the like.

Owner:HENAN KAITAN NEW MATERIAL +1

Method for treating coal chemical industry sewage

ActiveCN102351262AHigh chromaFailure to meet emission requirementsMultistage water/sewage treatmentTar working-up by water removalMacromolecular SubstancesSewage

The invention relates to a method for treating coal chemical industry sewage, which is a breakthrough in coking industry sewage treatment and mainly solves the problem that macromolecular substances in coking sewage can not be easily degraded. In the development process, the formation structure of the substances is analyzed: the larger the molecular weight is, the stronger the intermolecular power is, and the higher the boiling point of the substance is. Since nondegradable substances and degradable substances have different boiling points, the nondegradable substances in the coking sewage can be separated by a technical line of concentration by evaporation; and since the condensed sewage containing micromolecular substances, which is separated by evaporation, has strong biochemical quality and low salinity, the condensed sewage can easily reach the standard when being subjected to biochemical sewage treatment, and the treated water can be directly used as compensation water of circulating water, thereby recycling the sewage. The technology is mainly used in high-concentration coking sewage treatment industry, and can also extend to nondegradable-substance-containing sewage treatment in coal chemical industry.

Owner:JINNENG SCI & TECH

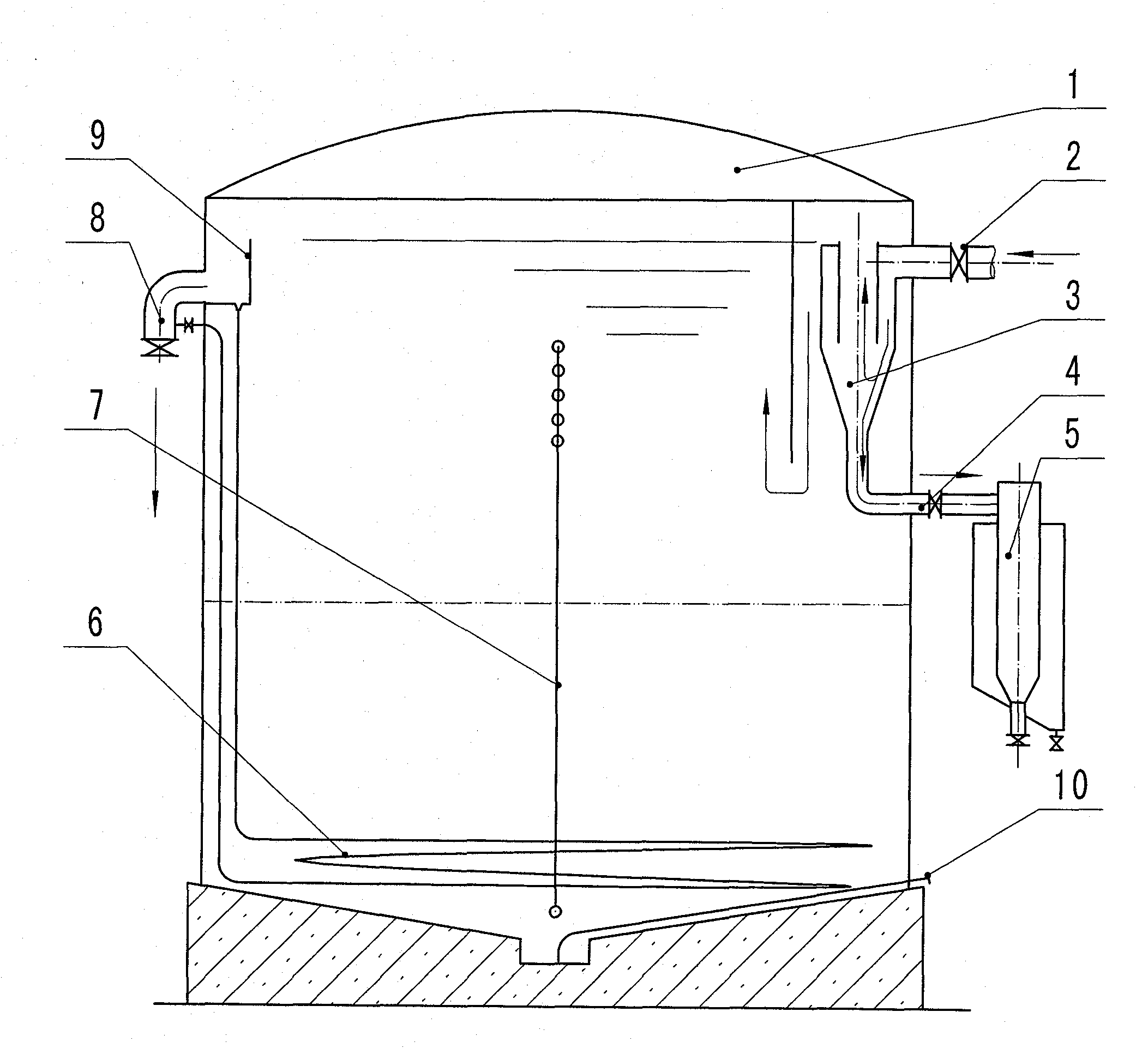

Movement part-free low-consumption and high-efficiency ammonia water, tar and tar residue separation dewatering integration tank

ActiveCN103252116AAvoid consumptionSave electricityCentrifugal force sediment separationTar working-up by water removalThermodynamicsAmmonia

The present invention provides a movement part-free low-consumption and high-efficiency ammonia water, tar and tar residue separation dewatering integration tank, which comprises a tank, a mixing liquid inlet pipe, an ammonia water outlet pipe, a tar outlet pipe, a tar residue outlet pipe, a heating coil pipe, a tar residue separator, a tar residue dewatering device and a cleaning pipe. The working principle is that: a mixing liquid entering the tank is separated through a tar residue separator centrifugal force effect to obtain tar residue, the tar residue is dewatered through the tar residue dewatering device, different specific gravities of hot ammonia water and tar are adopted to separate ammonia water and tar, and heat energy of hot ammonia water in the heating pipe is adopted to dewater the tar. A main purpose of the present invention is to achieve purposes of no movement part operation during an ammonia, tar and tar residue separation and dewatering process, material cost reduction, tar residue water content reduction, separation effect improvement and energy consumption reduction.

