Patents

Literature

37 results about "Flattop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flattop is a benchmark critical assembly that is used to study the nuclear characteristics of uranium-233, uranium-235, and plutonium-239 in spherical geometries surrounded by a relatively thick natural uranium reflector.

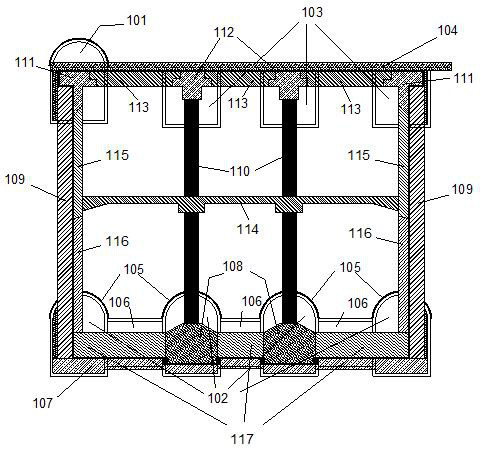

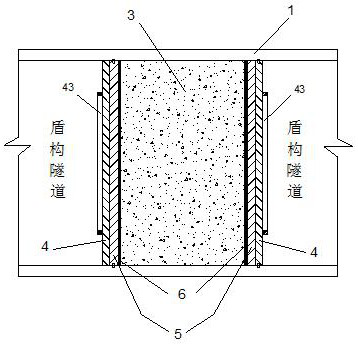

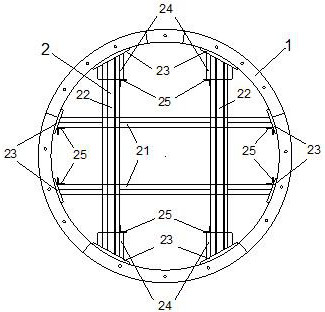

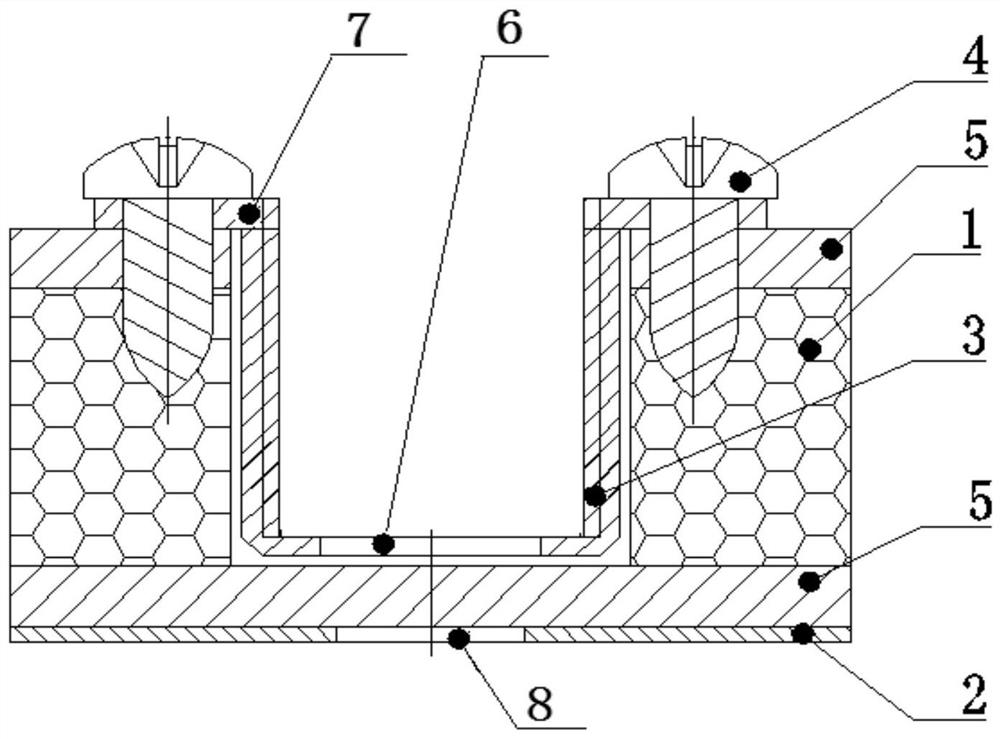

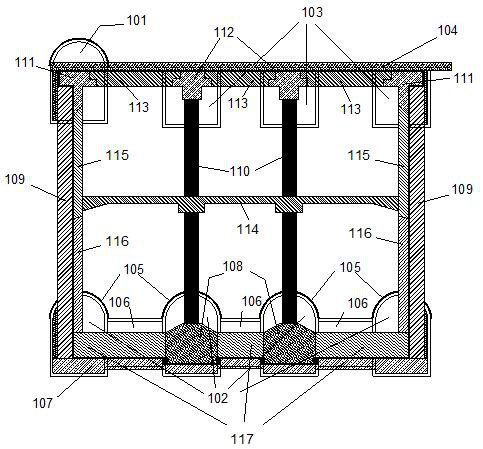

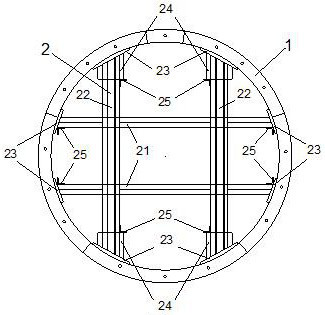

Construction method for excavating station structure by tunnel-first and station-later pipe roof hole pile method

ActiveCN111677520AReduce distortionReduce disturbanceUnderground chambersTunnel liningArchitectural engineeringEconomic benefits

The invention discloses a construction method for excavating a station structure by a tunnel-first and station-later pipe roof hole pile method. During construction, four pilot tunnels are arranged onan upper layer and a lower layer respectively, one advanced pilot tunnel is arranged in the upper-layer pilot tunnels, the advanced pilot tunnel is used as a working space for pipe roof piling, and no pipe roof support is arranged above the advanced pilot tunnel and the four lower pilot tunnels; a primary support is arranged and is of a vault straight wall structure, the pilot tunnels serve as working spaces of side piles and middle column steel pipe columns, and after the pipe roof piling is completed, the other three upper pilot tunnels on the upper layer are excavated through a flat-top straight wall structure. The construction method is also suitable for excavation of shallow-buried and deep-buried stations, ensures that environmental facilities are hardly influenced, further saves economic cost, has extremely high economic benefits and social value, and can be widely applied to similar projects.

Owner:HAINAN UNIVERSITY

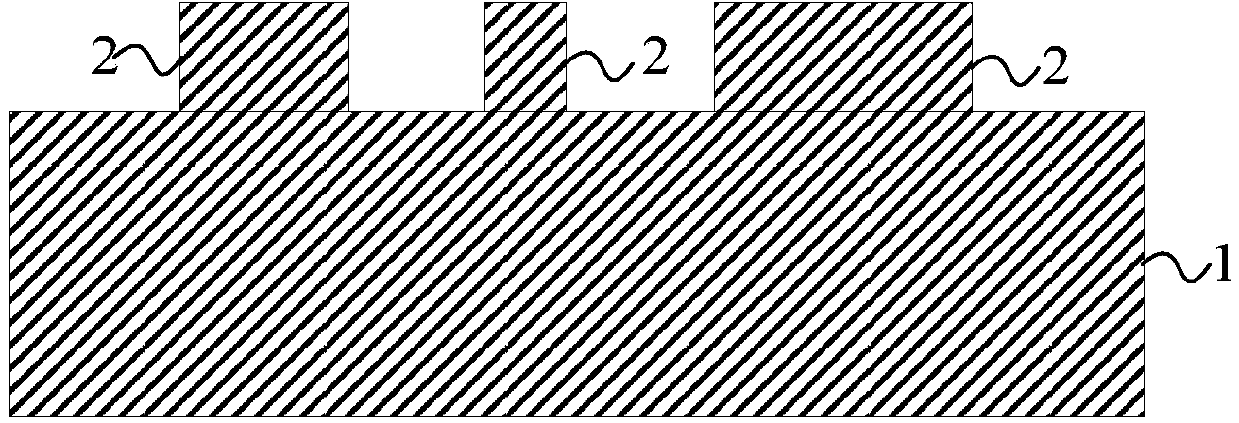

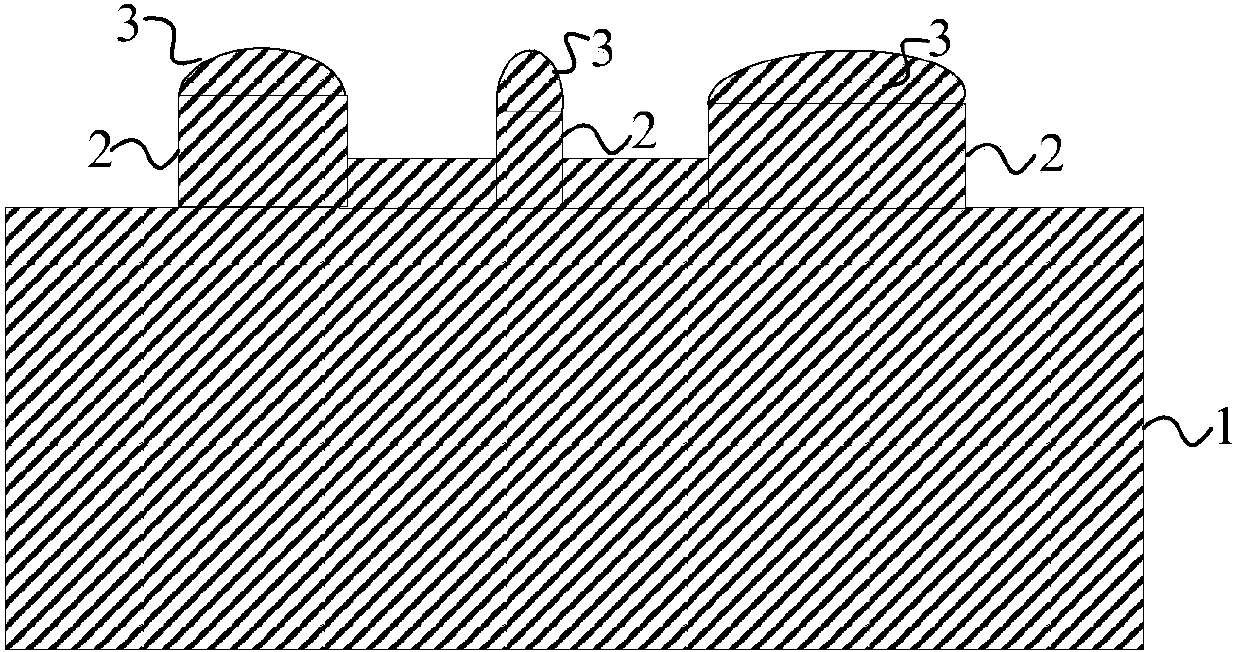

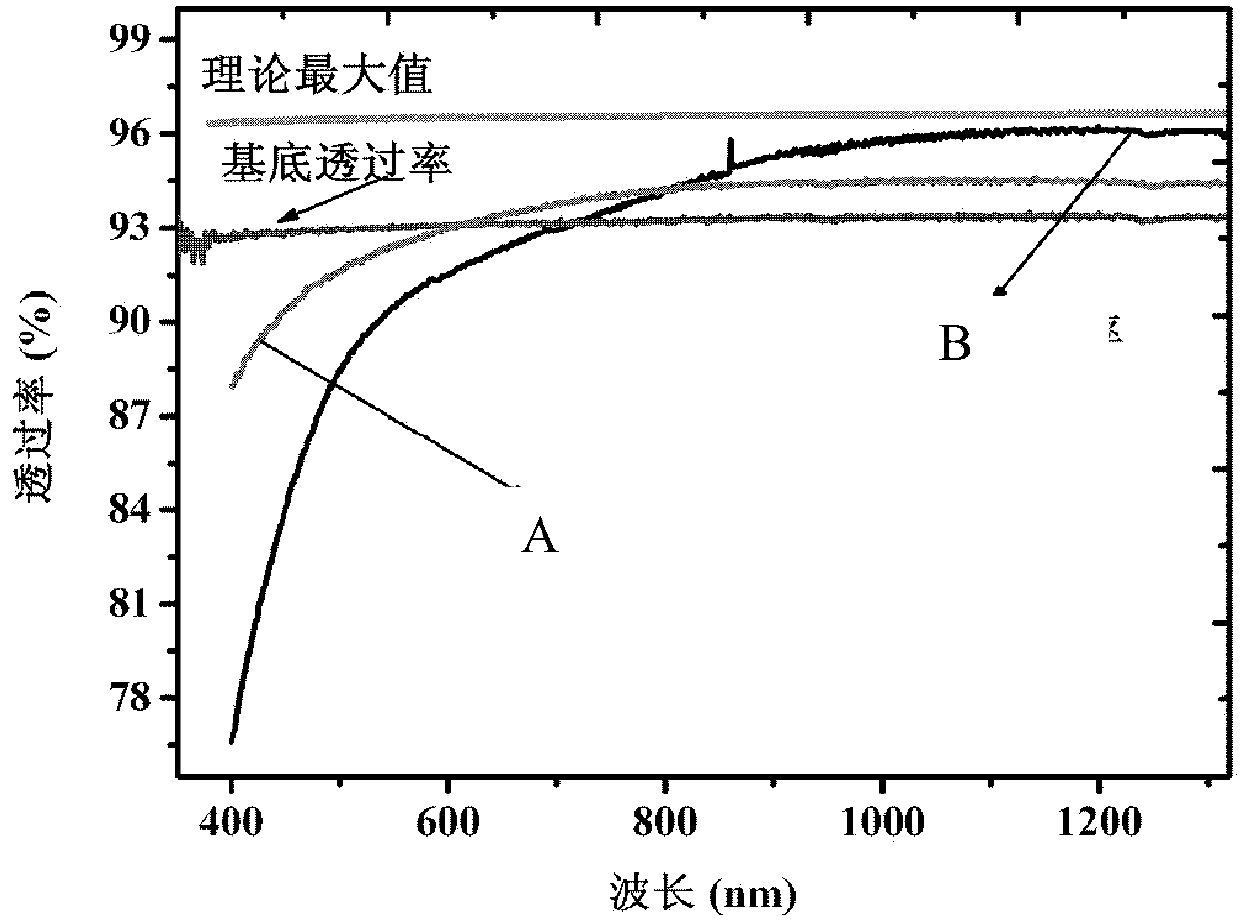

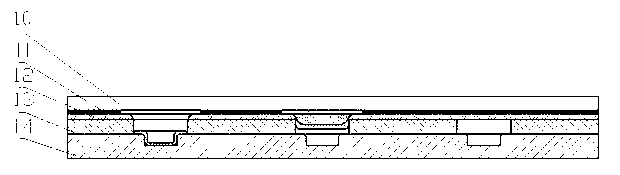

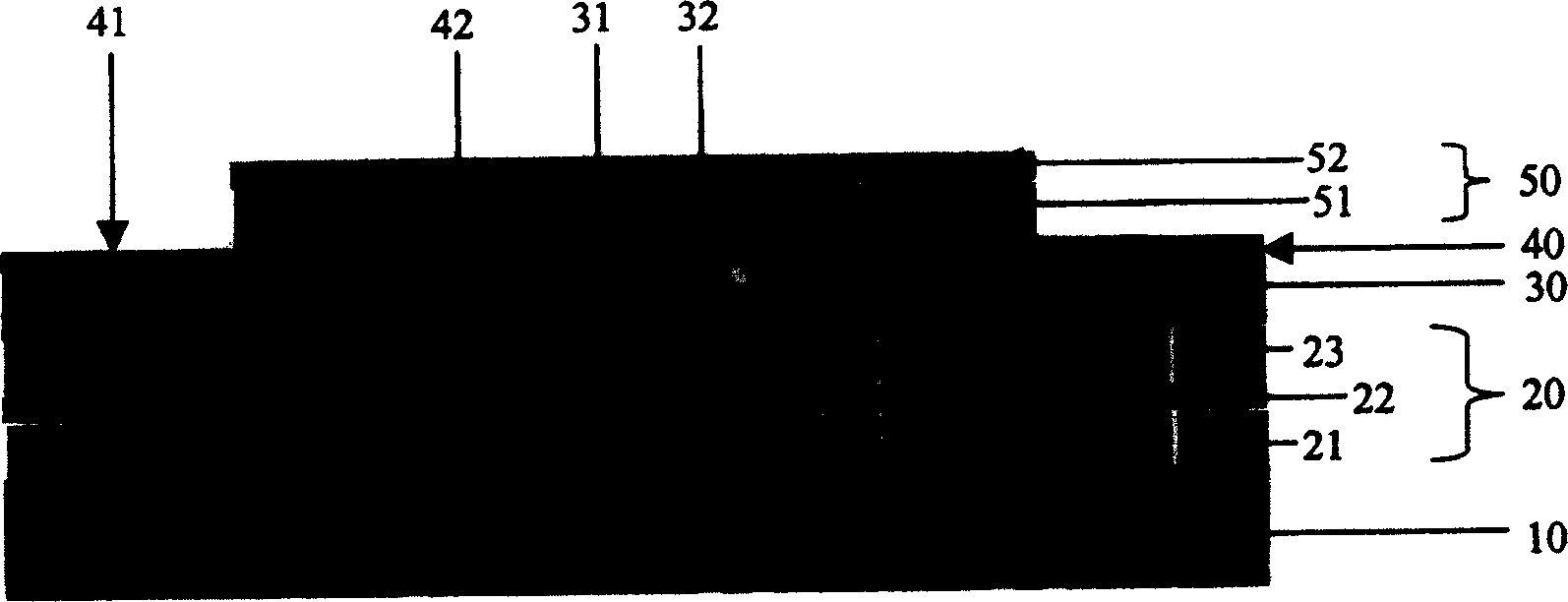

Subwavelength antireflective structure device and manufacturing method thereof

InactiveCN104049287AImprove anti-reflection abilityEasy to operateCoatingsSub wavelengthMaterials science

The invention provides a subwavelength antireflective structure device and a manufacturing method of the subwavelength antireflective structure device. The subwavelength antireflective structure device comprises a flat-top subwavelength antireflective structure, and the flat-top subwavelength antireflective structure comprises a substrate and a flat-top surface microstructure etched on the substrate; the subwavelength antireflective structure device further comprises a non-flat-top structure, obtained in an oblique incidence depositional mode, above the flat-top surface microstructure; the non-flat-top structure and the substrate are made of the same material. Compared with the prior art, the subwavelength antireflective structure device can enhance the antireflective effect of a flat-top subwavelength antireflective structure in the prior art.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

