Permanent magnetism synchronous electric machine - compressor system high speed operation control method

A permanent magnet synchronous motor and compressor system technology, applied in the direction of single motor speed/torque control, motor generator control, AC motor control, etc., can solve problems of little significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

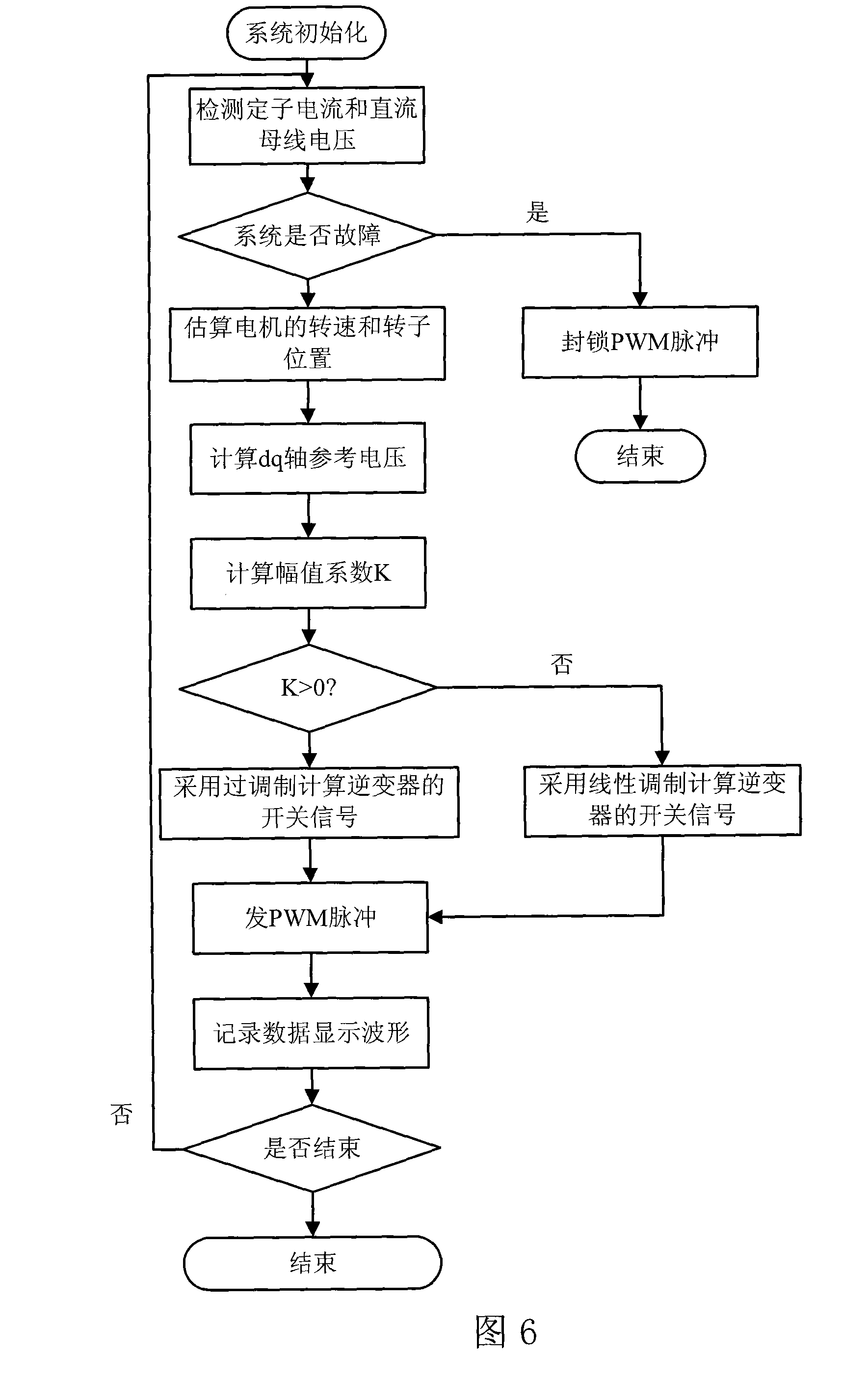

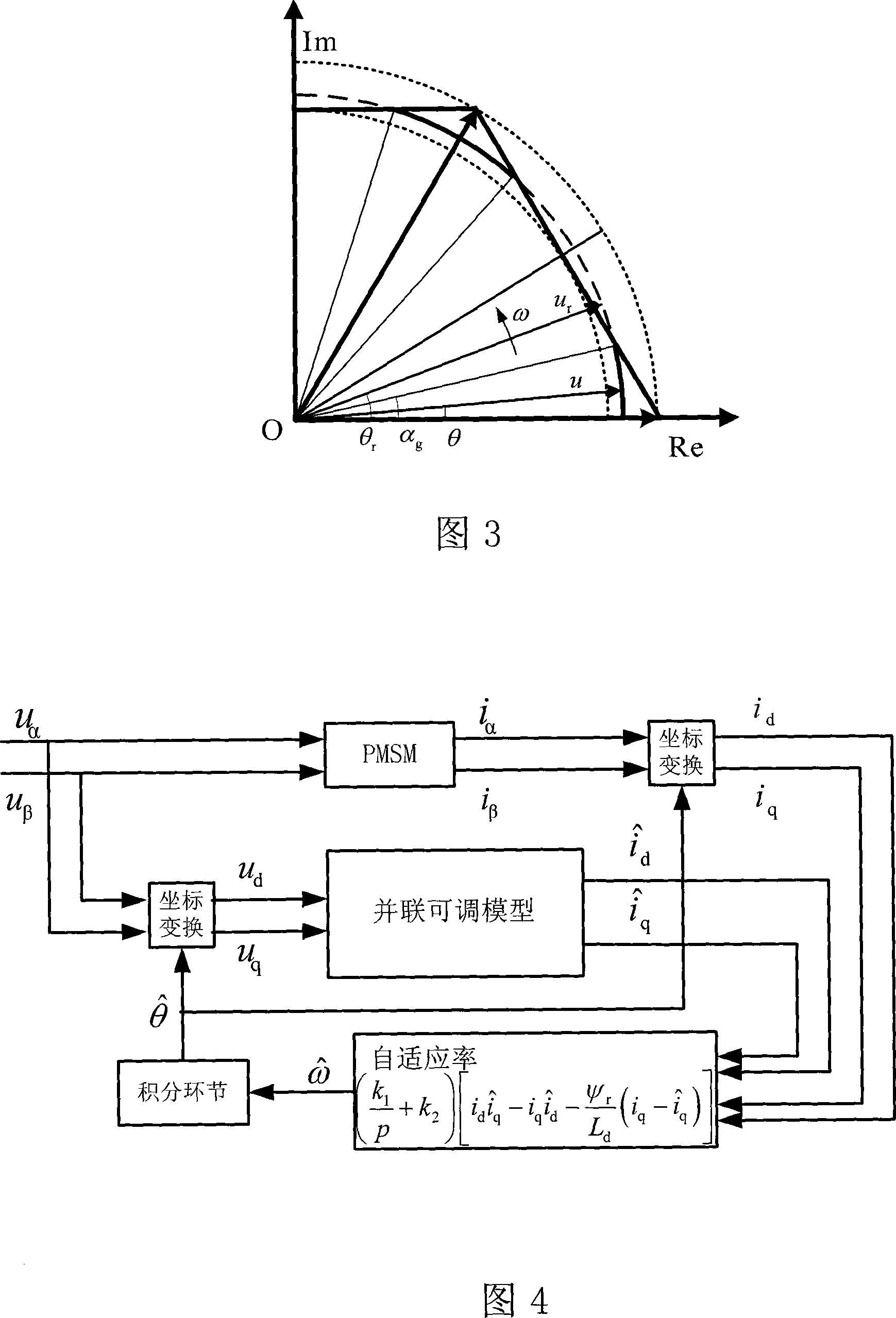

[0096] Fig. 4 is a structural block diagram of the hardware system of the present invention. The experimental hardware of the present invention adopts the motor control development system PE-Expert of Japan Myway Company, and this platform utilizes the DSP chip V85OIA4 of NEC Company, and adopts C language programming. The hardware system is mainly composed of PC, DSP board, A / D converter, D / A converter, PWM generator and two-level voltage inverter specially designed for AC motor vector control. The system of the present invention detects the current of the PMSM stator circuit and the DC bus voltage of the inverter through the sensor, uses the development system PE-Expert to perform AD conversion, and performs position sensorless vector control in its DSP, as well as coordinate transformation, PI adjustment and other modules . A single-mode overmodulation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com