Patents

Literature

420 results about "Ignition delay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

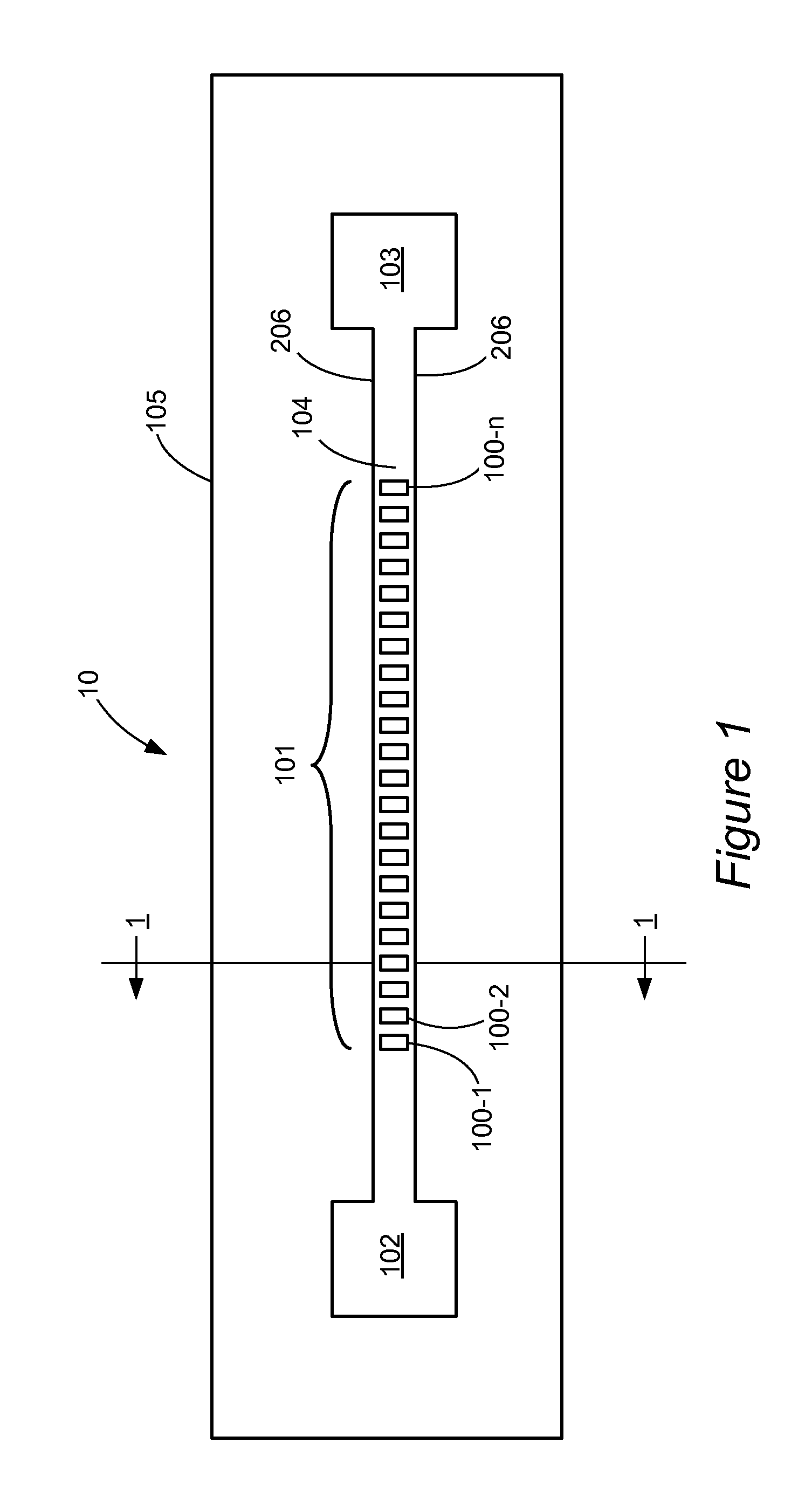

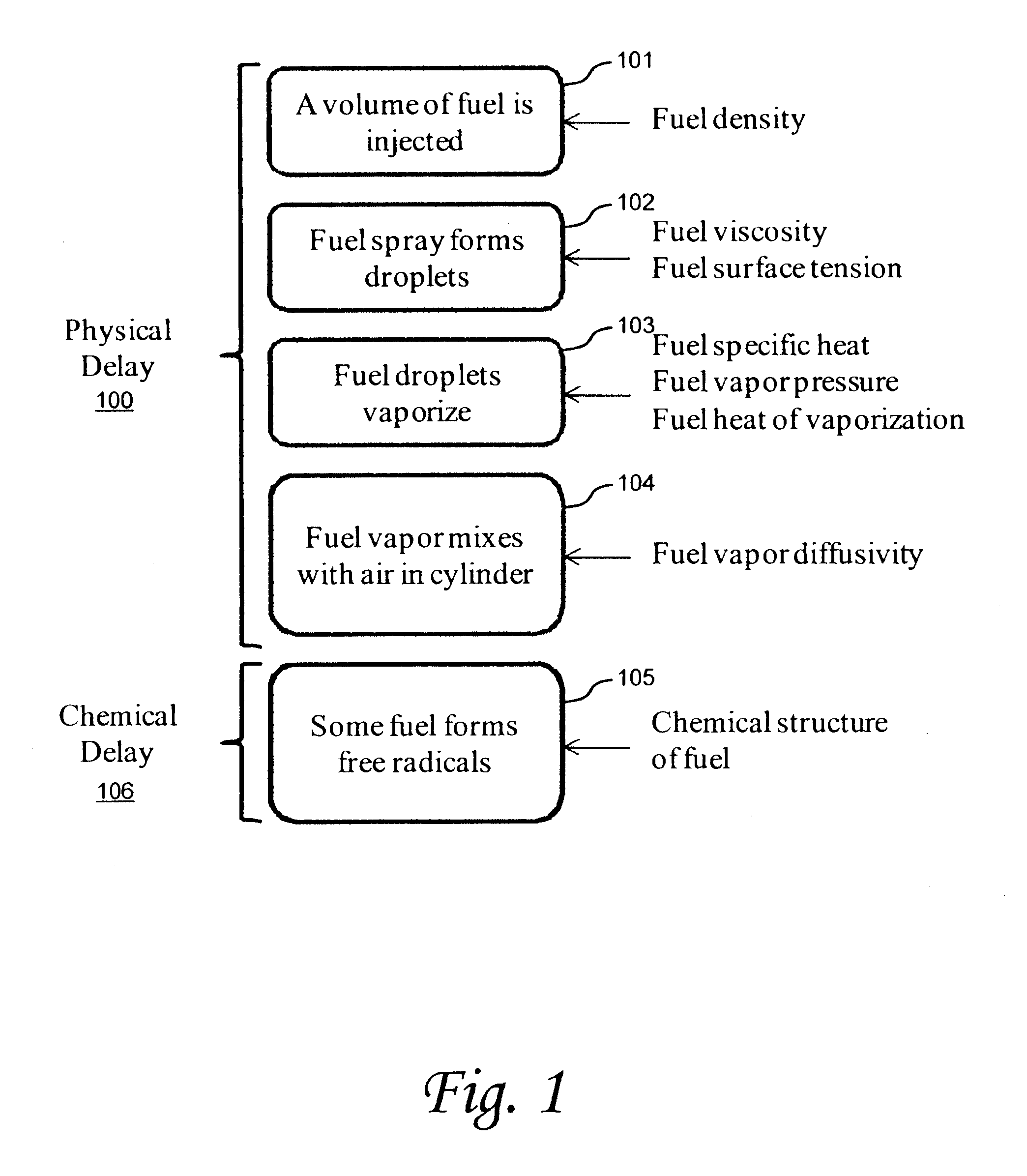

An ignition delay in a CI engine is the time taken by the fuel to auto-ignite after being injected into the engine cylinder. It can be called as the preparatory phase during which the fuel prepares to undergo auto-ignition. Ignition delay can be divided into two parts. Both these occur simultaneously.

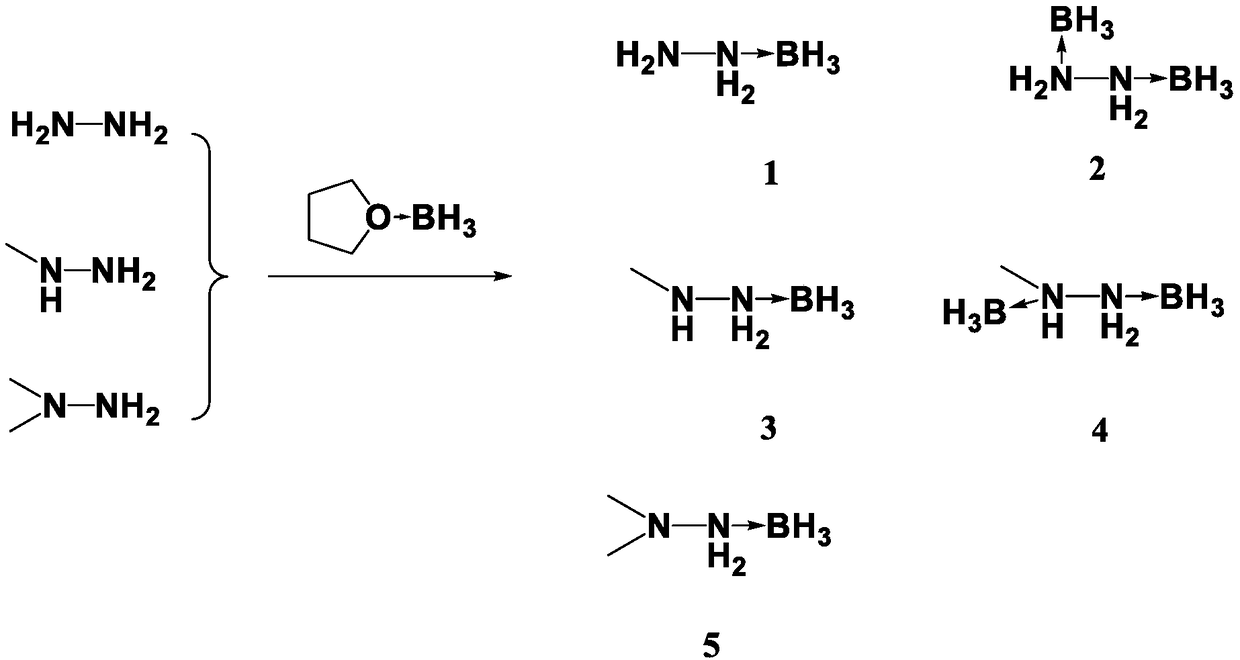

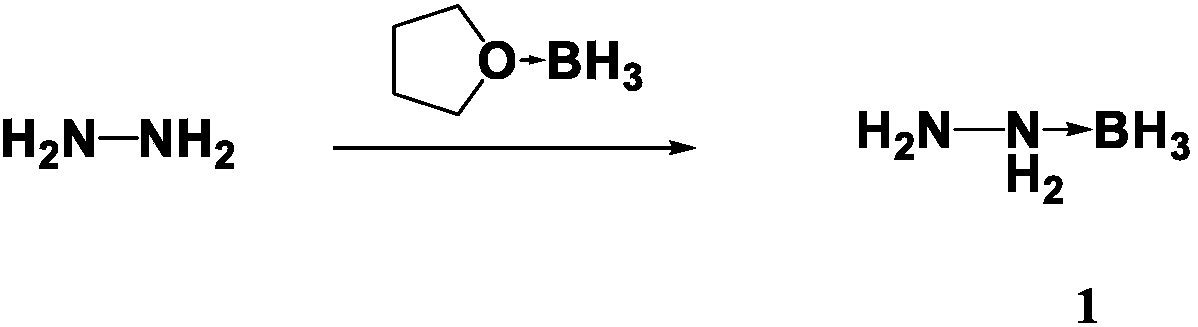

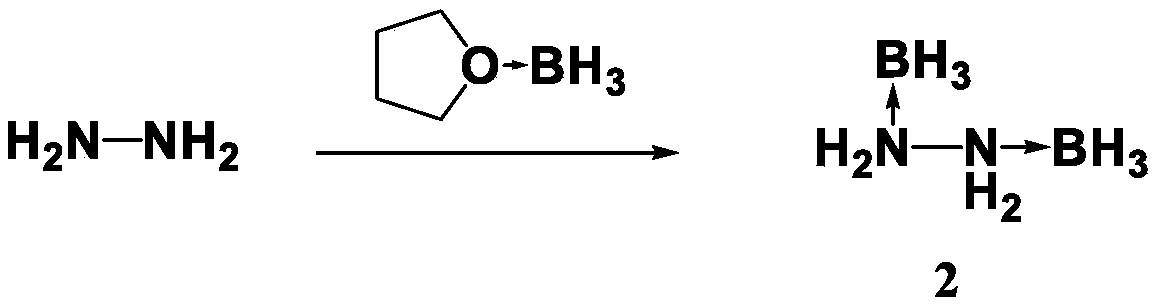

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Blended compression-ignition fuel containing light synthetic crude and blending stock

InactiveUS6056793AImprove performanceEmission reductionLiquid carbonaceous fuelsFuel additivesAlcoholIgnition delay

This invention is a composition of matter useful as a compression-ignition fuel. The composition has from about 30 to about 95 mass % of a light synthetic crude or syncrude, preferably from Fischer-Tropsch synthesis or related processes, and from about 5 to about 70 mass % of a blending stock that improves one or more desirable fuel property(s) including but not limited to pour point temperature, viscosity and emissions generated during combustion in a diesel engine. The blend stock preferably has an average molecular weight less than the average molecular weight of the light syncrude. Preferred blending stocks include hydrocarbons and oxygenates, such as alcohols, and ethers, having average molecular weights less than 200, preferably less than 160. The composition may optionally also contain pour point depressants, cetane improvers, carbon-containing compounds which react with water, and / or emulsifiers.

Owner:REG SYNTHETIC FUELS LLC +1

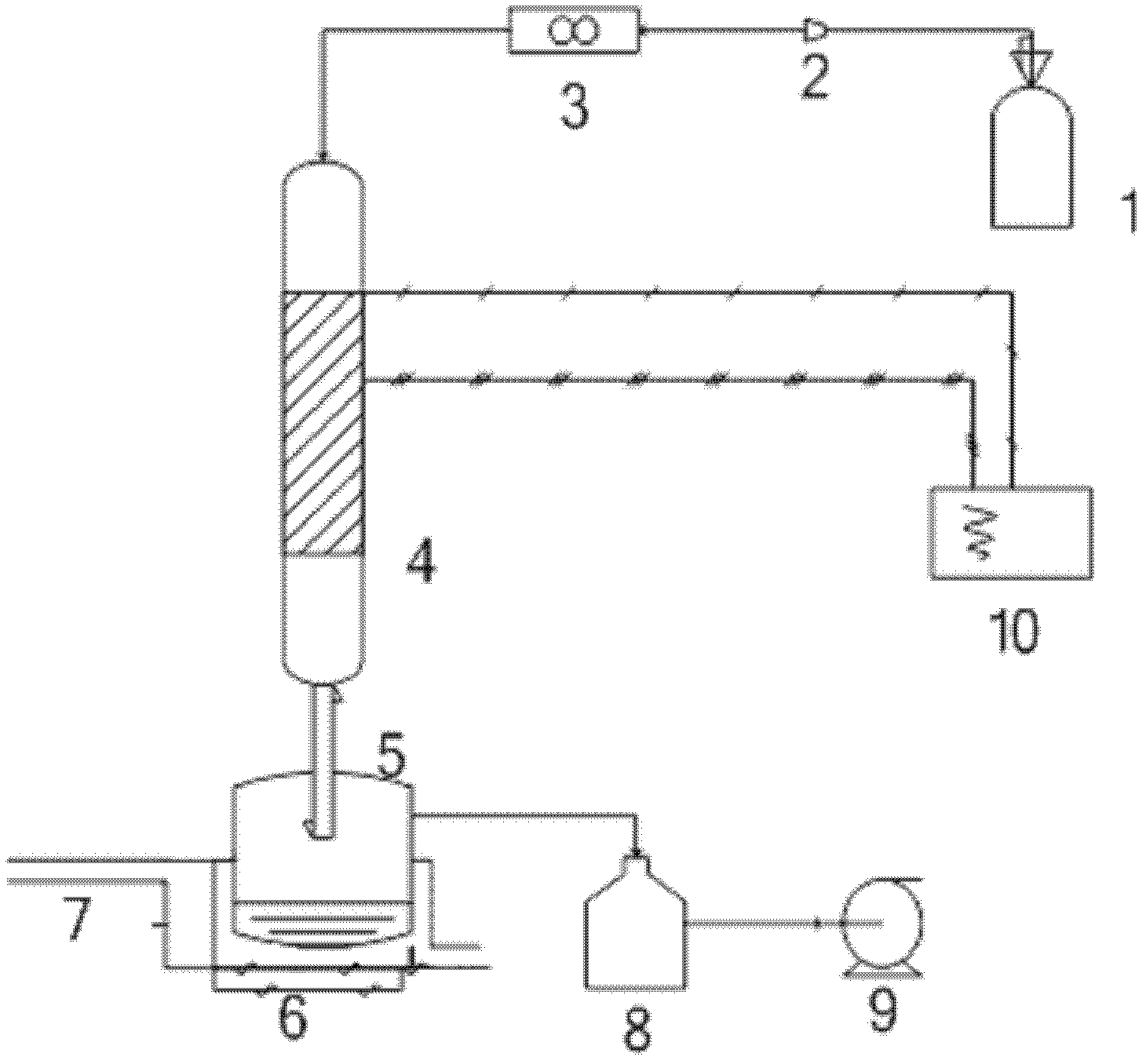

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

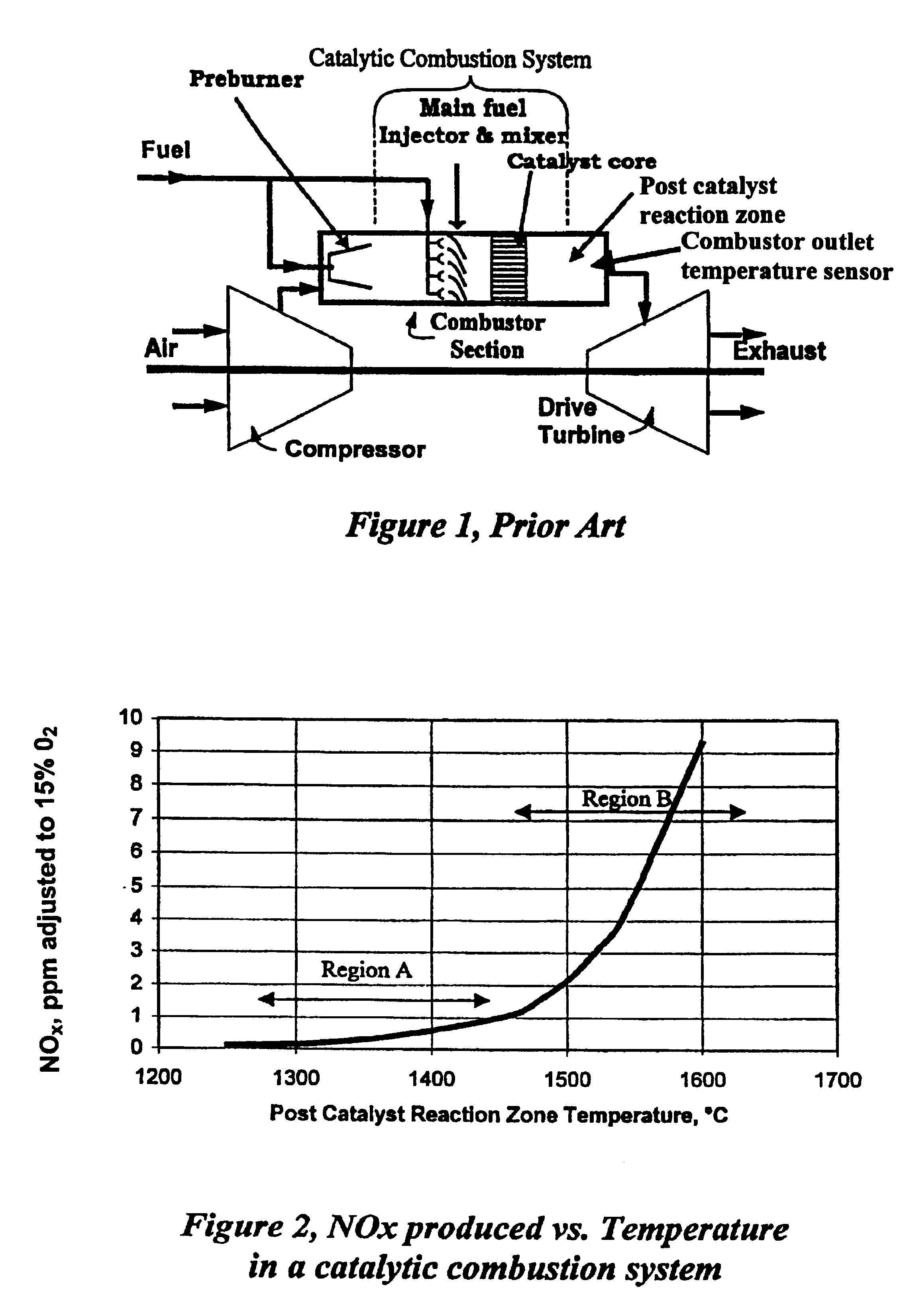

Method of thermal NOx reduction in catalytic combustion systems

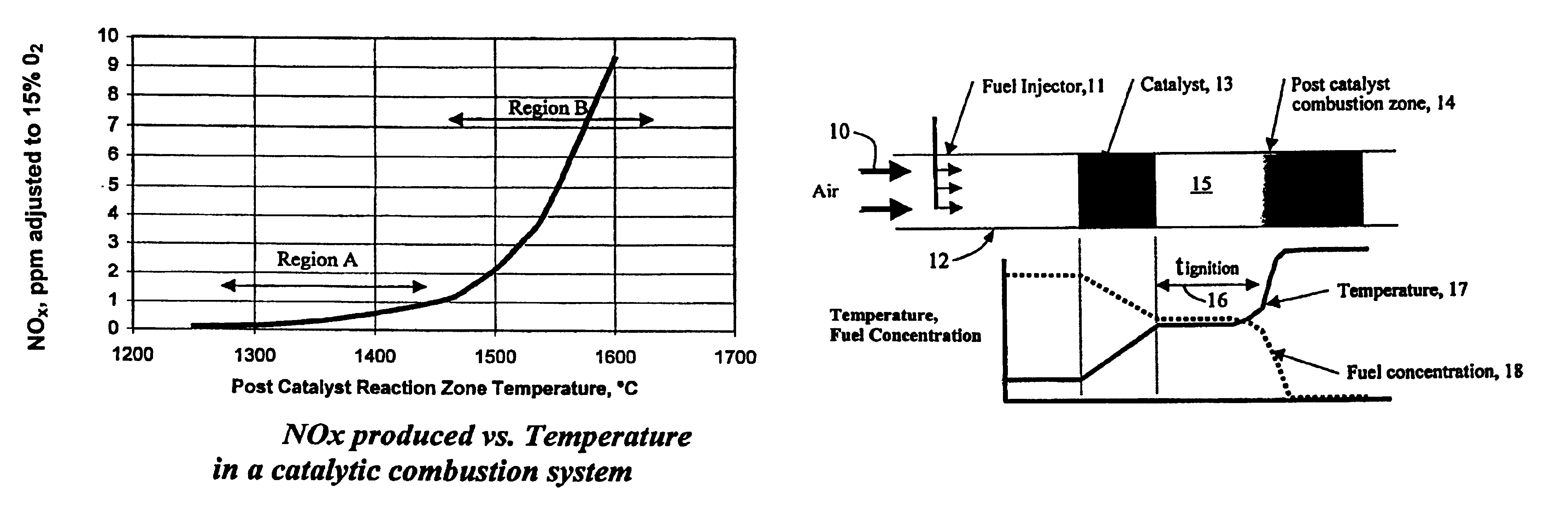

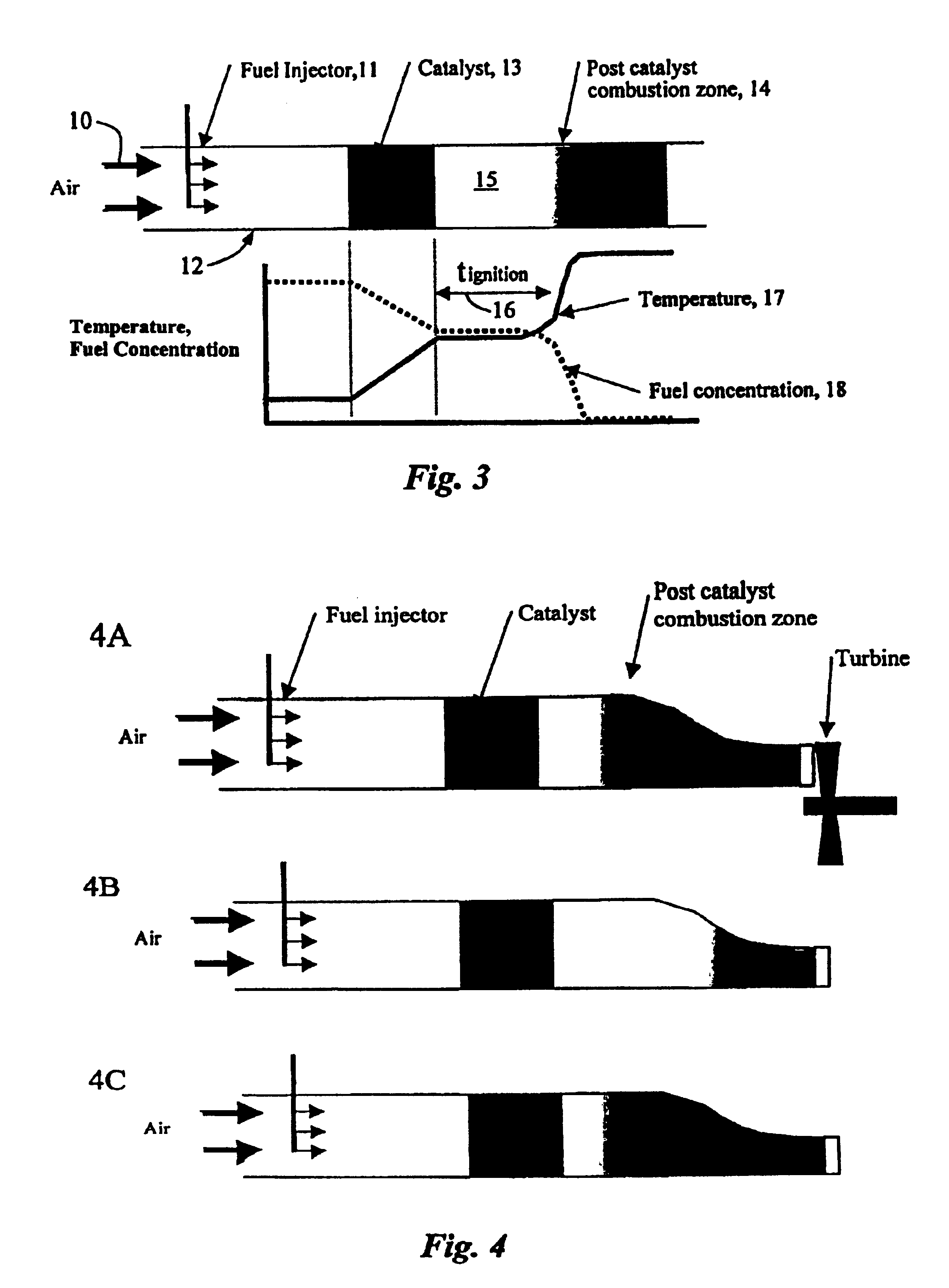

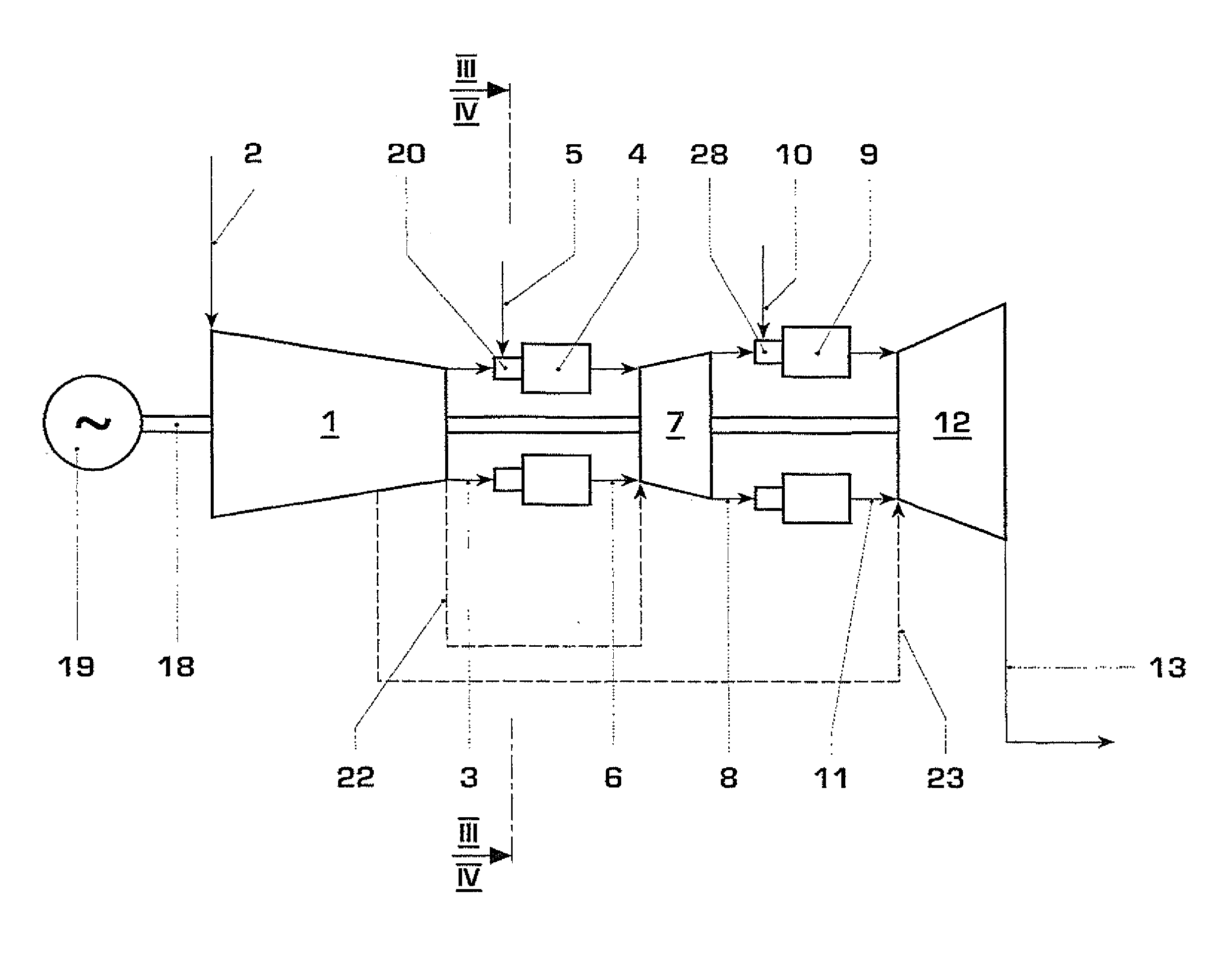

InactiveUS6718772B2Shorten the timeLower Level RequirementsContinuous combustion chamberTurbine/propulsion fuel supply systemsIgnition delayProduct gas

Methods and apparatus, both devices and systems, for control of Zeldovich (thermal) NOx production in catalytic combustion systems during combustion of liquid or gaseous fuels in the post catalytic sections of gas turbines by reducing combustion residence time in the HC zone through control of the HC Wave, principally by adjusting the catalyst inlet temperature. As the fuel / air mixture inlet temperature (to the catalyst) is reduced, the HC Wave moves downstream (longer ignition delay time), shortens the residence time at high temperature, thereby reducing thermal NOx production. The countervailing increase in CO production by longer ignition delay times can be limited by selectively locating the HC Wave so that thermal NOx is reduced while power output and low CO production is maintained. NOx is reduced to on the order of <3 ppm, and preferably <2 ppm, while CO is maintained <100 ppm, typically <50 ppm, and preferably <5-10 ppm.