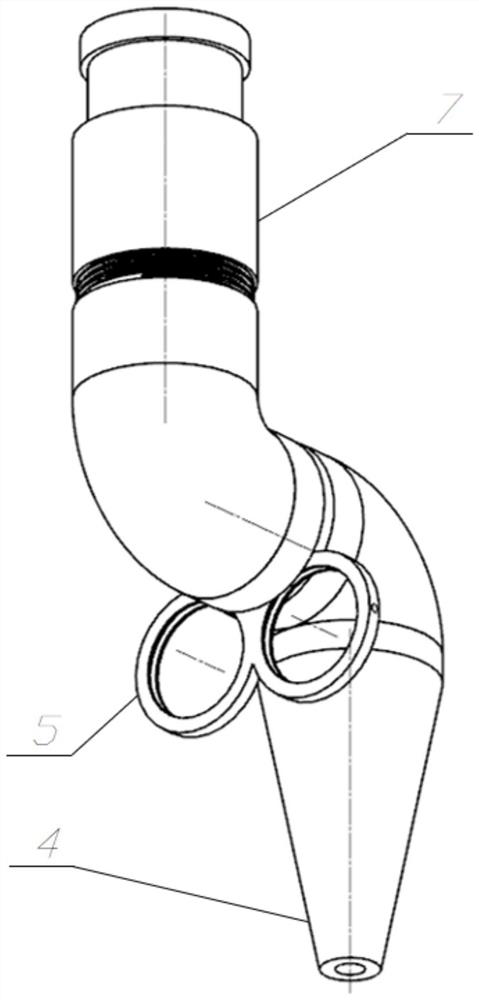

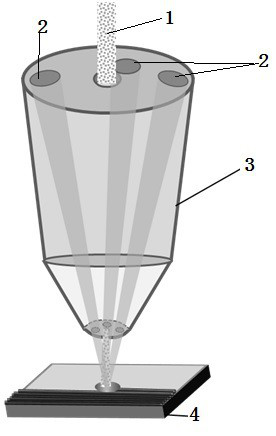

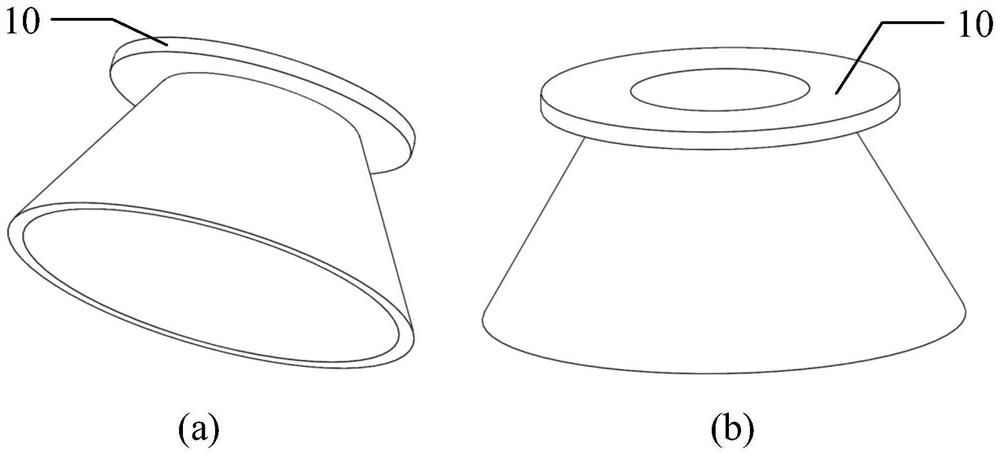

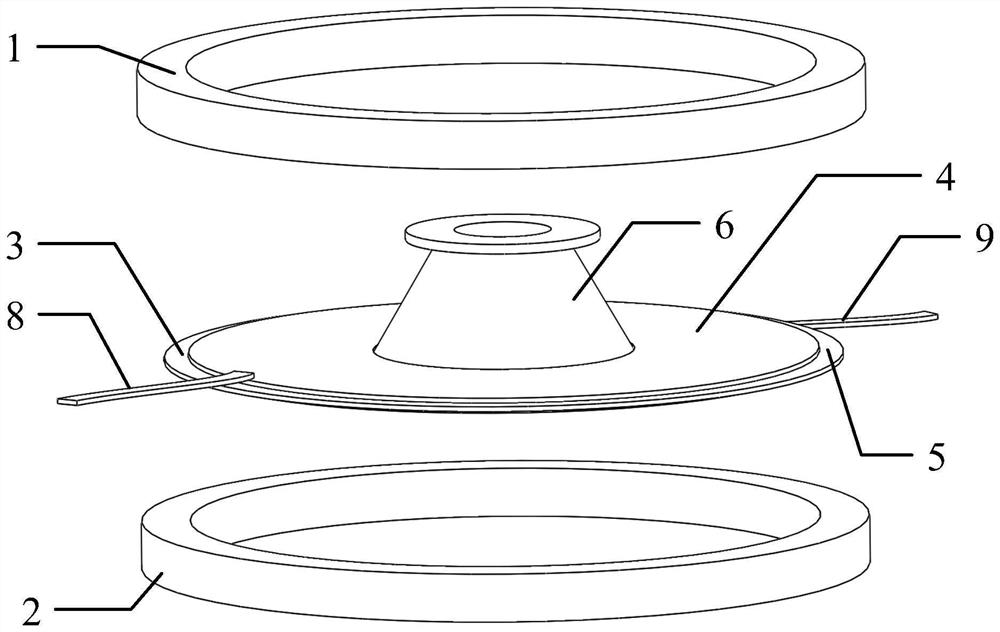

Device for heating to generate uniform motlen pool

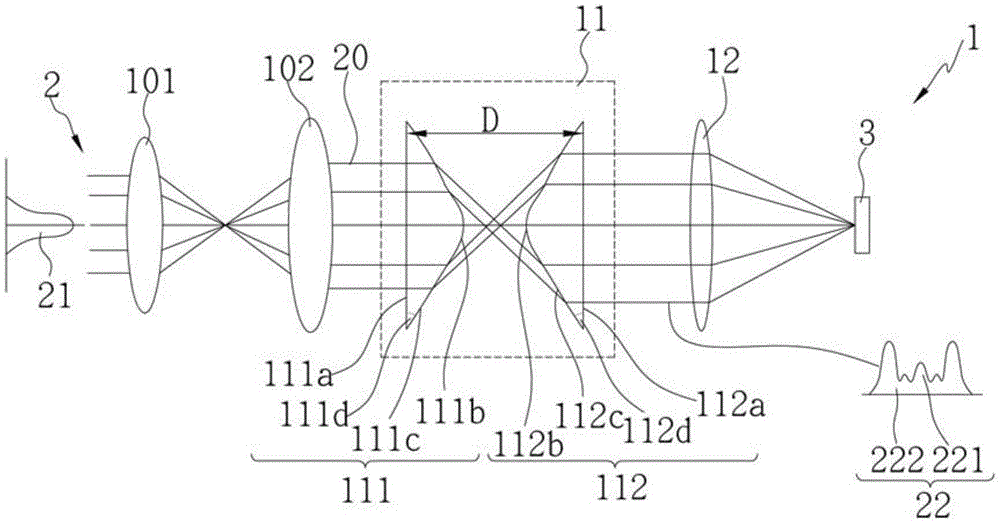

ActiveCN106814459AAvoid the problem of gasification splashReduce overlapLaser beam welding apparatusOptical elementsEngineeringAxicon

This disclosure provides a device for heating to generate a uniform molten pool, including: a source unit for generating an energy beam; a beam expanding / reducing unit positioned in an energy path of the energy beam for adjusting the diameter of the energy beam; a flat-top conical lens set positioned in the energy path and including at least two flat-top axicons, with the beam expanding / reducing unit positioned between the source unit and the flat-top conical lens set; and a focusing lens positioned in the energy path, with the flat-top conical lens set between the beam expanding / reducing unit and the focusing lens, and the energy beam being focused by the focusing lens. This disclosure generates a uniform molten pool to prevent vaporization splash due to overheating of the material during melting.

Owner:IND TECH RES INST

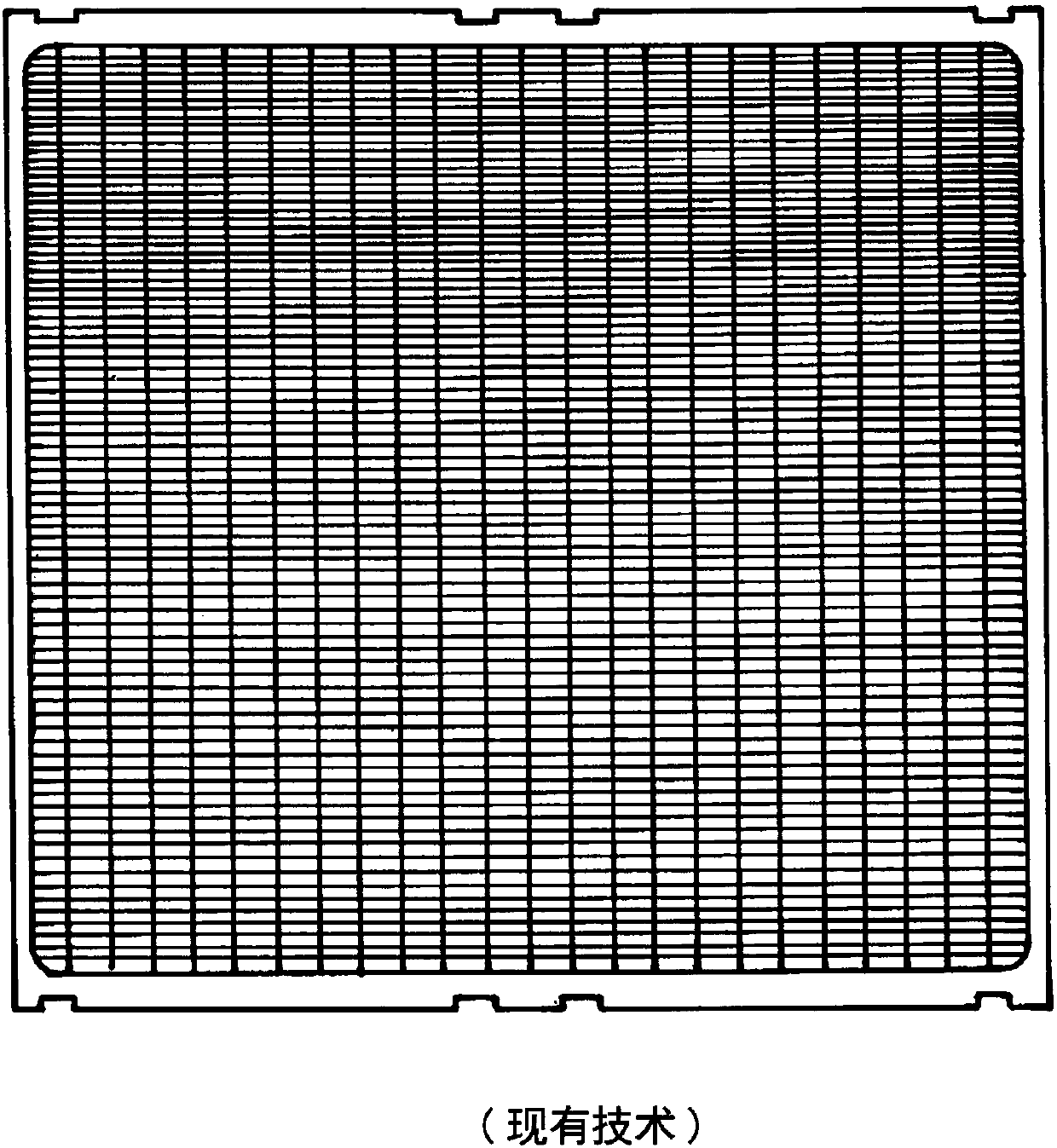

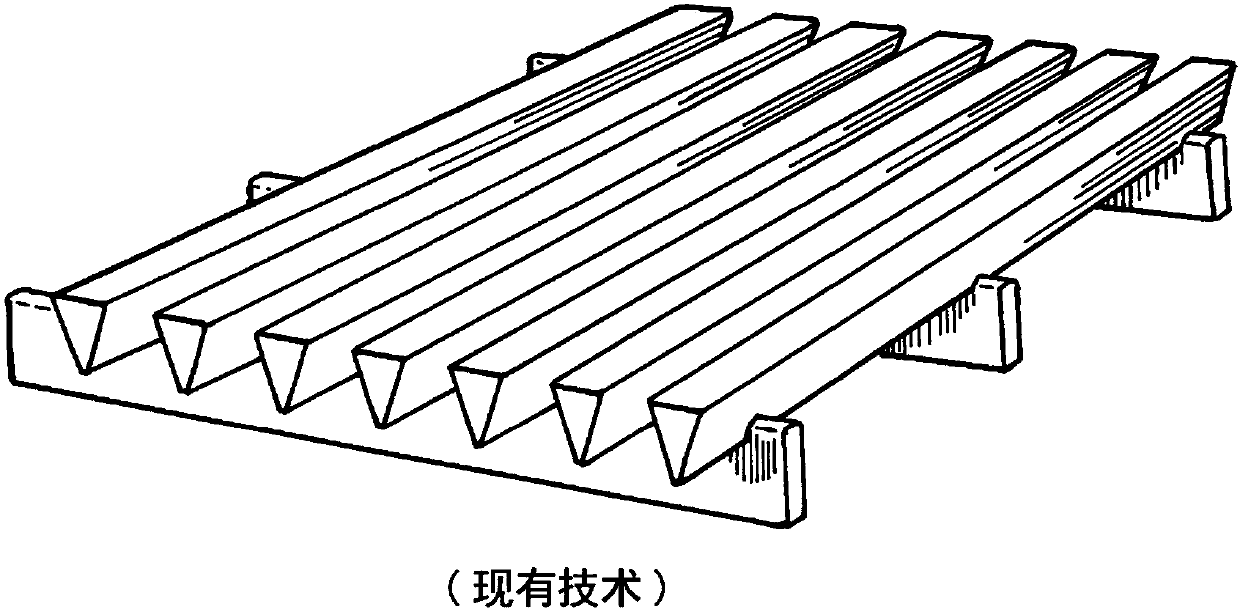

Screening panel

InactiveCN107847983AReduce premature damageLong wear lifeSievingScreeningWire rodStructural engineering

A mining screening panel which has a screening surface consisting of spaced stainless steel profiled wires supported on transversely extending spaced rods or bars in which the cross sectional shape ofthe profiled wires is a vertical truncated diamond. The top portion is an inverted wedge with a flat top with depending diverging sides and the bottom portion is a wedge with dependent converging sides with a flat or convex bottom. The widest portion of the vertical diamond constitutes the notional screening surface and defines the size of the screening aperture. The raised top above the notionalscreening surface provides the wire a wear surface above the aperture and this provides the wedge wire and aperture with a longer wear life, thus reducing change out periods and reduction in premature failure of wedge wire, which in turn reduces operating costs.

Owner:SCHENCK PROCESS AUSTRALIA

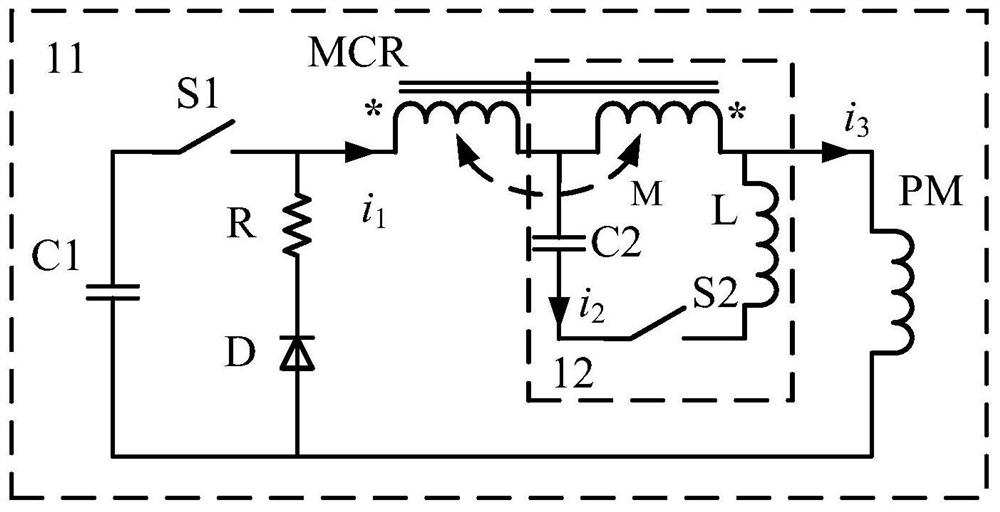

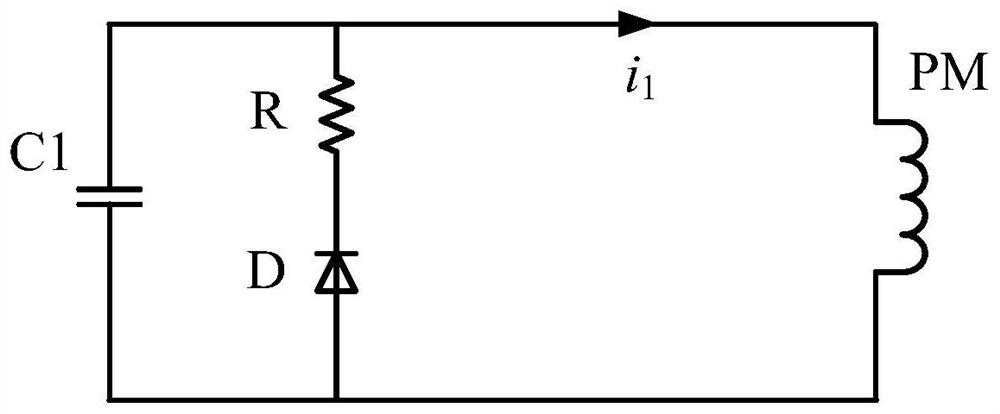

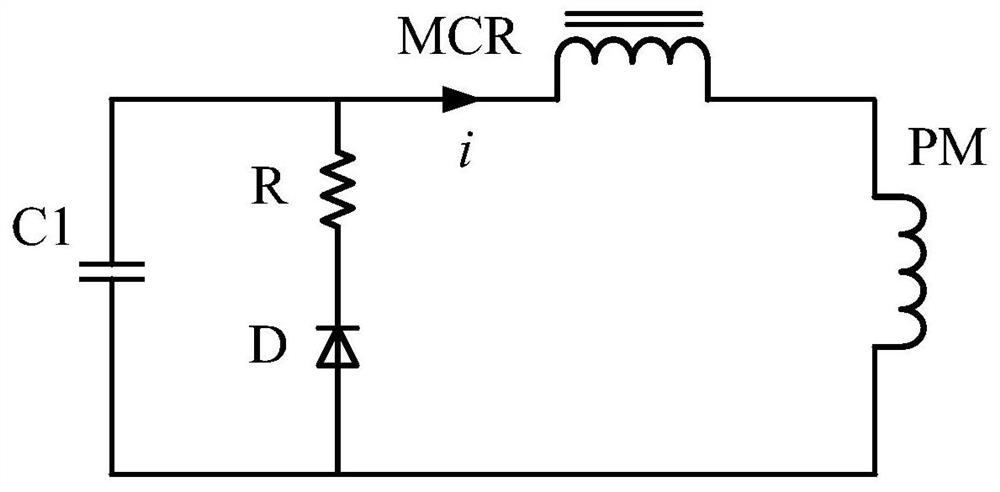

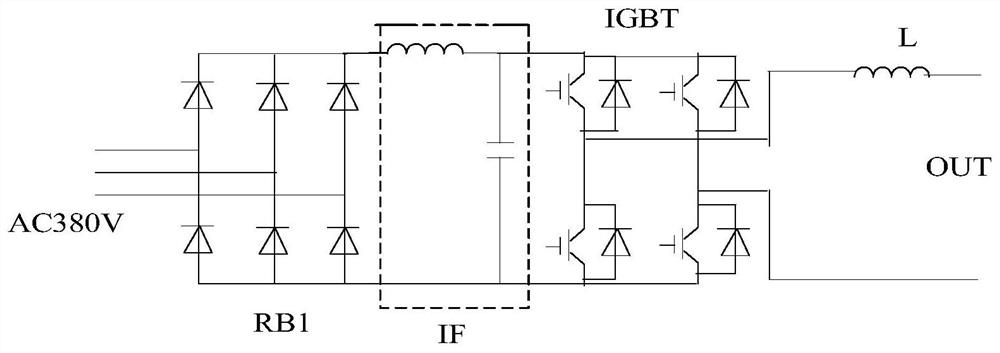

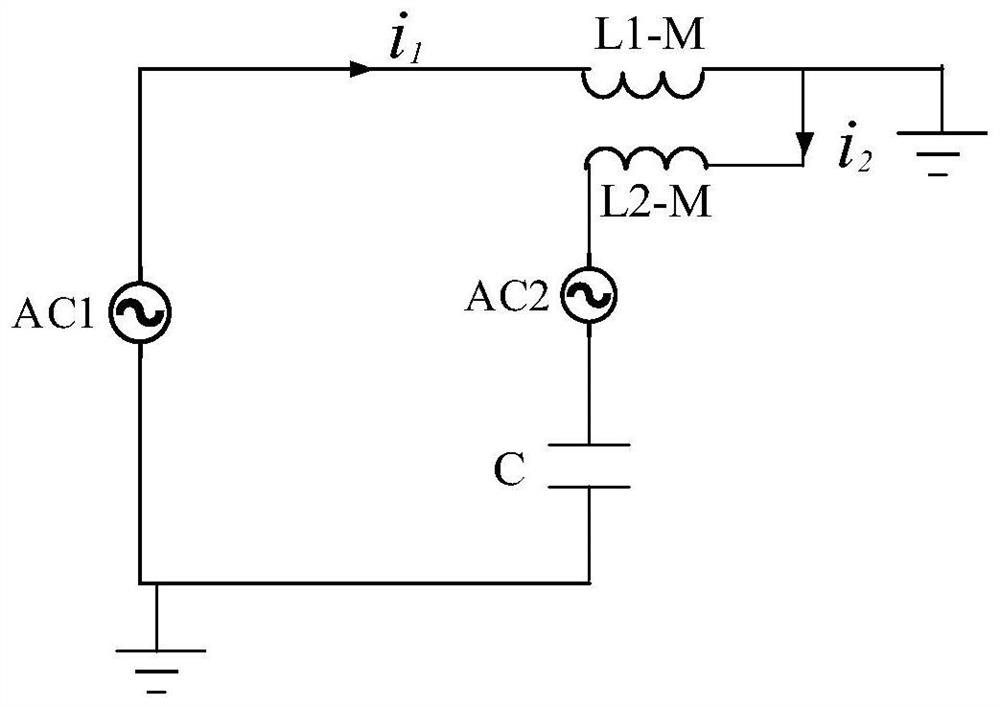

Circuit and method for generating flat-topped pulsed magnetic field

ActiveCN113595432ASimple structureReduce inductanceNuclear energy generationPulse generation by energy-accumulating elementHemt circuitsHigh field

The invention discloses a circuit and a method for generating a flat-topped pulsed magnetic field, and belongs to the technical field of high-intensity magnetic fields. The circuit comprises a main loop and a magnetic control loop. The main loop comprises a first capacitor, a first switch, a double-winding magnetically controlled reactor and a pulse magnet which are sequentially connected in series. The double-winding magnetically controlled reactor in the main loop comprises a first winding and a second winding which are connected in series, and the first winding and the second winding are the same in number of turns and opposite in winding direction. The magnetic control loop comprises a second capacitor, a second switch and an electric reactor which are sequentially connected in series and is connected to the two ends of a second winding of the magnetic control electric reactor. The main loop further comprises a follow current loop connected to the two ends of the first capacitor in parallel. The follow current loop comprises a resistor and a one-way conduction element which are connected to the two ends of the first capacitor. The flat-topped pulsed magnetic field is generated by regulating and controlling the inductance of the double-winding magnetically controlled reactor, and the flat-topped pulsed magnetic field generating device has the characteristics of simple circuit structure, reliable control, low manufacturing cost, high field intensity of the generated flat-topped pulsed magnetic field, good stability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

