Patents

Literature

31results about How to "Omit preprocessing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

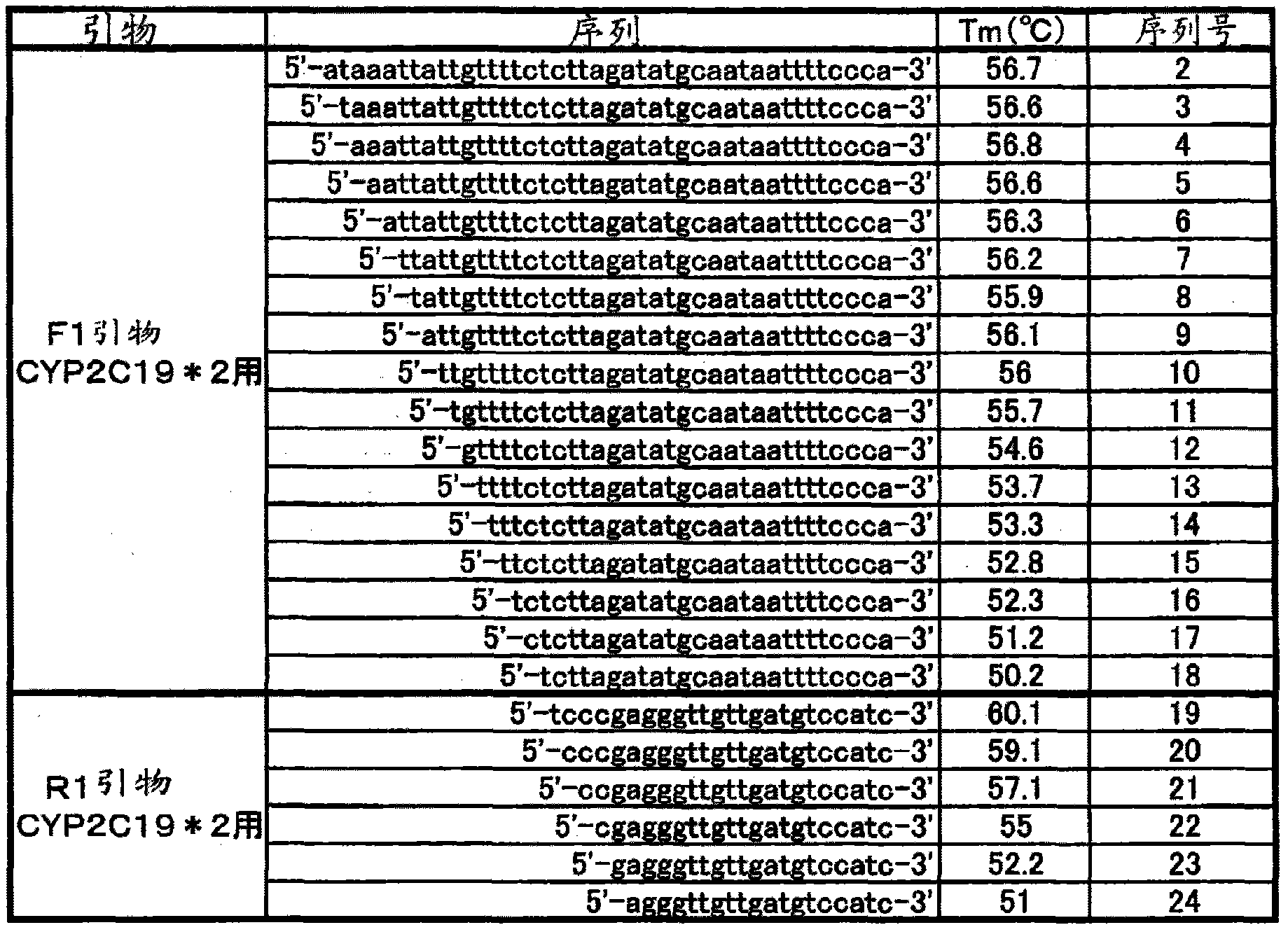

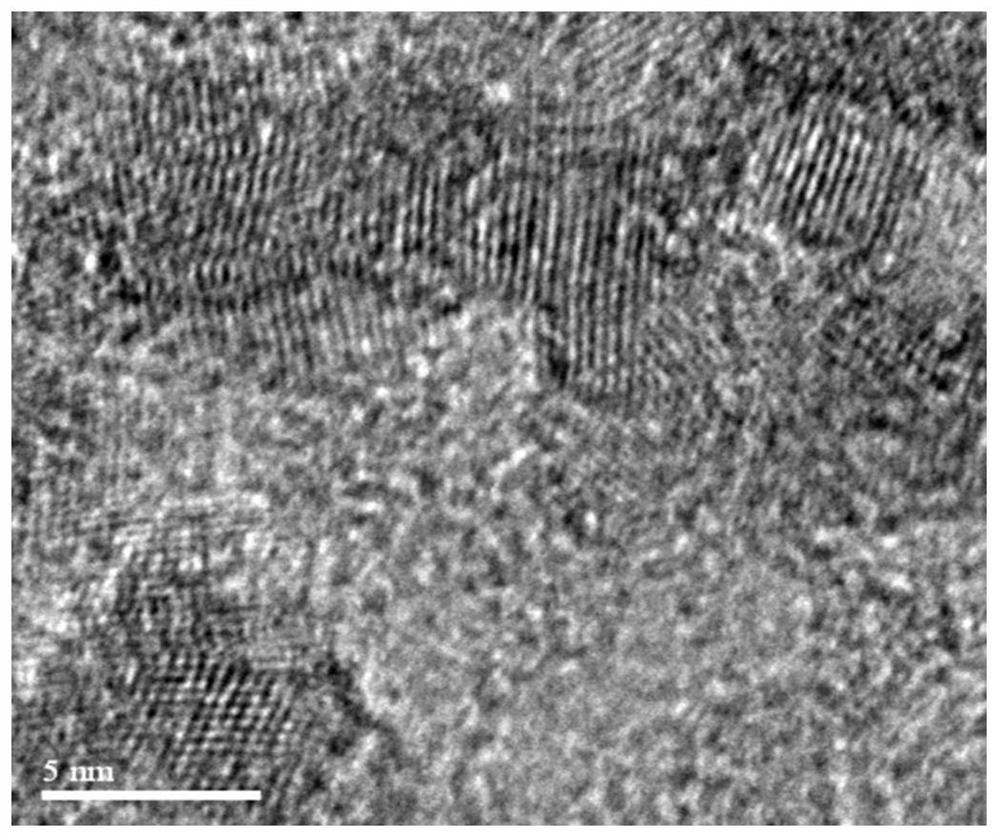

Double colour fluorescent chemical sensor used for visually detecting explosive and manufacturing method thereof

ActiveCN102095711AEasy to operateHigh sensitivityFluorescence/phosphorescenceQuantum dotSilicon nanoparticle

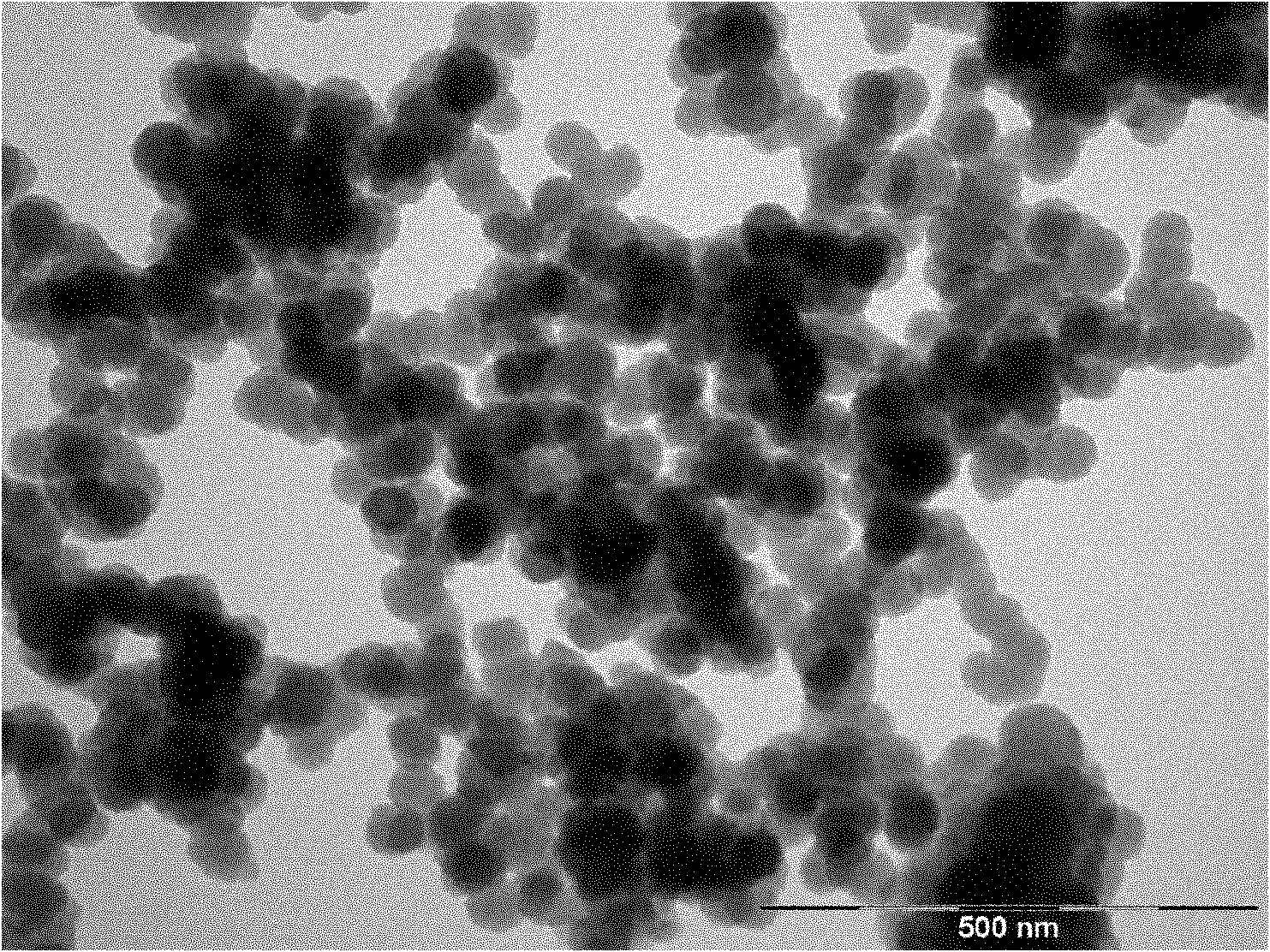

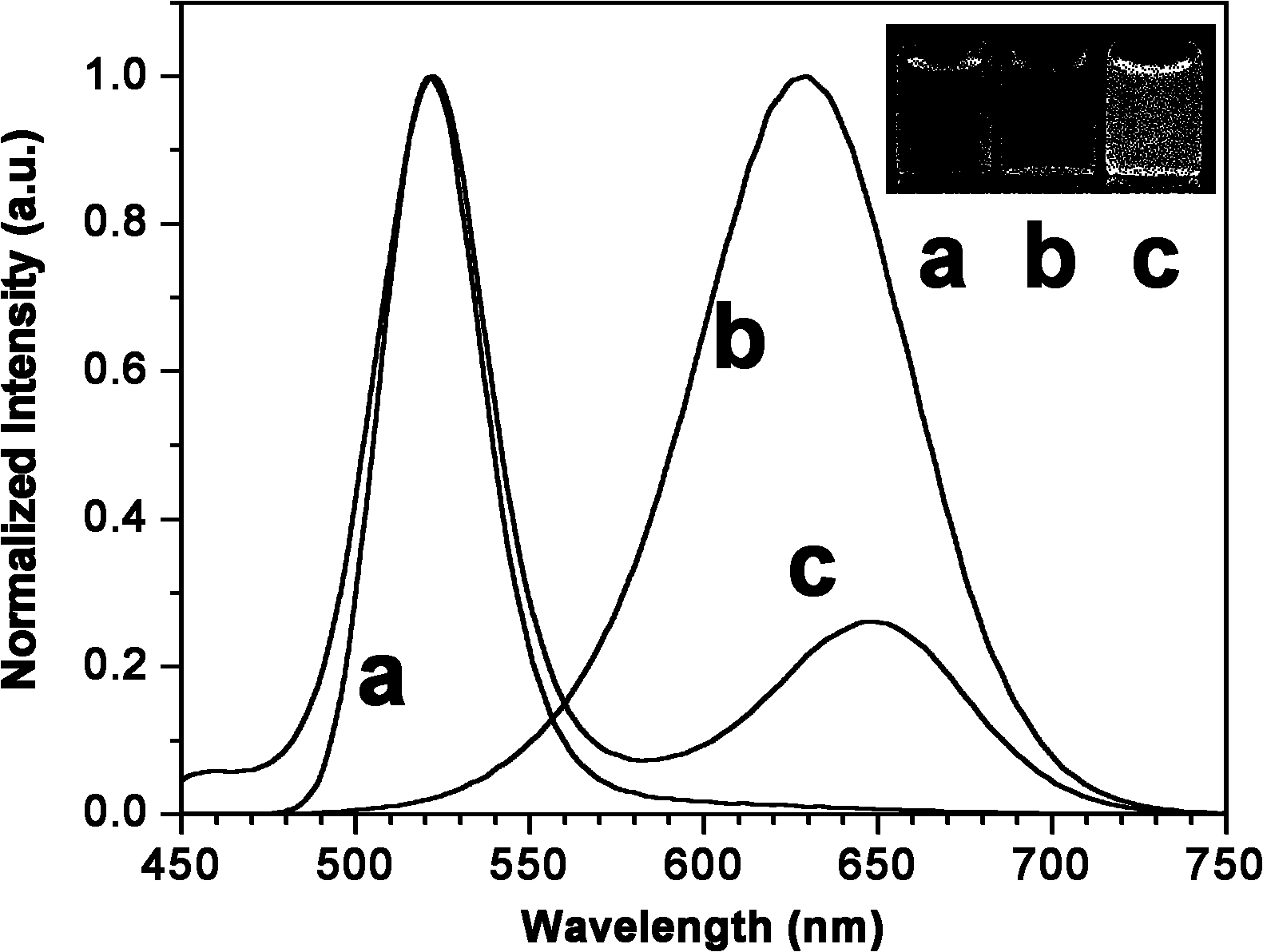

The invention relates to a double colour fluorescent chemical sensor used for visually detecting explosive, in particular to a paper-based or membrane-based sensor comprising a filter paper or glass slide substrate and double colour quantum dot superstructure silicon oxide nano particles uniformly distributed on the substrate. The method for manufacturing the sensor comprises the following steps of: firstly embedding red or green quantum dots into silicon oxide nano particles, aminating the surface of silicon oxide, then carrying out covalence coupling and coating a green or red quantum dot sensitive layer to obtain the double colour quantum dot superstructure silicon oxide nano particles, and finally processing to obtain the fluorescent chemical sensor. By applying the sensor, explosive residue with the trace of 5nanogram / mm<2> can be visually and rapidly detected online in real time. The fluorescence intensity of outer quantum dots is 2-10 times that of inner quantum dots.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

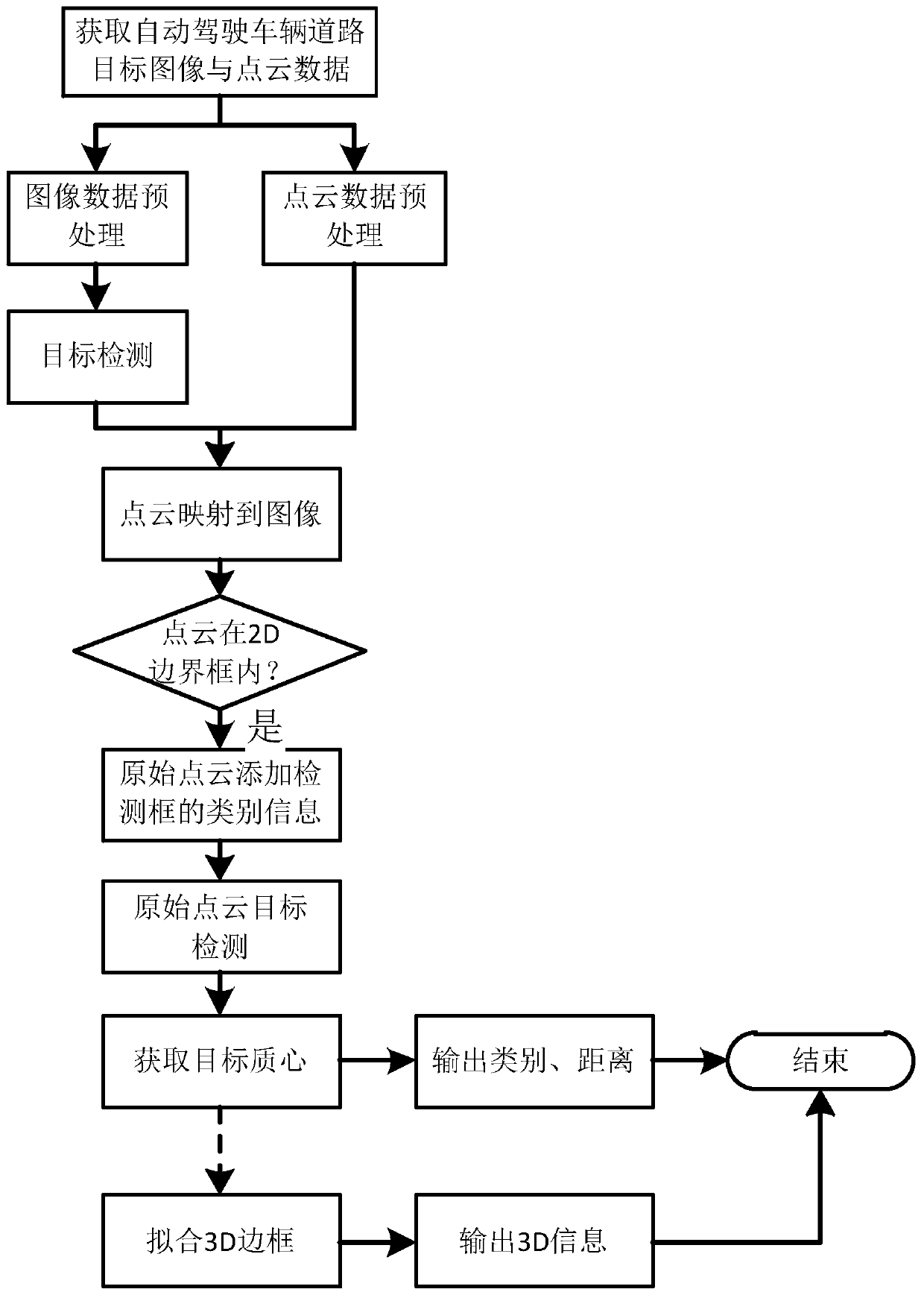

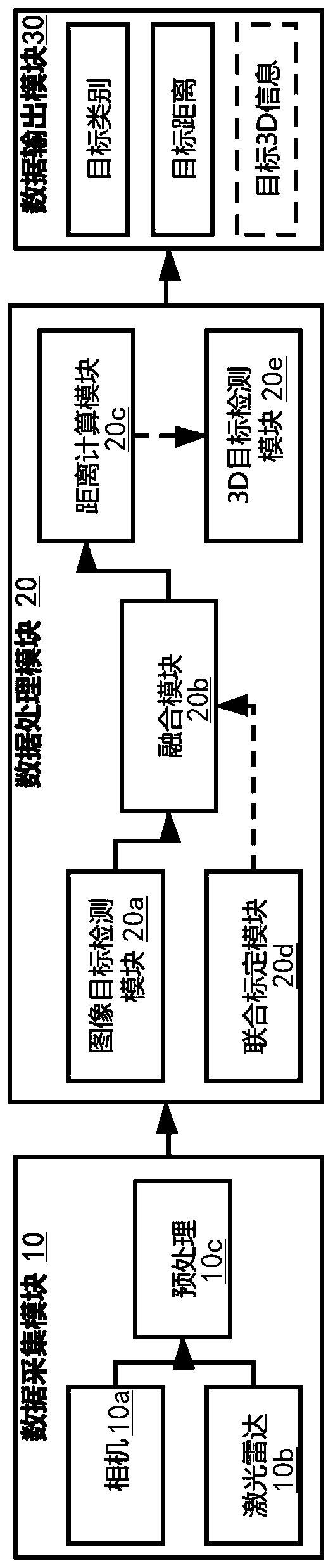

Method, system and device for detecting road target and distance of automatic driving vehicle

ActiveCN110988912AOmit preprocessingCalculation speedElectromagnetic wave reradiationLow speedPoint cloud

The invention belongs to the technical field of automatic driving, particularly relates to a method, a system and a device for detecting a road target and a distance of an automatic driving vehicle, and aims to solve the problems of low speed and low precision when the road target and the distance of the automatic driving vehicle are detected in the prior art. The method comprises the following steps: acquiring a road target image and point cloud data of an automatic driving vehicle, and respectively preprocessing the road target image and the point cloud data; obtaining category label information and 2D bounding box information of the target through a target detection network; performing fusion processing on the road target image and the point cloud data to obtain point cloud with image label information in a 2D bounding box; and obtaining a target point cloud through target detection, and taking the distance of the mass center of the target point cloud as the distance of the currenttarget. The method can calculate the actual distance of the target, is not liable to be affected by complex weather and geographical environment, just needs to process the point cloud data of the 2D detection frame, is high in speed, and is high in precision.

