Patents

Literature

271results about How to "No glitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black pigment ink for ink-jet printer and method for preparing the same

The invention provides a black ink for ink-jet printers, which comprises 10-30% of carbon black, 0.1-1.25% of amphiprotic polymerized substance, 0.1-1.5% of levelling agent, 10-30% of wetting agent, 0.05%-0.5% of defoaming agent and deionized water, 20-33% of carbon black dispersion liquid, 0.05-2% of surface active agent, 5-50% of humectant, 0.1-2% of pH regulator, 0.5-2% of drier, 0.1-0.5% of preservative agent, 0.1-0.5% of mold preventive, 0.01-0.5% of chelating agent, 0.1-2% of resin and deionized water.

Owner:大连思创信息材料有限公司

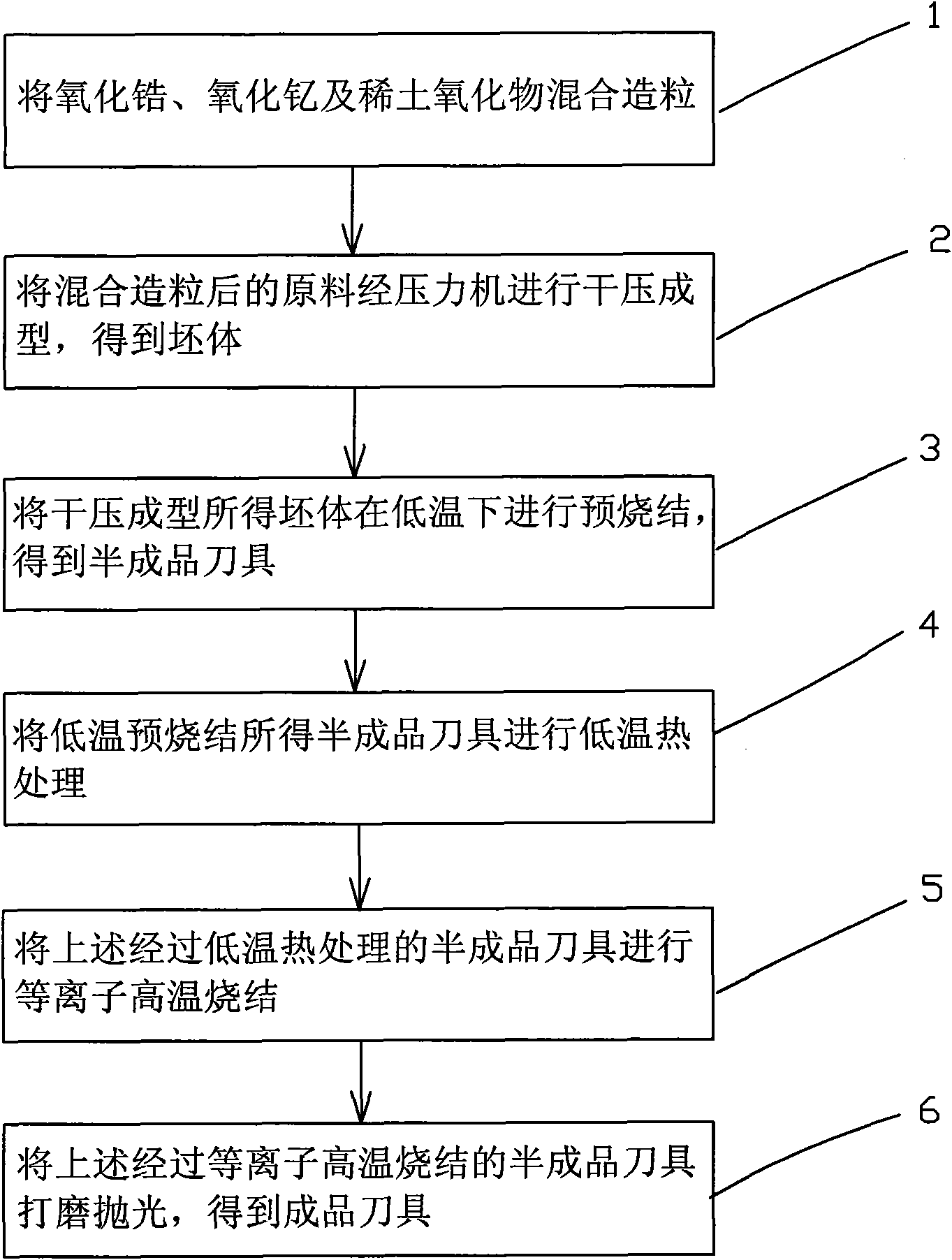

Super-strong and super-toughened ceramic cutter and manufacturing method thereof

ActiveCN101602111AImprove yield rateHigh hardnessCeramic shaping apparatusTurning toolsRare earthMaterials science

The invention relates to a super-strong and super-toughened ceramic cutter and a manufacturing method thereof. The ceramic cutter comprises the following components in portion by weight: 89 to 95 portions of zirconia, 2 to 8 portions of yttria, and 2 to 4 portions of rare earth oxide. The manufacturing method for the ceramic cutter comprises the following: step 1, mixing and granulating the zirconia, the yttria and the rare earth oxide; step 2, dry-pressing and molding the mixed and granulated raw materials by a press to obtain a blank; step 3, pre-sintering the blank obtained by the dry-pressing and molding at the low temperature to obtain a semi-finished cutter; step 4, thermally treating the semi-finished cutter obtained by the low-temperature pre-sintering at the low temperature; step 5, carrying out plasma high-temperature sintering for the semi-finished cutter which is thermally treated at the low temperature; and step 6, grinding and polishing the semi-finished cutter which is subjected to the plasma high-temperature sintering to obtain a finished cutter. The ceramic cutter has high hardness and good abrasion resistance, and has the remarkable advantages on thermal stability, heat conduction, corrosion resistance, oxidation resistance, high-temperature hardness, high-temperature strength, and the like. The method has the advantages of simple process and high production efficiency, and is favorable for mass mechanized production.

Owner:深圳市宏通新材料有限公司

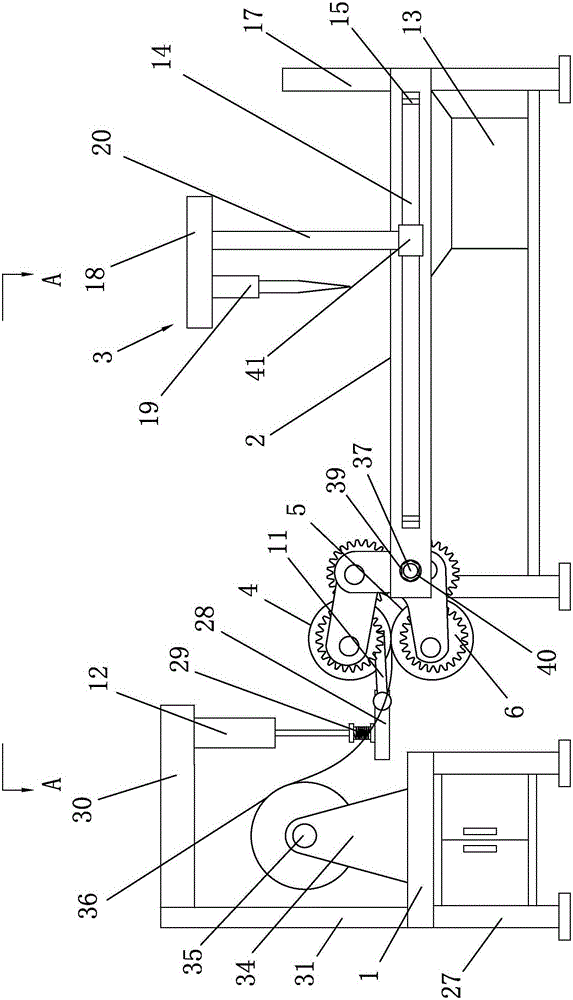

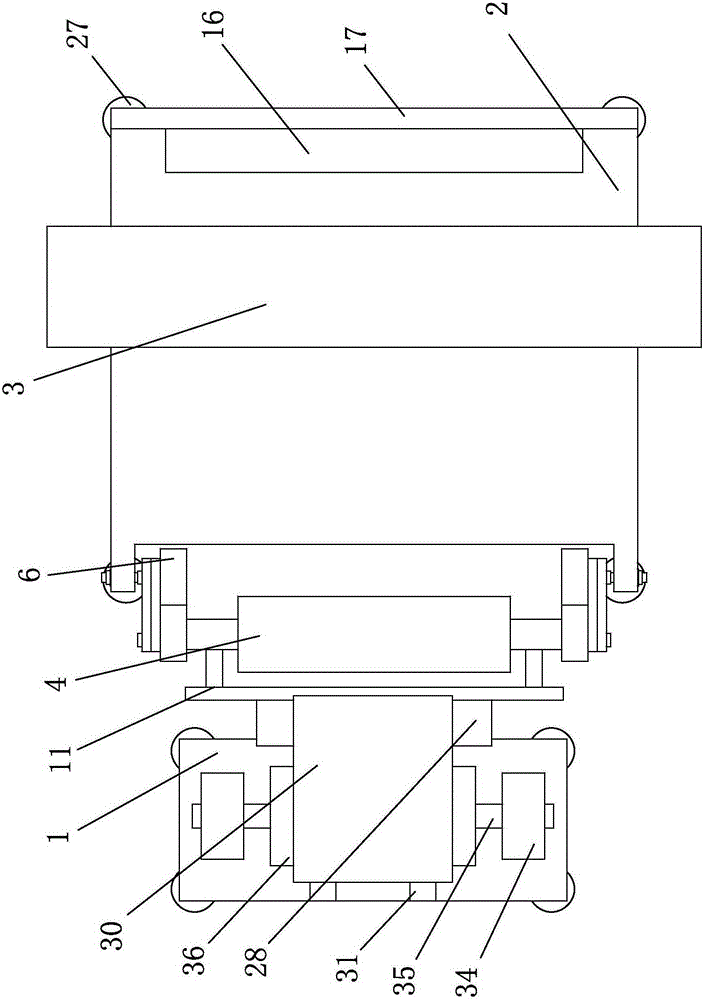

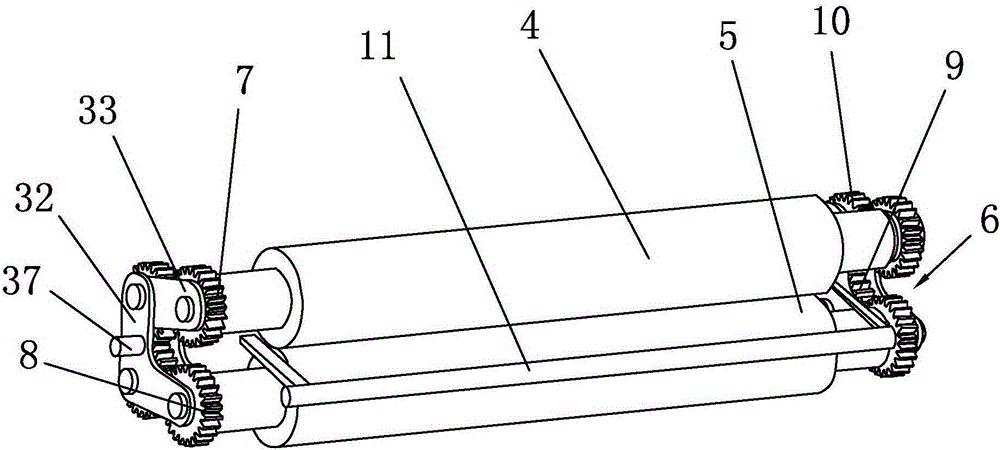

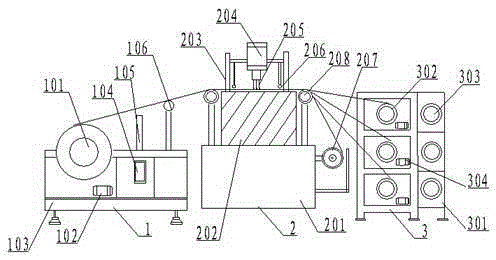

A cutting machine used for necktie fabric processing

InactiveCN105316928AImplement automatic transferIncrease transfer rateTextile selvedgesSevering textilesEngineeringMechanical engineering

The invention provides a cutting machine used for necktie fabric processing. The cutting machine comprises a material holding stand, a material feeding device, a cutting platform and a cutter device. The material feeding device comprises an upper clamping roller and a lower clamping roller. A driving lever device is arranged below the upper clamping roller and comprises a driving lever and a driving lever cylinder. The top surface of the cutting platform is provided with a material falling groove and a protecting plate. The cutter device comprises a horizontal guide rail and a cutting knife. A heating device is arranged in the cutter device and comprises a heater, a heat conduction plate and a heat conduction tube. The cutting machine is simple in structure and highly practical; with the material feeding device, fabric can be conveyed more conveniently; with a gear assembly, the length of fabric cutting can be controlled and the transmission is more stable; with the heating device, the temperature of the cutting knife can be made to rise and through high temperature cutting, cut fabric has the advantages of high quality, smooth cuts and zero burr and the processing of the next procedure is facilitated; energy consumption is reduced and the comprehensive utilization rate is increased.

