Patents

Literature

2145results about "Current controllers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

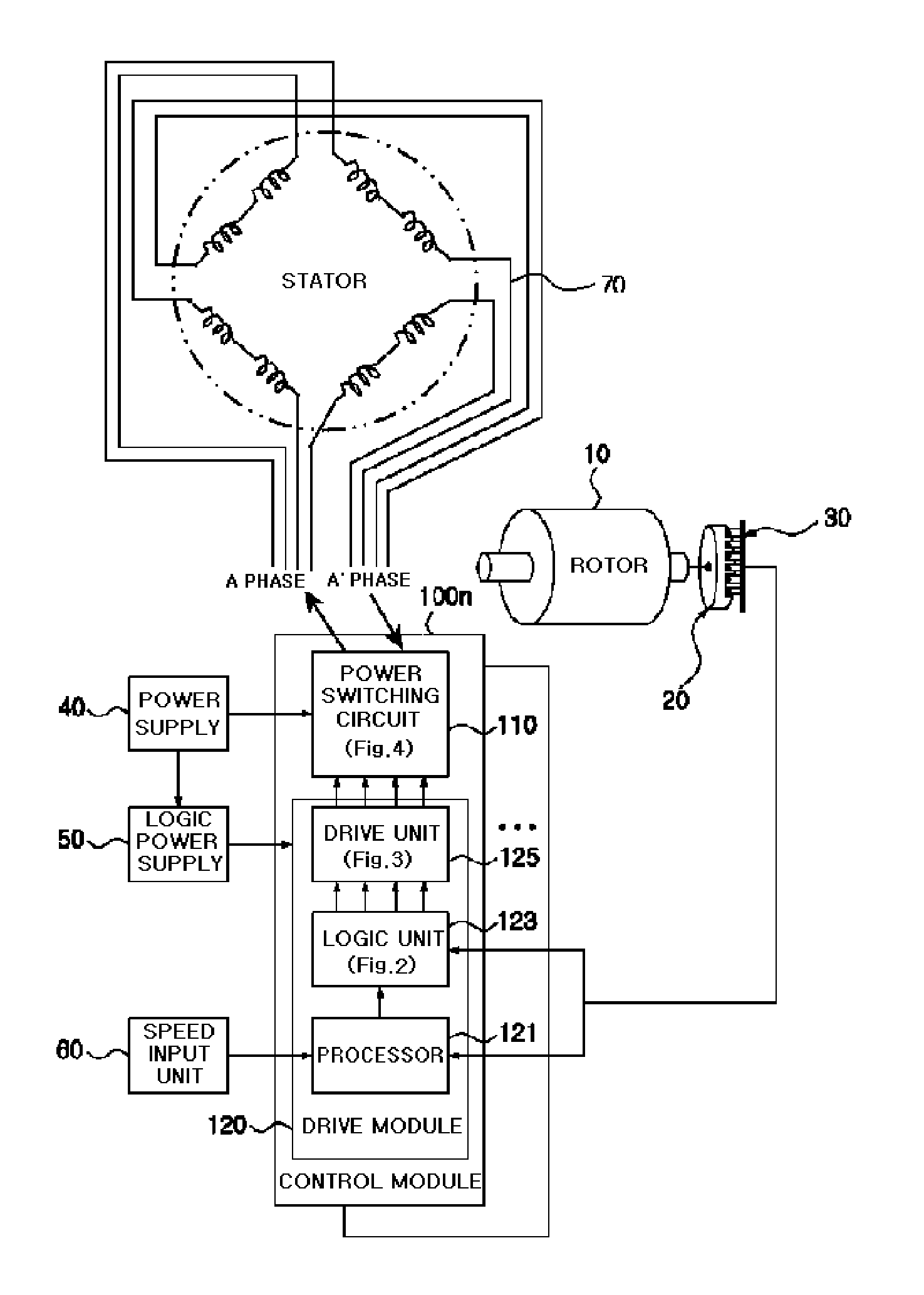

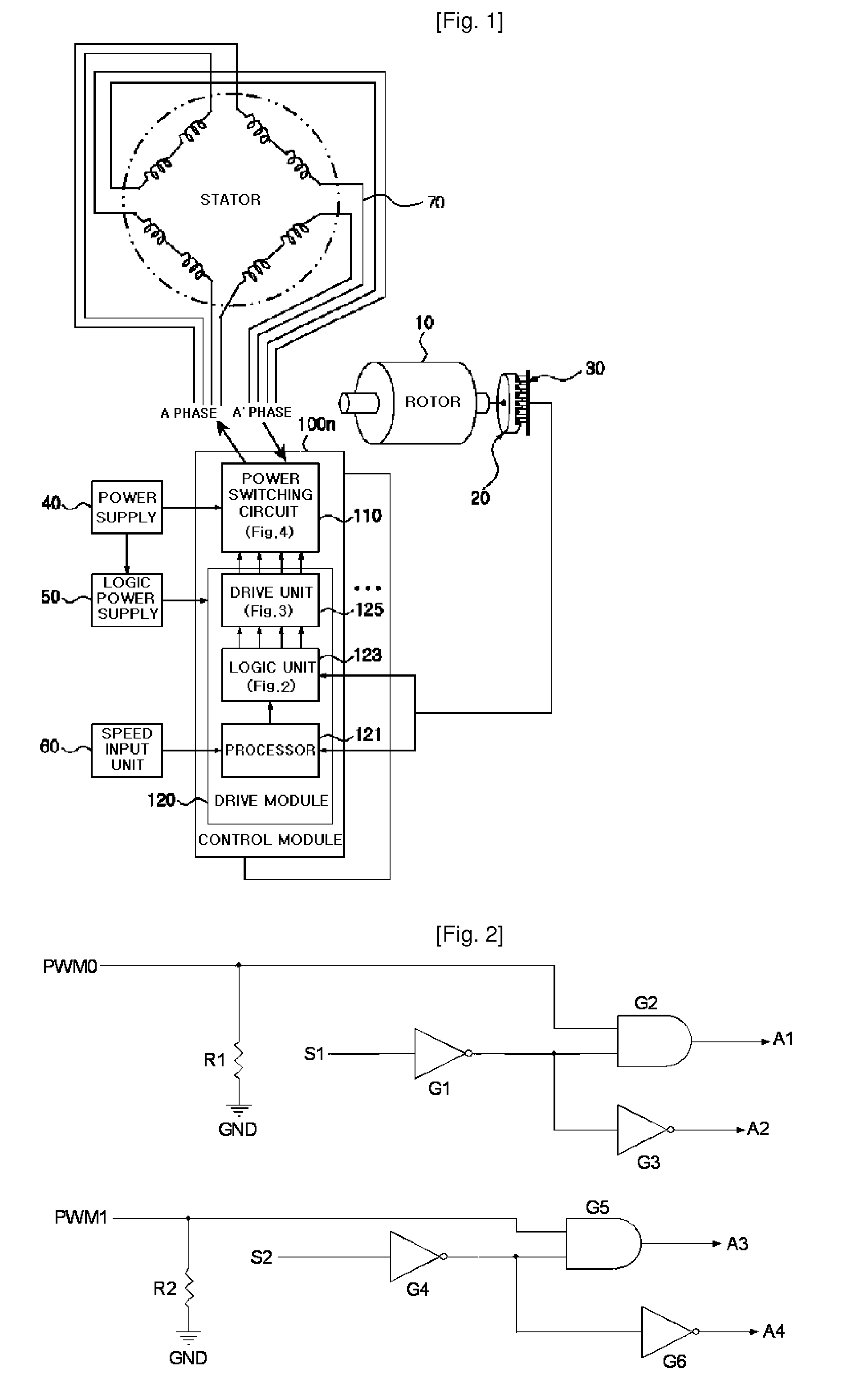

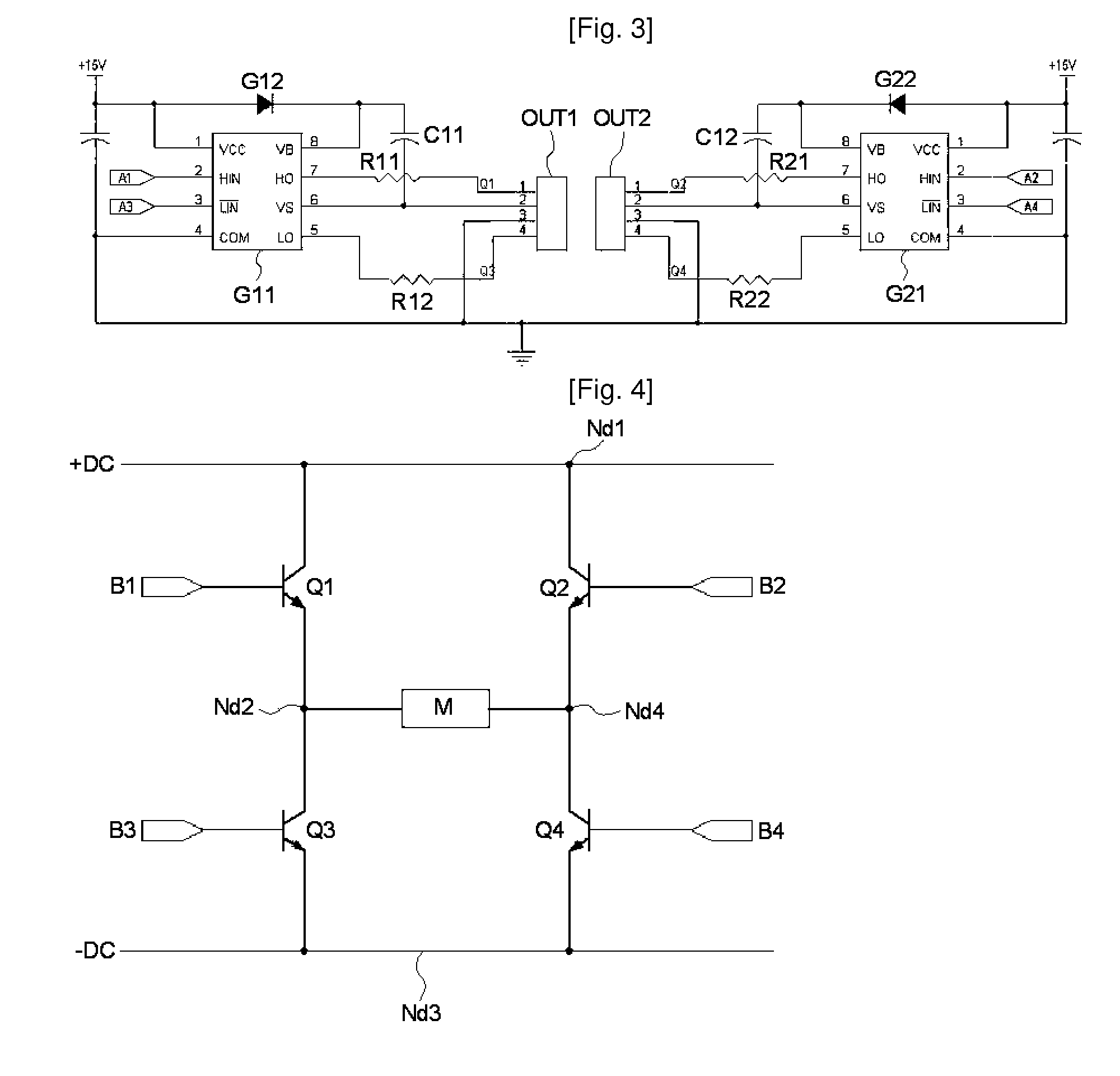

Apparatus and method for controlling hybrid motor

ActiveUS8228020B2Reduce capacityReduce electricity loadSingle-phase induction motor startersWindingsDriver circuitPower switching

An apparatus and method for controlling a hybrid motor, The hybrid motor, uses a permanent magnet instead of a field coil for a rotor, winds a coil round a stator in a multi-phase independent parallel manner, fixes a rectifying type encoder to the rotor and connects a sensor to a driving circuit. The apparatus comprises: an encoder attached to a rotor in cooperation with a pole sensor a speed input unit for generating a speed instruction signal a power switching circuit to generate motor driving signals; a drive module receiving the speed instruction signal and the sensor signal and outputting the speed instruction signal synchronized with the sensor signal as a driving motor signal; a power supply for applying a DC voltage to the power switching circuit; A logic power supply for converting the DC voltage into a logic voltage, and applying logic voltage to the drive module. The motor has n phases, n power switching circuits and n drive modules.

Owner:NAMYANG NEXMO CO LTD

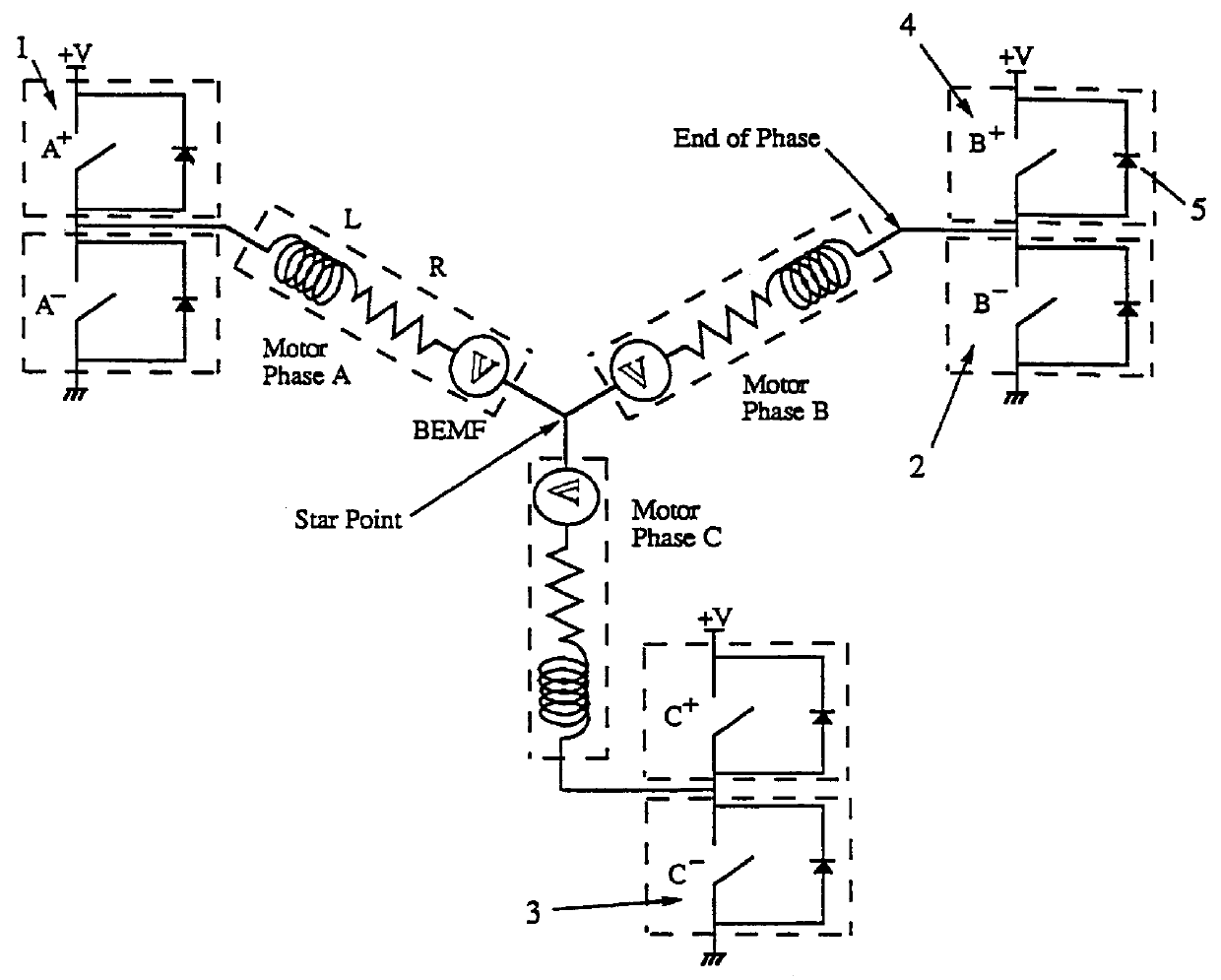

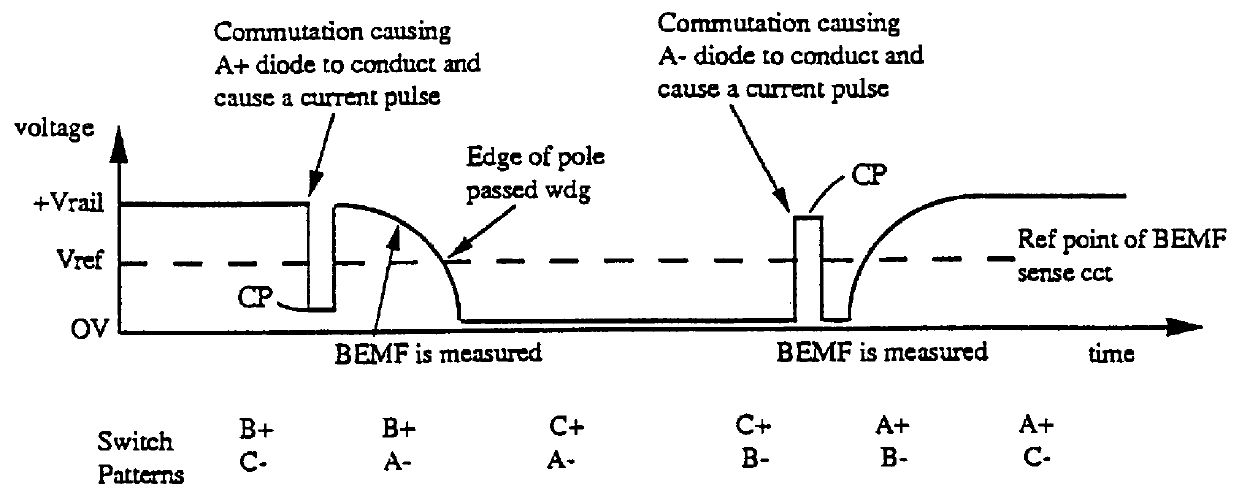

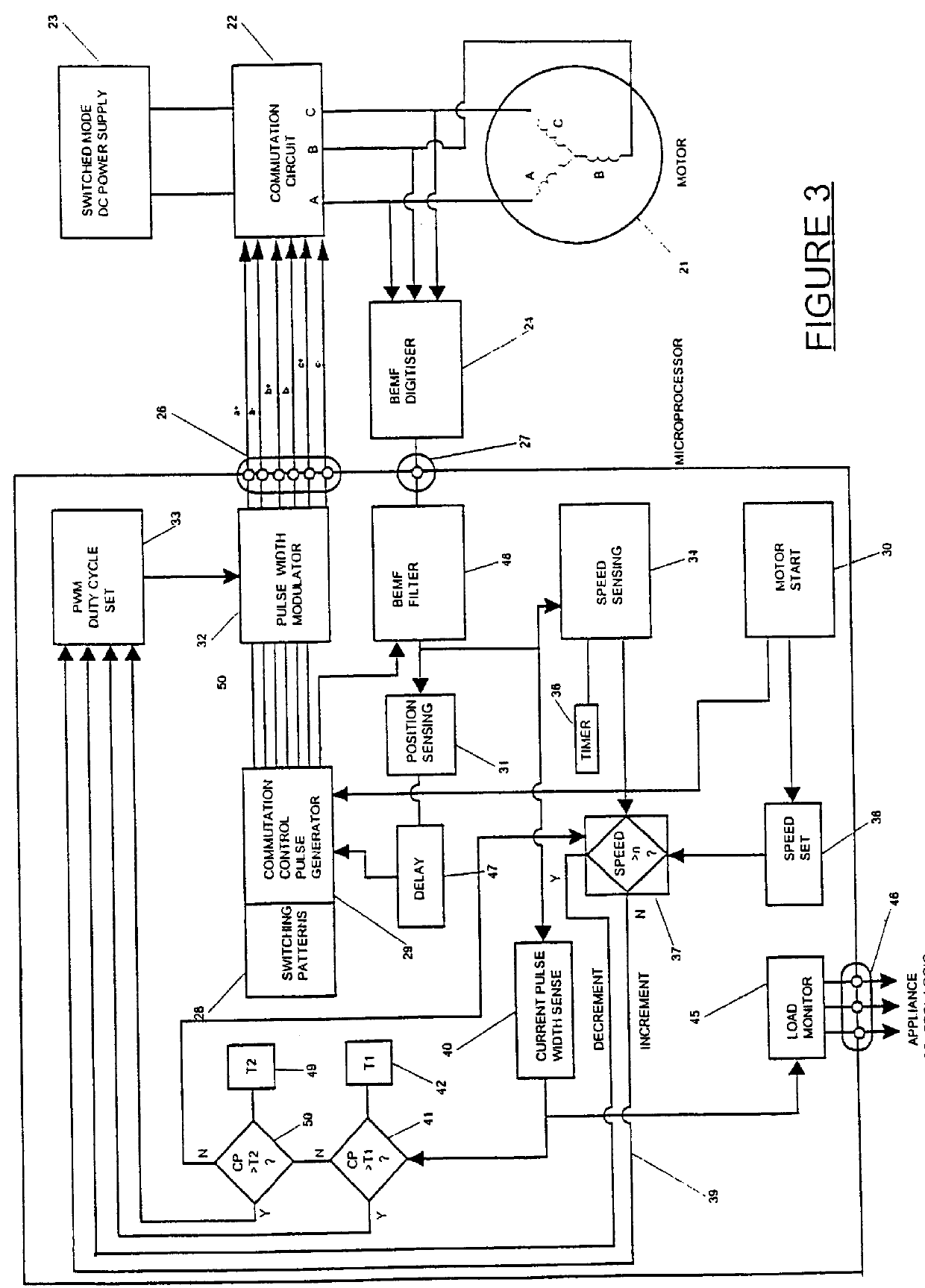

Brushless DC motor control

An electronically commutated brushless DC motor primarily for fractional horsepower applications of the type where at any instant one motor winding is unpowered and used to detect back EMF zero-crossings which information is used to initiate winding commutations. The duration of the pulse produced in this winding due to dissipation of stored energy by free-wheel diodes in parallel with the commutation devices after supply of current has been removed from this winding is used to provide a measure of motor current. This allows for simplified commutation device current limiting circuits and is available for control purposes which are a function of motor torque. There is also disclosed a method for maximizing useful power output by reducing the phase angle between the motor current and the back EMF. This is accomplished by introducing a delay in commutating the motor windings beyond the occurrence of each back EMF zero-crossing, with the delay being a function of the time between commutations.

Owner:FISHER & PAYKEL APPLIANCES LTD

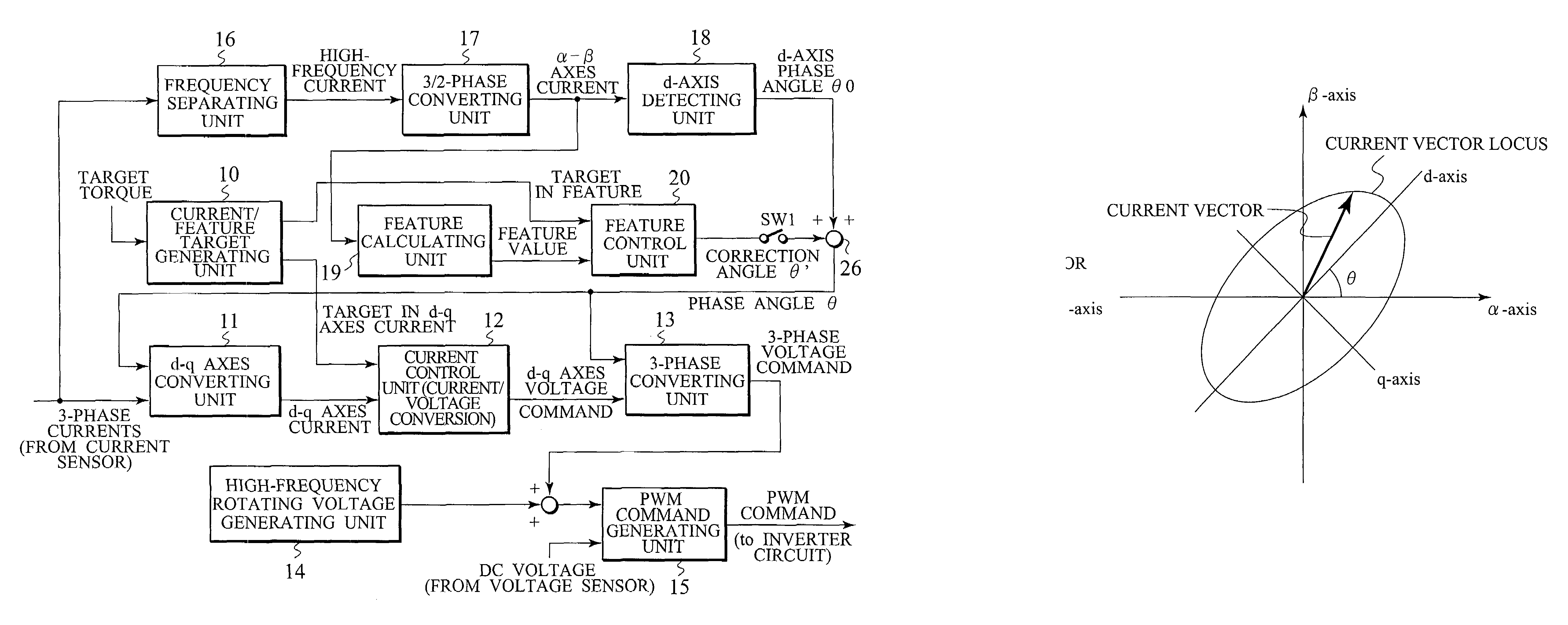

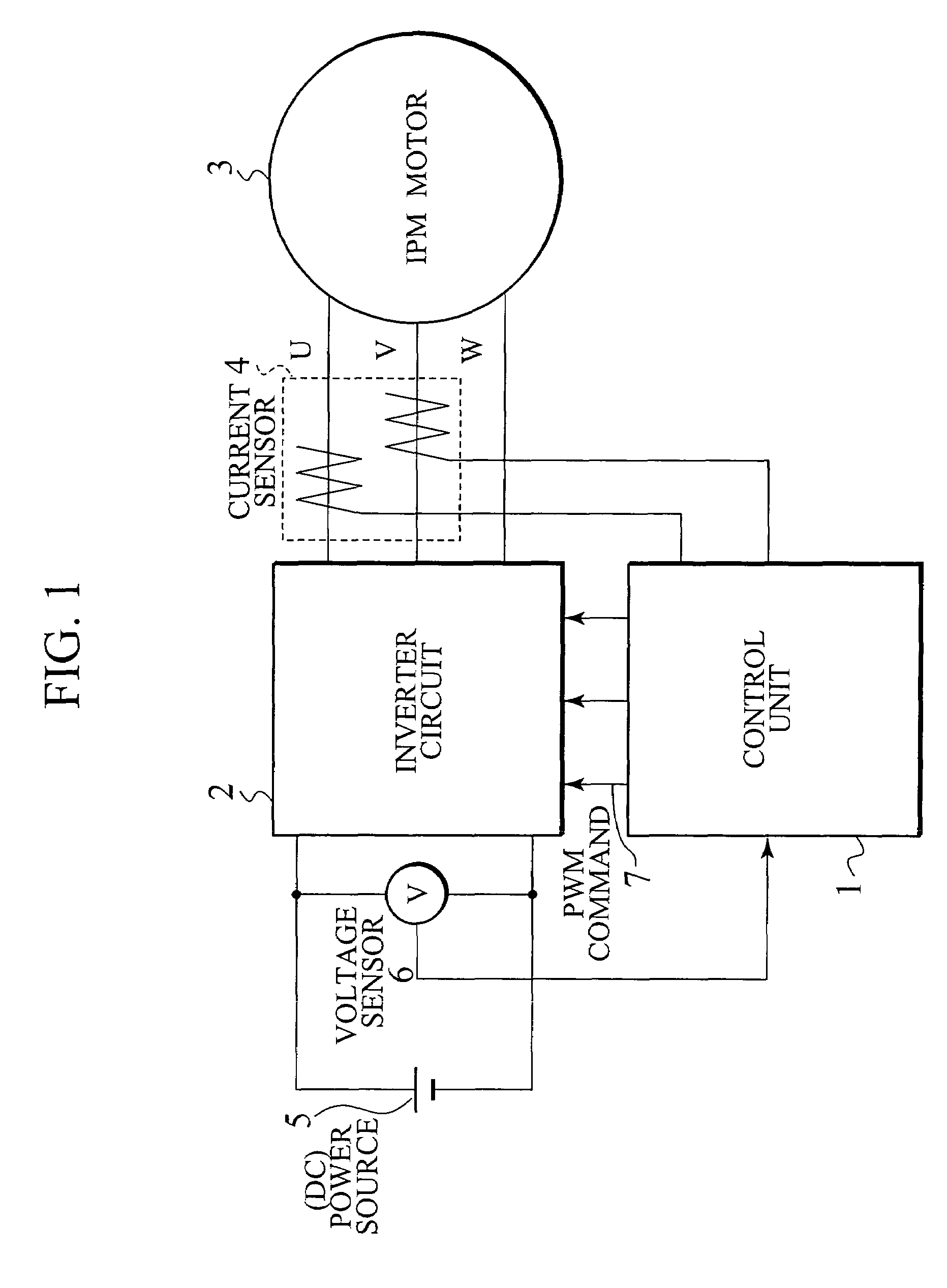

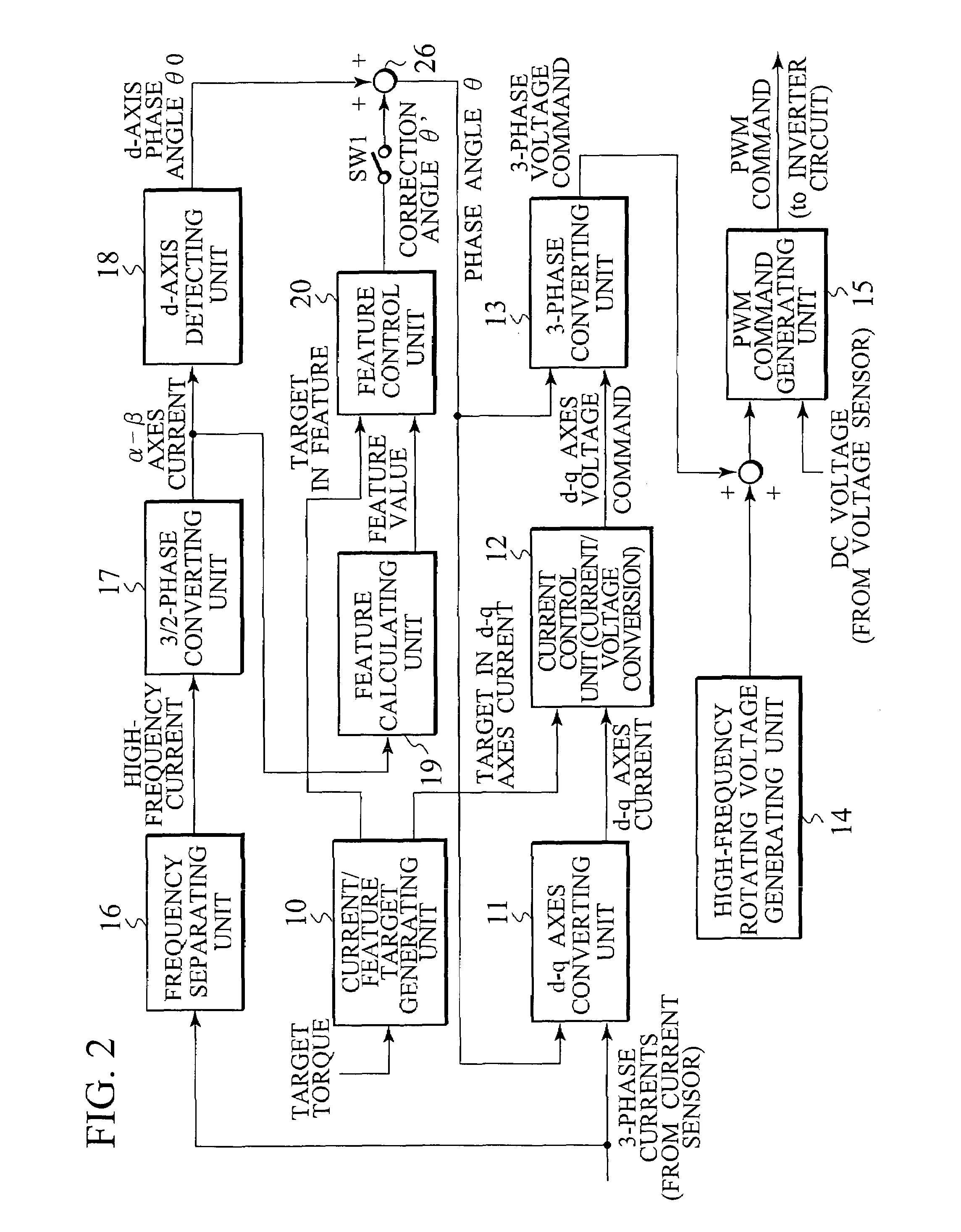

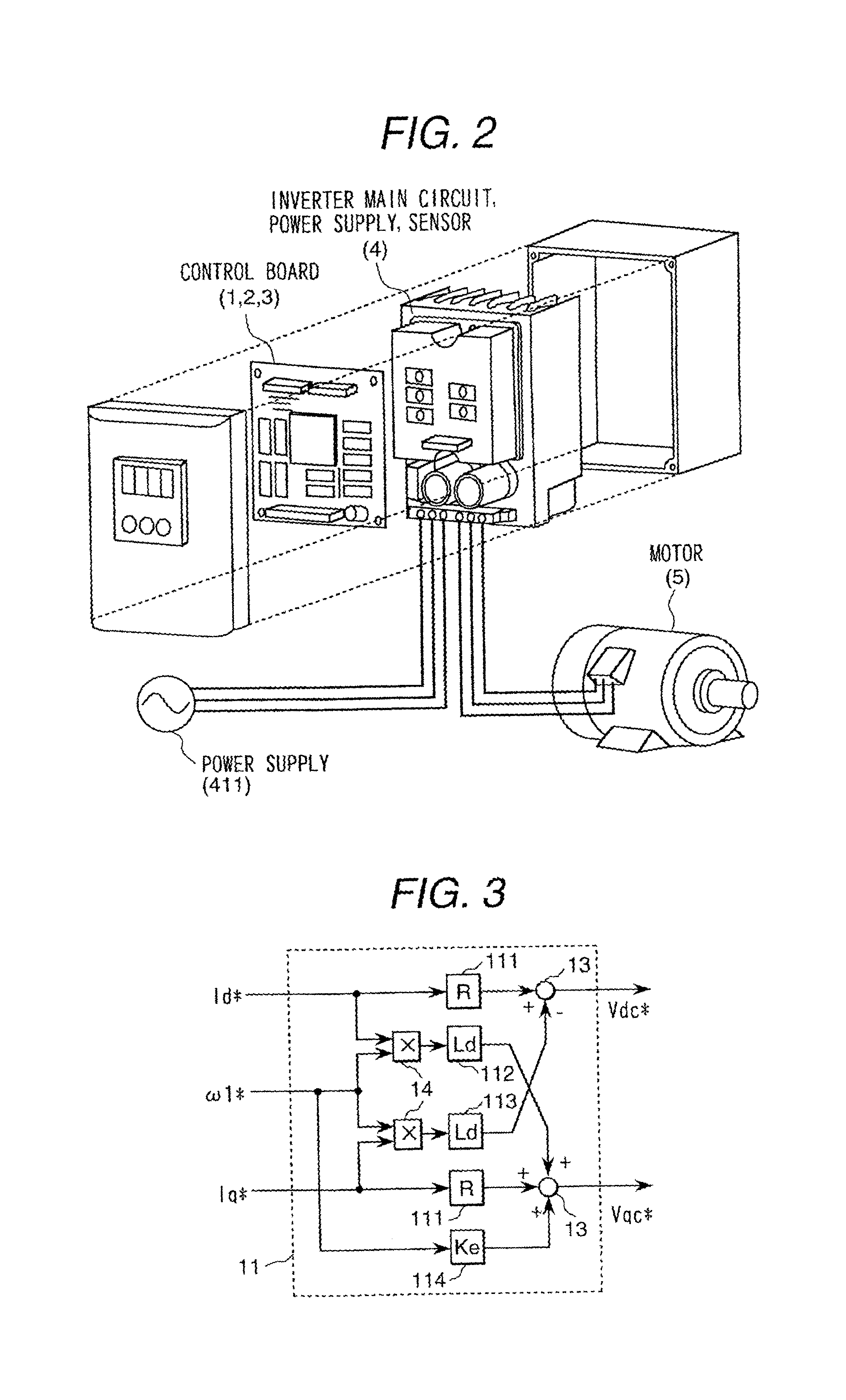

Control device for electric motor

ActiveUS7005828B2Improve artSingle-phase induction motor startersAC motor controlDriving currentAcquired characteristic

Corresponding to a target torque, the control device calculates a target value of a feature based on at least one of the length of a long axis of a current vector locus and the length of the short axis and further superimposes a superimposed current on a drive current for the motor, the superimposed current having a frequency different from the frequency of the drive current. Further, the control device detects an actual value of the feature based on at least one of the length of a long axis of a current vector locus of the superimposed current and the length of the short axis of the same and finally detects a phase angle of the motor based on the target value and the actual value for the feature. The manipulation of a detecting phase is performed by feedback of a feature obtained by the magnitude of the superimposed current. That is, when the actual feature is more than the target value, the detecting phase is advanced. Conversely, when the actual feature is less than the target value, the detecting phase is delayed.