Owner:程相魁

Improved tar dehydration method

InactiveCN108690646AGuaranteed qualifiedEnsure safe productionTar working-up by water removalVapor–liquid separatorTar

The invention discloses an improved tar dehydration method. The method comprises the following steps: tar separated from a vapor-liquid separator and ammonia water stand in a mechanical ammonia waterclarification tank, and tar residues and the ammonia water are preliminarily separated; the tar at the lower part of the mechanical ammonia water clarification tank flows into a tar clarification tank, and further stands, and the ammonia water and tar residues are removed; the tar at the lower part of the tar clarification tank is sent into a tar centrifuge in order to further remove water and tarresidues in the tar; the obtained tar is sent into a tar tank, and is continuously heated, the temperature of the tar tank in the early stage is ensured to be 88-92 DEG C, steam is increased when theliquid level of the tar tank reaches 10 m and no tar is fed to ensure that the temperature in the tar tank is 100 DEG C, the tar is heated for 24 h and then stands for 48 h, and a top liquid discharging valve is turned on to achieve liquid discharging and dehydration; the tar tank is heated to 100 DEG C after the dehydration, then is continuously heated for 24 h, and then stands for 48 h, and liquid discharging and dehydration are carried out again; and the tar is sampled and chemically analyzed after above two-stage heating, and is outwards distributed after moisture qualification.

Owner:XINJIANG BAYI IRON & STEEL

Coal tar pretreatment combined system and method

PendingCN106118703ATo achieve the purpose of dehydrationBreak the patternTar working-up by water removalDemulsifierSlag

The invention discloses a coal tar pretreatment combined system and method. The coal tar pretreatment combined system comprises a coal tar tank, a demulsifier tank, a separating and feeding buffer tank, a three-phase separator, a sewage tank, a slag tank, and an oil tank. The coal tar tank is connected with the separating and feeding tank through a coal tar pump, an automatic backwashing filter and a static mixer, and the demulsifier tank is connected with the static mixer through a demulsifier pump. Before separation, by adding the demulsifier, small-particle-size hydrone can be combined under the action of the demulsifier. Meanwhile, small-particle-size oil molecules can be combined to thereby break up the pattern of oil in water and water in oil thoroughly and release emulsified water from oil thoroughly. At this time, coal tar can be centrifugally separated, oil and water can be well separated and the purpose for dehydrated coal tar can be achieved.

Owner:BEIJING HUAFU ENG

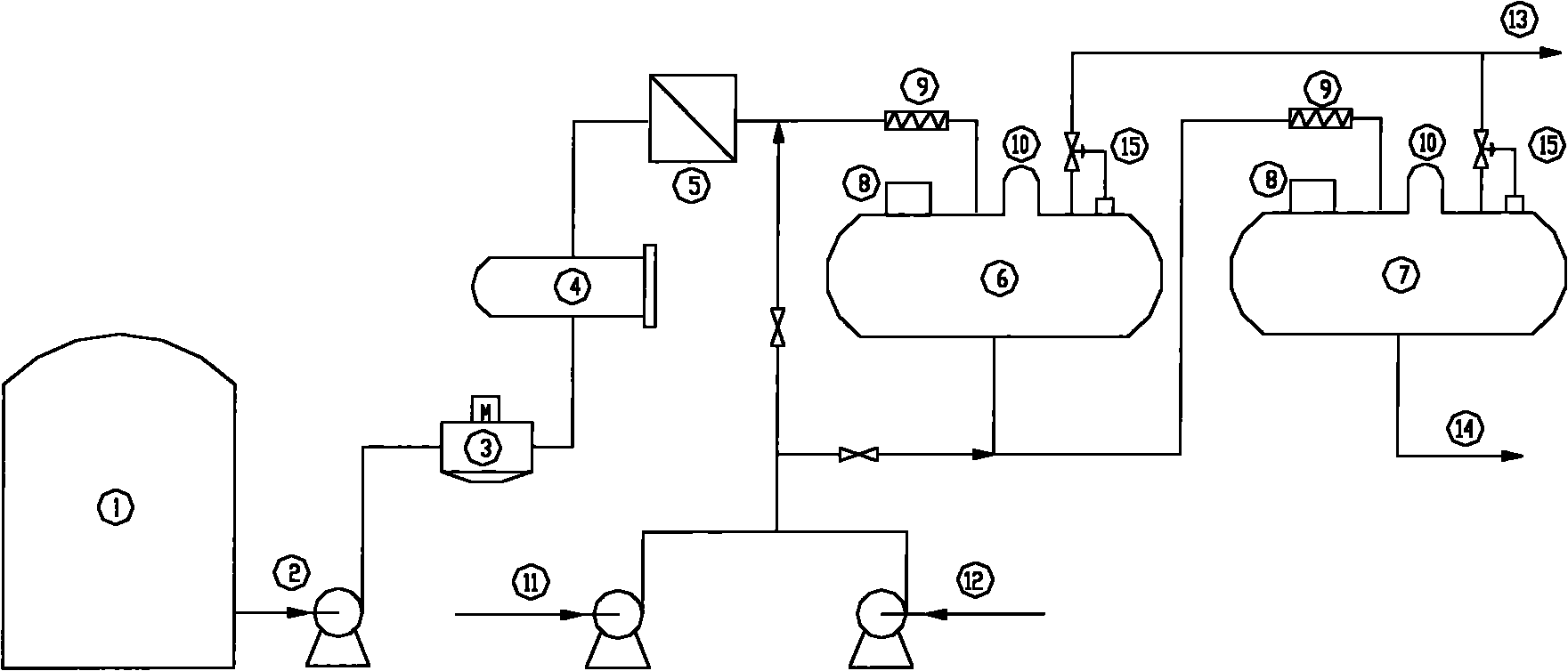

Process for preparing needle coke by utilizing coal tar

ActiveCN109439367AEfficient use ofExpand the range of raw materialsTreatment with hydrotreatment processesTar working-up by water removalFractionationCoal tar preparation