Owner:SHAOXING HENRY TIE FASHION

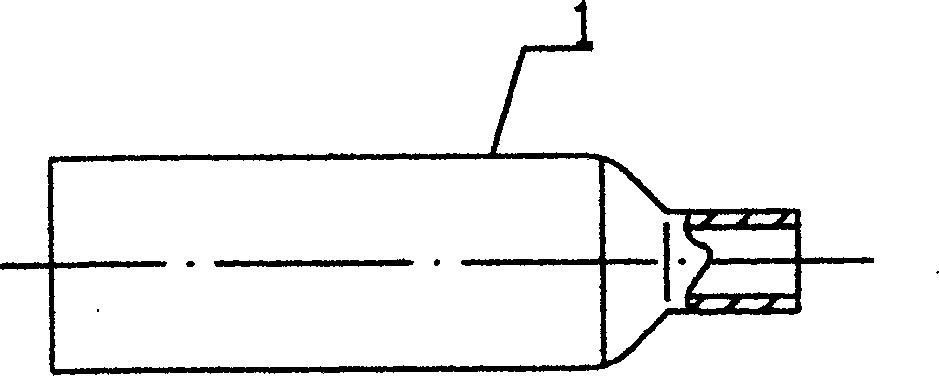

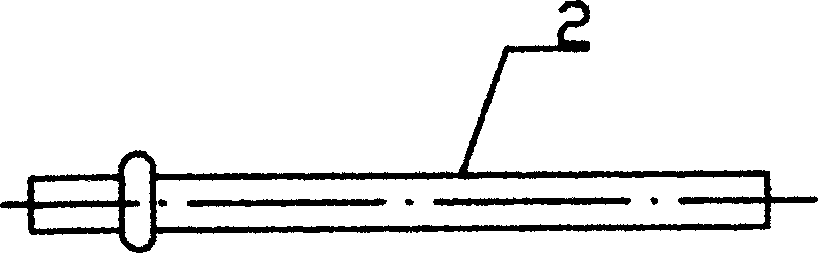

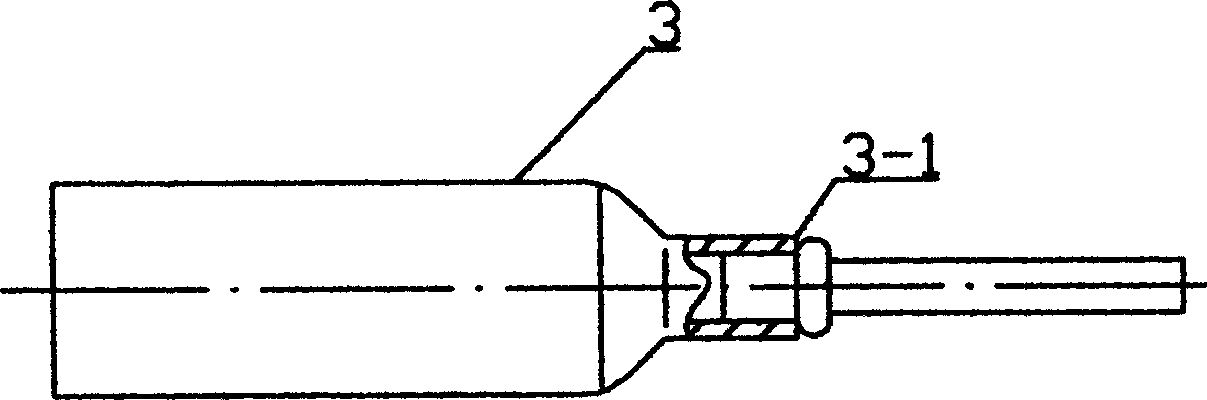

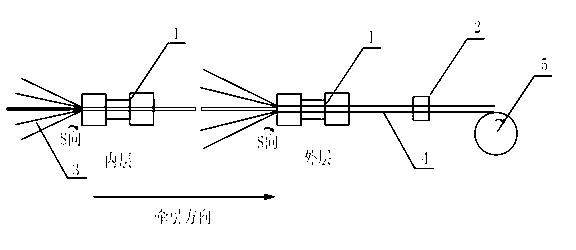

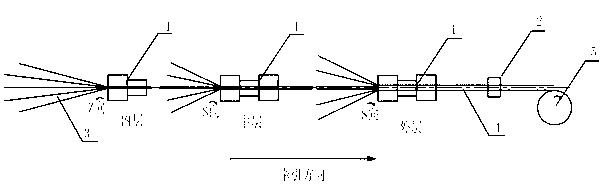

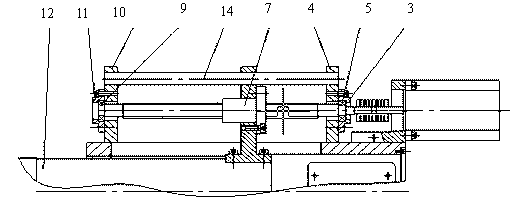

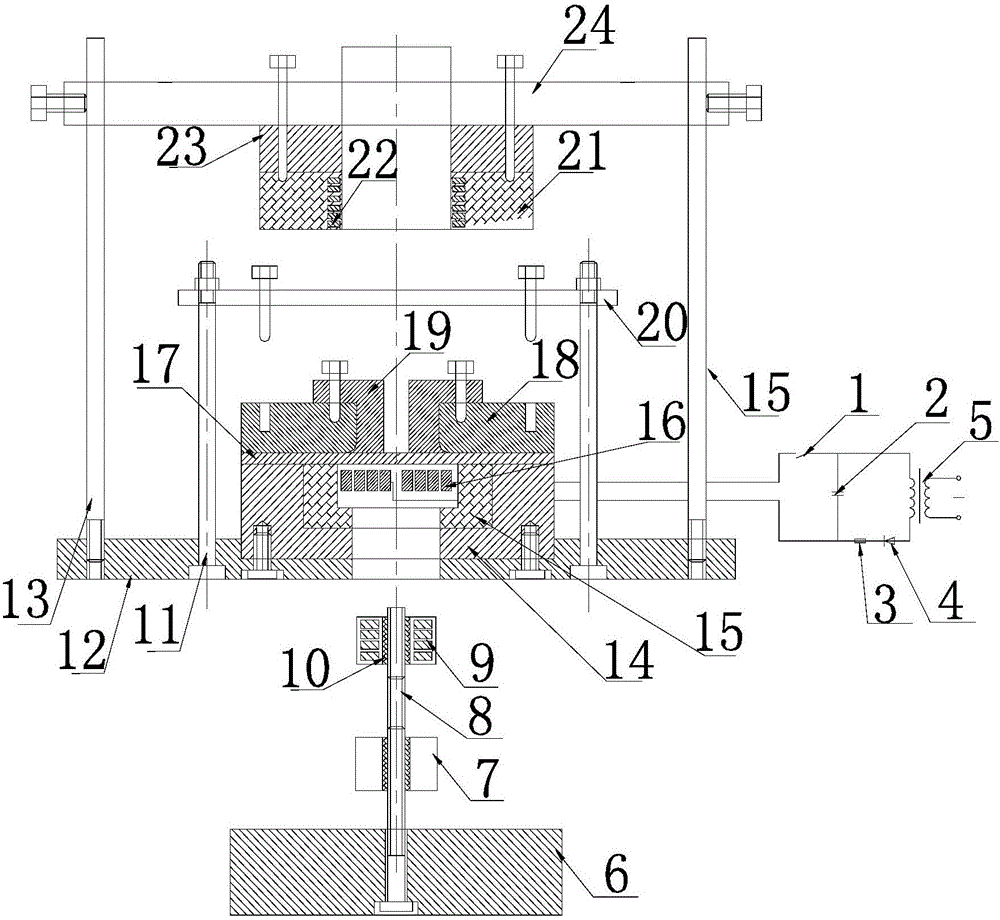

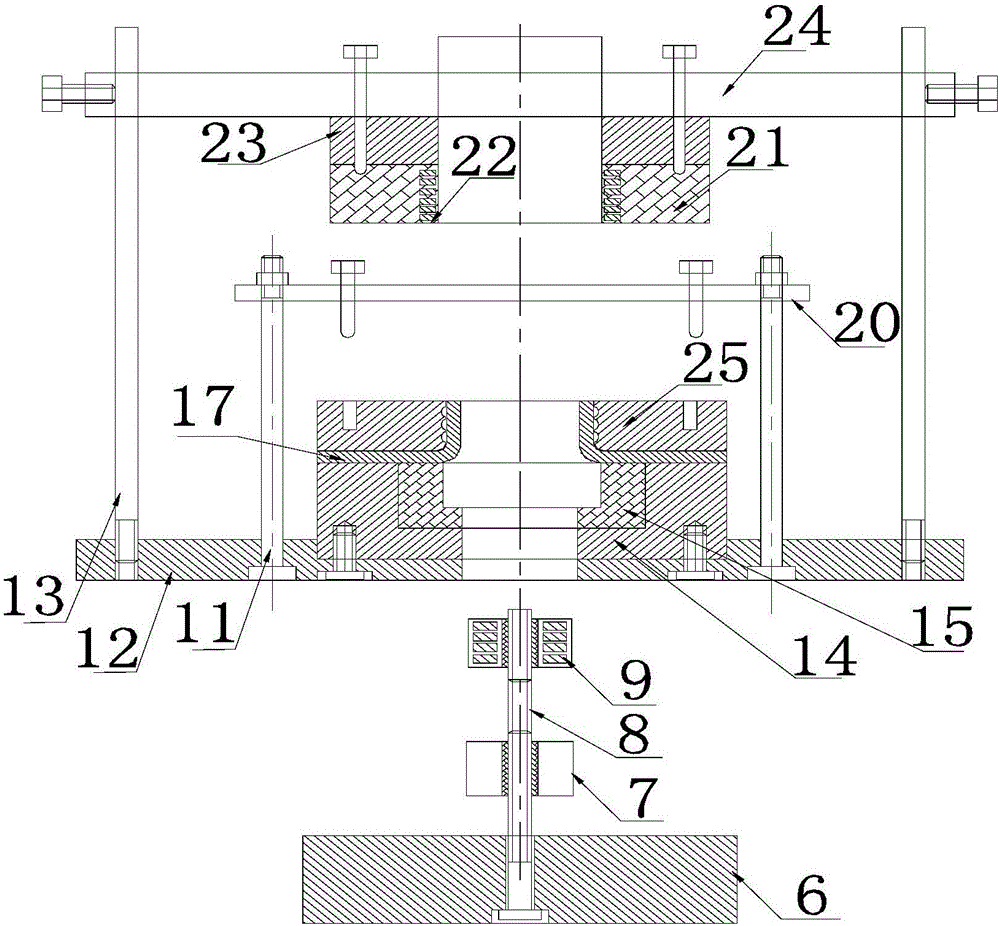

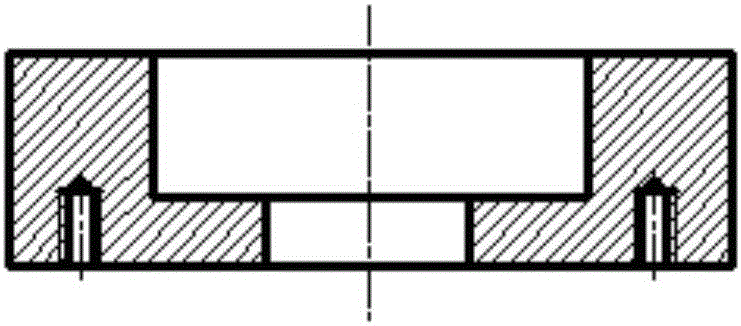

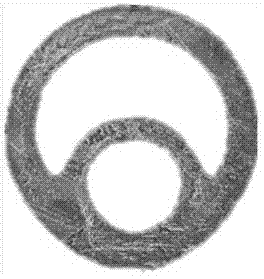

Method and apparatus for manufacturing reducing pipe

InactiveCN1528542ASleek appearanceIncrease productivityDrawing diesEngine componentsControl systemThin walled

The invention relates variable aperture tube making method and device, including tube end rotary forging and draw stretching. It first forges one end of the tube on the rotary forger into a smaller-aperture technical tube, which makes the stretching mould through to be clamped by the clamping module; using a hydraulic control system to drive clamping base and clamping module; inserting core rod with mould head in the copper tube to stretch by the stretching mould. It includes rotary forger and draw-stretching device. The clamping module, the stretching mould and the core rod makes up a stretching process line. The position of the core rod is adjustable and the stretching effect is good. The hydraulic control system is installed with travel switch to control stretching travel. It is applied to the control of thin-wall small-aperture copper tube and widely applied to cryogen pipeline in refrigerating industry.

Owner:广州冠华金属精工制造有限公司

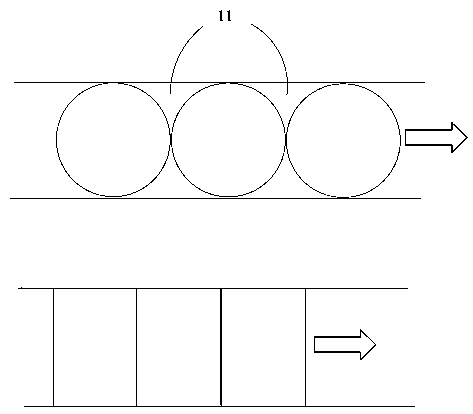

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

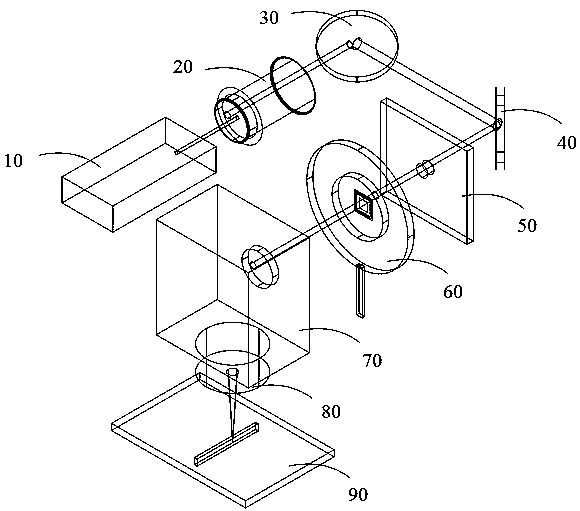

Laser shaping device

InactiveCN103645563AGood slit cutting effectImprove efficiencyOptical elementsLaser transmitterGaussian beam

The invention provides a laser shaping device. The laser shaping device comprises a laser emitter, a beam expanding lens, a spatial filter, a shaping lens and a focus lens; the spatial filter is arranged on an optical path of laser beams and arranged between the laser emitter and the focus lens; the shaping lens is arranged on the optical path of the laser beams and arranged between the spatial filter and the focus lens; the laser beams pass through the shaping lens and accordingly gauss beams emitted from the laser emitter are converted into flat-topped beams. According to the laser shaping device, the laser beams are converted into the flat-topped beams which are uniform in energy density distribution through the beam shaping lens, the energy distribution of the laser beams is the gauss distribution, and accordingly the shaped flat-topped beams can obtain good slit cutting effect and efficiency in comparison with the beams which are in gauss distribution, the slit edge can be smooth without burr, heat effect or taper and the like, and the application in the micro manufacture filed of a laser shaping cutting slit is expanded.

Owner:SUZHOU DELPHI LASER

Environment-friendly precoated sand for high-strength castings and preparation method thereof

InactiveCN109909444AImprove toughnessGood chemical resistanceFoundry mouldsFoundry coresFoundryHigh intensity

The invention relates to environment-friendly precoated sand for high-strength castings and a preparation method thereof. The precoated sand comprises the following raw materials of, in parts by weight, 100 parts of raw sand, 4-8 parts of a binder, 1-2 parts of a curing agent, 0.1-1 part of a lubricant, and 0.1-0.5 part of a refractory particle, wherein the raw sand is a mixture of silica sand andceramic foundry sand, and the binder is modified phenolic resin. According to the method, the precoated sand raw sand are designed, the phenolic resin is modified, the refractory particles are added,the modified phenolic resin and the mixture of the silica sand and the ceramic foundry sand are fully mixed, so that the effect of the binder is effectively exerted; the ferroferric oxide refractoryparticles are mixed into the mixture of the silica sand and the ceramic foundry sand, the problem that the casting size is changed due to expansion in the casting process is inhibited, the precoated sand is fully ensured to be used at a higher temperature, the precoated sand has higher strength and better liquidity, the shape of the sand core can be ensure to be complete and compact, so that the surface of an inner cavity of the casting is smooth and free of burrs.

Owner:广西兰科资源再生利用有限公司

Method for producing molybdenum electrode bar by means of precision forging

The invention discloses a method for producing a molybdenum electrode bar by means of precision forging. The method includes the steps of molybdenum powder selection, bar blank pressing, molybdenum bar blank sintering, straightening and forging. The problem that the specifications of the molybdenum bar blanks are unmatched with the forging means in the prior art is solved, and the molybdenum electrode bar produced by the method is uniform in size and quality and free of burrs and surface cracks.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Gas generator

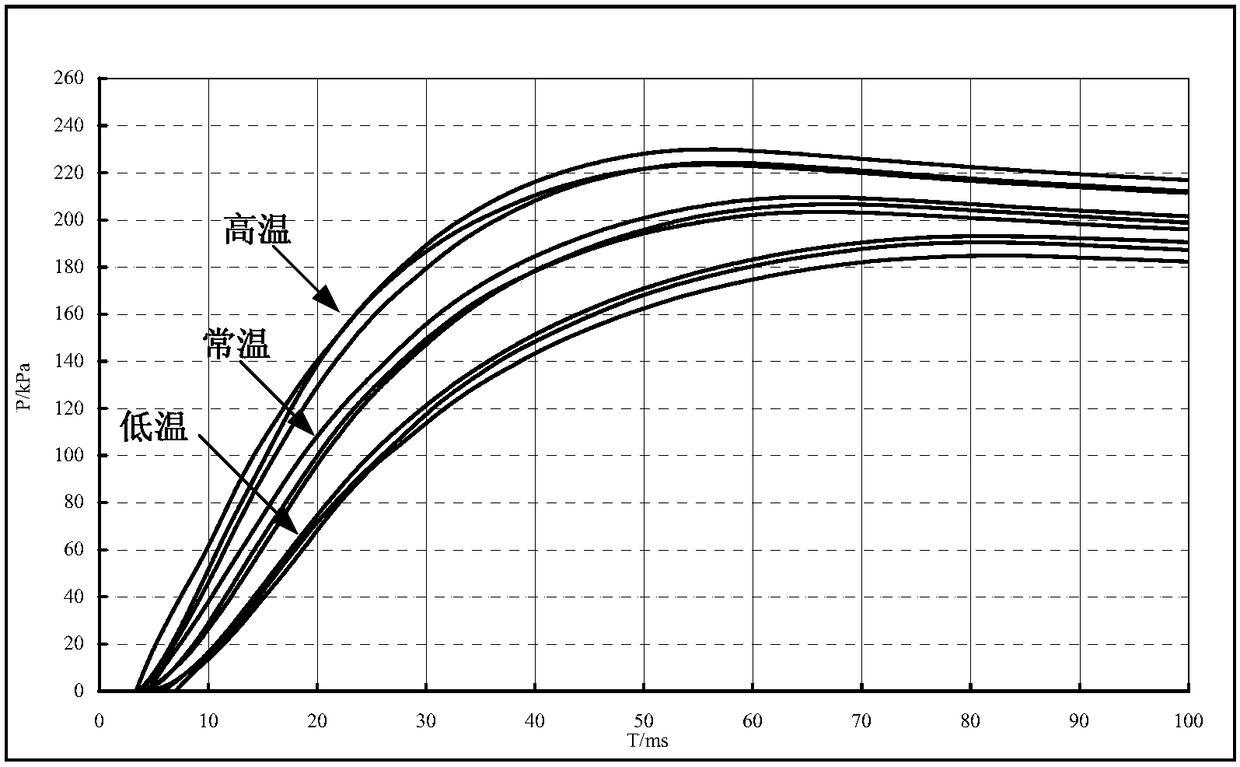

ActiveCN108218648AImprove ignition delayImprove the phenomenon of large fluctuationsPedestrian/occupant safety arrangementExplosive working-up apparatusIgnition delayBoron nitride

The invention relates to a gas generator. An ignition medicament composition adopted by the gas generator is prepared from the following components by mass percent: 40%-60% of strontium nitrate, 25%-40% of 5-amino tetrazole5-AT, 1%-20% of potassium nitrate, 1%-20% of mica powder, 0.5%-10% of aluminum oxide, 0.1%-10% of graphite, and 0.1%-10% of boron nitride. The ignition medicament component prevents the tablet from sticking a mold in a tableting process, the tableted tablet can well maintain the original gloss and form, the phenomenon that the ignition medicament is delay in ignition or large in fluctuation at low temperature of -40 DEG C, the impact range of the ignition medicament worked at the temperature of -40 to +90 DEG C is wider, and the ignition is more uniform when the propellant is ignited is more uniform, the consistency is better, and the ignition performance is obviously improved. Furthermore, the propellant composition adopted by the gas generator can well maintain theform before combustion after the tablet is combusted, thereby preventing the combusted tablet from melting and sputtering to damage the airbag, and the combustion speed is improved when the low-temperature ignition performance of the composition is obviously improved.