Owner:QINGDAO VEHICLE INTELLIGENCE PIONEERS INC

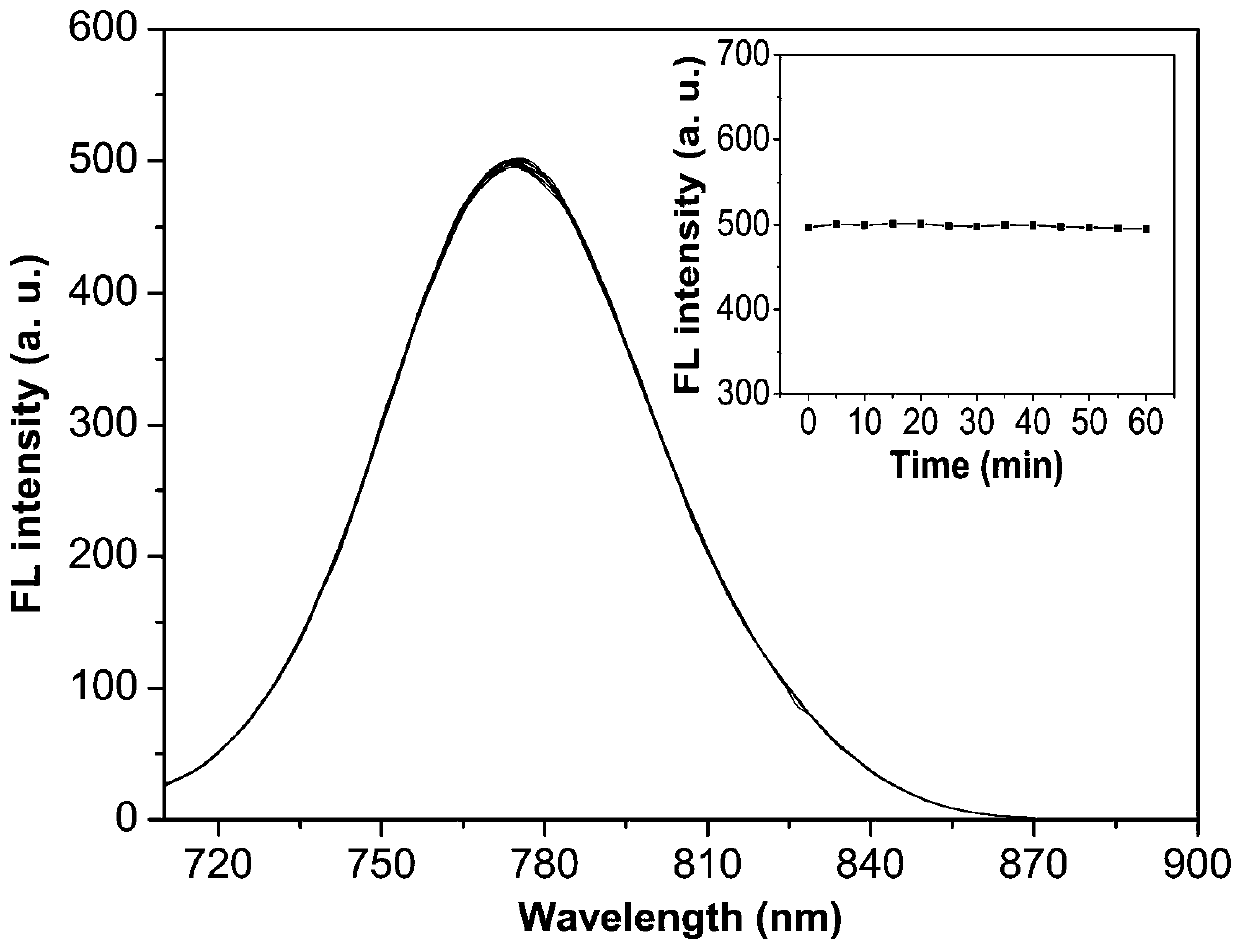

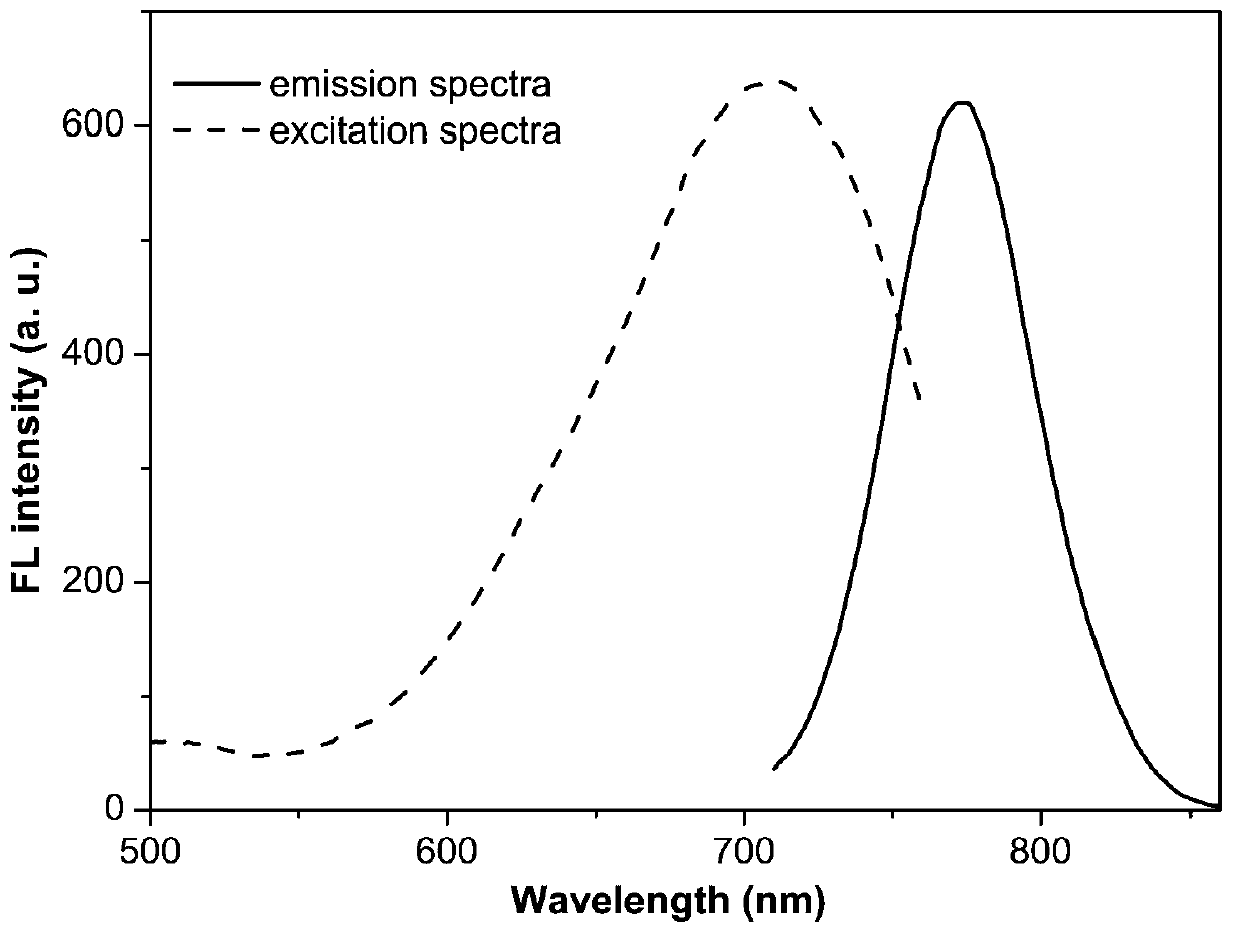

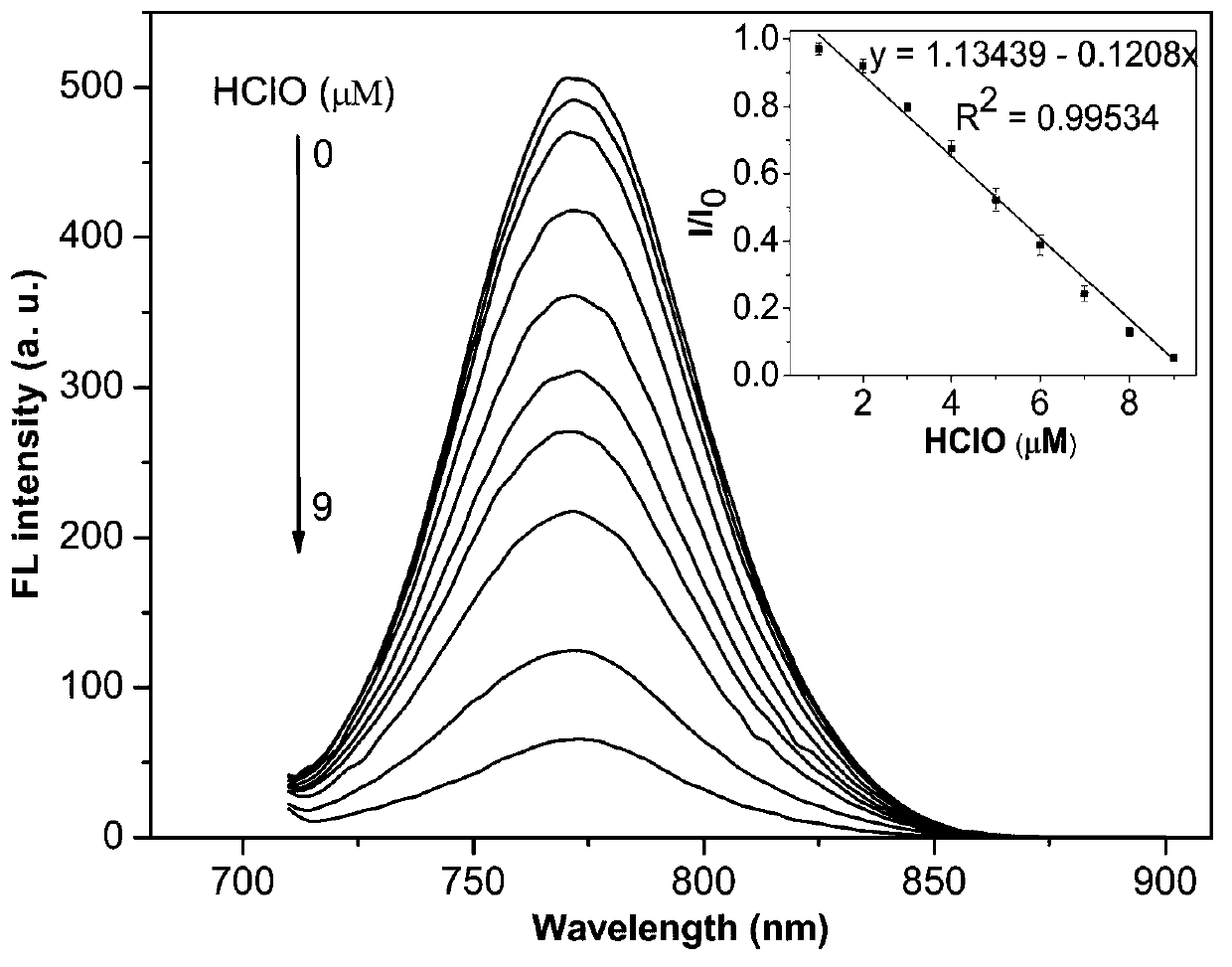

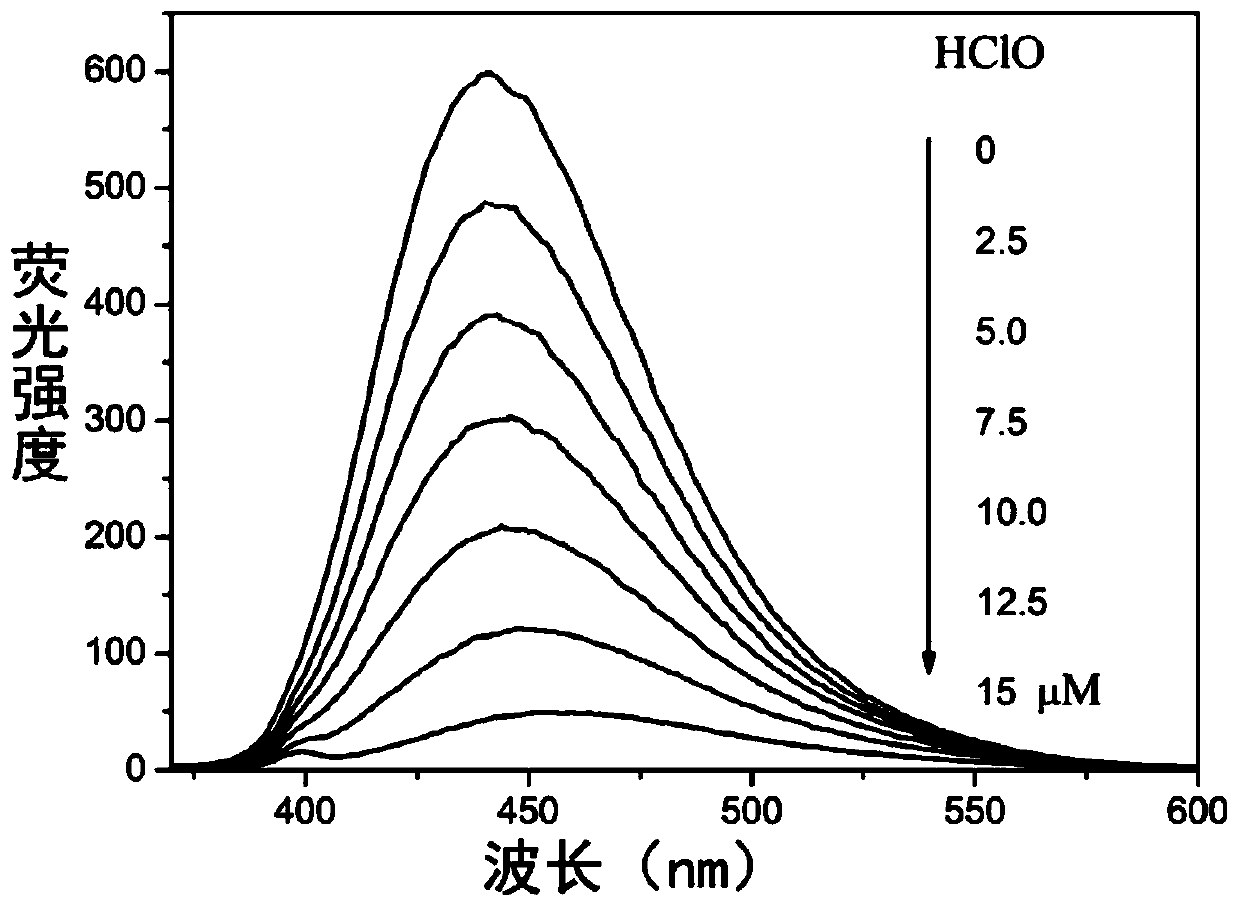

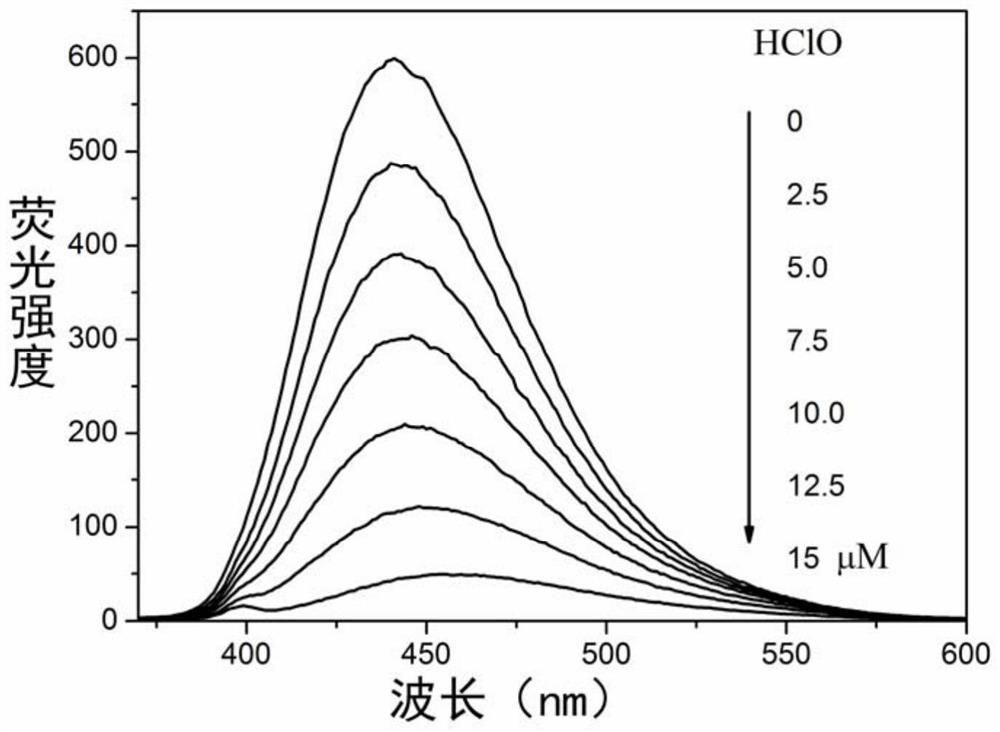

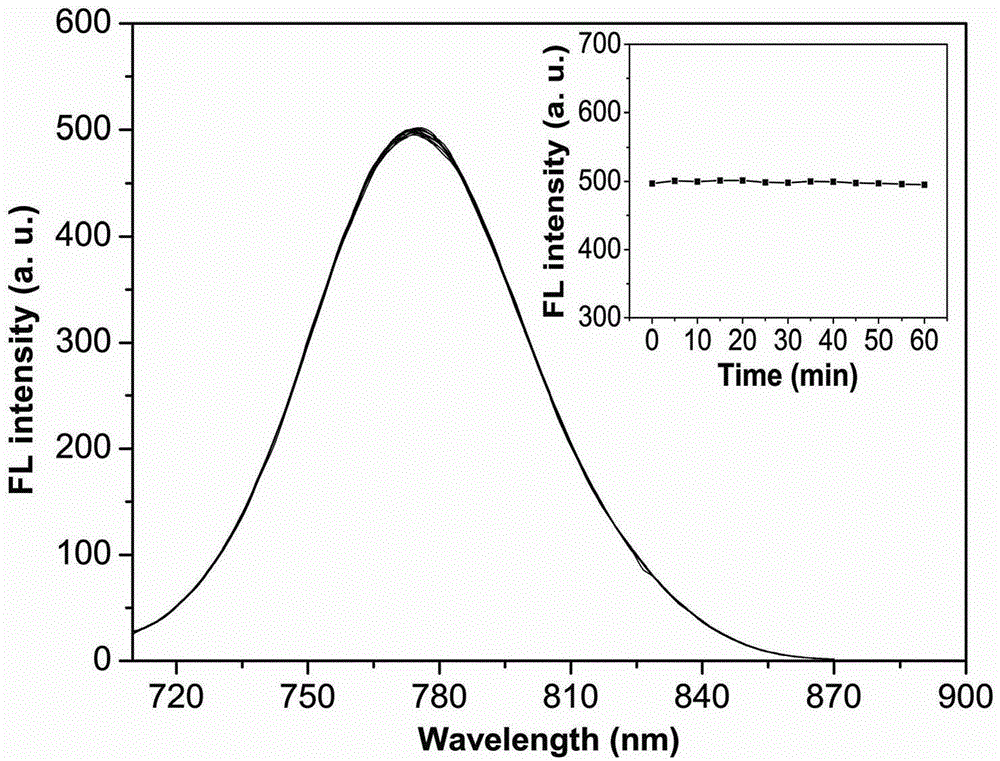

Difunctional near-infrared fluorescence molecular probe for detecting hypochlorous acid and preparation method for same

InactiveCN103342697ARealize detectionGood light stabilityOrganic chemistryFluorescence/phosphorescenceArylDouble bond

The invention discloses a difunctional near-infrared fluorescence molecular probe for detecting hypochlorous acid and a preparation method for the same. The difunctional near-infrared fluorescence molecular probe has the structure general formula defined in the specification, wherein R1 and R2 independently represent 2-pyridyl, 2-furyl, substituted 2-pyridyl, substituted 2-furyl, aryl or substituted aryl respectively; R3 is selected from methyl, ethyl or propyl; and X- is selected from Cl-, Br- or I-. The changes of the fluorescence intensity and the colour of the probe are caused due to the breakage of the double bonds of the fluorescence probe at the end of a chain under the oxidation of hypochlorous acid, so that the fluorescence probe can be used for visual detection for hypochlorous acid in an aqueous solution, and is suitable for detection for hypochlorous acid generated by enzymatic reaction in the condition of a physiological environment simultaneously, and a detection line can achieve 0.70mu mol / L. The method disclosed by the invention has the advantages of being capable of detecting hypochlorous acid with a fast speed and high selectivity, suitable for bioimaging, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for recovering platinum from aluminum-based catalyst only by dissolving carrier

InactiveCN108315564AOmit preprocessingGet in timeProcess efficiency improvementFiltrationDissolution

The invention relates to a method for recovering platinum from an aluminum-based platinum catalyst. The mode that an aluminum-based carrier is selectively dissolved, and the platinum is recycled froma small amount of insoluble residues through re-dissolving is adopted. The process route comprises the following steps of selective dissolving of the aluminum-based carrier, reduction precipitation, clarifying filtration, calcination for removing organic matters, oxidation dissolution of the platinum through inorganic acid, precipitation and reduction of the platinum, and