Spark plug

A technology of spark plugs and electrodes, applied in the field of spark plugs, can solve the problems of small sparks, low efficiency, and high explosion pressure of pistons, and achieve high explosion pressure, expand ignition area, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

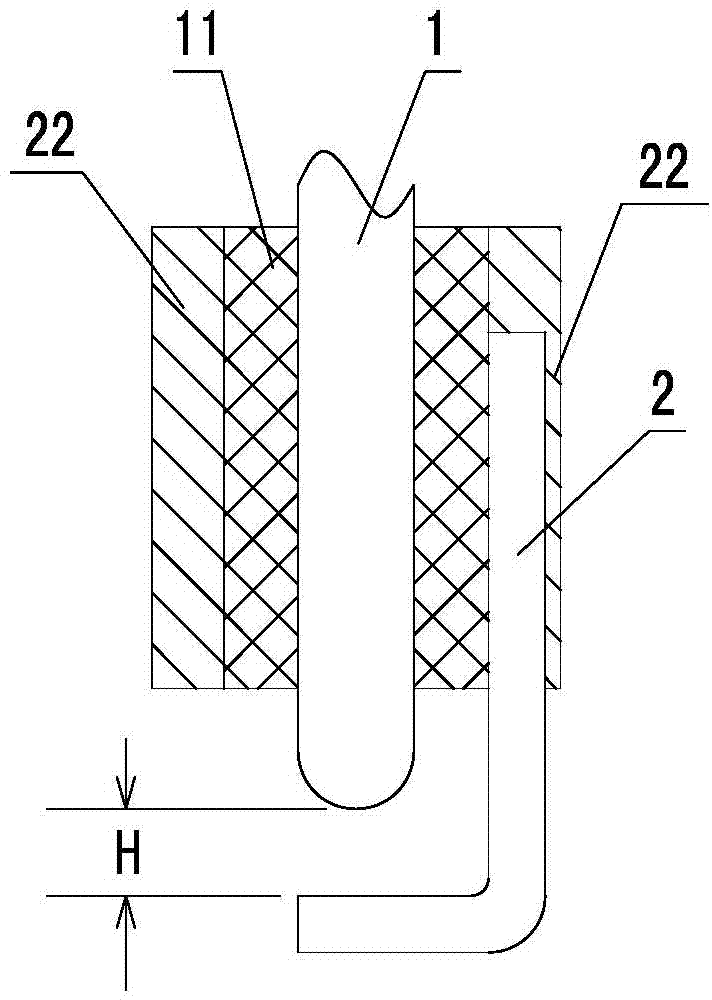

[0027] Such as figure 1 The shown spark plug includes an electrode A1 and an electrode B2, the lower end of the electrode B2 bends and extends below the electrode A1, and the distance H between the two is 1.2 mm. The electrode A 1 is fixedly connected to the casing 22 via the insulator 11 , and the electrode B 2 is fixedly connected to the casing 22 . The electrode A1 and the electrode B2 are respectively connected to two electrodes of a high voltage power supply capable of breaking down the electrode A1 and the electrode B2. In a gasoline engine, the casing 22 is fixedly connected with the machine body, the electrode A 1 discharges and breaks down the gas mixture between the electrode B 2 , discharges to the electrode B 2 to generate sparks, and achieves an ignition effect.

[0028] During specific implementation, optionally, the distance between the electrode A 1 and the electrode B 2 can be increased according to actual needs, such as 2 mm, 4 mm, 8 mm, and so on.

