Patents

Literature

702 results about "Coal Tar Pitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The primary routes of human exposure to coal tars and coal-tar products are inhalation, ingestion, and absorption through the skin. Exposure to coal tars and coal-tar pitches may occur at foundries and during coke production, coal gasification, and aluminum production.

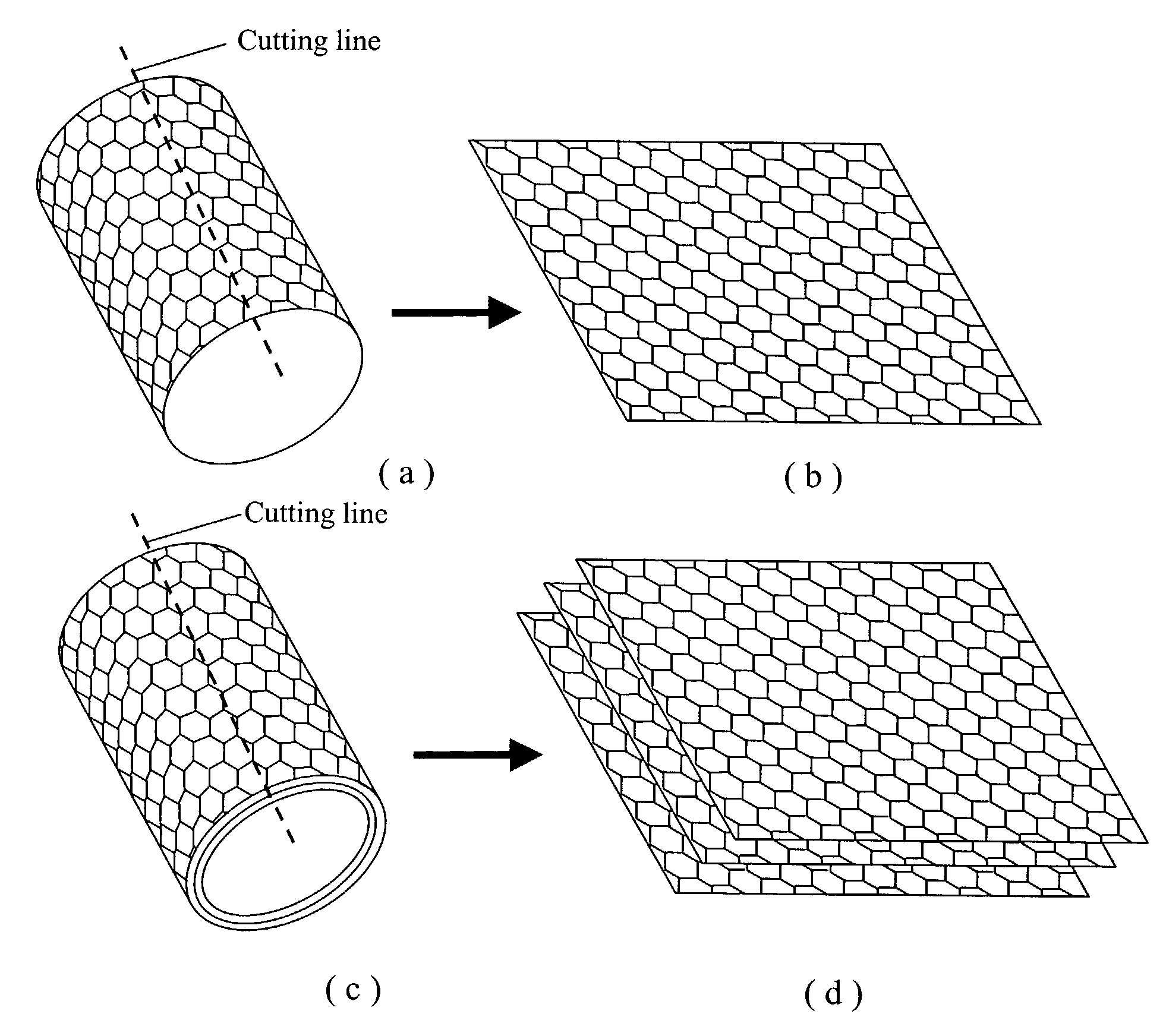

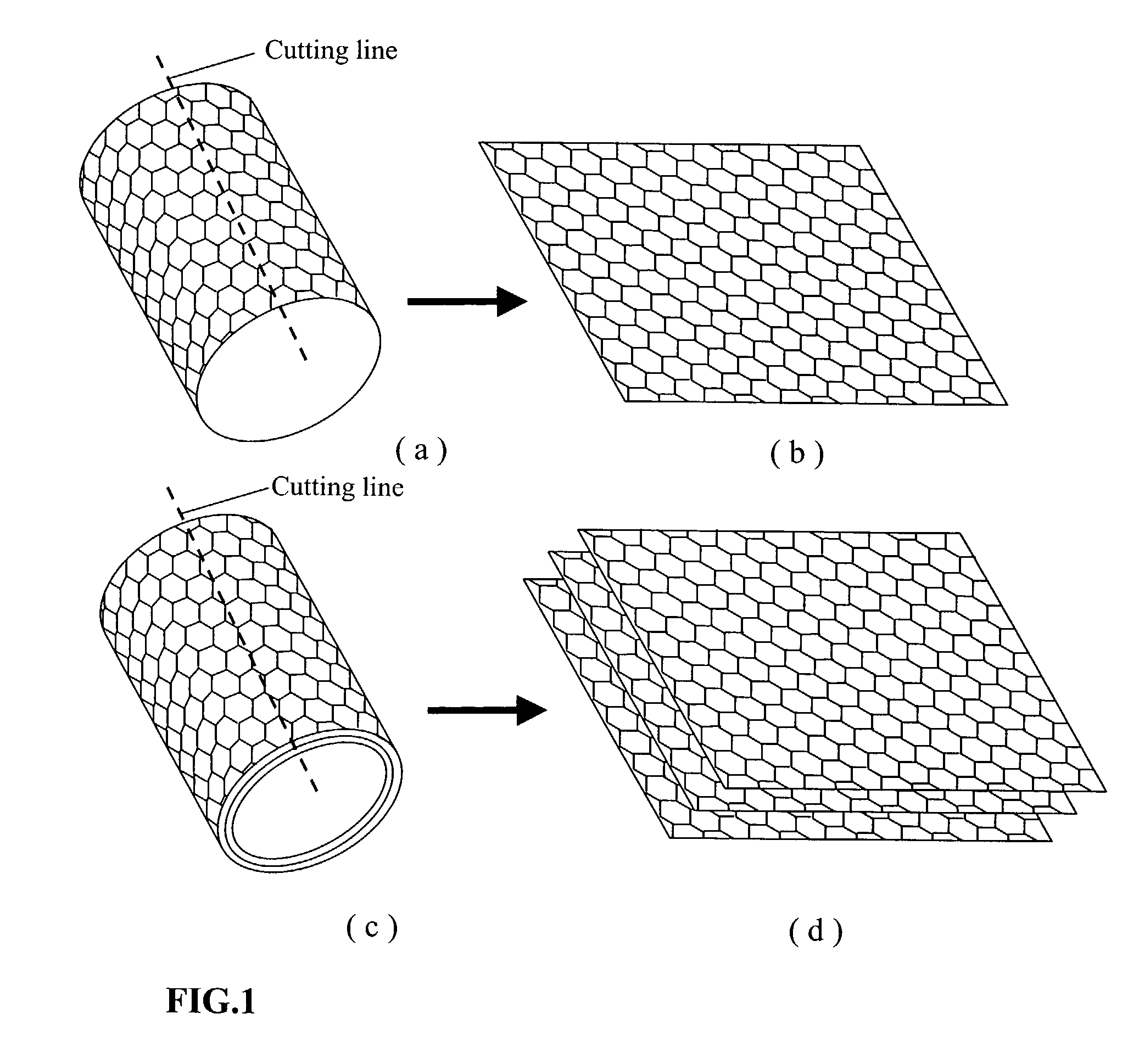

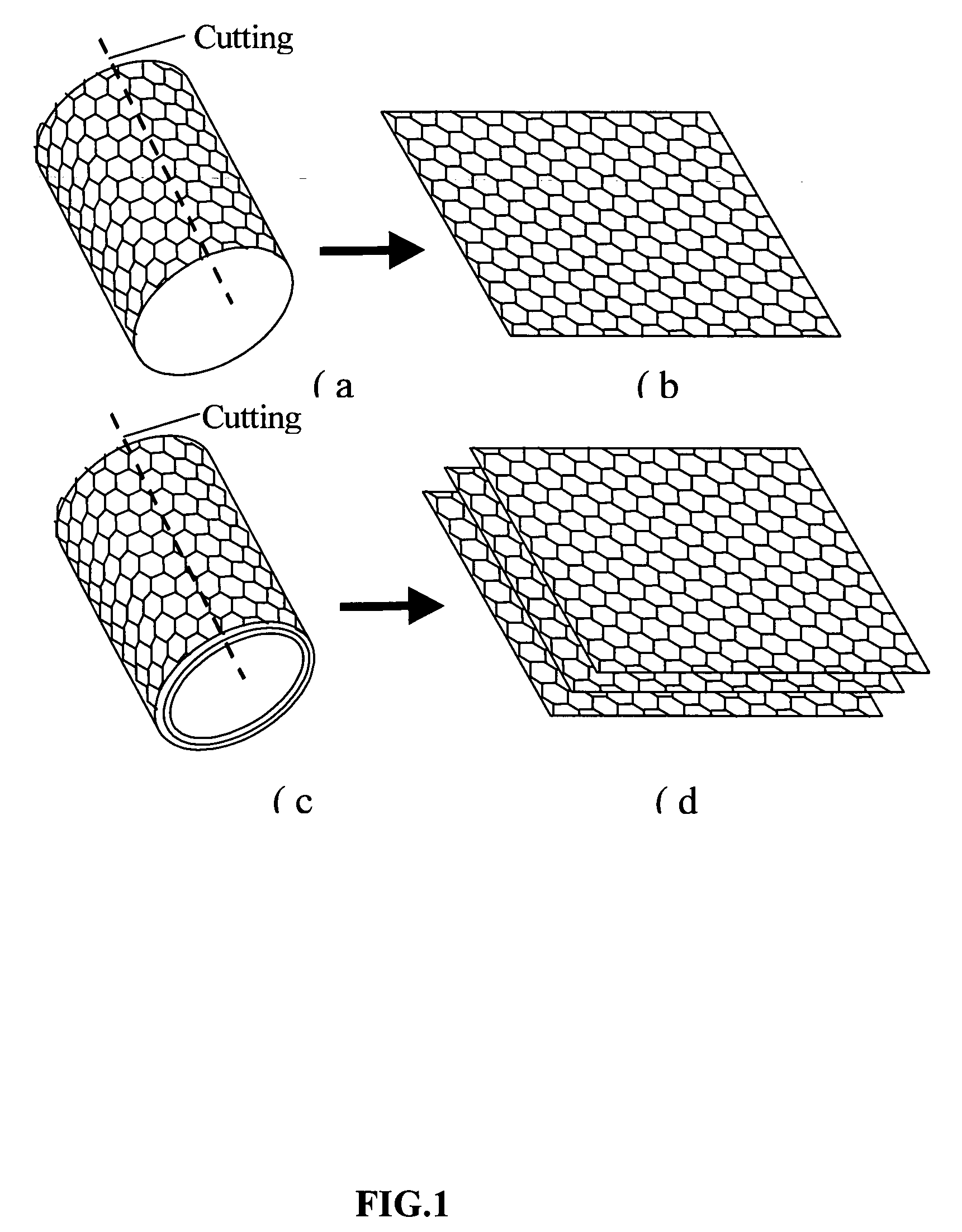

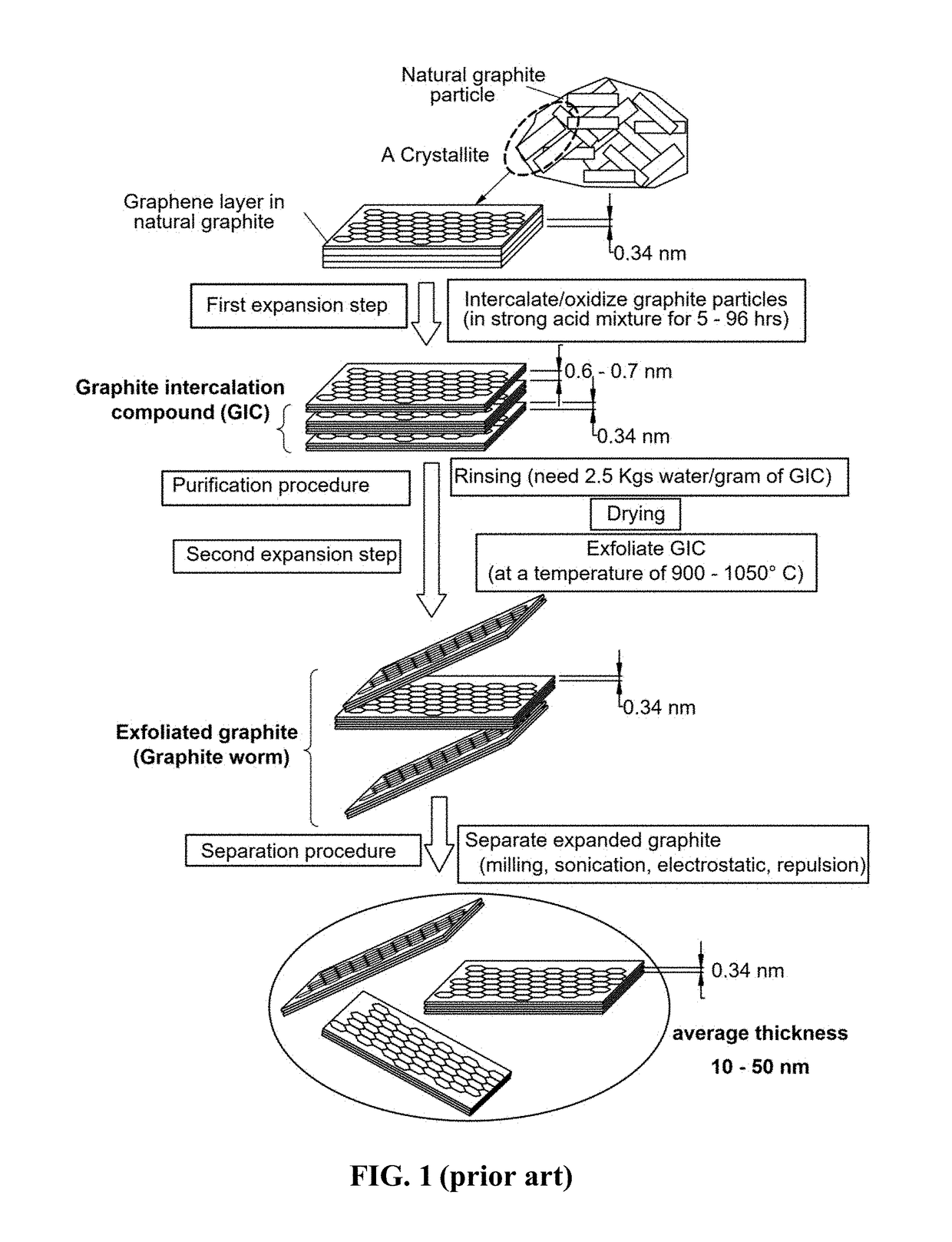

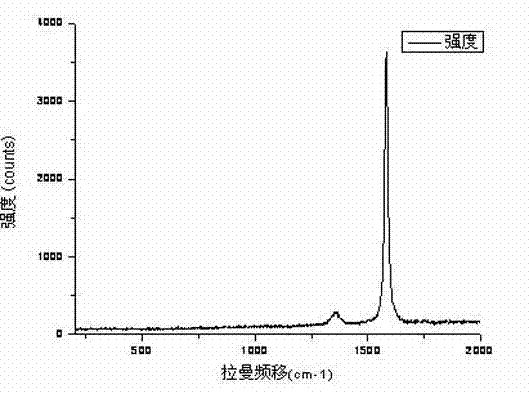

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

Process for nano-scaled graphene plates

A process for producing a nano-scaled graphene plate. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:JANG BOR Z

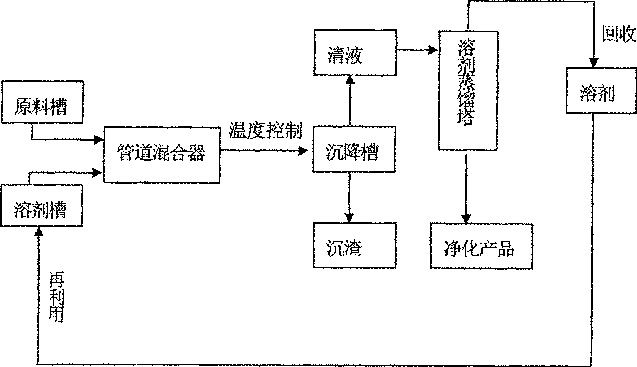

Fine purification method for coal tar pitch

InactiveCN101294090AImprove continuityImprove efficiencyWorking-up pitch/asphalt/bitumenOrganic filmFiber

The invention relates to a coal tar pitch refining method, in particular to a method for refining pitch for coal tar pitch needle coke, impregnant and binding agent for manufacturing high-power and ultrahigh-power graphite electrodes and pitch for manufacturing coal tar pitch carbon fibers. The method is characterized in that the method comprises the following steps: diluting coal tar pitch and the liquid containing coal tar pitch with organic solvent at a weight ratio of the organic solvent to coal tar pitch and the liquid containing coal tar pitch of 1:(5 to 30), removing impurities in the pitch solution by the combination of separation by a centrifuge and filtering with an organic film, and distilling and recovering the solvent in the refined mixture solution to obtain the coal tar pitch free of quinoline insoluble materials. The method has the advantages of good continuity of the separation process and high efficiency, and the pitch contains no quinoline insoluble materials.

