Patents

Literature

87results about How to "Develop circular economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Banana planting by-product fermented feed and processing method thereof

The invention relates to a banana planting by-product fermented feed and a processing method thereof. A tannin degradant, a fermenting agent, a moisture adsorbent, a nutritive additive and the like are added by taking banana stem leaves as main raw materials and one or more than one crop straw and pasture as auxiliary raw materials to prepare the fermented feed for feeding ruminants such as beefs, milch cows, sheep and the like through process links of equipment kneading, shaping, sealed anaerobic packaging and the like. The invention has simple process, high production rate and good technical economical efficiency, is simple and easy to apply and opens up the novel utilization way of the banana by-product; the fermented feed obviously reduces the adverse effect of tannin on the ruminants after being treated, has good feeding value, improved palatability and fragrant smell and meets the green concept; the product form is varied; and feed products have small volume and high density and can be stored and transported for long. The fermented feed has obvious social and economic benefits in the aspects of relieving the condition that the forage grass in the sheep / cattle farming in farming areas is insufficient, improving the growth effect of animals, reducing the feed cost, saving energy, improving efficiency and the like.

Owner:GUANGDONG OCEAN UNIVERSITY

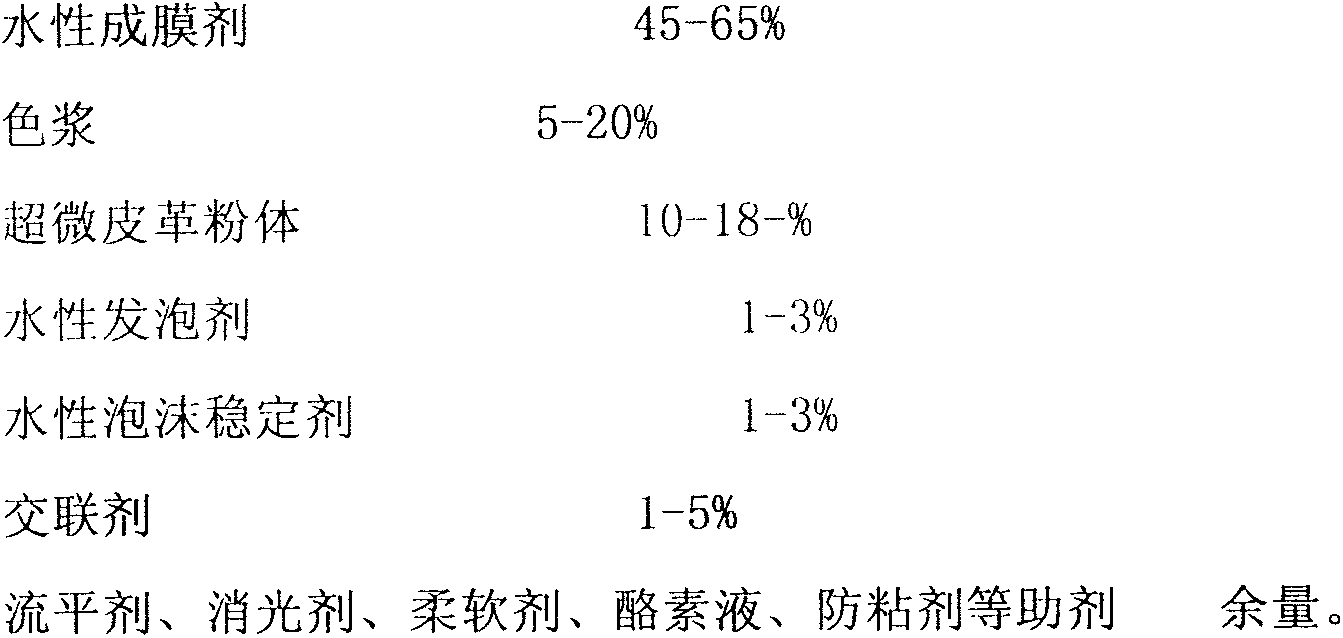

Clean production process for polyurethane synthetic leather base with ultramicro leather powder as filling material

InactiveCN103290701ARealize cleaner productionDevelop circular economySynthetic resin layered productsTextiles and paperWater basedFilling materials

The invention discloses a clean production process for a polyurethane synthetic leather base with ultramicro leather powder as a filling material. The process comprises the following steps: introducing air and water-based finishing slurry blended with ultramicro leather powder into a mixer according to a certain proportion and allowing a high-quality micro-foaming finishing agent to be formed under high-speed dispersion action of a stirring head; and coating the micro-foaming finishing agent and then drying and curing the micro-foaming finishing agent so as to prepare the synthetic leather base. The method provided by the invention has the advantages of simple preparation, easy control and the like, eliminates pollution of dimethyl formamide (DMF) produced in a wet production method for synthetic leather and reduces pollution of the industry of synthetic leather; and introduction of the natural ultramicro leather powder enables moisture and air permeability of polyurethane synthetic leather to be improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

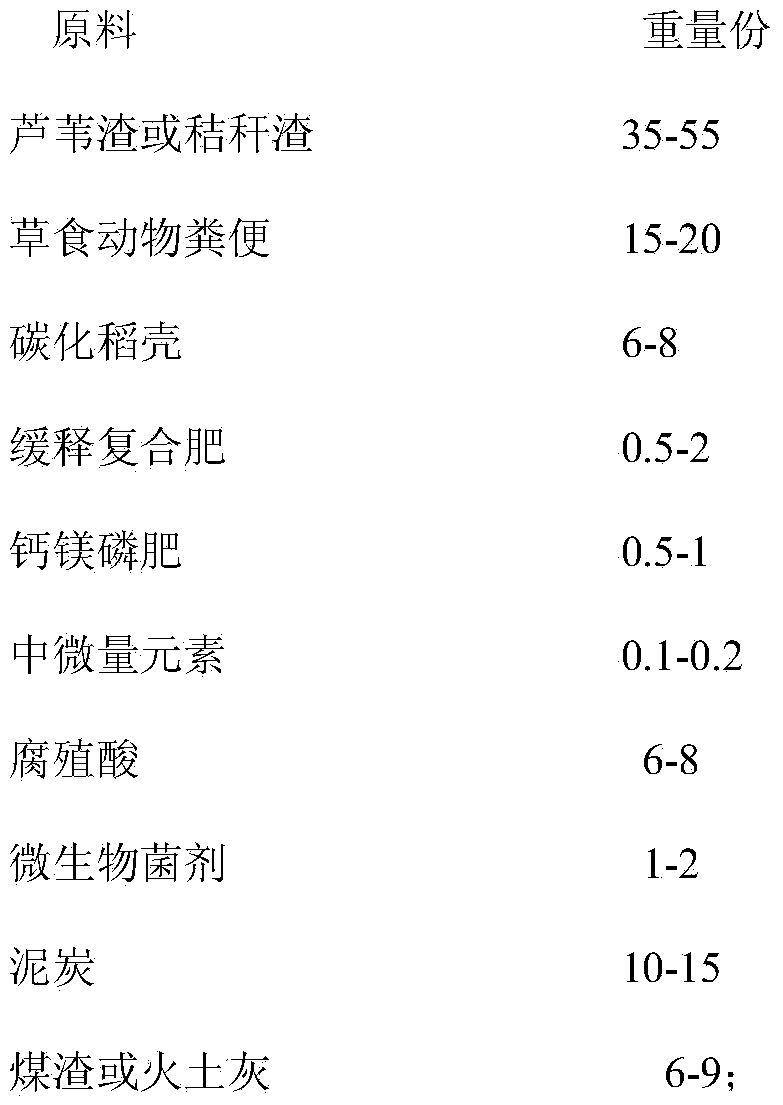

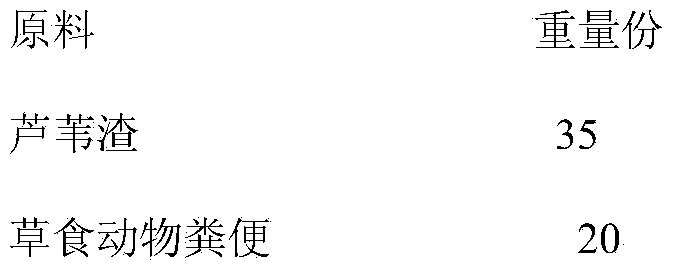

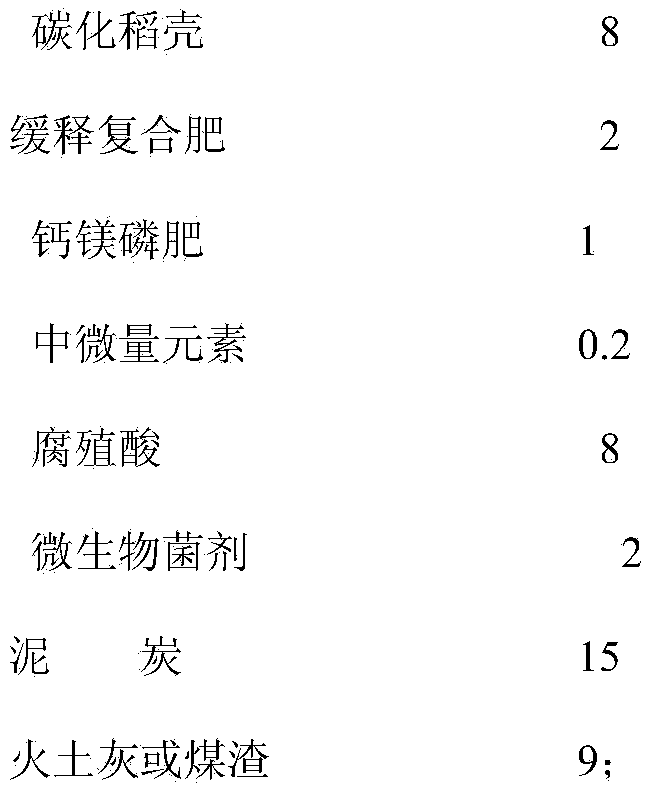

Vegetable and fruit biological activity seedling culture matrix as well as preparation method and application thereof

ActiveCN103626586ASufficient quantityThe source is stable and controllableFertilizer mixturesRoot systemDisease

The invention discloses a vegetable and fruit biological activity seedling culture matrix as well as a preparation method and application of the vegetable and fruit biological activity seedling culture matrix. The vegetable and fruit biological activity seedling culture matrix is prepared by adding auxiliary ingredients such as excrements of plant-eating animals, soil ash or coal slag, peat, a slow-release fertilizer, a calcium-magnesium phosphate fertilizer, medium trace elements and a microbial agent into papermaking wastewater serving as a main ingredient. The matrix is soft, loose, ventilating, water-saving and drought-resisting. The matrix for culturing vegetable and fruit seedlings can achieve the effects of high seedling emerge speed, short seedling age, seedling strengthening, quality improvement, root activity enhancement, disease resistance and improvement on seedling emerge rate and seedling rate; furthermore, the vegetable and fruit biological activity seedling culture matrix is convenient to transplant; the slow seedling period is short; stable yield and high yield of vegetables and fruits are guaranteed.

Owner:长沙浩博生物技术有限公司

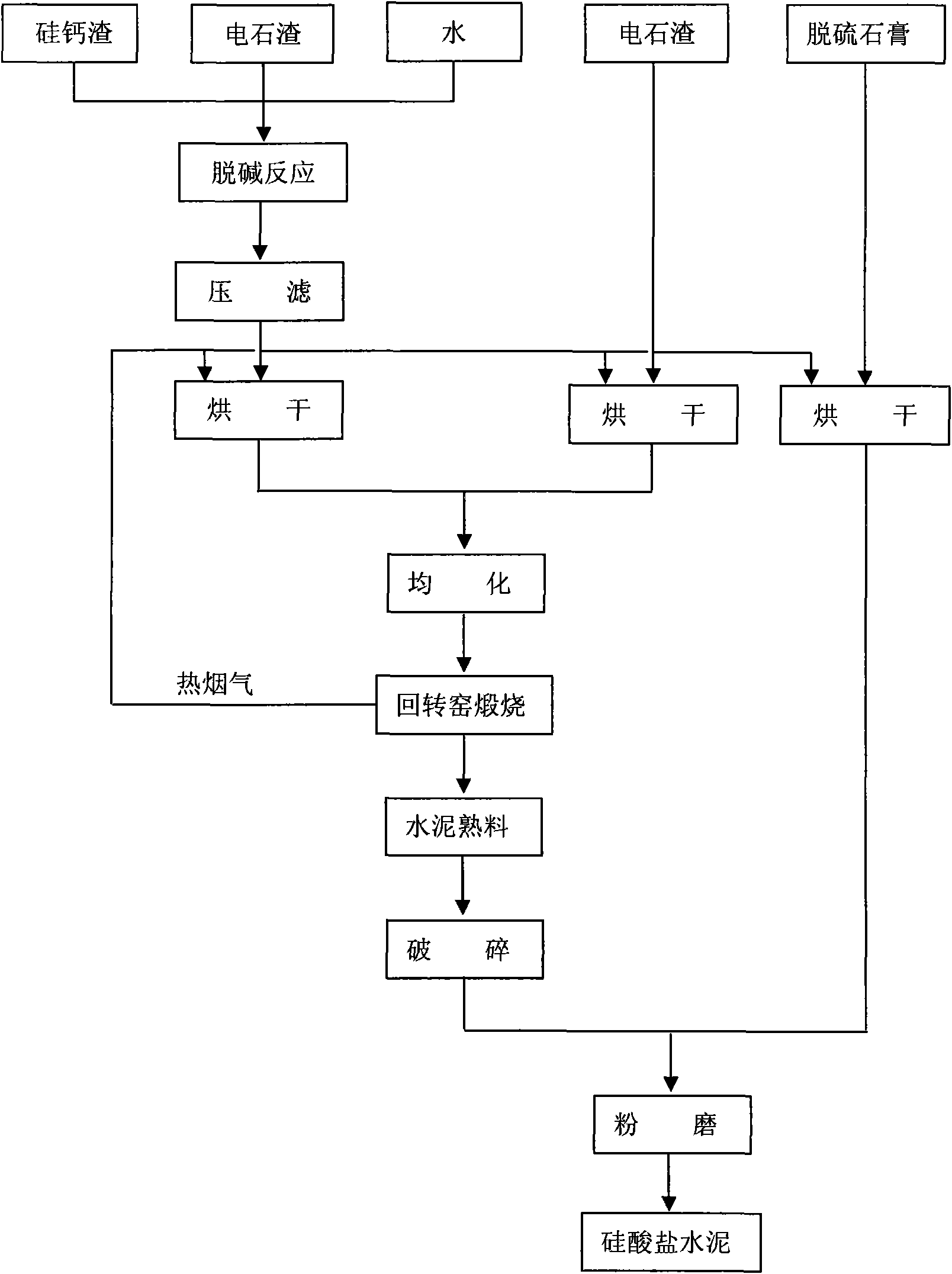

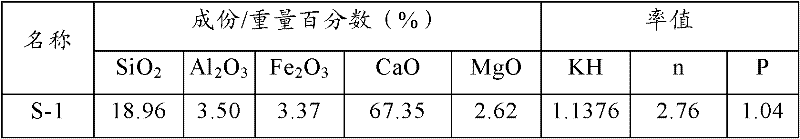

Method for producing silicate cement by using silico-calcium dregs and carbide dregs

InactiveCN101591150AReduce contentMeet the requirements of alkali contentCement productionCalcinationMaterials science

The invention provides a method for producing silicate cement by using silico-calcium dregs and carbide dregs, relating to the technical field of building materials. The method has the following steps: 1. adding carbide dregs and water into silico-calcium dregs followed by dealkalization and carrying out pressure filtering and drying on the dealkalized silico-calcium dregs if the alkali content in the silico-calcium dregs is high, or directly drying the silico-calcium dregs if the alkali content in the silico-calcium dregs is low; and drying the carbide dregs and desulfurated plaster respectively; 2. dosing and homogenizing the dealkalized silico-calcium dregs and carbide dregs after drying; 3. sending the homogenized crude materials into a rotary kiln for high temperature calcinations and obtaining the cement clinker after cooling; and 4. smashing the cement clinker and sending the smashed cement clinker and the dried desulfurated plaster into a cement grinding mill for grinding to prepare the silicate cement. Compared with the prior art, the method of the invention is simple in process, low in investment, low in production cost, low in energy consumption, and stable in the prepared silicate cement performance.

