A micro-laser outputting uniformly polarized light and its preparation method

A micro-laser and polarized light technology, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as large volume, unstable polarization, and complex structure, and achieve the effect of compact size, low cost, and easy direct coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the drawings and embodiments.

[0037] The working principle of the present invention is: the present invention fabricates a sub-wavelength metal grating on the P surface, and feedbacks the gain of the two polarization directions to different degrees through the sub-wavelength metal grating, thereby breaking the balanced state of the two polarization directions, thereby controlling its Polarization direction. The diffraction phase distribution that satisfies the VCSEL homogenization condition is designed by algorithm, and then the DOE is directly etched on the surface of the substrate layer. By controlling the phase of the polarization-stabilized Gaussian beam output by the VCSEL, it is realized under the condition of retaining the small volume advantage of the VCSEL, thereby Achieve polarization-stabilized, homogenized beams.

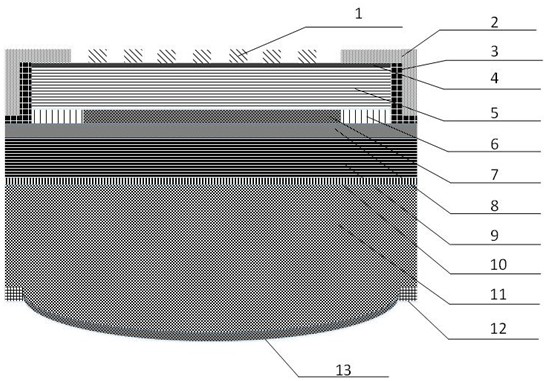

[0038] see figure 1 , a micro-laser that outputs uniformly polarize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com