Owner:ZIBO MINING GRP

Petroleum pitch-based carbon foam

InactiveUS6833012B2Useful and reliableImprove efficiencyPigmenting treatmentHarvestersLow densityNet shape

Petroleum or coal tar pitch-based cellular or porous products having a density of preferably between about 0.1 g / cm<3 >and about 0.8 g / cm<3 >are produced by the controlled heating of mesophase carbon materials derived from coal tar or petroleum pitch having a softening point in excess of about 300° C. and preferably between about 300 and about 400° C. in a "mold" and under a non-oxidizing atmosphere. The porous product thereby produced, preferably as a net shape or near net shape, can be machined, adhered and otherwise fabricated to produce a wide variety of low cost, low density products.

Owner:TOUCHSTONE RES LAB

Technology for preparing needle coke raw material from coal-tar pitch

ActiveCN103013566ASuitable for adjusting extraction volumeHigh desulfurization efficiencyWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansPtru catalystCoke

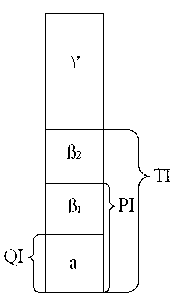

The invention provides a technology for preparing a needle coke raw material from coal-tar pitch. The technology comprises the following steps of 1, fully mixing asphalt and a solvent, and removing insoluble substances in the mixture by a physical separation method, wherein the solvent is a mixture of coal light oil and coal aromatic oil or is a mixture of BTX and coal aromatic oil; a mass ratio of the coal light oil or the BTX to the coal aromatic oil is in a range of (20: 80) to (95: 5); and a mass ratio of the solvent to the asphalt is in a range of 0.5 to 10, 2, feeding a clear liquor without the insoluble substances into a separator, and separating the light solvent from the clear liquor to obtain a heavy fraction having low QI, and 3, carrying out hydrotreatment on the heavy fraction in the presence of a hydrogenation catalyst at a temperature of 300 to 450 DEG C under the pressure of 5 to 20MPa. The needle coke raw material obtained by the technology has low sulfur content and a small expansion coefficient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

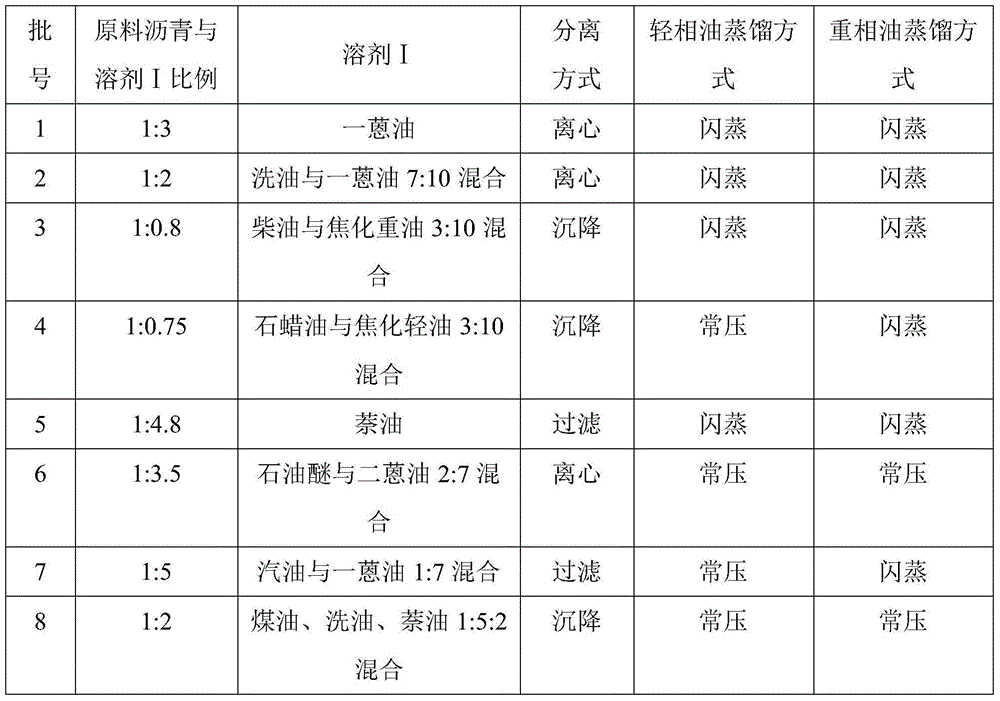

Novel process for eliminating quinoline insoluble substances in coal tar medium temperature pitch

InactiveCN101824329AAvoid power consumptionReduce manufacturing costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionQuinolineAliphatic hydrocarbon

The invention discloses a novel process for eliminating quinoline insoluble substances in a coal tar medium temperature pitch. The invention comprises the following steps: using the coal tar pitch as raw material, mixing with a solvent according to a certain proportion, and continuous extracting and settling separation for the settling separation of the quinoline insoluble substances in the pitch to obtain a clarified liquid and sediments. The invention is characterized in that the coal tar pitch material uses the coal tar medium temperature pitch; the coal tar medium temperature pitch and a mixed solvent of an aromatic hydrocarbon solvent and an aliphatic hydrocarbon solvent according to a certain proportion are preheated and respectively sent to a multi-level static mixer for even mix according to a proportion of 1:0.8-1.2 by weight to produce a mixing oil; and the continuous extracting and settling separation is carried out for eliminating the quinoline insoluble substances in the coal tar medium temperature pitch. Since the technical proposal is used, the invention has low cost and high separation efficiency, and the refine pitch after clarifying fully satisfies the requirement of producing needle coke or as an impregnant pitch.

Owner:朱兴建

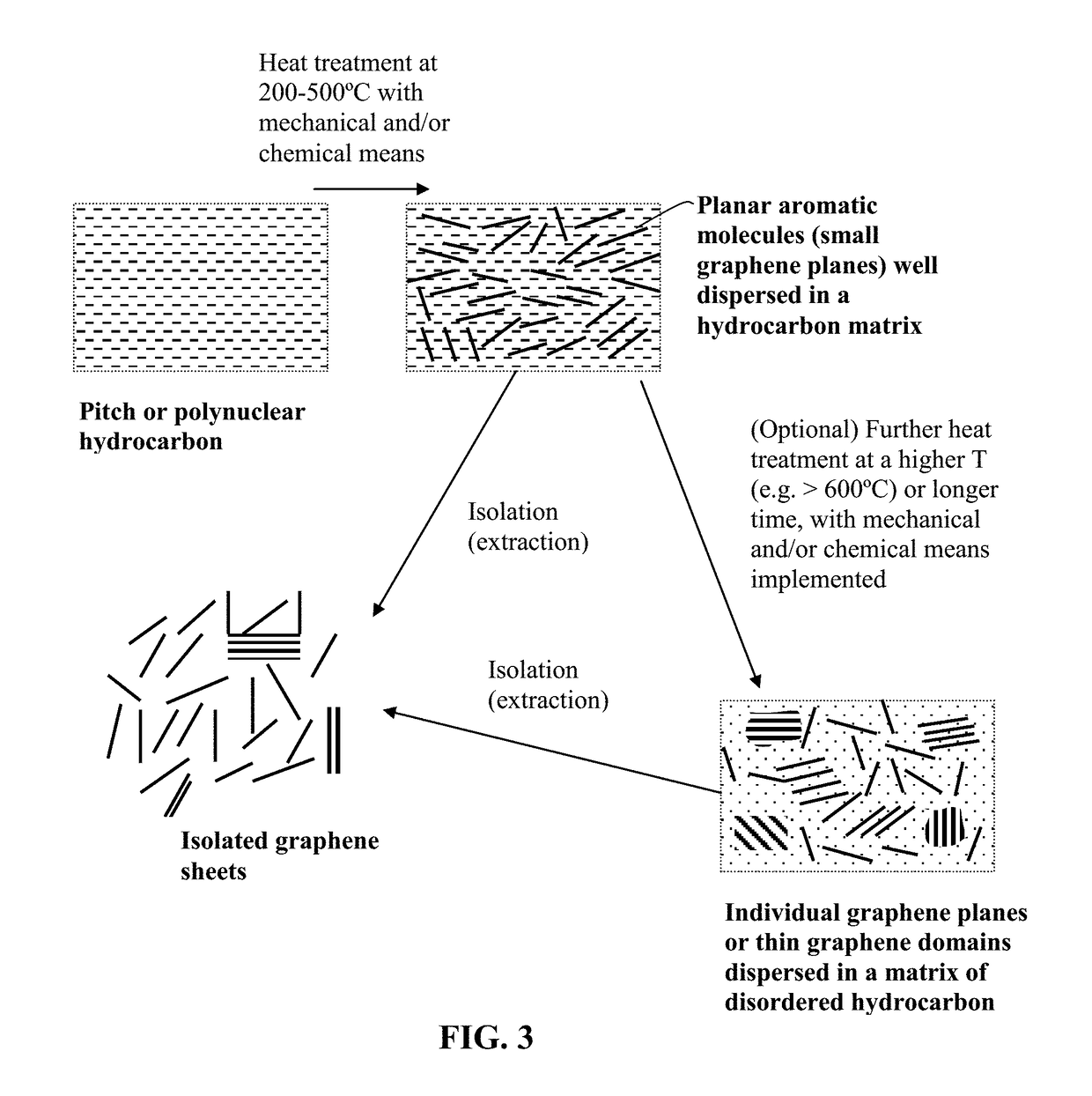

Production of graphene materials directly from carbon/graphite precursor

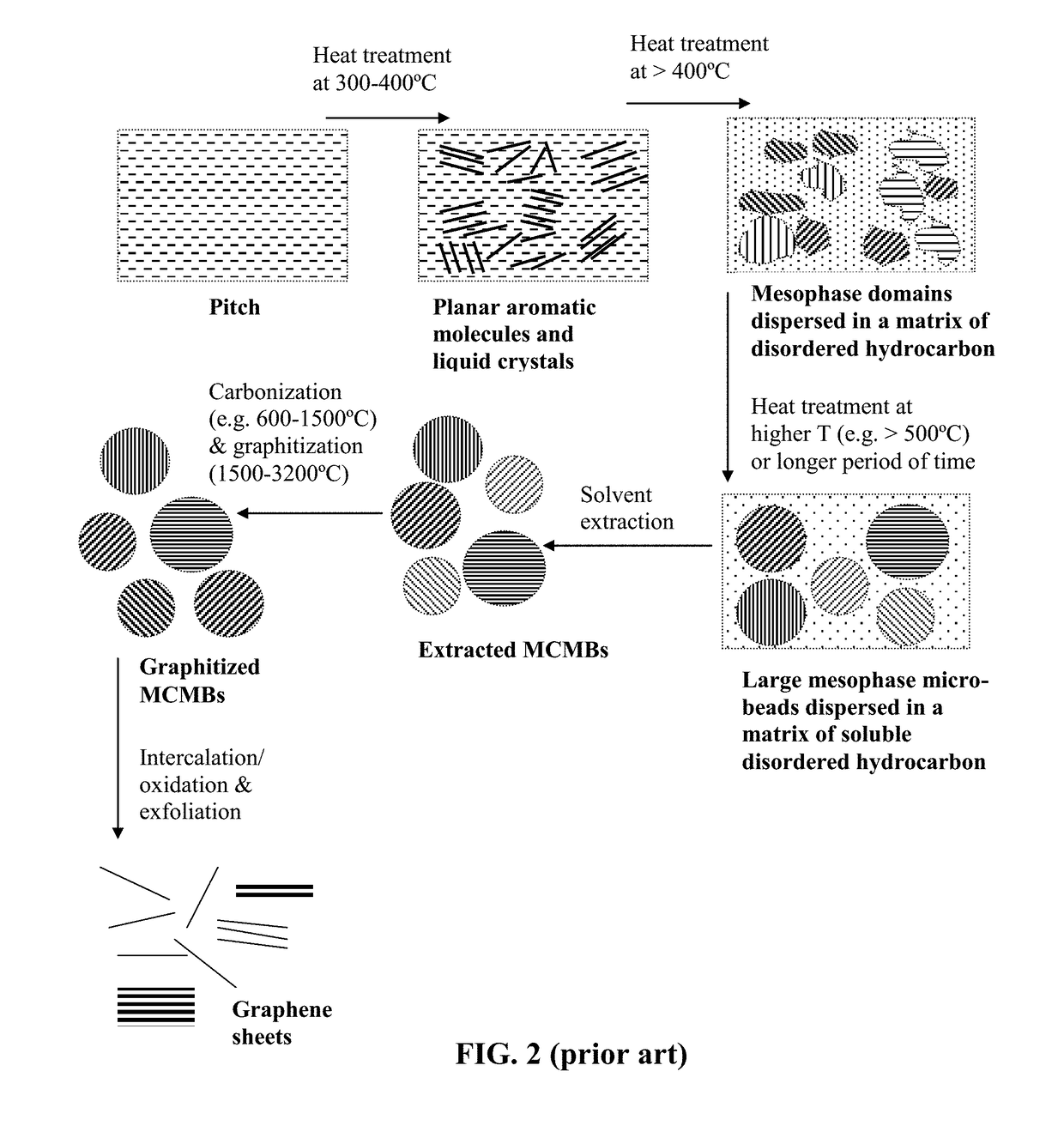

Provided is a method of producing isolated graphene sheets directly from a carbon / graphite precursor. The method comprises: (a) providing a mass of aromatic molecules wherein the aromatic molecules are selected from petroleum heavy oil or pitch, coal tar pitch, a polynuclear hydrocarbon, or a combination thereof; (b) heat treating this mass and using chemical or mechanical means to form graphene domains dispersed in a disordered matrix of carbon or hydrocarbon molecules, wherein the graphene domains are each composed of from 1 to 30 planes of hexagonal carbon atoms or fused aromatic rings having a length or width from 5 nm to 20 μm and an inter-graphene space between two planes of hexagonal carbon atoms or fused aromatic rings no less than 0.4 nm; and (c) separating and isolating the planes of hexagonal carbon atoms or fused aromatic rings to recover graphene sheets from the disordered matrix.

Owner:GLOBAL GRAPHENE GRP INC

Graphite electrode for electrothermic reduction furnaces, electrode column, and method of producing graphite electrodes

InactiveUS20050254545A1Low production costElectric discharge heatingConductive materialGraphite electrodeCrystal structure

A graphite electrode for an electrothermic reduction furnace is formed from anode grade coke and graphitized at a graphitization temperature below 2700° C. The resulting electrode is particularly suited for carbothermal reduction of alumina. It has an iron content of about 0.05% by weight, a specific electrical resistivity of above 5 μOhm·m, and a thermal conductivity of less than 150 W / m·K. The graphite electrode is manufactured by first mixing calcined anode coke with a coal-tar pitch binder, and a green electrode is formed from the mixture at a temperature close to the softening point of the pitch binder. The green electrode is then baked to carbonize the pitch binder to solid coke. The resultant carbonized electrode, after further optional processing is then graphitized at a temperature below 2700° C. for a time sufficient to cause the carbon atoms in the carbonized electrode to organize into the crystalline structure of graphite.

Owner:SGL CARBON SE

High-softening-point coal-tar pitch production method

ActiveCN102732280AHigh purityLow impurity contentWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

The invention relates to a high-softening-point coal-tar pitch production method, which is mainly and technically characterized in that the method comprises the following steps of: (1) adding low-QI (Quality Index) purified coal-tar pitch into a stirring tank, continuously feeding air into the stirring tank, carrying out stirring in the process of feeding air, and carrying out air oxidation under the condition of 200-300 DEG C, wherein the oxidation time is 4-12 h; and (2) after the oxidation is completed, adding the pitch into a film evaporator, carrying out thin-film distillation on the pitch at a temperature of 300-350 DEG C and under a vacuum negative pressure of 0.05-0.099 Mpa, removing light components in the pitch, and carrying out distillation treatment on the obtained product for one to four hours so as to obtain high-softening-point coal-tar pitch. The method disclosed by the invention is reasonable in design; and the softening point of high-softening-point coal-tar pitch produced by taking the low-QI purified coal-tar pitch as raw materials reaches 270-290 DEG C, and the high-softening-point coal-tar pitch is low in impurity content, high in purity, simple in production process, energy-saving and environmental-friendly, and can be widely applied to the production of cathode materials jackets for lithium ion batteries and carbon fibers.

