Patents

Literature

1627results about How to "Realize cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

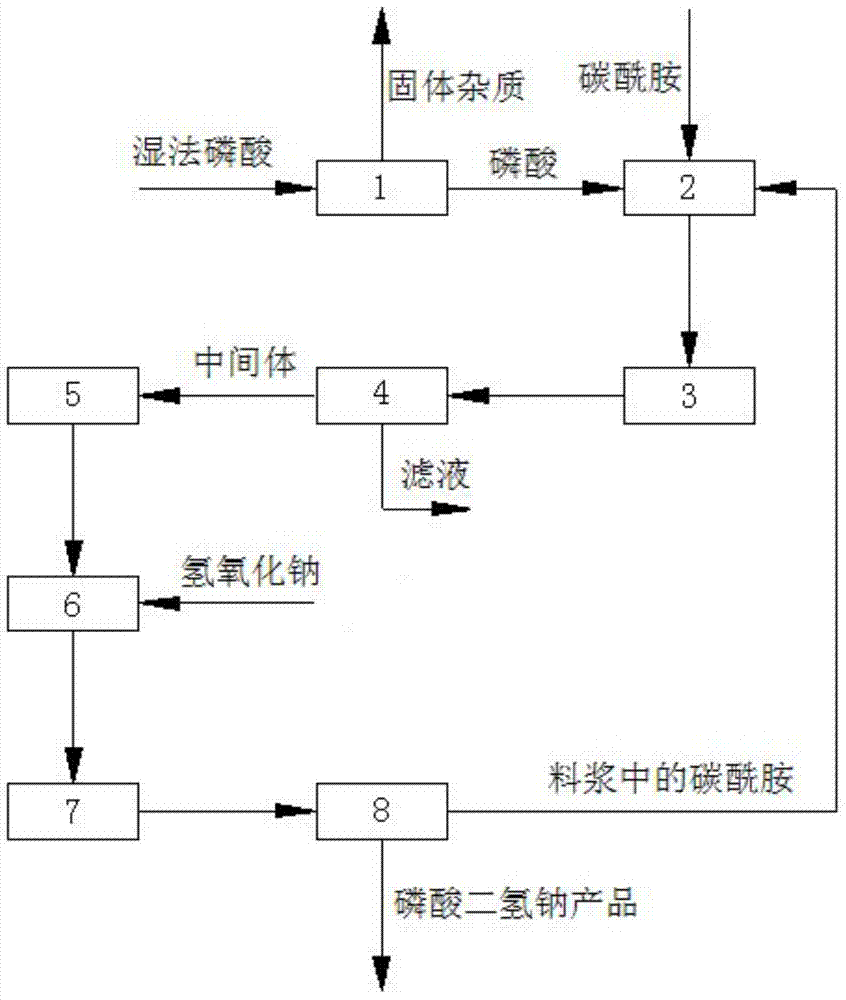

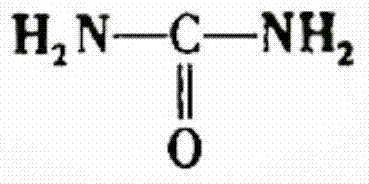

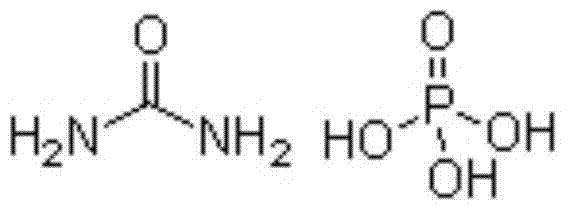

Method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process

InactiveCN103787293AReduce manufacturing costShort process routePhosphorus compoundsHigh energyPhosphoric acid

The invention discloses a method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process. The method comprises the steps of carrying out reaction on carbamide and the phosphoric acid by the wet process to obtain intermediate, and then carrying out a reaction on the intermediate and sodium hydroxide to obtain the sodium dihydrogen phosphate product. The method is short in process route, low in energy consumption, stable in product quality, low in production cost, convenient to operate and safe in production; the by-product slurry can be completely recycled; the whole production process is environment-friendly, clean and free from pollution as well as emission of waste gas, waste water and waste residue; therefore, the method responses to the policy of energy conservation and emission reduction as well as clean production, and solves the problems of complicated technology, unstable product quality, high energy consumption, environmental pollution and the like in the prior art; the obtained sodium dihydrogen phosphate product has the purity of more than or equal to 98%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

