Patents

Literature

42results about How to "Take full advantage of enhancements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light armored armor and preparation method thereof

ActiveCN104848748AGuaranteed decentralizationImprove bindingLaminationLamination apparatusHigh intensityGraphene

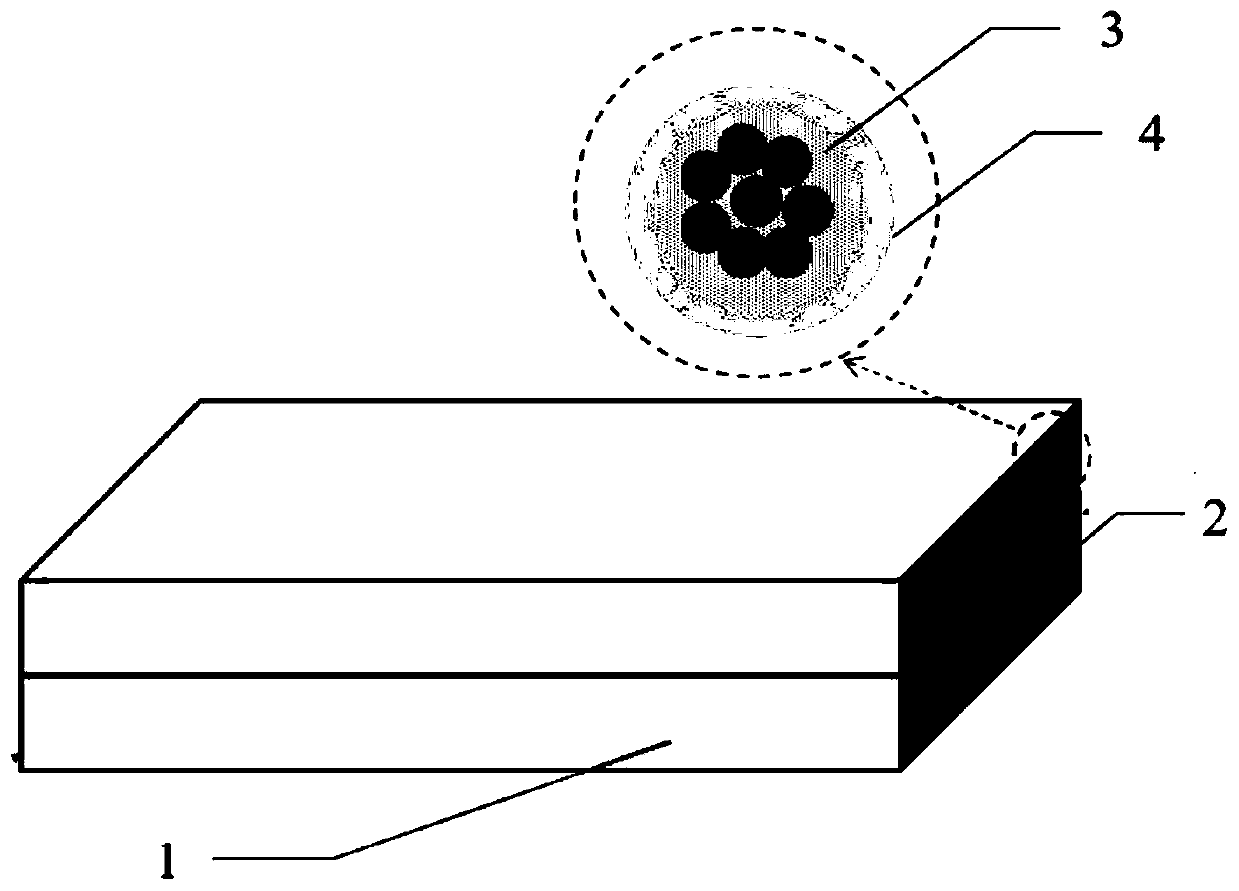

The invention discloses a light armored armor and a preparation method thereof. The armored armor is in a sandwich structure; a core plate is made of novel aluminum matrix composite of composite enhancing silicon carbide and graphene; a face plate and a back plate are made of 5083 and 7A21 high-intensity aluminum alloy; the core plate, the face plate and the back plate are glued through metallic glue; the composite of the core plate is graphene or silicon carbide enhanced aluminum matrix composite and prepared through the pressure infiltration technology; an infiltration framework is silicon carbide and graphene cold pressing block which are uniformly mixed. According to the light armored armor and the preparation method thereof, the core plate is obtained due to infiltration of aluminum alloy through the silicon carbide and graphene composite framework, the silicon carbide enhancement is used, the enhancement and toughening functions to the aluminum alloy from the graphene are fully played, the ballistic performance of the core plate is improved, and the light armored armor having a good application prospect is finally obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

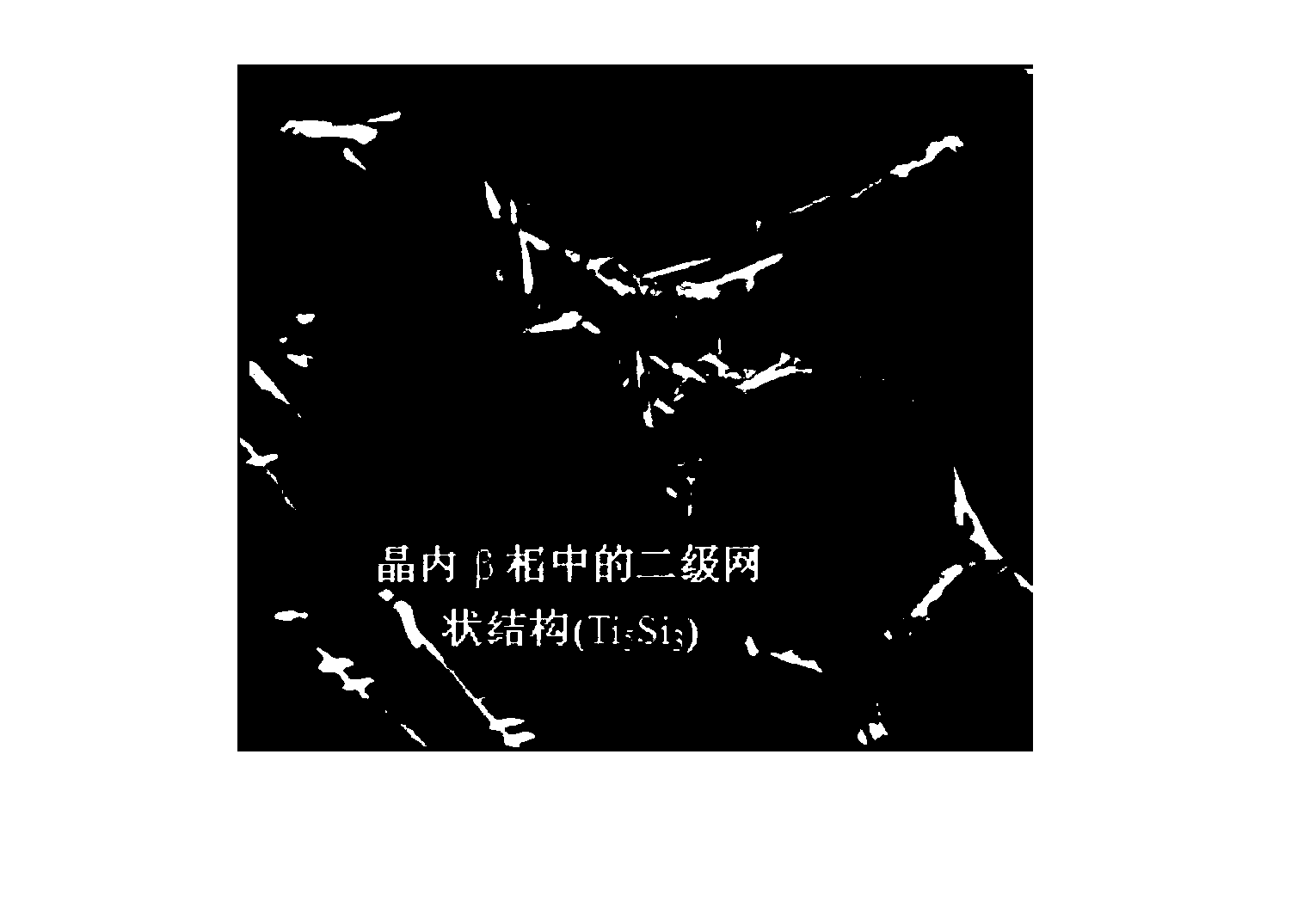

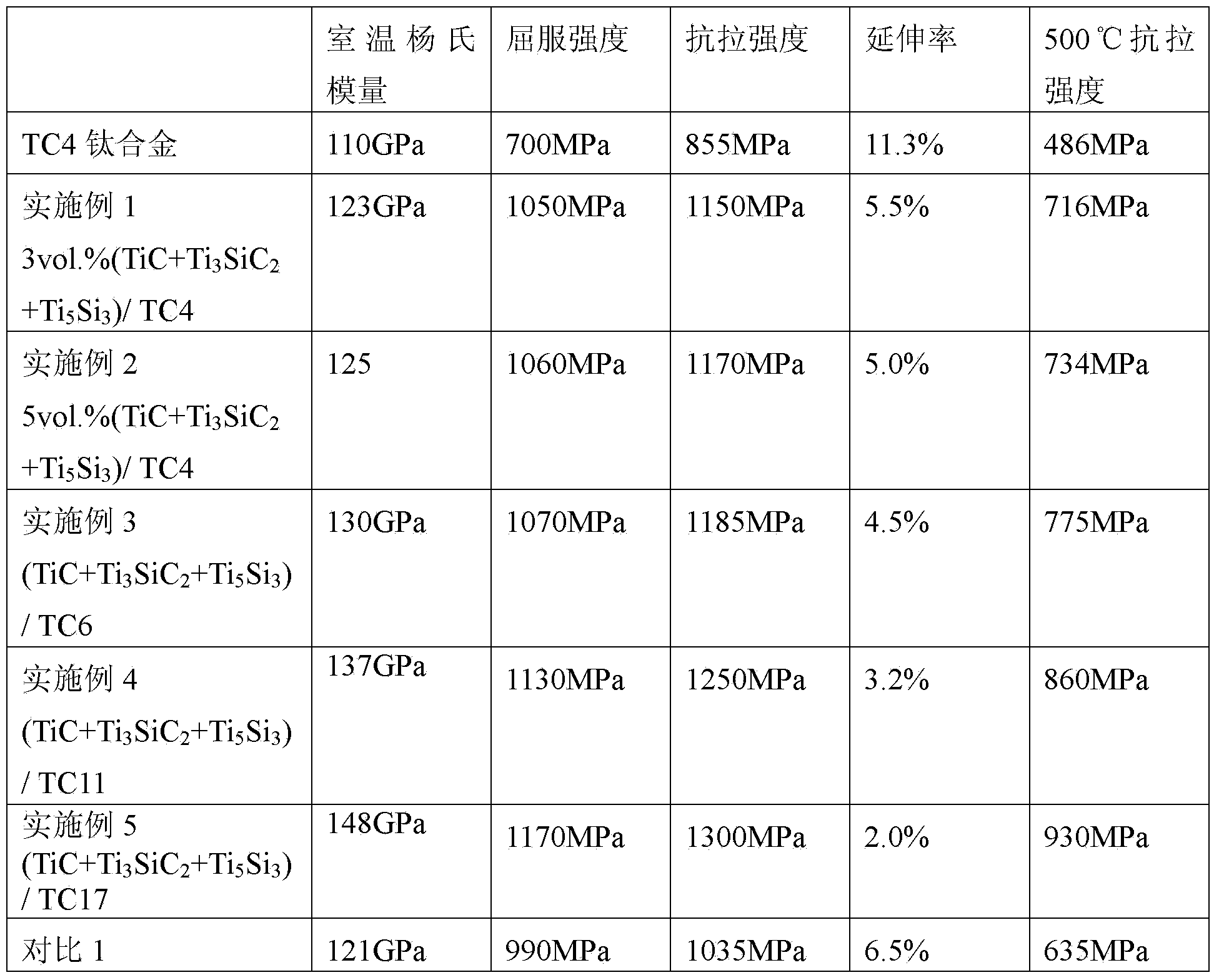

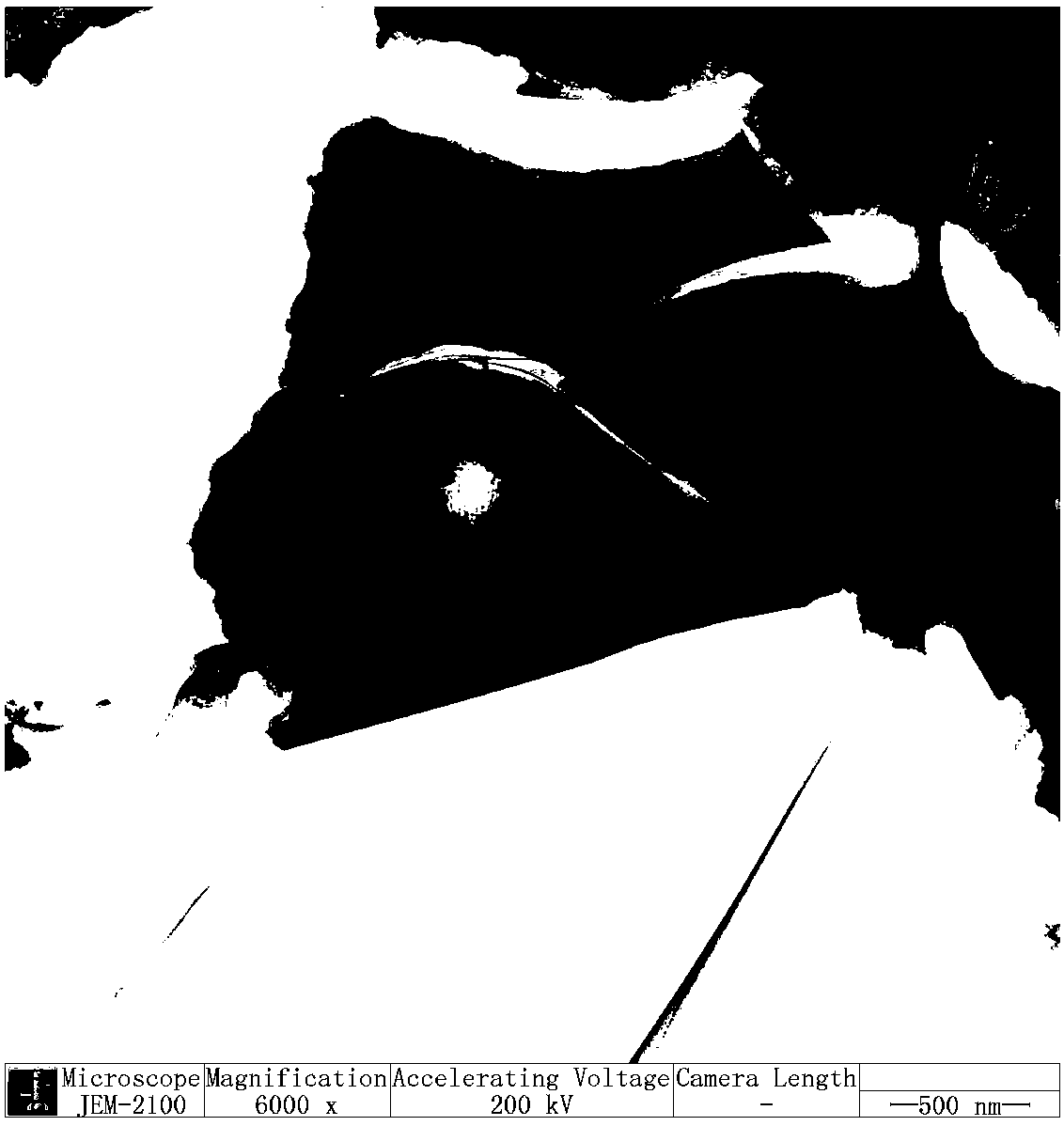

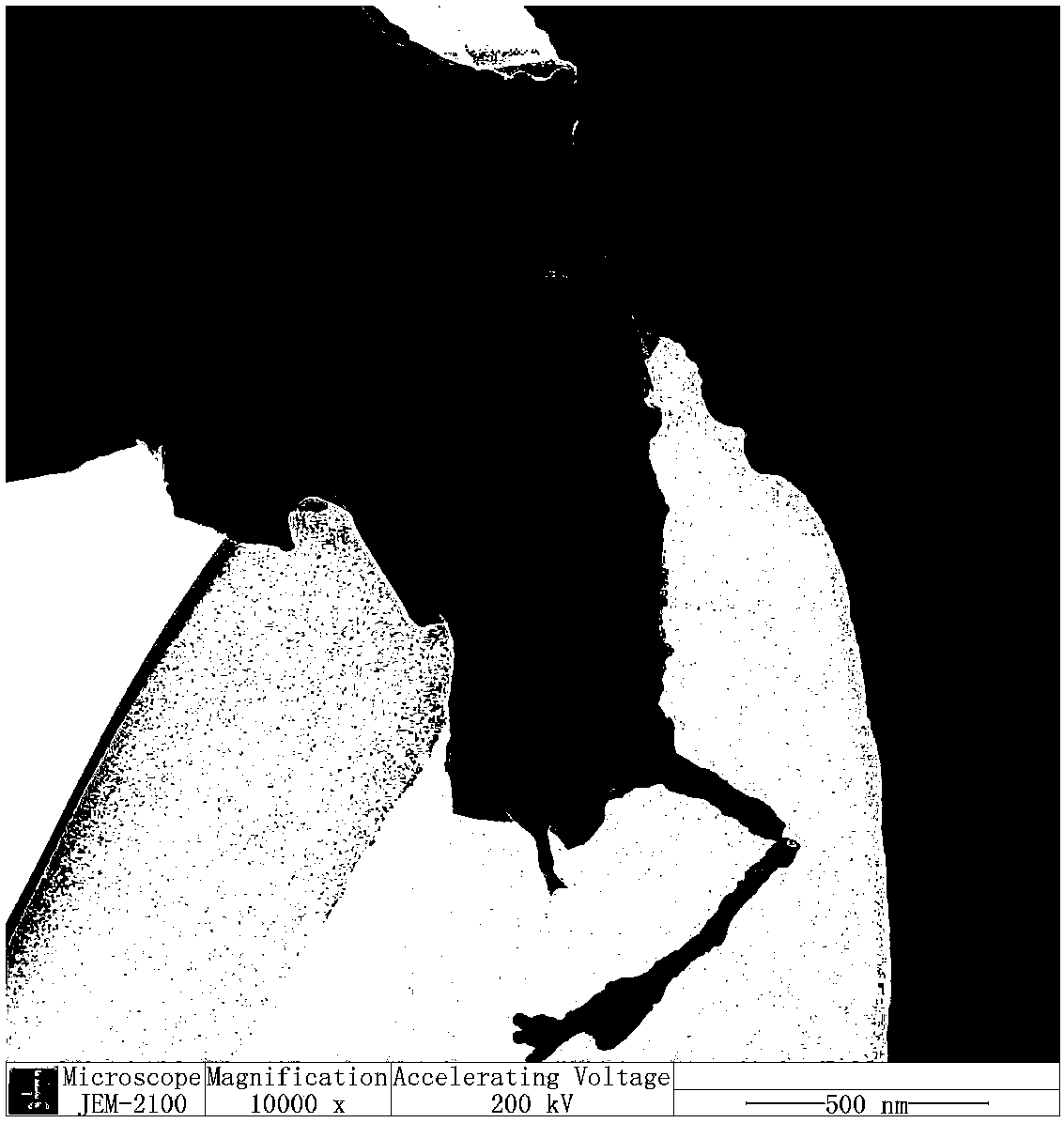

Titanium-based composite material with two-stage net structures and preparation method of titanium-based composite material