Owner:TONGFANG ENVIRONMENT

Method for producing fiber grade polyester chip with waste pure polyester garments

InactiveCN101856874AImprove the technical content of recyclingIncrease added valueFlat articlesFiberPolyester

The invention relates to a method for producing a fiber grade polyester chip with waste pure polyester garments, which comprises the following steps: 1) removing buttons from waste pure polyester garments with the same color, removing polyester fiber, then utilizing a crusher to break the pure polyester garments into cloth pieces, and drying; 2) feeding the dried cloth pieces into a screw melt extruder continuously, and after vacuum melting, and controlling the drop range of the intrinsic viscosity of the cloth pieces between 5% and 10%; and 3) feeding the waste pure polyester melt extruded by the screw melt extruder into a reaction kettle, carrying out liquid-phase tackifying through ethylene glycol reaction, finely filtering the melt after being tackified, and finally extruding chips. The invention adopts renewable raw materials and is low in cost.

Owner:ZHEJIANG FUYUAN RENEWABLE RESOURCE

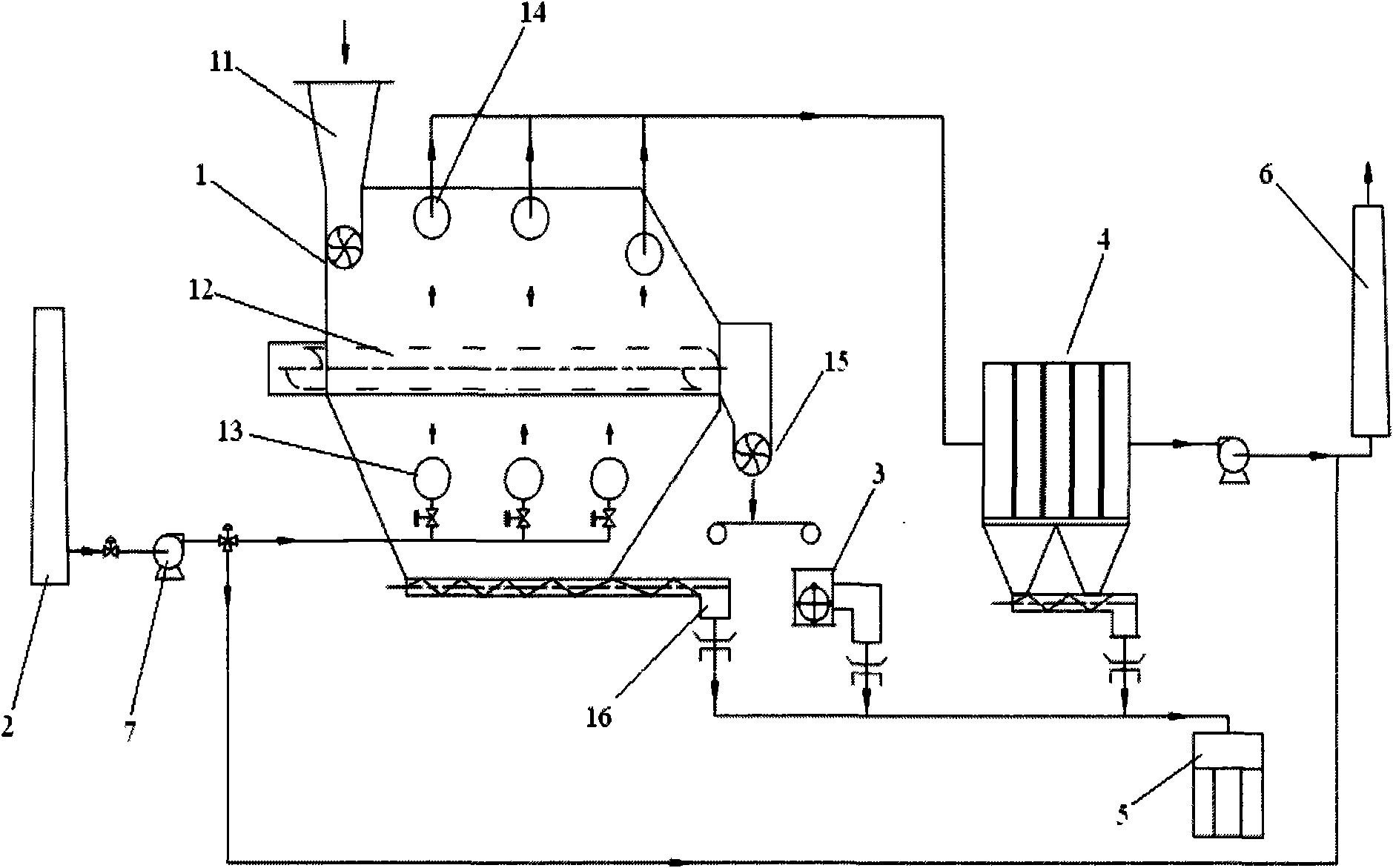

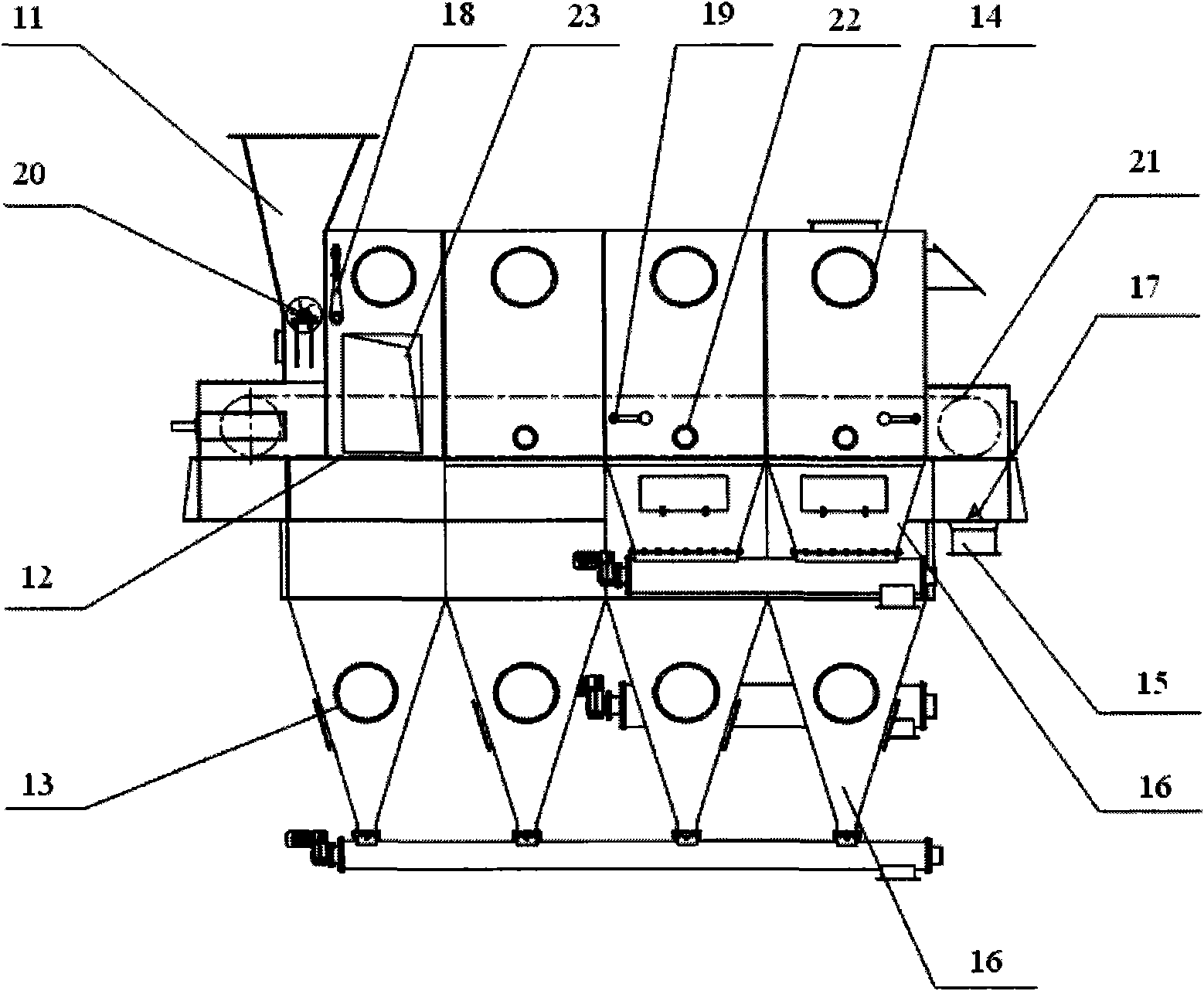

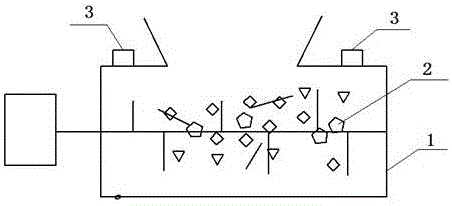

Coking coal pretreatment method and special device thereof

InactiveCN101643657AIncrease productionQuality improvementGas current separationCoke ovensLiquid wastePretreatment method

The invention discloses a coking coal pretreatment method and a special device thereof. The coking coal pretreatment method comprises the following steps: transferring blending coal for coking into a humidifying and classifying bed through a feeding device; blowing the blending coal for coking into a fluidization state with waste and heat gas; regulating and controlling moisture; fractionating the blending coal by grain sizes; reducing the moisture content of the bending coal to 6-8 percent with heat gas in the humidifying and classifying bed; dividing the coal into two grain size levels, wherein one grain size level is less than or equal to 3mm, and the other grain size level is greater than 3mm; discharging fine grain coal with a grain size which is less than or equal to 3mm from the humidifying and classifying bed, and transporting the fine grain coal to a pulverizer chamber for pulverization; and transporting the pulverized fine grain coal into a coal tower. The special device comprises the humidifying and classifying bed, a coke oven chimney, the pulverizer, the coal tower and a tail gas treating device. The coking coal pretreatment method can increase the output of a coke oven, improves the quality of the coking coal, reduces the energy consumption of the coke oven and the exhaust of waste gas and waste liquid, is applied to a coal pretreatment technology in a coking industry and can realize the purposes of energy saving, emission reduction and circular economy development.