Owner:NISSAN MOTOR CO LTD

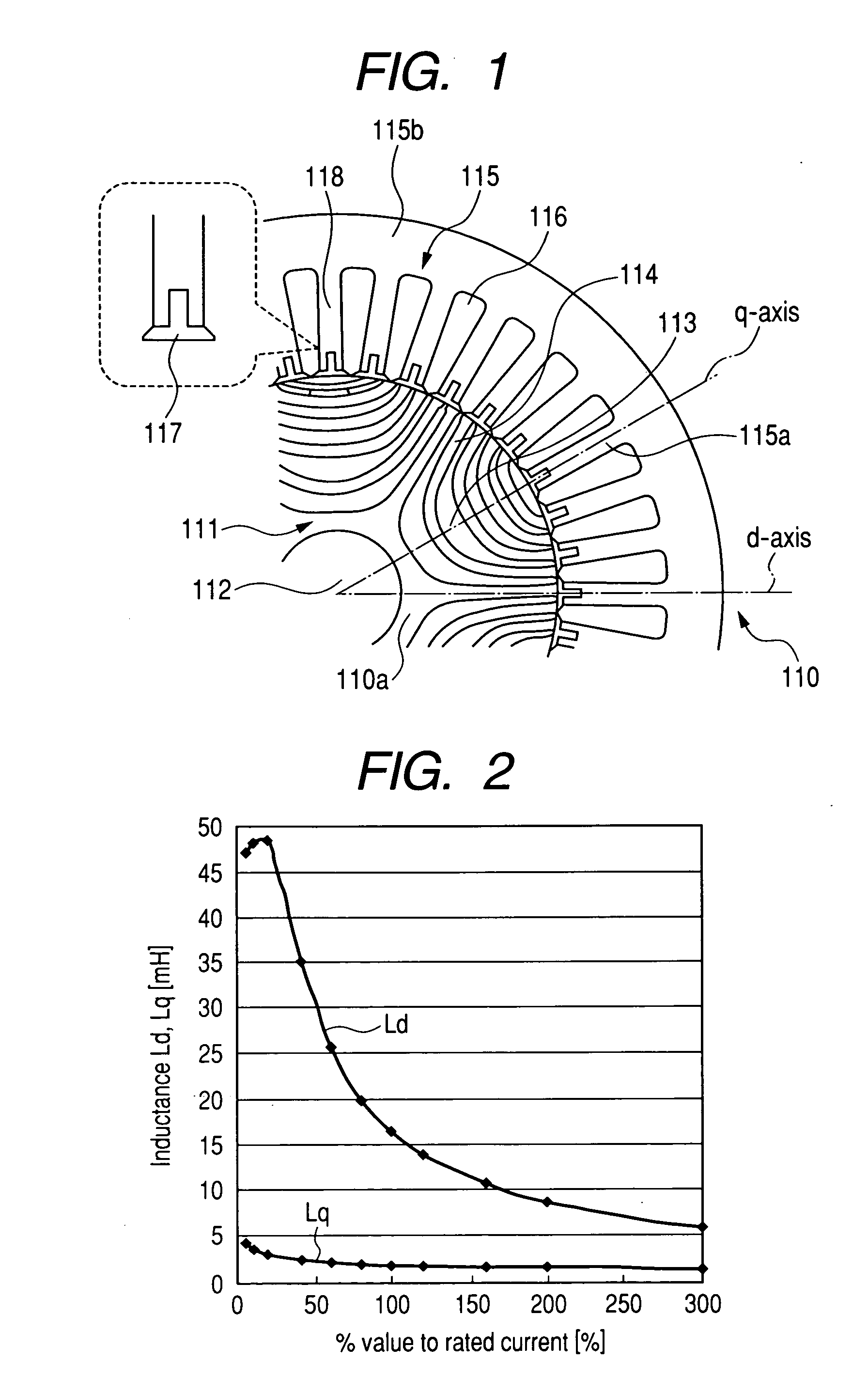

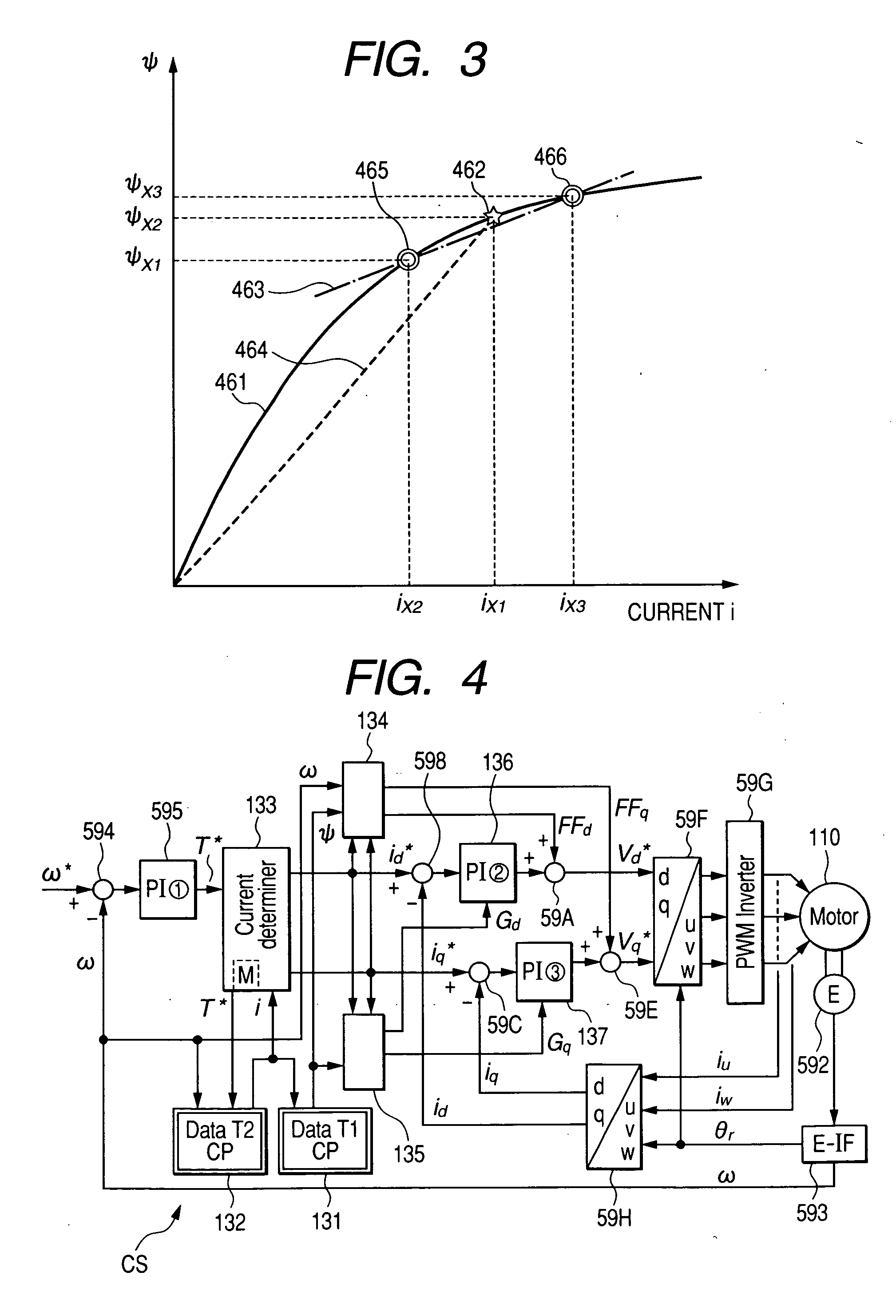

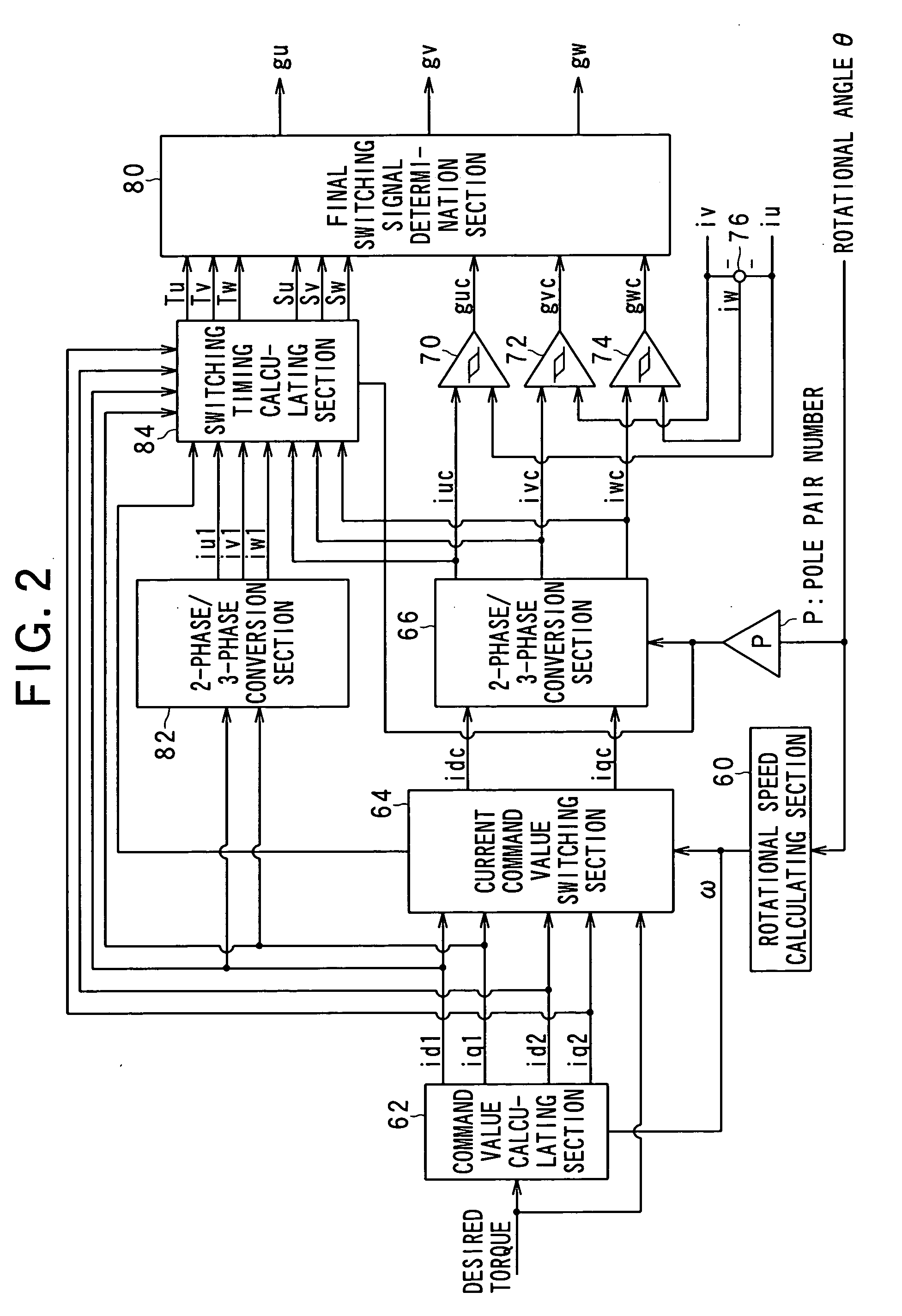

System and method for controlling motor using parameter associated with magnetic flux

InactiveUS20080129243A1Reliably graspTorque ripple controlSynchronous motors startersDriving currentOperating point

A control method for a motor that rotates based on flux linkages to a winding member of the motor when the winding member is energized by a drive current is provided. The method includes storing magnetic-state information indicative of a relationship between each of a plurality of predetermined operating points of the drive current and a magnetic-state parameter associated with the flux linkages. The method includes obtaining at least one of command information associated with an operating state of the motor and detection information associated with the operating state of the motor. The method includes referencing the magnetic-state information with the use of the obtained at least one of the command information and detection information to obtain a value of the magnetic-state parameter based on a result of the reference. The method includes controlling an output of the motor based on the obtained value of the magnetic-state parameter.

Owner:DENSO CORP

Electric motor and motor control

InactiveUS8575873B2Reduce noiseHigh complexitySingle-phase induction motor startersTorque ripple controlElectric machinePermanent magnet motor

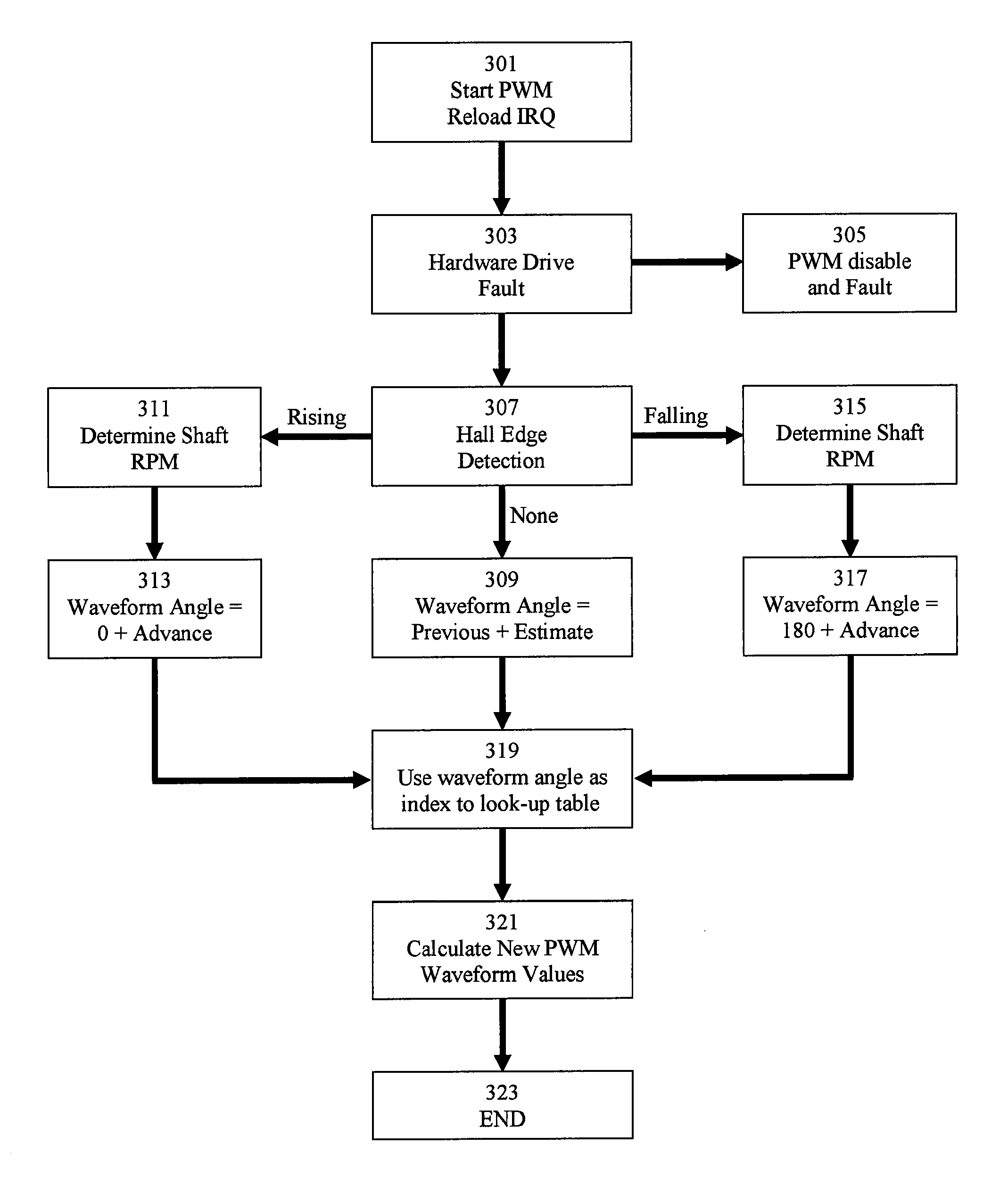

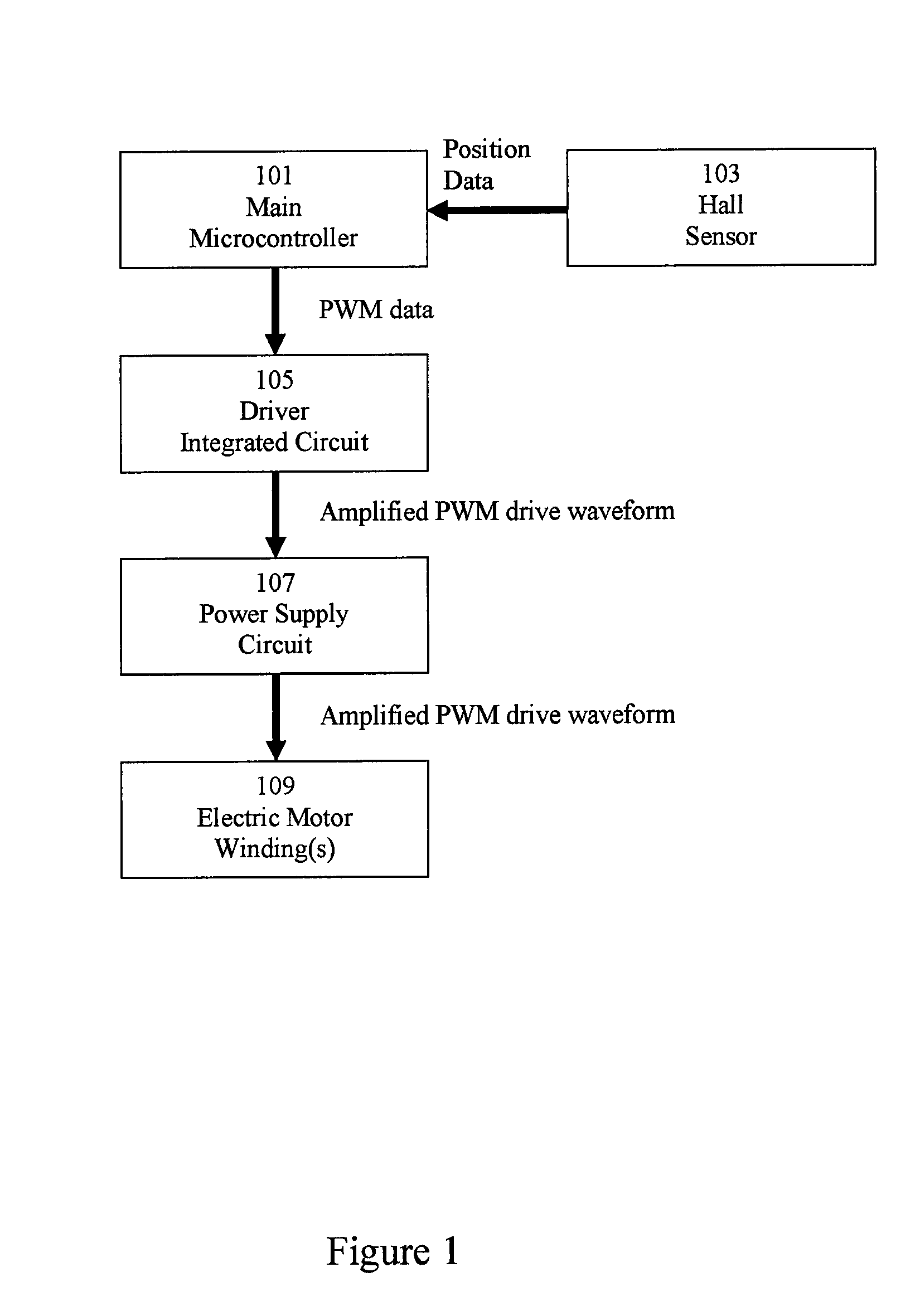

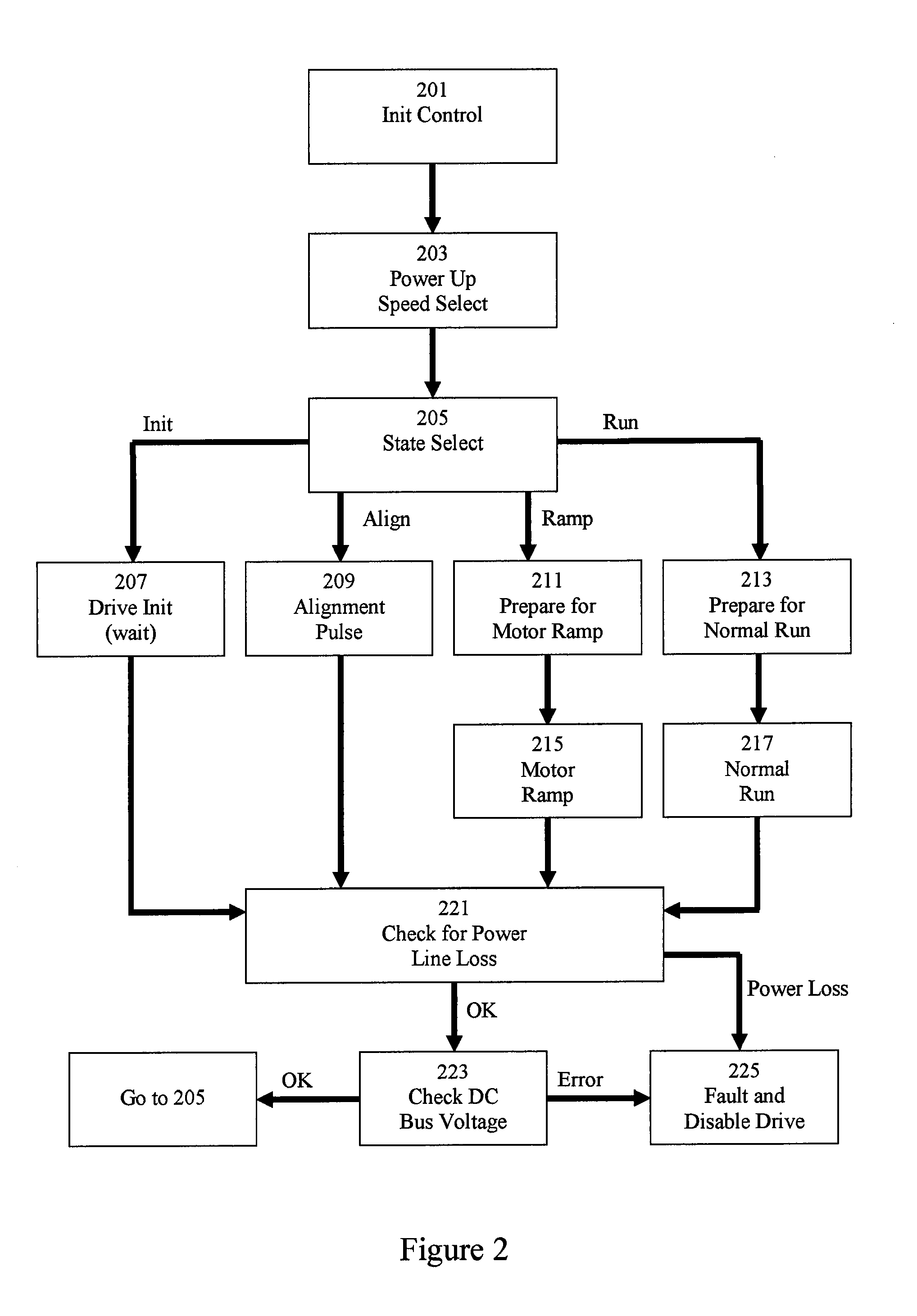

Various embodiments of an electric motor and electronic control for an electric motor are disclosed. An exemplary electric motor comprises a single-phase brushless permanent magnet electric motor. In exemplary embodiments, the electronic motor control is configured to commutate an electric motor at a frequency other than line frequency, perform pulse width modulation, and drive the electric motor with a drive waveform that approximates the counter-electromotive force of the motor.

Owner:NIDEC MOTOR CORP

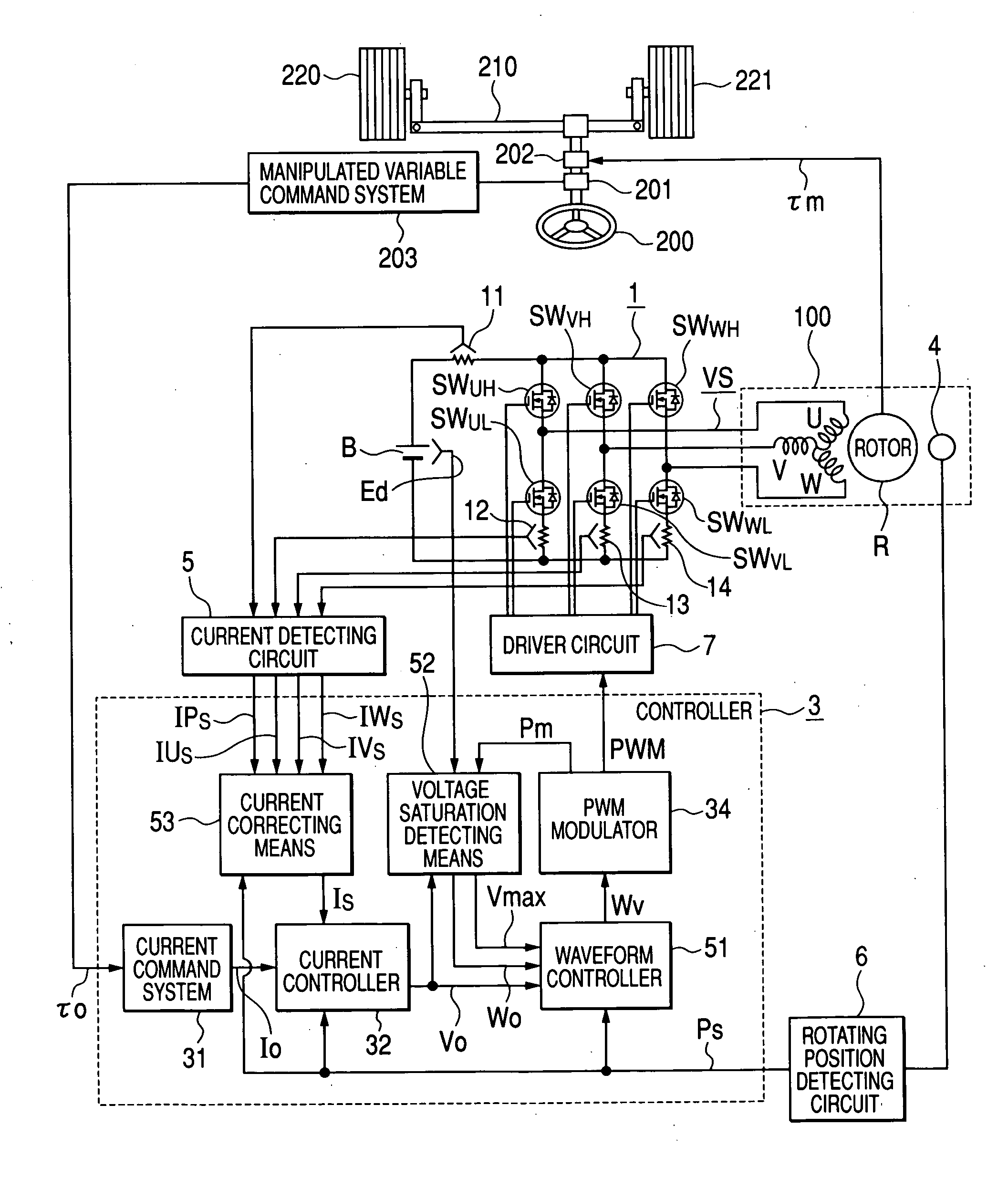

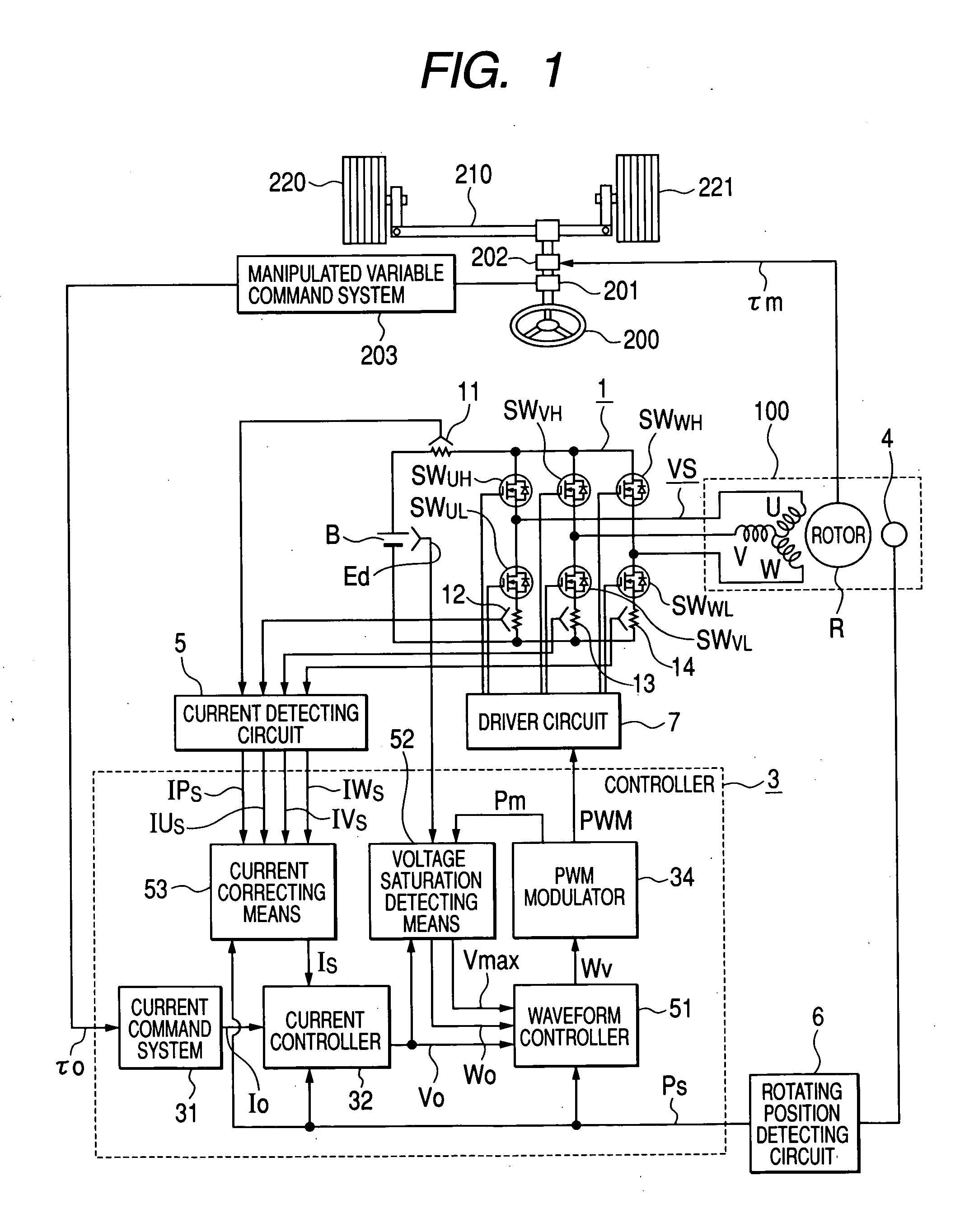

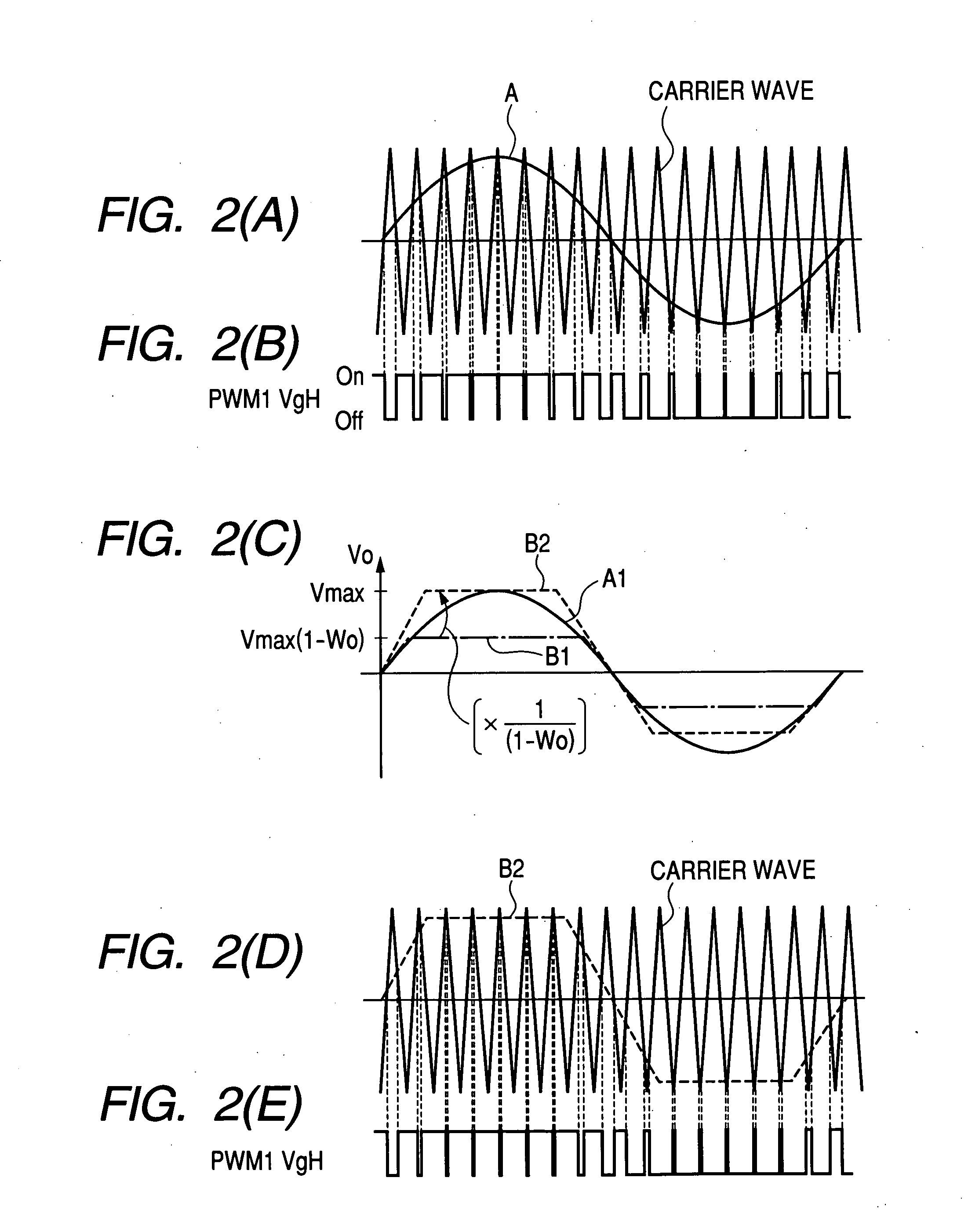

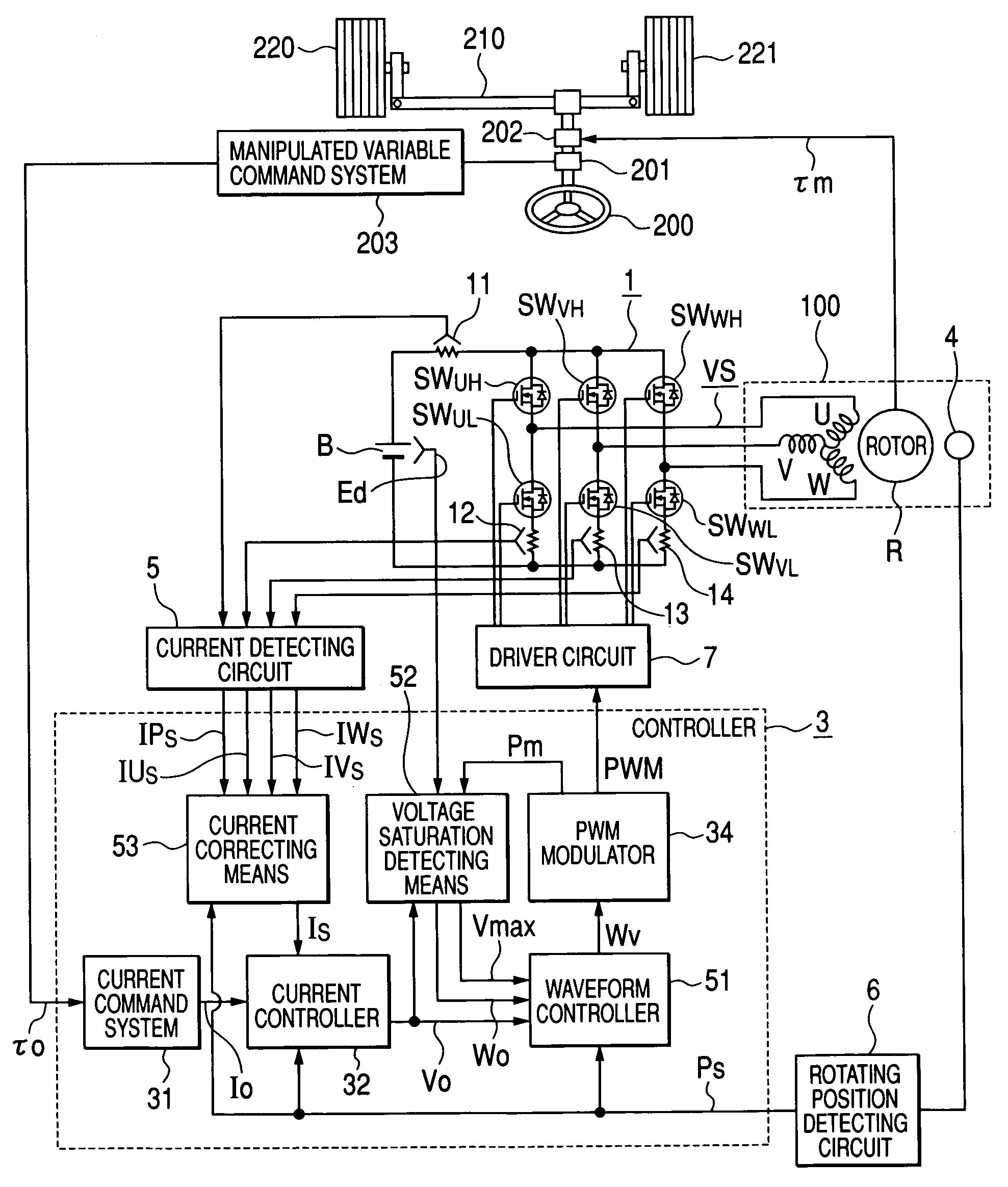

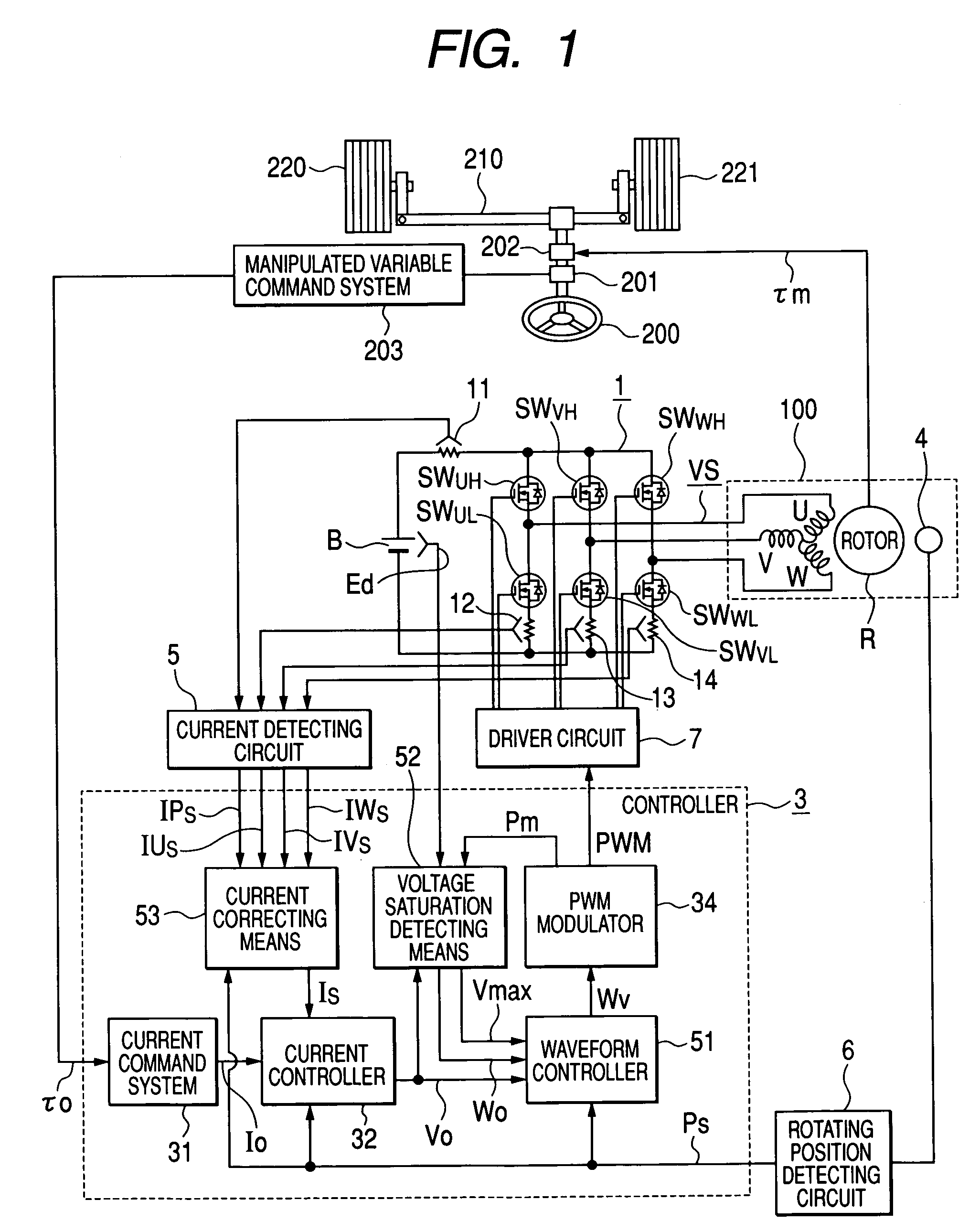

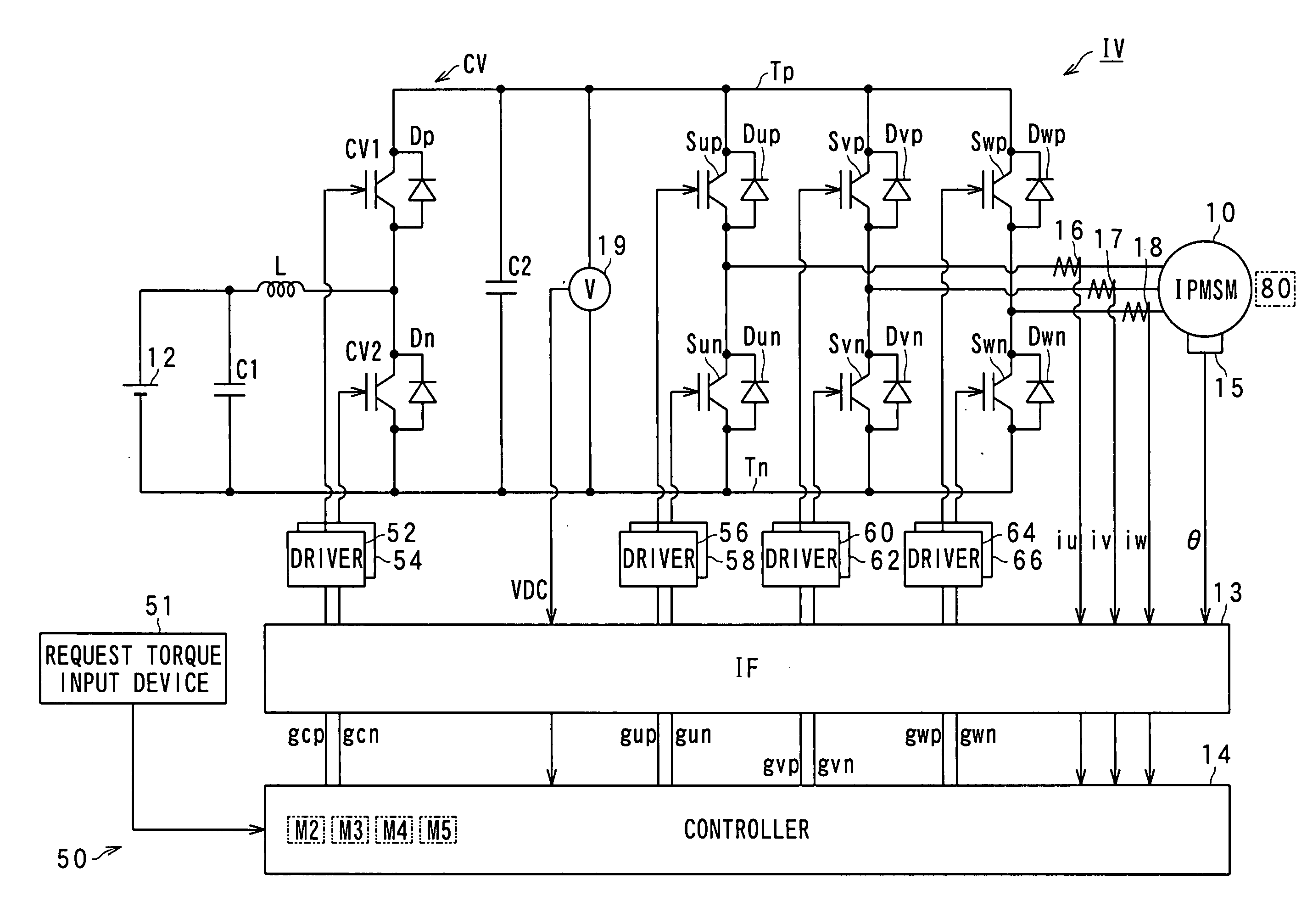

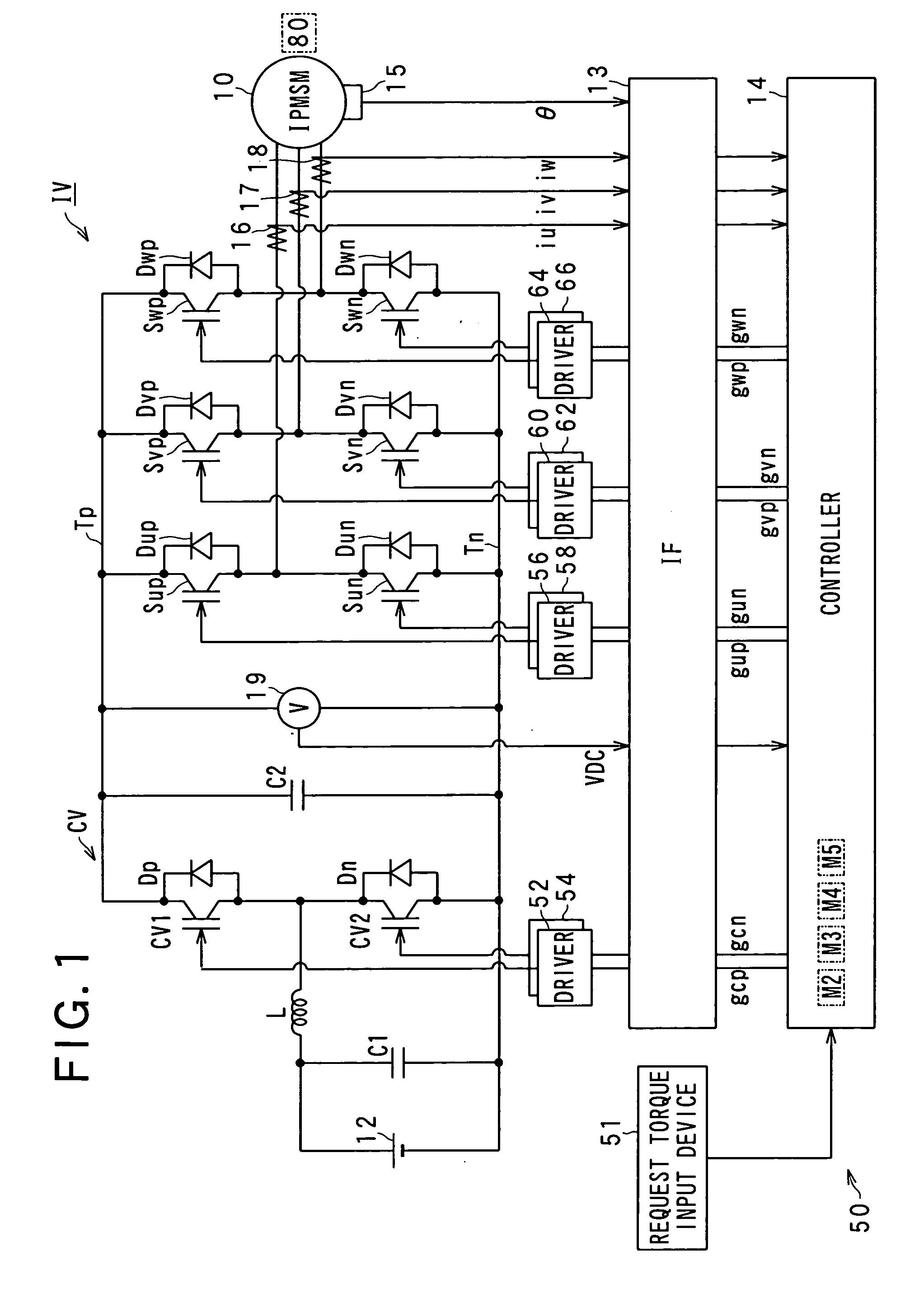

Motor drive apparatus, electric actuator and electric power steering apparatus

ActiveUS20060001392A1Increase driving speedHigh areaTorque ripple controlDC motor speed/torque controlElectric power steeringHigher order harmonics

In an operation range of an actuator subjected to quick acceleration and deceleration, a motor drive apparatus, an electric actuator and an electric power steering apparatus capable of continuous torque control up to the high drive speed and high torque area. A controller comprises a voltage saturation detecting means for detecting the voltage saturation of the output voltage of an inverter circuit, based on the battery voltage, and a waveform controller that converts the drive waveform of the inverter circuit into the waveform created by superimposing harmonics of high odd-numbered order on a sinusoidal wave as a fundamental wave of the modulated wave modulated by a PWN carrier wave; and continuously changes the ratio of superimposing the high-order harmonics in response to the voltage saturation detected by a voltage saturation detecting means. This arrangement allows the controller to continuously change the drive waveform of the inverter circuit.