Owner:KAWASAKI HEAVY IND LTD

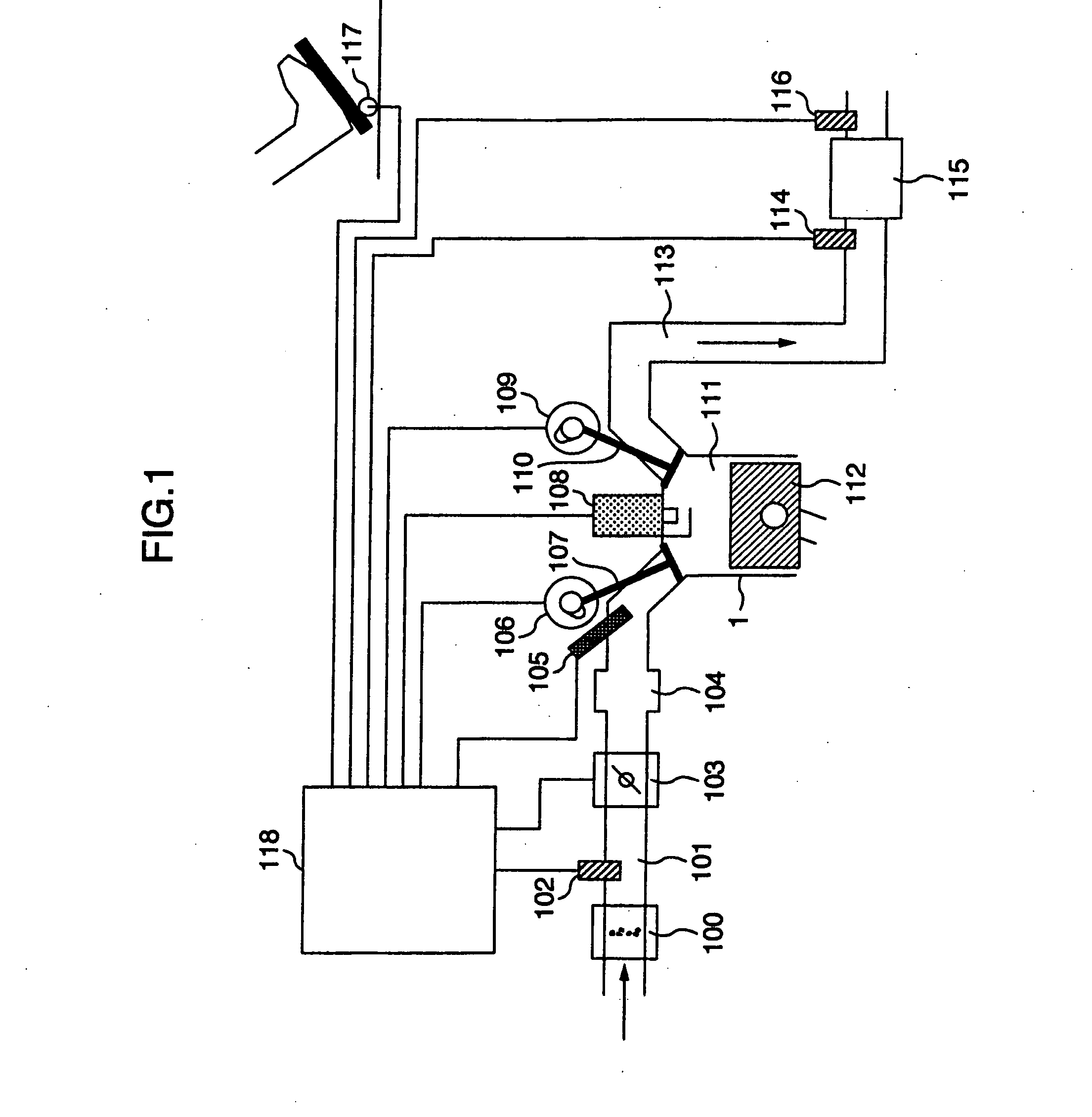

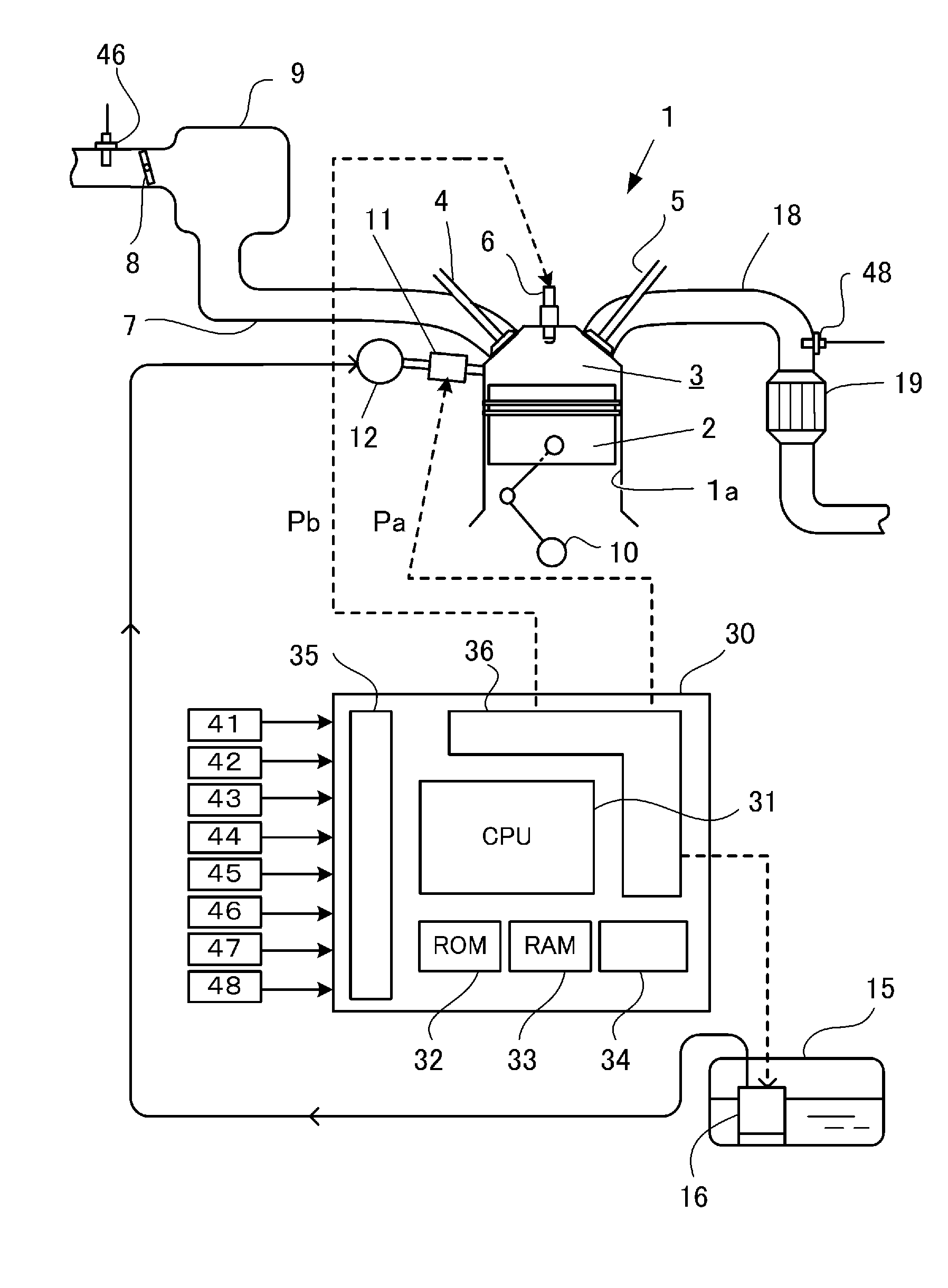

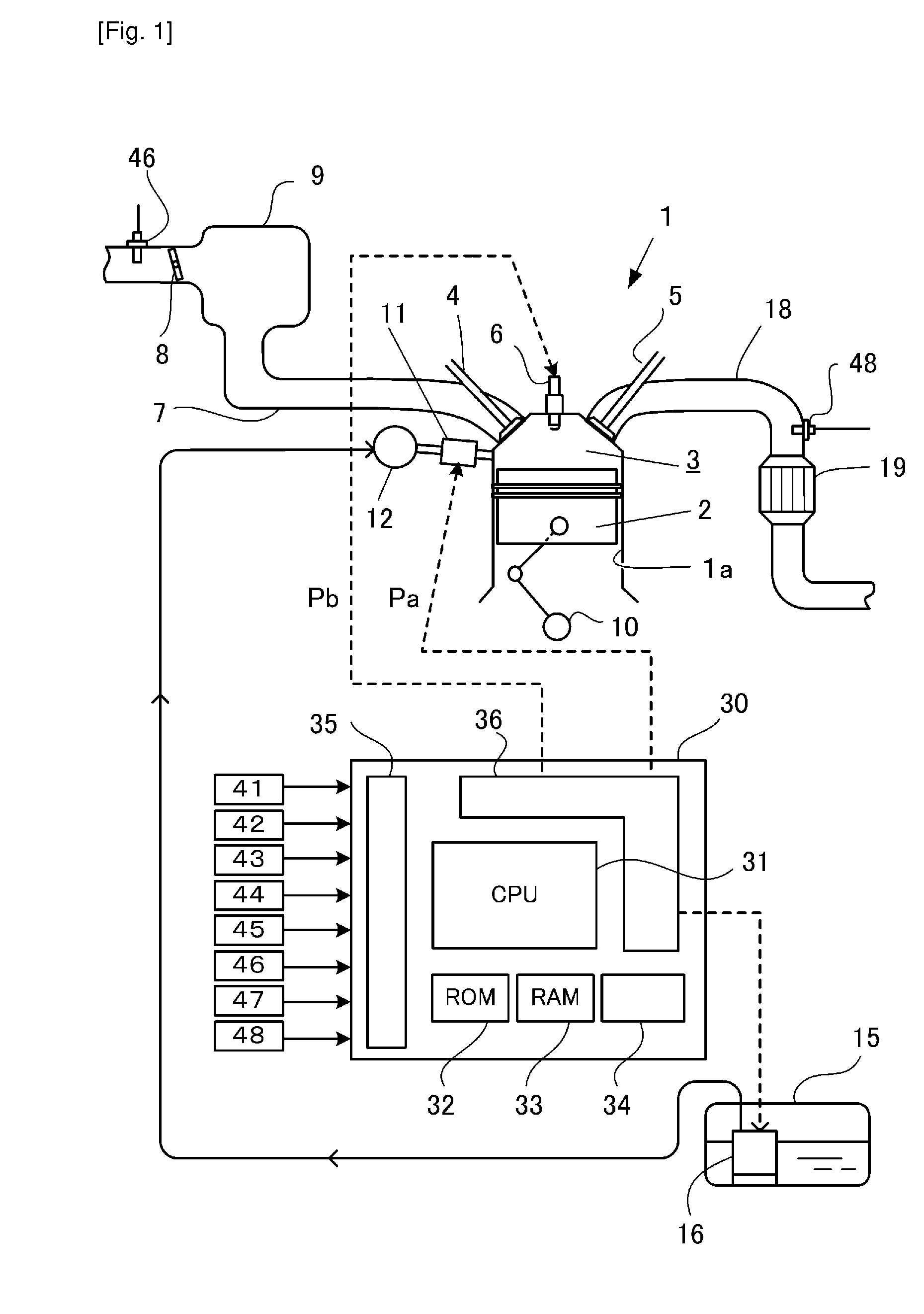

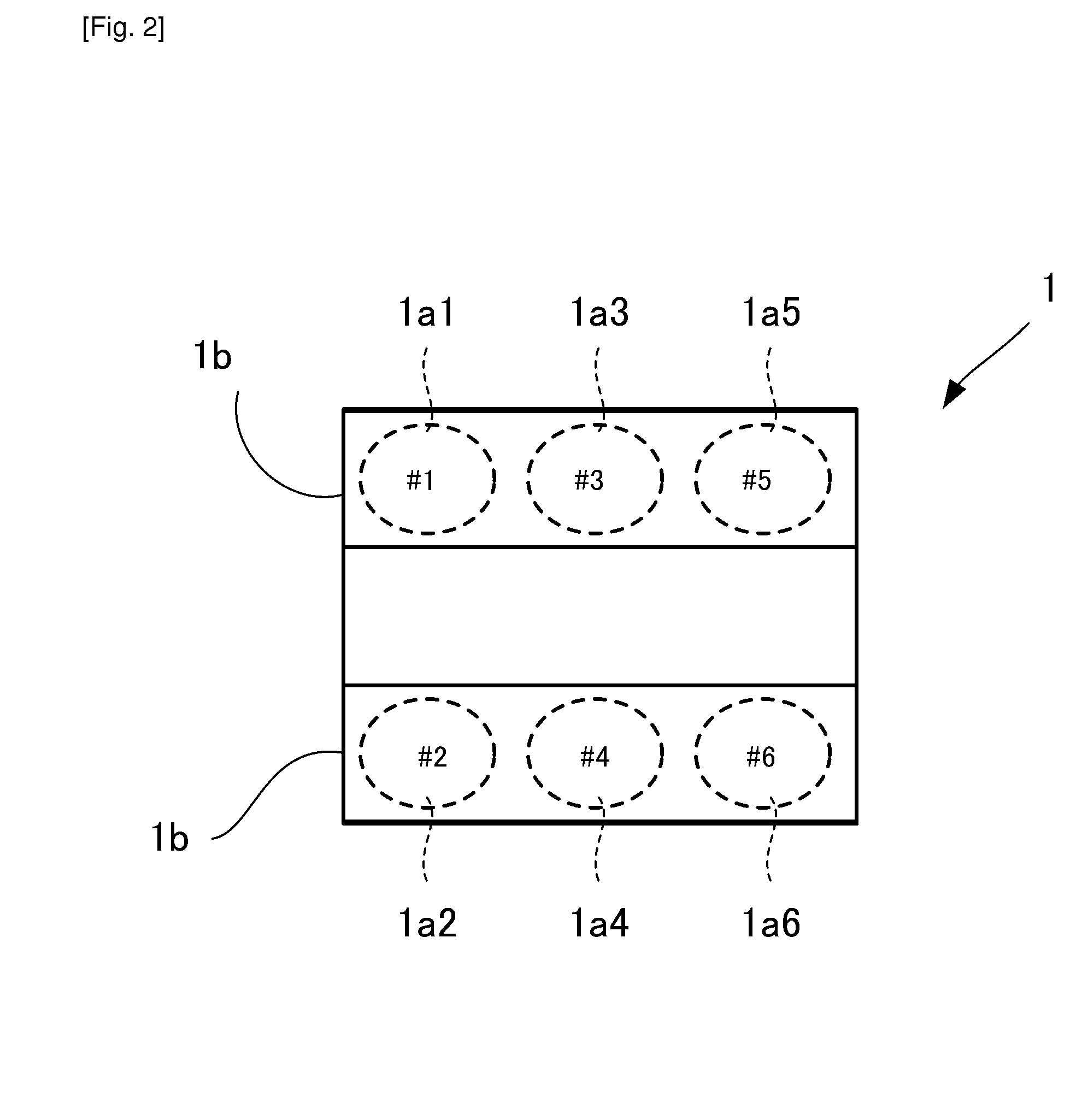

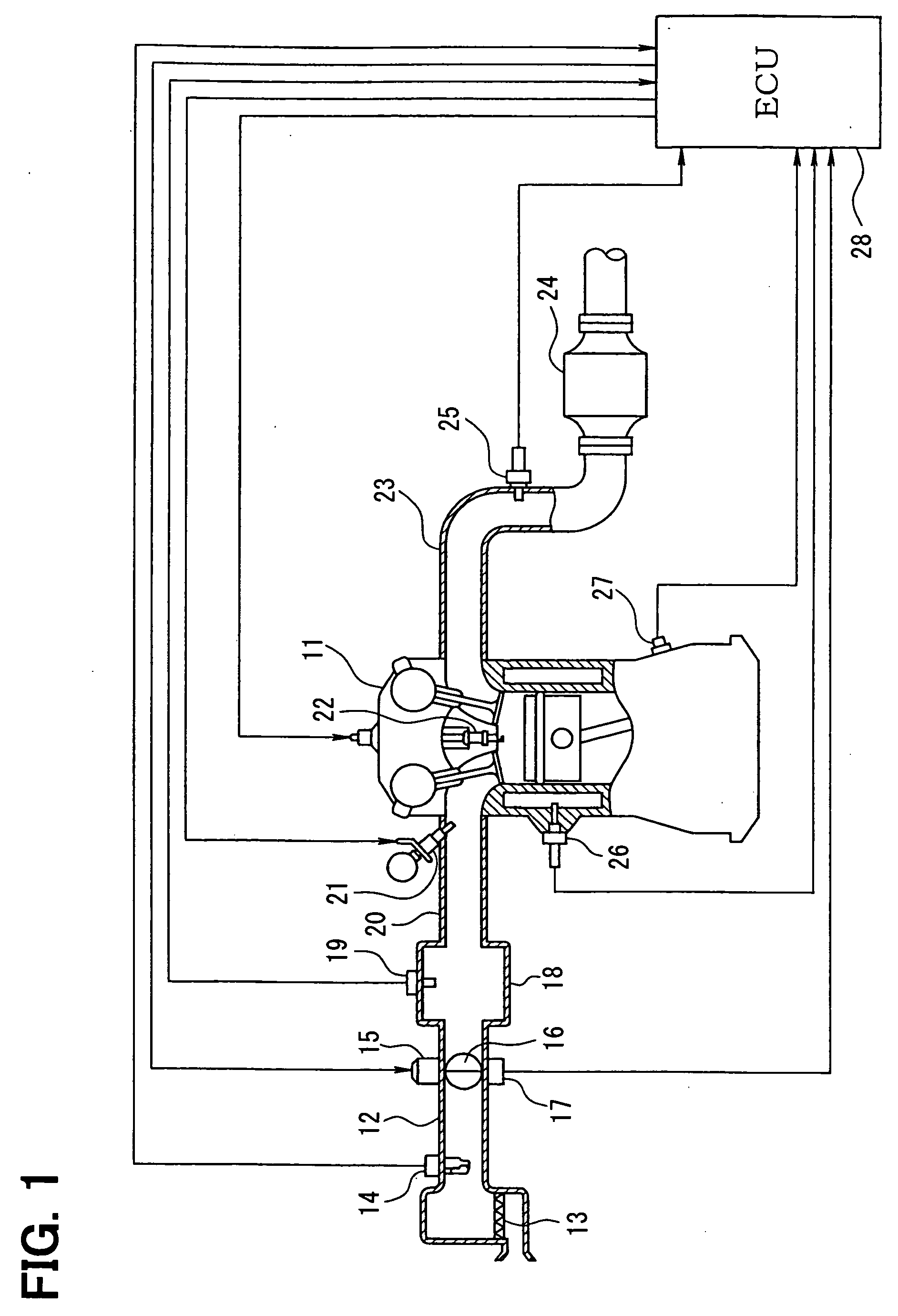

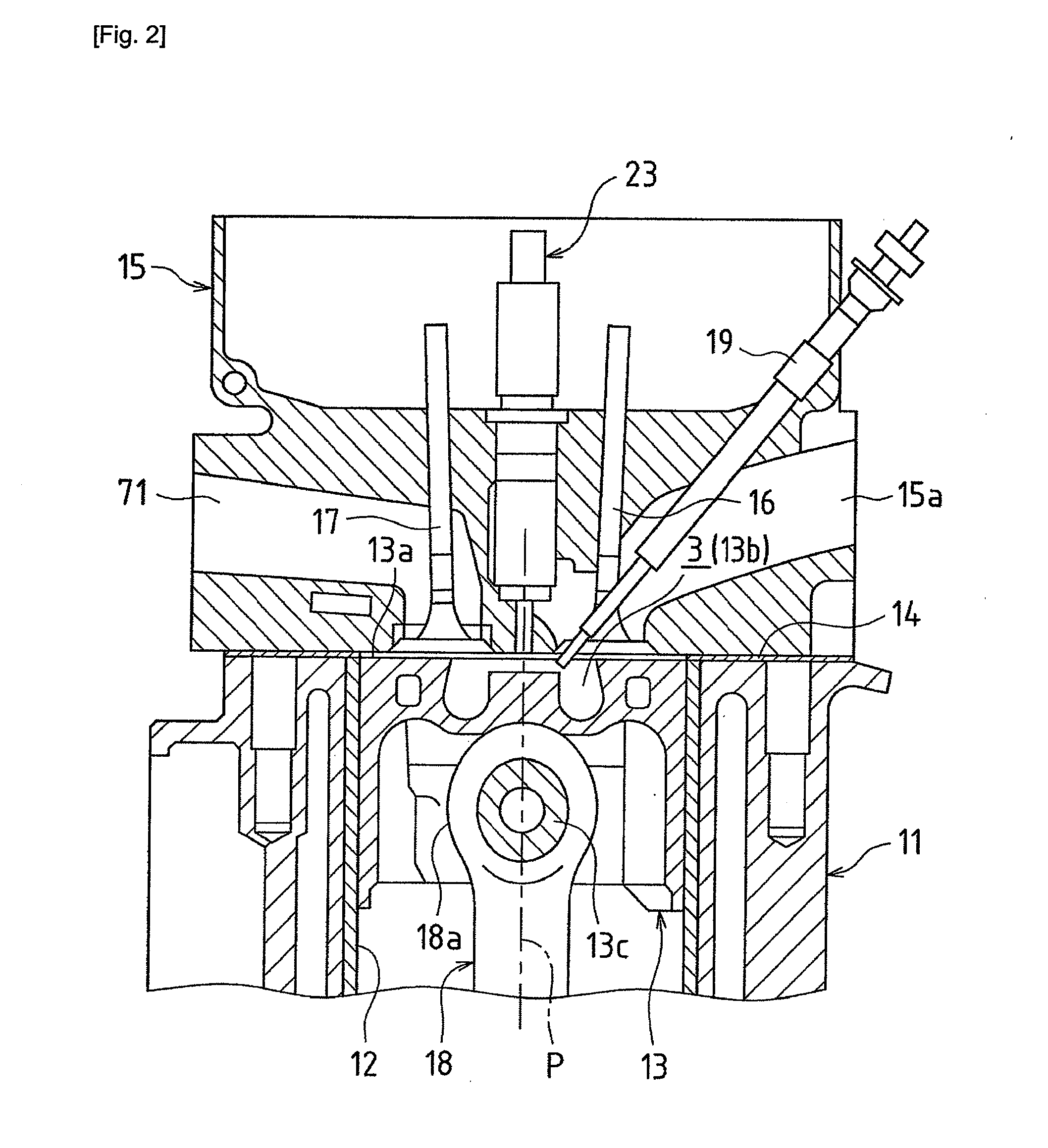

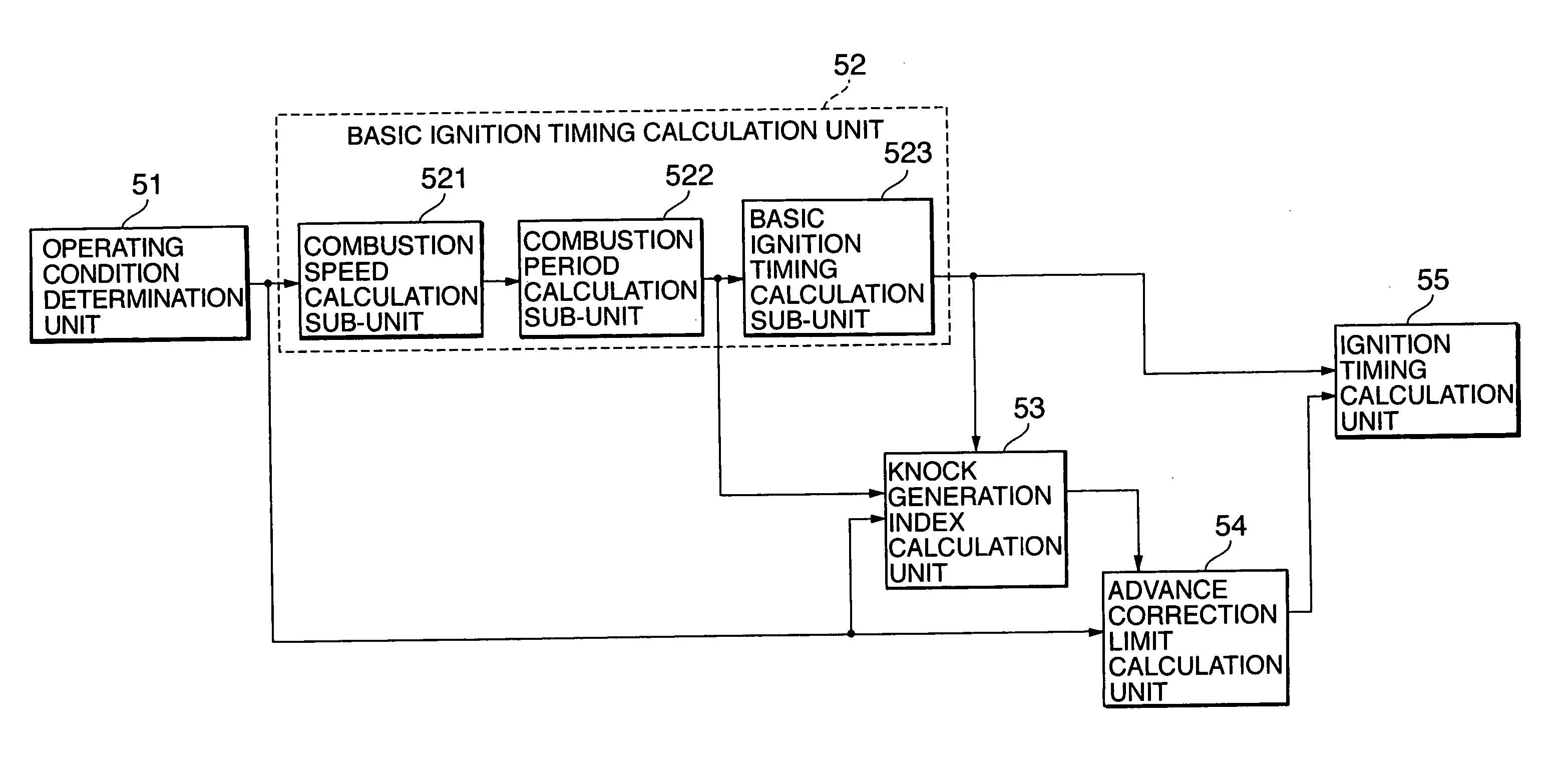

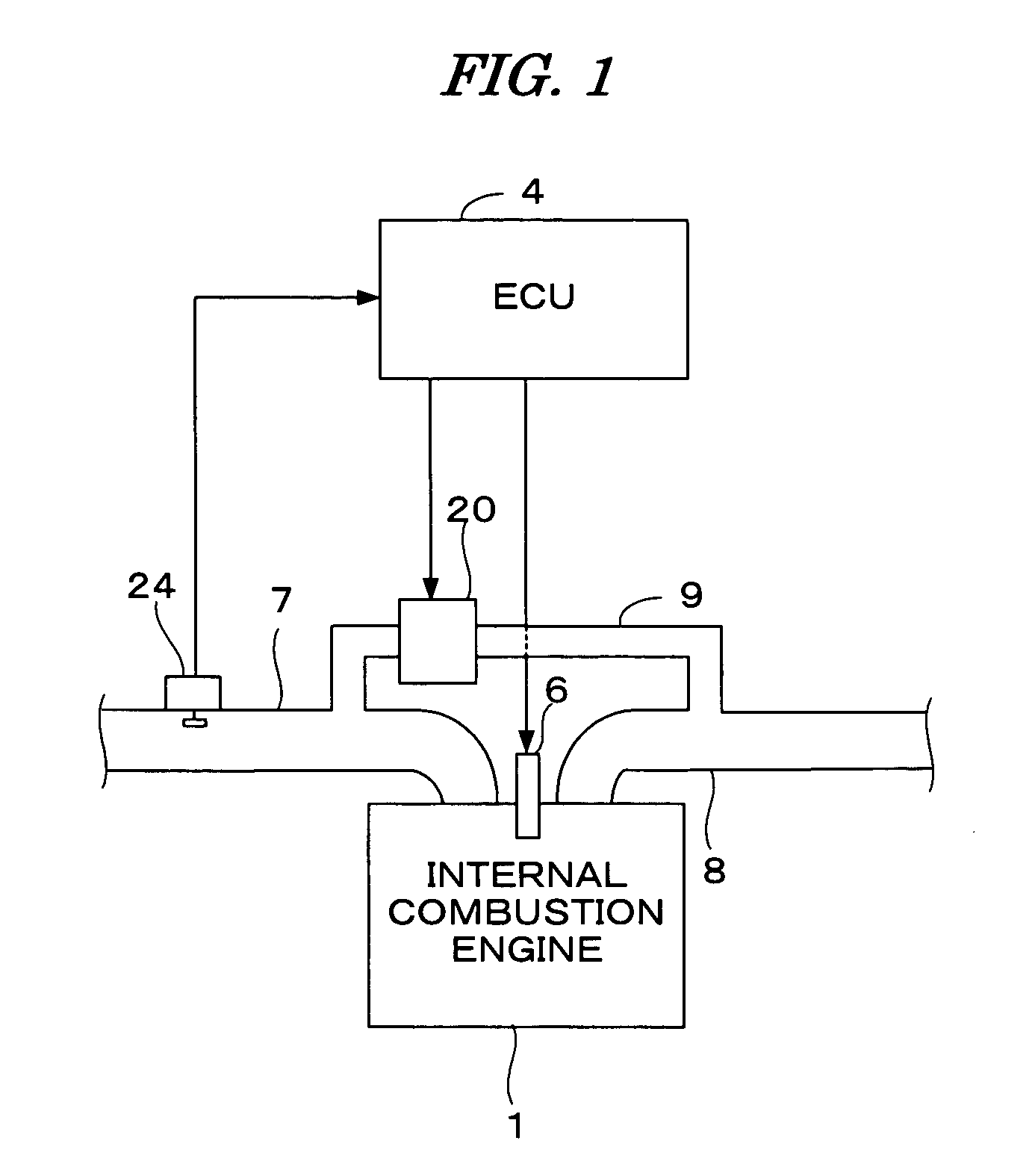

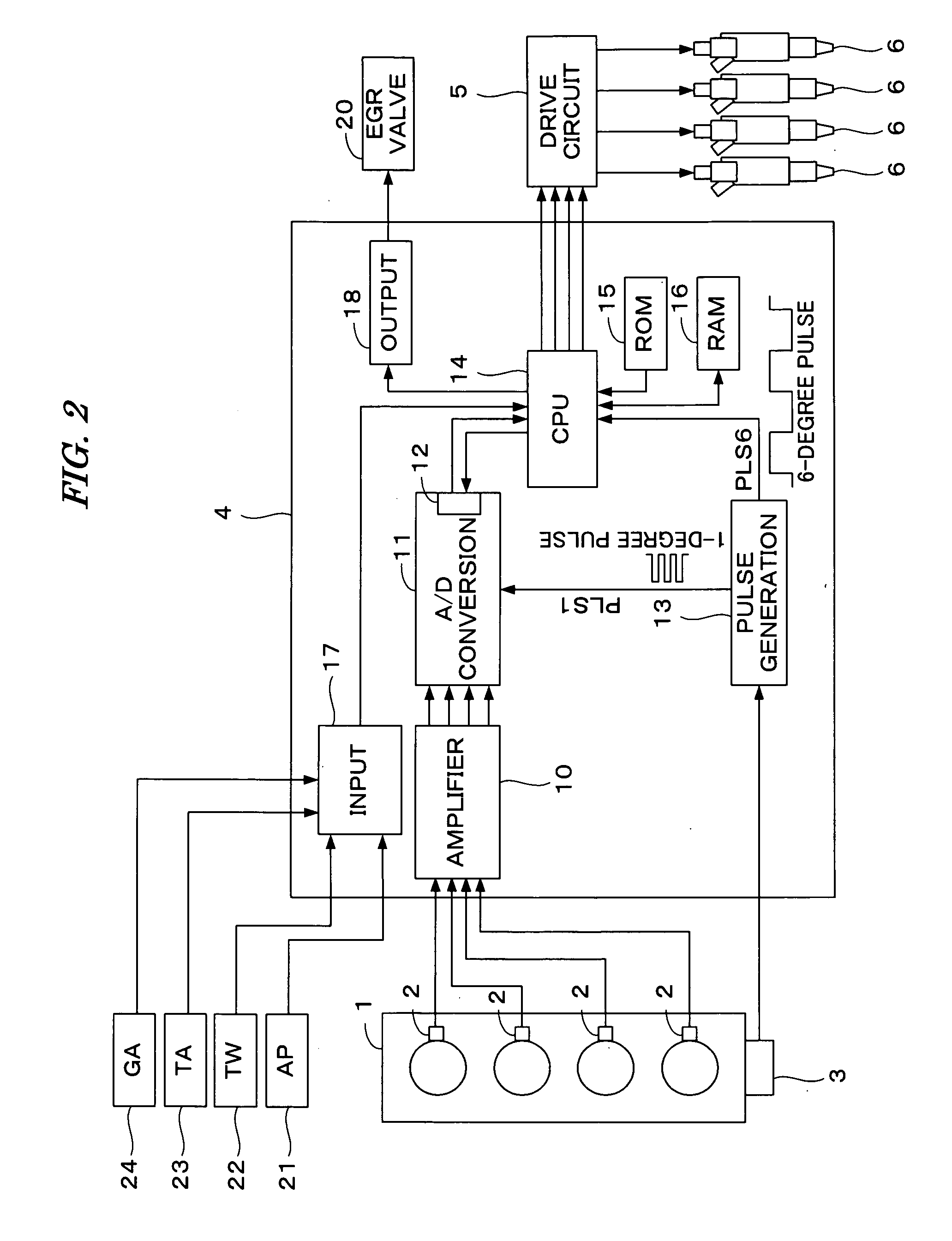

Control Method and Control Device for Engine

InactiveUS20090017987A1High-precise engine torque controlHigh precision controlElectrical controlInternal combustion piston enginesIgnition delayIgnition timing

In a control method and control device for an engine, in order to prevent torque control precision from deteriorating while performing an ignition retard control in a variable valve engine, when a torque down control is carried out by using the ignition retard, combustion duration is calculated in consideration of valve timing or an engine rpm for each driving state, and a characteristic of a reference ignition timing efficiency curve is corrected on the basis of a difference between the combustion duration and a combustion duration reference value which is set in advance.

Owner:HITACHI LTD

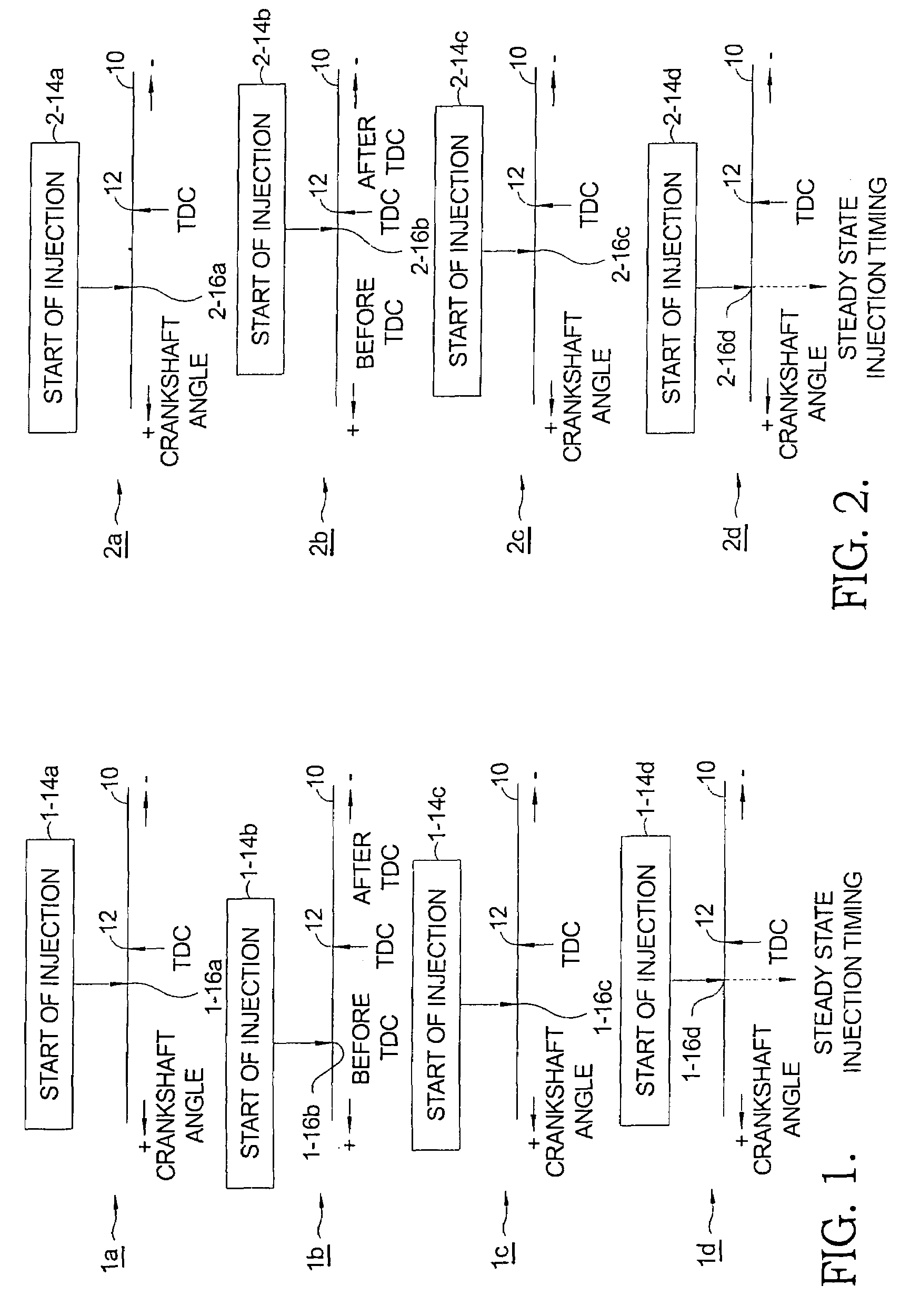

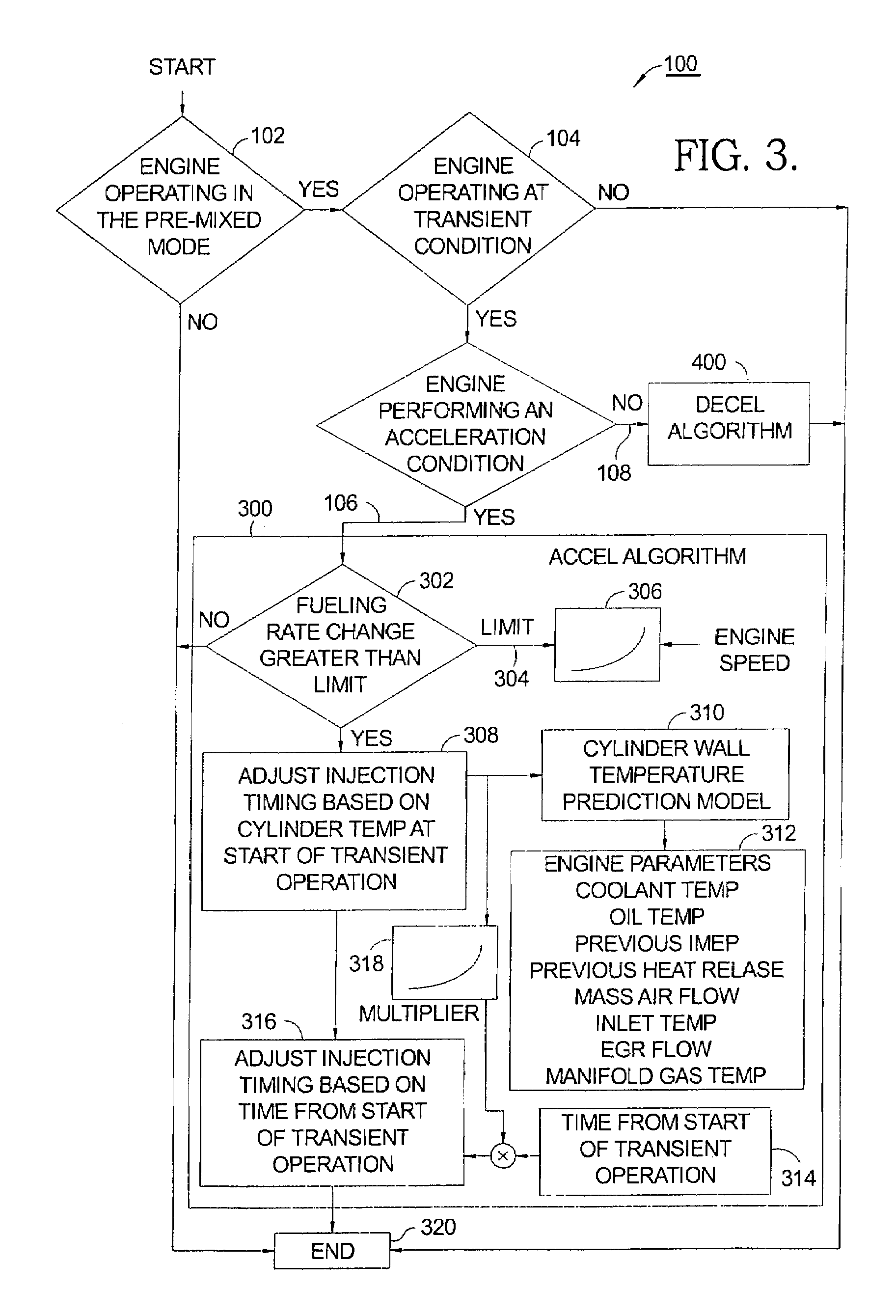

Method for compensating injection timing during transient response of pre-mixed combustion