Owner:袁长胜

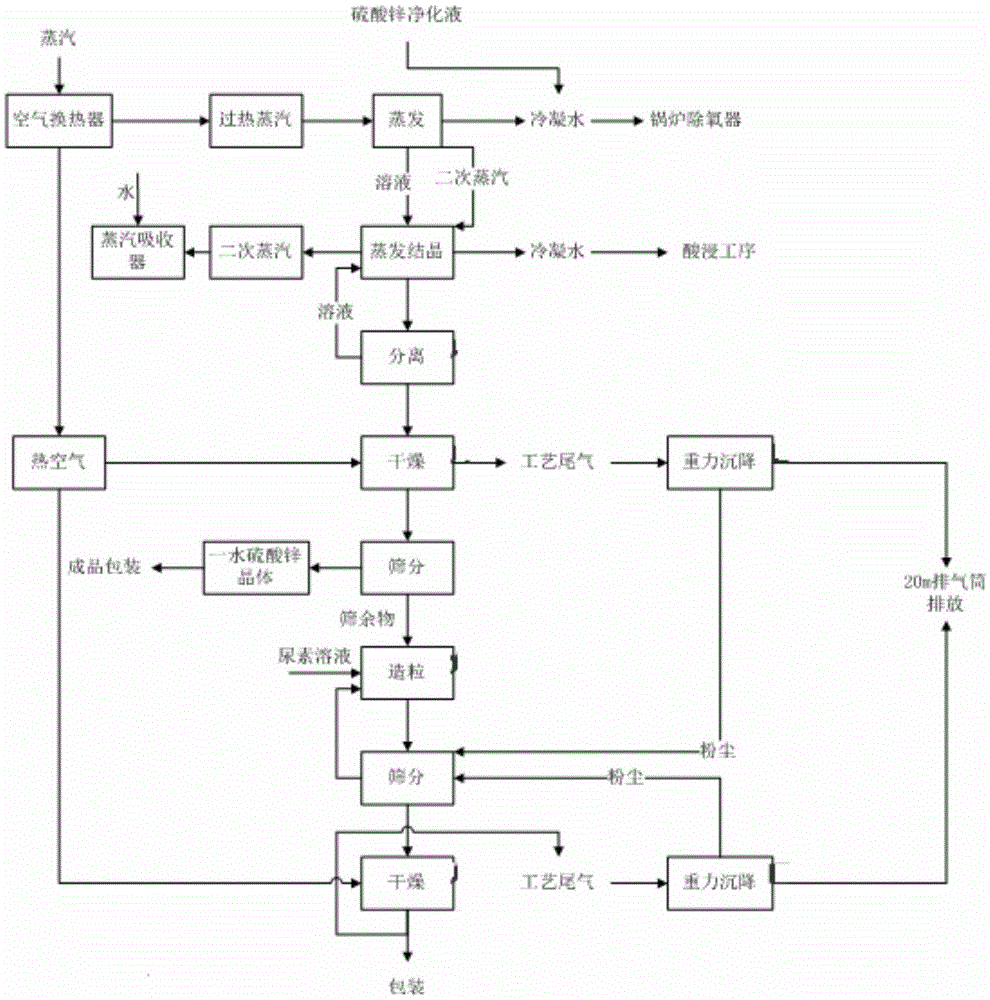

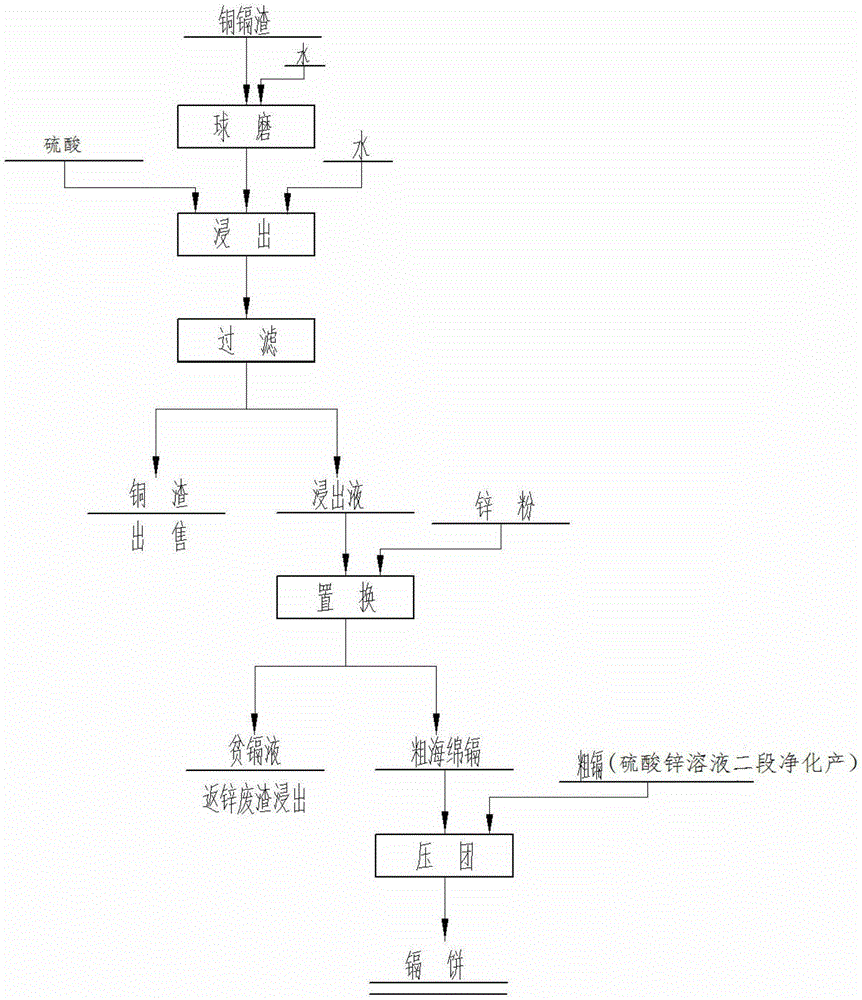

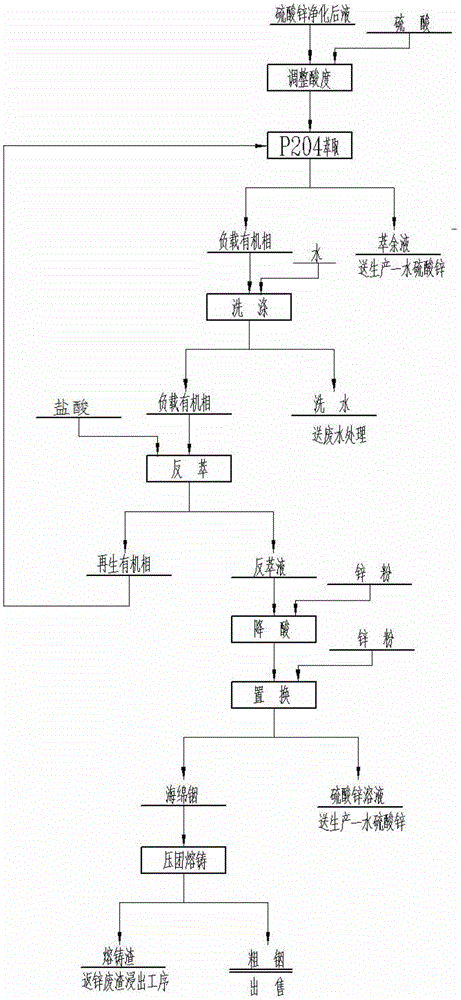

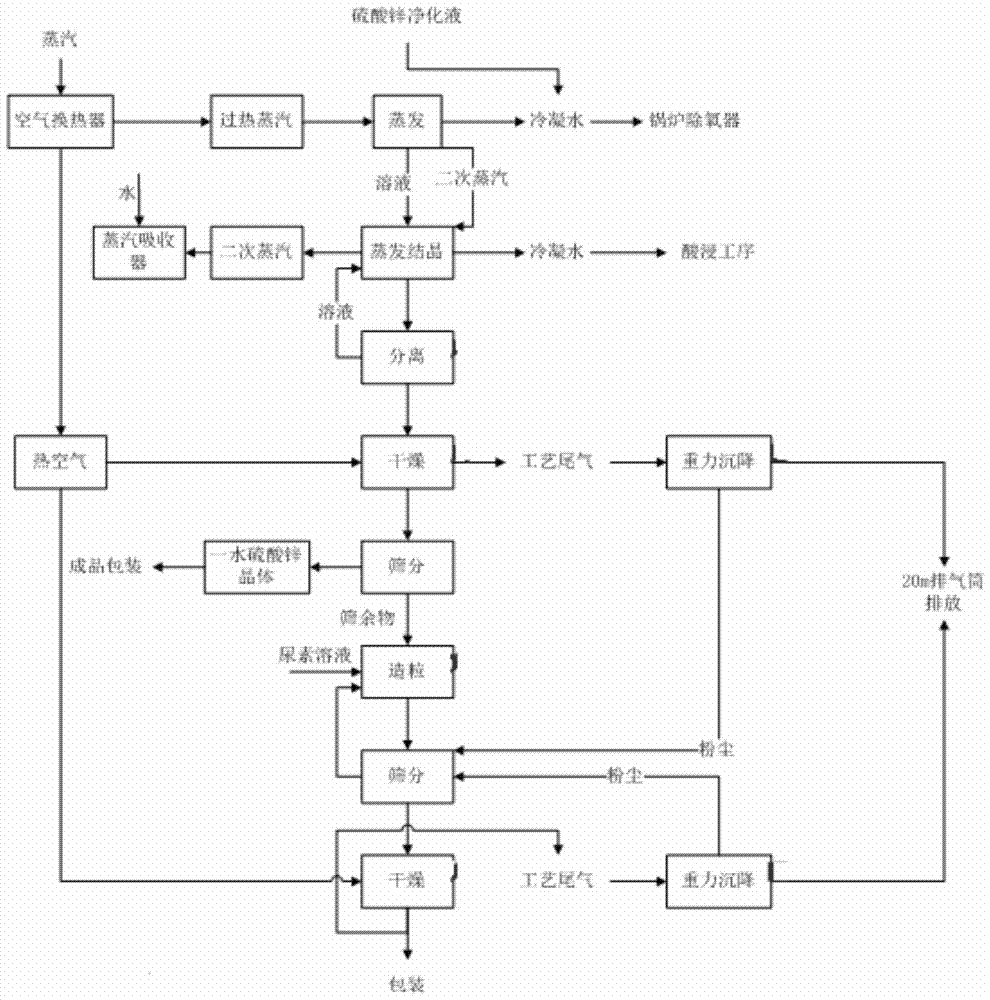

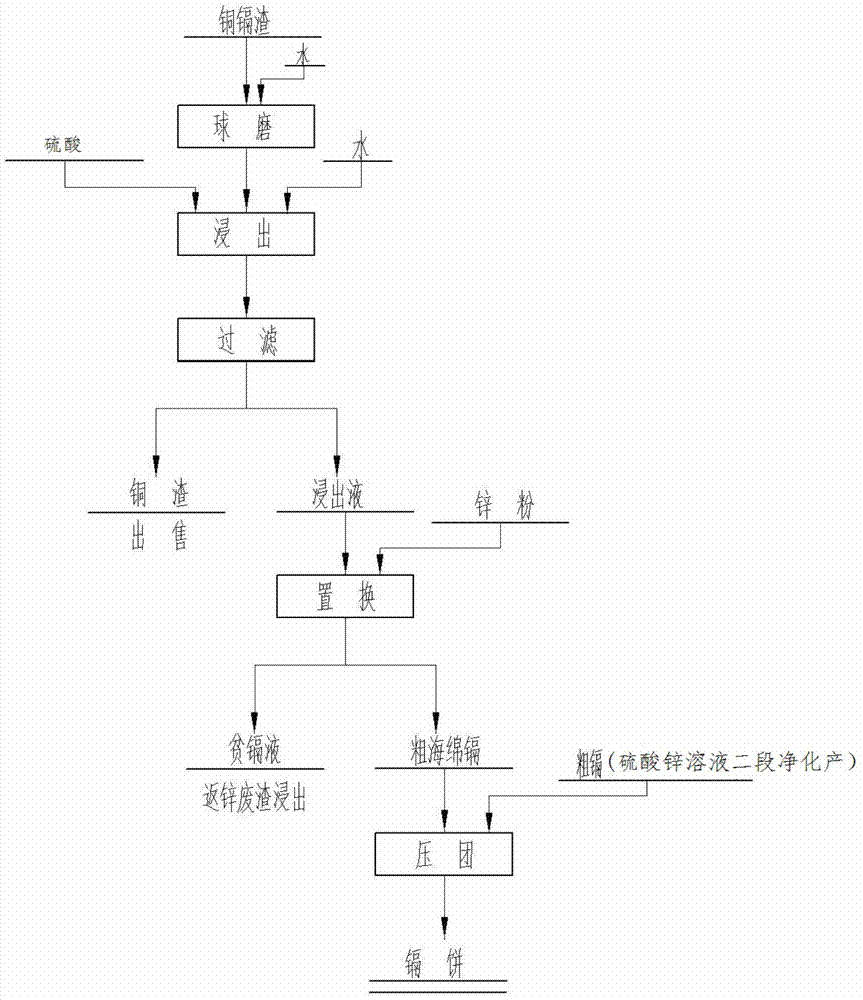

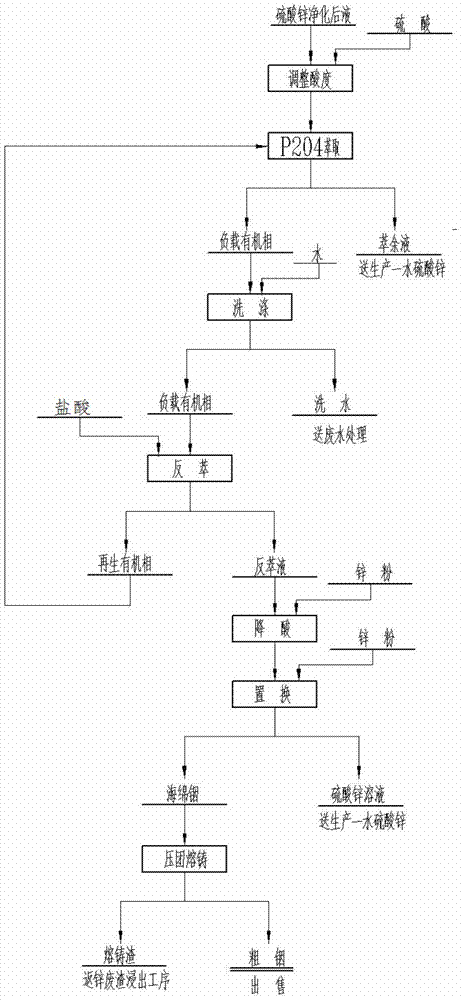

Process for producing zinc sulphate monohydrate from waste acid and waste zinc dross

ActiveCN105274342AAchieve recyclingStructural changeProcess efficiency improvementIndiumCadmium Cation

A process for producing zinc sulphate monohydrate (feed grade) from waste acid and waste zinc dross includes the steps of (a) sulfuric acid leaching, (b) deironing, (c) purification for copper and cadmium removal, (d) dechloridation, (e) defluorination, (f) indium and cadmium extraction and (g) evaporative crystallization. The feed-grade zinc sulphate monohydrate is produced from the waste acid, waste zinc dross and the like, comprehensive utilization of waste is achieved, and the production cost of raw materials is reduced, so that resources are saved. Therefore the waste of massive zinc enterprises in China is recycled to produce economic benefits, the waste is changed into the valuable, a disadvantage is turned into an advantage, secondary utilization of the waste is achieved, comprehensive recycling of waste acid and waste dross resources is achieved, solid and liquid are separated, and the concentration crystallization and drying technology, the energy saving technology and the like are improved. The work of energy conservation, water conservation, comprehensive utilization, environment protection and the like is completed, the social benefits are remarkable, and remarkable environmental protection benefits and economic benefits are achieved.

