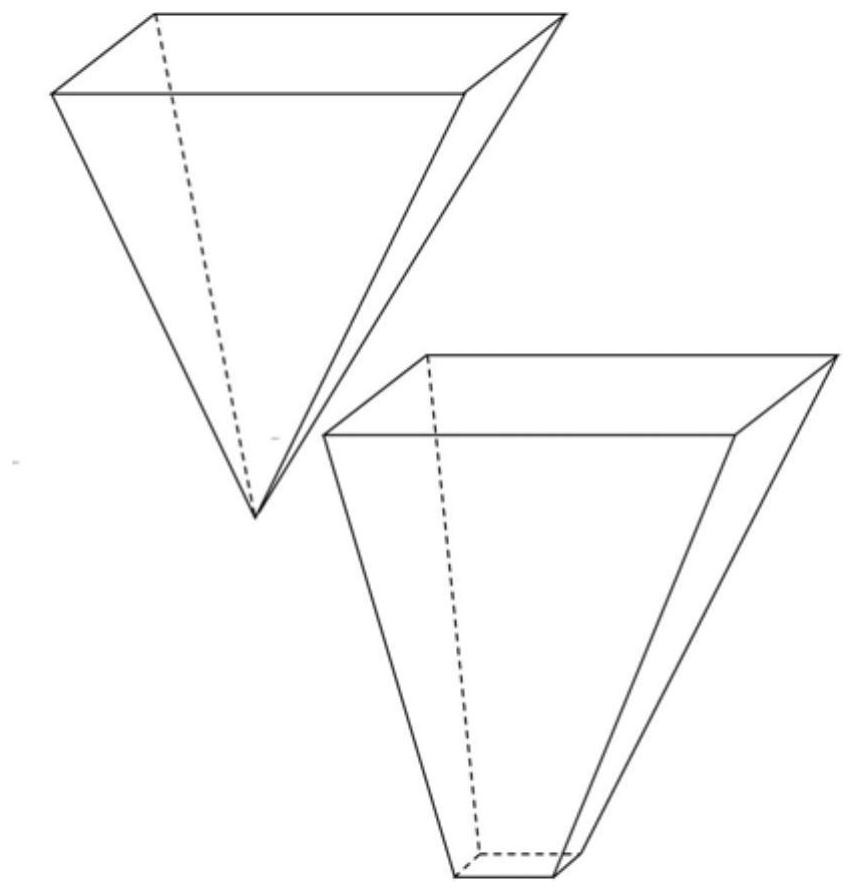

Manufacturing method and system for anti-reflective micro-nano structure with inverted pyramidal truncated/square pyramidal shape

A technology of quadrangular truncated pyramid and micro-nano structure, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of limited processing capacity and poor shape control ability, so as to improve shape control ability, increase reduction and increase The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

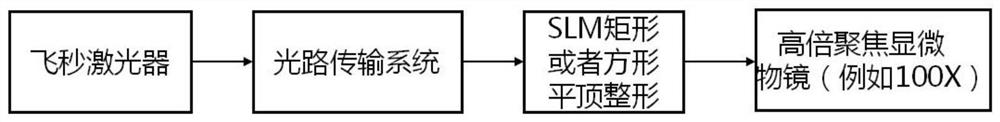

[0029] The shaping system of the present invention is composed of a femtosecond laser, optical path transmission, SLM rectangular flat-top shaping unit and a 100X tight focusing objective lens.

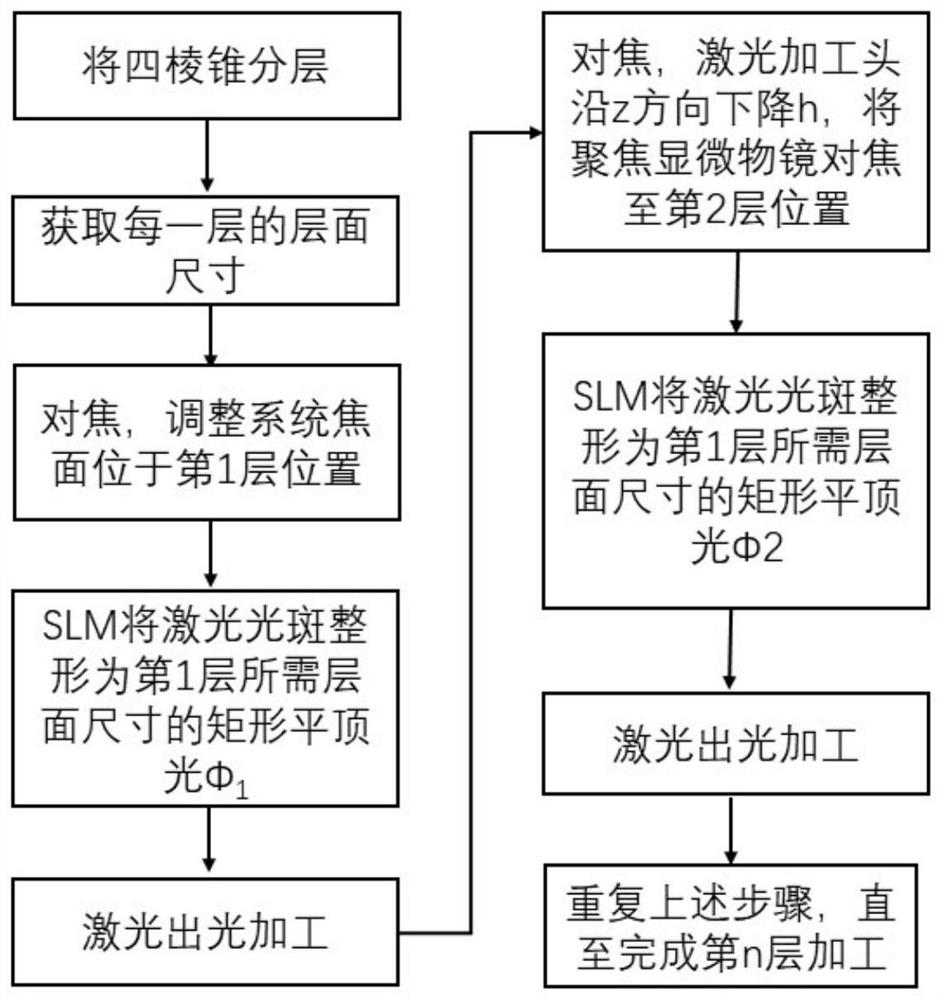

[0030] Taking the inverted square pyramid as an example, the specific process of its production method is as follows:

[0031] 1) The optical tight focus design is adopted to further compress the theoretical focal depth of optical shaping: a 100X focusing microscope objective lens is used, and the theoretical focal depth is ≤1μm; according to optical theory, the larger the magnification, the smaller the focal depth, and the smaller the focal depth, the The more conducive to layered manufacturing, and the higher the accuracy.

[0032] 2) According to the different material substrates (metal and non-metal materials) of the shape of the inverted pyramid truncated pyramid to be processed, and different laser process parameters (power, repetition frequency, single pulse energy), determine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com