Device and method for femtosecond laser processing nozzle tangential hole

A femtosecond laser processing, femtosecond laser technology, applied in auxiliary devices, laser welding equipment, metal processing equipment, etc., can solve the problems of reduced atomization performance, difficult chip removal, recast layer and splash adhesion, etc. The effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

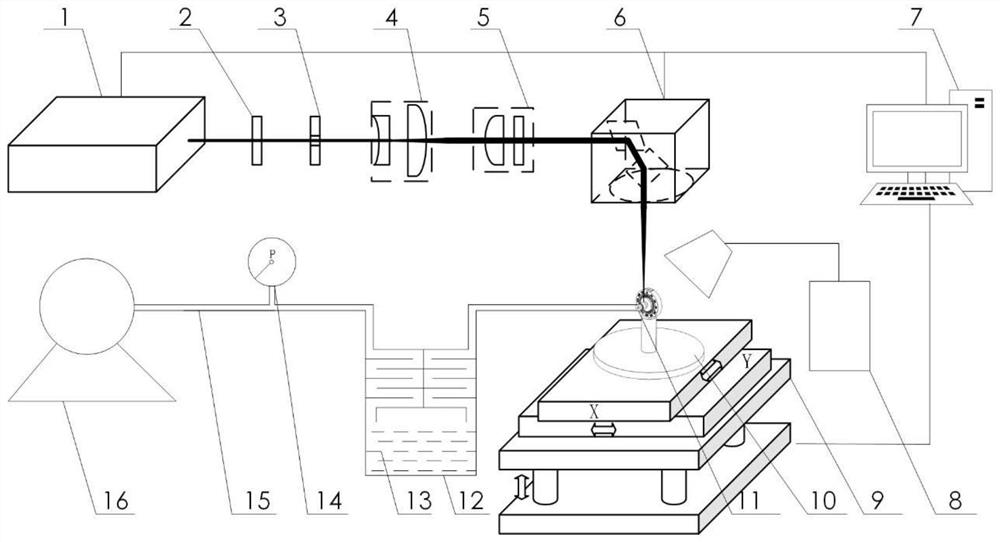

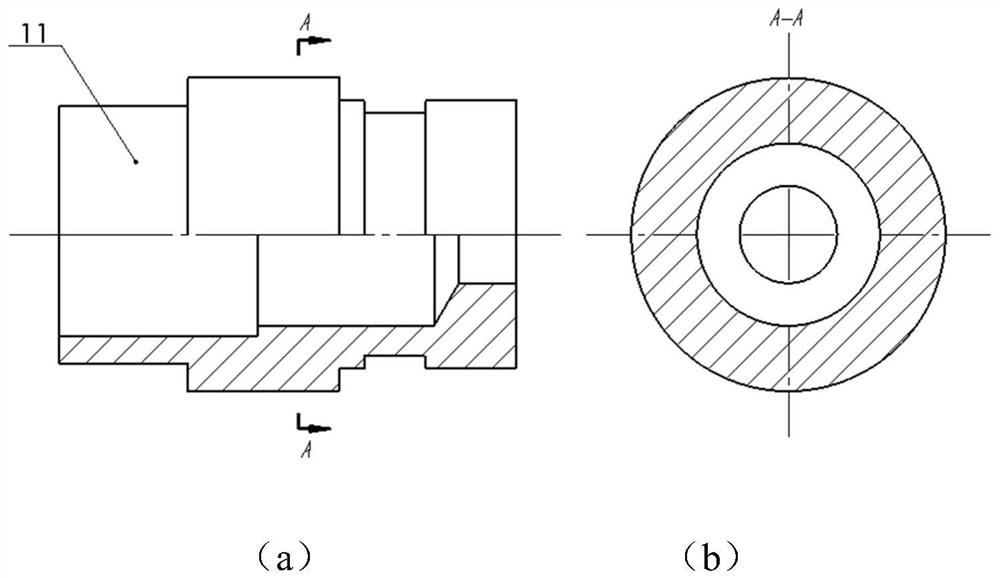

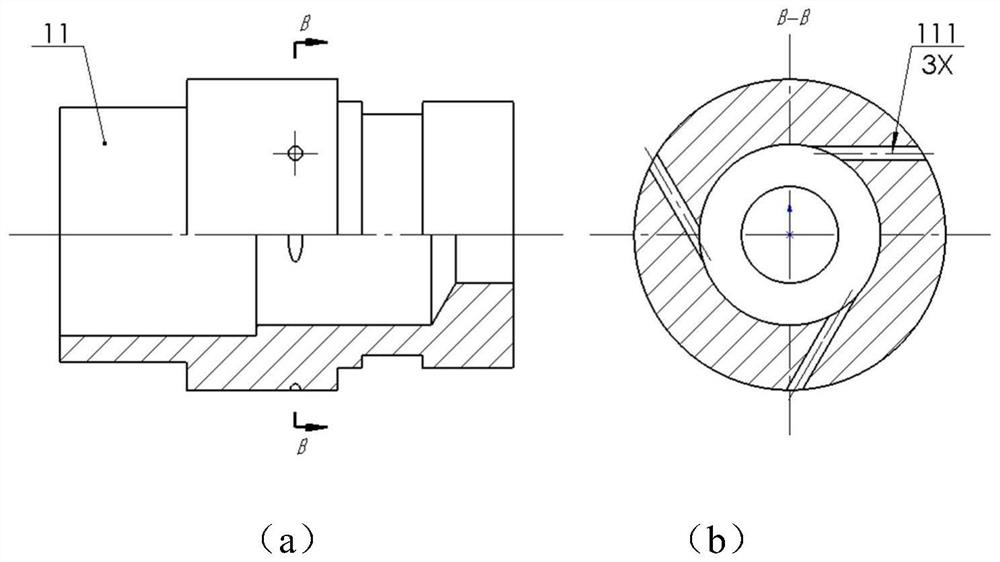

[0044] Embodiment 1 takes the machining of a nozzle workpiece with three tangential holes as an example. figure 2 is the structural schematic diagram of the nozzle workpiece without the tangential hole being machined according to the present invention, image 3 It is a schematic structural diagram of the nozzle workpiece after machining the tangential hole according to the present invention.

[0045] like figure 1 As shown, a device for femtosecond laser processing nozzle tangential holes provided by the present invention includes a femtosecond laser 1, Wave plate 2, diaphragm 3, beam expander 4, spatial light shaper 5, scanning galvanometer 6, computer 7, dust collector 8, CNC motion platform 9, fixture 10, filter system 12, water 13, pressure gauge 14. Sealing tube 15 and vacuum pump 16. The femtosecond laser 1 is placed horizontally on an optical platform, and the generated laser light paths are sequentially fixed and installed through screw connections Wave plate 2,...

Embodiment 2

[0059] In the second embodiment, when the nozzle workpiece 11 with four tangential holes is processed, the corresponding rotation angle indicator plate 106 with four mounting holes and four anti-injury blocks 107 on the opposite wall can be replaced for processing four Nozzle workpiece 11 with tangential hole. Each time a tangential hole at a position is processed, the rotation angle indicating plate 106 is rotated clockwise to an angle of 90°, and the rest of the processing methods are basically the same as those described in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com