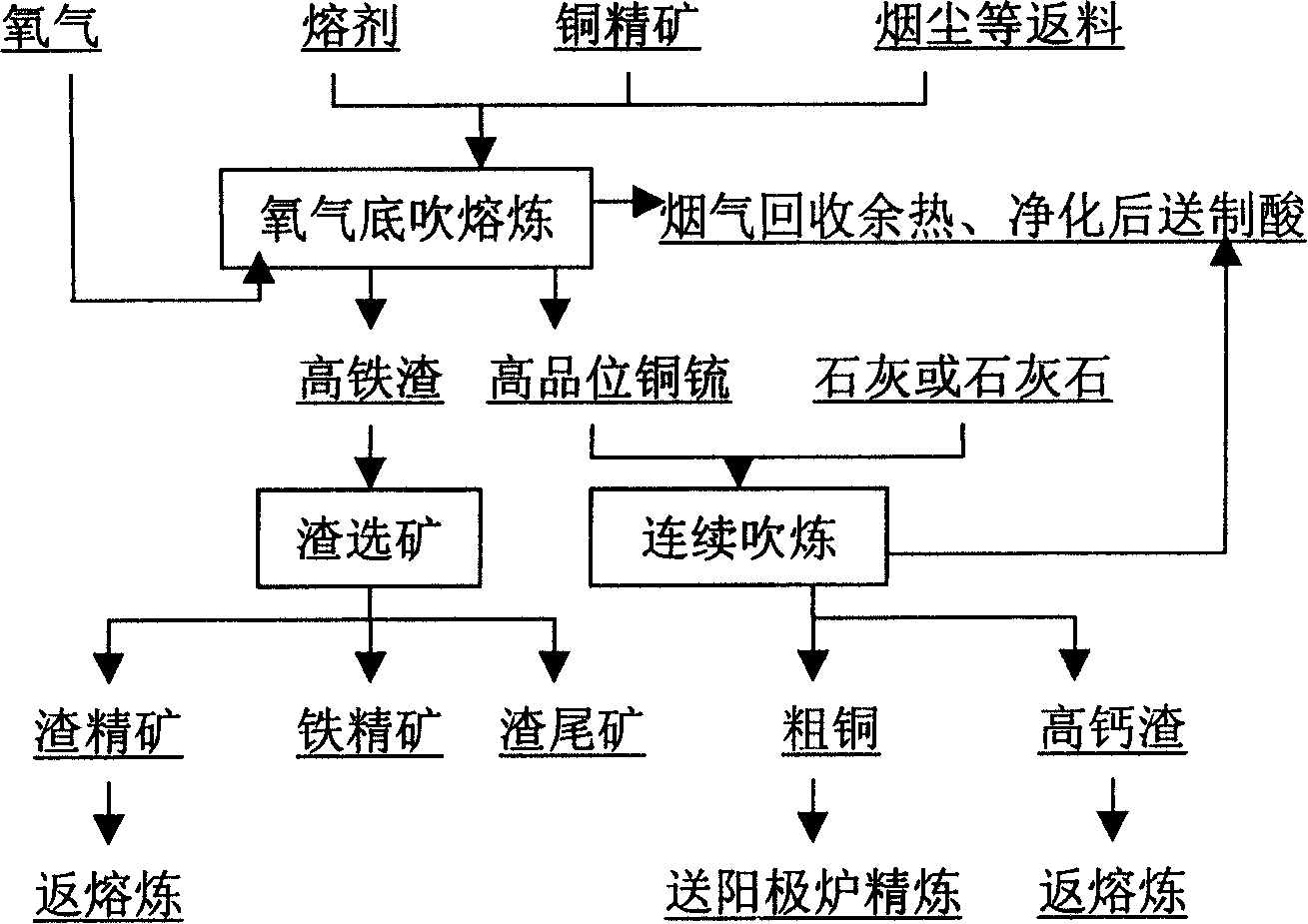

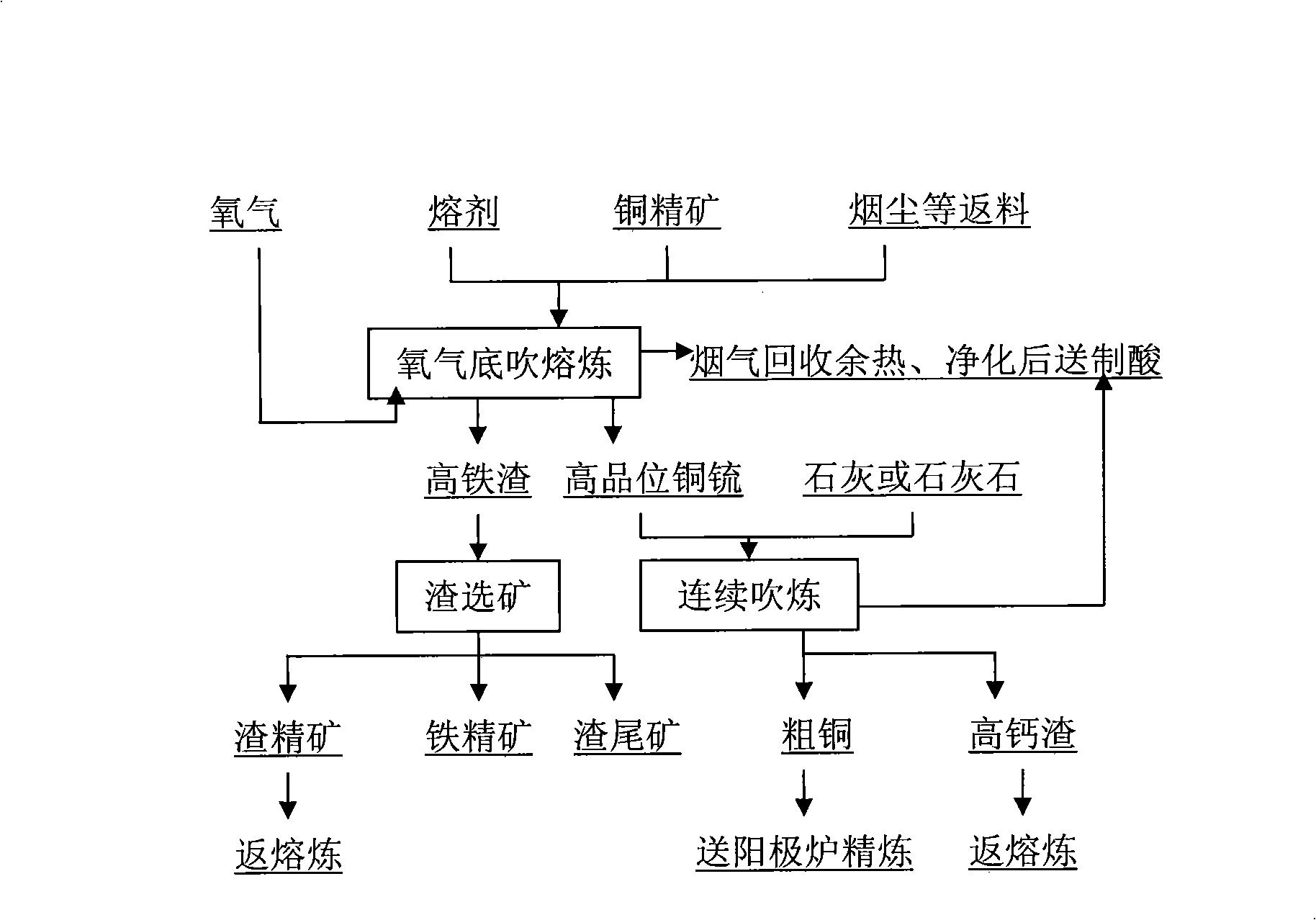

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

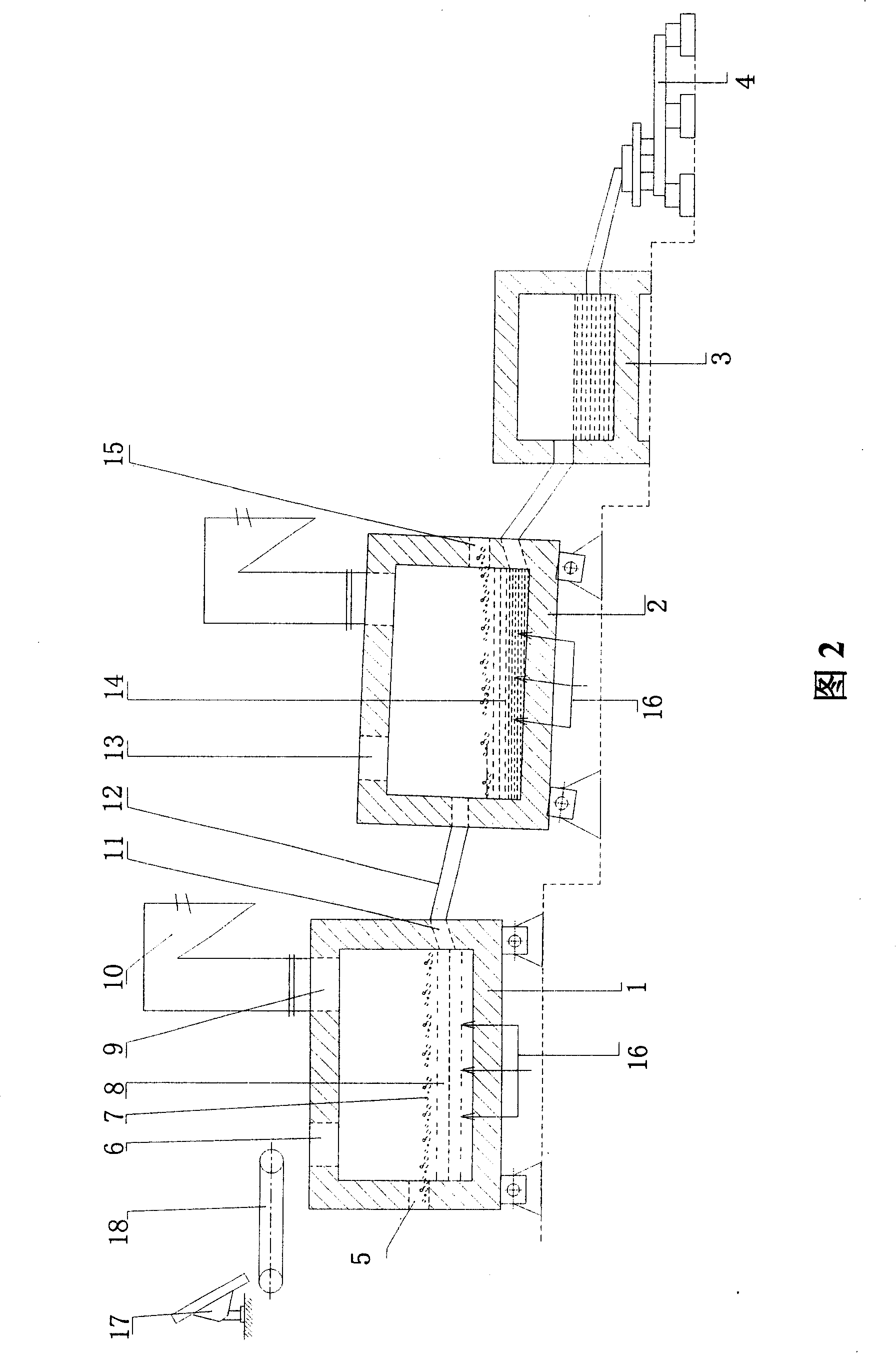

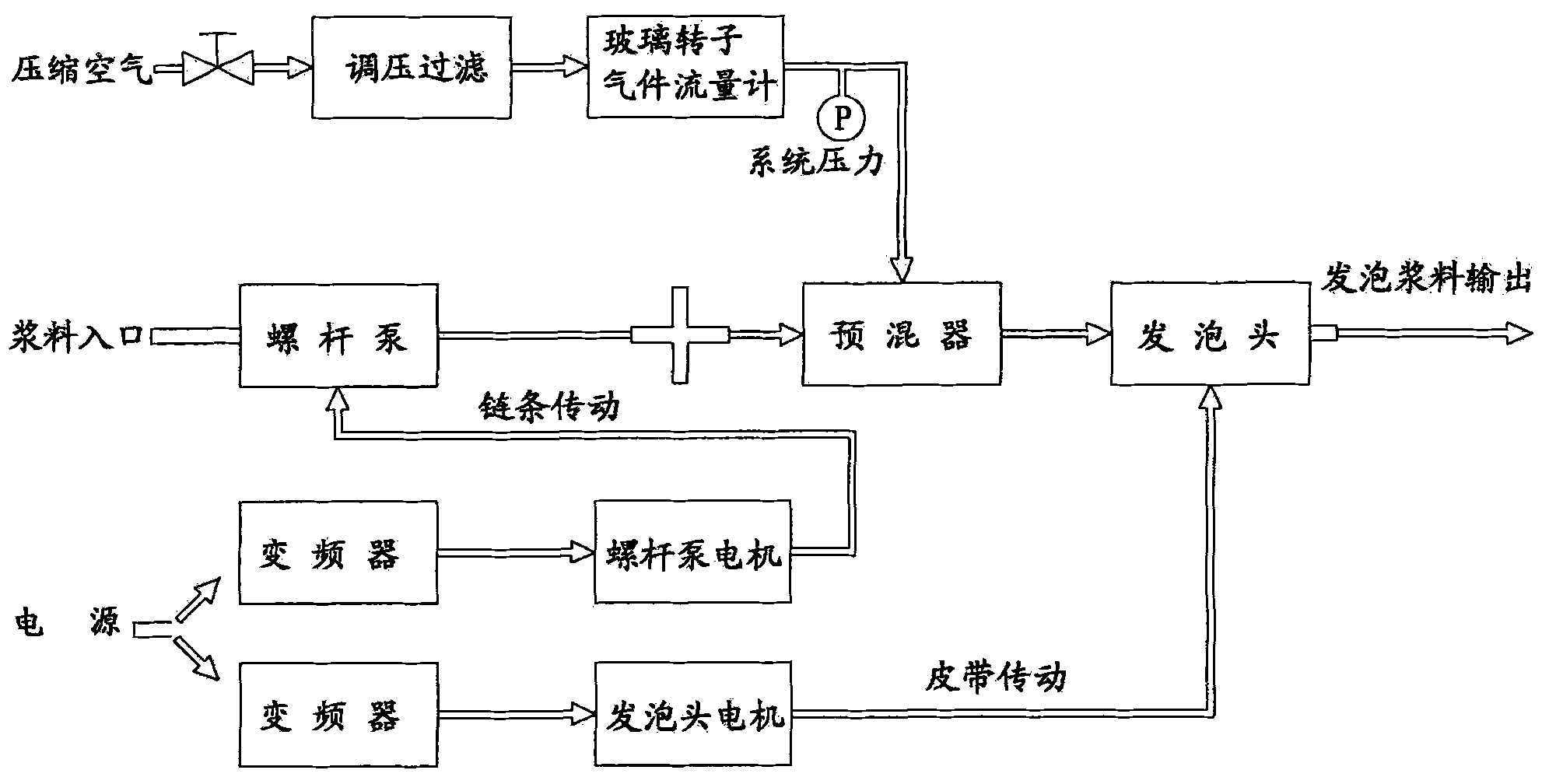

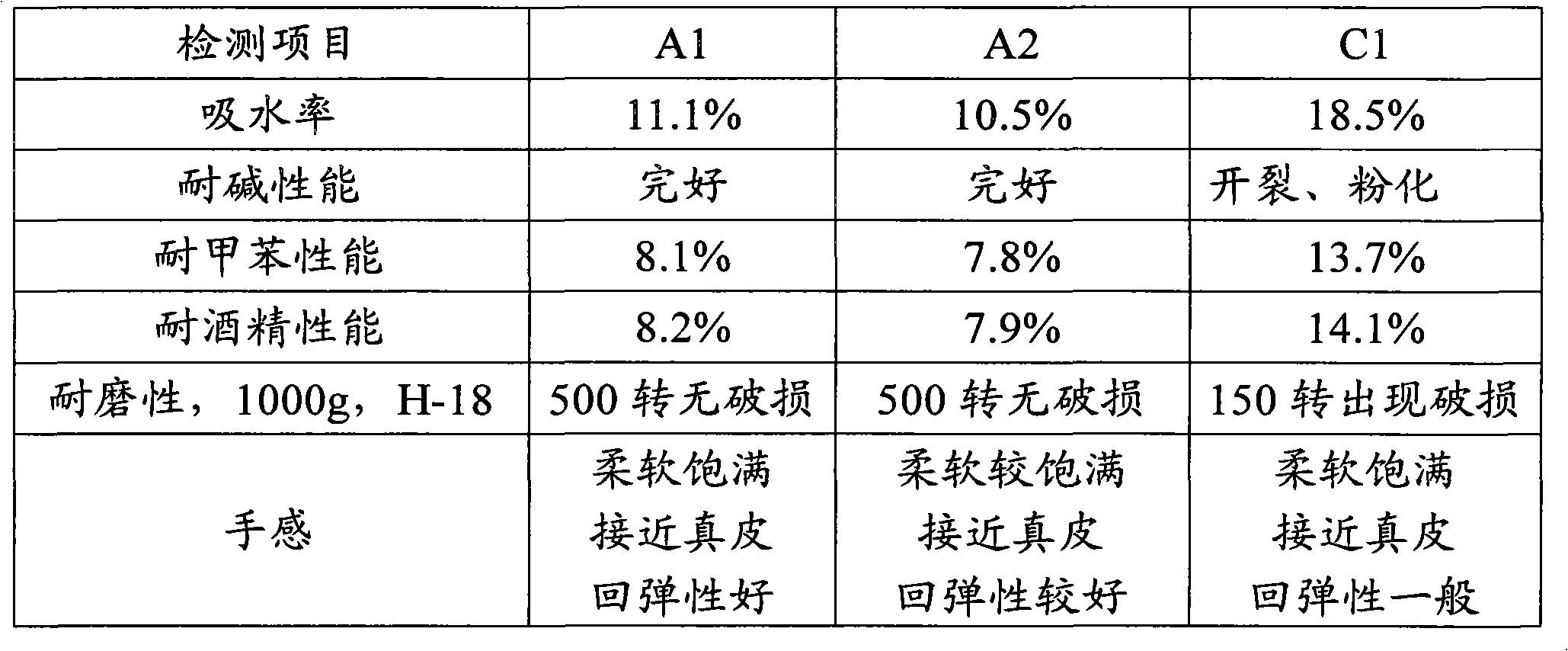

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

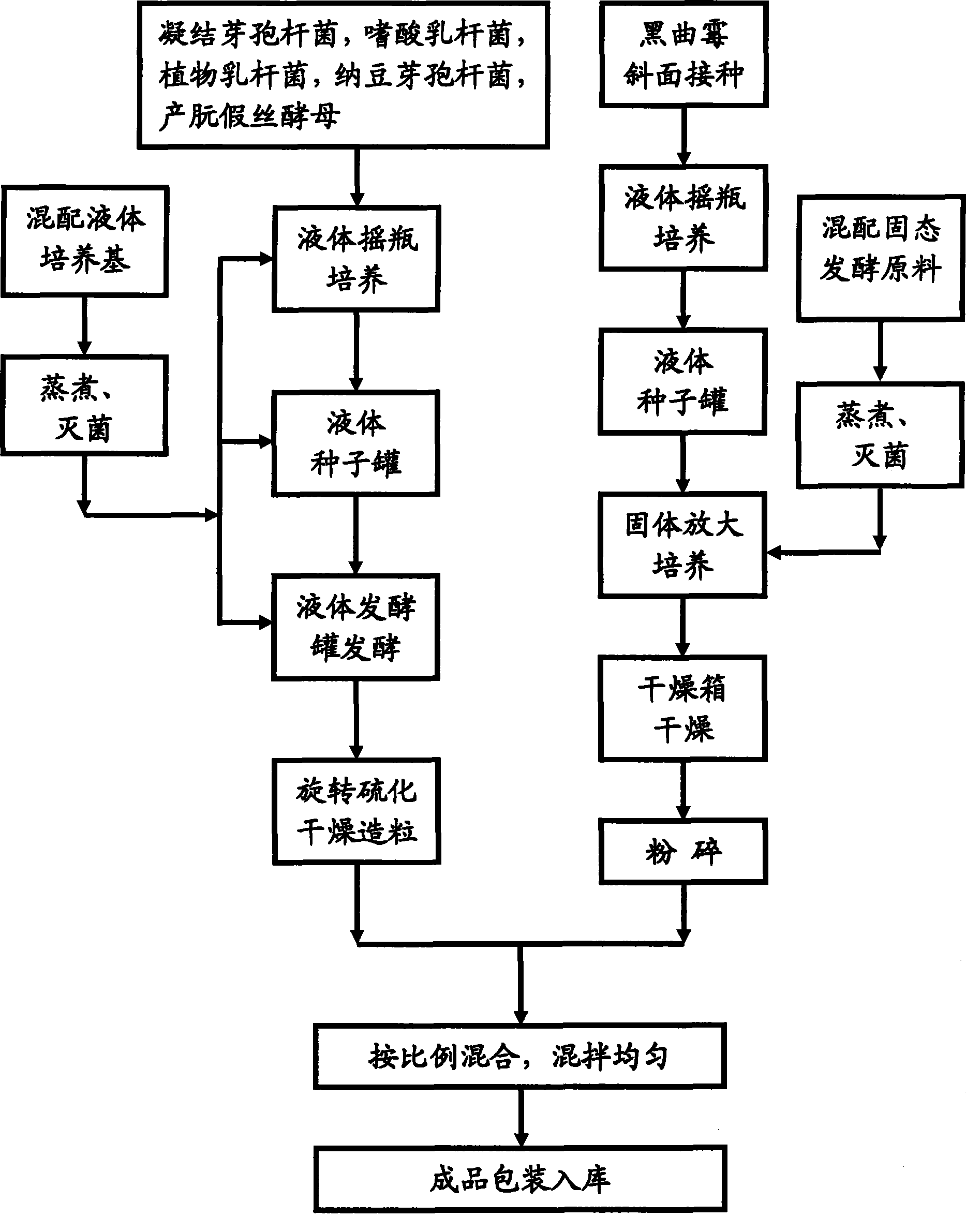

Additive agent for feeding microorganism viable bacteria and production method

InactiveCN101473896AIncrease food intakeImprove digestibilityAnimal feeding stuffDiseaseMicroorganism

The invention relates to a feeding addition agent for microorganism viable bacteria and a preparing method thereof. The addition agent consists of 1.5-2.5 parts of bacillus coagulans viable bacteria powder, 0.5-2.0 parts of lactobacillus acidophilus viable bacteria powder, 1.0-2.5 parts of lactobacillus plantarum viable bacteria powder, 0.5-2.5 parts of bacillus natto viable bacteria powder, 0.5-1.5 parts of candida utili viable bacteria powder and 2-4.5 parts of aspergillus niger viable bacteria powder. Each gram of the content of viable bacteria is as follows: bacillus coagulans is not less than 1.0*10cfu / g; lactobacillus acidophilus is not less than 1.0*10cfu / g; lactobacillus plantarum is not less than 1.0-10cfu / g; bacillus natto is not less than 1.0*10cfu / g; aspergillus niger is not less than 1.0*10cfu / g; and candida utili is not less than 1.0*10cfu / g. The invention has the advantages that the composition is reasonable, the preparation method is scientific, the usage scale is wide, the operation is simple and easy to master, and the cost is low. In addition, the invention can be used as the feeding stuff agent for various poultries, thus increasing the use ratio of the feeding stuff addition agent and strengthening the anti-disease ability of the poultries.

Owner:北京阔利达生物技术开发有限公司 +1

Technique for cleanly recovering byproduct methyl chloride of glyphosate acid

InactiveCN1446782ARealize cleaner productionEasy to operateGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationPhosphorus acidChloride

A process for recovering chloromethane from the tail gas exhausted in the procedure of preparing glyphosate by phosphorus acid-phytanic acid method is disclosed. As said tail gas contains chloromethane (20-90%) and impurities (methanol, methylal, H2O and hydrogen chloride), it uses solvent to absorb impurities, or condenses the impurities, or convents the impurities to chloromethane, so obtaininghigh-purity chloromethane.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

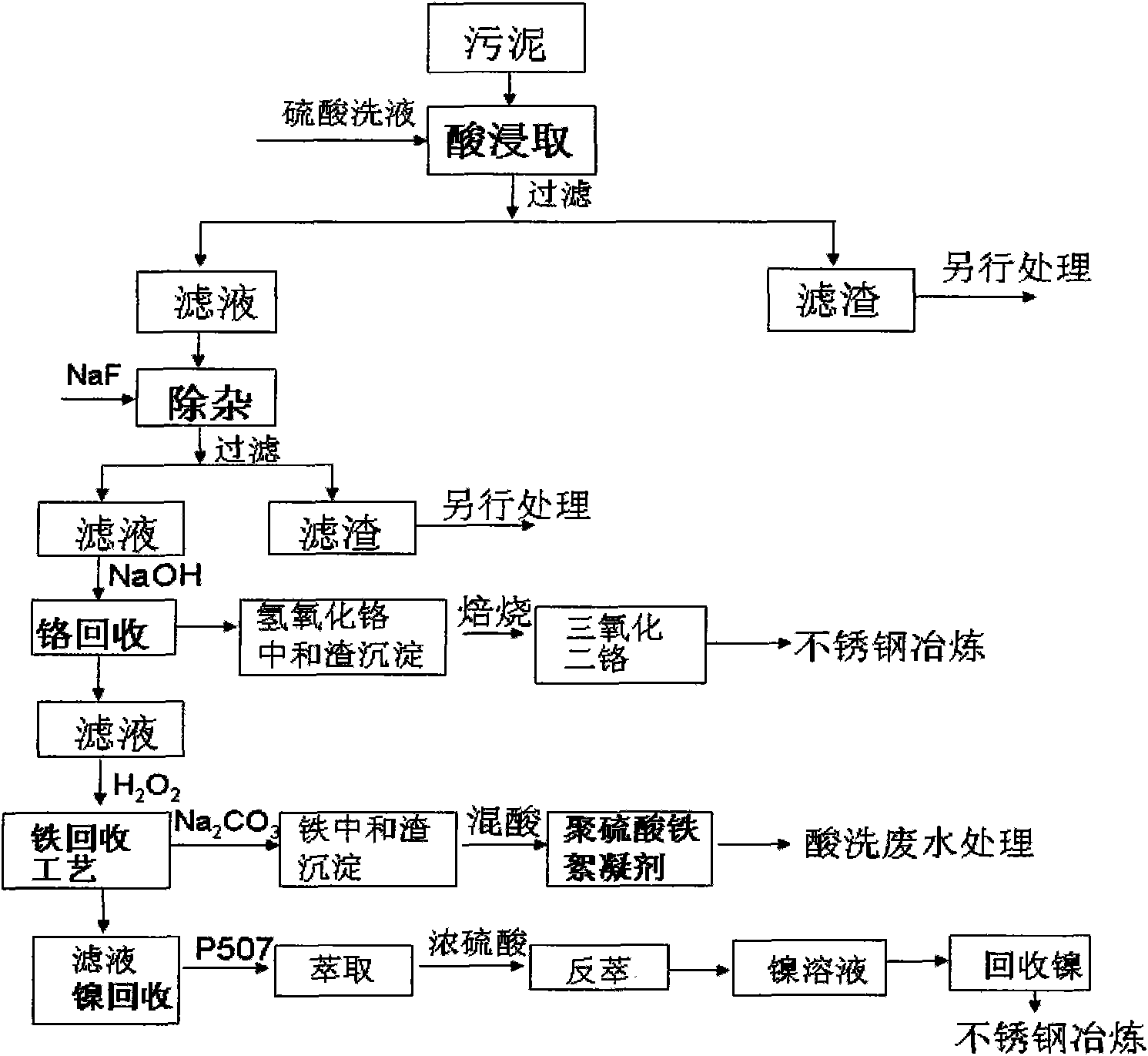

Recovery and comprehensive utilization method of heavy metals in stainless steel pickling wastewater sludge

InactiveCN101618892AImprove efficiencyAvoid secondary pollutionSludge treatmentChromium trioxideSolubilityHeavy metals

The invention relates to a recovery and comprehensive utilization method of heavy metals in stainless steel pickling wastewater sludge and discloses a method for recovering and recycling nickel and chrome in sludge generated during the treatment process of stainless wastewater. The method comprises the following steps: leading waste liquid during the pickling process to be directly used for leaching metal ions in the sludge to save the consumption of reagents; adding a certain quantity of acid or alkali in each reaction tank through arranging a plurality of reaction tanks; controlling a pH value; effectively separating various matters according to different solubility of inorganic compounds; researching and developing a recycling technology of the heavy metals in the stainless steel industrial sludge, wherein the recovery efficiency of the heavy metals like the chrome and the nickel is high; leading the recovered heavy metals to be used for smelting stainless steel; leading recovered iron to be used for preparing an efficient flocculating agent; and leading the flocculating agent to be used for sewage treatment to realize sewage reuse and save the treatment cost. The invention has the advantages of simple process and easy operation, as well as popularization and application.

Owner:SOUTHEAST UNIV

Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

The amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent is prepared through the following steps: 1) free radical copolymerizing reaction of four kinds of monomers in certain proportion in water soluble medium; 2) crosslinking reaction through introducing crosslinking agent after the polymerization. The present invention proposes that the amphoteric ionic polymer can raise the saturated added amount of concrete super-plasticizing agent, and introduces amphoteric ion concept into the molecular design of concrete admixture. The concrete super-plasticizing agent of the present invention has high water reducing rate, can eliminate the environmental pollution caused by concrete water reducing agent and reduce the added amount while ensuring the outstanding dispersivity and slump maintaining capacity.

Owner:JIANGSU SOBUTE NEW MATERIALS

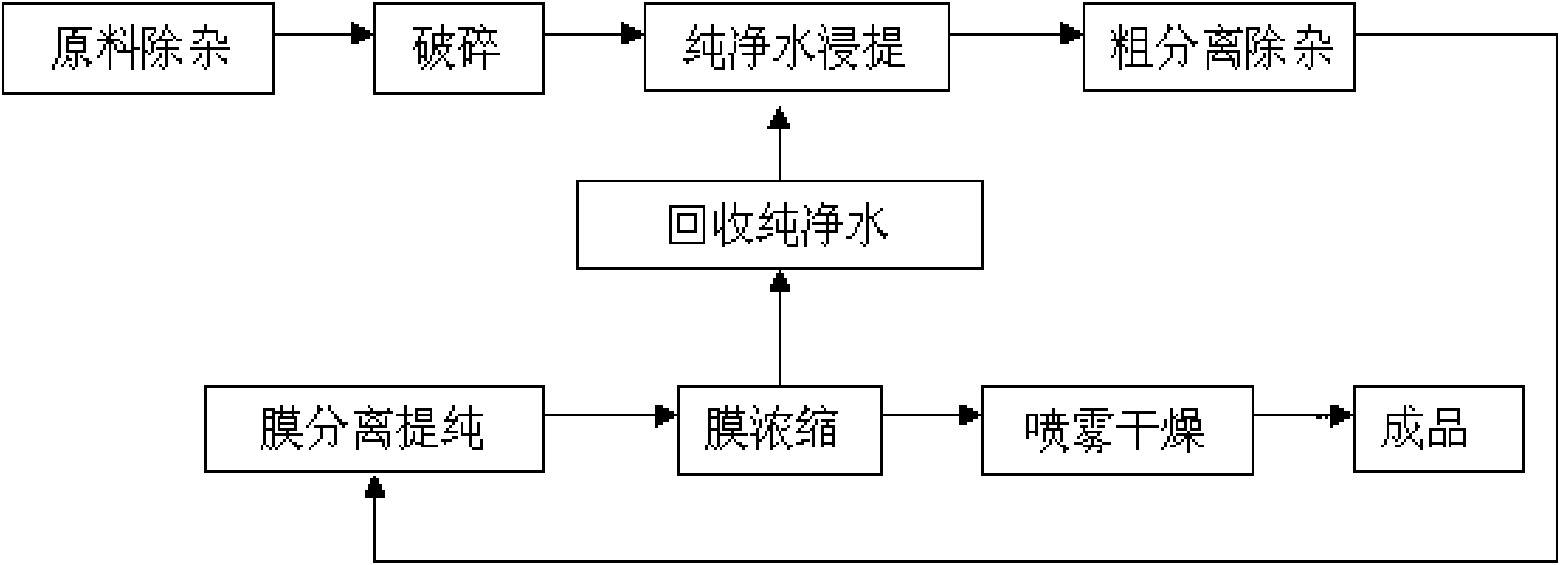

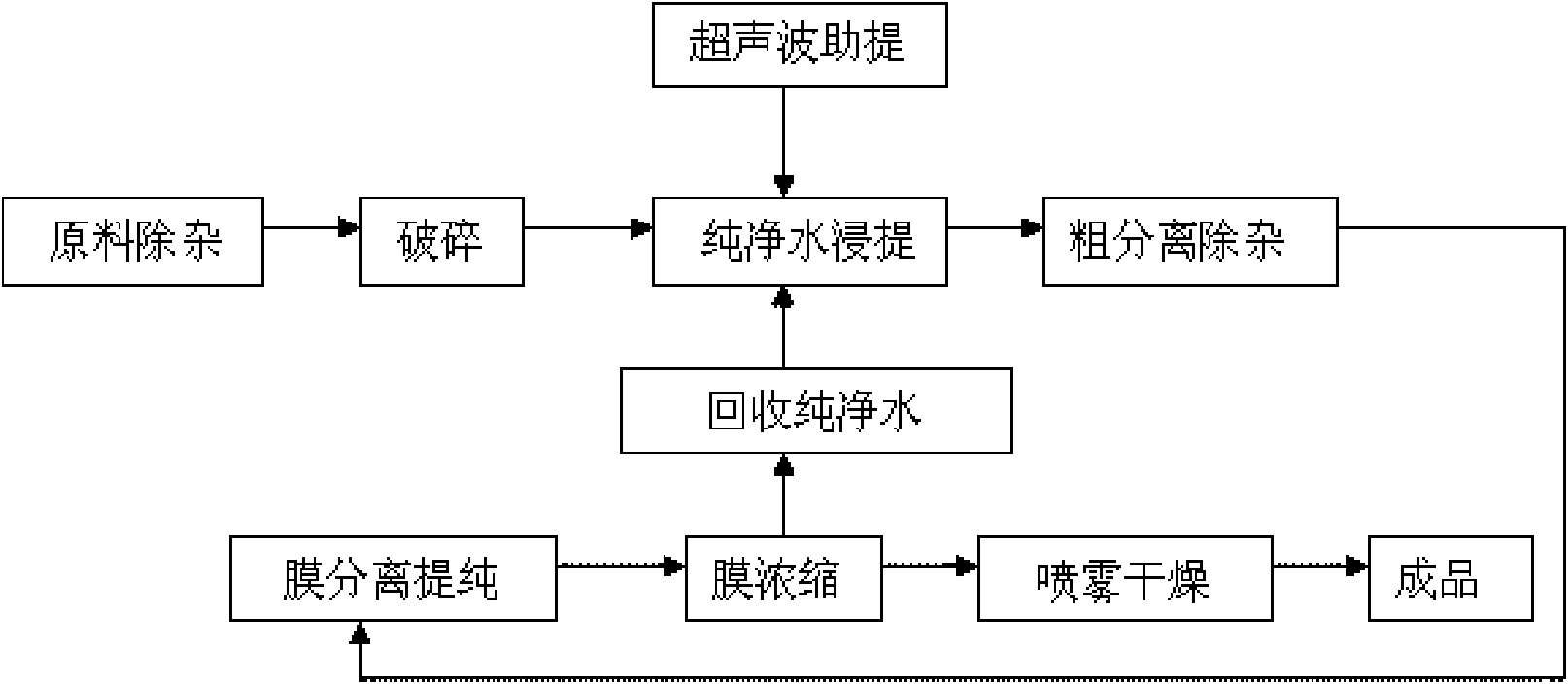

New process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology

InactiveCN101659794AImprove environmental performanceImprove extraction efficiencySemi-permeable membranesNatural dyesFiltration membraneUltrafiltration

