Patents

Literature

35 results about "Coal tar preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing honeycomb active carbon from coal and coal tar

InactiveCN101503191ASimple ingredientsLow costCarbon compoundsWorking-up peatActivated carbonCarbonization

The invention provides a method for preparing honeycomb-like activated carbon by using coal and coal tar, which takes coal dust and the coal tar as raw materials to prepare the honeycomb-like activated carbon by grinding the coal dust, charge mixture, vacuum pugging, seal aging, vacuum extruding and moilding, drying, carbonization and activation. The method for preparing the honeycomb-like activated carbon only takes the coal tar as cementing agent, so as to overcome the defect that multiple cementing agents are needed to be applied in the technique, thus having the characteristics of simple raw materials, low production cost and easy industrialization. The produced honeycomb-like activated carbon has the characteristics of large geometric area and specific surface area, high mechanical strength and the like, and can be applied for the treatment of waste gas and waste water and catalyst carrier.

Owner:BEIJING UNIV OF CHEM TECH

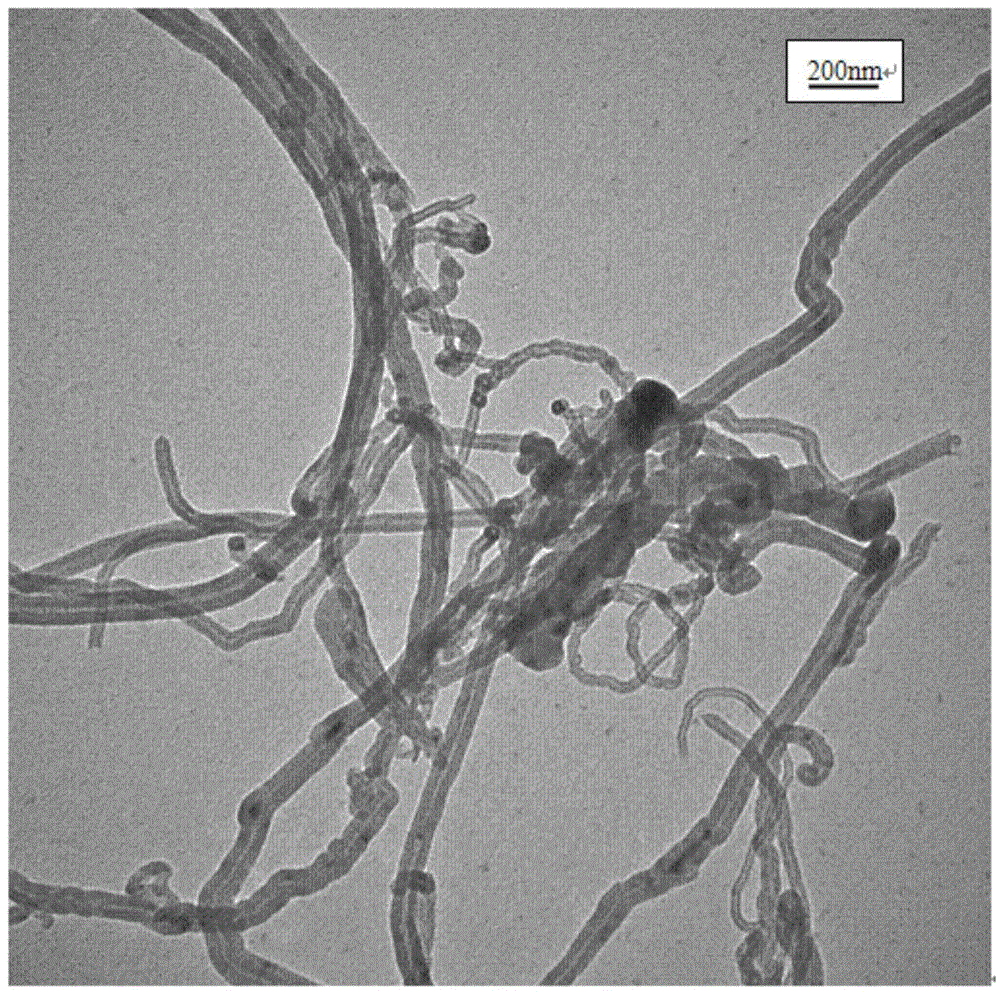

Method for preparing carbon nanotubes by adopting coal tar

InactiveCN104555989AAvoid scorchingLow catalytic pyrolysis activityMaterial nanotechnologyFurnace temperatureIntermediate frequency

The invention discloses a method for preparing carbon nanotubes by adopting coal tar. The method comprises the following steps: 1, soaking ferroferric oxide powder in a SnCl2 solution to perform sensitization, and plating nickel on the surface of the ferroferric oxide powder by adopting physical deposition to obtain an iron-containing catalyst; 2, introducing a protective gas into a coal tar vaporizer to blow away and vaporize the coal tar, thereby obtaining a mixed gas of the coal tar and the protective gas after vaporization; 3, putting the iron-containing catalyst into a corundum boat, putting the corundum boat into a tubular furnace, introducing the mixed gas when the furnace temperature rises to 400-600 DEG C, applying an intermediate-frequency induction power source to the tubular furnace at the same time, stopping introducing the mixed gas and turning off the intermediate-frequency induction power source after 20-30 minutes, and cooling along with the furnace to obtain a semi-finished product; and 4, sieving the semi-finished product in water, and drying an oversize product to obtain the carbon nanotubes. According to the method disclosed by the invention, a coke coking byproduct namely the coal tar is adopted as a raw material for preparing the carbon nanotubes, and the average pipe diameter of the prepared carbon nanotubes is 28-60nm.