Owner:HITACHI ASTEMO LTD

Motor drive apparatus, electric actuator and electric power steering apparatus

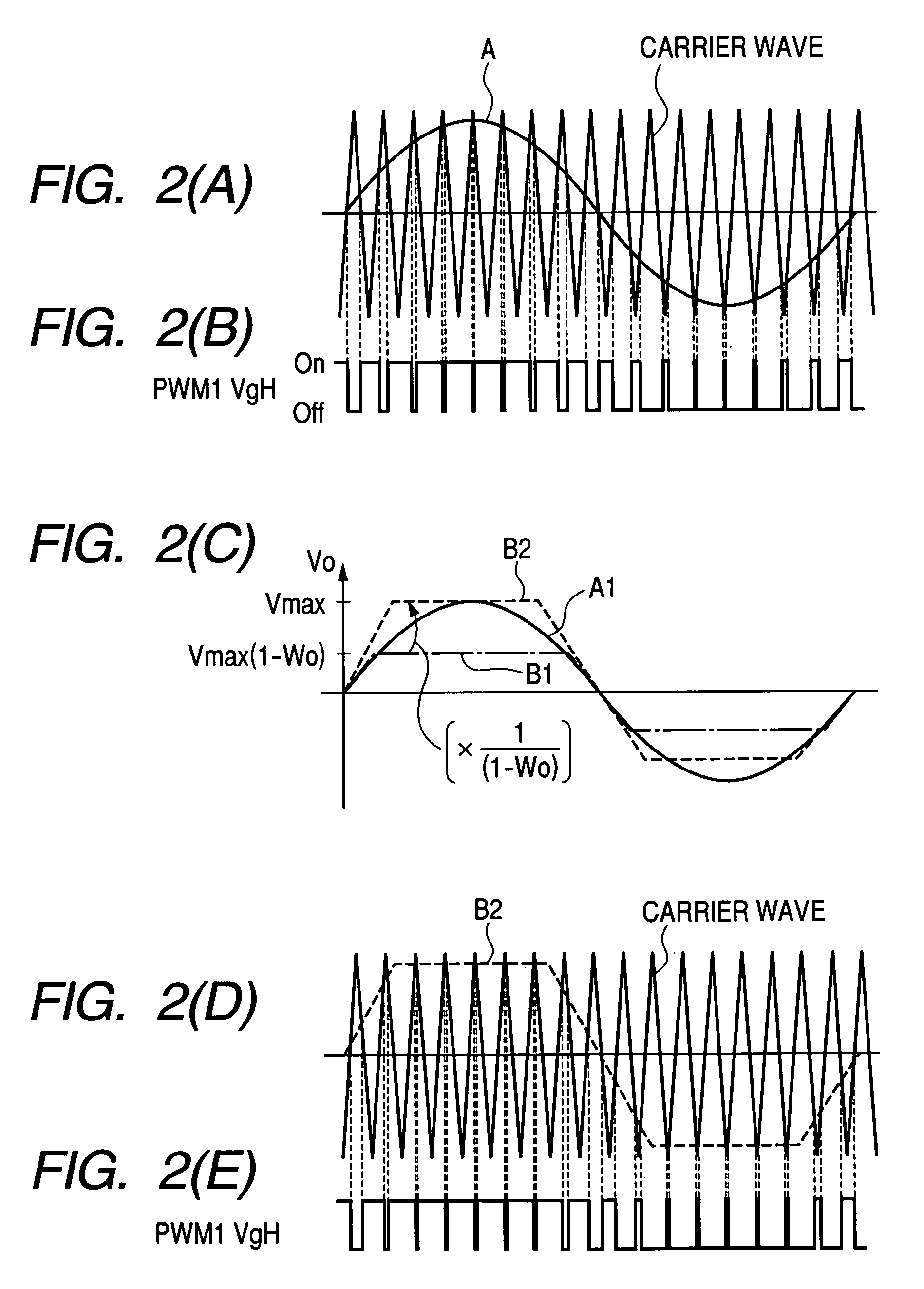

ActiveUS7161323B2Increase torqueTorque ripple controlDC motor speed/torque controlElectric power steeringMotor drive

The disclosure concerns a a motor drive apparatus, an electric actuator and an electric power steering apparatus capable of continuous torque control up to the high drive speed and high torque area, in order to enable quick acceleration and deceleration. A controller comprises a voltage saturation detecting apparatus for detecting the voltage saturation of the output voltage of an inverter circuit, based on the battery voltage, and a waveform controller that converts the drive waveform of the inverter circuit into the waveform created by superimposing harmonics of high odd-numbered order on a sinusoidal wave as a fundamental wave of the modulated wave modulated by a PWN carrier wave; and continuously changes the ratio of superimposing the high-order harmonics in response to the voltage saturation detected by a voltage saturation detecting means. This arrangement allows the controller to continuously change the drive waveform of the inverter circuit.

Owner:HITACHI ASTEMO LTD

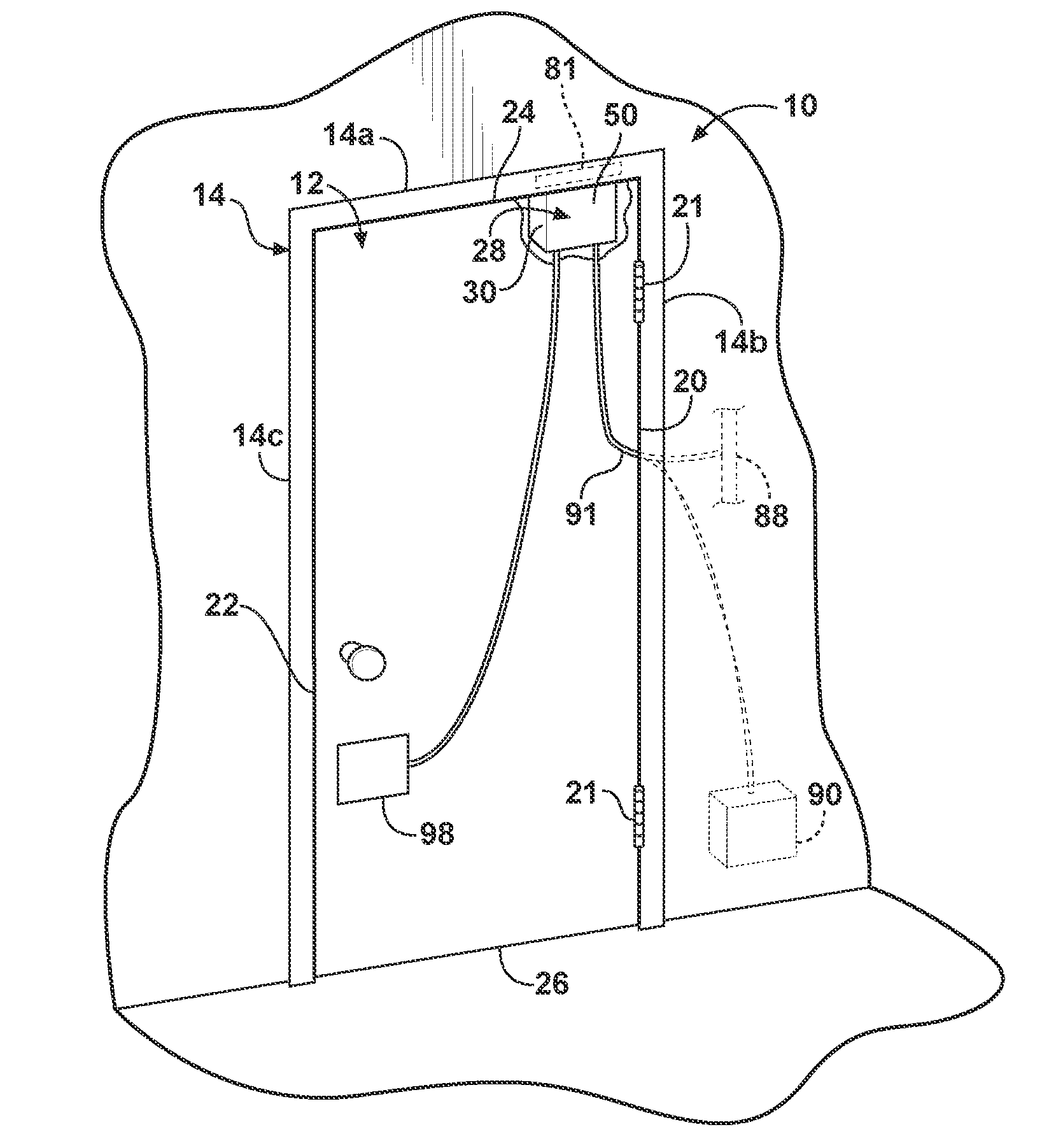

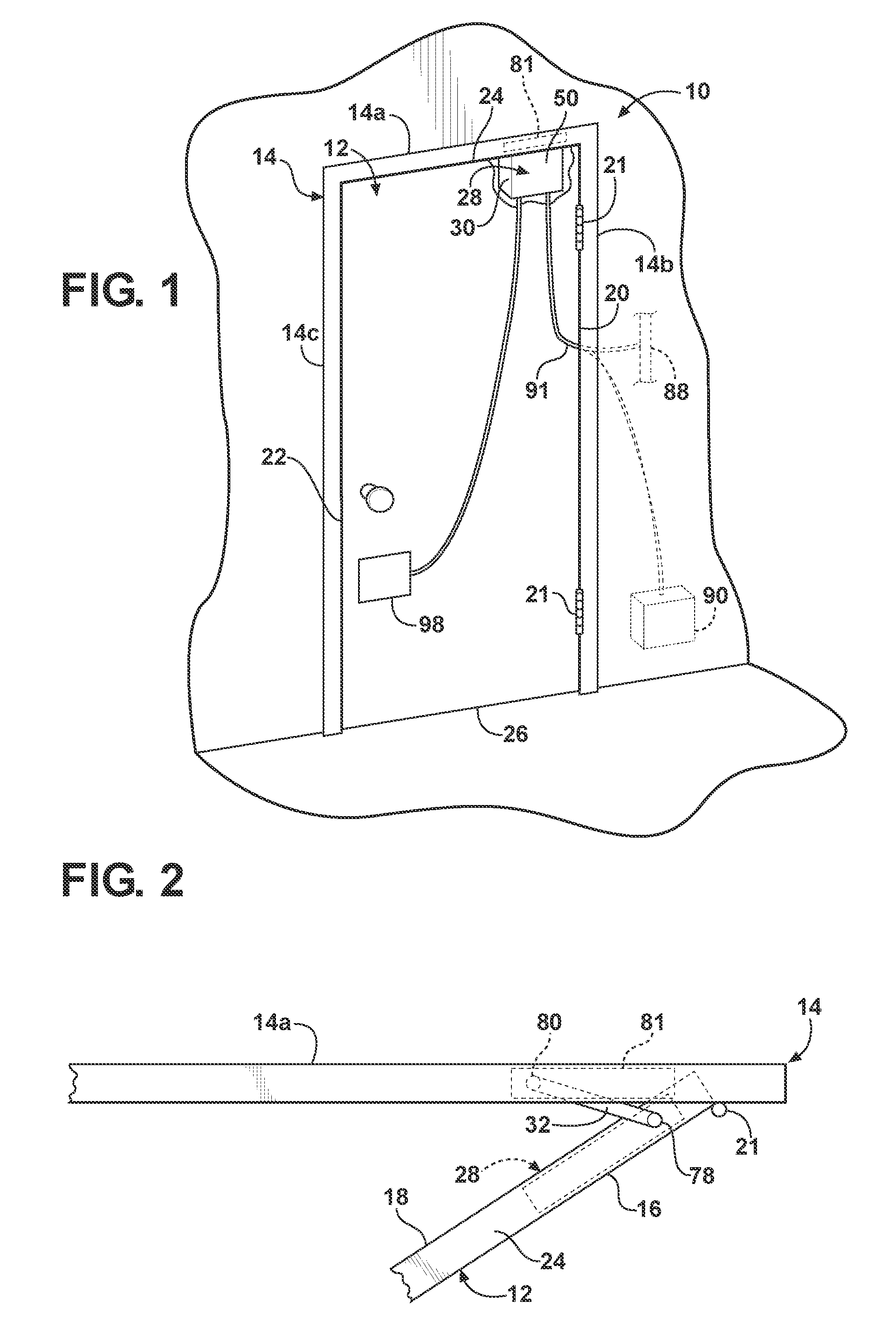

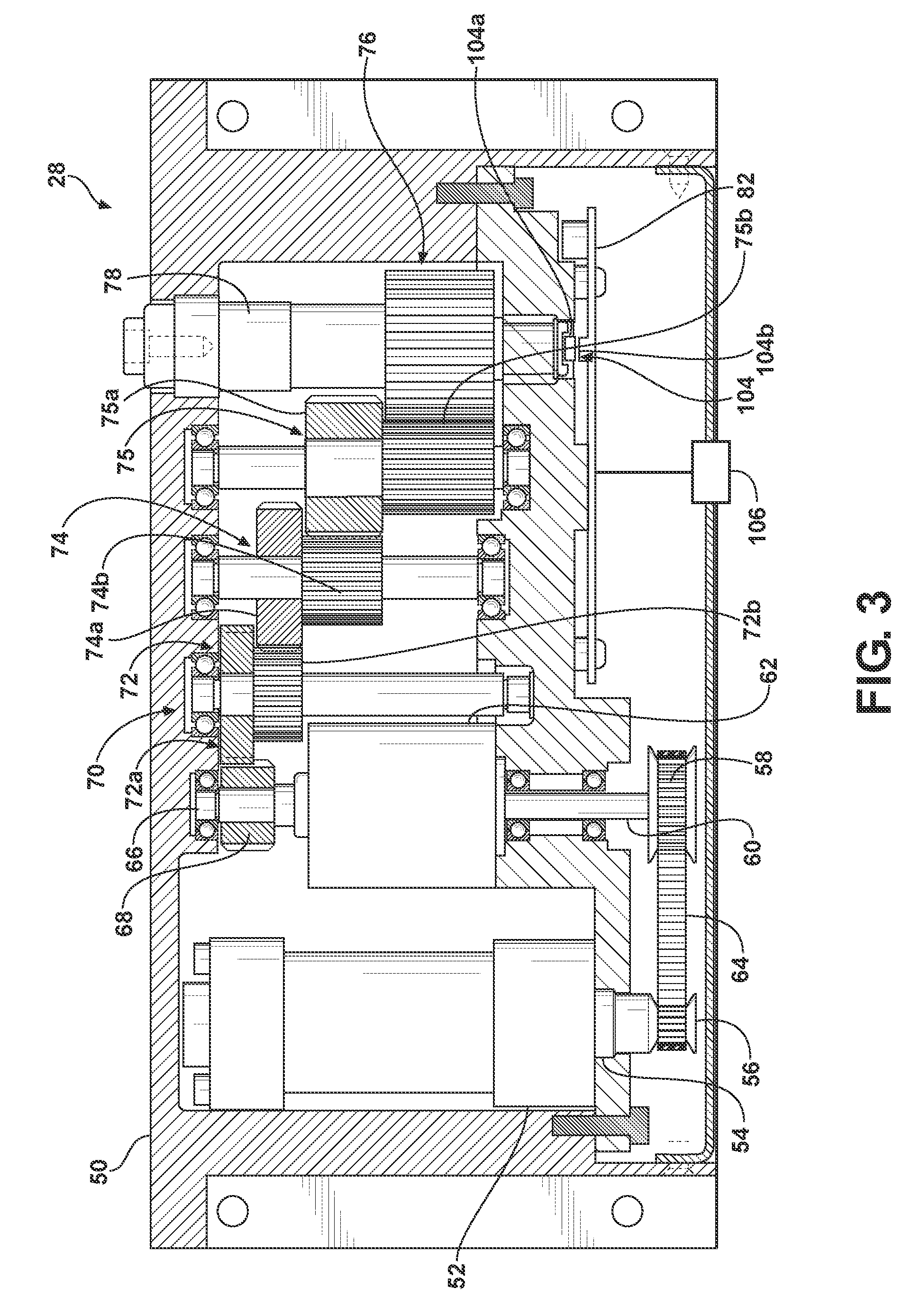

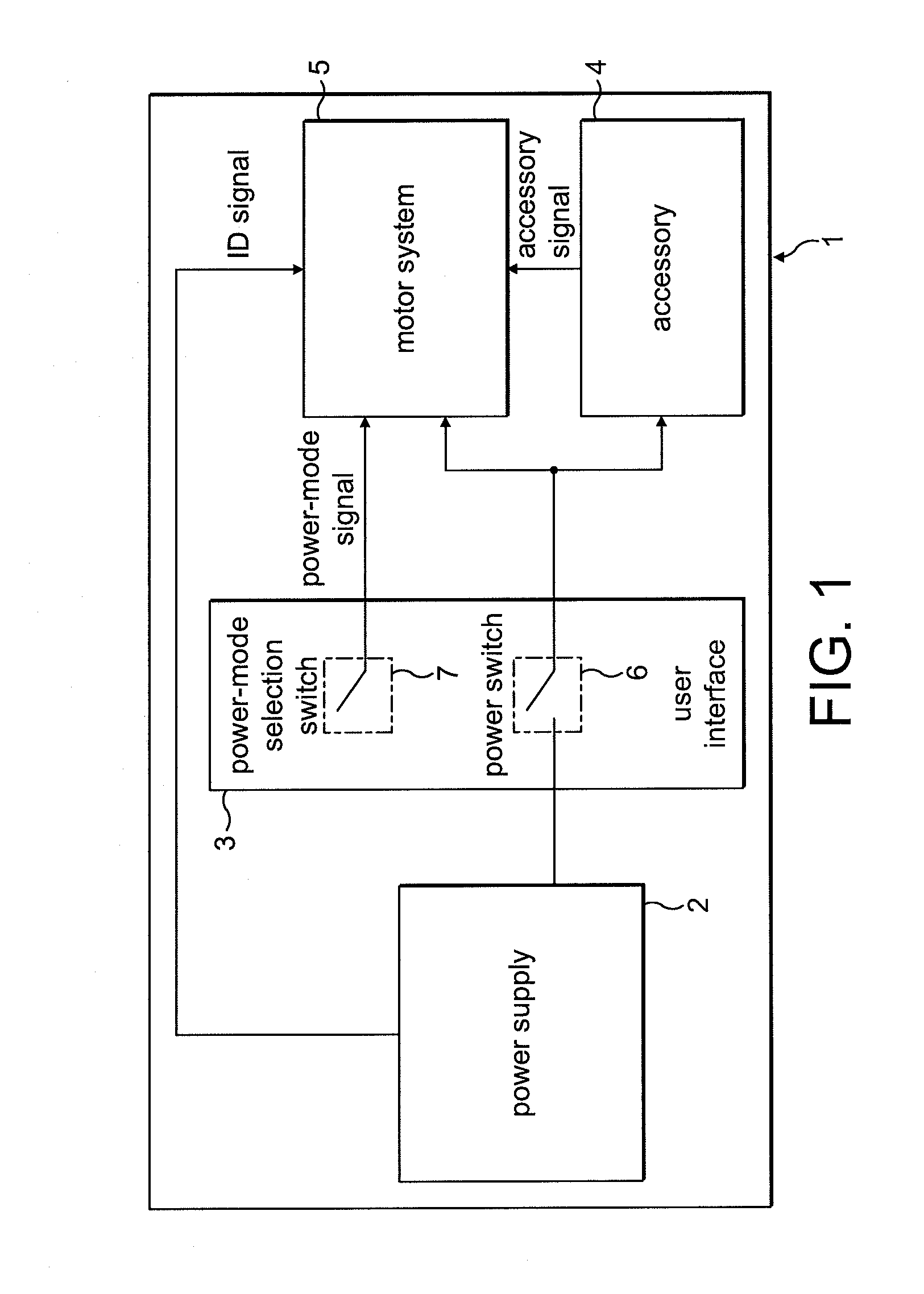

Method of controlling an automatic door system

A door position control including an electric door actuator having a motor and a motor controller in communication with a system controller. A motor actuation operation is selected from a plurality of predetermined motor actuation operations to provide control signals to the motor controller for controlling actuation of the motor for control of door movement. Control of door movement is effected with reference to parameters specific to an installation location including an angular sweep of the door between open and closed positions and with reference to an available bus voltage for supplying power to the motor.

Owner:GLOBE MOTORS

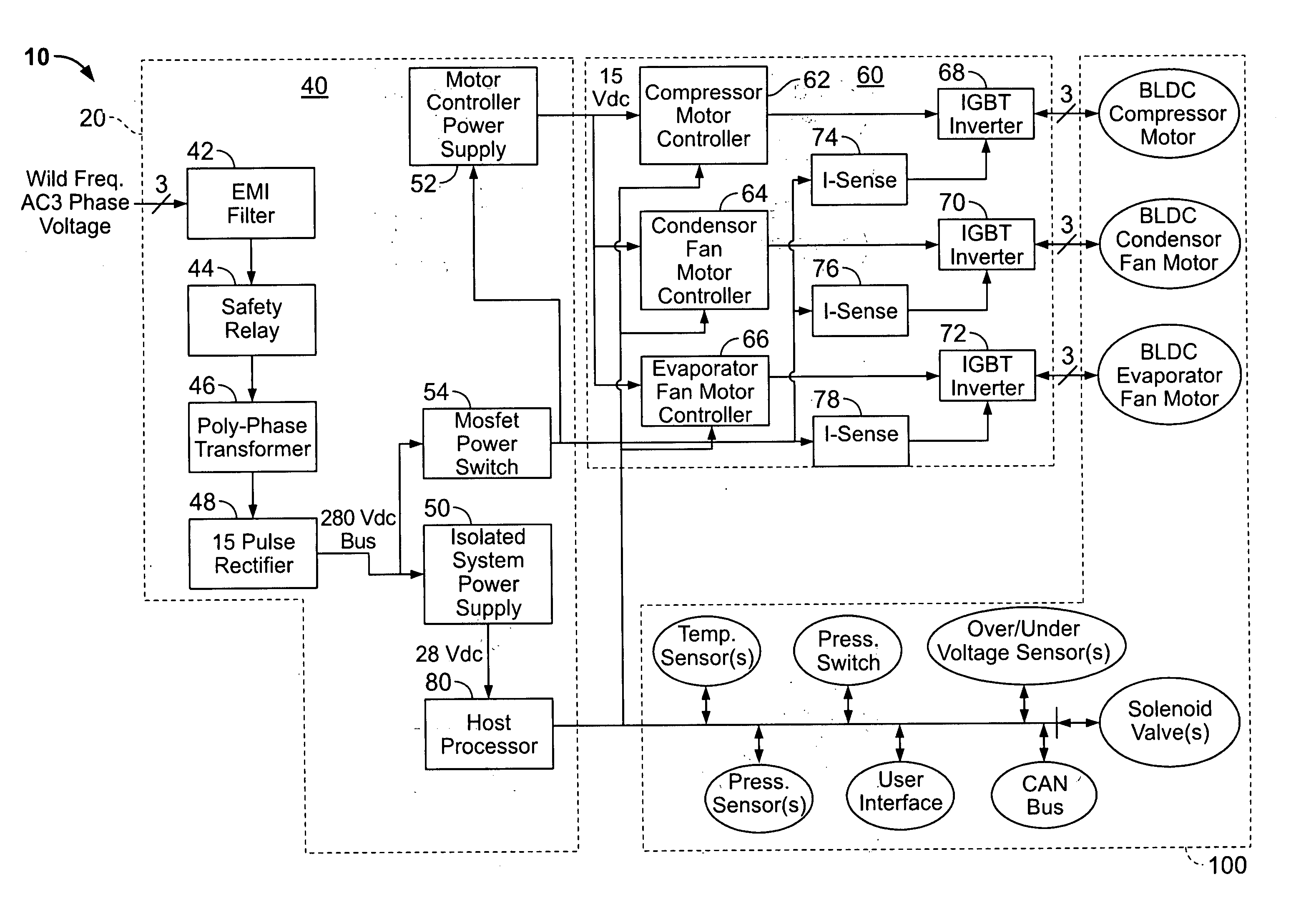

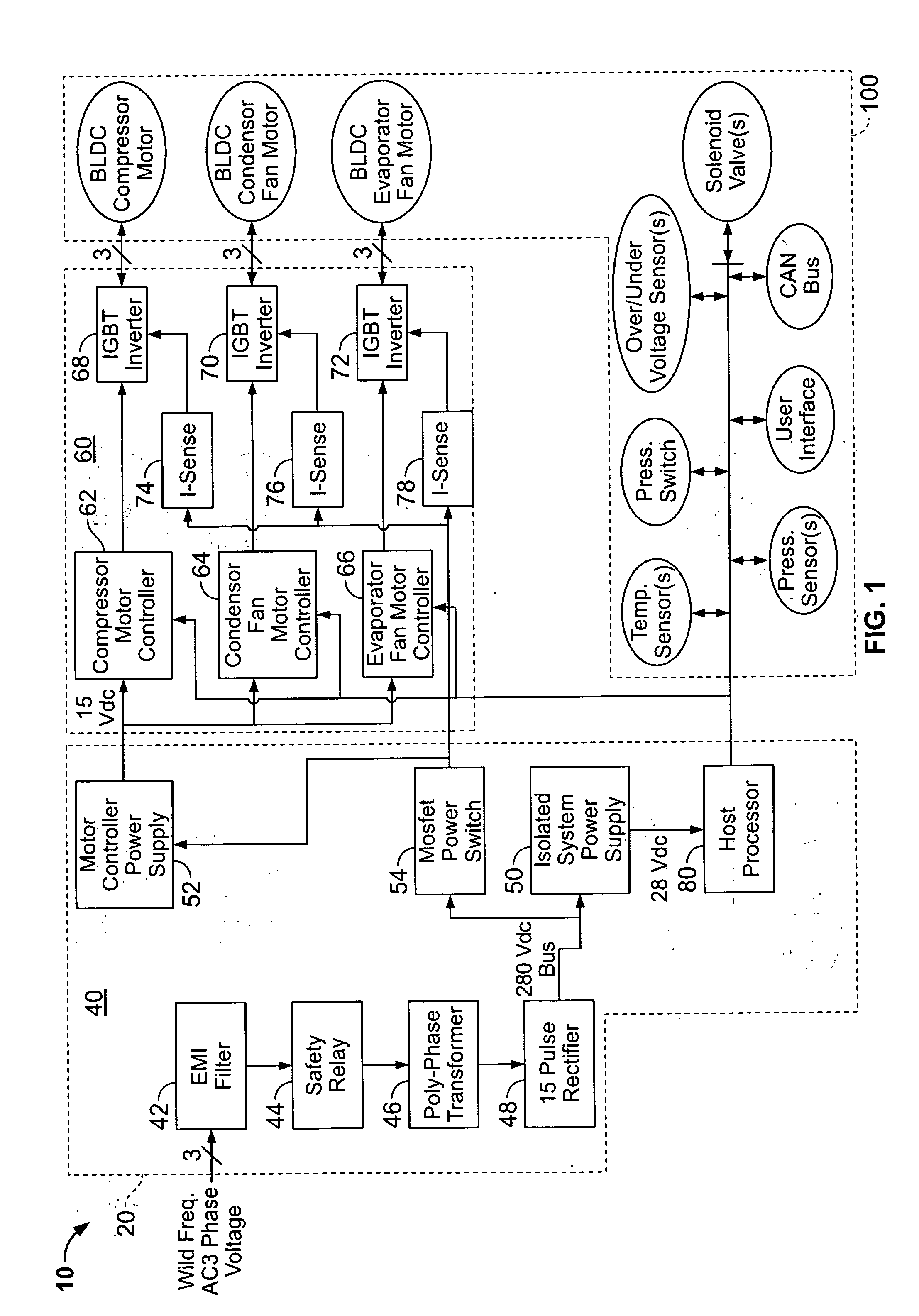

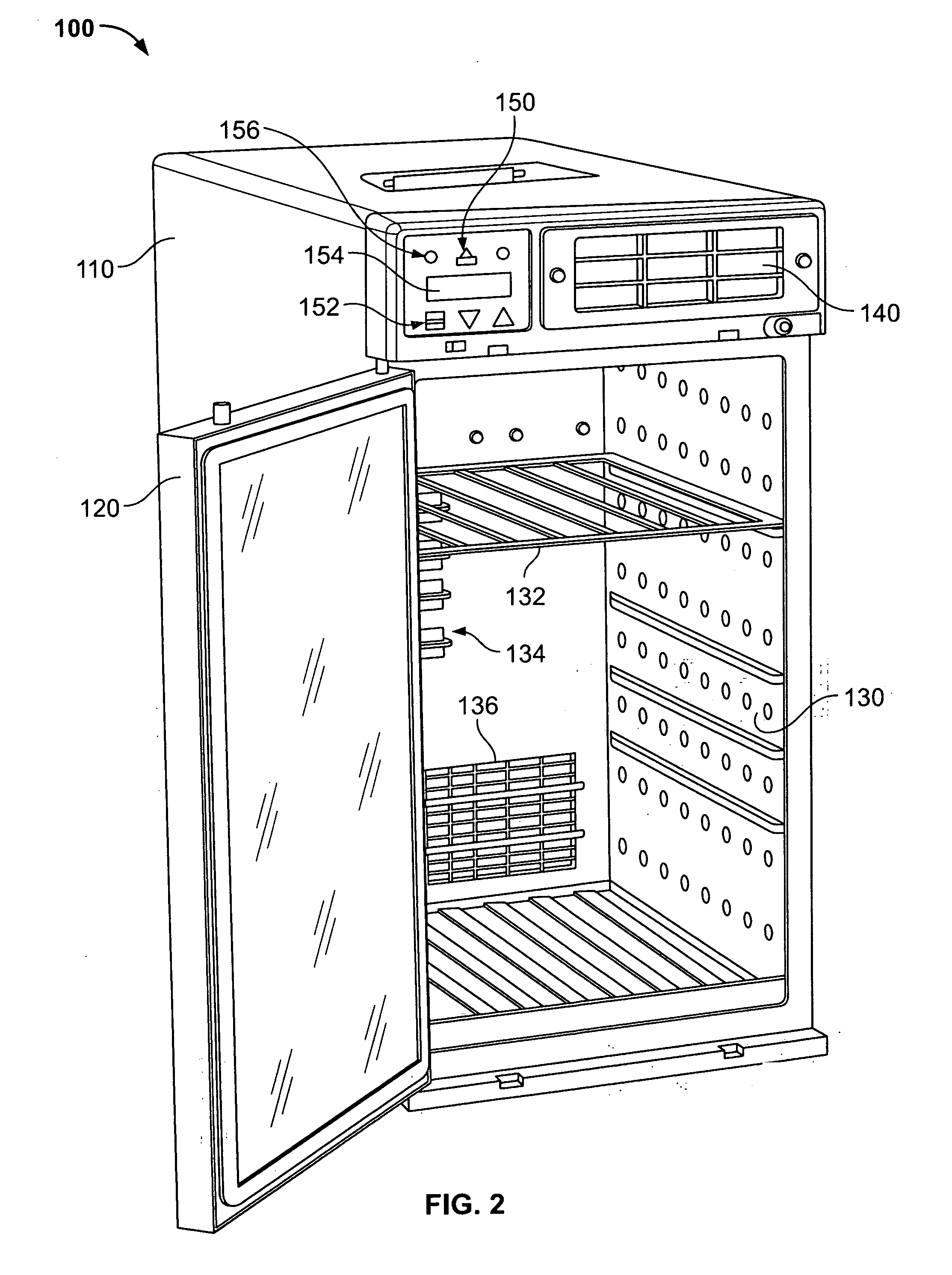

Wild frequency avionic refrigeration system and controller therefor

ActiveUS20080115512A1Air-treating devicesCompression machines with non-reversible cycleAviationControl signal

A wild frequency avionic refrigeration system and a controller therefore are provided. One embodiment of the refrigeration system includes: a refrigeration LRU including a vapor cycle system with a brushless DC compressor motor, a brushless DC condenser motor, a brushless DC evaporator motor and a plurality of sensors configured to output operating parameter data relative to the vapor cycle system; a power module configured to convert a wild frequency AC input voltage to at least one DC output voltage; a motor control module in communication with the brushless DC compressor, condenser and evaporator motors; and a processing module in communication with the plurality of sensors and the motor control module, wherein the processing module, according to the operating parameter data, outputs control signals to the motor control module for independently driving the brushless DC compressor, condenser and evaporator motors.

Owner:BE AEROSPACE INCORPORATED

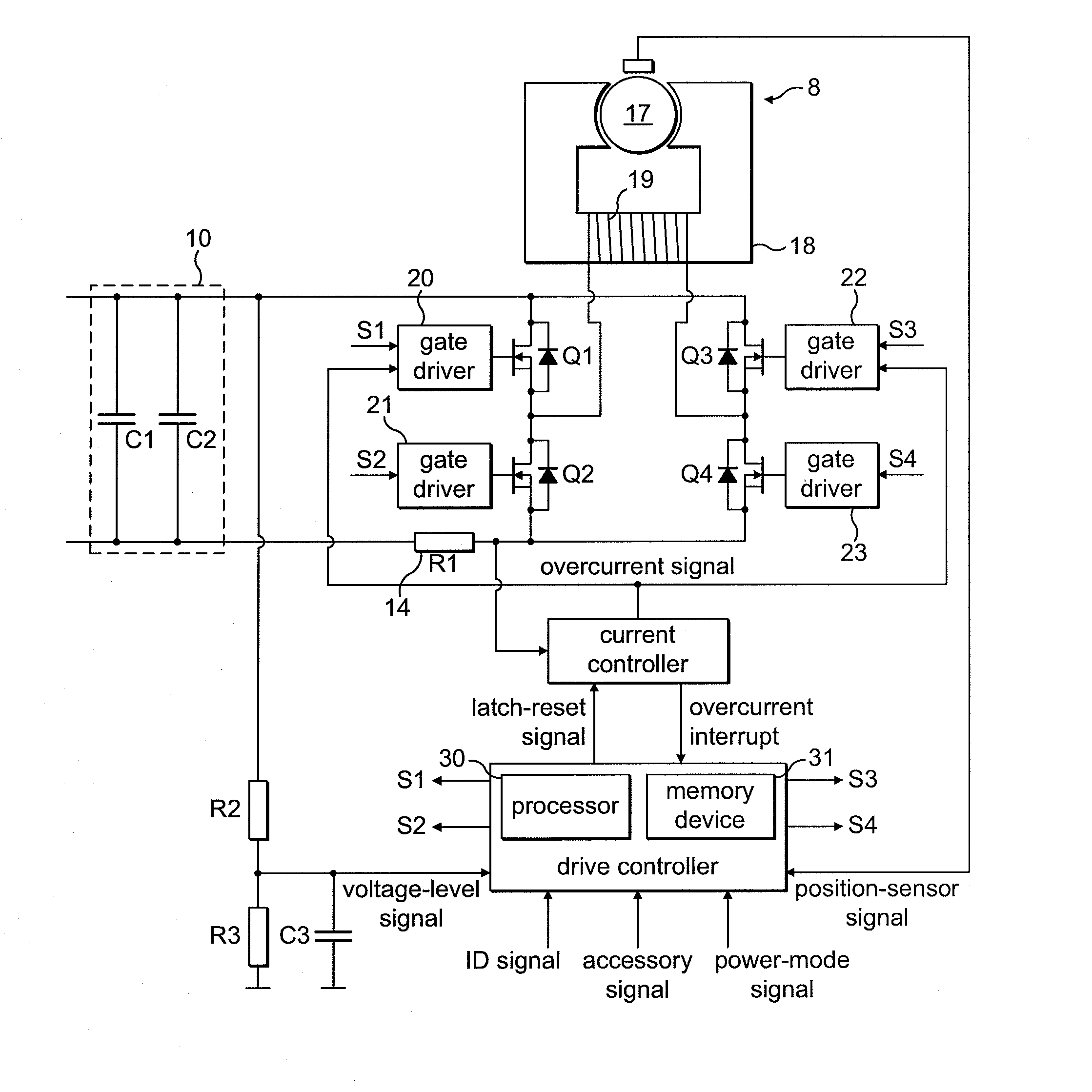

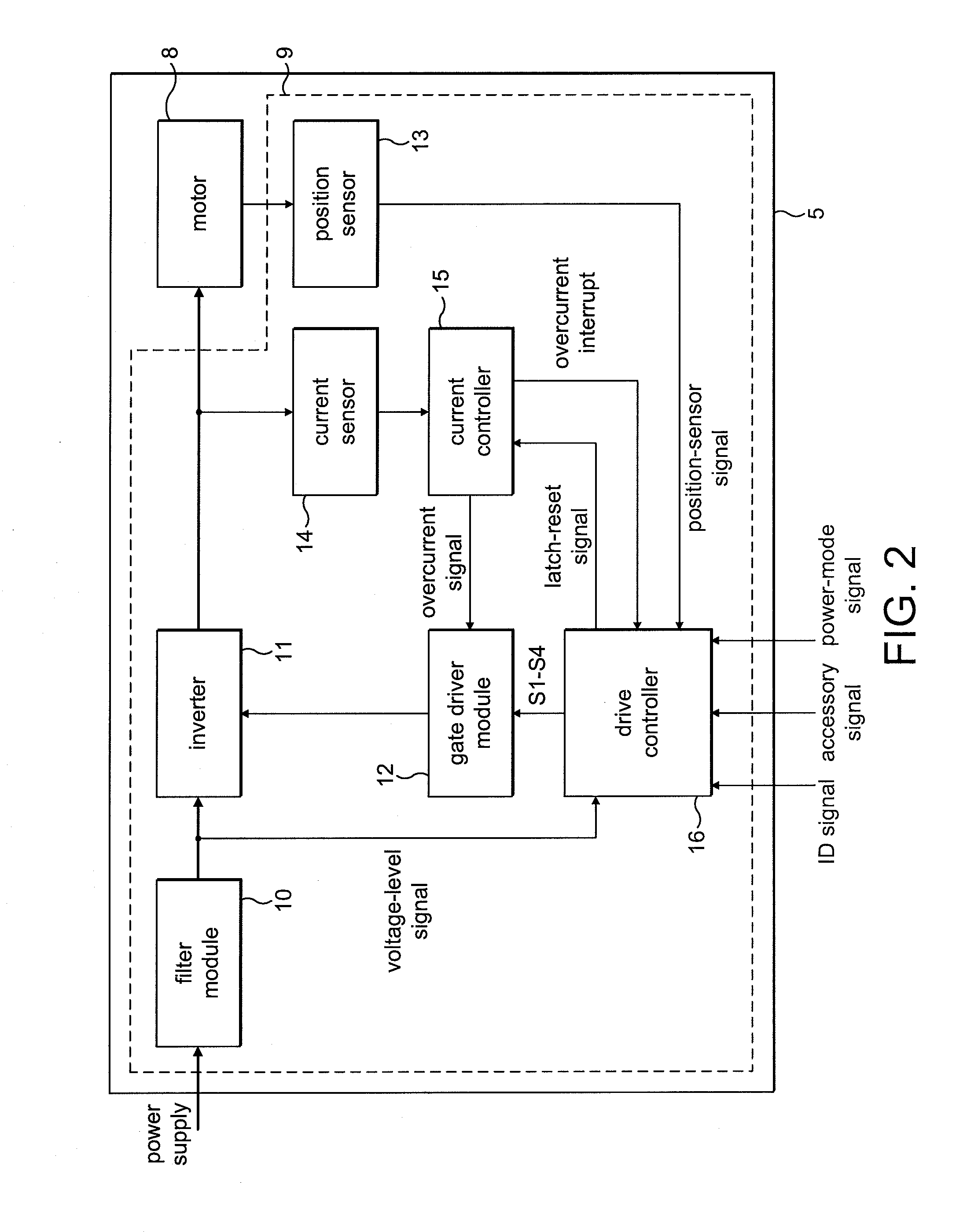

Current controller for an electric machine

ActiveUS20100253250A1Easy to assembleReduce control system costsConversion with intermediate conversion to dcEmergency protective arrangements for automatic disconnectionElectric machineEngineering

A current controller for an electric machine that includes an input, an output, a threshold generator and a comparator. The threshold generator stores a scaling factor and includes a PWM module that operates on a reference voltage to generate a threshold voltage. The duty cycle of the PWM module is then defined by the scaling factor. The comparator compares a voltage at the input against the threshold voltage and causes an overcurrent signal to be generated at the output when the voltage at the input exceeds the threshold voltage.

