Patents

Literature

267results about "AC motor direction control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

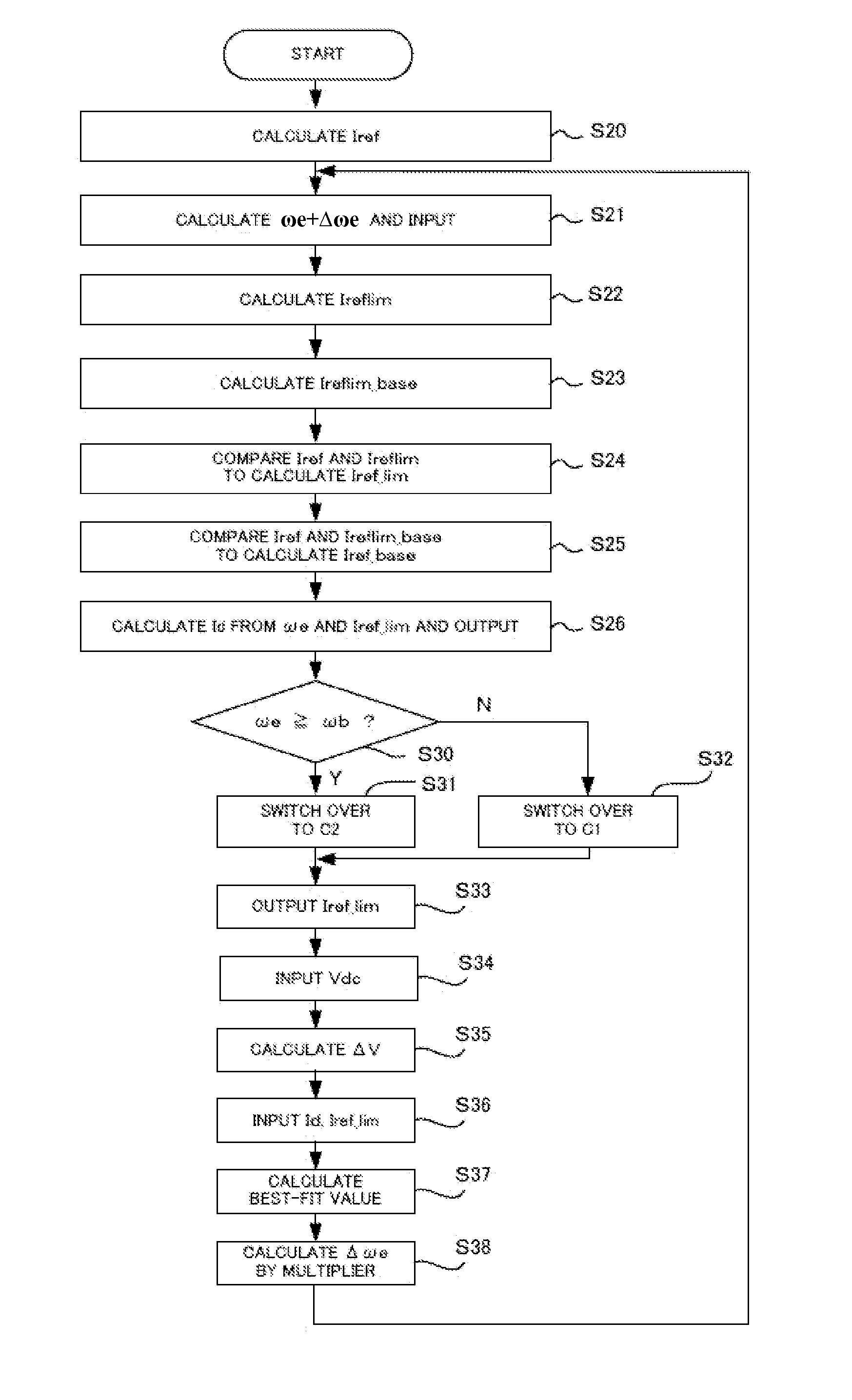

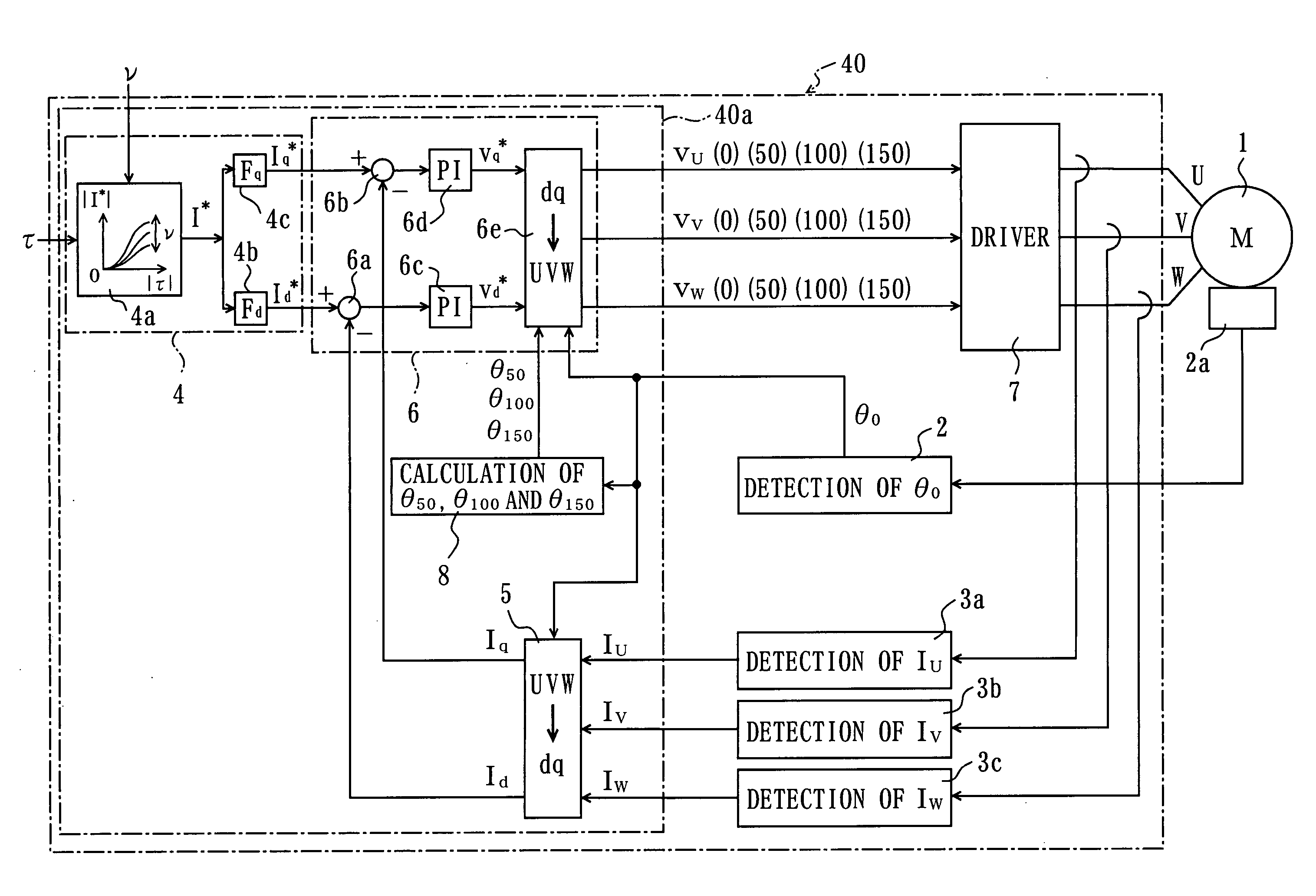

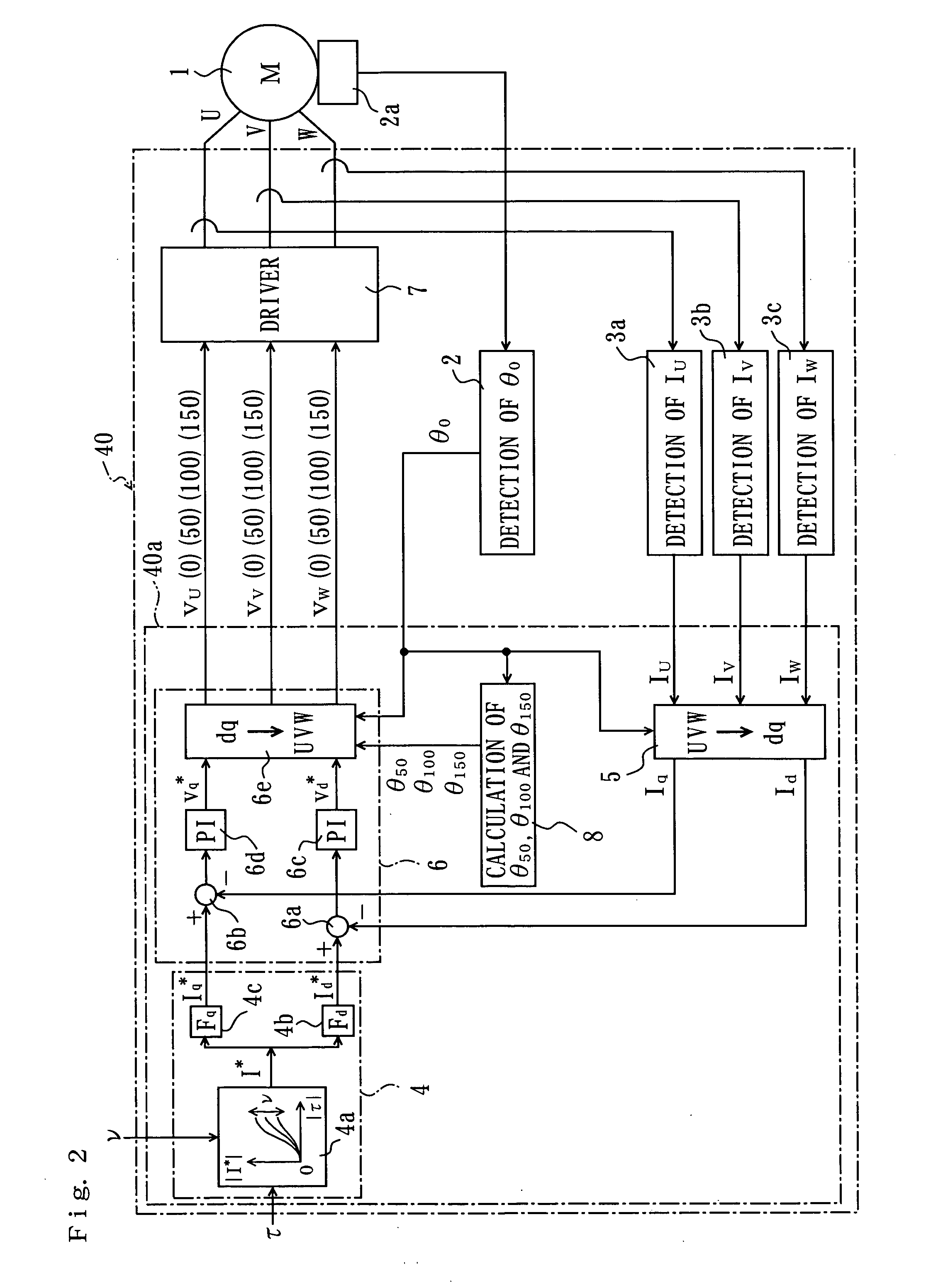

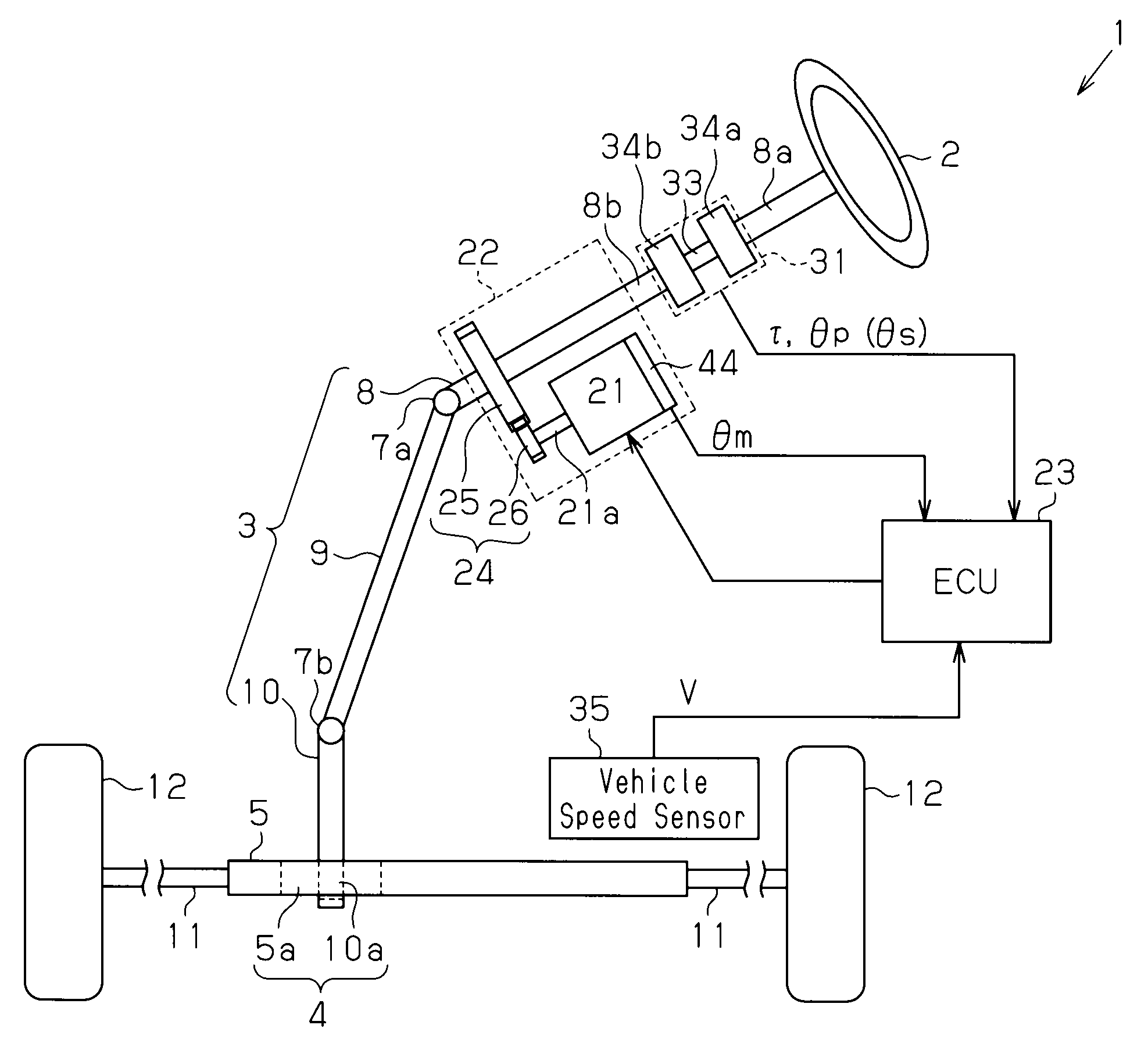

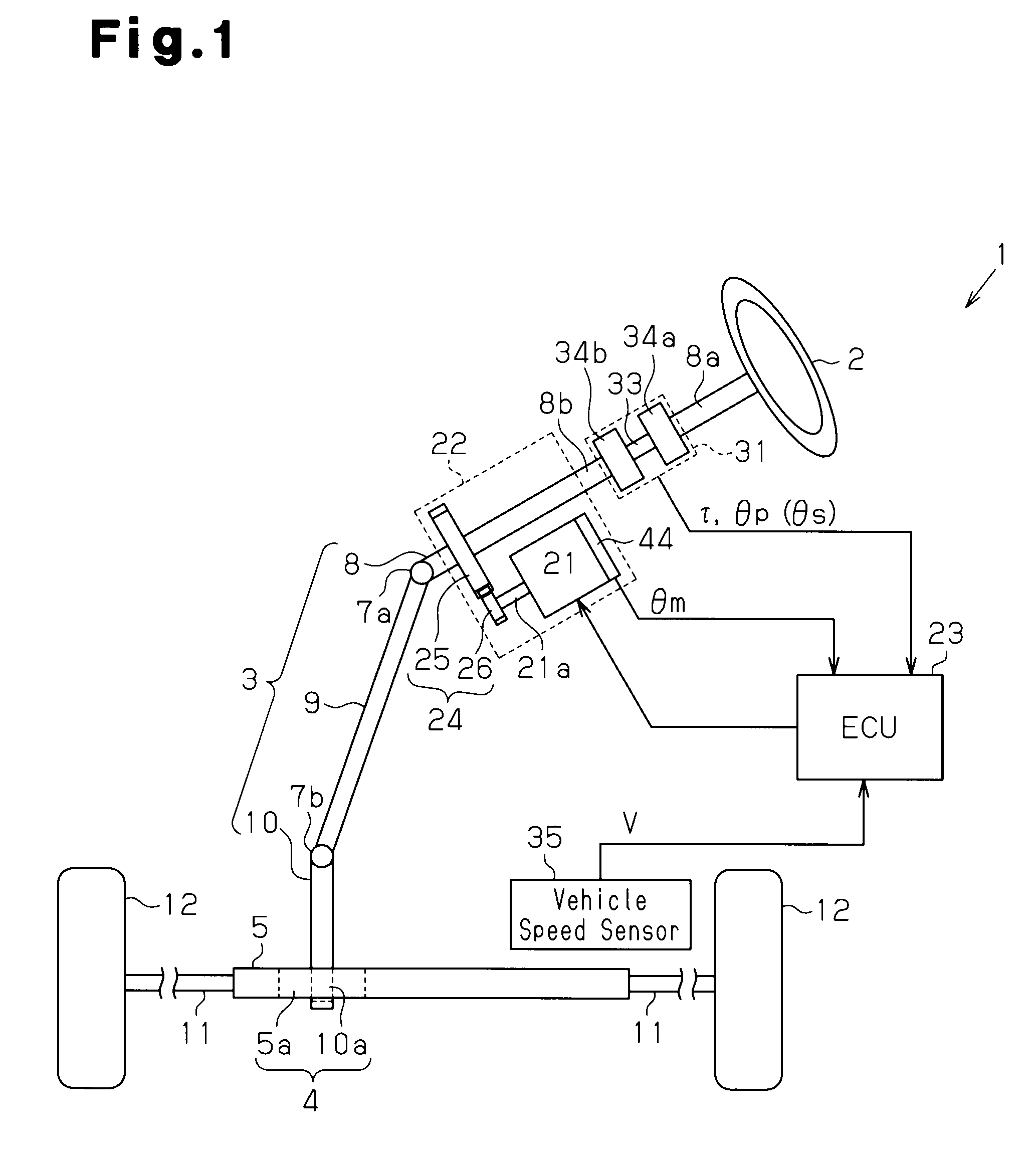

Method and apparatus for controlling electric power steering system

ActiveUS20090234538A1Efficient implementationSingle motor speed/torque controlDigital data processing detailsElectric power steeringControl vector

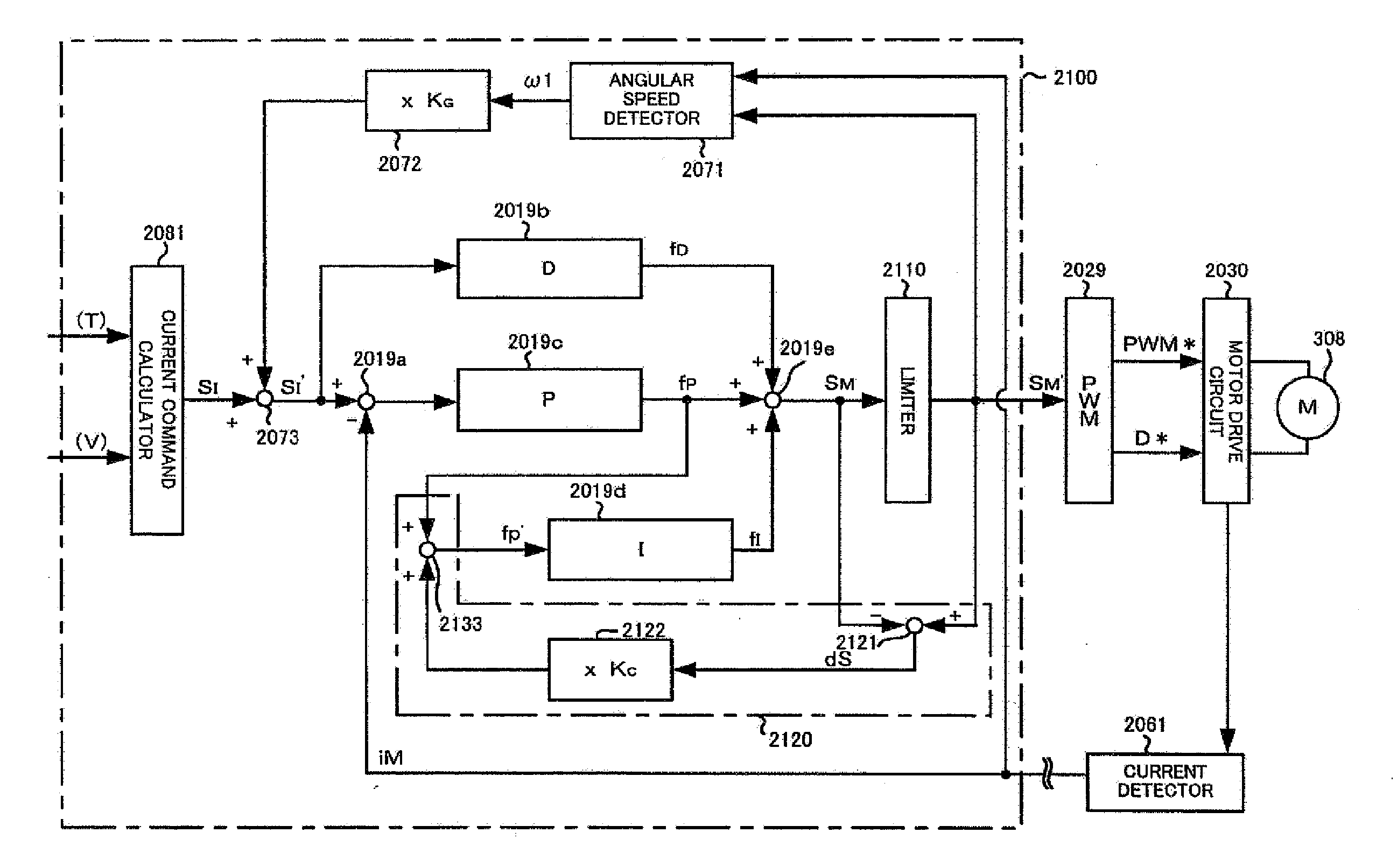

Disclosed herein is a method for controlling an electric power steering system, wherein a motor is controlled by vector control and driven by a current command value calculated on the basis of a parameter such as a steering torque to provide a steering assist power to a vehicle steering system, and further wherein the current command value is limited on the basis of desired output characteristics and a desired angular speed during a field-weakening control and a non-field-weakening control of the vector control.