sponge platinum products.According to the method, catalyst raw materials are not roasted, the small amount of remaining insoluble residues after the carrier is dissolved are only roasted, and energy consumption is greatly reduced. The process is simple and short, reagent consumption is less, and the recovery cost is low. Platinum recovery cannot be delayed, and the recovery timeliness is good. The platinum recovery ratereaches 98.2%, and the sponge platinum purity is greater than or equal to 99.95%.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

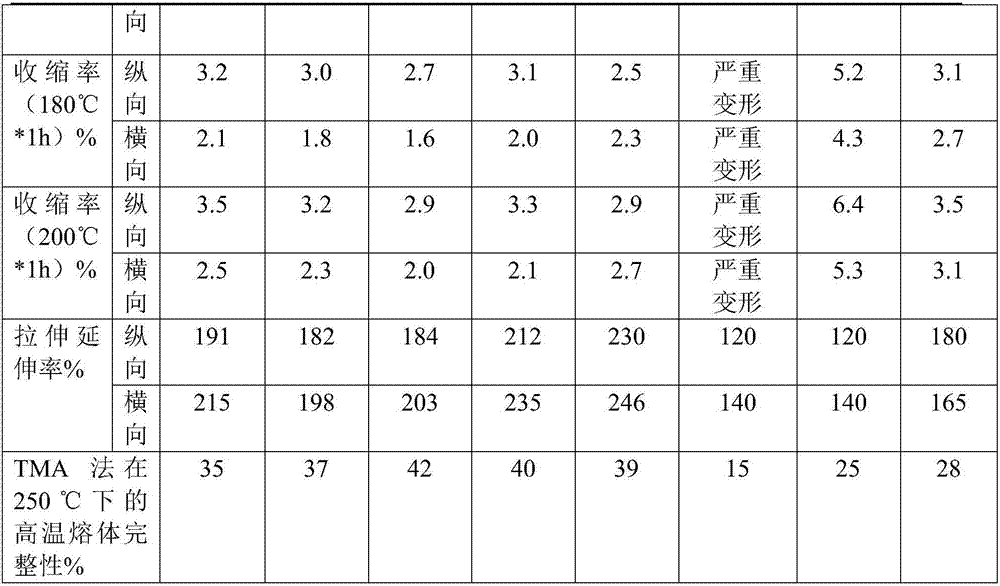

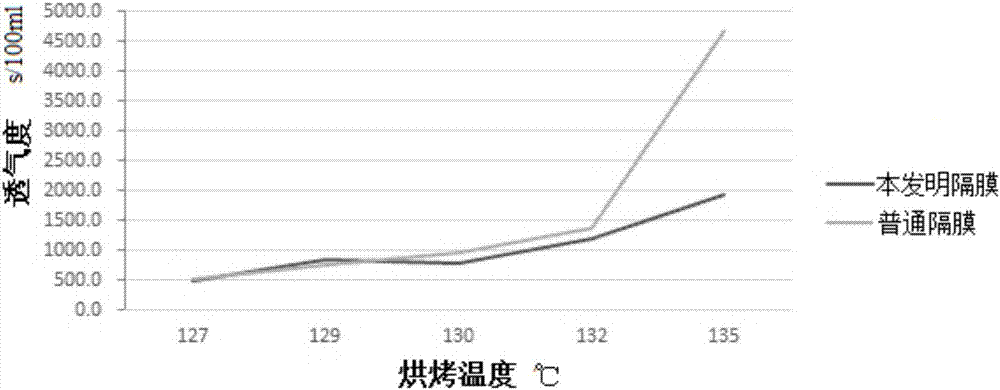

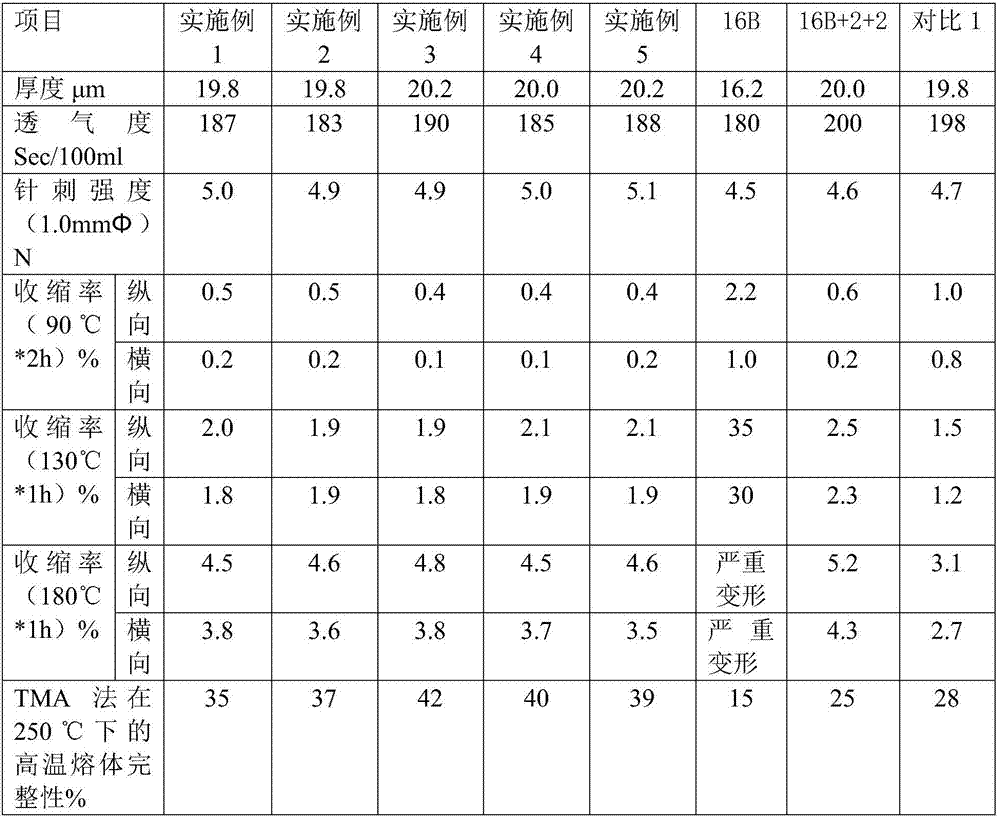

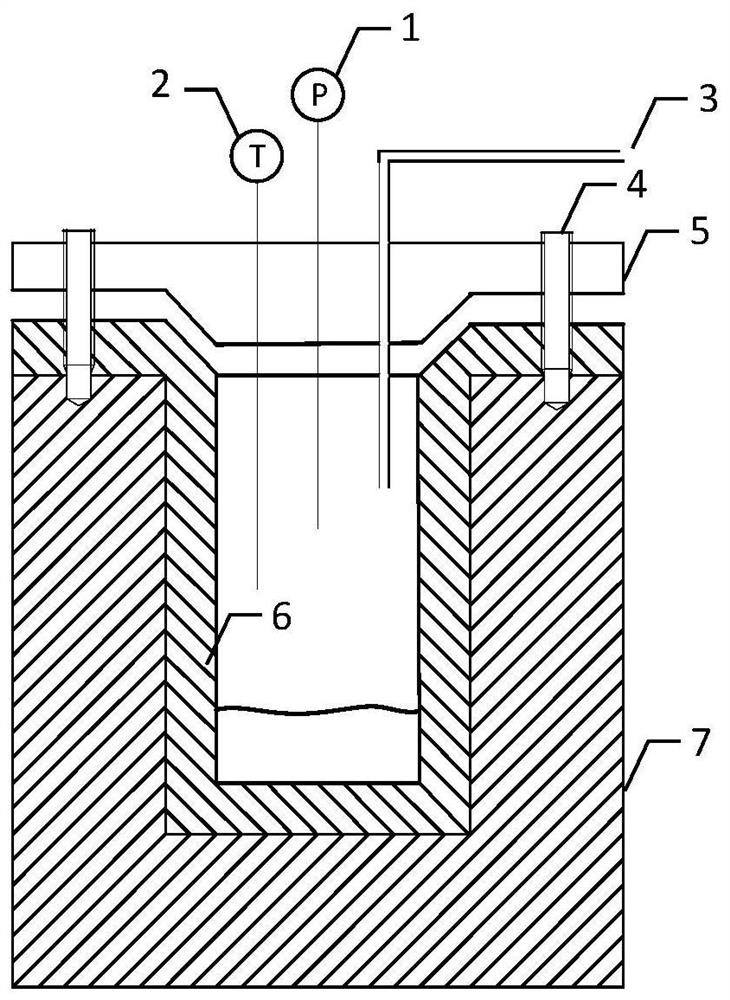

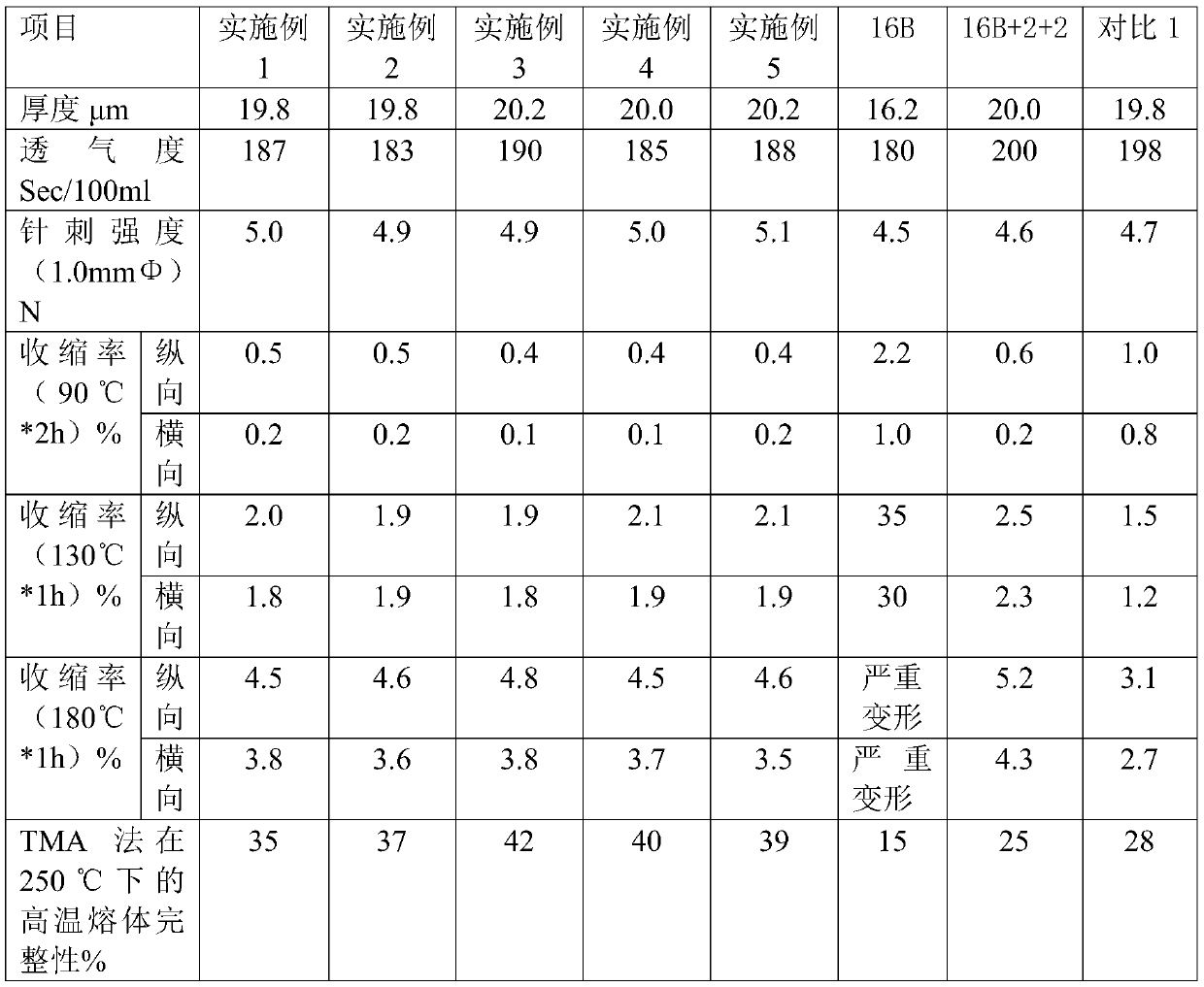

Preparation method of high-temperature-resistant low-resistivity lithium ion battery diaphragm

InactiveCN107342386AIncrease specific energyLow shrinkageSecondary cellsCell component detailsCarbon nanotubeSlurry

The invention relates to a preparation method of a high-temperature-resistant low-resistivity lithium ion battery diaphragm, and belongs to the technical field of battery diaphragms. A slurry layer is coated on one side end face or two side end faces of a basal membrane; then, after the slurry layer is dried, the high-temperature-resistant low-resistivity lithium ion battery diaphragm is obtained; the slurry layer is ceramic slurry or carbon nano tube modified ceramic slurry; and furthermore, the carbon nano tube modified ceramic slurry is at least coated on one side end face of the basal membrane. The invention further discloses a specific method for preparing the carbon nano tube modified ceramic slurry. By means of the preparation method in the invention, a steady and high-efficiency process is provided for producing the high-temperature-resistant low-resistivity lithium ion battery diaphragm; the prepared carbon nano tube modified ceramic slurry has low shrinkage ratio and high security of the ceramic slurry at high temperature, and also has high electric conductivity at normal temperature and low electric conductivity at high temperature of a carbon nano tube material; therefore, when the high-temperature-resistant low-resistivity lithium ion battery diaphragm is used in the field of electric automobiles, the charging time consumption problem of the electric automobiles can be solved; and the technical support is provided for development of clean energy automobiles.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

