Patents

Literature

90 results about "Insoluble residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insoluble residue. [in′säl·yə·bəl ′rez·ə‚dü] (geology) Material remaining after a geological specimen is dissolved in hydrochloric or acetic acid. That portion of an aggregate or cement which is not soluble in diluted hydrochloric acid.

Method of obtaining a product sugar stream from cellulosic biomass

InactiveUS20090023187A1Improve performanceHigh yieldSugar derivativesBiofuelsInorganic saltsAcetic acid

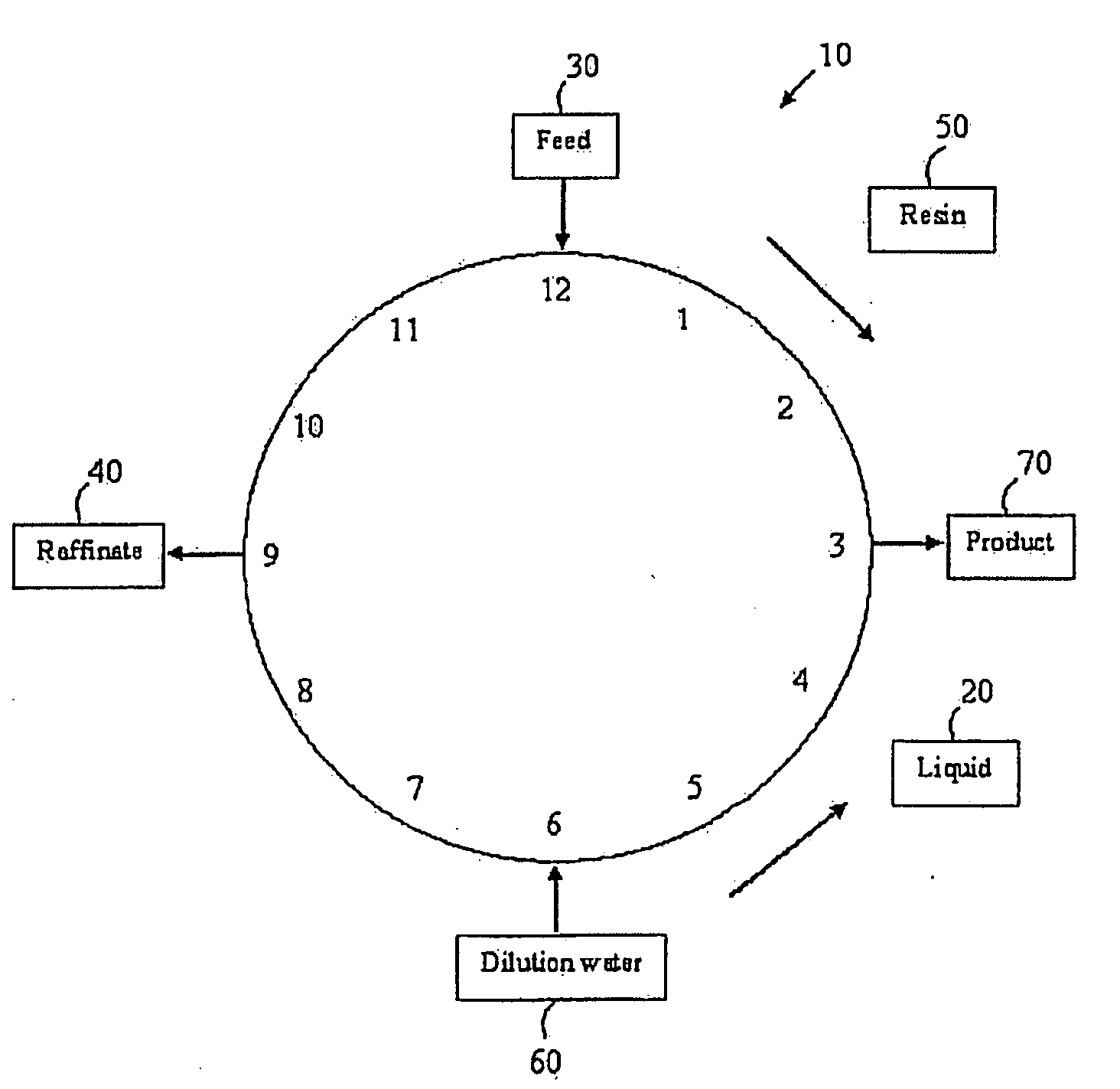

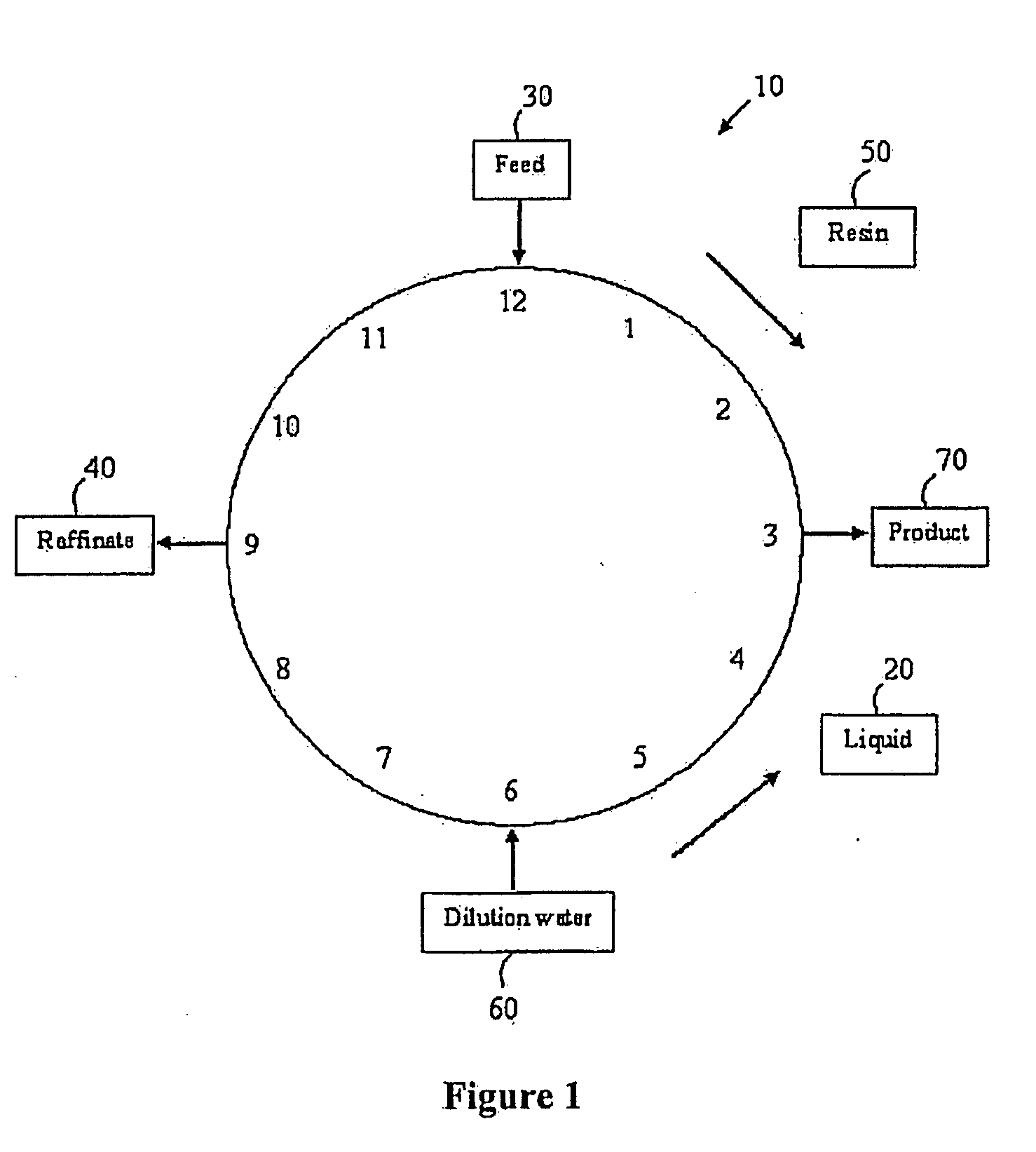

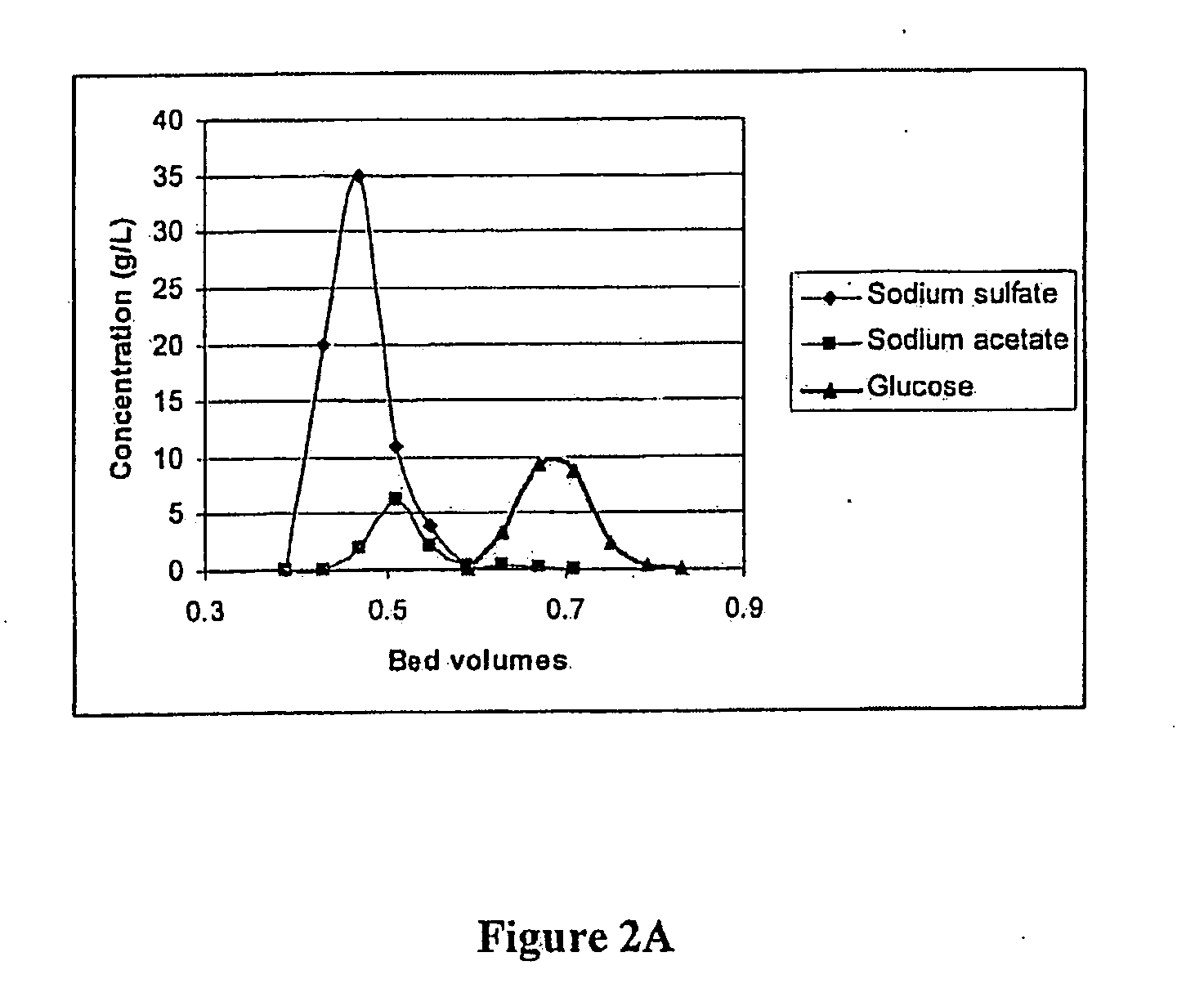

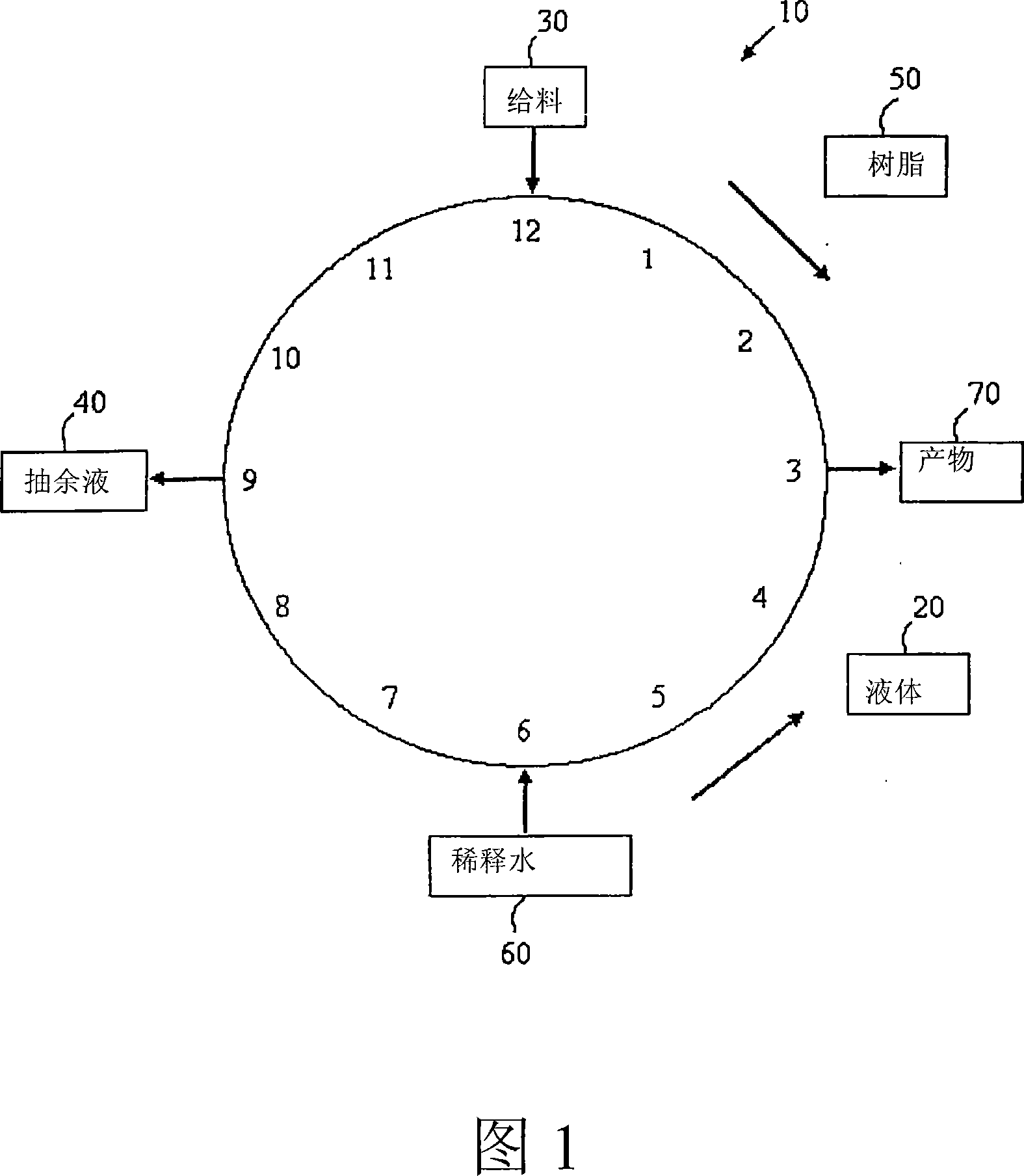

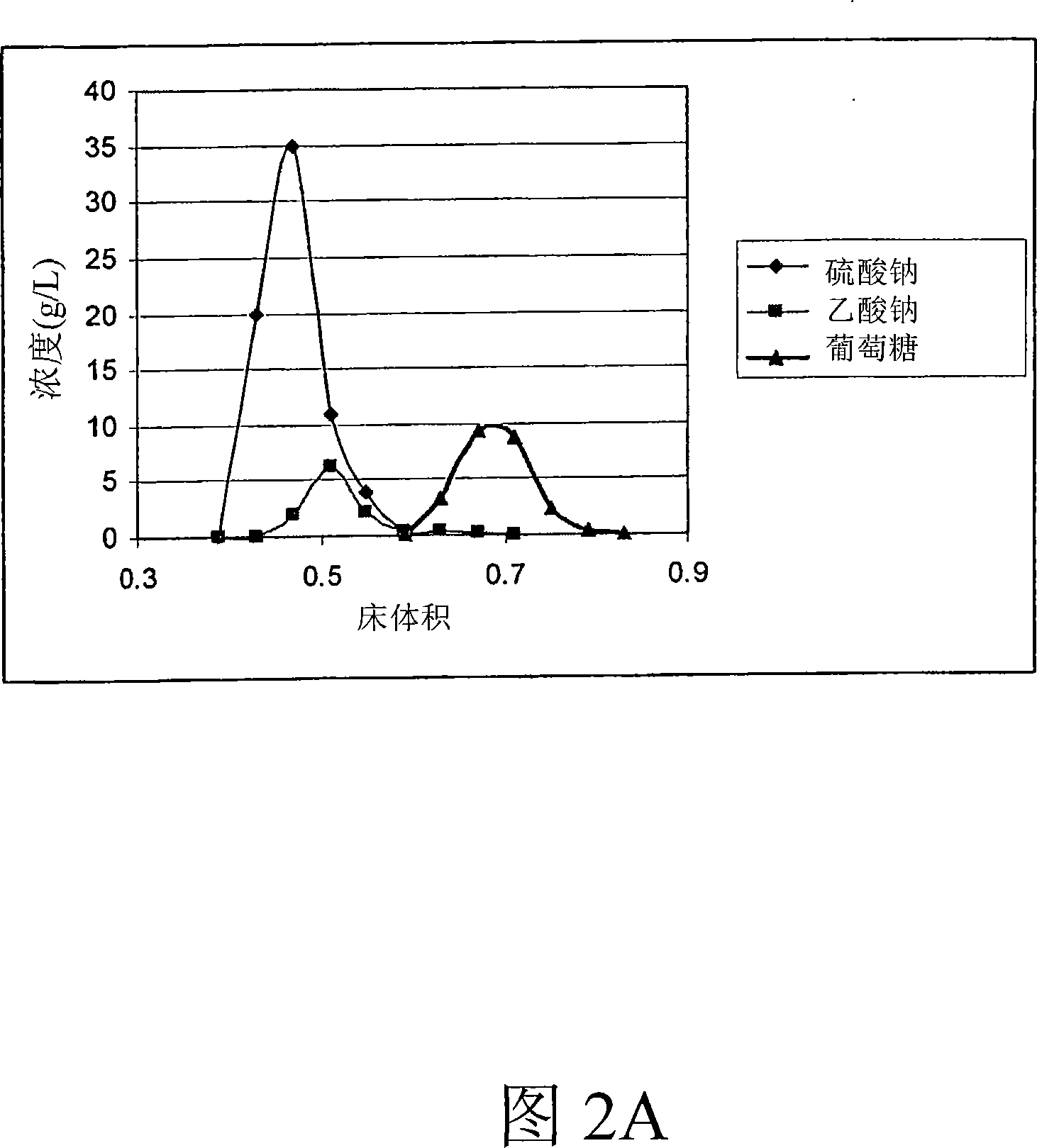

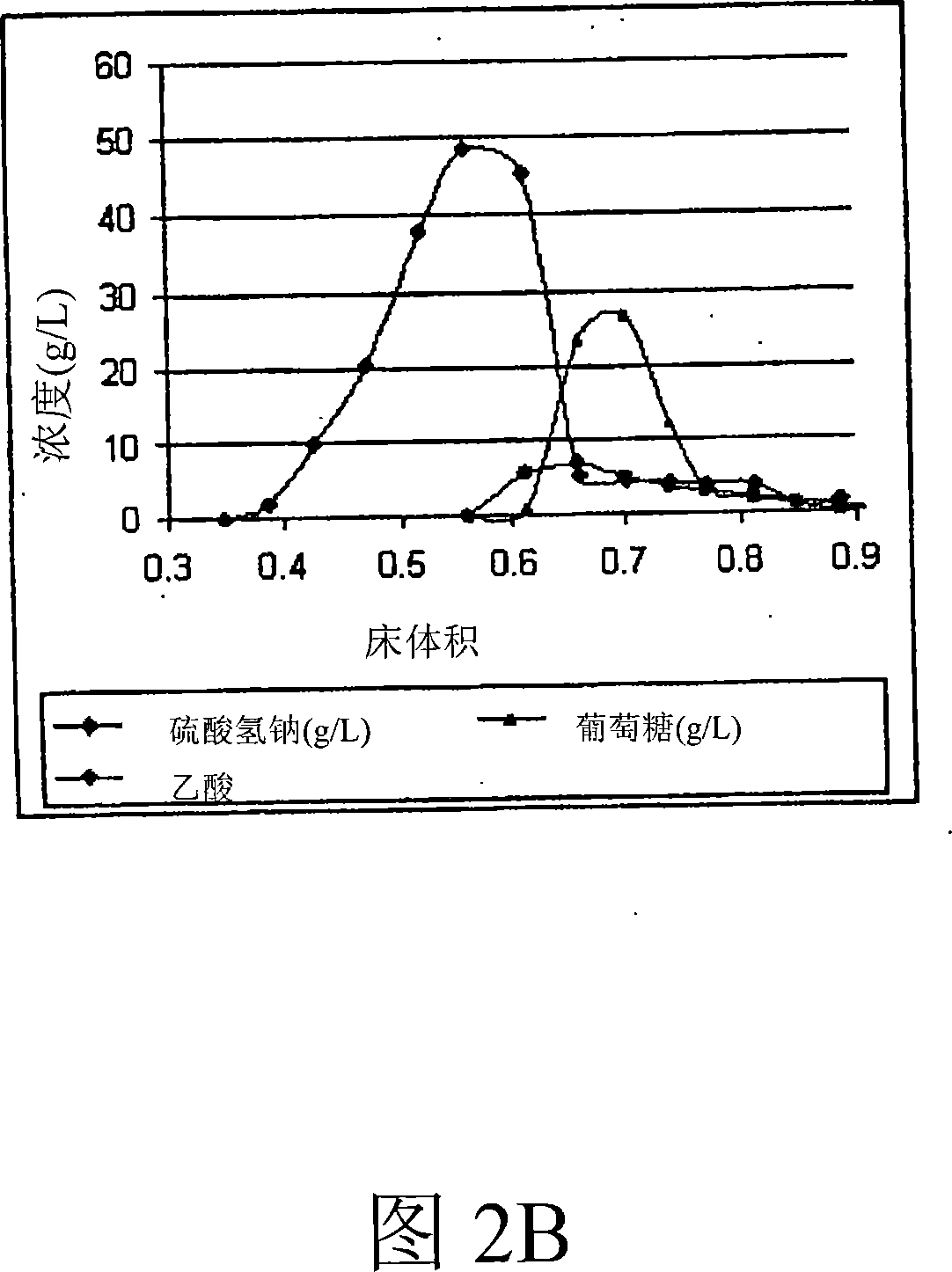

A process for obtaining a product sugar stream from cellulosic biomass is disclosed. In one process, the cellulosic biomass is pretreated at a pH between about 0.4 to 2.0 by adding one or more than one acid to produce a pretreated cellulosic biomass comprising acetic acid. One or more than one base is then added to the pretreated cellulosic biomass to adjust the pretreated cellulosic biomass to a pH of about 4.0 to about 6.0 to produce a neutralized cellulosic biomass comprising inorganic salt and acetate salt. The neutralized biomass is then hydrolyzed by cellulase enzymes to produce a crude sugar stream. Insoluble residue is separated from the crude sugar stream and the resulting clarified sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more raffinate streams and a product stream. The raffinate stream comprises inorganic salts and acetate salts, and the product stream comprises sugar. The product stream may then be fermented or otherwise further processed. In an alternate process, a product sugar stream is obtained from a crude sugar stream that is produced from conversion of cellulosic biomass to sugar. The cellulosic biomass may be produced using any suitable method. In this process the crude sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more than one raffinate stream comprising sulfate and acetate salts, and a product stream comprising sugar, and the product sugar stream is obtained.

Owner:IOGEN ENERGY CORP

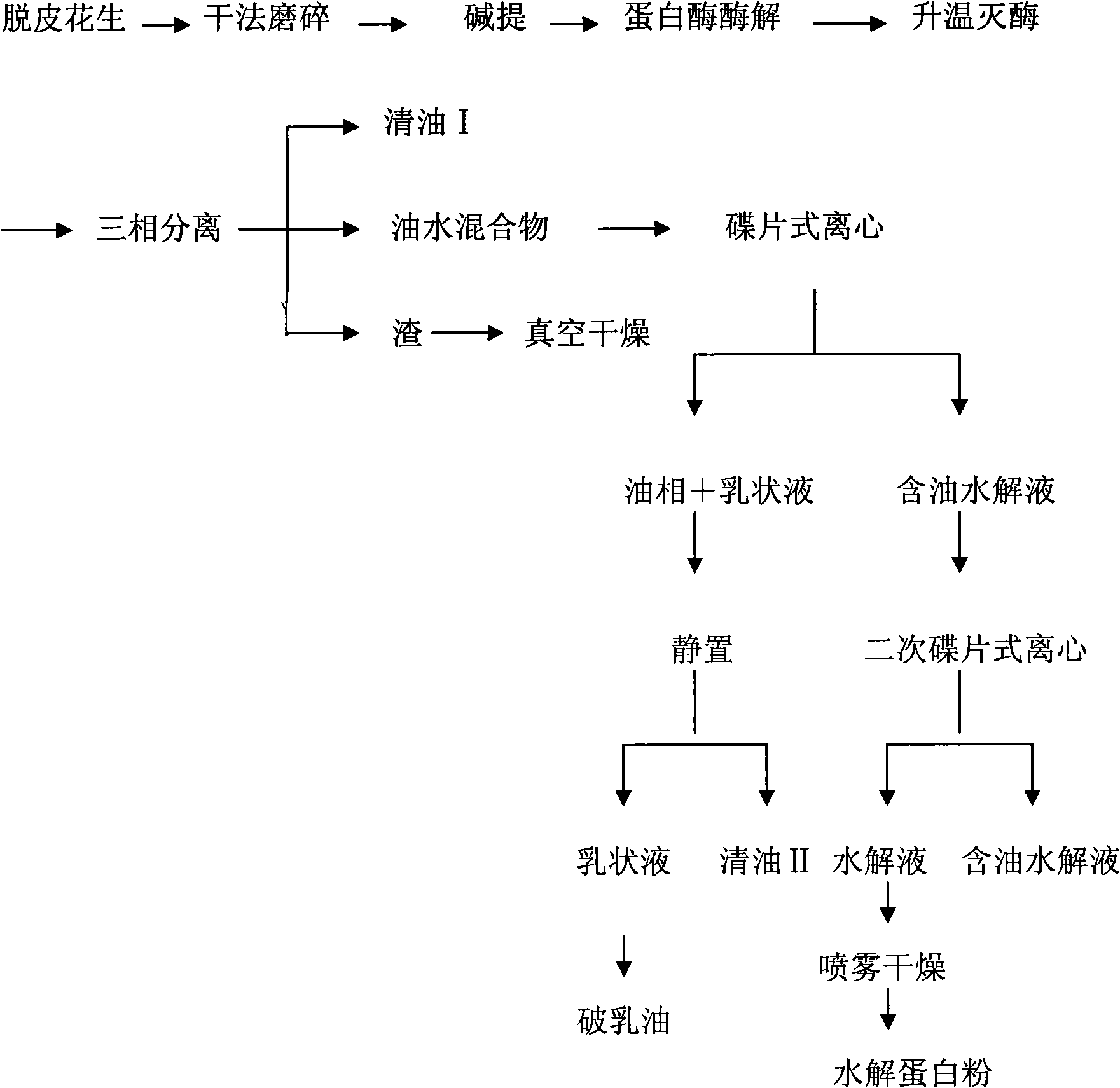

Medium test method for extracting oil and protolysate from peanut with water-enzyme method

InactiveCN101401658AHas a physiologically active functionProtein composition from vegetable seedsEdible oils/fatsHydrolysateInsoluble residue

The invention provides an intermediate test method for extracting oil and hydrolyzed protein from peanut by a water enzyme method, which belongs to the technical field of the application of biological technique in food industry. In the method, the peanut is used as a raw material, single alkali protease is used for enzymolysis, a three-phase separator is used to separate oil, oil-water mixture and insoluble residue simultaneously, a disc-type centrifuge is used to further separate the oil-water mixture so as to obtain emulsion and hydrolysate, wherein the emulsion is subjected to freezing, thawing and emulsion breaking to obtain emulsion breaking oil, and the hydrolysate is subjected to spray drying to obtain peanut hydrolyzed protein powder. The invention provides a better process for industrializing the method of extracting oil and hydrolyzed protein by the water enzyme method, and has the advantages of simple technological line and high utilization rate of products.

Owner:JIANGNAN UNIV

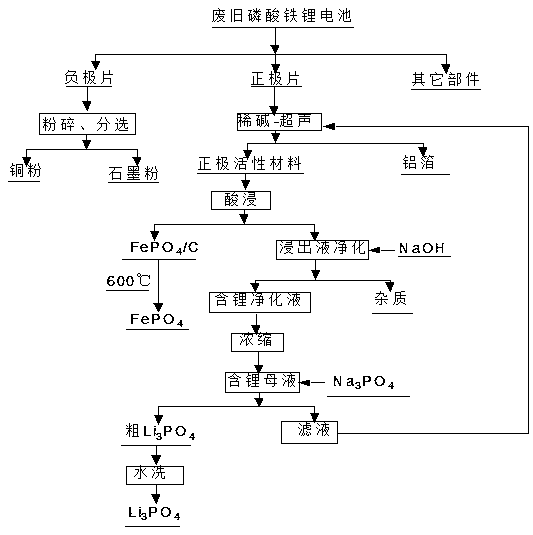

Recovery method for cathode material of waste lithium iron phosphate battery

InactiveCN107739830AEasy to separate naturallyLow costWaste accumulators reclaimingProcess efficiency improvementRecovery methodPhosphate

Owner:FUZHOU UNIV

Method of obtaining a product sugar stream from cellulosic biomass

InactiveCN101023179AHigh recovery rateIncrease concentrationBiofuelsFermentationInorganic saltsAcetic acid

