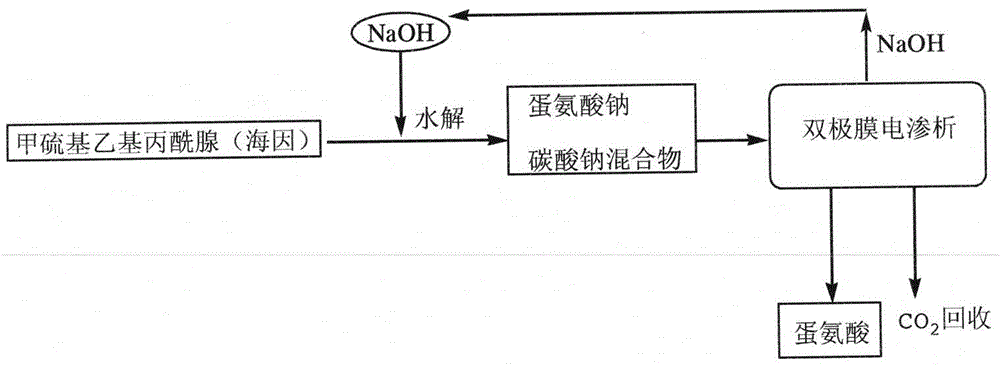

Method for preparing methionine and sodium hydroxide through bipolar membrane electrodialysis

A bipolar membrane electrodialysis and sodium hydroxide technology, applied in the chemical field of bipolar membrane electrodialysis technology, can solve the problems of low conversion rate, high energy consumption, low alkali concentration, etc., and achieve significant industrial application value and environmental benefits. , the effect of enhancing the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