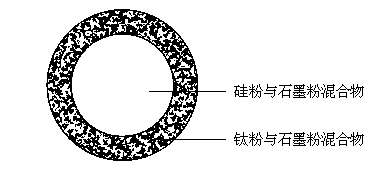

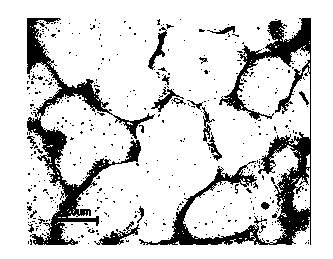

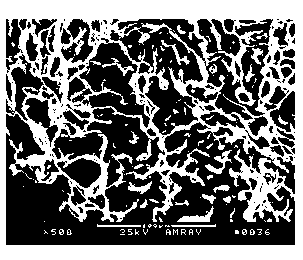

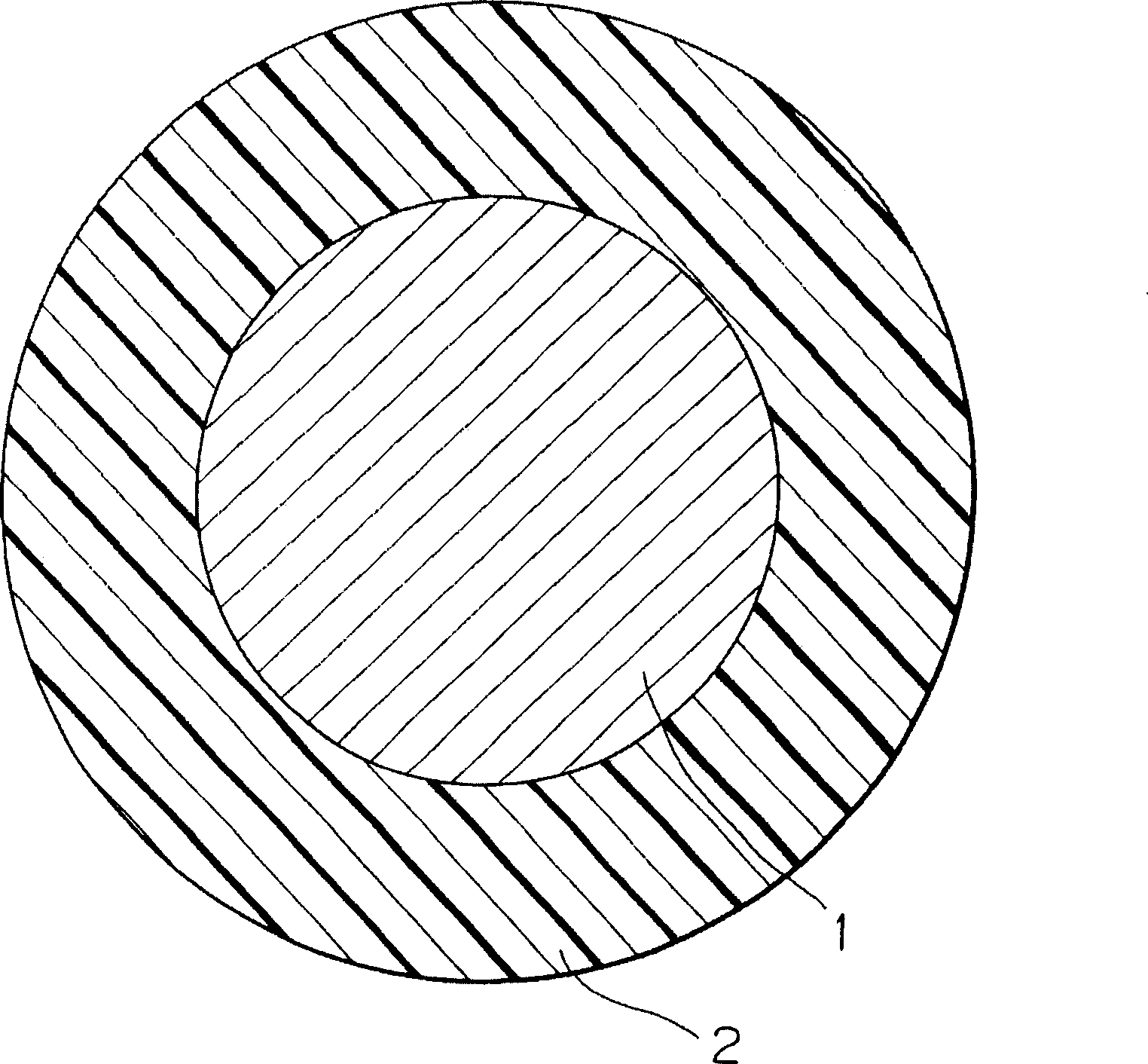

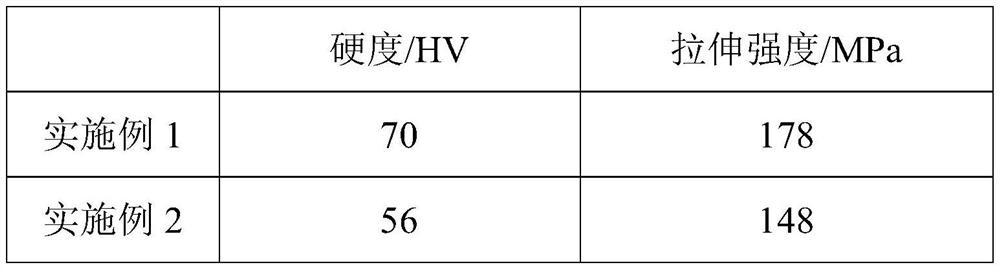

In-situ SiC-TiC particle mixing enhanced aluminum-based composite material and preparation process thereof

The invention relates to the technical field of non-continuous enhanced metal-based composite materials, and in particular relates to an in-situ SiC-TiC particle mixing enhanced aluminum-based composite material and a preparation process thereof. For overcoming the defects of high preparation cost, complicated process and poor wettability and compatibility of particles and substrates in the prior art, the invention provides the in-situ SiC-TiC particle mixing enhanced aluminum-based composite material and the preparation process thereof. The preparation process comprises the following steps: firstly, preparing in-situ reaction system press cakes: dividing the designed press cakes into inner and outer layers, wherein the mass ratio of the inner layer to the outer layer is 3:10, and then pressing by a pressure machine; then, preparing Al-4.5Cu based alloy by taking pure Al and Al-50% Cu as raw materials; and finally adding the press cakes in Al-4.5Cu melt to carry out in-situ reaction. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the in-situ produced SiC particles are fine and reach micron scale.

Owner:XIAN TECH UNIV

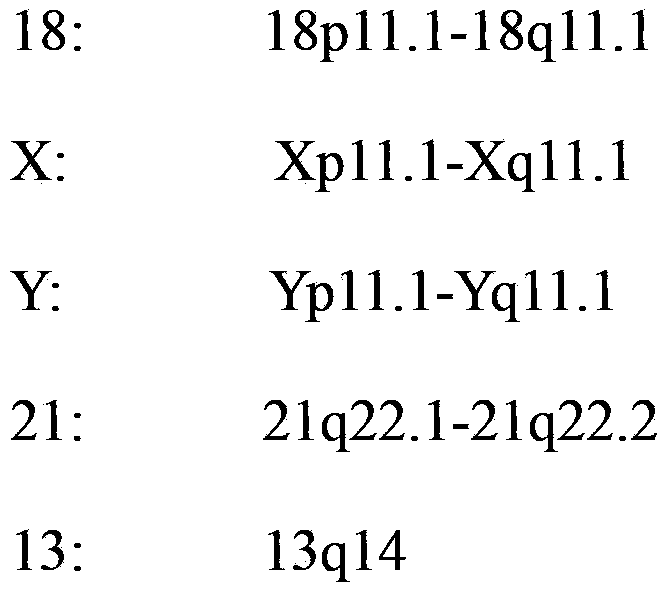

Fluorescence in-situ hybridization method capable of improving covariance

ActiveCN103451287AOmit preprocessingImprove accuracyMicrobiological testing/measurementFluorescence/phosphorescenceFluorescenceSpecimen preparation

The invention relates to a fluorescence in-situ hybridization technology, and discloses a fluorescence in-situ hybridization method capable of improving covariance. The fluorescence in-situ hybridization method capable of improving covariance comprises the steps of slide specimen preparation, probe and chromosome covariance and hybridization, washing and dyeing after hybridization, and signal detection. According to the fluorescence in-situ hybridization method capable of improving covariance disclosed by the invention, a method of probe and chromosome covariance and hybridization is adopted on the basis of the prior art, the operation is simple, the reaction steps are reduced, experimental time is shortened, and a toxic and teratogenic denaturant does not need to be used, thus decreasing experimental cost, and avoiding the harm of the denaturant to experimental operating personnel and environment. The invention provides a fluorescence in-situ hybridization method capable of improving covariance, which is accurate in location, high in sensitivity, high in experimental efficiency, good in stability, simple to operate, and has environment-friendly effect.

Owner:曾艳

Preparation method of self-cooled and hole-closing-resistant lithium ion battery diaphragm

The invention discloses a preparation method of a self-cooled and hole-closing-resistant lithium ion battery diaphragm, and belongs to the technical field of the battery diaphragm. The slurry layer is arranged at one side end surface or two side end surfaces of a basement membrane, thereby obtaining the self-cooled and hole-closing-resistant lithium ion battery diaphragm after the drying; the slurry layer is the ceramic slurry or the erythritol modified ceramic slurry, the erythritol modified ceramic slurry is at least coated at one side end surface, and the specific method for preparing the erythritol modified ceramic slurry is disclosed. The preparation method disclosed by the invention provides the stable and efficient process of the self-cooled and hole-closing-resistant lithium ion battery diaphragm; the prepared erythritol modified ceramic slurry has low shrinkage and high security at the high temperature of the ceramic slurry.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

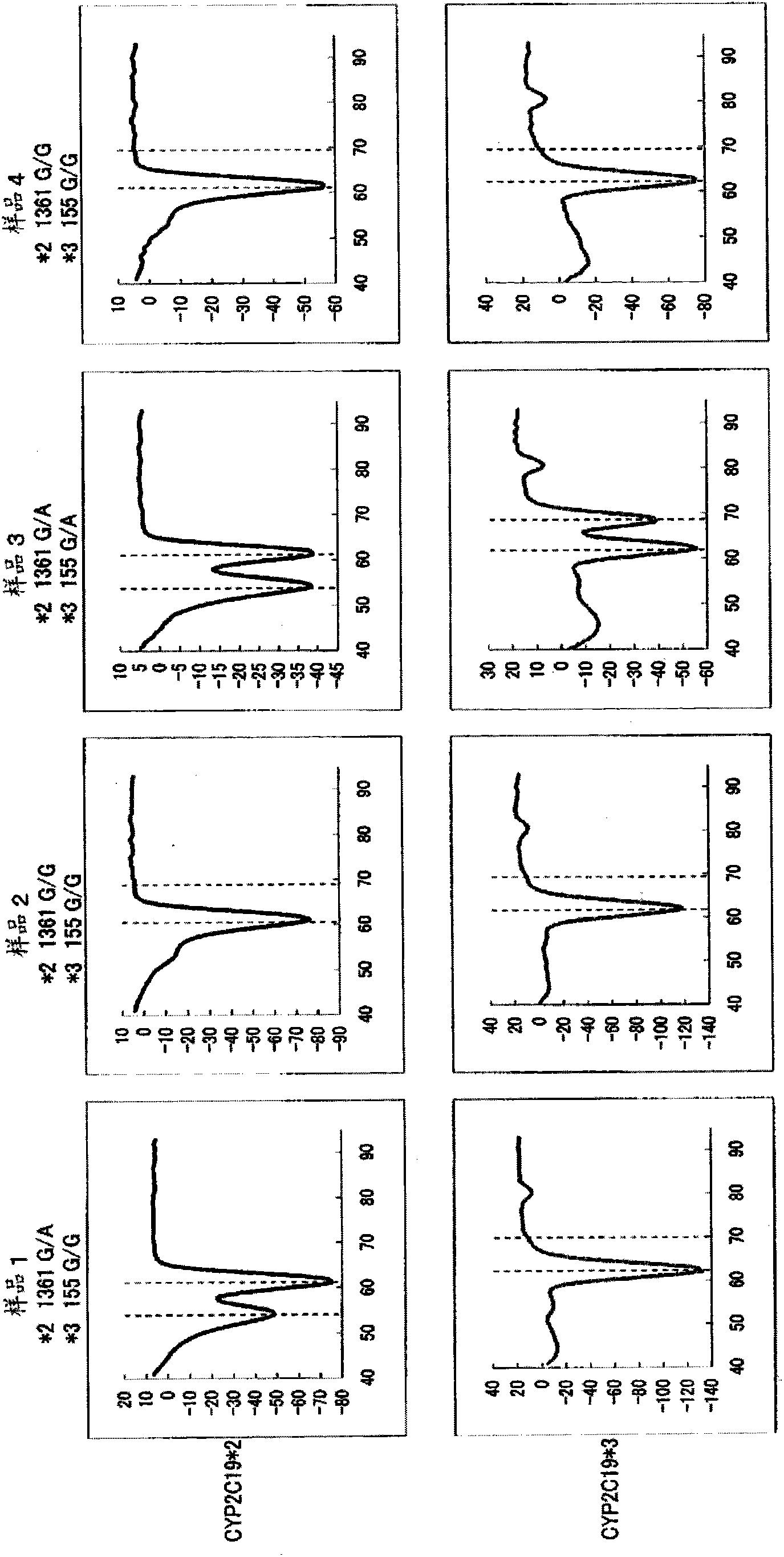

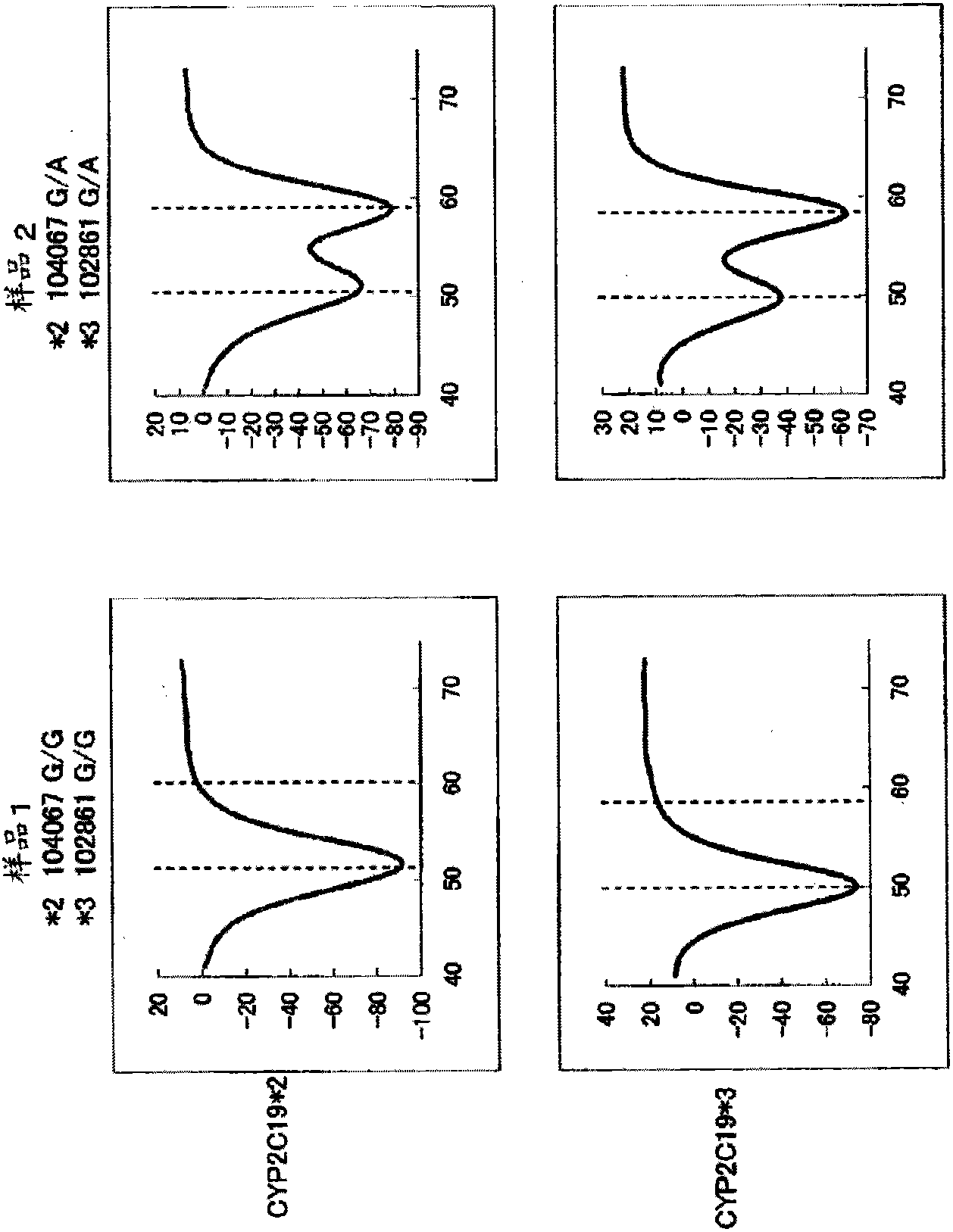

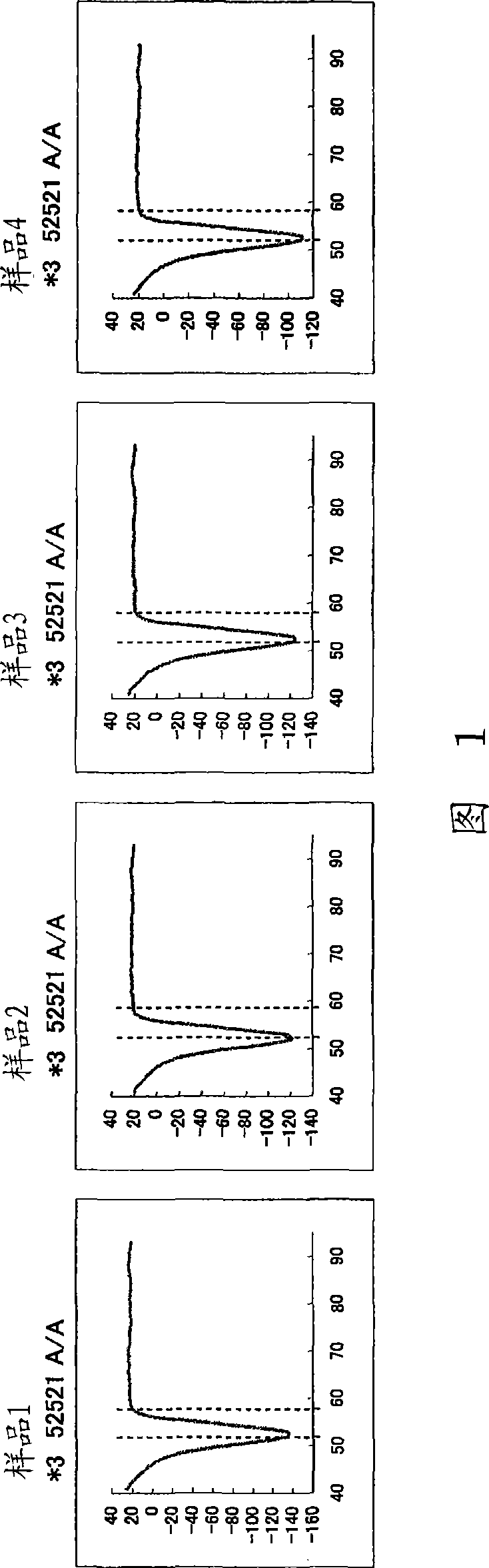

Primer pair for cyp2c19 gene amplification, reagent for cyp2c19 gene amplification containing same and use thereof

InactiveCN102277424ALow costFully automatedMicrobiological testing/measurementFermentationForward primerBase J

The present invention provides a primer pair for amplifying a target region containing a detection target site in the CYP2C19 gene using a gene amplification method, which can specifically amplify the region. Two primer pairs each including a forward primer containing the base sequences of SEQ ID NO: 12 and SEQ ID NO: 32 and a reverse primer containing the base sequences of SEQ ID NO: 22 and SEQ ID NO: 48 were used. By using this primer pair, two regions of the CYP2C19 gene containing the occurrence sites of two polymorphisms (CYP2C19 gene*2, CYP2C19*3) can be amplified simultaneously in the same reaction solution.