A process for obtaining a product sugar stream from cellulosic biomass is disclosed. In one process, the cellulosic biomass is pretreated at a pH between about 0.4 to 2.0 by adding one or more than one acid to produce a pretreated cellulosic biomass comprising acetic acid. One or more than one base is then added to the pretreated cellulosic biomass to adjust the pretreated cellulosic biomass to a pH of about 4.0 to about 6.0 to produce a neutralized cellulosic biomass comprising inorganic salt and acetate salt. The neutralized biomass is then hydrolyzed by cellulase enzymes to produce a crude sugar stream. Insoluble residue is separated from the crude sugar stream and the resulting clarified sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more raffinate streams and a product stream. The raffinate stream comprises inorganic salts and acetate salts, and the product stream comprises sugar. The product stream may then be fermented or otherwise further processed. In an alternate process, a product sugar stream is obtained from a crude sugar stream that is produced from conversion of cellulosic biomass to sugar. The cellulosic biomass may be produced using any suitable method. In this process the crude sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more than one raffinate stream comprising sulfate and acetate salts, and a product stream comprising sugar, and the product sugar stream is obtained.

Owner:IOJIN ENERGY LTD

Method for recycling platinum and rhodium from binary aqua regia insoluble slag

InactiveCN101476044AEmission reductionImprove protectionProcess efficiency improvementIsolation effectRecovery method

The invention relates to a precious-metal recovery method, specifically relates to a method of recovering platinum / rhodium from insoluble residue of dualistic royal water for solving problems of the existing platinum / rhodium recovering method that the process flow is lengthy and complicated, operational process is dangerous, the isolation effect is bad, and the like. The method comprises steps of preprocessing the insoluble residue of royal water by using barium superoxide, oxidizing the platinum and rhodium thereof, dissolving the oxidized platinum and rhodium in hydrochloric acid; using ammonium chloride to deposit platinum after being converted to a sodium type, adding hydrazine hydrate for recovering the spongy platinum, complexing by adding sodium nitrite into the filter liquor after platinum deposition, depositing rhodium by using ammonium chloride, adding hydrochloric acid for dissolving and sodium type conversion, eliminating base metal in the liquid by using ion exchange resin, finally using hydrazine hydrate and hydrogen gas flame for recovering rhodium powder. The method is a precious-metal-resource secondary recovery utilization and purification method, and has advantages of simple technique, short purification period, convenient operations, high coefficient of recovery, little discharging of waste gas and waste matter, and environment protection, and the like.

Owner:CNOOC TAIYUAN PRECIOUS METALS

Temperature resistant water base fracturing fluid thickening agent and preparation thereof

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

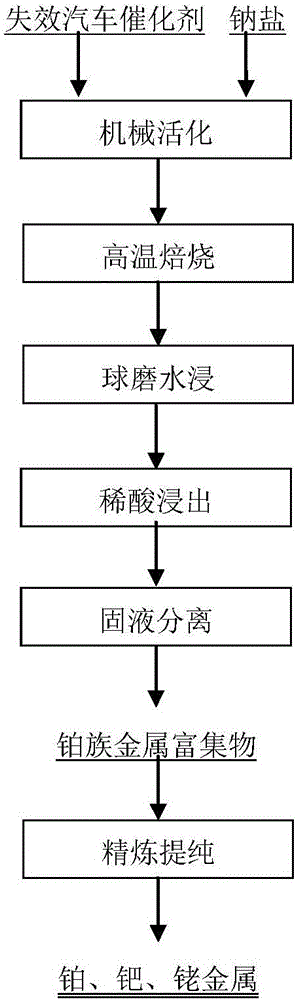

Method for recycling platinum group metal from ineffective automobile catalysts

ActiveCN106011477AHigh reactivityFully dispersedProcess efficiency improvementWater immersionBiological activation

The invention discloses a method for recycling platinum group metal from ineffective automobile catalysts. The method includes the steps of (1) mechanical activation, (2) high-temperature roasting, (3) ball-milling water immersion, (4) diluted acid leaching and (5) platinum group metal refining. Platinum group metal enriched products obtained in the step (4) are processed according to existing refining processes, so that platinum group metal products are obtained. The ineffective automobile catalysts are processed through the method of combining mechanical activation, sodium salt roasting, water immersion and acid leaching, the reaction activity of materials is improved through mechanical activation, phase transformation of catalyst carrier components occurs due to sodium salt roasting, insoluble residues are enriched with the platinum group metal after water immersion and acid leaching, and separation between carriers and the platinum group metal is achieved. Equipment needed for the method is conventional metallurgical equipment, the technological process is simple, industrial implementation is easy, and the total recovery rate of the platinum group metal is larger than 98%.

