Patents

Literature

8921results about "Labelling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

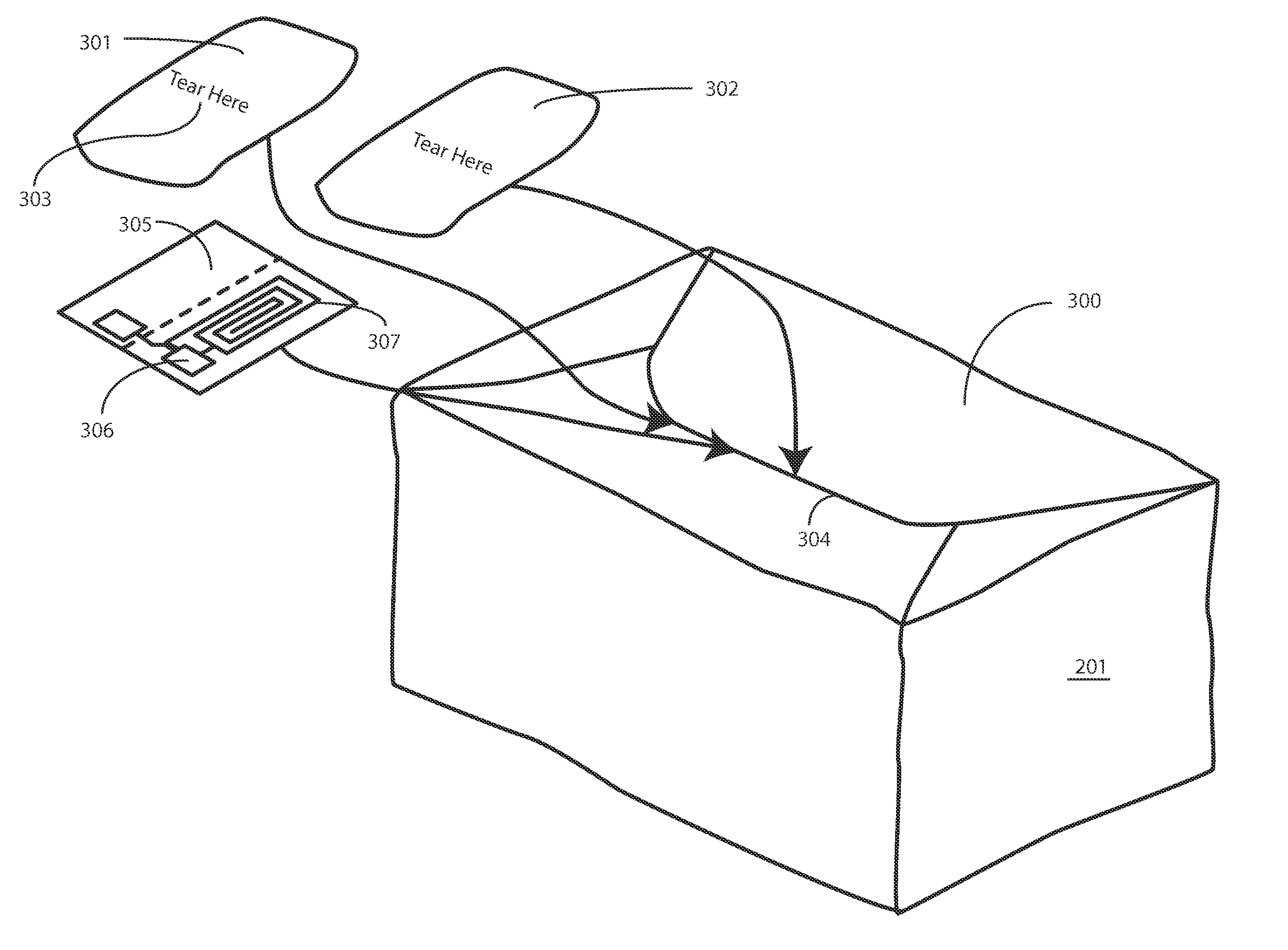

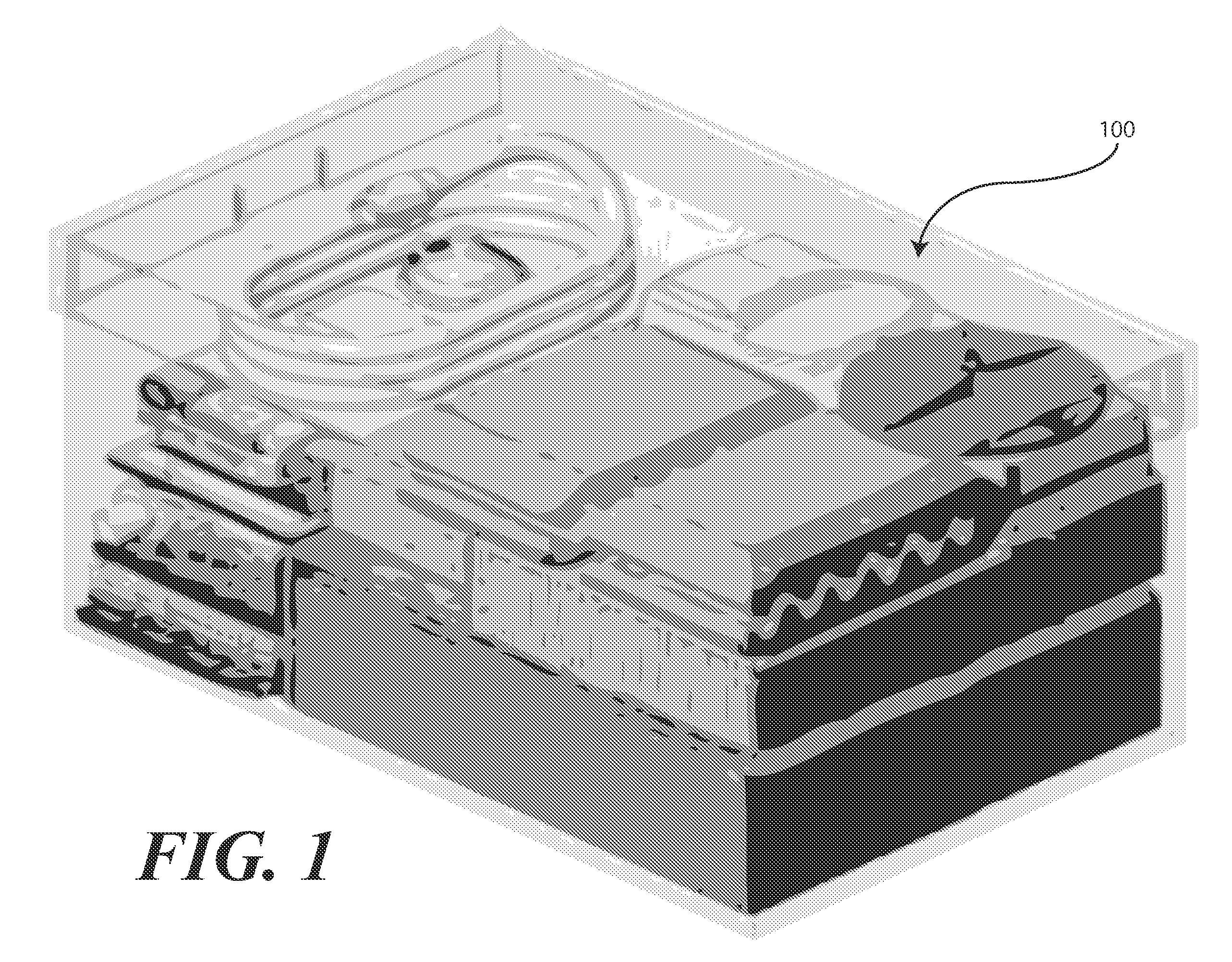

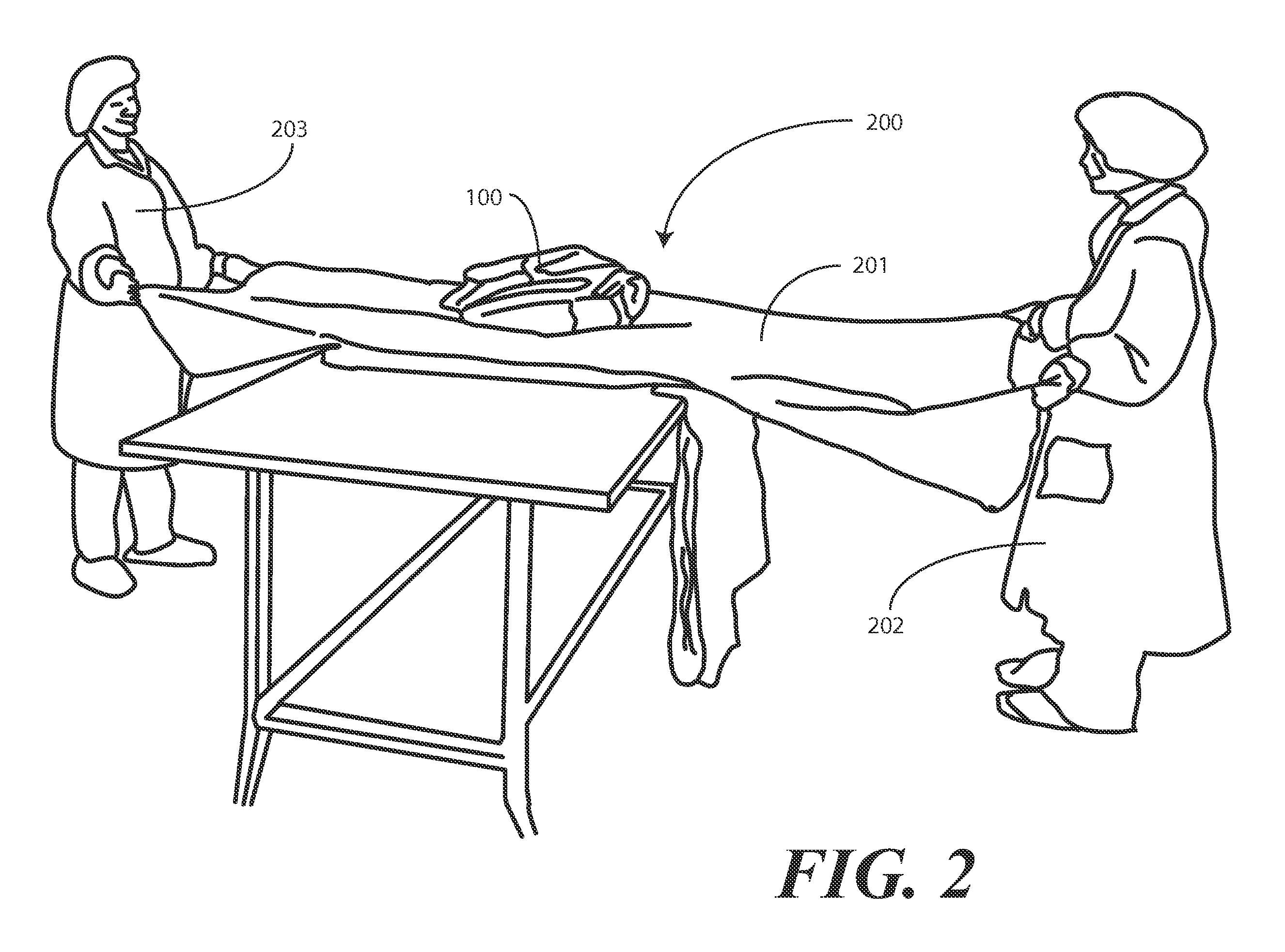

System and Method for Surgical Pack Manufacture, Monitoring, and Tracking

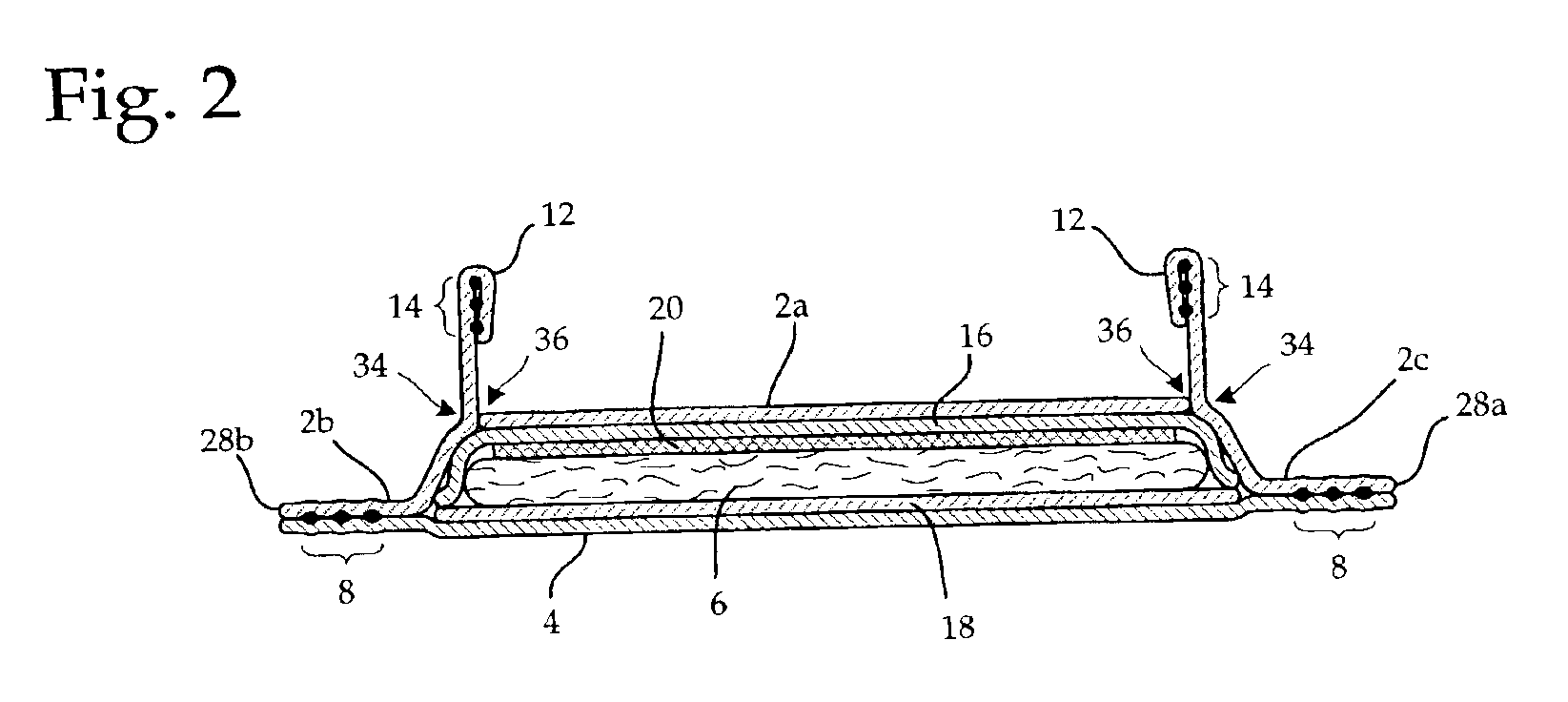

A wrapped surgical pack (400) includes a plurality of adhesive bindings (301,302) that retain an identification device (305) against an outer wrap (201) of the wrapped surgical pack (400). The identification device (305) is capable of being read by a remote reader (801). When the wrapped surgical pack (400) is opened, the physical structure of the identification device (305) is altered, thereby allowing one or more processors operable with the remote reader (801) to detect the opening event. A system (800) using the identification device (305) can be used for order fulfillment, inventory management, location tracking, and other systems.