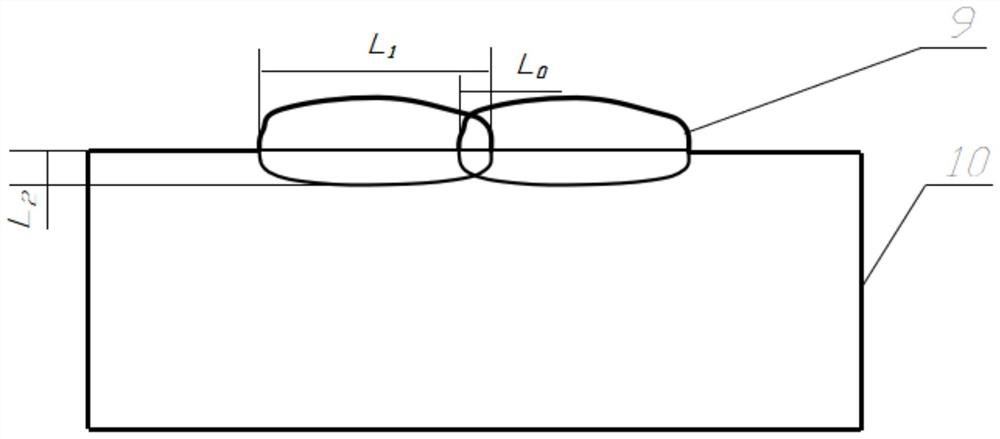

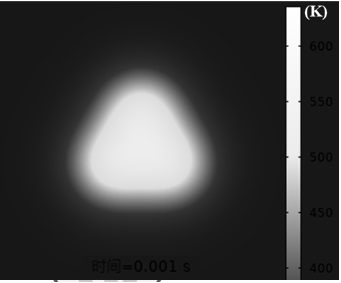

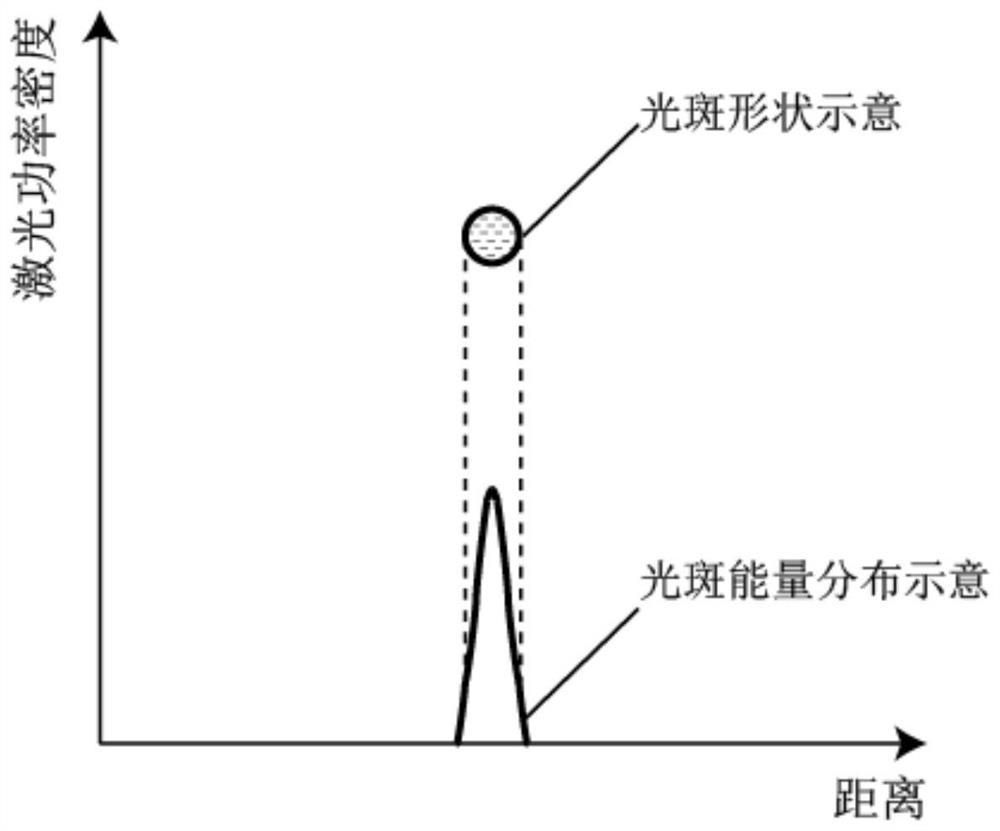

Laser spot shaping device and method for preparing single cladding layer

ActiveCN112501606AIncreasing the thicknessHigh hardnessMetallic material coating processesOptical elementsGeneration rateLight spot

The invention provides a laser spot shaping device and a method for preparing a single cladding layer. The method comprises the following steps that laser technological parameters are set, the a laserbeam is bunched through the laser spot shaping device, and the laser beam is shaped into a flat-top light spot with a certain shape and size; and a base body is preheated at a certain temperature before cladding, then a WC ceramic particle reinforced phase with a certain ratio is added into cladding powder, cladding is carried out by adopting a mode of single-layer multi-channel overlapping and synchronous powder feeding, finally remelting treatment is carried out after cladding is finished, and a sample is taken out and treated in an air cooling mode. The method for preparing a single cladding layer has the advantages of simple structure and low manufacturing cost. The cladding layer with high thickness, high hardness and low crack generation rate can be prepared by the method, and the cladding layer has the advantages of high bonding strength, short preparation time, high efficiency, uniform heating, smooth surface, few cladding defects and the like.