Owner:ARKRAY INC

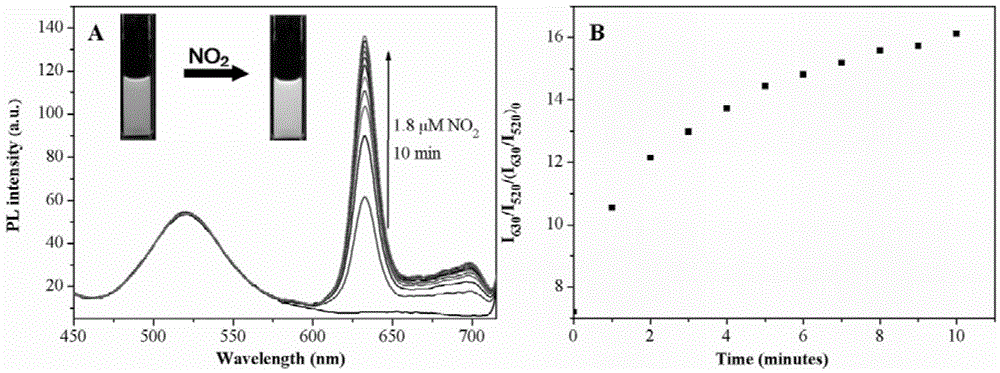

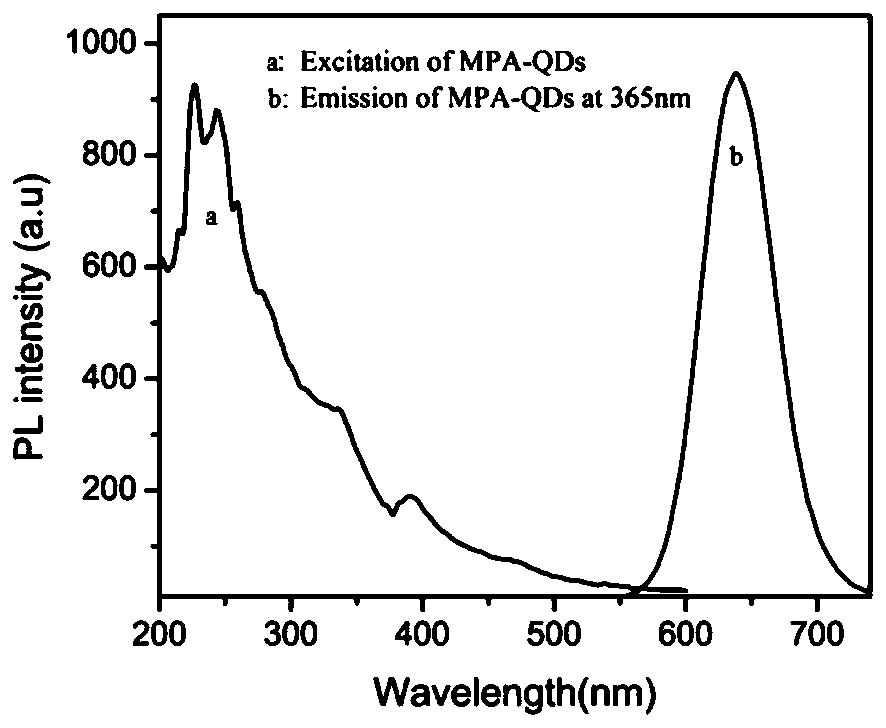

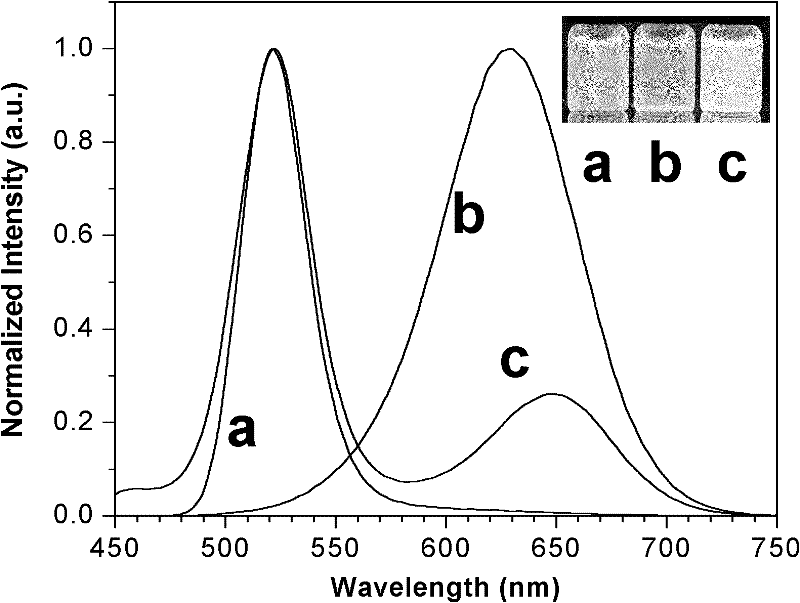

A dual-emission fluorescent chemical sensor and its preparation method and application

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Metal matrix composite material, preparation method thereof and application of composite material

ActiveCN109136611AImprove mechanical propertiesGood binding propertiesMetal matrix compositeMetal powder

The invention discloses a metal matrix composite material, a preparation method thereof and an application of the composite material. The metal matrix composite material comprises a metal matrix bodyand MoAlB particles distributed in the metal matrix body, and transition layers continuously wraps the surfaces of the MoAlB particles. The preparation method of the metal matrix composite material includes the steps: (1) mixing MoAlB powder and metal powder to obtain MoAlB-metal mixed powder; (2) heating the MoAlB-metal mixed powder, and cooling the heated MoAlB-metal mixed powder to obtain the metal matrix composite material. The metal matrix composite material effectively solve the problem of poor binding force between a reinforcement phase and the metal matrix body in the prior art, reinforced effects are sufficiently played, the mechanical property of the metal material is improved, the method is simple and environmentally friendly, mass production is facilitated, and the composite material is applied to aeronautics, astronautics, ships, rail traffic, automobiles, nuclear industry and ordnance industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

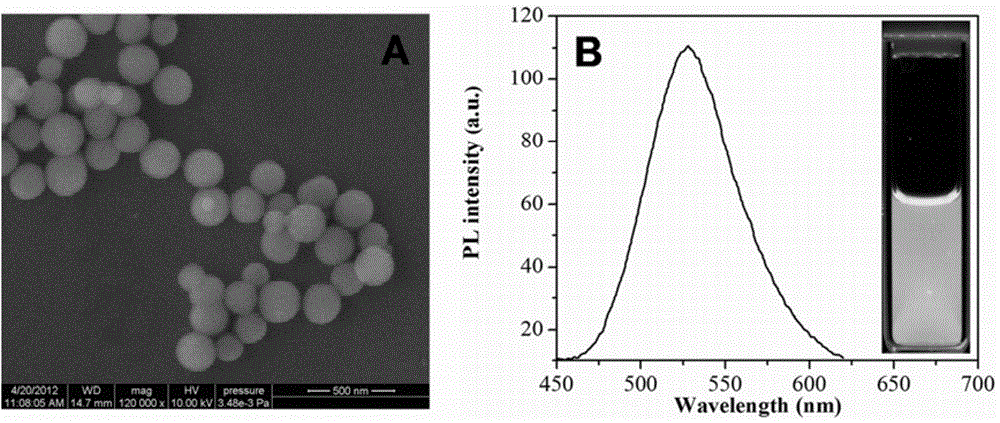

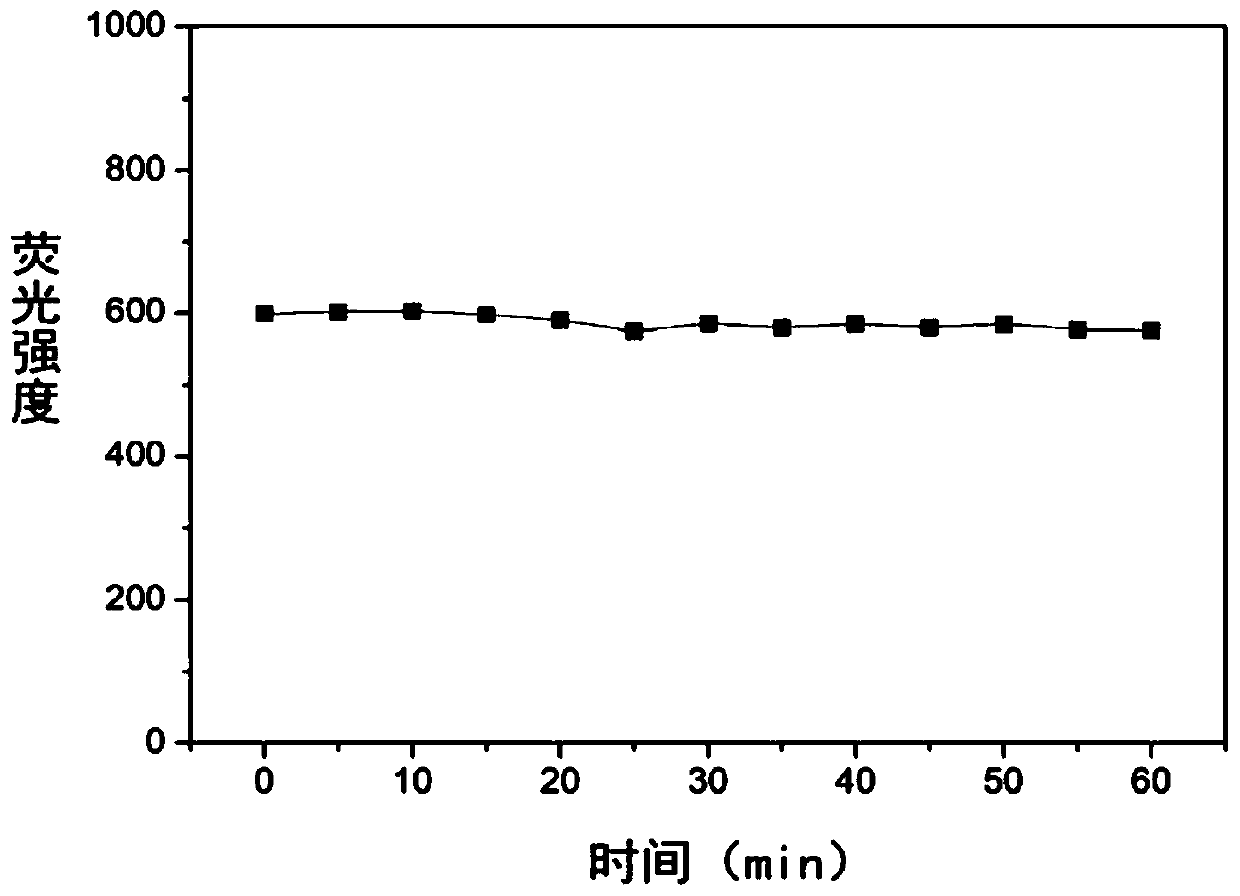

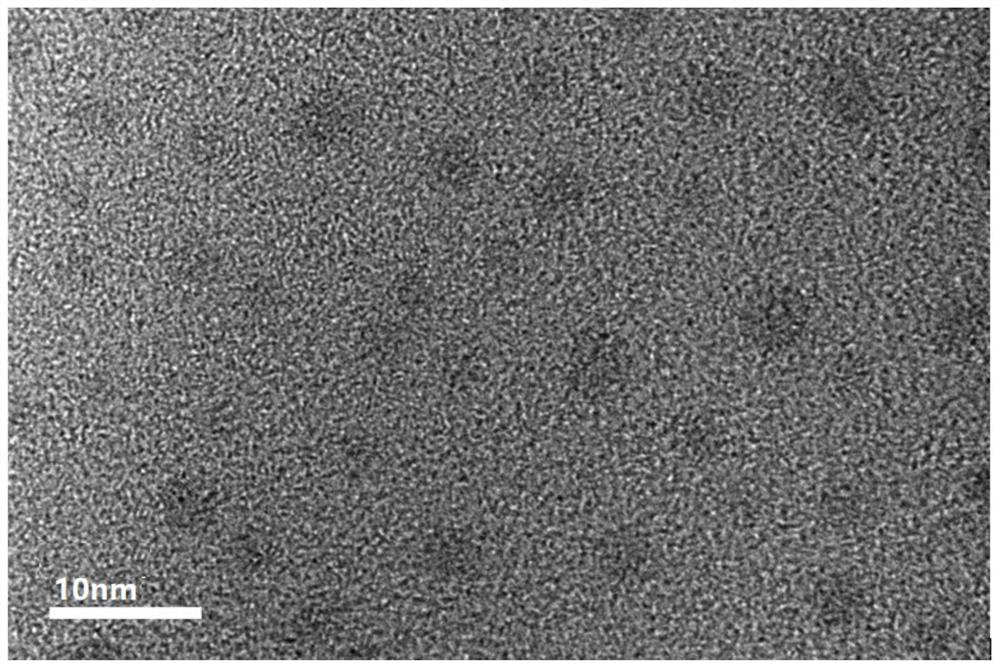

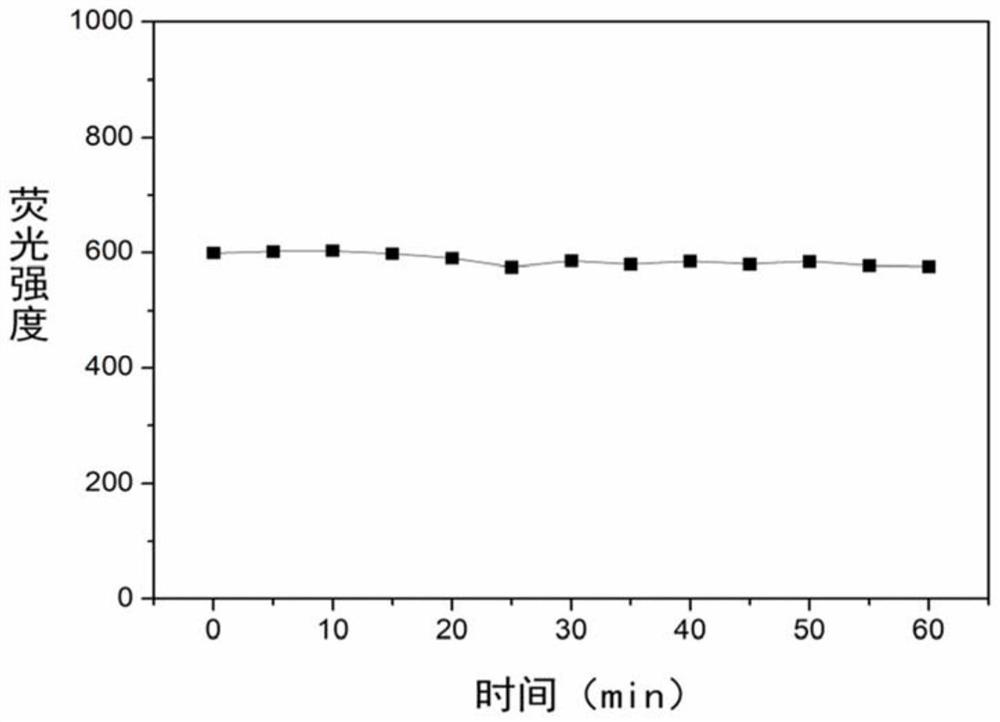

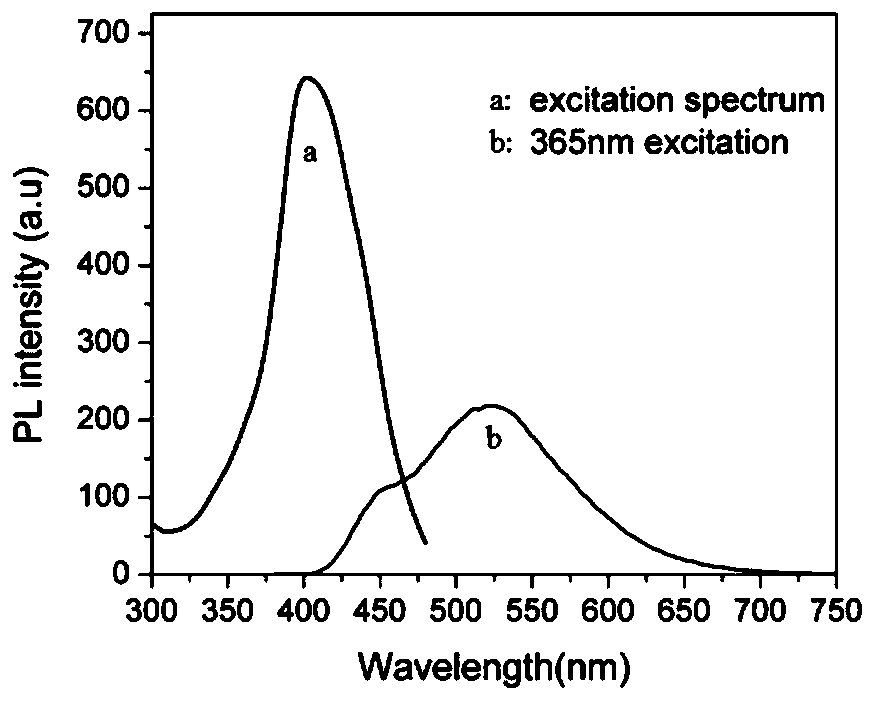

Polyethyleneimine modified ascorbic acid carbon nanodots, preparation method and application

ActiveCN109991200ARealize detectionConvenient on-site visual inspectionFluorescence/phosphorescenceFreeze-dryingCarbon nanodots

The invention discloses a preparation method of polyethyleneimine modified ascorbic acid carbon nanodots. The method comprises the following steps of adding polyethyleneimine to a reaction kettle containing ascorbic acid solution, wherein the molar ratio of polyethyleneimine to ascorbic acid is 0.05-1:1; heating to 180-220DEG C after sealing, reacting for 5-7h, cooling and filtering, dialyzing for6-10h, replacing with ultra-pure water at intervals of 1.5-2.5h, and freeze-drying to obtain carbon nano-point powder. And application of ascorbic acid carbon nanodots as a fluorescent probe in visual detection is also provided. The probe provided by the invention is sensitive to hypochlorous acid response having a detection limit of 14nmol / L, has high selectivity and good stability to hypochlorous acid to enable long-term preservation and use, is simple in synthesis, and researches portable hypochlorous acid detection test papers to achieve the purpose of simple, rapid and visual detection of hypochlorous acid, which is beneficial to the popularization and application of commercialization.