Owner:DYSON TECH LTD

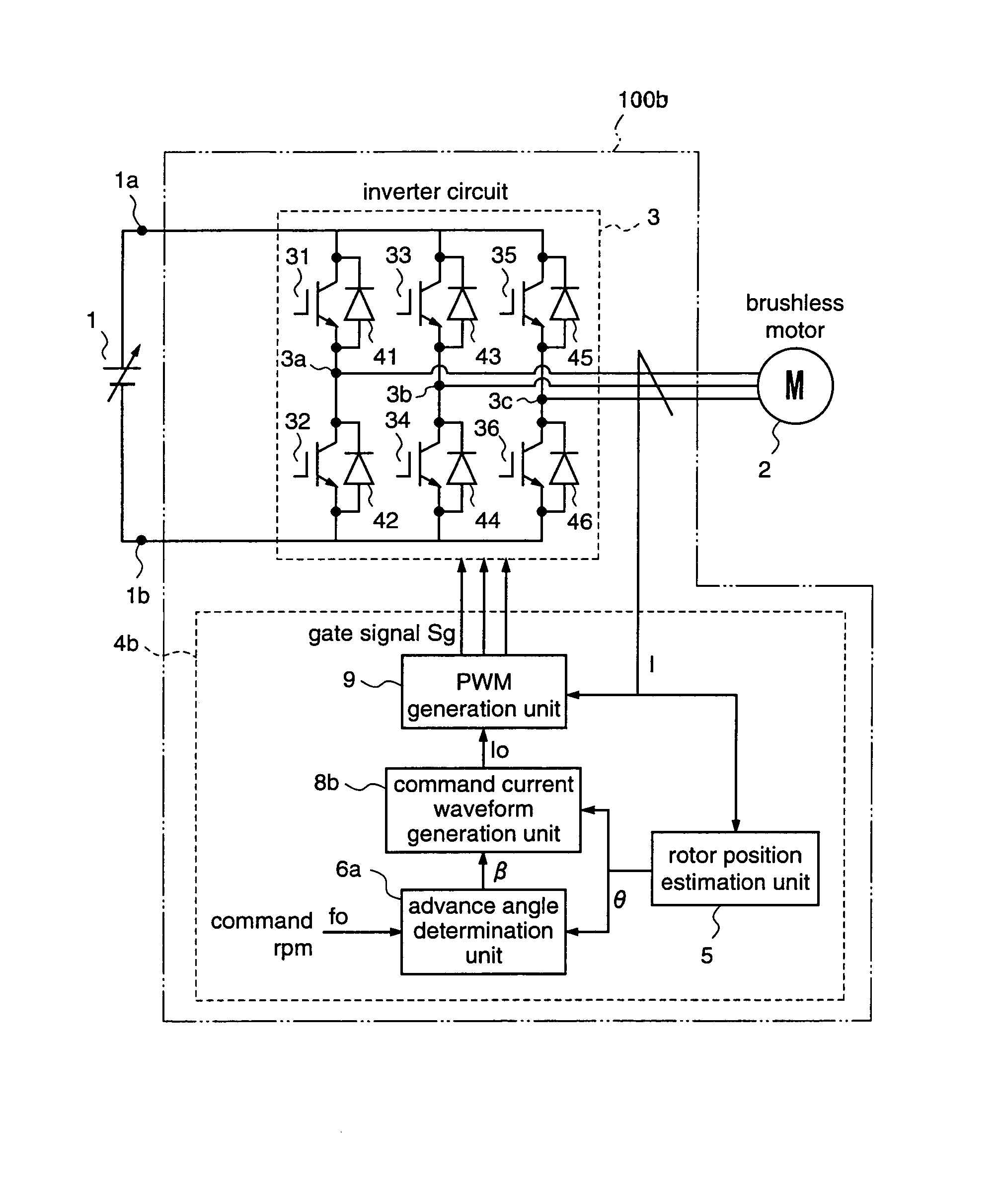

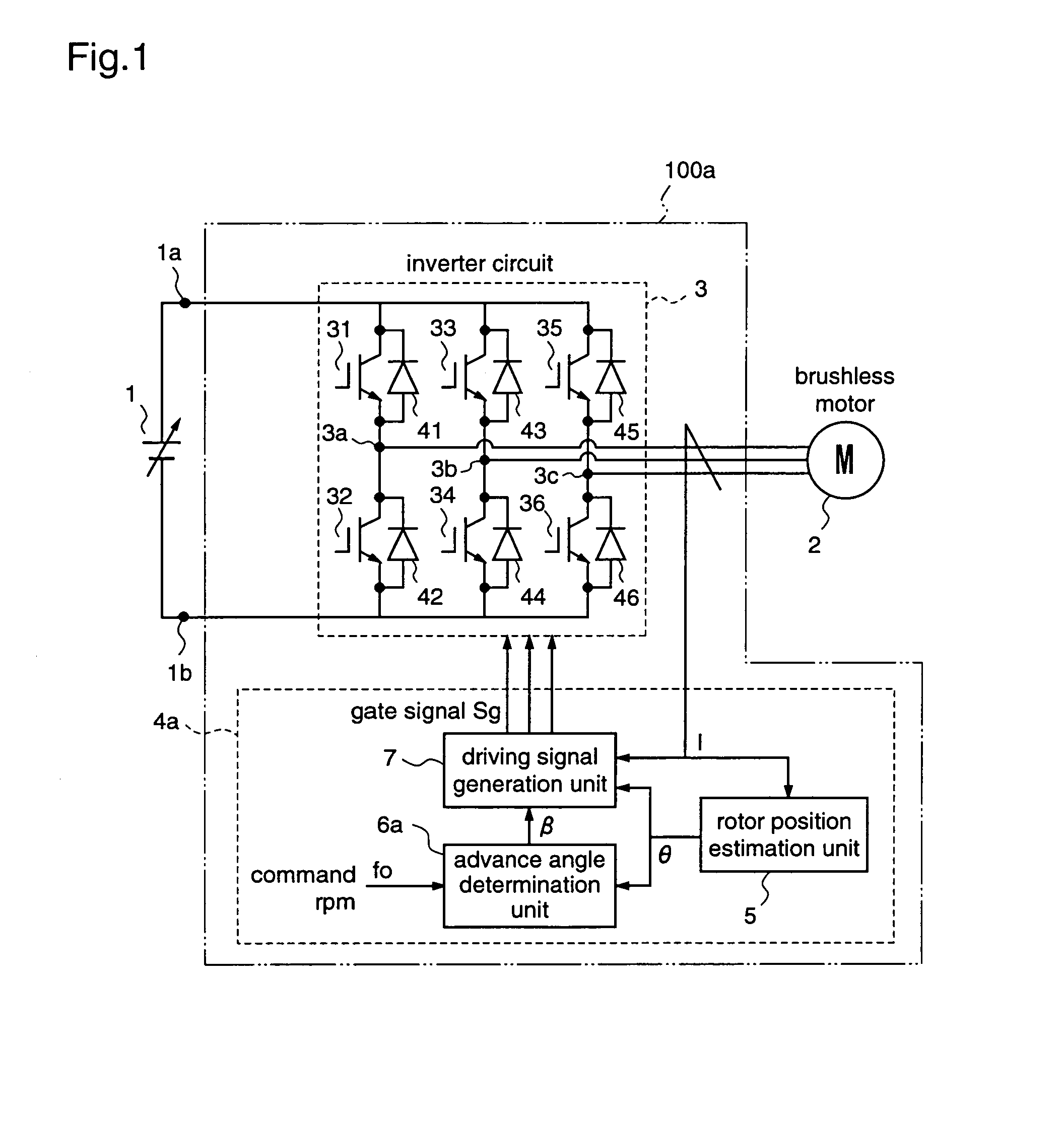

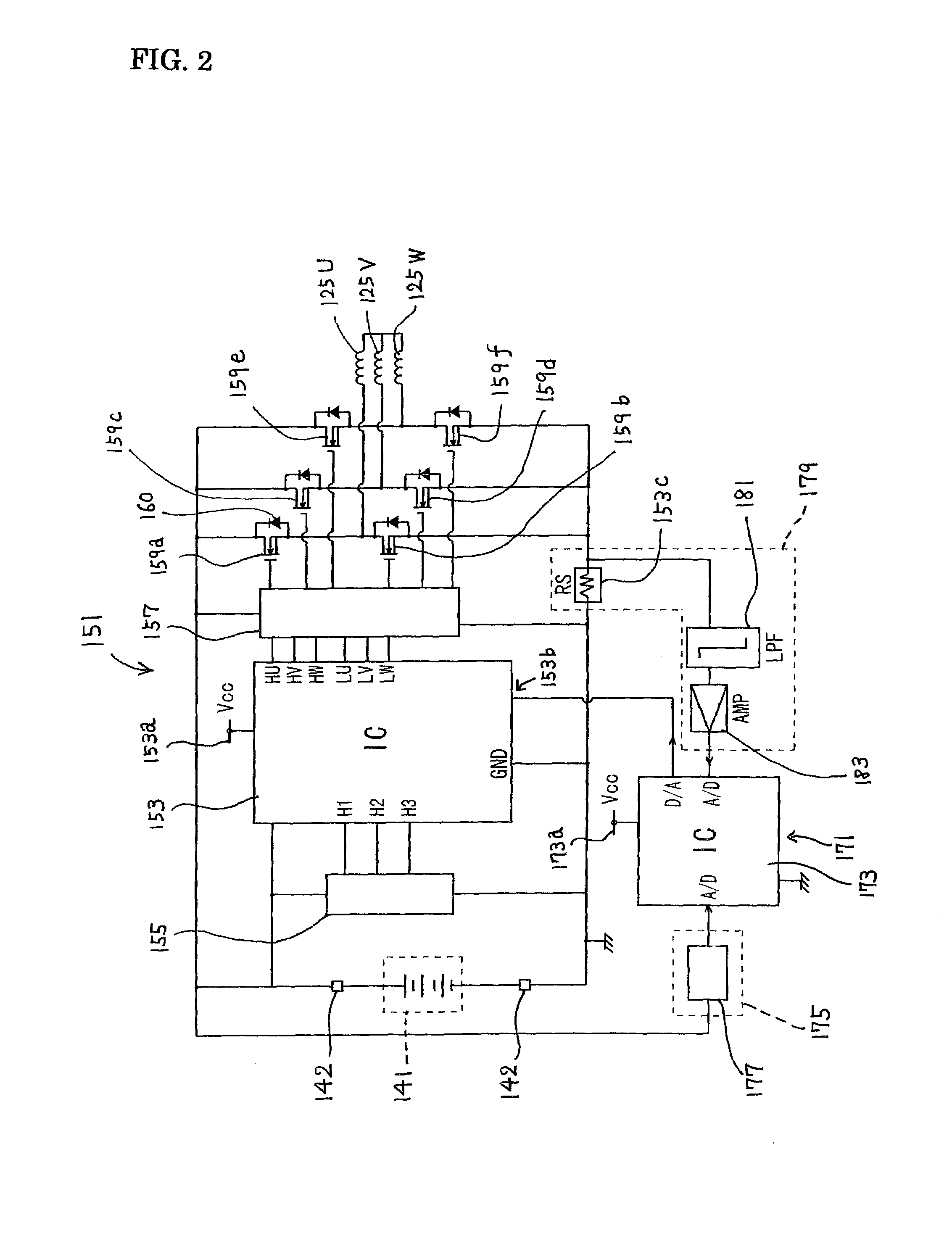

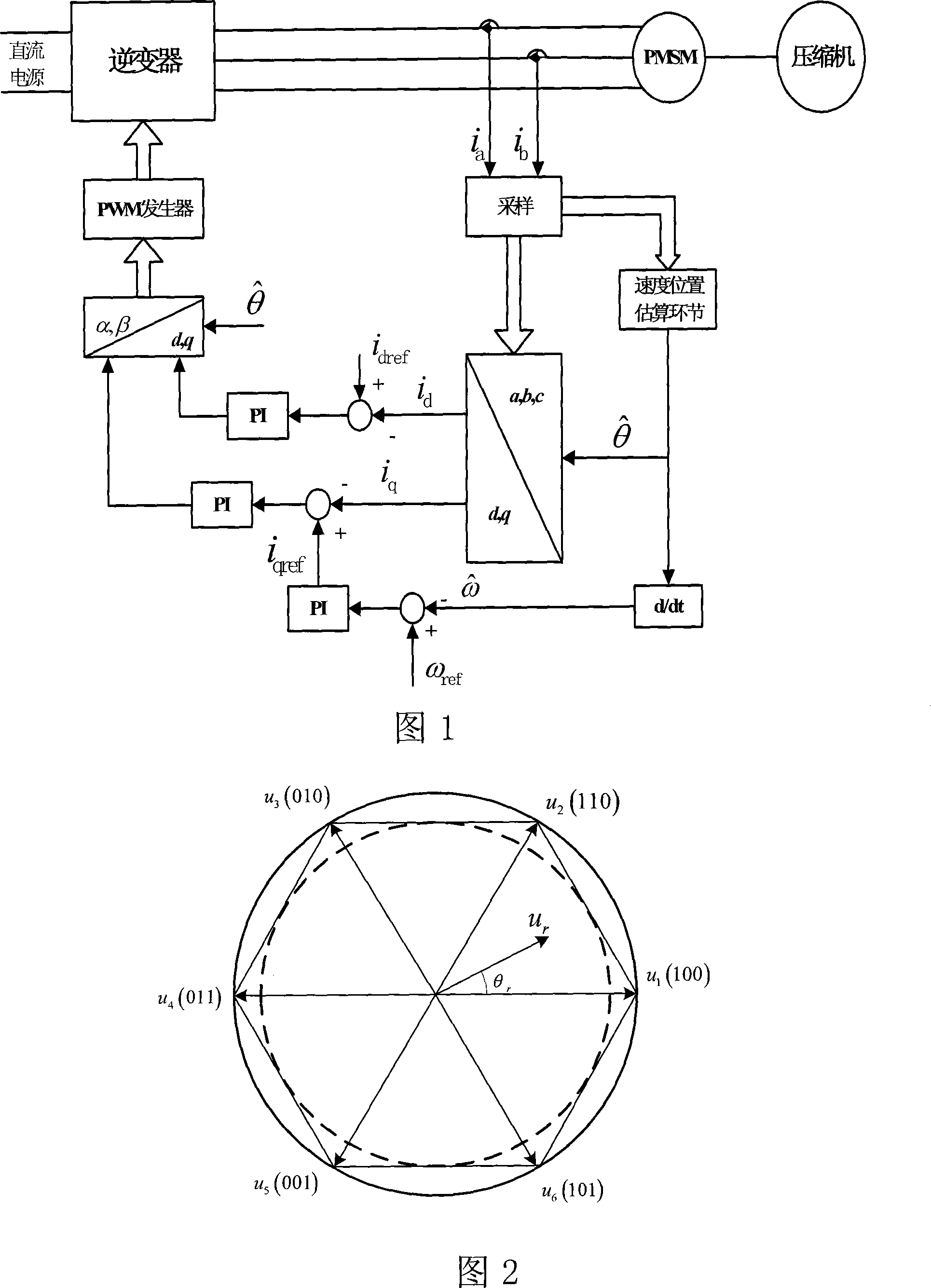

Motor driving apparatus

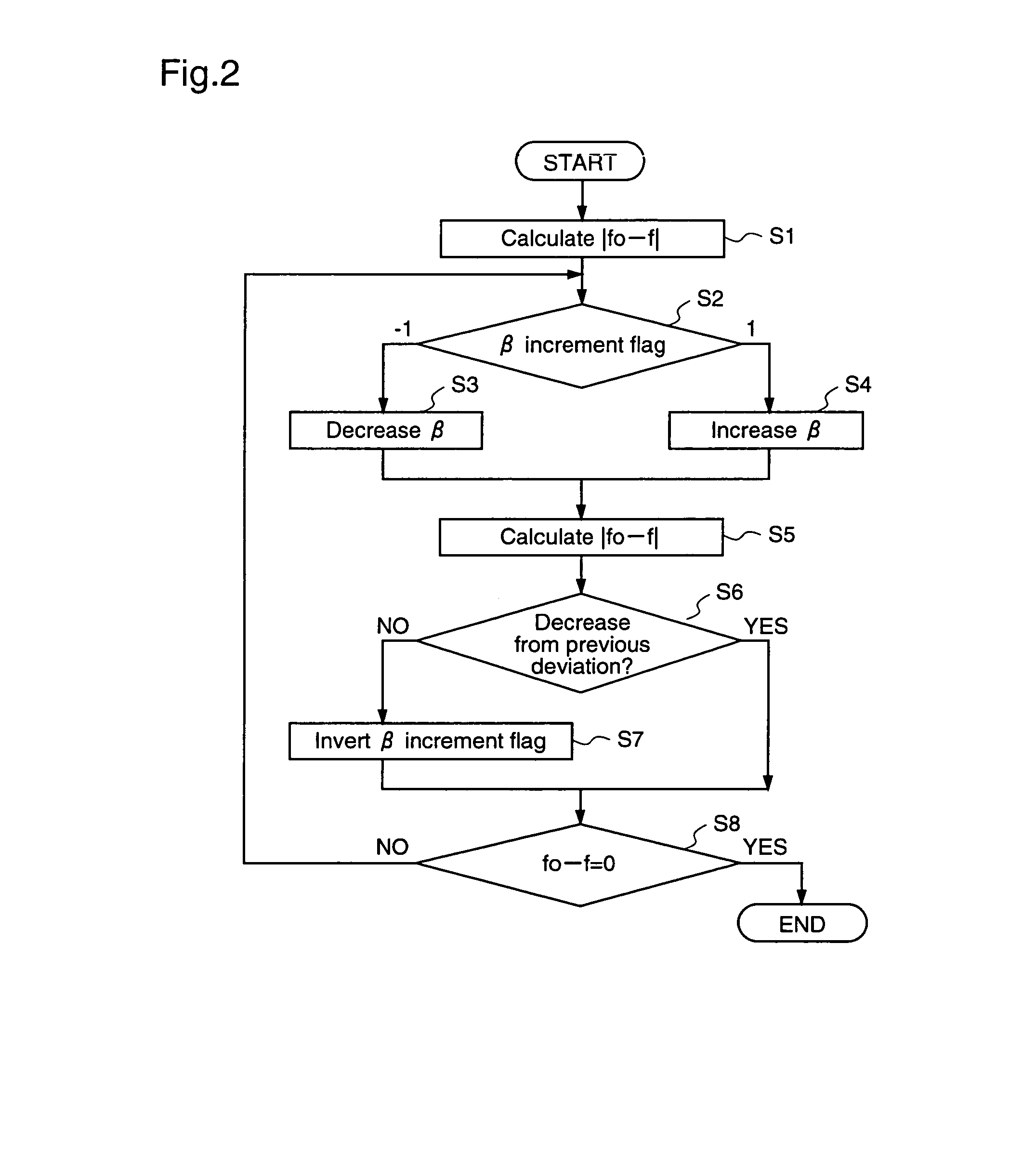

ActiveUS7176644B2Low costIncrease freedomSynchronous motors startersVector control systemsBrushless motorsMotor drive

A motor driving apparatus includes an inverter circuit for converting an output voltage of a power supply into a three-phase AC and outputting the same to the brushless motor, a rotor position estimation unit for estimating a rotor position of the brushless motor, and an inverter control unit for controlling the inverter circuit so that the brushless motor is driven by a current based on the estimated rotor position. The inverter control unit determines an advance angle of the current supplied to the brushless motor with respect to the estimated rotor position so as to minimize a deviation between a command rpm and an actual rpm. Therefore, it is possible to perform stable weak field control for the brushless motor, independently from the input voltage of the inverter circuit, without using predetermined control variables such as table values.

Owner:III HLDG 7

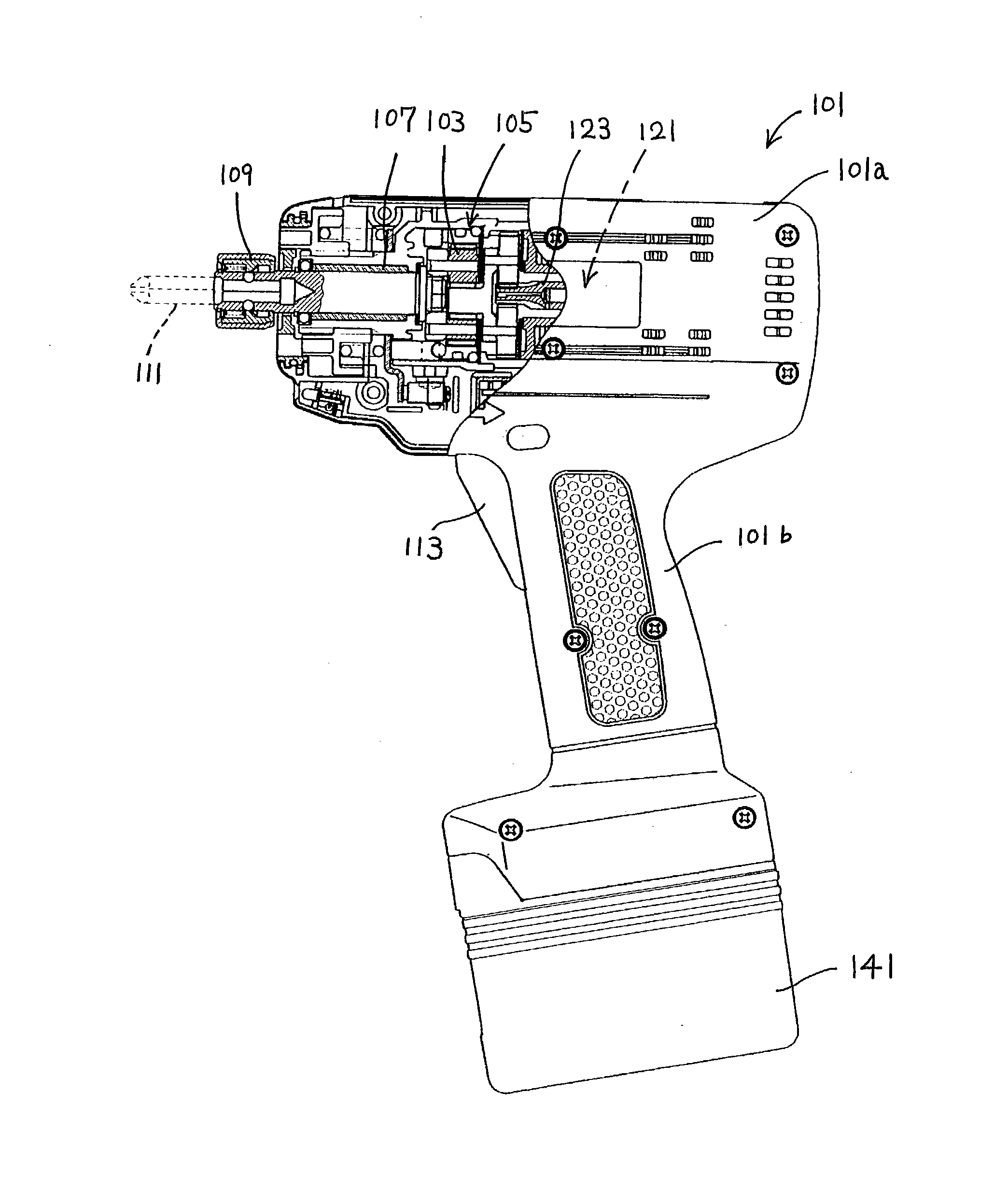

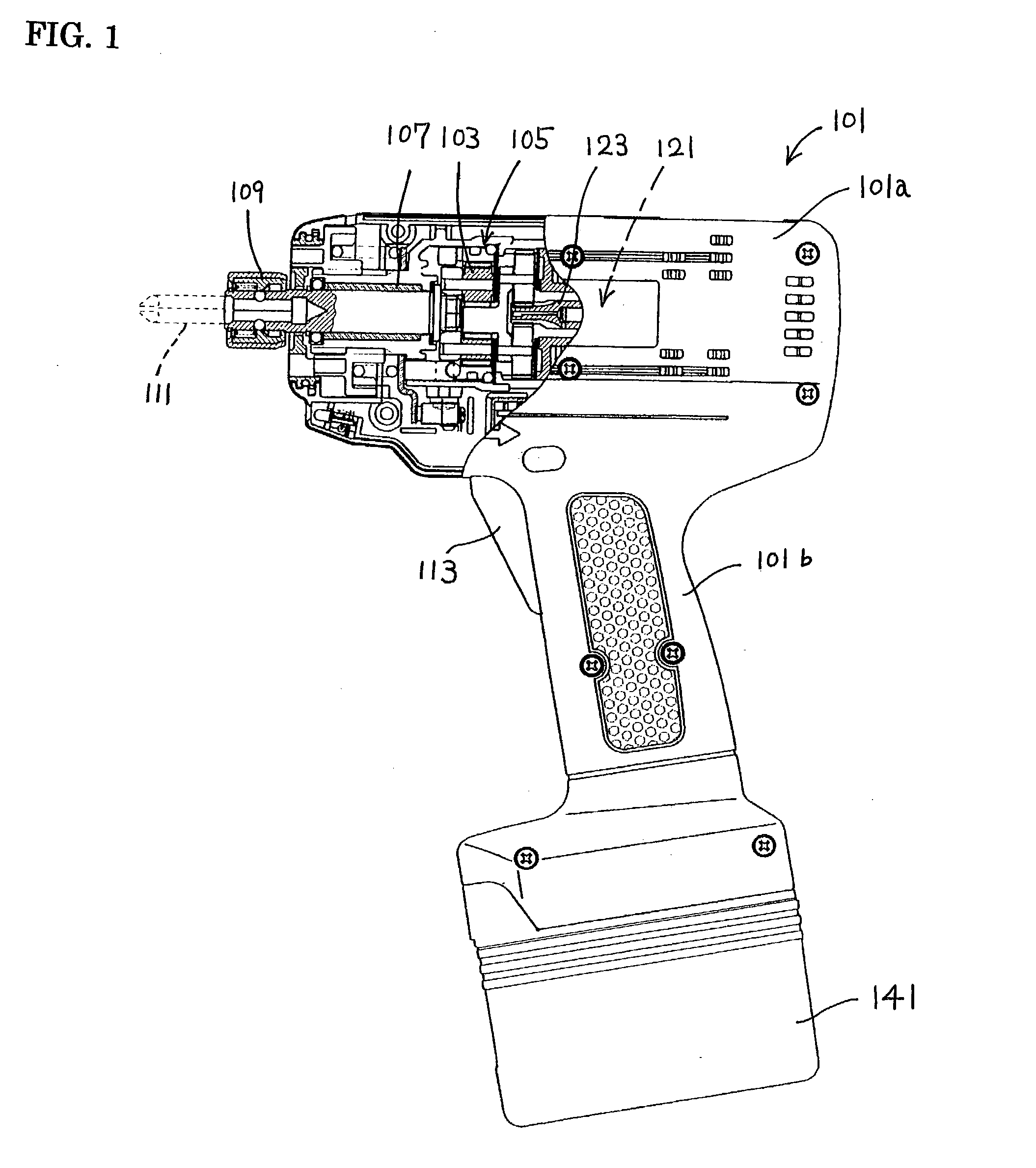

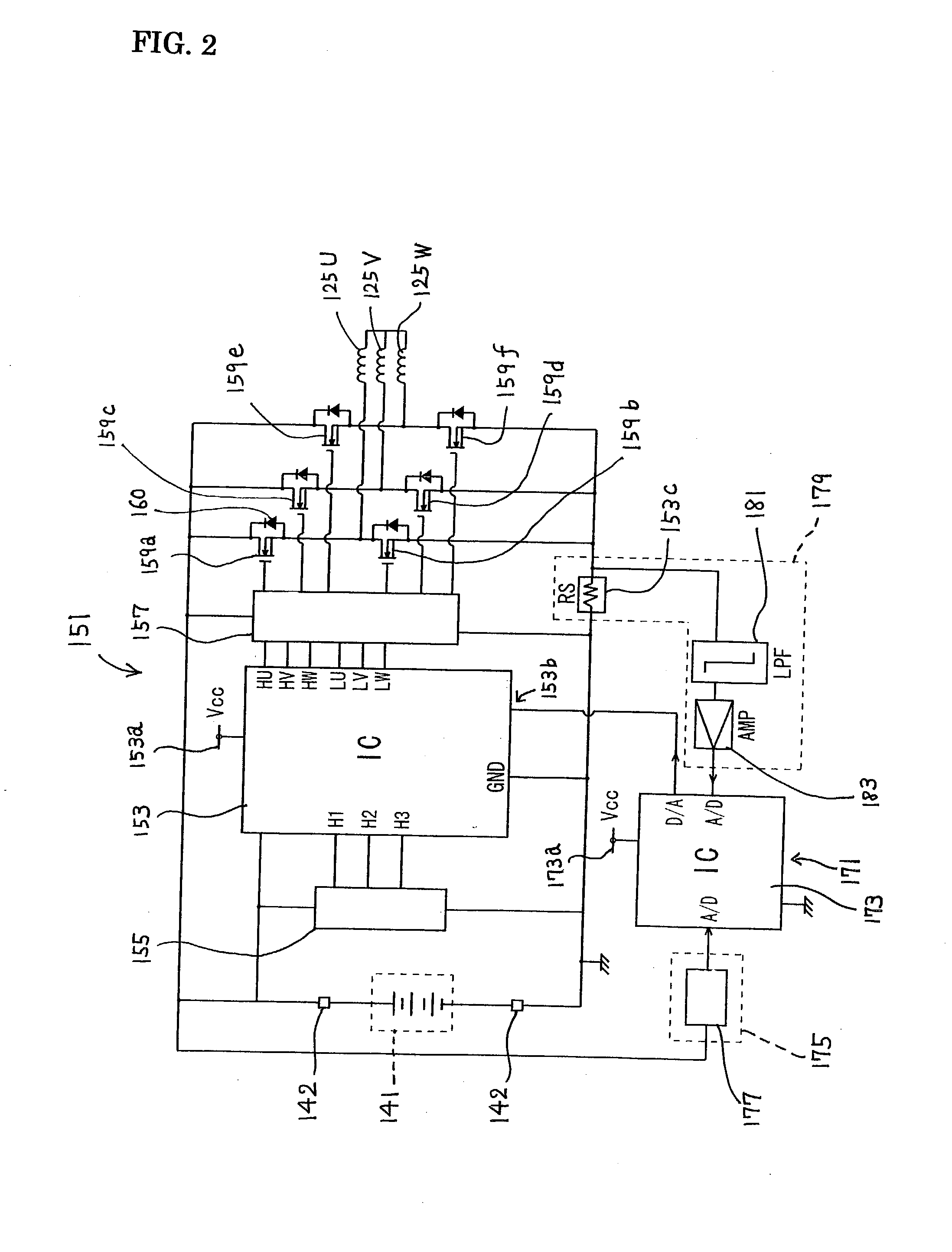

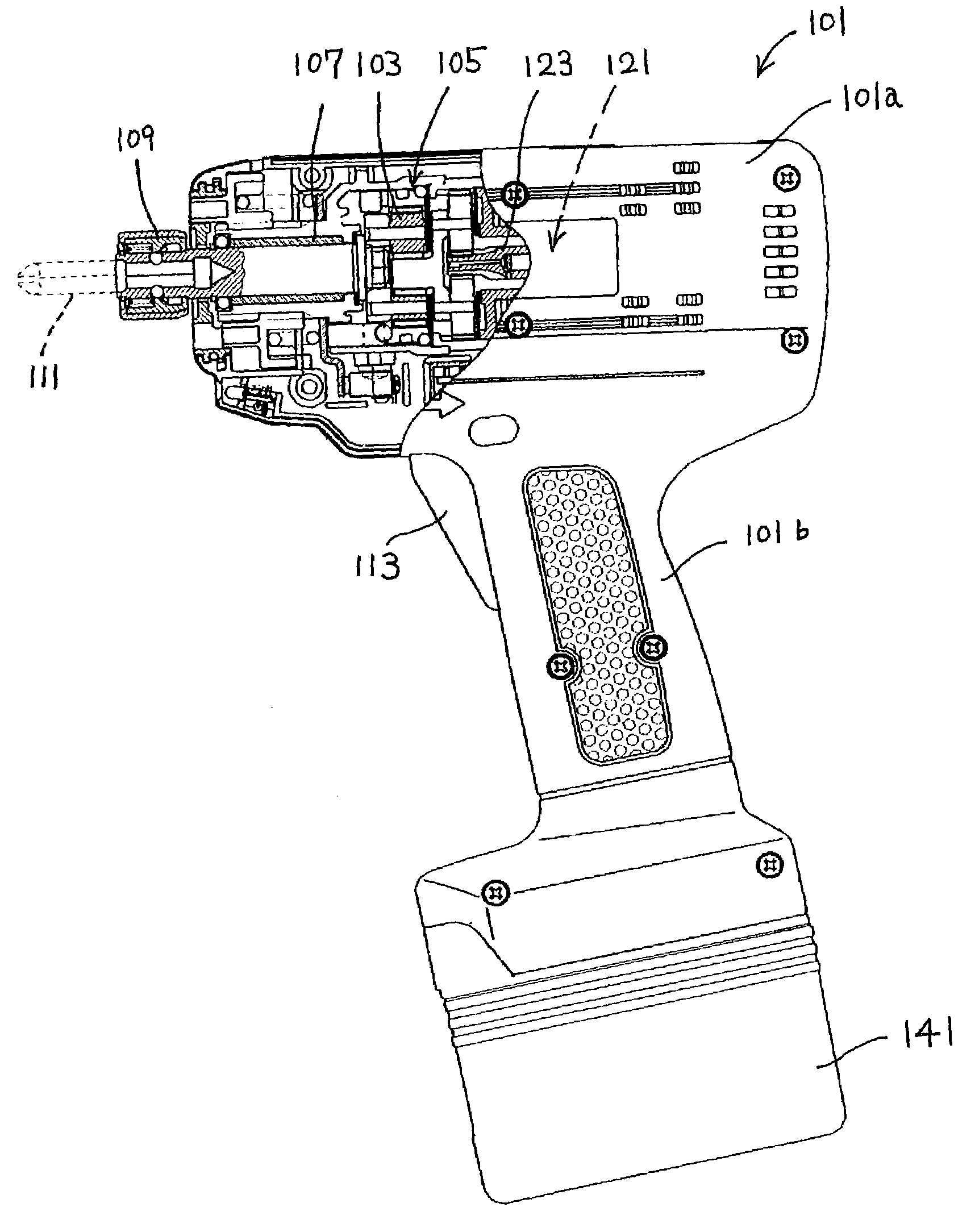

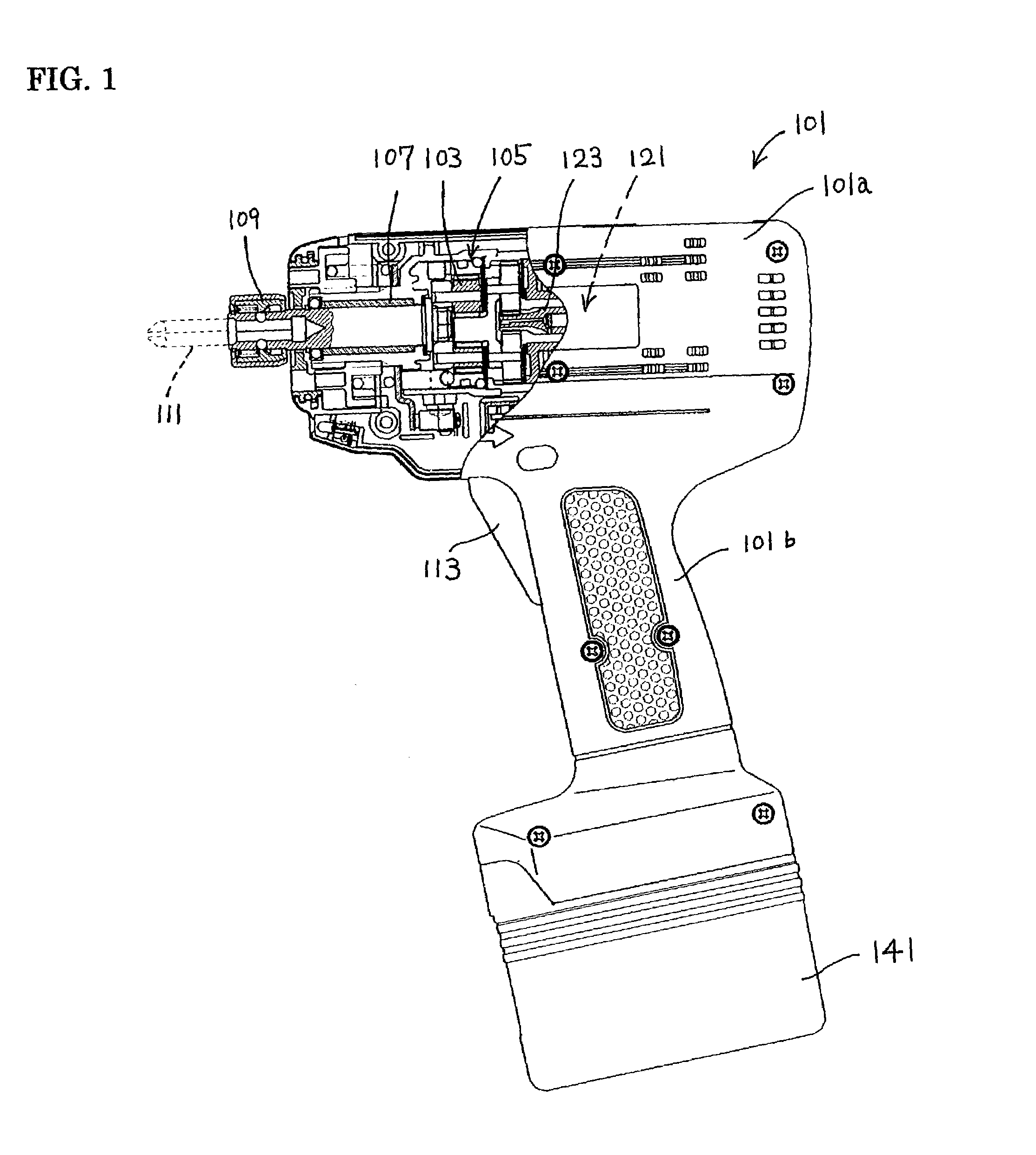

Power tool

It is an object of the present invention to provide a technique to increase efficiency of the output torque of the blushless motor to drive a power tool. A representative power tool may comprise a tool bit, a brushless motor to drive the tool bit, a battery to operate the brushless motor and a control device. The control device may operate the brushless motor by means of the battery. The control device may include an advance angle controlling section to control an advance angle of the brushless motor. According to the present teachings, the advance angle of the brushless motor may be determined based upon indexes that reflect working condition of the tool bit when the brushless motor is under the operation. By reflecting the working condition of the tool bit to the determination of the advance angle of the brushless motor, the brushless motor can be operated with higher efficiency under the various working condition such as a hard joint operation and a soft joint operation.