ActiveUS7475671B1Avoid lostElectrical controlInternal combustion piston enginesCombustion chamberIgnition delay

Owner:DELPHI TECH IP LTD

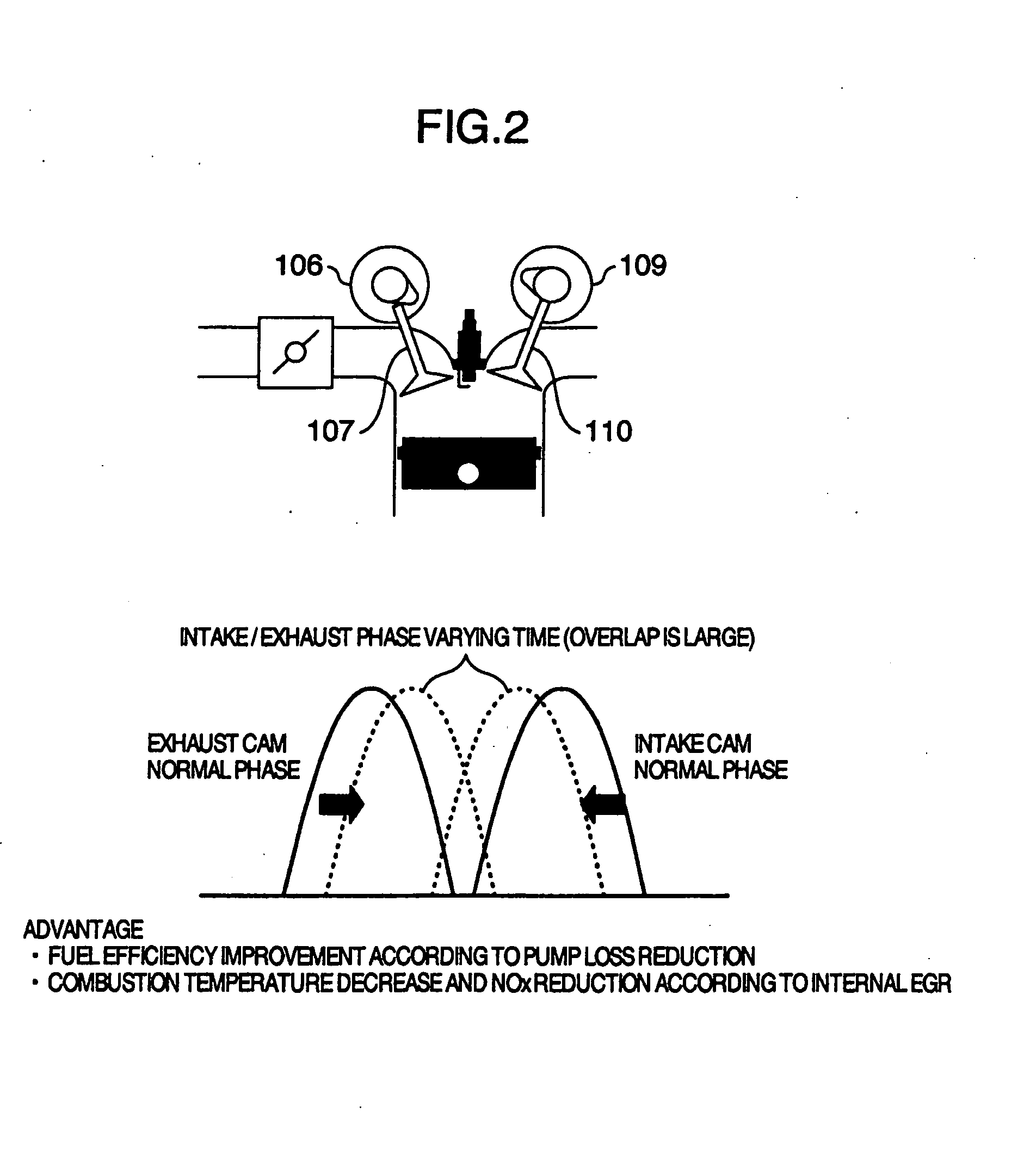

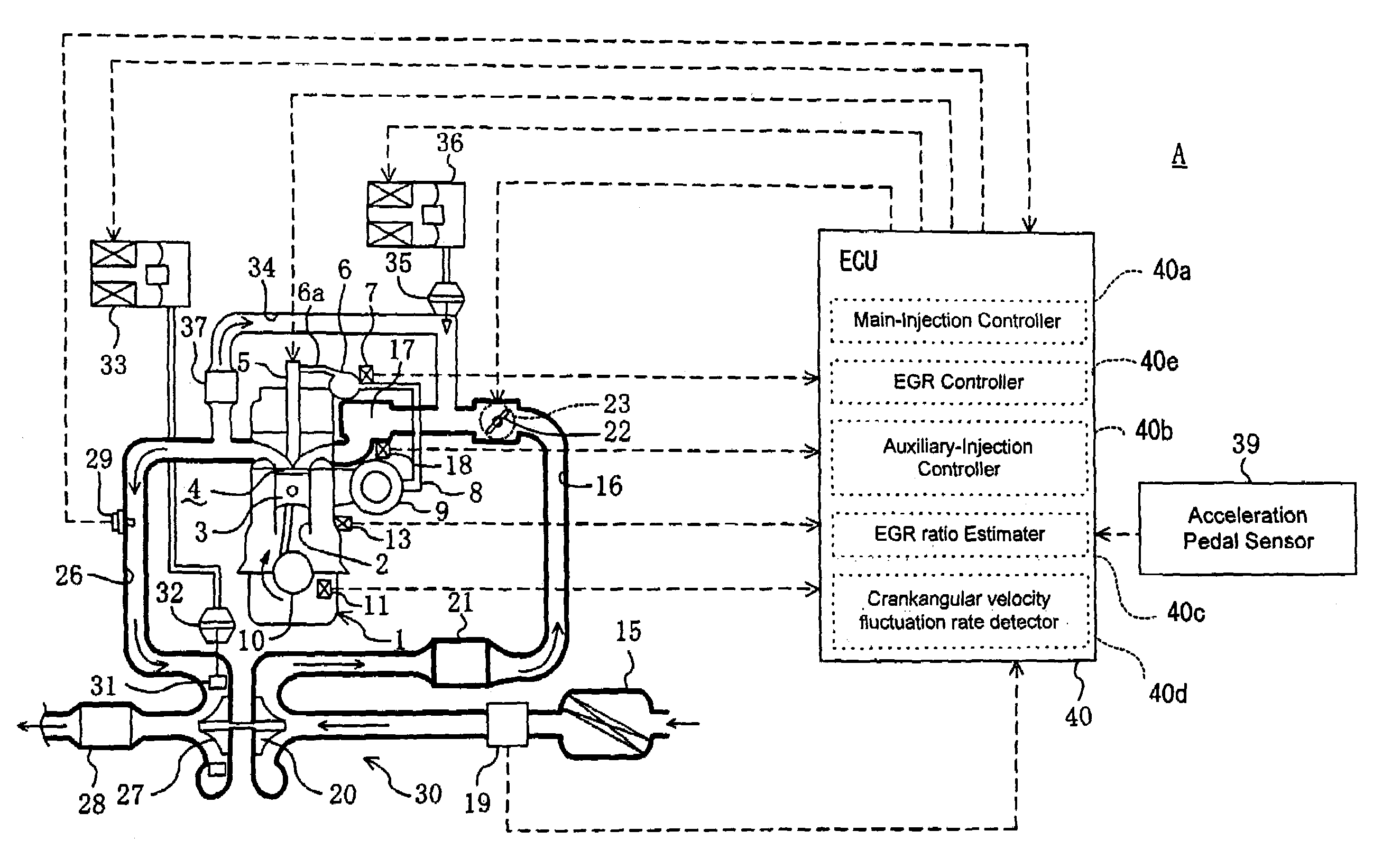

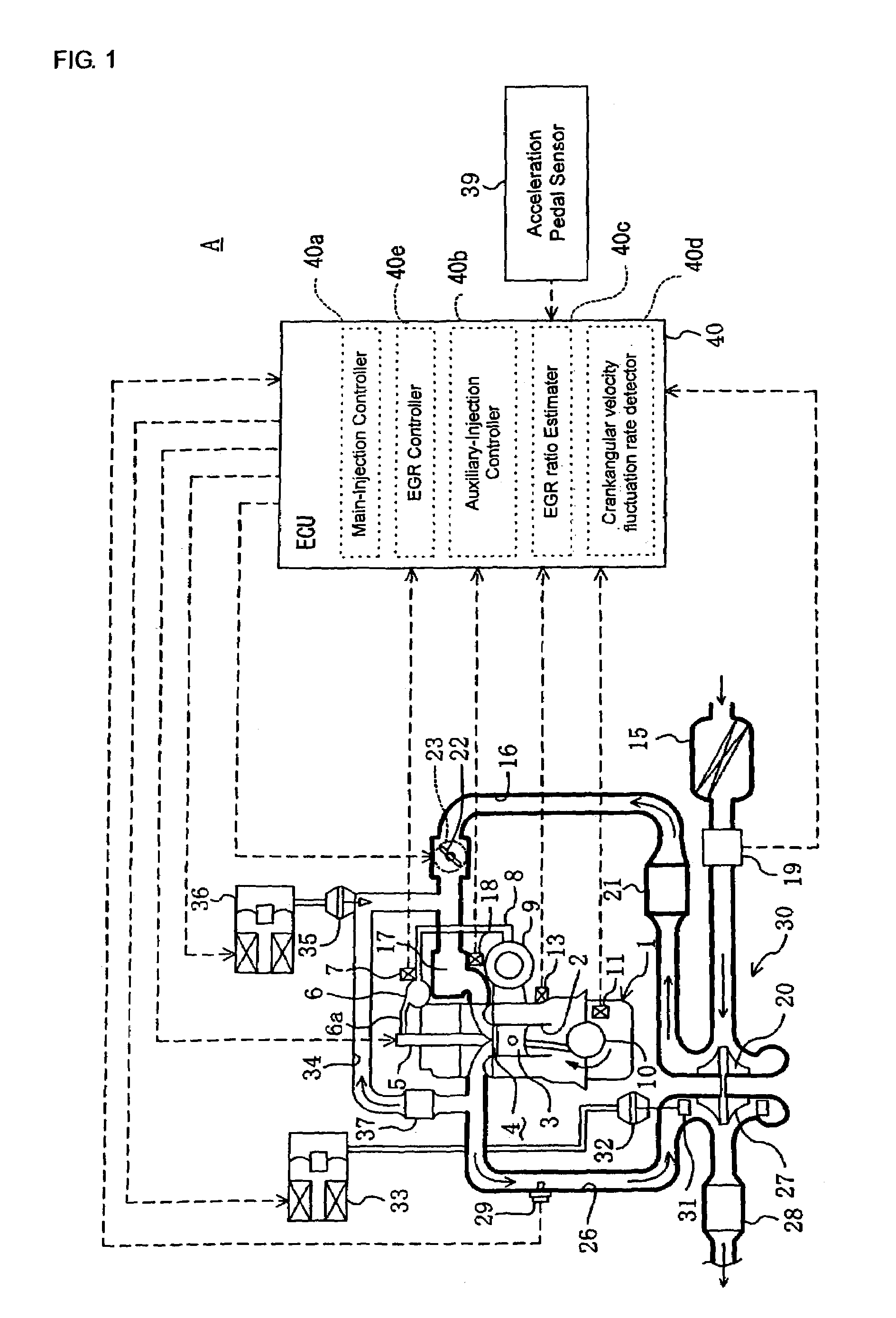

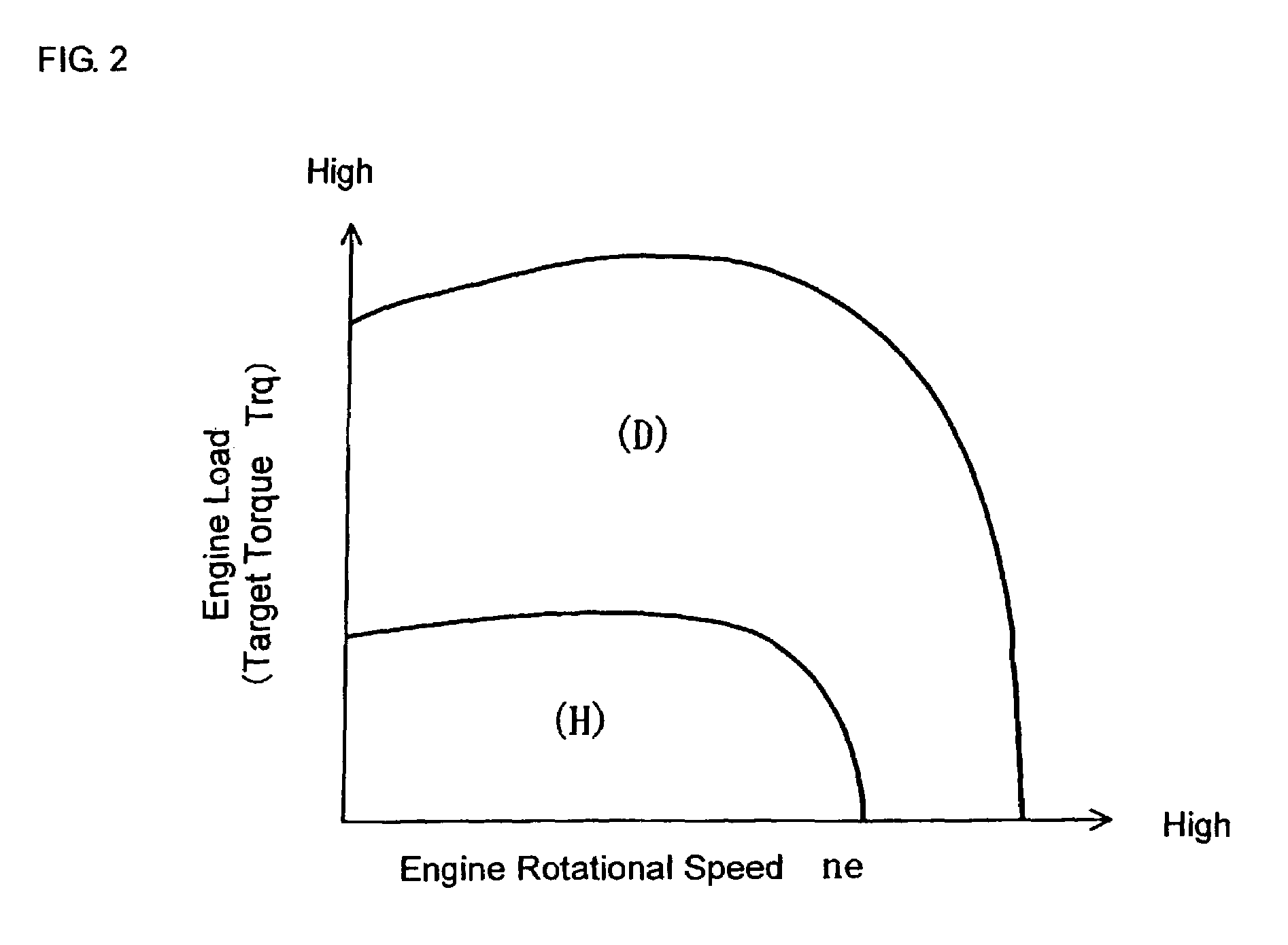

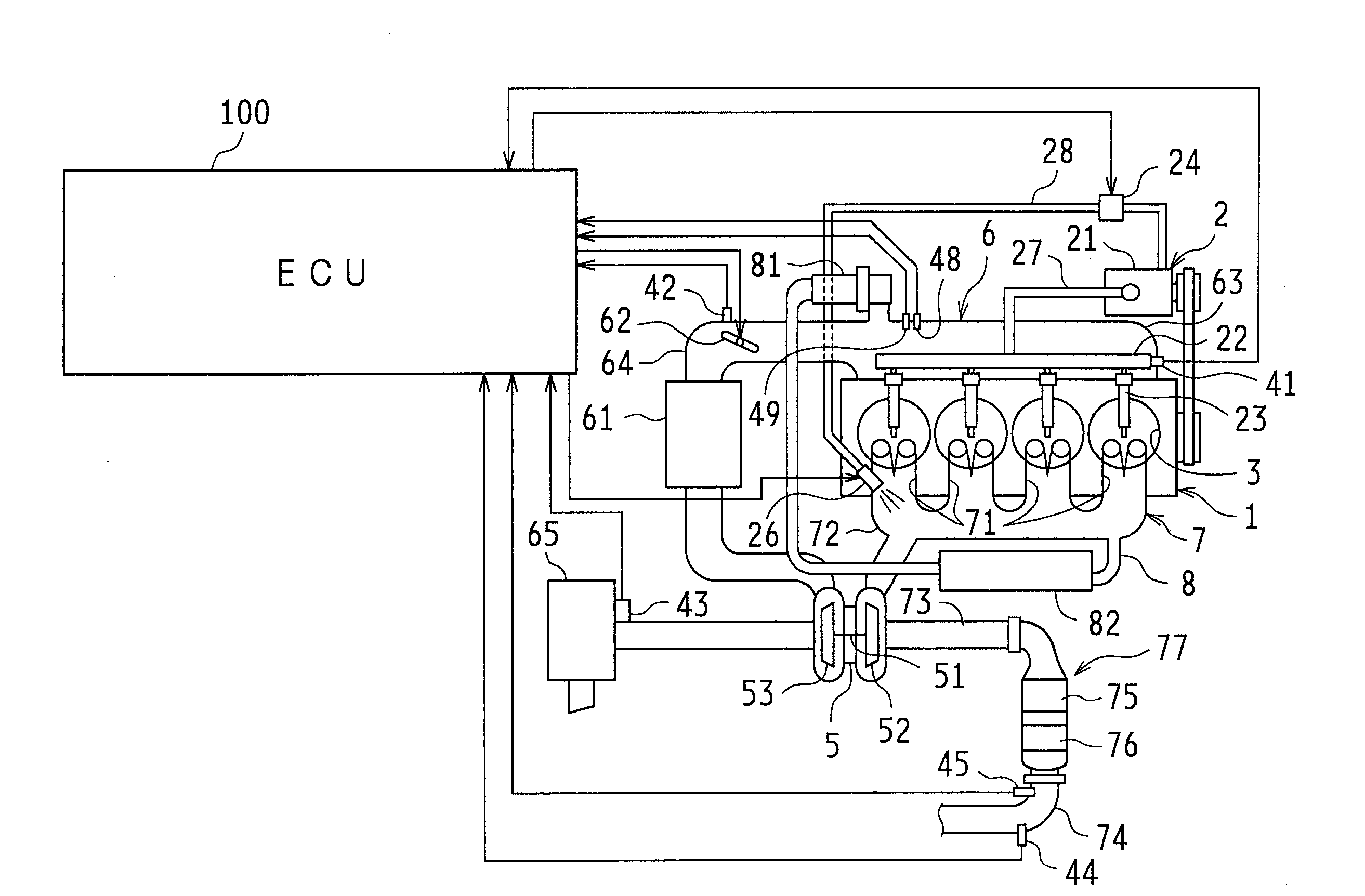

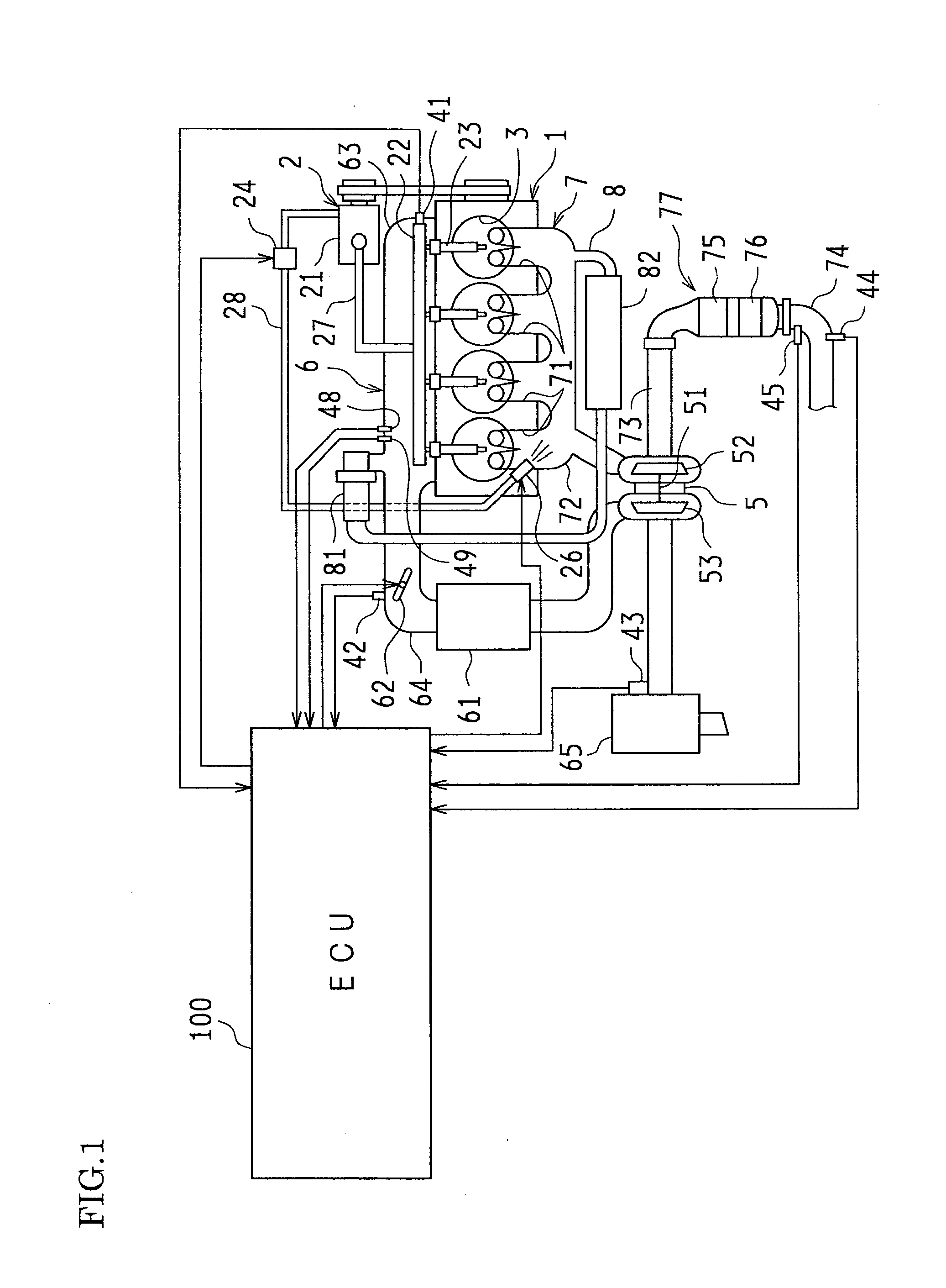

Combustion control apparatus for an engine

InactiveUS6964256B2Improve fuel efficiencyElectrical controlNon-fuel substance addition to fuelCombustion chamberLow load

To optimize an ignition timing of premixture for improving fuel efficiency regardless of significant change in an EGR ratio or a fluctuation in temperature of recirculated exhaust gas and temperature in a combustion chamber, there is provided a control apparatus for a diesel engine which controls an injector extending into the combustion chamber to execute a main-injection for injecting fuel and increasing the EGR ratio, so as to attain the premixed compressive ignition combustion while the engine is in the premixed combustion region on the low load side. Just before or after a cool flame reaction occurs in the mixture formed by the main-injection, an auxiliary-injection is executed so that the latent heat of vaporization of the fuel decreases the temperature of the mixture to delay the ignition to a timing near TDC. The auxiliary-injection amount is adjusted according to the estimated value of EGR ratio or the change in the crank angular velocity to optimize the ignition timing of the mixture.

Owner:MAZDA MOTOR CORP

Misfire detection apparatus for internal combustion engine

InactiveUS20100294027A1Accurate detectionReduce rotationInternal-combustion engine testingElectrical controlLow loadIgnition delay

Structured with a rotational fluctuation measuring section 51 measuring a rotational fluctuation amount DTdi, a misfire judging section 55 judging a misfire by comparing the rotational fluctuation amount with a judging threshold value, a low load judging section 56 judging an internal combustion engine operating under a low load condition, and an ignition angle judging section 57 judging an ignition angle exceeding an ignition delay angle, wherein the misfire judging section 55 has a map M1 with judging threshold values th1 with respect to rotational speeds ne of the engine and a map M2 with judging threshold values th2 with rotational fluctuation amounts larger than the map M1, and judges the misfire based on the maps M1 and M2 when the engine is operating under the low load condition with the ignition angle exceeding the ignition delay angle and, in other cases, based only on the map M1.

Owner:TOYOTA JIDOSHA KK

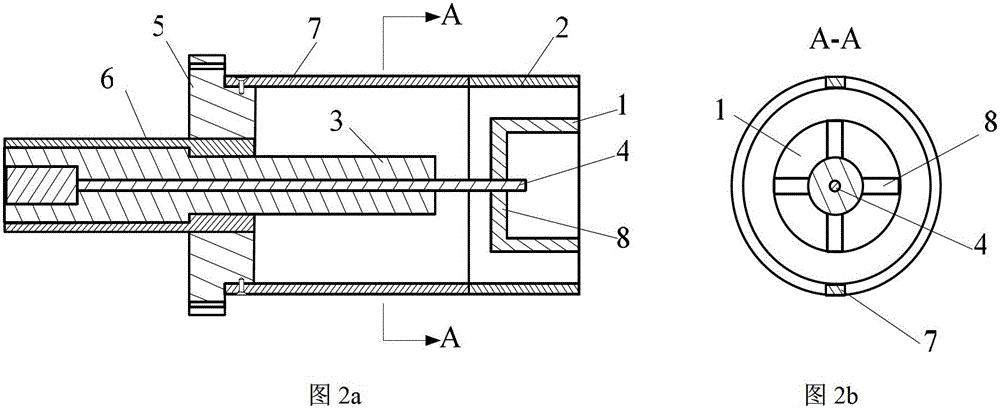

Annular discharge based transient state plasma igniter

ActiveCN102913365AIncrease the ignition areaEasy to igniteEngine ignitionMachines/enginesChemical reactionReaction rate

The invention relates to an annular discharge based transient state plasma igniter. An insulation sleeve is located in an insulation protection sleeve, and one end of the insulation sleeve is located in a cathode. An anode conduction rod is located in the insulation sleeve, and one end of the anode conduction rod is arranged in a center hole of the cathode. One end of the insulation protection sleeve is arranged in a fixing base. The anode is located in the cathode. The transient state plasma igniter is provided with a mixed gas channel. According to the invention, high-energy nanosecond pulse is used to discharge electricity to form a local high temperature area, and a large quantity of active particles are activated to ignite combustible mixed gas in an extremely short period of time. The ignition area is large, and the mixed gas can be ignited by multiple points; the ignition time is extremely short, and the ignition delay time is shorter; the ignition energy can be well coupled with the gas mixture, macromolecule hydrocarbon fuel in the ignition area is ionized as active particles with low activation energy, so that the chemical reaction of the mixed gas is faster, the reaction time is shorter, and the ignition success rate is high.

Owner:AIR FORCE UNIV PLA

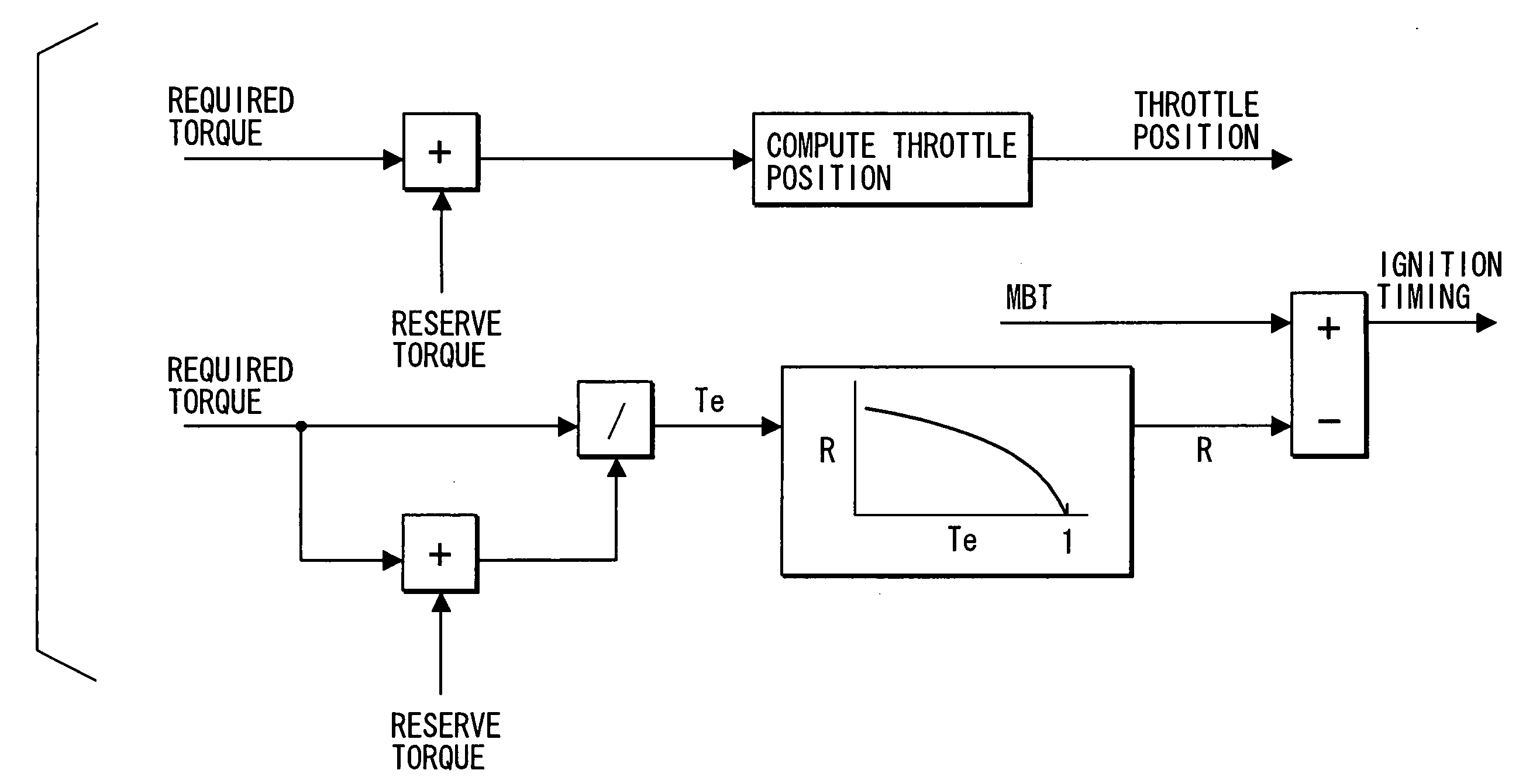

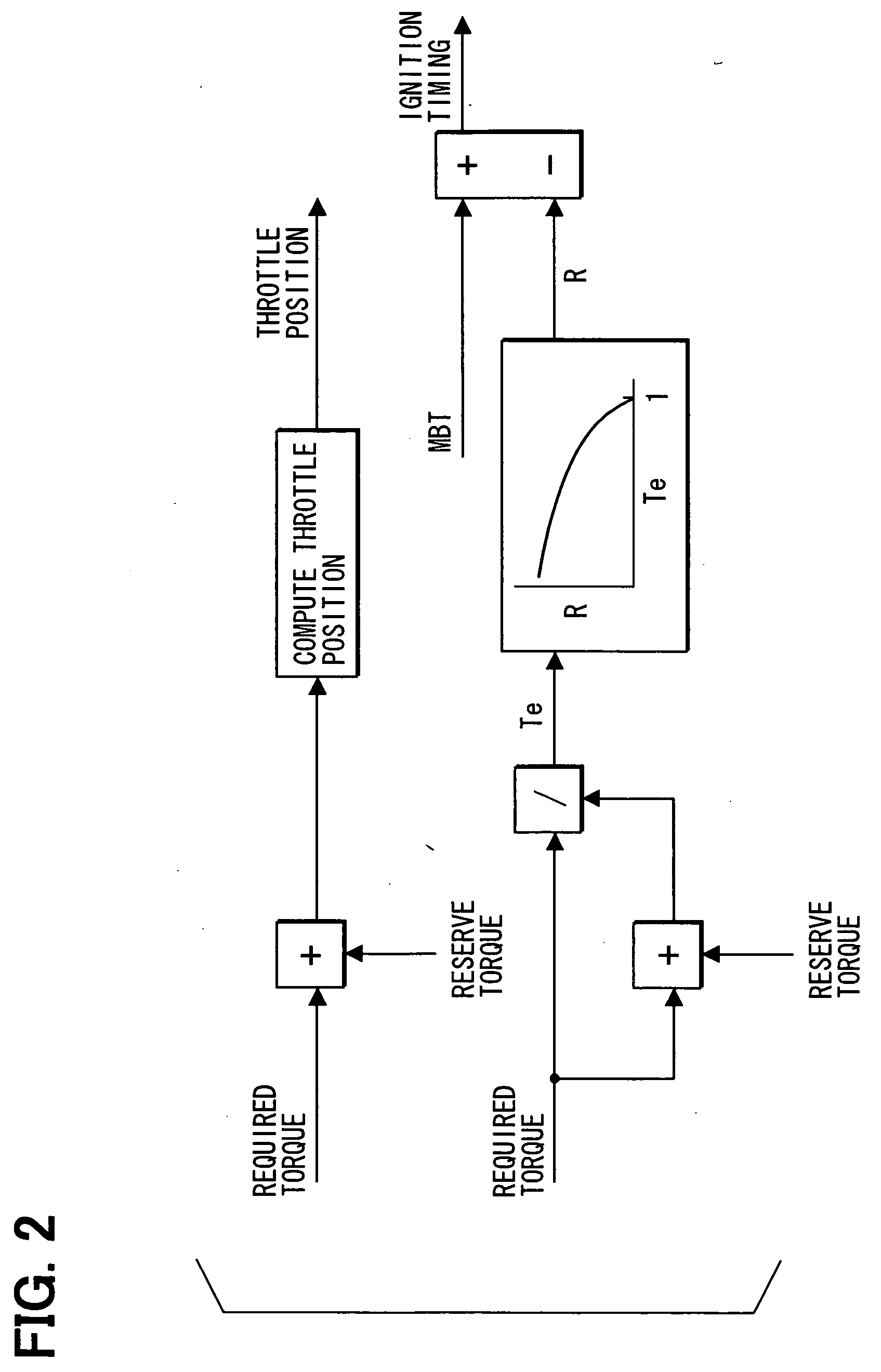

Torque controller for internal combustion engine

InactiveUS20060102143A1Increment of exhaust gas temperature can be restrictedElectrical controlIdling devicesIgnition delayIgnition timing

A throttle position corresponding to a R-R torque representing a torque in which a reserve torque is added to a required torque at MBT is computed. The throttle position is offset by an amount of a reserve torque in a torque increasing direction. An ignition retard amount for obtaining the required torque is computed based on a ration between the required torque and the R-R torque to cancel an increment in torque due to the offset of the throttle position. Because the offset amount of the ignition timing in the retard direction can be computed without an estimated torque which is determined based on the intake air flow rate including the leak air, it is restricted that the ignition retard amount becomes too large even if the large amount of leak air is generated at the throttle valve.