Owner:KUNMING INST OF PRECIOUS METALS

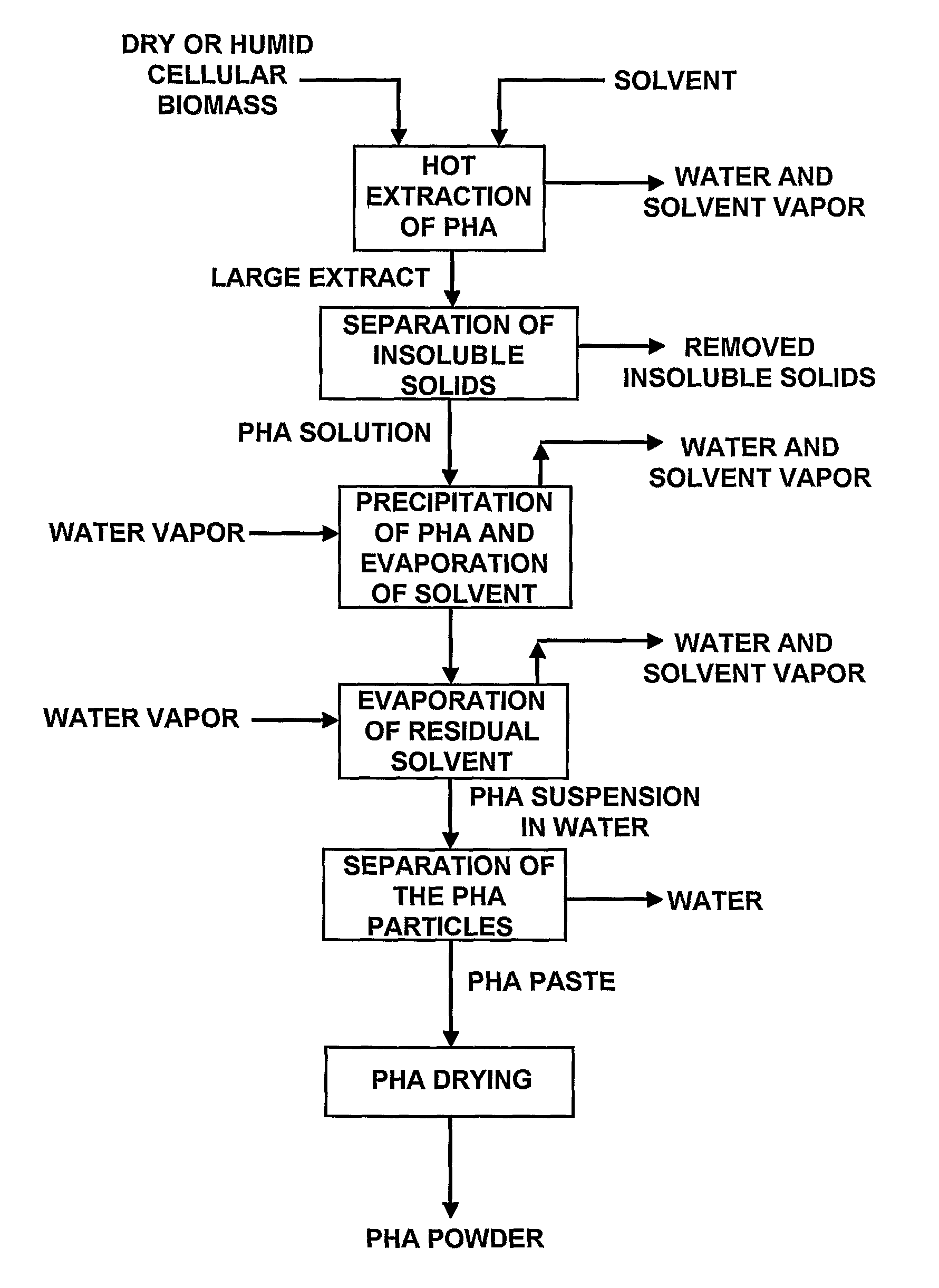

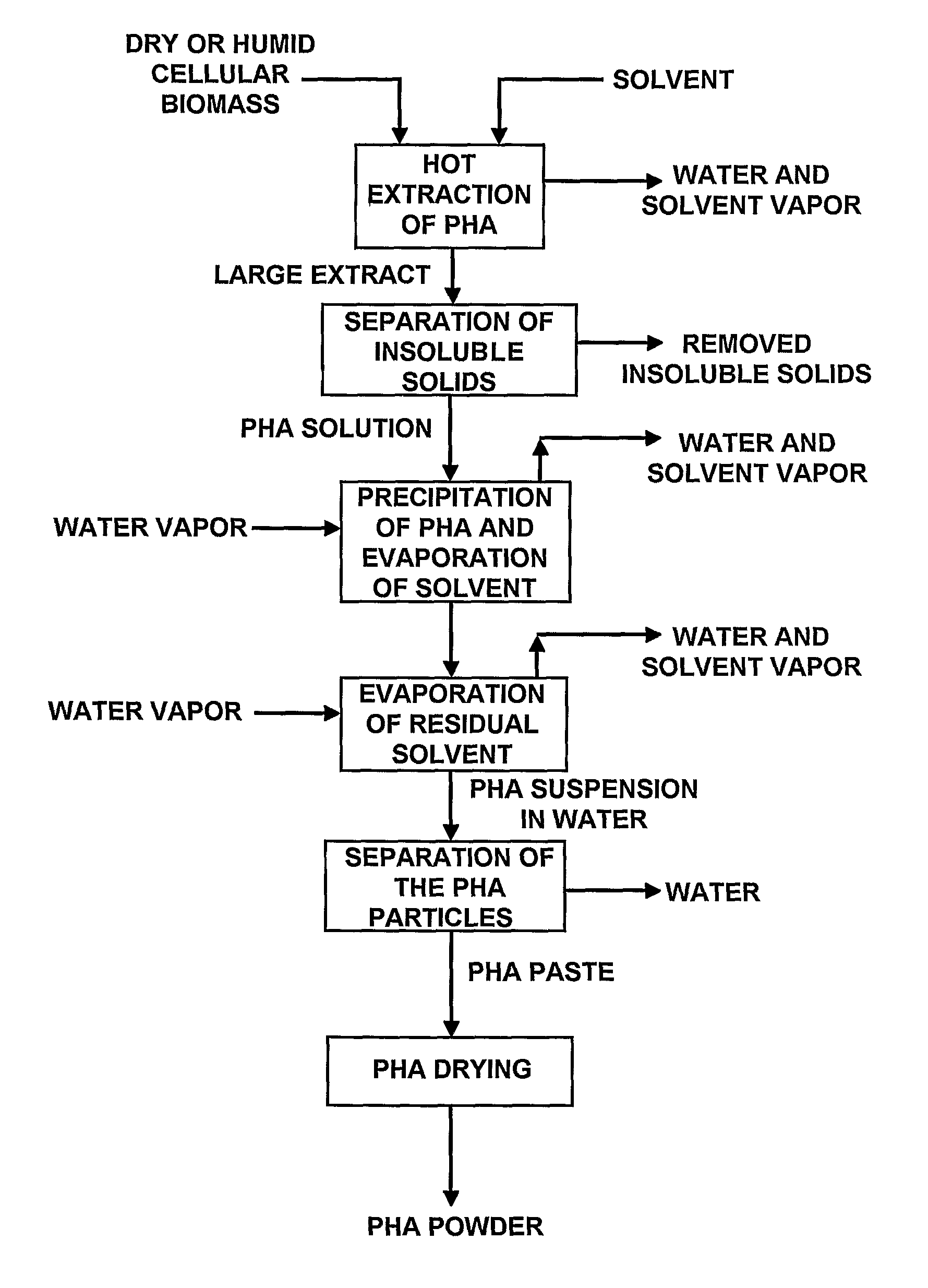

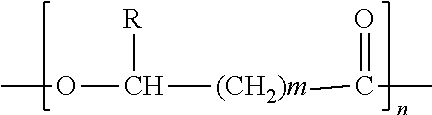

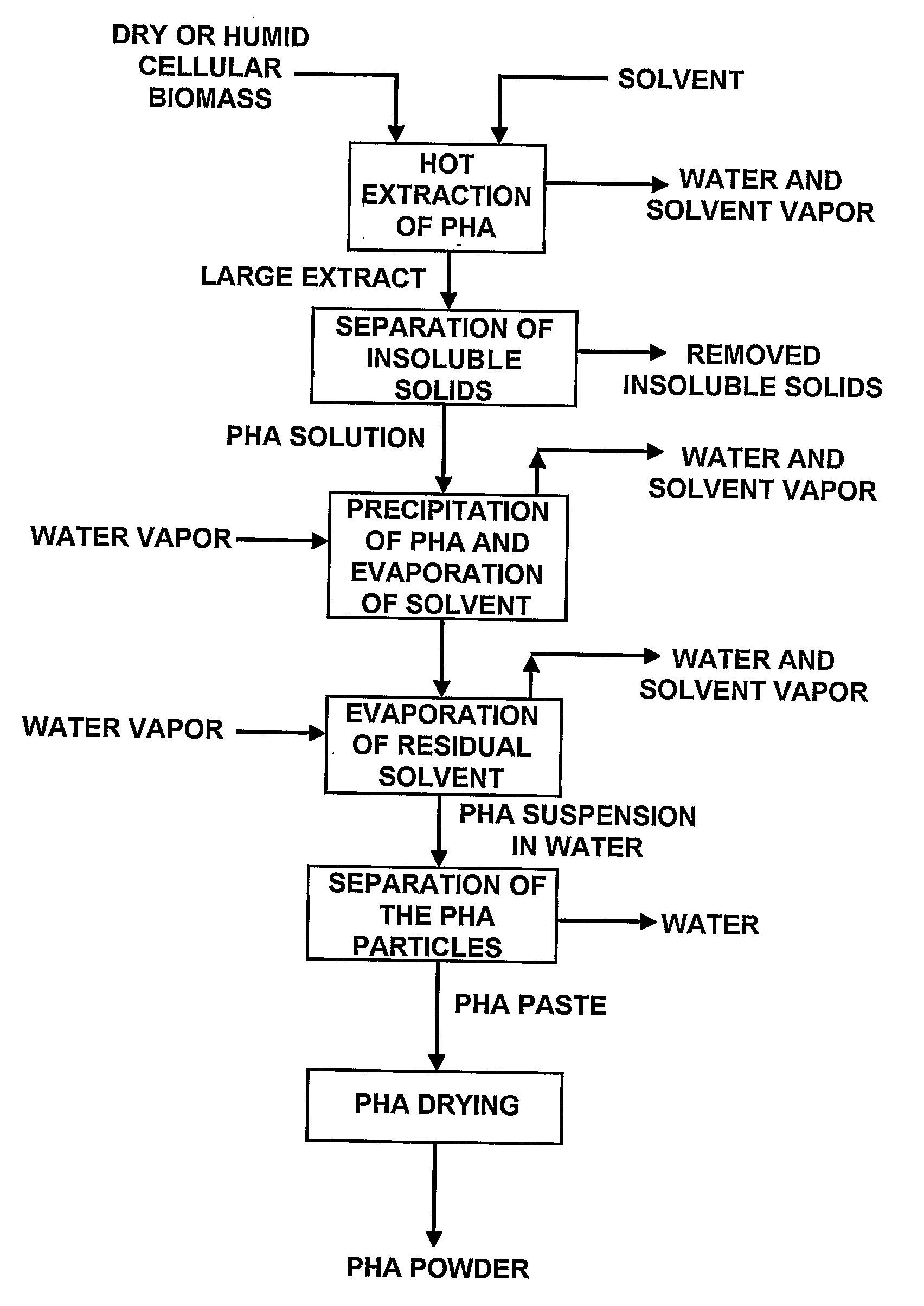

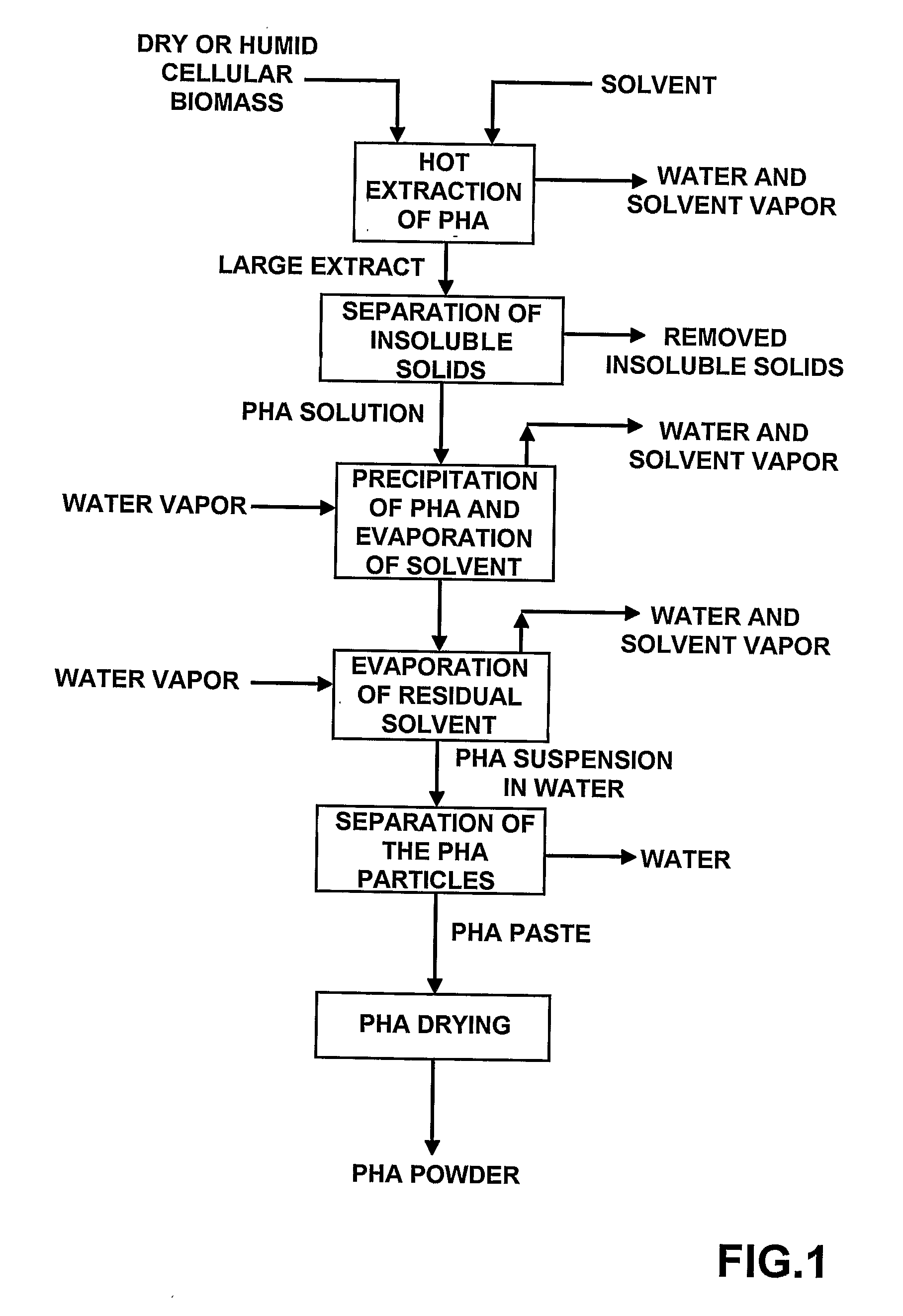

Process for extracting and recovering polyhydroxyalkanoates (PHAs) from cellular biomass

ActiveUS8357508B2Simple facilitiesReduce energy consumptionMicrobiological testing/measurementFermentationSolvent evaporationInsoluble residue

Owner:PHB IND

Method for recovering platinum from aluminum-based catalyst only by dissolving carrier

InactiveCN108315564AOmit preprocessingGet in timeProcess efficiency improvementFiltrationDissolution

The invention relates to a method for recovering platinum from an aluminum-based platinum catalyst. The mode that an aluminum-based carrier is selectively dissolved, and the platinum is recycled froma small amount of insoluble residues through re-dissolving is adopted. The process route comprises the following steps of selective dissolving of the aluminum-based carrier, reduction precipitation, clarifying filtration, calcination for removing organic matters, oxidation dissolution of the platinum through inorganic acid, precipitation and reduction of the platinum, and sponge platinum products.According to the method, catalyst raw materials are not roasted, the small amount of remaining insoluble residues after the carrier is dissolved are only roasted, and energy consumption is greatly reduced. The process is simple and short, reagent consumption is less, and the recovery cost is low. Platinum recovery cannot be delayed, and the recovery timeliness is good. The platinum recovery ratereaches 98.2%, and the sponge platinum purity is greater than or equal to 99.95%.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

New method for obtaining cellulose-rich material from straws by two-step method by adopting ionic liquids

ActiveCN103757959AAvoid decompositionAvoid degradationPaper material treatmentCellulosePretreatment method

The invention relates to a new method for obtaining a cellulose-rich material by quickly dissolving straws at low temperature by two steps by utilizing A and B ionic liquids. The new method is characterized by soaking the straws in an A ionic liquid aqueous solution at low temperature for a short time to obtain part of lignin-free insoluble residues in the first step, and completely dissolving the remaining residues in the B ionic liquid in a short time in the second step to obtain the cellulose-rich material which has changed cellulose crystal form and obviously reduced degree of crystallinity and is beneficial for subsequent conversion. Compared with other pretreatment methods, the method has the beneficial effects that the solution temperature is relatively low, the time is short, the method is convenient and simple to operate, and high-yield 5-hydroxymethyl furfural can be obtained through catalytic conversion of the obtained cellulose-rich material. Not only can corrosion of instruments caused by traditional acid-alkali pretreatment methods be avoided but also the pretreatment energy consumption is reduced to a greater extent. The environment-friendly low-energy-consumption treatment mode can help achieve effective pretreatment of the straws, and has great significance in solving the problem of biomass resource utilization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for simultaneously preparing pyromellitic acid and terephthalic acid with coal serving as raw material

InactiveCN102816061AStable decompositionSimple componentsOrganic compound preparationCarboxylic preparation by ozone oxidationIsomerizationPotassium

Disclosed is a method for simultaneously preparing a pyromellitic acid and a terephthalic acid with coal serving as a raw material. The method includes firstly, adding potassium hydroxide, a coal sample and distilled water in a high pressure kettle to perform a reaction, cooling after the reaction to obtain an oxidation product, filtering and removing insoluble residues to obtain a filter liquor, acidizing the filter liquor by a concentrated sulfuric acid to enable a water soluble acid to be completely free, extracting a processed solution by butanone to obtain an extract liquor, subjecting the extract liquor to a vacuum evaporation to obtain a concentrate, recycling the butanone, subjecting the concentrate to a vacuum drying to obtain the water soluble acid, subjecting the water soluble acid to a selective decarboxylation in a mixed medium of an sulfuric acid, potassium acid sulfate and the distilled water to obtain the pyromellitic acid, adding coal acids and catalysts which remain after the preparation of the pyromellitic acid in a reacting kettle to perform a constant temperature isomerization reaction of the coal acids to obtain a filter liquor, cooling the filter liquor after the reaction, adjusting potential of hydrogen (pH) of the filter liquor by an diluted hydrochloric acid, precipitating the terephthalic acid in a sedimentation mode, filtering, washing and drying to obtain the refined terephthalic acid. By means of the method, the pyromellitic acid and the terephthalic acid can be simultaneously prepared, the reaction conditions are mild, conditions for devices are low, the terephthalic acid is a main product due to a high yield, and the pyromellitic acid is an auxiliary product.

Owner:LIUPANSHUI NORMAL UNIV

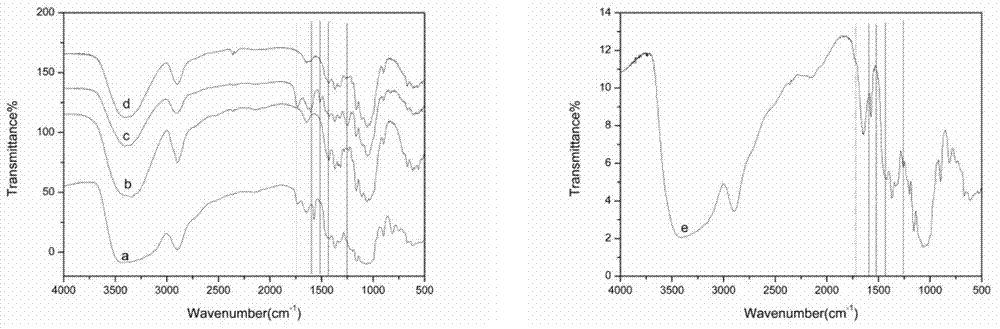

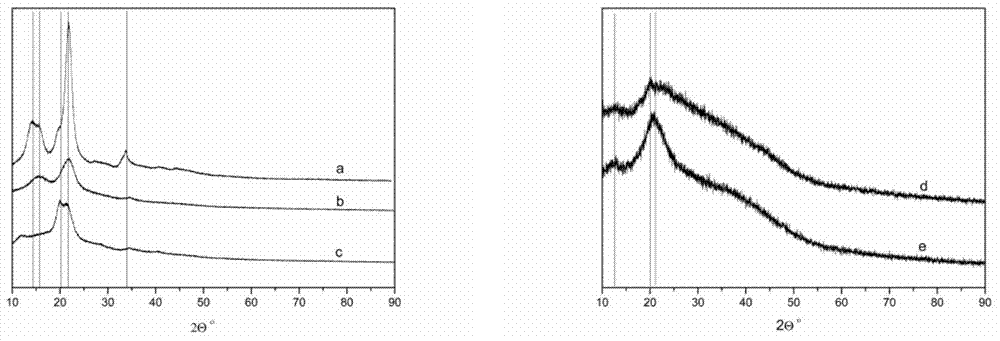

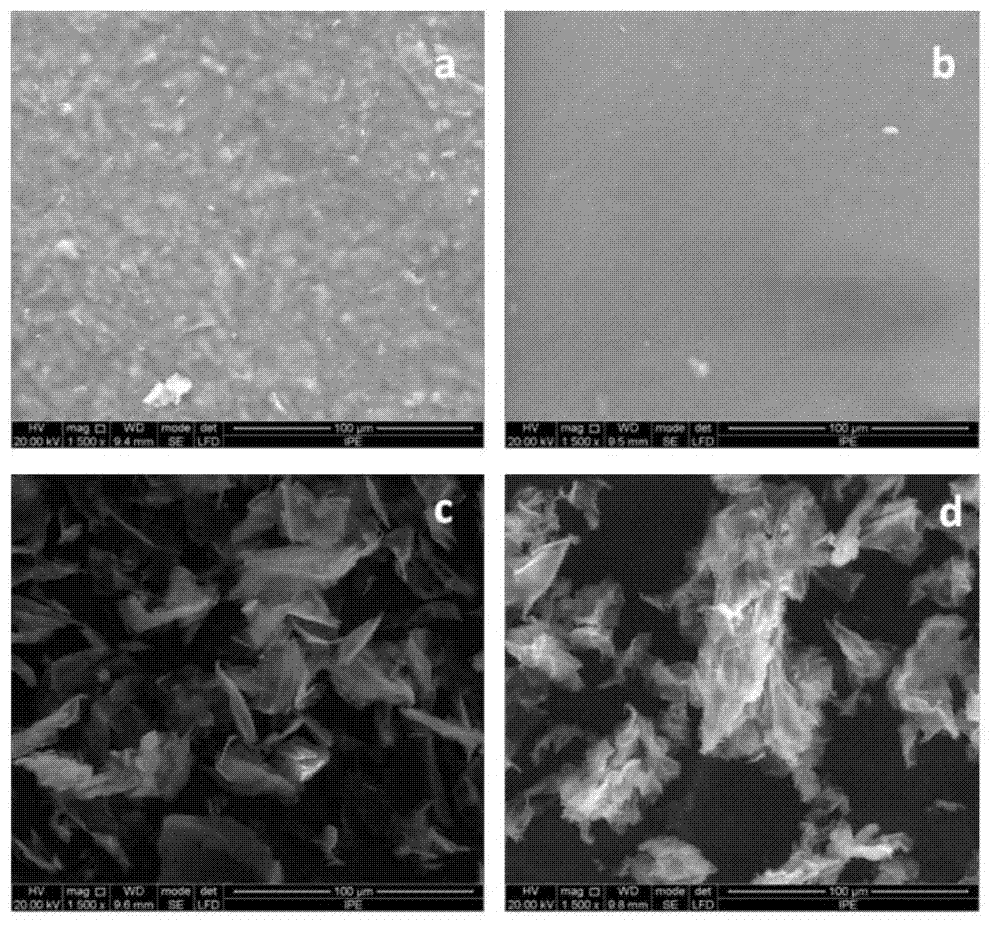

Method for enriching platinum group metal and rare earth in failed automobile exhaust purification catalyst

ActiveCN110055423AFacilitate subsequent extractionComprehensive recycling benefits are goodProcess efficiency improvementRare-earth elementLanthanum

The invention relates to a method for enriching platinum group metal and rare earth in a failed automobile exhaust purification catalyst. The metod comprises the steps that the failed automobile exhaust purification catalyst is finely ground and then is subjected to pressure leaching in a sodium hydroxide solution, gamma-A12O3 in the crystal is partially dissolved, and cordierite carrier in the catalyst is converted into sodalite which is easy to dissolve in an acidic system; acid leaching is carried out on the produced pressure leaching residue, rare earth elements enter the acid leaching solution, and platinum, palladium and rhodium elements are remained in the residue, so that separation of platinum, palladium and rhodium and rare earth is realized; and sodium sulfate is added into theacidic leaching solution to form a rare earth sulfate complex salt precipitate, rare earth elements are recycled, and acidic insoluble residues are further treated to recycle platinum, palladium and rhodium metal. The leaching rate of lanthanum and yttrium reaches 95% or more, platinum, palladium and rhodium in the failed automobile tail gas purification catalyst is enriched by 13 times or more, the subsequent extraction of noble metal is facilitated, and the comprehensive recovery rate of lanthanum and yttrium elements reaches 90% or more.