Owner:内蒙古隆通碳纤维技术有限公司

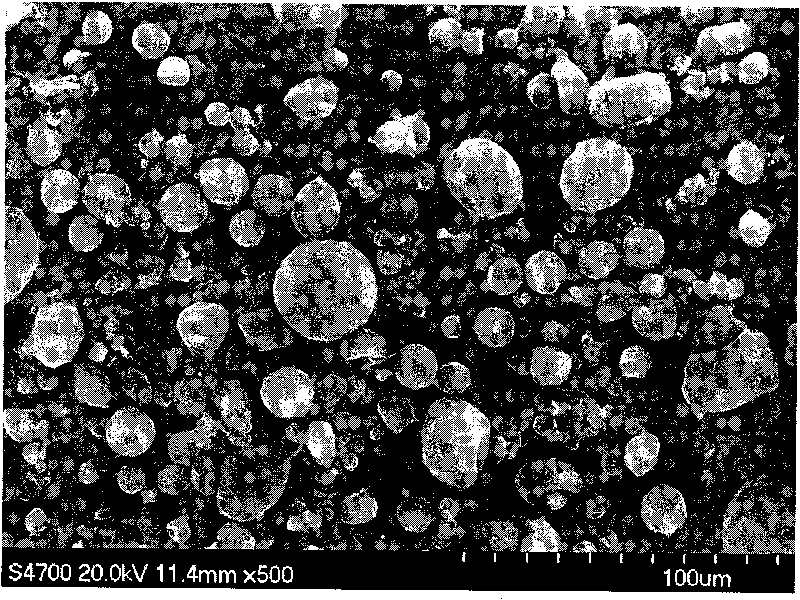

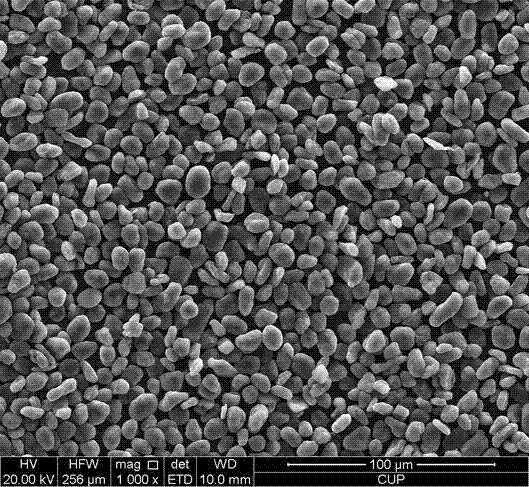

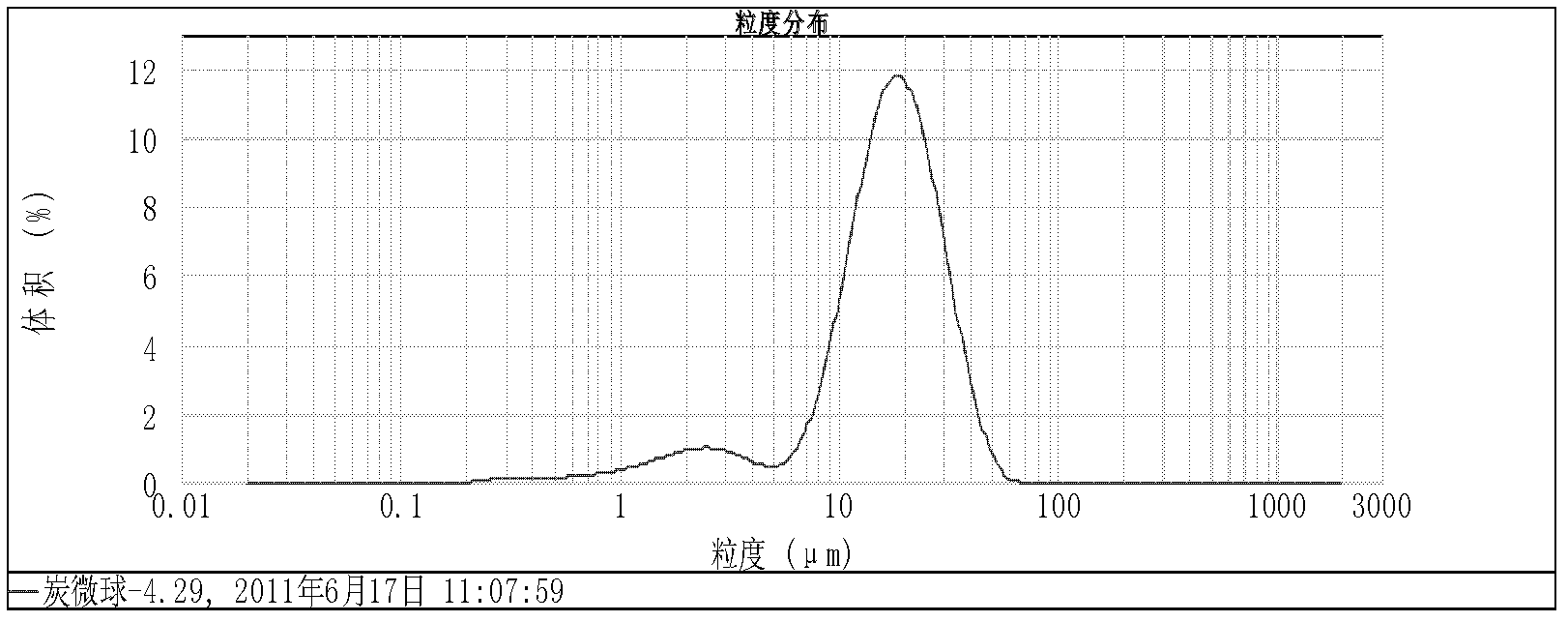

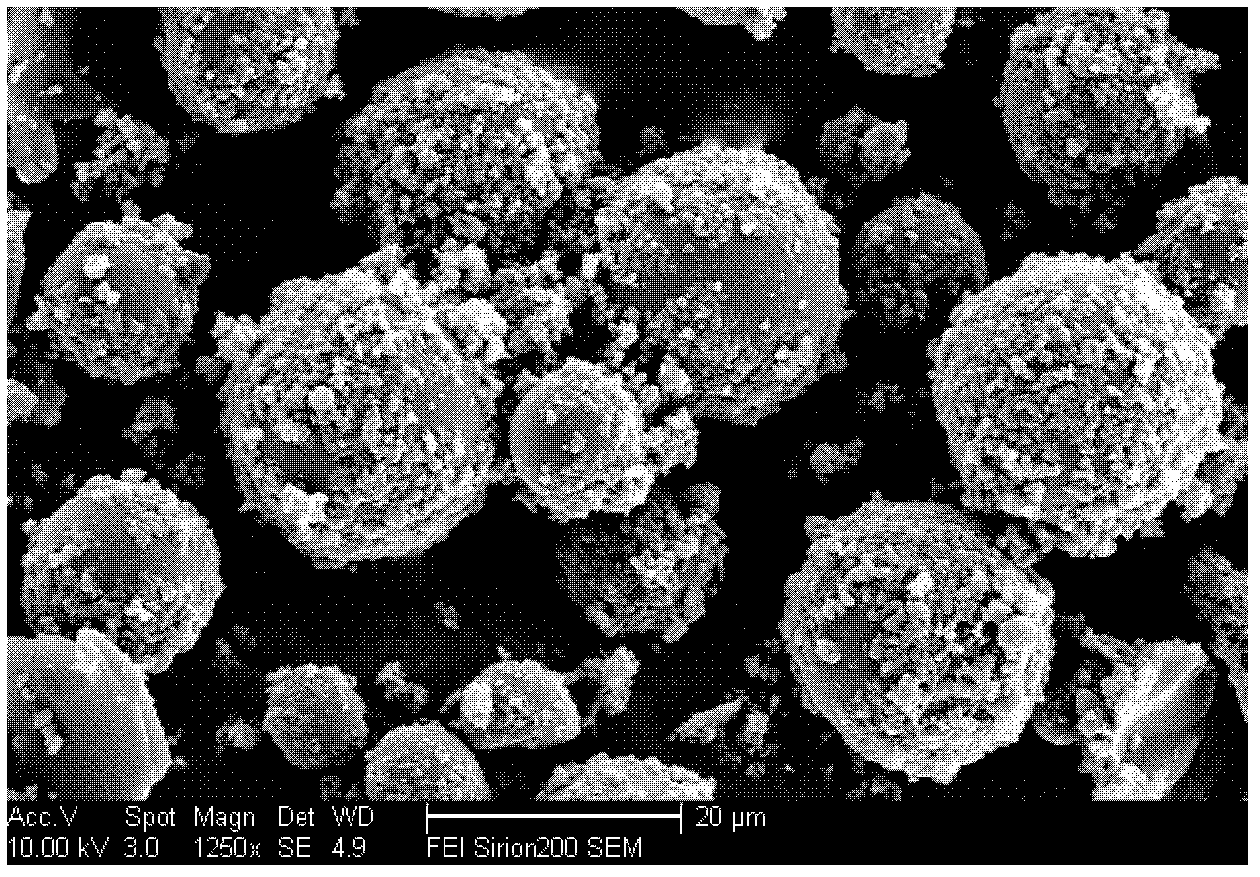

Activated carbon microspheres and preparation method thereof

InactiveCN101717085AImprove adsorption capacityWon't happenMicroballoon preparationMicrocapsule preparationActivated carbonMicrosphere

The invention relates to activated carbon microspheres and a preparation method thereof. The diameter of the activated carbon microspheres is between 10 and 40 nm, the BET specific surface area is between 2,500 and 3,600m<2> / g, the total pore volume is between 2.5 and 3.2cm<3> / g, the mescopore pore volume is between 1.6 and 2.2cm<3> / g, and an average pore size is between 2.8 and 3.1nm. The preparation method for the activated carbon microspheres comprises the steps of: firstly, performing pre-oxidation on a mixture of coal tar pitch and an annexing agent; secondly, activating the mixture by using a strong basic compound; thirdly, cleaning by using a detergent; finally, drying to obtain the activated carbon microspheres.

Owner:BEIJING UNIV OF CHEM TECH

Purification method for coal pitch

InactiveCN101475820AImprove solubilityImprove purification effectWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberPurification methods

The invention relates to a method for purifying coal tar pitch, which is characterized in that the method comprises the following steps: using mid-temperature coal tar pitch or coal tar maltha as a raw material, and using a mixed solvent consisting of arene from coking and coal oil or light diesel fuel from petrifaction to perform sufficient mixing and dissolving at certain temperature; performing centrifugal separation to remove the residue, and distilling the obtained clear solution to remove and reclaim the solvent so as to obtain the purified pitch with the content of quinoline undissolved substances of between 0.01 and 0.04 percent. The method has the advantages of simple process, low production cost, high separation efficiency and lower QI content; besides, the purified pitch can completely meet the requirements on producing the products of needle coke, carbon fiber and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