Owner:DENSO CORP

Fuel injection control apparatus of internal combustion engine

InactiveUS20100312454A1Suppress peakReduce combustion noiseElectrical controlInternal combustion piston enginesLower limitIgnition delay

In one embodiment, a total fuel injection amount is calculated from a torque required by an engine. A division ratio of a pre-injection amount that achieves both suppression of ignition delay of fuel from a main injection and suppression of a peak value of a heat production ratio of combustion from the main injection is calculated. Upper and lower limit guards are given to the obtained divided amount, and the divided injection amount is calculated. The injection amount of the main injection is obtained by subtracting the divided injection amount from the total fuel injection amount.

Owner:TOYOTA JIDOSHA KK

Fire resistant paint, articles of manufacture, an apparatus for manufacture and a process for manufacture thereof

InactiveUS20130288031A1Reduce volatilityLow heat release rateFireproof paintsWater-setting substance layered productFlame spreadHeat resistance

A fire and heat resistant composition for providing or enhancing the fire resistance of a material. The composition consists of both chemical and physical integration. Physical application is a coating composition containing materials including a fire and heat resistance means, lower peak heat release means, lower heat released per unit time means, higher temperature gradient means, low flame spread means, high ignition delay means, low peak heat release means, low total heat release means, high thermal stability means, elastic and coating thickness encasement means and heat. Chemical applications consist of chemical additive which are naturally more fire safe.

Owner:L M J NATION SECURITY

Anti-static non-ignition wear-resisting floor material and its construction method

This invention relates to an electrostatic prevention misfire wear-resisting floor stuff construction method. The process includes: (1) acoording to weight ratio of 1 : 1 to 4: 0.01 to 0.5, respectively get cement, weai-resisting misfire materials and conducting material, intensive mixing to prepare electrostatic prevention misfire wear-resisting floor stuff;(2) concrete construction; (3) lay conduct net on the surface of fundi concrete, conduct net is good ground;(4) lay electrostatic prevention misfire wear-resisting floor stuff on the surface of concrete, make conduct net lay middle of electrostatic prevention misfire wear-resisting floor stuff, and the layer thickness is greater than 3mm;(5)do polishing treatment to the floor. This floor has no spark while stricked or abraded by ironware or grinding wheel; surface resistance is between 105 and 109 and electrostatic prevention performance meets the challenge.

Owner:上海恒方防腐工程有限公司

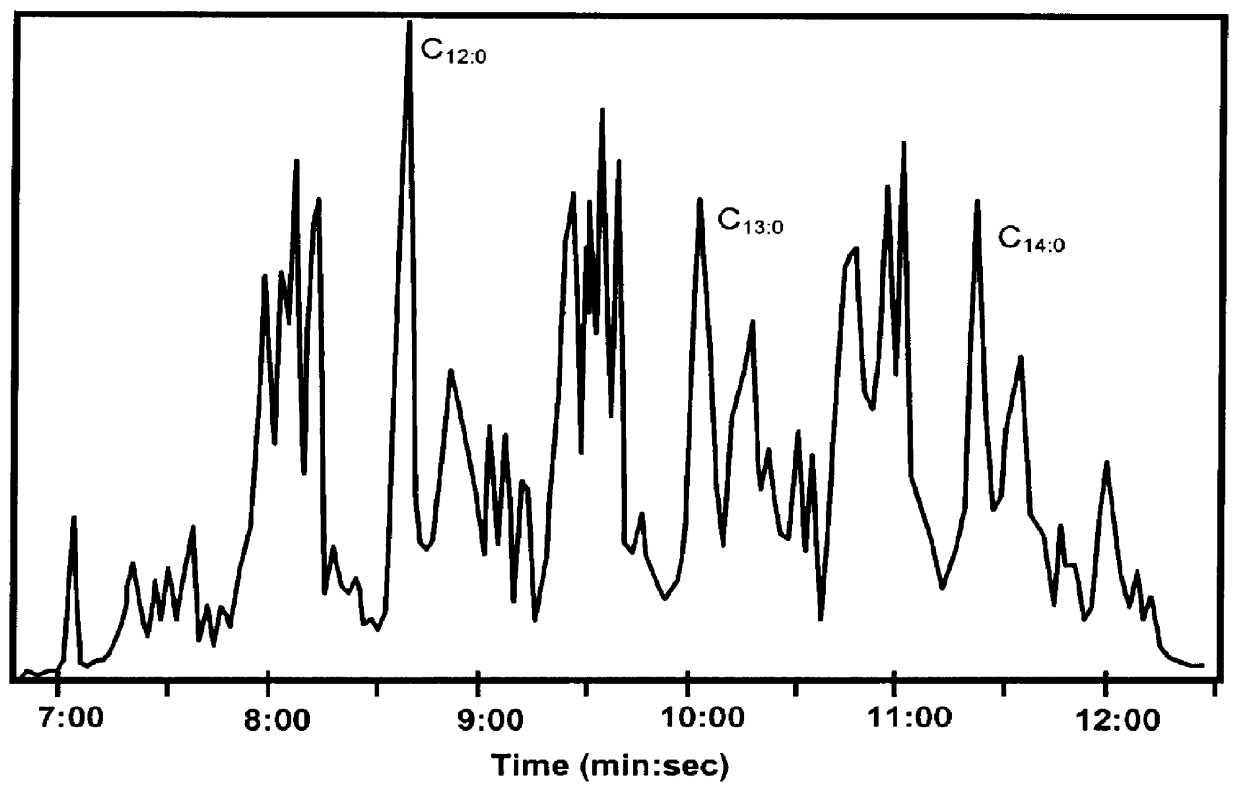

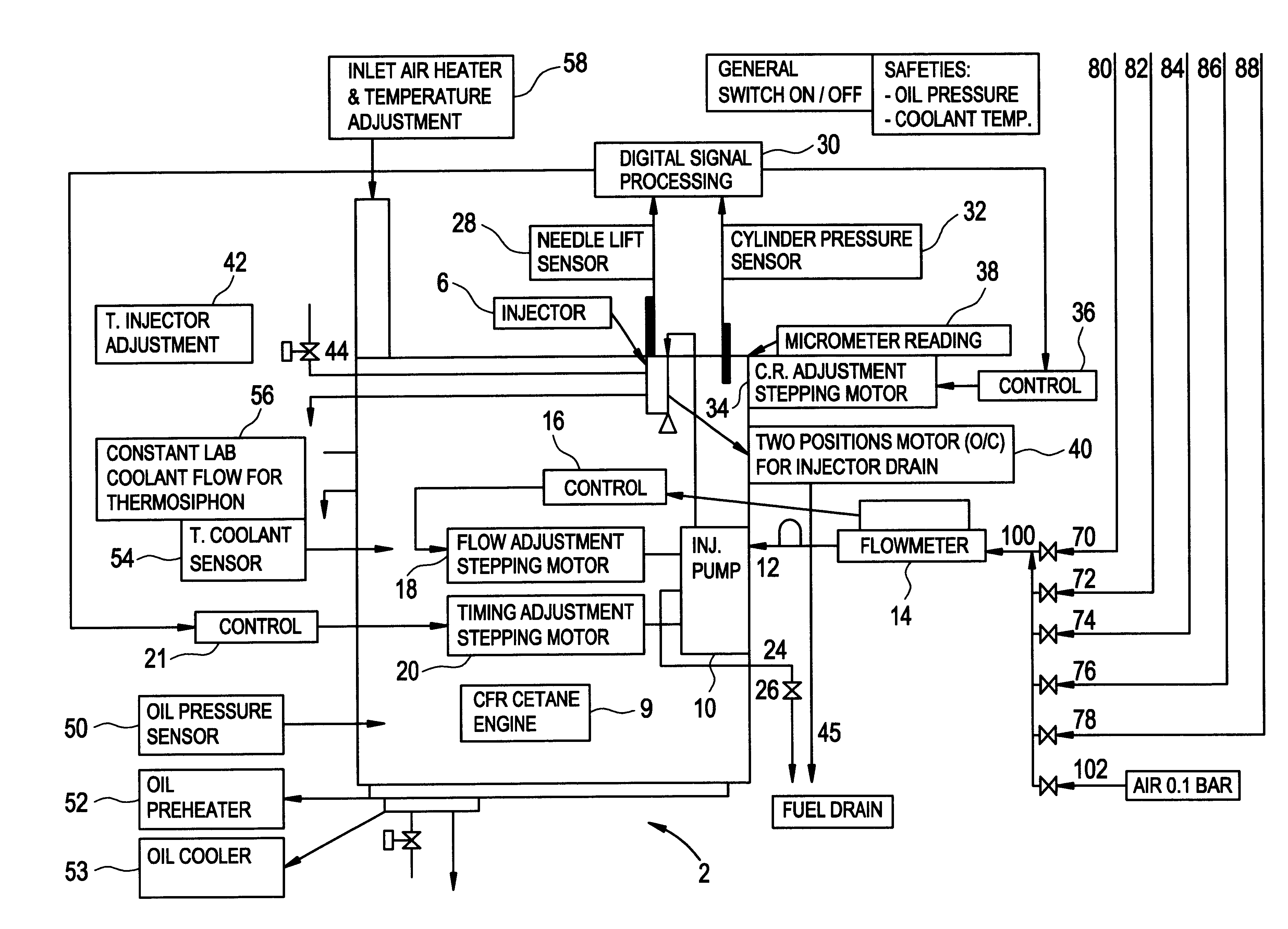

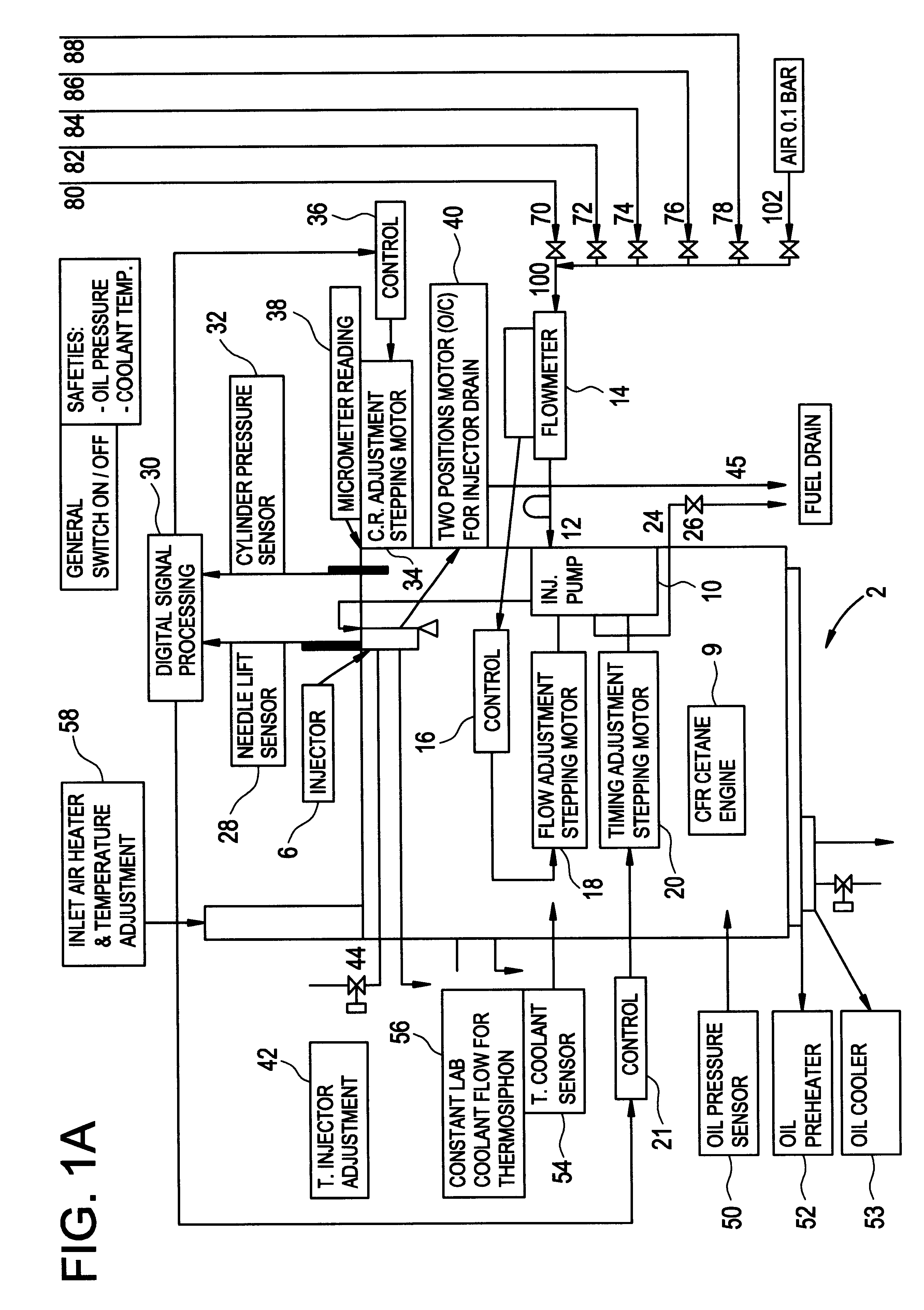

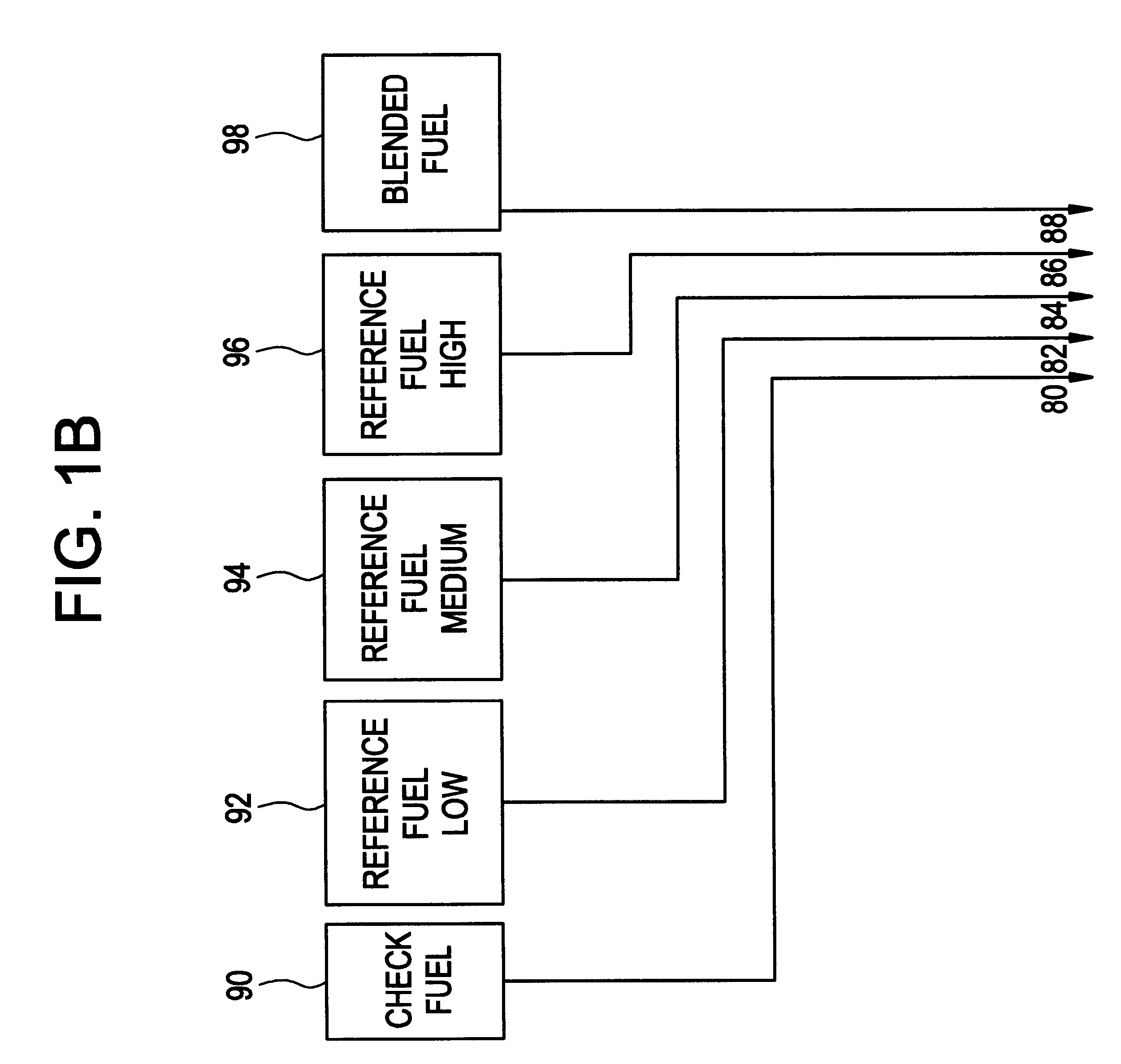

Method and apparatus for measuring cetane number of diesel fuel

A method of continually measuring the cetane number of a diesel fuel, the method comprising the steps of:(a) providing a diesel engine having means for selectively supplying at least three diesel fuels to the engine, a first actuator for varying the injection timing of the engine, a second actuator for varying the fuel flow of the engine, and a third actuator for varying the compression ratio of the engine;(b) providing a first supply of a diesel fuel of known cetane number, a second supply of a diesel fuel of different known cetane number and a third supply of a diesel fuel of unknown cetane number to be measured, the third supply being connected to a diesel fuel blending system;(c) in a first cycle selectively and alternately supplying the first, second and third supplies to the diesel engine, and for each supply, controlling the first actuator to achieve an injection timing of a predetermined angle before top dead centre, controlling the second actuator to achieve a predetermined fuel flow and controlling the third actuator to achieve a predetermined diesel fuel ignition delay by varying the compression ratio of the engine;(d) determining the cetane number of the third supply by linear interpolation of the pre-chamber plug positions, corresponding with the respective compression ratio values, for the three supplies; and(e) periodically repeating steps (c) and (d) in further cycles to yield a series of cetane number values of the third supply.

Owner:FINA RES SA

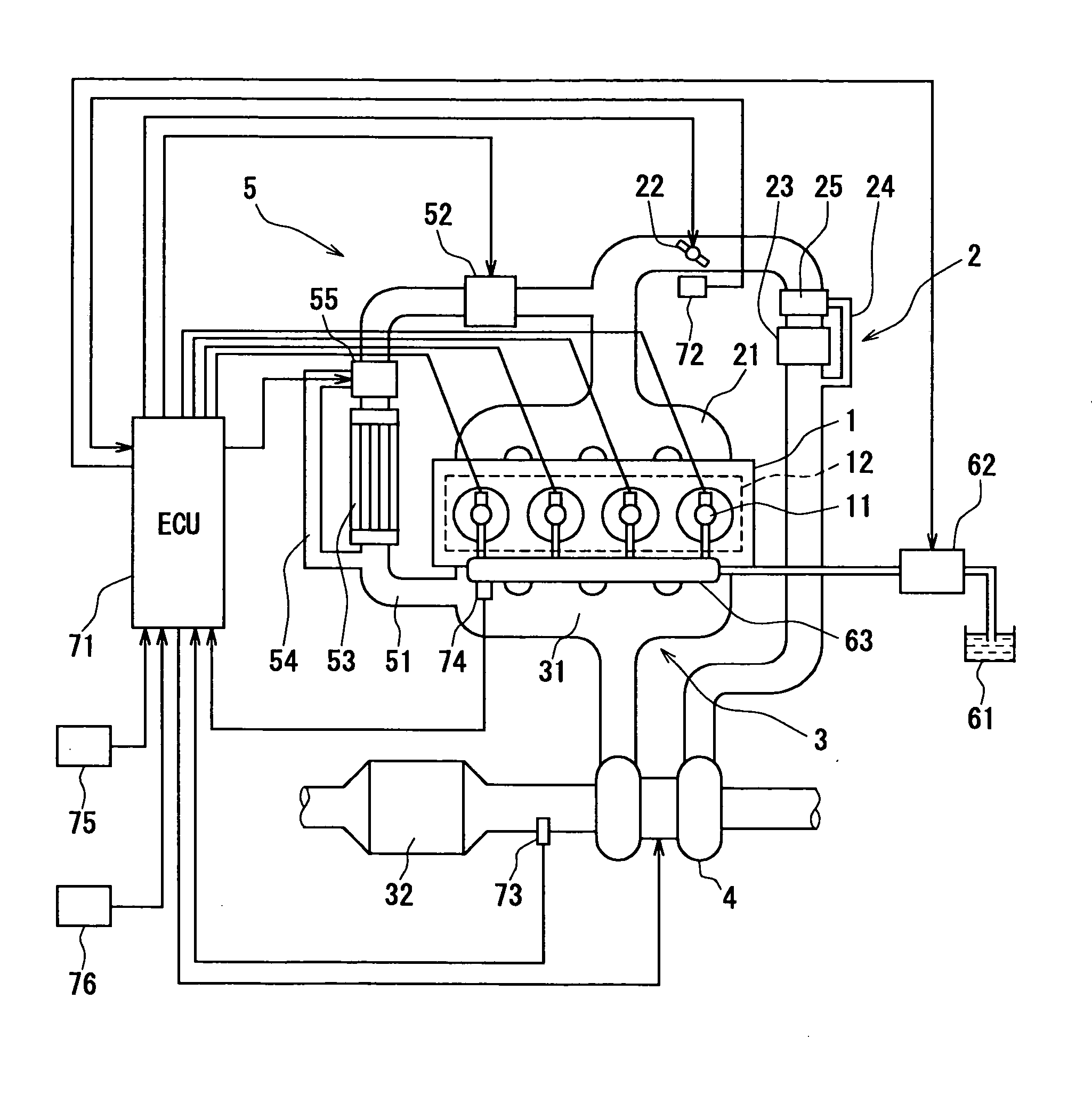

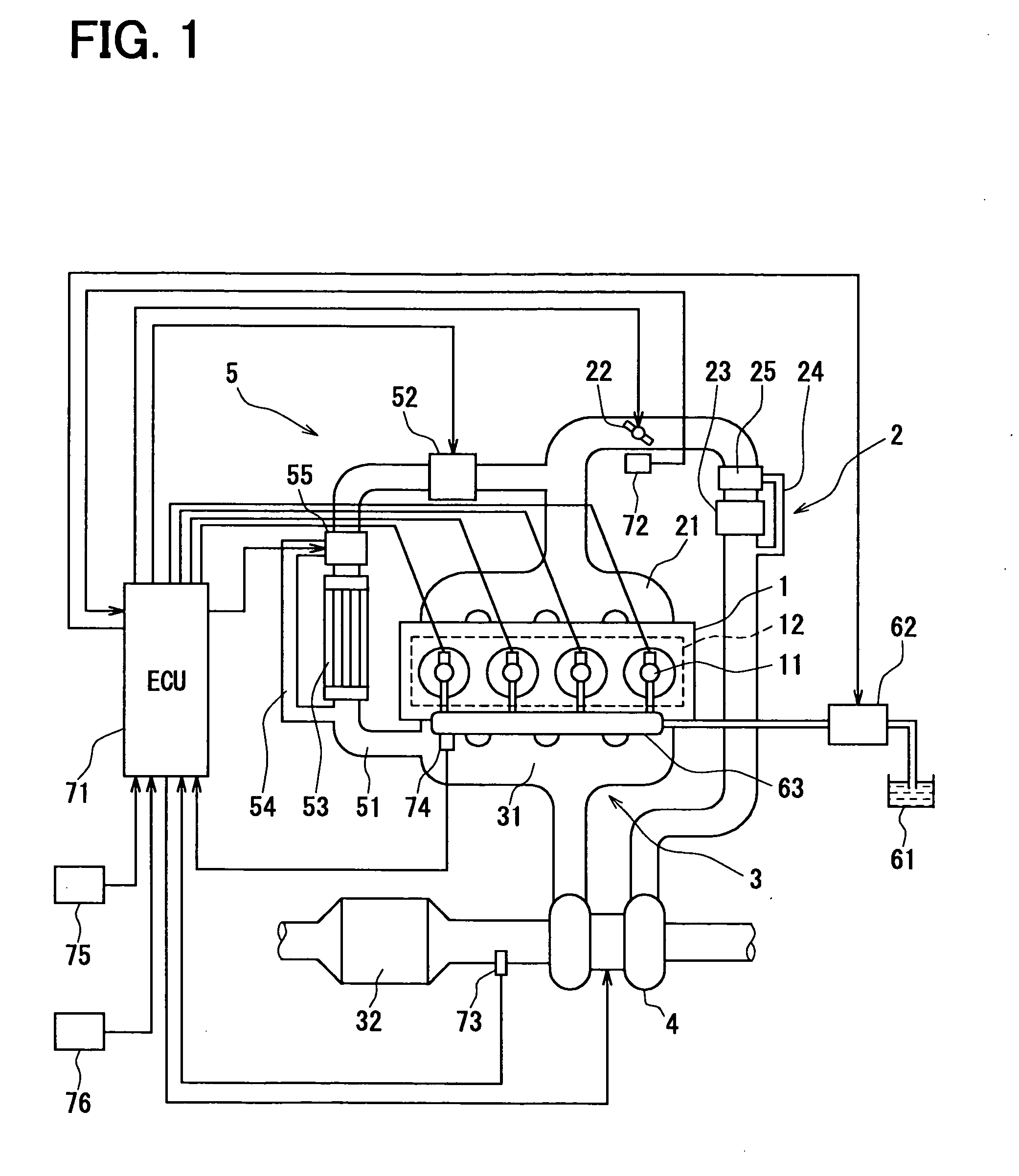

Combustion control apparatus of internal combustion engine

ActiveUS20120143479A1Improve exhaust emissionsPromote combustionElectrical controlInternal combustion piston enginesExternal combustion engineIgnition delay

During high-load operation of an engine, fuel for initial slow-burning combustion and premixed combustion is injected into a combustion chamber by continuous fuel injection, then fuel injection is paused, and fuel for diffusion combustion is injected after a predetermined interval has elapsed. Also, the fuel injection amount in the continuous fuel injection is set higher than the fuel injection amount for diffusion combustion. A spray autointerference cooling effect is achieved by the continuous fuel injection, thus promoting ignition delay so as to increase the proportion of premixed combustion, thereby suppressing the production of smoke. This enables high-volume EGR to be performed, thus enabling reducing the amount of NOx produced.

Owner:TOYOTA JIDOSHA KK

Engine exhaust gas purifier

InactiveUS20080022972A1Inhibit productionEmission reductionElectrical controlNon-fuel substance addition to fuelCombustion chamberTop dead center

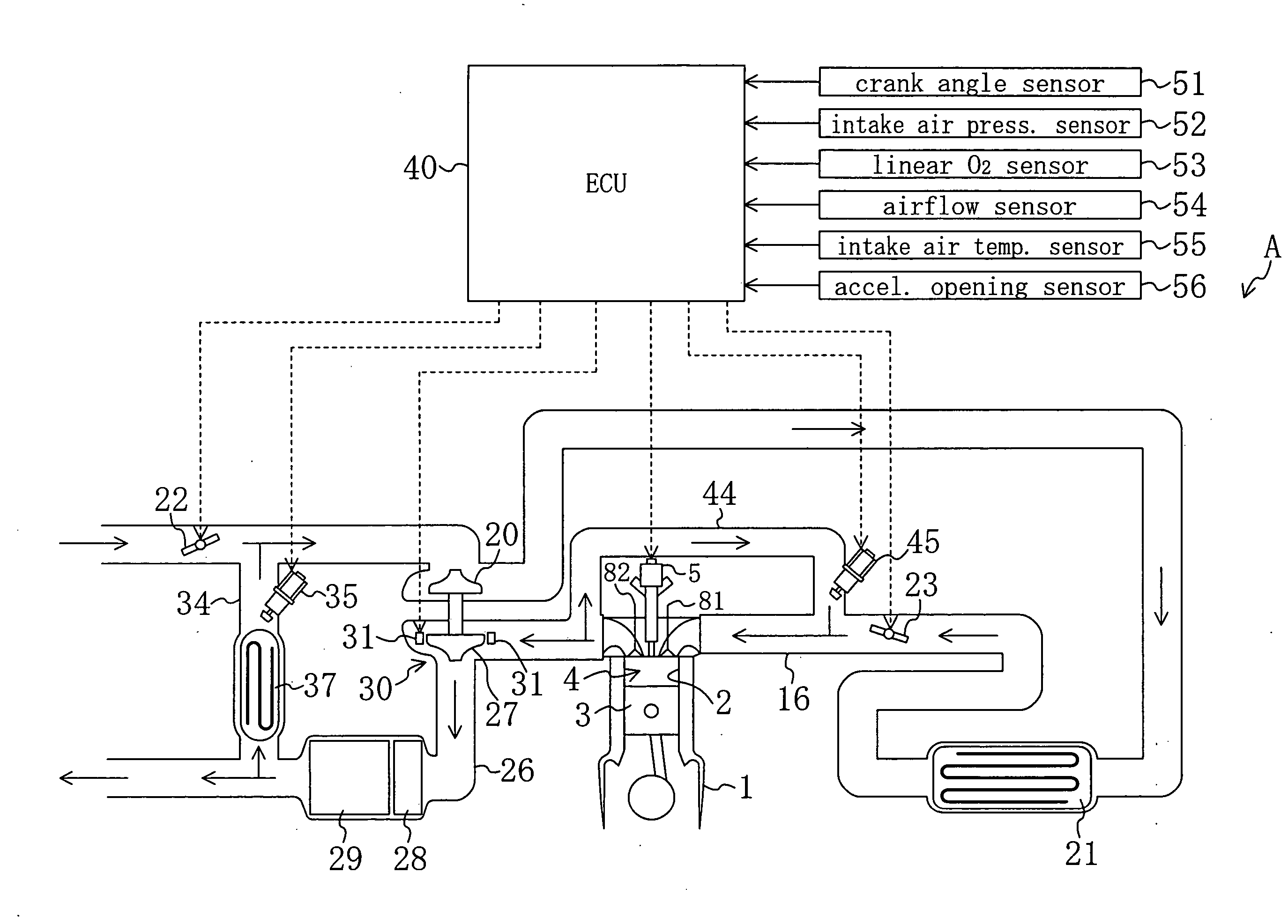

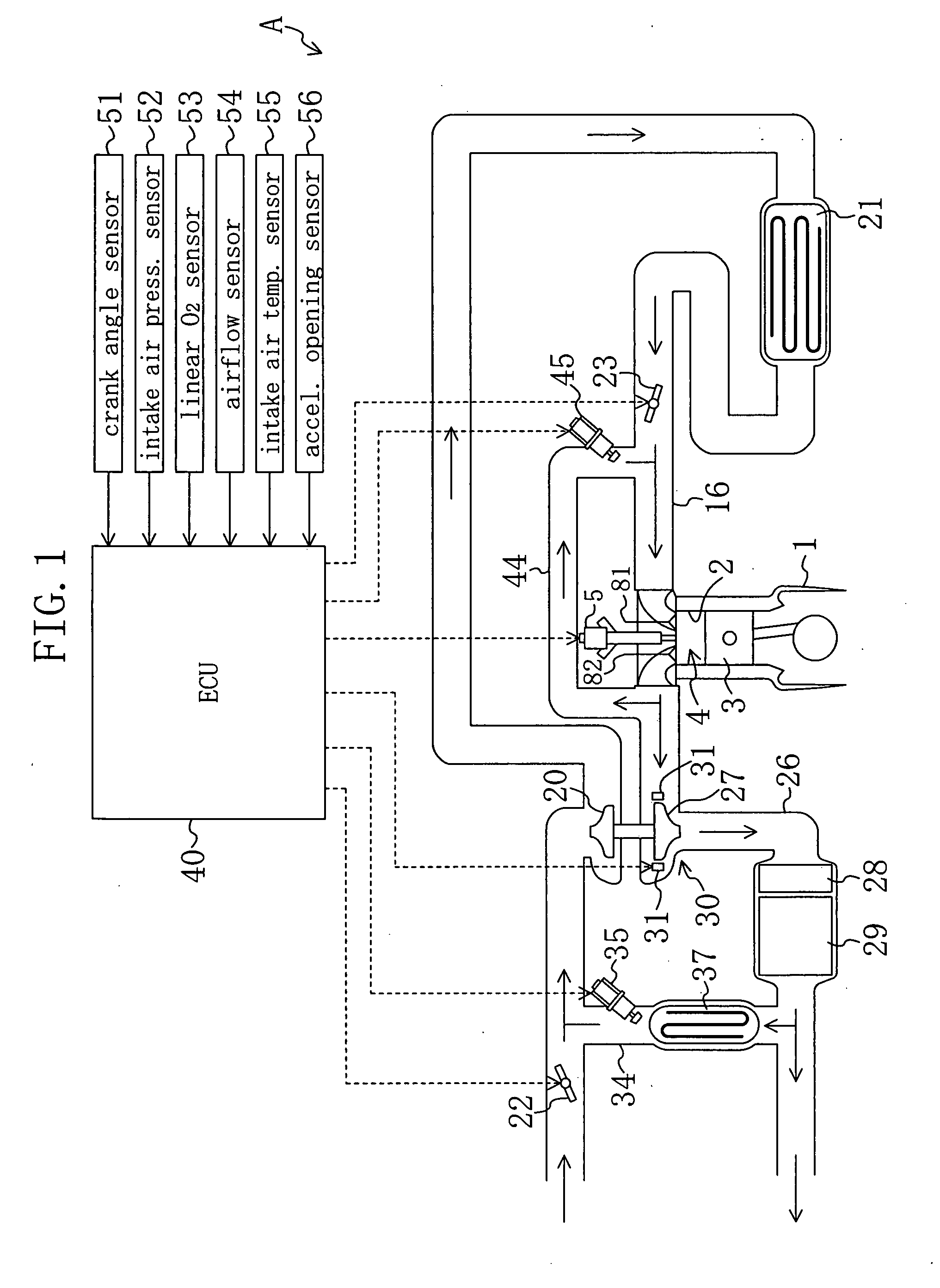

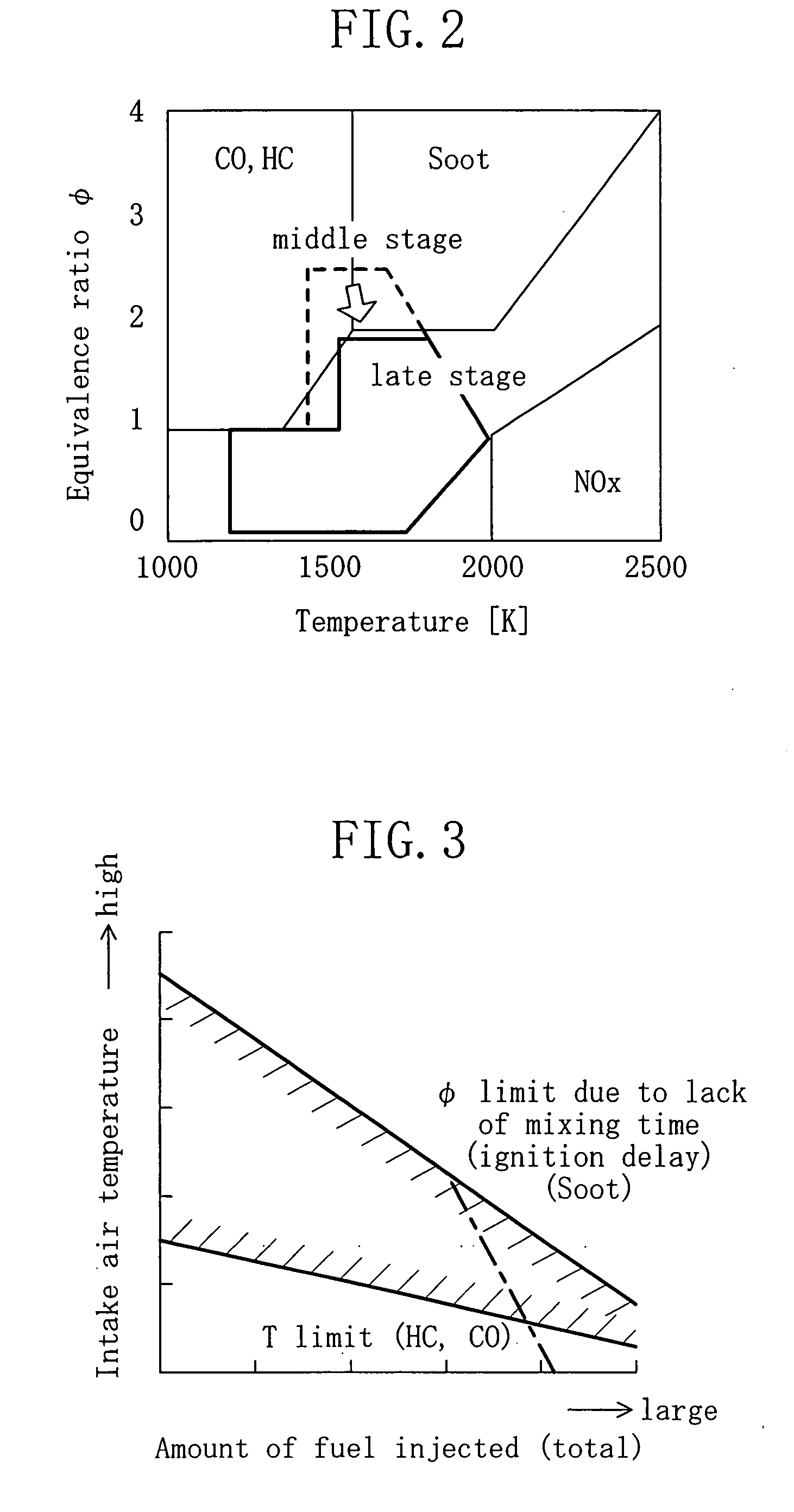

An engine exhaust gas purifier includes: an injection controller allowing a fuel injection valve to inject fuel near the top dead center on each compression stroke; an EGR amount controller for controlling the amount of exhaust gas recirculated into a combustion chamber; an excess air ratio controller for controlling the excess air ratio so that the local equivalence ratio in a late combustion stage is lower than the equivalence ratio at which soot is produced; and an intake air temperature controller for controlling the temperature of intake air after being mixed with exhaust gas. The intake air temperature controller controls the temperature of intake air within a temperature range lower than an upper temperature limit below which a predetermined ignition delay time can be secured and higher than a lower temperature limit above which the production of HC and CO can be avoided.