Owner:CENT SOUTH UNIV

Process for Extracting and Recovering Polyhydroxyalkanoates (Phas) From Cellular Biomass

Owner:PHB IND

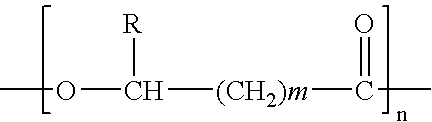

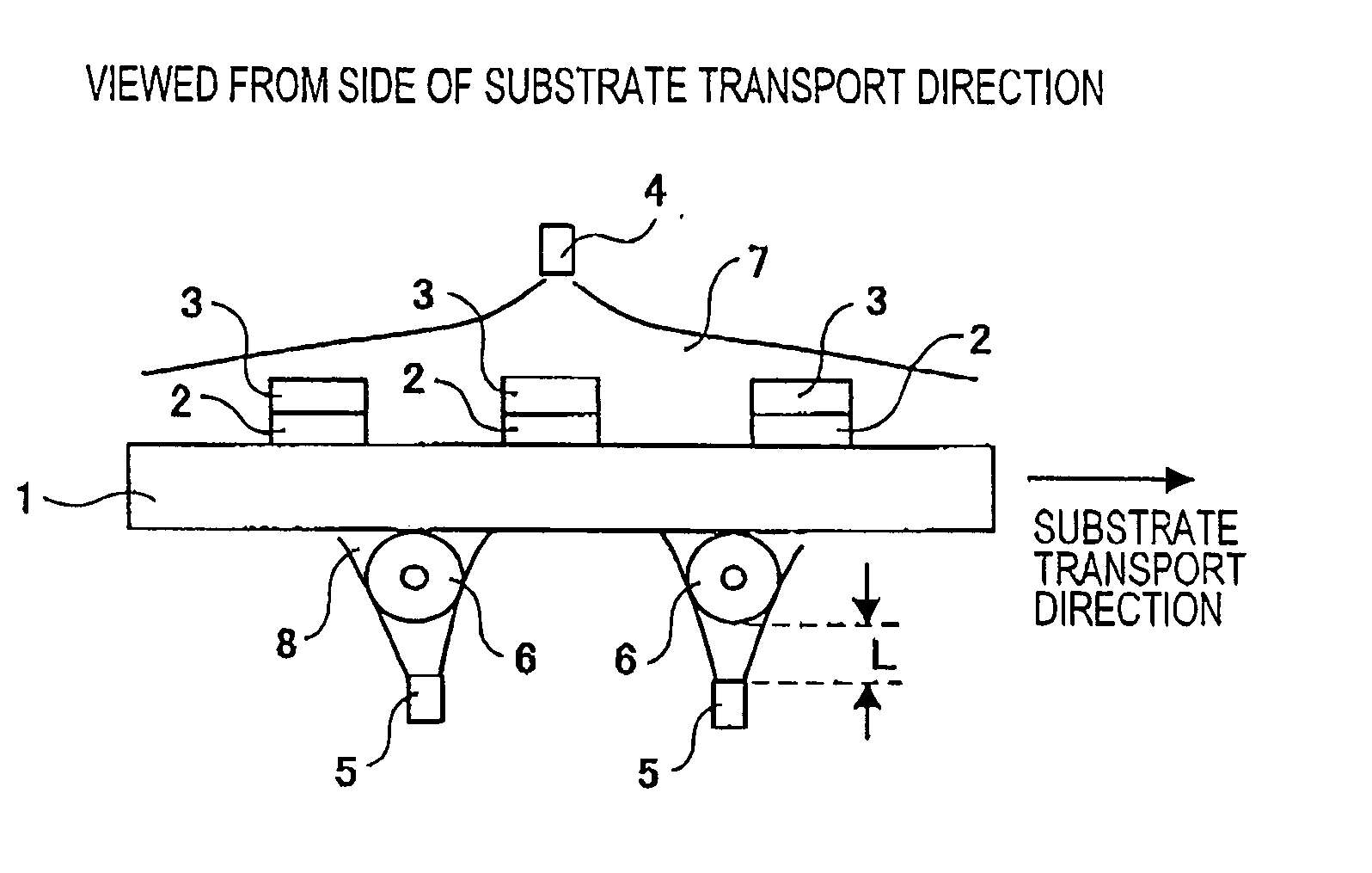

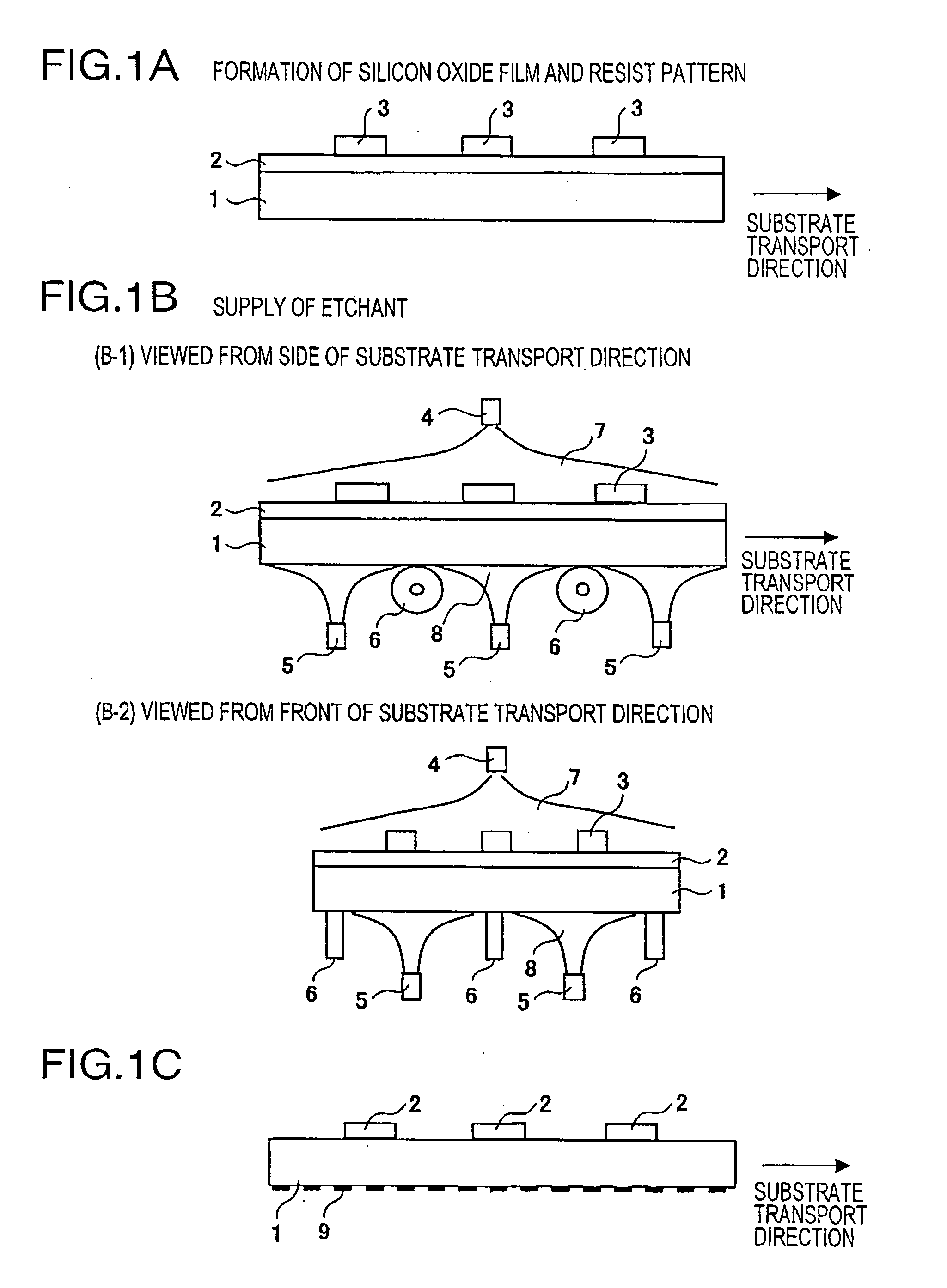

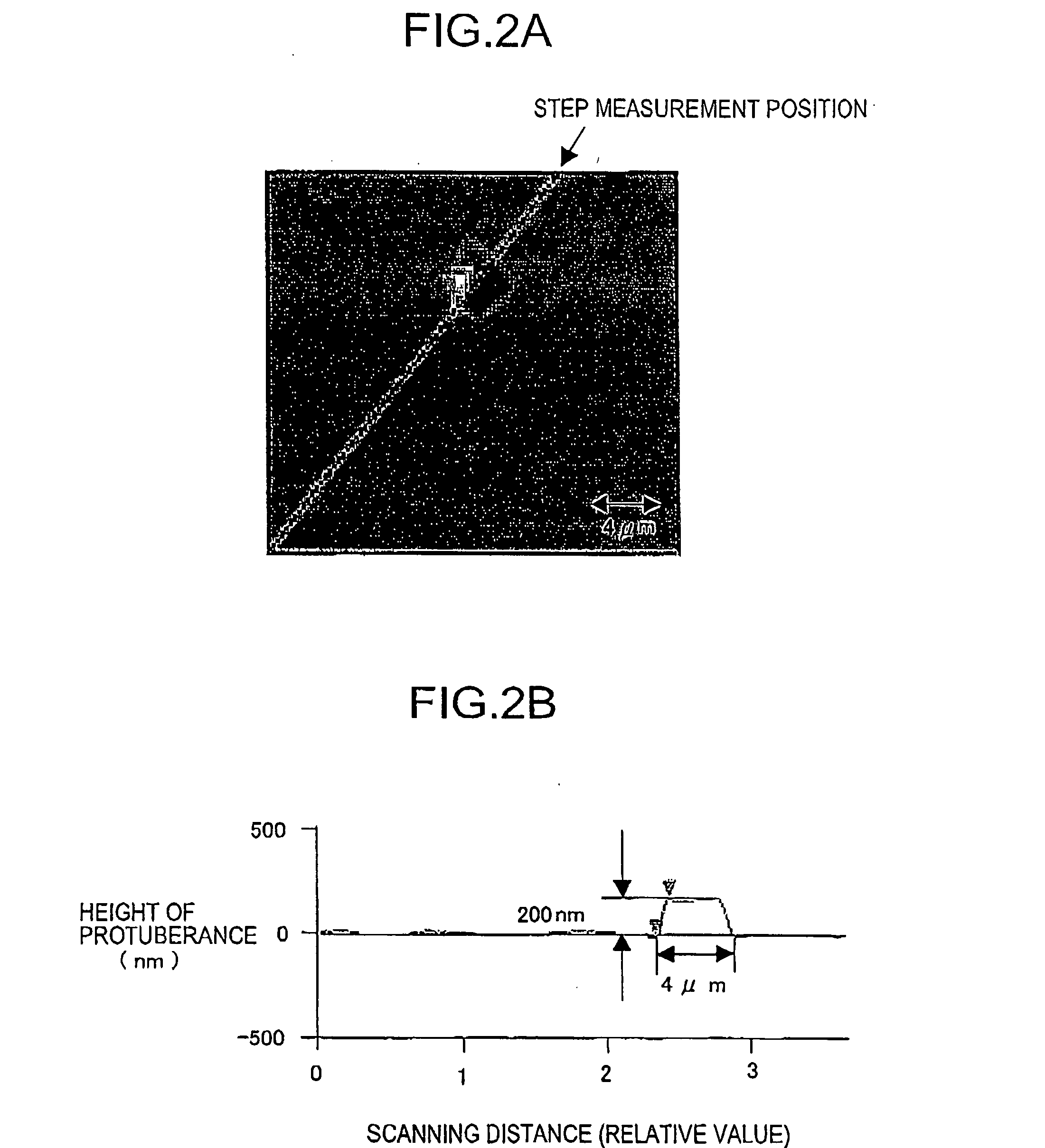

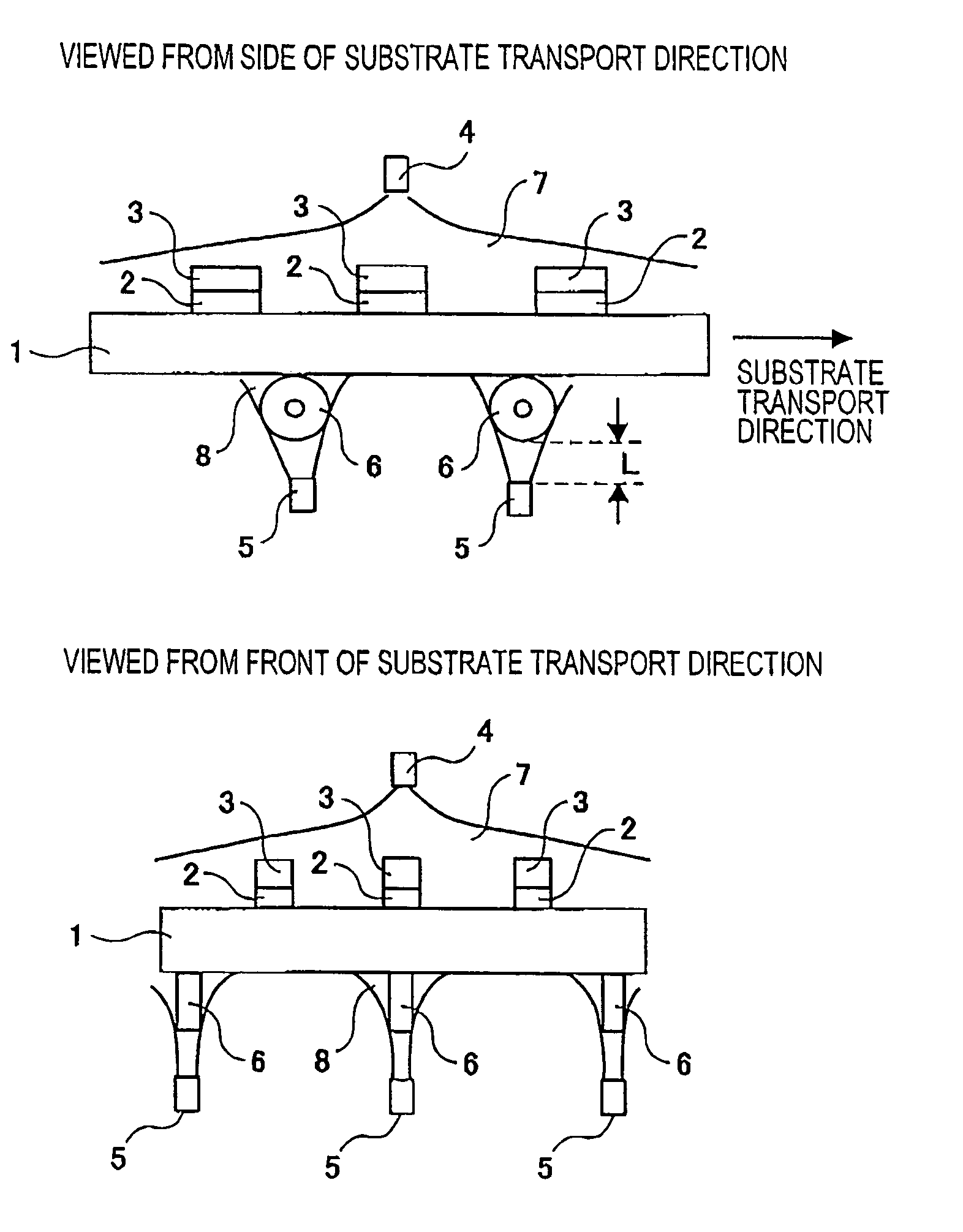

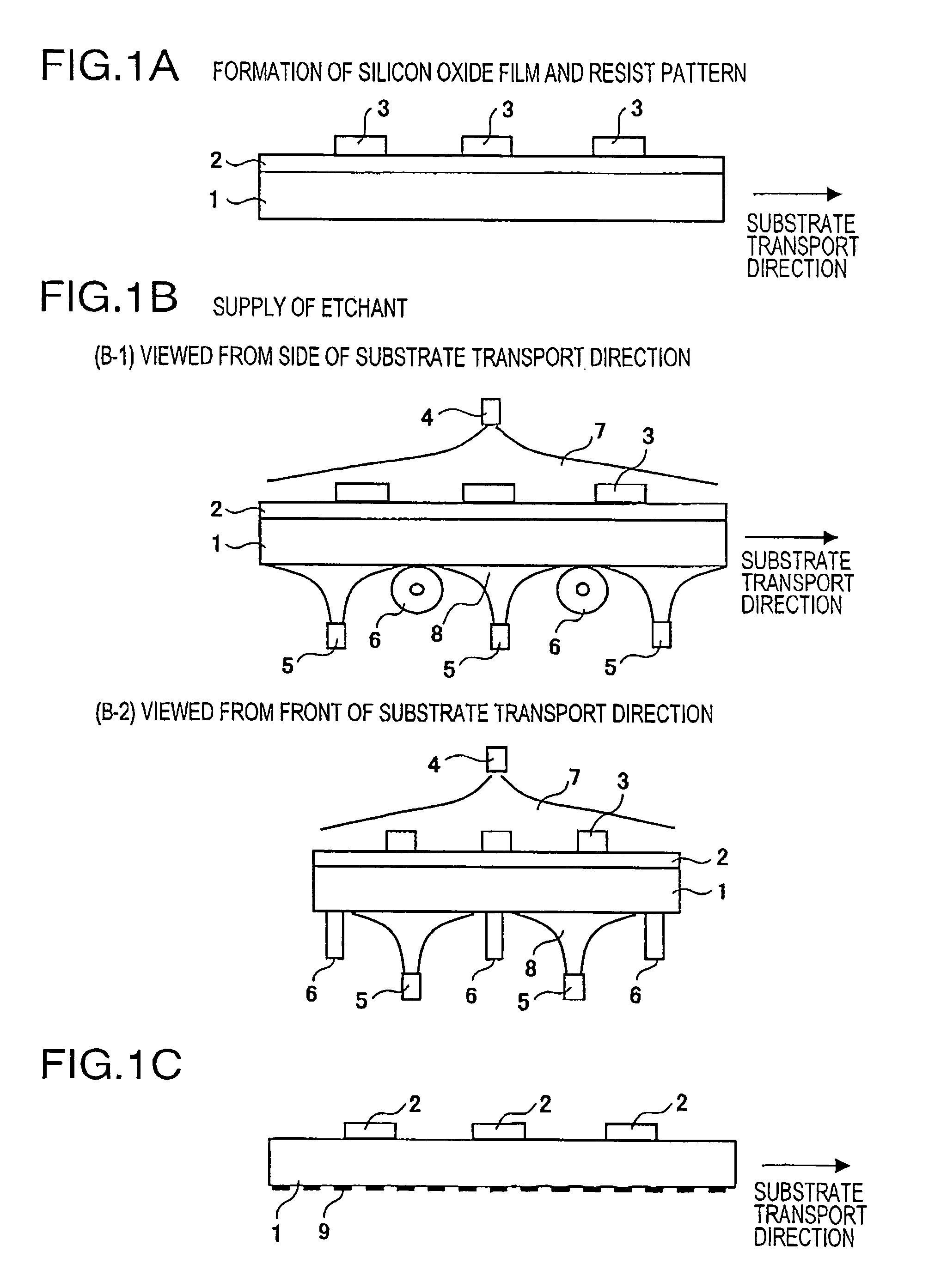

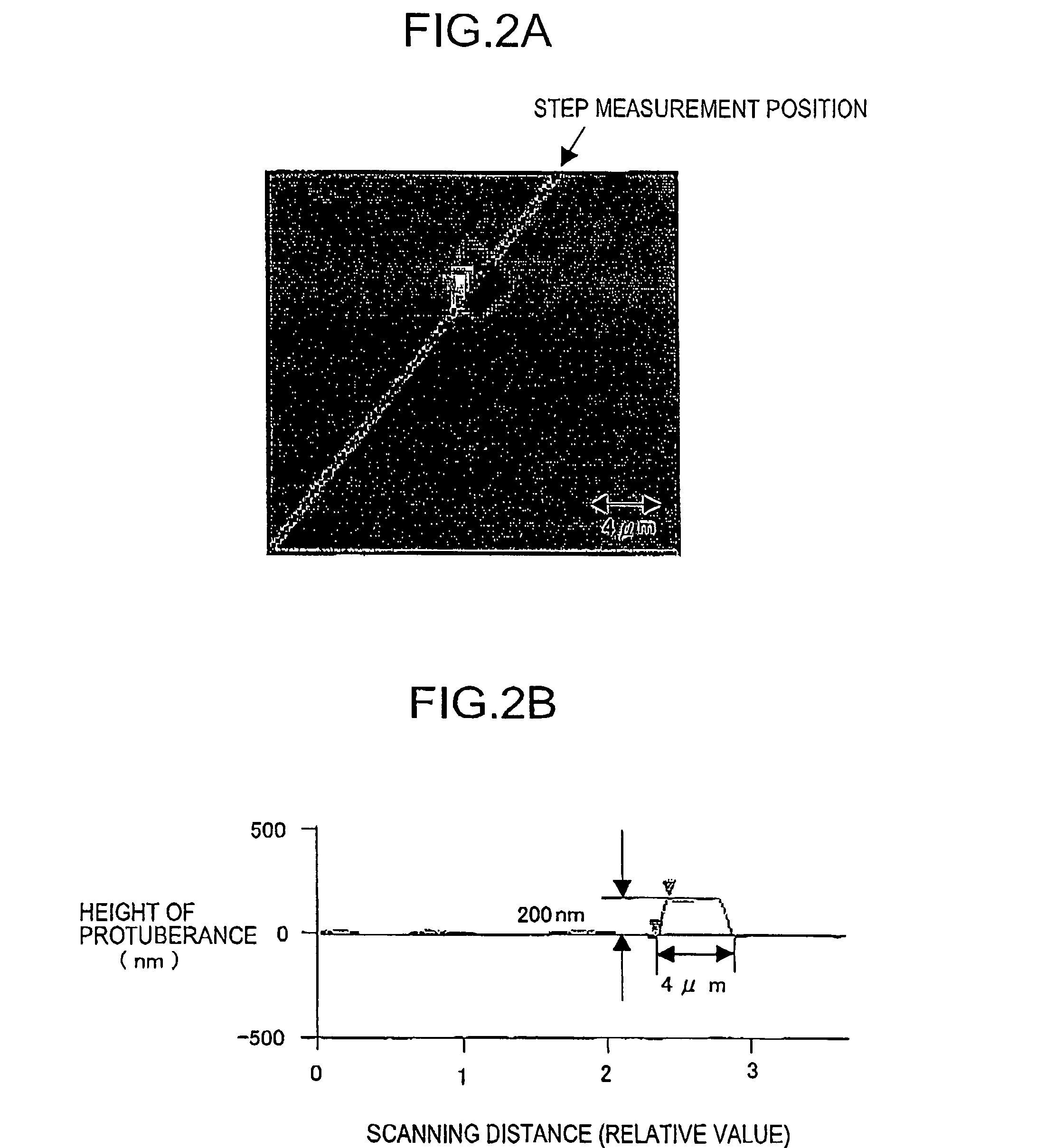

Method for manufacturing display device and display device manufacturing apparatus