Owner:HUBEI HANGPENG CHEM POWER TECH

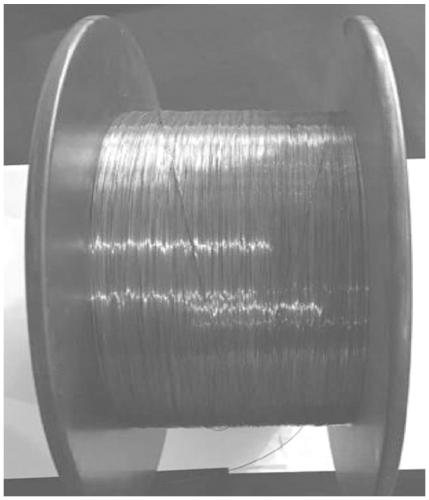

Preparation method of aluminum alloy wire for metal 3D printing

ActiveCN110273076AHigh strengthGuaranteed molding accuracyAdditive manufacturing apparatusIncreasing energy efficiencyVacuum induction furnace7075 aluminium alloy

The invention relates to a preparation method of an aluminum alloy wire for metal 3D printing. The method particularly aims at a 7075 aluminum alloy wire for metal 3D printing. The preparation method of the wire comprises the steps of alloy dosing, pressing forming, vacuum induction furnace smelting, alloy pouring, forging, rotary forging, wire drawing, continuous electrolytic washing and heat treatment straightening. The surface quality of the aluminum alloy wire obtained by the adoption of the method is improved remarkably, in the 3D printing process, the wire feeding speed is stable, and strength and mobility are good.

Owner:CHONGQING MATERIALS RES INST

Starch toothpick and its production process

Starch toothpick is cylindrical toothpick made of starch and with conic point in one end and two ring notches in the other end. It is produced by using the material including corn starch in 97.89 wt%, sweet potato 1.96 wt%, edible solid sorbic alcohol 0.11 wt%, edible alum 0.03 wt% and edible pigment 0.01 wt% as well as water in 30 wt% of the said material and through mixing, extrusion to form and freezing at -22 deg.c for 12 hr, drying in a water heating drying room at 45 deg.c for 24 hr, cutting into sections and grinding and formation in a toothpick grinding machine. it is degradable and no environmental pollution and no damage to teeth.

Owner:吴兴录

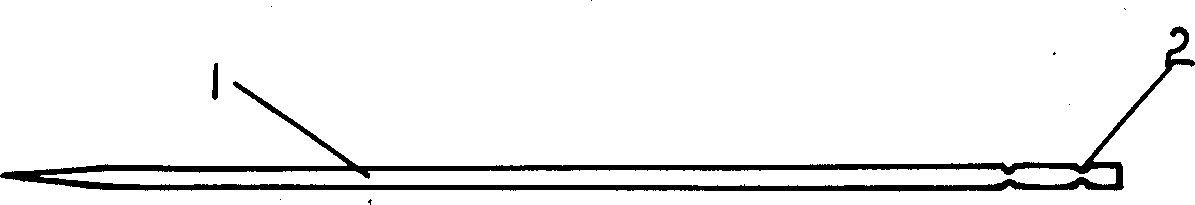

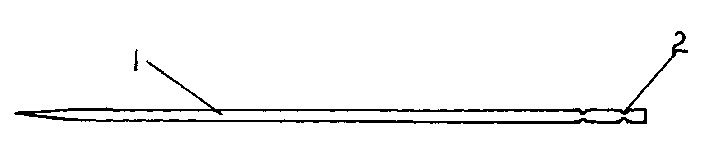

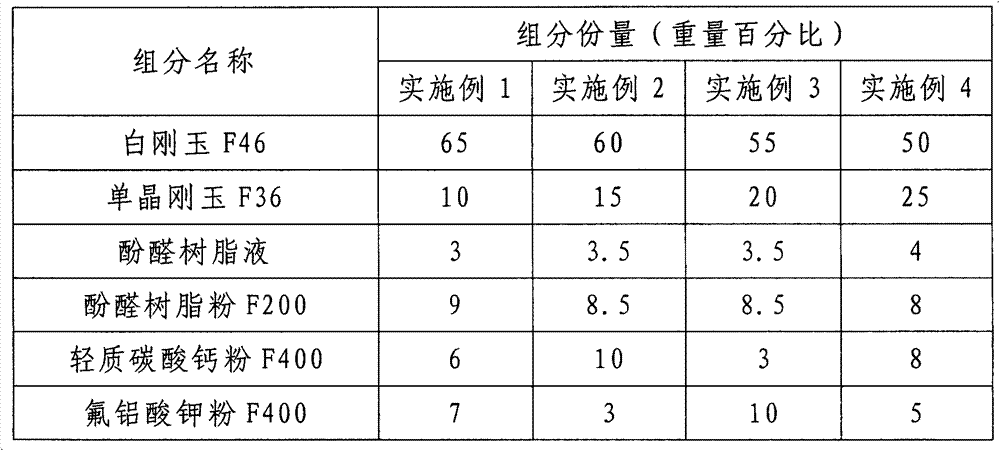

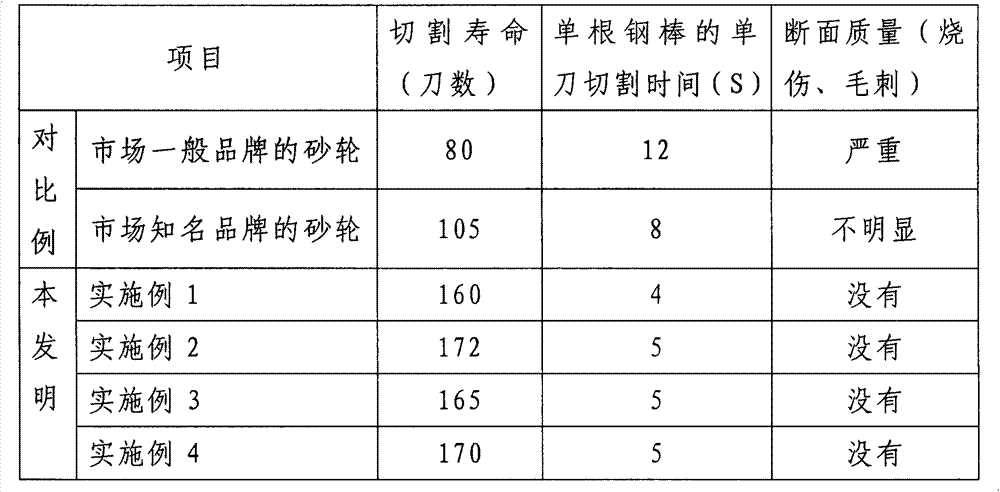

Thin resin wheel

InactiveCN103042476AImprove cutting effectReduce cutting heat generationBonded abrasive wheelsPotassiumGrinding wheel

The invention discloses a thin resin wheel. The thin resin wheel is 105mm to 125mm in diameter and 0.8mm to 1.0mm in thickness. The components of the thin resin wheel comprise white corundum, monocrystalline corundum, phenolic resin powder, resorcin-formalin, light calcium carbonate powder and potassium fluoroaluminate powder, are simple and easy to allocate, have no special requirements for forming process and can be produced by conventional process. The thin resin wheel manufactured is narrow in cuts, long in cutting service life, quick to cut and low in generated cutting heat, so that cut section has no defects such as erosion, burrs and flanges.

Owner:泰州苏蒙砂轮有限公司

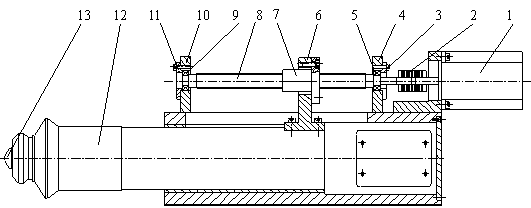

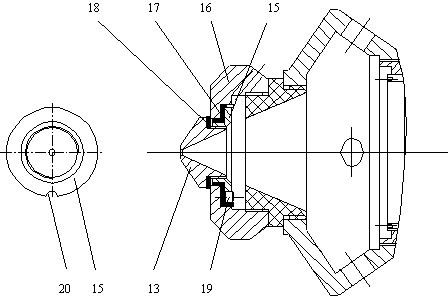

Laser cutting head follow-up device

InactiveCN103071934AGood anti-loose effectConsistent cuttingLaser beam welding apparatusLaser processingBall screw

The present invention belongs to the technical field of laser machining equipment, and particularly relates to a laser cutting head follow-up device. The laser cutting head follow-up device comprises a stepping motor, a coupling, a bearing seat I, a shaft end support I, a rolling bearing I, a nut seat, a ball screw nut, a ball screw, a rolling bearing II, a shaft end support II, a bearing seat II, a sleeve and a nozzle. The laser cutting head follow-up device has the advantages that a guide rail is reduced, the ball screw simultaneously has the effects of transmission and guiding, a half-arc groove milled on the excircle of the nut is matched with a cylindrical pin and has good anti-loose effect, capacitive sensing is adopted, the rotation of the stepping motor is controlled through electric signals, the distance between the laser nozzle and the surface of a cut work piece can be automatically adjusted, automatic focusing is always performed, work pieces are artistic, uniformly cut and formed, and have no burrs, and the cutting quality and the cutting efficiency are greatly improved.

Owner:浪潮数字(山东)科技有限公司

Magnesium-lithium alloy foil and preparation method and application thereof

ActiveCN111004951AShort preparation processImprove efficiencyTemperature control deviceMetal rolling arrangementsIngotAluminum foil

The invention belongs to the technical field of magnesium-lithium alloy materials, and particularly relates to a magnesium-lithium alloy foil and a preparation method and application thereof. A magnesium-lithium alloy cast ingot is coiled into an alloy coiled tape with the thickness of 1.5-3.5 mm through large-deformation hot extrusion cogging, then, multi-pass coiling type cooling rolling is conducted through a four-roller aluminum foil rolling mill provided with a tension roller set and a coiling machine, and thus the magnesium-lithium alloy foil is obtained, wherein the minimum thickness ofthe magnesium-lithium alloy foil can be rolled to 0.014 mm. The foil is short in preparation process, high in efficiency, small in residual stress, fine in grain, smooth, free of burrs and high in yield, and the yield can reach 80% or above. The magnesium-lithium alloy foil is used for preparing a vibrating diaphragm or a vibrating diaphragm dome base material, and has good shock absorption performance and high fidelity.

Owner:郑州轻研合金科技有限公司

Device and method for directly manufacturing packaging bag before cut-off of workpiece marginal material

ActiveCN105563890AMaintain appearance performanceMaintain heat seal strengthEnvelopes/bags making machineryFold-formingEngineering

The invention discloses a device and method for directly manufacturing a packaging bag before cut-off of a workpiece marginal material. The device comprises a rack and also comprises a feed roller group, a folding forming mechanism, a middle-seal heat-seal cutting tool, a bottom-seal heat-seal cutting tool, a cooling sealing mechanism, a marginal material cut-off mechanism, a cut-off mechanism and a pulling mechanism which are sequentially located on the rack. By means of the device for directly manufacturing the packaging bag before cut-off of the workpiece marginal material, the problem that the packaging bag can be directly manufactured only through separated cutting is solved, so that the production cost is reduced, and the production period of products is shortened. According to the method, as the packaging bag is formed firstly and then marginal material cut-off is conducted, the phenomena of defective products caused by back seal exposure and many rework hours in the bag manufacturing process are eliminated; an adjusting screw rod is additionally arranged on the marginal material cut-off mechanism so that a marginal material cutting blade can be freely adjusted in a certain range; when a packaging film is moved unstably on the bag manufacturing device, adjustment and deviation rectification of EPC, middle-seal hot-stamped strip positions and the like are not needed, and a worker only needs to adjust the position of the marginal material cutting blade through the adjusting screw rod; and accordingly, great convenience is brought to operation for the worker.