Owner:MEDLINE IND LP

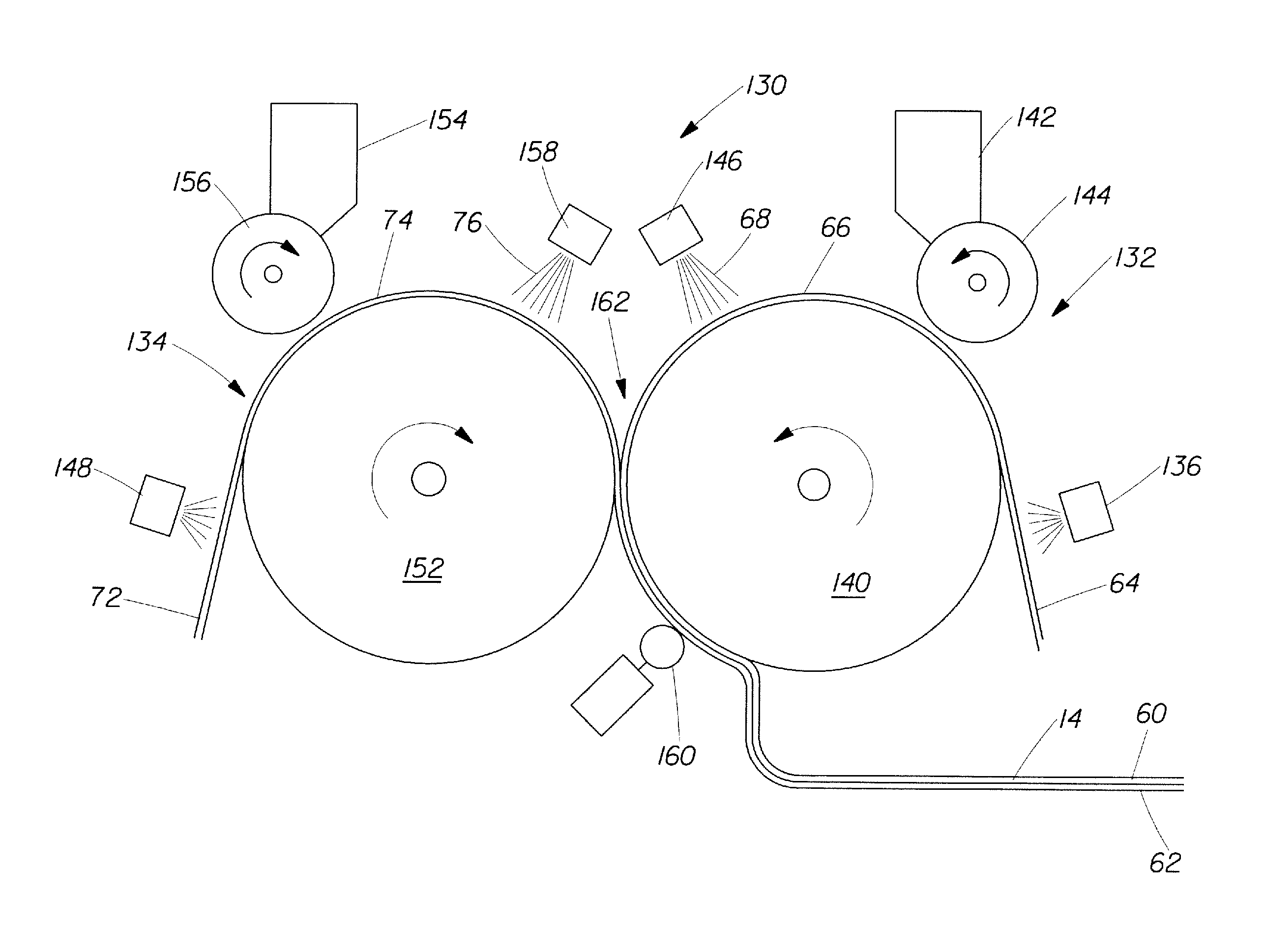

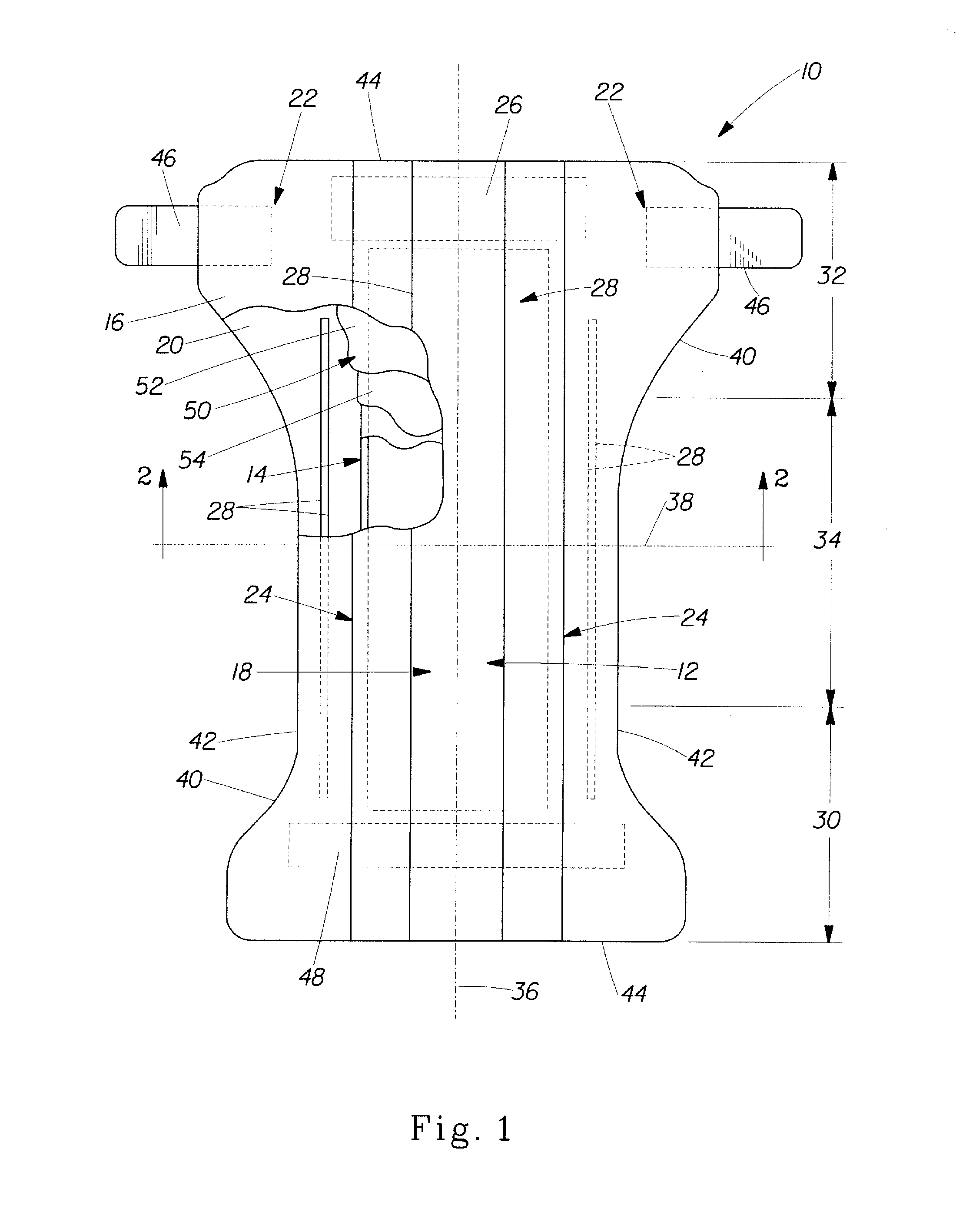

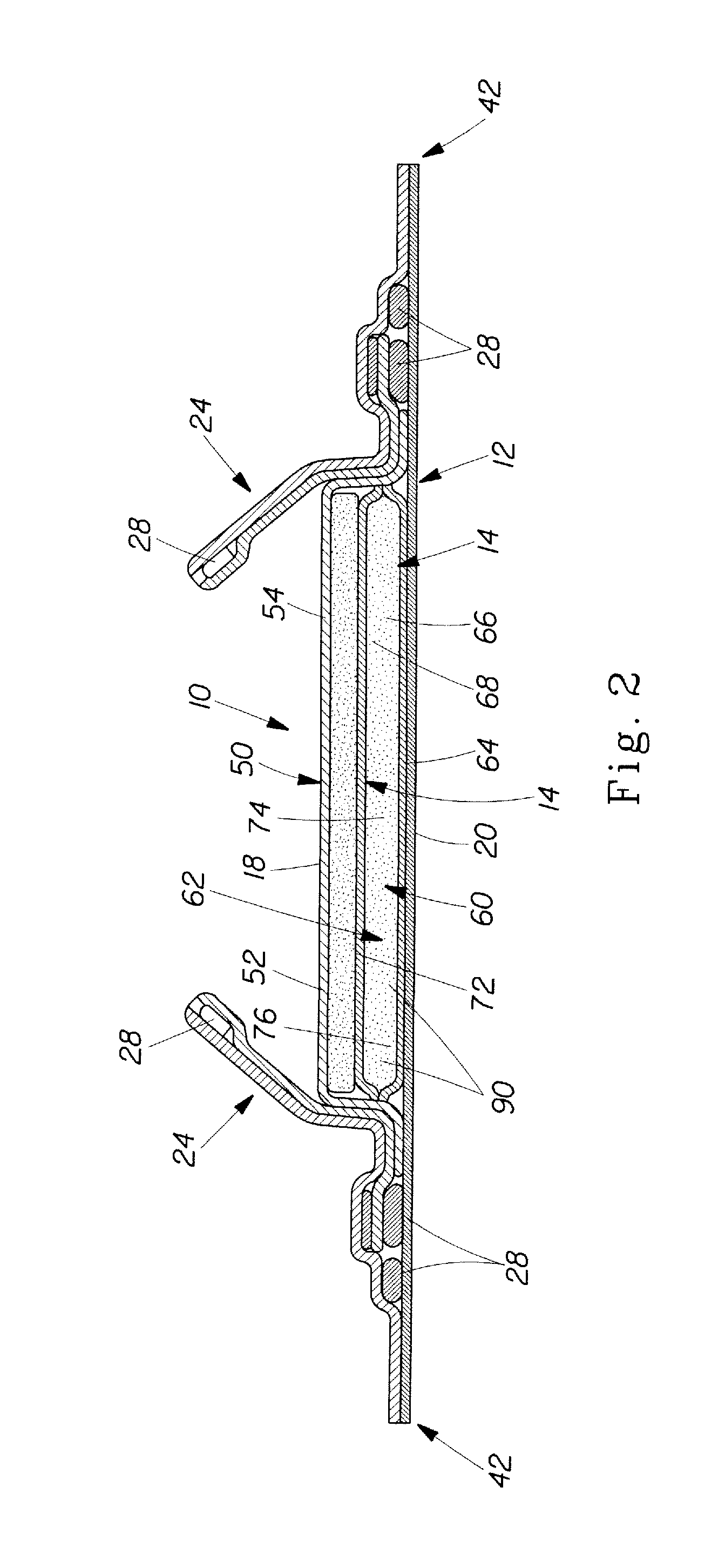

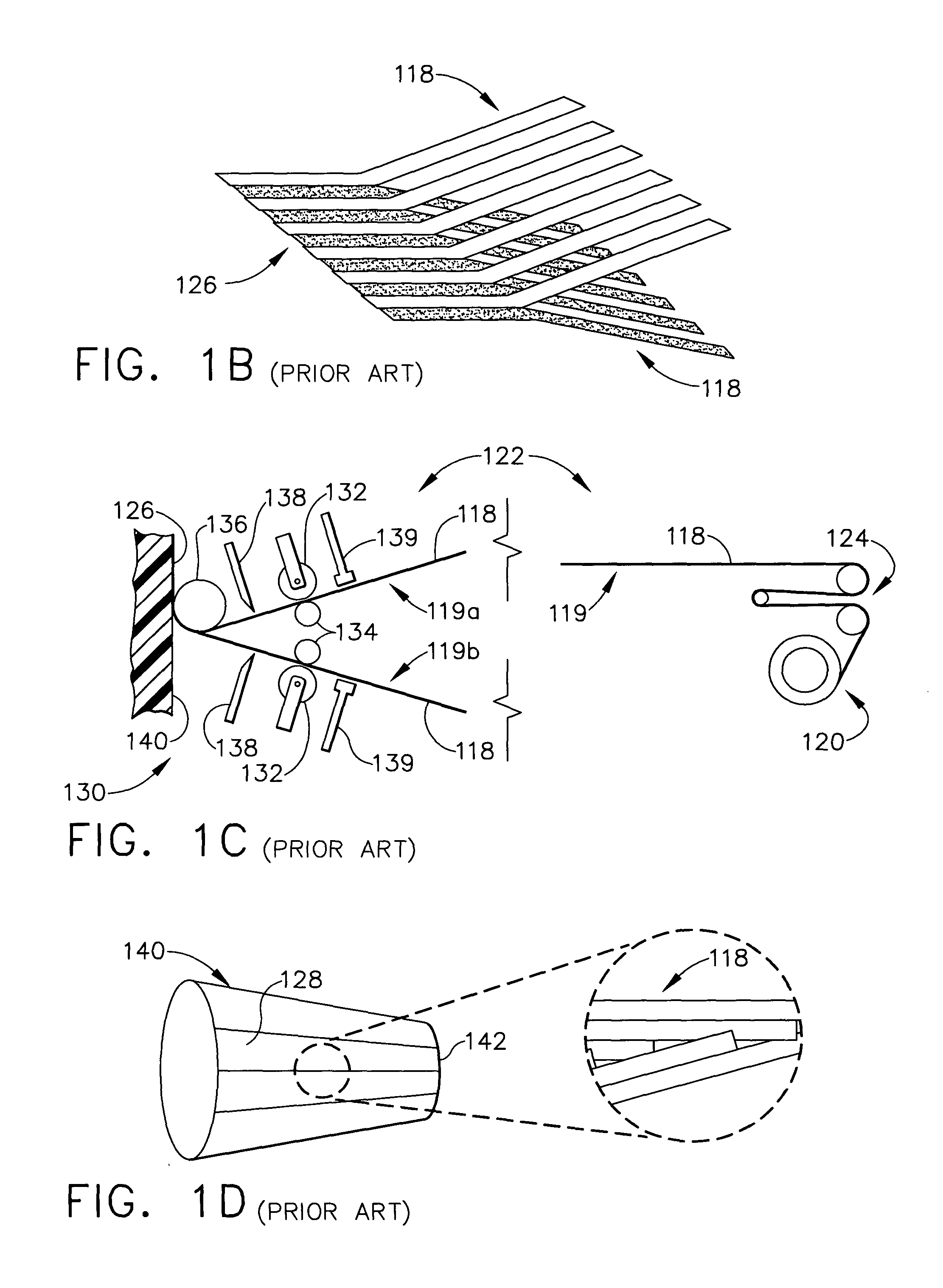

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

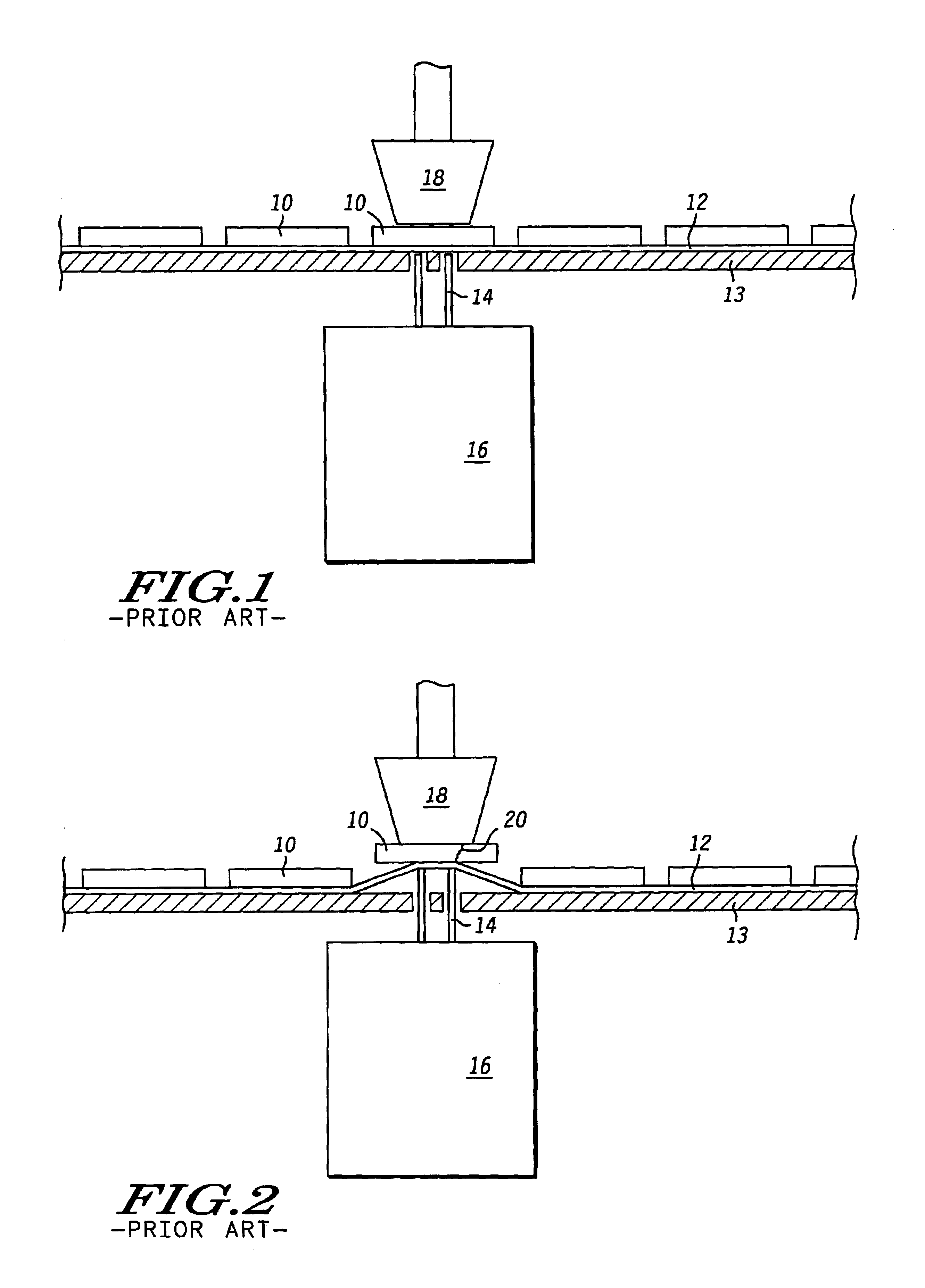

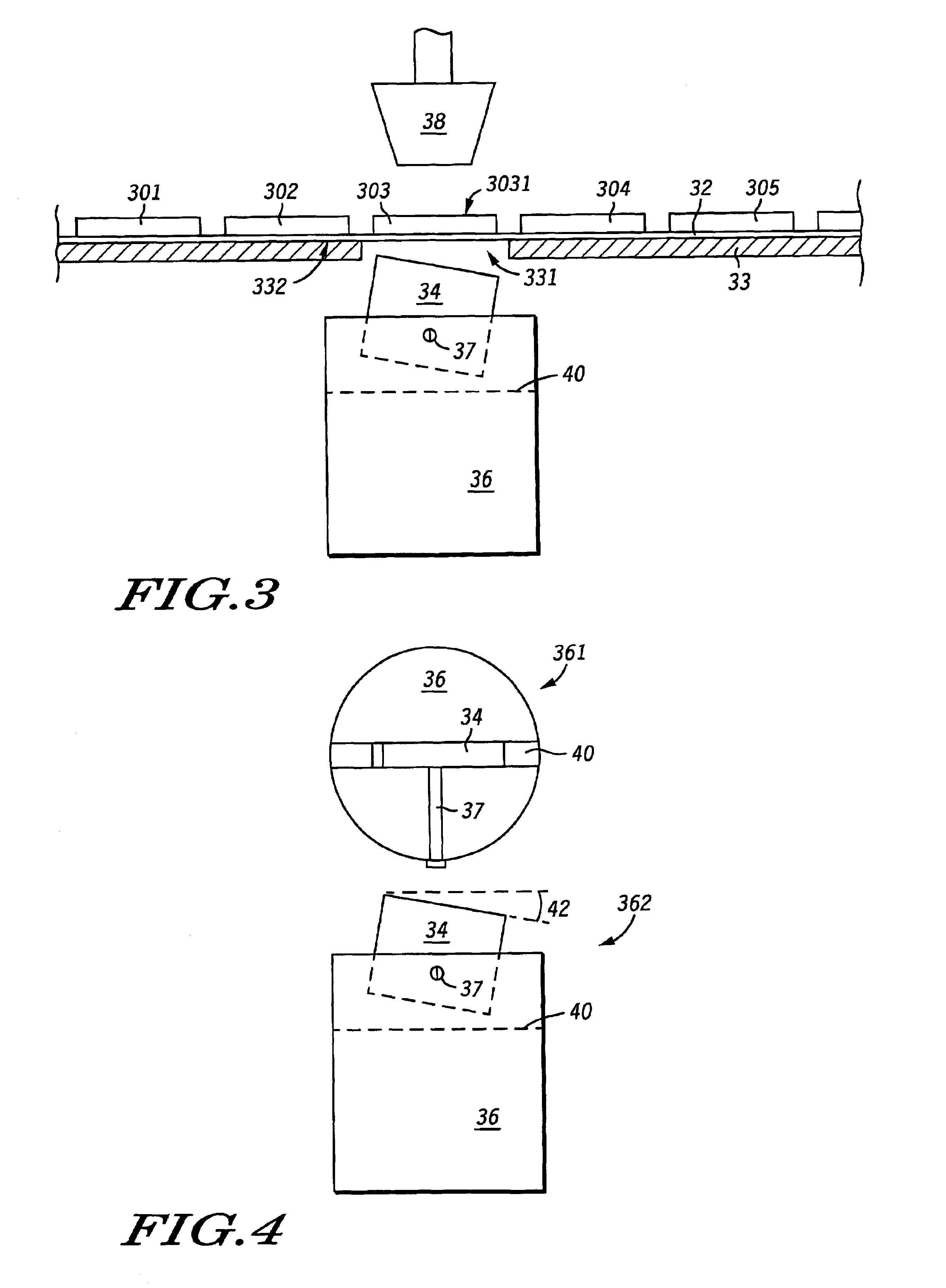

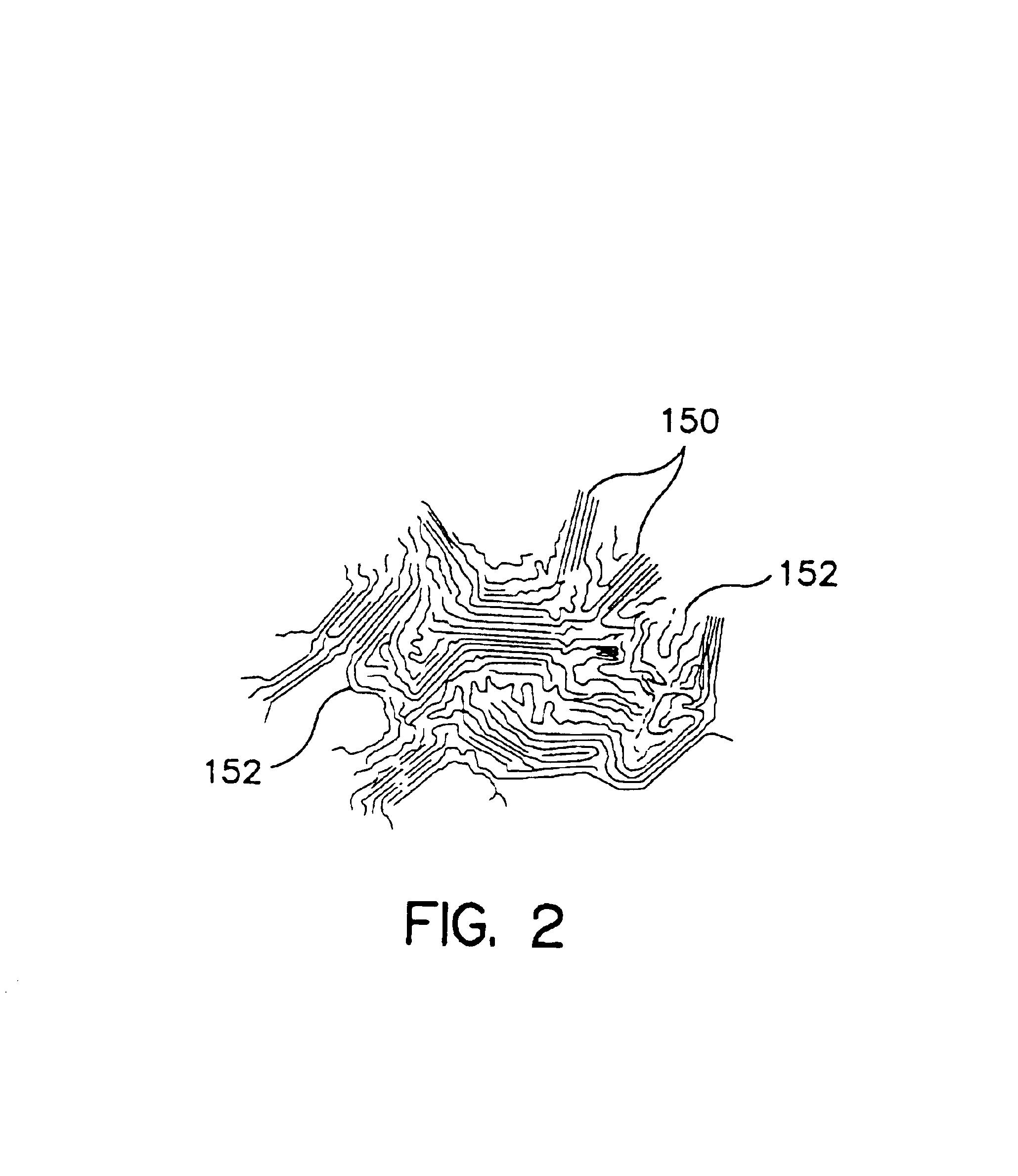

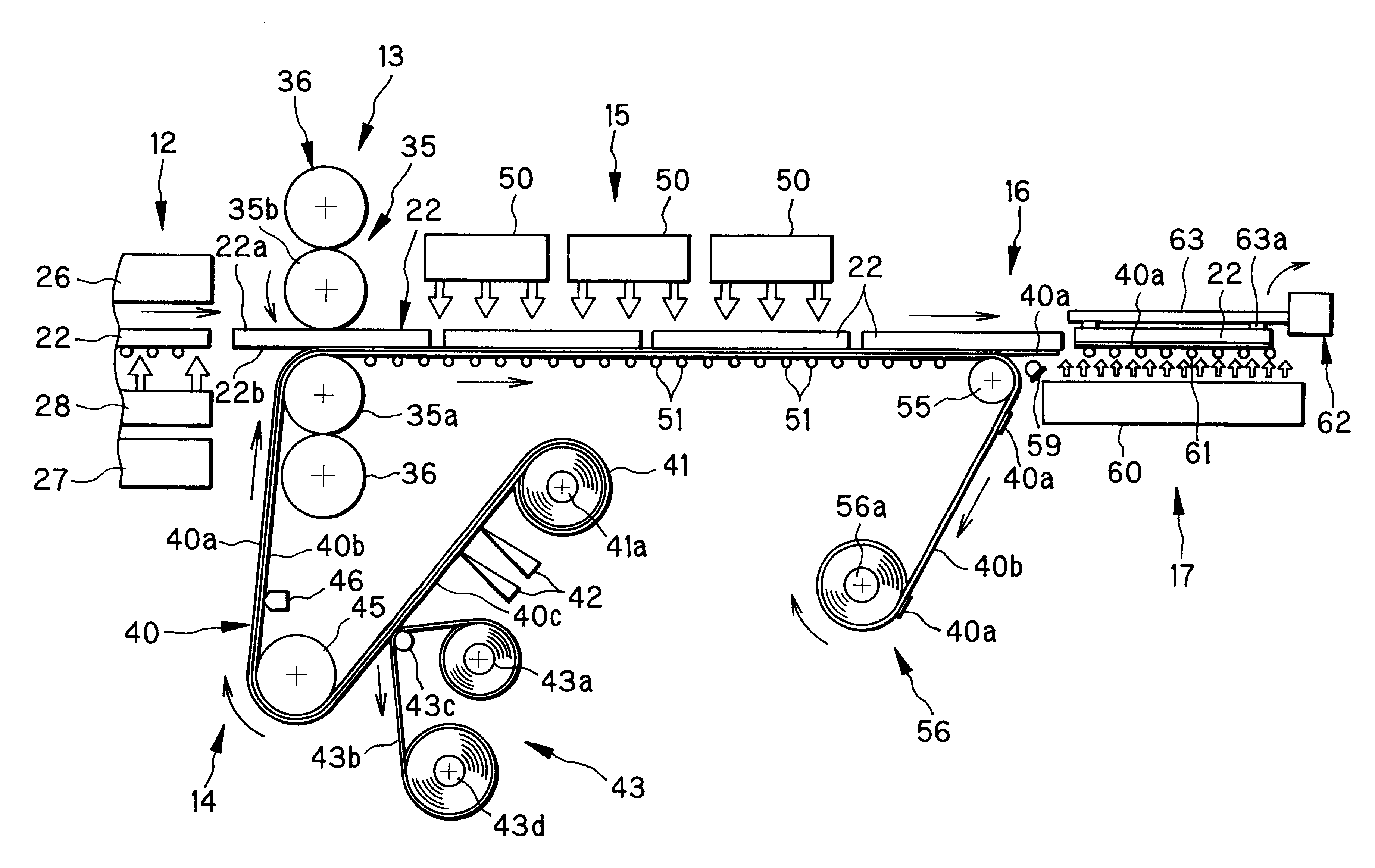

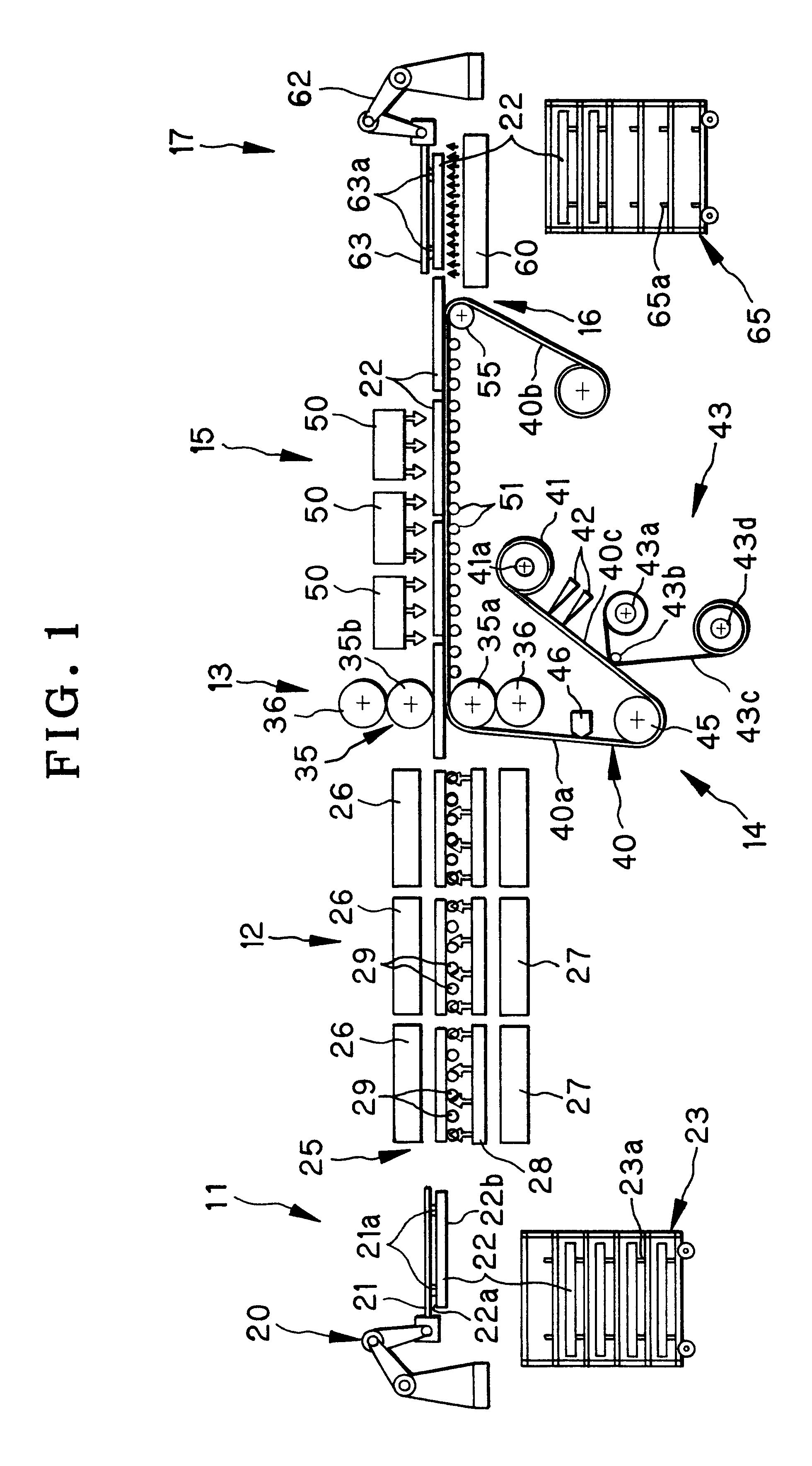

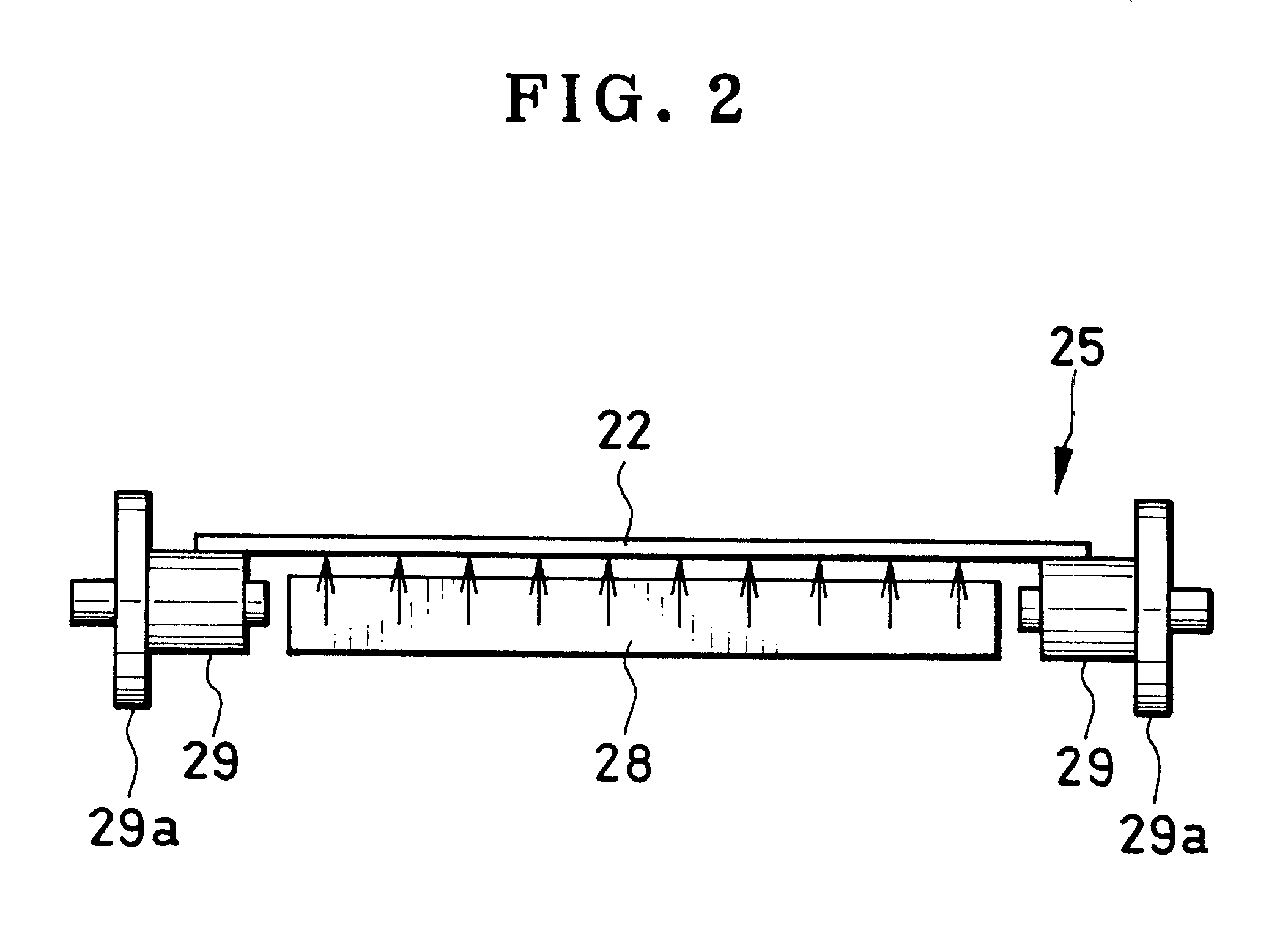

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

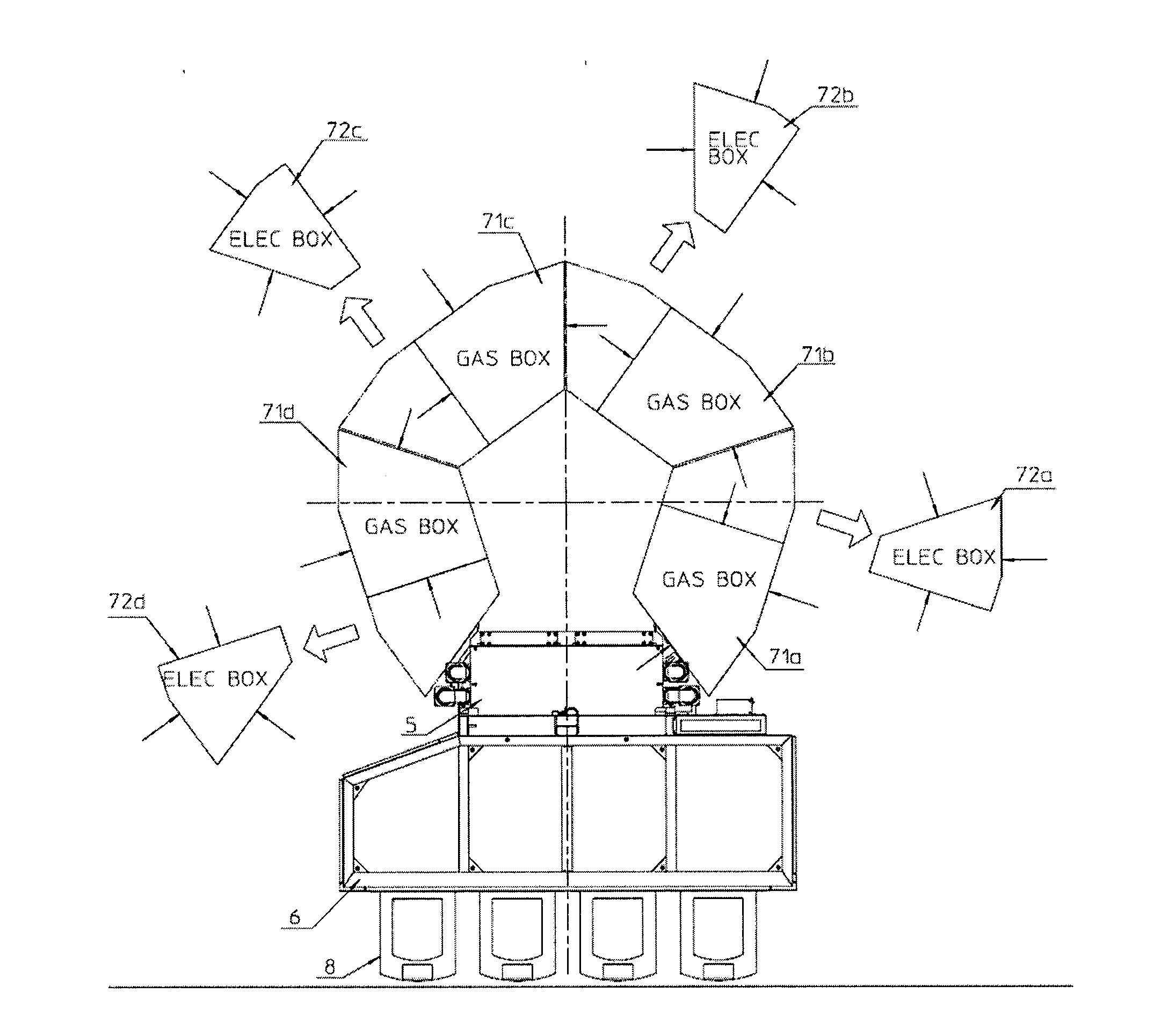

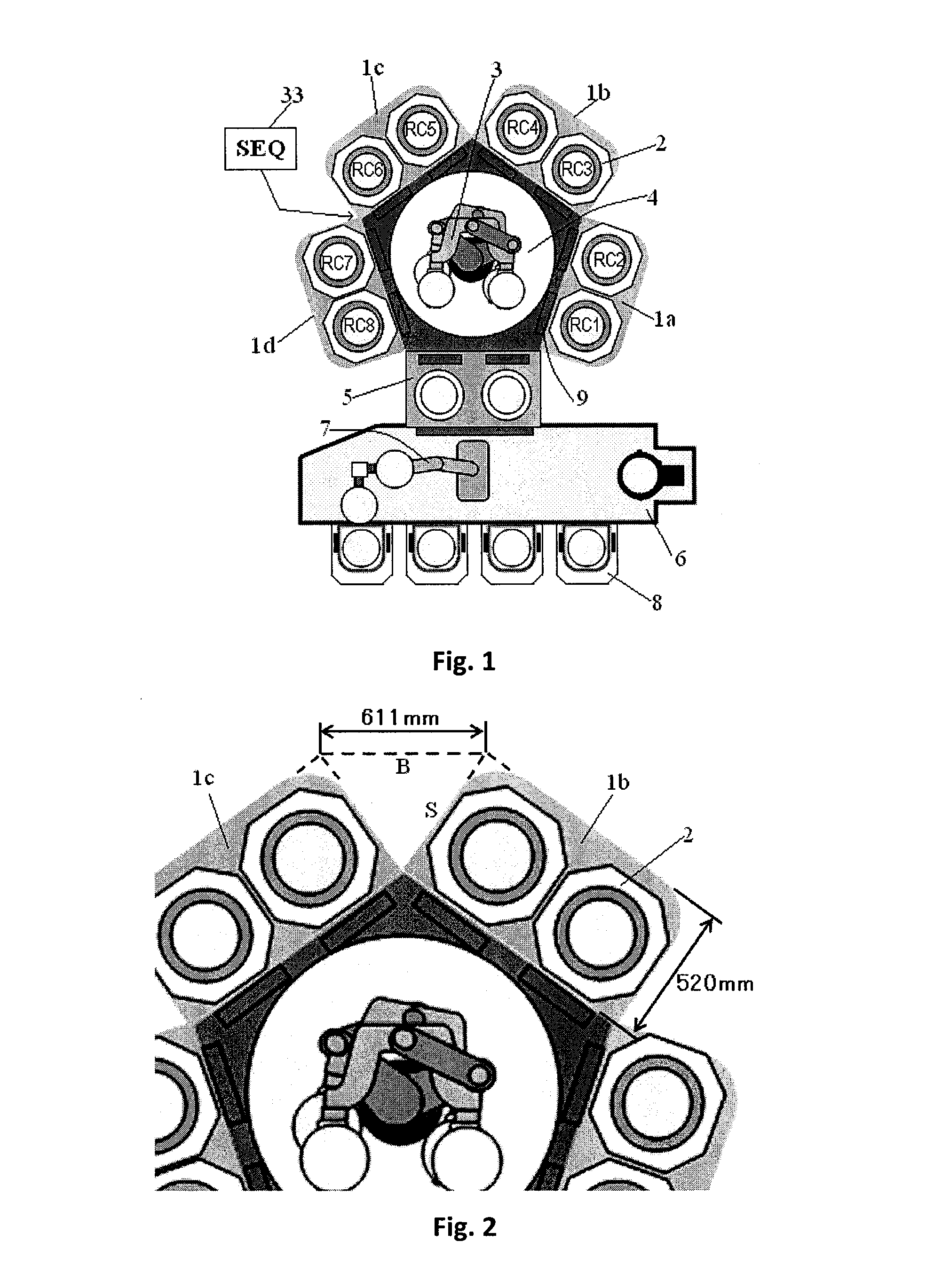

High-Throughput Semiconductor-Processing Apparatus Equipped with Multiple Dual-Chamber Modules

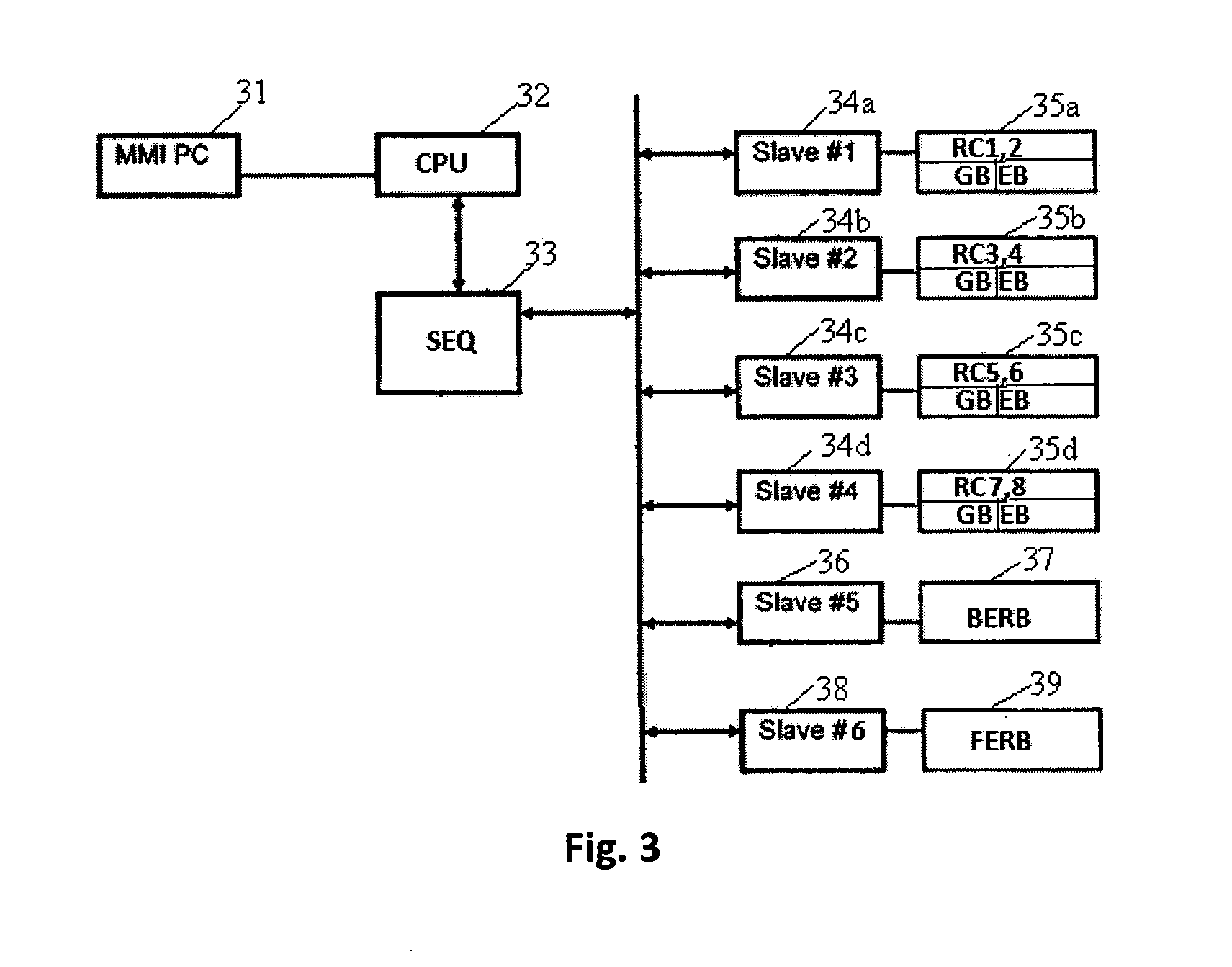

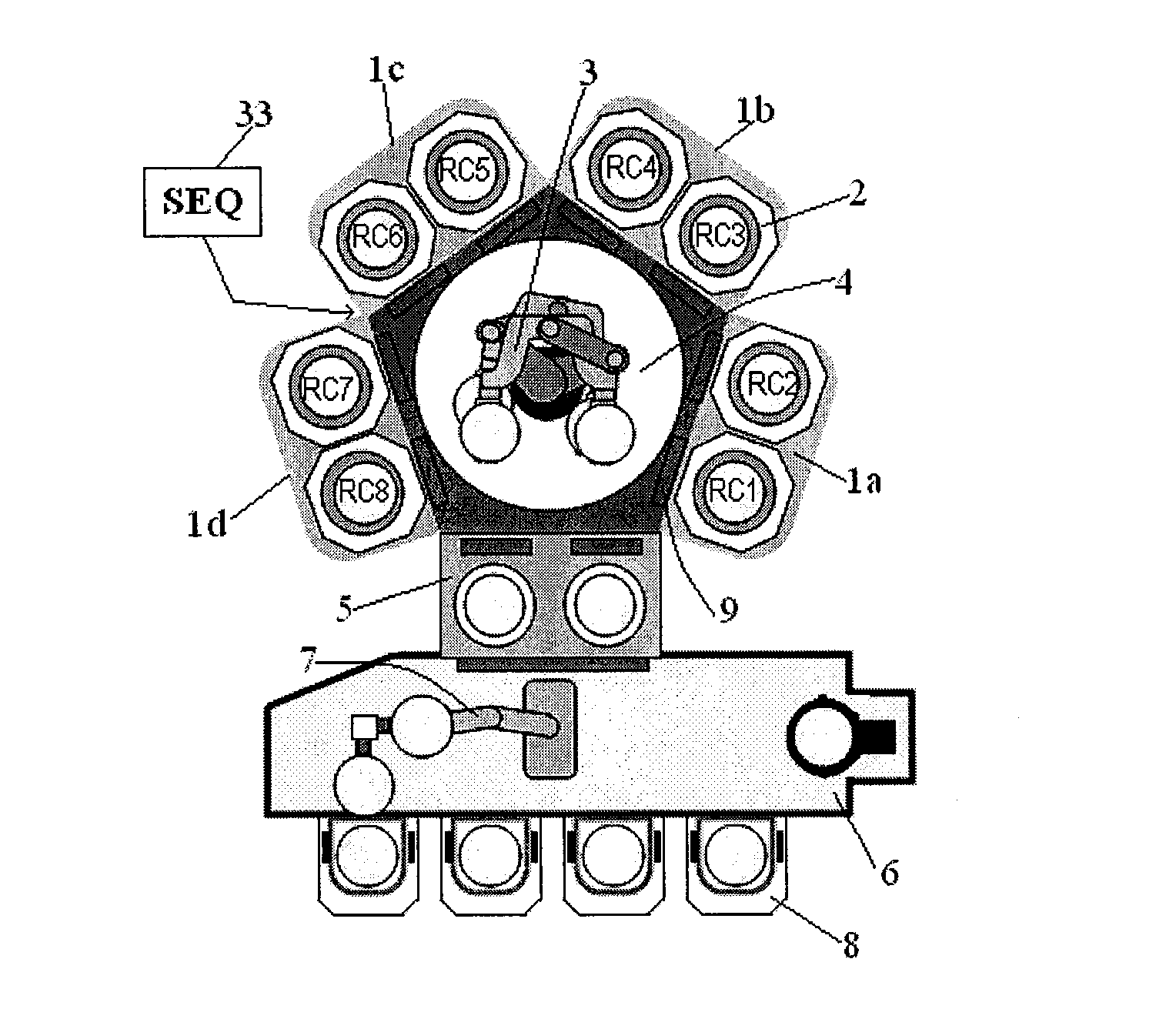

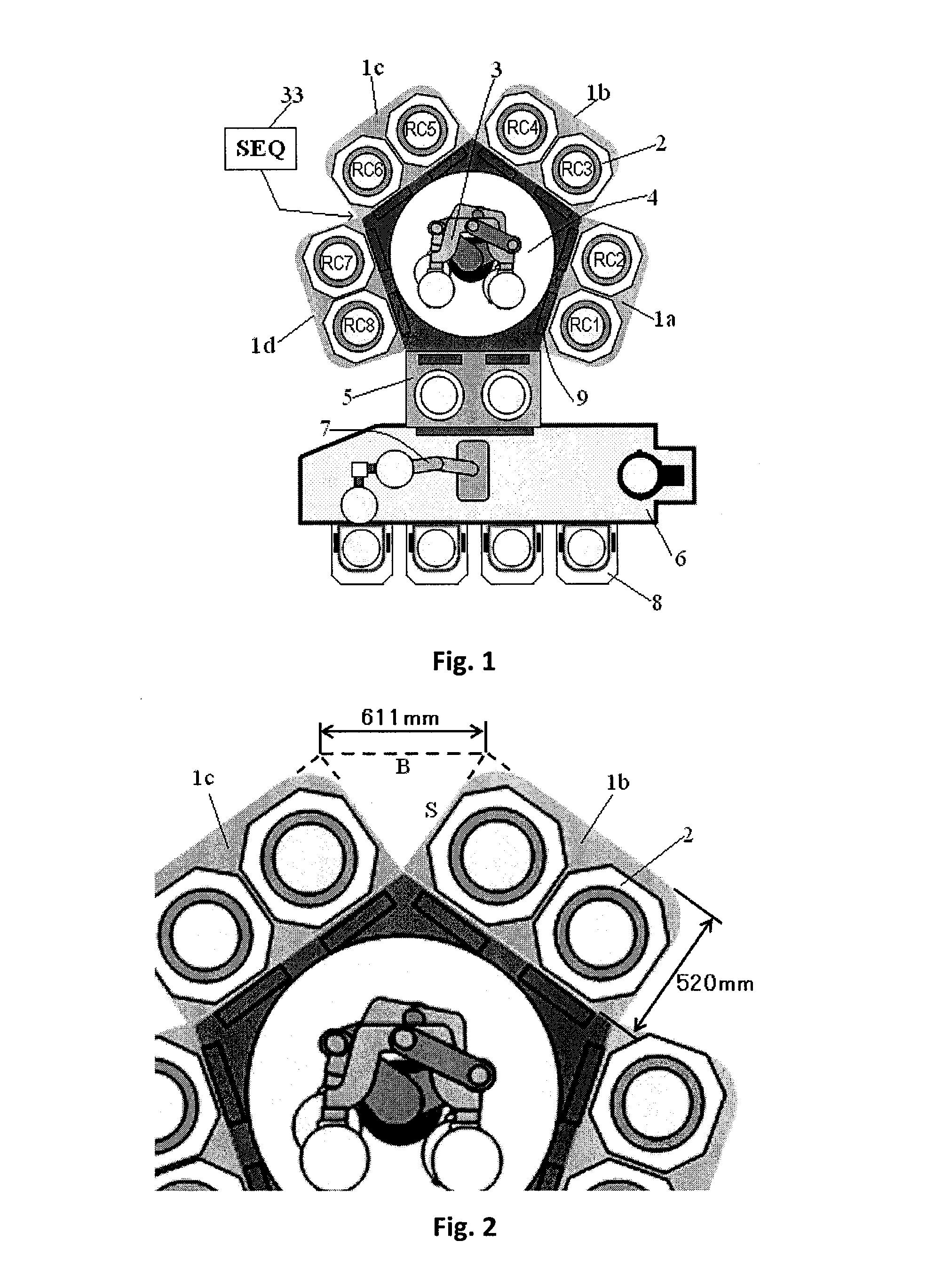

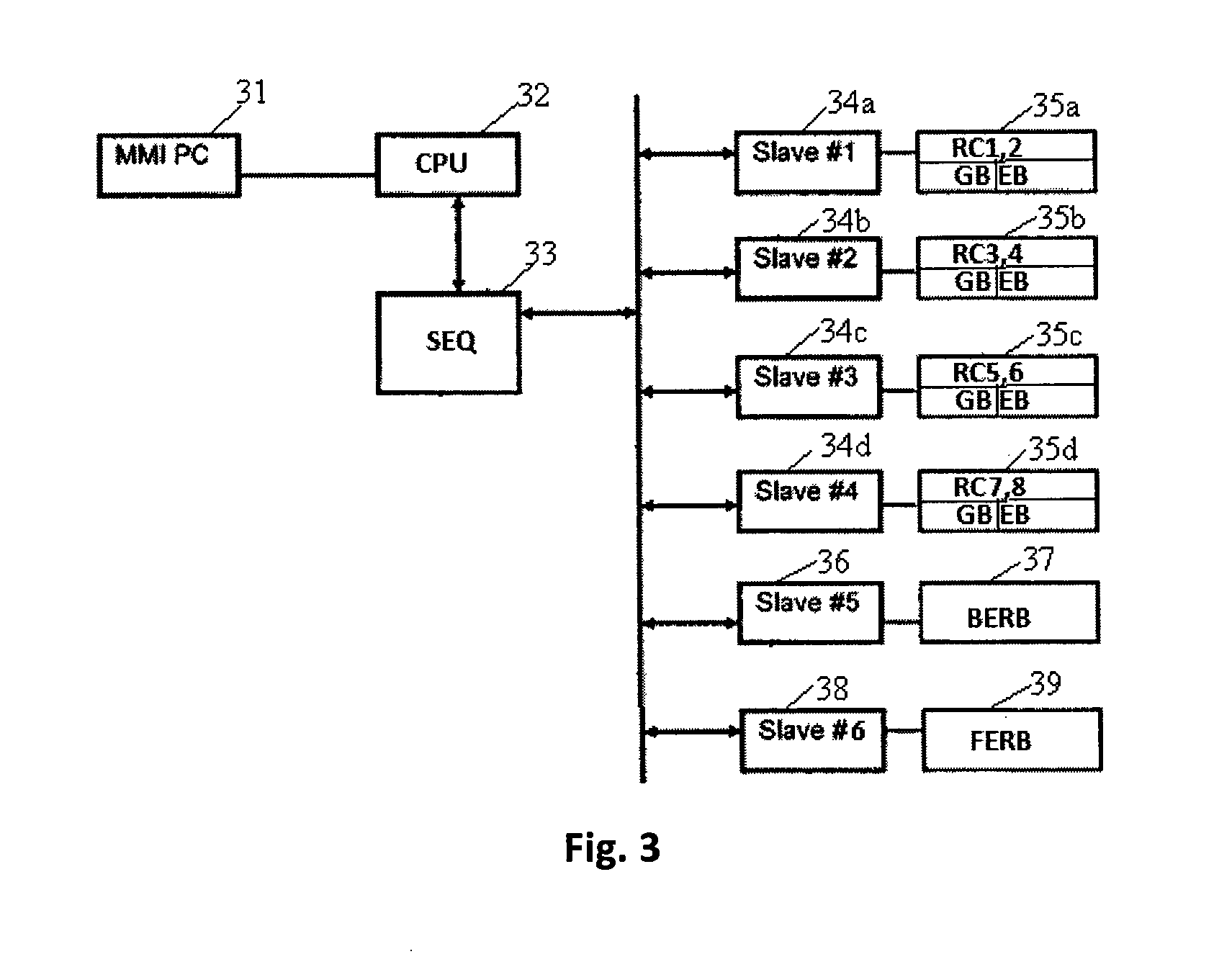

A wafer-processing apparatus includes: eight or ten reactors with identical capacity for processing wafers on the same plane, constituting four or five discrete units, each unit having two reactors arranged side by side with their fronts aligned in a line; a wafer-handling chamber including two wafer-handling robot arms each having at least two end-effectors; a load lock chamber; and a sequencer for performing, using the two wafer-handling robot arms, steps of unloading / loading processed / unprocessed wafers from / to any one of the units, and steps of unloading / loading processed / unprocessed wafers from / to all the other respective units in sequence while the wafers are in the one of the units.

Owner:ASM JAPAN

High-throughput semiconductor-processing apparatus equipped with multiple dual-chamber modules