Owner:湖南鑫海环保科技有限公司

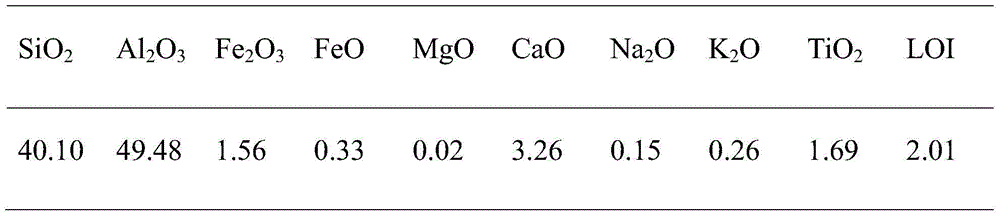

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

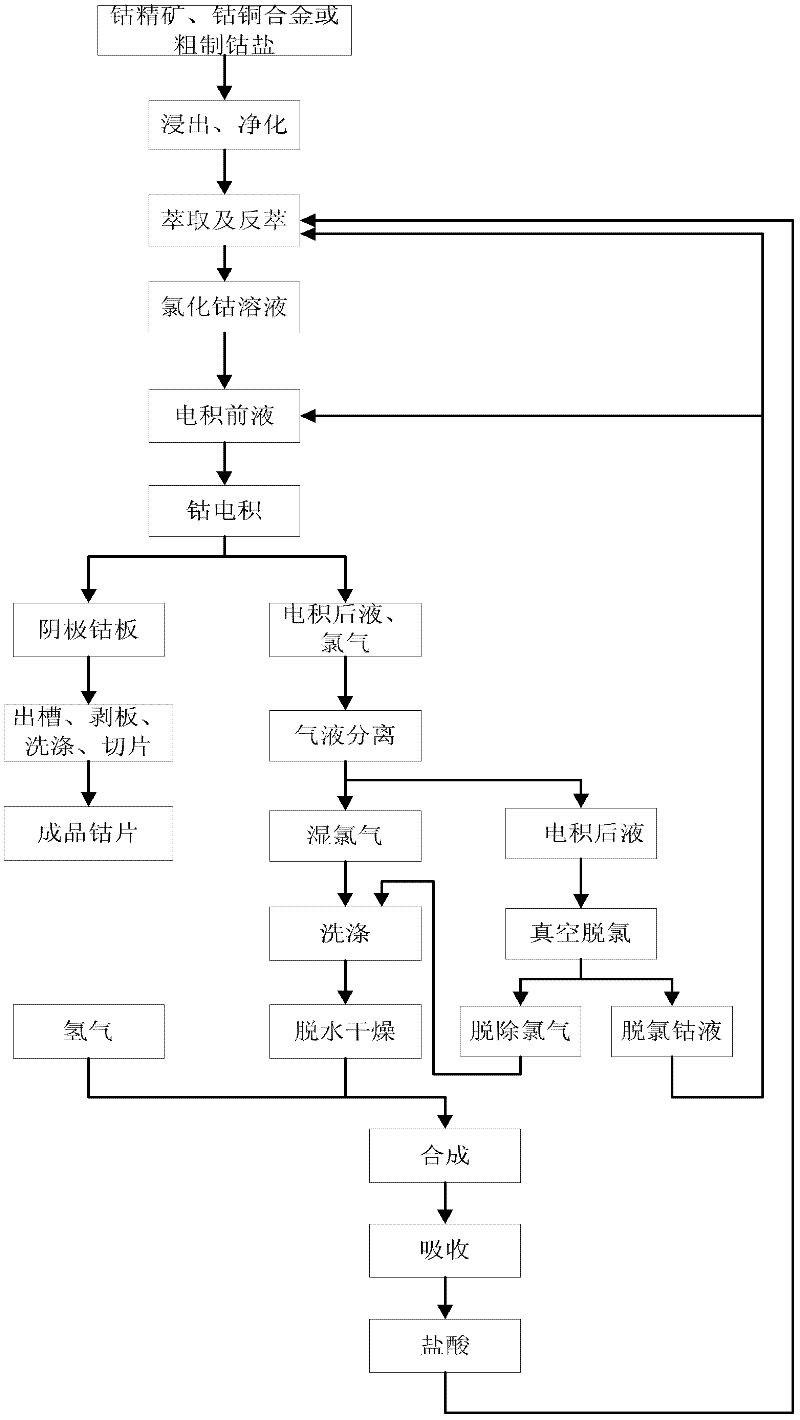

Method for preparing electric deposited cobalt

InactiveCN102330111AHigh purityAvoid emissionsChlorine/hydrogen-chlorideElectrolysis componentsIonCopper

The invention relates to a method for preparing electric deposited cobalt by circulating hydrochloric acid. At present, various preparation processes of the electric deposited cobalt have huge potential hazard risk to the environment. The preparation process comprises the following steps of: leaching and purifying cobalt concentrate, copper-cobalt alloy or crude cobalt salt as raw materials; then extracting by adopting P507 to extract the cobalt; back extracting to obtain cobalt chloride solution with hydrochloric acid; deoiling the cobalt chloride solution and then mixing the denoiled cobalt chloride solution with part of electric deposited liquid to obtain front electric deposited liquid; carrying out electric deposition in an airtight electrolytic cell to obtain the electric deposited cobalt; allowing chlorine gas generated in the electric deposited process and back electric deposited liquid to enter the interior of an electric deposited circulating tank; after the mixture is separated by a gas-liquid separator, separating wet chlorine gas from the electric deposited liquid; and carrying out vacuum antichloration on the electric deposited liquid and returning the treated electric deposited liquid to work procedures of preparing the front electric deposited liquid and back extracting the P507. The electric deposited cobalt obtained in the invention has high purity; a byproduct hydrochloric acid has high purity and is recycled; and the discharge of the chlorine gas or chloride ions is avoided; and the influence on the environment in the treatment process by other treatment methods of the chlorine gas is avoided.

Owner:ZHEJIANG HUAYOU COBALT

Cement-free calcination-free shale pressing bearing brick and preparation thereof

InactiveCN101209909AImprove performance indicatorsLow costSolid waste managementEngineeringCalcination

The invention relates to a cement-free and baking-free shale suppression bearing brick and a manufacturing method thereof, which relates to a construction-used bearing brick and a manufacturing method thereof. Ordinary shale is used as main raw material and various 'wastes' are used as ingredients in the method; no open fire, waste gas, ash or waste water is produced in the manufacturing process which ensures low water and electricity consumption; various primary technical performances of a product are excellent. The method comprises steps that: (1) the materials are prepared according to following weight ratio: 40 to 50 percent of shale rock, 20 to 21 percent of auxiliary material, 4 to 6 percent of taillings powder, 7 to 9 percent of heavy calcium carbonate, 4 to 6 percent of gravel soil, 3 to 4 percent of alkali residue, 4 to 7 percent of construction waste, 5 to 6 percent of MSH polymerization condensate material especially used for shale and proper amount of water; (2) raw material treatment; the primary material and the auxiliary material are grinded; (3) ingredient stirring; (4) well-proportioned mixing and ageing; (5) mulling and plasticizing; (6) suppressing and forming; (7) steaming, pressing and solidification into finished product. The practice of the invention is environment friendly, and the quality of manufactured products is excellent, which reaches the standard of the bearing brick but has low cost and can be taken as the bearing brick for replacing a clay brick.

Owner:天津国威科技有限公司

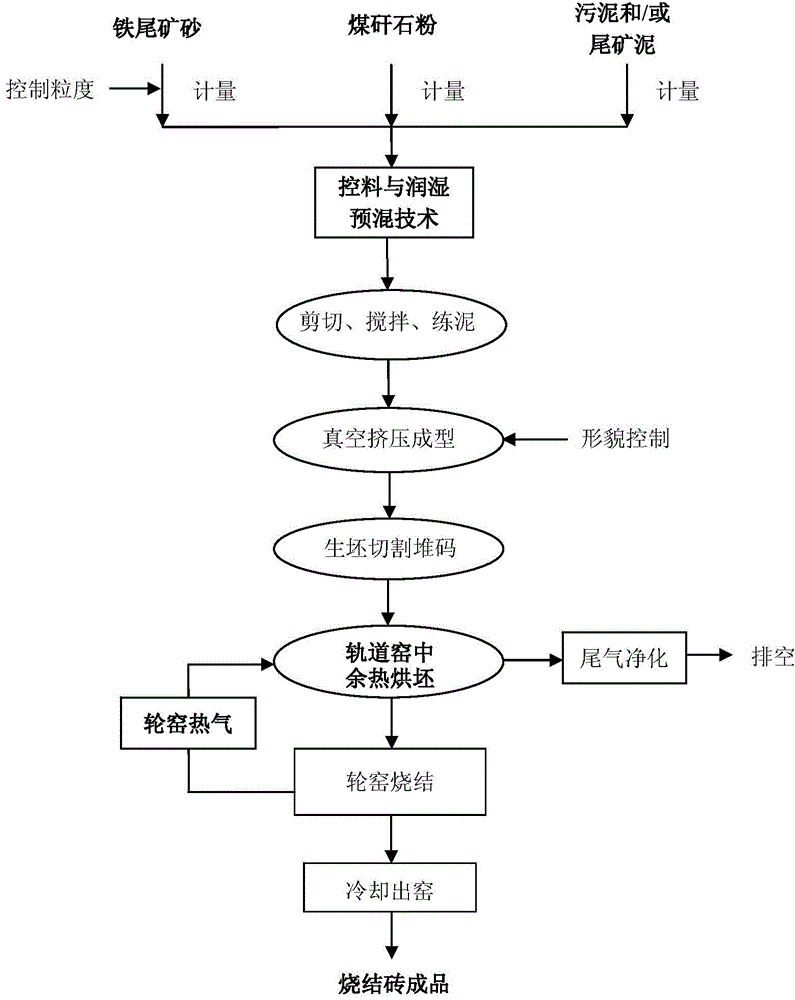

Fired brick and preparation method thereof

InactiveCN104944922ASolve insufficient resourcesSave fuelCeramic materials productionClaywaresSludgeToxic industrial waste

The invention provides a fired brick and a preparation method thereof. The fired brick mainly comprises the following raw materials in weight part: 40-80 parts of iron tailings, 20-60 parts of gangue, 1-10 parts of an auxiliary agent and 7-25 parts of water. The sum of the weight parts of the iron tailings and the gangue is 100 parts. The sludge and / or the mud tailings is adopted as the auxiliary agent. The fired brick is porous, large in compressive strength and good in weather resistance. The radionuclide content of the fired brick is in line with the national standard requirements. Large amounts of solid wastes in metallurgical mines and industrial waste residues can be fully utilized to prepare novel tailings-based building materials. Therefore, the fuel is saved and resources are fully utilized. The circular economy is developed and the environment is protected.

Owner:平泉市莱蒂建材有限公司 +1

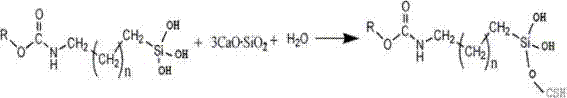

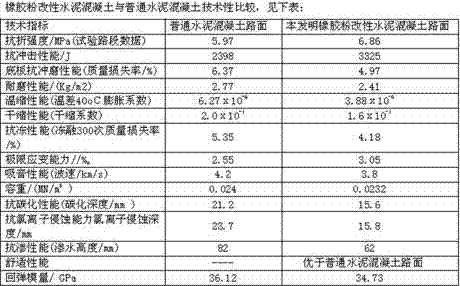

Rubber powder modified cement concrete pavement and manufacturing method thereof

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

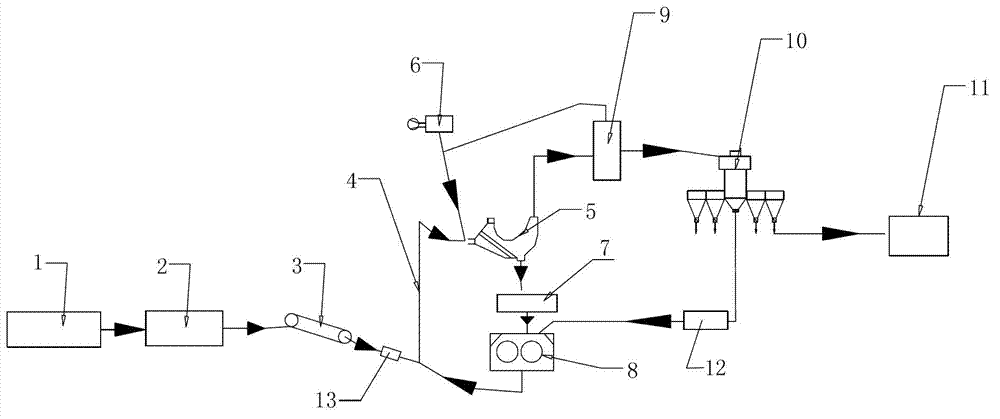

Steel slag powder producing method employing roller press

InactiveCN103041904ARealization of high value-added utilizationReduced use of high added valueGrain treatmentsSlagClosed loop

The invention relates to the technical field of recycling of steel slag, in particular to a steel slag powder producing method employing a roller press. The method is characterized in that a closed loop formed by a high-pressure roller press, a bucket elevator, a static powder concentrator and a dynamic powder concentrator produces the steel slag powder; and the specific surface area of an obtained steel slag powder product is larger than 450m<2> / kg, the iron content is lower than 0.1% after the steel slag powder passes through a plurality of magnetic separation devices, and the negative pressure operation is adopted inside the static powder concentrator. Compared with the prior art, the method has the benefits that the closed loop and the negative pressure operation are adopted, therefore dust is little, the energy is saved, and the environment is protected; partial hot gas is recovered, and the heat energy utilization rate is improved; only the high-pressure roller press is adopted for grinding, so that the technological process is simple, and the investment is small; and the iron content is lower than 0.1%, the product quality is improved, the high value-added utilization of steel tailings is achieved, land-occupation stacking of the steel tailings is reduced, the environmental pollution is reduced, and the circular economy is developed.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION