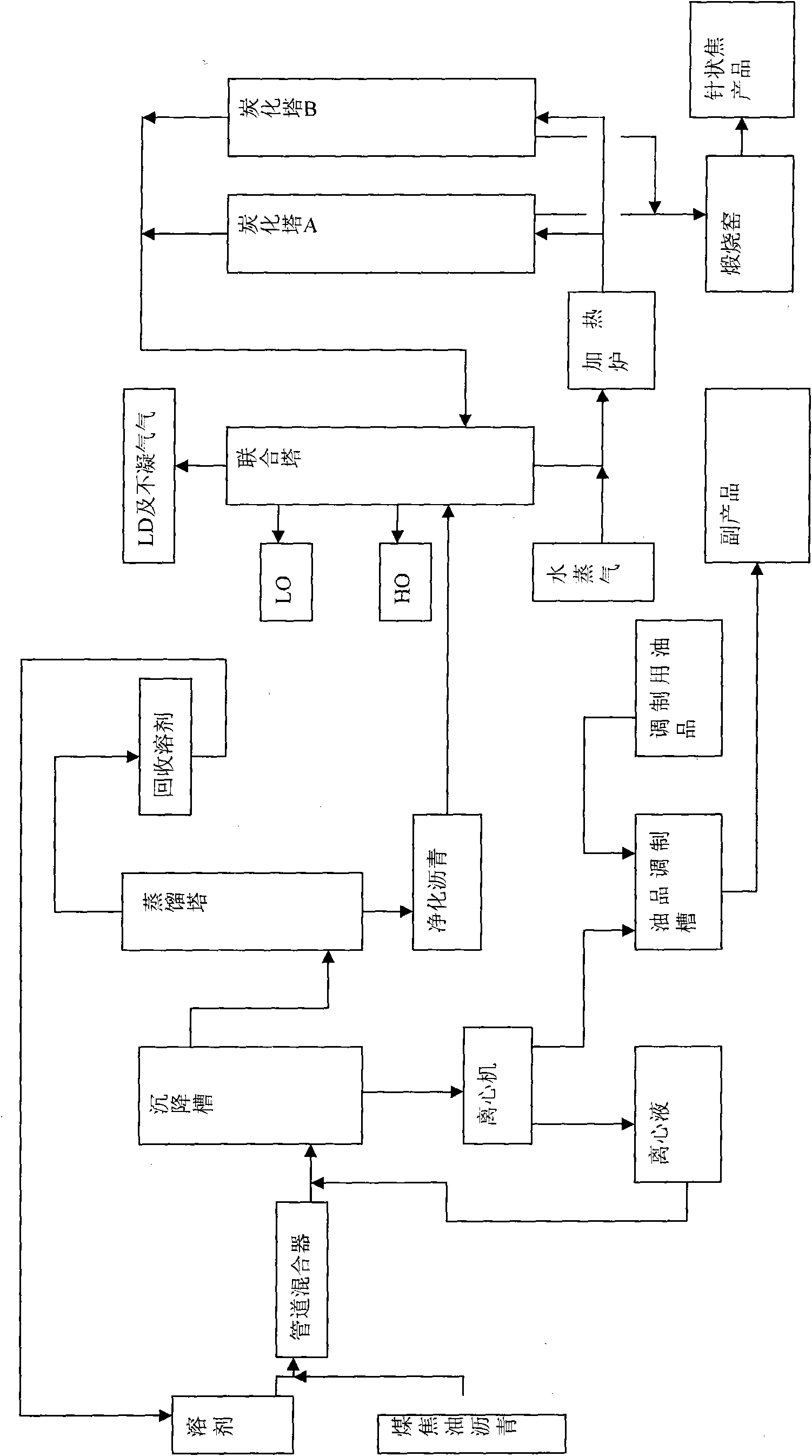

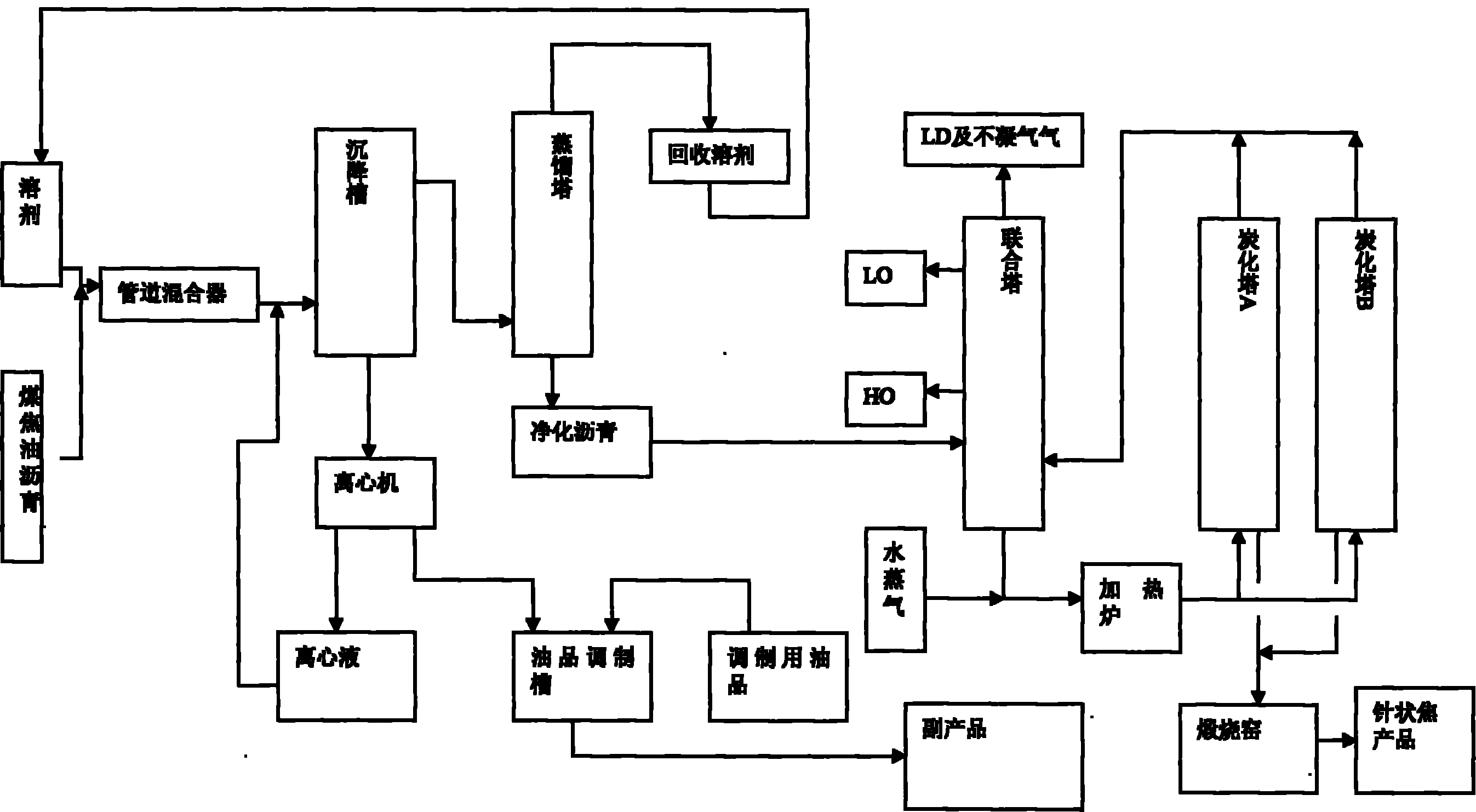

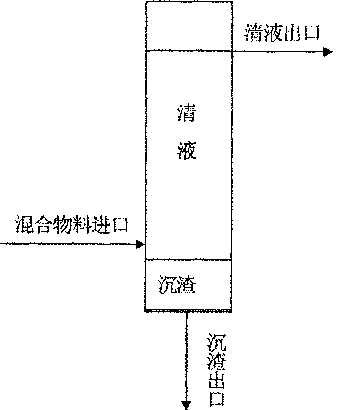

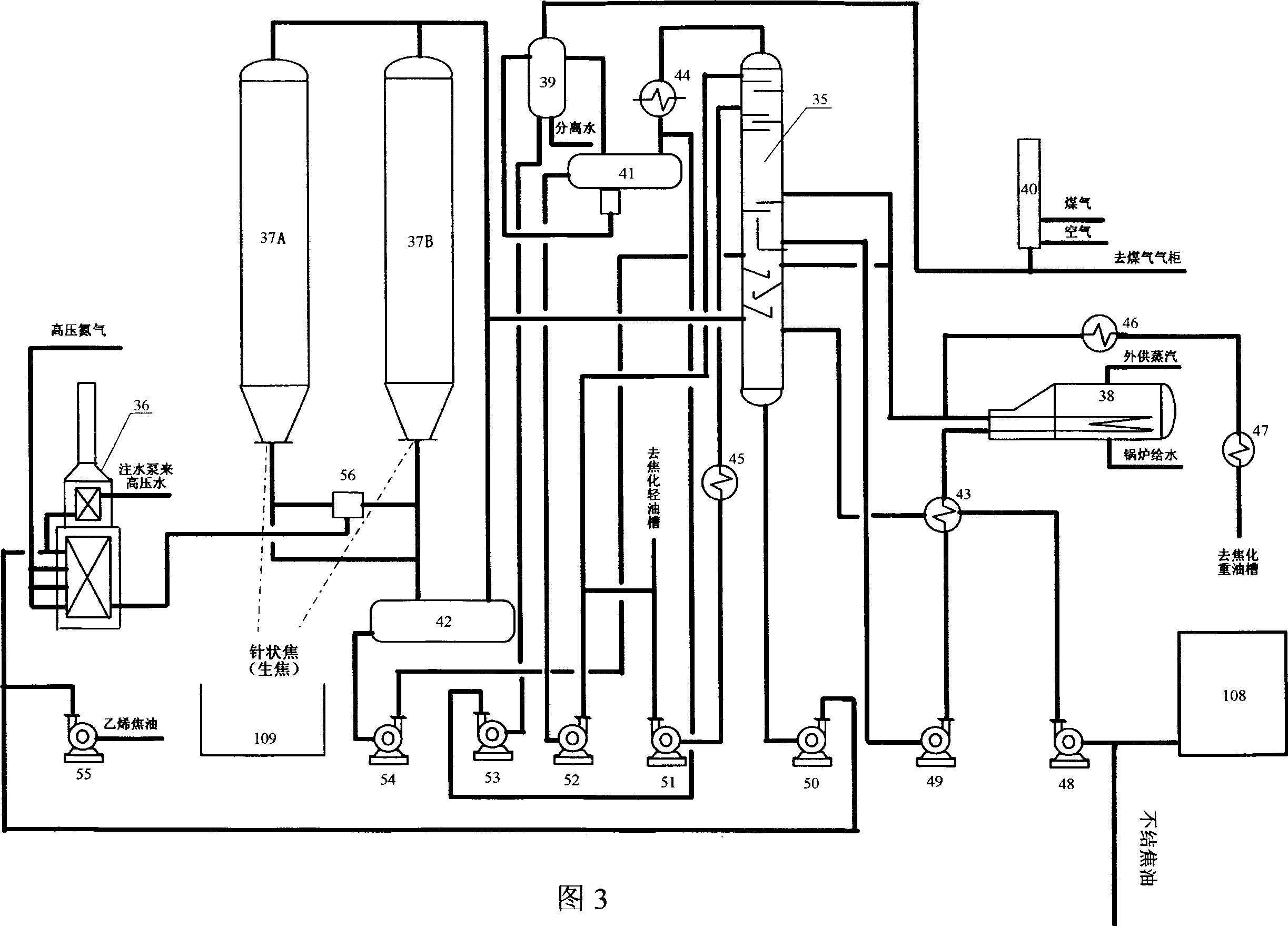

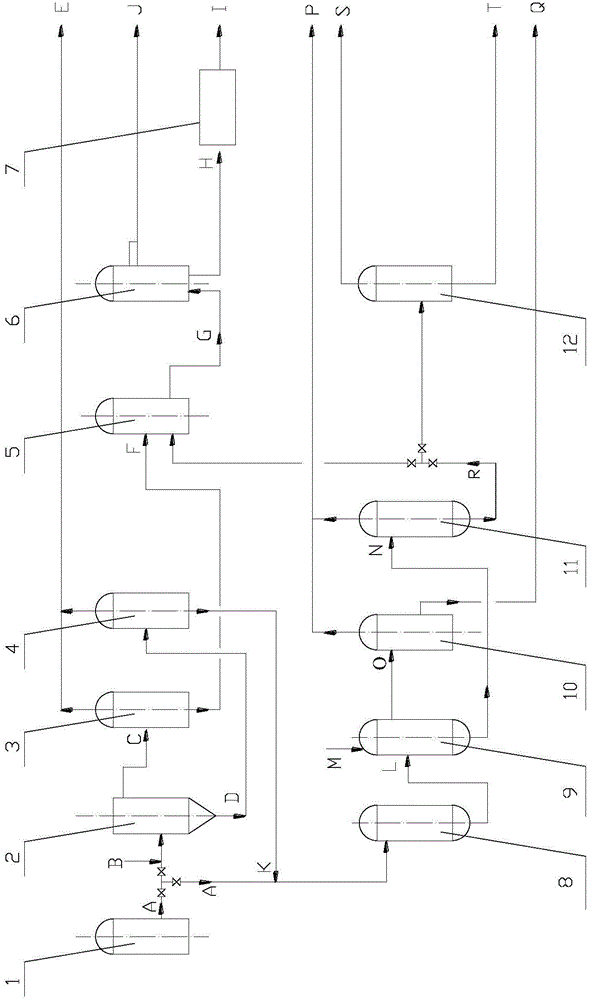

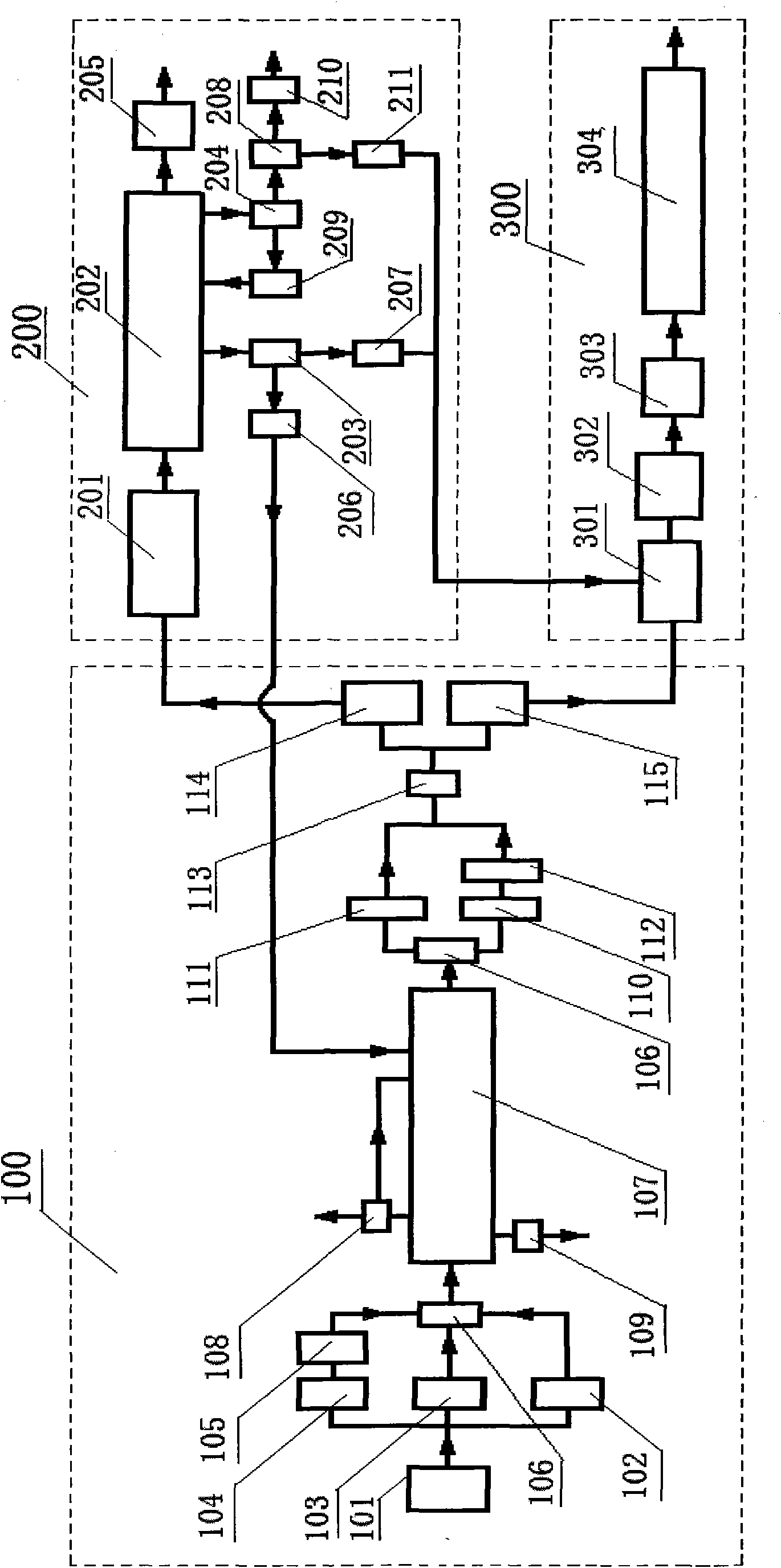

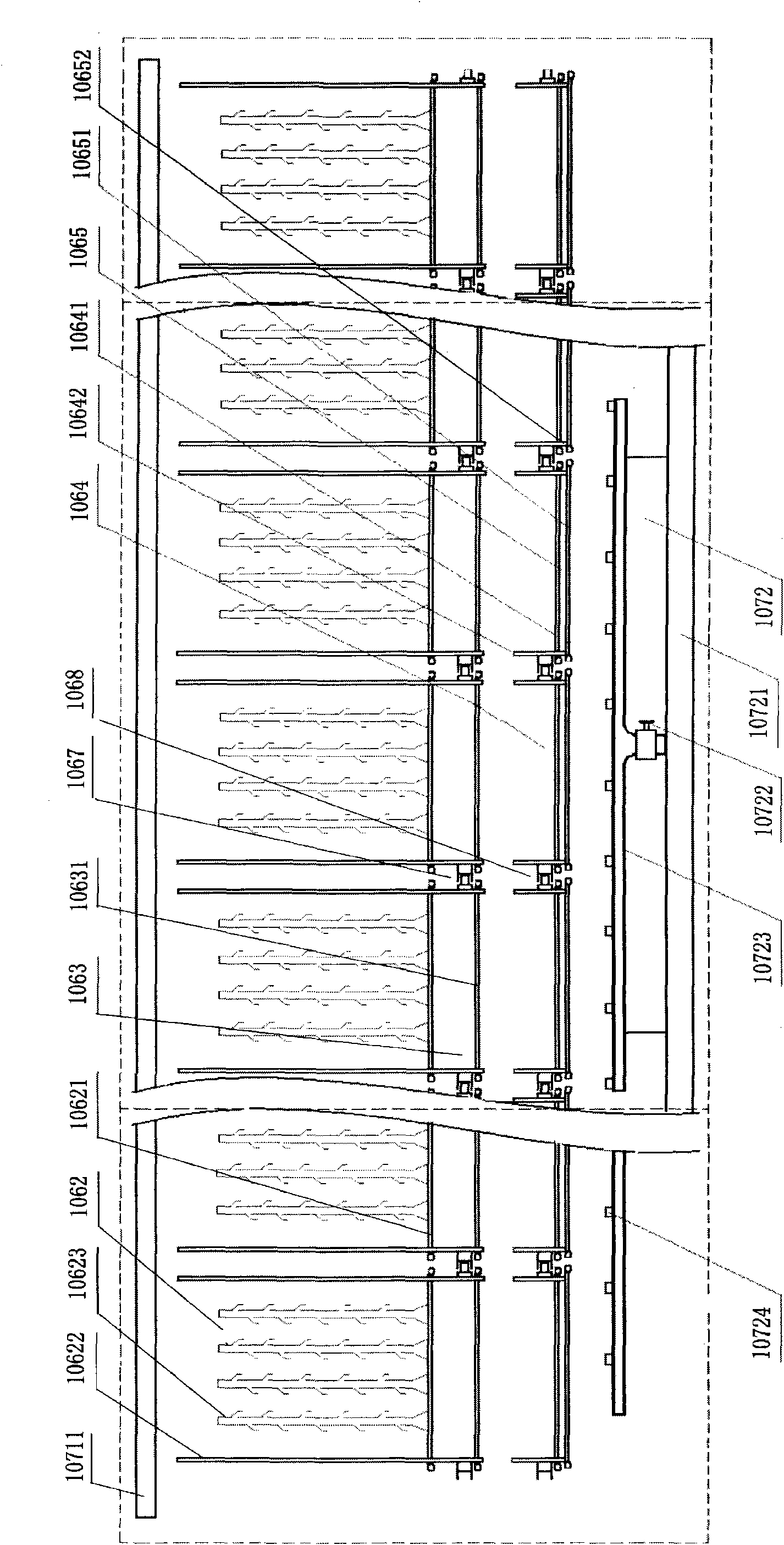

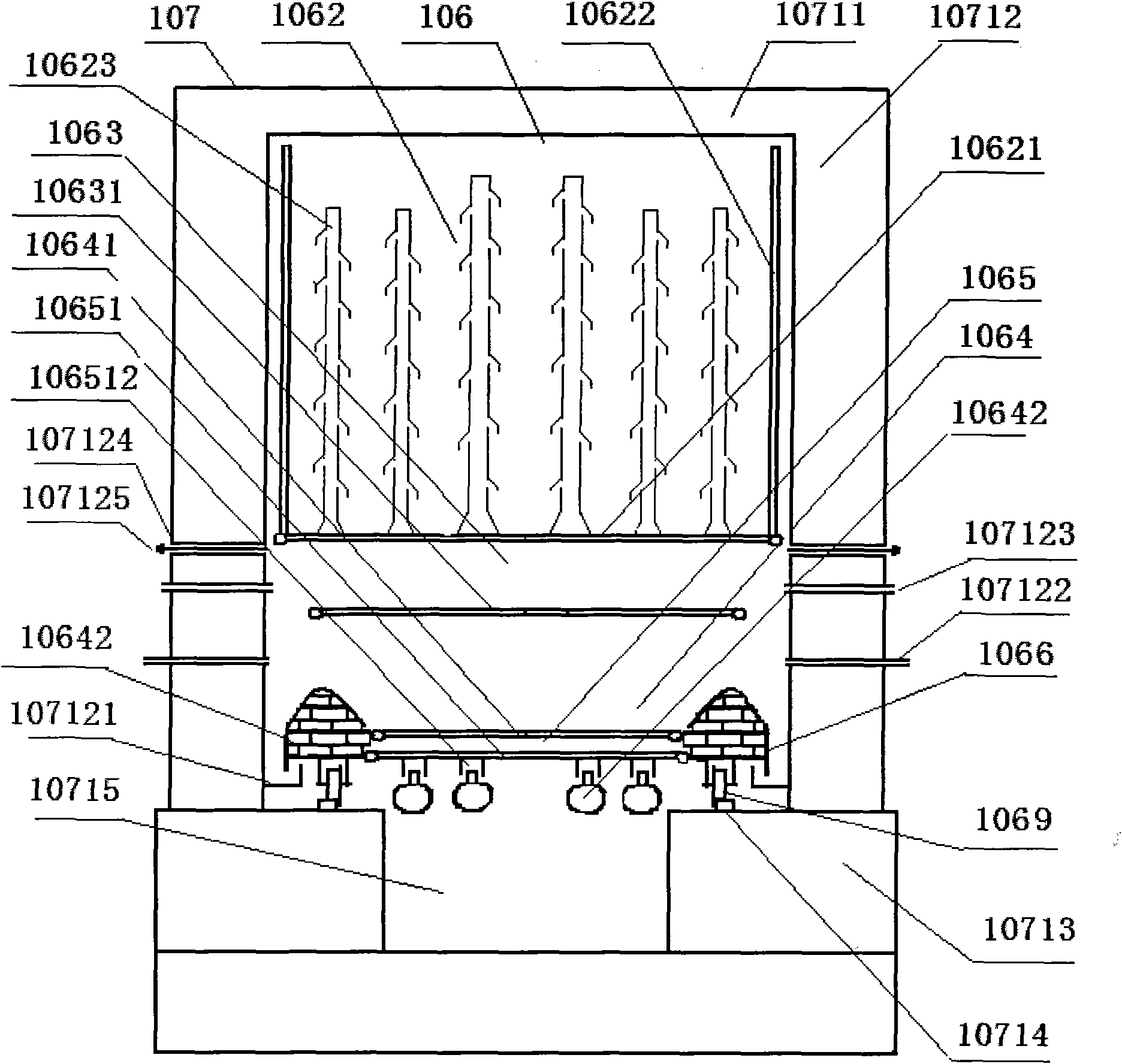

Production method and system of coal-series needle coke

The invention relates to a production method of needle coke, in particular to a production method of coal-series needle coke and a method for producing the coal-series needle coke by obtaining purified asphalt from which quinoline insoluble (QI) is removed by a solvent treatment method and carbonizing the purified asphalt. The invention also relates to a system for implementing the production method of the coal-series needle coke. In the production method of the coal-series needle coke, a settling tank is taken as settling equipment; the mixture of coal tar asphalt and a solvent is continuously introduced into the inlet of the settling tank; and a settled light phase and a settled heavy phase are continuously discharged out of the settling equipment respectively. In the production system of the coal-series needle coke, a settling tank is taken as settling equipment. Technical problems such as an unclear interface between the light phase and the heavy phase, realization of continuous production by using a plurality of stirring kettles alternatively, light phase loss during intermittent operation and large solvent loss caused by solvent settling by using the stirring kettles in the prior art are solved.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Method for extracting, producing and purifying pitch with mixed solvent

ActiveCN101787299AHigh yieldSatisfy productivityWorking-up pitch/asphalt/bitumen by selective extractionFiberQuinoline

The invention relates to a preparation method for purifying pitch, which comprises the steps of completely removing quinoline insolubles (QI) through extracting coal tar pitch with mixed solvent to obtain the purified pitch without QI. The purified pitch produced by the method can meet the requirement of producing carbon fiber and needle coke. The method has simple process, convenient preparation, easy operation, environmental protection and no pollution.

