Processing process for preparing various asphalt and fuel oil with coal tar

A processing technology and fuel oil technology, applied in the direction of tar processing by distillation method, can solve the problems of inability to produce high softening point asphalt and low quinoline insoluble asphalt, etc., to improve the added value and the quality of asphalt, stable quality, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

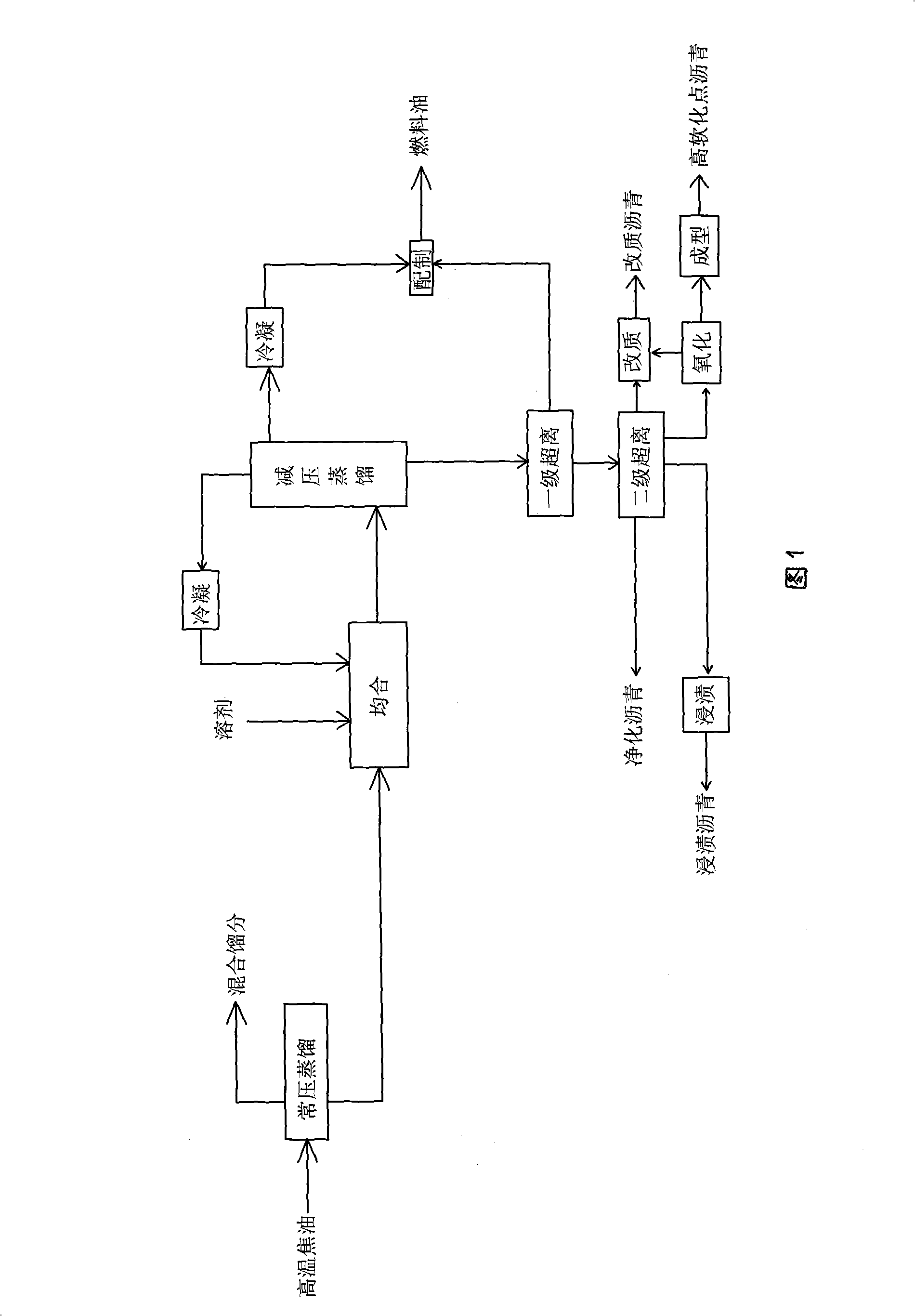

Method used

Image

Examples

Embodiment 1

[0025] 1. Atmospheric distillation

[0026] Heat 50kg of coal tar to 350°C and enter the atmospheric rectification tower. After a period of total reflux, and when all the parameters of the tower are stable, start to cut off the 230°C mixed distillate at the top of the tower. 45% of the mixed fraction is sold as chemical raw material, and 55% of the soft asphalt fraction is distilled from the bottom of the tower.

[0027] 2. Vacuum distillation

[0028] Add 5kg of solvent oil to the soft asphalt fraction distilled from the bottom of the atmospheric distillation tower. The solvent oil is a mixed solvent based on NMP (pyrrolidone). After being evenly mixed with the soft asphalt, it is heated to 360°C and enters the vacuum distillation tower for rectification. , the 195°C light component cut from the top of the tower is condensed and used as solvent oil for soft asphalt blending, the 200°C light component cut from the side line at the upper part of the tower is condensed and then...

Embodiment 2

[0050] 1. Atmospheric distillation

[0051] Heat 100kg of coal tar to 355°C and enter the atmospheric rectification tower. After a period of total reflux, and when the parameters of the tower are stable, start to cut off the 240°C mixed distillate at the top of the tower, and extract from the side line dianthracene oil section 45% of the mixed fraction is sold as chemical raw material, and 55% of the soft asphalt fraction is distilled from the bottom of the tower.

[0052] 2. Vacuum distillation

[0053]Add 12kg of solvent oil to the soft asphalt fraction distilled from the bottom of the atmospheric distillation tower. The solvent oil is a mixed solvent based on NMP (pyrrolidone). The 200°C light component cut from the top is condensed and used as solvent oil for soft asphalt blending. The 202°C light component cut from the side line at the upper part of the tower is condensed and then goes to the preparation process to produce fuel oil. The distillate at the bottom of the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com