Owner:MAZDA MOTOR CORP

Gas turbine with water injection

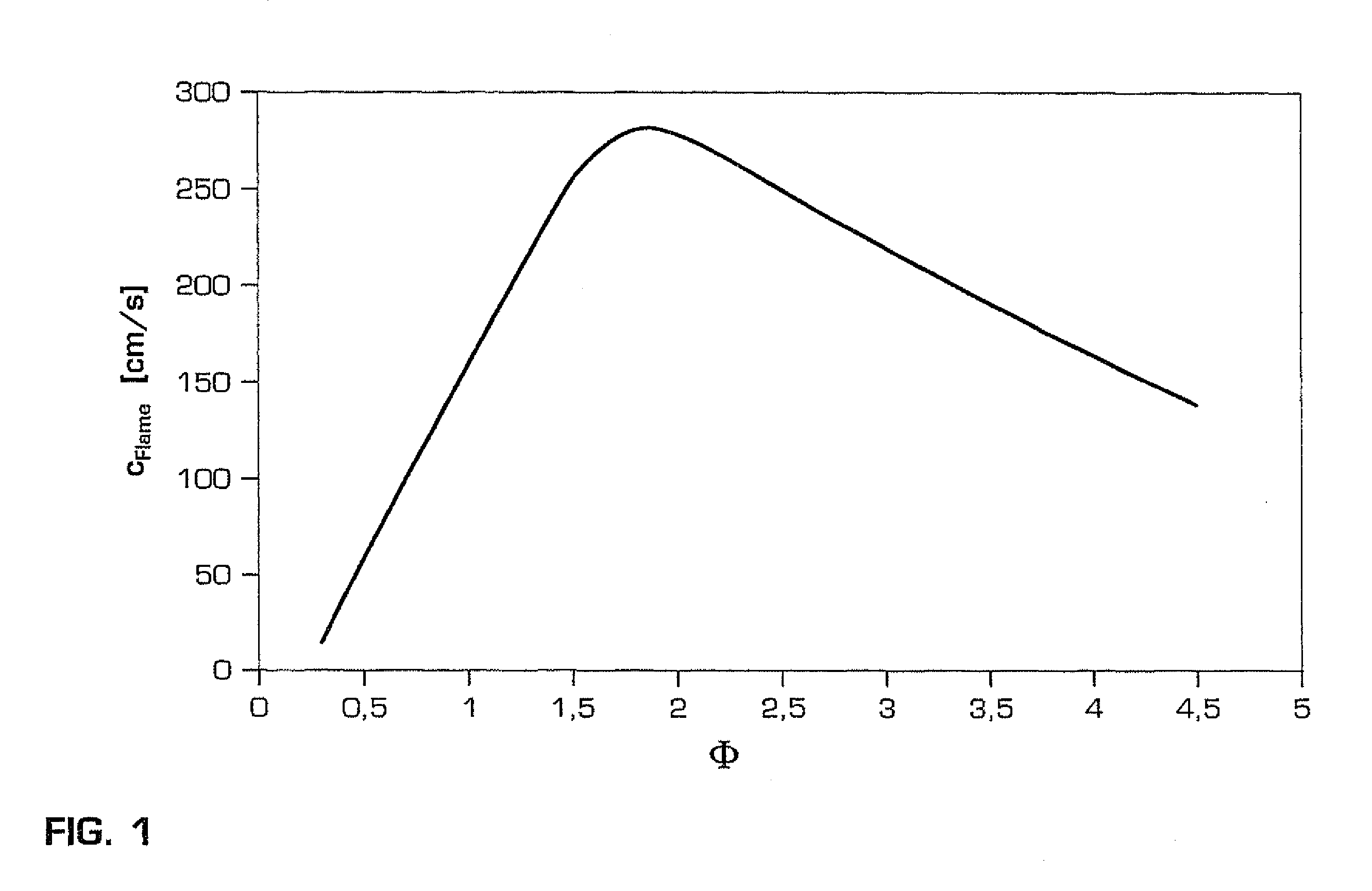

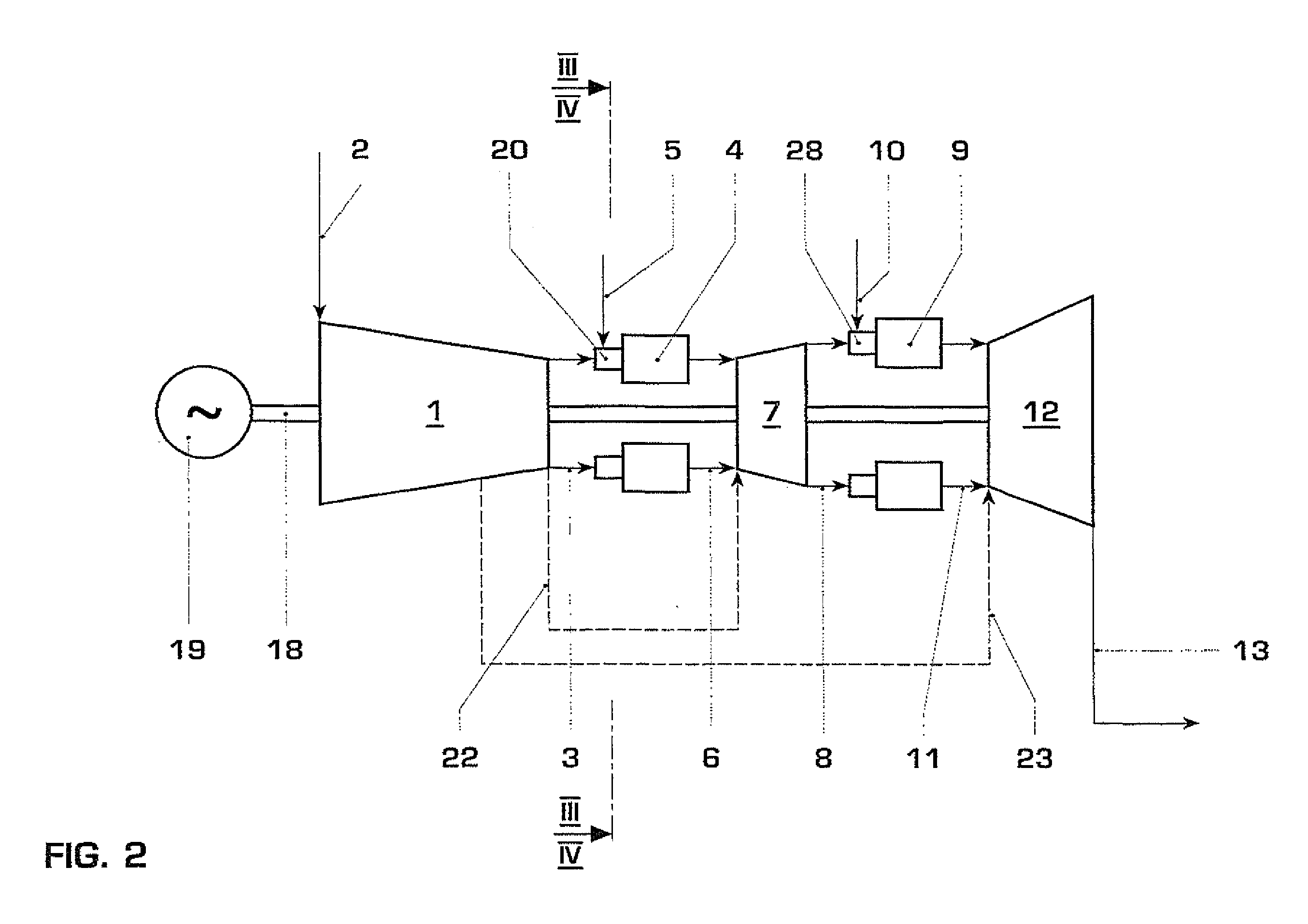

ActiveUS20100146984A1Reduce burnShorten speedContinuous combustion chamberGaseous fuel feeder/distributionHydrogenCombustor

Reliable, low-NOx-emission operation of a gas turbine plant with hydrogen-rich fuel gas, and a gas turbine plant with a device for water injection into hydrogen-rich fuels in a gas turbine, involves suitable water injection (21), a water-fuel gas mist, i.e., a fuel gas in which fine water droplets are suspended, is created in the fuel gas feed line (15). This mist is introduced into the burners (20) of the gas turbine. As a result of the water-fuel gas mist, four effects are combined for ignition delay and reduction of the flame velocity of hydrogen-rich fuel gas. When using a water-fuel gas mist, the water, in a directed manner, reaches the region in the burner (20) in which it directly has the greatest possible effect upon the flame or the flame velocity.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Compression ignition internal combustion engine

InactiveUS20050092286A1Strong penetrating powerImprove atomization abilityElectrical controlInternal combustion piston enginesIgnition delayInternal combustion engine

A compression ignition engine injects fuel through injection holes of an injector at a substantially constant injection rate to atomize the fuel so that the fuel can be easily vaporized and to make the fuel penetrate an atmosphere inside a cylinder. A spatial distribution of the injected fuel in which mixing of the fuel and air is promoted as the fuel recedes from the injection hole and the fuel reaches a premixing space where the fuel is premixed with the air is provided. The engine controls oxygen concentration inside the cylinder and an ignition delay so that a ratio of a quantity of the fuel injected before a start of ignition to a total fuel injection quantity falls within a range from 25% to 50% and so that the premixed gas formed in the premixing space is combusted serially.

Owner:DENSO CORP

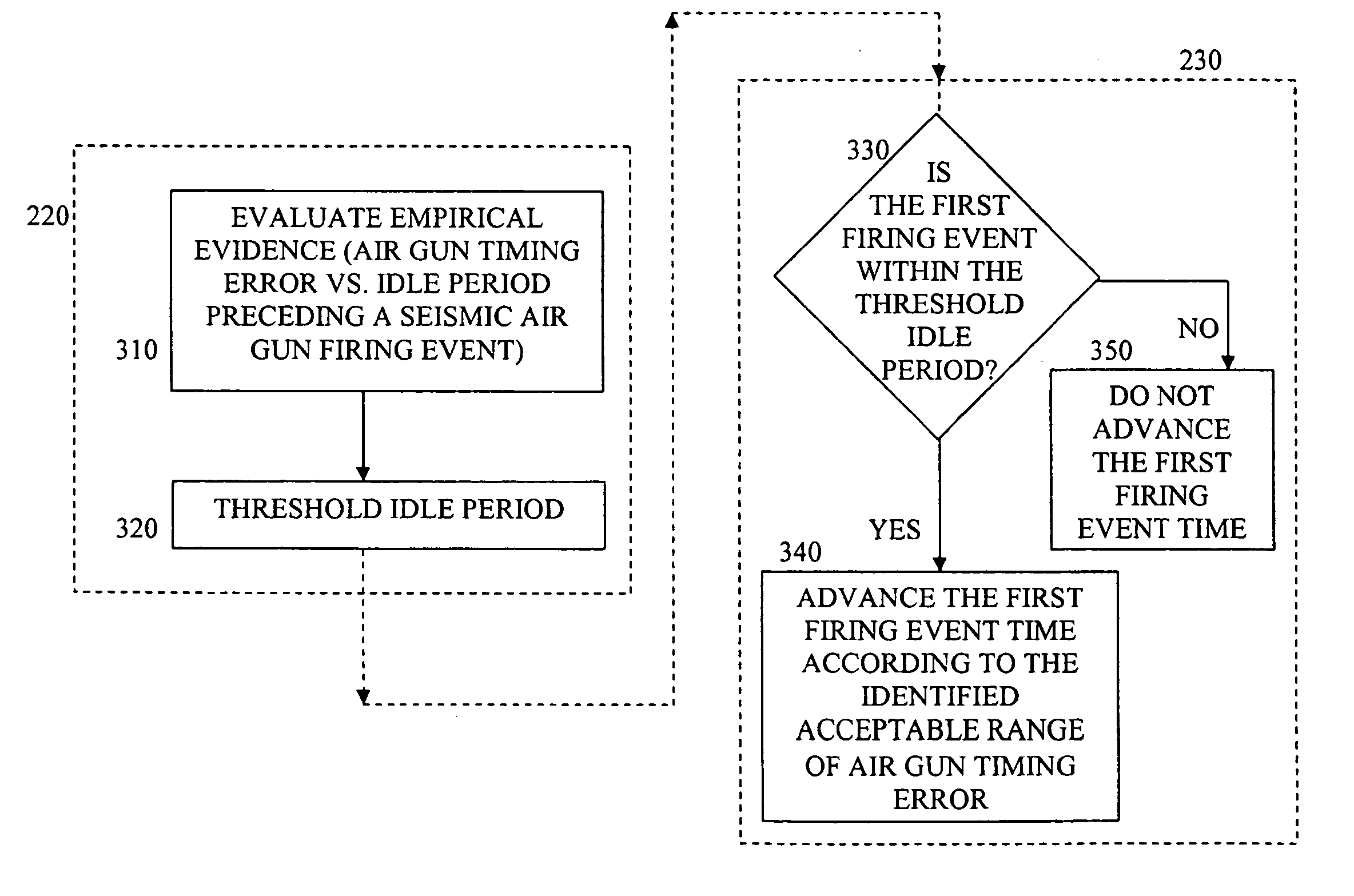

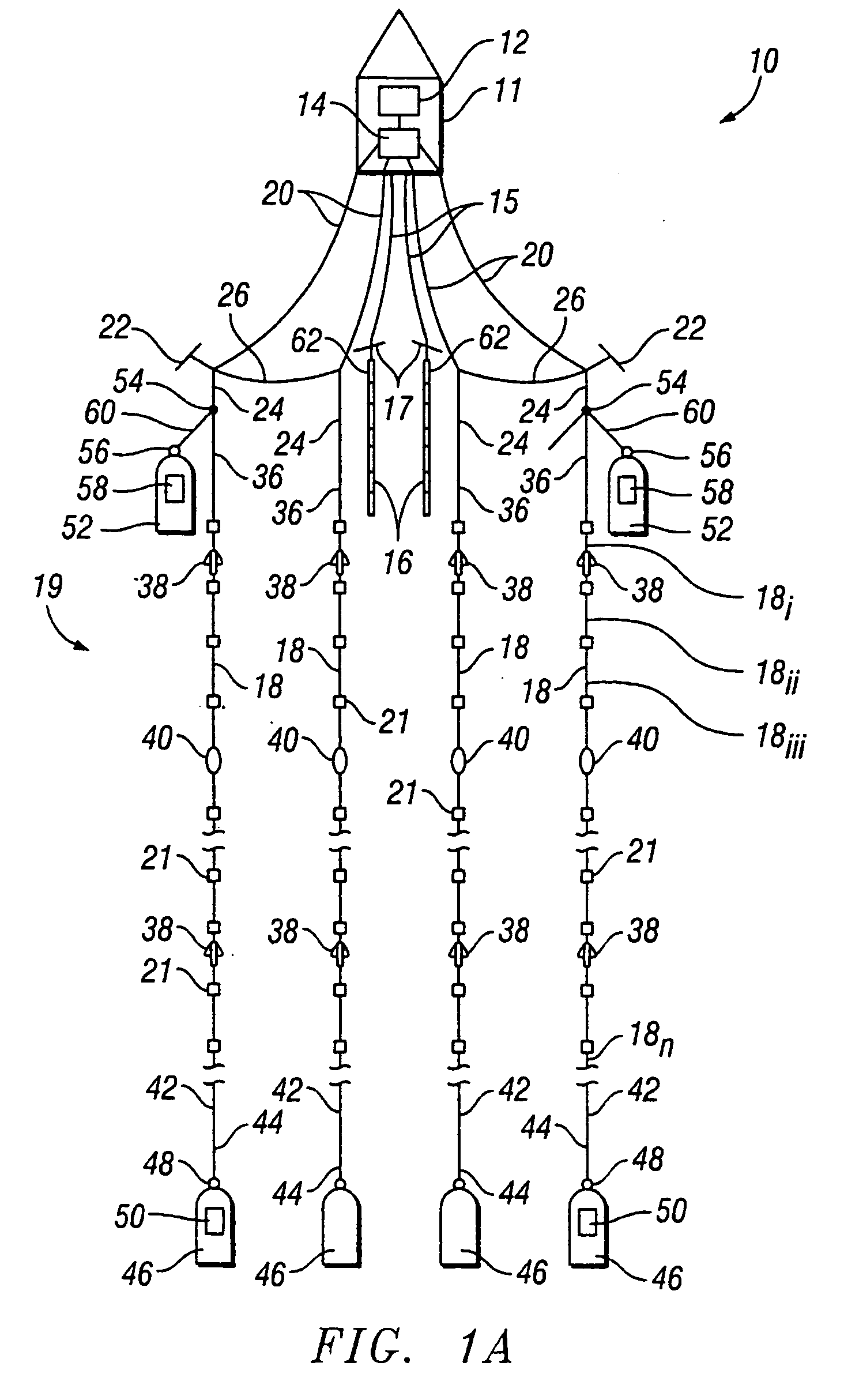

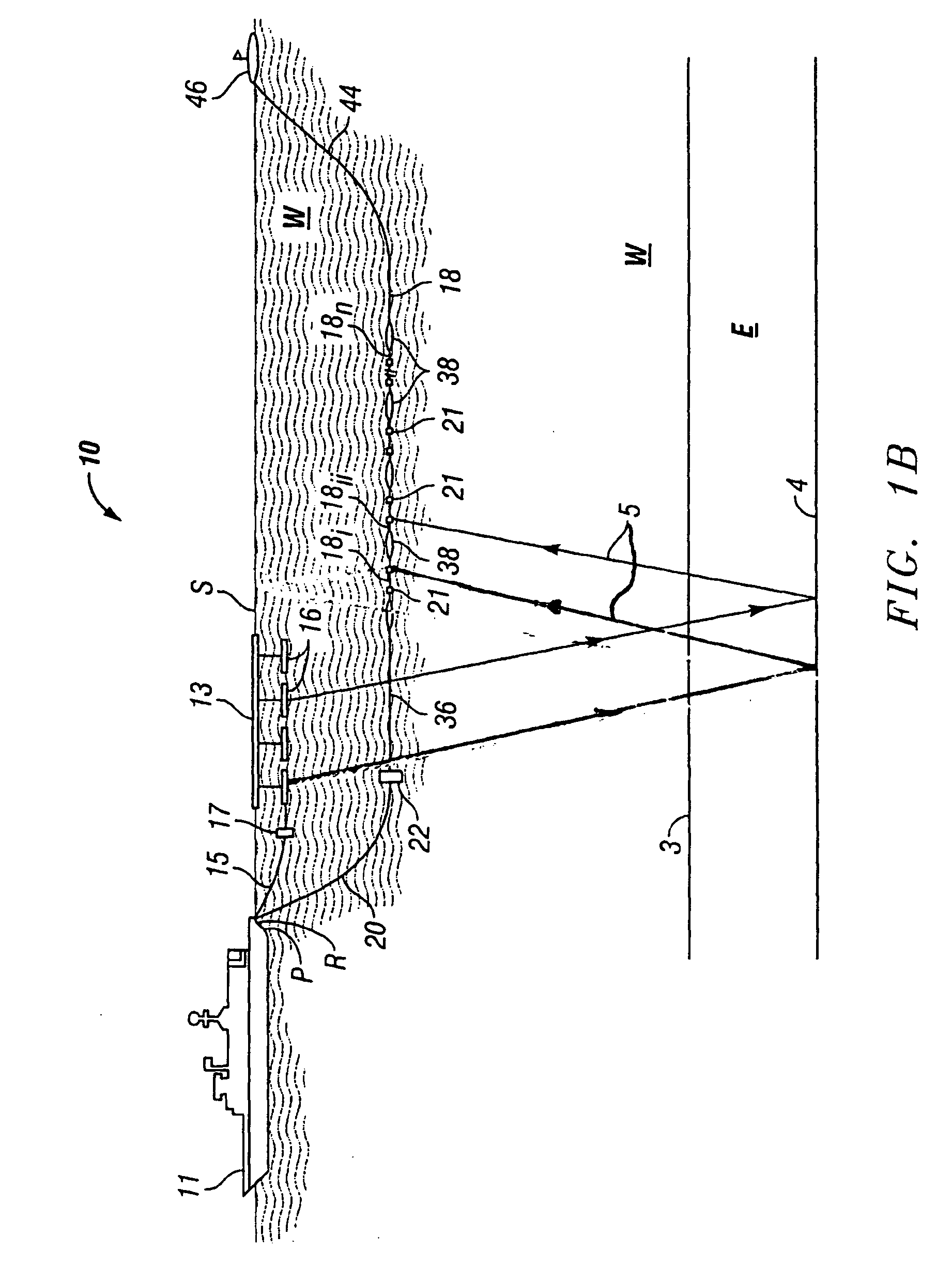

Marine seismic air gun timing

InactiveUS20070115757A1Avoid changeSeismic energy generationSeismology for water-covered areasIgnition delayEngineering

A method for controlling timing error in the firing of an idle seismic air gun comprises the steps of identifying an acceptable range of seismic air gun timing error, and identifying a relationship between seismic air gun timing error and an idle period preceding a seismic air gun firing event. The first firing event time following an idle period is then compensated according to the identified relationship to control the timing error within the identified acceptable range. The invention may be implemented using computer means such as machine-readable storage media. The invention may be applied to advantage when air gun firing delays are experienced, such as during selective changes from one air gun group to another air gun group for purposes of achieving a desired center-of-source position.

Owner:WESTERNGECO LLC

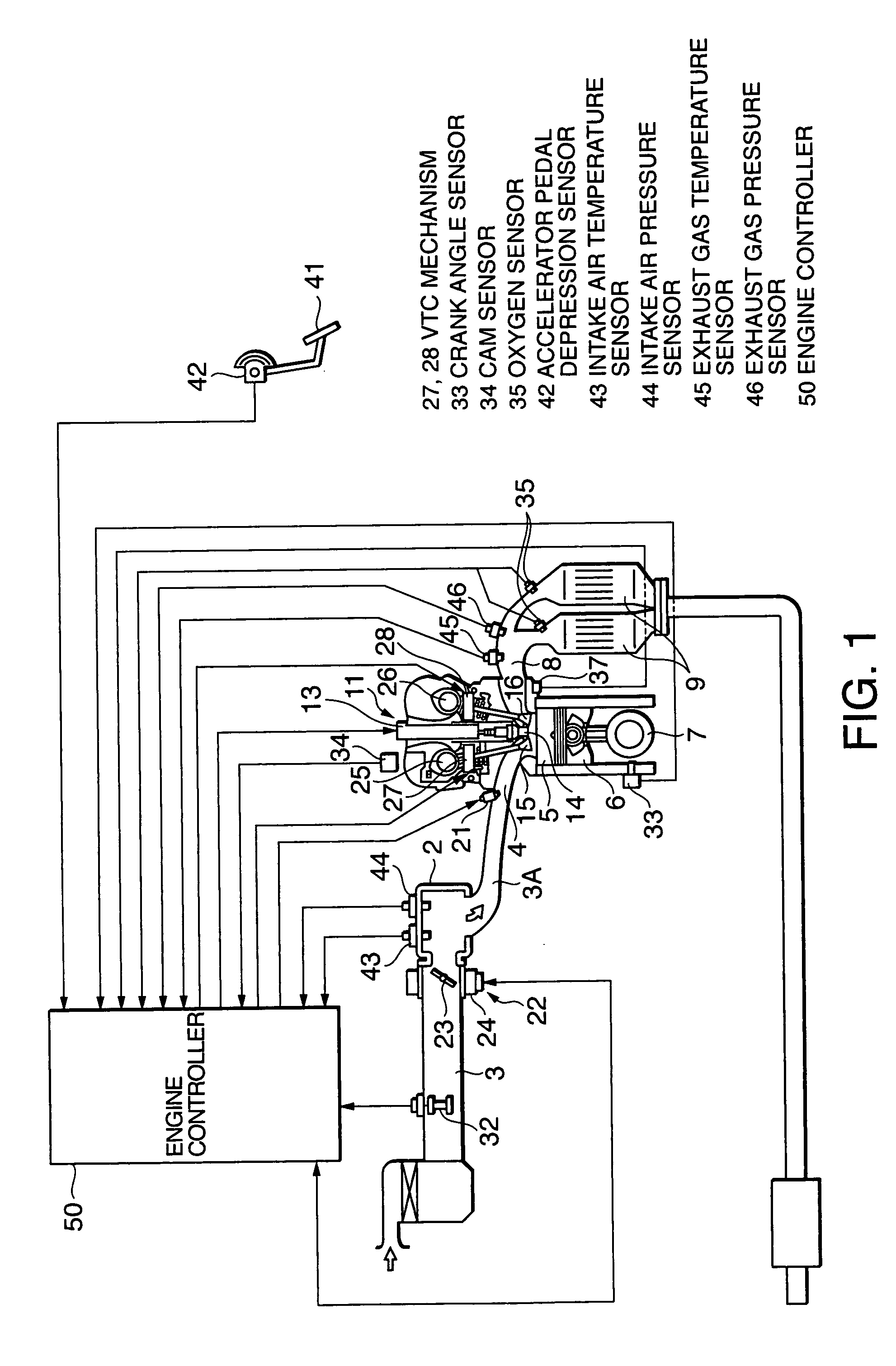

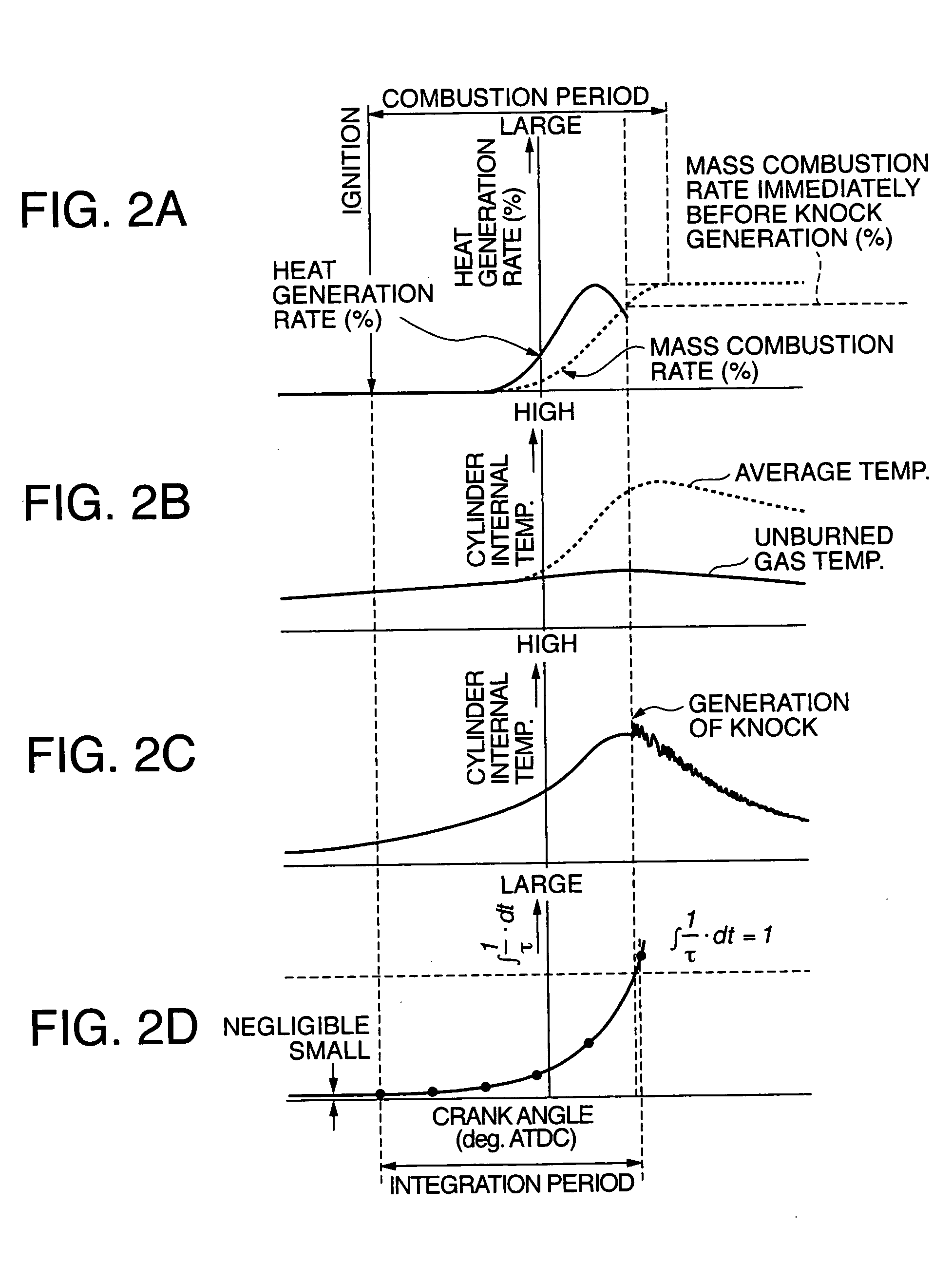

Ignition timing control for internal combustion engine

InactiveUS20050188954A1Easy to controlAnalogue computers for vehiclesElectrical controlIgnition delayIgnition timing

An internal combustion engine (1) causes an air / fuel mixture in a cylinder to combust due to ignition by a spark plug (14). An engine controller (50) calculates an ignition delay of the gas in the cylinder on the basis of an operational state of the engine (1)(53), and it calculates a knock generation index which is an indicator of the occurrence of knock on the basis of the ignition delay (53). The controller (50) calculates a limit ignition timing at which knock is not generated, on the basis of the knock generation index (54), and by controlling the ignition timing of the spark plug (14) to the limit ignition timing (55), appropriate control of the ignition timing is achieved by means of a small number of adaptation steps.

