Expansion-controllable plugging agent

A technology of plugging agent and toughening agent, which is applied in the field of plugging agent, can solve problems such as the inability to accurately grasp the opening size of formation leaky seams, non-expandable plugging materials, loss of manpower, material resources, and financial resources, and achieve good reliability. Deformability and adaptability, shallow plugging depth, effect of reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

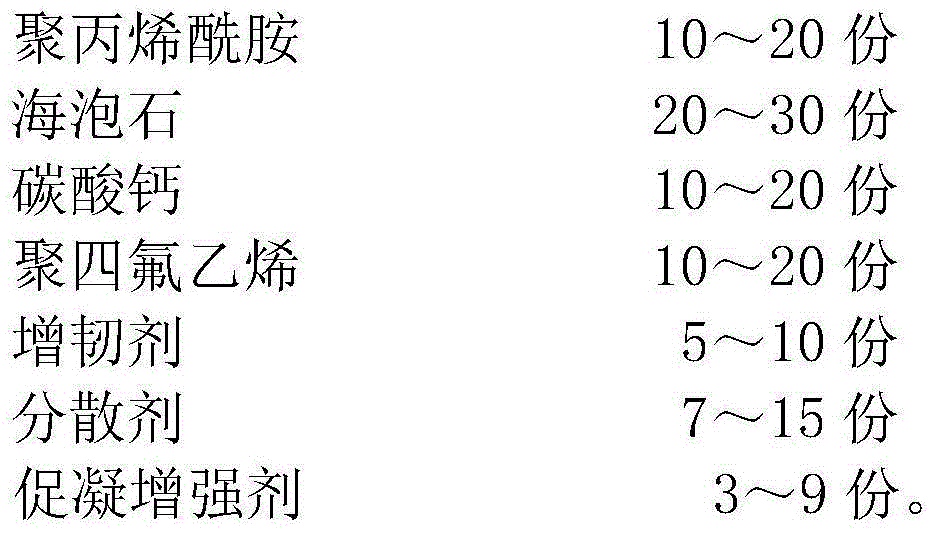

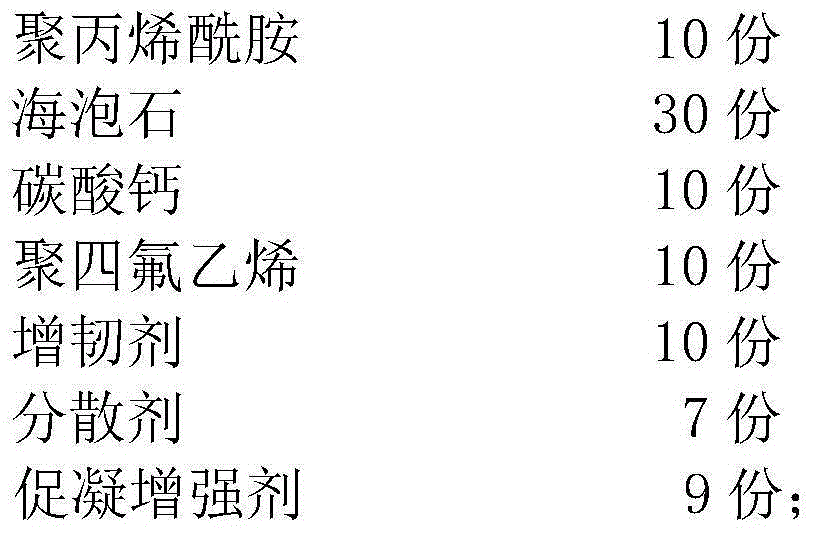

[0025] 1) Take the raw material by the following parts by weight:

[0026]

[0027] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0028] The toughening agent is fiber cotton; the coagulation accelerator is 10 parts of salt gypsum, 10 parts of silicon dioxide and 8 parts of sodium sulfate; the dispersant is a mixture of 8 parts of sodium tripolyphosphate and 10 parts of sodium hexametaphosphate; Parts are parts by weight.

[0029] The particle size of sepiolite is 0.2mm; the particle size of polytetrafluoroethylene is 0.08mm; calcium carbonate is composed of fine calcium carbonate with a particle size of 0.012mm, medium calcium carbonate with a particle size of 0.192mm and coarse calcium carbonate with a particle size of 0.322mm It is mixed according to the mass ratio of 1:2:3.

Embodiment 2

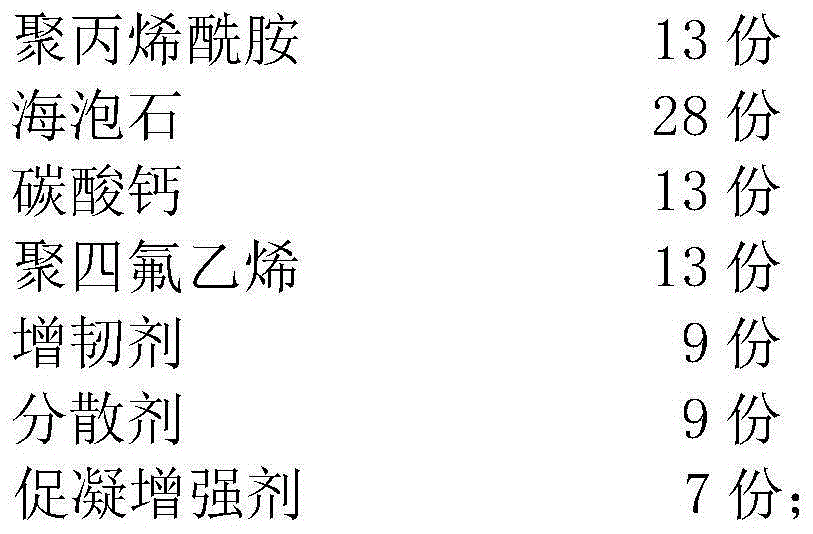

[0031] 1) Take the raw material by the following parts by weight:

[0032]

[0033] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0034] The toughening agent is fiber cotton; the coagulation accelerator is 13 parts of salt gypsum, 9 parts of silicon dioxide and 7 parts of sodium sulfate; the dispersant is a mixture of 9 parts of sodium tripolyphosphate and 9 parts of sodium hexametaphosphate; Parts are parts by weight.

[0035] The particle size of sepiolite is 0.4mm; the particle size of polytetrafluoroethylene is 0.06mm; calcium carbonate is composed of fine calcium carbonate with a particle size of 0.015mm, medium calcium carbonate with a particle size of 0.190mm and coarse calcium carbonate with a particle size of 0.353mm It is mixed according to the mass ratio of 1:2:3.

Embodiment 3

[0037] 1) Take the raw material by the following parts by weight:

[0038]

[0039]

[0040] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0041] The toughening agent is fiber cotton; the coagulation accelerator is 15 parts of salt gypsum, 8 parts of silicon dioxide and 6 parts of sodium sulfate; the dispersant is a mixture of 11 parts of sodium tripolyphosphate and 8 parts of sodium hexametaphosphate; Parts are parts by weight.

[0042] The particle size of sepiolite is 0.5mm; the particle size of polytetrafluoroethylene is 0.05mm; carbon calcium carbonate is composed of fine calcium carbonate with a particle size of 0.017mm, medium calcium carbonate with a particle size of 0.187mm and coarse carbonate with a particle size of 0.374mm. Calcium is mixed in a mass ratio of 1:2:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com