Owner:JIANGSU UNIV

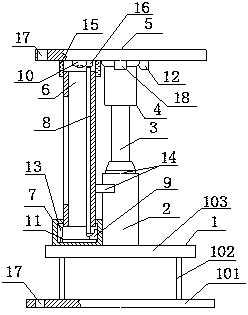

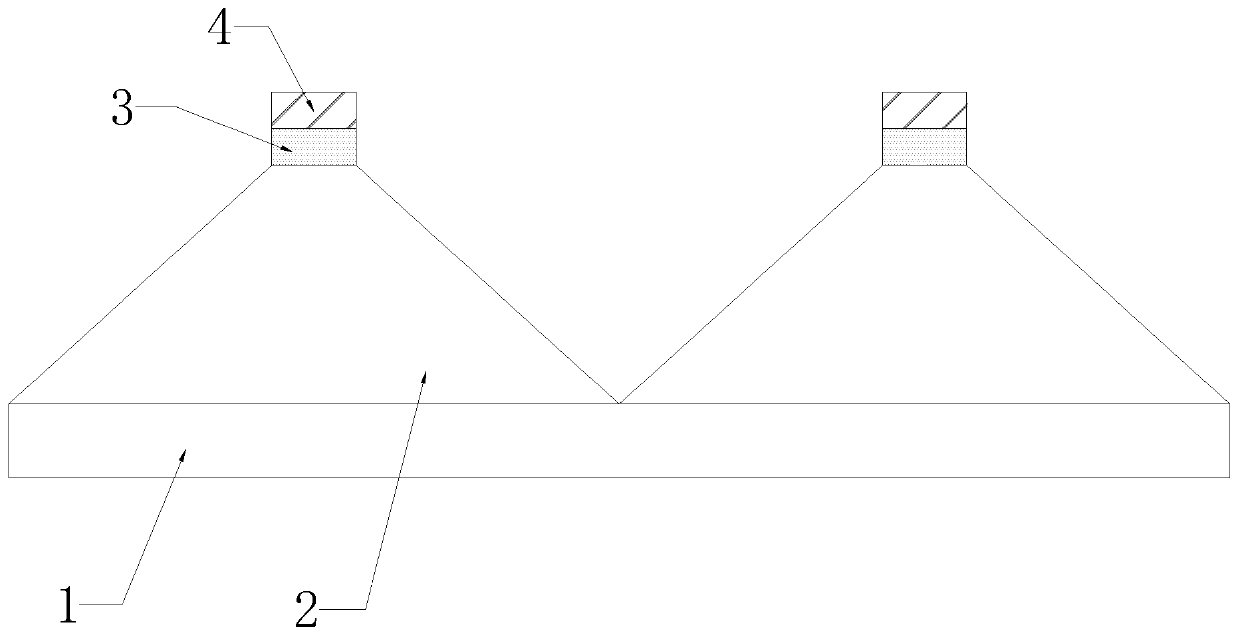

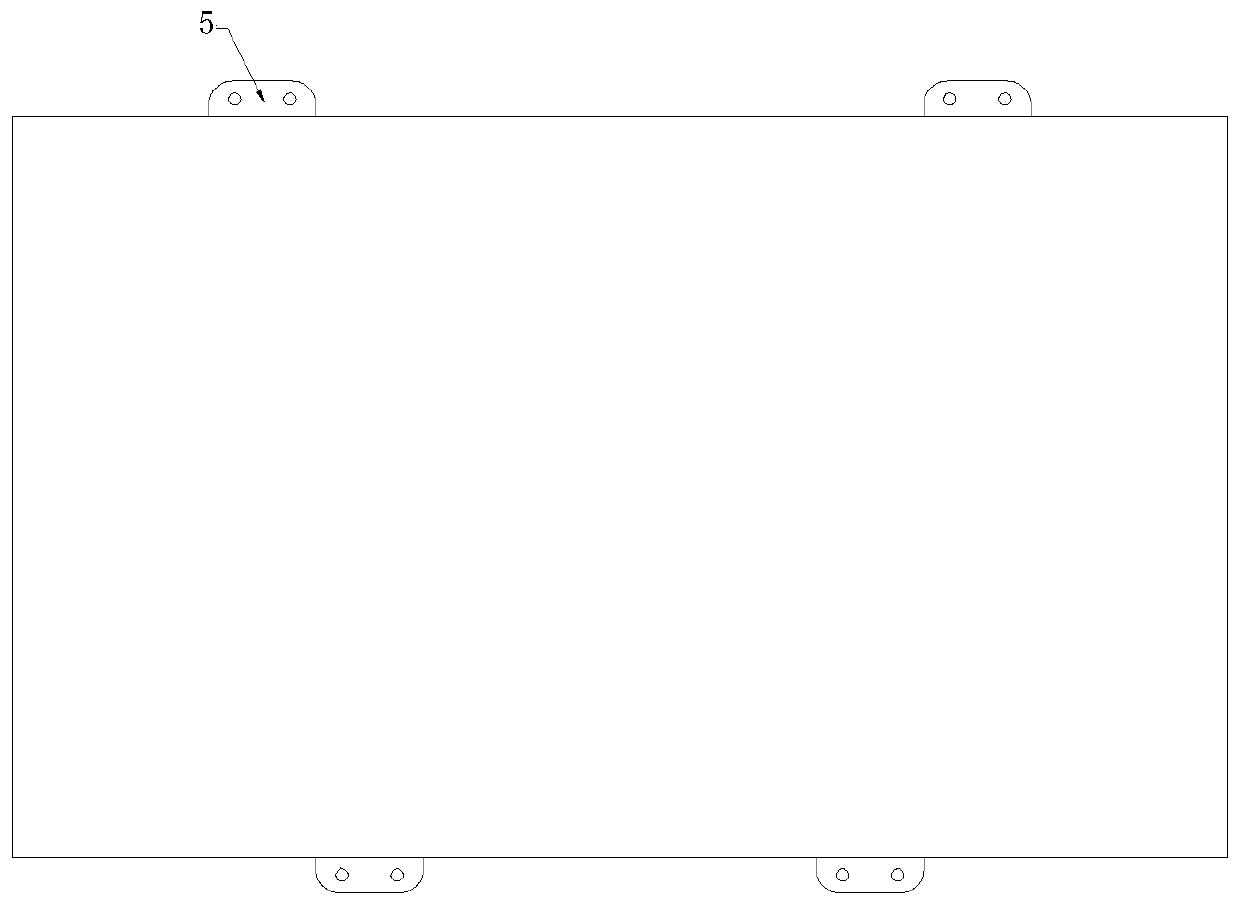

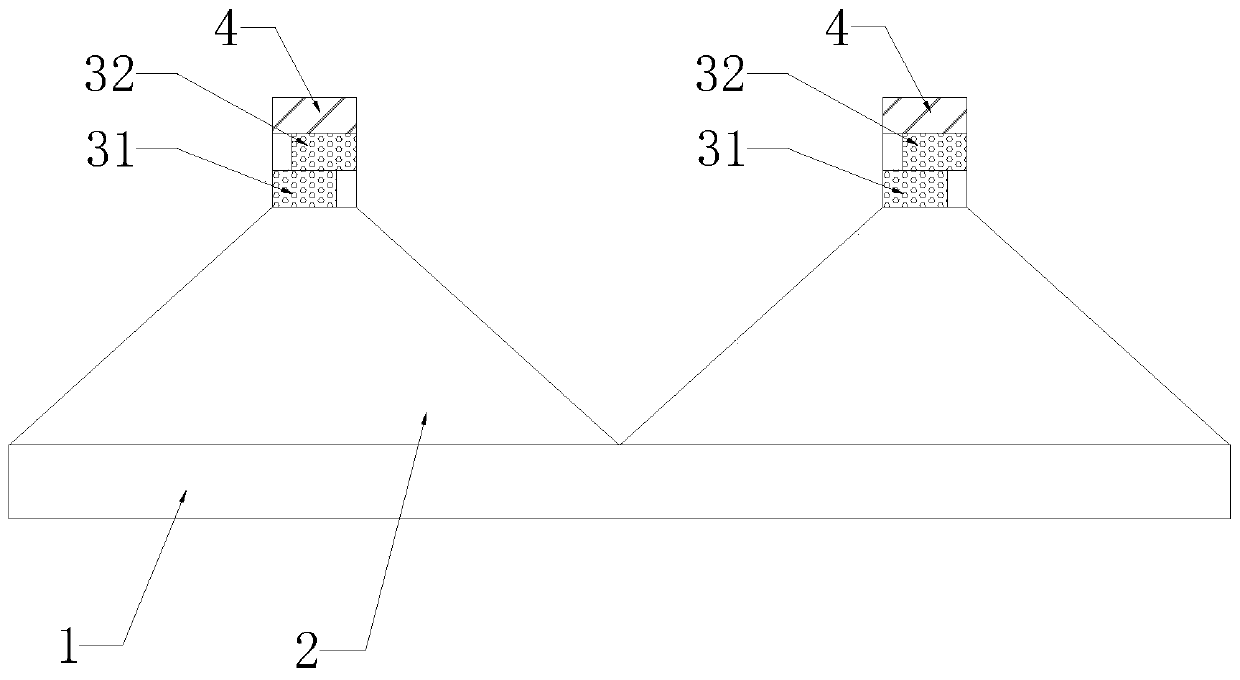

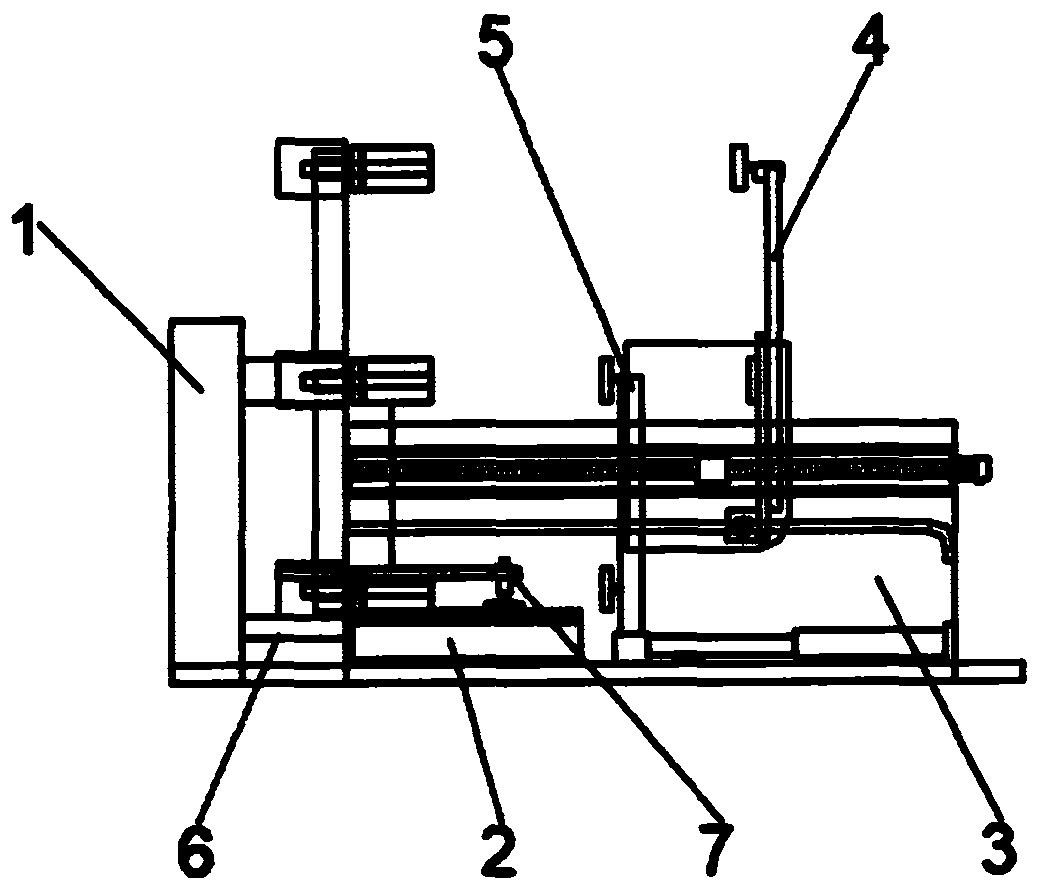

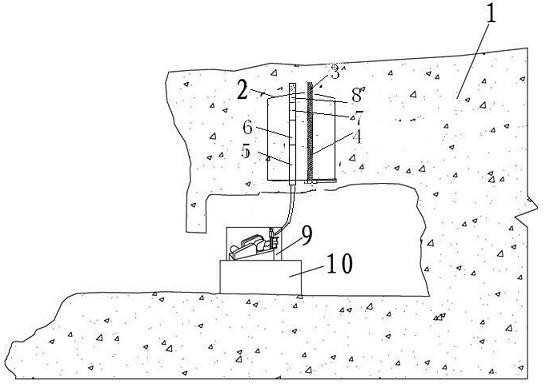

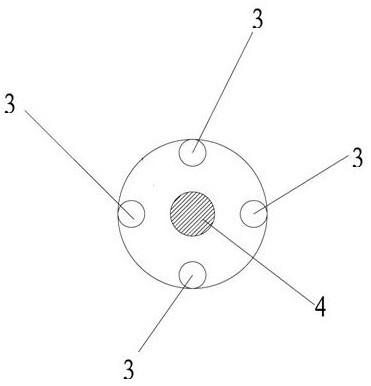

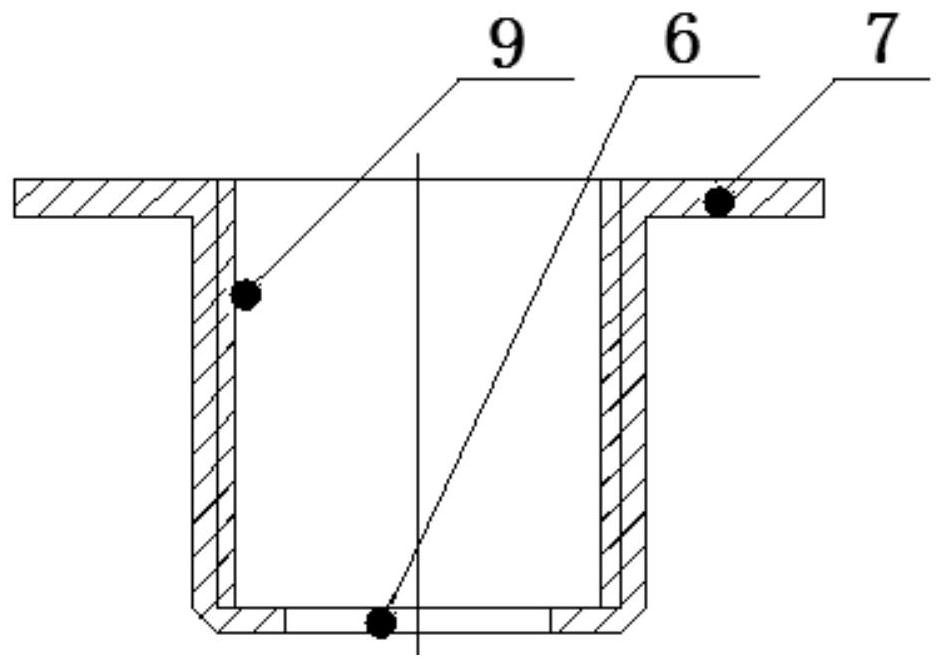

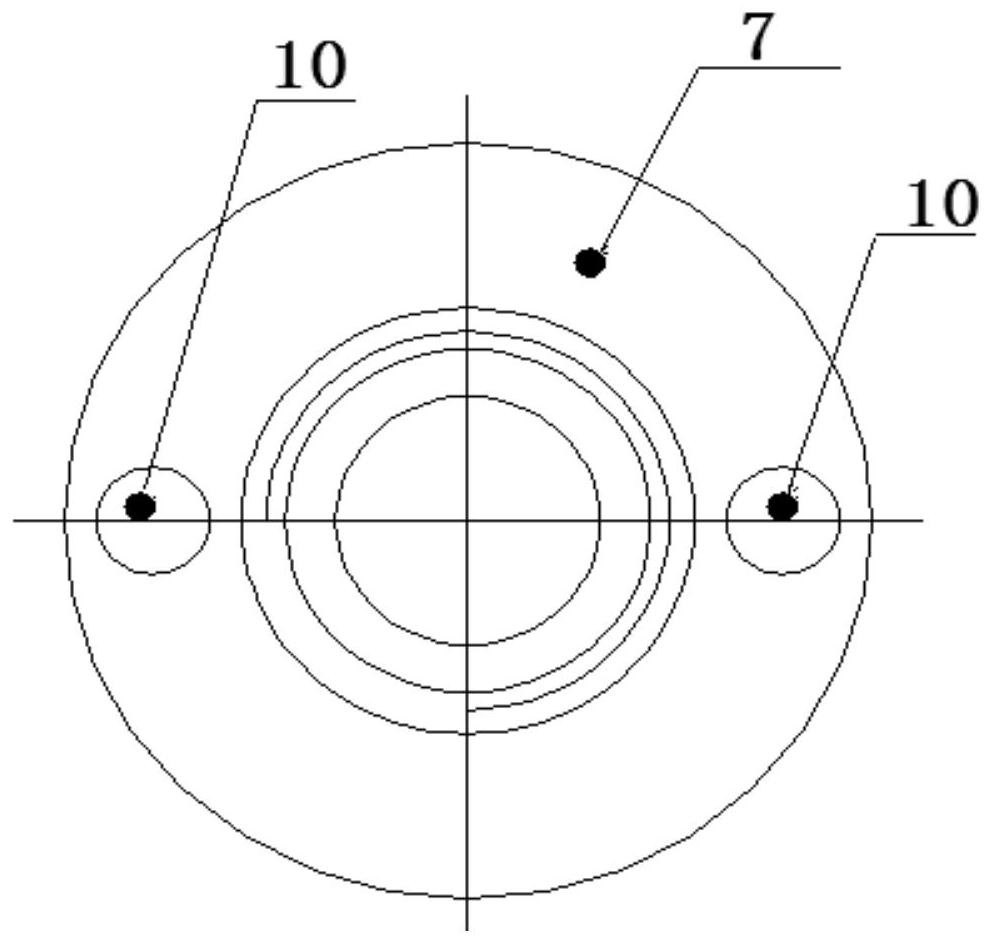

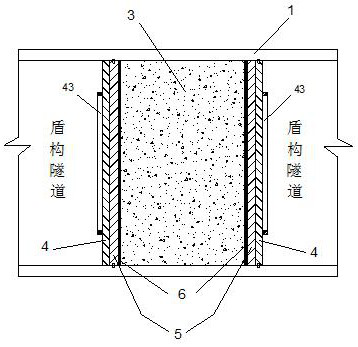

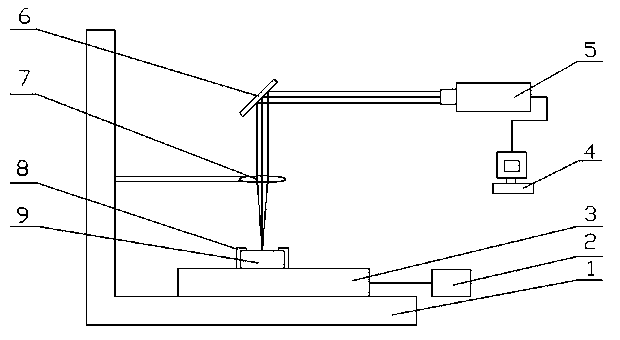

Permanent support device for monitoring displacement of flat top guide hole top plate and support monitoring method

PendingCN110863519ASolve the problem that the measurement points are often destroyedMeet the needs of continuous displacement monitoring operationsFoundation testingExcavationsLaser transmitterControl engineering

The invention discloses a permanent support device for monitoring displacement of a flat top guiding hole top plate. The permanent support device comprises a bearing base, a bearing column, a guidingscrew rod, a bearing screw sleeve, a supporting plate, a sheath pipe, a control room, a traction pull rope, a pressure sensor and a control circuit. The upper end surface of the bearing base is connected with the bearing column. The upper end surface of the bearing column is connected with the guiding screw rod through a positioning mechanism. The bearing screw sleeve is in meshing connection withthe guiding screw rod. The upper end surface of the bearing screw sleeve is hinged to the lower end surface of the supporting plate. The sheath pipe is connected with the bearing column through the positioning mechanism. The lower end surface communicates with a control room. The traction pull rope and a laser transmitter are located in the sheath pipe. A support monitoring method of the permanent support device comprises the two steps of equipment assembly and support monitoring. The permanent support device is simple in system composition, flexible and convenient to install, daily operateand maintain, has little influence on site construction, and can be widely applied to guiding hole support and top plate settlement monitoring in subway station hole pile method construction.

Owner:BCEG CIVIL ENG +1

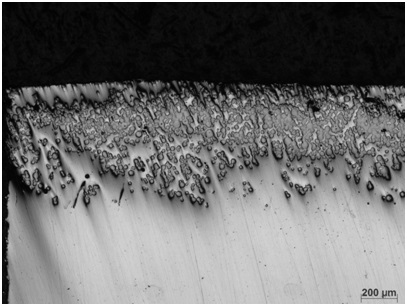

Laser additive technology for preparing tungsten-copper composite material with infinite thickness

ActiveCN113042746ASimple manufacturing processAchieve preparationAdditive manufacturing apparatusManufactured materialLaser additive manufacturing

The invention discloses a laser additive preparation method of an infinite-thickness tungsten-copper composite material. A copper substrate, copper powder and tungsten powder are used as raw materials, a laser additive system is adopted, laser adopts a mode that a plurality of beams of light are converged into flat-top light, tungsten powder and copper powder are synchronously and alternately fed by adopting the center of a cladding head to form combination in which the light coats the powder, and a tungsten-copper alloy layer and a copper layer are alternately formed on the copper substrate. In the alloying stage, the tungsten powder is sent out, copper on the surface of the pure copper is melted, and the tungsten powder is alloyed to form the tungsten-copper alloy layer; and in the copper layer cladding stage, only copper powder is sent out, and copper cladding is carried out on the tungsten-copper alloying layer line by line, so that a copper deposition layer is formed. According to the laser additive preparation method, the laser cladding technology and the laser alloying technology are organically combined, the tungsten-copper density difference is changed into the advantage, and the hysteresis effect of a static magnetic field inhibits movement of tungsten particles in a molten pool; and the tungsten-copper composite layer prepared through laser additive manufacturing can achieve manufacturing of large-size components through multi-layer accumulation.

Owner:ZHEJIANG UNIV

Scratch-resistant brightness enhancement film

The invention discloses a scratch-resistant brightness enhancement film. The film comprises a base material, a prism layer is arranged on the outer surface of the upper end of the base material, a reflecting layer is arranged on the outer surface of the upper end of the prism layer, and a rough layer is arranged on the outer surface of the upper end of the reflecting layer. According to the scratch-resistant brightness enhancement film, the base material is mainly made of a PET material, the thickness is 15 to 300 [mu]m. The prism layer adopts a flat-top microstructure, a reflecting layer is added to the flat top area, the invalid light source which originally passes through the flat top area is reflected to the backlight module reflector plate and then is recycled. When passing through the prism microstructure again, the recovered light can pass through the prism inclined plane effective area or be reflected again and recovered. The rough layer is additionally arranged on the flat topreverse side layer plane, the adsorption phenomenon between the plane structure and the upper layer optical film can be avoided, and therefore under the condition that the abrasion resistance of thebrightness enhancement film is improved, the optical function and adsorption avoiding can be achieved at the same time, and better use prospects are brought.

Owner:苏州龙桥光电有限公司

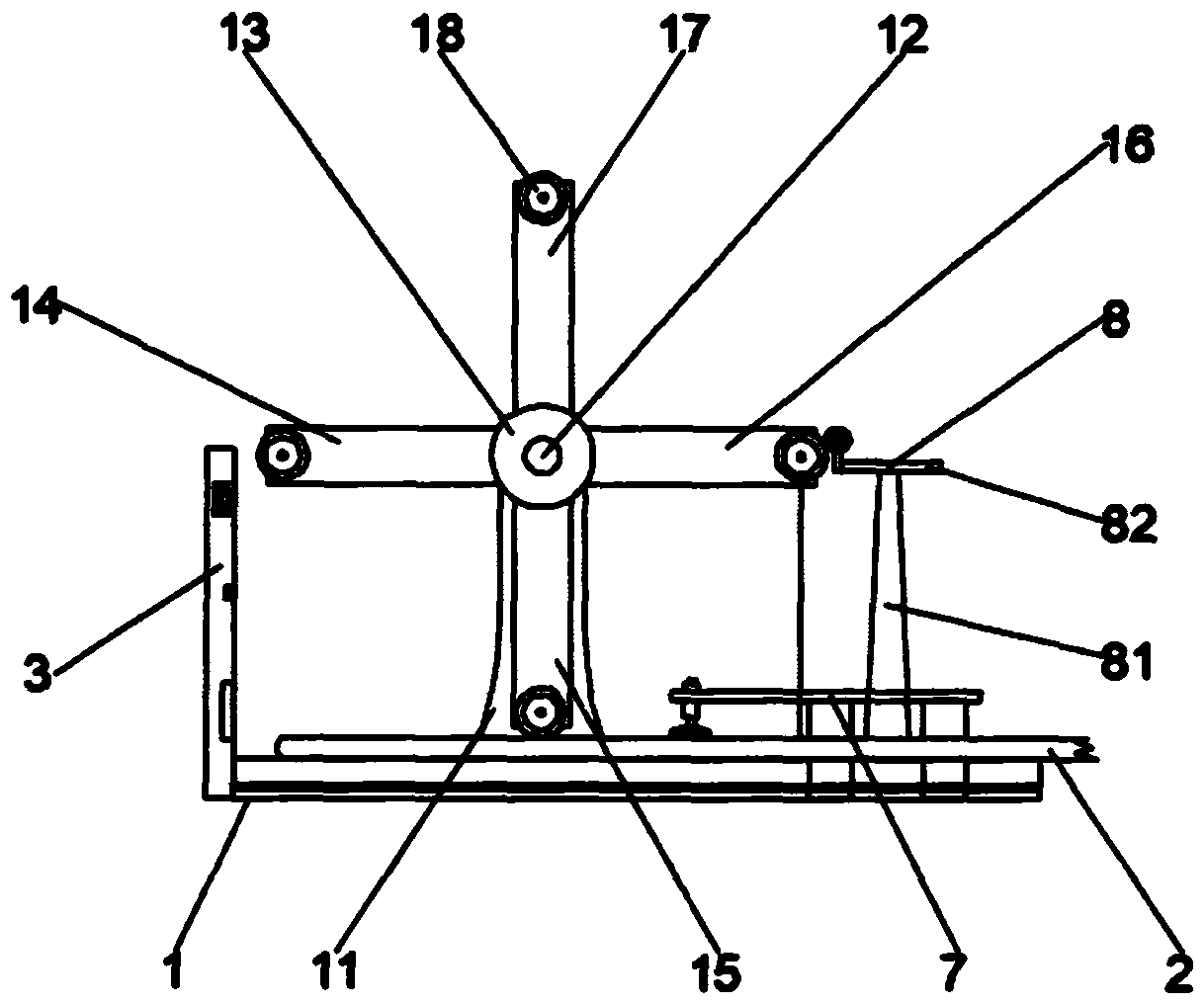

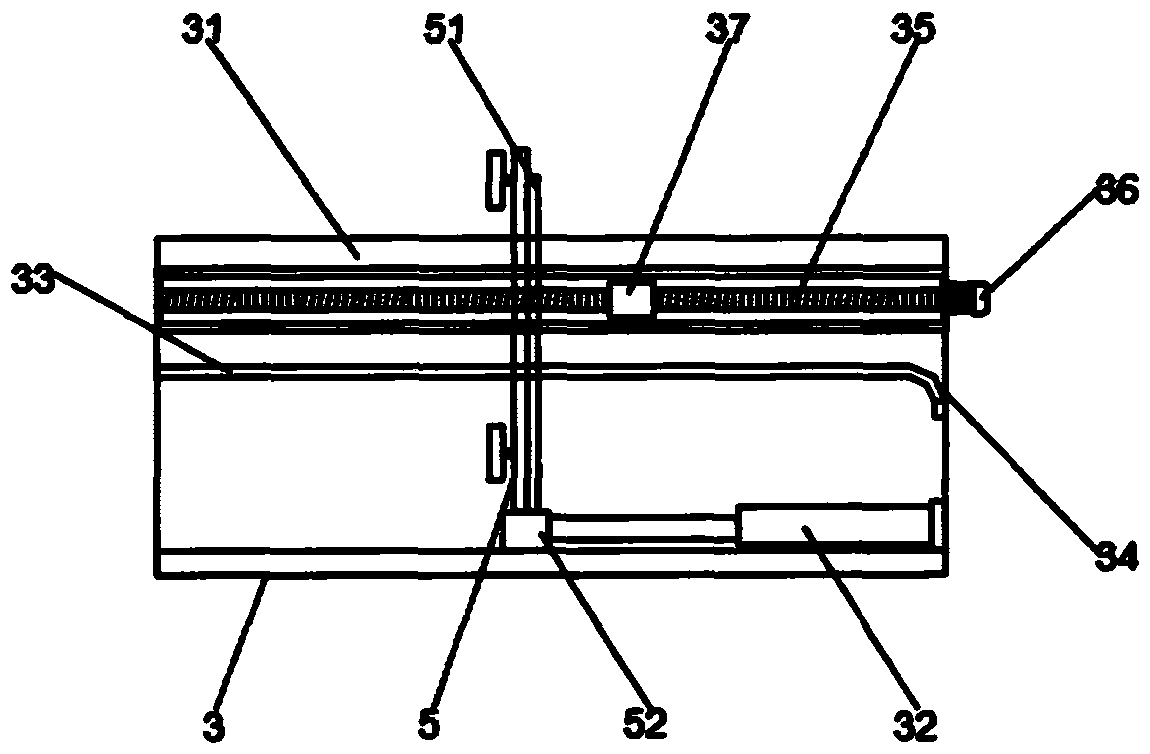

Flat top and flat cover structure automatic labeling device

PendingCN110949810AImprove labeling efficiencyAchieve stabilityLabelling machinesStructural engineeringConveyor belt

The invention discloses a flat top and flat cover structure automatic labeling device and relates to the technical field of paper tube processing. The flat top and flat cover structure automatic labeling device comprises an alternating assembly, a track assembly, a feeding-in and taking-out assembly, a first fixing assembly and an edge folding assembly. A driving belt is mounted below one side ofthe alternating assembly. The track assembly is mounted on the side, close to the driving belt, of the alternating assembly. The feeding-in and taking-out assembly is mounted on the middle portion ofthe track assembly. The first fixing assembly is mounted on one side of the feeding-in and taking-out assembly. The edge folding assembly is mounted on the side, far away from the track assembly, of the alternating assembly. The alternating assembly comprises a stand column, a main rotary shaft, a rotary support, a first moment arm, a second moment arm, a third moment arm, a fourth moment arm androtary fixing tubes. The flat top and flat cover structure automatic labeling device can realize a mechanized form in the whole automatic tube body labeling process, achieves labeling automation, greatly improves the production efficiency and qualified rate and saves a lot of manpower resources.

Owner:LANGFANG JUNXING YIMEI PACKAGING PROD CO LTD

Inverted grouting method suitable for flat-top cave roof rock mass anchoring engineering

ActiveCN112942339ASolve the problem of decreased anchoring capacityFilled tightlyBulkheads/pilesPipeRock bolt

The invention relates to an inverted grouting method suitable for flat-top cave roof rock mass anchoring engineering. The inverted grouting method comprises the steps that in the anchor rod mounting process, a plurality of grouting pipes extending into drill holes by different lengths are buried, then a multi-time grading grouting and hole bottom grout returning method is adopted, through multi-time grouting, the gravity problem in the vertical grouting process from bottom to top is solved, the grout filling compactness is ensured, and the grouting quality of the anchoring engineering is effectively improved. The inverted grouting method breaks through the limitation of a traditional grouting method of stone cultural relic protection anchoring engineering, can be used for anchoring grouting in different directions and at different angles, provides a new grouting method for flat-top cave roof cracking rock mass anchoring engineering, and also provides a new thought for research and engineering application in the field of geotechnical engineering.

Owner:DUNHUANG ACAD

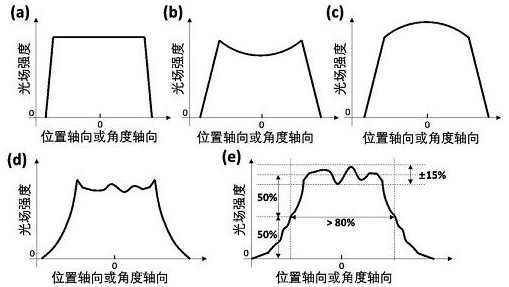

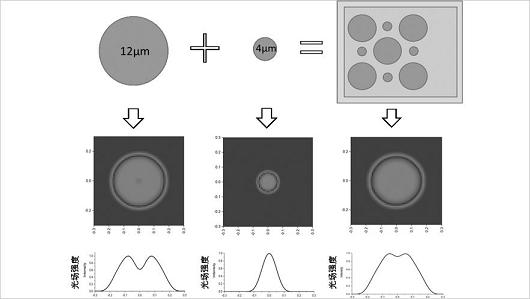

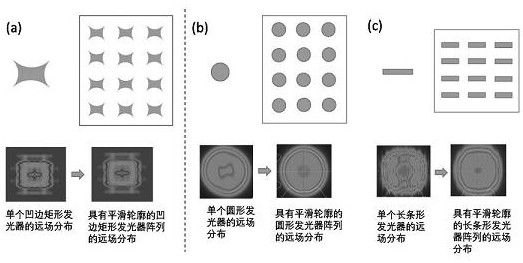

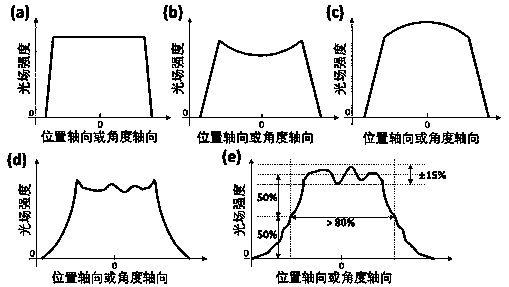

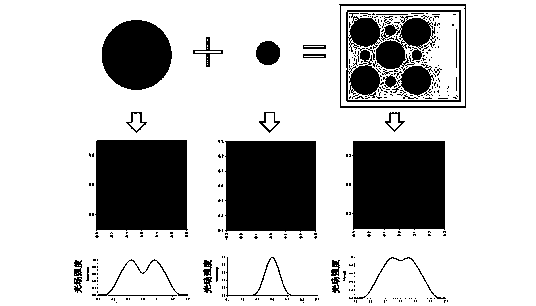

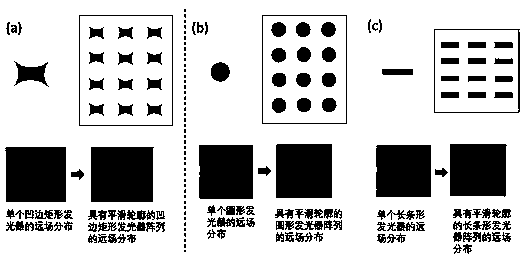

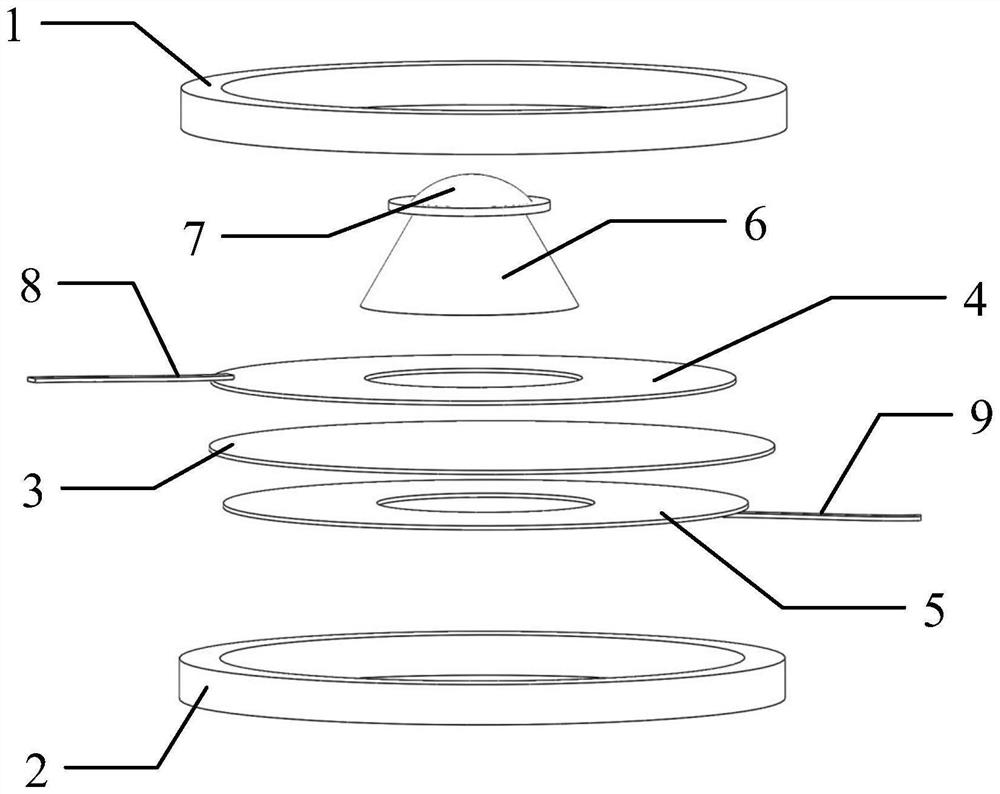

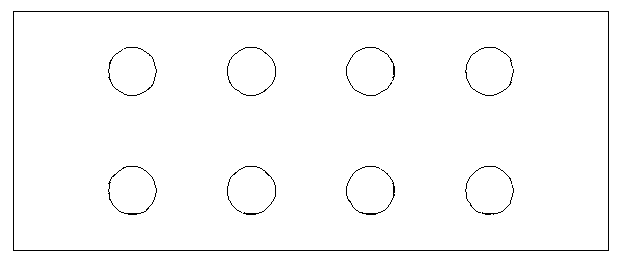

A vcsel array, manufacturing method, flat-top far-field generation method, and lighting module

ActiveCN110649466BUniform flat-top far-field distributionLow costSemiconductor laser arrangementsProjectorsEngineeringMaterials science

Owner:VERTILITE CO LTD

VCSEL array, manufacturing method thereof, flat-top far-field generation method and lighting module

ActiveCN110649466AEasy to controlLow costSemiconductor laser arrangementsProjectorsEngineeringMaterials science

The invention provides a VCSEL array, a manufacturing method thereof, a flat-top far-field generation method and a lighting module. Compared with a traditional VCSEL array, the VCSEL array of the invention can easily achieve a uniform flat-topped far field without arranging optical elements such as a diffuser, so that the cost of the array and the corresponding module is remarkably reduced while the requirements of TOF measurement and the like are well met. The elimination of the diffuser makes a corresponding sidewall column, a diffuser cover and other components omitted, so the thickness ofthe module is obviously reduced, and the module has multiple advantages which do not exist in the prior art.

