Economical chromium-manganese stainless steel smelting production method and system

A production method, stainless steel technology, applied in the direction of improving process efficiency, etc., can solve the problems of unsatisfactory yield of stainless steel scrap elements, high investment and operation costs, and large waste discharge, so as to achieve efficiency and environmental protection superiority, construction The effect of short cycle and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

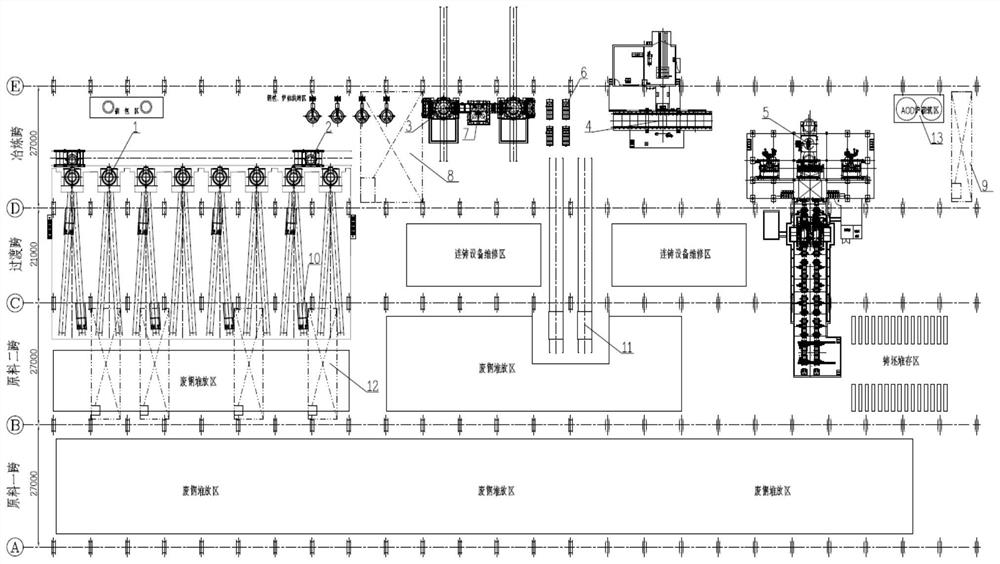

[0048] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments. Process method of the present invention except following content, all the other all adopt the routine method or device of this field. Unless otherwise specified, the following nouns and terms have the meanings commonly understood by those skilled in the art.

[0049] The terms "the", "said", "a" and "an" as used herein do not denote a limitation of quantity but mean that there is at least one of the referred item. Additionally, all ranges disclosed herein are inclusive of endpoints and are independently combinable.

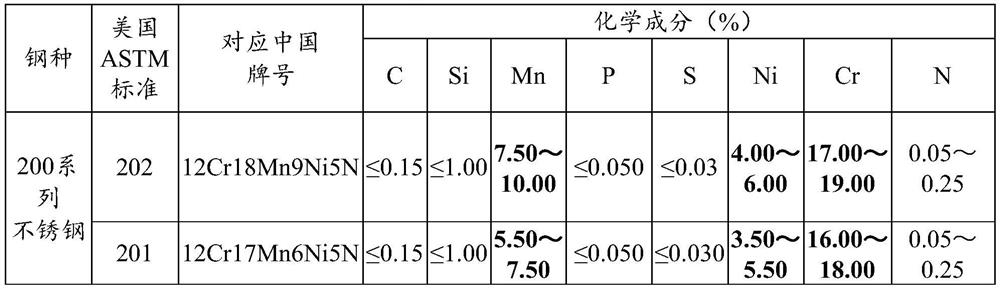

[0050] Specifically, an economical chromium-manganese stainless steel smelting production method of the present invention includes:

[0051] (1) stainless steel scrap is added to the alloy melting furnace, energized and melted to obtain the stainless steel mother liquor;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com