Owner:XIAN UNIV OF SCI & TECH

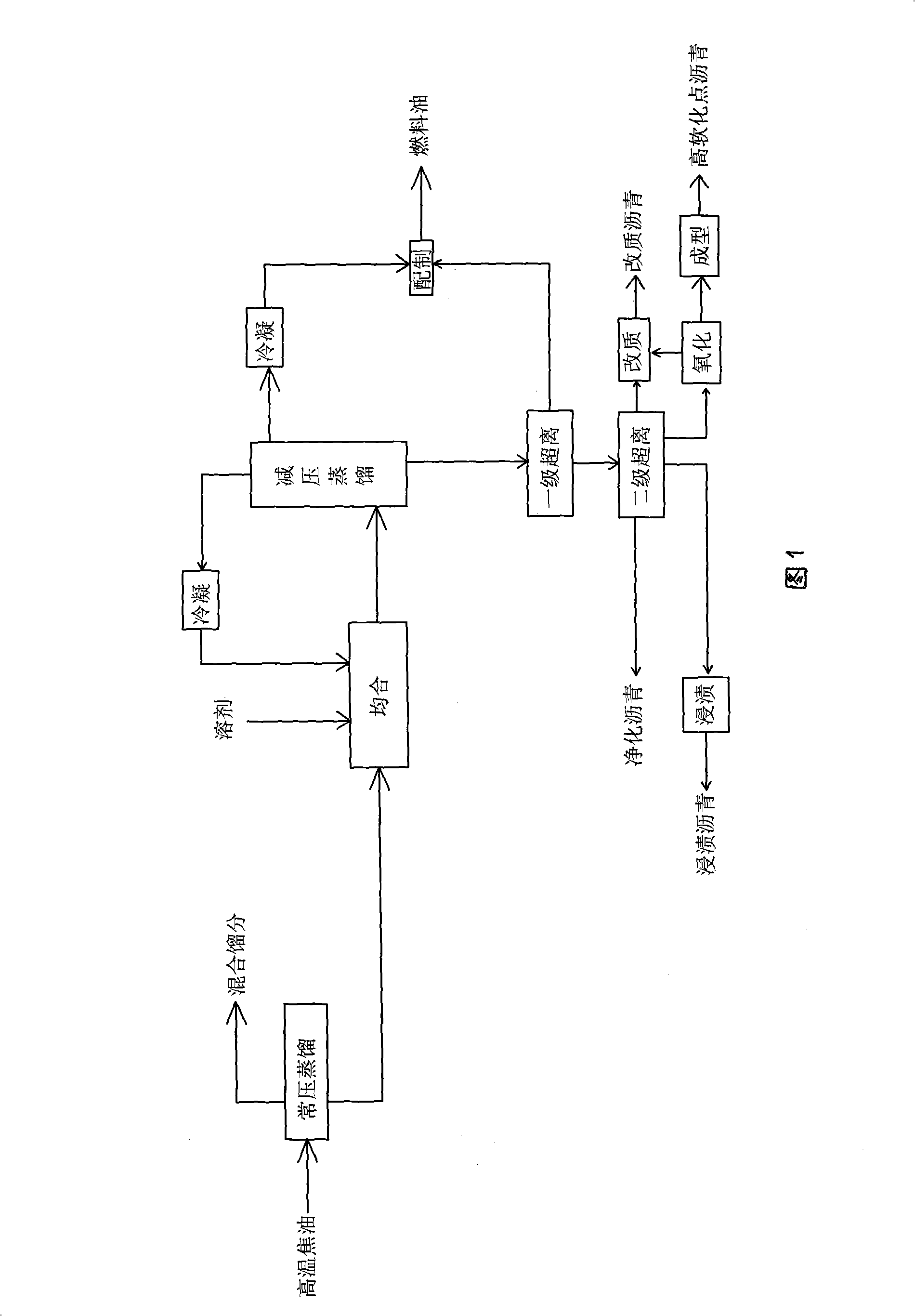

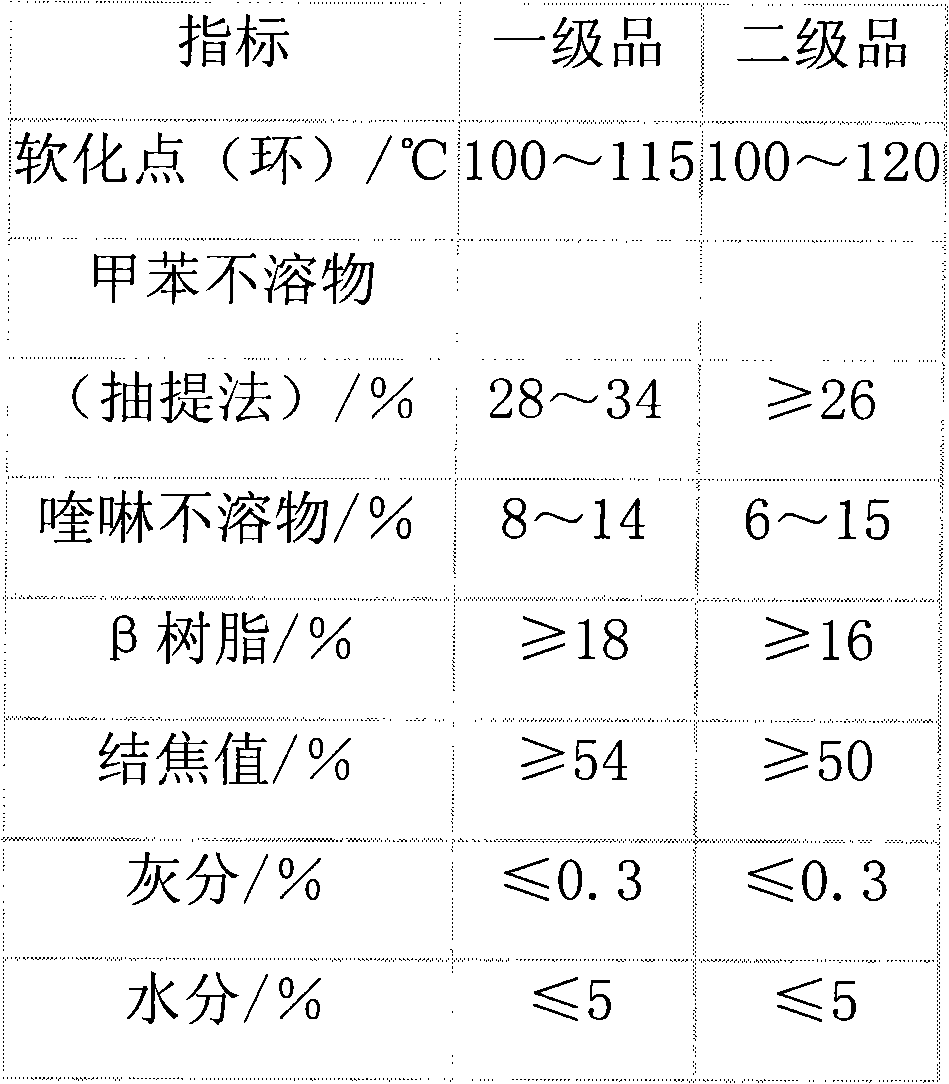

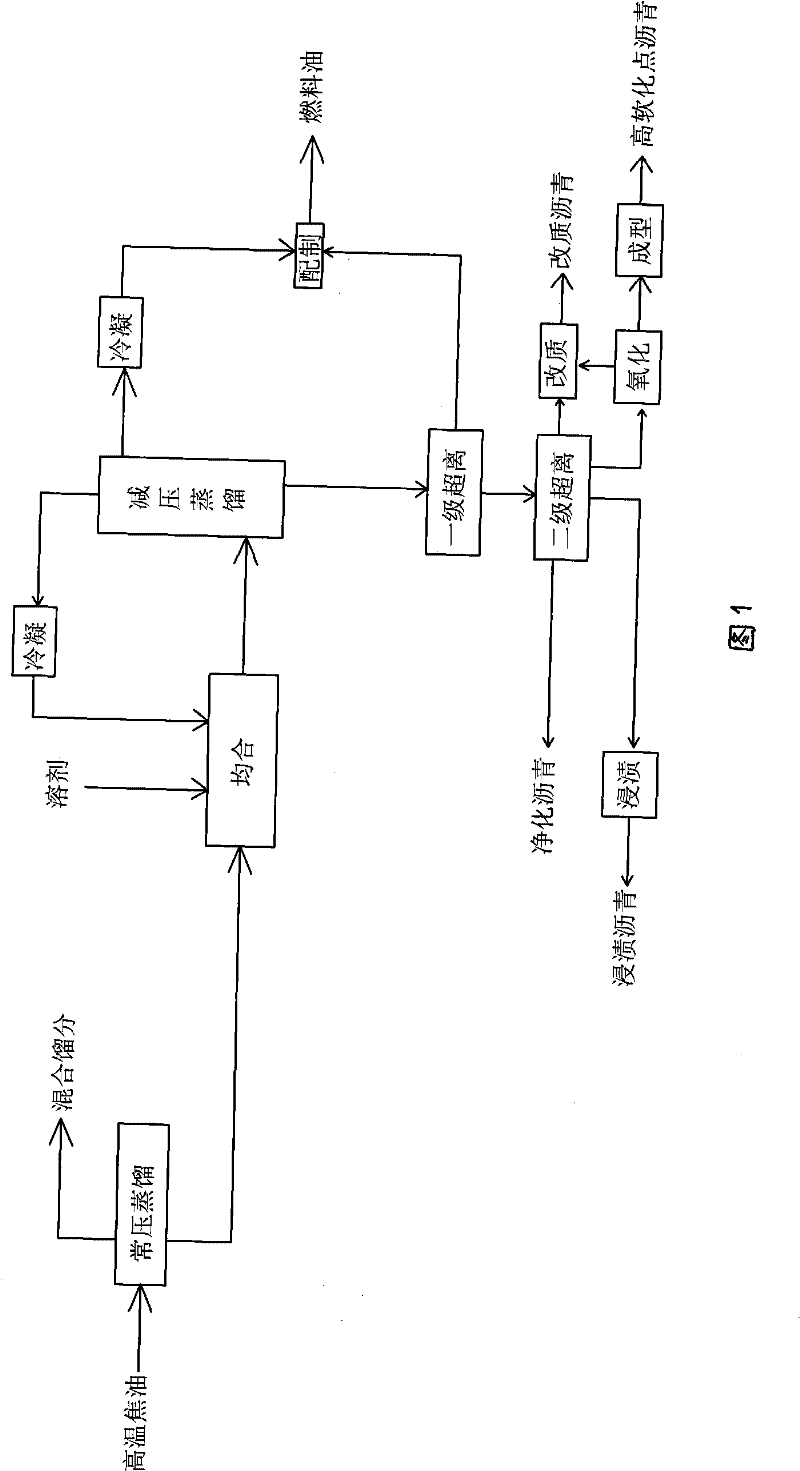

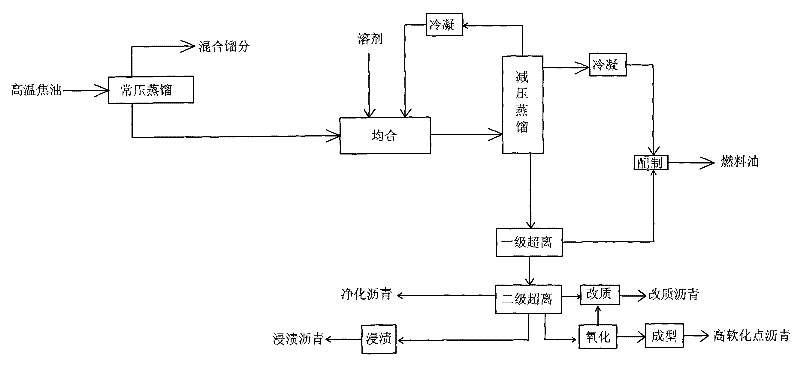

Processing process for preparing various asphalt and fuel oil with coal tar

ActiveCN101323788AImprove qualityIncrease added valueTar working-up by distillationCoal tar preparationFuel oil

The invention discloses a processing technology for preparing various pitches and fuel oils by coal tar which comprises the steps that: the coal tar is heated to 350 DEG C to 360 DEG C, rectified at ordinary pressure first and then at reduced pressure, primarily ultracentrifugated and secondarily ultracentrifugated to produce purified pitch, impregnating pitch, modified pitch, high softening point pitch and fuel oils. The invention has simple technology and convenient operation, can produce various high quality pitches and fuel oils and is characterized by less investment in devices and stable quality, thus better solving the problems of low general grade of pitches of China at present, unstable fraction of fuel oils and pitches and plenty of impurities and being quite applicable to the processing and producing of the fuel oils.

Owner:浙江美阳国际工程设计有限公司

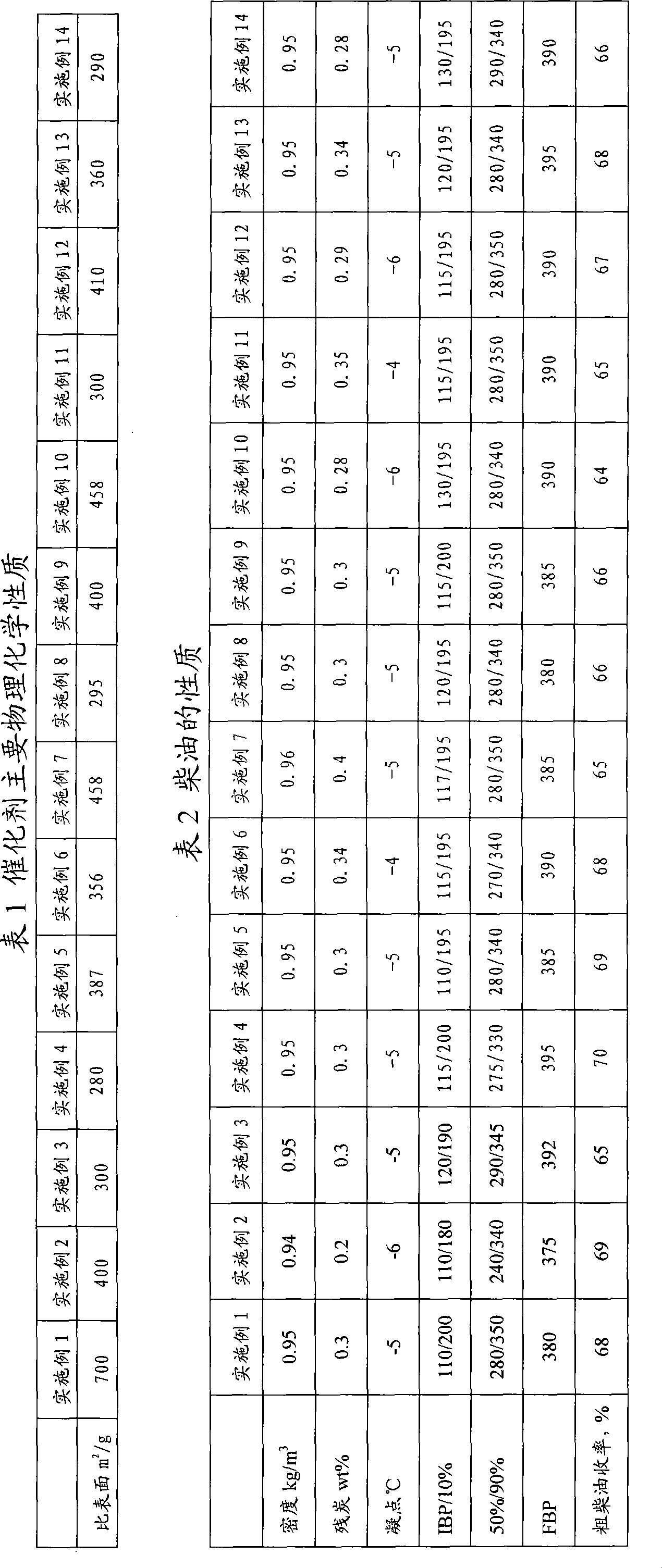

Method for preparing diesel from coal tar

ActiveCN101376816ASimple processHigh yieldTar working-up by distillationTar working-up by chemical refiningRoom temperatureCoal tar preparation

The invention discloses a method for preparing diesel oil from coal tar. In the method, the coal tar and a catalyst are added into a reactor; after the reactor is closed, the temperature of the reactor is heated to 320-400 DEG C and the temperature is maintained for 0 to 20 minutes; after the temperature is reduced to the room temperature, a reactor product is taken out from the reactor; then distilling and separating are carried out; the cut fraction of 80 to 280 DEG C is taken out, thus obtaining the diesel oil. The method provided by the invention has the advantages of simple technique, low requirements to devices and high conversion rate. The invention belongs to the field of preparing diesel oil from coal tar.