Owner:GUANGZHOU NOVEL PACKAGING

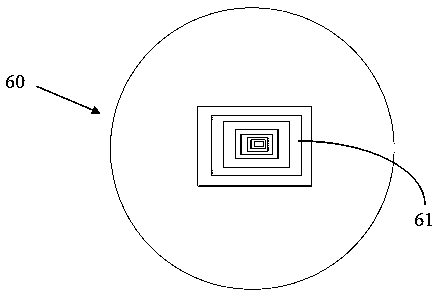

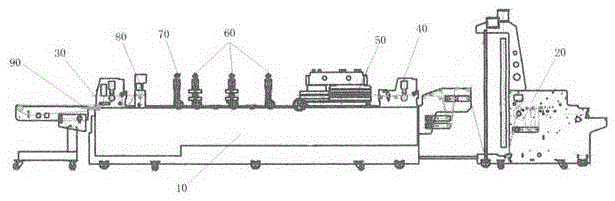

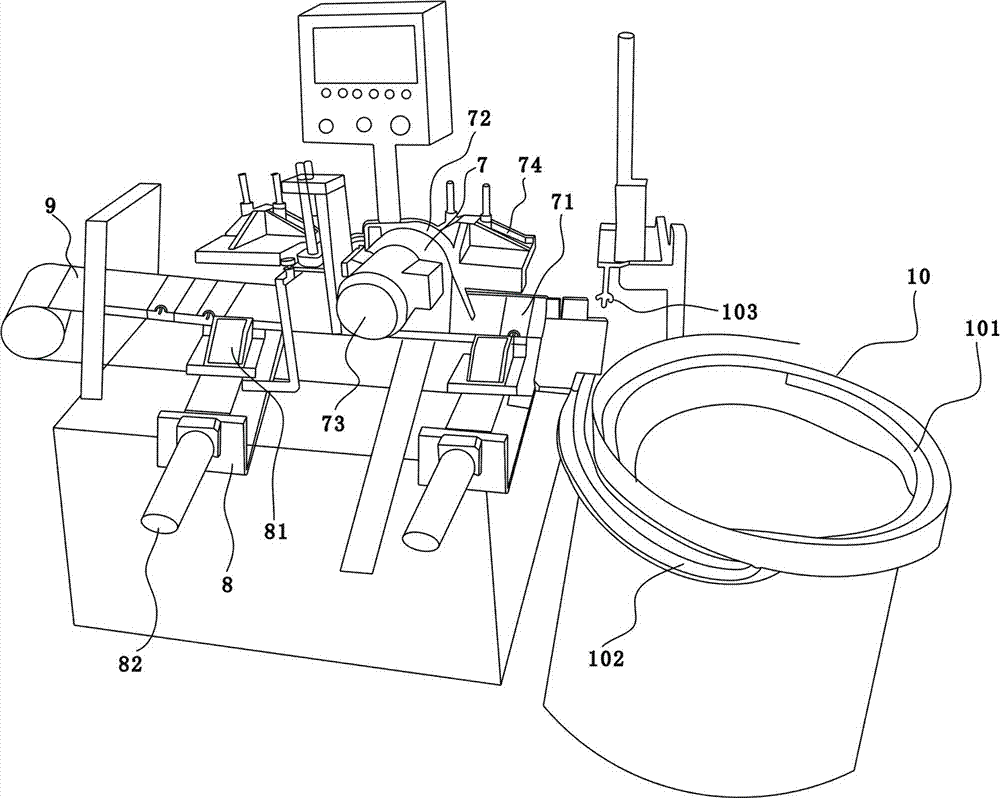

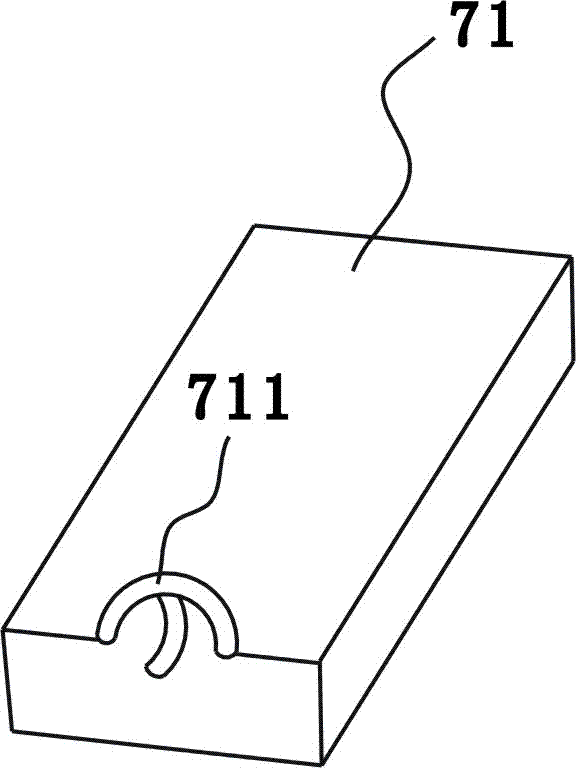

Insulation paper forming machine

The invention relates to the technical field of power capacitors and provides an insulation paper forming machine high in production efficiency and capable of effectively guaranteeing product qualityin order to overcome the defects that when workers conduct indentation, angle cutting and cutting on insulation paper at present, obtained insulation paper finished products of various specificationsare poor in size accuracy consistency and low in production efficiency. The insulation paper forming machine comprises a machine frame, a material shaft, an indentation mechanism, a conveying device,an angle cutting mechanism and a cutting-off mechanism, wherein the material shaft, the indentation mechanism, the conveying device, the angle cutting mechanism and the cutting-off mechanism are fixedly installed on the machine frame in sequence in the moving direction of insulation paper; the material shaft is used for holding insulation paper rolls; the indentation mechanism is used for pressingfolding marks on insulation paper; the conveying device is used for providing power for forward moving of insulation paper; the angle cutting mechanism is used for cutting angles of insulation paperaccording to actually needed shapes of edges of insulation paper; and the cutting-off mechanism is used for cutting off continuous insulation paper obtained after indentation and angle cutting.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

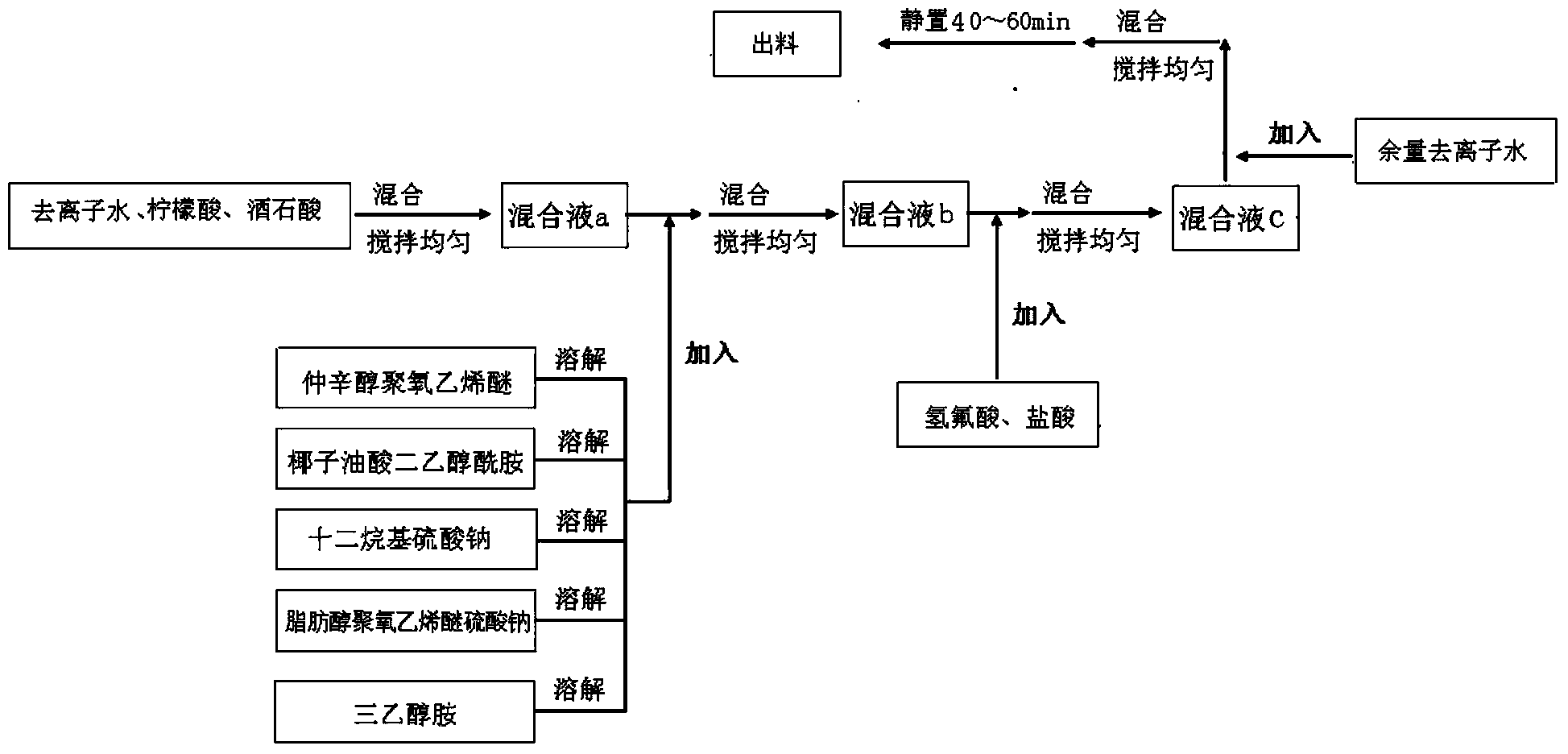

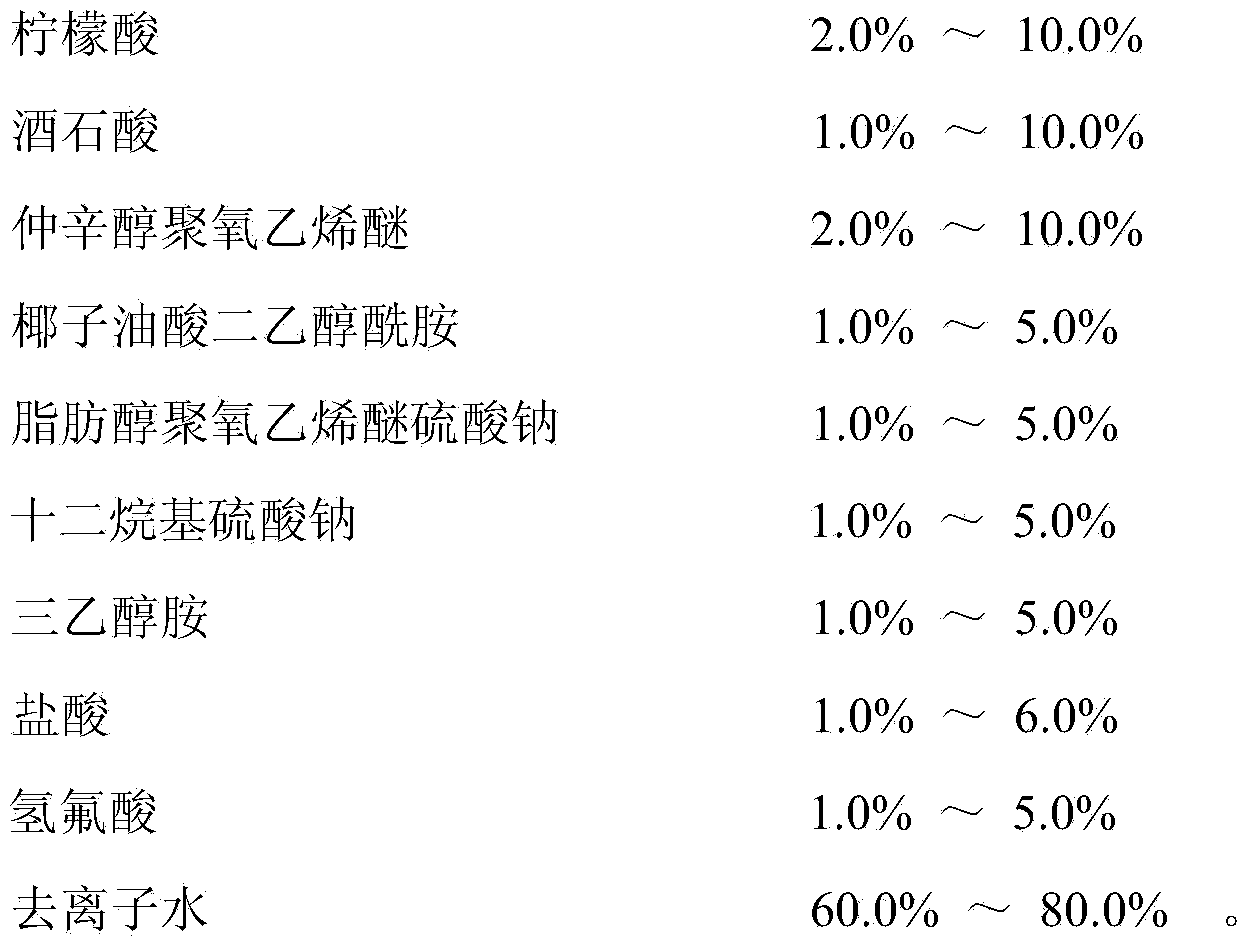

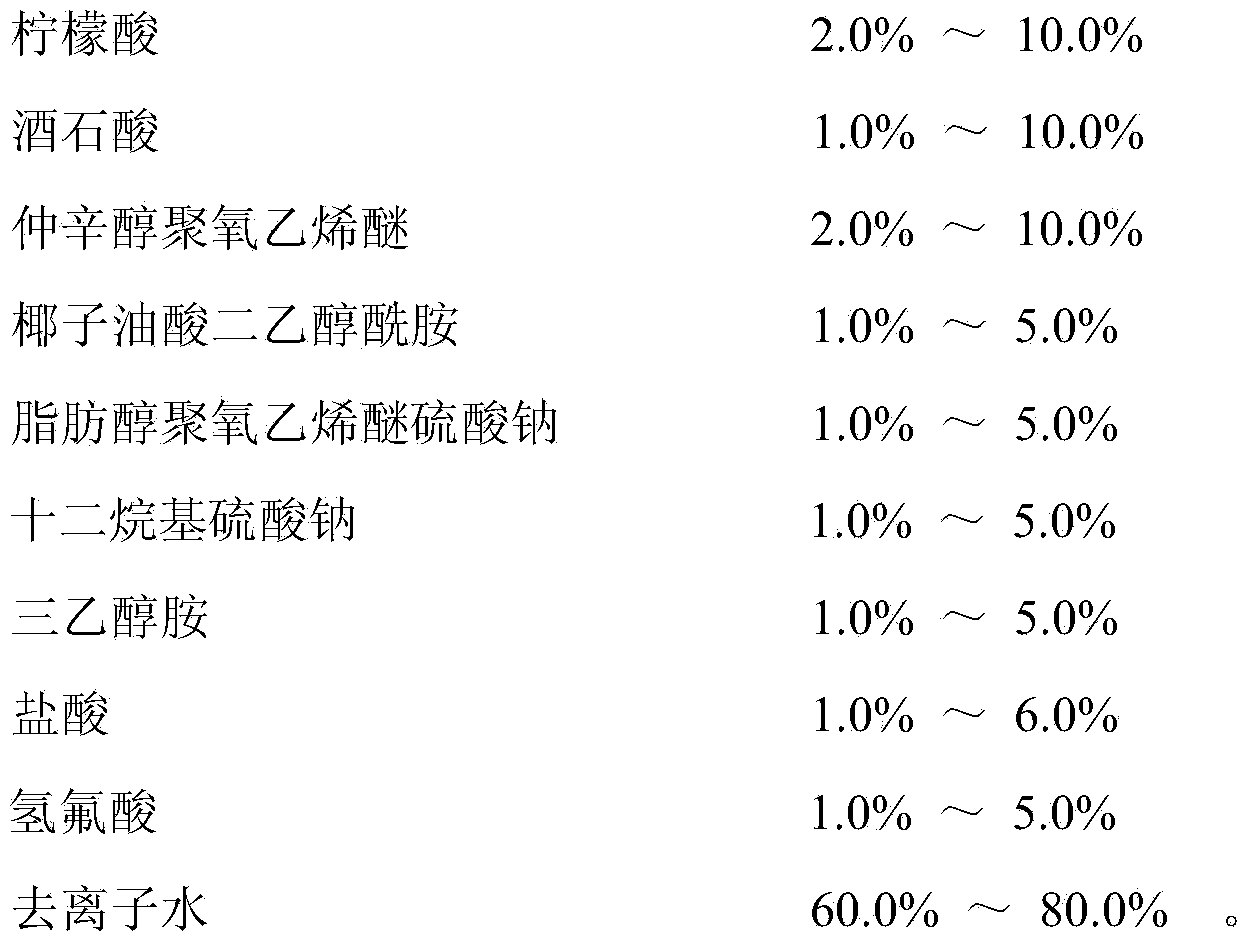

Treating agent for aluminum case of controller of electric bicycle and preparation method of treating agent

The invention discloses a treating agent for an aluminum case of a controller of an electric bicycle and a preparation method of the treating agent, and belongs to the technical field of chemical descaling. The treating agent consists of citric acid, tartaric acid, octanol polyoxyethylene ether, coconut oil diethanoamine, sodium sulfate fatty alcohol-polyoxyethylene ether, lauryl sodium sulfate, lauryl sodium sulfate, triethanolamine, hydrochloric acid, hydrofluoric acid and deionized water. The components are mixed and uniformly stirred to obtain the treating agent. The treating agent is a cleaning agent which is good in descaling effect, strong in cleaning force, convenient to use, environment-friendly, high in biodegradation rate and green and environment-friendly. In addition, the treating agent is extremely low in corrosion rate to equipment.

Owner:江苏省轻工业科学研究设计院有限公司

Aluminium belt cutting machine

InactiveCN1974149AEasy to operateEasy to debugMetal working apparatusArticle deliveryMetal foilKnife blades

The present invention discloses one kind of aluminum belt cutting machine with convenient operation, straight cutting, no bur and stable and reliable operation. The aluminum belt cutting machine includes one chassis, one driving mechanism, two collecting shafts, two cutting blade shafts with cutting blades, several guide shafts and one unwinding frame. Two adjacent disc cutting blades separately on two cutting blade shafts constitute one cutting edge. There is also one deviation corrector set between the unwinding frame and the chassis. The aluminum belt cutting machine is used in cutting aluminum belt as well as other metal or non-metal foil.