InactiveCN104294075ATake full advantage of enhancementsIncrease room temperature modulusTitanium matrix compositesDouble phase

The invention relates to a titanium-based composite material with two-stage net structures and a preparation method of the titanium-based composite material. According to the invention, the mechanical property of a non-continuous reinforced titanium-based composite material can be further improved. The titanium-based composite material with the two-stage net structures uses SiC as a reinforcement raw material and uses an alpha and belta double-phase titanium alloy as a matrix. The preparation method comprises the following steps: 1, powder mixing by a ball mill; 2, hot pressing sintering. According to the (TiC,Ti3SiC2 and Ti5Si3) / Ti titanium-based composite material with the two-stage net structures,disclosed by the invention, a hard ceramic reinforcement is successfully introduced into a softer beta phase in a netted form to form the titanium-based composite material with the two-stage net structures, so that a room temperature modulus, intensity and heat resistance of the titanium-based composite material are further improved and the reinforcing effect of the net structures is sufficiently played.

Owner:HARBIN INST OF TECH

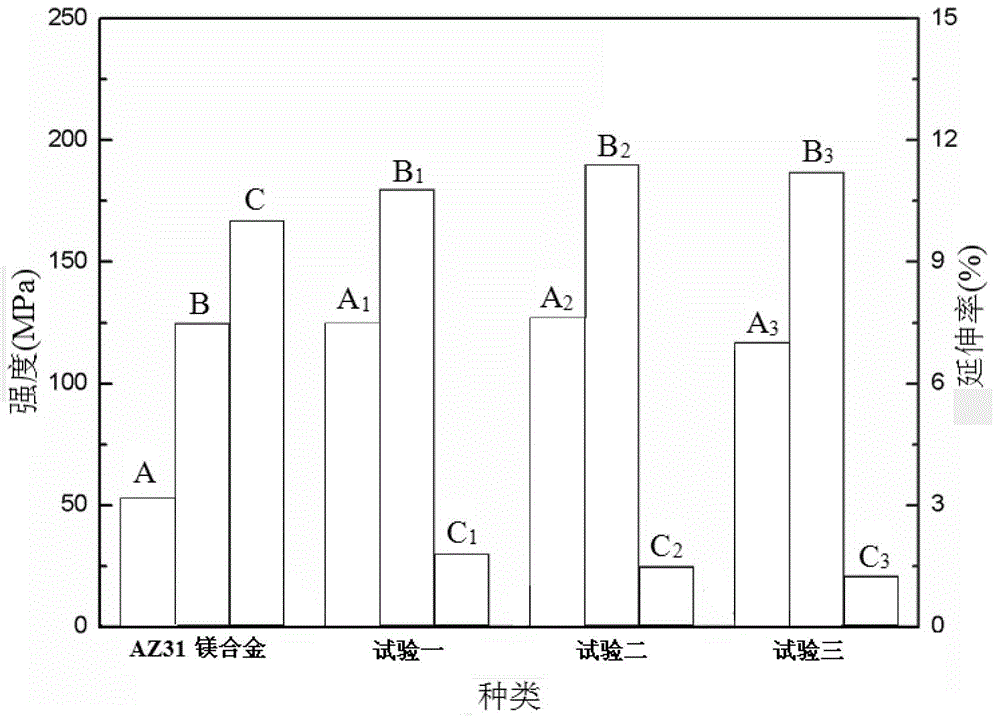

Preparation method of double-size silicon carbide particle hybrid reinforced magnesium matrix composite material

InactiveCN102943198AWell mixedSolve the problem of uniform dispersionMagnesium matrix compositeSemi solid

The invention discloses a preparation method of a double-size silicon carbide particle hybrid reinforced magnesium matrix composite material, and aims at solving the problem that in the prior art, the compatibility between the silicon carbide particles and the magnesium alloys is bad so that the silicon carbide particles are easy to aggregate. The preparation method comprises the steps of: (1) mixing to obtain double-size silicon carbide particles; and (2) placing the double-size silicon carbide particles in a semi-solid magnesium matrix and carrying out stirring, ultrasonic dispersion and die-casting to obtain the double-size silicon carbide particle hybrid reinforced magnesium matrix composite material. The preparation method has the advantages that (1) the problem that the silicon carbide particles are difficultly and evenly dispersed in the matrix is effectively solved so as to give full play to the particle reinforcement effect; and (2) the mechanical property is remarkably improved. The preparation method is mainly used for preparing the double-size silicon carbide particle hybrid reinforced magnesium matrix composite material.

Owner:HARBIN INST OF TECH

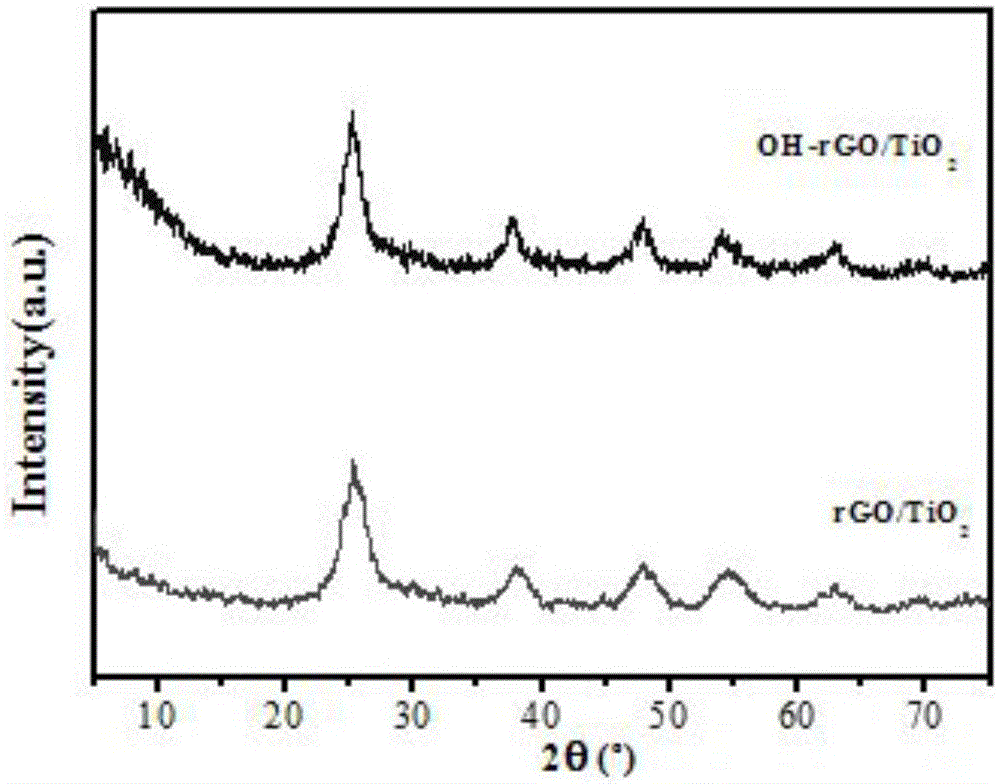

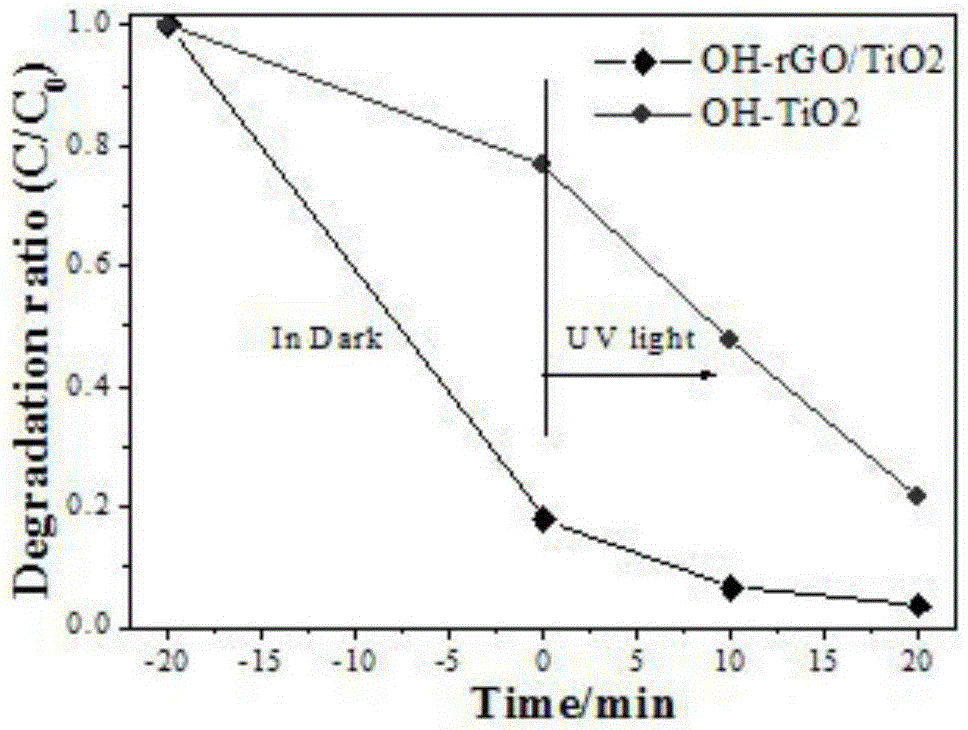

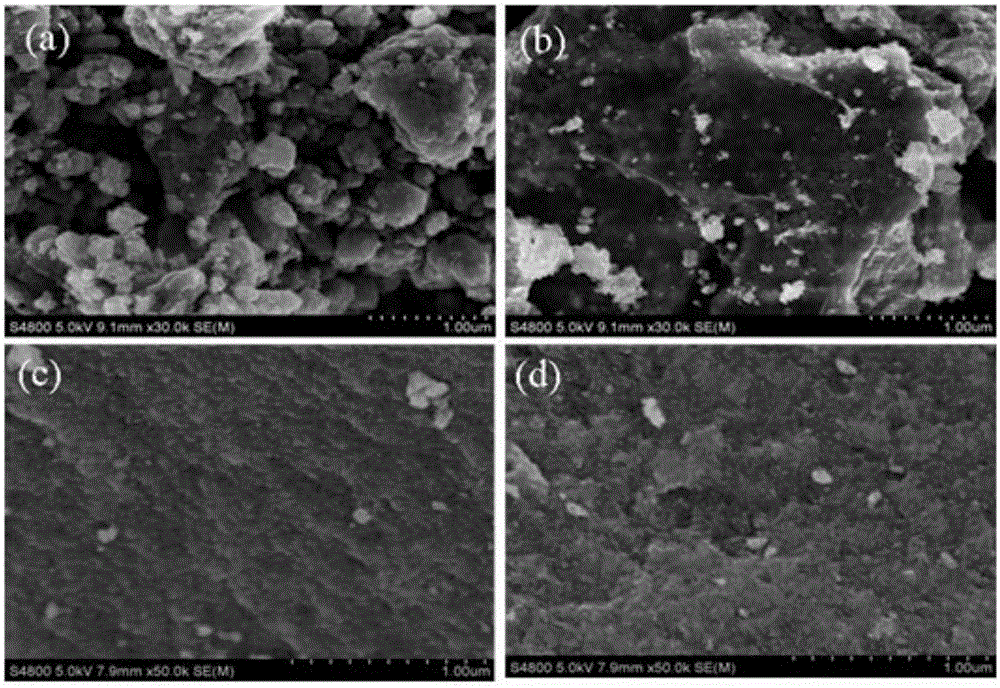

Preparation method of hydroxylation titanium oxide/graphene visible light catalysis material

ActiveCN105148894AImprove conductivityTake full advantage of enhancementsPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic water splittingOxygen vacancy

The invention relates to a preparation method of a surface hydroxylation titanium oxide / graphene visible light catalysis material. According to the method, butyl titanate, graphene and nitrate serve as raw materials, organic electrolyte serves as surfactant, and the surface hydroxylation graphene / TiO<2> catalysis material is obtained through the steps of sol application, thermostatic water bath, ultraviolet irradiation, microwave irradiation, washing, drying and the like. The preparation method has the greatest advantage that ultraviolet pre-oxidation and microwave irradiation are utilized for achieving surface hydroxylation, the preparation process is simple, the energy consumption is low, rapid synthesis can be achieved, and large-scale production is easy to achieve; meanwhile, more defects such as oxygen vacancy and Ti<3+> are caused to a composite by surface hydroxylation, surface activity is increased, forbidden bandwidth of the composite is decreased, the spectral response range is widened, the obtained graphene / TiO<2> catalysis material is great in absorption performance and high in activity, durability and antibacterial performance, and the preparation method has a wide application prospect in fields such as sewage treatment, photocatalytic water splitting, air purification, solar cells, antibacterial materials and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

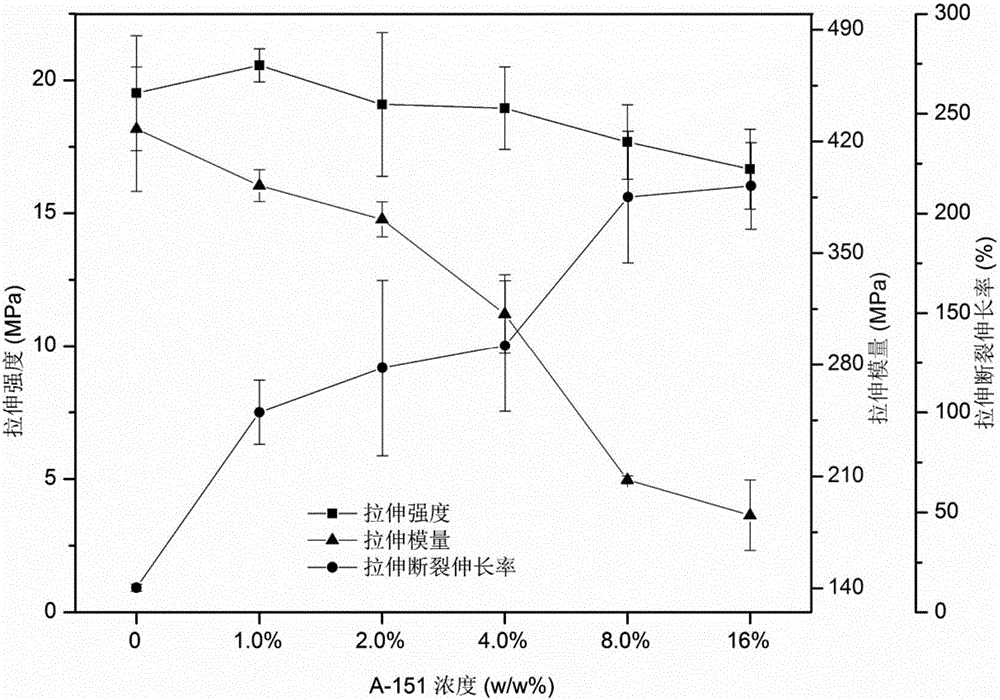

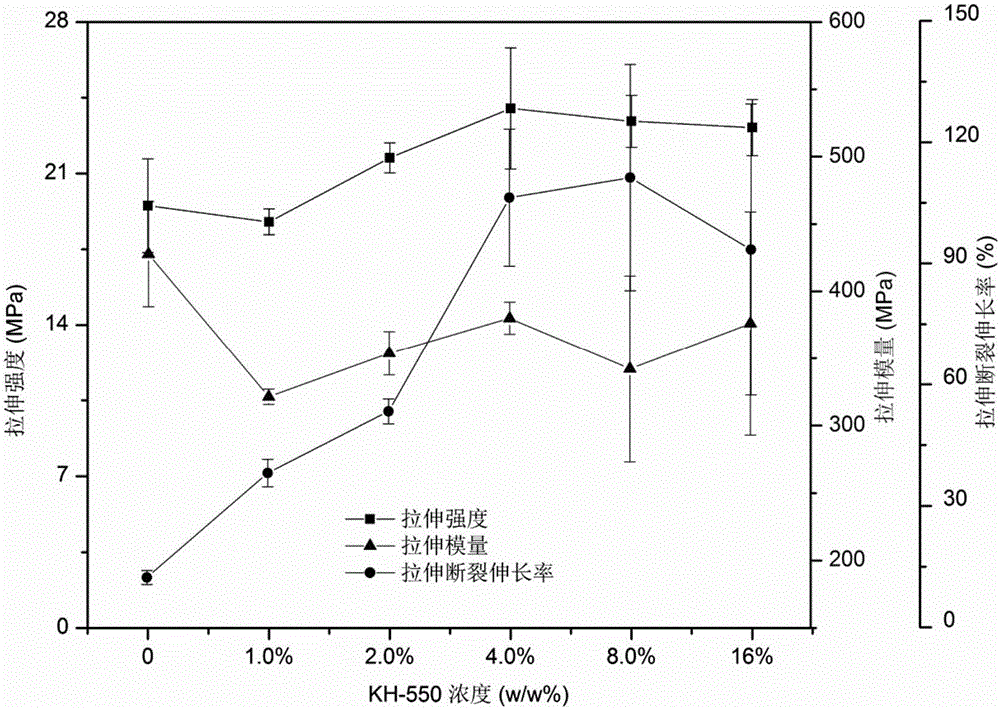

Method for preparing polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film

InactiveCN106009570ASolve the problem of poor tensile toughnessResolve Tensile StrengthOrganic solventSolvent evaporation

The invention discloses a method for preparing a polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film. The method comprises the following steps: (1) performing surface modification treatment on bamboo nano-cellulose whiskers to obtain modified bamboo nano-cellulose whiskers; (2) performing surface modification treatment on ultrafine bamboo charcoal particles to obtain modified ultrafine bamboo charcoal particles; (3) conducting a solution pouring-solvent evaporation method: adding an organic solvent into polylactic acid, heating and stirring till polylactic acid is completely dissolved, then adding the modified bamboo nano-cellulose whiskers and the modified ultrafine bamboo charcoal particles, performing dispersion treatment to obtain a blend system, pouring the blend system in a die to manufacture a film, and drying to obtain the polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film. The method provided by the invention can endow a composite material with favorable tensile strength and tensile modulus of elasticity while toughening the polylactic acid composite material.