Owner:NSK LTD

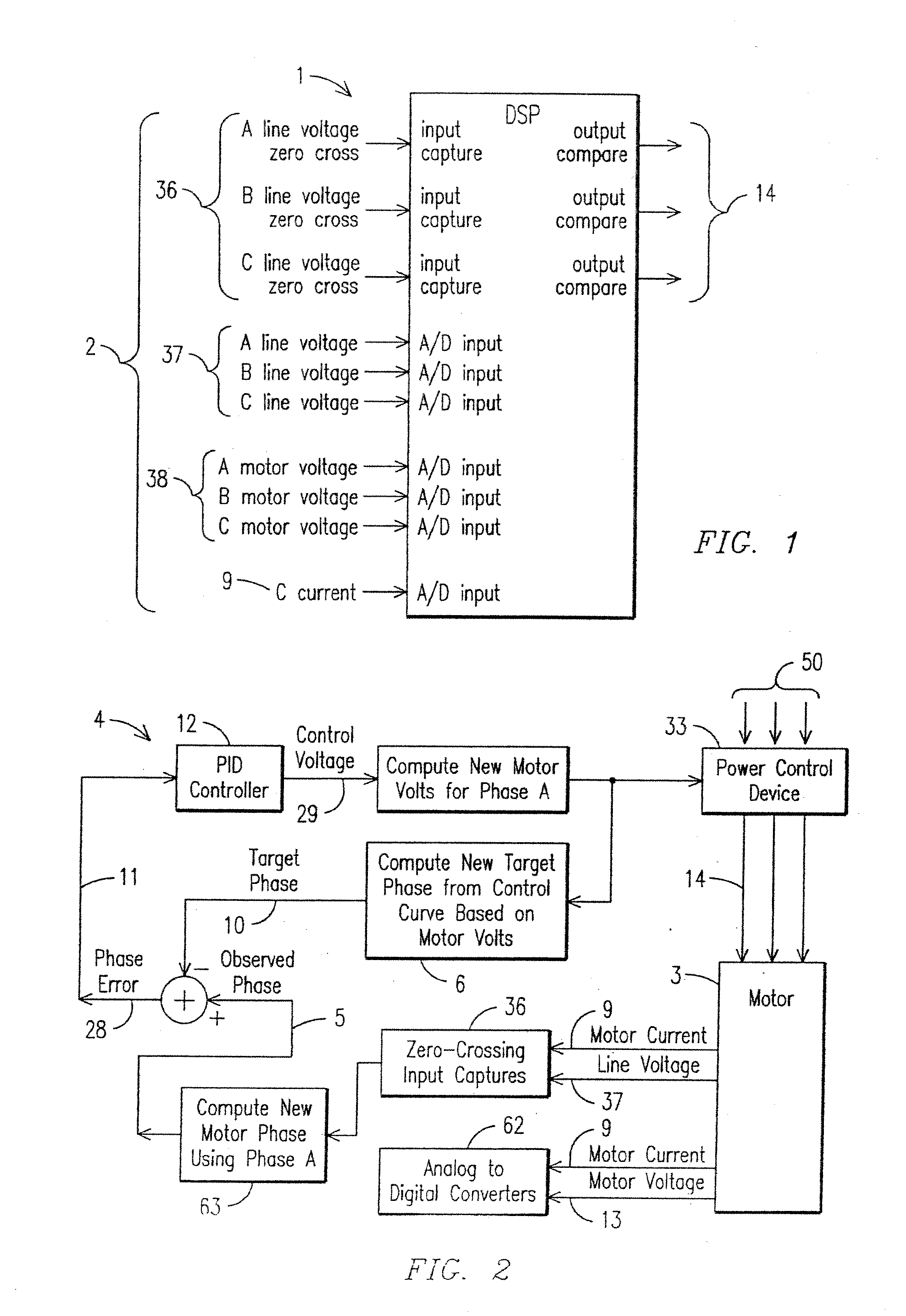

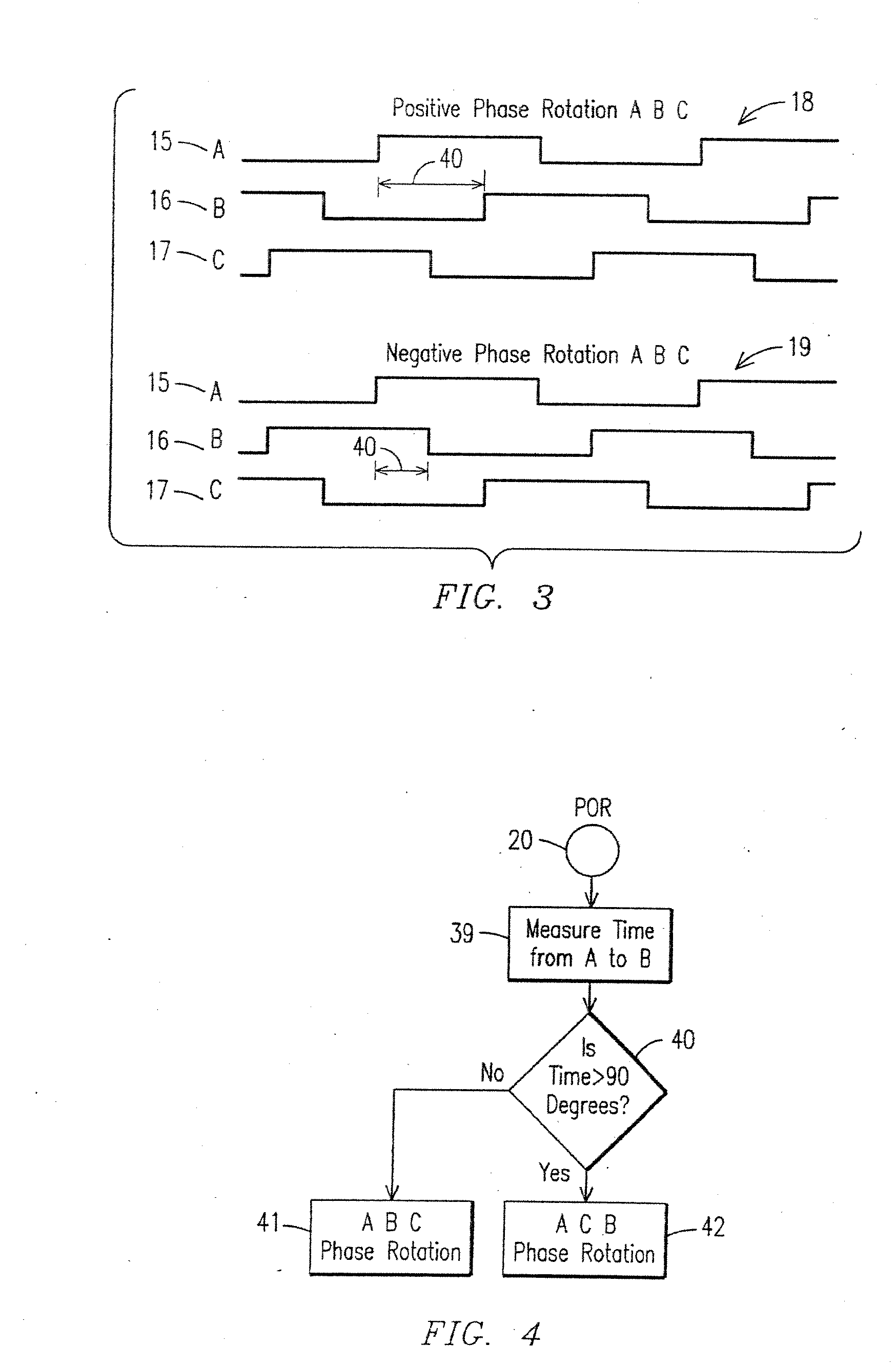

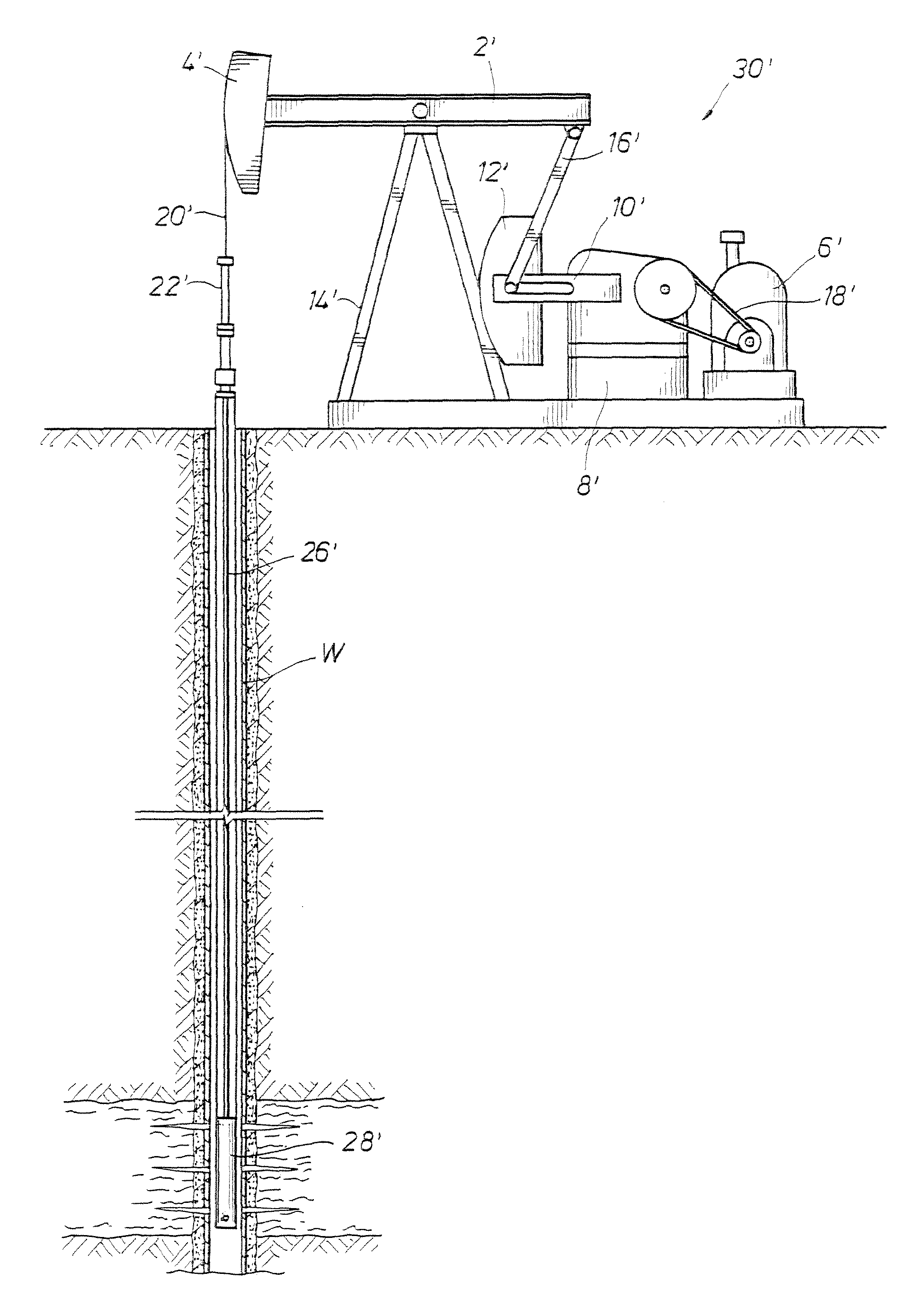

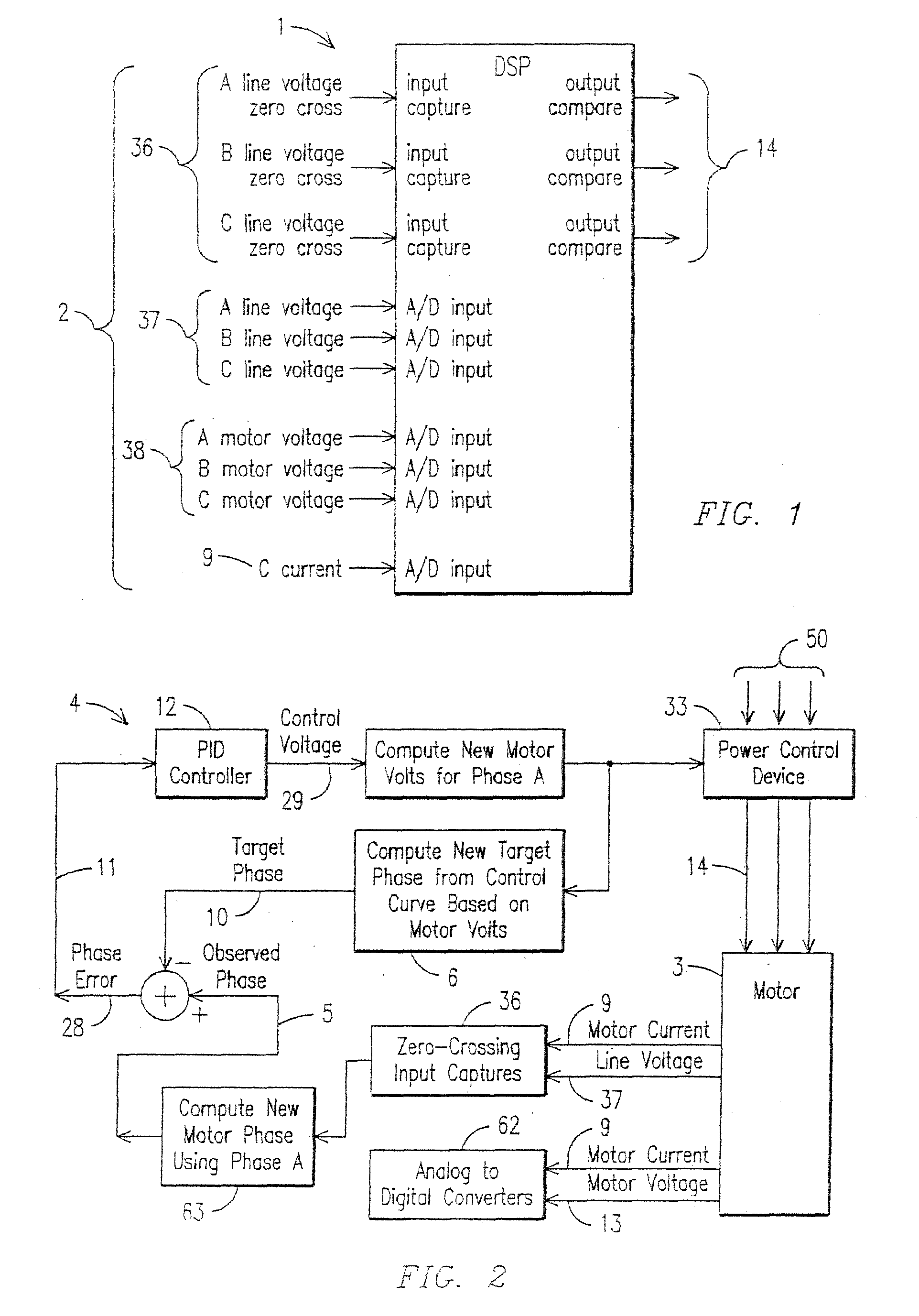

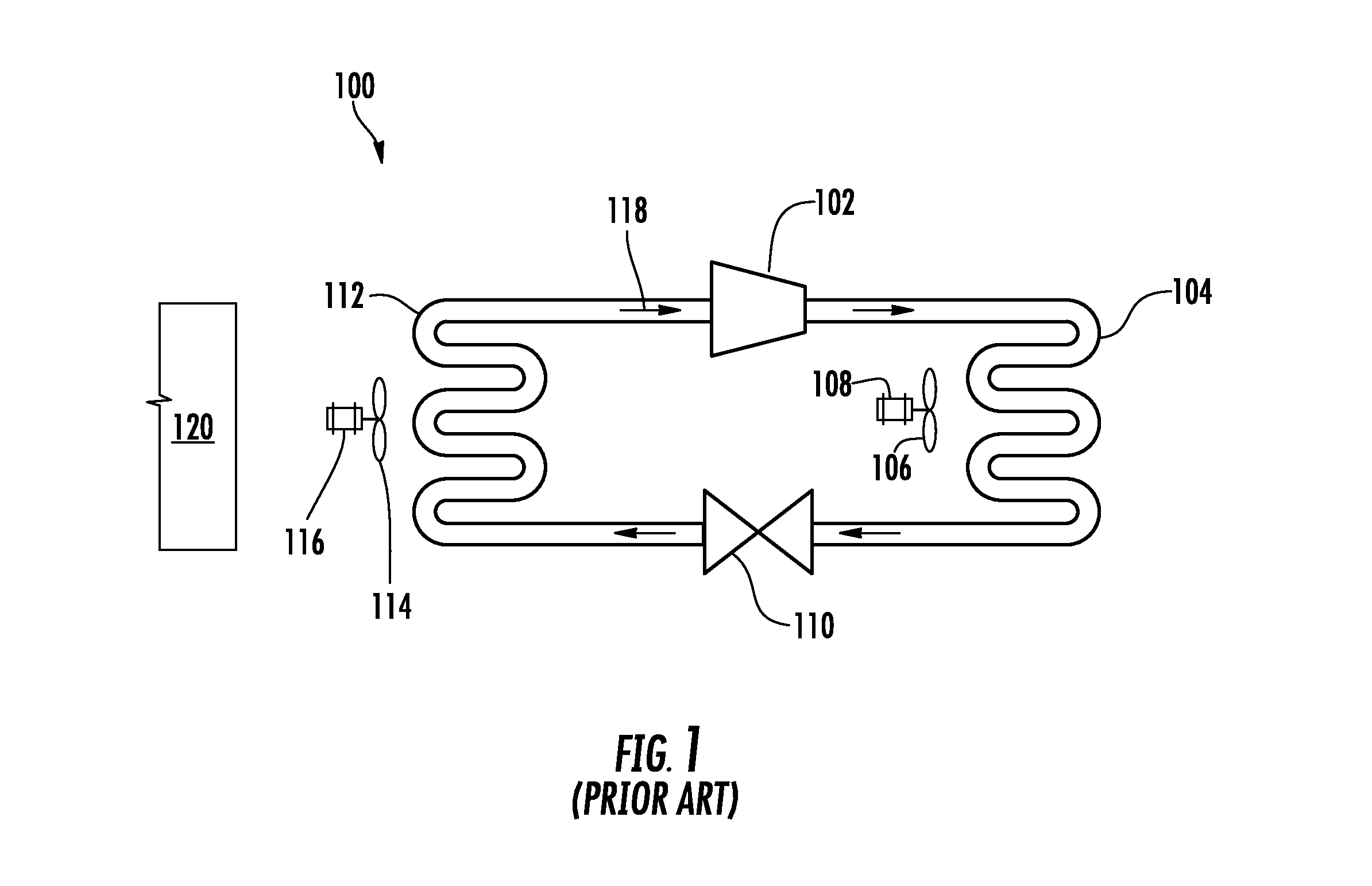

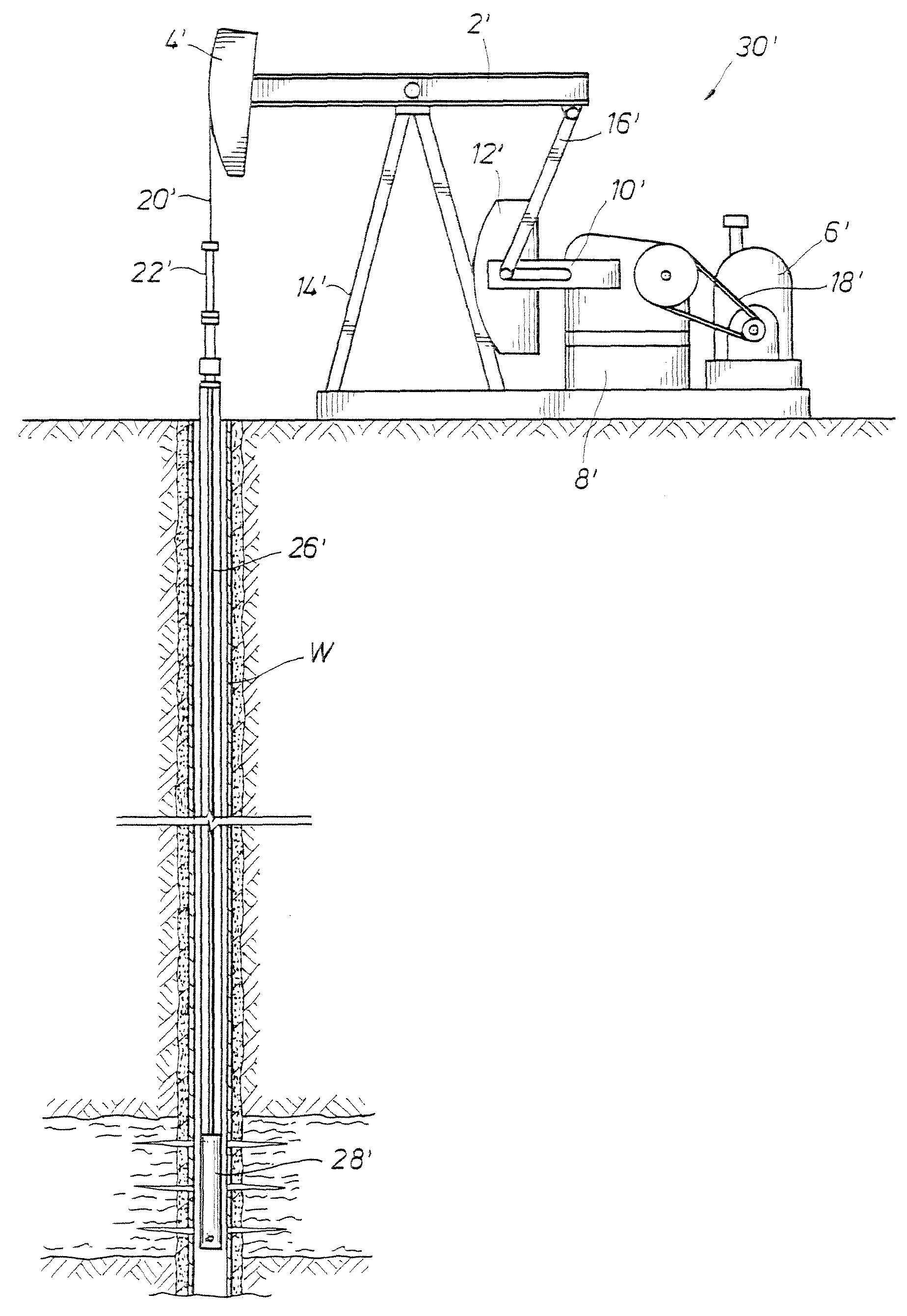

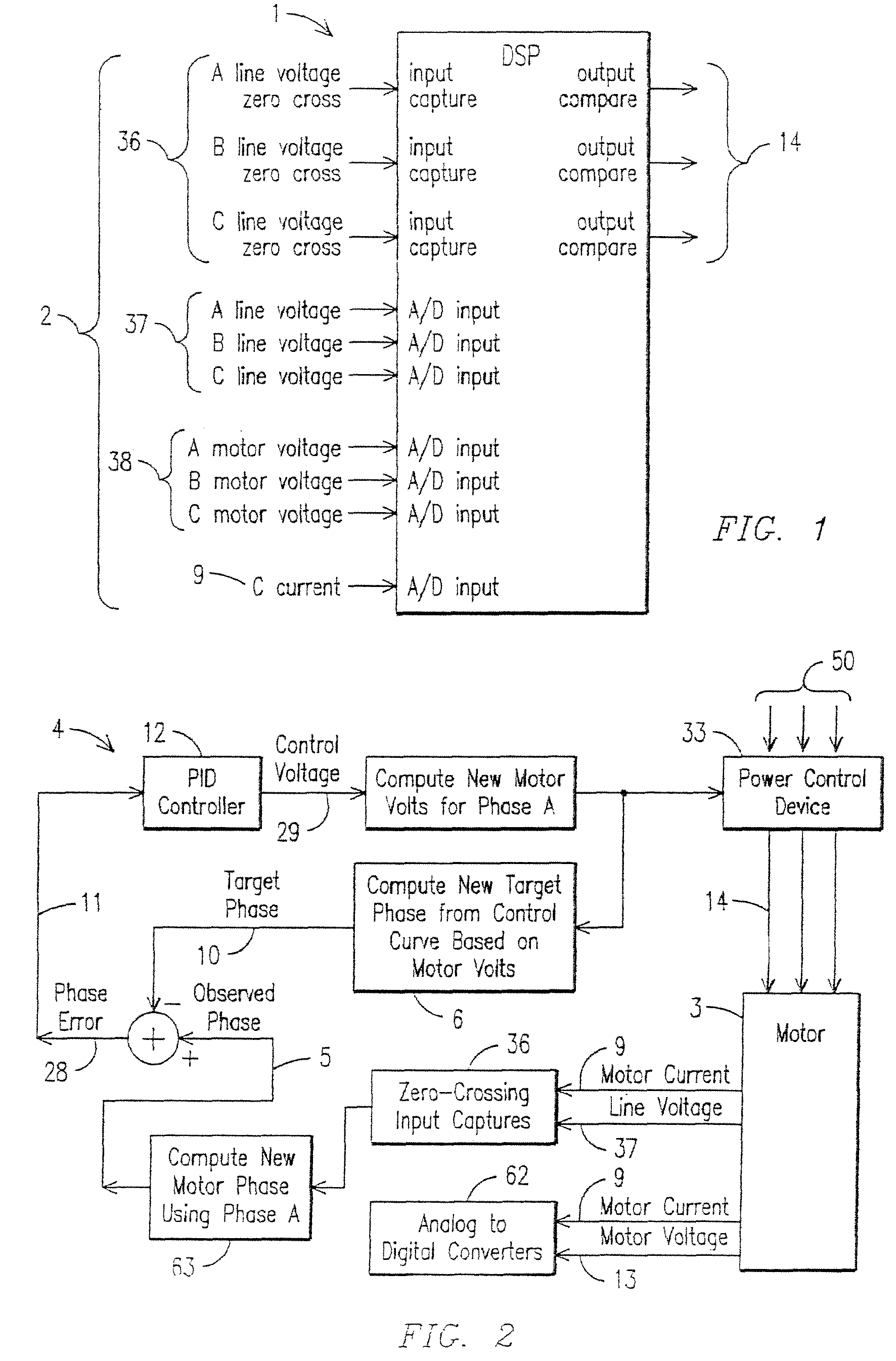

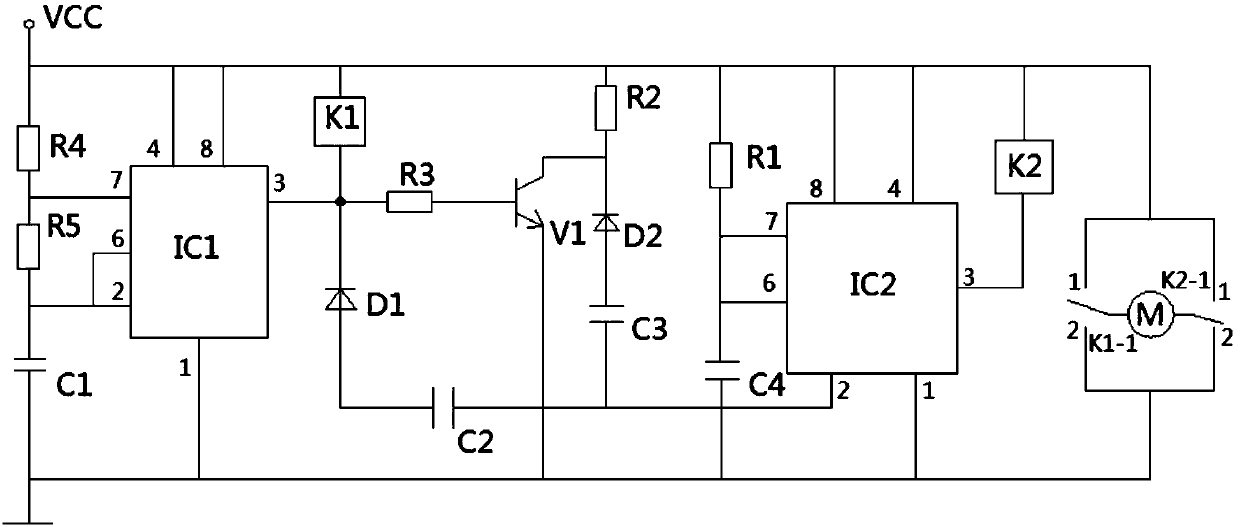

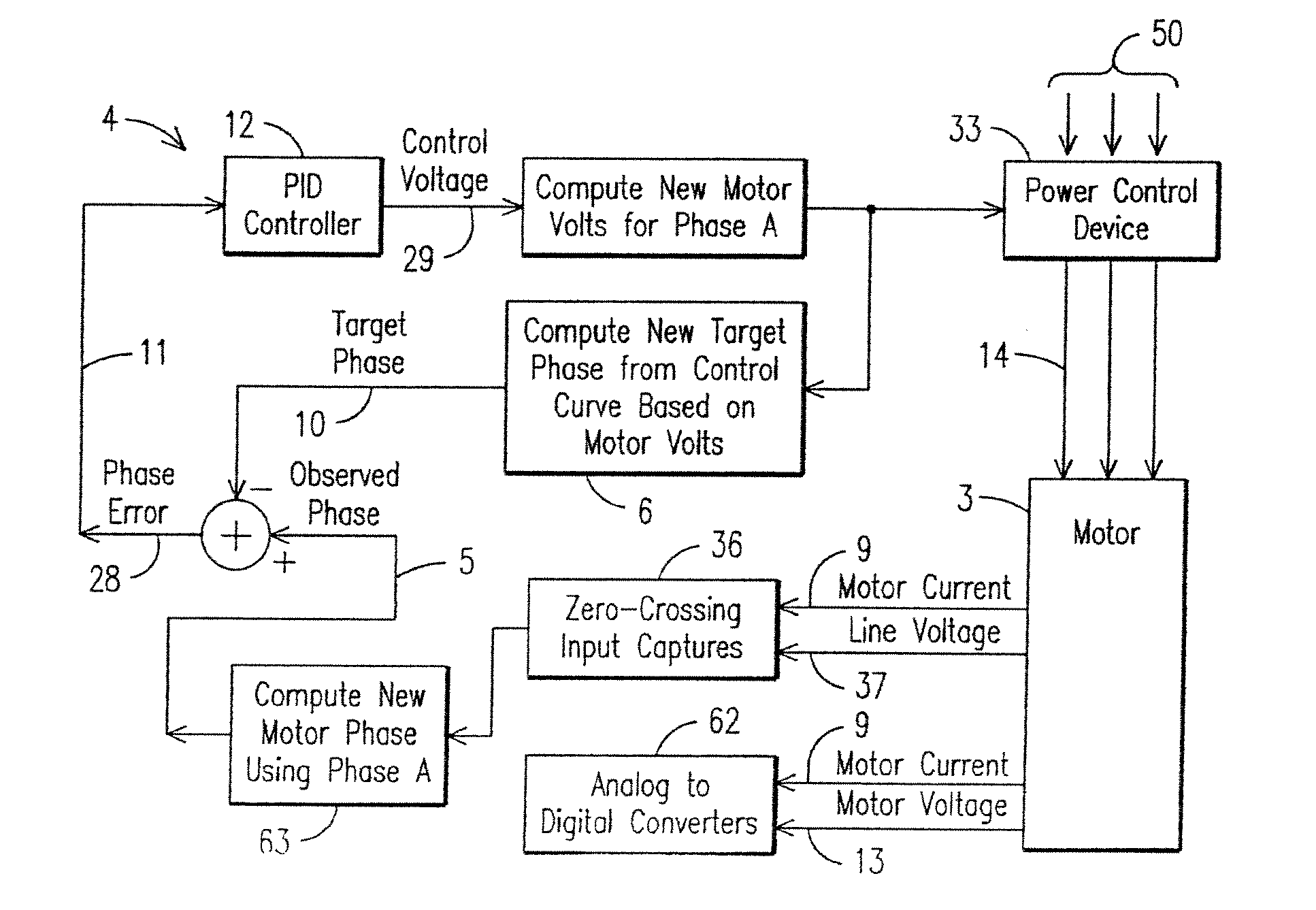

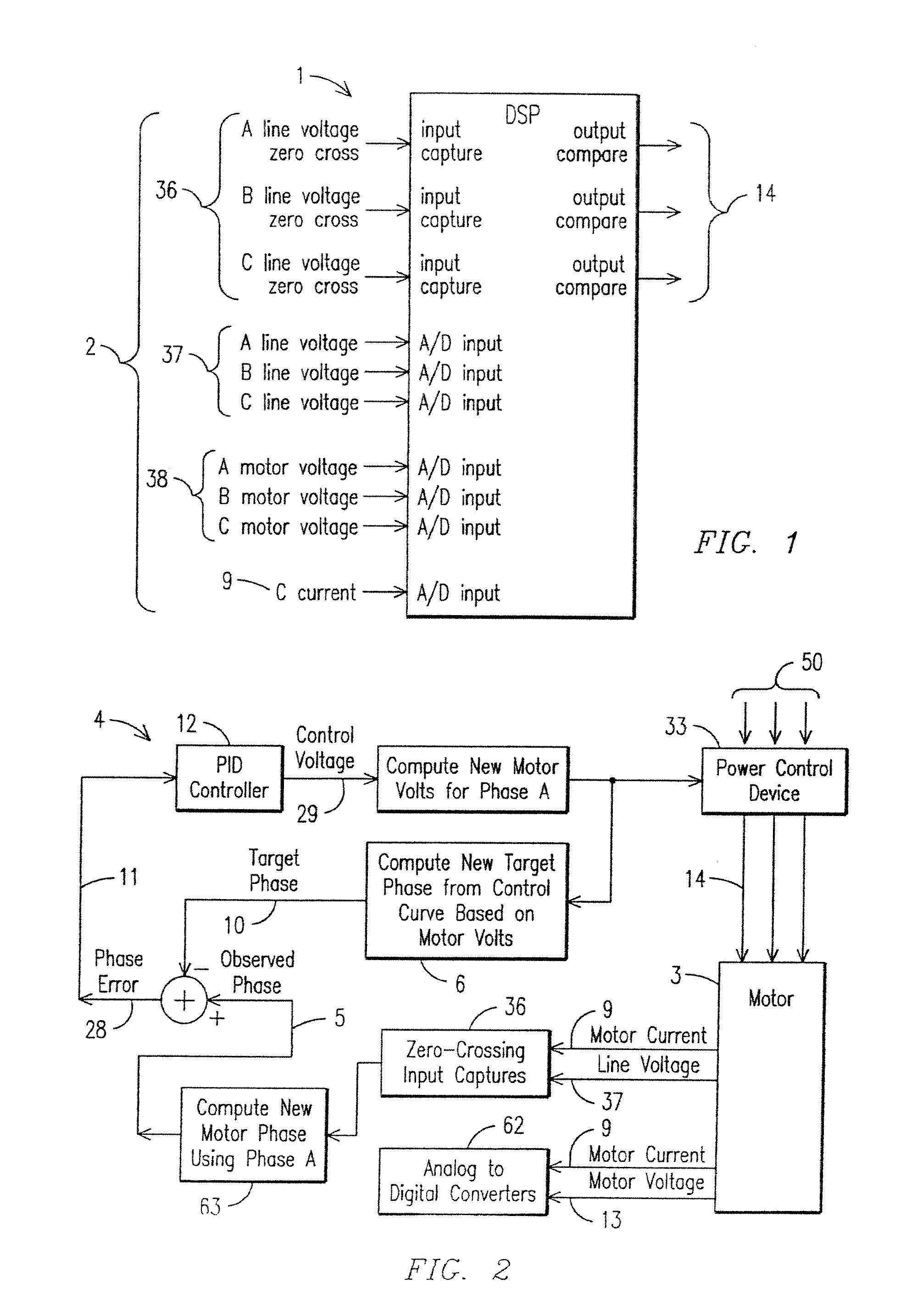

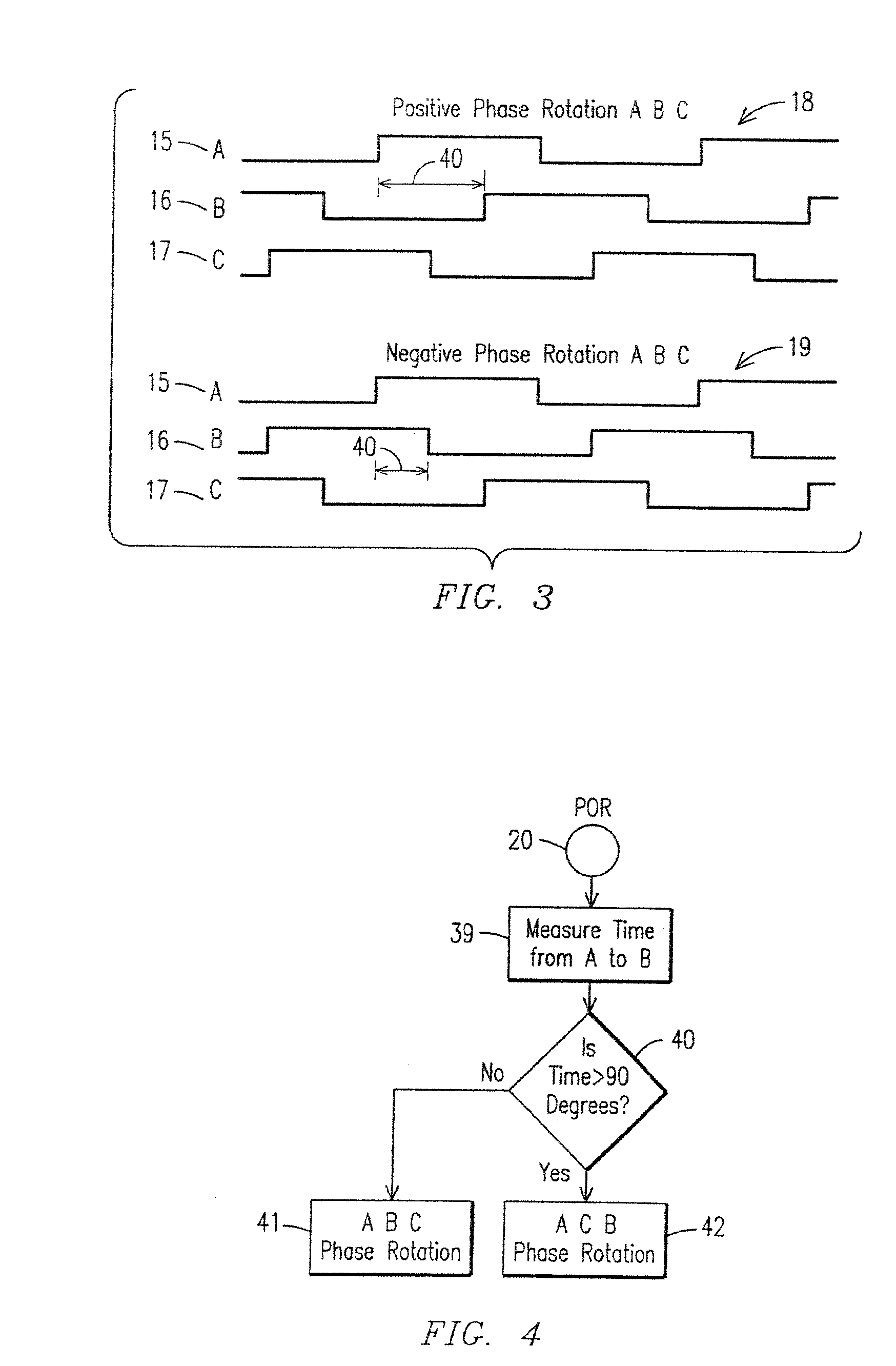

Energy Saving System and Method for Devices with Rotating or Reciprocating Masses

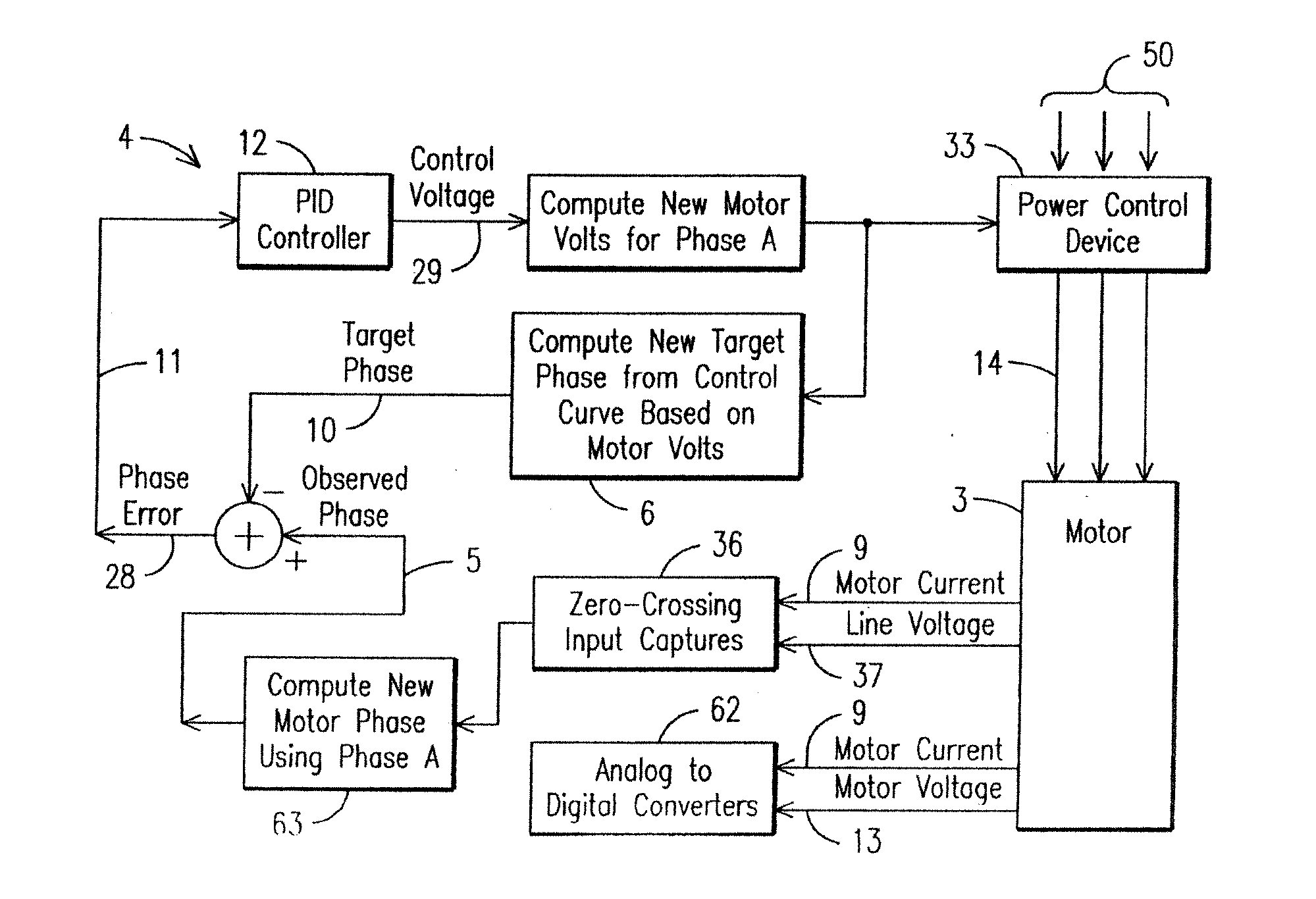

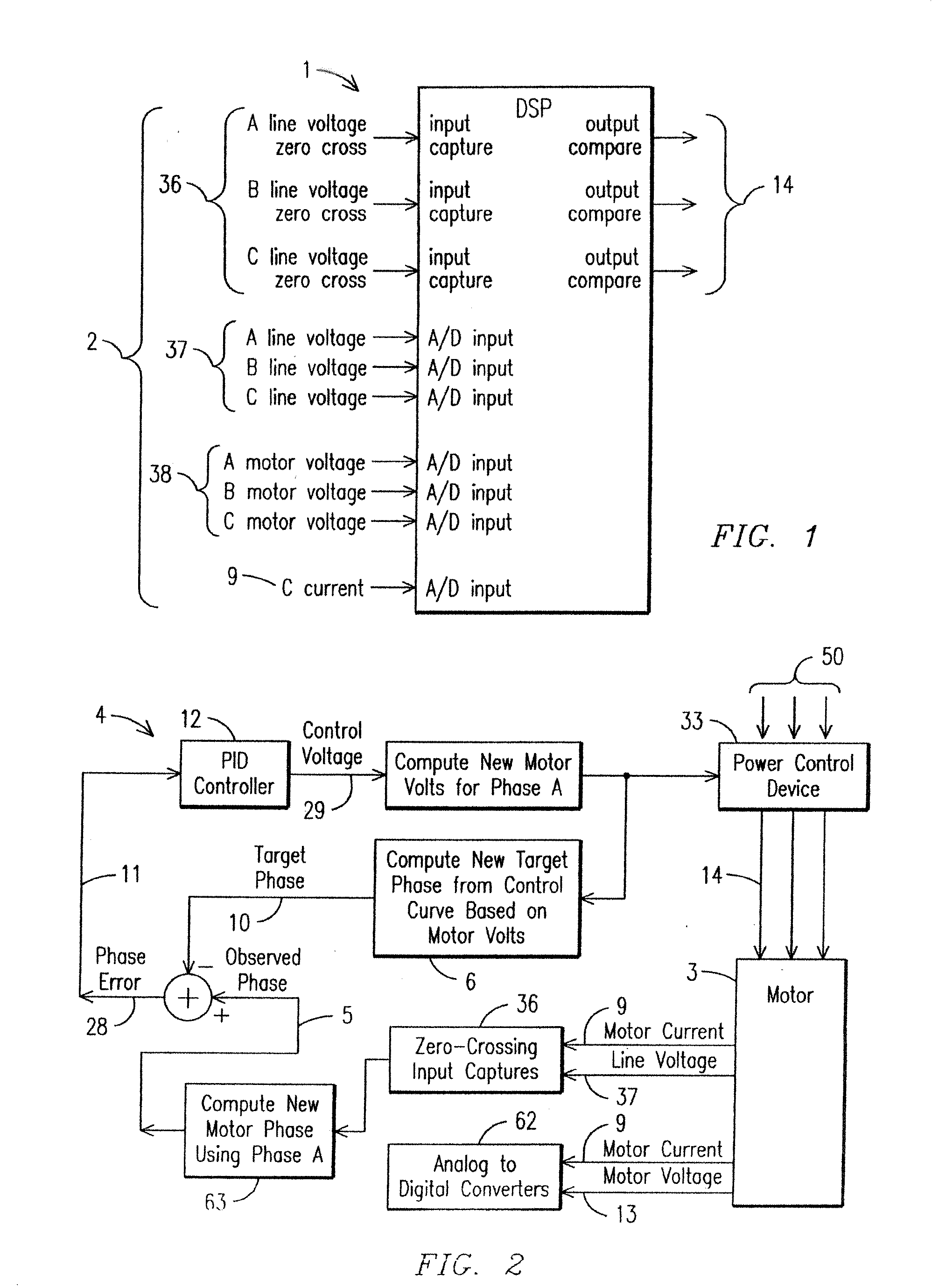

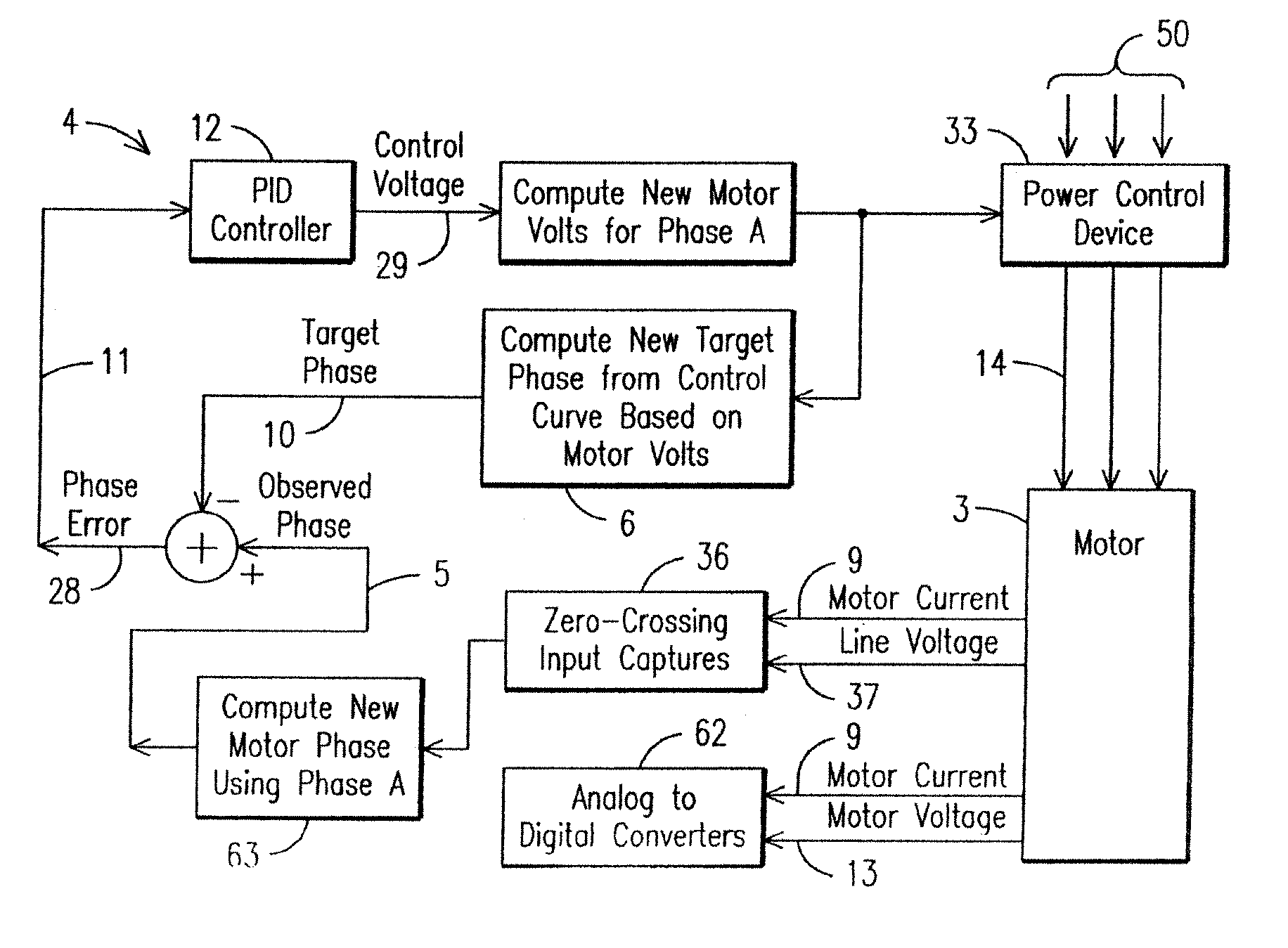

InactiveUS20100320956A1Save energyDoes not consume energyPower network operation systems integrationAC motor direction controlControl systemClosed loop

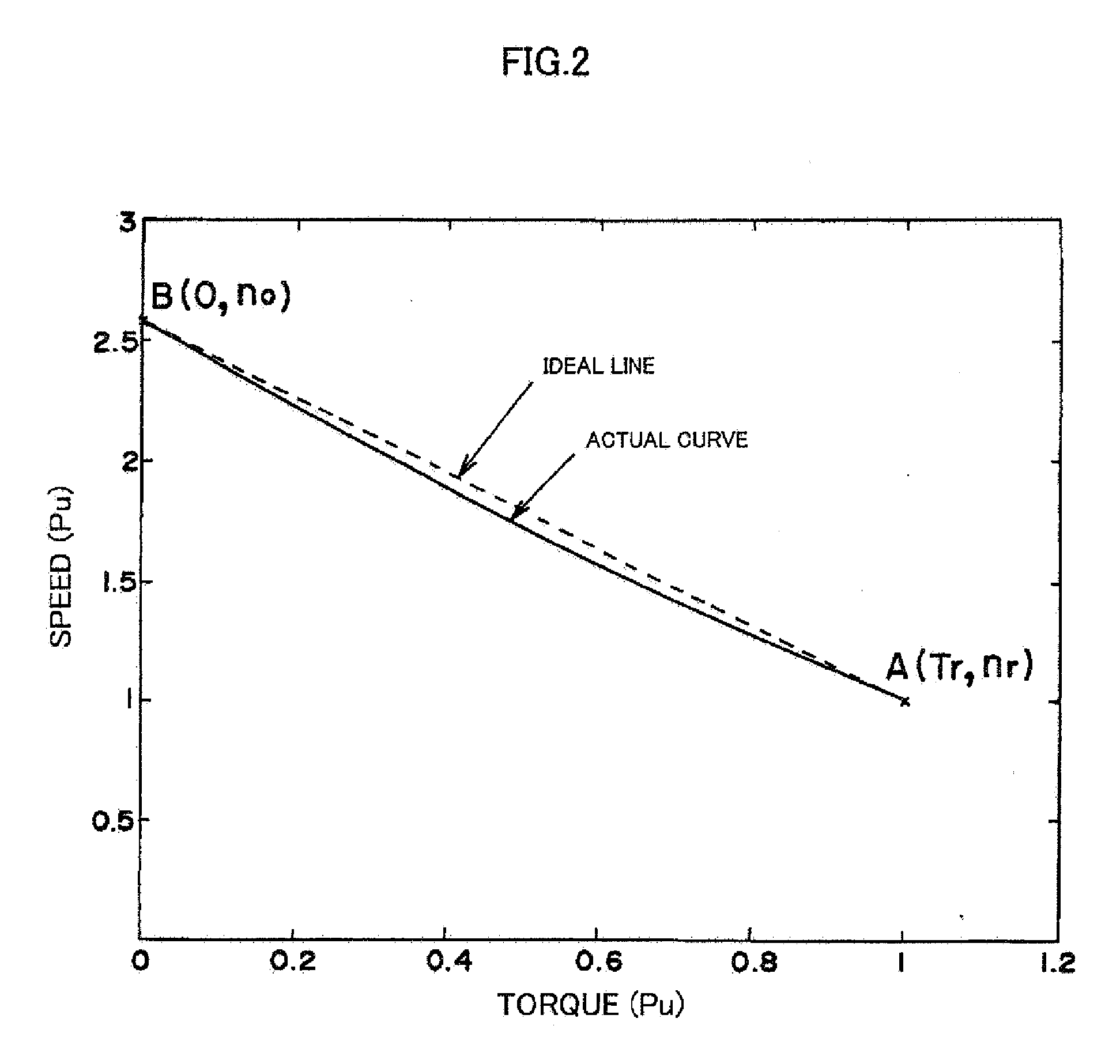

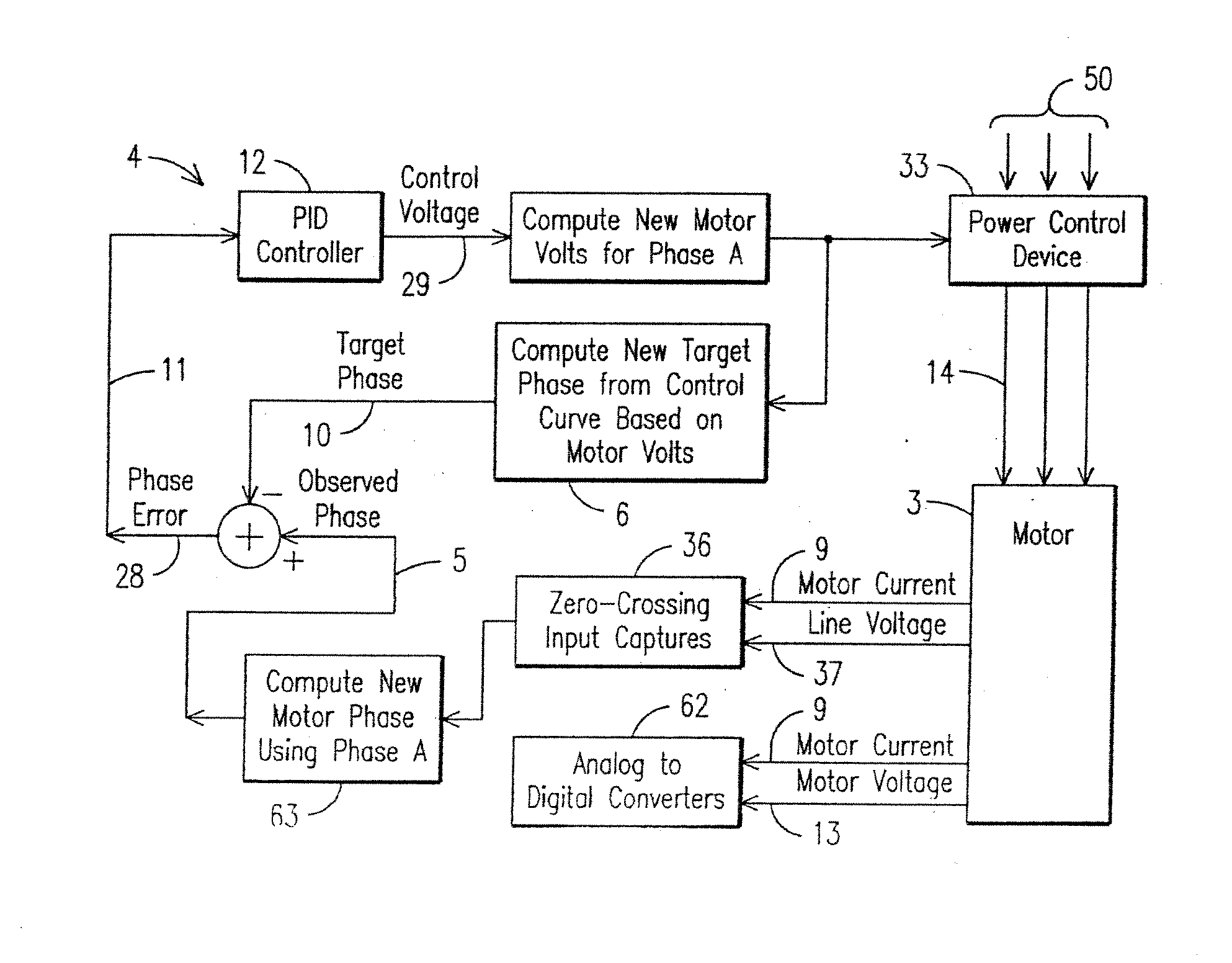

A system and method are provided for reducing the energy consumed by a pump jack electric motor by reducing the supply voltage to the motor when the motor would be generating energy in open loop mode. By substantially eliminating the energy generation mode, the braking action of the utility grid in limiting the acceleration of the motor and system that would otherwise occur is substantially removed. The motor and system will speed up, allowing the natural kinetic energy of the cyclic motion to perform part of the pumping action. A closed loop controller in electrical connection with the motor computes the necessary information from the observed phase angle between the voltage and current supplied to the motor. By reducing the supply voltage to the motor, the observed phase angle may be reduced to a target phase angle value. By allowing some current flow, primarily of a reactive nature, an observable feedback parameter may be used in the closed loop control system as an indication of the load condition, to which the closed loop motor controller may react, supplying power when needed, such as in the energy consumption mode. The electric motor may be effectively turned off, but without completely cutting the power to the motor. During both the energy consumption mode and the period that open loop energy generation would be occurring, the closed loop motor controller may reduce the observed phase angle to a target phase angle by reducing the supply voltage. Any further reduction in the observed phase angle below the target phase angle may be interpreted as an increase in motor load, to which the motor controller may respond by increasing the supply voltage to the motor until the target phase angle is once again reached.

Owner:THE POWERWISE GRP

Method to save energy for devices with rotating or reciprocating masses

ActiveUS20110080130A1Highly variation of loadImprove energy savingMotor/generator/converter stoppersDC motor speed/torque controlLoop controlReciprocating motion

A system and method are disclosed for turning off the voltage to a pump jack electric motor during predetermined periods of time to save energy. In the method, the motor's response to closed-loop control may be evaluated over several pump strokes. The periods of the pump stroke when it is feasible to turn off the motor may be identified. The consistency of the measurements over several strokes may be evaluated. The motor may be turned off during predetermined periods on subsequent pump strokes when each pump stroke shows sufficiently similar behavior to that predicted during the closed-loop control process. The system may return to the closed-loop control process after a predetermined period of time to adjust to any changes in the system.