The invention relates to a new process for extracting high-purity gardenia yellow pigment by a membrane separation and purification technology. The new process comprises processes of purified water leaching, crude separation and impurity removal, membrane separation and purification, and membrane concentration. After purified water extraction and ultrasonic assisted extraction, raw gardenia is separated by three centrifuges with different specifications and then obtained leaching liquor enters a membrane separation, purification and concentration system which consists of a microfiltration membrane (MF), an ultrafiltration membrane (UF), a nano-filtration membrane (NF) and a reverse osmosis membrane (RO), thus an OD value of the obtained gardenia yellow pigment can be controlled below 0.4 and color number can be increased to be more than 400. The finished product obtained by the process has no residual organic solvent and completely meets technical requirements for exporting to developed countries, including Europe and America, etc. as well as developed areas. The process is safe and clean in the whole production process, capable of realizing zero pollution and zero emission, has high environmental protection performance, and has advantages of greatly reducing energy consumption and lowering production cost due to the membrane concentration technology. The process further has advantages of simple process, stable product quality, high purity, etc.

Owner:广西山云生化科技股份有限公司

Method of esterifying in ion liquid [Hmim]+ BF4-

InactiveCN1405140ASynthetic method is simpleLow costOrganic compound preparationCarboxylic acid esters preparationSolventIon

The invention relates to a method for making esterification in ion liquid [Hmim](+)BF4(-), i,e, methyl imidazole salt tetrafluoroborate which can be used as solvent and catalyst. in the esterification reaction the fatty acid or aromatic acid and straight chain alcohol or branched chain alcohol are undergone the processes of stirring, heating, standing still and gravity settling so as to obtain the esterified product. Its conversion rate is 80-100%, its selectivity is 100%, and its conversion rate is high, and its catalyst can be repeatedly and circularly used, etc.

Owner:EAST CHINA NORMAL UNIVERSITY

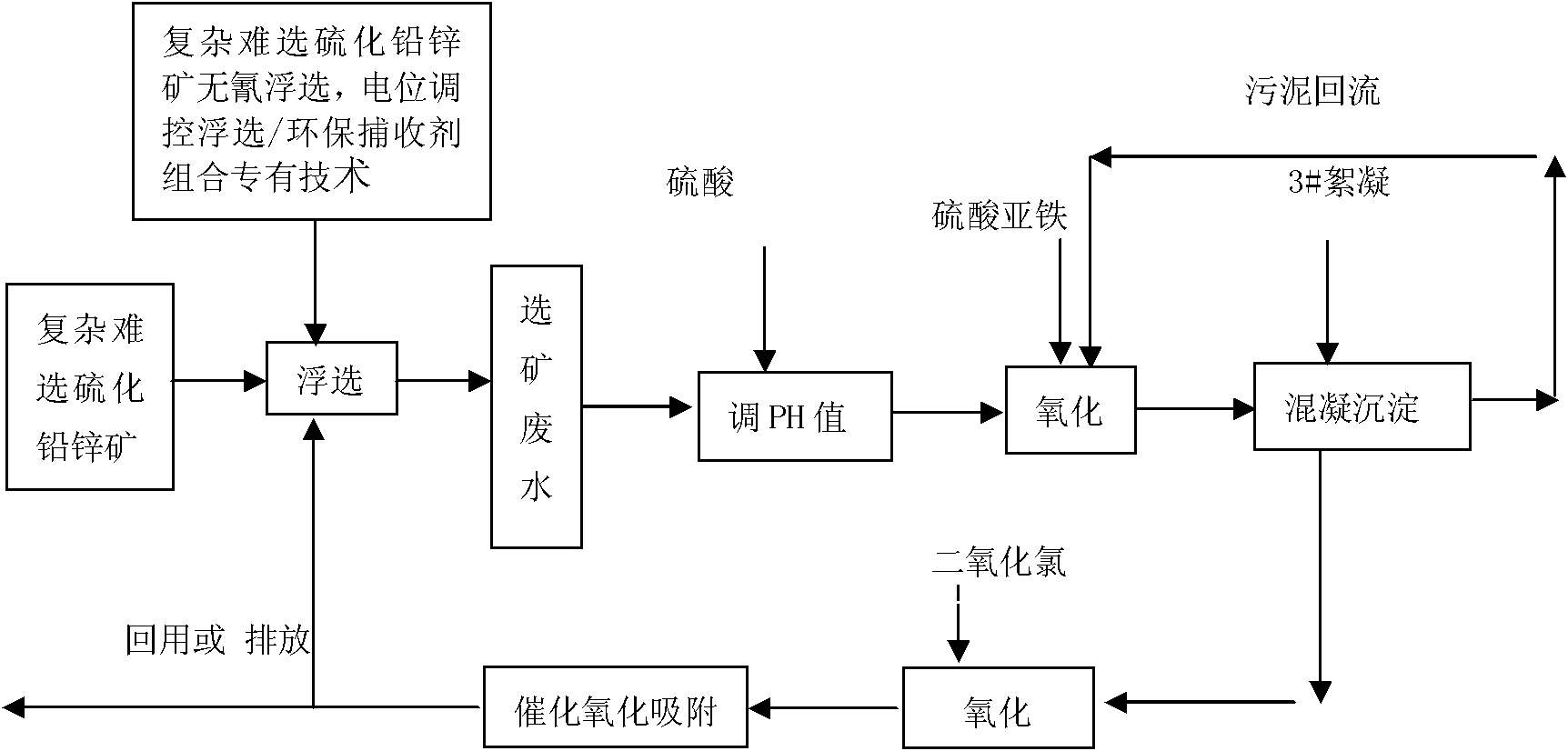

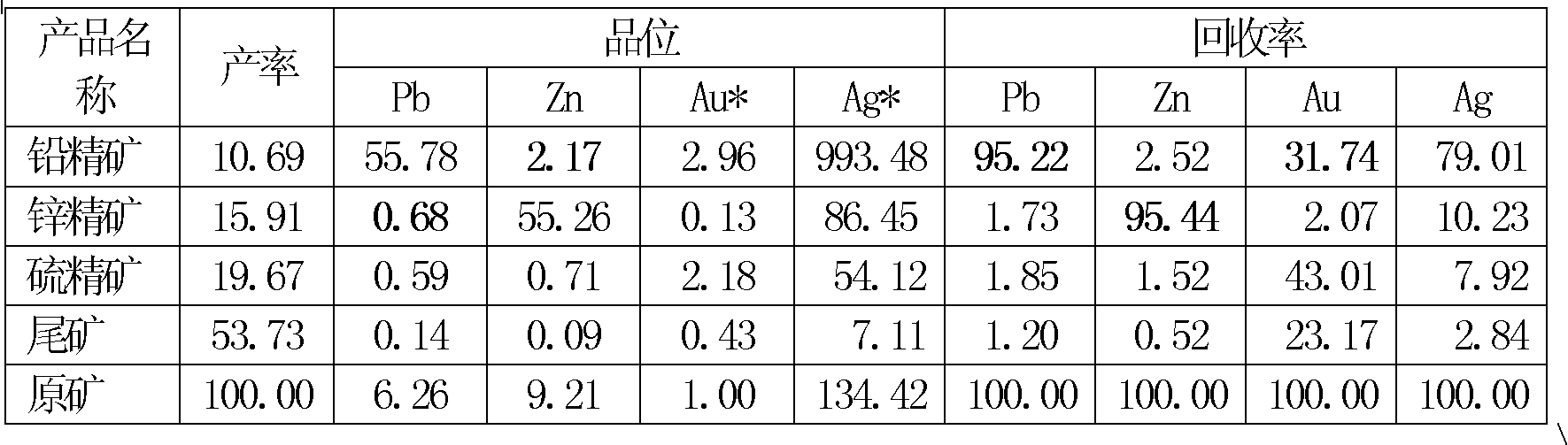

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720AEliminate the effects ofExtended service lifeWaste water treatment from quariesMultistage water/sewage treatmentActive carbonNovel technique

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the pH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

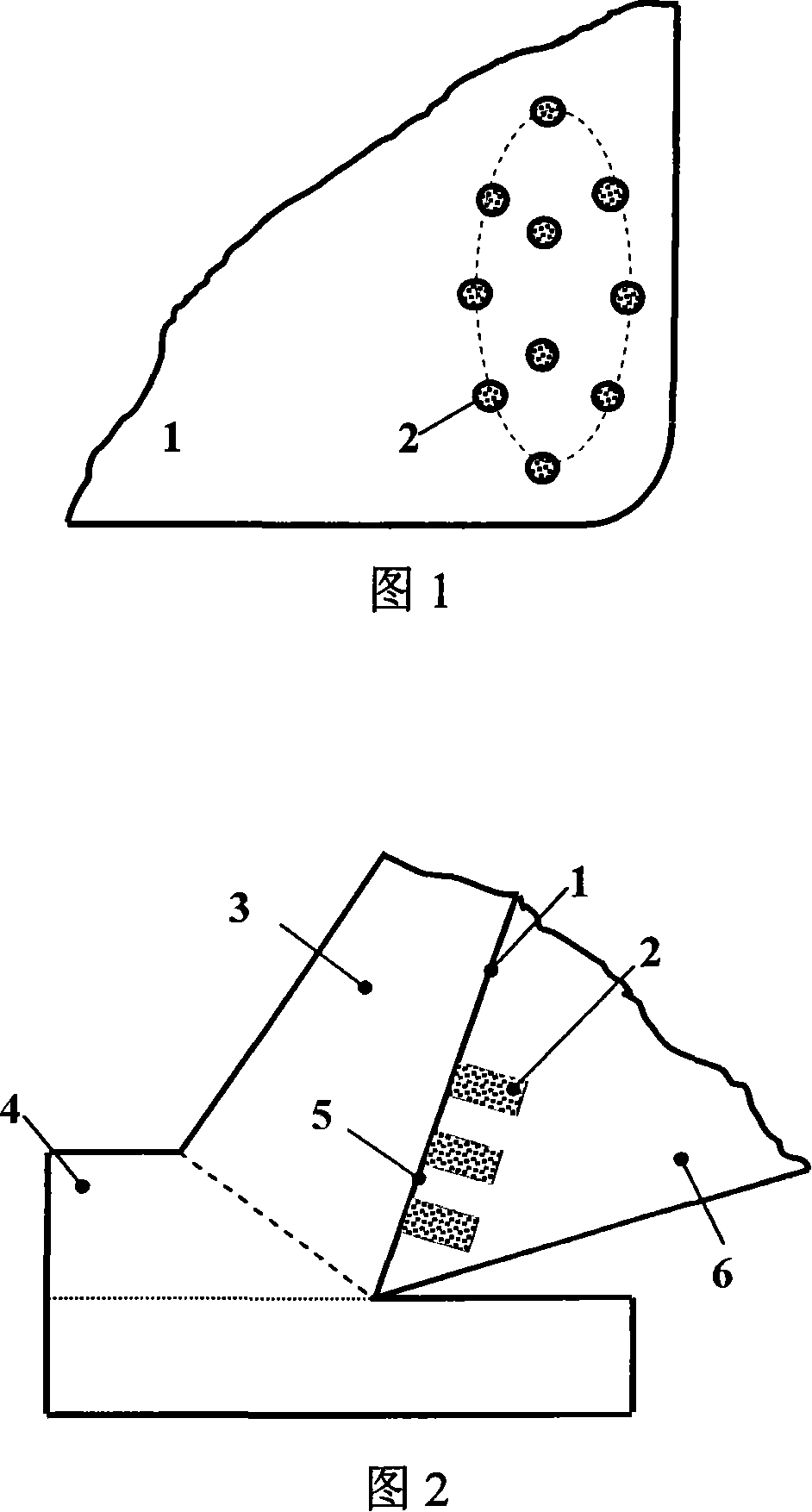

Micro-chamber self-lubricating knife tool and preparation method thereof

InactiveCN101125371AExtend your lifeAvoid pollutionTurning toolsBase-materialsEngineeringCutting fluid

The present invention belongs to the technical filed of mechanical cutting tool production, particularly relating to a microcell automatic lubricating cutting tool and the preparation method of the cutting tool. The rack face cutting contacting area of the microcell automatic lubricating cutting tool is provided with a plurality of micro pores which are used for filling the solid lubricant. When the cutting tool is used for dry cutting, the solid lubricant inside the micro pores is softened due to the high temperature and is coated on the rack face of the cutting tool to produce the called microcell effect and to form a continual solid lubricating layer in the rack face cutting contacting area of the cutting tool, which achieves the aim of preventing sticking, reducing frication, decreasing abrasion and prolonging the use time of the cutting tool. The microcell automatic lubricating cutting tool can be widely used for dry cutting and the cutting processing of intractable material. The present invention has the advantages of overcoming the environment pollution caused by cutting fluid, achieving the clean production and decreasing the cost.

Owner:SHANDONG UNIV

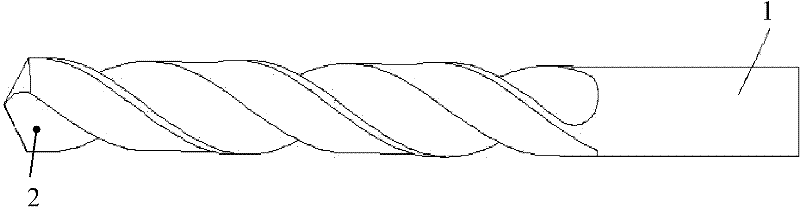

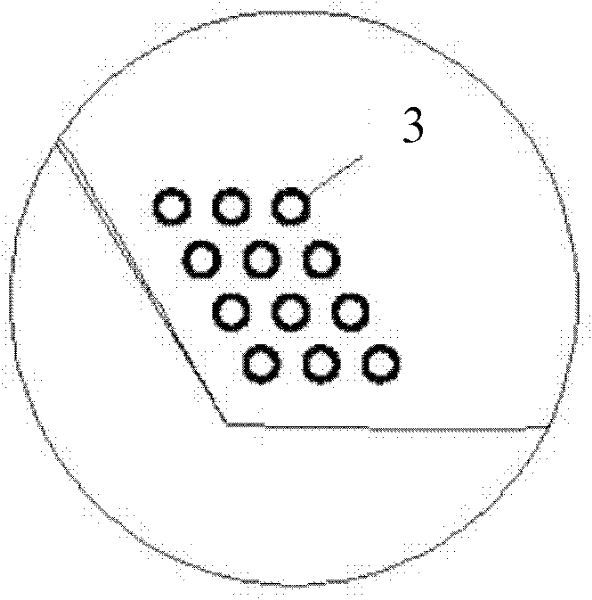

Micro-texture self-lubricating drilling bit and manufacturing method thereof

InactiveCN102189287AExtend your lifeAvoid pollutionTransportation and packagingTrepanning drillsManufacturing technologyEngineering

The invention belongs to the technical field of mechanical cutting tool manufacturing, and in particular relates to a micro-texture self-lubricating drilling bit and a manufacturing method thereof. A knife-chipping contact area of the rack face of the micro-texture self-lubricating drilling bit is provided with a plurality of micro-textures which are filled with a solid lubricant; during dry drilling, under the action of high temperature, the solid lubricant in the micro-textures is rapidly softened and is applied to the rack face of the drilling bit; a continuous solid lubricating layer is formed on the knife-chipping contact area of the rack face of the drilling bit, thereby being capable of preventing bonding, decreasing friction, reducing abrasion and prolonging the service life of the drilling bit. The micro-texture self-lubricating drilling bit can be widely applied to the drilling and machining of dry-type drilling and difficulty-machined materials, can overcome the environmental pollution caused by cutting fluid, realizes clean production and reduces the cost.