Owner:HANERGY TECH

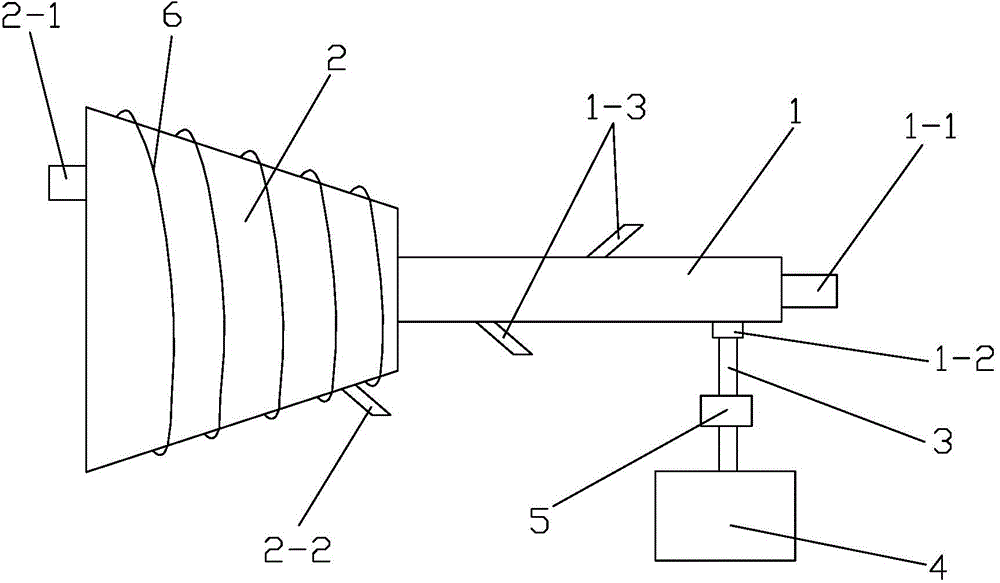

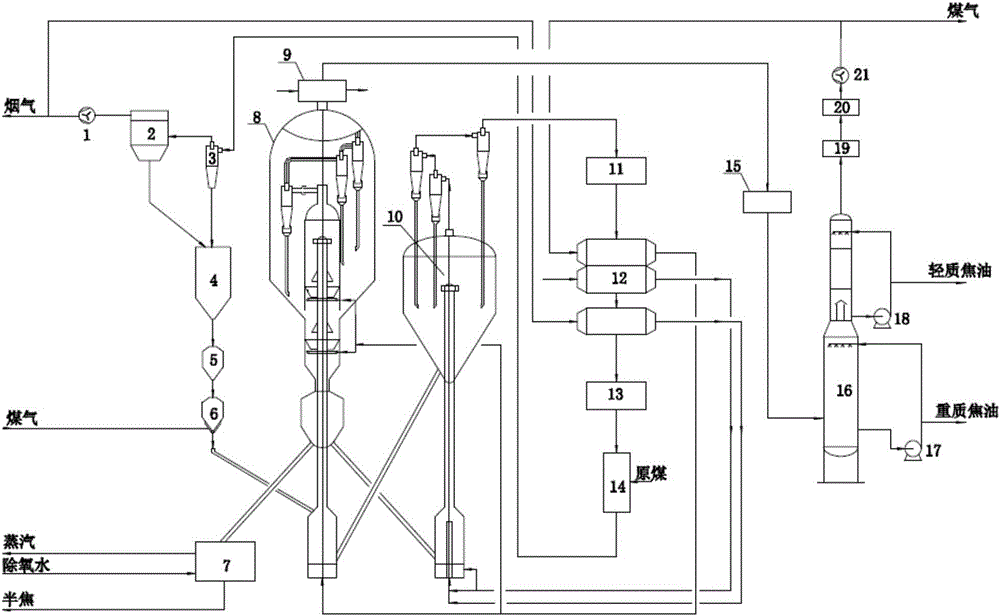

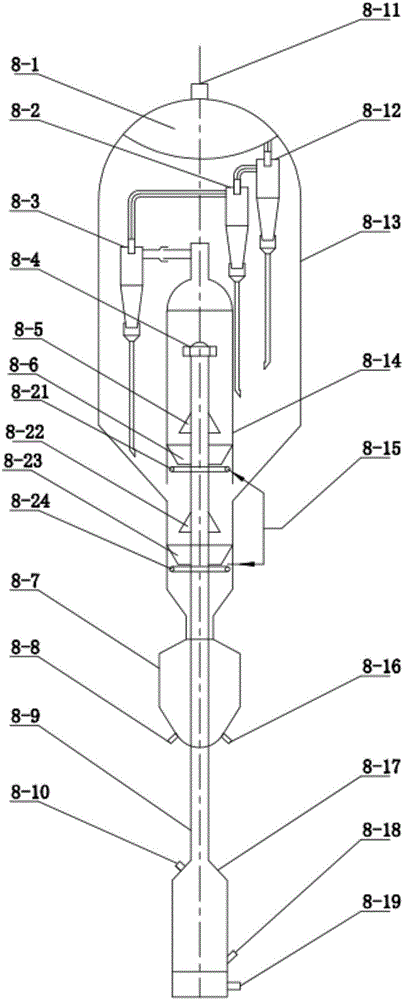

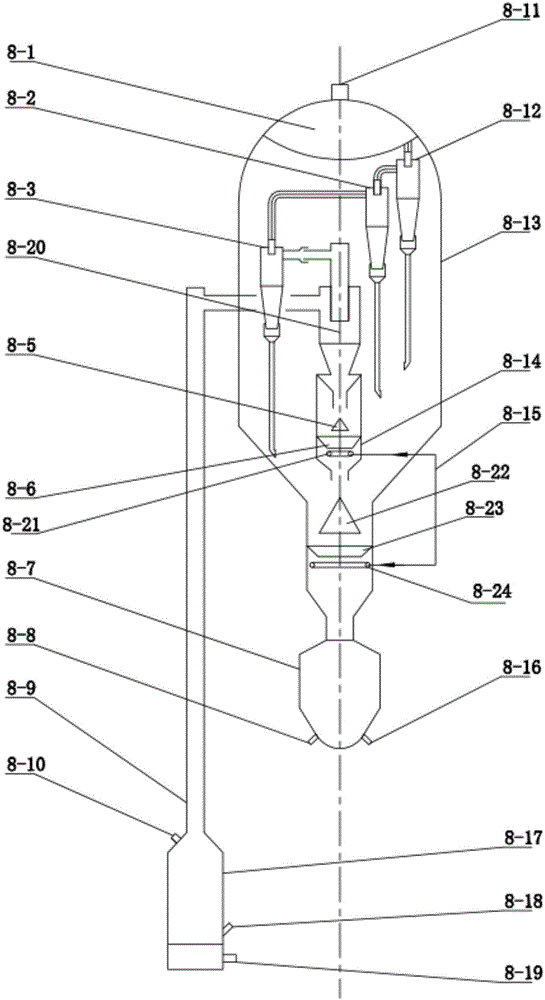

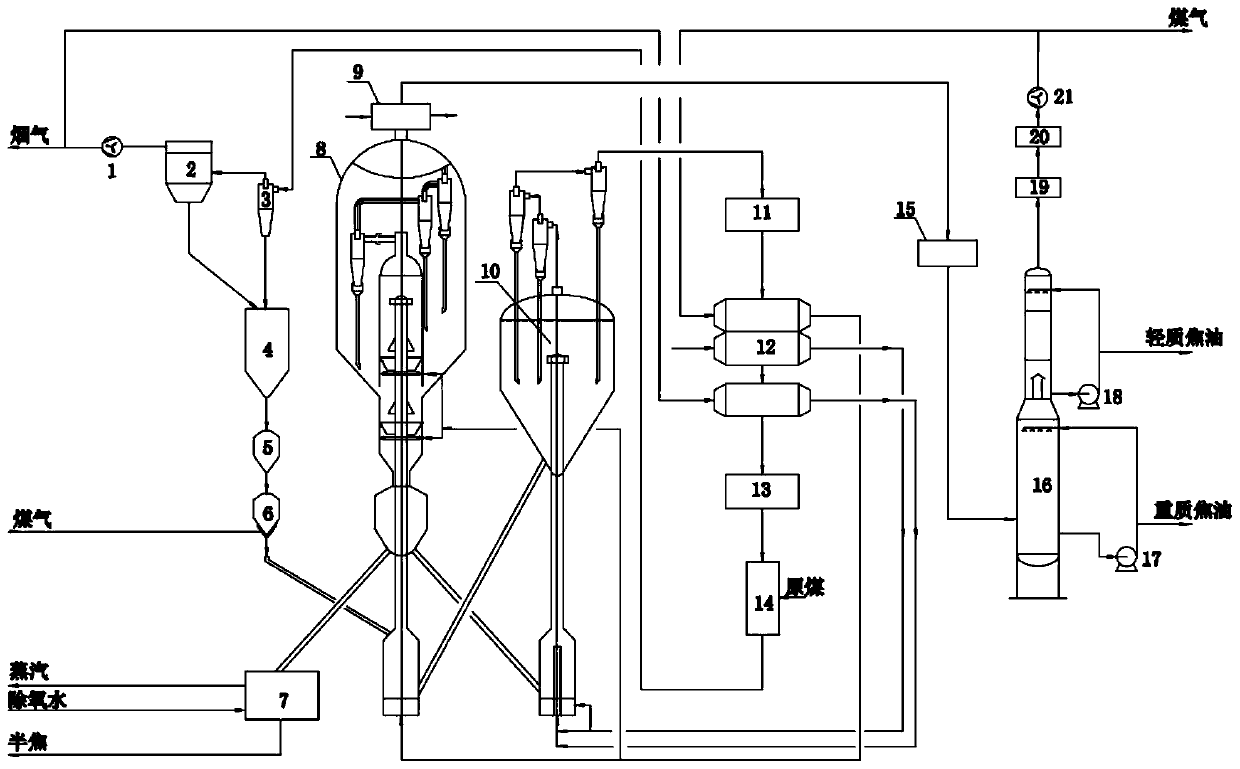

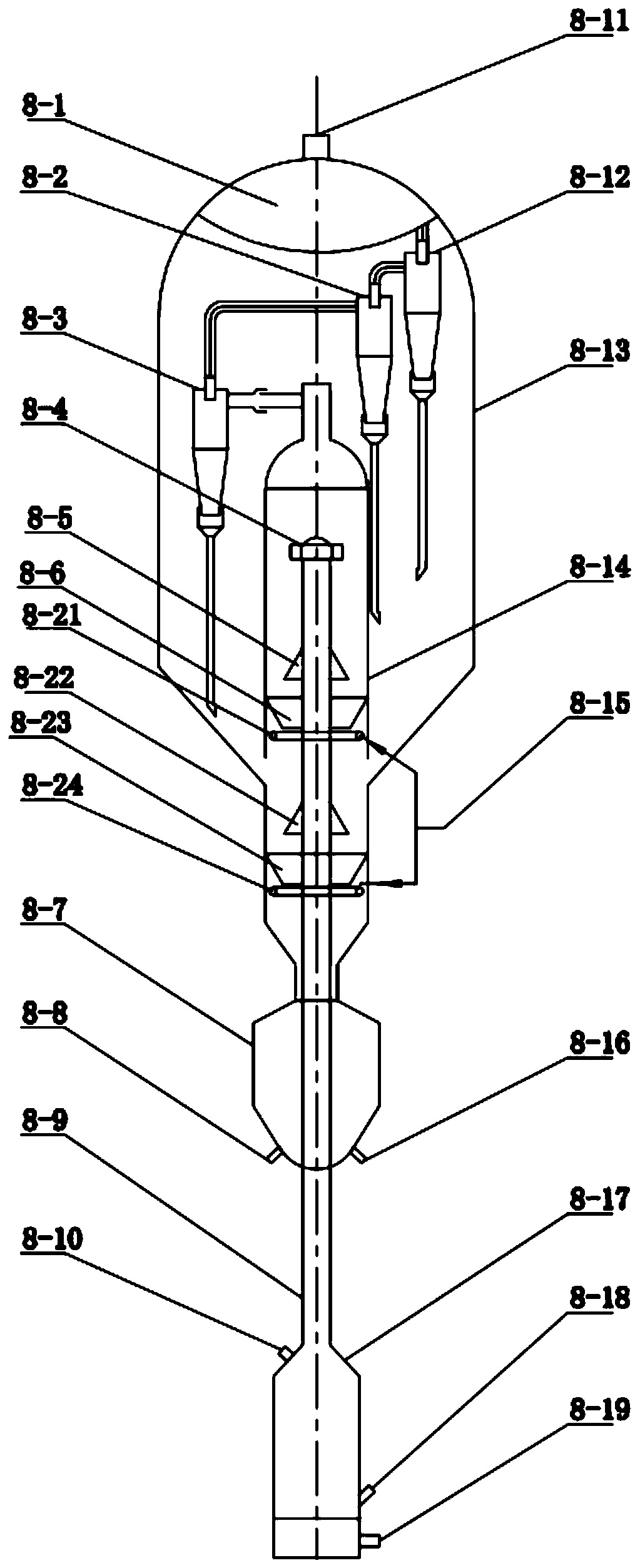

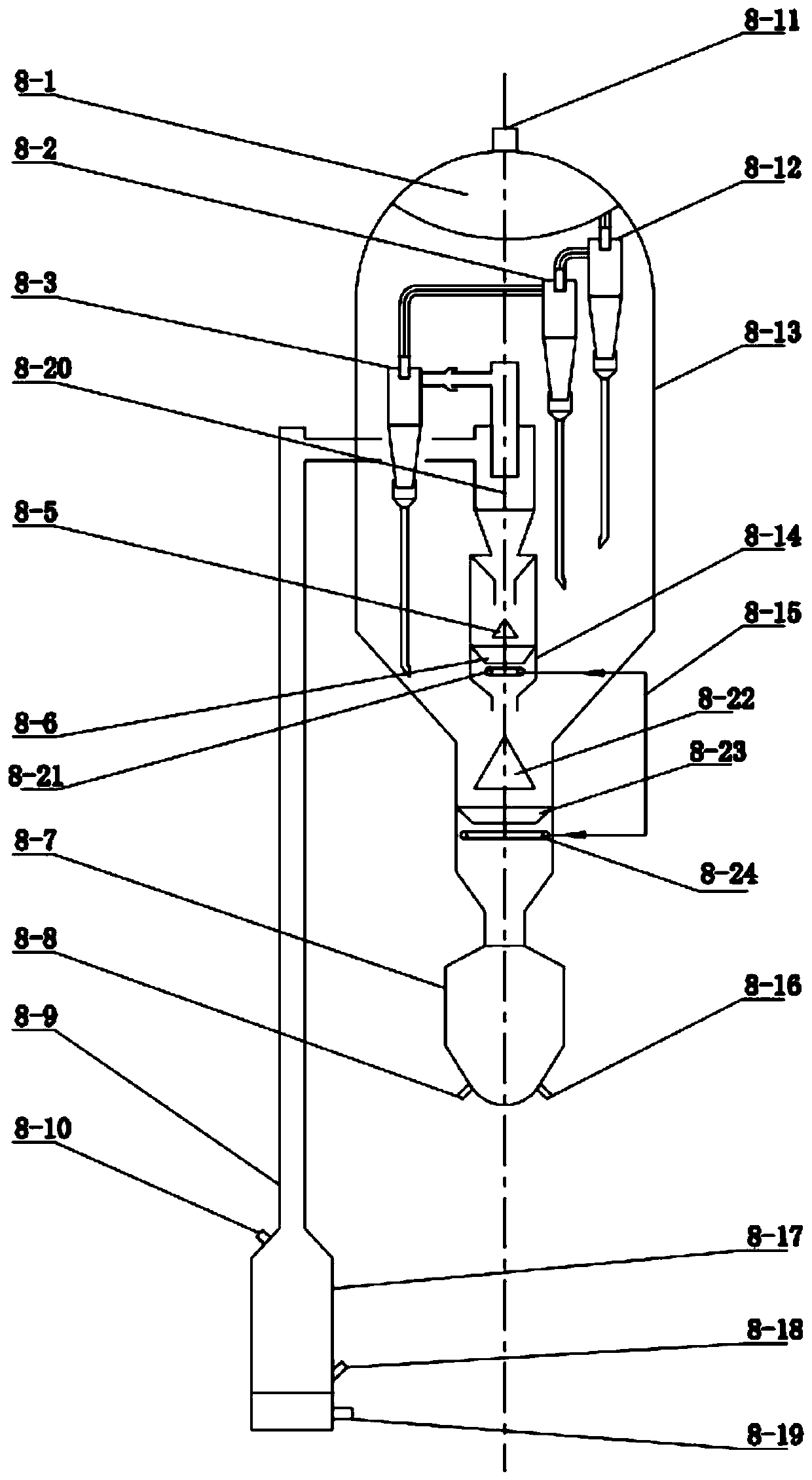

System and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with solid heat carrier

ActiveCN106753491AHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierHigh energy

The invention relates to a system and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with a solid heat carrier. The system comprises a raw coal primary processing apparatus, a pyrolytic reaction separator, a semi-coke heating separator, a recycling apparatus, a coak tar recovering apparatus and a semi-coke cooling apparatus; a part of semi-coke powder discharged from the pyrolytic reaction separator enters the semi-coke heating separator, high-temperature smoke discharged from the semi-coke heating separator enters the recycling apparatus, the coal tar recovering apparatus produces coal tar and coal gas, and the semi-coke cooling apparatus produces semi-coke. In the existing coal tar preparation method, the coal pyrolytic optimization of the coal is not good, so that the existing coat tar preparation method has the technical problems of low oil yield, high investment and high energy consumption. The system for preparing the coal tar, gas and semi-coke by activating the coal gas and flash pyrolysing the coal with the solid heat carrier is rapid in pyrolysis, rapid in output and rapid in cooling.