Owner:MAKITA CORP

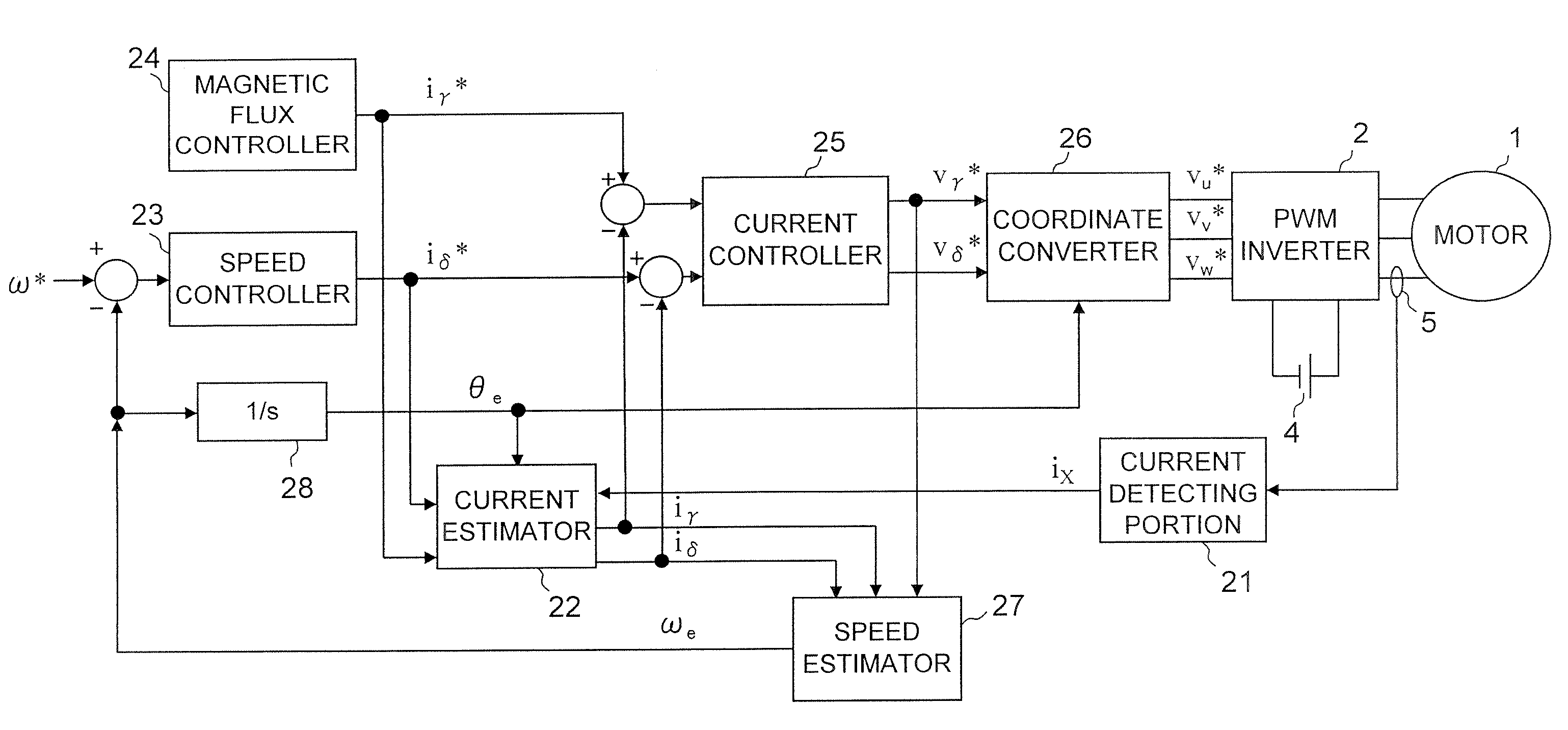

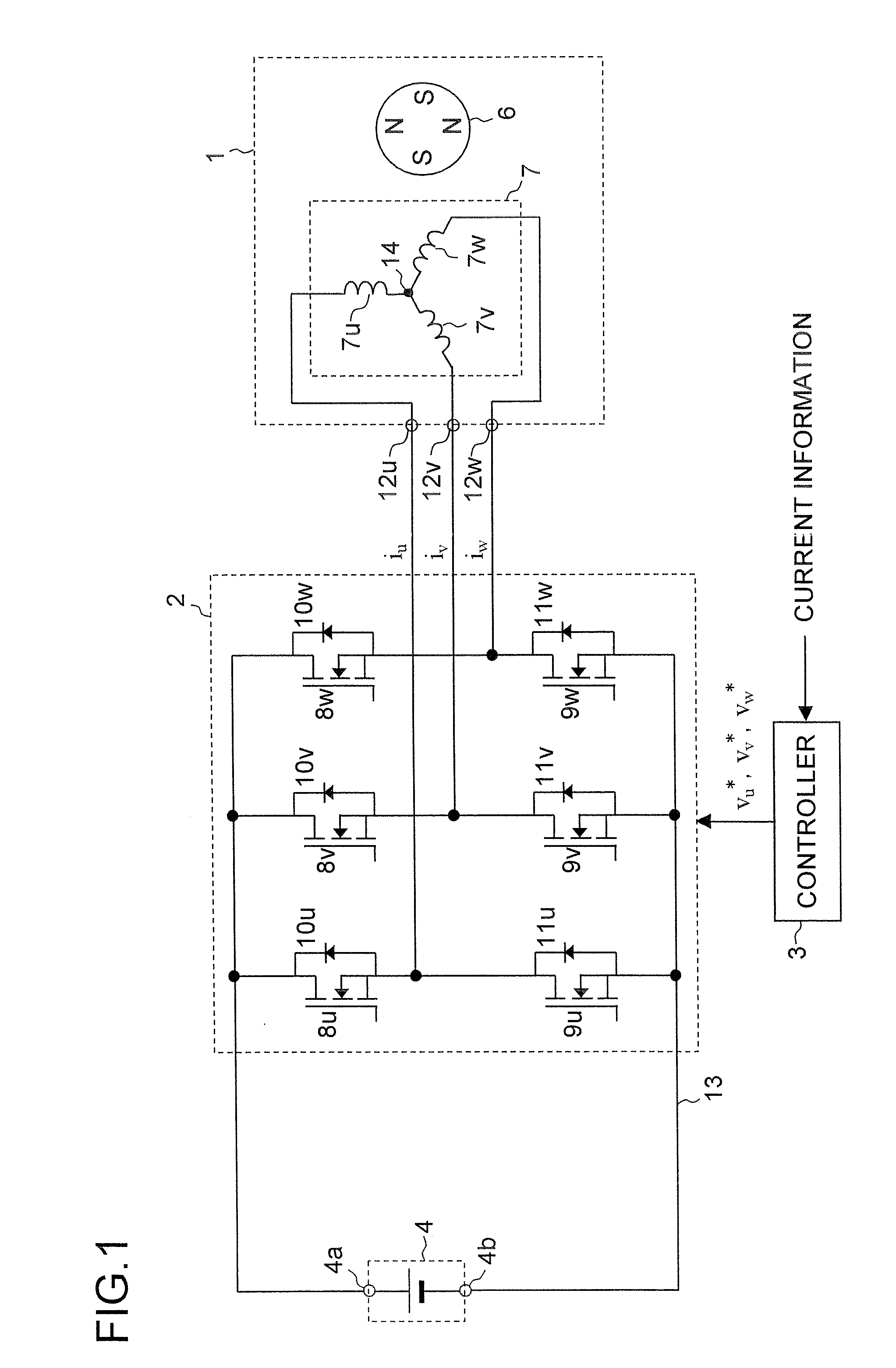

Motor control device

A motor control device includes a current detecting portion that detects phase current of one phase among three phase currents supplied from an inverter to a motor, and a current estimator that estimates phase current of phases other than the detected phase current by using a specified current value indicating current to be supplied to the motor, and derives control current corresponding to the specified current value from the estimated phase current and the phase current of one phase. The motor control device controls the motor via the inverter so that the control current follows the specified current value.

Owner:III HLDG 12 LLC

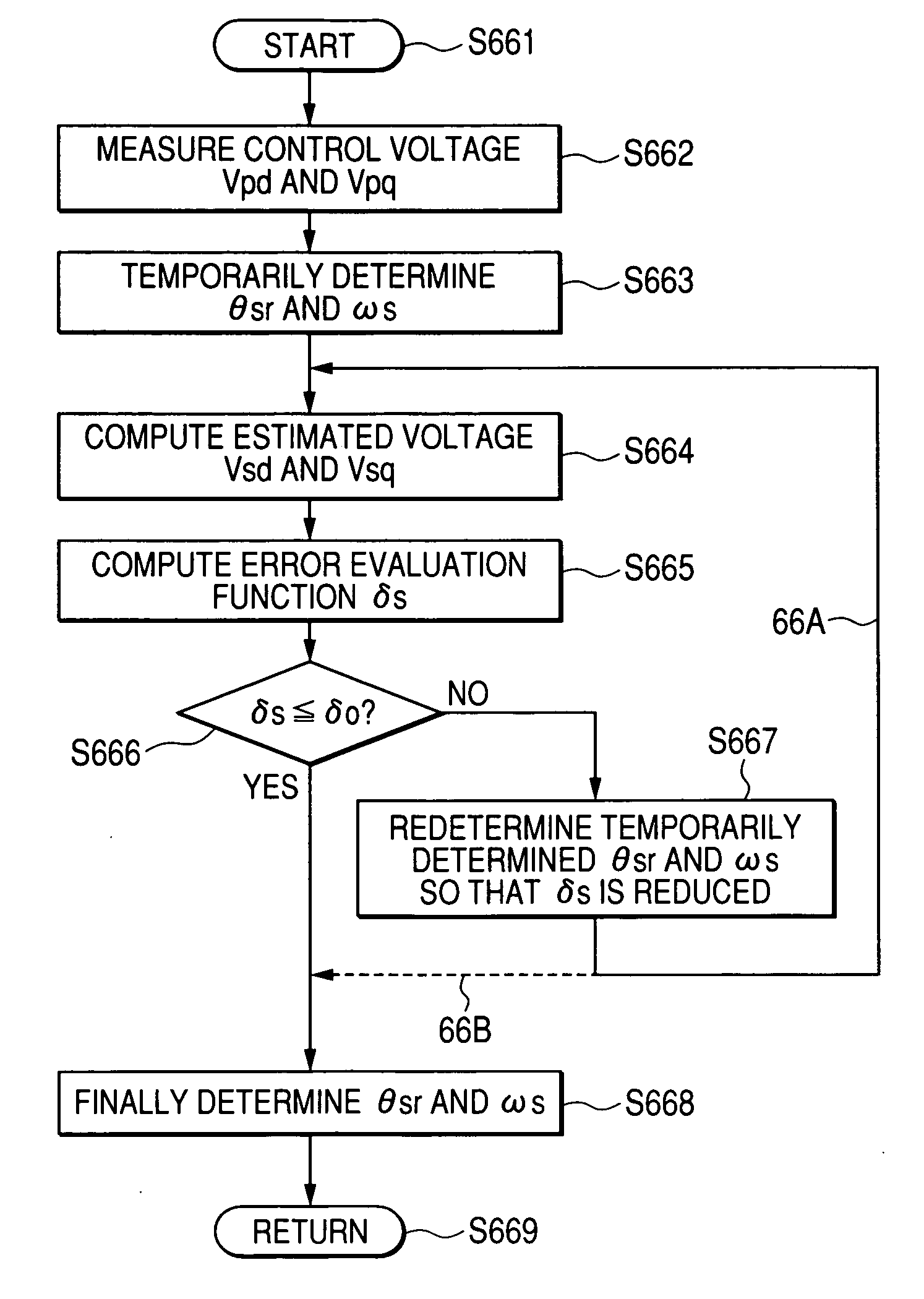

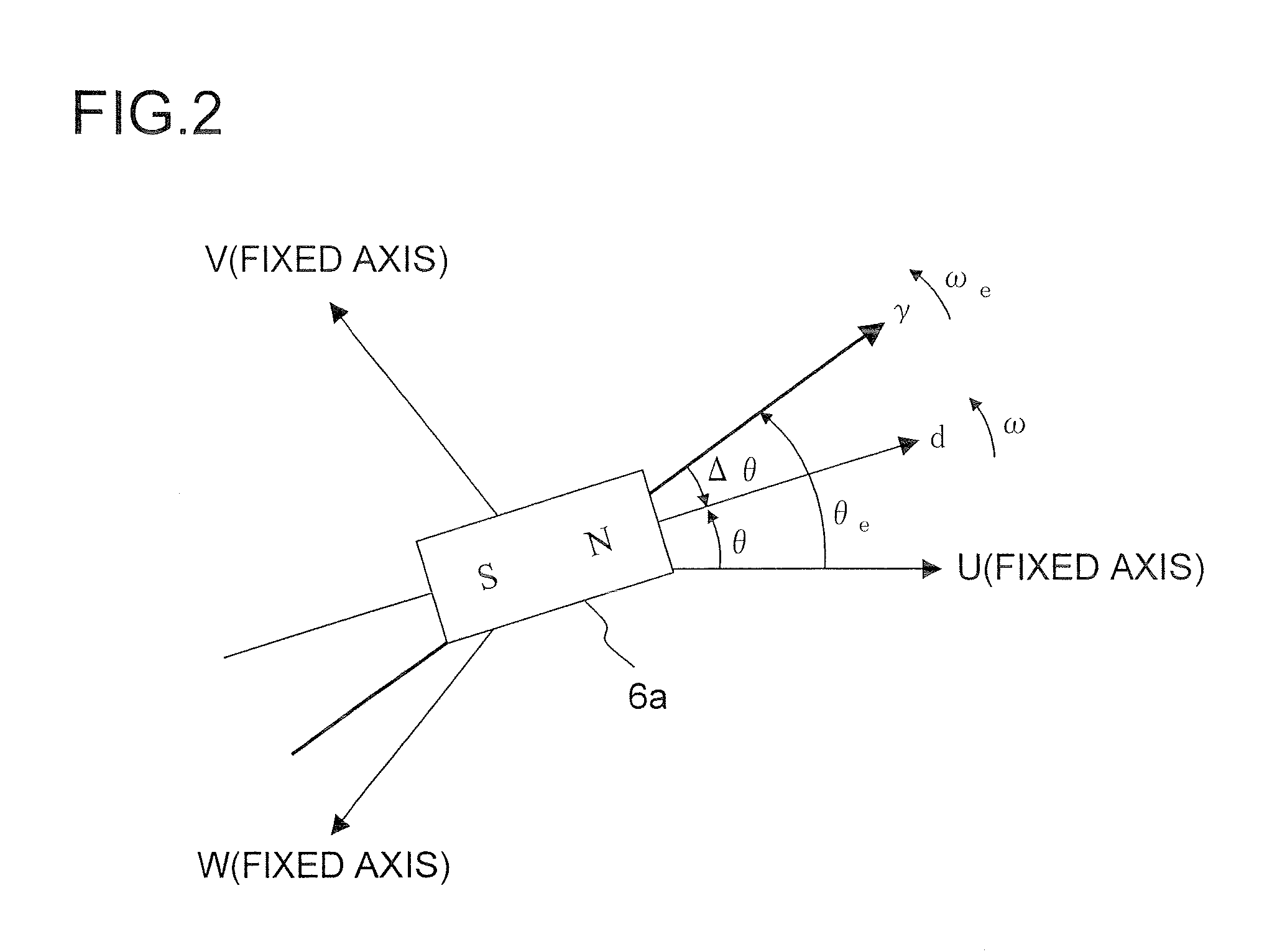

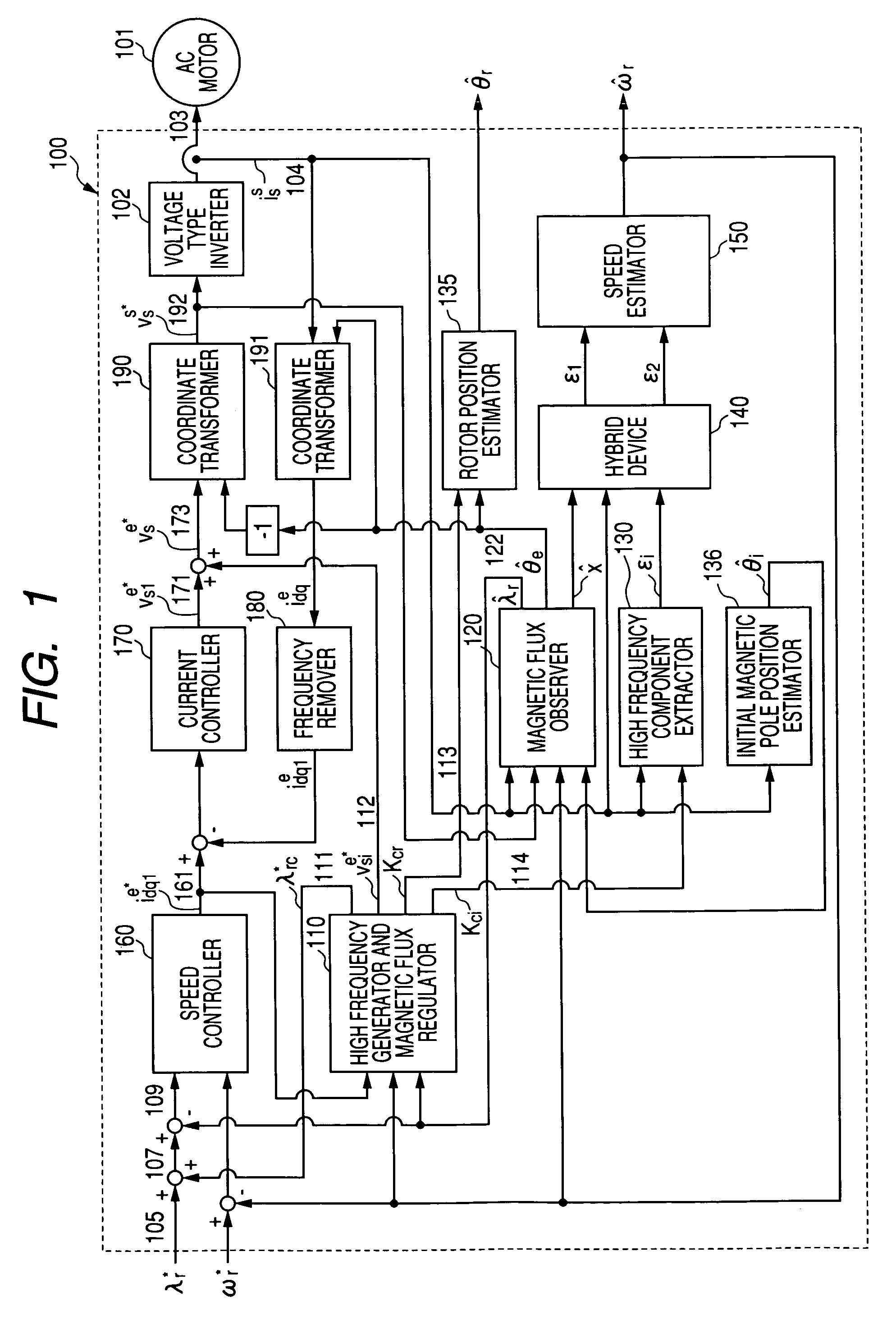

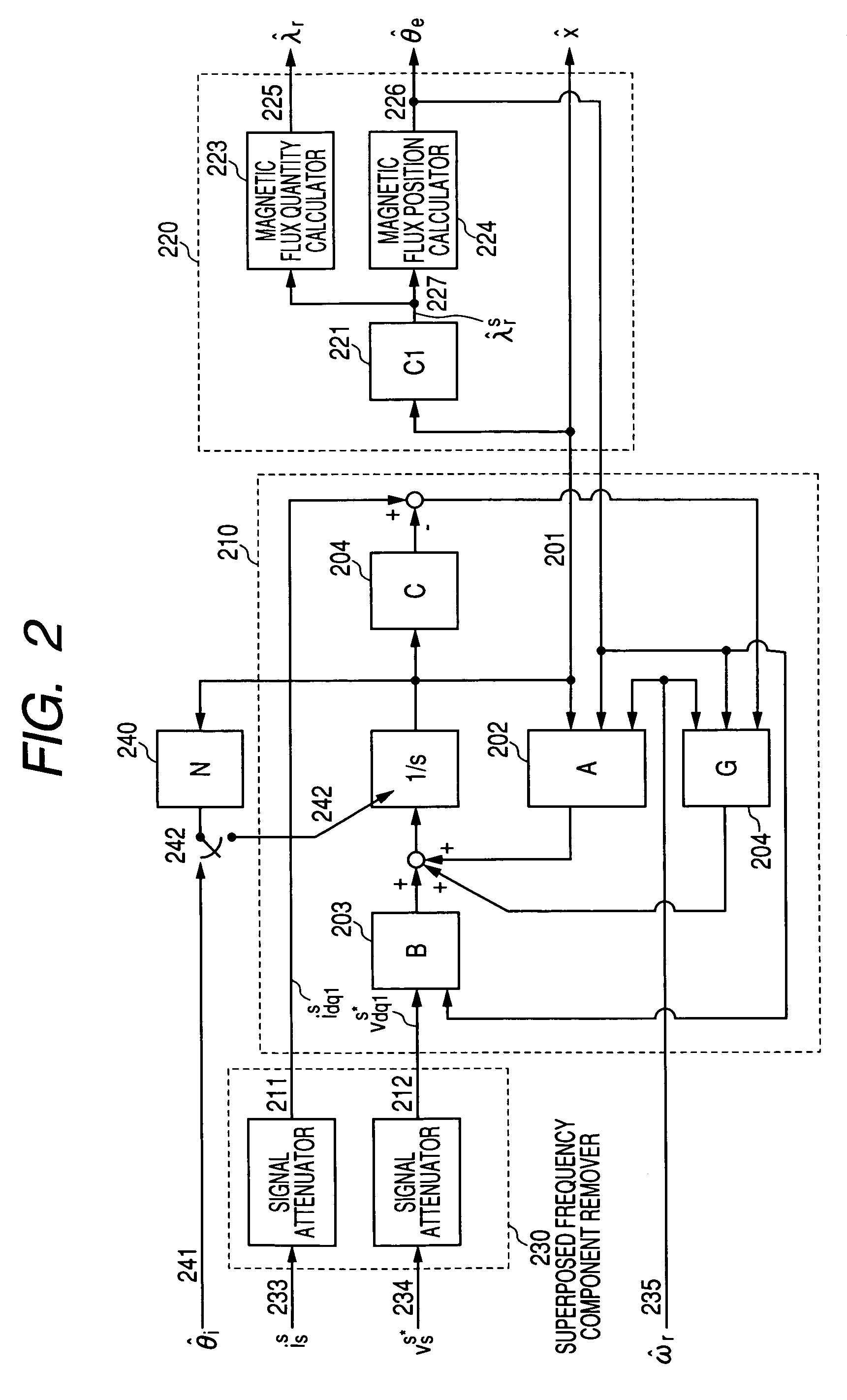

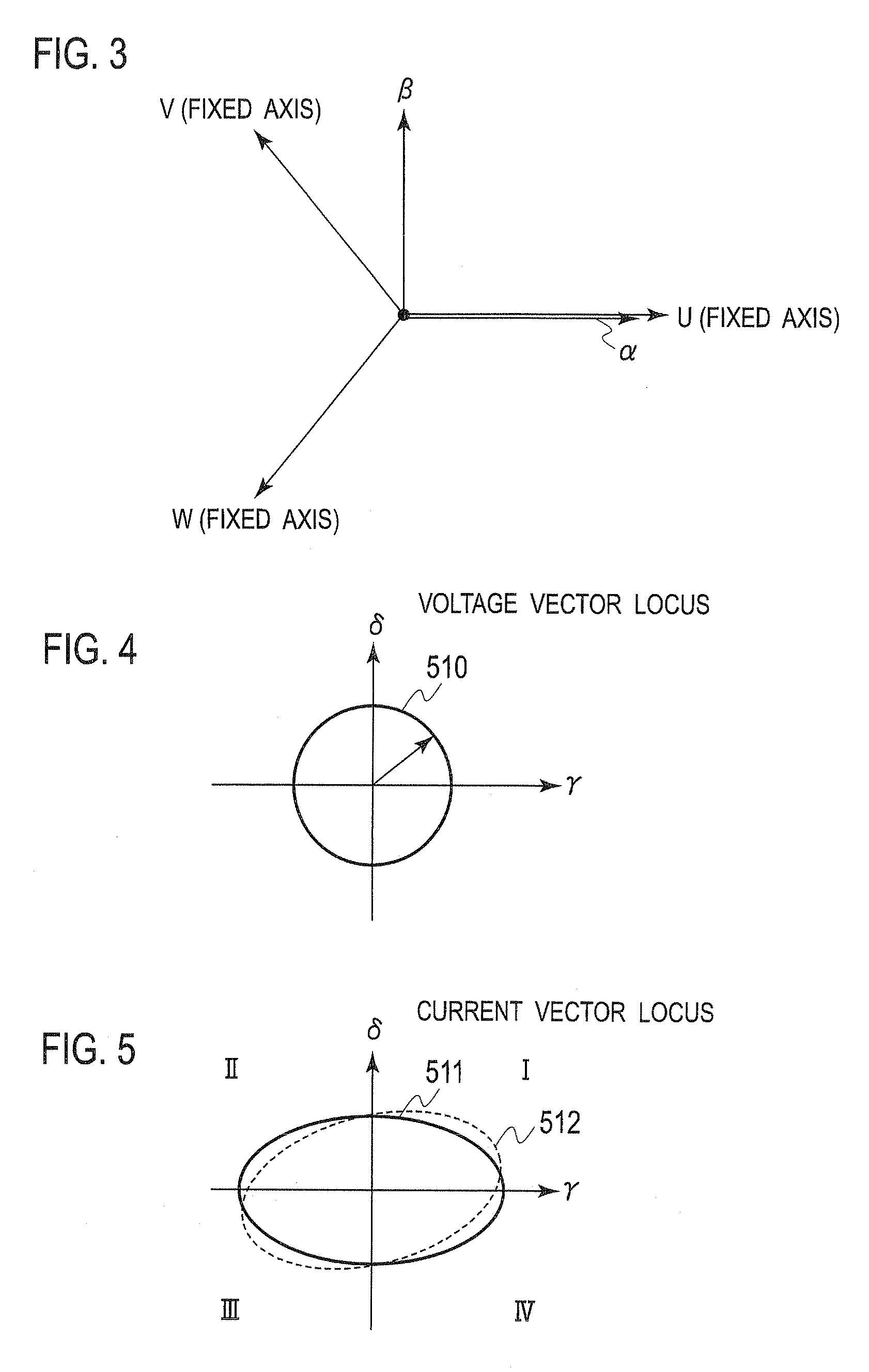

Sensorless controller of AC motor and control method

InactiveUS7045988B2Improve efficiencyMagnetic saliency at the high frequency is reducedVector control systemsSingle motor speed/torque controlLow speedSignal on

Owner:YASKAWA DENKI KK

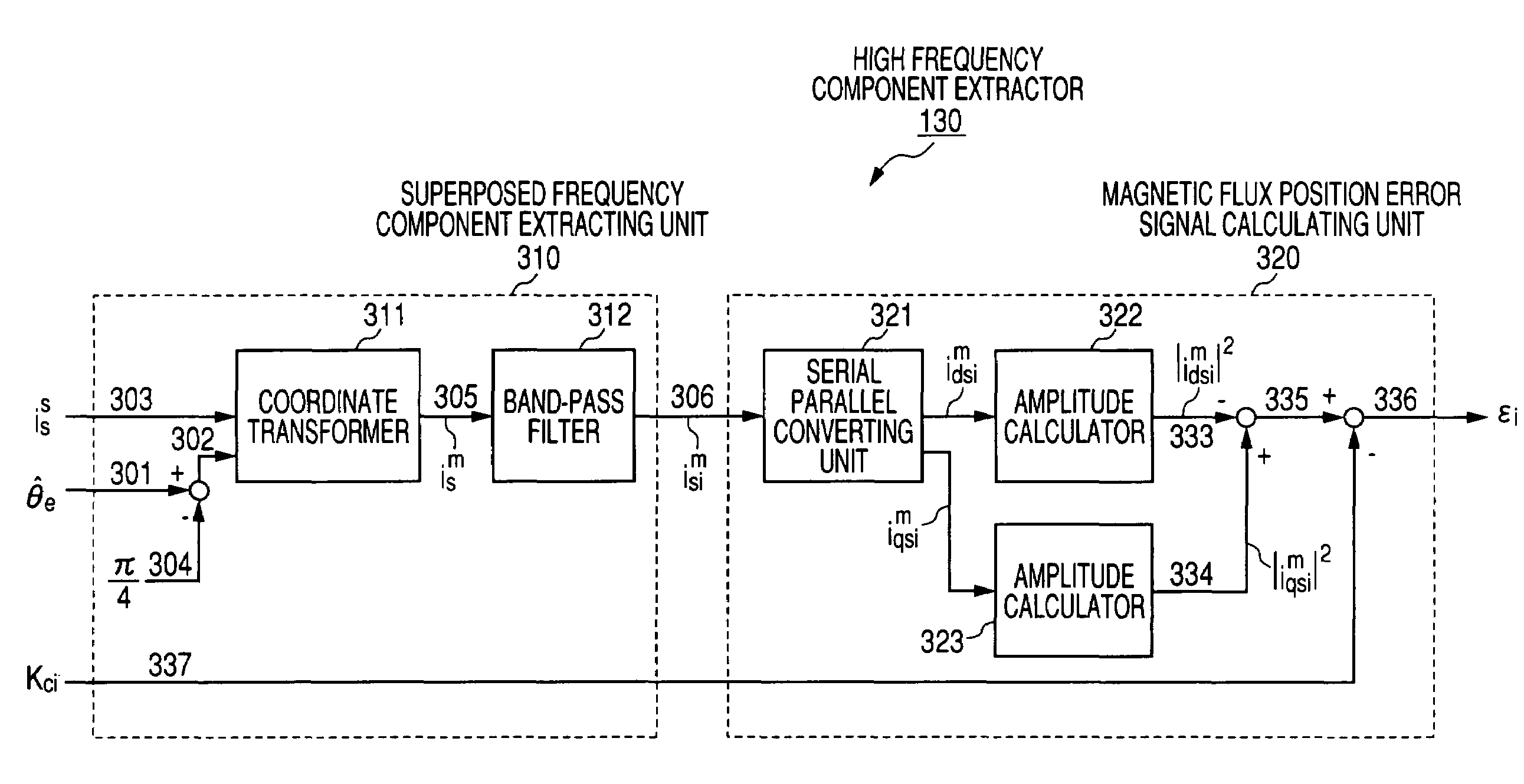

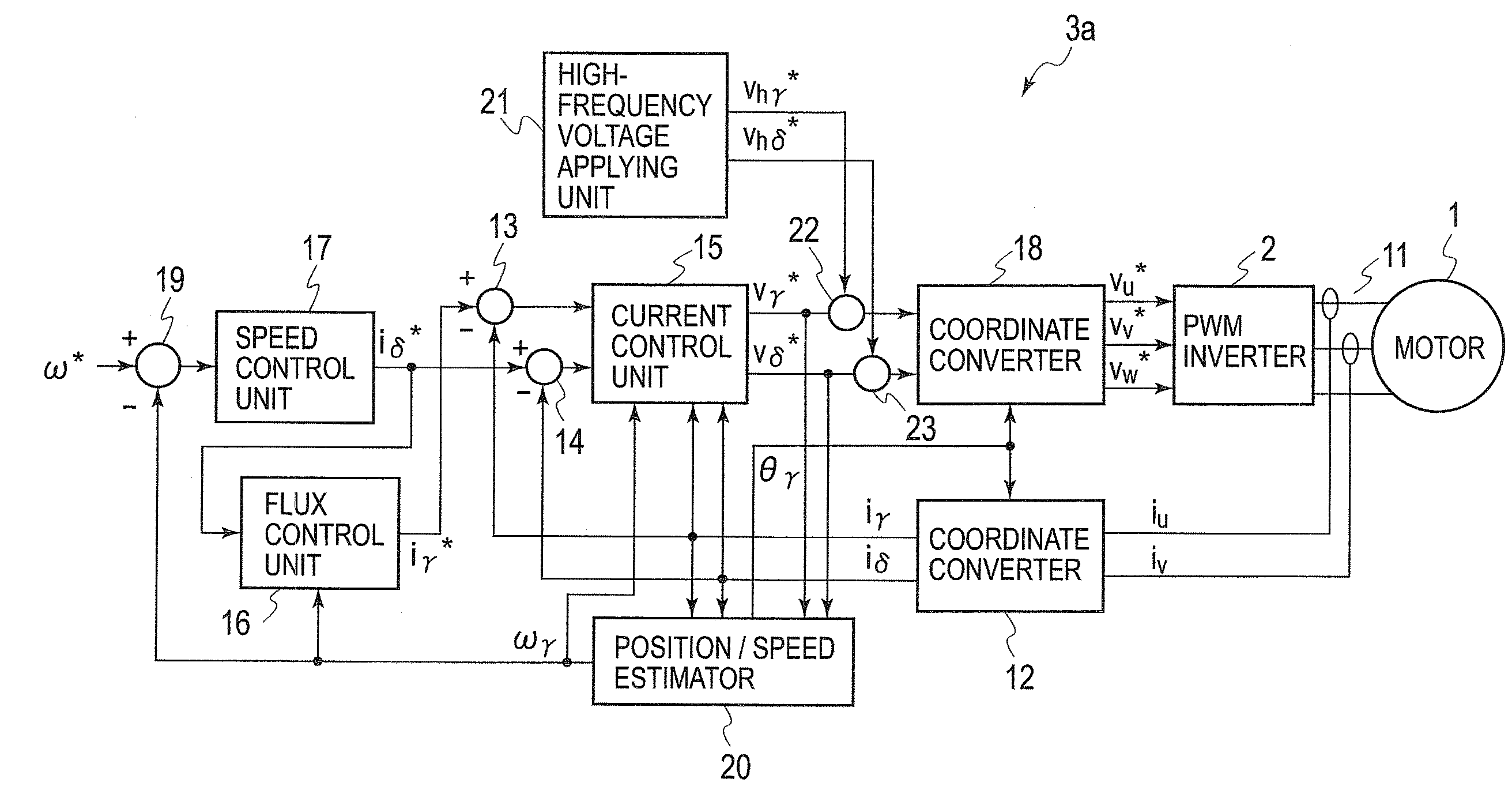

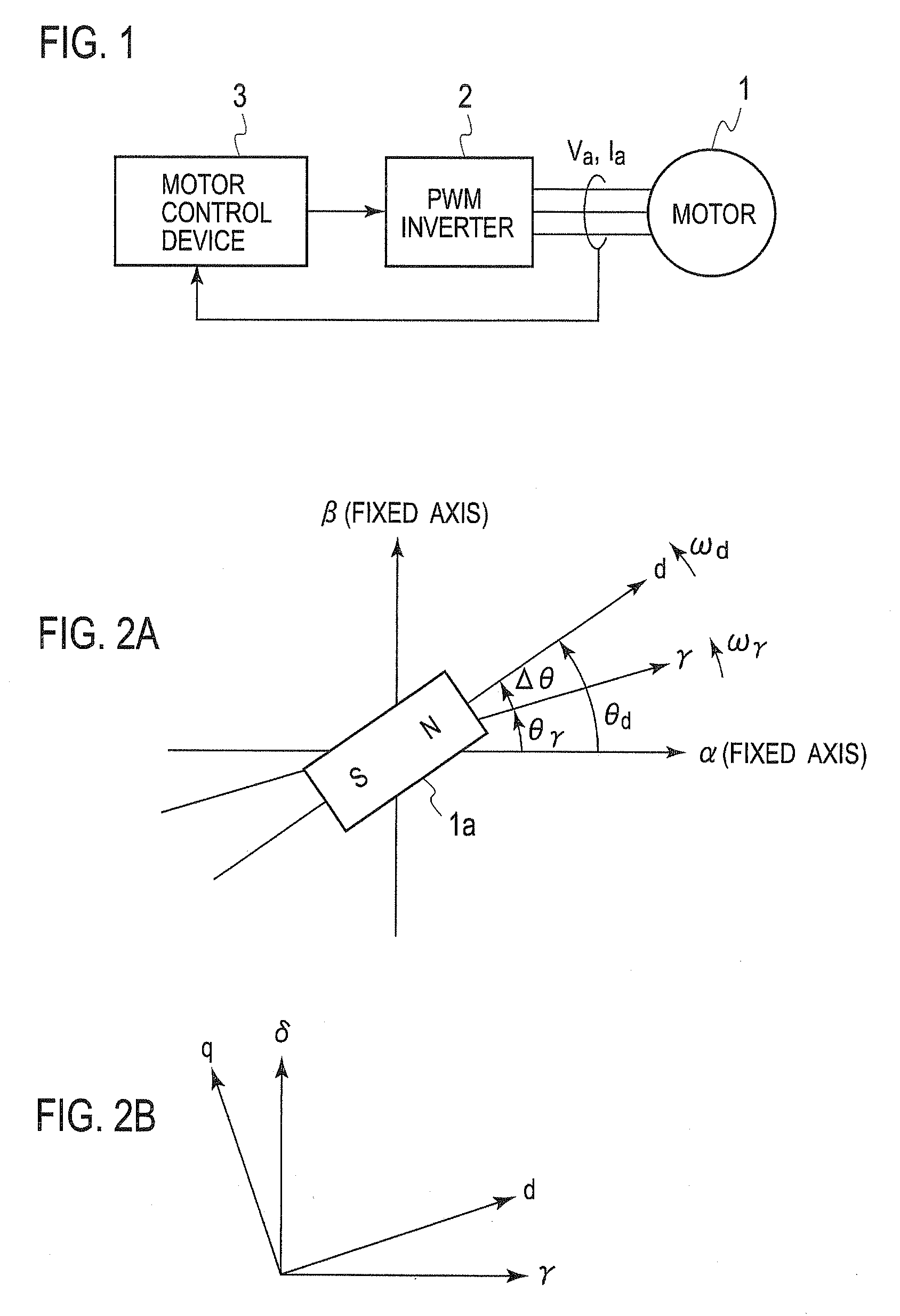

Motor Control Device

ActiveUS20100045218A1Stable positionShort amount of timeSynchronous motors startersVector control systemsMagnetic polesEngineering

To estimate an initial magnetic pole position in a short time, estimated axes for control that correspond to the d-axis and the q-axis are set as the γ-axis and the d-axis, and a high frequency rotation voltage or alternating voltage on the γδ coordinate system is applied to the motor. A high frequency current ih that flows in the motor due to the application of the high frequency voltage is extracted from a detected motor current (armature current) and a direct current component (ihγ×ihd)DC of a product of the γ-axis and d-axis components of the high frequency current ih is derived. On the other hand, the γ′-axis component ichγ and the δ′-axis component ichd of the high frequency current ih that are shifted by p / 4 in electric angle from the γ-axis and the d-axis are obtained and a direct current component of their product (ichγ×ichd)DC is obtained. Thereafter, the magnetic pole position is estimated by computing the axial error Δθ between the γ-d axes utilizing the two direct current components.