Owner:SHANDONG UNIV

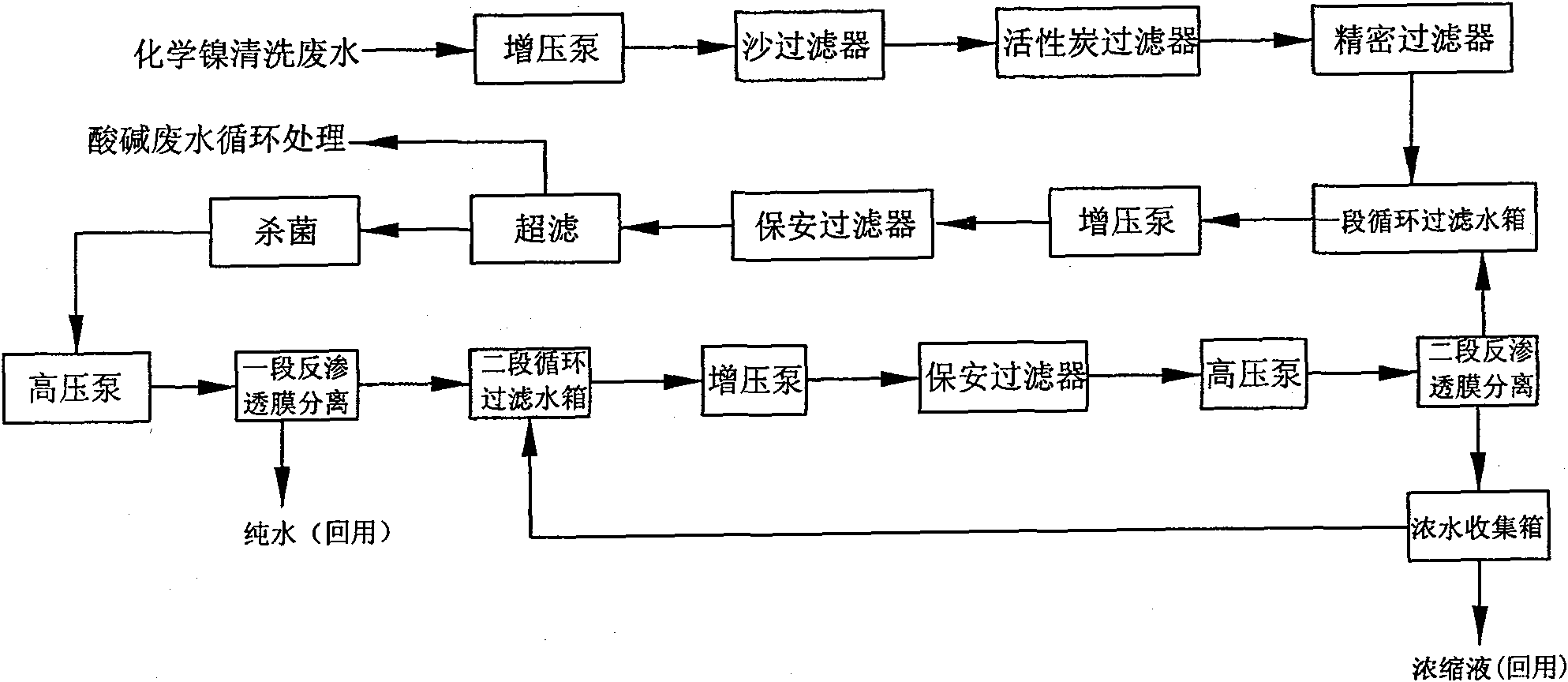

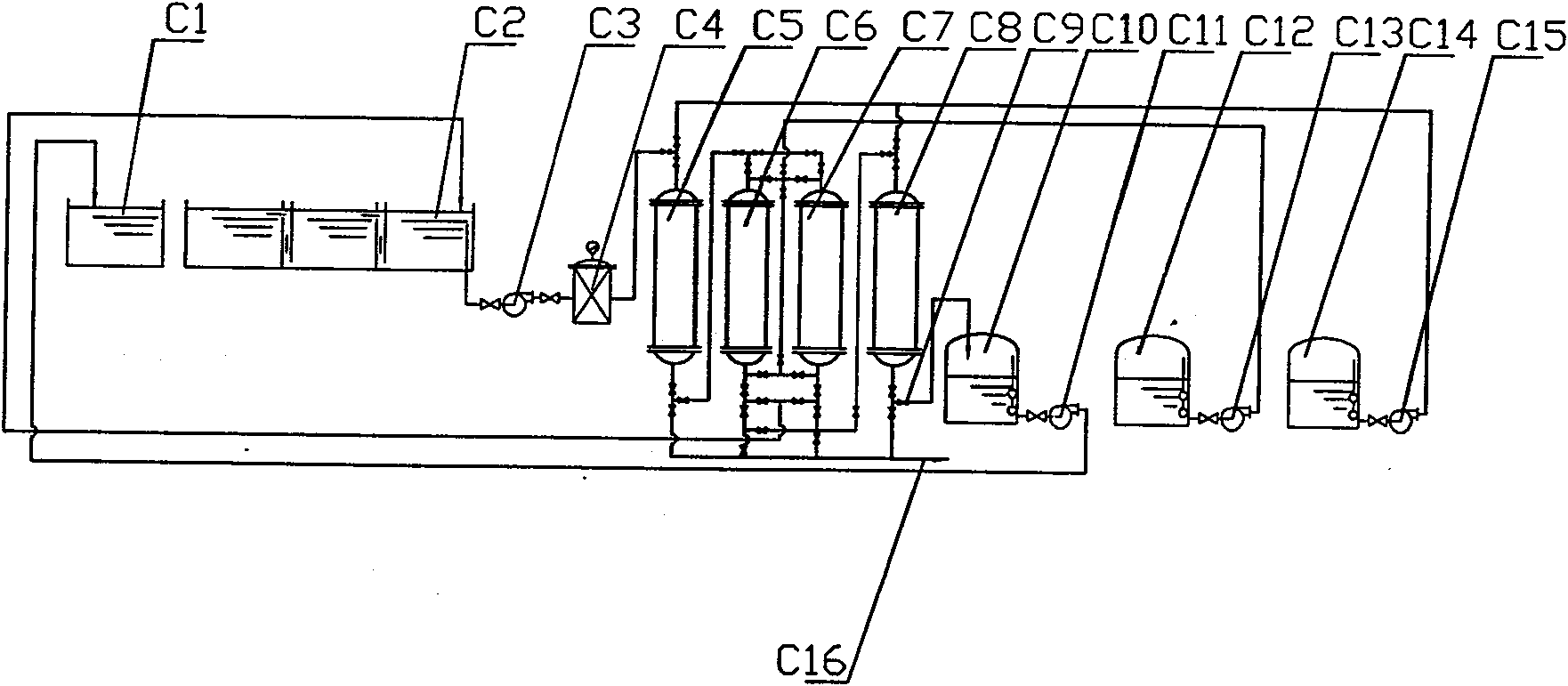

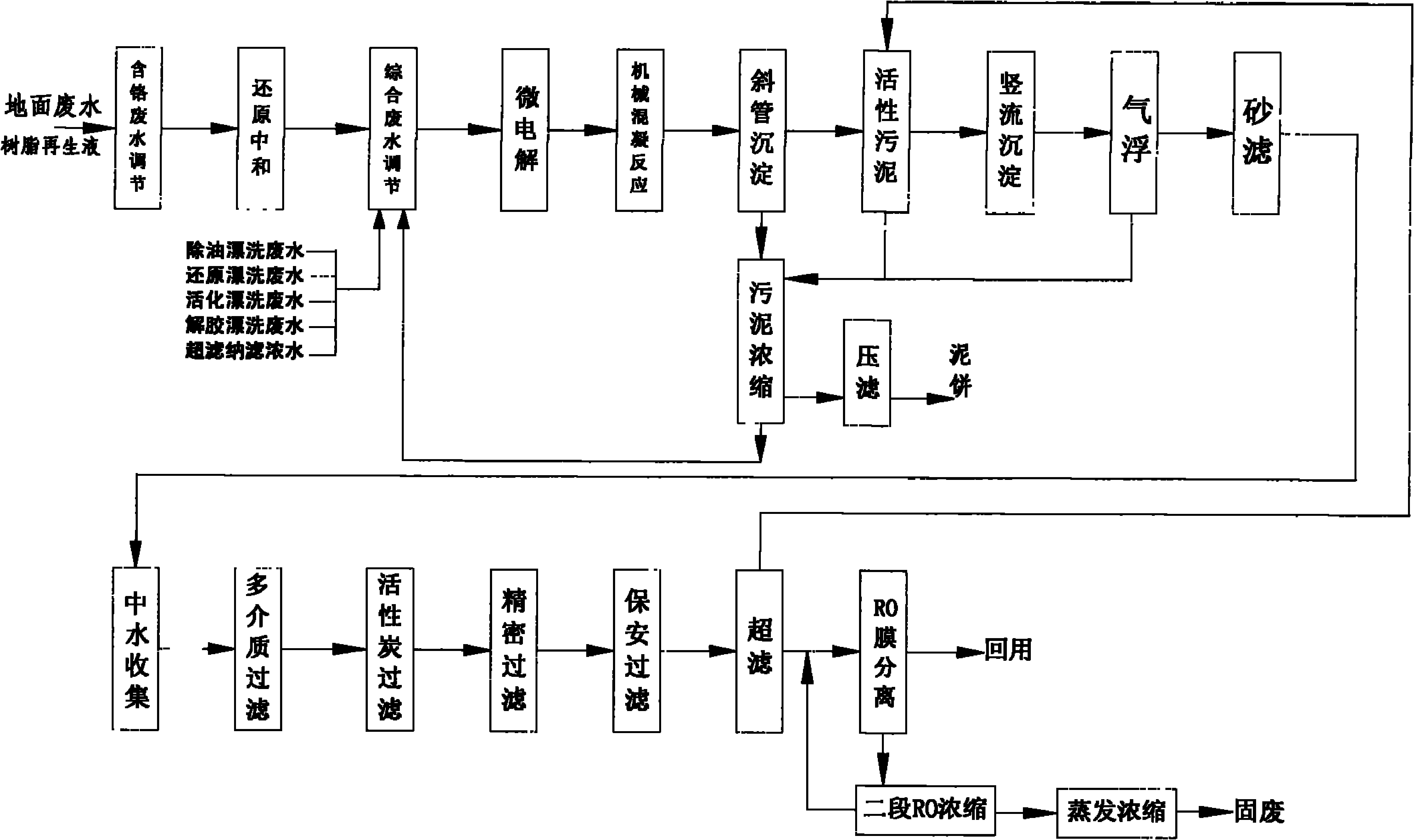

Method for classifying, treating and recycling plating washing water on line

ActiveCN101891323AAvoid cross contaminationStrong targetingWater contaminantsWater/sewage treatment by ion-exchangeCopper platingWater cycling

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Owner:NANJING YUANQUAN TECH CO LTD

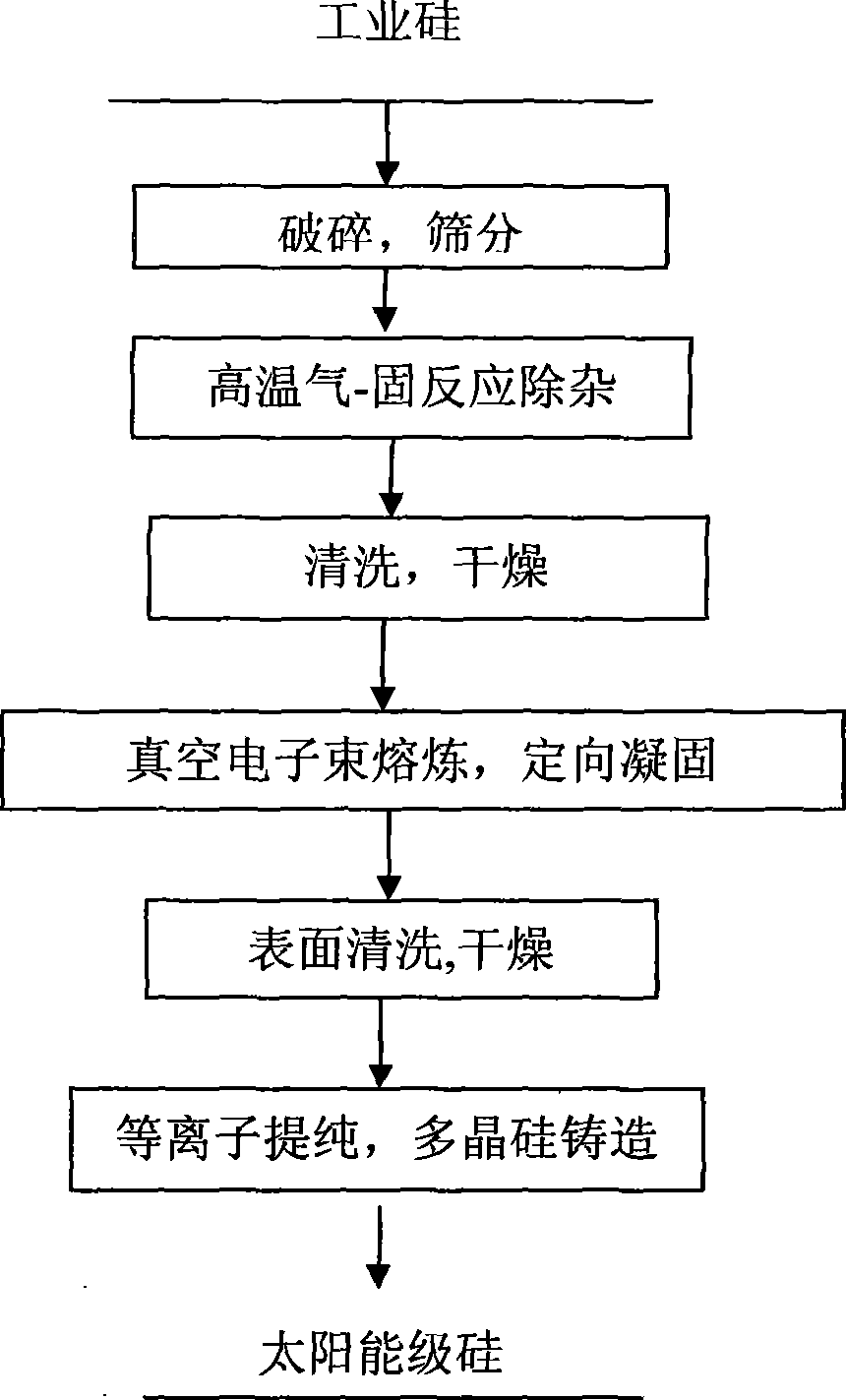

Method for purifying industrial silicon for preparing solar grade silicon

ActiveCN101475174ADirect preparationRemove difficult problemSilicon compoundsPre treatmentHigh activity

The invention discloses a method for preparing solar-grade silicon through purification of industrial silicon (2N). The method comprises that: the industrial silicon is subjected to primary pulverization pretreatment and is put into a high-temperature solid-phase reaction furnace; the industrial silicon and active gas are subjected to gas-solid reaction at high temperature to achieve the aim of removing metal impurities; then crystalline silicon is cleaned; the purity of the crystalline silicon reaches as high as 99.999 percent (5N), and is further subjected to vacuum melting of electron beams and oriented condensation treatment; finally, active atmosphere plasma is adopted to further purify the crystalline silicon, and volatile elements which have high activity and are easily oxidized to generate high saturated vapor pressure are removed; and polysilicon is cast in an integrated furnace for casting plasma polysilicon and is directly used for manufacturing a cell chip. The method combines high-temperature gas-solid reaction to remove the metal impurities, the electron beams to remove the volatile elements and a plasma purification and casting integrated furnace technology, improves the purity of the polysilicon to 99.99999 percent (7N) and, fully meets requirement of a solar cell industry on the solar-grade silicon.

Owner:晶海洋半导体材料(东海)有限公司 +1

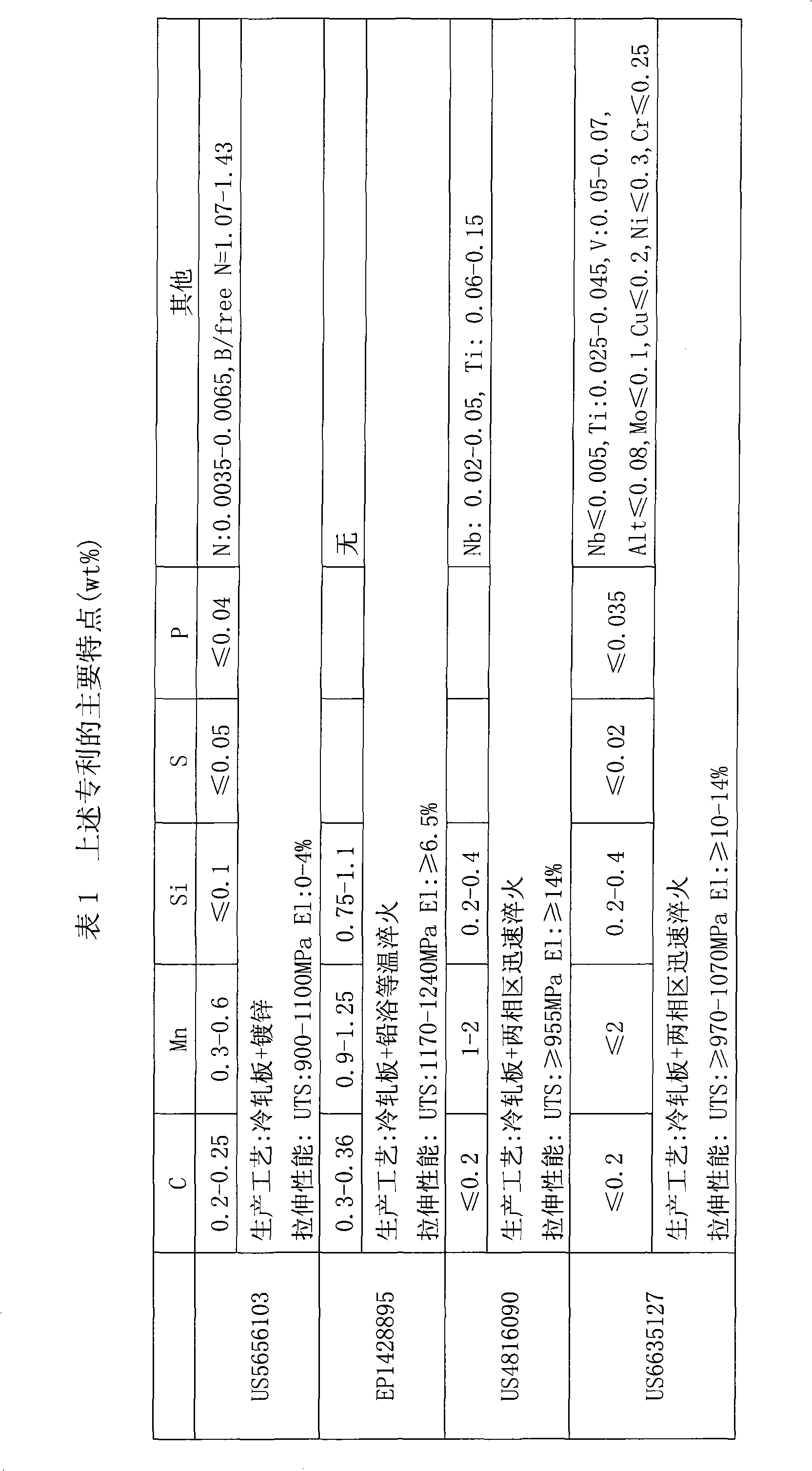

Economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and manufacturing method thereof

The invention discloses economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.25 to 0.42 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, less than or equal to 0.08 percent of Al, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steelmaking process for clean steel smelting controlled in inclusion forms, a hot rolling process, a cold rolling process and a bluing-annealing process. The manufacturing method can realize the clean production of high-strength binding strip steel, reduces production processes, improves the production efficiency, and can obtain the economical high-strength binding strip steel with well matched strength and plasticity and the tensile strength more than or equal to 1,000 MPa while significantly reducing production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