Owner:NISSAN MOTOR CO LTD

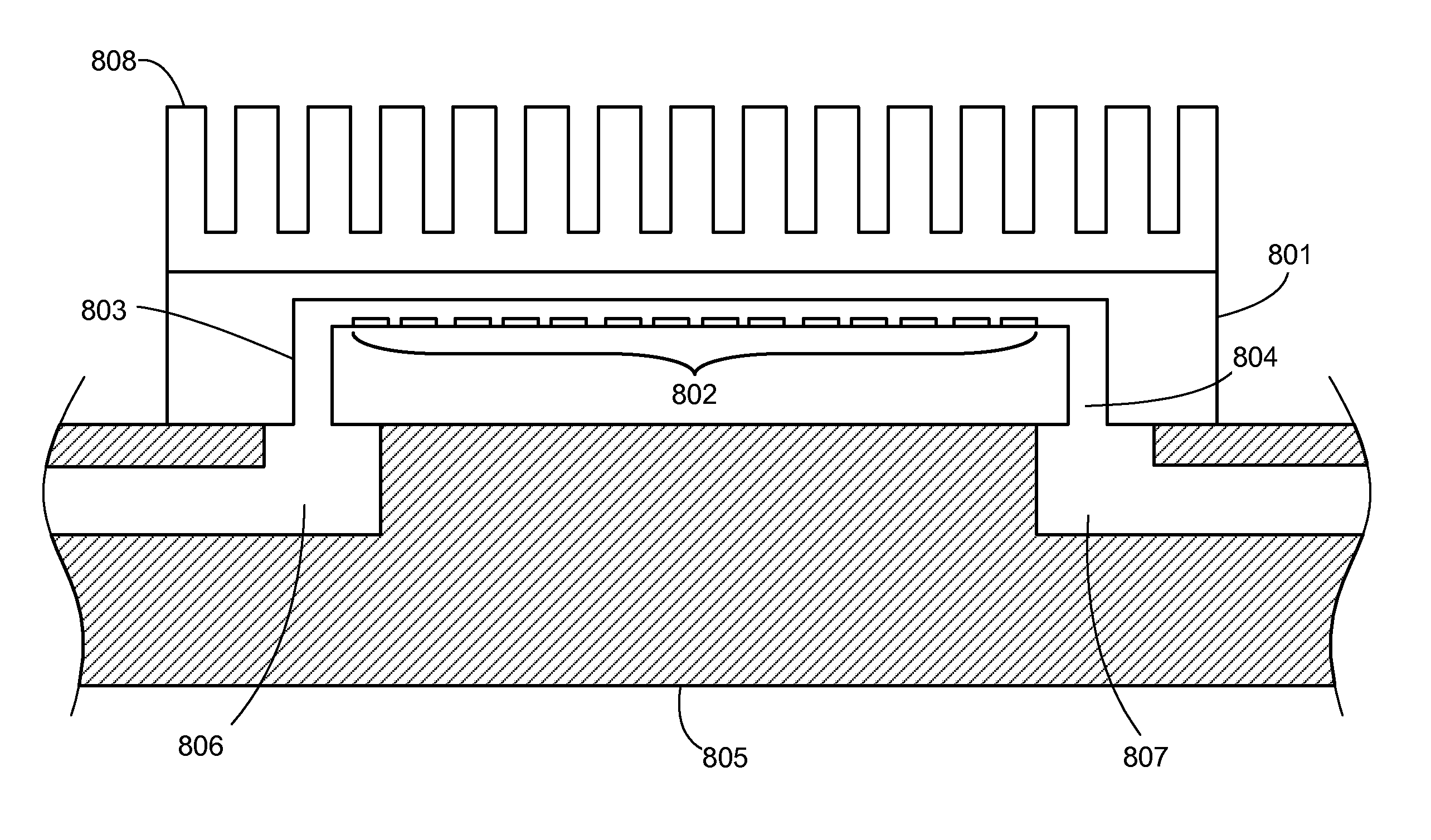

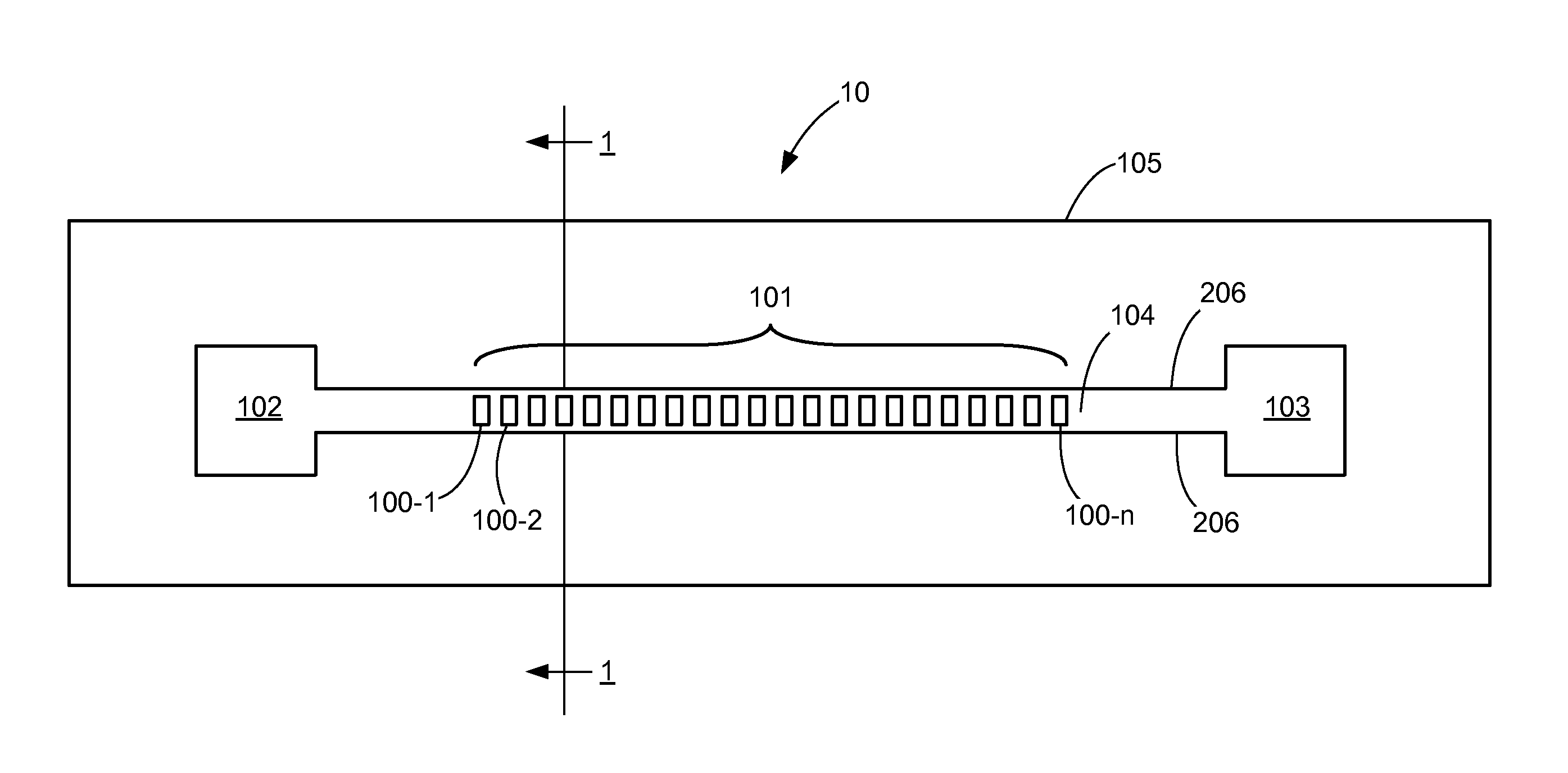

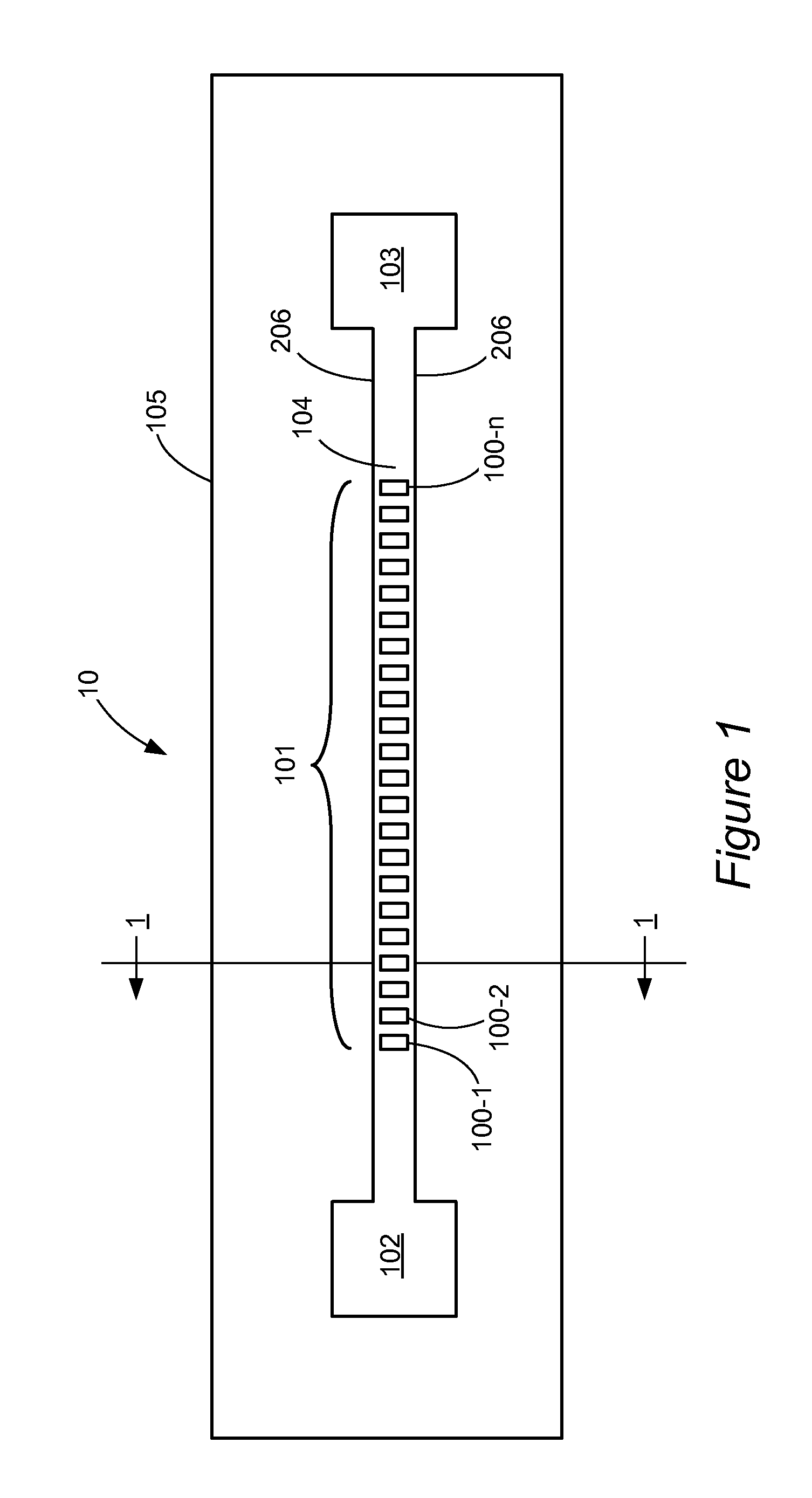

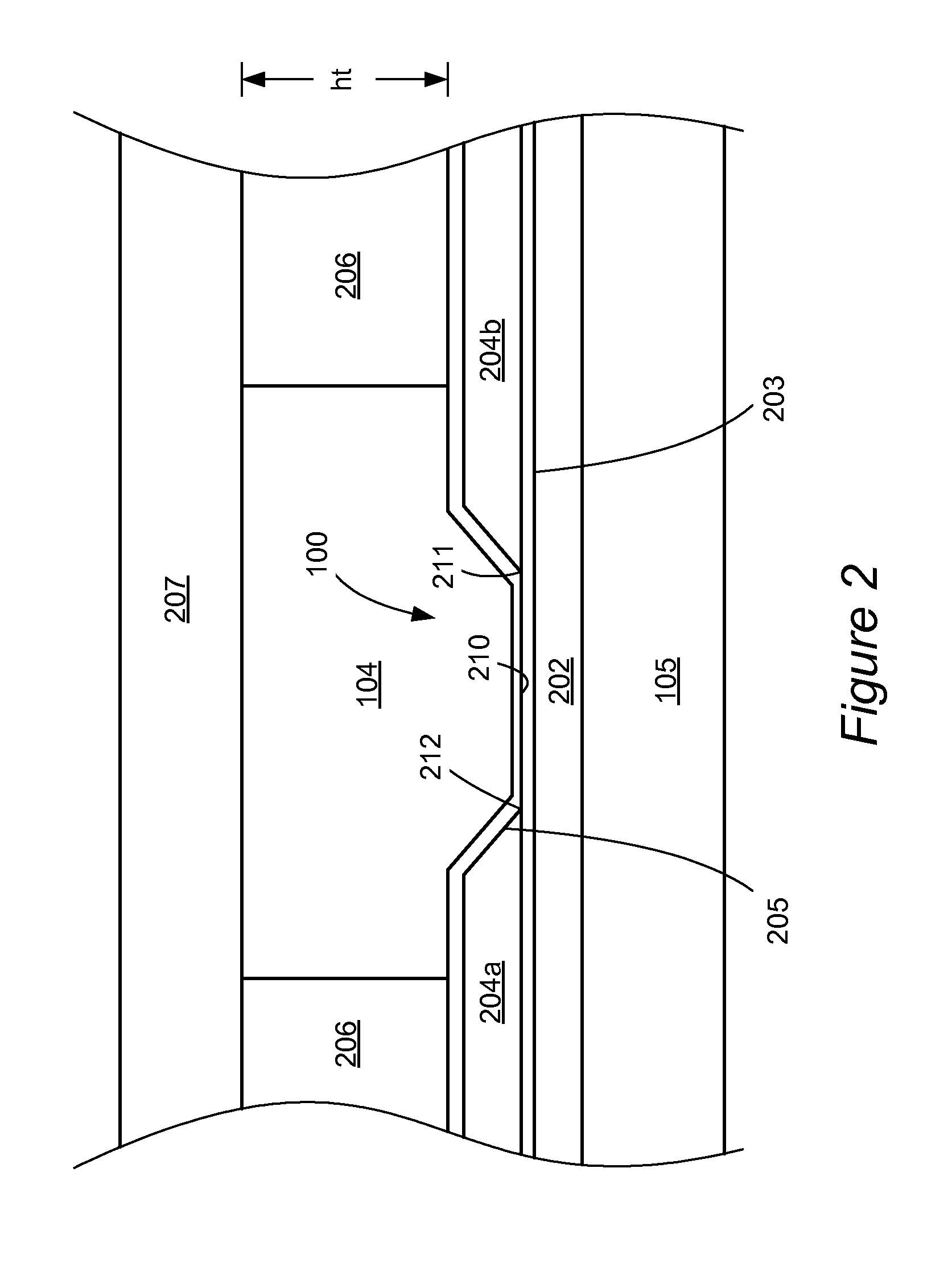

Micro-fluidic pump

A micro-fluidic pump comprises one or more channels having an array of resistive heaters, an inlet, outlet and a substrate as a heat sink and a means of cooling the device. The pump is operated with a fire-to-fire delay and / or a cycle-to-cycle delay to control the pumping rate and minimize heating of liquid inside the pump during its operation.

Owner:SHANGHAI AUREFLUIDICS TECH CO LTD

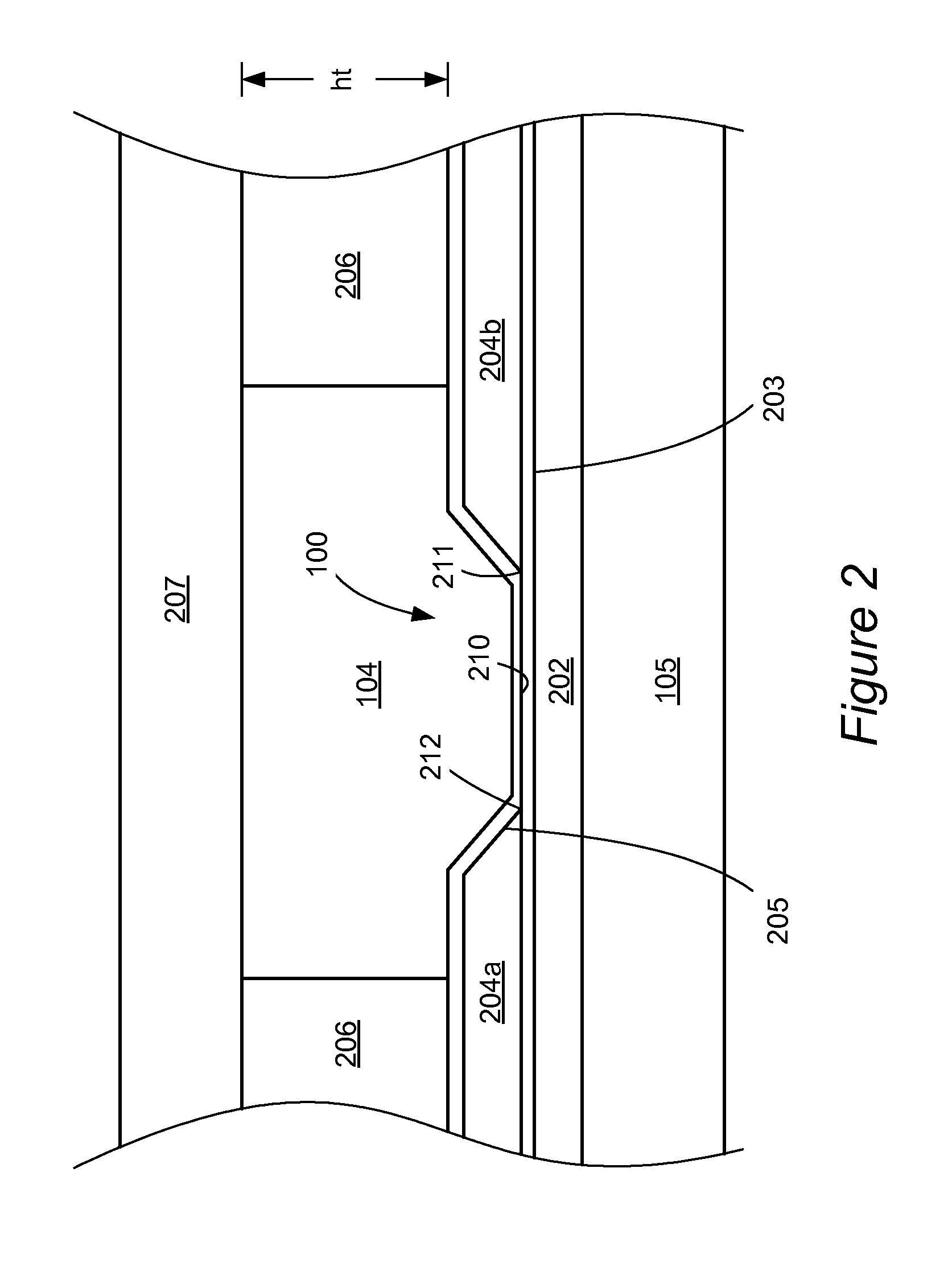

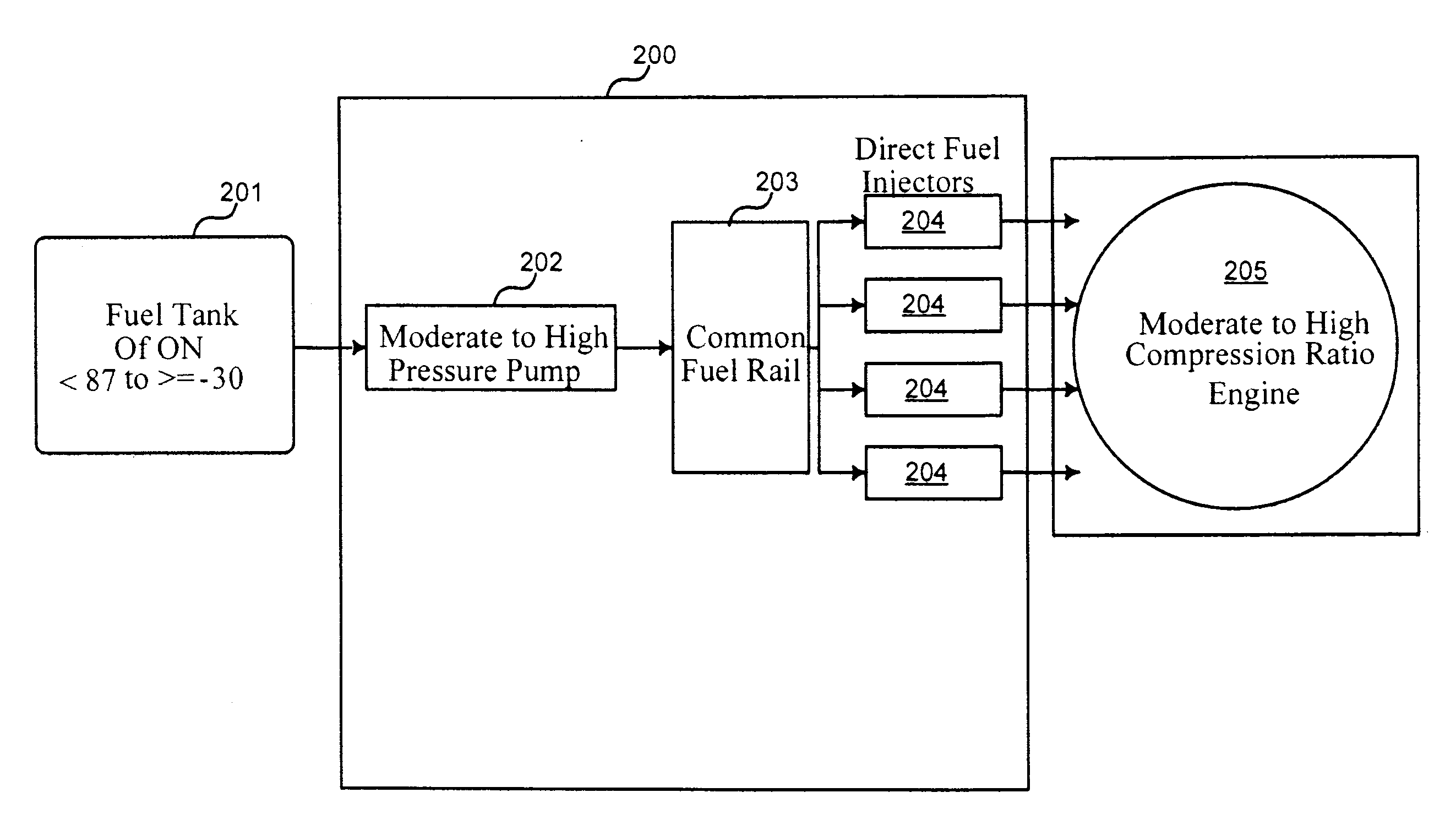

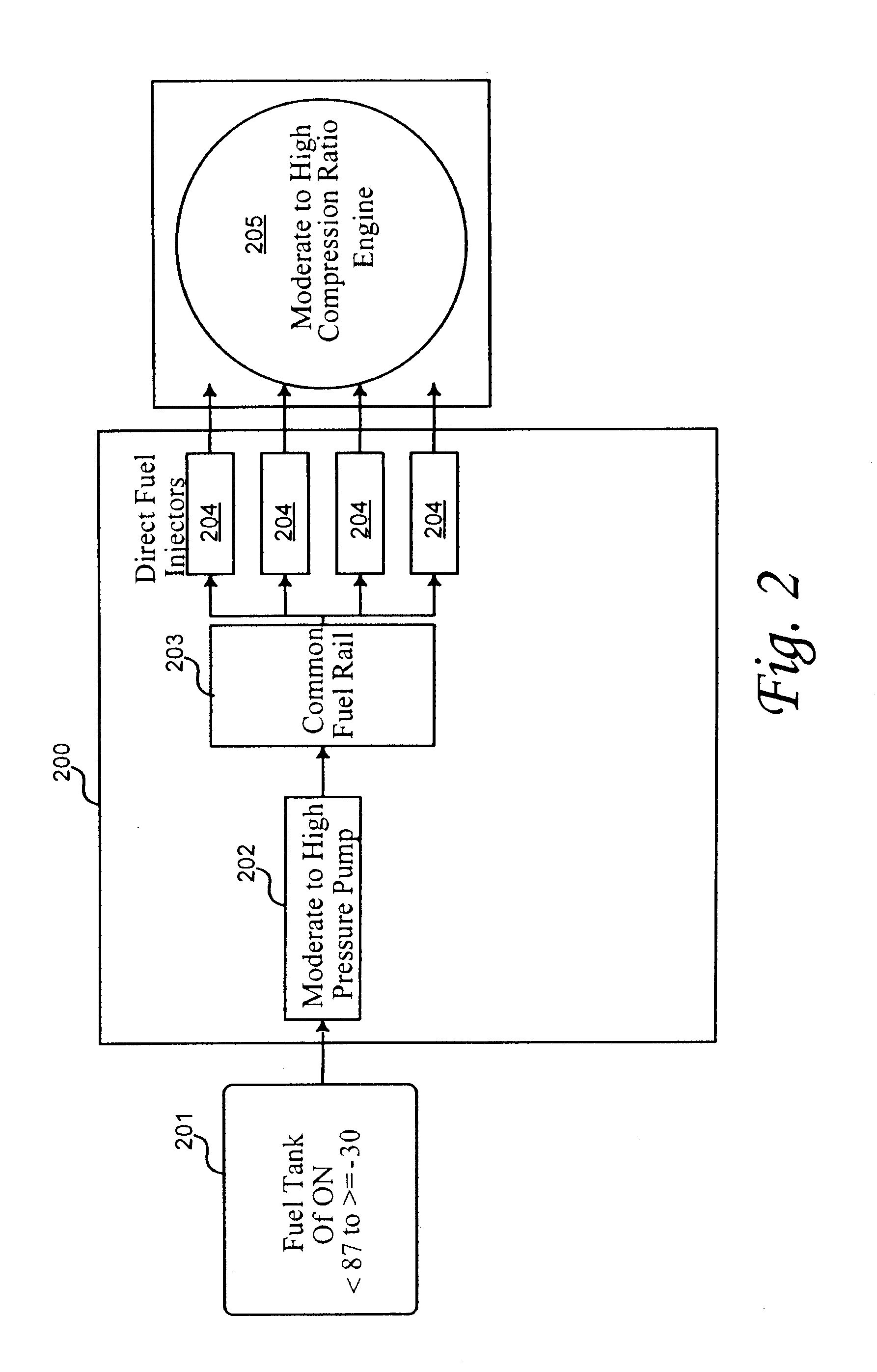

Low octane fuel for gasoline compression ignition

InactiveUS20110209686A1Shorten ignition delayCompression ignition characteristicCombustion enginesSolid fuelsIgnition delayAutomotive fuel

The present invention provides an automotive fuel injection system for a compression ignition engine, comprising a fuel injector configured to receive a fuel having an octane rating between 87 and −30 and configured to meter the fuel into the compression ignition engine, and a heater coupled to the fuel injector and configured to heat the fuel injector such that the fuel is heated to a predetermined minimum temperature, whereby the ignition delay of the fuel is reduced below a predetermined maximum ignition delay.

Owner:TRANSONIC COMBUSTION

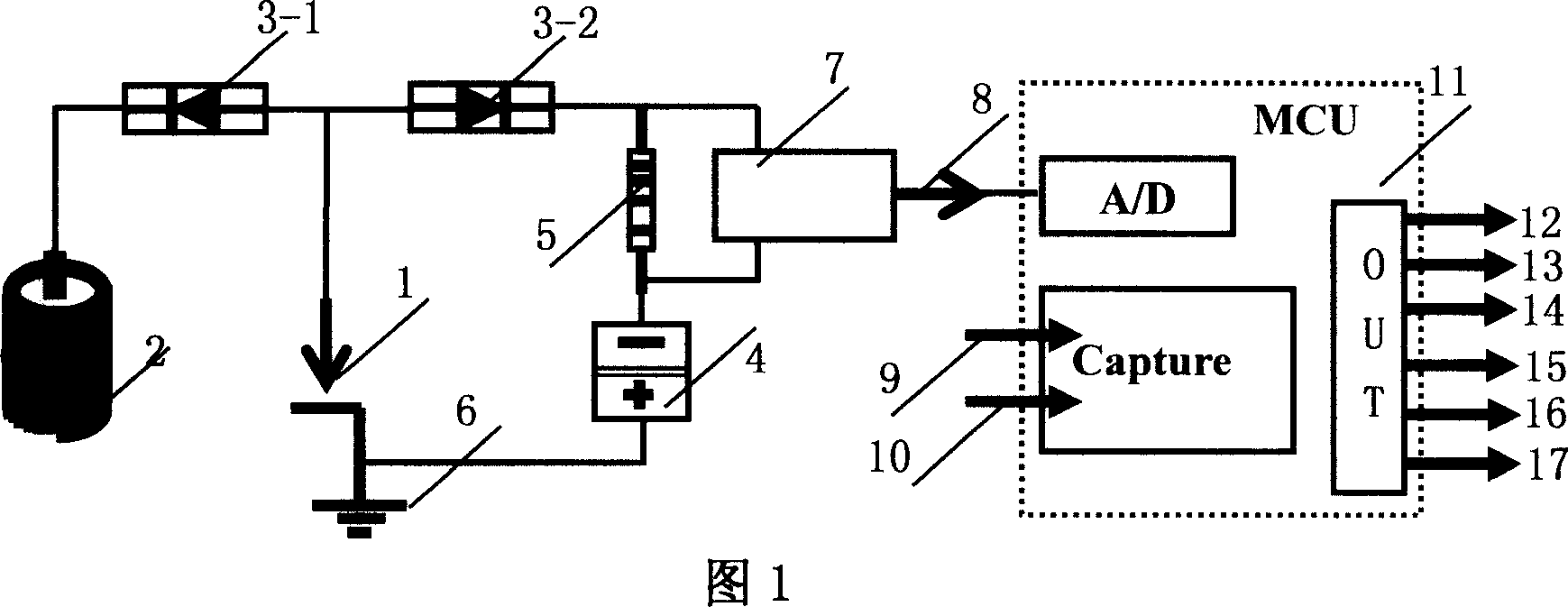

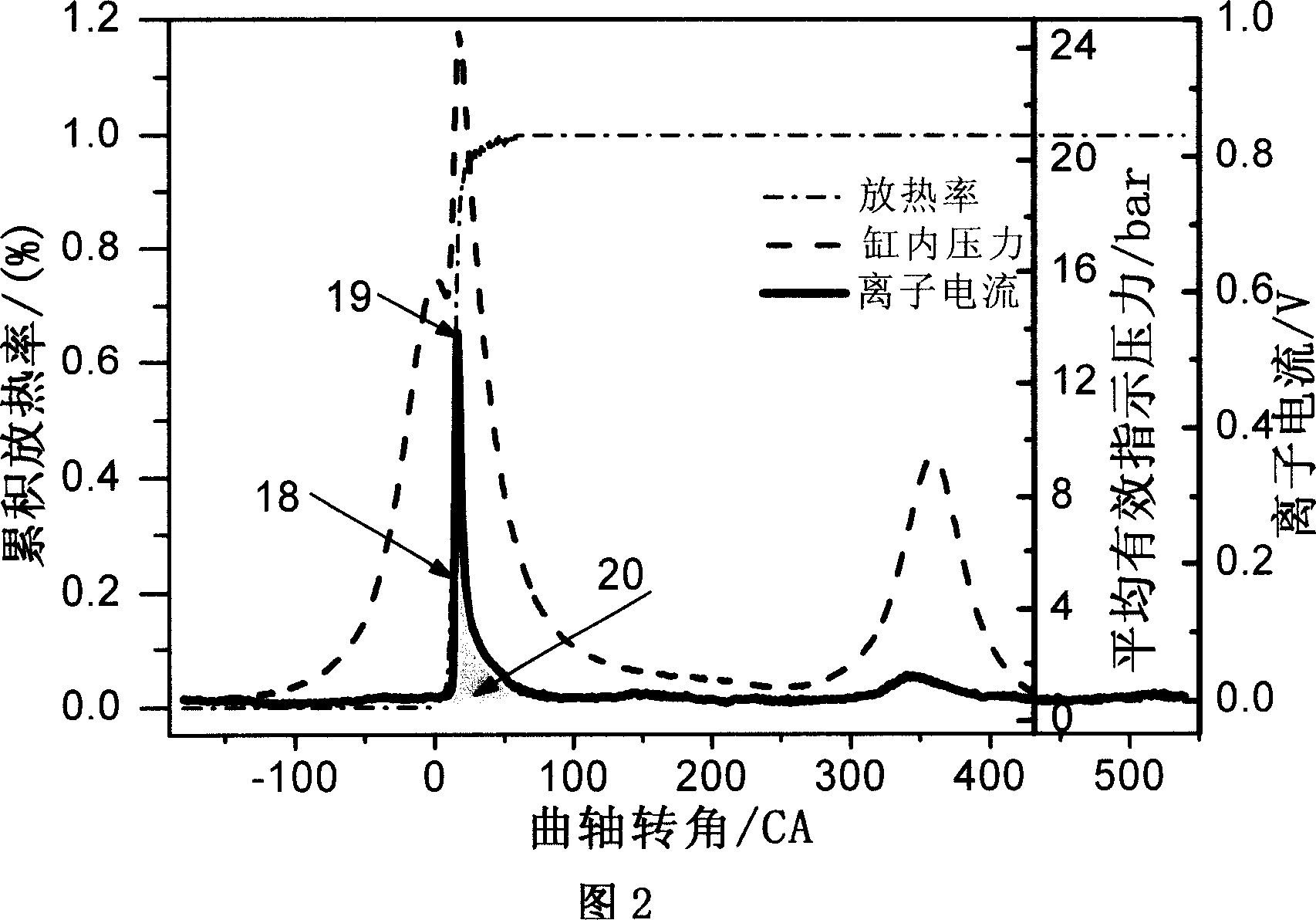

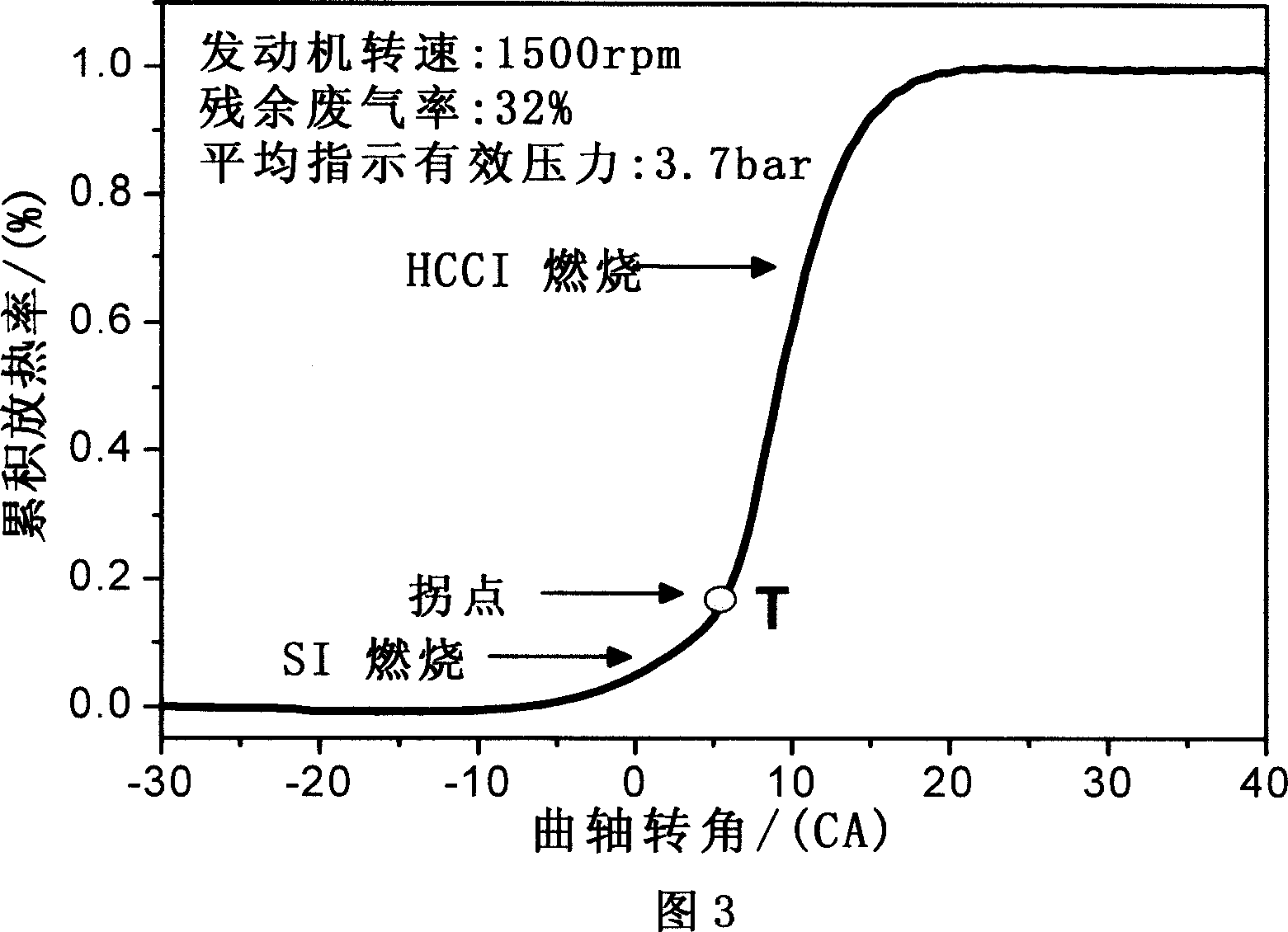

Combustion information online detecting device for homogeneous compression-ignition and flame-ignition dual-mode gasoline engine

The invention relates to a uniform compression-ignition and splash ignition petrol engine burning information online detector, wherein it uses splash plug ion current to online detect the uniform compression-ignition state, to realize closed control of dual-mode burning. The invention is characterized in that: high-pressure ignition coil is serially connected to two one-way connectors, direct-current power module and detecting resistance; the splash plug is connected between two one-way connectors; the signal processing module is parallel connected to two ends of detecting resistance; the signal processing module processes the signal of detecting resistance to obtain one group of ion current character signal relative to burning; and it uses dynamic recursive program to obtain burning phase, instruction average effective pressure and mixing heating rate character value. The invention is characterized in that: it uses the ion current generated by splash plug, calculates the online internal burning phase, load, mixing heating rate character value and abnormal burning parameter, to directly support feedback information for the smooth transition between two burning modes.