Owner:ASM JAPAN

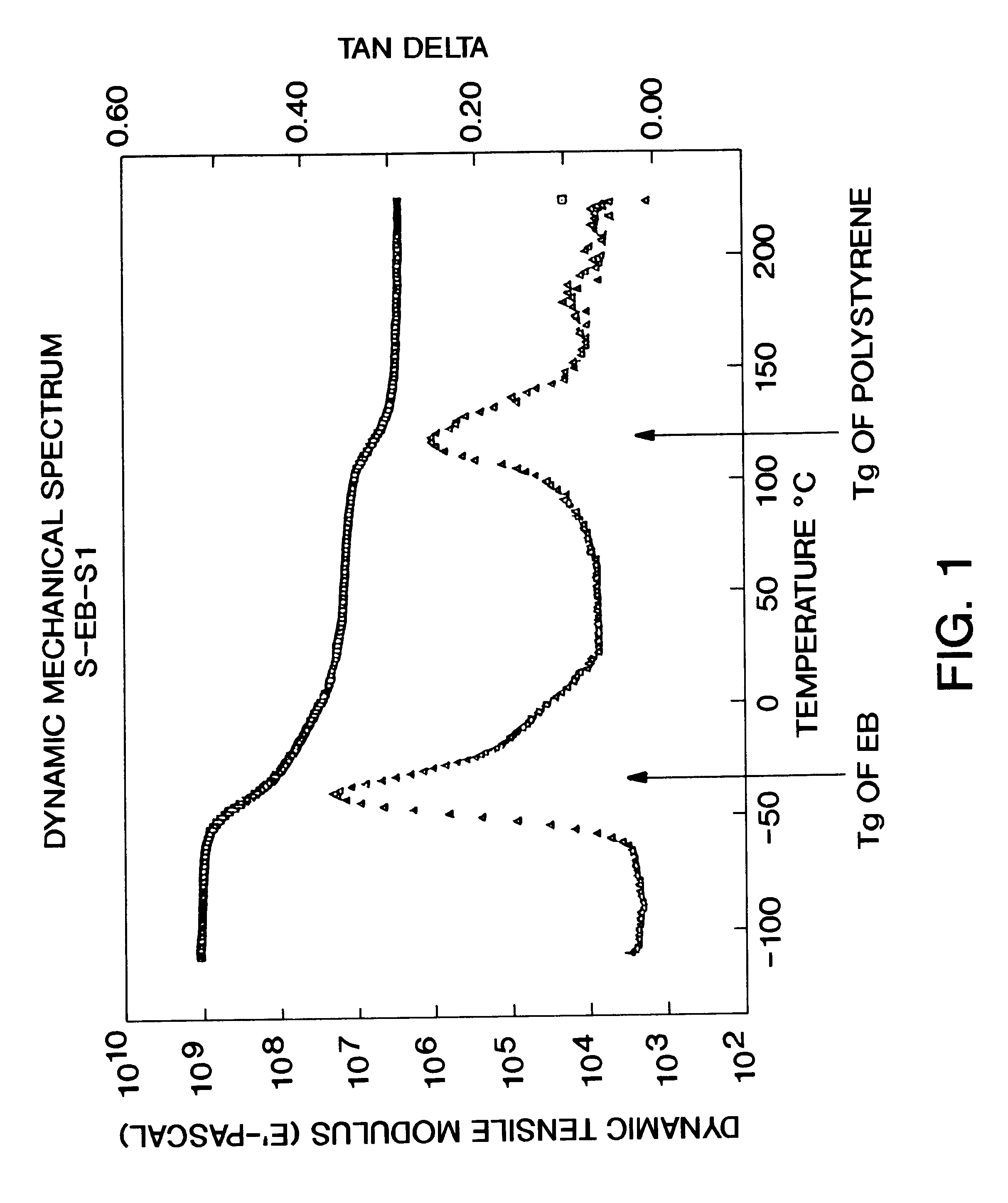

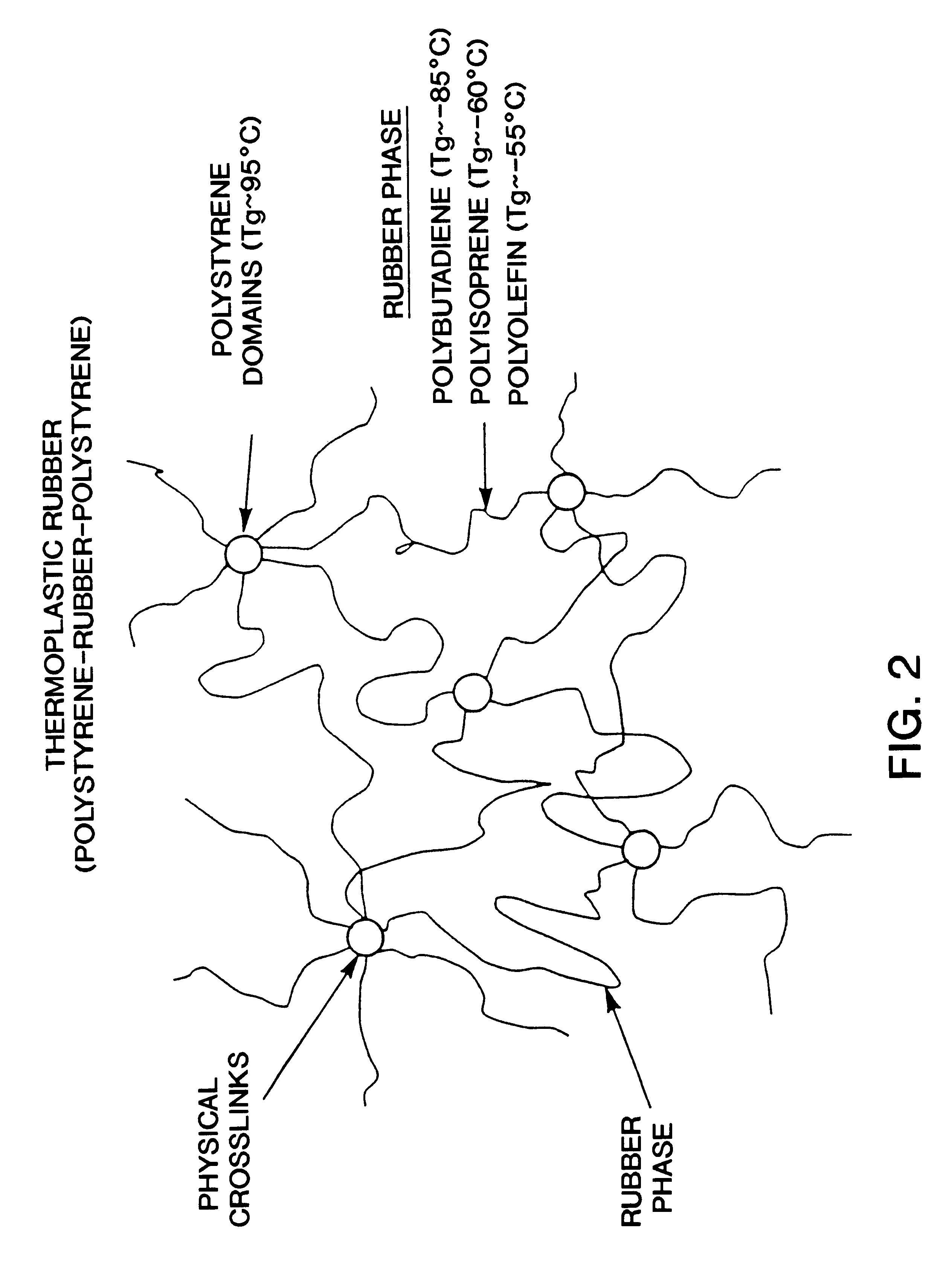

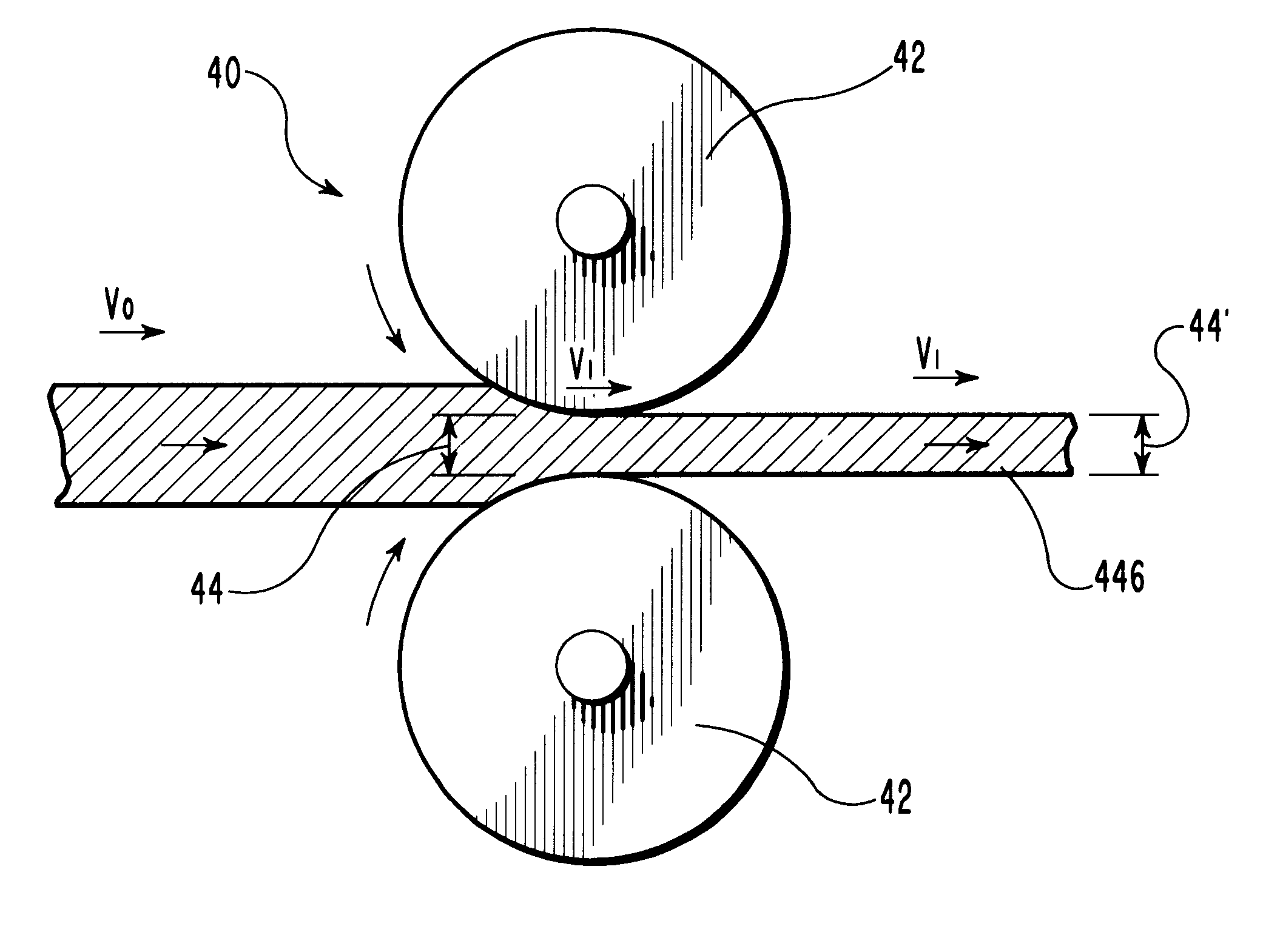

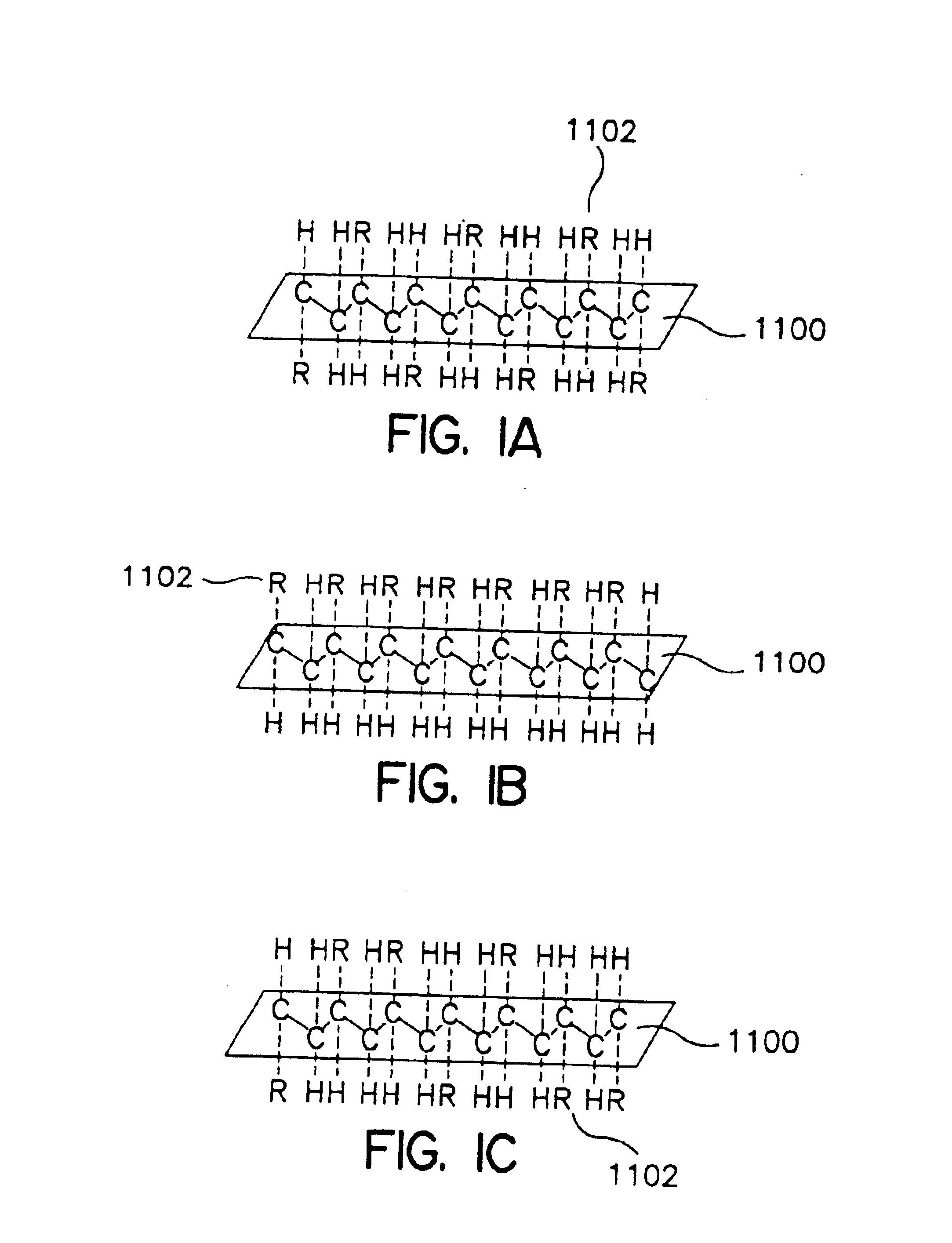

Dimensionally stable, breathable, stretch-thinned, elastic films

A method for producing a stretch-thinned elastic article having dimensional stability over time and at elevated temperatures in which a thermoplastic block copolymer is melt-processed into a stretchable article such as a film or fiber. The article is then conditioned at an elevated temperature greater than or equal to a glass transition temperature (Tg) of a hard phase of the thermoplastic block copolymer. The article is stretch-thinned at the elevated temperature to a desired percentage stretch, forming a stretch-thinned article, after which it is cooled to a temperature below the glass transition temperature of the hard phase of the thermoplastic block copolymer. Films produced by this method are suitable for use in durable and disposable articles including personal care articles such as diapers, incontinence wear, training pants, and feminine care articles, as well as wound dressings, wipes, towels, napkins, and protective apparel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

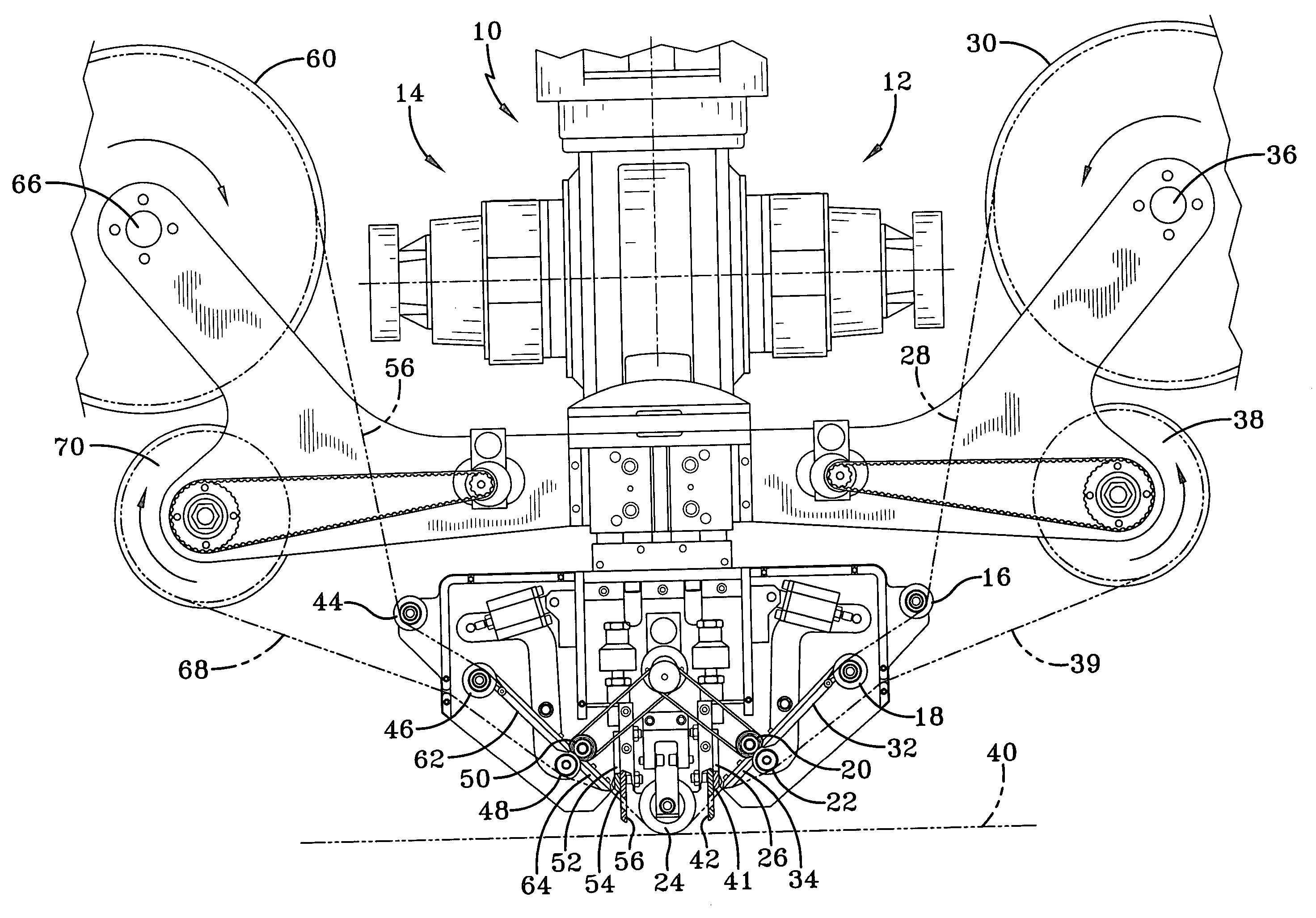

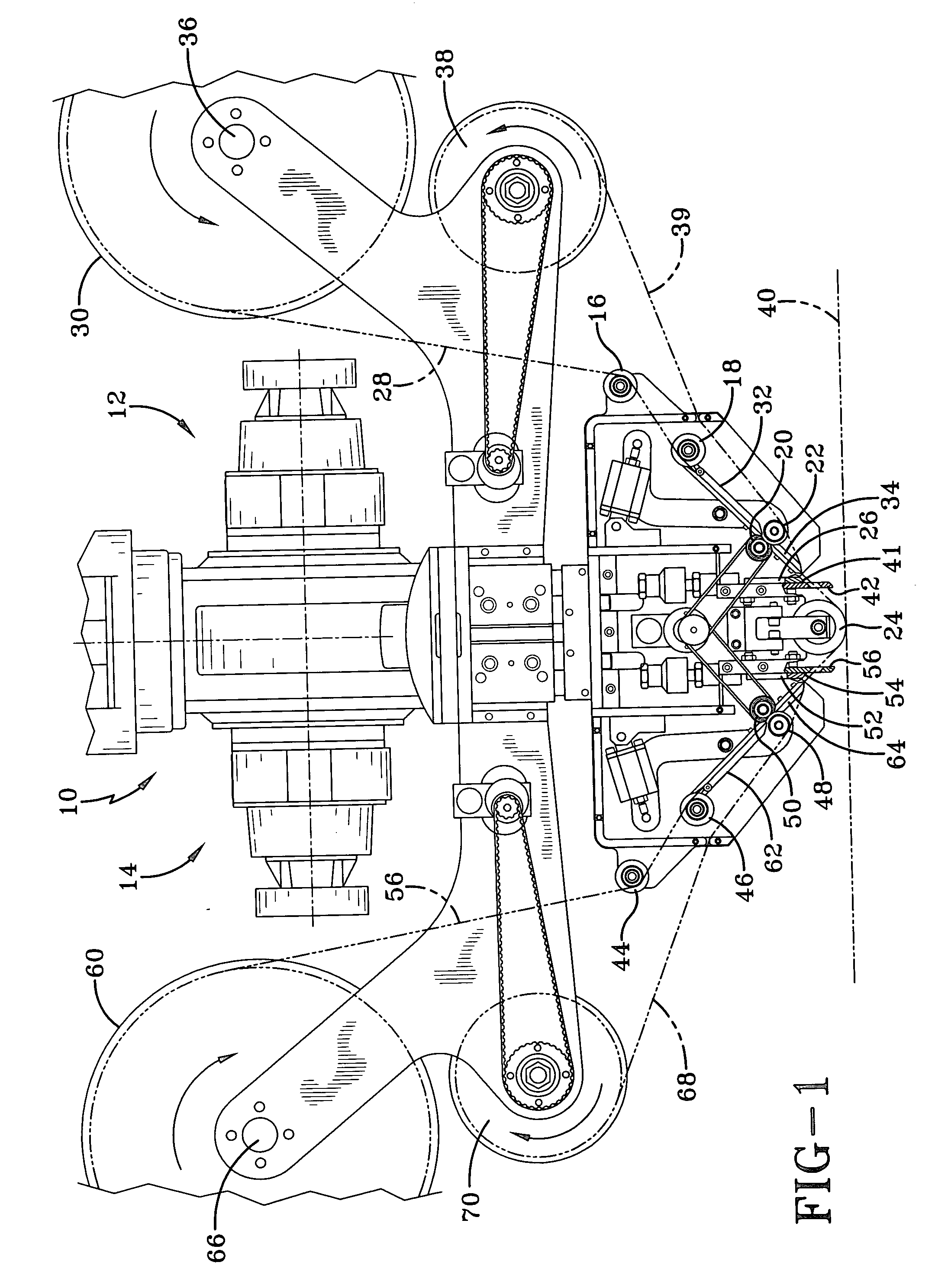

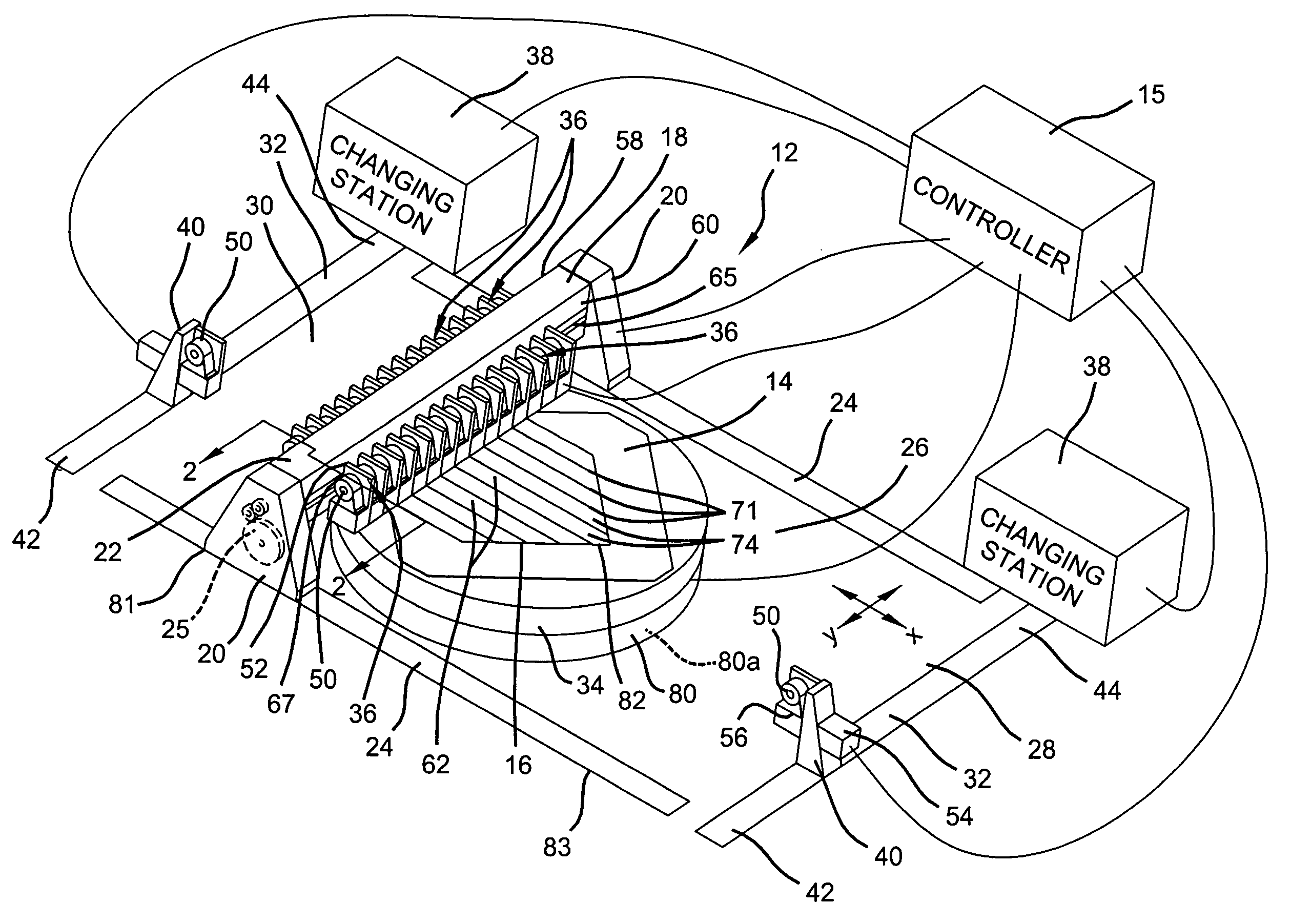

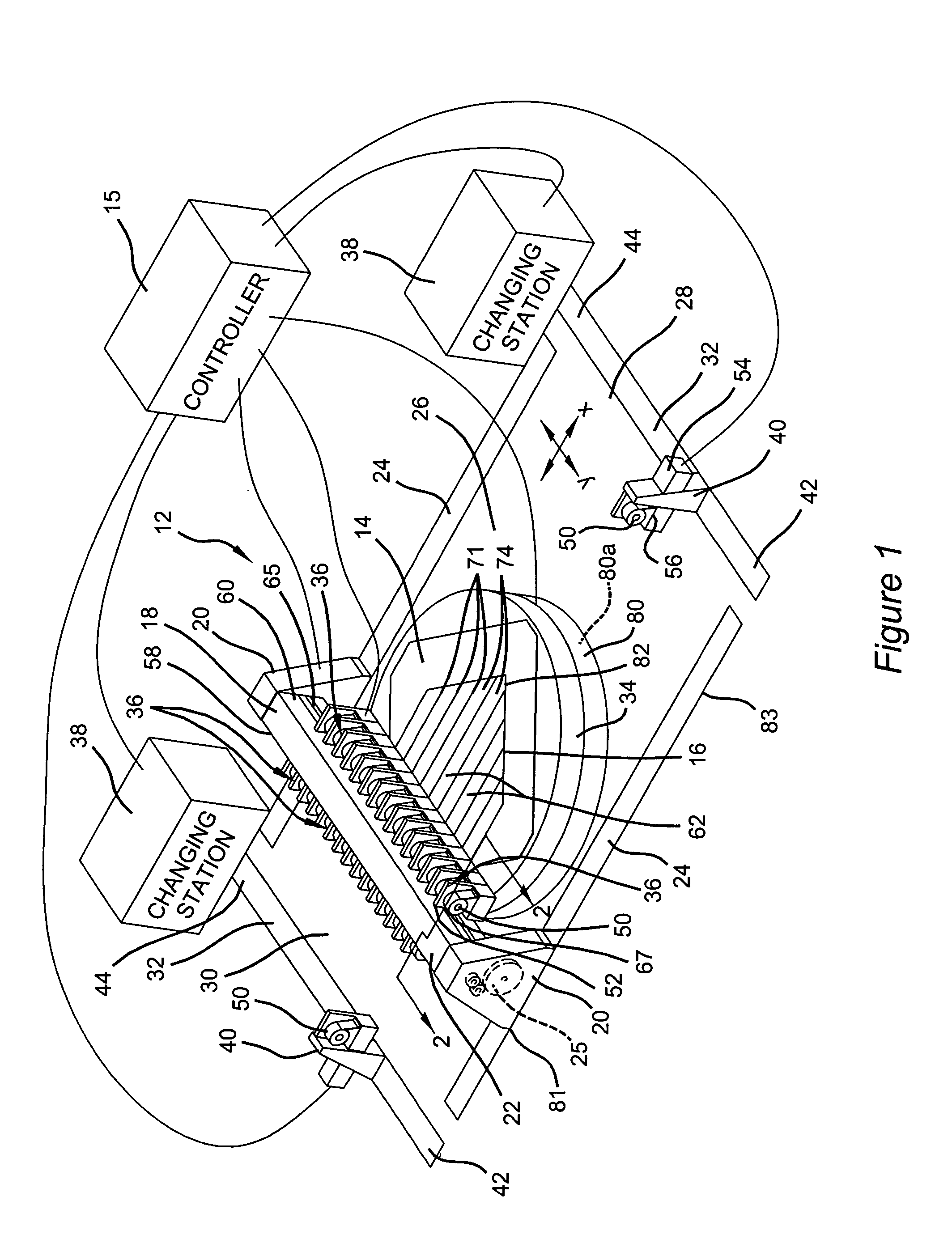

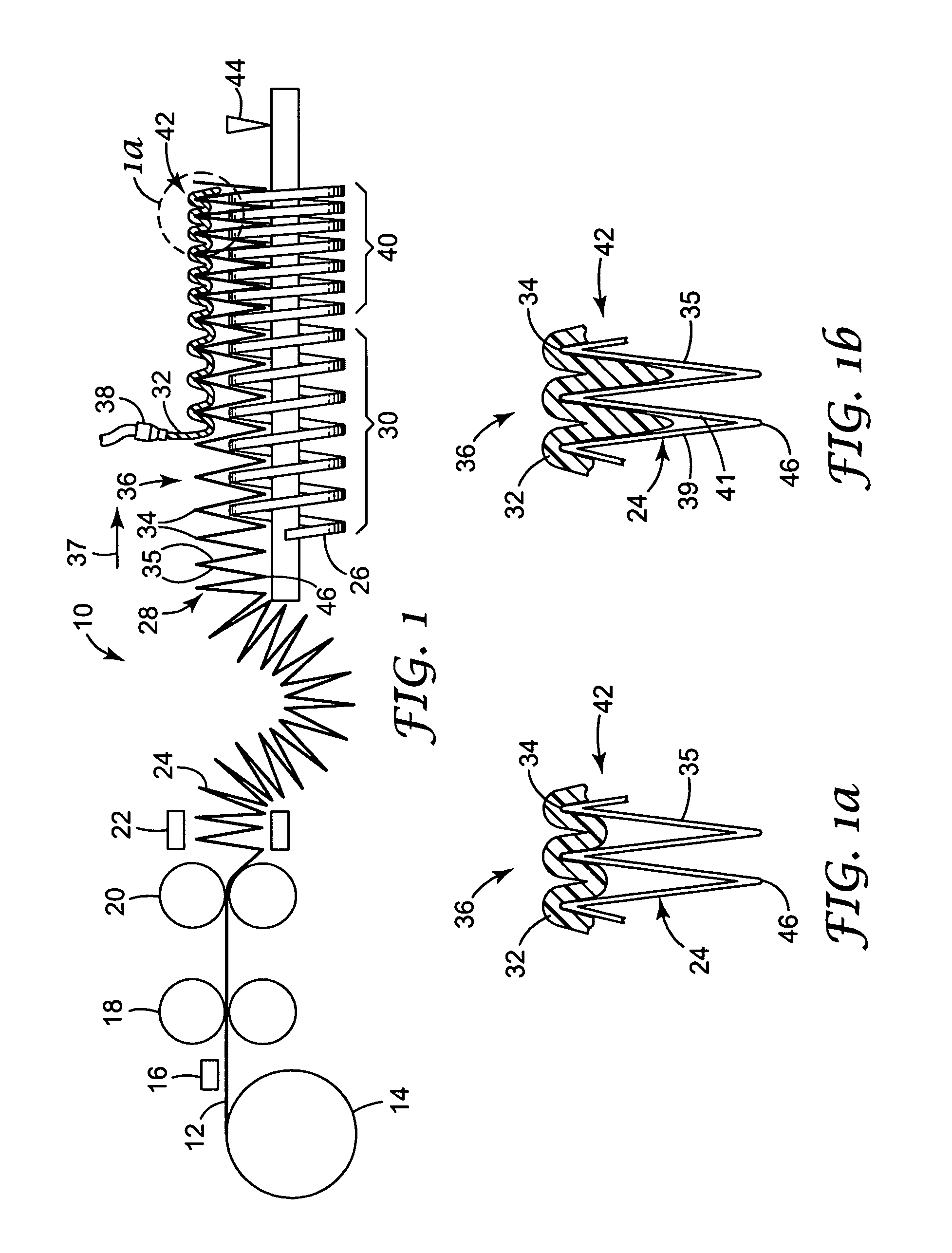

Multiple tape laying apparatus and method

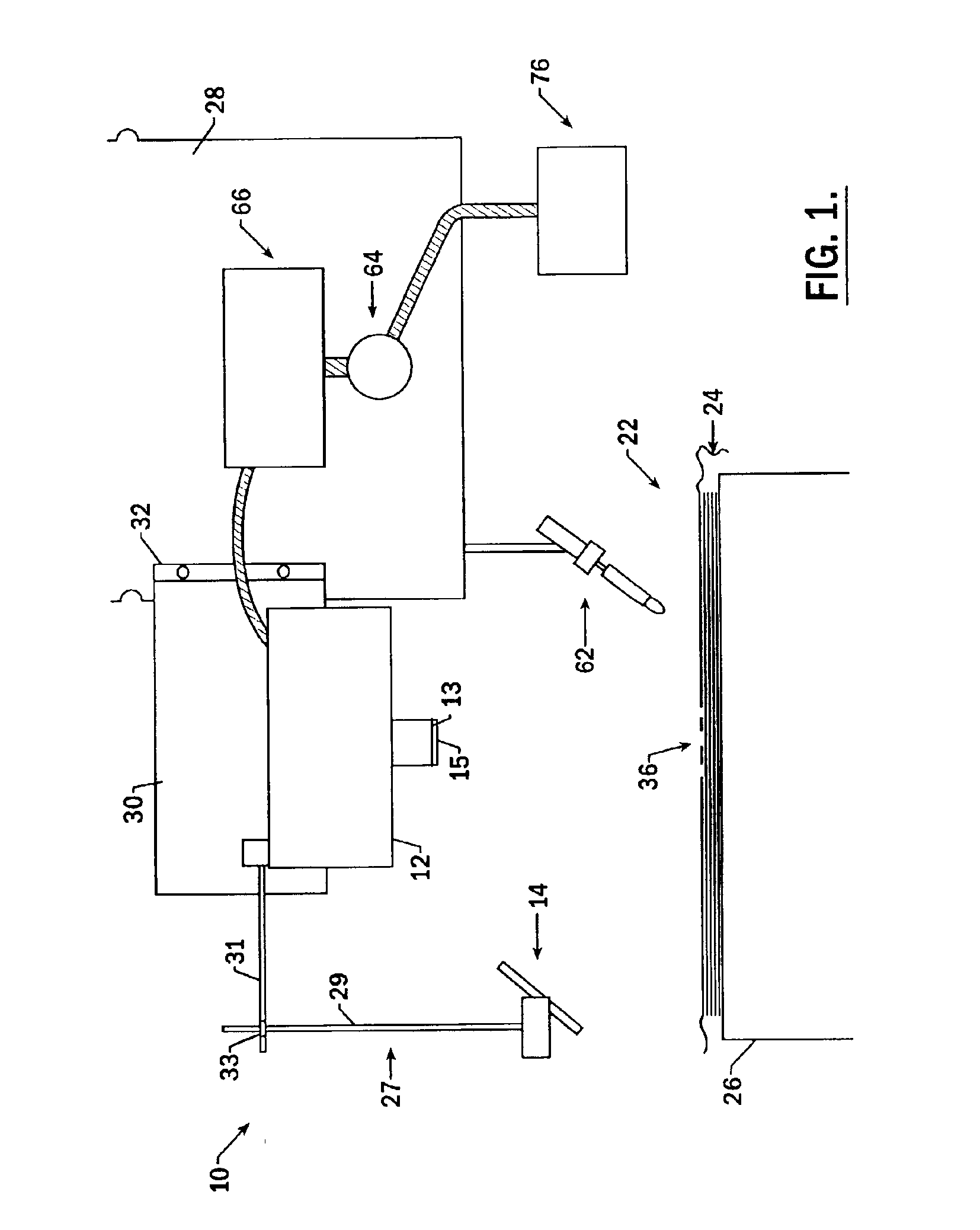

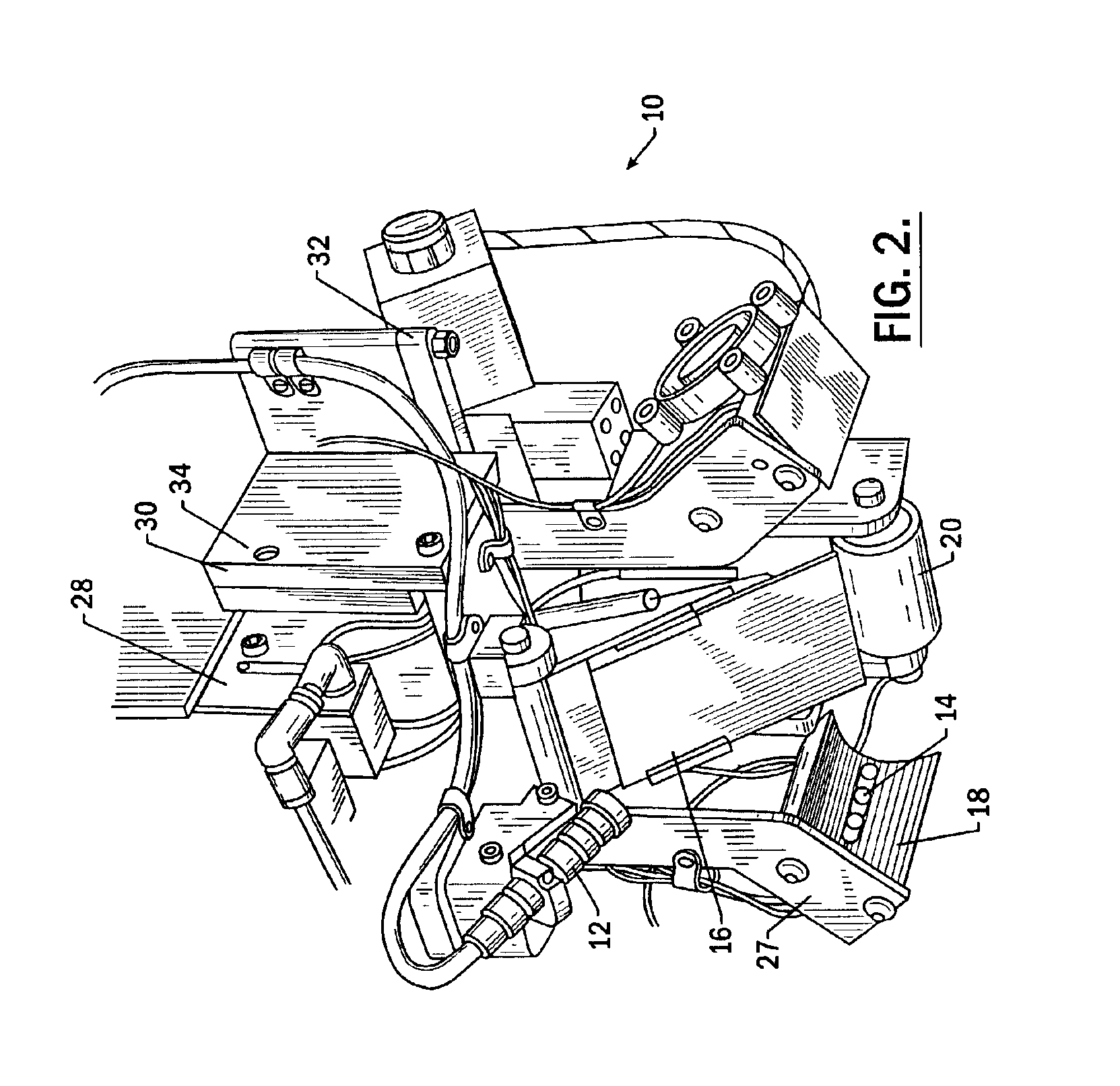

ActiveUS20050061422A1Satisfactory depositionAvoid stickingLamination ancillary operationsPaper/cardboard articlesFiberMultiple layer

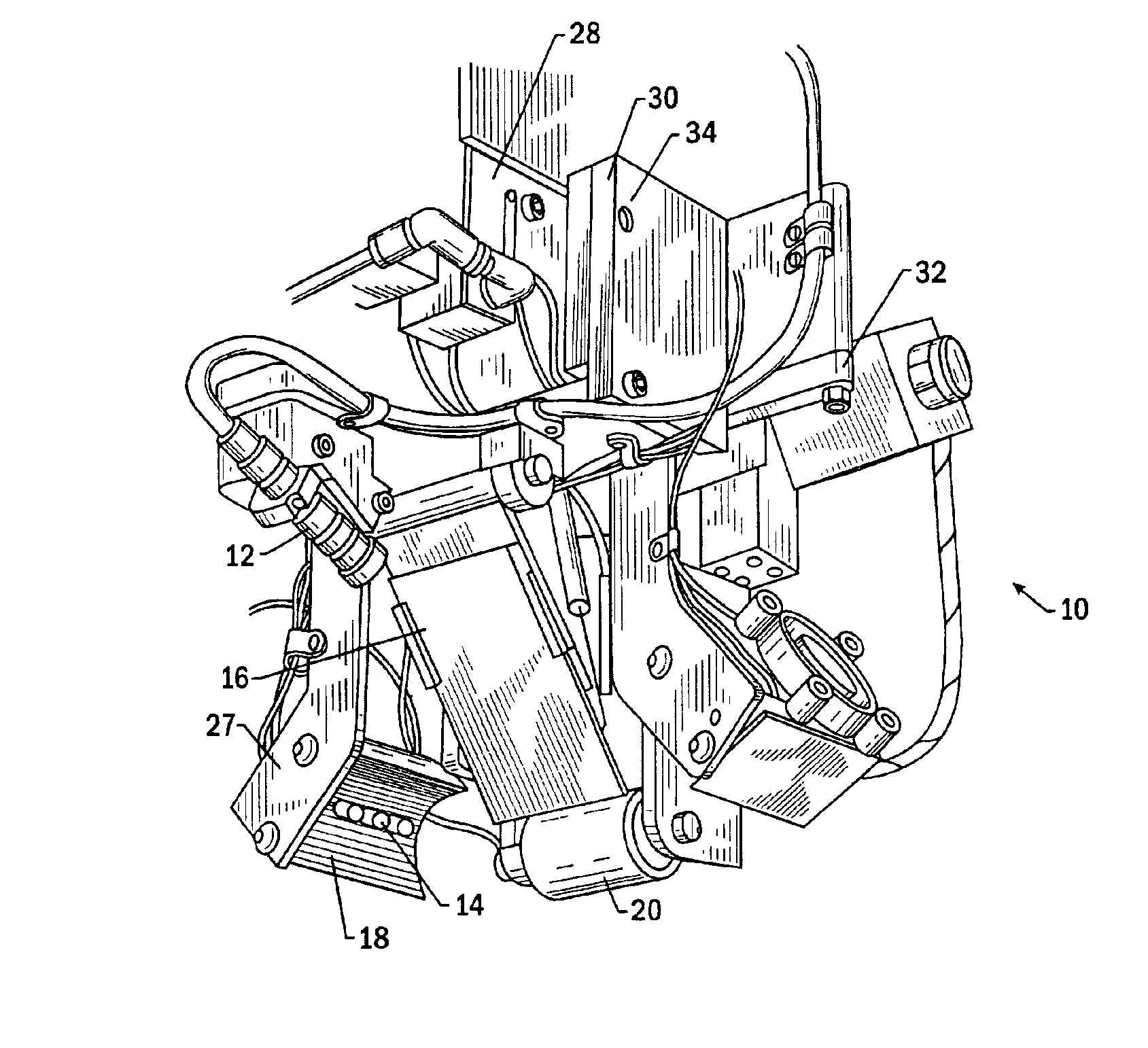

A fully automated method and apparatus is disclosed to laminate various structural articles with multiple layers of a resin impregnated fiber tape. The fiber tape is deposited with a tape laying member moving alternately in different travel directions. The tape laying member removes all backing layers from the tape being employed, then deposits the unbacked tape on the surface of the structural article and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present apparatus to increase throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