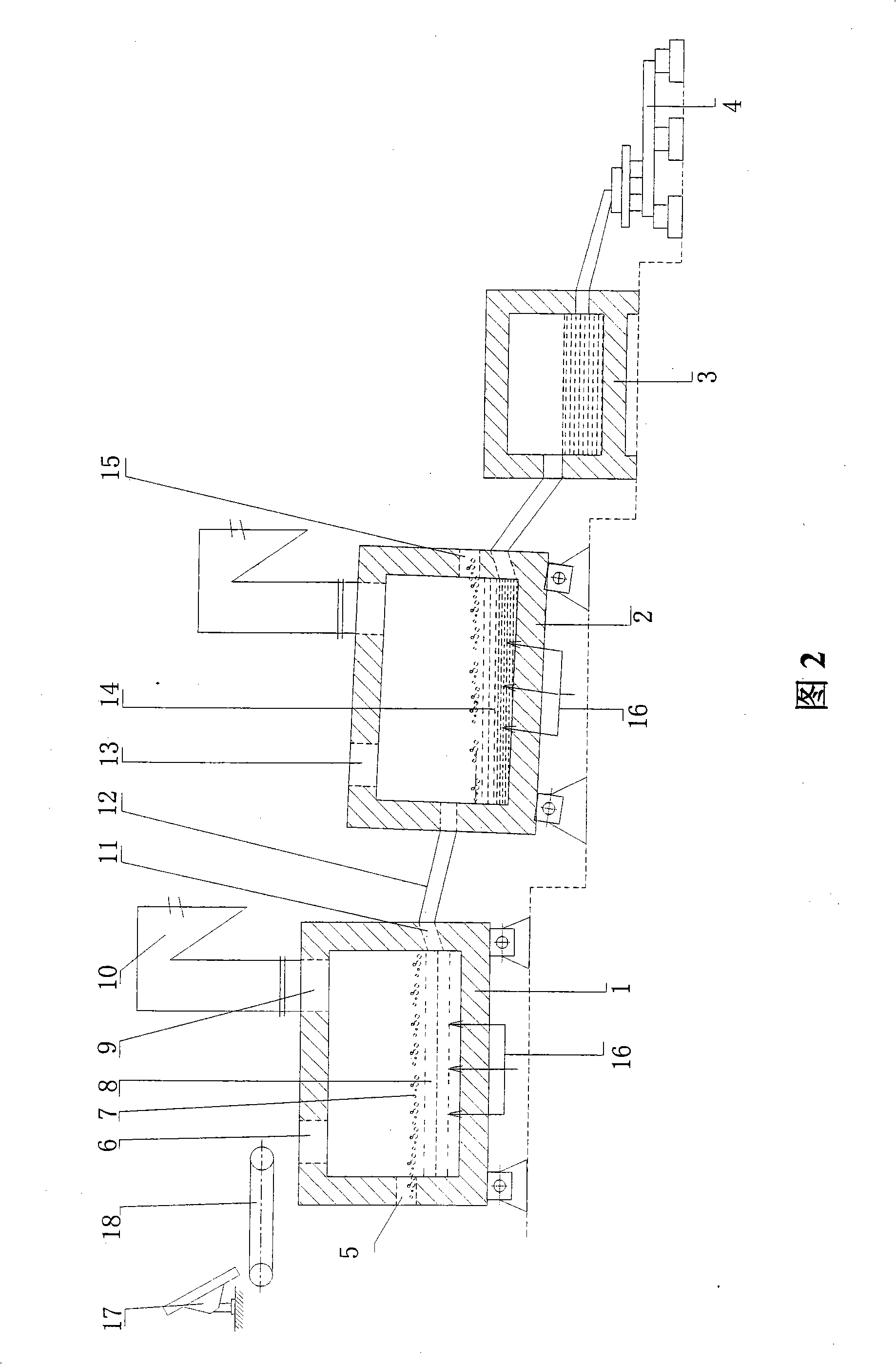

Oxygen bottom blowing continuous copper smelting apparatus

InactiveCN101328543ALess slagHigh yieldRotary drum furnacesCrucible furnacesSmelting processLiquid copper

The invention provides an oxygen bottom blowing continual copper smelting device used in the continual copper smelting process. The device is characterized in that the device comprises an oxygen bottom blowing smelting furnace, an oxygen bottom blowing converting furnace, an anode furnace and an anode plate casting machine, wherein the oxygen bottom blowing smelting furnace and the oxygen bottom blowing converting furnace are connected by a first chute, so that liquid copper matte smelted by the oxygen bottom blowing smelting furnace can be continuously injected into the oxygen bottom blowing converting furnace through the first chute to obtain coarse copper by the continuous converting of the oxygen bottom blowing converting furnace; the oxygen bottom blowing converting furnace and the anode furnace are connected by a second chute, so that the coarse copper can flow in the anode furnace through the second chute and is subjected to refining by the anode furnace to obtain anode copper; and the anode furnace and the anode plate casting machine are connected by a third chute, so that the anode copper can flow into the anode plate casting machine through the third chute and is subjected to casting by the anode plate casting machine to obtain the copper anode plate.

Owner:CHINA ENFI ENGINEERING CORPORATION

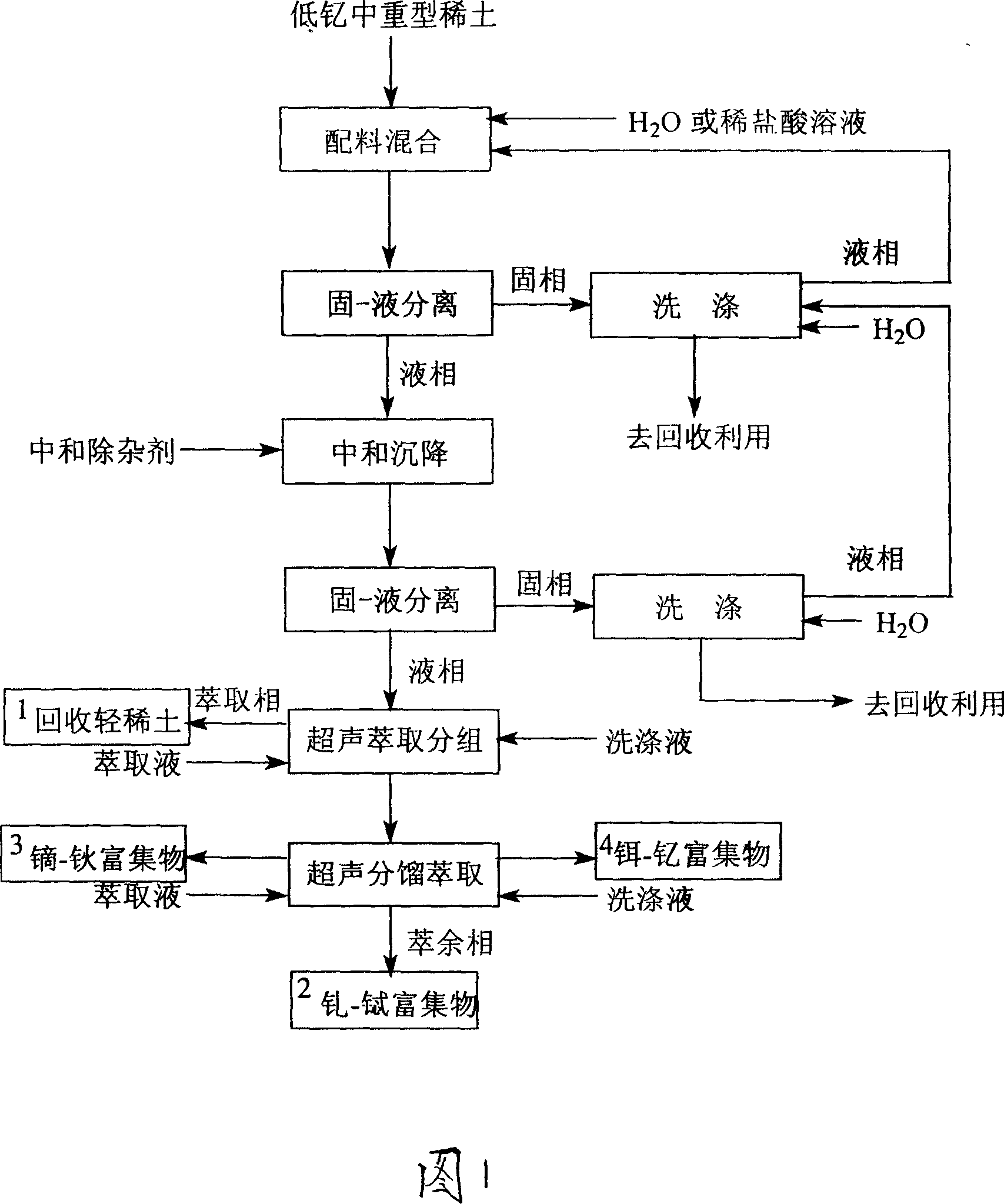

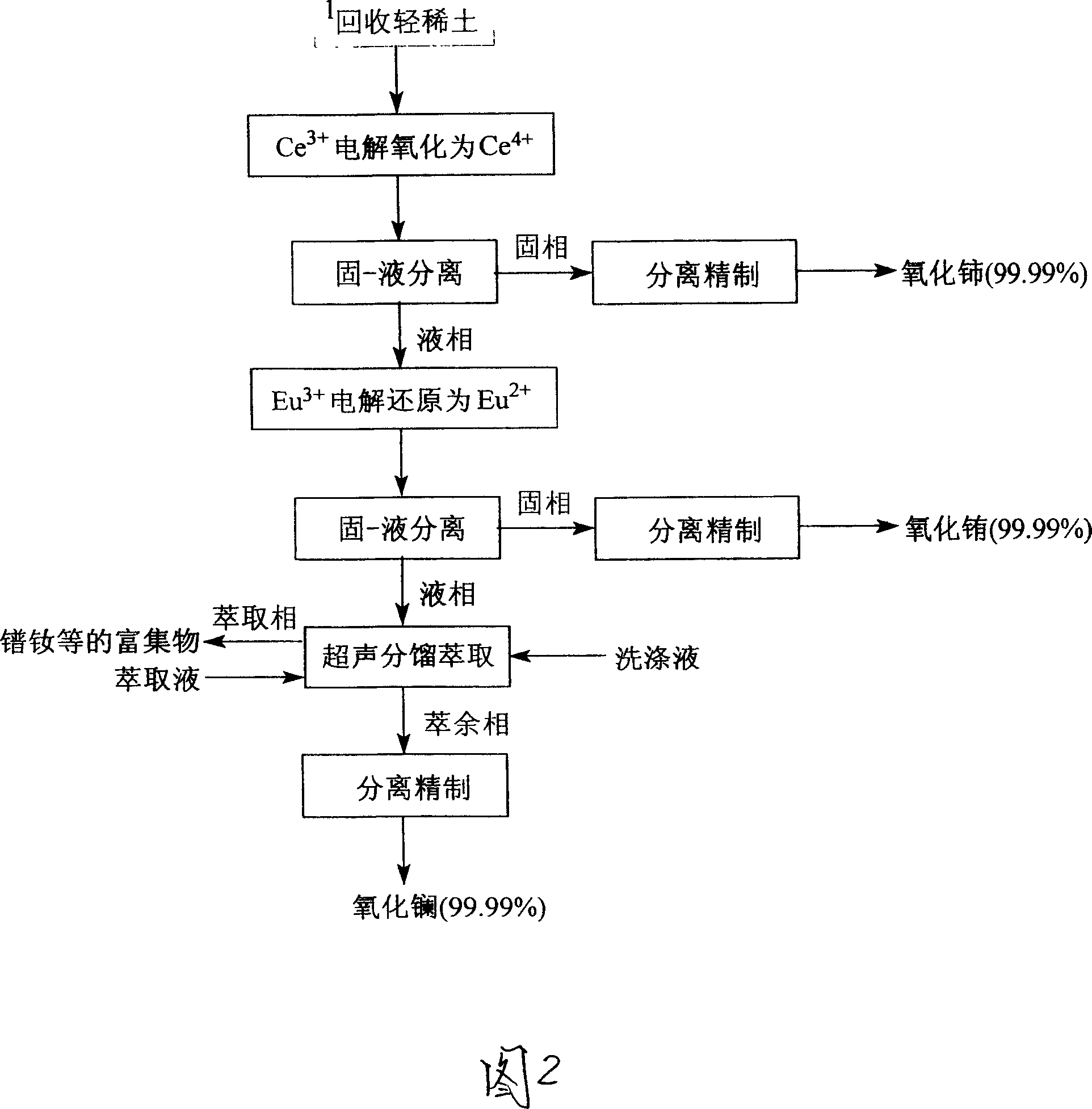

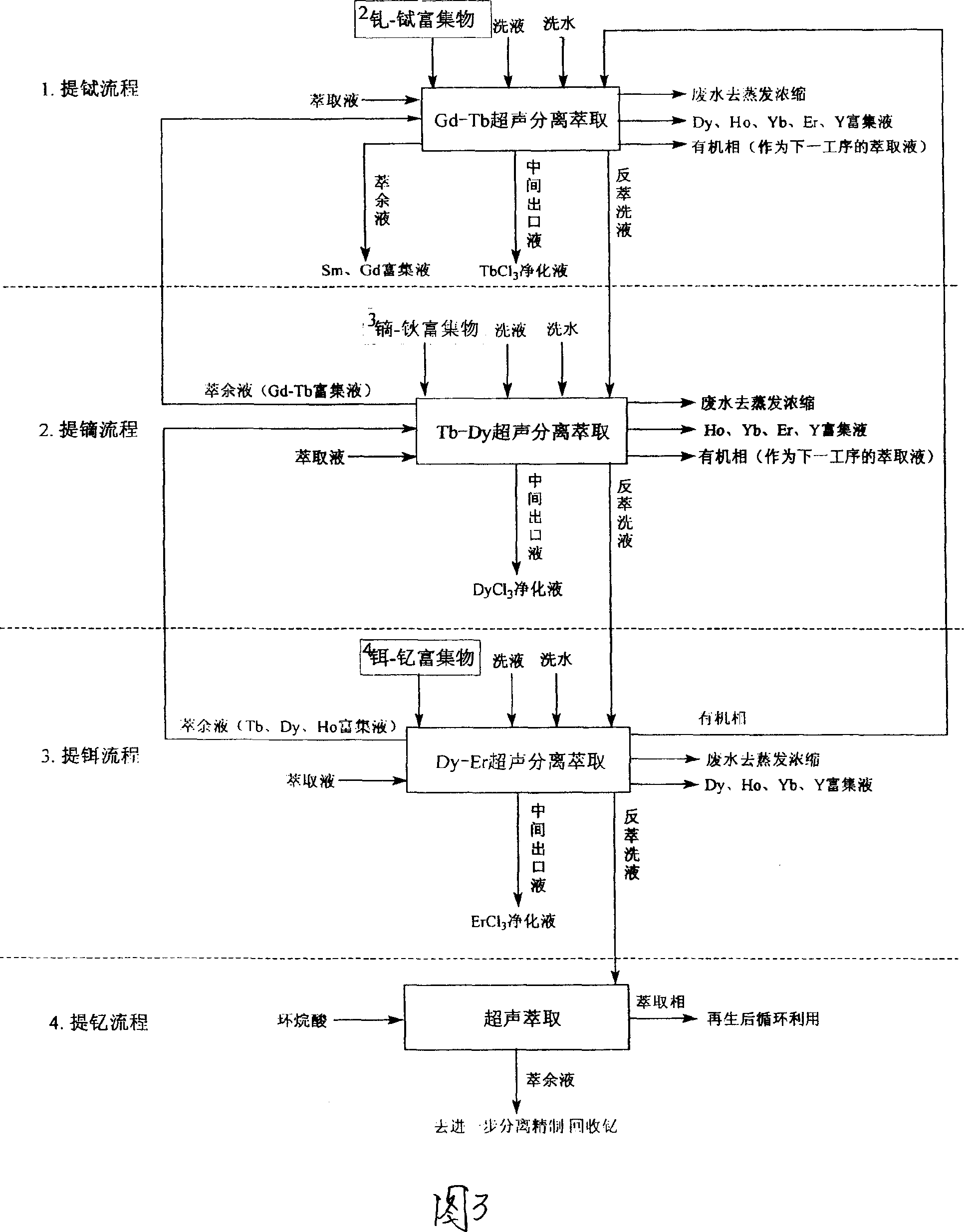

Method for separating highly-pure rare-earth oxide from yttrium-rich rare earth mine

InactiveCN101012501AIncrease concentrationReduce processingProcess efficiency improvementRare earthYttrium

The invention discloses a full-separating method of high-purity rare earth oxide from low-yttrium middle-heavy rare earth rare earth ore, which is characterized by the following: adopting enriched yttrium rare earth ore as raw material; producing high-purity Y2O3, La2O3, Ce2O3, Pr5O11, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3, Er2O3 and Y2O3 through ultrasonic extracting-electrochemical, quantivalence-changing and chemical coupling technique; obtaining the product.