Owner:ZHEJIANG UNIV

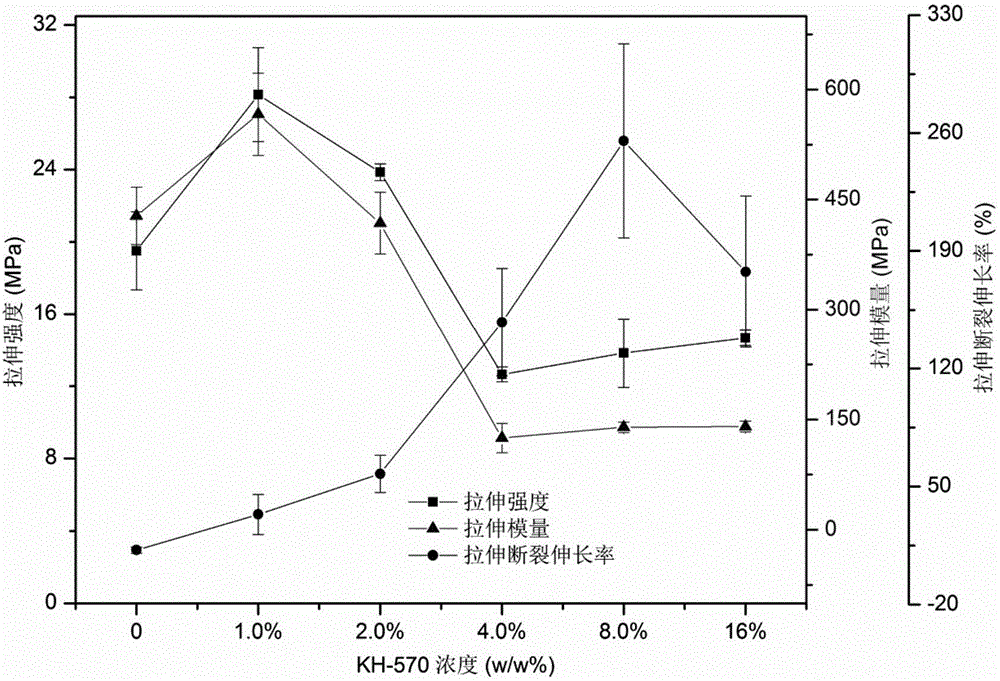

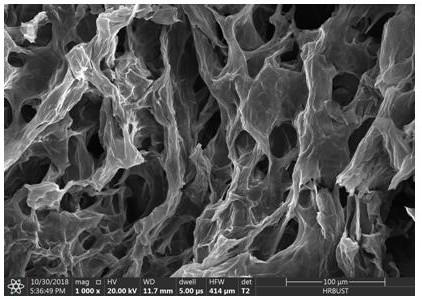

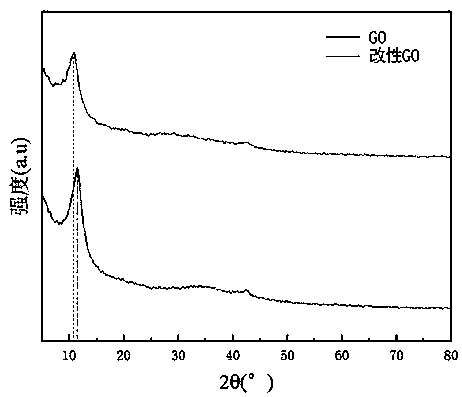

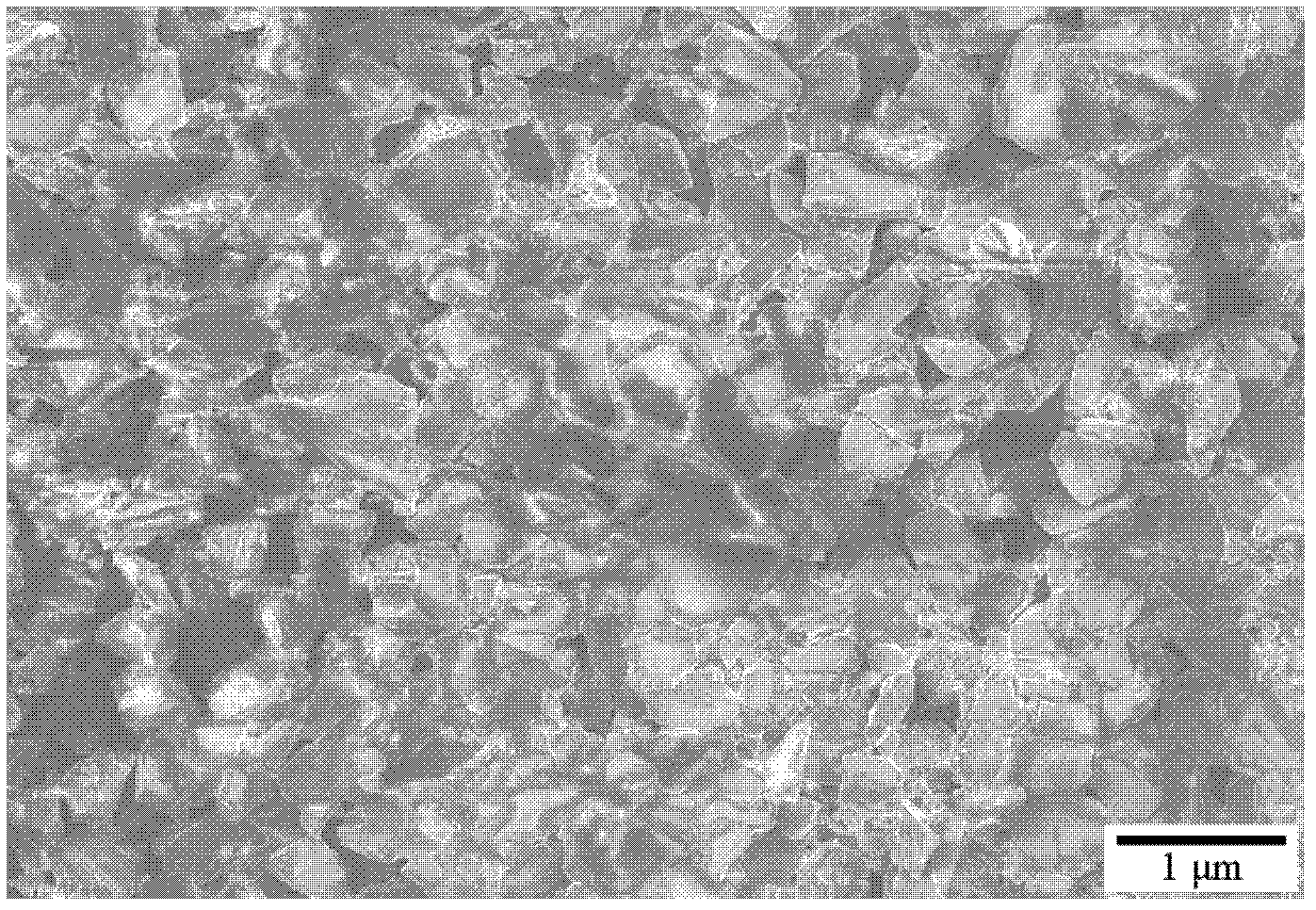

Method for preparing montmorillonite/graphene oxide aerogel/epoxy resin composite material

The invention provides a method for preparing a montmorillonite / graphene oxide aerogel / epoxy resin composite material and relates to a study on single-aspect performance of a double-phase composite material or epoxy resin. The method for preparing the montmorillonite / graphene oxide aerogel / epoxy resin composite material comprises the following steps: after adding expanded graphite to a container under a condition of ice-water bath, adding a mixed solution of concentrated sulfuric acid and concentrated nitric acid to the container; adding potassium permanganate to the container; stirring and heating an obtained mixture; after adding hydrogen peroxide to the mixture till a solution becomes luminous yellow, adjusting the PH value of the solution to 7; centrifuging the solution; freezing and drying the solution to obtain graphene oxide aerogel; taking the graphene oxide aerogel and adding the graphene oxide aerogel to acetone solution; carrying out ultrasonic treatment on an obtained mixture to obtain modified graphene oxide under the nitrogen protection; adding acetone to the modified graphene oxide and modified montmorillonite mixture; adding pre-heated epoxy resin to the modified graphene oxide and modified montmorillonite mixture in advance; and ultrasonically stirring, vacuumizing, heating, curing and cooling an obtained mixture to obtain a three-phase composite material. Themethod for preparing the montmorillonite / graphene oxide aerogel / epoxy resin composite material is used for preparing the montmorillonite / graphene oxide aerogel / epoxy resin composite material.

Owner:HARBIN UNIV OF SCI & TECH

Method for performing surface modification on metal by ultrasonic nano-welding

ActiveCN102500912ATake full advantage of enhancementsGood interface wettabilityNon-electric welding apparatusMechanical bondMetal substrate

The invention relates to a method for performing surface modification on a metal by ultrasonic nano-welding and belongs to the technical field of nanomaterials. The method comprises the following steps: cleaning a to-be-treated region of the surface of the metal, coating a nanopowder material on the metal surface after cleaning, and performing ultrasonic nano-welding process on the nanopowder material on the metal surface to obtain a modified metal surface. The method is simple to operate and has controllable welding parameters. The nanomaterial and the welding region of the metal substrate form a local miscible body, leading to good interface infiltration, which enhances mechanical bonding effect and gives full play to reinforcement function of the nanomaterial. The nanomaterial is distributed densely and uniformly on the metal surface, and the surface is smooth and clean and has no cracks or air hole.

Owner:SHANGHAI JIAO TONG UNIV

Polylactic acid nanometer complex concurrently having toughness and strength, and preparation method thereof

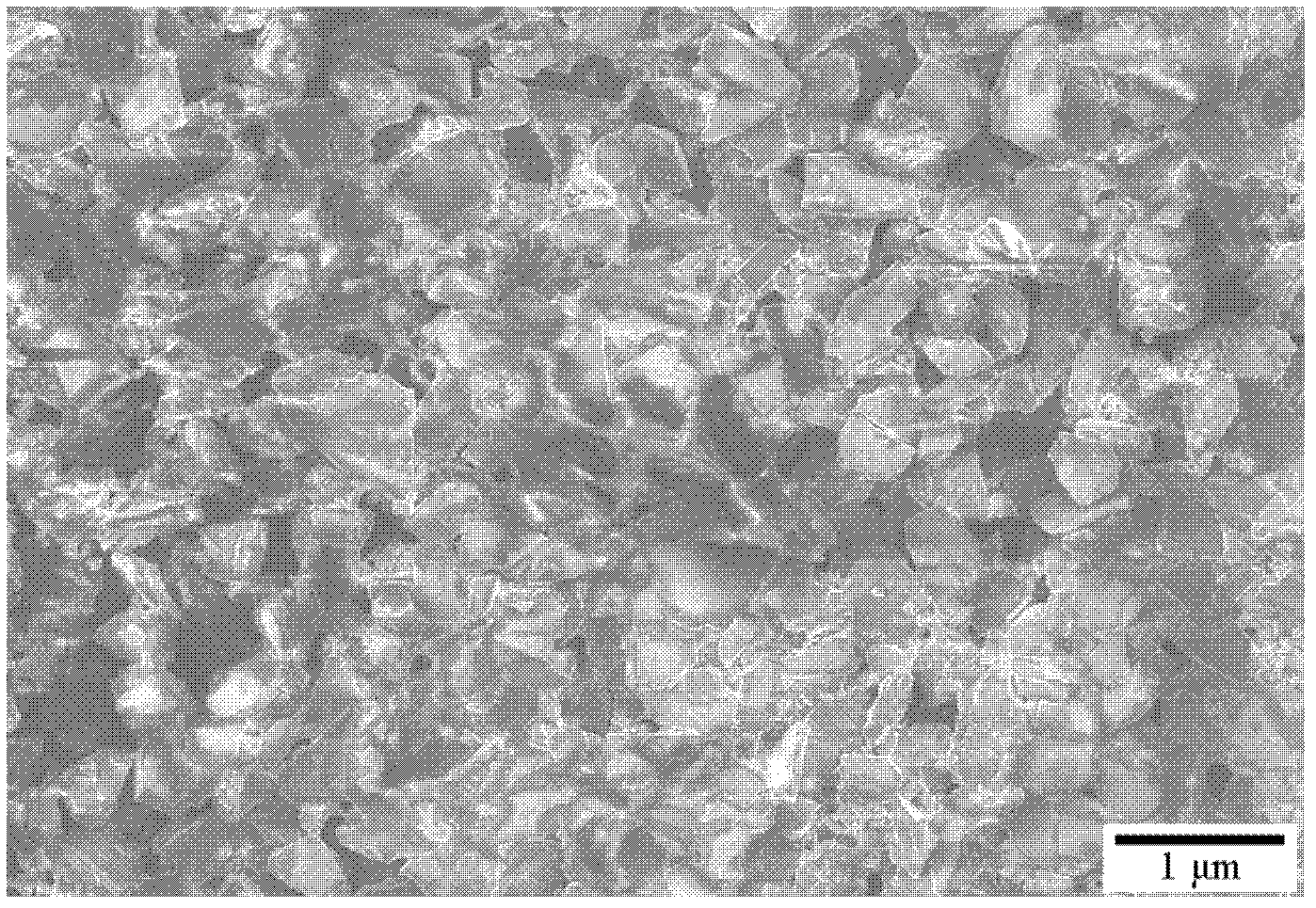

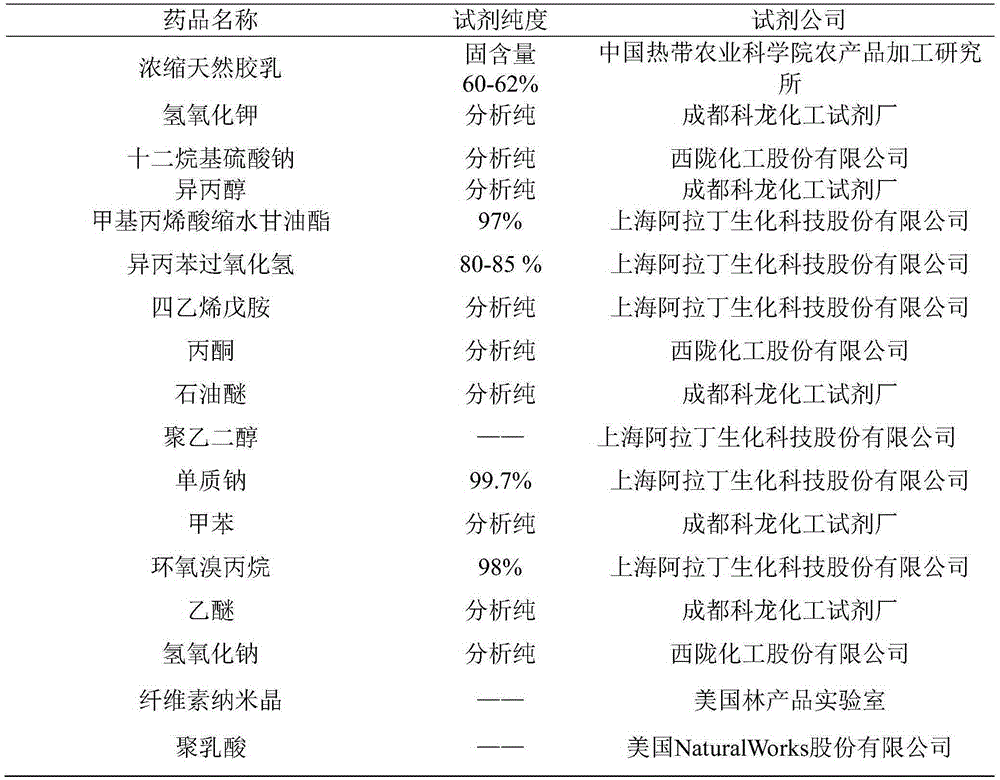

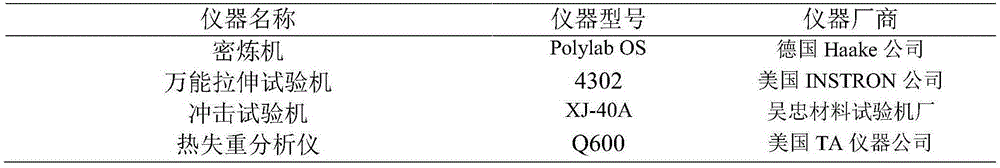

The present invention discloses a polylactic acid nanometer complex concurrently having toughness and strength, and a preparation method thereof, and belongs to the field of polymer materials, wherein the complex comprises a polylactic acid matrix resin, a toughening agent and a reinforcing agent. The preparation method comprises: adding natural latex and deionized water to a reactor, and adding potassium hydroxide and sodium lauryl sulfate; introducing protective gas, adding isopropyl alcohol, uniformly mixing, adding glycidyl methacrylate, heating, and adding an initiator and a catalyst; carrying out a reaction, drying, carrying out immersion washing, drying, extracting, and drying to obtain NR-g-GMA; adding polyethylene glycol, elemental sodium wire and toluene to the reactor, carrying out a reflux reaction, cooling, adding epibromohydrin, carrying out a reaction, filtering, adding the filtrate to ether, precipitating, washing, and drying to obtain PEG-EP; adding a NaOH solution to a cellulose nano-crystal aqueous solution, uniformly mixing, adding the PEG-EP, carrying out a reaction, carrying out dialysis, and drying to obtain CNC-g-PEG; and carrying out melt blending on the dried polylactic acid matrix resin, the NR-g-GMA and the CNC-g-PEG so as to obtain the complex.