Owner:ZHANGJIAGANG LIANYI ELECTRONICS

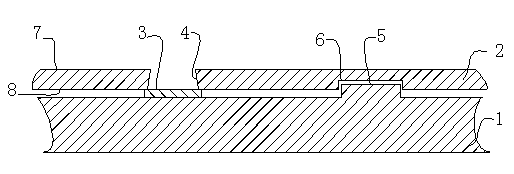

A preparation method for a vapor plating mask plate

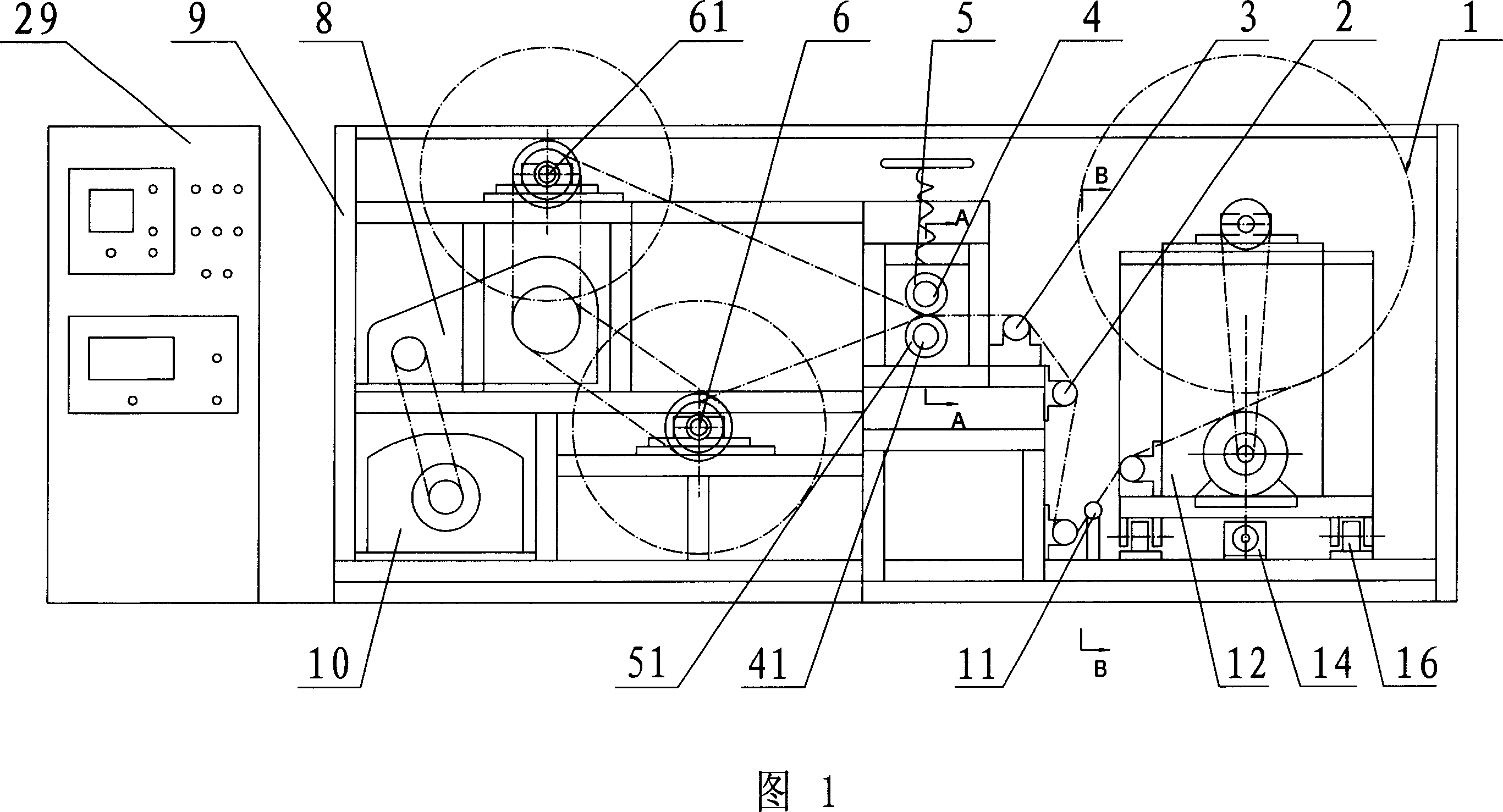

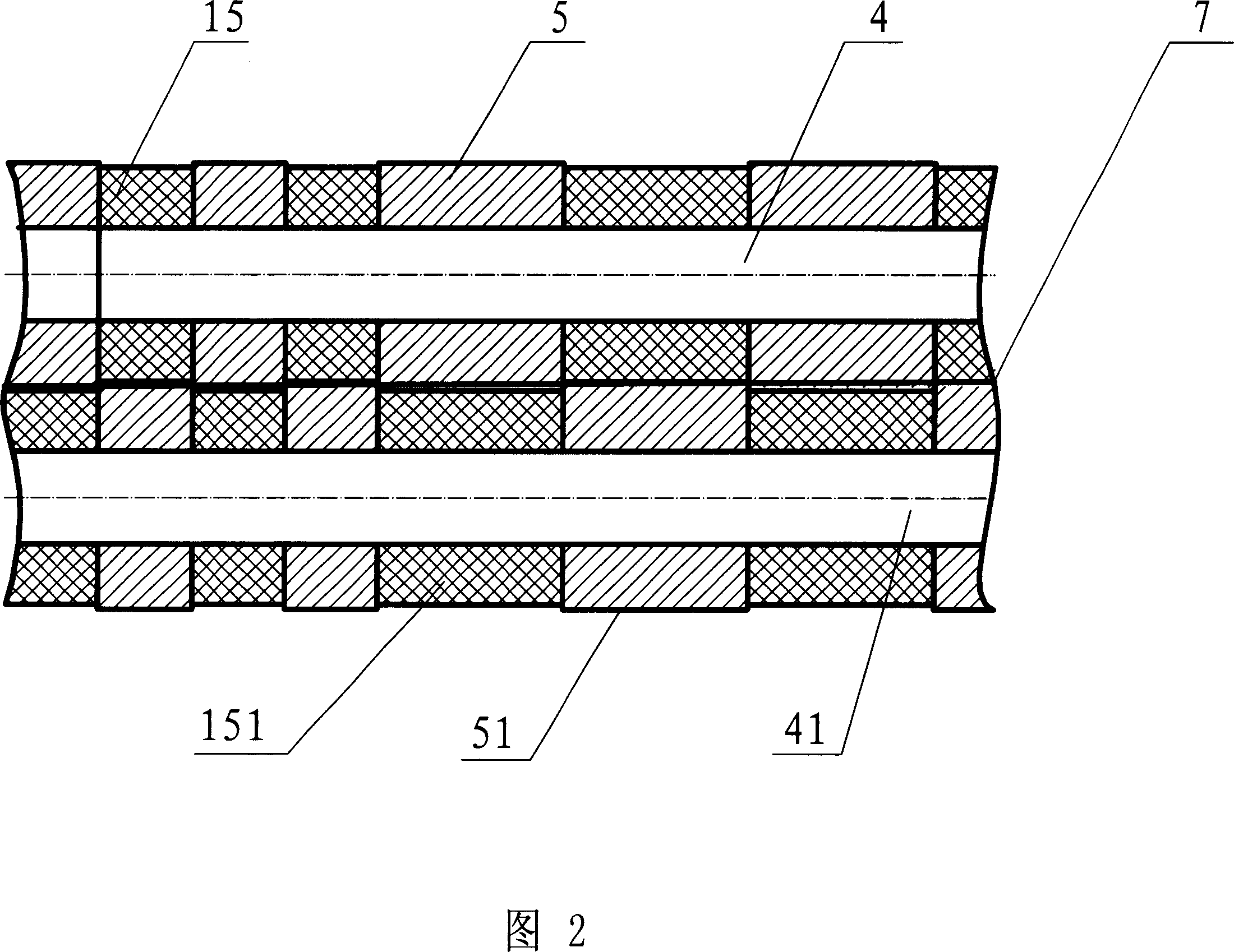

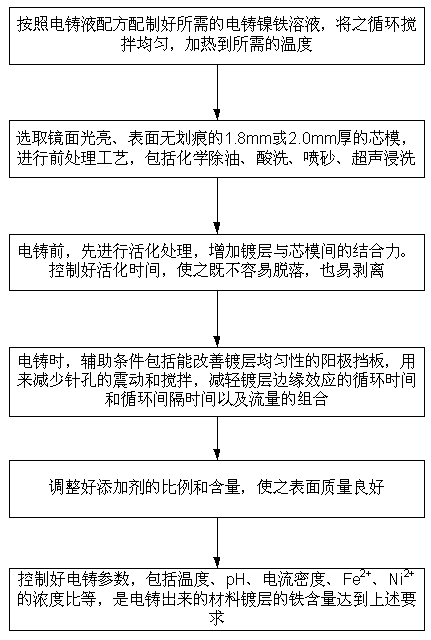

InactiveCN103205784AReduce usageGood opening qualityVacuum evaporation coatingSputtering coatingAlloy coatingMetal anode

The invention discloses a preparation method for a vapor plating mask plate. The mask plate is produced from a nickel-iron alloy material by using an electroforming process. The nickel-iron alloy material comprises two elements of nickel and iron, with an iron content being 56%-62%. In a preparation method for the nickel-iron alloy material, an electroforming method is adopted, a sulfate system is used as an electroforming solution, a metal cathode and a metal anode are placed in the electroforming solution, and the nickel-iron alloy is deposited on the cathode; wherein the electroforming solution concretely comprises: 220-260g / L nickel sulfate, 30-50g / L nickel chloride, 40-50g / L boric acid, and 21-25g / L ferrous sulfate. According to the preparation method of the invention, the electroforming process is employed to replace an etching process, openings of obtained products are smooth, have good quality, no blurs, and high accuracy; by employing the process, the use amount of nickel is reduced, the cost is low, the three-waste management burden is alleviated, and an alloy coating with the iron content in the range of 56%-62% can be obtained, which means large flat surface metal mask coatings with different magnetisms can be obtained.

Owner:KUN SHAN POWER STENCIL

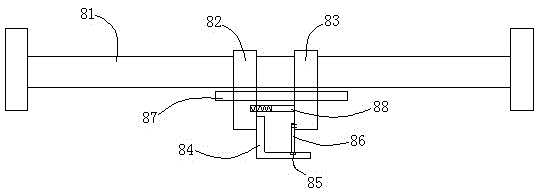

Magnetic pulse forming-based panel and pipe connection method and device

The invention discloses a magnetic pulse forming-based panel and pipe connection method and device, belongs to the field of metal material processing and forming and aims at solving the problems of low mold exchange efficiency and high large coil manufacturing cost in a multi-procedure processing process of a magnetic pulse forming technology. The method comprises the following steps of firstly punching a blank; then forming the flanged edge of a magnetic pulse; and finally installing a connection pipe fitting by using a magnetic pulse forming technology. Multi-procedure processing and forming are completed by using a coil, the forming process is fast and efficient, a formed workpiece is high in processing precision, free of a burr, small in resilience and free of a crack, a subsequent cleaning procedure and post-weld heat treatment are not needed, and the forming limit of the material and the processing flexibility of panel and pipe electromagnetic pulse connection are significantly improved. The magnetic pulse forming-based panel and pipe connection method and device are suitable for panel and pipe connection.

Owner:XIANGTAN UNIV

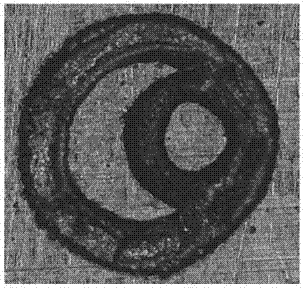

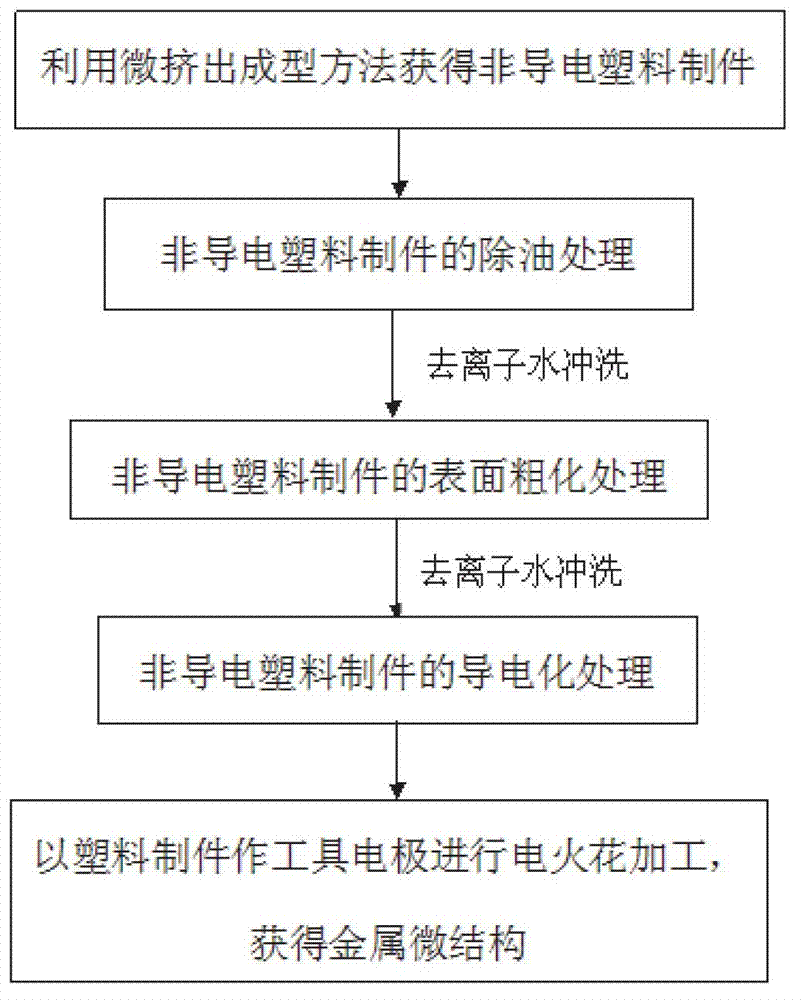

Method using non-conductive plastic as electrode micro-machining structure

InactiveCN102950343ADeep diameterSimple processElectrical-based machining electrodesEngineeringMetal microstructure

The invention discloses a method using a non-conductive plastic as an electrode micro-machining structure, and belongs to the technical field of micro-machining. The method is characterized in that a non-conductive plastic piece with needed size and shape is obtained by a plastic micro-extrusion and forming method, the non-conductive plastic piece is subjected to pretreatment, surface roughening treatment and conductive treatment, the non-conductive plastic piece is used as a tool electrode and is subjected to electric spark processing, and then a metal microstructure is manufactured. The method has the advantages and beneficial effects that the characteristics of easy deformation and easy tensioning of the plastic are utilized, the limitations of size and shape of the tool electrode processed by electric spark are broken through, the process is simple, the manufacture cost is low, and a microstructure with larger depth-radius ratio can be processed highly efficiently and precisely.

Owner:DALIAN UNIV OF TECH

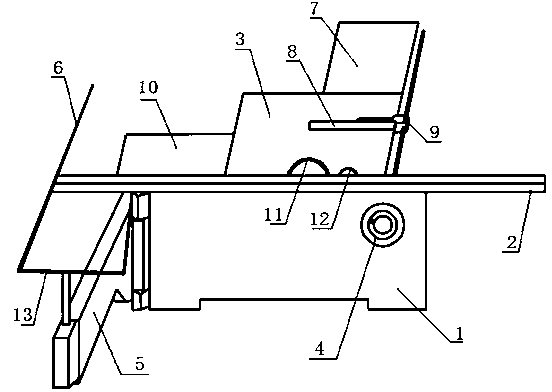

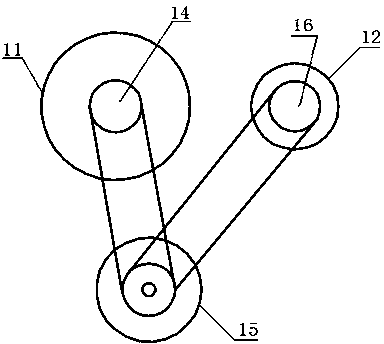

Precision bench saw for manufacturing furniture

The invention discloses a precision bench saw for manufacturing furniture. The precision bench saw comprises a frame, wherein the frame is provided with a push bench and a workbench; the workbench is provided with a main saw and a grooving saw; the main saw is connected with a motor through a revolving shaft; and the grooving saw is connected with the motor through a grooving saw revolving shaft. The precision bench saw has the characteristics of simple structure, high plate edge processing smoothness, high straightness, freeness from burrs, no need of planing, and high working efficiency.