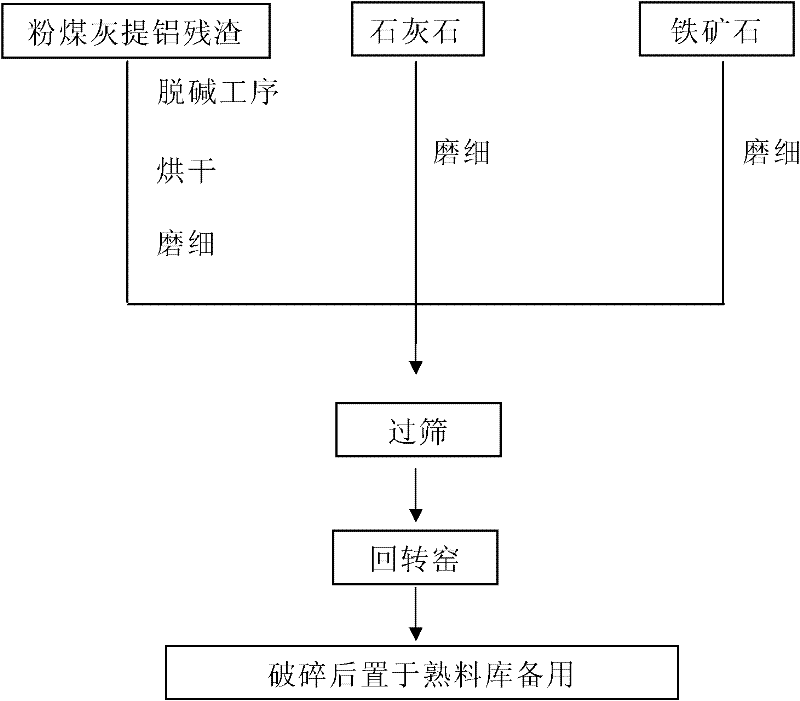

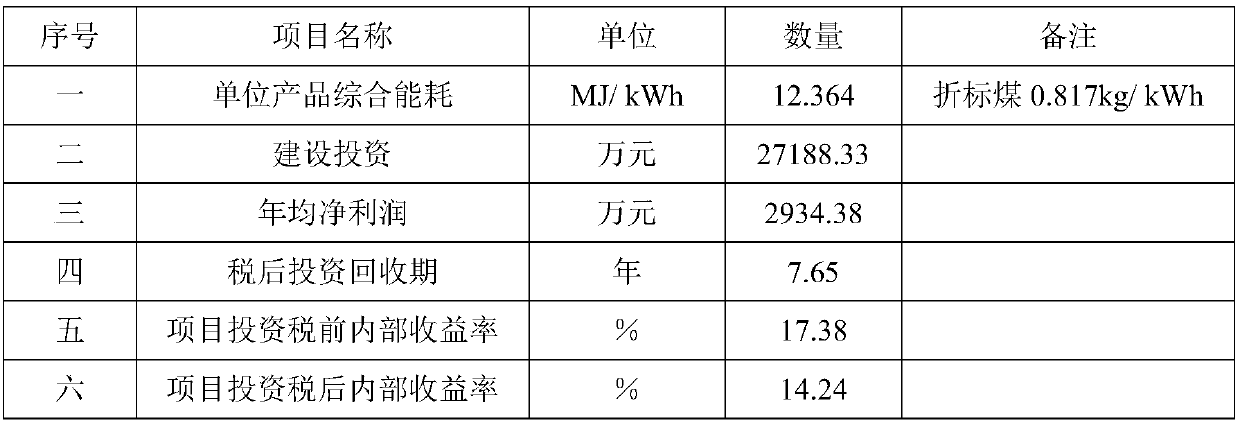

Cement clinker and preparation method thereof

InactiveCN102344258ARaw materials are easy to obtainScientific and reasonable processCement productionCircular economyCoal

The invention discloses cement clinker and a preparation method thereof. The cement clinker is prepared from the following raw materials in part by weight: 60-88 parts of aluminum extracted coal ash residue, 38-10 parts of limestone and 1-3 parts of iron ore. The preparation method of the cement clinker comprises the following steps of: firstly, grinding the raw materials; then, homogenizing the ground raw materials; and finally calcining the raw materials to obtain the cement clinker. The invention overcomes various defects in the prior art, simple raw materials and high utilization rate are realized, and the traditional cement production process does not need to be improved. The obtained portland cement has high early strength, and the amount of strength increase is stable without great fluctuations. Compared with the traditional cement clinker production process, the preparation method can enable the consumption of limestone for each ton of cement clinker is lowered by 60-90%, the emission amount of CO2 is lowered by 60-90%, energy consumption is lowered by more than 30%, and the production capacity of single kiln is improved by 30%. The preparation method is a cyclic and economic project tightly linked to aluminum extraction from coal ash.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Preparation method for phosphogypsum baking-free brick

The invention discloses a preparation method for a phosphogypsum baking-free brick. The preparation method comprises the following steps of (1), guiding byproduct phosphogypsum produced in a phosphoric acid production process out of a phosphoric acid system for stacking to be used as a material for producing the phosphogypsum baking-free brick, metering, and uniformly mixing the phosphogypsum, yellow phosphorus residue and lime in a weight proportion of 55:(41-43):(2-4) to prepare three material solid phases which are conveyed to a digestion bin. The brick disclosed by the invention can replace the clay brick for use, and a great deal of phosphogypsum can be digested, so that not only is waste residue piling and maintaining pressure of light phosphatic fertilizer enterprises relieved, but also environment is protected and land is saved. According to the invention, production materials are from various industrial waste residues, and therefore, the preparation method has the remarkable advantages of low production cost, simple process, strong operability and environment friendliness.

Owner:云南常青树化工有限公司

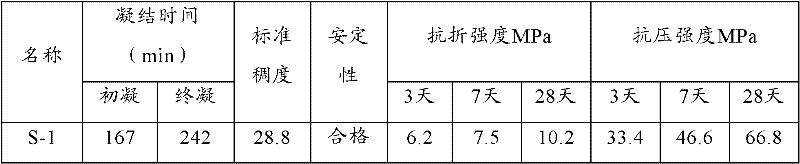

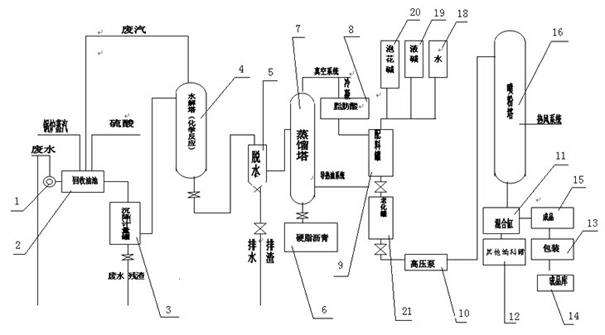

System device for extracting swill-cooked dirty oil as well as application method of extracted swill-cooked dirty oil and swill-cooked dirty oil

InactiveCN102586042AEmission reductionPrevent inflowFatty acids production/refiningDetergent powders/flakes/sheetsPollutant emissionsProcess engineering

The invention discloses a system device for extracting waste-swill-cooked dirty oil and an extraction method. The system device comprises a recycle pool, a sedimentation measuring tank, a hydrolyzer, a drain sump, a distillation tower system, a fatty acid material tank, a soap powder compounding tank, an aging tank, a high pressure pump, a spray tower, a heating and vacuum system, a mixed cylinder and a finished product warehouse; and the method comprises digestion, sedimentation, hydrolyzation, oil-water separation, dehydration, distillation, condensation, soap power compounding, aging, airflow drying, mixing and packaging. Therefore, the environment is protected and improved, wastes of high energy consumption, high pollution and resources industries are utilized efficiently and comprehensively, the pollutant emission is reduced, swill-cooked dirty oil is prevented from flowing back onto dinner tables to harm human health, harmful wastes harming environment and human life safety are turned into valuable things; and stearin pitch is used as raw materials of sand consolidation agent and rubber accelerator, the soap powder is applied as raw materials of washing powder or soap, and the system device and the extraction method are widely used in recycle industry of swill-cooked dirty oil.

Owner:杨解定

Polyolefin foaming material recycling method and device

ActiveCN106608006AThe application market is hugeImprove protectionPlastic recyclingMechanical material recoveryFiberPolymer science

The invention belongs to the technical field of the recycling of foaming materials, and particularly relates to a polyolefin foaming material recycling method and device. The method comprises the following steps: crushing and stirring a polyolefin foaming material, and adding an adhesive and reinforcing fiber during the stirring process so as to form a molding standby material, and then putting the molding standby material into a heating-pressurizing vessel for molding so as to obtain a polyolefin crushed material foaming product which can be widely applied to the fields of heat preservation, buffering, packaging and the like. According to the method and the device provided by the invention, not only is the technical problem that a cross-linking polyolefin foaming material cannot be recycled solved, but also the production cost is low; and accordingly the method and the device serve as the critical technology about environmental protection, development of the circular economy and practice of the sustainable development concept in the field of polyolefin cross-linking foaming.

Owner:SHANDONG TAISHAN SPORTS EQUIP CO

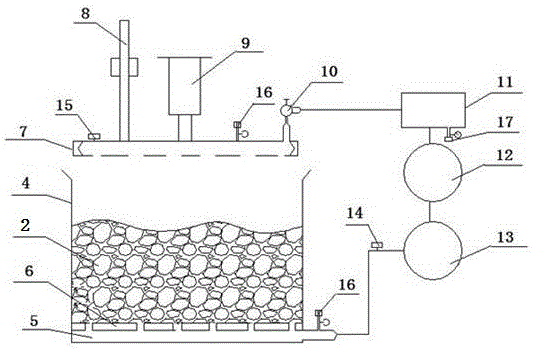

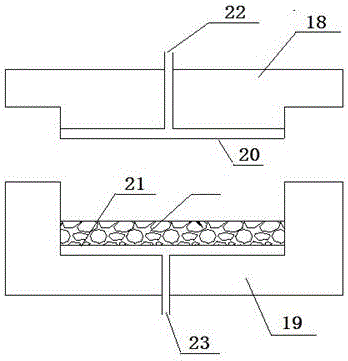

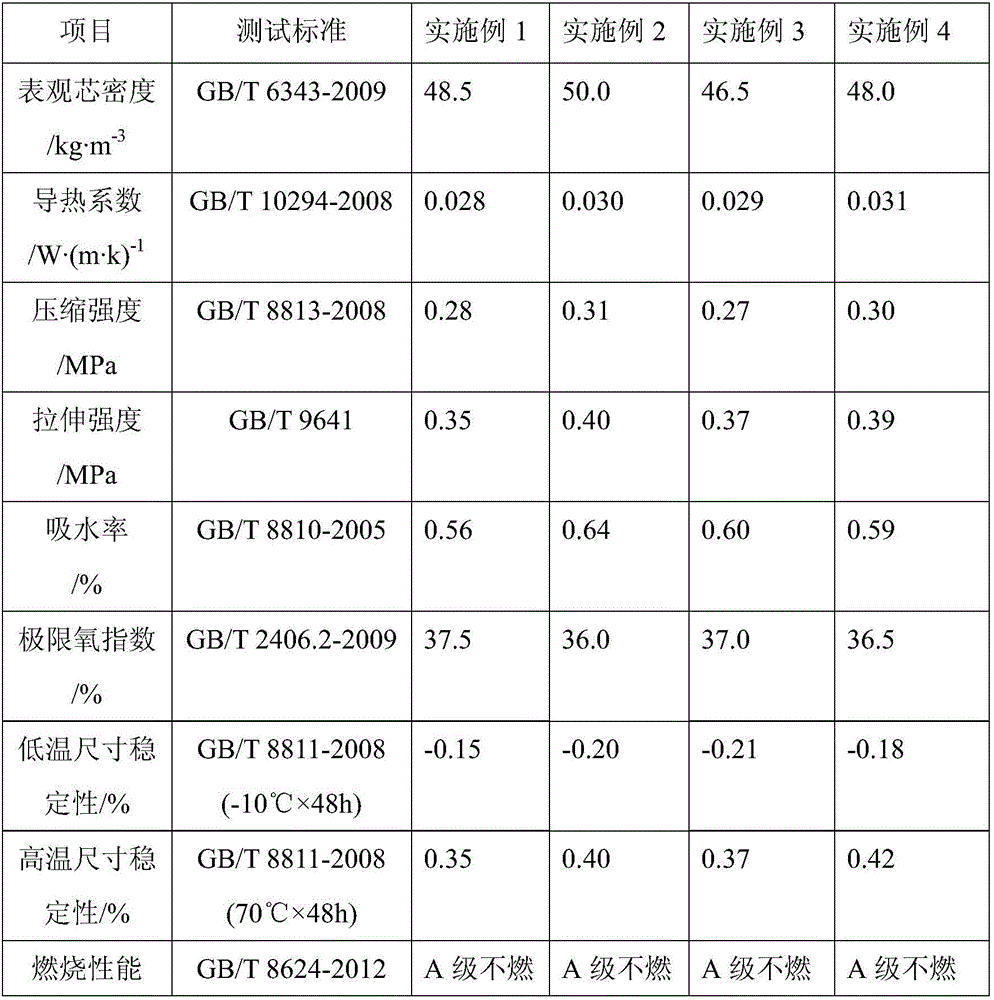

Desulphurization gypsum-polyurethane compounded fireproof and heat-preservation board and preparing method thereof

The invention discloses a desulphurization gypsum-polyurethane compounded fireproof and heat-preservation board. The desulphurization gypsum-polyurethane compounded fireproof and heat-preservation board comprises ingredients A and ingredients B. The ingredients A comprise polyether polyol, polyester polyol, polypropylene glycol, structural flame resistant polyol, modified desulphurization gypsum powder, a foam stabilizer, a gel-type catalyst, a trimerization catalyst, a liquid fire retardant and a foaming agent; the ingredients B comprise polyaryl polymethylene isocyanate. A preparing method includes the steps that the ingredients A are stirred to be even, the foaming agent is added, then the ingredients B are added, the mixture is stirred at the high speed to be poured into a constant temperature mold, foamed, cured and demolded, and the desulphurization gypsum-polyurethane compounded fireproof and heat-preservation board is prepared. According to the desulphurization gypsum-polyurethane compounded fireproof and heat-preservation board and the preparing method, a by-product desulphurization gypsum of the coal electricity plant industry is fully used, desulphurization gypsum powder is successfully and organically modified, and the compatibility between the desulphurization gypsum powder and a raw polyurethane material is enhanced; the product has high fireproof performance and good mechanical performance at the same time, and combustion performance can meet the A-grade requirement of the national standard.