The invention belongs to the technical field of preparation of needle coke and specifically relates to a process for preparing needle coke by utilizing coal tar. The process comprises the following steps: 1, a mixing and settling unit, mixing the coal tar and the fraction lower than 210 DEG C, and performing heating, standing and settling; 2, a filtering unit, pressurizing and filtering the supernatant liquid so as to obtain filtrate; 3, a fractionation unit, fractionating the filtrate in a fractionating tower to obtain four fractions; 4, a hydrocracking unit, performing hydrocracking on the fraction of 210-230 DEG C to obtain hydrocracked fraction; 5, a 1# pressurized polycondensation unit, reacting the fraction of 230-300 DEG C in a 1# pressurized polycondensation device to obtain 1# polycondensate; 6, a 2# pressurized polycondensation unit, carrying out a reaction of the fraction of higher than 300 DEG C in a 2# pressurized polycondensation device to obtain 2# polycondensate; 7, a coking unit, coking the 1# polycondensate and 2# polycondensate to obtain green needle coke; 8, a calcination unit, performing high-temperature calcination on the green needle coke, thereby obtaining the finished needle coke. Therefore, comprehensive utilization of the coal tar is realized.

Owner:山西中科化美科技有限责任公司

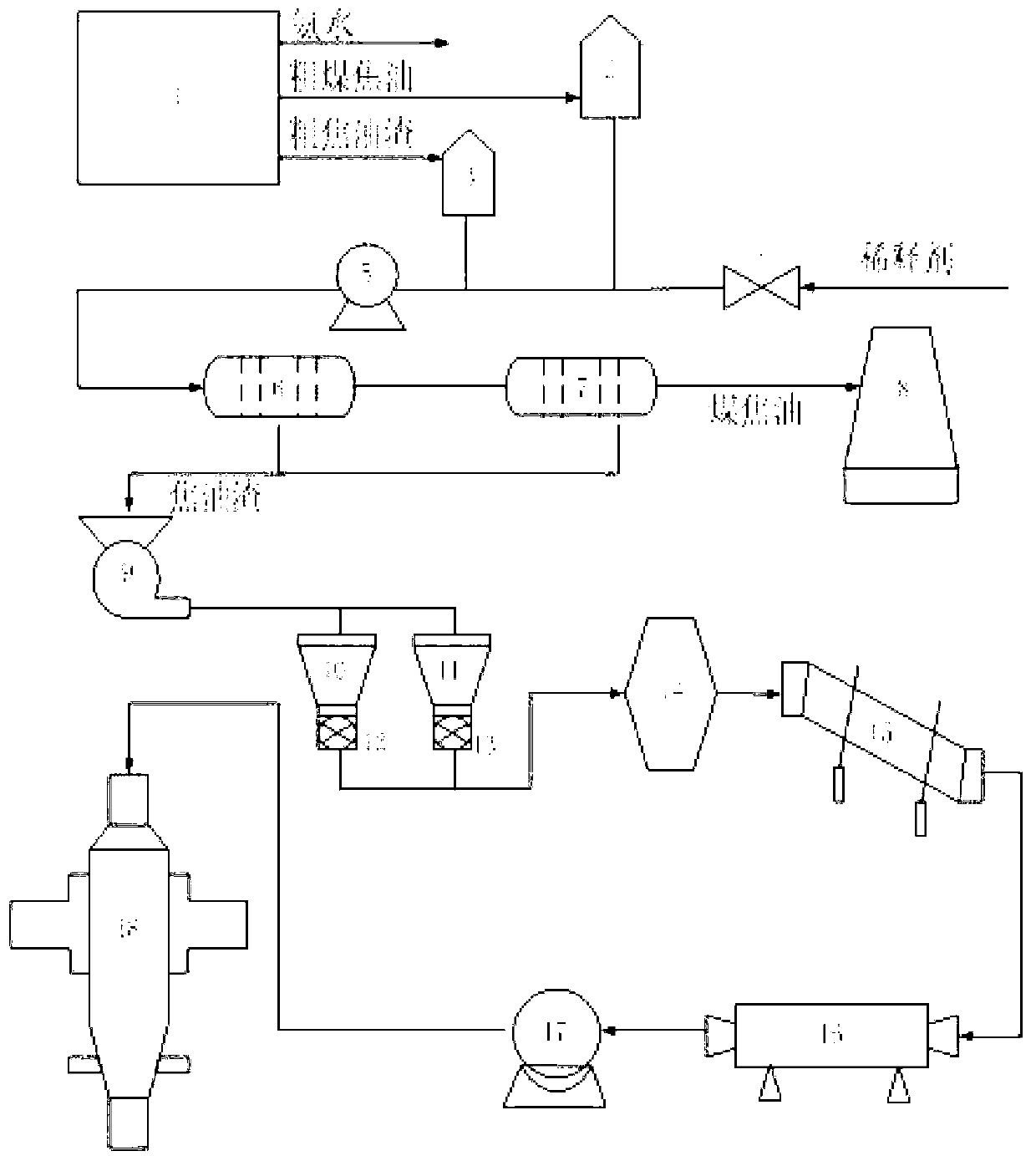

Resourceful treatment system of coking distillation residues and treatment method thereof

