Distributed frequency conversion box and conveying system

A distributed, inverter technology, applied in the control system, motor/generator/inverter limiter, output power conversion device, etc., can solve the problems of high inverter cost, power grid impact, and small power range. , to achieve the effect of small grid impact, high protection level and wide power range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

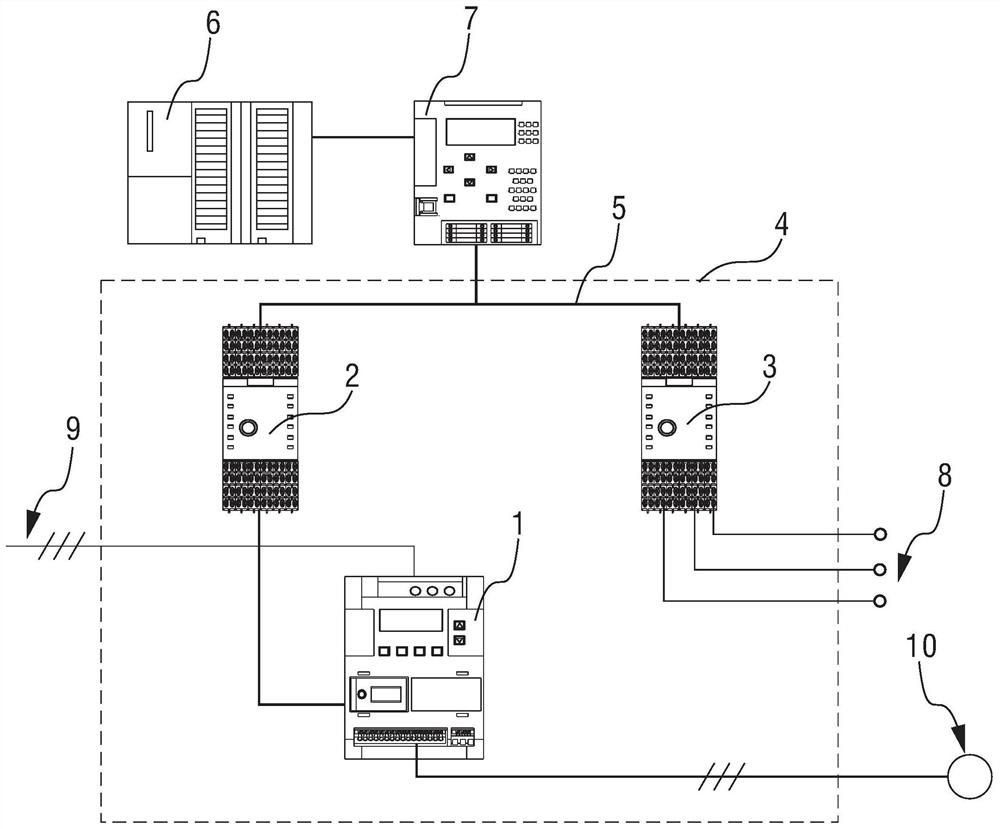

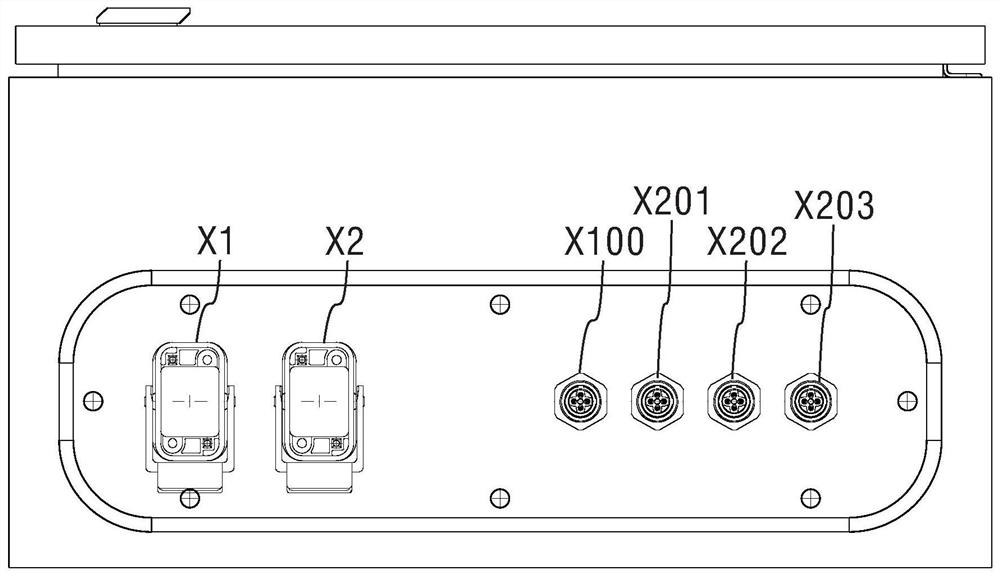

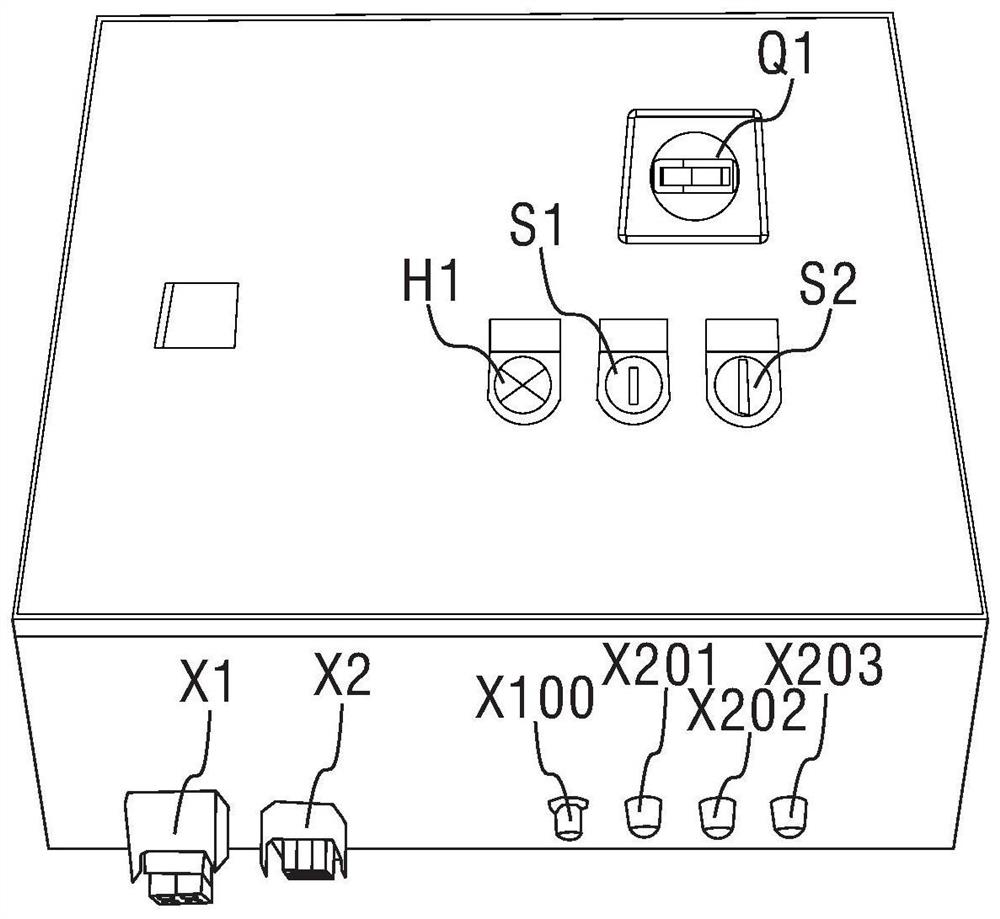

[0025] In the embodiment of the present invention, in order to obtain an adjustable-speed motor driver with a wider power range and a smaller power grid impact start at a lower cost, it is considered to use a lower-cost cabinet-mounted inverter with a protection level below IP65 , such as the V20 inverter to control the external variable frequency motor, and in order to achieve AS-I communication, consider using the first interface conversion module such as the AS-I SlimLine module to integrate the DI / DO point of the cabinet-mounted inverter into the AS-I The bus is finally sent to the programmable logic controller PLC for control and feedback. At the same time, add at least one second interface conversion module such as AS-ISlimLine module to collect other I / O signals on site. And in order to improve the protection level, it is considered to adopt the IP65 protection level standard to design the box body that accommodates the cabinet-mounted inverter and the interface convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com