InactiveUS20050037628A1Display quality is deterioratedReduce displayElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

Where a thin film formed on a glass substrate is etched with a solution containing a fluoride, insoluble residues formed by the reaction of the solution with glass substrate components adhere to the back of the substrate to cause etching non-uniformity called roller marks. So, a solution is supplied directly to supporting member for supporting the glass substrate, or concentratedly to region where the substrate and the supporting member come into contact and from a position opposite to the transporting direction of the substrate, or to both the supporting members and regions where the substrate and the supporting members come into contact. This enables the roller marks to be kept from forming, consequently making it possible to improve display quality of display devices.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

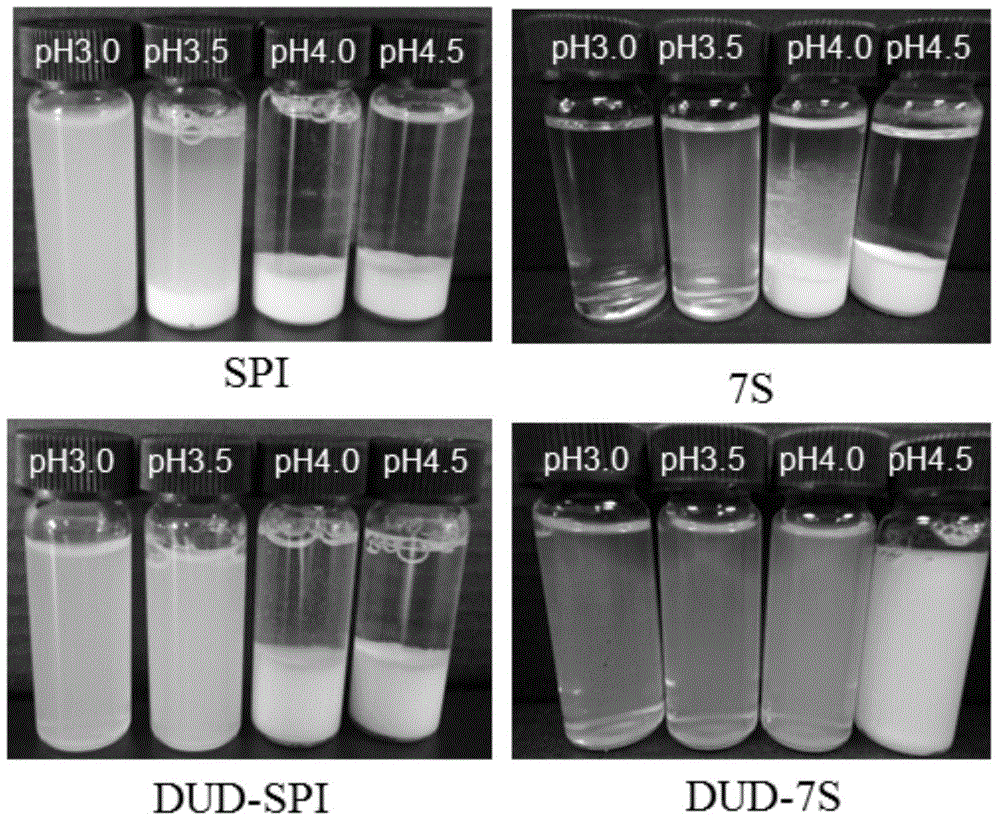

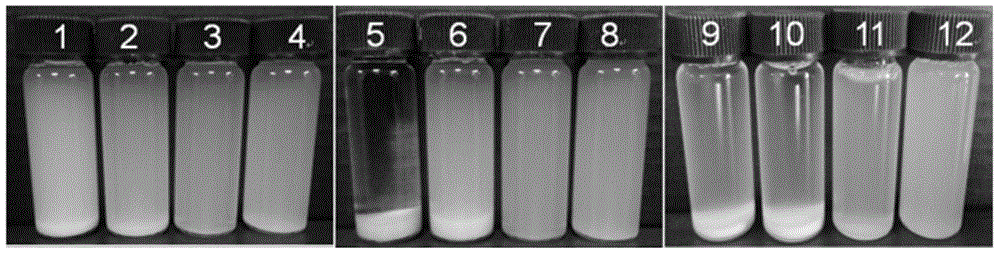

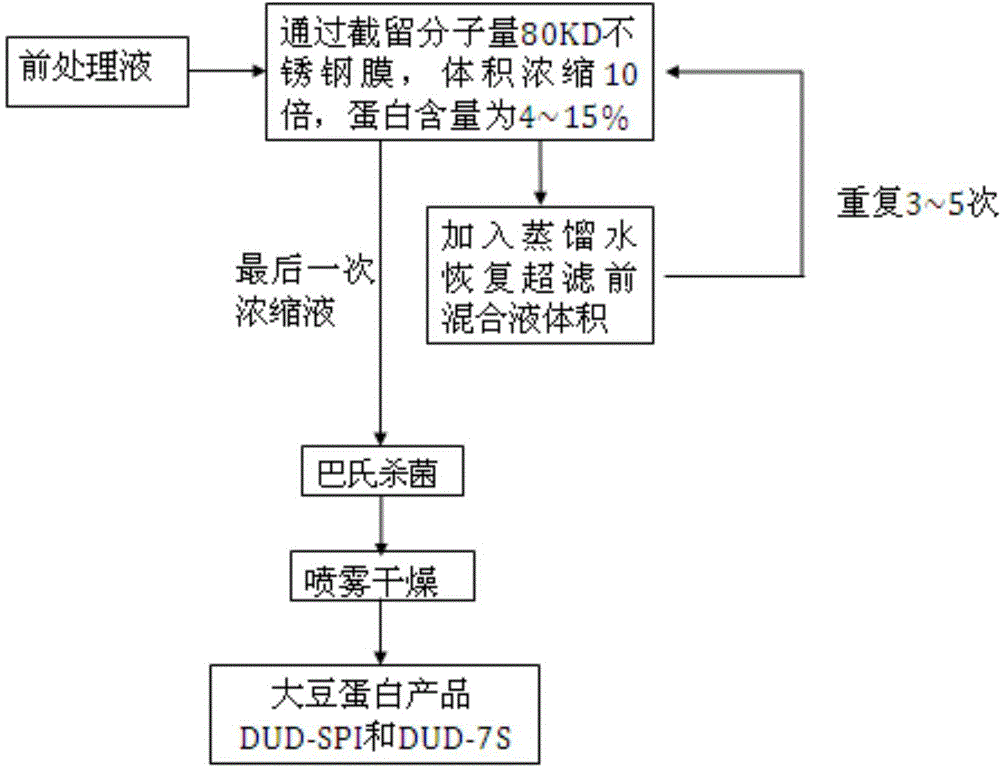

Acid-soluble soybean protein and preparation method and application of acid-soluble soybean protein in acid beverage

ActiveCN104543329AHigh protein purityFine foamProtein composition from vegetable seedsFood preparationSolubilityWater baths

The invention belongs to the fields of soybean protein deep processing and functional beverage, and discloses acid-soluble soybean protein and a preparation method and application of the acid-soluble soybean protein in acid beverage. The method comprises the following steps: firstly, mixing extract liquid with bean pulp, centrifugally separating and removing insoluble residues; taking supernatant liquid, adding phytase to the supernatant liquid to carry out enzymolysis, and adjusting the pH value; and carrying out cyclic ultrafiltration percolation concentration under a water bath condition, repeatedly diluting and concentrating protein for a plurality of time, and carrying out pasteurization and spray drying on the concentrated protein liquid, so as to obtain an acid-soluble soybean protein product. The purity of the obtained protein can be 90%-99%; the content of phytic acid is only 0.665%-0.694%; the nitrogen solubility index within the pH being 3.0-4.0 is 45%-90%; enzymatic hydrolysate is relatively good in foaming property, relatively excellent in foam stability; the acid-soluble soybean protein can be applied to preparation of various functional beverage when being dissolved into sports beverage, carbonated beverage, fruit juice and the like.

Owner:SOUTH CHINA UNIV OF TECH

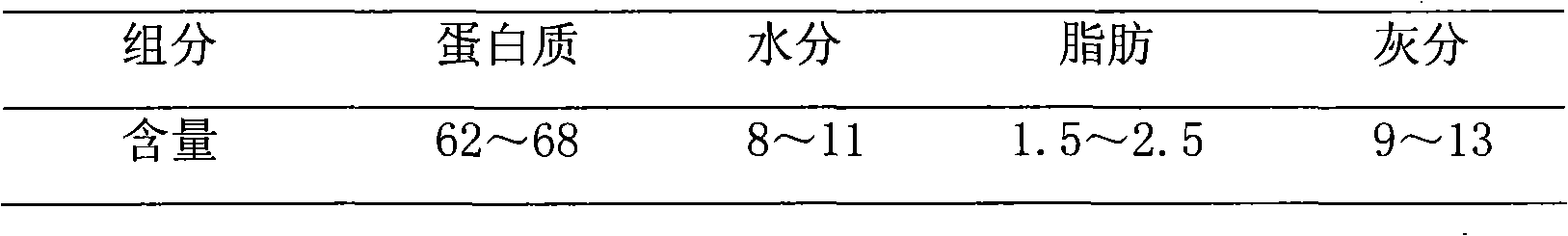

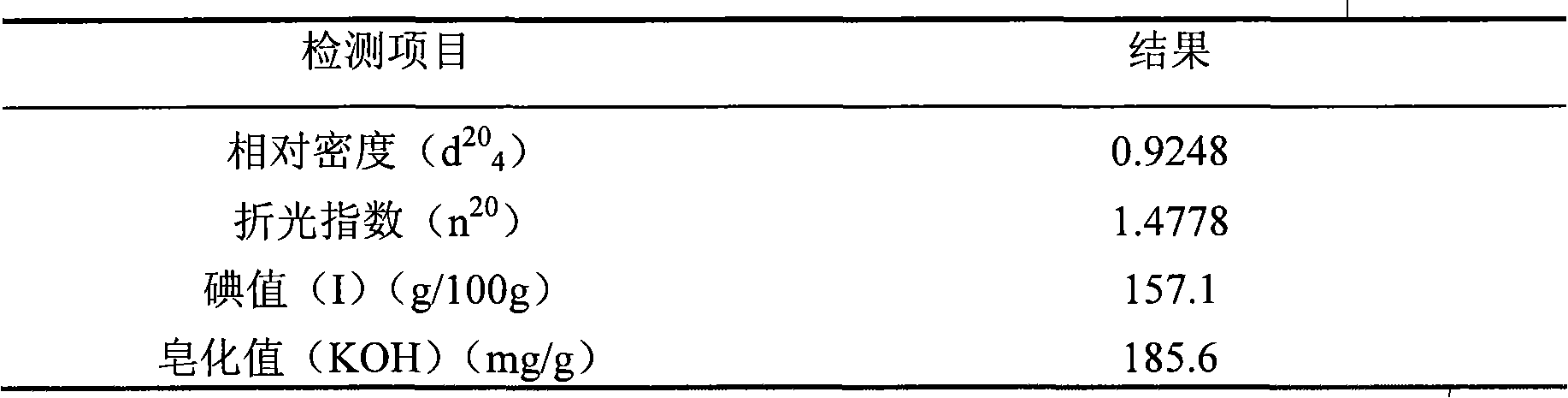

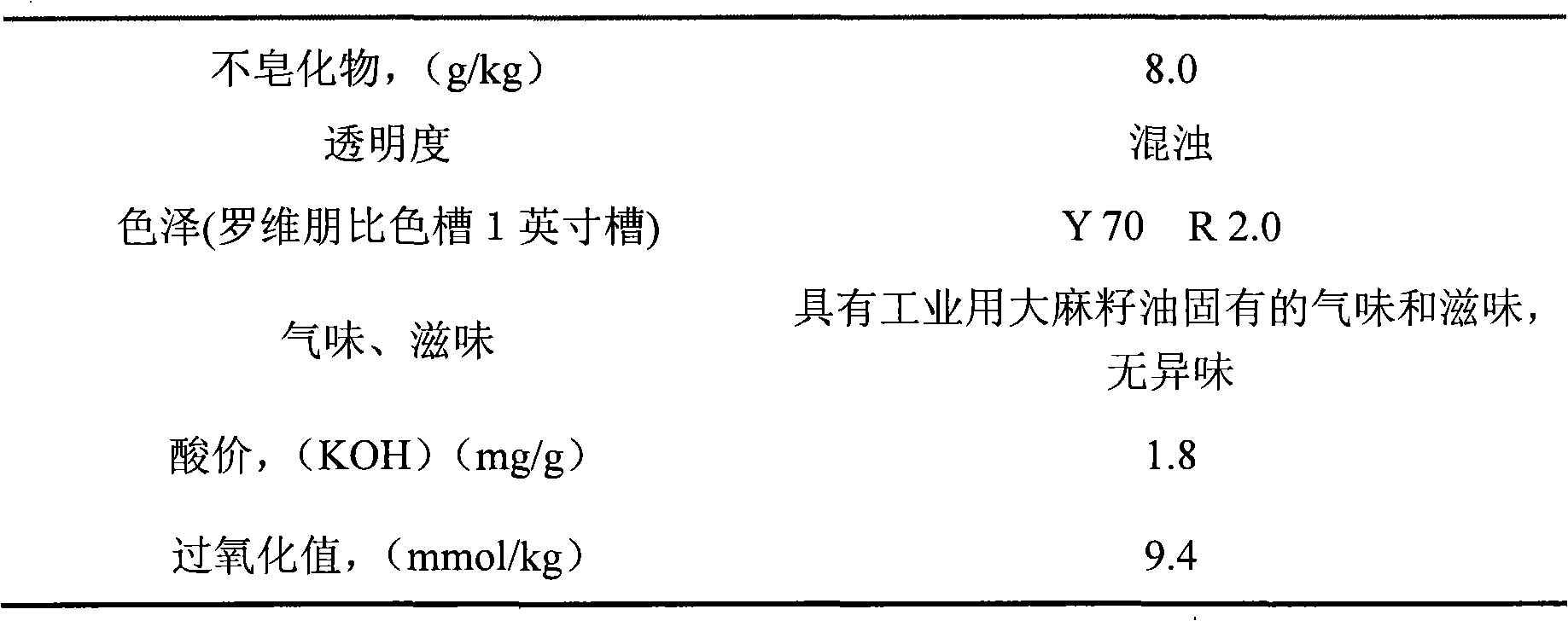

Industrial hempseeds isolated protein powder and preparation method thereof

InactiveCN101589760AAppropriate and uniform particle sizeAppropriate size and uniformProtein composition from vegetable seedsFood preparationFiberEmulsion

The invention discloses an industrial hempseeds isolate protein powder of which the protein purity is above 92%. The invention also provides a preparation method of the industrial hempseed isolated protein powder, comprising the following steps: (1) purifying and decorticating industrial hempseeds according to grading, and obtaining low temperature protein meal by CO2 supercritical fluid extraction; (2) dissolving the desolventized protein meal in alkaline liquor, adjusting the PH value to 8-10 to obtain protein emulsion, removing insoluble residue and fibre by filtering; (4) taking supernatant liquor and adding acid liquor to adjust the PH value to 4.5-5, centrifugalizing to take the precipitation; (5) adding alkaline liquor to adjust the PH value to 6-7, obtaining the industrial hempseeds isolate protein powder by spray drying. The invention has the advantages of simple process, low cost and high protein extraction efficiency. The produced industrial hempseeds isolate protein powder has high nutritional value and a wide application prospect.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