Owner:VERTILITE CO LTD

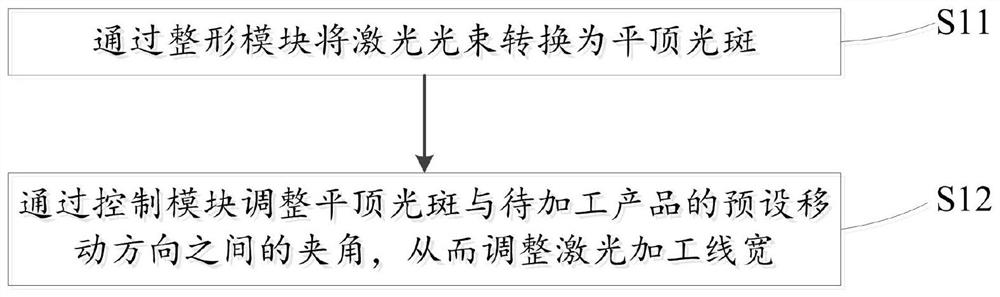

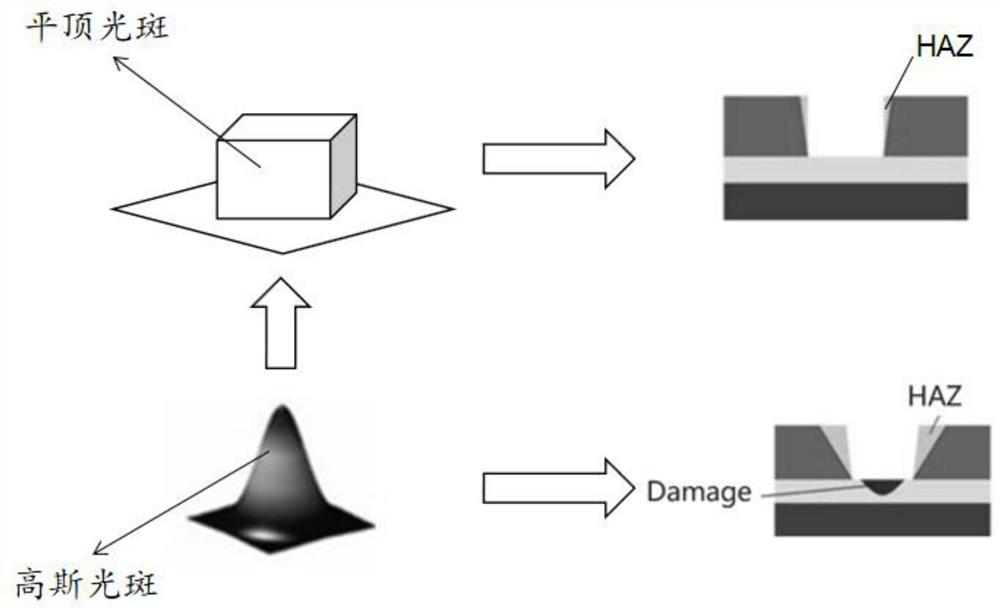

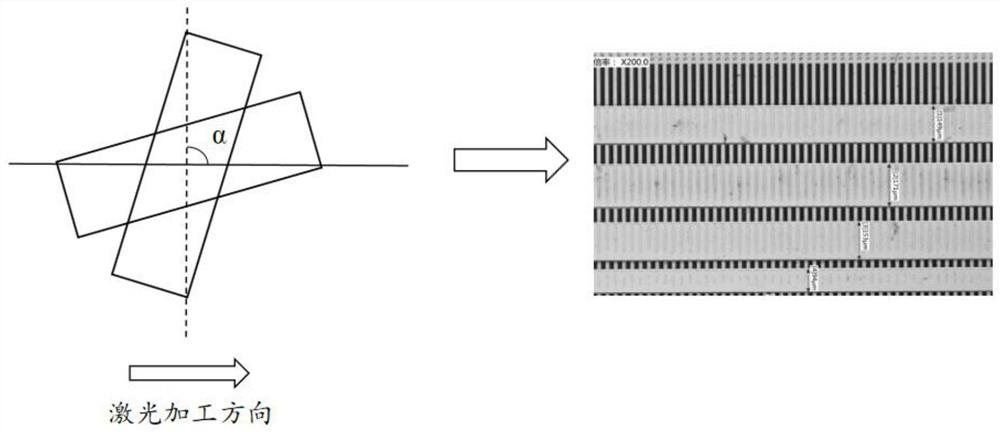

Laser machining method and device capable of changing line width

PendingCN113275736AEvenly distributedImprove the quality of laser processingLaser beam welding apparatusLaser processingLight spot

The invention relates to a laser machining method and device capable of changing the line width. The laser machining method comprises the steps of converting a Gaussian light spot into a flat-topped light spot through a shaping module; and adjusting an included angle between the flat-topped light spot and a preset moving direction of a to-be-processed product through a control module so as to adjust the laser machining line width to adapt to different machining widths. By means of the laser machining method and device capable of changing the line width, the included angle between the flat-topped light spot and the preset moving direction can be adjusted for the different line widths, repeated laser machining is not needed, and the laser machining time is saved.

Owner:苏州科韵激光科技有限公司

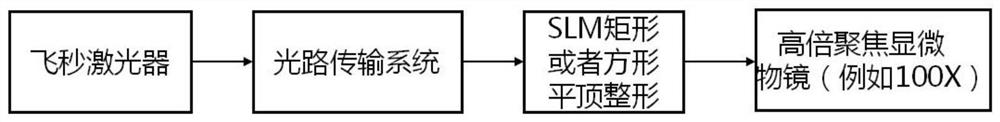

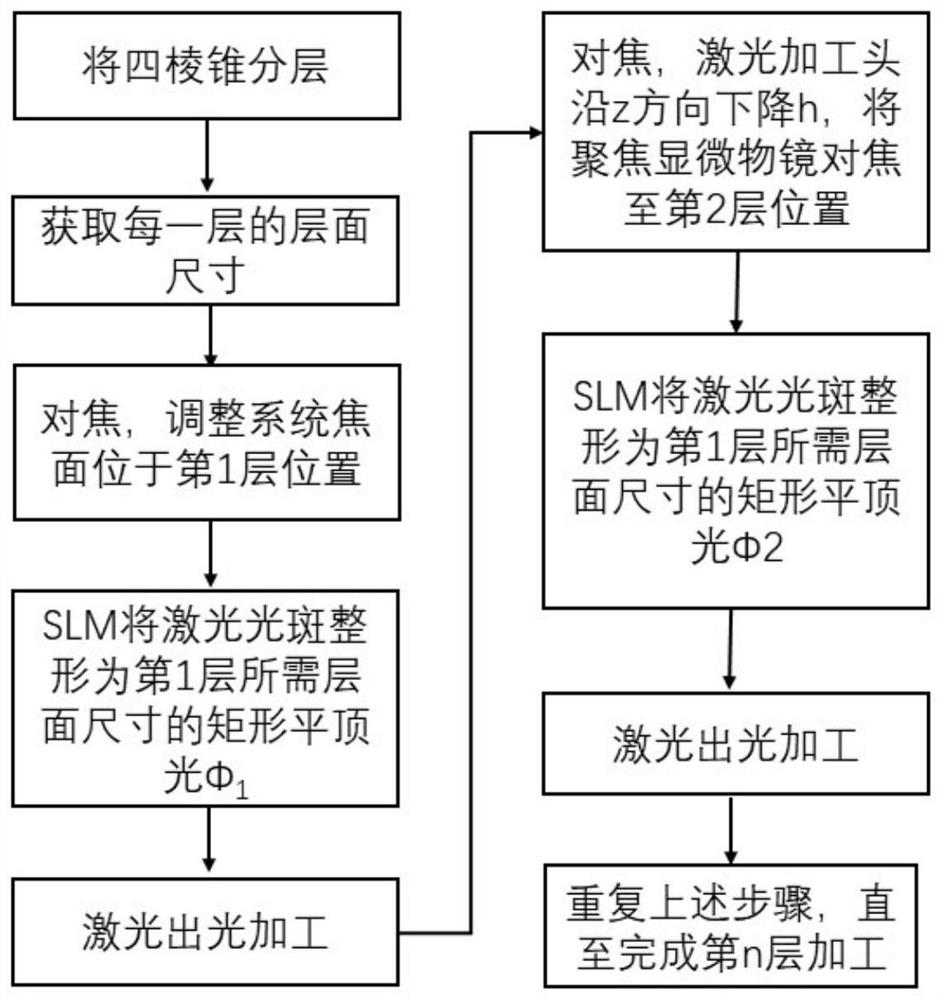

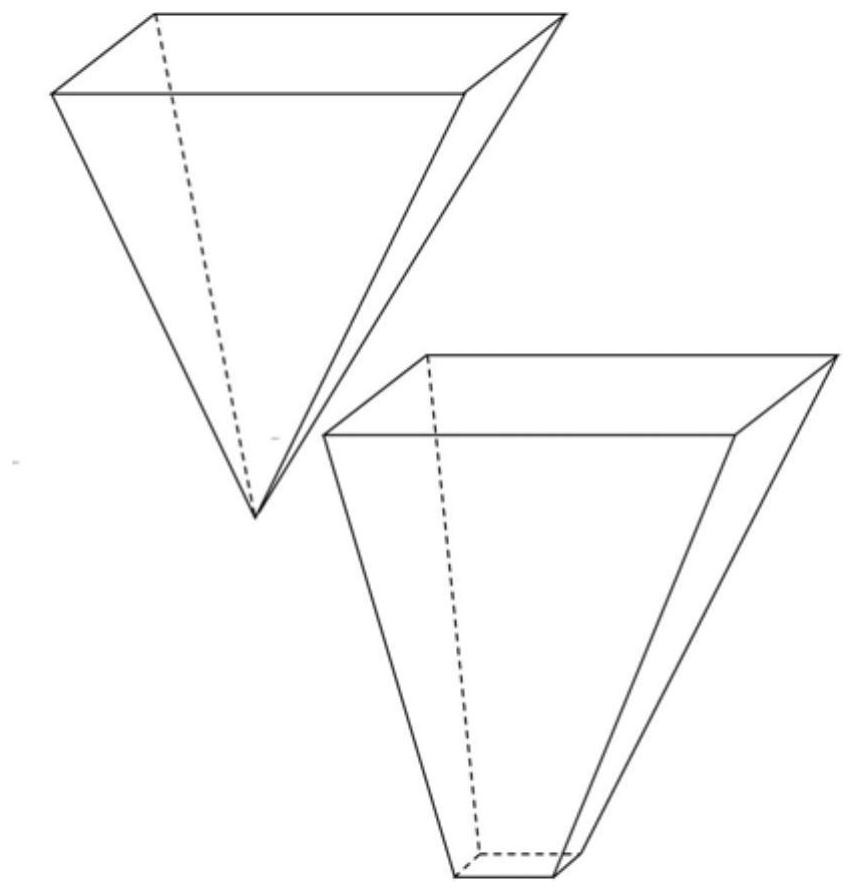

Manufacturing method and system for anti-reflective micro-nano structure with inverted pyramidal truncated/square pyramidal shape

ActiveCN111055009BEasy to processImprove the anti-reflection and anti-reflection rateLaser beam welding apparatusMicron scaleNano structuring

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Integral type flat top plate structure of railway vehicle

PendingCN113859283AGuaranteed StrengthGuaranteed stiffnessRailway roofsRailway lightingIntelligent lightingClassical mechanics

An integral type flat top plate structure of a railway vehicle is characterized in that the integral type flat top plate structure comprises an inner light-transmitting PC plate, an outer light-transmitting PC plate and a middle interlayer foam honeycomb, a decorative film adheres to the exposed face of the outer light-transmitting PC plate, light-transmitting holes are locally formed in a spotlight area of the decorative film, and an embedded type threaded sleeve is installed on the back face of a flat top plate and used for installing and fixing a spotlight body of a lighting system. A spotlight hole is formed in the bottom of the threaded sleeve, and a fastening nut is arranged at the tail of the spotlight and used for fixing an optical fiber light source connected into the lamp body. On the premise that the strength and the rigidity of the flat top plate are guaranteed, the overall weight can be effectively reduced, and the purpose of reducing the weight of the whole vehicle is achieved. The embedded threaded sleeve is installed on the flat top plate and used for installing and fixing the spotlight body of the intelligent lighting system, the situation that holes are additionally formed in the flat top plate for spotlight installation is avoided, meanwhile, the spotlight body and the top plate are integrated, and the integrity and attractiveness of the flat top plate are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

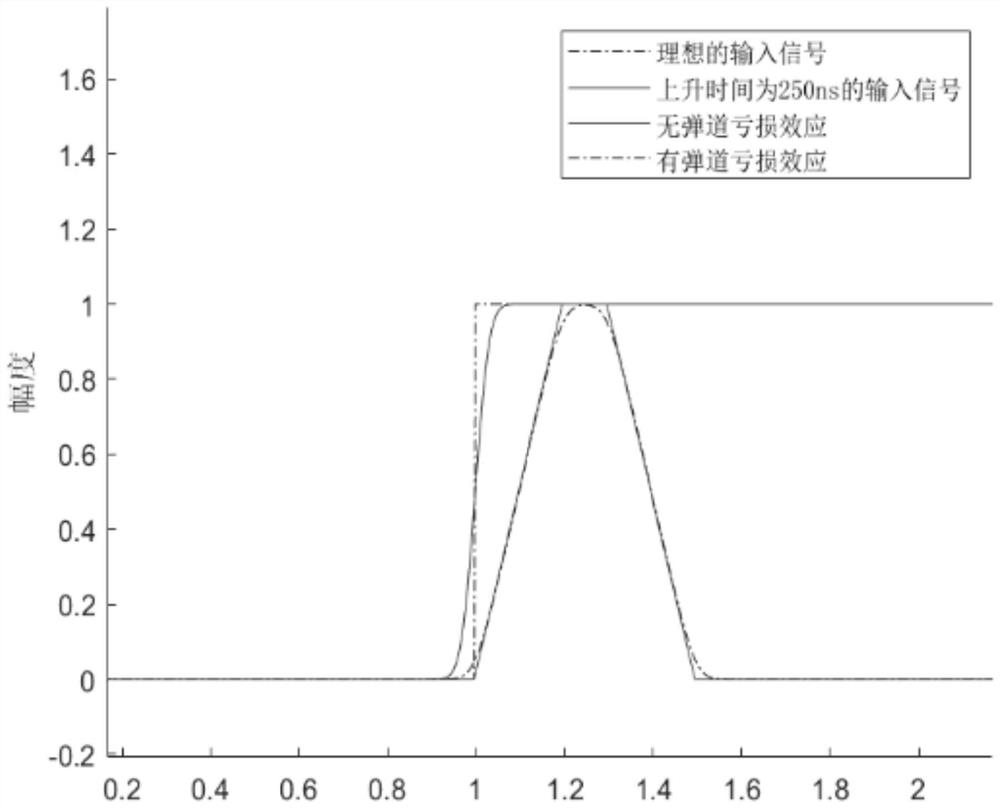

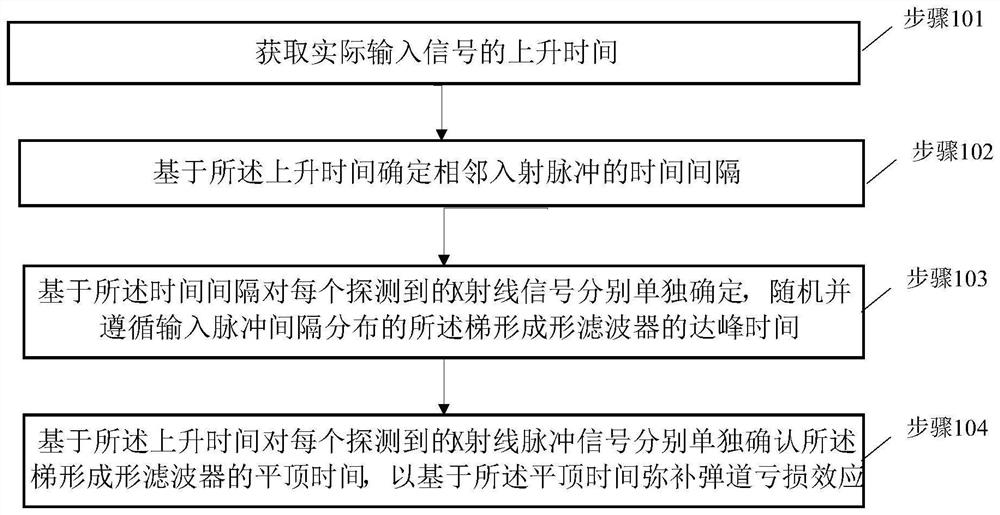

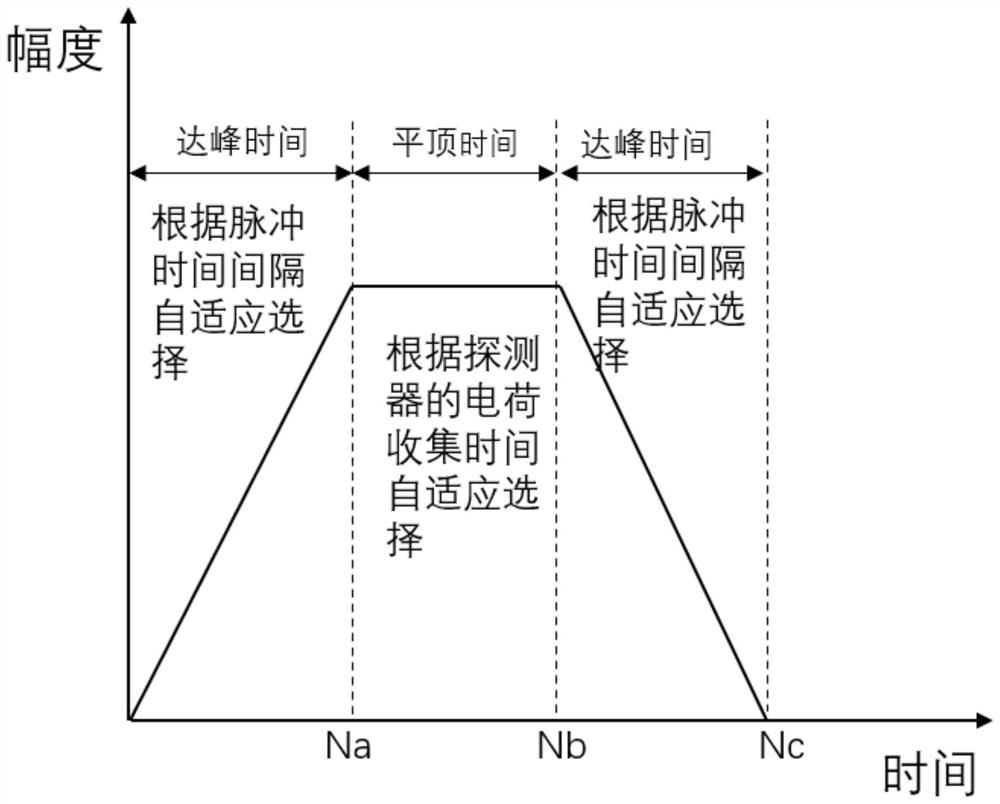

Forming time adaptive digital pulse filtering method and device and electronic equipment

PendingCN114660650AHigh pulse count rateImproved energy resolutionImpedence networksRadiation intensity measurementNuclear radiationCounting rate

The invention discloses a digital pulse filtering method and device with self-adaptive forming time and electronic equipment, and relates to the technical field of nuclear radiation detection. The method comprises the following steps: acquiring rise time of an actual input signal; determining a time interval of adjacent incident pulses based on the rise time; on the basis of the time interval, the peak reaching time of the trapezoidal shaping filter which is randomly distributed according to the input pulse interval is independently determined for each detected X-ray signal, so that the higher pulse counting rate is realized; and based on the rise time, separately confirming the flat-top time of the trapezoidal shaping filter for each detected X-ray pulse signal, so as to compensate for the ballistic loss effect based on the flat-top time. The method is adaptive to the flattop time of the trapezoidal filter, and the flattop time of each detected X-ray is independently selected, so that higher energy resolution is realized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

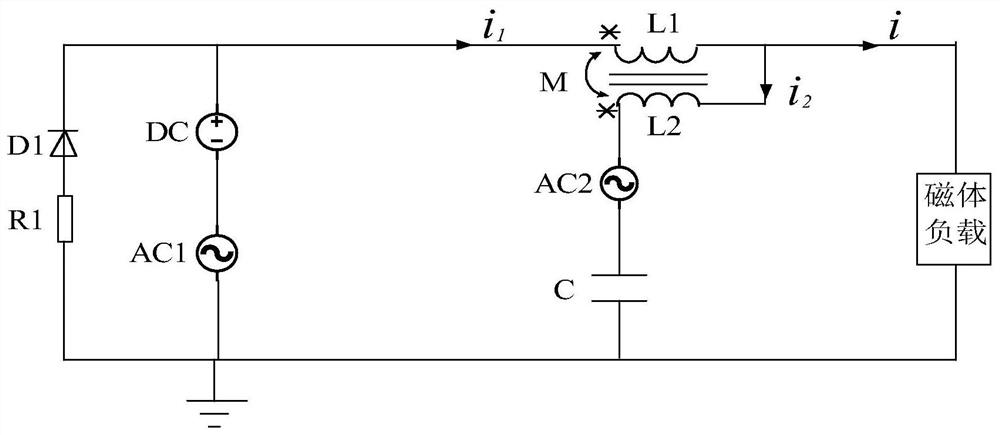

A flat-top pulse strong magnetic field realization device

ActiveCN111342696BGood compensationLow powerElectric pulse generator circuitsPower conversion systemsCapacitanceAc components

The invention discloses a device for realizing flat top pulsed strong magnetic field, which belongs to the technical field of pulsed strong magnetic field. Including: the main discharge circuit composed of the main power supply, the primary side of the coupling transformer, and the magnet load connected in sequence; the compensation discharge circuit composed of the secondary side of the coupling transformer, the AC compensation power supply, the compensation capacitor, and the magnet load connected in sequence; the resistor and the diode connected in series Finally, the freewheeling circuit of the magnet load formed by connecting in parallel at both ends of the main power supply; among them, the compensation discharge circuit can compensate the fundamental frequency ripple component, high frequency ripple and switching ripple component in the magnetic field, resulting in a high stability flat top pulsed magnetic field. The invention adopts the method of combining passive magnetic flux coupling filtering and active filtering to offset the AC component of the main power supply current, realize a high-stability DC current waveform, and then generate a high-stability flat-top pulse strong magnetic field on the magnet load .