ActiveCN103275742AAchieve primary separationLow ashTar working-up by water removalTar working-up by distillationFractionating columnCrusher

The invention discloses a resourceful treatment system of coking distillation residues. The system comprises a horizontal-flow type sedimentation tank, a coal tar tank, a coal tar residue tank, a series-connected centrifugal separator, a distillation tower, a pulverizer, a charging hopper, a discharging hopper, a uniformly-mixing bucket, a drying kiln, a ball crusher, a pelletizer and a vertical furnace. The invention also discloses a treatment method of the coking distillation residues in the system. The method comprises the following steps of: primarily separating ammonia water, coal tar and coal tar residues by virtue of the horizontal-flow type sedimentation tank; separating coarse coal tar and coarse tar residues which are obtained by primary separation for twice by virtue of the series-connected centrifugal separator; feeding the separated coal tar to the distillation tower to distill; feeding the separated tar residues to the pulverizer to pulverize and uniformly mixing with pellet raw materials; drying, pulverizing and pelletizing; and feeding to the vertical furnace to incinerate. According to the system, the coal tar and the tar residues are effectively separated by using a repeatedly-separating device, the coal tar is distilled into fractions with different boiling points through the distillation tower, and the tar residues and the pellet raw materials are fed to the vertical furnace to incinerate after being uniformly mixed, dried, pulverized and pelletized, so that resource recycling is realized while environment protection is realized at the same time.

Owner:SOUTHEAST UNIV

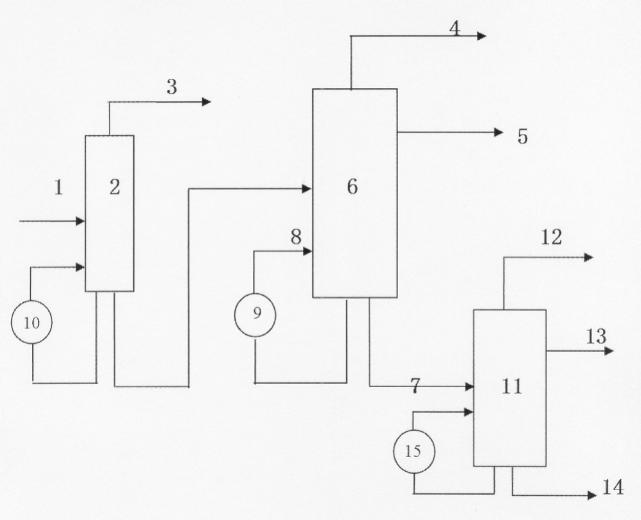

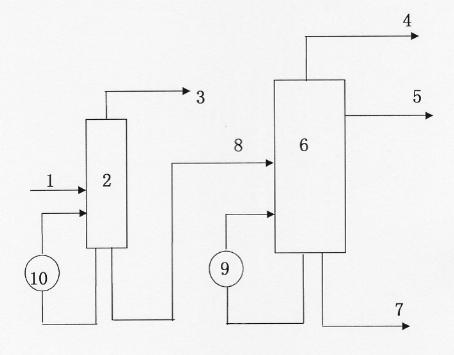

Coal tar alkali-free short-flow normal/reduced-pressure distillation process and device

ActiveCN102161903AReduce sodium ion contentAvoid corrosionTar working-up by water removalTar working-up by distillationAlkali freeDistillation

The invention relates to a coal tar alkali-free short-flow normal / reduced-pressure distillation process and a coal tar alkali-free short-flow normal / reduced-pressure distillation device. In the process, raw material coal tar is subjected to heat exchange and delivered to a dehydrating tower, and light oil distillate and water are collected from the top of the dehydrating tower; coal tar at the bottom of the dehydrating tower is subjected to heat exchange and delivered to a main tower, and a carbolic oil distillate is collected from the top of the main tower; a mixed oil distillate is collected from a lateral line; soft asphalt or carbon black oil is collected from the bottom of the tower; and the bottom material of the main tower is pumped out, heated and returned to the bottom of the main tower to serve as a heat source for the main tower. Normal-temperature operation is adopted in the dehydrating tower, normal-pressure or reduced-pressure operation is adopted in the main tower, and all distillates are not added with alkali in the whole flow. The device comprises the dehydrating tower, the main tower and a heating furnace, wherein the bottom of the dehydrating tower is connected with the middle of the main tower through a pipe; the bottom of the main tower is connected with a soft asphalt or carbon black oil pipe; the middle of the main tower is connected with a mixed oil pipe; and the top of the main tower is connected with a carbolic oil pipe. The process and the device have the advantages that: the flow is short; alkali is not added; direct super-heated steam is not used; new process waste water is avoided; energy consumption is low; product quality is high; and the like.