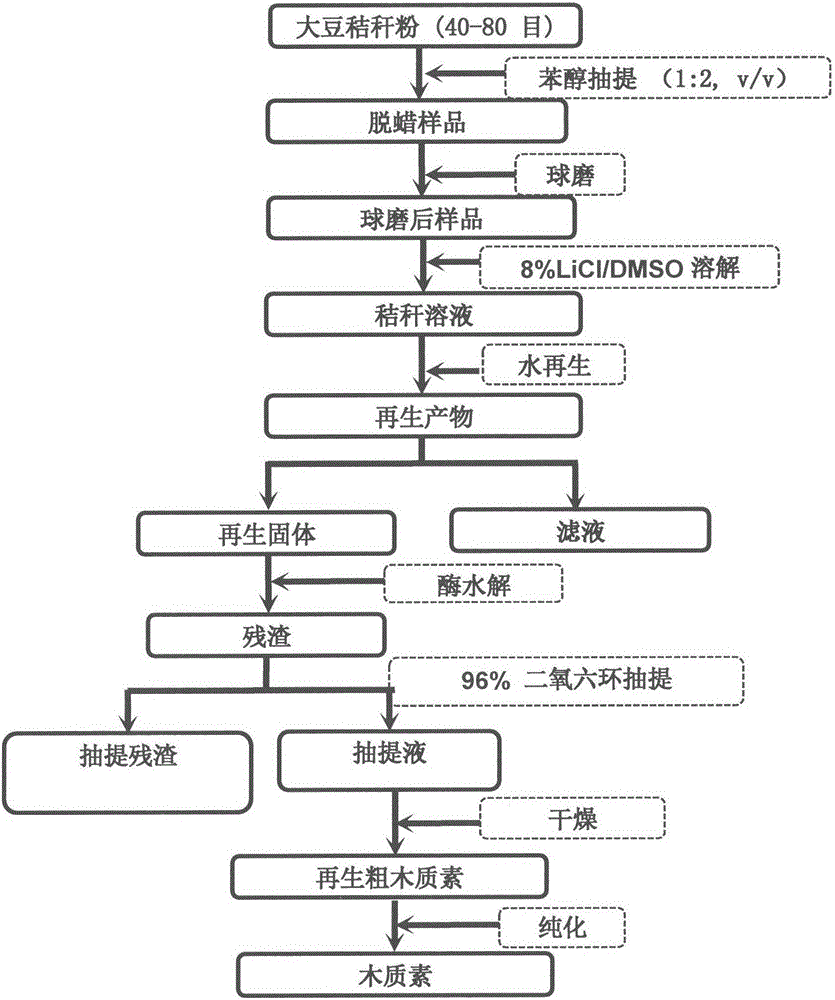

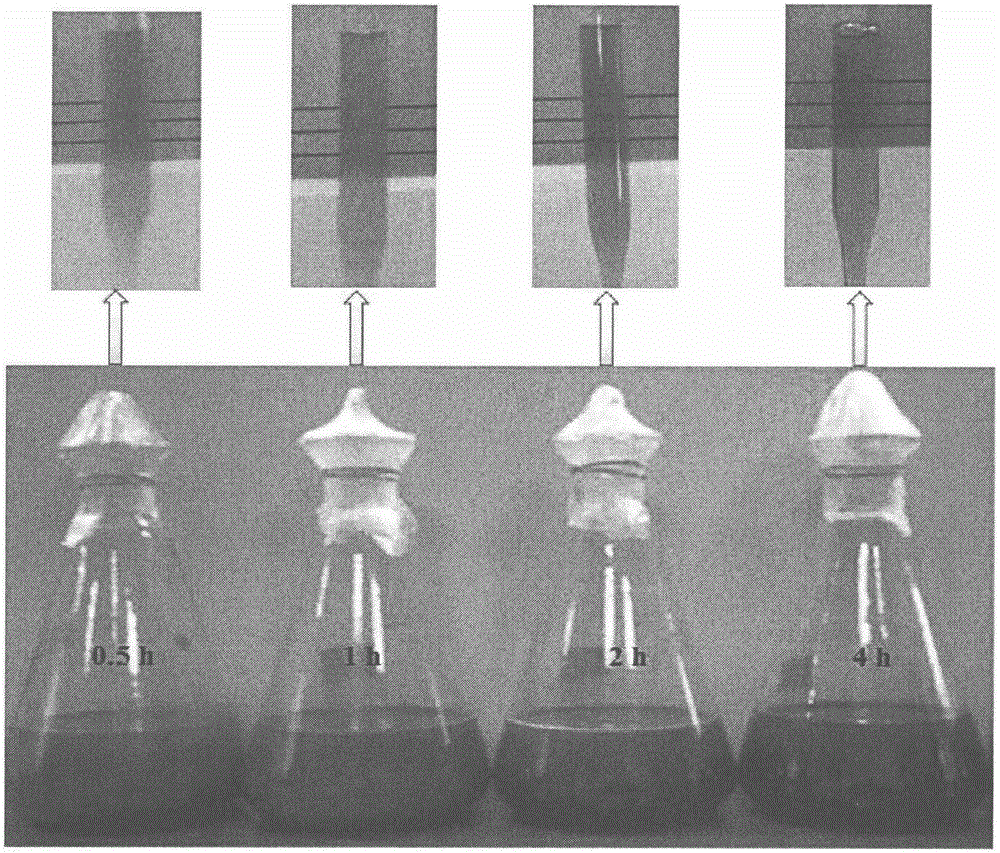

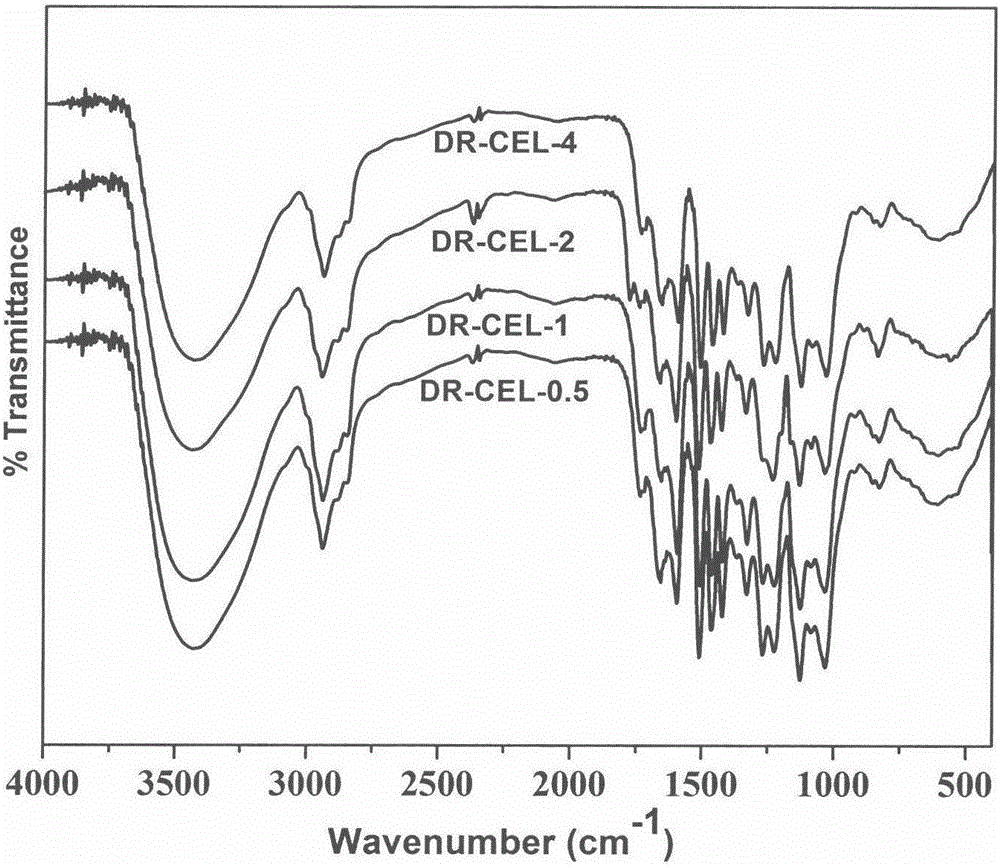

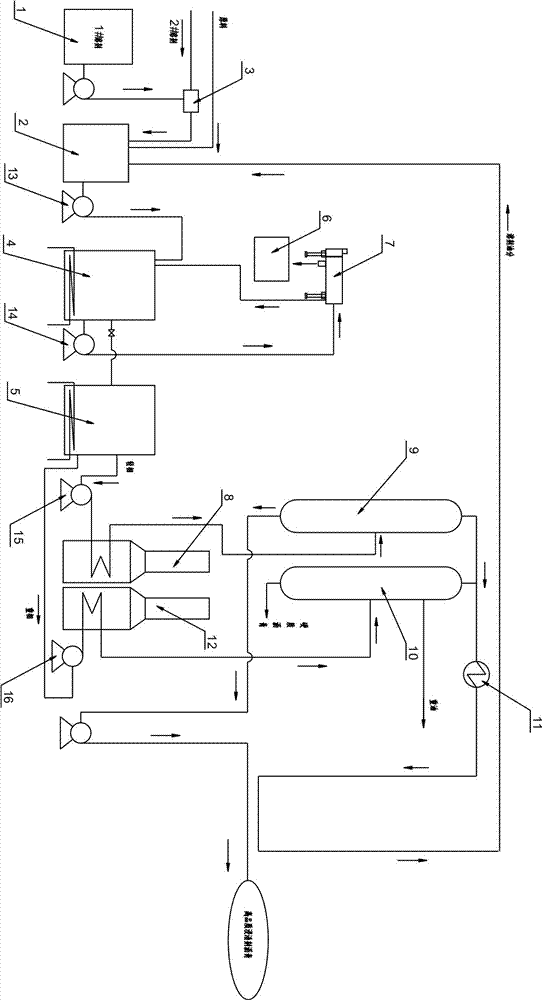

Extraction method for dissolved-regenerated lignin

The invention relates to an extraction method for dissolved-regenerated lignin. The method consists of: crushing lignocellulose and conducting ball milling treatment, then dissolving the ball milled lignocelluloses powder in a 8% LiCl / DMSO mixed solution, carrying out magnetic stirring at room temperature for 24h to obtain a lignocellulose solution, adding the lignocellulose solution into certain amount of distilled water, performing stirring to disperse it uniformly, conducting centrifugal separation on regenerated lignocellulose and performing washing with distilled water, hydrolyzing the regenerated lignocelluloses in enzyme, then carrying out centrifugal separation on the regenerated supernatant and insoluble enzymolysis residue, washing the insoluble residue with a buffer solution, and then performing washing with deionized water so as to obtain enzyme hydrolysis residue, using a dioxane aqueous solution to extract the enzyme hydrolysis residue, then performing rotary evaporation to remove the dioxane aqueous solution therein to obtain crude lignin, and dissolving the crude lignin in acetic acid, then adding the mixture into a large amount of distilled water to precipitate and regenerate lignin, thus obtaining the wood fiber dissolved-regenerated lignin. The method provided by the invention has a simple process and can extract lignin efficiently.

Owner:NANJING FORESTRY UNIV

High-quality impregnant asphalt production process

InactiveCN103242880AHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionKeroseneDistillation

The invention discloses a high-quality impregnant asphalt production process. The high-quality impregnant asphalt production process is characterized by comprising the following steps of: mixing first solvent coal oil and second solvent washing oil for extraction by using a pipeline mixer, and then feeding the mixture into a stirring tank; feeding raw material coal asphalt into the stirring tank for stirring; pumping the stirred raw material coal asphalt into a first settling tank through an oil pump; pumping a heavy phase part in the first settling tank into a quinoline insoluble centrifugal removal device through the oil pump, and centrifugally removing quinoline insoluble residue; returning a material from which the quinoline insoluble residue is removed into the first settling tank; when the storage amount of mixed liquid in the first settling tank reaches the limit, enabling the mixed liquid to enter into a second settling tank, and standing; after lamination occurs in the second settling tank, heating a light phase component in the second settling tank through a first heating furnace, and pumping the light phase component into a first depressurizing distillation tower for depressurizing distillation; and removing a solvent, and thus obtaining a target product, namely high-quality impregnant asphalt. The high-quality impregnant asphalt production process is used for producing the high-quality impregnant asphalt. The product yield is high and can exceed 60 percent. The temperature of a softening point of a product is 70 to 90 DEG C. The ash content can be controlled to be 0.01 to 0.1 percent.

Owner:武汉钢铁有限公司

Clean temporary plugging agent and preparation method thereof

InactiveCN108485623AHigh temperature resistanceThe synthesis process is simple and safeDrilling compositionEpoxyDissolution

The invention belongs to petroleum natural gas technology yield increase, and discloses a clean temporary plugging agent. The clean temporary plugging agent is prepared from the following raw materials in parts by mass: 10 to 13 percent of acrylamide, 10 to 13 percent of acrylic acid, 0.3 to 0.5 percent of caustic soda flakes, 0.08 to 0.1 percent of initiators, 7 to 9 percent of low-temperature-resistant glue epoxy resin, 0.5 to 0.8 percent of surfactants and the balance of water. The invention also provides a preparation method of the clean temporary plugging agent. The clean temporary plugging agent has the advantages that the clean temporary plugging agent does not contain inorganic solid phase particles; the damage of the temporary plugging agent to the stratum after the dissolution isreduced; the preparation method of the clean temporary plugging agent is simple and safe; the high-temperature-resistant and salt-resistant capability are realized; great construction pressure can beborne; the high-temperature resistance can be realized; the insoluble residue content is very low; the dissolution speed is controllable; the consumption is low; the use is simple.

Owner:四川申和新材料科技有限公司

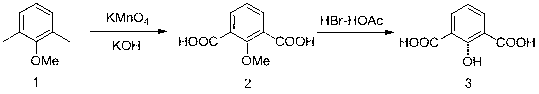

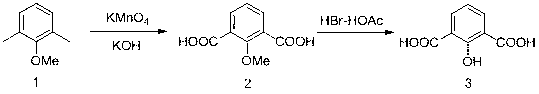

Preparation method of 2-hydroxyisophthalic acid

InactiveCN103159620AReaction raw materials are readily availableMild conditionsOrganic compound preparationCarboxylic compound preparationPotassium manganateSide reaction

The invention discloses a synthesis method of a drug intermediate 2-hydroxyisophthalic acid, which comprises the following steps: sufficiently dispersing 2,6-dimethylanisole used as a raw material in an alkaline potassium permanganate solution, reacting under reflux for 4 hours, carrying out vacuum filtration to remove insoluble residues, and acidifying the filtrate with hydrochloric acid to obtain an intermediate 2-methoxyisophthalic acid; and dissolving the 2-methoxyisophthalic acid in an HBr-HOAc solution, refluxing while stirring until no gas is emitted, cooling, precipitating a crude product, and recrystallizing to obtain the 2-hydroxyisophthalic acid pure product. The method has the advantages of cheap and accessible raw material, mild and controllable reaction conditions, simple equipment, fewer side reactions, high yield and lower cost, and is convenient to operate and suitable for popularization.

Owner:GUANGXI NORMAL UNIV

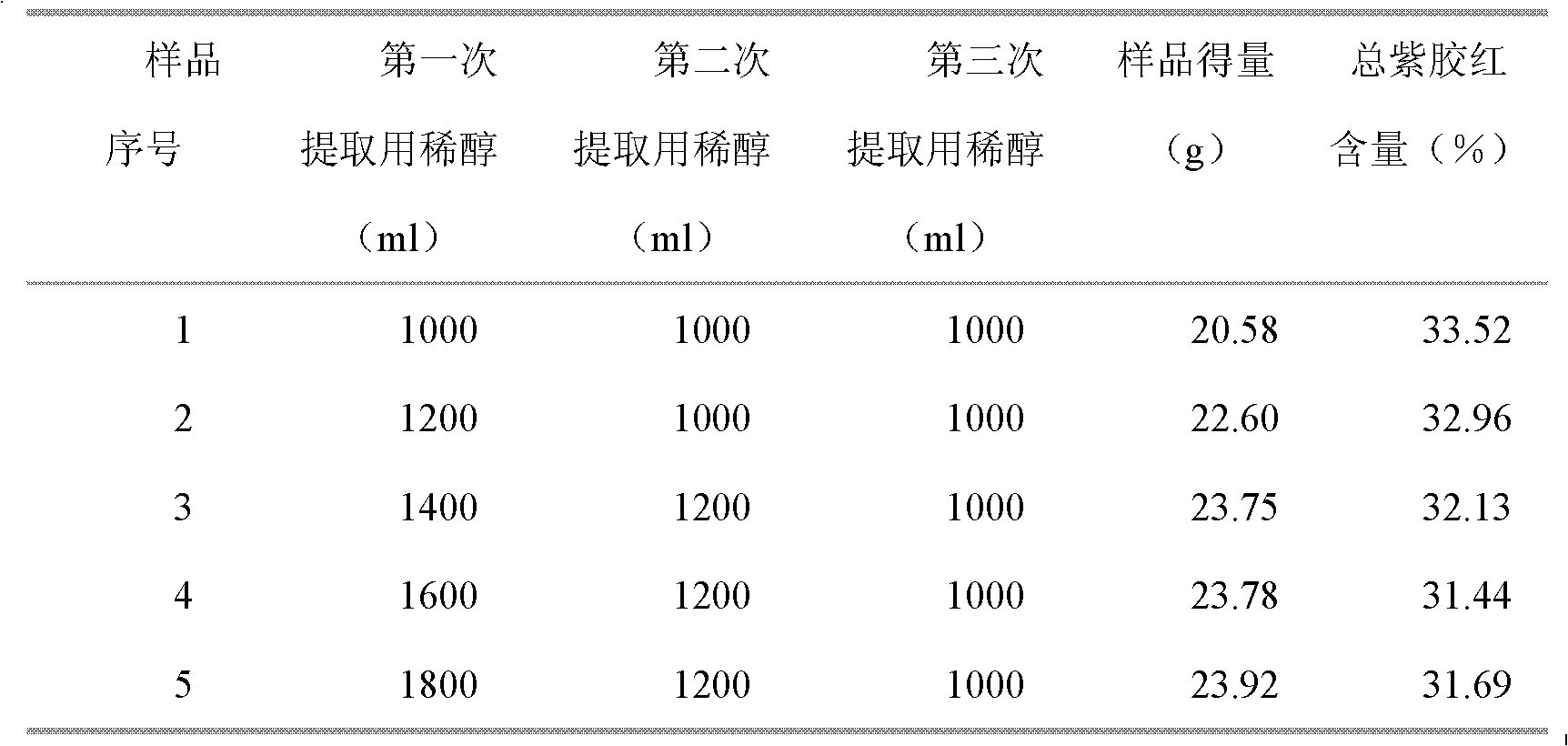

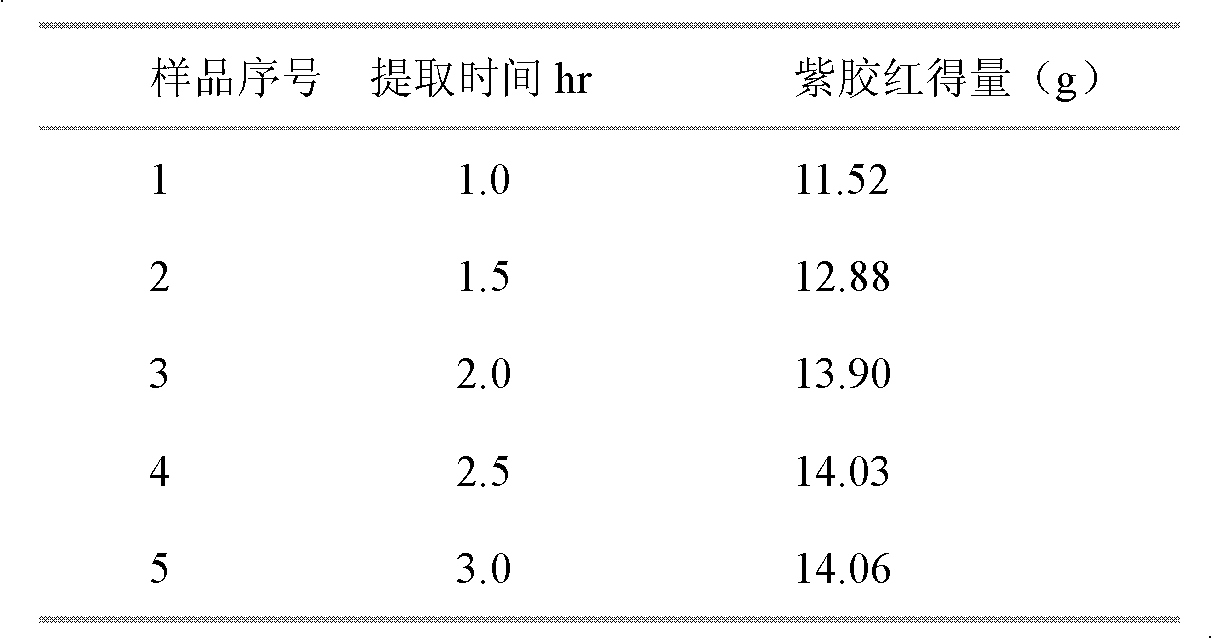

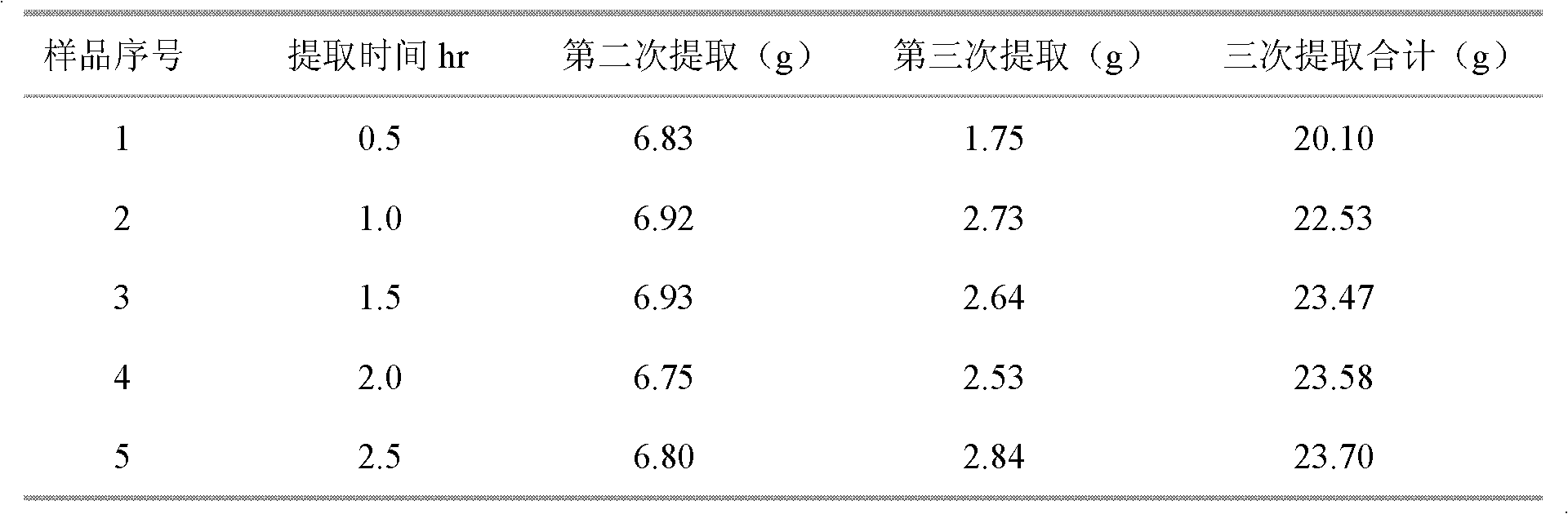

Method for extracting lac red pigment

InactiveCN101817993AAchieve non-toxic emissionsIncrease concentrationNatural dyesChemistryInsoluble residue

The invention discloses a method for extracting lac red pigment. The method comprises the following steps of: (1) smashing a dry lac material and immersing the smashed material in ethanol; and heating and refluxing the solution for extraction; (2) filtering liquid obtained by the step (1) for chromatography with a macroporous adsorption resin and eluting the liquid; and (3) concentrating eluent obtained by the step (2) and drying the eluent to obtain the lac red pigment. The method has the advantages that: (1) by using the characteristic that the lac red pigment has better solubility in solution of dilute alcohol, extracting solution is filtered and extracted by using the solution of dilute alcohol for many times; the extracting solution is adsorbed by the macroporous adsorption resin andeluted by concentrated ethanol; and the eluent is concentrated, dried and smashed to obtain concentrated and odorless lac red pigment; (2) by adopting the solution of ethanol for extraction, insoluble residue serving as a lac byproduct can be used as an industrial raw material; (3) the extracting solution passes through the macroporous adsorption resin; and the pigments of effluent are adsorbed completely and can be recycled after distillation.