Owner:常州市西南化工研究所 +2

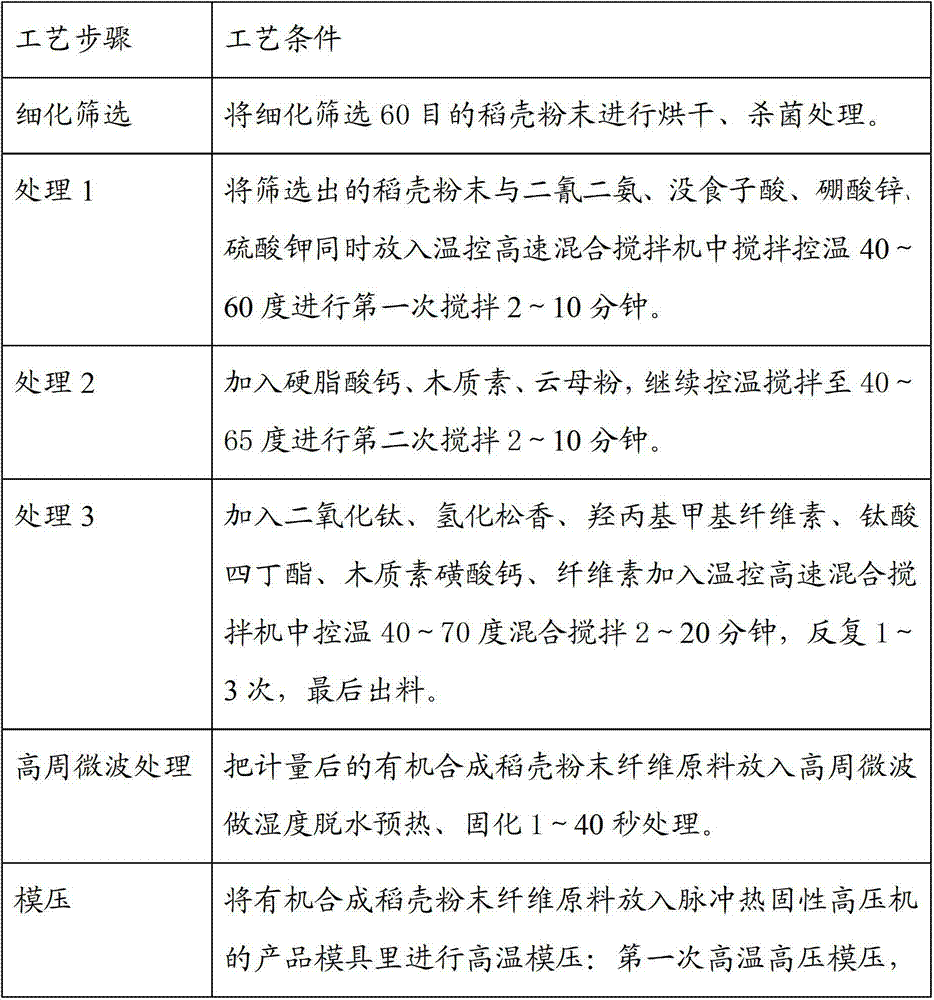

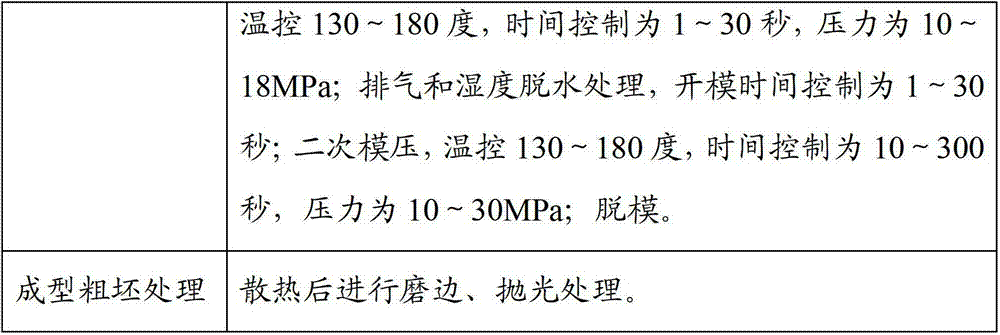

Plant fiber environment-friendly material as well as preparation method and application thereof

InactiveCN103113753AWide variety of sourcesEvenly distributedWood working apparatusFlat articlesFiberWide field

The invention discloses a plant fiber environment-friendly material and a preparation method thereof as well as application of the material in tableware, toys, furniture, decoration or wall. The preparation method comprises the following steps of: pretreating, grinding and screening the plant fiber; mixing the screened plant fiber powder with an adhesive and a modification aid, and stirring at high temperature, wherein the adhesive mainly adopts hydroxypropyl methyl cellulose; filtering with a riddler, and dehydrating and preheating the screened organic synthesis plant fiber raw material; and performing high-temperature die pressing. According to the plant fiber environment-friendly material as well as the preparation method and application thereof, the product has good performance and additional functionality, can be applied to wider fields, conforms to relatively high requirements on using safety, and facilitates environmental protection so as to overcome the shortcomings of the existing plant fiber environment-friendly material and a preparation method and application thereof.

Owner:王丹 +2

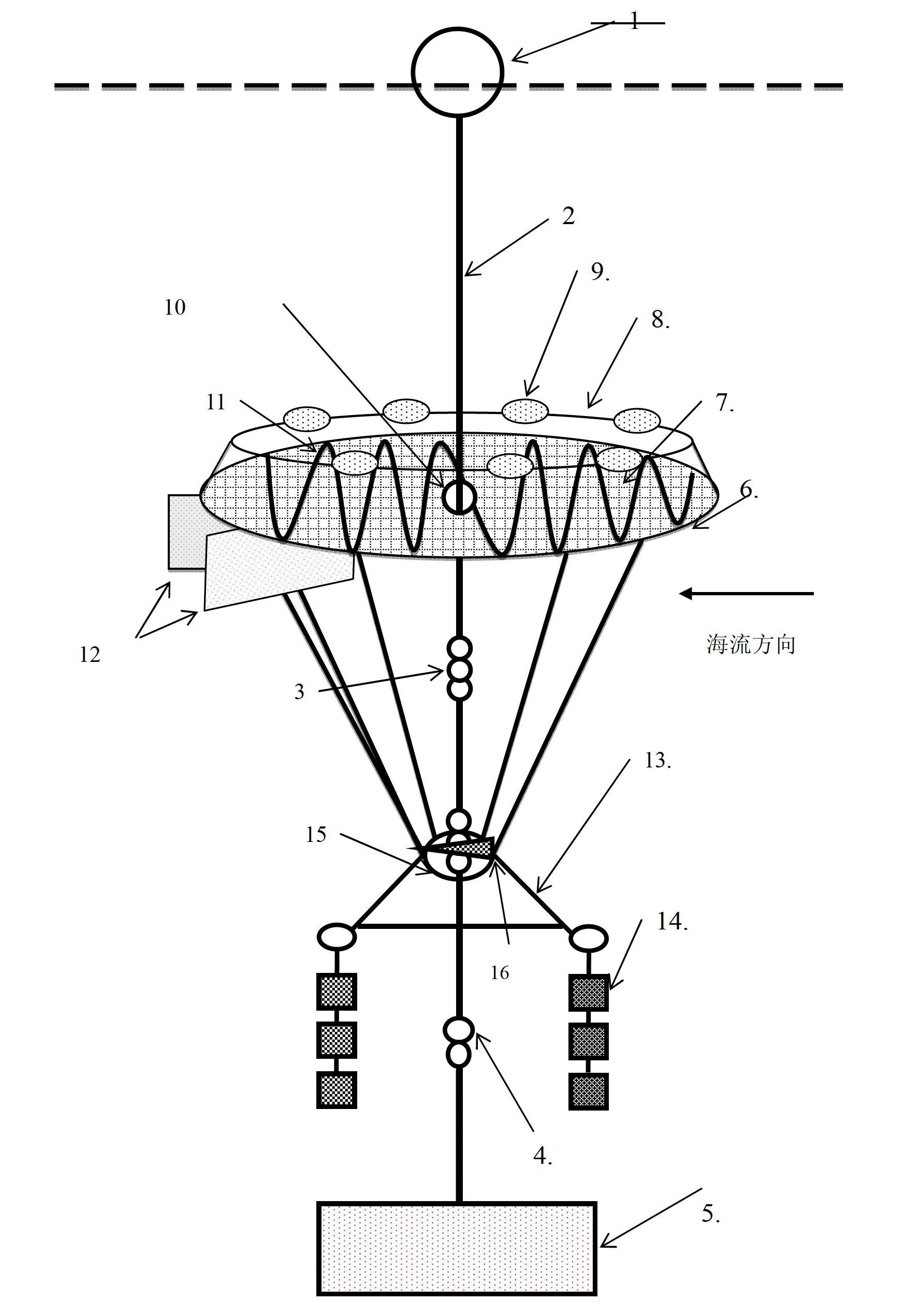

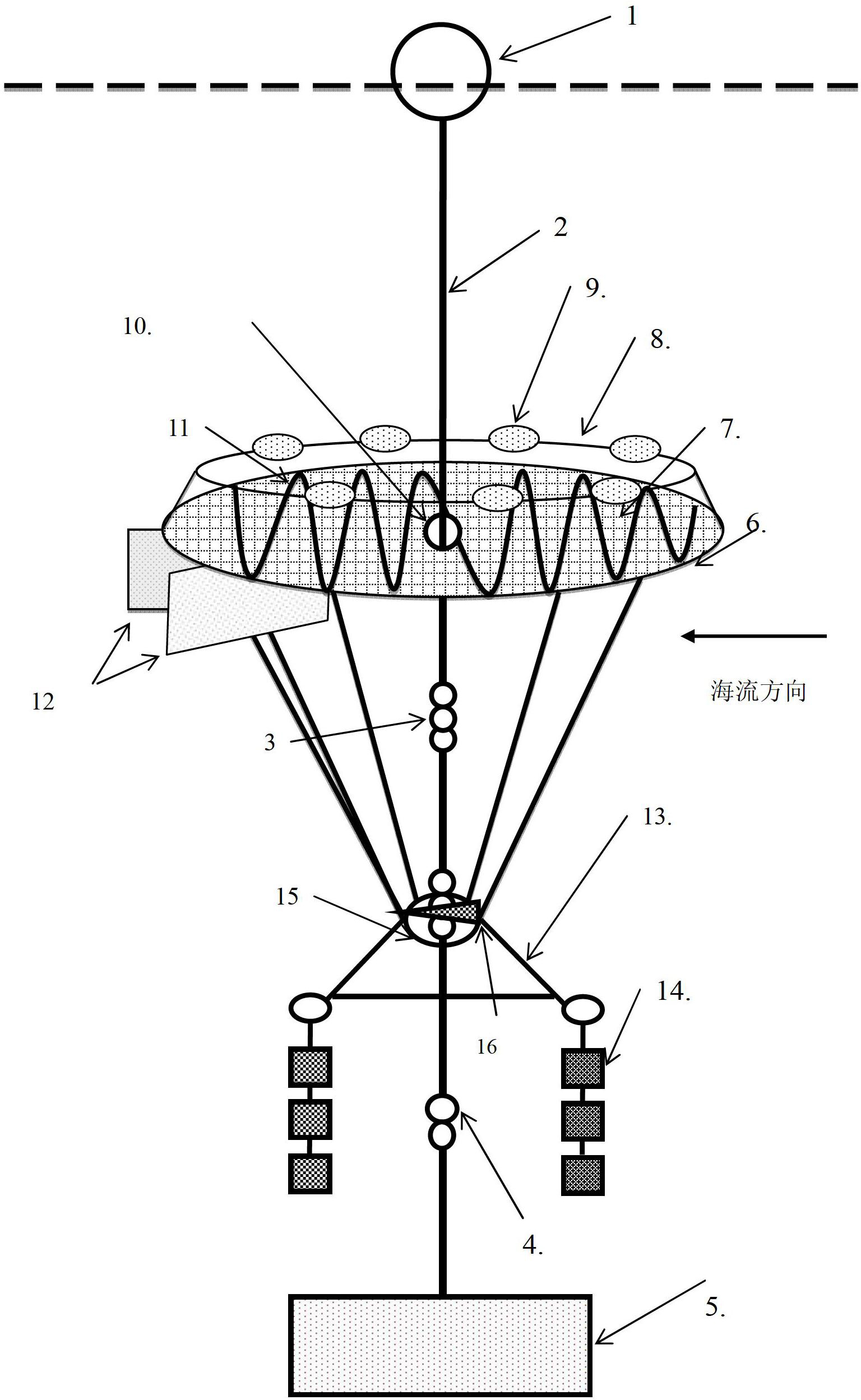

Adjustable deep sea algae aquaculture floating bed

InactiveCN102668967ASolve the problem that it is impossible to carry out large-scale algae breedingSuitable for growthClimate change adaptationCultivating equipmentsUnderwaterAlgae

The invention relates to a macrophytic algae aquaculture facility suitable for open type deep waters, in particular to an adjustable deep sea algae aquaculture floating bed, which substantially comprises a main anchor cable, a sea algae aquaculture floating bed and a weight system, wherein a mooring rope of the main anchor cable consists of a main float ball, a center circle, a chain ring, a lower circle, a rotating ring and a dropstone, and the sea algae aquaculture floating bed comprises a buoyancy framework, a bottom net, a purse net, a center circle, an oblique stay cord, a weight system and a guide plate. The adjustable deep sea algae aquaculture floating bed is a movable type floating bed frame, wherein the bottom portion of the adjustable deep sea algae aquaculture floating bed is provided with the bottom net, the middle portion of the bottom net is provided with a round iron ring, and the periphery of the movable type floating bed frame is inwardly obliquely provided with a circle of purse net. The weight system comprises a weight hanging rack, a weight block and a position card bolt. The adjustable deep sea algae aquaculture floating bed uses a double-buoyancy system, and can be guaranteed in an upright posture underwater through own bigger buoyancy of the movable type floating bed frame, can be accurately fixed on a scheduled water layer through a buoyancy system of the main anchor cable, and is more convenient to adjust the scheduled water layer by integrally arranging the adjustable deep sea algae aquaculture floating bed and the weight system in a micro buoyancy state.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

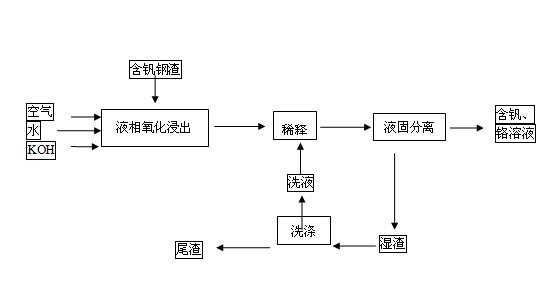

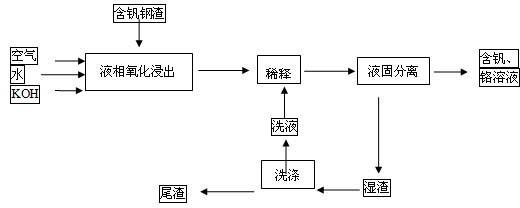

Method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide

ActiveCN102071321AHigh single recovery rateReduce productionProcess efficiency improvementSlagPotassium

The invention relates to a method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide, and belongs to the technical field of metallurgy. The invention adopts a technical scheme that: the steel slag together with water and potassium hydroxide is added into a reactor, the mixture is decomposed under normal pressure, and then the obtained reaction slurry is cooled and diluted by a diluent to obtain mixed slurry containing the potassium hydroxide, potassium vanadate, potassium silicate, potassium chromate and tailings; the alkalinity of the potassium hydroxide in the mixed slurry is controlled to be more than or equal to 100g / L, the mixed slurry is filtered and separated while the temperature is kept to be 80 to 130 DEG C to obtain the tailings and vanadium and chromium-containing water solution. The method has the advantages that: the high-temperature roasting is avoided, the reaction time is shortened, the single high-efficientextraction and simultaneous extraction of the vanadium and the chromium are realized; atmospheric pollutant as Cl2, HCl, dust, SO2 and the like caused by roasting are effectively avoided in the vanadium extraction process; and compared with the conventional roasting process, the generated amount and the discharged amount of waste water are effectively reduced, and clean production is realized.