Owner:BAOSTEEL ENG & TECH GRP

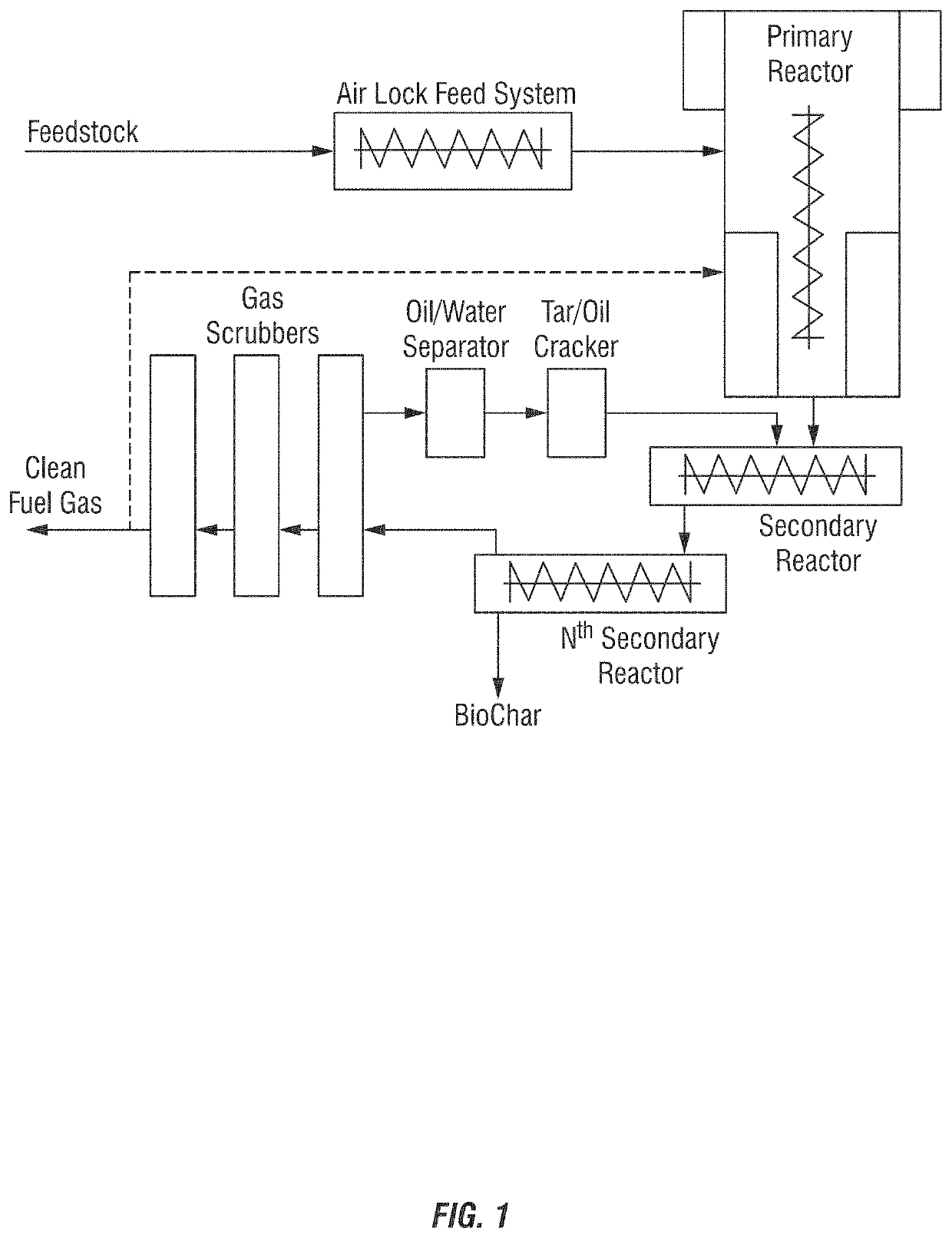

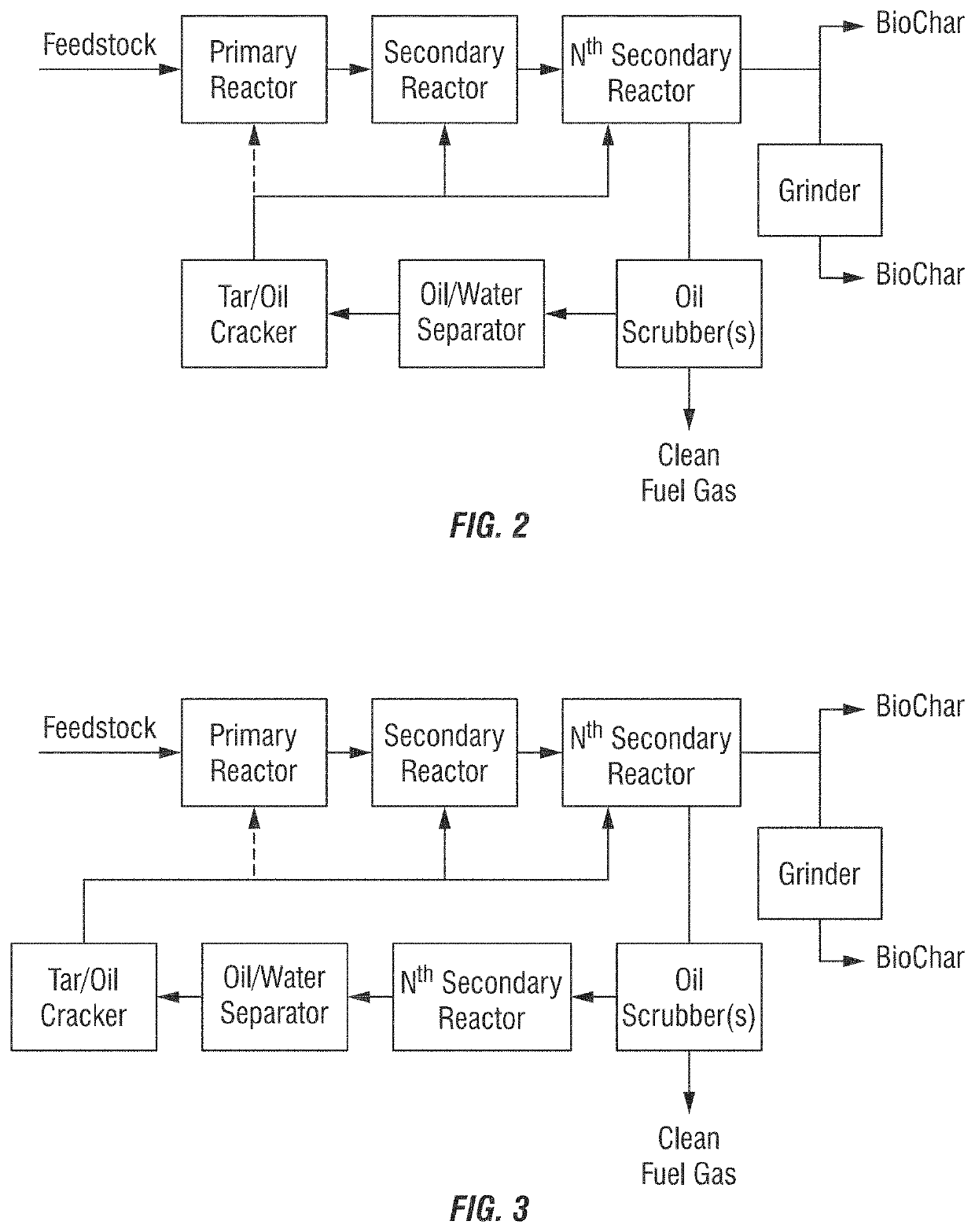

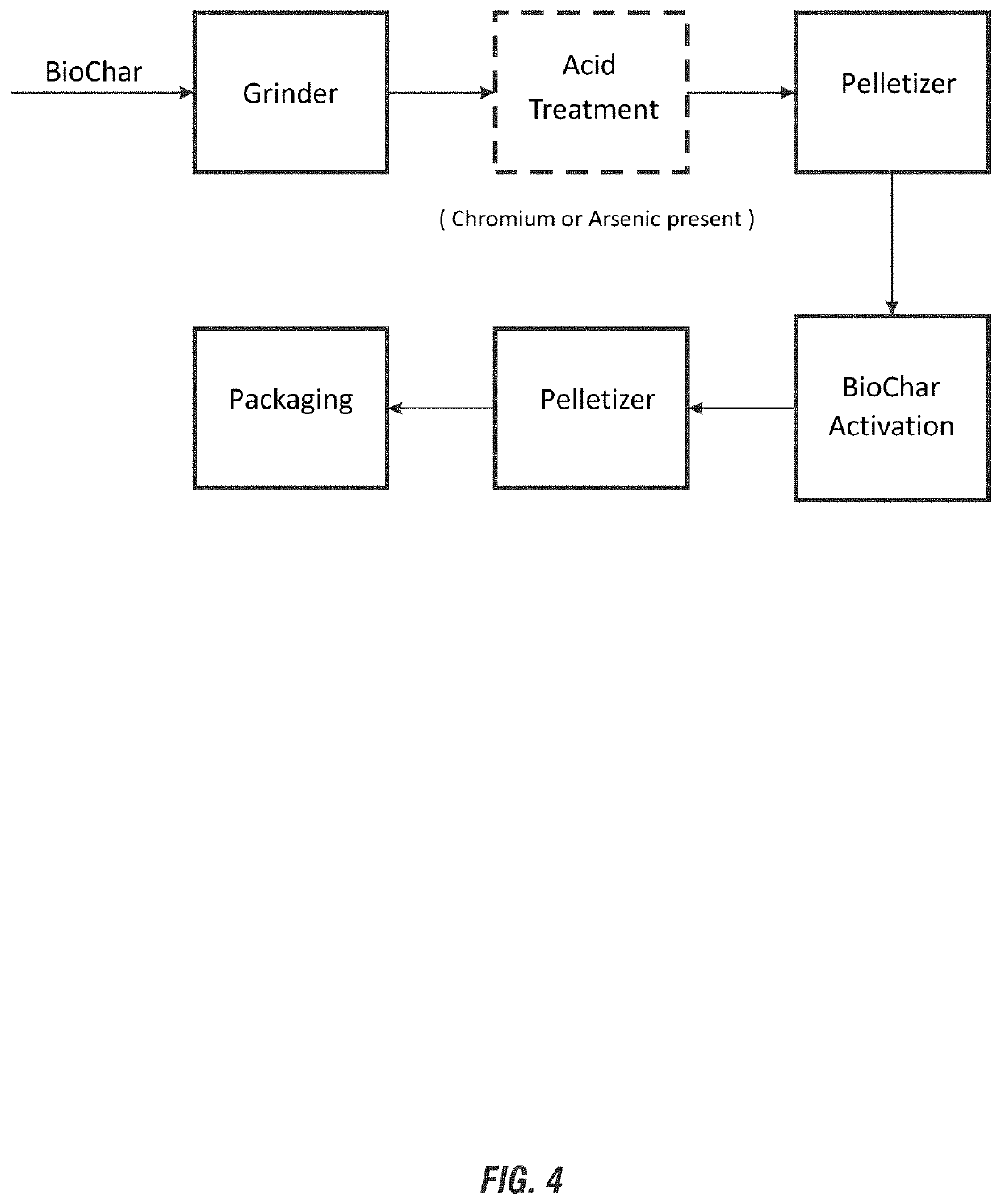

Multistage thermolysis method for safe and efficient conversion of treated wood waste sources

ActiveUS20190367814A1Easy to cleanEfficient methodTransportation and packagingGaseous fuelsHalogenBiochar

Clean, safe and efficient methods, systems, and processes for utilizing thermolysis methods to processes to convert various treated wood sources, such as rail road ties, cross ties, RR crossing roadways, telephone poles, utility poles, cross arm members, bridge timbers, decking, walkways, dock timbers and wharf pilings, lake and ocean pier / pilings, landscaping timbers and edging, treated outdoor engineering structural and other reinforced wood composites, and other end-of-life treated wood materials, into a Clean Fuel Gas and Biochar are disclosed. The invention processes the treated wood sources using thermolysis methods to destroy and / or separate halogen and other dangerous components to provide a Clean Fuel Gas and Biochar source.