Owner:贵州黔城黔测检测技术有限公司

Heat treatment method for wood

InactiveCN106217532AGood dimensional stabilityAvoid failureRadiation/waves wood treatmentWood treatment detailsAnhydrous ethanolMicrowave

The invention discloses a heat treatment method for wood. Firstly, clay paste is prepared; then the surface of the wood is smeared with the clay paste; then, microwave treatment is conducted; then, treatment is conducted in a high-temperature heat treatment tank; a clay paste coating is removed; treatment is conducted in the high-temperature heat treatment tank; then, the wood is soaked in anhydrous ethanol for a period of time and treated once again in the high-temperature treatment tank; and finally steam-injection humidity regulation is conducted. Compared with the prior art, the heat treatment method for the wood is easy to operate and easy to achieve, the occurrence rate of the defects such as cracking and deforming of a traditional heat treatment for the wood is decreased, and the mechanical strength, waterproof performance and flame retardant property of the wood can be effectively improved.

Owner:ANHUI CHANGFA IND

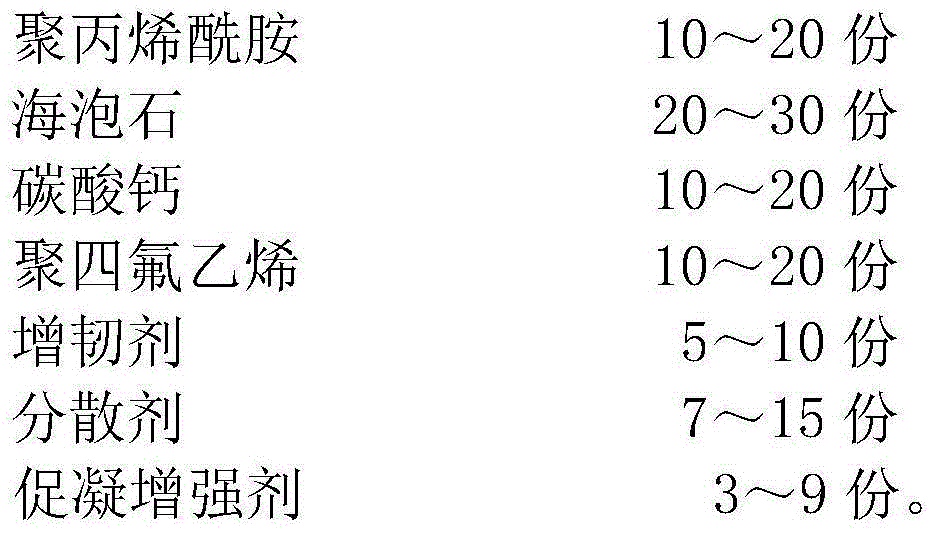

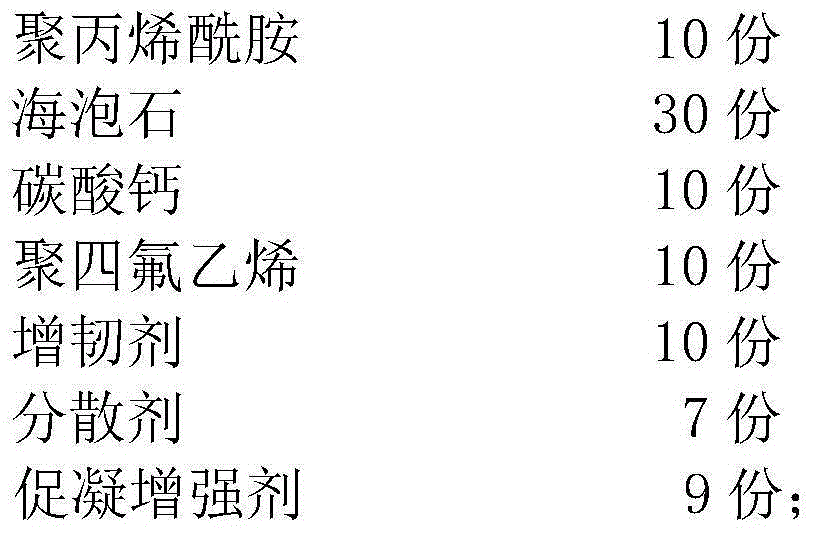

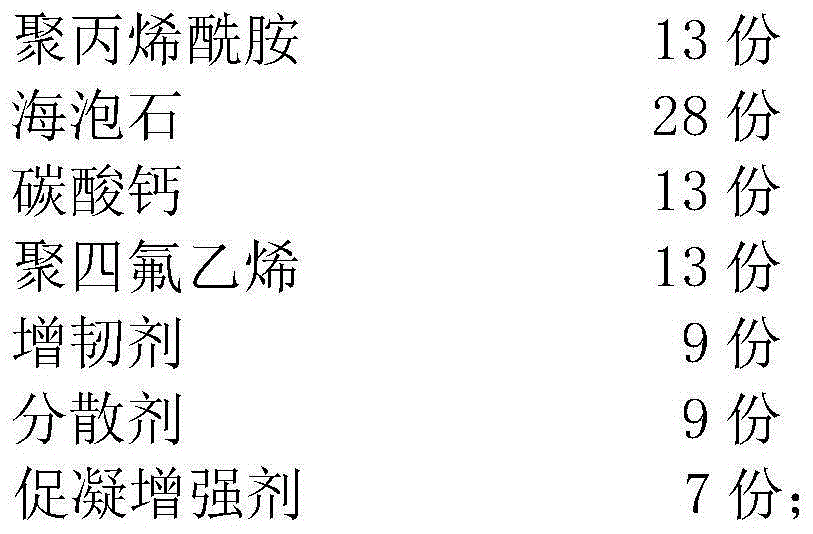

Expansion-controllable plugging agent

The invention relates to the technical field of a plugging agent, especially to an expansion-controllable plugging agent. The expansion-controllable plugging agent is prepared from the following raw materials, by weight, 60-80 parts of polyacrylamide, 10-20 parts of meerschaum, 10-20 parts of teflon, 5-10 parts of a flexibilizer, 7-15 parts of a dispersant and 3-9 parts of a coagulant enhancer. The expansion-controllable plugging agent can control expansion speed, has good deformability and adaptability, can reduce permeability of a plugged zone, enhance strength of the plugged zone and raise pressure-bearing capacity of the plugged zone, is low-cost, is non-toxic, harmless and pollution-free, and is green and environmentally friendly.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