Owner:陕西凯德利能源科技有限公司

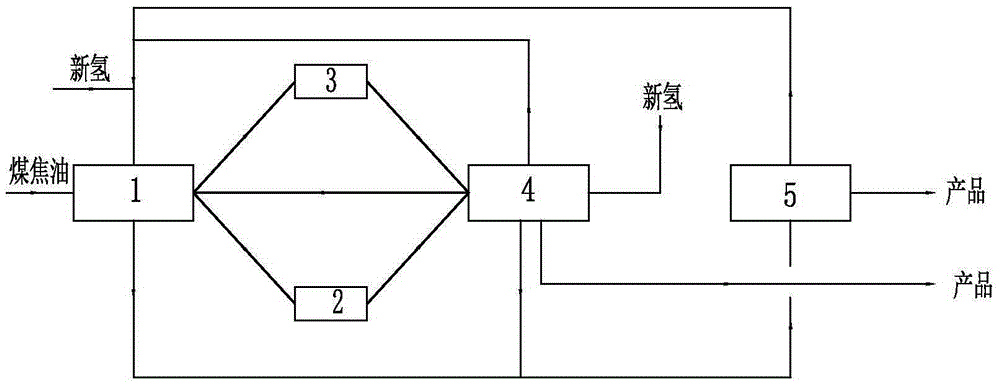

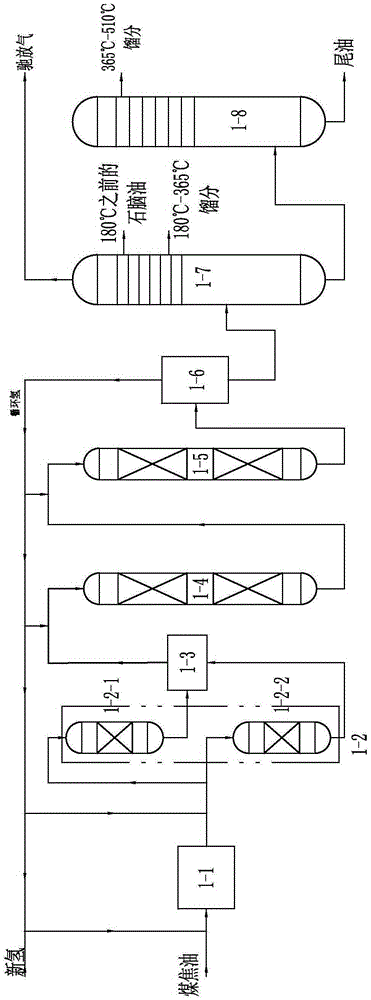

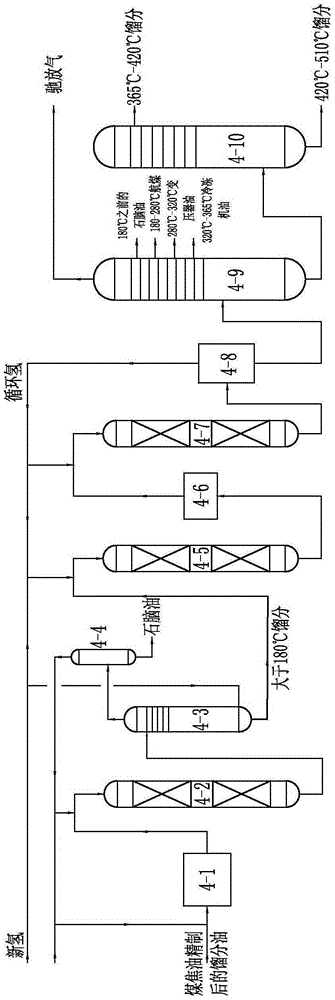

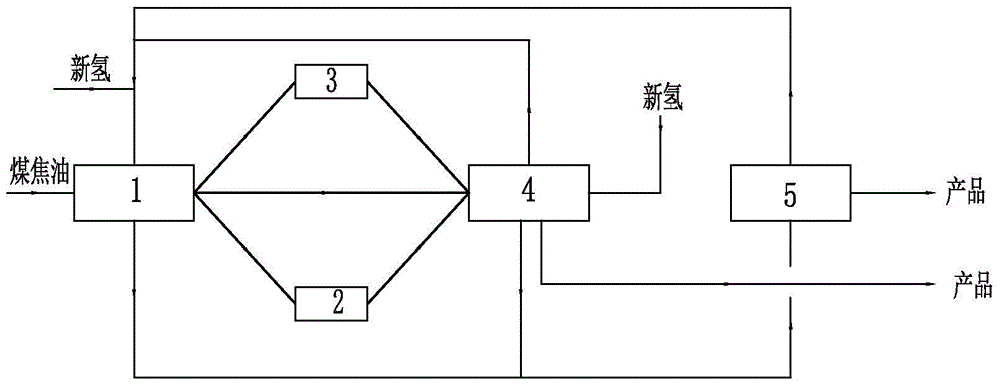

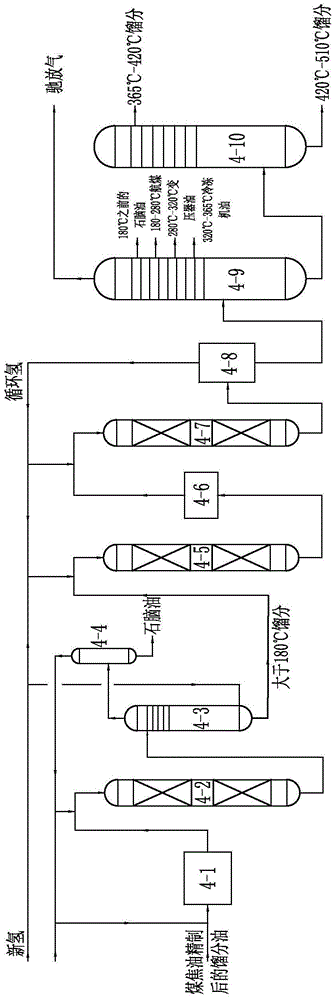

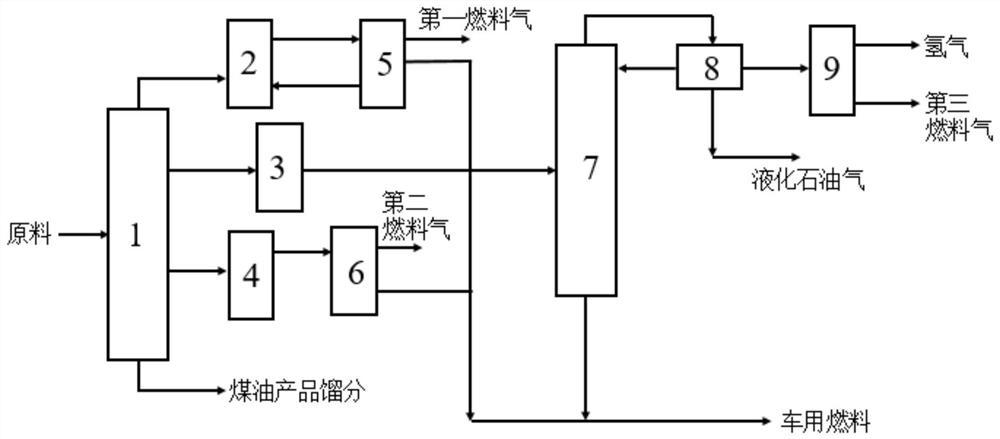

System and method for preparing high-octane gasoline, aviation kerosene and naphthenic base oil with total-hydrogen-type coal tar

ActiveCN105419864AIncrease profitImprove anti-carbon performanceMolecular sieve catalystsTreatment with hydrotreatment processesIsomerizationHydrogen

The invention relates to a system and method for preparing high-octane gasoline, aviation kerosene and naphthenic base oil with total-hydrogen-type coal tar. The system is formed by a coal tar refining device, a distillate oil deep refining, isomerization-visbreaking and post-refining device and a naphtha dehydrogenizing and aromatic extraction device. The method includes the steps that coal tar serves as a raw material, is subjected to hydrorefining, deep refining, isomerization visbreaking and post-refining treating, and then is subjected to a naphtha dehydrogenizing technology and an aromatic extraction technology, and the high-octane gasoline, the aviation kerosene and the naphthenic base oil are obtained. Meanwhile, a mass of hydrogen is generated to serve as supplemented hydrogen of coal tar hydrogenation, the obtained product oil is good in quality, and after detecting is carried out according to the national standard, various detected indexes meet the national standard.

Owner:王树宽

Method for manufacturing ultrahigh-modulus graphite fiber continuous filament from coal tar

The invention provides a method for manufacturing ultrahigh-modulus graphite fiber continuous filament from coal tar, belonging to a manufacture method of a graphite fiber. The method comprises the following steps of: extracting coal tar step by step with an organic solvent to obtain a pure pitch component; polymerizing the pure pitch component at a high temperature and high pressure to obtain a mesophase pitch with a moderate softening point, mesophase content not less than 98% and excellent spinnability; and performing fusion and continuous spinning on the mesophase pitch, and performing continuous oxidation, carbonization and graphitizing treatment to obtain the ultrahigh-modulus graphite fiber continuous filament with modulus not less than 600GPa. According to the method, the raw materials are readily available, the cost is low, the process is simple, the energy consumption is low, and the industrialization is facilitated.

Owner:SHANDONG RUICHENG AEROSPACE CARBON MATERIAL CO LTD

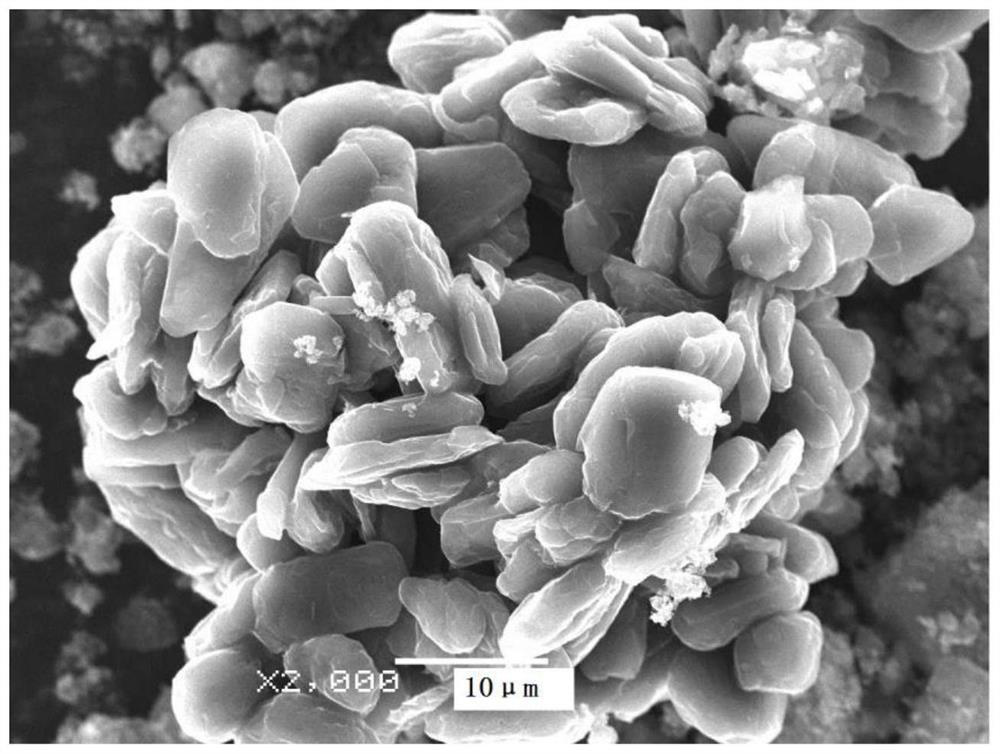

Process for preparing needle coke by utilizing coal tar

ActiveCN109439367AEfficient use ofExpand the range of raw materialsTreatment with hydrotreatment processesTar working-up by water removalFractionationCoal tar preparation

The invention belongs to the technical field of preparation of needle coke and specifically relates to a process for preparing needle coke by utilizing coal tar. The process comprises the following steps: 1, a mixing and settling unit, mixing the coal tar and the fraction lower than 210 DEG C, and performing heating, standing and settling; 2, a filtering unit, pressurizing and filtering the supernatant liquid so as to obtain filtrate; 3, a fractionation unit, fractionating the filtrate in a fractionating tower to obtain four fractions; 4, a hydrocracking unit, performing hydrocracking on the fraction of 210-230 DEG C to obtain hydrocracked fraction; 5, a 1# pressurized polycondensation unit, reacting the fraction of 230-300 DEG C in a 1# pressurized polycondensation device to obtain 1# polycondensate; 6, a 2# pressurized polycondensation unit, carrying out a reaction of the fraction of higher than 300 DEG C in a 2# pressurized polycondensation device to obtain 2# polycondensate; 7, a coking unit, coking the 1# polycondensate and 2# polycondensate to obtain green needle coke; 8, a calcination unit, performing high-temperature calcination on the green needle coke, thereby obtaining the finished needle coke. Therefore, comprehensive utilization of the coal tar is realized.

Owner:山西中科化美科技有限责任公司

Device and process for preparing phenolic resin from coal tar

ActiveCN106543389ARelieve stressLow viscosityTar working-up by chemical refiningBenzaldehydeDistillation

The invention discloses a device and a process for preparing phenolic resin from coal tar. The process includes: taking methyl benzene or benzene as a solvent, taking acid or alkaline as a catalyst, subjecting the coal tar or distillation fractions thereof to phenolic polymerization reaction with formaldehyde, benzaldehyde, paraformaldehyde and furfural under certain conditions, filtering reaction products through a closed rotary drum vacuum filter to obtain the phenolic resin as well as solvent-containing dephenolized coal tar, rectifying the solvent-containing dephenolized coal tar to realize separation of water and the solvent, and recover the solvent to realize solvent recycling. Cheap medium-and low-temperature coal tar high in phenol content is adopted for phenolic polymerization reaction with aldehydes to prepare the phenolic resin, and phenolic substances in the medium-and low-temperature coal tar can be completely removed by further reaction. Therefore, phenol removal steps are simple, solvent recycling is realized, economy and environment friendliness are achieved, and a novel coal tar processing method simple in process, low in production operation cost, remarkable in economic benefit and easy for industrialization is provided.