Owner:CHZ TECH LLC

Method for preprocessing raw materials of hydrogenation process

ActiveCN101955793AEfficient dehydrationGuaranteed uptimeDewatering/demulsification with mechanical meansHydrocarbon oil crackingSolubilityPretreatment method

The invention relates to a method for preprocessing raw materials of a hydrogenation process. The raw materials of the hydrogenation process and inert gases are mixed to remove water in oil by utilizing the proportional difference of moisture pressure in the inert gases under different pressures, and the inert gases can be recycled. By adopting the method provided by the invention, the water in oil containing mechanical impurities can be effectively removed, especially the water in coal tar fraction with high water emulsifiablility and solubility can be continuously removed to ensure that the water content is less than 300 mu g / g and meets the requirement for feeding of the hydrogenation process. The method has the advantages of capability of long-period and continuous operation, low energy consumption and better environment protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tar residue resource utilization process

InactiveCN111961492AReduce usageReduce difficultyTar working-up by water removalSpecial form destructive distillationPhenolMaterials science

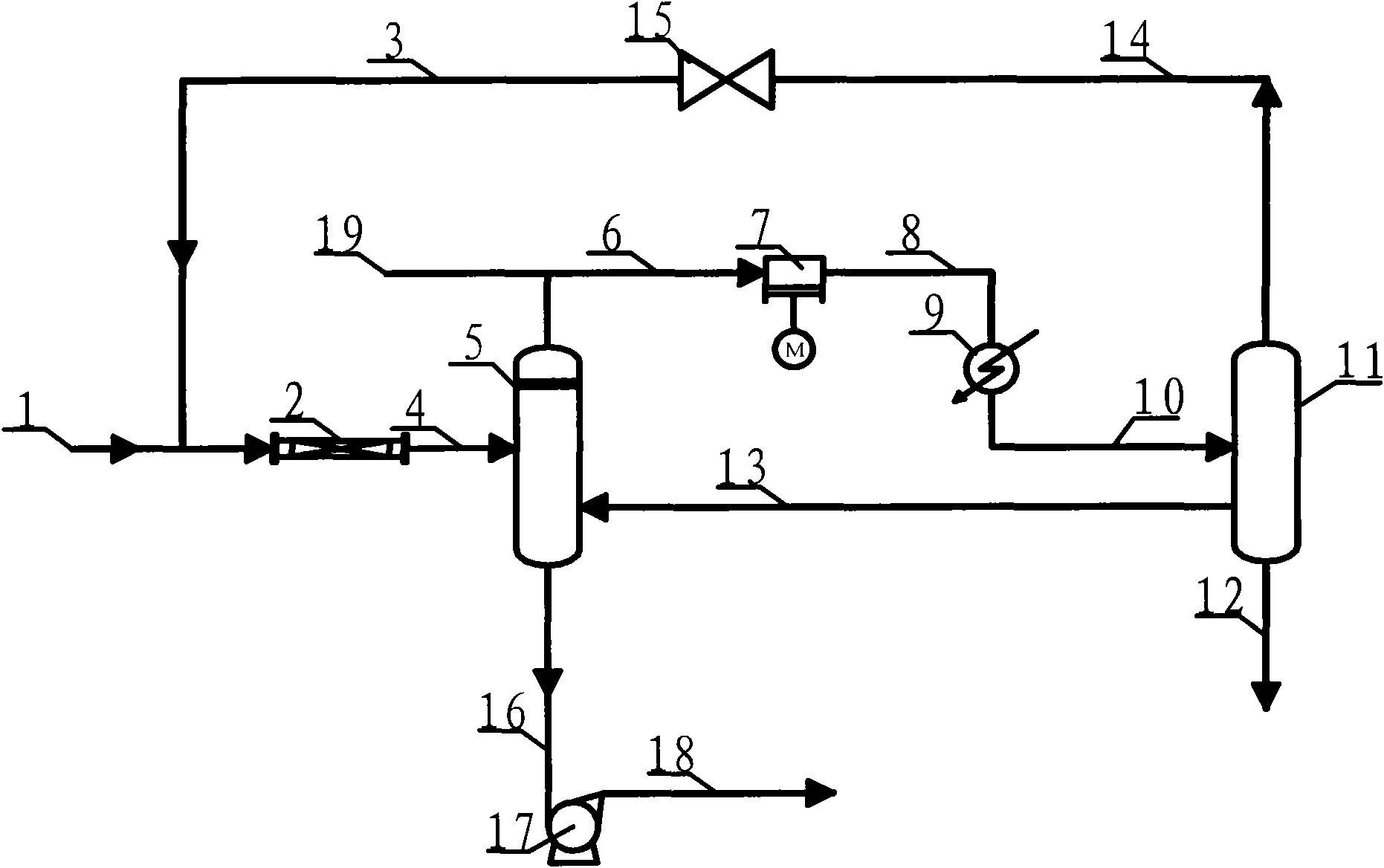

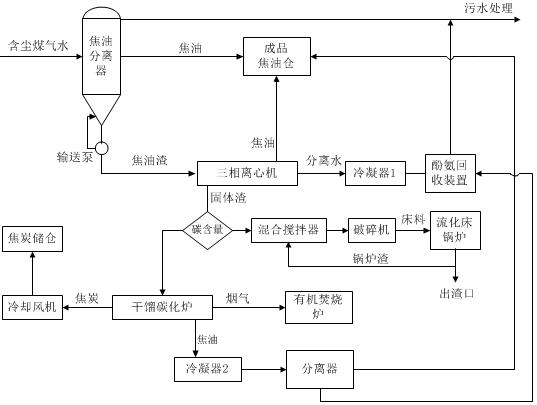

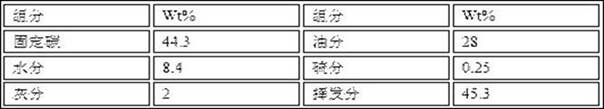

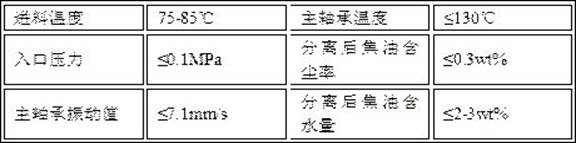

The invention provides a tar residue resource utilization process. Tar, solid residues and water which are obtained after tar residues in the coal gasification process are centrifuged through three-phase centrifugation. Judging the next solid slag treatment process according to the carbon content of the separated solid slag, and carrying out dry distillation on the solid slag to prepare coke whenthe carbon content of the solid slag is greater than or equal to 45%; when the carbon content of the solid slag is less than 45%, the solid slag and the fluidized bed boiler slag are mixed and crushedto serve as a fluidized bed material to enter a furnace for combustion, and phenol ammonia in water generated in the process is removed through a phenol ammonia recovery device. In the process, the tar residue inlet pressure of a three-phase centrifugal machine is