Owner:HEBEI IRON AND STEEL

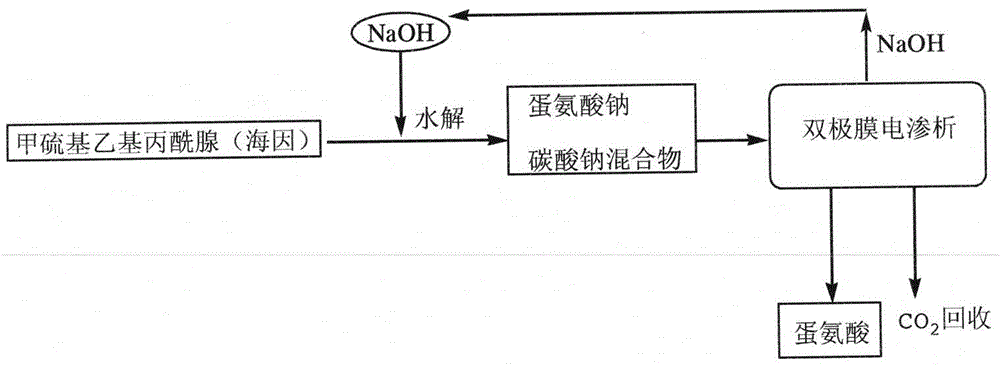

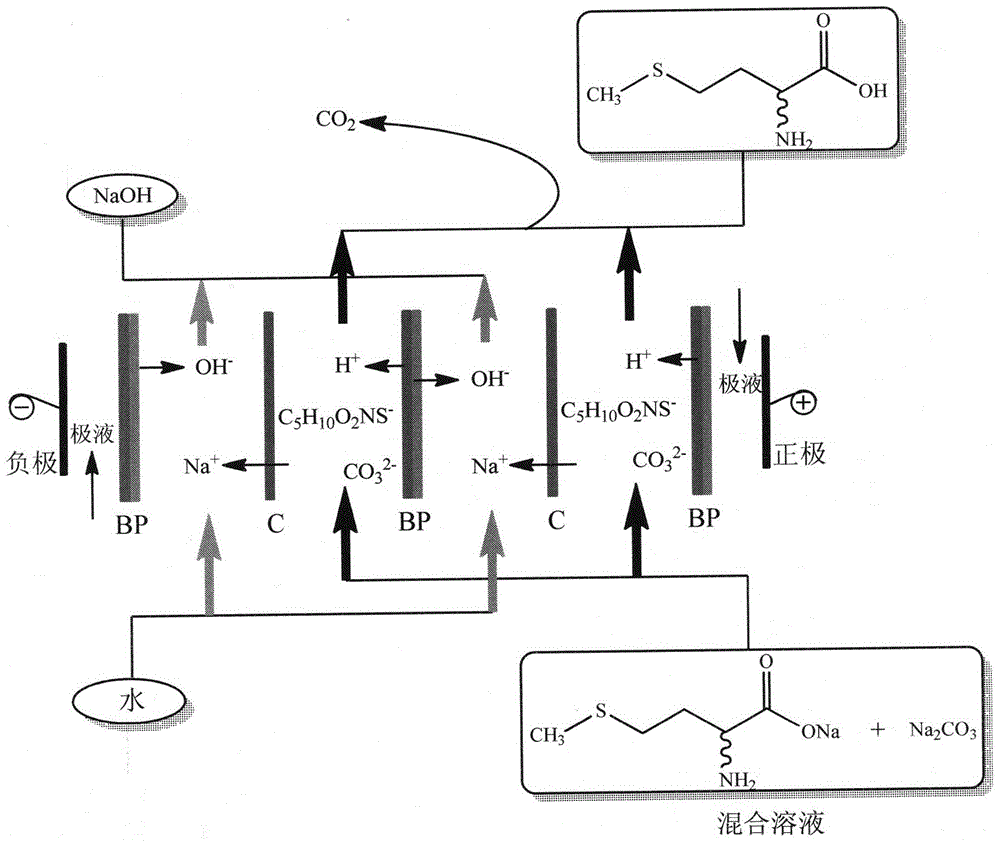

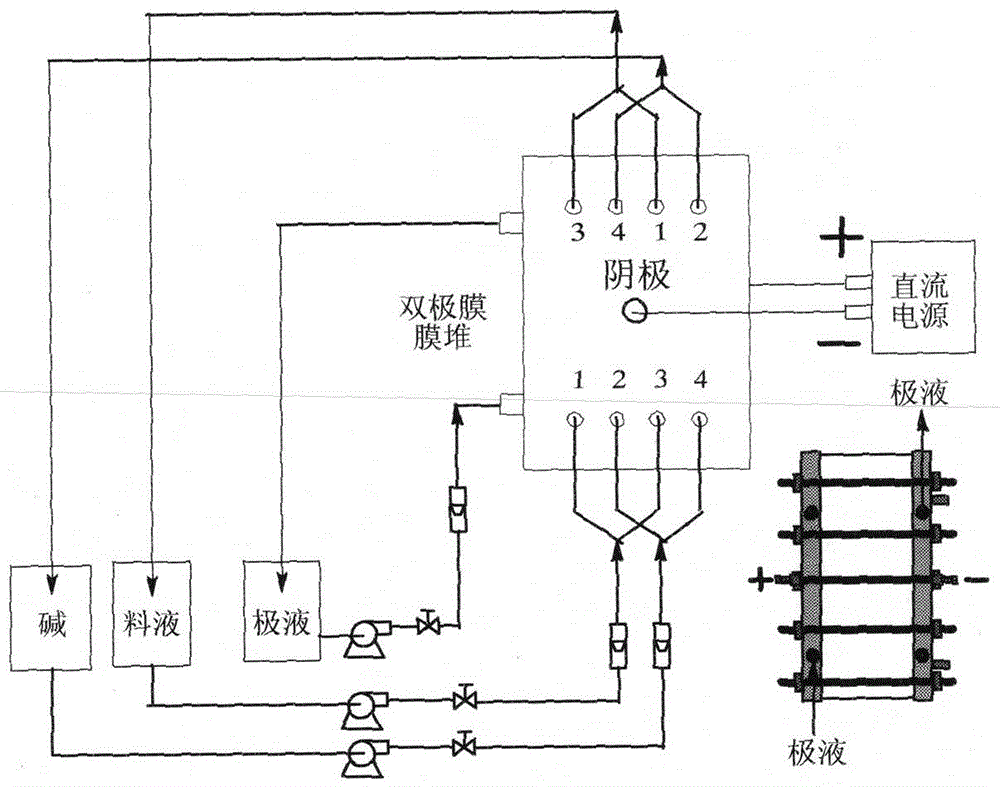

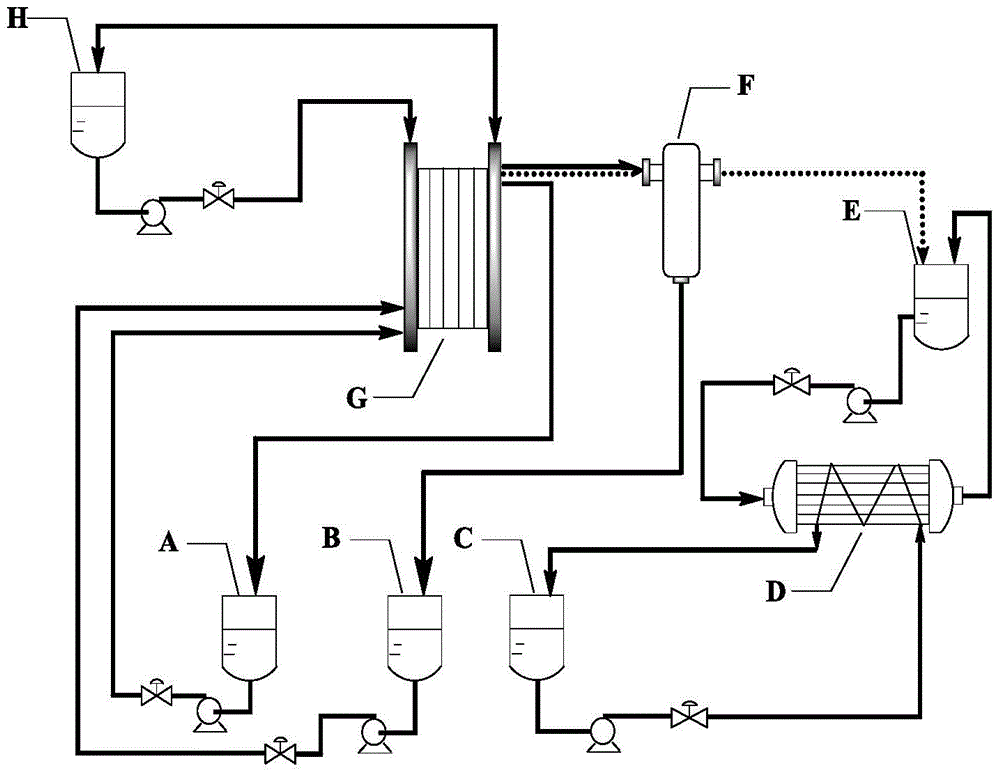

Method for preparing methionine and sodium hydroxide through bipolar membrane electrodialysis

InactiveCN103933861ARealize cleaner productionSignificant industrial application valueOrganic compound preparationAlkali metal hydroxidesMethionine recyclingHydrolysate

The invention discloses a method for preparing methionine and sodium hydroxide through applying a bipolar membrane electrodialysis technology. The method comprises the specific process: diluting a methylthioethyl hydantoin (hydantoin) hydrolysate to one-third to one-fifth of the original concentration, and filtering with a microporous filter; then pumping the hydrolysate into one of a salt chamber or a salt / acid chamber of a bipolar membrane electrodialysis device, and injecting a certain concentration of an electrolyte solution into other compartments; connecting a cathode and an anode of the bipolar membrane electrodialysis device respectively with a negative electrode and a positive electrode of a direct-current power source, starting the bipolar membrane electrodialysis device, controlling the current density of a direct-current electric field to be 50-150 mA / cm<2> and the temperature at 20-40 DEG C, and thus obtaining methionine with higher purity in an acid chamber, wherein the methionine recycling rate reaches more than 95% and the current efficiency reaches about 70%; and at the same time, collecting obtained carbon dioxide, and thus obtaining sodium hydroxide with the concentration of 4-6% in an alkali chamber. The method has the advantages of high yield, no pollution, less use of raw materials, and good application prospects.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

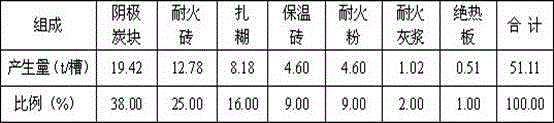

Deep comprehensive resource utilization method for electrolytic cell overhaul slag

ActiveCN102978659AHigh purityAchieve recyclingElectrolysis componentsSolid waste disposalMetallurgical slagBrick

The invention discloses a deep comprehensive resource utilization method for electrolytic cell overhaul slag. The method is characterized by comprising the following steps of: sorting electrolytic cell overhaul slag, respectively obtaining electrolyte blocks, cathode bars, waste cathode carbon blocks, waste refractory bricks, waste insulating bricks, waste heat-insulating plates, waste paste and residual mixed slag charge; respectively leaching the sorted blocks in water, crushing and leaching after the blocks are selected, recovering the selected blocks, grinding and floating the residual powder, selecting carbon powder and refractory material powder, and manufacturing a metallurgical slag former from the residual powder. According to the method, fluoride salts which are difficultly removed in the electrolytic cell overhaul slag are separated, the recycling value of the electrolytic cell overhaul slag is improved, waste materials are changed into valuable materials, economic and pollution-free recovery of the electrolytic cell overhaul slag is realized, and the pollution hidden danger is fundamentally eliminated.

Owner:周俊和 +1

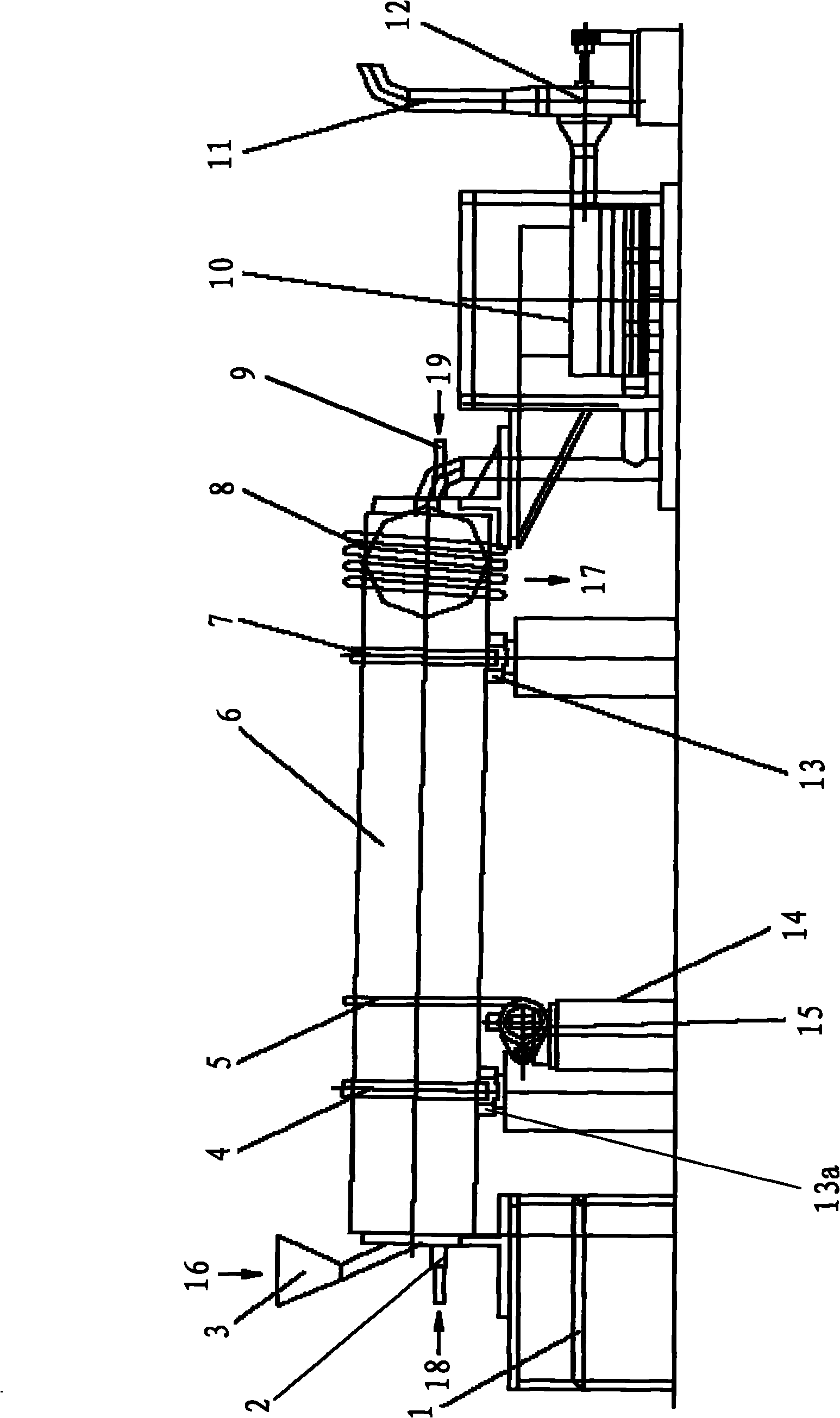

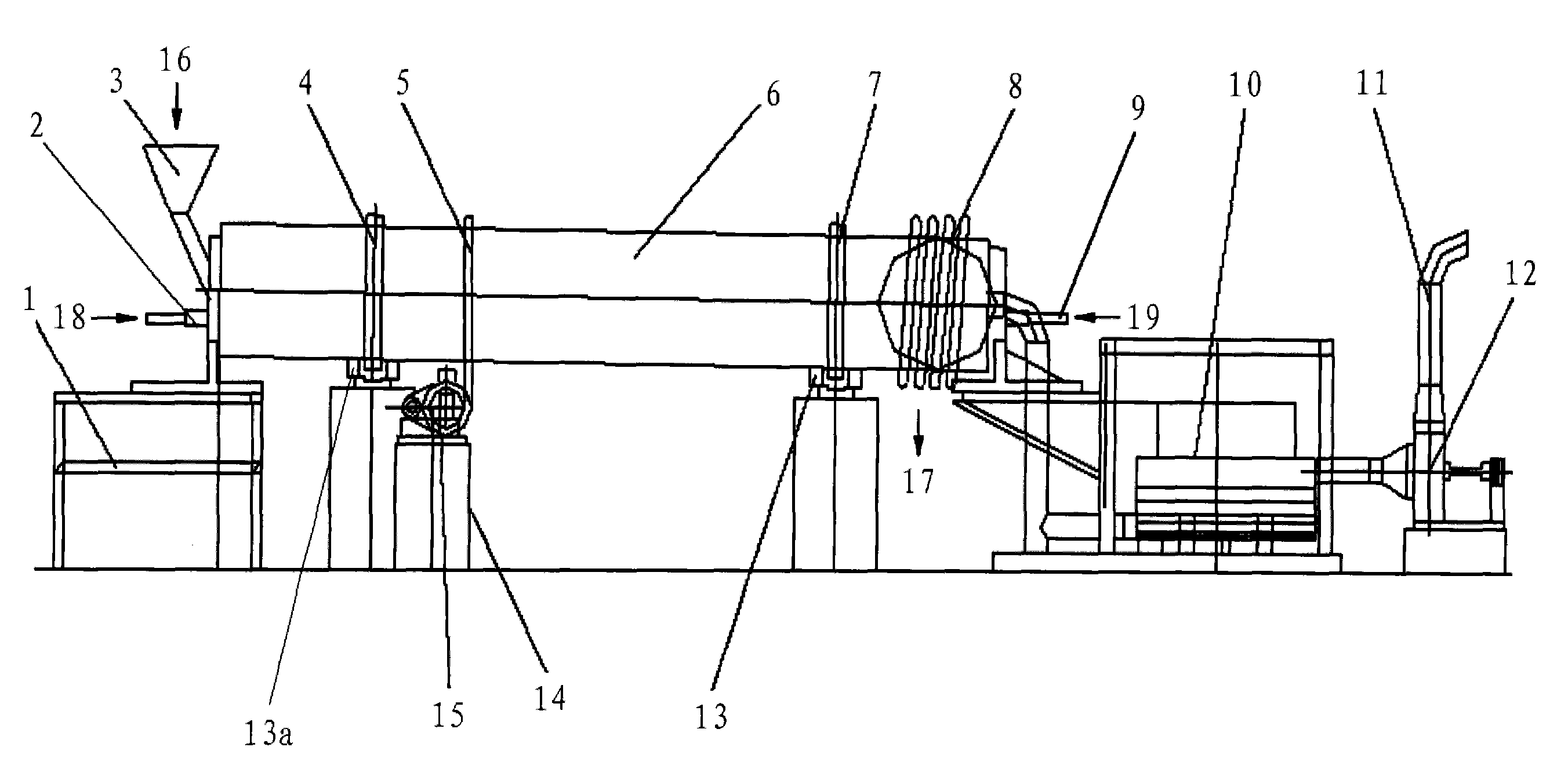

Carbonization and activation integrated activated carbon production method and equipment

The invention relates to a carbonization and activation integrated activated carbon production method and carbonization and activation integrated activated carbon production equipment. The production method comprises the following steps of: preparing a raw material, namely dissociating a coal material at a high speed, pre-oxidizing in an oxygen-rich environment to ensure that the coal material has primary adsorption property, adding solid coal pitch in the coal mixing process, pressing a dissociated and pre-oxidized semi-finished product for forming, and crushing and granulating to form a carbonization and activation raw material; performing carbonization and activation integrated production, namely feeding the raw material into a carbonization and activation integrated furnace, preheating the raw material by using high-temperature flue gas returned to a furnace body, transferring the preheated raw material to a furnace tail from a furnace head with the rotation of the furnace body, and activating the raw material by using mixed gas sprayed from throat tubes of the furnace head and the furnace tail; and cooling the activated raw material by using a cooling system and discharging out of the furnace body. The activation rate is high, yield is high, cost is low, and autothermal equilibrium and product upgrading are realized; meanwhile, environmental pollution is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

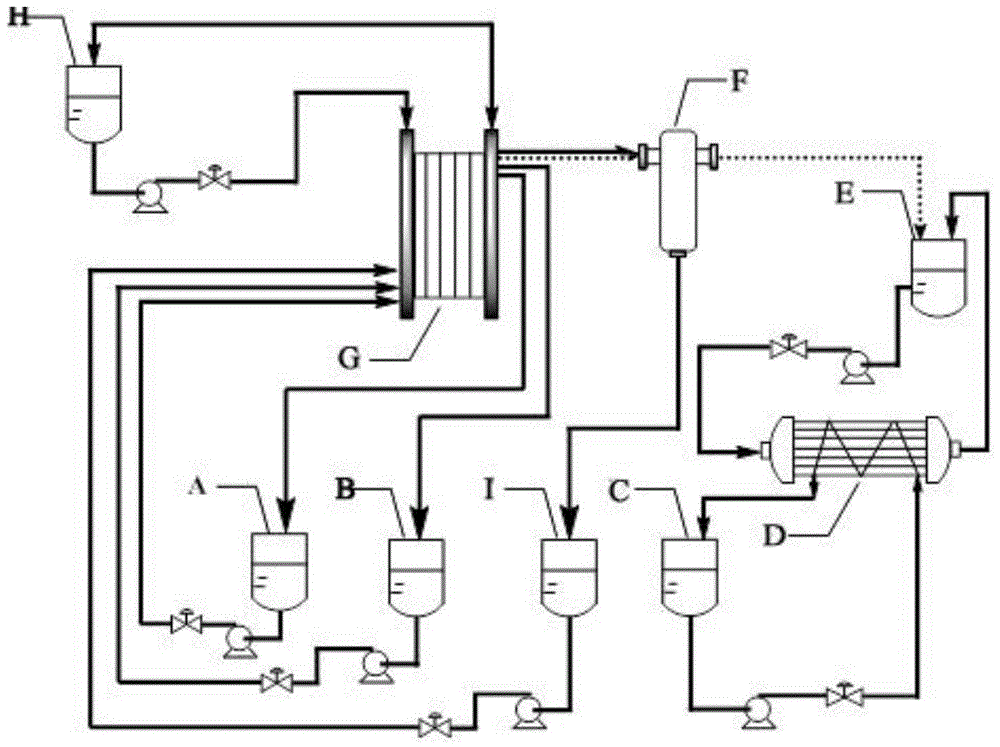

Method and device for preparing methionine and recovering by-product-carbon dioxide

ActiveCN105671587ARealize cleaner productionReduce energy consumptionElectrolysis componentsElectrolytic organic productionHydantoin derivativesCo2 absorption

The invention discloses a method for preparing methionine and recovering a by-product-carbon dioxide. The method comprises the steps that a methionine salt and carbonate mixed solution obtained by hydrolyzing methylmercapto-ethyl hydantoin with alkali is filtered through a microporous membrane, and then filtrate is delivered to a bipolar membrane electrodialysis system to be subjected to electrodialysis treatment, so that acid liquor A and alkali liquor A are obtained; the alkali liquor A is treated continuously and cyclically, and the acid liquor A is subjected to gas-liquid separation, so that gaseous carbon dioxide and acid liquor B are obtained; the acid liquor B is delivered back into the bipolar membrane electrodialysis system to be subjected to cyclic treatment till the pH value of the acid liquor B is 3.8-4.5, the reaction is completed, a methionine solution is prepared, and the methionine is prepared through concentration and crystallization of the methionine solution; the gaseous carbon dioxide is introduced into an absorption cell, and carbon dioxide on the upper portion of the absorption cell absorbs mother liquor, is subjected to membrane distillation and concentration and then is circulated back to the absorption cell; carbonate crystals are grown at the bottom of the absorption cell and guided out from the bottom of the absorption cell; and carbonate is recovered through solid-liquid separation. According to the method for preparing the methionine and recovering the by-product-carbon dioxide, the gaseous carbon dioxide is recycled, so that carbon emission is reduced, and energy resources are saved through the membrane distillation technique.