Owner:NORTHWEST UNIV(CN)

Method for preparing fuel oil

InactiveCN102002387AHigh yieldSimple processMolecular sieve catalystsTreatment with plural serial stages onlyCoal tar preparationFuel oil

The invention discloses a method for preparing fuel oil. In the method, high-temperature reaction, distilling separation and other processes are performed on coal tar used as a raw material under the action of a catalyst to prepare fuel oil. The method for preparing fuel oil from coal tar has the advantages of simple process, low requirement on equipment, high conversion rate and high fuel oil yield rate of more than 64% and belongs to the field of the preparation of fuel oil from coal tar.

Owner:邵素英

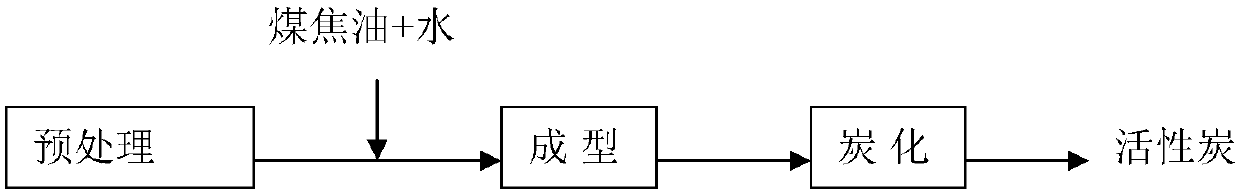

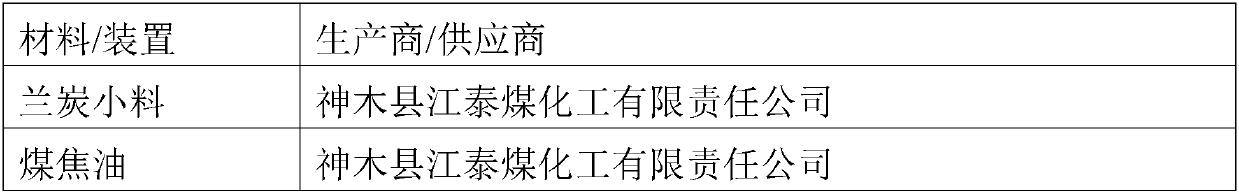

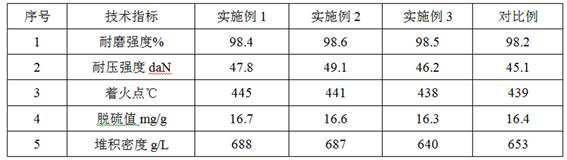

Method for preparing active carbon by use of semicoke and coal tar and active carbon obtained by method

ActiveCN107915224AHigh mechanical strengthImprove adsorption capacityCarbon compoundsActivated carbonCoal tar preparation

The invention relates to a method for preparing active carbon by the use of semicoke and coal tar and the active carbon obtained by the method. The method of the invention comprises the following steps: (1) pretreatment: crushing semicoke until D95 of particles is less than or equal to 0.15 mm; (2) moulding: uniformly mixing the particles obtained in the step (1) and medium and low temperature coal tar and water, and carrying out extrusion moulding on the mixture to obtain an active carbon precursor, wherein weight ratio of the particles to the medium and low temperature coal tar is within therange of 1.5-3.0:1; and (3) charing: carrying out air pre-oxidation on the active carbon precursor at the temperature of 150-200 DEG C, charing at 780-920 DEG C, and cooling to obtain the active carbon. The method of the invention has the following characteristics: production technology is simplified; production efficiency is raised; production cost is reduced; and the prepared active carbon hasvery good mechanical strength and adsorptive property.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Method for preparing clean fuel oil from coal tar

InactiveCN102766477APlay the role of extractionPlay the role of hydrogenationTar working-up by solvent extractionHydrogenRoom temperature

The invention relates to a method for preparing clean fuel oil from coal tar, belonging to the field of coal tar reprocessing. The method comprises the following steps: mixing coal tar and a specific solvent, holding the mixture in a high-pressure autoclave at constant temperature for several hours, cooling to room temperature, separating the reaction liquid, and extracting to obtain the fuel oil. In the coal tar supercritical extraction process, the solvent has the functions of both extraction and hydrogenation, and the coal tar is lightened under the condition of no need of high-temperaturehigh-pressure catalyst, thereby saving abundant energy sources and hydrogen resources.

Owner:韩钊武

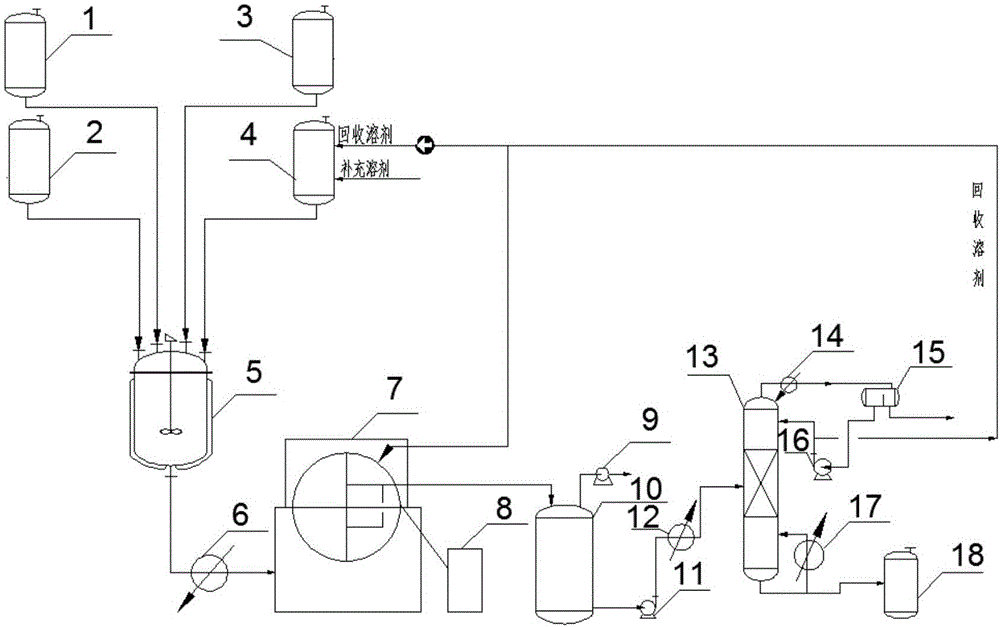

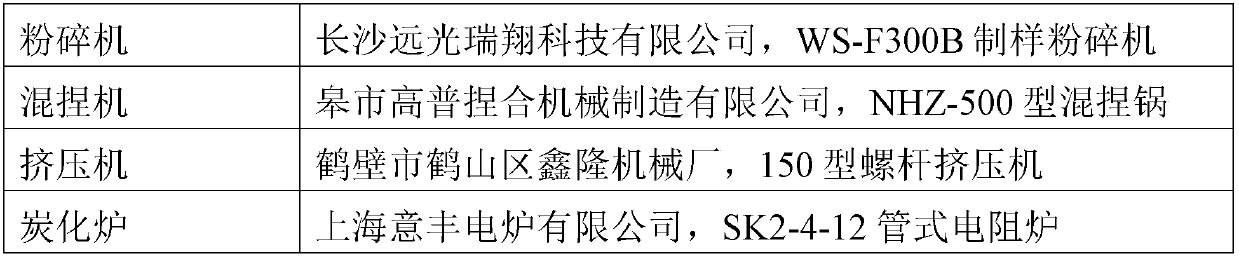

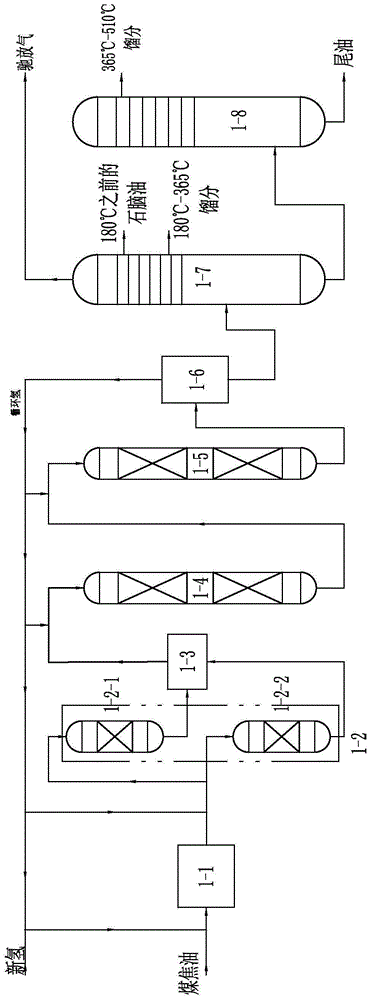

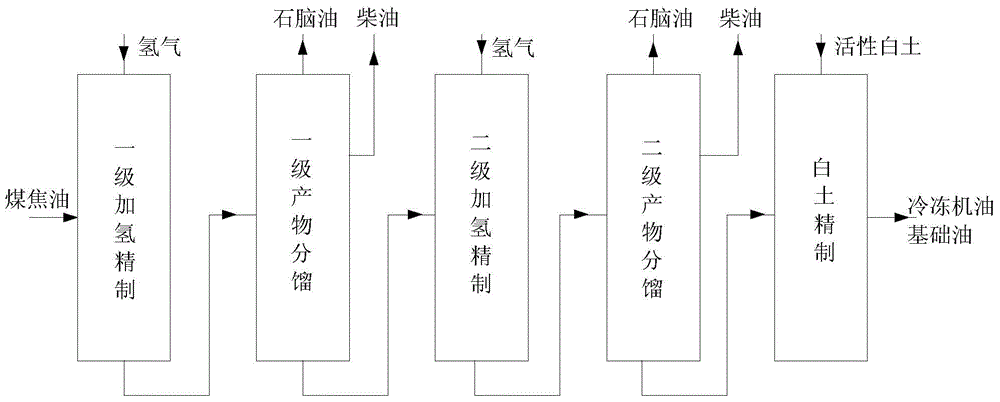

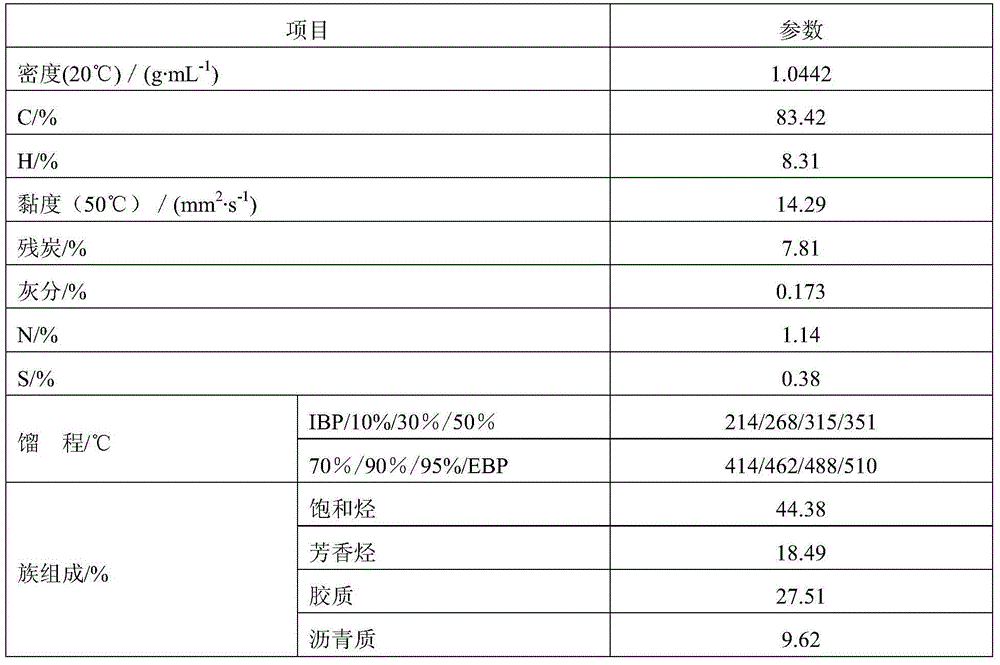

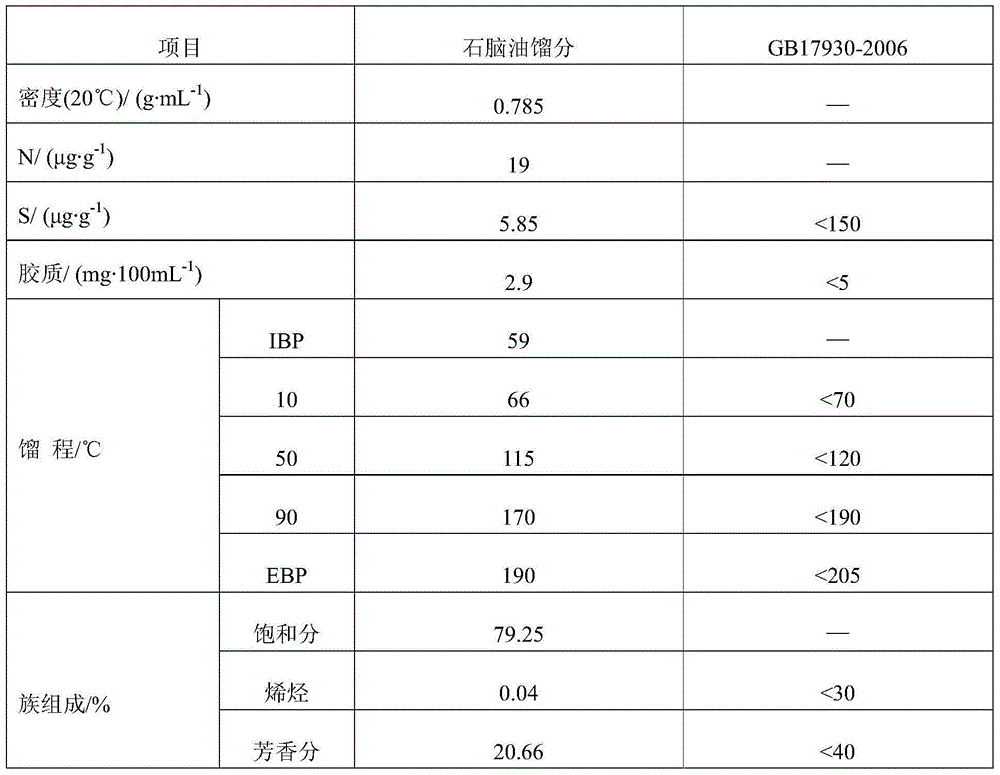

Method for producing naphthenic base refrigerating machine oil base oil by using coal tar oil