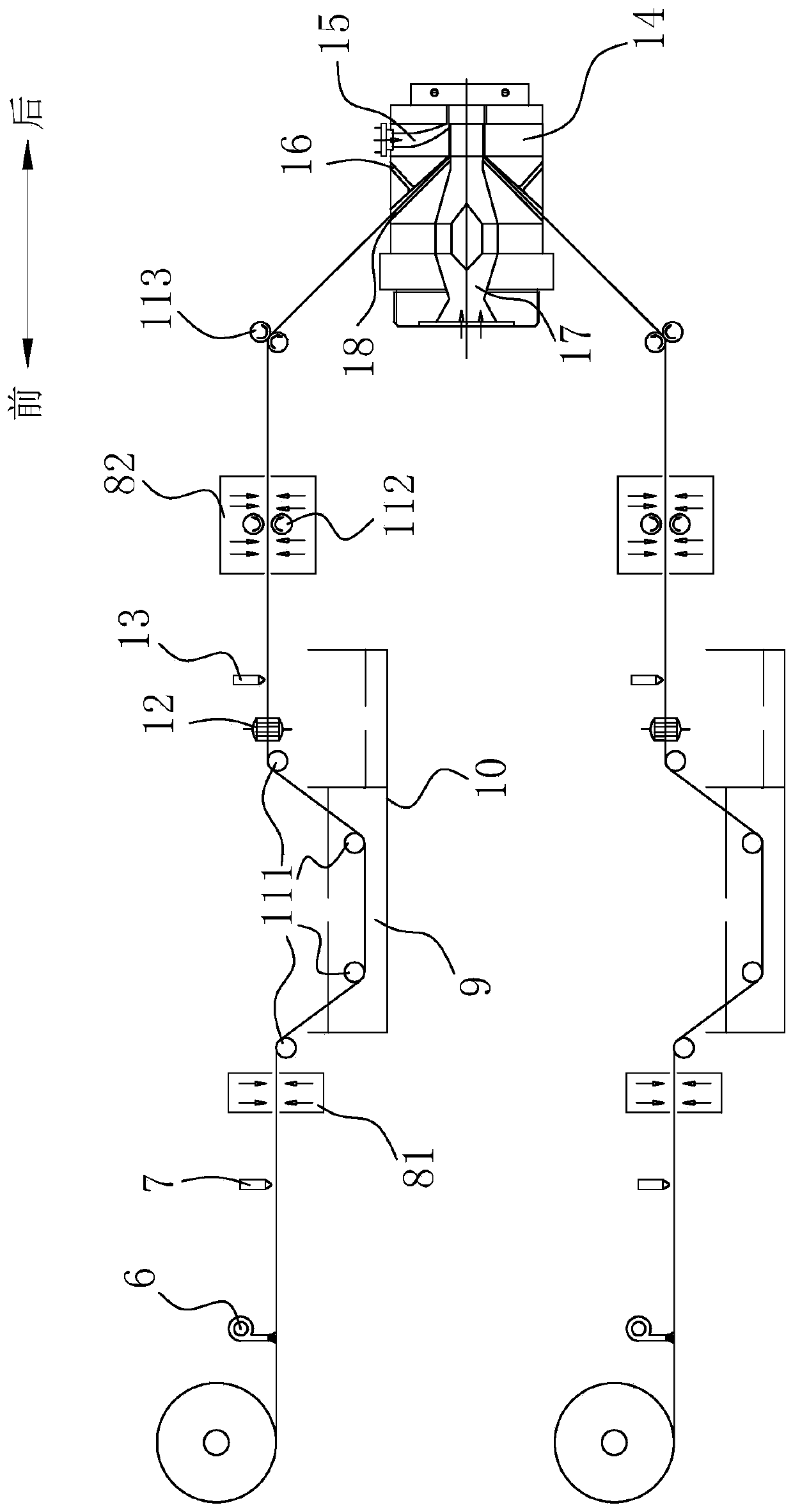

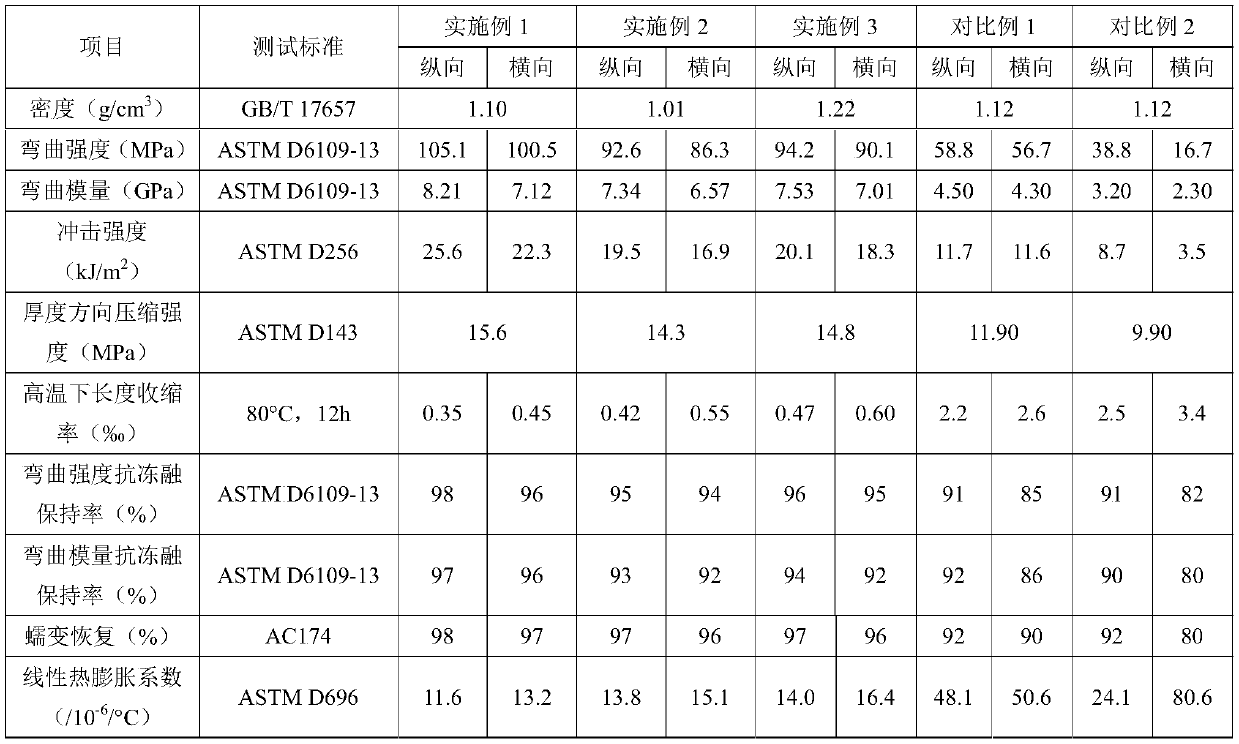

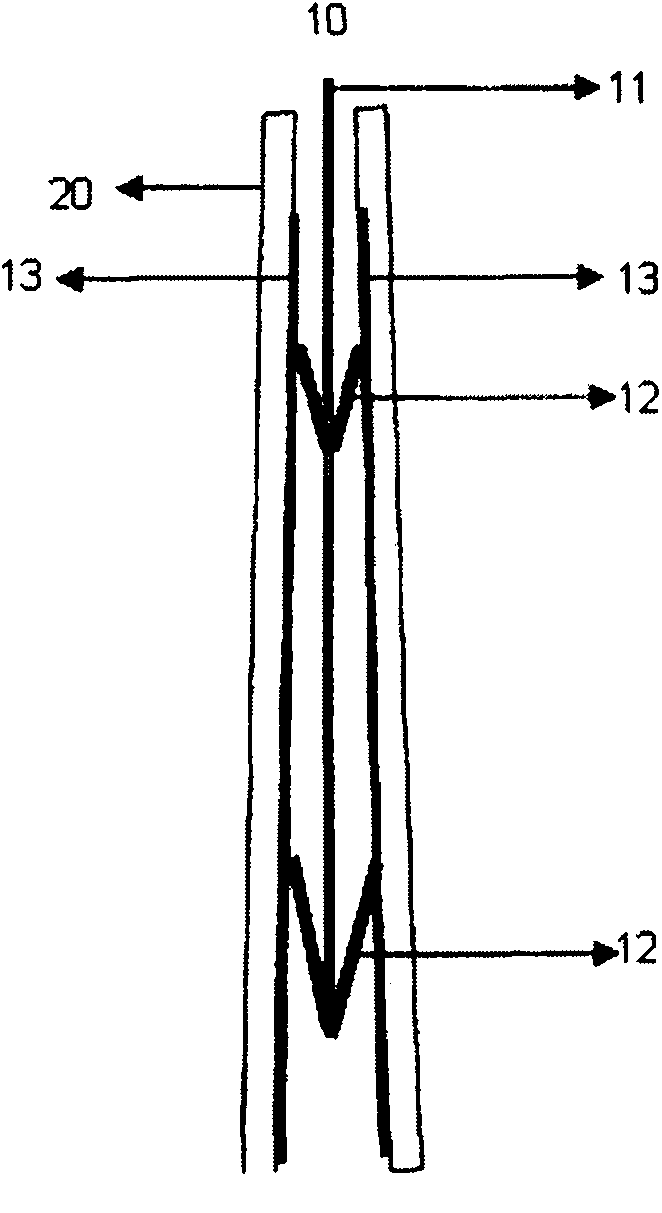

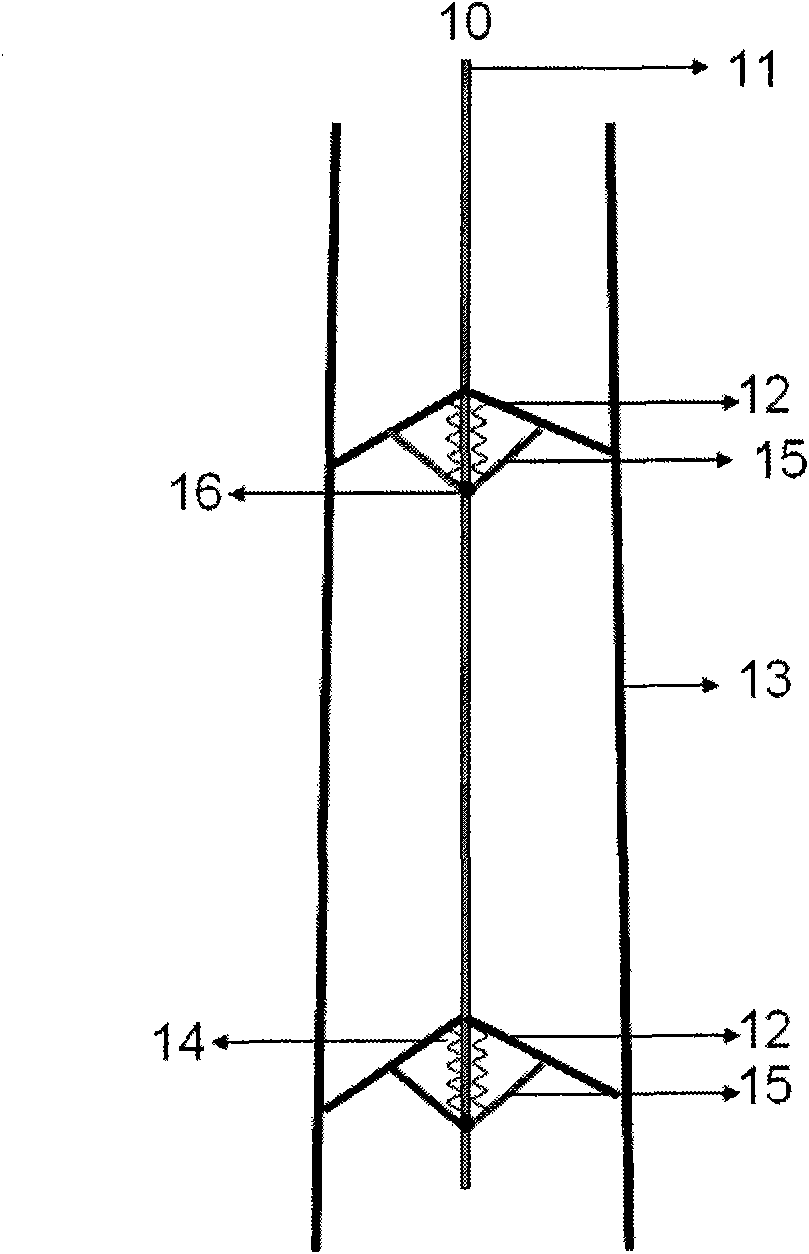

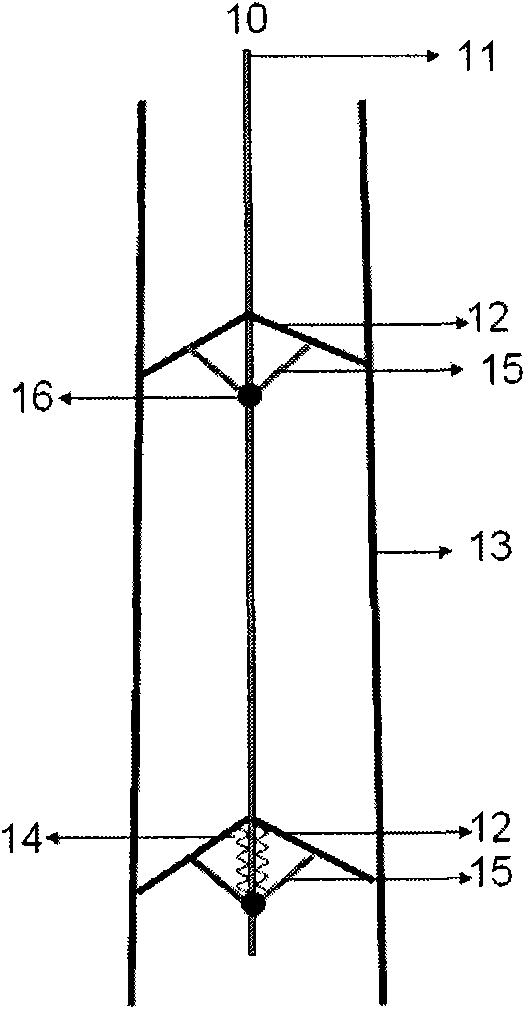

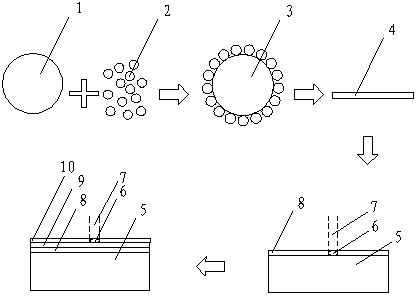

Continuous fiber cloth three-dimensional reinforced wood-plastic composite material as well as production method and equipment thereof

ActiveCN111421926AReduce defectsStrong controllability of curing degreeLamination ancillary operationsSynthetic resin layered productsFiberWood-plastic composite

The invention discloses a continuous fiber cloth three-dimensional reinforced wood-plastic composite material and a production method and equipment thereof. The reinforced wood-plastic composite material comprises a wood-plastic core layer; a wood-plastic surface layer is arranged outside the wood-plastic core layer, and thermosetting resin impregnated fiber cloth is arranged on at least one sidebetween the wood-plastic core layer and the wood-plastic surface layer. Experimental data show that the transverse / longitudinal bending property, the transverse / longitudinal tensile property, the transverse / longitudinal impact property, the transverse / longitudinal creep property, the compression property in the thickness direction, the dimensional stability of boiling at 100 DEG C and the surfacehardness of the reinforced wood-plastic composite material in some embodiments of the invention are remarkably improved.

Owner:SOUTH CHINA AGRI UNIV

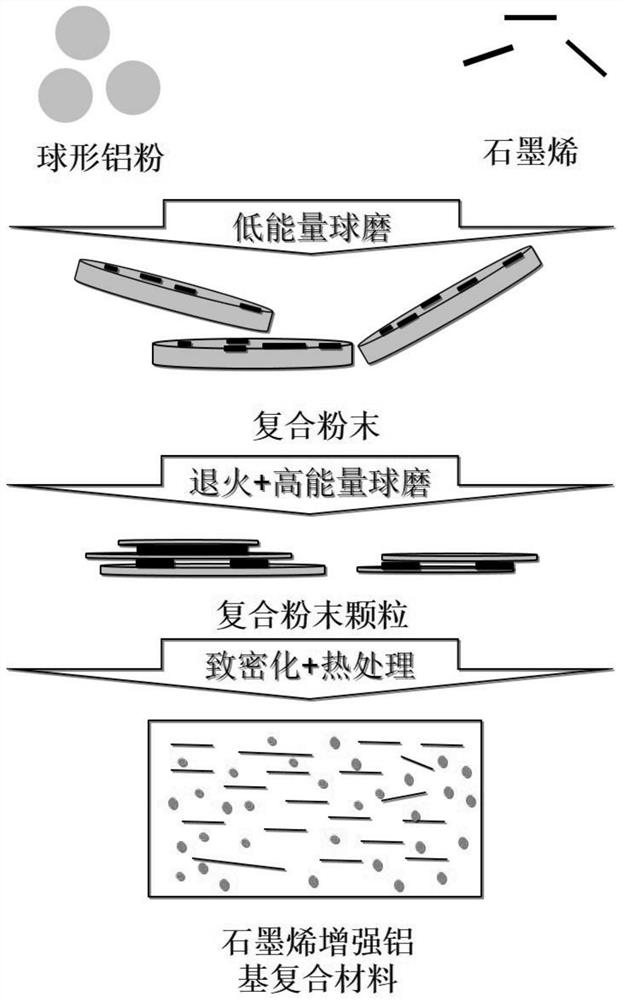

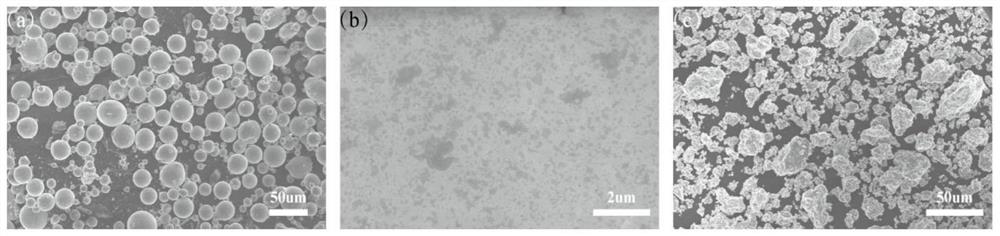

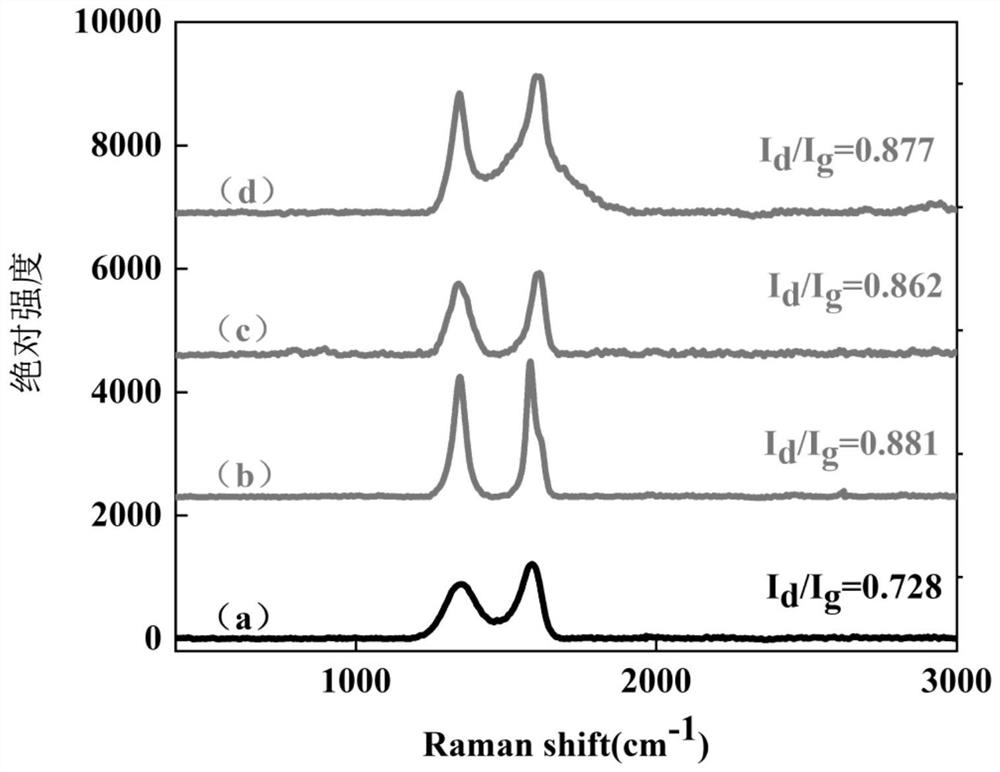

Powder metallurgy preparation method of graphene reinforced aluminum-based composite material

InactiveCN112725660AEvenly dispersedImproves Structural IntegrityTransportation and packagingMetal-working apparatusHigh energyGraphite

The invention provides a powder metallurgy preparation method of a graphene reinforced aluminum-based composite material, which comprises the following steps: preparing graphene-aluminum composite powder by long-time low-energy ball milling in advance, annealing, and carrying out short-time high-energy ball milling, densification processing and heat treatment to finally obtain the composite material. Uniform compounding of matrix powder and graphene is achieved through long-time low-energy ball milling, meanwhile, interface reaction can be avoided, and the structural integrity of graphene is protected; the annealed composite powder can improve the plastic deformation capacity of the composite powder while improving the quality of the graphene; short-time high-energy ball milling is performed, so that composite powder is welded into particles, and the quality of graphene is not damaged; and in addition, for the composite material of a aluminum alloy matrix, the uniformly dispersed graphene promotes the precipitation of fine dispersed precipitated phases in the matrix, and the mechanical properties of the composite material are further improved. The method is beneficial to protecting the integrity of the graphene structure to the maximum extent, exerts the graphene strengthening potential, saves energy and time, and is suitable for batch preparation and production.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of phenyl silsesquioxane/oxidized graphene/polyimide three-phase compound film

InactiveCN108250749AExcellent dielectric propertiesGood thermal propertiesPolymer scienceIn situ polymerization

The invention relates to the technical field of insulating materials, in particular to a preparation method of a phenyl silsesquioxane / oxidized graphene / polyimide three-phase compound film so as to solve the problem that an existing compound film cannot give consideration to reduction of dielectric constant and improvement of thermal properties and mechanical properties at the same time. The preparation method comprises the steps that oxidized graphene is prepared through an improved Hummers method; and the phenyl silsesquioxane / oxidized graphene / polyimide three-phase compound film is preparedby adopting an in-situ polymerization method. The preparation method is applied to preparation of the phenyl silsesquioxane / oxidized graphene / polyimide three-phase compound film.

Owner:HARBIN UNIV OF SCI & TECH

Telegraph pole strengthening device and strengthening method thereof

InactiveCN101769087ATake full advantage of enhancementsImprove installation efficiencyTowersEngineering

Owner:EI DU PONT DE NEMOURS & CO

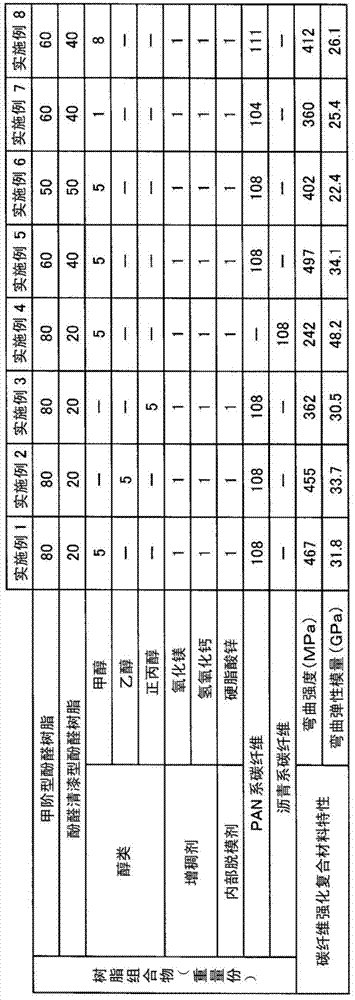

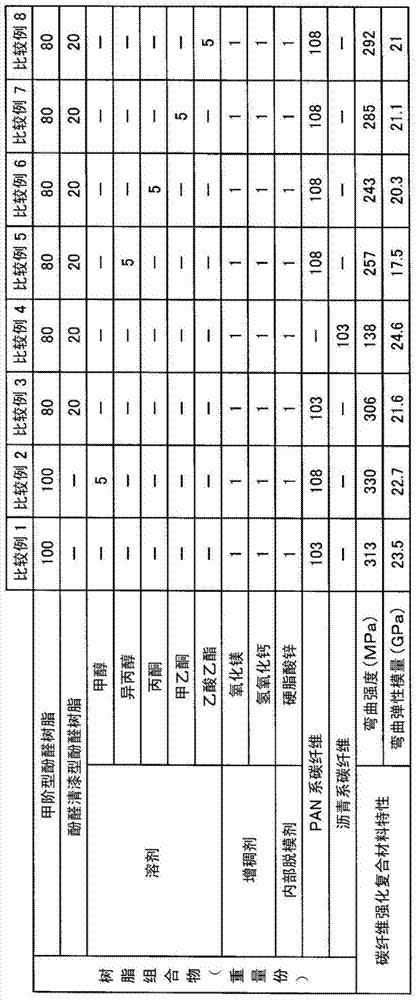

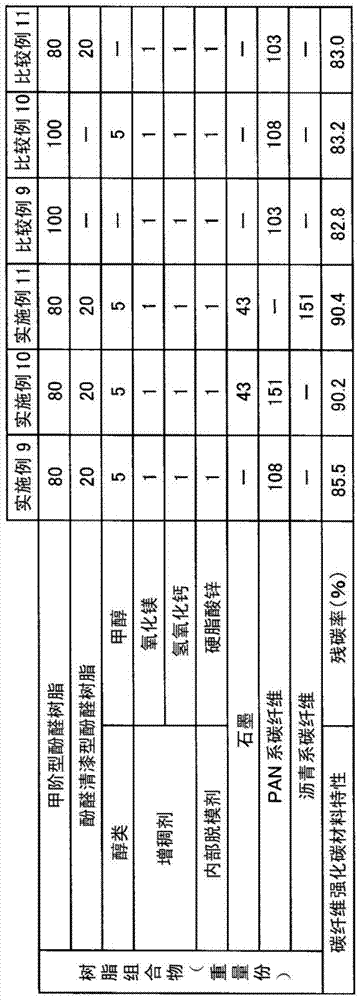

Resin composition, carbon fiber-reinforced composite material precursor obtained using the resin composition, carbon fiber-reinforced material, and carbon fiber-reinforced carbon material

InactiveCN104755554AImprove flame retardant performanceImprove heat resistanceConjugated synthetic polymer artificial filamentsCoatingsFiberHeat resistance