Owner:WEST ANHUI UNIV

Polyethyleneimine-modified ascorbic acid carbon nanodots, preparation method and application

ActiveCN109991200BRealize detectionConvenient on-site visual inspectionFluorescence/phosphorescenceFluoProbesFreeze-drying

The invention discloses a preparation method of polyethylenimine-modified ascorbic acid carbon nano-dots, comprising the steps of: adding polyethyleneimine into a reaction kettle containing ascorbic acid solution, and the molar ratio of polyethyleneimine to ascorbic acid is 0.05-1 : 1, heat to 180-220°C after sealing, react for 5-7h, cool and filter, dialyze for 6-10h, change ultrapure water every 1.5-2.5h, freeze-dry to obtain carbon nano-dot powder; and ascorbic acid carbon nano-dot Application of fluorescent probe in visual detection of hypochlorous acid. The probe of the present invention is sensitive to hypochlorous acid, and the detection limit is 14nmol / L; it also has high selectivity to hypochlorous acid, good stability, can be stored and used for a long time, and the synthesis is simple, and a portable hypochlorous acid has been developed The detection test paper realizes the purpose of simple, rapid and visual detection of hypochlorous acid, and is conducive to commercial promotion and application.

Owner:WEST ANHUI UNIV

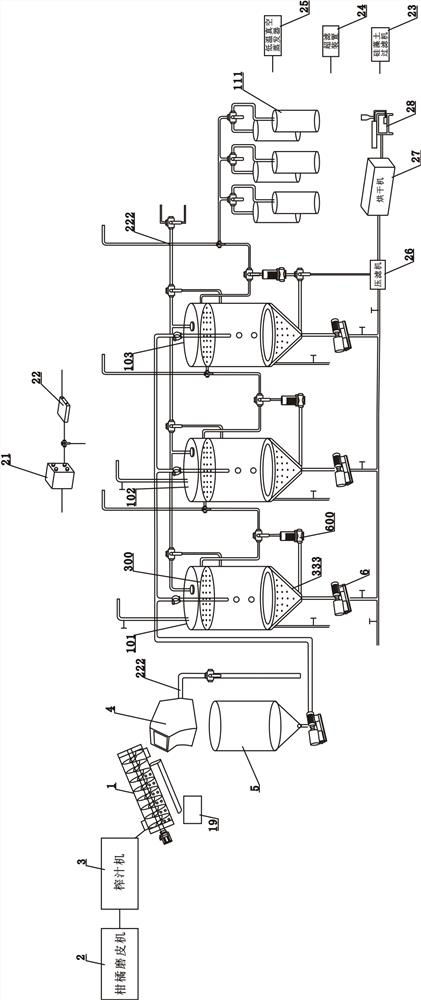

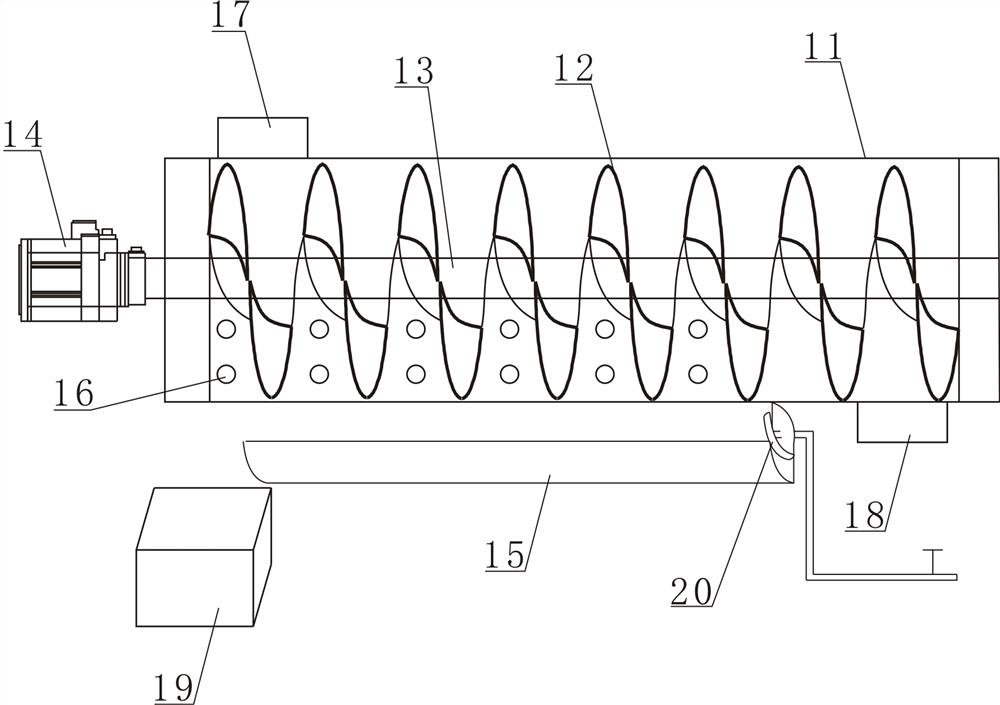

Citrus peel progressive extraction method and citrus peel progressive extraction device

PendingCN112604319AImprove qualityReduce consumptionJuice extractionEssential-oils/perfumesProcess engineeringHesperidin

The invention discloses a citrus peel progressive extraction method and a citrus peel progressive extraction device, which can recover citrus peel essential oil and citrus kernels by performing pretreatment and progressive extraction on citrus peels. The high-added-value products such as citrus peel infusion syrup, hesperidin, pectin and dietary fibers can be sequentially obtained in the progressive extraction process of the citrus peel, and the method has extremely important economic value; according to the method and the device disclosed by the invention, the extraction of citrus immersion syrup, hesperidin and pectin and the purification treatment of dietary fiber raw materials can be sequentially completed under the condition of not transferring citrus peels, the traditional complicated extraction operation is converted into simple, convenient, systematized and continuous operation, the labor efficiency is greatly improved, and the material and power consumption is reduced; according to the method, a two-time or three-time leaching phase process is adopted, so that the concentration of the extract in the leaching solution is greatly improved, the product recovery rate is increased, the citrus peel is fully utilized in a real sense, and an extremely important new resource is expanded for the development of the food processing industry.

Owner:曾祥奎

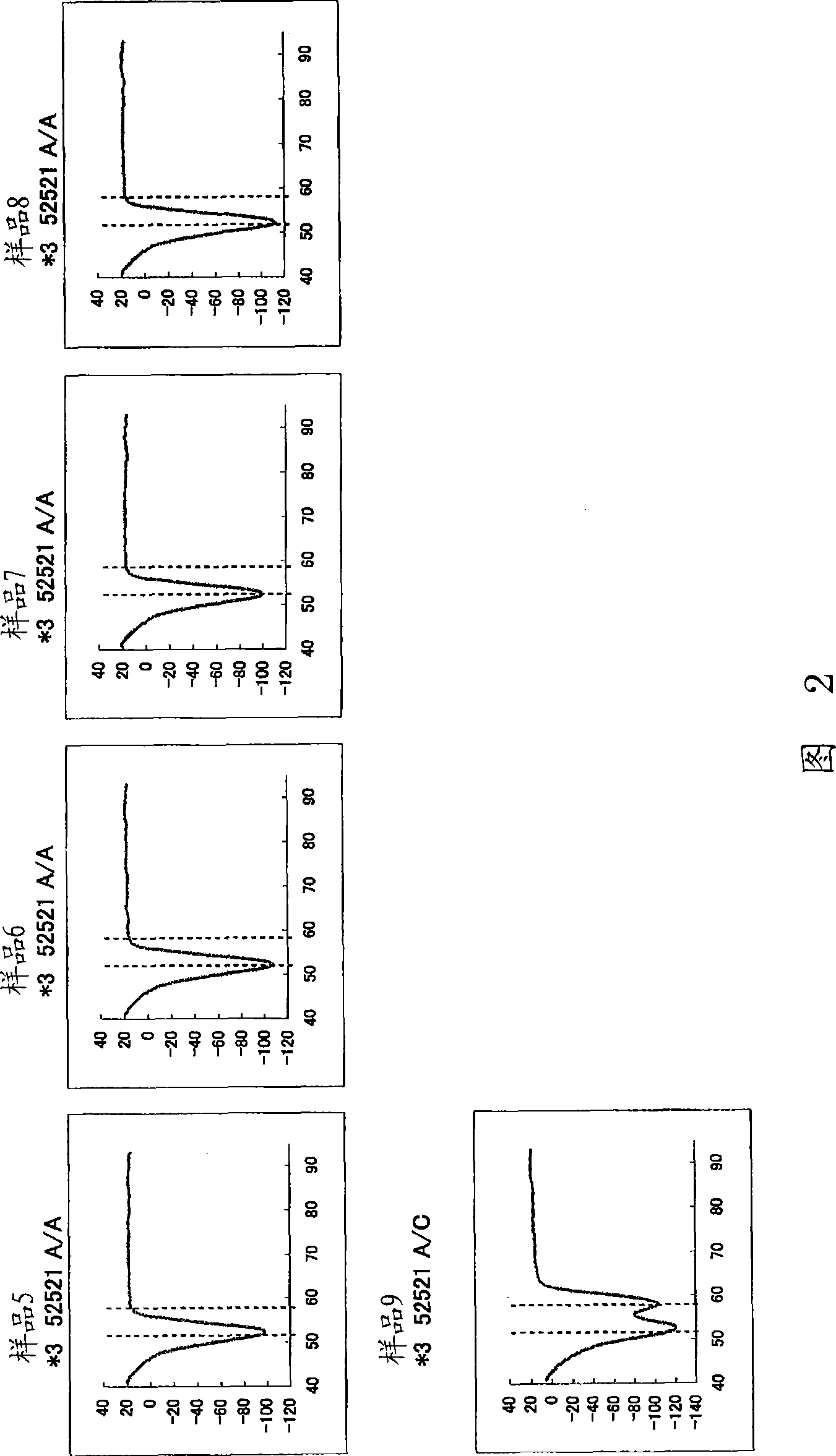

Primer set for amplification of CYP2C9 gene, reagent for amplification of CYP2C9 gene comprising the same, and use of the same

InactiveCN101443448APolymorphism is simplePolymorphic shorteningMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementForward primerNucleotide sequencing

Disclosed is a primer set for amplifying a region in CYP2C9 gene that contains a detection target site having CYP2C9*3 therein by a gene amplification method, which enables to amplify the region specifically. A pair of primer set is used, which comprises a forward primer comprising a nucleotide sequence depicted in SEQ ID NO:4 and a reverse primer comprising a nucleotide sequence depicted in SEQ ID NO:17. The primer set enables to amplify a region containing a site having a polymorphism CYP2C9*3 occurring in CYP2C9 gene in a specific manner and with a high degree of efficiency.

Owner:ARKRAY INC

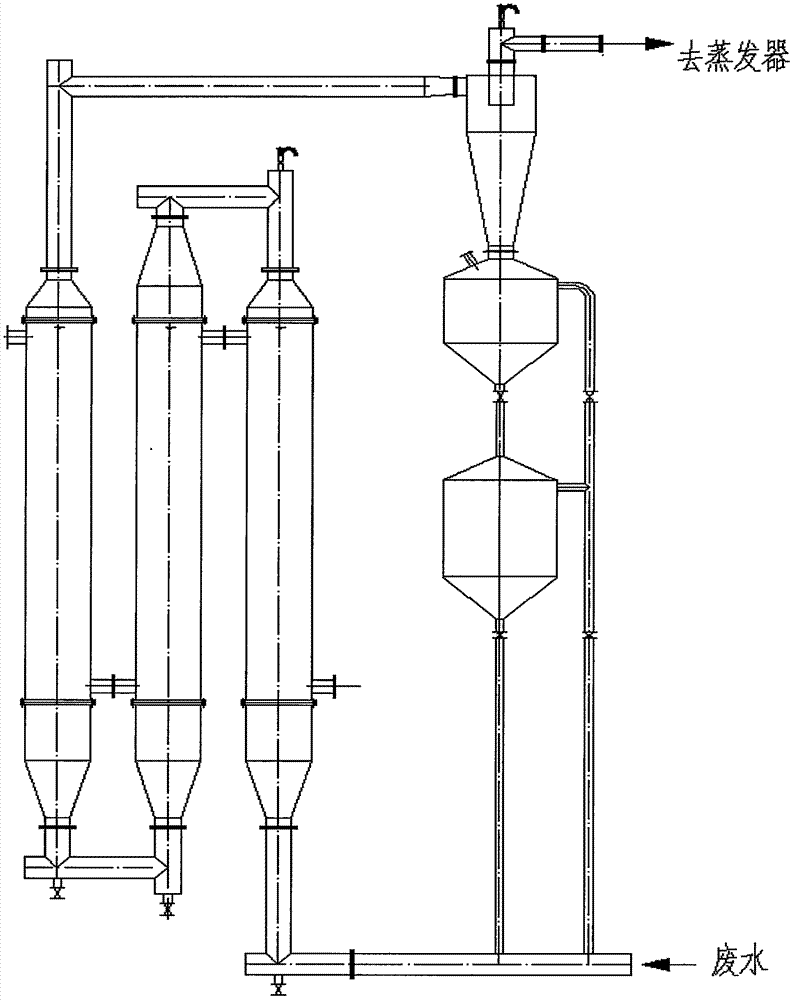

TPL preheating scale prevention process in wastewater industry

InactiveCN107129058AAvoid badReduce pollutionScale removal and water softeningShell and tube heat exchangerHeat resistance

The invention relates to a TPL preheating scale prevention process in a wastewater industry. The process comprises the following steps: utilizing a TPL preheating scale prevention process on a preheating part, enabling materials to be mixed with zirconia particles before entering a shell and tube heat exchanger, enabling the materials to flow in the heat exchanger, enabling the separated calcium sulfate crystal and zirconia solid particles to be rubbed and collided with one another, and enabling the solid particles and the tube walls to be also rubbed and collided with one another, so that disturbance on a flow boundary layer is increased due to jump of the solid particles nearby the wall surfaces of heat exchange tubes, adsorption deposition of dirt components in the wall surface can be prevented or retarded, the flow boundary layer of fluid is damaged by friction and collision of the solid particles and the heat exchange tube walls, heat resistance of convective heat transfer is reduced, and the convective heat transfer coefficient is increased. According to the TPL preheating scale prevention process in the wastewater industry disclosed by the invention, the scale formation problem of a preheater is effectively solved, the energy-saving effect is obvious, the technology is mature and reliable, the heat transfer efficiency is improved, and the fire coal usage amount and environmental pollution are reduced; moreover, the cleaning period is prolonged, the actual production time is increased, and the labor intensity is reduced.

Owner:BEIJING PUREN MEIHUA ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH

Biological treatment oxidation process for aluminum substrate

InactiveCN107841741AImprove corrosion resistanceImprove bindingMetallic material coating processesInorganic ChemicalHigh energy

The invention relates to a method using biological oxidation. An aluminum substrate is treated through acidophilic bacteria in an acid environment and is washed with circulation water, so that a compact alumina film is formed on the aluminum substrate. High-pollution and high-energy-consumption inorganic chemical oxidation and electro-oxidation are avoided, a compact aluminum oxide layer is formedon the surface of the aluminum substrate, higher insulation and heat conduction properties are achieved, the compact oxide layer has the characteristics of uniformity, stability and consistency, theheat conduction and insulation properties of an aluminum-based copper clad plate are greatly improved, and industrial pollution and energy loss are not generated.

Owner:乾乐欣展新材料技术(上海)有限公司

A dual-functional near-infrared fluorescent molecular probe for detecting hypochlorous acid and its preparation method

InactiveCN103342697BGood light stabilityAvoid interferenceOrganic chemistryFluorescence/phosphorescenceBifunctionalDouble bond

The invention discloses a difunctional near-infrared fluorescence molecular probe for detecting hypochlorous acid and a preparation method for the same. The difunctional near-infrared fluorescence molecular probe has the structure general formula defined in the specification, wherein R1 and R2 independently represent 2-pyridyl, 2-furyl, substituted 2-pyridyl, substituted 2-furyl, aryl or substituted aryl respectively; R3 is selected from methyl, ethyl or propyl; and X- is selected from Cl-, Br- or I-. The changes of the fluorescence intensity and the colour of the probe are caused due to the breakage of the double bonds of the fluorescence probe at the end of a chain under the oxidation of hypochlorous acid, so that the fluorescence probe can be used for visual detection for hypochlorous acid in an aqueous solution, and is suitable for detection for hypochlorous acid generated by enzymatic reaction in the condition of a physiological environment simultaneously, and a detection line can achieve 0.70mu mol / L. The method disclosed by the invention has the advantages of being capable of detecting hypochlorous acid with a fast speed and high selectivity, suitable for bioimaging, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Preliminary cleaning rainwater collection module and preparation method thereof

The invention provides a preliminary cleaning rainwater collection module. The preliminary cleaning rainwater collection module is prepared from, by weight, 15-20 parts of an ethylene-vinyl acetate copolymer, 8-14 parts of 2-methyl methacrylate, 15-20 parts of deionized water, 11-15 parts of water soluble acrylic resin, 14-17 parts of nanometer activated carbon, 1-3 parts of acetamide, 2-4 parts of antioxidant, 5-9 parts of calcium carbonate, 4-7 parts of carbon black, 6-12 parts of kieselguhr and 1-2 parts of a dispersing agent. The rainwater collection module can perform preliminary cleaning on rainwater in the water storage process, can remove particulate matter contained in rainwater, and saves the cost. An implementation method is simple and has the wide application prospect.