Owner:NANJING UNIV

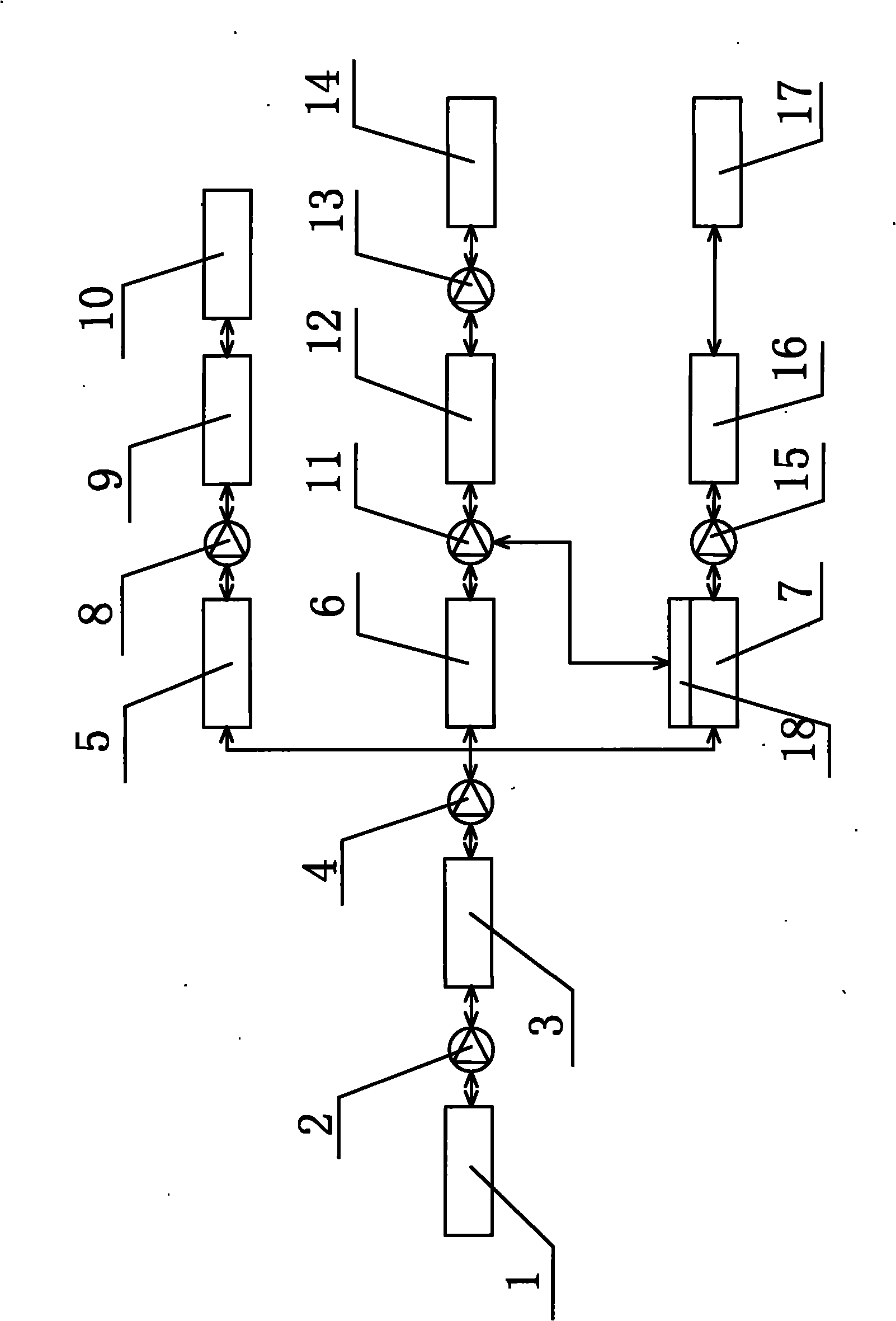

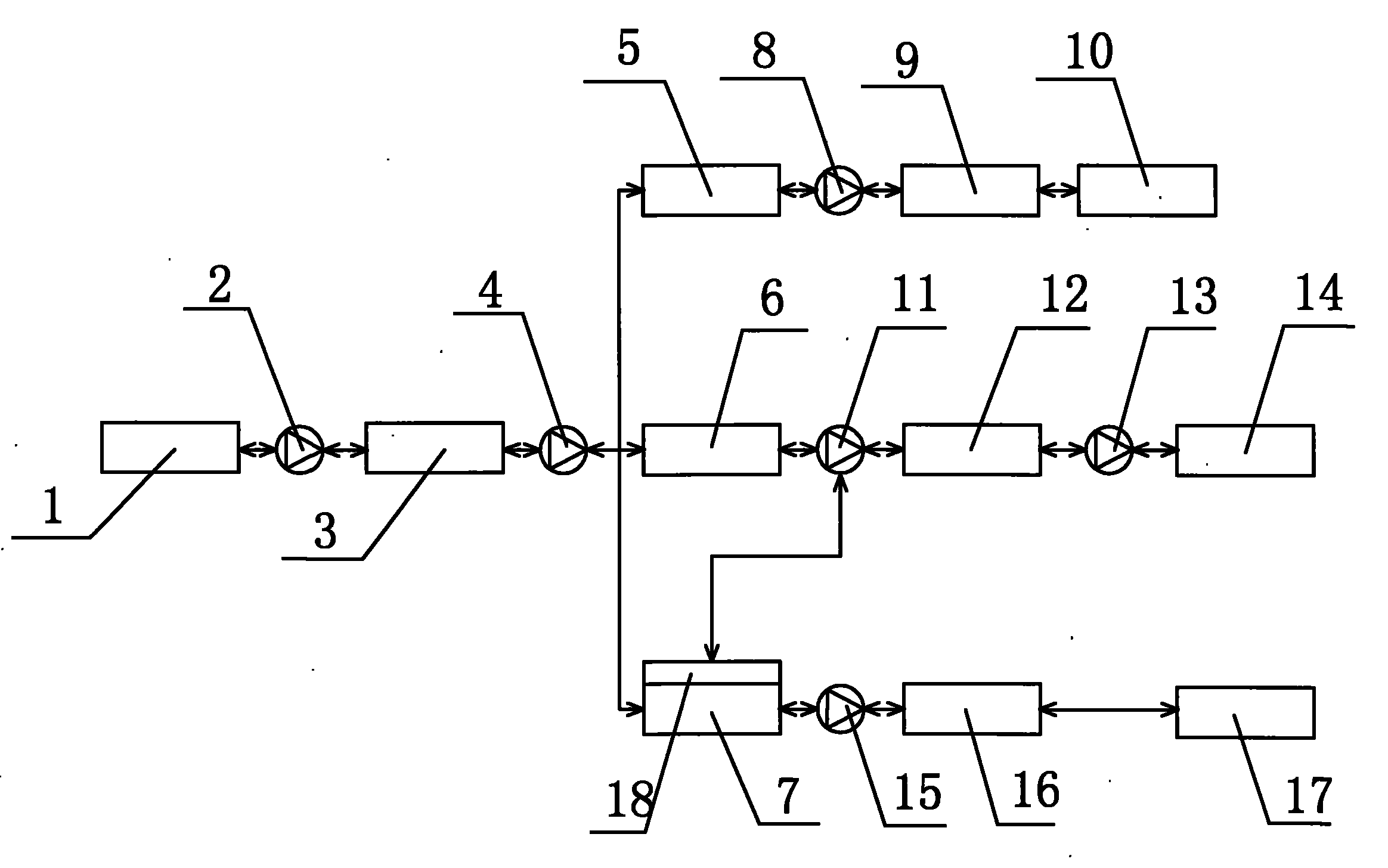

Heating and cooling system using swallet waste heat by industrial and mining enterprises

InactiveCN101893348ADoes not consume water resourcesChange energy structureHeat recovery systemsInsulationWater sourceResource utilization

The invention discloses a heating and cooling system using swallet waste heat by industrial and mining enterprises, relating to the field of residual heat waste heat resource utilization. The heating and cooling system comprises a well-head freeze protection water source heat pump unit (5), a worker bath water source heat pump unit (6), an industrial heating and cooling water source heat pump unit (7), a mine water recycle pump (2), a primary water recycle pump (4), three secondary water recycle pumps, a bath water heating recycle pump (13), two plate-type heat exchangers and a sub-water catcher (17). In the invention, a water source heat pump technology is used and reclaimed water waste heat in a mine water treatment plant is comprehensively utilized for worker bath, industrial heating in winter, well-head freeze protection and cooling of office buildings and apartment blocks in summer; a coal-fired boiler system is thoroughly replaced; a water source heat pump system only extracts the heat of the reclaimed water of the treated mine water and domestic sewage, and additional water resources are not consumed; and the heating and cooling system has the advantages of remarkable energy saving effect, obvious economic benefit, outstanding environmental benefit and the like.

Owner:SHANDONG TONGFANG ENERGY ENG TECH

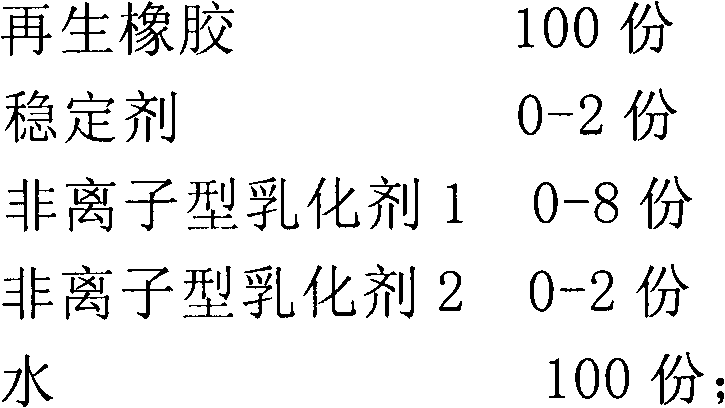

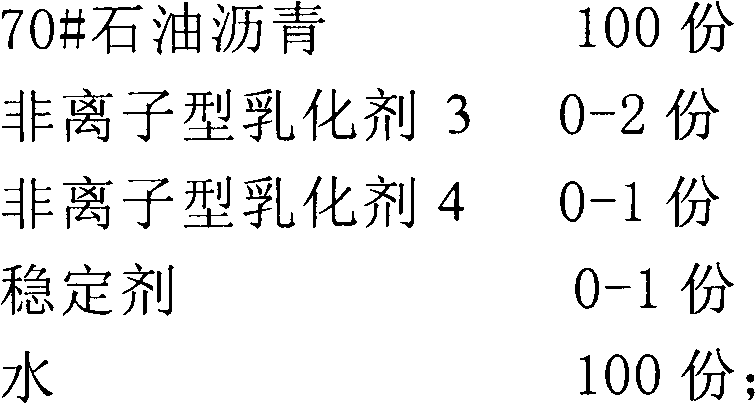

Preparation method of liquid rubber asphalt water-proof paint

ActiveCN102492365AHeat resistantImprove aging resistanceReclaimed rubber coatingsChloropene polymer coatingsCrack resistancePolymer science

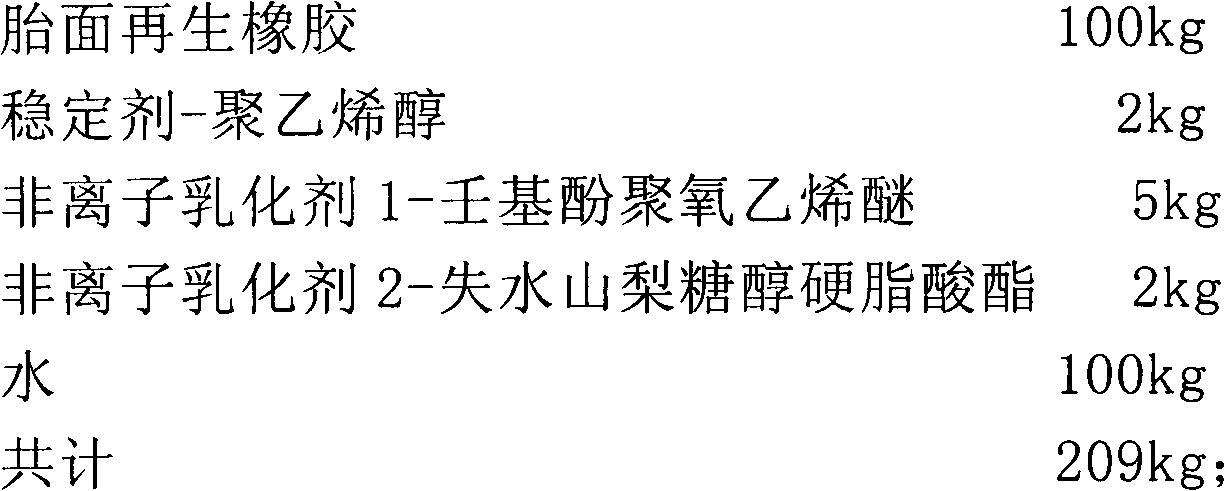

The invention provides a preparation method of liquid rubber asphalt water-proof paint and relates to a preparation method of water-proof paint. The preparation method provided by the invention is a preparation method of a rubber asphalt emulsion by taking a non-ionic surfactant as an emulsifying agent. The preparation method comprises the following steps: 1, preparing a non-ionic reclaimed rubber emulsion from the following components in parts by weight: 100 parts of reclaimed rubber, 0-2 parts of stabilizing agent, 0-8 parts of non-ionic emulsifying agent 1, 0-2 parts of non-ionic emulsifying agent 2 and 100 parts of water; 2, preparing a non-ionic asphalt emulsion from the following components in parts by weight: 100 parts of 70# petroleum asphalt, 0-2 parts of non-ionic emulsifying agent 1, 0-1 part of non-ionic emulsifying agent 2, 0-1 part of stabilizing agent and 100 parts of water; and 3, preparing the liquid rubber asphalt water-proof paint from the following components in parts by weight: 70-80 parts of non-ionic reclaimed rubber emulsion, 20-30 parts of chloroprene rubber latex and 100 parts of non-ionic asphalt emulsion. The liquid rubber asphalt water-proof paint prepared by using the method can be widely used in projects with high thermal resistance requirement and railway, highway, municipal bridges and building waterproof and anticorrosive projects which have high crack resistance requirements.