controlled to be 0-0.1 Mpa, the inlet temperature is controlled to be 65-90 DEG C, the rotating speed of the centrifugal machine is 2000-3500r / min, and the differential speed is 17-40r / min; wherein the dry distillation temperature is 650 + / -50 DEG C, and the dry distillation time is 2 hours; after solid slag and fluidized bed boilerslag are mixed and stirred, solid particles with the diameter of 6-8 mm are crushed to serve as bed materials; and the phenol-ammonia recovery device controls the phenol content at an outlet to be less than or equal to 800mg / L and the ammonia content to be less than or equal to 300mg / L. The process is high in tar residue treatment efficiency, less in pollution, energy-saving and emission-reducing.

Owner:新疆新业能源化工有限责任公司

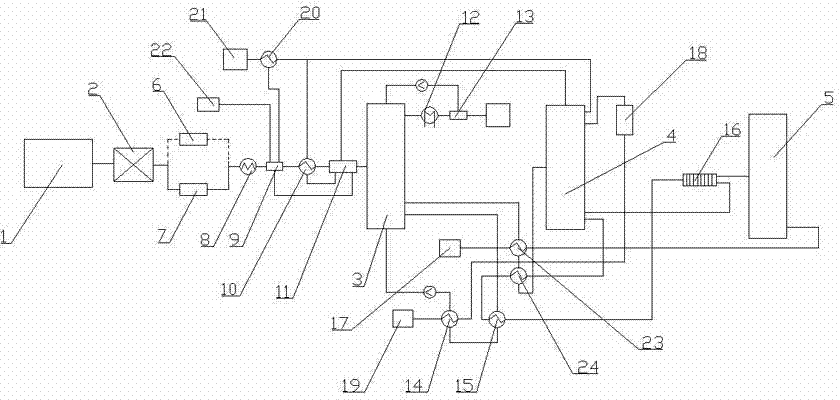

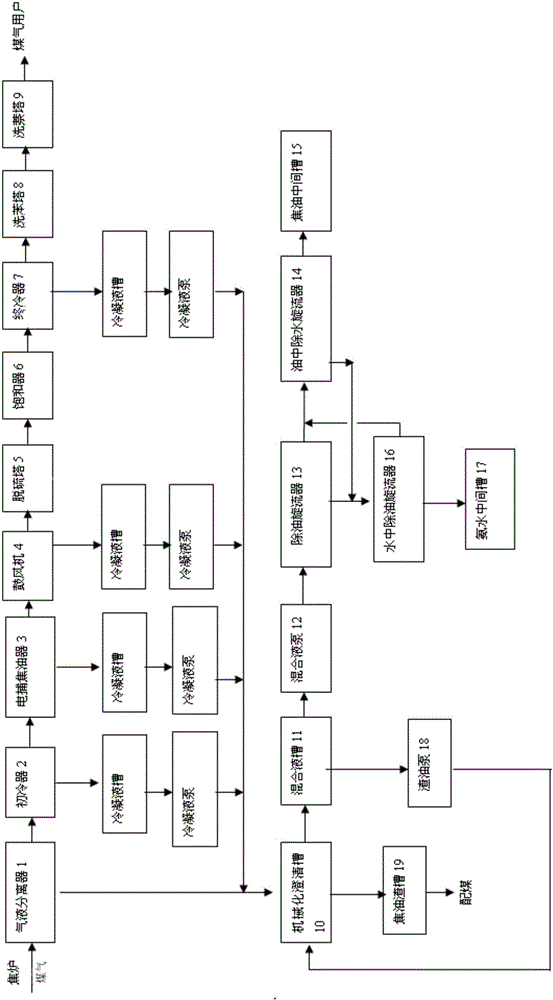

Coke oven gas purification system and condensate treatment subsystem thereof

InactiveCN106010670AShort separation timeEasy to separateWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentEngineeringRotational flow

The invention discloses a condensate treatment subsystem of a coke oven gas purification system. The condensate treatment subsystem comprises a mechanical clarifying tank, a tar residue tank, a mixed liquid tank, a residual oil pump, a mixed liquid pump, an oil removal hydrocyclone, an in-water oil removal hydrocyclone, an ammonia water middle tank, an in-oil water removal hydrocyclone and a tar middle tank; residues, oil and water in condensate produced in the gas purification process are separated in the rotational flow centrifugal sedimentation principle, immediate treatment of the condensate is realized, the separation time is short, the separation effect is better, equipment is reduced, the investment is low, and small areas are occupied. The invention further provides the coke oven gas purification system containing the condensate treatment subsystem.

Owner:SHANDONG IRON & STEEL CO LTD

Popular searches

General water supply conservation Ammonia preparation/separation Tar working-up by thermal treatment Bulk chemical production Combustible gas production Treatment with plural serial stages only Dispersed particle separation Waste based fuel Gas purification by non-gaseous materials condensation Liquid separation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com