Owner:刘秀芹

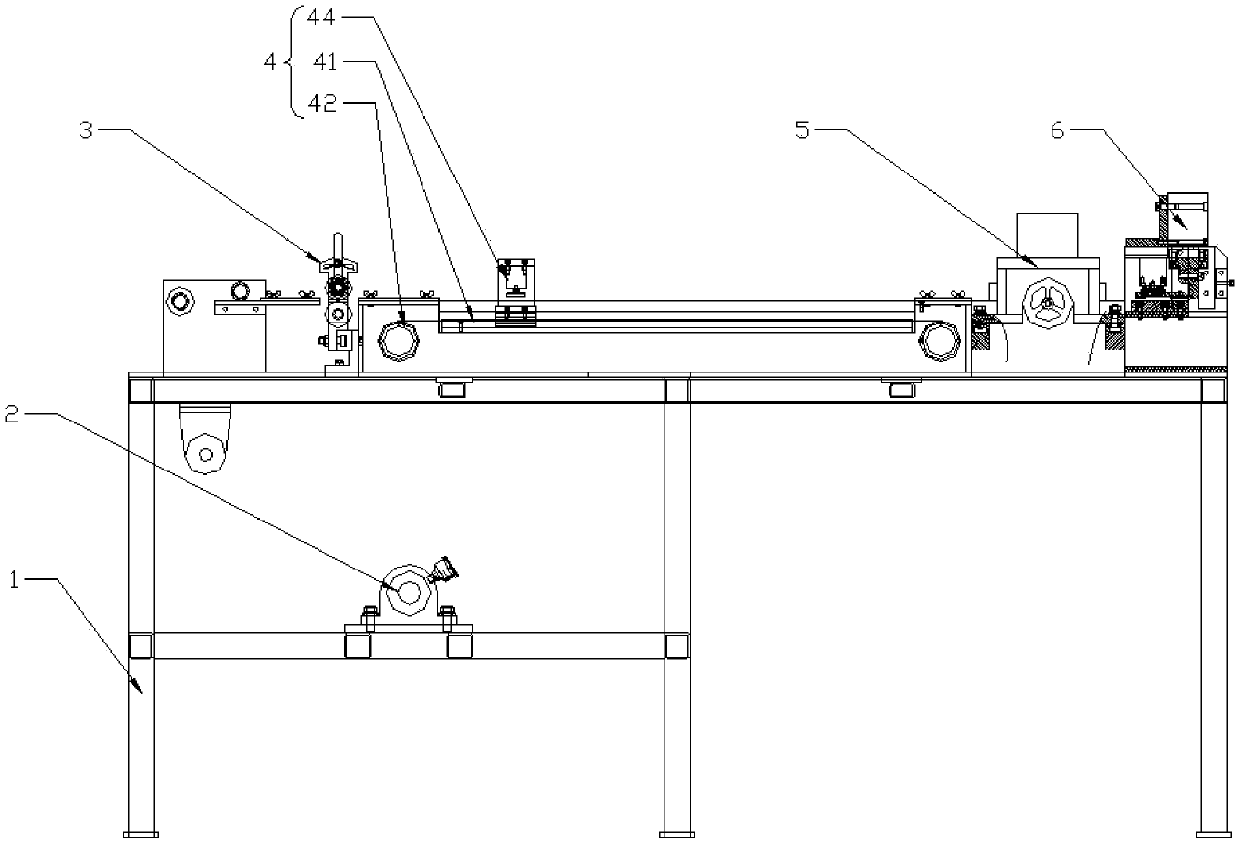

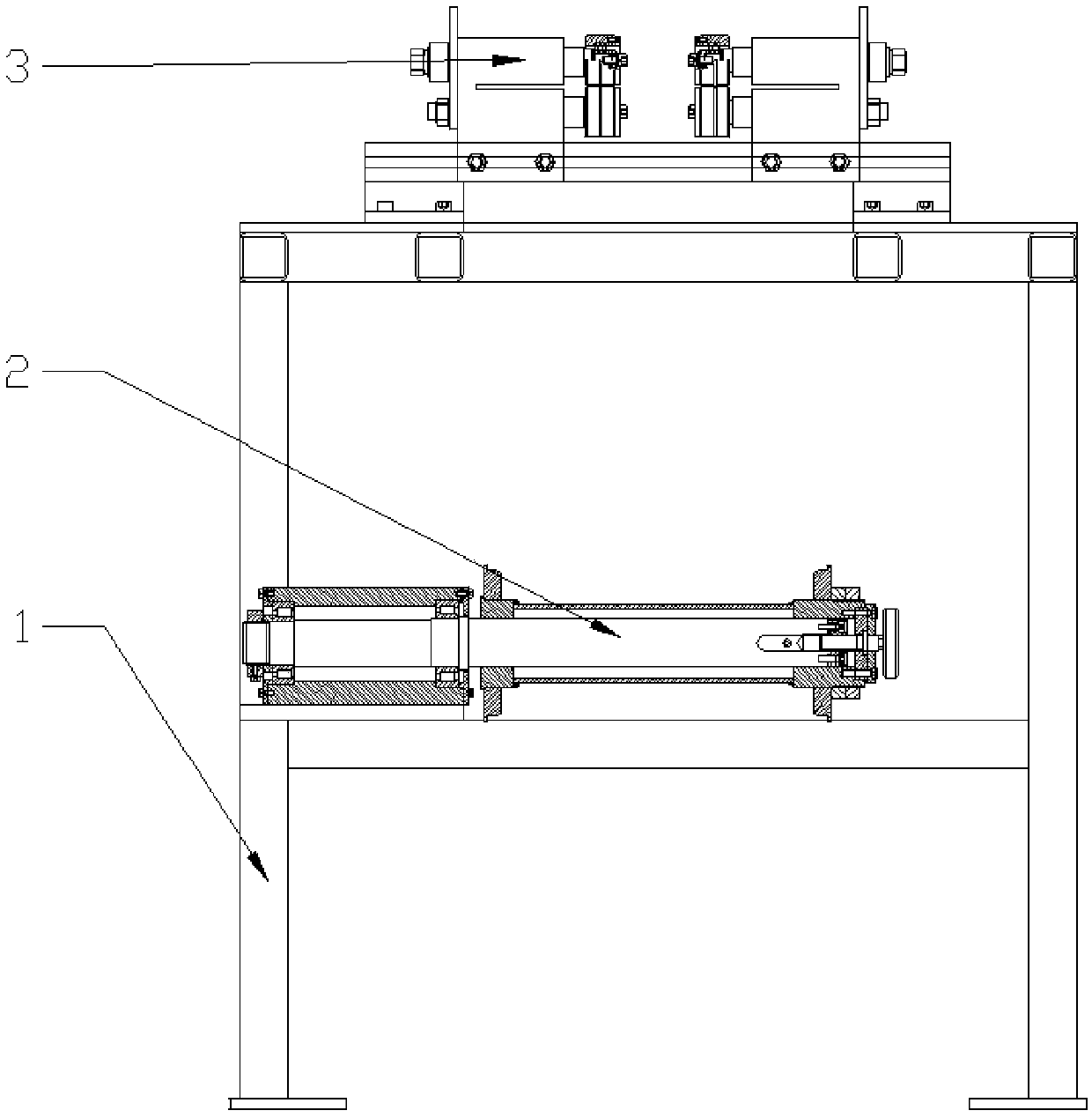

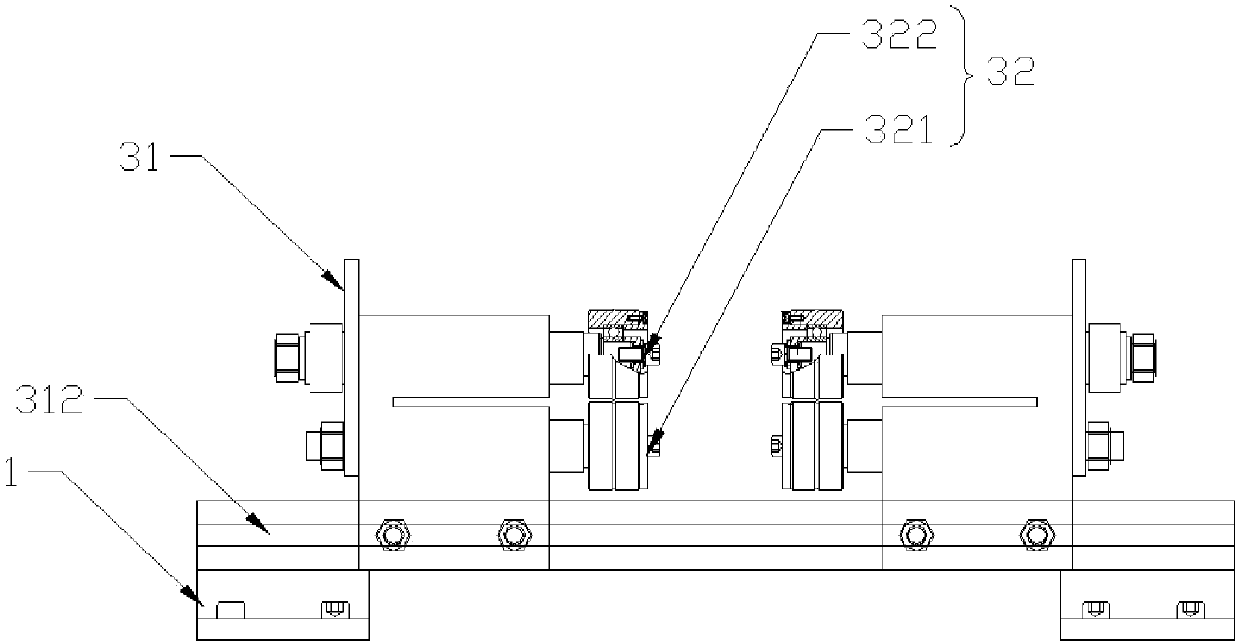

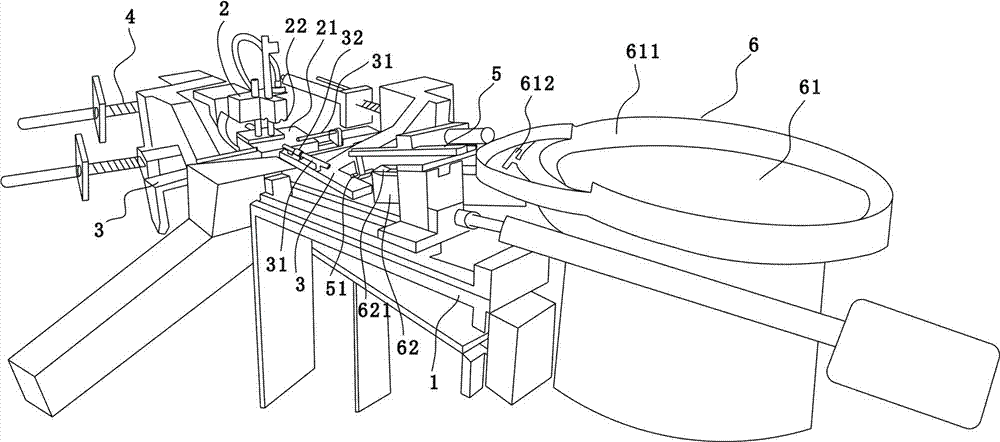

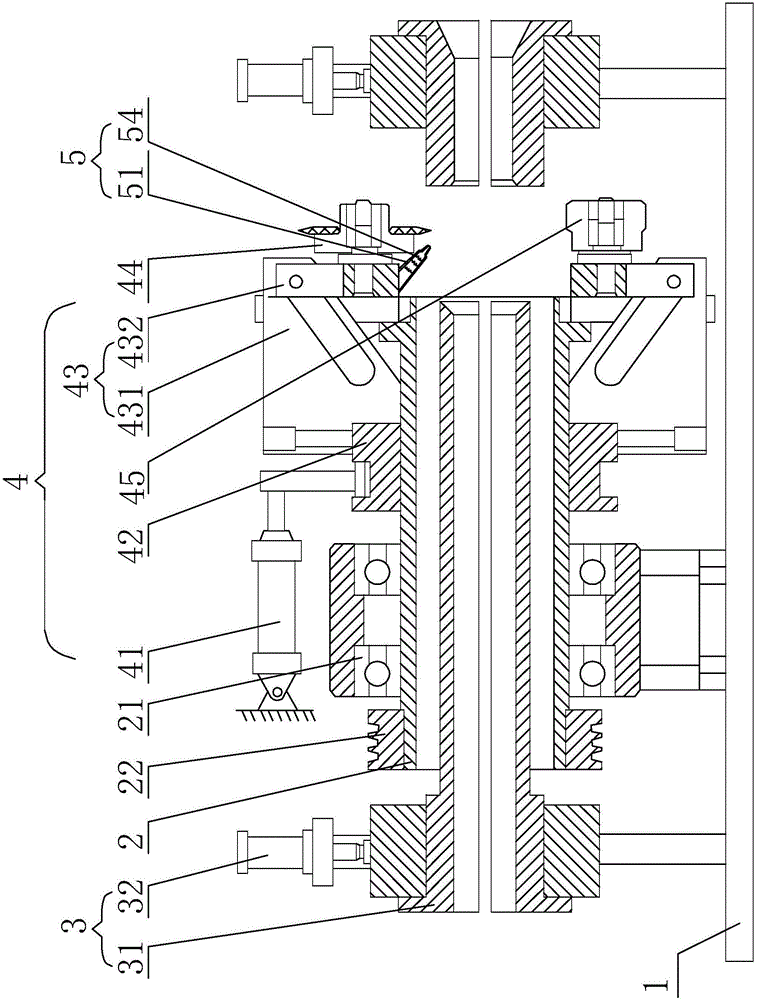

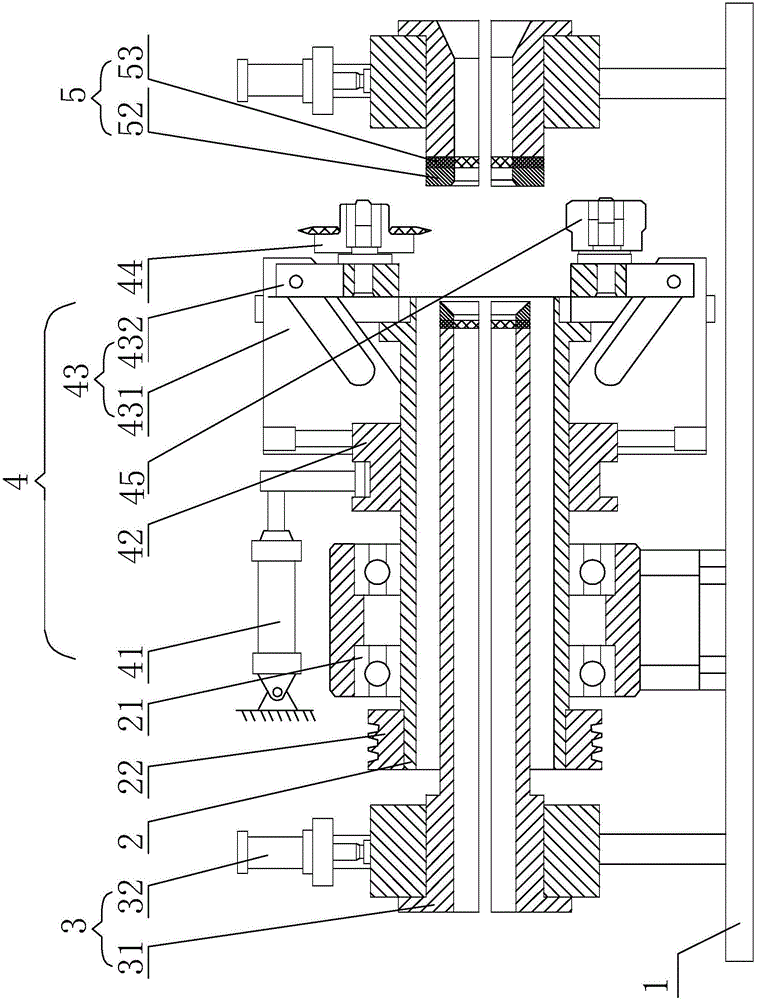

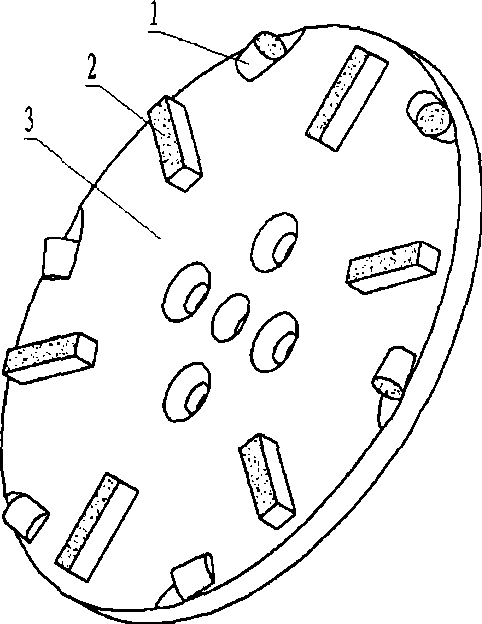

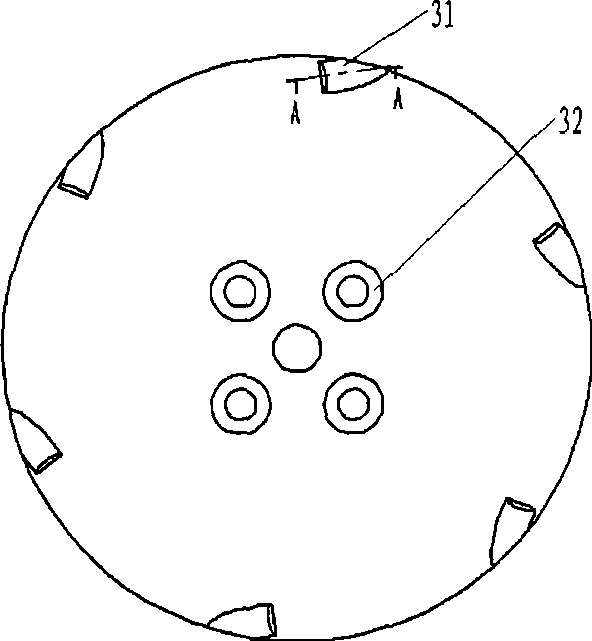

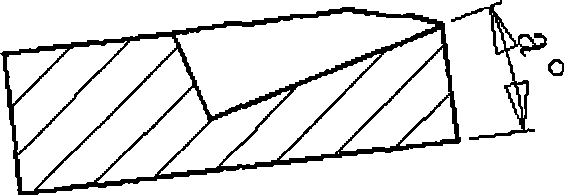

Elbow forming machine

ActiveCN104117559ARealize fully automatic pipe bendingSimple processing technologyMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention provides an elbow forming machine which comprises a bearing table, a first fixed piece, forming pieces and first driving pieces. The first fixed piece is fixed to the bearing table and comprises a first workbench and a second workbench which is arranged above the first workbench and is capable of moving vertically. A machined piece is placed on the first workbench. A fixing groove for fixing machined piece branch pipes is formed in the second workbench. The number of the forming pieces is equal to that of the machined piece branch pipes. The forming pieces are hinged to the second workbench and provided with ejector pins sliding in the length direction of the forming pieces. Guide sleeves for guiding the moving direction of the ejector pins are arranged outside the ejector pins. When the machined piece is clamped by the first workbench and the second workbench, the ejector pins are coaxially embedded in the machined piece. The first driving pieces correspond to the forming pieces one to one and drive the forming pieces to rotate.

Owner:SHAOXING WANZHAO REFRIGERATION EQUIP CO LTD

Clipping device for pipes

InactiveCN106217467ACause some damagesSo as not to damageMetal working apparatusEngineeringHuman health

The invention discloses a clipping device for pipes. The clipping device comprises a device base, a rotating cylinder and a clamping device; the rotating cylinder is provided with a cutting device used for cutting the pipes and the rotating cylinder is further provided with a heating device for heating and softening cut openings of the pipes; fragments and floating dust do not occur after the pipes are heated and softened, dedusting effects are better, environment and human health are not damaged, no extra dust collection equipment needs to be arranged, working noises are reduced, cost is reduced, and funding is reduced; notches are flatter, and cutting effects are better; the clipping device is particularly suitable for hard large-caliber PVC pipes, the cutting difficulty of the large-caliber PVC pipes can be greatly reduced, the cut end faces are flat, smooth, attractive and free of burrs, the pipes are not damaged, knives are not snapped, and cutting efficiency is improved; and the clipping device is simple in structure and practical.

Owner:司徒文芳

Superhard material cutting tool and preparation method thereof

ActiveCN101502926AGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

The invention relates to a superhard material cutting tool and a preparation method thereof, which belongs to the technical field of superhard material. The superhard material cutting tool comprises a steel matrix and a cutting tool bit. The cutting tool bit consists of a polycrystalline diamond compact (1) and a diamond tool bit (2); 1 to 12 inclined cylindrical tanks used for welding the diamond compact are distributed on the outer circle surface of the steel matrix, and the center line of the inclined cylindrical tank forms a cutting angle with the cutting face; the diamond tool bit is welded on the surface of the steel matrix. The polycrystalline diamond compact is combined by PCD and cemented carbide matrix and is sintered from the mixture of diamond and the metal powder after being compacted; the structure thereof is in the shape of cylinder, ladder or squareness; the fringe area of the clad compact is the cutting blade. The superhard material cutting tool solves the materials hard to be processed in the cutting field, and ensures the surface of the machined part free of burr, nick, spray and chatter mark; the cutting and grinding combination not only improves the cutting speed, but also ensures the cutting quality.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Transparent tape slitting machine