Owner:SANYO ELECTRIC CO LTD

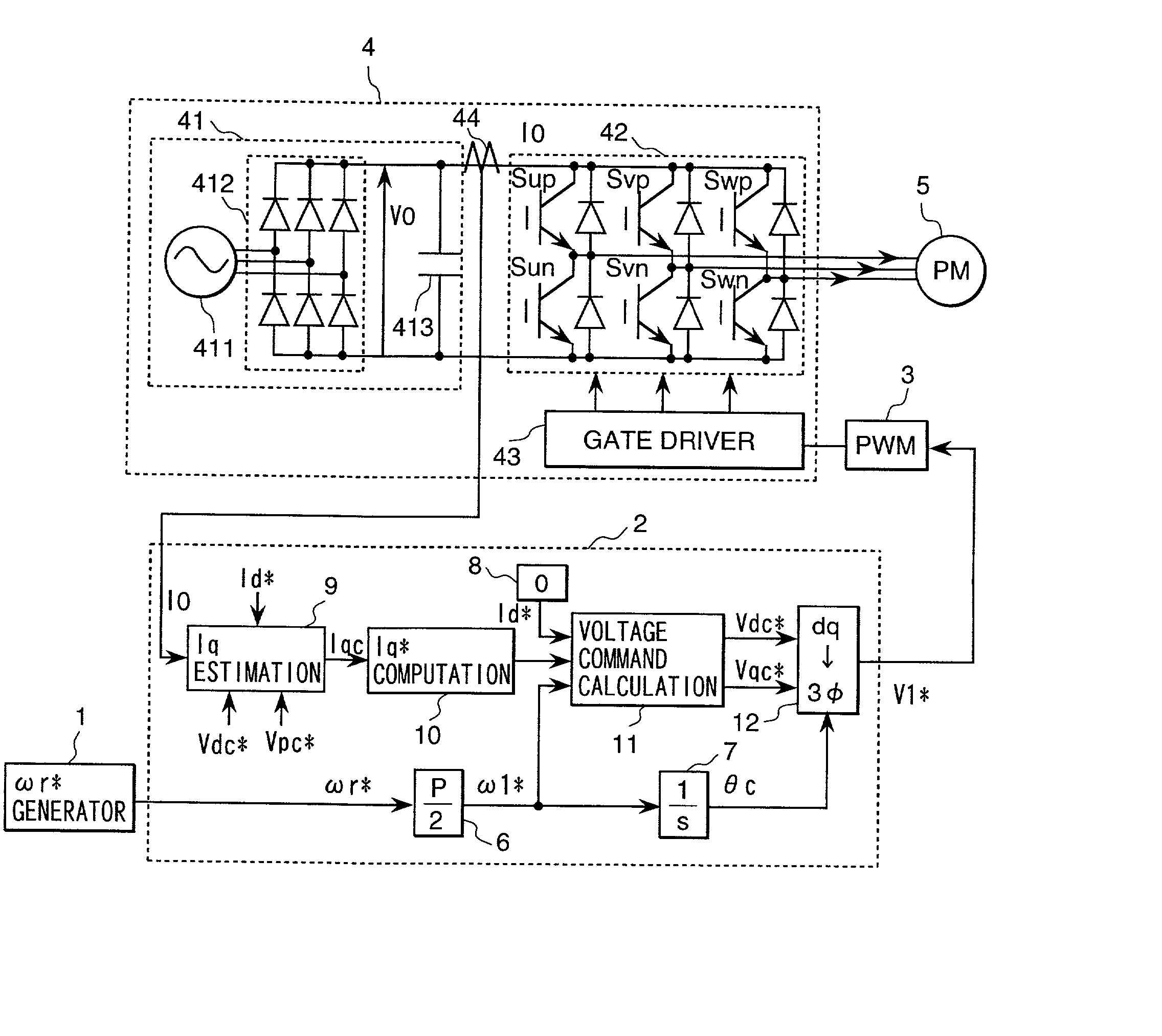

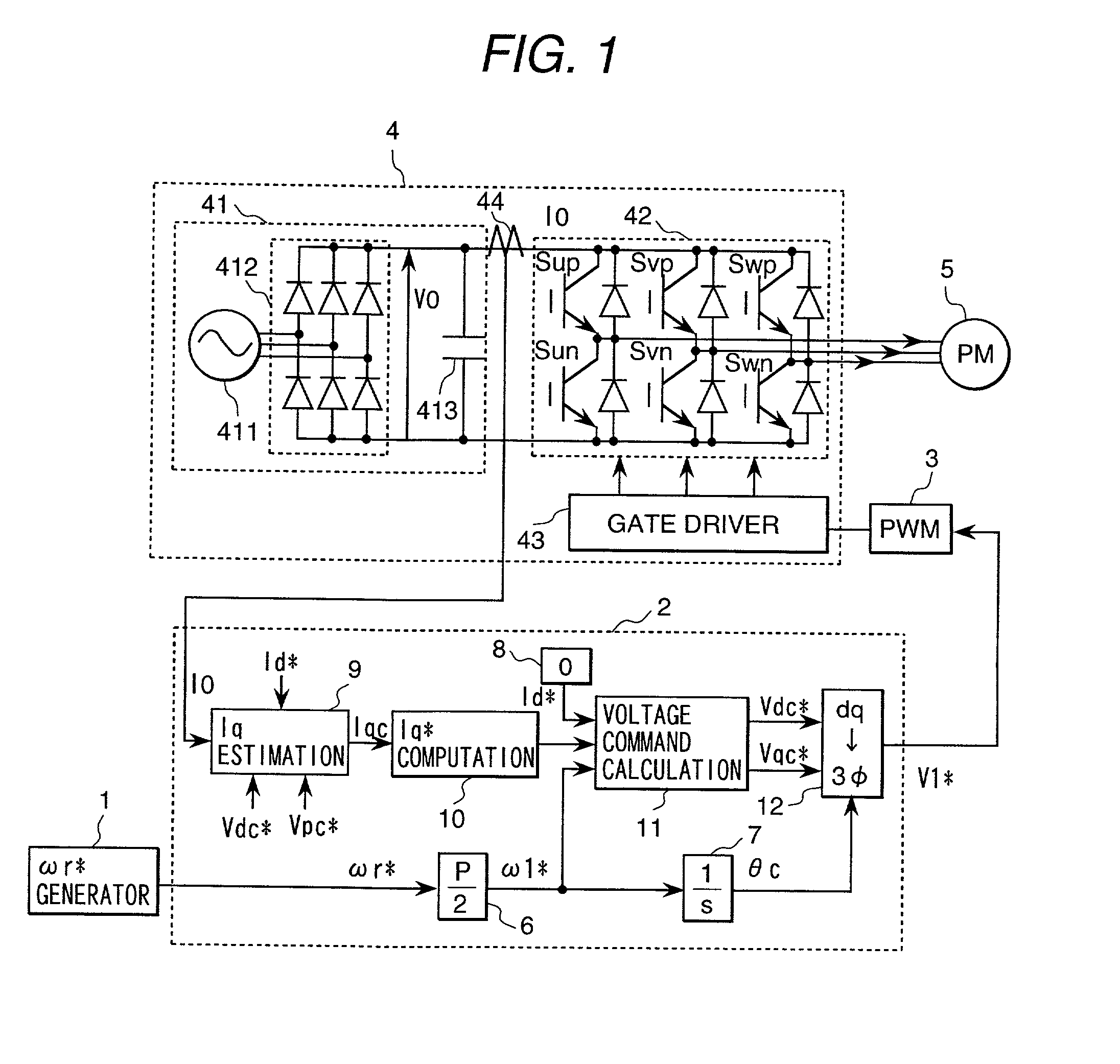

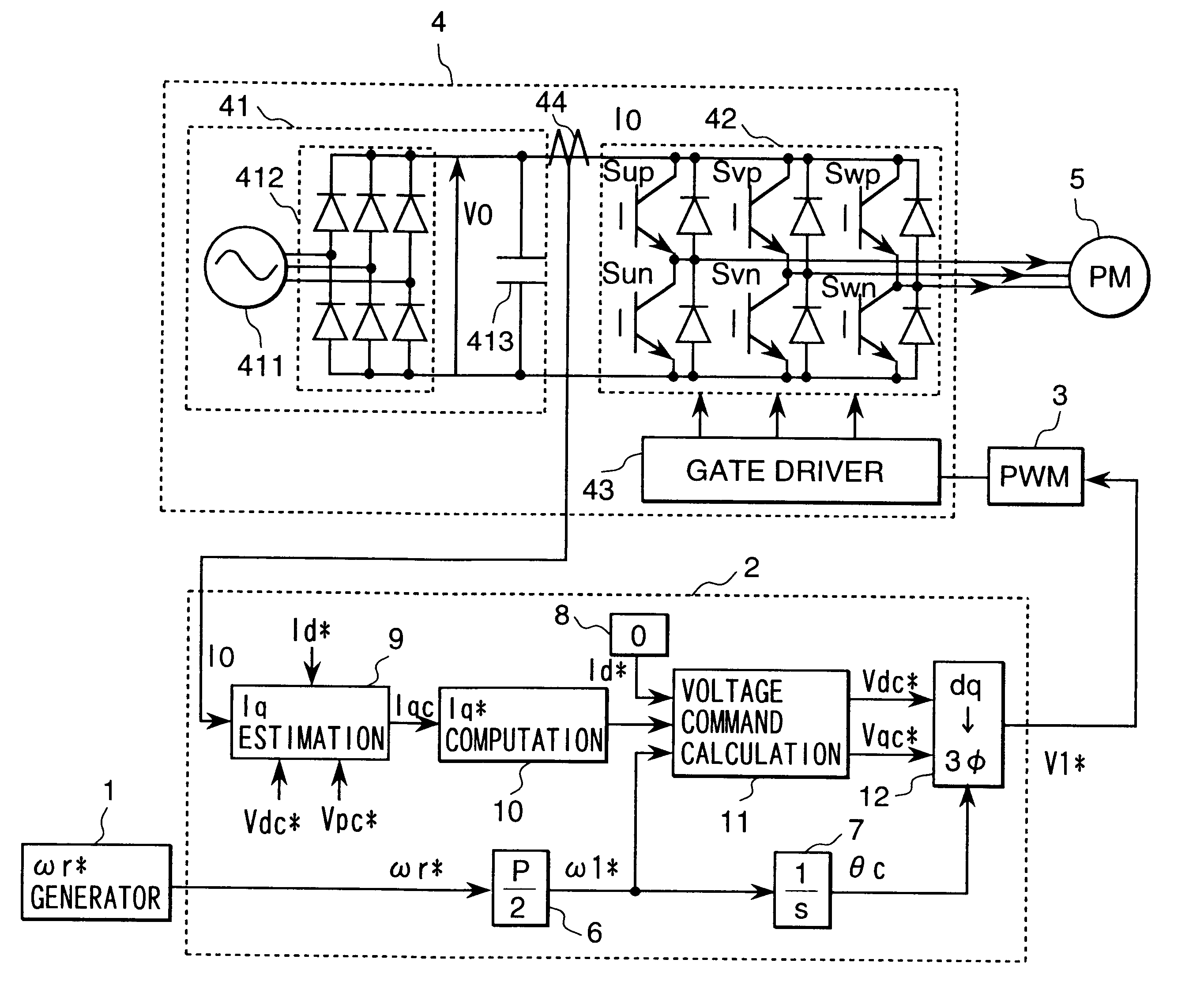

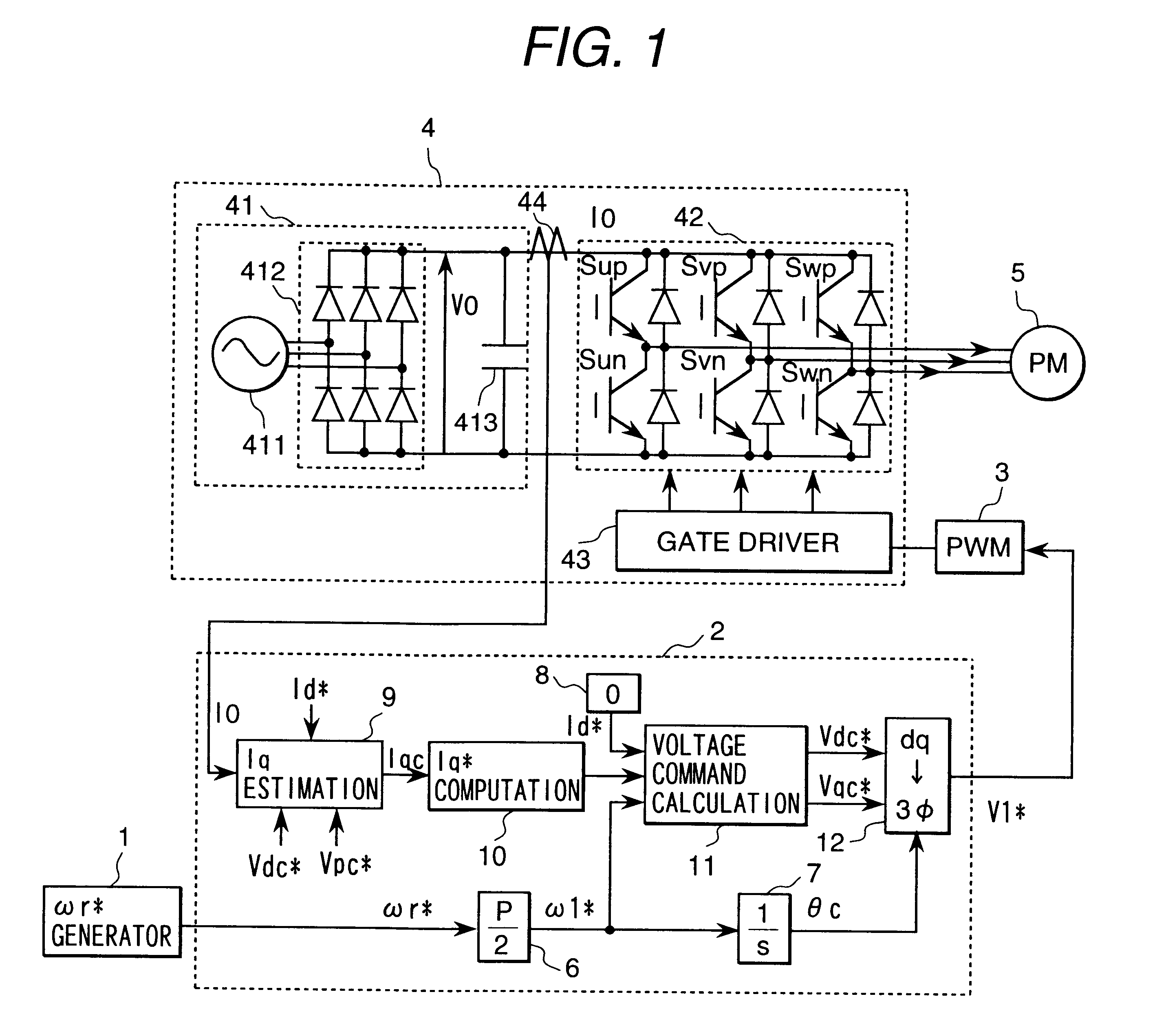

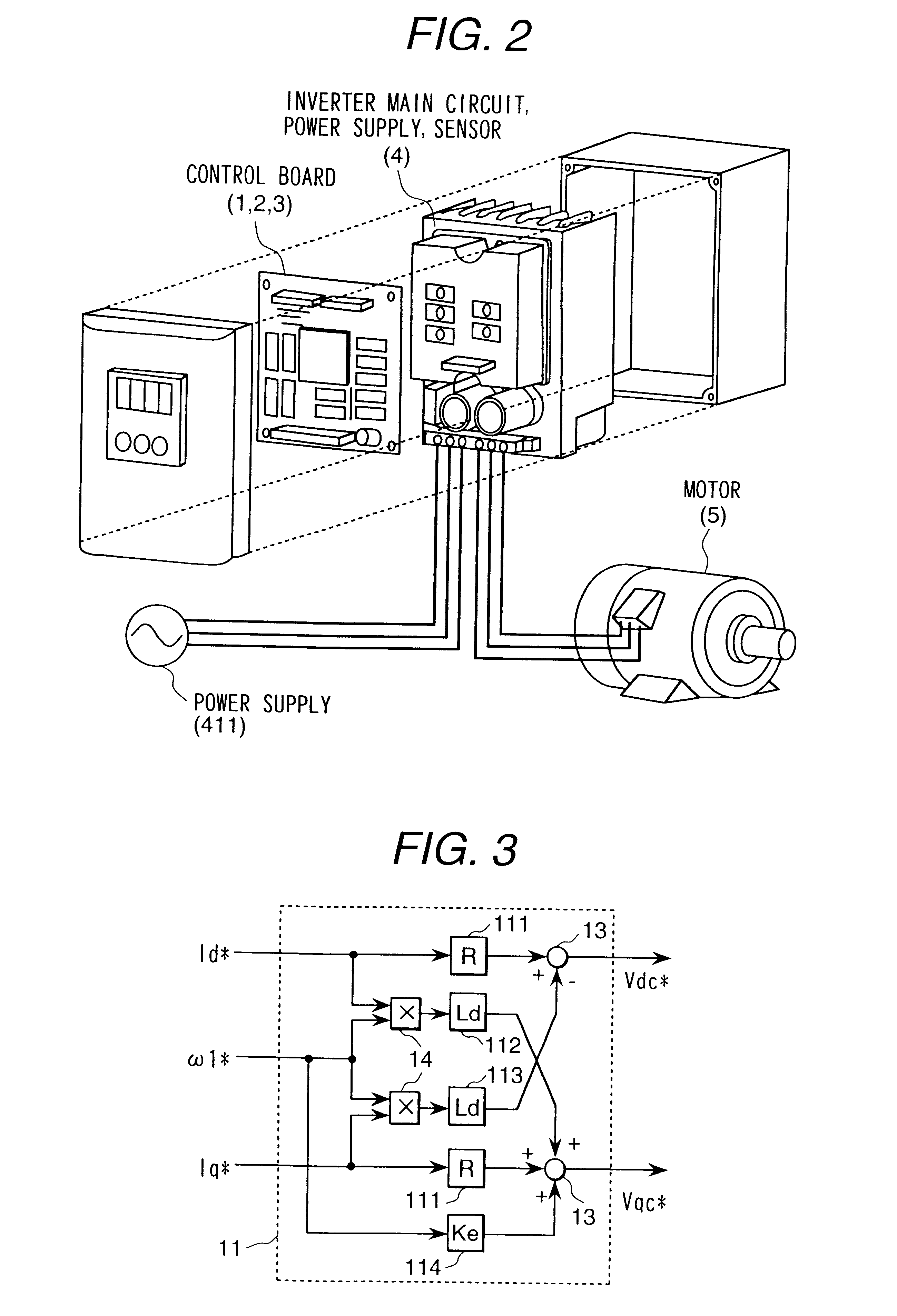

Sensorless control system for synchronous motor

InactiveUS20030030404A1DC motor speed/torque controlSynchronous motors startersSynchronous motorDc current

A synchronous motor drive system in accordance with the present invention detects a DC current of an inverter which drives a synchronous motor, and based on the magnitude of the current, estimates torque current components that flow through the motor, and then based on the estimated value, determines the voltage which is applied to the motor, and finally estimates and computes the magnetic pole axis located inside the motor using the estimated value of the torque current.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Power tool

InactiveUS7007762B2Increase efficiency of output torqueEasy to operateDrilling rodsConstructionsBrushless motorsEngineering

It is an object of the present invention to provide a technique to increase efficiency of the output torque of the blushless motor to drive a power tool. A representative power tool may comprise a tool bit, a brushless motor to drive the tool bit, a battery to operate the brushless motor and a control device. The control device may operate the brushless motor by means of the battery. The control device may include an advance angle controlling section to control an advance angle of the brushless motor. According to the present teachings, the advance angle of the brushless motor may be determined based upon indexes that reflect working condition of the tool bit when the brushless motor is under the operation. By reflecting the working condition of the tool bit to the determination of the advance angle of the brushless motor, the brushless motor can be operated with higher efficiency under the various working condition such as a hard joint operation and a soft joint operation.

Owner:MAKITA CORP

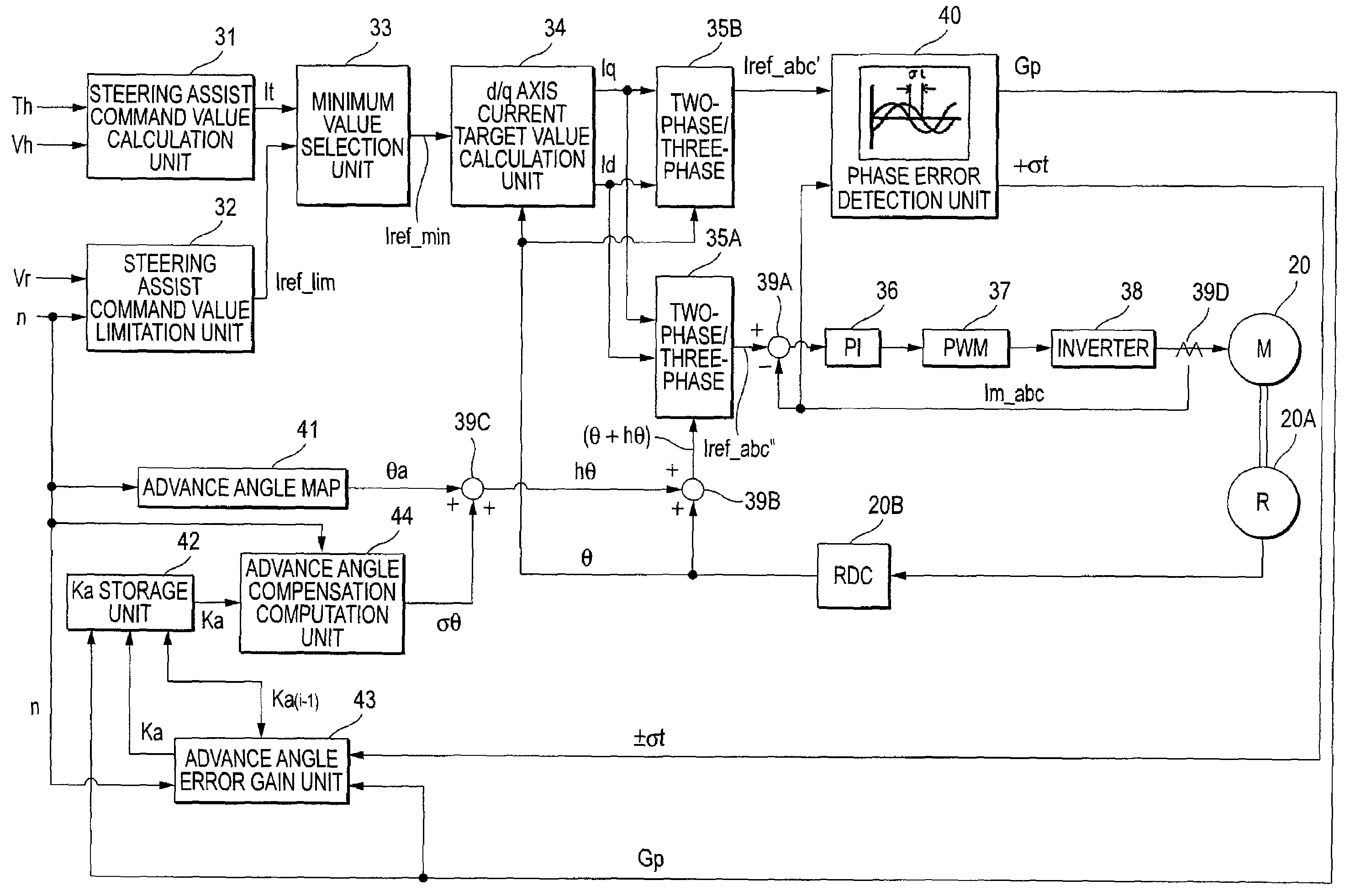

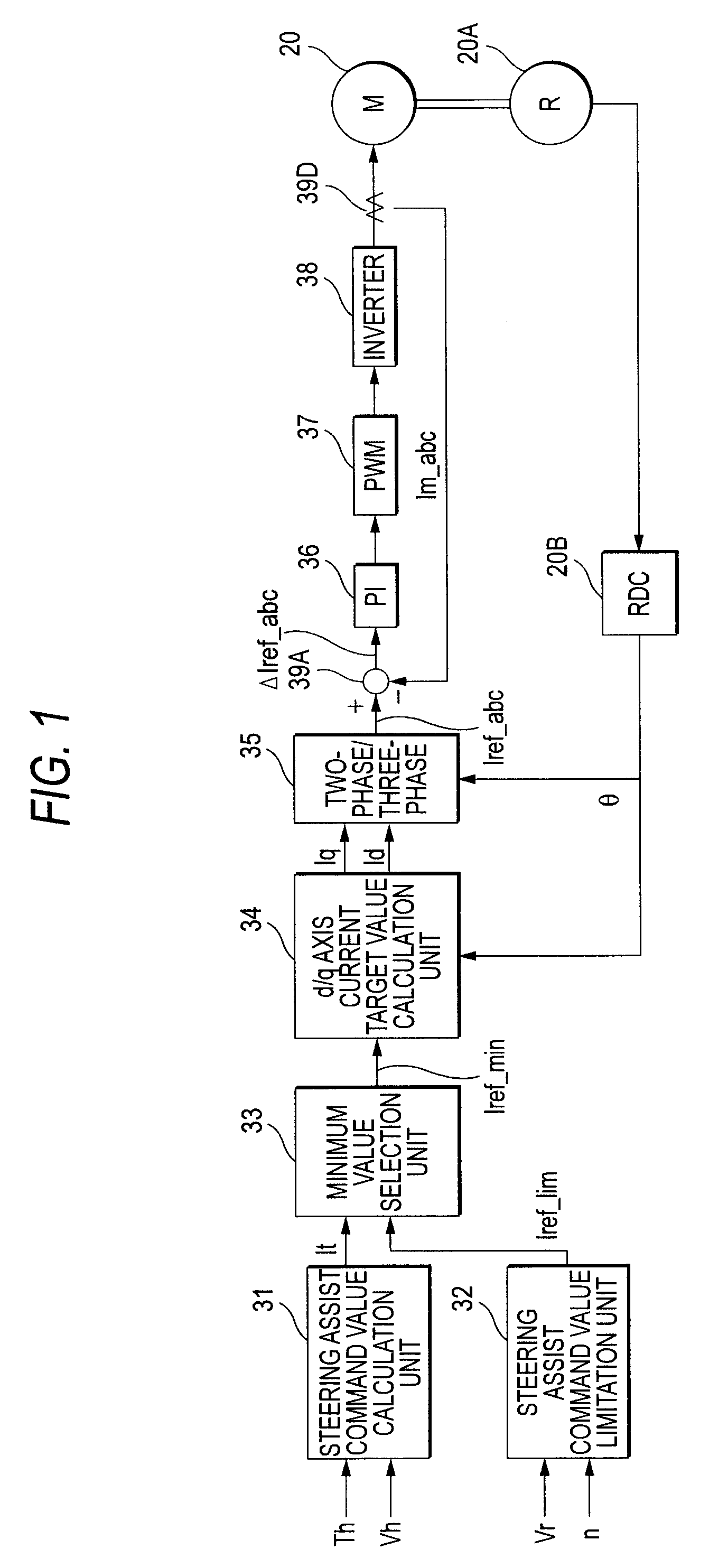

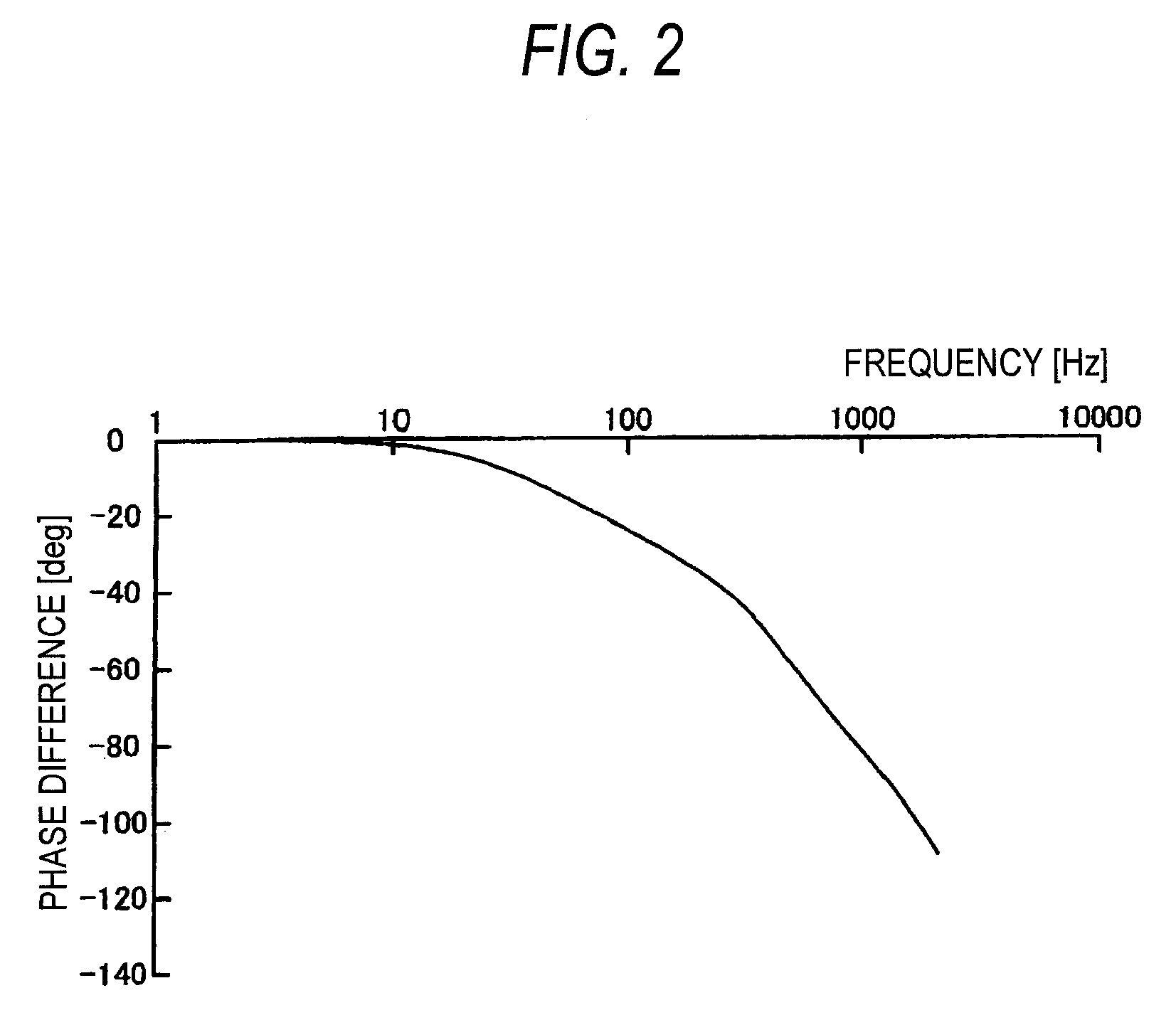

Control device for electric power steering apparatus

InactiveUS20080201041A1Reliable compensationPhase differenceTemperatue controlSingle motor speed/torque controlElectric power steeringControl vector

A control device for an electric power steering apparatus includes a control unit which controls a motor giving steering assist force to a steering system according to a current command value computed based on steering toque and vehicle speed in a vector control manner and an advance angle map for compensating for a phase lag occurring in a motor current relative to the current command value. Advance angle compensation is made for the current command value based on the advance angle map.

Owner:NSK LTD

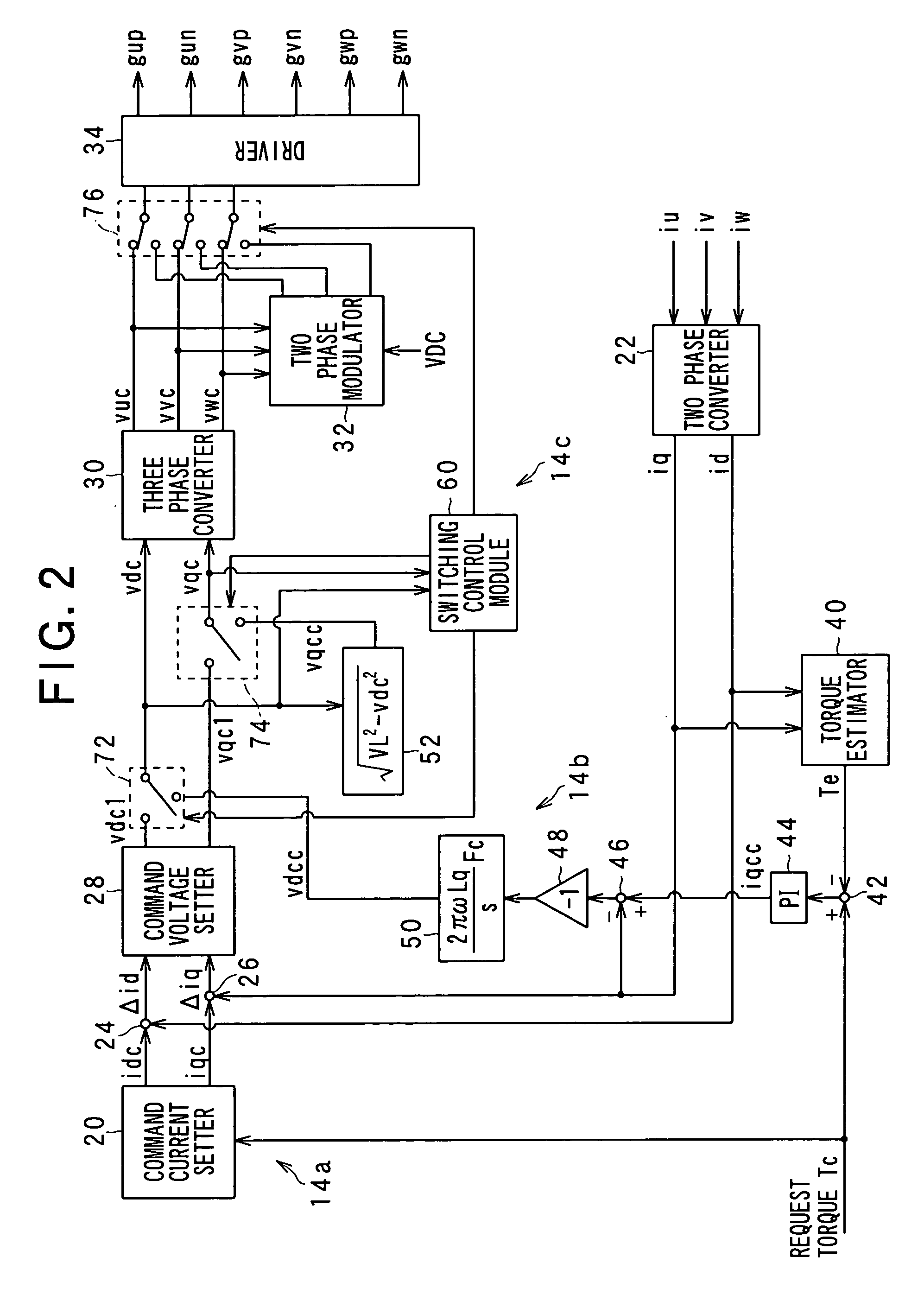

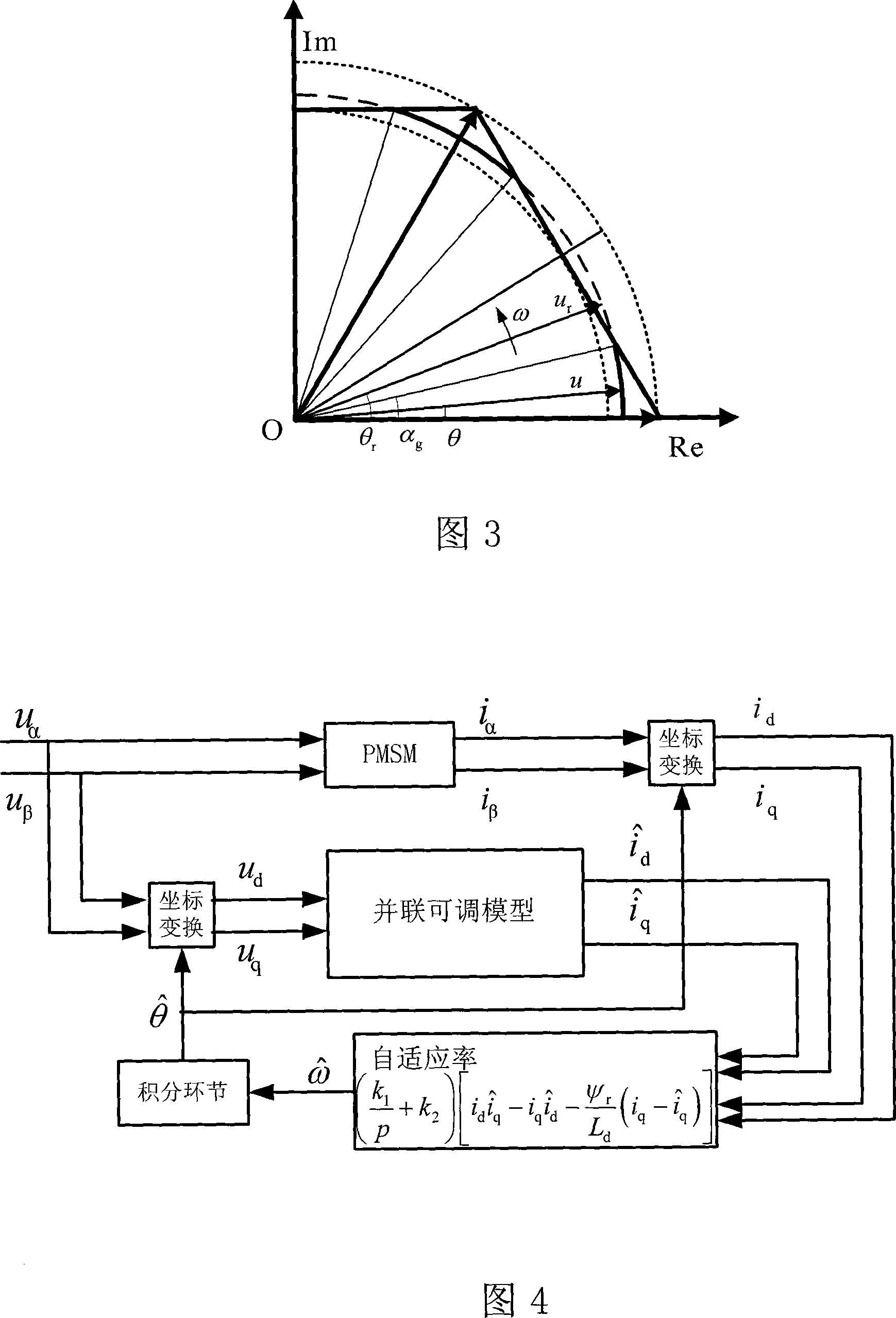

Apparatus for carrying out improved control of rotary machine

ActiveUS20090322264A1Easy maintenanceHigh levelCommutation monitoringDC motor speed/torque controlControl variableVoltage

In an apparatus, a first drive unit drives, in a first range of a voltage utilization factor, a switching member to thereby control an output voltage of the power converter to be matched with a command voltage. A second drive unit drives, in a second range of the voltage utilization factor, the switching member to thereby generate a value of a controlled variable of a rotary machine. The second range of the voltage utilization factor is higher than the first range thereof. An estimating unit estimates, during the switching member being driven by the second drive unit, a value of a parameter associated with the output voltage of the power converter. The estimated value is required for the first drive unit to generate the value of the controlled variable generated by the second drive unit.

Owner:DENSO CORP

Sensorless control system for synchronous motor

InactiveUS6690137B2DC motor speed/torque controlSynchronous motors startersSynchronous motorControl system

A synchronous motor drive system in accordance with the present invention detects a DC current of an inverter which drives a synchronous motor, and based on the magnitude of the current, estimates torque current components that flow through the motor, and then based on the estimated value, determines the voltage which is applied to the motor, and finally estimates and computes the magnetic pole axis located inside the motor using the estimated value of the torque current.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

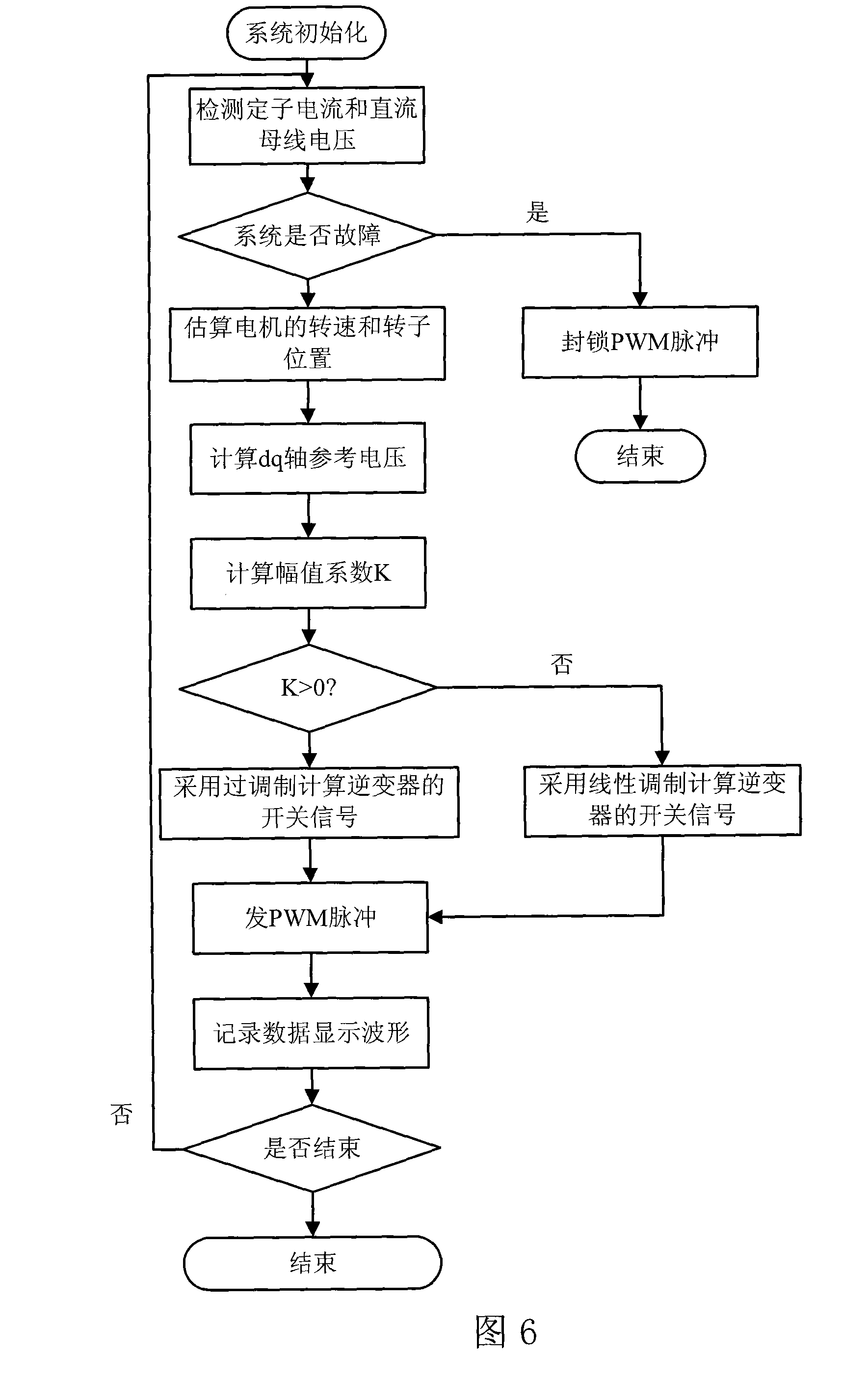

Permanent magnetism synchronous electric machine - compressor system high speed operation control method

InactiveCN101252336AImprove voltage utilizationAC motor controlVector control systemsPhase currentsSynchronous motor

Disclosed is a high-speed control method for a permanent magnet synchronous motor-compressor system, including the following steps: initial design is carried out; a motor is detected through DSP, including detecting the two-phase current of the stator of the motor, the voltage Udc of a DC generatrix; the voltage of a d-p shaft is calculated; faults of overcurrent, overpressure and undervoltage are detected; if any fault exists, the PWM pulse signals are blocked and then the control program is paused; if no fault exists, the following steps will be carried out; the rotating speed of the motor and the position of the rotor are identified in the process of speed-position estimation; the current and the voltage of the reference d-q shaft of the motor are calculated; switching signals of an inverter are acquired through haplotype over-modulation; the data are recorded and waveforms are displayed; judgment of whether to pause the control program is carried out; if not, the second step is carried out again; if yes, the control program will be paused. The control method applies haplotype over-modulation method into the permanent magnet synchronous motor-compressor system, realizing sensorless over-modulation to the synchronous motor-compressor vector control system.