Owner:THE POWERWISE GRP

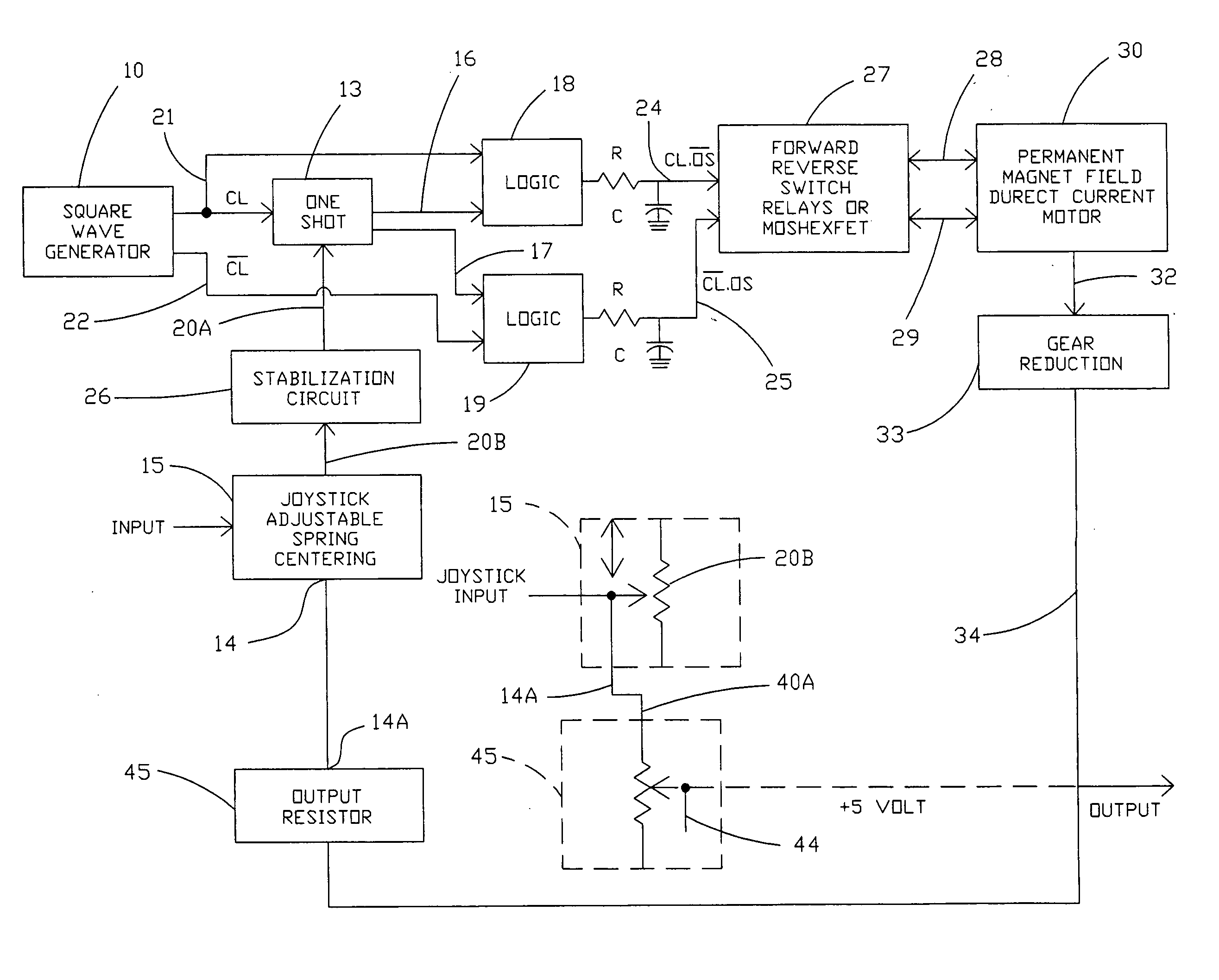

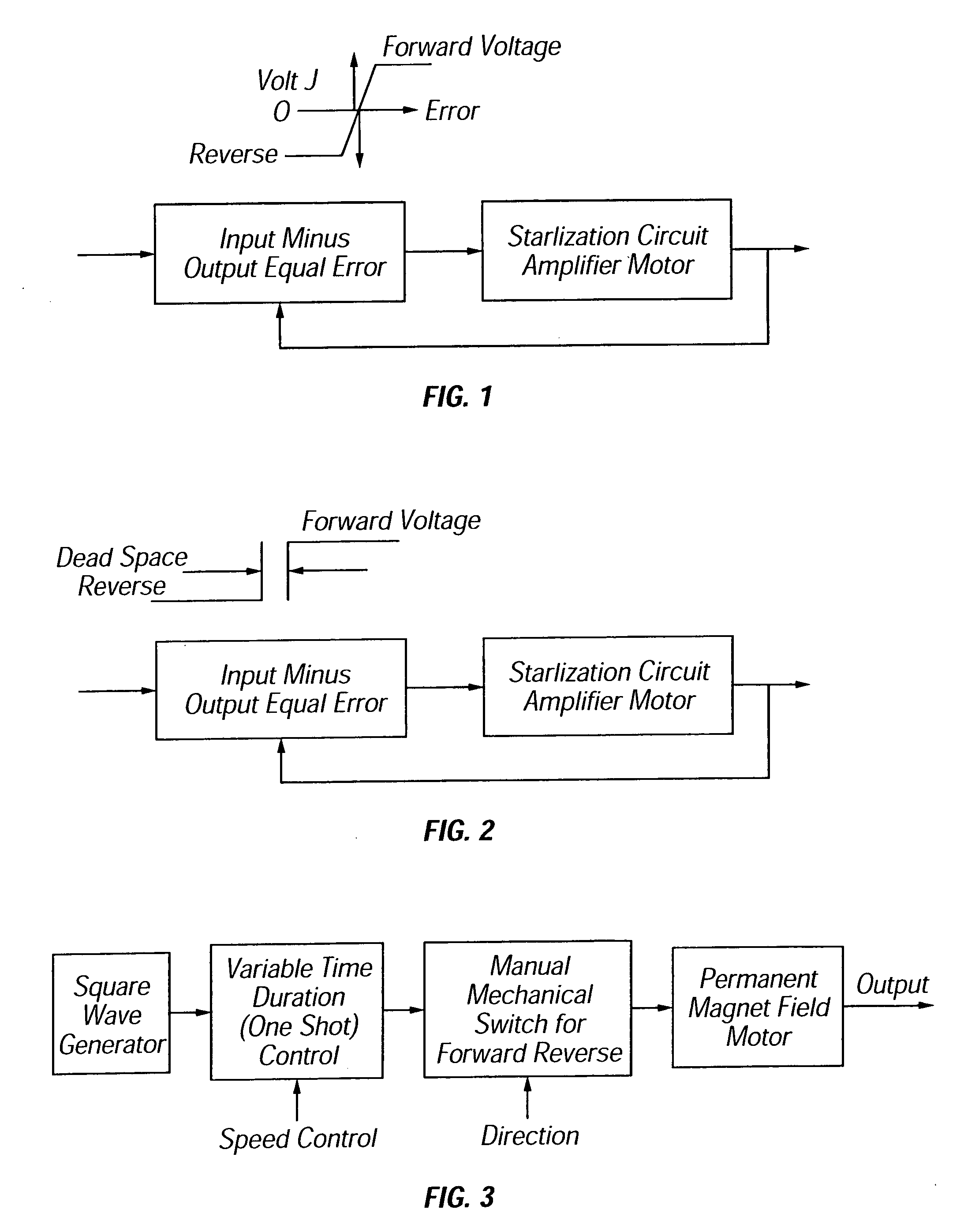

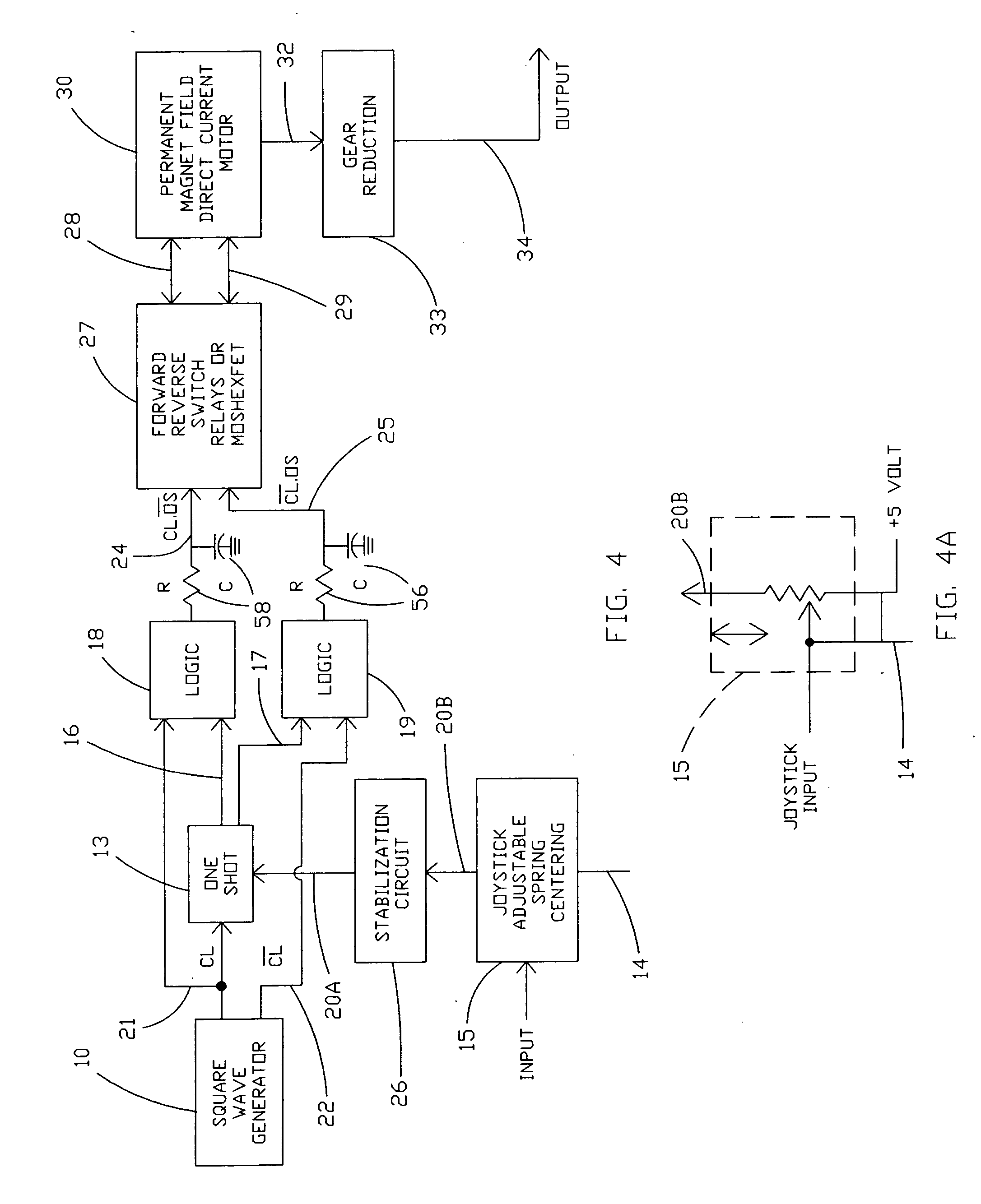

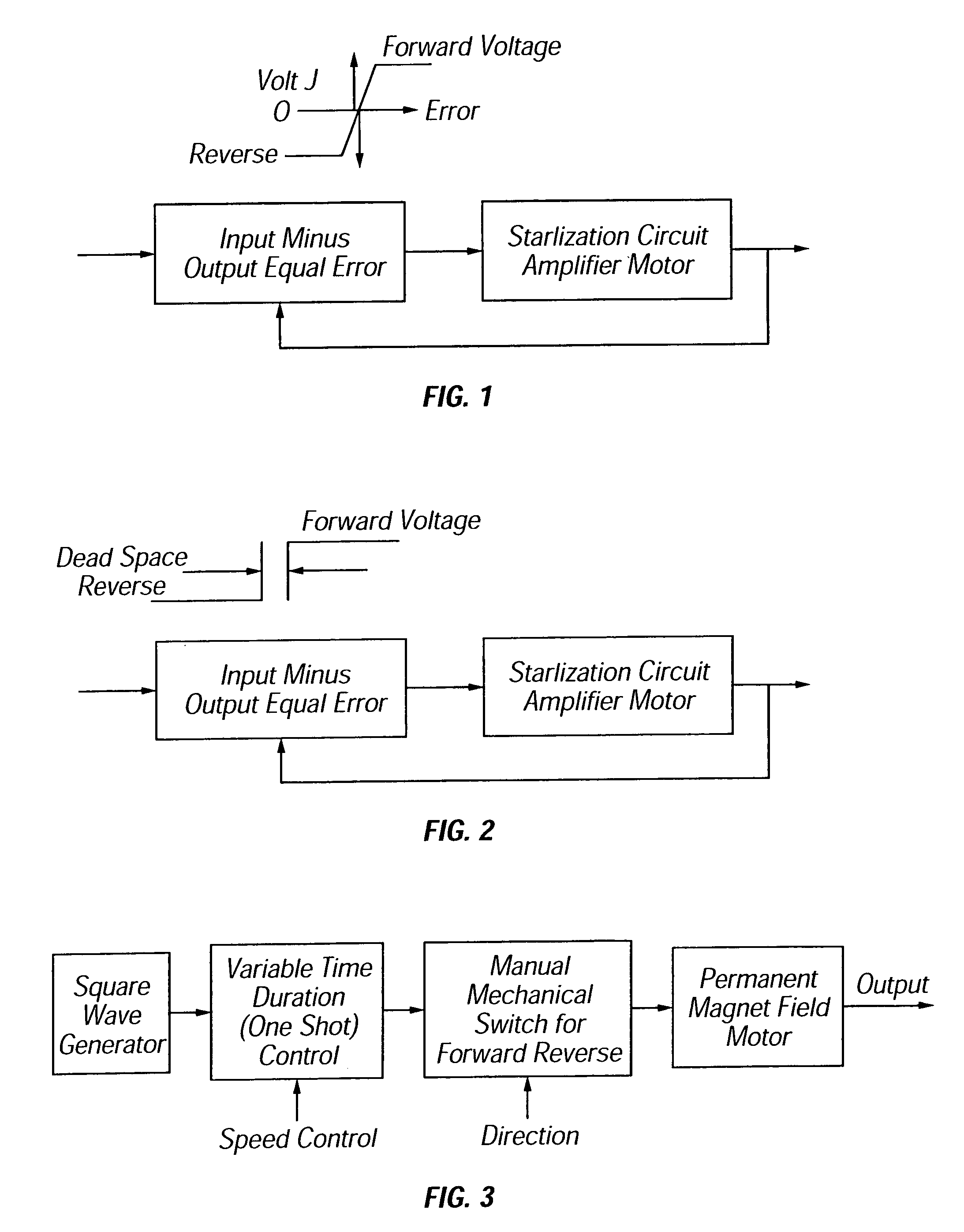

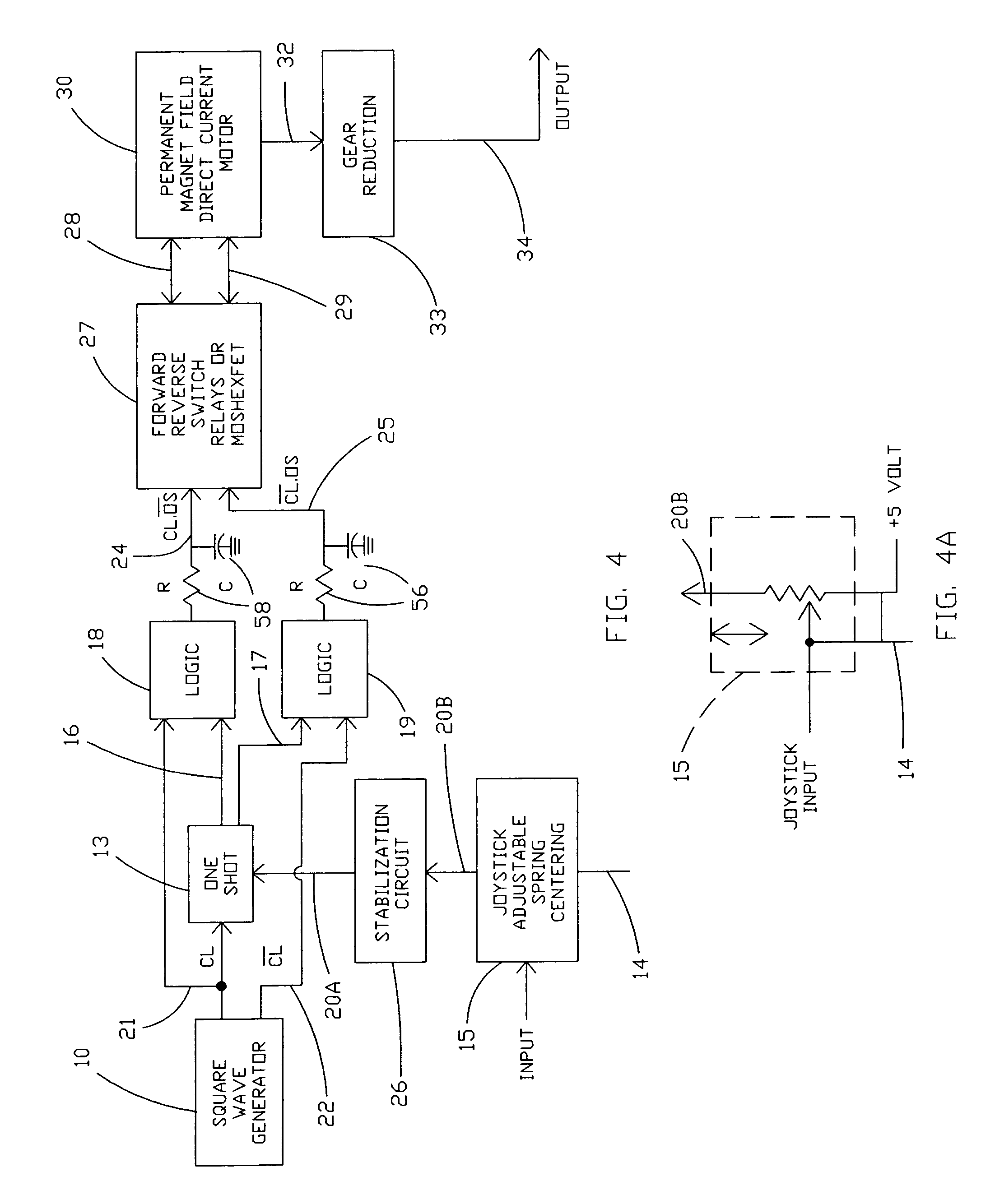

Digital motor control system and method

ActiveUS20060291820A1Improve energy efficiencyStable servo controlField or armature current controlDynamo-electric converter controlMotor speedJoystick

A digital motor control system utilizes time duration electric pulses generated by digital logic to control the motor speed and direction of rotation of a D.C. or A.C. motor. The digital logic produces width modulated pulses that can be connected to large or small electric motors by mechanical or electrical relays or switches to provide efficient motor control with little control circuit power loss. The mechanical or electrical switches are responsive to the digital logic to change motor direction or remove power from the motor windings. A variable control element such as a computer joystick can be utilized to control both direction and speed of the motor. The system can be configured as an open loop system or as a closed loop servo with a feed back element to control the rotational position of the motor.

Owner:KOBAYASHI HERBERT S

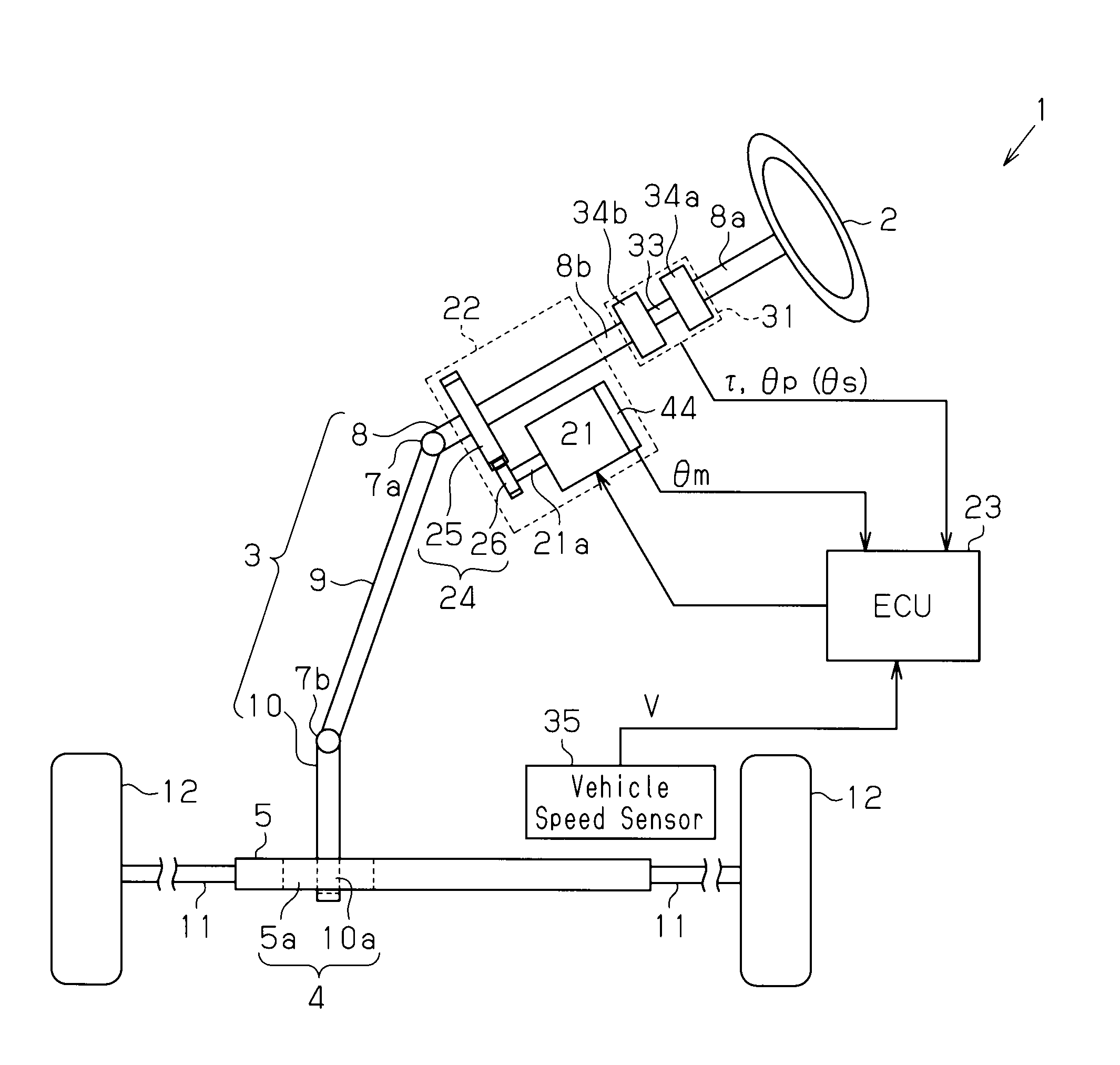

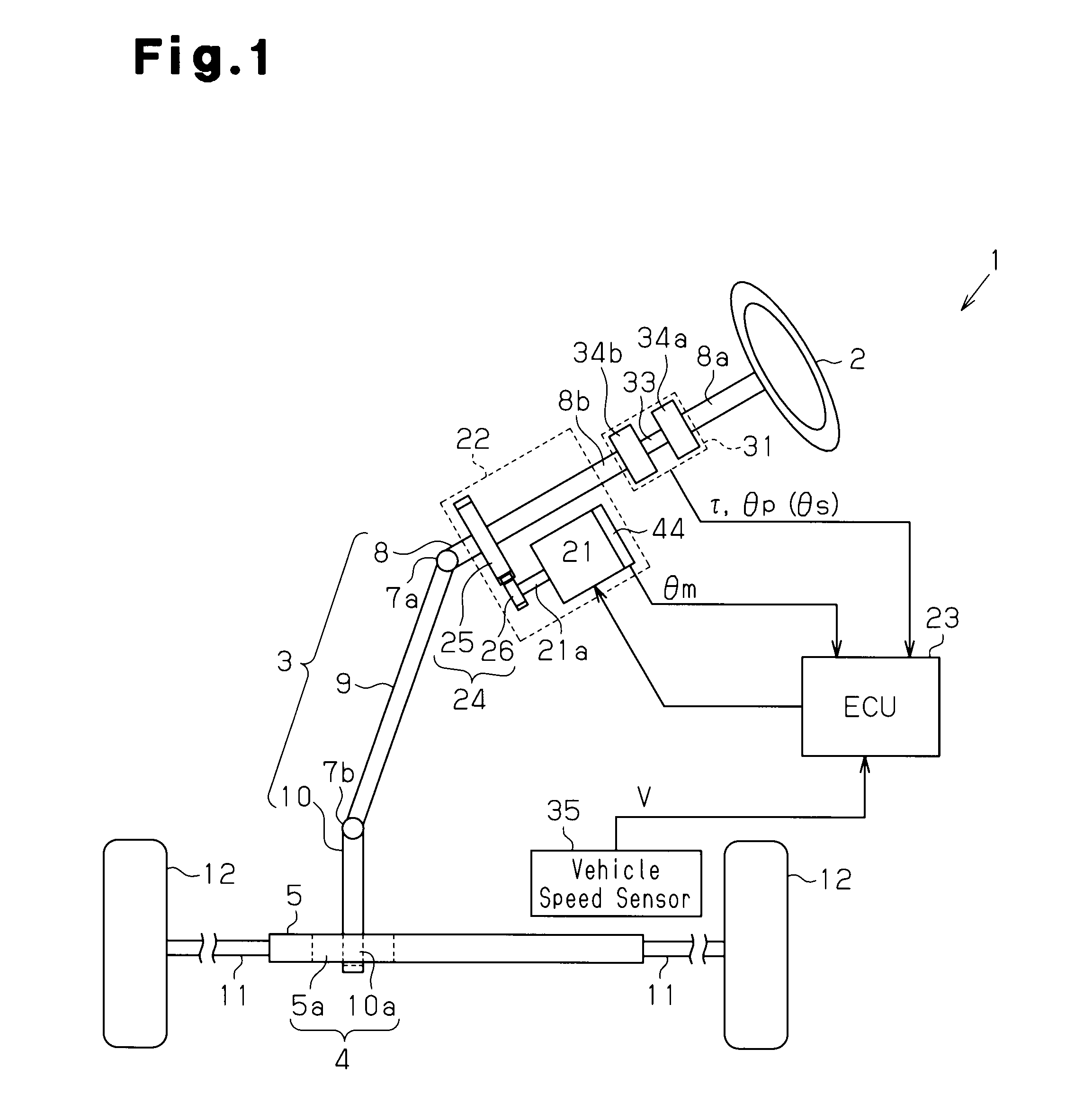

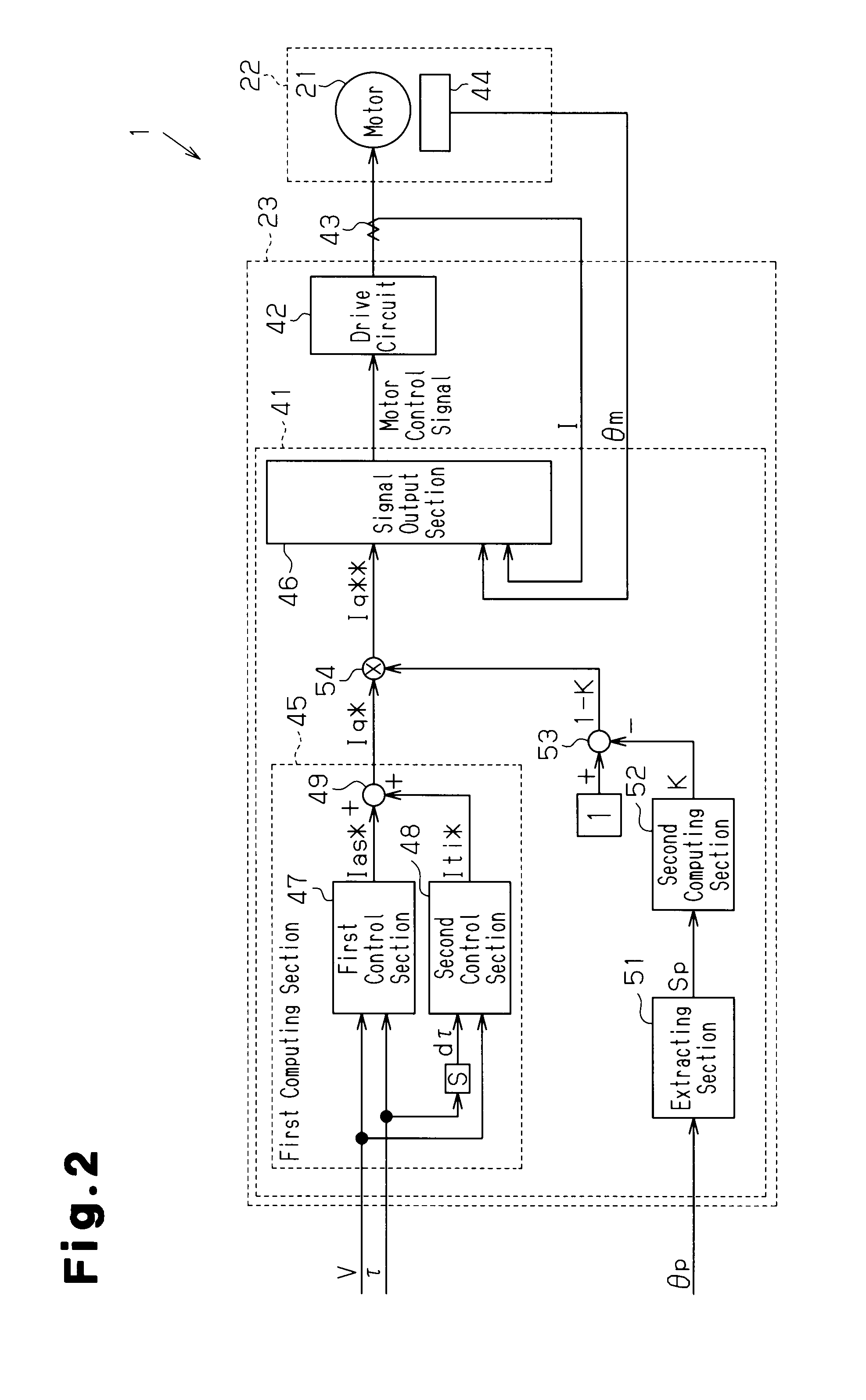

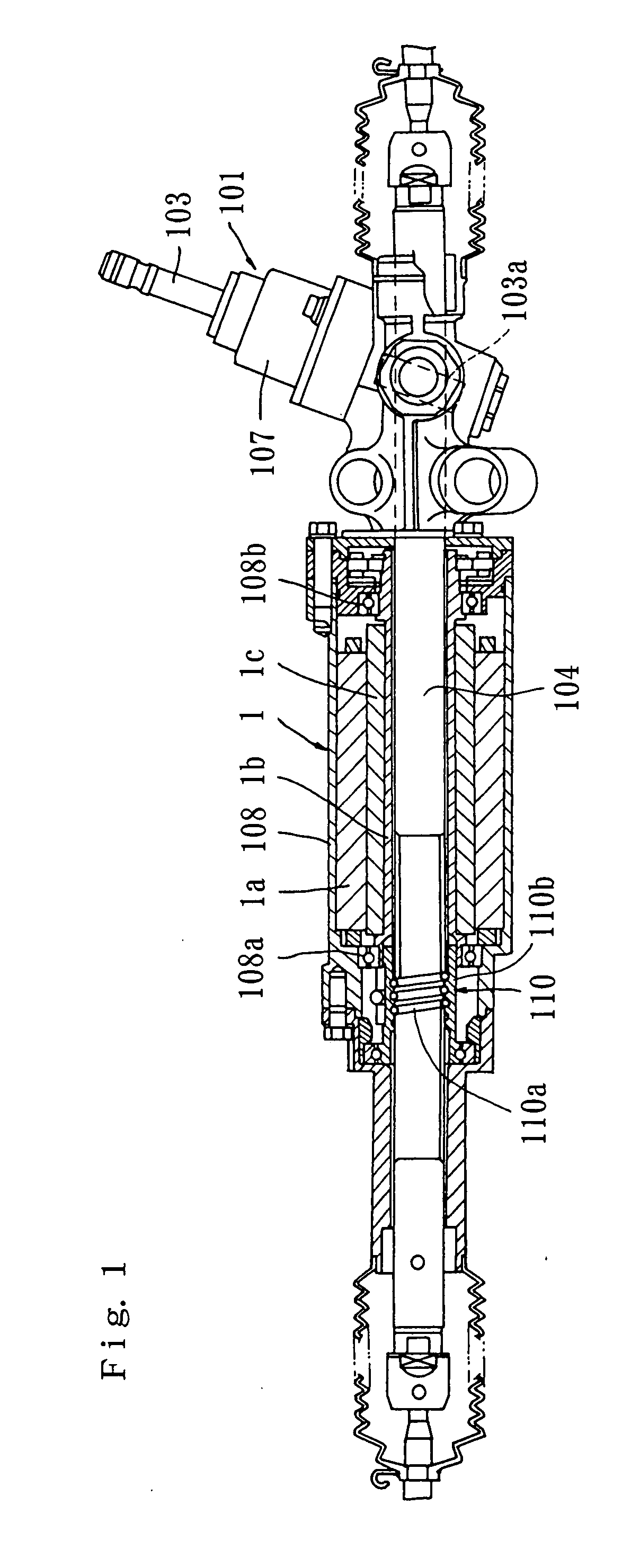

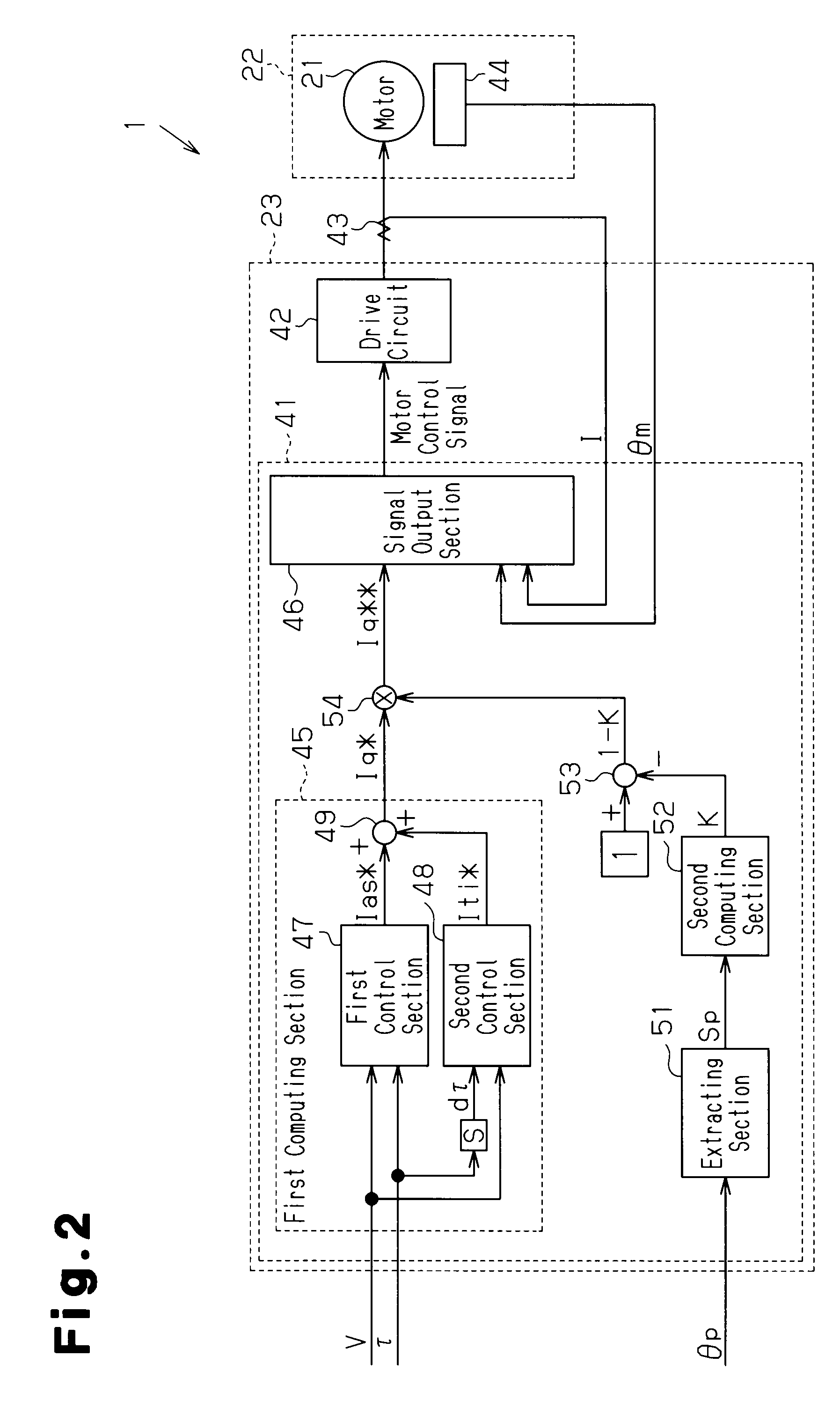

Electric power steering apparatus

InactiveUS20080277192A1Suppress noiseElectronic commutation motor controlVector control systemsMicrocomputerElectric power steering

A microcomputer is provided with an extracting section capable of extracting a specific frequency component from an input signal. The extracting section extracts, from a pinion angle corresponding to a signal indicating the state of a steering system, a frequency component corresponding to a vibration that increases generation of a rattling noise in a speed reducing mechanism. The extracting section outputs an effective value of the extracted frequency component as a power spectrum. If the power spectrum output from the extracting section is equal to or more than a predetermined threshold value, the microcomputer outputs a motor control signal to reduce the assist force generated by the EPS actuator.

