Method for directly recovering and producing electrowinning cobalt from waste and old lithium ionic cell

A lithium-ion battery, electrowinning technology, applied in the improvement of process efficiency, instruments, optics, etc., can solve the problems of low product added value, high cost, and high equipment requirements, and achieve high product added value, short reaction process, raw materials. low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After the waste lithium-ion battery is disassembled by professional equipment, the positive and negative electrode wastes are sorted to obtain the positive electrode sheet whose active material is lithium cobalt oxide. Take 800g of the waste material, soak in 4L N-methylpyrrolidone (NMP) at 130°C for 60min, then use 28KHz ultrasonic vibration for 10min, the active material lithium cobaltate will be separated from the aluminum foil, remove the aluminum foil, and separate N-methylpyrrolidone by suction filtration (NMP) and black solid powder materials such as lithium cobalt oxide and acetylene black. The organic solvent N-methylpyrrolidone (NMP) can be recycled after being treated, and the black powder is washed and dried. The analysis results showed that the residual cobalt on the aluminum foil accounted for about 0.23% of the total cobalt.

Embodiment 2

[0023] After the waste lithium-ion battery is disassembled by professional equipment, the positive and negative electrode wastes are sorted to obtain the positive electrode sheet whose active material is lithium cobalt oxide. Take 800g of the waste material, soak in 4L N-methylpyrrolidone (NMP) at 100°C for 60min, then use 28KHz ultrasonic vibration for 10min, the active material lithium cobaltate will be separated from the aluminum foil, remove the aluminum foil, and separate N-methylpyrrolidone by suction filtration (NMP) and black solid powder materials such as lithium cobalt oxide and acetylene black. The organic solvent N-methylpyrrolidone (NMP) can be recycled after being treated, and the black powder is washed and dried. The analysis results showed that the residual cobalt on the aluminum foil accounted for about 3.46% of the total cobalt.

Embodiment 3

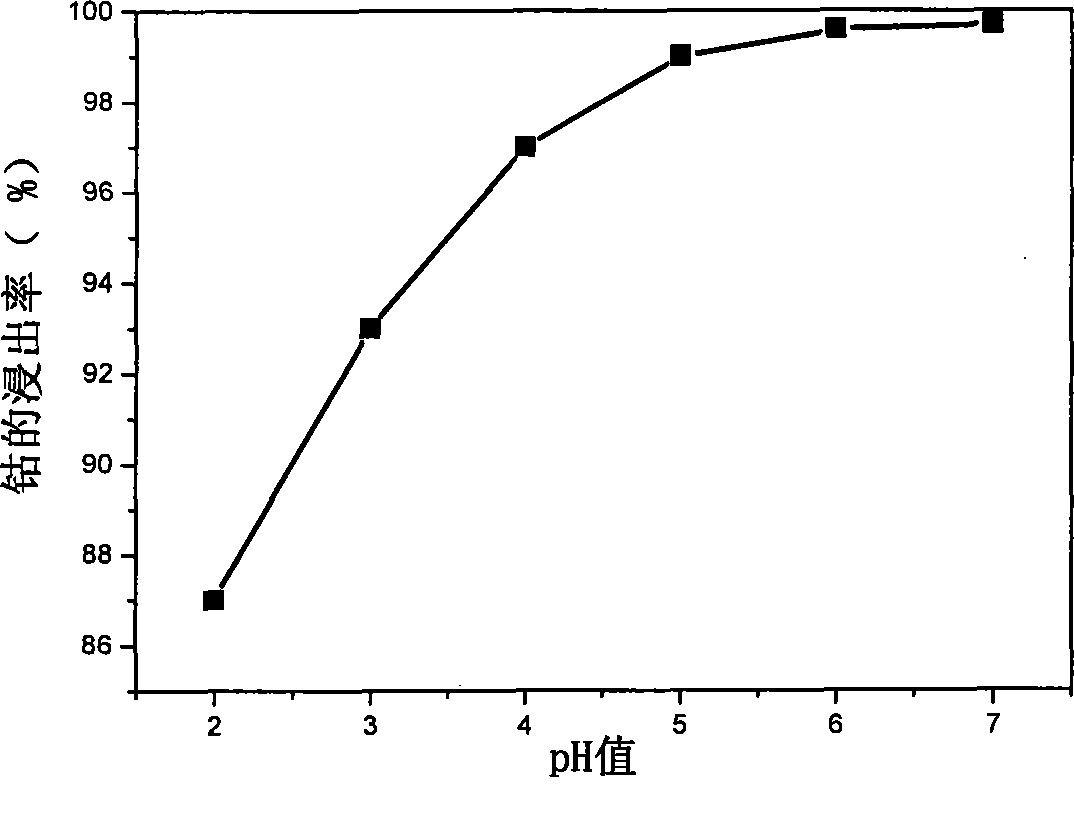

[0025] Configuration contains H 2 o 2 Concentration is 0.5mol / L, HCl concentration is 1L of the mixed solution of 6mol / L, weighs 150g of the black powder obtained in Example 1, transfers it to a 2L glass beaker, pours the above mixed solution slowly, and keeps the solution at a constant temperature of 70°C in a water bath , and use a polytetrafluoroethylene stirrer to continuously stir, after leaching for 40 minutes, filter and separate the insoluble residue while it is hot, and dilute the obtained filtrate to 2L after repeated washing. After testing, the cobalt residue in the filter residue accounts for about 0.34% of the total cobalt content; the main metal contents in the obtained filtrate are as follows:

[0026] element co Li Al Cu Ni Fe mn Mg Ca Content (g / L) 42.02 4.86 0.21 0.02 0.08 0.03 0.05 0.02 0.02

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com