Method for production of purified coal tar pitch from high temperature coal tar

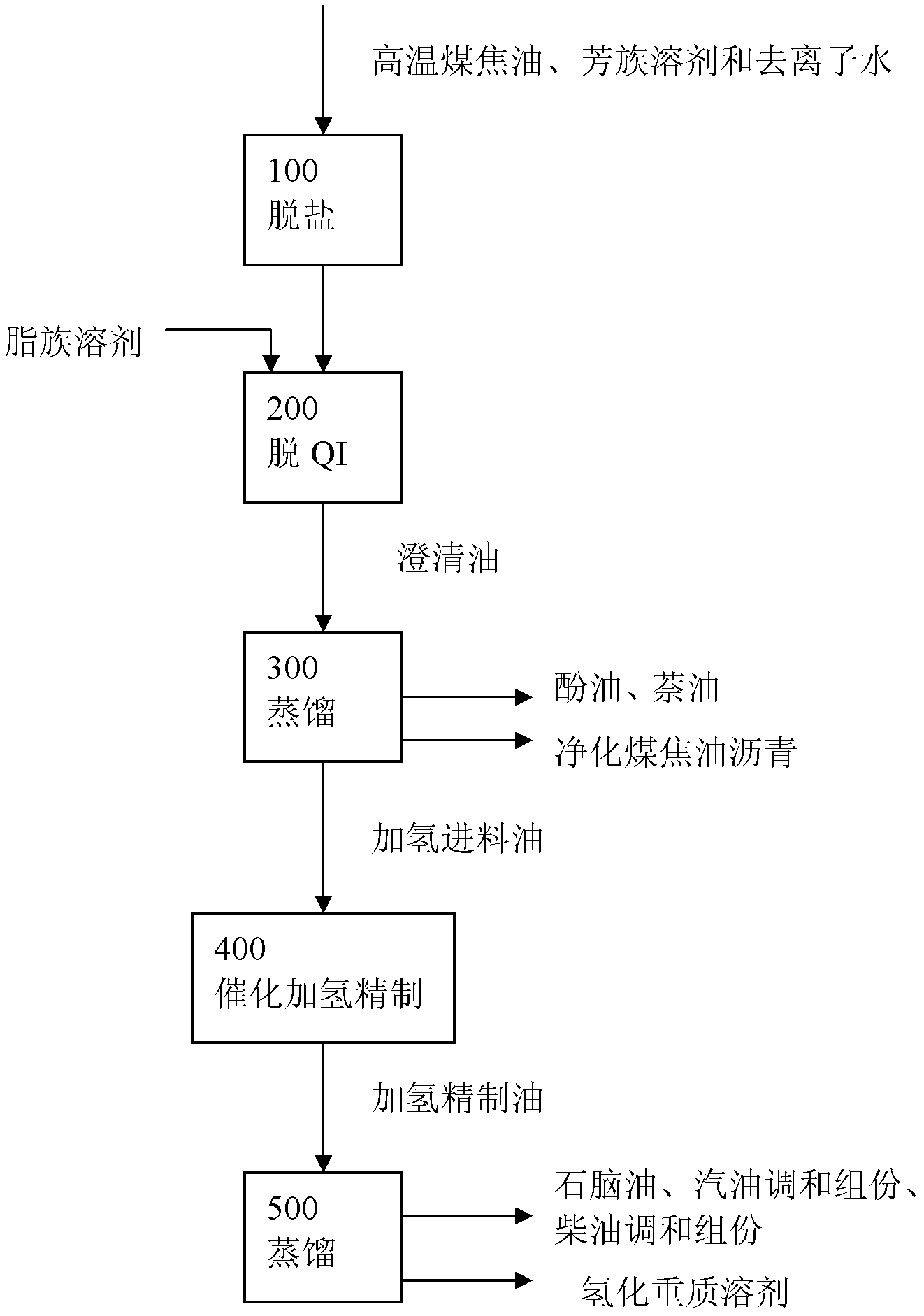

A technology for high-temperature coal tar and coal tar pitch, which is used in tar processing by distillation, tar processing by chemical extraction, petroleum industry, etc. Low insoluble matter and metal content, and the effect of increasing the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