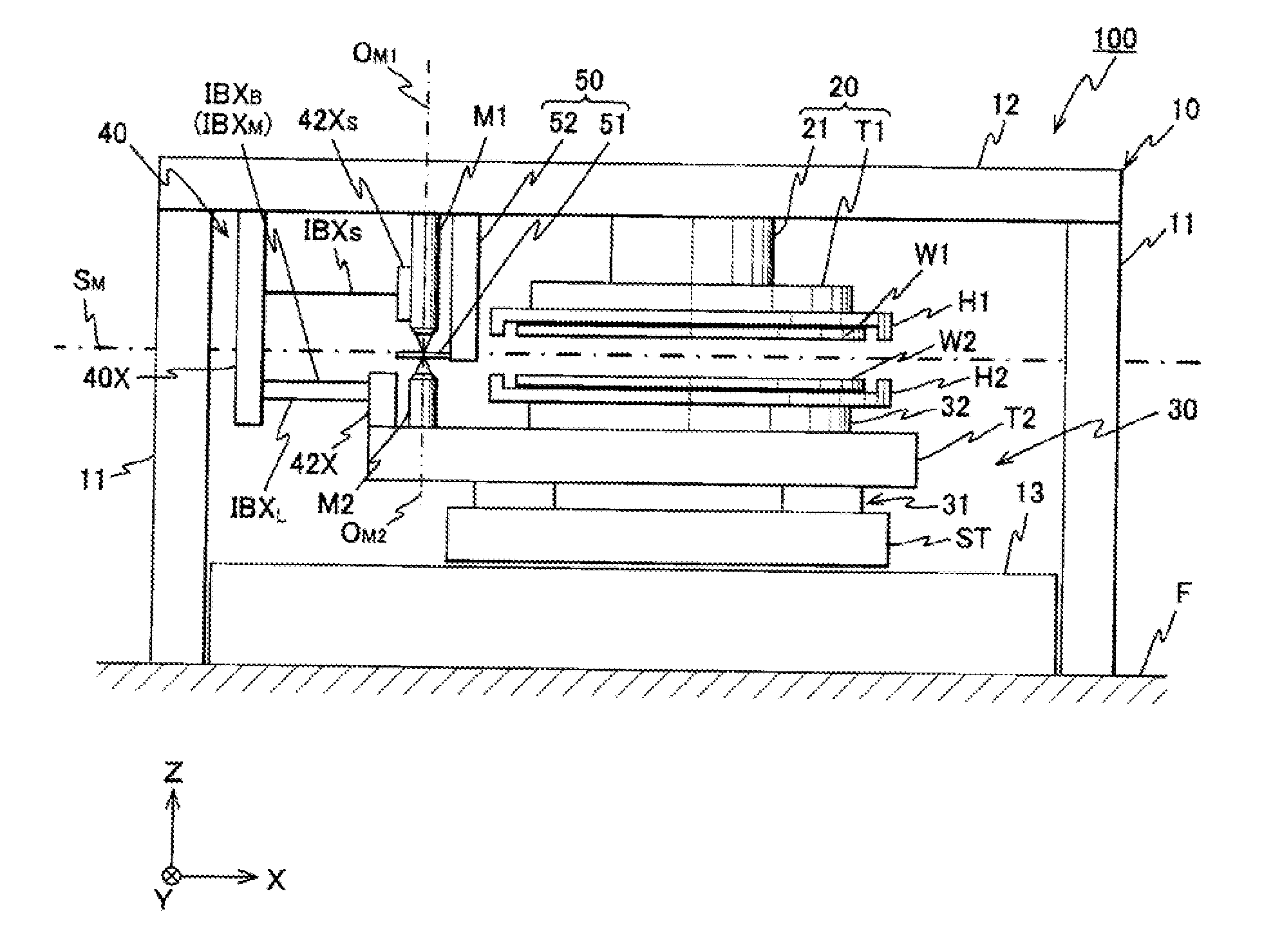

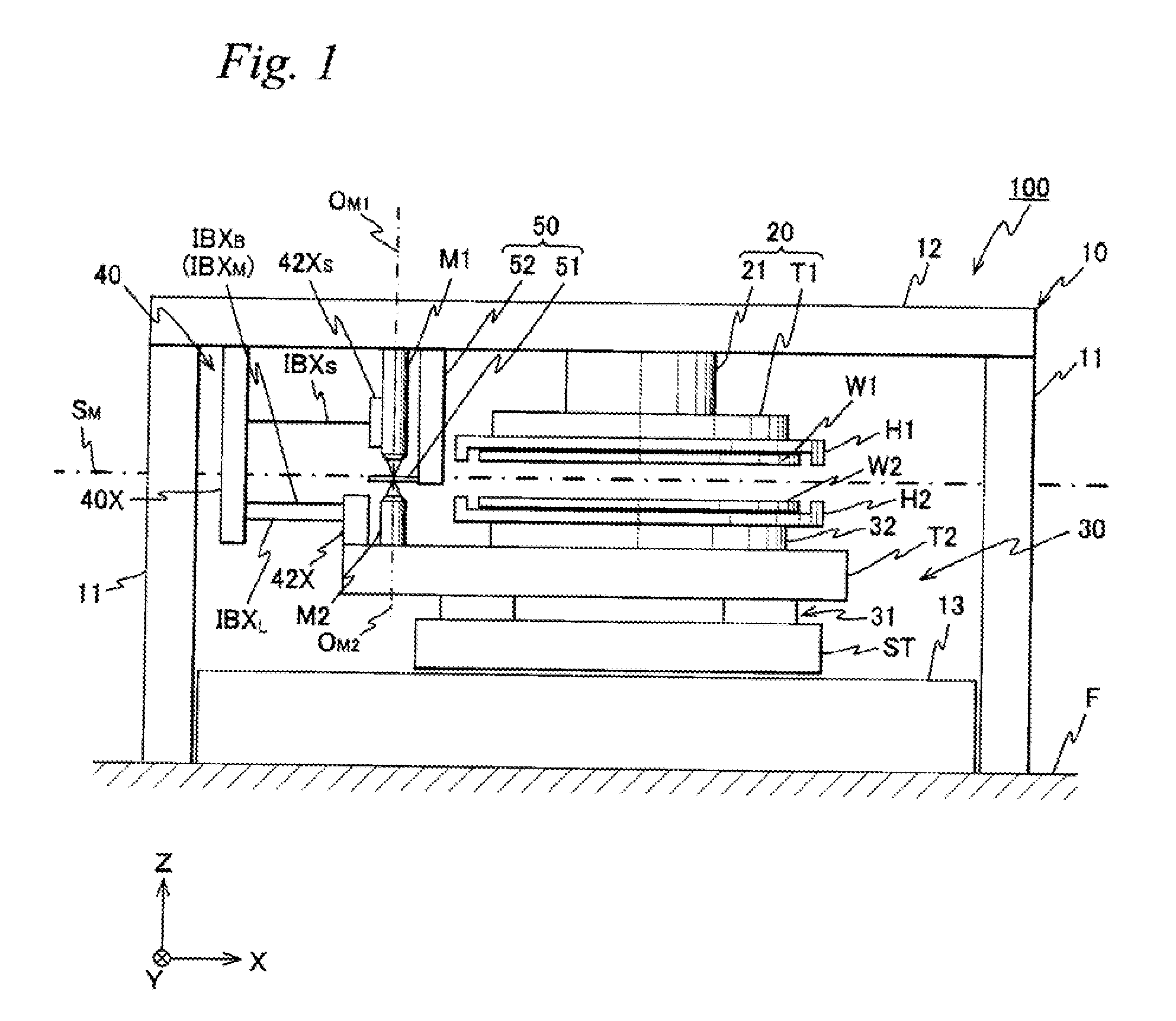

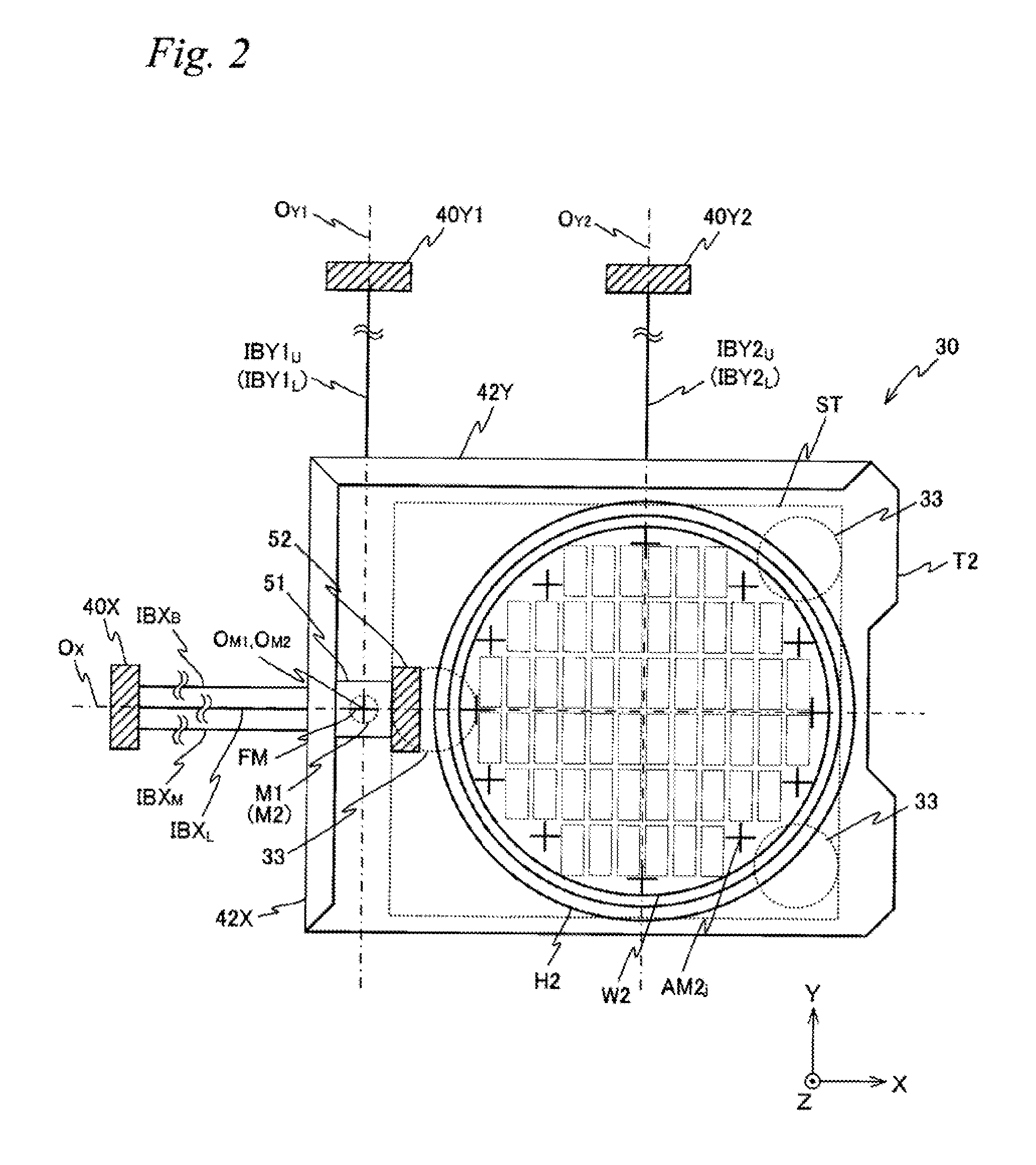

Substrate Bonding Apparatus and Substrate Bonding Method

ActiveUS20100139836A1Improve accuracyPrecise alignmentLamination ancillary operationsSemiconductor/solid-state device testing/measurementEngineering

A substrate bonding apparatus is equipped with a first table that holds one wafer of two wafers, a stage device that holds the other wafer in an orientation capable of opposing to the one wafer and that is movable at least within an XY plane, an interferometer system that measures positional information of the stage device within the XY plane, a first mark detection system that can detect subject marks including alignment marks on the other wafer held by the stage device, and a second mark detection system fixed to a part (the second table) of the stage device that can detect subject marks including alignment marks on the one wafer held by the first table.

Owner:NIKON CORP

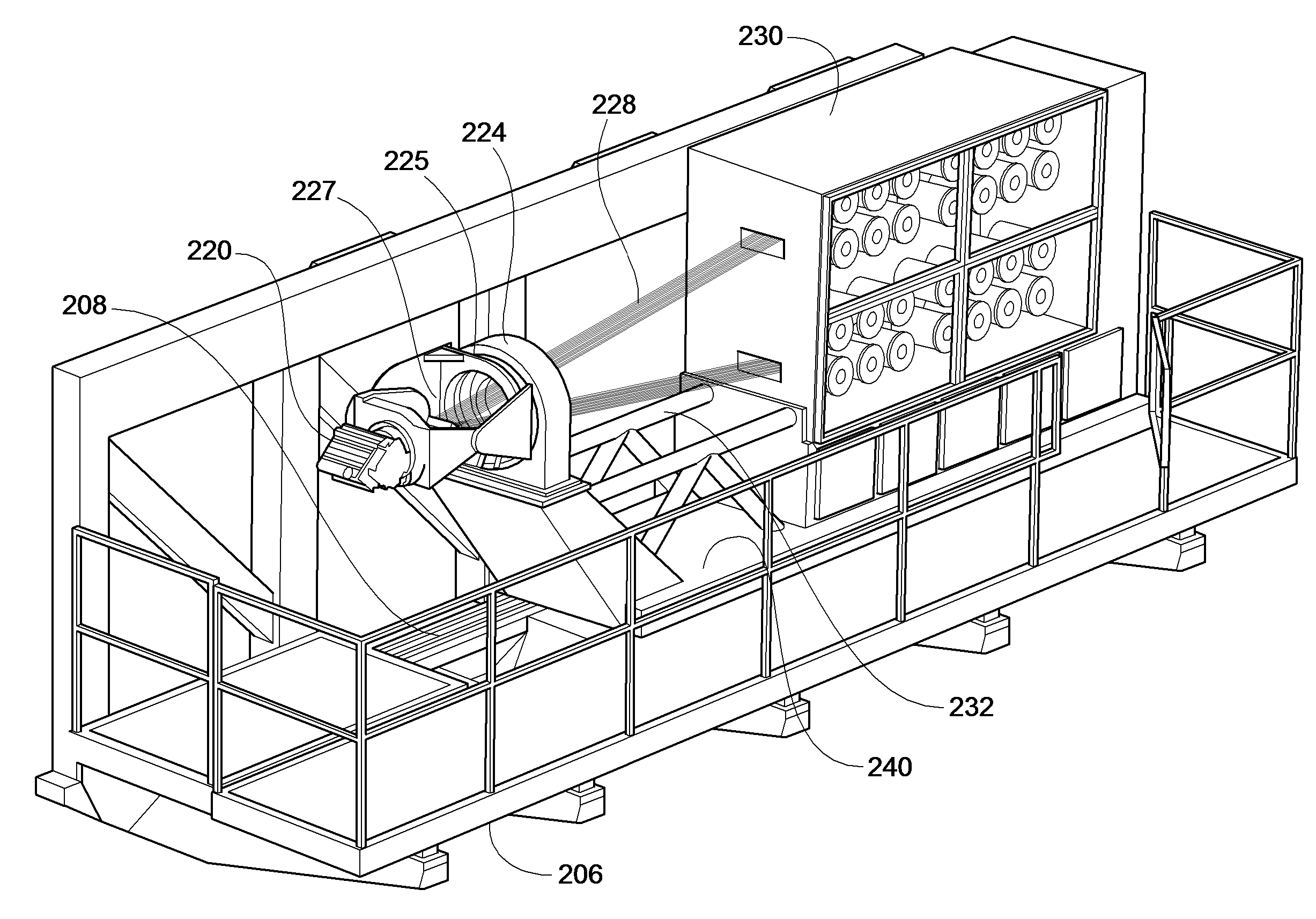

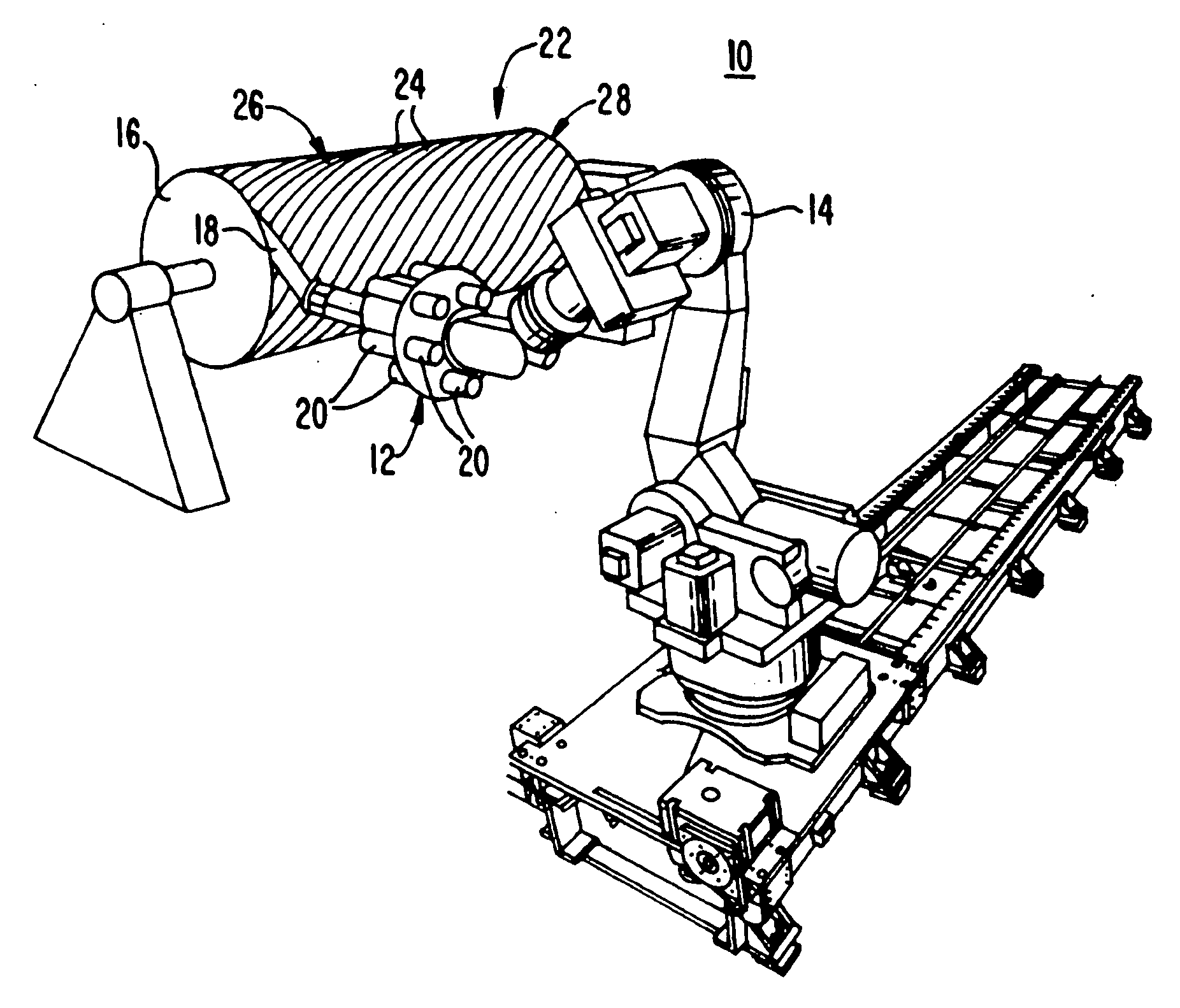

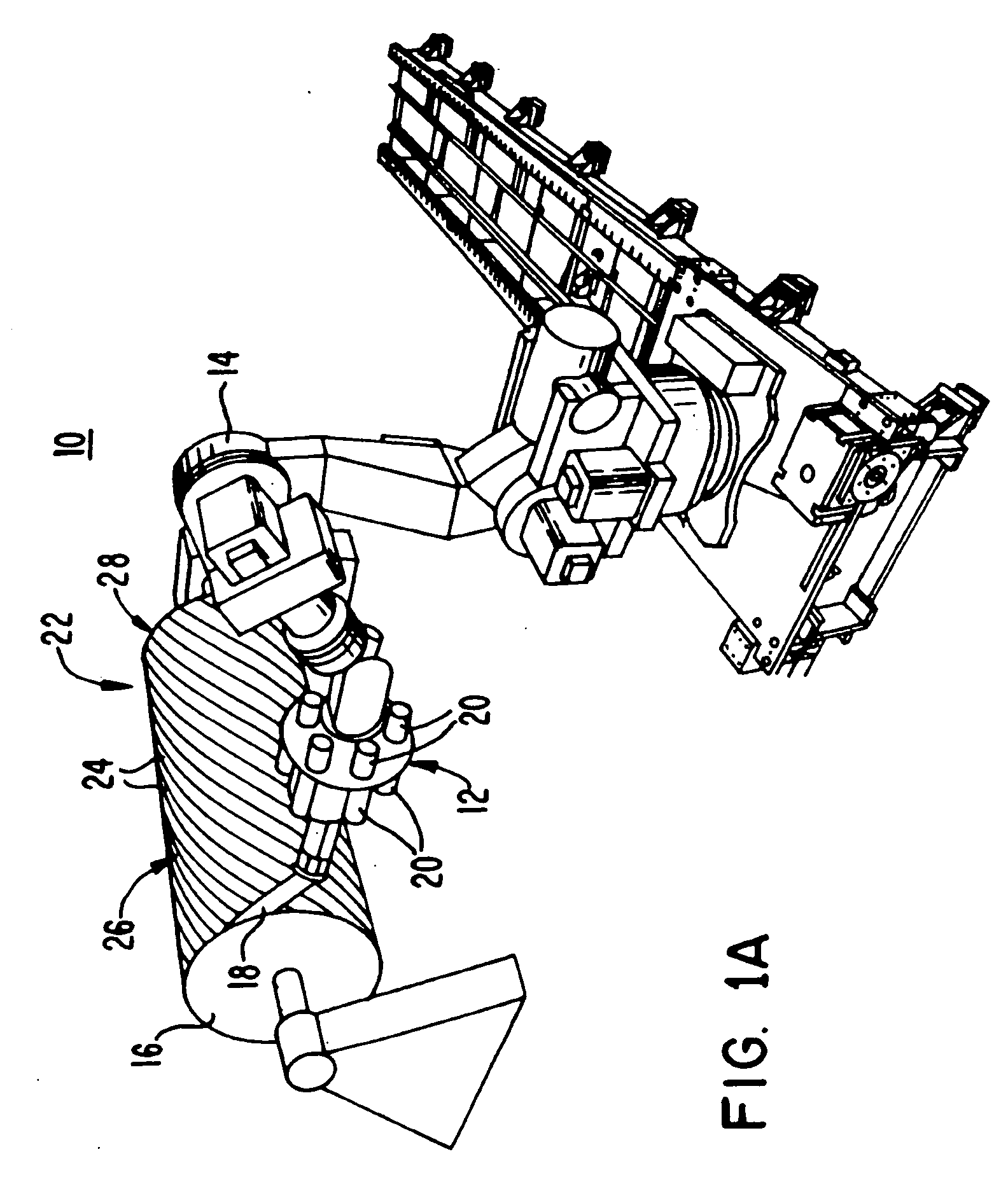

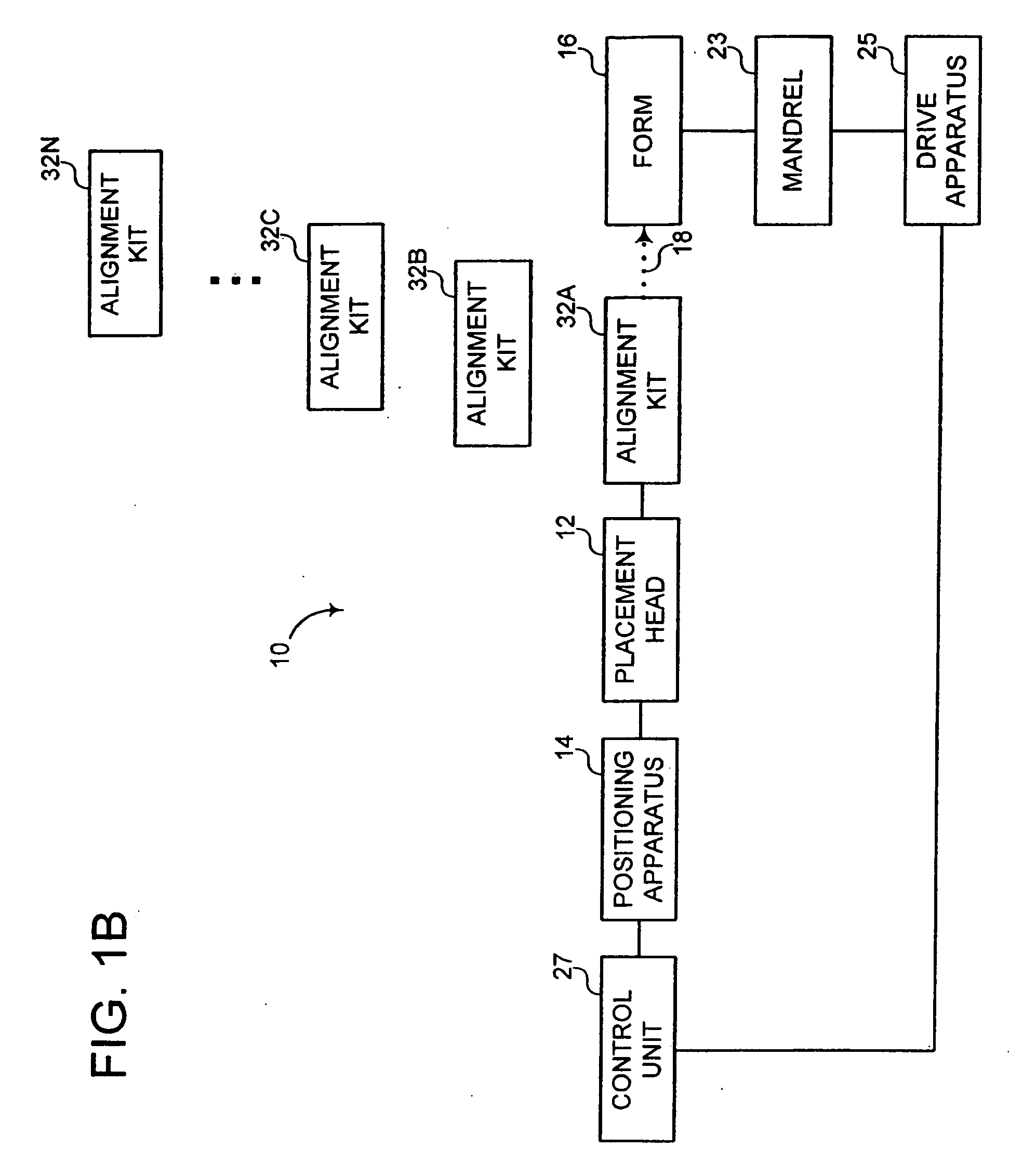

Fiber Placement Machine Platform System Having Interchangeable Head and Creel Assemblies

Owner:INGERSOLL MACHINE TOOLS

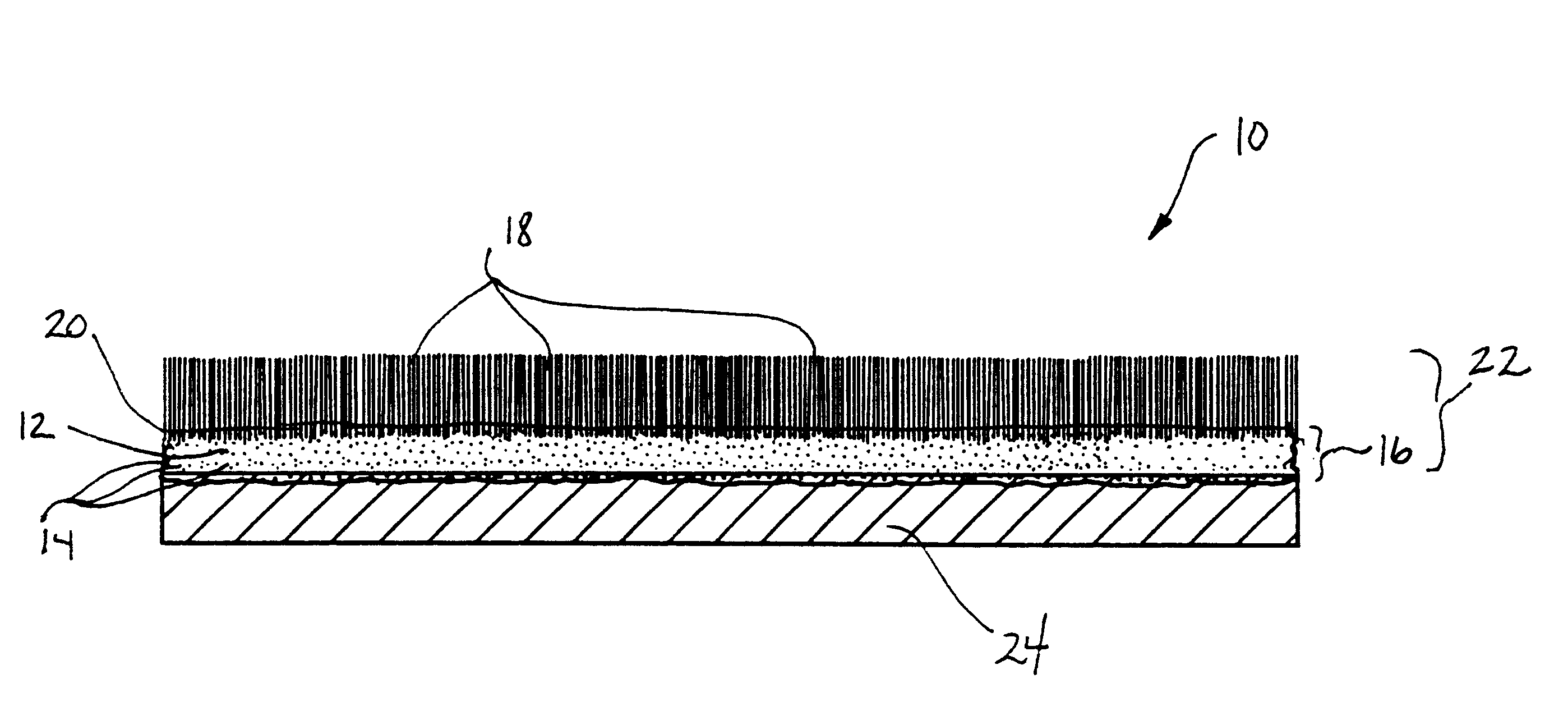

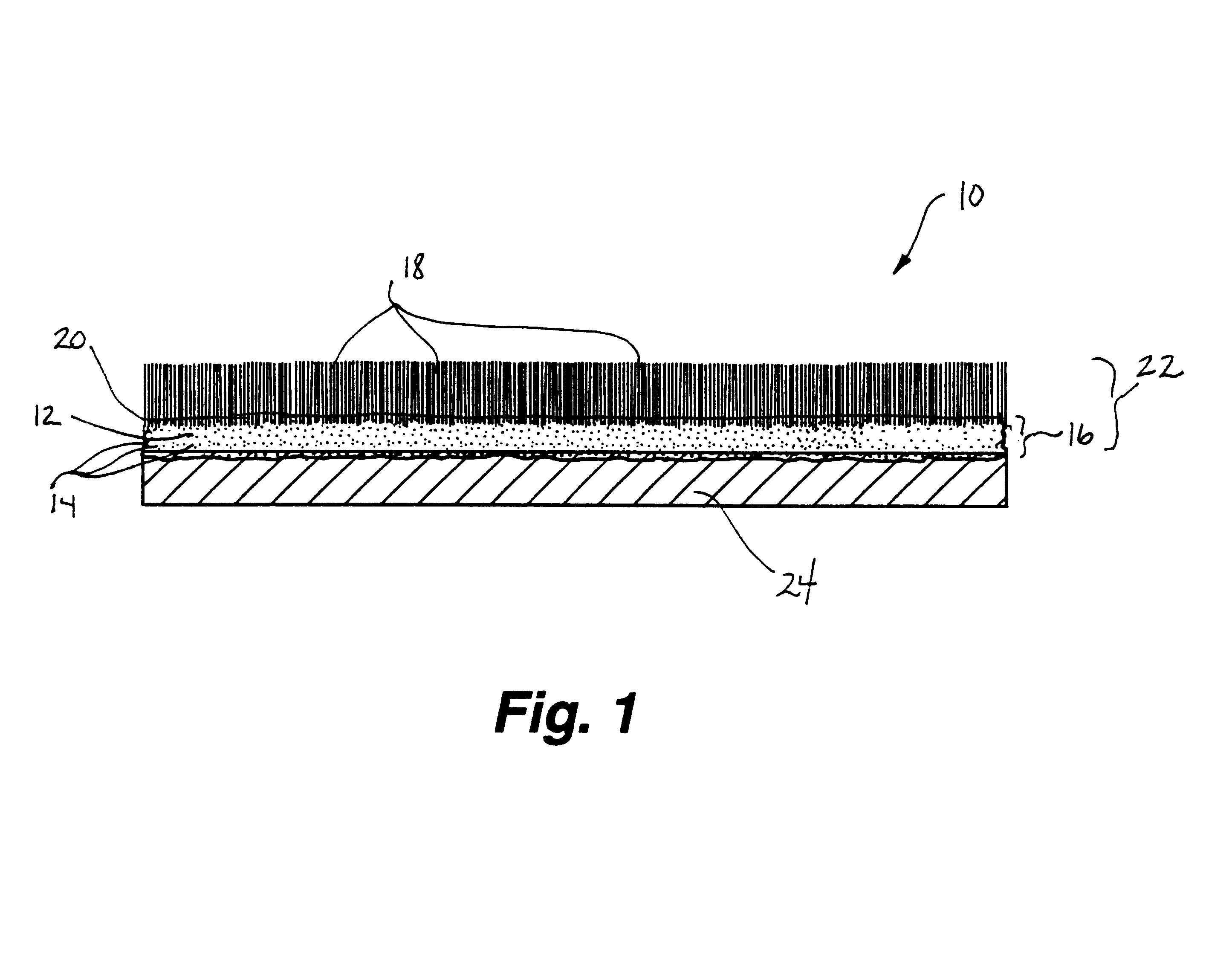

Fabric coating containing energy absorbing phase change material and method of manufacturing same

InactiveUS6514362B1Evenly dispersedEqually distributedDecorative surface effectsHeat storage plantsMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric. In an alternative embodiment, an extensible fabric is coated with an extensible binder containing microencapsulated phase change material to form an extensible, coated fabric. The coated fabric is optionally flocked. The coated fabrics are manufactured using transfer techniques.