Owner:HEFEI REYAO ENVIRONMENTAL PROTECTION BUILDING MATERIAL TECH

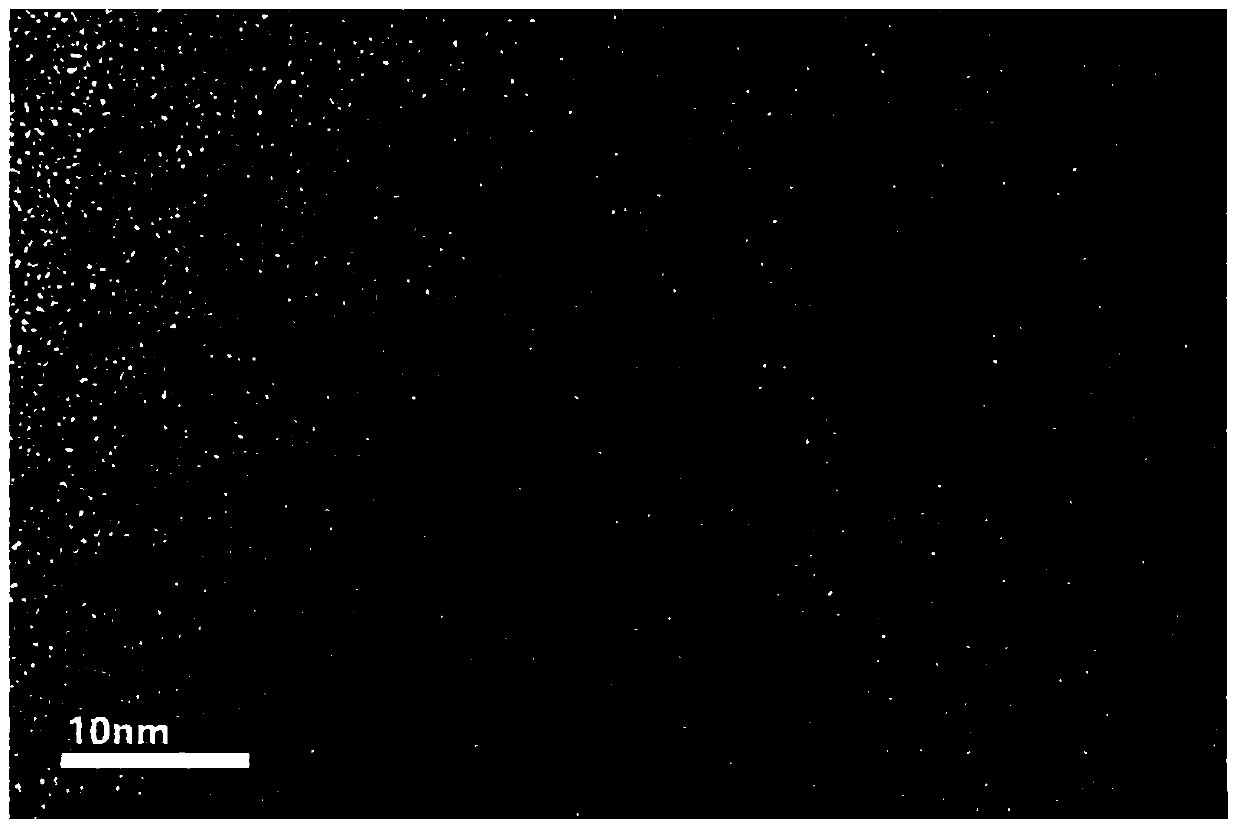

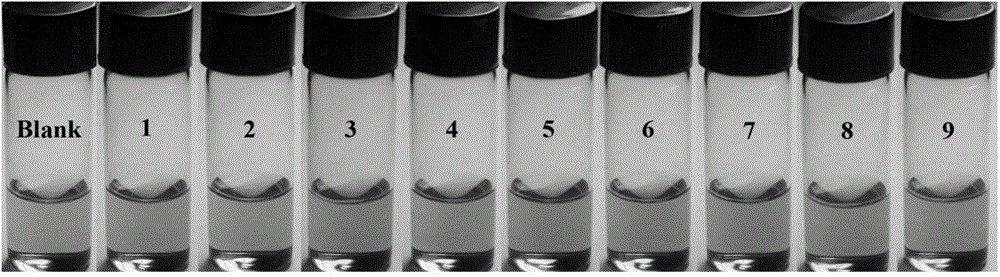

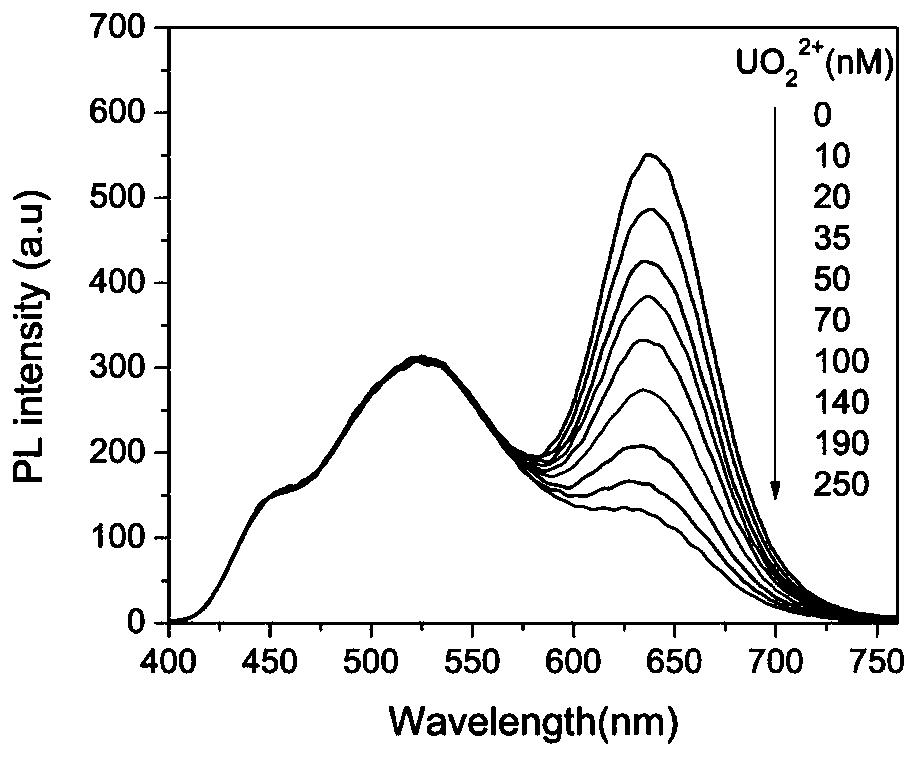

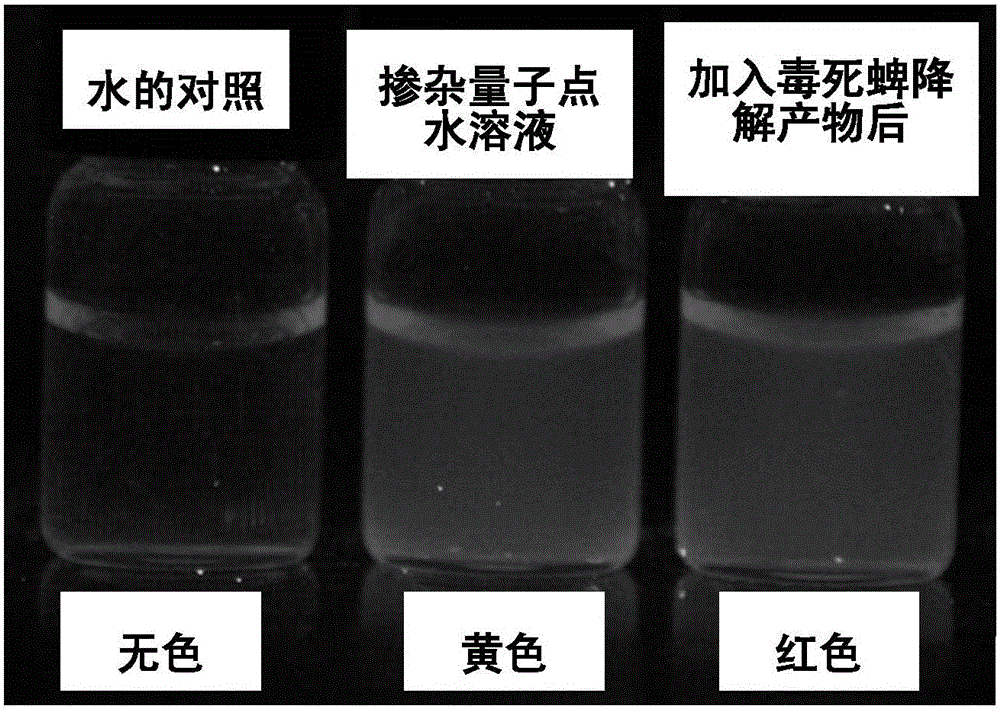

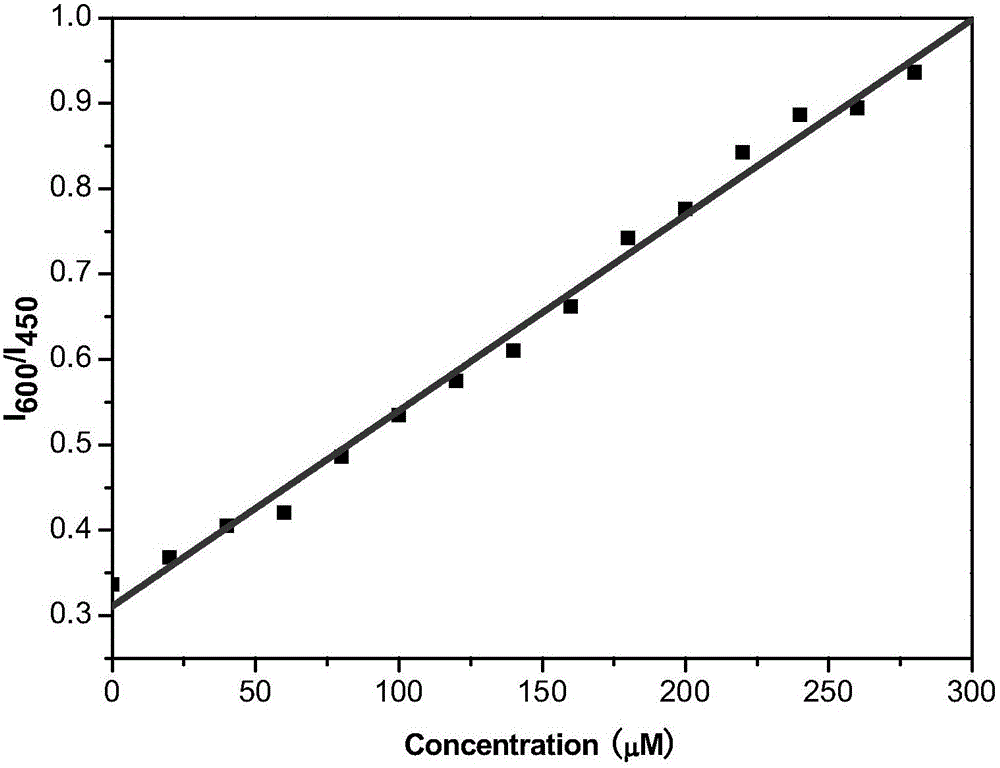

A dual-channel fluorescent uranyl ion probe and its application

InactiveCN107828417BRealize visual detectionAvoid interferenceMaterial nanotechnologyNanoopticsUltravioletUranyl

The invention belongs to the field of analysis methods of radioactive elements, and particularly relates to a method for analyzing and detecting trace radioactive elements by a double-channel fluorescent uranyl ion probe. The probe is established on the basis of a semiconductor quantum dot-carbon quantum dot double-channel fluorescent signal with a method mainly comprising the following steps: (1)synthesizing a green fluorescent carbon quantum dot; (2) synthesizing a red fluorescent cadmium quantum dot; (3) preparing the probe. The detection principle is that uranyl ions can quench fluorescence of the red quantum dot, while the green fluorescence signal of the carbon quantum dot remains stable and unchanged, and quantitative detection of a to-be-detected sample is realized by testing thelinear relationship between concentration of the sample and the ratio of the red fluorescence signal to the green fluorescence signal. With adoption of the method, use of large-scale instruments can be avoided to a certain extent, all that is required is only one hand-held ultraviolet lamp for visual detection, operation is simple, convenient and quick, the pretreatment process is omitted, and high-sensitivity selective detection of the trace uranyl ions in a solution can be realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

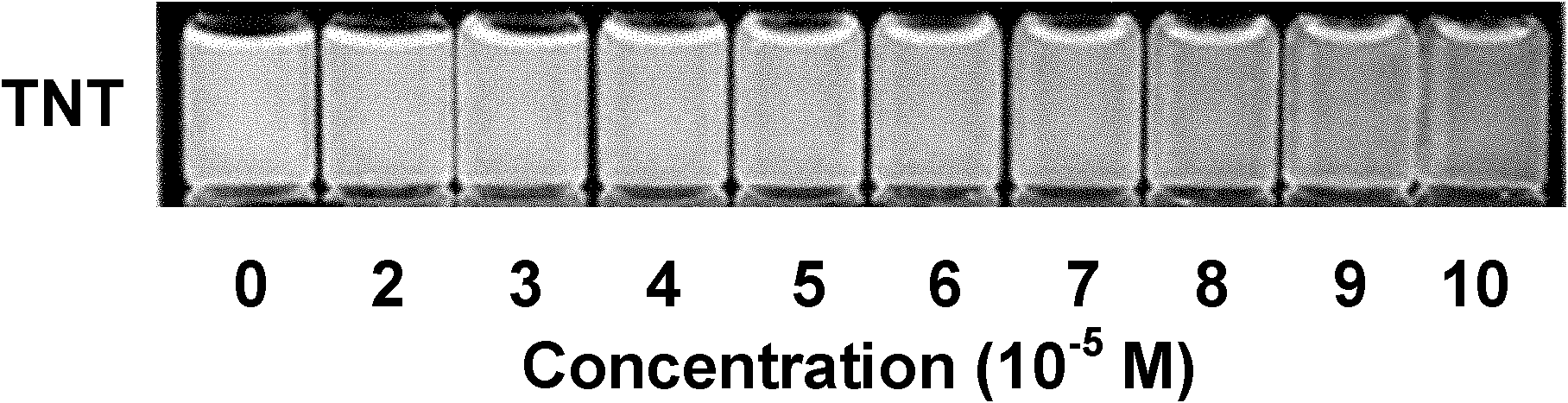

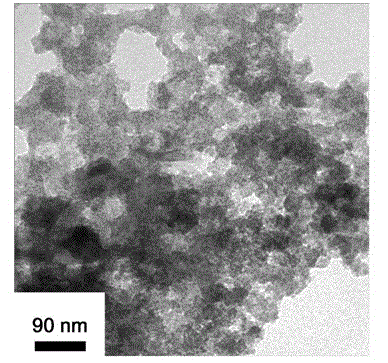

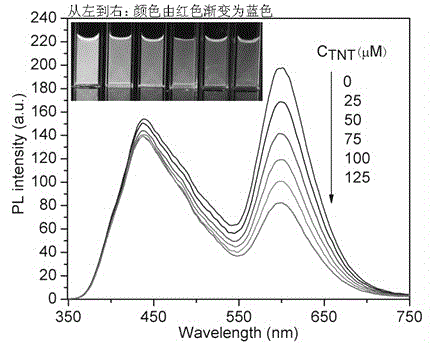

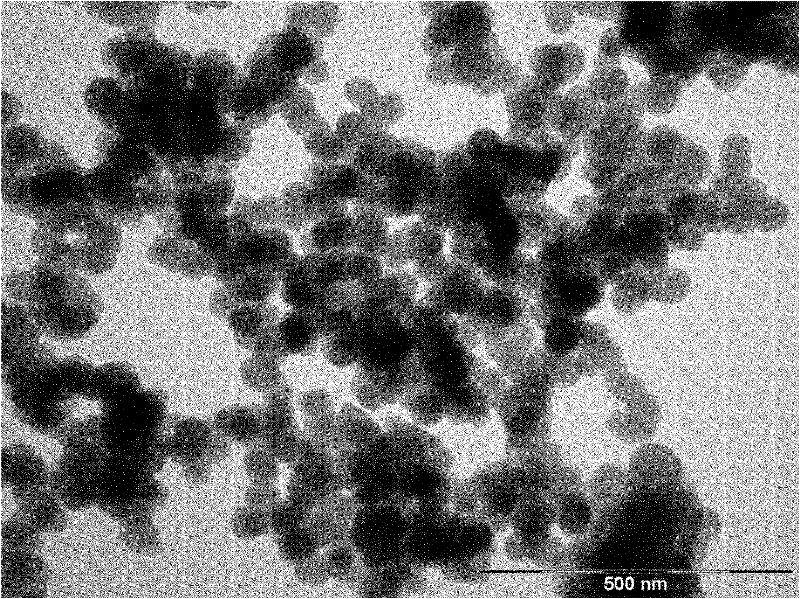

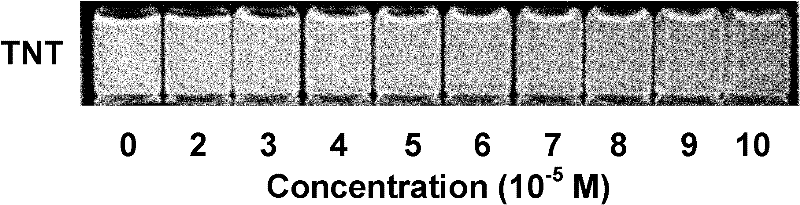

Double-color nanocomposite as well as paper sensor for visually detecting trinitrotoluene based on composite and manufacturing method thereof

InactiveCN103525413BReduce usageAvoid interferenceFluorescence/phosphorescenceFluorescenceUltraviolet

The invention discloses a two-color nanocomposite with two-color ratio fluorescence, and also discloses a fluorescent paper sensor for visual analysis and detection of trace amounts of explosive TNT (TNT) residues on the surface of different objects and a preparation method thereof. The paper sensor prepared by the invention is easy to carry and operate, and is convenient for real-time online on-site visual detection of explosive TNT, and can visually detect traces of TNT residues with a lower limit as low as 11.35 nanograms per square millimeter. The method of the present invention can avoid the use of large-scale instruments to a certain extent, and only needs a hand-held ultraviolet lamp to carry out visual detection. The operation is simple, convenient and fast, with high sensitivity and remarkable effect; The interference of substances, good selectivity, but also omitted the pretreatment process. The prepared paper sensor can detect explosive TNT in real-time and on-site visualization.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A kind of aluminum substrate surface biological treatment oxidation process

InactiveCN107841741BImprove corrosion resistanceImprove bindingMetallic material coating processesInorganic ChemicalHigh energy

The invention relates to a method using biological oxidation. An aluminum substrate is treated through acidophilic bacteria in an acid environment and is washed with circulation water, so that a compact alumina film is formed on the aluminum substrate. High-pollution and high-energy-consumption inorganic chemical oxidation and electro-oxidation are avoided, a compact aluminum oxide layer is formedon the surface of the aluminum substrate, higher insulation and heat conduction properties are achieved, the compact oxide layer has the characteristics of uniformity, stability and consistency, theheat conduction and insulation properties of an aluminum-based copper clad plate are greatly improved, and industrial pollution and energy loss are not generated.