ActiveCN103436290AImprove use valueQuality improvementTreatment with hydrotreatment processesLubricant compositionNaphthaCoal tar preparation

The invention relates to a method for producing naphthenic base refrigerating machine oil base oil by using coal tar oil. The method comprises the following steps of: (1) carrying out first-stage hydrofining on the coal tar oil; (2) carrying out fractional distillation on a first-stage hydrofining product; (3) carrying out secondary-stage hydrofining on residual oil fractions; (4) carrying out fractional distillation on secondary-stage hydrofining oil; (5) carrying out clay refining on refrigerating machine oil distillate oil, thus obtaining high-additional value products such as the naphthenic base refrigerating machine oil base oil, naphtha oil, diesel oil and refrigerating machine oil base oil. The method has the advantages that the hydrogenation industrial chain of the coal tar oil is extended, the utilization value of the coal tar oil is increased, and the refrigerating machine oil base oil with the high quality is obtained.

Owner:王树宽

Method for preparing diesel through coal tar

ActiveCN104987882AReduce cumbersome stepsReduce design difficultyMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsLiquid productHydrogen

The invention discloses a method for preparing diesel through coal tar. Hydrogen and the coal tar are distilled and mixed and then enter a reactor with the hydrogen and oil volume ratio of 850:1100. The reaction temperature is 290-365 DEG C, the reaction pressure is 2-9 MPa, and the air speed is 2-4 / h. A reaction is conducted under the action of catalyst, and a liquid product is obtained after gas-liquid separation.

Owner:辽宁东颢化工有限公司

System and method for preparing high-octane gasoline, jet fuel, and naphthenic base oil from full-hydrogen coal tar

ActiveCN105419864BIncrease profitImprove anti-carbon performanceMolecular sieve catalystsTreatment with hydrotreatment processesIsomerizationNaphtha

The invention relates to a system and method for preparing high-octane gasoline, aviation kerosene and naphthenic base oil with total-hydrogen-type coal tar. The system is formed by a coal tar refining device, a distillate oil deep refining, isomerization-visbreaking and post-refining device and a naphtha dehydrogenizing and aromatic extraction device. The method includes the steps that coal tar serves as a raw material, is subjected to hydrorefining, deep refining, isomerization visbreaking and post-refining treating, and then is subjected to a naphtha dehydrogenizing technology and an aromatic extraction technology, and the high-octane gasoline, the aviation kerosene and the naphthenic base oil are obtained. Meanwhile, a mass of hydrogen is generated to serve as supplemented hydrogen of coal tar hydrogenation, the obtained product oil is good in quality, and after detecting is carried out according to the national standard, various detected indexes meet the national standard.

Owner:王树宽

Method of preparing asphalt modifier with waste lubricant, gear oil and coal tar

InactiveCN109575613ARaw materials are cheap and easy to getSimple production processBuilding insulationsAging resistanceCoal tar preparation

The invention relates to the technical field of asphalt modifiers, in particular to a method of preparing an asphalt modifier with waste lubricant, gear oil and coal tar. The method includes: mixing waste lubricant, gear oil and coal tar, using concentrated sulfuric acid as a catalyst to carry out intermolecular dewatering reaction under heating, flocculating, precipitating, filtering, and dryingto obtain the asphalt modifier. The waste lubricant, the gear oil and coal tar are used as raw materials; the concentrated sulfuric acid is used as the catalyst; the raw materials are low in price andeasy to attain; the production process is simple, convenient to perform and control and low in production cost. The asphalt modifier prepared herein helps improve strength and toughness of asphalt, improve pavement performance of an asphalt mixture at a high temperature, reduce permanent deformation at the high temperature, and improve the properties of the asphalt, such as rut resistance, fatigue resistance, aging resistance, resistance to low temperature cracking, and ability to resist low temperature fatigue.

Owner:佛山市光烨环保科技有限公司

Method for preparing clean fuel oil from coal tar

InactiveCN102766477BPlay the role of extractionPlay the role of hydrogenationTar working-up by solvent extractionHydrogenCoal tar preparation

The invention relates to a method for preparing clean fuel oil from coal tar, belonging to the field of coal tar reprocessing. The method comprises the following steps: mixing coal tar and a specific solvent, holding the mixture in a high-pressure autoclave at constant temperature for several hours, cooling to room temperature, separating the reaction liquid, and extracting to obtain the fuel oil. In the coal tar supercritical extraction process, the solvent has the functions of both extraction and hydrogenation, and the coal tar is lightened under the condition of no need of high-temperature high-pressure catalyst, thereby saving abundant energy sources and hydrogen resources.

Owner:韩钊武

Processing process for preparing various asphalt and fuel oil with coal tar

ActiveCN101323788BImprove qualityIncrease added valueTar working-up by distillationCoal tar preparationFuel oil

The invention discloses a processing technology for preparing various pitches and fuel oils by coal tar, which comprises the steps that: the coal tar is heated to 350 DEG C to 360 DEG C, rectified at ordinary pressure first and then at reduced pressure, primarily ultracentrifugated and secondarily ultracentrifugated to respectively produce purified pitch, impregnating pitch, modified pitch, high softening point pitch and fuel oils. The invention has simple technology and convenient operation, can produce various high quality pitches and fuel oils and is characterized by less investment in devices and stable quality, thus better solving the problems of low general grade of pitches of China at present, unstable fraction of coal tar pitches and plenty of impurities and being quite applicableto the processing and producing of the coal tar.

Owner:浙江美阳国际工程设计有限公司

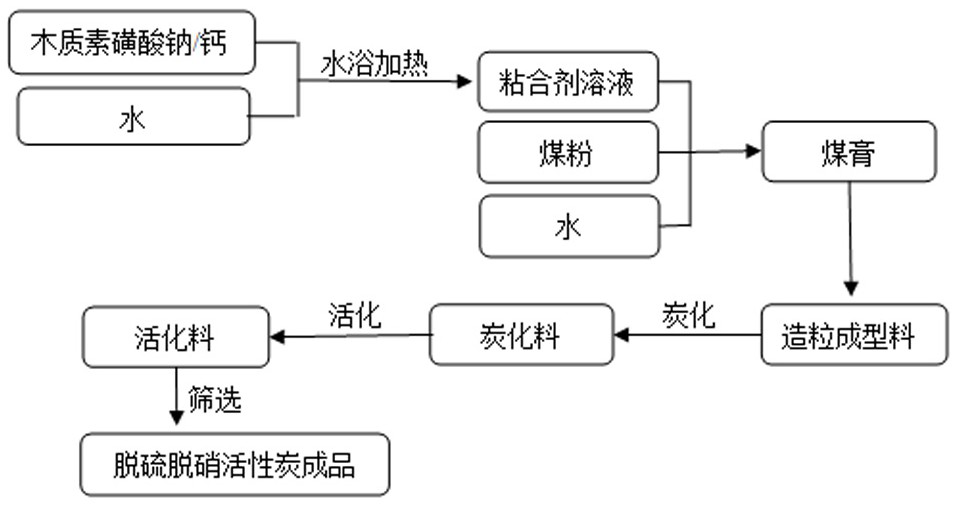

Method for coal-tar-free preparation of desulfurization and denitrification activated carbon

PendingCN113401899AReduce Occupational Health HazardsLow priceCarbon compoundsActivated carbonAdhesive

The invention relates to preparation of activated carbon, in particular to a method for coal-tar-free preparation of desulfurization and denitrification activated carbon. The method comprises the following steps: 1) preparation of an adhesive solution: mixing sodium / calcium lignosulfonate with water, conducting standing in a water bath, and obtaining the adhesive solution after the sodium / calcium lignosulfonate is completely dissolved; and 2) preparation of desulfurization and denitrification activated carbon: mixing the adhesive solution obtained in the step 1) with pulverized coal and water in proportion to form coal paste, conducting molding by a granulator, conducting carbonizing and activating, conducting discharging, and conducting cooling and screening to obtain the desulfurization and denitrification activated carbon. The adhesive used in the invention is non-toxic and odorless, and can effectively reduce occupational health hazards to field operators. The adhesive is low in price and small in dosage, adhesive powder is dissolved in water to be prepared into a solution for use, and the preparation cost of the desulfurization and denitrification activated carbon is effectively reduced. In the using process of the adhesive, no organic matter volatilizes, and the problem of environmental pollution in the production process of desulfurization and denitrification activated carbon is solved.

Owner:SHANXI XINHUA CHEM

Method for preparing porous carbon material by using coal tar generated in cog process

ActiveUS20200316559A1Increase capacitanceHigh adsorption rateCarbon compoundsOther chemical processesPorous carbonWater vapor

A method for preparing a porous carbon material by using coal tar generated in a coke oven gas (COG) process is provided. The method includes: removing quinoline insoluble (QI) by mixing tetrahydrofuran (THF) with coal tar generated in a COG purification process; distilling coal tar by adding a phenolic resin to the QI-removed coal tar, and heating the same at a temperature of 100° C. to 330° C.; carbonizing the distilled coal tar by heating the same at 350° C. to 600° C.; mixing a carbide after the carbonization step and the coal tar, which has been distilled before the carbonization, and grinding / granulating the same; mixing the ground / granulated carbide and the coal tar, which has been distilled before the carbonization, with a pore forming agent, and heat treating the same at 300° C. to 500° C.; and forming pores by making the heat treated carbon material come into contact with water vapor at 700° C. to 1000° C.

Owner:POSCO CHEM

A system and method for producing coal tar, coal gas and semi-coke by solid heat carrier activated gas flash pyrolysis coal

ActiveCN106753491BHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierThermodynamics

Owner:陕西凯德利能源科技有限公司

A method for preparing negative electrode material by dry distillation of coal tar at medium and low temperature

ActiveCN109319774BPromote circulationStrong anti-attenuation abilityCarbon compoundsCell electrodesElectrical batteryCoal tar preparation

The invention provides a method for preparing a negative electrode material by using medium and low temperature dry distillation coal tar. The medium and low temperature coal tar is used as a raw material, and the negative electrode is controlled by adjusting the content of quinoline insoluble matter, carbonization conditions, and graphitization conditions in the negative electrode material precursor preparation raw material. The structure of the material is used to prepare the negative electrode material. Compared with the existing technology, the beneficial effects of the present invention are: 1) The negative electrode material prepared by the present invention has high charging and discharging efficiency of the battery for the first time, stable battery performance, excellent cycle performance, outstanding anti-attenuation ability, and a gram specific capacity of up to 360mAh above. 2) The process method of the present invention is simple and feasible, easy to realize industrial production, provides a new way for the deep processing of medium and low temperature dry distillation coal tar, and significantly improves the added value of medium and low temperature dry distillation coal tar. 3) Conform to the country's call for efficient use of energy and alleviate the energy shortage.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