Owner:OUTLAST TECH LLC

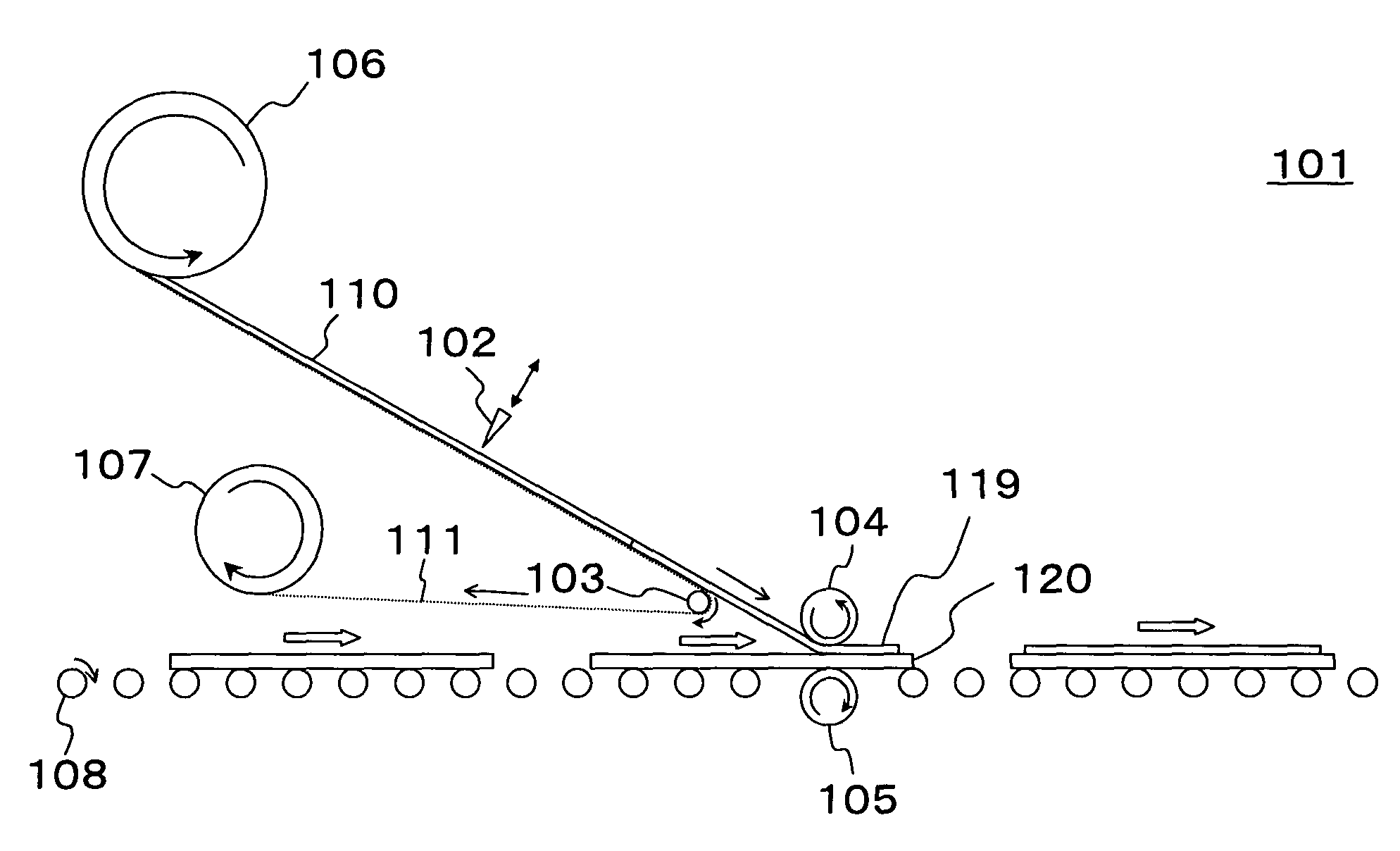

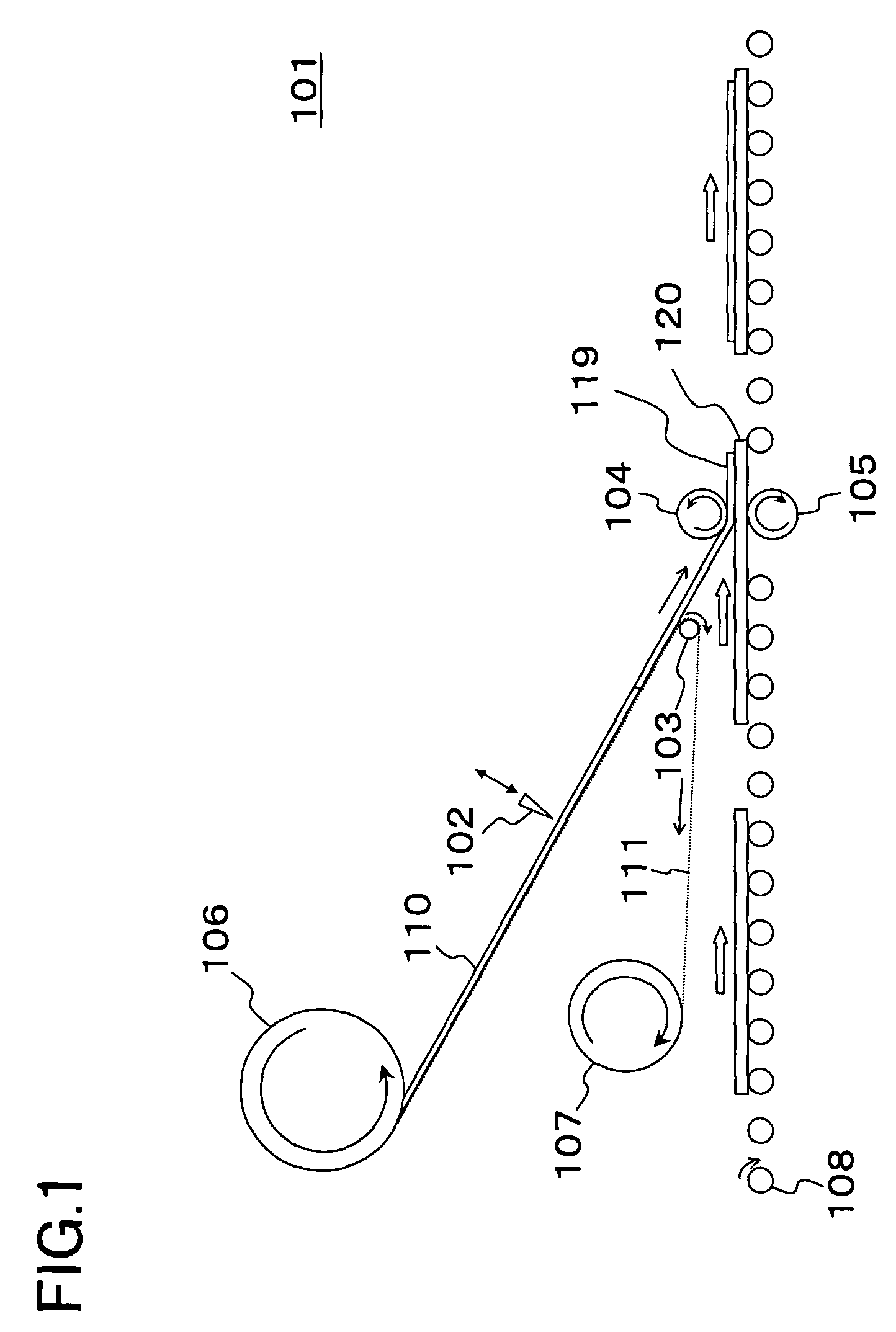

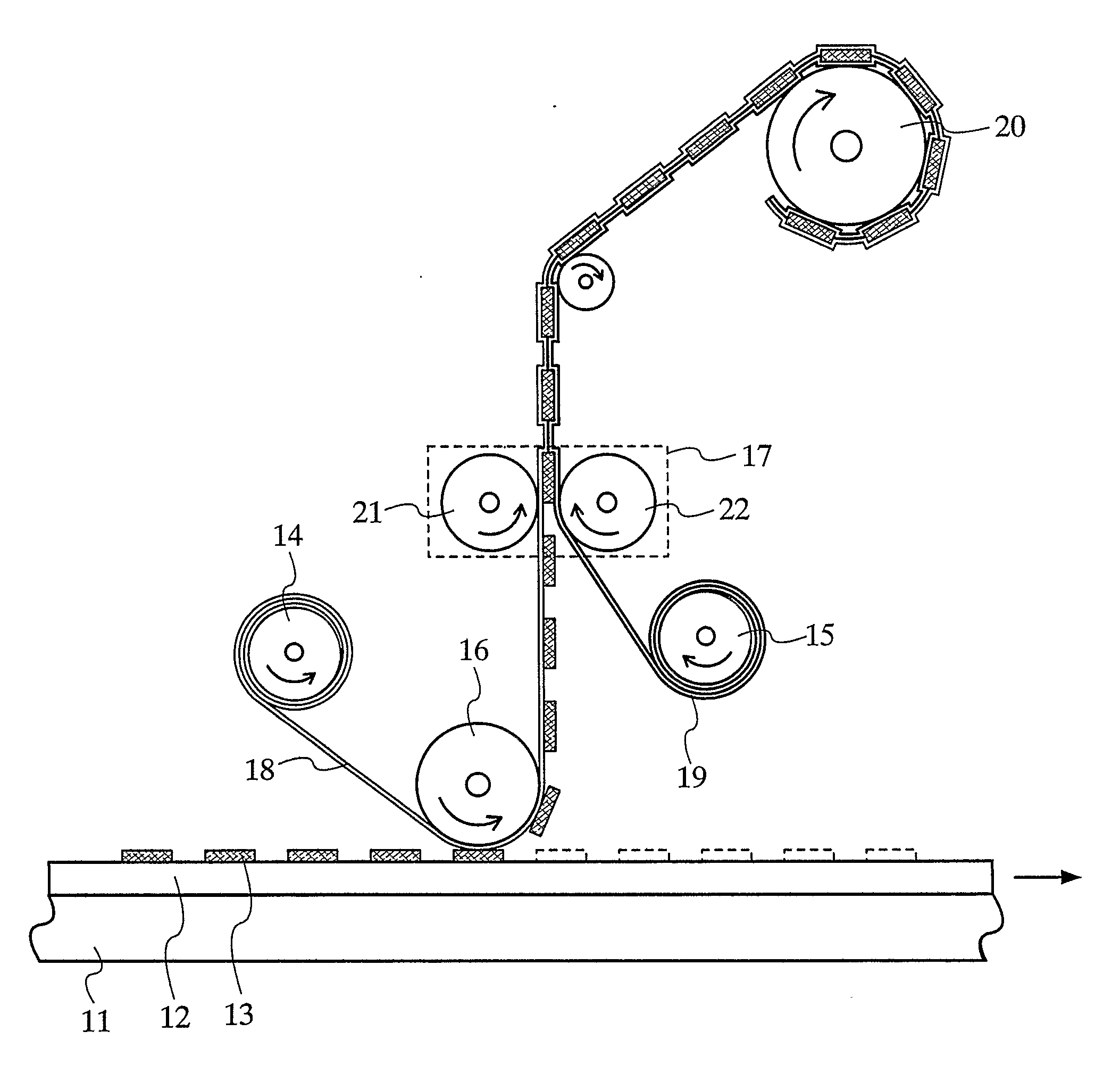

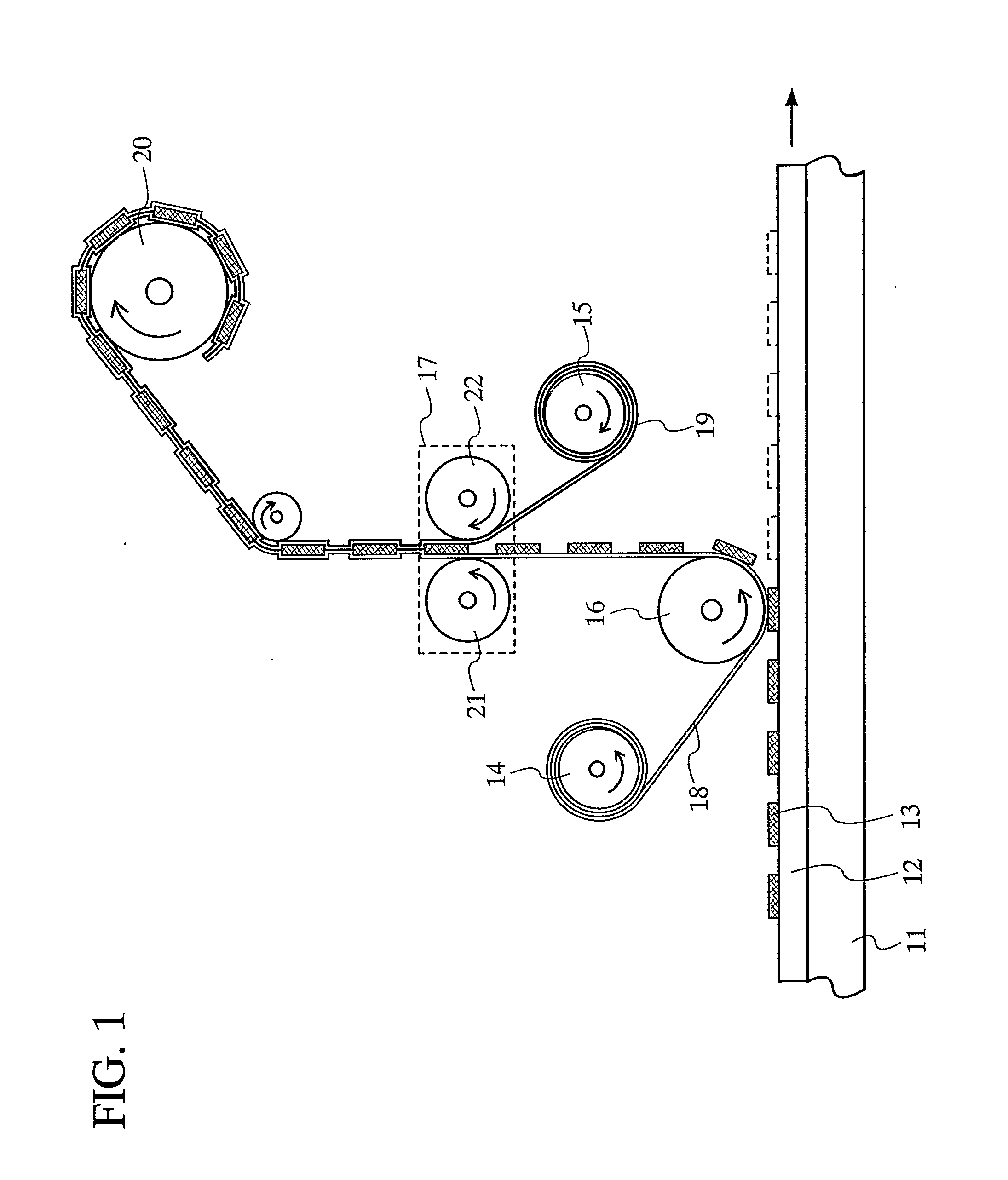

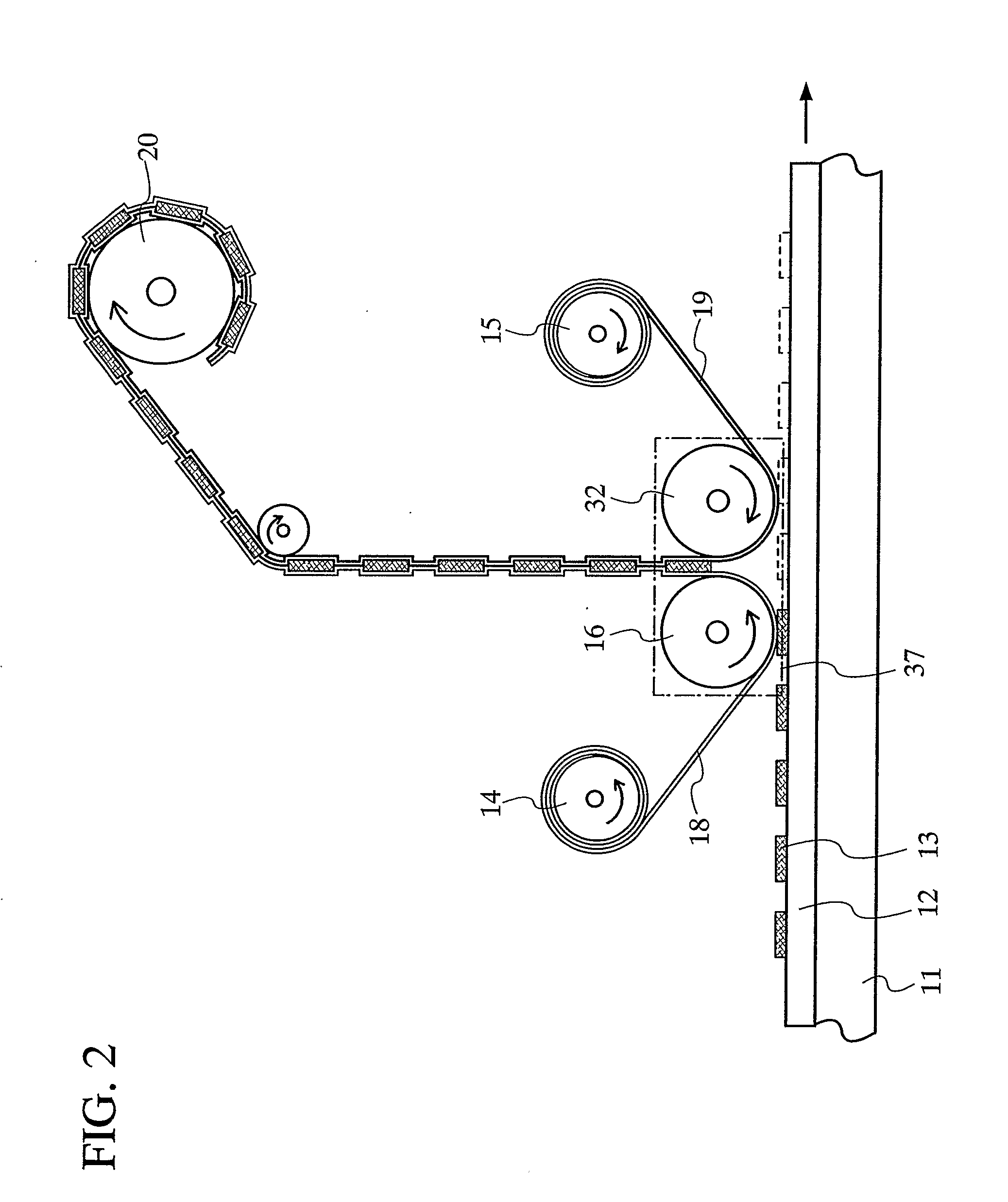

Method and apparatus for bonding polarizing plate

ActiveUS20050016670A1Easy to controlProhibit stop markLamination ancillary operationsDecorative surface effectsPolarizerEngineering

Owner:FUJIFILM CORP +1

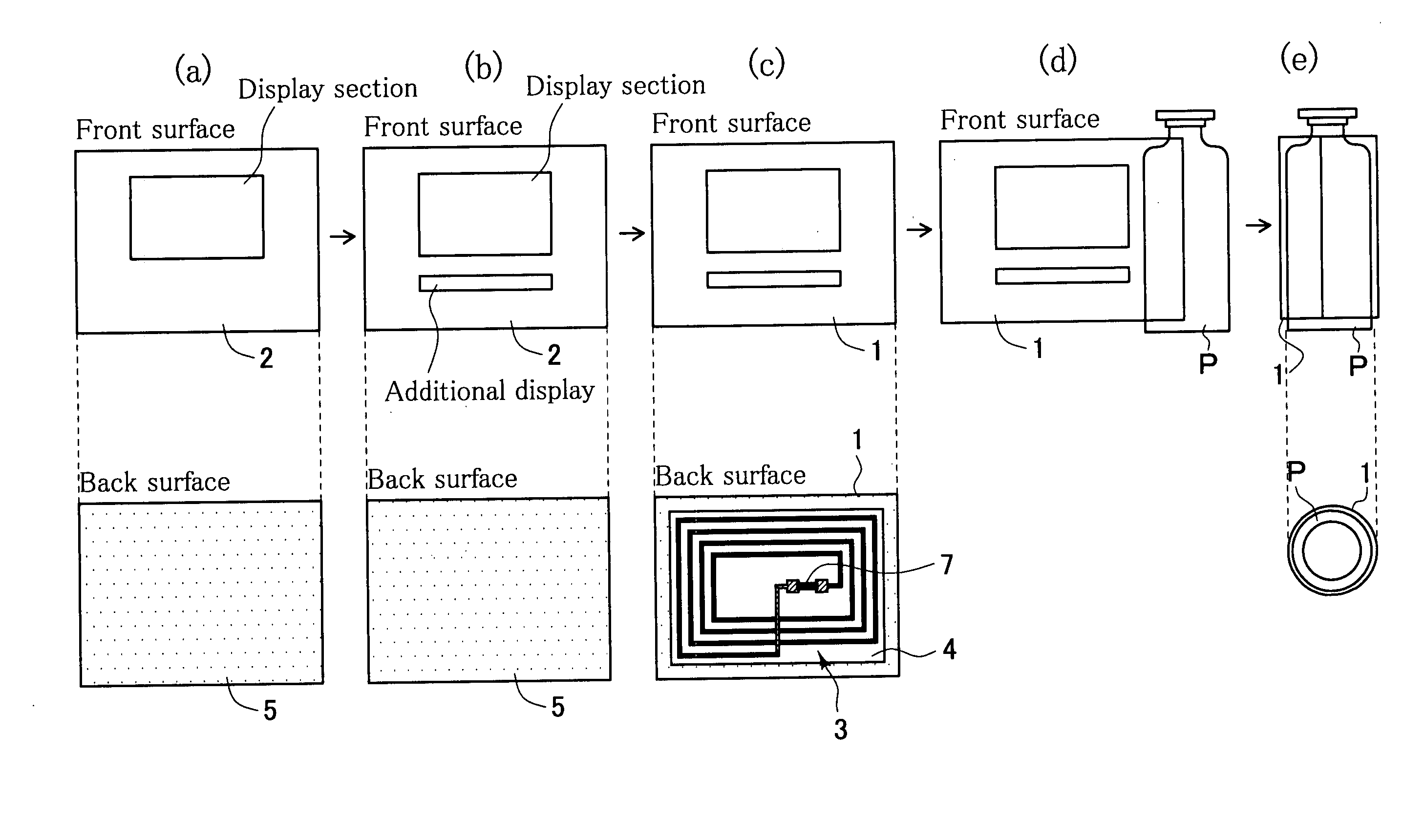

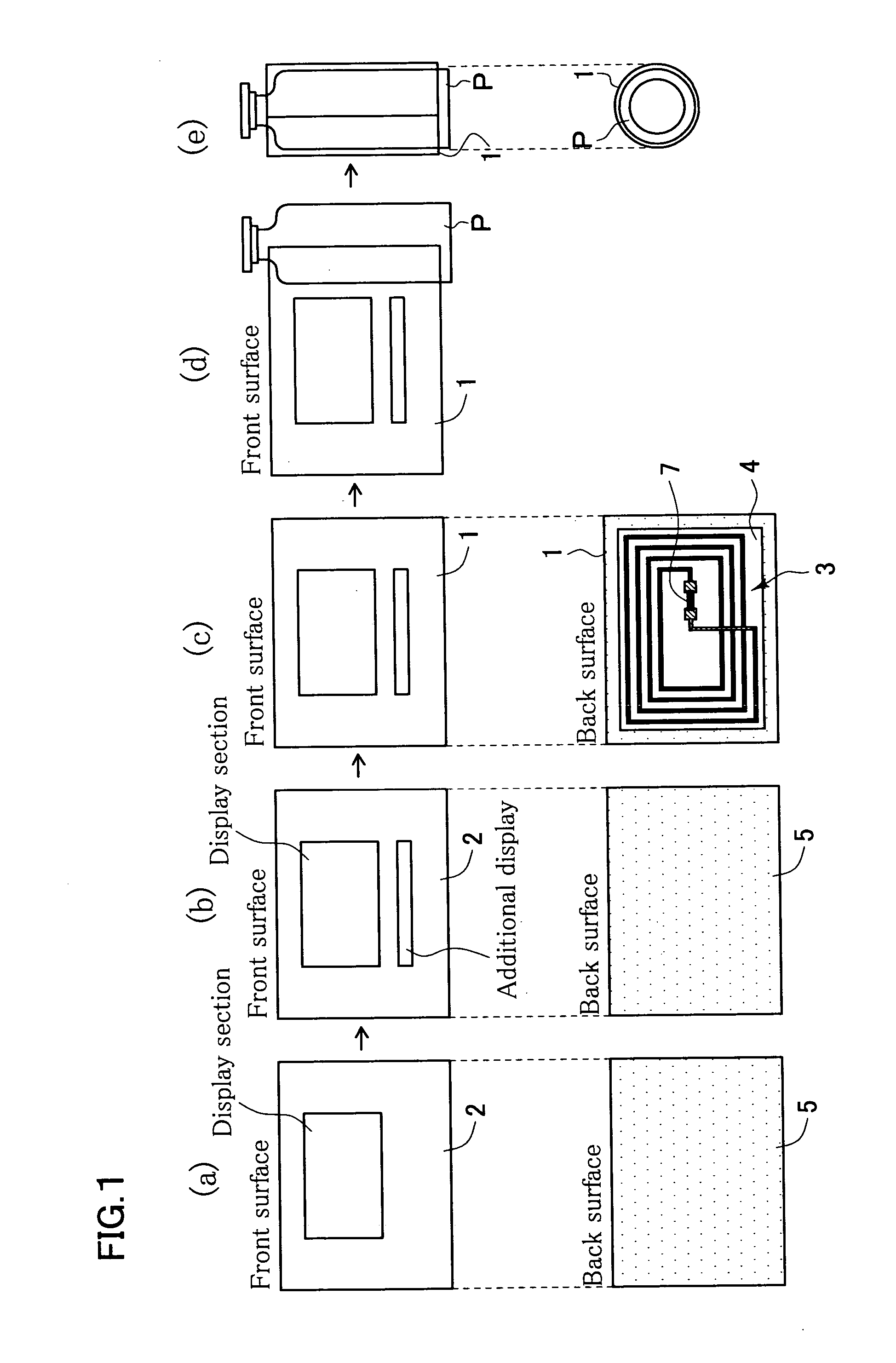

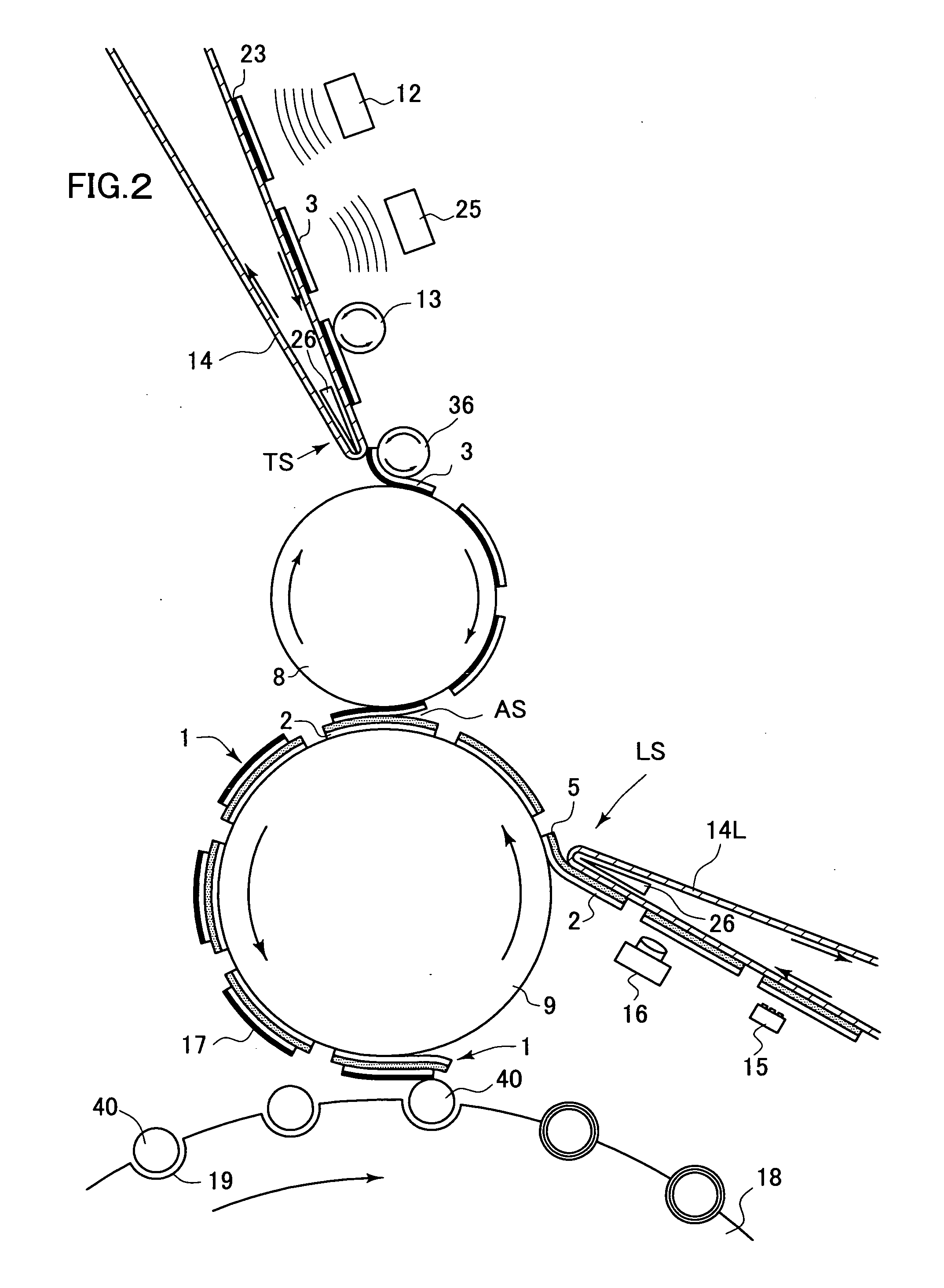

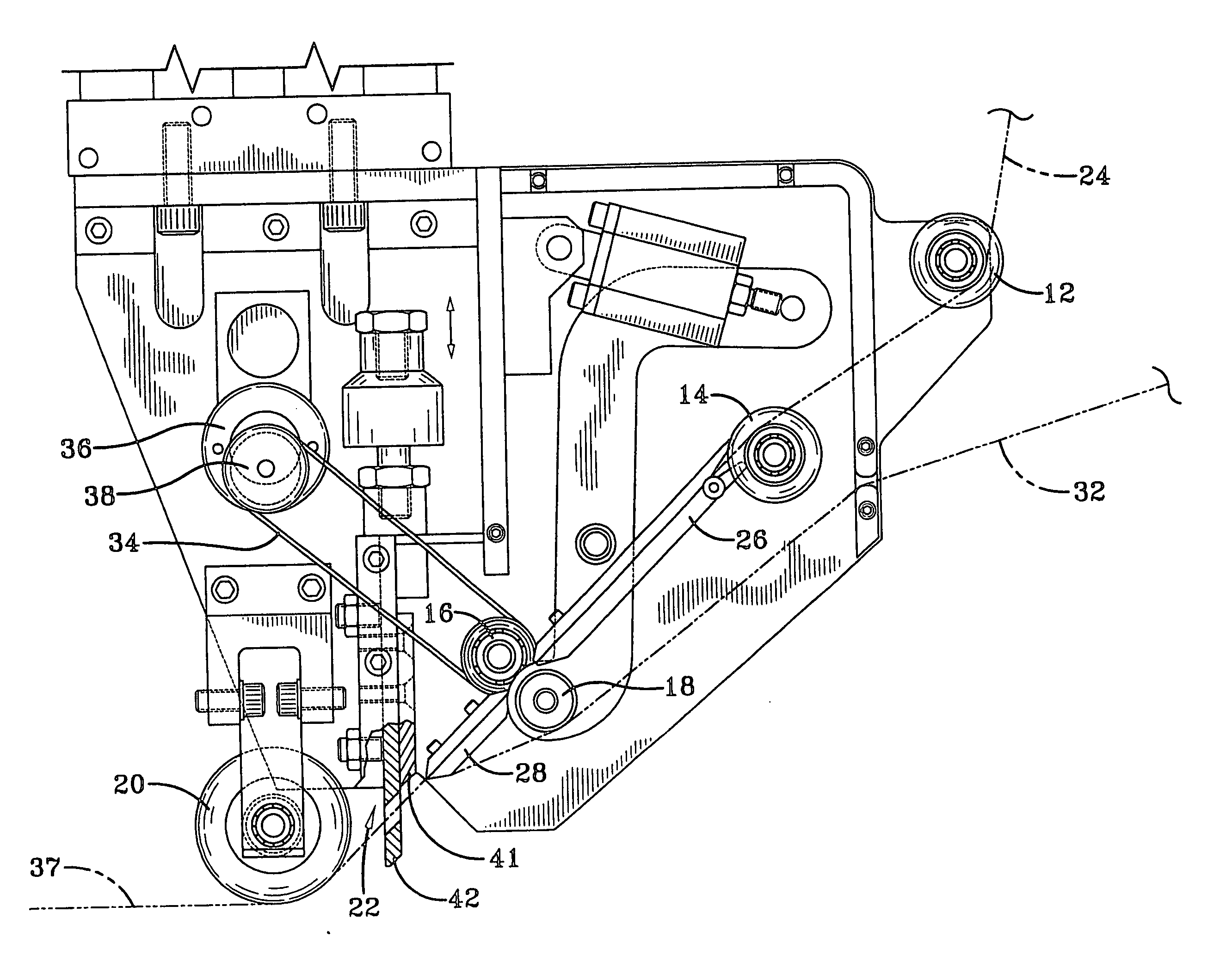

Affixing Method of Rfid Label and its Affixing Apparatus

InactiveUS20070252700A1Low costEliminate the problemSemiconductor/solid-state device manufacturingSubscribers indirect connectionEngineeringElectrical and Electronics engineering

A display label, having a display section on a surface thereof and an adhesive surface on a back surface thereof, and an IC tag, provided with an antenna coil and an IC chip so as to transmit information through non-contact communication, are prepared. After writing information on the IC chip, reading test is applied, so as to separate non-defective ID tags and defective ID tags. After printing addition display on the surface of the display label, a non-defective ID tag is adhered on an adhesive surface thereof, so as to form an RFID label. Then the RFID label is affixed to an object-to-affix such as a container. An affixing method of an RFID label and its affixing method are provided, wherein an ID tag is less likely to be damaged, since the ID tag is not adhered on a display label while printing additional display.