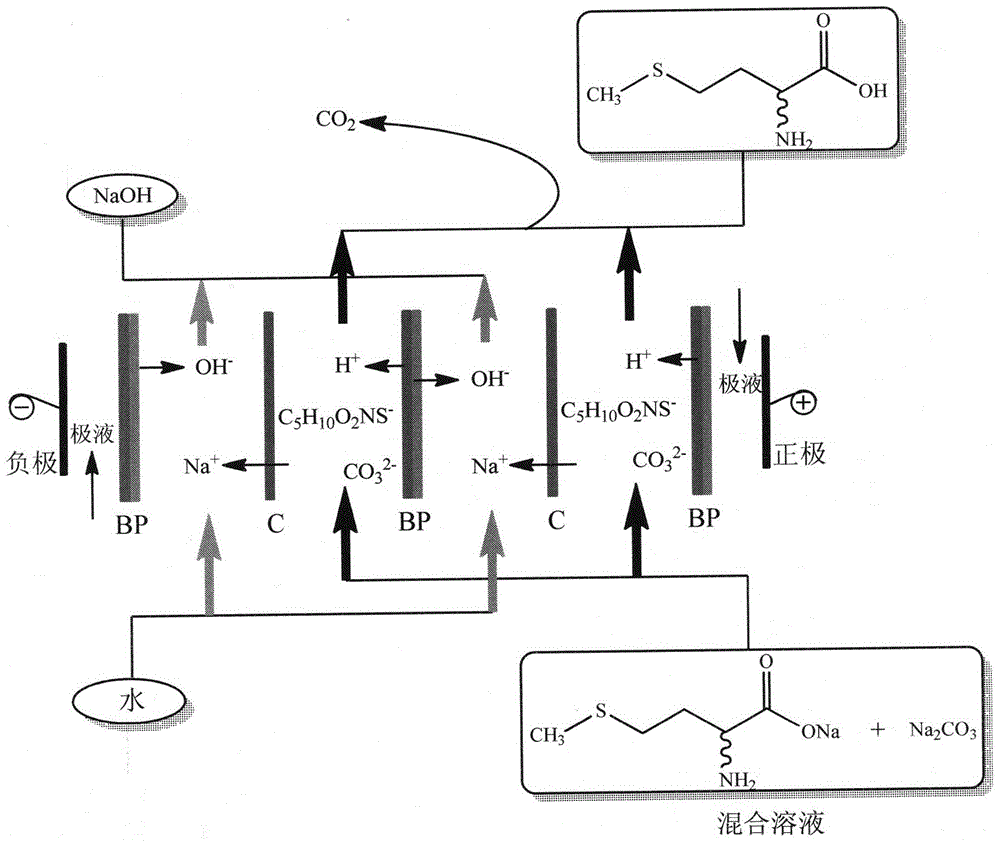

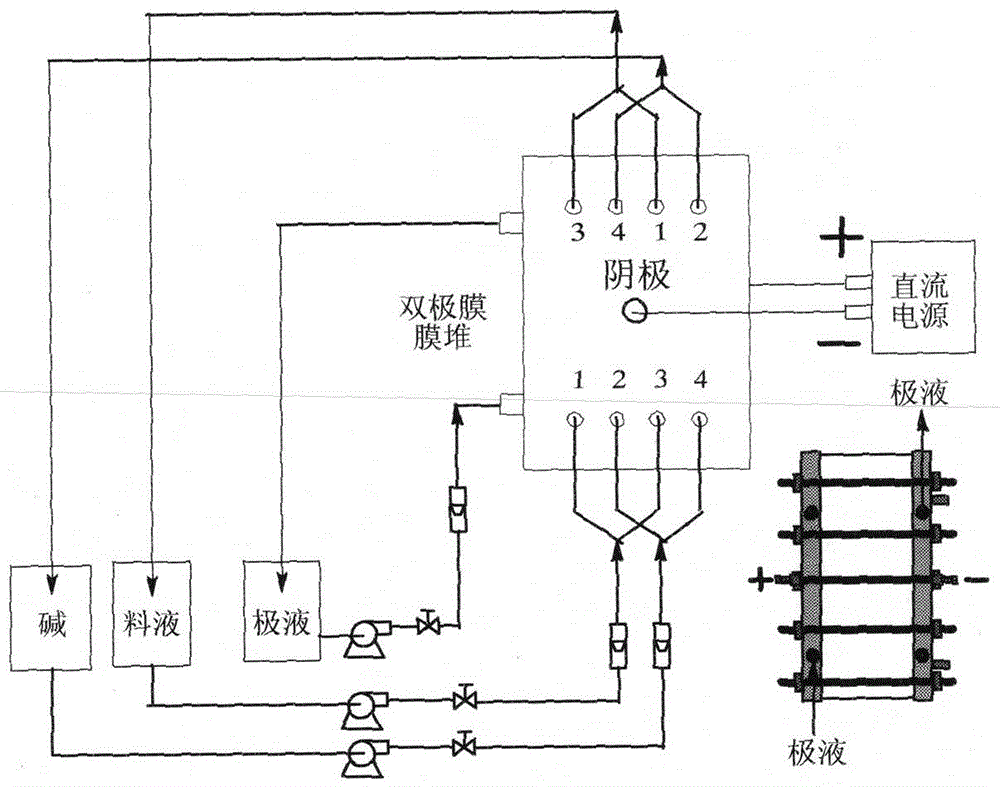

[0032] Pump 0.5 liters of 4.25% sodium methionine and 2.5% sodium carbonate feed solution into the salt chambers of 5 groups of 9*21 three-compartment bipolar membrane electrodialysis membrane stacks, and circulate at a flow rate of 25L / h. 0.5 liters of purified water are pumped into the acid chamber and alkali chamber of the membrane stack respectively, and circulated at the same flow rate of 25L / h. Then pump 0.5L sodium sulfate with a concentration of 3% into the electrode eluent chamber, and circulate at a flow rate of 25L / h. Turn on the DC power supply, keep the temperature of the acid chamber at a constant temperature of 35 degrees, and control the current density at 150A / m 2 , reacted for 3 hours, the acid chamber obtained about 2.4% methionine, the conversion rate of sodium methionine was about 85%, and the recovery rate of methionine was 80%. The alkali room obtains about 1.8% sodium hydroxide solution, and the energy consumption is 7kWh / kg methionine.

Embodiment 3

[0034] Pump 20 liters of feed solution with a concentration of 4.25% sodium methionine and 2.5% sodium carbonate into the acid / salt chambers of 20 groups of 20*40 two-compartment bipolar membrane electrodialysis membrane stacks, and circulate at a flow rate of 300L / h , pump 20 liters of purified water into the alkali chamber of the membrane stack, and also circulate at a flow rate of 300L / h. Then pump 5L of sodium sulfate with a concentration of 3% into the electrode eluent chamber, and circulate at a flow rate of 200L / h. Turn on the DC power supply, keep the temperature of the material liquid chamber at a constant temperature of 35 degrees, and control the current density at 500A / m 2 , reacted for 3 hours, the conversion rate of sodium carbonate reached 99%, the conversion rate of sodium methionine reached more than 95%, the energy consumption was 1.8kWh / kg methionine, the current efficiency was about 75%, and the recovery rate of sodium methionine reached 95%. The concentra...

Embodiment 4

[0036] Pump 1L solution concentration of 17% sodium methionine and 10% sodium carbonate into the dilute / salt chambers of 5 groups of electrodialysis membrane stacks with a size of 9*21cm, and circulate at a flow rate of 40L / h. Purified water is pumped into the concentrated chamber of the membrane stack and circulated at a flow rate of 40L / h, and then 0.5L sodium sulfate with a concentration of 3% is pumped into the electrode eluent chamber and circulated at a flow rate of 25L / h. Turn on the DC power supply, keep the temperature of the material liquid chamber at a constant temperature of 35 degrees, and control the current density at 500A / m 2 , reacted for 1.5 hours, the sodium carbonate shifted 90%, and the methionine content in the concentrated chamber was 1%. Dilute the feed solution after electrodialysis by 4 times, that is, pump 0.5 liter of feed solution with a concentration of 4.25% sodium methionine and 0.25% sodium carbonate into 5 groups of 9*21 two-compartment bipola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com