Owner:沈建立

Process for continuously removing quinoline insolubles in coal tar pitch

ActiveCN101508903ALow QI contentHigh recovery rateWorking-up pitch/asphalt/bitumen by selective extractionAliphatic hydrocarbonQuinoline

The invention provides a process for continuously removing quinoline insolubles from coaltar asphalt. In the process, after a working procedure of mixing materials and solvent, the mixture continuously enters to the lower part of a settling tank; a mixture separating working procedure is carried out in the settling tank; clear solution separated from the mixture is continuously discharged from the upper part of the settling tank, and sediments are sent out from the bottom of the settling tank; the solvent consists of aliphatic hydrocarbon and aromatic hydrocarbon according to the proportion of 1 to 0.5-1 to 1.5; and the flow ratio of pit asphalt and the solvent in the materials is 1 to 0.6-1 to 2.0. The OI content in the purified asphalt is low, and the clear solution loss of the supernatant clear solution is reduced due to the continuous operation, thus the purified asphalt product has high yield coefficient and the solvent also has higher recovery coefficient.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

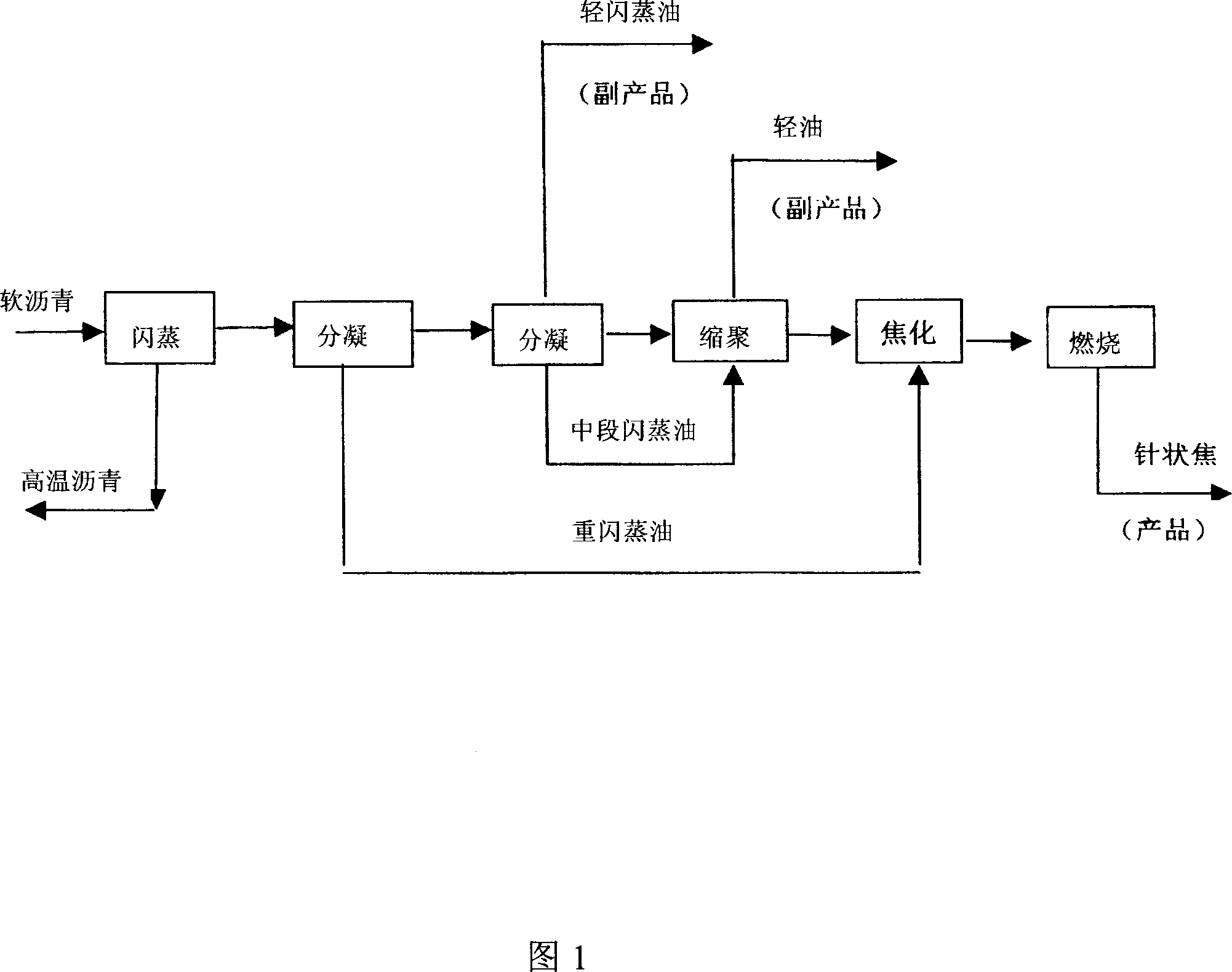

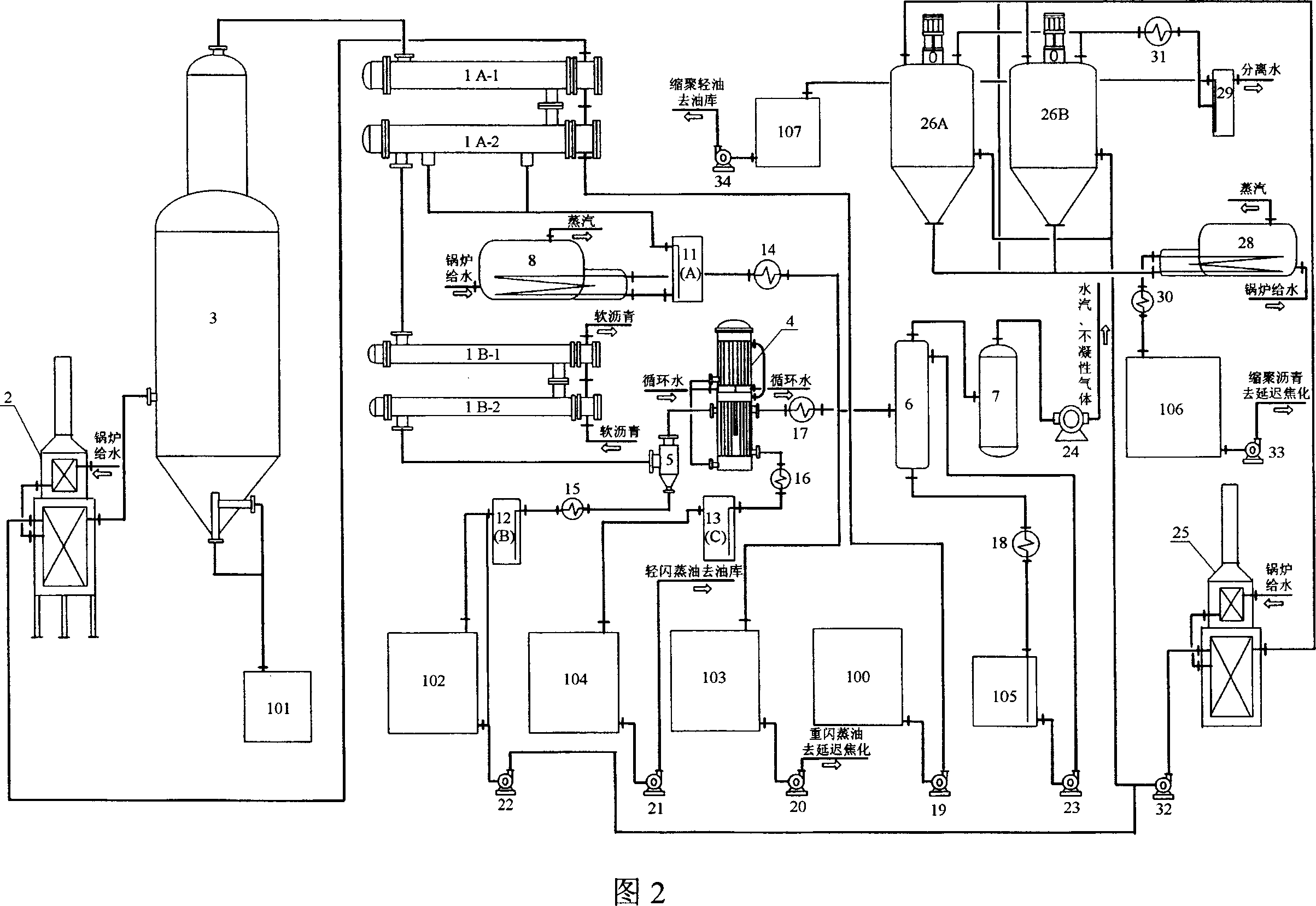

Industrial producing process for coal series needle coke

ActiveCN1944578AHigh molecular weightSmall molecular weightCoking carbonaceous materialsGraphite electrodeGraphite

The industrial producing process of coal series needle coke includes the following steps: stepped condensing the flash oil produced in vacuum flashing of coal tar pitch to obtain three, heavy, medium and light, fractions; polycondensating the medium fraction in an improved pitch circulating process to obtain condensed pitch; delay coking the condensed pitch and the heavy fraction and injecting N2 into the un-coked oil in the later coking stage to perform the final heating and coke drawing of the needle coke forming course; and final high temperature calcining to obtain coal series needle coke. Thus produced coal series needle coke has low thermal expansion coefficient and may be used in producing high power and super high power graphite electrode.

Owner:山西宏特煤化工有限公司

Lithium ion power battery composite cathode material and its preparation method

The invention relates to a battery cathode material, mainly relates to a lithium ion power battery composite cathode material and its preparation method, and belongs to the lithium battery making field. The lithium ion power battery composite cathode material is characterized in that the lithium ion power battery composite cathode material comprises a core-shell structure composed of a natural graphite matrix and a hard carbon layer coated on the surface of the natural graphite matrix, and a secondary modification layer for modifying the core-shell structure through adopting a modifying agent; the above coating is hard carbon formed through pyrolysis of a thermosetting resin; the thermosetting resin is at least one selected from a phenolic resin, an epoxy resin and a furan resin; and the modifying agent is at least one selected from coal tar pitch and petroleum asphalt. The lithium ion power battery composite cathode material having good electrochemical performances comprising capacity, first efficiency, cycle, rate and the like is prepared through adopting the primary coating and secondary modifying method.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

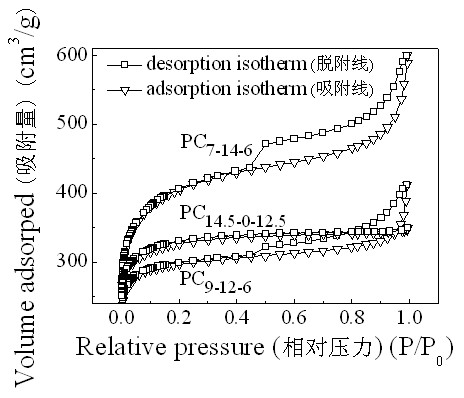

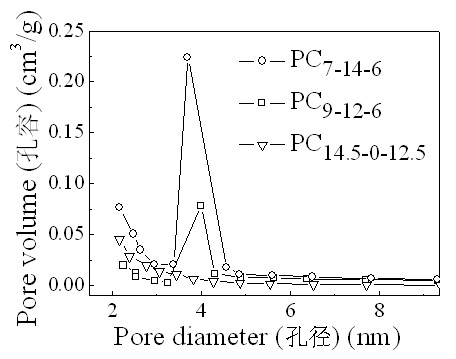

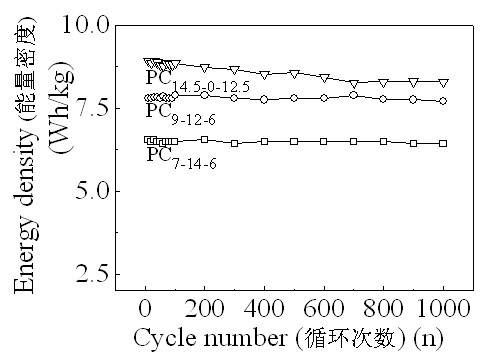

Method for preparing porous carbon material by using magnesium oxide template in cooperation with activation of potassium hydroxide

The invention discloses a method for preparing a porous carbon material by using a magnesium oxide template in cooperation with the activation of potassium hydroxide, and belongs to the technical field of carbon materials and microwave chemistry. The method comprises the following steps of: grinding coal tar pitch serving as a carbon source, nano magnesium oxide serving as a template and the potassium hydroxide serving as an activating agent; transferring the mixture to a corundum crucible; and putting into a microwave reactor, performing one-step microwave heating activation, and thus obtaining the porous carbon material for an electrochemical capacitor, wherein the specific surface area of the obtained porous carbon material is between 439 and 1,394m<2> / g, the total pore volume is between 0.23 and 0.94cm<3>, the average pore size is between 1.95 and 3.36mm, the ratio of the volume of a non-micro pore to the total pore volume is between 26.1 and 86.2 percent, and the porous carbon yield is between 37.8 and 84.9 percent. The invention has the advantages that: the method is quick and energy-saving; and the prepared porous carbon is used as an electrode material of the electrochemical capacitor and has extremely high stability and high comprehensive performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

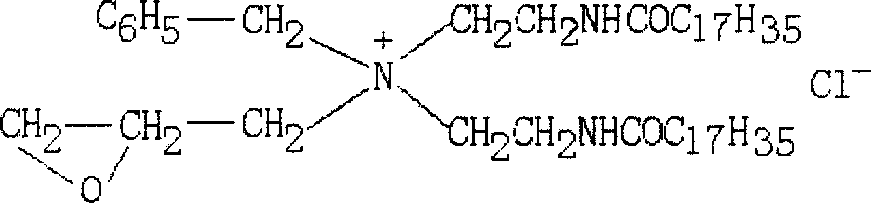

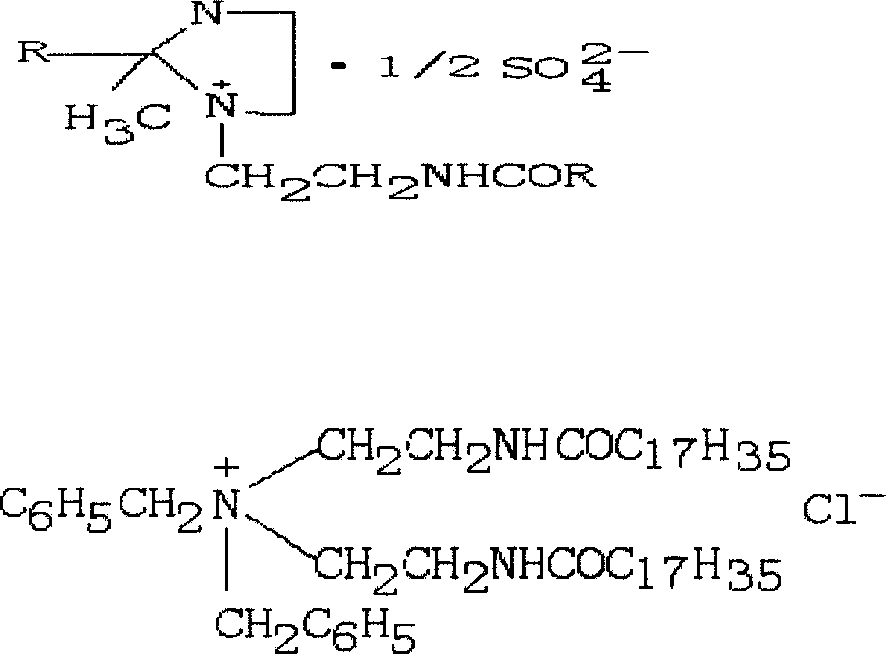

Oil soluble cationic broad-spectrum temporary blocking agent in use for drilling fluid

ActiveCN101092556AImprove the degree of perfectionImprove water absorptionDrilling compositionSolubilityHydroxyethyl cellulose