InactiveCN105383989AImprove cutting efficiencyUniform qualityArticle deliveryEngineeringUltimate tensile strength

The invention discloses a transparent tape slitting machine. The transparent tape slitting machine comprises a pay-off device, a cutting device and a take-up device. The pay-off device comprises a pay-off base, and a pay-off rotary shaft is fixedly disposed on the pay-off base. The cutting device comprises a cutting base; a supporting plate is disposed at the upper end of the cutting base; two supporting stand columns in the vertical direction are disposed at the upper end of the supporting plate; the upper ends of the supporting stand columns are connected with a supporting transverse beam structure; a cutting air cylinder is disposed in the middle of the supporting transverse beam; a cutting air cylinder spindle mechanism is disposed at the lower end of the cutting air cylinder; cutters are disposed on the spindle mechanism. By means of the transparent tape slitting machine, the tape slitting efficiency is improved, the labor intensity of slitting work is relieved, and the tape slitting quality is uniform.

Owner:TAICANG ZHONGHOU MECHANICS CO LTD

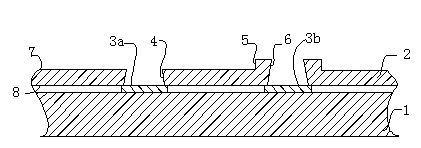

A hybrid production process for a step stencil

InactiveCN103203955AMix crafting improvementsQuality improvementPhotomechanical apparatusPlate printingEngineeringPre treatment

A hybrid production process for a step stencil. Specifically, The process flow is as follows: electroforming a first electroformed layer: core mold treatment->pre-treatment (degreasing, pickling and sandblasting)->film mounting 1->exposure 1->single sided development 1-> electroforming 1->stripping; electroforming up steps on a printing surface: pre-treatment (pickling and sandblasting)->double sided film mounting->double sided exposure->double sided development->electroforming 2->stripping; and etching down steps on a PCB surface: PCB surface etching->film stripping->follow-up treatment (degreasing and pickling). By employing the process, a metal stencil having the PCB surface with down steps and the printing surface with up steps can be produced. The pattern areas of the metal stencil have openings with good quality, smooth hole walls, and no undesirable phenomena of blurs, jags, etc.; the position precision of the opening pattern area is high; and the thickness uniformity of the stencil is good, uniformity COV being less than 10%.

Owner:KUN SHAN POWER STENCIL

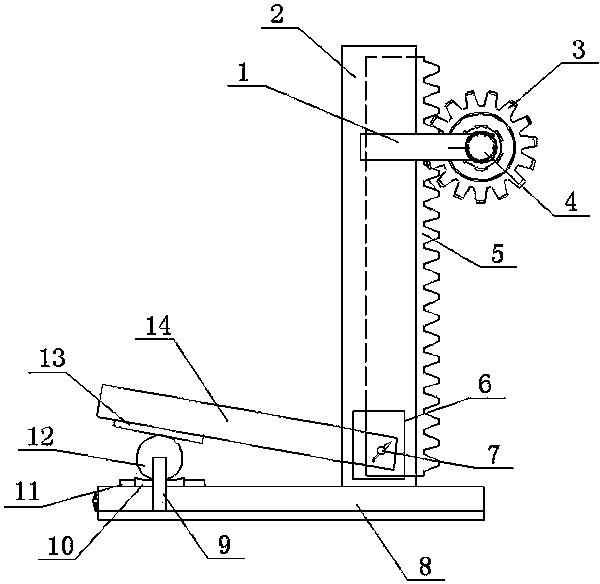

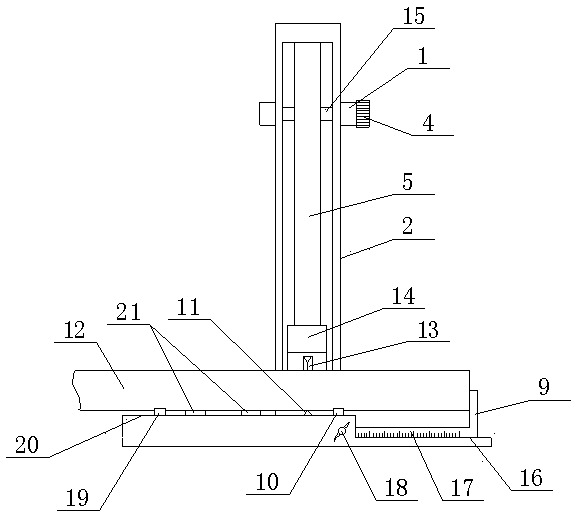

Glass pipe cutting device

ActiveCN104030559ASimple structureEasy to useGlass severing apparatusFixed frameArchitectural engineering

The invention relates to a glass pipe cutting device, which belongs to the field of experimental tools. The glass pipe cutting device comprises a base, a rack, a gear, an upper blade, a lower blade and a blade fixing rod, wherein the rack is fixed on the right side of the base through a rack fixing frame, the gear is fixed on the upper part of the rack fixing frame through a gear fixing frame and engaged with the rack, the right end of the blade fixing rod is fixedly connected with the lower end of the rack through an adjusting screw, the upper blade is fixed on the left lower side of the blade fixing rod, the lower blade is fixed on the left middle part of the base and leveled to the upper blade, a glass pipe is arranged between the upper blade and the lower blade, the front side of the lower blade is provided with a first glass pipe supporting block, the rear side of the lower blade is provided with a second glass pipe supporting block, and the left part of the base is provided with a length positioning scaleplate. The glass pipe cutting device is simple in structure, convenient to use, capable of rapidly cutting different glass pipes of different model numbers, level in incision, free from burrs and high in safety performance.