Owner:TIANJIN UNIV

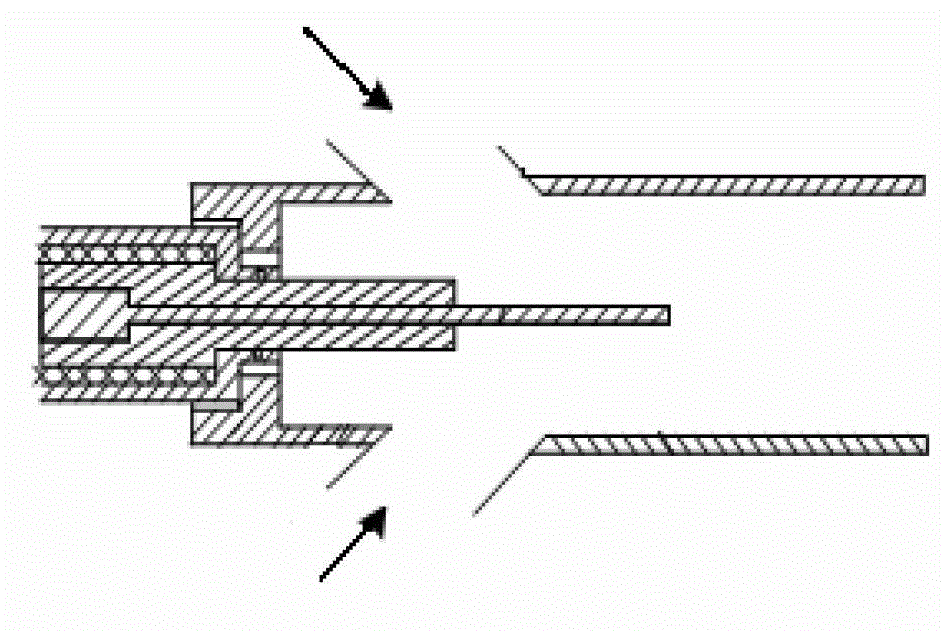

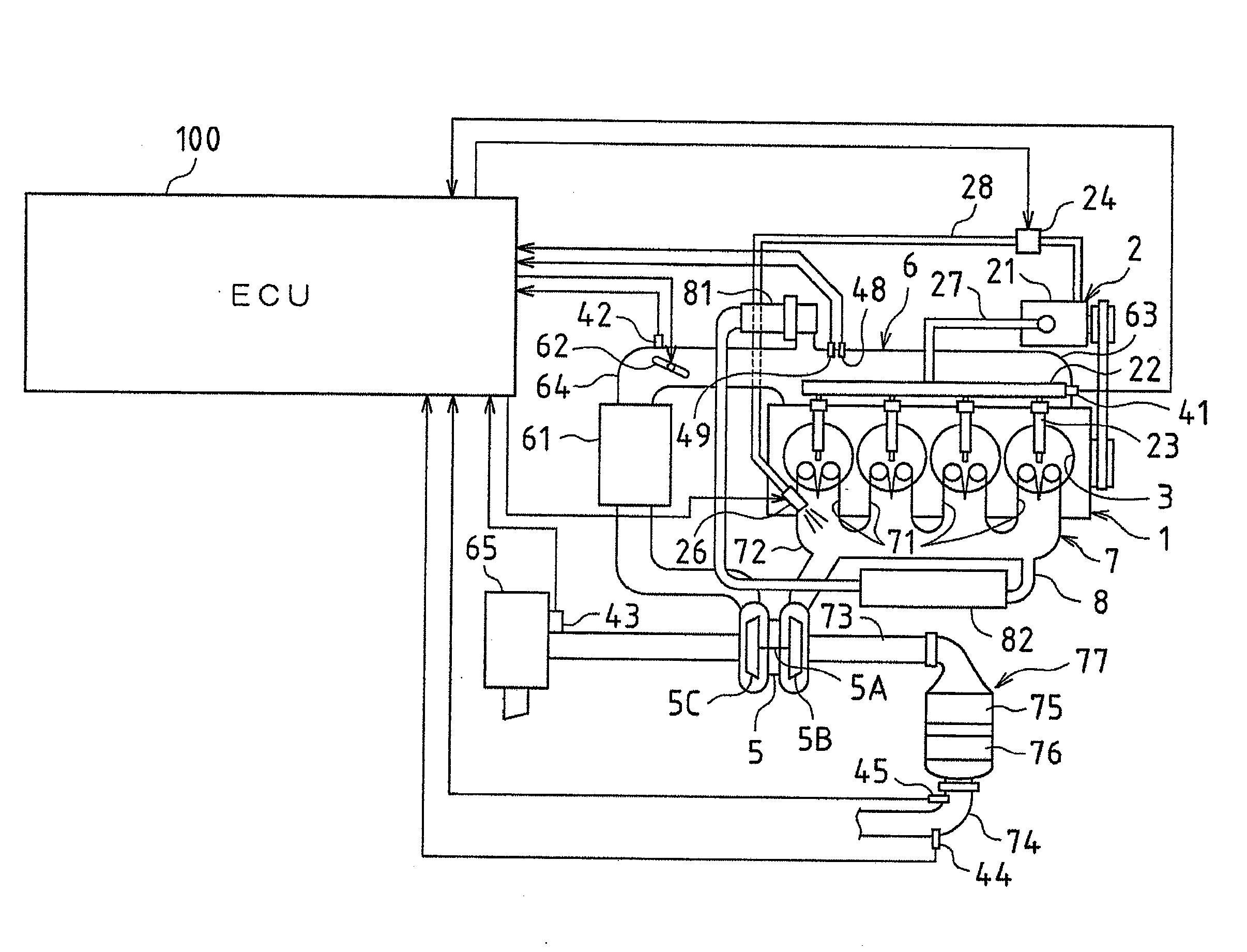

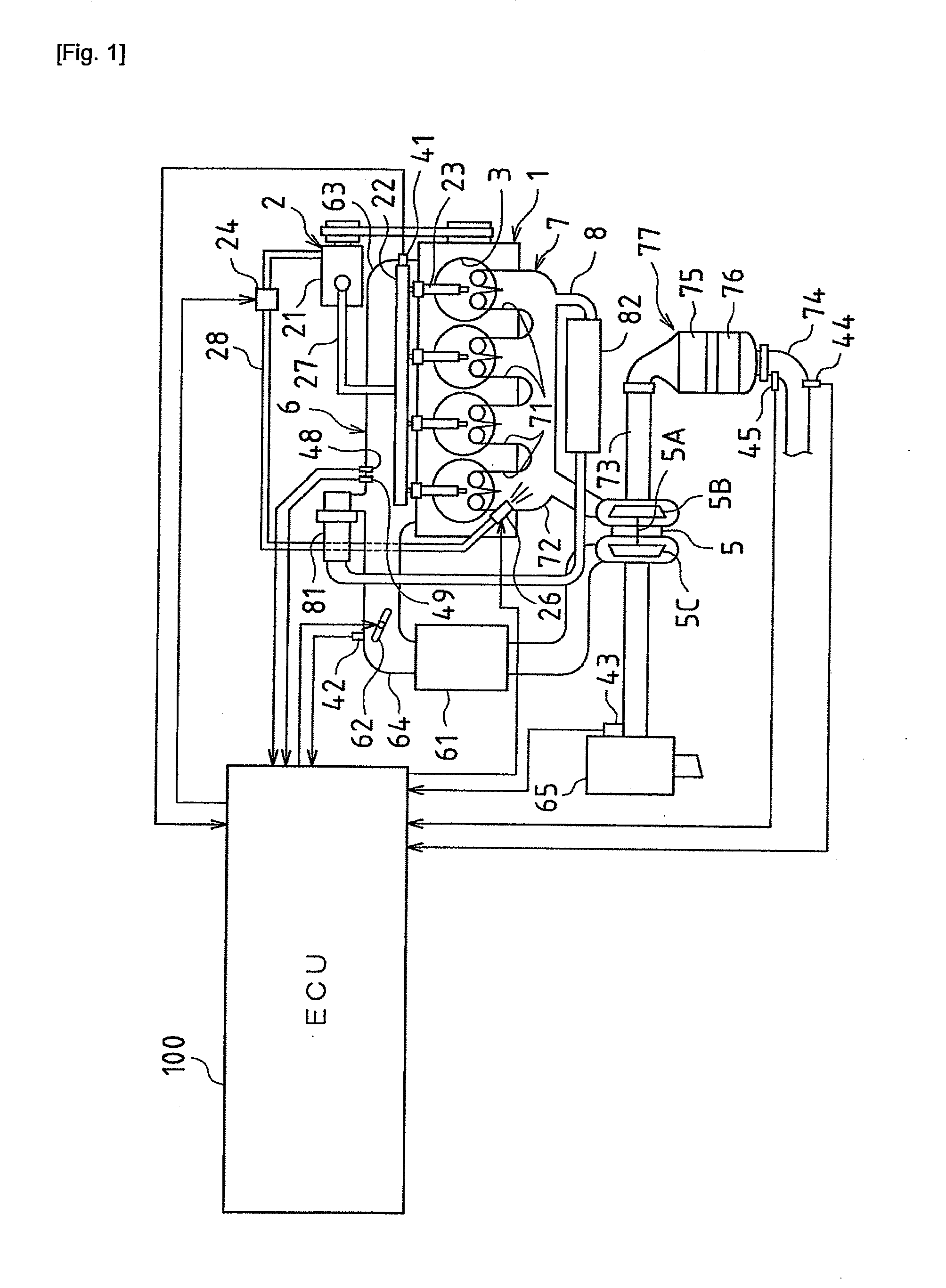

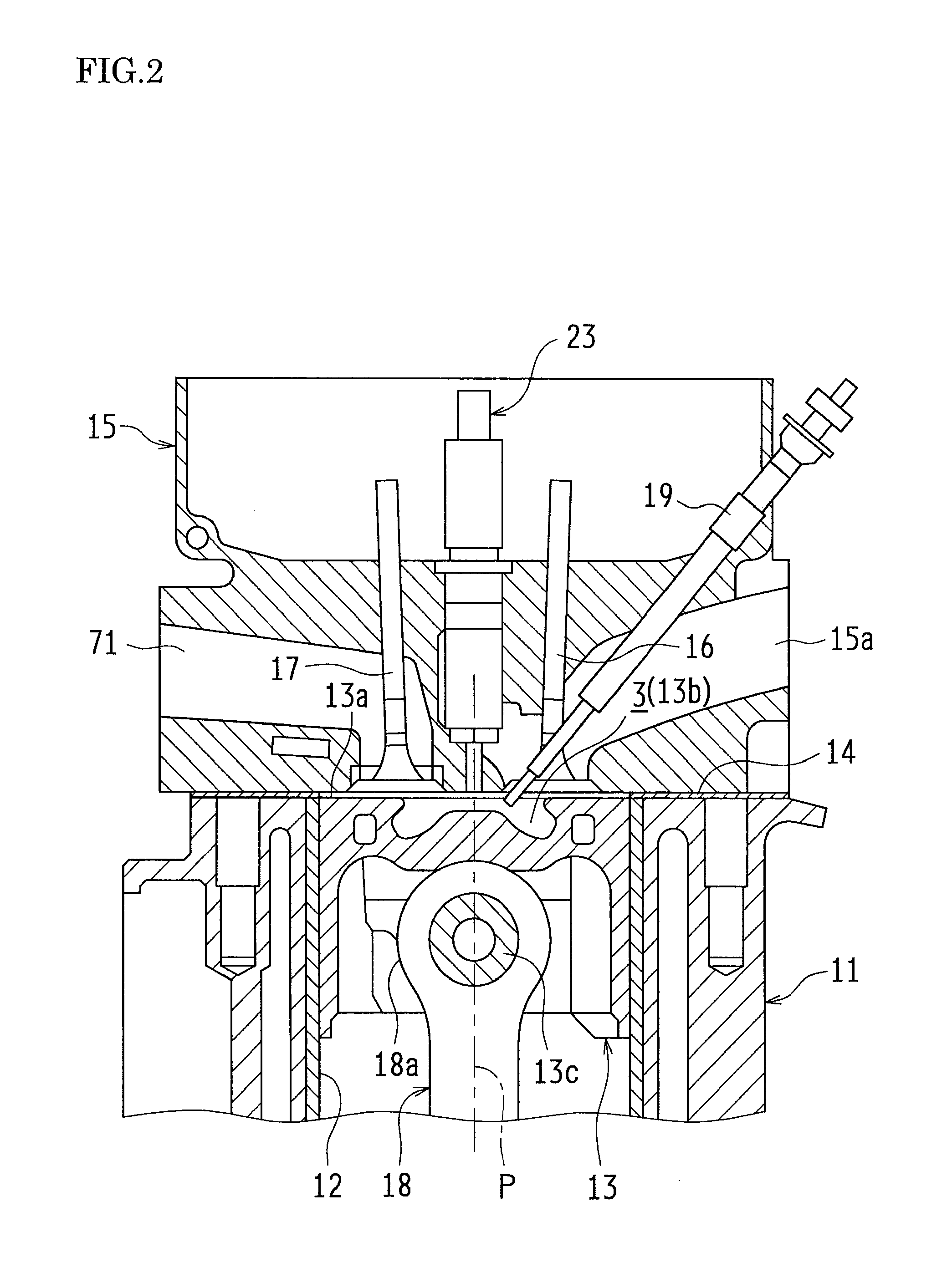

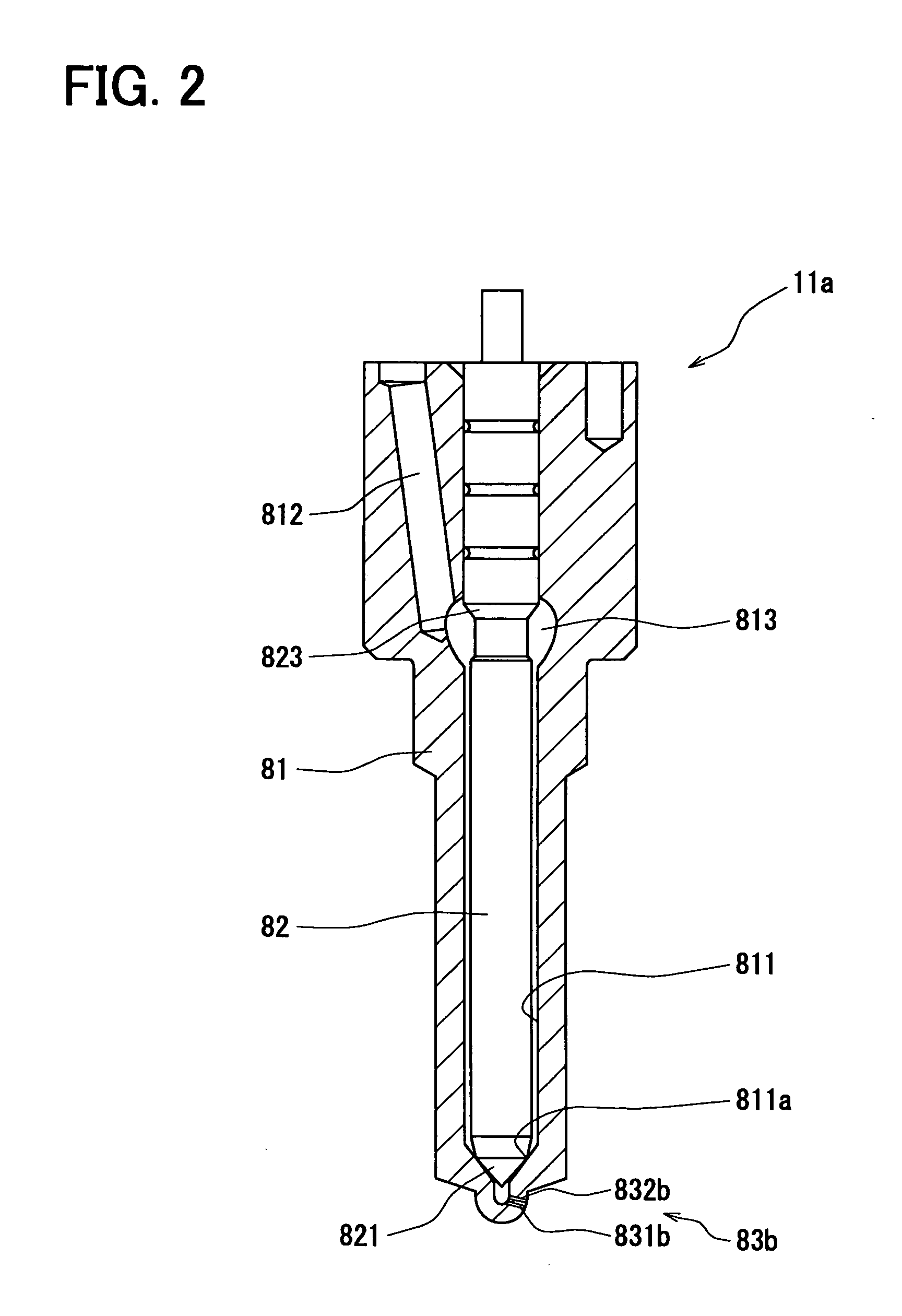

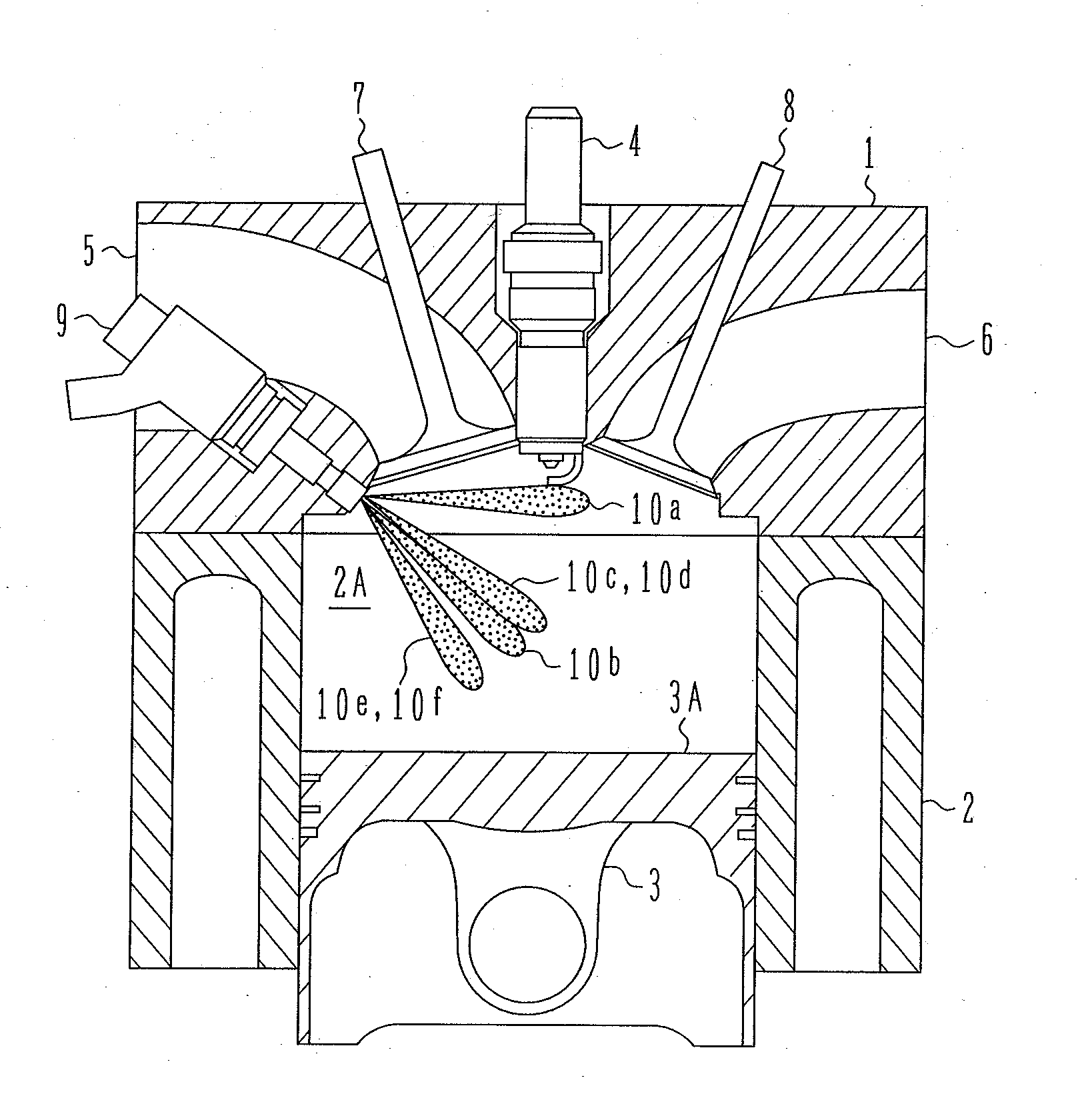

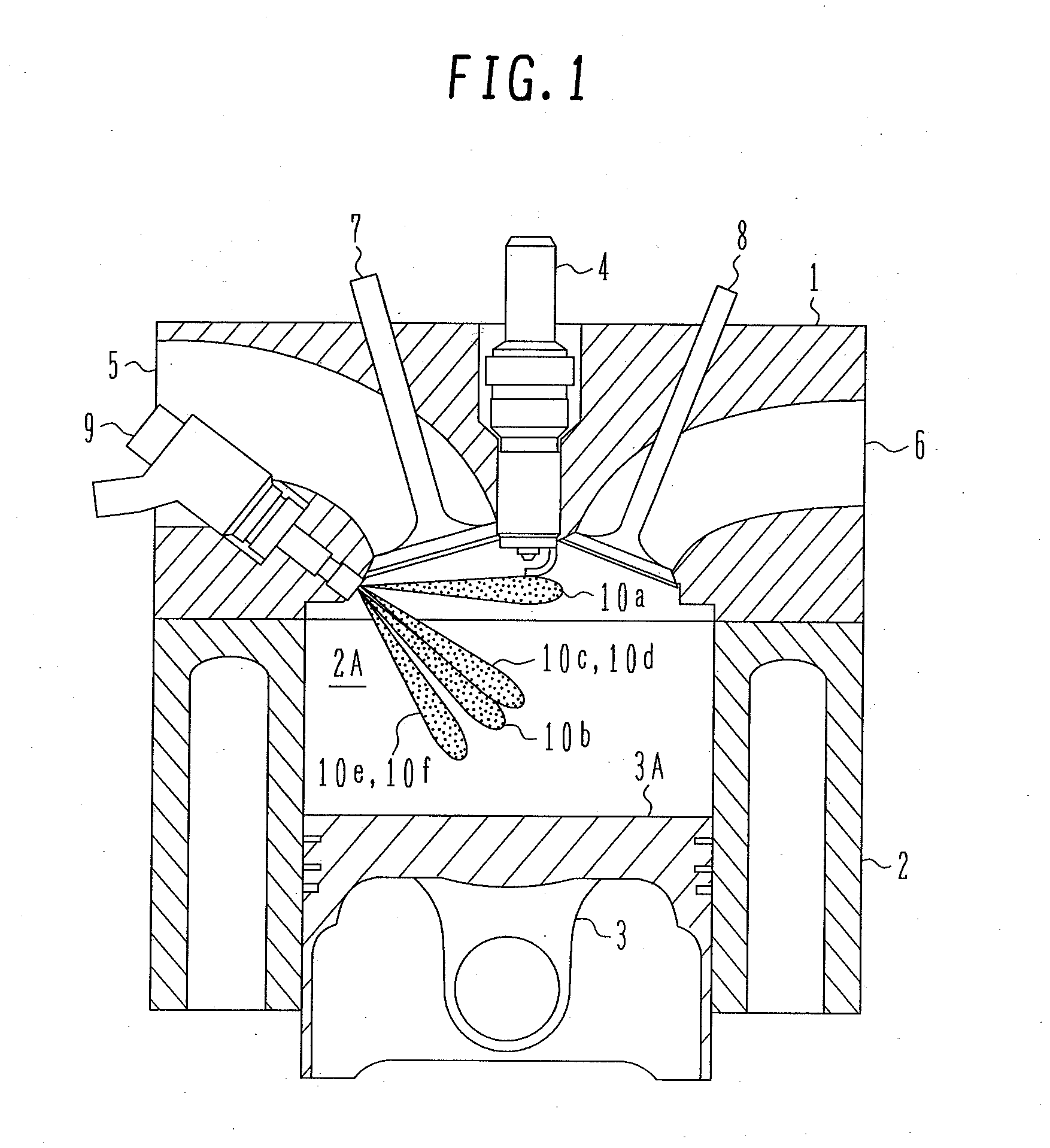

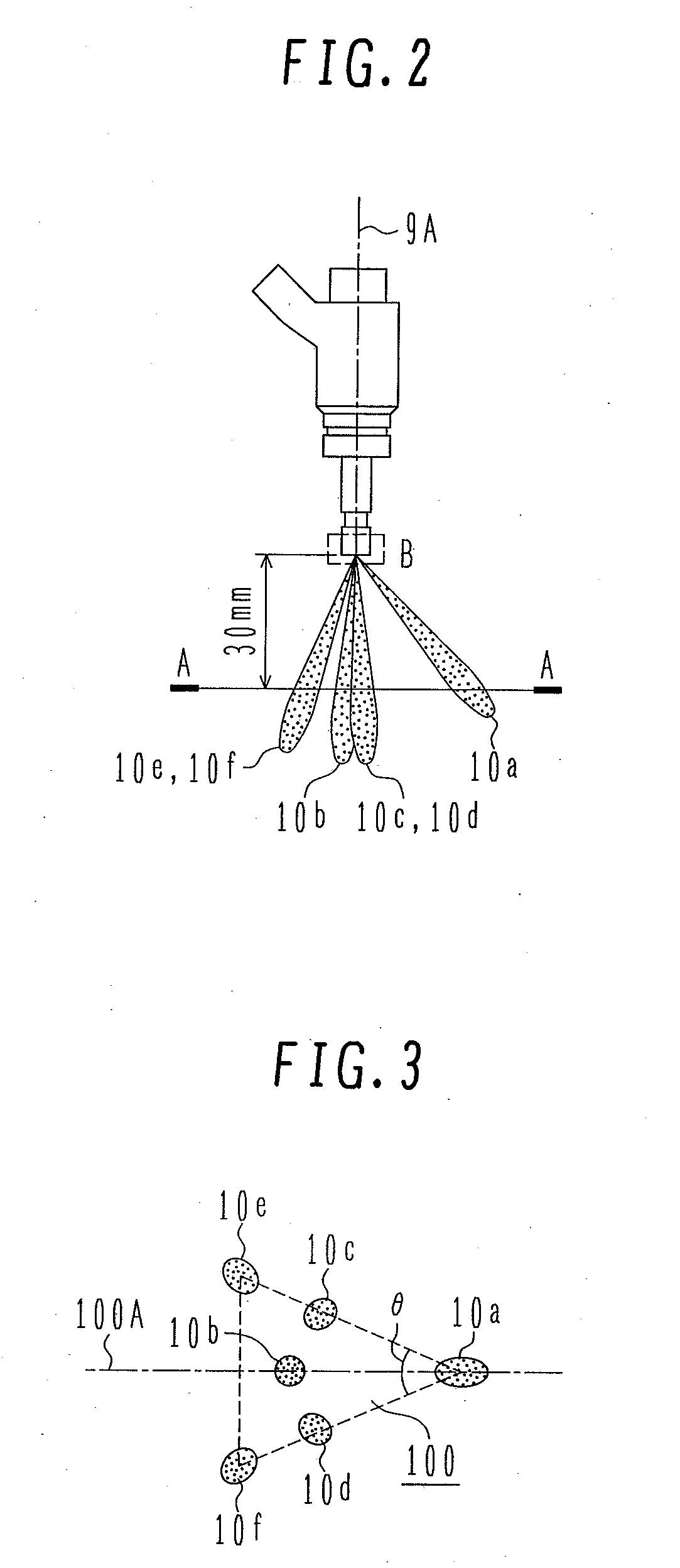

Direct Injection Internal Combustion Engine and Injector Used for Direct Injection Internal Combustion Engine

InactiveUS20080196691A1Promote combustionIncrease exhaust temperatureElectrical controlInternal combustion piston enginesInjection pointIgnition delay

It is necessary to attain the combustion stability when performing ignition retarding in order to reduce exhaust gas and raise the exhaust gas temperature under a cold start condition, as well as soot reduction under a fully open throttle valve condition.An injector according to the present invention comprises: a plurality of fuel passages having an axis line inclined with respect to a valve operation axis line at a nozzle end; wherein inclined axis lines of at least three of the fuel passages have a spreading angle, none of them intersecting with each other, and three injection points are formed in a plane perpendicular to a valve operation axis line to form a triangle; and wherein at least one center-oriented fuel passage having an injection point around the center of the triangle is provided.

Owner:HITACHI LTD

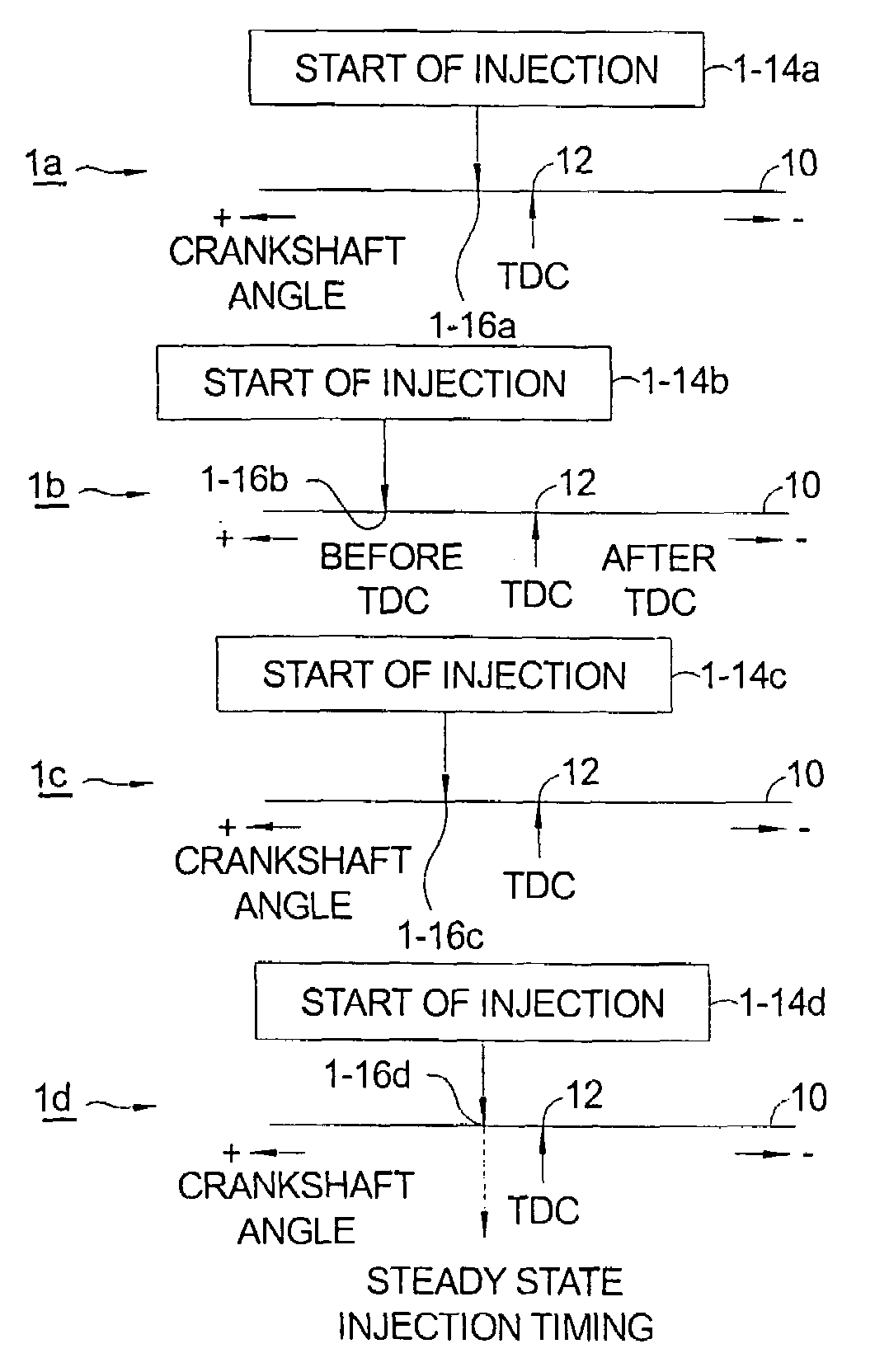

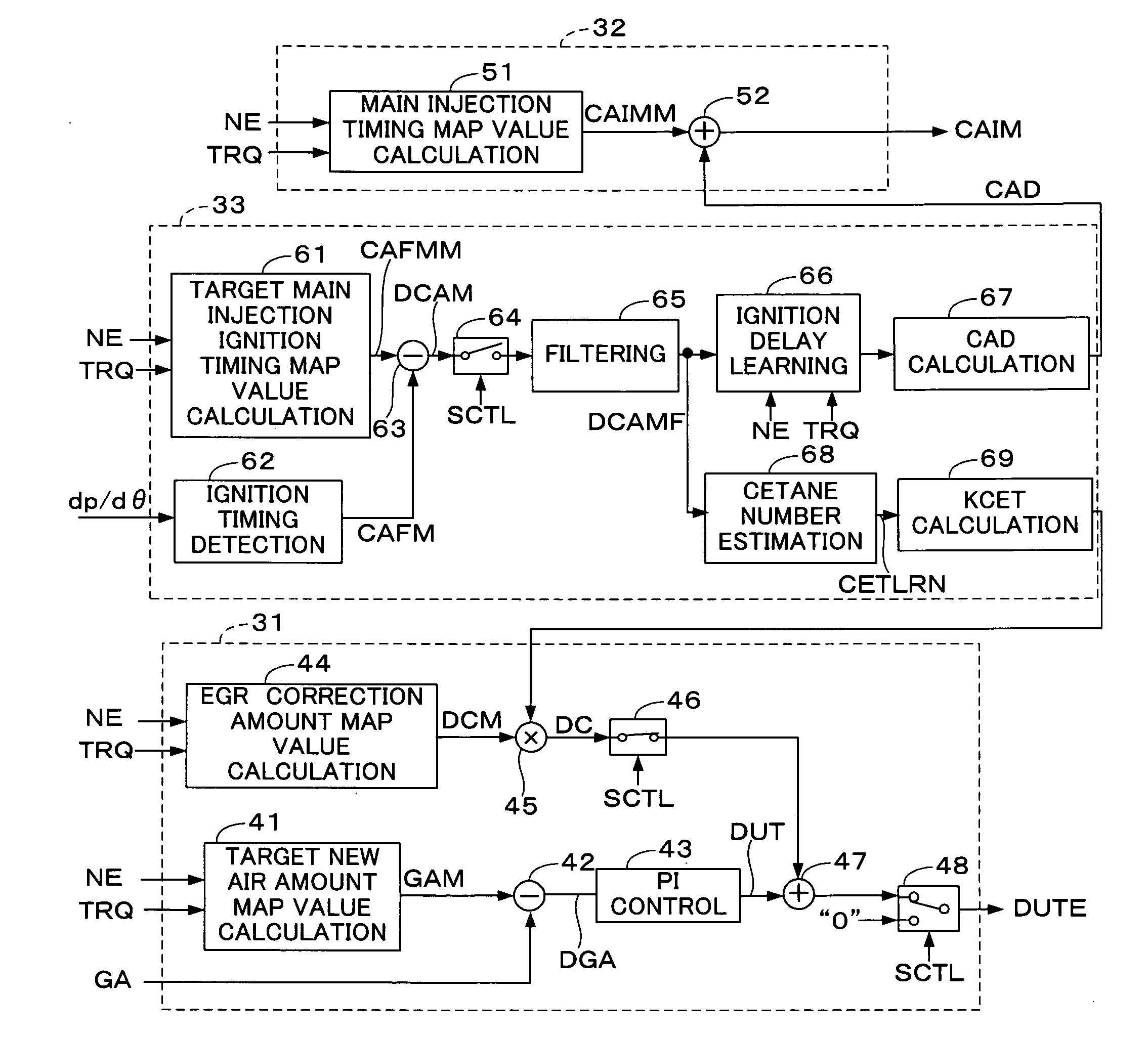

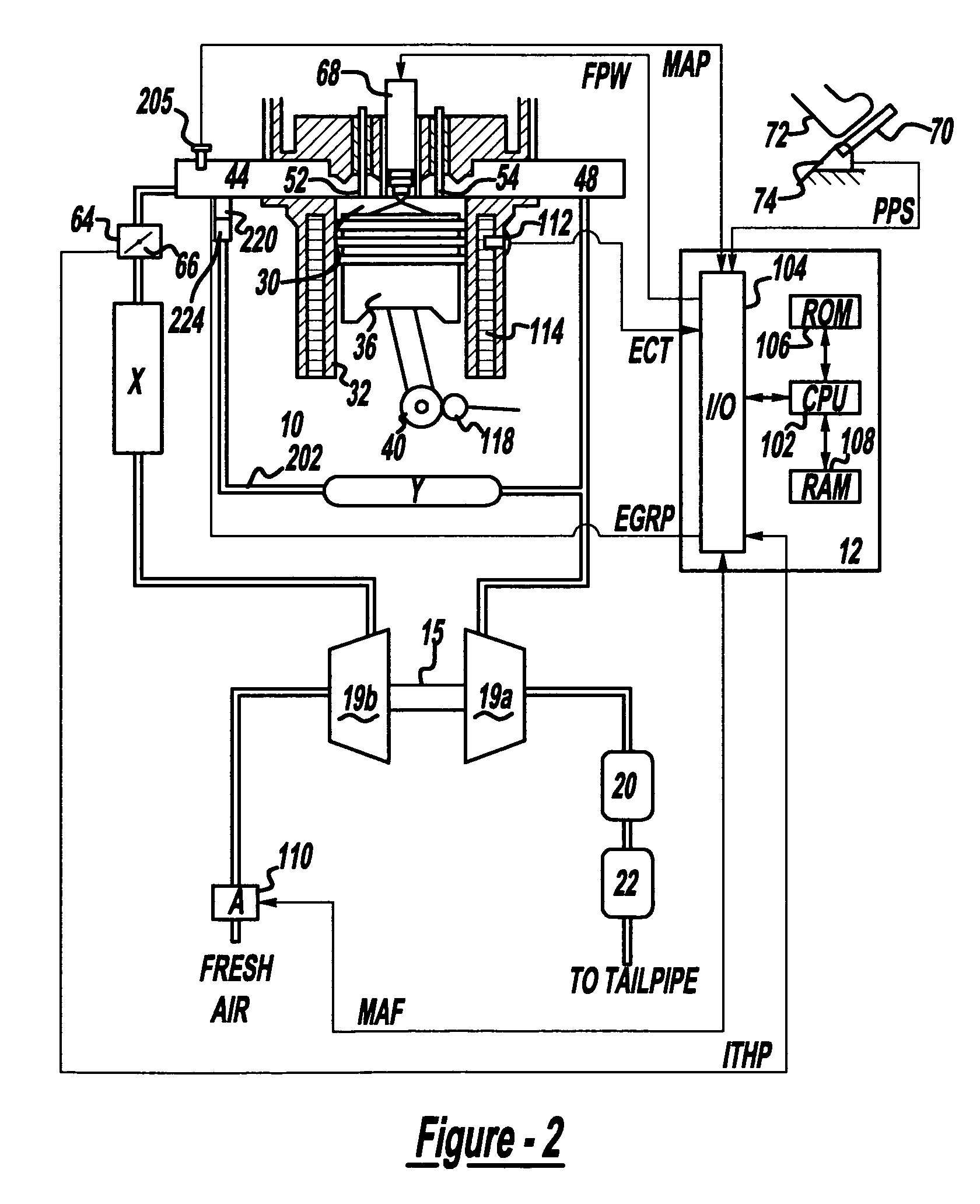

Control system for internal combustion engine

InactiveUS20070012290A1Prevent ignition timingReduce controlElectrical controlInternal combustion piston enginesCombustion chamberControl system

A control system for an internal combustion engine having a fuel injector located in a combustion chamber of the engine for injecting fuel into the combustion chamber. The fuel injection timing stored in a fuel injection timing map is retrieved according to the detected engine operating condition to determine the fuel injection timing. An actual ignition timing of the fuel injected into the combustion chamber is detected. An ignition delay of the actual ignition timing with respect to the target ignition timing, which is set according to the engine operating condition and a fuel injection timing correction amount, is calculated according to the calculated ignition delay. The fuel injection timing is corrected with the fuel injection timing correction amount, and the fuel injection is executed according to the corrected fuel injection timing.