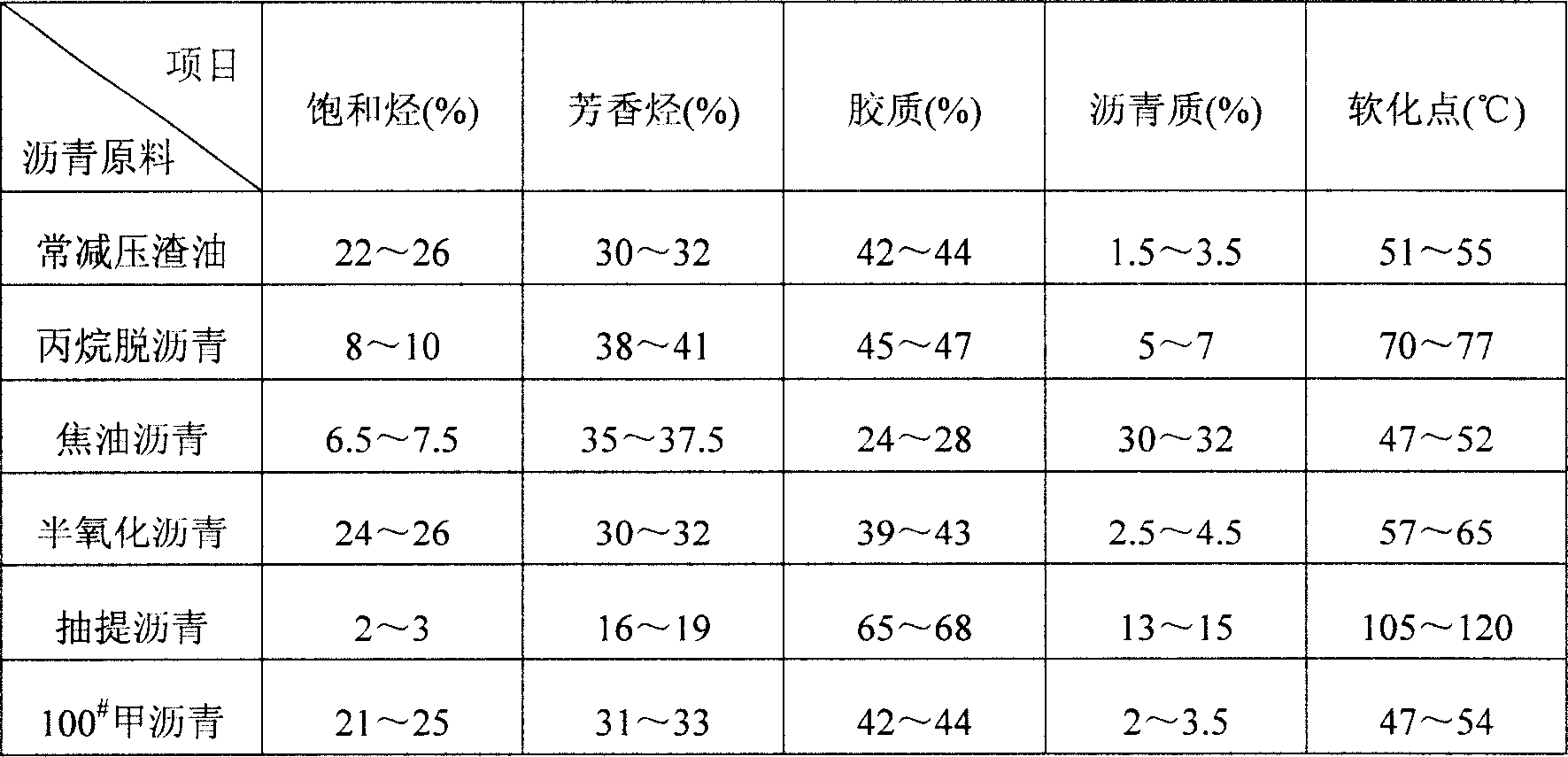

This invention relates to an oil-soluble cationic broad-spectrum temporary blocking agent for well drilling fluid. The oil-soluble cationic broad-spectrum temporary blocking agent comprises: oil-soluble materials 50-74%, SBS triblock copolymer 0.2-0.44%, epoxypropylbenzyl di(stearamide ethyl) ammonium salt 0.50-0.89%, cationic surfactant imidazoline 0.62-0.96%, dibenzyl-di(stearamide ethyl) ammonium salt 0.62-0.96%, carboxymethyl cellulose or hydroxyethyl cellulose 0.17-0.84$, CaCl2 0.2-0.25%, and water as balance. The oil-soluble materials include residue asphalt (softening point = 51-55 deg.C), semi-oxidized asphalt (softening point = 57-65 deg.C), ethylene pyrolysis coal tar pitch (softening point = 47-52 deg.C), propane-removed asphalt (softening point = 70-77 deg.C), extracted asphalt (softening point = 105-120 deg.C), and 100# heavy oil asphalt (softening point = 47-54 deg.C) at a weight ratio of 1:(1.88-2.5):(1.25-1.88):(3.12-3.75):(2.5-3.12):(1.5-2). The oil-soluble cationic broad-spectrum temporary blocking agent has such advantages as high oil solubility, high softening degree, wide softening point range, strong positive electricity, high lubricity, good fluid-loss inhibitive effect, high recovery rate of core permeability, low temporary blocking depth, high strength, good de-blocking effect, no pollution, low labor intensity, little influence on well drilling fluid construction performance, and simple process.

Owner:PETROCHINA CO LTD

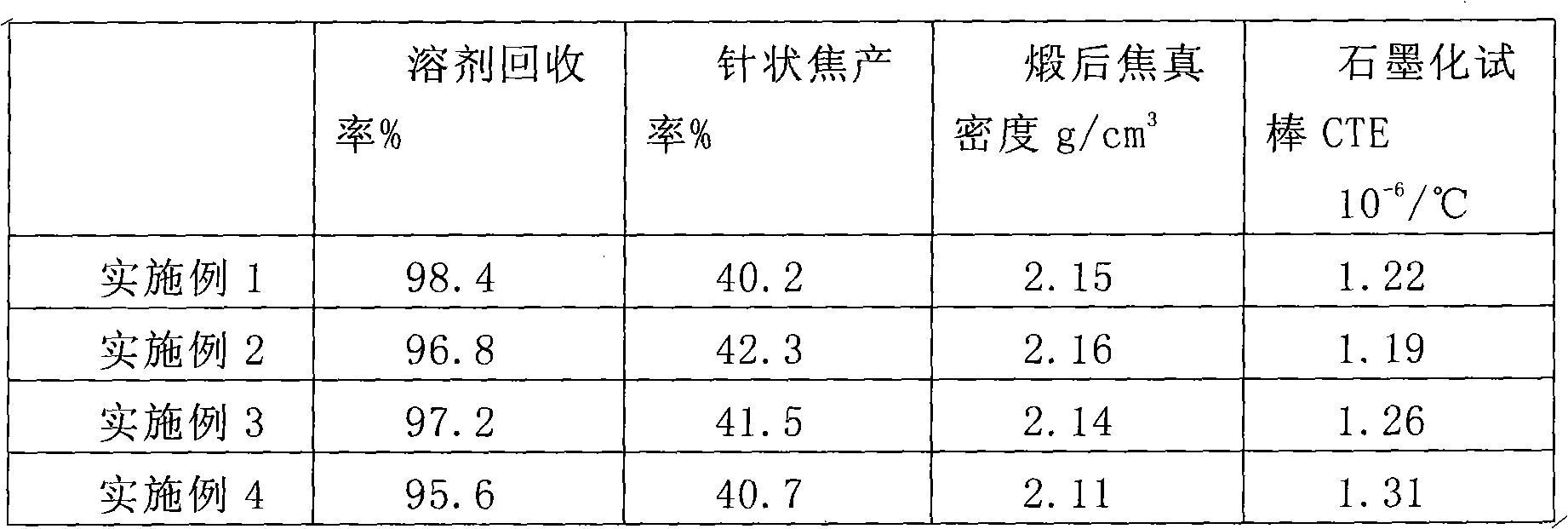

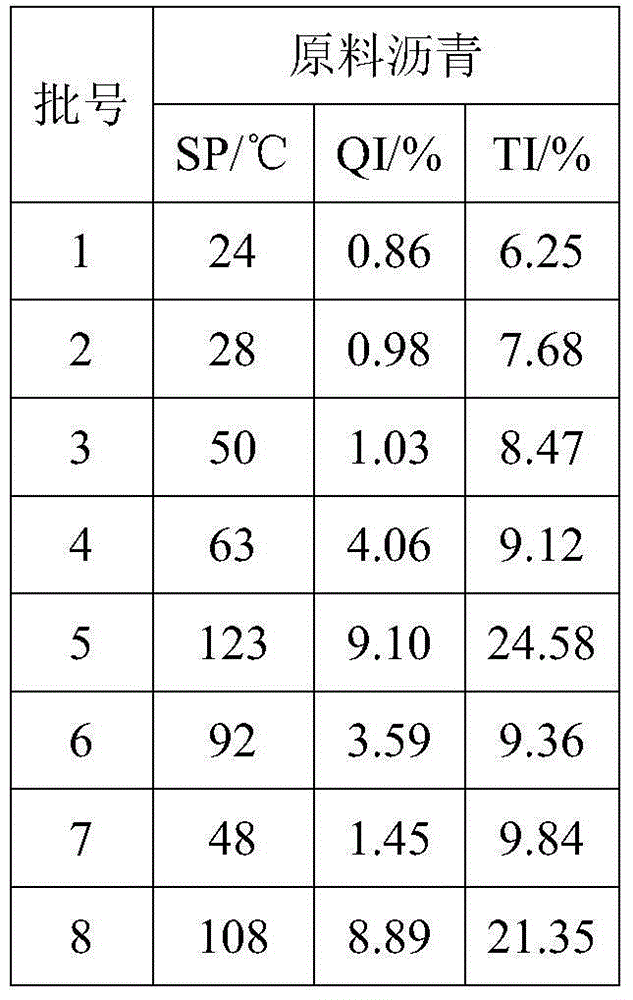

Co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt

ActiveCN104650938AHigh degree of processingLow costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionMicrosphereEconomic benefits

The invention relates to a co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt; heavy phase asphalt generated by raw material asphalt pre-treatment and raw material asphalt are mixed to produce mesocarbon microbeads, the byproduct asphalt of the production of misocarbon microbeads and the refined asphalt obtained by the raw material asphalt pre-treatment are mixed as a needle coke raw material; the technique comprises the steps of raw material asphalt pre-treatment, polymerization, polymerization product separating and drying, byproduct asphalt processing, coking and sintering. Compared with the prior art, the technique related by the invention has the following beneficial effects: (1) the coal tar asphalt processing degree is high, the cost is low, the varieties are diversified, the added value of the product is high, and the maximal economic benefit is realized; (2) the waste discharge is avoided during the whole production process, and the optimal environmental benefit is realized; (3) the process is flexible, the operation is simple, and the high-efficiency combination of needle coke, mesocarbon microbeads and high-quality asphalt is realized; and (4) the product index is flexible and adjustable, so as to adapt to market variations in time and improve the market risk resisting capability of an enterprise.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Catalyst used for coal tar pitch hydrocracking lightening reaction

InactiveCN102029157AEasy to makeLow costMolecular sieve catalystsHydrocarbon oil crackingPtru catalystMetallic sulfide

The invention relates to a catalyst used for coal tar pitch hydrocracking lightening reaction. The preparation method of the catalyst comprises the following steps: taking an inorganic porous material as a carrier; selecting at least one of alumina, silica gel containing alumina, MCM-41 (mobile crystalline material-41) and SBA-15 (santa barbara amorphous-15); loading one or two of metal elements Fe, Ni, Co and Mo of active components onto the carrier in the form of metallic oxide or metallic sulphide by adopting a vacuum immersion method, wherein the metallic oxide or metallic sulphide content of the active components is 1-20wt% of the catalyst; then drying for 1-14 hours under the conditions that nitrogen is used for protection, normal pressure is kept and the temperature is 70-120 DEG C; and then roasting at the temperature of 500 DEG C for 3 hours. The catalyst in the invention has the advantages of simple preparation process, high catalytic activity, less reaction coking and high cracked light oil yield, thus being especially applicable to hydrocracking lightening of heavy component and pitch in coal tar, and the catalyst in the invention can cause conversion per pass of coal bar pitch to reach more than 70%.

Owner:TONGJI UNIV

Double-component epoxide resin type anti-rust lacquer and preparation thereof

InactiveCN101372600AHarm reductionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyLacquer

The invention provides double-component epoxy resin anticorrosive paint and a preparation method thereof. Component A comprises the compositions by weight percentage of 15-25 percent of epoxy resin, 10-20 percent of modified petroleum resin, 30-40 percent of pigment, 2-5 percent of fillers, 5-6 percent of promoter and 10-20 percent of solvent. Component B comprises the compositions by weight percentage of 50-60 percent of polyamide curing agent, 10-20 percent of modified cashew oil curing agent and 30-40 percent of solvent. The viscosity of the component A is 3.0-8.0Pa.s. The weight ratio of component A to component B is 2-6 to 1. The paint contains no coal tar pitch. Damages to human bodies and the environment are greatly reduced. One-time thick membrane spraying construction can be implemented. And the paint has good chemicals resistance and corrosion resistance, can be used as paint for ballast water tank and accords with requirements of IMO convention. The process method has the advantages of convenience, simplicity, energy saving performance and low cost. Good membrane forming performance and good storing stability can be shown at room temperature.

Owner:上海华谊精细化工有限公司上海开林造漆厂

Metal corrosion resistant coating and its manufacturing process

InactiveCN1789360AGood weather resistanceAccelerated corrosionAnti-corrosive paintsBituminous coatingsViscosityMetal

The invention discloses long-acting metal anticorrosive paint used in metal member and equipment and preparing method, which is made by stirring and grinding coal tar pitch, organic polymolecularity resin, antirusting agent and auxiliary agent and then adding curing agent after adjusting viscosity. The metal anticorrosive paint possesses good weatherability and corrosion resistance, and can be used in metal member, metal member, building, underground engineering, ship and other preservative engineering.

Owner:刘赞成

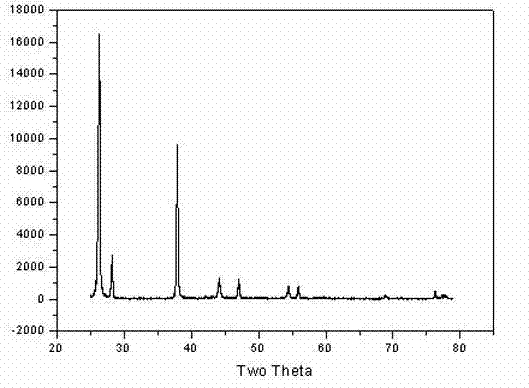

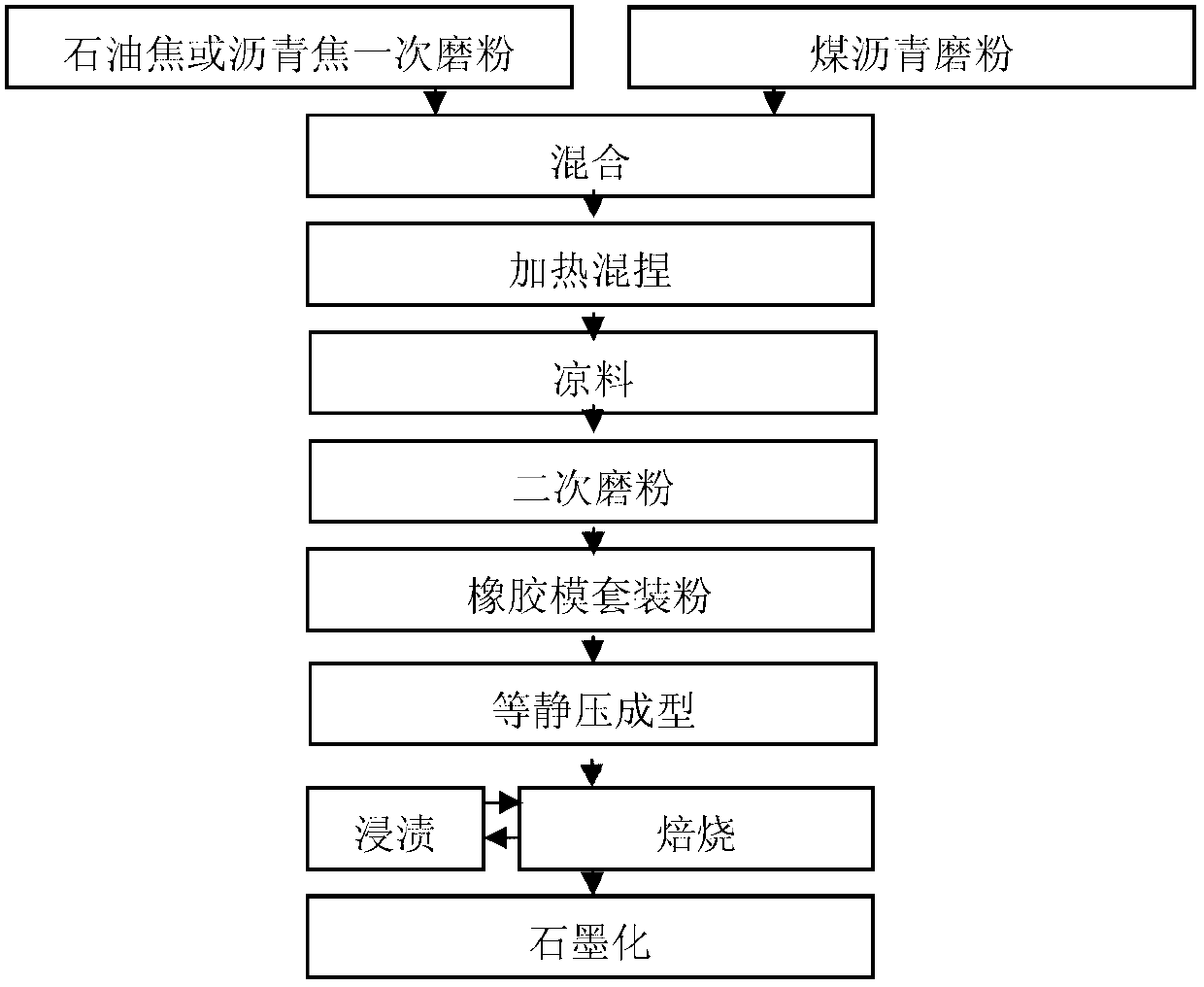

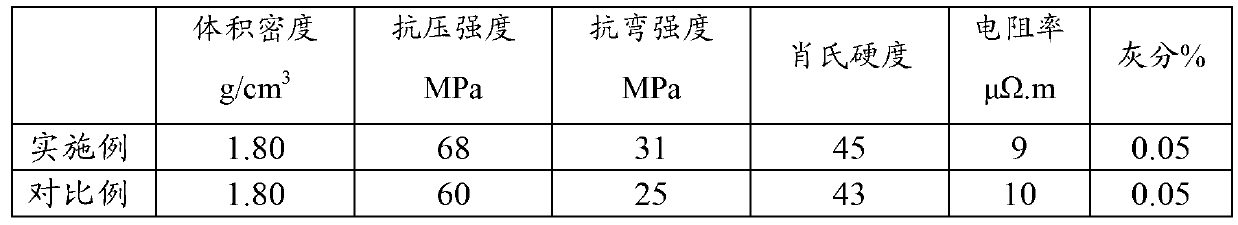

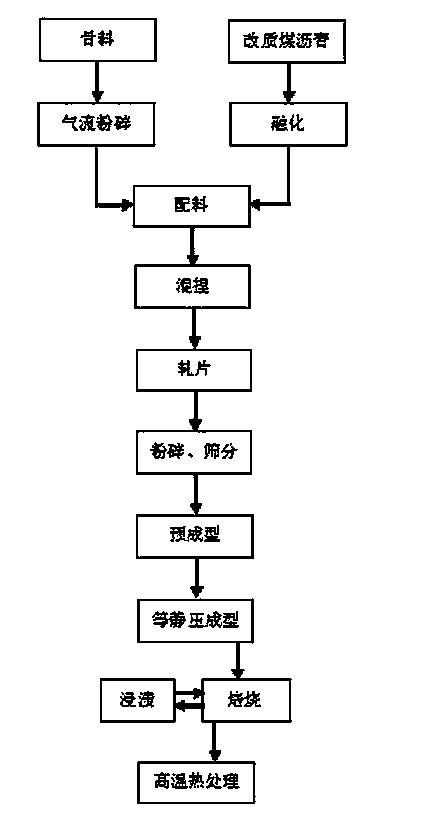

Preparation method of isostatic pressing formed graphite

InactiveCN103121671AIncrease the pre-mixing processTo achieve the purpose of structural homogeneityCarbon compoundsGraphiteCoal

The invention discloses a preparation method of isostatic pressing formed graphite. The preparation method comprises the following steps of: preliminarily grinding, grinding coal tar pitch and mixing the coal tar pitch powder with coke powder aggregate. According to the preparation method disclosed by the invention, the coke powder aggregate and the coal tar pitch powder are sufficiently mixed, so that the coal tar pitch powder is molten, sufficiently permeates into the air holes of the aggregate particle fine powder and can be uniformly coated on the surface of the particle fine powder during the next heating and kneading process, thereby achieving the purpose of homogenizing the material structure. The isostatic isotropic graphite material prepared by the preparation method disclosed by the invention is fine and compact in structure, good in uniformity, excellent in mechanics performance, wearable and isotropous.