Owner:IWATA LABEL CO LTD +1

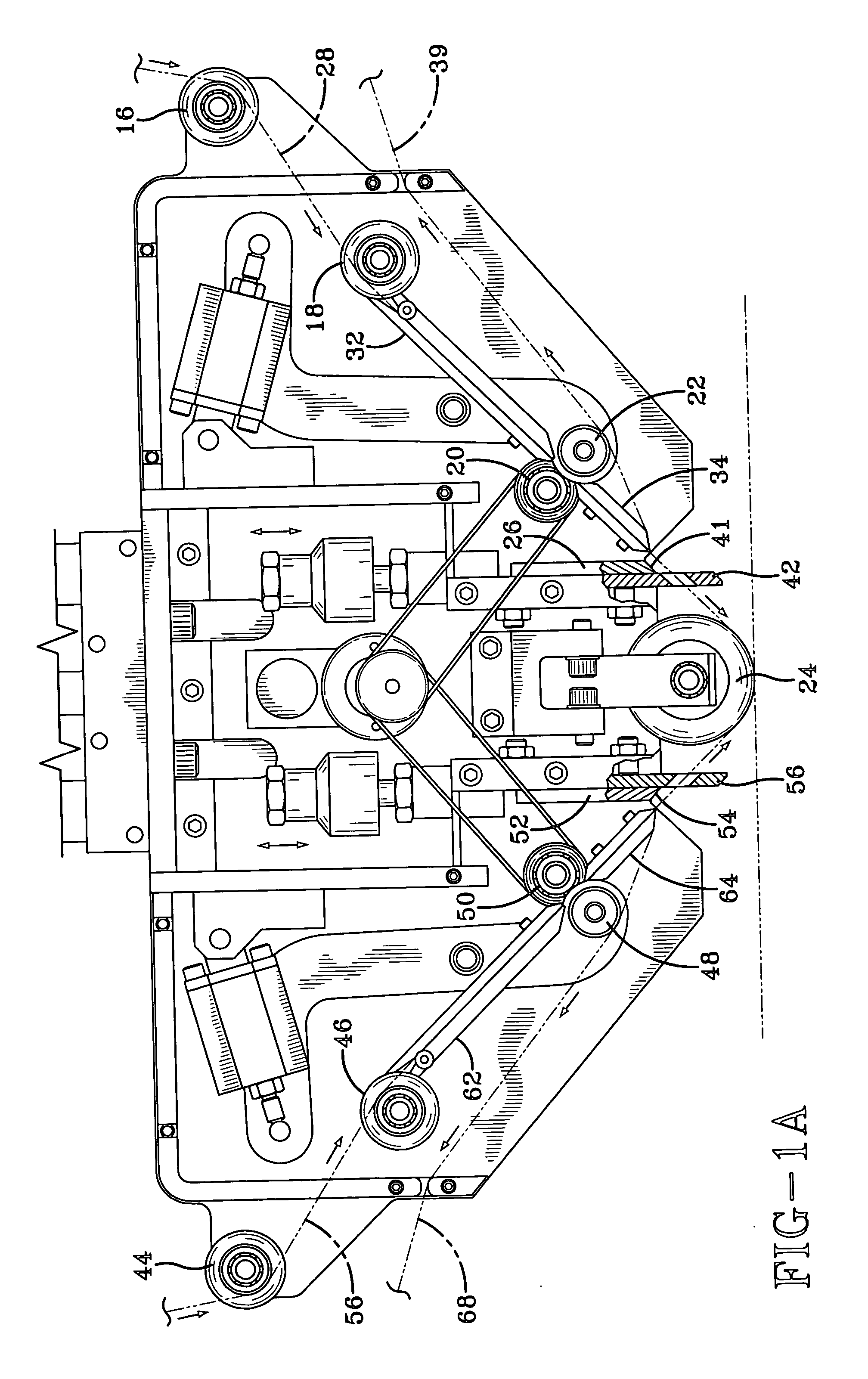

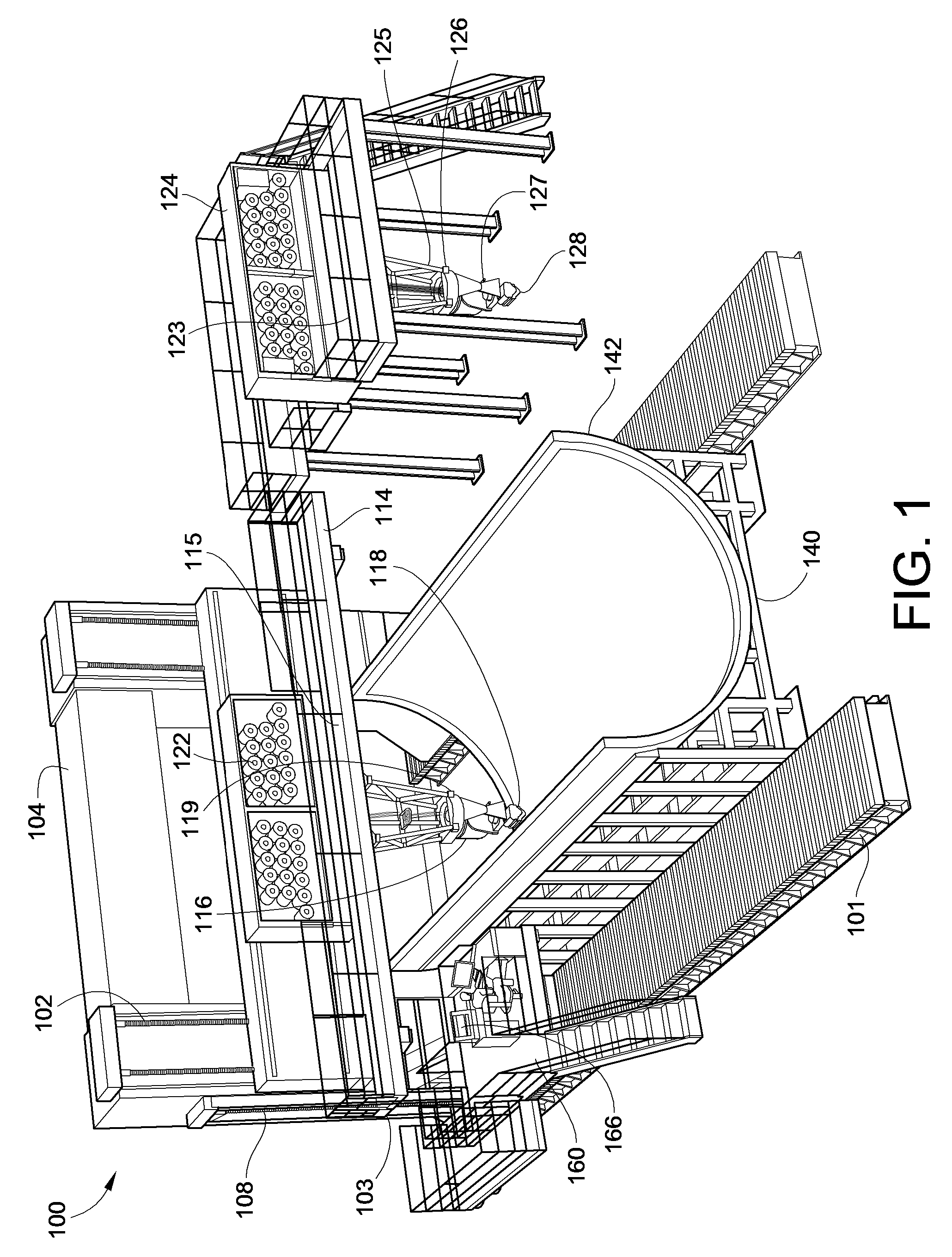

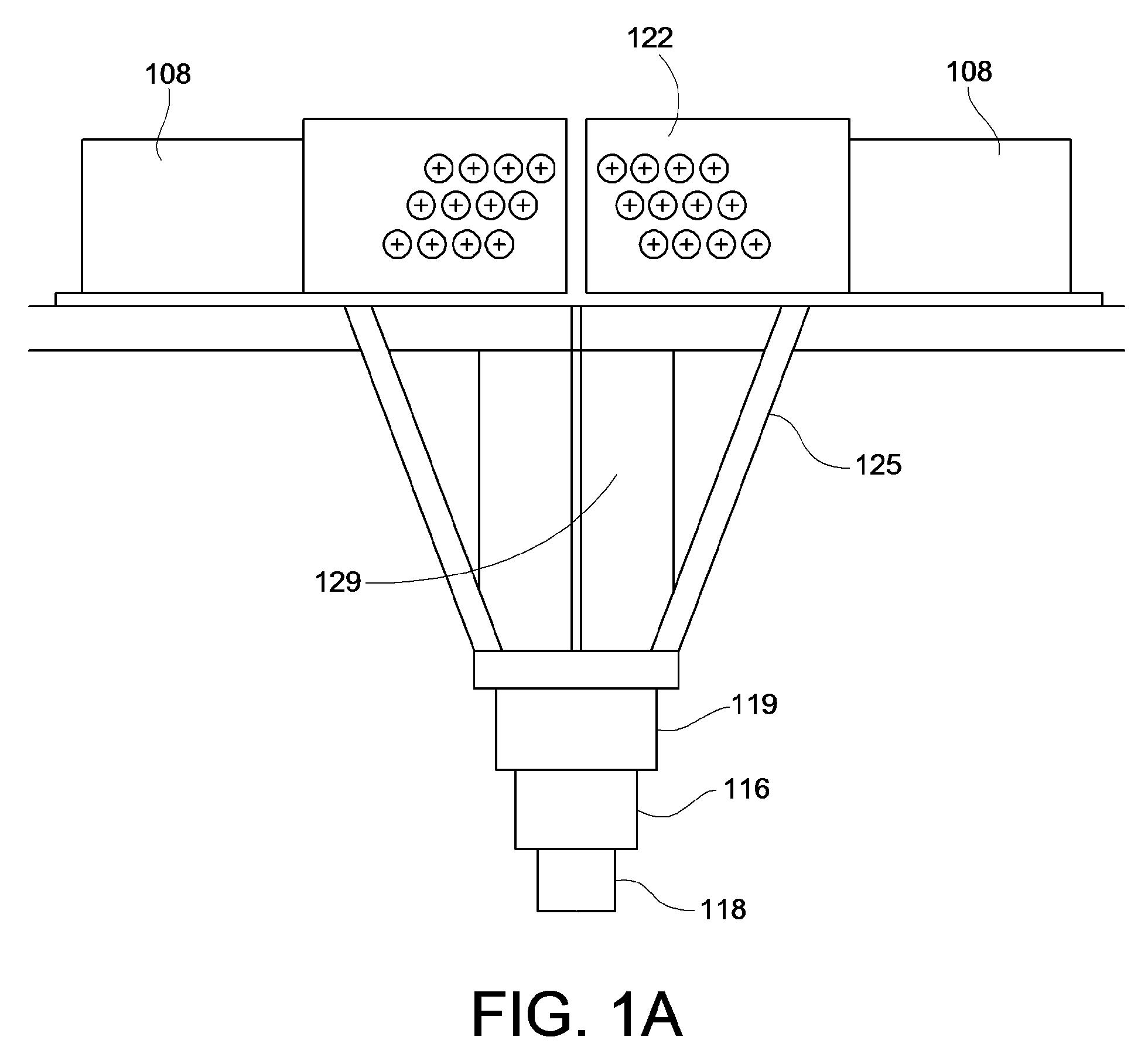

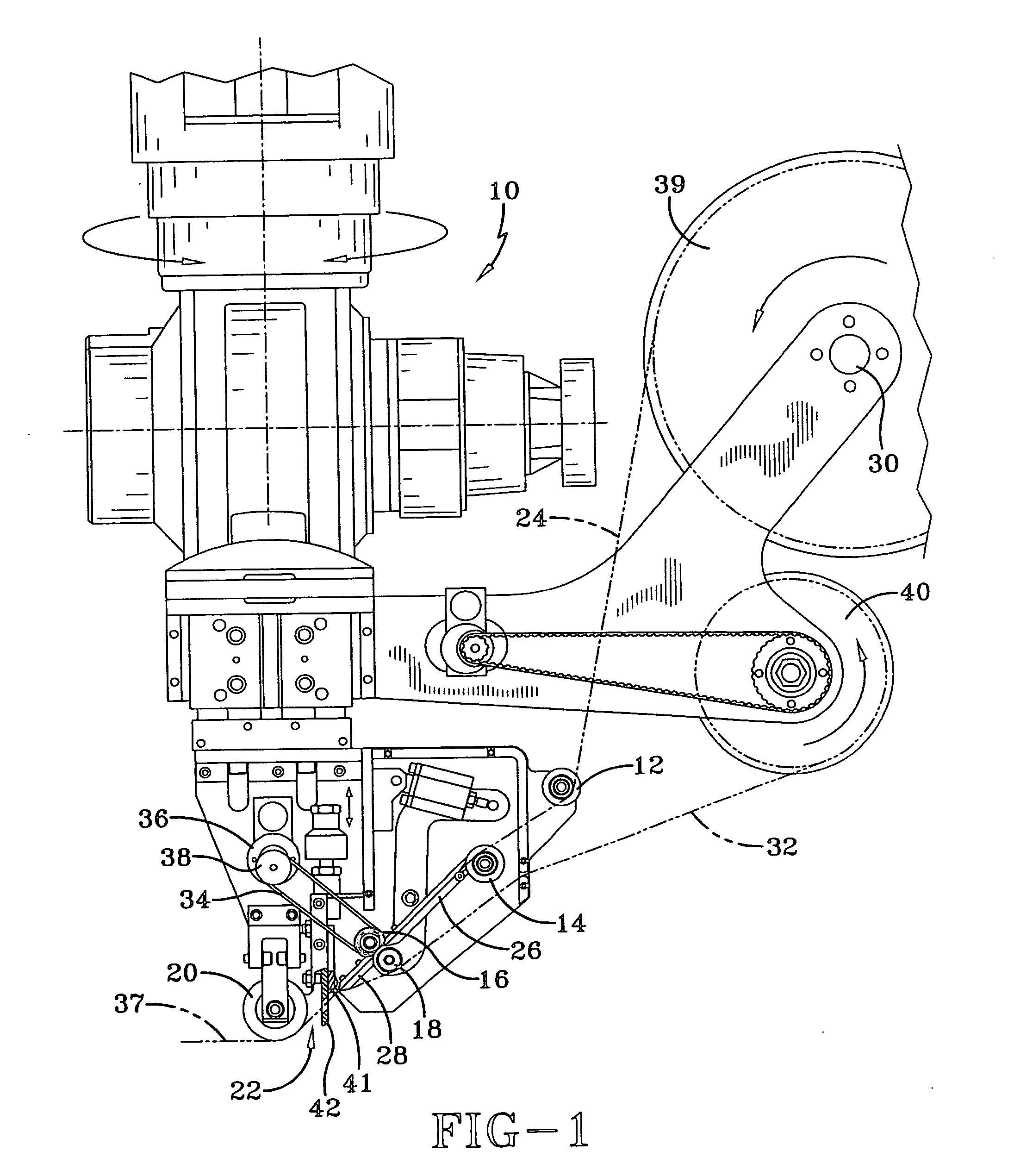

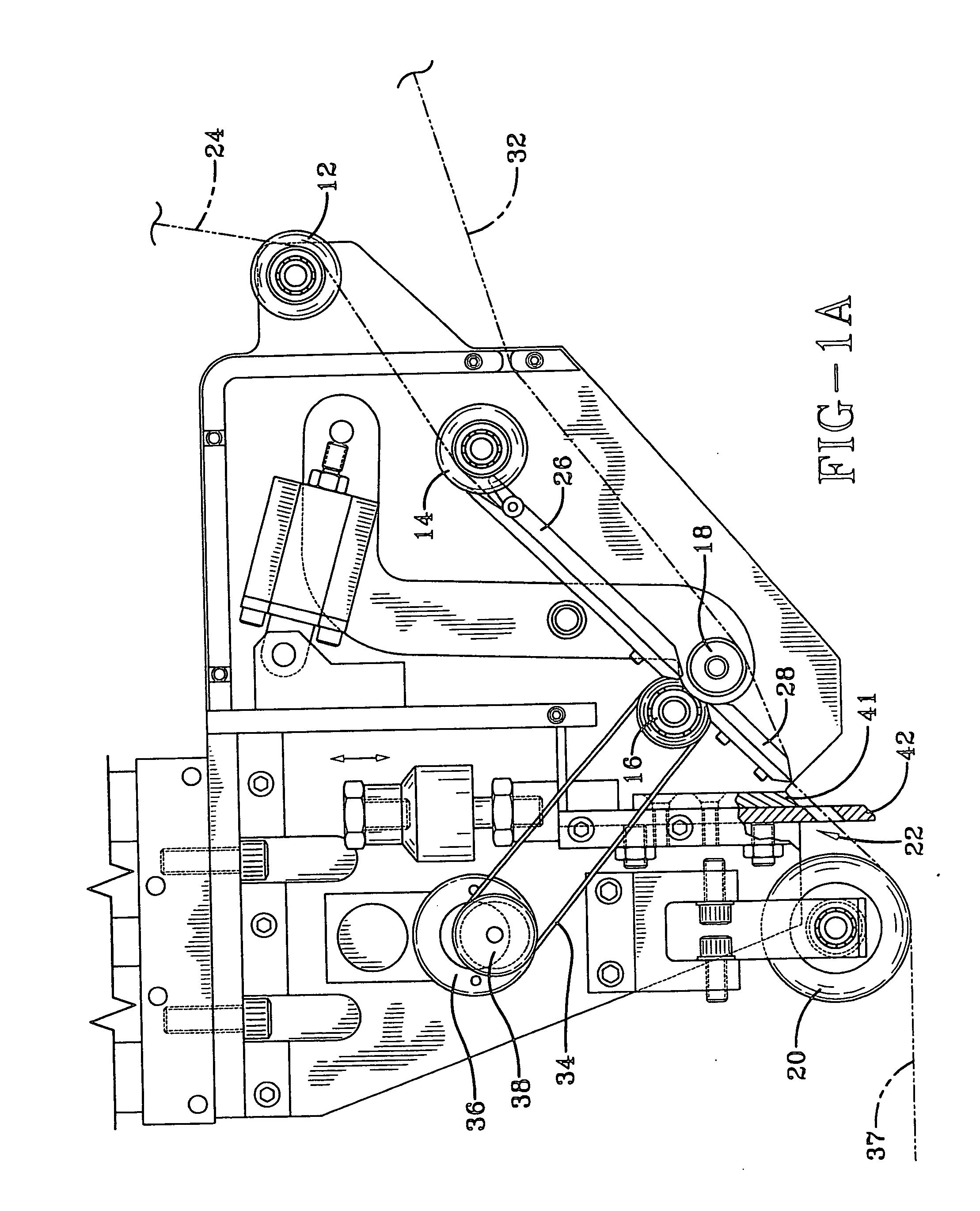

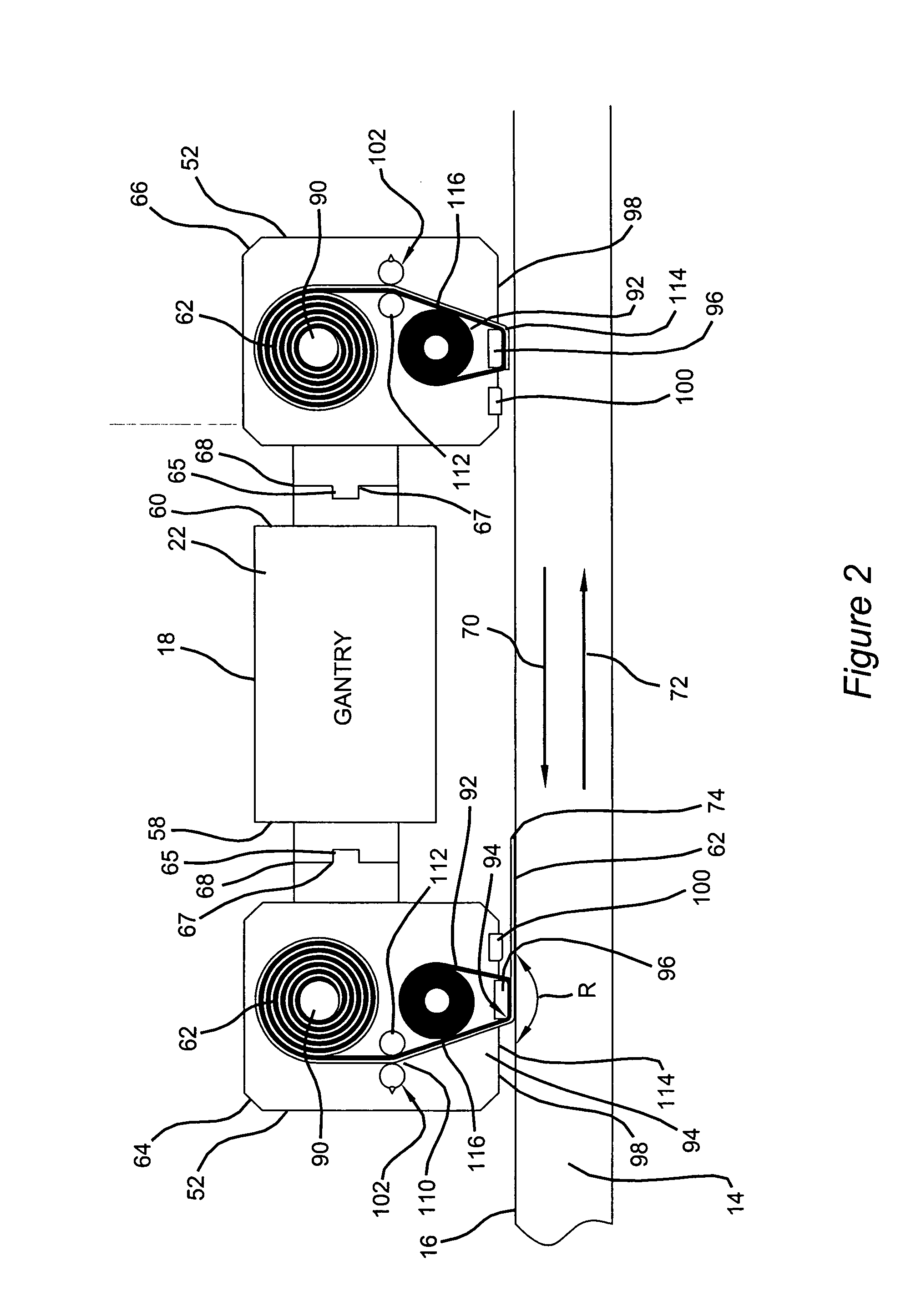

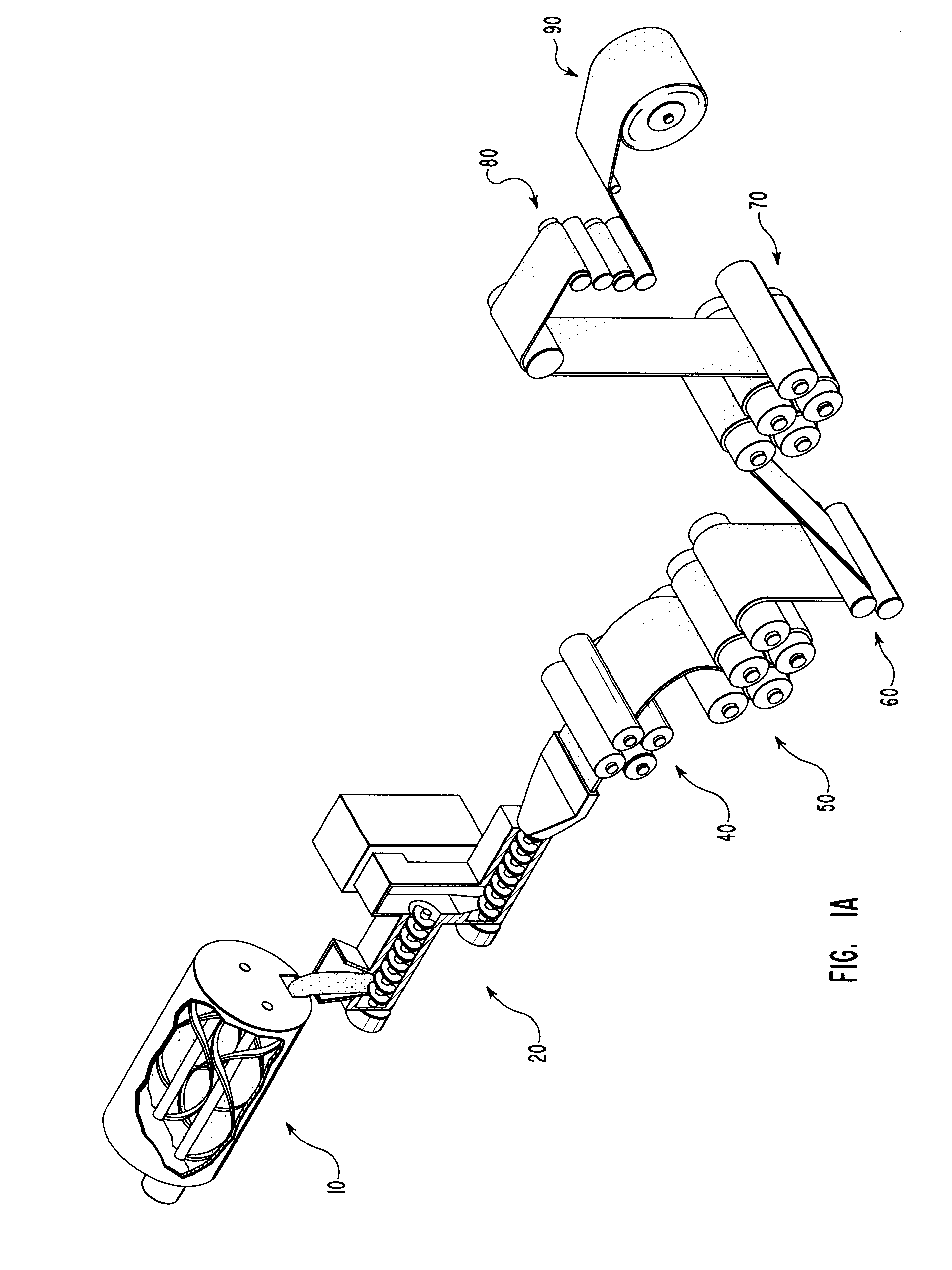

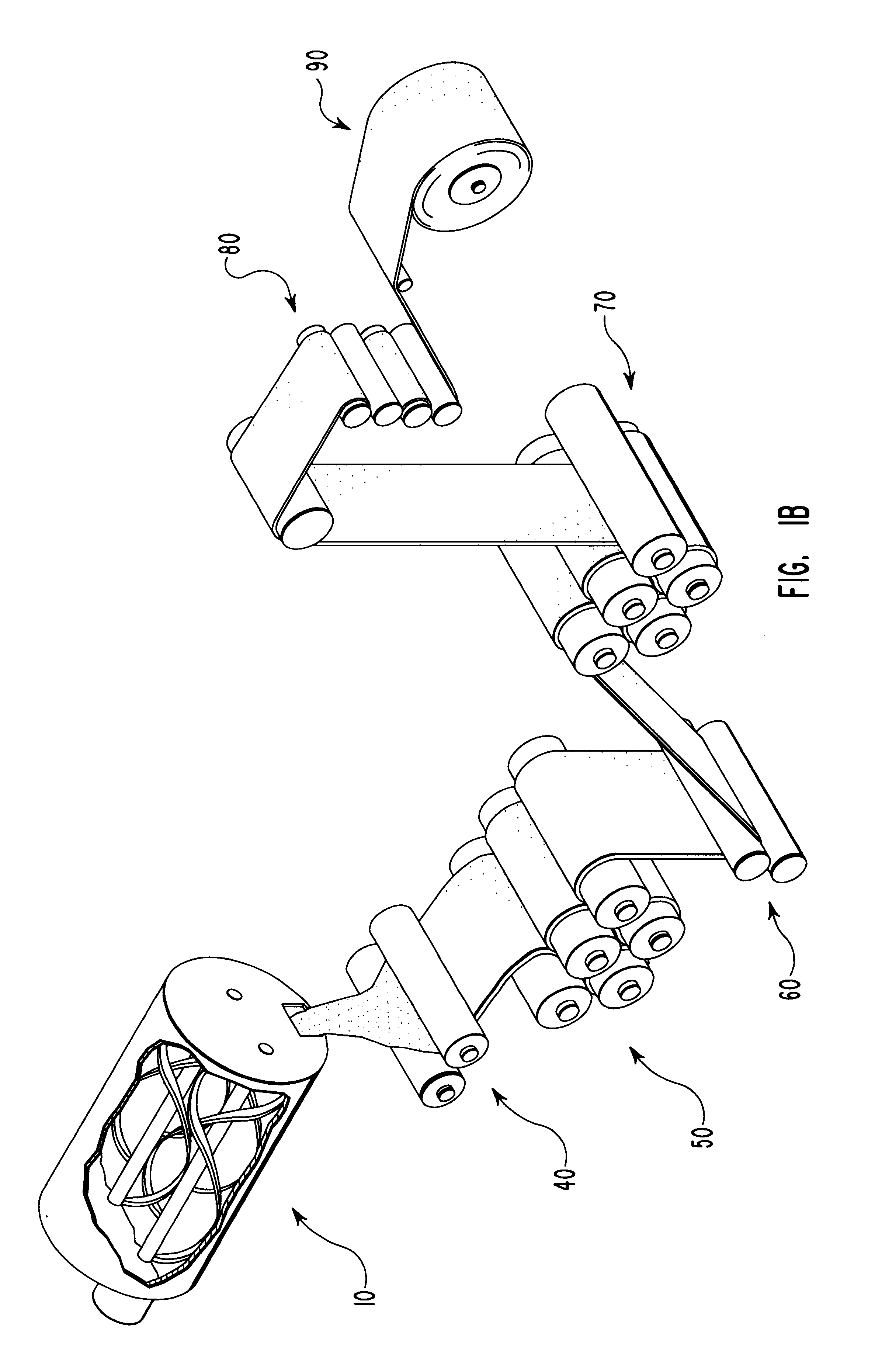

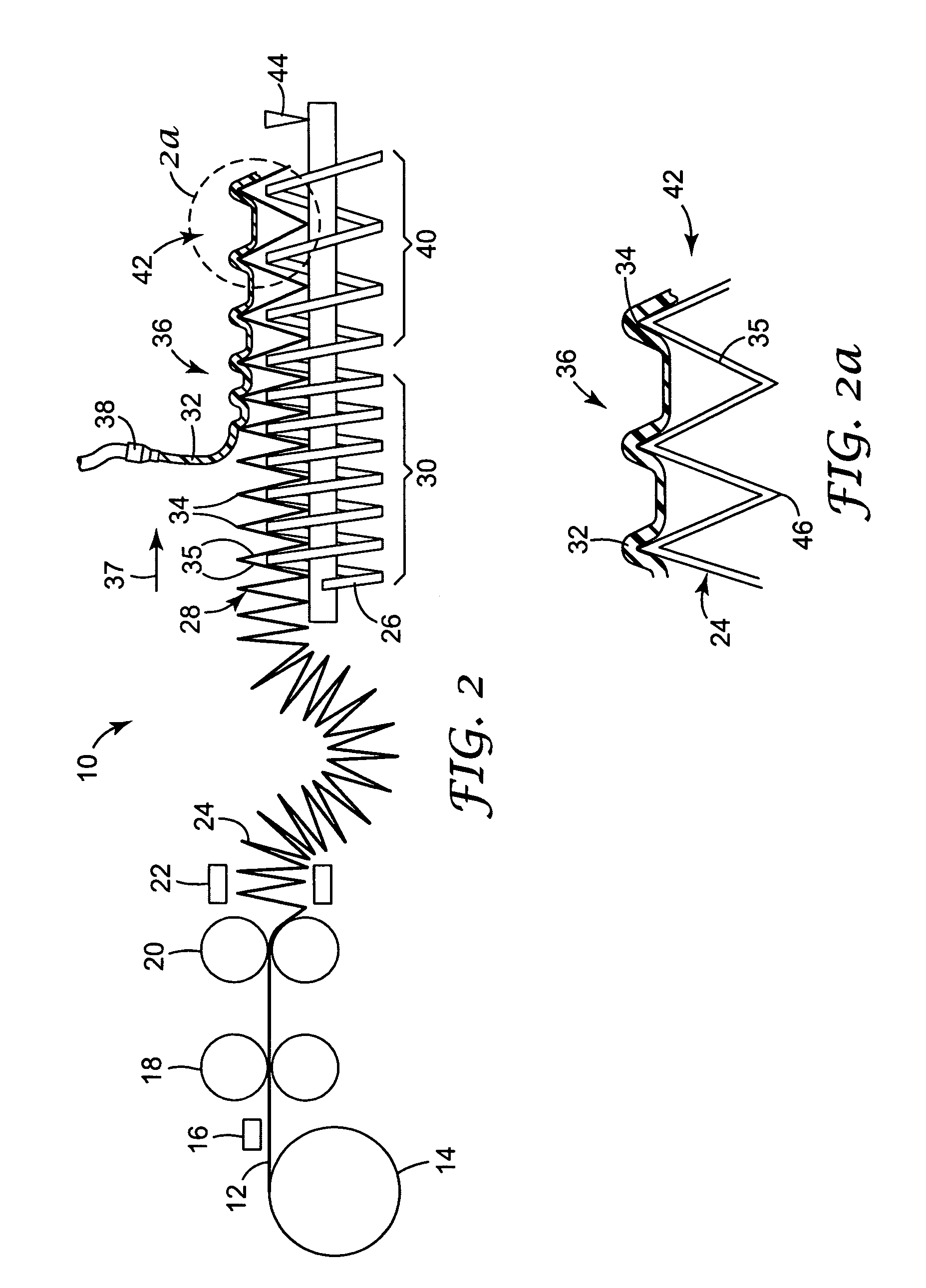

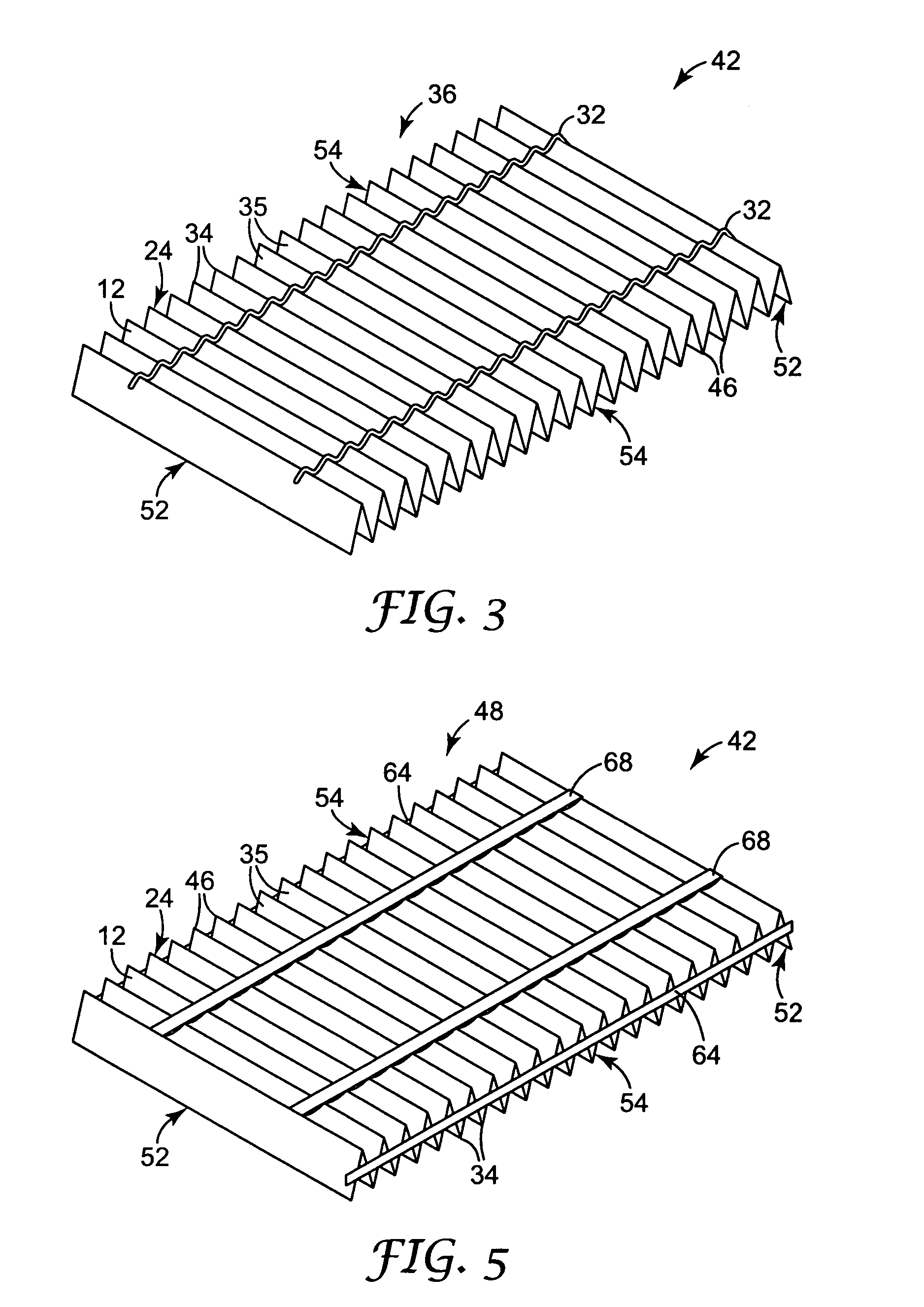

Composite tape laying apparatus and method

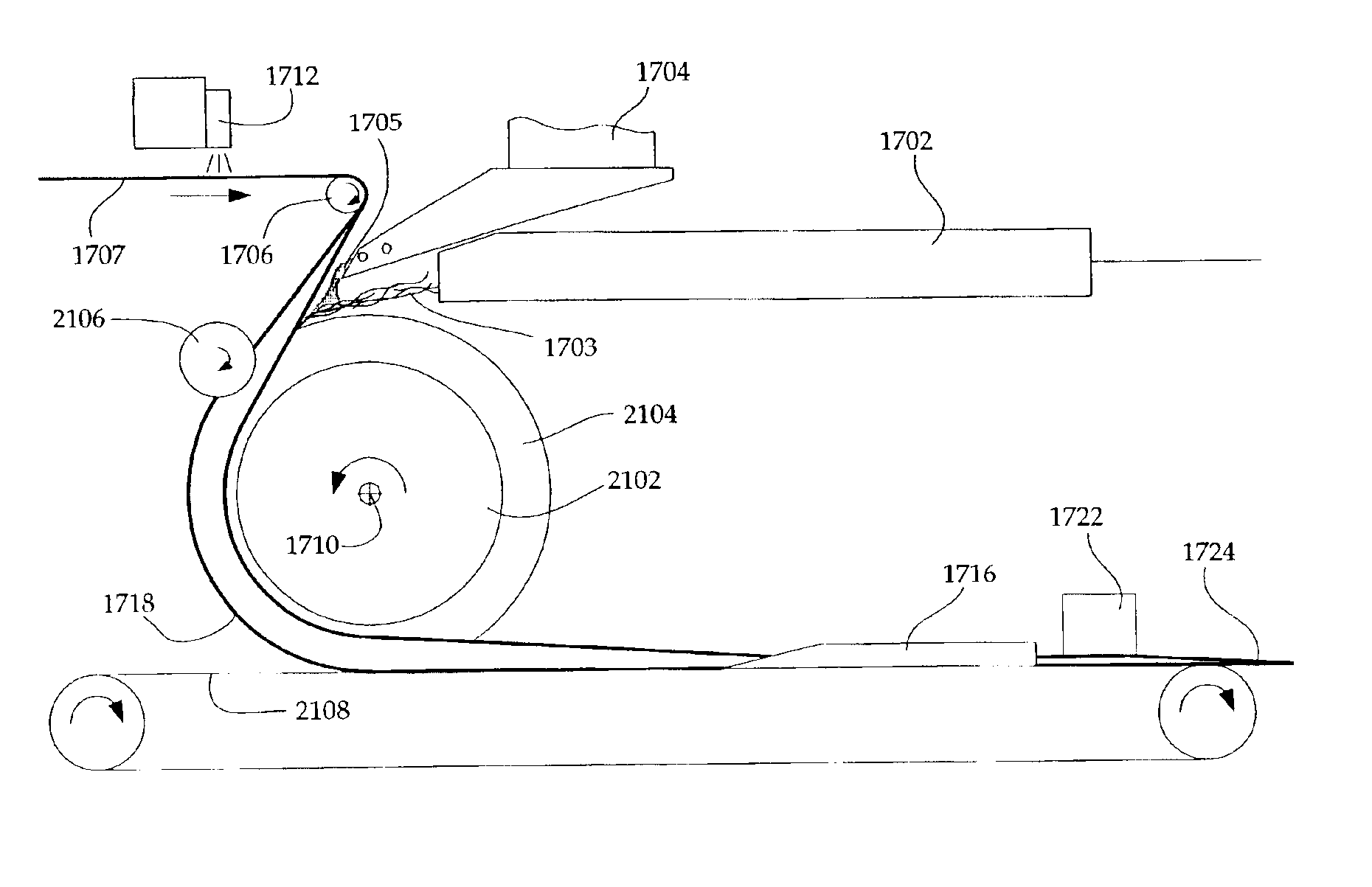

ActiveUS20050109451A1Simple procedureMaximizes material throughputLamination ancillary operationsControlling laminationFiberMagnetic tape

A fully automated method and apparatus is disclosed to laminate various structural articles with a layer of resin impregnated fiber tape. The tape laying member removes a releasable backing layer from the tape being employed, then deposits the unbacked tape on the surface of the structural article, and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present tape laying member to increase tape throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

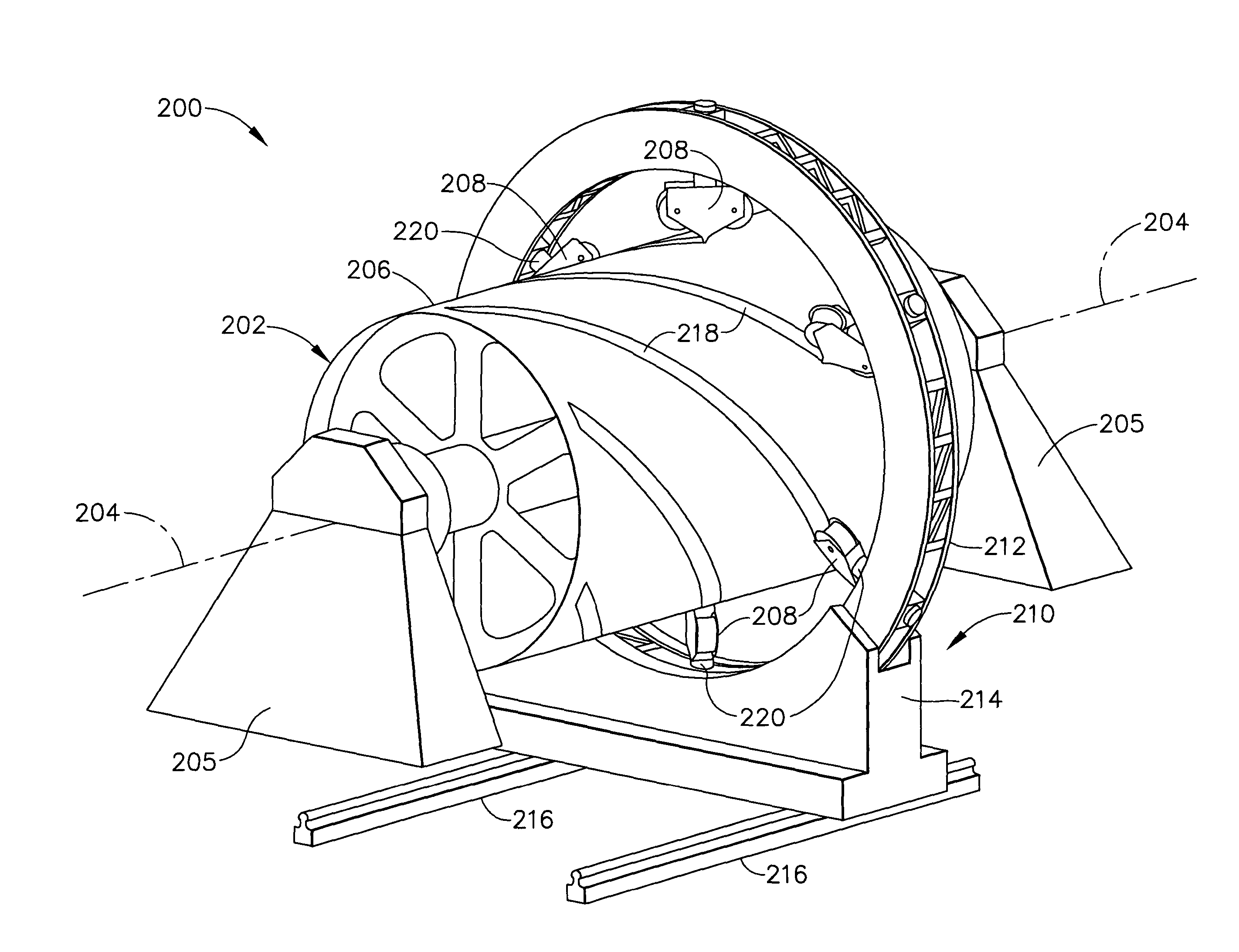

Multiple head automated composite laminating machine for the fabrication of large barrel section components

An aircraft part manufacturing device for automated composite lamination on a mandrel surface of a tool having a rotational axis includes a mechanical supporting structure that supports multiple material delivery heads. The tool is moveable and rotatable relative to the mechanical supporting structure. The mechanical supporting structure provides for axial translation of the material delivery heads relative to the mandrel surface while the mandrel surface is rotated for laying down courses of composite material over the entire mandrel surface of the tool. The position and movement of each of the plurality of material delivery heads is individually adjustable. Arm mechanisms provide motion of each material delivery head in a direction normal to the mandrel surface; rotation about an axis normal to the mandrel surface; circumferential position adjustment in a hoop direction relative to the mandrel surface; and axial position adjustment relative to the other material delivery heads.