Owner:TSINGHUA UNIV

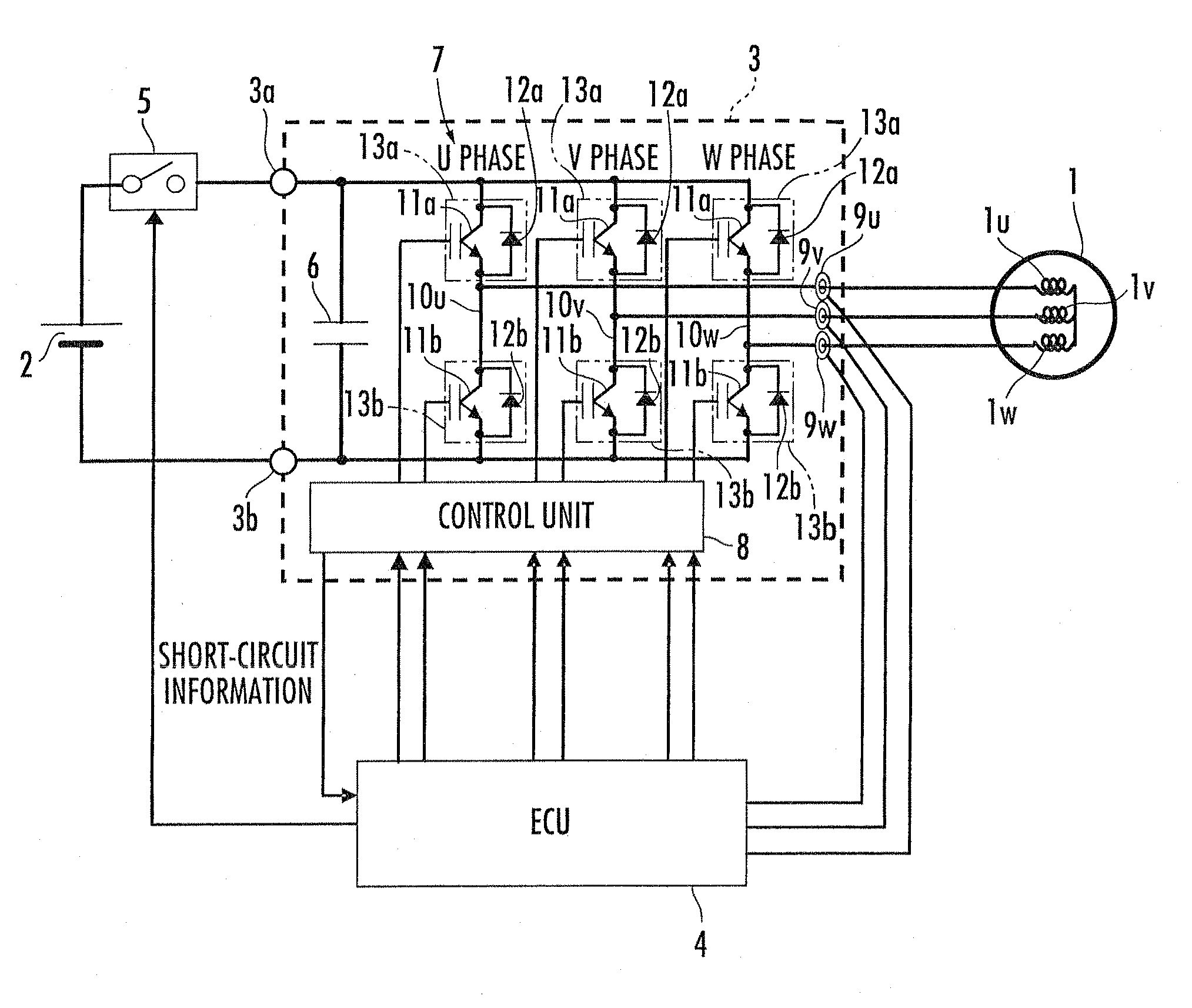

Controller for motor, and vehicle

InactiveUS20100036555A1More currentHigh currentCommutation monitoringSingle motor speed/torque controlElectrical polarityEngineering

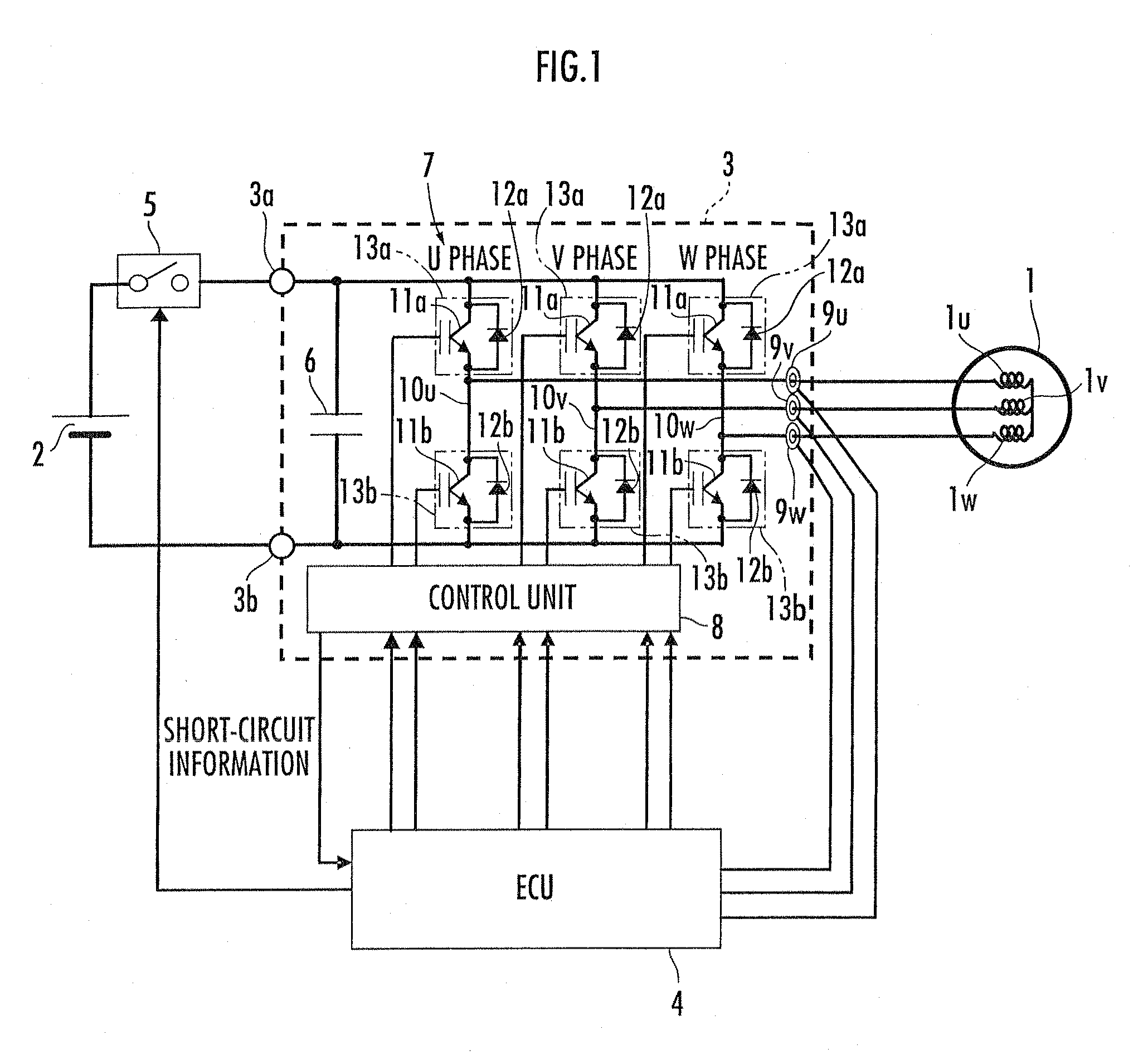

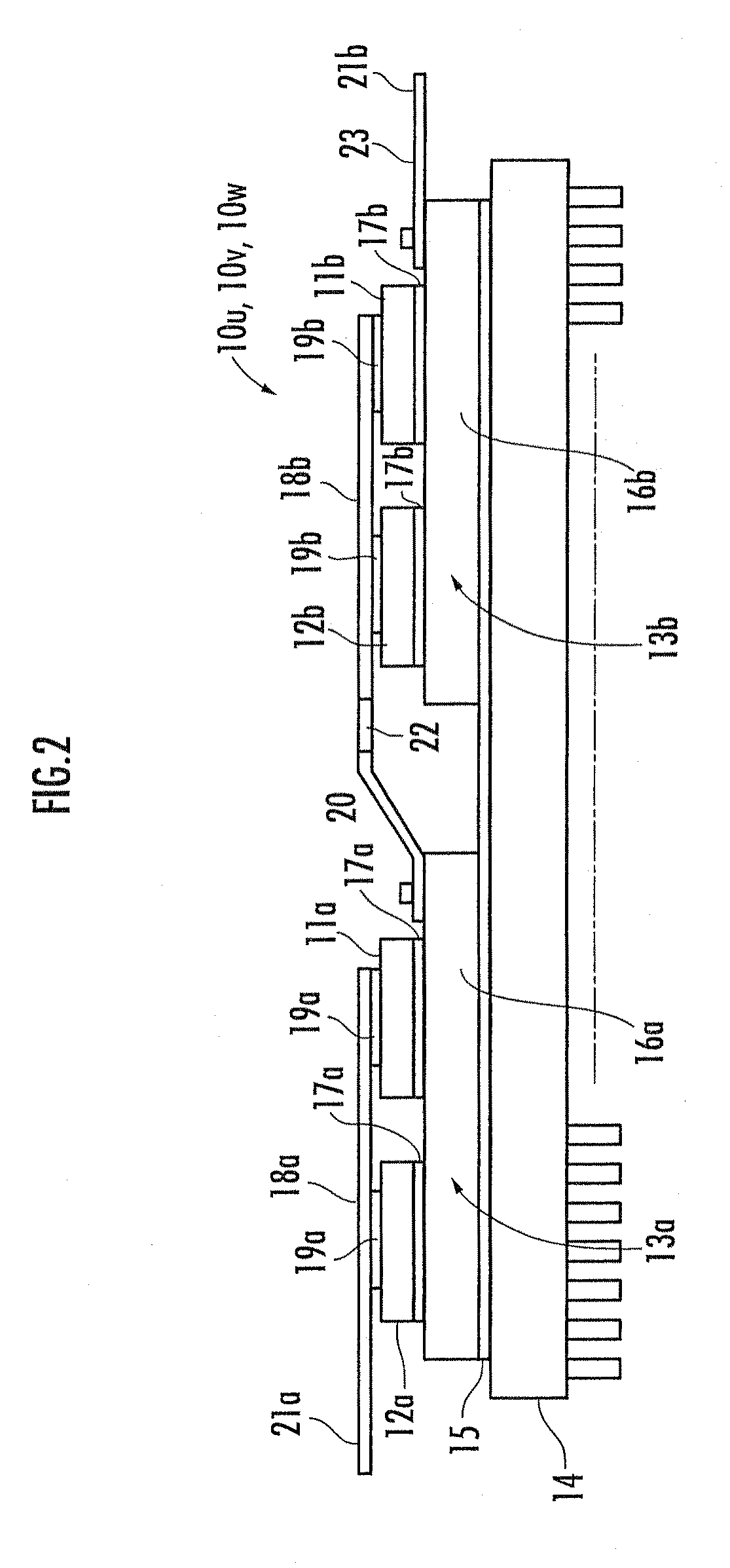

When a short-circuit failure of any of switch portions (13) including switch elements (11) and parallel-connected feedback diodes (12) of an inverter circuit (7) is detected during the operation of a motor (1), a switch portion (13) where the short-circuit failure has occurred is checked for whether it is on the positive polarity side or the negative polarity side. The switch elements (11) are so controlled that all the switch portions (13) on the same polarity side as where the short-circuit has occurred are brought into a conducted state and all the others disconnected. This prevents a large electric current from flowing into each switch portion of the inverter circuit without requiring any switch to block the power distribution between a motor and the inverter circuit when a short-circuit failure of the switch portion of the inverter circuit occurs.

Owner:HONDA MOTOR CO LTD

Rotating machinery controller

ActiveUS20080211450A1Reduce power lossVoltage utilization factor is increasedSingle-phase induction motor startersMotor/generator/converter stoppersHysteresisLower limit

A rotating machinery includes a first control member for performing rectangular wave control by operating the switching devices of an inverter such that an on-state and an off-state occur once for one cycle period in electrical angle of a motor, a second control member for operating the switching devices on the basis of a magnitude relation between upper and lower limits of a predetermined hysteresis region and an actual current flowing through the motor, and a switching member for, when the actual current deviates from the hysteresis region while the rectangular wave control is undertaken, switching the control to an instantaneous current value control performed by the second control member.

Owner:DENSO CORP

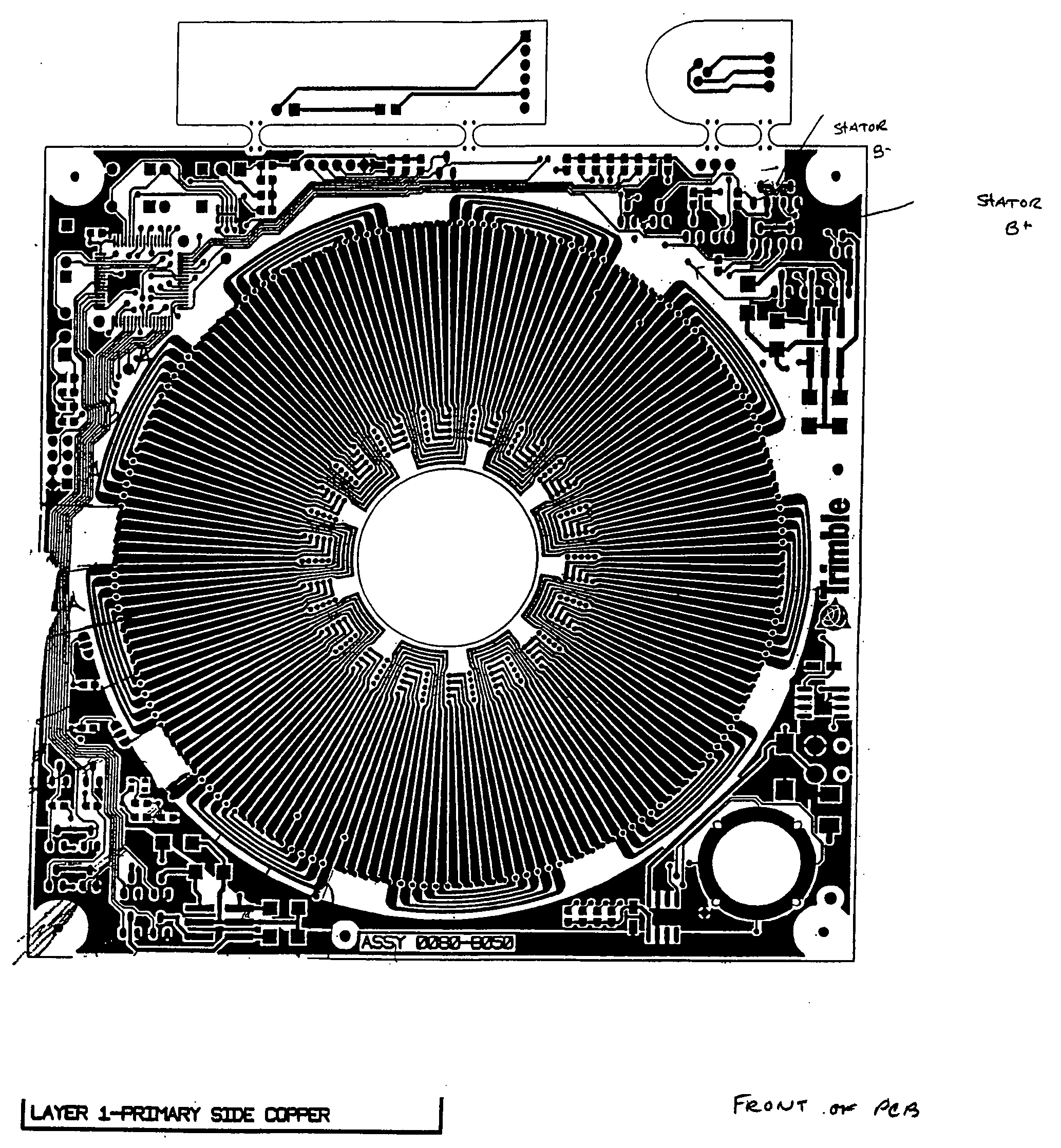

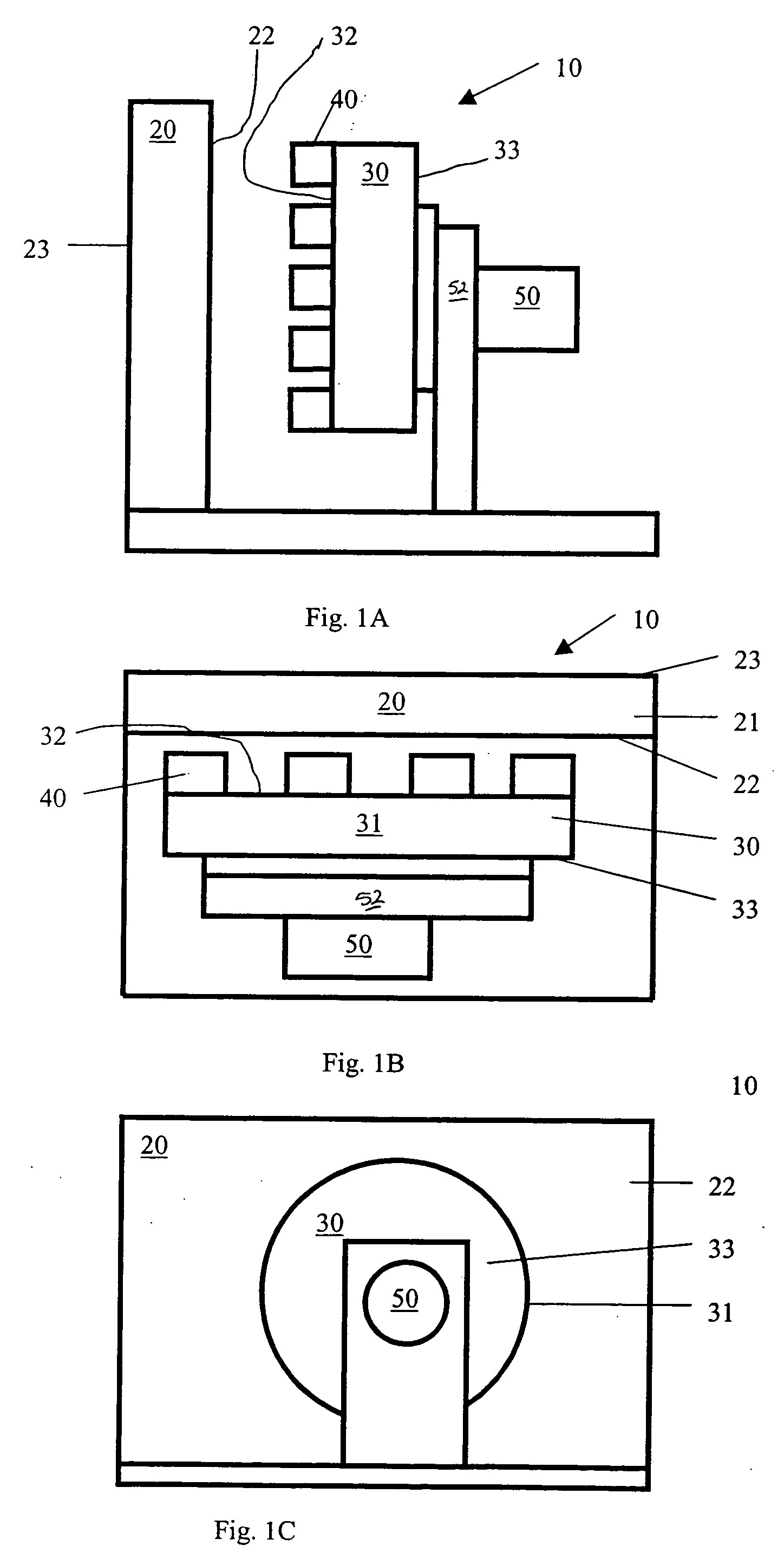

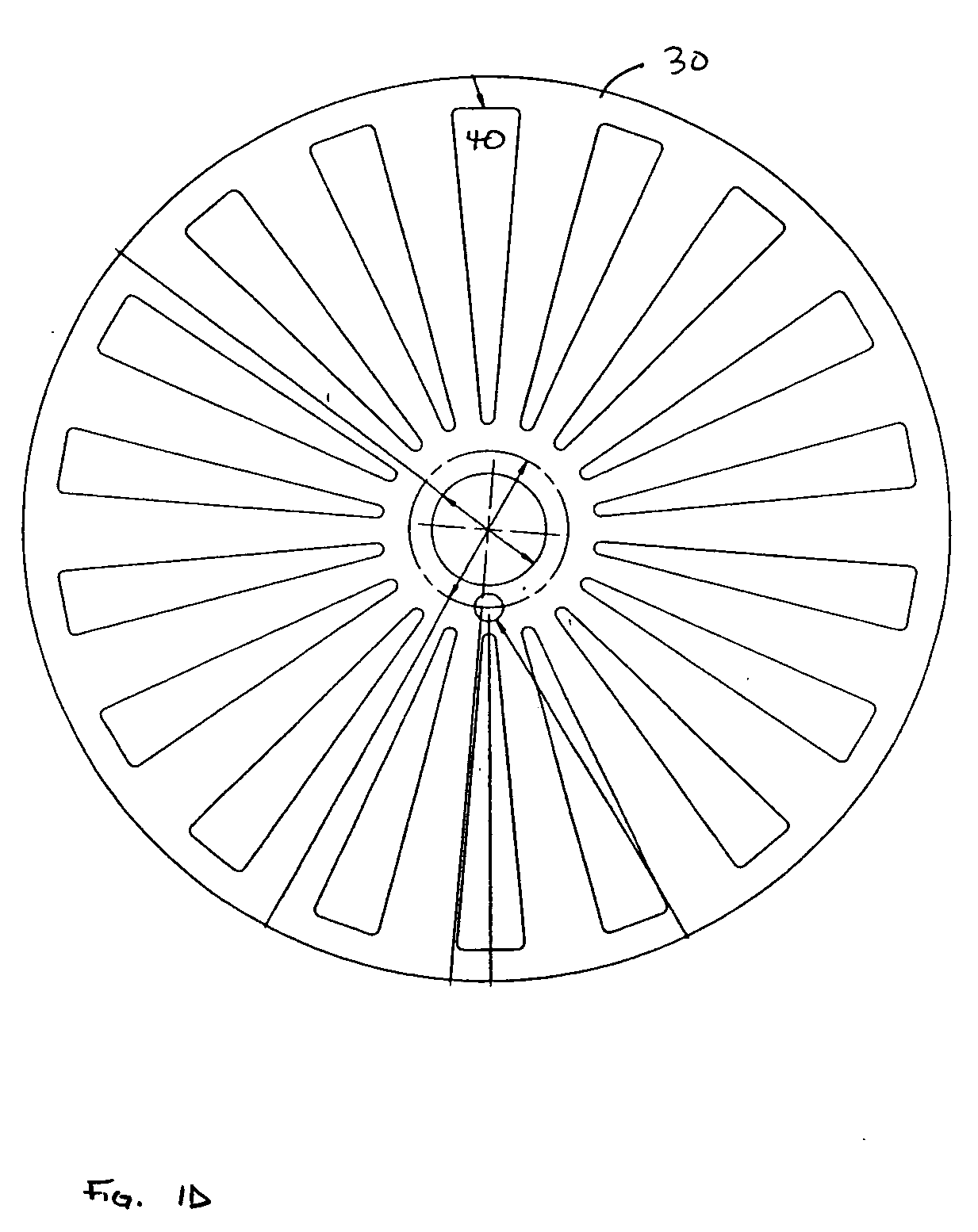

Printed circuit board motor

InactiveUS20060055265A1Easy to controlCurrent consumptionAssociation with control/drive circuitsMagnetic circuit rotating partsElectrical conductorAverage current

A printed circuit board motor is disclosed. The motor comprises a rotor plate embedded with magnets, an axle, and a printed circuit board stator. The printed circuit board comprises two conductors printed on the same surface or on opposite surfaces of the printed circuit board The two conductors produce alternating “square wave” patterns. The printed circuit board circuitry causes the direction of the current flow to reverse at intervals. The rotor rotates in response to the current flow in the stator. The rotation rate can be accurately controlled. The torque and average current consumption can be controlled by “chopping” the current with high frequency modulation whose duty cycle is proportional to the torque and average current consumption which will prolong the battery life of the motor.

Owner:TRIMBLE NAVIGATION LTD

Method and apparatus for controlling electric power steering system

ActiveUS20090234538A1Efficient implementationSingle motor speed/torque controlDigital data processing detailsElectric power steeringControl vector

Disclosed herein is a method for controlling an electric power steering system, wherein a motor is controlled by vector control and driven by a current command value calculated on the basis of a parameter such as a steering torque to provide a steering assist power to a vehicle steering system, and further wherein the current command value is limited on the basis of desired output characteristics and a desired angular speed during a field-weakening control and a non-field-weakening control of the vector control.

Owner:NSK LTD

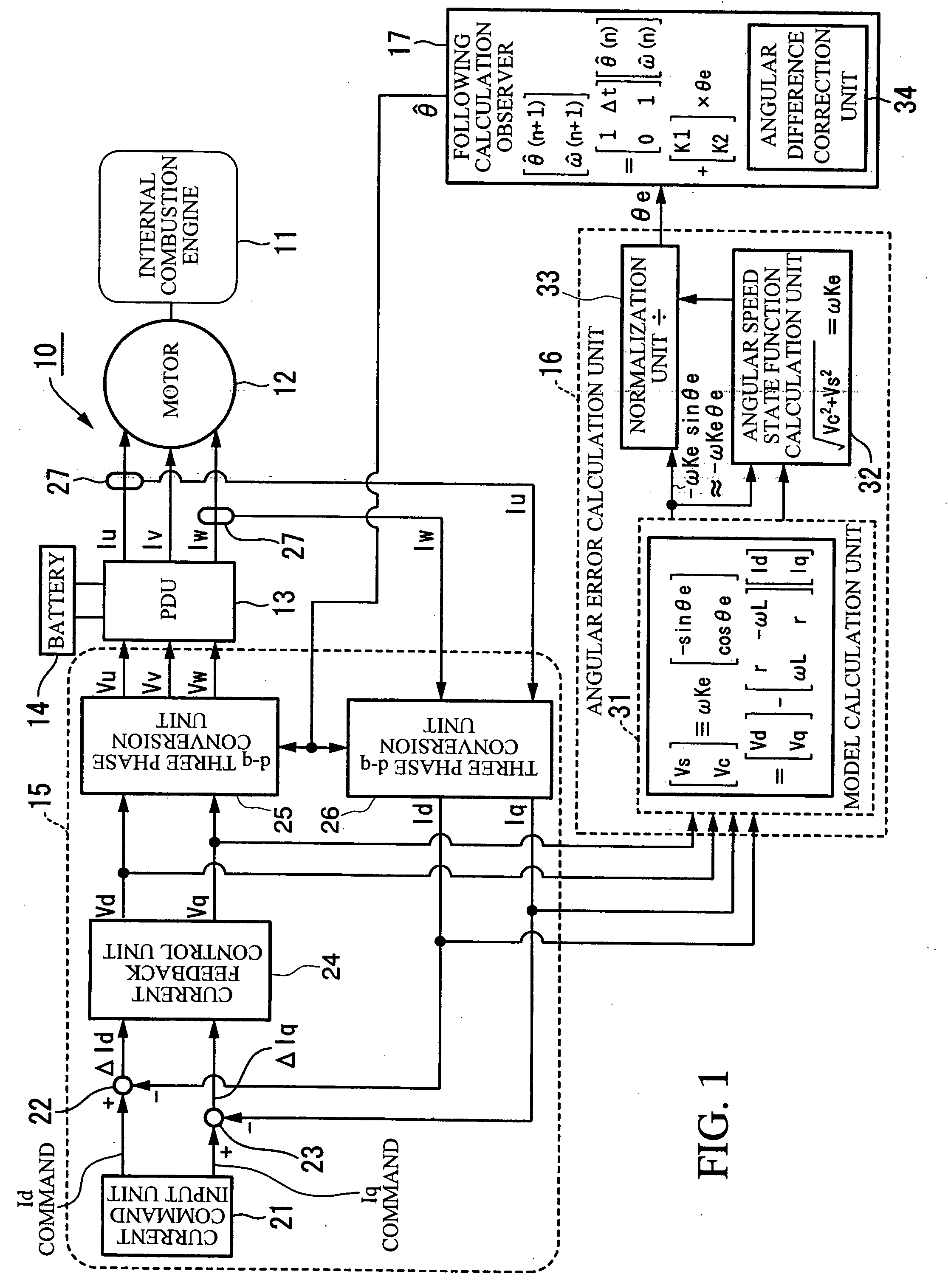

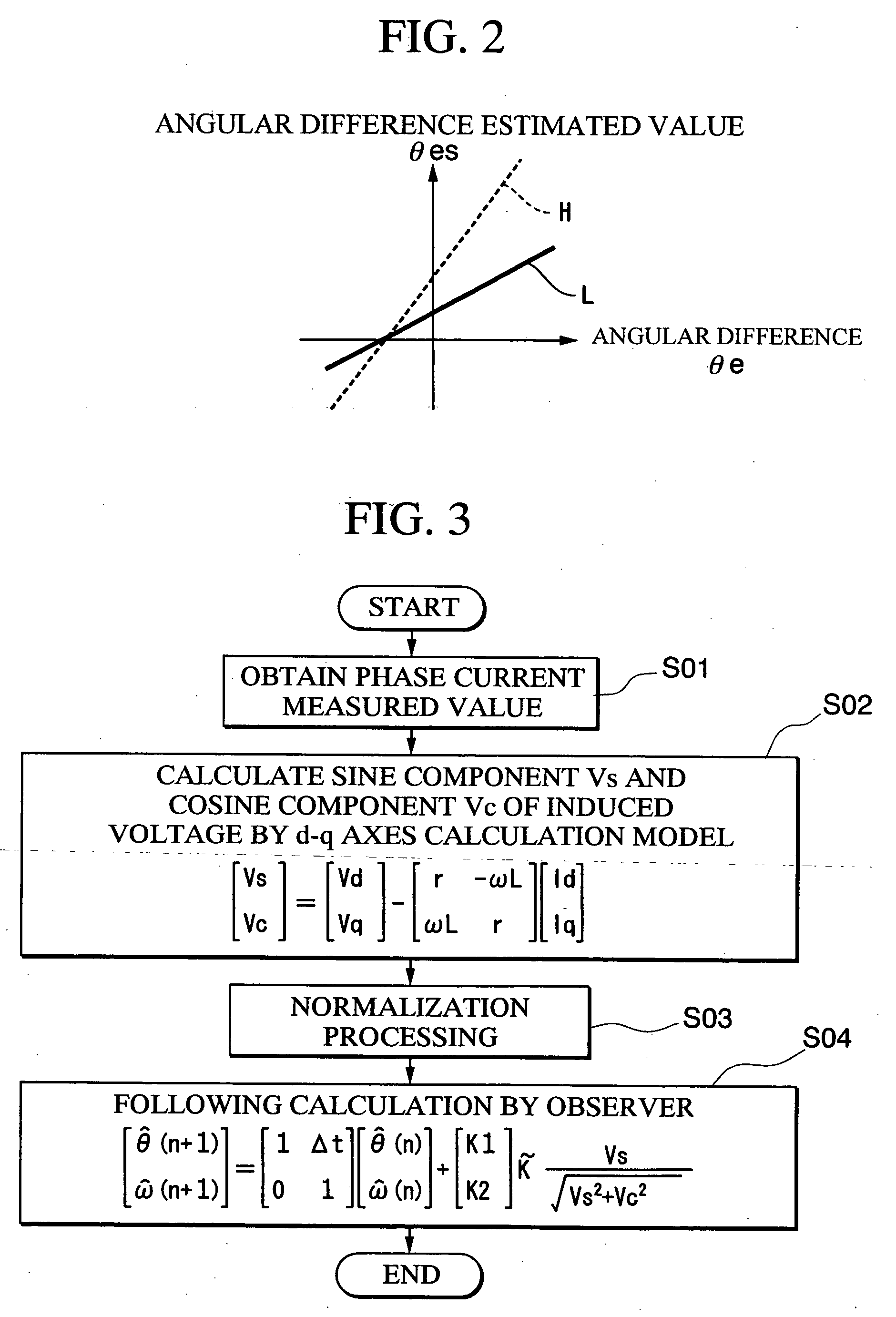

Control apparatus for brushless DC motor

ActiveUS20050029972A1Improve estimation accuracySynchronous motors startersVector control systemsPhase currentsConductor Coil

Owner:HONDA MOTOR CO LTD

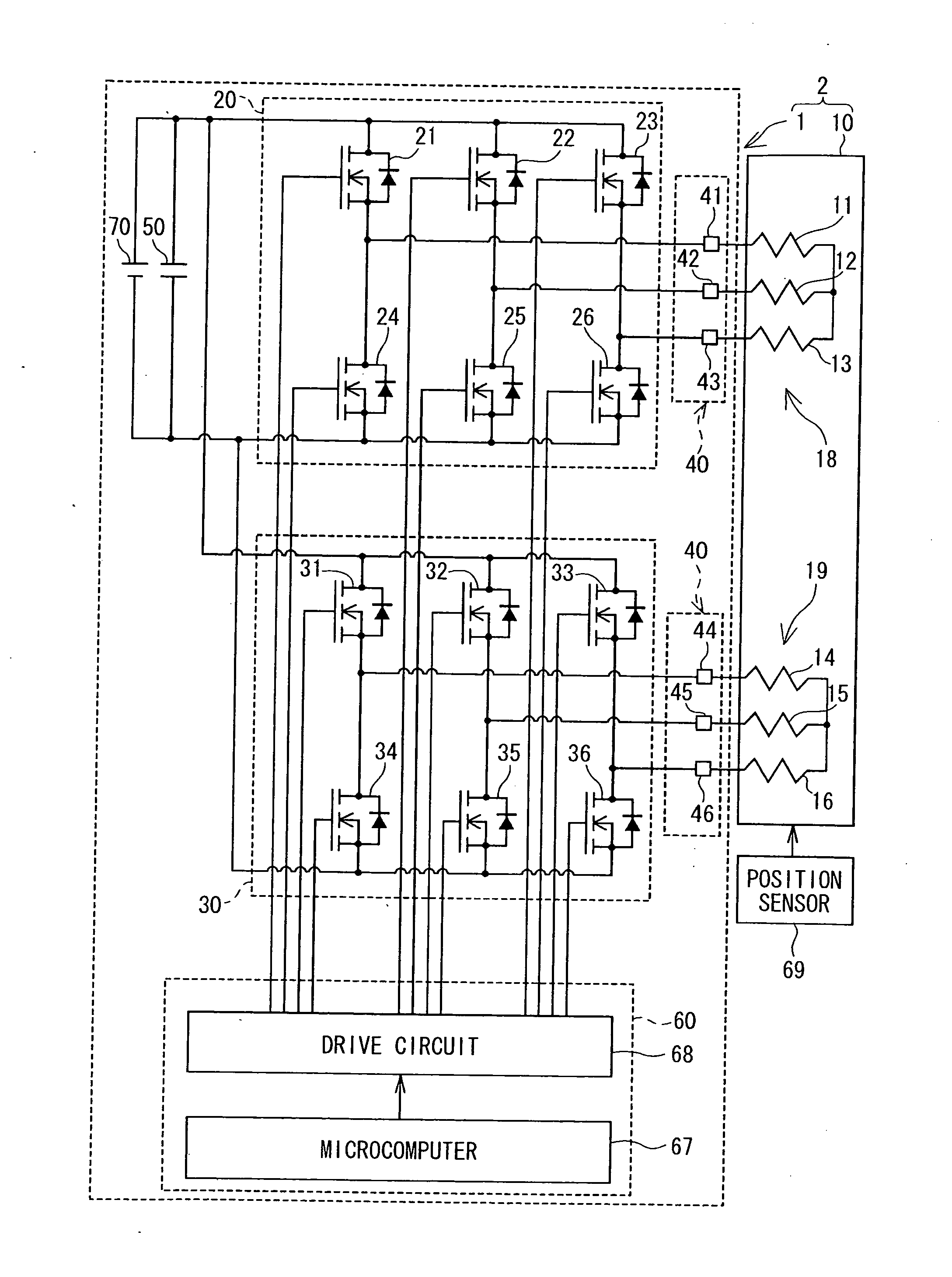

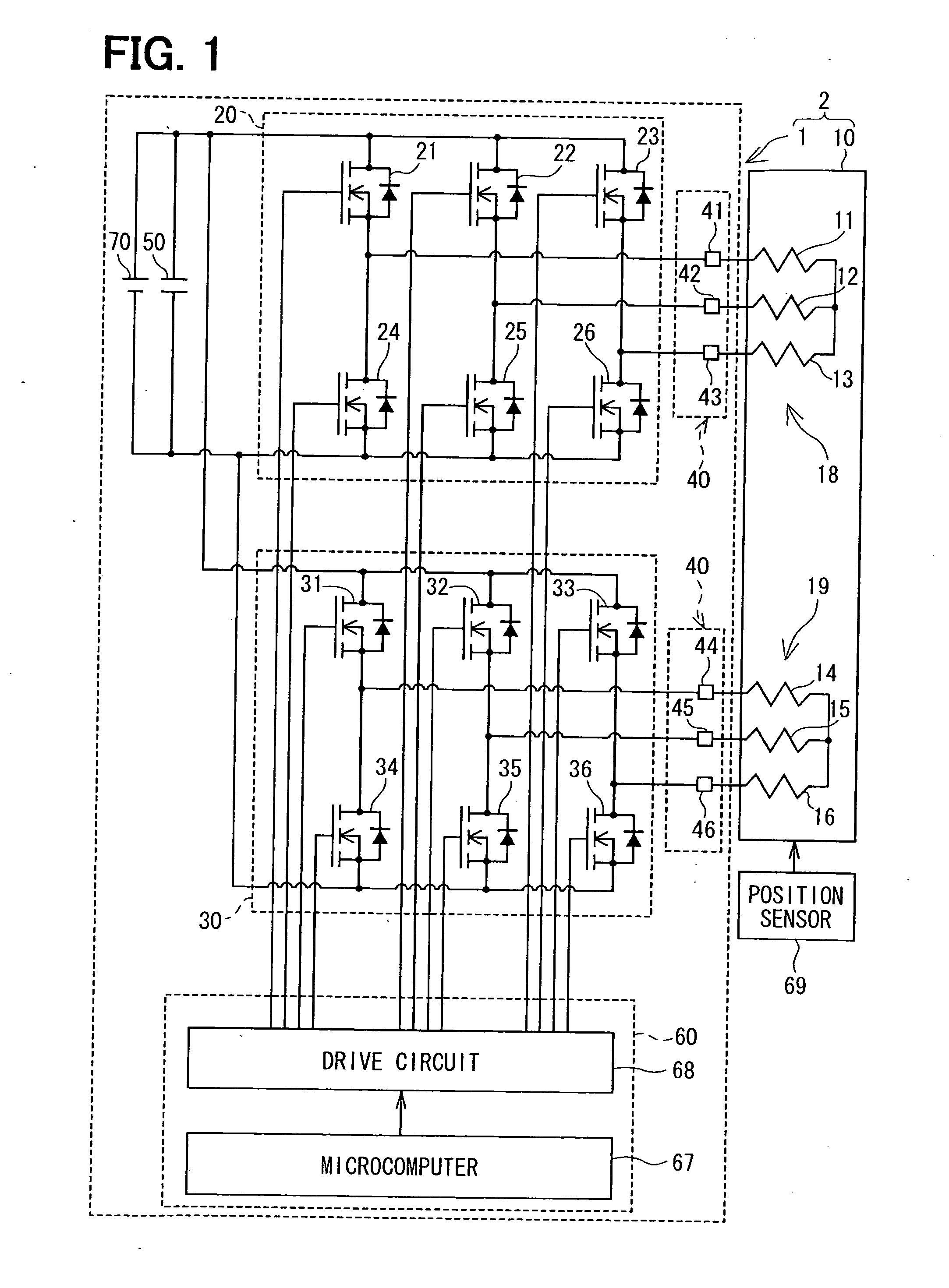

Electric power converter, driving apparatus and electric power steering apparatus

ActiveUS20120049782A1Total current dropExpand the adjustment rangeSynchronous motors startersVector control systemsElectric power steeringPhase shifted

A control unit of an electric power converter, which is used in a three-phase motor having two winding wire systems, performs for a first duty instruction signal regarding a voltage applied to a first winding wire group a flatbed two-phase modulation process, and performs for a second duty instruction signal regarding a voltage applied to a second winding wire group a flattop two-phase modulation process. By phase-shifting the second duty instruction signal by 30° from the first duty instruction signal, a timing of maximum value of the first duty instruction signal is shifted from a timing of minimum value of the second duty instruction signal. Even when the maximum value is greater than a center output value and the minimum value is smaller than the center output value, overlapping of capacitor discharge is avoided, thereby reducing a ripple electric current.