Owner:HUAZHONG UNIV OF SCI & TECH

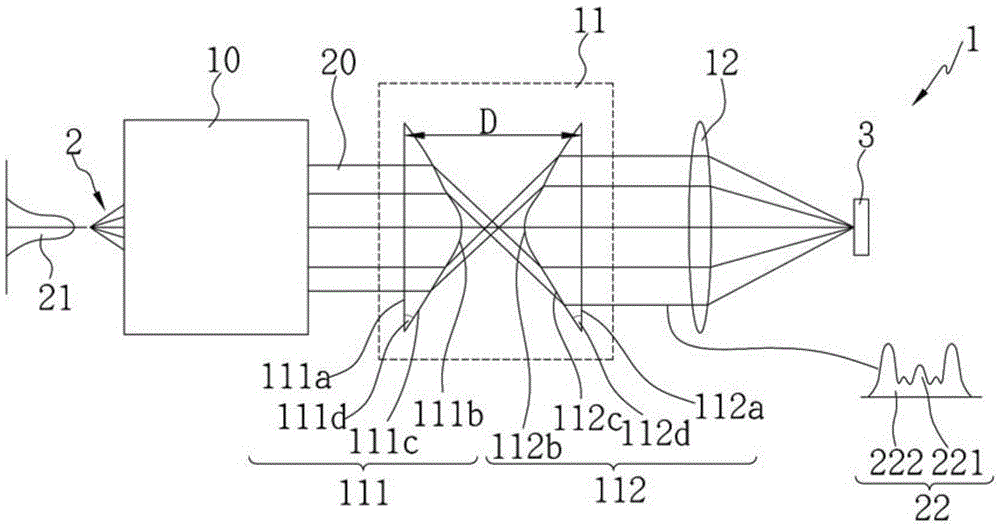

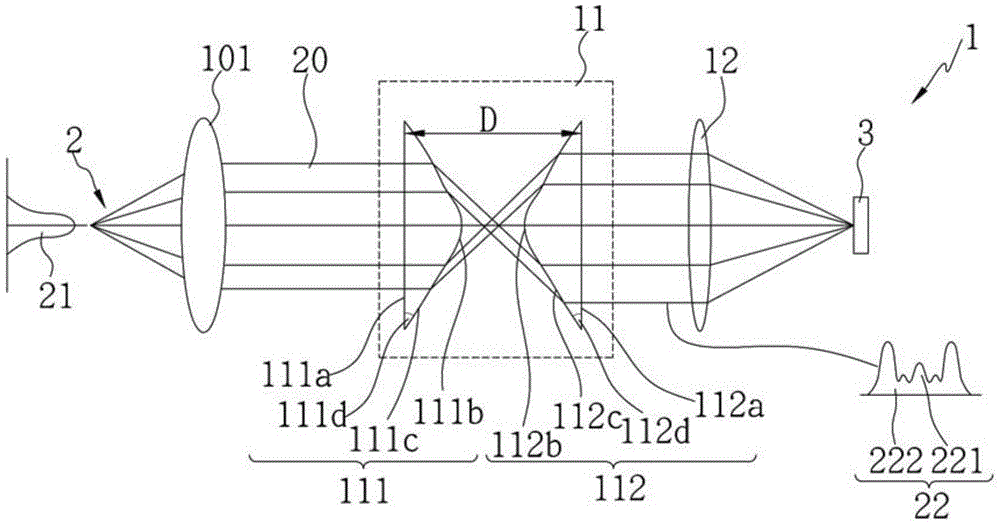

Zoom system and method without mechanical moving part

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

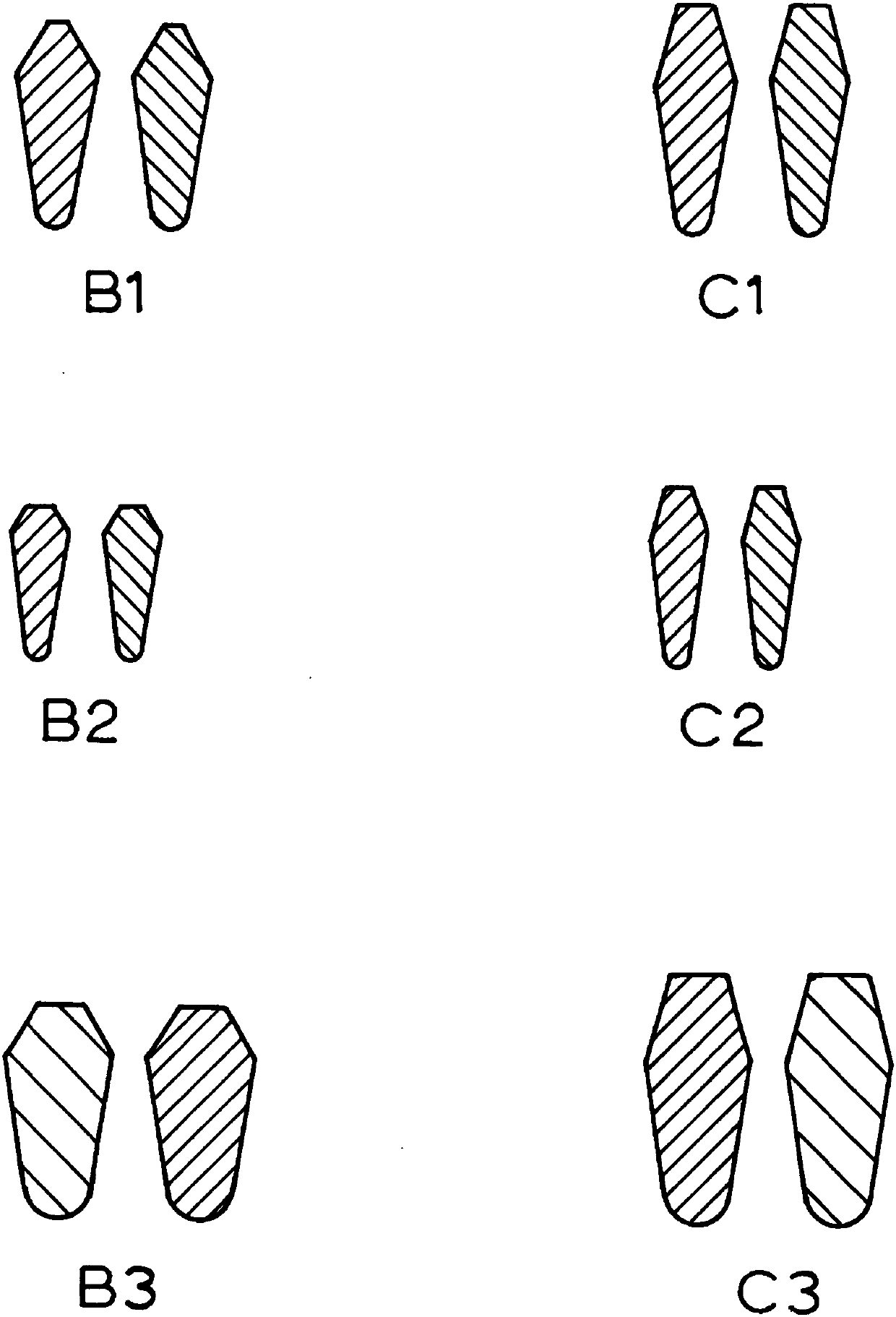

Reflective material mold with flat-top microprism array and preparation method thereof

ActiveCN113635495BReduce wear rateExtended service lifeOptical articlesOptical elementsBlind zoneBlind spot

The invention discloses a reflective material mold with a flat-top microprism array and a preparation method thereof. The reflective material mold is formed by a unit flat-top microprism array, and the side surfaces of the unit flat-top microprisms are quadrangular. The present invention uses a V-shaped knife to plan a fine V-shaped groove in the first direction, and then enters the next planing direction to plan a fine V-shaped groove after the first direction is completely planed. The structure has the same unit planar The reflective material mold of the top microprism array; this preparation method not only reduces the number of planing times, improves the mold production efficiency, and reduces the difficulty of planing, but also produces a flat top microprism array reflective material that meets the large-angle incidence and observation conditions. Maintaining the superior characteristics of high retroreflection coefficient helps to improve the visibility of reflective signage in large viewing angle range, especially on high-speed entrance and exit ramps, interchange curve guide roads and other road sections with large visual blind spots, and improves the safe driving factor .

Owner:福建跃发光新材料股份有限公司

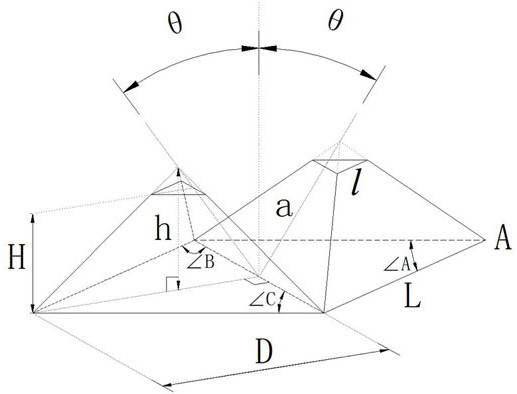

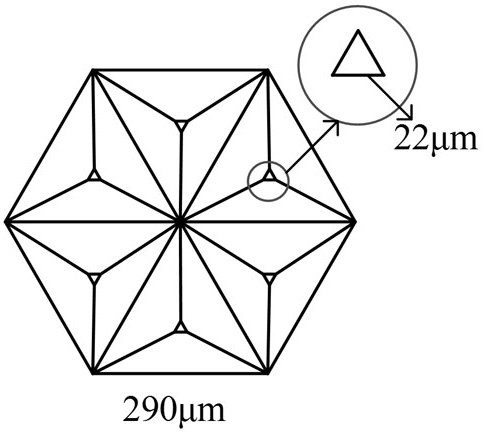

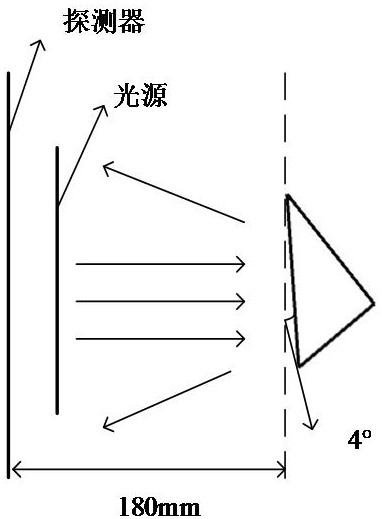

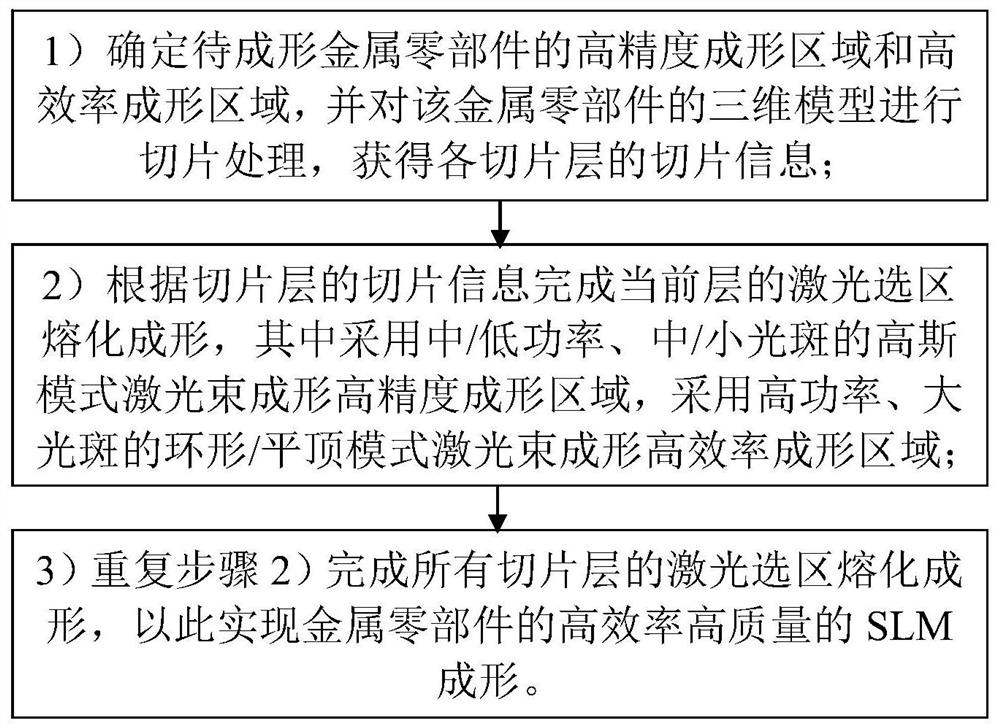

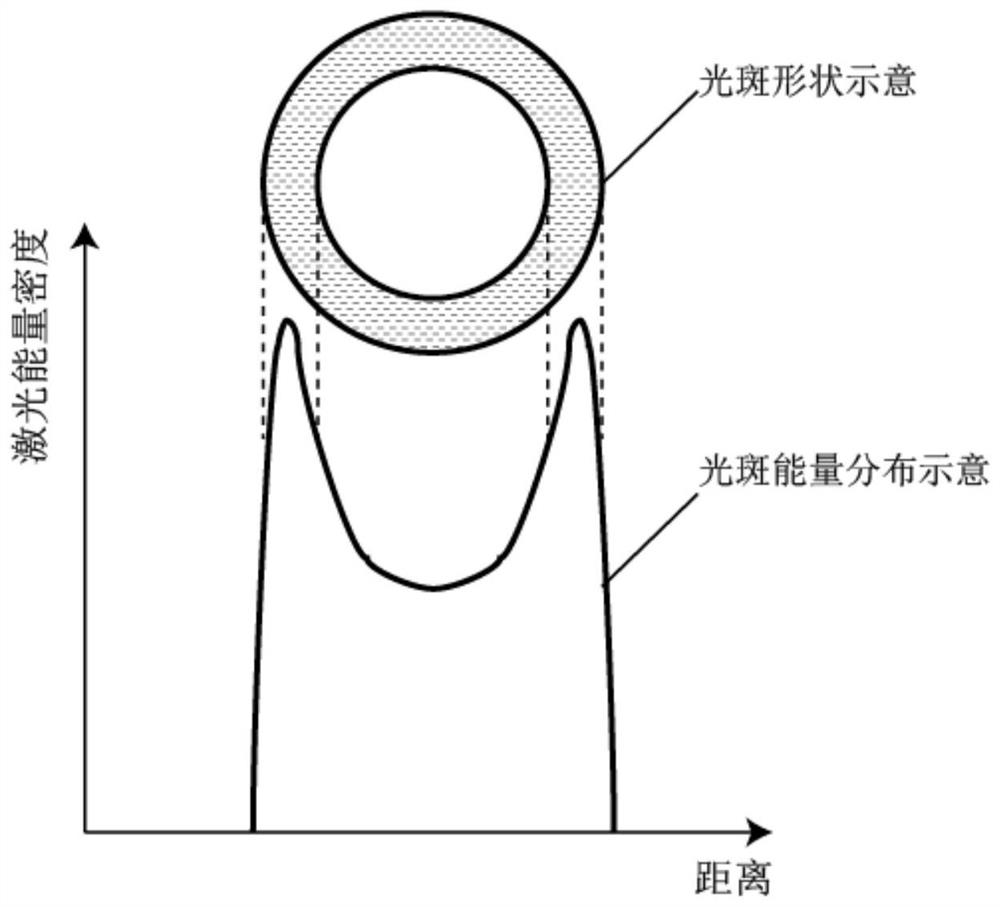

A dual-beam slm forming method and system that takes into account forming efficiency and forming quality

ActiveCN112276081BUniform temperature distributionReduce residual stressAdditive manufacturing apparatusIncreasing energy efficiencyDual beamLaser beams

The invention belongs to the technical field of advanced manufacturing, and specifically discloses a double-beam SLM forming method and system that takes both forming efficiency and forming quality into consideration. High-precision forming of parts, using high-power, large-spot laser beam with energy distribution in a ring or flat-top mode to achieve high-efficiency forming of metal parts, so as to achieve high-efficiency and high-quality SLM forming of metal parts. The invention can realize the close metallurgical combination of the high-efficiency forming area and the high-precision forming area, effectively suppress the formation of internal metallurgical defects such as insufficient fusion and large particle inclusions, significantly reduce the residual stress of the forming material, and realize the high efficiency of metal parts. High quality SLM forming.

Owner:HUAZHONG UNIV OF SCI & TECH

The Construction Method of Excavating the Station Structure by Tunnel First and Then the Station Pipe-curtain Pile Method

ActiveCN111677520BReduce economic costsUnderground chambersTunnel liningPilot holeArchitectural engineering

The invention discloses a construction method for excavating a station structure by first tunneling and then station pipe curtain hole pile method. During construction, four pilot tunnels are respectively arranged on the upper and lower floors, wherein there is a leading pilot tunnel in the upper layer pilot tunnel, and the preceding pilot tunnel is used to excavate the station structure. As the working space for the installation of pipe curtains, there is no pipe curtain support above the first pilot tunnel and the four lower pilot tunnels, and the primary support is provided with a vaulted straight wall structure. The pilot tunnels are used as side piles and central steel pipe columns. Space, after the installation of the pipe curtain is completed, the remaining three upper pilot holes on the upper floor will be excavated with a flat roof and straight wall structure. It is also suitable for the excavation of shallow and deep buried stations, which ensures that the environmental facilities are almost unaffected, and thus saves economic costs. It has strong economic benefits and social value, and can be widely used in similar projects.