Owner:天津四十二站检测技术有限公司

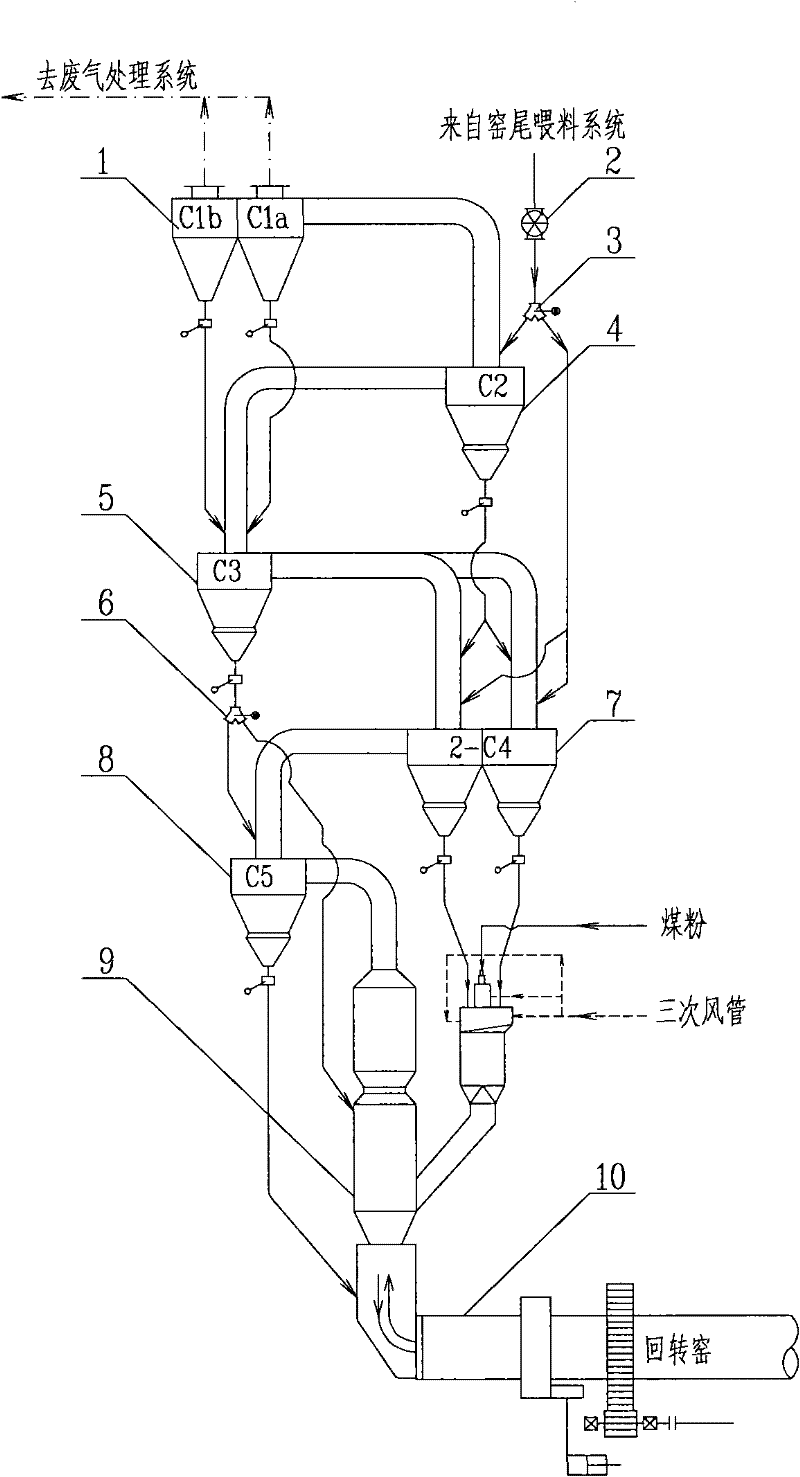

A method for producing cement clinker with unlimited compatibility with carbide slag and limestone as raw materials

ActiveCN102260052ARealize resource utilizationSolve the problem of stacking and polluting the environmentClinker productionCalcium in biologySlag

The invention relates to an unlimited compatible method for producing cement clinker by using carbide slag and limestone as raw materials, belonging to the technical field of resources and environment. The method uses the carbide slag as the calcareous raw materials, and the cement clinker is calcined by using a novel dry technology, which is characterized in that: either 100 percent of carbide slag or 100 percent of limestone can be used as the calcareous raw materials, or the carbide slag and the limestone can be mixed at any ratio for use. A main process comprises the following steps of: (1) kiln rear feeding, in which a preheater can be switched between the stage 3 and the stage 5 through changing a position of a material feeding point; (2) raw material pre-decomposition, in which a five-stage preheater which is switchable to a three-stage preheater and an enhanced suspension spray type decomposition furnace are used in order to combust the fuels and decompose the raw materials, wherein the outlet temperature of the decomposition furnace is controlled between 700 and 890 DEG C; and (3) rotary kiln calcining, in which the decomposed raw materials enter the kiln to be calcined into the cement clinker. The method has the characteristics of high resource regeneration level of the carbide slag, obvious energy-saving and emission-reduction effect, strong system compatibility andthe like.

Owner:成都建筑材料工业设计研究院有限公司

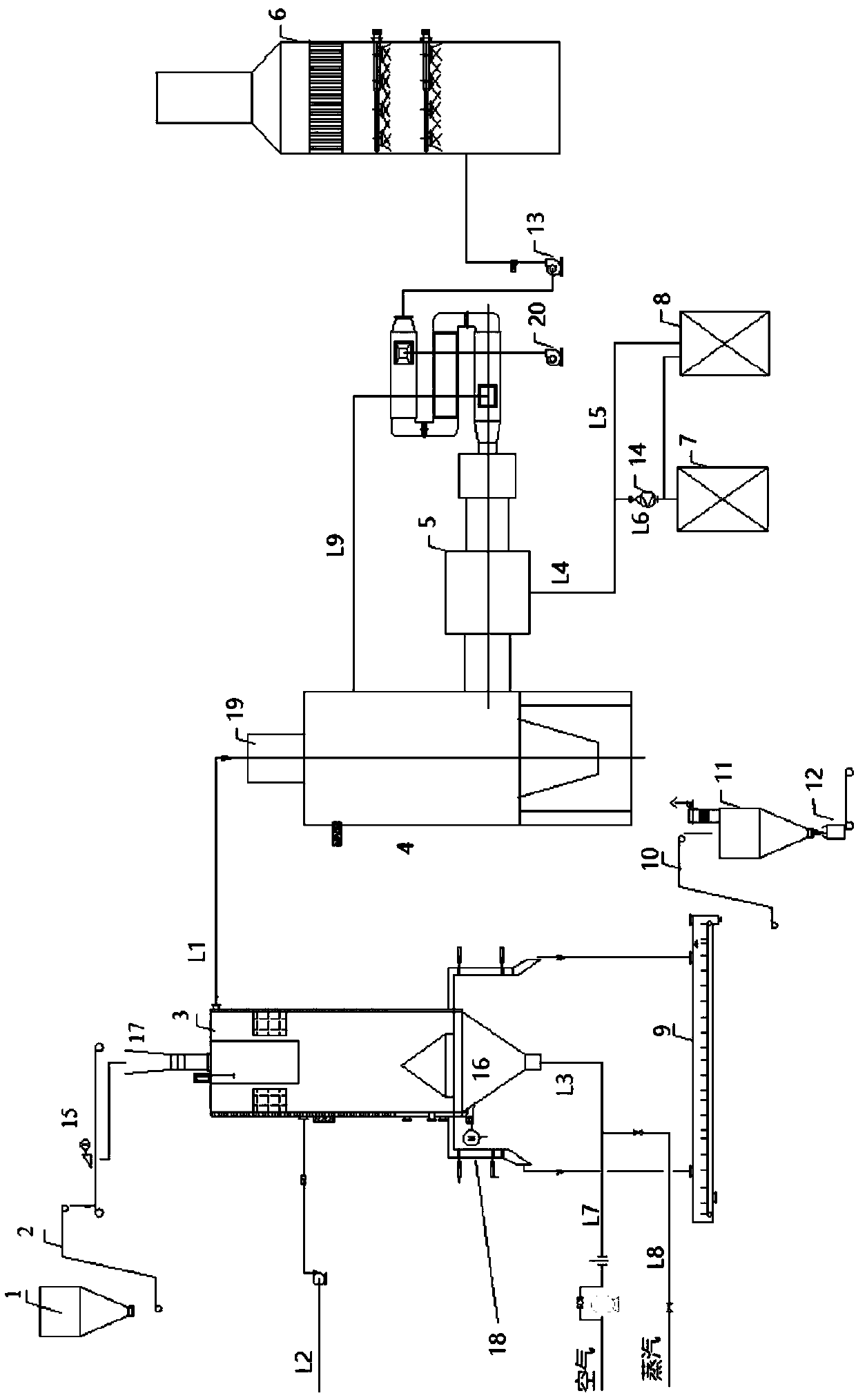

Device and technology for poly-generation of carbon, heat and electricity based on biomass gasification

PendingCN109679695ADevelop circular economyReduce dosageEnergy inputGasification processes detailsElectricityFixed bed

The invention discloses a device and a technology for poly-generation of carbon, heat and electricity based on biomass gasification. The technology comprises steps of biomass transport, biomass gasification, boiler processing, electricity generation, desulphurization and dust removal. A large-dip-angle belt is adopted to perform continuous automatic feeding for biomass transport; a composite gasification fixed bed gasification technology with combination of upper and lower suction is adopted for biomass gasification, and a byproduct is a carbonized material; steam produced by a boiler after burning of gasified gas enters a steam turbine for generating electricity and then passes through a heat exchange station for providing a heat source for heating; a scattering tower based desulphurization and dust removal integration technology is adopted for desulphurization and dust removal. The device and the technology have the advantages of being environmentally friendly and safe and realizingpoly-generation of carbon, heat and electricity.

Owner:XINDI ENERGY ENG TECH

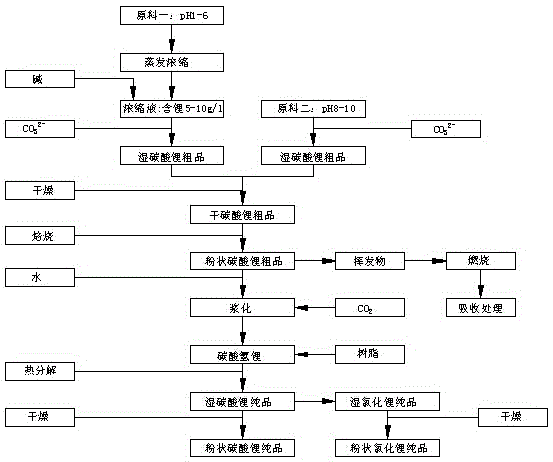

Technological method for recycling lithium from lithium-containing waste liquid of medicine and synthetic plastics industries

ActiveCN105129826ASolve the problem of saving resourcesSolve environmental problemsLithium halidesLithium carbonates/bicarbonatesPlastics industryDecomposition

The invention discloses a technological method for recycling lithium from lithium-containing waste liquid of medicine and synthetic plastics. The technological method comprises the following steps of: (1) preparing feedstocks; (2) evaporating and concentrating the feedstocks so as to obtain crude lithium carbonate; (3) drying the crude lithium carbonate; (4) calcinating the dried lithium carbonate so as to obtain crude powdery lithium carbonate; (5) adding water into the crude powdery lithium carbonate so as to pulpify the crude powdery lithium carbonate, and introducing CO2 into the lithium carbonate slurry so as to acidify the lithium carbonate slurry; (6) performing resin purification on the acidified lithium carbonate slurry so as to obtain lithium bicarbonate purified liquid; (7) heating the lithium bicarbonate purified liquid for decomposition and washing and separating the liquid so as to obtain wet pure lithium carbonate; and (8) drying the wet pure lithium carbonate so as to obtain powdery pure lithium carbonate; or acidifying the wet pure lithium carbonate, then concentrating and crystallizing the acidified lithium carbonate, and drying the crystallized lithium carbonate so as to obtain the powdery pure lithium carbonate. The technological method disclosed by the invention is simple in process, high in recycling rate, controllable in cost, and easy to popularize and apply in industrial production. Through the recycling of the lithium-containing waste liquid resources in the medicine and synthetic plastics industry, a national precious rare resource is saved.

Owner:江西环锂新能源科技有限公司

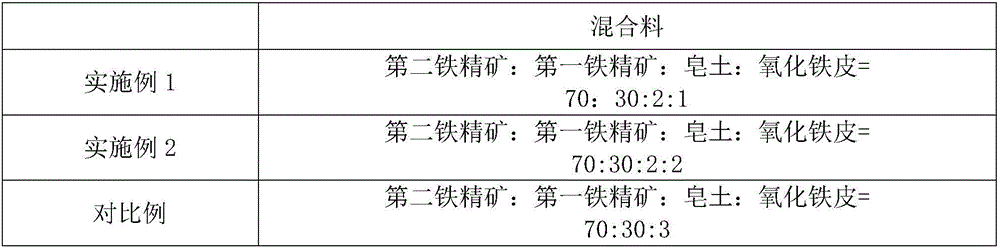

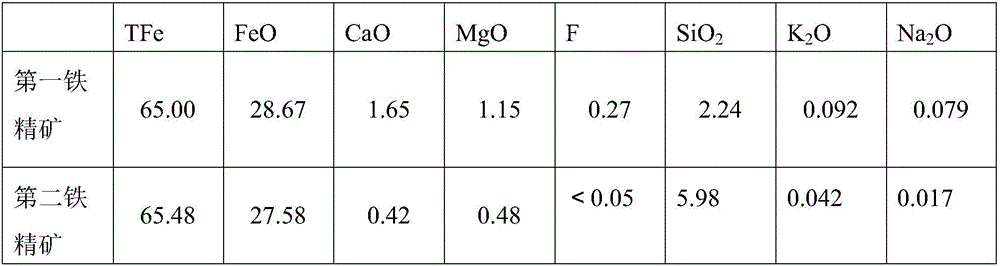

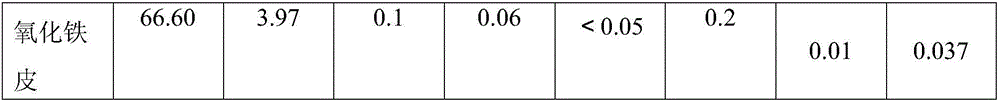

Preparation method for oxidized pellet ore raw materials and oxidized pellet ore

InactiveCN106636622ARealize rational utilizationMeet blast furnace needsCircular economyCompressive strength

The invention provides a preparation method for oxidized pellet ore raw materials and oxidized pellet ore. The oxidized pellet ore raw materials comprises first iron concentrate, second iron concentrate and continuous cast and rolled steel oxide scale according to the weight ratio of (0-30): (60-100): (1-5). In the preparation method for the oxidized pellet ore raw materials and the oxidized pellet ore, a certain proportion of oxidized pellet ore prepared from continuous cast and rolled steel oxide scale is matched and added in the oxidized pellet ore raw materials, and in combination with the comprehensive strength of the oxidized pellet ore prepared through a corresponding process, the rotating drum strength and the metallurgical properties, the blast furnace requirements can all be met; and meanwhile reasonable utilization of continuous cast and rolled steel iron-containing dust mud can be achieved, the circular economy is developed, and green steel and iron are made.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