Owner:ASAHI YUKIZAI KOGYO CO LTD

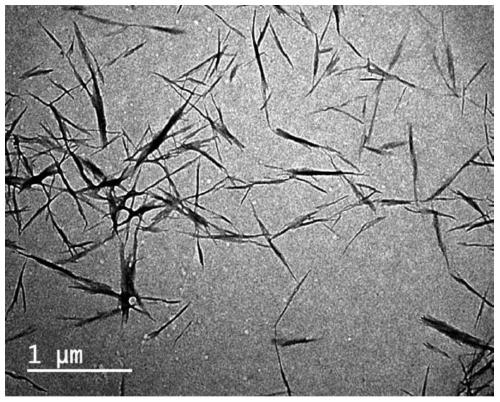

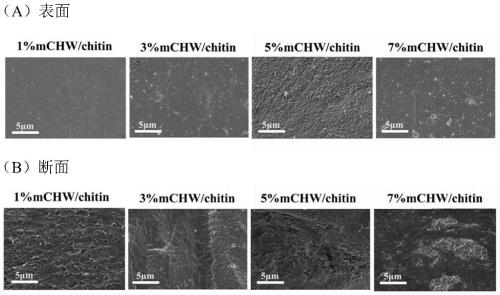

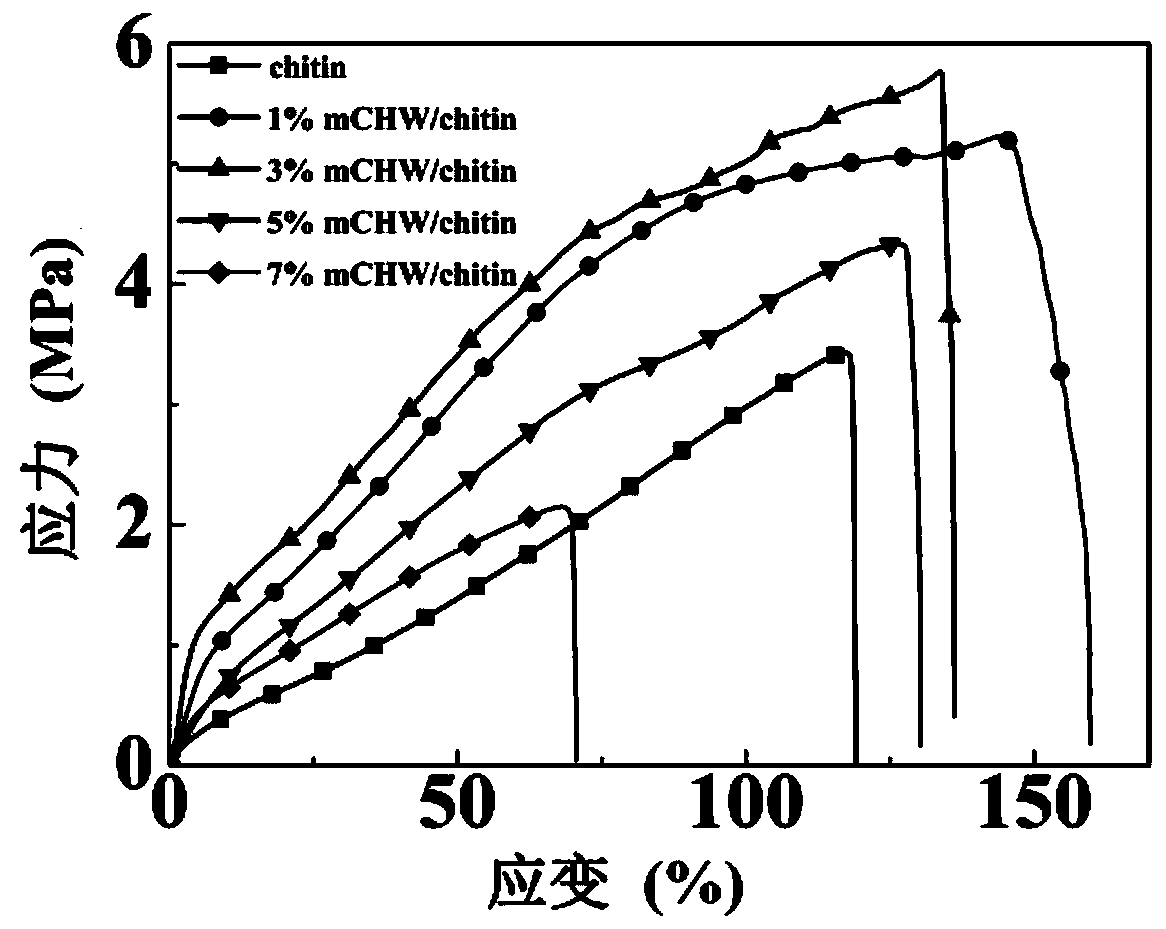

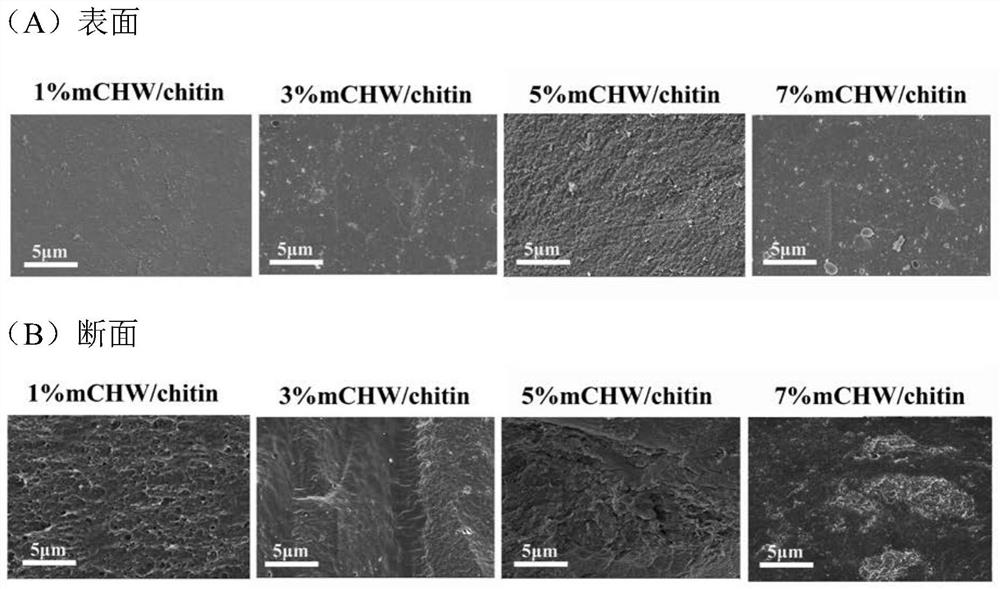

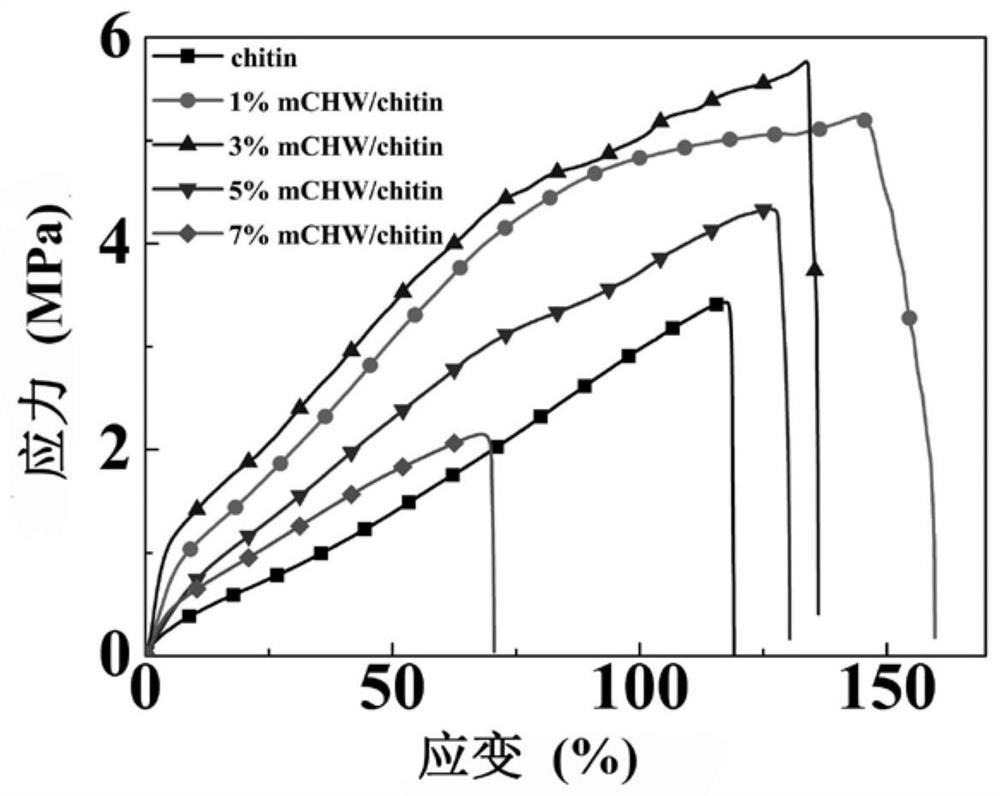

High-strength chitin composite hydrogel material as well as preparation method and application thereof

ActiveCN111592693AHigh strengthLow costPharmaceutical delivery mechanismProsthesisBone tissueElectronegativity

The invention belongs to the field of biomedical materials, and discloses a high-strength chitin composite hydrogel material as well as a preparation method and application thereof. The composite hydrogel material is composed of chitin as a matrix and chitin whiskers with electronegativity on the surface as a reinforcing filler. The chitin whisker with surface electronegativity is used as a reinforcing filler to be compounded with a chitin matrix; the groups with negative charges on the surfaces of the whiskers can form strong electrostatic repulsive force, so that uniform dispersion of the chitin whiskers in a chitin matrix is effectively promoted, and meanwhile, good interface bonding with the matrix can be realized, so that the reinforcing effect of the whiskers is fully exerted, and the chitin composite hydrogel material is endowed with excellent mechanical properties. In addition, the chitin composite hydrogel material disclosed by the invention has good biocompatibility and osteogenic activity, and has a good application prospect in the biomedical fields of bone tissue repair and the like.

Owner:JINAN UNIVERSITY

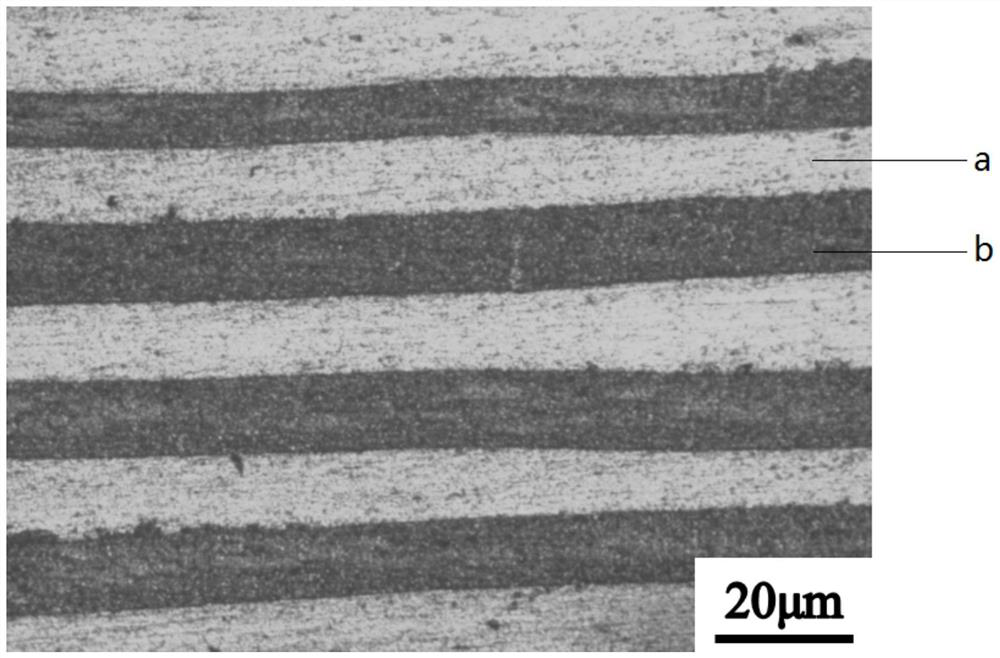

Preparation method of high-strength and high-toughness graphene reinforced aluminum matrix composite

The invention provides a preparation method of a high-strength and high-toughness graphene reinforced aluminum matrix composite, and relates to a preparation method of an aluminum matrix composite. The preparation method aims to solve the problems that graphene is not uniformly dispersed in an aluminum matrix during preparation of the aluminum matrix composite, and the strength and toughness of the prepared composite are inverted. The preparation method comprises the steps that graphene micro-sheets and aluminum metal powder are used for preparing the graphene micro-sheet reinforced aluminum matrix composite with the thickness being 2-2.5 times of the thickness of a product, the graphene micro-sheet reinforced aluminum matrix composite and an aluminum alloy plate are stacked for accumulative composite rolling deformation treatment, and heat treatment is carried out. According to the preparation method, the multi-pass accumulative composite rolling technology is utilized for enabling sheet layers of the graphene micro-sheets to be gradually opened, material grains are greatly refined, a composite interface is formed, the toughness of the obtained composite is not reduced while the strength of the composite is increased, and the problem that the strength and toughness of the graphene reinforced aluminum matrix composite are inverted is solved. The preparation method is suitable for preparing the graphene reinforced aluminum matrix composite.

Owner:HARBIN INST OF TECH

Preparation method of blend fiber-reinforced polycaprolactone composite material of polycaprolactone/full-degraded natural fiber

InactiveCN103525046AGood dispersionAvoid clumpingConjugated cellulose/protein artificial filamentsMelt spinning methodsDispersityFully developed

The invention provides a full-degraded polycaprolactone composite material which is prepared from the following raw materials in parts by weight: 1-9 parts of blend fiber, and 1-9 parts of polycaprolactone, wherein an antioxidant accounts for 0.1-1% of total mass of the raw materials; the blend fiber is prepared from a natural fiber and the polycaprolactone, of which the ratio is (0.5-1):(1-1) w / w in a melt spinning manner; the draw ratio of the blend fiber is (5-100):1. By adopting the full-degraded polycaprolactone composite material, the natural fiber and the polycaprolactone are creatively blended, melted, spun and cut, and then blend fiber staples and the polycaprolactone are blended to pelletize. Thus, not only is the dispersity of the fiber in the polycaprolactone greatly improved, but also aggregation clustering of the fiber inside polycaprolactone matrix is effectively avoided; the enhancement effect of the fiber is fully developed; the performance of the composite material is obviously improved; furthermore, other chemicals are not introduced to the technology disclosed by the invention; the safety of the product is ensured.

Owner:NINGXIA GREEN BIODEGRADABLE PROD

3D concrete material for printing

PendingCN114163201AStrong adhesionImprove adhesionAdditive manufacturing apparatusSolid waste managementRiver sandSilicate Cement

The invention discloses a 3D concrete material for printing, which is prepared from the following components in percentage by weight: 20 to 30 percent of Portland cement, 12 to 16 percent of sulphoaluminate cement, 6 to 8 percent of compound fiber, 10 to 20 percent of mineral admixture, 20 to 40 percent of compound fine aggregate, 0.5 to 1 percent of water reducing agent, 0 to 1 percent of accelerator, 1 to 2 percent of cellulose ether and 10 to 12 percent of water. According to the 3D printing concrete material disclosed by the invention, the formula of the cementing material is adjusted, and the Portland cement and the sulphoaluminate cement with the early strength characteristic are jointly used as the cementing material, so that the early hydration speed and the early strength of concrete can be adjusted, and a rapid hardening effect is achieved; the recycled fine aggregate is used for partially replacing traditional fine aggregate such as natural river sand, smooth pumping of materials in the 3D printing process is facilitated, and recycling of waste resources can be achieved; the steel fibers and the basalt fibers are used together, so that the investment cost can be reduced, the composite material is more suitable for being used in various environments, and the fiber reinforcement effect can be fully exerted.

Owner:南京绿色增材智造研究院有限公司

3D printing method of continuous fiber self-enhancement composite material

InactiveCN110920063AFacilitate stress transferImprove recycling ratesAdditive manufacturing apparatusManufacturing recyclingHigh polymerSelf reinforced

The invention discloses a 3D printing method of continuous fiber self-enhancement composite material. The 3D printing method comprises the following steps: at first, establishing a three-dimensional model of a self-enhancement composite material workpiece, and deriving the three-dimensional model as an stl formatted file; determining a printing temperature interval, wherein the self-enhancement composite material is thermoplastic high polymer material with different physical forms and is provided with a reinforced phase and a matrix base, the reinforced phase and the matrix base have the samechemical construction and different melting points, the reinforced phase is continuous fiber, and the matrix phase is resin; the printing temperature scope is higher than the melting point of the matrix phase and is lower than the melting point of the reinforced phase; preparing the self-enhancement composite material through 3D printing, finally, recycling the self-enhancement composite material,physically crushing the self-enhancement composite material, heating the crushed self-enhancement composite material to above the melting point to completely melt the self-enhancement composite material, and recycling the self-enhancement composite material as the raw material. On one hand, the 3D printing method solves the problems that the interfacial properties are poor and recycling is difficult when 3D printing is carried out on the composite material, and on the other hand, low-cost rapid manufacturing of the continuous fiber self-enhancement composite material is realized.