Owner:JTEKT CORP

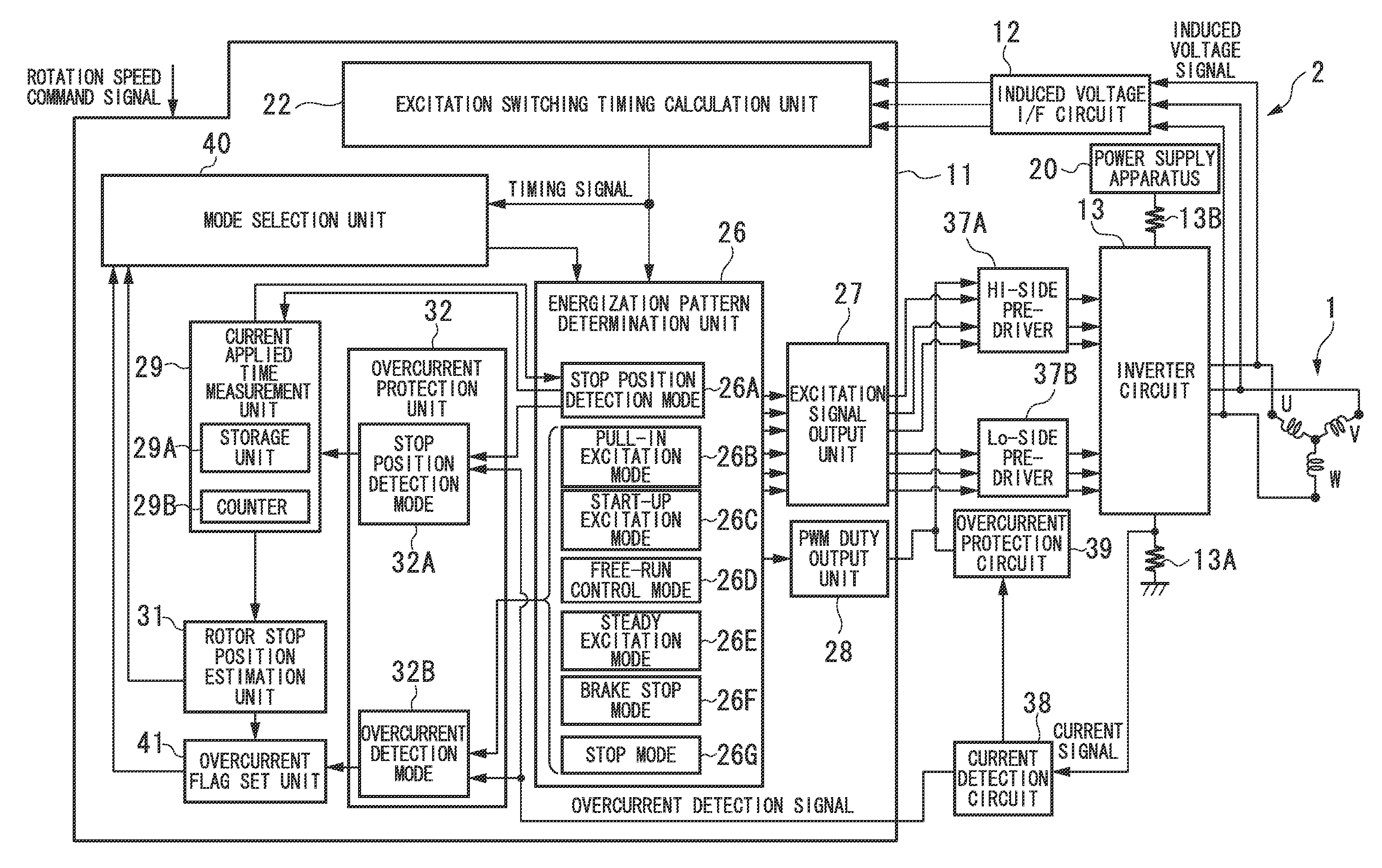

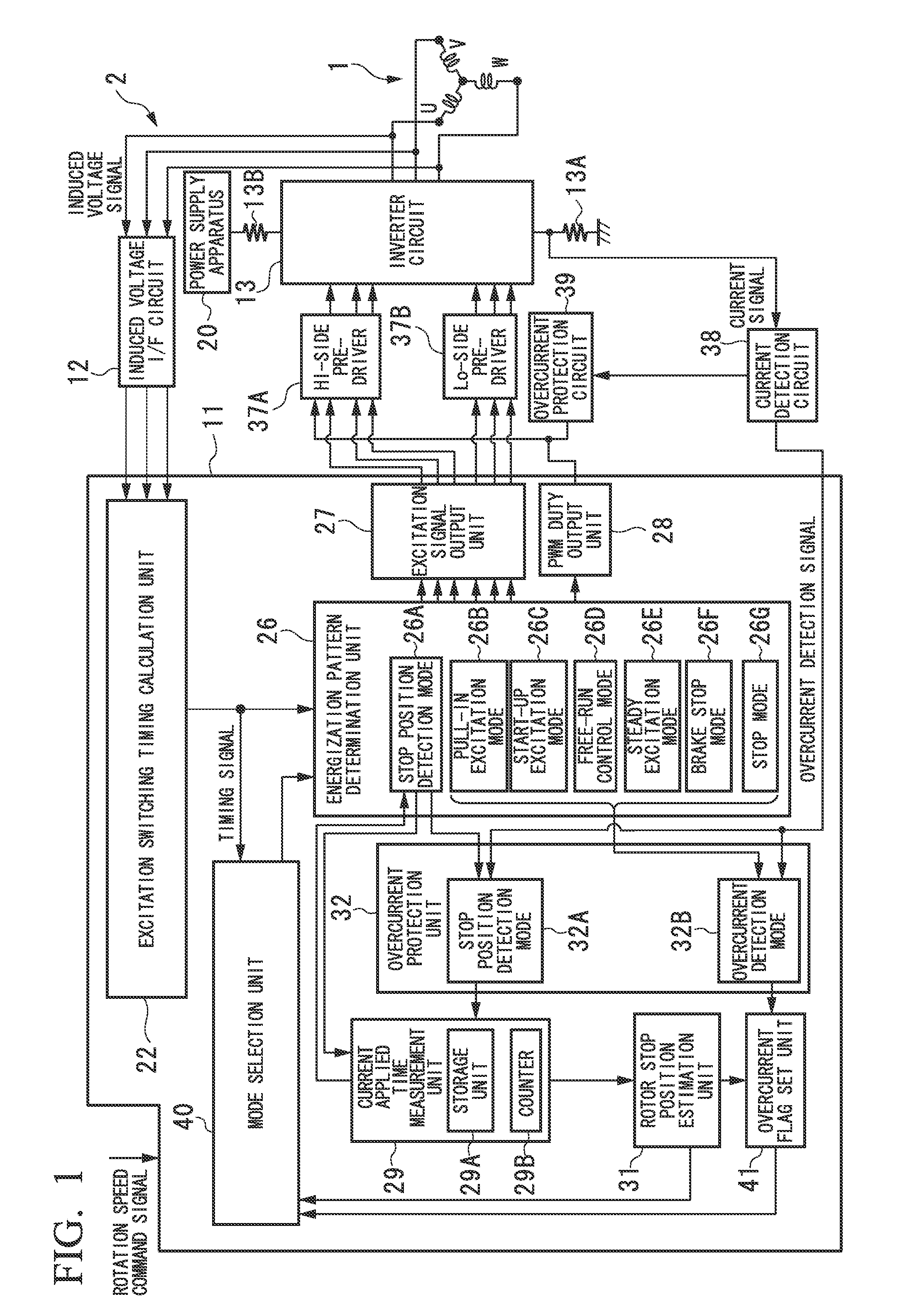

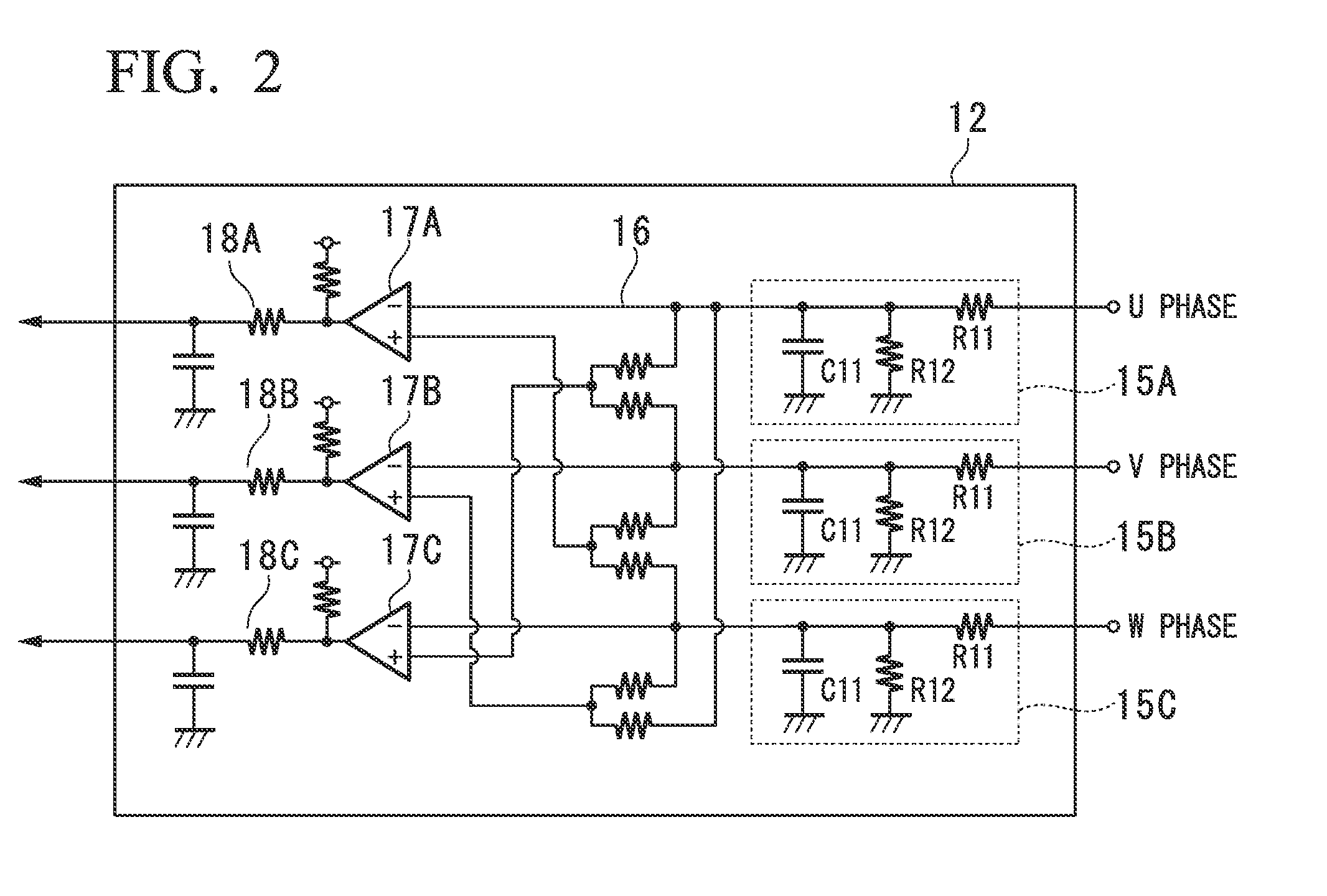

Driving apparatus and stop position detection method

InactiveUS20130043817A1Reduce loadMaintain powerMotor/generator/converter stoppersSynchronous motors startersElectric motorDuty cycle

A driving apparatus including an inverter unit for energizing the coil by switching ON and OFF of the switching element, an energization pattern determination unit for selecting a plurality of energization patterns, each of which indicates a direction of a current that flows through the coil, one by one when driving of a motor is started, and energizing the coil by switching ON and OFF of the switching element based on a selected energization pattern at a duty ratio corresponding to a value of a maximum current capable of being supplied by the power supply apparatus, a current applied time measurement unit for measuring an energization time, which is a time until a value of the current flowing through the coil reaches a predetermined target current value for each energization pattern, and a rotor stop position estimation unit for estimating a position at which the rotor stops.

Owner:MITSUBA CORP

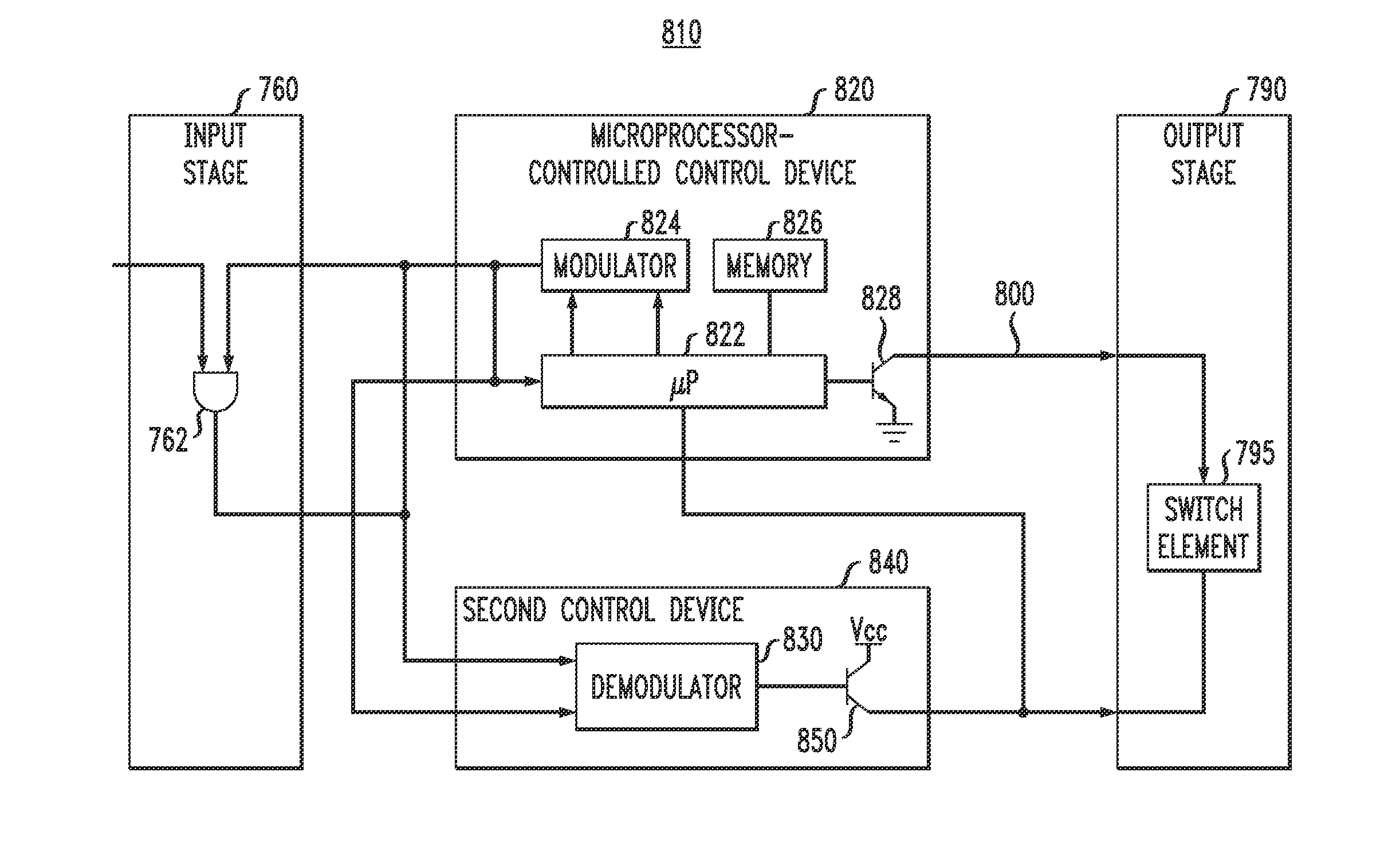

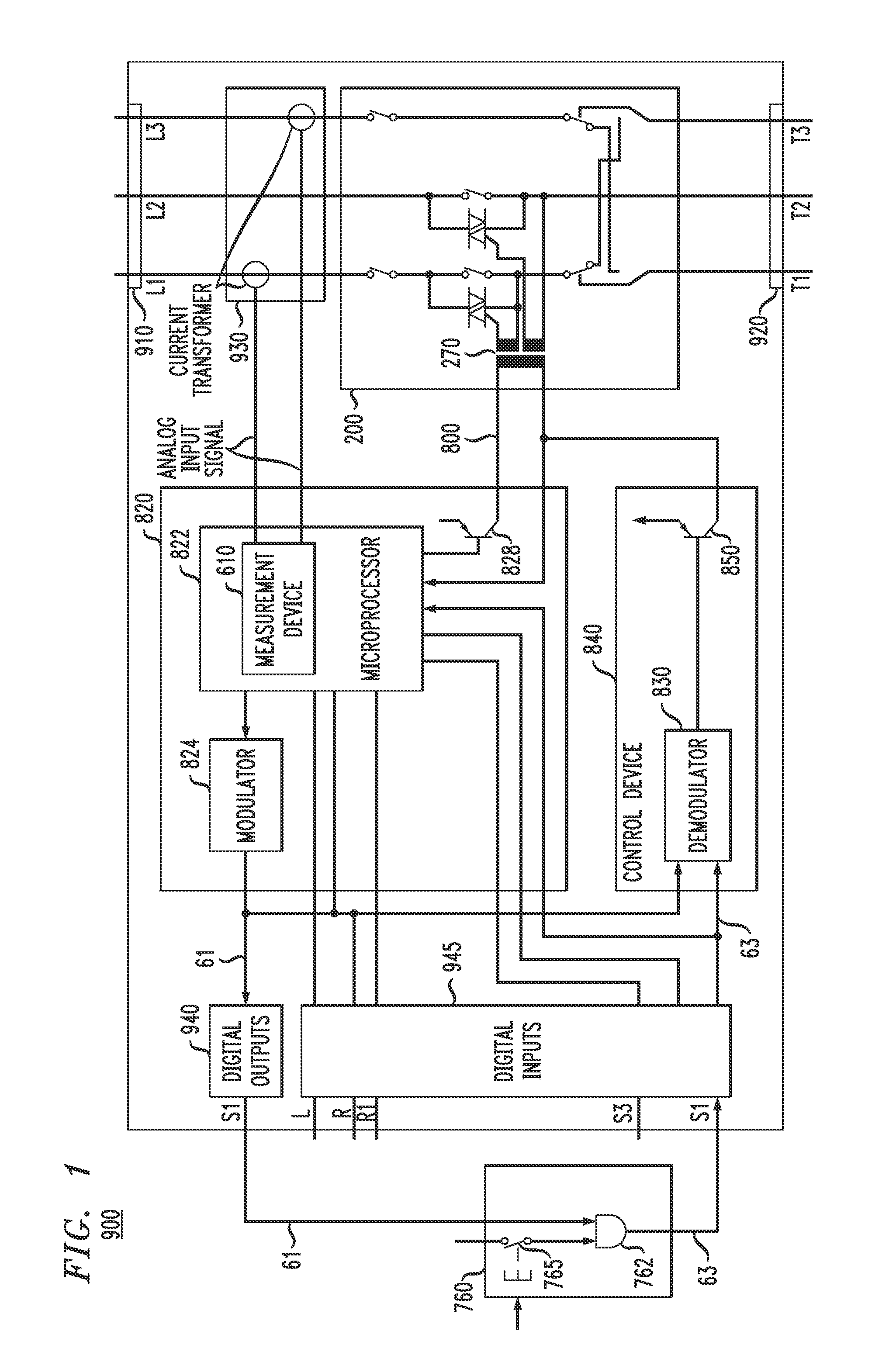

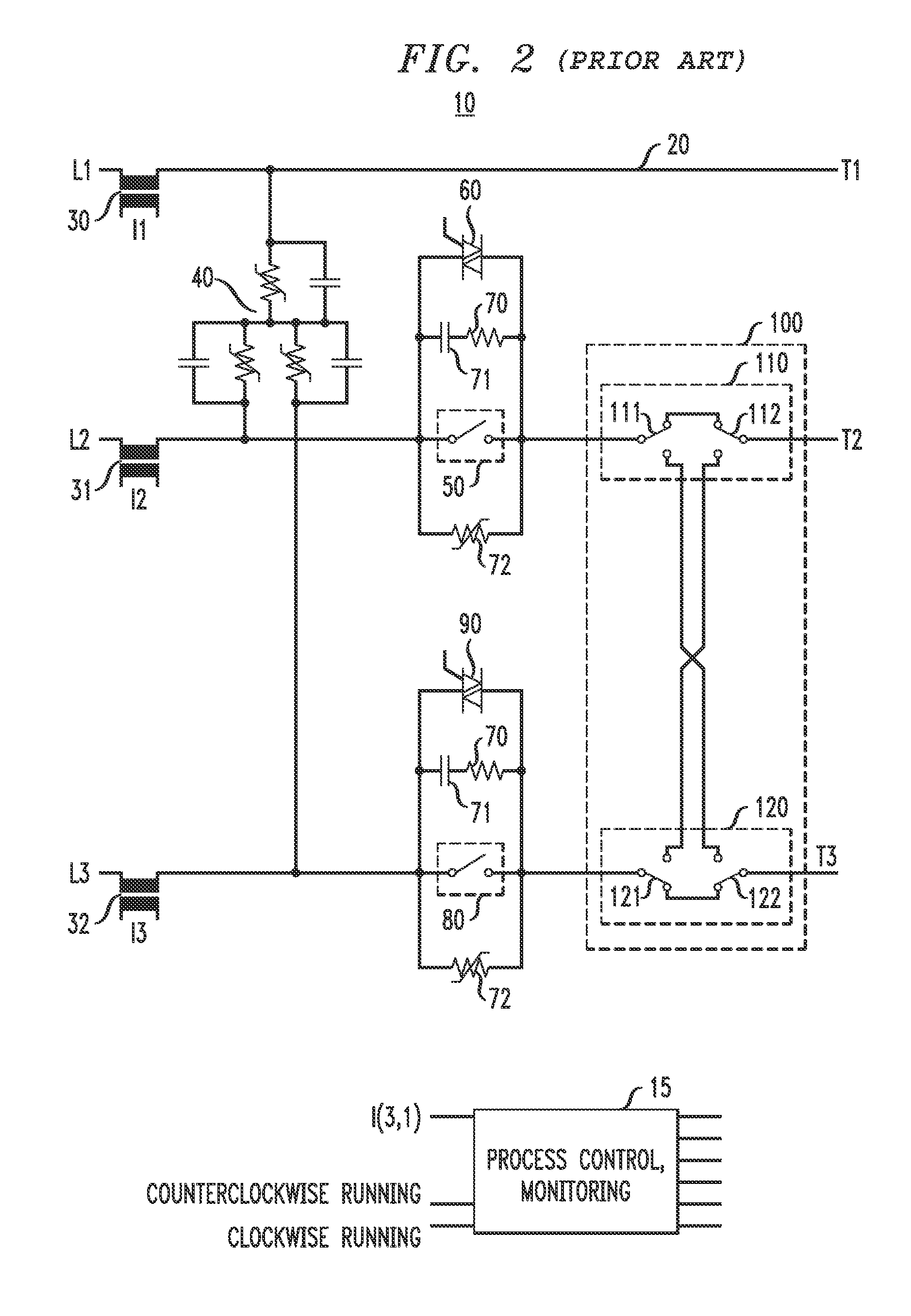

Safety switching device for setting a safety-related device to a safe state

Owner:PHOENIX CONTACT GMBH & CO KG

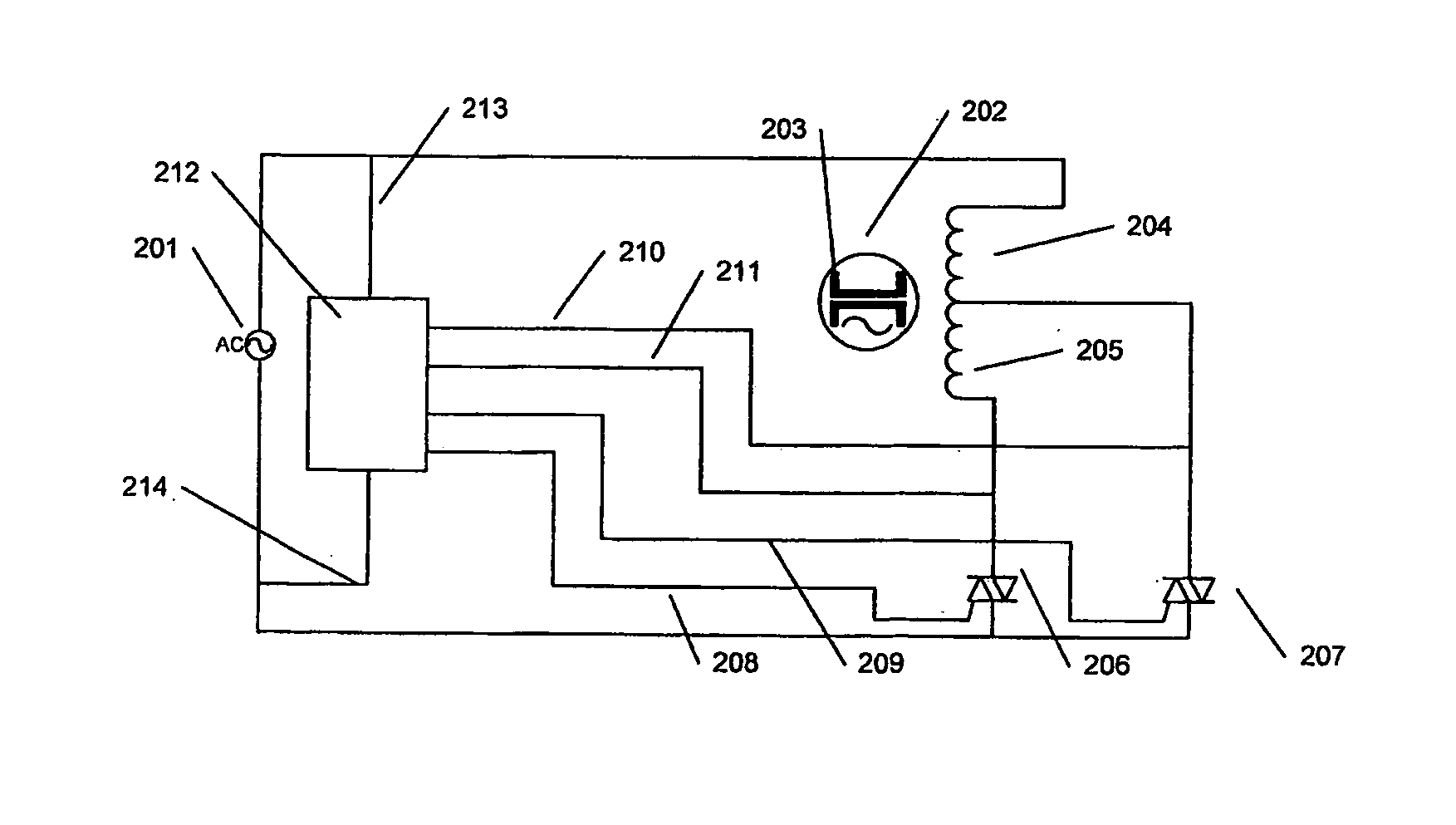

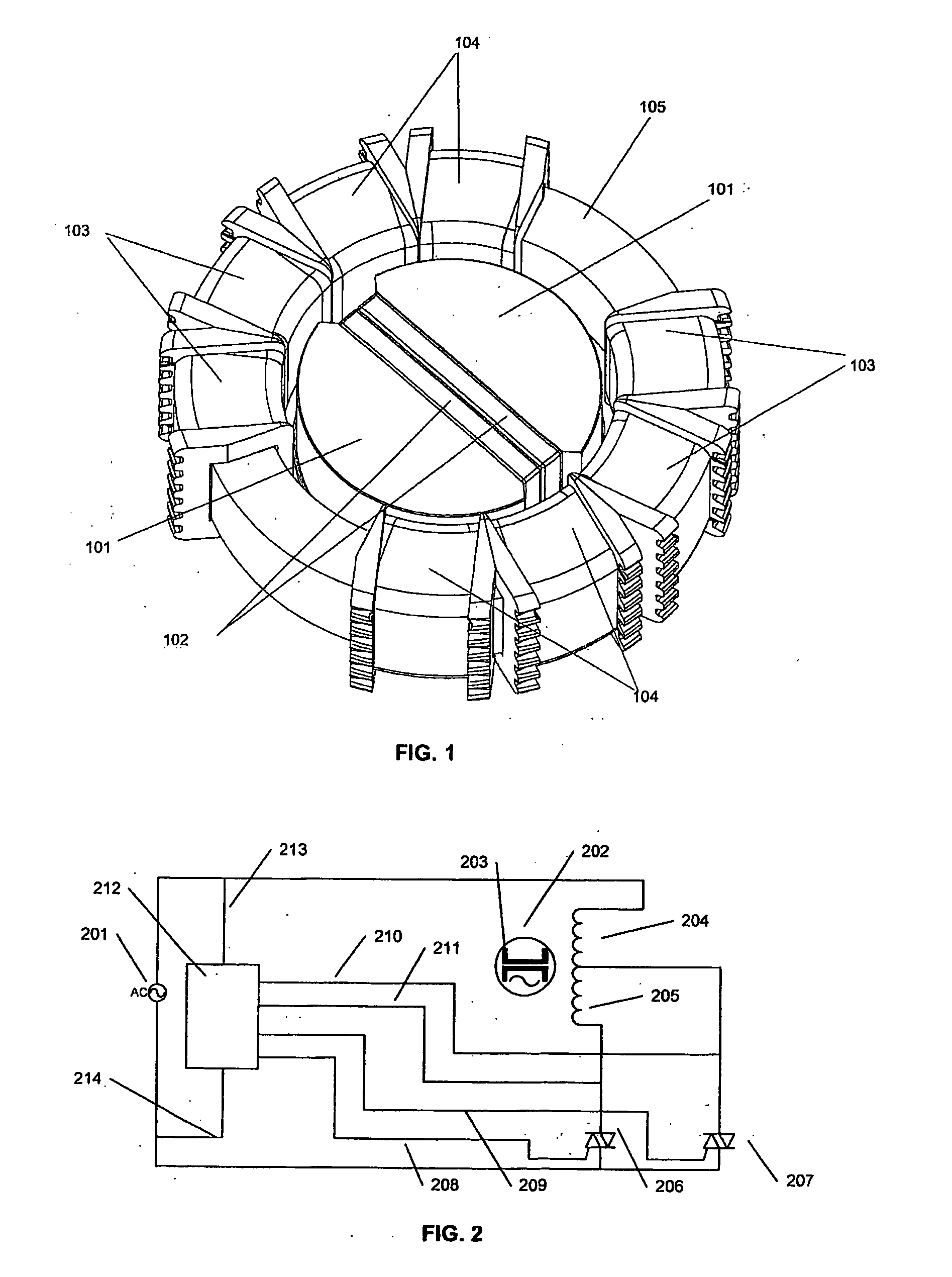

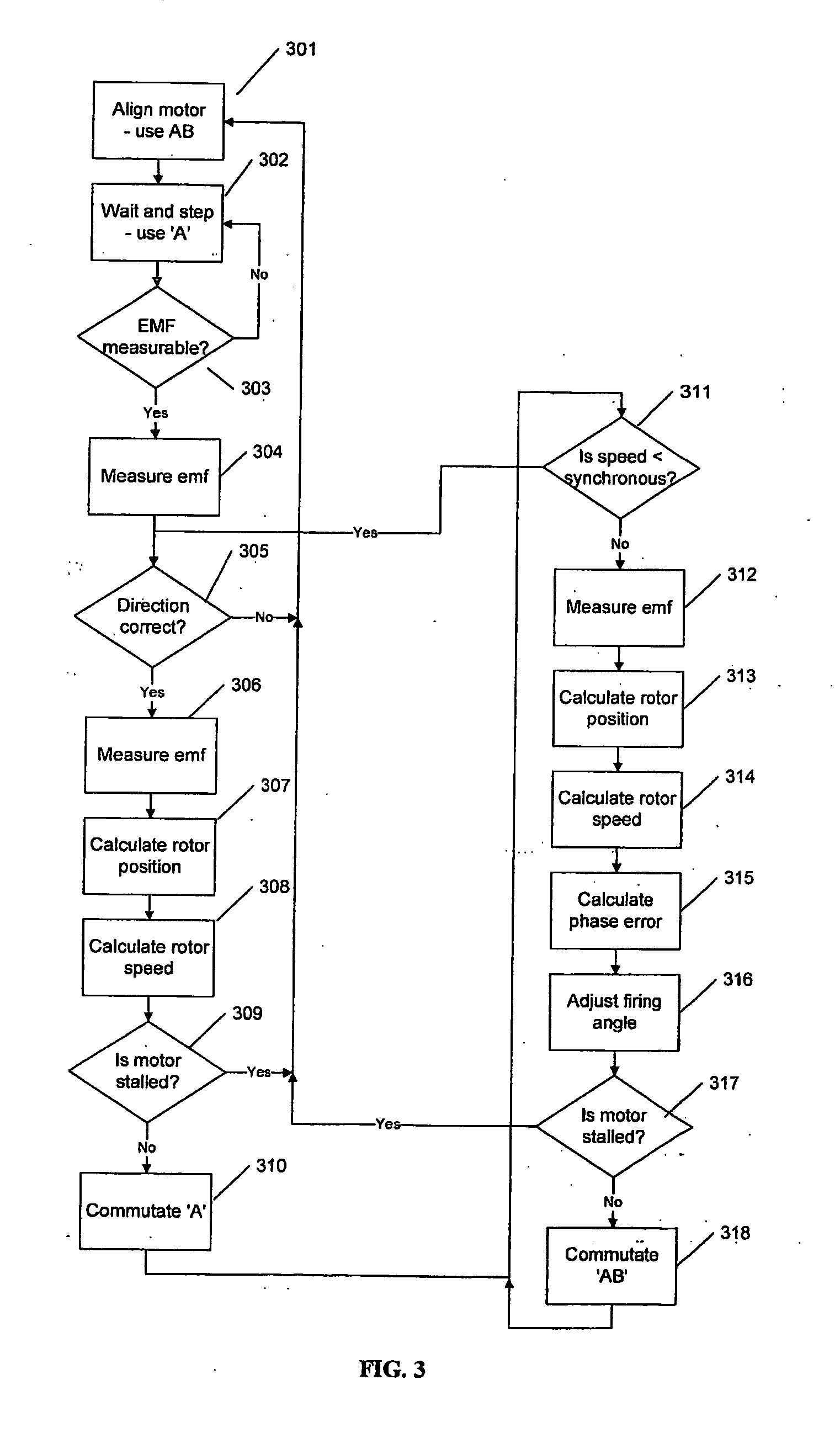

Control of synchronous electrical machines

ActiveUS20100207557A1Motor/generator/converter stoppersCommutation monitoringSynchronous motorEngineering

A synchronous motor having phase windings which are split or tapped and in which the conduction angle of the applied alternating current is varied at one or more taps to allow the motor to start in a controlled direction and be torque controlled to synchronous speed.

Owner:WELLINGTON DRIVE TECHNOLOGIES

Energy Saving System and Method for Devices with Rotating or Reciprocating Masses

ActiveUS20120213645A1Save energyDoes not consume energyFlexible member pumpsPump controlControl theoryKinetic energy

A system and method are provided for reducing the energy consumed by a pump jack electric motor by reducing the supply voltage to the motor when the motor would be generating energy in open loop mode. By substantially eliminating the energy generation mode, the braking action of the utility grid in limiting the acceleration of the motor and system that would otherwise occur is substantially removed. The motor and system will speed up, allowing the natural kinetic energy of the cyclic motion to perform part of the pumping action.