Owner:HAINAN UNIV

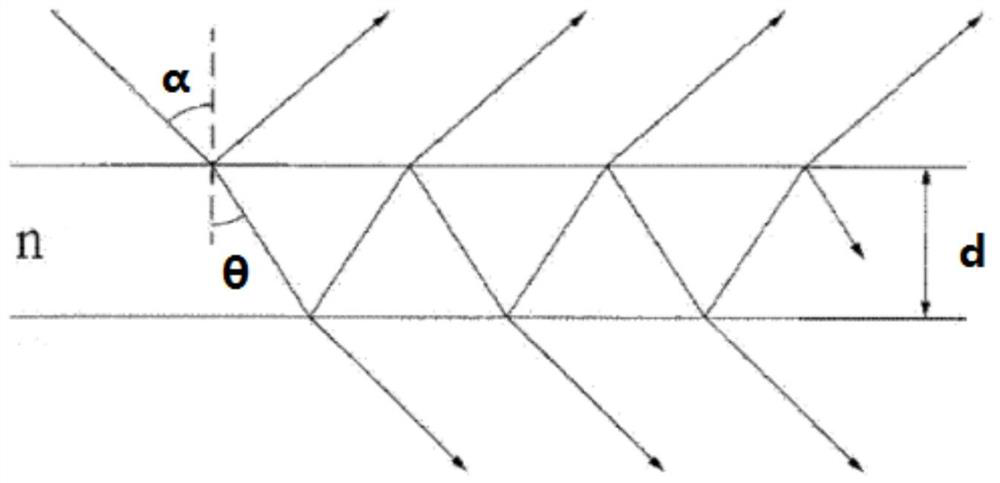

A micro-laser outputting uniformly polarized light and its preparation method

ActiveCN109346922BSimple structureCompact and tinyLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserDistributed Bragg reflector

The invention relates to a miniature laser capable of outputting uniform polarized light and a preparation method thereof. The laser comprises a P-surface electrode, a P-surface distributed bragg reflector, an N-surface distributed bragg reflector, a substrate layer and an N-surface electrode, wherein metal grating of sub-wavelength is manufactured on the surface of the P-surface distributed braggreflector; the metal grating is connected with the P-surface electrode, and the period of the metal grating is smaller than the wavelength of a vertical cavity surface emitting laser; the surface ofthe substrate layer is a spherical surface; and a DOE layer is etched in one side, towards the N-surface electrode, of the substrate layer. According to the laser, a beam shaping system is not needed,and the flat top polarized light can be output by only needing process design and the using the device characteristics; and in addition, the laser has the advantages of simple structure, small and compact size, low manufacturing cost, and can be highly integrated in some equipment, and has very important application prospect.

Owner:XIAN TECH UNIV

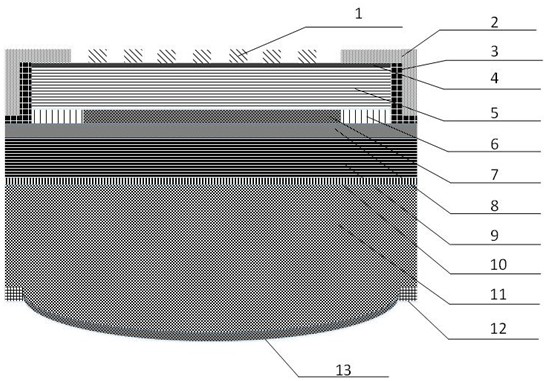

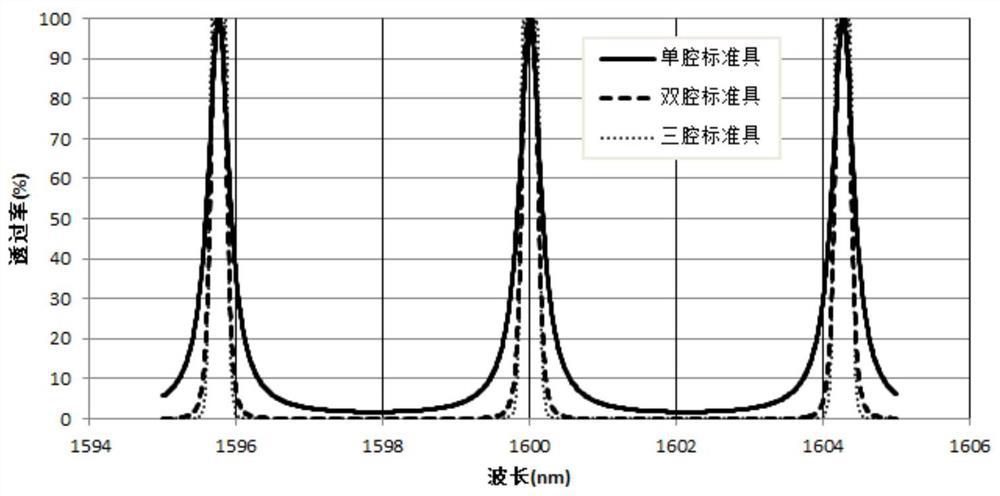

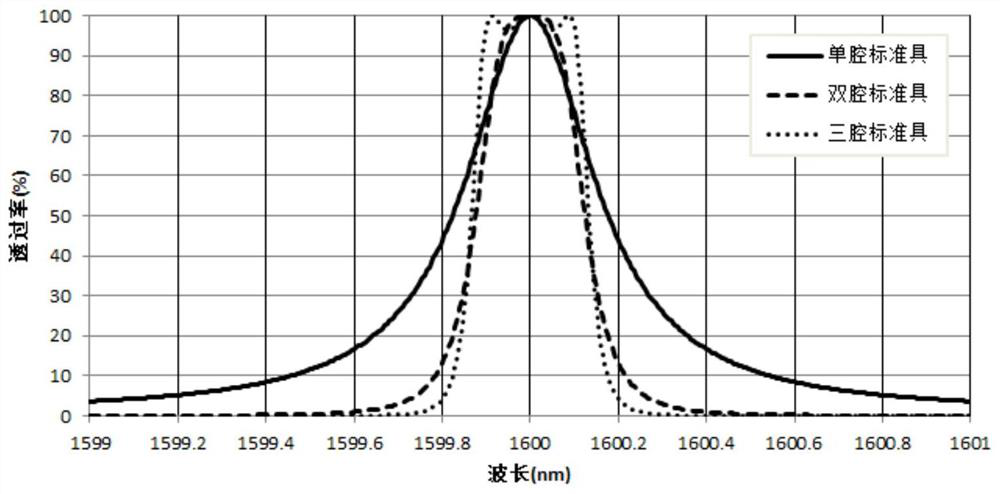

Air layer coupling etalon

PendingCN112241034ALow refractive indexReduce sensitivityOptical elementsEngineeringMechanical engineering

The invention discloses an air layer coupling etalon which comprises more than two single-cavity etalon bodies with the same free spectral range, fineness and transmission peak, the single-cavity etalon bodies are sequentially attached and fixed together, and every two adjacent single-cavity etalon bodies are coupled through an air layer. The double-cavity, three-cavity or multi-cavity etalon hasthe advantages of low sensitivity (the spectrum changes along with the thickness of the coupled air layer), easiness in processing and mass production, small size, low cost and the like besides high fineness and transmission peak height flat top type of the corresponding double-cavity, three-cavity or multi-cavity etalon in the prior art.

Owner:FUZHOU PHOTOP QPTICS CO LTD

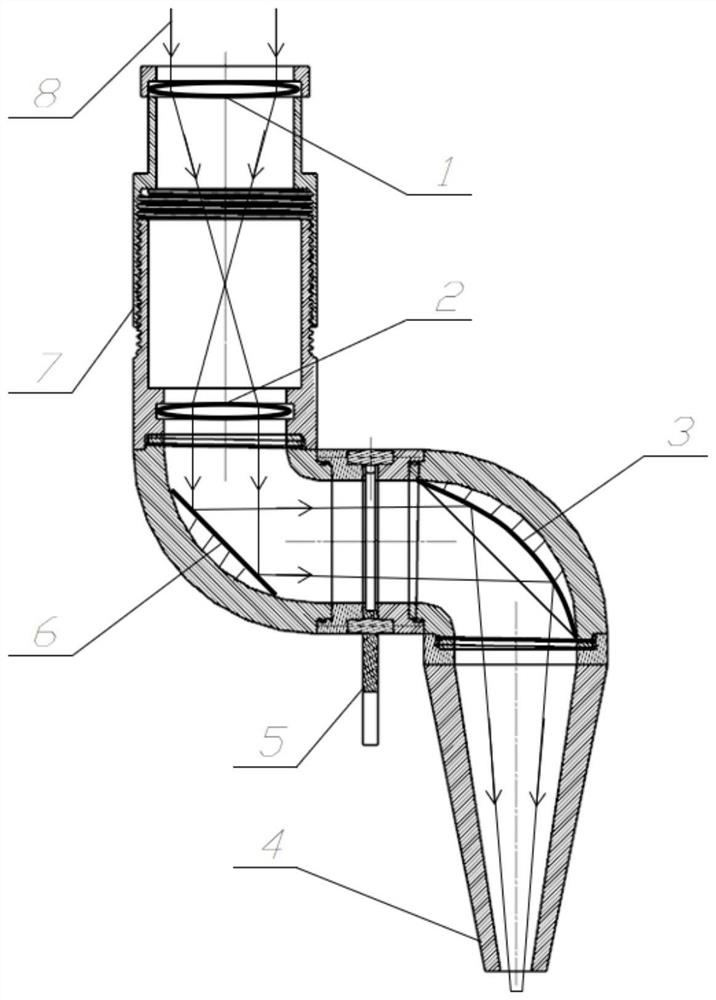

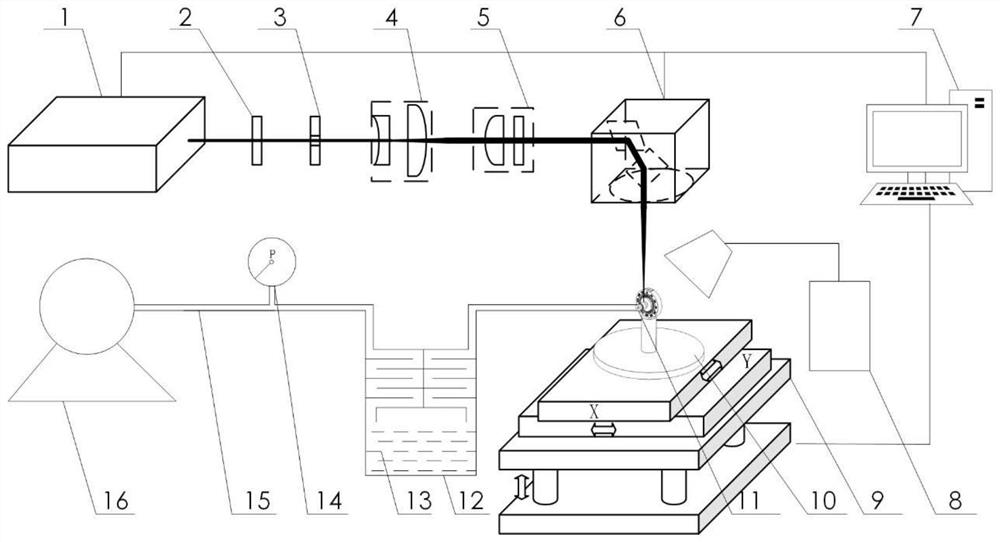

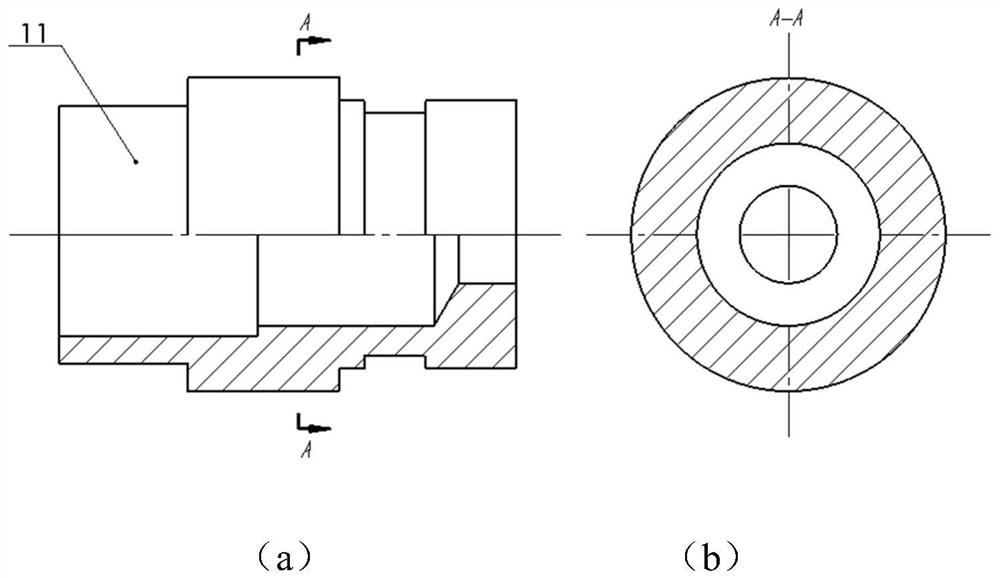

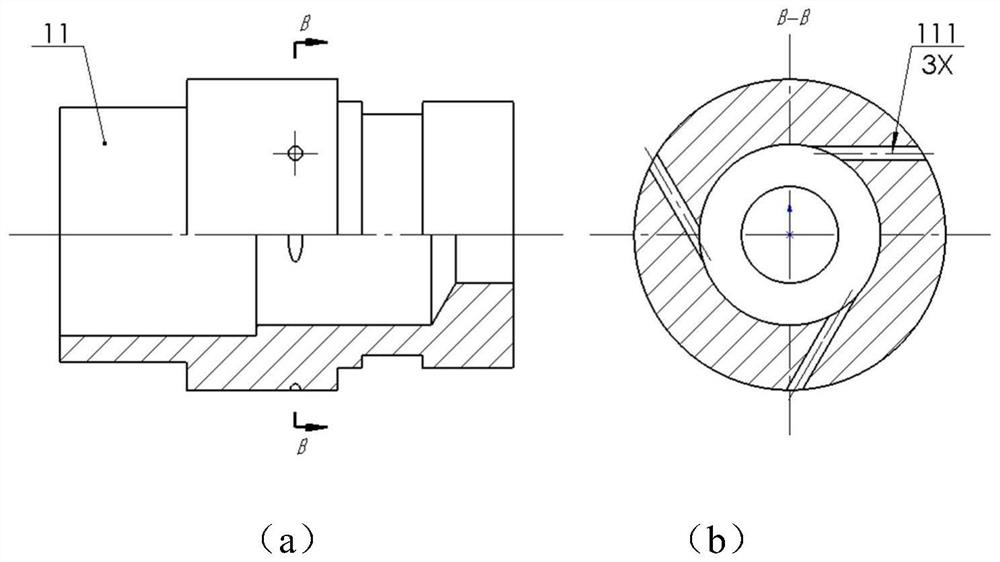

Device and method for femtosecond laser processing nozzle tangential hole

ActiveCN113492270BHigh precisionQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesLaser processingFemto second laser

The invention provides a femtosecond laser processing device and method for nozzle tangential hole, which relates to the field of laser precision processing. Computer, CNC three-axis motion platform, vacuuming device, fixture, filter system, sealing tube, pressure gauge and vacuum pump; the principle of this technical solution is to use circularly polarized femtosecond laser with flat top light distribution to make nozzle tangential holes The uniform and precise processing of the machine is achieved through the protective block in the fixture to achieve back injury protection at the exit of the tangential hole. The negative pressure generated by the vacuum pump can not only monitor the breakdown of the hole, but also avoid the generated plasma to the laser. shielding. The invention can effectively improve the machining accuracy of the current nozzle tangential hole, avoid the defects of recast layer and thermal influence, and propose a solution for back injury protection, which is helpful to improve the liquid flow performance of the nozzle product.

Owner:XI AN JIAOTONG UNIV

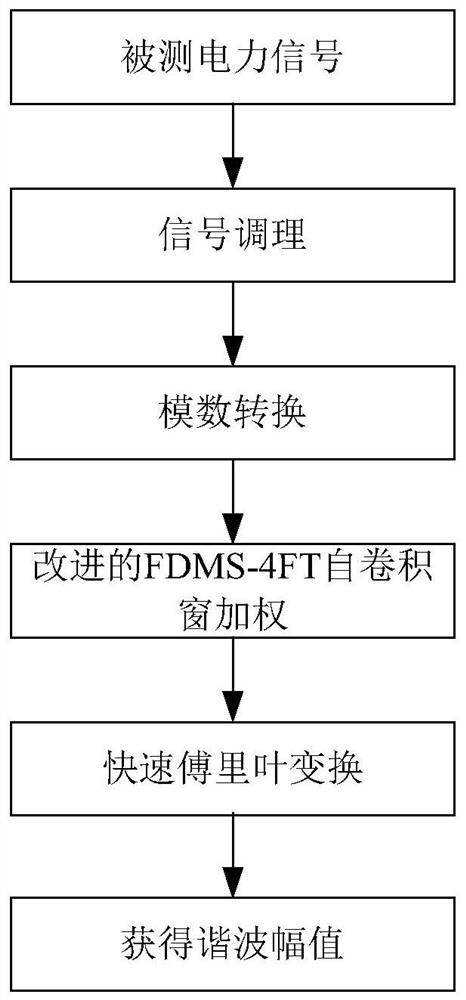

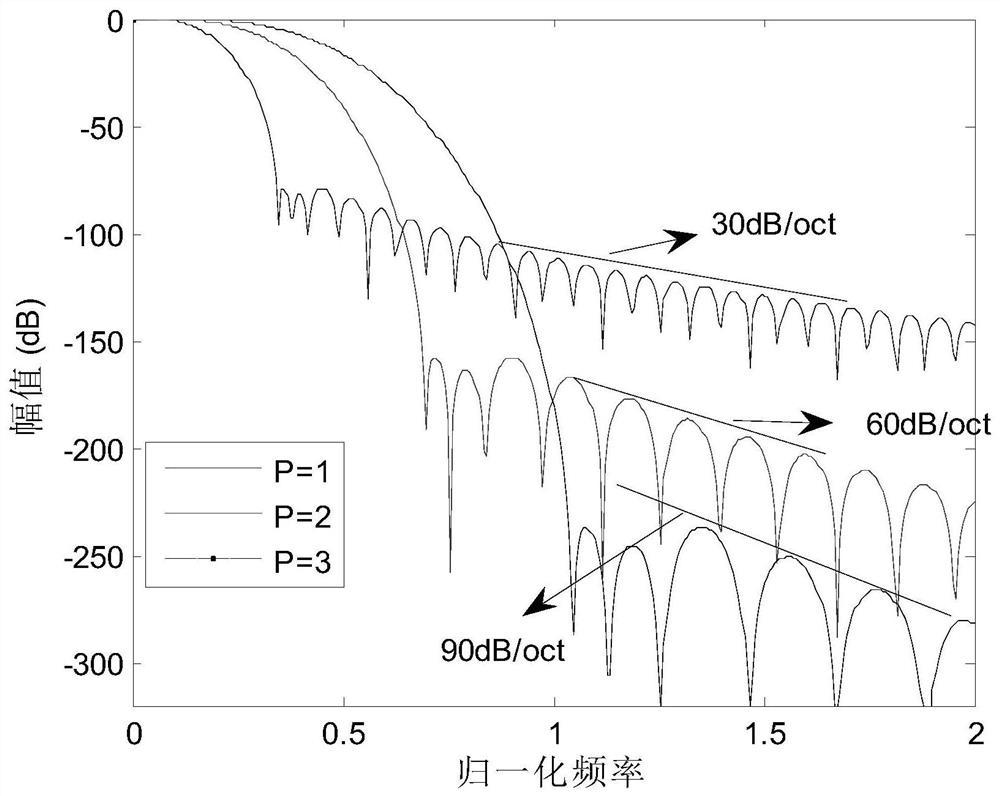

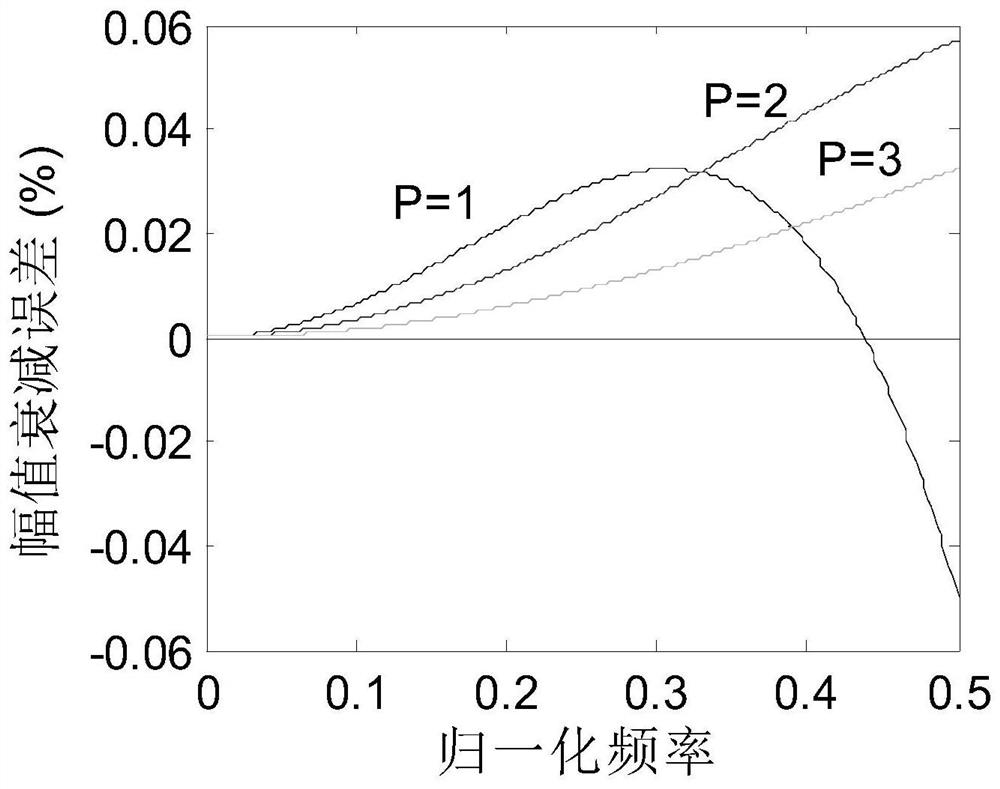

An improved flat-top self-convolution window weighted power harmonic amplitude estimation method

ActiveCN111222088BLow sidelobe peak levelsFast sidelobe decay rateComplex mathematical operationsElectric power systemPetal

An improved flat-top self-convolution window-weighted power harmonic amplitude estimation method. The FDMS-4FT window is selected as the parent window for time-domain self-convolution to obtain a new flat-top window function; compared with the traditional classic flat-top window function, the flat-top window has lower side lobe peak levels and faster Sidelobe decay rate. In order to make the new flat-top self-convolution window have a flatter main lobe while having excellent side lobe performance, the coefficients of the flat-top self-convolution window are optimized so that it has a flatter main lobe than the parent window. flap, thereby improving the accuracy of power harmonic amplitude estimation. When this window function is applied to the harmonic amplitude estimation of power system, it is not affected by fundamental frequency fluctuations, etc., and there is no need to correct the harmonic amplitude calculation results, and the amplitude measurement results can be obtained directly, with a small amount of calculation, and With high accuracy.