Owner:浙江佰辰低碳科技有限公司

Clean reclaiming process for byproduct chloromethane of glyphosate acid

InactiveCN1629112ARealize cleaner productionEasy to operateGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationPhosphorous acidForeign matter

The discharged exhaust gas during the glyphosate acid production process through phosphorous acid alkyl acid includes 20-90% of methyl chloride, methanol, formaldehyde dimethyl acetal, water, hydrogen chloride and other foreign matter, by solvent absorption of foreign matter, condensation impurity or charging part of the foreign matter such as methanol, formaldehyde dimethyl acetal into hydrochloride-containing liquid and converting it into methyl chloride, high purity of methyl chloride can be obtained. The process not only solves the problem of environmental pollution in the glyphosate acid production, the production cost can also be lowered substantially.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

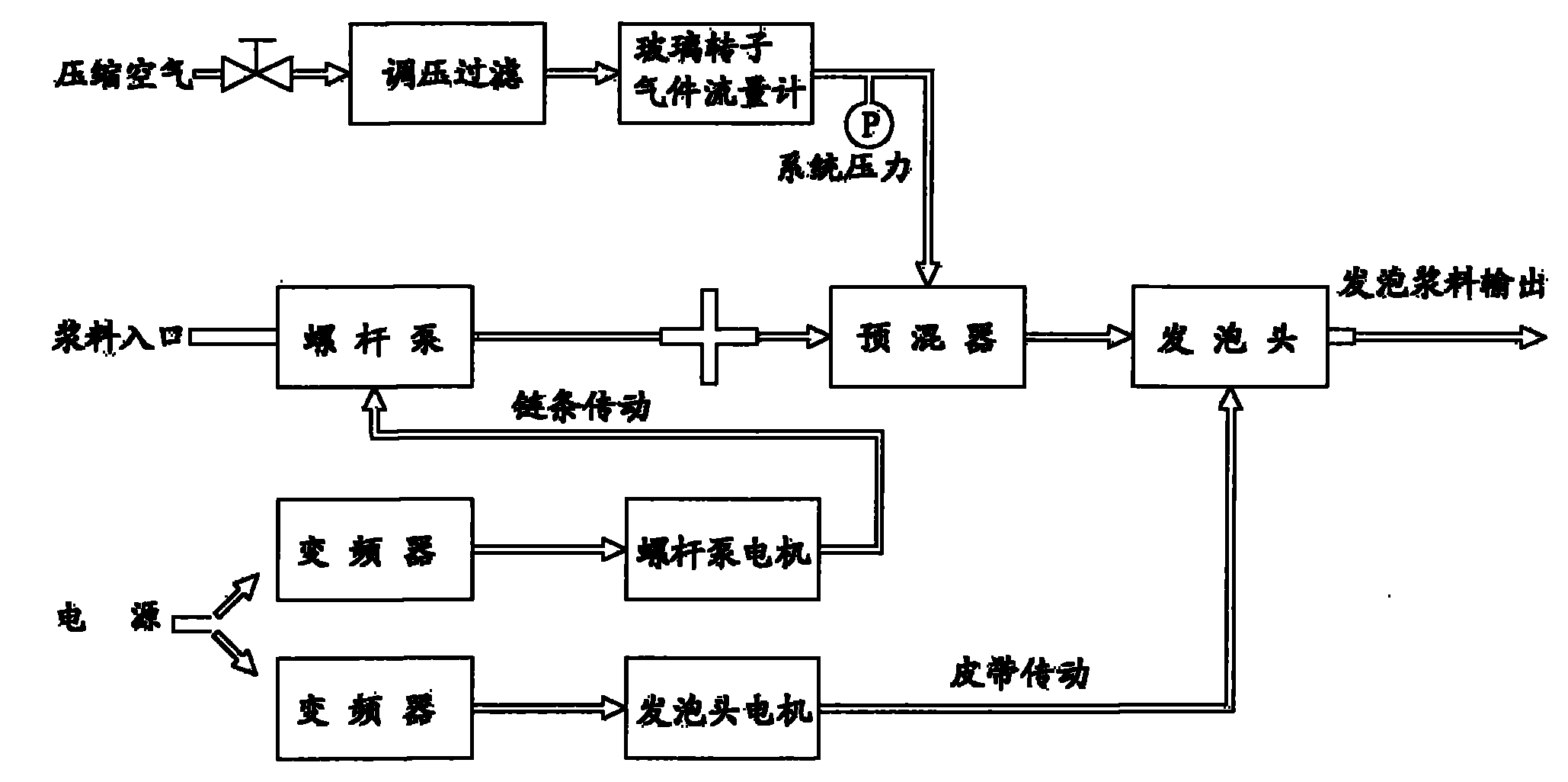

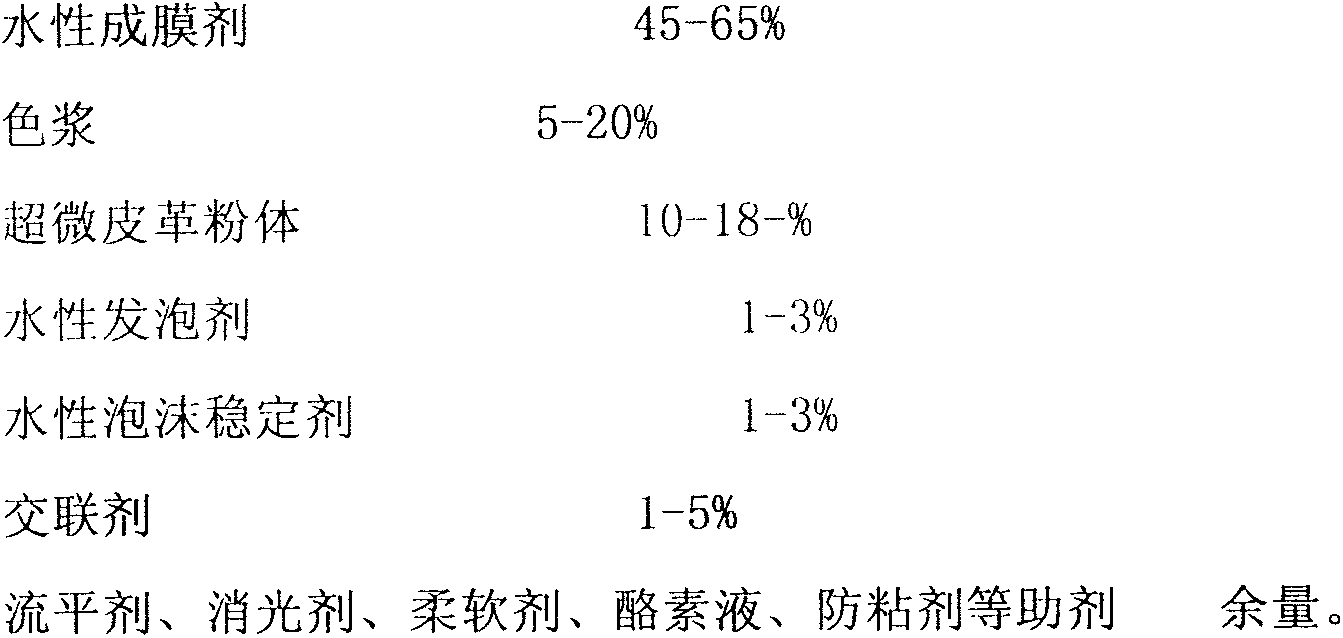

Clean production process for polyurethane synthetic leather base with ultramicro leather powder as filling material

InactiveCN103290701ARealize cleaner productionDevelop circular economySynthetic resin layered productsTextiles and paperWater basedFilling materials

The invention discloses a clean production process for a polyurethane synthetic leather base with ultramicro leather powder as a filling material. The process comprises the following steps: introducing air and water-based finishing slurry blended with ultramicro leather powder into a mixer according to a certain proportion and allowing a high-quality micro-foaming finishing agent to be formed under high-speed dispersion action of a stirring head; and coating the micro-foaming finishing agent and then drying and curing the micro-foaming finishing agent so as to prepare the synthetic leather base. The method provided by the invention has the advantages of simple preparation, easy control and the like, eliminates pollution of dimethyl formamide (DMF) produced in a wet production method for synthetic leather and reduces pollution of the industry of synthetic leather; and introduction of the natural ultramicro leather powder enables moisture and air permeability of polyurethane synthetic leather to be improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

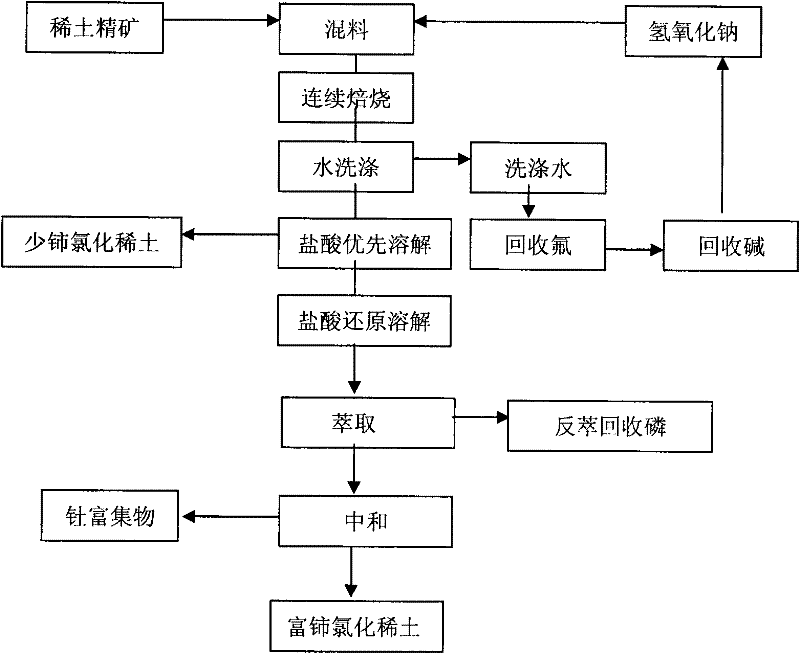

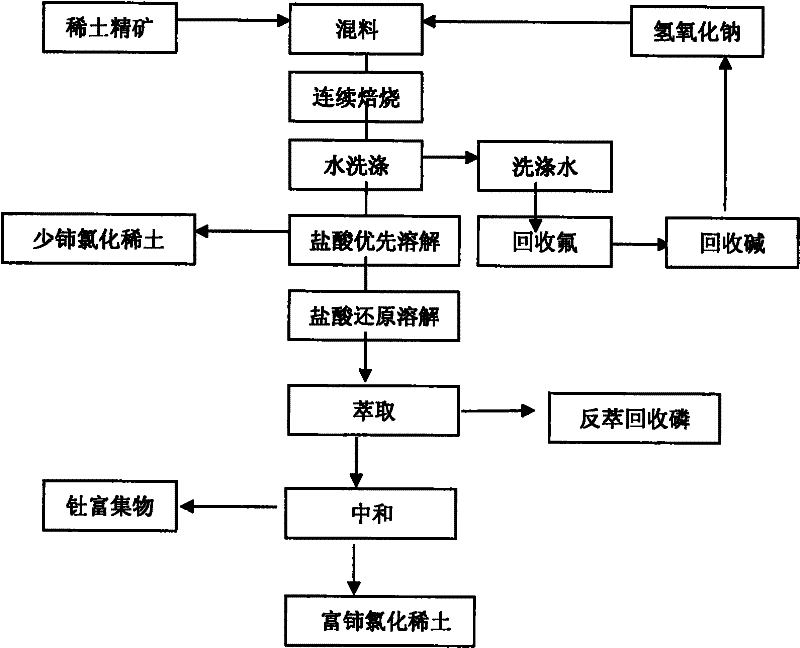

Process for comprehensively recovering liquid alkali roasting resource of mixed rare earth concentrate

InactiveCN102212674ASolve environmental pollutionRealize clean productionProcess efficiency improvementDecompositionCerium

The invention relates to a decomposition process for comprehensively recovering a liquid alkali roasting resource of mixed rare earth concentrate, comprising the following steps of: mixing and roasting the mixed rare earth concentrate and sodium hydroxide according to a weight ratio, wherein the roasting temperature is 200-600 DEG C, and the roasting time is 0.5-4 h; watering the roasted mineral water to be neutral; preferentially dissolving an alkali cake by using hydrochloric acid to obtain a less cerium chlorinated rare earth solution; reducing and dissolving residues by using hydrochloric acid after the hydrochloric acid is preferentially dissolved to obtain a rich cerium chlorinated rare earth solution; after extracting and recovering phosphorus of the rich cerium chlorinated rare earth solution, neutralizing the rich cerium chlorinated rare earth solution to obtain thorium enrichment content; recovering fluorine and sodium hydroxide in a roasted mineral water solution; and after extracting and separating the less cerium chlorinated rare earth solution, recovering calcium chloride. The mixed rare earth concentrate is processed by using the method disclosed by the invention. The continuous production of liquid alkali roasting mixed rare earth concentrate is realized. Tetravalent cerium and trivalent rare earth are separated preferably. Rare earth, thorium, fluorine, phosphorus, calcium and the like are comprehensively recovered. Waste gas and radioactive waste residues are avoided. Cleaner production and resource comprehensive recovery are realized.

Owner:BAOTOU RES INST OF RARE EARTHS

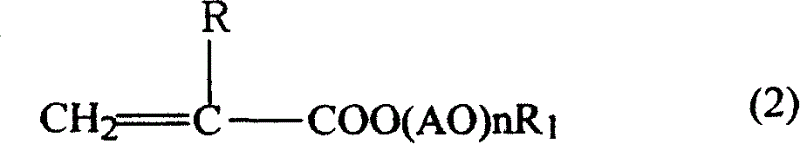

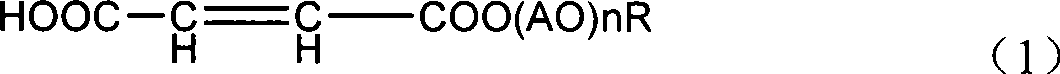

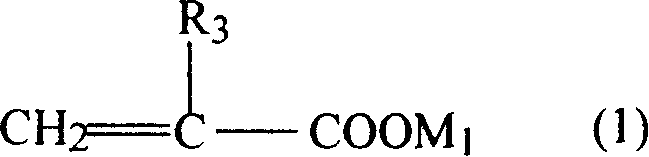

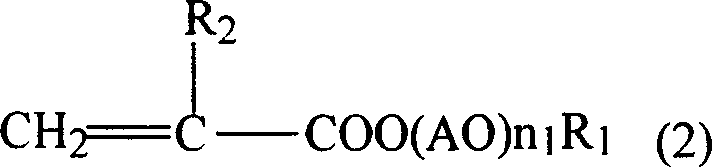

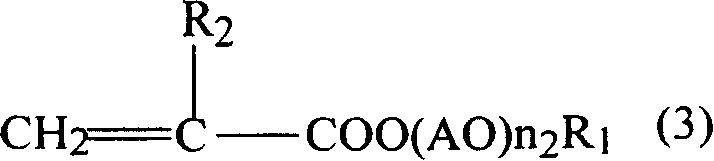

Design and preparation of coagulation time controllable high performance polycarboxylic acid water reducing agent

The invention relates to the design and synthesis of a poly carboxylic acid water reducing agent, the coagulating time of which can be controlled. The poly carboxylic acid water reducing agent is prepared by co-polymerize the following three monomers in water: the monomer a occupying 30 to 70 percent and indicated by a general expression 1, the monomer b occupying 10 to 50 percent and indicated by the general expression 2, and the monomer c occupying 10 to 40 percent and indicated by the general expression 3. The coagulating time is controlled by the monomer a which is made by condensing maleic anhydride and polyoxyethylene monoalkyl ether. The length of a polyoxyethylene monoalkyl ether chain controls the change of the coagulating time: the longer the chain, the shorter the coagulating time is; and the shorter the chain is, the longer the coagulating time is. The monomer a does not contain inhibitive substances in the process of synthesis, therefore, the water reducing agent is easy to be controlled in the coagulating process. The poly carboxylic acid water reducing agent is suitable for the construction of concrete under different temperature conditions: under higher temperature, the water reducing agent with longer coagulating time can be adopted, and under lower temperature, the water reducing agent with shorter coagulating time can be adopted. The poly carboxylic acid water reducing agent has good adaptability to cement and admixtures and has the advantages of low mixing quantity, good slump constant hold facility and water segregation resistance, and the like.

Owner:武汉格瑞林建材科技股份有限公司

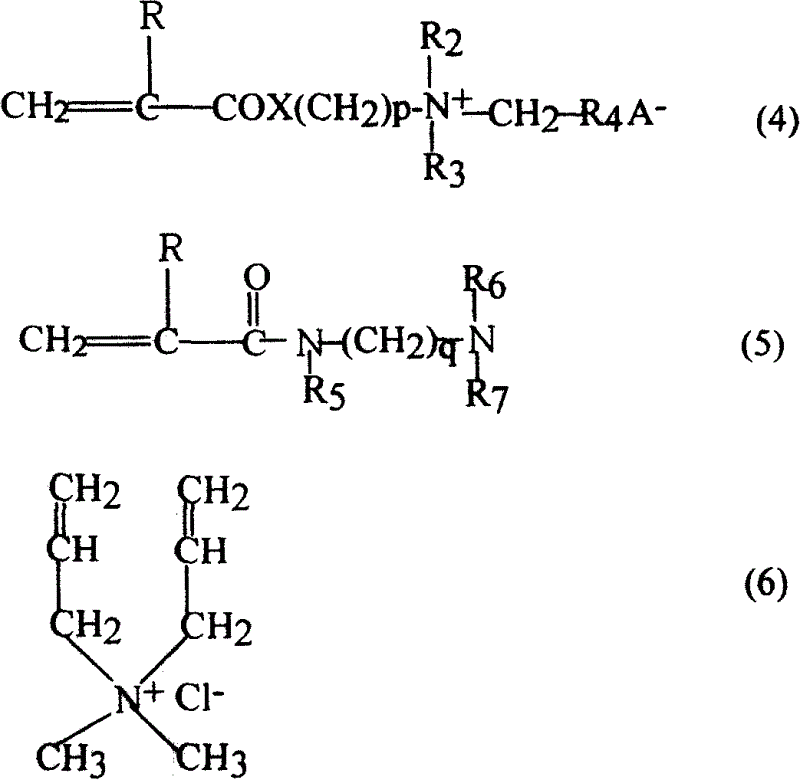

Multifunctional carboxylic-acid comb-shape graft copolymer concrete superplasticizer

The multifunctional super concrete plasticizing agent of carboxylic acid comb grafting copolymer is prepared through the water free radical copolymerization of the following monomers: monomer A with the general expression I in 10-40 wt%, monomer B with the general expression II in 30-70 wt%, monomer C with the general expression III in 10-50 wt%, monomer D with the general expression IV in 3-15 wt%, monomer F with the general expression VI in 0-15 wt%, and reactive defoaming agent E in 0.2-2 wt% of the sum of foregoing five kinds of monomer. The present invention can reduce the shrinkage of concrete, and has good adaptability on cement and admixture material, good dispersivity and slump maintaining performance, high weeping resistance and resolution resistance, small pumping drag, product yield near 100 % and no waste produced in the production process.

Owner:JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com