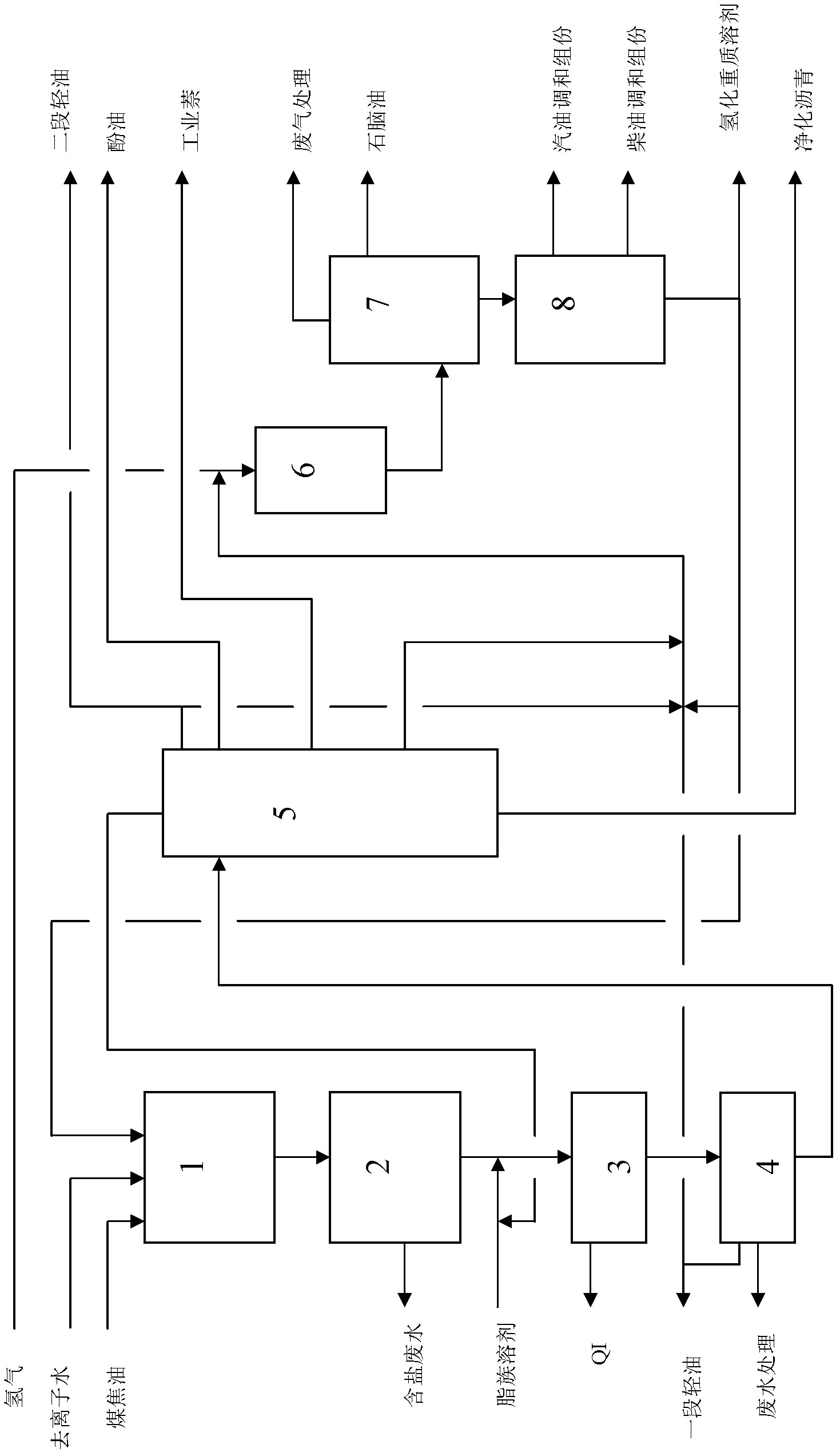

Method used

Image

Examples

Embodiment 1

[0071] The hydrofining reaction is carried out on a double reaction tube continuous hydrogenation reaction device. Two 200ml reaction tubes can be used in series or in parallel, placed in a fixed aluminum block heating furnace, and share a set of feeding system and cooling separation system , by a computer for self-control and monitoring operations. The protection and demetallization catalyst is installed in the first reaction tube, which is used in series with the second reaction tube filled with the refined catalyst for hydrogenation refining reaction.

[0072] The hydrodemetallization catalyst described in the first reaction tube is supported by alumina, with a pore volume of 0.82ml / g and a specific surface area of 187.8m 2 / g, the pore diameter is 12.1nm, and the metal composition is: 15.4wt% molybdenum oxide, 2.3wt% nickel oxide. The upper part of the second reaction tube is filled with hydrofining catalyst A and the lower part is filled with refined catalyst B. Hydrof...