Owner:THE BOEING CO

Parallel configuration composite material fabricator

Owner:THE BOEING CO

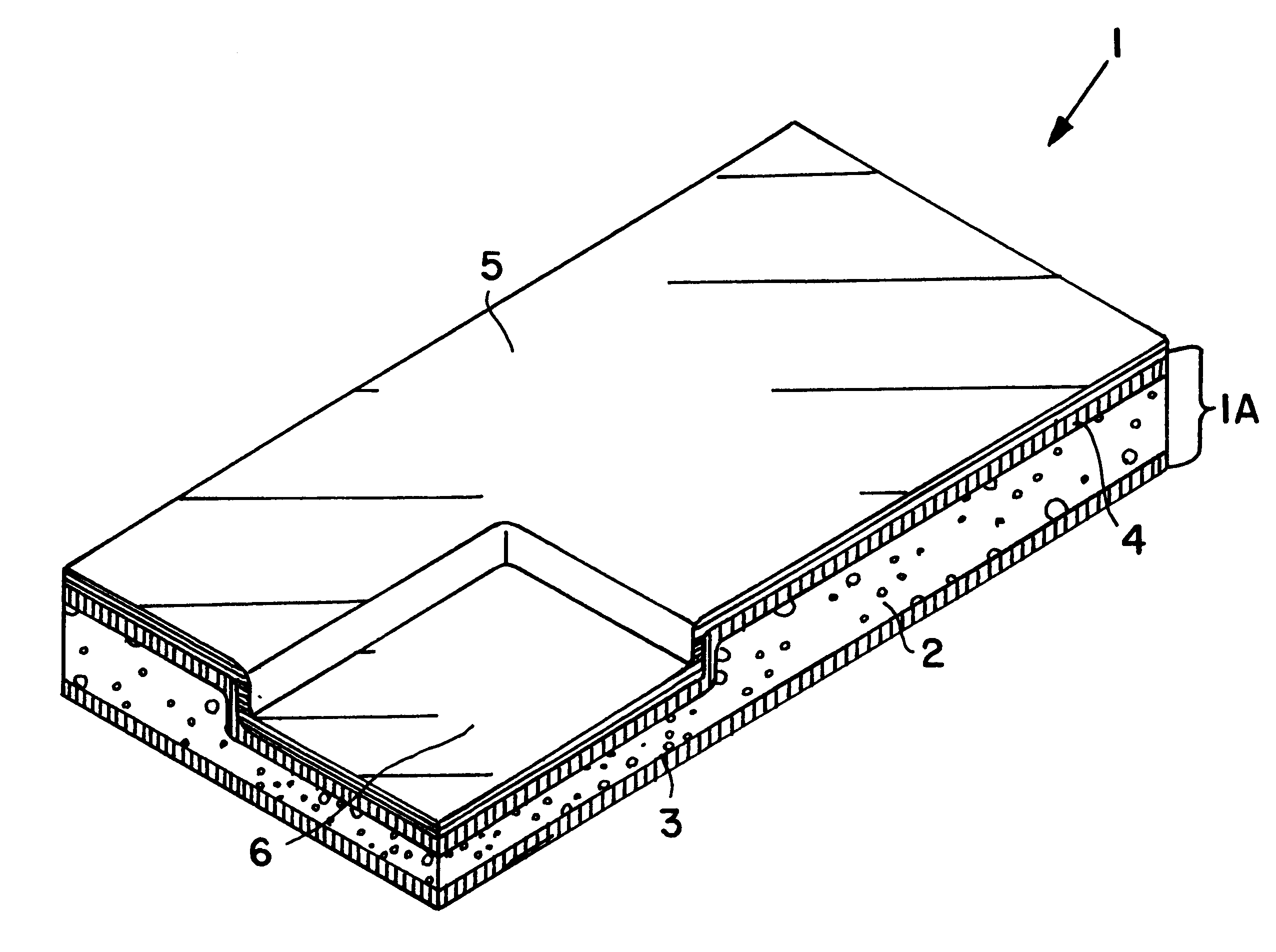

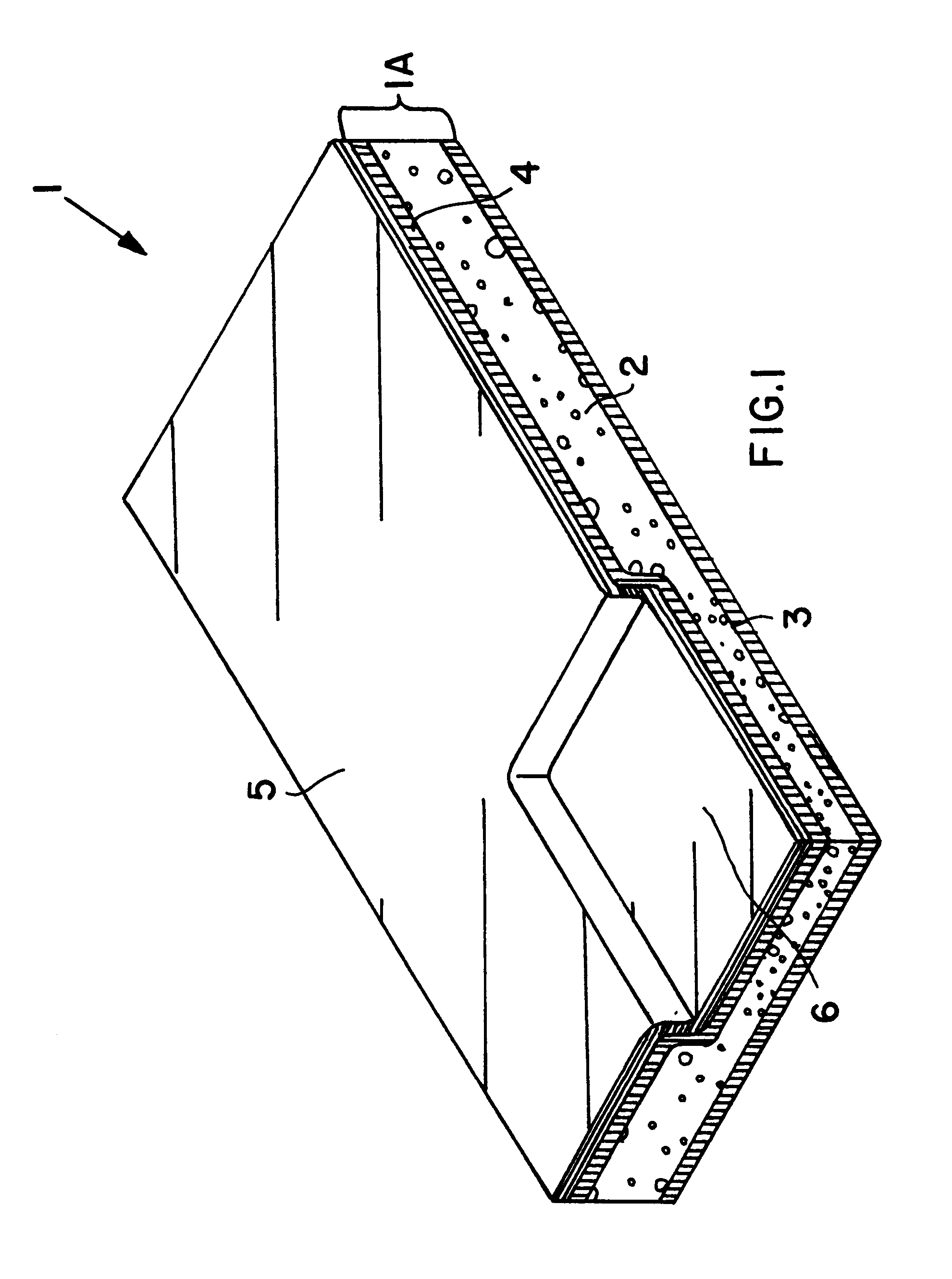

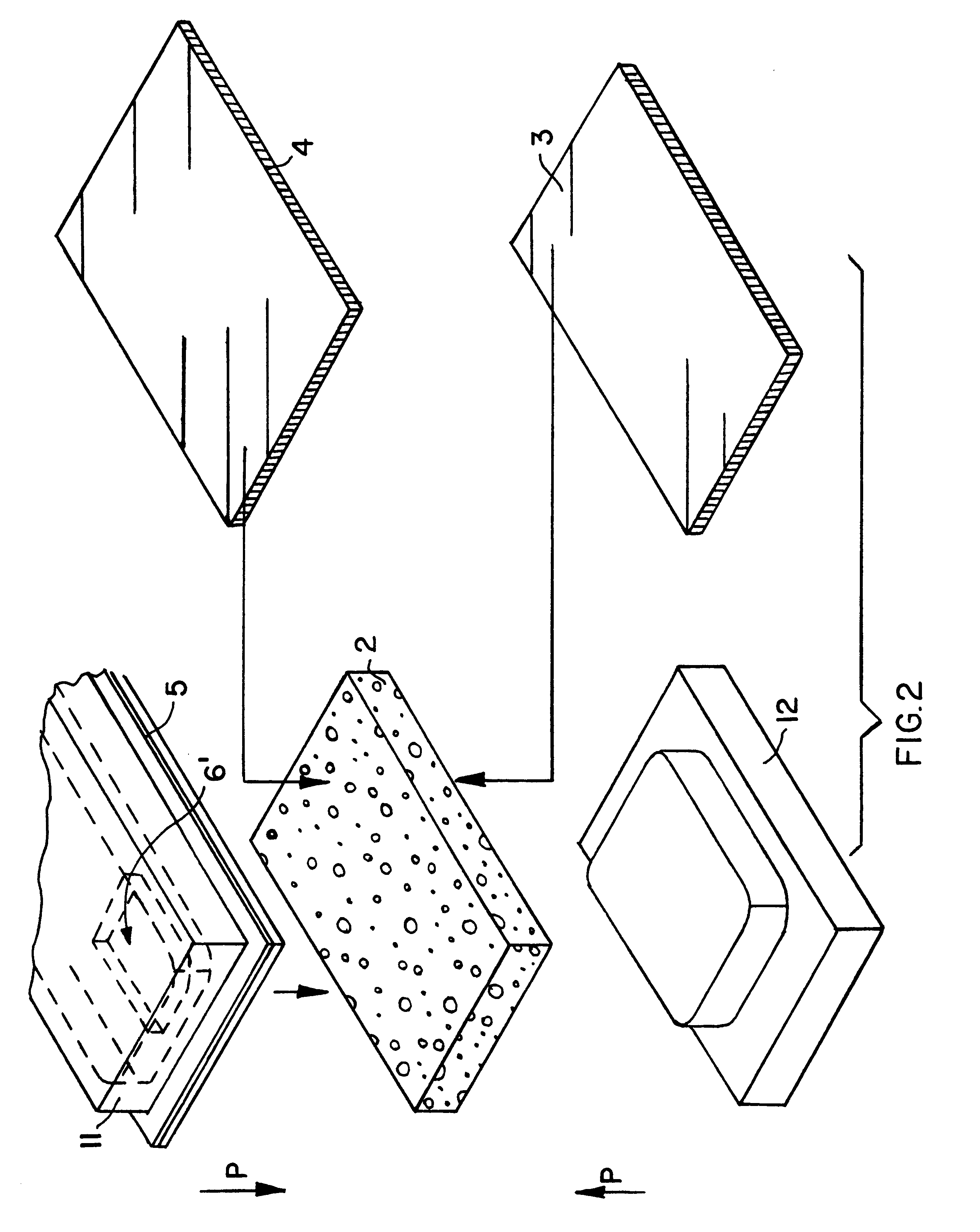

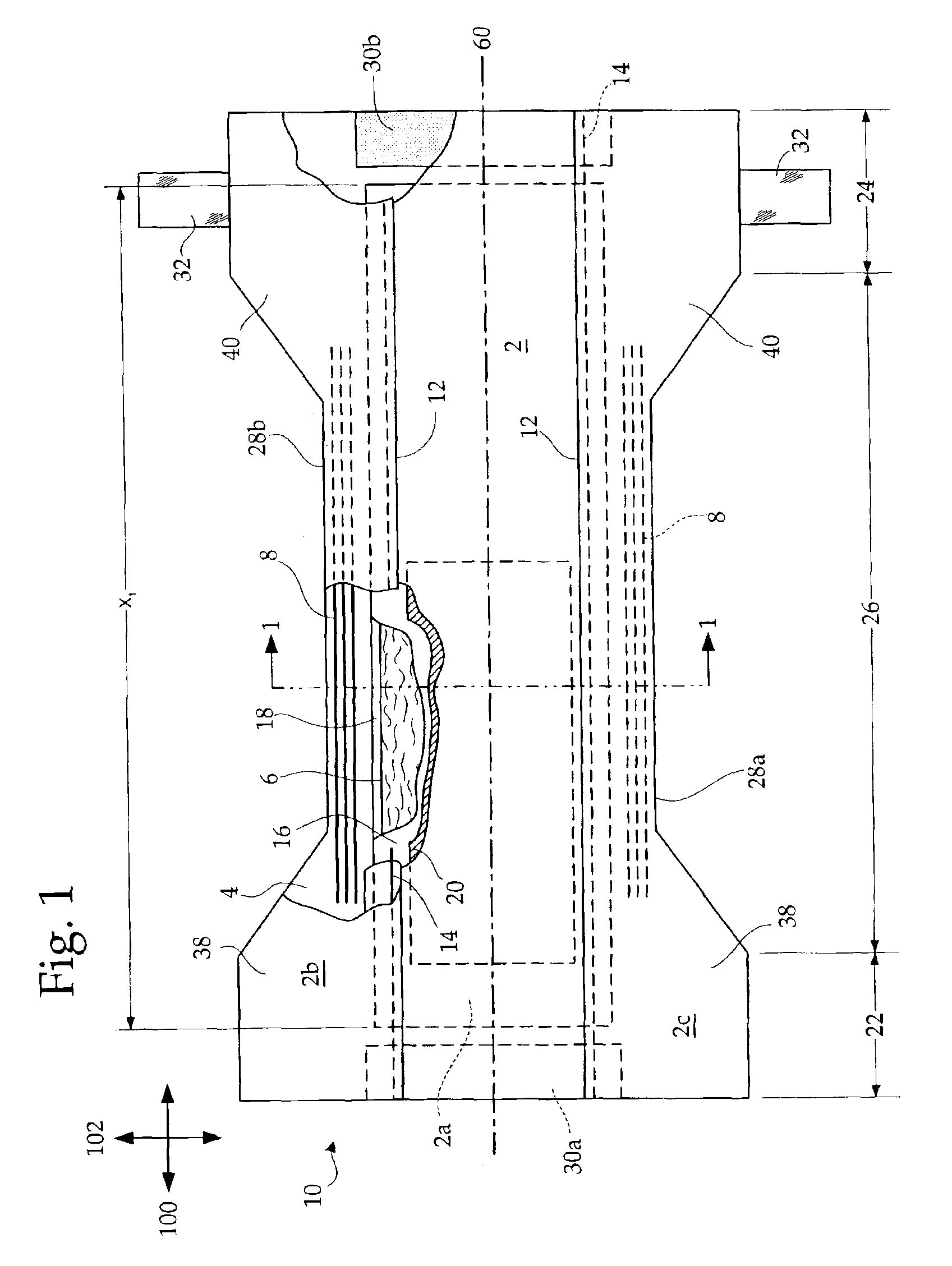

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

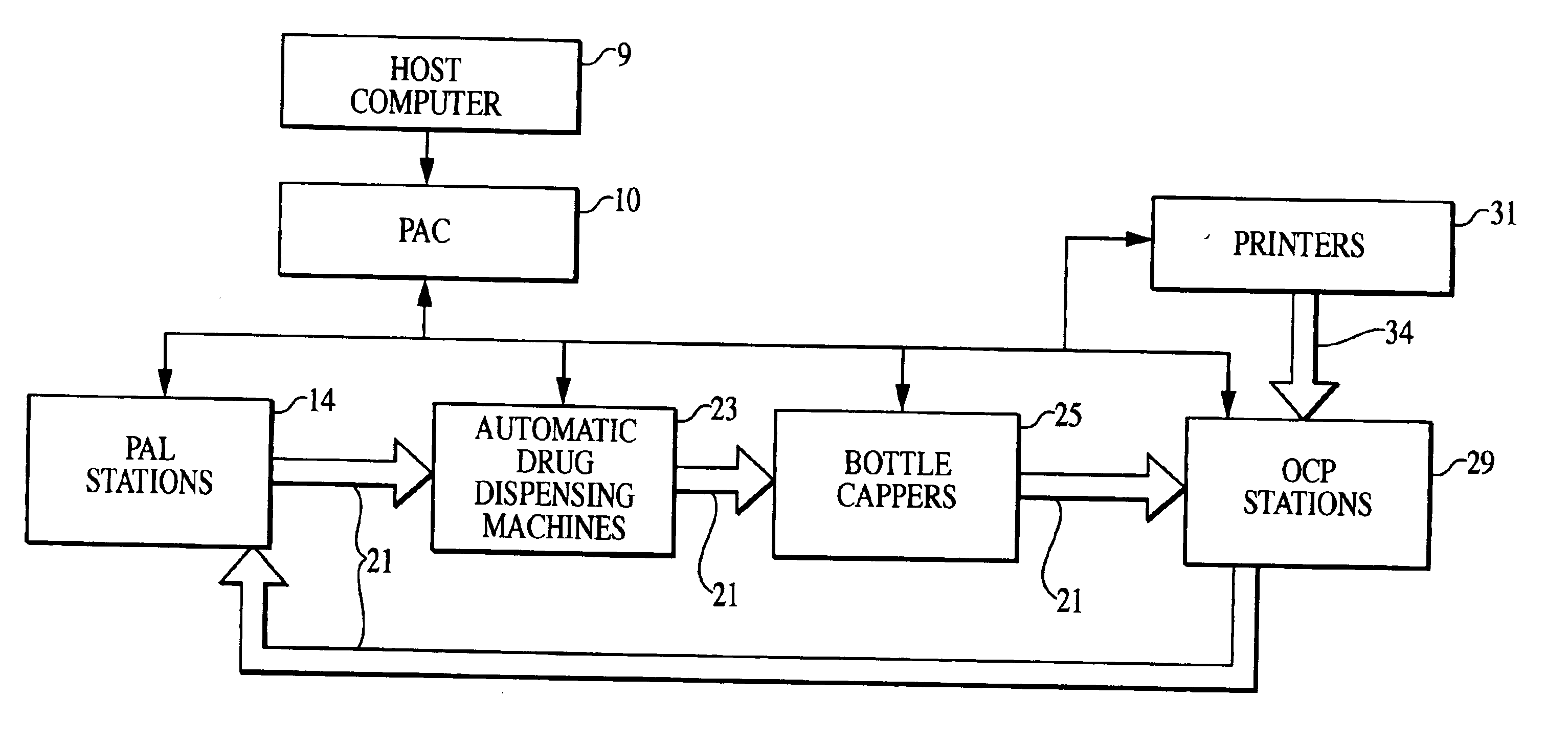

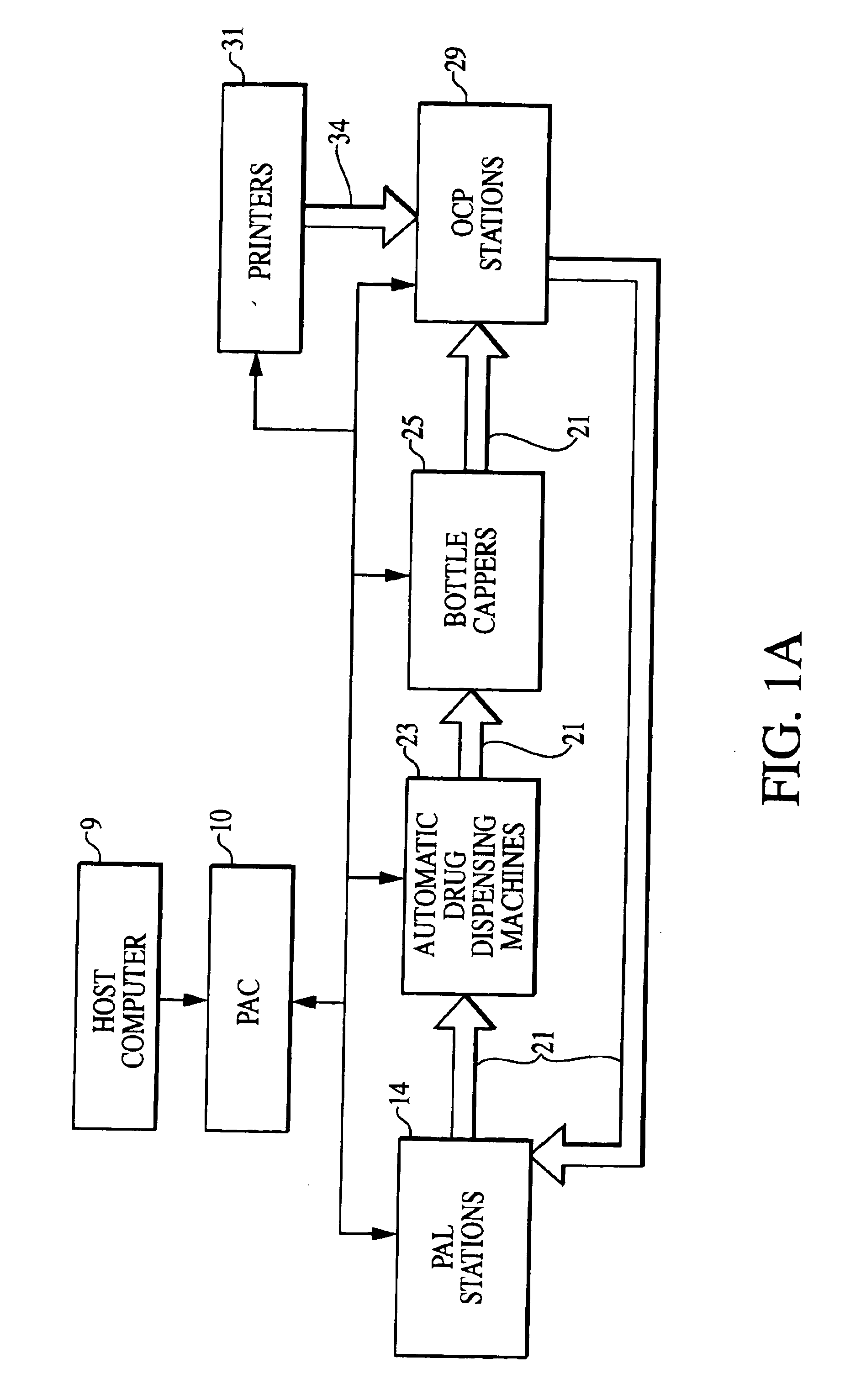

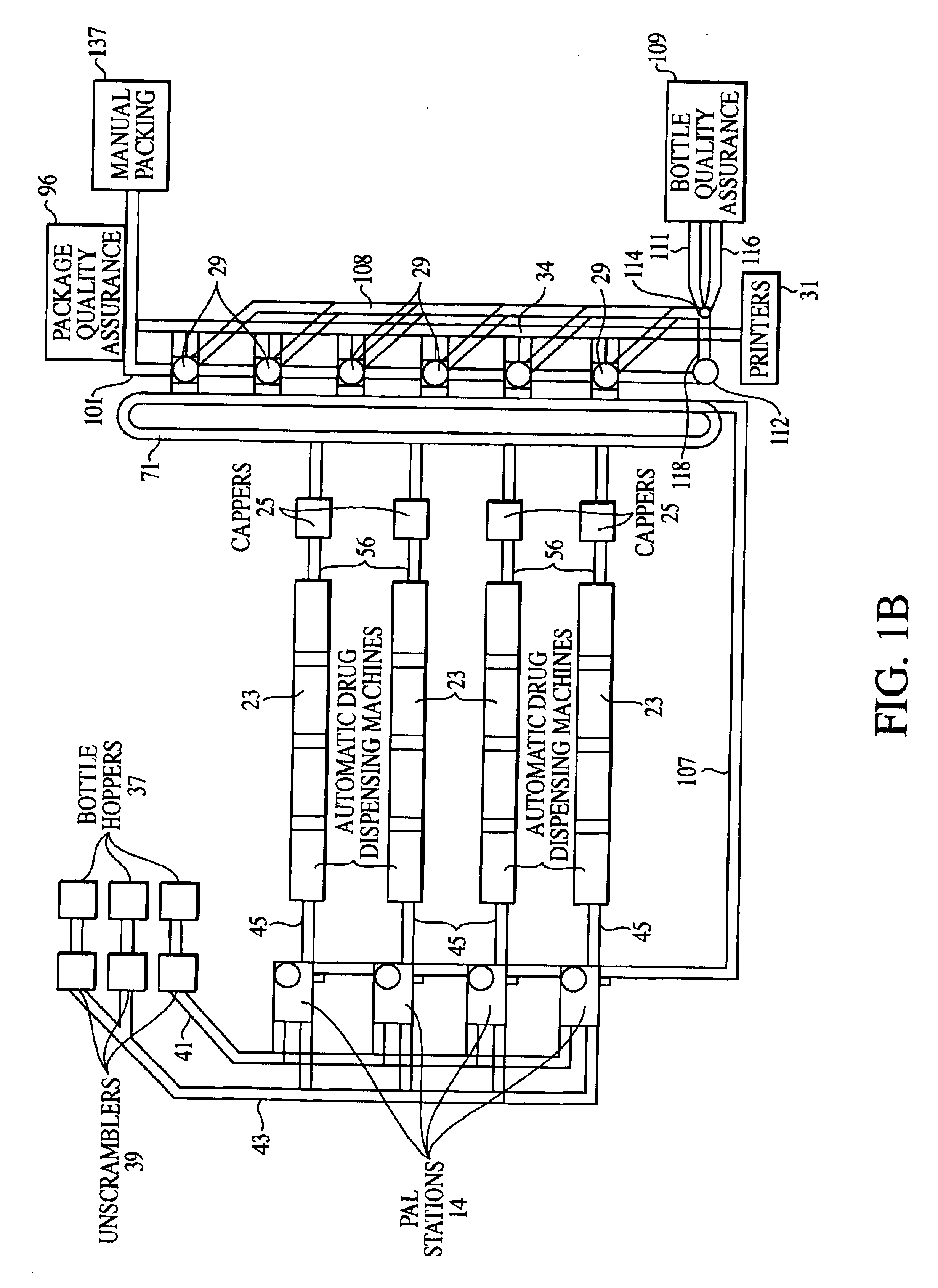

Automated prescription filling system/method with automated labeling and packaging system/method automated order consolidation system/method

Computer assisted systems, methods and mediums for filling one or more orders. One embodiment of the present invention is a system that includes an order consolidation station configured to receive at least one bottle containing pills individually counted and / or at least one package containing pharmaceutical products without having been designated for any of the orders when the package was created and / or at least one literature pack optionally including patient specific information. The order consolidation station is further configured to combine automatically the received bottle and / or package and / or literature pack into a container to be sent to a recipient including, for example, mail order pharmacies, wholesalers and / or central fill dealers for subsequent distribution or sale including retailer distribution or sale. The bottle is specifically designated for the order, and the order generally includes at least one prescription for the package.

Owner:EXPRESS SCRIPTS STRATEGIC DEV INC

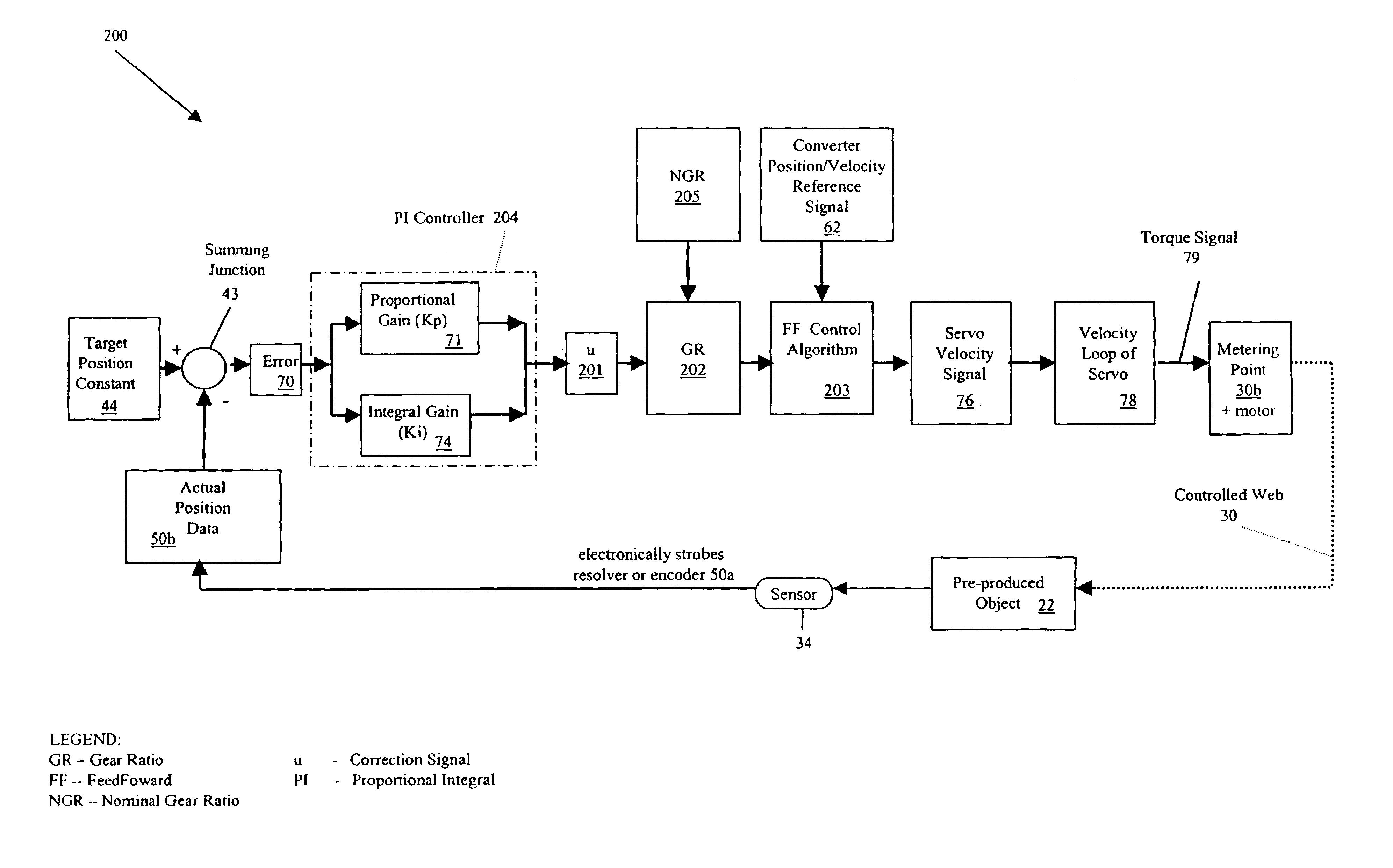

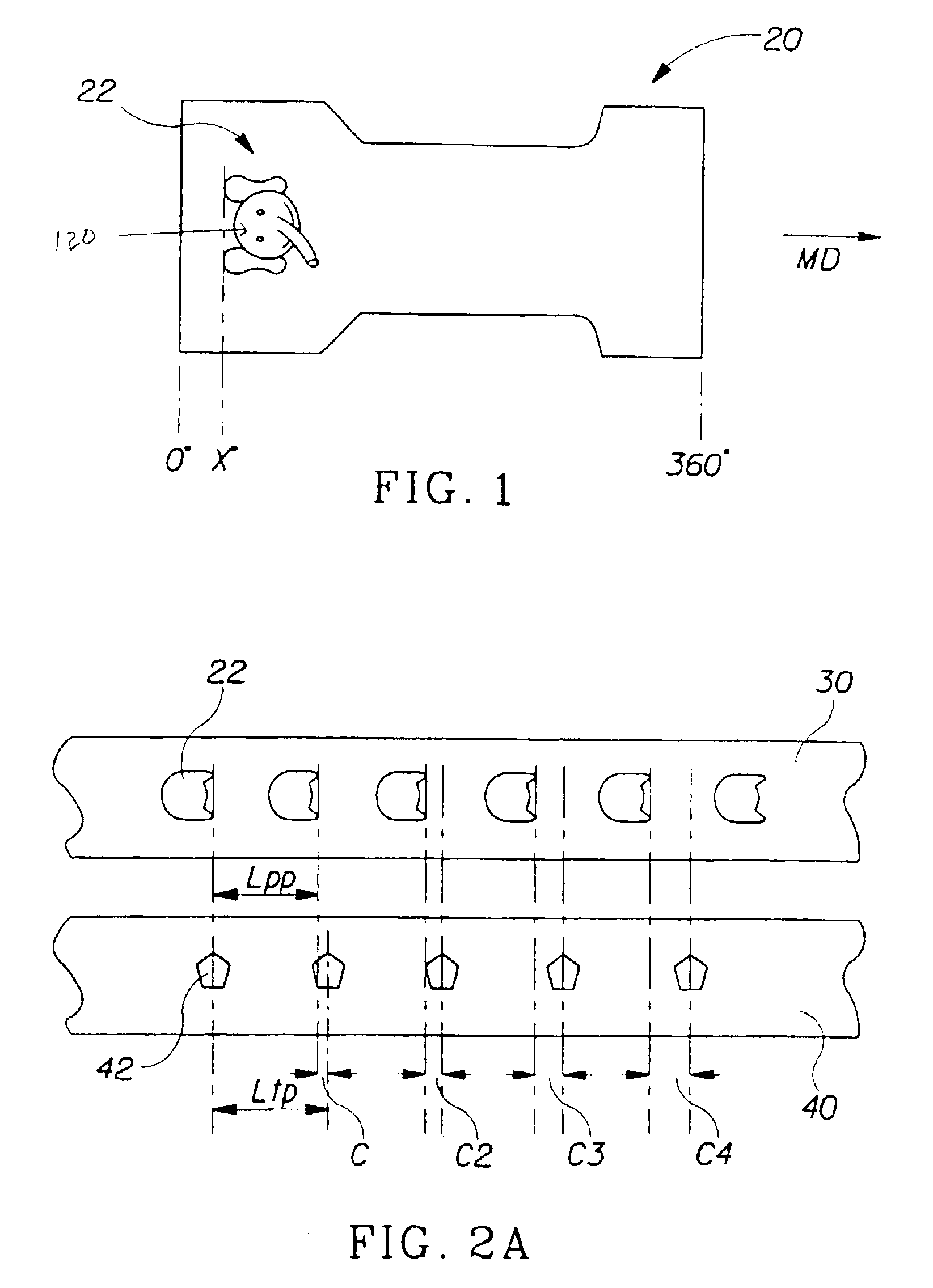

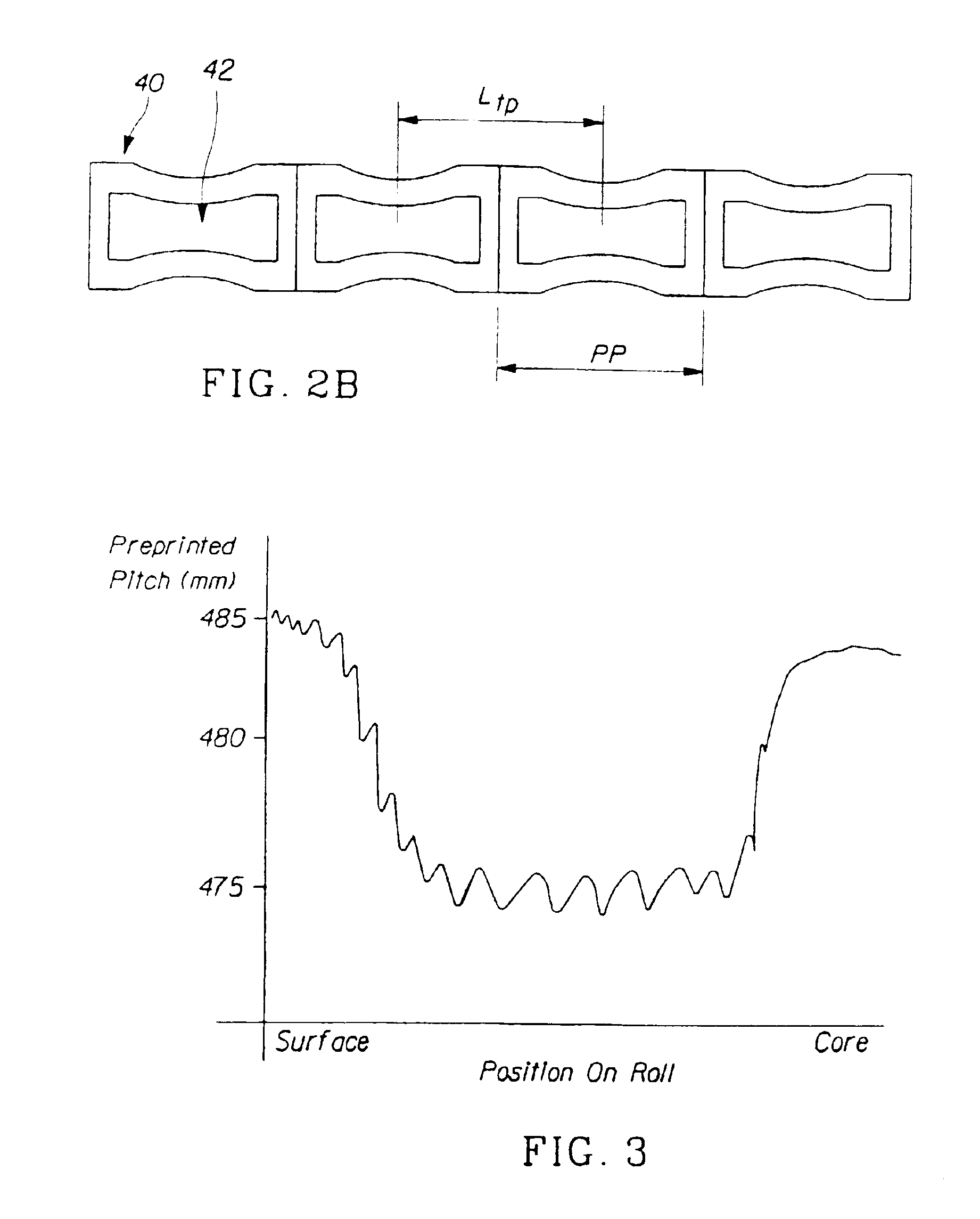

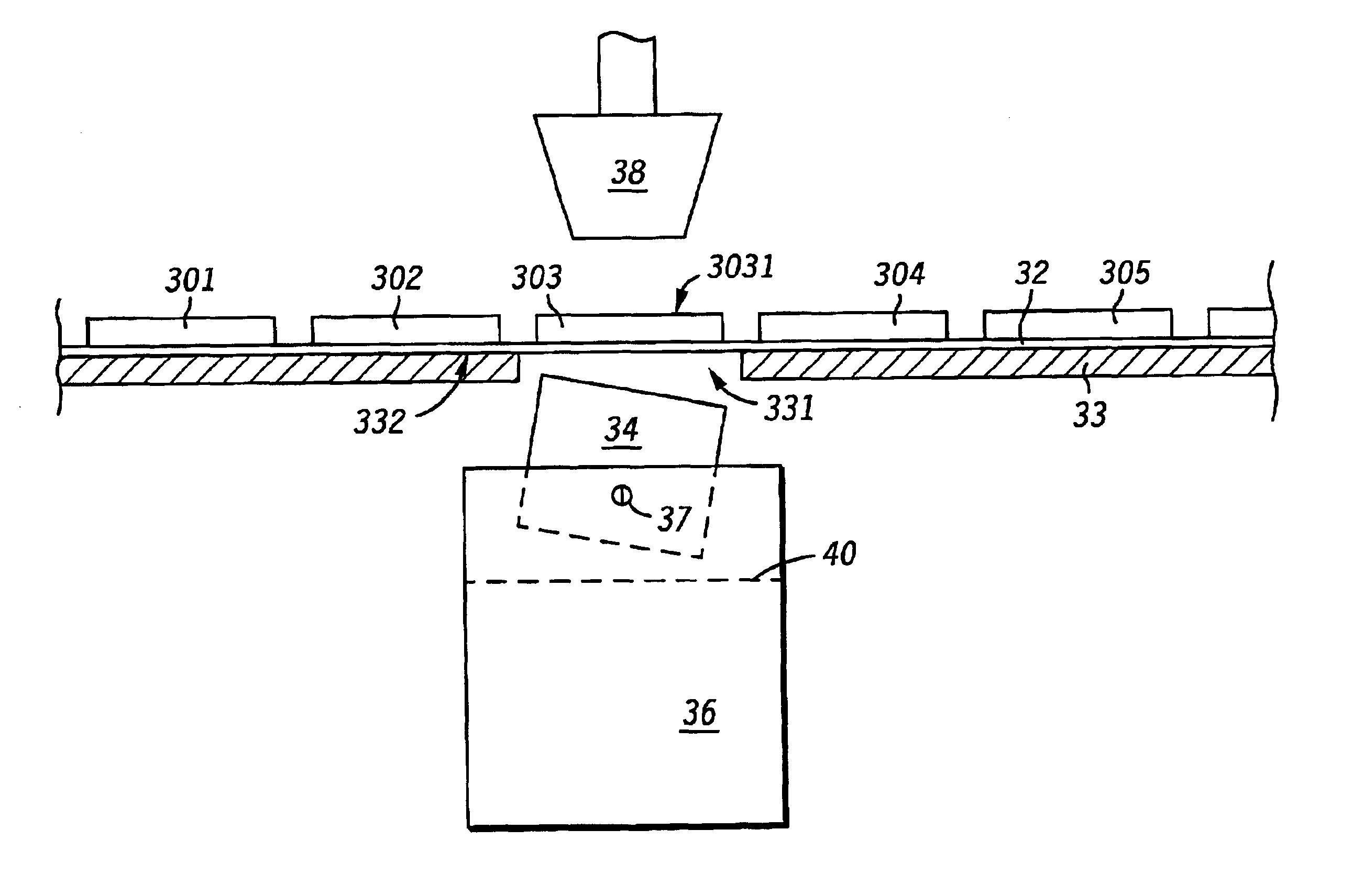

Method and system for registering pre-produced webs with variable pitch length

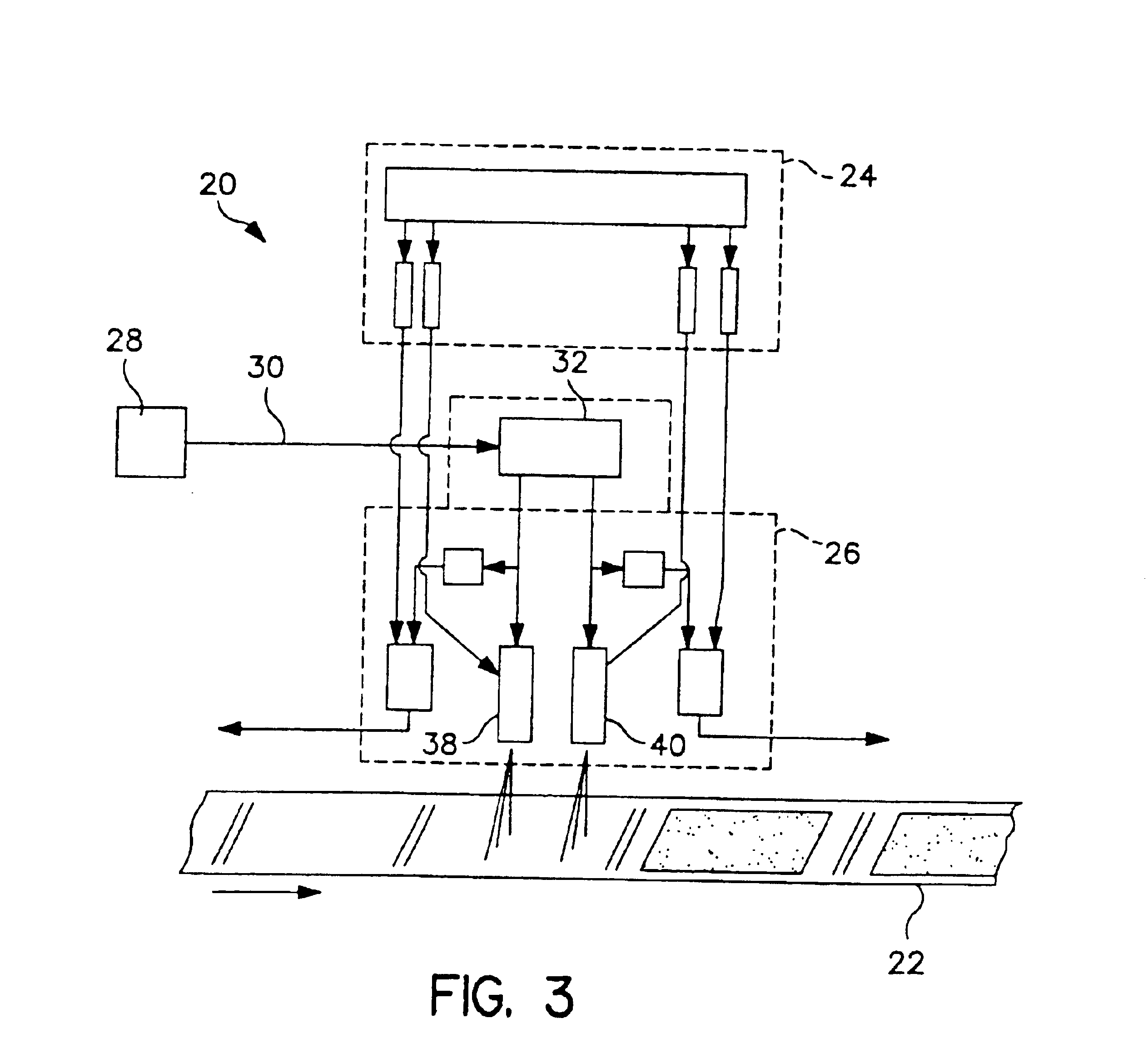

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

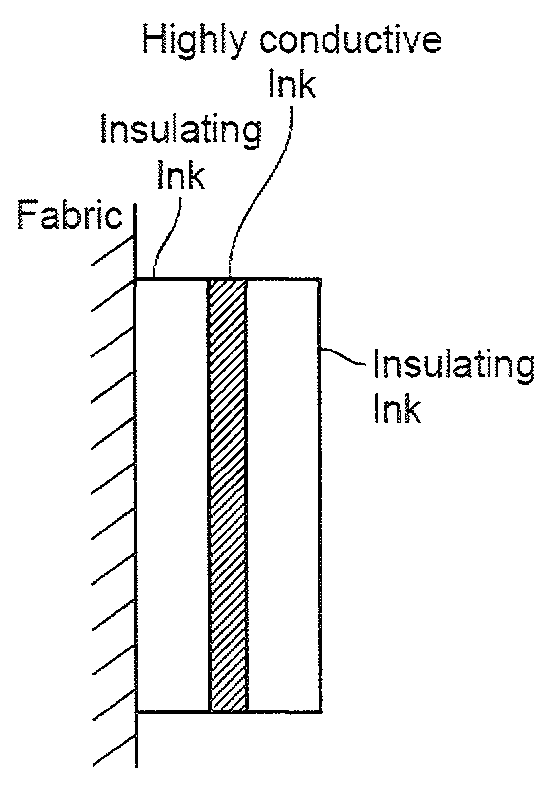

Methods of making garments having stretchable and conductive ink

InactiveUS8945328B2Robust detectionComfortable holding positionBioelectric signal measurementDecorative surface effectsAdhesiveEngineering

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Process for disengaging semiconductor die from an adhesive film

Owner:NXP USA INC

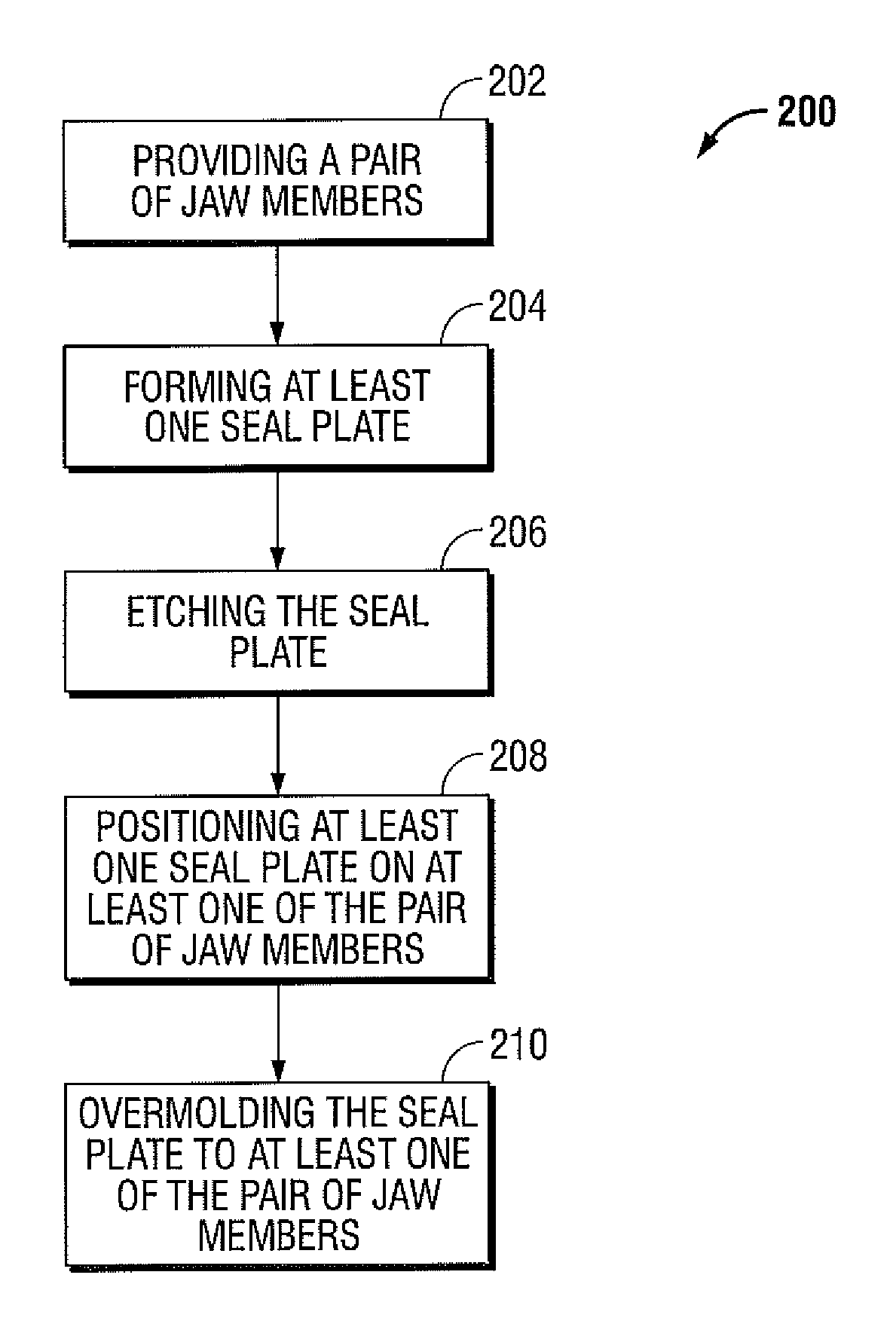

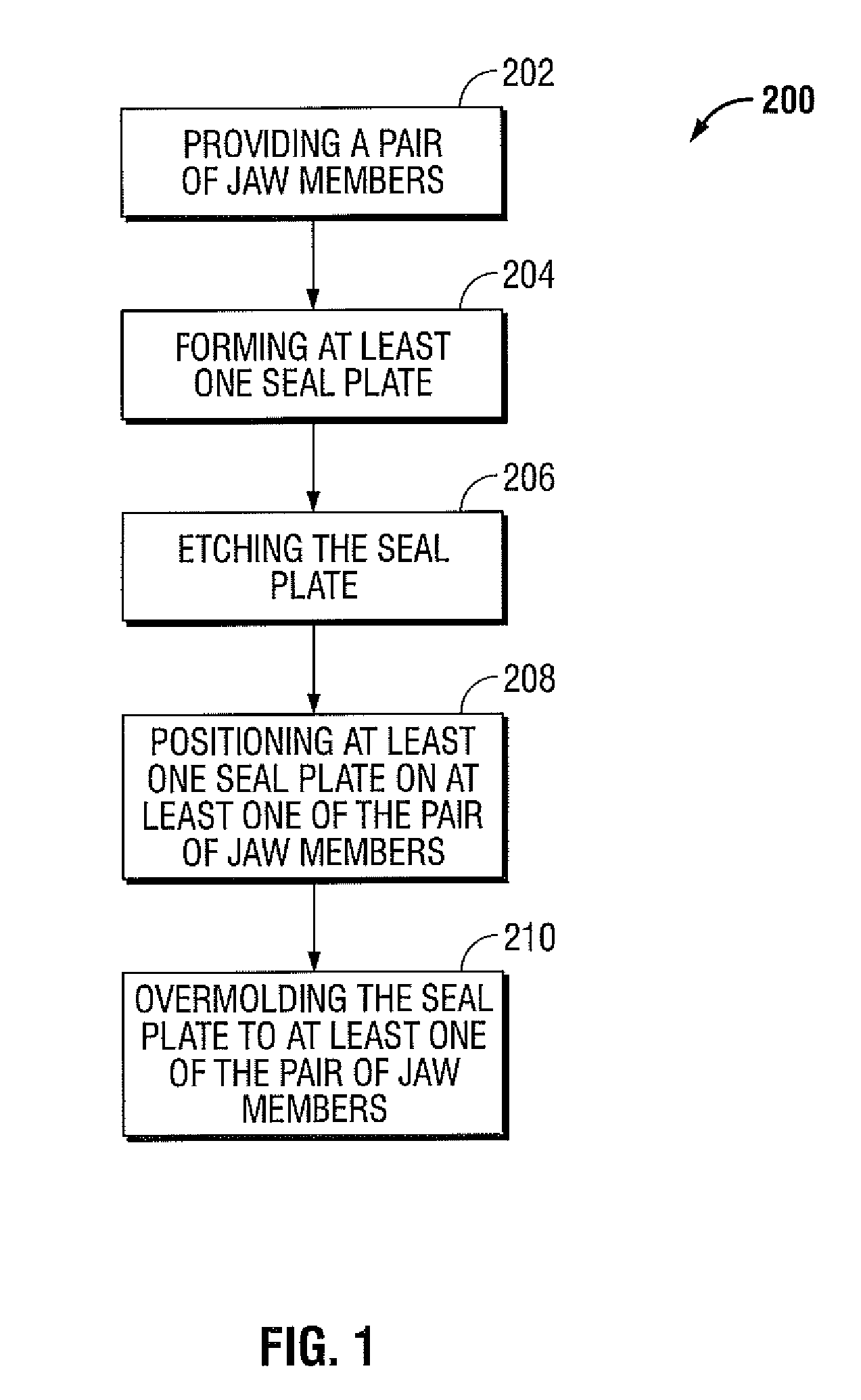

Method for manufacturing electrosurgical seal plates

ActiveUS8112871B2Avoid flowMeet the height limit requirementsContact member manufacturingLamination ancillary operationsEngineeringActuator

A method of manufacture for an end effector assembly is provided. The method includes providing a pair of jaw members. A step of the method includes forming one or more seal plates positionable on one of the pair of jaw members. Etching a dam along a side of the one or more seal plates is a step of the method, wherein the etched dam inhibits the flow of a plastic on the one or more seal plate such that a height of the plastic with respect to the at least one seal plate during an overmolding process may be controlled. The method includes positioning the one or more seal plates on the one of the pair of jaw members; and overmolding the seal plate to one or more of the pair of jaw members.