Owner:THE POWERWISE GRP

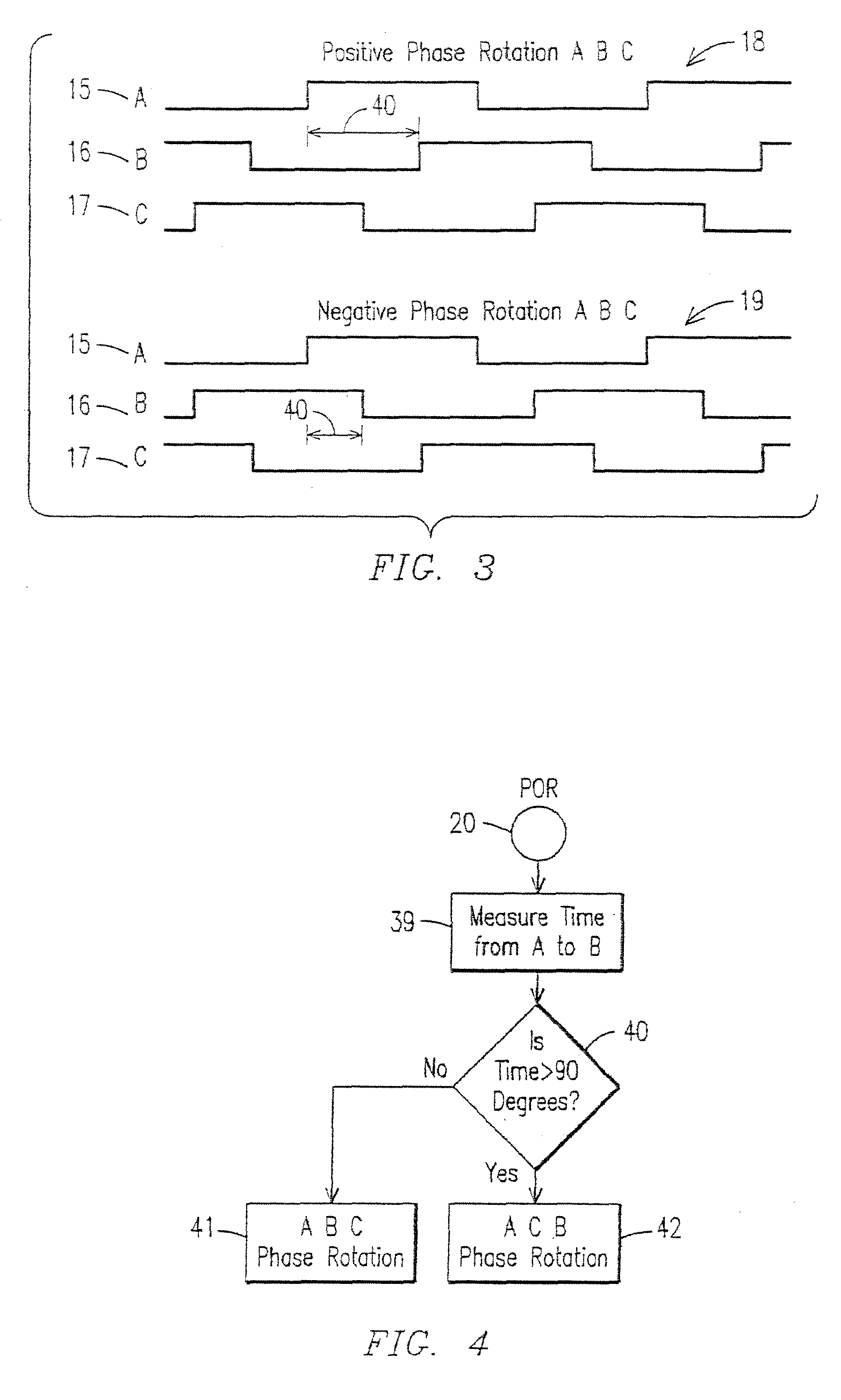

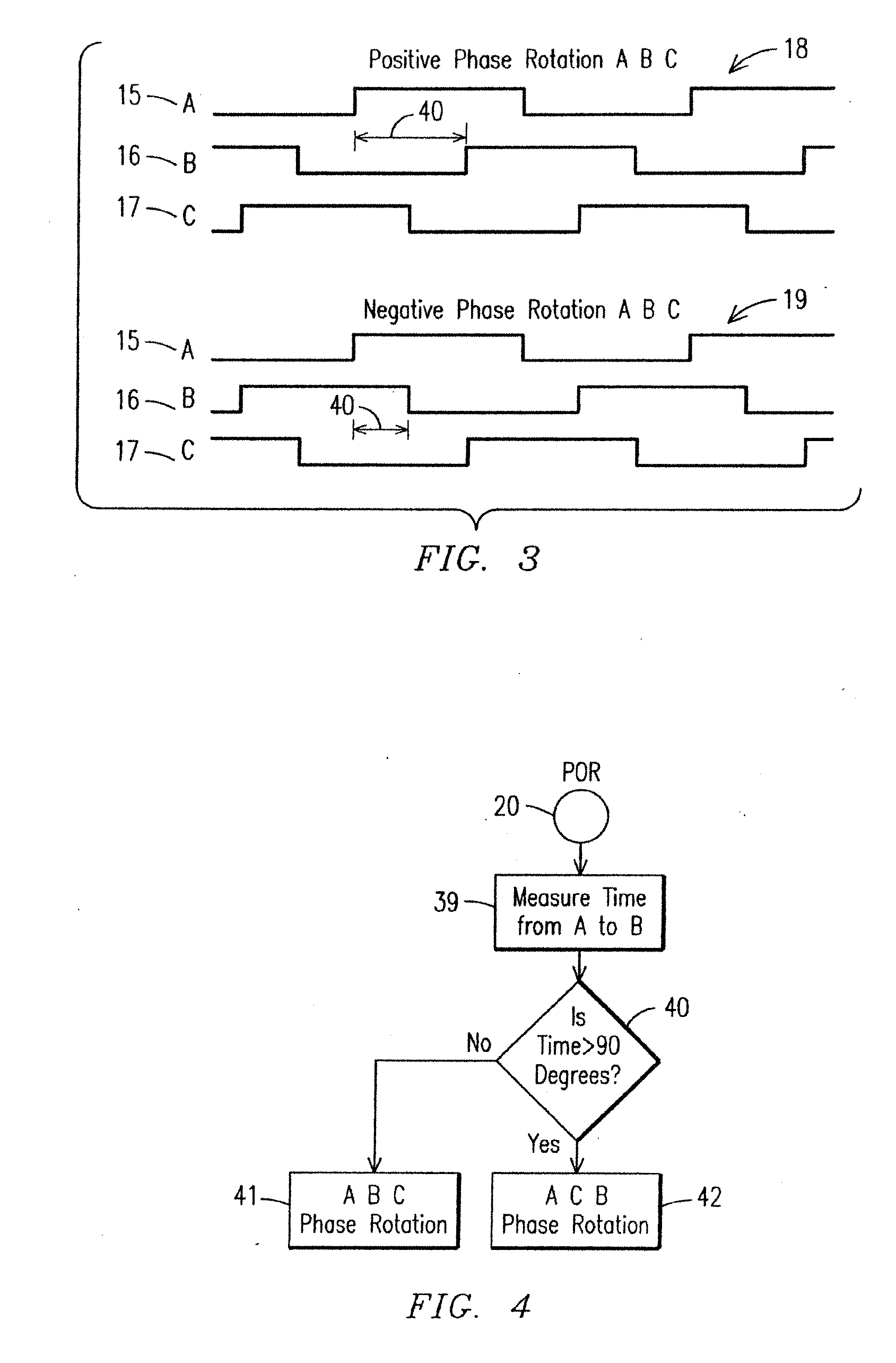

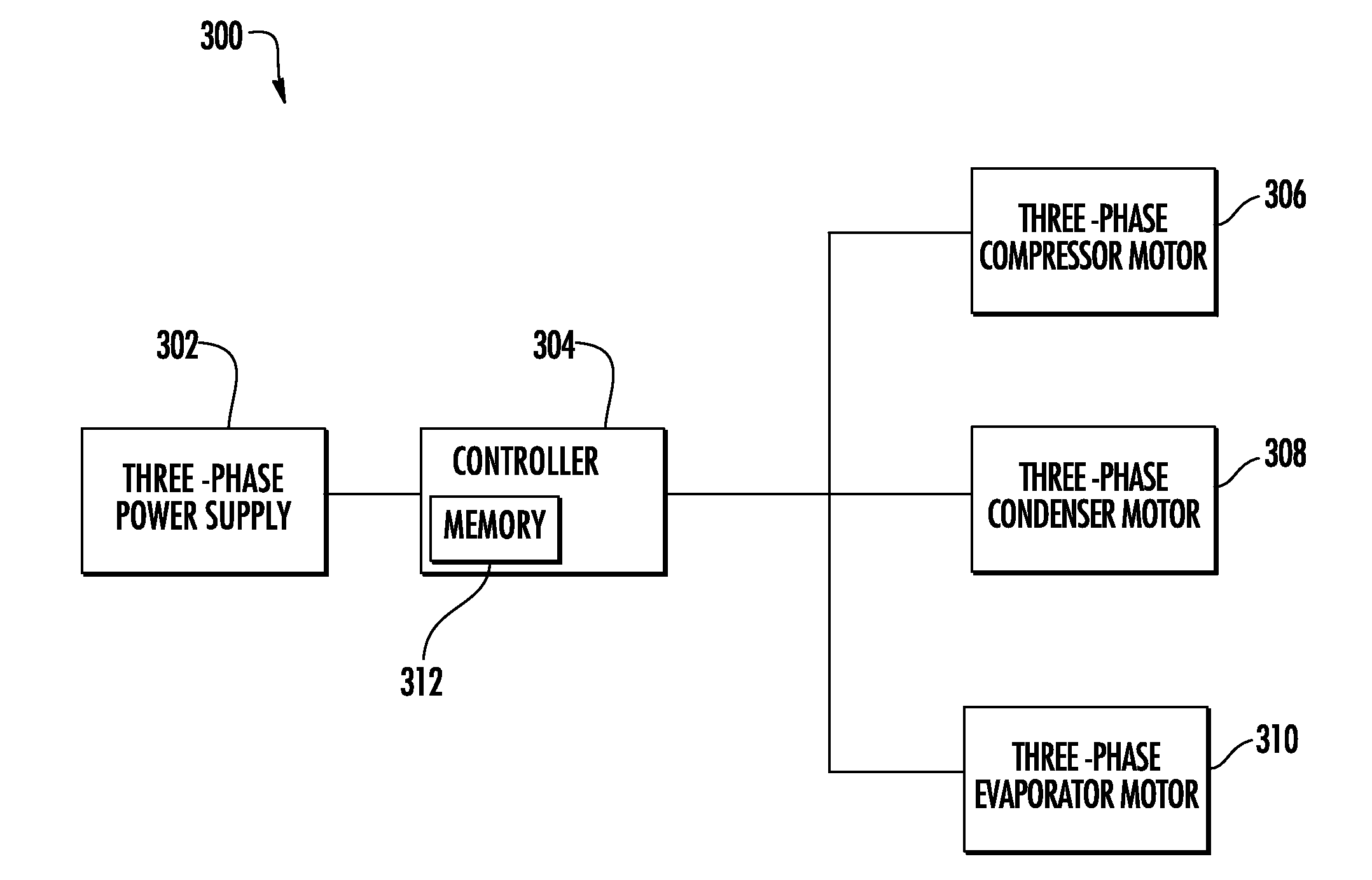

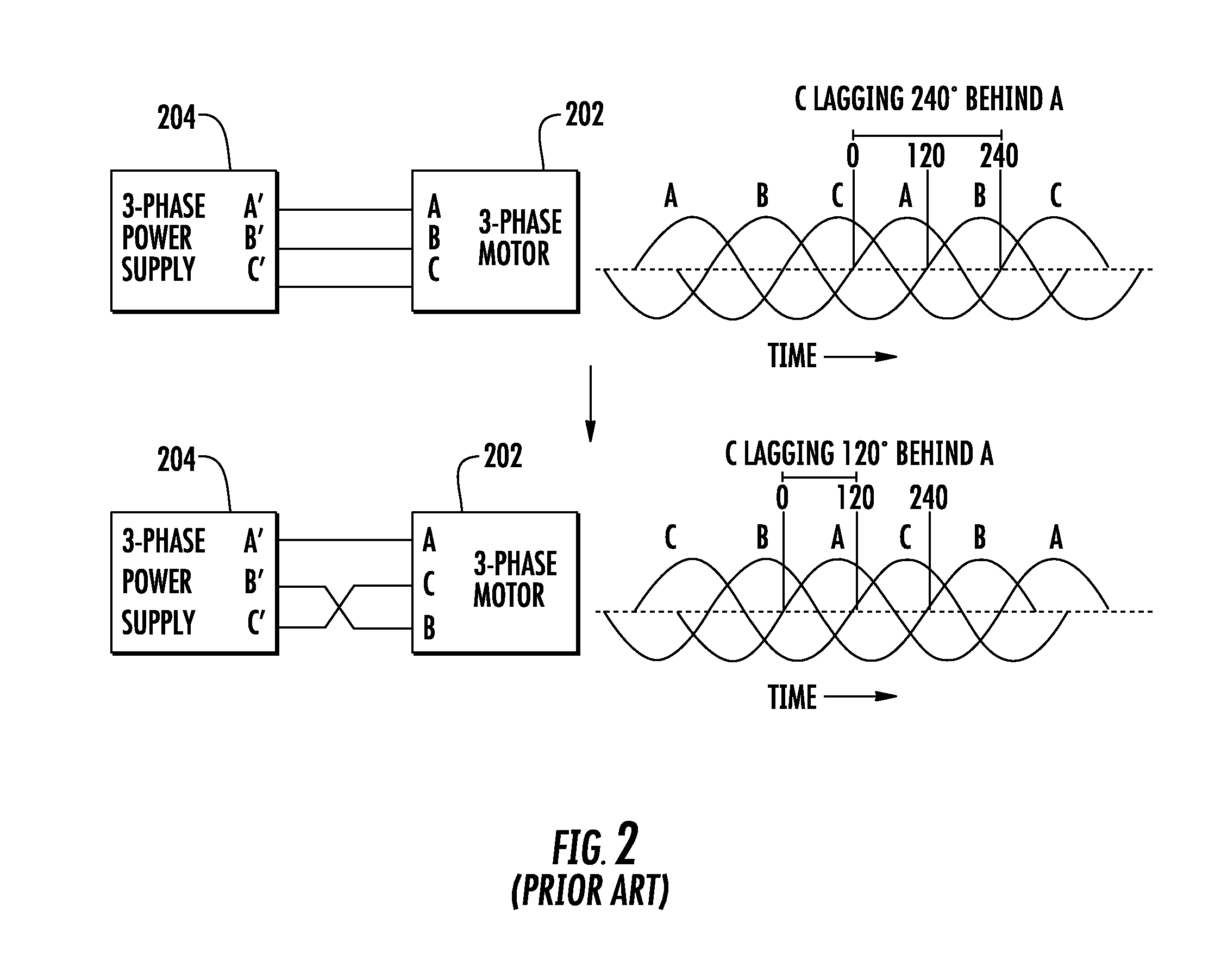

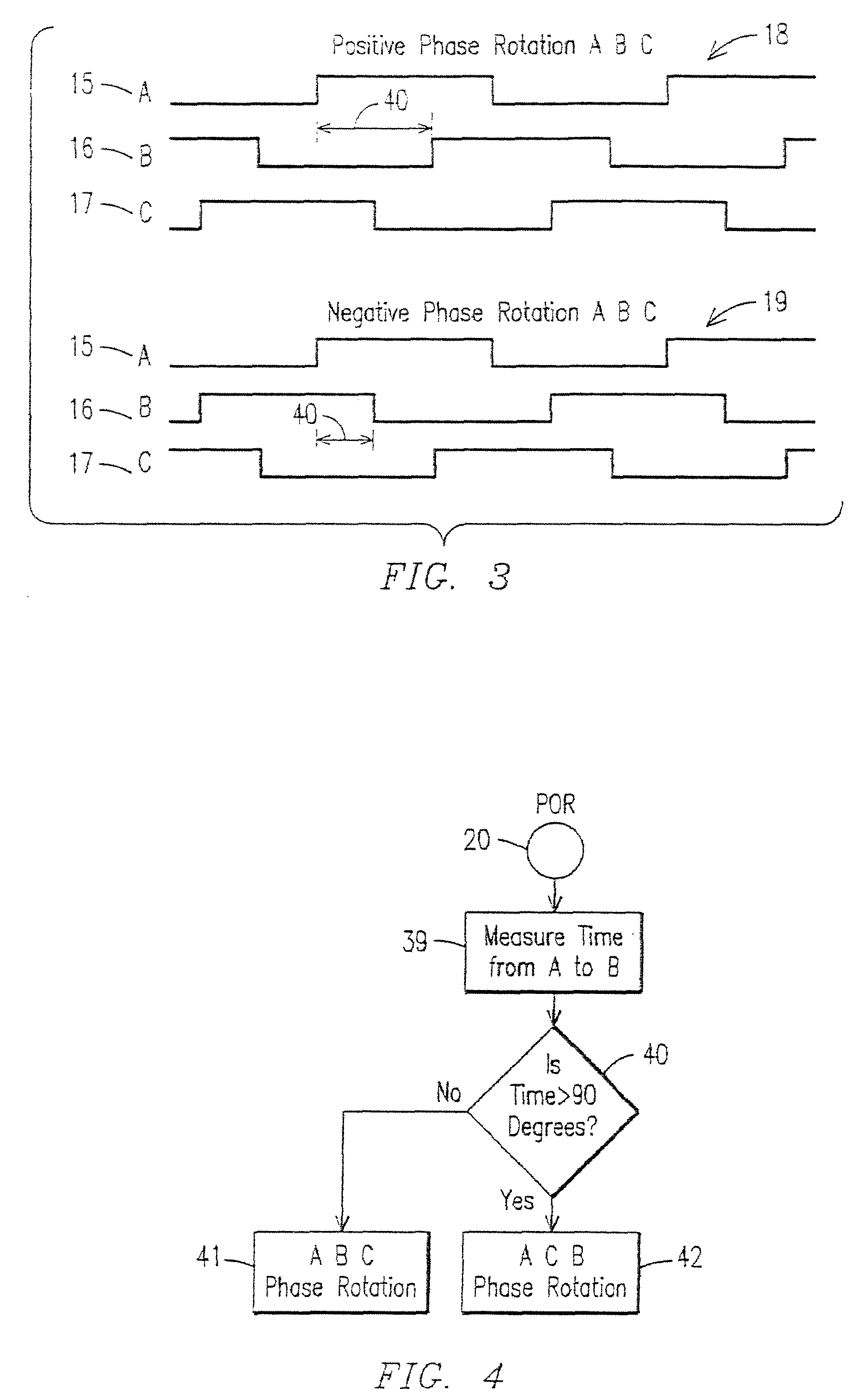

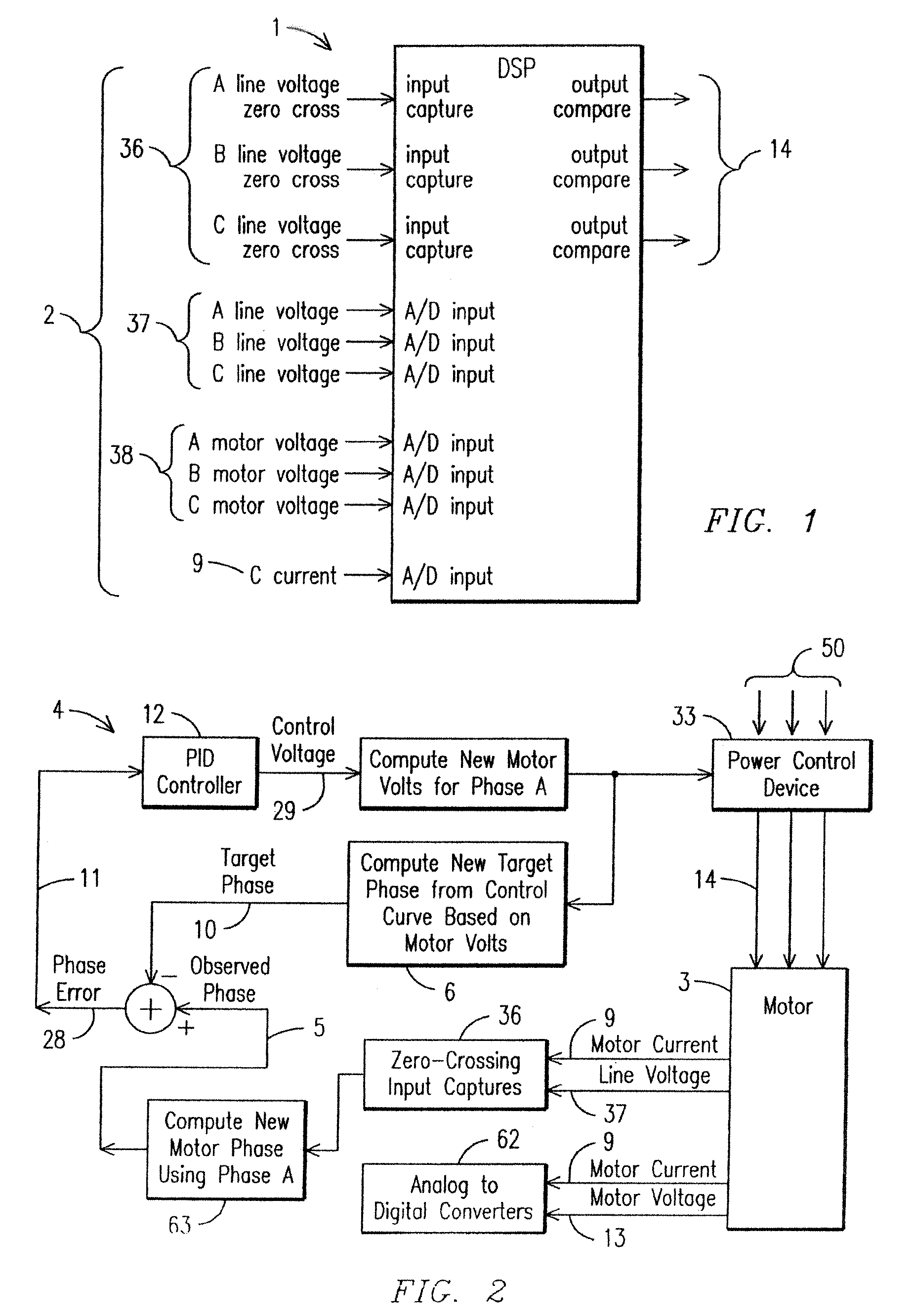

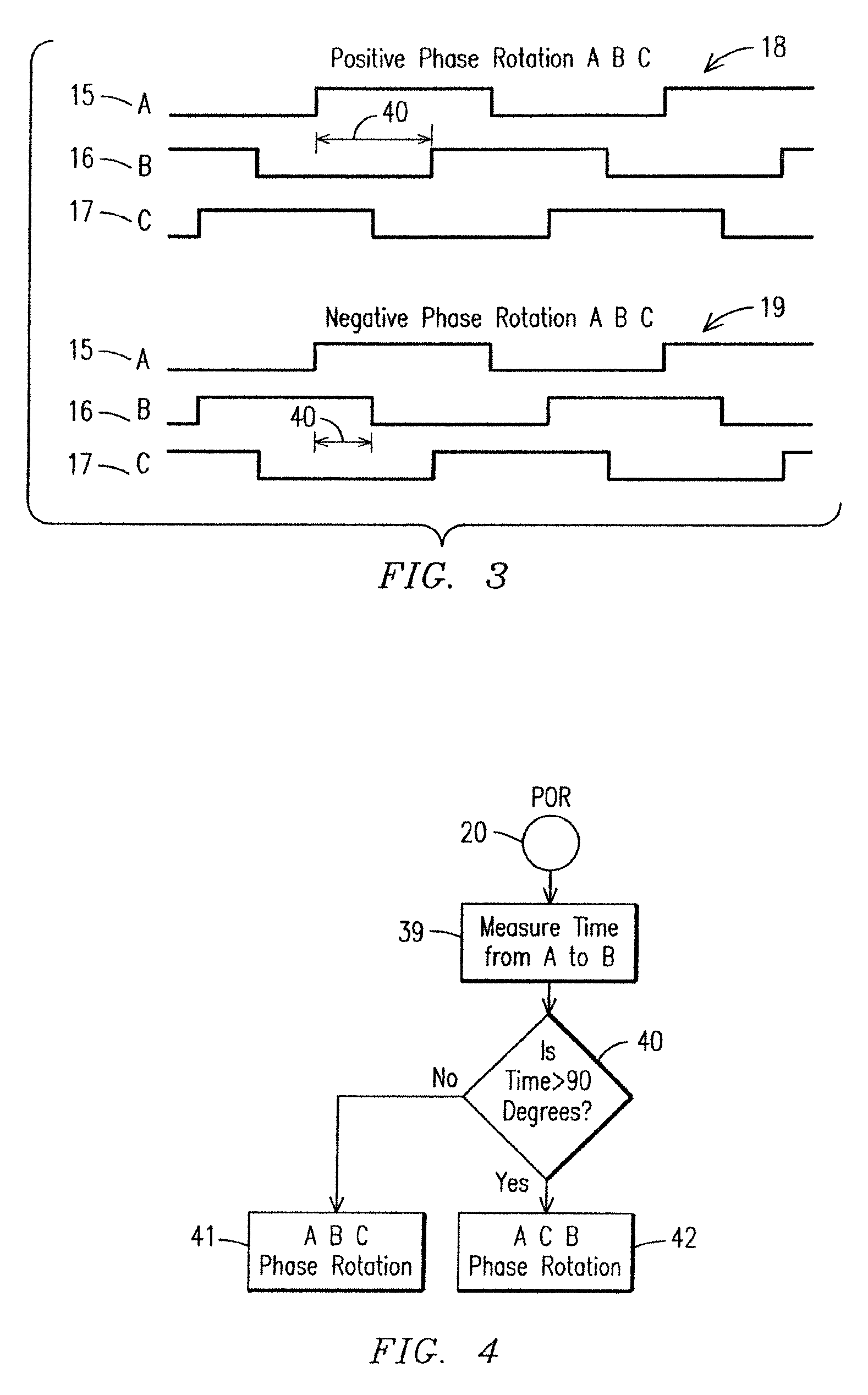

Method for Determining Proper Wiring of Multiple 3 Phase Motors in a Single System

ActiveUS20130162177A1Less-efficient operationMultiple dynamo-motor startersDynamo-electric converter controlNormal modeThree-phase

A method for determining proper wiring of multiple three-phase motors in a refrigeration system is disclosed. The method may include energizing a plurality of three-phase motors with a first input phase rotation and recording performance data, energizing the plurality of three-phase motors with a second input phase rotation and recording the performance data, evaluating the performance data and determining if each of three-phase motors is properly wired, operating the refrigeration system in a normal mode if all of the three-phase motors are properly wired, or operating the refrigeration system in a less efficient mode if at least one three-phase motor is improperly wired.

Owner:CARRIER CORP

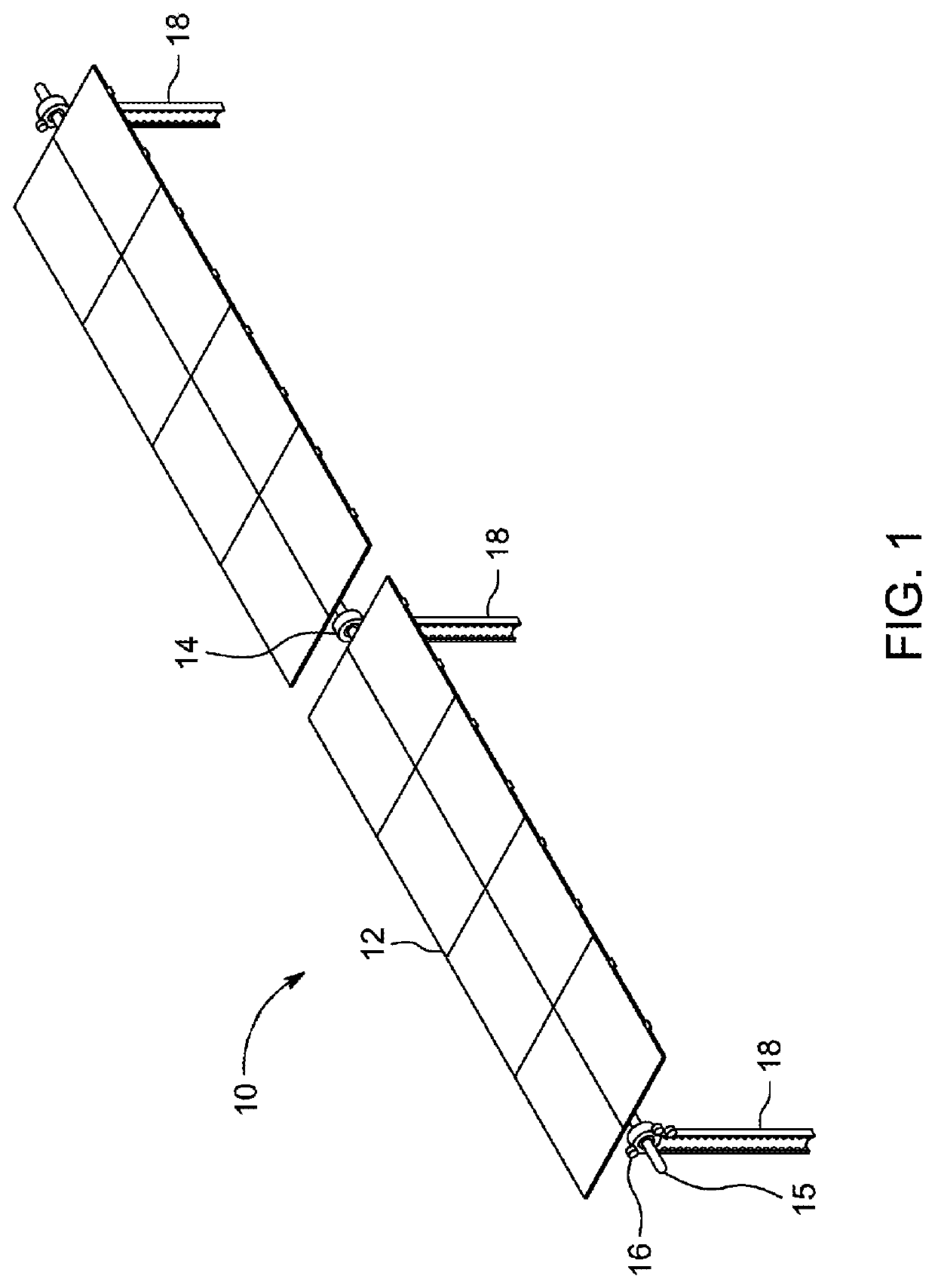

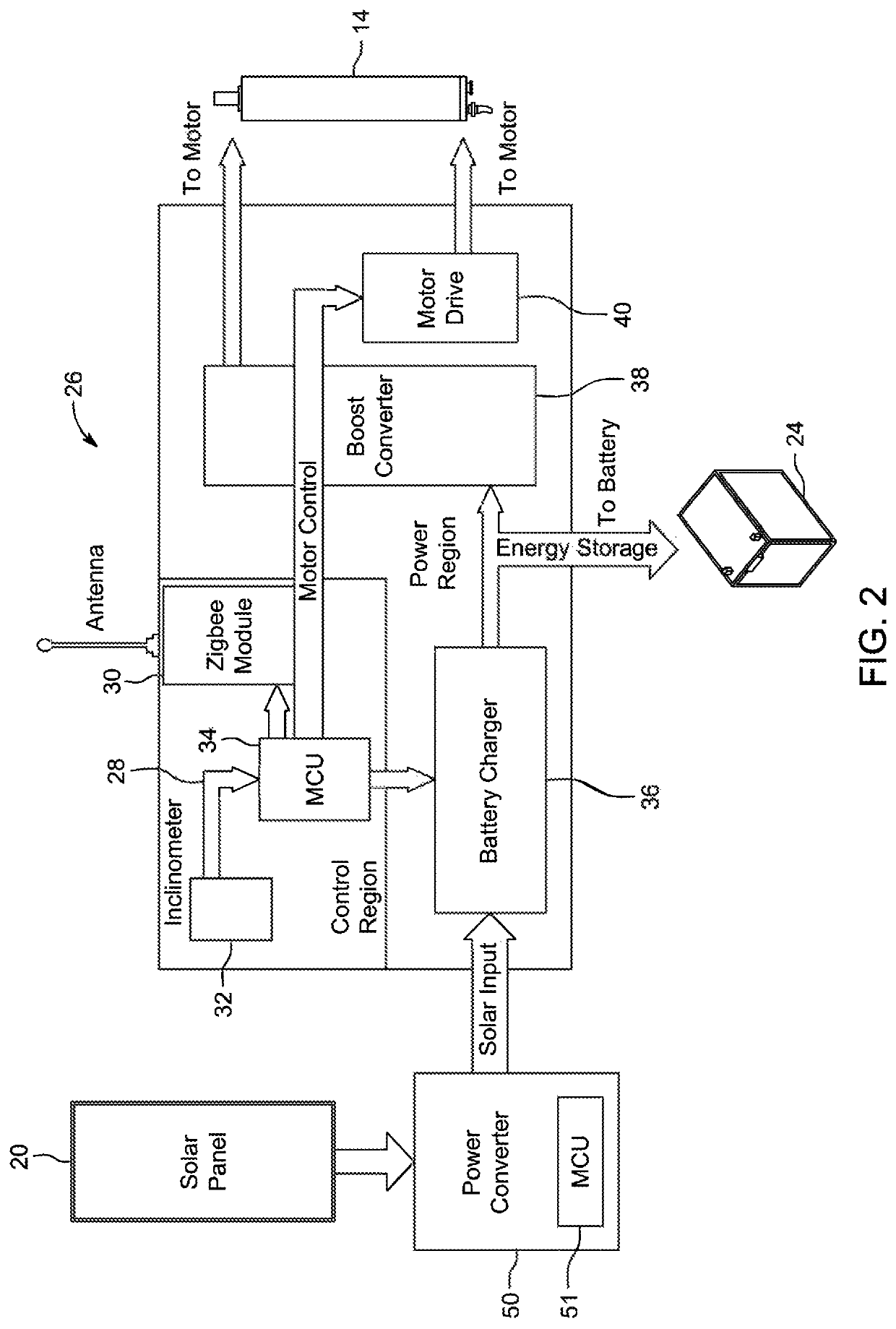

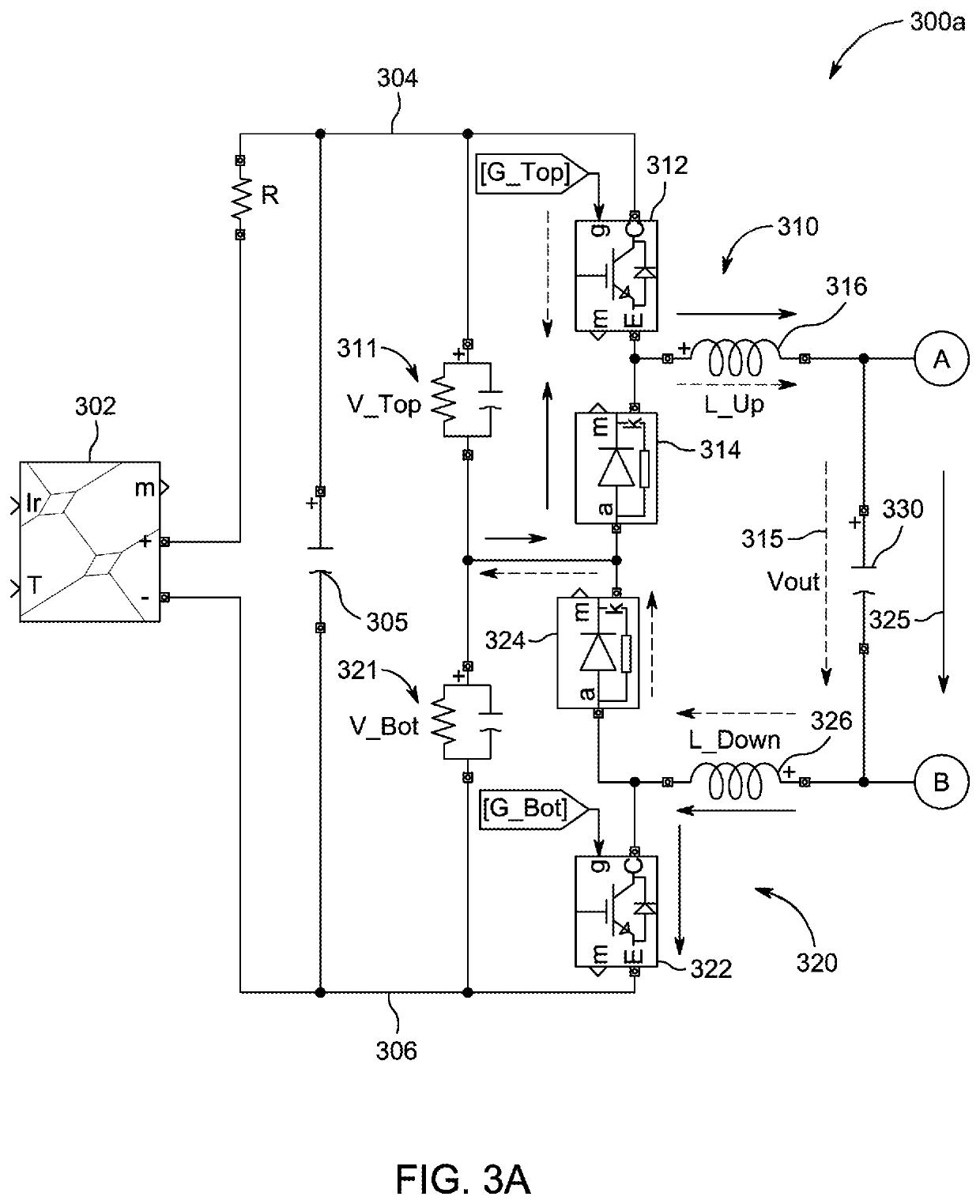

Power converters and methods of controlling same

ActiveUS10651739B1Eliminate needPhotovoltaic supportsBatteries circuit arrangementsConvertersControl theory

A power converter converts a medium-voltage output from a solar module to an appropriate voltage to power a solar tracker system. The power converter includes a voltage divider having at least two legs, a first semiconductor switch subassembly coupled in parallel with a first leg of the voltage divider, and a second semiconductor switch subassembly coupled in parallel with a second leg of the voltage divider. In implementations, the signals for driving the semiconductor switches of the first and second semiconductor switch subassemblies may be shifted out of phase from each other. In implementations, if the bus voltages to the semiconductor switches are not balanced, the pulse width of the driving signal of the semiconductor switch supplied with the higher bus voltage is decreased for at least one cycle.

Owner:NEXTRACKER LLC

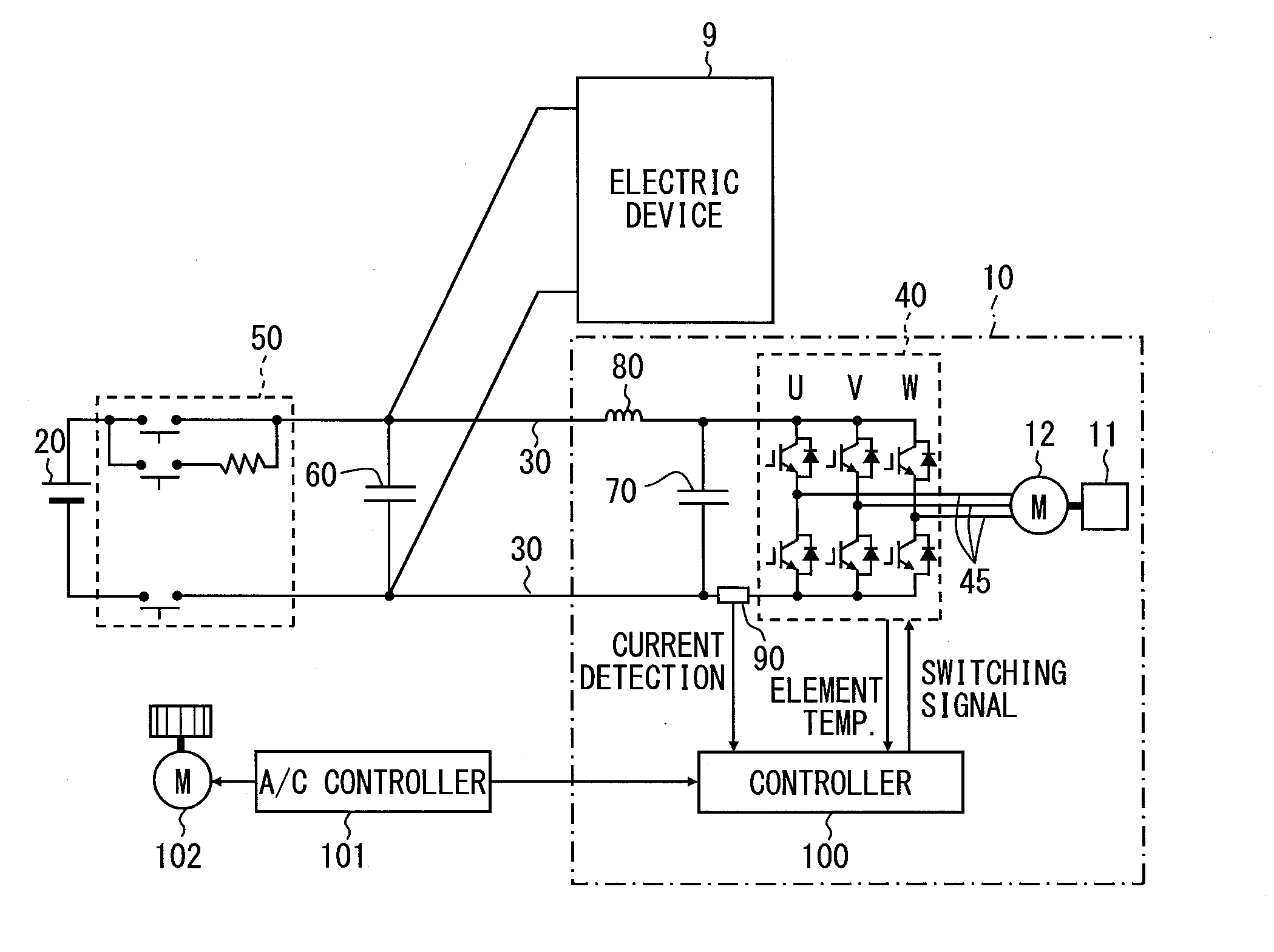

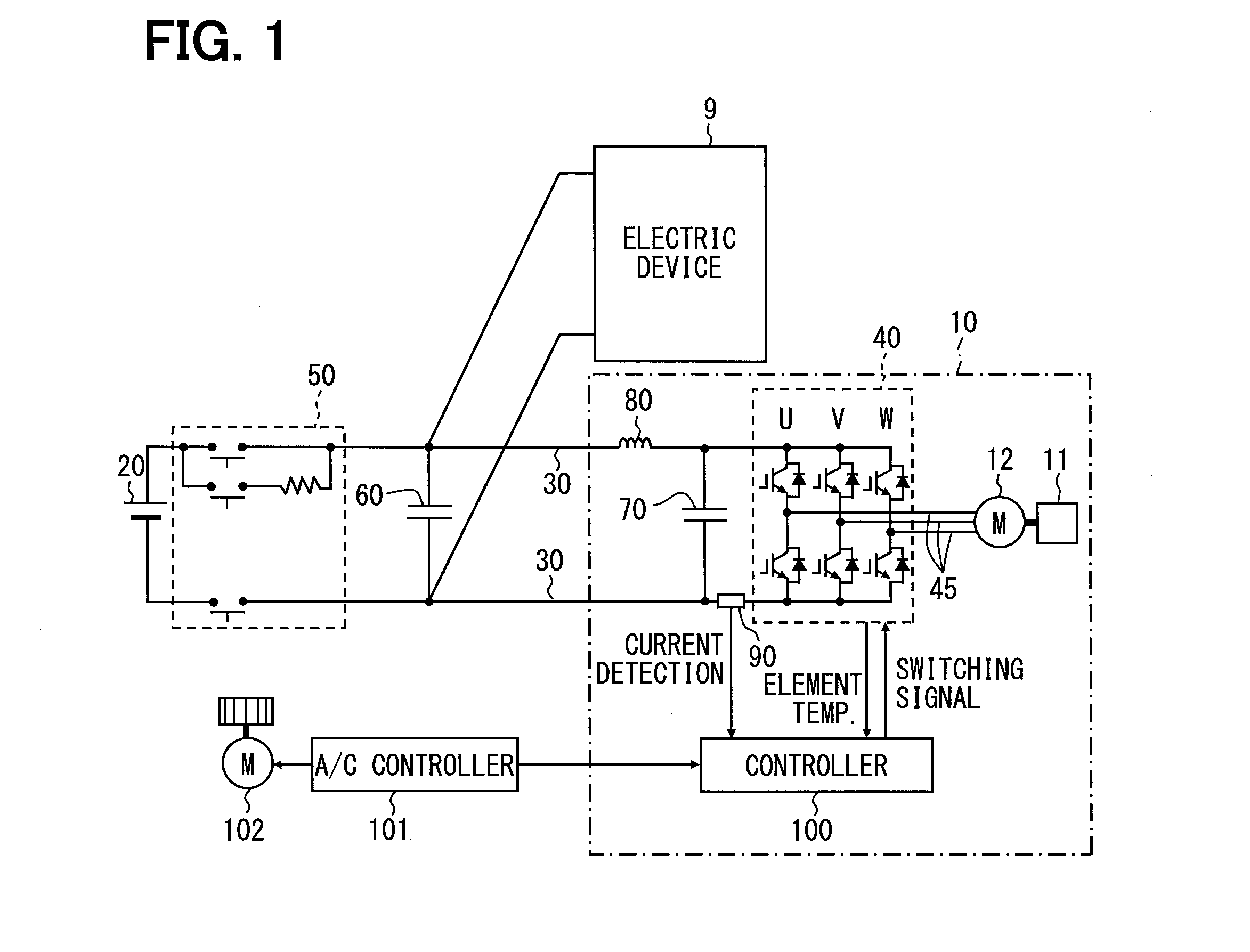

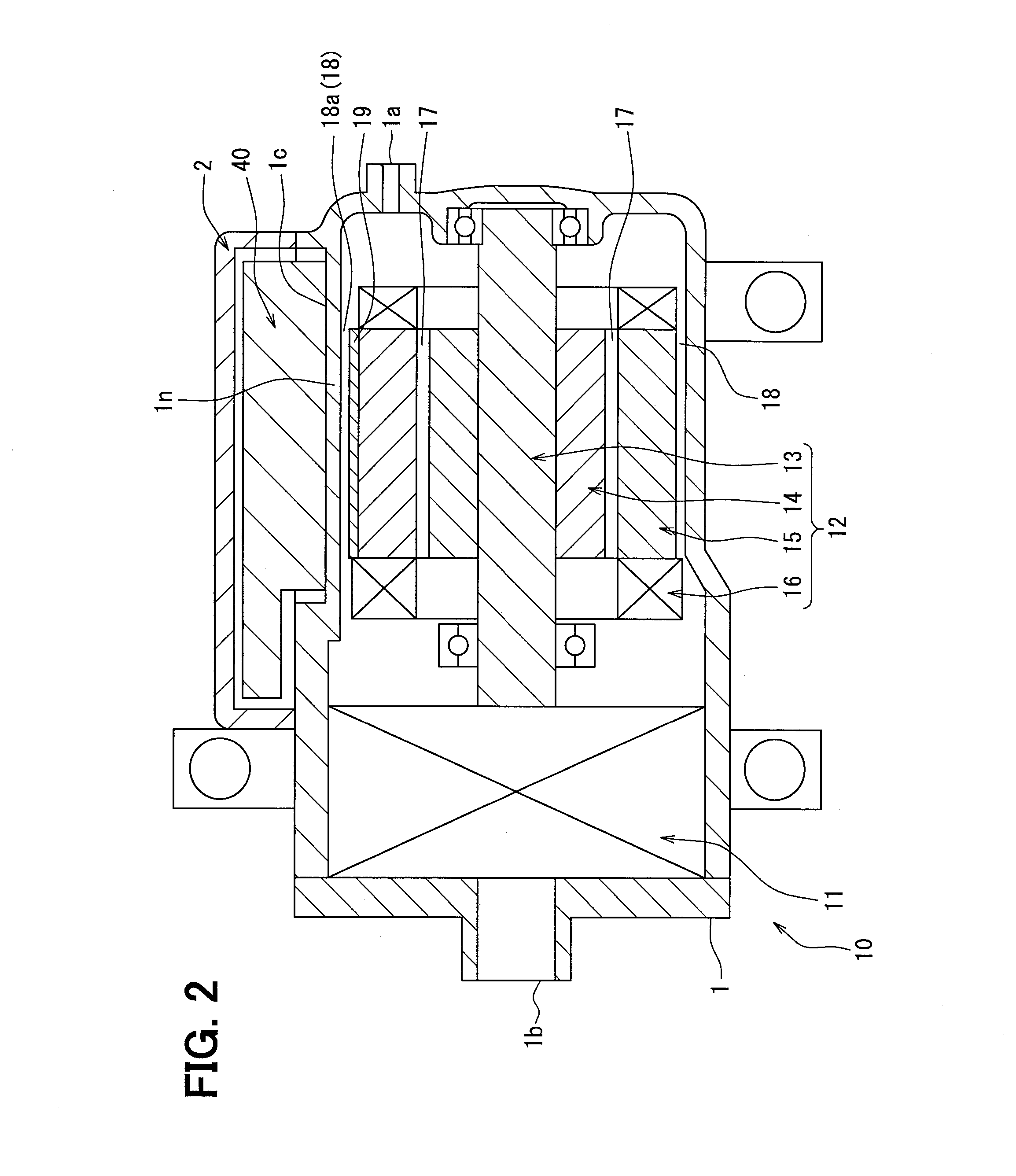

Electric compressor

ActiveUS20150295532A1Reduce in quantityReduce the temperatureDC motor speed/torque controlTemperatue controlEngineeringTemperature drop

A controller for an electric compressor sets a temperature rise region A, a temperature drop region B, and a steady region C from change in temperature of switching elements, and sets a carrier frequency for each of the set regions. In the region A, the carrier frequency is changed according to the element temperature so that the carrier frequency decreases with increase of the element temperature at startup of a motor. In the region B and the region C, the carrier frequency is changed according to the number of revolutions of a compression mechanism, so that the carrier frequency decreases with increase of the number of revolutions of the compression mechanism, regardless of the element temperature.

Owner:DENSO CORP

Method to save energy for devices with rotating or reciprocating masses

ActiveUS8698446B2Highly variation of loadImprove energy savingDC motor speed/torque controlSynchronous motors startersLoop controlReciprocating motion

A system and method are disclosed for turning off the voltage to a pump jack electric motor during predetermined periods of time to save energy. In the method, the motor's response to closed-loop control may be evaluated over several pump strokes. The periods of the pump stroke when it is feasible to turn off the motor may be identified. The consistency of the measurements over several strokes may be evaluated. The motor may be turned off during predetermined periods on subsequent pump strokes when each pump stroke shows sufficiently similar behavior to that predicted during the closed-loop control process. The system may return to the closed-loop control process after a predetermined period of time to adjust to any changes in the system.