Owner:SICHUAN GUANGHAN SHIDA CARBON

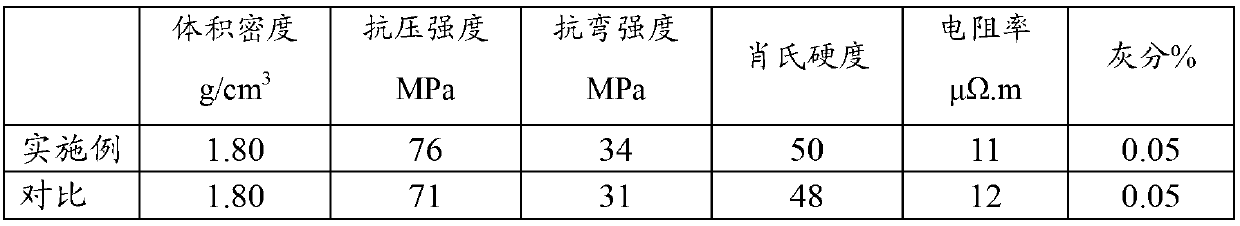

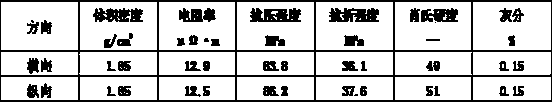

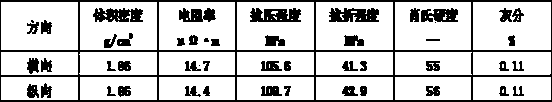

Preparation method of isostatic pressing microcrystalline graphite product

The invention relates to a preparation method of an isostatic pressing microcrystalline graphite product. The isostatic pressing microcrystalline graphite product comprises the following components by weight: 35-50% of microcrystalline graphite, 10-25% of artificial graphite, 10-25% of electrically calcined pitch coke and 30-40% of modified coal tar pitch. The isostatic pressing microcrystalline graphite product is obtained by the steps of pretreating raw material, burdening, kneading, rolling, fragmenting and pulverizing, preforming, performing isostatic compaction, roasting, dipping, performing heat treatment under high temperature and the like. The unique part in the method is the usage of the natural microcrystalline graphite as a main aggregate, the resource can be used in a reasonable mode, high temperature graphitization heat treatment at more than 2500 DEG C on the product is not required, so that preparation period can be shortened, and the energy consumption is greatly reduced. The prepared isostatic pressing microcrystalline graphite has the advantages of high volume density, mechanical strength, low resistivity, fine and compact structure, and isotropy.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

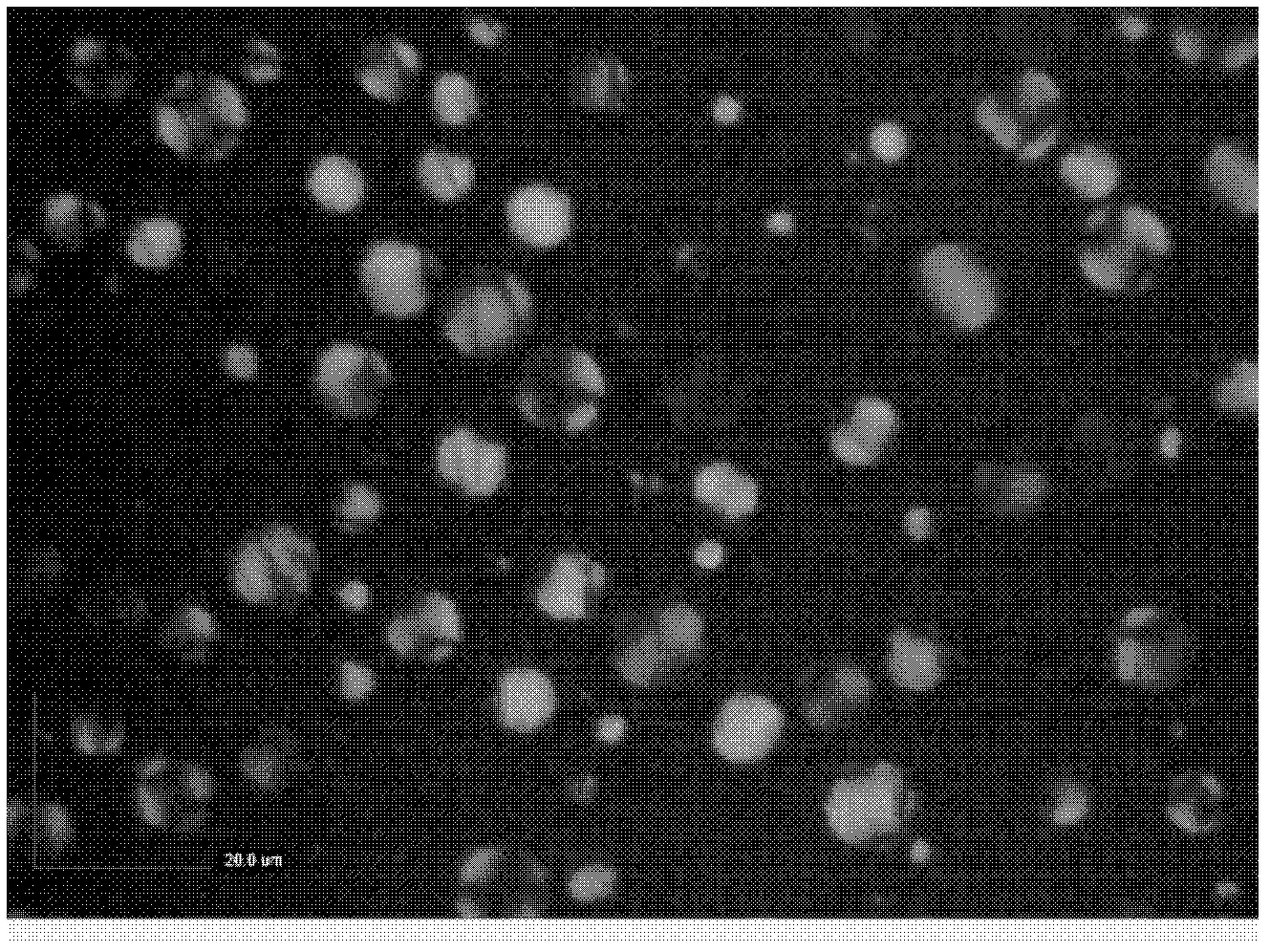

Method for preparing mesocarbon microbeads by copolycondensation

InactiveCN102491307ASolve the uniform dispersionNarrow particle size distributionCarbon preparation/purificationOrganic solventMicrosphere

The invention provides a method for preparing mesocarbon microbeads by copolycondensation, which belongs to the technical field of deep processing of coal and is characterized by comprising the following process procedures of: mixing coal tar pitch with coal liquefaction residue pitch in proportion, further heating the mixture at 300-350 DEG C till a low velocity state is obtained, reacting at 390-450 DEG C under a pressure of 0.2-2MPa for 5-12h after stirring uniformly to generate pitch containing the mesocarbon microbeads, subsequently washing with light fraction of coal tar and an organic solvent to obtain the mesocarbon microbeads. According to the invention, the coal tar pitch and the coal liquefaction residue pitch are used as raw materials in copolycondensation reaction; the problems that a large quantity of nucleation promoter needs to be added in preparation of MCMB (mesocarbon microbeads) by using the coal liquefaction residue as the raw material, especially in industrial scale, and the addition of the large quantity of nucleation promoter results in homodisperse are solved; furthermore, no compatilizer needs to be added. The prepared MCMB is narrower in particle size distribution, the yield can reach 30% and the product has good sphericity.

Owner:ZIBO MINING GRP

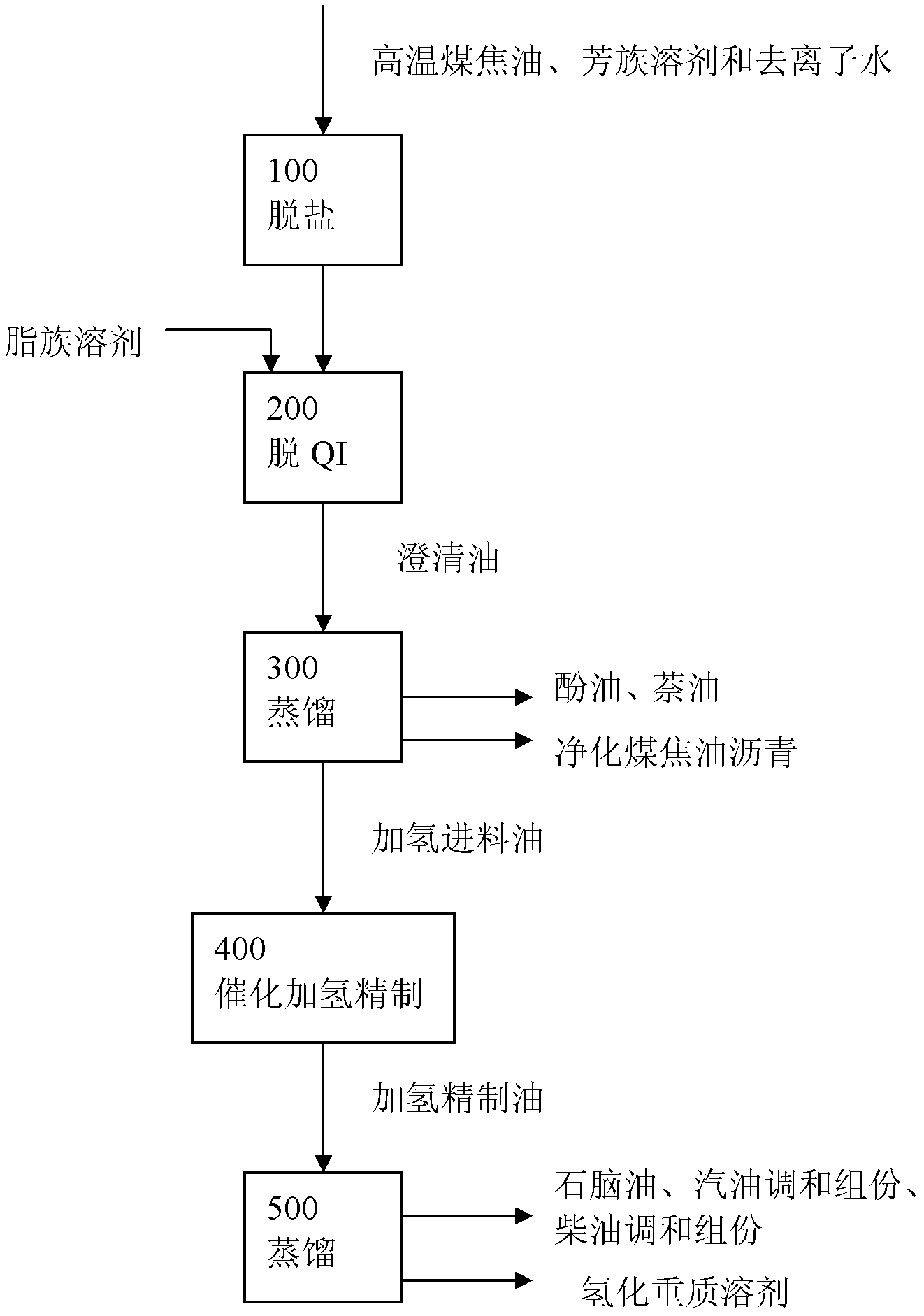

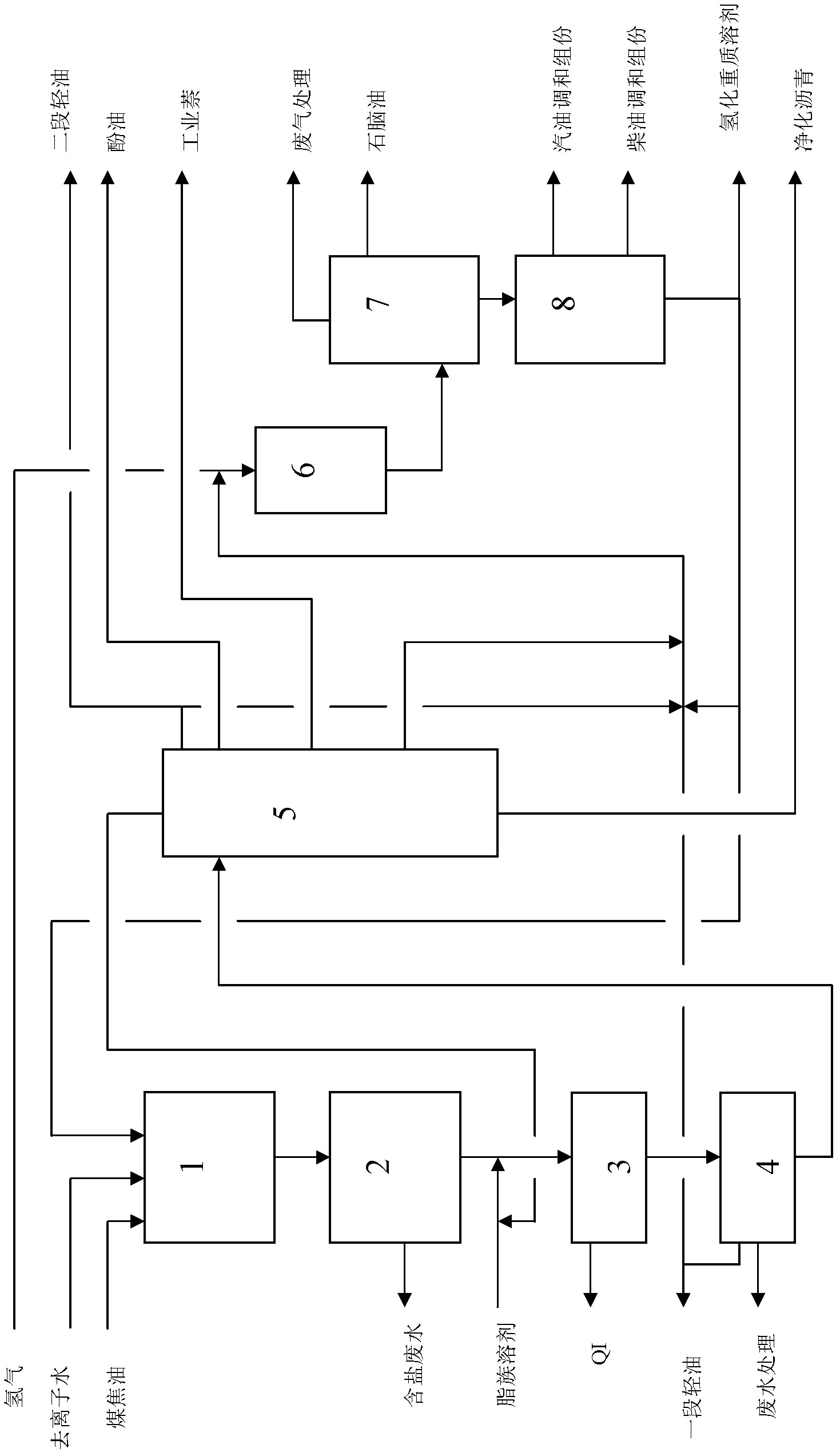

Method for production of purified coal tar pitch from high temperature coal tar

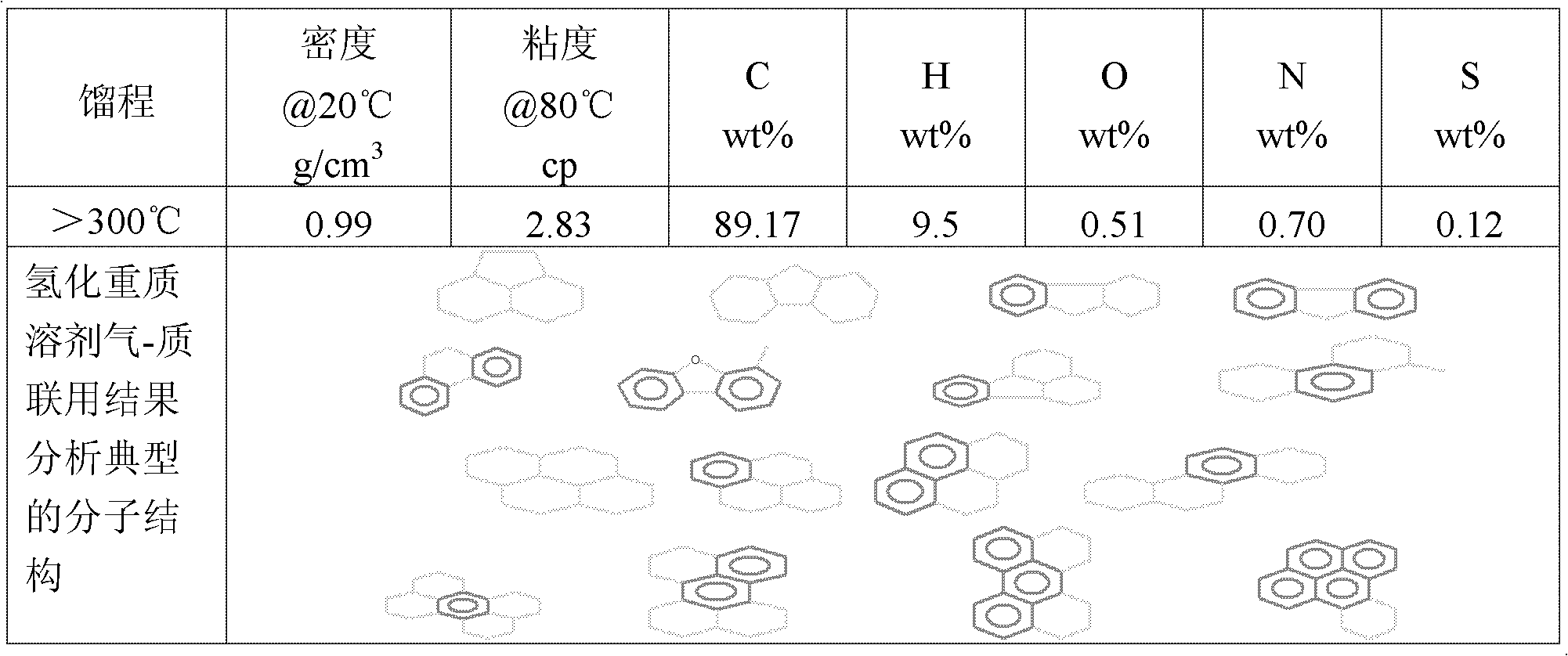

ActiveCN103205272AImprove product added valueLow quinoline insolublesTreatment with hydrotreatment processesTar working-up by distillationSolventPhenol