Embodiment 2

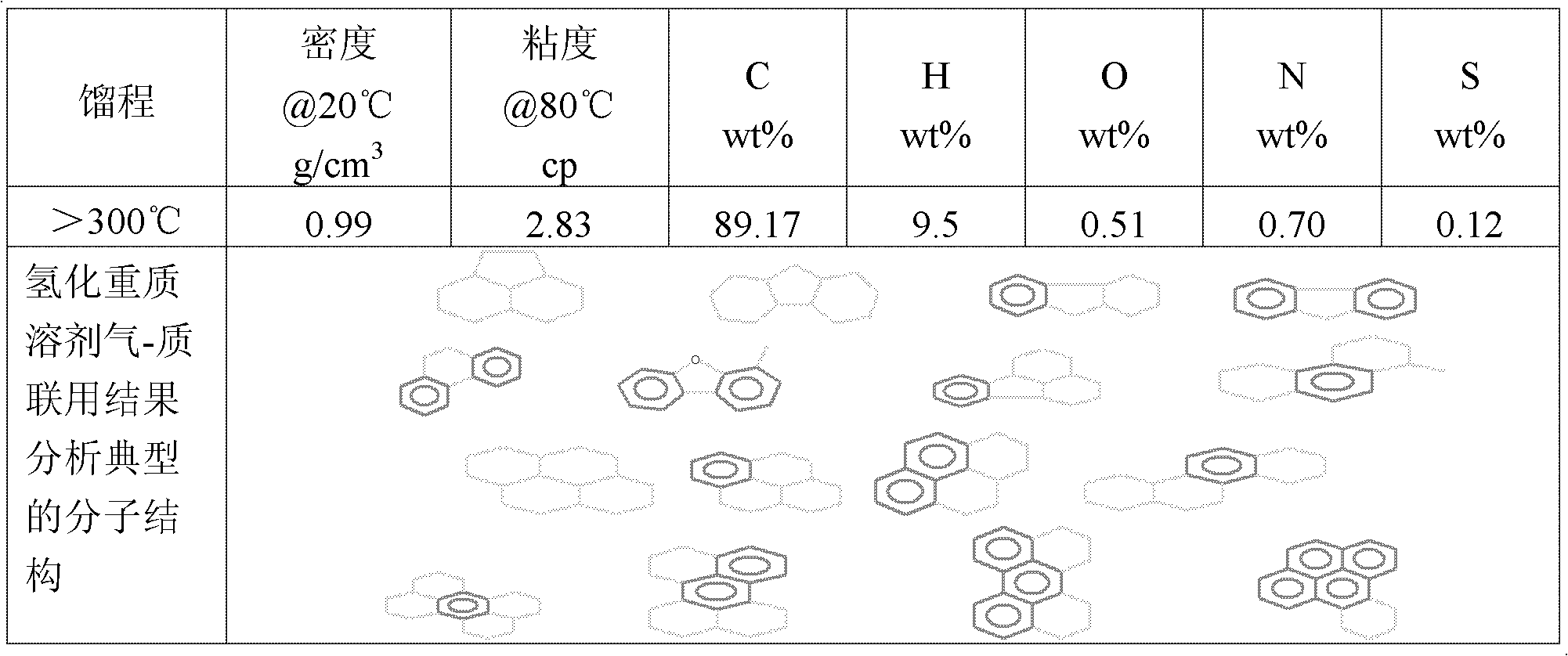

[0079]Mix the high-temperature coal tar shown in Table 2-1 with the hydrogenated heavy solvent and deionized water shown in Table 1 at a ratio of 1:0.5:0.5 and wash with water, then enter the centrifuge to remove most of the saline content, wash with water for 3 Second-rate. After washing, the coal tar enters the de-QI blending tank, and n-octane is added therein, and the ratio is adjusted to tar: hydrogenated heavy solvent: n-octane=1: 0.5: 0.5, and the above operating conditions are deslagging temperature 80°C, stirring Speed 120rpm, stirring time 5min. After stirring, the mixture enters the centrifuge, the separation factor is 2500, and the QI is removed to obtain purified clarified oil. The clarified oil is separated from water and one stage of light oil, n-octane, two stages of light oil, phenol oil, naphthalene oil, and washing oil with a distillation device. Mixed oil with hydrogenated heavy solvent and anthracene oil, purified asphalt. The properties of clarified o...

Embodiment 3

[0089] With the high-temperature coal tar shown in Table 2-1 and the hydrogenated heavy solvent obtained in Example 2, deionized water is fully mixed with 1: 0.75: 3 and washed with water and enters the centrifuge to remove most of the saline content therein. Wash 1 time with water. After washing, the coal tar enters the QI-removing compounding tank, and n-octane is added therein, and the ratio is adjusted to tar: hydrogenated heavy solvent: n-octane=1: 0.75: 0.75, and the QI is removed under the conditions of Example 2 to obtain purification The clarified oil, the clarified oil is separated from water and one stage of light oil, n-octane, two stages of light oil, phenol oil, naphthalene oil, mixed oil of wash oil and hydrogenated heavy solvent anthracene oil and purified asphalt by distillation device, purified asphalt analysis See Table 3-1.

[0090] The mixed oil of first-stage light oil, second-stage light oil, wash oil, hydrogenated heavy solvent and anthracene oil is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com