Owner:THE POWERWISE GRP INC

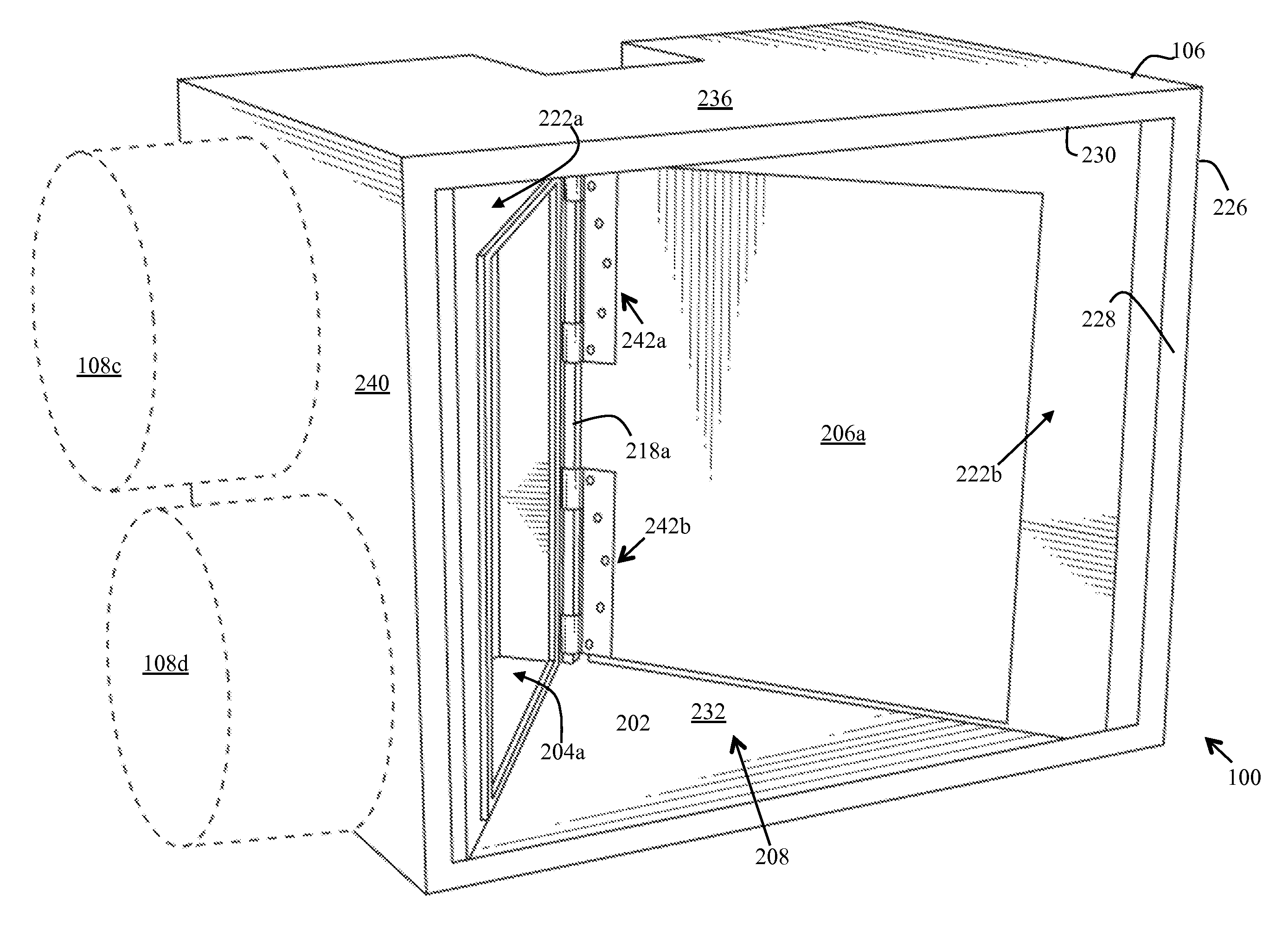

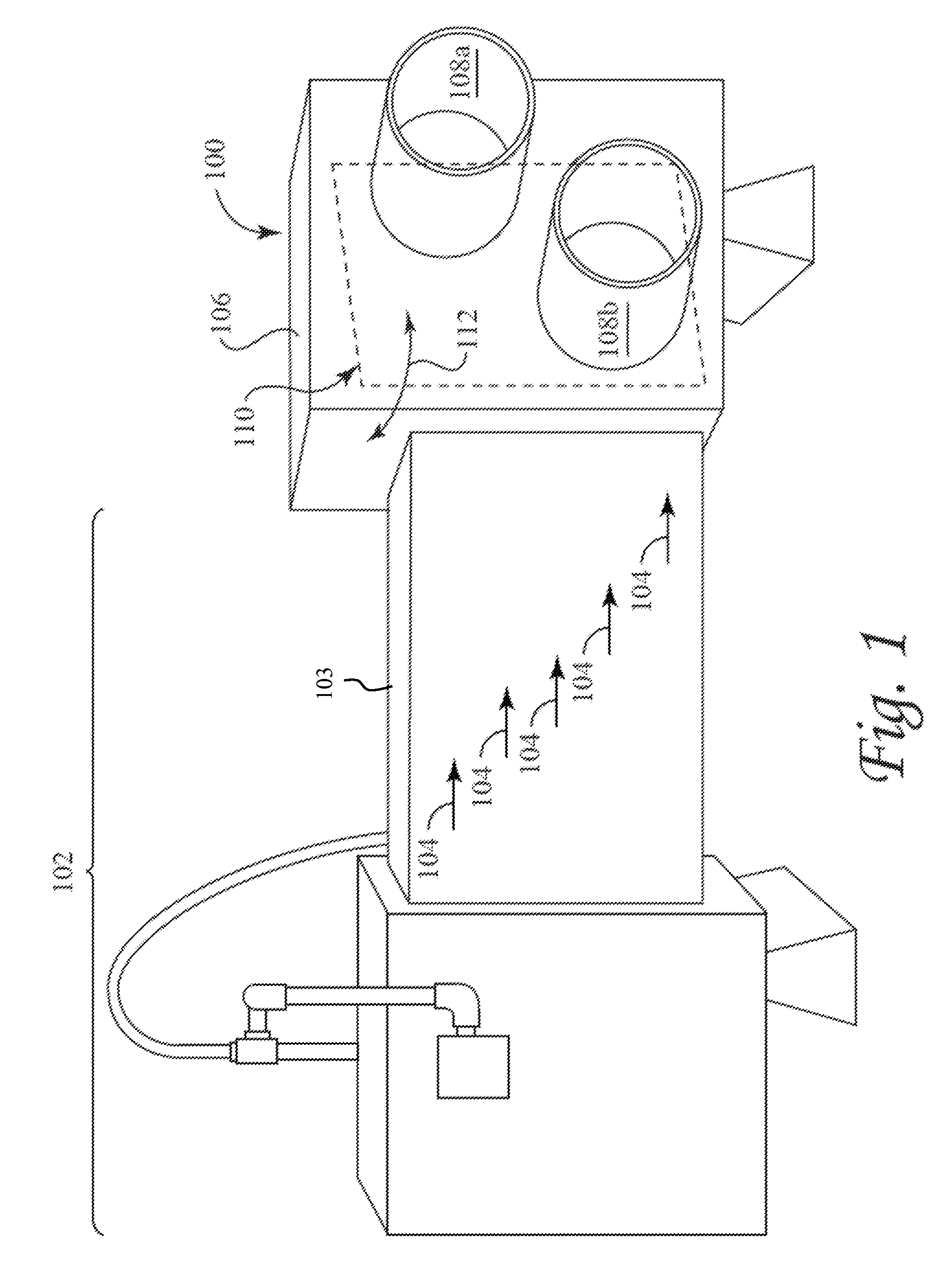

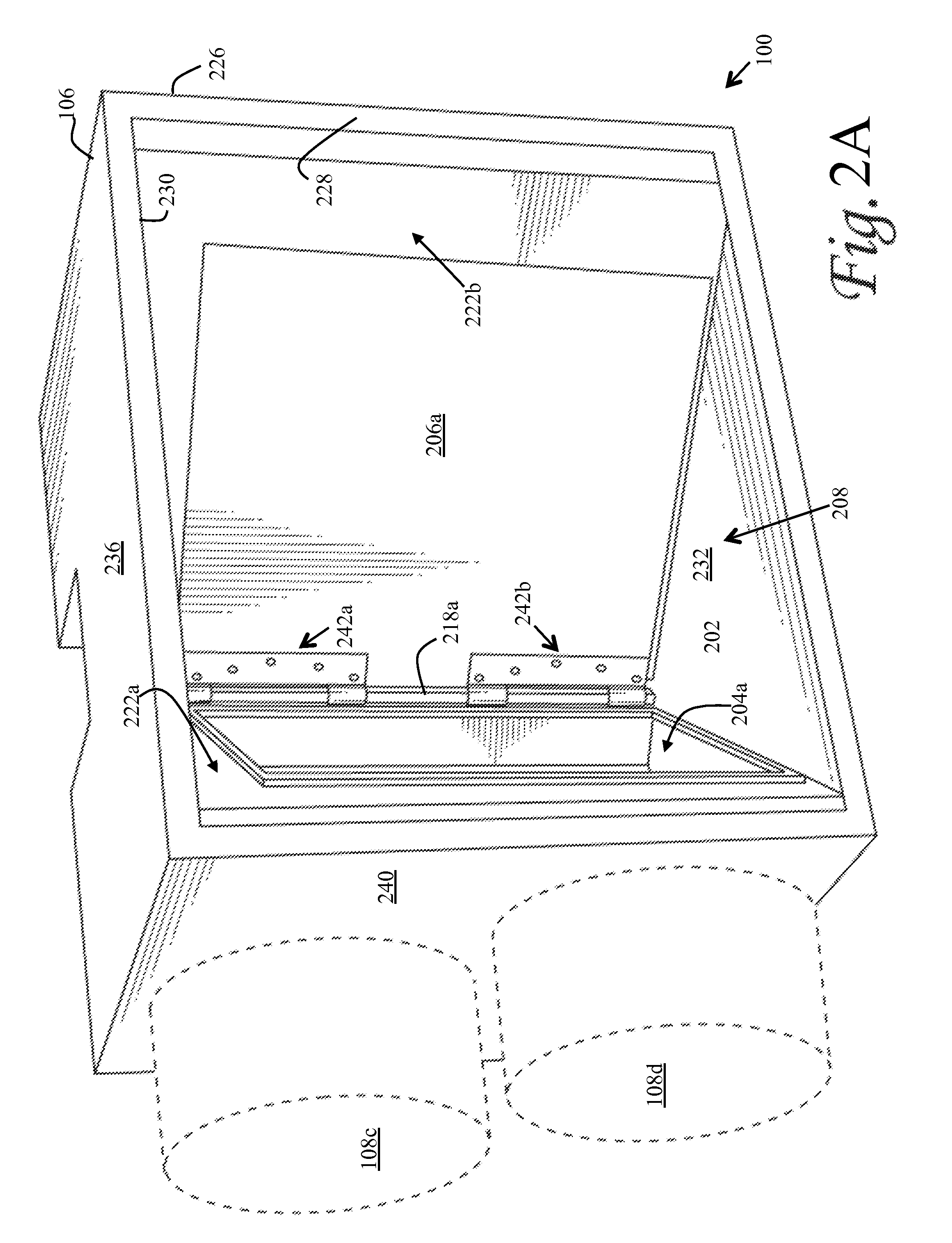

Integrated self-contained plenum module

Owner:CONTRERAS JOAQUIN DANIEL

Method and apparatus for controlling electric power steering system

ActiveUS8285451B2Efficient implementationDigital data processing detailsSingle motor speed/torque controlElectric power steeringControl vector

Disclosed herein is a method for controlling an electric power steering system, wherein a motor is controlled by vector control and driven by a current command value calculated on the basis of a parameter such as a steering torque to provide a steering assist power to a vehicle steering system, and further wherein the current command value is limited on the basis of desired output characteristics and a desired angular speed during a field-weakening control and a non-field-weakening control of the vector control.

Owner:NSK LTD

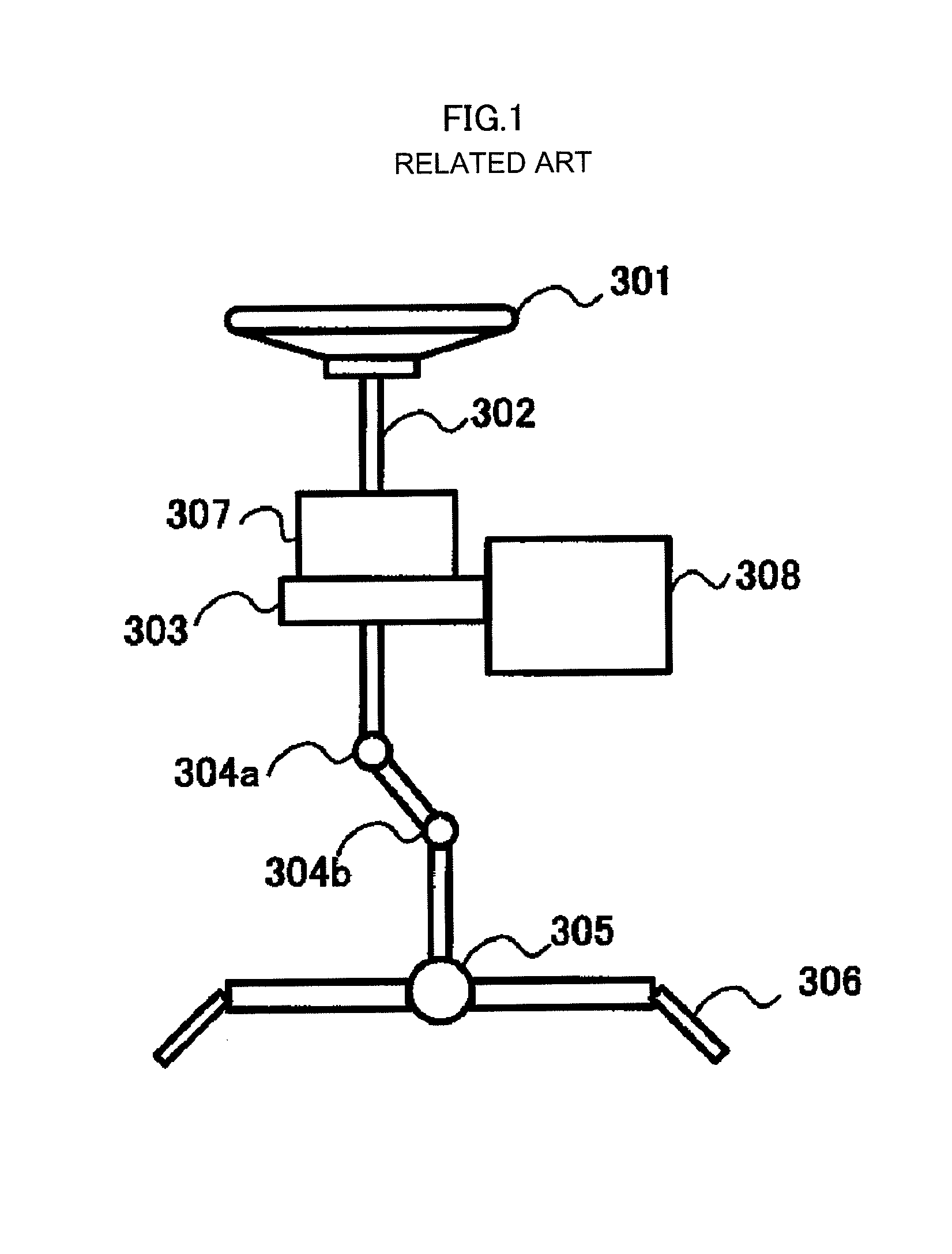

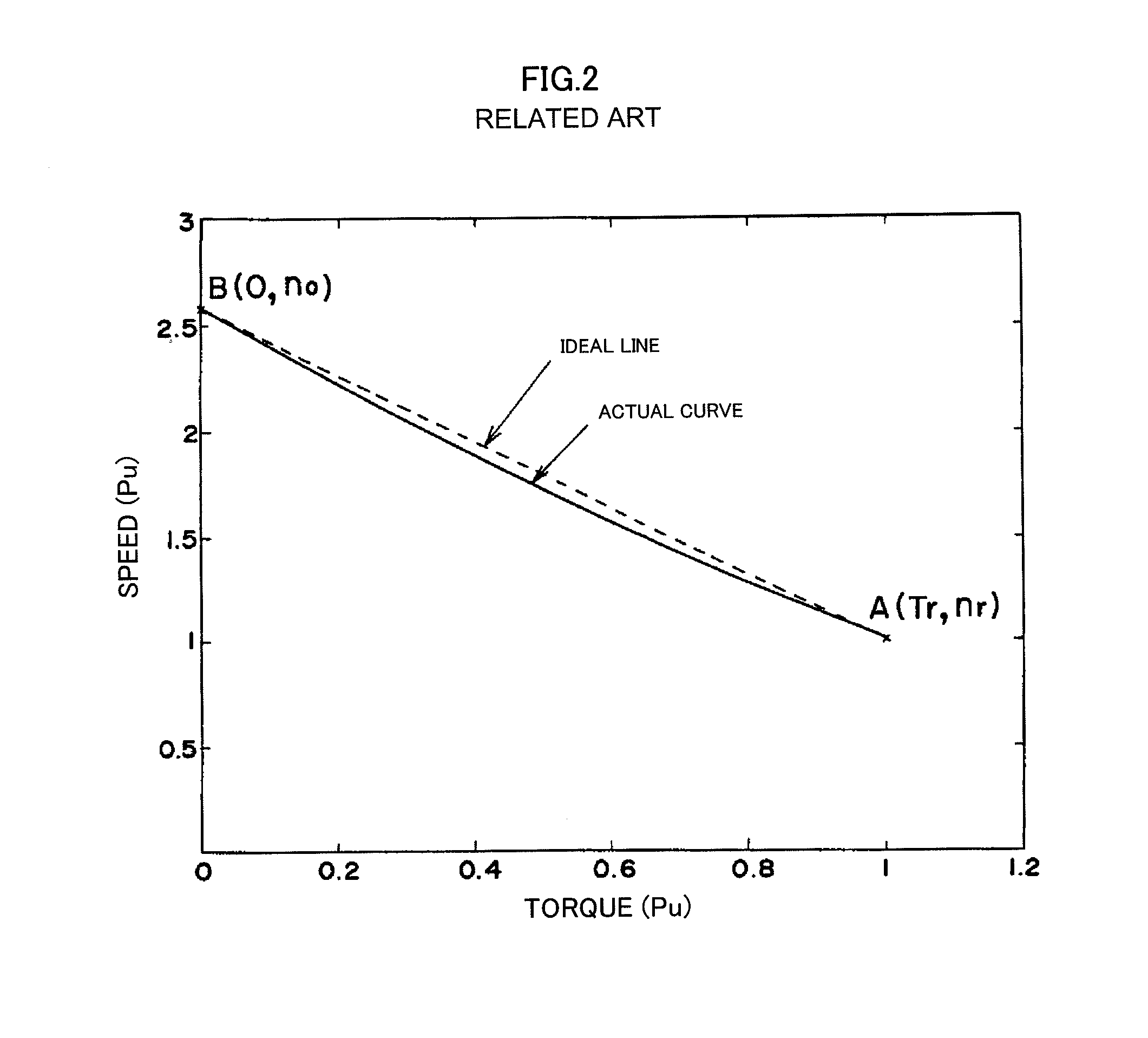

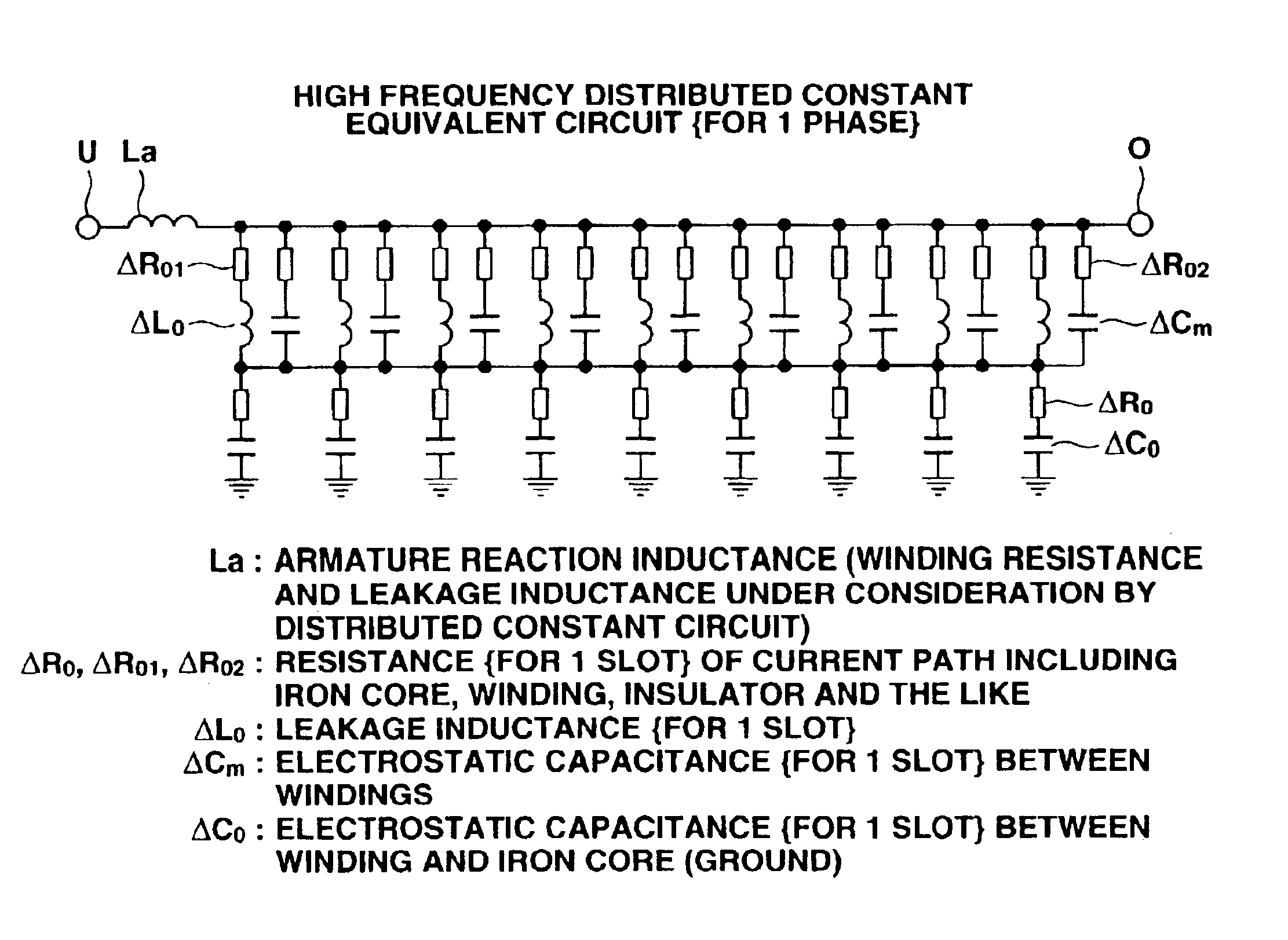

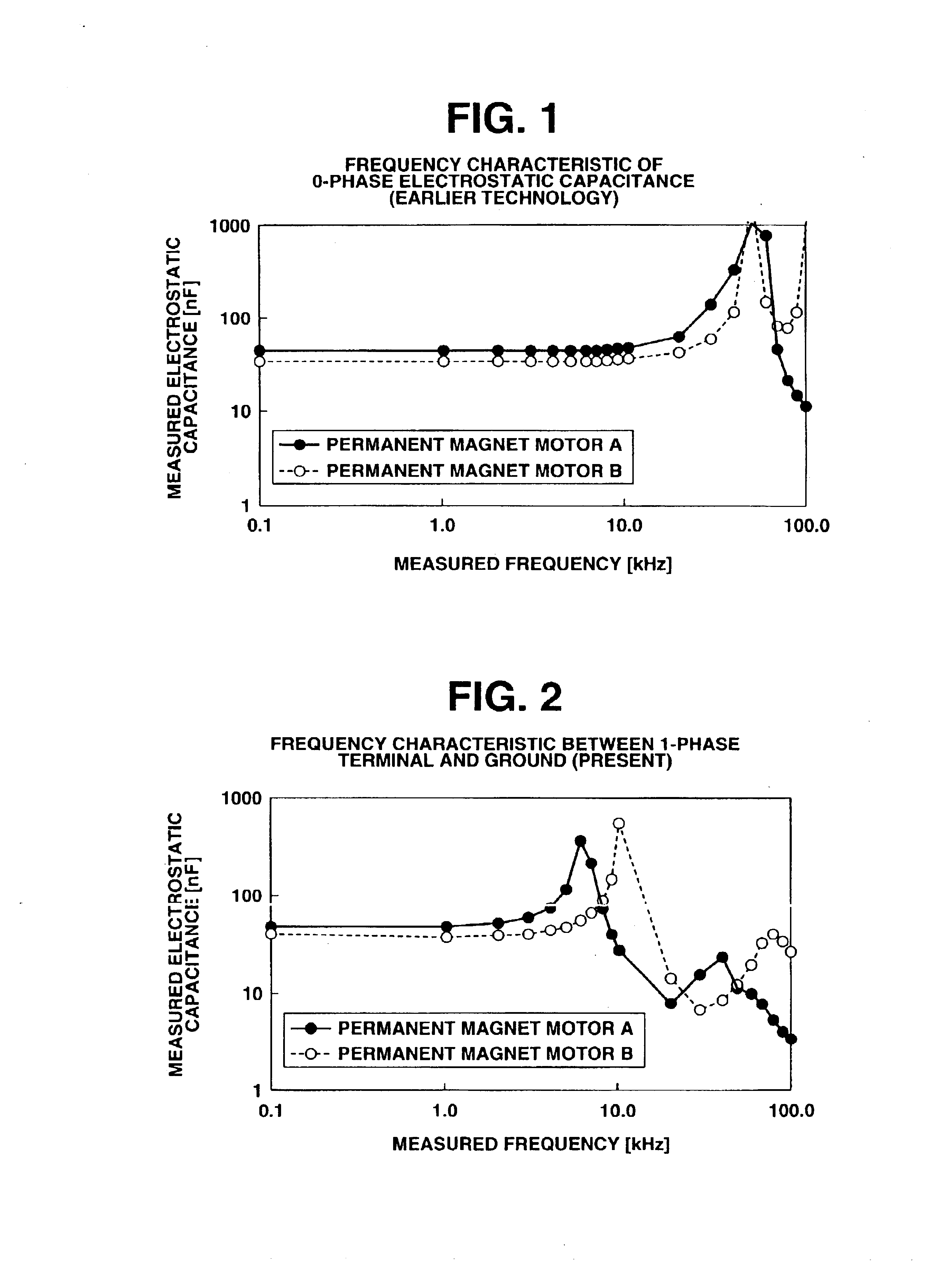

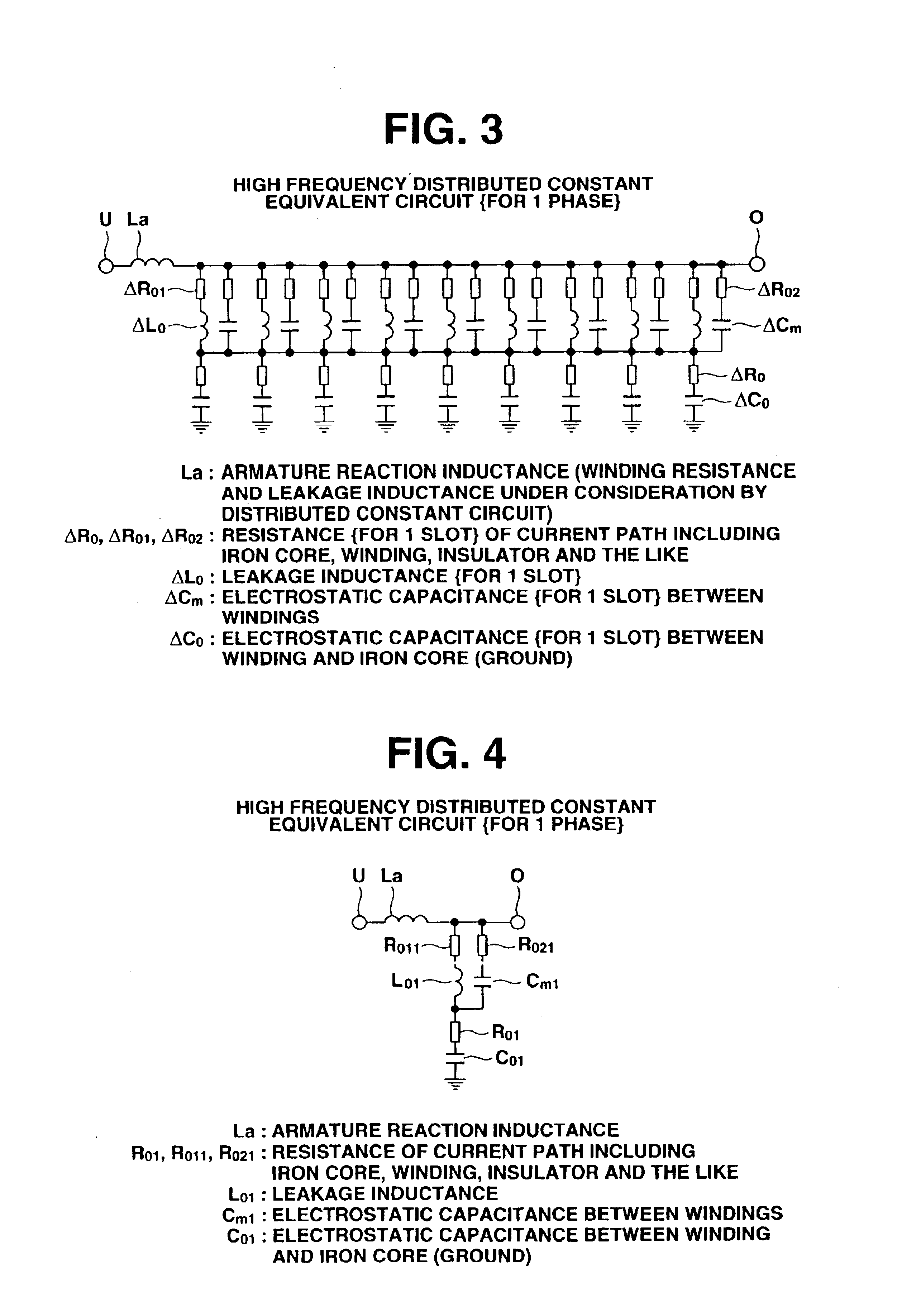

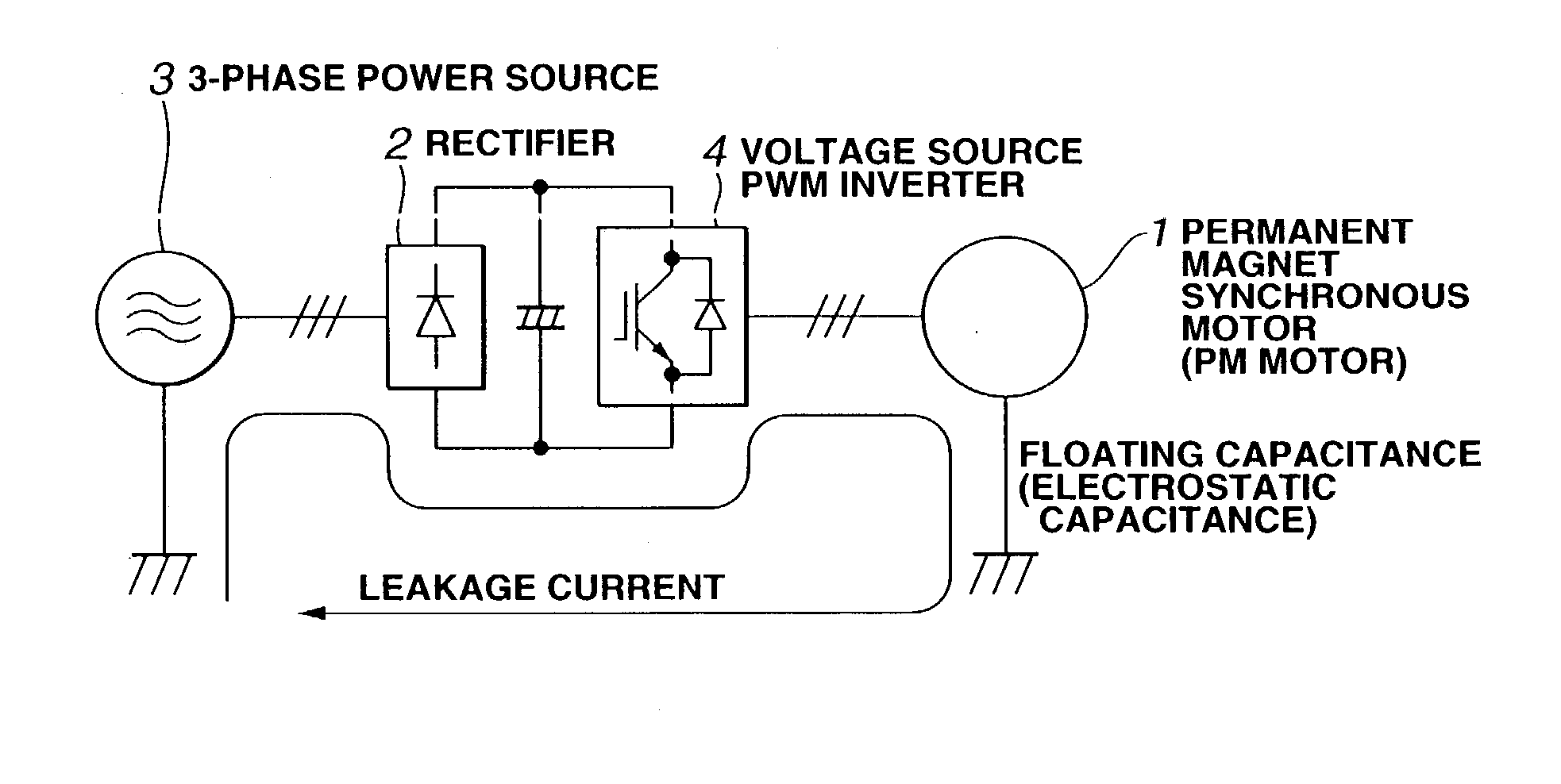

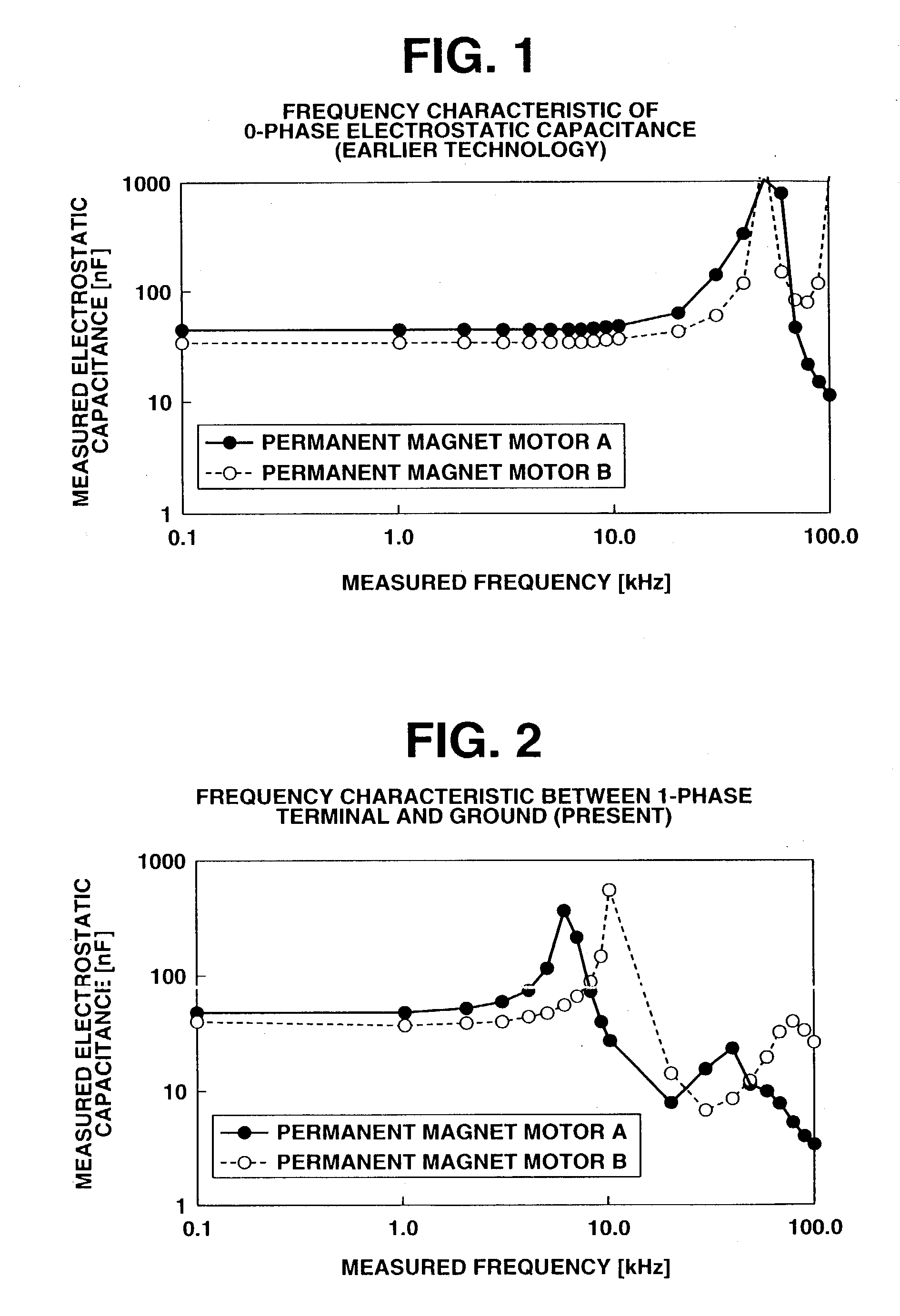

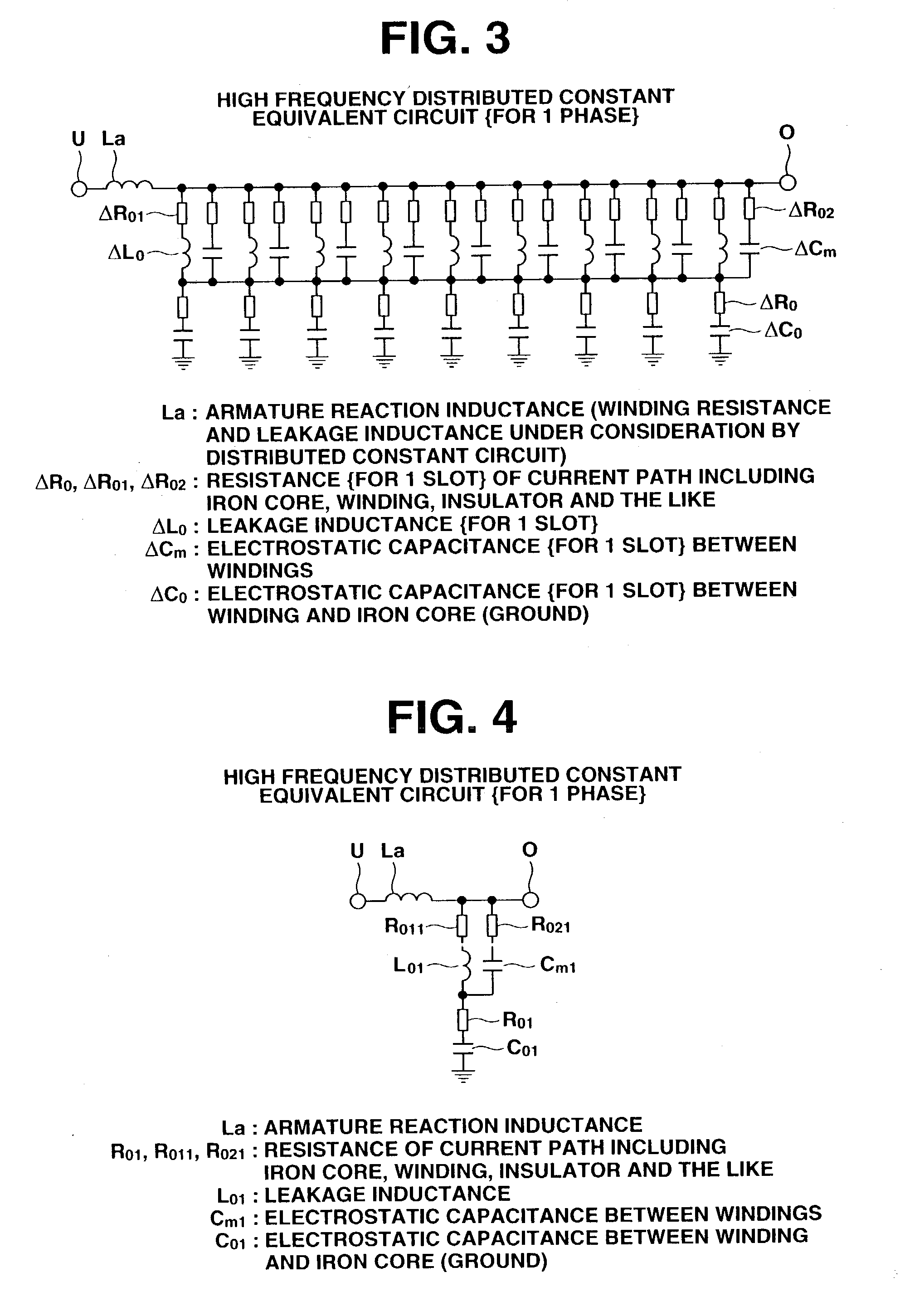

Permanent magnet synchronous motor driving system, and method of testing permanent magnet synchronous motor driving system

InactiveUS6870347B2Reduce leakage currentSynchronous motors startersVector control systemsCapacitancePermanent magnet synchronous motor

A permanent magnet synchronous motor driving system includes: 1) a permanent magnet synchronous motor, and 2) an inverter. The permanent magnet synchronous motor includes three phase terminals. A resonant frequency is generated between an inductance and a ground electrostatic capacitance which are measured between the following: a) one of the three phase terminals of the permanent magnet synchronous motor, and b) a ground. The inverter drives the permanent magnet synchronous motor. The inverter generates a carrier frequency. The resonant frequency of the permanent magnet synchronous motor is free from a conformance with the carrier frequency of the inverter and is free from a proximity of the carrier frequency of the inverter.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