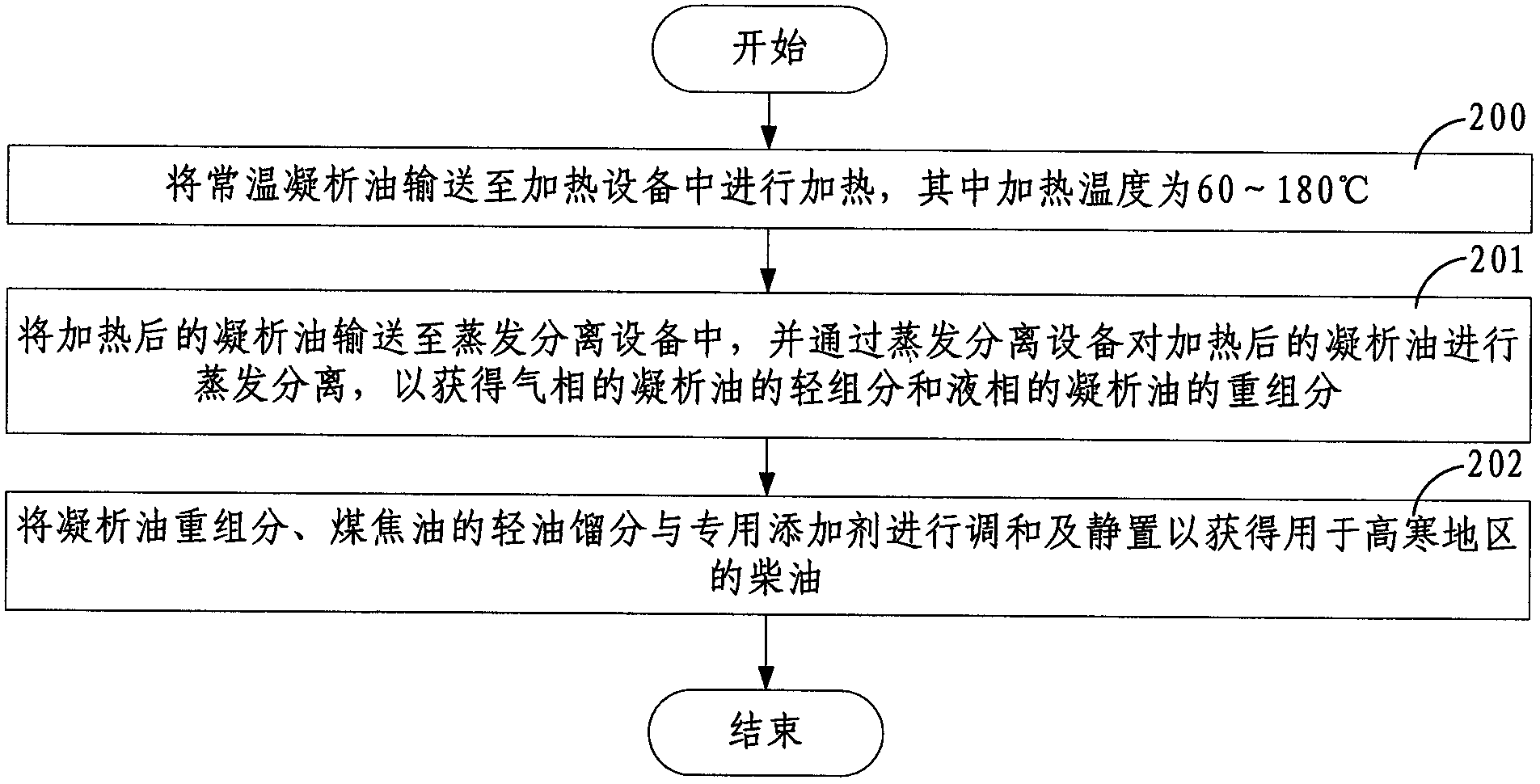

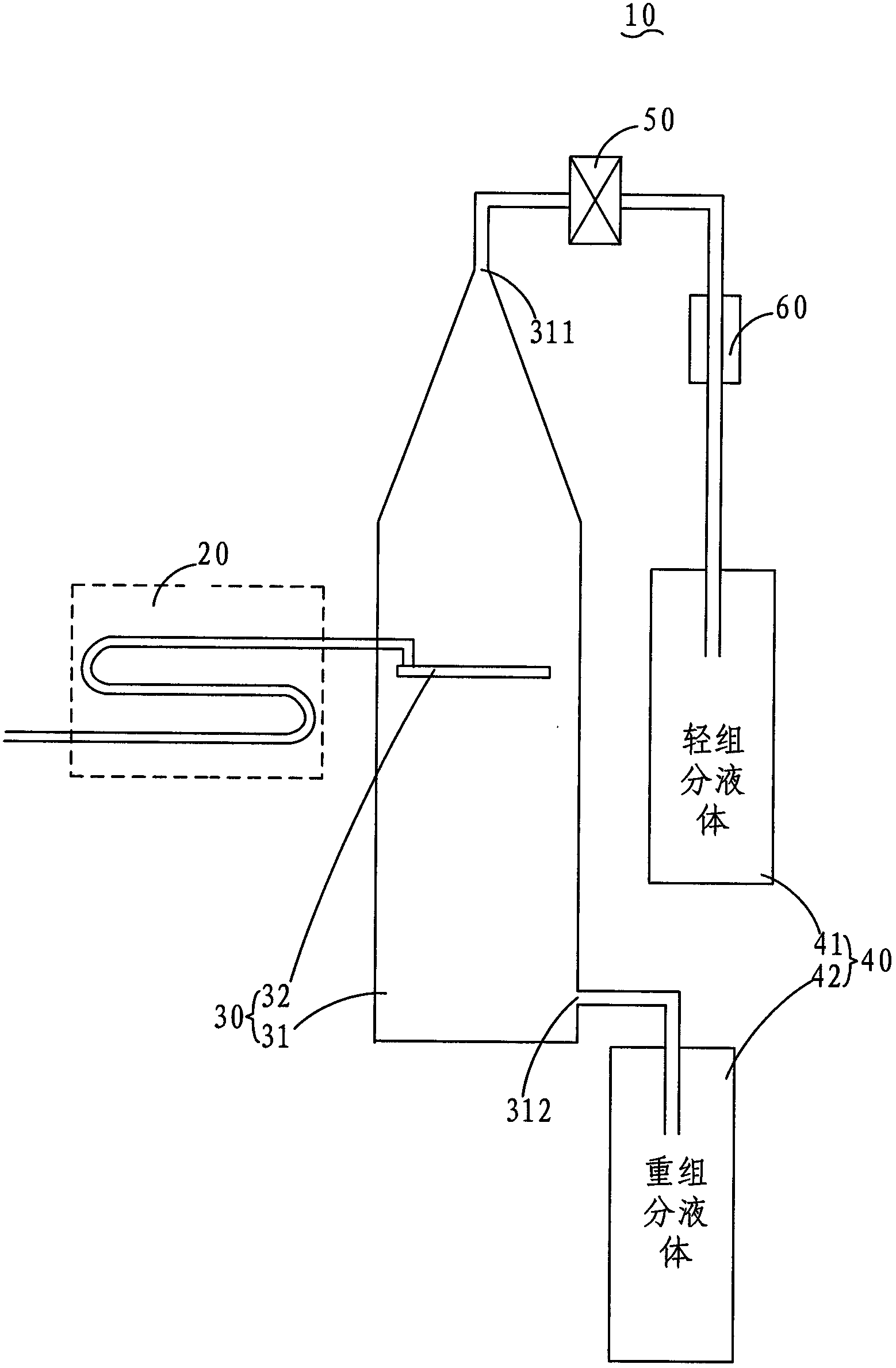

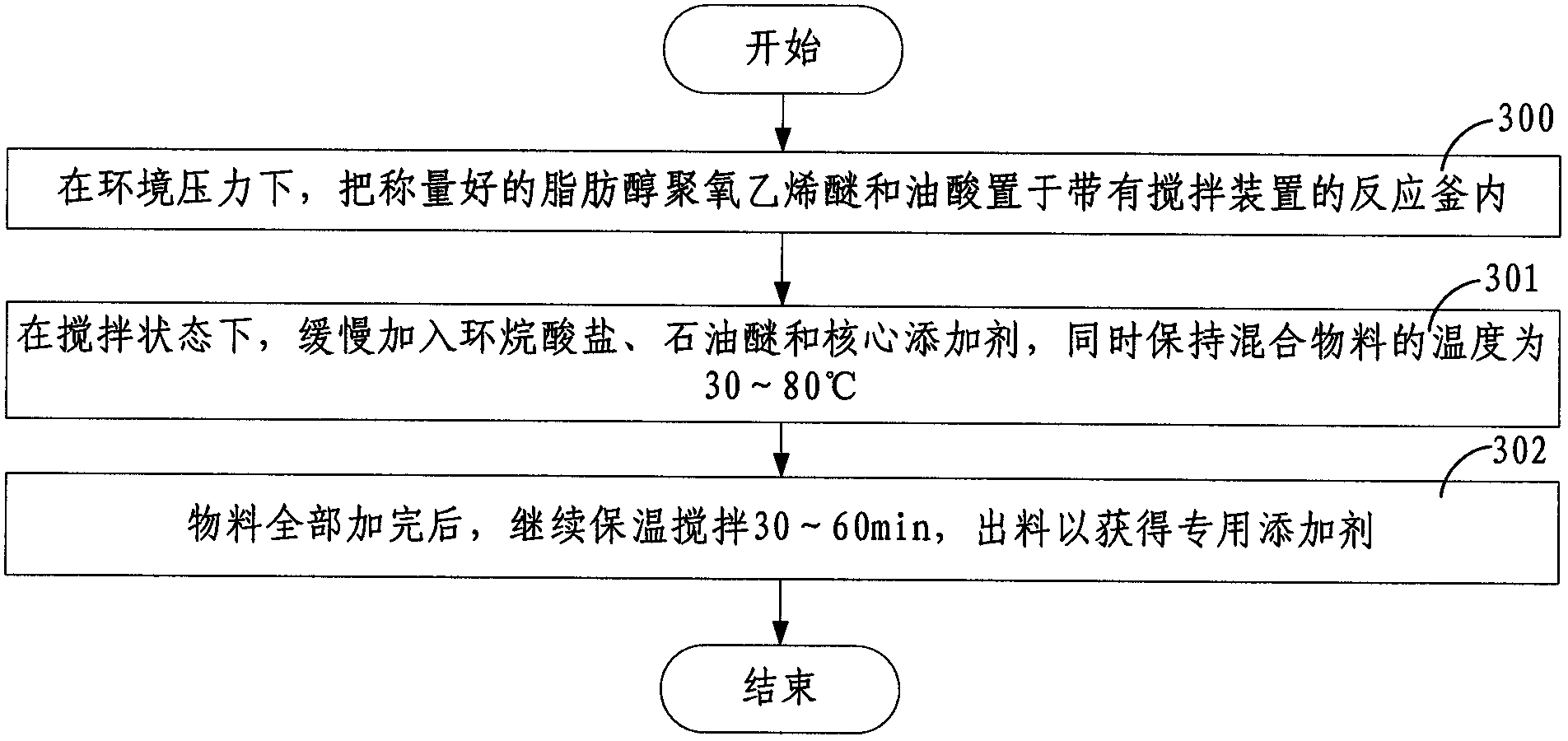

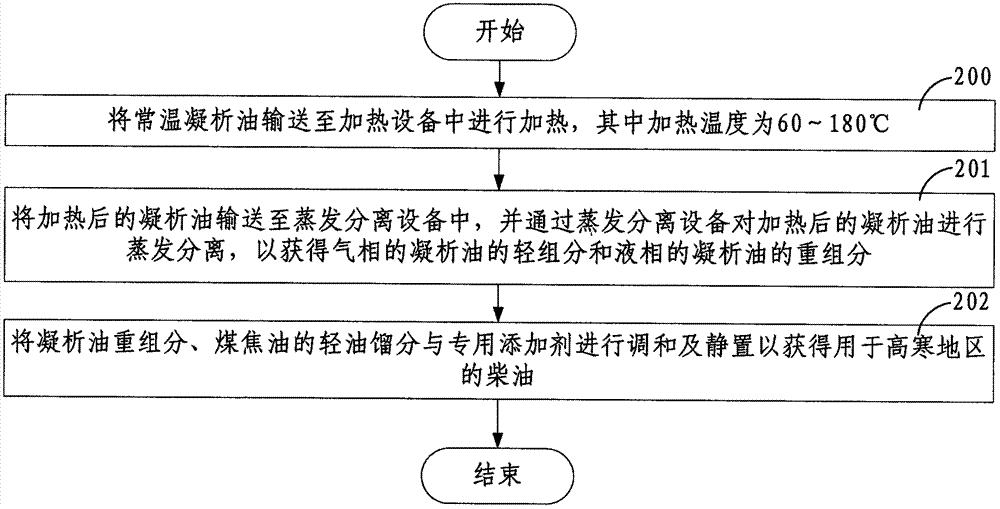

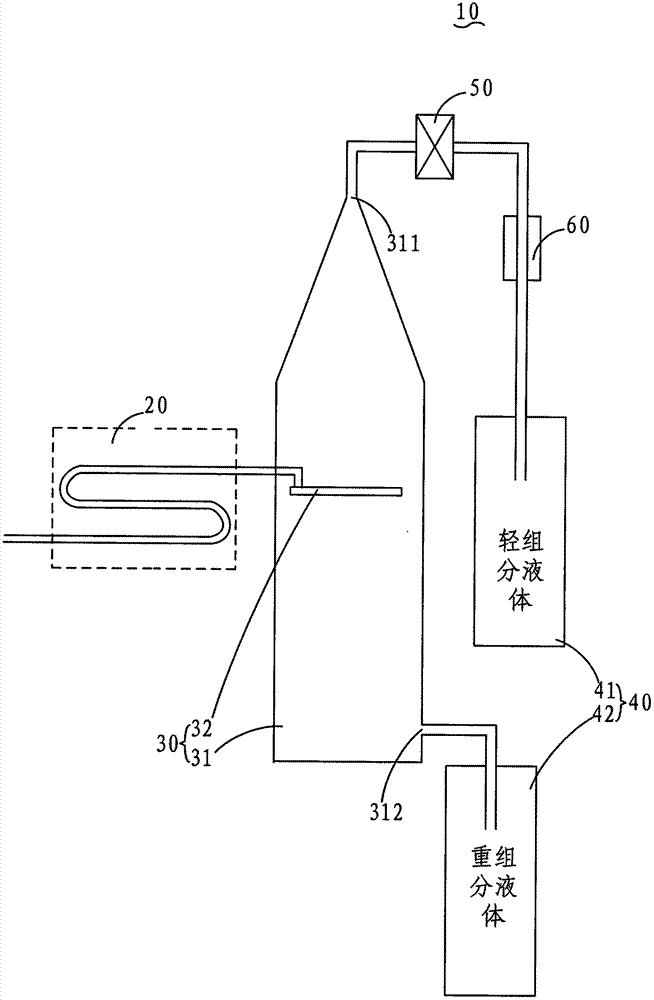

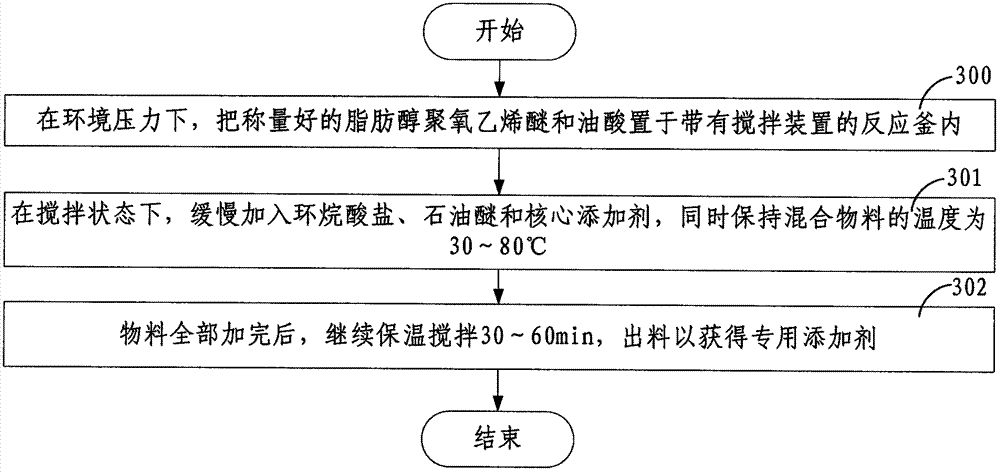

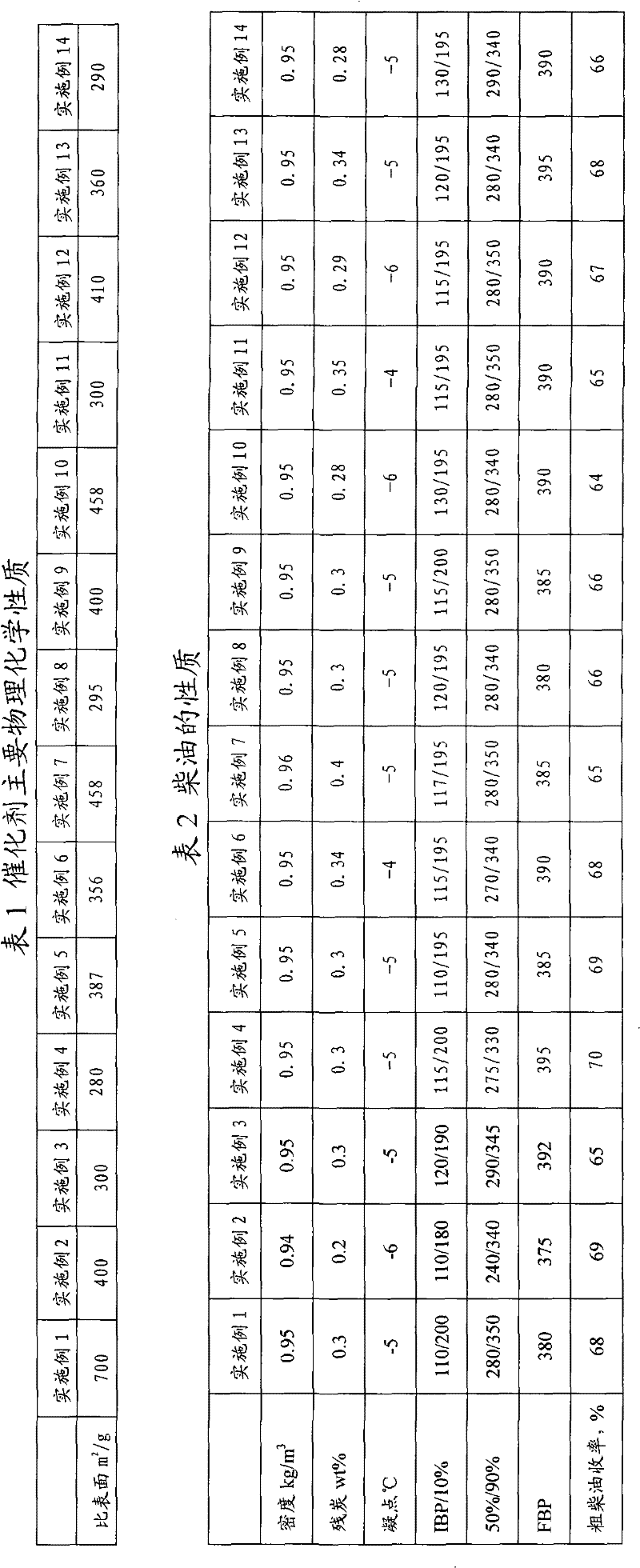

Method for preparing diesel oil for alpine regions with gas condensate and coal tar

InactiveCN103113936BImprove use valueIncrease productionHydrocarbon distillationLiquid carbonaceous fuelsCoal tar preparationEvaporation

The invention provides a method for preparing diesel oil for alpine regions with gas condensate and coal tar. The method comprises the following steps of: transferring the gas condensate under normal temperature to heating equipment to be heated, wherein the heating temperature is 60-180 DEG C; transferring the heated gas condensate to evaporation separation equipment to undergo evaporation separation to obtain light components and heavy components of the gas condensate; and blending the heavy components of the gas condensate, light oil fractions of the coal tar and a special additive and standing to obtain the diesel oil, wherein the specific steps are as follows: pumping the heavy components of the gas condensate, the light oil fractions of the coal tar and the special additive into a reaction kettle with a stirring device according to the predetermined weight percent, stirring the materials for 30-60min, discharging the product and storing the product in a storage tank statically for 24h to obtain the diesel oil; and the weight percents of the heavy components of the gas condensate, the light oil fractions of the coal tar and the special additive are respectively 20-70%, 20-60% and 10-20%.

Owner:宁夏易星能源科技开发有限公司

A kind of method that utilizes coal tar to prepare diesel oil

ActiveCN104987882BReduce cumbersome stepsReduce design difficultyMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsLiquid productHydrogen

The invention discloses a method for preparing diesel through coal tar. Hydrogen and the coal tar are distilled and mixed and then enter a reactor with the hydrogen and oil volume ratio of 850:1100. The reaction temperature is 290-365 DEG C, the reaction pressure is 2-9 MPa, and the air speed is 2-4 / h. A reaction is conducted under the action of catalyst, and a liquid product is obtained after gas-liquid separation.

Owner:辽宁东颢化工有限公司

Method for preparing honeycomb active carbon from coal and coal tar

InactiveCN101503191BSimple ingredientsLow costCarbon compoundsWorking-up peatActivated carbonCarbonization

The invention provides a method for preparing honeycomb-like activated carbon by using coal and coal tar, which takes coal dust and the coal tar as raw materials to prepare the honeycomb-like activated carbon by grinding the coal dust, charge mixture, vacuum pugging, seal aging, vacuum extruding and moilding, drying, carbonization and activation. The method for preparing the honeycomb-like activated carbon only takes the coal tar as cementing agent, so as to overcome the defect that multiple cementing agents are needed to be applied in the technique, thus having the characteristics of simple raw materials, low production cost and easy industrialization. The produced honeycomb-like activated carbon has the characteristics of large geometric area and specific surface area, high mechanical strength and the like, and can be applied for the treatment of waste gas and waste water and catalyst carrier.

Owner:BEIJING UNIV OF CHEM TECH

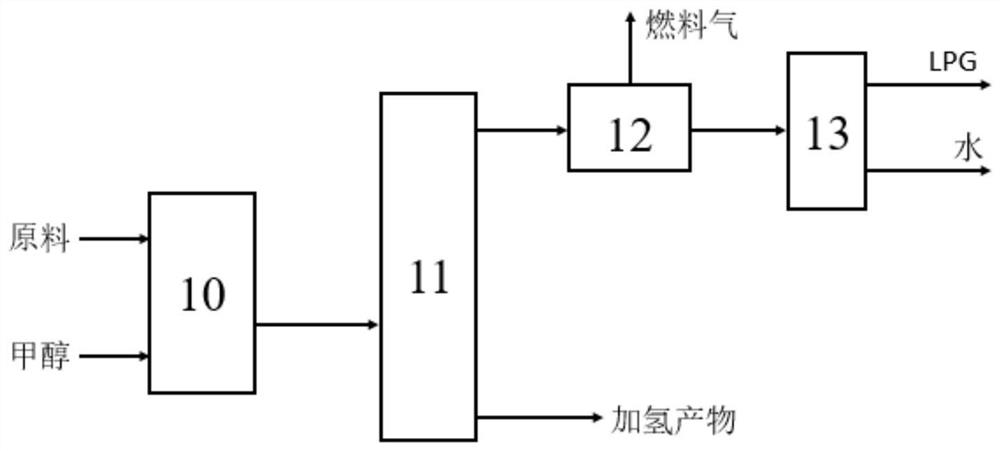

Method for preparing vehicle fuel from light coal tar

InactiveCN111704940ATake advantage ofHigh purityLiquid carbonaceous fuelsThermodynamicsCoal tar preparation

The invention relates to a method for preparing vehicle fuel from light coal tar. According to the method, the light coal tar is subjected to fractionation, different isomerization treatment processesare adopted for different fractionation products, the vehicle fuel with the high octane number is obtained, and coal tar resources are fully utilized. The method has the advantages of being high in product purity, high in yield, simple in process and wide in application range.

Owner:新疆宣力环保能源股份有限公司

Method for producing naphthenic base refrigerating machine oil base oil by using coal tar oil

ActiveCN103436290BImprove use valueQuality improvementTreatment with hydrotreatment processesLubricant compositionNaphthaCoal tar preparation