Embodiment 2

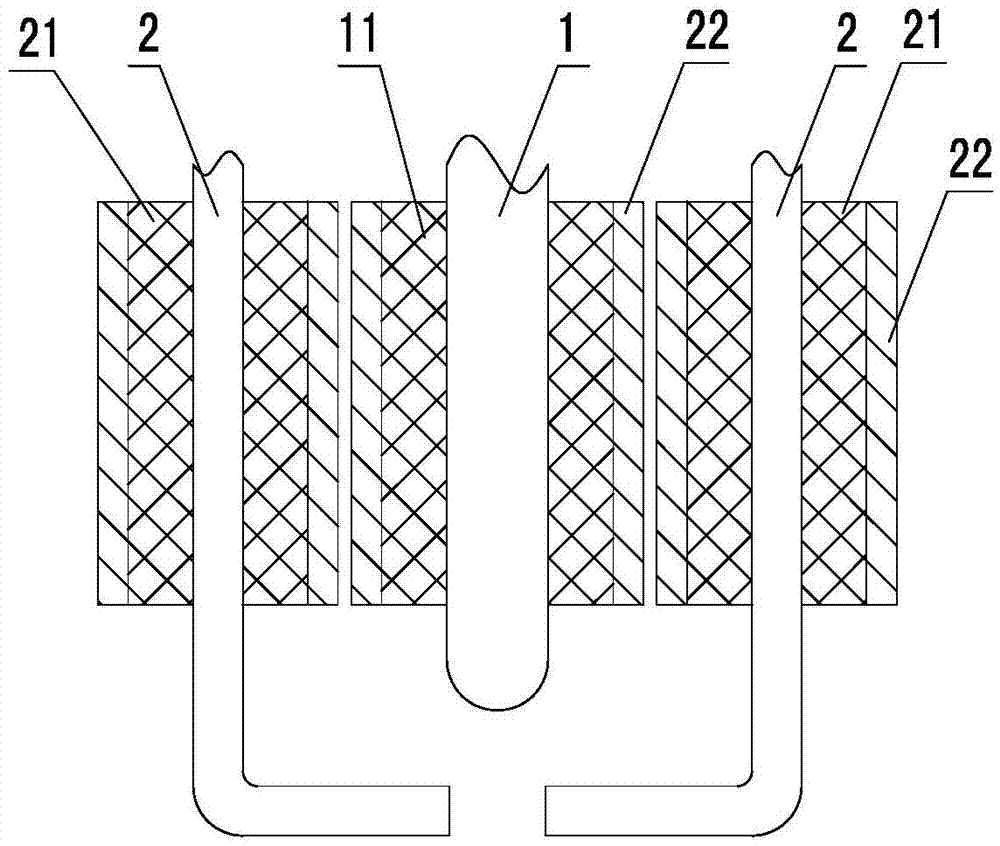

[0030] Such as figure 2 The spark plug shown is based on Embodiment 1: the electrode B 2 is fixedly connected to the housing 22 through an insulator 21, and the electrode B 2 is set to two, and the two electrodes B 2 are distributed around the electrode A1.

[0031] In practical applications, several electrodes B2 can be arranged around the electrode A1, and the electrode A1 can simultaneously discharge all the electrodes B2, generate multiple electric sparks, and increase the Large ignition area effect.

Embodiment 3

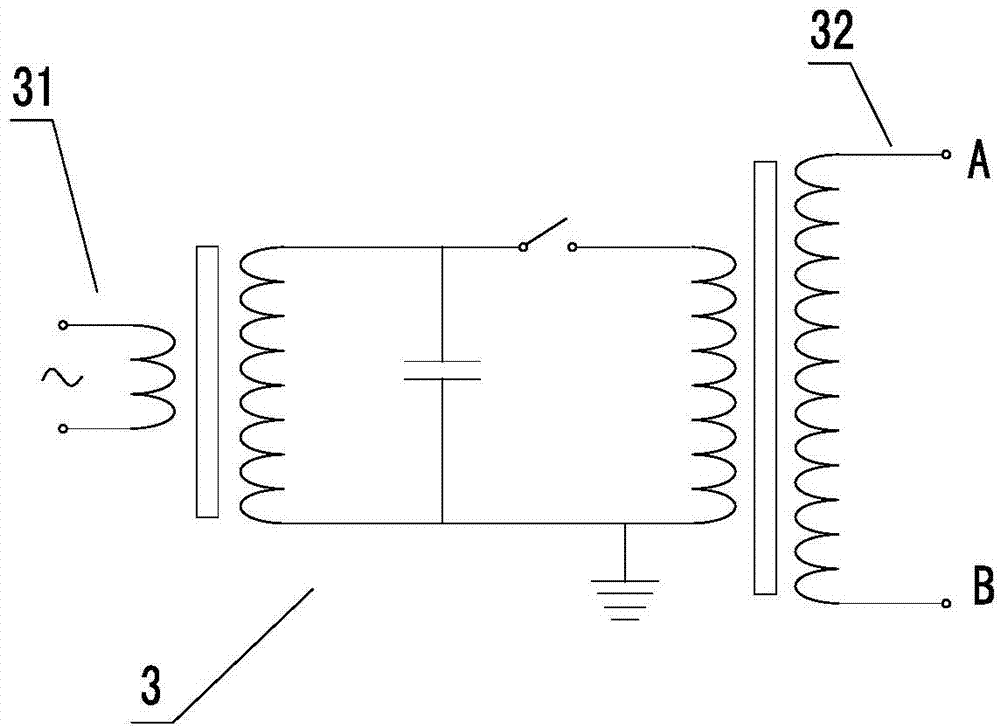

[0033] Such as image 3 In the shown Tesla coil 3, its input terminal 31 is connected to alternating current, and after the voltage rises through the two-stage transformer, the output terminal 32 outputs a voltage sufficient to break down the mixture between the electrode A1 and the electrode B2. . The electrode A1 of the spark plug in the above-mentioned embodiment 1 or embodiment 2 can be connected to the A contact point of the output end 32. When the spark plug of embodiment 1 is used, since the electrode B2 and the body are connected through The casing 22 is fixedly connected together, so the B contact of the output end 32 is selected to be connected to the body; and the engine using the spark plug of embodiment 2, since the electrode B 2 and the body are insulated, The B contact of the output terminal 32 is connected to the electrode B2.

[0034] Compared with the traditional spark plug structure, the distance between the electrode A1 and the electrode B2 increases in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com