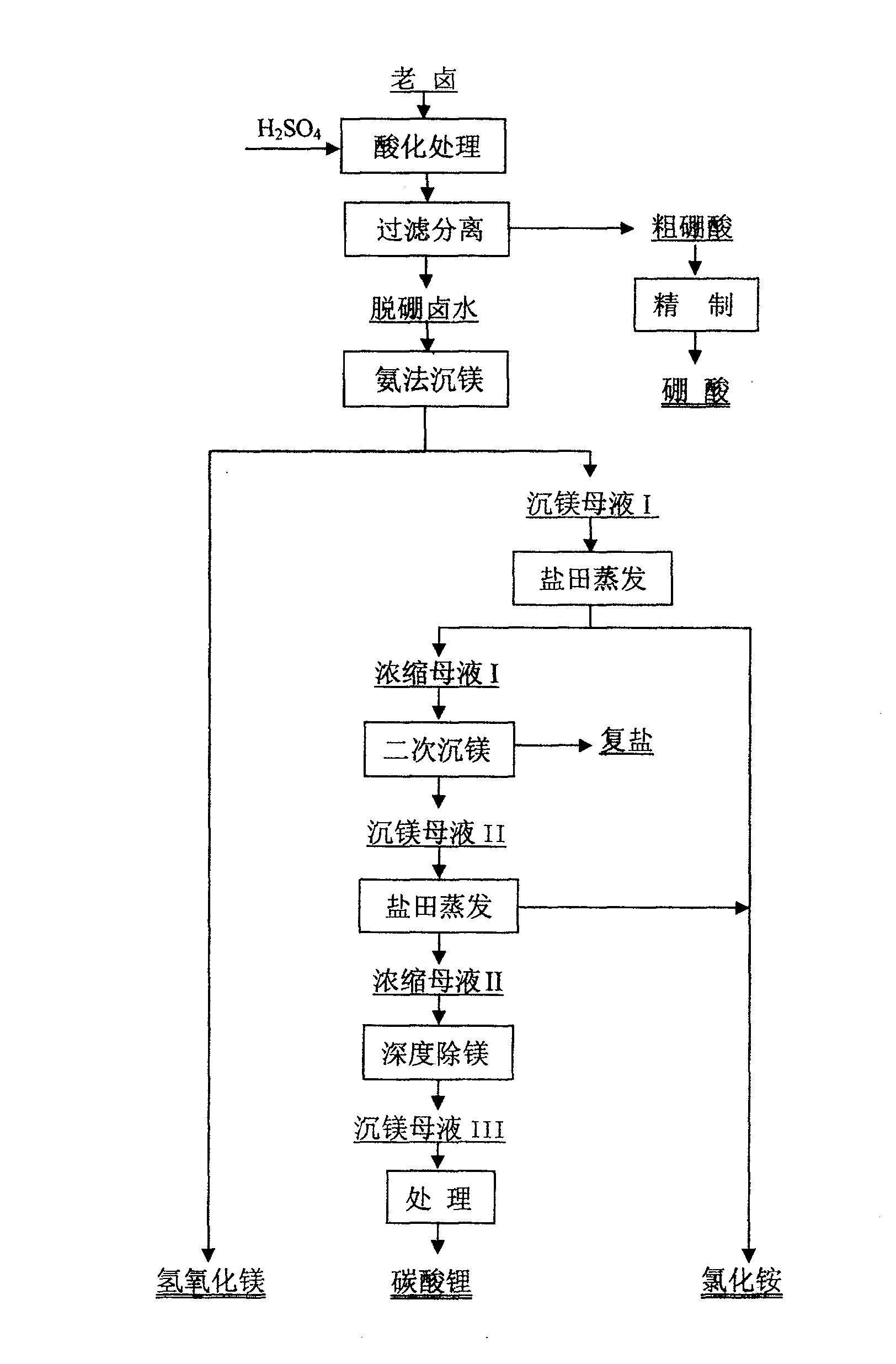

Method for combined extracting boron, magnesium and lithium from salt lake bittern

InactiveCN100528753CEfficient use ofIncrease profitBoron-oxygen compoundsNitrogen and non-metal compoundsEcological environmentResource utilization

The present invention relates to the development and comprehensive utilization of salt lake resources, in particular to a kind of salt lake brine containing boron, magnesium, and lithium as raw materials, and adopts a combined separation and extraction process to prepare boric acid, magnesium hydroxide, lithium carbonate, and ammonium chloride respectively. A method for jointly extracting boron, magnesium and lithium from salt lake brine. The method of the present invention uses the brine containing boron, magnesium, lithium, etc. after being concentrated and removed most of sodium and potassium by the salt field method as raw material, and undergoes acidification treatment to prepare boric acid; magnesium precipitation by ammonia method; concentration by salt field method; magnesium precipitation by carbonate; Secondary magnesium precipitation mother liquor salt field method concentration; sodium hydroxide solution deep magnesium precipitation; sodium carbonate solution reaction method to prepare lithium carbonate. The recovery rates of boron, magnesium and lithium are over 87%, 95% and 92% respectively. The method has the characteristics of simple process, less investment in equipment, high resource utilization rate, high recovery rate of boron, magnesium and lithium, good product quality, low production cost, and no "three wastes", which fully meets the requirements of developing circular economy and improving the ecological environment of salt lakes. Require.

Owner:WESTERN MINING GROUP +1

Method for preparing aluminum-magnesium silicate from fly ash

ActiveCN106145129AAvoid damageHigh puritySilicon compoundsCircular economyAluminum magnesium silicate

The invention discloses a method for preparing aluminum-magnesium silicate from fly ash. Fly ash which is huge in emission amount and pollutes the environment after being emitted is fully used as the raw material, the defect that the yield and cost of an existing aluminum-magnesium silicate preparation method is limited by distribution and reserves of natural aluminum-magnesium silicate ore is overcome, circular economy and saving economy can be developed, and damage of fly ash emission to the natural ecological environment can be reduced. Besides, the performance of an aluminum-magnesium silicate product prepared through the method meets the industrial standard, and purity, whiteness and the like of the product are even better than industrial product indexes.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

River bottom sludge sintered ceramsite and preparation method thereof

InactiveCN108147781ADevelop circular economyHigh strengthCeramic materials productionCeramicwareSocial benefitsSludge

The invention especially relates to river bottom sludge sintered ceramsite and a preparation method thereof. According to the river bottom sludge sintered ceramsite and the preparation method thereof,the sintered ceramsite prepared by utilizing river bottom sludge, yellow river silt and coal ash as main raw materials is superior to the national standard and has good performance of a high strength, a low water absorption rate and the like. Therefore, circular economy of river improvement is developed, land is saved, pollutant discharge is reduced, production cost is reduced, and good social benefits and economical benefits are achieved.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

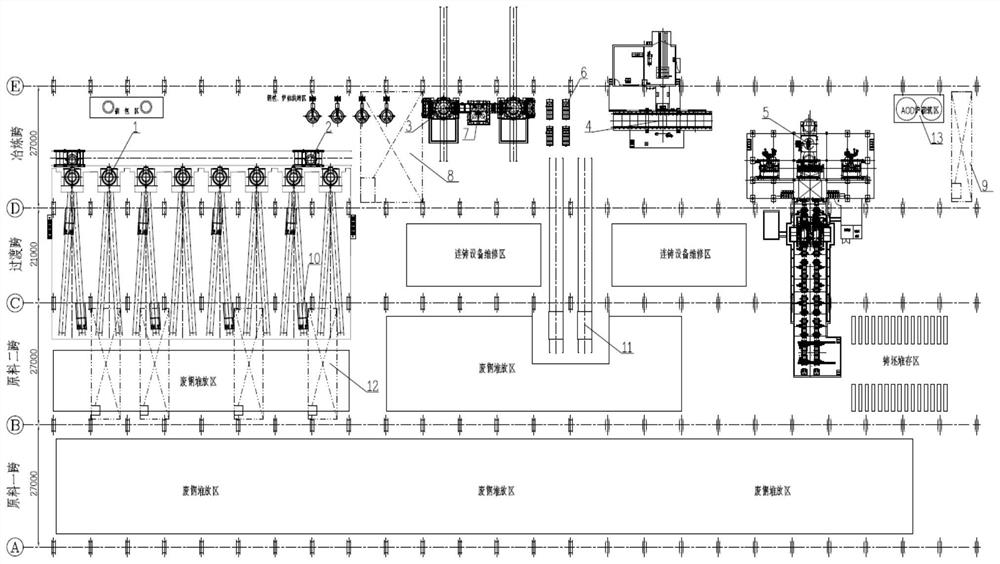

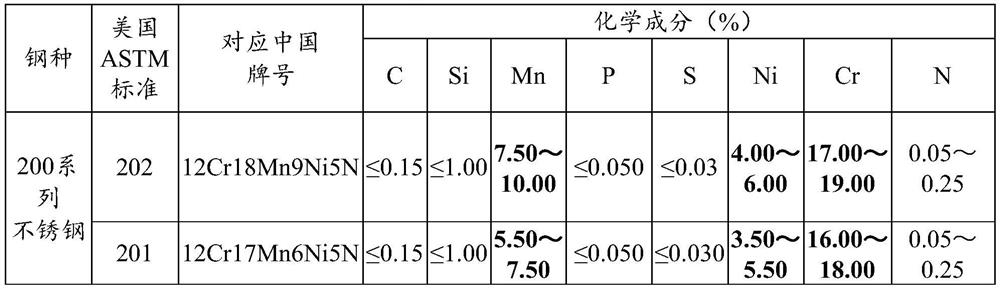

Economical chromium-manganese stainless steel smelting production method and system

InactiveCN111663071ASmall impact on the power gridRun smoothlyProcess efficiency improvementScrapDecarburization

The invention belongs to the technical field of stainless steel smelting, and relates to an economical chromium-manganese stainless steel smelting production method and system. The economic chromium-manganese stainless steel smelting production method comprises the following steps: (1) adding stainless steel scrap into an alloy melting furnace, and melting the scrap with electricity to obtain stainless steel mother liquor; (2) sampling and analyzing the stainless steel mother liquor, and submitting components to an AOD refining process; (3) mixing the stainless steel mother liquor in an AOD refining converter, completing decarburization, chromium preservation and component adjustment through a process control model, and obtaining liquid stainless steel; and (4) transferring the liquid stainless steel into an LF ladle refining furnace, and carrying out continuous casting after slagging and desulfurization. The economic chromium-manganese stainless steel smelting production method is high in element yield, low in investment and operation cost, and capable of saving energy, reducing emission, and meeting the sustainable development concept.

Owner:BERIS ENG & RES CORP

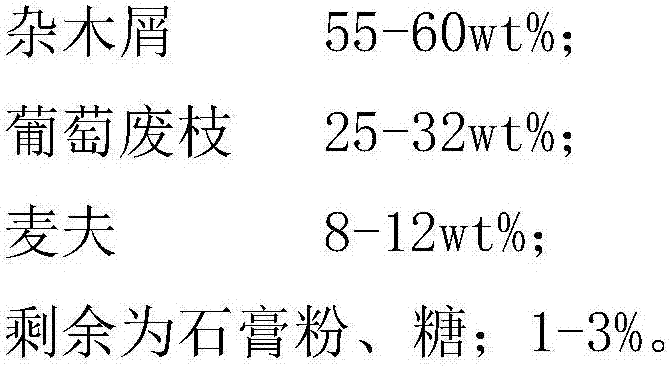

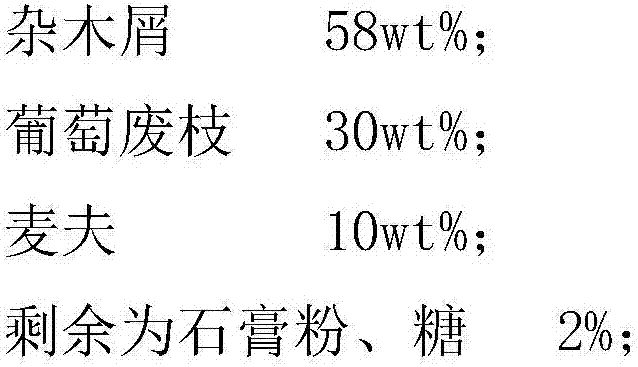

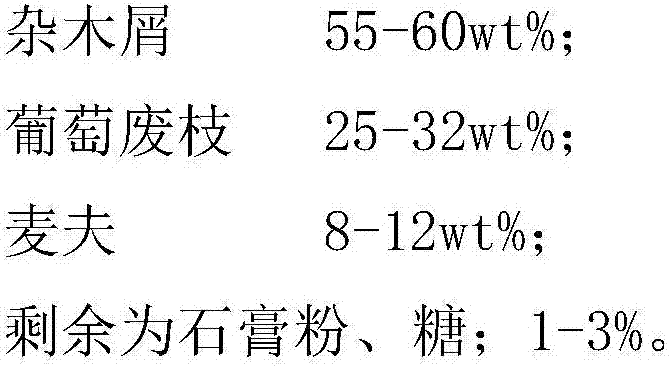

Black fungus cultivation substitutive material utilizing grape waste branches and cultivation method

InactiveCN107188655AExcellent black fungus productsHigh yieldCalcareous fertilisersHorticultureBiotechnologyBud

The invention discloses a black fungus cultivation substitutive material utilizing grape waste branches and a cultivation method. The cultivation method comprises the following steps: preparing fungus sticks by utilizing the grape waste branches as a raw material; then carrying out high-pressure sterilization, fungus inoculation and cultivation, inducing primordium formation, digging holes in the peripheries of the walls of black fungus sticks when black fungus primordia appear in bag walls of the fungus sticks, adding oxygen, and promoting the growth of black fungus buds; finally, carrying out fix planting in a land, and producing black fungus. Compared with the prior art, the black fungus sticks prepared by the method are more ventilated, mycelia growth is facilitated, and the yield of the black fungus is favorably increased; the fungus cultivation time of the black fungus is greatly shortened and is ahead of time for about 15 days.

Owner:诸暨市泉润食用菌栽培场

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com