Owner:DENSO CORP

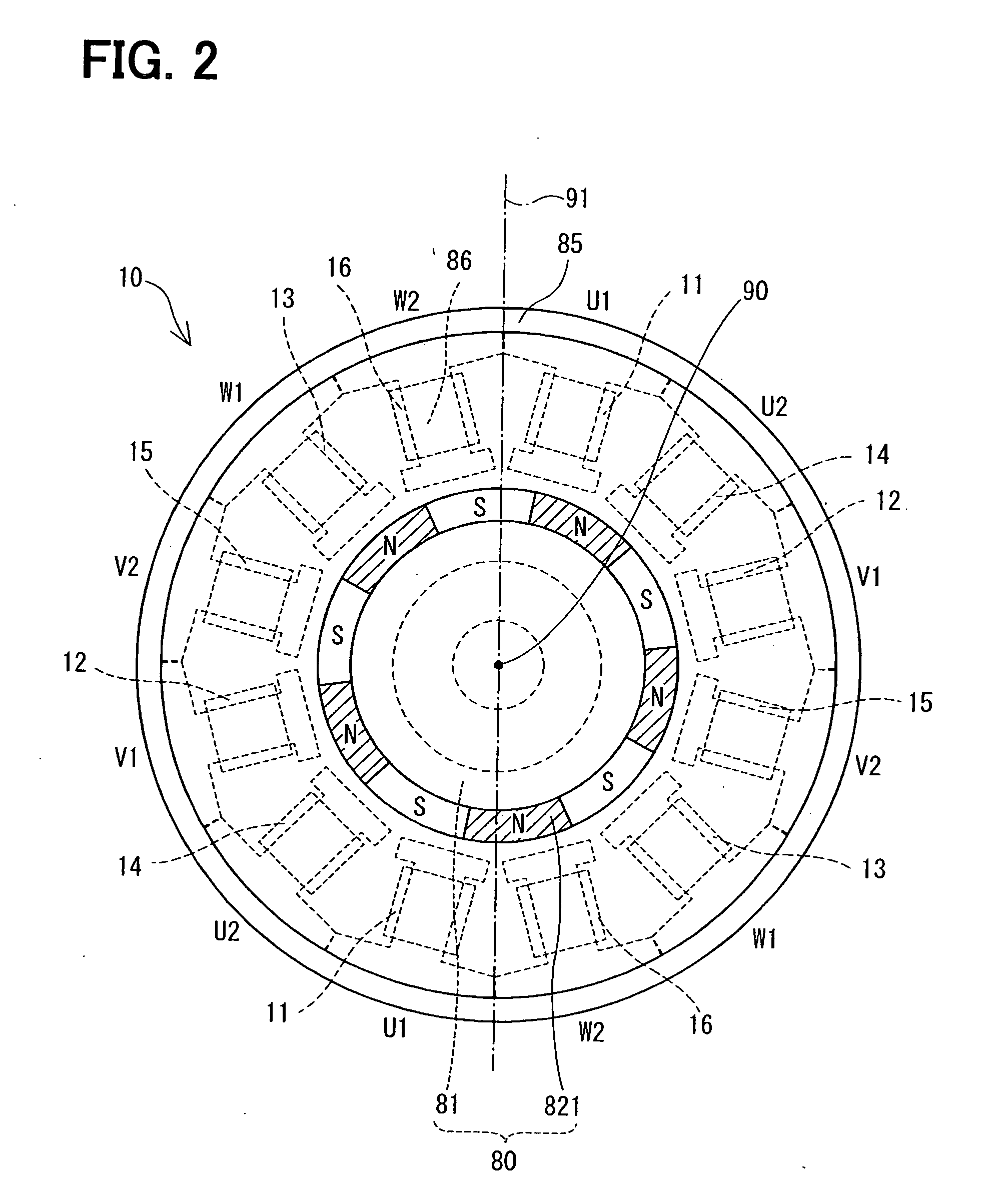

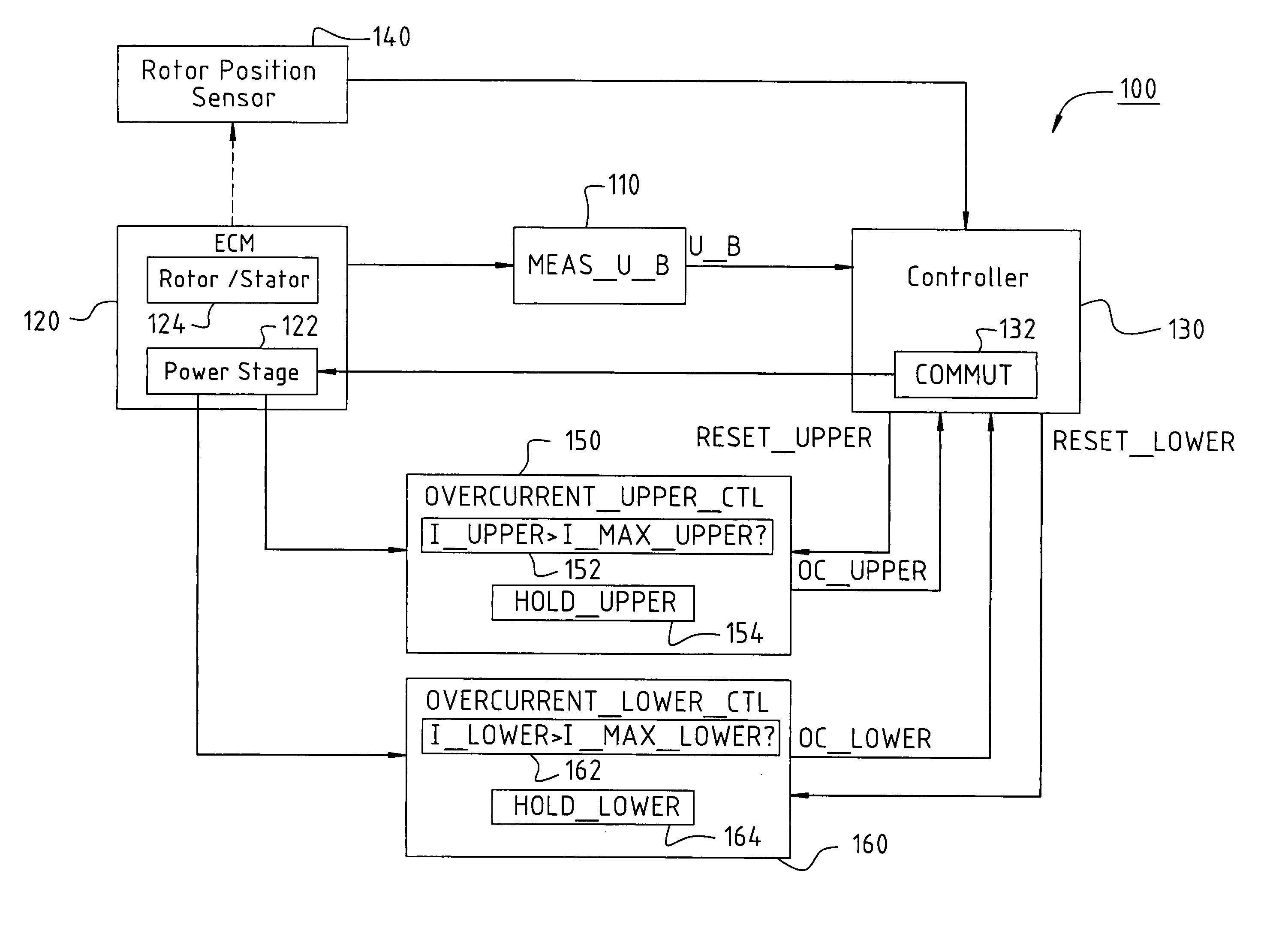

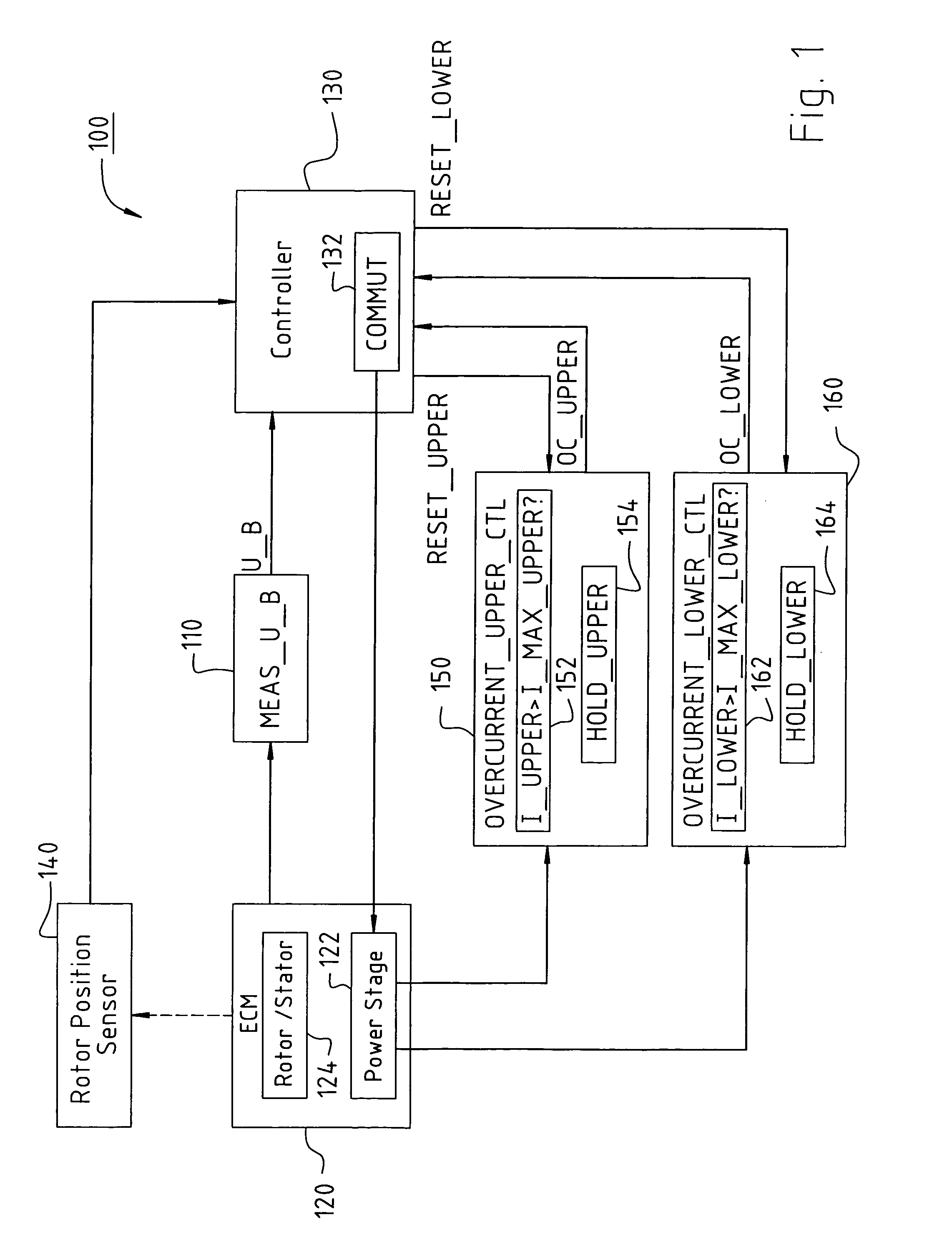

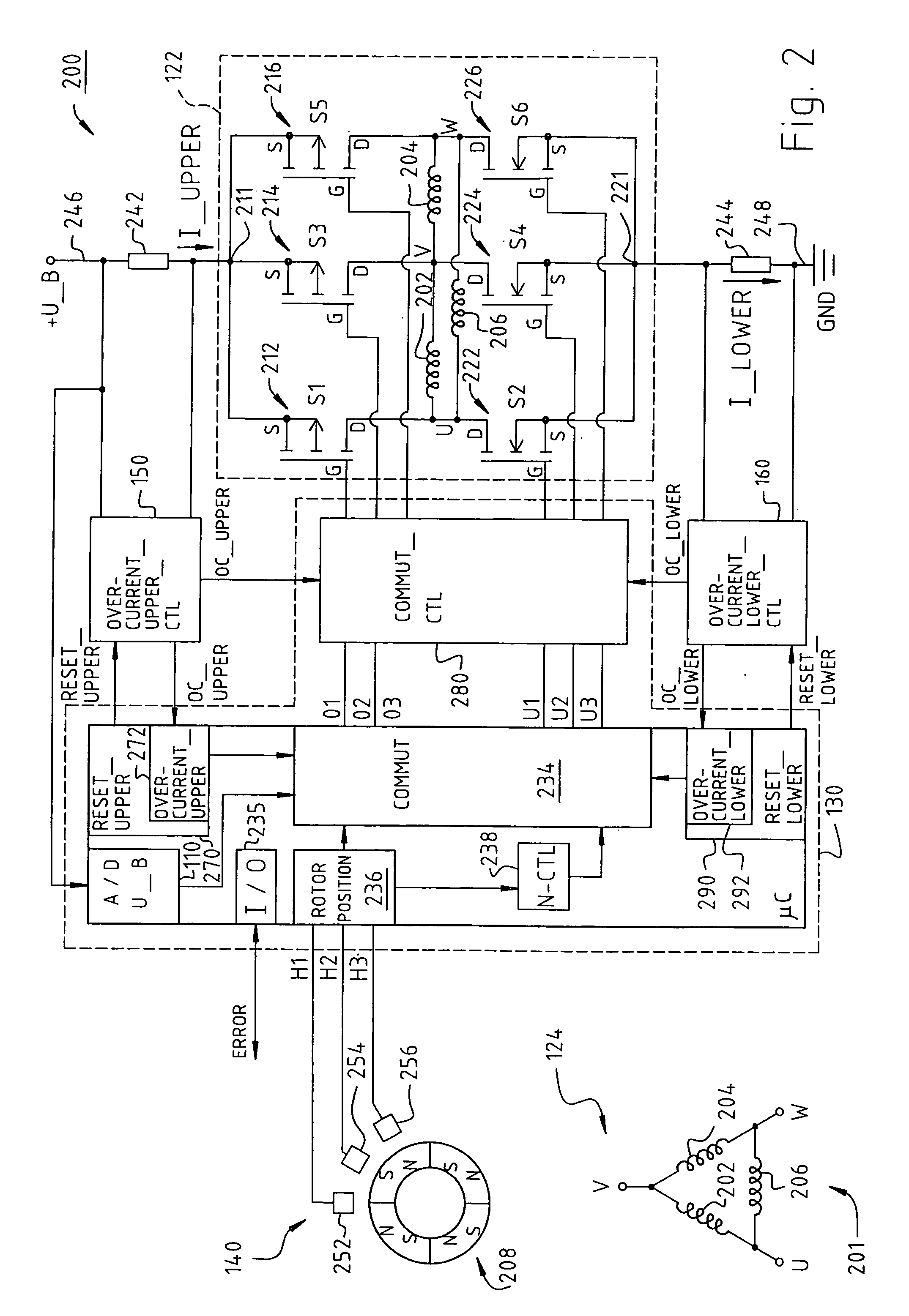

Electronically commutated motor (ECM) and method of controlling an ecm

InactiveUS20070024225A1Protection from damageProtection from destructionCommutation monitoringMotor/generator/converter stoppersEngineeringLimit value

An electronically commutated motor comprises a rotor (208); a stator (201) electromagnetically interacting with the rotor (208), which stator is formed with a stator winding (202, 204, 206); a power stage (122) controlling the currents flowing in the stator winding (202, 204, 206) during operation; at least one current measuring element (242, 244) for sensing a measured value for the currents (I_UPPER, I_LOWER) flowing in the power stage, and an overcurrent measuring element (152, 162) for evaluating an associated measured value and for sensing a current whose absolute value exceeds a predetermined limit value (I_MAX_UPPER, I_MAX_LOWER); a holding element (154, 164) associated with the overcurrent measuring element (152, 162), configured, when an overcurrent occurs in the associated current measuring element (242, 244), to generate an overcurrent signal (OC_UPPER, OC_LOWER), to store the signal, and to deliver a signal to the power stage (122).

Owner:EBM PAPST ST GEORGEN & -

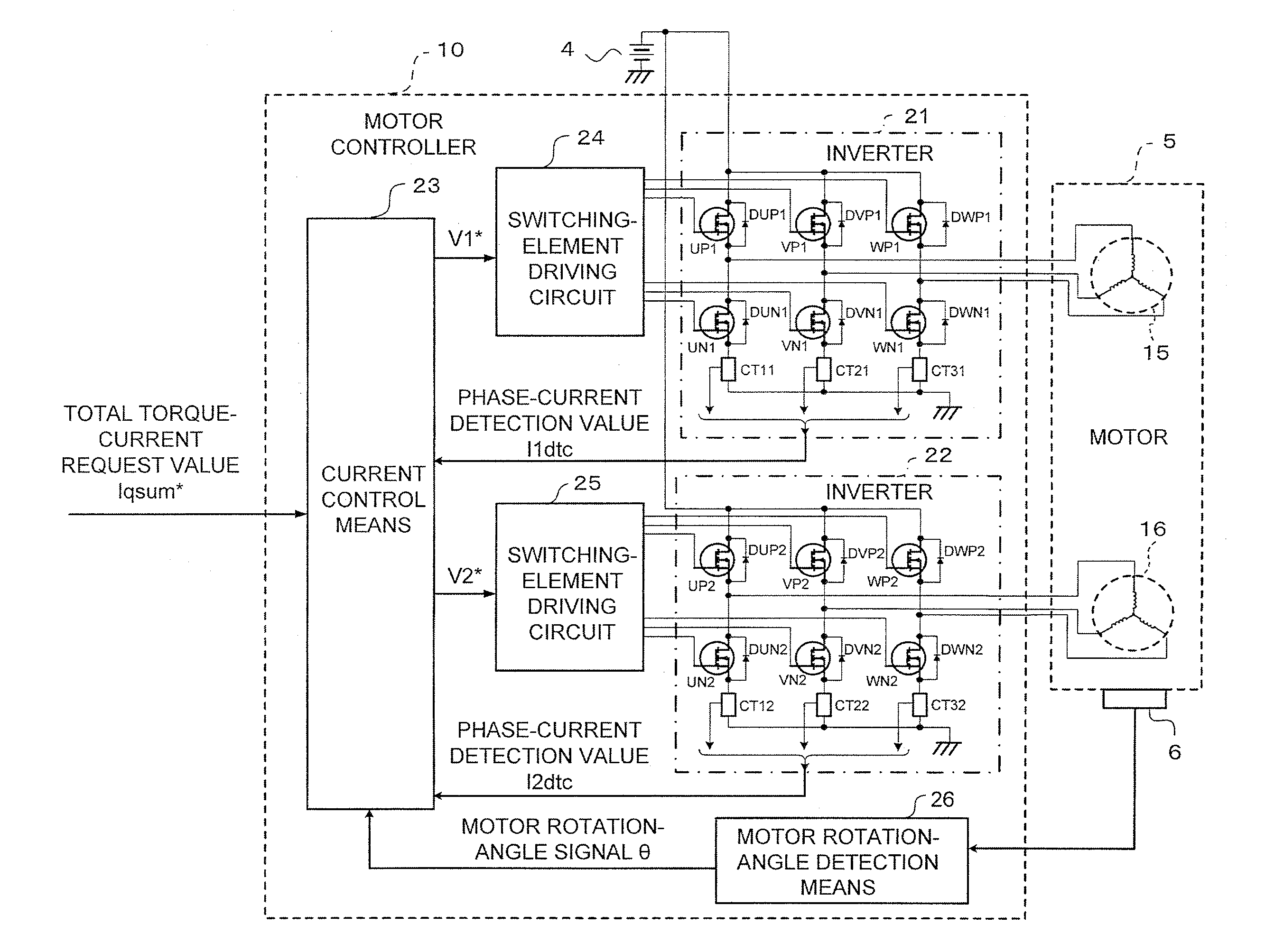

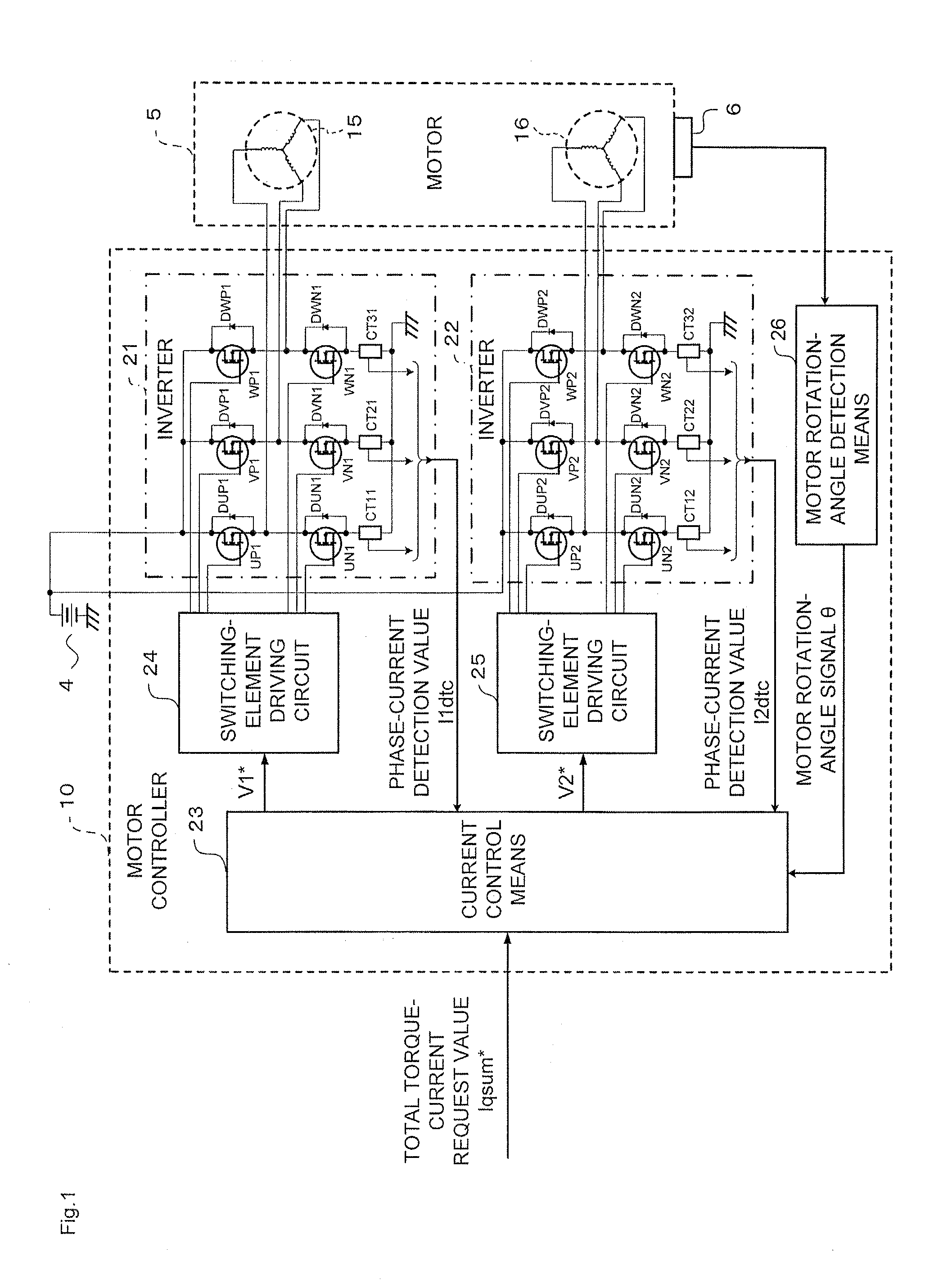

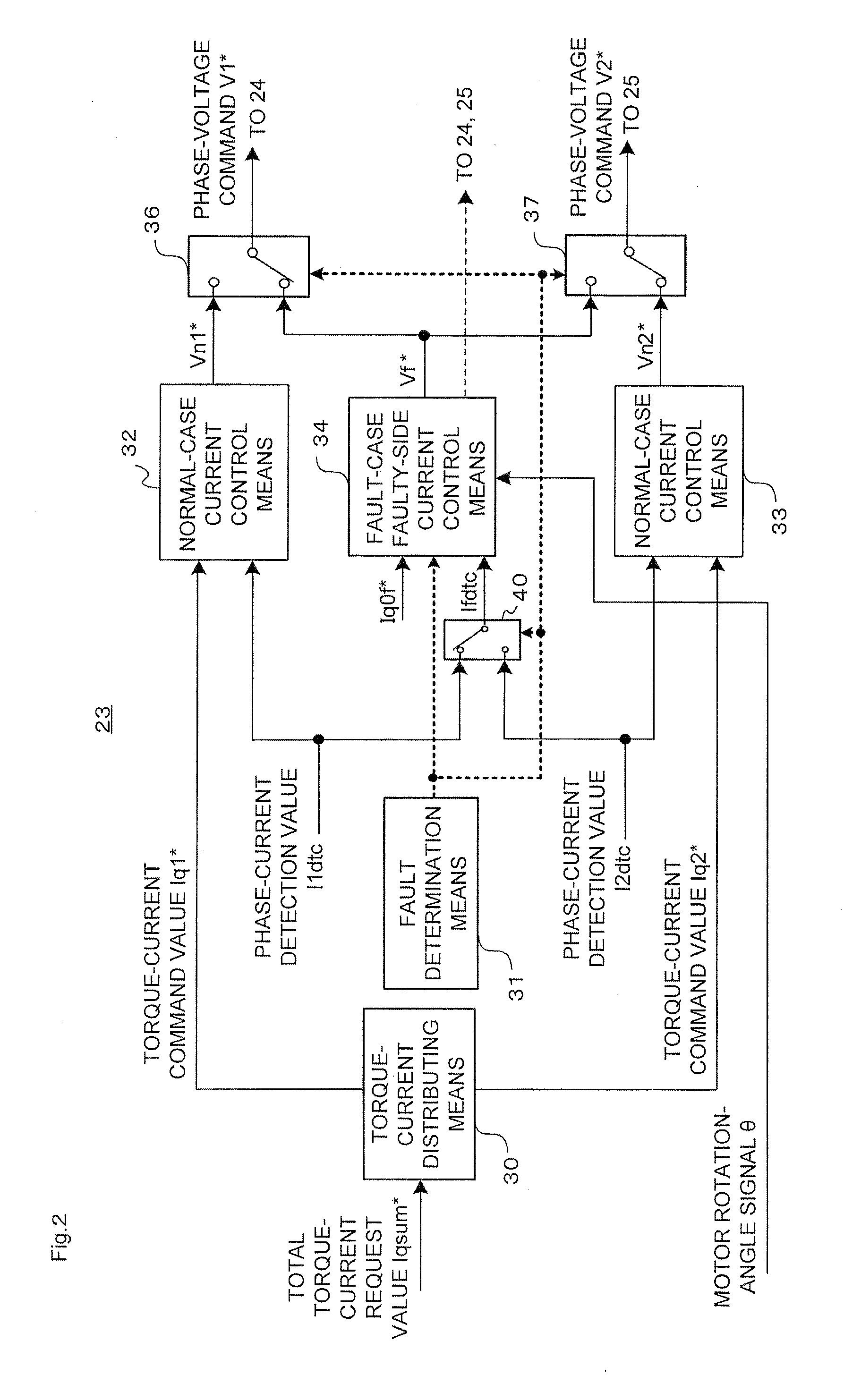

Motor controller and electric power steering device using the same

ActiveUS20130299271A1Low costSmall sizeCommutation monitoringMotor/generator/converter stoppersElectric power steeringMotor controller

Provided are a motor controller for suppressing a torque pulsation with a simple configuration and obtaining a sufficient output torque in the case of an open-type fault occurring in any one of windings of a motor and inverters, and an electric power steering device using the motor controller. In the motor controller for controlling a current supplied from and a voltage applied from a power source with respect to the motor including winding sets of a plurality of systems, when a fault determination unit (31) determines the occurrence of the open-type fault, the supply of the currents to the windings of one of the systems in which the fault has occurred is stopped by control performed on switching elements included in the inverter of the faulty system, whereas the supply of the currents to the windings of the normal system in which the fault has not occurred is continued.

Owner:MITSUBISHI ELECTRIC CORP

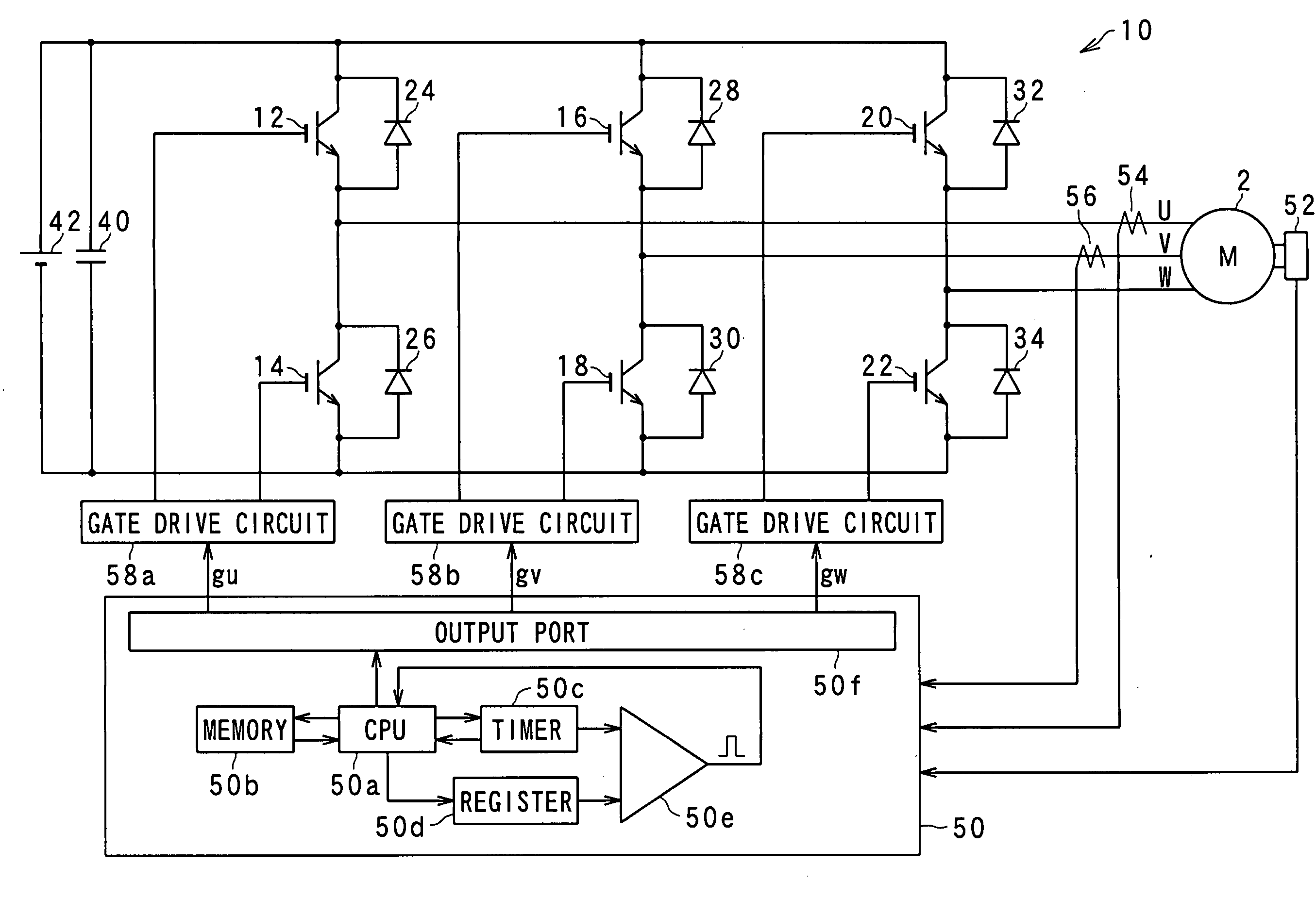

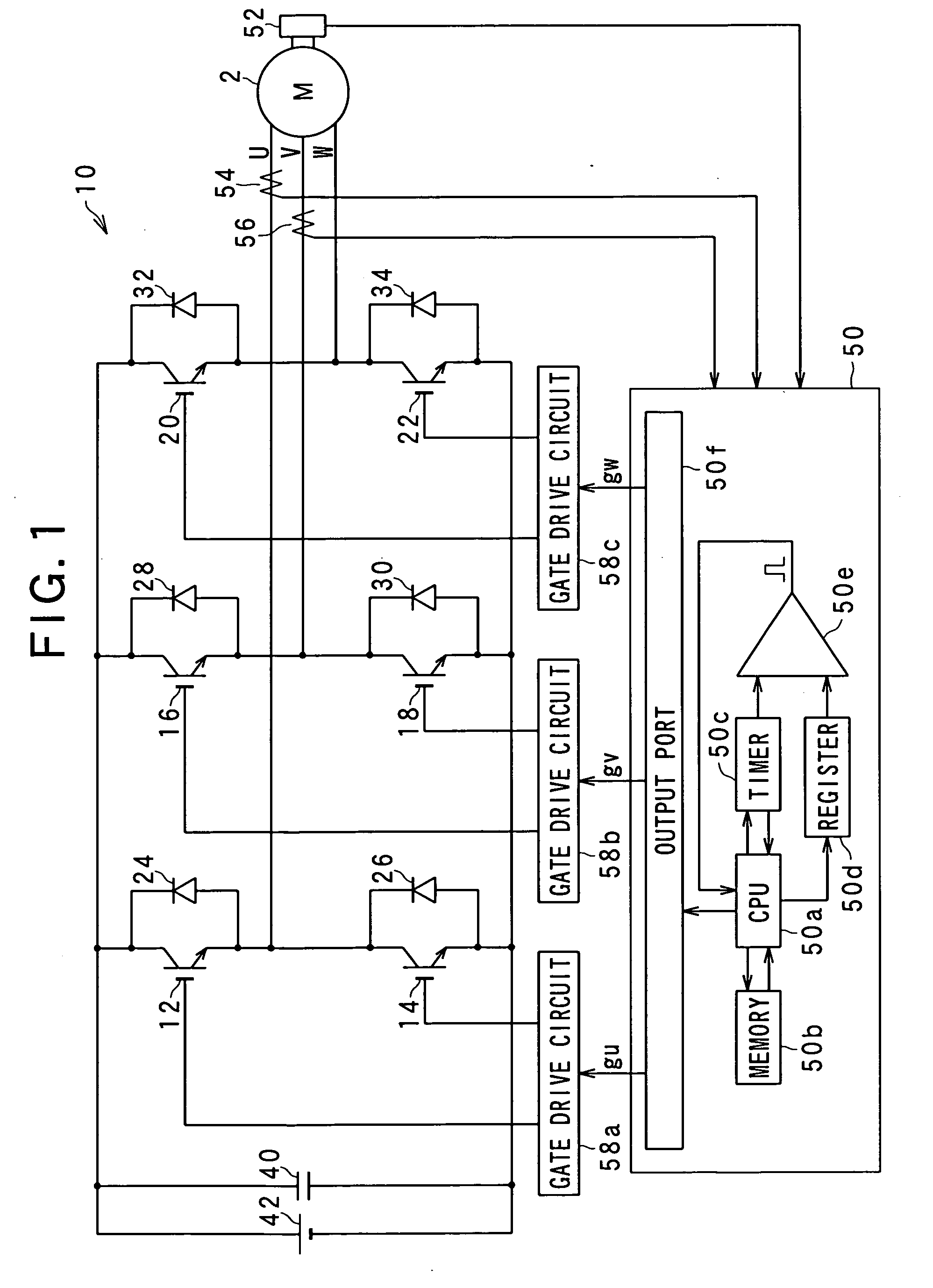

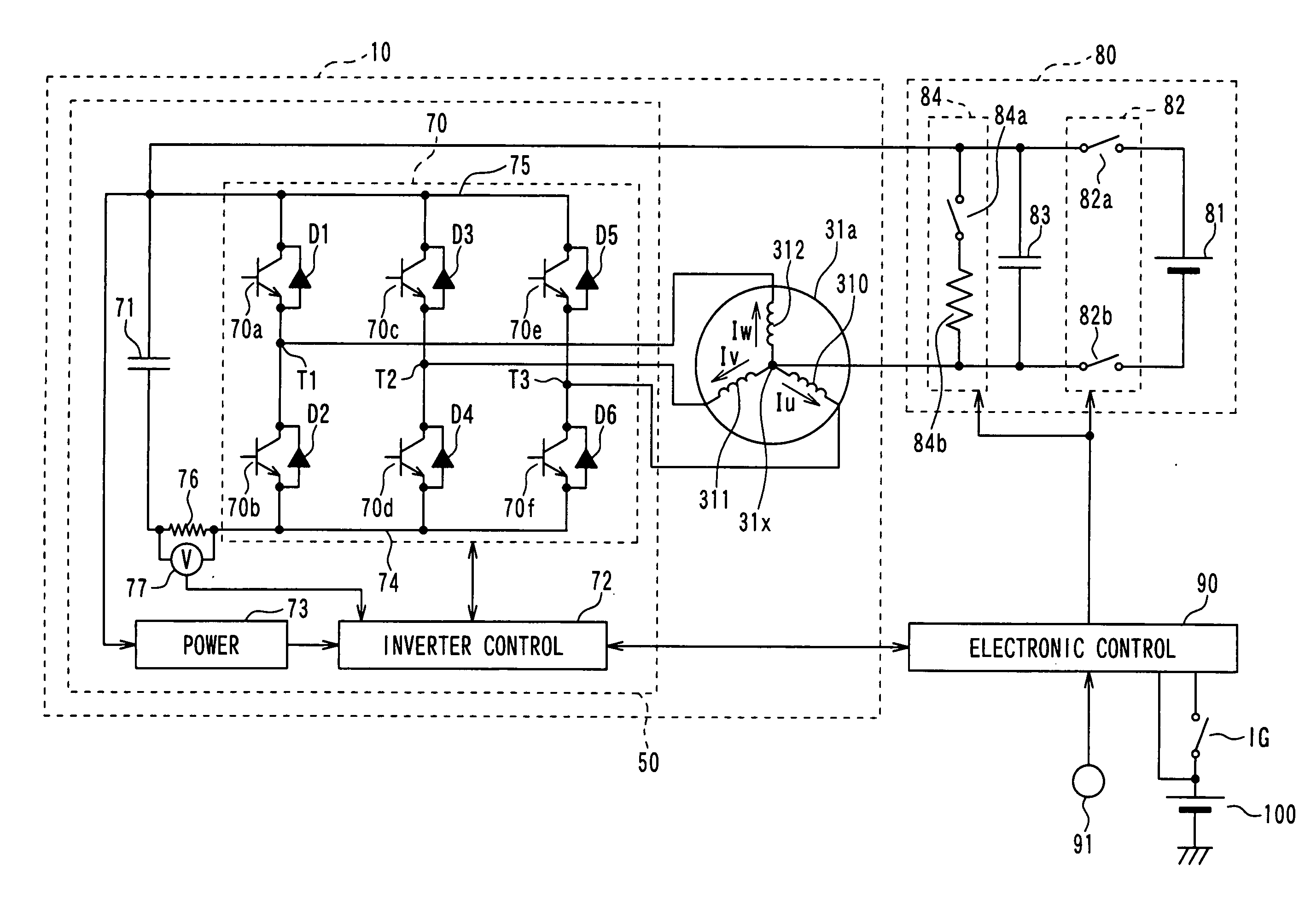

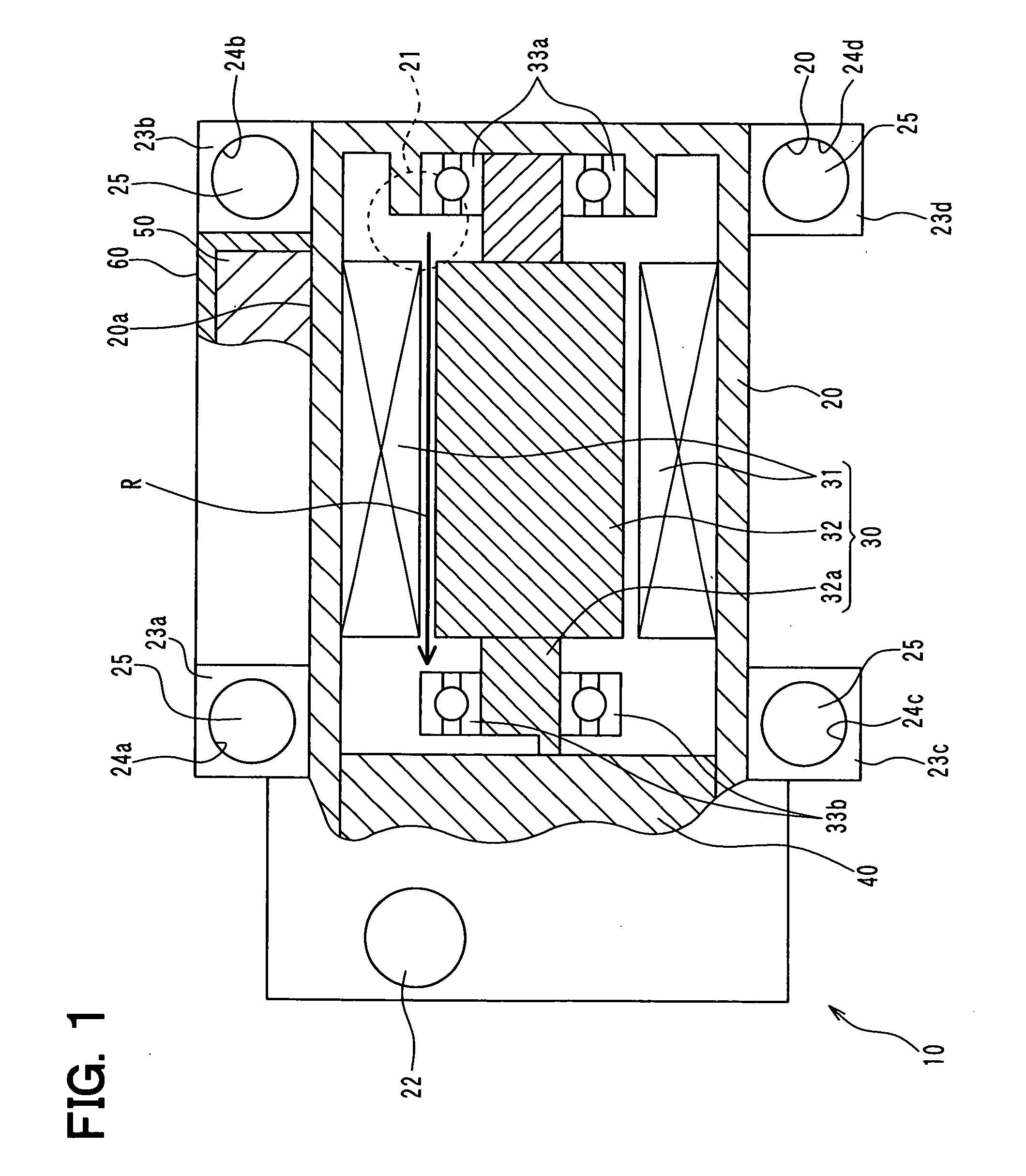

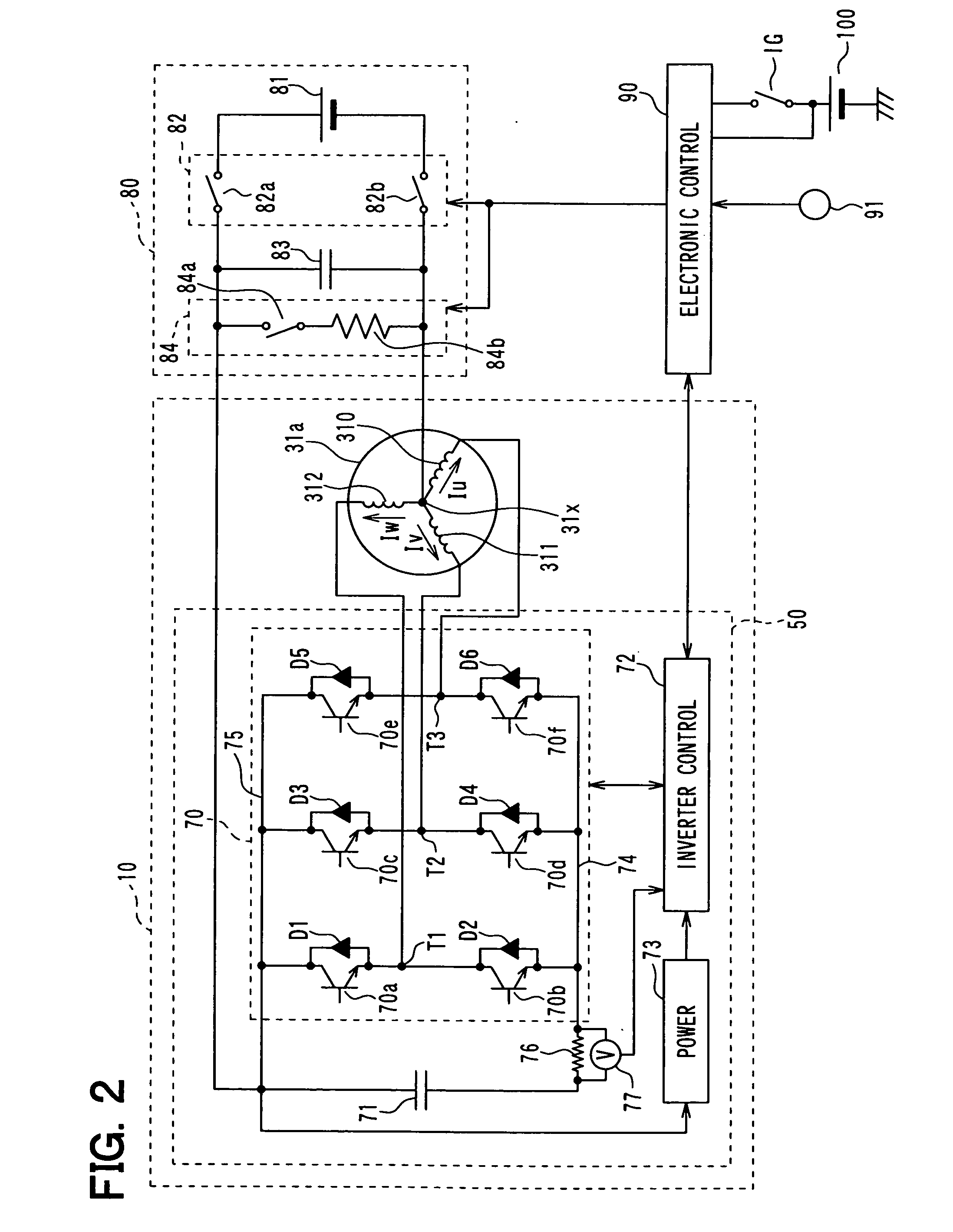

Driving apparatus for a vehicle-mounted electric motor

An inverter circuit for a motor outputs three-phase AC currents, which are outputted from common connection points to stator coils, based on output voltage of a DC power source and a power supply capacitor by a switching operation of transistors. An inverter control circuit determines that a system main relay is turned off, upon receiving a main relay-off signal from an electronic control unit. The inverter control circuit turns on the low-side transistors, while turning off the high-side transistors. A discharge current flows from the positive electrode to the negative electrode of the power supply capacitor through the stator coil and the low-side transistors, so that electric charge stored in the power supply capacitor is discharged.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com