The invention relates to a method for producing naphthenic base refrigerating machine oil base oil by using coal tar oil. The method comprises the following steps of: (1) carrying out first-stage hydrofining on the coal tar oil; (2) carrying out fractional distillation on a first-stage hydrofining product; (3) carrying out secondary-stage hydrofining on residual oil fractions; (4) carrying out fractional distillation on secondary-stage hydrofining oil; (5) carrying out clay refining on refrigerating machine oil distillate oil, thus obtaining high-additional value products such as the naphthenic base refrigerating machine oil base oil, naphtha oil, diesel oil and refrigerating machine oil base oil. The method has the advantages that the hydrogenation industrial chain of the coal tar oil is extended, the utilization value of the coal tar oil is increased, and the refrigerating machine oil base oil with the high quality is obtained.

Owner:王树宽

Method for preparing diesel oil for alpine regions with gas condensate and coal tar

InactiveCN103113936AImprove use valueIncrease productionHydrocarbon distillationLiquid carbonaceous fuelsCoal tar preparationCoal tar product

The invention provides a method for preparing diesel oil for alpine regions with gas condensate and coal tar. The method comprises the following steps of: transferring the gas condensate under normal temperature to heating equipment to be heated, wherein the heating temperature is 60-180 DEG C; transferring the heated gas condensate to evaporation separation equipment to undergo evaporation separation to obtain light components and heavy components of the gas condensate; and blending the heavy components of the gas condensate, light oil fractions of the coal tar and a special additive and standing to obtain the diesel oil, wherein the specific steps are as follows: pumping the heavy components of the gas condensate, the light oil fractions of the coal tar and the special additive into a reaction kettle with a stirring device according to the predetermined weight percent, stirring the materials for 30-60min, discharging the product and storing the product in a storage tank statically for 24h to obtain the diesel oil; and the weight percents of the heavy components of the gas condensate, the light oil fractions of the coal tar and the special additive are respectively 20-70%, 20-60% and 10-20%.

Owner:宁夏易星能源科技开发有限公司

Method for preparing diesel from coal tar

ActiveCN101376816BSimple processHigh yieldTar working-up by distillationTar working-up by chemical refiningRoom temperatureCoal tar preparation

The invention discloses a method for preparing diesel oil from coal tar. In the method, the coal tar and a catalyst are added into a reactor; after the reactor is closed, the temperature of the reactor is heated to 320-400 DEG C and the temperature is maintained for 0 to 20 minutes; after the temperature is reduced to the room temperature, a reactor product is taken out from the reactor; then distilling and separating are carried out; the cut fraction of 80 to 280 DEG C is taken out, thus obtaining the diesel oil. The method provided by the invention has the advantages of simple technique, low requirements to devices and high conversion rate. The invention belongs to the field of preparing diesel oil from coal tar.

Owner:HANERGY TECH

Method for preparing special asphalt by separating coal tar step by step

ActiveCN108148612BMolecular weight controllableMeet the requirements of high value-added productsTar working-up by distillationTar working-up by solvent extractionCoal tar preparationProcess engineering

The invention relates to a method for preparing special asphalt from coal tar through progressive separation. The method comprises the following specific steps: proportionally adding a mixed solvent Ainto the coal tar, carrying out stirring, carrying out standing, and carrying out layering, so as to obtain an upper-layer mixed solution A; taking the upper-layer mixed solution A, carrying out filtering, and carrying out distilling to recover the mixed solvent A, so as to obtain a first-stage separated product of the coal tar; proportionally adding a mixed solvent B into the first-stage separated product of the coal tar, carrying out stirring, carrying out standing, and carrying out layering, so as to obtain an upper-layer mixed solution B; taking the upper-layer mixed solution B, and carrying out distilling to recover the mixed solvent B, so as to obtain a light component of the coal tar; proportionally adding a mixed solvent C into the light component of the coal tar, carrying out intensive mixing, carrying out standing, and carrying out layering, so as to obtain an upper-layer mixed solution C; taking the upper-layer mixed solution C, carrying out filtering, and carrying out distilling to recover the mixed solvent C, thereby obtaining the special asphalt. According to the method, the special asphalt can be obtained from the coal tar through progressive separation at normal temperature under normal pressure and can be applied to high-end carbon-material raw materials, and the requirements of subsequent preparation on products with high added values are met.

Owner:SHANDONG RUICHENG AEROSPACE CARBON MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com