The invention relates to a method for production of purified coal tar pitch from high temperature coal tar. The method includes: mixing the high temperature coal tar with a hydrogenation heavy solvent and deionized water, and then removing salt to obtain salt removed high temperature coal tar; mixing the salt removed high temperature coal tar with an aliphatic solvent, and then removing quinoline insolubles to obtain clarified oil; distilling the clarified oil to obtain the aliphatic solvent, phenol oil, naphthalene oil, purified coal tar pitch and mixed oil of light oil, washing oil, anthracene oil and the hydrogenation heavy solvent, and taking the mixed oil as catalytic hydrogenation feed oil; subjecting the catalytic hydrogenation feed oil to catalytic hydrofining to obtain hydrofined oil; distilling the hydrofined oil to obtain a naphtha component, a gasoline blending component, a diesel oil blending component and the hydrogenation heavy solvent. The method greatly enhances the added value of products processed from high temperature coal tar, and the purified asphalt has low content of quinoline insolubles and metals.

Owner:易高碳材料控股(深圳)有限公司

Carbon brush used for low-abrasion motor and mixed with nanocopper and preparation method thereof

InactiveCN104901116AImprove performanceImprove conductivityRotary current collectorBrushes manufactureEpoxyLow noise

The invention relates to the field of carbon brush technology, in particular to a carbon brush used for a low-abrasion motor and mixed with nanocopper and a preparation method thereof. In the carbon brush, middle-temperature coal tar pitch, conductive silica gel and epoxy resin are mixed and used as a bonding agent. The composite bonding agent has higher comprehensive performance and electrical conducting performance, and is anti-abrasion and not liable to crack. Via the mixed nanocopper, oxidized grapheme and nanocarbon sol, electrical conductivity of materials is effectively improved, frictional coefficient is reduced, and flexibility of materials is improved. The prepared carbon brush has high electrical conducting performance, is low in abrasion rate, operates stably, generates low noise and small sparks, has stable size, and will not damage a rotator and a stator.

Owner:ANHUI A NAIL TRADE

Large-scale brown coal quality-improving process and apparatus

InactiveCN102757833AImprove utilizationComprehensive utilization of product quality improvementSolid fuelsSpecial form destructive distillationBrown coalMicrowave

The invention belongs to the technical field of brown coal quality improving, and relates to a large-scale brown coal quality-improving process and a large-scale brown coal quality-improving apparatus. According to the invention, an interrelated large-scale continuous brown coal quality-improving system is composed of three modules which are a tunnel internal-heat drying module, an external-heating microwave destructive distillation module, and a powdery brown coal molding and drying module. Because of large-amount water discharging, a brown coal block large-capillary framework is collapsed, so that the brown coal is naturally broken into small blocks and powder without mechanical disruption. The small-block brown coal is subjected to destructive distillation under high-temperature hot wind external heating and microwave coupling, until the blocks turn into semi-coke; water-containing coal gas, water-containing coal tar, anhydrous gas, and anhydrous coal tar are respectively obtained by destructive distillation. With a binder of the water-containing coal tar and coal tar pitch (one or a mixture thereof), the powdery brown coal is subjected to kneading and aging; the material is processed into granules by using a vacuum extrusion granulator; and the particles are processed by using a low-temperature microwave drying device, so that high-quality brown coal particles with high strength, low moisture absorption, and high heat value are obtained. The brown coal particles can endure long-distance transportation.

Owner:周灿旭

Petroleum pitch-based carbon foam

InactiveUS20030071384A1Useful and reliableEasy to implementPigmenting treatmentHarvestersLow densityNet shape

Petroleum or coal tar pitch-based cellular or porous products having a density of preferably between about 0.1 g / cm3 and about 0.8 g / cm3 are produced by the controlled heating of mesophase carbon materials derived from coal tar or petroleum pitch having a softening point in excess of about 300° C. and preferably between about 300 and about 400° C. in a "mold" and under a non-oxidizing atmosphere. The porous product thereby produced, preferably as a net shape or near net shape, can be machined, adhered and otherwise fabricated to produce a wide variety of low cost, low density products.

Owner:TOUCHSTONE RES LAB

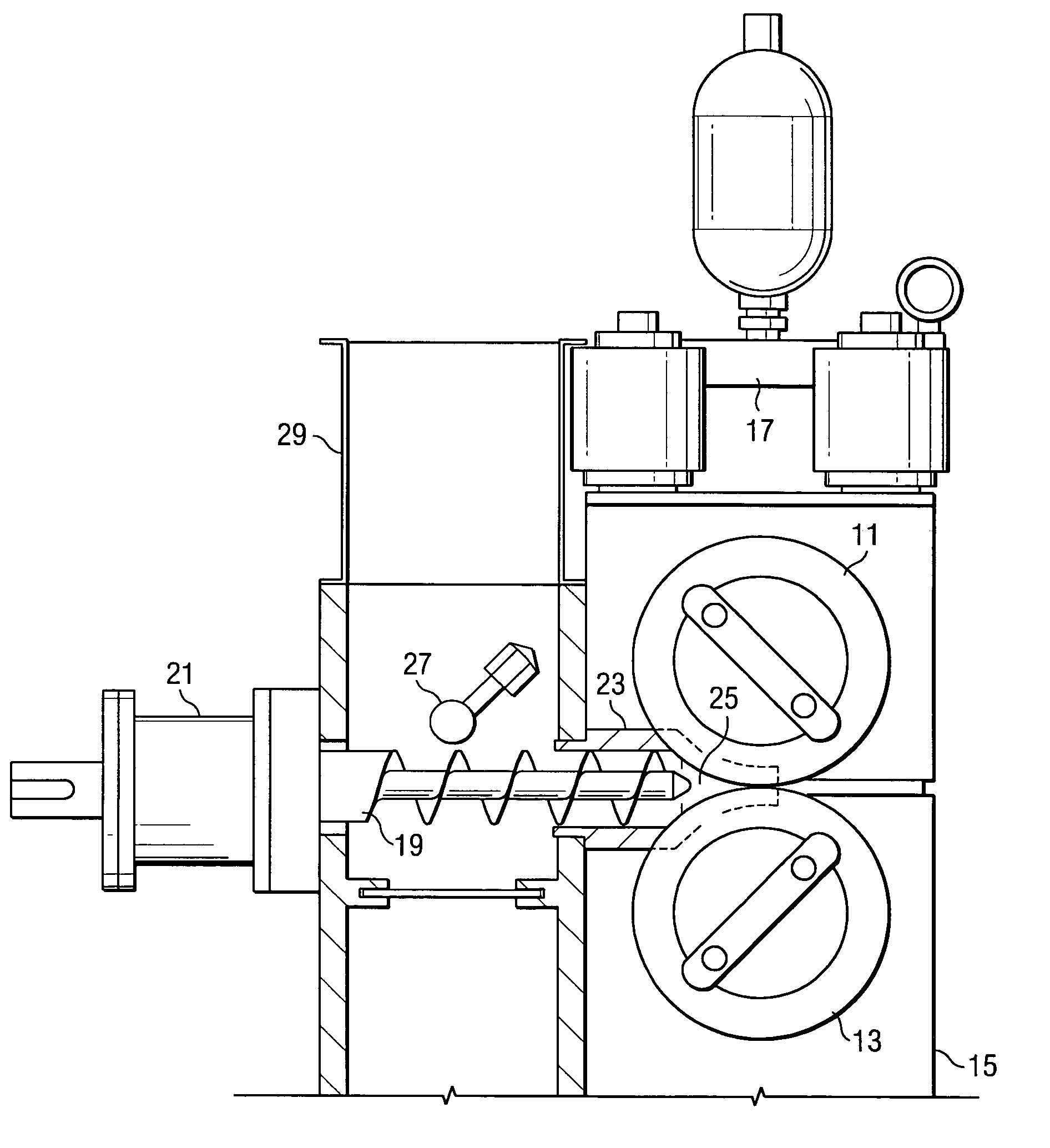

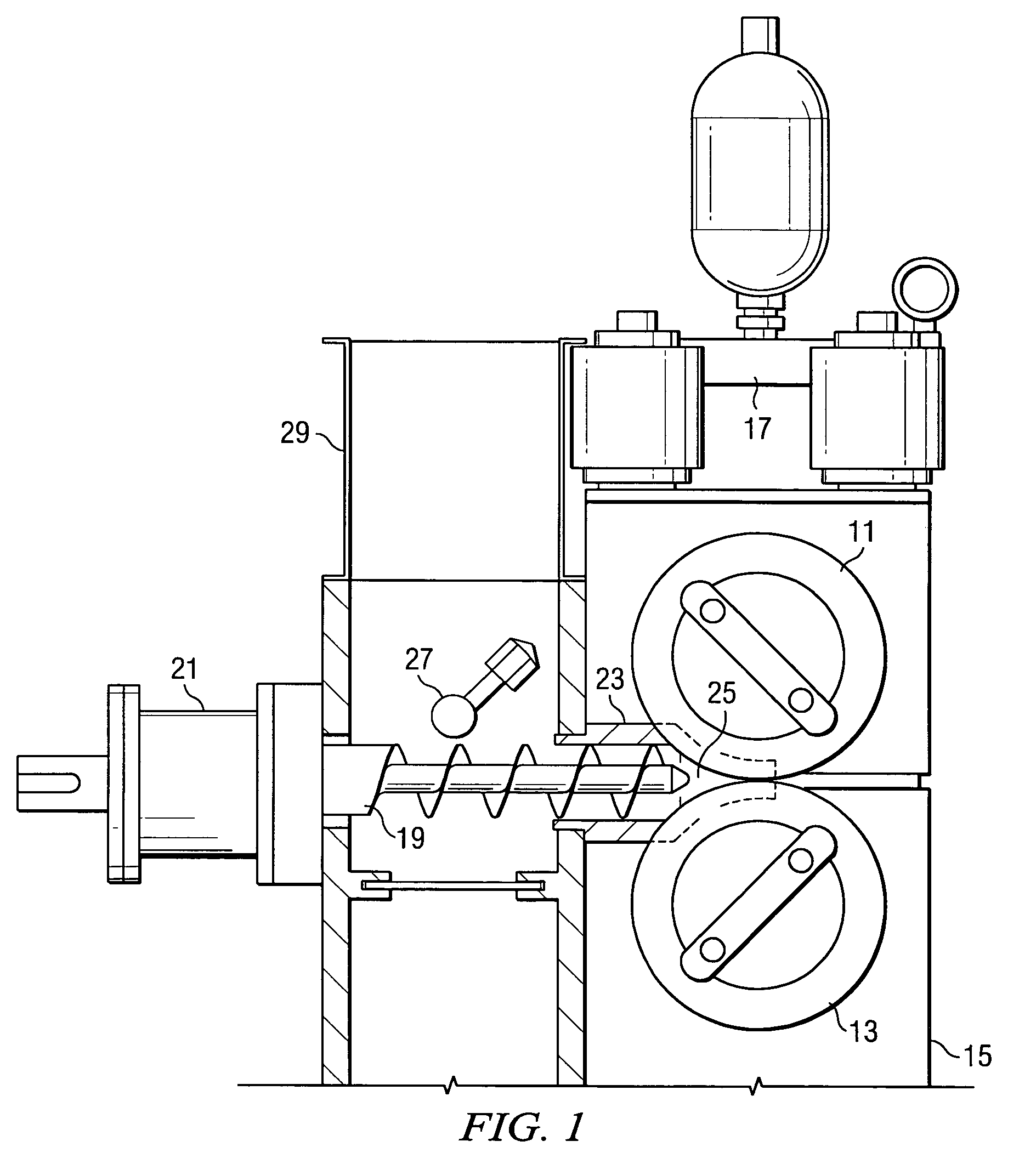

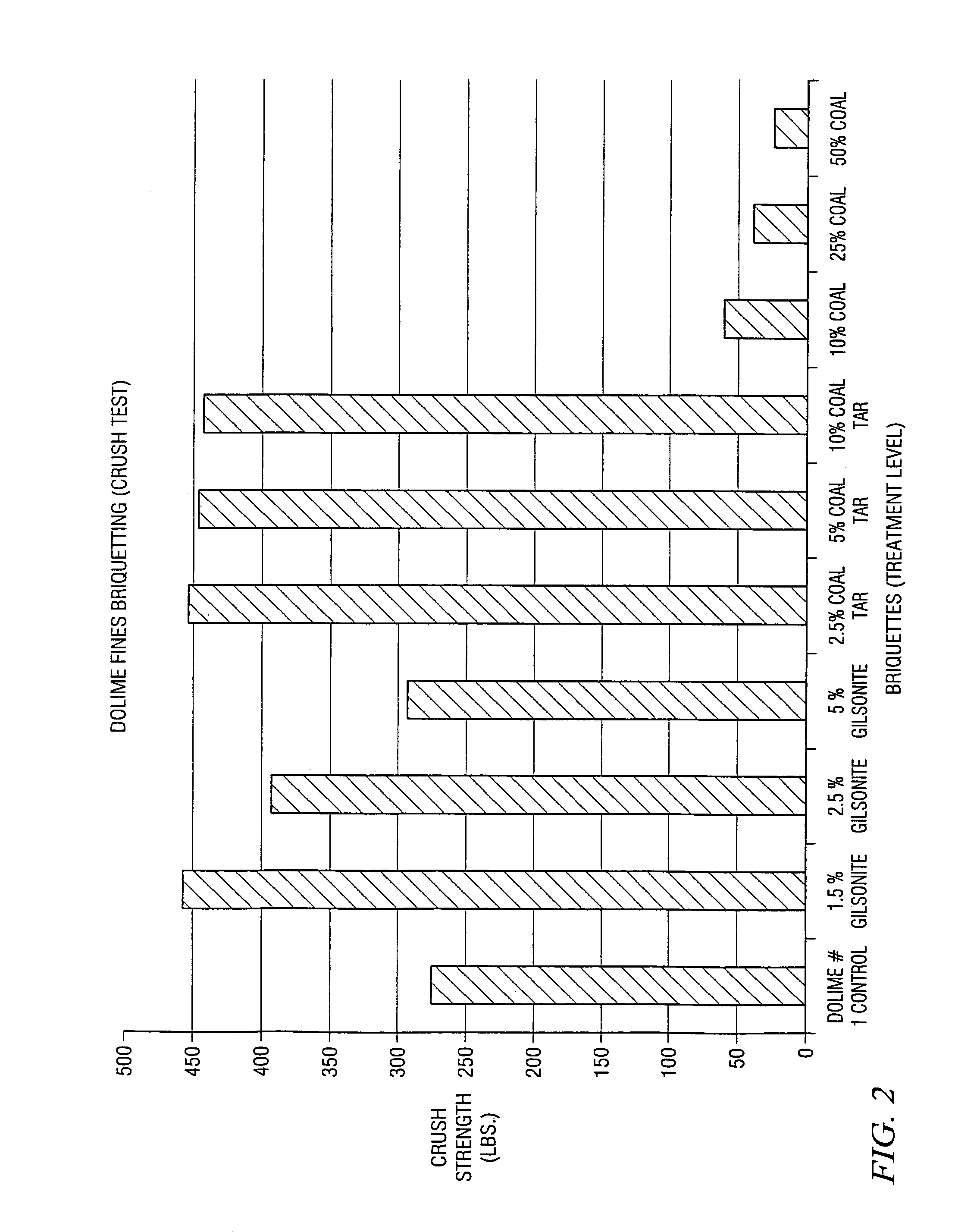

Briquetting of lime based products with carbon based additives

A method is shown for briquetting quicklime fines. A source of quicklime or dolomitic quicklime fines is combined with a binder in the form of a pseudo-plastic carbon containing material which will deform under briquetting conditions of elevated temperature and pressure and flow and which will also return to a solid phase and bind the quicklime fines upon cooling. An external force is applied to the mixture of fines and binder, as with a briquetting machine, sufficient to form the mixture into a briquette having requisite strength and durability characteristics. Suitable classes of carbon containing materials include Gilsonite®, a solid coal tar pitch and recycled plastics such as polyethylene and polypropylene.

Owner:LHOIST NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com