Owner:ZHEJIANG OCEAN UNIV

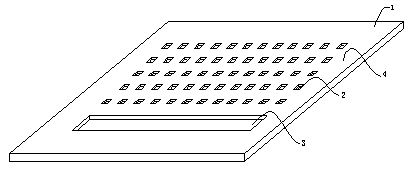

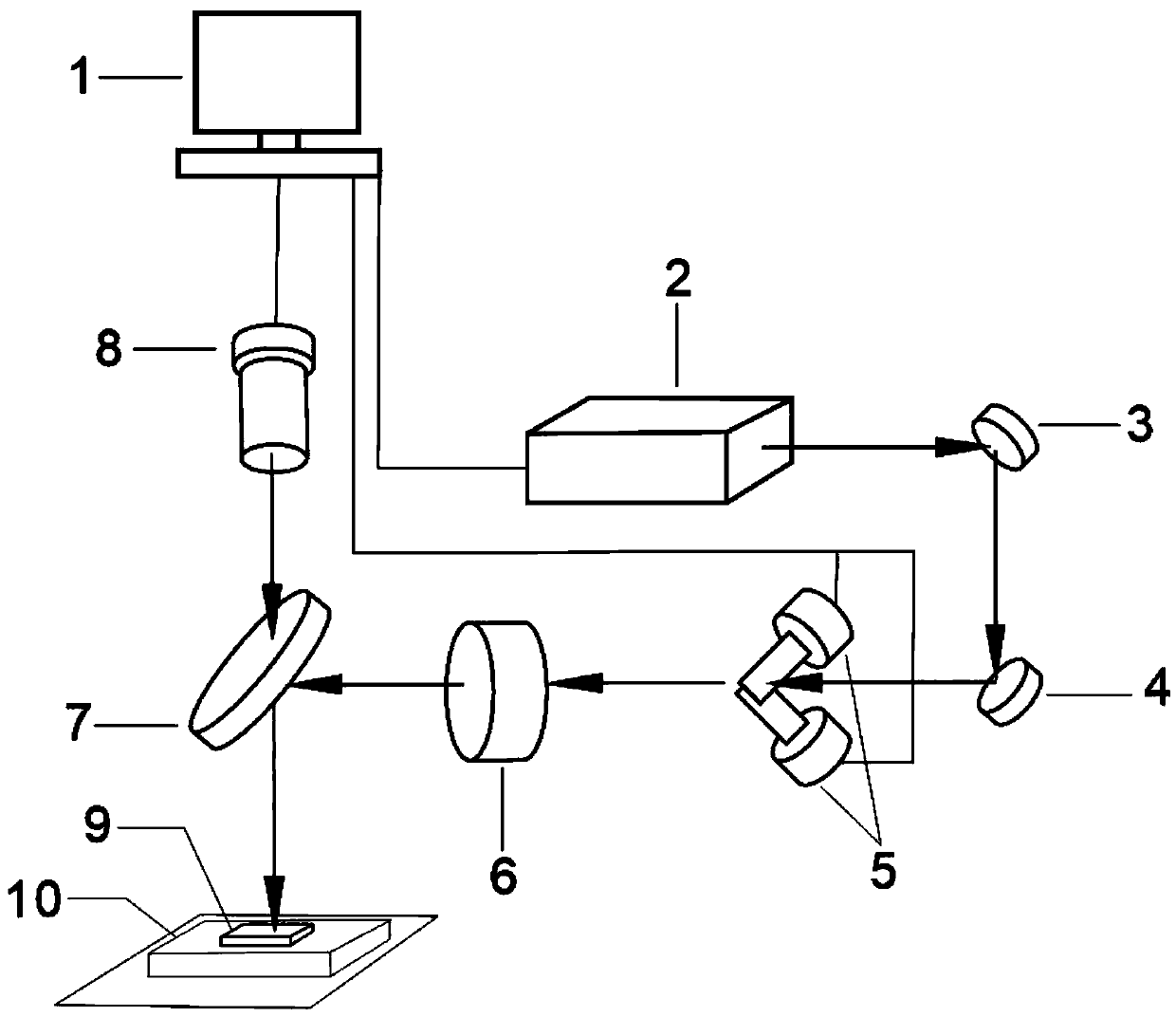

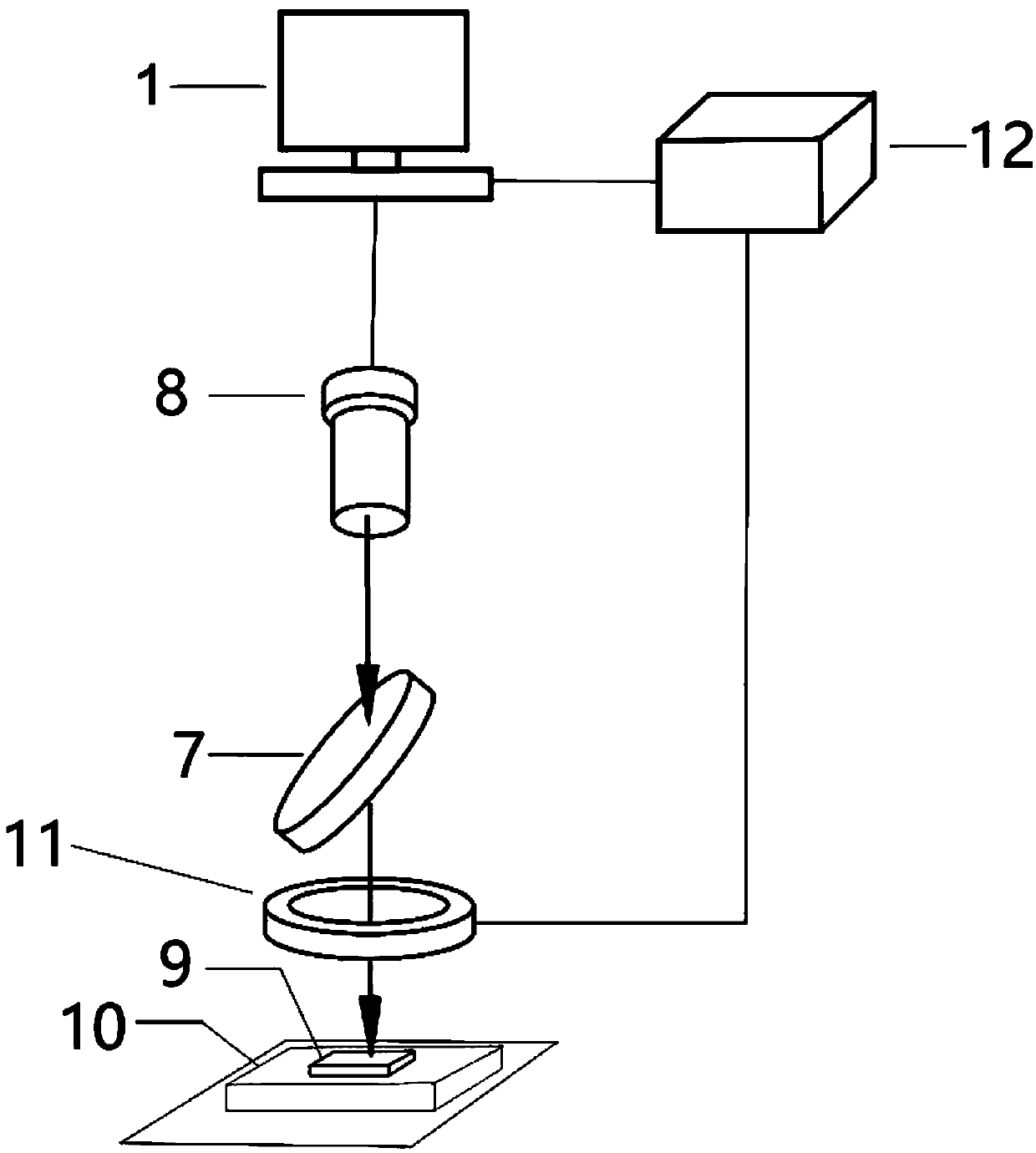

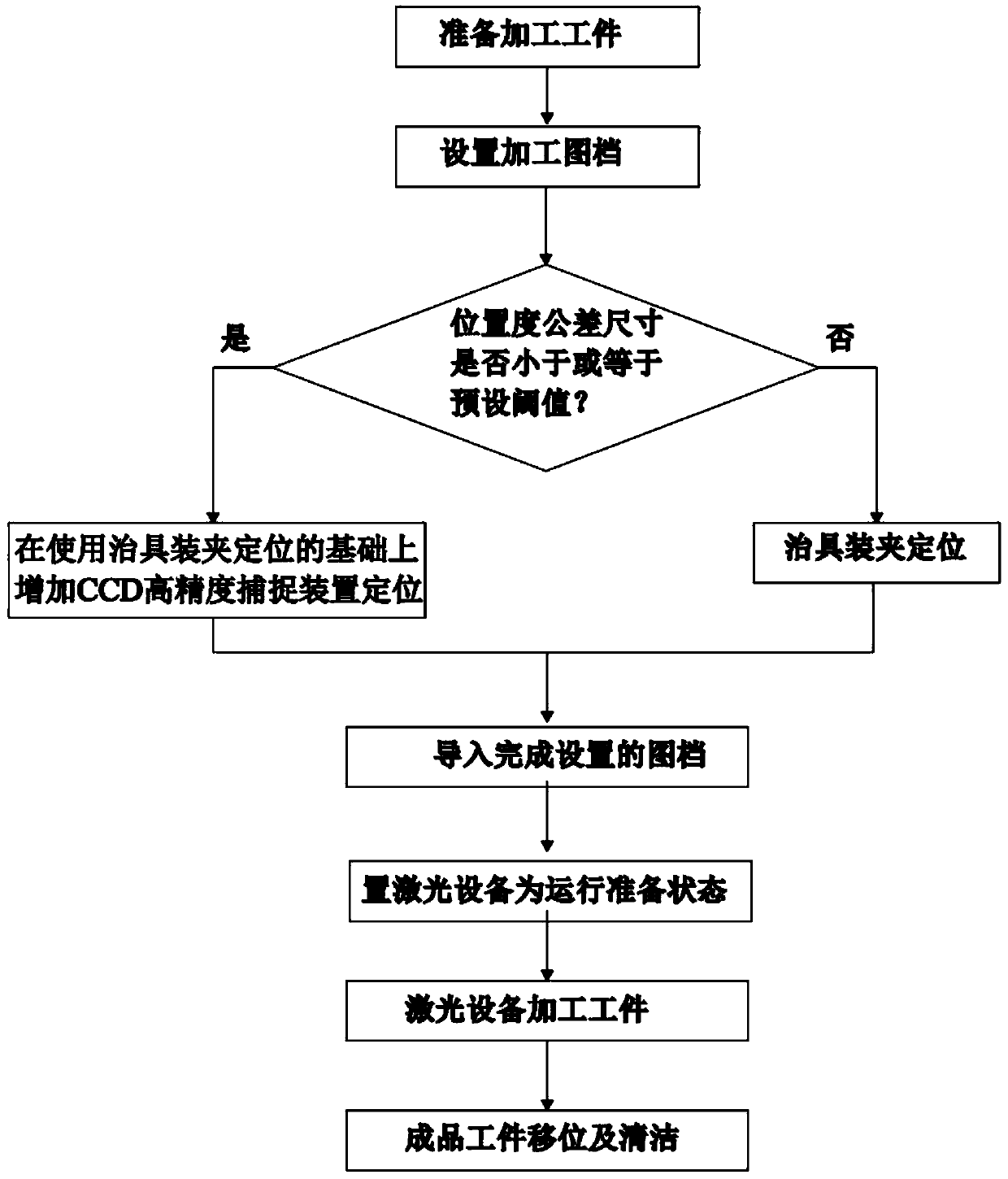

Method for processing precise light sensitive hole through ultrasonic laser processing and laser equipment

The invention relates to the technical field of laser processing and provides a method for processing a precise light sensitive hole through ultrasonic laser processing. The method comprises the following steps of preparing a workpiece to be processed and spraying printing ink on the surface of the workpiece to be processed; setting a drawing file of the light sensitive hole to be processed according to the processing requirements; importing the set drawing file of the light sensitive hole into laser equipment; controlling a laser beam emitted from the laser equipment to be projected onto thesurface of the workpiece to be processed through an optical system, and carrying out gasification treatment on an ink layer on the surface of the workpiece to be processed according to the preset drawing file to form the precise light sensitive hole; and taking out the processed workpiece with the formed light sensitive hole from the laser equipment. The method is simple in process. The aperture of the processed light sensitive hole is small and can reach up to 0.02 mm or less. The light sensitive hole is good in consistency, smooth in edge, free of burrs, high in roundness, free of overflow plating and good in light transmitting effect.

Owner:HANS LASER TECH IND GRP CO LTD

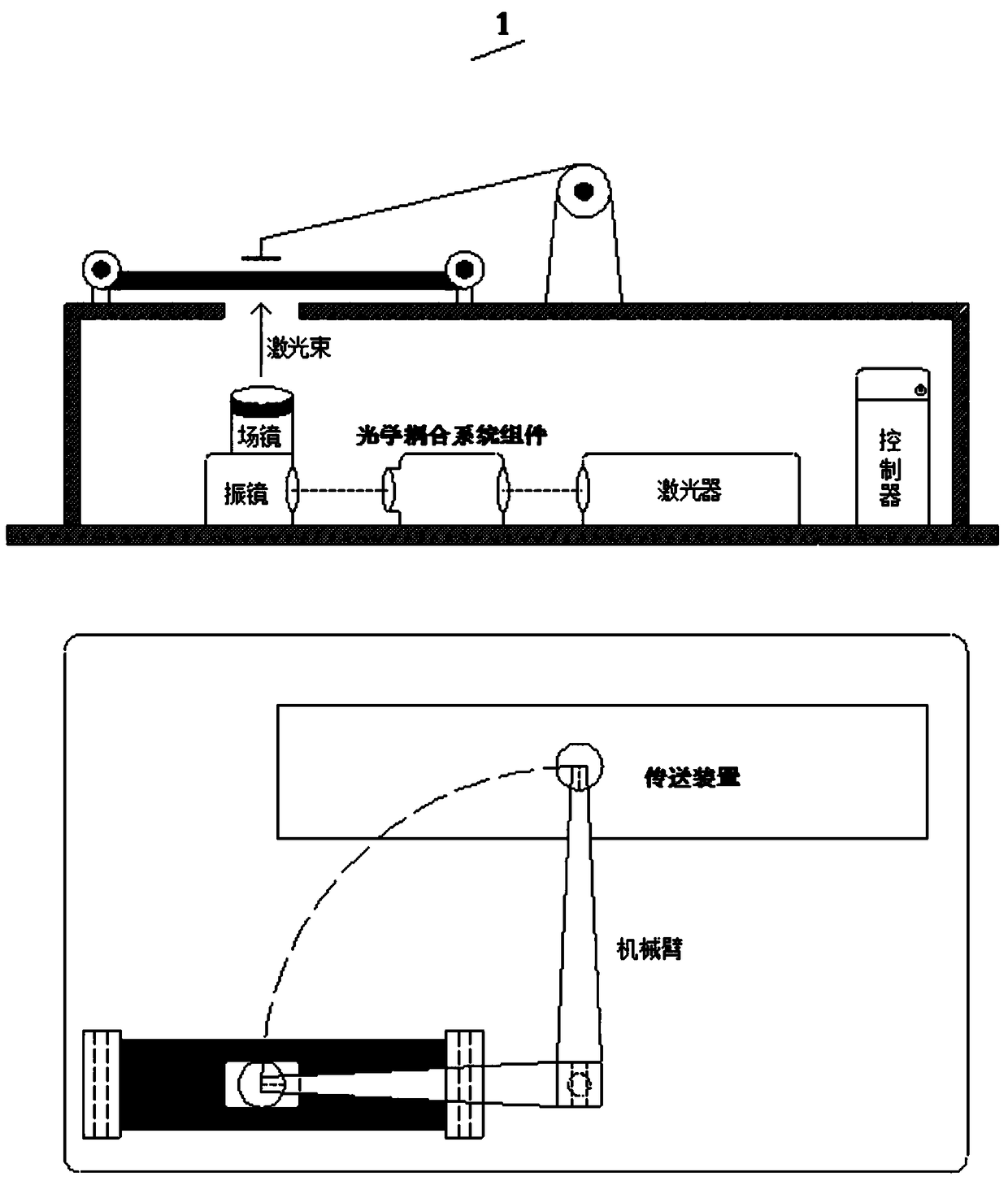

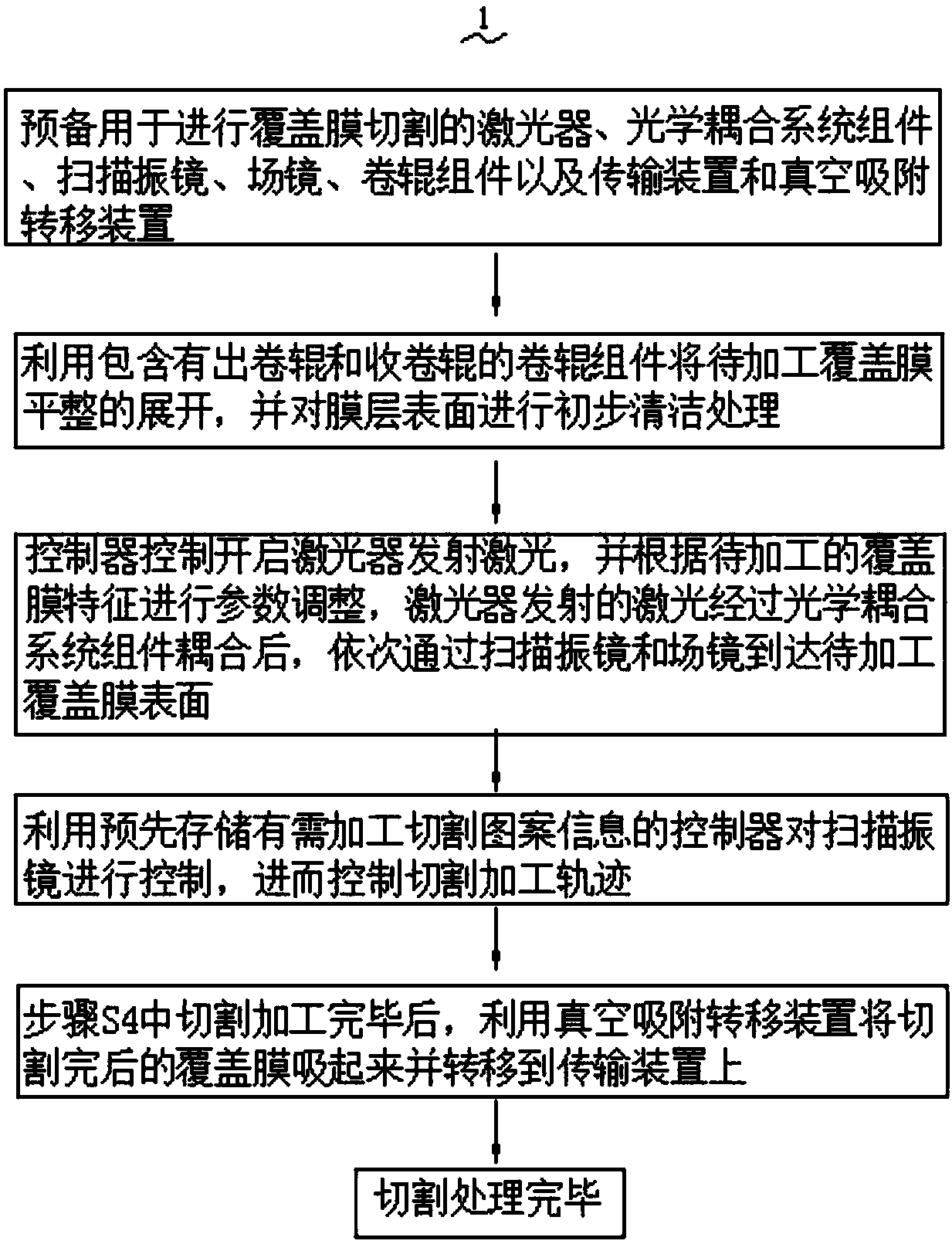

Roll-to-roll covering film laser cutting system and cutting method

InactiveCN108067752AImprove work efficiencyContour edges are neat and smoothLaser beam welding apparatusIdeal machineGalvanometer

The invention provides a roll-to-roll covering film laser cutting system and cutting method. The system comprises a controller, a laser device used for emitting a laser beam, an optical coupling system assembly arranged on the front portion of the laser device and used for coupling the laser beam, a scanning galvanometer used for controlling the moving track of the laser beam, a field lens arranged on the output end of the scanning galvanometer, a rolling roller assembly used for unfolding and folding a covering film, a transmission device used for conveying the machined film material and a vacuum absorption transfer device. The optical coupling system assembly is located between the laser device and the scanning galvanometer; the vacuum absorption transfer device comprises a mechanical arm used for transferring the covering film to the transmission device from the rolling roller assembly. According to design, production cost is greatly reduced, product quality is improved, due to thefact that the laser focusing spot is only tens of microns, high-density circuit and micro hole machining can be achieved, due to the advantages, circuit design development space is achieved, and the system is an ideal machining tool of PI covering film windowing.

Owner:深圳光韵达激光应用技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com