Owner:乾乐欣展新材料技术(上海)有限公司

Rotating body for image forming apparatus

InactiveCN1892497AOmit preprocessingOmit postprocessingShaft and bearingsSynthetic resin layered productsBiological activationImaging equipment

A rotating body for an image forming apparatus is provided having a substrate; and a covering layer adhered to the surface of the substrate, the surface being subjected to activation by silicifying it with flame. The rotating body of present invention can exhibit excellent adhesiveness between the substrate and the covering layer, even if primer treatment is not carried out on the surface of the substrate.

Owner:NITTO KOGYO KK

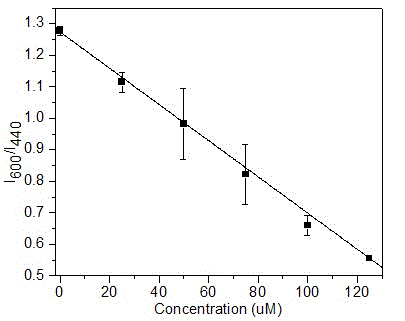

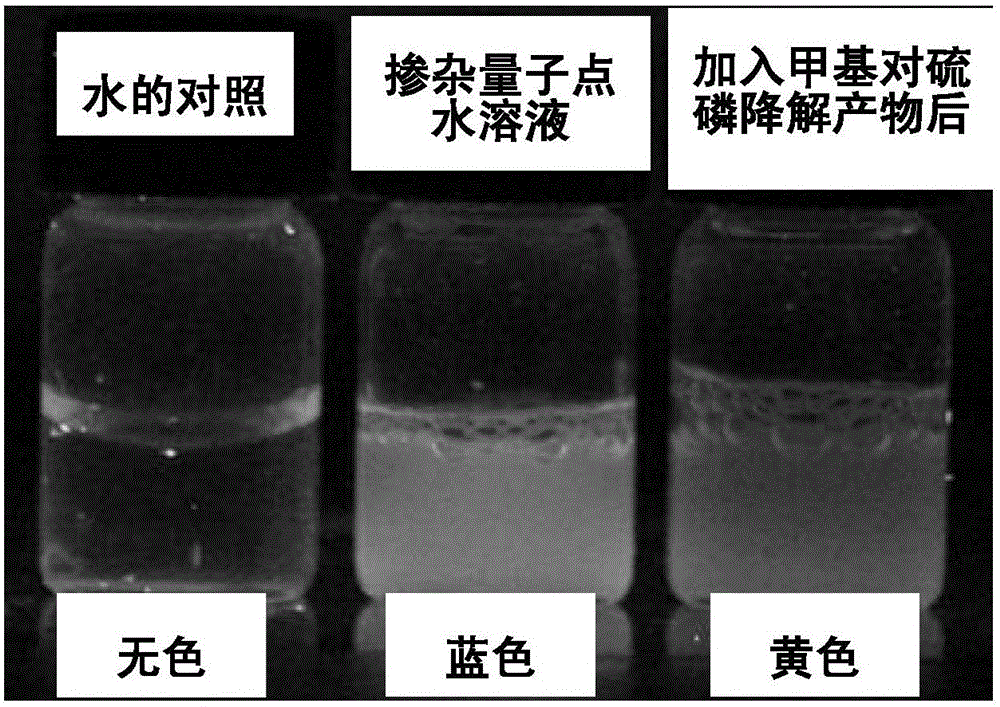

A method for the visual detection of organophosphorus pesticide residues by doped quantum dot ratiometric fluorescence method

InactiveCN103411935BRealize visual detectionReduce usageFluorescence/phosphorescenceQuantum dotFluorescence ratio

The invention relates to a method for visualized detection of organophosphorus pesticide residue by a doped quantum dot ratio fluorescence technique. Being a standard curve method, the method includes preparation and quenching of a double-fluorescence emission quantum dot, establishment of a standard curve and detection of organophosphorus pesticide residue. The method is characterized in that: the standard curve is determined under ultraviolet irradiation and is a curve about the corresponding relationship of a fluorescence ratio and a sample concentration, i.e. the standard curve is established by adding sample solutions with gradient concentrations into a quenched doped quantum dot probe dispersion fluid with a concentration of 30-40mcg / ml in order under ultraviolet irradiation, and determining fluorescence ratios successively. For the quenched doped quantum dot, a quenching agent is employed to quench the double-fluorescence of the doped quantum dot probe dispersion fluid to fluorescence intensity that no longer reduces. The method provided in the invention realizes sensitive and high selectivity detection of organophosphorus pesticide residue.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

An improved co-denaturation fluorescence in situ hybridization method

ActiveCN103451287BOmit preprocessingImprove accuracyMicrobiological testing/measurementFluorescence/phosphorescenceFluorescenceSpecimen preparation

The invention relates to a fluorescence in-situ hybridization technology, and discloses a fluorescence in-situ hybridization method capable of improving covariance. The fluorescence in-situ hybridization method capable of improving covariance comprises the steps of slide specimen preparation, probe and chromosome covariance and hybridization, washing and dyeing after hybridization, and signal detection. According to the fluorescence in-situ hybridization method capable of improving covariance disclosed by the invention, a method of probe and chromosome covariance and hybridization is adopted on the basis of the prior art, the operation is simple, the reaction steps are reduced, experimental time is shortened, and a toxic and teratogenic denaturant does not need to be used, thus decreasing experimental cost, and avoiding the harm of the denaturant to experimental operating personnel and environment. The invention provides a fluorescence in-situ hybridization method capable of improving covariance, which is accurate in location, high in sensitivity, high in experimental efficiency, good in stability, simple to operate, and has environment-friendly effect.

Owner:曾艳

Double colour fluorescent chemical sensor used for visually detecting explosive and manufacturing method thereof

ActiveCN102095711BFacilitate online visual inspectionEasy to carryFluorescence/phosphorescenceSilicon oxideWavelength

The invention relates to a double colour fluorescent chemical sensor used for visually detecting explosive, in particular to a paper-based or membrane-based sensor comprising a filter paper or glass slide substrate and double colour quantum dot superstructure silicon oxide nano particles uniformly distributed on the substrate. The method for manufacturing the sensor comprises the following steps of: firstly embedding red or green quantum dots into silicon oxide nano particles, aminating the surface of silicon oxide, then carrying out covalence coupling and coating a green or red quantum dot sensitive layer to obtain the double colour quantum dot superstructure silicon oxide nano particles, and finally processing to obtain the fluorescent chemical sensor. By applying the sensor, explosive residue with the trace of 5nanogram / mm<2> can be visually and rapidly detected online in real time. The fluorescence intensity of outer quantum dots is 2-10 times that of inner quantum dots.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

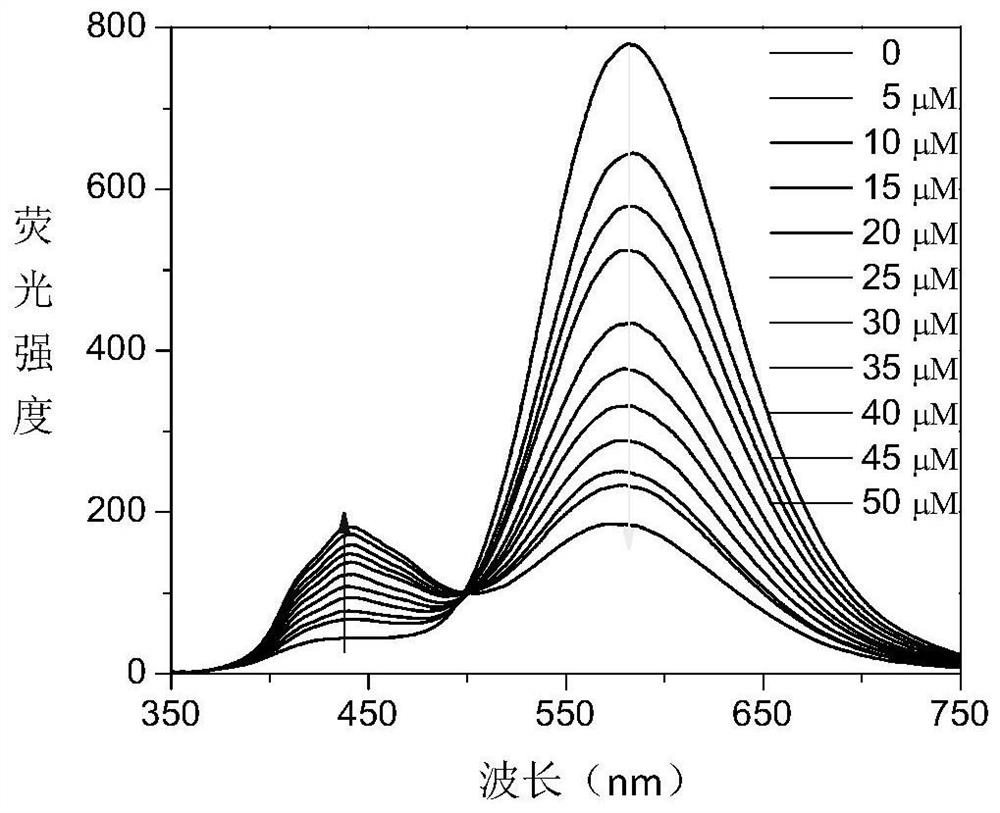

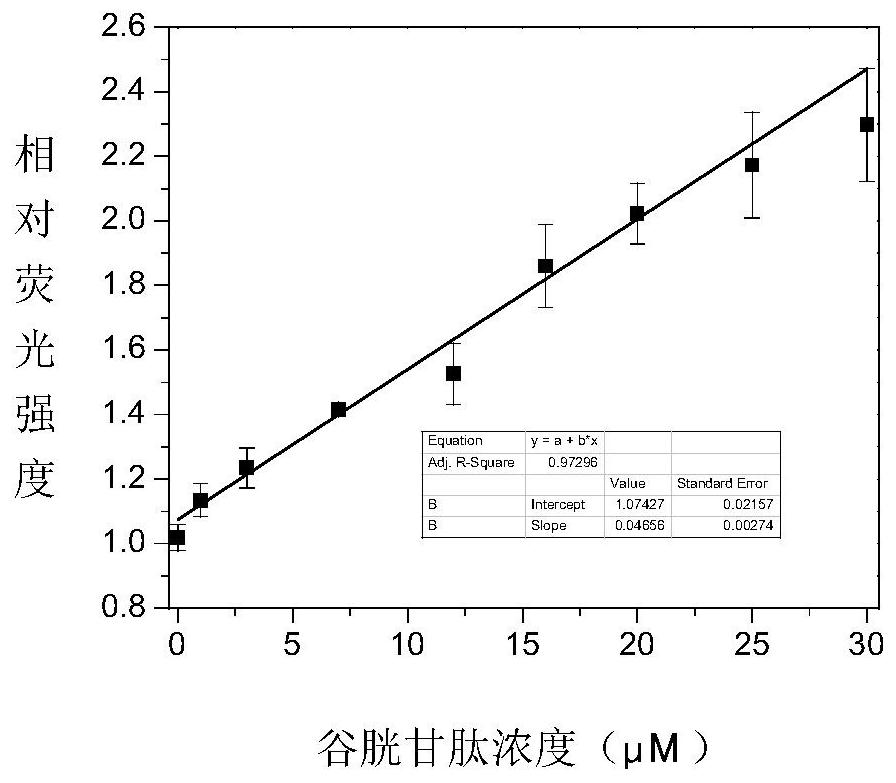

A method for the detection of sulfhydryl biomolecules based on dual-emission fluorescence detection of doped ZnS nanocrystal probes

ActiveCN108181276BAchieve sensitive detectionAvoid interferenceFluorescence/phosphorescenceBio moleculesUltraviolet

The invention discloses a method for detecting mercapto boimolecules based on dually-emitted fluorescence of a zinc sulfide-doped nano crystal probe, which belongs to the technical field of chemical measurement. The method comprises the following steps: preparing zinc sulfide-doped nano crystals, modulating a dually-emitted fluorescence signal, establishing a standard curve, and detecting the mercapto biomolecules, wherein the standard curve is a curve of a correspondence between the variation of a dually-emitted fluorescent signal intensity specific value determined under the excitation of ultraviolet rays and a concentration of a substance to be detected, i.e. the standard curve which is established by successively adding a sample solution of the substance to be detected with a gradientconcentration into a zinc sulfide-doped nano crystal probe modulated via the spectrum with concentration being 1 to 100 microgrammes per milliliter under the excitationof the ultraviolet rays and gradually determining a specific value of the fluorescence intensity. By adopting the method, the interference of other impurities in the sample can be effectively avoided, the selectivity is good, a pretreatment process is omitted, and the sensitive detection for the mercapto biological active molecules such as glutathione, cysteine, homocysteine can be achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of metal matrix composite material and its preparation method and application

The invention discloses a metal matrix composite material, a preparation method thereof and an application of the composite material. The metal matrix composite material comprises a metal matrix bodyand MoAlB particles distributed in the metal matrix body, and transition layers continuously wraps the surfaces of the MoAlB particles. The preparation method of the metal matrix composite material includes the steps: (1) mixing MoAlB powder and metal powder to obtain MoAlB-metal mixed powder; (2) heating the MoAlB-metal mixed powder, and cooling the heated MoAlB-metal mixed powder to obtain the metal matrix composite material. The metal matrix composite material effectively solve the problem of poor binding force between a reinforcement phase and the metal matrix body in the prior art, reinforced effects are sufficiently played, the mechanical property of the metal material is improved, the method is simple and environmentally friendly, mass production is facilitated, and the composite material is applied to aeronautics, astronautics, ships, rail traffic, automobiles, nuclear industry and ordnance industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

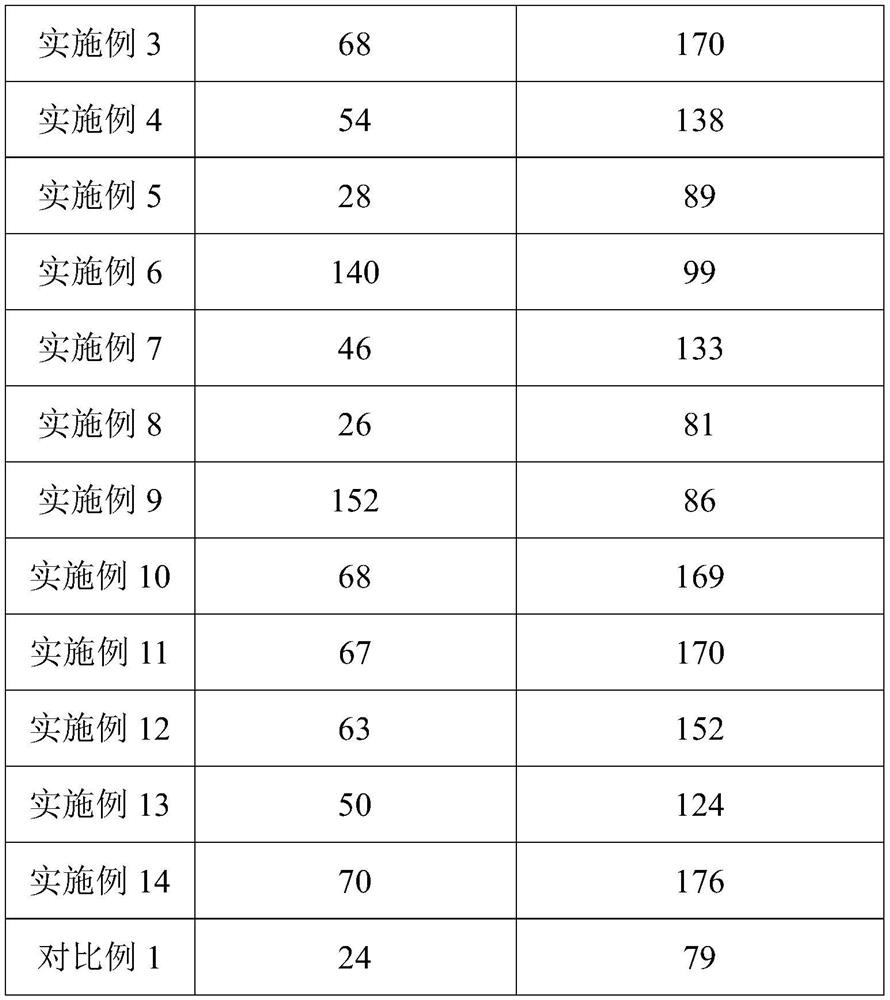

Dry type hydrothermal device and method

InactiveCN112999980AOmit preprocessingSave waterPressure vessels for chemical processWater vaporPhysical chemistry

The invention relates to a dry type hydrothermal device and method, and belongs to the field of water heating. The dry type hydrothermal device comprises a pressure gauge, a thermometer, an inert gas port, a flange, a reaction kettle cover, an inner kettle body and an outer kettle body. Compared with the traditional water heating method, the reaction kettle is pressurized by using inert gas instead of water vapor pressurization of the traditional hydrothermal method, and the hydrothermal reaction is carried out at a set temperature by directly using the moisture of the material, so that the pretreatment process of the hydrothermal reaction material is omitted, a large amount of water resources are saved, and the cost is reduced; meanwhile, the water content of the hydrothermal product is low, the treatment cost of subsequent drying or secondary utilization is reduced, and the cost is further reduced.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of lithium-ion battery diaphragm of self-cooling anti-closing

ActiveCN107302075BReduce the temperatureDelayed obturatorCell component detailsPhysical chemistryErythritol

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com