Owner:烟台开发区绿源生物工程有限公司

Waste residue comprehensive utilization method for trichlorosilane leaching system

ActiveCN104445281ATake advantage ofReduce pollutionSolid waste managementSolid waste disposalFiltrationTap water

The invention discloses a waste residue comprehensive utilization method for a trichlorosilane leaching system. The waste residue comprehensive utilization method comprises the following steps: filter pressing a leaching waste residue mixed solution formed by the leaching system by using a filter press to obtain leaching waste residue; putting the leaching waste residue into a drum mixer, adding an appropriate amount of tap water, and stirring to obtain a slurry; discharging the slurry to a dissolving tank by utilizing a high potential difference, adding the appropriate amount of the tap water, mechanically stirring to dissolve for 1.5-4 hours, and obtaining a feed liquid containing sodium chloride; filter pressing the feed liquid to obtain insoluble residue and filtrate, storing the insoluble residue for later use, performing secondary refined filtration on the obtained filtrate, injecting a refined filtration mother liquid into a double-effect evaporator through a centrifugal pump to evaporate and crystallize, and obtaining a finished product, sodium chloride with the purity of more than 99%. According to the waste residue comprehensive utilization method for the trichlorosilane leaching system, soluble salt and insoluble salt are effectively separated, and a purpose of recycling leaching waste residue in a classifying manner is achieved; the environment pollution and the wasting of resources are reduced, and the economic benefits are increased.

Owner:河南尚宇新能源股份有限公司

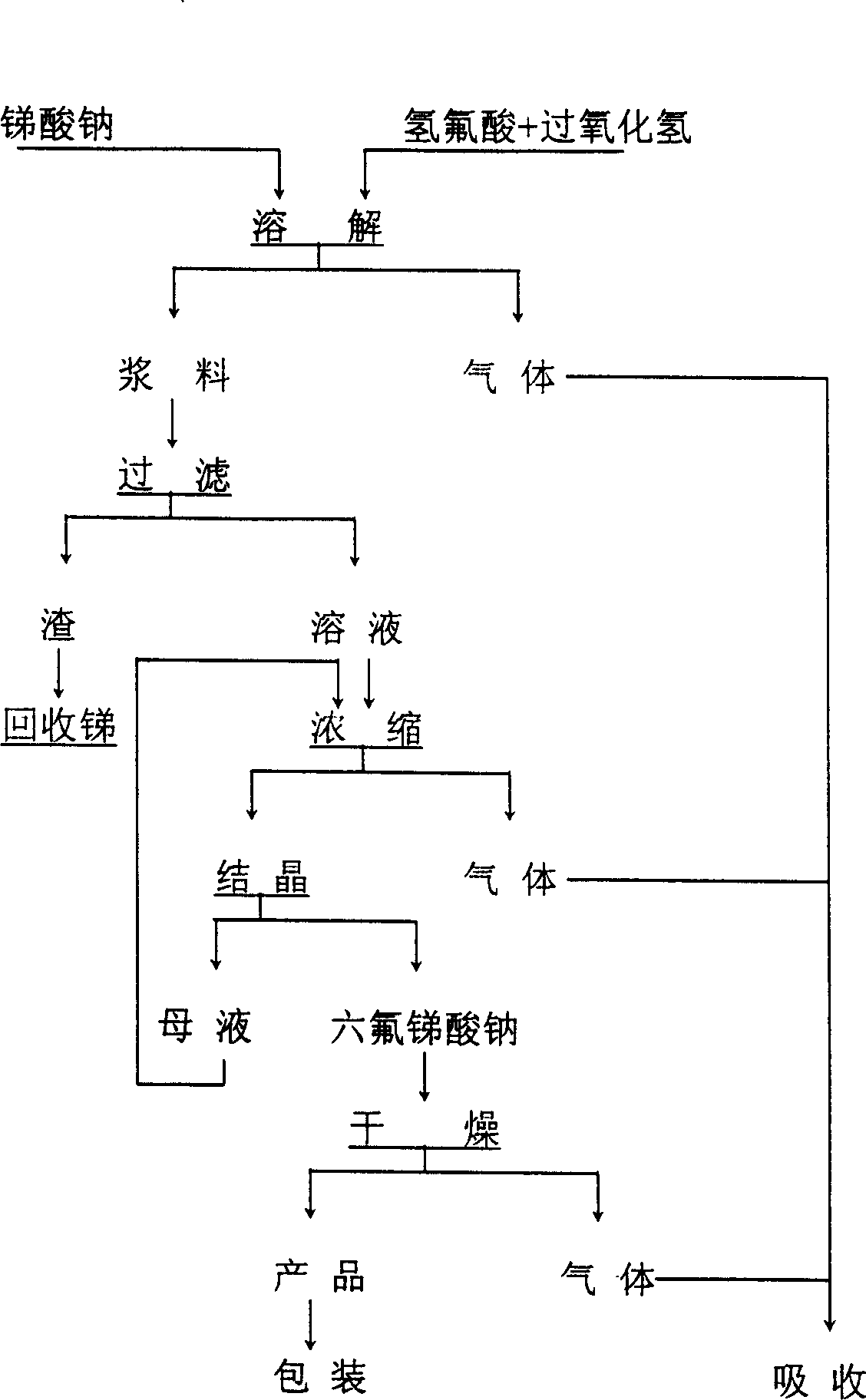

Method for preparing sodium hexafluoroantimonate

InactiveCN1743273AReduce productionEasy to control stoichiometryAntimonates/antimonitesChemical industryHydrofluoric acid

This method relates to the preparation of fine chemicals in chemical industry, especially the method for the preparation of sodium hexafluoroantimonate(Na3SbF6) with sodium antimonate(Na3SbO4) as raw material, which is as follow: first, after reaction between Na3SbO4 and fluohydric acid in proportion of 1: 6.6~9.5 under 50-100 degree C, filtrate to remove insoluble residue and condense the filter liquor under 95~136 deg.c; then cool, crystallization and centrifugal separation to obtain the product Na3SbF6, then the mother liquor is returned for recondensation. Advantages: directly product Na3SbF6 to save the preparation if the intermediate product of H3SbF6 or SbF5, easy and accurate control to stoichiometry of sodium and antimony; lower comprehensive cost.

Owner:CENT SOUTH UNIV

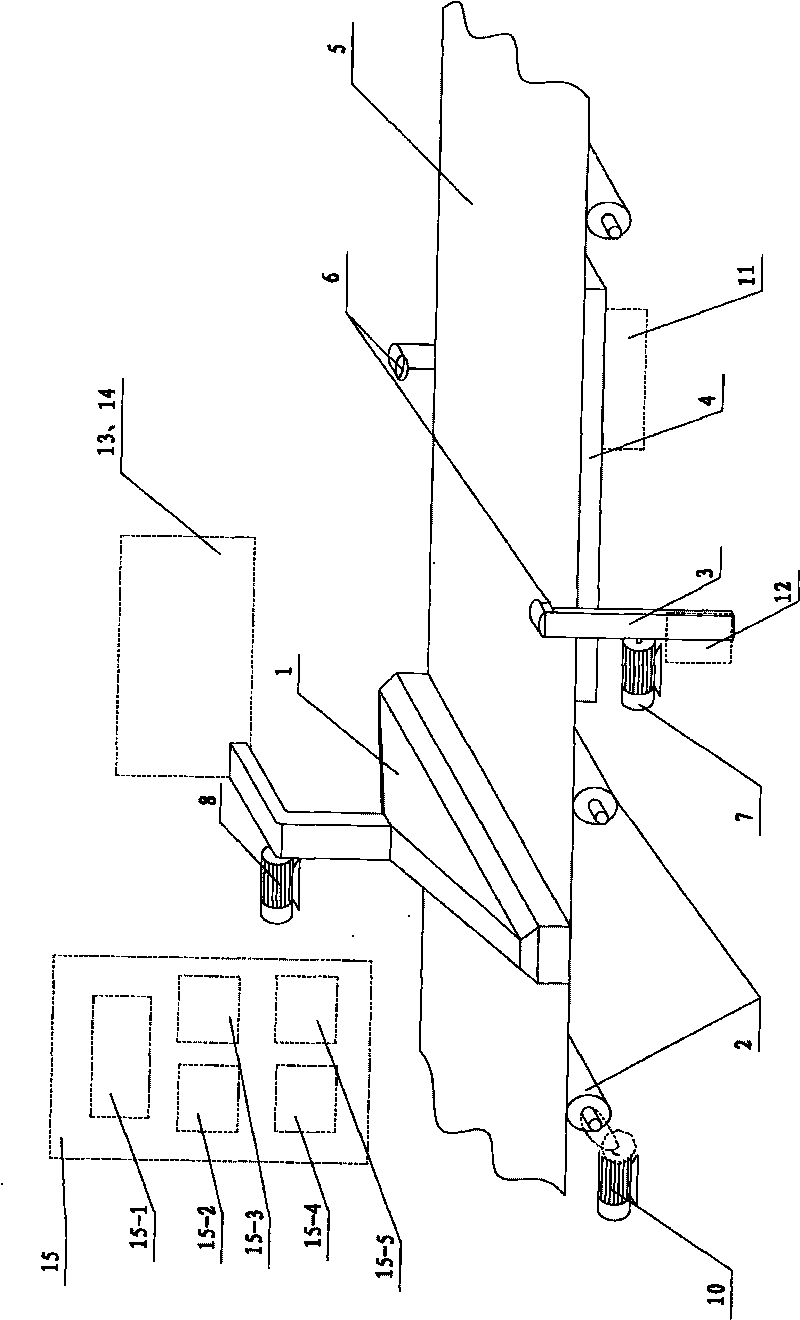

Jean laser singeing machine

The invention discloses a jean laser singeing machine and relates to jean dyeing and finishing equipment. The jean laser singeing machine comprises a feed unit, a fluffing unit, a laser singeing unit, a fluff collecting unit and a control unit, wherein, a jean cloth cover is arranged above a feed carrier roller and a static generating plate, a towing variable-frequency motor is connected with the feed carrier roller by a connector, a laser generating head is meshed with a rack on a supporting guide board through a precision gear, the rack of the supporting guide board is meshed with a gear on a main shaft of a height adjustment stepping motor, a collector is arranged above the jean cloth cover, a fluff absorbing motor is connected with a fan in the collector through a connector, the power supply end of the fluff absorbing motor is connected with the control output end of an intensity controller through a connecting cable, and an outlet of the collector is connected with a fluff collecting case. The invention ensures securer singeing operation by using laser and is superior to the conventional singeing with respects to preventing fire danger and reducing insoluble residues. The invention has the advantages of higher energy utilization ratio and low air pollution.