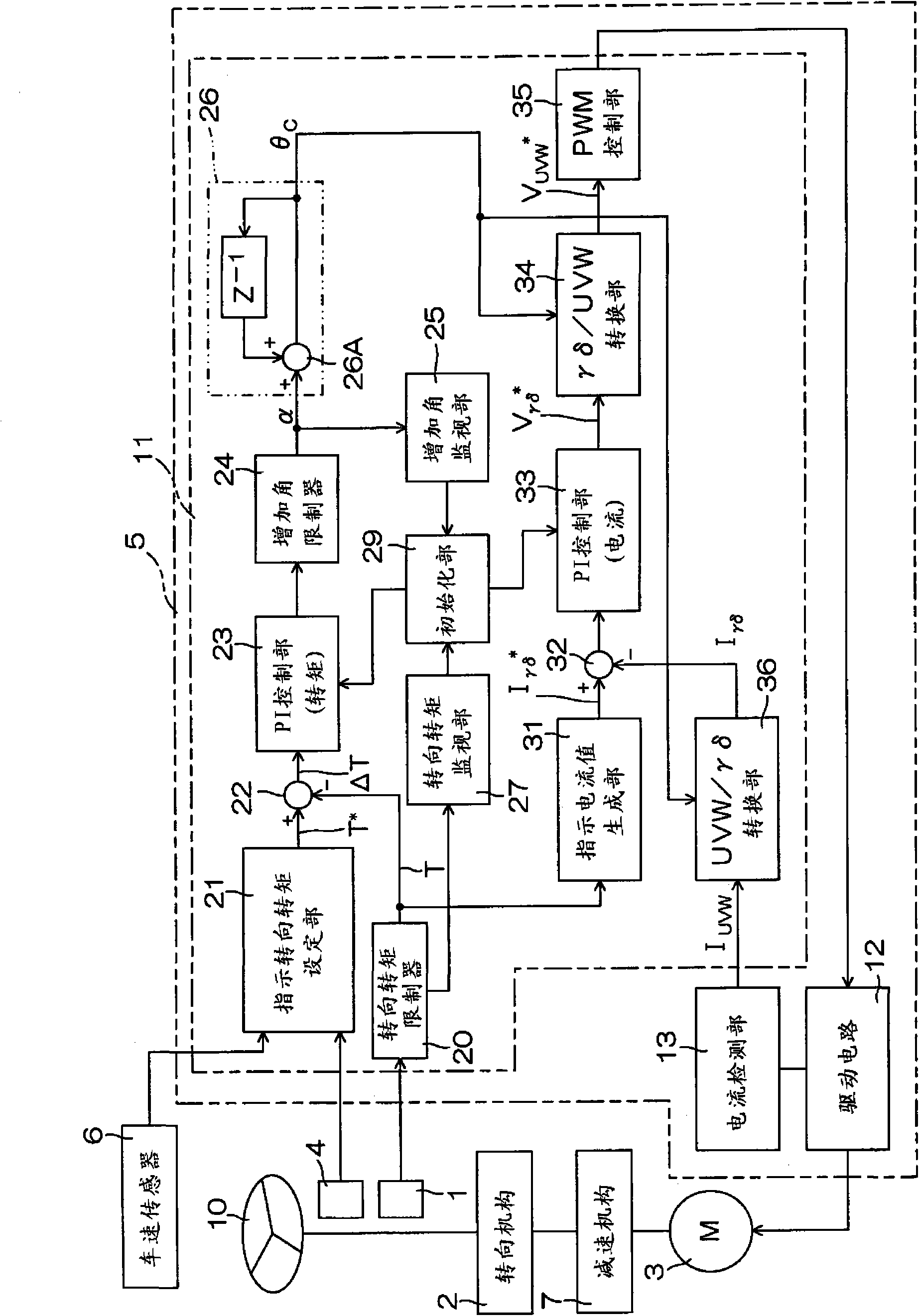

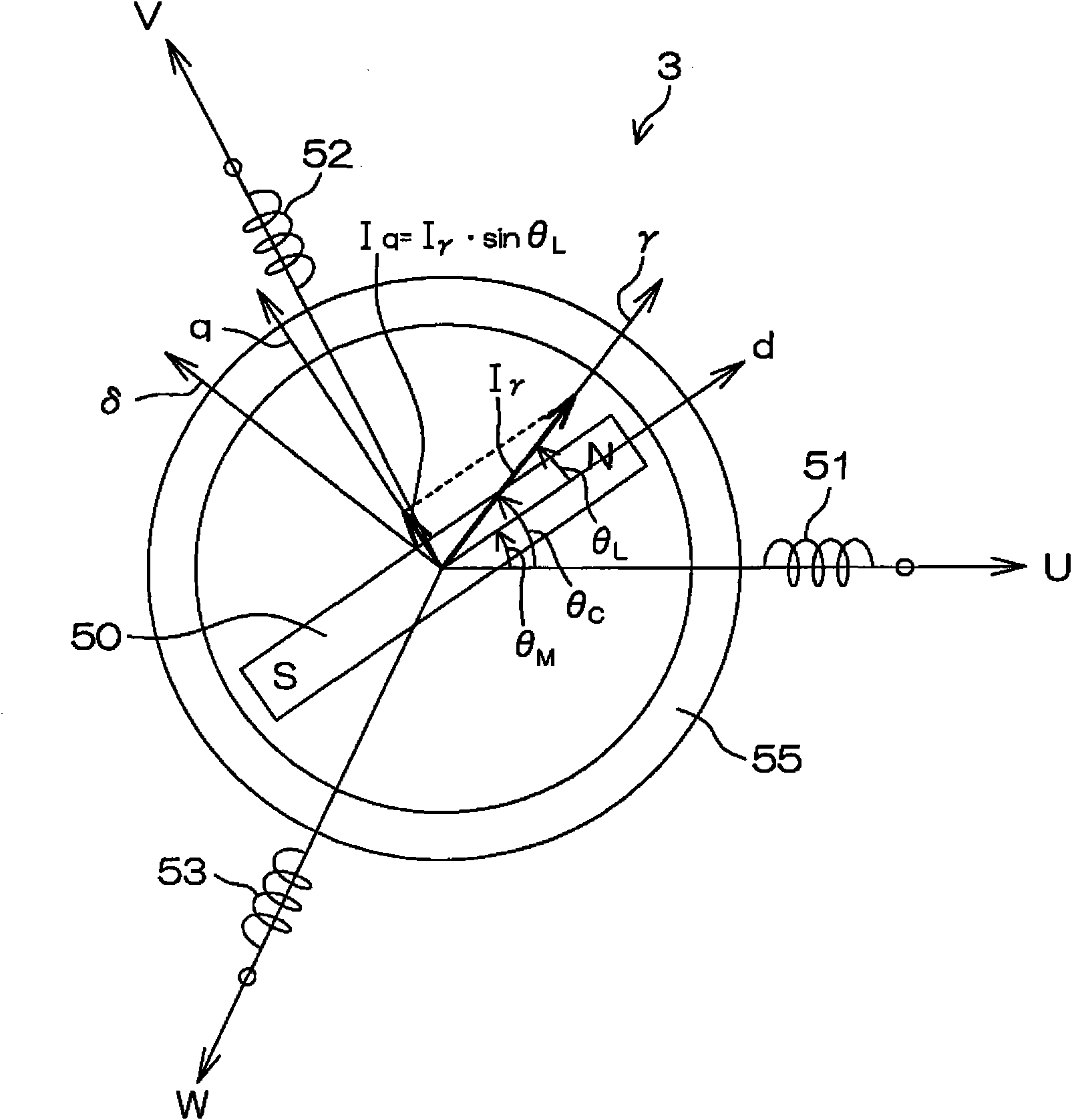

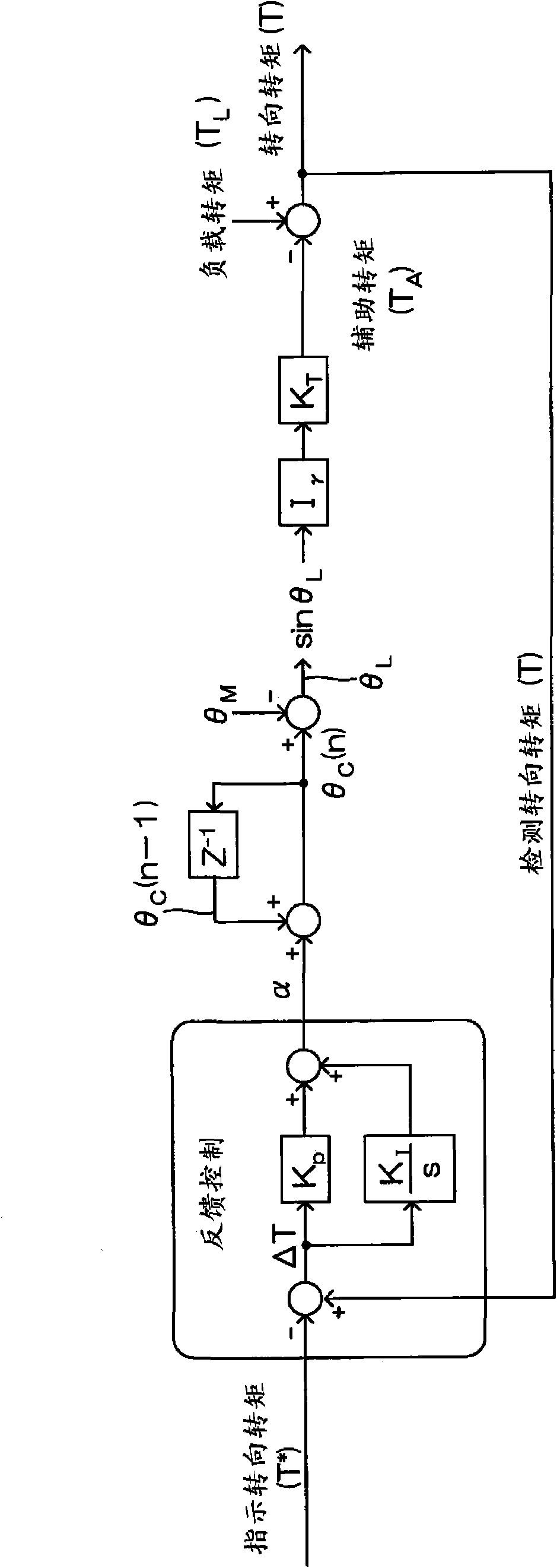

Electric motor controller and electric motor controller for vehicle steering apparatus

InactiveCN101795106AProhibited actionVector control systemsSingle motor speed/torque controlMotor driveChange control

The present invention provides an electric motor controller and an electric motor controller for vehicle steering apparatus. The electric motor controller comprises a current drive unit driving the motor based on an axis current value in a rotating coordinate system that rotates in accordance with a control angle that is a rotational angle used in a control, an addition angle calculation unit calculating an addition angle that is added to the control angle, a control angle calculation unit obtaining a current value of the control angle by adding the addition angle to an immediately preceding value of the control angle in each predetermined calculation cycle, a torque detection unit detecting a torque that is applied to a motor driven member except a motor torque, a changing unit changing a parameter for controlling the electric motor in accordance with a detected torque that is detected by the torque detection unit, and a suspending unit suspending the operation of the changing unit, until an absolute value of the detected torque becomes equal to or smaller than a predetermined value.

Owner:JTEKT CORP

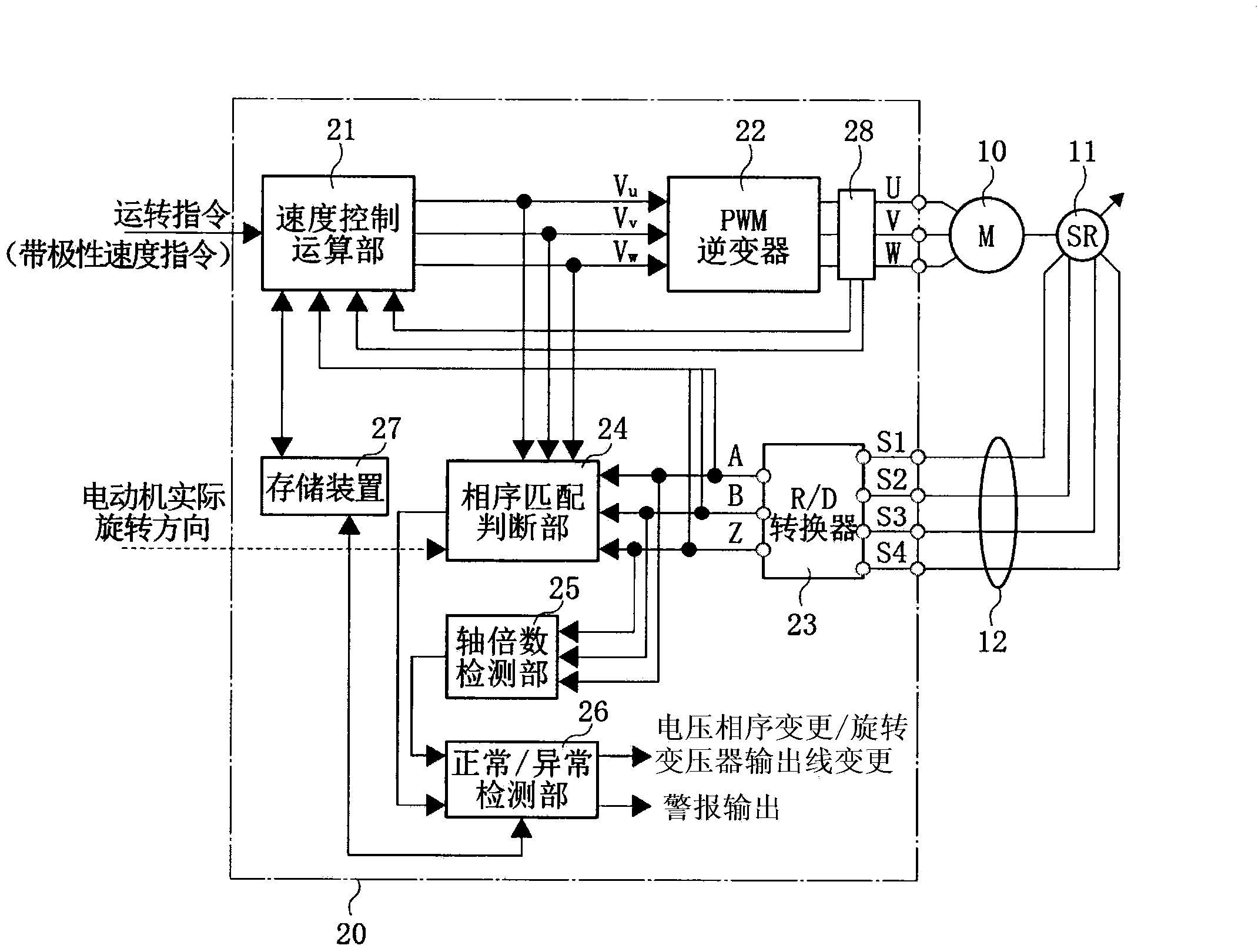

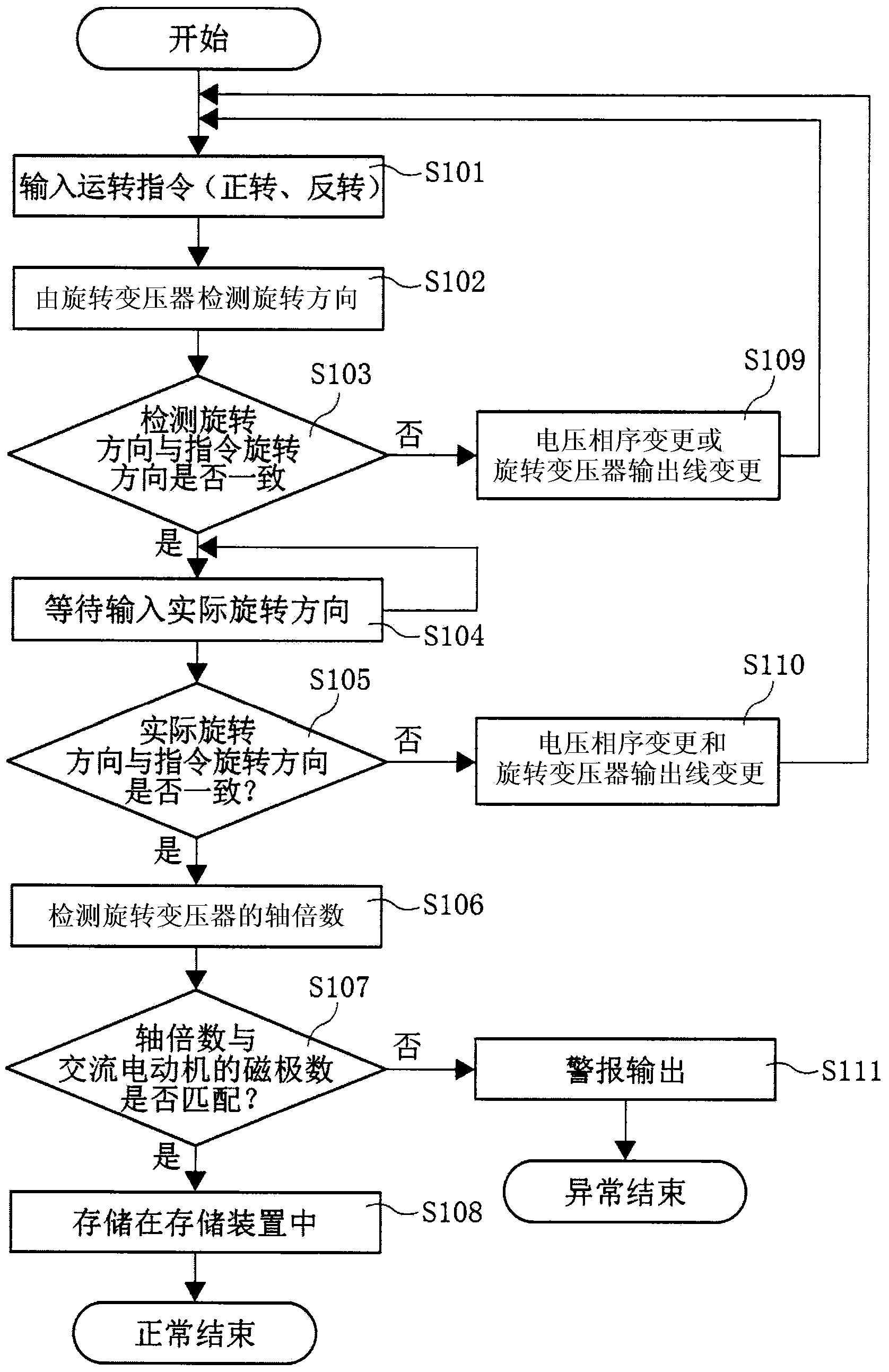

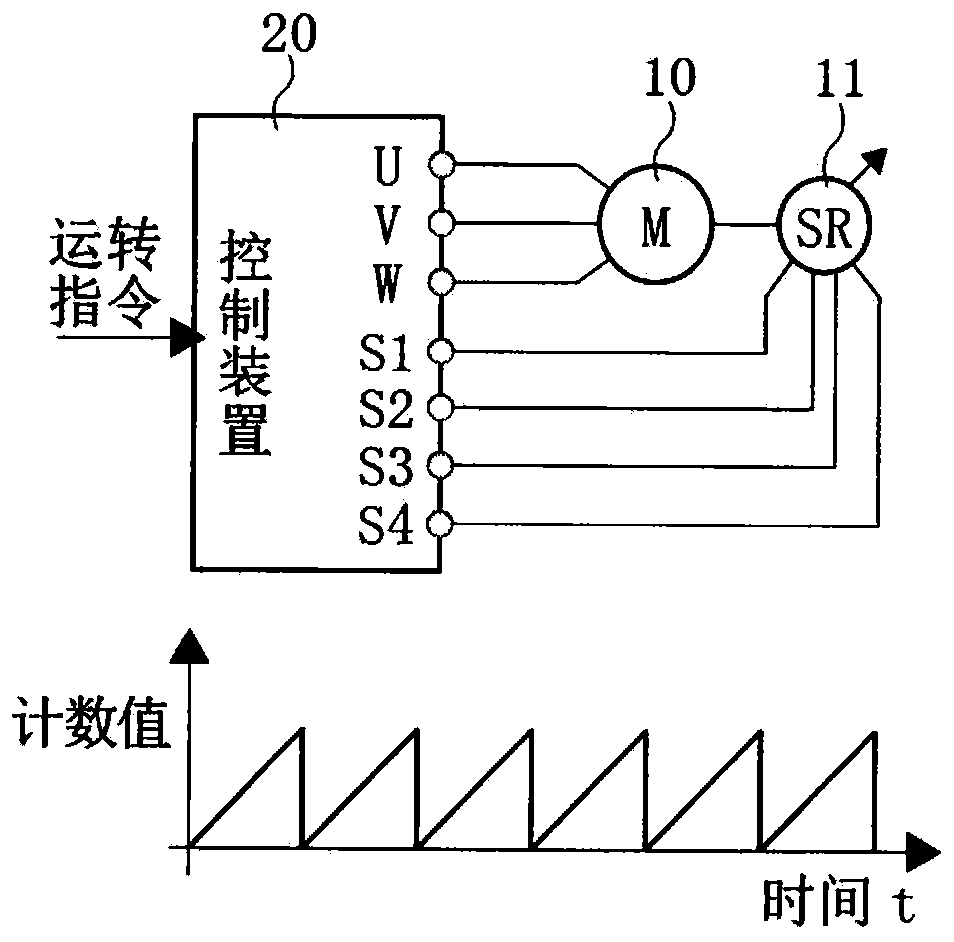

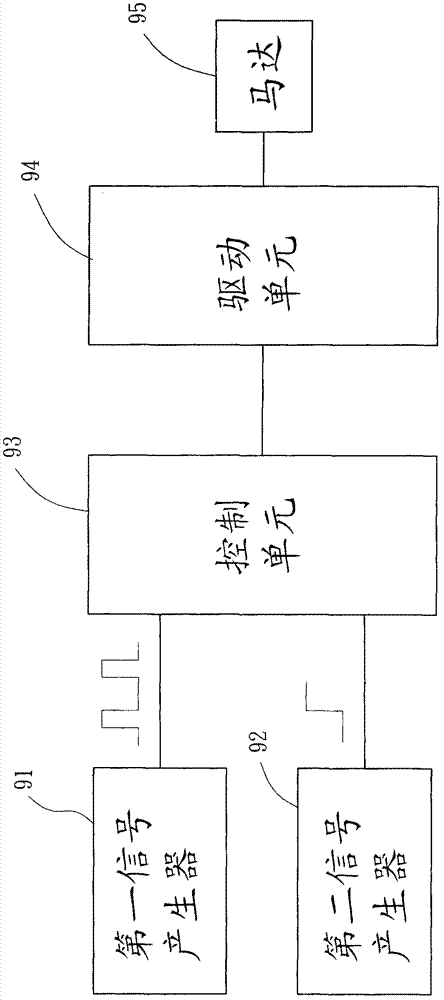

AC motor control device and control method

ActiveCN103986387AGuaranteed normal operationUrge inspectionVector control systemsDynamo-electric converter controlAnomaly detectionMagnetic poles

The invention provides an AC motor control device and a control method. The device comprises a phase sequence matching determination part, a shaft multiple detection part and a normality / anomaly detection part, wherein in first determination processes, the phase sequence matching determination part determines whether an instruction rotating direction provided by an AC motor operation instruction is consistent with a detection rotating direction obtained according to output signals of a rotating voltage transformer; in second determination processes, when that the instruction rotating direction is consistent with the detection rotating direction is determined, whether the instruction rotating direction is consistent with an actual rotating direction is determined; when that the instruction rotating direction is consistent with the actual rotating direction is determined, a shaft multiple is detected according to the output signals of the rotating voltage transformer; the normality / anomaly detection part, according to the determination results of the phase sequence matching determination part, detects the phase sequence of voltage applied on the AC motor or output wire distribution of the rotating voltage transformer are normal / abnormal; in third determination processes, the normality / anomaly detection part determines whether the shaft multiple detected by the shaft multiple detection part is matched with a magnetic pole number of the AC motor.

Owner:FUJI ELECTRIC CO LTD

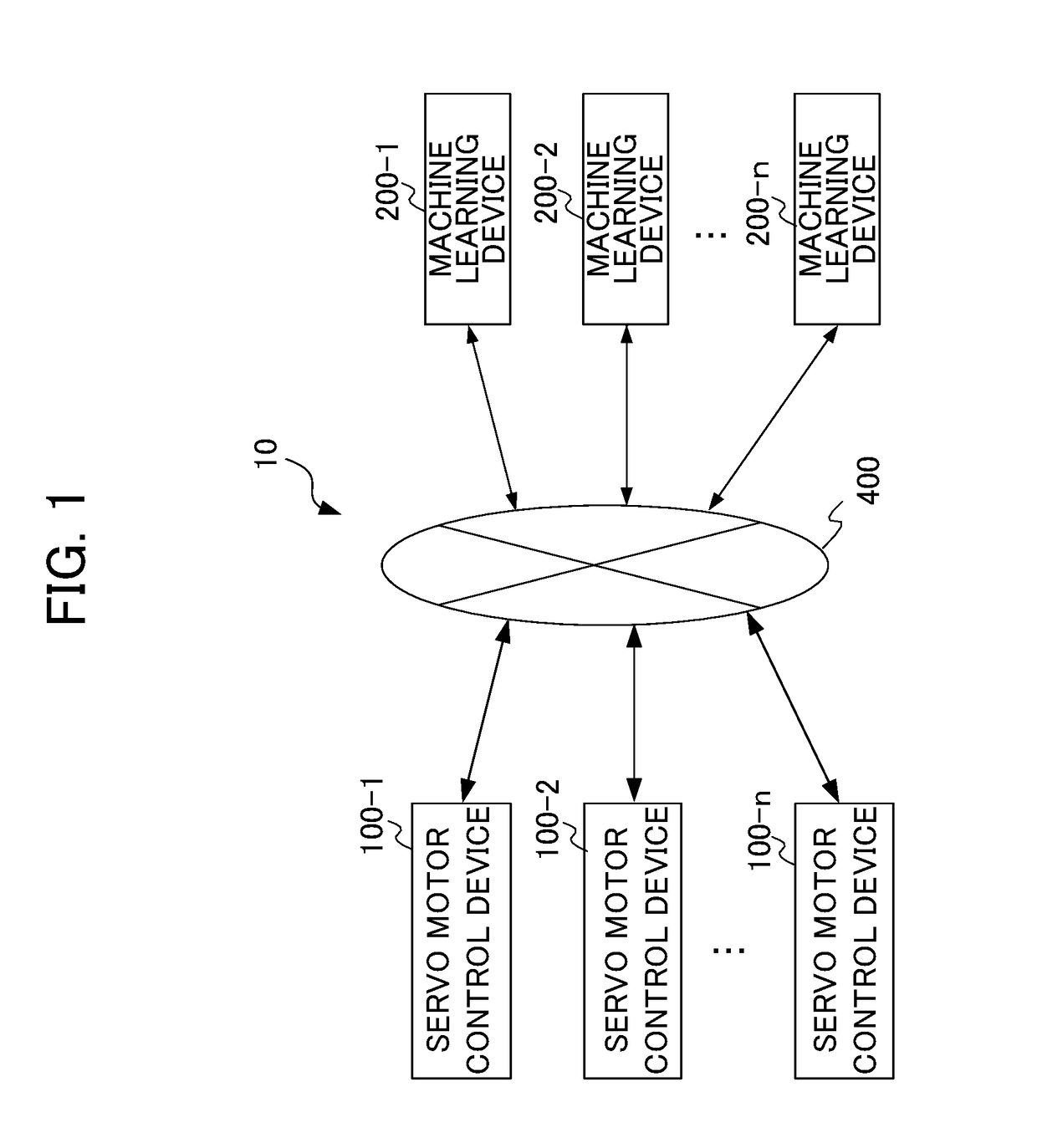

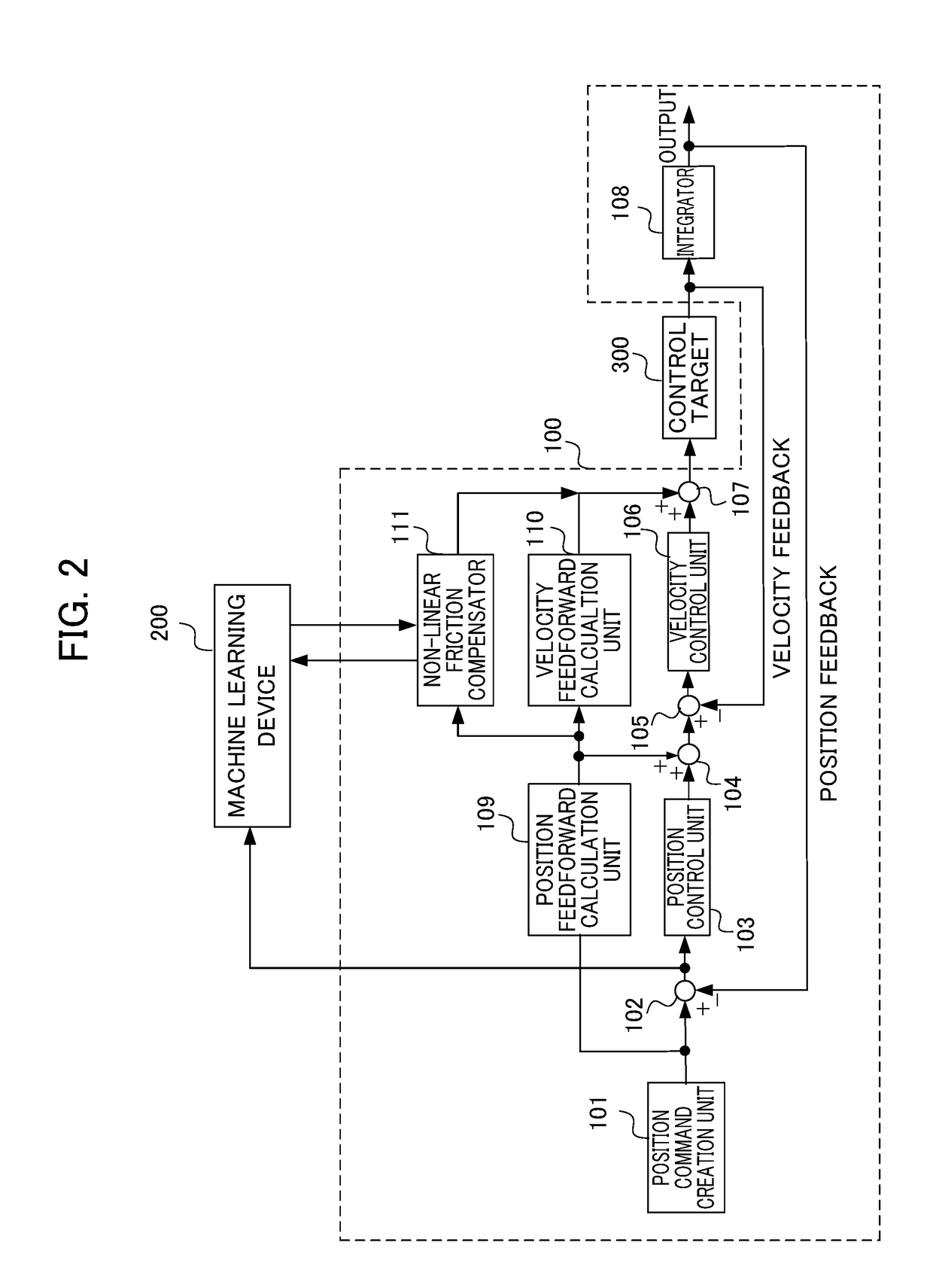

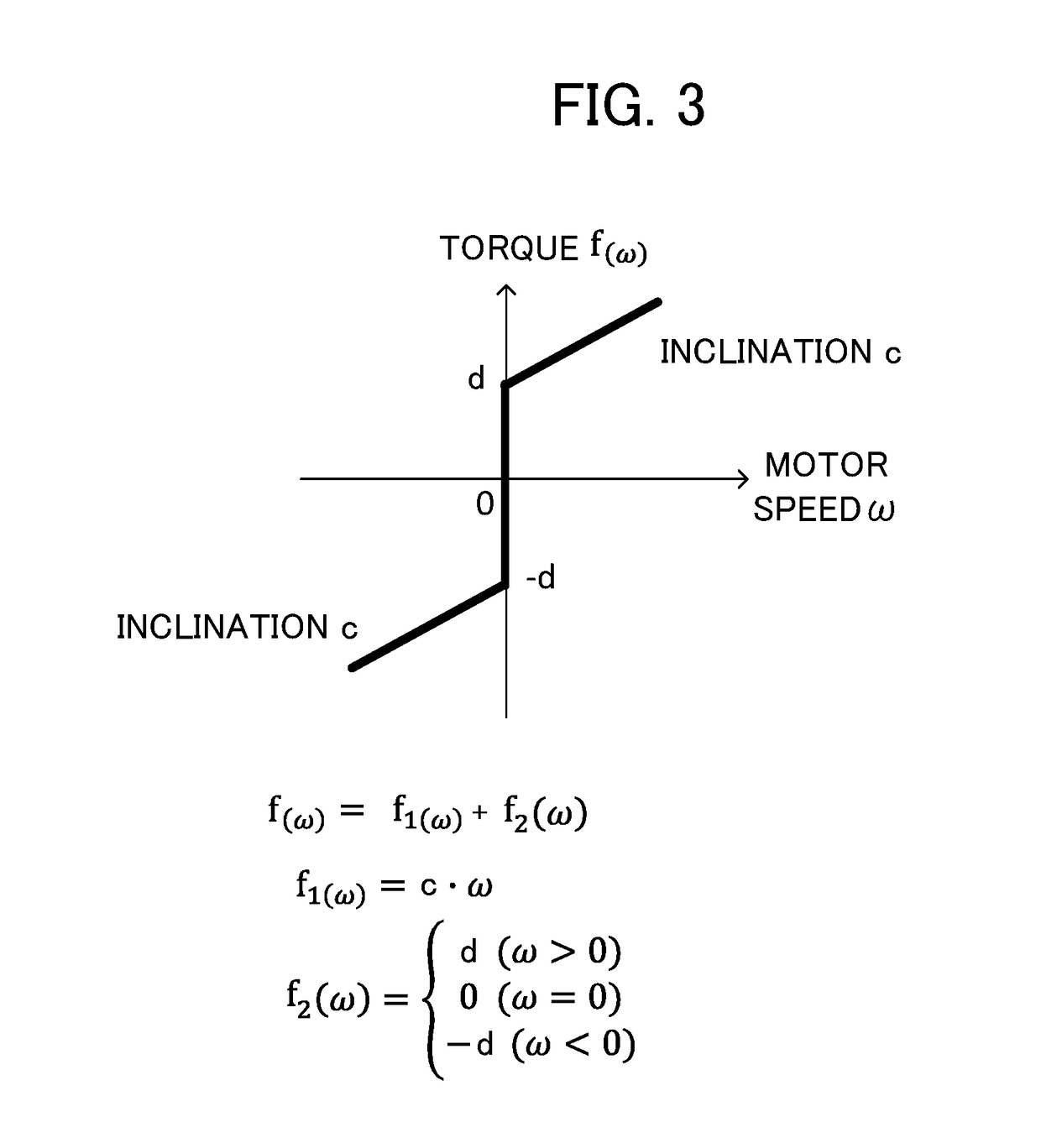

Machine learning device, servo motor control device, servo motor control system, and machine learning method

ActiveUS20190028043A1Improve responsivenessImprove servo performanceElectric motor controlVector control systemsMotor controlPosition error

A machine learning device is configured to perform machine learning with respect to a servo motor control device including a non-linear friction compensator that creates a compensation value with respect to non-linear friction on the basis of a position command, the machine learning device including: a state information acquisition unit configured to acquire state information including a servo state including position error, and combination of compensation coefficients of the non-linear friction compensation unit, by causing the servo motor control device to execute a predetermined program; an action information output unit configured to output action information including adjustment information of the combination of compensation coefficients; a reward output unit configured to output a reward value in reinforcement learning, based on the position error; and a value function updating unit configured to update an action value function on the basis of the reward value, the state information, and the action information.

Owner:FANUC LTD

Energy saving system and method for devices with rotating or reciprocating masses

ActiveUS8698447B2Does not consume energySave energyMotor/generator/converter stoppersSynchronous motors startersReciprocating motionControl theory

A system and method are provided for reducing the energy consumed by a pump jack electric motor by reducing the supply voltage to the motor when the motor would be generating energy in open loop mode. By substantially eliminating the energy generation mode, the braking action of the utility grid in limiting the acceleration of the motor and system that would otherwise occur is substantially removed. The motor and system will speed up, allowing the natural kinetic energy of the cyclic motion to perform part of the pumping action.

Owner:THE POWERWISE GRP

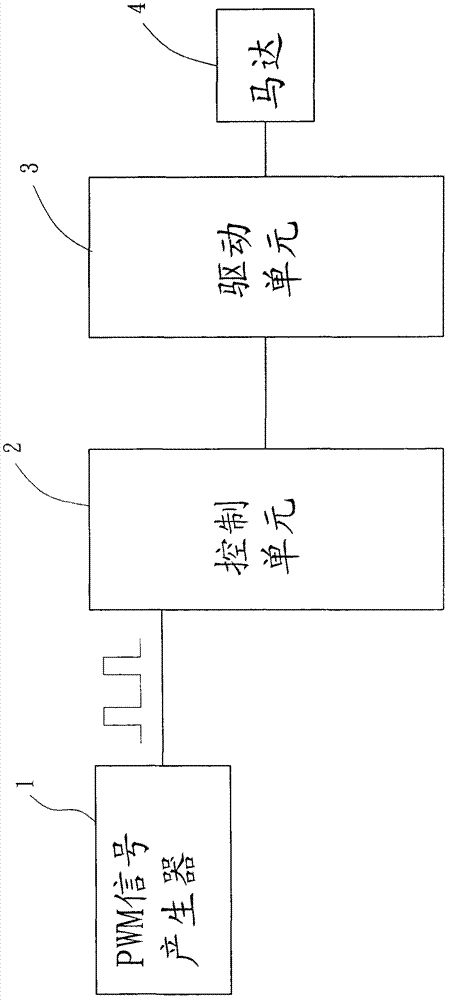

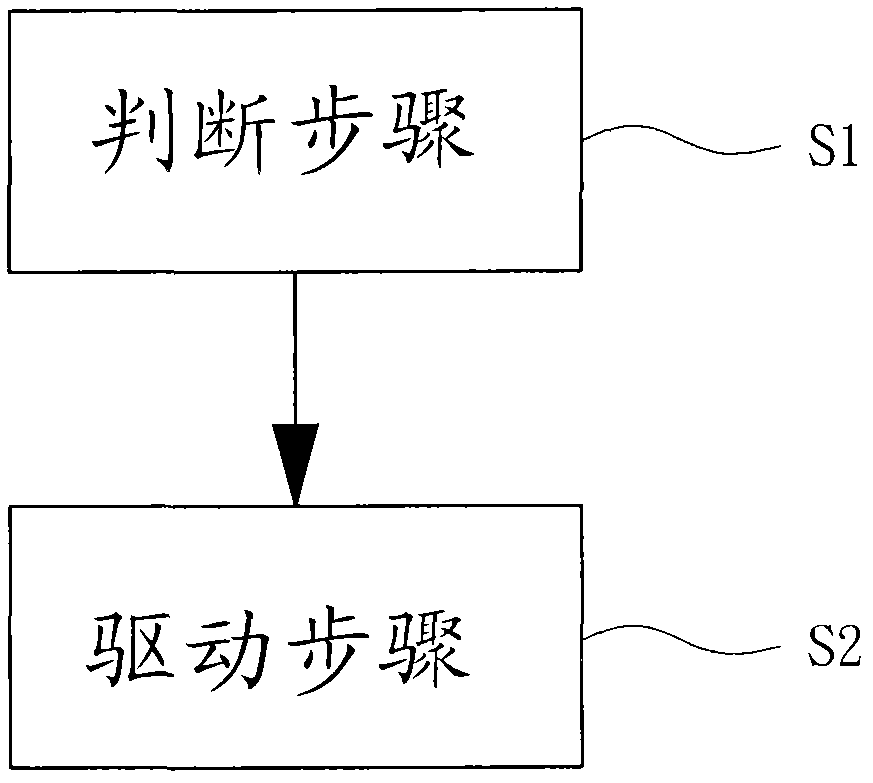

Motor control method

A motor control method comprises: inputting a PWM signal into a control unit for the control unit to obtain a direction command and a speed command by an identification rule, and generating a control signal according to the direction and speed commands by the control unit; and generating a driving signal according to the control signal by the driving unit for driving a motor to operate according to the direction and speed commands.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

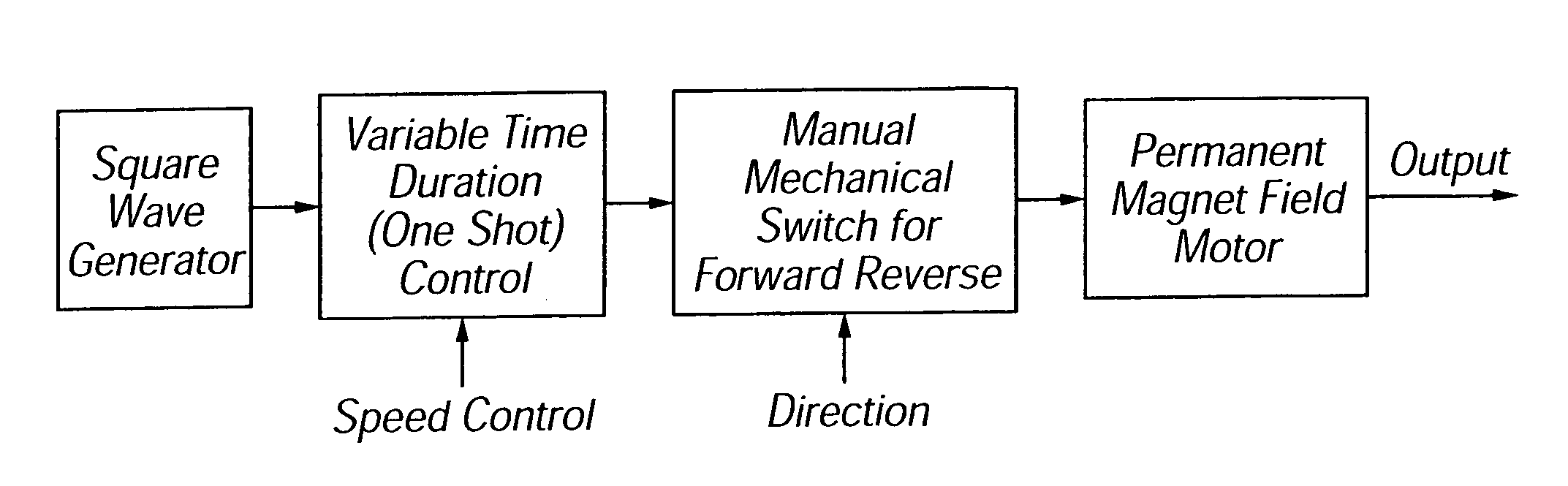

Digital motor control system and method

ActiveUS7421193B2Stable controlEnergy stabilityField or armature current controlDynamo-electric converter controlMotor speedJoystick

A digital motor control system utilizes time duration electric pulses generated by digital logic to control the motor speed and direction of rotation of a D.C. or A.C. motor. The digital logic produces width modulated pulses that can be connected to large or small electric motors by mechanical or electrical relays or switches to provide efficient motor control with little control circuit power loss. The mechanical or electrical switches are responsive to the digital logic to change motor direction or remove power from the motor windings. A variable control element such as a computer joystick can be utilized to control both direction and speed of the motor. The system can be configured as an open loop system or as a closed loop servo with a feed back element to control the rotational position of the motor.