Owner:TYCO HEALTHCARE GRP LP

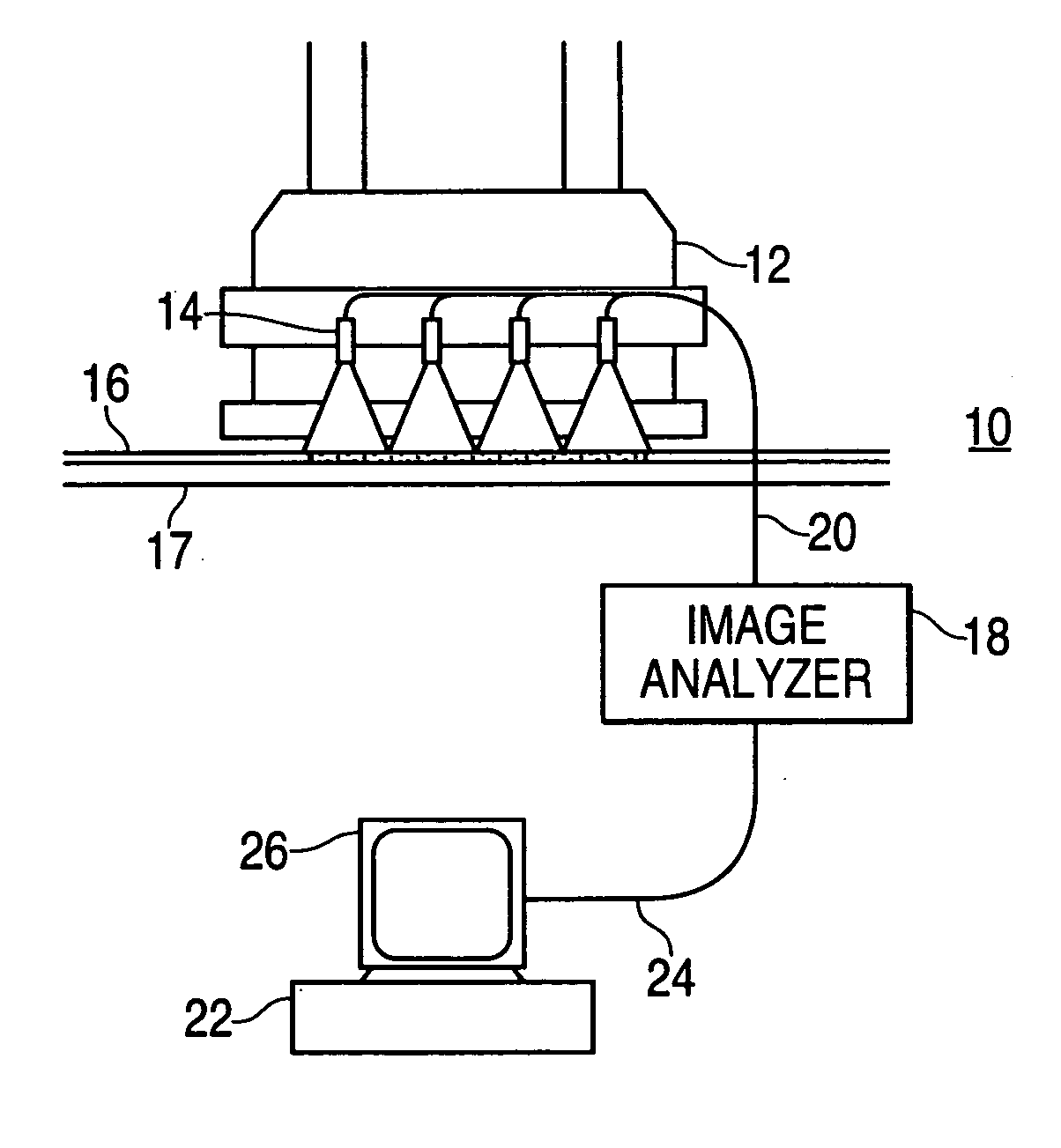

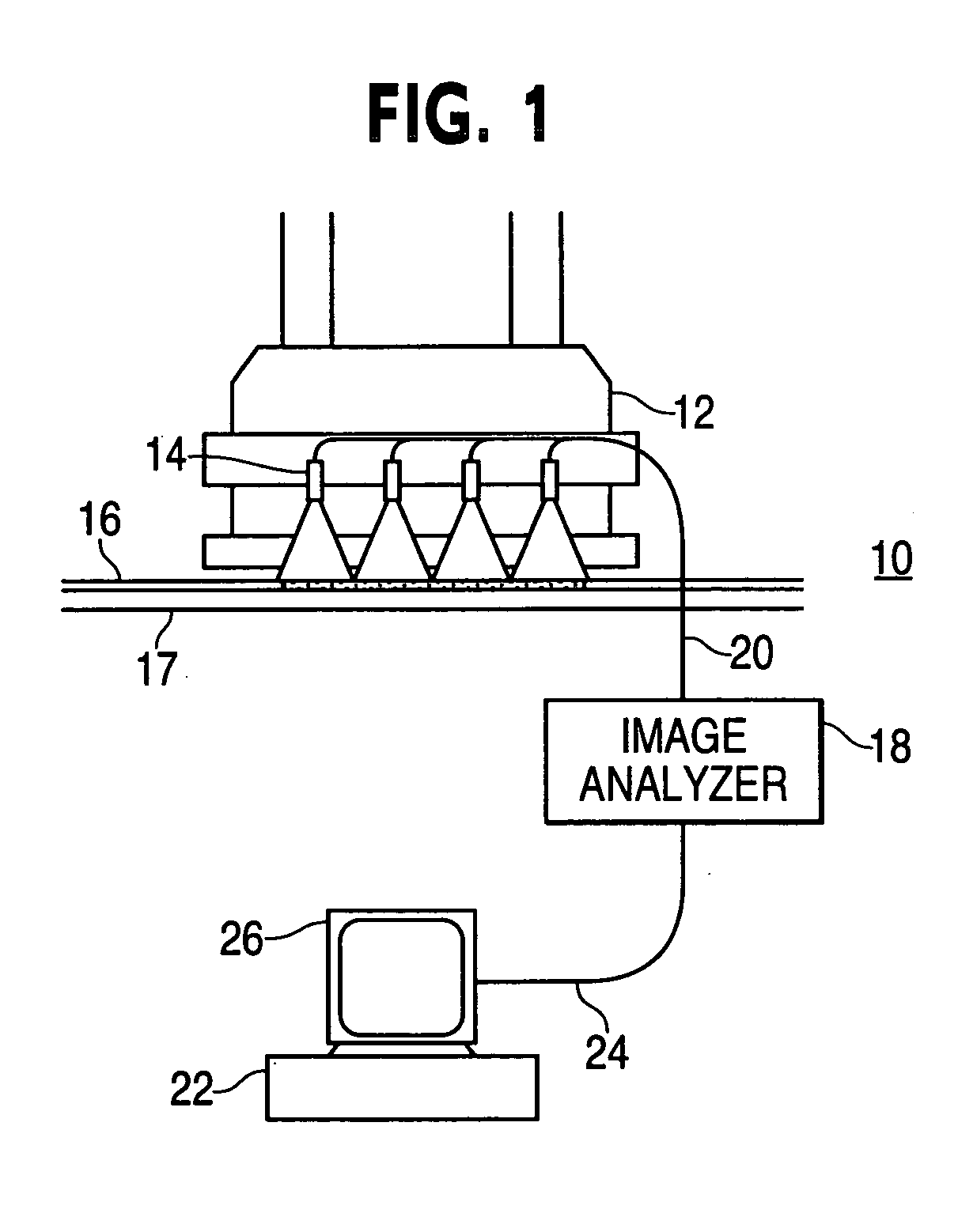

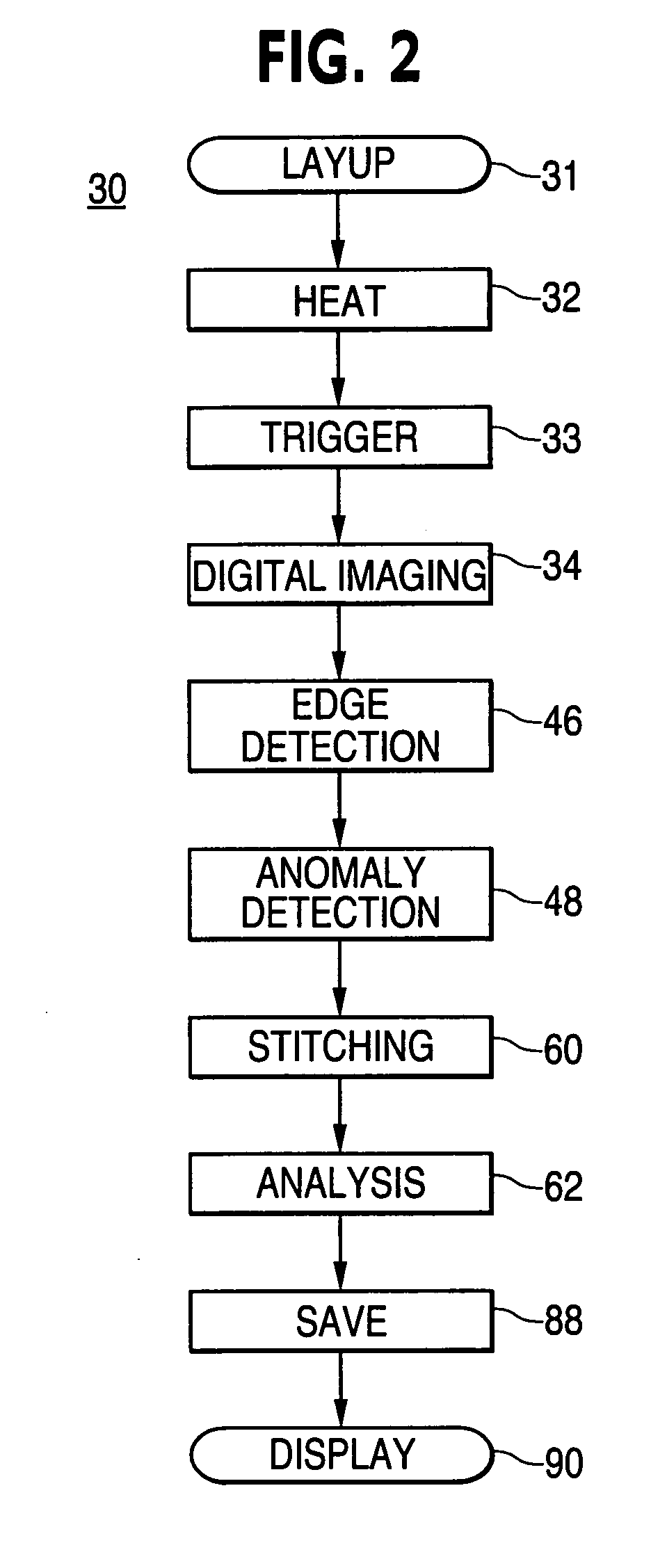

Real-time infrared thermography inspection and control for automated composite material layup

ActiveUS20060191622A1Slight variationImage enhancementRadiation pyrometryComputer visionDigital image data

A real-time thermal imaging apparatus and method includes multiple digital infrared cameras mounted to an automated composite material layup device to record digital infrared images of the composite material surface on a real-time basis during a composite material layup process. The digital infrared cameras are triggered periodically to produce digital images of the composite material. The digital image data is sent to an image analyzer which detects edges of and anomalies in the composite material and generates alarm and other process control signals. The image analyzer also aggregates the digital images from the multiple cameras and the digital images recorded over a sequence in time to produce a continuous virtual digital image of the composite material surface. The digital image data and associated analysis results are saved and may be displayed on a real-time basis or at a later time.

Owner:THE BOEING CO

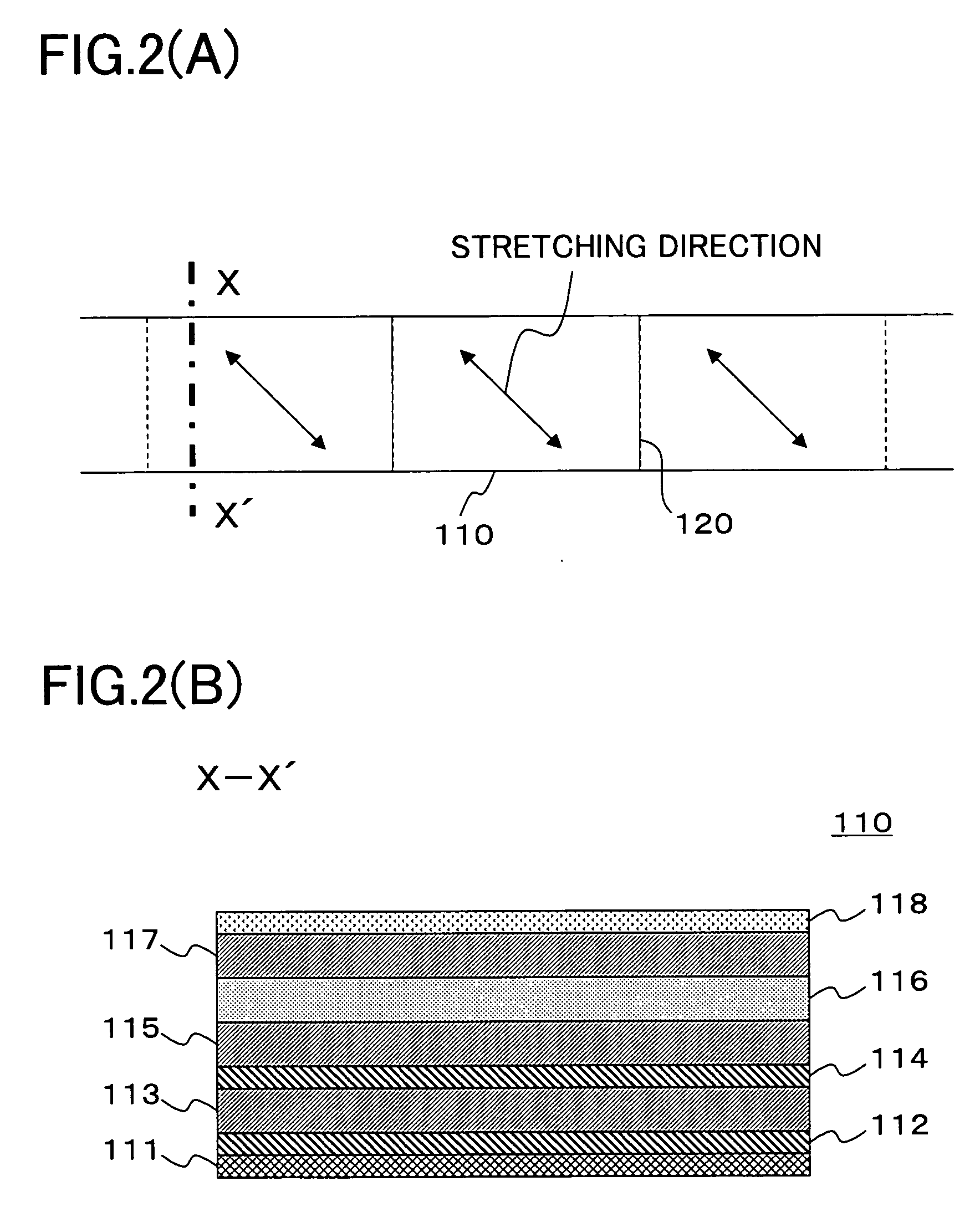

Laminating System

InactiveUS20080044940A1Increase productivityShorten production timePaper/cardboard wound articlesSemiconductor/solid-state device detailsEngineeringIntegrated circuit

It is an object of the invention to improve the production efficiency in sealing a thin film integrated circuit and to prevent the damage and break. Further, it is another object of the invention to prevent a thin film integrated circuit from being damaged in shipment and to make it easier to handle the thin film integrated circuit. The invention provides a laminating system in which rollers are used for supplying a substrate for sealing, receiving IC chips, separating, and sealing. The separation, sealing, and reception of a plurality of thin film integrated circuits can be carried out continuously by rotating the rollers; thus, the production efficiency can be extremely improved. Further, the thin film integrated circuits can be easily sealed since a pair of rollers opposite to each other is used.

Owner:SEMICON ENERGY LAB CO LTD

Method of forming self-supporting pleated filter media

The method of forming pleated filter media includes providing a generally planar web of filter material, folding the web to form a pleated web having a plurality of fold lines, arranging the plurality of pleats in a first spaced configuration defined by a first distance between adjacent pleat tips, applying a continuous strand of adhesive to the web, and adjusting the arrangement of the plurality of pleats into a second spaced configuration defined by a second distance between adjacent pleat tips. The web has a front face and a rear face. Each fold line is intermediate oppositely sloping first and second wall surfaces. The plurality of fold lines form a plurality of pleats having a first plurality of pleat tips and a second plurality of pleat valleys. The second distance is different from the first distance.

Owner:3M INNOVATIVE PROPERTIES CO

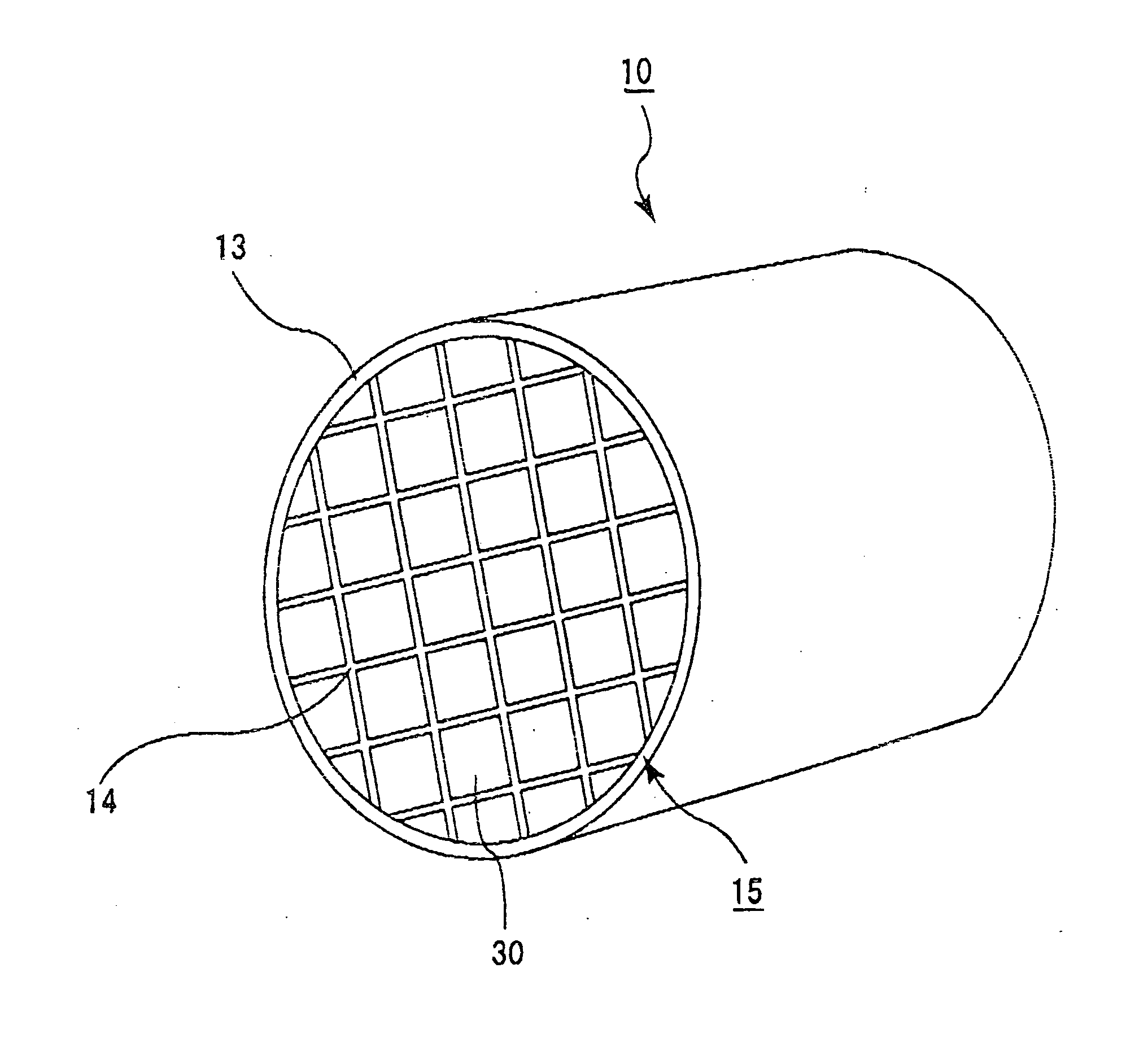

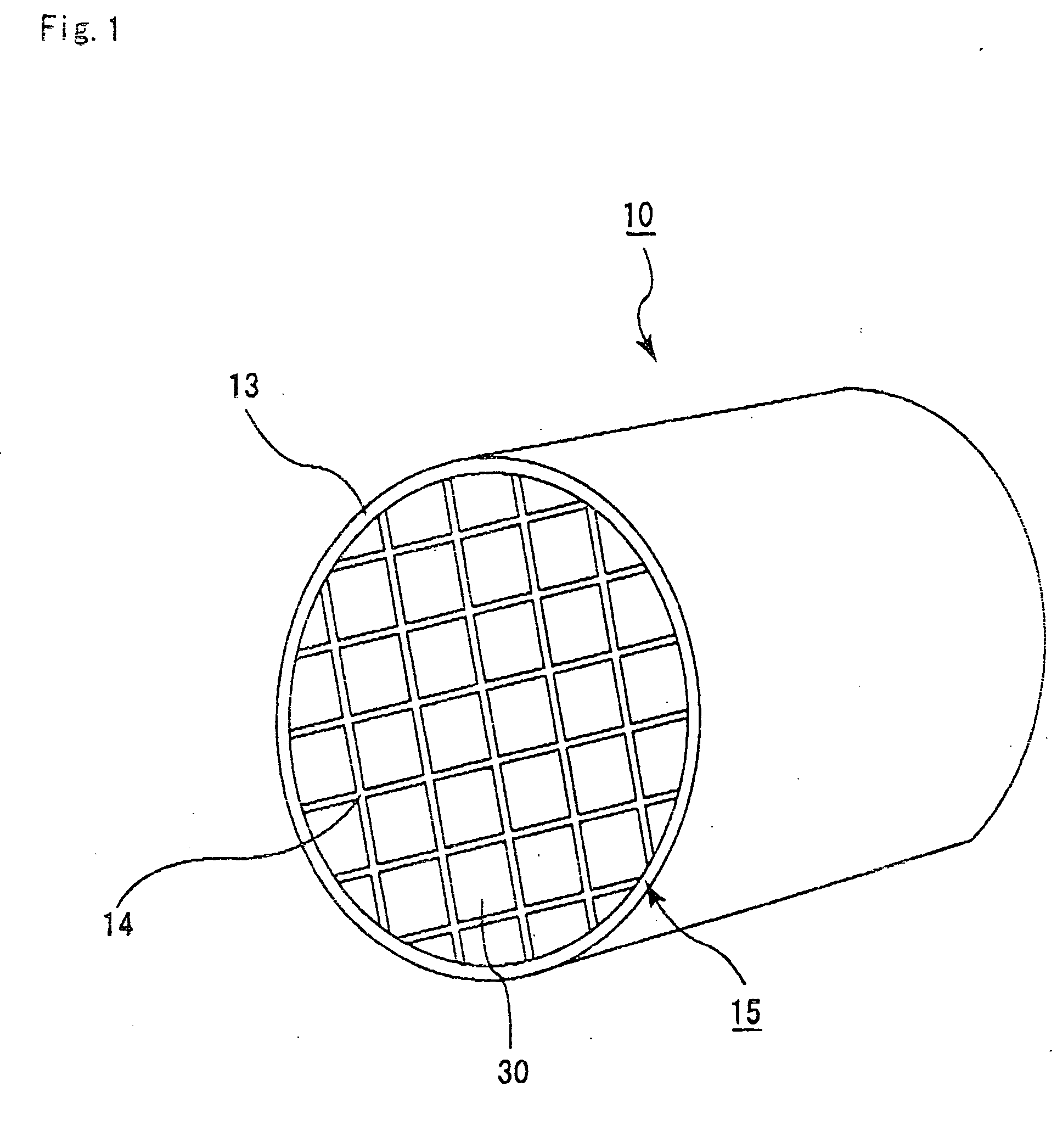

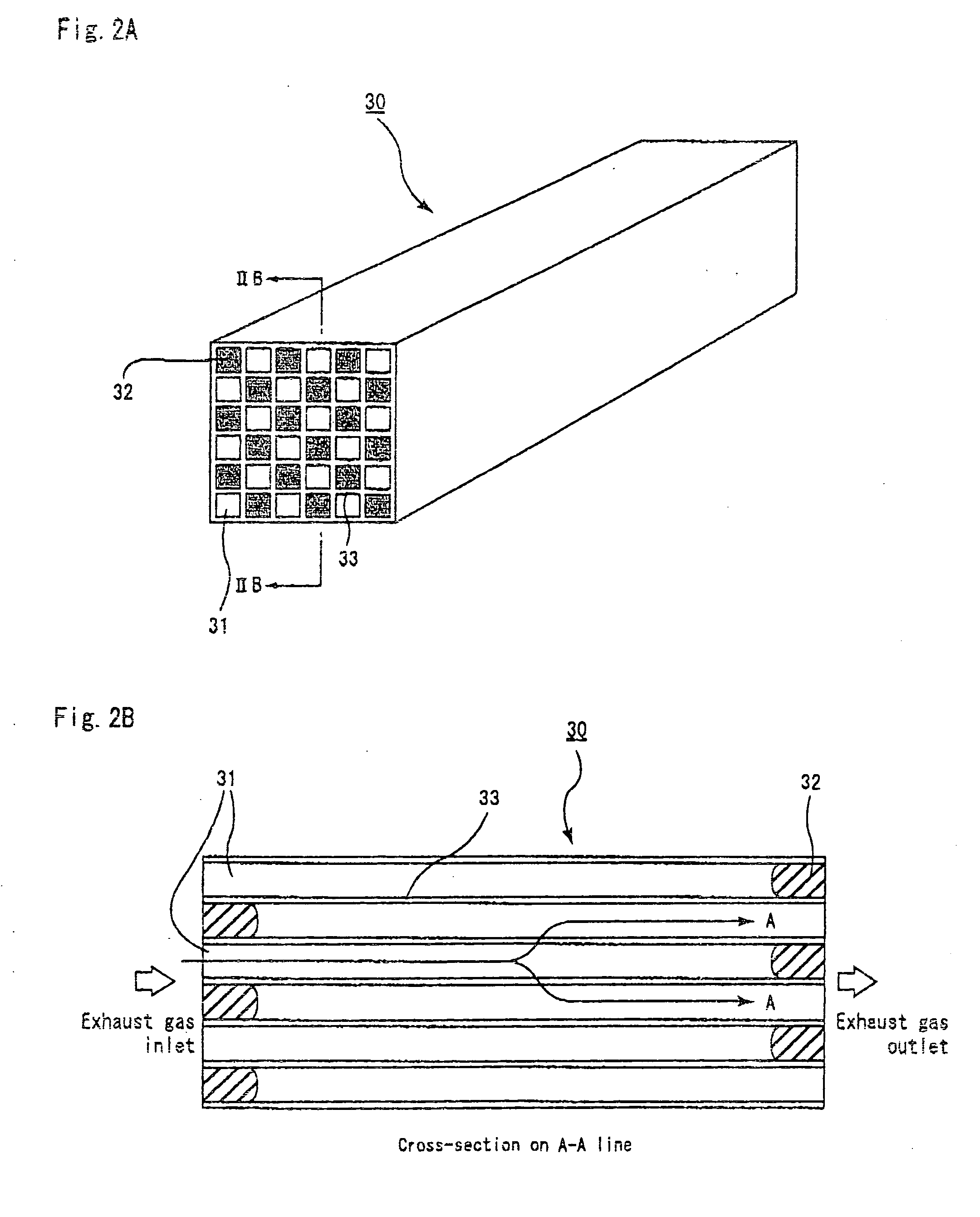

Ceramic structure, method of manufacturing ceramic structure, and device for manufacturing ceramic structure

ActiveUS20050178098A1Hardening the bonding materialCombination devicesAuxillary pretreatmentMetallurgyAdhesive

A ceramic structure includes a plurality of porous ceramic members each being warped, each of the plurality of porous ceramic members having a bonding portion and end portions at both ends of each of the plurality of porous ceramic members in a longitudinal direction of each of the plurality of porous ceramic members, and an adhesive provided only on the bonding portion between the plurality of porous ceramic members to connect the plurality of porous ceramic members except for the end portions of the plurality of ceramic members.

Owner:IBIDEN CO LTD

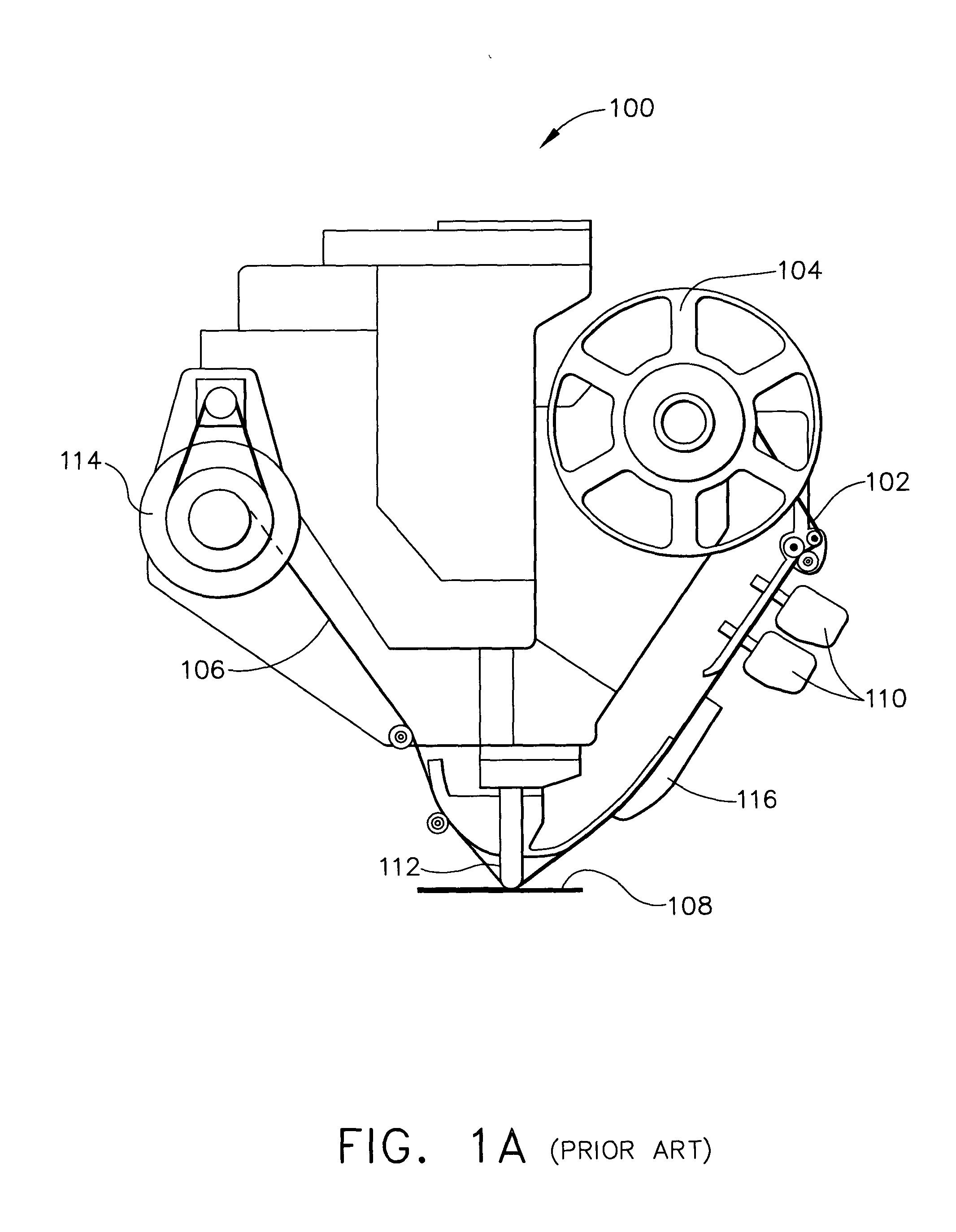

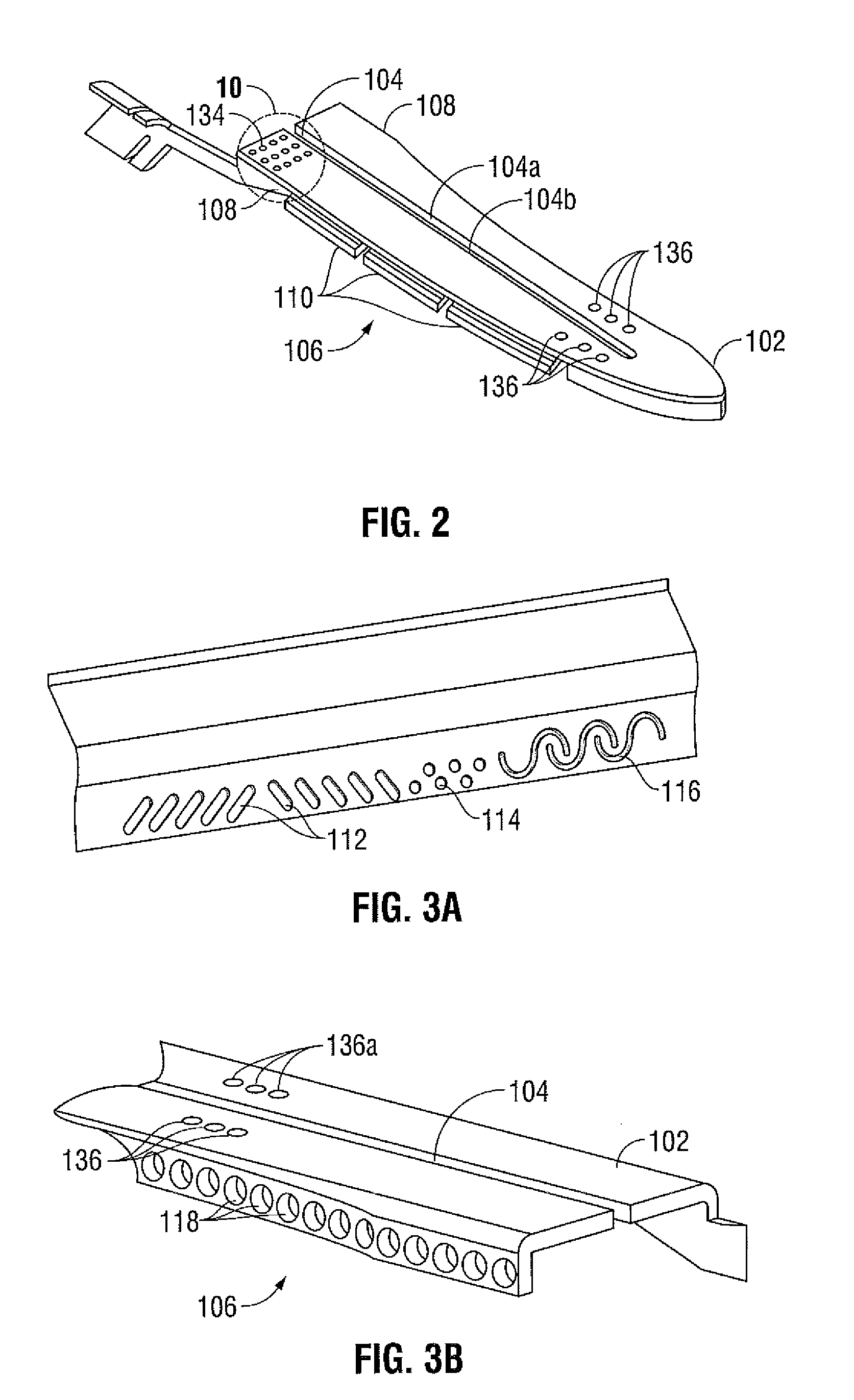

Tow width adaptable placement head device and method

InactiveUS20070029030A1Lamination ancillary operationsControlling laminationEngineeringMechanical engineering

Owner:THE BOEING CO

System for identifying defects in a composite structure

InactiveUS6871684B2Accurate identificationShorten the timeRadiation pyrometryInvestigating composite materialsComputer scienceStructural integrity

The present invention provides an improved system for identifying defects in a composite structure by providing a light source such that defects, and in particular dark defects on a dark background and / or light defects on a light background, can be identified by capturing images of the illuminated composite structure. In particular, the improved system for identifying defects in a composite structure may provide a reflective surface, dispersion elements, and multiple and / or moveable light source(s) and / or camera(s) in order to ensure that the most accurate images of any area of the composite structure, even curved or contoured areas, are captured and processed. As a result, the system of the present invention permits the operator to quickly identify and correct defects which would otherwise create structural flaws or inconsistencies that may affect the integrity of the composite structure.

Owner:THE BOEING CO

Laminated structures

InactiveUS6887941B2High bonding strengthImproved performance characteristicsControlling laminationSynthetic resin layered productsHot meltAlpha-olefin

Hot-melt, pressure-sensitive adhesive compositions of amorphous polyalphaolefin and crystalline polypropylene have improved bond strength over the amorphous polyalphaolefin alone. The adhesive compositions improve dynamic shear strength, dynamic peel strength, as well as static peel strength. The adhesive compositions are particularly suitable for use in absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method and apparatus for forming tow-based absorbent structures with a single casing sheet

InactiveUS6923926B2Easy to operateIncrease line speedMechanical working/deformationDough shapingParticulatesEngineering

An apparatus and method for forming tow-based absorbent structures having a single casing sheet are disclosed. The apparatus has a tow supply mechanism for providing tow material, a particulate matter supply mechanism for providing particulate matter, and a casing sheet supply mechanism for providing casing sheet material. The apparatus also has a vacuum draw roll having a foraminous center surface that has a width defined by a first edge and a second edge and is rotatable about a first axis. The vacuum draw roll is positioned to receive the tow material, the particulate matter and the casing sheet material to form a open core composite supply. The apparatus also has one or more angled surfaces positioned to create one or more obtuse angles in the open core composite supply, and one or more folders to further fold the one or more obtuse angles in the open core composite supply to form a folded core composite supply.

Owner:PARAGON TRADE BRANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com