Owner:LANYAN GROUP

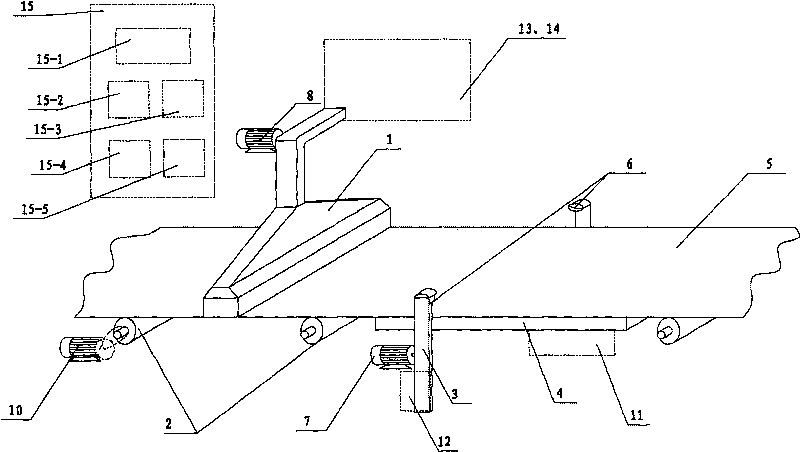

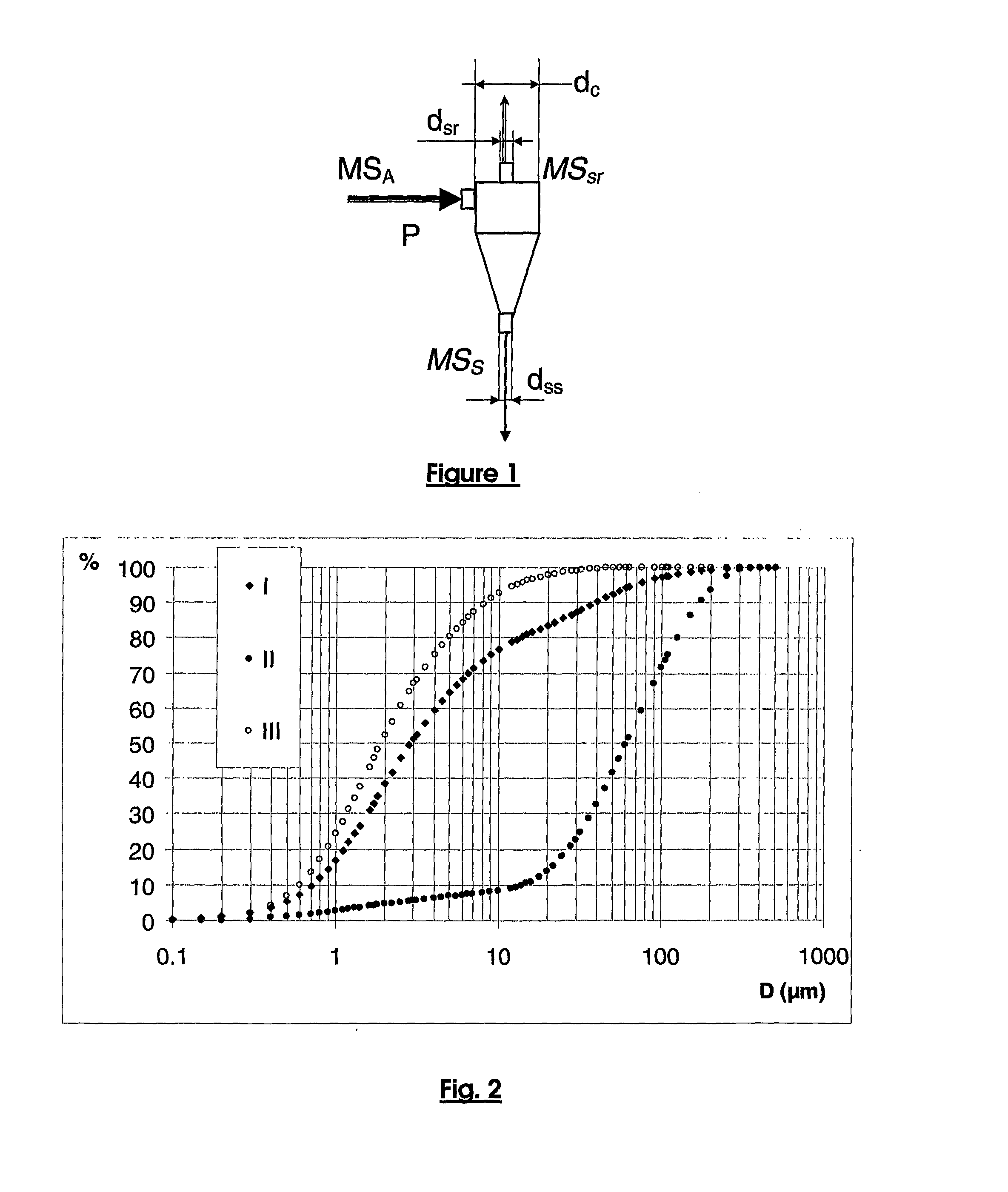

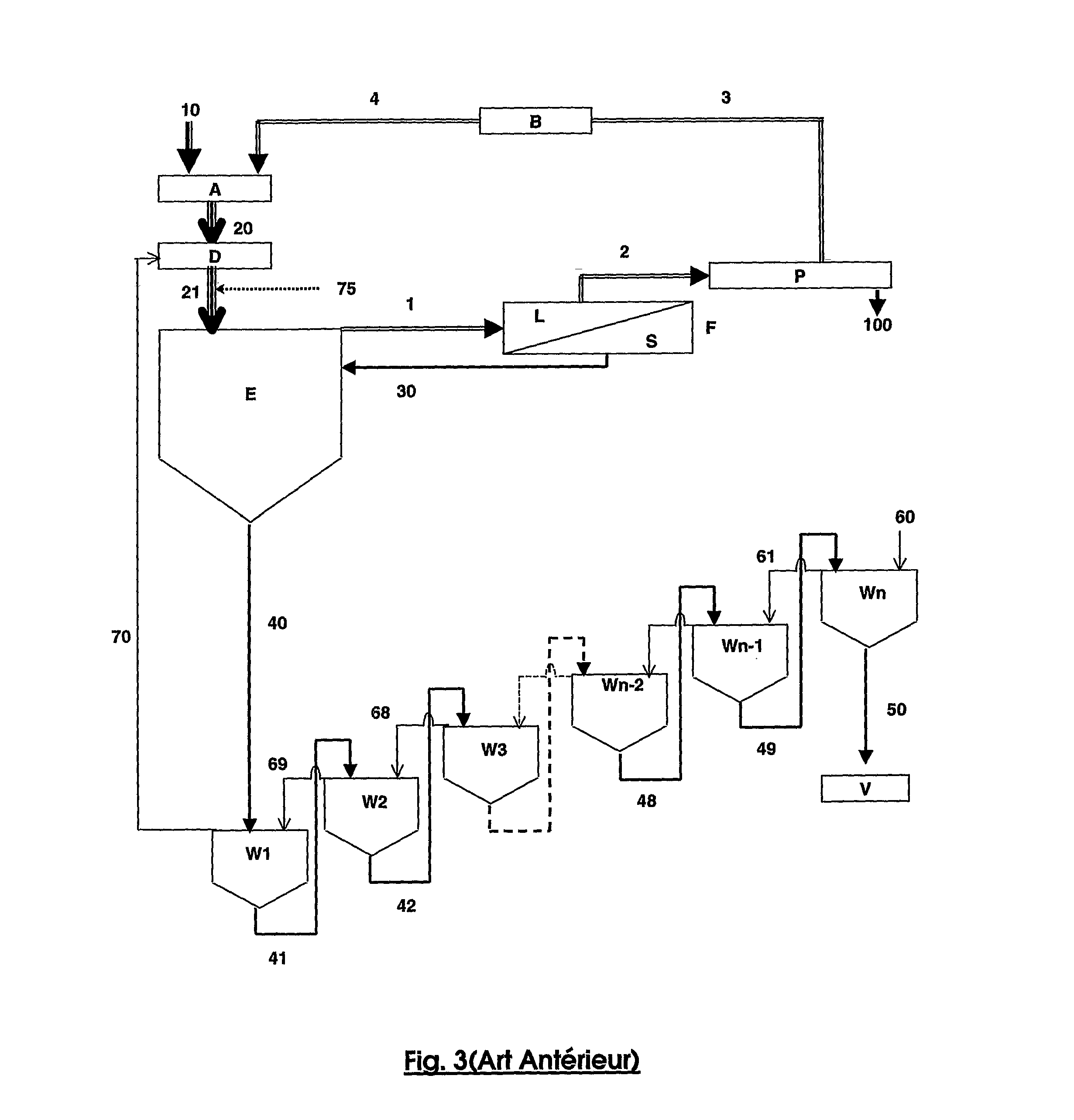

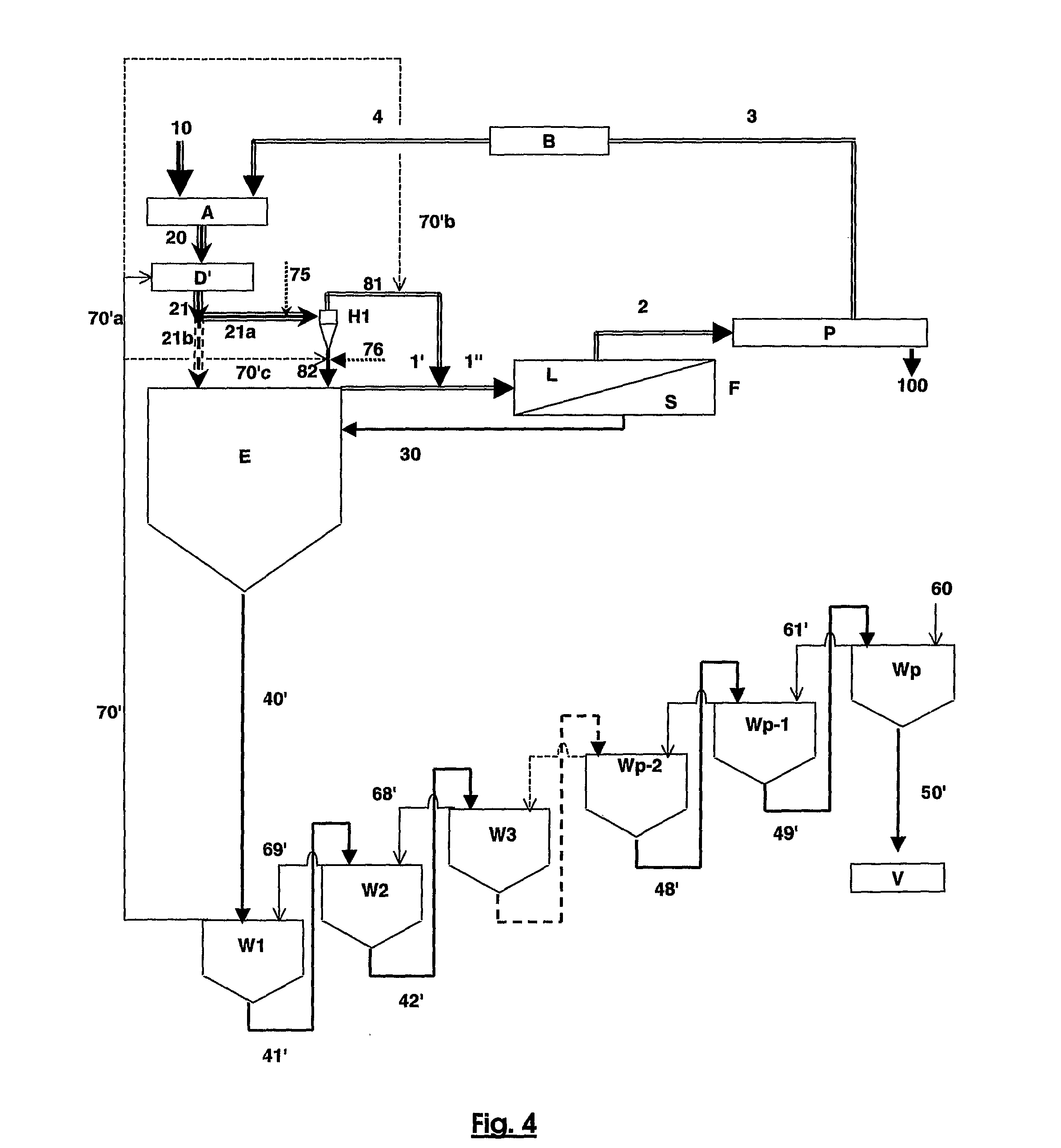

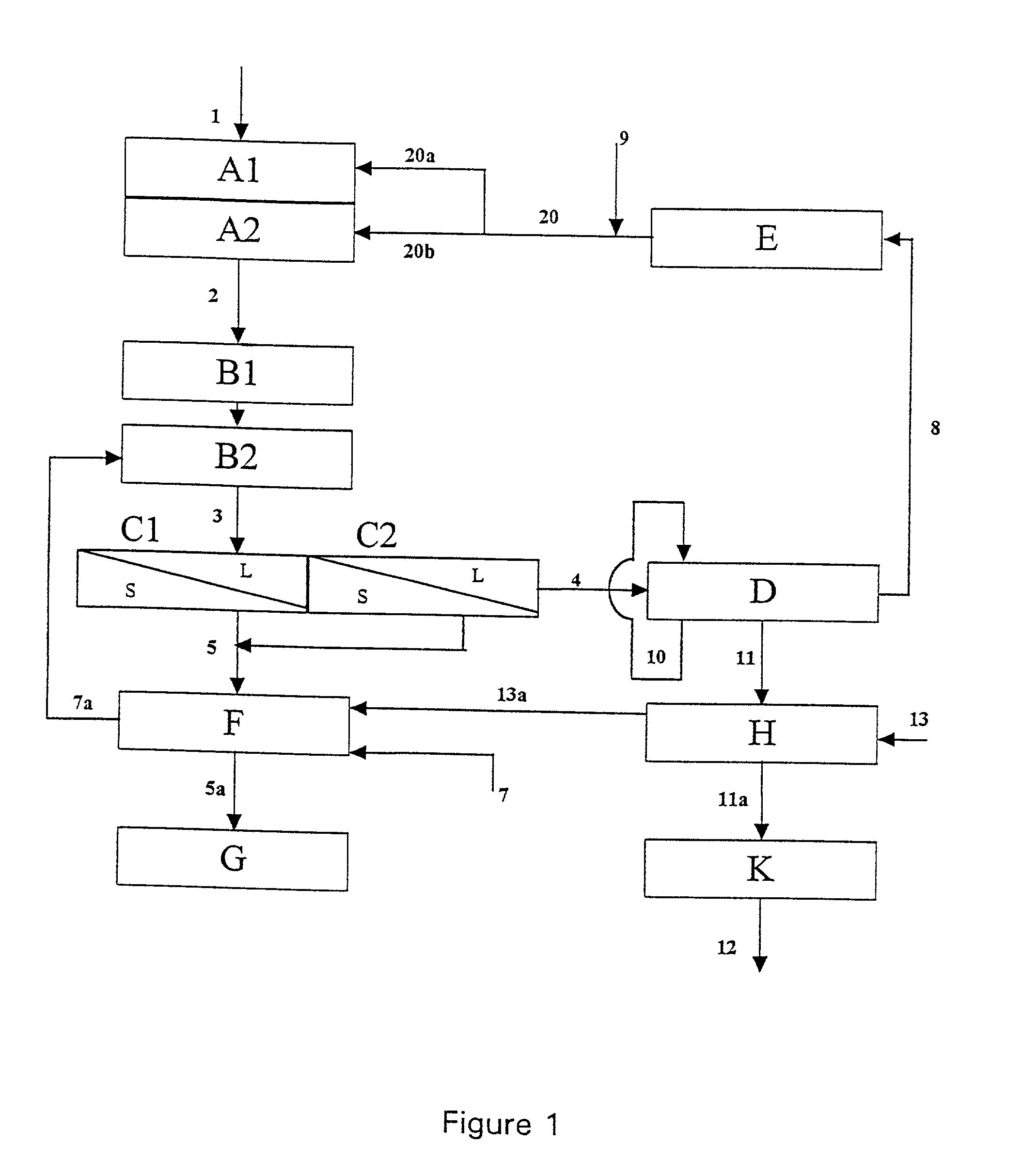

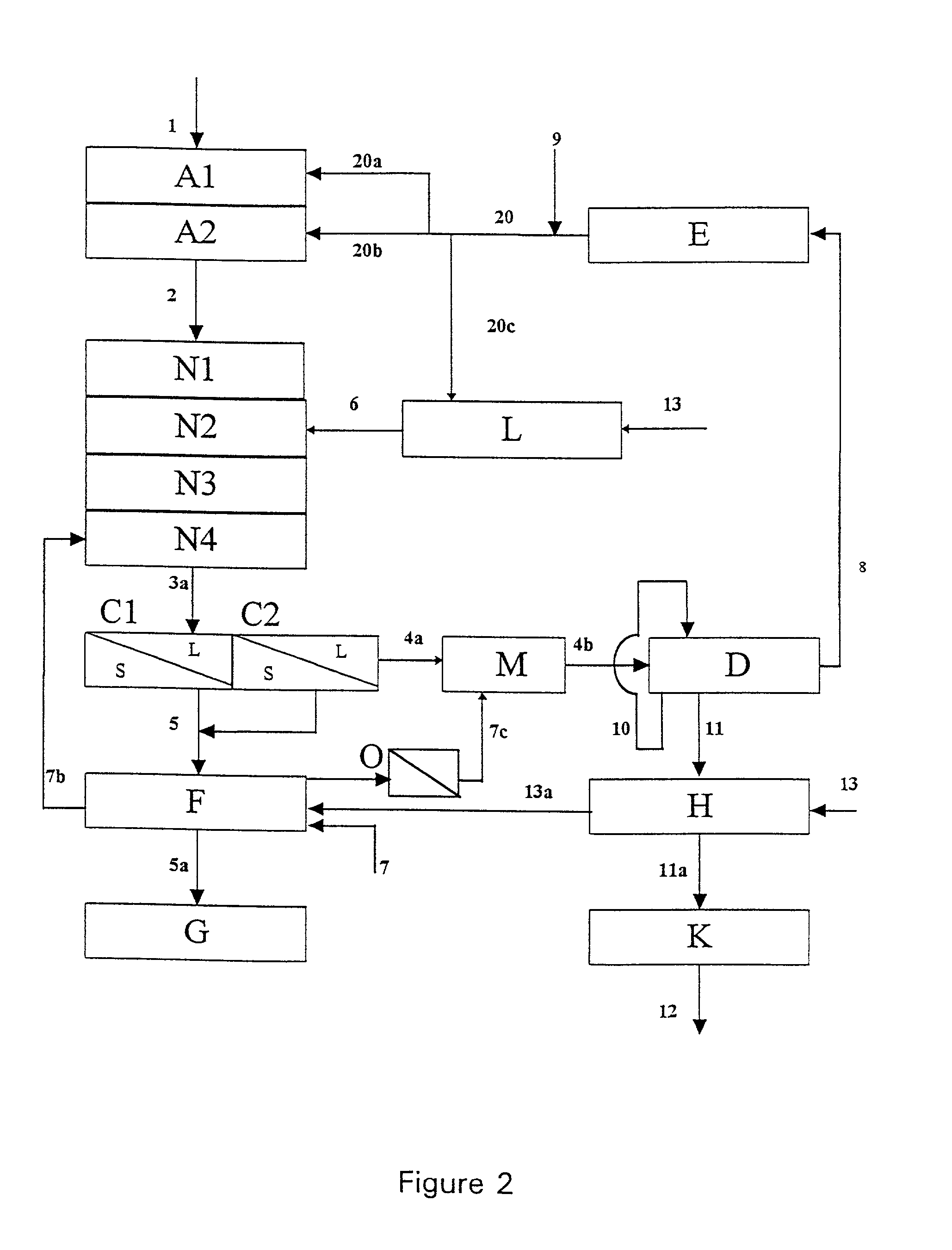

Bayer Process for Production of Alumina Trihydrate, the Said Improvement Relating to Separation of Aluminate Liquor and Insoluble Residues

InactiveUS20070243118A1Increasing caustic soda contentIncrease residueCentrifugal force sediment separationThin material handlingAluminateSodium aluminate

A process for the production of alumina trihydrate by alkaline digestion of bauxite using the Bayer process in which aluminate liquor and insoluble residues are separated using a solid / liquid separation device (E; W2; DC) characterised in that the said slurry (21a; 41; 230′) is at least partially passed through a hydrocyclone (H1; H21; H22; H3) to improve and accelerate the separation of the sodium aluminate liquor from the insoluble residues in the slurry (21a; 41; 230′) containing the said liquor and the said residues and that supplies or is derived from the said liquid—solid separation device. In a first embodiment, at least one hydrocyclone is used at the upstream side of the settler—thickener, as clarifier of the pregnant liquor. In a second embodiment, at least one hydrocyclone is used as a thickener of insoluble residue mud. In a third embodiment, a hydrocyclone is used in combination with the causticisation settler.

Owner:ALUMINUM PECHINEY

Resin composition

ActiveUS20130237658A1Good molding effectPigmenting treatmentPigment pastesAcetic acidPolyester resin

Provided is a resin composition that includes calcium carbonate contained in a polyester resin, a polyamide resin, or at thermosetting resin and that achieves good moldability. The resin composition includes calcium carbonate having a pB ranging from 6.0 to 8.5 and a 1N acetic acid-insoluble residue or 30% by mass or more and the calcium carbonate is contained in a polyester resin, a polyamide resin, or a thermosetting resin.

Owner:SHIRAISHI CENT LAB

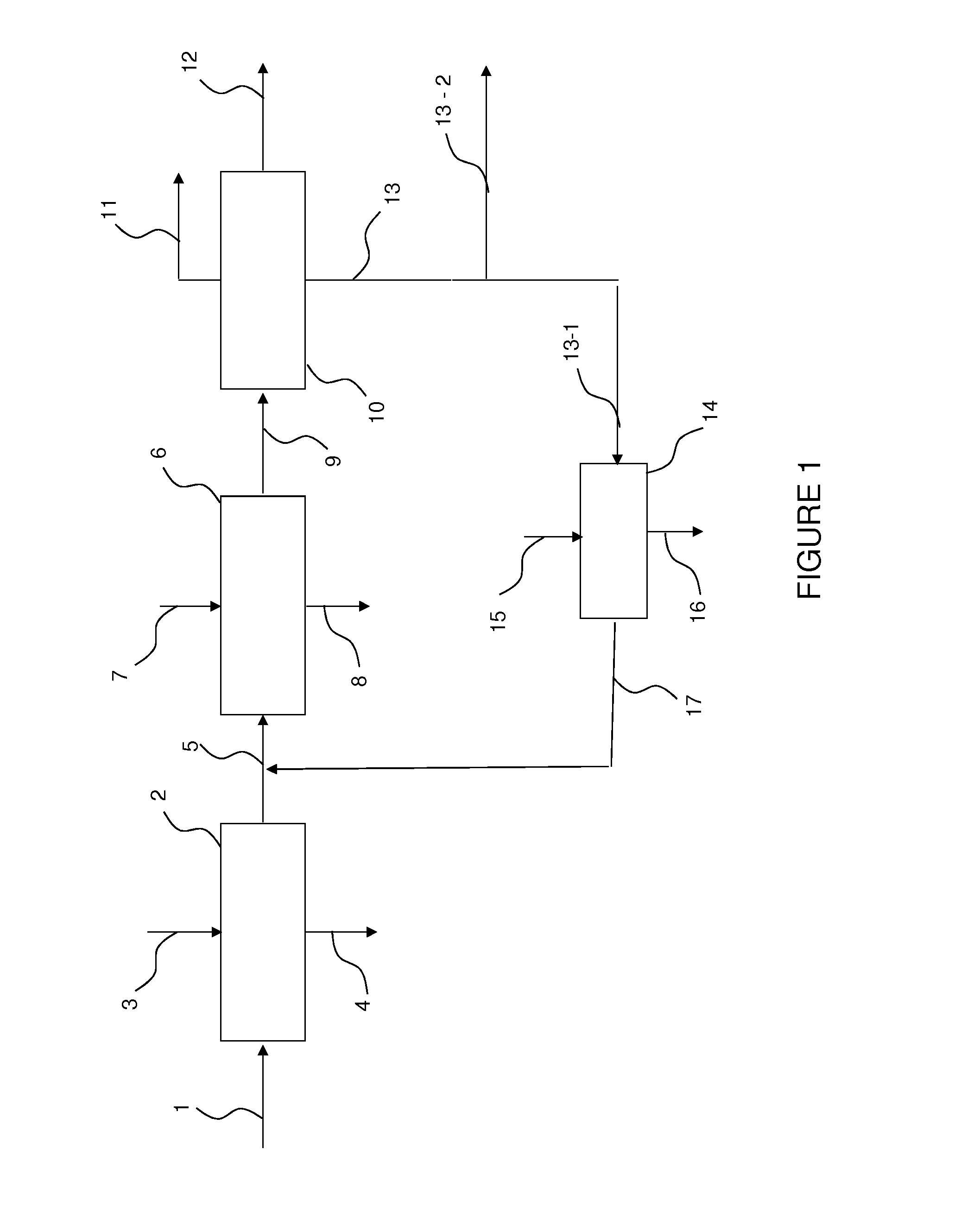

Method for producing alcohols and/or solvents from paper pulps with recycling of the non-hydrolysated plant material in a regeneration reactor

This invention describes a process for the production of alcohols and / or solvents from cellulosic or lignocellulosic biomass that comprises at least the following stages:a) Alkaline chemical pretreatment of a cellulosic or lignocellulosic substrate;b) Optionally washing of the pretreated substrate;c) Enzymatic hydrolysis of the substrate that is pretreated and optionally washed using cellulolytic and / or hemicellulolytic enzymes that produce a hydrolyzate and a water-insoluble residue;d) Microorganism fermentation of the hydrolyzate that is obtained from stage c) and production of a fermentation must that contains at least one alcohol and / or solvent;e) Separation / purification of alcohol and / or solvent, andf) Separation of a cake that contains the insoluble residue,in which at least a portion of the cake that is obtained in stage f) is sent into at least one reactor for regeneration of cellulose, before being recycled downstream from stage a) for alkaline chemical pretreatment.

Owner:INST FR DU PETROLE

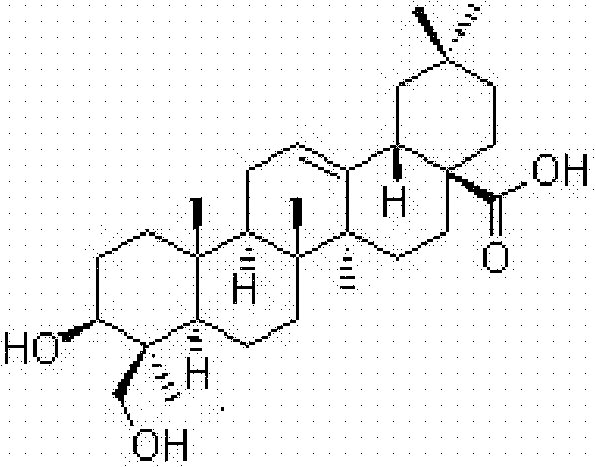

Extraction method of hederagenin

InactiveCN102633857AAvoid lostEfficient separation and purificationSteroidsFiltration membraneInsoluble residue

The invention relates to an extraction method of hederagenin, and in the method, Chinese medicinal material teasel root is used as a raw material. The method comprises the following steps: a, adding hydrochloric acid or sulphuric acid into a 30-55% ethanol solution to prepare a 1.5-4N hydrochloric acid or sulphuric acid ethanol mixed solution; b, hydrolyzing the crushed teasel root in the hydrochloric acid or sulphuric acid ethanol mixed solution in the step a, filtering, and washing insoluble residues with water until the insoluble residues are neutral; c, extracting the residues obtained in the step b with an ethanol solution in a refluxing condition to obtain ethanol extract; and d, filtering the ethanol extract obtained in the step c through an ultrafiltration membrane with molecular weight cutoff of 3,000-8,000Da to obtain permeate, filtering the permeate with a nano-filtration membrane with a molecular weight cutoff of 200-600Da to obtain concentrate, and drying the concentrate to obtain the hederagenin. The method is simple and convenient in operation and simple and short in steps, so that the extraction quality and the extraction rate can be greatly improved.

Owner:JILIN UNIV

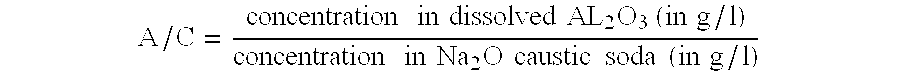

Method for processing bauxite rich in alumina monohydrate

InactiveUS20010012498A1Easy to settleLow viscosityGallium/indium/thallium compoundsBeryllium compoundsAluminateFiltration

Process for treating alumina monohydrate-based bauxite by high-temperature caustic digestion characterized in the following series of operations: a) digestion of the bauxite at a temperature in excess of 200° C. with a liquor concentrated to more than 160 g Na2O / liter and having a A / C weight ratio between 0.45 and 0.75, for a contact time which is sufficient to extract the aluminate monohydrate and to attain a A / C ratio between 1.10 and 1.20; b) cooling of the slurry and introducing alumina trihydrate in said slurry, at a temperature of less than 200° C., in order to obtain a A / C ratio of the aluminate liquor between 1.20 and 1.30; c) first diluting to a concentration between 160 and 175 g Na2O / liter; d) settling to separate the insoluble residue from a sodium aluminate liquor with an A / C ratio between 1.20 and 1.30; e) filtering the aluminate liquor; f) lowering the aluminate liquor with a complementary dilution before or during crystallization; g) after separation of the alumina trihydrate by filtration, recycling the spent liquor which, after concentration, is reused as digestion liquor with a caustic concentration above or equal to 160 g Na2O / liter.

Owner:ALUMINUM PECHINEY

Method for manufacturing display device that includes supplying solution to the underside of a glass substrate

InactiveUS7119027B2Reduce displayDecorative surface effectsElectroluminescent light sourcesDisplay deviceEngineering

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com