Annular discharge based transient state plasma igniter

A plasma point, annular discharge technology, applied in the direction of engine ignition, machine/engine, engine components, etc., can solve the problems of increasing the ignition area, unfavorable discharge, reducing power supply requirements, etc., to achieve large ignition area, small breakdown voltage, Conducive to the effect of igniting the mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

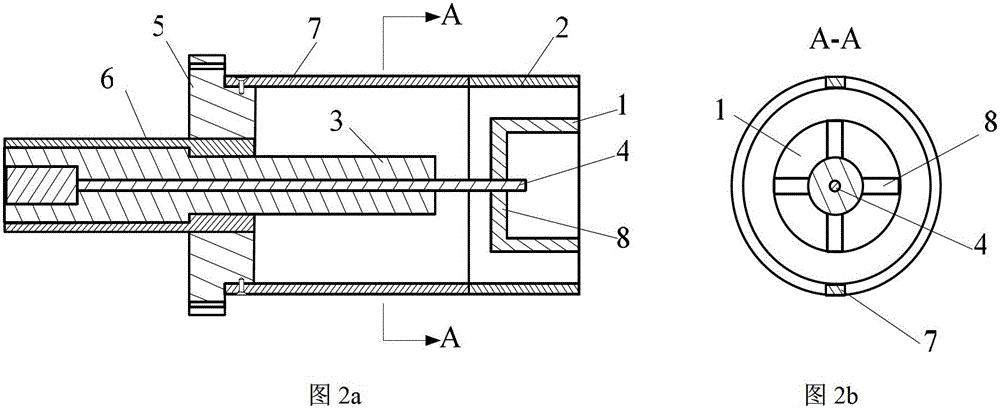

[0032] This embodiment is a transient plasma igniter based on annular discharge, which is used for ignition of internal combustion engines, including anode 1, cathode 2, insulating sleeve 3, anode conducting rod 4, fixing seat 5, insulating protective sleeve 6 and cathode connection pole 7. as attached figure 2 shown. A pair of cathode connecting rods 7 protruding axially are symmetrically distributed on the end surface of one end of the cathode 2 , and the other ends of the two cathode connecting rods 7 are fixed on the outer circular surface of the fixing seat 5 . The anode 1 is located inside the cathode 2 . One end of the insulating protective sheath 6 is located in the inner hole of the fixing seat 5 . The insulating sleeve 3 is installed in the inner hole of the insulating protective sleeve 6 , and one end of the insulating sleeve 3 extends between the two cathode connecting rods 7 of the cathode 2 .

[0033] The anode 1 is annular and made of high temperature resis...

Embodiment 2

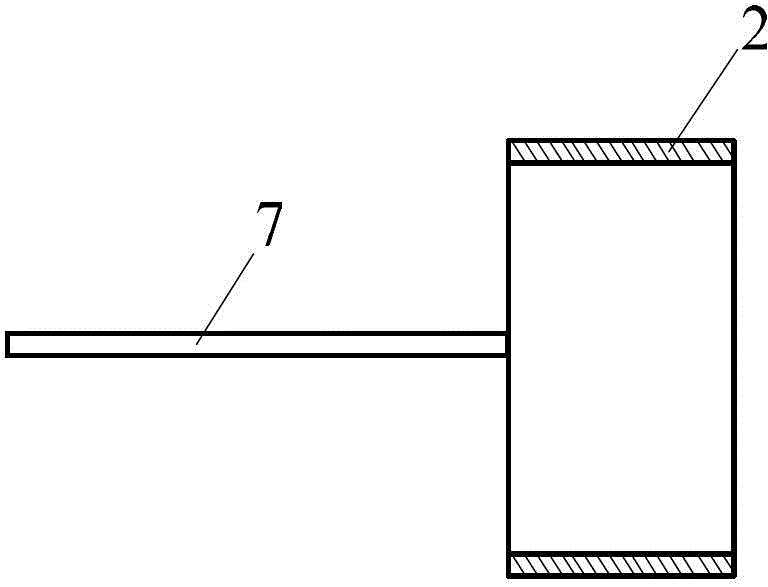

[0044] This embodiment is a transient plasma igniter based on annular discharge applied to a pulse detonation engine, including an anode 1, an insulating sleeve 3, an anode conducting rod 4, an insulating protective sleeve 6, a cross rib 8, and a detonation tube 9. The air intake hole 10 and the fixing seat 5. structure as attached Figure 7 shown.

[0045] In this embodiment, the detonation tube 9 is used as the cathode, and the anode 1 is discharged and ignited. The inlet end of the detonation tube 9 is fixed on the end face of one end of the fixing base 5 by screws. One end of the insulating sheath 6 is put into the central hole of the fixing seat 5, one end of the insulating sheath 3 is put into the said insulating sheath 6, and the other end of the insulating sheath 3 penetrates into the inner hole of the detonation tube 9 middle. The anode conducting rod 4 is loaded into the insulating sleeve 3 , and the anode 1 is installed at the end of the anode conducting rod 4 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com