Owner:XI AN JIAOTONG UNIV

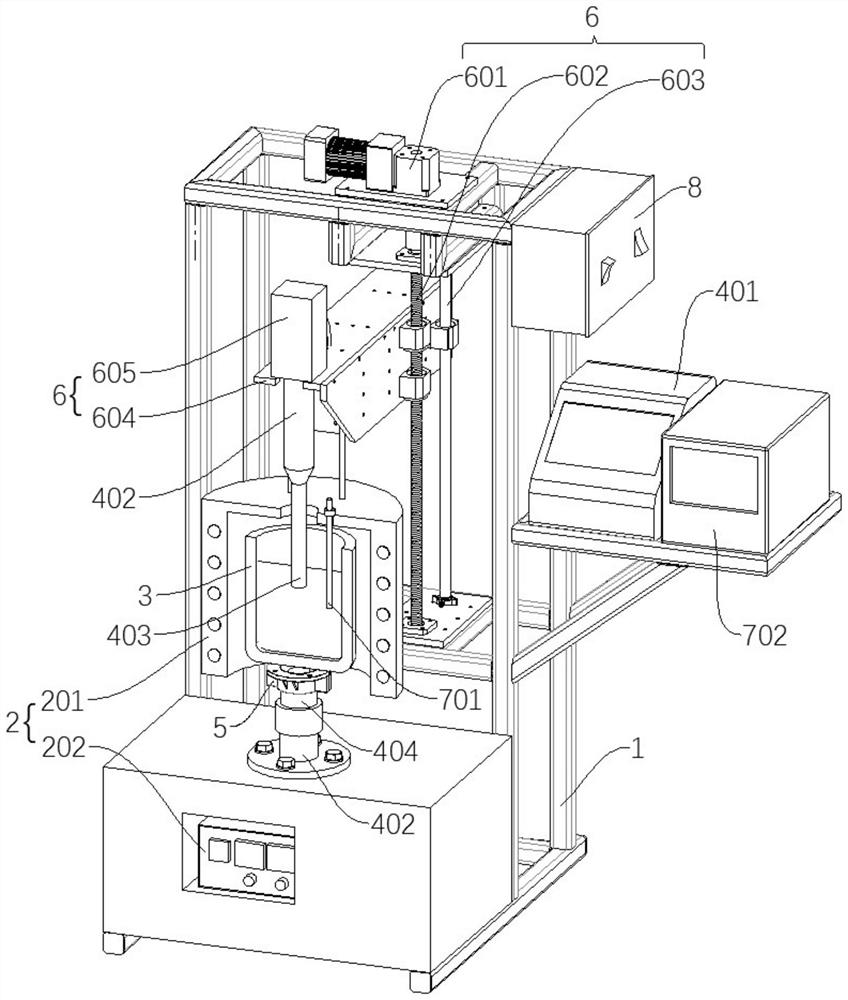

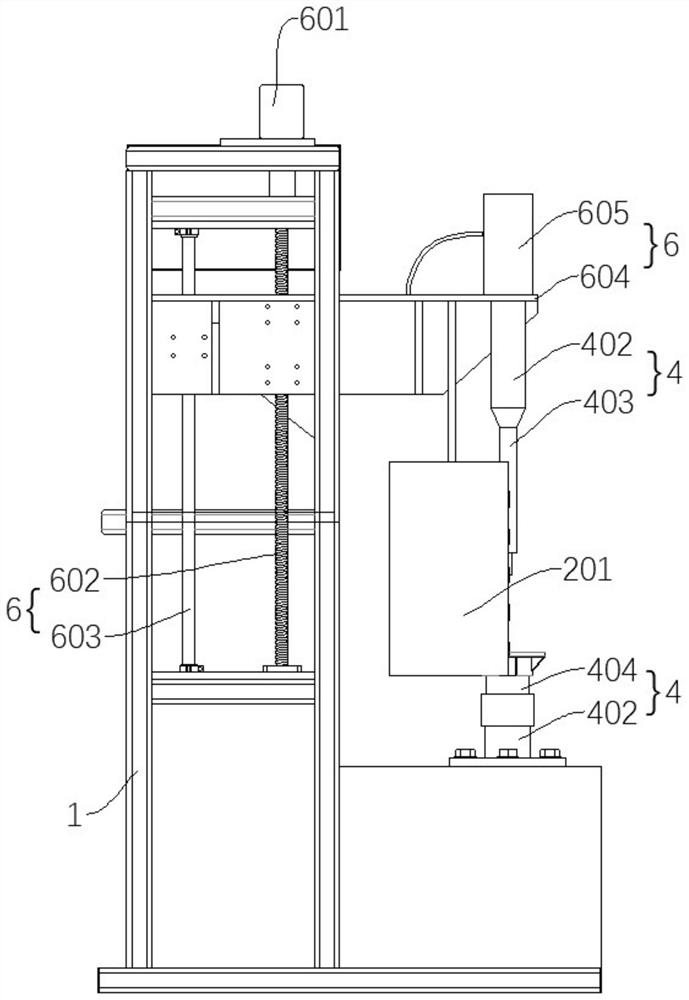

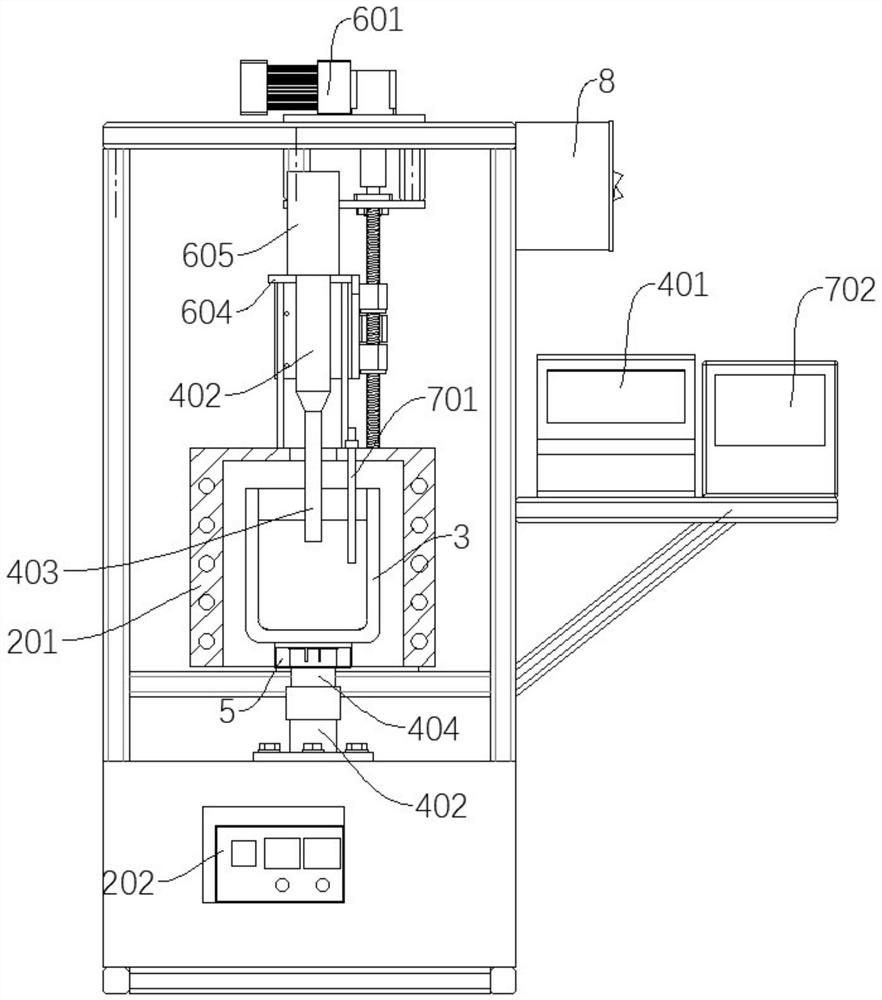

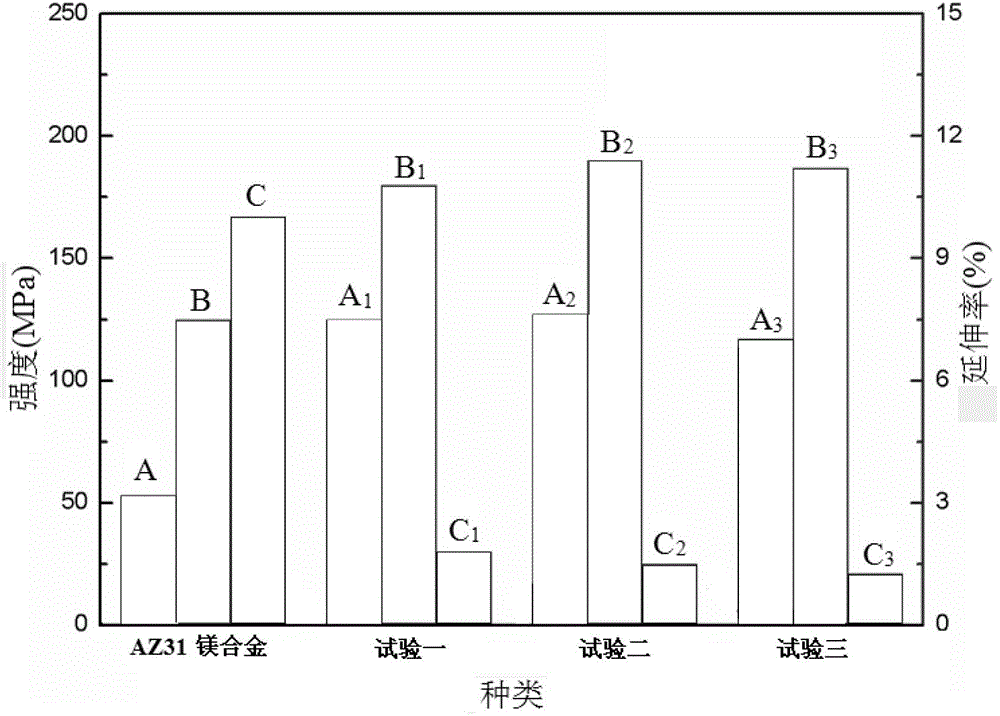

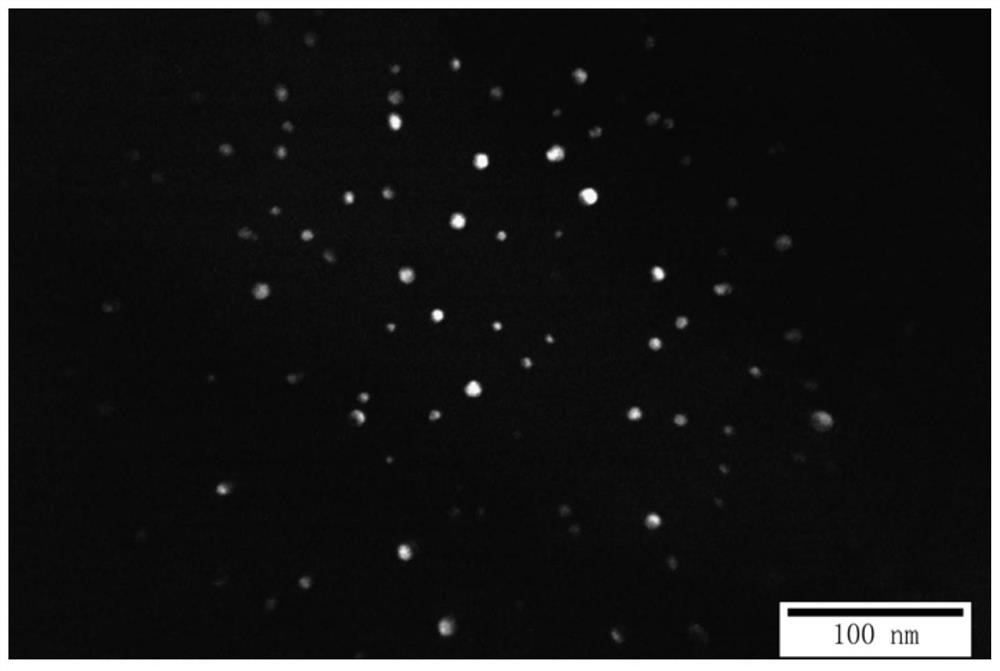

Preparation device and preparation method of rare earth magnesium alloy

ActiveCN113999980AImprove the cavitation effect inside the meltImprove liquidityProcess efficiency improvementMg alloysCrucible

The invention discloses a preparation device of a rare earth magnesium alloy. The preparation device comprises: a machine table; a heating furnace, which is connected with the machine table; a crucible, which is positioned in the heating furnace; and an ultrasonic assembly. The ultrasonic assembly comprises: an ultrasonic controller and a plurality of transducers which are electrically connected with the ultrasonic controller; an immersion type amplitude-change pole, which is connected with the transducers, wherein the end part of the immersion type amplitude-change pole is positioned in the crucible; and a leading-in type amplitude-change pole, which is connected with the transducers, wherein the leading-in type amplitude-change pole is located on the outer side of the crucible, and the leading-in type amplitude-change pole and the immersion type amplitude-change pole are oppositely arranged. According to the invention, the problems that magnesium alloy rare earth and other high-specific-weight components are prone to sedimentation, and rare earth phases are prone to enrichment in a grain boundary can be effectively solved.

Owner:HEFEI UNIV OF TECH

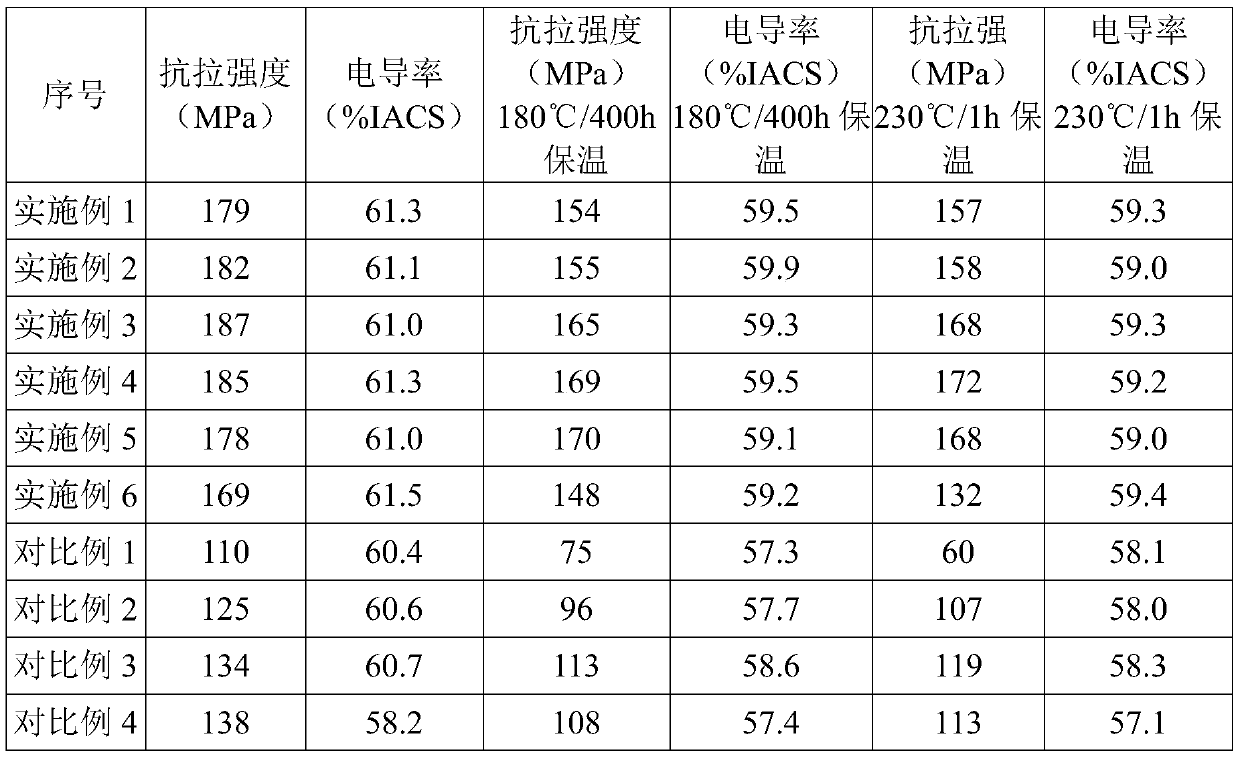

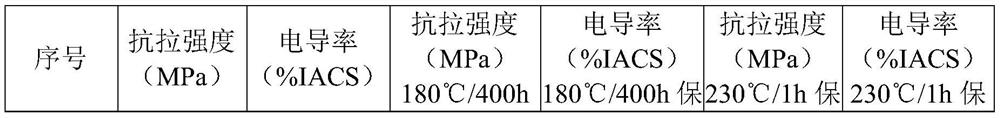

High-strength, high-conductivity and high-heat-resistance aluminum-base composite for tension joint splice and preparing method

The invention provides a high-strength, high-conductivity and high-heat-resistance aluminum-base composite for a tension joint splice and a preparing method. Through the design of an aluminum-zirconium alloy base system, nano-copper grows on a graphene surface to serve as an enhancing phase, powder is blown by inert gas into an aluminum melt, and a cast structure with evenly-distributed graphene is obtained. The graphene has a unique two-dimensional wrinkled surface, surface-growing copper nanoparticles form graphene@copper, the wettability of the graphene and the aluminum melt is increased, particle refined grains as non-uniform nucleation have high chemical stability, and the particle refined grains and an Al3Zr phase jointly improve the heat stability of the aluminum-base composite. Bymeans of the composite, the problem that a limited one-series alloy tension joint splice is not sufficient in strength and heat resistance in the application process is solved, the aluminum-base composite produced through a casting method keeps the conductivity higher than 61% IACS, the strength is improved by 30% or above, and the heat resistance is improved by 20-40% or above.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV +2

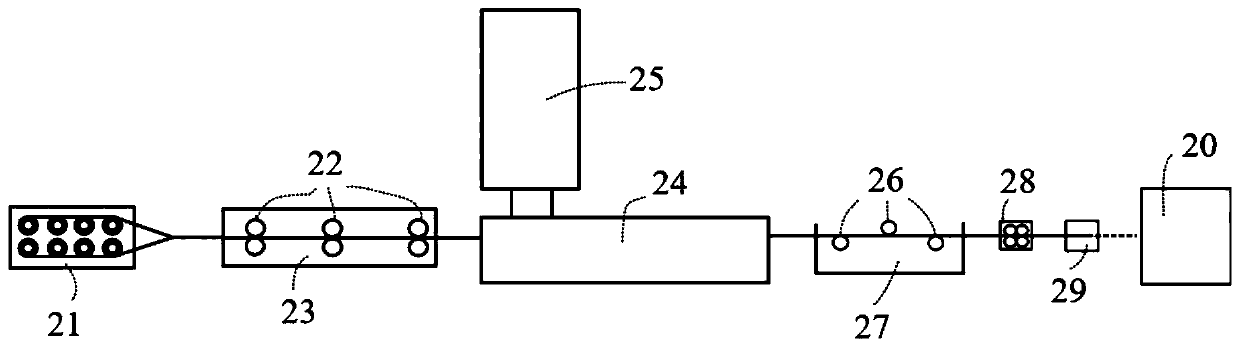

Nylon composite material, and raw materials, device and method for preparation of same