Owner:HONDA MOTOR CO LTD

Control method for preventing explosion venting of dry dedusting system in converter smelting process

ActiveCN102952917AReduce CO contentSolve the problem of ignition lagManufacturing convertersIgnition delayNitrogen gas

The invention discloses a control method for preventing explosion venting of a dry dedusting system in converter smelting process. The control method includes the steps of: firstly adding steel scraps into a converter, and then feeding molten iron into the converter; supplying oxygen to the liquid surface of the molten iron from the top through a oxygen lance, feeding stirring gas into the molten iron from the bottom to dephosphorizing the molten iron, at the same time controlling the oxygen supply intensity at all periods of time, and purging a flue of the converter for 90seconds through nitrogen 30seconds before the dephosphorization process is finished; bringing up the oxygen lance after the dephosphorization process is finished and conducting rapid deslagging operation to the converter; and decarbonizing the molten iron, bringing up the oxygen lance after the decarbonization process is finished, and then tapping of molten steel is carried out. According to the invention, in the method, the nitrogen purging time is set through a PLC(Programmable Logic Controller) program, the opening degree of an oxygen flow valve of the converter is set to be 40% and the oxygen release point of the oxygen lance of the converter is set to be 13.73m. Therefore, the problem of ignition delay upon release of oxygen is solved and the problem that explosive gas mixture is easy to produce in the dephosphorization process after the oxygen lance is brought up is avoided. The control method is simple and effective and is low in cost.

Owner:BEIJING SHOUGANG CO LTD

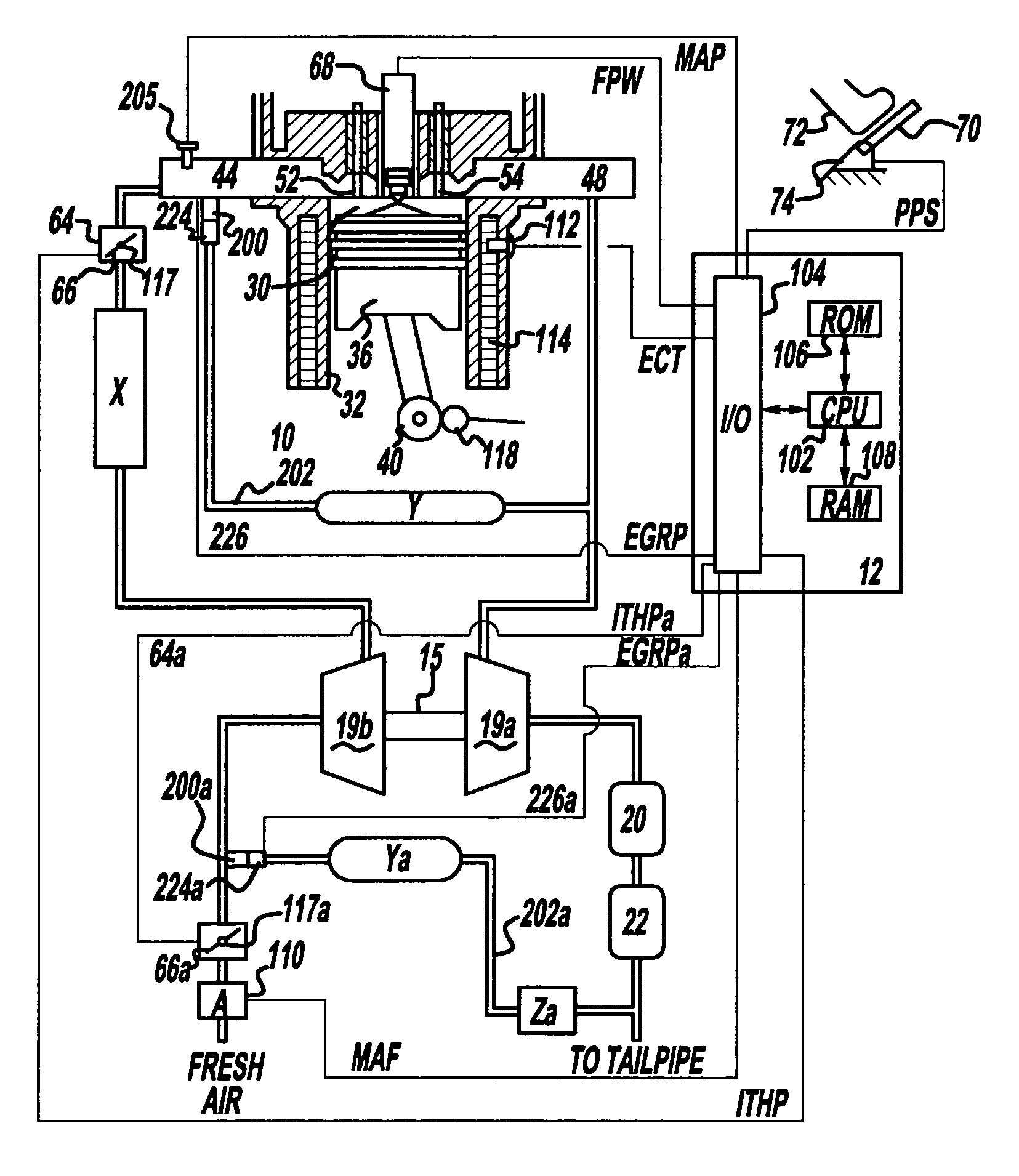

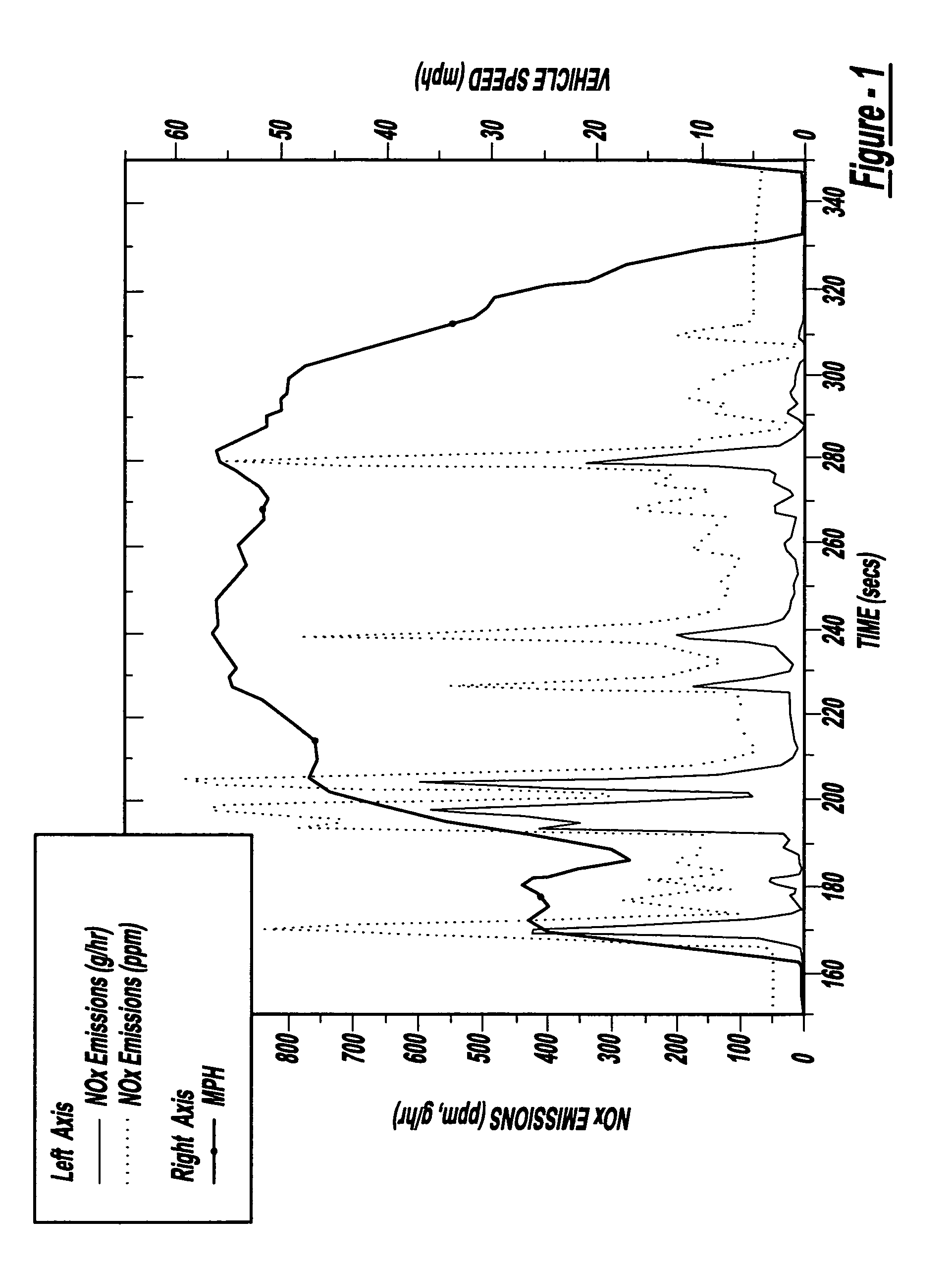

System and method for reducing NOx emissions during transient conditions in a diesel fueled vehicle with EGR

InactiveUS7273045B2Electrical controlNon-fuel substance addition to fuelCombustion chamberDual stage

The present invention is a dual-stage fuel injection strategy for compression ignition engines in which 15-40% of the fuel is injected into the combustion chamber no later than about −20 to −30 CA ATDC and as early as IVC. The remaining fuel is then injected in one or more fuel pulses, none of which start before about −20 to −30 CA ATDC. The fuel injected early in the compression stroke forms a lean mixture that burns with low soot and low NOx emissions. The combustion of that fuel serves to increase in-cylinder temperature such that the ignition delay of subsequent fuel injection pulses is short. This mode is utilized when it is predicted that a NOx spike is imminent. Various other alternative methods for reducing NOx spikes are also disclosed such as specialized EGR systems that can provide EGR with low manifold vacuum.

Owner:FORD GLOBAL TECH LLC

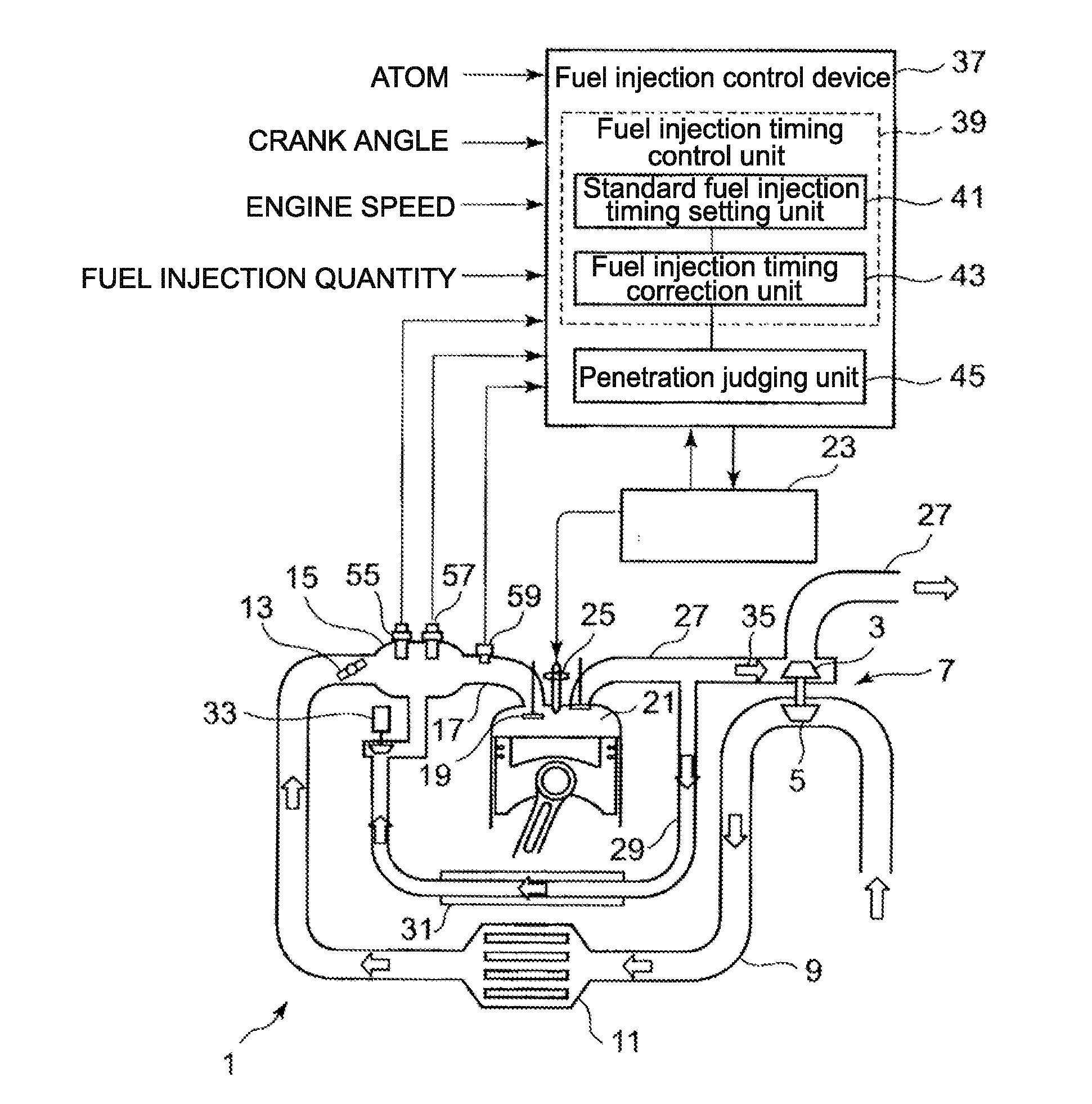

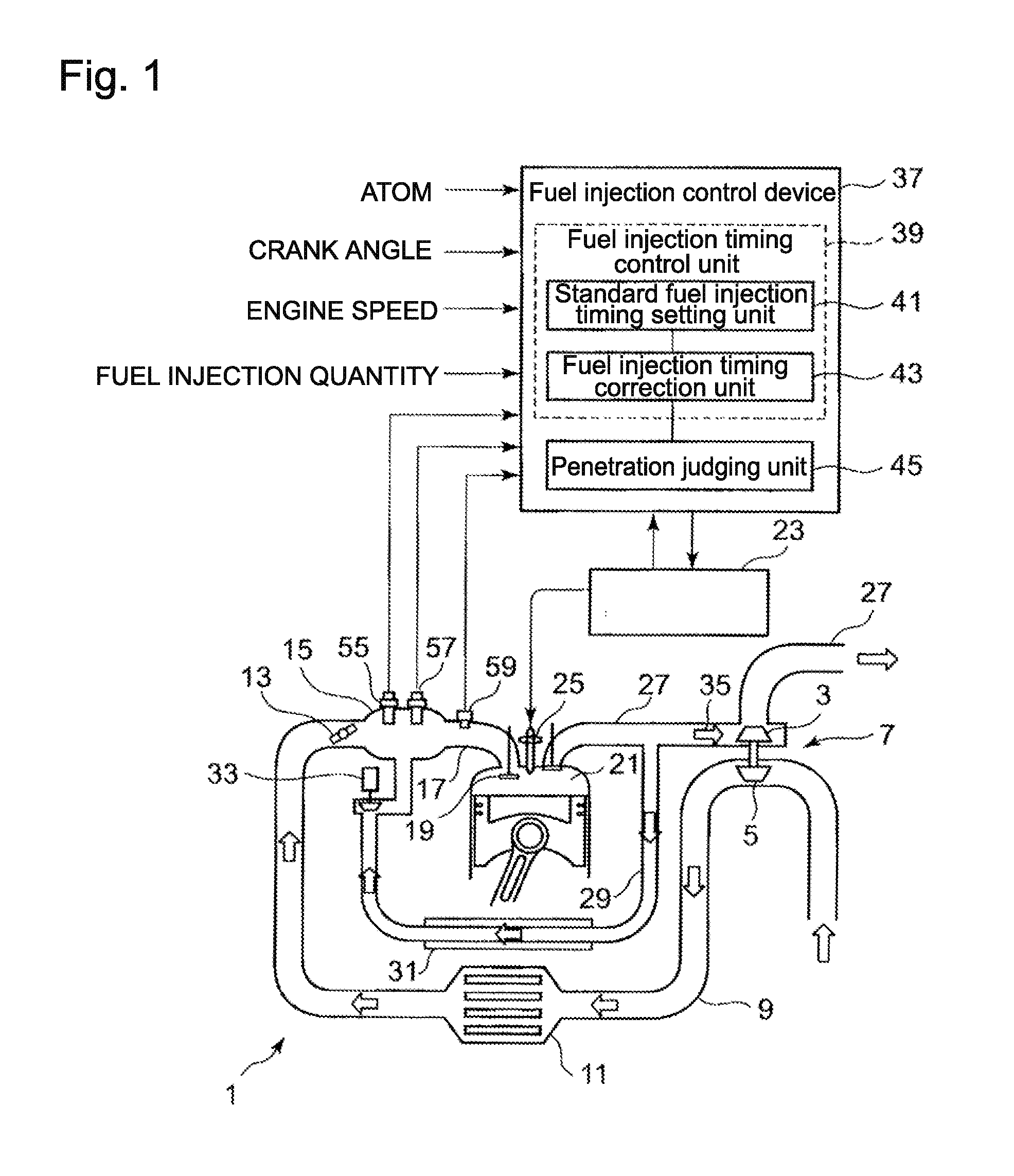

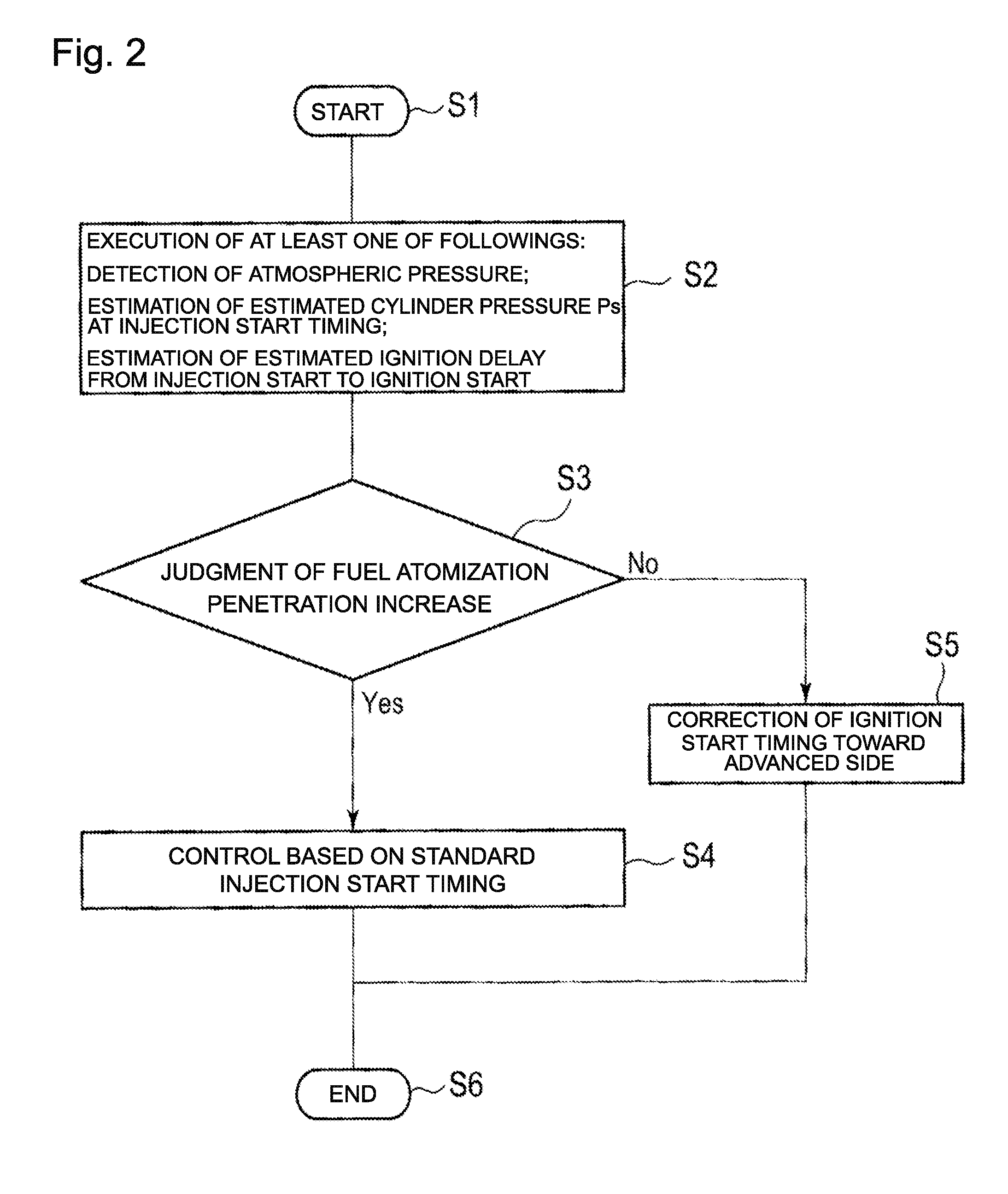

Fuel injection control device and method of diesel engine

A fuel injection control device provided with: a standard fuel injection timing setting unit 41 which previously sets a standard fuel injection timing with respect to engine speed and fuel injection quantity; an injection penetration judging unit 45 which judges whether or not the penetration of the fuel atomization in a cylinder is in an increasing condition, by use of at least one out of a detected ambient pressure from an ambient pressure sensor, an estimated cylinder pressure at an injection start timing, and an estimated ignition delay from an injection start timing to a combustion start timing; and a fuel injection timing correction unit 43 which corrects the fuel injection timing toward an advanced timing angle and constrains the penetration of the fuel atomization, in a case where the penetration judging unit judges that the penetration of the fuel atomization is in an increasing condition.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

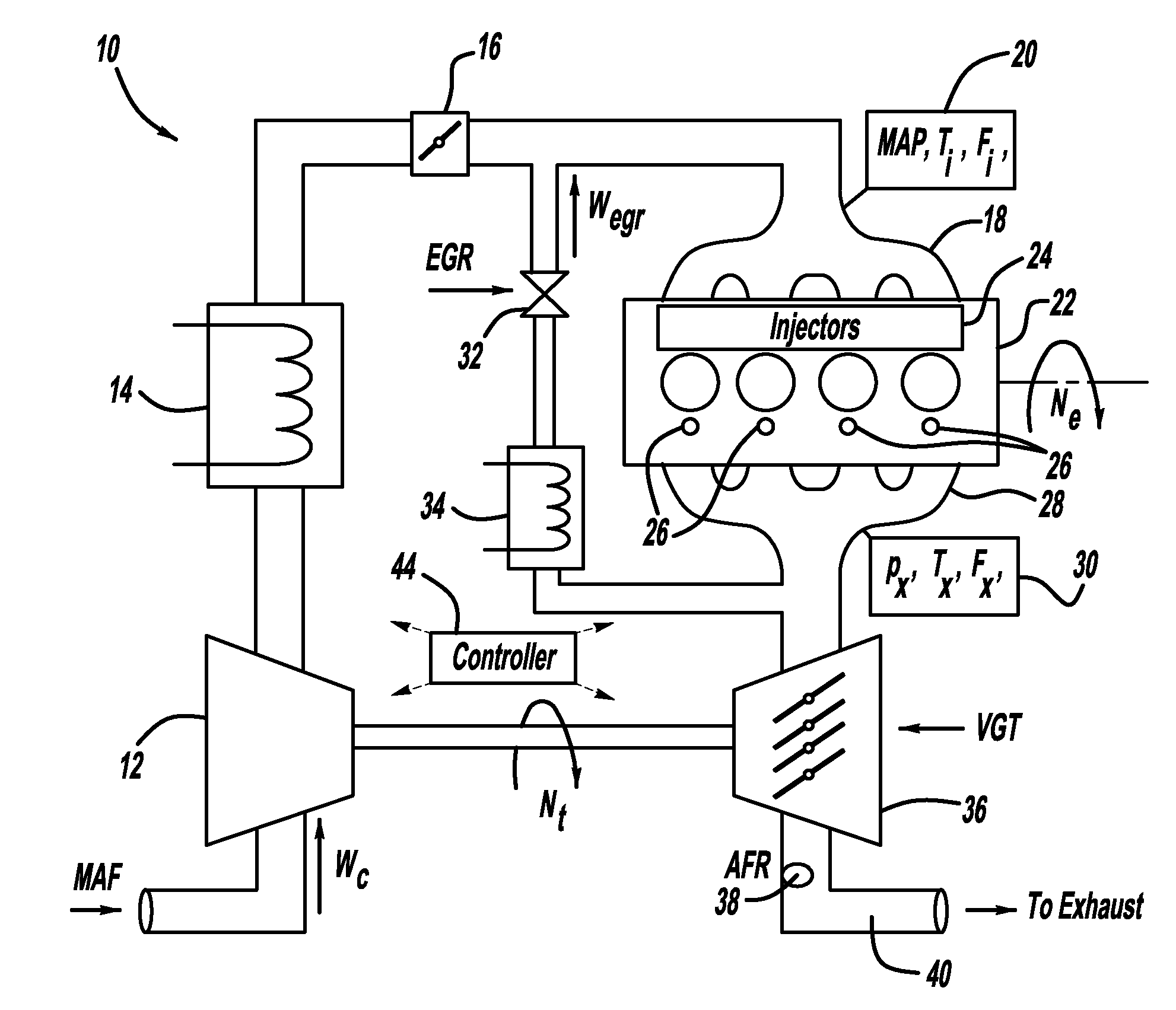

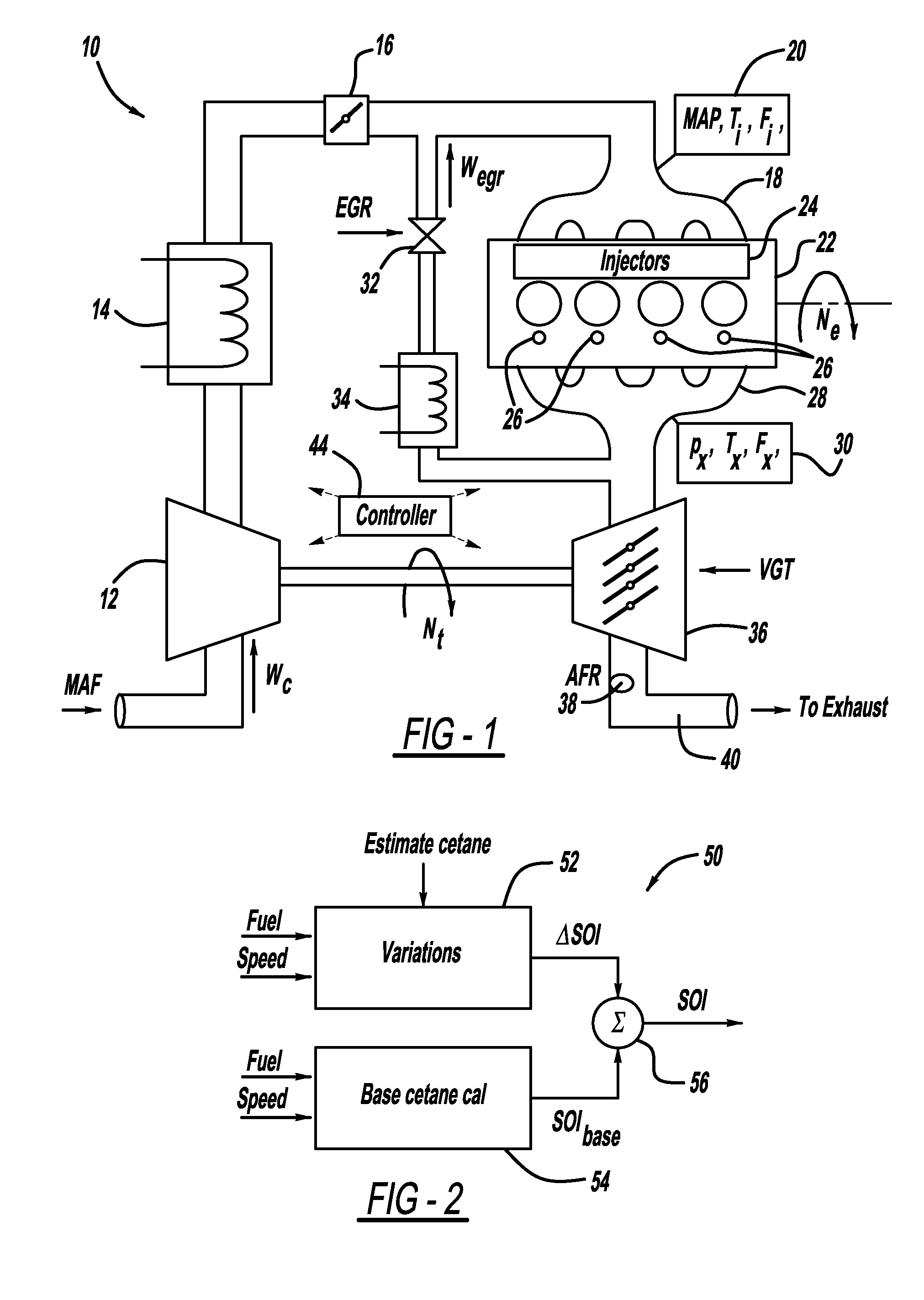

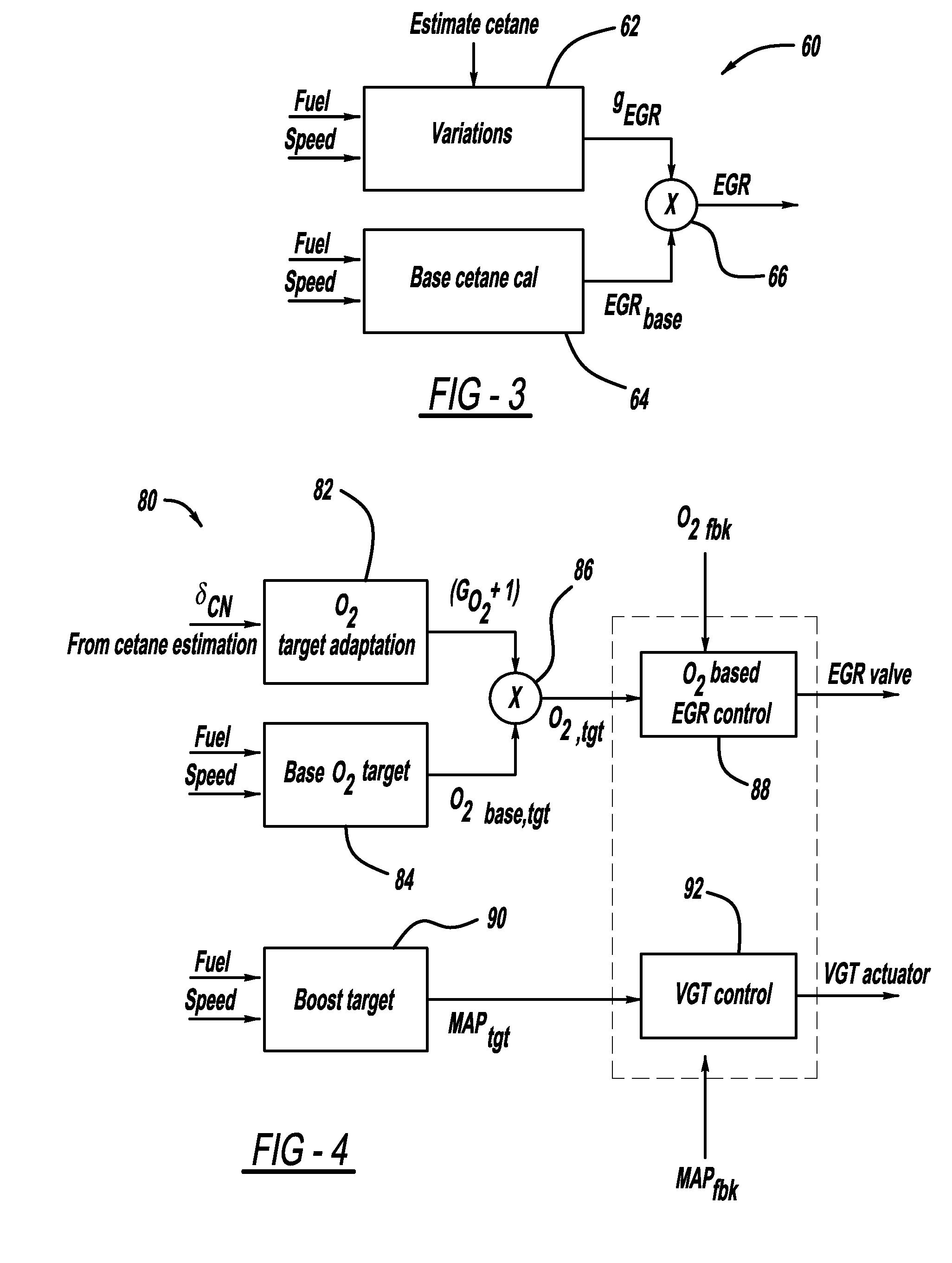

Adaptive diesel engine control for cetane variations

InactiveUS20110208408A1Optimize engine operationAltering natureAnalogue computers for vehiclesElectrical controlIgnition delayOxygen

A method and system for adaptively controlling a diesel engine to account for variations in the cetane number of the diesel fuel being used. An engine controller includes various control modules with algorithms for estimating the fuel cetane number, or determining the ignition delay that the engine is experiencing, or both. With this information, the controller can adjust the amount of exhaust gas recirculation that is used, thus varying the amount of oxygen that is available in the intake charge to burn the fuel. The controller can also adjust the timing of the fuel injection event, as another way of altering the nature of combustion. Using these techniques, the controller can optimize the engine operation based on the fuel currently being used.

Owner:GM GLOBAL TECH OPERATIONS LLC

Micro-fluidic pump

ActiveUS20130202278A1Reduce heatWater heatersPumpsElectrical resistance and conductanceIgnition delay

A micro-fluidic pump comprises one or more channels having an array of resistive heaters, an inlet, outlet and a substrate as a heat sink and a means of cooling the device. The pump is operated with a fire-to-fire delay and / or a cycle-to-cycle delay to control the pumping rate and minimize heating of liquid inside the pump during its operation.

Owner:SHANGHAI AUREFLUIDICS TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com