Owner:JIANGSU ELECTRIC POWER CO

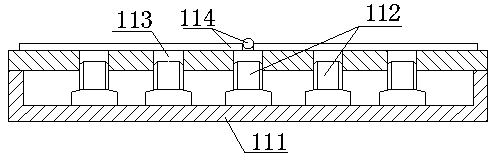

Method and device for forming and assembling microscale part

ActiveCN102274887BAchieve fixationRealize the assemblyLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses a method and a device for forming and assembling a microscale part, and is applied to the forming and the assembly of micro-precision parts such as integrated circuits and microelectronic products. According to the method, flat top type strong pulse laser illuminates on a restraint layer to form pressure wave to impact a target and make the target locally and rapidly expanded; a micro-blanking material flying at a high speed is obtained under the action of a cutting mould; the micro-blanking material flies at a high speed and then hits against a part to be assembled, so the surface appearance of the part to be assembled is copied and microscale forming is formed; and the speed of the formed microscale part is reduced to zero, the formed microscale part is attached onto the upper surface of the part and then assembled, and the positioning and the installation of the microscale part are performed, so the integration of the forming and the assembly of the microscale part is realized. By the method, the forming and the assembly of the microscale part can be realized simultaneously; therefore, the method is a modern micro-device making method which integrates the processing and the assembly of the microscale part, and has the processing characteristics of high flexibility and high efficiency. Moreover, rapid industrialized production in a large scale is easyto realize.

Owner:SANMENXIA ZHONGYUAN PRECISION

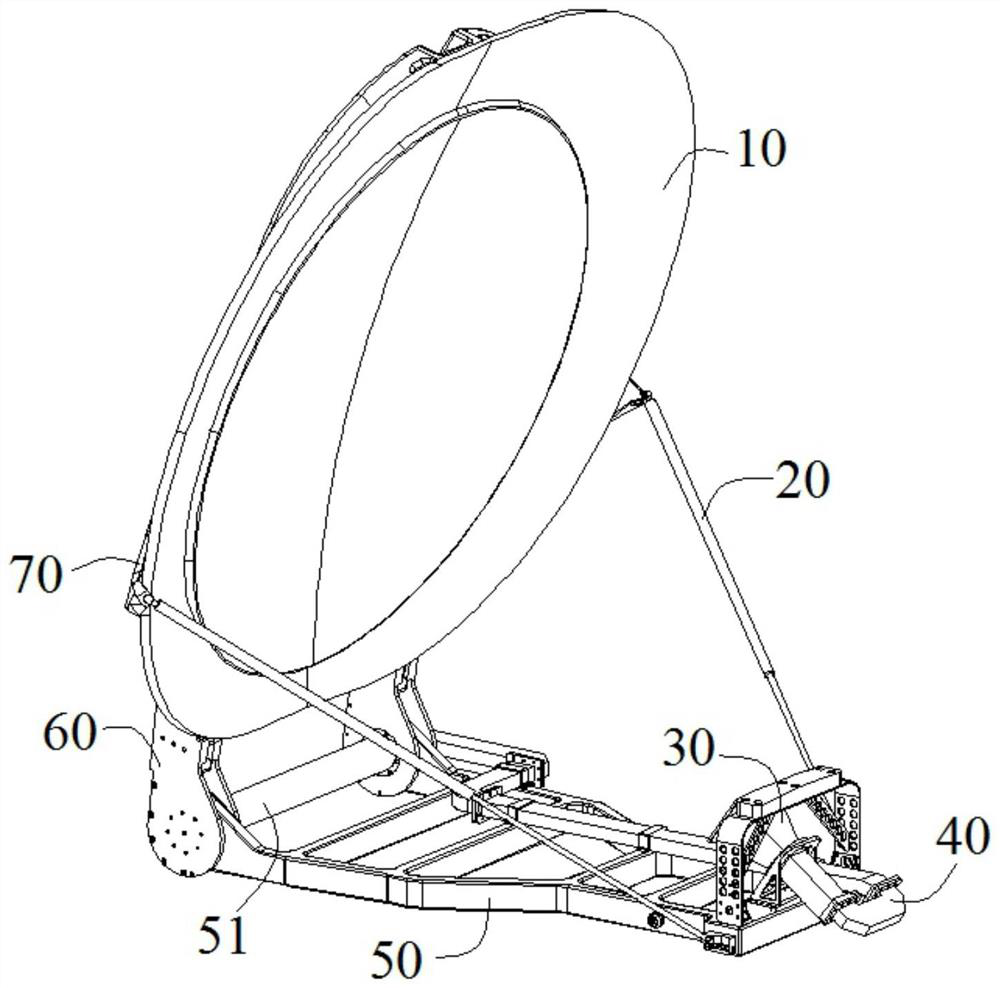

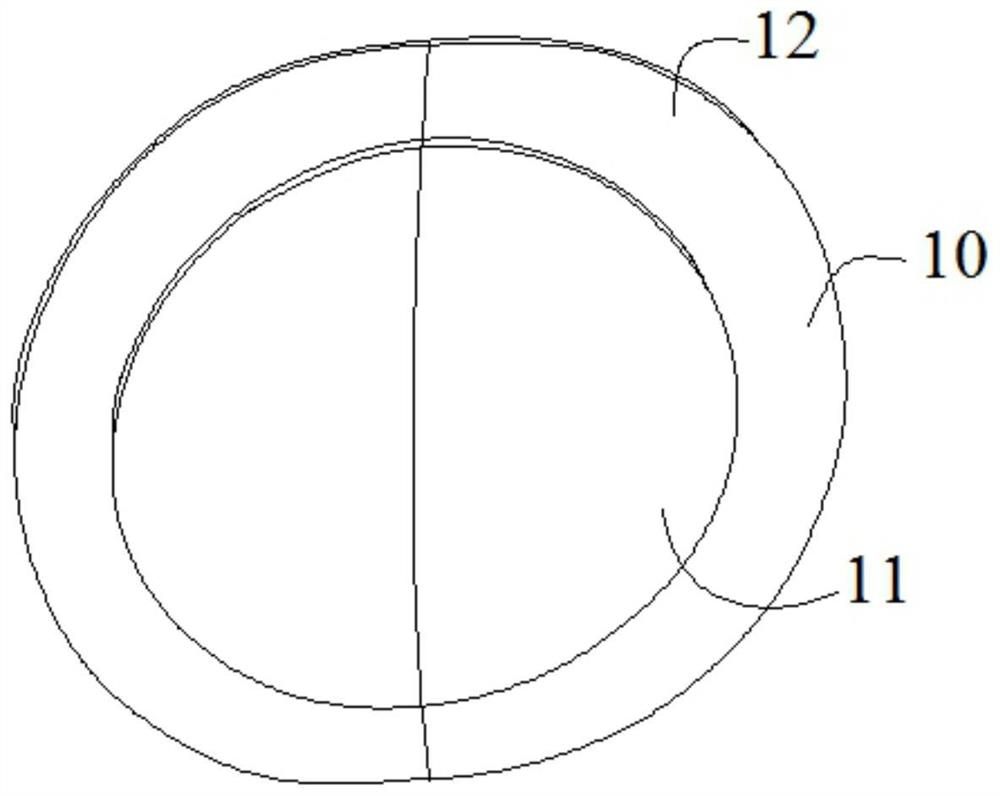

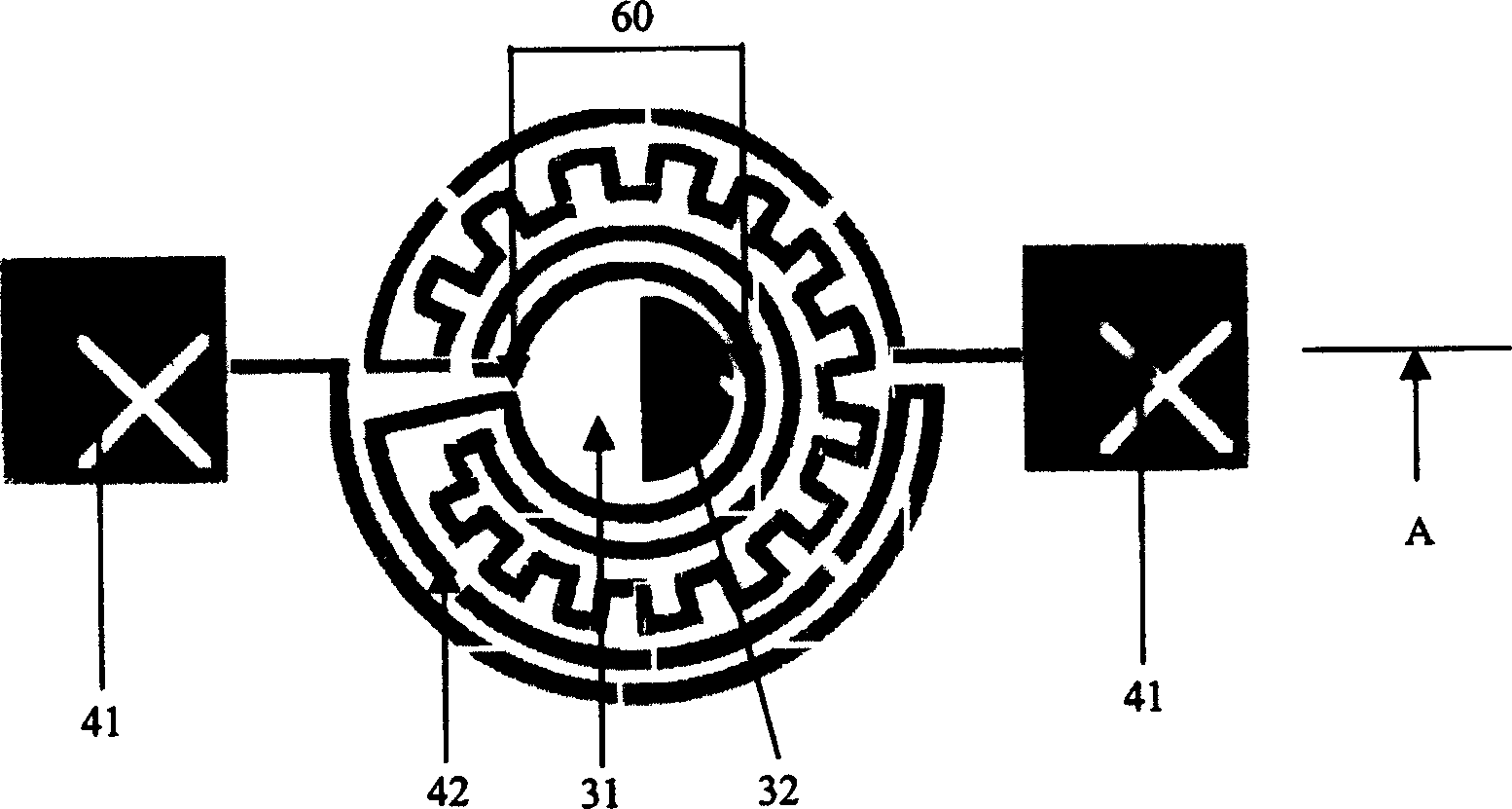

Reflector antenna assembly with flat-top directional diagram

ActiveCN113054441AReduce complexityReduce the difficulty of debuggingAntenna supports/mountingsAntennas earthing switches associationMechanical engineeringOptics

The invention discloses a reflector antenna assembly with a flat-top directional diagram, the front surface of a reflector antenna is a reflector, the reflector is a paraboloid, and the paraboloid comprises a central reflection area and an edge reflection area; the central reflection area is circular, the edge reflection area is annular, and the inner periphery of the edge reflection area is connected with the outer periphery of the central reflection area; the connecting edge of the central reflection area and the edge reflection area has a depth difference, and the depth difference is used for enabling the reflection surface to form a wave beam with a flat-top directional diagram; the antenna assembly can be formed through a small number of parts, the complexity of the antenna assembly and the debugging difficulty of the antenna assembly can be reduced, the reflecting surface of the paraboloid-shaped reflecting surface antenna is divided into the central reflecting area and the edge reflecting area, the surface of the central reflecting area and the surface of the edge reflecting area have the depth difference, a wave beam with a flat-topped pattern characteristic can be formed through the reflector antenna, and multiple satellites can be tracked at the same time.

Owner:XIAN HENGDA MICROWAVE TECH DEV

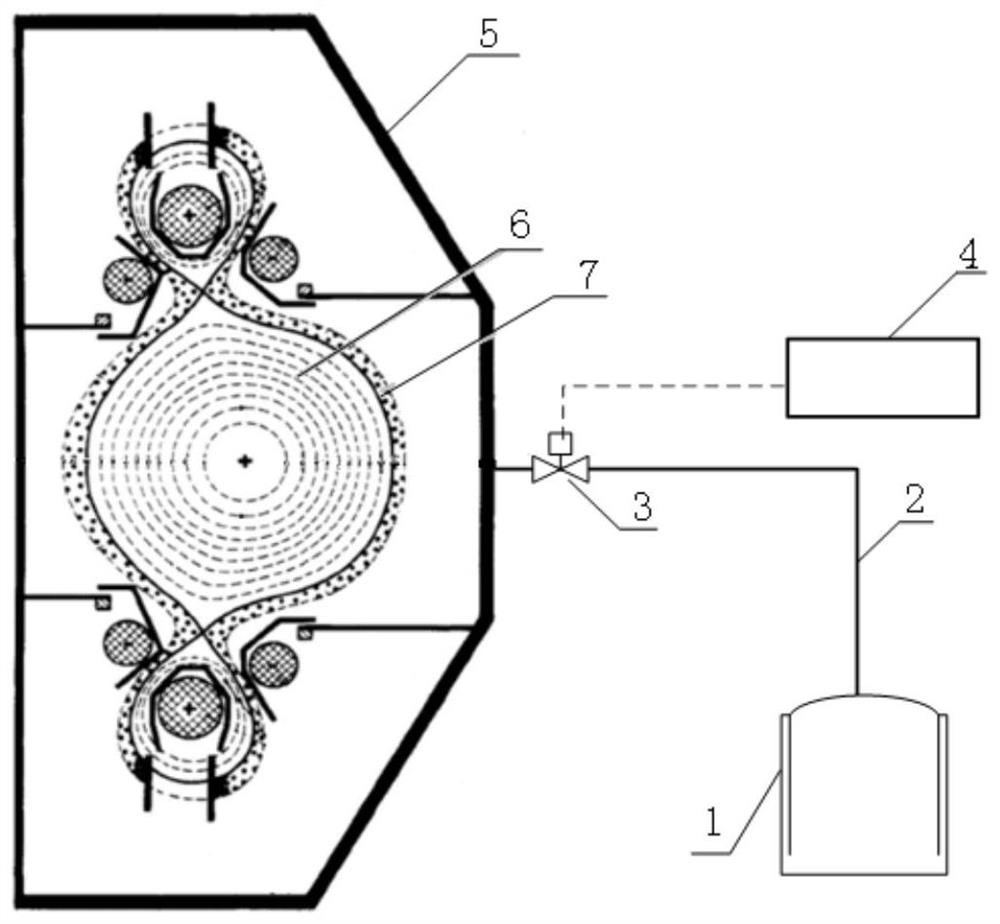

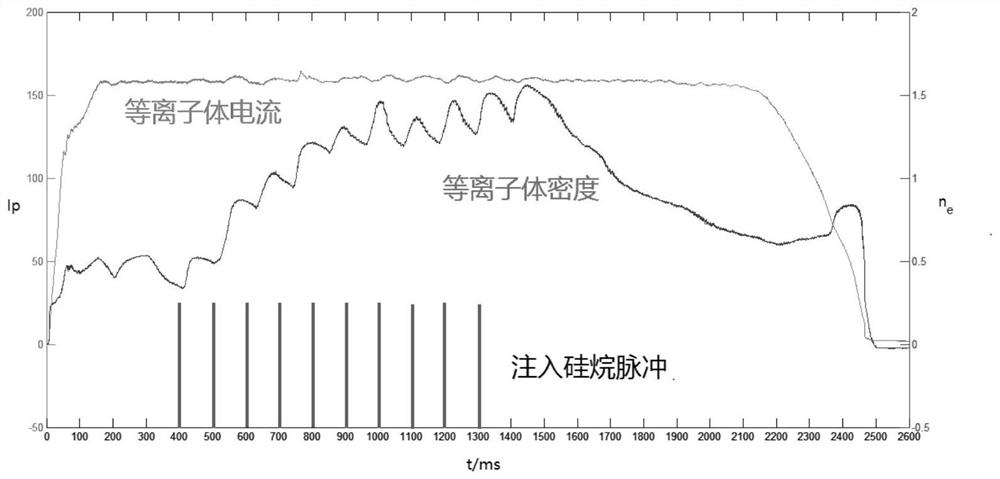

Online surface coating silicification wall treatment method for fusion device

ActiveCN113913778AReduce oxygen impuritiesImprove operating parametersNuclear energy generationChemical vapor deposition coatingEngineeringHelium gas

The invention belongs to a vacuum technology in the field of fusion, and particularly relates to an online surface coating silicification wall treatment method for a fusion device. Mixed gas of deuterium silane and helium is used as working gas for silicification wall treatment, an injection point is arranged on a vacuum chamber, a piezoelectric crystal valve is used for supplying gas, a pulse working mode is adopted, and the gas supply pulse moment is 300-1800 ms of a flat top section where plasma of an HL-2A device operates; and after entering the vacuum chamber, the deuterium silane-helium mixed gas moves to the scraping layer area along the radial direction, and then deposits on the inner wall of the vacuum chamber to form a silicification wall under the action of the plasma. The silicification film formed by the method has very strong adsorbability to oxygen, oxygen impurities in the vacuum chamber can be reduced in real time, and device wall conditions are optimized, so that plasma operation parameters are improved.

Owner:SOUTHWESTERN INST OF PHYSICS

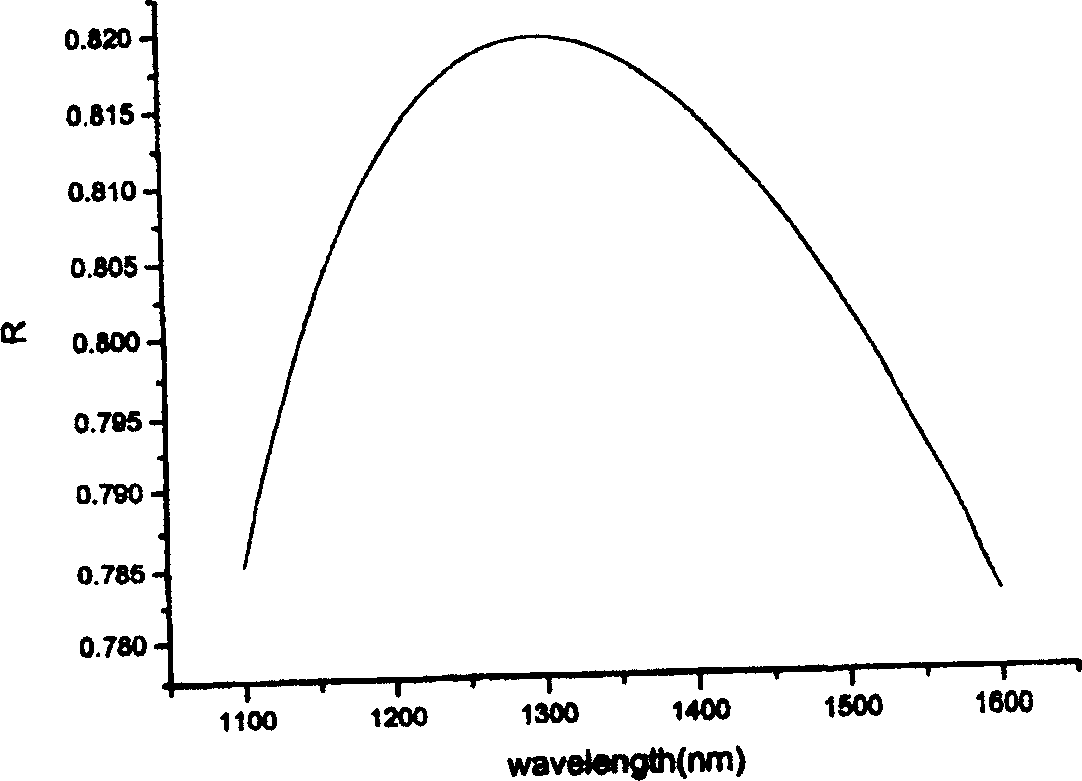

Narrow band thermal-optically tuned Fabry-Perot filter with flattop and steep belt edge response

InactiveCN1300959CEasy to implementEasy to integrateCoupling light guidesElectromagnetic transmissionEngineeringNarrow band

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com