The invention discloses a nylon composite material, and raw materials, a device and a method for preparation of the same, belonging to the field of high-molecular composite materials. The preparationmethod for the nylon composite material comprises the following steps: S1, pretreatment of continuous glass fibers: immersing the continuous glass fibers in a dopamine solution for 0.5-5 h, then adding a Tris buffer solution into the dopamine solution to adjust the pH value of the dopamine solution to 8-9, continuing immersion for 4-6 h, and then successively carrying out drying, washing and drying to obtain the pretreated continuous glass fibers; and S2, coating treatment: subjecting the pretreated continuous glass fibers to heating and pre-dispersion by heating at 240-260 DEG C, then immersing the continuous glass fibers in melt water obtained by melt extrusion of nylon, a compatibilizer, a lubricant and an antioxidant, and performing cooling, pelletizing and optional odor removal to obtain the nylon composite material. The nylon composite material obtained by using the method provided by the invention has high mechanical strength and is free of floating fibers on the surface.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

A kind of lightweight armor bulletproof board and preparation method thereof

ActiveCN104848748BGuaranteed decentralizationImprove bindingLaminationLamination apparatusHigh intensityCvd graphene

The invention discloses a light armored armor and a preparation method thereof. The armored armor is in a sandwich structure; a core plate is made of novel aluminum matrix composite of composite enhancing silicon carbide and graphene; a face plate and a back plate are made of 5083 and 7A21 high-intensity aluminum alloy; the core plate, the face plate and the back plate are glued through metallic glue; the composite of the core plate is graphene or silicon carbide enhanced aluminum matrix composite and prepared through the pressure infiltration technology; an infiltration framework is silicon carbide and graphene cold pressing block which are uniformly mixed. According to the light armored armor and the preparation method thereof, the core plate is obtained due to infiltration of aluminum alloy through the silicon carbide and graphene composite framework, the silicon carbide enhancement is used, the enhancement and toughening functions to the aluminum alloy from the graphene are fully played, the ballistic performance of the core plate is improved, and the light armored armor having a good application prospect is finally obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

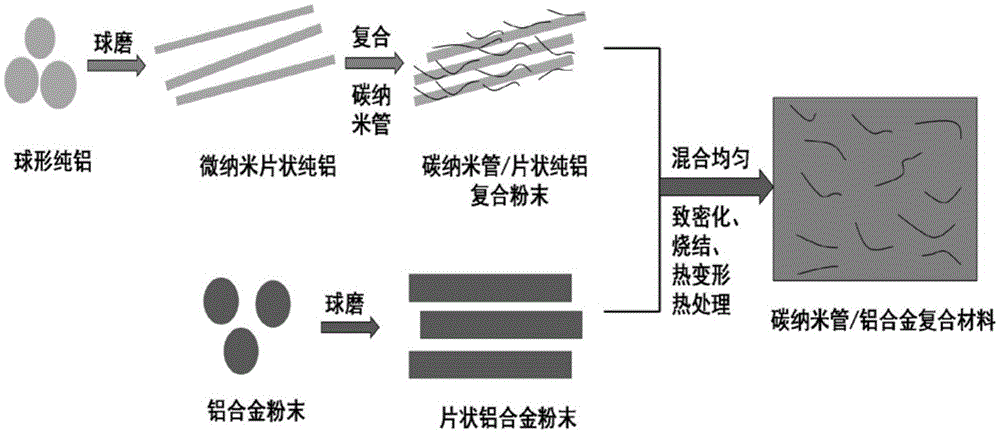

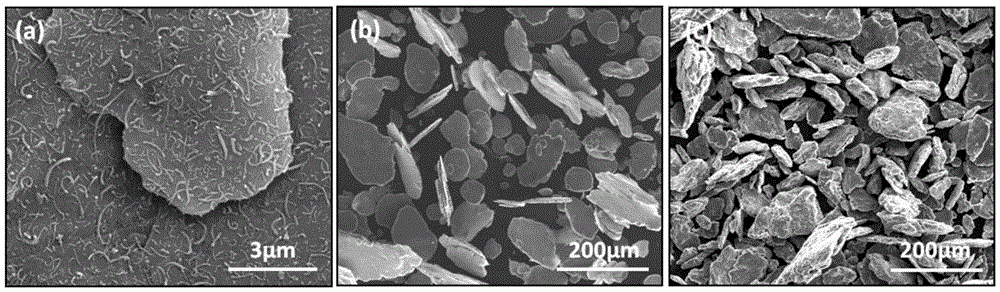

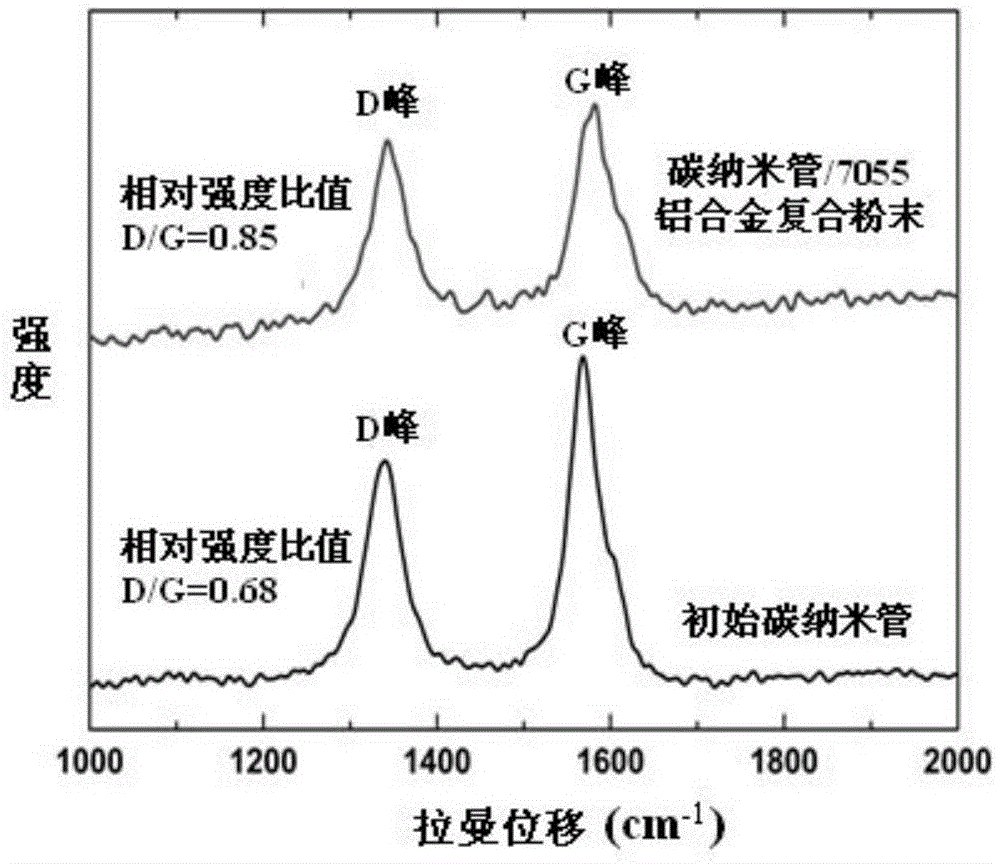

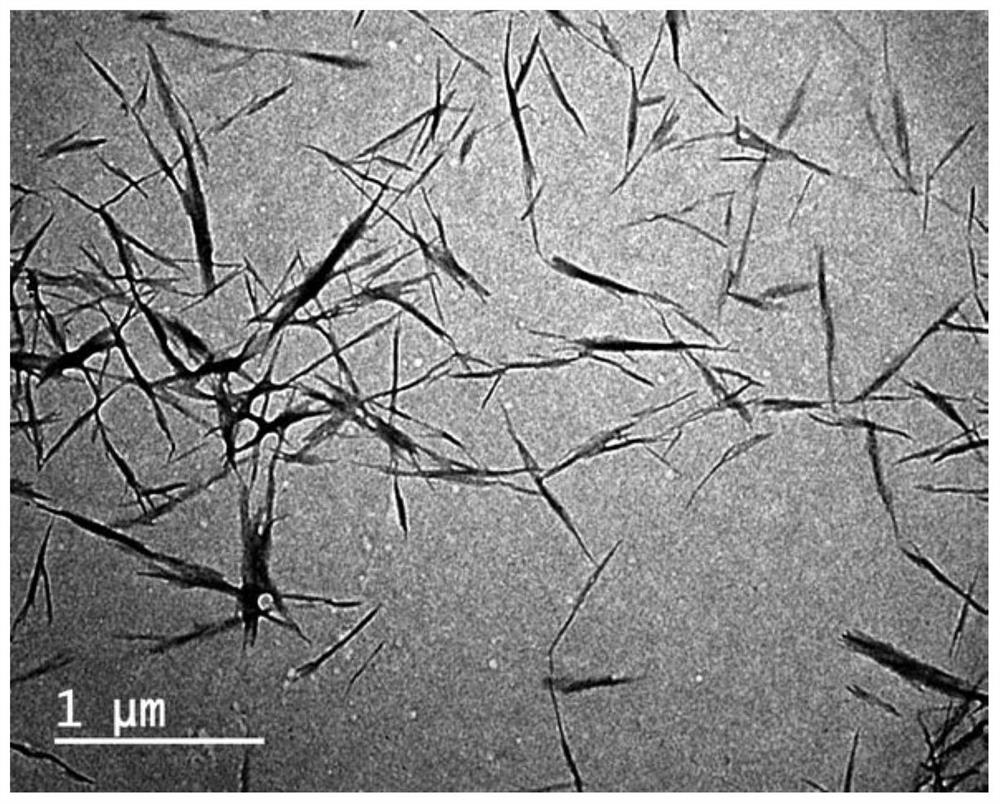

A powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminium alloy composite material. According to the powder metallurgy preparation method, slurry mixing method or in-suit growth method is adopted for pre-preparation of carbon nanotube / pure aluminium flaky composite powder; the carbon nanotube / pure aluminium flaky composite powder is mixed with aluminium alloy powder according to a certain ratio; an obtained mixture is subjected to densifying, sintering, thermal deformation processing and heat treatment so as to obtain the carbon nanotube reinforced aluminium alloy composite material. The powder metallurgy preparation method is capable of solving problems that dispersion of carbon nanotube in aluminium alloy powder is difficult to realize, and hydrolysis is easily caused, so that it is beneficial for preparation of the carbon nanotube / aluminium alloy composite material with high strength, high modulus, and high plasticity.

Owner:SHANGHAI JIAOTONG UNIV

A kind of high-strength chitin composite hydrogel material and its preparation method and application

ActiveCN111592693BHigh strengthLow costPharmaceutical delivery mechanismProsthesisPolymer scienceBone tissue

The invention belongs to the field of biomedical materials, and discloses a high-strength chitin composite hydrogel material, a preparation method and application thereof. The composite hydrogel material of the present invention is composed of chitin as a matrix and chitin whiskers with negatively charged surfaces as reinforcing fillers; the negatively charged chitin whiskers as reinforcing fillers are composited with the chitin matrix, and The negatively charged groups on the surface of the whiskers can form a strong electrostatic repulsion force, which can effectively promote the uniform dispersion of chitin whiskers in the chitin matrix, and at the same time achieve a good interface combination with the matrix, so as to give full play to the enhancement effect of the whiskers. Endow the chitin composite hydrogel material with excellent mechanical properties; at the same time, the chitin composite hydrogel material of the present invention has good biocompatibility and osteogenic activity, and has good application prospects in biomedical fields such as bone tissue repair .

Owner:JINAN UNIVERSITY

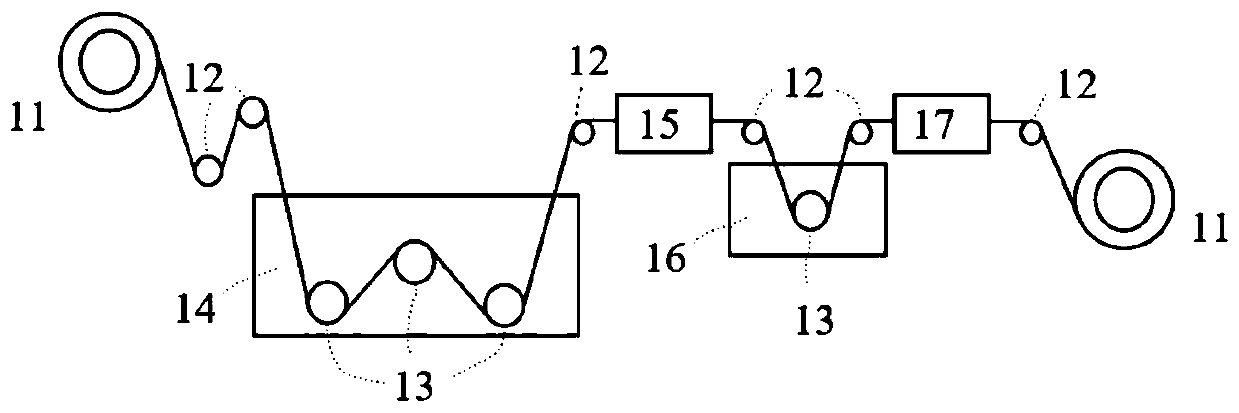

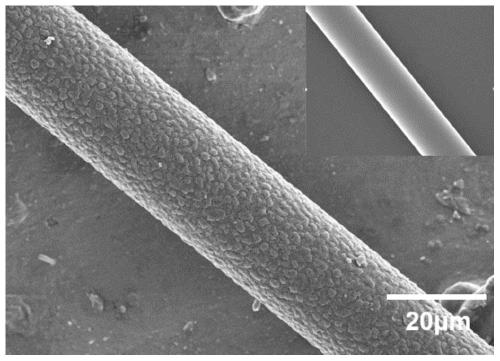

A kind of carbon fiber surface treatment method for reinforcing thermoplastic resin

ActiveCN110344252BGood dispersionTake full advantage of enhancementsCarbon fibresThermoplasticPolymer science

The invention relates to a carbon fiber surface treatment method for reinforcing thermoplastic resin. Under the protection of protective gas, the carbon fiber bundle coated with thermosetting sizing agent a is induced to heat and solidify the original sizing agent layer; the cured carbon fiber The bundles are bent by rollers and spread out into monofilaments; then they pass through the impregnation tank equipped with sizing agent b, which is a solution or emulsion of thermoplastic resin; the impregnated carbon fibers are dried in a drying oven to obtain processed reinforcement The carbon fiber bundle for thermoplastic resin, the carbon fiber bundle for reinforcing thermoplastic resin contains 2.5-20% of the above-mentioned thermoplastic resin; finally, the obtained carbon fiber bundle for reinforcing thermoplastic resin is wound up or directly cut into pellets. The carbon fiber processed by the method can form an ideal bonding interface with the thermoplastic resin, and the fiber is easy to disperse, so the reinforcing effect of the carbon fiber in the thermoplastic can be fully exerted, and has high application value in the field of thermoplastic reinforced plastic.

Owner:湖州艾历克工业材料有限公司

A kind of preparation method of double size silicon carbide particle hybrid reinforced magnesium matrix composite material

InactiveCN102943198BWell mixedSolve the problem of uniform dispersionMagnesium matrix compositeSemi solid

The invention discloses a preparation method of a double-size silicon carbide particle hybrid reinforced magnesium matrix composite material, and aims at solving the problem that in the prior art, the compatibility between the silicon carbide particles and the magnesium alloys is bad so that the silicon carbide particles are easy to aggregate. The preparation method comprises the steps of: (1) mixing to obtain double-size silicon carbide particles; and (2) placing the double-size silicon carbide particles in a semi-solid magnesium matrix and carrying out stirring, ultrasonic dispersion and die-casting to obtain the double-size silicon carbide particle hybrid reinforced magnesium matrix composite material. The preparation method has the advantages that (1) the problem that the silicon carbide particles are difficultly and evenly dispersed in the matrix is effectively solved so as to give full play to the particle reinforcement effect; and (2) the mechanical property is remarkably improved. The preparation method is mainly used for preparing the double-size silicon carbide particle hybrid reinforced magnesium matrix composite material.

Owner:HARBIN INST OF TECH

A high-strength and high-heat-resistant carbon nano-aluminum matrix composite material and its preparation method

The invention provides a high-strength and high-heat-resistant carbon nano-aluminum matrix composite material and its preparation method. The basic system design of aluminum-zirconium alloy is adopted, and nano-alumina is grown on the surface of graphene as a reinforcing phase. The powder is blown into the aluminum melt by inert gas. A cast structure with uniform distribution of graphene is obtained. Graphene has a unique two-dimensional wrinkled surface, and the surface grows alumina nano-particles to form graphene@alumina, which increases the wettability of graphene and aluminum melts, and serves as particles for non-uniform nucleation to refine the grains. Good chemical stability, and Al 3 The Zr phase jointly improves the thermal stability of the aluminum matrix composites. The invention solves the problem of insufficient strength and heat resistance in the application process of 1-series alloy splicing fittings, and the density of the aluminum-based composite material produced by the casting method reaches 100%, the strength is increased by more than 30%, and the heat resistance is increased by 30-50% ℃ or more.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV +2

Method for preparing metal-based gradient coating with enhanced laser-cladding ceramic nano-particles

InactiveCN102441672BEasy reunionTake full advantage of enhancementsLaminationLamination apparatusCompression moldingStress relieving

A method for preparing a metal-based gradient coating with enhanced laser-cladding ceramic nano-particles includes the steps that a plurality of groups of mixed powder of micron metal powder and ceramic nano-particles in a certain proportion are prepared into coated composite powder with uniformly dispersed nano-particles by means of mechanical composite, wherein the content of the ceramic nano-particles in the groups of mixed powder of the micron metal powder and the ceramic nano-particles in a certain proportion is gradually increased; laser-cladding sheets are pressed by means of compression molding; and the metal-based gradient coating with the nano-particles gradually is increased along the thickness direction by means of multilayer laser-cladding. The method has the advantages that the nano-particles can have excellent toughness by the aid of a dispersion strengthening mechanism for the nano-particles, the problem of easiness in cracking of a clad layer can be hopefully solved by the aid of a stress relieving mechanism for the gradient coating, excellent performances can be achieved by the aid of reinforcement of the nano-particles and the gradient coating, and accordingly the metal-based gradient coating can be applied to the surfaces of key parts such as aviation turbine engine blades and the like.

Owner:TONGLING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com