Owner:KOBAYASHI HERBERT S

Controller for brushless motor

ActiveUS20060208690A1Reduce update frequencyReduce noiseSingle-phase induction motor startersSynchronous motors startersBrushless motorsEngineering

In a controller for brushless motor which suppresses the generation of abnormal noise when the motor current is controlled by updating voltages applied to the coils, the present values of the applied voltages to the coils are calculated from the d axis target current, the q axis target current, the d axis actual current, the q axis actual current, and the present value of the detected rotational position of the rotor. The updating period of the applied voltages is set as a period that is shorter than this calculation period. The predicted value of the rotational position at a point in time at which the applied voltages are updated until the next calculation of the present values of the applied voltages is determined in accordance with the present value, a past value of the detected rotational position, and the applied voltage updating period. The predicted values of the applied voltages are calculated from the predicted value of the rotational position, the d axis target current, the q axis target current, the d axis actual current, and the q axis actual current. The applied voltages are updated in accordance with the present values and predicted values of the applied voltages.

Owner:JTEKT CORP

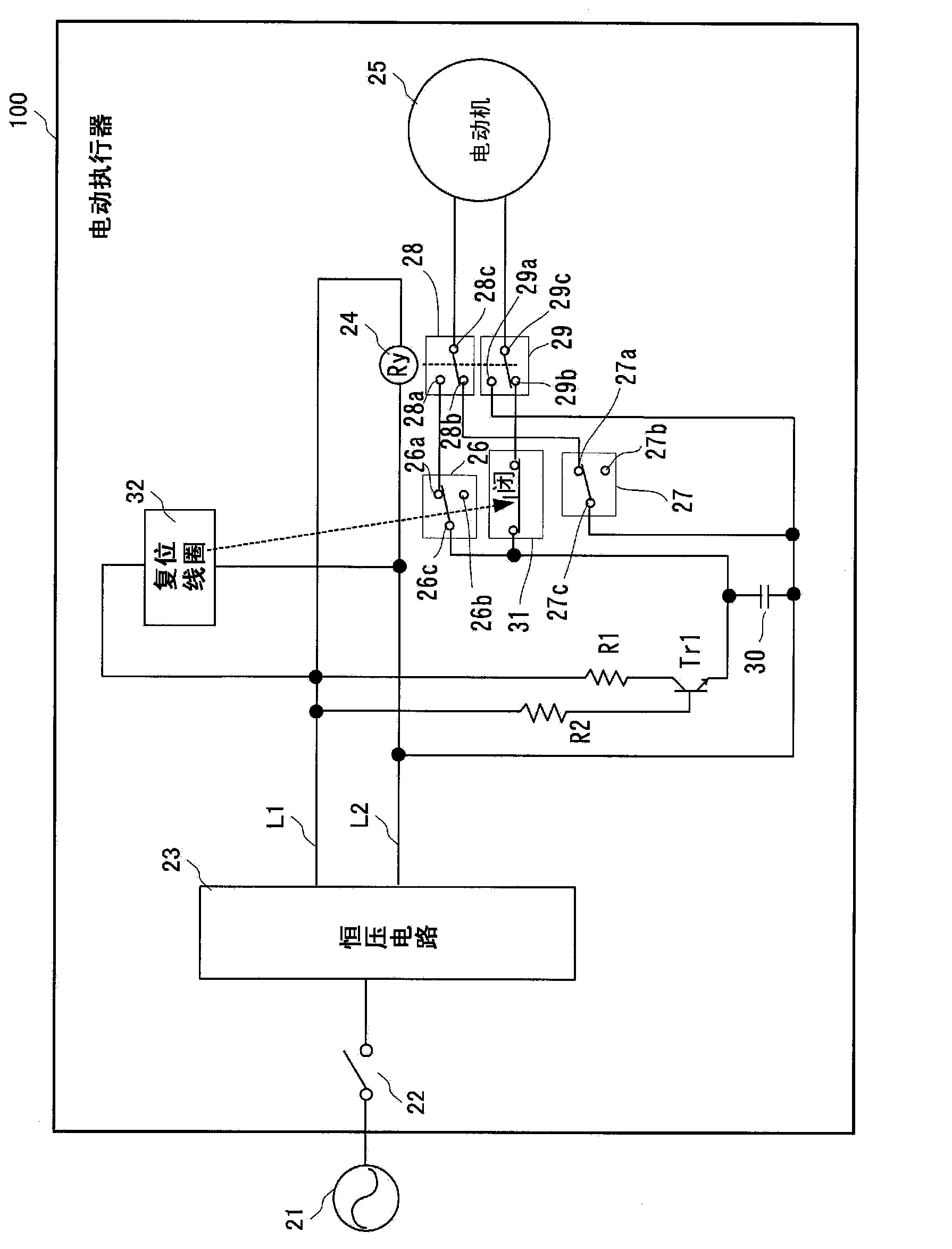

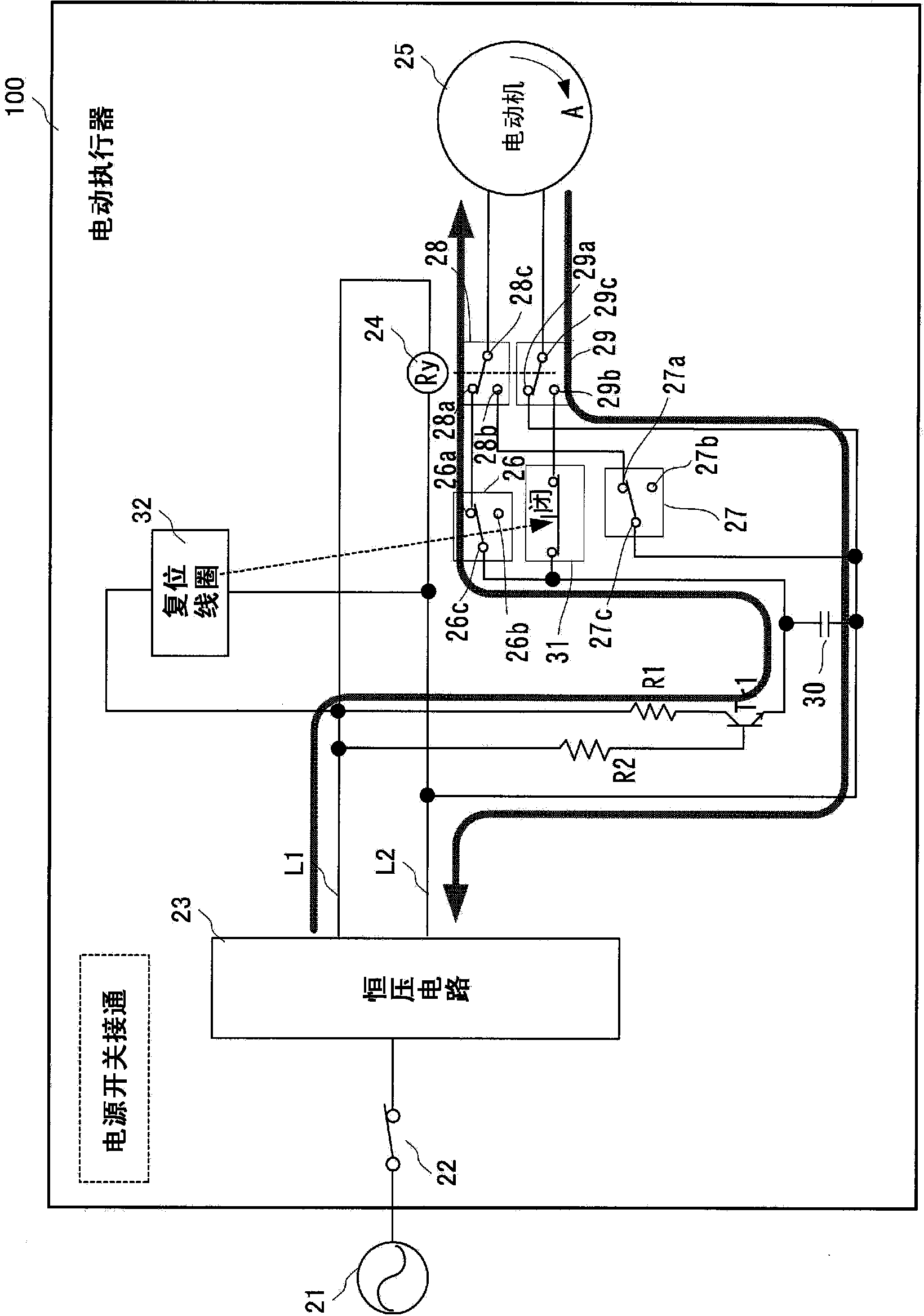

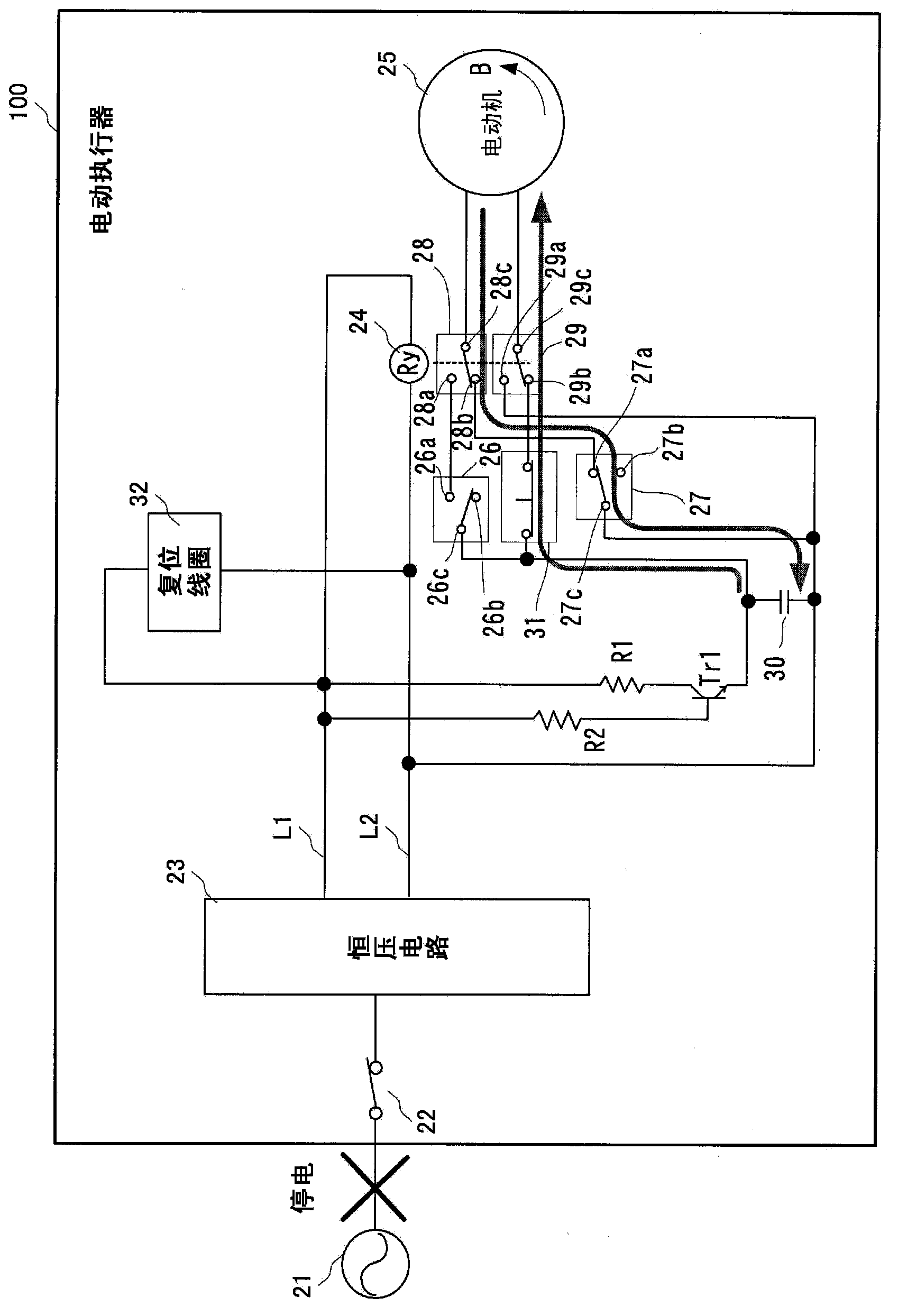

Electric actuator

InactiveCN103388701ANot limited by timeMaintenance is not limited by timeOperating means/releasing devices for valvesElectric motor controlElectricityElectric power system

An electric actuator has a motor, an electricity storing body, a switch and a resetting unit. The switch is provided in a supply path of electric power from the electricity storing body to the motor. The switch opens the supply path for electric power from the electricity storing body to the motor, in response to an instruction from an operator. The resetting unit is operated through receiving a supply of electric power from the external power supply when the external power supply has been restored from being cut off. The resetting unit closes the switch that is provided in the supply path of electric power from the electricity storing body to the motor.

Owner:YAMATAKE HONEYWELL CO LTD

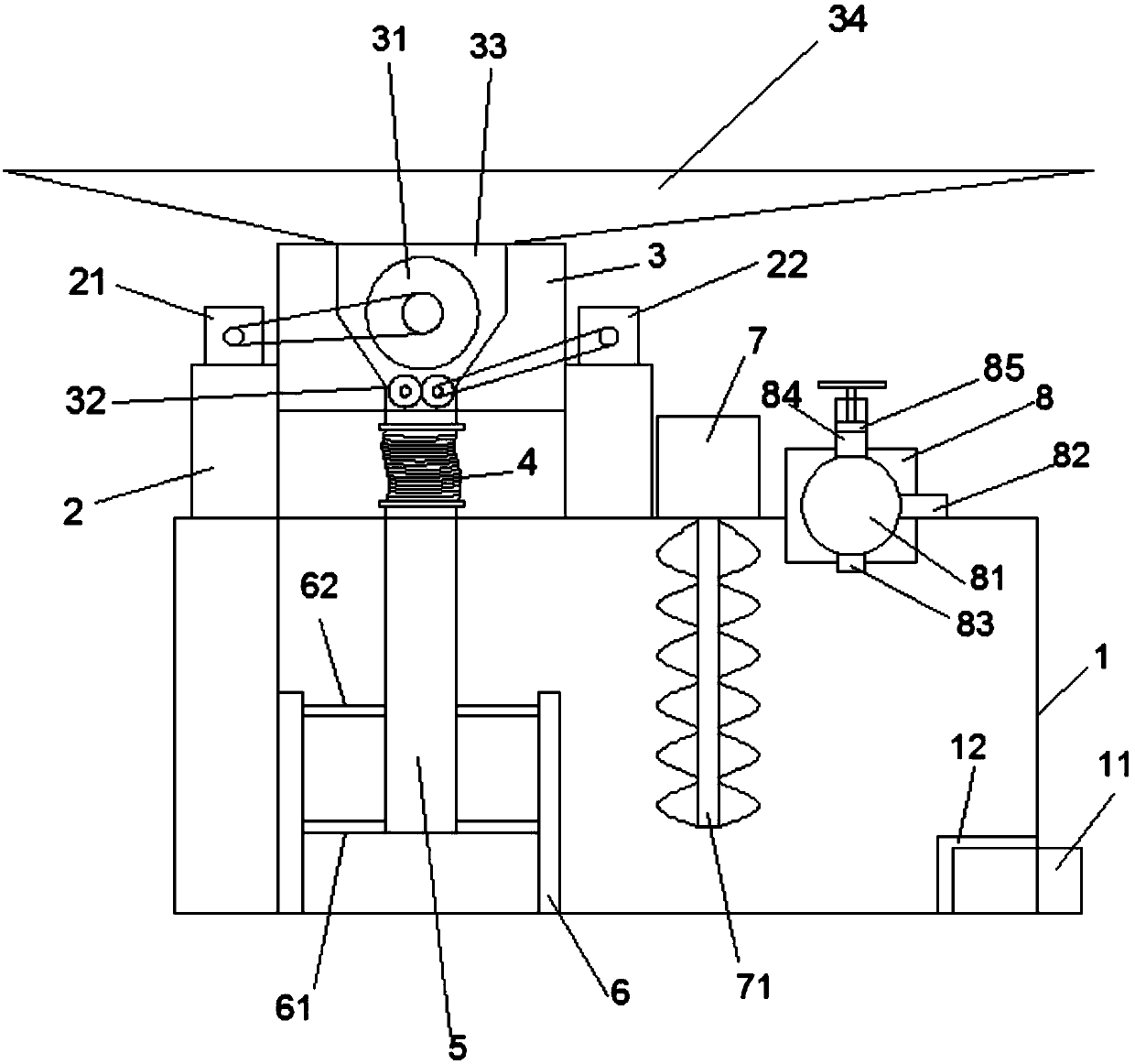

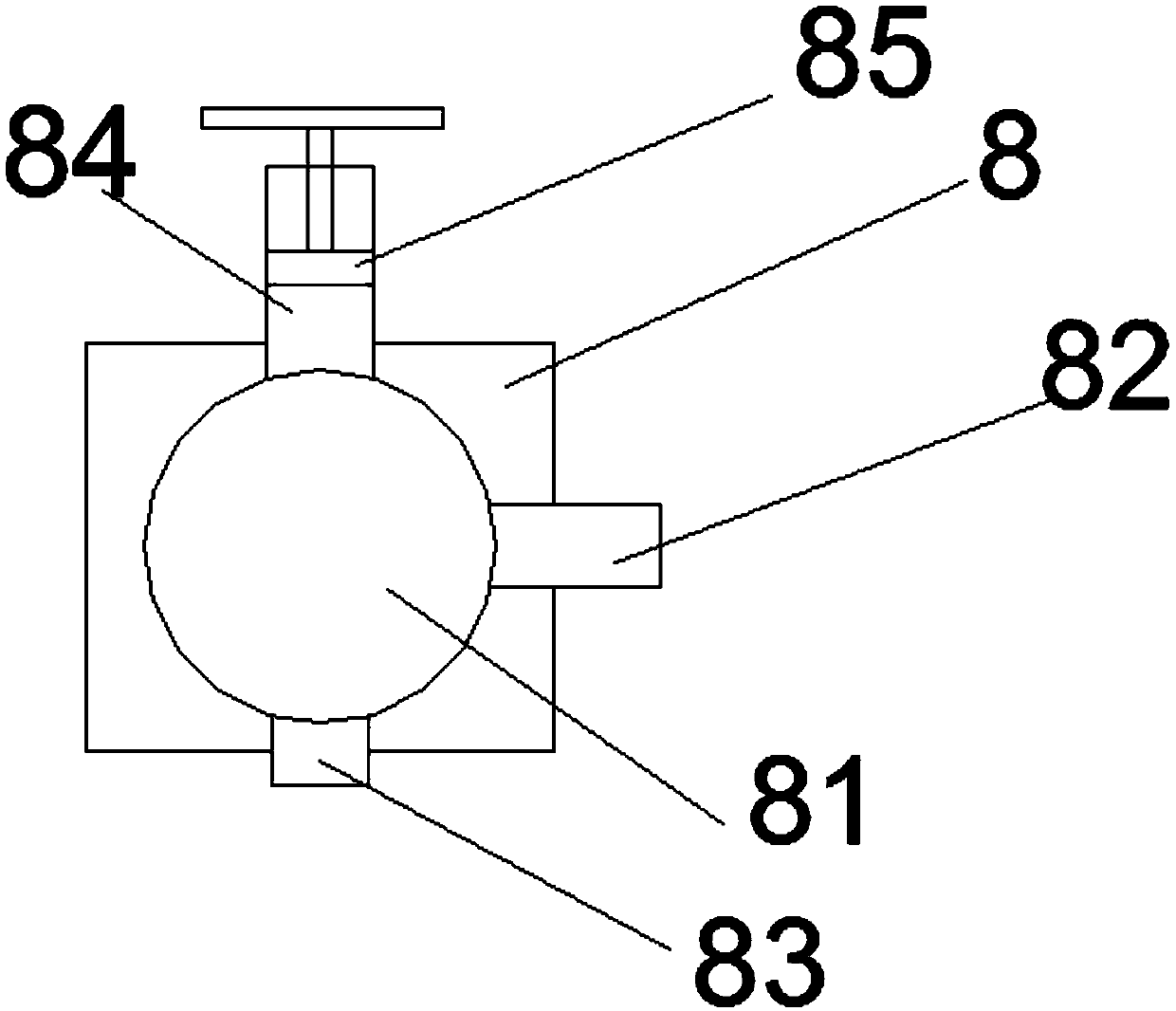

Rainwater collection and purification filtering box

InactiveCN107893468ARealize wet and dry separationAvoid cloggingTreatment involving filtrationMultistage water/sewage treatmentRainwater harvestingProcessing cost

The invention discloses a rainwater collection and purification filtering box. The rainwater collection and purification filtering box comprises a reaction pond and a water inlet box, two supporting bases are arranged at the top of the reaction pond, the water inlet box is erected between the two supporting bases, a first motor and a second motor are arranged on the two supporting bases respectively, the water inlet box is internally provided with a water inlet hopper, and a rainwater collection groove which is opened upwards is formed above the water inlet hopper. By forming the rainwater collection groove which is opened upwards, rainwater can be collected on a large scale; through the arrangement of a smashing roller and squeezing rollers, chunky waste in the rainwater is crushed, and it is avoided that sundries with a large size clog a water inlet; meanwhile, through a processing filtering net and a secondary filtering net, small-particle waste mixed in the rainwater are stopped ina sundry partition box, and separating dry space from moist space of the rainwater is achieved; through a quantitative liquid supplying opening, purifying agent liquor is quantitatively putting intothe purifying pond, the processing cost is reduced, and the phenomenon of secondary pollution caused by too much putting of the purifying agent liquor is effectively avoided.

Owner:曹波

Energy saving system and method for devices with rotating or reciprocating masses

ActiveUS8823314B2Does not consume energySave energyMotor/generator/converter stoppersSynchronous motors startersClosed loopElectrical connection

Owner:THE POWERWISE GRP

Electric power steering apparatus

InactiveUS7909131B2Suppress noiseElectronic commutation motor controlVector control systemsMicrocomputerElectric power steering

Owner:JTEKT CORP

Permanent magnet synchronous motor driving system, and method of testing permanent magnet synchronous motor driving system

InactiveUS20030132727A1Reduce leakage currentSynchronous motors startersVector control systemsCapacitancePermanent magnet synchronous motor

A permanent magnet synchronous motor driving system includes: 1) a permanent magnet synchronous motor, and 2) an inverter. The permanent magnet synchronous motor includes three phase terminals. A resonant frequency is generated between an inductance and a ground electrostatic capacitance which are measured between the following: a) one of the three phase terminals of the permanent magnet synchronous motor, and b) a ground. The inverter drives the permanent magnet synchronous motor. The inverter generates a carrier frequency. The resonant frequency of the permanent magnet synchronous motor is free from a conformance with the carrier frequency of the inverter and is free from a proximity of the carrier frequency of the inverter.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

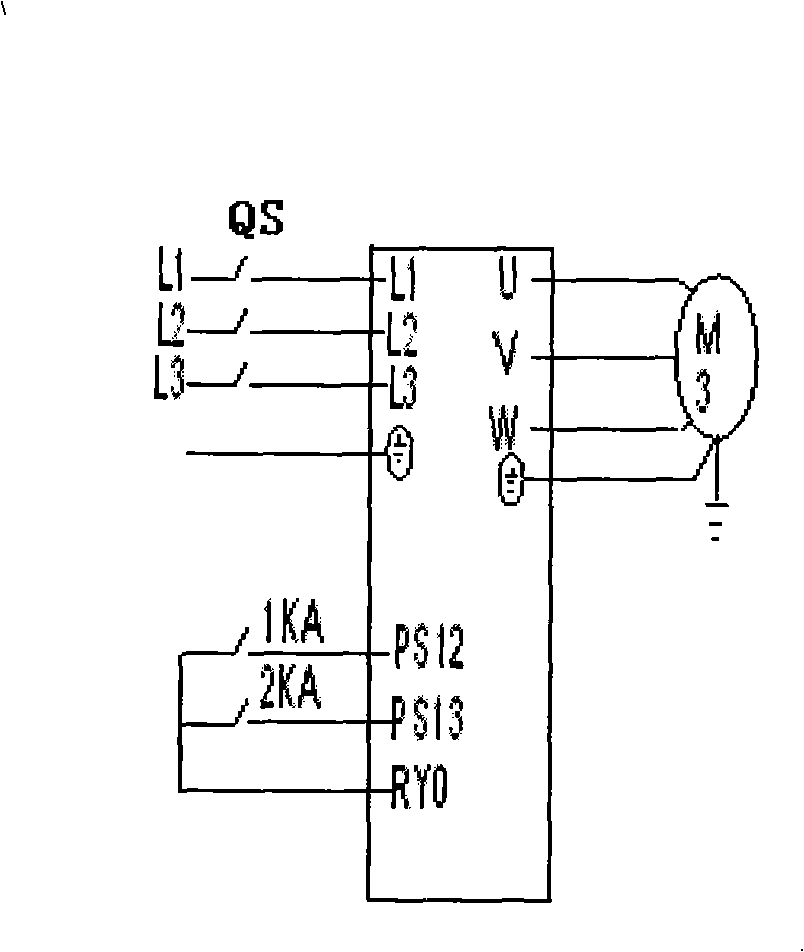

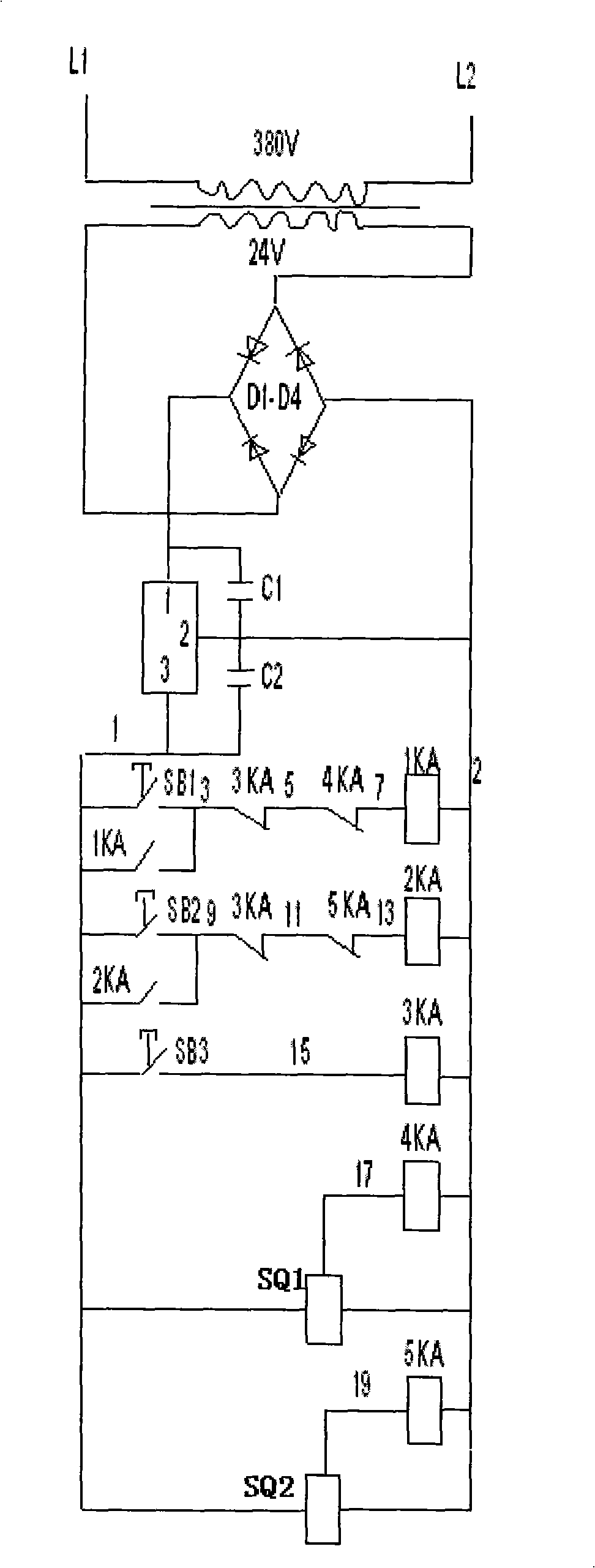

Semi-automatic layout machine

InactiveCN101403897AImprove performanceHigh speedAC motor direction controlUnfolding thin materialsGeneral purposeTransformer

The invention relates to a cloth laying machine used for producing household textile products, in particular to a semi-automatic cloth laying machine. The technical proposal is that the cloth laying machine comprises an original cloth laying machine, and the cloth laying machine is characterized in that one side of the original cloth laying machine is provided with a control box in which a circuit breaker, a transformer, a general purpose relay, push buttons and a rectifying and voltage stabilizing device are arranged, the other side of the original cloth laying machine is provided with a frequency converter, a motor and a proximity switch, the proximity switch (SQ) is connected with 4KA and 5KA arranged in the control box, a forward enabling signal and a backward enabling signal of the frequency converter are connected with 1KA and 2KA arranged in the control box, and output terminals U, V and W of the frequency converter are respectively connected with the motor. The cloth laying machine has the beneficial effects that the improved cloth laying machine has stable performance, is safe and reliable, improves the speed, greatly improves the working efficiency, reduces labor and reduces working intensity; lay cloth orderly, stably and uniformly, meets the process requirements and guarantees the product quality.

Owner:DONGYING TANSIS TEXTILE

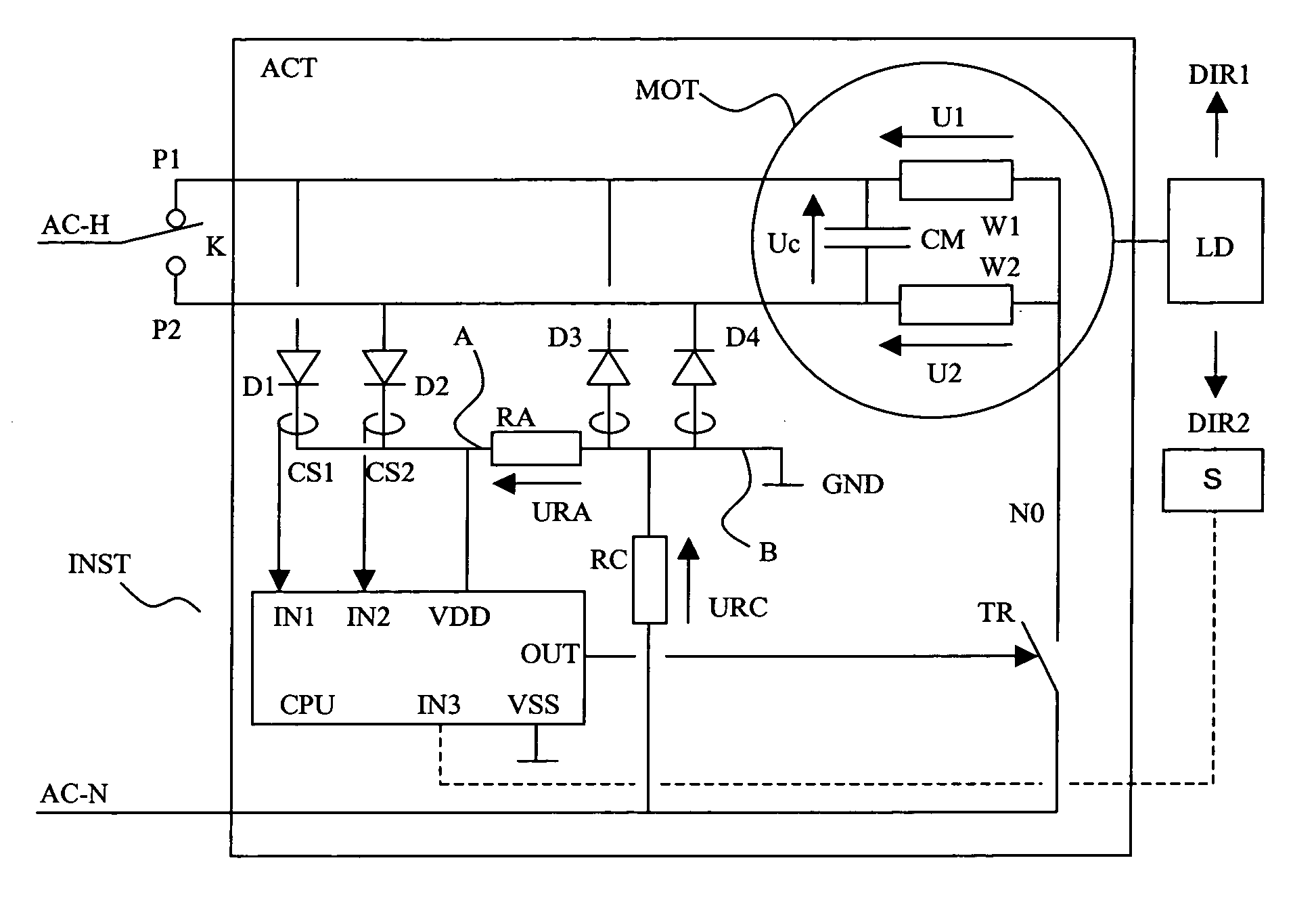

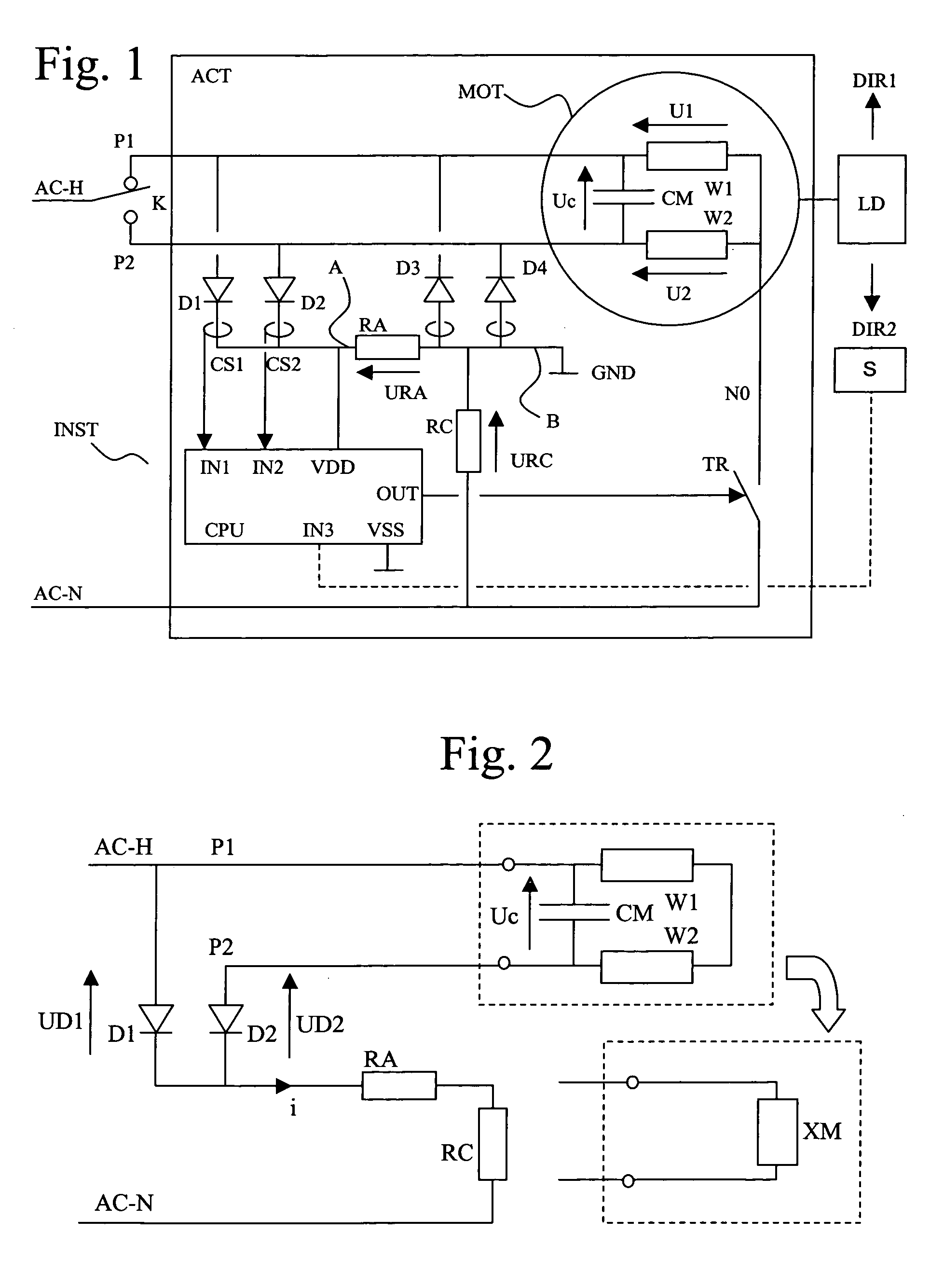

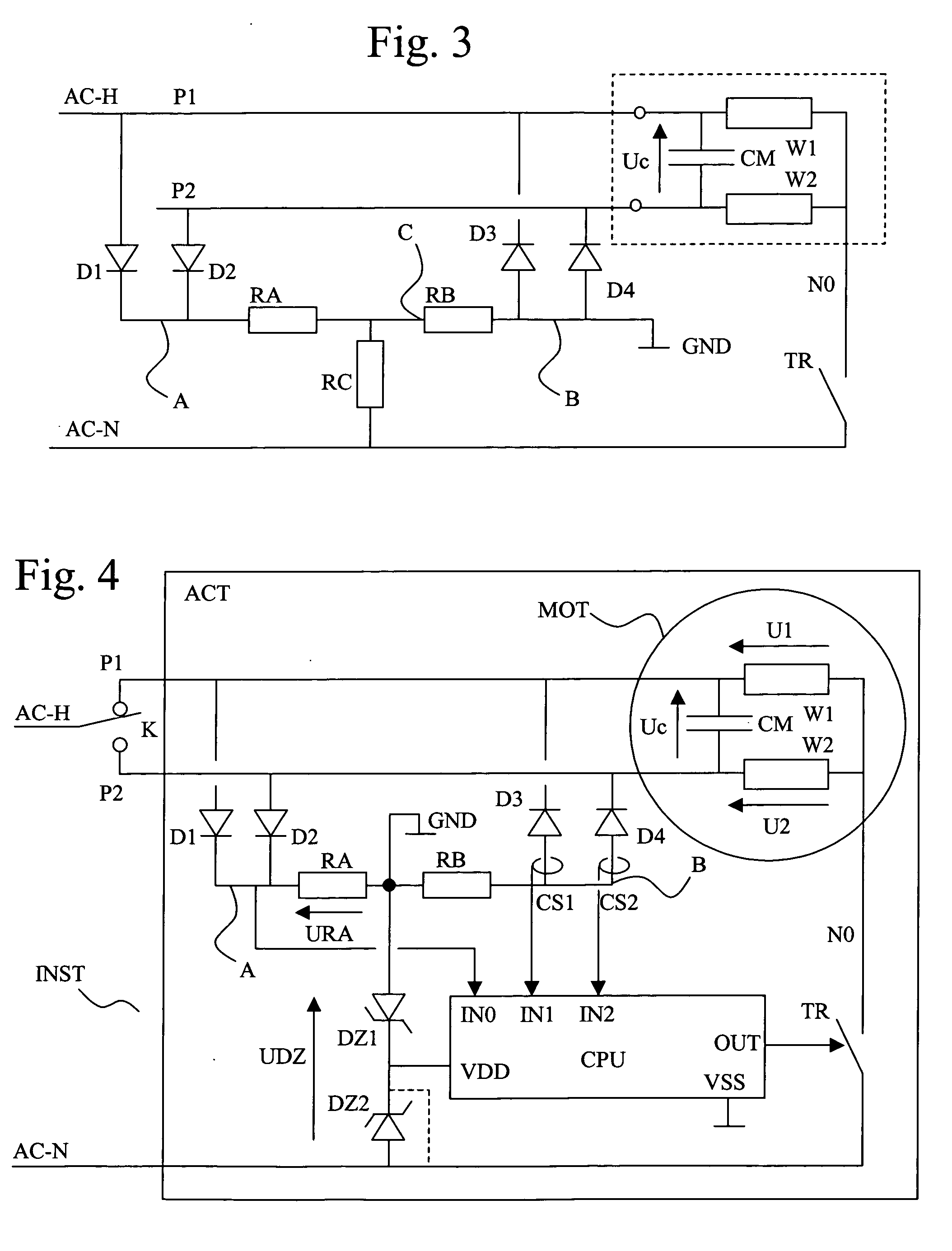

Actuator for operating a roller blind and method of operating such an actuator

InactiveUS20060284590A1Easy to identifySingle-phase induction motor startersMotor/generator/converter stoppersResistive circuitsElectrical resistance and conductance

The actuator (ACT) is intended to be linked to phase (AC-H) and neutral (AC-N) conductors. It comprises a motor (MOT) provided with windings (W1, W1), a capacitor (CM) disposed between two ends of the windings and the terminals of which form a first (P1) and a second (P2) phase terminal. It includes a switch (TR) controlled by an electronic unit (CPU) to link the common end of the windings to the neutral conductor, at least one pair of diodes (D1, D2; D3, D4), the diodes of one and the same pair being connected by an electrode of the same type to a resistive circuit (RA, RB, RC, DZ1, DZ2) connected to the neutral conductor, the other electrode of each diode being respectively linked to the first and second phase terminals and means (CS1, CS2) of detecting the state of conduction of the diodes.

Owner:SOMFY SAS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com